Extraction and preparation method for micromolecule fishskin collagen peptide

A technology of fish skin collagen and collagen peptide, which is applied in the preparation method of peptide, chemical instrument and method, peptide and other directions, can solve the problems of wide molecular weight distribution, high price of protease, limited application scope, etc. The effect of reducing the amount of protease and shortening the time of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

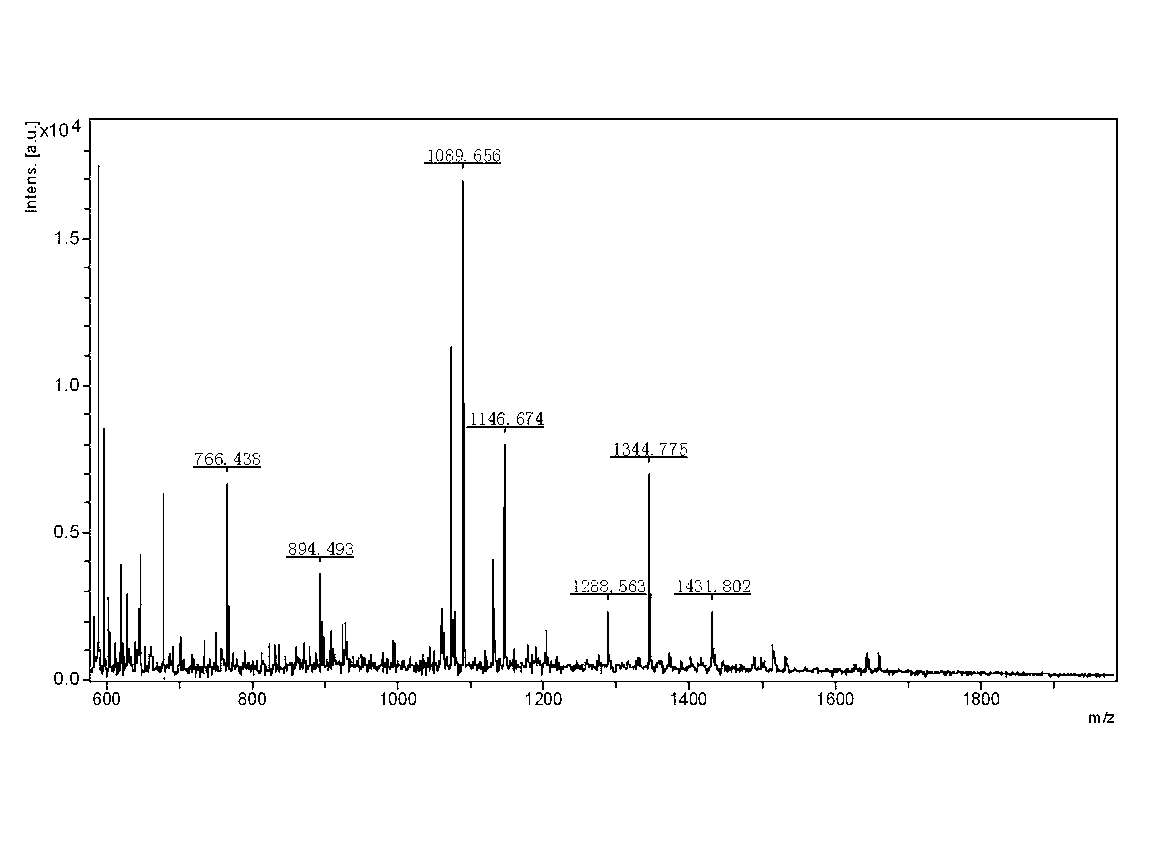

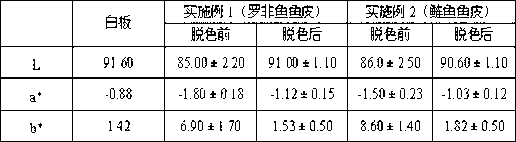

[0031] Add 50L of 0.01M NaOH solution containing 20% (v / v) absolute ethanol to 10 kg of tilapia fish skin, soak for 12h at 20°C, rinse with tap water, then add 50L of 0.05M HCl solution Soak at 20°C for 1h, rinse with tap water until the pH is 3, use a separate high-consistency refiner to grind the treated fish skin, heat at 90°C for 60min, and then use sodium hydroxide to adjust its pH Adjust to 8.0, then add 2 g of collagenase, enzymolysis at 55°C for 4h, use hydrochloric acid to adjust the pH of the enzymolysis solution to 5.0, add 20 g of papain, after enzymolysis at 55°C for 1h, The ultrafiltration membrane with a molecular weight cut-off of 5000 Daltons is used for separation, and the solution that fails to pass through the ultrafiltration membrane is recovered to the papain enzymatic hydrolysis step for continued use. Desalting and concentrating a sodium filter membrane with a molecular weight cut-off of 200 Daltons can obtain 7L of collagen peptide solution with a Br...

Embodiment 2

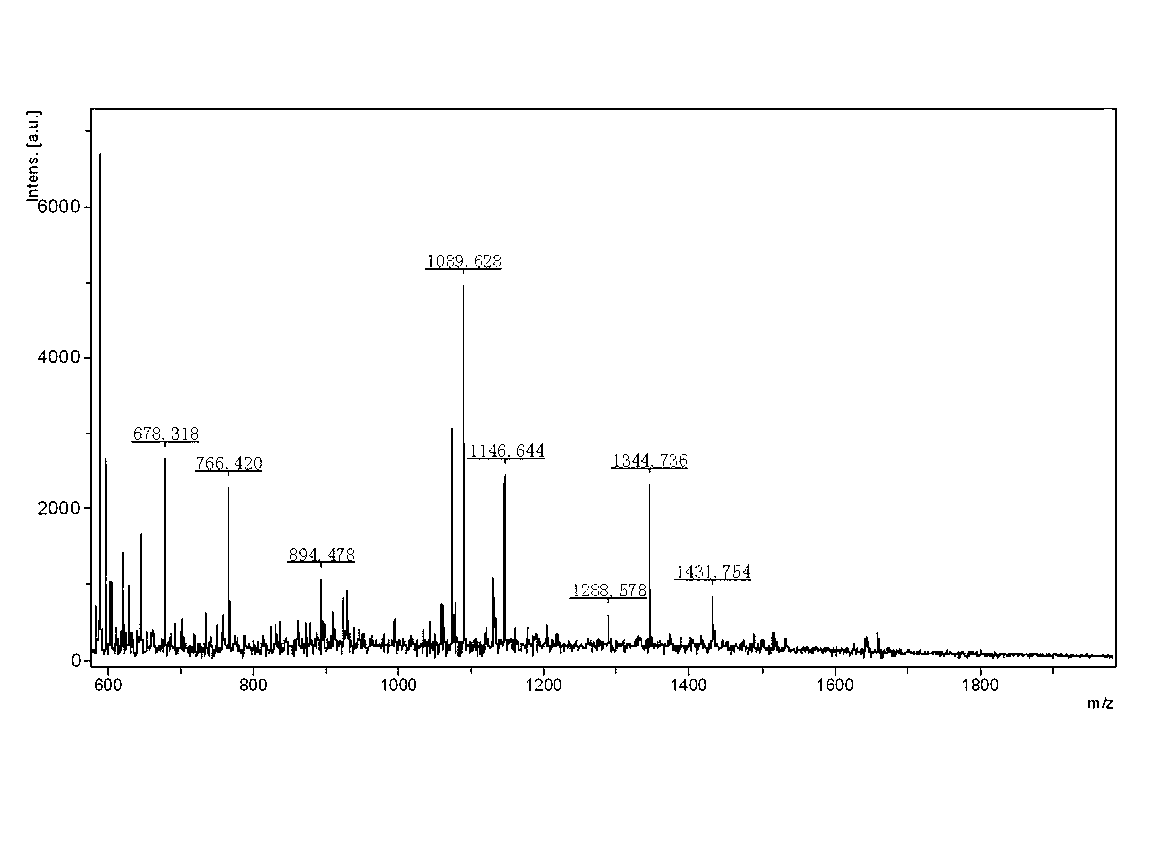

[0033] Add 40L of 0.05M NaOH solution containing 20% (v / v) absolute ethanol to 10 kg silver carp skin, soak at 4°C for 24h, rinse with tap water, add 70L of 0.20M HCl solution in the Soak at 4°C for 3 hours, rinse with tap water until the pH is 5, use a separate high-consistency refiner to grind the treated fish skin, heat at 100°C for 30 minutes, and then use sodium hydroxide to adjust its pH to 9.0, then add 5 g of collagenase and 5 g of alkaline protease, enzymolysis 1h at 45 ° C, utilize hydrochloric acid to adjust the pH of the enzymolysis solution to 6.0, add 50 g of bromelain, and hydrolyze at 50 ° C After 4 hours of enzymatic hydrolysis, use an ultrafiltration membrane with a molecular weight cut-off of 2000 Daltons to separate, the solution that fails to pass through the ultrafiltration membrane is recovered to the bromelain enzymatic hydrolysis step for continued use, and the filtrate that passes through the ultrafiltration membrane is heated at 90°C Inactivate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com