Patents

Literature

728results about "Warping machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

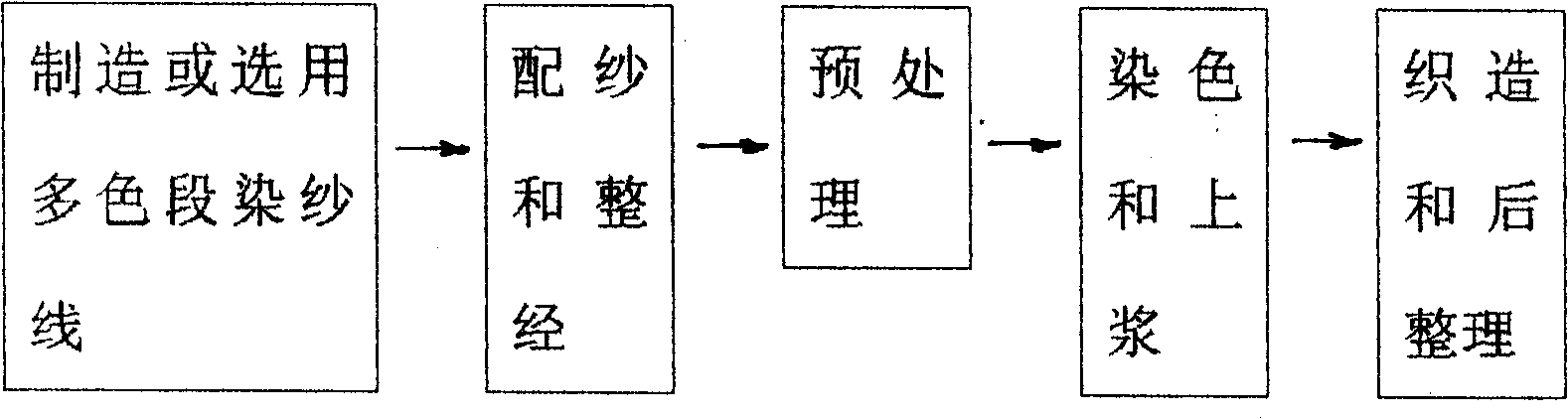

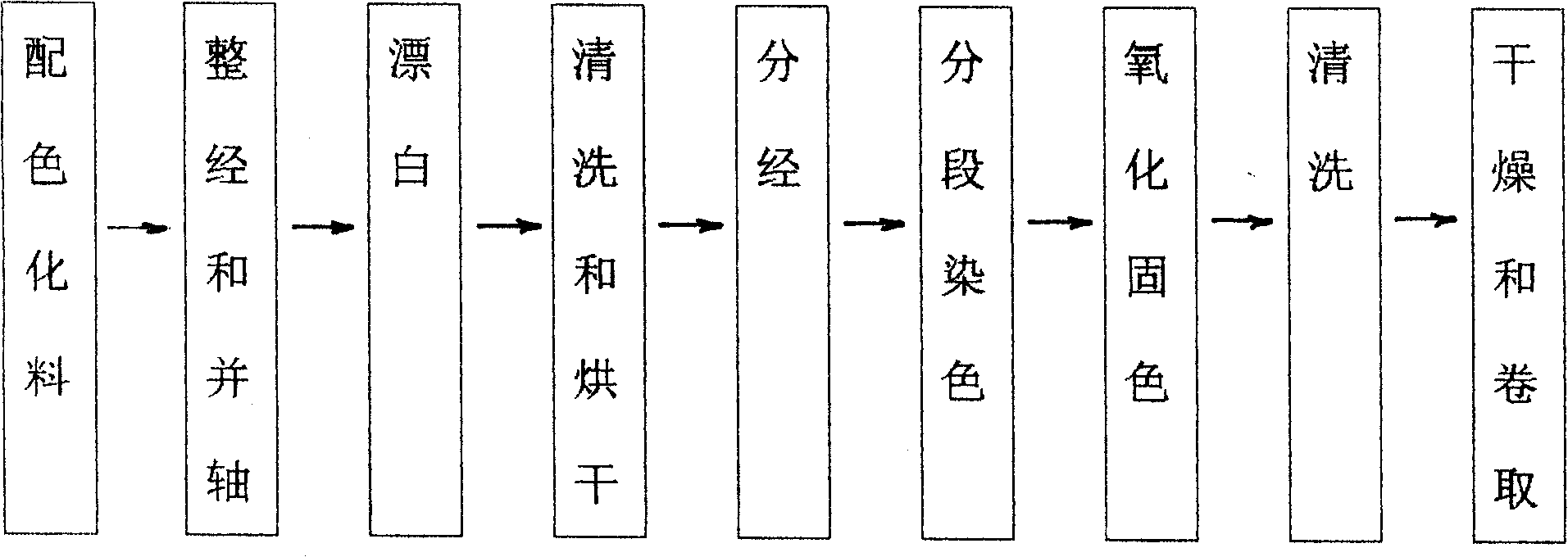

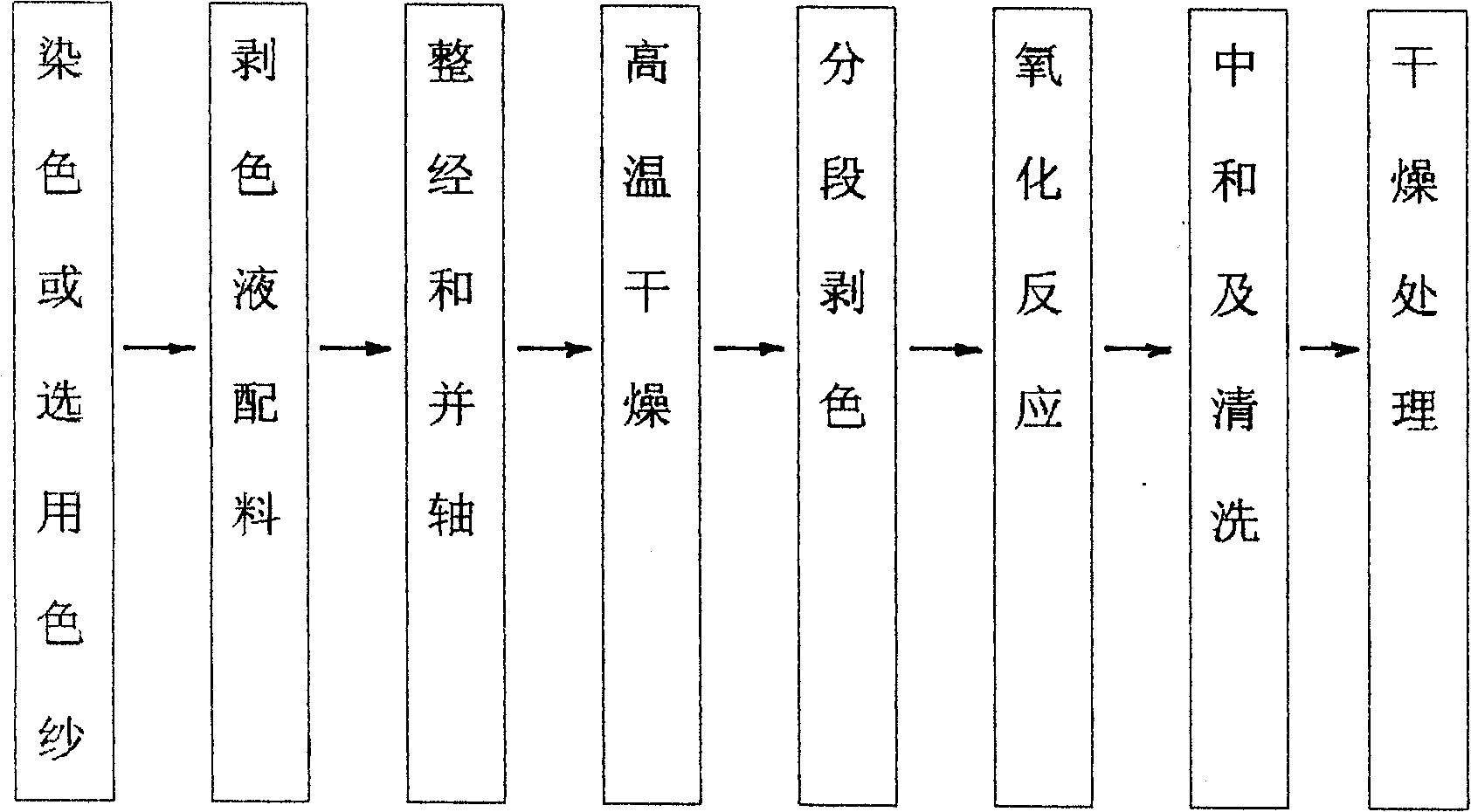

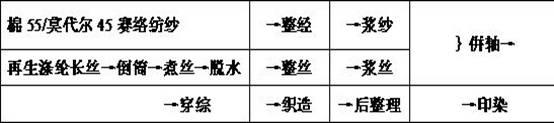

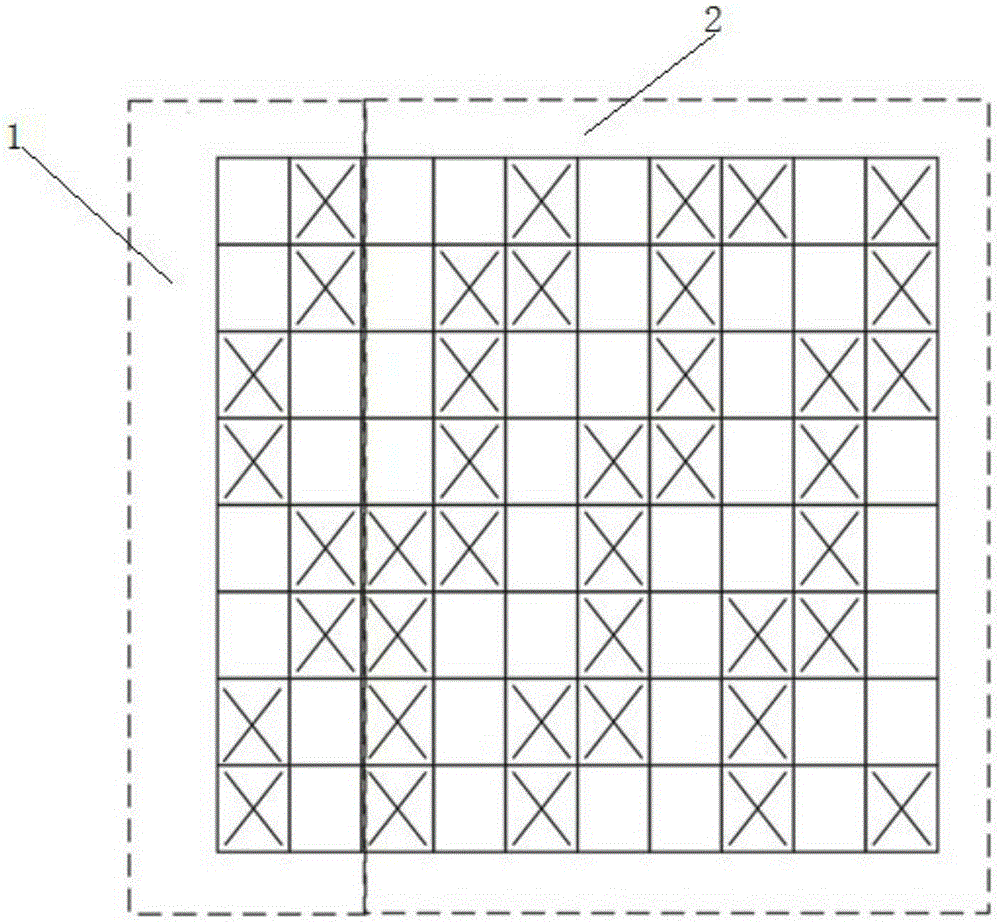

Production process for color-mixing denim and the color-mixing denim made thereby

InactiveCN101289777AEasy to produceFashionableMercerising of yarns/threads/filamentsWarping machinesYarnSurface layer

The invention relates to mixed denim and a technique for producing the same. The technique is as follows: firstly, multi-color segment dyeing yarns are adopted to be arranged and combined into bottom colored flower patterns of the denim; secondly, a main fundamental color required by the denim is dyed for the second time on a surface layer of the denim yarns; thirdly, partial colors on the surface layer of the denim are locally peeled off and internal colors of the yarns and the bottom colored flower patterns of the denim are exposed, thereby the mixed effect that the boundary of the flower patterns is blurred and the color is soft is protruded. The technique for producing the mixed denim comprises the following steps of: production of the multi-color segment yarns, yarn mixing and warping, pretreatment, dyeing and sizing, weaving and after finishing. The mixed flower patterns reach the effects of roughness, rusticity, rich color, softness and naturalness, and the techniques such as flower production, dyeing, sizing and so on can be finished once simultaneously, thereby the technique reduces labor duplication, saves a great deal of energy and can obviously reduce the production cost and the pollution of the mixed denim and the multi-color segment dyeing yarns.

Owner:刘林泉

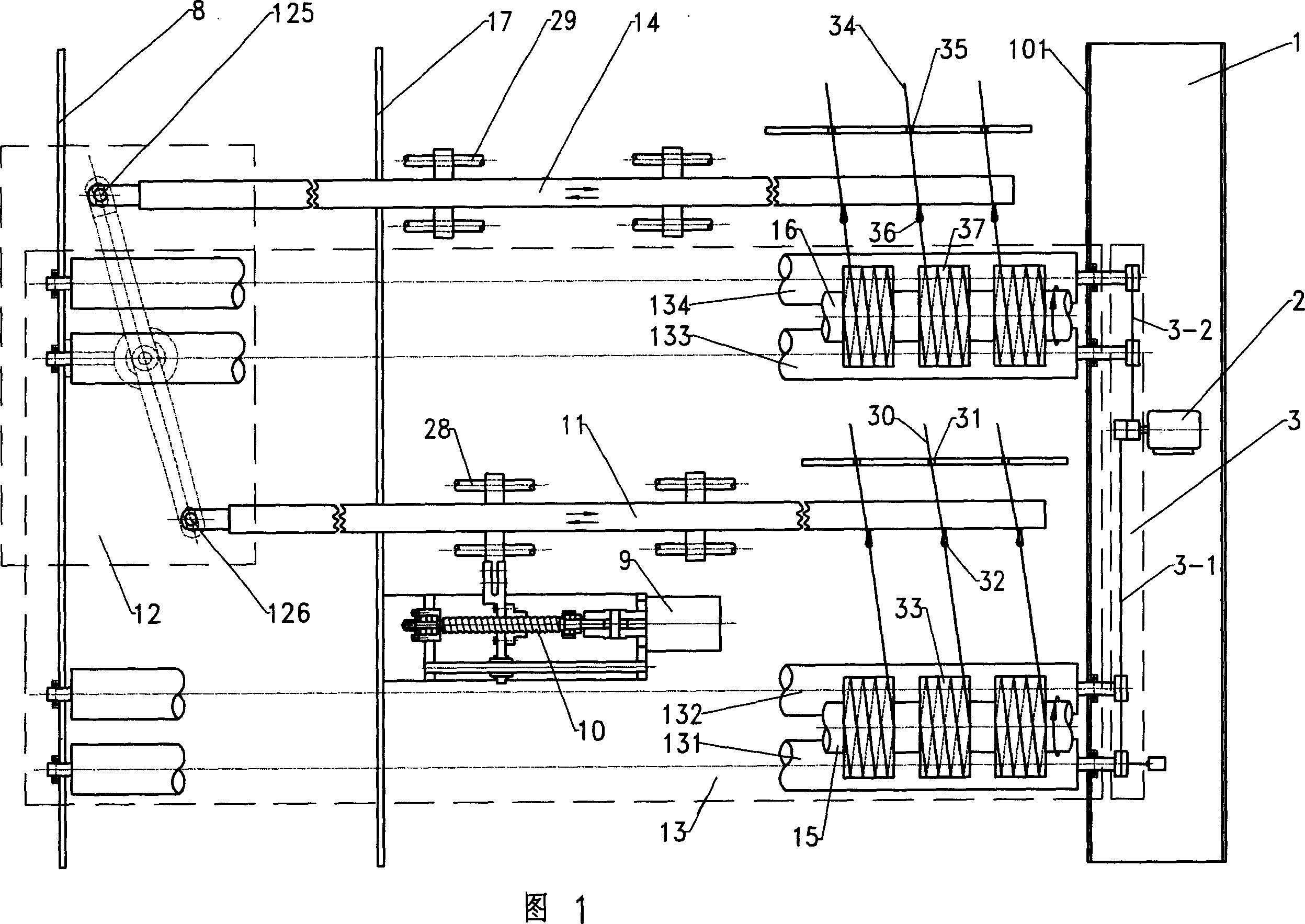

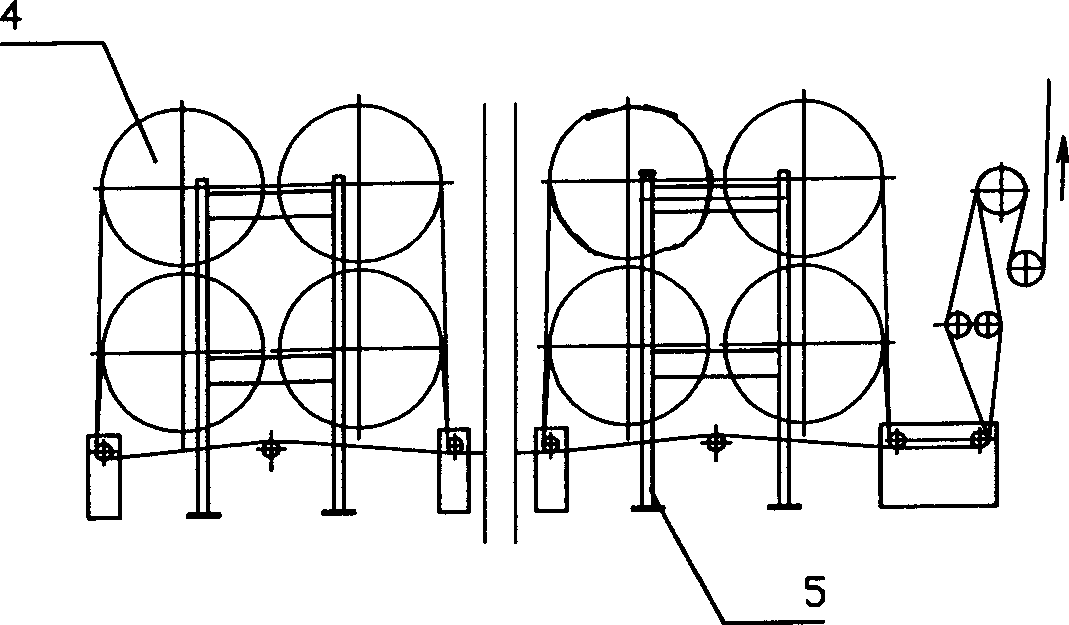

Double-layer warp beam warper

InactiveCN1928175ASave energySimple structureWarping machinesTextiles and paperServo actuatorBall screw

A double-layer beam warper, comprising machine head, left wallboard of machine head, electromotor, middle wallboard, tail wallboard, servo-actuator, ball screw, contains connecting rod mechanism, double layer roll mechanism and synchro actuating mechanism. Connecting rod mechanism is firmly joined to tail wallboard. Servo-actuator through ball screw and connecting rod mechanism drive upper and lower guide needle bars, arranged in parallel, whose swing are equal and swing direction are inverse, move to and fro in horizontal direction respectively. Upper and lower 0 roll, set among left wallboard of machine head, middle wallboard, tail wallboard, is driven by electromotor run-in synchronism and upper and lower beam rotate synchronously by friction force of upper and lower roll. Because of uniform diameter and rotational speed of upper and lower roll, linear speed of upper and lower beam are stationary so as to ensure beaming of high efficiency and quality. The invention is characterized in simple structure, convenience adjusting, stationary performance and energy conservation.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

Anti-twisting type sectional warping machine

The invention discloses an anti-twisting type sectional warping machine. The anti-twisting type sectional warping machine comprises a bobbin creel, a yarn fixing rack, a yarn distributing device and a drum, wherein the bobbin creel comprises a rack, yarn guiders, a flexible cover and yarn cone shafts; yarn cones are placed on the yarn cone shafts; the yarn cone shafts are fixed on the rack; each yarn cone shaft is provided with the corresponding yarn guider; and the flexible cover is fixed on the rack and covers the yarn cones. The anti-twisting type sectional warping machine is simple in structure; the circumstance that warp yarns are twisted together and are knotted in a warping process is avoided effectively; and the warping efficiency is improved.

Owner:佛山市三水三强塑胶有限公司

Warp-knitting polyester fabric and processing method thereof

InactiveCN101709531AGuaranteed tensile strengthGreat tractionPattern makingWarp knittingPolyesterSurface layer

The invention relates to a warp-knitting polyester fabric and a processing method thereof, which belong to the fields of a polyester fibre product and a processing technique thereof. The warp-knitting polyester facing material comprises a surface layer tissue, a bottom layer tissue and an inner layer tissue positioned between the surface layer tissue and the bottom layer tissue, wherein the used raw material of the surface layer tissue is FDY bright yarn of 50D / 36F; the used raw material of the bottom layer tissue is spandex yarn of 40D; and the used raw material of the inner layer tissue is FDY bright yarn of 50D / 36F or 75D / 36F. Because the invention adopts the raw materials of the surface layer tissue, the inner layer tissue and the bottom layer tissue to form the warp-knitting polyester fabric, favorable pull tension exists between the surface layer tissue and the bottom layer tissue, and the tensile strength of the facing material is ensured, so that the warp-knitting polyester fabric has durability; the raw materials of the surface layer tissue and the inner layer tissue adopt the bright yarn, so that a beautiful feel can be presented; the bottom layer tissue adopts the spandex yarn, so that elasticity can be presented; and the technological steps adopted by the method can prevent floss faces from generating the phenomena of wool collapse and wool reversal, so that flosses have strong upright feel, and the floss faces are plump.

Owner:XIONGYING KNITTING & DYEING CHANGSHU

High counts and high density down-proof fabric production method

The invention discloses a manufacturing method of high count and high density down-proof cloth. The cloth of the invention is made from a long-staple cotton combed yarn after procedures of warping, sizing, reeding, air-jet weaving, cloth inspecting, finishing, packing and stocking, etc. The sized yarn is made from mixed slurry of PVA and etherifying starch and sized by double-clip-double-nip and high temperature sizing; the weaving adopts the air-jet weaving and the ratio of a weft tension peak value and weft tension strength is controlled to be less than or equal to 55 percent. The invention is characterized by simple operation, easy control, high production efficiency and product quality, high cloth quality of produced products, smooth, even and clean cloth surface, soft and fine texture, erect and smooth hand feeling, special high moisture absorption and discharging performance, and the invention resembles to imitating the style of silk fabric, which is beneficial for improving downstream processing procedure and processing quality.

Owner:丁宏利

Super-smooth warping method of yarns with many drafted fibers

ActiveCN105274695AAvoid gatheringWrap tightlyWarping machinesOther manufacturing equipments/toolsFiberYarn

The invention relates to a super-smooth warping method of yarns with many drafted fibers and belongs to the textile processing technical field. According to the method of the invention, on each yarn warping mechanism of a warping machine, a false twisting device is adopted to make the trunk of a yarn rotate; a drafted fiber directional stretching device is adopted to directionally eject steam flows so as to directionally stretch the drafted fibers of the yarn, so that some of the drafted fibers of the yarn forwards and orderly wrap the trunk of the yarn, and therefore, the drafted fibers can be prevented from being entangled to from neps when randomly or vertically winding the trunk of the yarn; a drafted fiber vortex wrapping device is adopted to reversely wrap the other drafted fibers of the yarn on the trunk of the yarn, so that the other drafted fibers of the yarn and the forwards and orderly wrapped drafted fibers can be closely tangled in a cross manner; and therefore, progressive complete wrapping and cross tight wrapping of the drafted fibers of the yarns can be realized, and winding tightness and firmness of the drafted fibers can be greatly increased, and the problem of series rebound of the drafted fibers of the yarns in a warping procedure and subsequent procedures of warping can be solved, and super-smooth warping of the yarns with many drafted fibers can be realized. The device of the invention has the advantages of reasonable structure and convenient operation.

Owner:WUHAN TEXTILE UNIV

PTT (poly(trimethylene terephthalate)) memory fabric production process

InactiveCN101736487ASoft touchShinyWarping machinesHeating/cooling textile fabricsFiberPolyethylene terephthalate

The invention relates to a PTT (poly(trimethylene terephthalate)) memory fabric, in particular to a PTT memory fabric production process. The production process comprises the following steps of: batch warping, starching, shaft combining, leasing, looming healding, weaving, pretreatment of dying and finishing, alkali quantity decreasing, dying, waterproof processing and thermal forming. The fabric has unique memory function and comfortable hand feel, the performance of smoothing by touching the fabric enables the product to achieve an effect of totally ironing free, and favorable draping effect and recovery capability enable the fabric to become one of fashionable functional fabrics. Fibers of the fabric are completely biodegradable under certain condition and the fabric is an environmental-protection and green product.

Owner:杭州宏峰纺织集团有限公司

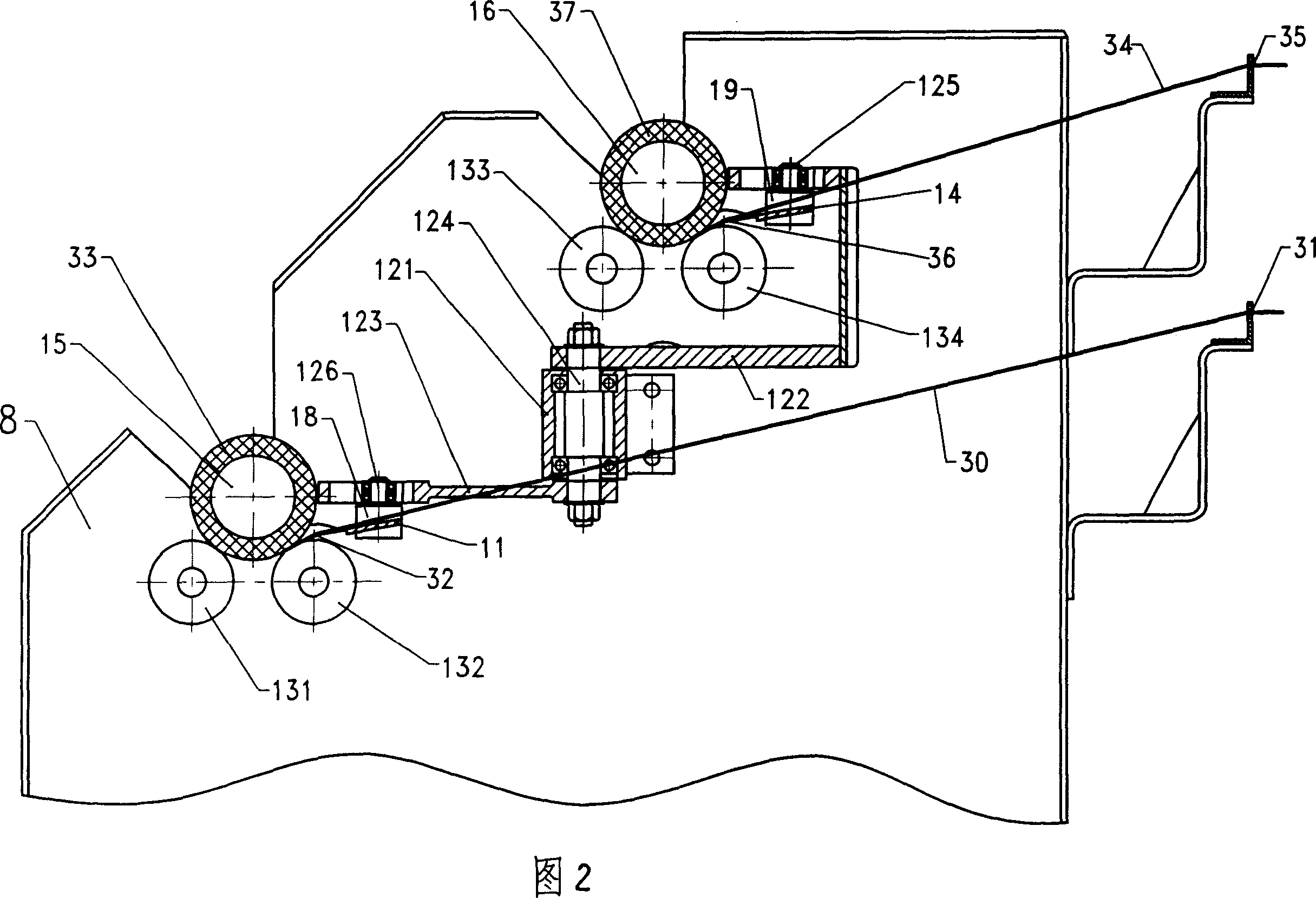

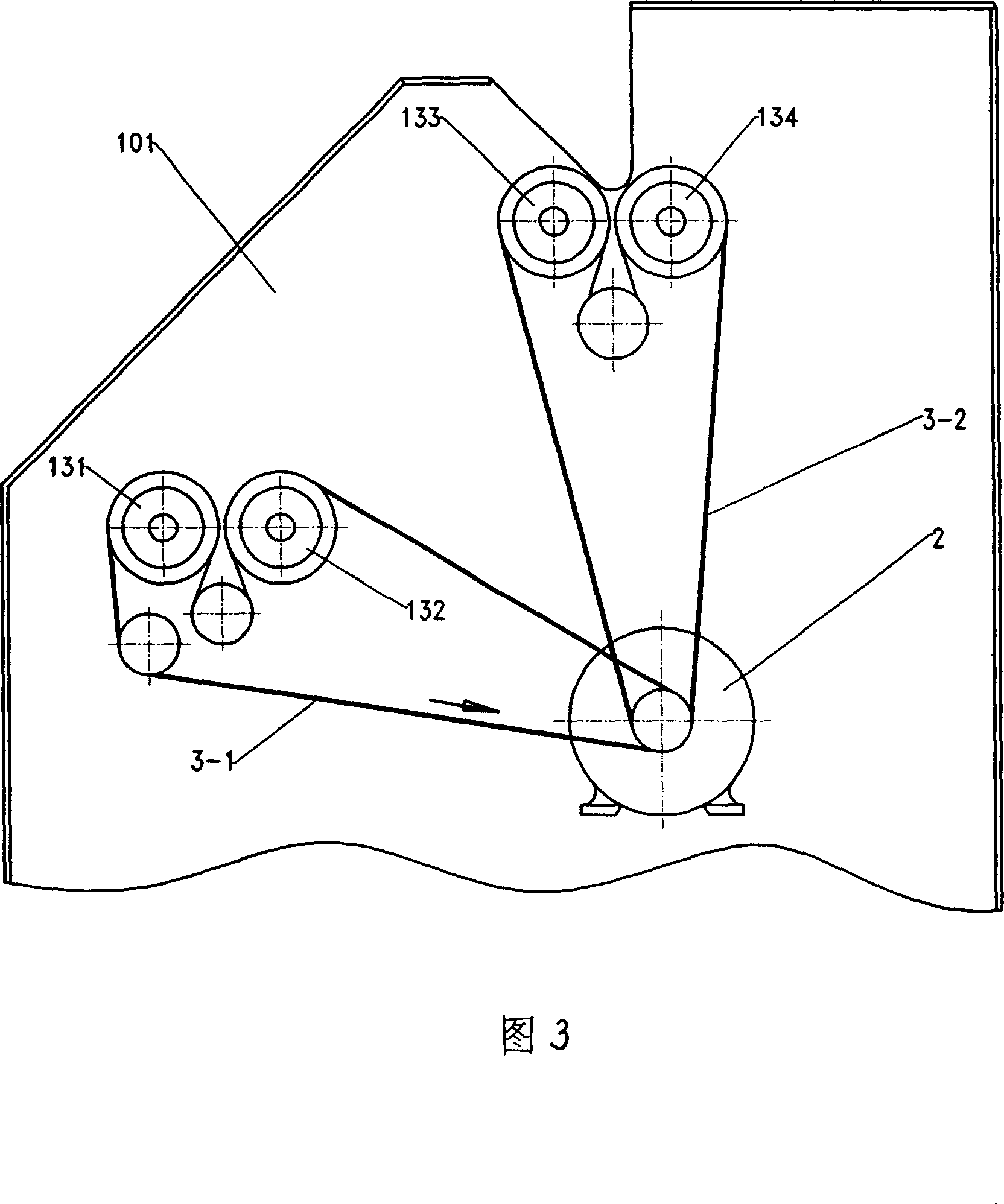

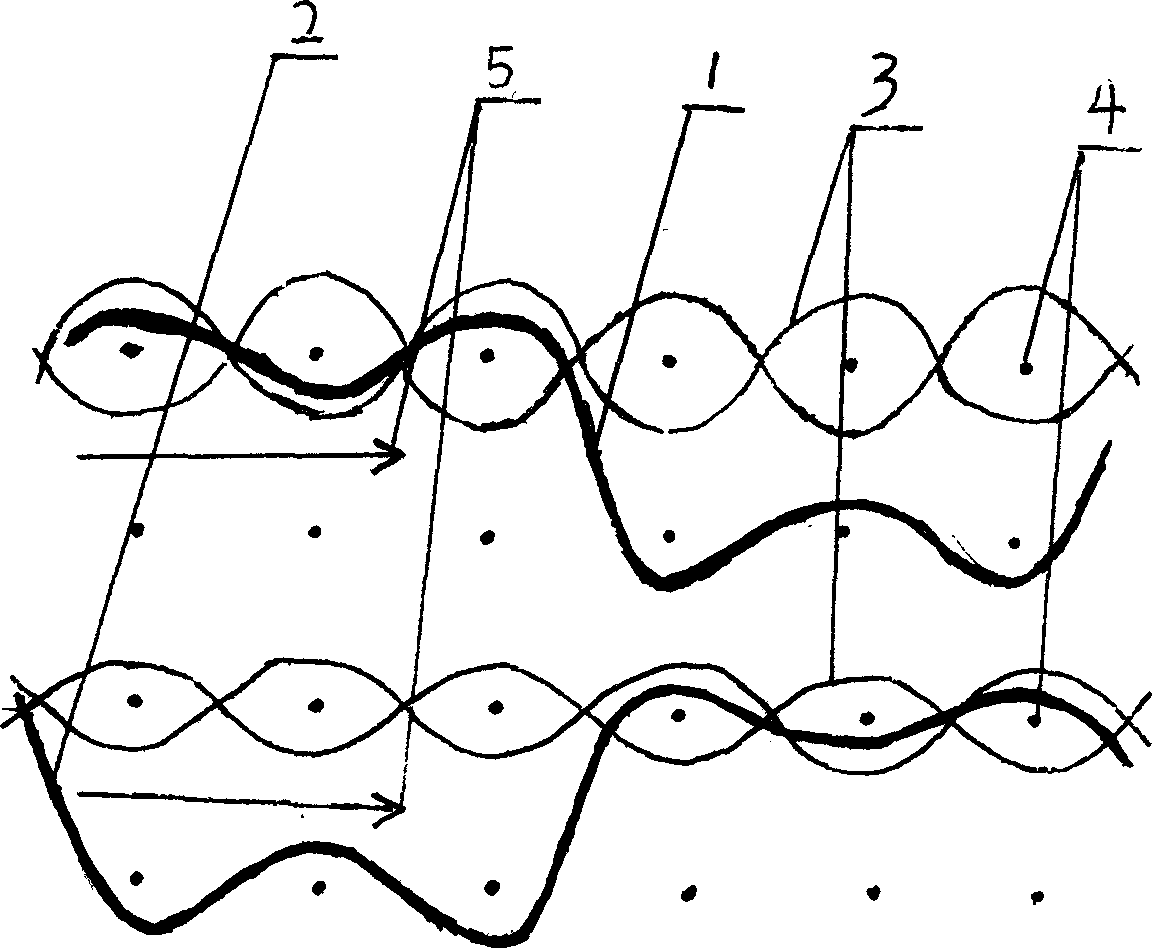

Warp dyeing and multi-shaft winding process, warp dyeing and multi-shaft winding machine

This invention belongs to the yarn dye technique filed, the main technique as follows: unreeling a plurality of t yarns which reel around the warping shaft in parallel, then laminating the unreeled yarns to the flake yarns, and then dyeing them into the indigo colour or disparting them into many flake yarns with lesser head share after dyeing by coating, then reeling the flake yarns around another pluralities of warp beams which is for the warp thread cartridge-made machine to produce the cheese. The character of this invention is that it combines the warp thread dyeing with the multiracial convolution, so the technique flow process is short.

Owner:祁江汀

Clean wiping cloth and its producing process

The clean wiping cloth and its production process belong to the field of weaving technology. The clean wiping cloth is produced with composite polyester-Jinlun yarn as material and through the steps of compounding twisting, warping, weaving, opening, and gluing to set. In the opening step, the composite polyester-Jinlun yarn is soaked in sodium hydroxide solution of concentration 6-8 g / L at 98-105 or 1 hr. The high efficiency clean wiping cloth made of superfine fiber has fine fuzzy fibers in much greater quantity than that in common fabric, high dirt holding capacity, no dust, high hygroscopicity and high cleaning power.

Owner:沂水恒泰纺园有限公司

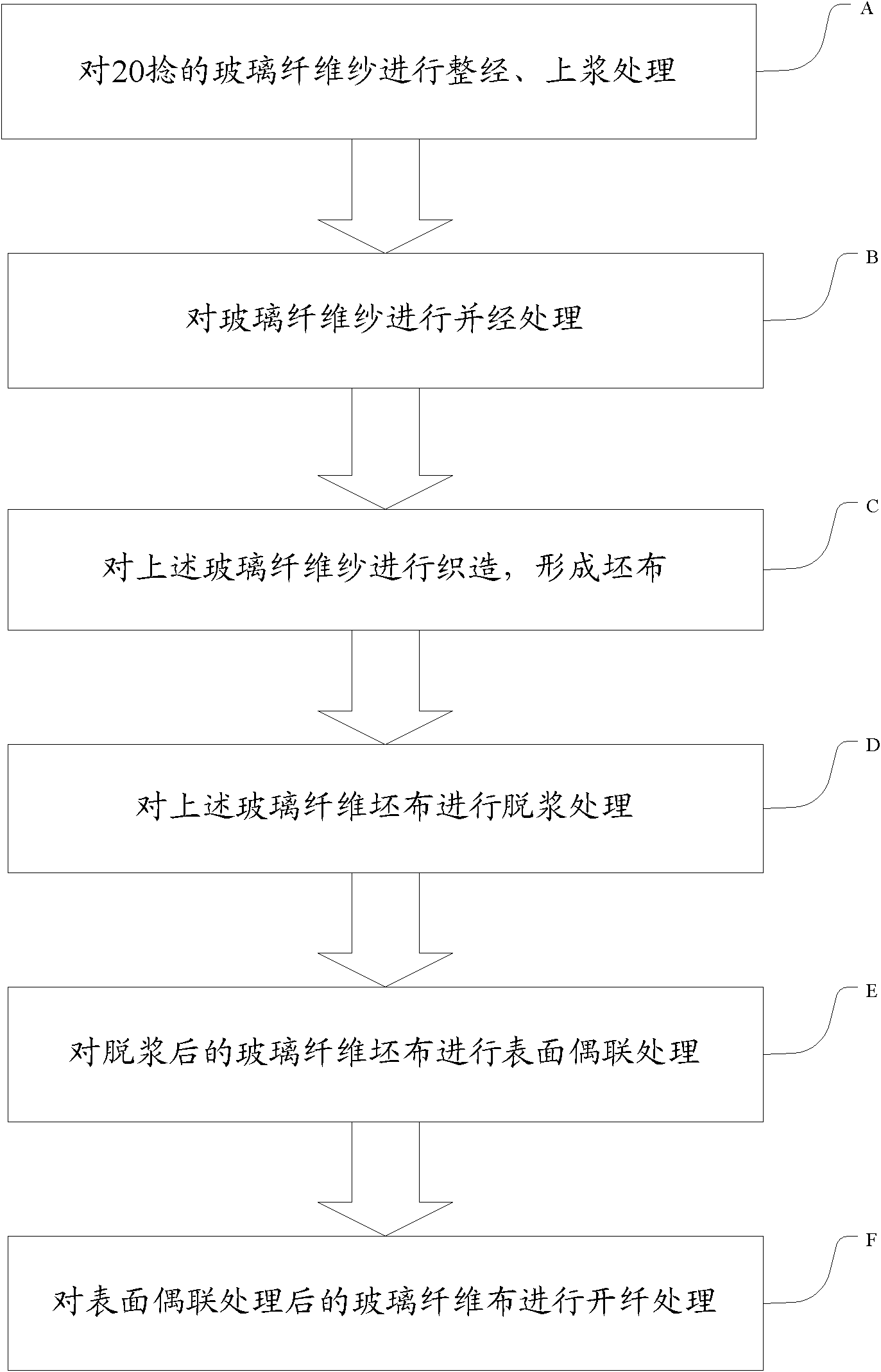

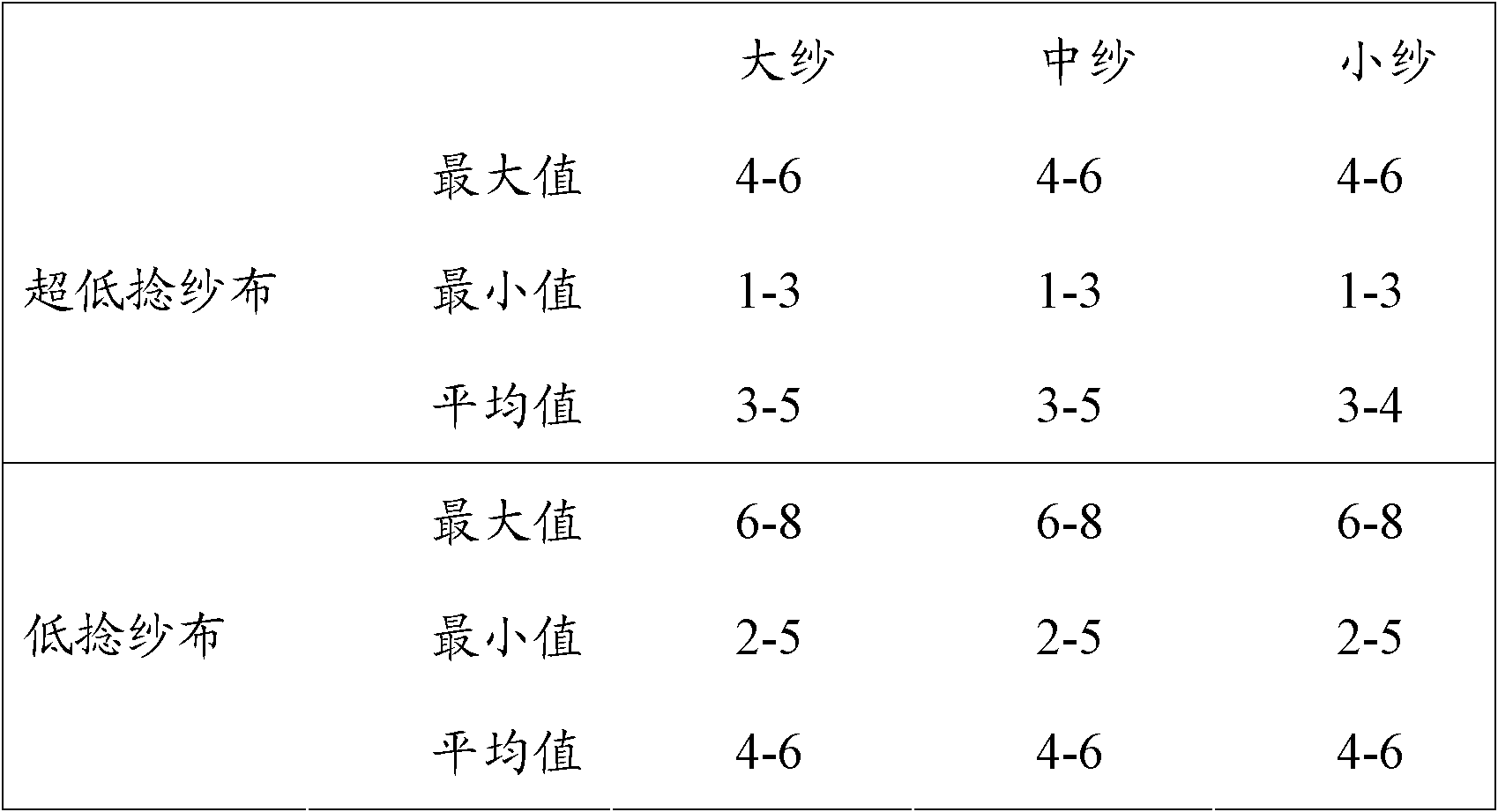

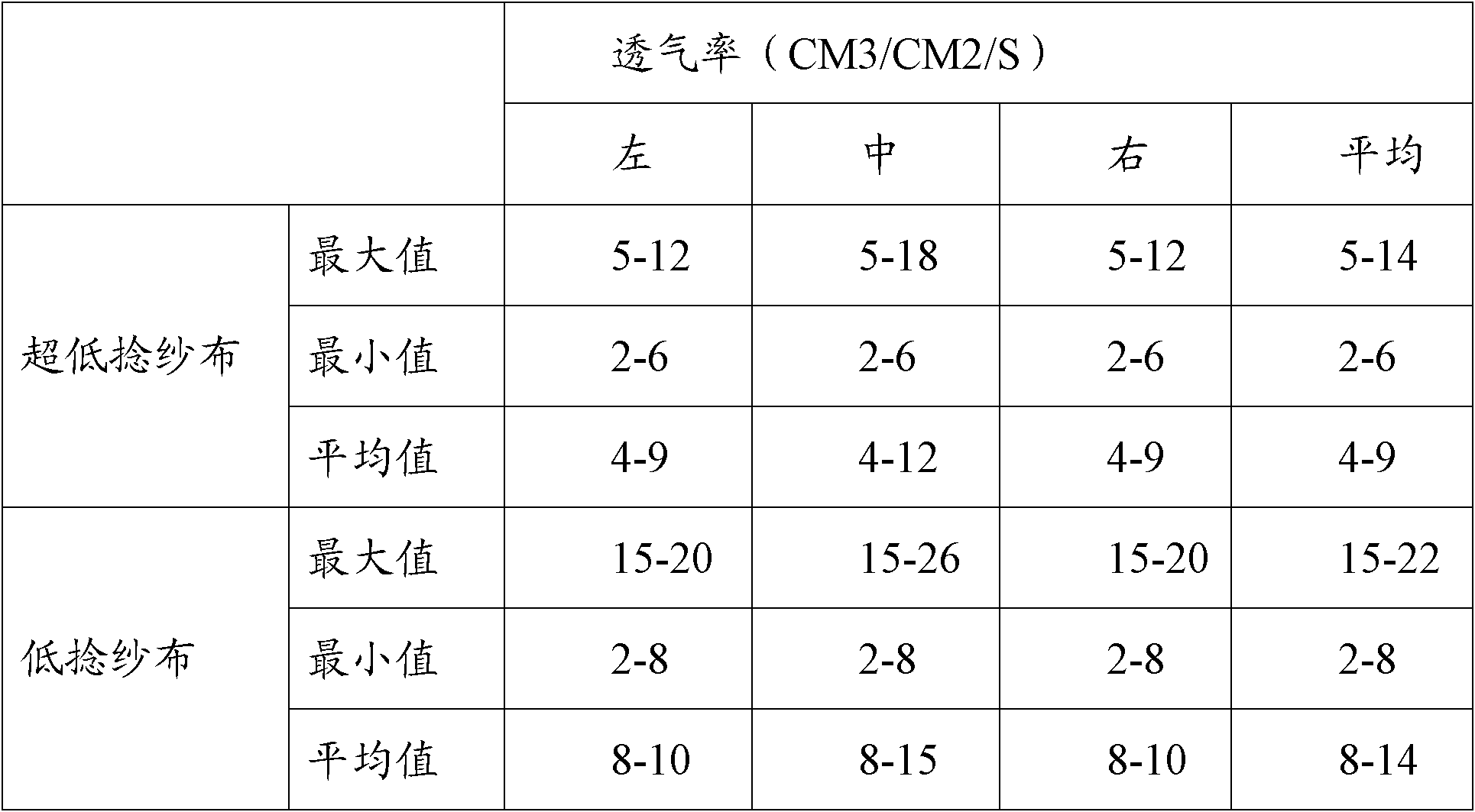

Production method for super-low-twisted electronic grade glass fiber cloth

Owner:建滔(广东)电子专用材料有限公司

Processing method for terylene ultra-fine fiber blanket

InactiveCN1804177AImprove lodging resistanceReflect warmthBlanketWarp knittingCooking & bakingUltra fine

The manufacture method for a full-terylene ultrafine fiber blanket comprises: preparing the DTY silk, warping, weaving, splitting, dyeing or printing, loose baking, fixing color, sorting, thermal setting, sorting the fluff on back, sewing, and finishing the product. This invention meshes the DTY silk before warping to make up ultrafine denier silk with high F number and endow the fiber well resistance to lodging, increases gram weight to 300-500g / m2 and velvet height to 4.5-8mm, and improves the velvet texture.

Owner:常熟市锦绣经纬编有限公司

Preparation method of waterproof shell fabric

The invention discloses a preparation method of a waterproof shell fabric. The preparation method comprises the steps of examining precursor fiber, treating warp, weaving on a weaving machine and cropping; the warp treatment comprises six steps, namely hanging yarn, beaming, slashing, combining axles, leasing, as well as drafting and scrabbling reed. Starching is performed on warp, reasonable technological parameters are adopted, and specific sizing percentage control is performed, so that the inner layer of yarn is immersed in seriflux, cohesive force between fibers is increased, and breaking-resisting strength of yarn is improved; a layer of protective film is formed on the surface of the yarn, so that the yarn is smoother and wear-resisting, the warp can bear strong mechanical action of the weaving machine and repeated abrasion among yarns, the end breakage rate of the warp during weaving is reduced, and the weavability of the warp and the quality of the waterproof shell fabric are improved.

Owner:江苏晨越高新材料有限公司

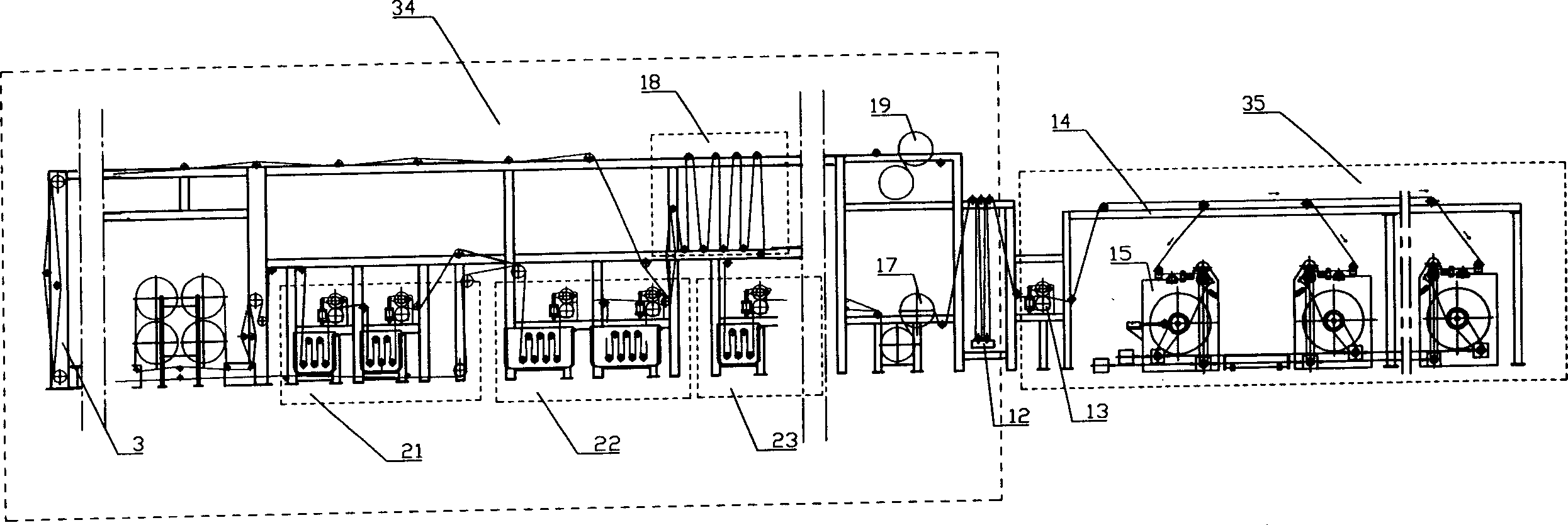

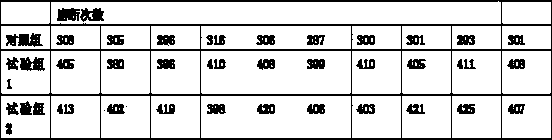

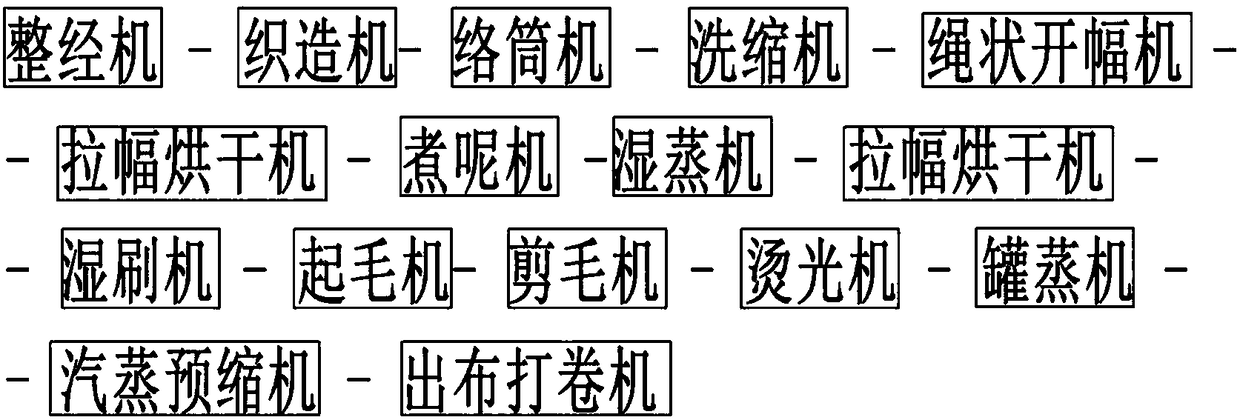

Cashmere fabric assembly line and process

InactiveCN108251936ALiquid/gas/vapor treatment machines driving mechanismsWarping machinesWinding machinePulp and paper industry

The invention relates to a cashmere fabric assembly line and a process. The cashmere fabric assembly line comprises a warping machine, a weaving machine, a winding machine, a washing shrinking machine, a rope opener, a stentering drying machine, a crabbing machine, a wet steaming machine, another stentering drying machine, a wet brushing machine, a raising machine, a shearing machine, a natural luster finishing machine, a pot steaming machine, a steam pre-shrinking machine and / or a cloth discharge rolling machine which are sequentially connected with one another according to working procedures. The cashmere fabric assembly line and the process have the advantages of reasonable design, compact structure and convenience in use.

Owner:安美桥(南宫)羊绒制品有限公司

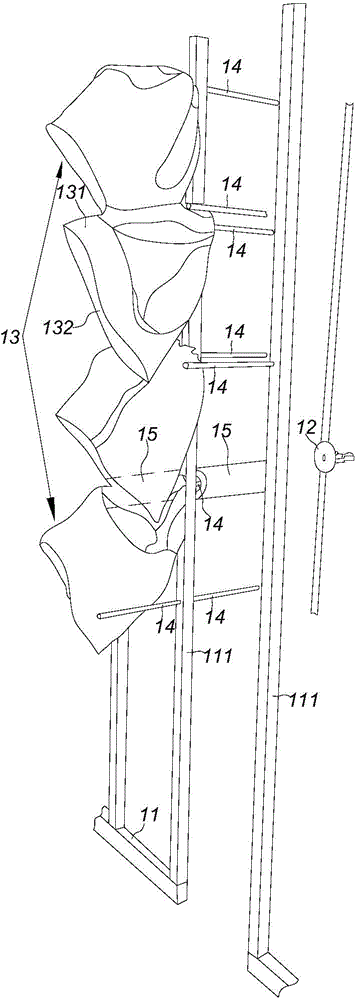

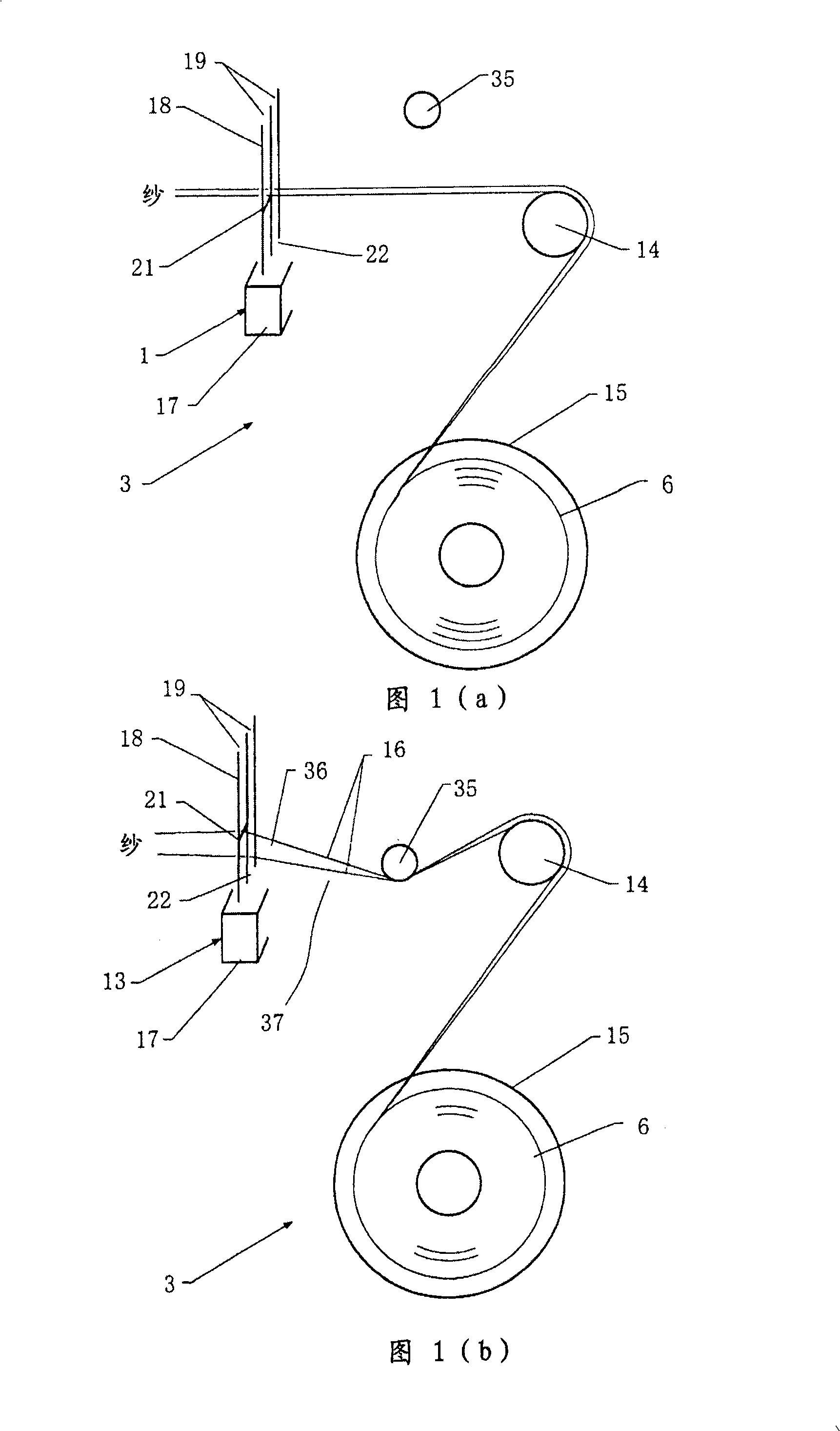

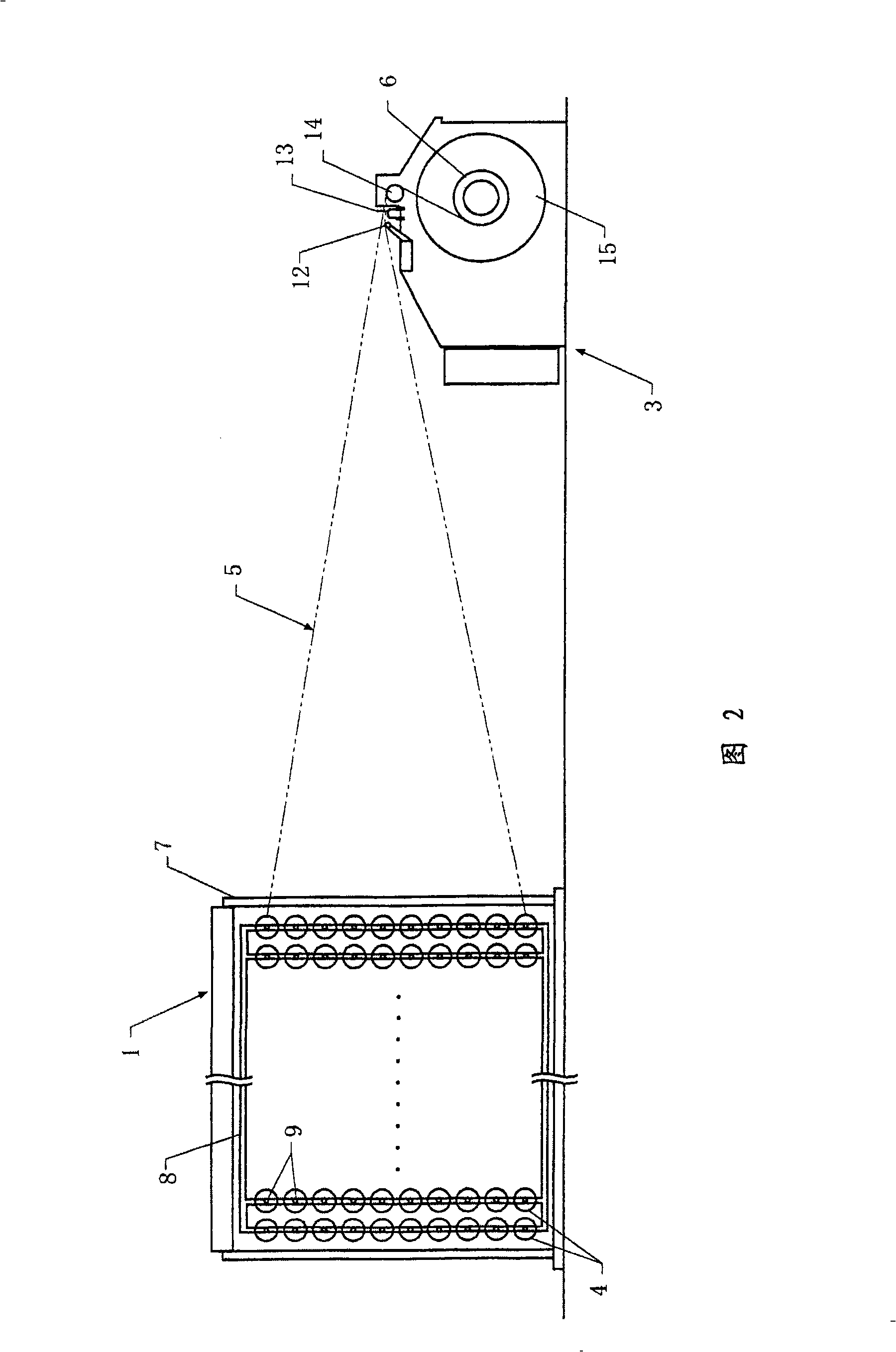

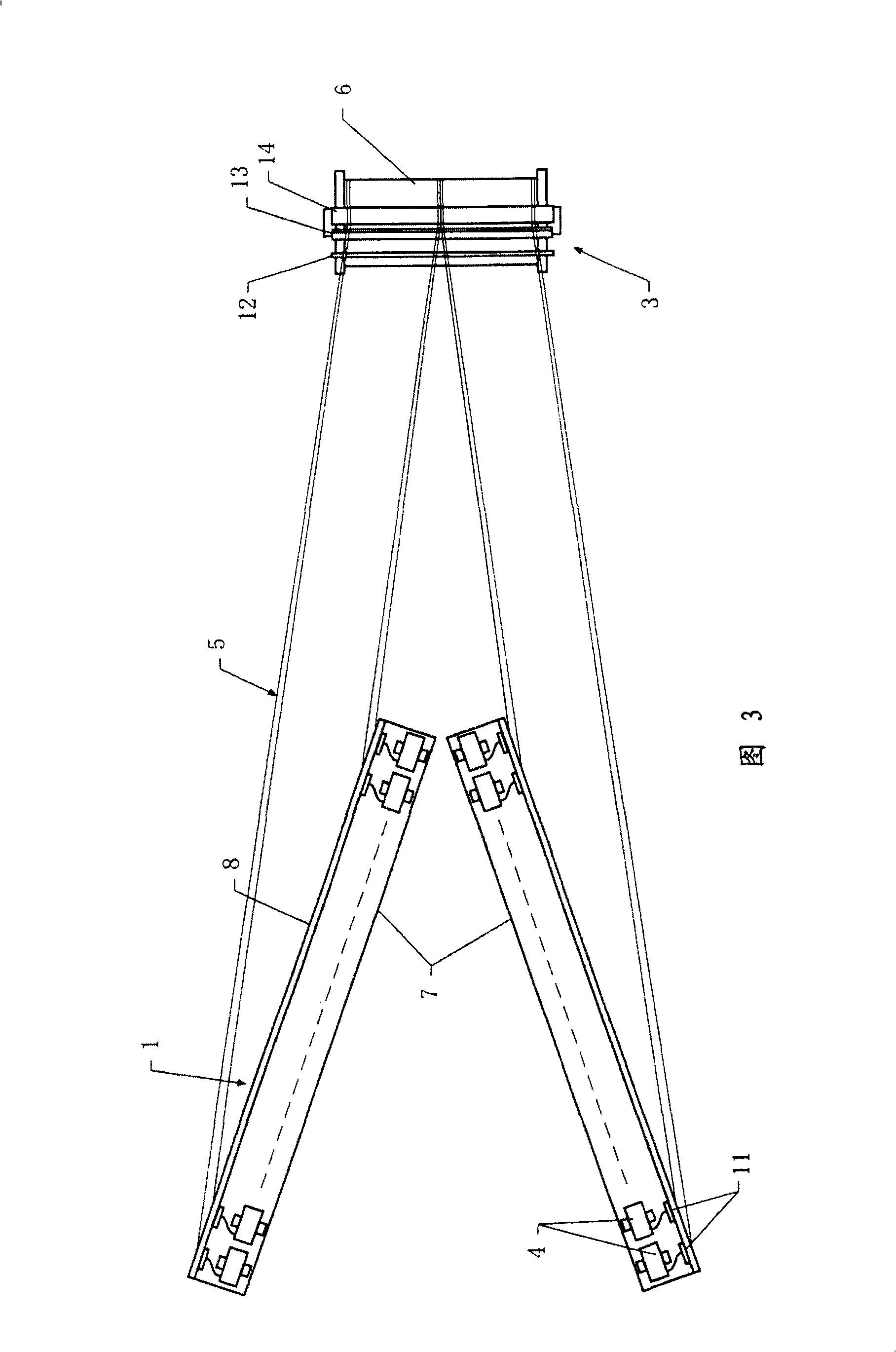

Beaming method of warp shaft

InactiveCN101338467AEasy to completeWarping machinesOther manufacturing equipments/toolsYarnEngineering

The invention relates to a beaming method for warp shaft. the method comprises guiding a yarn set (5) guided from a plurality of yarn supply bodies (4) to a coiling apparatus (3) including a reed (13), in a beaming method for the warp shaft of forming the warp shaft by coiling into warp slice with the coiling apparatus, as the reed, reed with steps of a high step section (21) of a yarn through section (19) between reed needles (18) and a low non-step section (22) of the yarn through section are formed according specified space; after the coiling of the warp shaft, the yarn set and the reed with the step section are moved respectively, a portion of the yarn set is contacted with the step section, left section of the yarn set is divided into more than two unit warp slices by the upper part of the non-step section, separated belts are inserted into between a plurality of warp slices, and each unit warn slices are cut between the reed with step and the belt.

Owner:TSUDAKOMA KOGYO KK

Preparation method for multicolour section linnet

The invention relates to linnet, particularly to a preparation method for multicolour section linnet. The preparation method comprises the following steps: spinning of linnet yarn, beaming in batches, slashing and combing bobbins, drafting and denting, weaving, desizing and refining, dying, heat shaping, calendering and full decatizing. The multicolour section linnet prepared with the preparation method has the multicolor effect, is smooth in hand feeling, ventilate, moisture conductive, and excellent in elasticity.

Owner:富丽达集团控股有限公司

Bamboo charcoal fiber fabric for home textiles

ActiveCN104264279AGood flexibilityImprove loftPile loops cuttingConjugated cellulose/protein artificial filamentsScreen printingPolymer science

The invention relates to a preparation method of a textile, in particular to bamboo charcoal fiber fabric for home textiles. The preparation method comprises the following steps: preparation of bamboo charcoal micropowder emulsion, preparation of viscose, preparation of bamboo charcoal fiber filaments, and preparation of gray fabric, and further comprises the specific steps: spinning, warping, slashing, weaving, two-bath dyeing, postprocessing of the fabric, scutching, dehydrating, drying and sewing, wherein during the spinning process, the cotton fiber is used for the warp direction, modal fiber or covered spandex filaments and bamboo charcoal fiber filaments are used for the weft-wise direction; the two-bath dyeing method comprises pad dyeing and dyeing the same color; the jacquard weaving method comprises first-time loose drying, velvet piling, second-time loose drying, and preparing the pattern screen printing plate for chromatography; the drying temperature for the first-time loose drying in the jacquard weaving step is 130-140 DEG C, and the drying time is 5-9 minutes; the drying temperature for the second-time loose drying is 70-90 DEG C, and the drying time is 15-22 minutes. The bamboo charcoal fiber fabric for the home textiles prepared by the method is soft and good in the antibacterial activity.

Owner:汕头市粤宝利实业有限公司

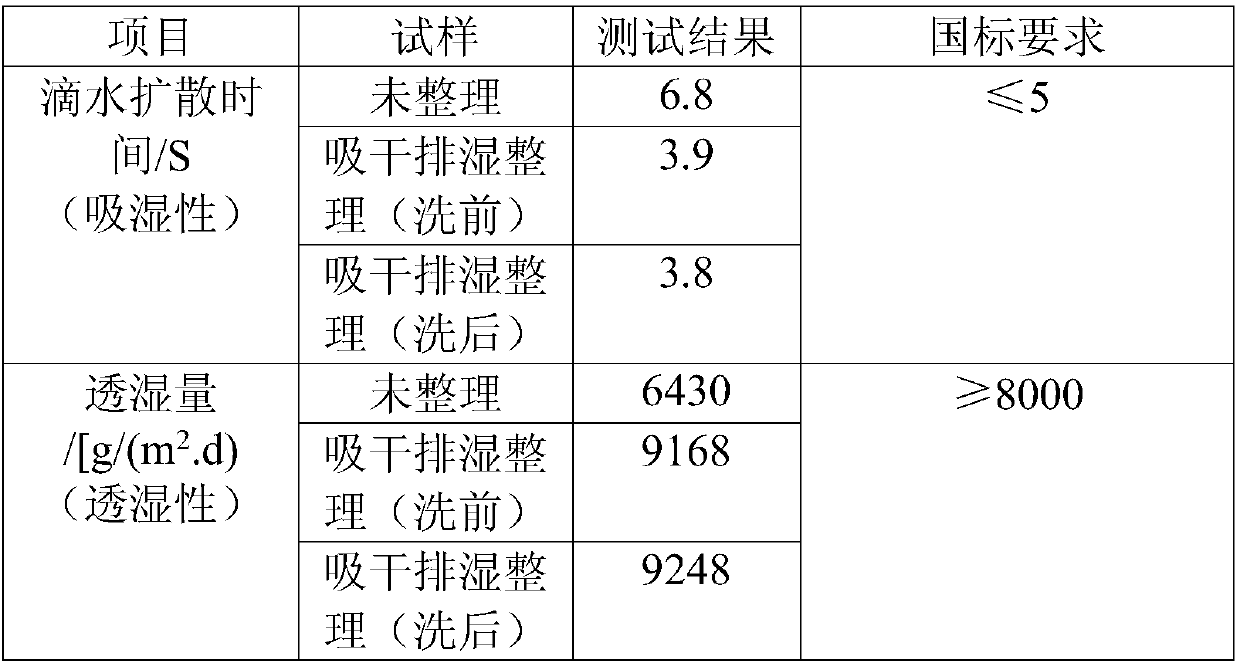

Production technology of quick-dry terylene yarn-dyed seersucker fabric

The invention discloses a production technology of a quick-dry terylene yarn-dyed seersucker fabric. The production technology comprises the following steps of product design, spooling, warping, slashing, drafting, weaving and quick-dry finishing. According to the production technology, the quick-dry after-finish technology is adopted to conduct after-finishing on the terylene / cotton seersucker fabric, the fabric cost is low, the yield is high, the quick-dry performance, the breathability, the comfort, the shape-preserving performance and other performance of the fabric reach a high level, andrequirements of ordinary consumers can be completely met.

Owner:IANGSU COLLEGE OF ENG & TECH

Production technology of cool high-grade simulated down poplin bedding fabric

InactiveCN105155096AFlat surfaceWith wear resistanceWarping machinesDyeing processAir-jet loomEngineering

The invention discloses a production technology of cool high-grade simulated down poplin bedding fabric. Yarn formed by ultra-high molecular weight polyethylene staple fibers and viscose staple fibers in a blending mode serves as a raw material of the cool high-grade simulated down poplin bedding fabric. The cool high-grade simulated down poplin bedding fabric is prepared through a weaving production method. Specifically, warp yarn and weft yarn are made from blended yarn of the ultra-high molecular weight polyethylene staple fibers and the viscose fibers, beam warping is performed in batches, a warp beam is manufactured through slashing, the cool high-grade simulated down poplin bedding fabric formed by blending the ultra-high molecular weight polyethylene staple fibers and the viscose staple fibers is produced on an air jet loom, and after sorting of fabric which is taken off from the machine, the finished product is obtained through dyeing or printing after desizing. The cloth cover of the cool high-grade simulated down poplin bedding fabric is smooth, cool, pliable and tough, ultra high in abrasion resistance, capable of absorbing moisture and breathable, the fabric can give full play to the unique excellent performance of the ultra-high molecular weight polyethylene fibers, because ultra-high molecular weight polyethylene fiber products have certain anti-pricking and anti-cutting performance, the fabric can also be used for manufacturing anti-pricking and anti-cutting cases, and therefore the application range and the application field of the fabric can be widened.

Owner:IANGSU COLLEGE OF ENG & TECH

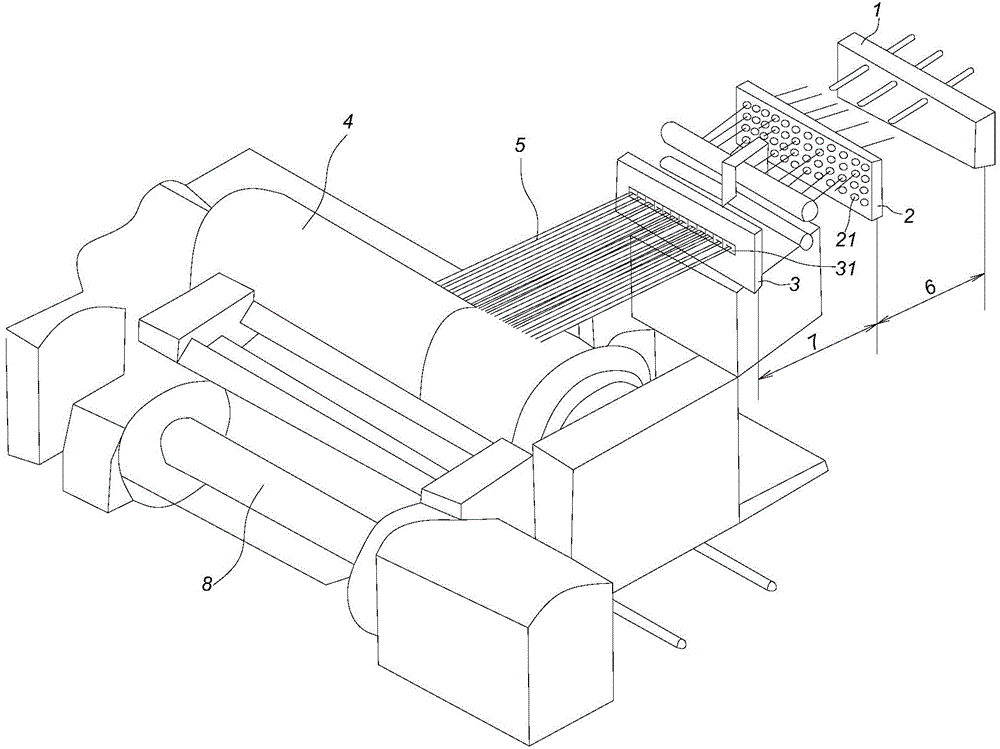

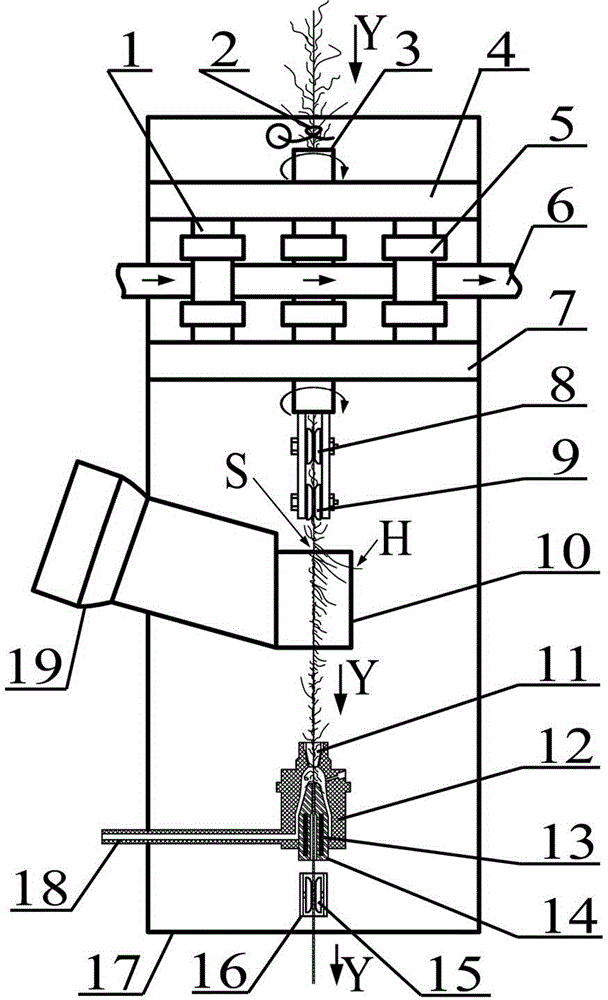

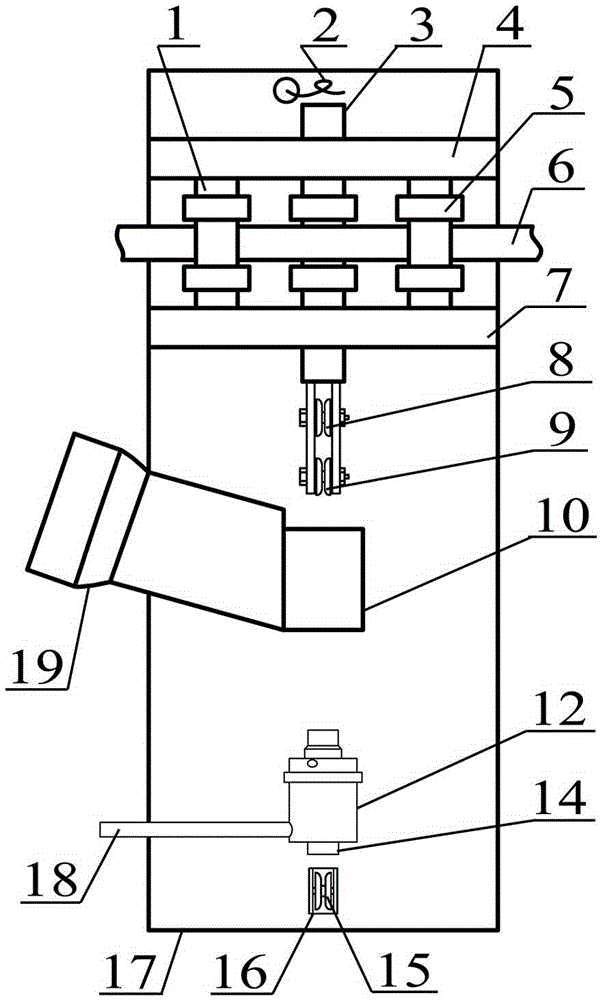

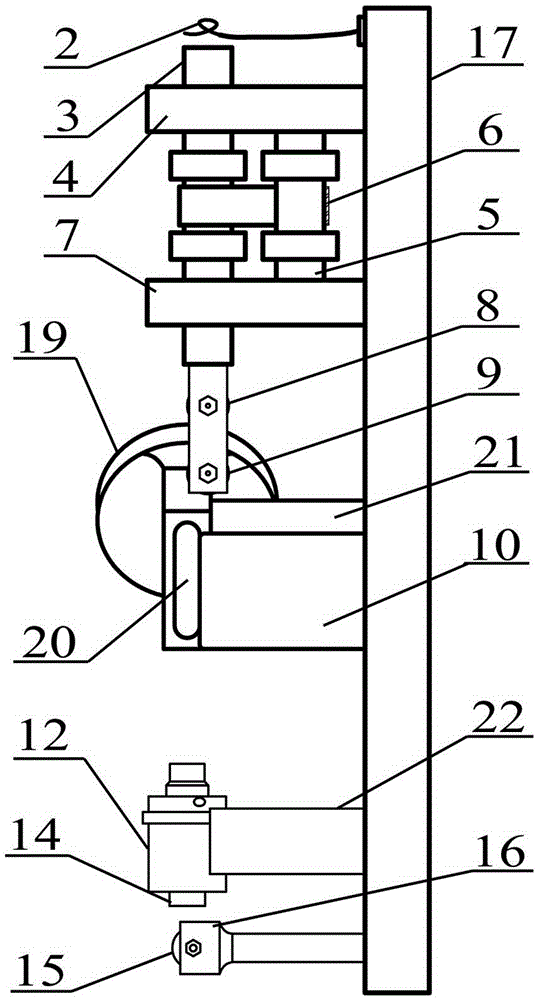

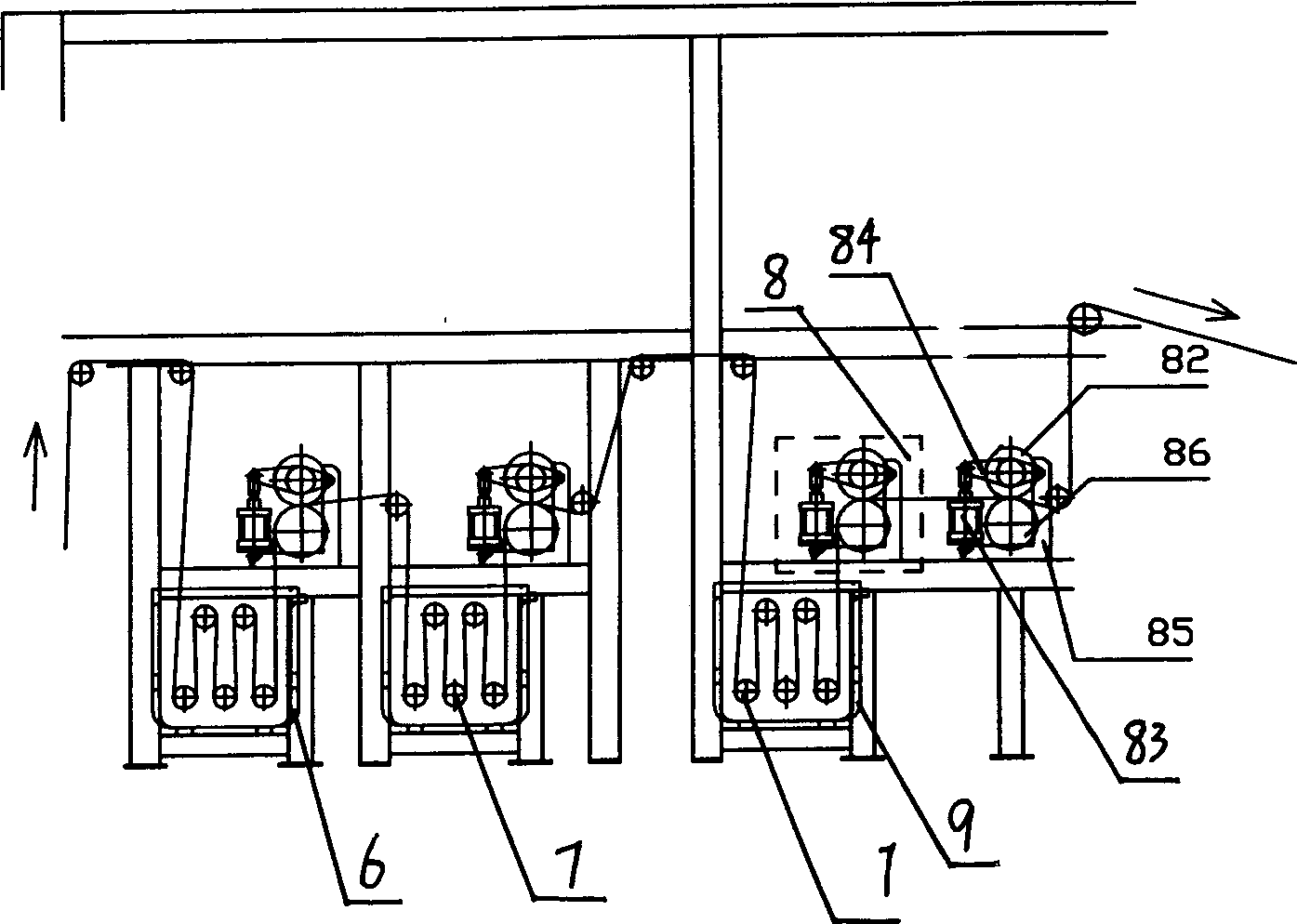

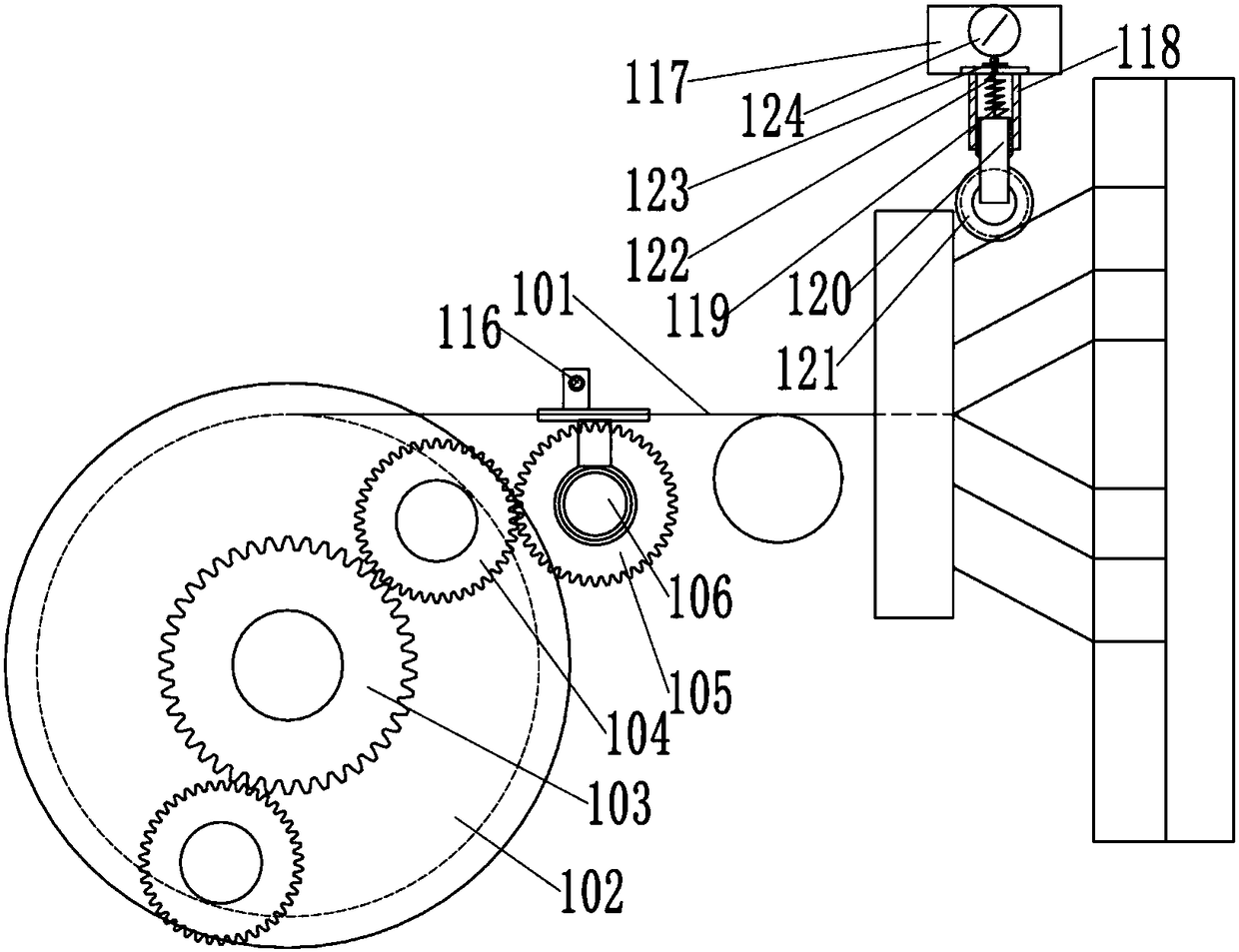

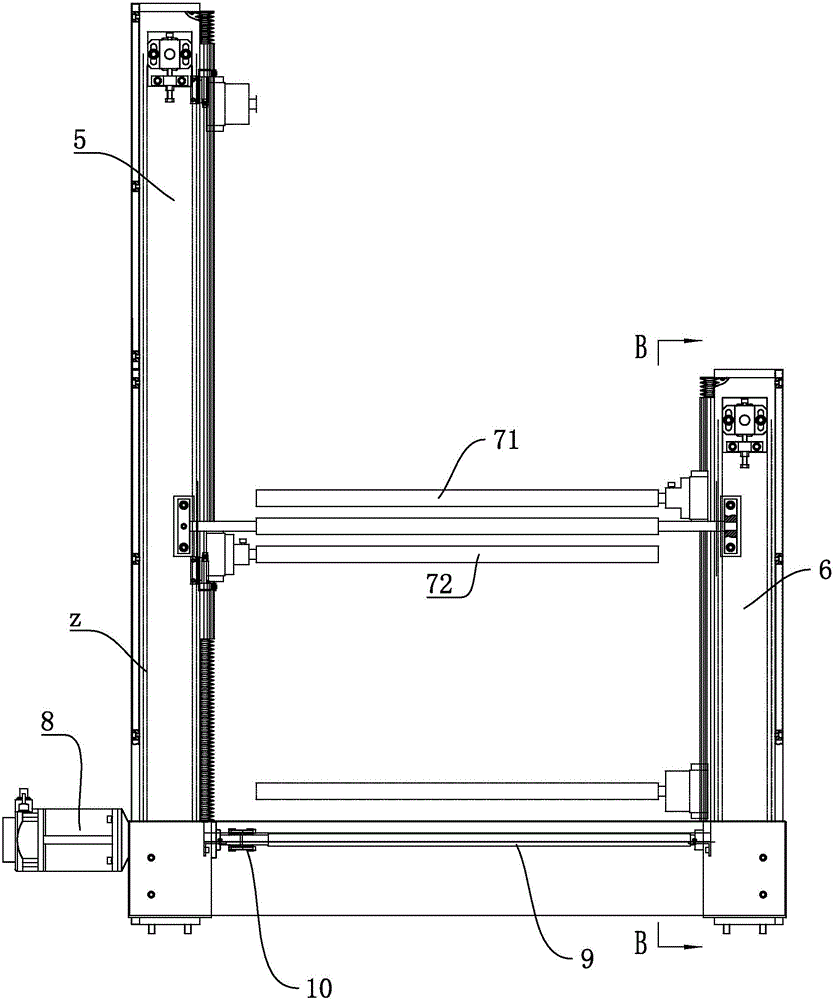

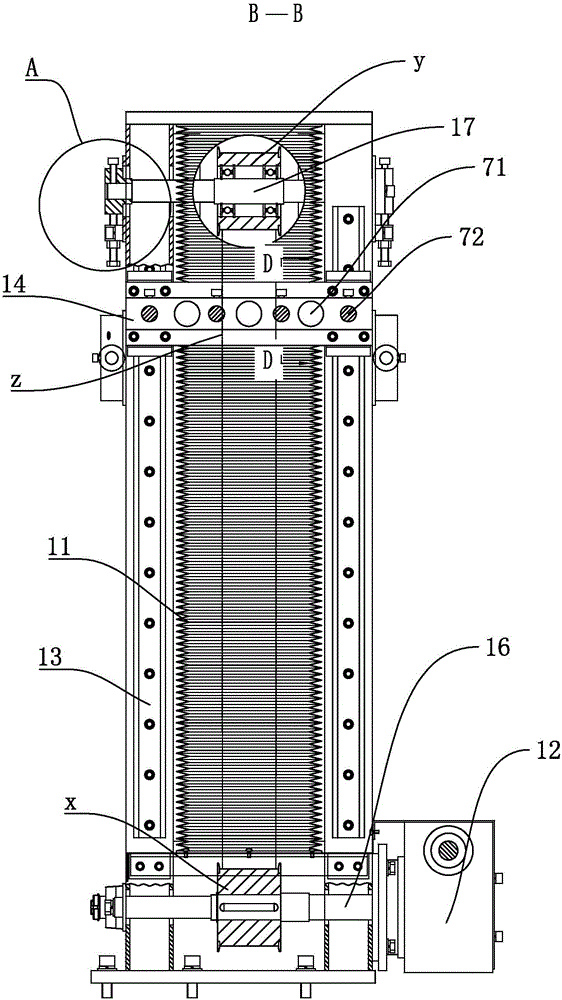

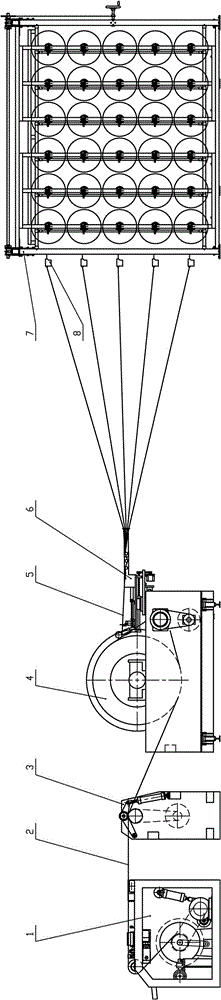

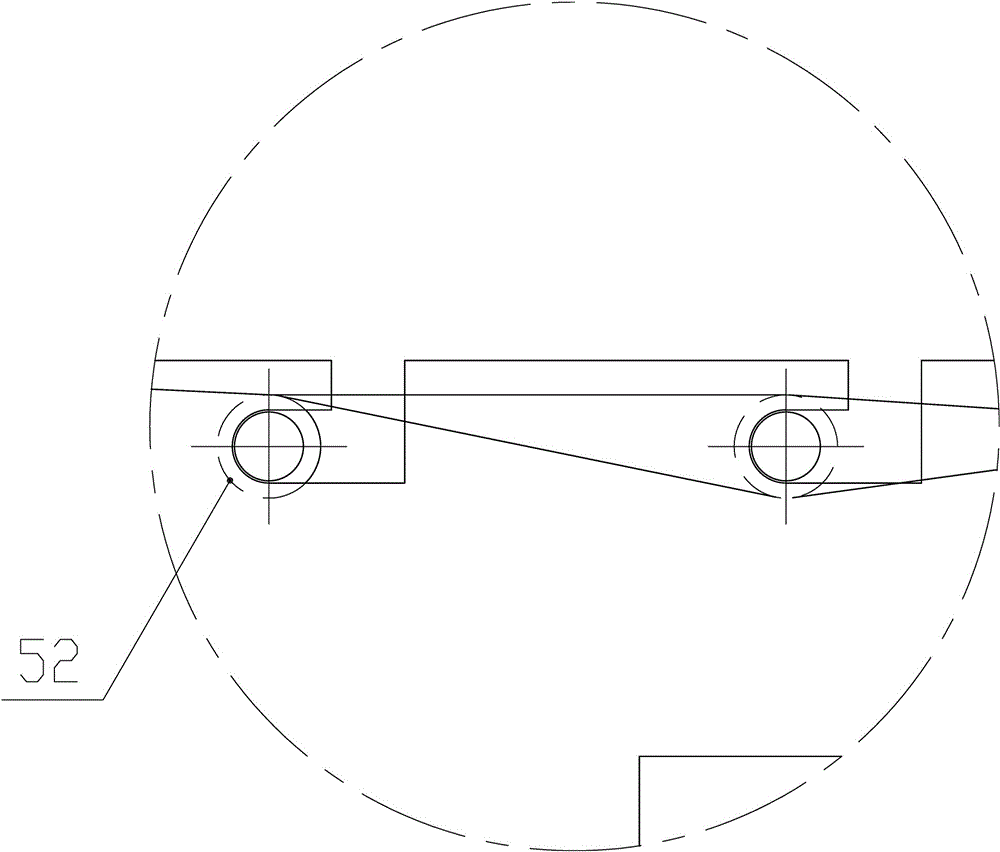

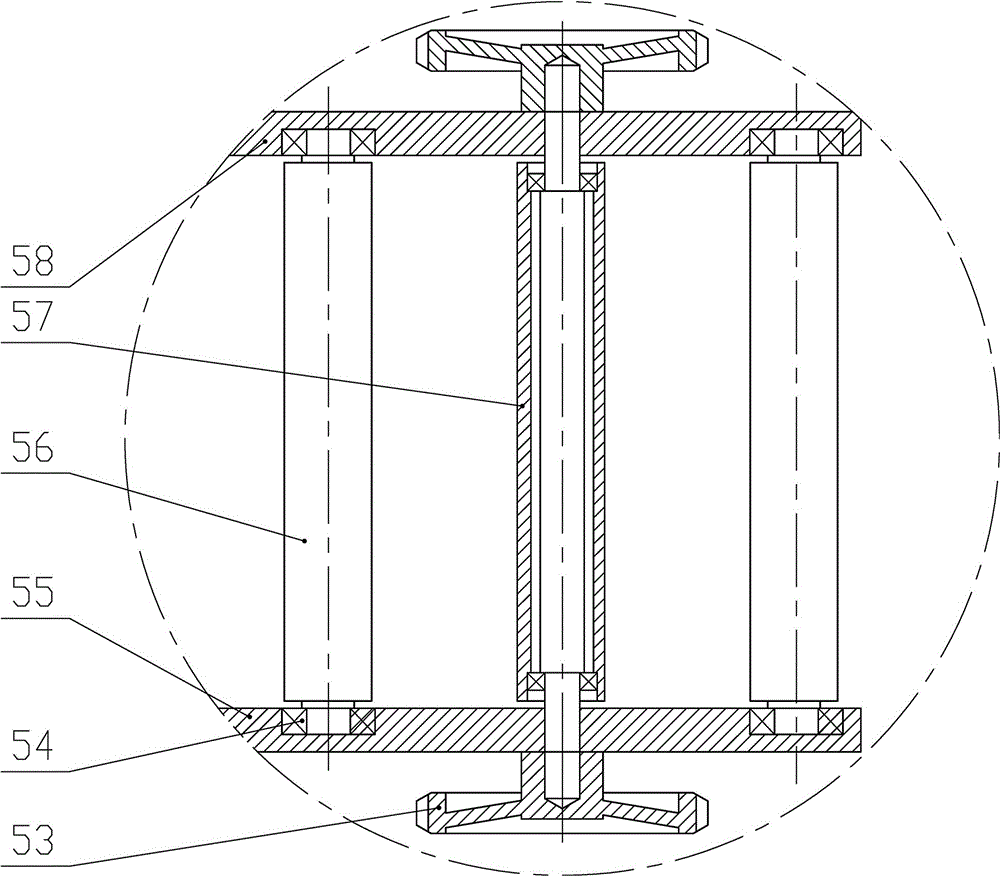

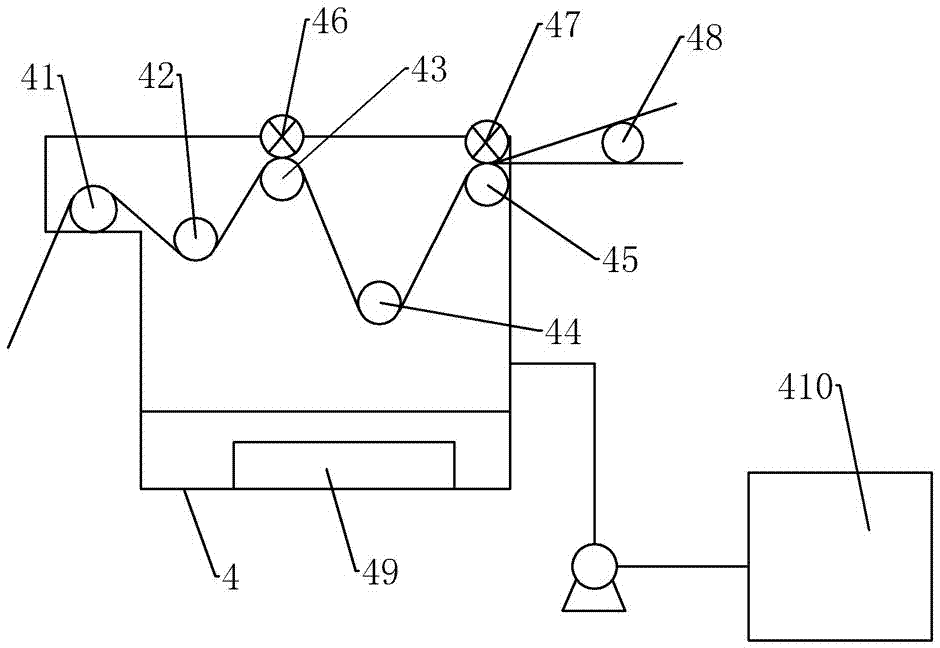

Sectional warping machine and yarn storing, yarn feeding and leasing system thereof

ActiveCN105908314AImprove transmission stabilityHigh precisionWarping machinesLeasingYarn tensionLinear drive

The invention discloses a yarn storing, yarn feeding and leasing system of a sectional warping machine. The system is characterized in that a yarn storing unit, a yarn feeding unit and a leasing unit which are sequentially arranged are included; the yarn storing unit comprises a long stand column, an upper yarn storing roller arranged on the long stand column, a short stand column, a lower yarn storing roller arranged on the short stand column and a linear driving device used for driving the upper yarn storing roller and the lower yarn storing roller to vertically rise and fall; the yarn feeding unit comprises a box, a yarn pressing rubber roller and a yarn guiding roller which are arranged on the box, a driving device d used for driving the yarn guiding roller to rotate and a reciprocating mechanism used for driving the yarn pressing rubber roller to abut against and be separated from the surface of the yarn guiding roller; the leasing unit comprises wallboards, linear guide rails, a leasing reed and a three-segment driving device used for driving the leasing reed to slide on the linear guide rails. Accordingly, the same length and equal tension among yarn and among strips during sectional warping are guaranteed through the yarn storing unit, the yarn feeding unit and the leasing unit, and the sheet yarn tension also can be strictly controlled when broken ends are processed.

Owner:江阴市四纺机新科技制造有限公司

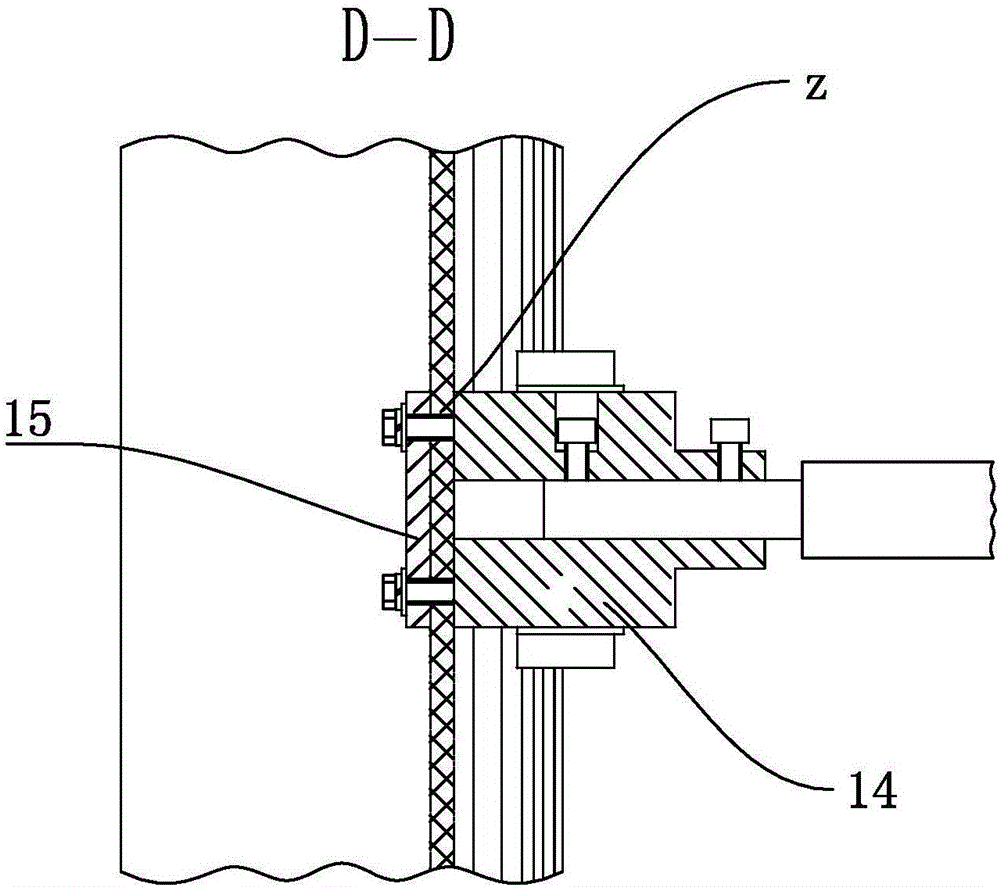

Method of producing high-grade shift fabric interwoven with recycled polyester filament yarns and modal cotton

ActiveCN102493086AMeet needsReduce manufacturing costWarping machinesWoven fabricsEngineeringColor changes

A method of producing shift fabric interwoven with recycled polyester filament yarns and modal cotton includes: firstly, siro-spinning cotton 55 / modal 45 into yarns; secondly, pretreating the recycled polyester filament yarns; thirdly, re-beaming; fourthly, drafting; fifthly, weaving; and sixthly, post-finishing and dyeing. The recycled polyester filament yarns and the cotton 55 / modal 45 siro-spun yarns are re-beamed and subjected to different pretreatment and are then interwoven into a gray fabric, the gray fabric is dyed into shell fabrics in various colors to substitute yarn dyed fabrics, and one gray fabric can be dyed into the shell fabrics in various required colors according to color change of pigments, so that production cost is reduced greatly, production period is shortened greatly, and requirements of various customers are also met. The shell fabric is interwoven with two types of raw materials, so that the problem of post-dyeing wrinkling is solved, the recycled polyester filament yarns and the cotton 55 / modal 45 siro-spun yarns are interwoven into the shell fabric which can serve as the shell fabric of high-grade shirts.

Owner:DANYANG DANSHENG TEXTILE

Weaving process for aloe fiber small jacquard fabric

The invention discloses a weaving process for an aloe fiber small jacquard fabric. The process comprises the following steps: a spooling process, a beaming process, a slashing process, a drawing-in process, and a weaving process. The produced fabric warp yarns and weft yarns respectively use yarns in extra white, grass green, and deep blue colors as mass tone, cooperated with organization design, color of the fabric is bright, grids and figures are clear, and cloth is smooth, and the fabric is comfortable to wear. The fabric has strong stereo perception, and is preferred by consumers. The fabric can be used for shirts, bedclothes, aviation trim, etc. Through analysis and optimization on manufacturing process, weaving efficiency reaches up to 93%, and the process satisfies requirement of improving product grade for enterprises.

Owner:IANGSU COLLEGE OF ENG & TECH

Method for weaving pure China hemp high-count weak strength yarn home textile fabric

The invention discloses a method for weaving a pure China hemp high-count weak strength yarn home textile fabric, which comprises the following steps of: performing micro tension control on China hemp high-count weak strength yarns on a warping machine, wherein the open length of a warp beam is 2,400 millimeters, the tension of a tension rod is 4 to 10 grams, the number of the total warps is 18,338 to 23,520, the number of single shaft heads is 750 to 1,040, the number of parallel cylinders is 20 to 28 and the volume of filling cylinders is 750 to 1,040; performing sizing, wherein the tension is 4,000 to 4,100N, the sizing mode is single immersion and single pressing, the size force is 18 to 24KN, the wet elongation is 0.1 to 0.2 percent, sheet yarns are prevented from being twisted, the backing-off tension of the warp beam is 650 to 750N, the volume of a size tank is 320 liters and the size immersion length is 60 to 80 centimeters; performing up and down alternated lease by adopting a STAUBLI OPAL-3600 automatic lease machine made in Switzerland, and performing drafting by adopting a STAUBLI DELTA 110-3600 automatic drafting machine made in Switzerland; and performing low-tension weaving by using a broad-breadth single weaving shaft loom, wherein the feeding tension is 3,000 to 4,000N, the speed is 450n / min, the height of a rear beam is less than 4 centimeters, the temperature of a weaving workshop is 25 to 30 DEG C, and the relative humidity is 68 to 72 percent. According to the method, the efficiency of a fabric machine is improved, the discharge quality is ensured, the yarns are well enhanced, the weaving broken ends of the fabric machine are reduced, and the fabric quality is good.

Owner:JIANGSU YUEDA HOME TEXTILE

Production process of joint weak twist towel

The invention discloses a process for producing a plied towel with weak twist. The process provided by the invention comprises the following steps of: spinning, beaming, slashing, weaving, carrying out a post-treatment on textiles, scotching, dehydrating, drying and sewing; warp yarns are selected from cotton fibers with good quality grade to spin by a twist degree of 48-57 twist degrees / 10 centimeters to obtain single yarns; then the single yarns are processed by two-for-one twisting and plying by the twist degree of 23-32 twist degrees / 10 centimeters; the monofilament yarns of ground warp yearns are completely the same with the warp yarns and the twist degree for two-for-one twisting and plying is 50-58 twist degrees / 10 centimeters; after the yarns are beamed, the same slurry is used for respectively starching according to different slurry sucking performances of the ground warp yearns and the warp yearns, and appropriate opening time and looming tensile force of the weaving machine are utilized. Compared with the zero-twist towel, the producing process provided by the invention avoids adding PVA (Polyvinyl Alcohol) reduces the environmental pollution and resource waste; and the process also keeps the advantages of the zero-twist towel that the hand feeling is comfortable and the water absorbability is good; meanwhile, compared with the single-yarn towel, the hairiness amount is less and the appearance of the washed towel is better.

Owner:LOFTEX INDS

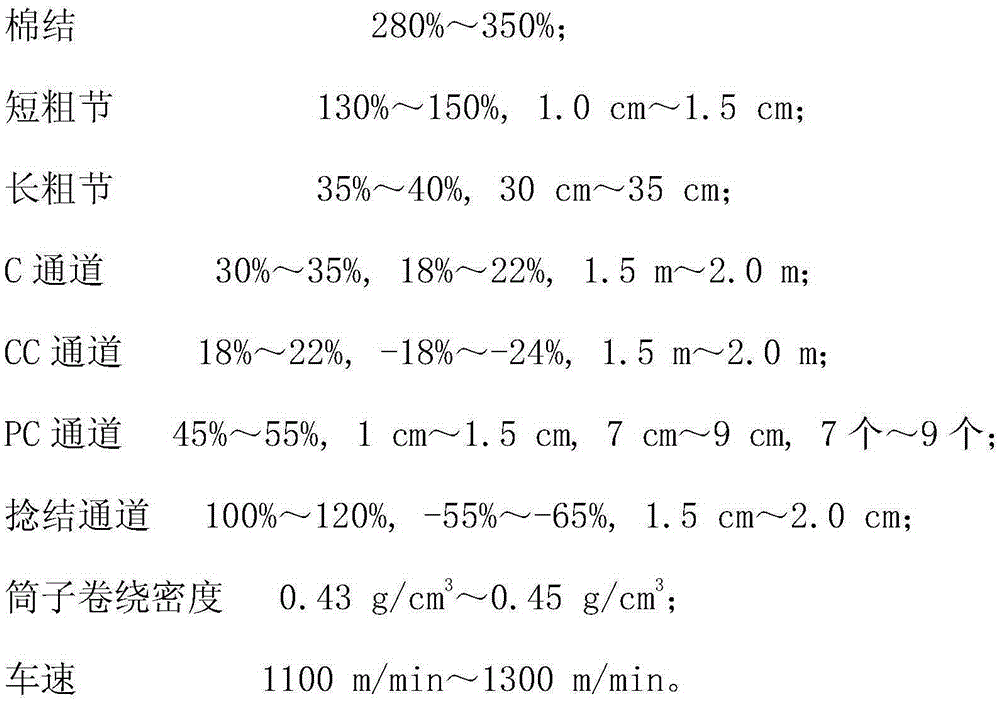

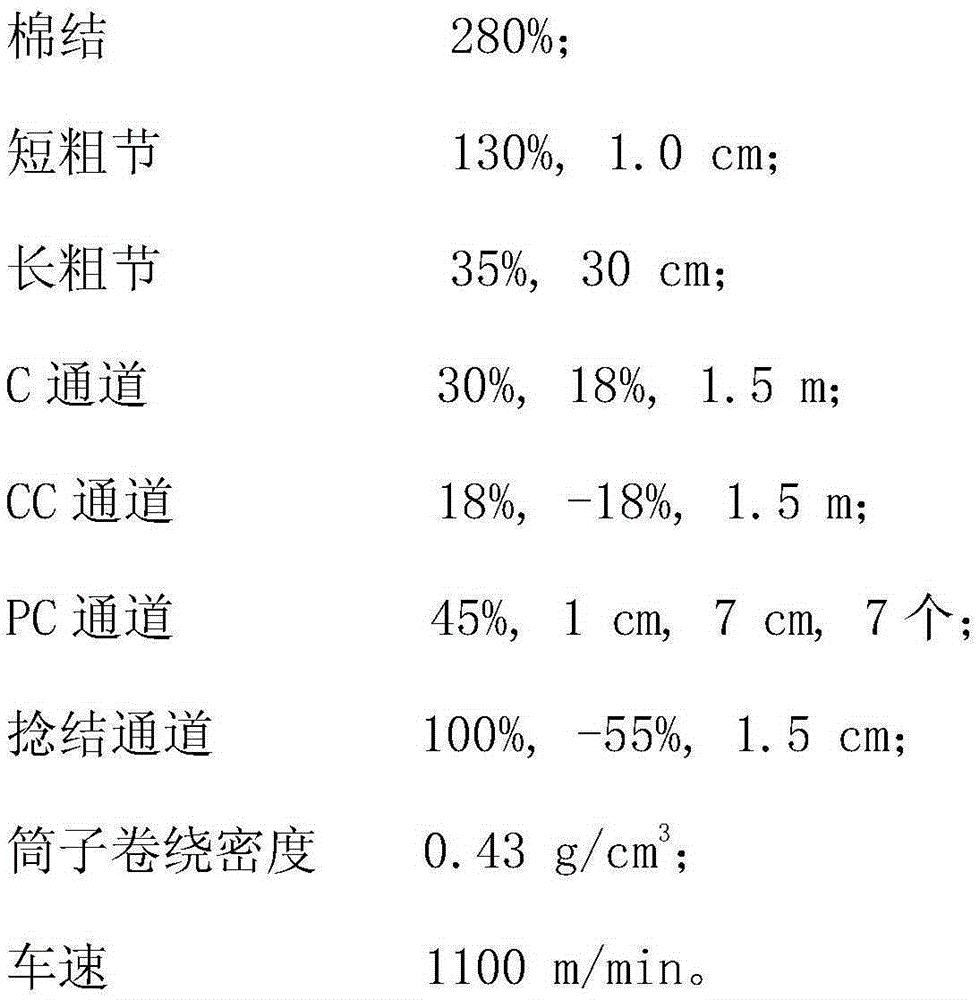

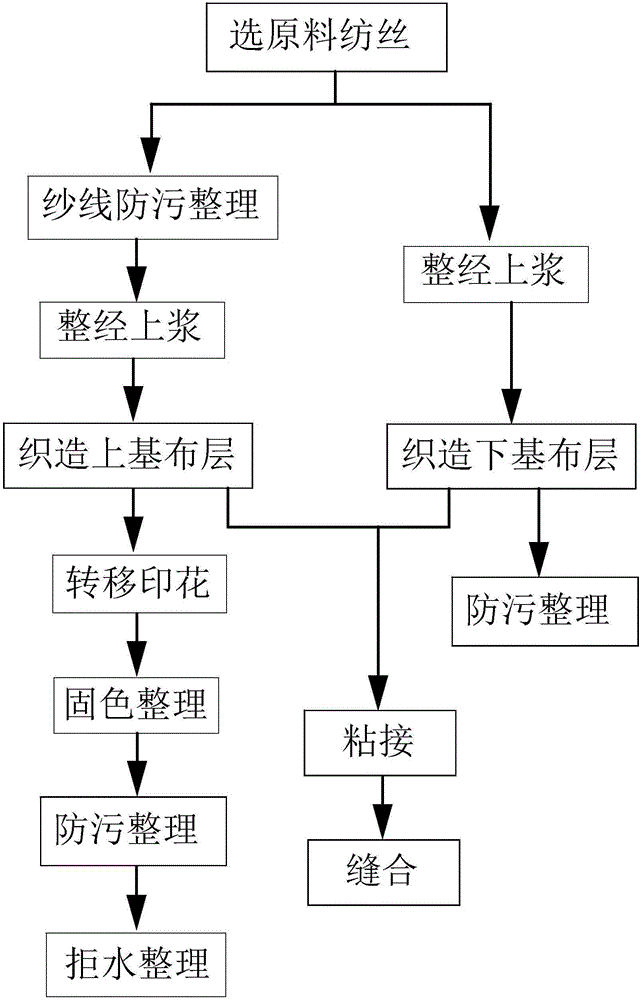

Production method of antifouling sofa fabric

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

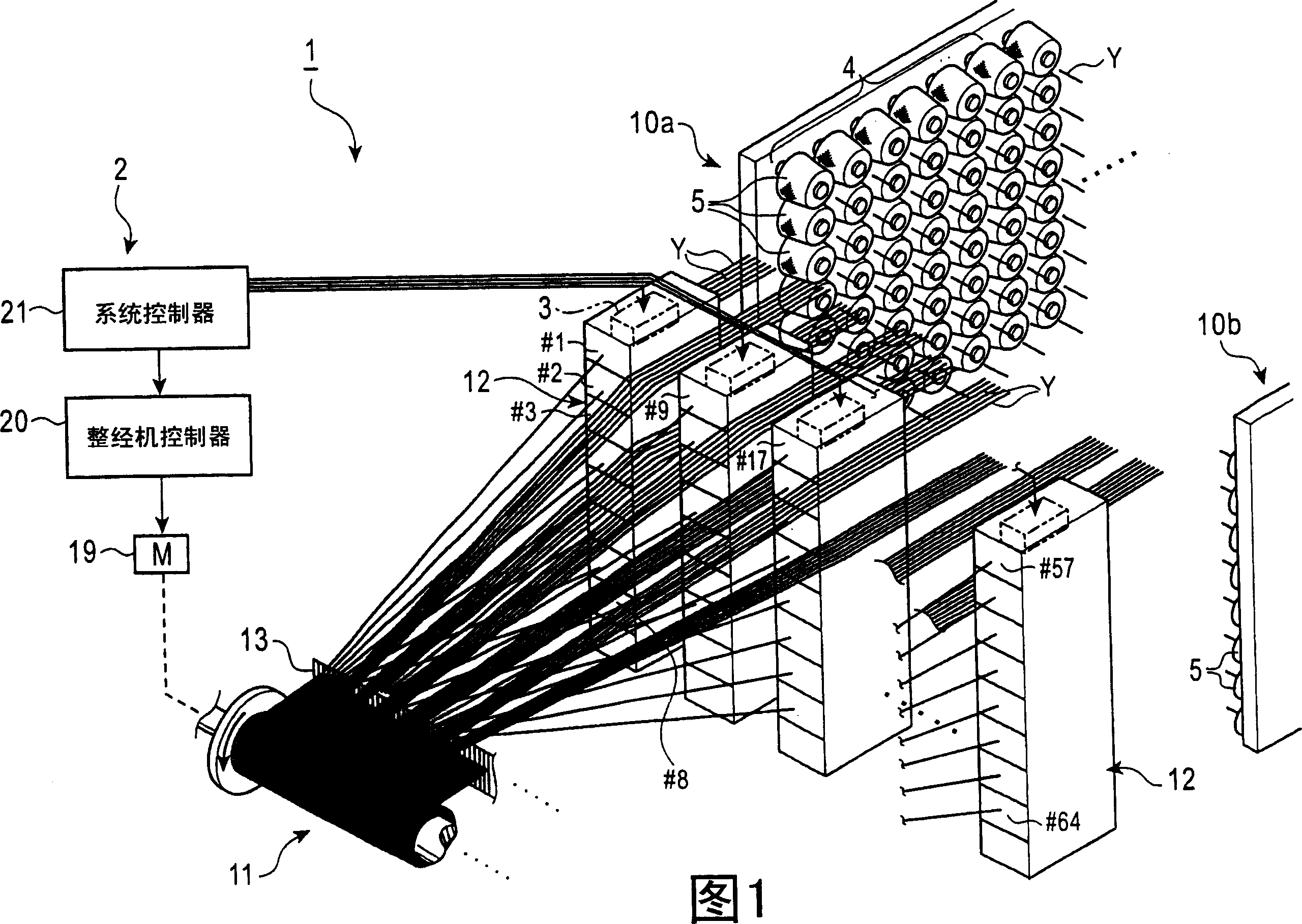

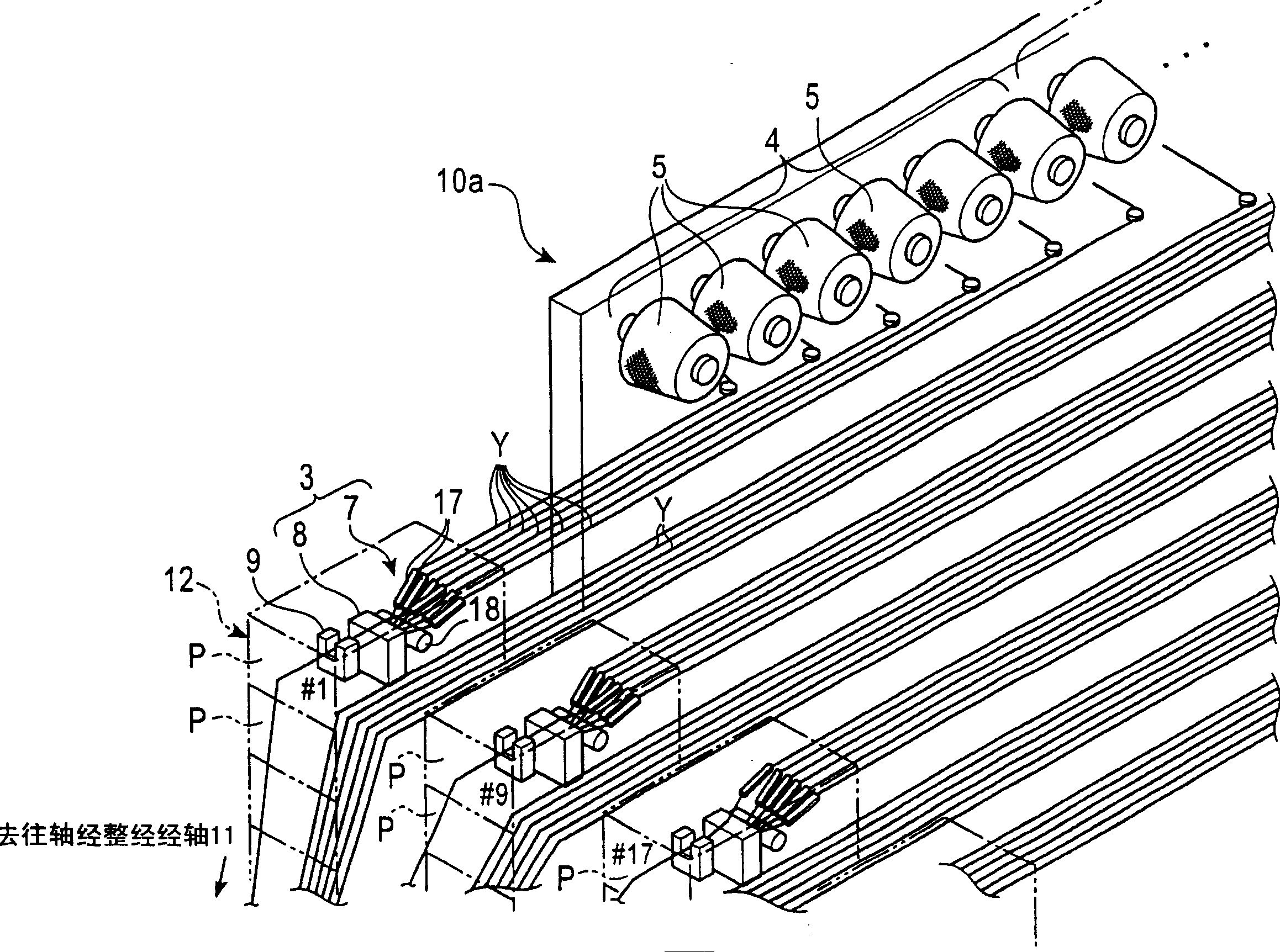

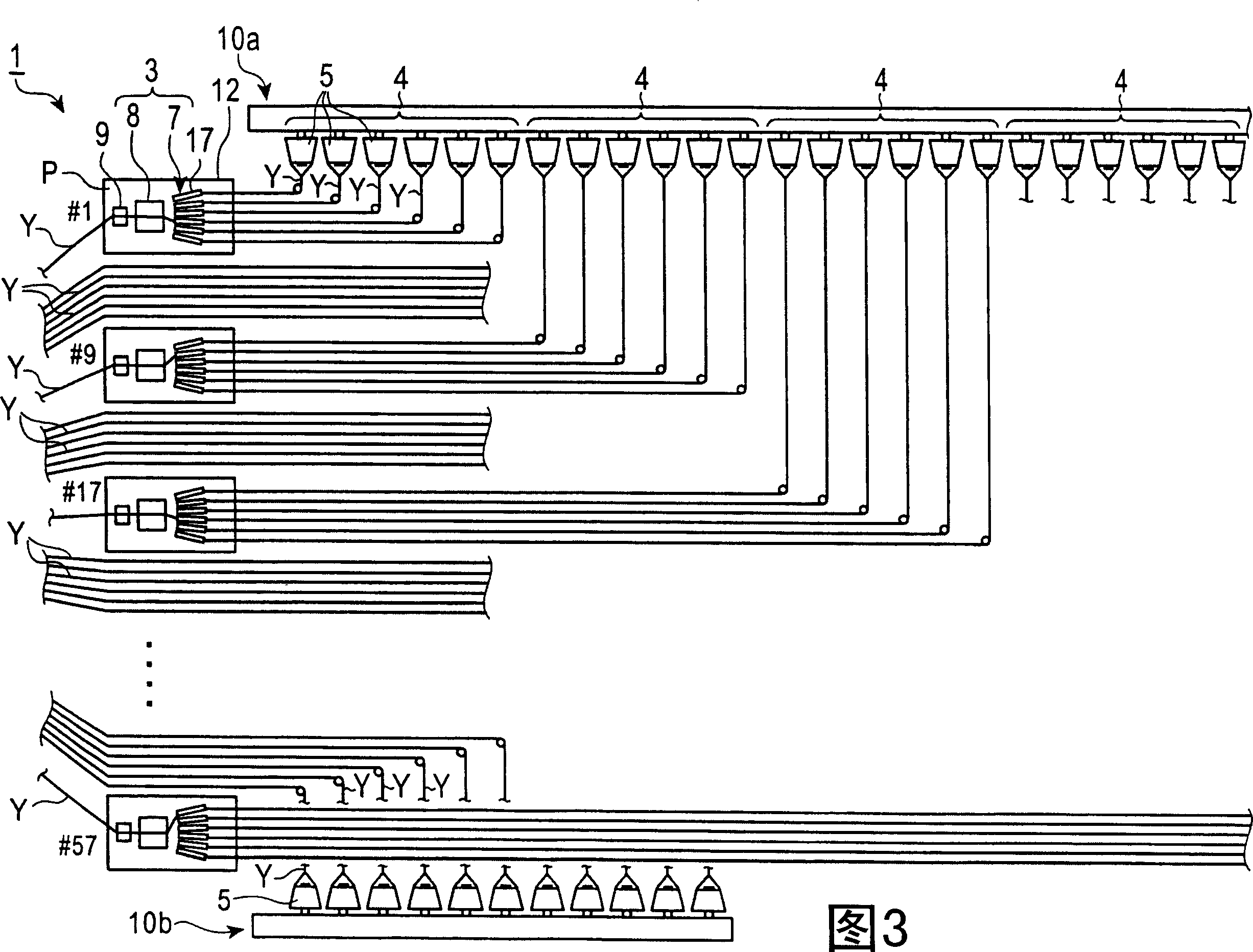

Warping system and warping method

Owner:MURATA MASCH LTD +1

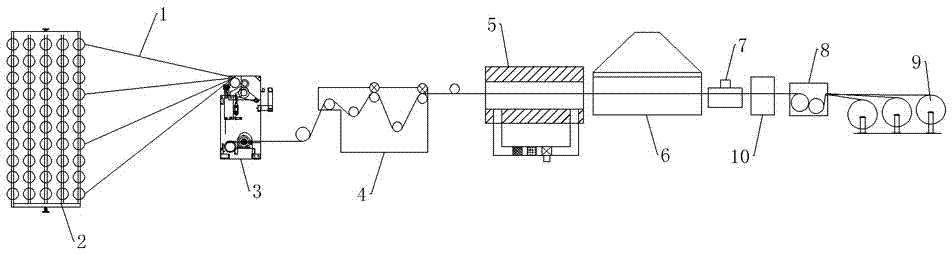

Warping knitting sectional copy warping machine

ActiveCN106435906ASolve warping problems that require more headsCompact structureWarping machinesOther manufacturing equipments/toolsProcess equipmentBobbin

The invention relates to a warping knitting sectional copy warping machine, which comprises a bobbin creel, a silk collecting plate, a straining equalization roller device, a lease device, a coiler device, a beaming device and an electric control center. Total ends of pan head warp can be divided into a plurality of ends according to the requirement of slitting process. Yarn on cones of the bobbin creel which has fewer ends comparatively is pulled into the coiler device and yarn on cones is rolled over a huge roller one by one, and then all yarn on cones is pulled into the beaming device in neat array, through a drawing device and a waxing and oiling device. After being reversed in a constant amplitude, yarn on cones is rolled over the pan head for warping knitting machine and weaving. The warping knitting sectional copy warping machine adopts a way that utilizing less yarn on cones to gain warping pan heads having more ends in warp, in order to satisfy the particular needs of warping knitting weaving techniques. The warping knitting sectional copy warping machine is applicable to the needs of many varieties, small batch, sample- making and fast supply, and has advantages of saving production costs, compact design, original concept, practical and operational utilization and providing novel process equipment for warping knitting weaving.

Owner:射阳县杰力纺织机械有限公司

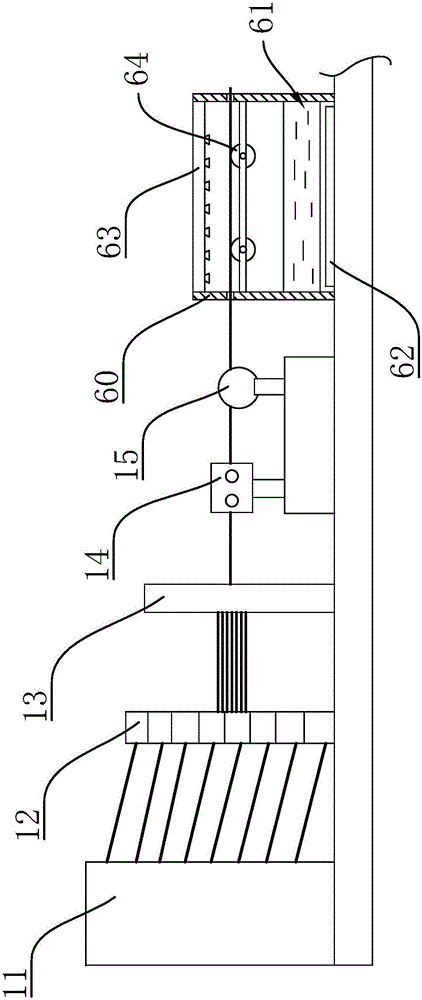

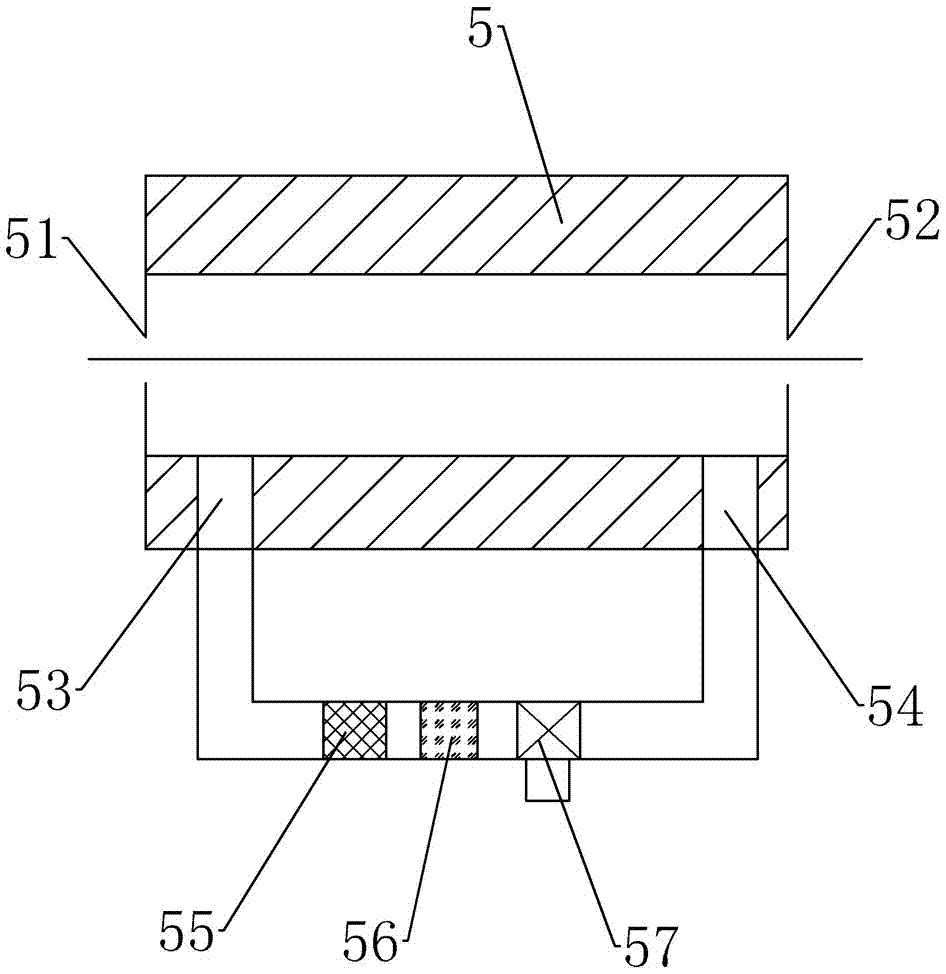

Aramid filament warping, sizing and drawing equipment

PendingCN107130381AAvoid markingsAvoid entanglementSucessive textile treatmentsCreelsBobbinStructural engineering

The invention discloses aramid filament warping, sizing and drawing equipment. The aramid filament warping, sizing and drawing equipment comprises a warping mechanism, a sizing mechanism and a re-beaming mechanism which are arranged along the advancing direction of aramid filaments sequentially, the warping mechanism comprises a bobbin creel, a destaticizing device and a tension frame, the sizing mechanism comprises a size box, a preheating oven, a drying room, a waxing device and a take-up device which are arranged along the advancing direction of the aramid filaments sequentially, a drawing roller is arranged on the inner side of a filament inlet of the size box, a first sizing roller, a second sizing roller, a third sizing roller and a fourth sizing roller are arranged in the size box along the advancing direction of the aramid filaments sequentially, a first squeezing roller is arranged at the top of the second sizing roller, and the re-beaming mechanism comprises a beam creel. The aramid filament warping, sizing and drawing equipment is applicable to processing the aramid filaments, is simple in structure, convenient to use and higher in working efficiency, and can achieve centralized control.

Owner:盐城市荣意来纺机有限公司

Stitch slipping resisting light and thin fancy crepe georgette shell fabric and weaving method thereof

InactiveCN105420884AWith anti-scratch functionAnti-scratch function is not easyWarping machinesWoven fabricsYarnEngineering

The invention discloses stitch slipping resisting light and thin fancy crepe georgette shell fabric and a weaving method thereof. The stitch slipping resisting light and thin fancy crepe georgette shell fabric is formed by interweaving warp yarns and weft yarns. The warp yarns are 20 / 22 denier real silk of a 26T / 2S2Z type. The weft yarns are 20 / 22 denier real silk of a 26T / 1S1Z type. The warp density of the stitch slipping resisting light and thin fancy crepe georgette shell fabric is 86 pieces per centimeter. The weft density of the stitch slipping resisting light and thin fancy crepe georgette shell fabric is 60 pieces per centimeter. Eight fancy twills are adopted in inner texture of the stitch slipping resisting light and thin fancy crepe georgette shell fabric, and two-up and two-down warp-ribs are adopted in side texture. The manufactured light and thin fancy crepe georgette shell fabric can resist stitch slipping, and yarn drawing is not caused easily; moreover, the processing technology is simple and easy to operate, the technological content of the shell fabric is increased, no additional production cost is increased, and the shell fabric is easy to apply and popularize in the market.

Owner:SUZHOU SILKCUBE TEXTILE

Linen warp beam dyeing process

InactiveCN106120207AReasonable process structureEnsure consistencySucessive textile treatmentsWarping machinesYarnState of art

The invention proposes a flax warp beam dyeing process, which includes three processes of loose warping, dyeing and sizing; wherein, the dyeing process includes pretreatment, dyeing and posttreatment, wherein the dyeing is based on the dyeing depth of the flax yarn Make different adjustments. The beneficial effects of the present invention are: the flax yarn dyeing process of the present invention is completed through three processes of warping, dyeing and sizing, which is related to the prior art. The process structure is reasonable, and the color of the product can be guaranteed through beam dyeing. The consistency ensures the quality of the product. At the same time, it reduces the related operating procedures, thereby saving the production cost and improving the dyeing efficiency. Moreover, the operation is convenient, the product quality is high, and the economic benefits are improved.

Owner:南通市联缘染业有限公司

Anti-static flame-retardant fabric and production method thereof

InactiveCN106283329AHigh strengthSoft touchWarping machinesHeat resistant fibresPulp and paper industryTextile production

The invention belongs to the technical field of production of textiles and particularly relates to anti-static flame-retardant fabric and a production method thereof. The fabric is twill consisting of warp and weft, wherein the warp consists of folded yarns of double blended yarn and conductive yarn, the blended yarn is formed by blending flame-retardant viscose, aramid fibers and acrylic fibers, and the conductive yarn is formed by doubling polyester filament yarn and polyester conductive filaments; the weft consists of folded yarns of double blended yarn, and the blended yarn is formed by blending flame-retardant viscose, aramid fibers and acrylic fibers. The production method of the fabric comprises steps as follows: 1) a warping process; 2) a sizing process; 3) reeding; 4) a weaving process. Two pieces of warp of the anti-static flame-retardant fabric are spaced reasonably, and the fabric touches soft, is good in breathability, good in anti-static property and high in strength and has better wearing comfort.

Owner:JIHUA 3509 TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com