Patents

Literature

185results about How to "Improve loft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plant culture medium and module therof

InactiveCN106106106APromote absorptionAgainst infringementGrowth substratesCulture mediaBiotechnologyBiogenic peptide

The invention relates to a plant culture medium and a module thereof. The medium is characterized by comprising following raw material including 20-40 parts by weight of peat soil, 15-25 parts by weight of compost excrements of livestocks, 15-25 parts by weight of humic acid, 10-25 parts by weight of nitrogen-phosphorus-potassium mixed fertilizers, 3-15 parts by weight of expanded perlites, 3-15 parts by weight of shiitake fungus or fermented straw fine fibers, 3-10 parts by weight of amino acid, 0.1-3 parts by weight of probiotics, 0.1-3 parts by weight of protease, 0.1-3 parts by weight of marine bioactive extracts, 0.1-3 parts by weight of antimicrobial peptides, 0.1-3 parts by weight of rooting agents and 0.1-3 parts by weight of microelements. The marine bioactive extracts adopt sea algae extracts or mussel extracts. The probiotics utilize bacillus subtilis strains. The protease utilizes papain. The module is low in weight, convenient in transport, convenient in application and good in water permeability and air permeability and satisfies all kinds of nutrition needed by plants.

Owner:林志仓

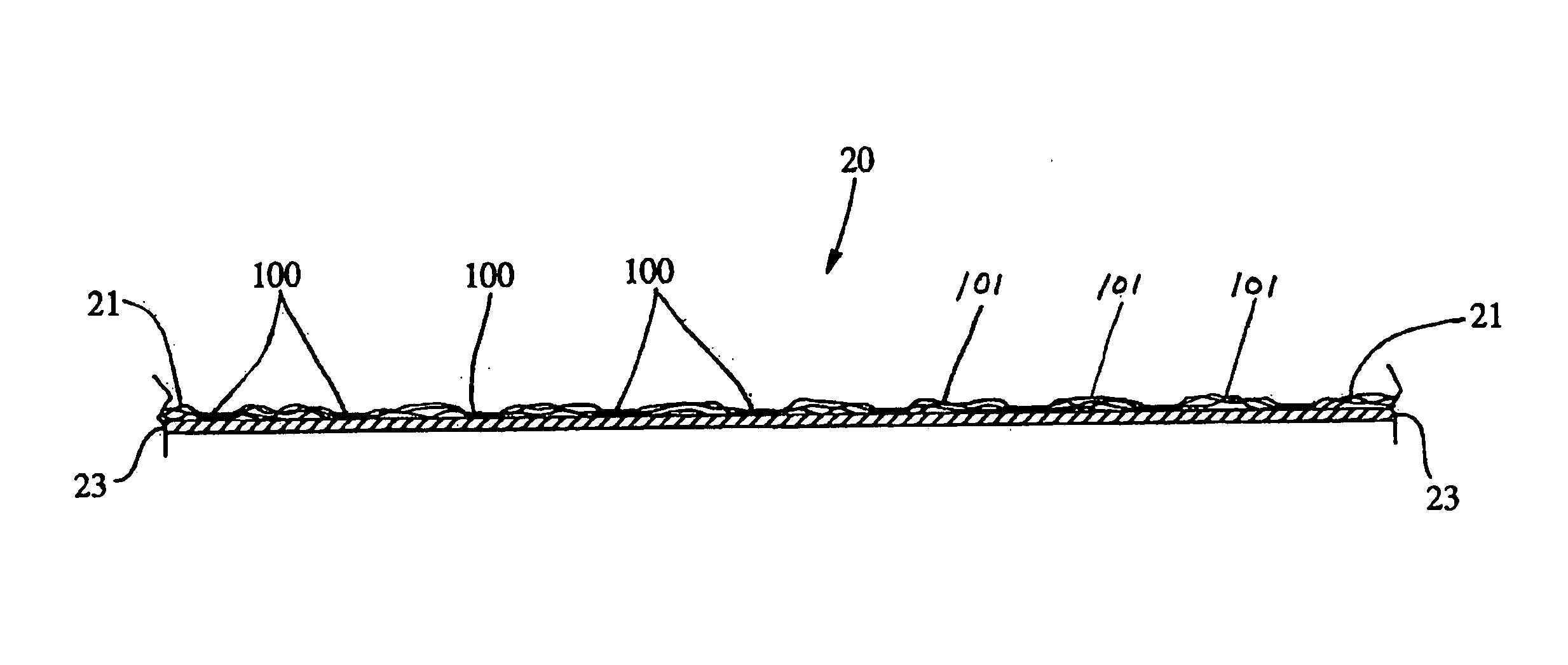

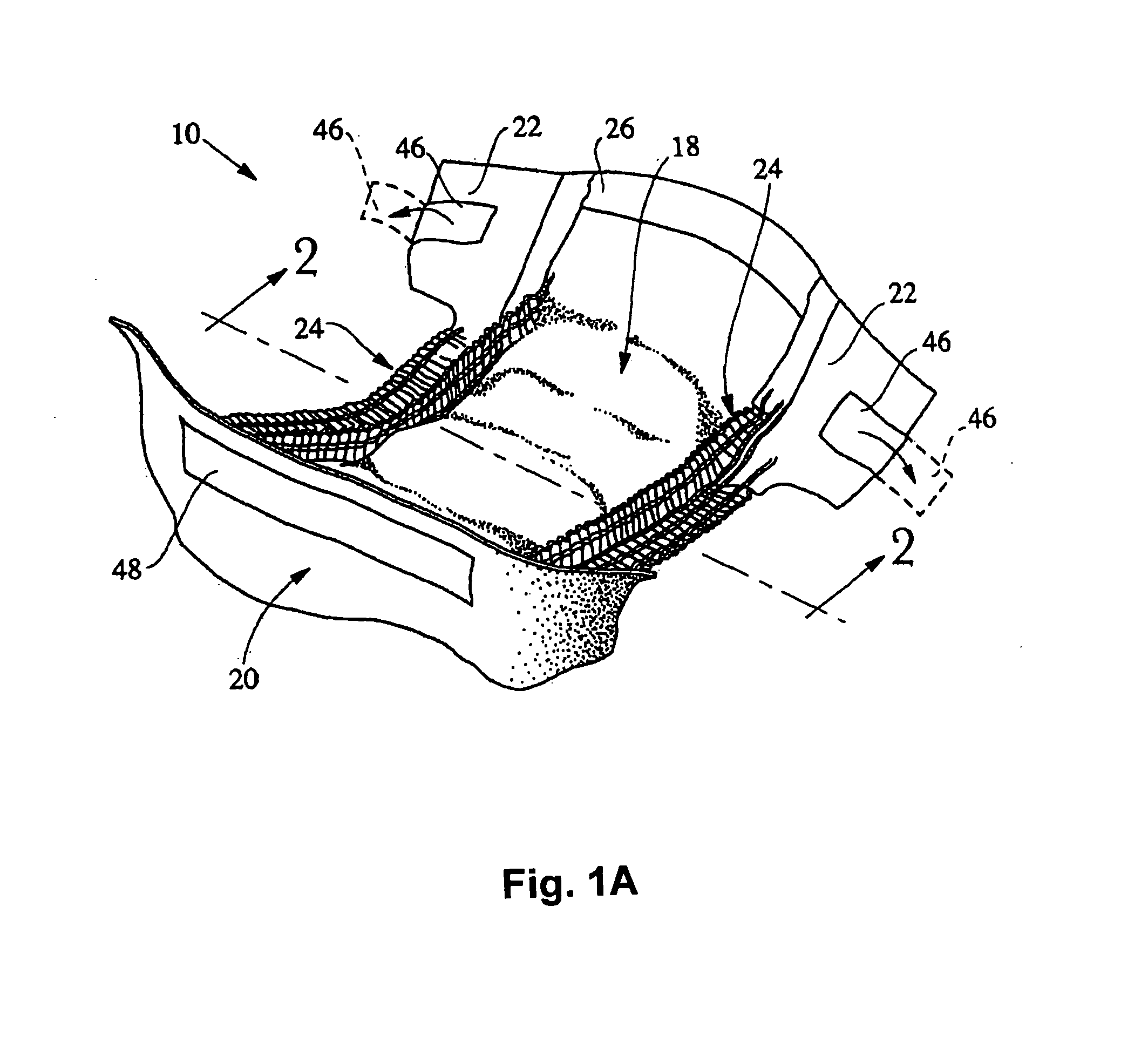

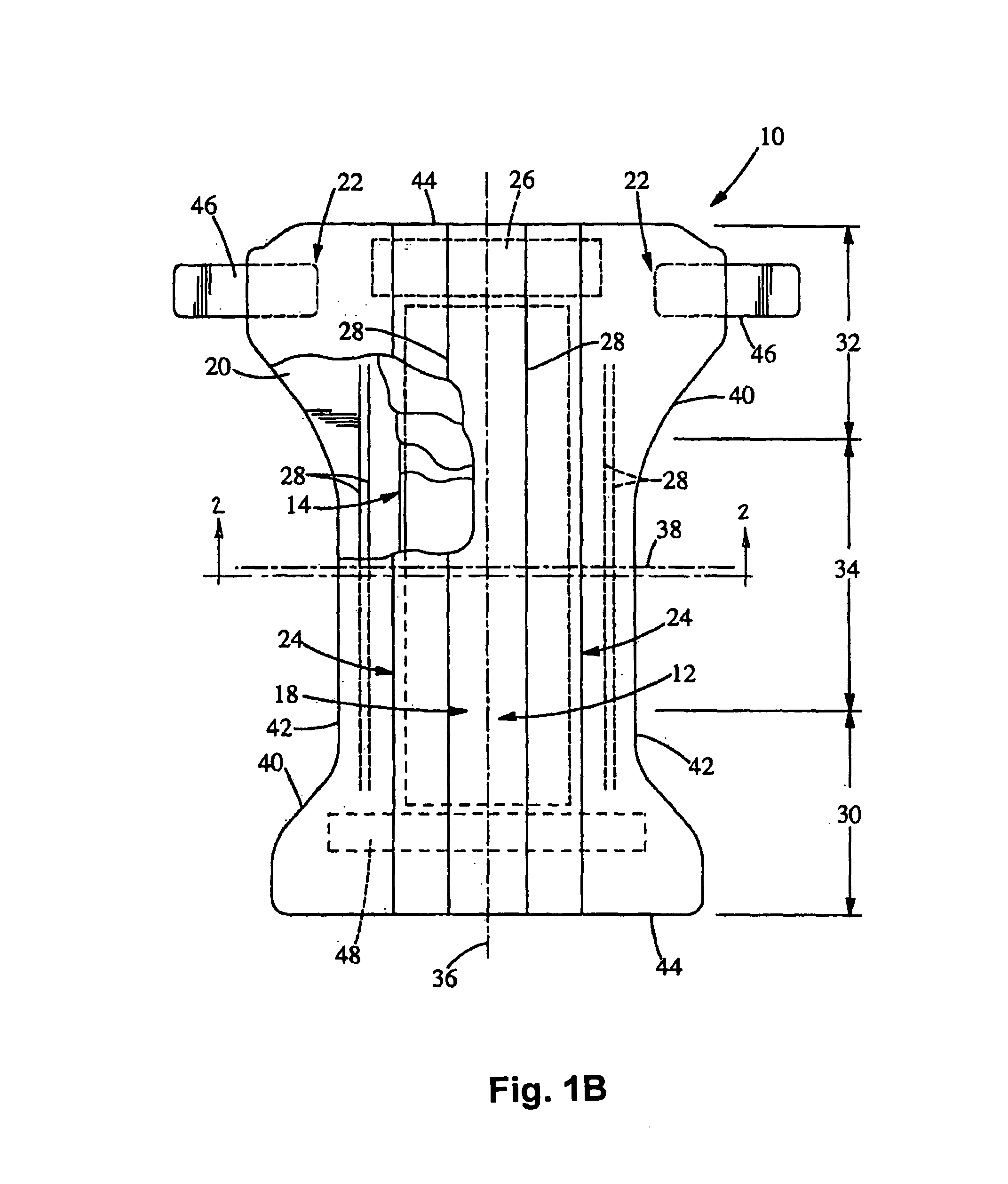

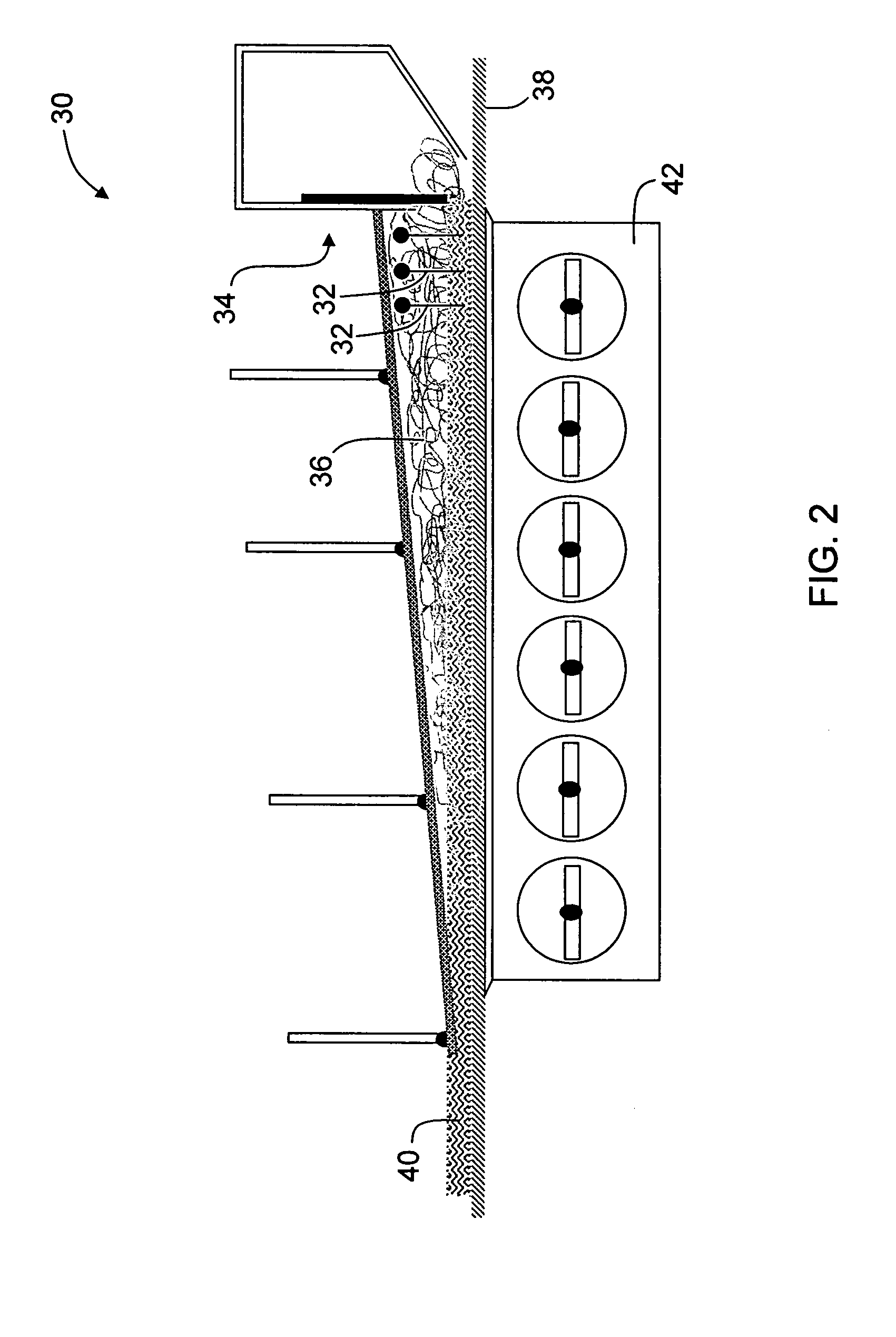

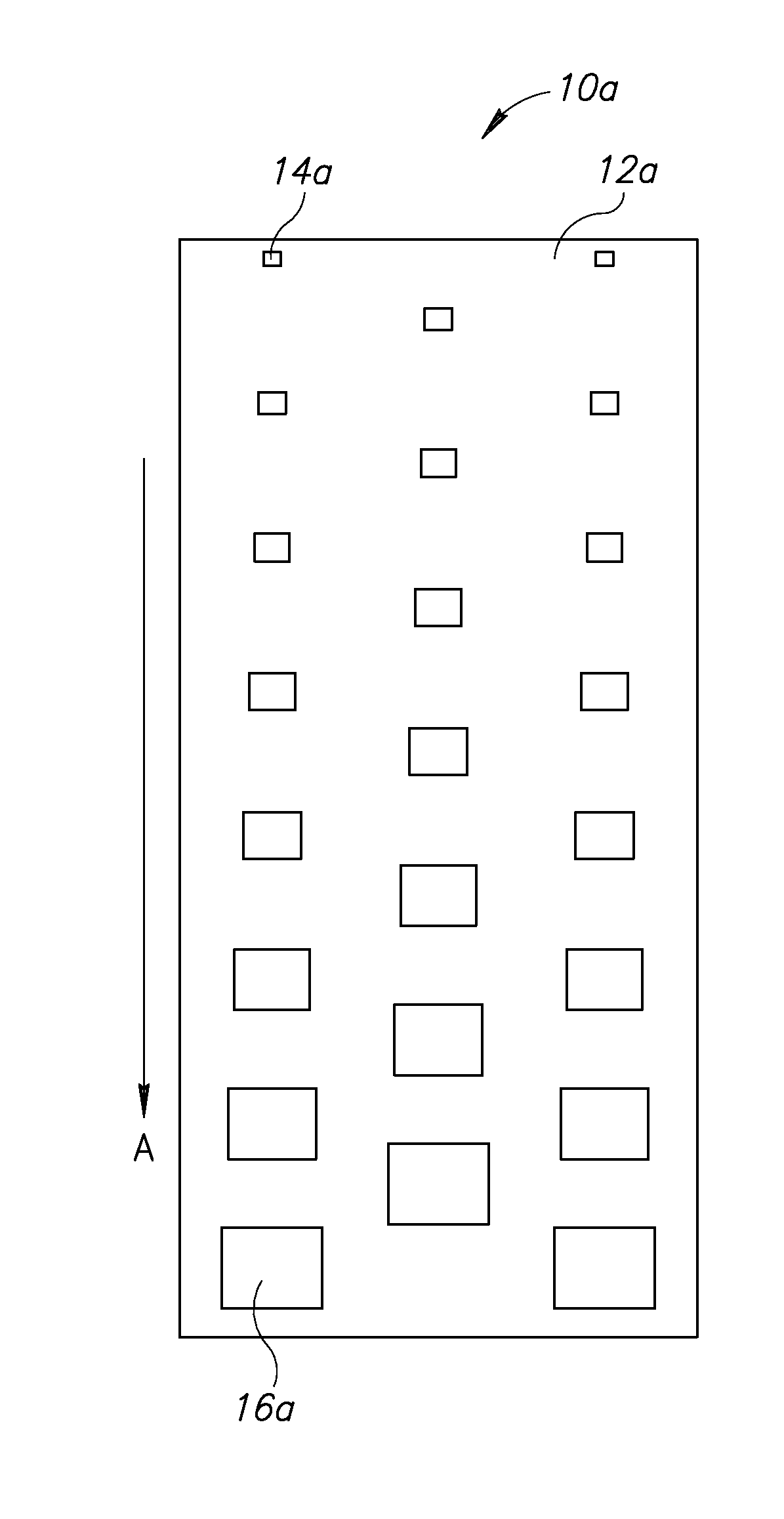

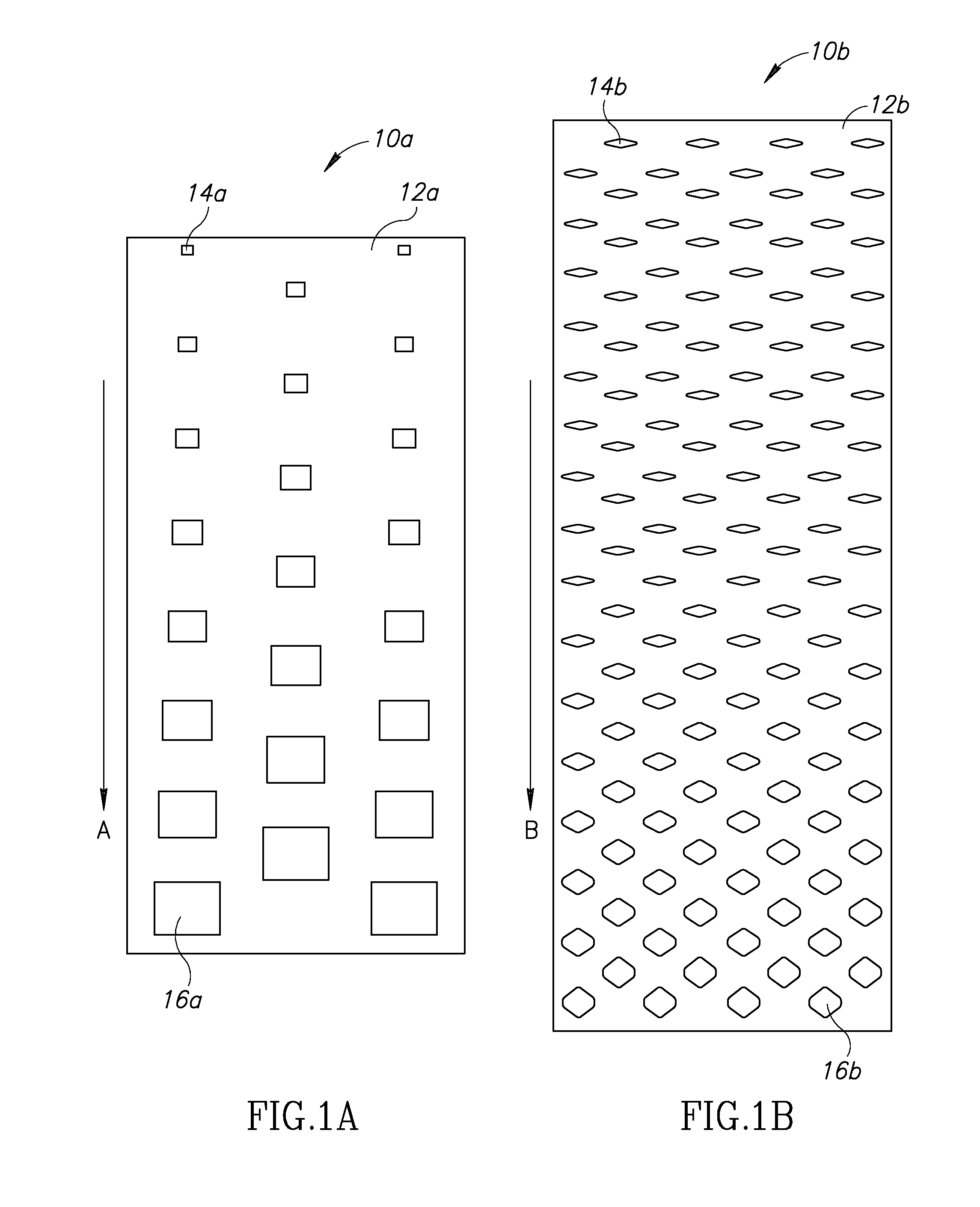

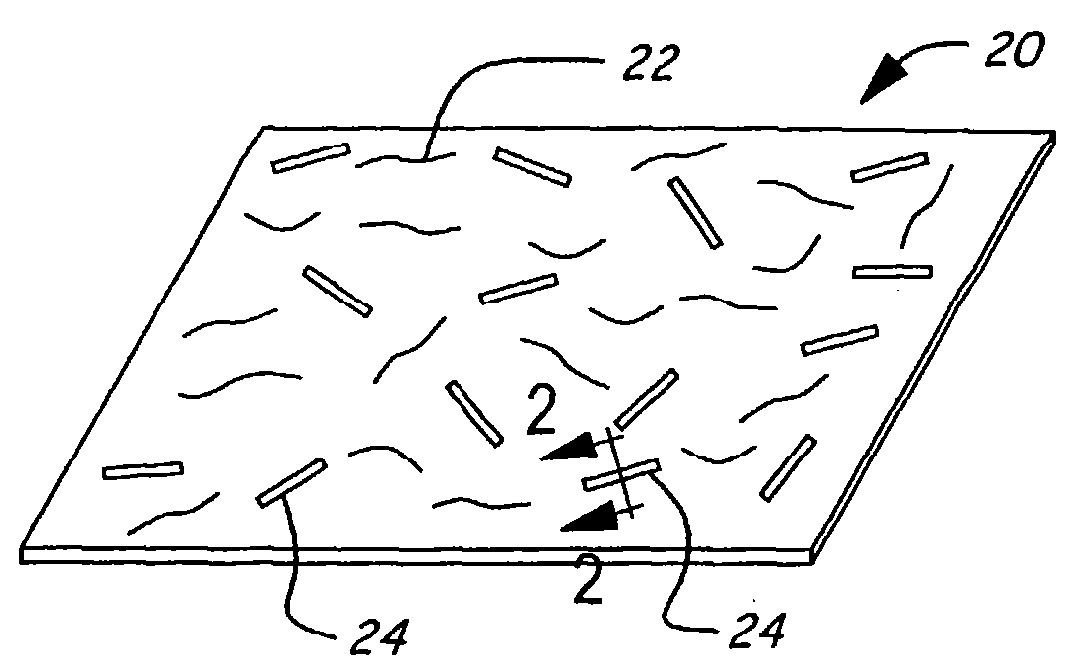

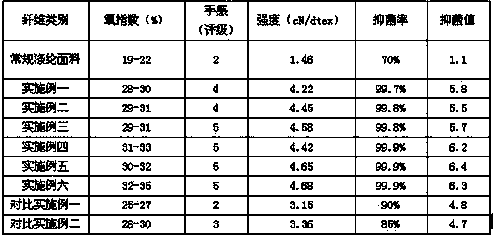

Nonwoven webs with enhanced loft and process for forming such webs

InactiveUS20140072767A1Good flexibilityImprove loftSynthetic resin layered productsNon-woven fabricsEngineeringFelted

The present invention relates to a process of forming a soft bulky nonwoven web from a batt using thermobonding and to a soft bulky nonwoven web with a bond impression pattern and shape. The process comprises several steps including feeding a batt to a nip between first and second surface of first and second roller, where at least the first of the surfaces comprises spaced apart bonding protrusions surrounded by recessed areas. The bonding protrusions and the bond impression shape in the web exhibit a ratio of the greatest measurable width to the greatest measurable length of at least 1:2.5 and the perimeters thereof comprise a convex portion. The bonding protrusions are symmetric and / or have a certain angle to the machine direction.

Owner:PEGAS NONWOVENS

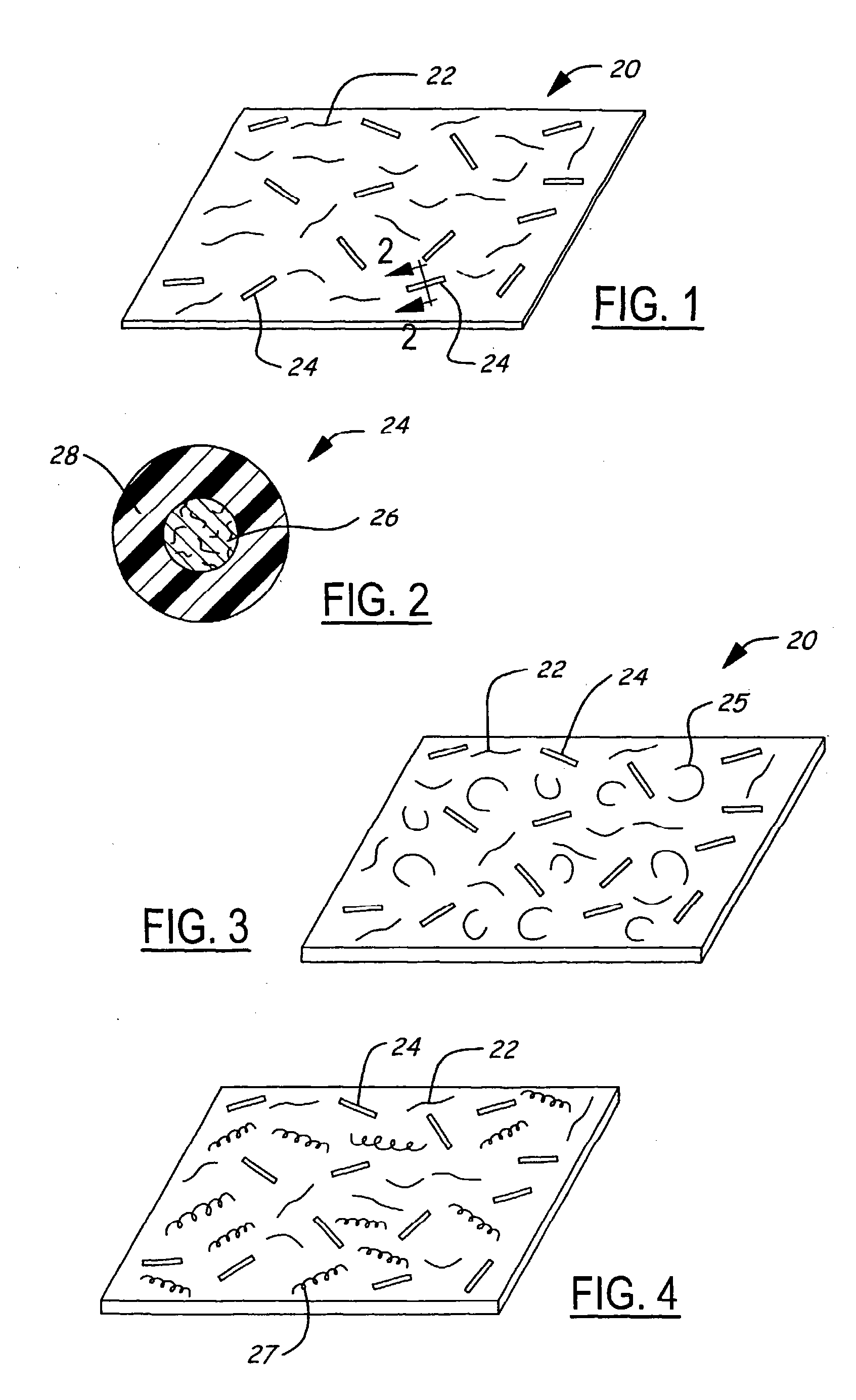

Air-laid web with hollow synthetic fibers

InactiveUS20040103970A1Increase ratingsIncrease resistanceWood working apparatusAbsorbent padsPolyesterPolyolefin

The present invention relates to a single layer air-laid composition comprising: hollow synthetic fiber, absorbent and a binder system. The hollow fiber comprises from about 10 to about 50 percent by weight of said composition. The hollow synthetic fiber has a denier of between about 2 to about 18. The hollow synthetic fiber is selected from the class of polyolefins, polyesters, polyamides, acrylics, as well as mixtures and copolymers thereof. The absorbent comprises from about 40% to about 80% of the weight of said composition. The absorbent is a natural absorbent, or a synthetic absorbent, or a mixture of these. The natural absorbent is selected from the class of wood pulp fluff, cotton, cotton linters, and regenerated cellulose fibers, or a mixture of these. The synthetic absorbent is selected from the class of agar, pectin, guar gum, and synthetic hydrogel polymers. The binder fiber comprises from about 3 to about 15 percent by weight of said composition.

Owner:INVISTA NORTH AMERICA R L

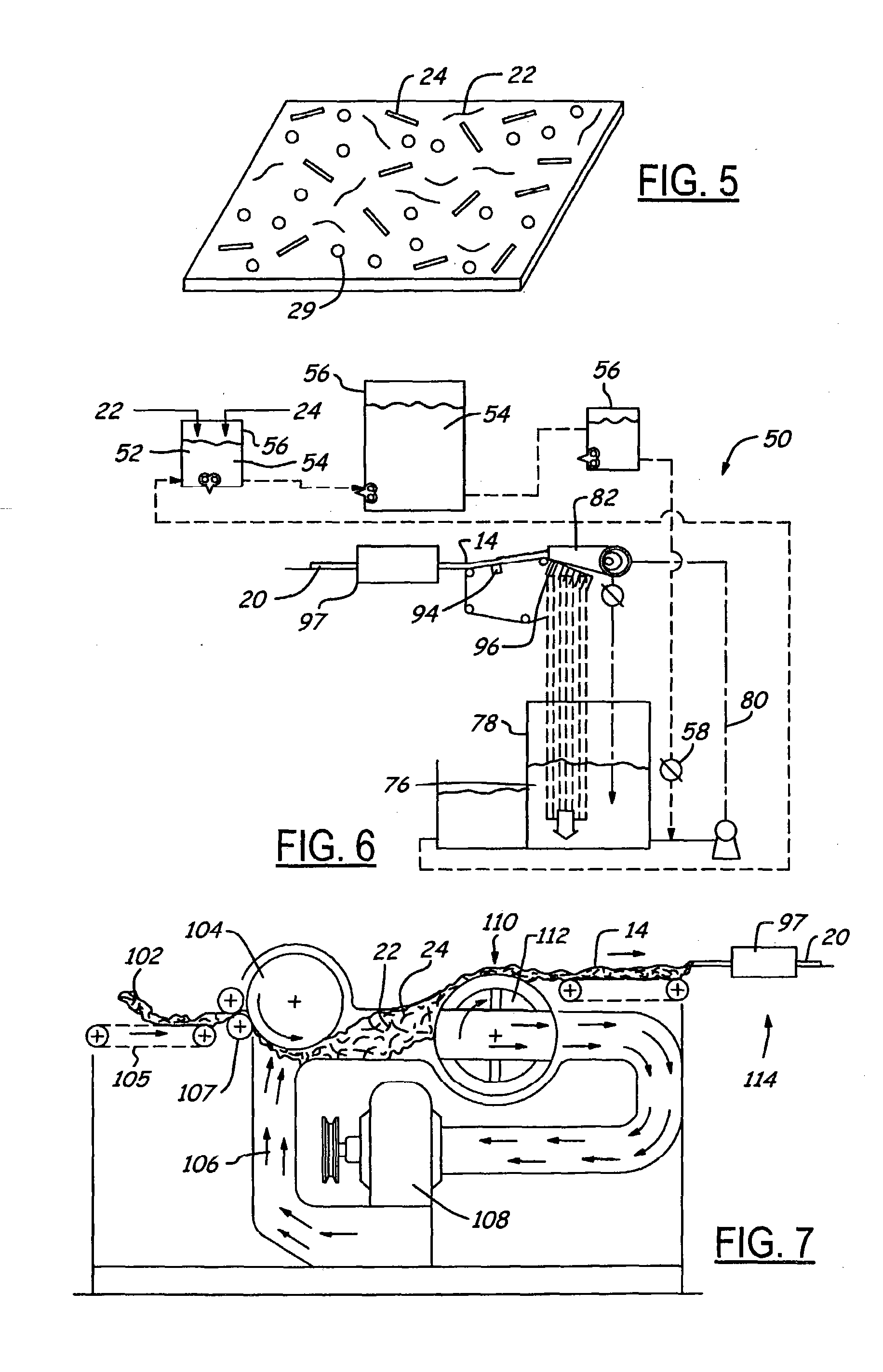

Method of increasing loft in a porous fiber reinforced thermoplastic sheet

A method of fabricating a porous, fiber-reinforced thermoplastic sheet having increased lofting properties is provided. The method includes adding reinforcing fibers having an average length of about 5 mm to about 50 mm, and thermoplastic resin powder particles to an agitated aqueous foam to form a dispersed mixture, laying the dispersed mixture of reinforcing fibers and thermoplastic resin particles down onto a support structure, evacuating the water to form a web, generating a z-axis orientation of a portion of the reinforcing fibers, heating the web above the glass transition temperature of the thermoplastic resin, and pressing the web to a predetermined thickness to form a porous thermoplastic composite sheet having a void content of about 1 percent to about 95 percent.

Owner:AZDEL INC

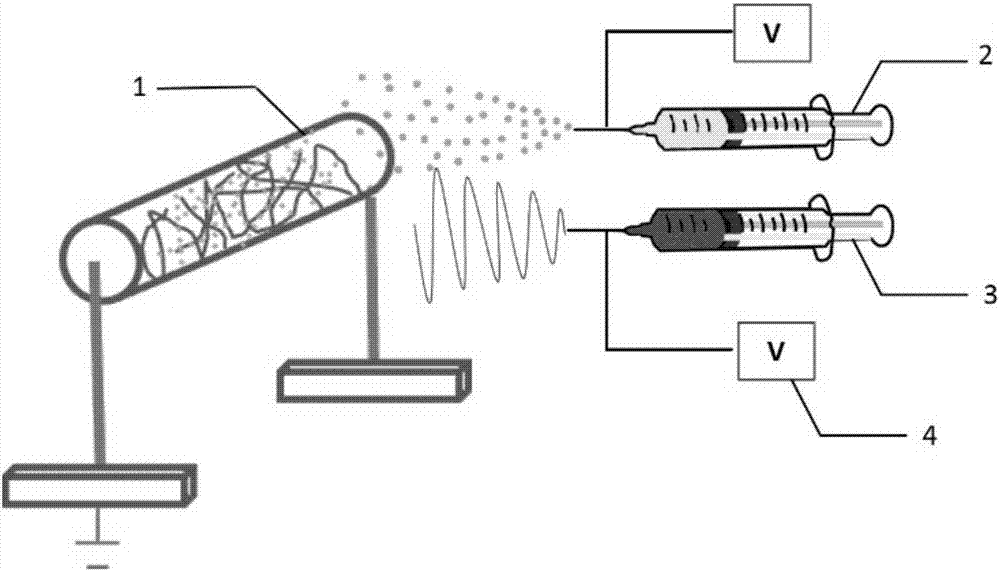

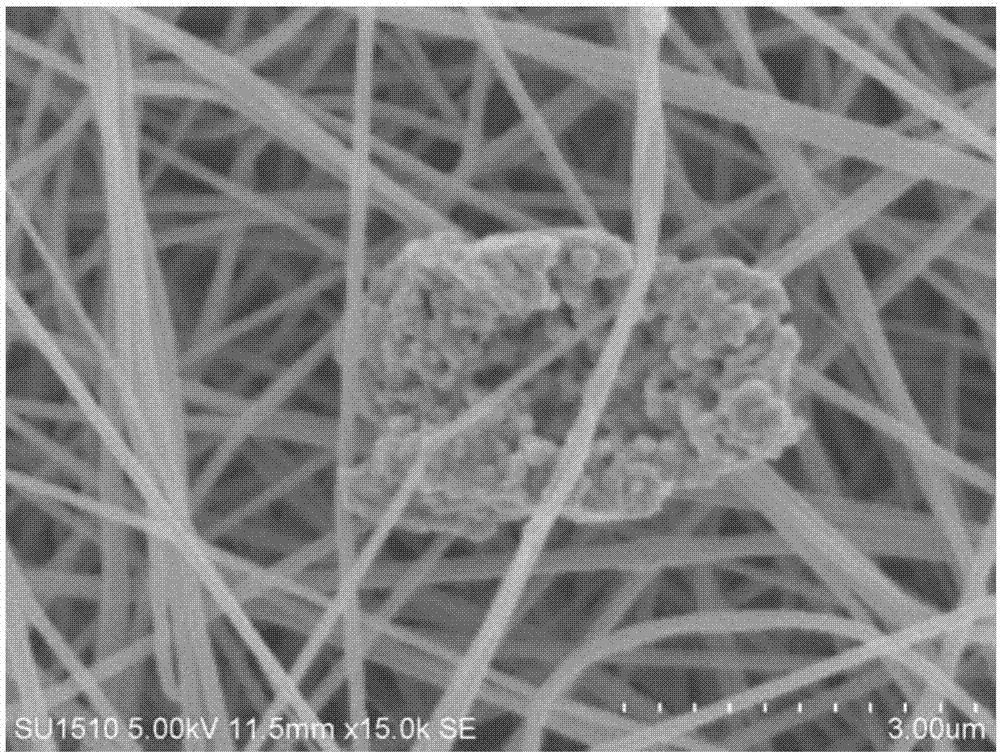

Composite nanofiber membrane and preparation method and application thereof

InactiveCN107299456AHigh porosityImprove breathabilityElectro-spinningNon-woven fabricsFiberPorosity

The invention discloses a composite nanofiber membrane and a preparation method and application thereof. The composite nanofiber membrane is prepared from electrostatic nanofiber deposition foam material. Compared with the prior art, the composite nanofiber membrane has the advantages that by the utilization of an electrostatic spraying technology, foaming particles or foaming short fibers are prepared and deposit on the surface of electrostatic nanofibers, so that the composite nanofiber membrane with controllable thickness is obtained, and the porosity, air permeability and filling power of the nanofiber membrane are improved. By the utilization of the method, the resistance to impact load, heat insulation, sound insulation, specific strength and other physical and mechanism properties of the nanofiber membrane are improved. With the method, the pressure drop and resistance of the nanofiber membrane are reduced, the preparation technology is simple, and cost is low.

Owner:JIANGNAN UNIV

Compressible, low-weight insulation material for use in garments

InactiveUS20170028669A1Improve breathabilityRaise the ratioLayered productsOvergarmentsFiberMaterial Perforation

A compressible insulating material for use in active garments and other gear is provided herein. The material comprises an insulating material including one or more types of fiber, with portions of the insulating material removed or cut to improve the warmth-to-weight and compression characteristics of the insulating material. In some embodiments, the insulating material is an elastic insulating material that defines perforations or other features that expand or contract depending on stretching or relaxation of the elastic insulating material. Stretching and relaxation may vary an insulating property of the compressible, low-weight insulating material. The material may further be secured to a stretch-resistant material to provide a reference point for stretching and for and elastic memory. A garment comprising one or more panels of a compressible, low-weight insulating material as described herein is also provided. Strategic placement of the insulating material can improve ventilation of the garment during activities.

Owner:PATAGONIA

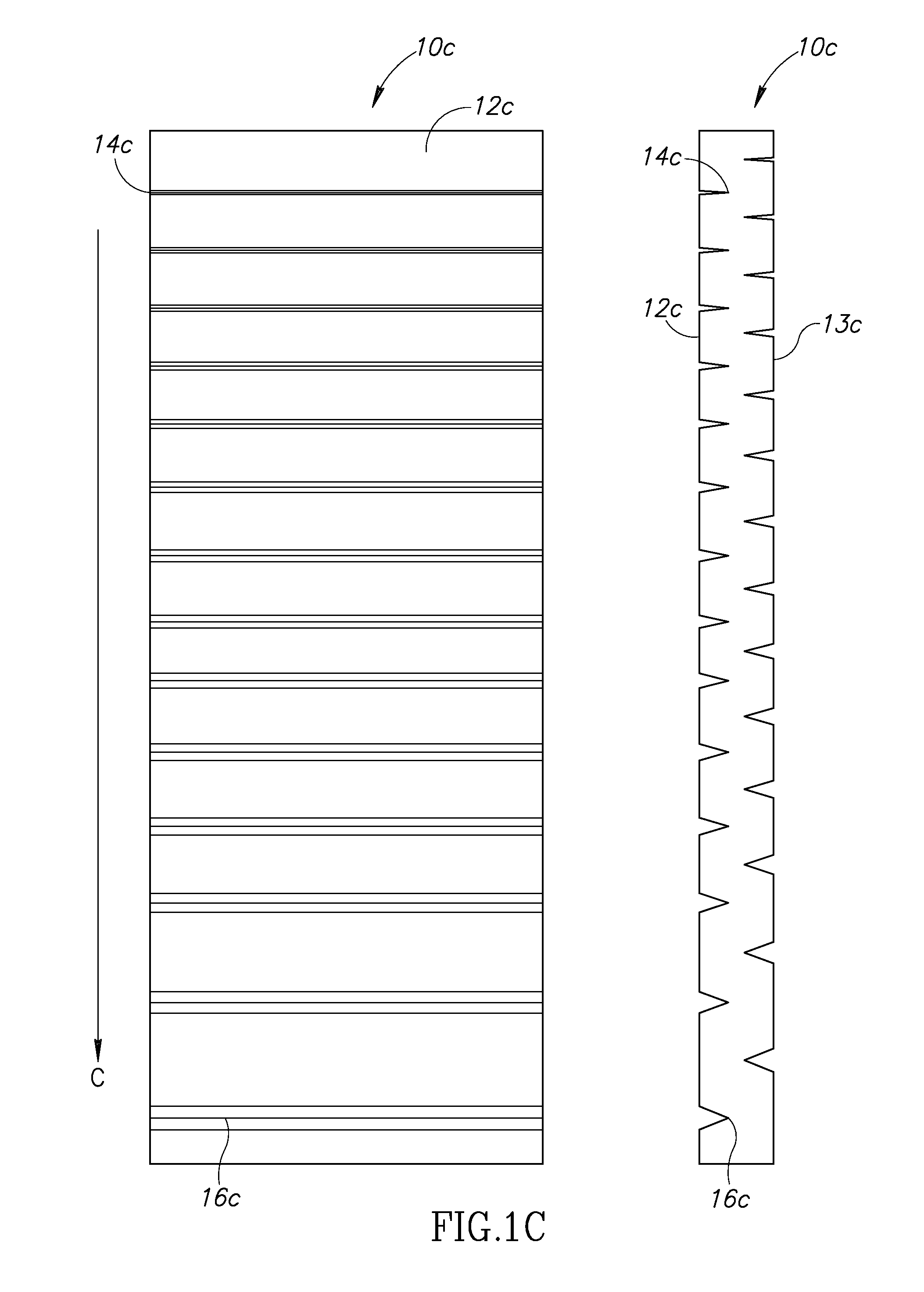

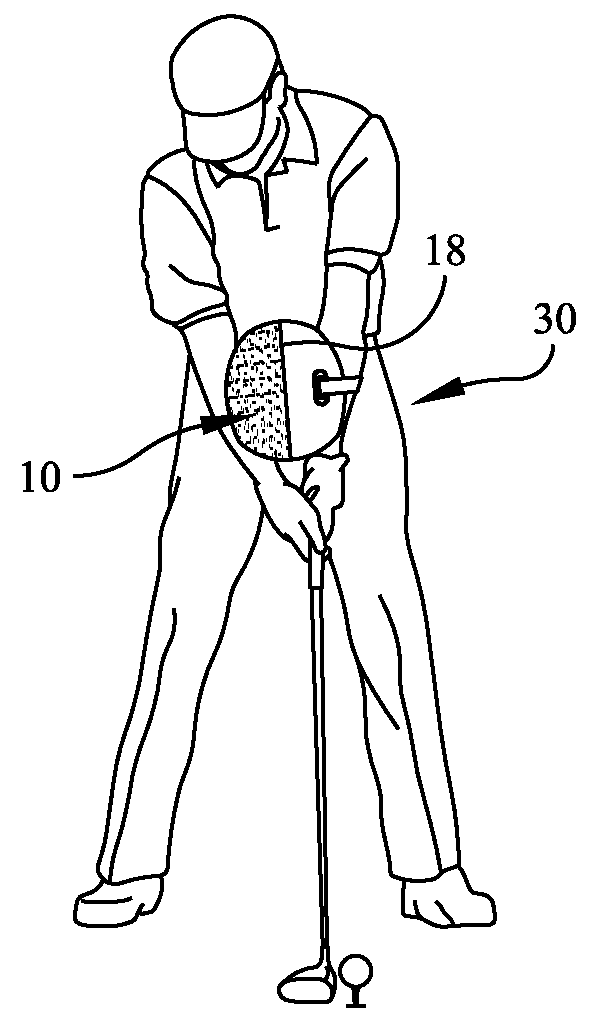

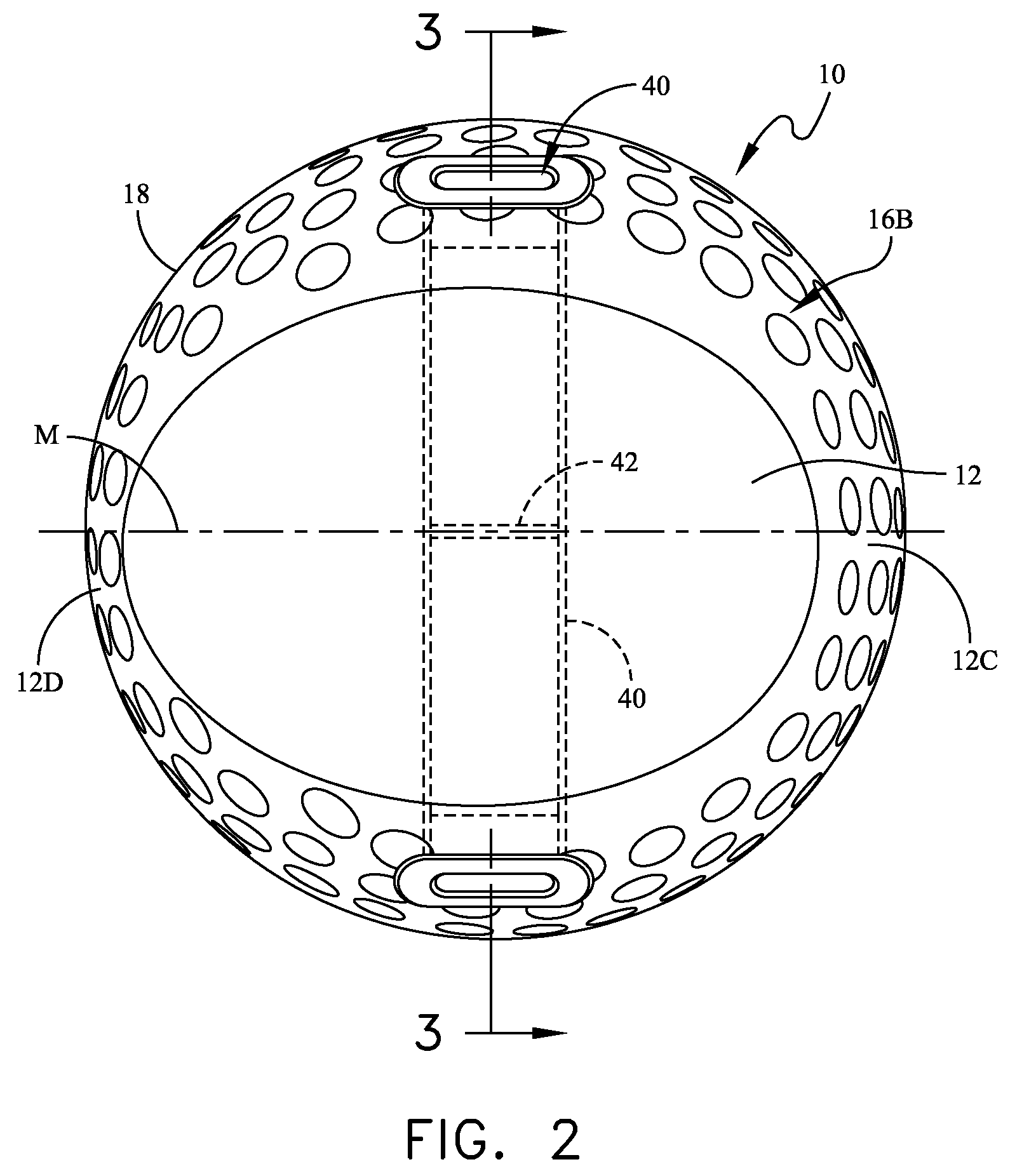

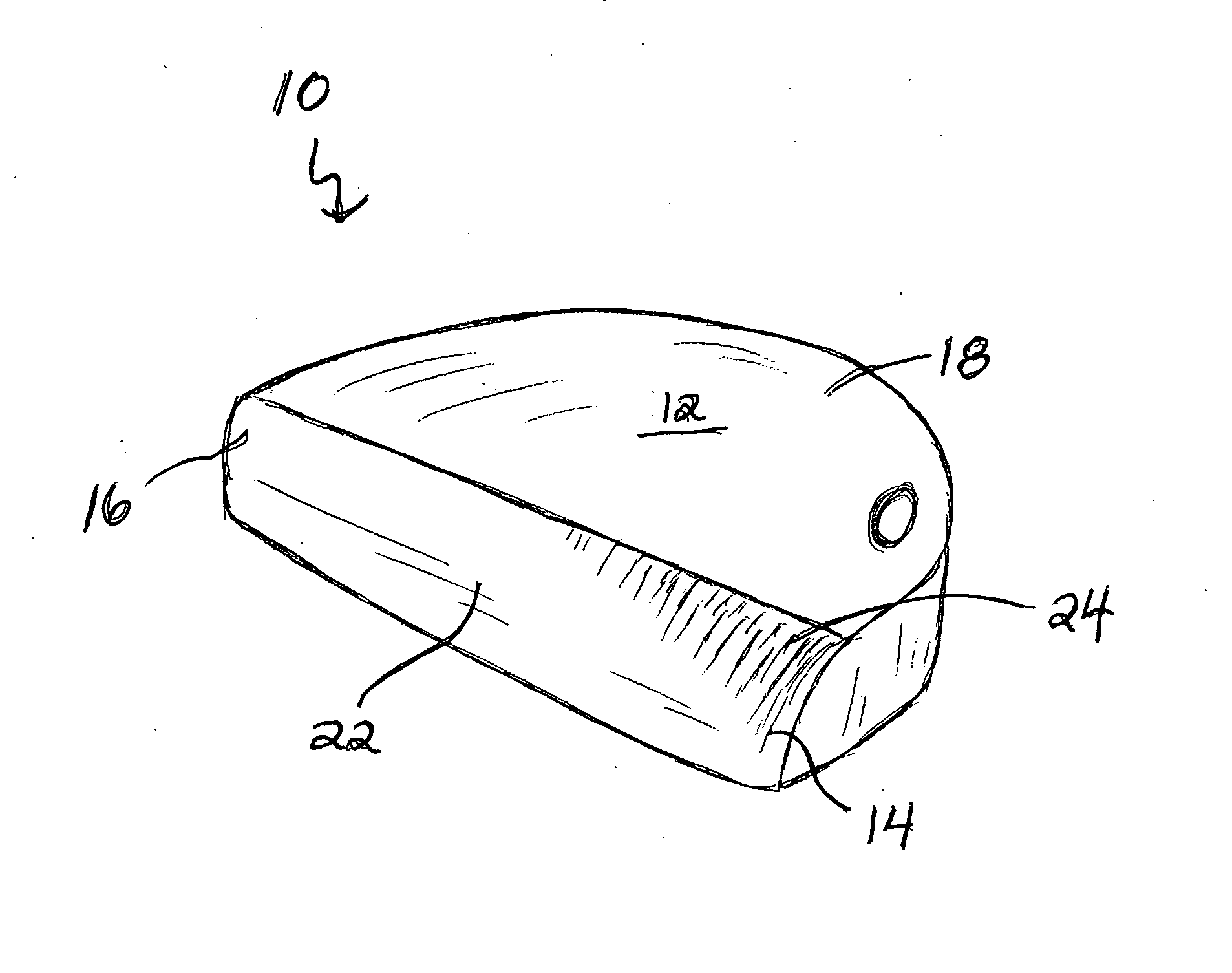

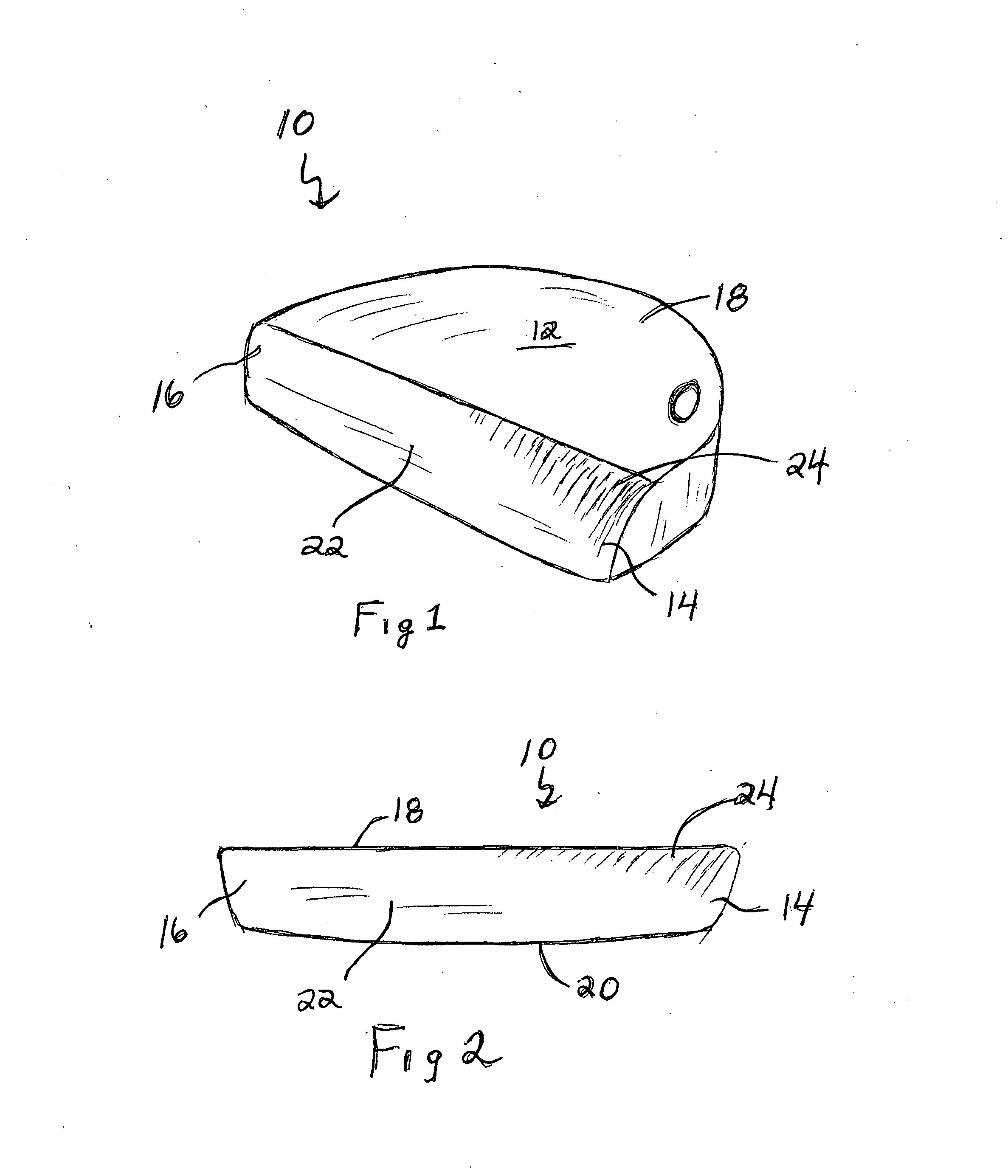

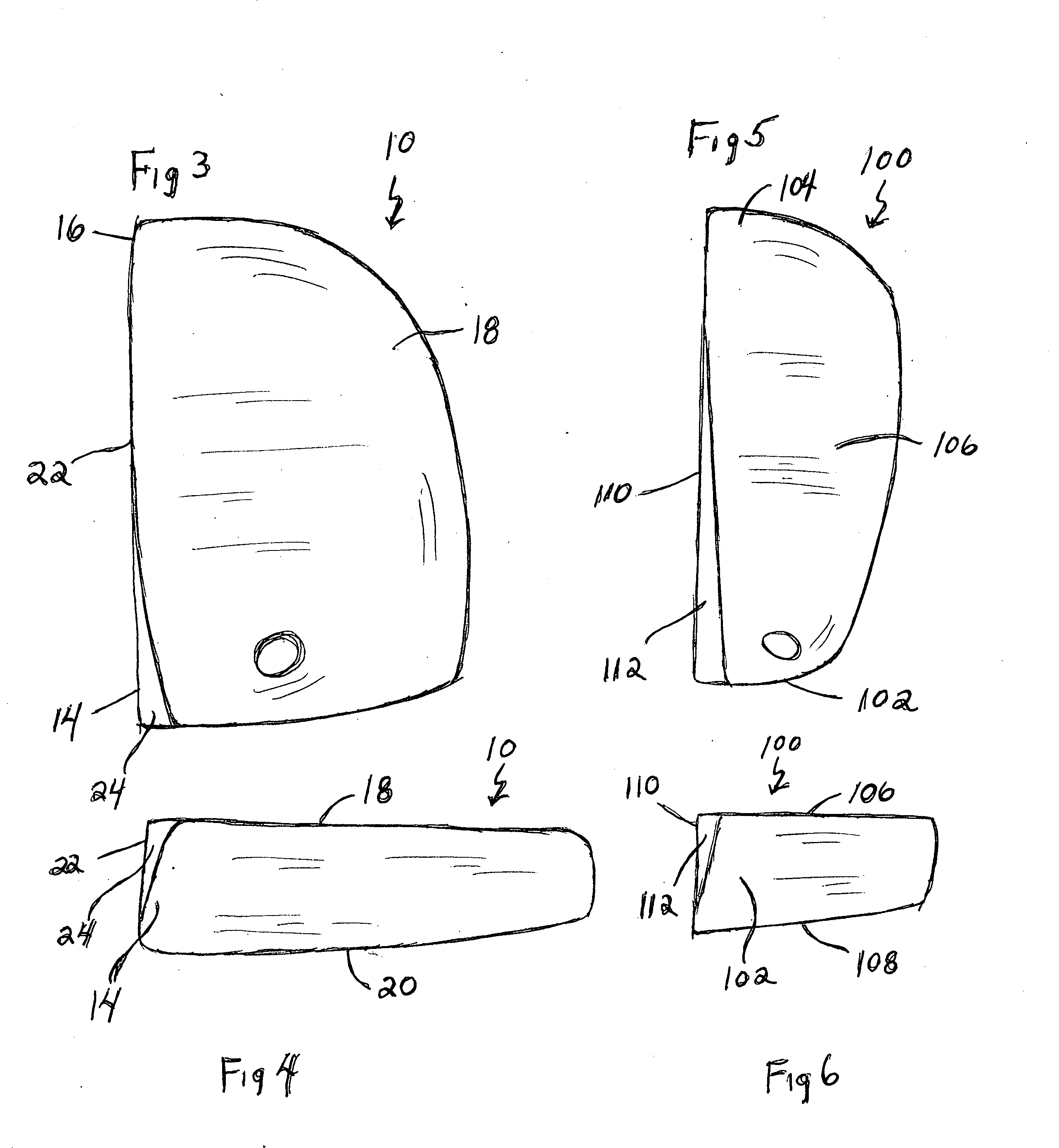

Golf swing training aid

ActiveUS7758437B1Improve loftImproving their golf swingGolf clubsGolfing accessoriesEngineeringGolf Ball

Owner:SPIRIT MERCHANDISE GROUP

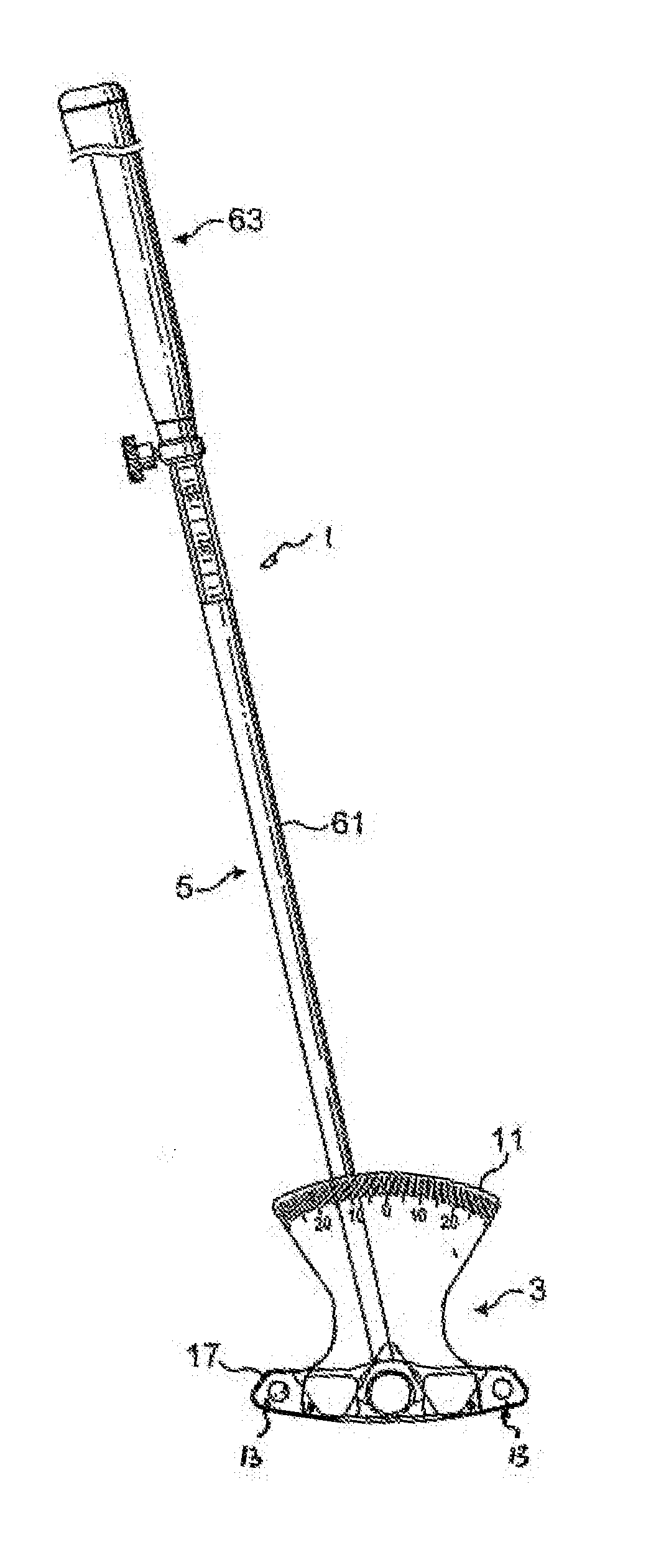

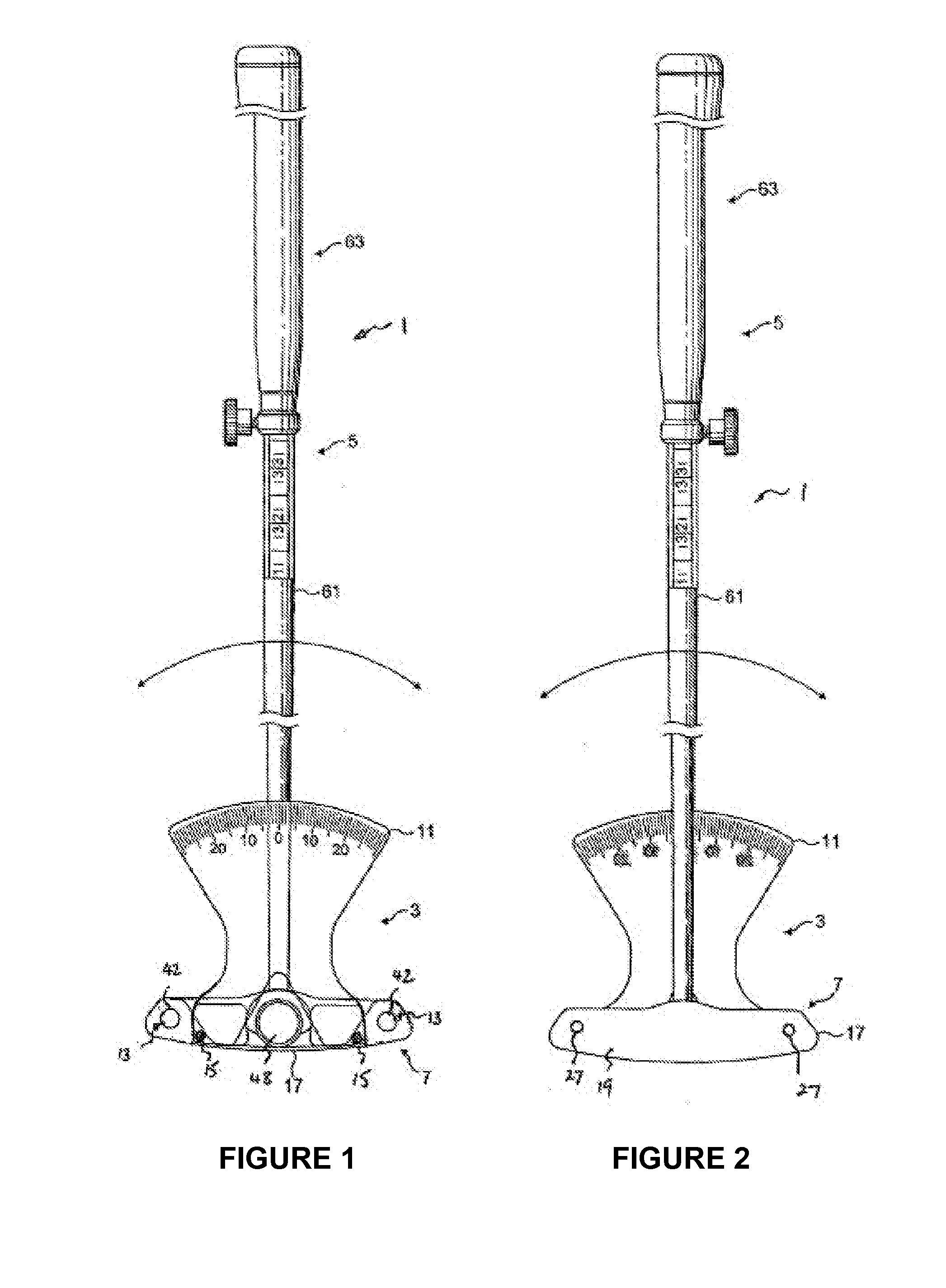

Golf putters

InactiveUS20110230275A1Promote resultsImprove performanceGolfing accessoriesGolf clubsOffset distanceEngineering

A fitting or coaching device (100) for use in fitting golf clubs or assisting golf trainers, the device having a head (102) with a striking face (120) and a shaft (131) slideably mounted to the head (102). The slideable mounting of the shaft (131) enables adjustment of its position to vary its offset distance from the striking face (120). The device (100) preferably includes an offset scale (141d). In preferred embodiments, the slideable mounting is in the form of a screw adjustment or a rack and pinion arrangement. In a less preferred embodiment, the slideable mounting is provided by an engaging portion (140) slideably receivable within a guide (141b) and securable thereto by a fastener or clamp (145), wherein the engaging portion (140) has a complementary shape to the guide (141b). In preferred embodiments, the position of the shaft (131) is movable between a first position behind the striking face (120) and a second position is in front of the striking face (120).

Owner:HICKS DAVID RAYMOND

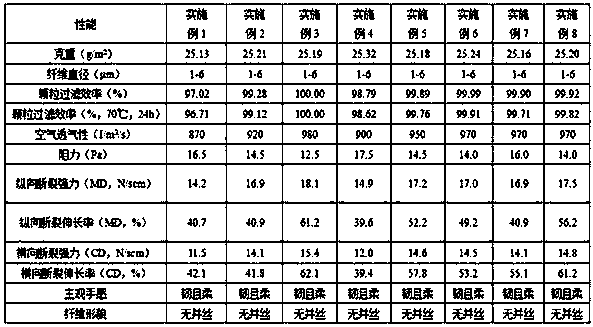

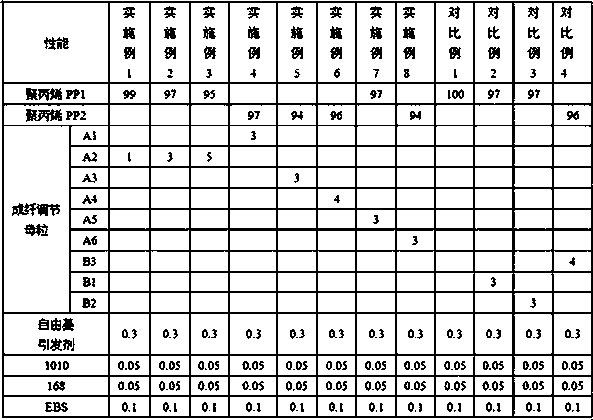

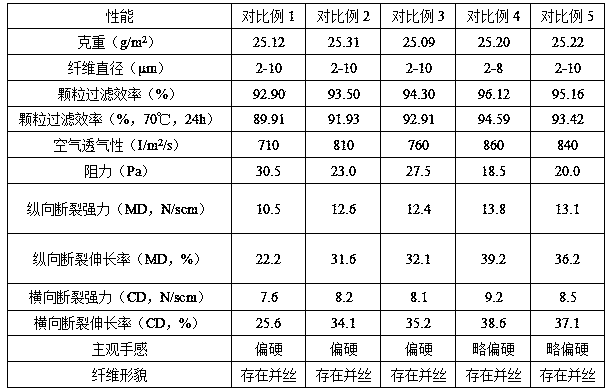

Melt-blown polypropylene composition as well as preparation and application thereof

ActiveCN111410793AImprove uniformityReduce parallel wireFiltration separationMonocomponent polyolefin artificial filamentPolypropyleneWoven fabric

The invention discloses a melt-blown polypropylene composition as well as a preparation method and application thereof. The melt-blown polypropylene composition is prepared from the following components in parts by weight: polypropylene resin 90-99 parts, fiber-forming masterbatch 0.5-10 parts, free radical initiator 0.1-1 parts, wherein the fiber-forming masterbatch includes the following components: polypropylene resin 30 to 90 parts by weight, hyperbranched associative polymer 5 to 35 parts, and interfacial barrier agent 5 to 35 parts. The melt-blown non-woven fabric fiber produced by the melt-blown polypropylene composition prepared by the invention has uniform diameter, good hand feeling and bulkiness and good filtering rate, and the safety of a mask is effectively improved.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

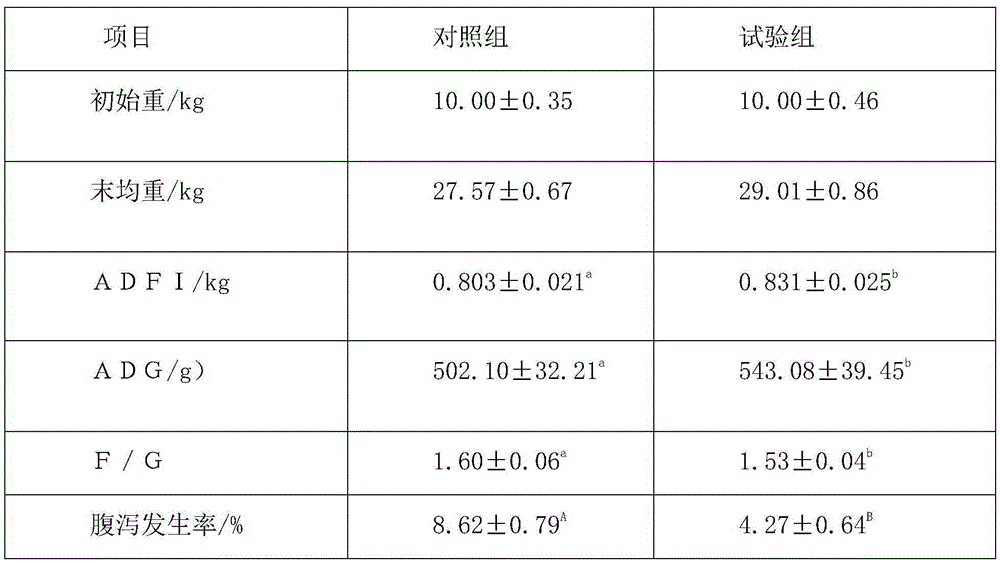

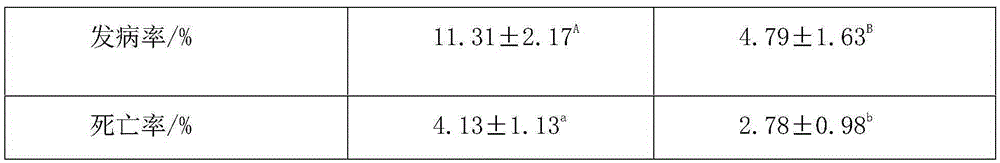

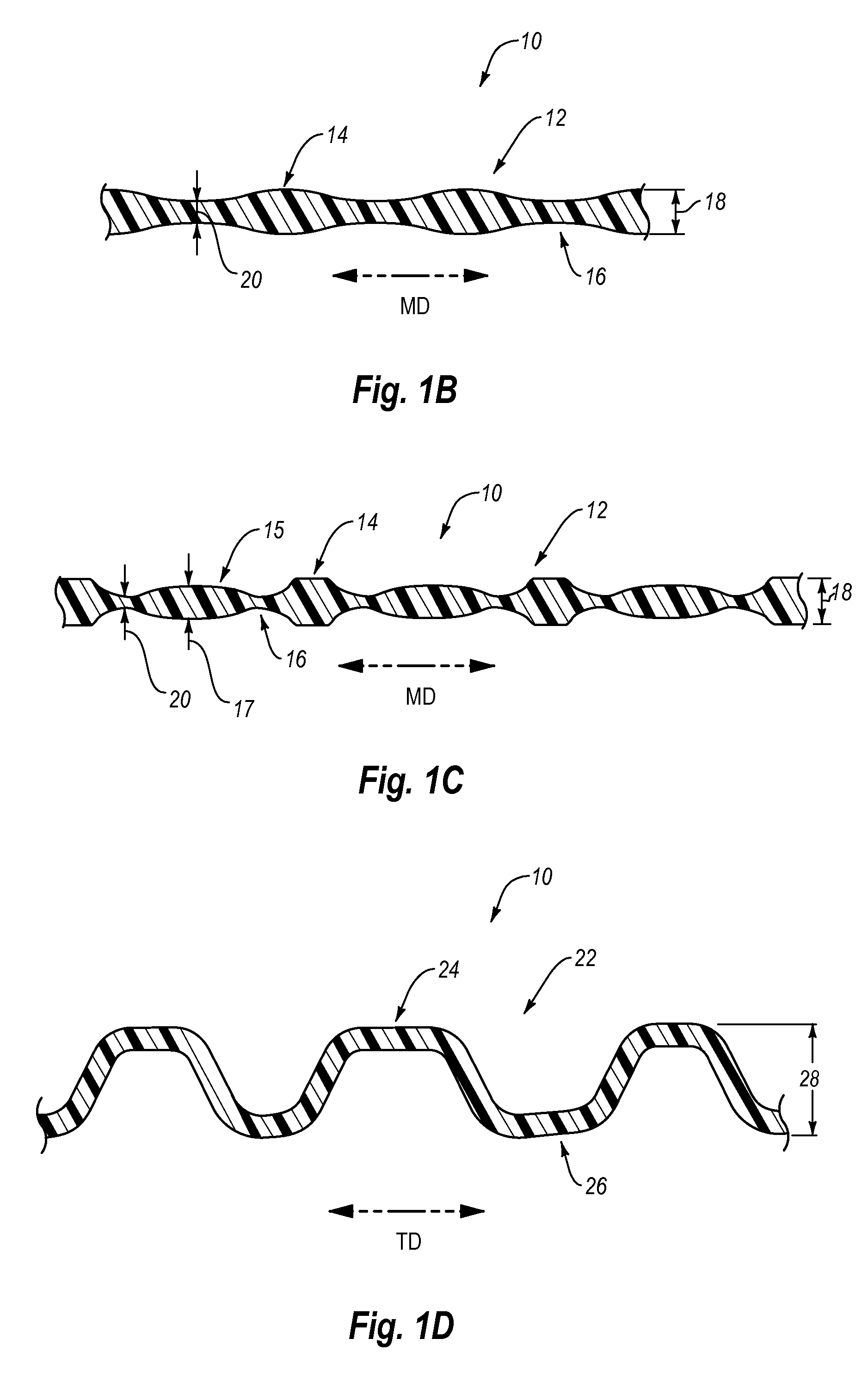

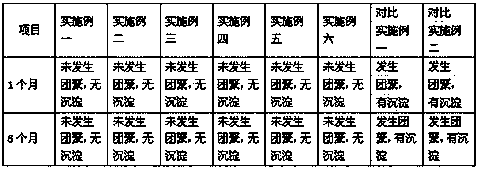

Antibiotic-free weaned-piglet complete feed and preparing method thereof

InactiveCN105410404AImprove loftReduce hardnessFood processingAnimal feeding stuffNutritive valuesAnimal science

The invention discloses an antibiotic-free weaned-piglet complete feed and a preparing method thereof. The antibiotic-free weaned-piglet complete feed is antibiotic-free efficient complete feed capable of meeting the nutritional requirements of weaned piglets, promoting digestion and using of nutrient substances, improving the immunity function and the resistance of piglet bodies and reducing the diarrhea rate. The preparing method includes the steps that in the formula proportion, weighed corn, weighed high protein bean pulp and weighed extruded soybeans are smashed to be subjected to first-time high-temperature pelletizing, thin smashing is carried out after pellets cool, then weighed imported fish meal, weighed calcium hydrophosphate, weighed mountain flour, weighed salt, weighed soybean oil, weighed whey powder, weighed feed grade lysine, weighed methionine, weighed threonine, weighed premixed materials for the weaned piglets and compounded Chinese herbal medicine are mixed to be even, then second-time low-temperature pelletizing is carried out, cooling is carried out, then a finished product is packed, and the weaned piglets can be directly fed. Particles of the weaned-piglet feed produced with the preparing method are good in filling power, low in hardness, good in water dissolving performance, high in nutritive value, good in palatability, sanitary and safe, the diarrhea rate is reduced, the feed use ratio of the weaned piglets is increased, the production performance of the weaned piglets is improved, and antibiotic harm is avoided.

Owner:HENAN INST OF SCI & TECH

Conformable surfacing veil or reinforcement mat

InactiveUS20050032452A1Good flexibilityHigh melting pointNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolyethylene terephthalate

A conformable surfacing veil having an improved soft feel is formed by admixing a thermoplastic sheath-core bicomponent fiber with a regularly or irregularly shaped structural fiber to form a core composition for the mat. The bicomponent fiber is formed from a core material and a sheath material. Suitable core material include thermoplastic polymers such as polyethylene terephthalate that have a higher melting point than the sheath like polymer. Suitable sheath materials include polyethylene, polypropylene, and copolyesters having softening points lower than the core material. Thus, when the mixture of structural fibers and bicomponent fibers is heated above the softening point of the sheath materials, the bicomponent fiber will fuse to the structural fibers. The surfacing veils can then be laminated to other reinforcing mats for use as a reinforcement for plastic articles.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Method for bleaching grey down feather

InactiveCN101705612AThe whiteness is obviously improvedDown damage is smallBleaching apparatusIonChemistry

The invention discloses a method for bleaching grey down feather. The method comprises the following steps: firstly, using ferrous ions to conduct pretreatment on down feather to be treated, then conducting selective oxidation bleaching on the down feather, and finally using thiourea dioxide to conduct reduction bleaching on the down feather, and using clear water to wash the down feather, and drying. The method can effectively eliminate the natural pigment in the down feather, and has less damage to the down feather; the selective oxidation bleaching and reduction bleaching by using the thiourea dioxide (TDO) are combined to treat the down feather; after the TDO is applied to conduct reduction bleaching under the mild condition on the down feather treated by selective oxidation bleaching, thus improving the whiteness of the down feather, leading the decolorization and bleaching of the grey down feather to achieve high-level whiteness, and inhibiting the color reversion of the down feather; and the TDO is an acid reducing agent, can play the role of strong reducing property under the acidulous and neutral conditions, is suitable for the stability condition of the protein fiber in the down feather, and has little damage to the fiber. The whole process for decolorizing and bleaching the down feather is conducted at low temperature, thus not only ensuring the little damage to the fiber, and good bulkiness, but also being beneficial to energy conservation and environmental protection.

Owner:萧山区质量计量监测中心 +1

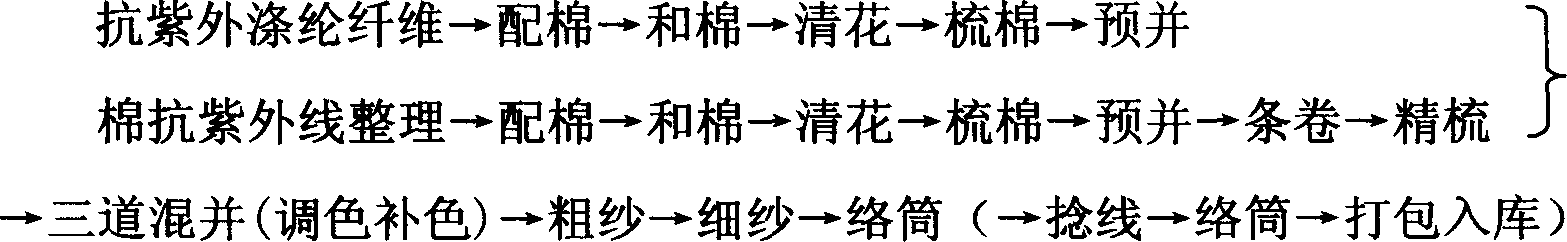

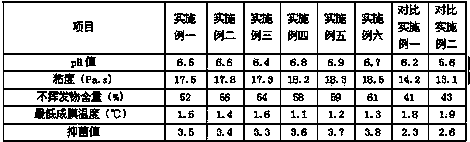

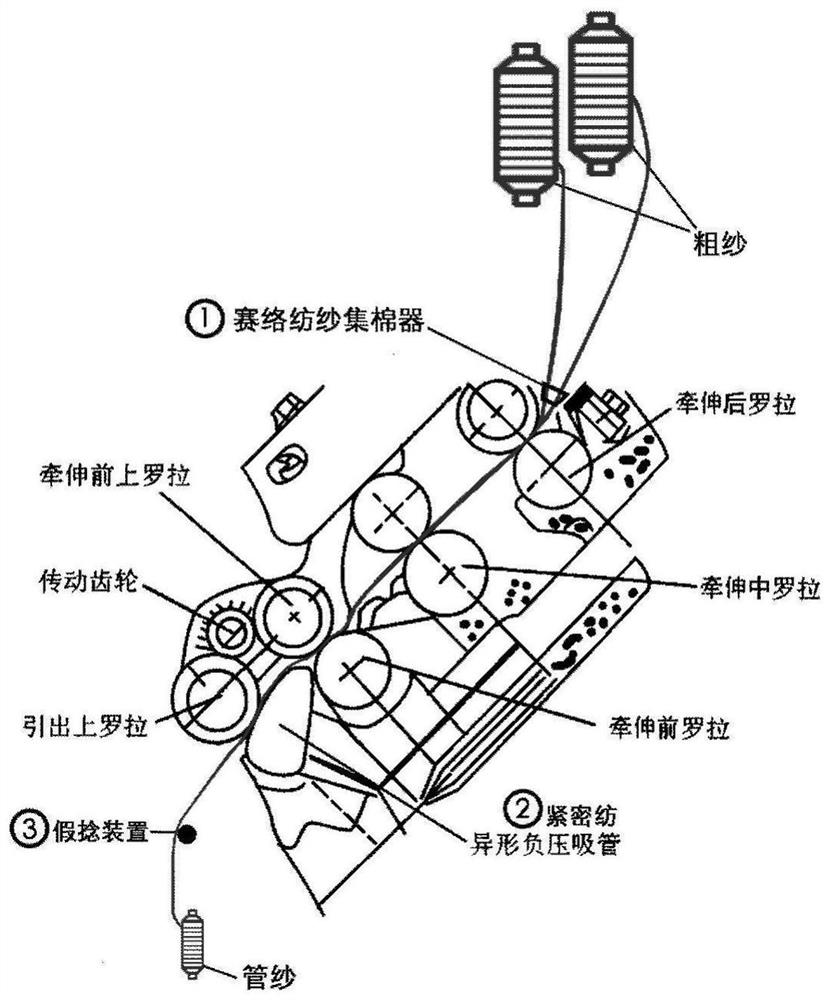

Anti-ultraviolet ray mixed color spinning thread and its producing method

The invention belongs to engineering area in weaving industry in which said uviofast colored spinning thread is characterized in that it includes two or more than two varied colors cotton-dispersing fibres or uviofast polyester fibre, collated with uviofast. Coefficient UPF of plus material of textile, machined by purifying uviofast colored spinning thread, for guarding ultraviolet ray, can reach more than 30 after 10 times wash measuring and the coefficient UPF of polyester fibre can reach more than 50 after 30 times wash measuring. Uviofast colored spinning thread of the invention is widely applied in various clothes, sports suit, sportswear, tame and so on.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Bamboo charcoal fiber fabric for home textiles

ActiveCN104264279AGood flexibilityImprove loftPile loops cuttingConjugated cellulose/protein artificial filamentsScreen printingPolymer science

The invention relates to a preparation method of a textile, in particular to bamboo charcoal fiber fabric for home textiles. The preparation method comprises the following steps: preparation of bamboo charcoal micropowder emulsion, preparation of viscose, preparation of bamboo charcoal fiber filaments, and preparation of gray fabric, and further comprises the specific steps: spinning, warping, slashing, weaving, two-bath dyeing, postprocessing of the fabric, scutching, dehydrating, drying and sewing, wherein during the spinning process, the cotton fiber is used for the warp direction, modal fiber or covered spandex filaments and bamboo charcoal fiber filaments are used for the weft-wise direction; the two-bath dyeing method comprises pad dyeing and dyeing the same color; the jacquard weaving method comprises first-time loose drying, velvet piling, second-time loose drying, and preparing the pattern screen printing plate for chromatography; the drying temperature for the first-time loose drying in the jacquard weaving step is 130-140 DEG C, and the drying time is 5-9 minutes; the drying temperature for the second-time loose drying is 70-90 DEG C, and the drying time is 15-22 minutes. The bamboo charcoal fiber fabric for the home textiles prepared by the method is soft and good in the antibacterial activity.

Owner:汕头市粤宝利实业有限公司

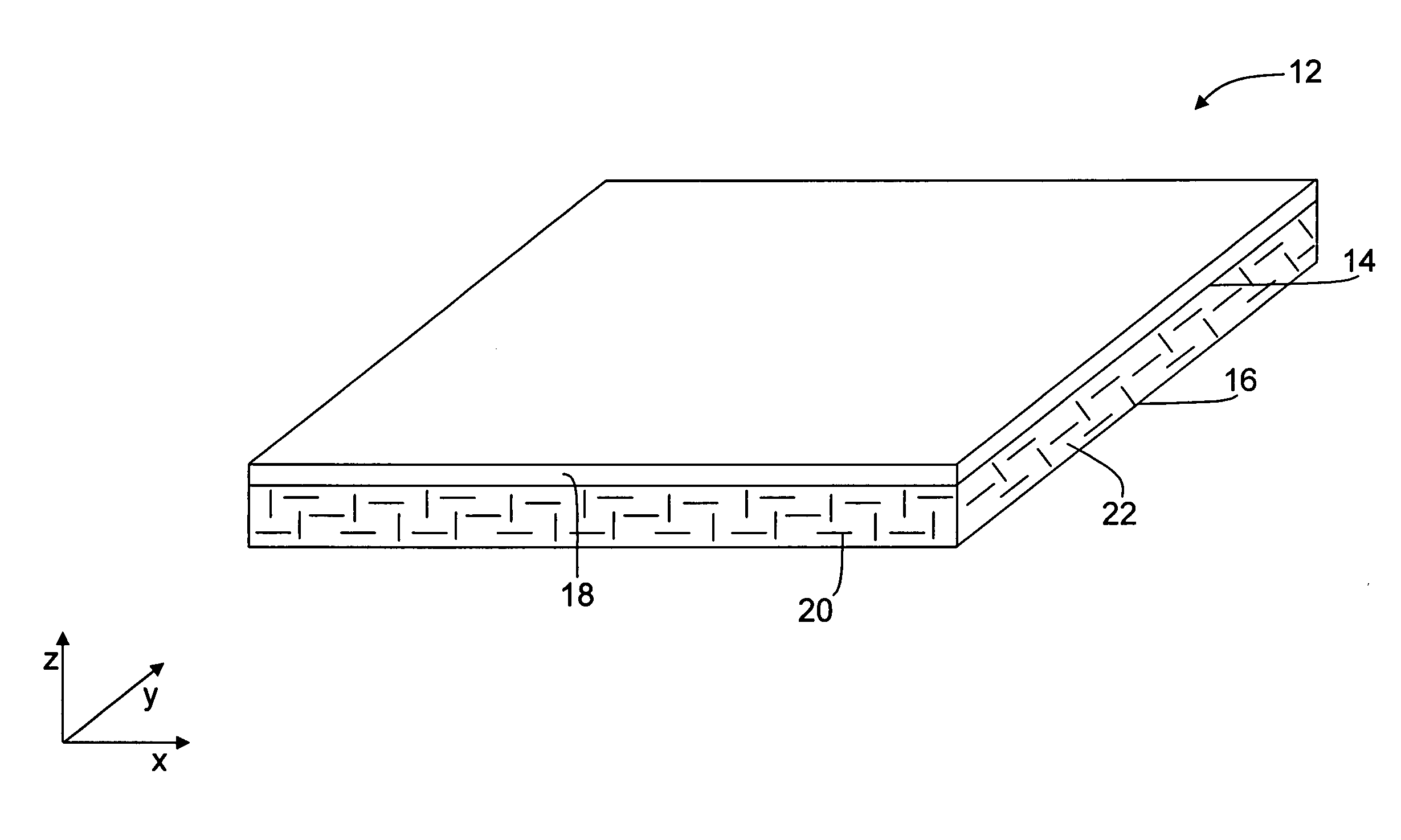

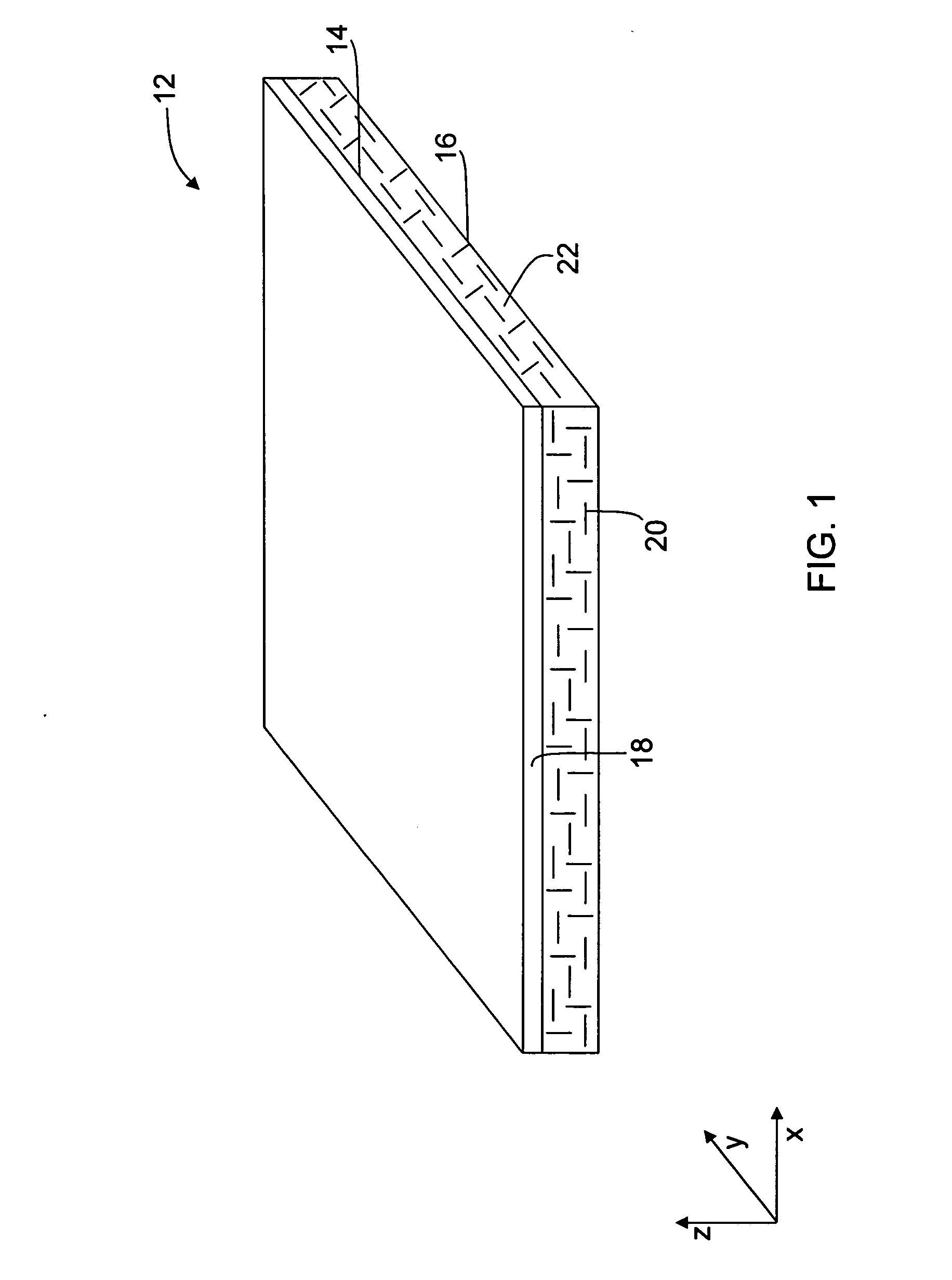

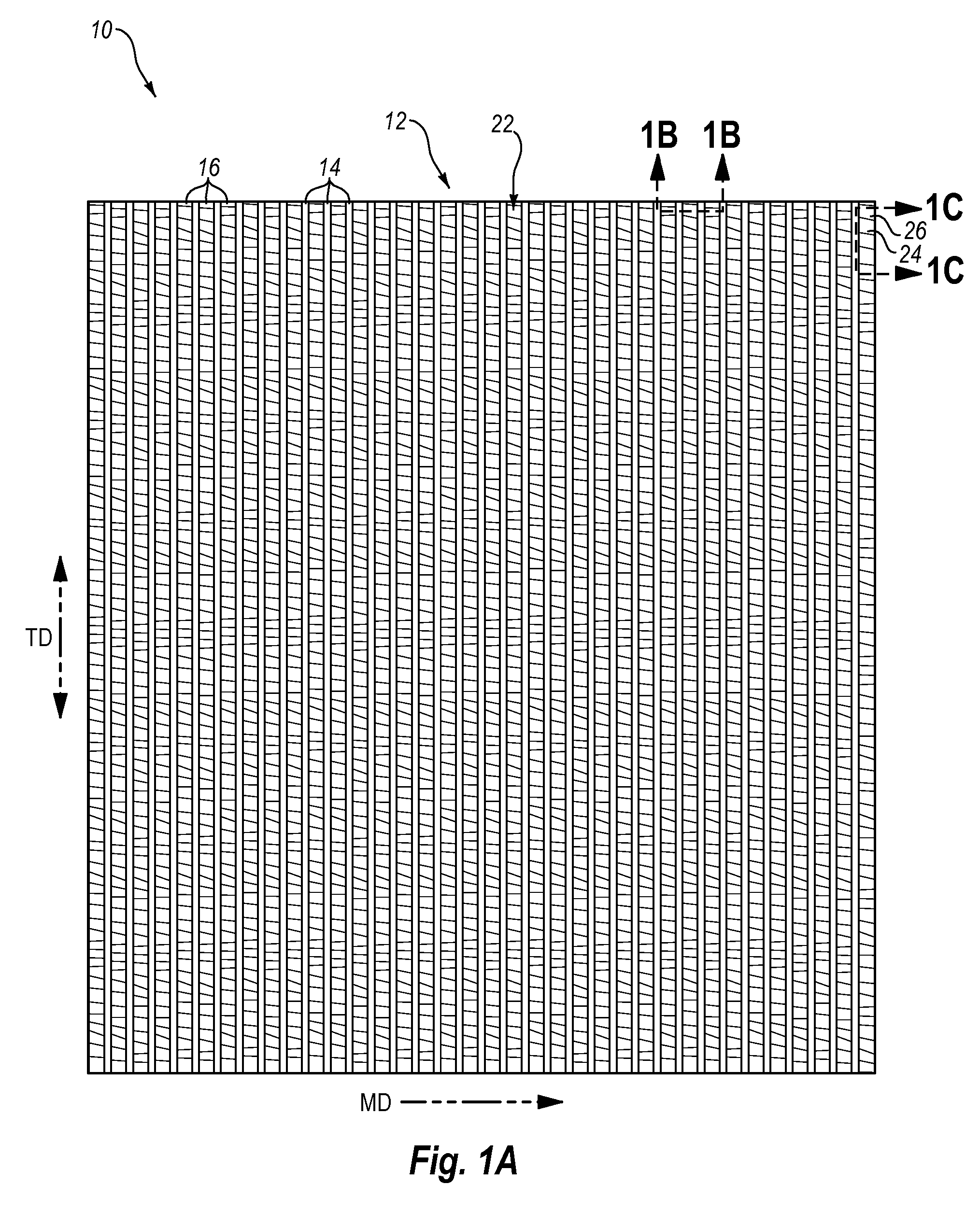

Incrementally-stretched thermoplastic films with enhanced look and feel and methods for making the same

ActiveUS8734016B2Improve loftPerception of thicknessBag making operationsBox making operationsEngineeringLook and feel

Methods of increasing the perceived thickness and strength of a thermoplastic film include incrementally stretching thermoplastic films in the machine direction. In one or more implementations, methods of incrementally stretching thermoplastic films include reducing the gauge of the films while increasing a loft of at least a portion of the film. The methods can involve cold stretching the films and imparting rib patterns and alternating peaks and valleys into the film. The linear ribs can have alternating thick and thin gauges.

Owner:THE GLAD PROD CO

Production method of health bamboo fiber fabric for home textiles

The invention relates to a preparation method of textiles, in particular to a production method of a health bamboo fiber fabric for home textiles. The method comprises the following steps: preparing antibacterial bamboo fibers, to be specific, electrostatically spraying antibacterial solutions on the surfaces of the bamboo fibers, performing microwave treatment, vacuumizing until the vacuum degree is minus 0.04MPa to minus 0.03MPa, and then performing microwave wood pulp cooking, wherein the microwave frequency is 100-250MHz, the microwave treatment time is 2-5 min, the electrostatic spraying distance is 80-100mm, the spraying voltage is 90-120V, and the air pressure is 0.05-0.08Mpa; dyeing; performing colored spinning; mixing the dyed bamboo fibers with modal fibers and cotton fibers with different colors, and then performing blowing, cotton carding, three-time drawing, roving, spinning, spooling and two-time thread twisting, wherein the content of the bamboo fibers accounts for 60-75 percent of the total fiber content in the colored spinning process; performing the jacquard weaving step comprising first-time loose drying, velvet cutting, second-time loose drying and manufacturing of an overprinted pattern screen printing plate. The health bamboo fiber fabric for the home textiles, which is prepared by the method, is high in softness, high in antibacterial activity and good in health care effect.

Owner:湖南梦洁新材料科技有限公司

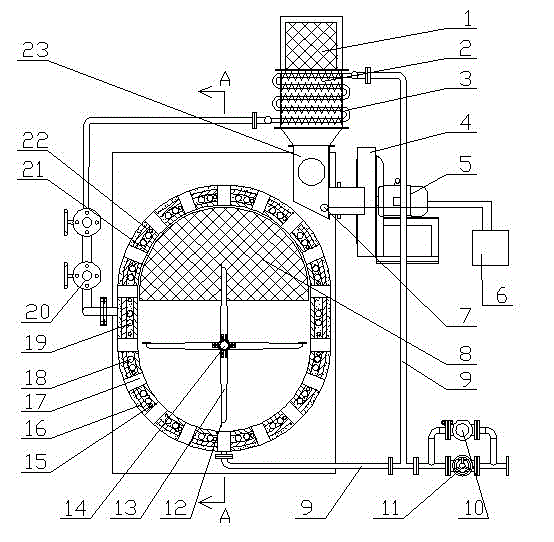

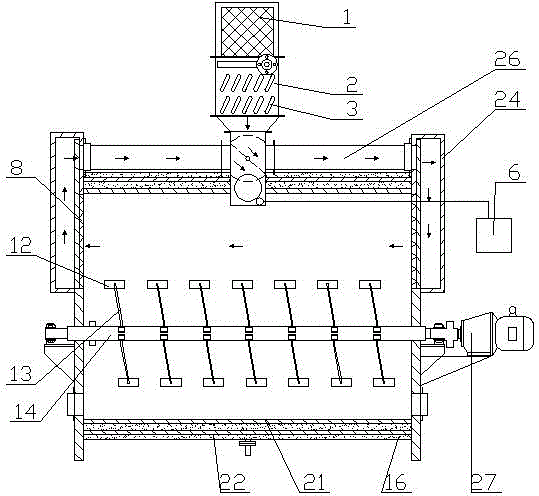

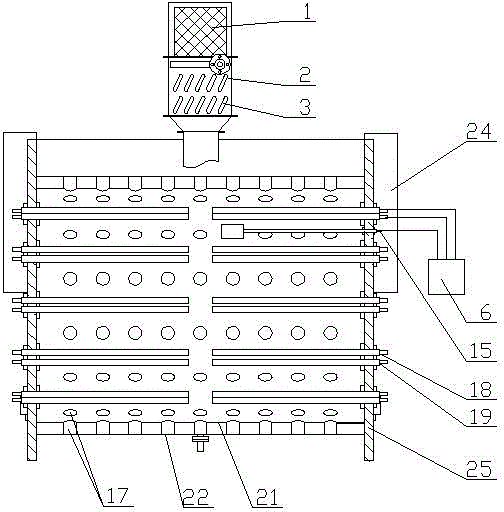

Temperature-controlled heat-conducting oil down drying machine

InactiveCN102878785AReasonable structureImprove loftDrying solid materialsDrying machines with non-progressive movementsAir preheaterHeat conducting

The invention relates to a temperature-controlled heat-conducting oil down drying machine, wherein the interlayer of a barrel body of the down drying machine is filled with heat-conducting oil; a plurality of temperature sensors are distributed in the heat-conducting oil uniformly; a plurality of groups of electric heating tubes are arranged in the interlayer of the barrel body uniformly; sieve plates are arranged on the end covers of the left end and the right end of the barrel body respectively; air tanks are arranged outside the sieve plates; an air flue is connected between the left air tank and the right air tank; an air inlet and a suction opening are connected in the middle of the air flue through a four-way reversing valve; the air inlet is sequentially connected with an air preheater and a fan cover; a radiator connected with the inner cavity of the barrel body is arranged outside the air preheater; air is heated through external heat source; the suction opening is sequentially connected with a dehumidifying draft fan and a driving motor I of the dehumidifying draft fan; a humidity sensor is arranged at the suction opening; and the motor I, the humidity sensor, the electric heating tubes and the temperature sensors are respectively connected with a programmable logic controller (PLC).

Owner:徐州腾宇羽绒制品设备有限公司

Method for preparing bamboo charcoal fiber fabric for home textiles

ActiveCN104294402AGood flexibilityImprove loftSucessive textile treatmentsWoven fabricsYarnPolymer science

The invention relates to a method for preparing textiles and in particular relates to a method for preparing a bamboo charcoal fiber fabric for home textiles. The method comprises the following steps: preparing bamboo charcoal micro powder emulsion, namely adding a dispersing agent and bamboo charcoal micro powder into deionized water, stirring, thereby obtaining uniformly dispersed bamboo charcoal micro powder emulsion, wherein the concentration of the bamboo charcoal micro powder is 50-80g / L, and a weight ratio of the dispersing agent to the bamboo charcoal micro powder is (6-9):100; preparing viscose; preparing bamboo charcoal fiber yarns, namely mixing the viscose and the bamboo charcoal micro powder emulsion to be uniform according to a weight ratio 100:(20-30), and feeding the yarns into a spinning machine to prepare the bamboo charcoal fiber yarns; preparing a gray fabric, comprising the sub-steps of spinning, warping, slashing, weaving, performing fabric after-treatment, scotching, dehydrating, drying and sewing, wherein cotton fibers are adopted in the warp direction during spinning, and modal fiber or covered spandex yarns and bamboo charcoal fiber yarns are adopted in the weft direction; and performing jacquard weave, comprising primary loose drying, cutting velvet, performing secondary loose drying and manufacturing overprinted pattern screen. The bamboo charcoal fiber fabric for home textiles prepared by the method is high in softness and antibacterial activity.

Owner:江苏宜妆生物科技有限公司

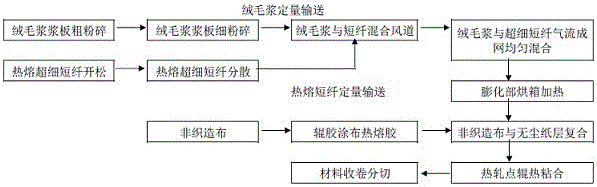

Integrally-formed low-gram-weight composite air-laid paper

ActiveCN106012309AImprove drynessMeet the strength requirements of high-speed productionNon-woven fabricsAdhesivesComing outSurface layer

The invention relates to integrally-formed low-gram-weight composite air-laid paper. A low-gram-weight air-laid paper layer prepared from fluff pulp and superfine hot-melting staple is arranged on the surface layer of the air-laid paper, and a non-woven cloth layer prepared from hot-melting chemical fiber is arranged on the bottom layer of the air-laid paper. Fluff pulp boards are roughly smashed and fine smashed for fiber decomposition to form fluff pulp fiber, the fluff pulp fiber and the superfine hot-melting staple are quantitatively and uniformly sprayed on a net band, and the superfine hot-melting staple and the fluff pulp fiber are subjected to heat bonding through an oven air duct to form the low-gram-weight air-laid paper layer; the non-woven cloth layer is subjected to glue applying or directly compounded with the air-laid paper layer coming out of the oven air duct to form the low-gram-weight composite air-laid paper. According to the low-gram-weight composite air-laid paper, the heat bonding of the air-laid paper layer and the non-woven cloth layer is achieved through hot pressing points or ultrasonic waves. Due to integrally-formed composite non-woven cloth, the strength of the composite air-laid paper is much higher than that of traditional air-laid paper, and the strength requirement for air-laid paper materials during high-speed production on a moisture-absorption article device is met.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

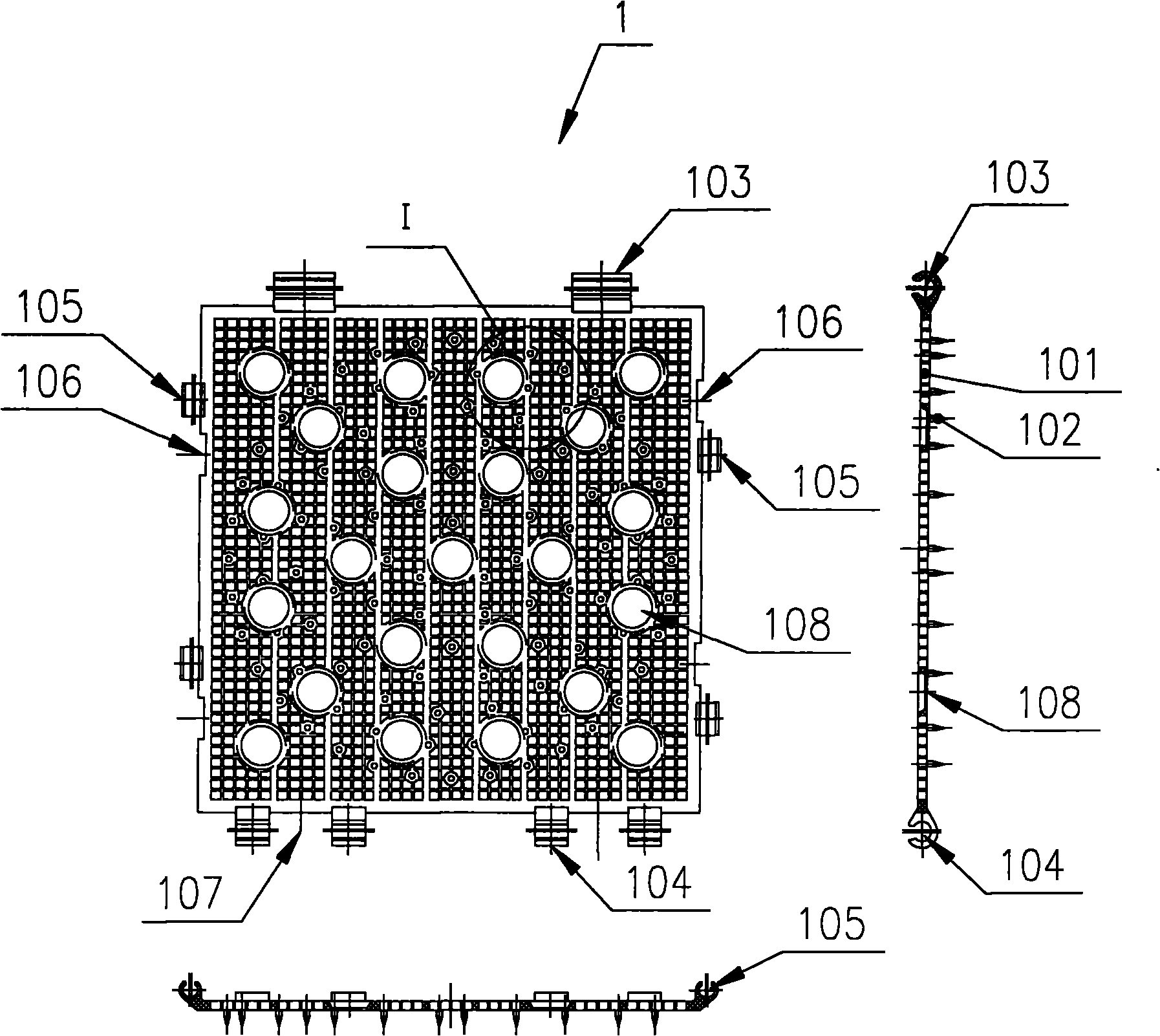

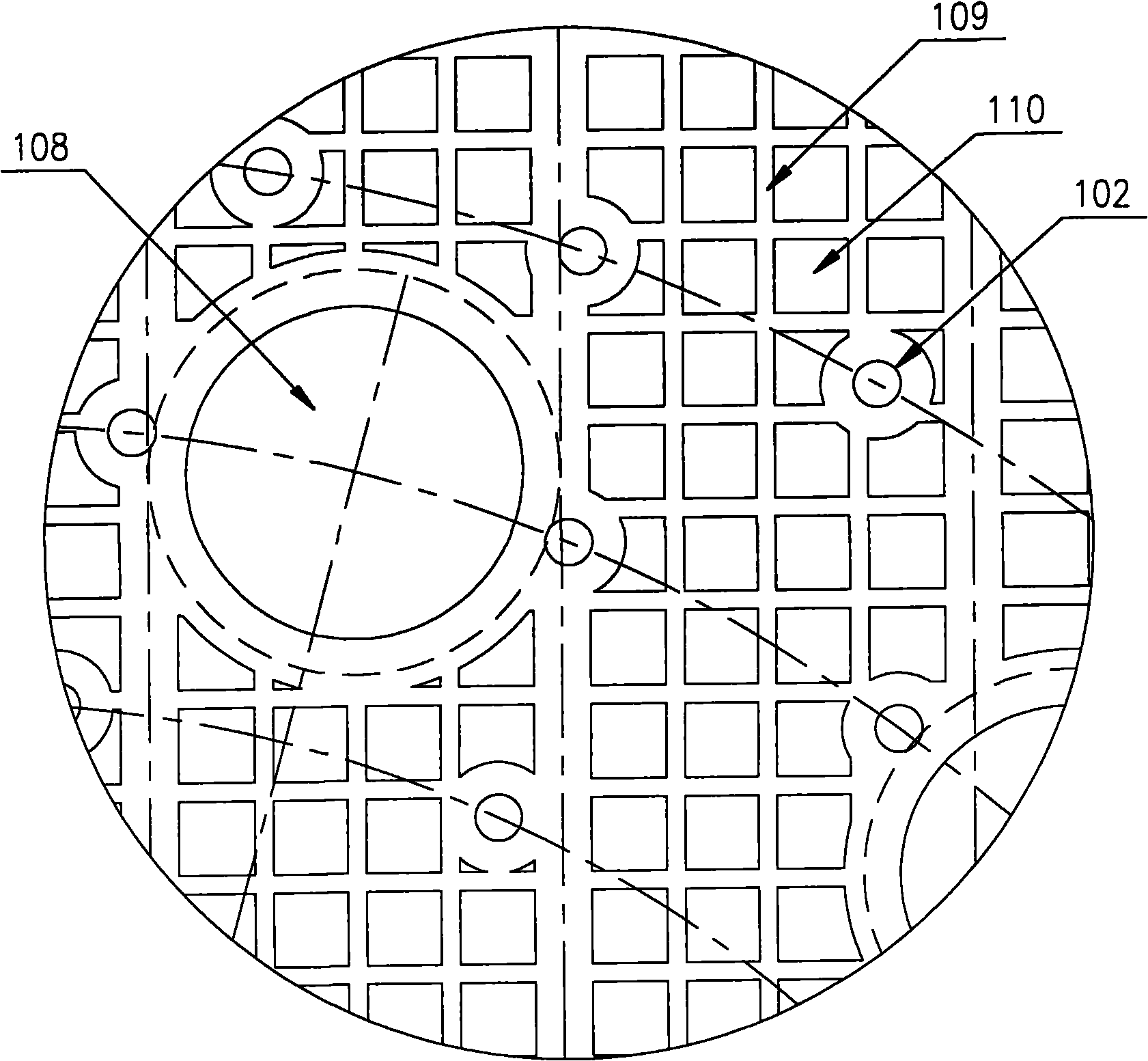

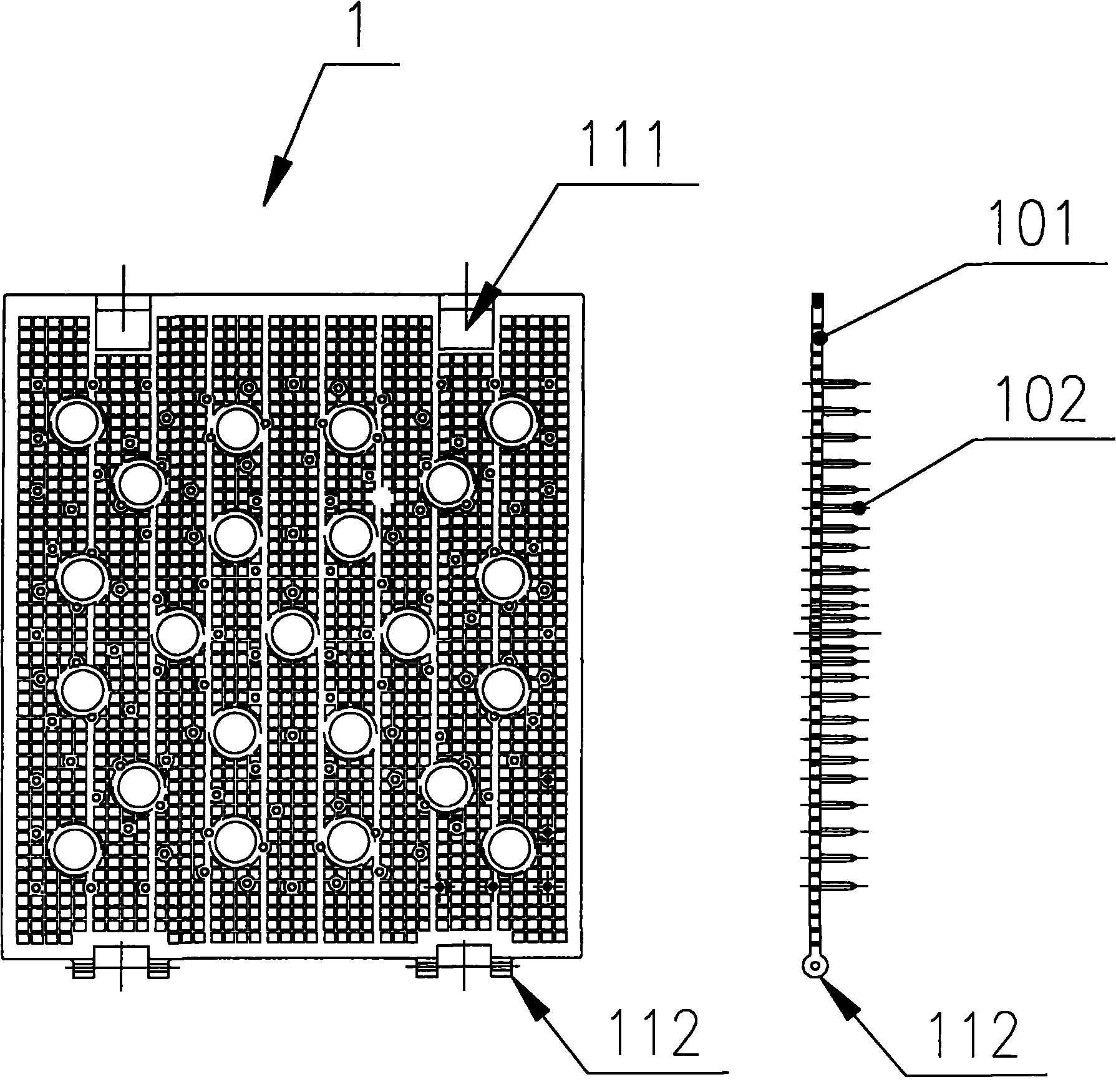

Needle curtain sheet and seaweed or vegetable cake making device provided with same

ActiveCN102038227ASimple structureStrong adhesionFood preparationVegetable processingMachining process

The invention provides a needle curtain sheet (1) for seaweed or vegetable processing equipment. The needle curtain sheet (1) comprises a curtain sheet body (101) and needles (102) which are arranged on the curtain sheet body (101), wherein the curtain sheet body (101) is provided with a first through hole (110) and a second through hole (108), and connecting pieces (103, 104 and 105) which are connected with a curtain frame (2). The needle curtain sheet has a simple structure and high adhesion; and the needles, the curtain sheet body and the connecting pieces can be integrally manufactured, so the needle curtain sheet can be formed at one time by a die pressing method. The needle curtain sheet is used in a seaweed or vegetable cake making device, so that the condition that a vegetable cake accidentally falls off during processing is obviously reduced and even basically eliminated, yield and production efficiency are improved, and raw material loss and energy consumption are reduced.

Owner:连云港市赣榆区知识产权维权援助中心(连云港市赣榆区知识产权保护与服务中心)

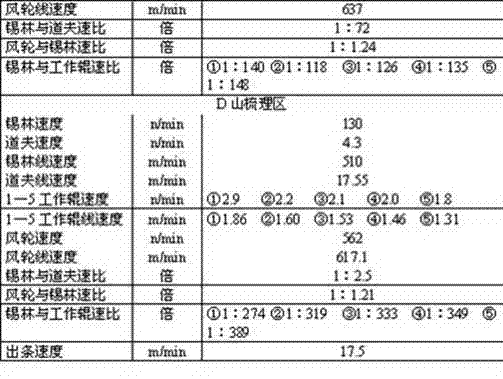

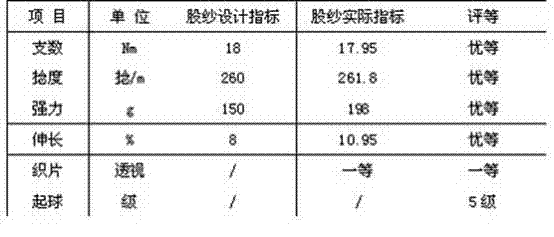

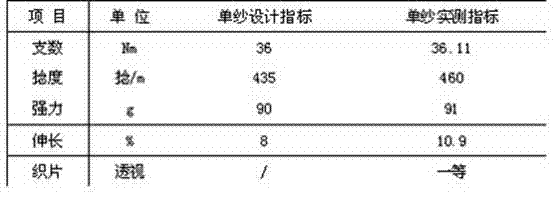

Cashmere-Apocynum venetum roving blended yarn and production method thereof

The invention relates to cashmere-Apocynum venetum blended yarns. The number of roving yarns is 28-36Nm, and the raw material proportioning is as follows: 30% of Apocynum venetum and 70% of cashmere, wherein the twist degree is 380 / 230-435 / 260 twist / m, the strength is 100 / 160-90 / 150g, and the elongation at break is 8%. The production method for the yarns comprises the steps of extracting and fine-combing the Apocynum venetum and then blending the treated Apocynum venetum with the cashmere; the Apocynum venetum extracting process comprises the steps of carrying out Aapocynum venetum peeling, impurity removing, biological enzyme degumming, water washing, drying, oiling, drying on Apocynum venetum stalks, and then obtaining refined dry Apocynum venetum; the Apocynum venetum fine-combing process comprises the following steps of carrying out nourishing, opening and slivering on the refined dry Apocynum venetum, and then obtaining fine-combing apocynum venetum; and the cashmere-Apocynum venetum blending process comprises the steps of carrying out blending oiling, nourishing, combing, spinning, spooling, doubling and double-twisting on the Apocynum venetum and cashmere fiber, to obtain finished products.

Owner:宁夏嘉源绒业集团有限公司

High-density microfiber wiping cloth and processing method thereof

InactiveCN103126625AHigh liquid absorption and retention rateFluffiness is goodCarpet cleanersFibre typesPolyesterMicrofiber

The invention discloses a high-density microfiber wiping cloth and a processing method thereof. The wiping cloth contains polyester and nylon composite filament, the splitting rate of which is more than 80% and filament number of which is from 0.01 dtex to 0.6 dtex, and the polyester and nylon composite filament is 20%-100% of the wiping cloth in weight. According to JIS1096826IA, the ventilation capacity of the wiping cloth is less than 50cm3 / cm2 / sec. The wiping cloth has the advantages of comfortable feeling, density, high fluid suction and fluid keeping, no harm to surface and high wiping performance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

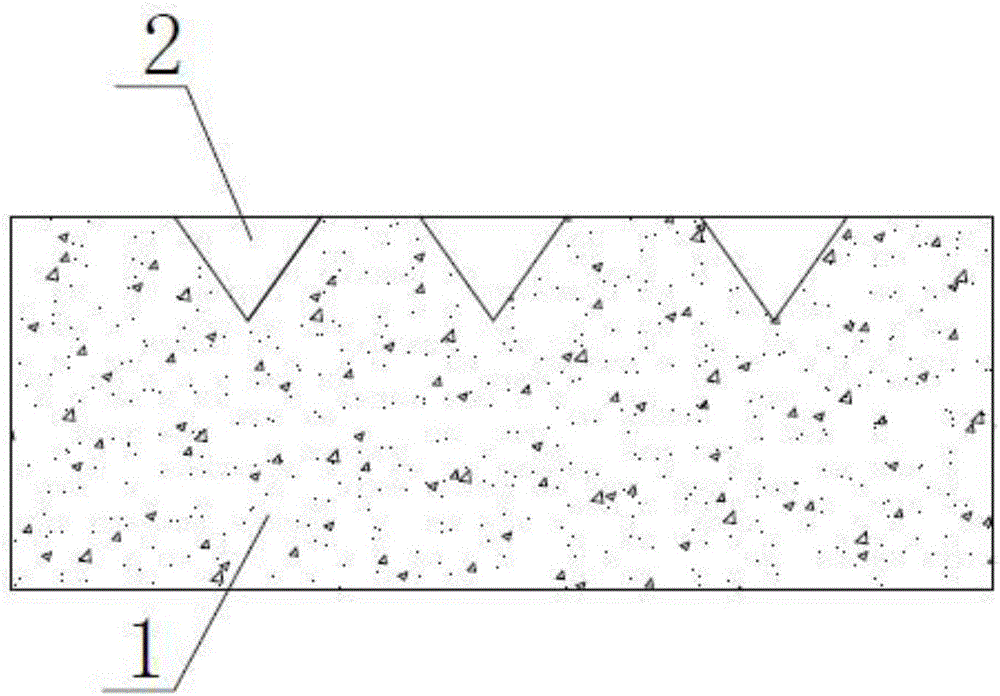

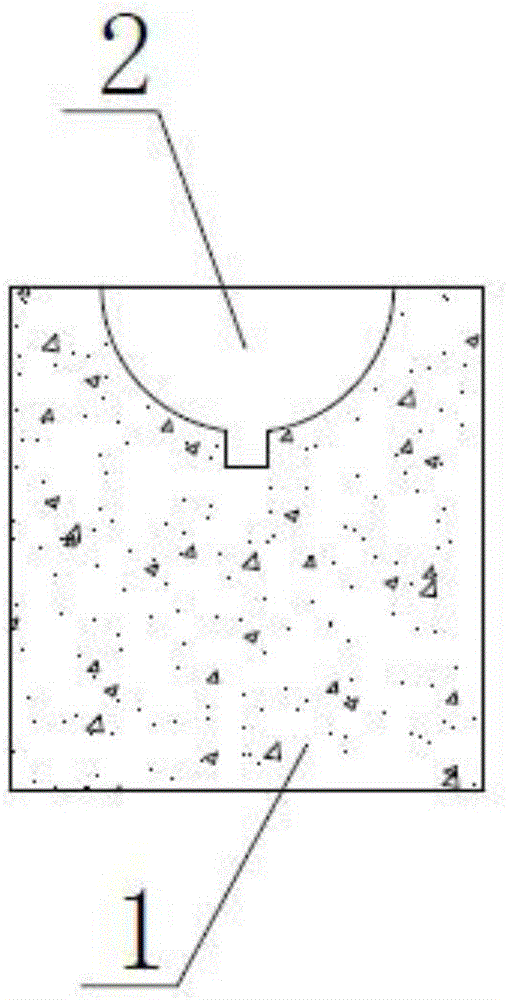

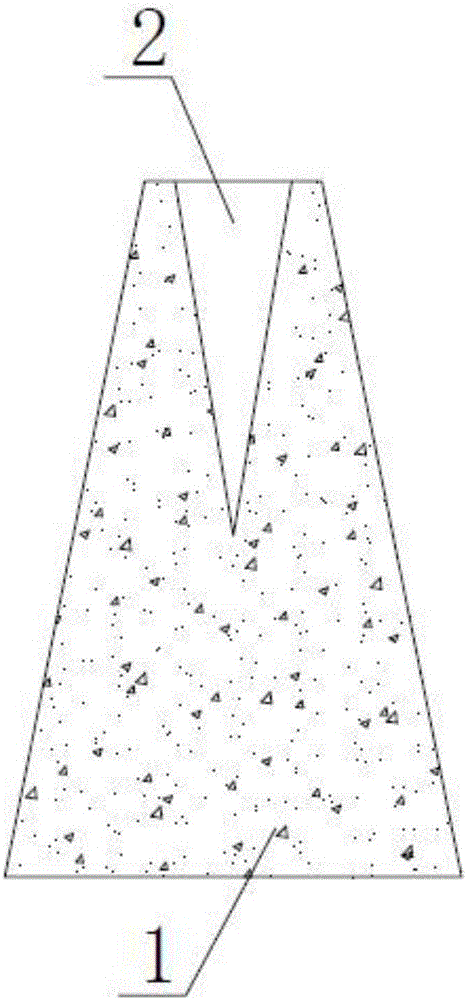

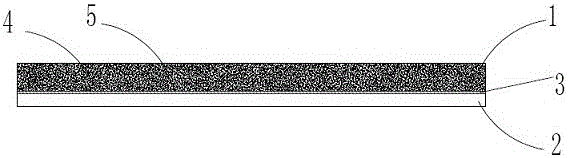

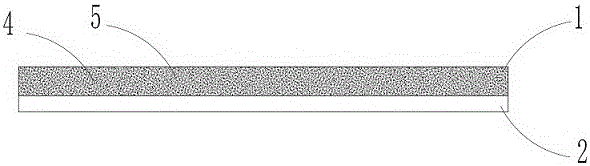

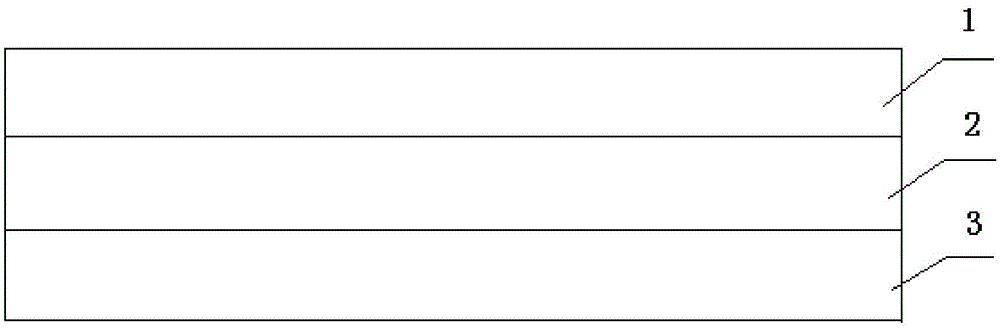

Layered structure filler and preparation method thereof

The invention provides layered structure filler which comprises first fiber wadding (1) and second fiber wadding (2) combined to the first fiber wadding (1). Through layered arrangement of the fiber wadding, the filler has excellent bulkiness and thermal insulation property, and independent and flexible layering and diversified combination of different composition fibers can be realized. A result shows that the provided layered structure filler is 1-10 cm thick and has a clo value larger than or equal to 5.0.

Owner:浙江名阁家纺有限公司

Production process for bamboo charcoal polyester staple fibre

InactiveCN102517686ARealize resource reuseReduce manufacturing costFilament forming substance formingArtificial filament heat treatmentPolyesterPolyethylene terephthalate glycol

The invention discloses a production process for a bamboo charcoal polyester staple fibre. In the production process, regenerative PET (Polyethylene Terephthalate) material is used as the material, and the finished product is acquired by pre-treating, rotary drum drying, melt spinning, cooling and forming, winding, drafting, curling, oil applying, thermosetting and cutting-off in sequence, wherein the rotary drum drying comprises the steps of firstly drying the regenerative PET material for 5.5h-6.5h and then adding bamboo charcoal master batches with the final mass fraction of 6%-8% and including bamboo charcoal with the mass fraction of 22%-27%; and the total drying time is 9.5h-10.5h; both the screw rod and the spinning beam of a screw extruder in the melt spinning step are at the temperature from 278 DEG C to 282 DEG C; cooling forming is realized through circular air blow, the temperature of the circular air is 22 DEG C to 26 DEG C, and the air velocity of the circular air is 4.0m / s-5.0m / s; the total draft multiple is 3.1-3.3 times; and the thermosetting temperature is 162 DEG C to 168 DEG C, and the thermosetting time is 13 minutes to 17 minutes. The production process can save the cost and is helpful for environmental protection; the produced product has a better smooth and comfortable hand feeling and moisture-absorption air permeability than those of a normal polyester staple fibre.

Owner:HANGZHOU BEST CHEM FIBER

Composite undertwisted yarn towel and production method thereof

The invention belongs to the field of textile products, and particularly provides a composite undertwisted yarn towel and a production method thereof. The composite undertwisted yarn towel is composedof terry yarn, body warp and weft, the body warp and the weft are normal towel yarn, the terry yarn is composite undertwisted yarn, the composite undertwisted yarn is formed by two kinds of different-thickness yarn, spun yarn is synthetic fiber staple fiber yarn or filament yarn thereof, rough yarn is pure cotton yarn or blended yarn of pure cotton and other yarn, the composite undertwisted yarnis subjected to beaming and slashing to form a warp beam, the warp beam is interwoven with the body warp and the weft through a terry cloth loom or warp knitting machine to form terry cloth in a weaving manner, through dyeing and finishing processing and sewing procedures, the composite undertwisted yarn towel is manufactured, compared with an untwisted yarn towel formed by a traditional PVA twisting and untwistingmethod, composite untwisted yarn has the similar hand softness and the similar appearance style, and however, the composite untwisted yarn has the advantages of being lower in feather shedding rate and more durable, so that the weaving efficiency can be obviously improved.

Owner:LOFTEX CHINA LTD

High-speed strong dehydration cylinder paper making machine

ActiveCN104727182AGuaranteed dehydration rateImprove sealingMachine wet endPress sectionEconomic benefitsEnergy conservation

The invention relates to the field of paper making machinery, in particular to a high-speed strong dehydration cylinder paper making machine. The cylinder paper making machine comprises a rack, a woolen blanket optimizing mechanism, a coucher mechanism, a mesh cage mechanism, a carrier roller mechanism, a drying cylinder mechanism and a woolen blanket, wherein the carpet circularly rotates via the woolen blanket optimizing mechanism, the coucher mechanism, the mesh cage mechanism and the carrier roller mechanism sequentially, a pressing roller is arranged at the right side of the mesh cage mechanism, and after passing the coucher mechanism, and the woolen carpet is pressed by the pressing roller to be tightly attached to the mesh cage mechanism to rotate; the mesh cage mechanism is a cylinder paper making machine suction negative-pressure mesh cage; the carrier roller mechanism includes a carrier roller pressurization mechanism and a cylinder paper making machine special three-suction area vacuum carrier roller. According to the high-speed strong dehydration cylinder paper making machine, the whole vehicle speed can be obviously accelerated, the energy input is saved, and the production efficiency is obviously improved; meanwhile, the filling power and the water-absorbing performance of a paper product are better, the additional valve of the product is increased, and more economic benefit is made for an enterprise.

Owner:河南兄弟实业有限公司

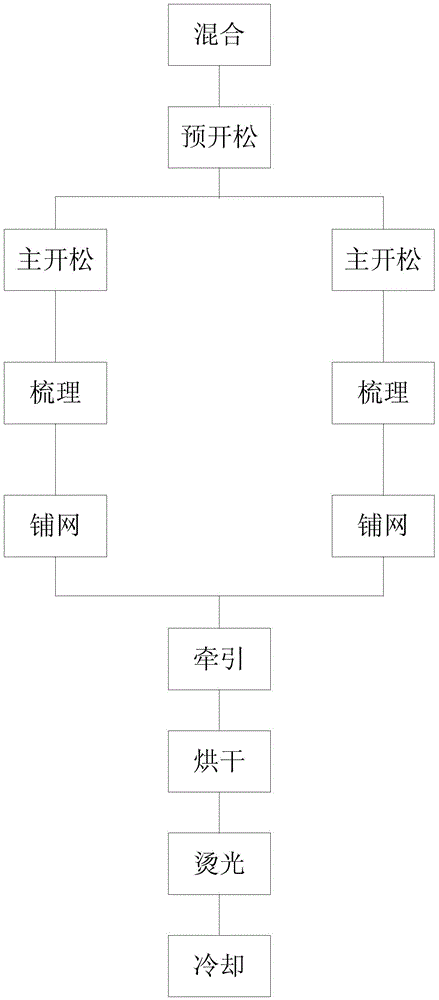

Manufacturing process of fluffy non-woven fabrics

The invention discloses a manufacturing process of fluffy non-woven fabrics. The manufacturing process comprises the following steps: a, opening and mixing curly hollow fibers and low-melting-point complex fibers; b, combing the above opened and mixed fibers to form a fiber web; c, performing hot wind penetrating bonding on the fibers; d, and rolling up. The beneficial effects of the manufacturing process of fluffy non-woven fabrics are that through the above steps, the curly hollow fibers and low-melting-point complex fibers can be fully mixed, and the fiber web which is firm in bonding is formed, and the obtained fluffy non-woven fabrics is advantaged by good filling power, high elasticity, and high porosity, and the fluffy non-woven fabrics has good permeable and water absorbing capability to satisfy application requirement, and the process is simple, material integrated cost is low, and production process is very environmentally friendly.

Owner:FOSHAN GOOD FEELING EISAI TECH CO LTD

Bird feather detergent and its producing method

InactiveCN1616626AResidue reductionReduce oxygen consumptionNon-ionic surface-active compoundsDry-cleaning apparatus for textilesCarboxymethyl celluloseAcetic acid

The bird feather detergent is produced through mixing water, EDTA disodium, sodium dodecyl benzene sulfonate, dodecanol polyoxyethylene ether, ethoxyl hendecyl carboxymethyl imidazoline, emulsifier NP and ethyl glycol acetate via stirring; adding sodium carboxymethyl cellulose aqua; and finally adding citric acid to regulate the pH to 5-6. The washed bird feather washed with the detergent has COD lower than 10 mg each 100g, cleanliness higher than 450 mm and fat residue rate lower than 1 %. The detergent has high defatting and detergence efficiency, less foam, antistatic effect, bird feather puffing and softening effect, low cost, convenient use, no toxicity and no environmental pollution.

Owner:YANGZHOU UNIV

Spun silk softening agent preparation method

The present invention discloses a spun silk softening agent preparation method, which comprises: 1) mixing 130 parts by mass of octamethyl tetrasiloxane and 43 parts by mass of polyethoxylated fatty alcohol, adding sodium hydroxide to adjust the pH value to 11, heating at a speed of 5 DEG C / min to achieve a temperature of 140 DEG C, carrying out a reaction for 8 h, cooling at a speed of 2 DEG C / min to achieve a temperature of 50 DEG C, and adding 24 parts by mass of ascorbic acid in a dropwise manner to adjust the pH value to 5 to obtain a first mixed solution; 2) obtaining a second mixed solution; 3) mixing the first mixed solution and the second mixed solution, adding sodium hydroxide to adjust the pH value to 11, heating to achieve a temperature of 90 DEG C, carrying out a reaction for 6 h, and cooling at a speed of 1 DEG C / min to achieve a room temperature; and 4) adding 1-2 parts by mass of ethylene glycol monostearate, 1 part by mass of hydroxypropyl methyl cellulose, 1 part by mass of sodium carbonate, 15 parts by mass of an amino silane coupling agent and 16 parts by mass of citric acid, and uniformly stirring to obtain the spun silk softening agent. The prepared spun silk softening agent is the non-ionic softening agent and has low environmental pollution, wherein the treated spun silk has characteristics of good bulkiness and good softness.

Owner:CHANGSHU MIAOQUAN SHENGDA AUX FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com