Refining process for tussah cut cocoon

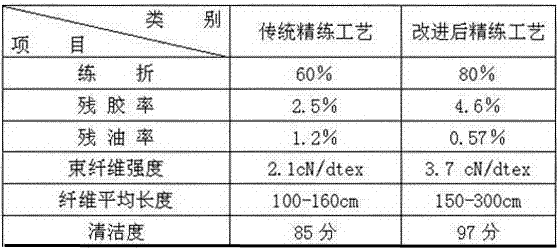

A cocoon cutting and refining technology, which is applied in the refining process of tussah cocoon cutting, can solve the problems of difficult oil removal, low cleanliness, and excessive sericin shedding, so as to improve the quality of boiled cocoons and achieve good impurity removal effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The scouring process of the tussah silkworm cutting mouth cocoon of the present invention is realized through the following steps:

[0034] ①. Presoaking: each immersion pool has a water capacity of 6 tons, heated to 40°C, added 3 kg of pharmaceutical additives sodium carbonate, 2 kg of 105 detergent, 400 kg of cocoons, PH value of 10, soaking time, 12 hours; keep turning and pulling in the middle to make it evenly soaked; rinse and dehydrate with cold water after leaving the pool;

[0035] ②Rinse and dehydrate: fully rinse and dry;

[0036] ③ Cocoon cooking: 1,500 kg of water per tube, heated to 100°C, adding 3 kg of pharmaceutical additives sodium carbonate, 2 kg of sodium bicarbonate, 1 kg of 105 detergent, T kg of pancreas and bleach, and the cocoon cooking time is 20 minutes, the pH value is 10, and 50 kg of dried cocoons are added to each tube;

[0037] ④ Rinse and dehydrate, fully rinse and dry;

[0038] ⑤ Bleaching: During scouring, the water volume per tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| residual oil rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com