Patents

Literature

756results about "Lappet-woven fabrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

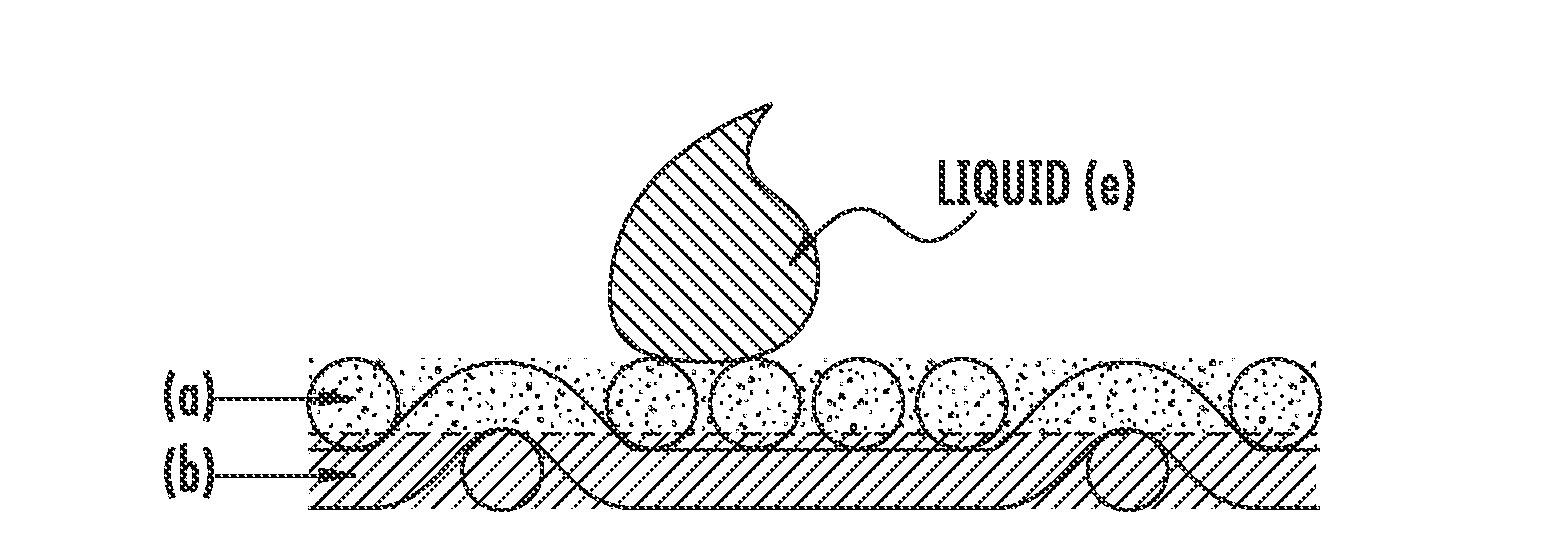

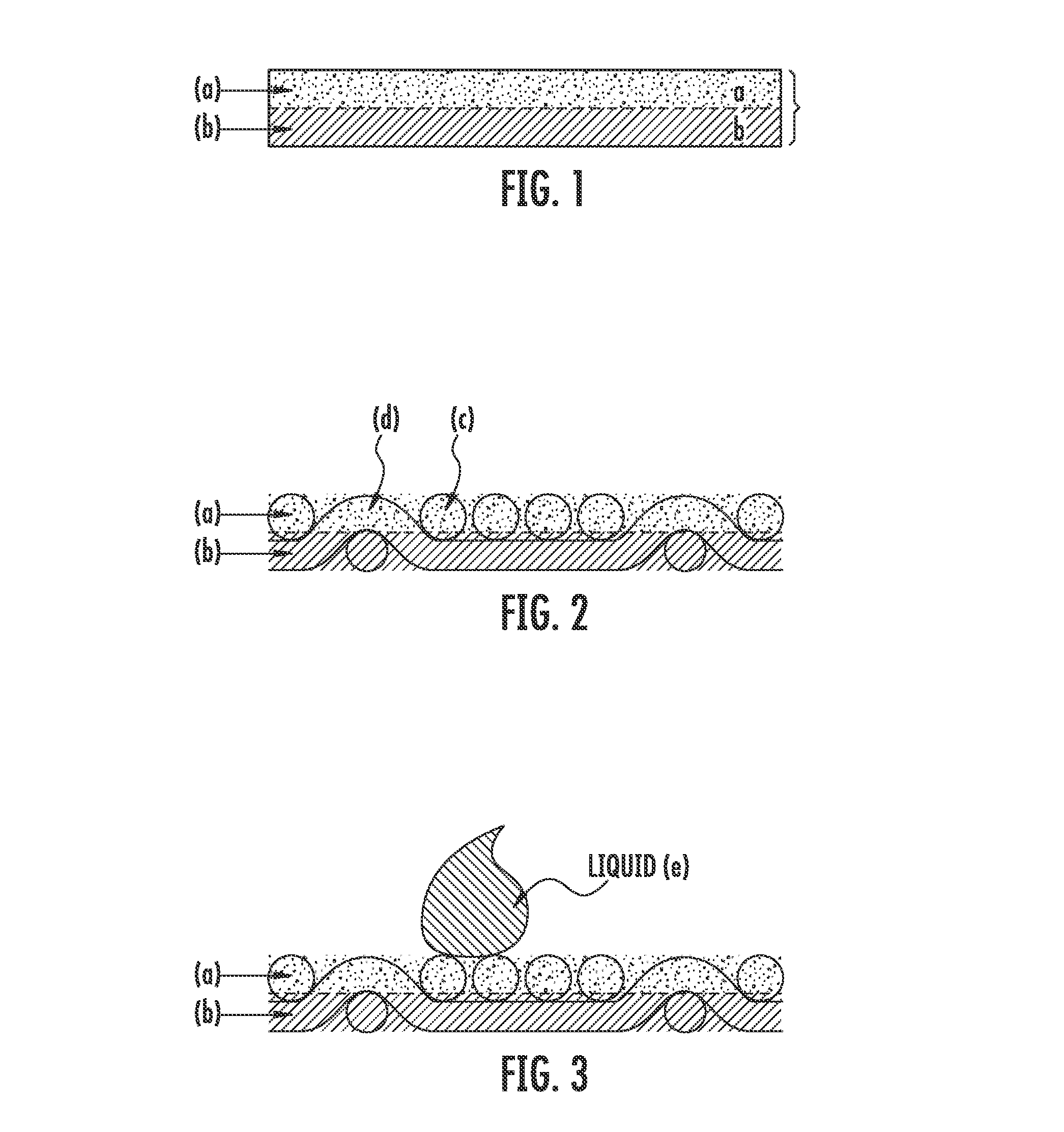

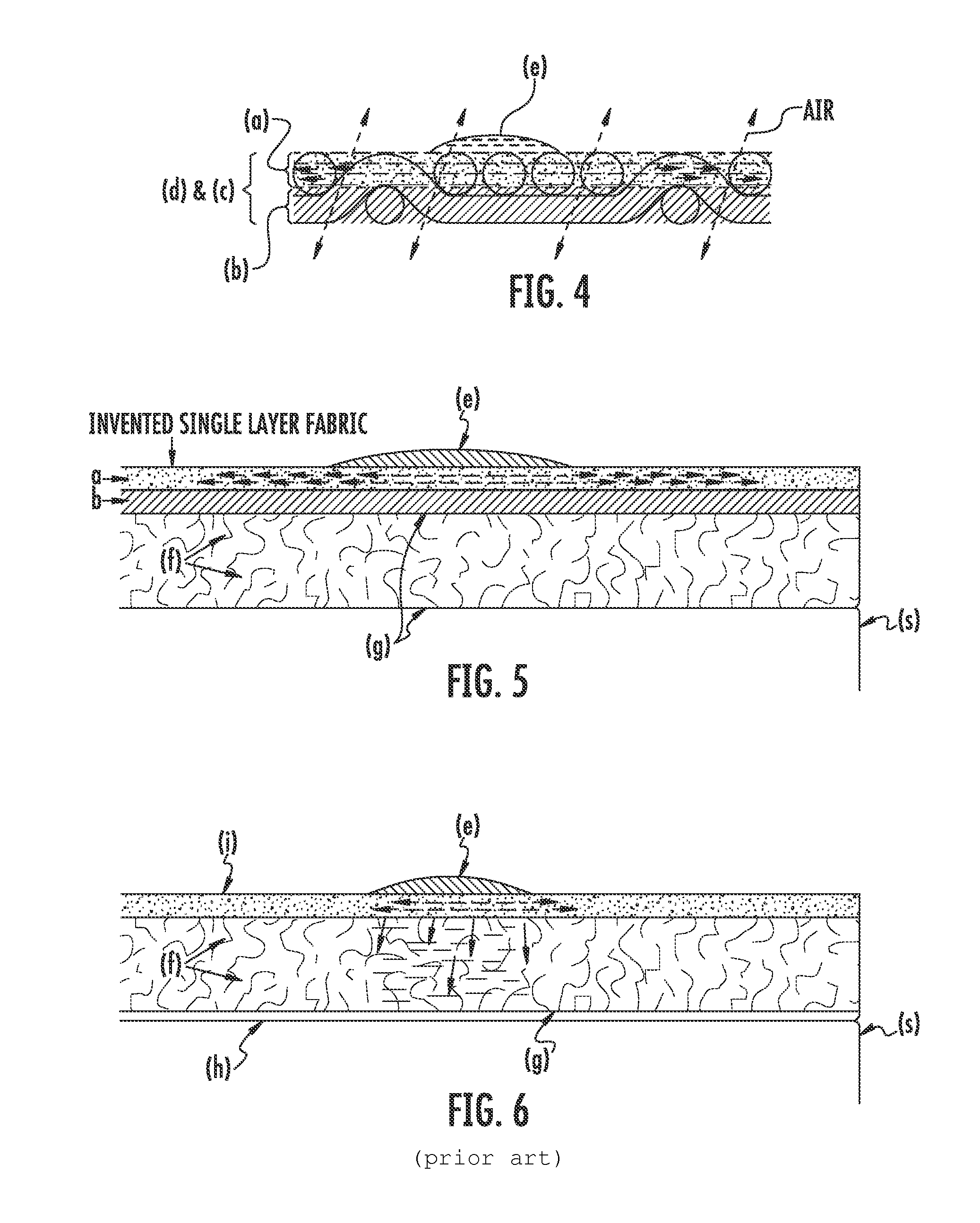

Semi-absorbent, semi-resistant, breathable fabric

A semi-absorbent, semi-resistant, breathable fabric includes a single-layer having a first, hydrophilic side that absorbs water, and a second, hydrophobic side; wherein the first, hydrophilic side of the single-layer fabric quickly spreads out a liquid that is absorbed laterally to a wider area such that the absorbed liquid does not seep or pass through to the second, hydrophobic side of the single-layer fabric under gravitational force. A method of making a semi-absorbent, semi-resistant, breathable fabric includes: subjecting a first side of a single-layer fabric to a hydrophilic amino functional polysiloxane softener; treating a second opposite side of the fabric with a fluorocarbon compound under low pressure such that the fluorocarbon compound penetrates no more than half of the fabric thickness; and drying and curing the fabric, preferably at a temperature of about 145° C. to 155° C. for about three minutes to about five minutes.

Owner:WELSPUN INDIA LTD

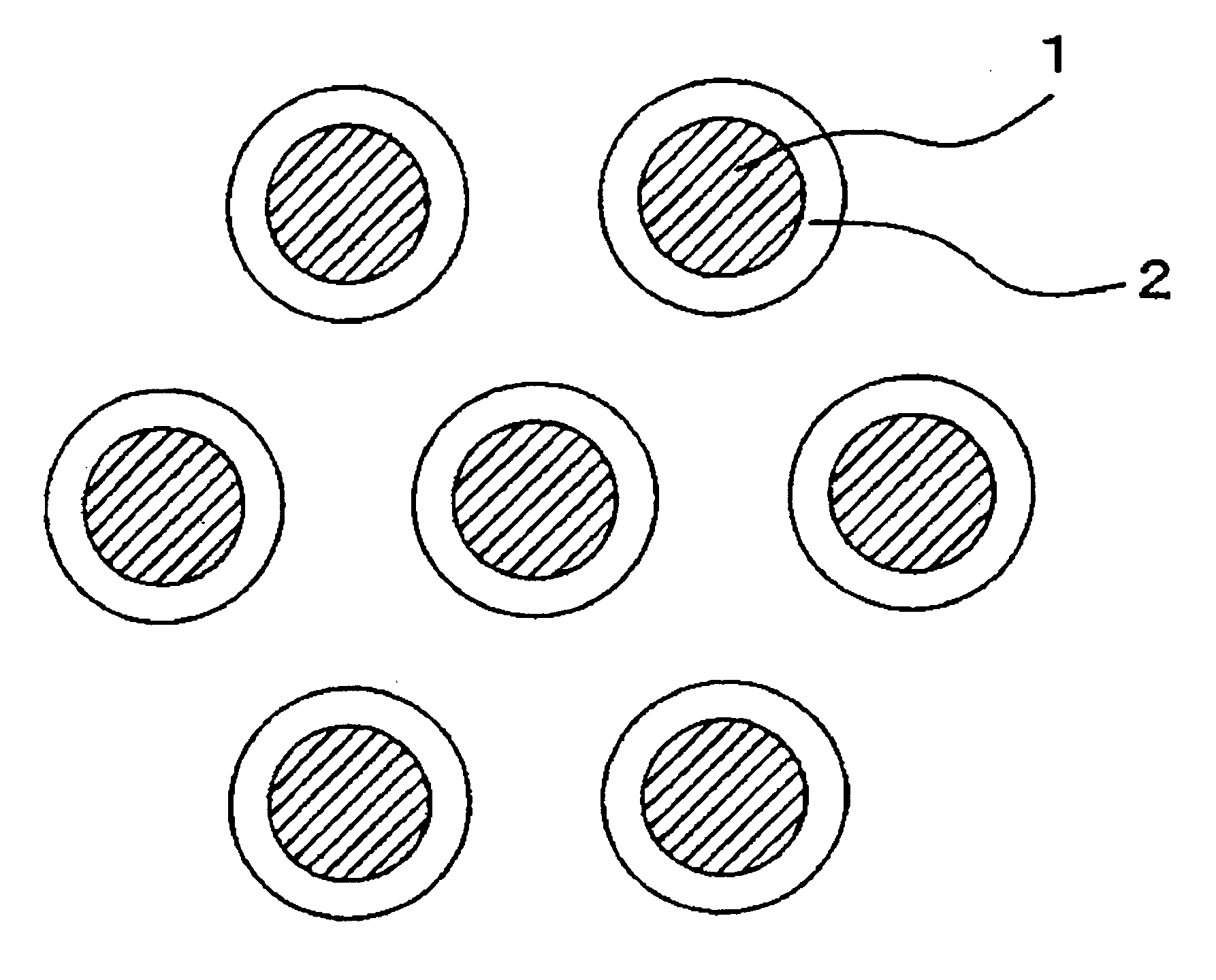

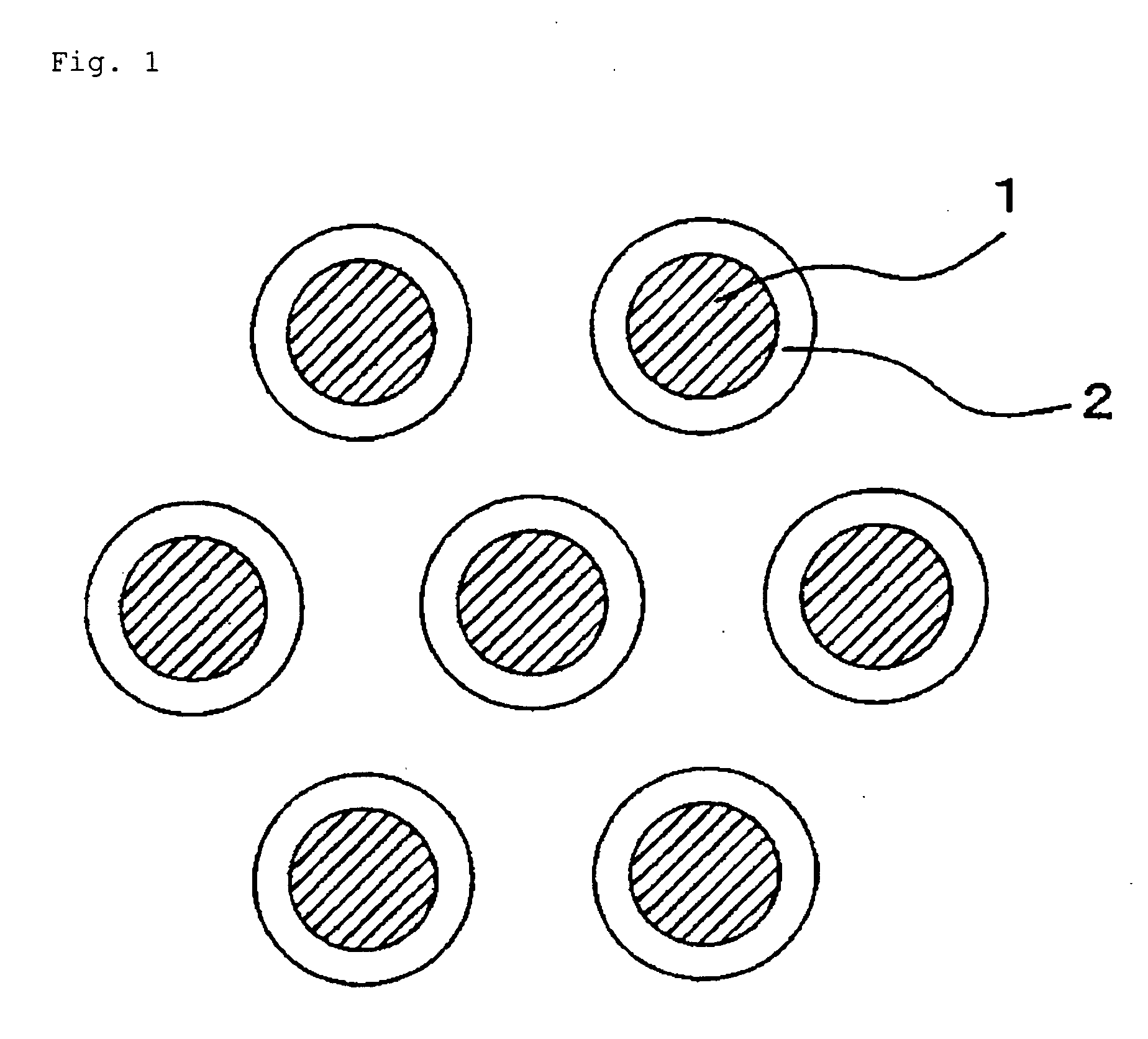

Woven or knitted fabric, diaphragm for speaker, and speaker

InactiveUS20070190881A1Low production costIncrease flexibilityFibre diaphragmsWeft knittingFiberEngineering

The invention aims to provide a woven / knitted fabric containing a conductive fiber preferably usable especially for a diagram for a speaker, and a diaphragm for a speaker and a speaker using the woven / knitted fabric. A woven / knitted fabric comprising a conductive fiber and a non-conductive fiber, wherein the woven / knitted fabric has a woven structure or a knitted structure of said non-conductive fiber and a continuous wiring forming a coil of the conductive fiber.

Owner:KB SEIREN LTD

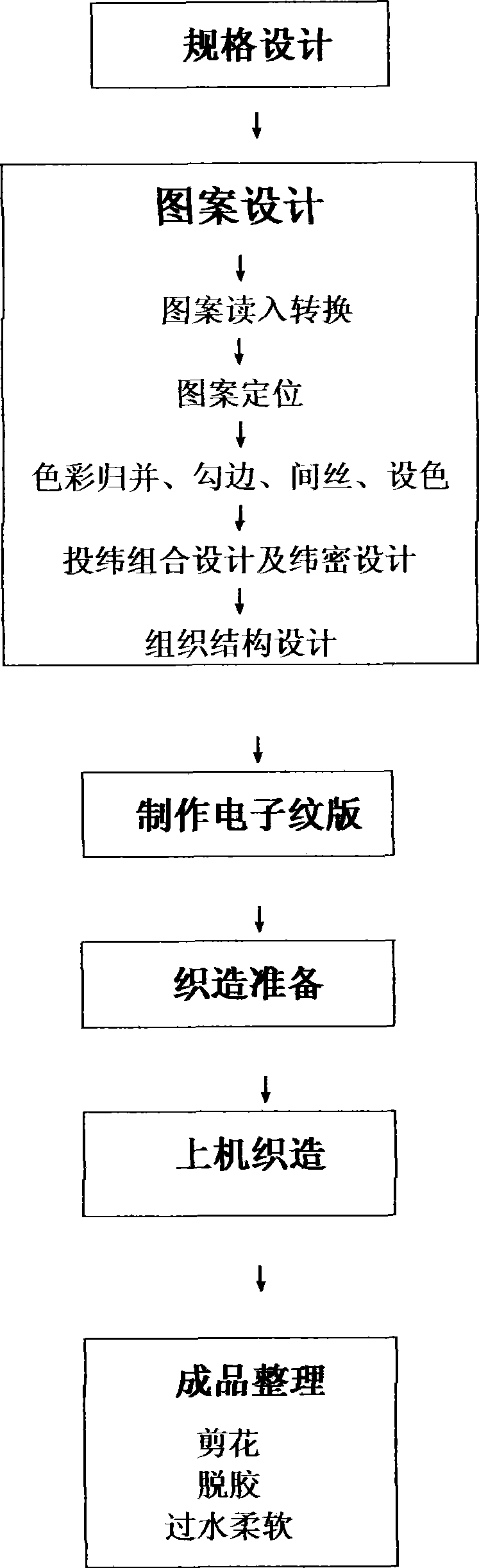

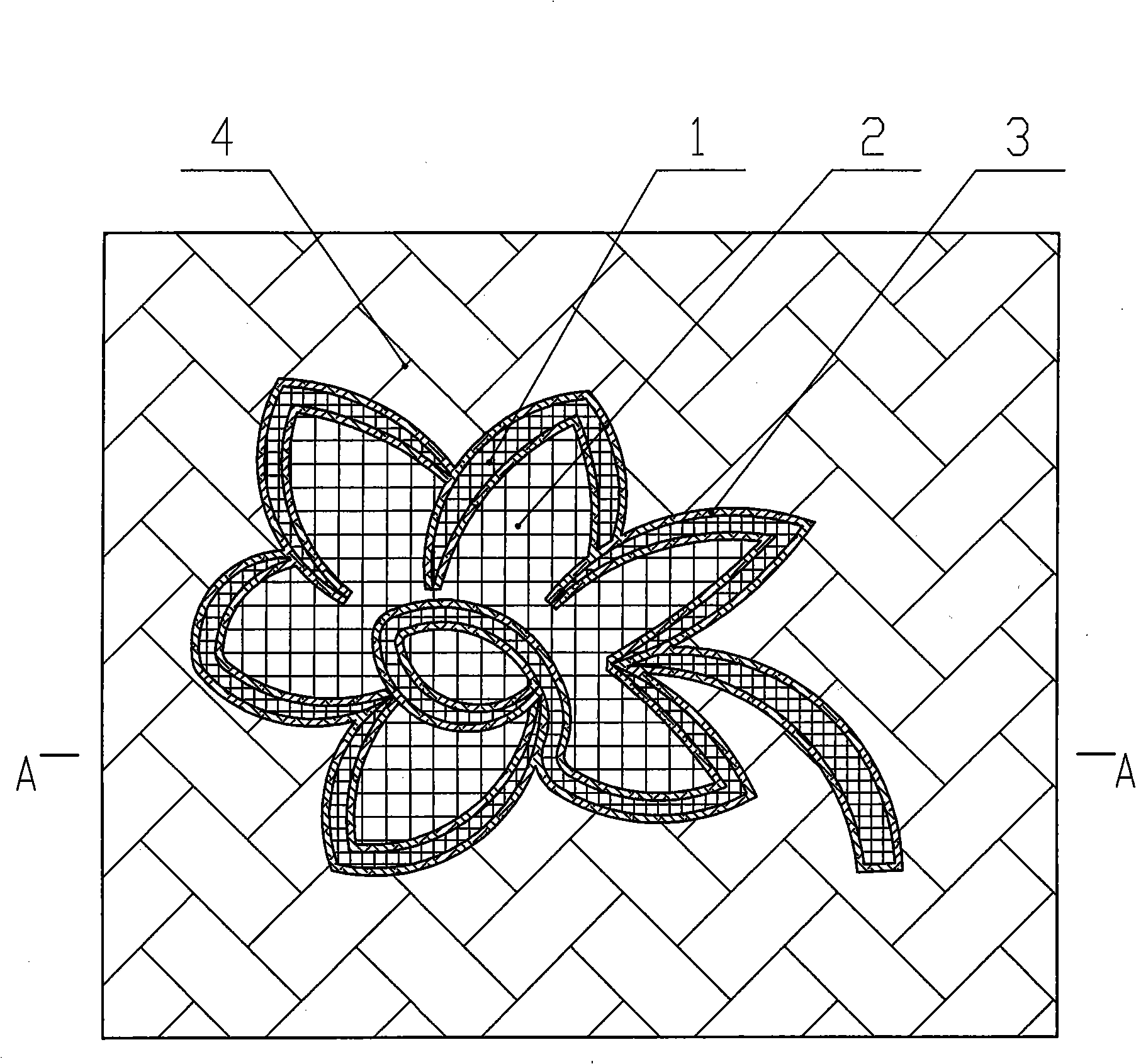

Production method of figured cloth different from embroidery characteristics

ActiveCN101423998AFeel goodStrong three-dimensional senseCard-punching apparatusSwivel-woven fabricsWork in processVolumetric Mass Density

The invention discloses a method for manufacturing jacquard fabrics different from embroidering properties, which comprises the following steps of specification design, pattern design, weaving preparation, weaving on a machine, and sorting of finished products, wherein the step of pattern design is to read target patterns of the jacquard fabrics to be manufactured into a computer, to adjust and position the position of the patterns on the fabrics according to the dimension of the finished products, to set a plurality of colors for the patterns, to merge the colors, and to manufacture an electronic pattern card through picking combinational design, longitude and latitude density design and weave construction design; and the step of sorting of the finished products is to perform trimming on the floating length of weft threads on the reverse side of semifinished products which are off the machine. The jacquard fabrics produced by the method have good hand feeling, strong third dimension, high ornamental value, and distinct contrast between rugged figured pattern and refined bottom plates, achieve the embroidering style after being subjected to two procedures of jacquard weaving and jacquard trimming, is accurate to position the patterns, are more suitable to be used as family spinning fabrics such as curtains and back cushions compared with the prior jacquard fabrics, and have the characteristics of short manufacturing time and low production cost.

Owner:DALI SILK ZHEJIANG

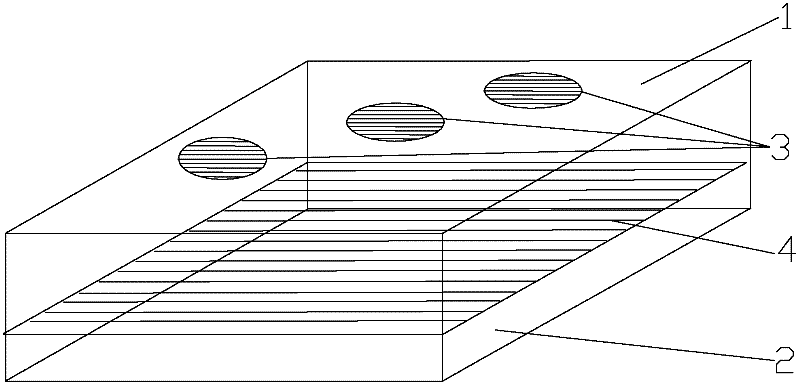

Three-layer fabric and tatting technique thereof

InactiveCN101660237ASimple weaving processEasy to produceSwivel-woven fabricsLappet-woven fabricsState of artSurface layer

The invention discloses a three-layer fabric and a tatting technique thereof. Side openings at both sides of the cloth width of the three-layer fabric are tatted into a single layer, a surface layer and a liner layer comprise foundation tissues and jacquard or pattern tissues, the foundation tissue of the surface layer is tatted by surface warp and surface weft, the jacquard or pattern tissue is tatted by liner warp and liner weft, the foundation tissue of the liner layer is tatted by the liner warp and the liner weft, the jacquard or pattern tissue is tatted by the surface warp and the surface weft, and a middle layer comprises a layer of middle weft and is clamped and fixed by a binding tissue in a complete tissue; at the junction of the foundation tissue and the jacquard or pattern tissue, surface-liner connection and liner-surface connection are carried out to form the binding tissue; the tatting technique comprises seven procedures of fabric design, warp beaming, loom tacking, tatting, desizing, softening and water washing, adopts a set of surface weft yarn system, a set of middle weft yarn system, a set of liner weft yarn system and two sets of warp yarn systems for tatting,and the tatting sequence is the surface firstly, the middle secondly and the liner thirdly or is reverse; and the invention solves the problem that the prior art is difficult to tatt a fabric which can be directly used for producing an air-conditioning bedding and has the required thickness, and has obvious use value and economic value.

Owner:孔伟文

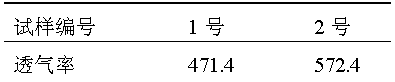

Heavy-twisted stranded elastic pure-cotton jacquard shell fabric and processing process thereof

InactiveCN102560812AGood moisture absorption and air permeabilityHigh resilienceFabric breaking/softeningSingeingEngineeringMoisture absorption

The invention discloses a heavy-twisted stranded elastic pure-cotton jacquard shell fabric, which comprises warps and wefts according to the proportion of 1:1, wherein the warps are JC5.8texX2 high-count stranded heavy-twister yarns, and the wefts are JC / S5.8tex / 5.8tex / 30D(denier) core spun yarns and JC5.8texX2. The fabric weaving structure is the small plain-weave jacquard structure. Special treatment methods are utilized in the steps of slashing, weaving, dyeing and finishing. The heavy-twisted stranded elastic pure-cotton jacquard shell fabric has the characteristics of fine moisture absorption and air permeability of pure cotton while having high elasticity, luster and smoothness, stiffness and high suspension effect, and is applicable to spring and summer clothing due to natural crinkling effect and cambric styles thereof. Besides, the heavy-twisted stranded elastic pure-cotton jacquard shell fabric which is popularized is development from single-yarn heavy twist to heavy strand twist and is the extension from singular plain weaves to jacquard varieties. By the special treatment method utilized in the processing process, quality and grade of the heavy-twisted stranded elastic pure-cotton jacquard shell fabric are improved evidently, and the breakthrough in research and development and process of the heavy-twisted stranded elastic pure-cotton jacquard shell fabric provides reference for development of high-end and individual spinning fabric and guidance for expanding the market.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

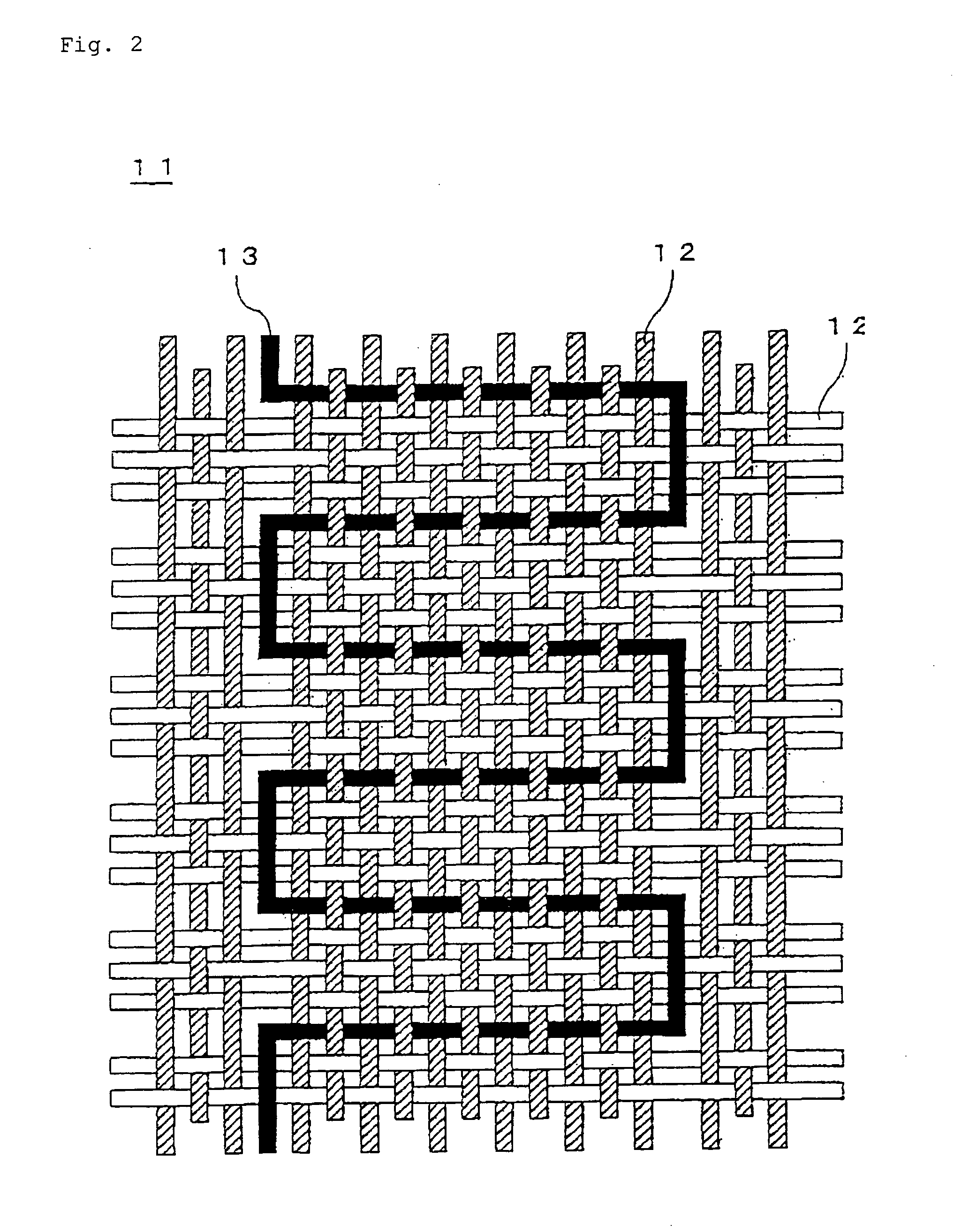

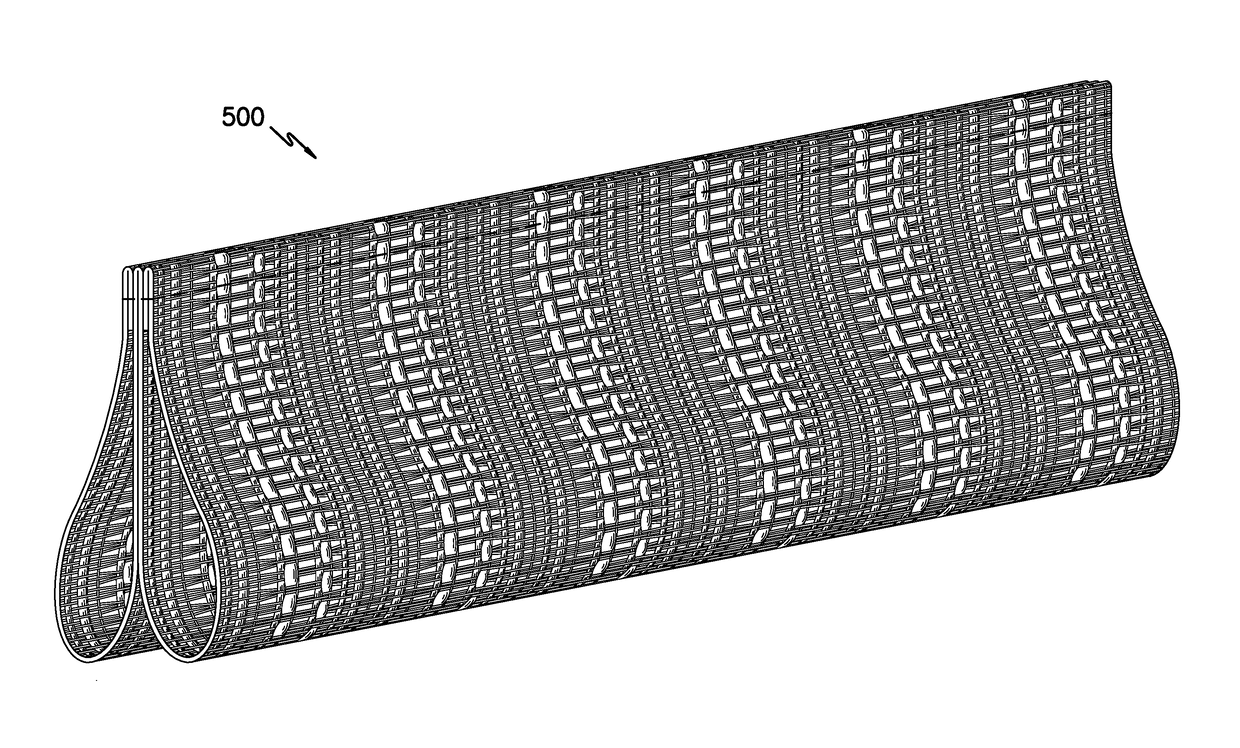

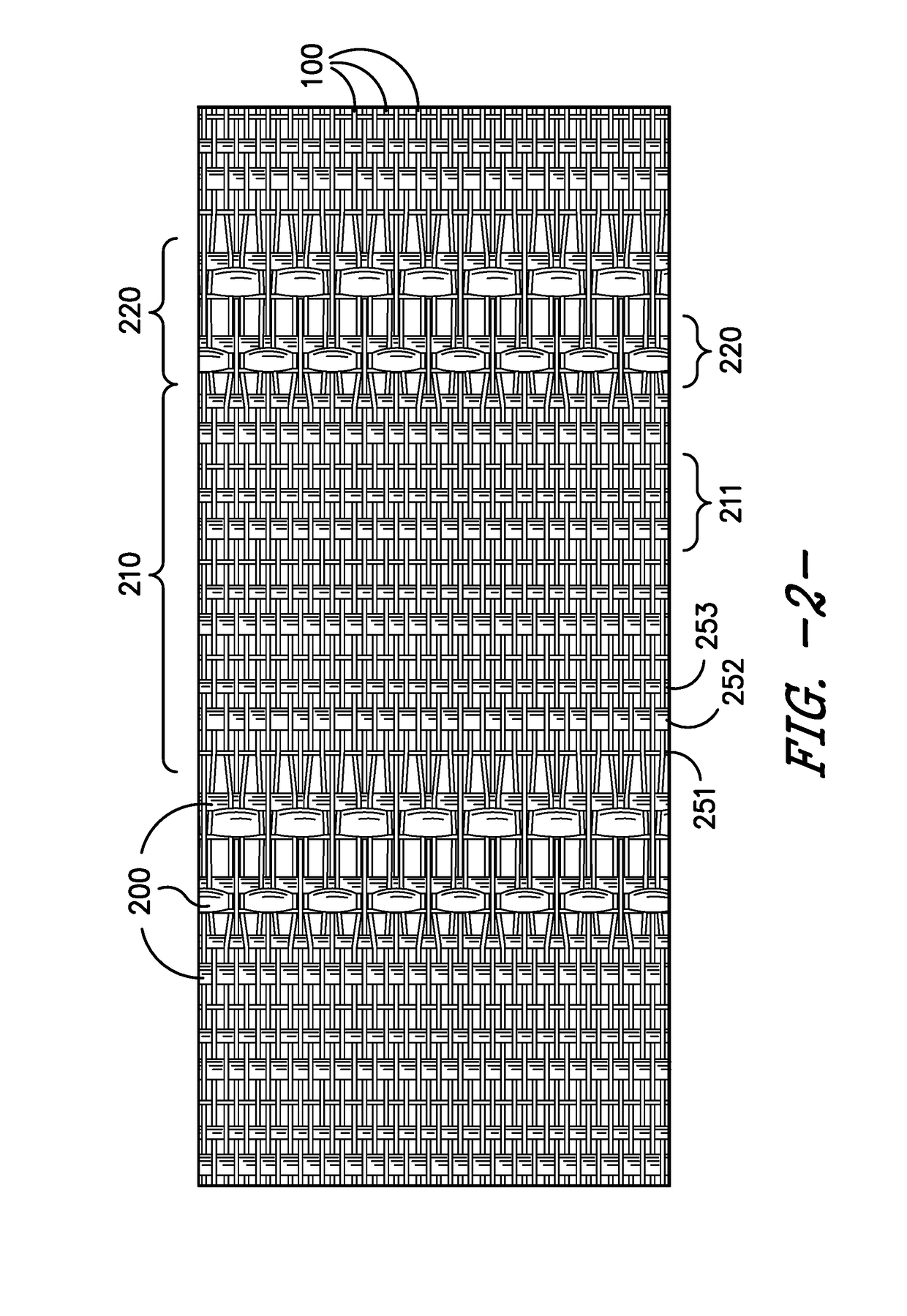

Partial float weave fabric

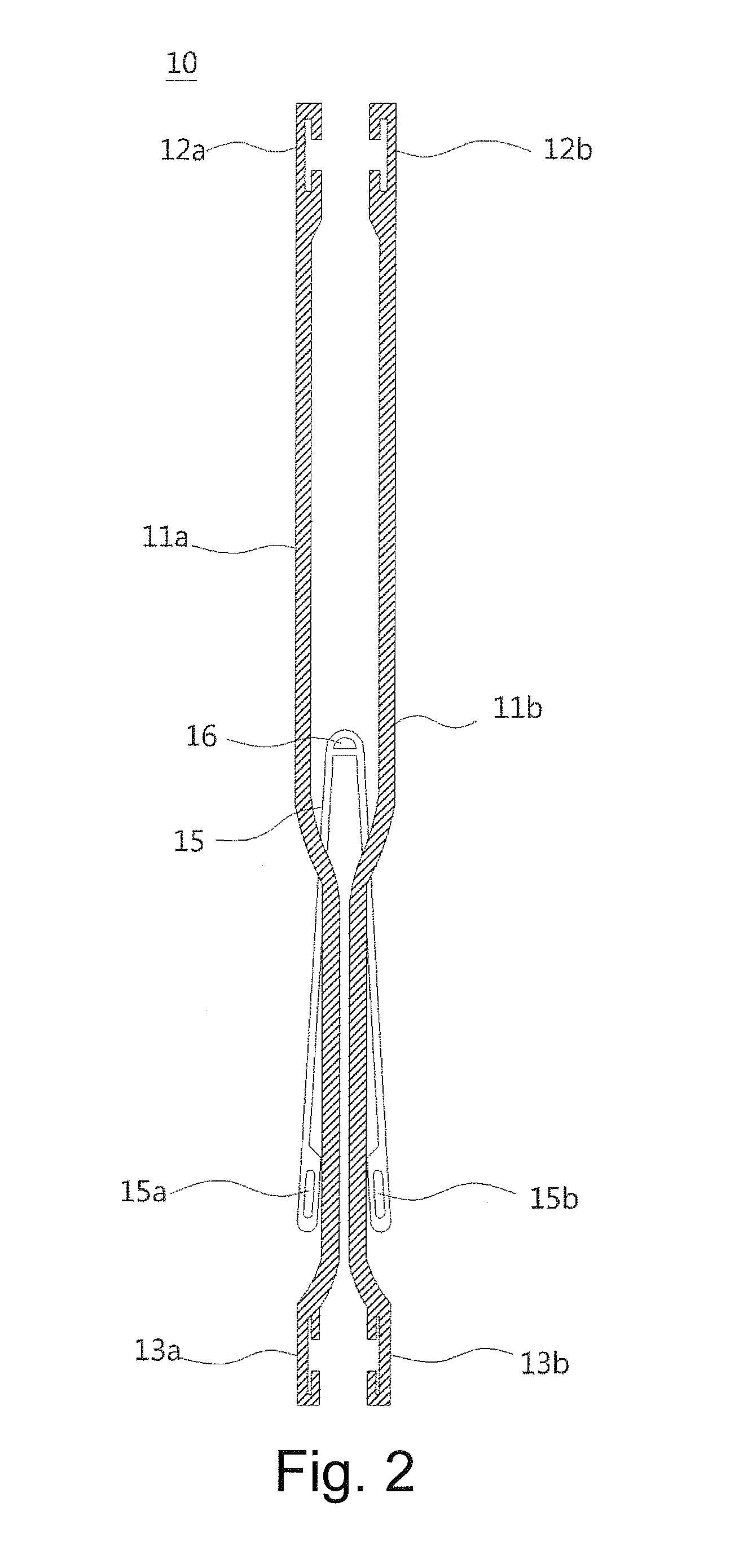

ActiveUS20170145603A1Optical fibre/cable installationCable installations in underground tubesEngineeringWeft yarn

A woven fabric containing an alternating pattern containing first weave zones and partial float weave zones. The woven fabric contains a plurality warp yarns arranged into groupings of warp yarns. In each first weave zone, the picks of weft yarns contain a repeating first weft pattern. In each partial float zone, the picks of weft yarns within the partial float weave zone contain a repeating second weft pattern of at least one monofilament yarn and at least one multiple-inserted multifilament yarn. Within the partial float zone, only a portion of the warp yarns within at least a portion of the warp groupings float over 3 weft yarns including floating over at least one multiple-inserted multifilament weft yarn in at least a portion of weft pattern repeats. An innerduct structure containing the woven fabric is also described.

Owner:MILLIKEN & CO

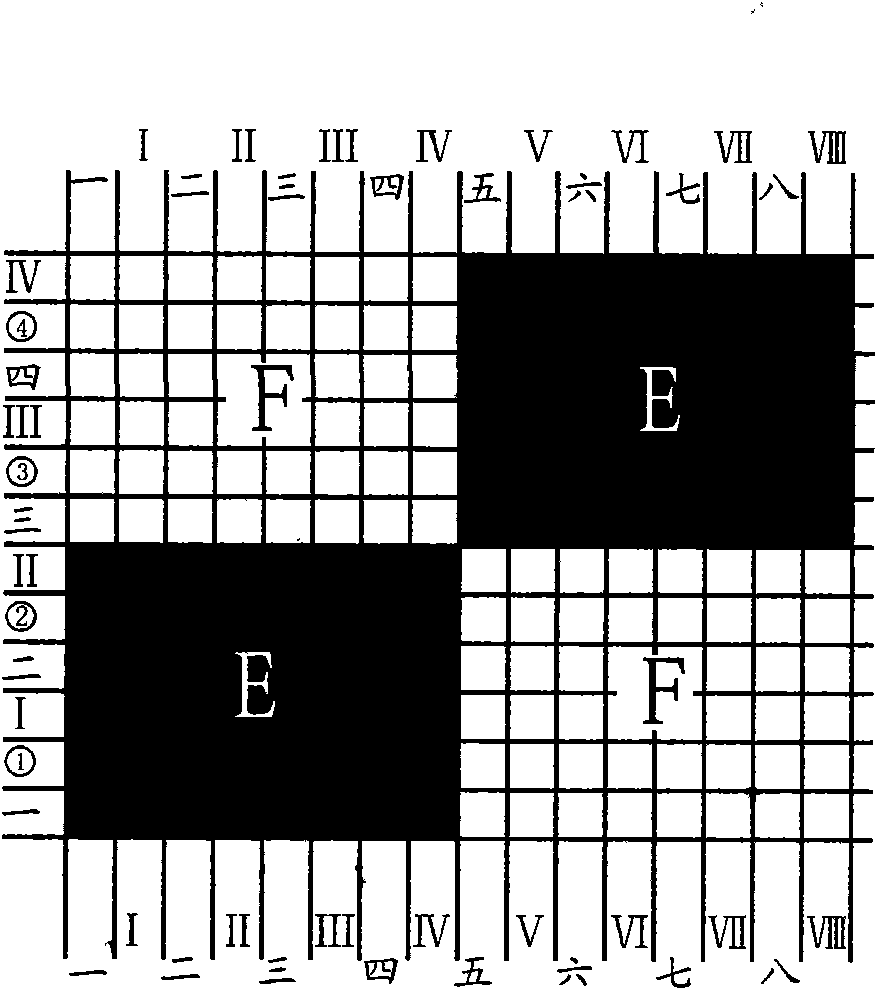

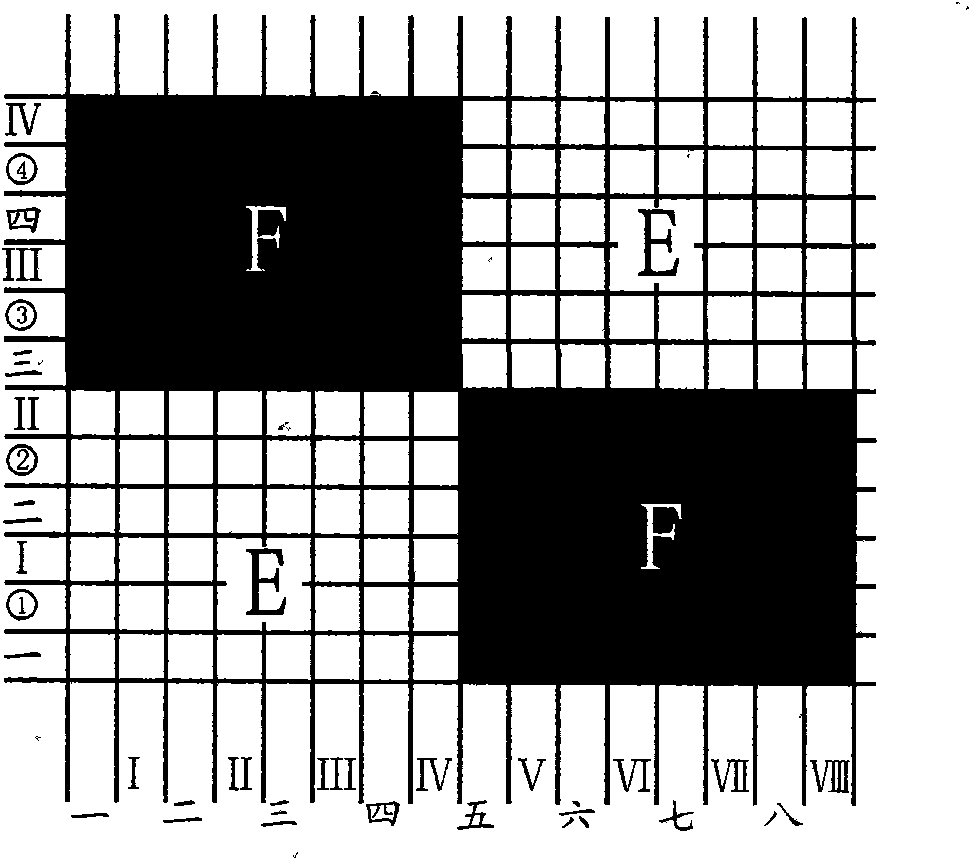

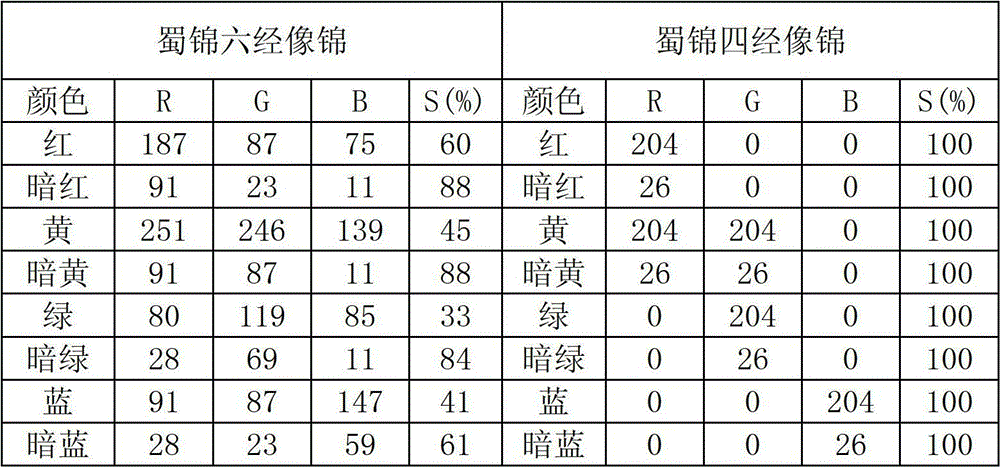

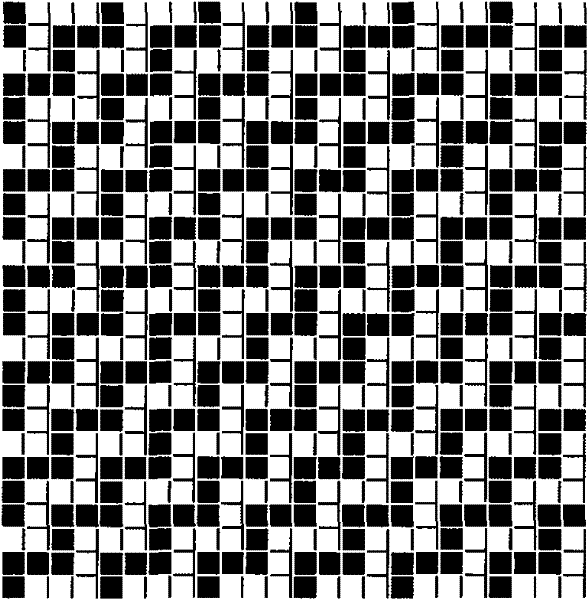

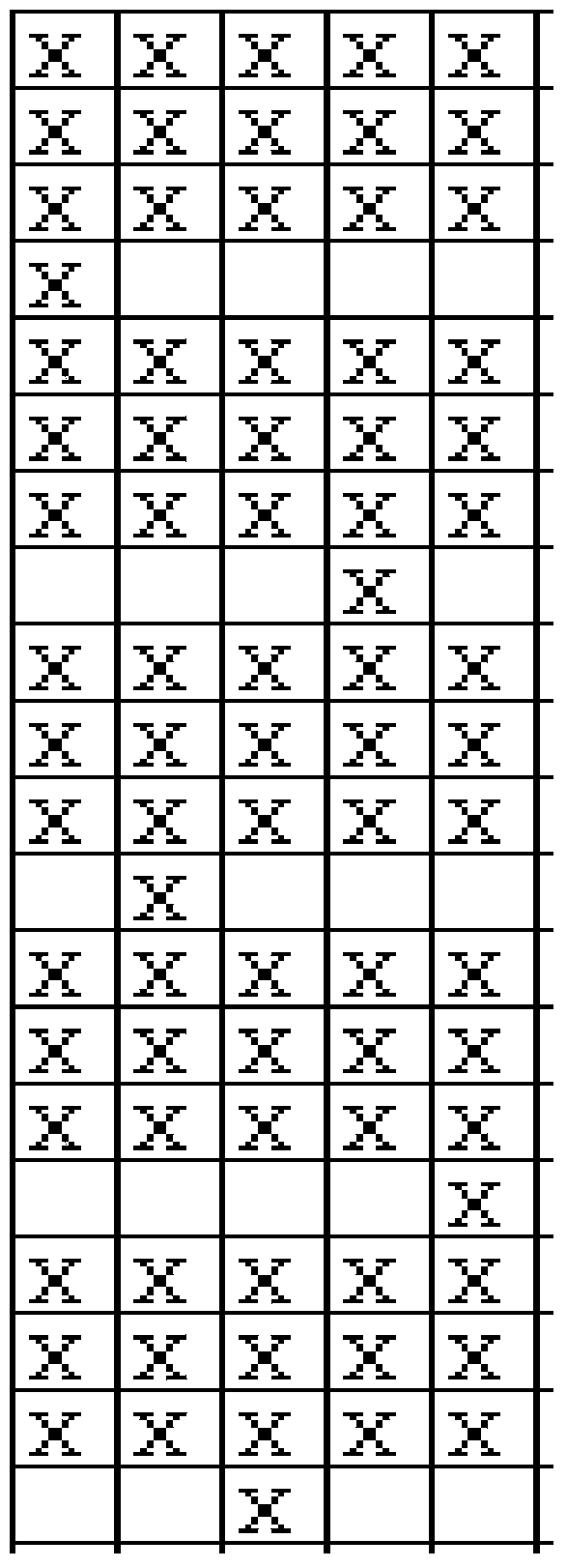

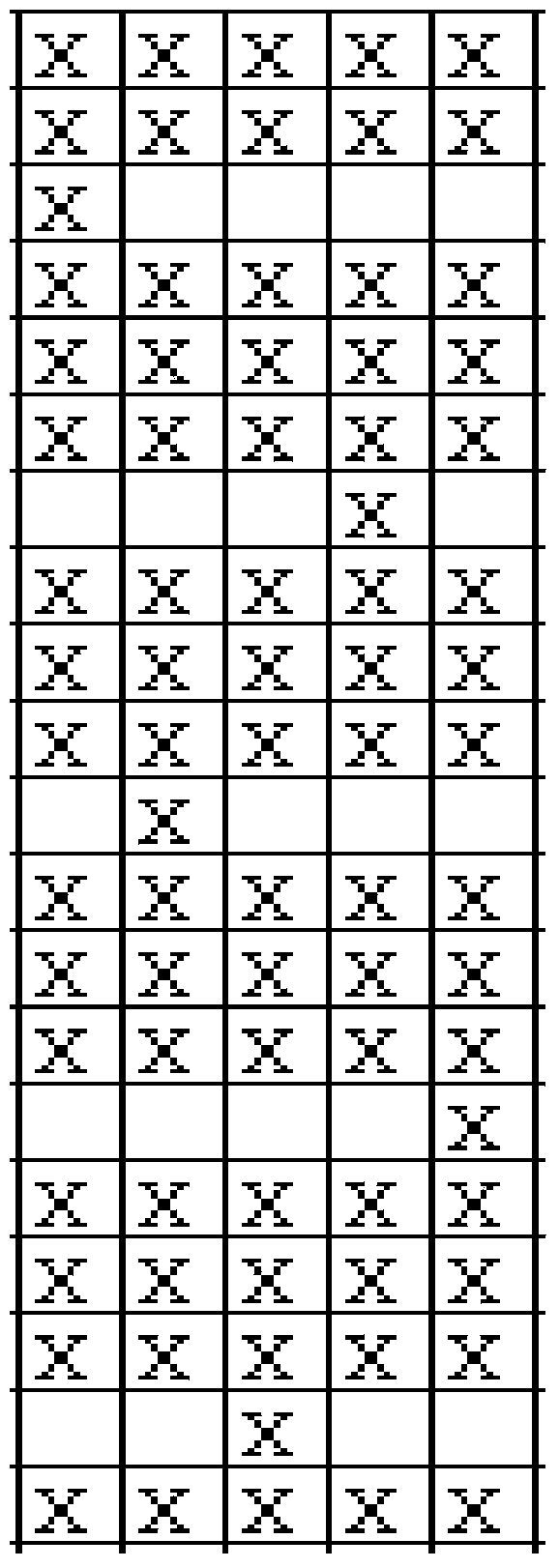

Colorful brocading technology

InactiveCN102747506ABright colorSubtle color changesSwivel-woven fabricsLappet-woven fabricsYarnEngineering

The invention discloses colorful brocading technology, comprising technology steps of manufacturing a pattern card, preparing a weaving machine and weaving by the machine. According to the invention, a warp direction uses six combinations of four silk yarns such as red, green, yellow and blue, namely red-yellow, red-green, red-blue, yellow-green, yellow-blue and green-blue; the six combinations are combined with black and white colors on a weft direction; the color of a whole color scheme is expressed by change of textile tissues; 19240 textile tissues (textile colors) are formed on the warp direction and the weft direction; a weft line also has grey capable of interweaving an upper layer and a lower layer of a double-layer textile; according to the invention, a four-warp brocade is a satin weave tissue; weft density is 90 yarn / cm; pixel is 900; color change of pictures is more exquisite; the satin weave tissue is used; thus, the pictures are characterized by more flat, thinner texture and high fineness.

Owner:CHENGDU QILI SILK

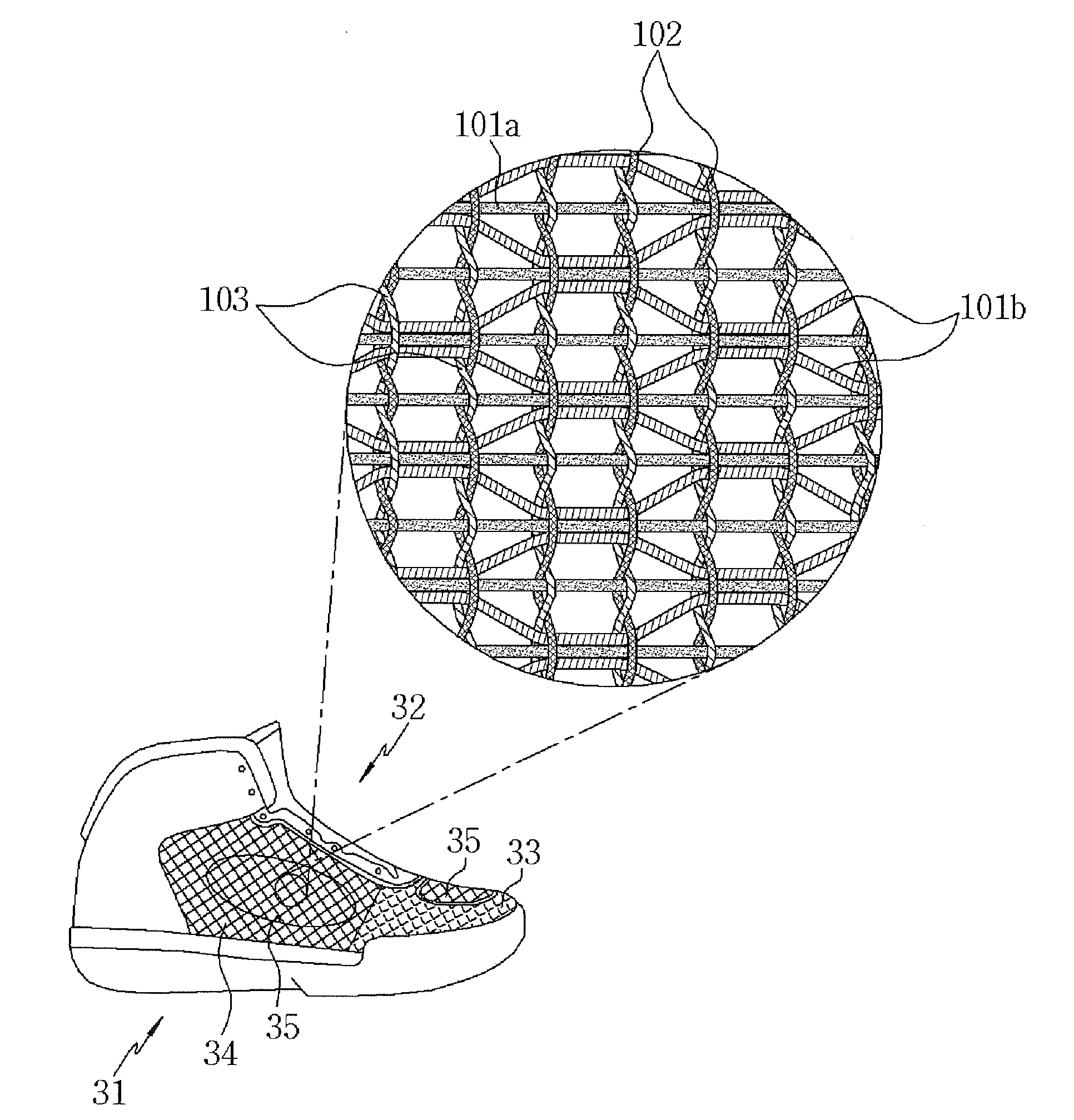

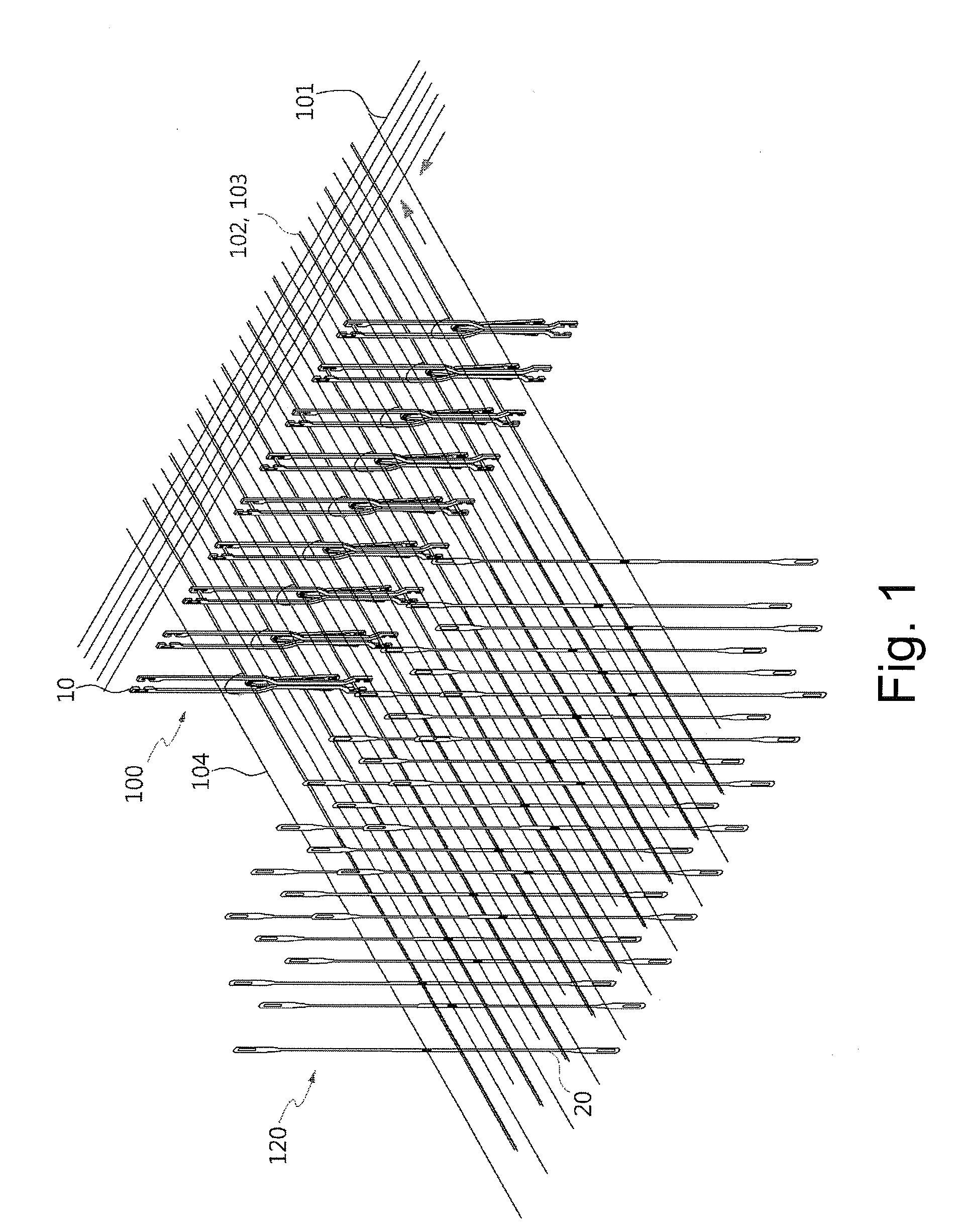

Loom for weaving fabric with two types of tissue, shoe upper woven using the same, and shoe

ActiveUS20160309843A1Improve productivityReduce processJacquardsLeno shedding mechanismEngineeringWoven fabric

Owner:SONG SOO BOK

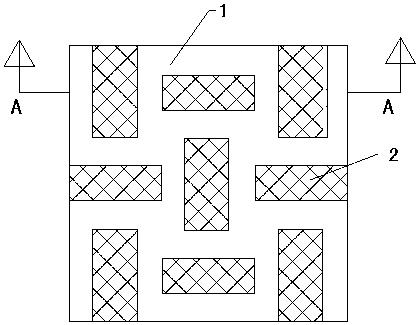

Preparation method of double-surface concave-convex bamboo fiber fabric

InactiveCN102995225AIncreasing the thicknessIncrease elasticitySwivel-woven fabricsLappet-woven fabricsFiberPolyester

The invention discloses a preparation method of a double-surface concave-convex bamboo fiber fabric, comprising the following steps: beaming, slashing, reeding and jacquard-interweaving, wherein in the process of jacquard-interweaving, the warp yarns account for 45-55% and the weft yarns account for 55-45%; and the warp yarns and the weft yarns are respectively bamboo fibers and polyester fibers. In comparison with the prior art, the core filling warp or core filling weft is added between the surface and inner wefts or between the surface and inner warps or between the surface and inner layers of the fabric, so that the fabric is thick and elastic, and the patterns, if quilted on the fabric, are permanently embossed, so the fabric is thick and decorative; by a remarkable difference of different materials as well as weft and warp yarns differing in thickness in shrinkage performance, a plastic effect is formed, and an original and unique double-surface concave-convex effect is guaranteed; the fabric is strong in three-dimensional sense, softer in touch and more friendly to the skin, and the fabric provides a more comfortable sleep microenvironment for the users; therefore, the purpose of the invention is achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

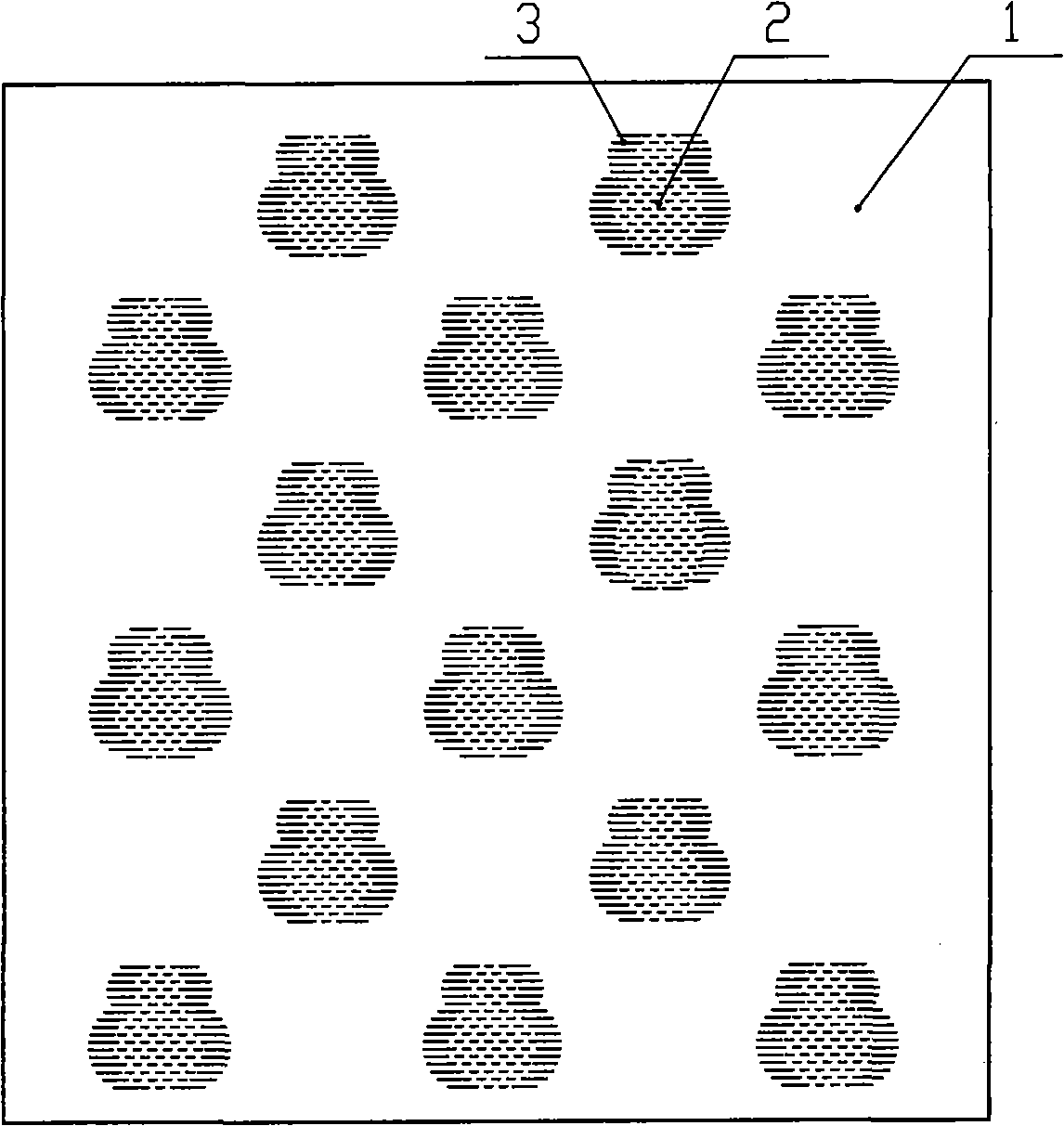

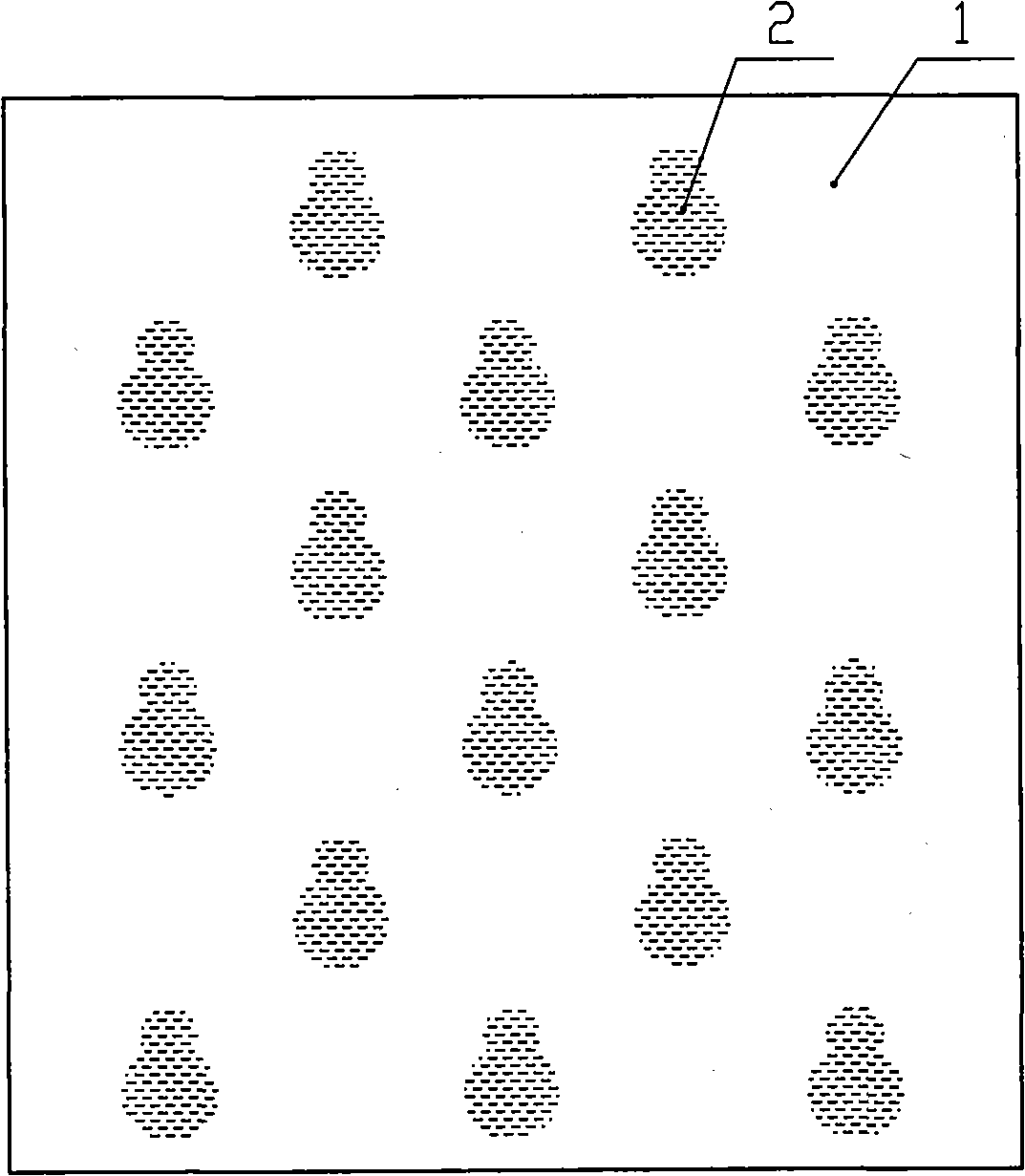

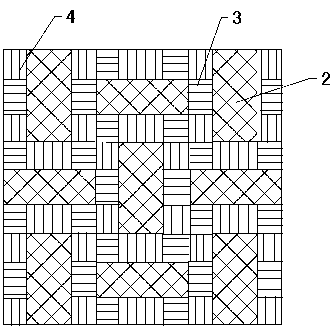

Concave-convex jacquard cloth and manufacturing method thereof

InactiveCN101260589AStrong three-dimensional senseAdd dimensionSwivel-woven fabricsLappet-woven fabricsEngineeringSurface structure

The invention relates to a concavo-convex jacquard which has a fabric surface with concavo-convex patterns and a manufacture method thereof. The surface of the concave-convex jacquard is provided with the concavo-convex patterns, warp yarns of the fabric are cotton yarns with two colors of A color and B color, weft yarns are cotton yarns and elastic yarns, wherein the cotton weft yarns are A color and the elastic weft yarns are B color, the convex part and the concave part of the patterns are both plain weave bag structures, the surface structure of the convex part is formed through interlacing the warp yarns with A color and the weft yarns with A color, the surface structure of the concave part is formed through interlacing the warp yarn with B color and the weft yarn with B color, the circumferences of the convex part and the concave part are dobby structures, and other structures of the fabric are jacquard structures formed through interlacing two warp yarns and two weft yarns. The concavo-convex jacquard solves the technical problem that the cloth surface of the prior jacquard is flat lacking vivid third dimension, which can not give persons a fresh feeling. The concavo-convex jacquard has fabric patterns with strong third dimension so as to bring stronger visual impact for the persons, and can be used for high grade home accessories and dress fabrics.

Owner:倪爱东

A kind of composite silk fabric and its production method

InactiveCN102268764AIncrease elasticityEasy to take care ofSwivel-woven fabricsLappet-woven fabricsPolyesterEngineering

The invention provides a composite silk fabric and a production method thereof. The composite yarn fabric is a double-layer fabric interwoven with polyester network yarn as the warp yarn, low elastic yarn as the first weft yarn, and composite yarn coated with spandex as the second weft yarn. The composite silk fabric can produce three-dimensional patterns, is easy to wash and quick-dry, and has good resilience performance.

Owner:LUOLAI LIFESTYLE TECH CO LTD

Silkworm pupa protein fiber blended yarns, moisture-absorbing suspension ultraviolet-resistant fabric, spinning method and production process

InactiveCN102995200AGood moisture absorptionMeet wear resistanceOpen work fabricsYarnYarnMoisture absorption

Owner:HENAN INST OF ENG

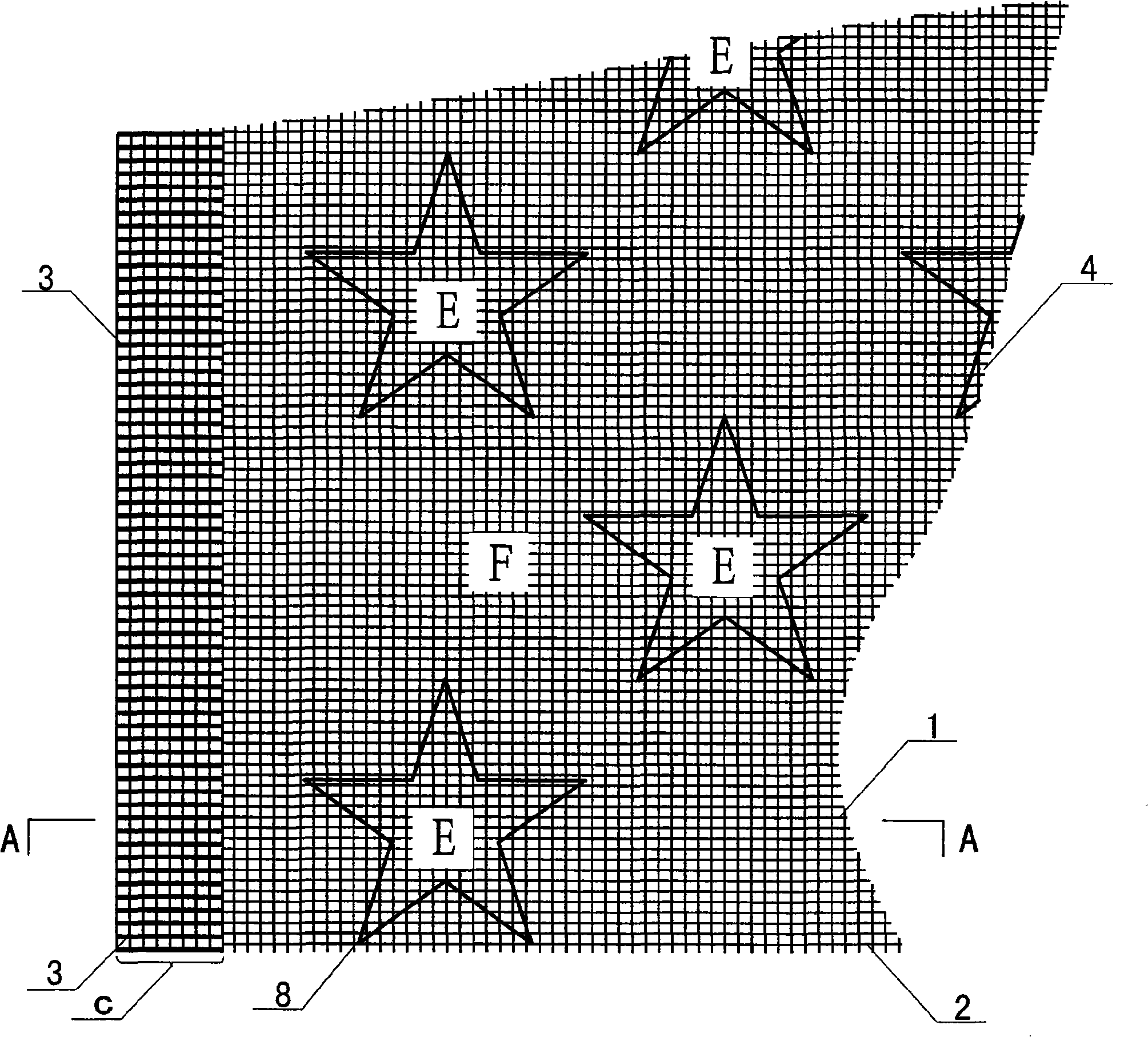

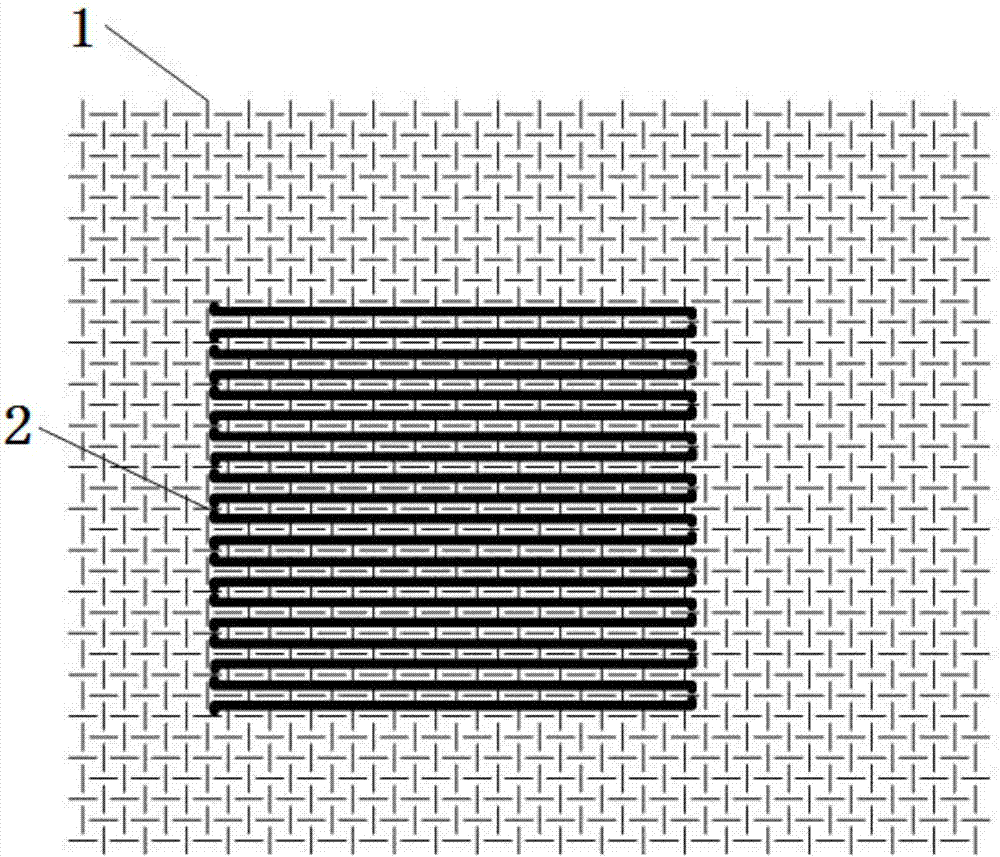

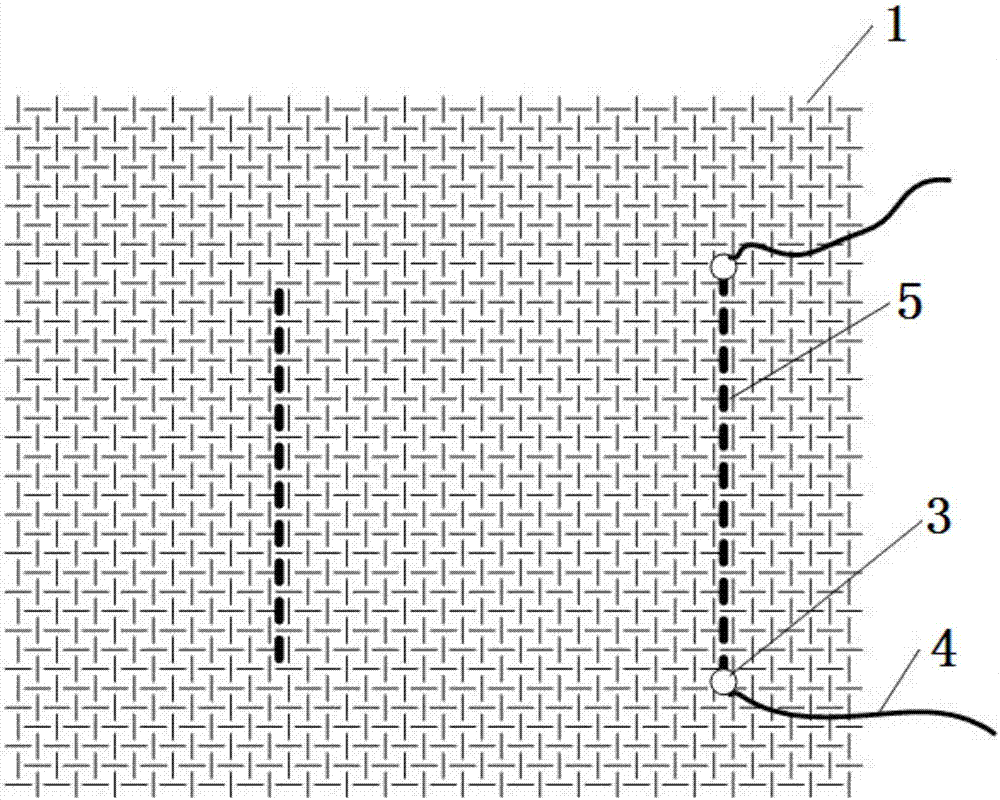

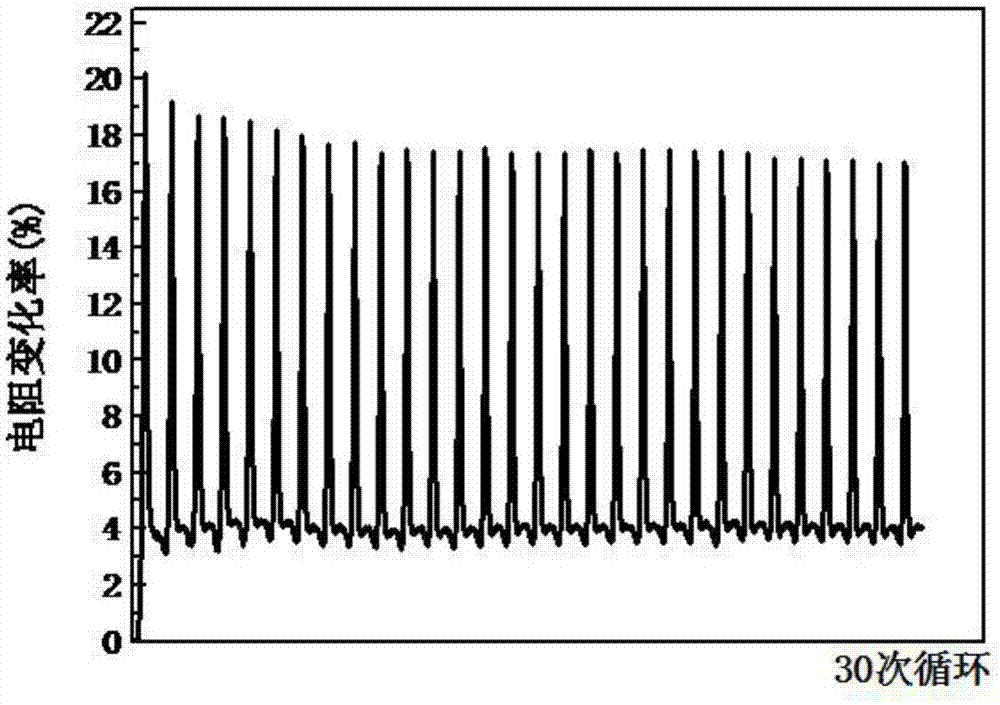

Flexible strain-sensing woven fabric and making process thereof

ActiveCN107385623AThe strain sensing function hasHigh sensitivitySwivel-woven fabricsLappet-woven fabricsYarnSurface pattern

The invention discloses a flexible strain-sensing woven fabric and a making process thereof. The flexible strain-sensing woven fabric comprises non-conducting elastic woven fabric and elastic conducting yarn, wherein the elastic conducting yarn is fixedly connected to the surface of the non-conducting elastic woven fabric as float yarn to form a float pattern, and connectors and leads for electric connection are arranged at the two ends of the elastic conducting yarn. The flexible strain-sensing woven fabric is simple in structure, good in flexibility, high in comfort and washable and has an omnidirectional strain sensing function, continuous production can be achieved, and the woven fabric is high in sensitivity, stability and applicability and has good application prospects in the field of intelligent textiles; besides, the flexible strain-sensing woven fabric has the advantages that the making process is simple, use is convenient, the surface pattern of the strain-sensing fabric can be designed and the fabric has attractiveness; the fabric has high practical value and is worthy of wide application and popularization, and compared with the prior art, the fabric has significant progress.

Owner:上海捻幅智能科技有限公司

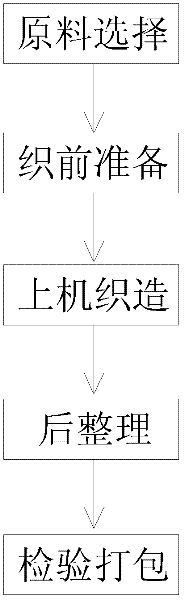

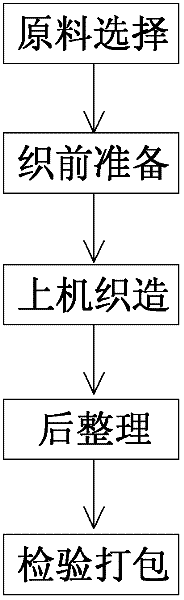

Jacquard black-out cloth and production method thereof

InactiveCN102517753AKeep shadingKeep breathableSwivel-woven fabricsLappet-woven fabricsYarnPolyester

The invention discloses jacquard black-out cloth and a production method thereof. The method sequentially includes steps: firstly, selecting raw materials; secondly, preparing before weaving; thirdly, using a loom for weaving; fourthly, post-finishing; fifthly, checking and packaging, and the like. The jacquard black-out cloth is made of warps and wefts by means of jacquard weaving, the warps include face warps and inner warps, the wefts include face wefts and inner wefts which are made of polyester black yarns, the face warps and the face wefts are interwoven into a face layer, the inner warps serve as a middle layer, and the inner wefts serve as an inner layer. The jacquard black-out cloth reserves characteristics of traditional black-out cloth such as light shading, breathability, softness to touch and the like, new characteristics such as diversity in style, layer evidence, richness in color and the like are added through variation of colors and stitches, fabrics produced by the production method have stable patterns and various functions such as light adjusting, privacy protecting, ornamenting, heat insulating, sun blocking, sound insulating, dust filtrating and the like, production process is simple, environment pollution and energy consumption caused by knurling and printing are reduced, production cost is greatly reduced, and popularization and application of the jacquard black-out cloth and the proeduction method are facilitated.

Owner:ZHEJIANG SANZHI TEXTILES

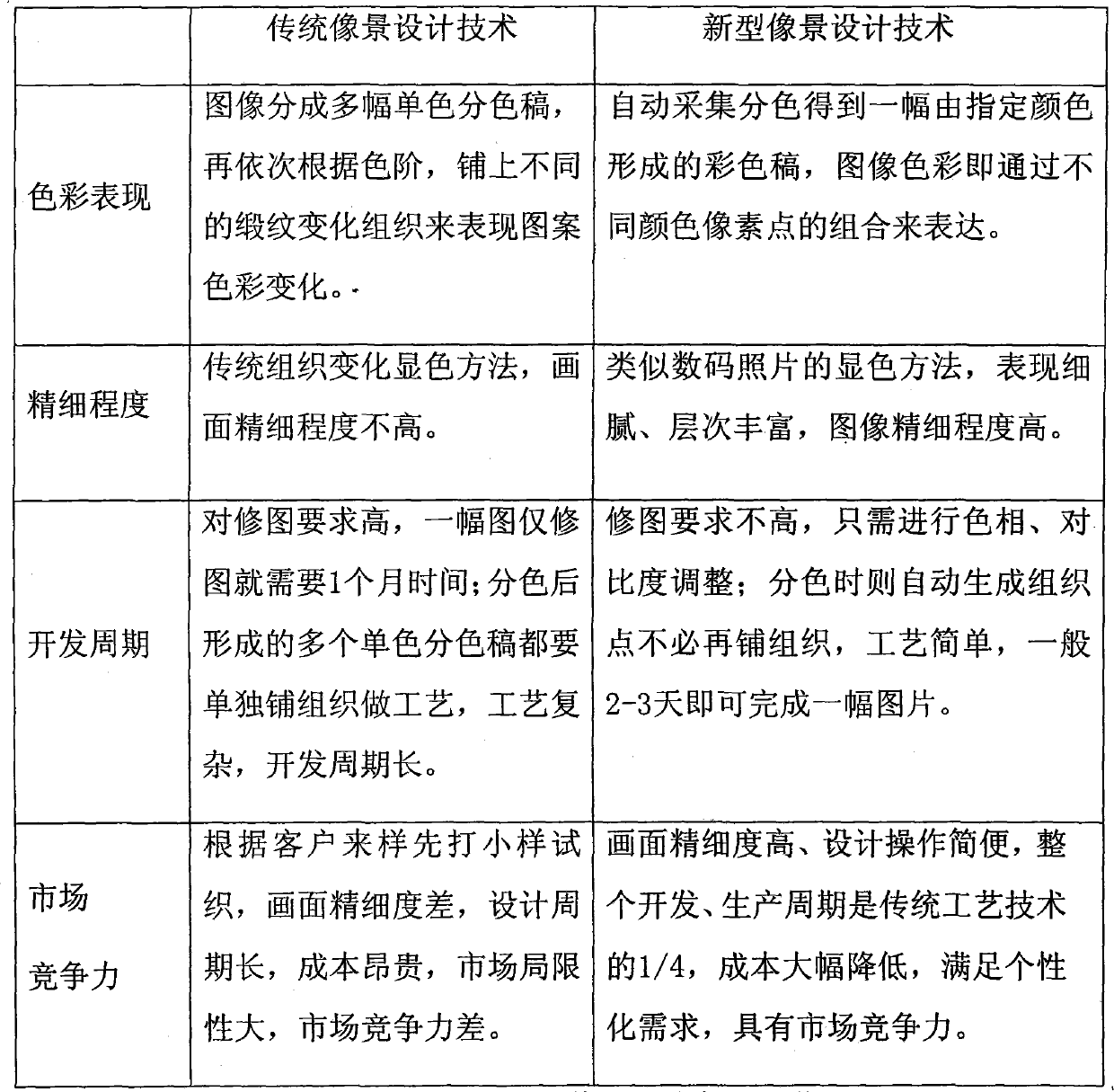

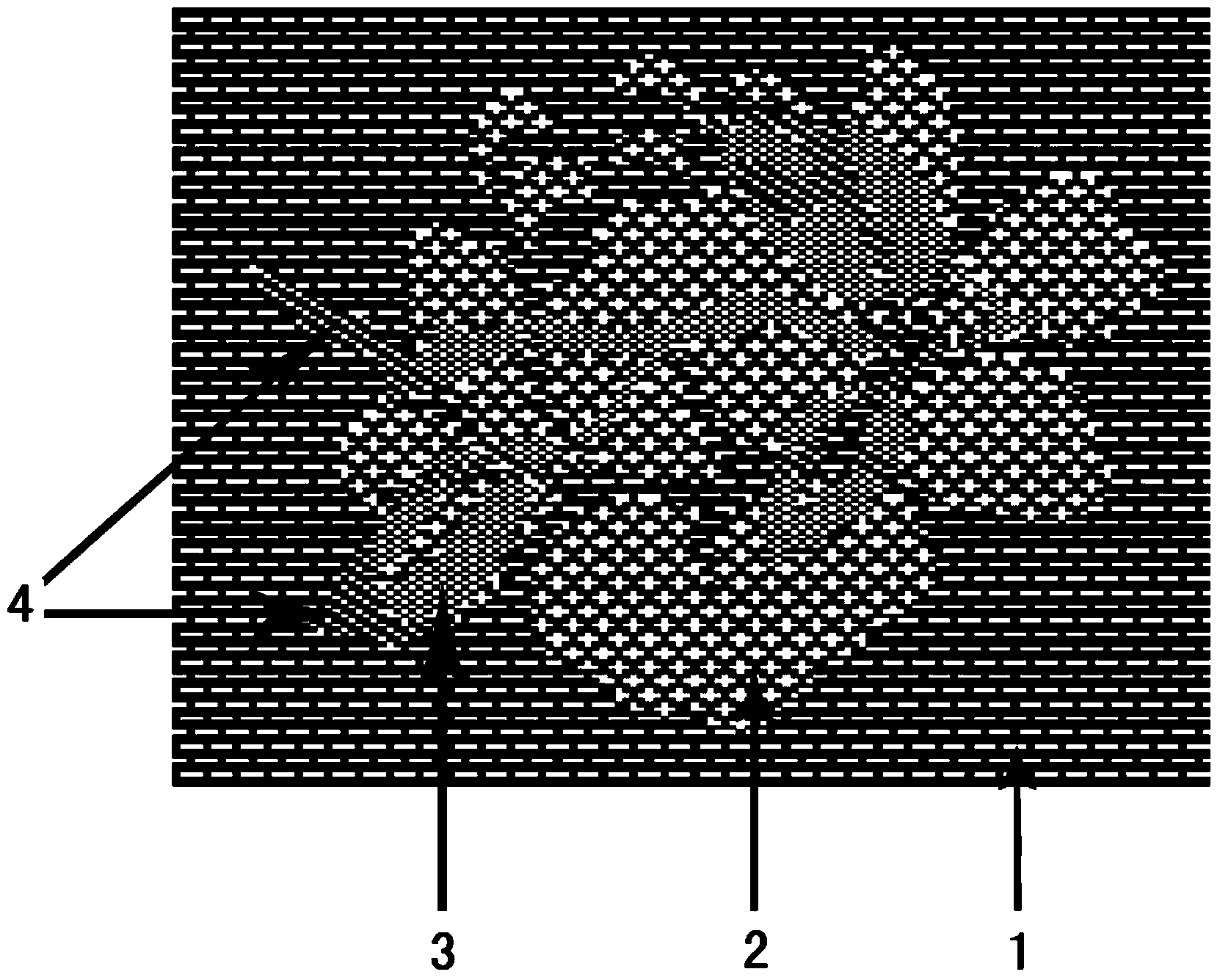

Manufacturing process of full-digital high-fineness image brocade fabrics

InactiveCN102560807AImprove color vibrancyHigh saturationSwivel-woven fabricsLappet-woven fabricsEngineeringDigital printing

A manufacturing process of full-digital high-fineness image brocade fabrics includes the following steps of scanning, image rectifying, color separating and processing. The manufacturing process has the advantages that design and development period is short, production time of conventional jacquard image fabric products is shortened, cost is reduced, expensive individual jacquard fabrics can be popularized in ordinary family, and the requirements of vast customers are met. Meanwhile, the full-digital high-fineness image brocade fabric has more layers and more exquisite styles as compared with conventional image fabrics, solves the problems of few layers and colors and poor fineness of conventional image jacquard fabrics, can be used for developing full-true-color picture works, has simulation effect as digital printing, breaks through limits of original products and can represent original appearance of pictures vividly and record time, events and characters with historical values by a unique presenting manner, thereby making permanent storage of wedding pictures, portraits and historical paintings come true. Further, application field of textiles is expanded and domestic demands of the market can be stimulated.

Owner:TIANJIN TEXTILE ENG RES INST

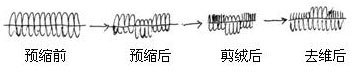

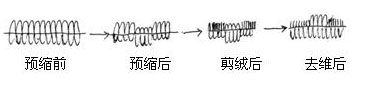

Method for processing blanched untwisted relief towels

ActiveCN102121156ASolve the problem that embossed towels cannot be producedImprove weaving efficiencyPile loops cuttingDomestic applicationsEngineeringWater soluble

The invention discloses a method for processing blanched untwisted relief towels. The method comprises the following steps: doubling and twisting high temperature water soluble vinylon yarns at the temperature being higher than 90 DEG C with the common cotton yarns to prepare untwisted water soluble yarns; arranging the obtained untwisted water soluble yarns and the common yarns at intervals in a ratio of 1:1 and warping the yarns to prepare wool warp beams and interweaving the wool warp beams with ground warp and weft yarns to form jacquard patterns; ensuring the untwisted parts to shrink and the parts needing to be sheared to protrude through squeezing, moistening and high temperature roller blanching; after drying, shearing the raised parts needing to be sheared on a shearing machine; dissolving out the water soluble yarns on the untwisted yarns with high temperature water at the temperature being higher than 90 DEG C to ensure the untwisted yarns to be untwisted and pop; and after washing, carrying out water removal, softening and drying to ensure the untwisted yarns to be fluffy and raised. Through changing the preshrinking method, the problem that the relief towels can not be produced with the high temperature water soluble untwisted yarns is solved and the effects of low cost, high weaving efficiency, strong third dimension of the relieves and high yield can be achieved.

Owner:NANTONG DADONG

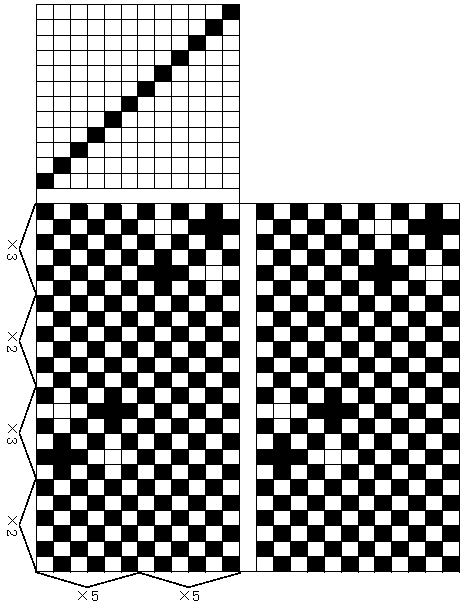

Production technology for all-cotton yarn-dyed weaving surface and inner layer exchange dobby

ActiveCN105177823AShorten speedUnleash your full potentialMulti-ply fabricsVegetal fibresYarnEconomic benefits

The invention discloses a production technology for all-cotton yarn-dyed weaving surface and inner layer exchange dobby. The technology comprises a spooling process, a warping-sizing process, a drawing-in process and a weaving process. According to the production technology, a warping-sizing combined technology is adopted, the stability of the sizing percentage can be guaranteed through low-temperature sizing, and a sizing agent which is low in polymerization degree and low in viscosity is mainly used as the sizing agent for low-temperature sizing; the technology of being low in loom speed, early for opening, late for rapier feeding and low in back rest is adopted by a loom, and thus conditions are created for improving the quality of the product and the production efficiency of the loom. After the measures are taken, the problems emerging in the production process are well solved, and good economic benefits are achieved.

Owner:南通金禧莱纺织科技有限公司

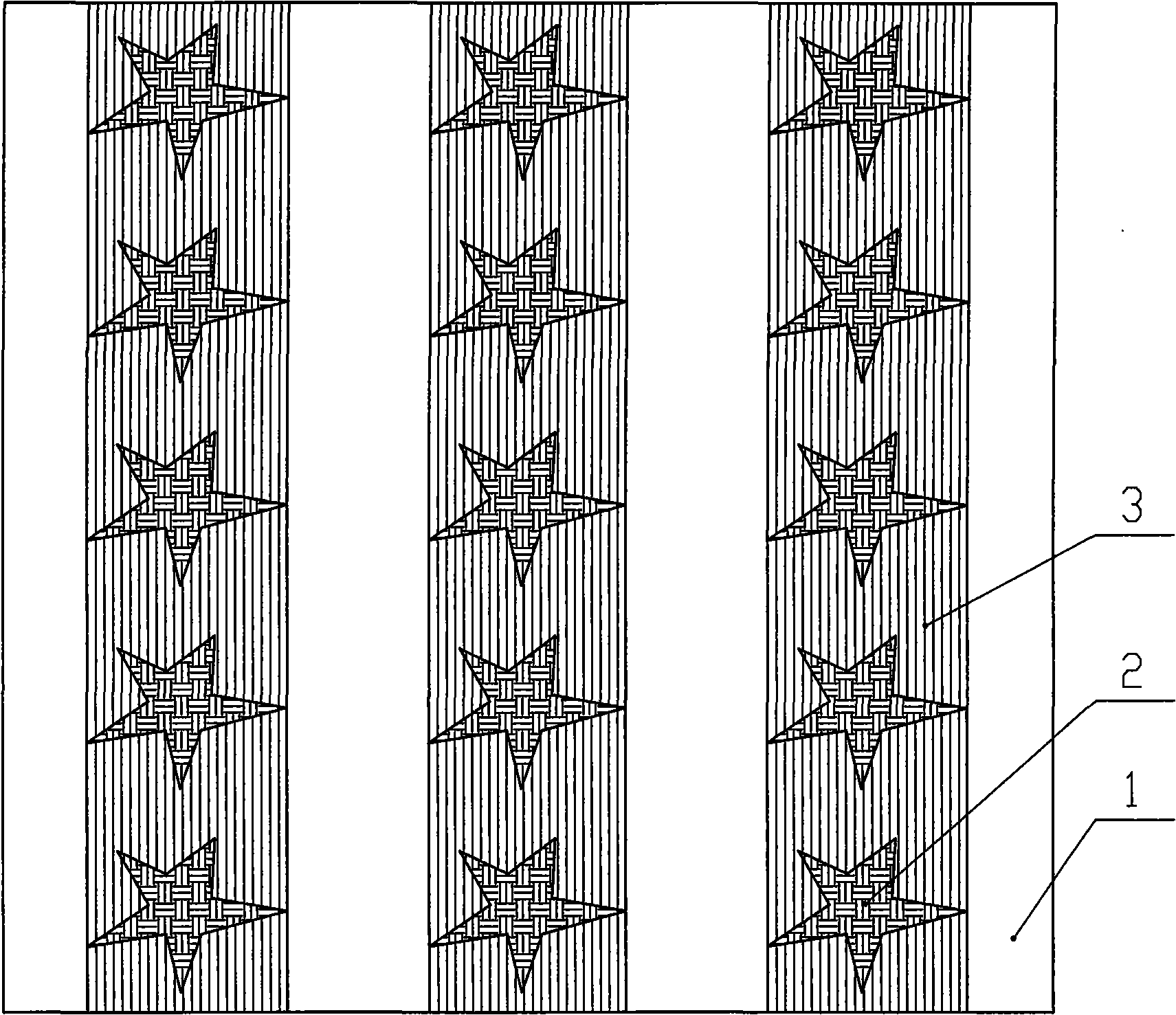

Cutting motif fabric and method of manufacture

The invention relates to a yarn-dyed fabric as well as the manufacturing method technology field thereof, in particular to a clipping and carving fabric which is applied in high-grade fashionable dresses, high-grade children dresses, high-grade bed clothes, etc., as well as the manufacturing method. The clipping and carving fabric is provided with a tabby bottom tissue and local additional tissues which are interwoven on the surface of the tabby bottom tissue. The clipping and carving fabric of the invention has the advantages of plump tissue effect like the feeling of attaching, rich meaning, perfect ornamental effect, embroidery visual effect, no bone on the fabric with patterns, soft feeling, and firm and permanent connection of the local additional tissues and the tabby bottom tissue.

Owner:倪爱东

Radiation-proofing fabric

InactiveCN101660241AImprove breathabilityImprove dyeing effectSwivel-woven fabricsLappet-woven fabricsPolyesterPolymer science

The invention relates to a radiation-proofing fabric which is a jacquard weave structure, takes 65D-85D polyester fiber as warp threads, and takes 8S-20S cotton fiber and 80D-100D metal wires as wefts, wherein the warp threads and the wefts are weaved, the total weight of the polyester fiber accounts for 32-52 percent of total weight of the fabric, the weight of the cotton fiber accounts for 36-56percent of total weight of the fabric, and the weight of the metal wires accounts for 8-15 percent, and the metal wire is made of copper, stainless steel and silver. Compared with the radiation-proofing fabric in the prior art, the radiation-proofing fabric in the invention has good air permeability, good dyeing effect and bright color and is artistic and elegant on the basis of ensuring excellent radiation-proofing performance and shielding effect, therefore, the radiation-proofing fabric is particularly suitable for manufacturing cheongsam, formal attire and the like for ritual girls.

Owner:WUJIANG CITY HAICHENG TEXTILE

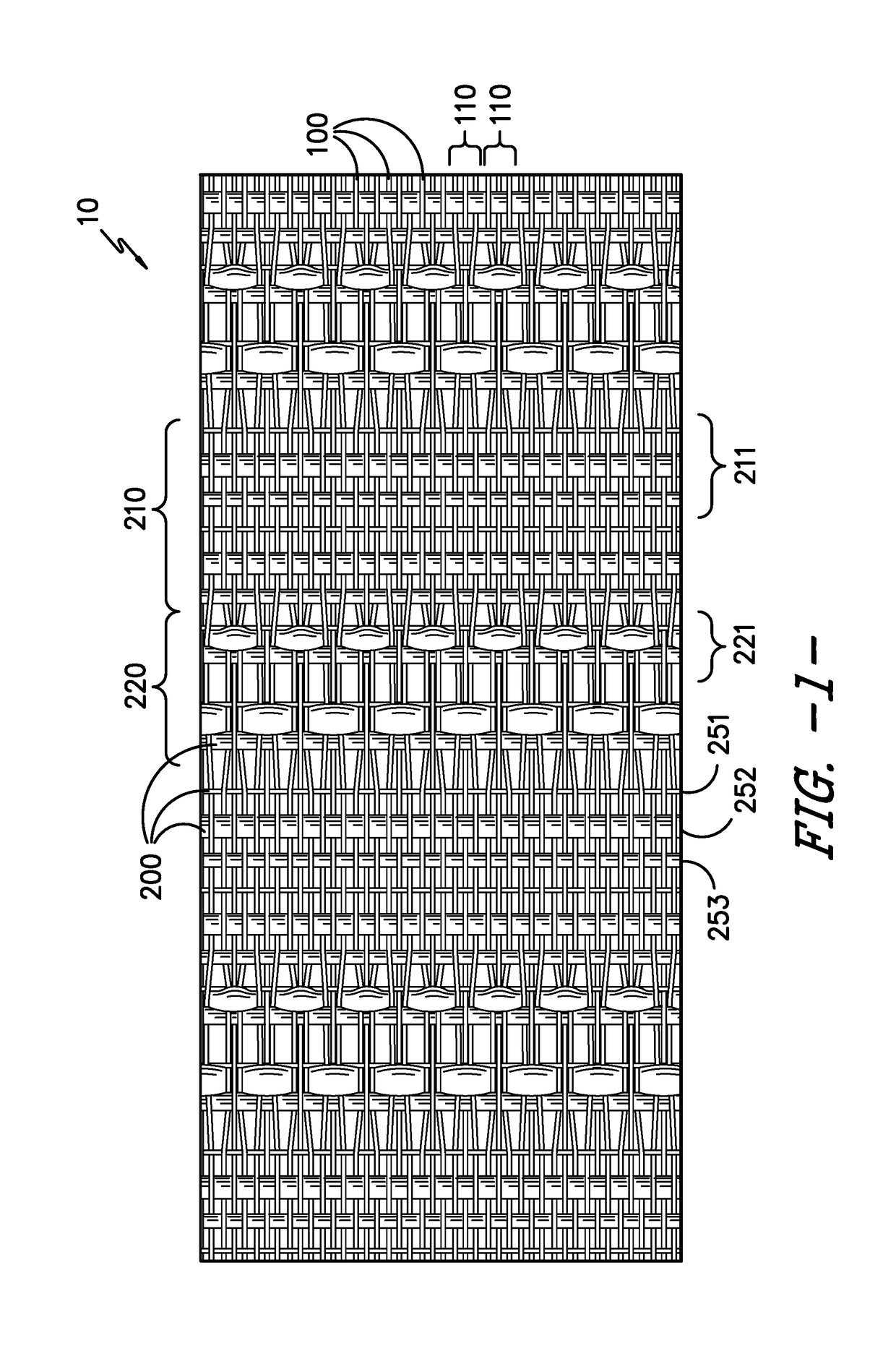

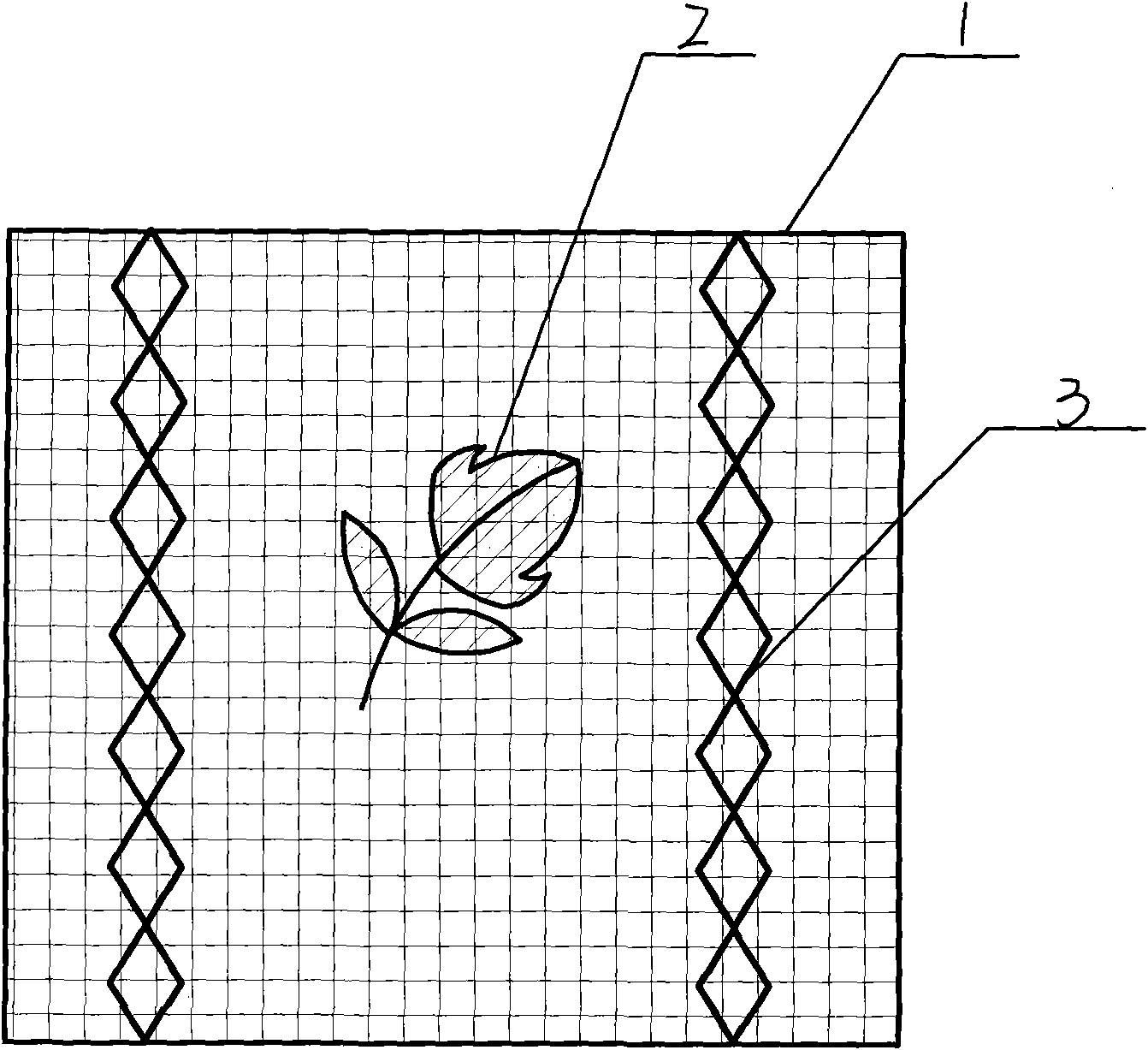

Method for preparing warm composite woven fabric

InactiveCN102181986AElasticIncreased warmth and bulkinessMulti-ply fabricsSwivel-woven fabricsYarnSurface layer

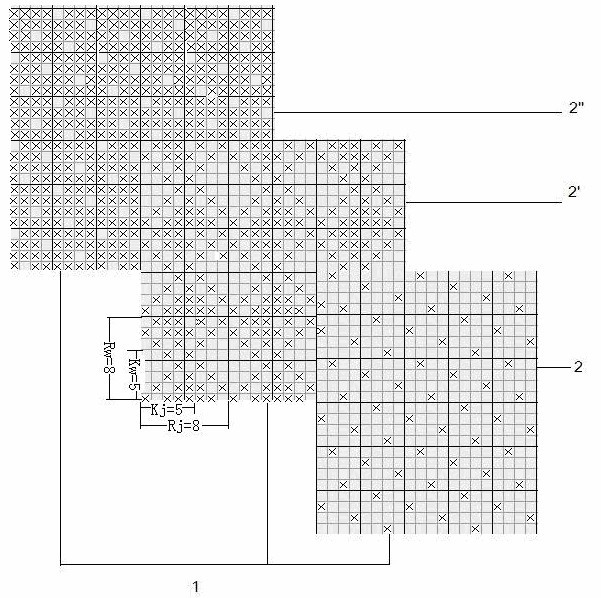

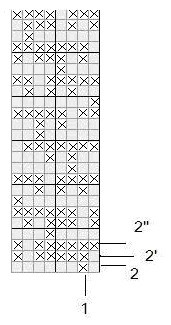

The invention relates to a method for preparing warm composite woven fabric. The warm composite woven fabric is prepared by interweaving a group of warp yarns (1) and three groups of filling yarns in an overlapped way, wherein the three groups of filling yarns are respectively face weft (2), intermediate weft (2') and back weft (2''), the face weft (2), the intermediate weft (2') and the back weft (2'') are arranged according to the proportion of 1:1:1, the warp yarn (1) and the face weft (2) are woven into satin weave which has 8 lines and 5 step weft faces and serves as a surface layer according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the back weft (2'') are woven into satin weave which has 8 lines and 5 step weft faces and serves as a lining according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the intermediate weft (2') take honeycomb weave as an intermediate layer in terms of Rj equal to Rw and equal to 8, and the Rj and the Rw are respectively the circulated yarn numbers of warp weave and weft weave. The warm composite woven fabric prepared by the method integrates the characteristics of light weight, super warm property, softness, comfortableness, moisture absorption, air permeability, bacterial resistance and bacterial restraint, and the production is simple and easy to implement.

Owner:江苏保丹服饰有限公司

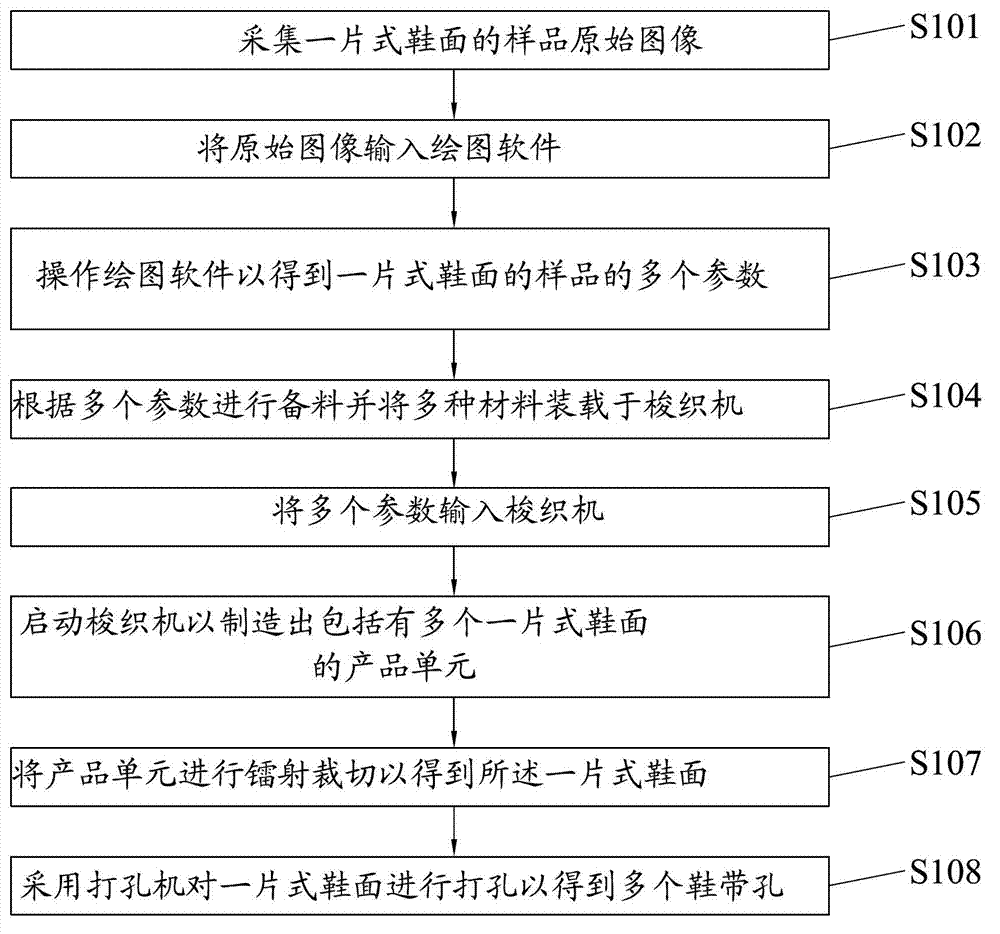

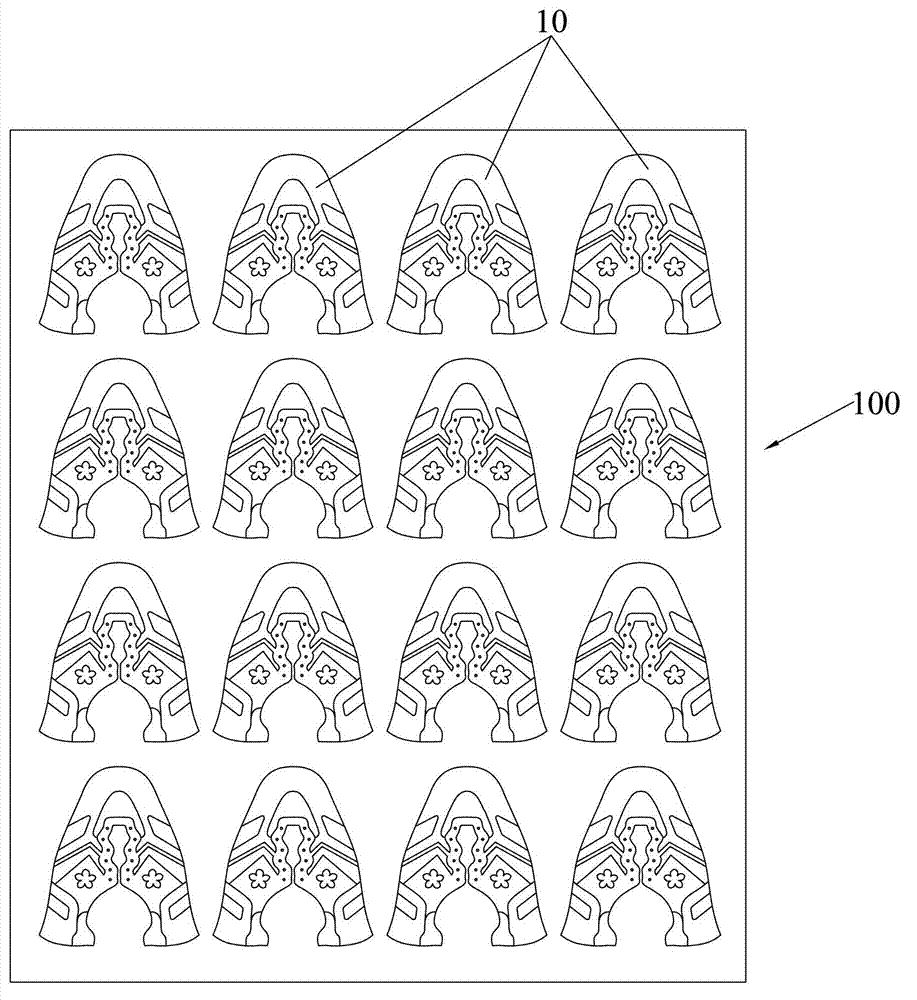

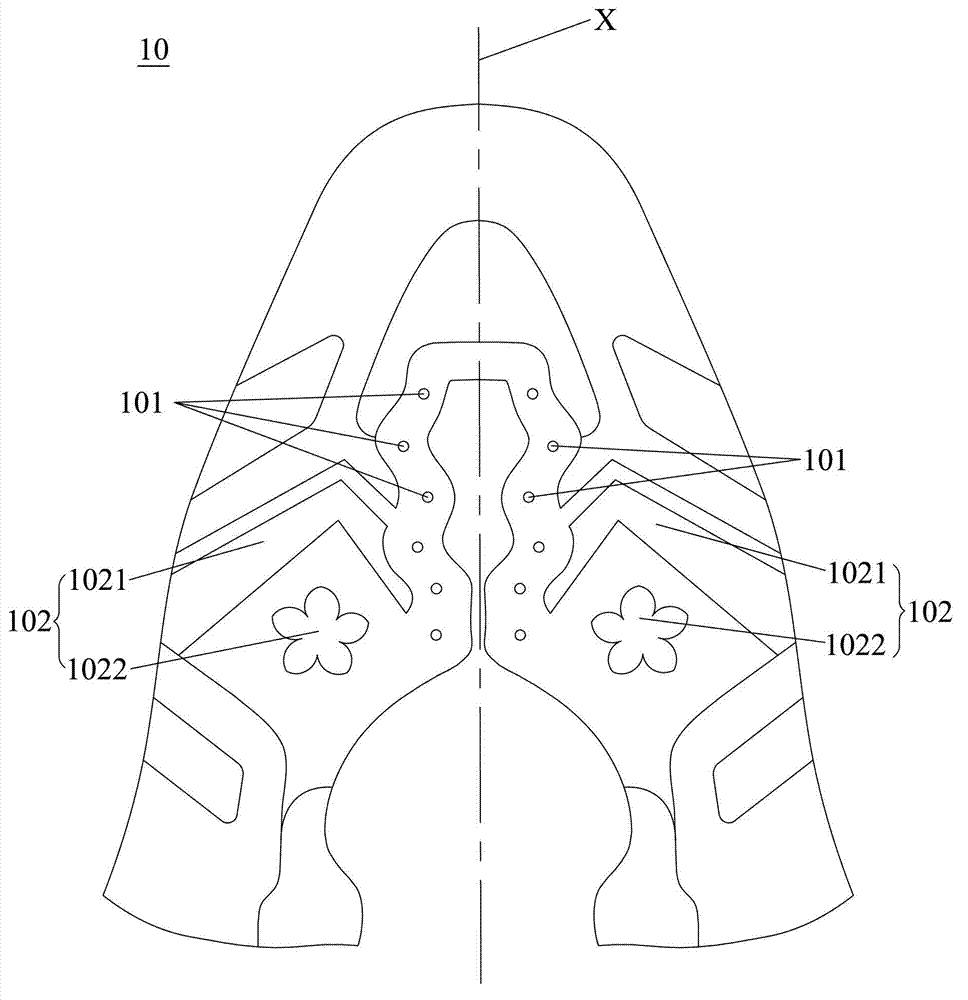

Manufacturing method of one-sheet type vamp

InactiveCN102920111ASimple manufacturing processReduce manufacturing difficultyShoemaking devicesHeelsMulti materialLaser cutting

The invention discloses a manufacturing method of a one-sheet type vamp, comprising the steps of (1), obtaining multiple parameters of a sample of the one-sheet type vamp, (2) preparing materials and loading the various materials at a shuttle loom, (3) inputting the multiple parameters into the shuttle loom, (4) starting the shuttle loom to manufacture a product unit comprising multiple one-sheet type vamps, and (5) performing laser cutting on the product unit to obtain the one-sheet type vamp. Compared with the prior art, the manufacturing method of the one-sheet vamp has the characteristics that after the parameters are input into the shuttle loom, the manufacturing process of the product unit comprising the multiple one-sheet type vamps is independently finished by the shuttle loom, the one-sheet type vamp can be obtained by convenient laser cutting, sewing by labor or a sewing machine is not needed, and printing and drying layer by layer like the conventional vamp manufacturing method is not needed, so the manufacturing process is simplified, the manufacturing difficulty is reduced, the work efficiency is improved and the labor cost is reduced.

Owner:DONGGUAN SUNSHINE TEXTILE

Large dense-weft jacquard gauze, clipped jacquard, colored woven cotton fabric

The invention discloses large dense-weft jacquard gauze, clipped jacquard and colored woven cotton fabric. The colored woven cotton fabric comprises a bottom plain part, a gauze part and a clipped large dense-weft jacquard; the gauze part and the clipped large dense-weft jacquard are woven on the bottom plain part; and the cover of the colored woven cotton fabric is in a concave-convex stereoscopic shape. The highly difficult technologies concerning the dense weft, the warp-weft jacquard, the large-jacquard gauze, the clipped large-jacquard and the like are integrated perfectly, thus the colored woven cotton fabric has diversified styles and patterns and more stereoscopic sense.

Owner:JIANGSU SHUNYUAN NEW MATERIAL TECH CO LTD

Man-made lawn and preparation method therefor

ActiveCN105568498AIncrease binding forceImprove pullout forceGround pavingsGeotextilesEngineeringLawn

The invention relates to a preparation method for a man-made lawn. The preparation method comprises the following steps: arranging warp yarns on a warp beam of a braiding machine, arranging weft yarns on the braiding machine in a direction perpendicular to the warp yarns, arranging man-made grass silk yarns on a yarn creel at the back part of the braiding machine, enabling the man-made grass silk yarns to participate in braiding of bottom cloth in a direction parallel to the warp yarns, and performing grass jacquard weaving treatment on the man-made grass silk yarns by utilizing jacquard equipment of the braiding machine; bypassing the bottom cloth for 2-10 circles by each man-made grass silk yarn to form a cluster of grass silk, setting the height of the grass silk cluster to be 10-70mm, and arranging 6-12 warp yarns between any two adjacent grass silk clusters; and arranging 3-8 weft yarns between any two adjacent grass silk clusters in the grass silk clusters arranged vertically. The preparation method is simple, easy to operate and convenient for industrial production, and pullout force of the grass silk can be increased; and the man-made lawn prepared with the method has the advantages of environmental protection, wide application range and high stability.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

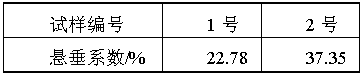

Ice-cold crotalaria fiber home textile plus material, preparation method of ice-cold crotalaria fiber home textile plus material, and home textile article made of ice-cold crotalaria fiber home textile plus material

The invention provides an ice-cold crotalaria fiber home textile plus material, which is obtained through the following steps that ice-cold fiber and crotalaria fiber are blended into yarns, and the yarns are knitted into a jacquard plus material. The plus material consists of the following ingredients in percentage by weight: 20 to 60 percent of ice-cold fiber and 40 to 80 percent of crotalaria fiber. The invention also provides a preparation method of the home textile plus material and a home textile article made of the home textile plus material. The ice-cold fire is applied to summer home textile products, and the ice-cold crotalaria fiber home textile plus material conforms to the life concepts of comfort, safety and health pursued by people at present. The obtained product has the characteristics of softness, pendency, special touch feeling, ventilation, moisture penetrability, simple and elegant laser and the like, the odor can be adsorbed, and the health care functions of antibacterium, antistatic effects, temperature reduction, heat radiation, cooling and comfort effects and the like are realized.

Owner:SHANGHAI SHUIXING HOME TEXTILE

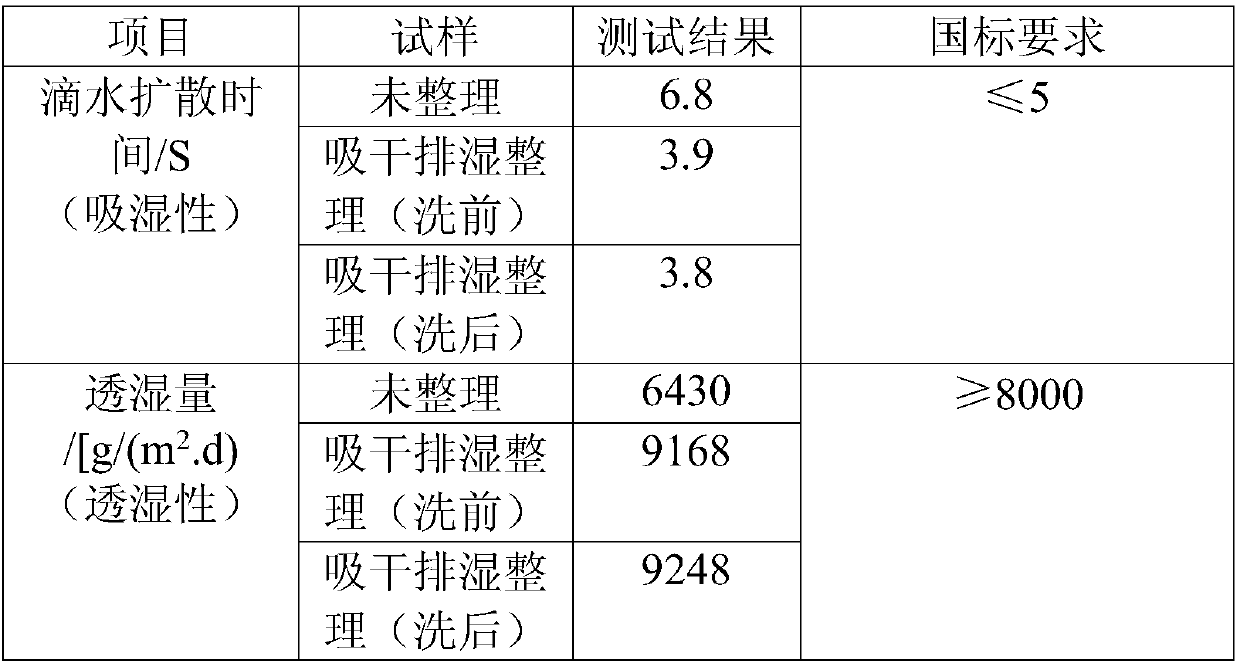

Production technology of quick-dry terylene yarn-dyed seersucker fabric

The invention discloses a production technology of a quick-dry terylene yarn-dyed seersucker fabric. The production technology comprises the following steps of product design, spooling, warping, slashing, drafting, weaving and quick-dry finishing. According to the production technology, the quick-dry after-finish technology is adopted to conduct after-finishing on the terylene / cotton seersucker fabric, the fabric cost is low, the yield is high, the quick-dry performance, the breathability, the comfort, the shape-preserving performance and other performance of the fabric reach a high level, andrequirements of ordinary consumers can be completely met.

Owner:IANGSU COLLEGE OF ENG & TECH

Two-side front jacquard satin towel and weaving process thereof

The invention discloses a two-side front jacquard satin towel and a weaving process thereof. The two-side front jacquard satin towel is formed by weaving warp yarns and weft yarns, the warp yarns are divided into four layers, the ground warps of the upper two warp yarn layers and the weft yarns are woven to form a front side pattern texture, the looped warps of the lower two warp yarn layers and the weft yarns are woven to form a reverse side pattern texture, the front pattern texture and the reverse side pattern texture are connected into a whole body through a plurality of uniformly-distributed tying textures formed by the looped warps and the weft yarns, the weft density of the weft yarns is 80-90 / cm, and the tying texture is wefted by 5-15. The double sides of the towel have different patterns or the same pattern, so that the towel can reach a new level in visual appearance, the new pattern development field is opened up, and compared with the traditional double-color weft satin jacquard towel, the two-side front jacquard satin towel has high level and has high market competitive power.

Owner:SUNVIM GROUP

Method for processing full real silk heterochromatic jacquard fabric

The invention discloses a method for processing a full real silk heterochromatic jacquard fabric. When a gray fabric is woven, a part of real silk yarns are modified real silk yarns treated by a cationic modifying agent; and when the gray fabric is further dyed in a bath, the acid dye has high dyeing rate on the real silk yarns modified by the cationic modifying agent under the condition of the neutral bath, and has low dyeing rate or cannot be dyed on the unmodified real silks, so the contrast effect of deep and light colors or white space is formed. Dyeing can be performed again after the gray fabric is woven, so the production efficiency of the fabric is effectively improved, the energy consumption is saved, the loss of real silks is reduced, and the consumption of real silk raw materials is saved; and meanwhile, different dyeing effects are realized by adjusting the ratio and the distribution of the modified real silk yarns and the real silk yarns in the gray fabric, namely the fabric changes color flexibly.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

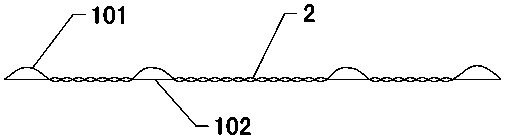

Novel concave-convex three-dimensional fabric and weaving method thereof

ActiveCN108468136AImprove comfortHigh flower effect is obviousHeating/cooling textile fabricsSwivel-woven fabricsYarnSurface layer

The invention discloses a novel concave-convex three-dimensional fabric and a weaving method thereof, and belongs to the technical field of textiles. The fabric is composed of a plurality of convex parts and a plurality of concave parts, and is characterized in that the corresponding convex parts are arranged on the periphery of each concave part, and the convex parts and the concave parts are formed by interweaving warps and wefts; the wefts comprise first wefts, second wefts and high-shrinkage yarn, and the fineness of the first wefts is larger than that of the second wefts; each convex partis composed of a surface layer structure and an inner layer structure, the surface layer structures are formed by interweaving the first warps and the second wefts, the inner layer structures are composed of weft float and warp float, the weft float is formed by the first wefts and the high-shrinkage yarn, and the warp float is formed by the second warps. The fabric has a concave-convex three-dimensional effect, the convex parts can be various patterns, the adjacent convex parts are naturally connected and smooth in transition, and the comfort degree of the fabric is enhanced.

Owner:江苏斯得福新材料有限公司

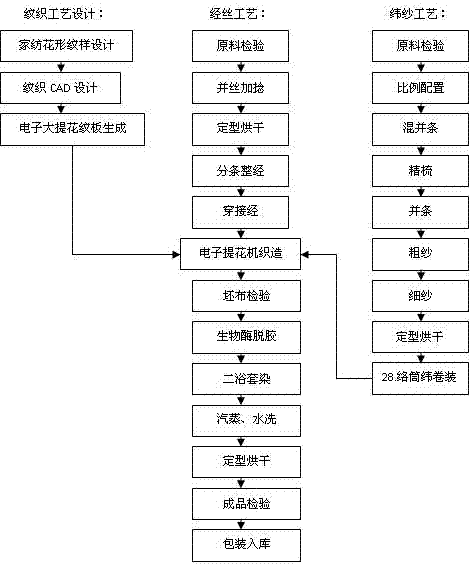

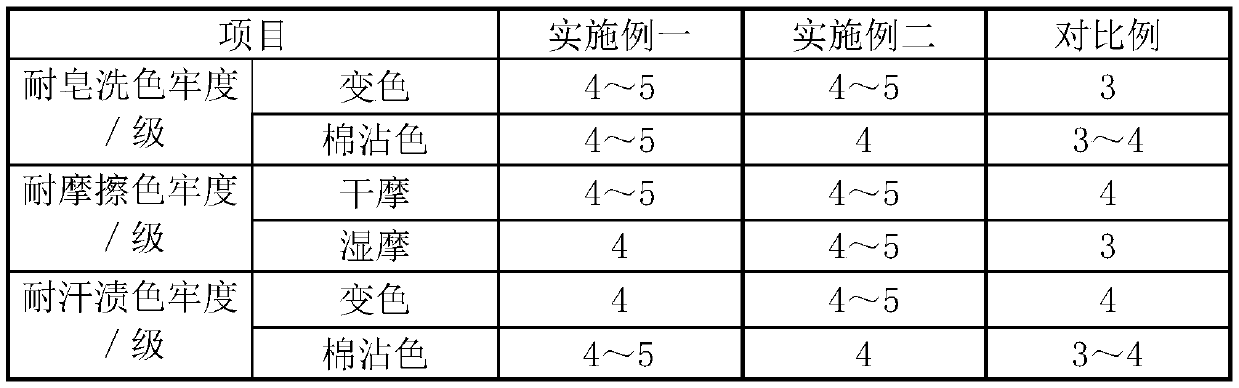

Multi-element blended yarn and cross interwoven jacquard textile fabric and production method thereof

InactiveCN104775222AImprove spinnabilityGood warmth retentionBiochemical treatment with enzymes/microorganismsDe-gumming silkEngineeringNatural fiber

The invention provides a multi-element blended yarn and cross interwoven jacquard textile fabric and a production method thereof. A multi-element blended yarn is used as a weft yarn, and silk is used as a warp yarn, and the multi-element blended yarns are interwoven with the silk; the multi-element blended yarn is formed by blending three fiber components such as hemp fibers, cotton fibers and protein composite renewable cellulosic fibers. The natural fibers and the functional fibers are woven in a jacquard weaving technology, so that the additional characteristics such as environmental-friendliness, softness, warmth, good brightness, top grade and luxury can be given to the textile fabrics.

Owner:JIUJIU SILK CO LTD

Production process of spandex jacquard four-faced elastic fabric

The invention discloses a production process of a spandex jacquard four-faced elastic fabric. The method comprises the following steps of step A, preparation of a polyester air coated yarn; step B, preparation of a warp yarn; step C, beaming; step D, sizing; step E, weaving; step F, desizing and vinylon dissolution; step G, dyeing and step H, shaping. The production process of the spandex jacquardfour-faced elastic fabric has the advantages that warp and weft yarns adopt a twisted yarn of a polyester ammonia covering yarn and water soluble vinylon, the method of adopting the polyester ammoniacovering yarn for active yarn feeding makes the twisted yarn have no elasticity, a conventional loom can be used for weaving, and vinylon dissolution is performed after weaving, so that the elasticity of warp and weft yarns is restored. And gaps reserved by the vinylon dissolution make the fabric have better air permeability.

Owner:JIAXING MINGYE TEXTILES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com