Patents

Literature

112results about How to "Improve degumming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silk fabric degumming method and apparatus thereof

ActiveCN102605439AShort degumming timeImprove degumming efficiencyDe-gumming silkAlkaline proteasePolymer science

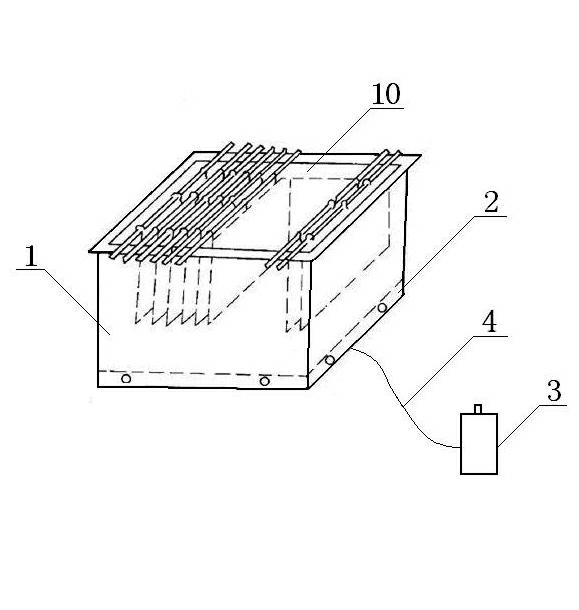

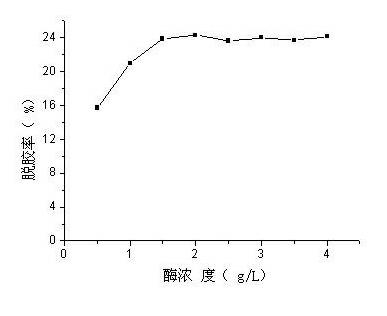

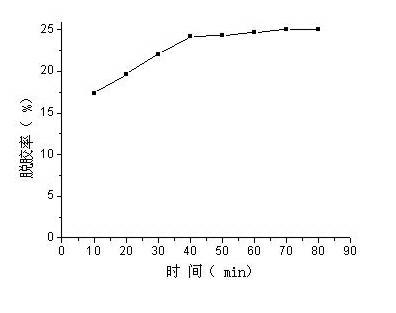

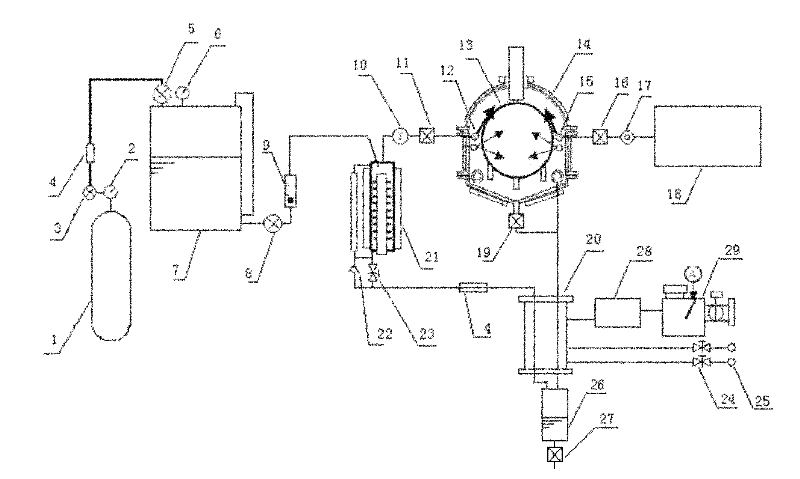

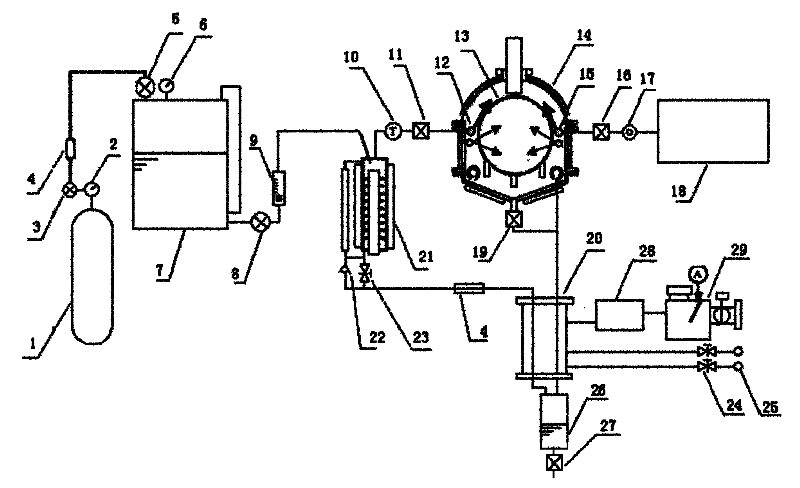

The invention discloses a silk fabric degumming method and a silk fabric degumming apparatus. The invention belongs to the technical field of silk degumming. The method is characterized in that the method comprises the steps that: water with a required volume is injected in a degumming tank according to the weight of silk fabric and a bath ratio of 1:40-50; a pH value of the water is regulated to 8.5-9.5; the water is heated to a temperature of 50-60 DEG C; 1.00-2.50g / L of alkali protease is added into the degumming tank; silk fabric is placed into the tank, and supersonic wave is started, wherein the supersonic wave frequency is 30-80KHz; the supersonic wave treatment is performed for 35-60min, and washing is carried out. According to the invention, factors influencing silk fabric degumming are analyzed, and optimal technical values of alkali protease concentration, degumming time, degumming temperature, pH value, and bath ratio are determined. Also, the degumming apparatus is improved, such that silk fabric degumming time is effectively reduced, and silk fabric degumming efficiency is greatly improved.

Owner:SHAOXING UNIVERSITY

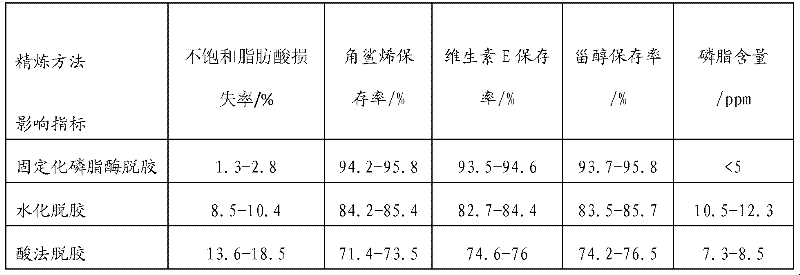

Refining crude oil of soybean by immobilized phospholipase

InactiveCN101092587AIncrease vitalityImprove stabilityFatty-oils/fats refiningFermentationPhospholipaseSoybean oil

This invention relates to a method for refining crude soybean oil with immobilized phosphatidase. The method solves the problems of unable control of temperature and pH value, poor degumming effect of soybean oil, and high cost faced by the present enzyme degumming method. The method in this invention comprises: preparing the reactive solution, preparing a mixed solution, preparing granular immobilized phosphatidase, pre-treating crude soybean oil, adding immobilized phosphatidase into crude soybean oil, stirring and centrifuging. The method has such advantages as high degumming efficiency (increased by 0.5-2%) and low cost (decreased by 1-3%).

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

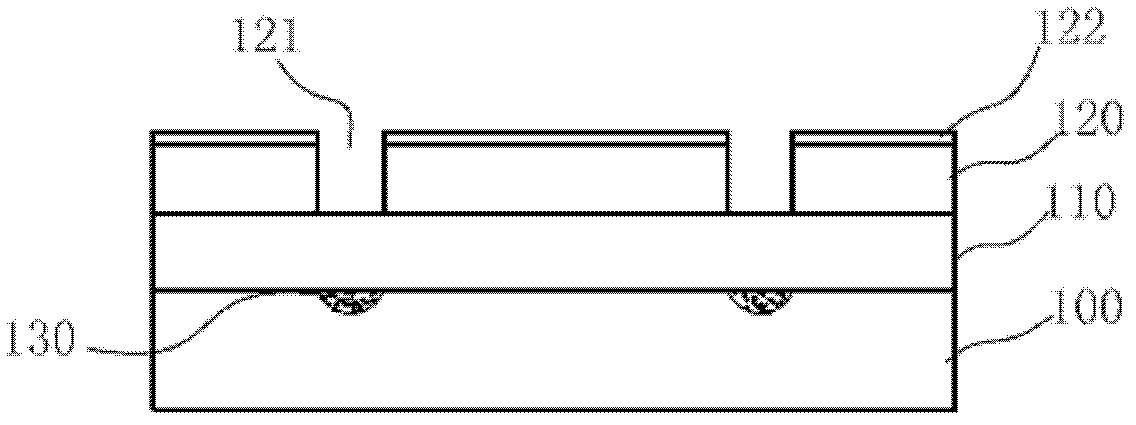

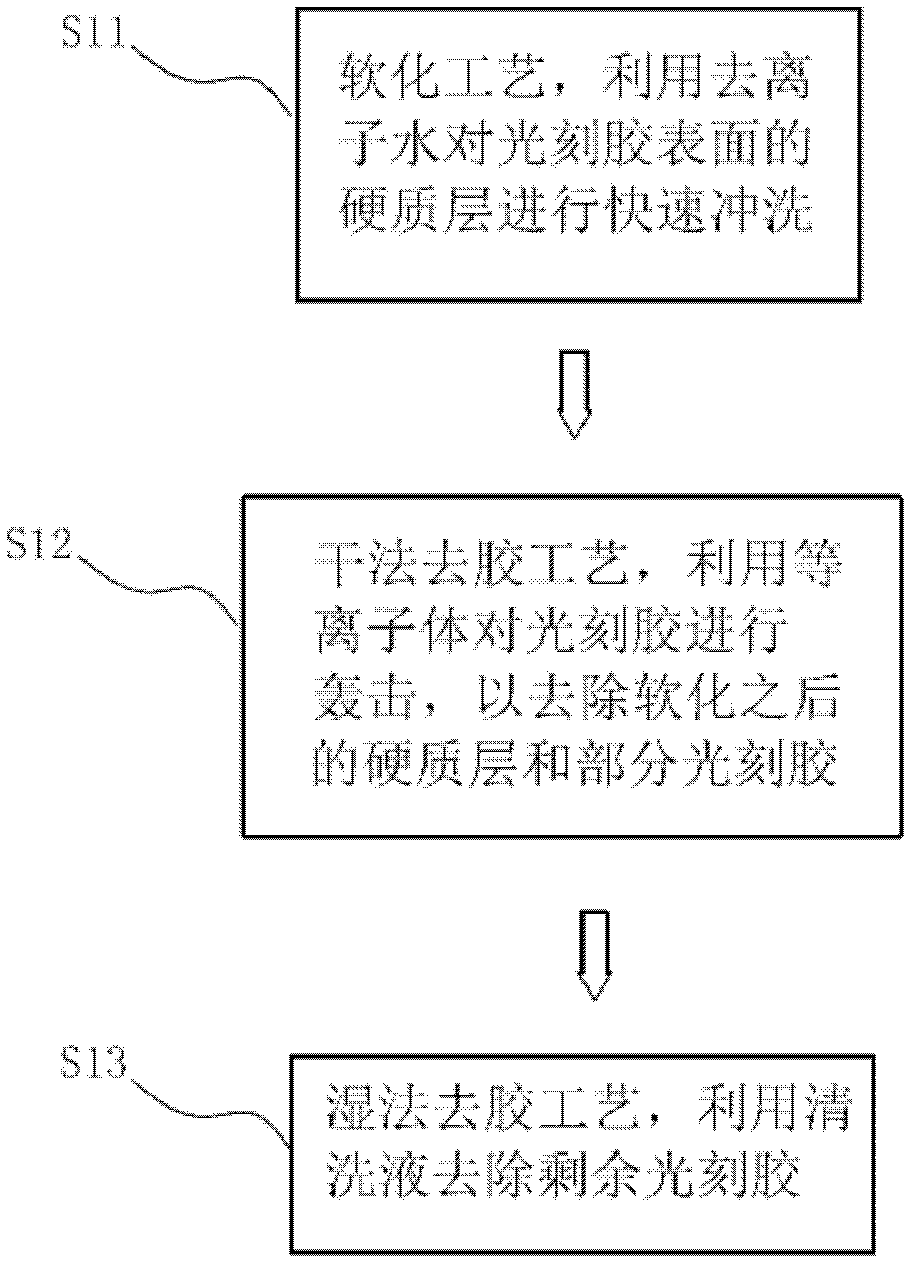

Photoresist removal method and semiconductor production method

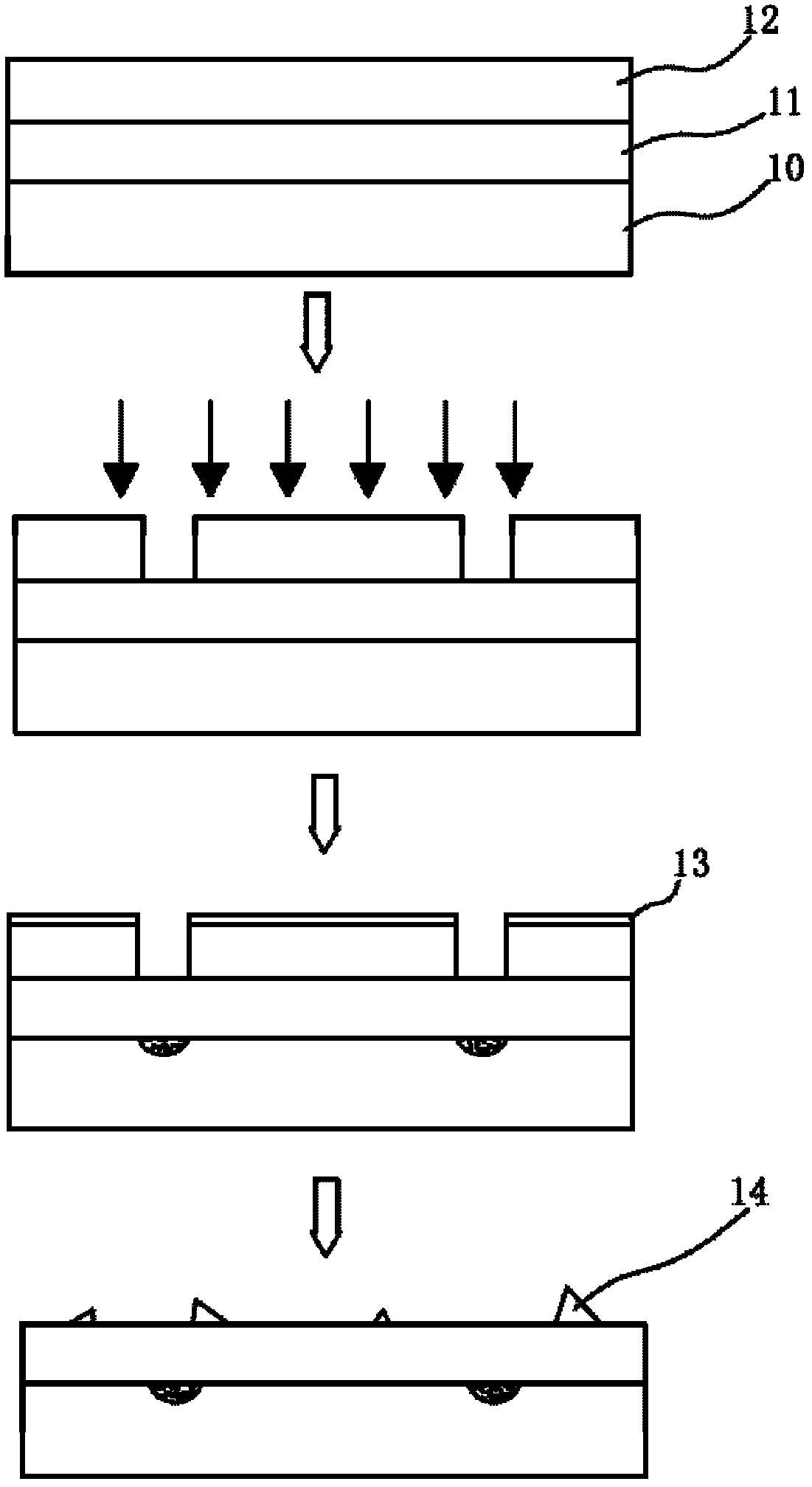

ActiveCN103107066AEfficient removalAvoid damageSemiconductor/solid-state device manufacturingPhotosensitive material processingPhotoresistSemiconductor

The invention relates to a photoresist removal method and a semiconductor production method. The photoresist removal method is that after ions are injected into the art, the photoresist with a surface on which a hard layer is formed is removed. The method comprises the following steps: a softening process is used; a dry stripping process and a wet stripping process are used, due to the fact that the softening process is conducted on the hard layer of the surface of the photoresist, and the hard layer of the photoresist caused by the ion injection process and the like is softened, and thereby the removal of the photoresist is enabled to be simplified. Meanwhile the fact that the semi-conductive product is not damaged during the photoresist removal process is guaranteed, and the yield of the semi-conductive product is greatly improved. The invention further provides a semiconductor production method which comprises the photoresist removal method.

Owner:CSMC TECH FAB2 CO LTD

Degumming technology of natural bamboo fiber

ActiveCN106012044AImprove degumming efficiencyImprove degumming effectFibre treatment to obtain bast fibrePlant fibreHigh pressure

The invention relates to a degumming technology of natural bamboo fiber, and belongs to the technical field of plant fiber manufacturing. The technology comprises the steps that bamboo chips are pretreated to be hammered into thin filaments, then the thin filaments are sequentially subjected to the processes such as acid soaking, steaming, fermenting, enzymolysis, bleaching, oiling, softening, dewatering, opening and drying, and the natural bamboo fiber is prepared. Accordingly, the acid soaking-high pressure steaming-microbial degumming composite technology is adopted, the synergist effect is generated among the steps, therefore, the degumming effect of the natural bamboo fiber is improved, and the prepared fiber has the advantages of being high in degumming efficiency and little in damage to the fiber intensity.

Owner:四川长盛新材料科技有限公司

Method for identifying varieties of residual silk of antique silk fabric based on immune trace method

ActiveCN107462728ATake advantage ofGood fluorescence stabilityBiological testingEnvironmental resistanceFluorescence

The invention relates to the field of detection of cultural relics and discloses a method for identifying the varieties of residual silk of antique silk fabric based on an immune trace method. The method comprises the following steps: preparing a fluorescent carbon point by taking a sweet potato as a carbon source, marking secondary antibodies of mulberry silk and tussah silk by using the fluorescent carbon point, hydrolyzing promiscuous antique silk fabric cultural relic samples by using ionic liquid and PM13-alkaline protease step by step, performing dialysis and purification after protein extracting liquid is obtained, performing SDS-PAGE gel electrophoresis, transferring the obtained protein band to a PVDF membrane, incubating silk primary antibodies and the secondary antibodies marked by the fluorescent carbon point, observing the immunofluorescence band in a gel imaging system, and identifying the varieties of the antique silk fabric. According to the method, the use amount of a chemical reagent is small, and the reaction is mild, environment-friendly and harmless; and when the antique silk fabric is detected, the method has the characteristics of small use amount of samples, intuitive performance, rapidness and high sensitivity.

Owner:ZHEJIANG SCI-TECH UNIV

Method for refining camellia seed crude oil beneficial to individuals with hypertension, hyperglycemia, hyperlipidemia

ActiveCN102504946AImprove heat resistanceReduce sensitivityFatty-oils/fats refiningCamellia oleiferaSecondary hyperlipidemia

The invention relates to a method for refining camellia seed crude oil, in particular to a method for refining the camellia seed crude oil by using immobilized phospholipase A1. The technical scheme of refining the camellia seed crude oil by using the immobilized phospholipase A1provided by the invention is realized by the following steps of: a, immobilizing phospholipase; b, carrying out pre-treatment on the camellia seed crude oil; c, adding the immobilized phospholipase into the camellia seed crude oil; and d, agitating and then centrifuging, namely realizing that the camellia seed crude oil is refined by using the immobilized phospholipase. The method for refining the camellia seed crude oil provided by the invention has the beneficial effects that unsaturated fatty acid is lost for 1-3% and is reduced by 15-20% compared with the loss of the unsaturated fatty acid in chemically-refined camellia seed oil; the immobilized phospholipase A1 is degummed to reduce phosphorus content in the oil to be lower than 5 mg / kg; the heat resistance of the immobilized phospholipase A1 is improved; the immobilized phospholipase A1 can keep a higher activity in a wider pH value range and the sensitivity of the immobilized phospholipase A1 to a reaction environment is reduced, so that the operation conditions are easier to control and implement.

Owner:FUJIAN CHUNHUI BIOLOGICAL ENG

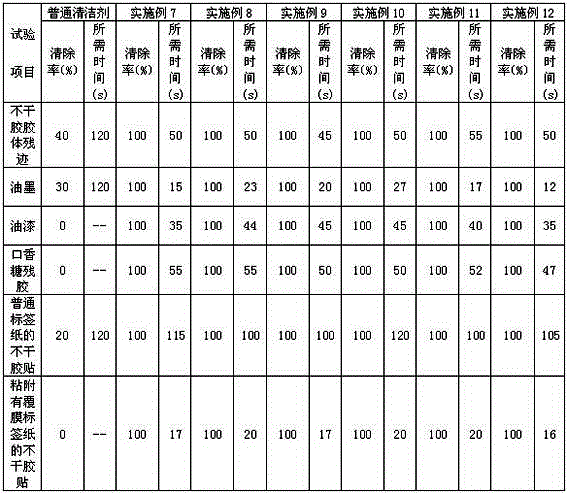

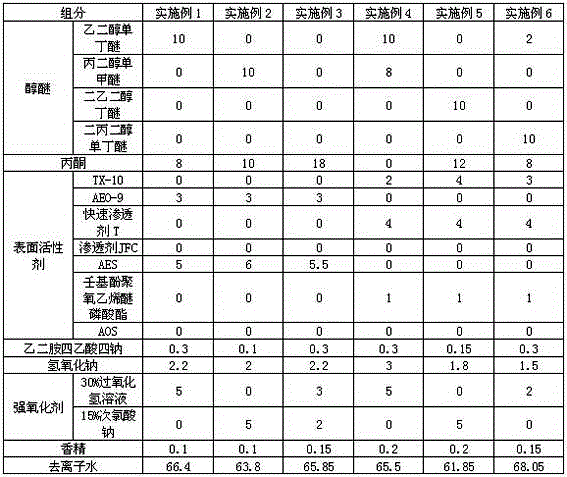

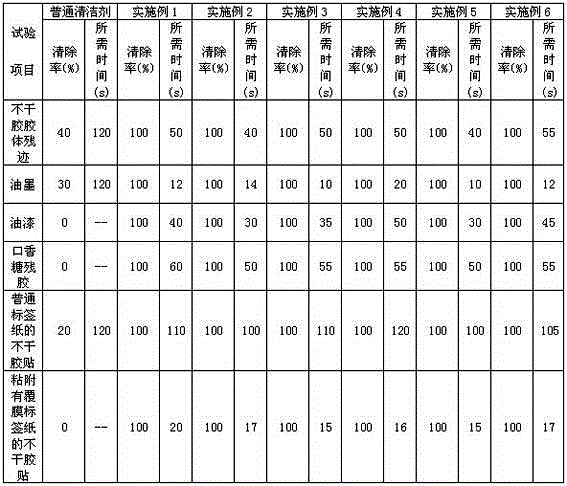

Adhesive sticker cleaner based on normal temperature water

InactiveCN104403851AEasy to combineHigh solubilizing powerSurface-active non-soap compounds and soap mixture detergentsAdhesiveChemical products

The invention discloses an adhesive sticker cleaner based on normal temperature water and belongs to the field of chemical products of everyday use. The adhesive sticker cleaner is prepared from the following ingredients in percentage by mass: 0-18.0 percent of alcohol ether, 0-18.0 percent of acetone, 7.0-11.0 percent of a surfactant, 0.1-0.3 percent of ethylenediamine tetraacetic acid tetrasodium, 1.0-3.0 percent of sodium hydroxide, 2.0-5.0 percent of a strong oxidant, 0.05-0.20 percent of essence and the balance of deionized water. The adhesive sticker cleaner has the advantages of being good in clearing effect and short in required time and can effectively and quickly clear various adhesive sticker labels or adhesive remnants thereof, clear advertising words and stains written on any object by printing ink and paint, and clear gum glue stuck on the grounds of public places. The adhesive sticker cleaner is low in cost and high in safety and has no environmental pollution.

Owner:LIUZHOU LIJIE TECH

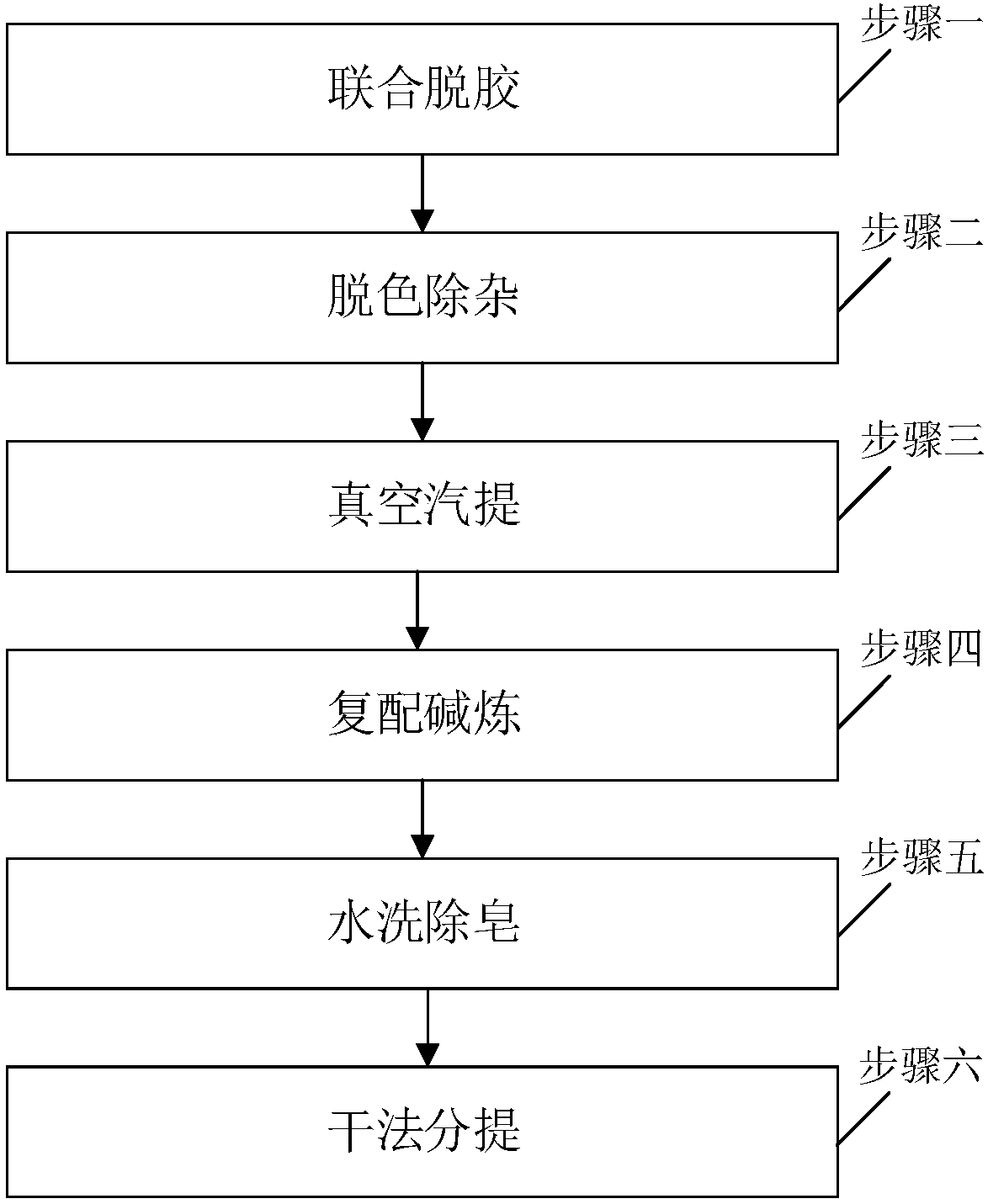

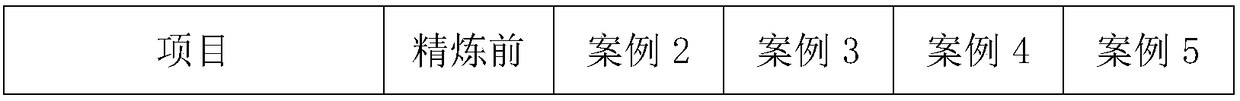

Method for preparing electric insulation oil from gutter oil

InactiveCN108359532ALow acid valueLowering the freezing pointFatty oils/acids recovery from wasteFatty substance recoveryOil processingGutter oil

The invention relates to the technical field of recycling of renewable resources, oil processing and electric insulation materials and provides a method for preparing electric insulation oil from gutter oil. The method comprises steps as follows: S1, combined degumming; S2, decoloration and impurity removal; S3, vacuum steam stripping; S4, compounding and alkali refining; S5, water washing and soap removal; S6, dry fractionation. According to the combined degumming technology, hydratable phospholipids and non-hydratable phospholipids can be effectively removed simultaneously, the degumming efficiency is high, the settling effect is good, and the refining effect of the following process is facilitated; through cooperation of vacuum steam stripping with compounding and alkali refining, the acid value of oil can be substantially reduced; through dry fractionation, the condensation point of oil can be further reduced according to specific demands.

Owner:武汉泽电新材料有限公司

Refining crude oil of soybean by immobilized phospholipase

InactiveCN100535094CIncrease vitalityImprove stabilityFatty-oils/fats refiningFermentationPhospholipaseSoybean oil

This invention relates to a method for refining crude soybean oil with immobilized phosphatidase. The method solves the problems of unable control of temperature and pH value, poor degumming effect of soybean oil, and high cost faced by the present enzyme degumming method. The method in this invention comprises: preparing the reactive solution, preparing a mixed solution, preparing granular immobilized phosphatidase, pre-treating crude soybean oil, adding immobilized phosphatidase into crude soybean oil, stirring and centrifuging. The method has such advantages as high degumming efficiency (increased by 0.5-2%) and low cost (decreased by 1-3%).

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Degumming method for camellia oil

InactiveCN101519623AImprove degumming efficiencyQuality improvementFatty-oils/fats refiningPhosphatidasePhospholipid

The invention discloses a degumming method for camellia oil, which comprises the following steps: heating primary camellia oil to between 40 and 70 DEG C, and adjusting the pH value of the primary camellia oil to between 3.0 and 6.5; adding phosphatidase and stirring the mixture under heat insulation condition; and finally filtering or centrifugally separating the mixture. The camellia oil degummed by the method has low content of phospholipid, and the camellia oil degumming efficiency is high; and the method has simple process, mild reaction conditions and easy control.

Owner:SOUTH CHINA AGRI UNIV

Method for degumming crude soybean oil by immobilized phosphatidase membrane

InactiveCN102399628AGood energyImprove degumming efficiencyFatty-oils/fats refiningSOYBEAN SEED OILSoybean oil

The invention relates to a method for degumming crude soybean oil by an immobilized phosphatidase membrane. The method allows problems that the soybean oil degumming effect is bad because the temperature and the pH are difficult to control in present enzyme degumming methods and the cost of the present enzyme degumming methods is high to be solved. The immobilization of an enzyme is in favor of the dispersion, the recovery and the reutilization of the enzyme, so the loss of the enzyme and the repollution of the residual enzyme are reduced. The method for degumming the crude soybean oil by the immobilized phosphatidase membrane comprises the following steps: 1, preparing a composite membrane; 2, immobilizing phosphatidase; 3, carrying out early stage processing on soybean oil; 4, adding the immobilized phosphatidase to the soybean oil; and 5, stirring, and centrifuging. So the crude soybean oil is degummed by the immobilized phosphatidase membrane. By adopting the method in the invention to degum the crude soybean oil, the degumming efficiency is 20-30% higher than the degumming efficiency of the present degumming methods, and the production cost is 20-40% lower than the production cost of the present degumming methods.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

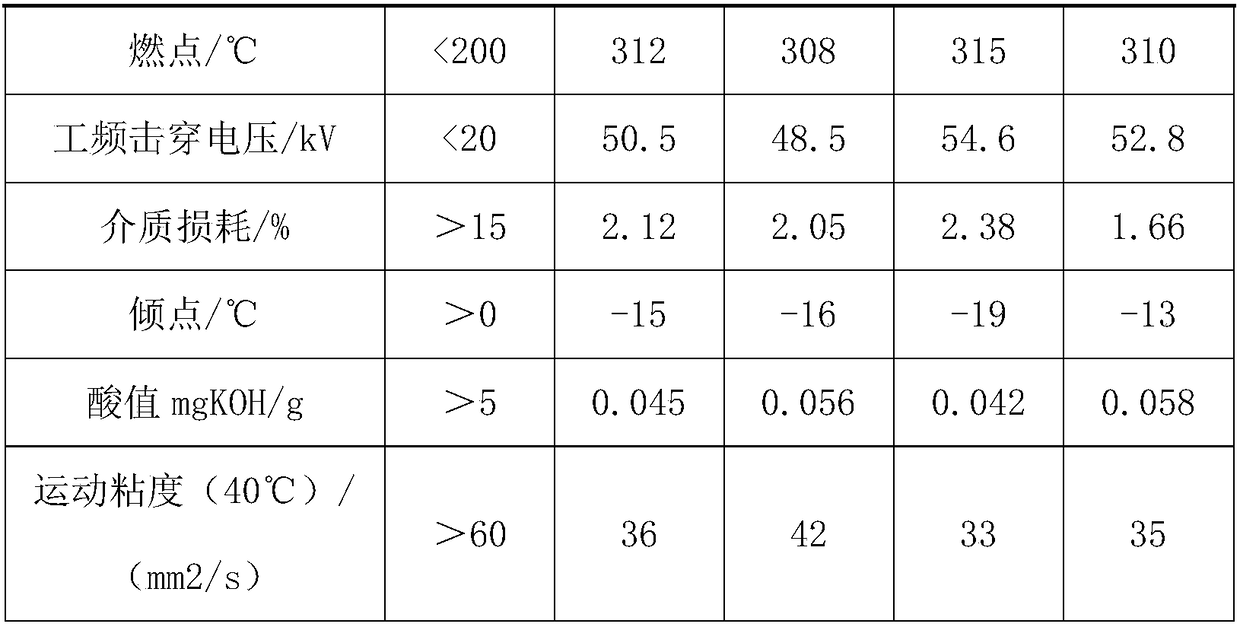

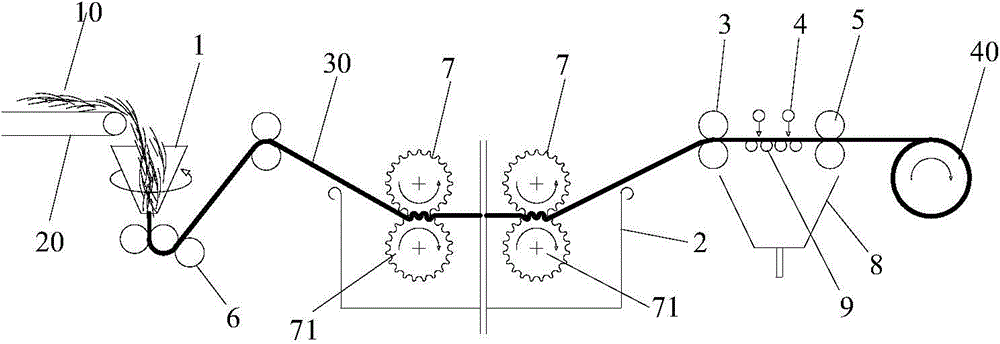

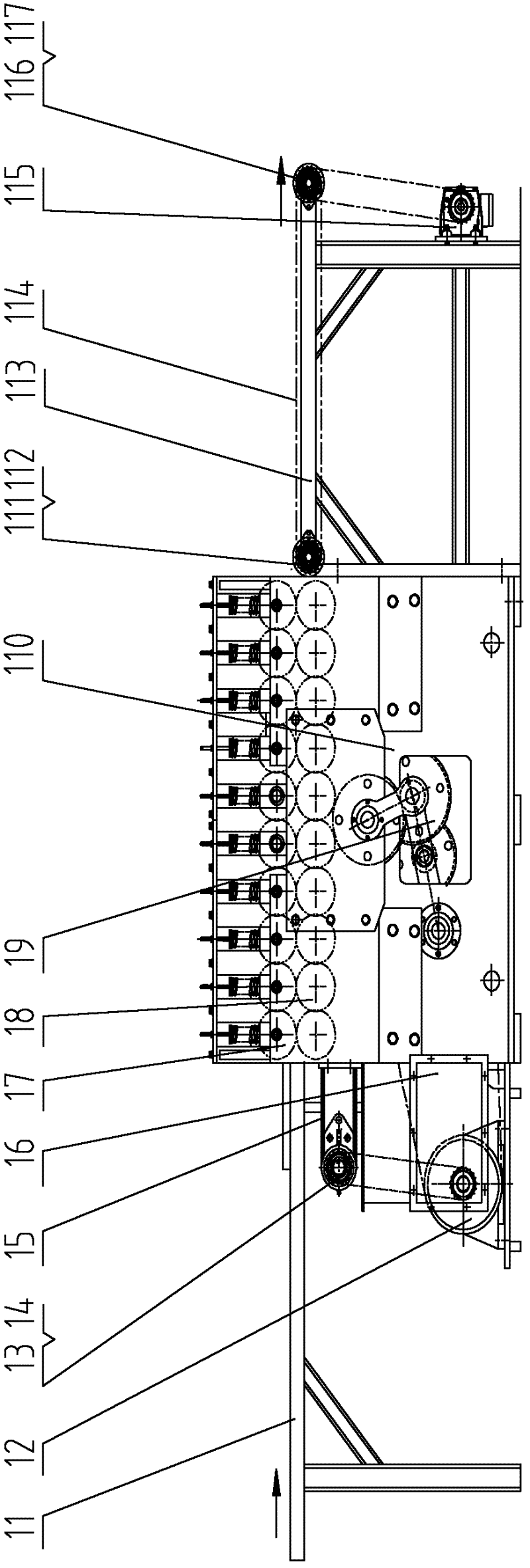

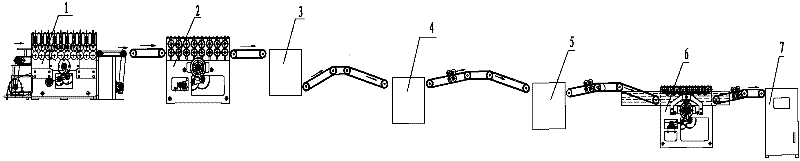

Bamboo fiber degumming process through continuous scouring and process device

ActiveCN104562220AImprove degumming efficiencyFully automatedVegetable materialMechanical fibre separationFiberMaterials science

The invention provides a bamboo fiber degumming process through continuous scouring and a process device. The process includes the following steps: making bamboo wood into bamboo filaments through a mechanical wire-dividing device, twisting the bamboo filaments into rope-form bamboo fibers through a twisting bucket, and then feeding the rope-form bamboo fibers into a scouring pool; kneading the rope-form bamboo fibers through a kneading roller while scouring in the scouring pool; washing and dry-rolling the bamboo fibers using a powerful water injector during the delivering process through a delivery roller to finally obtain bamboo fiber volumes. According to the invention, bamboo fiber scouring, kneading and splitting are performed concurrently, which solves the problems of automatic, continuous and overall delivery of the scattered bamboo fibers in the scouring pool, improves the bamboo fiber degumming efficiency, and lays a foundation for continuous and automated production of the bamboo fibers.

Owner:张毅

Ultrasonic-assisted rapeseed oil degumming method

InactiveCN110331038AImprove degumming efficiencyFatty-oils/fats refiningUltrasonic assistedEvaporation

The invention discloses an ultrasonic-assisted rapeseed oil degumming method, belonging to the technical field of food processing. The method comprises the following steps: (1) weighing crude rapeseedoil, heating to 40-80 DEG C, weighing citric acid with a mass ratio of 0.05-0.35%, weighing distilled water with a mass ratio of 1.5-4.0%, mixing and dissolving the citric acid and the distilled water, heating the citric acid solution to the same temperature as the crude rapeseed oil, adding the citric acid solution into the crude rapeseed oil, and stirring to allow the crude rapeseed oil to be hydrated for 10-60 min; (2) performing ultrasonic treatment with a frequency of 40 khz and a power of 150 w for 10 min to 30 min, performing room temperature standing for 5 min and then centrifuging at4800 r / min for 20 min; and (3) performing rotary evaporation on an upper oil layer at 0.09 MPa and 70 DEG C for removal of water to achieve ultrasonic-assisted degumming of the rapeseed oil. According to the invention, the ultrasonic treatment is applied in the rapeseed oil degumming process, and the degumming effect can be obviously improved.

Owner:江苏禾丰粮油工业有限公司 +2

Combined degumming technological method for jute or kenaf

InactiveCN106283210ADestroy the LCC connectionAvoid the use of strong acids and alkalisFibre treatment to obtain bast fibreOrganic solventSingle fiber

The invention relates to a combined degumming technological method for jute or kenaf. The method comprises the following steps: conducting organic solvent pretreatment on the jute or kenaf, conducting steam explosion and ammonia immersion treatment, then conducting ultrasonic bleaching to remove most gum in the original jute or kenaf, and relying on the residual gum to bond jute or kenaf single fiber and form a technological fiber capable of being utilized by textile processing. Test results show that by combination of the organic solvent, and the steam explosion and ammonia immersion methods, gum of hemicellulose, lignin and the like in the jute or kenaf can be effectively removed, the jute or kenaf fiber prepared by the method is high in splitting degree and good in flexibility, and the degumming method is low in cost, energy-saving, environment-friendly, simple to operate, and suitable for bast-fiber degumming treatment in spinning.

Owner:江西中创汇智智能科技有限公司

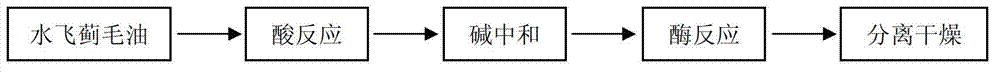

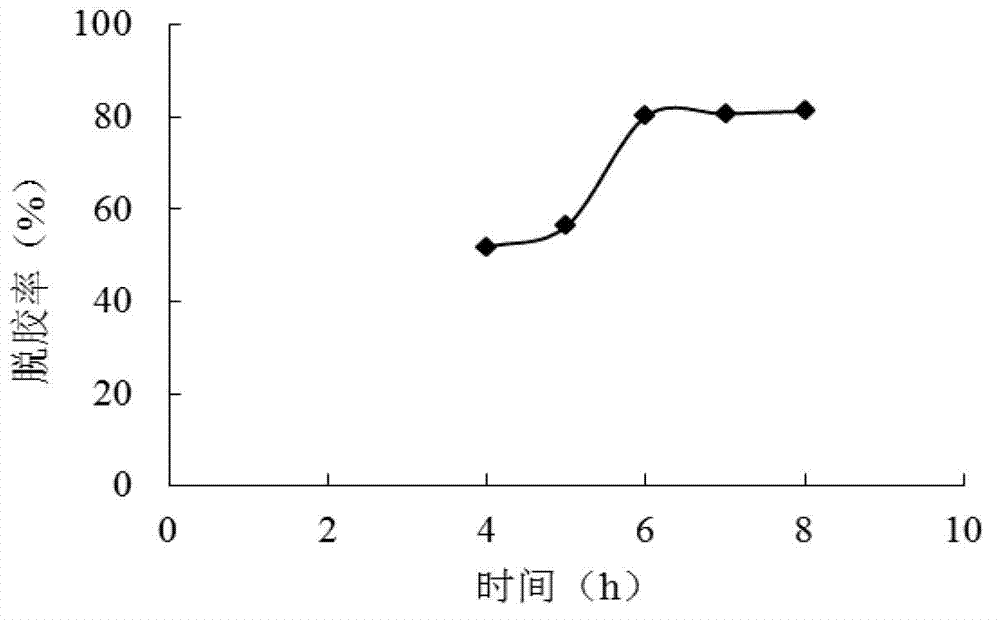

Method for degumming silybum marianum seed oil

InactiveCN102925288AImprove degumming efficiencyQuality improvementFatty-oils/fats refiningChemistryOil and grease

The invention discloses a method for degumming silybum marianum seed oil, relates to the technical field of refining of grease, and in particular relates to a method for degumming silybum marianum seed oil to remove nonhydratable phospholipid. The method specifically comprises acid reaction, alkali neutralization, enzyme reaction, separation and drying, wherein the acid used in the acid reaction is citric acid; and the enzyme used in the enzyme reaction is phospholipase. The method comprises the following steps: heating crude oil to 70 to 80 DEG C; adding 45 percent (w / v) citric acid solution; preserving heat for 20 to 30 minutes under the mechanical stirring condition; cooling the crude oil to 50 DEG C; adding 4 percent (w / v) NaOH solution; adjusting the pH value to 5 to 5.3; adding the phospholipase; stirring under the heat-preserving condition; and filtering or centrifugally separating. By the enzyme method degumming method, the phospholipid content of the silybum marianum seed oil is obviously reduced, the degumming efficiency is high and the advantages are obvious. The method is simple in process, mild in reaction condition, low in energy consumption and easy to control.

Owner:JIANGSU UNIV

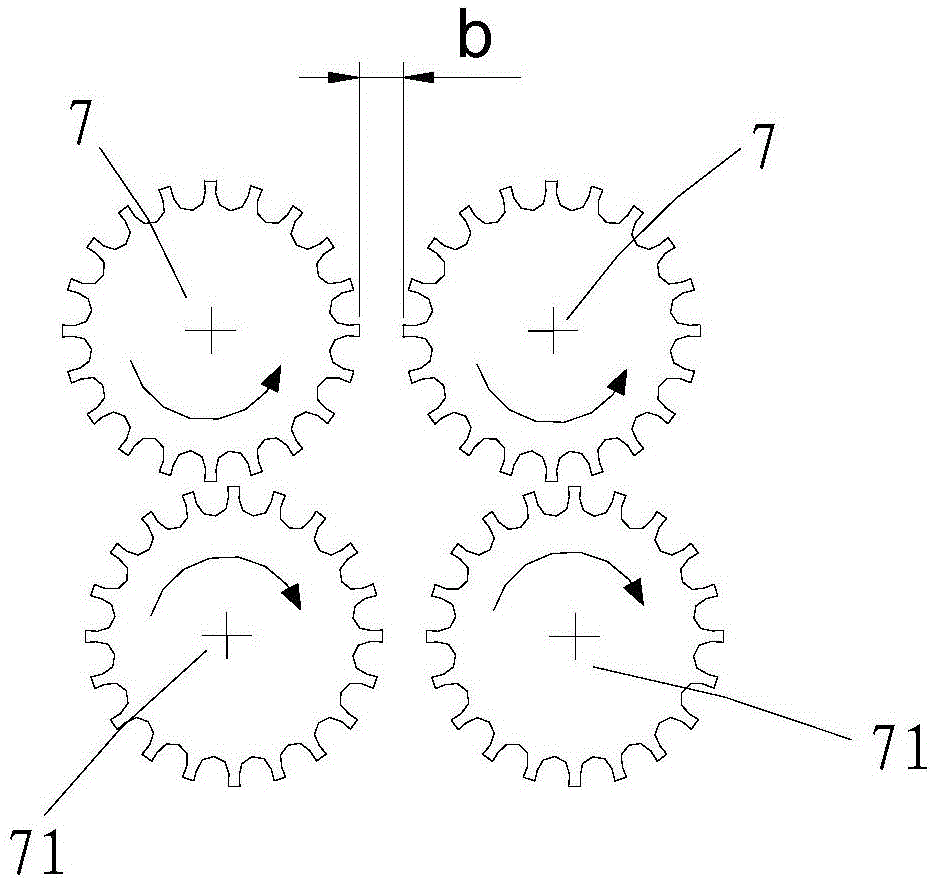

Biological degumming device and method for cotton stalk skin

InactiveCN102268742ALarge specific surface areaEasy to separateMechanical fibre separationFibre treatment to obtain bast fibrePulp and paper industryFermentation

The invention provides a bio-degumming device for cotton stalk barks, which comprises a cotton stalk bark-core separator, a fiber opening and bark removing machine, fermentation equipment, a linear ramie backing machine, an oil impregnating machine, drying equipment, wherein the cotton stalk bark-core separator comprises a roller support, a rolling and stripping mechanism, carrier gears and a transmission device; the rolling and stripping mechanism comprises a plurality of roller groups erected on the roller support in turn; each roller group consists of an upper roller and a lower roller, which are correspondingly arranged up and down; one end of the lower roller is provided with an input gear; each carrier gear is arranged between two adjacent lower rollers, and is meshed with input gears of the two adjacent lower rollers respectively; and the transmission device drives one of input gears to rotate. The invention also provides a bio-degumming method for the cotton stalk barks. The cotton stalk bark-core separator performs back-core separation on the cotton stalk barks, and cotton stalk barks with low impurity content are obtained, so that the cotton stalk barks can be subjected to bio-degumming, and the method is simple.

Owner:湖南润久科技有限公司

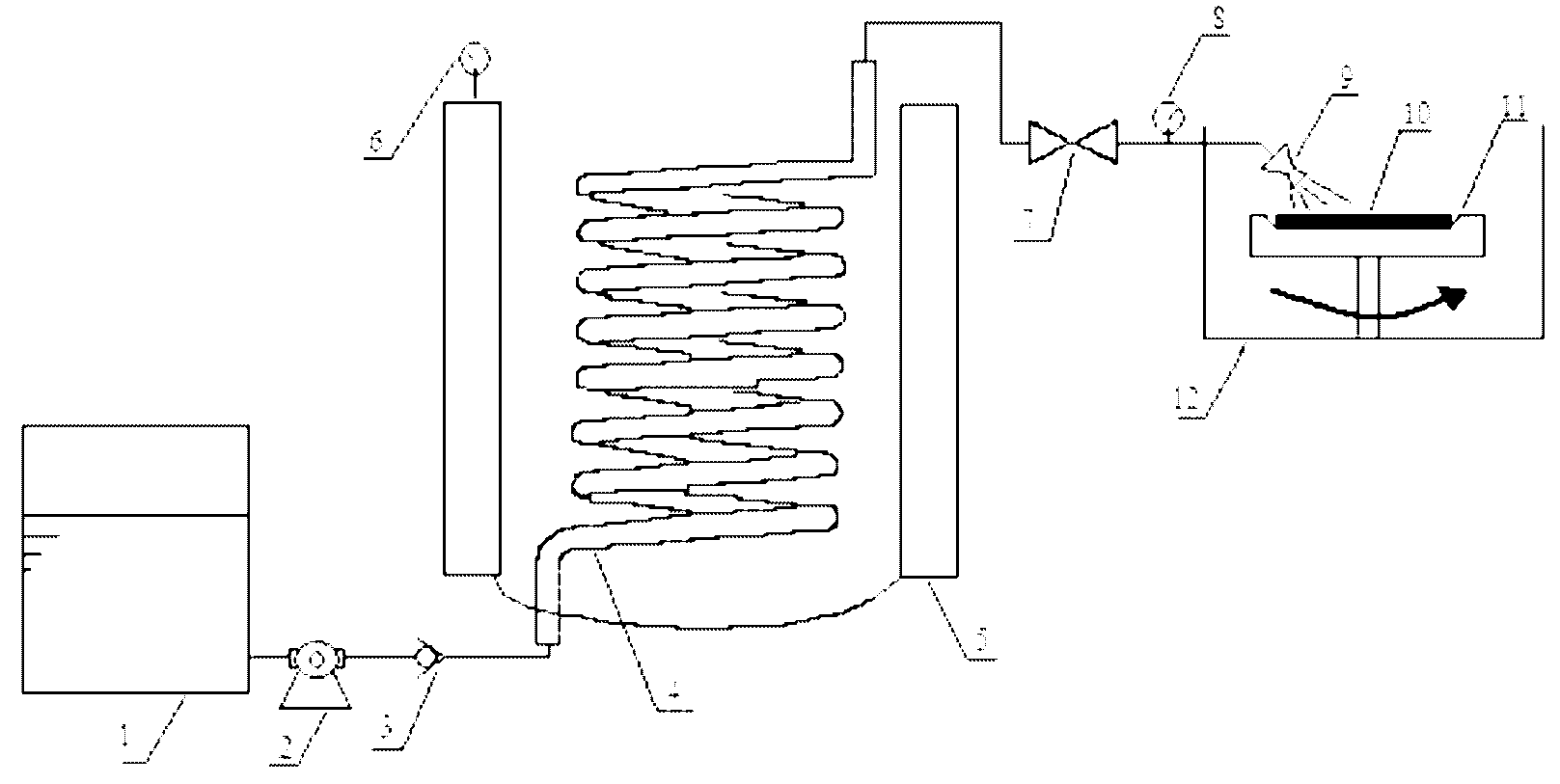

High temperature vapor and water mixed jet cleaning system and method thereof

InactiveCN102466988ALoss minimizationImprove degumming efficiencyPhotosensitive material processingCleaning using liquidsWater storageWater vapor

The invention discloses a cleaning system. The cleaning system which comprises two deionized water storage tanks, a control device for heating deionized water to be in a high temperature state, a cleaning cavity and a jet device for jetting a mixed fluid containing deionized water and high temperature vapor to the cleaning cavity is characterized in that: the outlet of one deionized water storage tank is connected with one inlet of the jet device through the control device, and the outlet of the other deionized water storage tank is connected with one inlet of the jet device; and the outlet of the jet device is connected with the inlet of the cleaning cavity. The invention also discloses a cleaning method. The cleaning method comprises the following steps: 1, forming the high temperature vapor; 2, forming the mixed fluid containing deionized water and the high temperature vapor; and 3, cleaning a sample wafer with the mixed fluid. According to the cleaning system and the cleaning method in the invention, all of an inorganic carbonization thick layer, a bottom organic photoresist and SU-8 cure-crosslinked by the bottom organic photoresist can be peeled, so the photoresist removal efficiency is substantially improved, there are no residues, and the loss of a substrate material is minimized.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

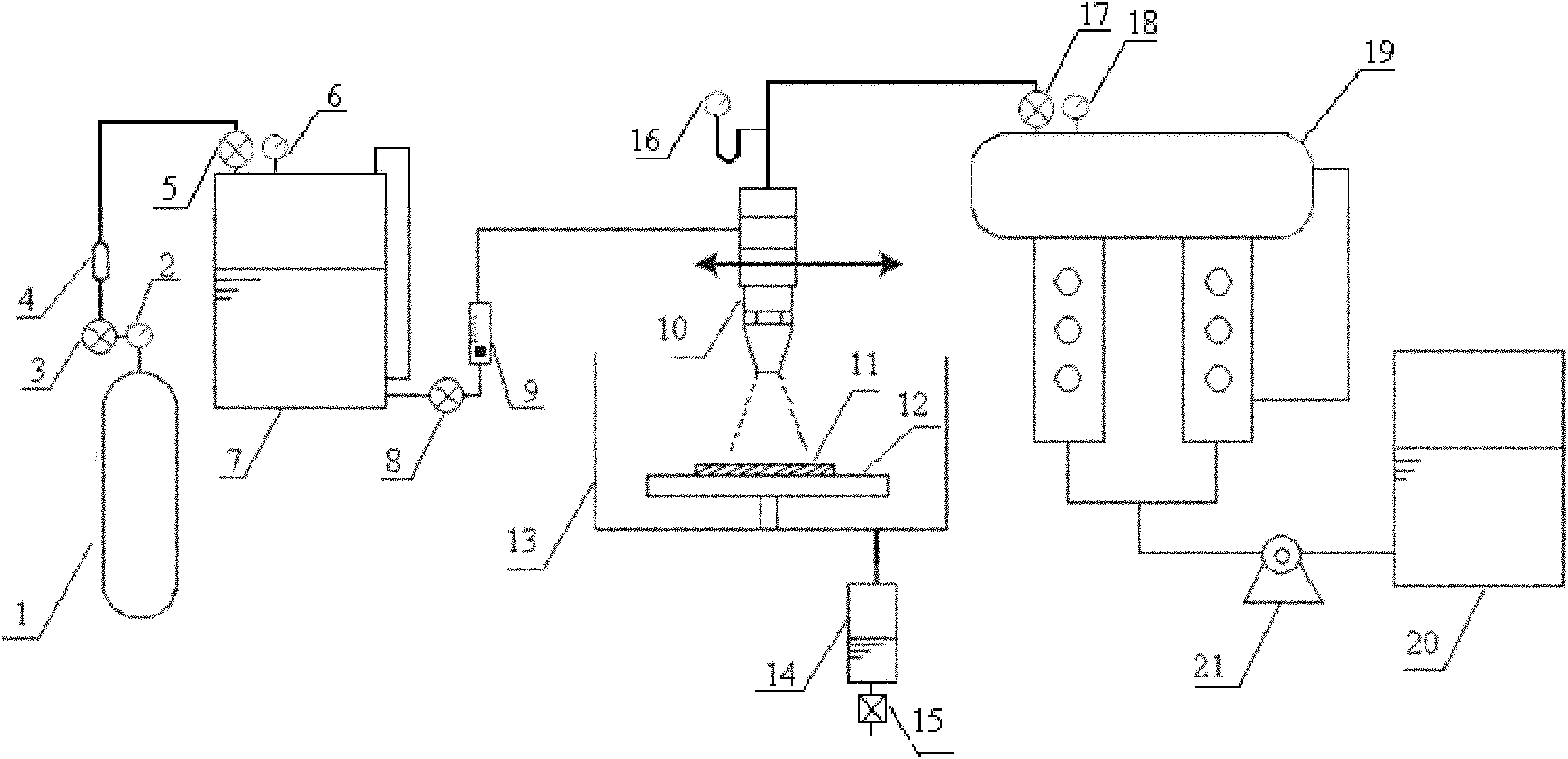

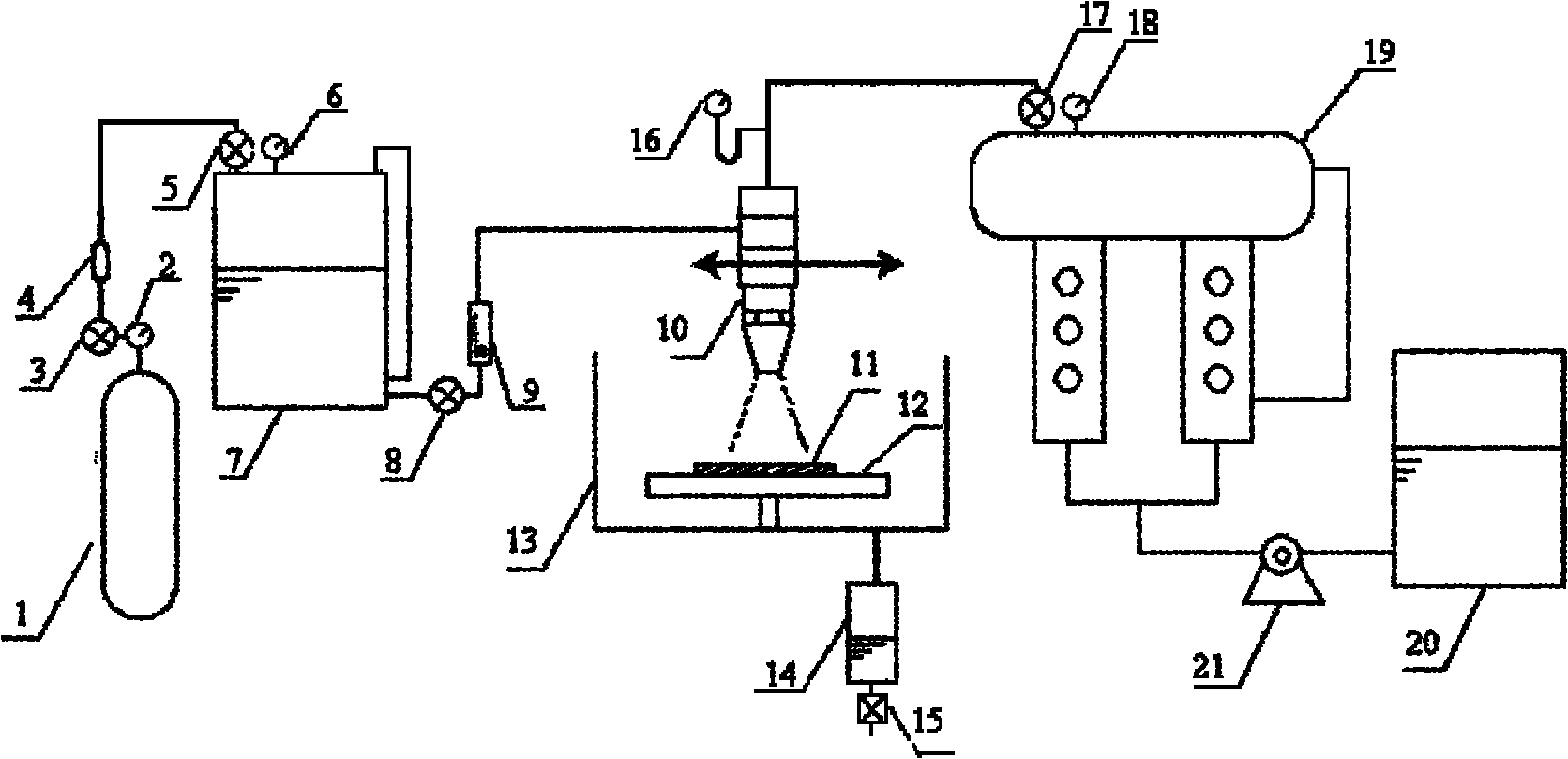

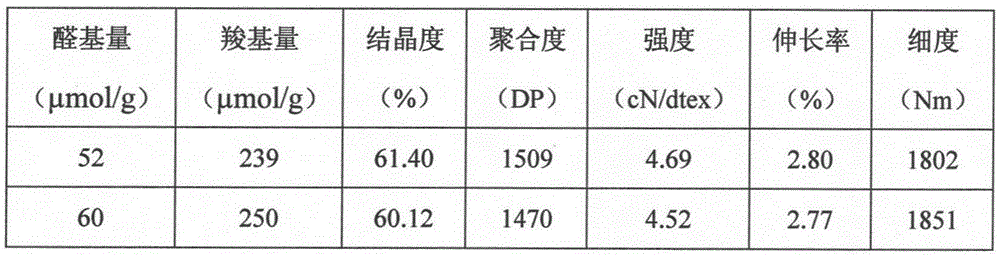

Regulation method of generation of oxidized cellulose in ramie oxidizing and degumming process

InactiveCN105239169ASave energy and chemical consumptionImprove degumming efficiencyFibre treatment to obtain bast fibreAldehydeOptimum control

The invention provides a regulation method of generation of oxidized cellulose in a ramie oxidizing and degumming process. The regulation method includes the following steps: preparing a degumming liquid and mixing raw hemp of ramie with the degumming liquid; regulating the pH of the degumming liquid; heating and stirring the mixture to fully removal colloid through oxidizing property of peroxides; on-line detecting generation quantity of the oxidized cellulose; and optimizing and regulating the pH, reaction temperature, reaction time and chemical reagent concentration in real time to control the aldehyde group content in the oxidized cellulose to be 15-40 [mu]mol / g and the carboxyl group content to be 120-200 [mu]mol / g, so that the fiber crystallization degree, polymerization degree, strength, breaking elongation and fineness of the prepared fine dry ramie fiber are maximum and the degumming efficiency and the physical mechanical performance are best within the ranges of the parameters. The method can increase degumming efficiency and reduce fiber damage, achieves best degumming effect, achieves optimum control in the preparation process of the ramie fiber, and has important theoretical meaning and application value.

Owner:DONGHUA UNIV

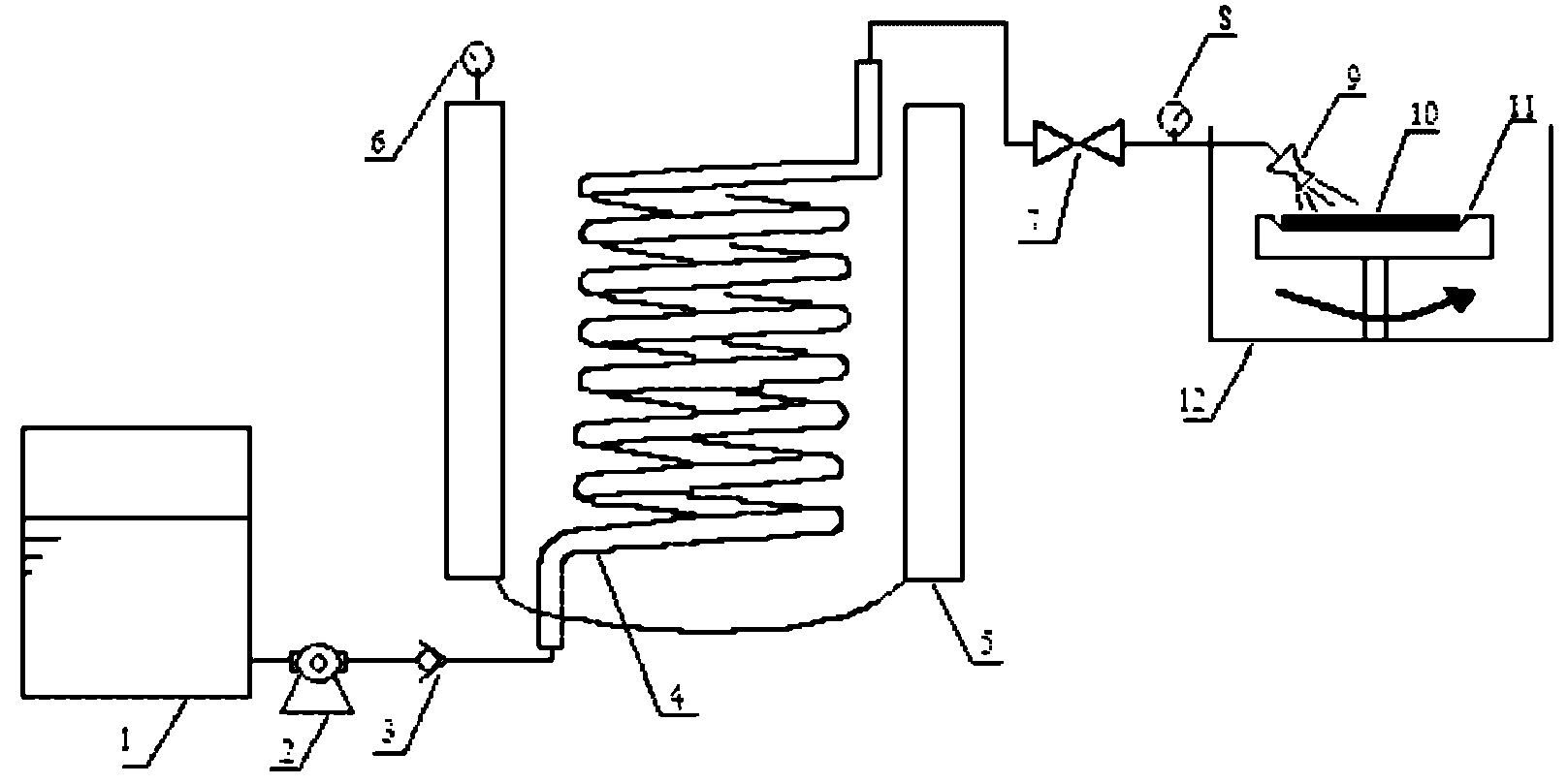

Device and method for removing glue from sample wafer

InactiveCN102338993ALoss minimizationAvoid damagePhotosensitive material processingResistWater vapor

The invention discloses a device for removing glue from a sample wafer. The device comprises a de-ionized water storage tank, a heat exchanger and a glue-removing chamber, wherein the de-ionized water storage tank is used for providing ultrapure de-ionized water; the heat exchanger is used for heating the ultrapure de-ionized water and causing the ultrapure de-ionized water to become a mixed fluid of water vapor and de-ionized water; the glue-removing chamber is used for removing the glue from the sample wafer by utilizing the mixed fluid; an outlet of the de-ionized water storage tank is connected to an inlet of the heat exchanger; and the outlet of the heat exchanger is connected to the inlet of the glue-removing chamber. The invention also provides a method for removing glue from the sample wafer. The method comprises the following steps of: forming the mixed fluid of water vapor and de-ionized water, and utilizing the mixed fluid to remove glue from the sample wafer. The method and device provided by the invention can be used for completely removing the organic optical resist and solidified optical resist from an inorganic carbonized thick layer and bottom. The glue-removing efficiency is high, no residue is left and the loss of a film material is minimized.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for preparing ramie based on oxidation reduction potential regulation

InactiveCN103938281AImprove degumming efficiencyReduce consumptionFibre treatment to obtain bast fibreReaction temperatureColloid

The invention provides a method for preparing ramie based on oxidation reduction potential regulation. The method comprises the steps of preparing a degumming solution, mixing raw ramie and degumming solution, adjusting pH value of the degumming solution, heating, stirring, and completely removing colloid by utilizing the oxidability of peroxides; optimizing and adjusting the pH value, the reaction temperature, the reaction time and the concentration of a chemical reagent in real time by detecting oxidation reduction potential (ORP) parameter in an online manner; and controlling the initial ORP value of the degumming solution between +320mV and +360mV, the residual gum content the prepared fiber is reduced to be below 2.3%, the polymerization degree, the strength and the elongation at break of refined dry flax are the maximum relatively, and the degumming efficiency and the physical and mechanical properties are the best within the range. According to the method, the change of the ORP value is changed to regulate the oxidation degumming process, the degumming efficiency is improved, the fiber damage is alleviated, the excellent degumming effect is achieved, the optimized control of the ramie preparation process is realized, and important theoretical and application significances are achieved.

Owner:DONGHUA UNIV +1

Enzymatic degumming process based on immobilized compound phospholipase

InactiveCN107267282AImprove hydrophilic abilityEasy to removeFatty-oils/fats refiningProteinase activityPhospholipase A2

The invention discloses an enzymatic degumming process based on immobilized compound phospholipase. The enzymatic degumming process comprises the following steps: A, preparing the immobilized compound phospholipase; B, applying the immobilized compound phospholipase to degumming of oils and fats, wherein the compound phospholipase contains phospholipase A1, phospholipase C, lipase and protease. According to the enzymatic degumming process based on the immobilized compound phospholipase, the phospholipase A1, the phospholipase C, the lipase and the protease which are used for degumming are immobilized on the same macroporous resin simultaneously firstly, then the macroporous resin immobilized with the phospholipase A1, the phospholipase C, the lipase and the protease is used for degumming the oils and fats, the phospholipase A1, the phospholipase C, the lipase and the protease play a synergistic role to degum the oils and fats, so that the immobilized compound phospholipase can be used repeatedly for degumming, enzyme residues are avoided in the oils and fats, the degumming efficiency is high, and oil yield is high.

Owner:ANHUI LEVEKING BIOTECH CO LTD

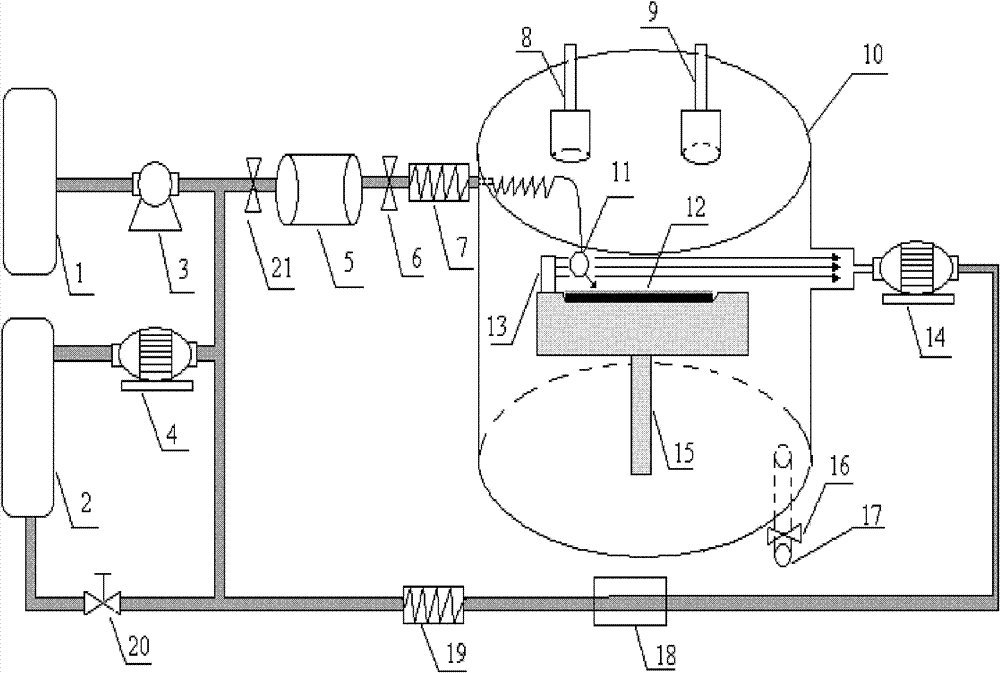

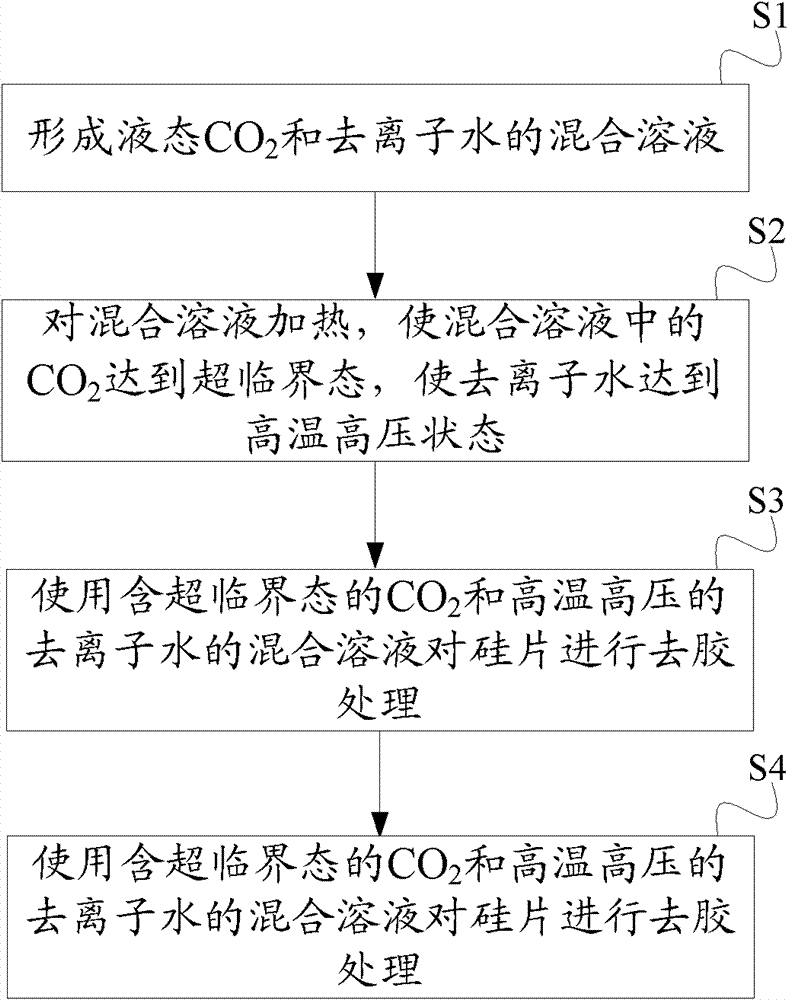

Silicon wafer degumming device

ActiveCN102298276BLoss minimizationAvoid damagePhotosensitive material processingWater storage tankProcess engineering

The invention discloses a silicon wafer degumming device, which comprises deionized water storage tank, a CO2 storage tank, a mixing tank, a heat exchanger and a reaction cavity, wherein the heat exchanger is used for heating a mixed solution, and the reaction cavity is used for degumming a silicon wafer; and an outlet of the deionized water storage tank and an outlet of the CO2 storage tank are connected with one end of a mixing tank, and the other end of the mixing tank is connected with an inlet of the reaction cavity through the heat exchanger. The invention also discloses a silicon wafer degumming method, which comprises the following steps of: heating the mixed solution so that CO2 in the mixed solution reaches a supercritical state and the deionized water reaches a high-temperature and high-pressure state; and degumming the silicon wafer by using the mixed solution containing the supercritical CO2 and the high-temperature and high-pressure deionized water. According to the device and method provided by the invention, organic photoresist on an inorganic carbonized thick layer and bottom are completely oxidized and dissolved, therefore the degumming efficiency is higher without residues, and the loss of film materials is minimized.

Owner:无锡影速半导体科技有限公司

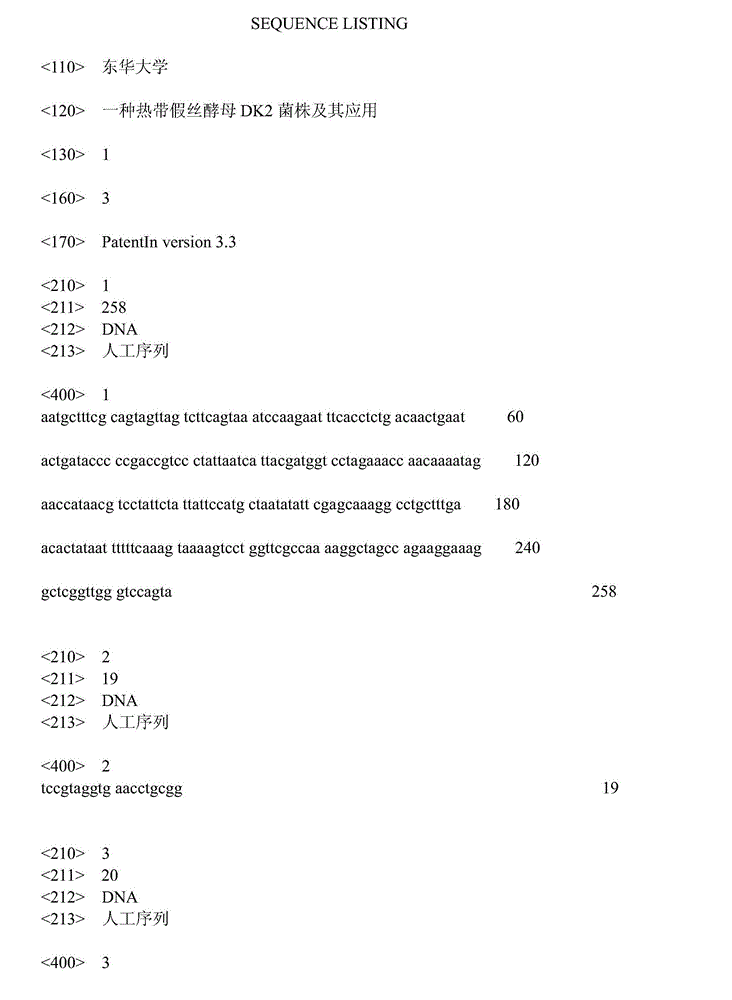

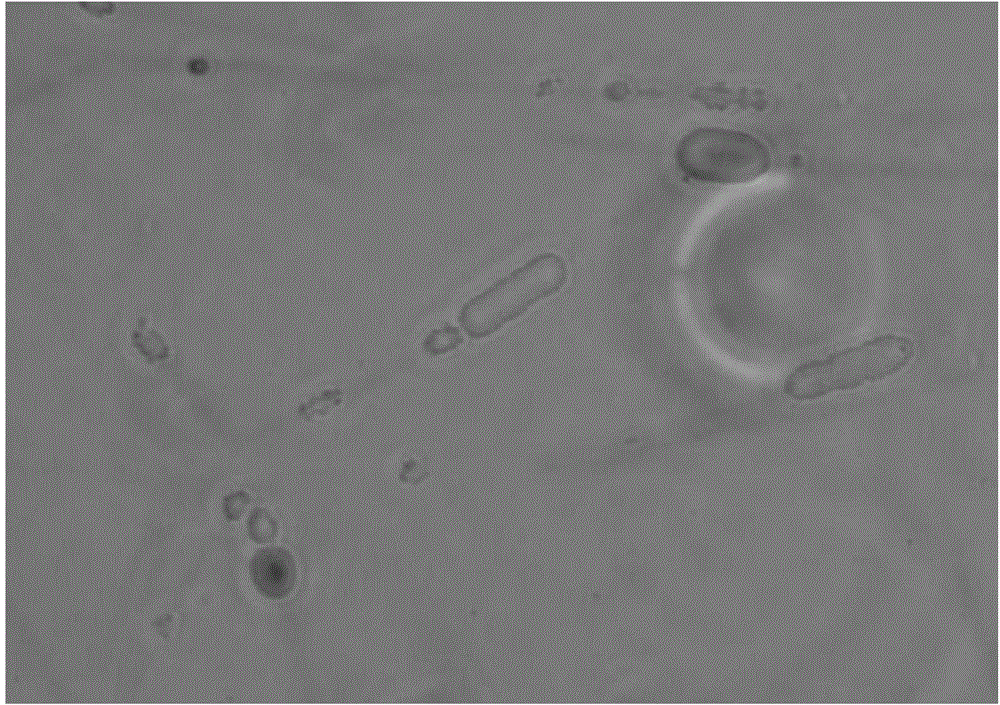

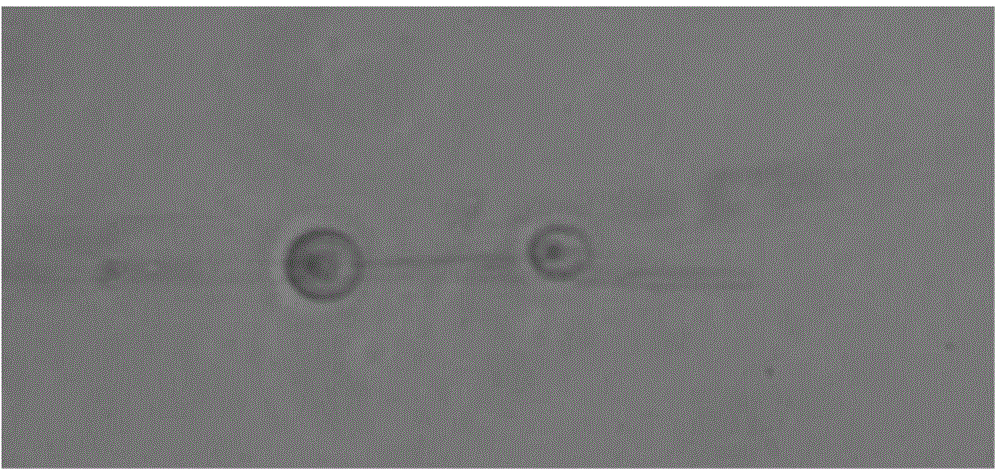

Candida tropicalis DK2 strain and application thereof

The invention relates to a Candida tropicalis DK2 strain and an application thereof. The ITS sequence of the strain is shown as SEQ ID NO:1. The strain is used for preparing flax, jute, kenaf or bamboo fibers through retting, scouring the flax, jute, kenaf or bamboo yarns and degumming the original hemp of flax, jute and kenaf or bamboo fabrics. The strain disclosed by the invention is short in growth period and is difficultly polluted, the treatment cost is low, the treated fibers are high in quality, the treatment environment is mild, the heat resistance is high, and environmental pollution is avoided; and moreover, the strain can be directly applied to degumming the flax, jute, kenaf or bamboo fibers and has the advantages of short degumming period, high fiber dispersion rate and high degumming efficiency.

Owner:DONGHUA UNIV

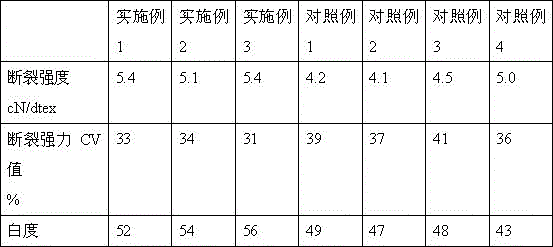

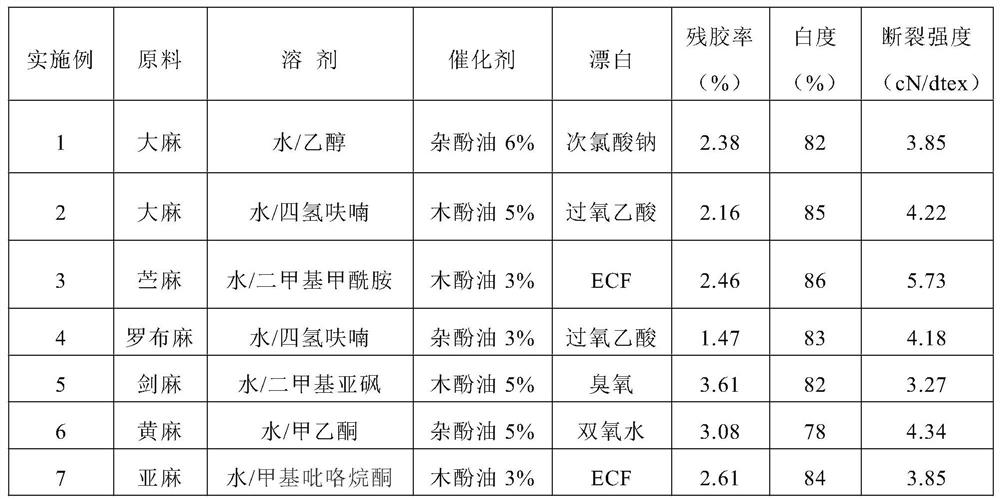

Method for degumming hemp

The invention relates to a method for degumming hemp. According to the method, an organic solvent is used as an extraction solvent, catalysts are adopted to degum hemp raw materials and remove lignin,the extraction process comprises four steps of catalytic cooking, solvent washing, water washing and bleaching, and the catalysts are selected from creosote, crosol, kreosote and / or creosote oil. According to the method, the technical problems of high energy consumption, large amount of waste water and high damage to the fiber strength of a conventional method for degumming hemp are avoided, andthe method has the advantages of high degumming efficiency, high product whiteness, high utilization ratio of raw materials, low equipment requirement, low cost, cleanness, energy conservation, environmental friendliness and safety and is suitable for large-scale industrial production.

Owner:湖南国麻新材料科技有限责任公司

Method of degumming natural fiber by phthalocyanine metal complex compound

InactiveCN101016654AIncrease profitReduce dosageOrganic-compounds/hydrides/coordination-complexes catalystsVegetable materialPhthalocyanineNatural fiber

The invention relates to a method for degumming phthalocyanine metal complex compound to prepare natural fiber, comprising (1) mixing plant fiber with peroxide degummed liquid which contains catalyst as phthalocyanine metal complex compound, while the mass ratio is 1:10-1:20, and degumming at 30-100Deg. C for 1-4h, then washing with water, (2), oiling and drying via general method to obtain the fiber used in weaving. The inventive method has simple process, short reaction time, and high degumming efficiency.

Owner:DONGHUA UNIV

High-temperature vapor-water mixed jet cleaning system and method

InactiveCN102476108ALoss minimizationImprove degumming efficiencyCleaning using liquidsCross-linkOzone generator

The invention discloses a cleaning system, which comprises an ozone generator, a deionized water storage tank, a control device, two nozzles and a cleaning chamber, wherein the control device is used for heating deionized water to a high temperature state; the outlet of the deionized water storage tank is connected with the nozzle inlet of one of the two nozzles through the control device; the outlet of the ozone generator is connected with the other nozzle inlet; and the outlets of the two nozzles are connected with the two inlets of the cleaning chamber respectively. The invention further discloses a cleaning method, which comprises the following steps of: forming vapor in a high-temperature state; jetting vapor and ozone to the cleaning chamber simultaneously; and cleaning a sample sheet with a mixed fluid consisting of high-temperature vapor and ozone. According to the cleaning system and the method disclosed by the invention, a thick inorganic carbonized layer, a bottom organic photoresist and cured and cross-linked SU-8 can be stripped fully, degumming efficiency is greatly increased, residues are eliminated, and the loss of a substrate material is minimized.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for degumming crude soybean oil by embed-crosslinked phospholipase A1 aggregate

ActiveCN102776065BImprove heat resistanceReduce sensitivityFatty-oils/fats refiningEconomic benefitsPhospholipase A1

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

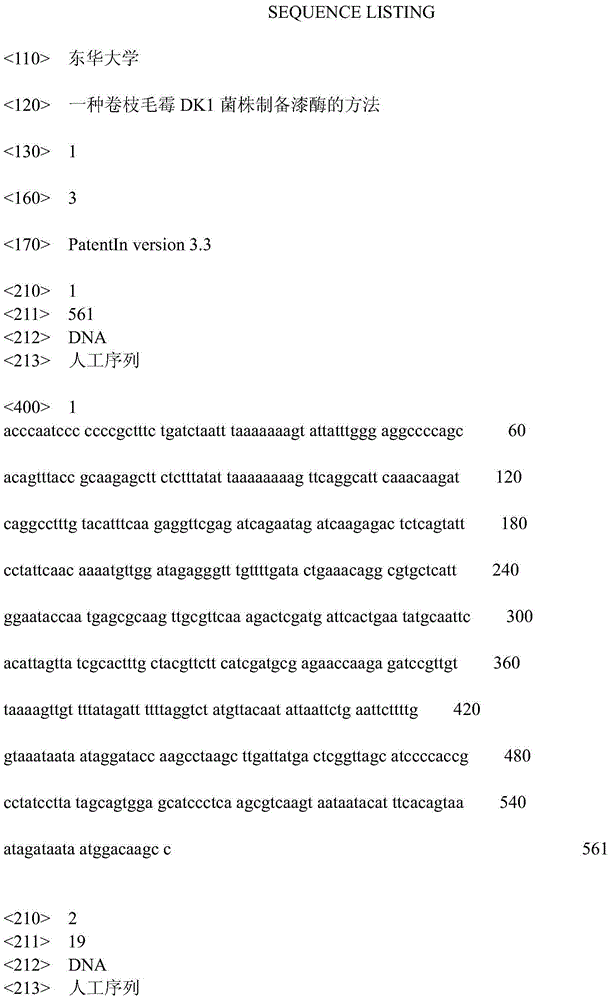

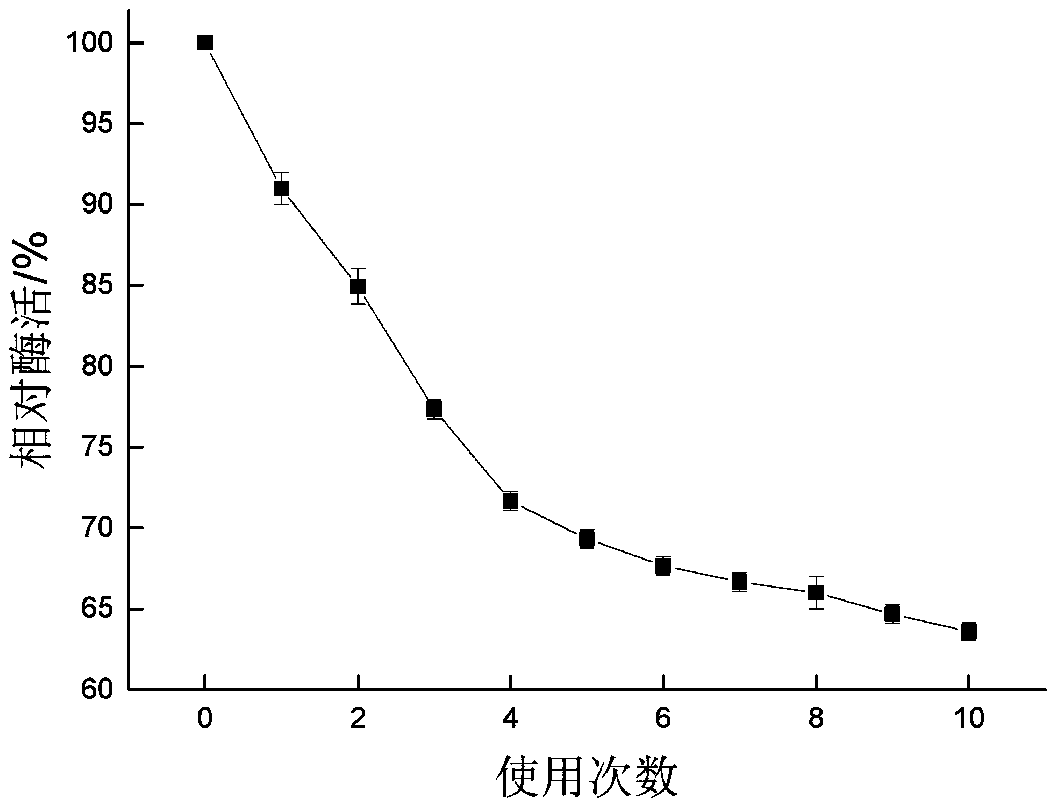

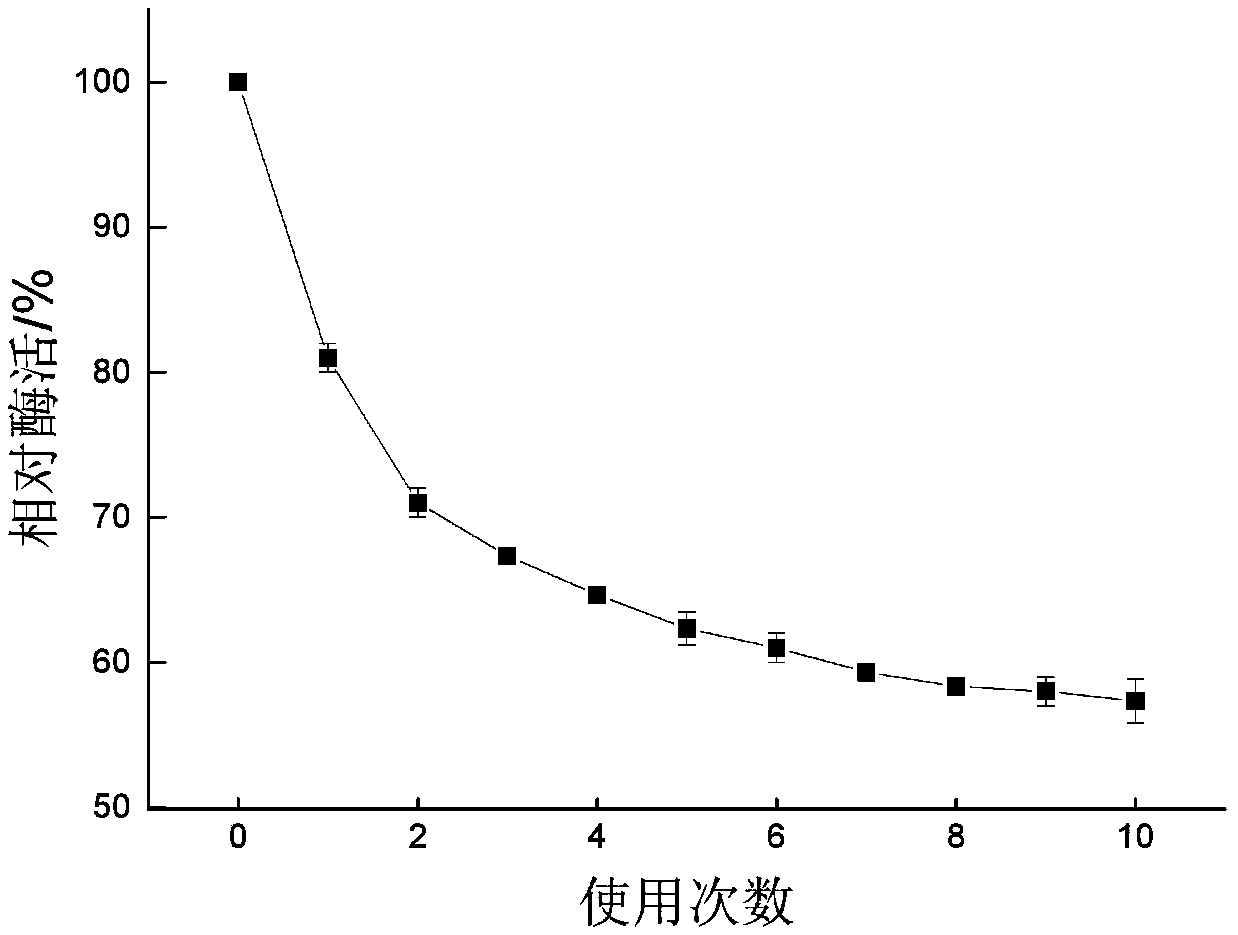

Method for preparing laccase by using mucor circinelloides DK1 strain

InactiveCN104611309AGood dispersionNo toxicityMicroorganism based processesOxidoreductasesCelluloseFiber

The invention relates to a method for preparing laccase by using a mucor circinelloides DK1 strain. The method comprises the following steps: (1) transferring the mucor circinelloides DK1 strain from a PDA slant culture medium into a triangular flask filled with a basic liquid medium, carrying out shaking culture, filtering the fermentation liquor to obtain mycelium, washing the mycelium by using sterile water, scattering, collecting the mycelium in the sterile water to prepare mycelium suspension, and preserving the suspension for later use; (2) putting an enzyme production culture medium into the triangular flask, inoculating the mycelium suspension, carrying out shaking culture, periodically extracting the fermentation liquor in the culture process, centrifuging, and taking the supernatant, thereby obtaining the crude enzyme liquor; and (3) centrifuging the crude enzyme liquor, and taking the supernatant, thereby obtaining the laccase. The method disclosed by the invention is simple in process, is suitable for large-scale industrial production and the like, and the prepared laccase can effectively remove non-cellulose colloid in flax, jute, kenaf or bamboo fibers, has the advantages of high degumming efficiency, short degumming period, high fiber dispersion rate, high refined dried-jute quality and the like and has good application prospects.

Owner:DONGHUA UNIV

Degumming liquid

The invention relates to a degumming solution and belongs to a chemical treatment solution, which is used for removing a fastening glue film adhering to the surface of mechanical parts. The invention provides a degumming solution that has a short degumming duration and has no corrosion to the mechanical parts. The invention consists of halogenated hydrocarbon, acetone, paraffin, white oil, a high molecular polymer and the latent solvent for the high molecular polymer. The degumming solution is characterized in that the weight percentage for the components is as follows: halogenated hydrocarbon 30 to 50 percent, white oil 4 to 10 percent, acetone 40 to 60 percent, high molecular polymer 0.05 to 0.1 percent, paraffin 0.5 to 2 percent and the rest is the latent solvent for the high molecular polymer.

Owner:SHENYANG POLYTECHNIC UNIV

Vegetable oil degumming method

PendingCN109694776AImprove degumming efficiencyHigh yieldFatty-oils/fats refiningChemistryPhospholipases C

The invention provides a vegetable oil degumming method, and relates to the technical field of enzymatic degumming of oils and fats. The method comprises the following steps: 1, immobilizing phospholipase; and 2, degumming oil by the immobilized phospholipase. The immobilization of the phospholipase includes immobilization of phospholipase A1 and immobilization of phospholipase C; and degumming ofoil comprises pretreatment of vegetable oil, primary degumming of the vegetable oil by using the immobilized phospholipase C; and secondary degumming of the primarily degummed vegetable oil by usingthe immobilized phospholipase A1. The method adopts an immobilized phospholipase C and phospholipase A1 combined degumming technology, and the degumming effects of the two enzymes on the oil are fullyshown, so the yield of the neutral oil is increased; and the immobilized phospholipase can be repeatedly used, so the production cost is saved.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com