Patents

Literature

288results about "De-gumming silk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silk fabric degumming method and apparatus thereof

ActiveCN102605439AShort degumming timeImprove degumming efficiencyDe-gumming silkAlkaline proteasePolymer science

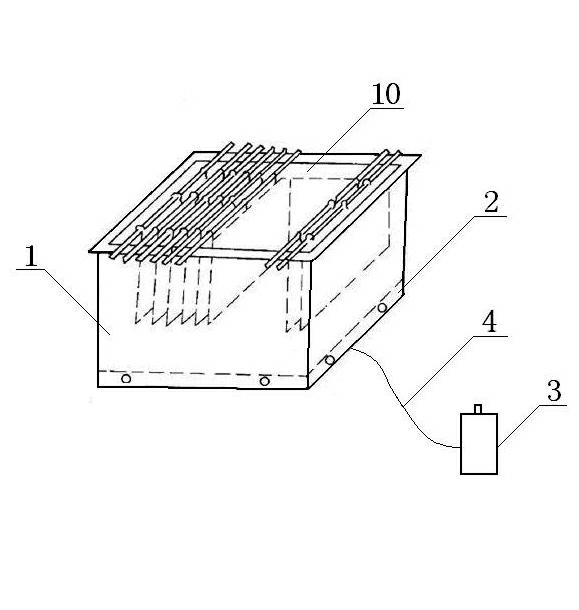

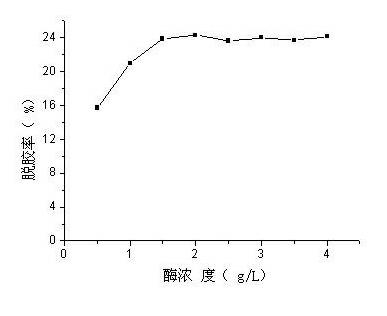

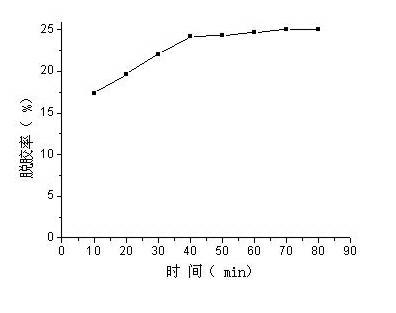

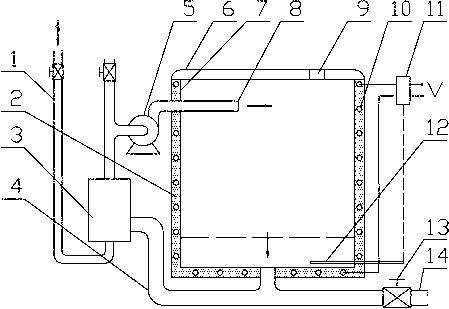

The invention discloses a silk fabric degumming method and a silk fabric degumming apparatus. The invention belongs to the technical field of silk degumming. The method is characterized in that the method comprises the steps that: water with a required volume is injected in a degumming tank according to the weight of silk fabric and a bath ratio of 1:40-50; a pH value of the water is regulated to 8.5-9.5; the water is heated to a temperature of 50-60 DEG C; 1.00-2.50g / L of alkali protease is added into the degumming tank; silk fabric is placed into the tank, and supersonic wave is started, wherein the supersonic wave frequency is 30-80KHz; the supersonic wave treatment is performed for 35-60min, and washing is carried out. According to the invention, factors influencing silk fabric degumming are analyzed, and optimal technical values of alkali protease concentration, degumming time, degumming temperature, pH value, and bath ratio are determined. Also, the degumming apparatus is improved, such that silk fabric degumming time is effectively reduced, and silk fabric degumming efficiency is greatly improved.

Owner:SHAOXING UNIVERSITY

Manufacturing method of washable mulberry silk quilt

The invention relates to a method for producing mulberry silk quilt which can be washed via water. Wherein, it comprises that degelatinizing the pod and using cotton machie to prepare cotton sheets, arranging cotton sheet in normal temperature to expand sericin; degelatinizing the cottom sheet; cooling, poaching, and neutralizing, adding flexible agent, filtering; adding water-resistant agent, drying at 100-150Deg. C for 30-60mins; tensioning the dried cotton sheet, to expand the cotton sheet, and packing it into coat.

Owner:潘新平

Functional silk non-woven xysma and producing process thereof

InactiveCN1552972AImprove insulation effectIncrease elasticityDe-gumming silkNon-woven fabricsCross-linkEmulsion

Functional silk non-woven wadding is prepared from natural silk, plant resin emulsion and inorganic nano bactericidal. The said emulsion is of self cross-linked anion resin, co-polymerized from acrylic diester, arylonitrile itaconic acid and N hydroxy acrylamide as cross-linking agent. The ratio of emulsion : silk is 100: (1.5-5.0) by dry weight. Silver ion nano bactericidal is also added into the wadding with the ratio of the bactericidal : silk is 100: (0.5-15.0). The product is soft and light, moisture-absorbing and gas permeable, high thermal insulation, elastic, water washing resistance, safety and usable widely.

Owner:丁永华

Tussah cocoon shell bio-enzyme degumming method and device

Owner:XIFENG SHENGSHI KAIFENG COCOON PRODS

Production method of natural colorful mulberry silk floss

InactiveCN102560696AReduce churnImprove protectionAnimal materialDe-gumming silkAlkaline waterColorful appearance

The invention discloses a production method of natural colorful mulberry silk floss. The traditional common technology is difficult to reserve the natural color of the colorful cocoons, and the color is faded into white in the processing process. The production method disclosed by the invention comprises the following steps of: selecting cocoons and removing impurities from colorful cocoons; permeating with alkaline water; reeling silk from cocoons to remove the pupa; cleaning and dewatering; adding a degumming agent to keep color and refining; removing gum and grease; decontaminating, rinsing and dewatering; adding a spun silk softening agent; regulating the pH value to 4-8; and dewatering and drying to obtain the silk floss. The method has the advantage of simple technology, and the produced silk floss has the advantages of colorful appearance, even color and luster, low trash content, soft mouthfeel, good tearing toughness and no peculiar smell and can achieve the standard of producing high-quality mulberry silk floss quilts.

Owner:HUZHOU ACAD OF AGRI SCI

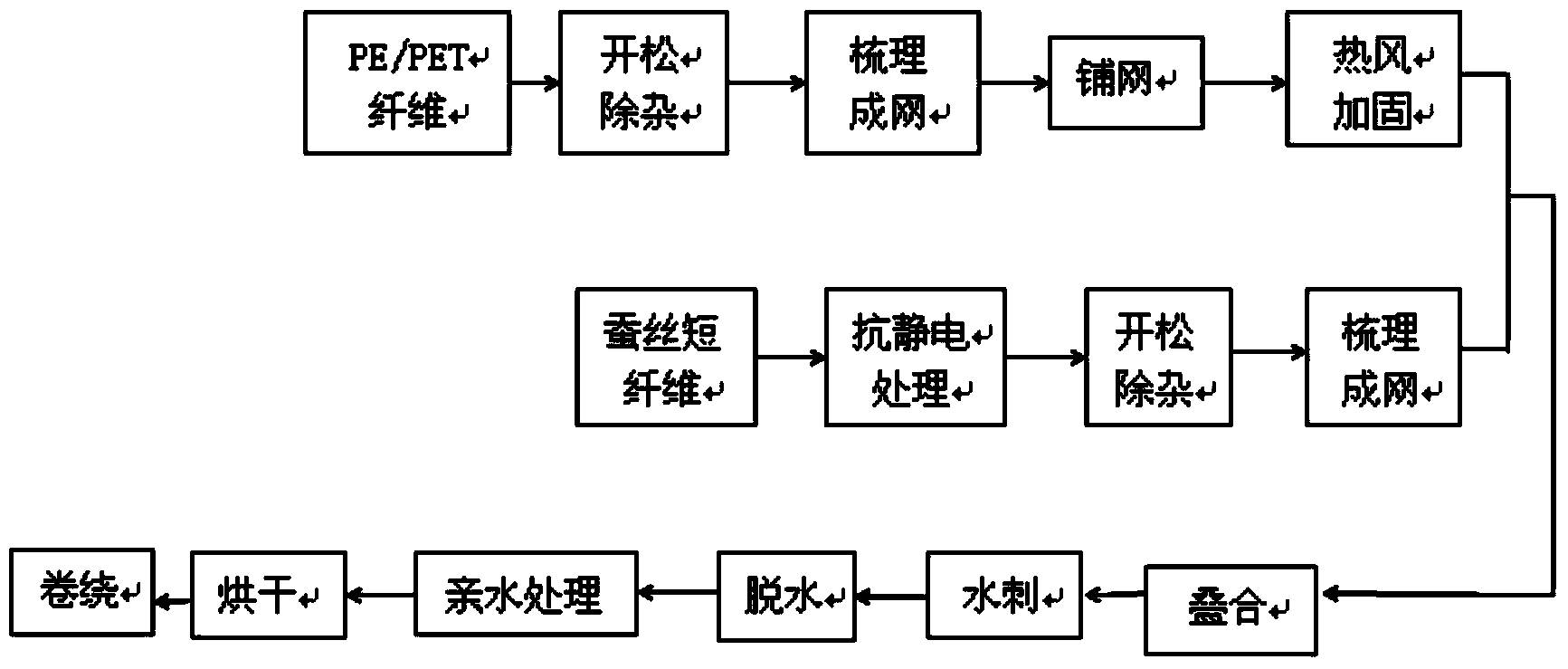

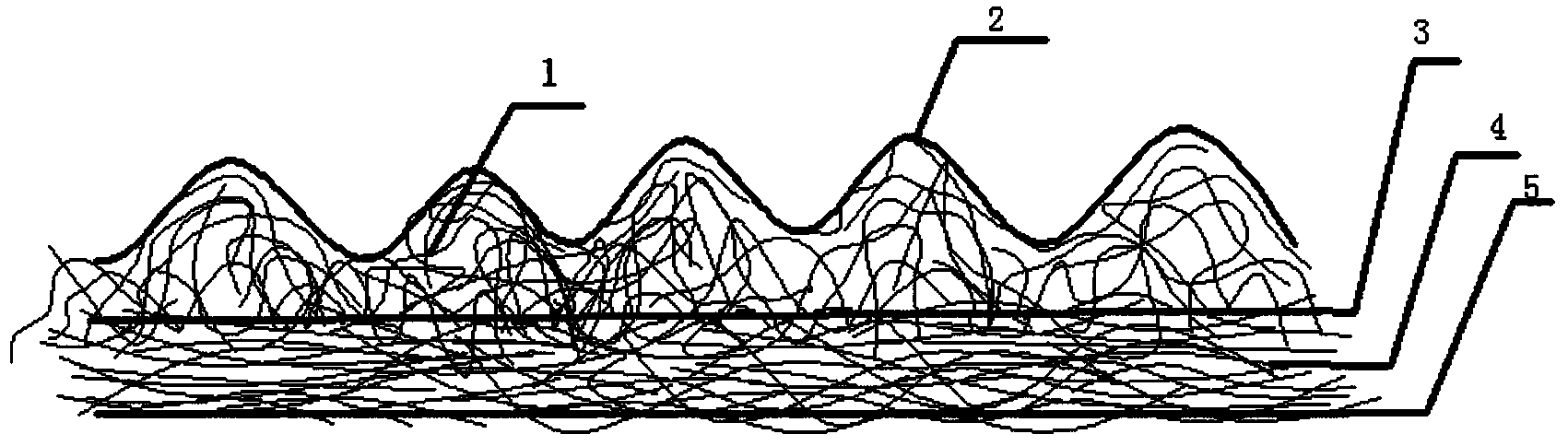

Silk/ES semi-perforated structure non-woven material and method for preparing same

The invention relates to a silk / ES semi-perforated structure non-woven material and a method for preparing the silk / ES semi-perforated structure non-woven material. The non-woven material is formed by compositing two fiber net layers. The two fiber net layers are combined through spunlace in a tangling mode. The surface-layer fibers are provided with holes, the bottom-layer fibers are not provided with holes, and accordingly a semi-perforated structure is formed. The preparing method includes the steps that silk fibers are fed into a cotton storage box, debonding and dissociation are carried out to make the silk fibers evenly mixed and opened, and then carding and net laying are carried out to acquire the surface-layer silk fiber net; opening, carding, net laying and hot air bonding and strengthening are carried out on ES fibers to acquire the bottom-layer fiber net; the surface-layer silk fiber net is laid on the bottom-layer fiber net, the surface-layer silk fiber net and the bottom-layer fiber net are put into a spunlace unit together, and after spunlace forming is finished, dewatering, hydrophilic treatment, drying, winding and cutting are carried out to acquire the silk / ES semi-perforated structure non-woven material. The non-woven material prepared according to the method is provided with the semi-perforated structure, silk utilization ratio is high, water permeation time is short, and reverse osmosis amount is small.

Owner:SHANDONG DERUN NEW MATERIAL TECH

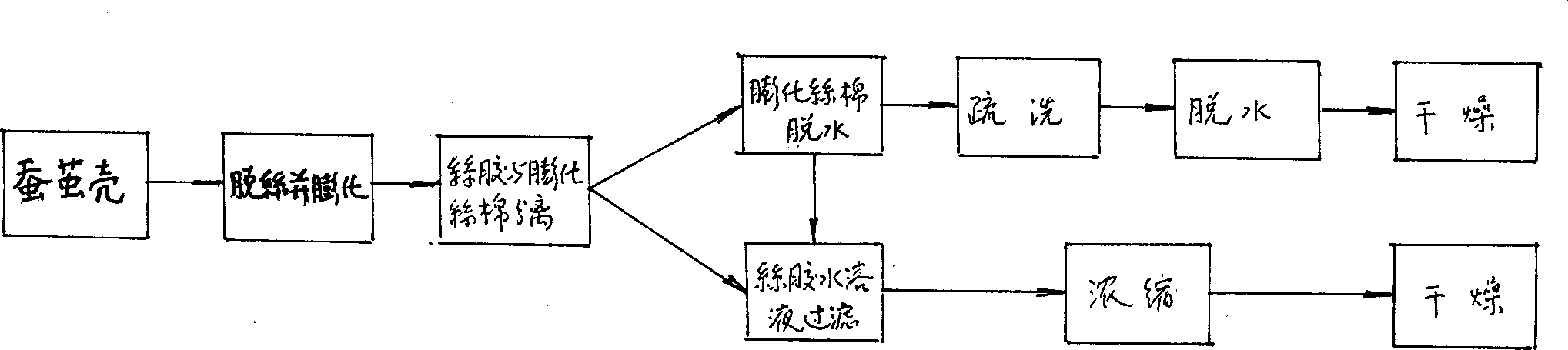

Process and apparatus for removing sericin from silkworm cocoon

A process for removing sericin from silkworm cocoons includes such steps as adding silkworm cocoons into a rotary container, sealing the container, high-temp. and high-pressure treating for a certain, time to strip sericin from silk, suddenly releasing pressure to make the cocoon become puffed silk floss separated from silk and sericin, separating sericin from silk, and dewatering each of them. Its apparatus is composed of the container with exploding membrane on the cover and drier.

Owner:江苏泗绢集团有限公司

Bamboo fiber and mulberry silk interwoven fabric and production process thereof

InactiveCN104294448AThe flashing effect is obviousFeel comfortableTextile solvent-dyeingAnimal materialFiberEngineering

The invention discloses a bamboo fiber and mulberry silk interwoven fabric. The bamboo fiber and mulberry silk interwoven fabric comprises warp and weft which are interwoven, the blending ratio of warp yarn made of mulberry silk to weft yarn made of bamboo fiber is 50:50, the warp density of the bamboo fiber and mulberry silk interwoven fabric is 80-120 pieces per centimeter, and the weft density of the bamboo fiber and mulberry silk interwoven fabric is 30-40 pieces per centimeter. The bamboo fiber and mulberry silk interwoven fabric is natural and environmentally friendly, the mulberry silk serves as the warp yarn, the bamboo fiber serves as the weft yarn, and the fabric has the advantages that the color flashing effect is obvious, the hand feeling is comfortable, and the fabric is deodorized and resistant to bacteria, fresh, cool, durable, wearproof, good in drooping effect and the like.

Owner:JIANGSU SUNSHINE

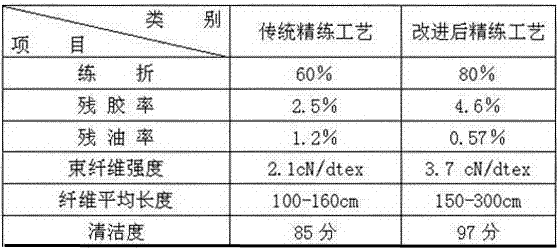

Refining process for tussah cut cocoon

ActiveCN103757713AQuality improvementImprove qualityDe-gumming silkBreaking strengthAgricultural engineering

The invention discloses a refining process for a tussah cut cocoon. The process is realized through the following steps of: pre-soaking, washing and dehydration, cocoon cooking, washing and dehydration, bleaching, washing and dehydration, softening, dehydration, drying, waste silk opening. The process provided by the invention solves the problems of difficult deoiling, excessive sericin shedding, crispy and breakable silk, undesirable silk floss bulking intensity and fibre breaking strength, low cleanliness and the like in traditional process technologies of tussah cut cocoon shells. According to the process, the product quality can reach and exceed the national industry standards, thereby improving the quality of tussah silk refined waste silk and tussah silk quilt products.

Owner:HENAN MINXING COCOON SILK

Method for producing silk quilt by utilizing sericin

InactiveCN103005932AImprove stabilityIncrease profitAnimal materialDe-gumming silkYarnBiochemical engineering

The invention relates to a process for producing a silk quilt by utilizing sericin, which comprises the following steps of: sequentially carrying out vacuum penetration and cocoon cooking on raw material cocoons; then carrying out one-particle hemming to form a yarn sheet; carrying out sericin fixation processing on the yarn sheet to enable the sericin to be fixed; and after carrying out post-treatment, drawing to form a silk quilt inner tube. The process is characterized in that in both the vacuum penetration and cocoon cooking processes, a raw silk softener is added; the yarn sheet is timely dried by infrared light or hot air after one-particle hemming is carried out to form the yarn sheet; before the sericin is fixed, the yarn sheet has sericin content of 15 percent to 26 percent; and the sericin is fixed by a cross-linking agent. According to the invention, the sericin can be reserved to the greatest degree; and denatured proteins of the silk quilt can be reduced, and silk fibers containing the sericin not only are soft, but also have stable performance.

Owner:ZHEJIANG SCI-TECH UNIV

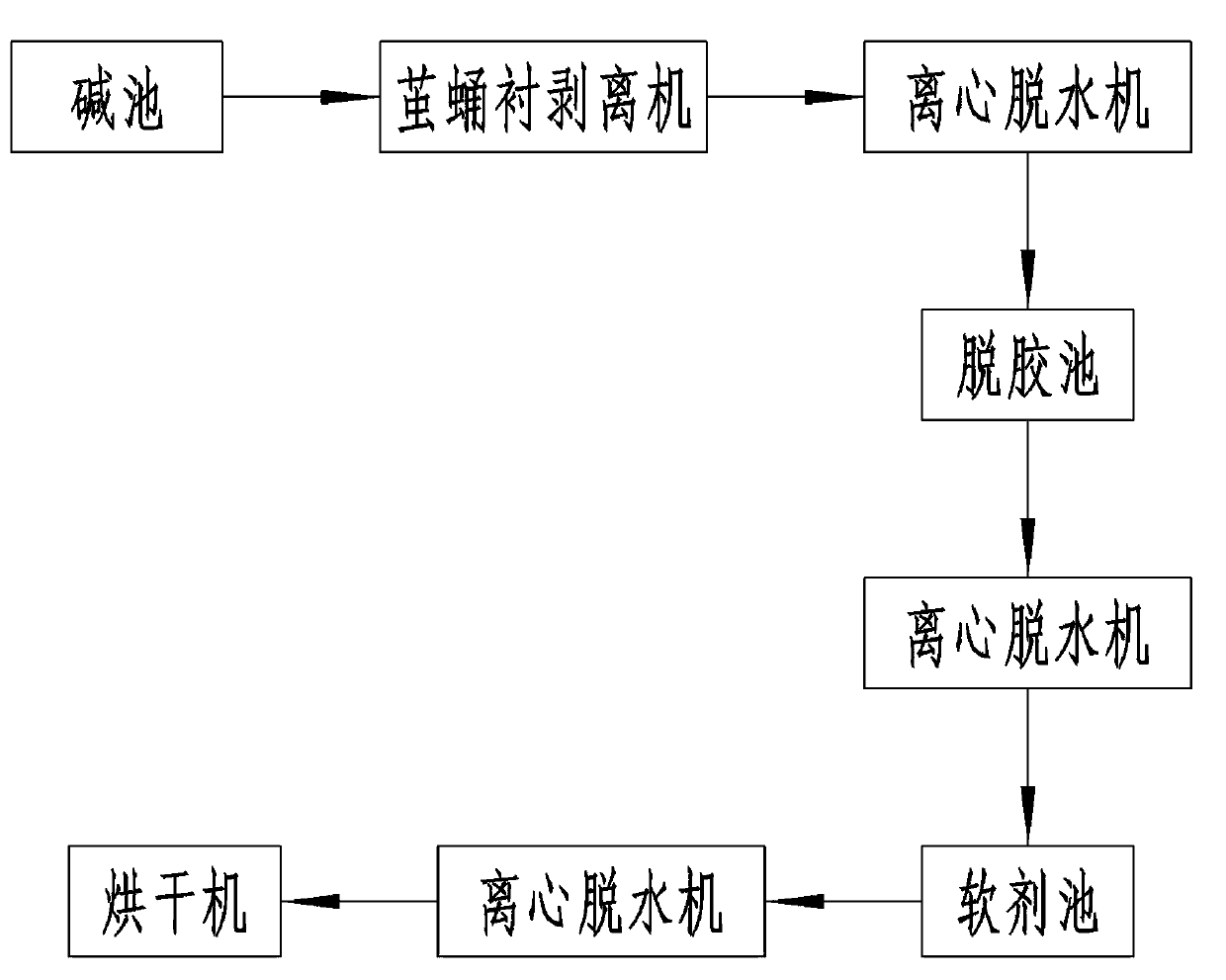

Method and device for processing silk floss winter clothes raw materials by silkworm light defective cocoon

InactiveCN104195649APerformance is not affectedIncrease productivityDe-gumming silkSilk obtainingPolymer scienceOrganic chemistry

The invention discloses a method and device for processing silk floss winter clothes raw materials by silkworm light defective cocoon. The method and device for processing the silk floss winter clothes raw materials by the silkworm light defective cocoon are achieved through the following steps of alkali soaking, cocoon stripping, cleaning and dewatering, degumming agent dipping, cleaning and dewatering, softening agent dipping, cleaning and dewatering, and drying. According to the method and device, the silkworm light defective cocoon is processed to be the silk floss winter clothes raw materials, light defective cocoon and basin residues are completely utilized, processed silk floss is soft and clean, the processing method and device are simple, the production efficiency is high, and the production cost is low.

Owner:YIZHOU ZHUANGGE SILK

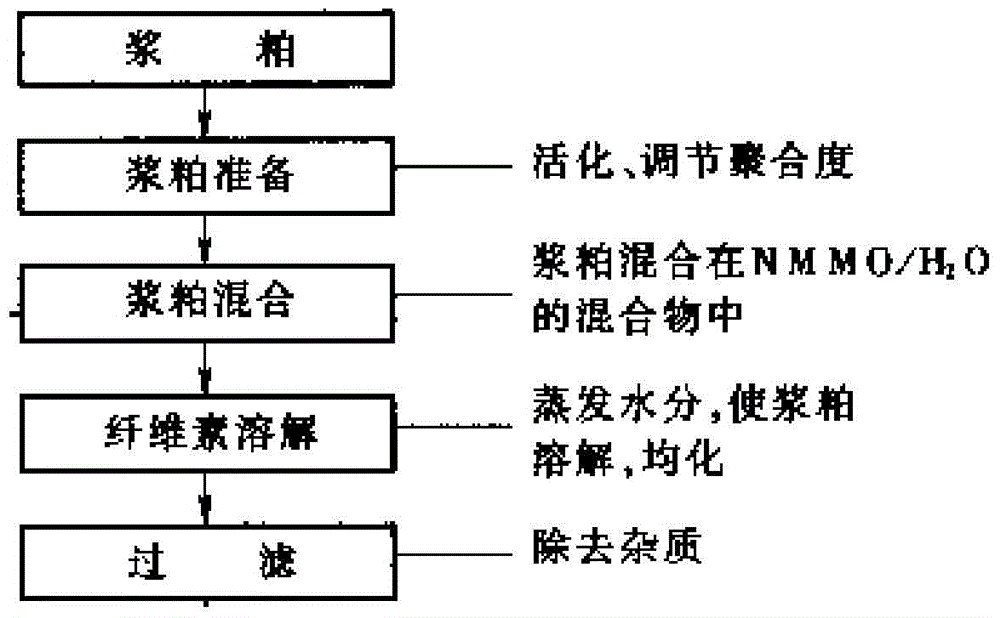

Preparation method of silk protein fibers

InactiveCN105803568AGood hygroscopicityHigh strengthConjugated cellulose/protein artificial filamentsFilament/thread formingCelluloseProtein solution

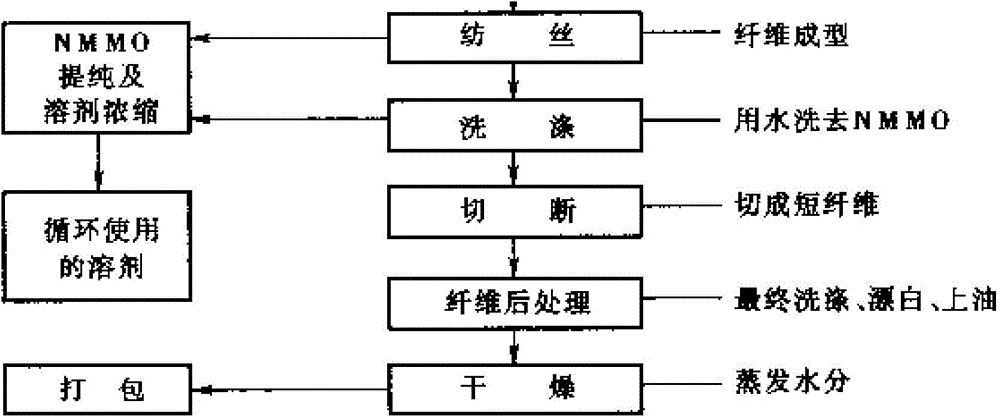

The invention discloses a preparation method of silk protein fibers. The preparation method comprises the following steps of: (1) after peeling off cocoon shells into fragments, degumming a sodium carbonate solution with the mass percent of 3% for three times, and putting the fragments into a vacuum drying box at the temperature of 75 DEG C and drying; then dissolving dried silk protein into a 1.5wt% NaOH solution; (2) carrying out slicing treatment on tree raw materials, and boiling, finely selecting before bleaching, bleaching, finely selecting after bleaching, pulping, dehydrating and drying to prepare pulp; (3) filling the pulp and liquid-state NMMO (Methylmorpholine-N-Oxide) into a mixing kneading tank and heating the mixture at vacuum to 90 DEG C, so as to prepare a spinning solution with the cellulose concentration of 10%-25%; and (4) proportioning and commixing a silk protein solution in the step (1) and the spinning solution in the step (3), and adding a nano aromatic auxiliary agent and spinning by adopting a dry-wet-method process. The silk protein fibers provided by the invention have soft luster and a smooth and soft hand feeling of real silk, and also keep good moisture absorption and high fiber strength of natural silk; and the silk protein fibers are more skin-friendly and comfortable.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Mulberry bark degumming method

The invention discloses a mulberry bark degumming method. The method comprises the following steps: removing surface layer spots and scabs from new sheared ramulus mori, peeling mulberry bark, and removing mulberry bark surface green peel; immersing the above obtained processed mulberry bark in water, striking, and washing by using clear water; carrying out steam explosion on the above obtained processed mulberry bark to obtain mulberry bark fibers, and washing the mulberry bark fibers by using clear water; carrying out microbial degumming on the washed mulberry bark fibers, washing fermented mulberry bark fibers by using clear water, and dehydrating; immersing the dehydrated mulberry bark fibers in an oil emulsion, taking out the immersed mulberry bark fibers, stacking, and oiling; and loosing the oiled mulberry bark fibers, drying the flattened mulberry bark fibers in an oven to obtain a finished degummed mulberry bark fiber product. The method adopts steam explosion physical effect to loosen gums and also adopts a biological technology to digest residual partial gums in order to realize cleaning and efficient degumming purposes and solve the technical problems of traditional mulberry bark degumming methods.

Owner:SOUTHWEST UNIVERSITY

Biological degumming cocoon reelability method for China oak silkworm

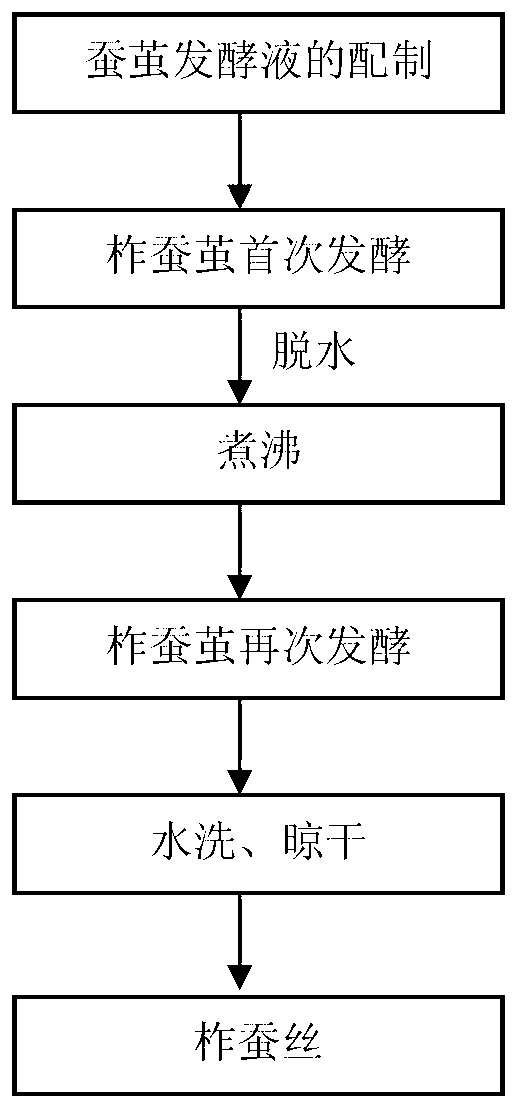

The invention relates to a biological degumming cocoon reelability method for China oak silkworm. The degumming cocoon reelability of the China oak silkworm is performed through a step-by-step microbial fermentation method, and the method comprises the following steps: (1) dissolving a composite fungicide special for biological degumming cocoon reelability of the China oak silkworm in water, adding brown sugar and EM ecological probiotics stock solution, and uniformly mixing to obtain the silkworm cocoon fermenting solution; (2) soaking the China oak silkworm in the fermenting solution for performing first fermentation; (3) taking out the China oak silkworm and dehydrating after the first fermentation, and boiling; (4) soaking the boiled China oak silkworm in the silkworm cocoon fermenting solution again, and performing second fermentation; and (5) taking out the China oak silkworm and dehydrating after the fermentation is ended, and washing and drying. The strength, elongation, cohesion, flexibility and other physical indexes of the China oak silkworm by employing the method are greatly improved, and the monofilament strength of the China oak silkworm is improved from the 3.4g / D in the original process to 3.55g / D in the process.

Owner:中蚕(大连)生物科技发展有限公司

Method for improving color concentration of natural colorful silk

InactiveCN101109150AIncrease contentMaintain color intensityAnimal materialDe-gumming silkThioureaPigment

The invention discloses a method for effectively increasing the pigment content in silk fibroin of silk from natural color silkworms. Wherein, urea and thiourea are used as pigment-transferring agent, and the fabric of silk from natural color silkworms is treated by hi-temp soaking or soaking-steaming so as to increase the content of natural pigment in silk fibroin of silk from the natural color silkworms. The content of natural pigment on the silk fibroin in fabric of silk from natural color silkworms treated by the invention is 2-3 times higher than that of non-treated fabric of silk from natural color silkworms with the same degumming rate after going through ordinary degumming process, this can not only maintain the color concentration of natural color silk, but also meet the requirement for silk fabric, and improves the actual use value and added value of natural color silk.

Owner:SUZHOU UNIV +1

Processing method for keeping color of color silks

InactiveCN101979725AWon't be lostAchieve color fixation effectSilk filament obtainingDe-gumming silkComputer sciencePigment

The invention discloses a processing method for keeping the colors of color silks. The method comprises the following steps of: (1) fully blending, peeling and selecting each batch of color cocoons to guarantee that reeled cocoon silks have a uniform color; (2) selecting the common collective control sample meeting control requirements; (3) soaking the cocoon silks accordant with the common collective control sample in hot water of which the temperature is 90 to 100 DEG C for 60 to 80 minutes, and steaming the cocoon silks in a steamer at the temperature of between 95 and 150 DEG C and the humidity of between 80 and 100 percent for 30 to 60 minutes; and (4) performing the traditional degumming treatment and subsequent traditional processes on the steamed cocoon silks. By the method, pigments can enter the interior of fibroin through steaming and does not fade after the silks are washed, so that color fixing effect is achieved.

Owner:GUANGXI GUIHUA SILK CO LTD

Treatment process for degumming and bleaching silk

ActiveCN104342916AImprove permeabilityGood effectDry-cleaning apparatus for textilesBleaching apparatusWater resourcesEngineering

The invention discloses a treatment process for degumming and bleaching silk. The treatment process comprises the following steps: carrying out pretreatment, namely firstly putting the silk into a closed container, introducing 20-50g / L active oxygen for carrying out the pretreatment on the silk; and then carrying out treatment of primary refining, secondary refining, bleaching, washing with water, and shaping. The treatment process disclosed by the invention has the beneficial effects that at the pretreatment stage, the silk is put in the closed container, the 20-50g / L active oxygen is introduced for carrying out the pretreatment on the silk, macromolecular chains of silk glue can be broken, and a silk-glue layer is cracked and loose, so that the permeation and the action of primary-refining liquid and secondary-refining liquid in the next procedure are accelerated, the action time is reduced, and the used amount of the primary-refining liquid and the secondary-refining liquid is reduced. The treatment process disclosed by the invention has the advantages that a water resource is saved, the used amount of chemicals is reduced, and the environment pollution is reduced.

Owner:HUZHOU NEW ZHONGHU KNITTED CLOTHING MAKING

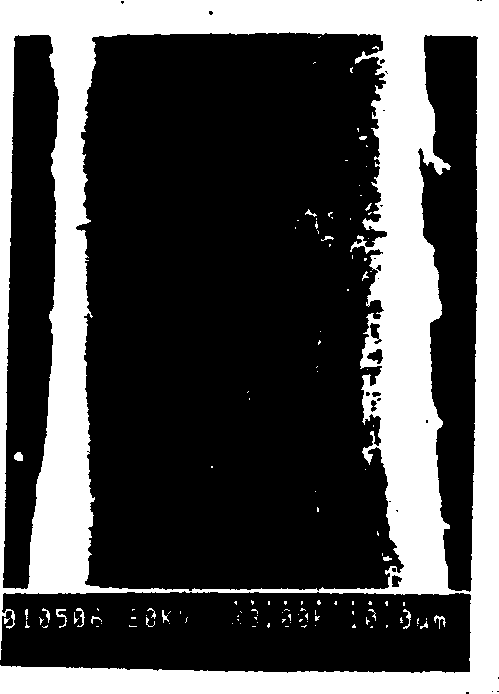

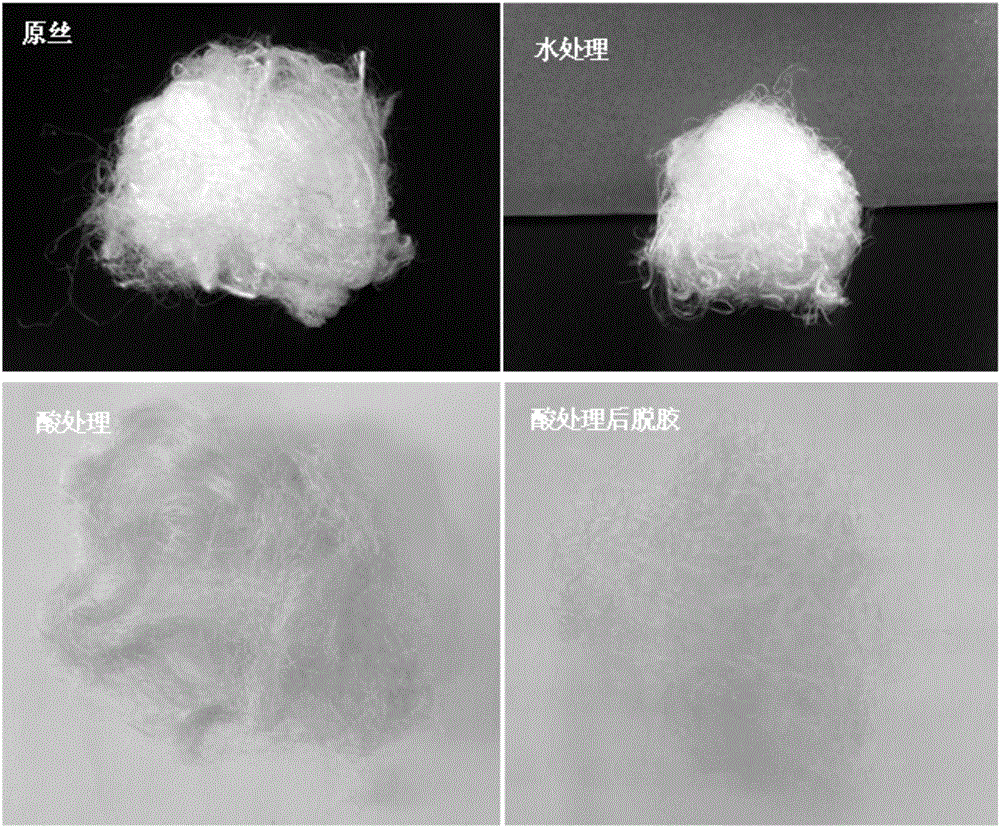

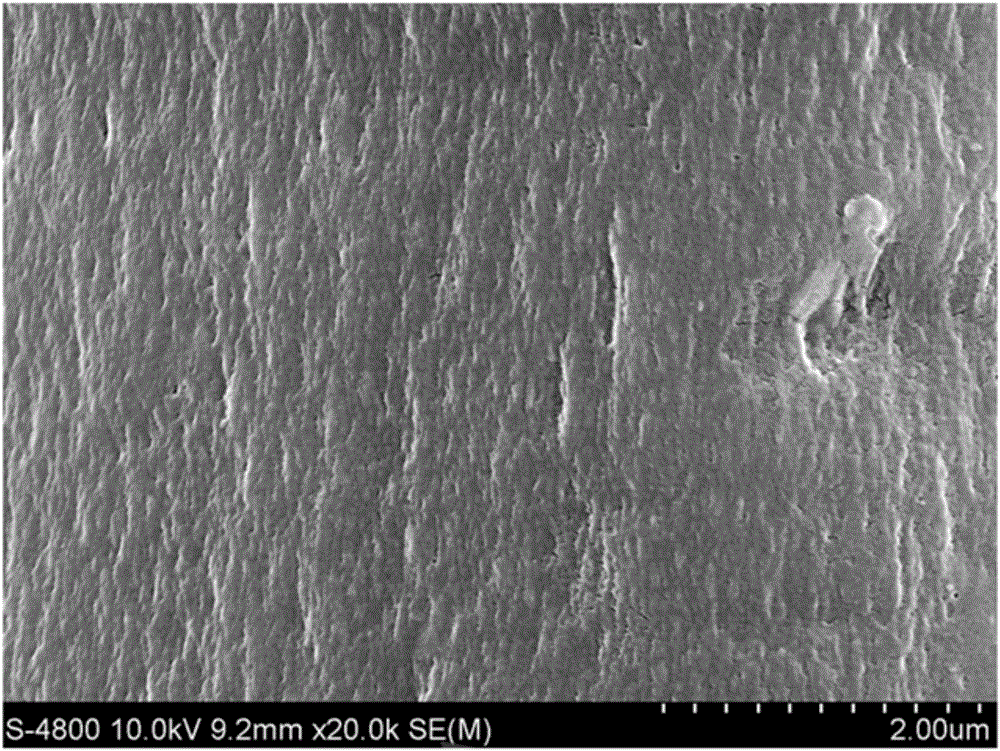

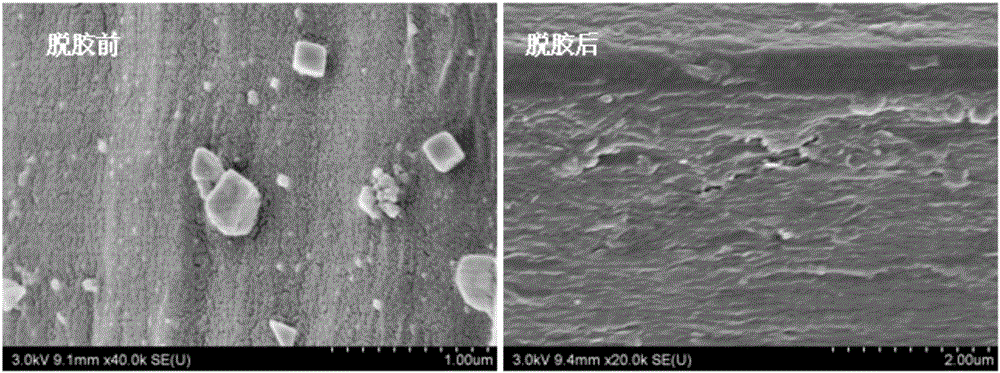

Antibacterial fibroin protein fiber and preparation method thereof

ActiveCN106835688AEvenly dispersedAvoid uneven loadBiochemical fibre treatmentDe-gumming silkBiocompatibility TestingAntibacterial agent

The invention provides antibacterial fibroin protein fiber and a preparation method thereof. The preparation method comprises the following steps: preparing a formic acid solution, adding silver salt into the formic acid solution, and stirring and dissolving; soaking a silk fiber which is not degummed or is partially degummed into the formic acid solution containing the silver salt, and performing lucifugal reaction for a period of time; completely washing the silk fiber product after the reaction, and drying to obtain a silver-containing silk fiber product; and performing degumming treatment on the silver-containing silk fiber product to obtain the antibacterial fibroin protein fiber. The preparation method provided by the invention is simple and easy in batched production; and in the prepared antibacterial fibroin protein fiber, the antibacterial agent nano-silver is mainly distributed in the fiber, so that excellent biocompatibility of the fibroin protein can be maintained, the biological toxicity exposed by the nano-silver is avoided, broad-spectrum antibacterial property is given to the fibroin protein fiber product, the antibacterial property is durable, and the antibacterial fibroin protein fiber is very suitable for people sensitive to the antibacterial agent and can serve as biological products such as antibacterial dressing and antibacterial suture lines.

Owner:杭州季盛新材料有限公司

Production method of pure silk quilt with jasmine flower fragrance

The invention provides a production method of a pure mulberry silk quilt with jasmine flower fragrance. The production method comprises the following steps: (1) putting matured silkworms on a spinning net; (2) stripping silk to obtain a crude soft piece; (3) degumming the crude soft piece; (4) cleaning with clean water and then dehydrating; (5) removing impurities, reshaping, and drying for later use; (6) picking and storing jasmine flowers; (7) taking the flowers and waiting for scenting; (8) parqueting and scenting by piling; (9) weighing the soft piece and pulling to be fluffy; (10) cutting the soft piece; (11) pulling the cut soft pieces open one by one, laying in a criss-cross manner, after laying is completed, checking and finishing, and removing impurities; (12) placing a silk-escape-preventing gauze above and below a finished soft bat respectively, so that silk escape is avoided; (13) covering the soft bat with a bat cover; and (14) quilting a seam between the bat cover and a silk floss bat and shaping. The mulberry silk quilt obtained by adopting the production method provided by the invention has no rib strip, no pupal fat and no chemical residue and is more natural and environment-friendly compared with the traditional silk quilt produced from silk floss; and the mulberry silk quilt has jasmine flower fragrance and also maintains the characteristics of the silk quilt of softness, breathability, closed fit and comfort.

Owner:GUANGXI GUIHUA SILK CO LTD

Nano-silver antibacterial cotton fabric

InactiveCN105088780AEvenly distributedImprove washabilityDe-gumming silkVegetal fibresProtein solutionFiber

The invention relates to a nano-silver antibacterial cotton fabric. The nano-silver antibacterial cotton fabric is prepared by placing cotton fibers into a sodium periodate solution to perform oxidation reaction in dark to obtain oxidized cotton fibers; preparing a pure silk fibroin protein solution; soaking the oxidized cotton fibers into the silk fibroin protein solution to react to obtain silk fibroin-grafted cotton fibers; soaking the silk fibroin-grafted cotton fibers into the silver nitrate solution; taking the silk fibroin-grafted cotton fibers out of the solution; and then heating the silk fibroin-grafted cotton fibers for 5 minutes in the microwave oven at the power of 800 W. According to the nano-silver antibacterial cotton fabric, the cotton fabric serves as a substrate; the nano-silver antibacterial cotton fabric is produced in situ by utilizing the silk fibroin protein through a microwave radiation method; and a layer of silk fibroin protein is grafted on the surface of the cotton fabric, so that the cotton fabric has the hand feeling and luster of silk.

Owner:SUZHOU ZHENGYECHANG INTELLIGENT TECH

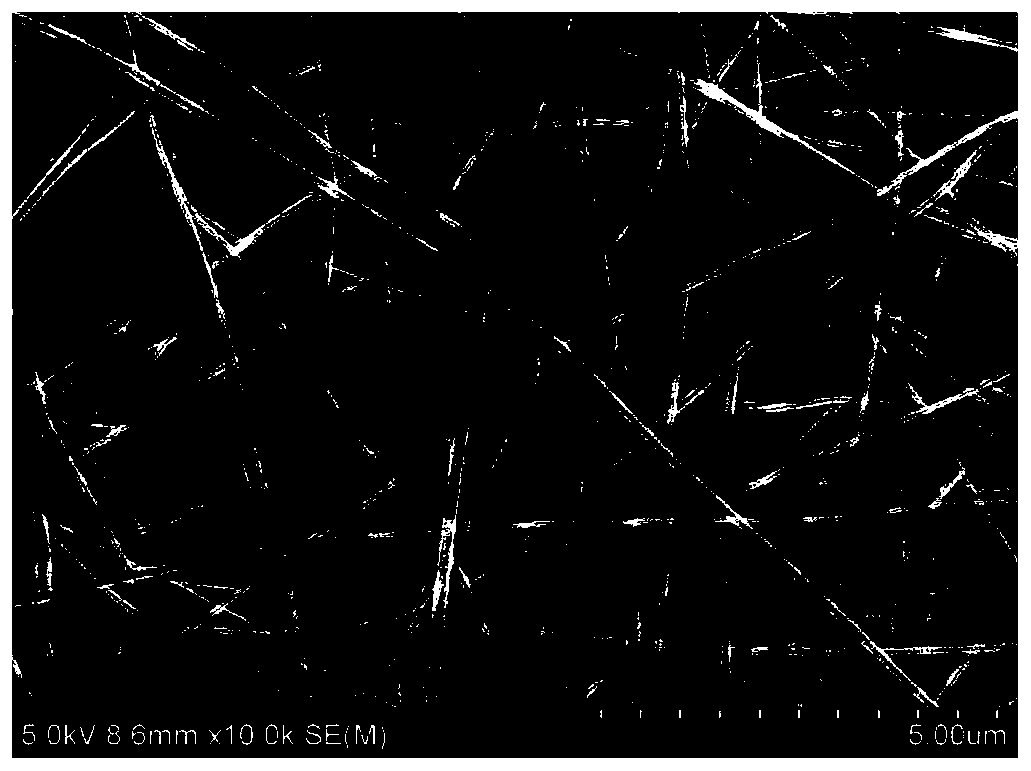

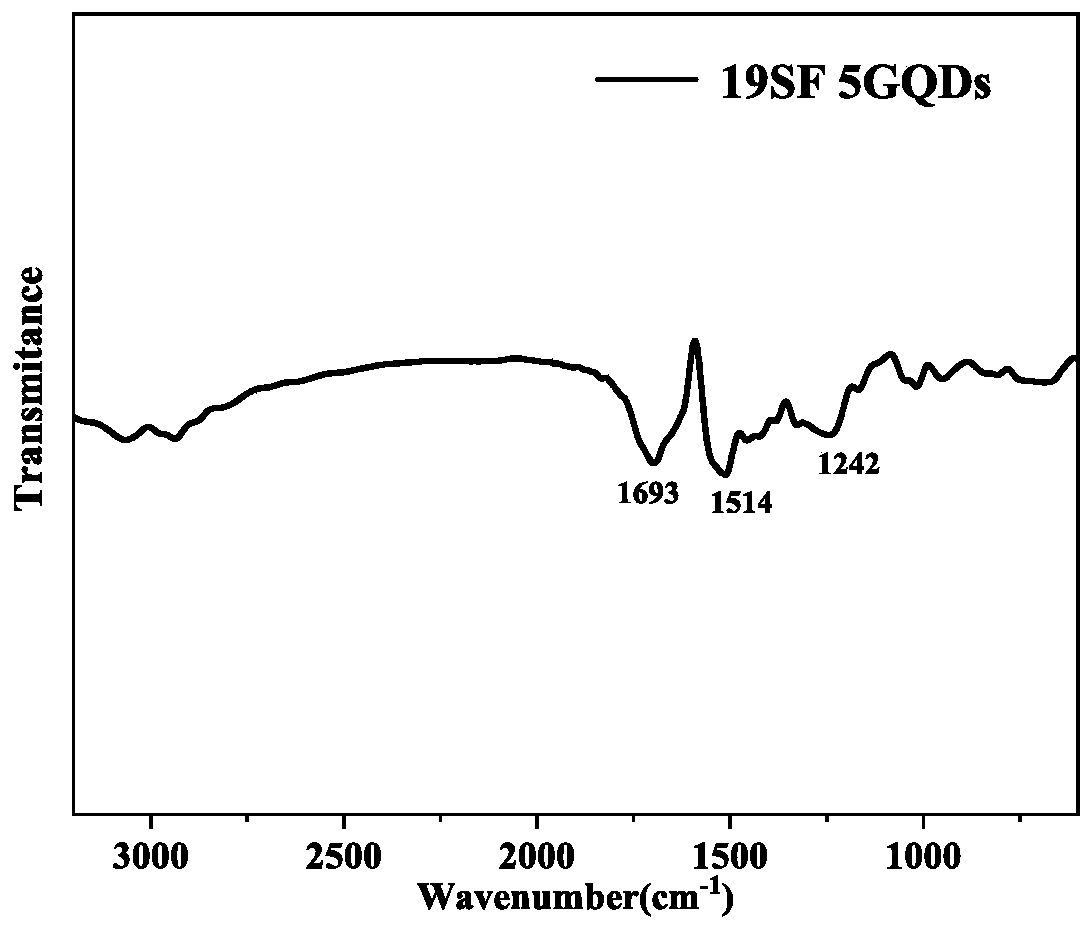

Sulfonic quantum dot/silk fibroin composite nanofiber membrane and preparation method and application thereof

PendingCN110453378AGood biocompatibilityPromote degradationMonocomponent fibroin artificial filamentElectro-spinningFiberFreeze-drying

The invention provides a sulfonic quantum dot / silk fibroin composite nanofiber membrane and a preparation method and application thereof. The preparation method comprises the following steps that degumming treatment is performed on natural silk, and silk fibroin is obtained; then, fibroin is dissolved in a lithium bromide water solution, and a silk fibroin sponge is obtained through dialysis, centrifugal and freeze drying; the silk fibroin sponge is dissolved into formic acid to be mixed to be uniform, then, a sulfonate graphene quantum dot water solution is ultrasonically and uniformly dispersed into a silk fibroin-formic acid solution, and a composite nanofiber membrane is prepared through electrostatic spinning equipment; mouse fibroblasts are used for performing cell viability evaluation on the composite nanometer member, and it shows that the composite nanometer membrane has the excellent biocompatibility. The prepared composite fiber membrane has the good biocompatibility and degradability, has the potential for promoting proliferation and differentiation of human bone marrow storm stem cells, and has the good biologic medical material application prospect.

Owner:SHANGHAI UNIV +1

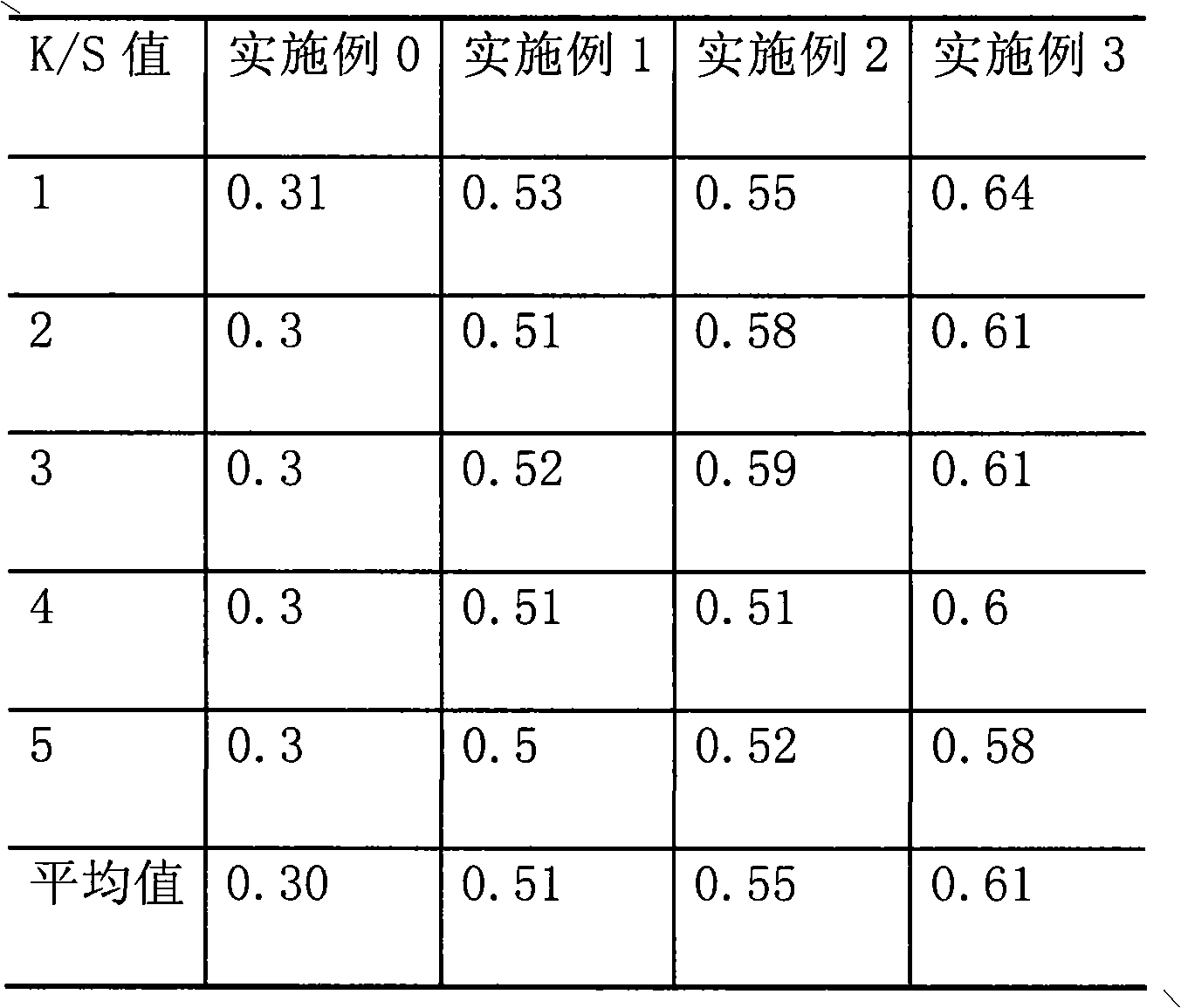

Method for improving color depth and light fastness of natural color silk fibers

InactiveCN102505464AIncrease color depthImprove light fastness levelDe-gumming silkLiquid/gas/vapor textile treatmentComputer visionColor strength

The invention belongs to the technical field of textile processing, and relates to a method for improving color depth and light fastness of natural color silk fibers, which includes steps: subjecting the natural color silk fibers to steam treatment, interlinking treatment, washing, graft treatment, washing, degumming, washing, washing, deepening and drying to obtain finished products. The naturalcolor silk fibers processed according to the technical scheme has the color depth 6-7 times of that of the natural color silk fibers conventionally scoured and degummed, and a K / S (color strength) value is increased by 582-613%, and the K / S value of the natural color silk fibers is reduced by 15-19% as compared with that of untreated natural color silk fibers. The color depth of the natural colorsilk fibers is improved evidently, and the light fastness level of the natural color silk fibers is also improved.

Owner:SUZHOU UNIV

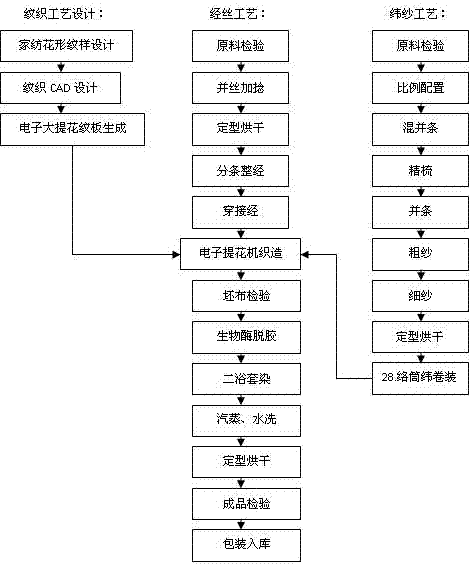

Multi-element blended yarn and cross interwoven jacquard textile fabric and production method thereof

InactiveCN104775222AImprove spinnabilityGood warmth retentionBiochemical treatment with enzymes/microorganismsDe-gumming silkEngineeringNatural fiber

The invention provides a multi-element blended yarn and cross interwoven jacquard textile fabric and a production method thereof. A multi-element blended yarn is used as a weft yarn, and silk is used as a warp yarn, and the multi-element blended yarns are interwoven with the silk; the multi-element blended yarn is formed by blending three fiber components such as hemp fibers, cotton fibers and protein composite renewable cellulosic fibers. The natural fibers and the functional fibers are woven in a jacquard weaving technology, so that the additional characteristics such as environmental-friendliness, softness, warmth, good brightness, top grade and luxury can be given to the textile fabrics.

Owner:JIUJIU SILK CO LTD

Environment-friendly silk degumming method

InactiveCN107268092AQuality improvementImprove the lubrication effectDe-gumming silkAlkaline proteaseWax

The invention mainly relates to the technical field of silk processing, and discloses an environment-friendly silk degumming method, which includes immersion, enzymolysis, fermentation and washing. The method is simple, conditions are mild, high temperature and high pressure are not needed, energy is saved, the method is suitable for batch processing, the degumming rate can reach 89.3 percent, obtain silk is fine and smooth, the color is bright and white-yellow, and economic income can be increased by 12.7 percent. pH of immersed silk is regulated to be alkaline, lipase is added to decompose grease and wax components in the silk, high-temperature cooking is avoided, so that energy is saved, pH is then regulated to be acidic, bromelain is added, and enzymic preparations with different pHs are sequentially used for enzymolysis. The conventional joint use of alkaline protease and surfactant is changed, the environment is protected, soluble impurities under different pHs are sufficiently removed, sericin and remaining fat are decomposed, and the silk degumming rate is increased.

Owner:HEFEI JUFENG THROWING

Initial refining process of macular cocoons

InactiveCN102134755APromote expansionEasy to spinAnimal materialDe-gumming silkSoap solutionAqueous solution

The invention discloses an initial refining process of macular cocoons, which is characterized in that the initial refining process is performed according to the following steps: soaking the macular cocoons in water solution at the temperature of 100 DEG C, using soda ash to regulate pH value to 10, soaking for 12 hours, soaking the macular cocoons after removing pupae in the water solution at the temperature of 60 DEG C, using the soda ash to regulate the pH value to 7.5, soaking for 10-12 hours, using a scutching machine to scutch the wet macular cocoons after low-temperature soaking, placing cocoon filaments after dehydration into the water solution at the temperature of 60-70 DEG C, adding hydrogen peroxide for bleaching, placing the cocoon filaments after bleaching into a refining cylinder, adding water, heating with steam to 60-70 DEG C, adding 105 textile soap solution which accounts for 2% of the weight of raw materials for refining for 1 hour, flushing the well refined cocoon filaments by using an automatic flushing machine, adding water for soaking the cocoon filaments after dehydration, adding a spun silk finishing agent which accounts for 4% of the weight of the raw materials, soaking for half an hour, drying the cocoon filaments after dehydration with the steam, selecting and removing impurities in the cocoon filaments after drying, and classifying.

Owner:NANCHONG YINHAI SILK

Method for producing washable fresh silkworm cocoon silk floss winter coat

InactiveCN104195647ASimple processing methodSimple equipmentSucessive textile treatmentsSilk filament obtainingBiologic ProductsBiological product

The invention discloses a method for producing a washable fresh silkworm cocoon silk floss winter coat. The method for processing silk floss winter coat raw materials through silkworm light defective cocoons includes the following steps of fresh cocoon treatment, alkali soaking, cocoon silk stripping, washing and dewatering, dipping in a degumming agent, washing and dewatering, dipping in a softening agent, dipping in silk protective essence, washing and dewatering, and drying. According to the method for processing the silk floss winter coat raw materials through fresh silkworm cocoons, the high-quality silk floss winter coat and fresh pupas are acquired, processed silk floss is soft and clean, the processing method and equipment are simple, production efficiency is high, production cost is low, the quality of the fresh pupas is good, and the pupas are good raw materials of food and biological products.

Owner:YIZHOU ZHUANGGE SILK

Application of protease and lipase to manufacture of mulberry silk product

InactiveCN102383202ASolve degummingSolve the problem of degreasingAnimal materialDe-gumming silkBiotechnologyEngineering

Application of protease and lipase to manufacture of a mulberry silk product has the following characteristics: the invention employs purified efficient alkaline lipase and protease and is accompanied with mature chemical refining method, so that silkworm cocoon or thin skin black cocoon that can not be used in silk reeling is mixed with alkaline lipase and protease, cooperated with a proper amount of surfactant, insulated naturally for 11.5-12.5 h with a bath ratio of 1:10-20 and a pH of 10.5-11 at 48-52 DEG C until cooled, taken from the pot, flushed, refined and treated with soft processing to obtain a fine draft sheet. The invention can well solve problems of degumming and oil removal in a prior silk spinning combing technology, reduce chemical raw material amount for producing per ton of silkworm fine dry draft by 2 / 3, save 5000 yuan of chemical material, 100 ton of water and 5 ton of coal for producing per ton of silkworm fine dry draft, promote application and popularization of industrial biological technology to silk inserts and processing of functional product, advance effective utilization and conversion increment of silk leftover and fill blanks of high quality velvet product home and abroad.

Owner:常德诺雅蚕丝制品有限公司

Degumming method of silk

The invention discloses a degumming method of silk. The method comprises the steps of firstly soaking the to-be-processed silk in an ammonia solution, heating, stirring, and filtering the solution to obtain silk, then arranging the silk into a 30% ethanol solution, heating the solution until the solution is boiled, maintaining the temperature for a given time, arranging the processed silk into a sodium bicarbonate solution, heating the solution to 70 to 80 DEG C, maintaining the temperature for 60 to 100 minutes in a stirring state, and cooling the solution to the room temperature; washing the processed silk by utilizing deionized water, and removing the glue proteins; finally drying the silk to obtain the degummed silk. By adopting the gumming method of the silk, the silk can be well degummed, and the degumming rate can reach more than 67.4 percent and can reach up to 80.5 percent.

Owner:WUXI CANMEI TECH

Method for purely-neutral enzyme-degumming and reelability of tussah cocoons

ActiveCN103469313AImproved biological enzyme methodAchieving zero emissionsDe-gumming silkAnimal ForagingHydrolysate

The invention discloses a method for purely-neutral enzyme-degumming and reelability of tussah cocoons. The method comprises the following steps of 1, pre-treatment in a neutral environment: immersing tussah cocoon shells in clear water of which the weight is 10-50 times weight of the tussah cocoon shells for 12-24h, carrying out heating to a temperature of 90-100 DEG C, and carrying out heat preservation for 1-4h, and 2, enzyme treatment: carrying out cooling to a temperature of 45-60 DEG C, adding 2079 alkaline protease and / or trypsin, wherein the weight of the 2079 alkaline protease and / or trypsin is 5-20% of that of the tussah cocoon shells, and carrying out heat preservation until raw silk degum content is less than or equal to 3%. The method abandons the existing alkaline degumming technology or other chemical technologies, does not use any chemical reagents, does not produce alkaline waste water, improves an alkaline biological enzyme method, and realizes thorough neutral degumming. The sericin hydrolysate obtained by the method can be recovered and used for foods, health products, cosmetics, forage or organic fertilizer. The method realizes zero discharge and is a purely-neutral, green and environmentally-friendly production technology.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for processing spun silk with natural colour silkworm

The present invention discloses a method for making natural color cocoon into spun silk. Said method includes the following steps: cutting cocoon and removing pupa, first water cooking, first cooling, first rinsing, secondary water cooking, secondary cooling, secondary rinsing, dewatering, drying and carding, in which the described secondary water cooking is characterized by that in the water cooking process an alkaline swelling agent and a neutral softening agent are added, the cocoon can be cooked until the surface silk gum of the silk is completely dissolved, and the cocoon layer is completely fluffed and can be opened.

Owner:桐乡市华神丝绸有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com