Composite undertwisted yarn towel and production method thereof

A production method and yarn twisting technology are applied to the composite low-twist yarn towel and its production field, which can solve the problems of water pollution and large consumption of vinylon, and achieve the effects of reducing hairiness, increasing the twist of whiskers, and eliminating the spinning triangle area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of composite low-twisted yarn towel and its production method

[0058] Take woven terry fabric as an example: the specific steps are as follows:

[0059] (1), the fiber selection of described composite low-twisted yarn: fine-count yarn 100% viscose fiber, thick-count yarn 100% cotton, wherein the viscose fiber adopts the trade name of 1.1dtexx38mm produced by Si Liya Group in Yibin, Sichuan Viscose fiber for Gracell.

[0060] (2), the coarse yarn yarn count of described composite low twist yarn is: 48.6tex, fine yarn 7.3tex;

[0061] (3), the twist of the coarse-count yarn of the composite low-twist yarn is: the twist coefficient is not higher than any twist corresponding to 295, the twist of the fine-count yarn is 130t / 10cm, and the twist direction of the coarse-count yarn and the fine-count yarn is both Z twist;

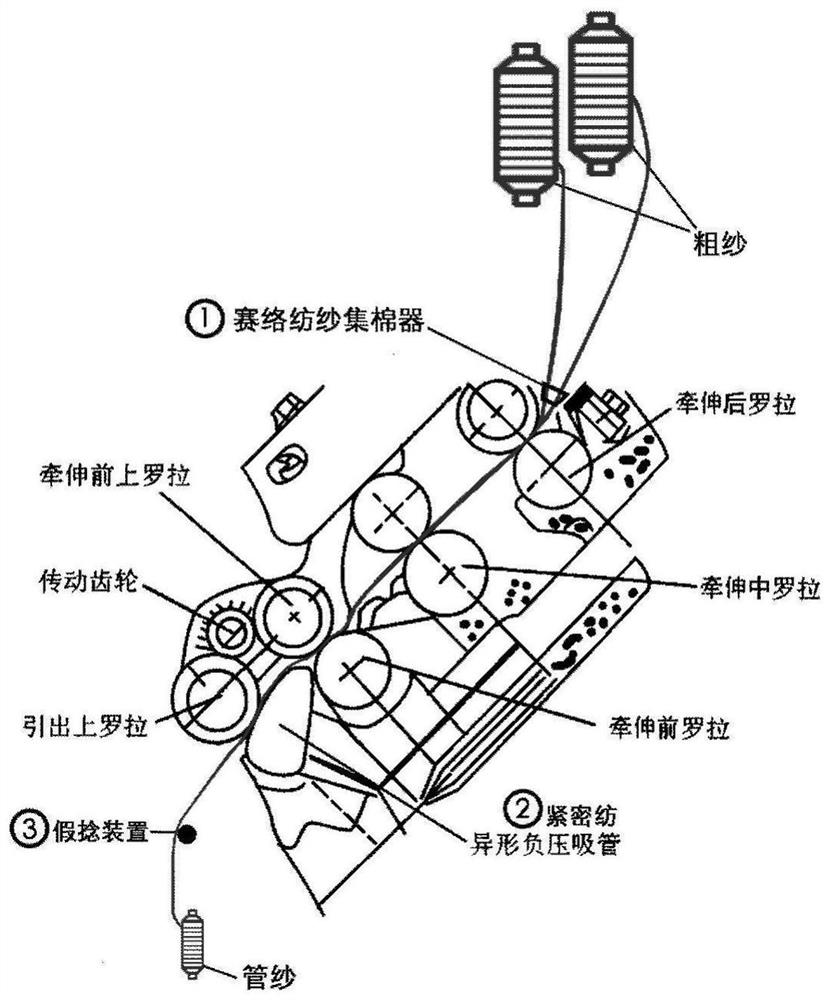

[0062] (4), the coarse count yarn of described composite low-twisted yarn is spun out on the spinning frame through reforming, as adopting Siro, c...

Embodiment 2

[0083] A kind of composite low-twisted yarn towel and its production method

[0084] Take woven terry fabric as an example: the specific steps are as follows:

[0085] (1), the fiber selection of described composite low-twist yarn: fine count yarn 100% modal fiber, and described modal fiber is the trade name LENZINGTM Modal produced by Austria Lenzing Company, and specification is the modal of 1.3dtex X38mm, coarse count yarn 100% cotton.

[0086] (2), the coarse yarn count of described composite low twist yarn is: 41.6tex, and fine count yarn is 7.3tex,

[0087] (3), the twist of the coarse-count yarn of the composite low-twist yarn is: the twist coefficient is not higher than any twist corresponding to 295, the twist of the fine-count yarn is 120t / 10cm, and the twist direction of the coarse-count yarn and the fine-count yarn is both Z twist.

[0088] (4), the coarse count yarn of described composite low-twisted yarn is spun out on the spinning frame through improvement or...

Embodiment 3

[0101] A kind of composite low-twisted yarn towel and its production method

[0102] Take woven terry fabric as an example: the specific steps are as follows:

[0103] (1), the fiber selection of described composite low-twisted yarn: 100% lyocell fiber of fine count yarn, wherein lyocell is the brand that Lenzing Company of Austria produces is LENZINGTM Lyocell A100, and specification is: 1.56dtex * 38mm, thick Count yarn 100% cotton.

[0104] (2), the thick yarn count of the composite low-twisted yarn is: 97.2tex, and the fine yarn count is 27.8tex,

[0105] (3), the twist of the coarse-count yarn of the composite low-twist yarn is: the twist coefficient is not higher than any twist corresponding to 295, the twist of the fine-count yarn is 120t / 10cm, and the twist direction of the coarse-count yarn and the fine-count yarn is both Z twist.

[0106] (4), the coarse count yarn of described composite low-twisted yarn is spun on the spinning frame through improvement or transfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Torsion | aaaaa | aaaaa |

| Torsion | aaaaa | aaaaa |

| Torsion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com