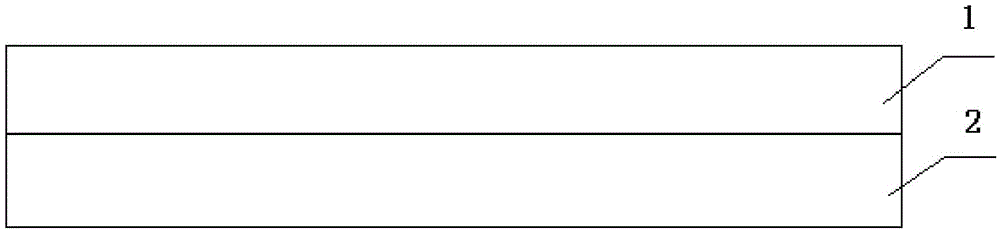

Layered structure filler and preparation method thereof

A layered structure and filler technology, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of independent layering defects of bulkiness and warmth retention fibers, and the inability to layer different fibers to achieve good bulkiness and warmth. The effect of warmth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

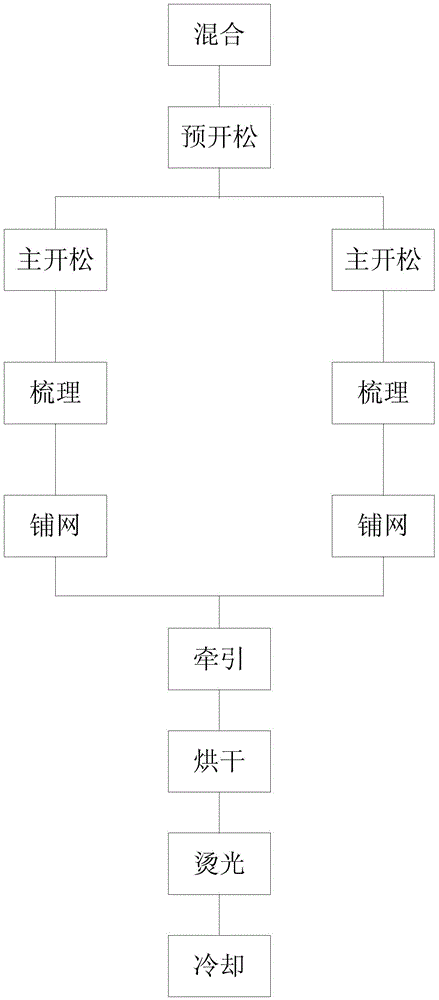

[0105] The present invention also provides a method for preparing the above layered structure filling, comprising the following steps:

[0106] A) mixing and stirring the fibers and pre-opening to obtain the first mixed fibers;

[0107] Mixing, stirring and pre-opening the fibers to obtain the second mixed fibers;

[0108] B) performing main opening, carding and laying of the first mixed fiber in sequence to obtain the first fiber flake precursor;

[0109] Performing main opening, carding and laying of the second mixed fibers in sequence to obtain a second fiber flake precursor, and laying on the first fiber flake precursor to obtain a layered structure filler precursor;

[0110] C) The layered structure filler precursor is sequentially drawn, dried, ironed and cooled to obtain a layered structure filler.

[0111] see image 3 , image 3 The process flow diagram for the preparation of the layered structure filler provided by the present invention. Specifically, in the pre...

Embodiment 1~28

[0200] Embodiments 1-28 are the preparation methods of two-layer structure fillers, specifically:

[0201] According to the raw material formula in Table 1, various baled fibers of different specifications used to prepare the first fiber flakes were uniformly stirred and mixed in a cotton mixing box according to a set ratio to obtain a mixed raw material.

[0202] The obtained mixed raw material is decomposed in the opener, so that the mixed raw material is in a fluffy state, no longer agglomerated, and the first mixed fiber is formed, and the first mixed fiber is transported to the next process through the cotton conveying fan .

[0203] At the same time, according to the raw material formula in Table 1, various baled fibers of different specifications used to prepare the second fiber flakes were uniformly stirred and mixed in the cotton mixing box according to the set ratio to obtain the mixed raw material.

[0204] The obtained mixed raw materials are preliminarily decompo...

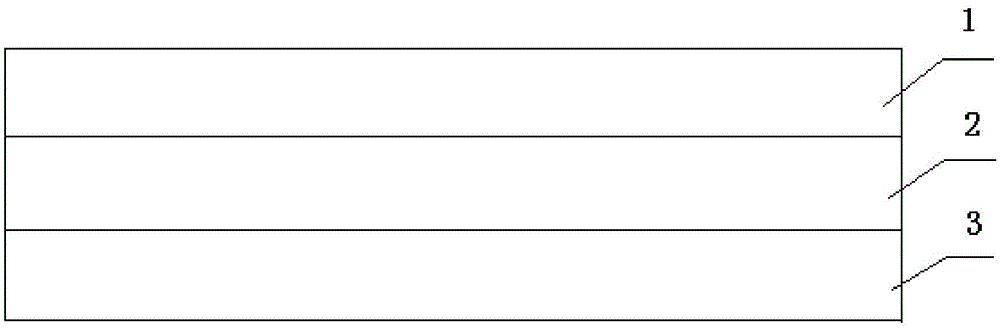

Embodiment 29~56

[0226] Examples 29-56 are the preparation methods of two-layer structure fillings, specifically:

[0227] According to the raw material formula in Table 3, various bundled fibers of different specifications used for preparing the first fiber flakes were uniformly stirred and mixed in a cotton mixing box according to a set ratio to obtain a mixed raw material.

[0228] The obtained mixed raw material is decomposed in the opener, so that the mixed raw material is in a fluffy state, no longer agglomerated, and the first mixed fiber is formed, and the first mixed fiber is transported to the next process through the cotton conveying fan .

[0229] At the same time, according to the raw material formula in Table 3, various baled fibers of different specifications used to prepare the second fiber flakes were uniformly stirred and mixed in the cotton mixing box according to the set ratio to obtain the mixed raw material.

[0230] The obtained mixed raw materials are preliminarily dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com