Modified resin composition and preparation method and application thereof

A technology of modified resin and composition, which is applied in the field of modified resin composition and its preparation, can solve the problems of limited application, adverse effects of resin material processability and heat resistance, large cracking of the punching edge of prepreg, etc., to achieve Excellent bonding performance, excellent mechanical properties, and low powder shedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

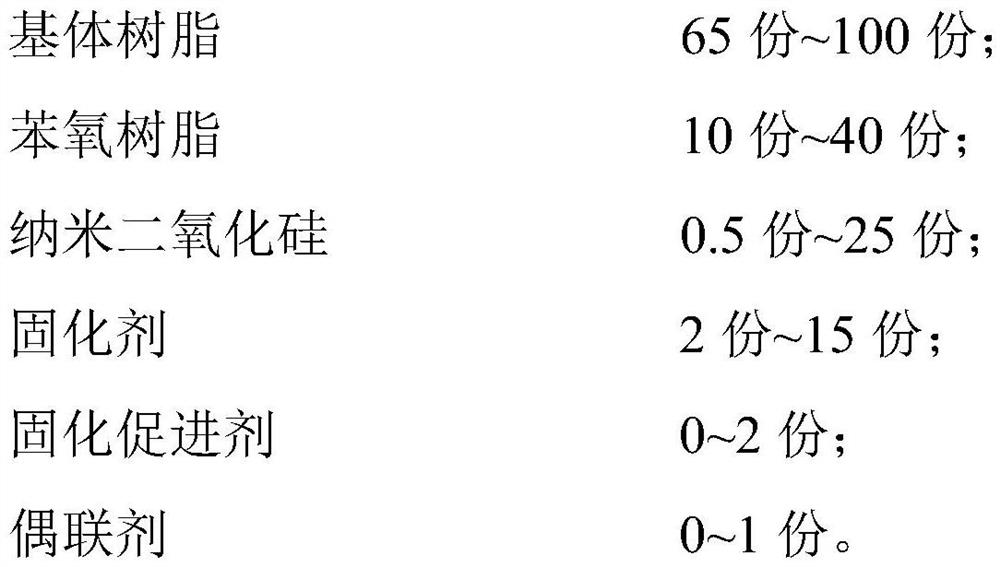

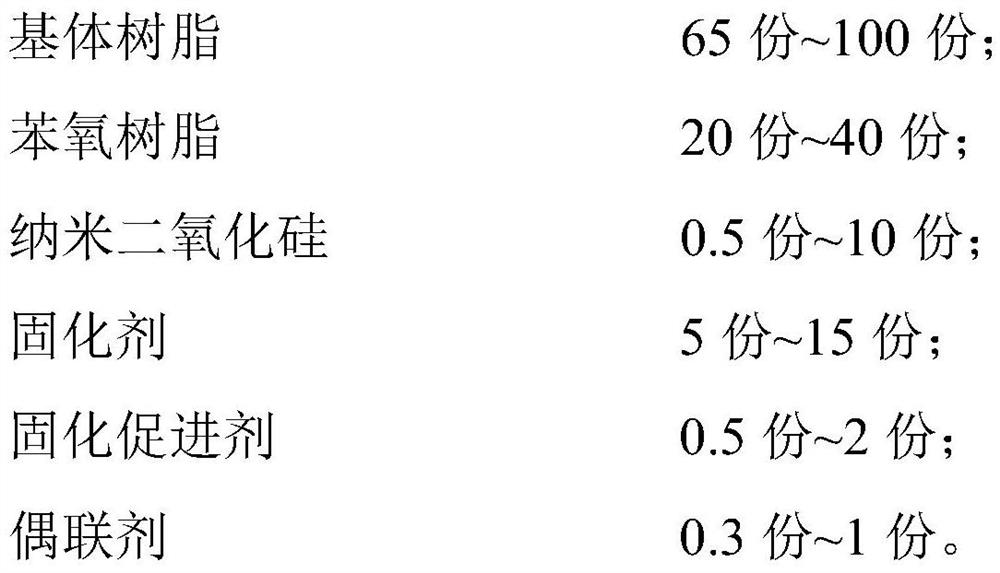

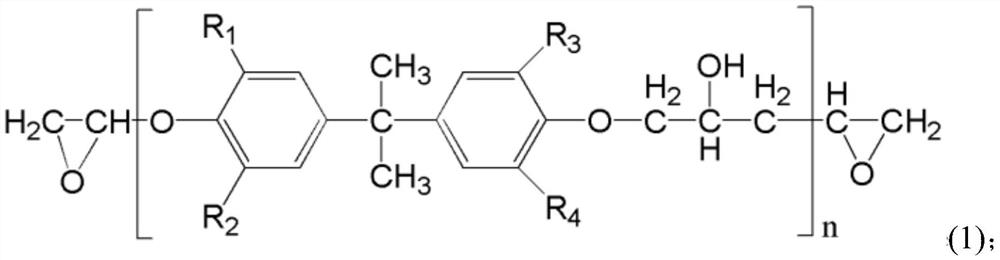

Method used

Image

Examples

Embodiment 1

[0087] 1) According to the number of parts by mass, in a dry four-necked flask equipped with a stirrer and a thermometer, add 0.3 parts of silane coupling agent, 100 parts of matrix resin (epoxy resin) and 3 parts of dimethylformamide, and stir at the same time Raise the temperature to 150° C., then add 0.5 parts of fumed nano-silica under stirring condition, keep the reaction for 2 hours, and cool to obtain nano-silica-modified epoxy resin.

[0088] 2) According to the number of parts by mass, after adding 5 parts of dicyandiamide and 100 parts of dimethylformamide into the batching bottle and fully stirring and dissolving, 10 parts of phenoxy resin, the nanometer dicyandiamide obtained in step 1) were sequentially mixed under stirring conditions. Add silicon oxide modified epoxy and 0.5 part of 2-methylimidazole into the batching bottle, stir evenly to prepare a glue.

[0089] 3) 1078 glass fiber cloth (basis weight 47.5g / m 2 ) placed in the glue solution obtained in step 2...

Embodiment 2

[0091] 1) According to the number of parts by mass, in a dry four-necked flask equipped with a stirrer and a thermometer, add 0.3 parts of silane coupling agent, 100 parts of matrix resin (epoxy resin) and 3 parts of dimethylformamide, and stir at the same time Raise the temperature to 150° C., then add 0.5 parts of fumed nano-silica under stirring condition, keep the reaction for 2 hours, and cool to obtain nano-silica-modified epoxy resin.

[0092]2) According to the number of parts by mass, after adding 5 parts of dicyandiamide and 100 parts of dimethylformamide into the batching bottle and fully stirring and dissolving, 40 parts of phenoxy resin, the nanometer dicyandiamide obtained in step 1) were sequentially mixed under stirring conditions. Add silicon oxide modified epoxy and 0.5 part of 2-methylimidazole into the batching bottle, stir evenly to prepare a glue.

[0093] 3) 1078 glass fiber cloth (basis weight 47.5g / m 2 ) placed in the glue solution obtained in step 2)...

Embodiment 3

[0095] 1) According to the number of parts by mass, in a dry four-necked flask equipped with a stirrer and a thermometer, add 0.3 parts of silane coupling agent, 100 parts of matrix resin (epoxy resin) and 3 parts of dimethylformamide, and stir at the same time Raise the temperature to 150° C., then add 25 parts of fumed nano-silica under stirring condition, keep the reaction for 2 hours, and cool to obtain nano-silica-modified epoxy resin.

[0096] 2) According to the number of parts by mass, after adding 5 parts of dicyandiamide and 100 parts of dimethylformamide into the batching bottle and fully stirring and dissolving, 10 parts of phenoxy resin, the nanometer dicyandiamide obtained in step 1) were sequentially mixed under stirring conditions. Add silicon oxide modified epoxy and 0.5 part of 2-methylimidazole into the batching bottle, stir evenly to prepare a glue.

[0097] 3) 1078 glass fiber cloth (basis weight 47.5g / m 2 ) placed in the glue solution obtained in step 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com