Patents

Literature

1588 results about "Alkaline protease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkaline protease. A protease works optimally at a pH of 8 to 11. Alkaline proteases are used in washing powders and hair removal from cattle hide, and are produced by bacteria, silkworms and other organisms.

Preparation method for feed without antibiotics

InactiveCN101642186AImprove digestion utilizationLower resistanceFood processingAnimal feeding stuffBiotechnologyCompound organic

The invention provides a preparation method for feed without antibiotics. Feed without antibiotics is complete pig feed without antibiotics, which is prepared from alkali protease and fermenting mixing feed of wholesome funguses and contains the wholesome funguses, a complex enzyme, complex organic acid and other microbe metabolites. The preparation method comprises the preparation steps: weighingthe raw materials of the fermenting feed: corn flour, bean dregs, fermenting bean dregs, fish meal and whey mist which are uniformly mixed; weighing immune polysaccharide, edible salt, calcium hydrophosphate, calcium carbonate, lysine, methionine, various vitamins and various minerals which are uniformly mixed; preparing wine making yeast, alkyl producing pseudofilament yeast, lactobacillus acidophilus, bacillus subtilis and bacillus licheniformis which are uniformly mixed; uniformly mixing all the raw materials and the funguses; adding water to the feed; bagging; sealing; fermenting until nogas is generated; discharging air; sealing again; sealing an outer packing bag and labeling to obtain a finished product. The feed without antibiotics prepared by the method has the advantages of good mouth feel, high nutritious value, easy assimilation and wide market prospect.

Owner:广东希普生物科技股份有限公司

High-purity fishy smell and foreign odor-free fish collagen protein peptide and preparation method thereof

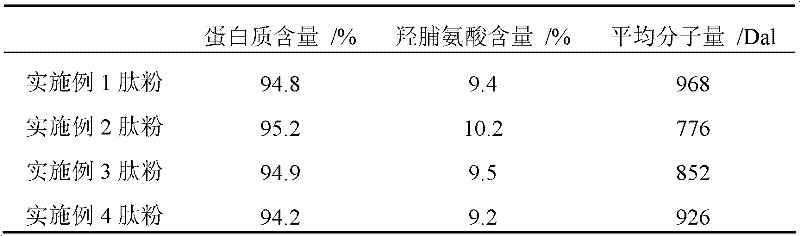

The invention discloses a high-purity fishy smell and foreign odor-free fish collagen protein peptide and a preparation method thereof. The preparation method comprises the following steps: cleaning fish skins, and then cutting into blocks and mincing; performing stirring treatment with NaCl solution; centrifugally degreasing to remove paraprotein; adding water to regulate the pH value of initial slurry to be 8.0-8.5; performing combined gradient enzymolysis on alkali protease and neutral protease; deactivating enzyme after the enzymolysis is ended; performing adsorption bleaching by activated carbon; and then performing rough filtration, fine filtration, evaporation concentration and spray drying to prepare the high-purity fishy smell and foreign odor-free fish collagen protein peptide. The high-purity fishy smell and foreign odor-free fish collagen protein peptide disclosed by the invention has a simple process and is easy to industrial production; fishy smell, foreign odor and non-collagen proteins are fully removed in production; the low-temperature biological enzymolysis technology is adopted, and other substances are not added, thereby, the product quality is improved; an obtained fish collagen protein peptide powder has the characteristics the content of amino acid hydroxyproline is not less than 9 percent, and the average molecular weight is lower than 1000Dal; no fishy smell or foreign odor cannot generated, and obvious fishy smell or foreign odor also cannot be generated through heating treatment under the acid conditions. The high-purity fishy smell and foreign odor-free fish collagen protein peptide can be widely applied to processing of various foods and cosmetics as a green functional ingredient.

Owner:广州合诚实业有限公司

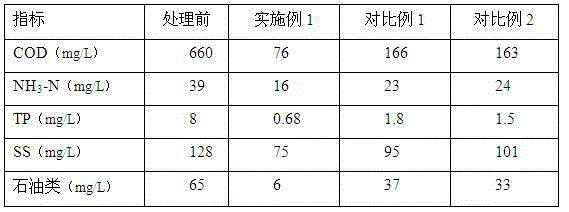

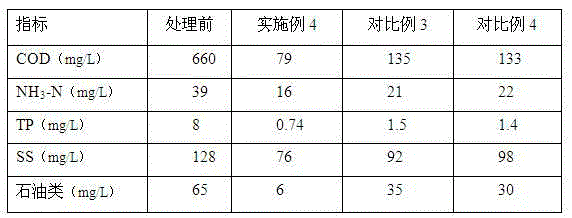

Water purifier for treating production wastewater of rubber accelerator NOBS and wastewater treatment method

ActiveCN104529062AHigh transparencyImprove water purification effectMultistage water/sewage treatmentNature of treatment waterPectinaseDesorption

The invention belongs to the technical field of environmentally water treatment and particularly relates to a water purifier for treating production wastewater of a rubber accelerator NOBS and a wastewater treatment method. The water purifier comprises a flocculating water purifier, a microbial water purifier and an enzyme preparation, wherein the flocculating water purifier consists of polyaluminum ferric chloride, polyacrylamide, ferrous sulfate and aluminum sulfate; the microbial water purifier consists of nitrobacteria powder, paracoccus denitrificans powder, thiobacteria powder, aniline degradation bacteria powder, flocculating bacteria powder, bacillus siliceous powder and bacillus subtilis powder; the enzyme preparation consists of pectinase, cellulose, oxidordeuctase, xylanase, alkaline protease and monoamine oxidase. The water purifier for treating sewage provided by the invention is good in water purification effect, quick in water purification speed, high in safety and free of secondary pollution. By using a material with a desorption capacity as a raw material, sewage is treated by being assisted by microorganisms, so that the water purifier is wide in application range, and the treated water is extremely high in transparency and can be recycled.

Owner:安徽优盾信息科技有限公司

Micromolecule walnut peptide and preparation method thereof

InactiveCN105002247AHigh egg contentLow costPeptide preparation methodsFermentationAlkaline proteaseProtein structure

The invention relates to a micromolecule walnut peptide and a preparation method thereof. The preparation method sequentially comprises the following steps of protein extraction, twice enzymolysis, filtering, purification, concentration and drying. In the twice enzymolysis process, alkaline protease with the mass being 1-3% that of the walnut protein is added into a walnut protein extracting solution for once enzymolysis; enzyme deactivation is performed on a once enzymolysis solution after the once enzymolysis is finished; one or more kinds of proteinase including the flavored proteinase, the neutral proteinase and the papain with the mass being 1-3% that of the walnut protein are added after the once enzymolysis solution obtained after enzyme deactivation is performed is cooled for secondary enzymolysis. According to the preparation method, the twice enzymolysis method is adopted, due to the specificity of the structure of the walnut protein structure, sufficient enzymolysis cannot be performed on the walnut protein through enzymolysis of one proteinase, and the twice enzymolysis method is adopted for ensuring that the enzymolysis is brought into play on the most suitable condition of each proteinase, and therefore the obtained walnut peptide content is high.

Owner:BEIJING TIANTAI BIOTECH

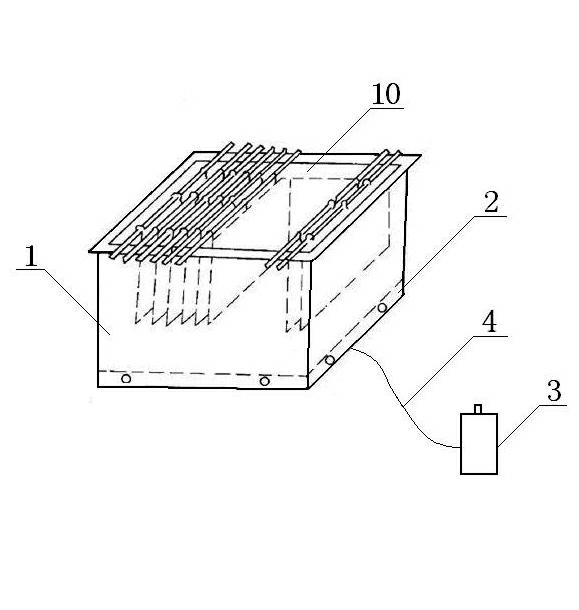

Silk fabric degumming method and apparatus thereof

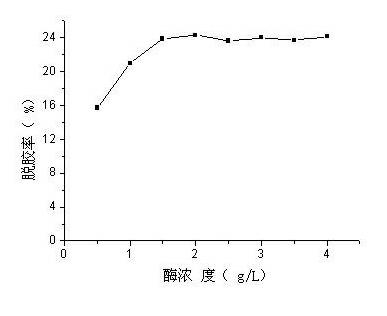

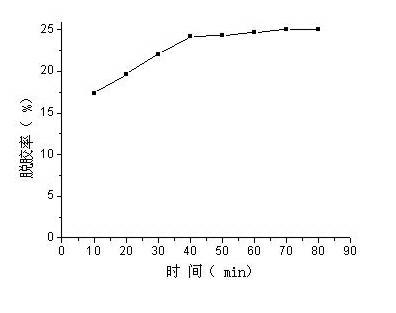

ActiveCN102605439AShort degumming timeImprove degumming efficiencyDe-gumming silkAlkaline proteasePolymer science

The invention discloses a silk fabric degumming method and a silk fabric degumming apparatus. The invention belongs to the technical field of silk degumming. The method is characterized in that the method comprises the steps that: water with a required volume is injected in a degumming tank according to the weight of silk fabric and a bath ratio of 1:40-50; a pH value of the water is regulated to 8.5-9.5; the water is heated to a temperature of 50-60 DEG C; 1.00-2.50g / L of alkali protease is added into the degumming tank; silk fabric is placed into the tank, and supersonic wave is started, wherein the supersonic wave frequency is 30-80KHz; the supersonic wave treatment is performed for 35-60min, and washing is carried out. According to the invention, factors influencing silk fabric degumming are analyzed, and optimal technical values of alkali protease concentration, degumming time, degumming temperature, pH value, and bath ratio are determined. Also, the degumming apparatus is improved, such that silk fabric degumming time is effectively reduced, and silk fabric degumming efficiency is greatly improved.

Owner:SHAOXING UNIVERSITY

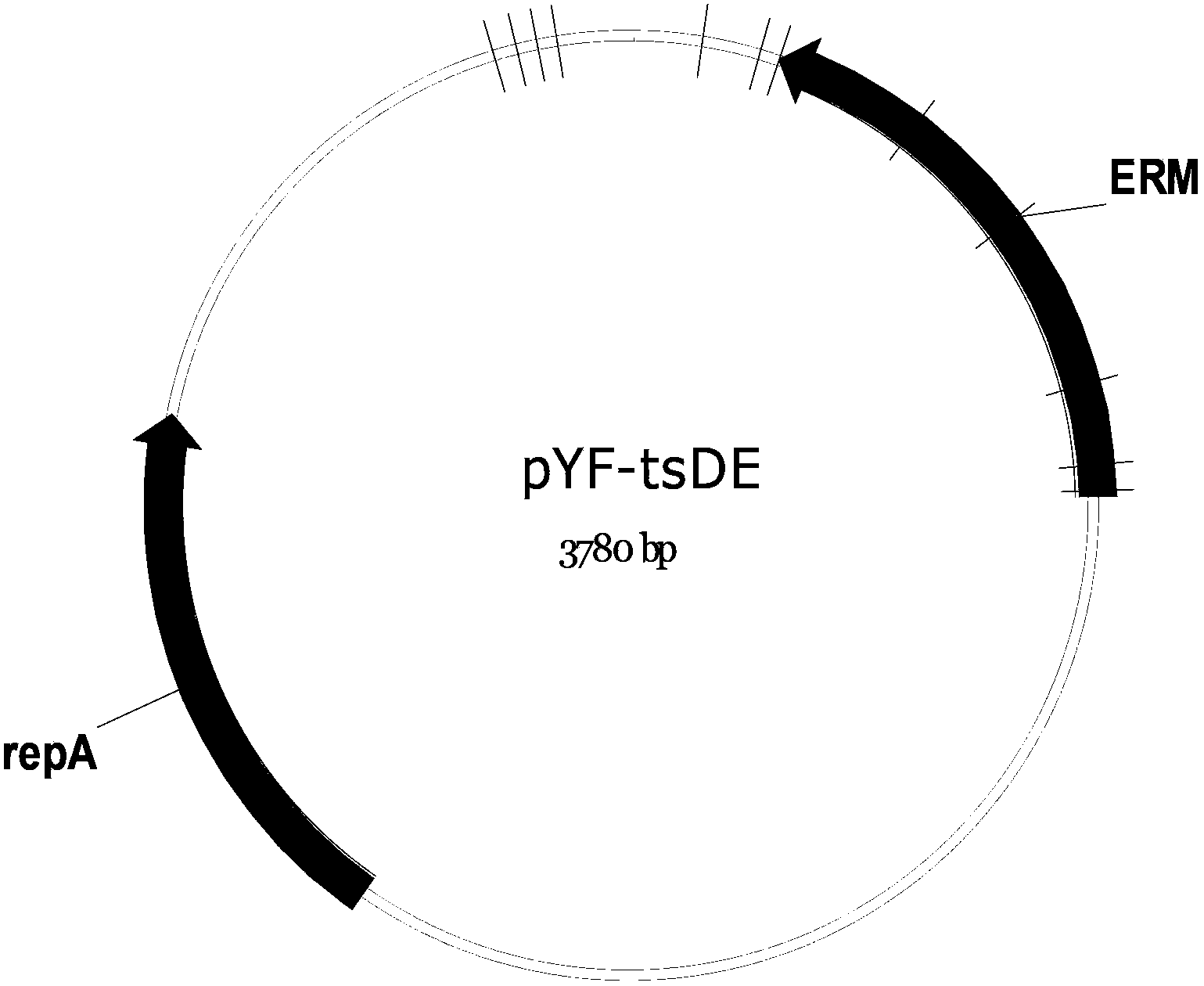

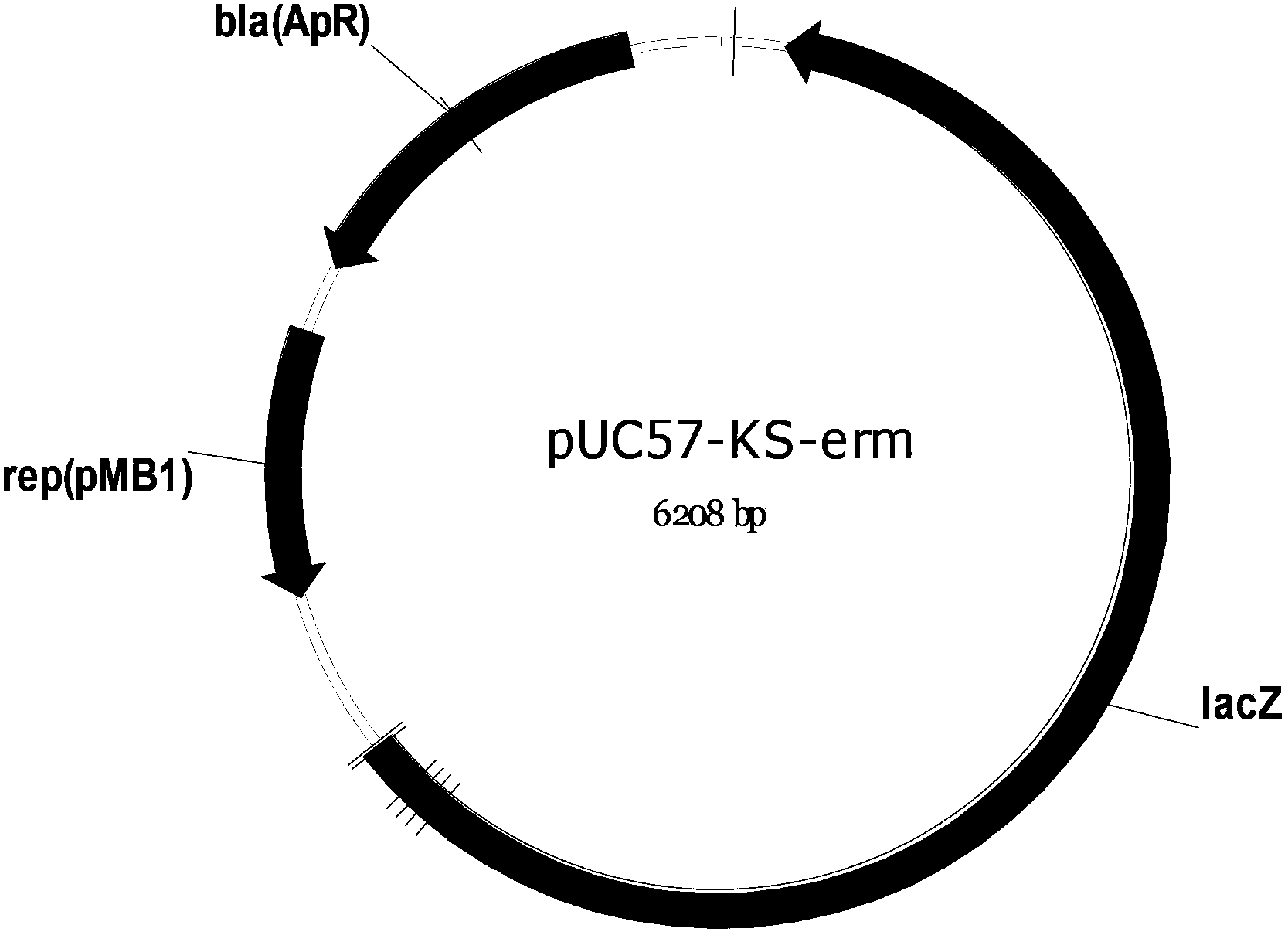

Bacillus subtilis strain capable of efficiently expressing exogenous secretory proteinase

The invention discloses a bacillus subtilis strain capable of efficiently expressing an exogenous secretory proteinase. A bacillus subtilis host bacteria capable of expressing exogenous protein is disclosed. A gene apr of a bacillus subtilis alkaline protease, and a gene npr and a spore forming gene spoIIAC of a bacillus subtilis neutral metalloproteinase are knocked out, wherein the bacillus subtilis alkaline protease and the bacillus subtilis neutral metalloproteinase are two exocrine proteinases in the bacillus subtilis host bacteria. The obtained bacillus subtilis host bacteria can be used for high-yield exogenous proteinases by genetic engineering manners. Based on this, a genetically engineered bacterium secreting pullulanase is constructed and can produce the pullulanase with a high yield. The genetically engineered bacterium secreting has a wide development prospect in industrial production by fermentation industry research.

Owner:NANJING BESTZYME BIO ENG CO LTD

Giant salamander active peptide and application

ActiveCN106047968AImprove immunityPromote proliferationPeptide preparation methodsFermentationFiltration membraneHydrolysate

The invention discloses a giant salamander active peptide and an application. The giant salamander active peptide is prepared by the following steps: conducting enzymatic hydrolysis on giant salamander meat which serves as a raw material by virtue of a complex enzyme of marine alkaline protease and papain; separating an enzymatic hydrolysate by virtue of a trypsin immobilized ultra-filtration membrane separator; and then conducting separation and purification by virtue of Sephadex LH-20 molecular sieve chromatography and high performance liquid chromatography, so that the giant salamander active peptide is obtained. The giant salamander active peptide is capable of effectively scavenging free radicals and boosting body immunity, and meanwhile, the active peptide can also promote proliferation of skin fibroblasts; therefore, the giant salamander active peptide has a broad application prospect in the fields of food, medicines and cosmetics.

Owner:ZHANGJIAJIE JINCHI ANDRIAS DAVIDIANUS BIOLOGICAL SCI

Method for preparing antihypertensive peptide by utilizing combined enzyme enzymolysis silkworm chrysalis protein

The invention relates to the technical field of biological engineering, in particular to a method for preparing antihypertensive peptide by utilizing combined enzyme enzymolysis silkworm chrysalis protein. The method comprises the following steps: dissolving degreased dry silkworm chrysalis powder or silkworm chrysalis protein powder in water in the mass ratio of 1: 7 to 8, adjusting the pH value of the dissolved solution to be 7.5 to 8.5, and then adding combined protease to carry out enzymolysis reaction, wherein the content of alkaline protease is 0.3 to 0.5 percent of the degreased dry silkworm chrysalis powder or the silkworm chrysalis protein powder, the content of papain is 0.05 to 0.1 percent, the content of neutral protease is 0.05 to 0.1 percent, the enzymolysis reaction temperature is 55 to 65 DEG C, and the enzymolysis reaction time is 180 to 240 minutes. The prepared antihypertensive peptide has higher restriction effect on the ACE activity, antihypertensive function on hypertensive patients, does not influence normotensive patients, plays the better health care effect and is safe, has no poison or side effect and is low in cost.

Owner:常州康和生物技术有限公司

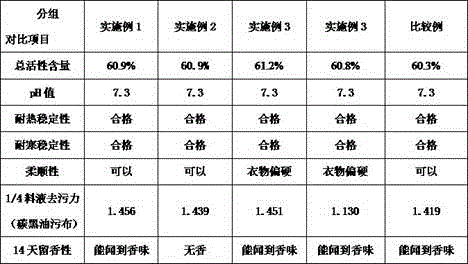

Softening clothes washing condensate ball and preparation method thereof

InactiveCN105779159ASuppresses volatile lossImprove stabilityOrganic detergent compounding agentsNon-ionic surface-active compoundsAlkaline proteaseAlcohol

The invention discloses a softening clothes washing condensate ball and a preparation method thereof.The clothes washing condensate ball is prepared from 25% to 35% of heterogeneous C13 fatty alcohol-polyoxyethylene ether, 10% to 20% of fatty alcohol-polyoxyethylene ether (9EO), 10% to 20% of polyoxyethylene fatty alcohol sodium sulfate, 5% to 10% of fatty alcohol-polyoxyethylene ether (7EO), 1.5% to 2.5% of washing synergist WR, 1.5% to 2.5% of alcohol alkoxylate, 0.8% to 1.5% of cationic softening agent, 0.02% to 0.05% of bactericide, 0.5% to 1.0% of microcapsule essence, 0.01% to 0.03% of alkaline protease and 20% to 38% of solvent (propylene glycol).The softening clothes washing condensate ball has the advantages of being high in fragrance giving performance, safe and convenient to use, good in washing capacity and softening effect and the like.

Owner:福建省金鹿日化股份有限公司

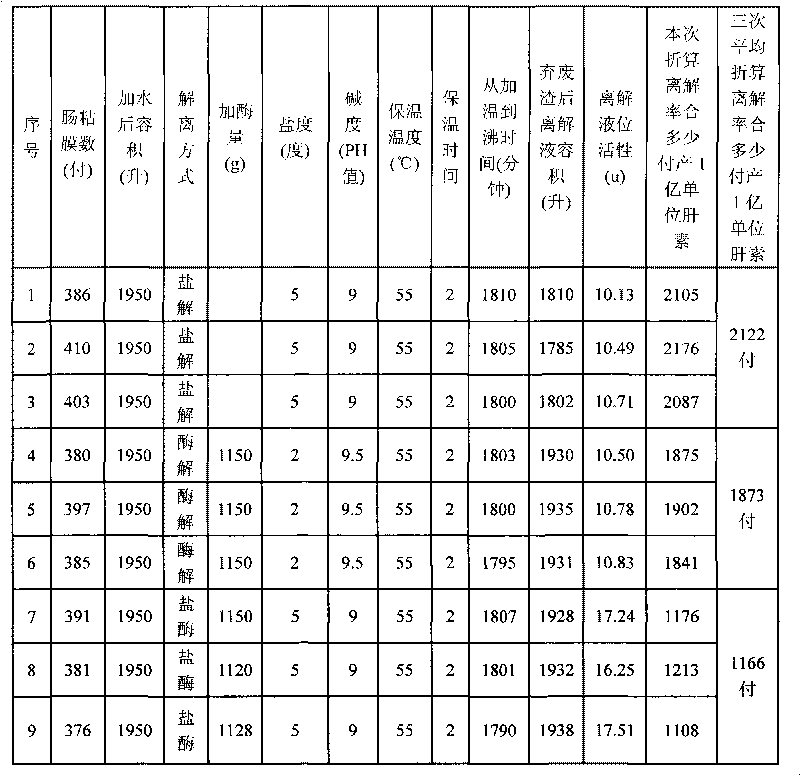

Method for preparing heparin sodium by combining enzymolysis and salt decomposition

The invention relates to a method for preparing heparin sodium by combining enzymolysis and salt decomposition, comprises the following steps: 1) dissociation: according to the weight ratio of 4-5:1 between water and chatterling mucosa, adding the water into the chatterling mucosa, and adding salt to adjust the solution salinity to be 5; adding alkali to adjust the pH value to be 9, and stirring and heating to 55 DEG C; carrying out heat preservation for 30min, and then adding alkali protease 2709 into a reaction tank according to the weight ratio of 2000-3000:1 between the chatterling mucosa and the alkali protease 2709; and carrying out heat preservation for 2h, heating to 85 DEG C and filtering; and 2) absorbing, eluting, precipitating, filtering and drying filtrate obtained in the step 1), and finally obtaining the heparin sodium. By adopting the technique combining enzymolysis and salt decomposition, the method leads heparin to be thoroughly dissociated from the chatterling mucosa, thus completing full extraction. On the basis of the prior art, the method increases about one third of unit production value and controls the increased cost not more than 1% of the increased production value.

Owner:叶青理

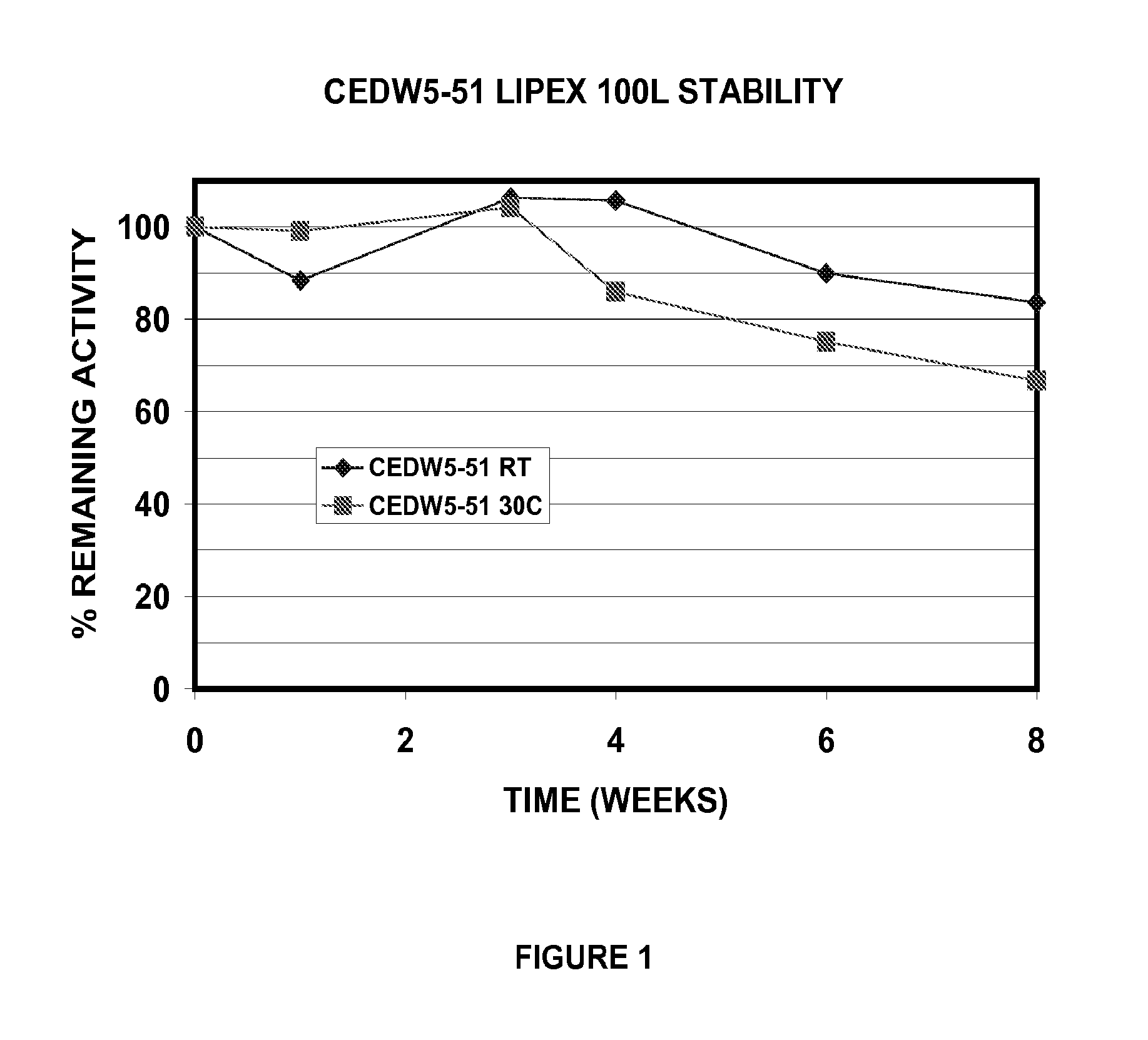

Liquid Detergent Compositions

InactiveUS20110015110A1Organic detergent compounding agentsNon-surface-active detergent compositionsAlkaline proteaseOrganic chemistry

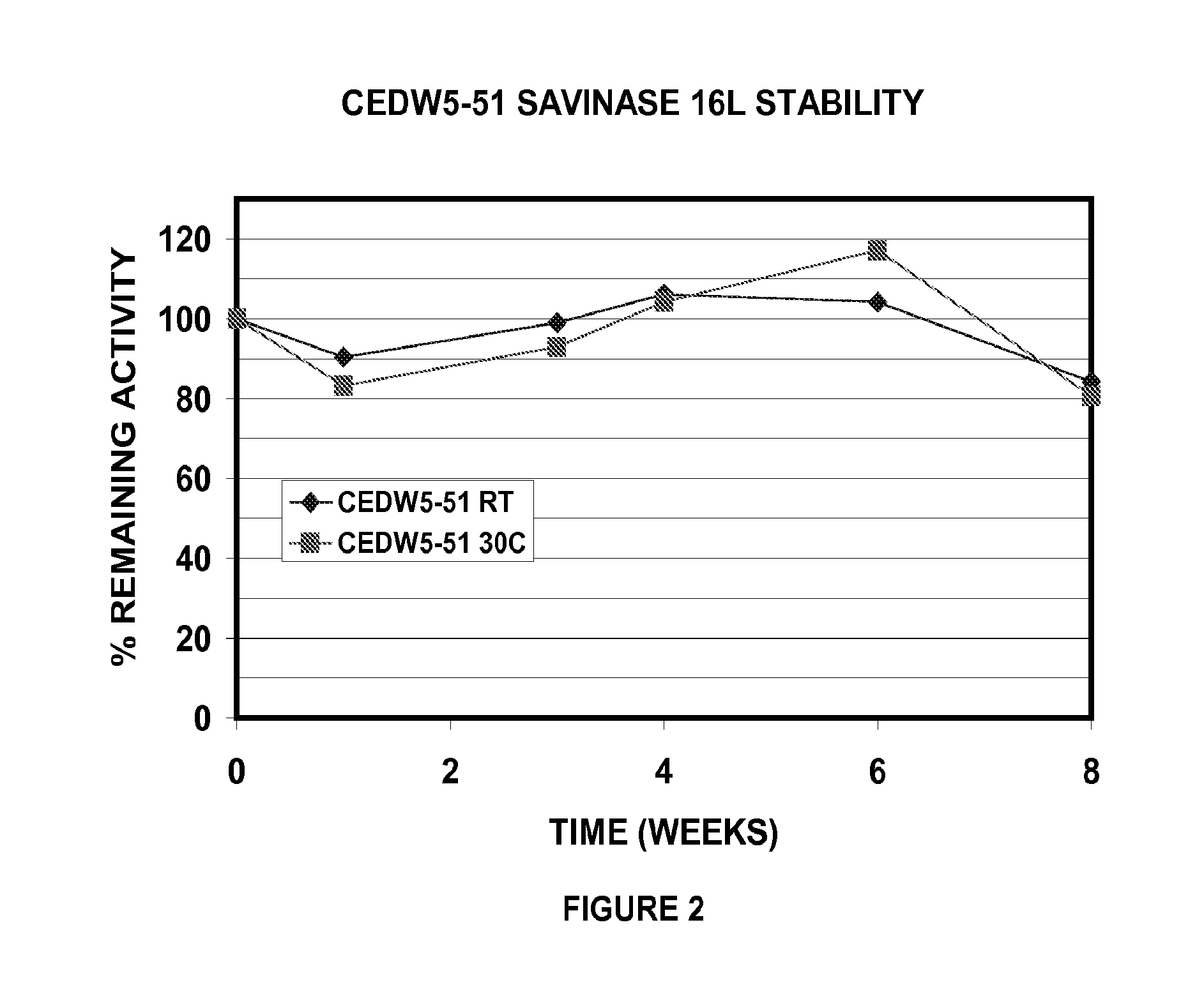

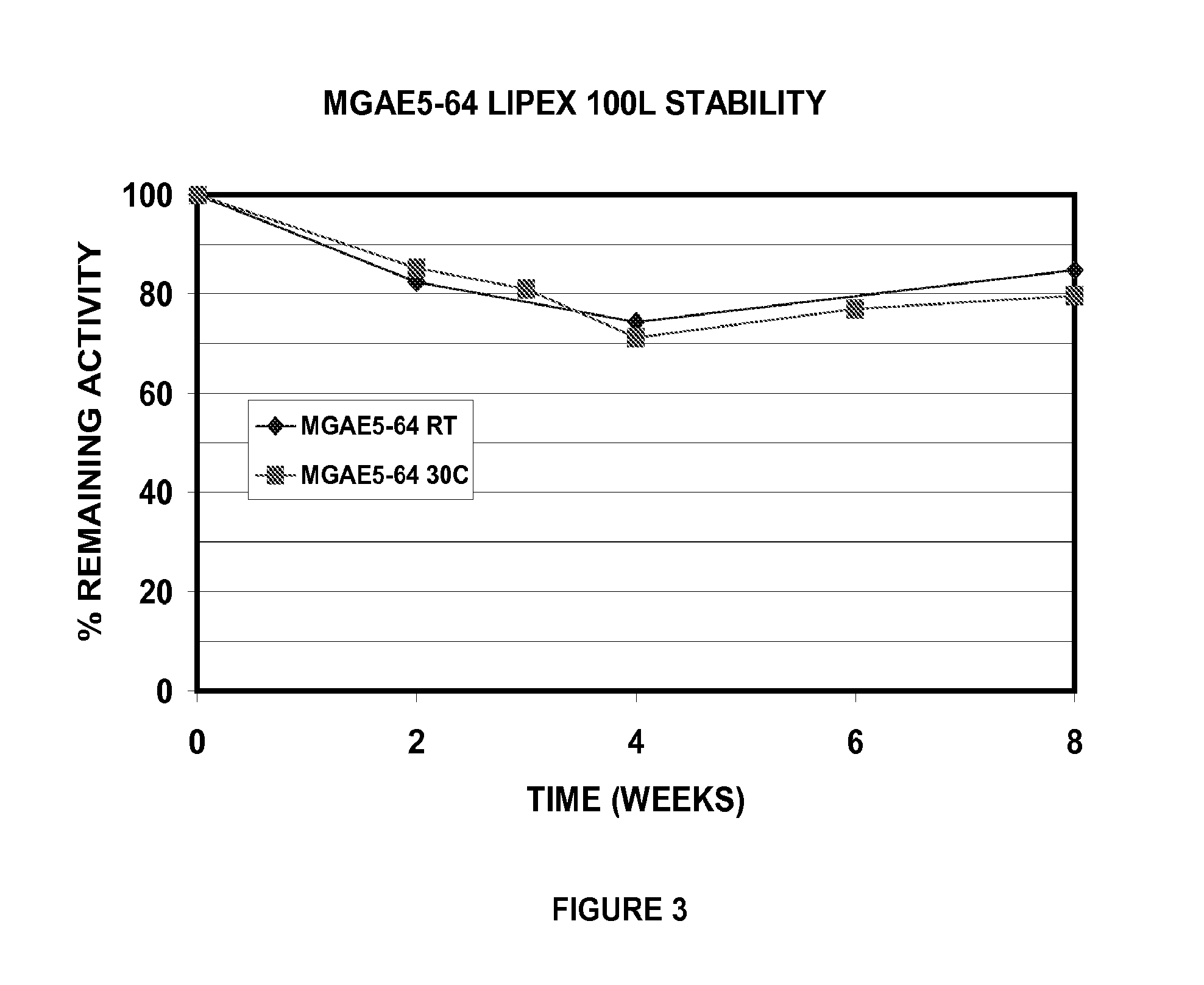

The present invention relates to aqueous liquid detergent compositions comprising an alkaline protease and / or one or more other non-proteolytic enzymes, and an enzyme stabilization system. The invention also relates to enhancing stability of the non-proteolytic enzymes in a liquid detergent composition comprising an alkaline protease.

Owner:NOVOZYMES AS

Machining method of recombined puffed pigskin

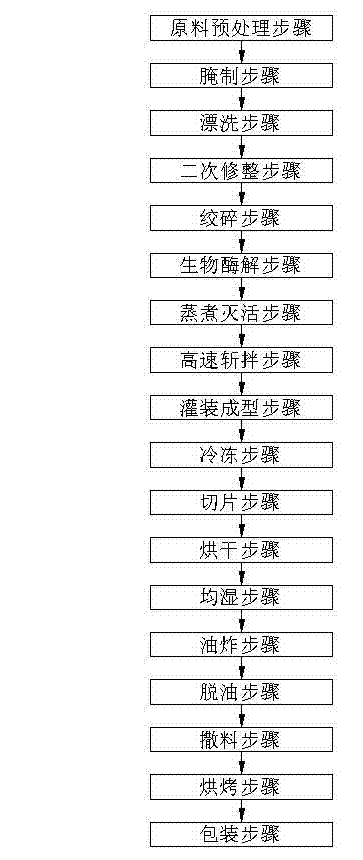

The invention relates to a machining method of recombined puffed pigskin. Currently, a machining method for manufacturing the puffed pigskin by utilizing crushed pigskin leftover materials does not exist. The machining method comprises the following steps of: pre-treating raw materials; pickling; picking in a pickling solution for 10-12 hours, wherein the pickling solution comprises the components of water, sodium hydroxide and potassium phosphate; rinsing; carrying out secondary finishing; crushing; carrying out biological enzymolysis: adding pigskin grains, alkaline protease and saline water into an enzymolysis fermenting pot, agitating uniformly and keeping the pH (Potential of Hydrogen) value of the system to be at 7-8 at a temperature of 40-55 DEG C, and then agitating and carrying out enzymolysis at an interval for 4-6 hours; cooking and inactivating; carrying out high-speed chopping: adding pigskin protein liquid into a chopping and mixing machine when the pigskin protein liquid is hot, and then adding glutamine transaminase, aspartame, I+G, soybean isolated protein, modified starch, mashed potato and water to carry out chopping and mixing; filling and molding; freezing; slicing; and drying. According to the machining method, the crushed pigskin leftover materials can be utilized to manufacture the puffed pigskin with a comfortable mouth feel and a special flavor.

Owner:ZHEJIANG QINGLIAN FOOD

Method for preparing superfine groundnut oil

ActiveCN101433244AThe preparation process conditions are simpleAroma production is easy to controlEdible oils/fatsNeutral proteaseHydrolysate

The invention discloses a method for preparing fragrant peanut oil, which comprises the following steps: 1) a raw material is pretreated, wherein a peanut raw material is selected, is mixed with water, then is soaked, and then is subjected to coarse grinding and fine grinding; 2) complex enzyme is hydrolyzed, wherein the complex enzyme with neutral protease or alkali protease and flavor enzyme is selected to perform hydrolysis on the pretreated peanut raw material; 3) auxiliary materials are added, wherein reducing sugar, amino acid and peanut oil are added into a hydrolysate of the peanut raw material obtained through the treatment in step 2); 4) fragrance is generated through a thermal reaction, wherein the hydrolysate of the peanut raw material and the auxiliary materials are stirred evenly, then are transferred into a high pressure reaction kettle to be heated, and then are cooled to room temperature; and 5) the fragrant peanut oil is prepared, wherein a reaction liquid obtained after the treatment in step 4) is added with refined peanut oil, is quickly stirred first, and then is slowly stirred under certain temperature conditions, and water and impurities are removed through centrifugal separation to obtain the fragrant peanut oil product. The method can obtain flavor precursors of the fragrant peanut oil, namely amino acid and small peptide through the hydrolysis of the peanut raw material by the complex enzyme, and form the peanut oil with peanut fragrance flavor through the heating.

Owner:嘉里特种油脂(上海)有限公司

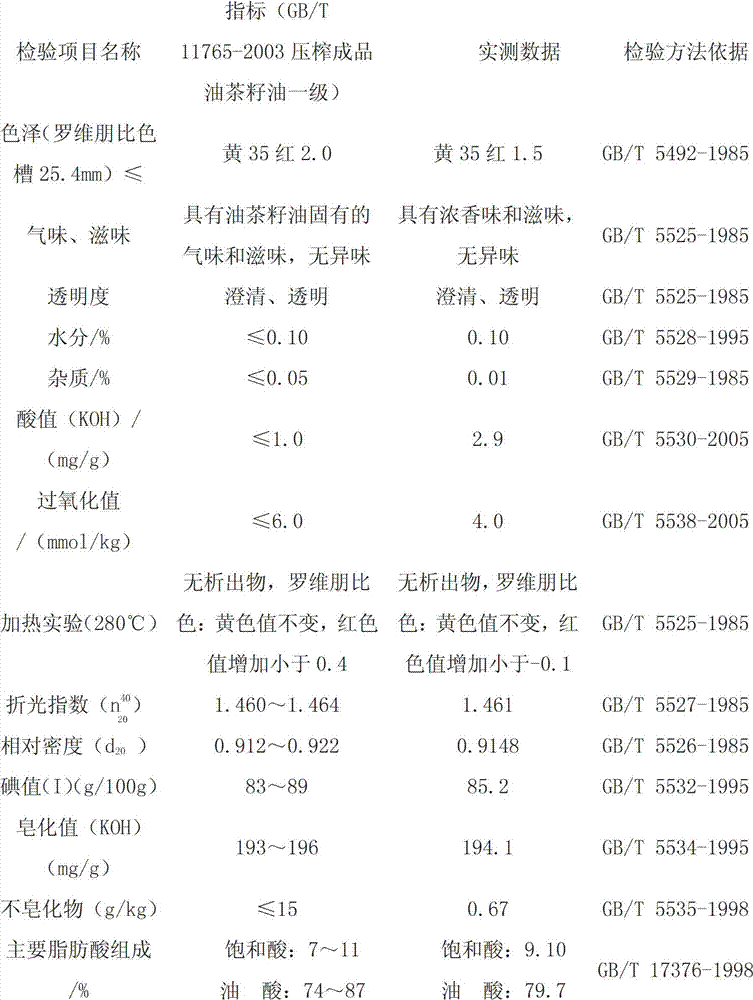

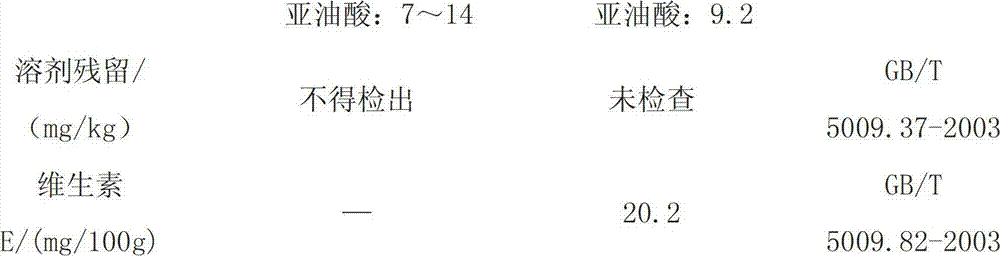

Preparation process for strong-flavor tea-seed oil and prepared strong-flavor tea-seed oil

InactiveCN102952624AStrong fragranceFull of nutritionFatty-oils/fats productionEdible oils/fatsFlavorAlkaline protease

The invention provides a preparation process for strong-flavor tea-seed oil. The preparation process comprises the following steps: firstly, crushing tea-seed dregs; then, adding water of certain volume to be mixed with the crushed tea-seed dregs, adding alkaline protease of certain amount to the mixture to carry out enzymolysis for certain time, carrying out enzyme deactivation to obtain enzymatic hydrolysate, adding leached and refined tea-seed oil to the enzymatic hydrolysate, heating the mixture to 130-145 DEG C, and mixing the mixture for reaction for 30 minutes; and finally, cooling and filtering the mixture to obtain the strong-flavor tea-seed oil. Through detection, the strong-flavor tea-seed oil prepared by the preparation process disclosed by the invention has color and luster of color yellow 30 and color red 2.1, an acid value of 0.4 mg of KOH / kg, and a peroxide value of 7.8 mmol / kg, thus reaching the standard of national first-level edible oil. Moreover, the extraction rate of the tea-seed oil under the condition is 38.71%, which is higher than the extraction rate in the traditional method by 9.85%.

Owner:安徽新世界绿洲茶油有限公司

Preparation of functional feed protein dried porcine saluble

InactiveCN101209082ASolve the current situation of shortageImprove hydrolysis effectAnimal feeding stuffAlkaline proteaseNeutral protease

The invention discloses a method for preparing functionality feed protein intestinal membrane albumen powder, which solves the problems that simultaneous hydrolyzing of multienzyme can affect the hydrolyzing degree and the acquiring rate of the protein peptide, more particularly, the lower acquiring rate of small peptide in the existing intestinal membrane albumen powder preparing technique. The technical scheme includes (1) treating before materials; (2) adding protease to hydrolyze; (3) adding a carrier; (4) preparing through sponging drying; wherein, in the step of hydrolyze the protease, hydrolyzing is carried through on any two of neutral protease, pawpaw protease and alkali protease by adopting a multienzyme grading hydrolyzing method. The functionality feed protein intestinal membrane albumen powder prepared by the method has the obvious advantages in the aspects of the acquiring rate of the protein peptide and the acquiring rate of the small peptide. The invention mixed to feed with other feeds can remarkably improve the performance trait of immature animals.

Owner:WUHAN POLYTECHNIC UNIVERSITY

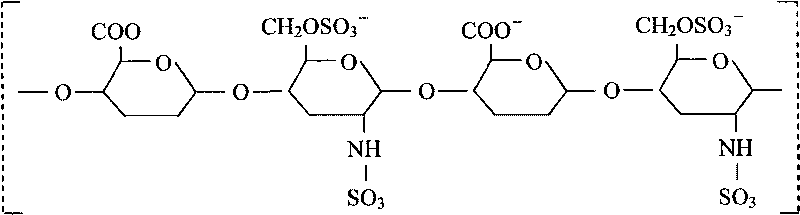

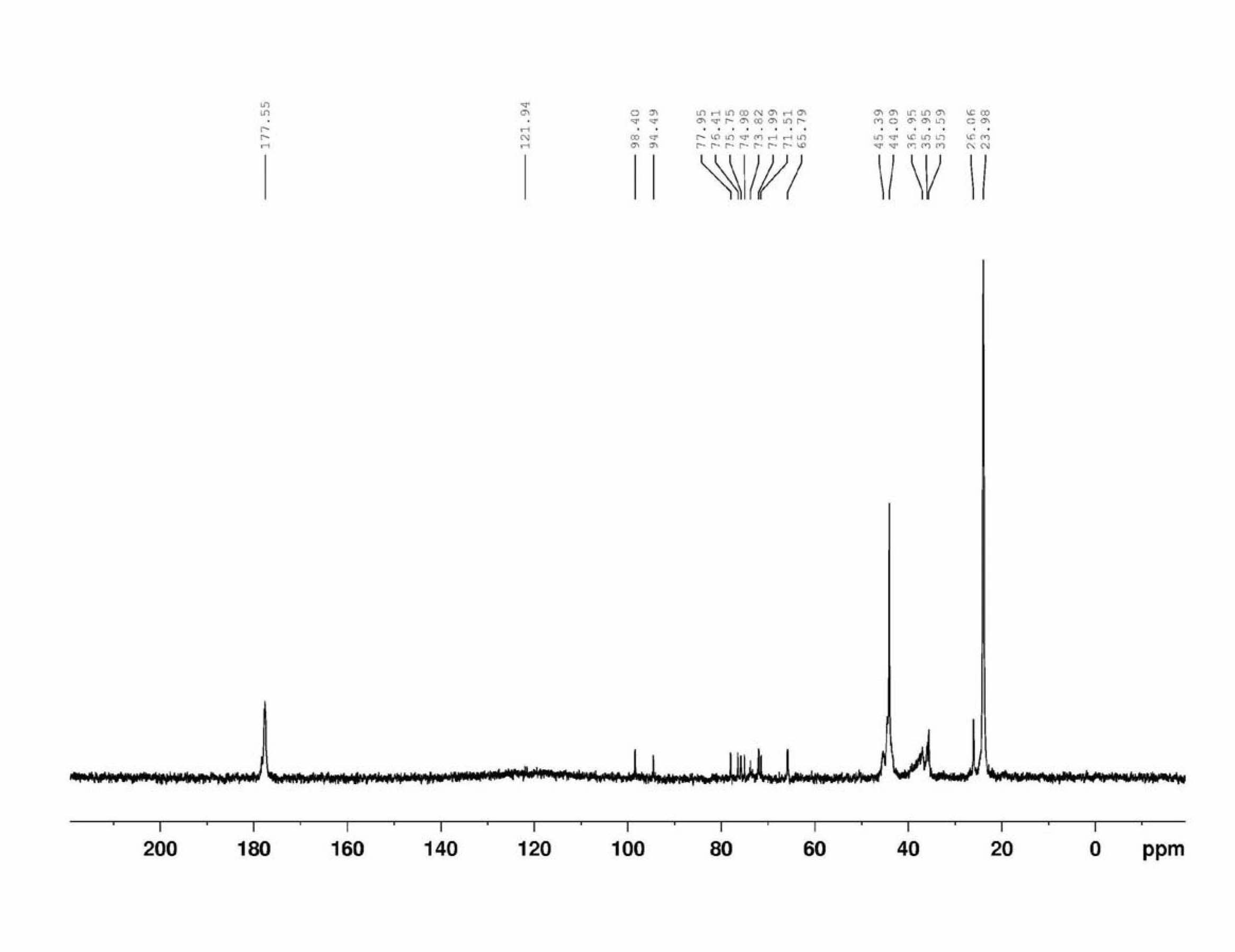

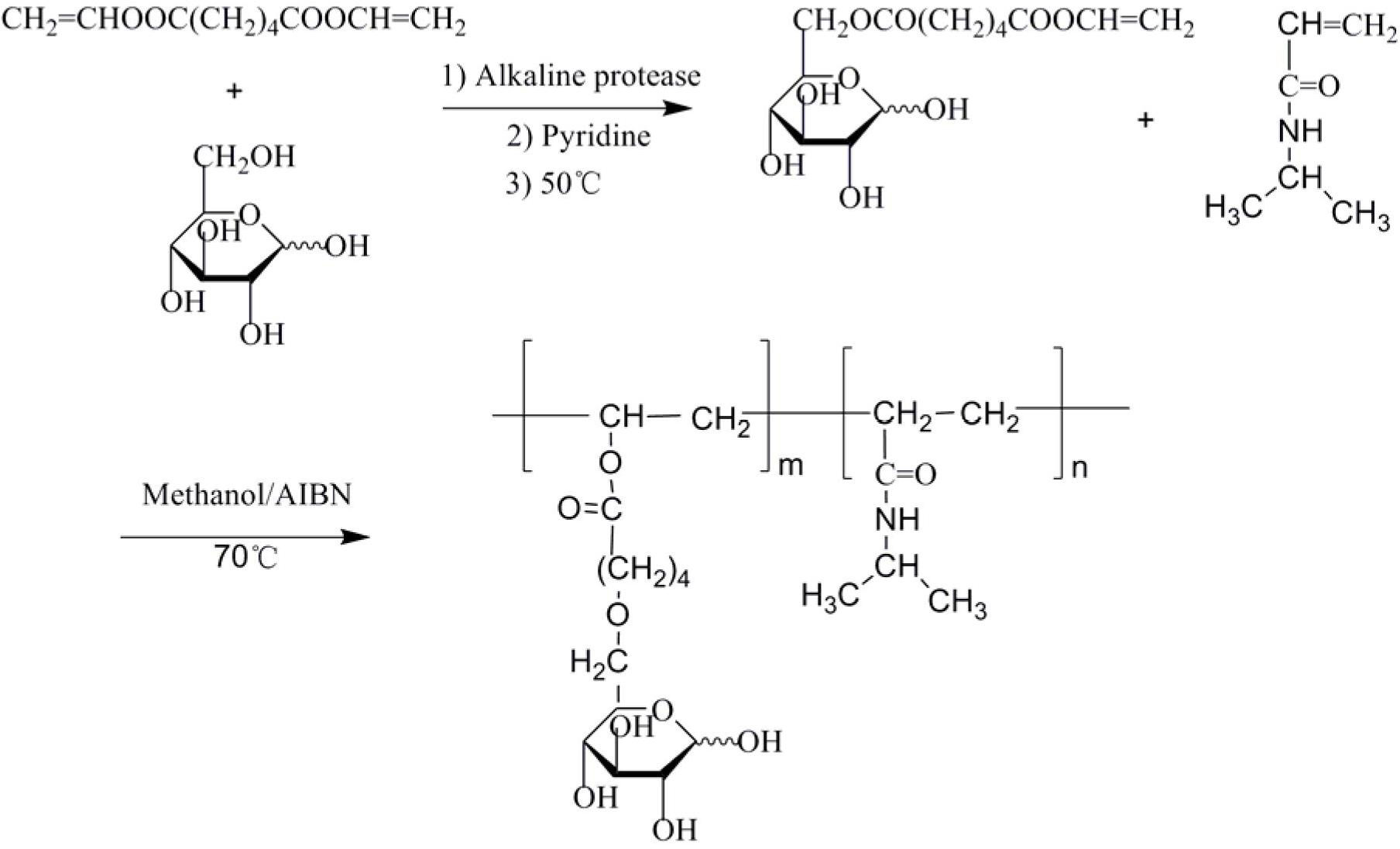

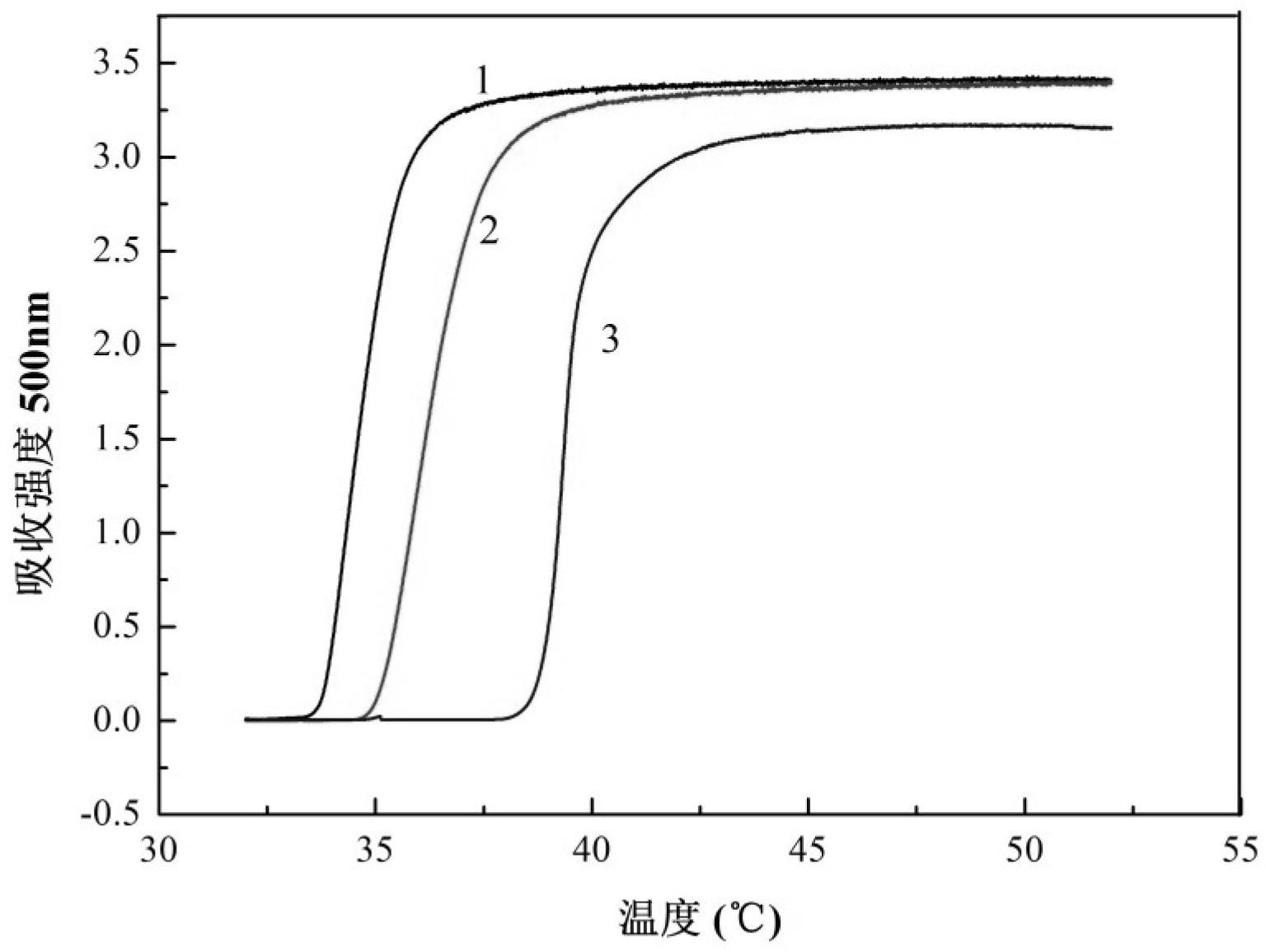

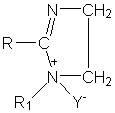

Preparation method of double-hydrophilic temperature response polymer

InactiveCN102659979ARich sourcesLow priceGenetic material ingredientsPharmaceutical non-active ingredientsHydrophilic monomerTemperature response

The invention relates to a preparation method of a double-hydrophilic temperature response polymer. The method comprises the following steps of: (1) preparing aliphatic diacid divinyl ester; (2) dissolving the aliphatic diacid divinyl ester and glucose into an organic solvent, and adding bacillus subtilis alkali protease or lipase AY30 to obtain a polymerizable saccharine hydrophilic monomer; and (3) dissolving the polymerizable saccharine hydrophilic monomer, an N-isopropylacrylamide monomer and an initiator into an organic solvent, performing a polymerization reaction under the protection of nitrogen gas at the temperature of 50-80 DEG C to obtain a polymer, repeatedly precipitating, and performing vacuum drying on an obtained precipitant to obtain the double-hydrophilic temperature response polymer. The method is simple, has mild reaction conditions, is easy, convenient and practicable for operating, and is easy for industrializing; and the obtained double-hydrophilic temperature response polymer can be applied in the fields of medicament targeted conveying, gene delivery, biological separation, membrane science and the like.

Owner:DONGHUA UNIV

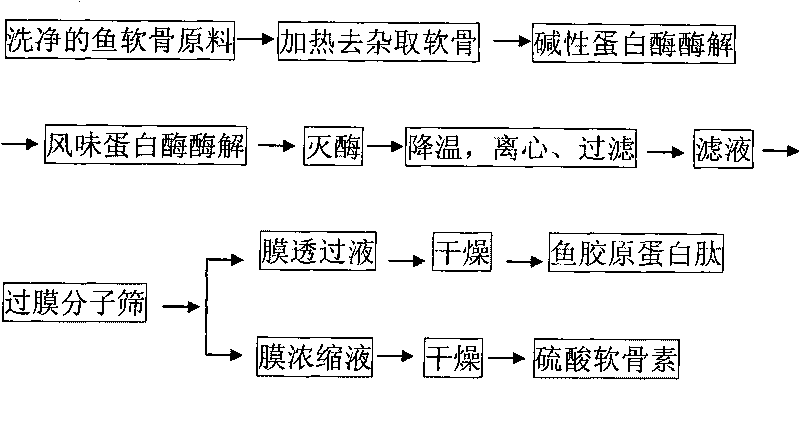

Preparation method of fish cartilage extracts and obtained product

ActiveCN101711591AImprove use valueLow costAnimal proteins working-upFood preparationPollutionImpurity

The invention discloses a preparation method of fish cartilage extracts and an obtained product, comprising the following steps: carrying out alkaline protease enzymolysis on fish cartilage to obtain enzymolysis liquid, carrying out flavorzyme enzymolysis, inactivating enzyme and removing impurities to obtain the fish cartilage extract. The invention overcomes the defects that the existing methodfor producing chondroitine and / or collagen peptide can not fully utilize the raw materials, the product has low effective components, the raw materials are threatened by pollution or the steps are complex and the like. The invention provides the preparation method of fish cartilage extracts and the obtained product. The invention can acquire lacking products in the market by a simple technical process, further improves use value of the raw materials, not only can solve the problem of lacking collagen peptide in the market and chondroitine, but also change waste material into useful things, reasonably and fully utilize natural resources, make the best use of things and reduce environmental pollution; the invention has the advantages of low raw material cost, high product security and highcontent of effective components.

Owner:SHANGHAI HUIWEN BIO TECH

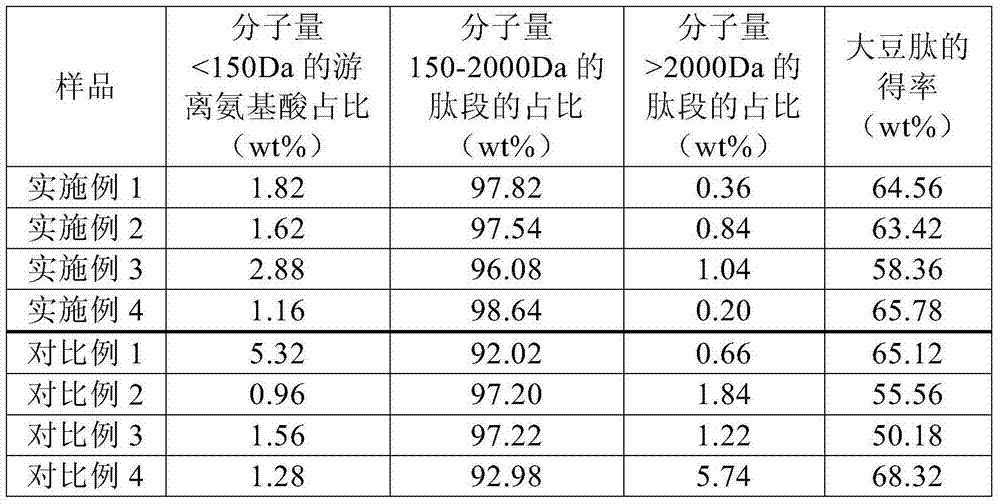

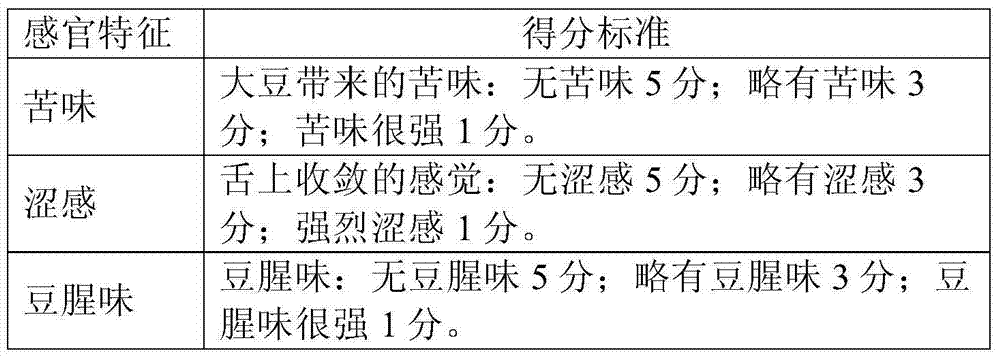

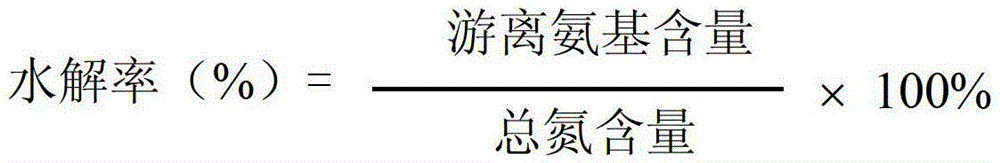

Method for preparing soybean peptides through enzymolysis of soy protein

ActiveCN104719611AReduce bitternessHigh yieldVegetable proteins working-upAlkaline proteaseNeutral proteinase

The present invention relates to a method for preparing soybean peptides through enzymolysis of soy protein, wherein the obtained soybean peptides have characteristics of low bitter taste and high yield, and the contents of free amino acids and the peptides having a molecular weight of less than 150 Da or greater than 2000 Da are low. The method comprises: adding water to soybean protein to prepare a 4-12 wt% soybean separation protein liquid, adjusting the temperature and the pH value, sequentially adding a proper amount of alkaline proteinase adopted as the endopeptidase, neutral proteinase and flavourzyme adopted as the exopeptidase, carrying out an enzymolysis reaction, adjusting the pH value of the enzymolysis liquid, carrying out enzyme inactivation, centrifugating, taking the supernatant, sterilizing, and carrying out spray drying to obtain the soybean peptide.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Preparation method of giant salamander skin collagen peptide

The invention relates to a preparation method of giant salamander skin collagen peptide. The method comprises the steps that degreasing and deodorization are conducted simultaneously on a giant salamander skin, black skin and impure protein are removed through alkali liquor, under the condition that the temperature ranges from 20 DEG C to 25 DEG C and the pressure ranges from 150 MPa to 300 MPa, pressure maintaining is conducted for 10-60 min, pH of the giant salamander skin processed through ultrahigh pressure is regulated to 8-10, alkaline protease with the weight of 2%-3% of the skin is added, at the temperature of 45-50 DEG C, continuous stirring and enzymolysis are conducted for 3-6 hours, the mixture is boiled for 1-2 min and cooled to 40 DEG C, pH of the mixture is regulated to 4-5, activated carbon with the mass of 1% of the mixture is added, and stirring and decoloration are conducted; under the condition that the rotating speed is 3000-4500 r / min, centrifugation is conducted on the processed mixture for 10-15 min, microfiltration through a filter membrane with the thickness of 0.45 micron, ultrafiltration through an ultrafiltration membrane with the molecular weight cut-off of 4-5 kD and nanofiltration through a nanofiltration membrane with the molecular weight cut-off of 2-3 kD are conducted on the mixture in sequence to obtain filter liquor, the filter liquor is concentrated to be one half of an original sample, and the concentrated liquor is freeze-dried and smashed to obtain giant salamander skin collagen powder. According to the preparation method of the giant salamander skin collagen peptide, the molecular weight of the collagen peptide is small, and over 90% of the molecular weight is smaller than 1000 Dalton.

Owner:CHONGQING KUIFENG FOOD CO LTD

Manufacturing process of three germ peptide

InactiveCN102894291AQuality improvementHigh nutritional valueFood preparationNutritive valuesNeutral protease

The invention discloses a manufacturing process of three germ peptide. The manufacturing process belongs to the technical field of food processing. The manufacturing process comprises the following steps of: mixing wheat germ, corn germ and rice germ in proportion to conduct micro-grinding screening, mixing and heating mixture with distilled water in proportion, adding cellulose to conduct a first enzymolysis, adjusting a pH value and a temperature, adding alkaline protease to conduct a second enzymolysis, adjusting the pH value and the temperature, adding neutral protease to conduct a third enzymolysis, adjusting the pH value and the temperature, adding flavour enzyme to conduct a fourth enzymolysis, then adjusting the pH value and the temperature to conduct enzyme inactivation, adding maltodextrin, and finally conducting homogeneity drying to obtain the three germ peptide. The manufacturing process has the beneficial effects that the wheat germ, the corn germ and the rice germ serve as raw materials, four times of biology enzymolysis techniques are used for conducting enzymolysis on celluloses containing in three germ into minuteness celluloses, polysaccharide and oligosaccharide and conducting enzymolysis on proteins into polypeptide, small peptide and functional oligopeptides, and the three germ peptide with good quality and a high nutritive value is obtained.

Owner:JIANGSU MAIKAILE BIOLOGICAL TECH

Method for extracting rice protein powder by utilizing enzyme-alkali method

The invention provides a method for extracting rice protein powder by utilizing enzyme-alkali method. The method in the invention takes rice residue as raw materials and comprises the following steps: washing with water, eliminating sugar, carrying out milling refining on the colloid, eliminating residue starch by utilizing starch enzyme, pre-extracting alkali protease, adding alkali for extraction, centrifuging and taking the supernate to mix to neutrality, inactivating enzymes and sterilizing, and spraying and drying to obtain the rice protein powder. The rice protein powder produced by utilizing the process has faint yellow color, delicate taste and good solubility, and can be maintained well from physicochemical function. The invention has simple process, few investment device, high yield and purity of products, good solubility, and easily-controlled product quality, is suitable for practice popularization and provides a new route for the extraction of rice protein.

Owner:长沙湘博医药科技有限公司

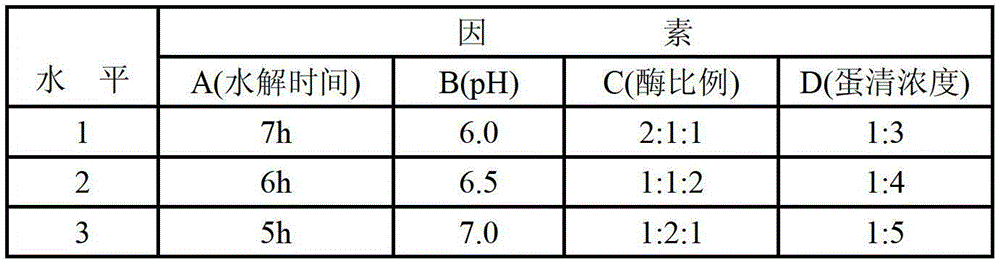

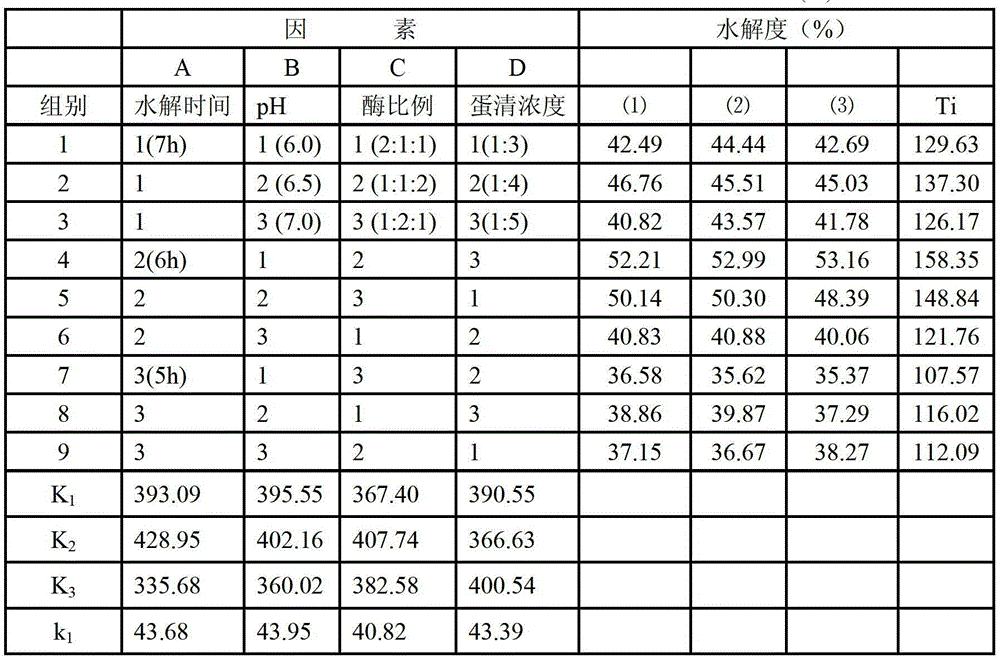

Method for hydrolyzing egg-white proteins by various proteases

InactiveCN103146791AHigh yieldIncrease the degree of hydrolysisFermentationAlkaline proteaseNeutral protease

The invention belongs to the field of food processing, and relates to a method for hydrolyzing egg-white proteins by various proteases. The method comprises the following steps of: first, heating obtained egg white to degenerate; and then, hydrolyzing egg-white proteins simultaneously or in stages by using two or more of compound protease, neutral protease, alkaline protease and flavourzyme. According to the invention, different enzymes are combined in use and compensate one another in enzyme acting sites, so that the degree of hydrolysis is improved, and the yield of egg-white protein peptide is increased.

Owner:YANGZHOU UNIV

Method for improving enzymolysis efficiency of crude heparin sodium extraction technology

The invention relates to a method for improving enzymolysis efficiency of a crude heparin sodium extraction technology. The method can effectively improve enzymolysis efficiency, decompose impurity proteins, improve crude product quality, improve a yield and increase economic benefits. The method comprises the following steps of 1, dissolution: preparing mucous membrane water, 2, acid protease catalysis: heating the mucous membrane water, adding acid protease into the mucous membrane water based on the number of small intestines of the pig, adjusting a pH, adding metal ions into the mixed solution based on the number of small intestines of the pig, adjusting salinity by sodium chloride, and carrying out a thermal insulation reaction process, 3, alkaline protease catalysis: carrying out heating, adding two alkaline proteases into the reaction produce based on the number of small intestines of the pig, adding a pH value and salinity, carrying out a thermal insulation reaction process, carrying out heating and carrying out a thermal insulation reaction process, and 4, filtration on the enzymolysis mother liquor by a combined filter cloth, introduction of the filtered enzymolysis mother liquor into an adsorption tank, and follow-up processes.

Owner:杭州惠顺生物科技有限公司

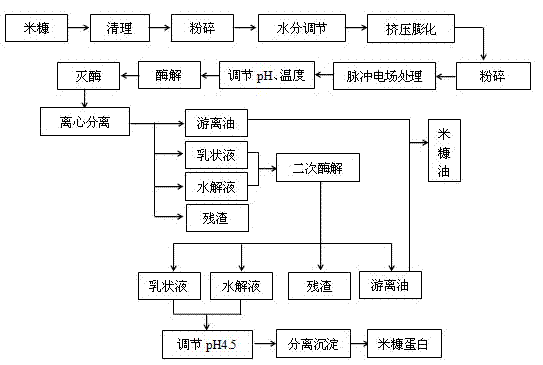

Method for synchronously preparing high-stability rice bran oil and rice bran protein

The invention relates to a method for synchronously preparing high-stability rice bran oil and rice bran protein, and belongs to a vegetable oil and protein extraction processing technology. The method comprises the steps of (1) grinding rice bran and then carrying out extrusion processing to obtain an expanded product; (2) mixing the ground expanded product with water to obtain a mixed liquid, and treating the mixed liquid by using a pulsed electric field; (3) adding alkaline protease into the mixed liquid which is treated by using the pulsed electric field, and carrying out enzymolysis to obtain enzymatic hydrolysate; carrying out enzyme deactivation on the enzymatic hydrolysate, and then carrying out centrifugal separation to obtain free oil, an emulsion, the hydrolysate and residue; separating the free oil, and standing still to obtain the rice bran oil; (4) collecting the hydrolysate and the emulsion, adding neutral protease into the collected hydrolysate and emulsion, carrying out secondary enzymolysis and centrifugal separation, and freeze-drying to obtain the rice bran protein. The method is simple in required processing equipment, low in cost and high in rice bran oil extraction rate, and the high-quality rice bran protein can be obtained at the same time.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

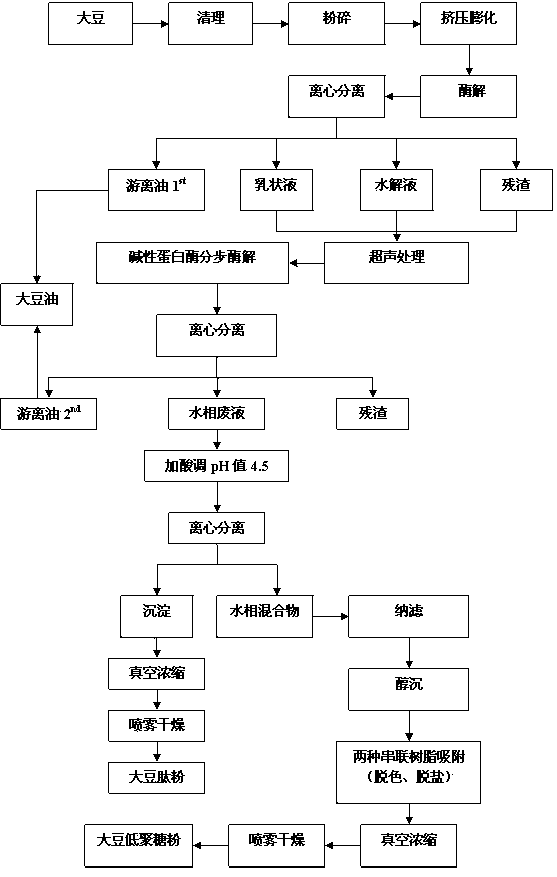

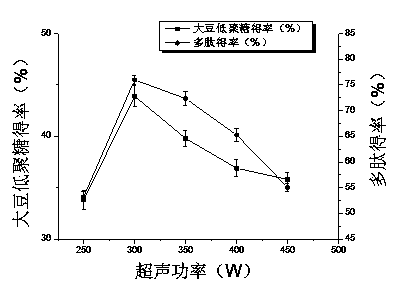

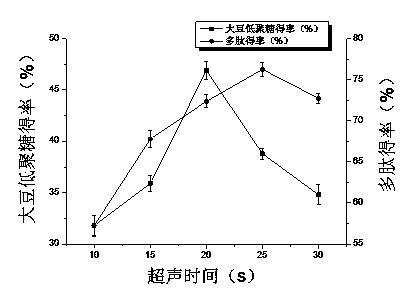

Method for simultaneously extracting soybean peptide and soybean oligosaccharide from aqueous phase produced through aqueous enzymatic method

ActiveCN103589766AFacilitated releaseHigh yieldFermentationFatty-oils/fats productionHydrolysateEthanol precipitation

The invention discloses a method for simultaneously extracting soybean peptide and soybean oligosaccharide from an aqueous phase produced through the aqueous enzymatic method and belongs to the technology of gain and oil bioprocessing. The method comprises the following steps: (1) soybeans are extruded and puffed, and then mixed with water for enzymolysis, and centrifugal separation is performed after enzymolysis, so that free oil, an emulsion, a hydrolysate and residues are obtained; (2) the emulsion, the hydrolysate and the residues are subjected to ultrasonic treatment to obtain a mixed liquor, two types of alkaline protease are added into the mixed liquor for step-by-step enzymolysis, centrifugal separation is performed after enzymolysis, so that free oil, an aqueous phase waste liquor and residues are obtained; (3) the acid deposition is performed on the aqueous phase waste liquor and then centrifugal separation is performed on the aqueous phase waste liquor to obtain sediment and aqueous phase mixture, and the sediment is subjected to vacuum concentration and spray drying to obtain soybean peptide; nanofiltration and ethanol precipitation are performed on the aqueous phase mixture to obtain sediment, and the sediment is subjected to decolorization and desalination treatment, and then subjected to vacuum concentration and spray drying to obtain the soybean oligosaccharide. According to the method, the aqueous phase mixed system formed during oil production through the aqueous enzymatic method is fully utilized, so that the waste is reduced, and the soybean peptide and the soybean oligosaccharide can be simultaneously obtained; the method has an excellent application prospect.

Owner:SHANDONG WONDERFUL IND GROUP

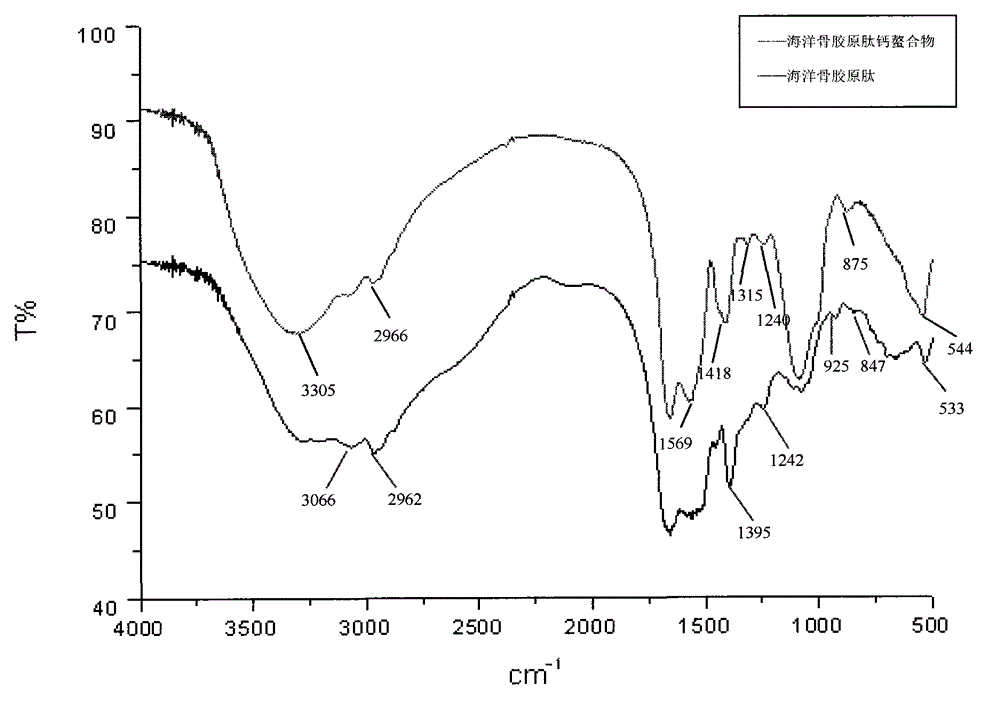

Preparation method of oceanic ossein peptide calcium chelate biological calcium supplement

ActiveCN102871121ASource securityPromote absorptionFood preparationAlkaline proteaseAnhydrous ethanol

A preparation method of an oceanic ossein peptide calcium chelate biological calcium supplement includes the steps of enzymolysis, chelation and precipitation. Enzymolysis includes adding alkaline protease in fish bones for enzymolysis, and adding papain for enzymolysis to obtain ossein peptide. Chelation includes adding calcium source into ossein peptide solution for chelation reaction. Precipitation includes precipitating chelation liquid with anhydrous ethanol to obtain oceanic ossein peptide calcium chelate. Waste fish bones of oceanic fish product processing are used as raw material to prepare faint yellow powdered fish ossein peptide without fishy smell, and the fish ossein peptide is chelated with calcium chloride. The oceanic ossein peptide calcium chelate is dissolved into faint yellow liquid under meta-acid conditions. Structural identification of the chelate with Fourier transform infrared spectrum shows that calcium ions are combined with -COOH and amino in polypeptide to form coordinate bonds, and accordingly a novel oceanic ossein peptide calcium chelate is generated. Waste fish bones of oceanic fish product processing are used as raw material to prepare ossein peptide, resources are fully utilized, raw material is safe and nontoxic, no harmful substances are participated and generated in the preparation, process is simple, cost is low, and the oceanic ossein peptide calcium chelate is applicable to preparation of health care products and drugs for calcium supplement.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Color silk floss quilt and preparation method thereof

ActiveCN102127862AAvoid churnHas antibacterial effectBiochemical fibre treatmentBed-coversAlkaline proteaseQuality standard

The invention discloses a method for preparing a color silk floss quilt, which comprises the following steps of: (1) blanking color silkworm cocoons into a silk floss machine, spraying by using spray solution and making silk floss slices, wherein the spray solution is mixed solution of sodium hydroxide and an expanding agent; (2) refining and degumming the obtained silk floss slices in alkaline-protease-containing degumming solution at the temperature of between 35 and 45 DEG C in a bath ratio of 1:30-50 for 80 to 120 minutes, wherein the using amount of alkaline protease is 35 to 60 activityunits per millimeter; (3) heating the degumming solution to the temperature of higher than 95 DEG C, and keeping for 45 to 60 minutes to inactivate the alkaline protease; and (4) washing, performing aftertreatment, dehydrating, drying, manually garnetting and making the color silk floss quilt according to the conventional method. The preparation method can effectively prevent pigments in the color silkworm cocoons from being lost; and the obtained color silk floss quilt can meet the quality standard of high-class products and has an antibacterial effect.

Owner:NANTONG LOVER APPL

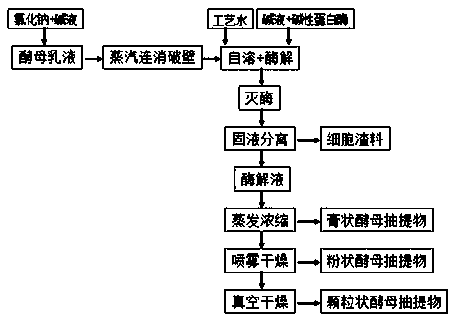

Method of breaking yeast cell wall and preparing yeast extract

InactiveCN104161259ARich sourcesAchieve dissolutionFood ingredientsFood preparationAlkaline proteaseYeast cell extract

The invention relates to a method of breaking yeast cell wall and preparing a yeast extract. Yeast emulsion is used as the raw material, sodium chloride is added into the yeast emulsion, the pH value of the yeast emulsion is regulated, so that the diluted yeast cell solution becomes basic or weakly basic, the yeast cell wall is broken through steam jet continuous sterilization, the wall-broken yeast cell solution is diluted with water to proper temperature and concentration, the pH value of the diluted yeast cell solution is regulated, so that the diluted yeast cell solution becomes basic or weakly basic, and alkaline protease is added into the yeast cell solution to perform autolysis and enzymolysis. The yeast cell solution is subjected to enzyme deactivation, centrifugal separation, evaporation and concentration and blending, so as to produce the yeast extract. The yeast emulsion is used as the raw material, the drying energy consumption of yeast cells is reduced, sodium chloride as the plasmolysis additive is added, in the basic or weakly basic condition, the common wall breaking action of the steam jet continuous sterilization is performed, so that the wall-breaking effect of the yeast cells is good, the dissolution rate of proteins is high, the protease easily acts, the alkaline protease is added, and thus the yield of the hydrolyzed protein and free amino nitrogen is high. The all-breaking rate of the yeast cells is obviously increased, and the content of total nitrogen and amino state nitrogen in the yeast extract is increased.

Owner:GUANGXI XIANGGUI BIOTECH CO LTD

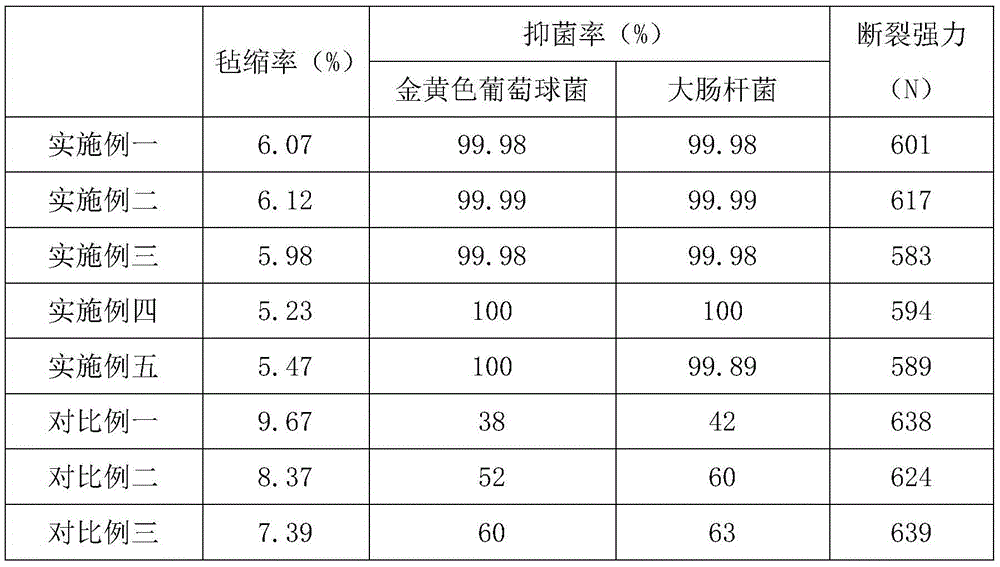

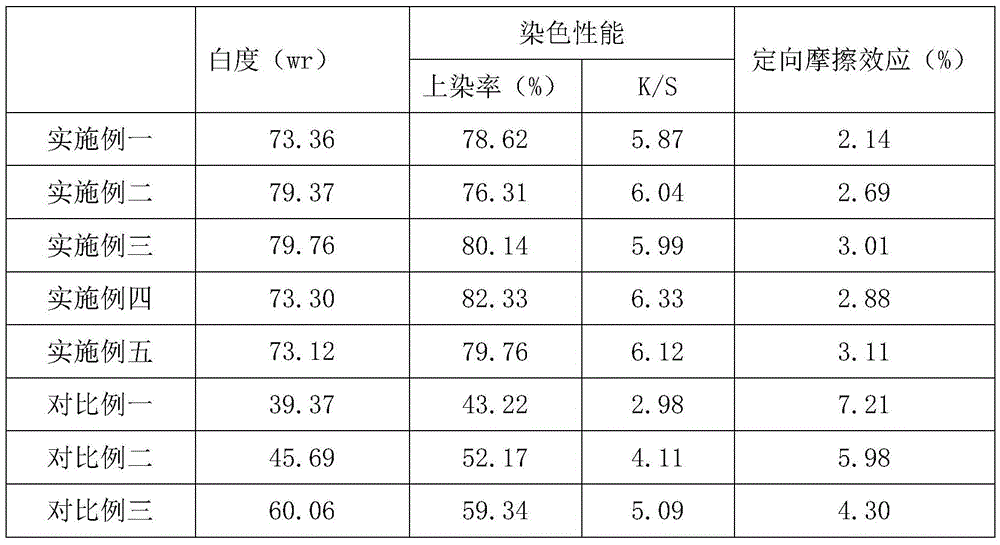

Antibacterial and anti-felting wool fabric finishing method

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

Preparation process of sesame oil with strong flavor

InactiveCN103666744AReduce manufacturing costReduce labor intensityFatty-oils/fats productionBiotechnologyMaillard reaction

The invention provides a preparation process of sesame oil with strong flavor. The sesame oil with strong flavor is prepared via a Maillard reaction. The process comprises the following steps: smashing high-temperature sesame cakes; adding water for dissolving, and mixing; adding alkaline protease for performing enzymolysis; deactivating the enzymatic hydrolysate; mixing the enzymatic hydrolysate with refined sesame oil; heating to 130-150 DEG C; making amino acid in sesame undergo the Maillard reaction with reducing sugar generate a substance with strong flavor; after finishing the reaction, cooling, centrifuging and filtering to obtain the sesame oil with strong flavor. The obtained sesame oil has the advantages of strong flavor, good product quality, low process cost, high yield and easiness in popularizing.

Owner:湖北长坂雄风植物油股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com