Patents

Literature

10051 results about "Nano silicon dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon dioxide nano particles are known as Nano Silica, it is also called Silica nano-particles. It is used particularly in the Biomedical researches.

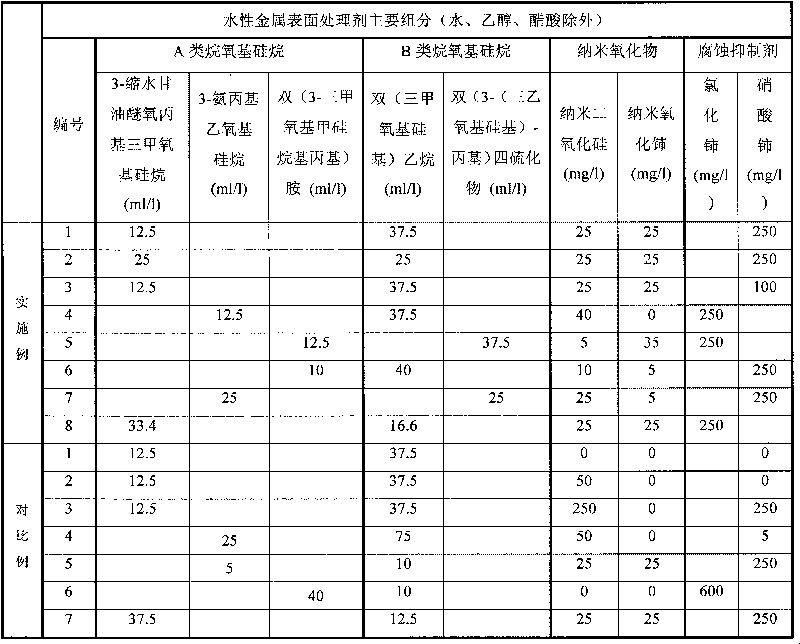

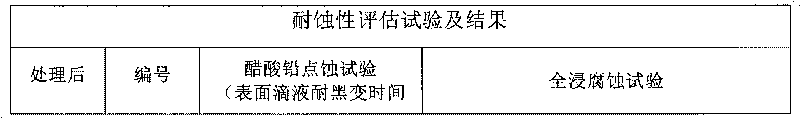

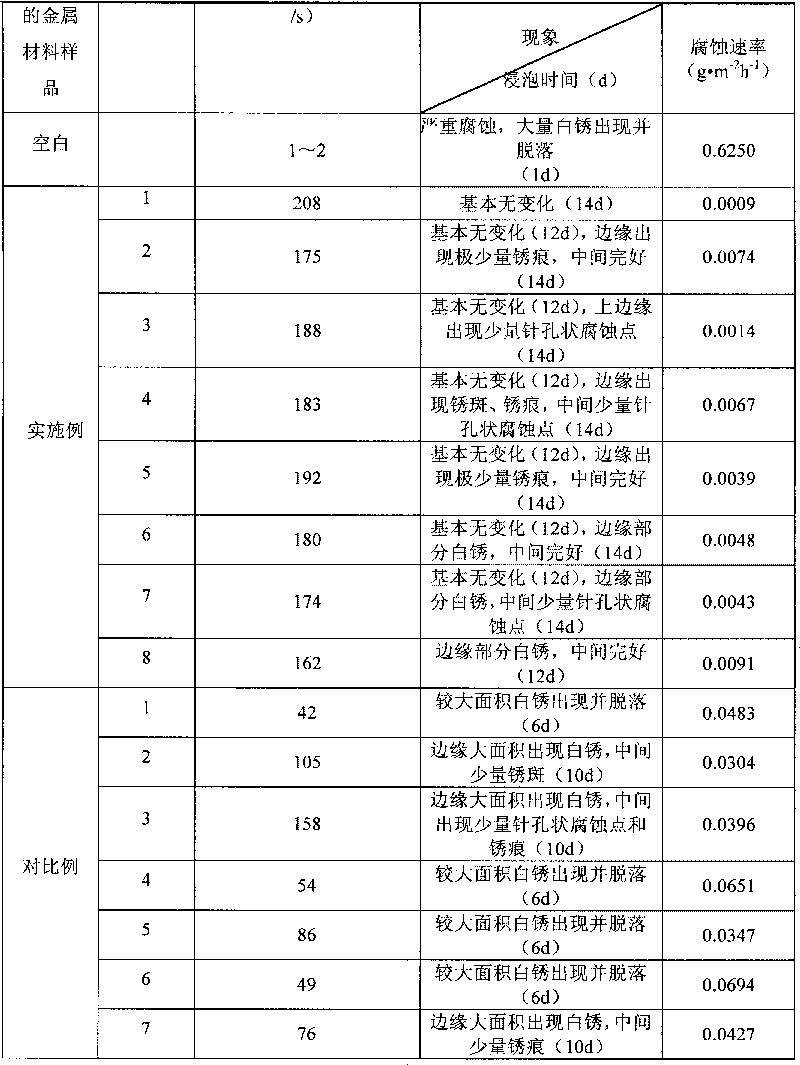

Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

ActiveCN101717930ASimple processApplicable industrial scaleMetallic material coating processesWater basedEpoxy

The invention discloses an environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface. The treatment agent is water-based silane solution which consists of at least one alkoxy silane containing epoxy or at least one alkoxy silane containing amino, at least one disilyl silane, nano-silicon dioxide, rare earth salt type corrosion inhibitor or rare earth salt type and rare earth nano oxide, water, or acetic acid and a small amount of ethanol. The metal material is coated by using the silane solution for impregnation, brushing, spraying or spin-coating, a siloxane layer is formed on the metal surface, then the long-acting corrosion resistance is formed by curing for 3 hours at the temperature of 100 DEG C, and a nano organic silane film which has close bonding force with a coating is formed. Nanoparticles can not only improve the corrosion resistance and enhance the mechanical strength of the silane film in a coating layer, but also realize the synergistic corrosion resistance with the corrosion inhibitor. The technology has the advantages of simple process, greenness, environmental protection and strong practicality.

Owner:HAISO TECH

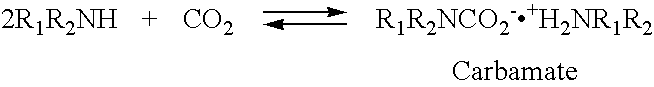

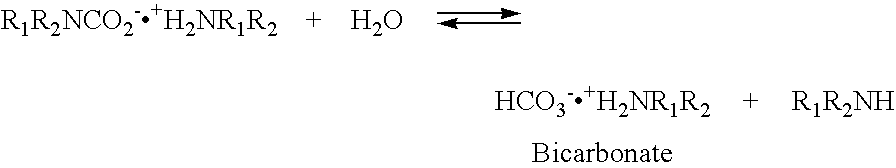

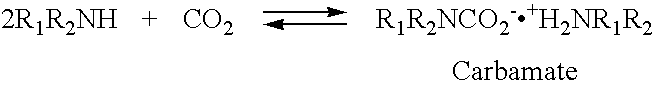

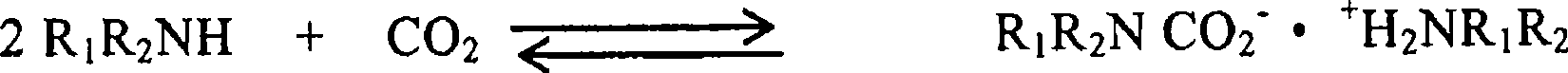

Nano-structure supported solid regenerative polyamine and polyamine polyol absorbents for the separation of carbon dioxide from gas mixtures including the air

ActiveUS20080293976A1Increased CO absorption capacityIncreased COMaterial nanotechnologyElectrolysis componentsPolyolSorbent

The invention relates to regenerative, supported amine sorbents that includes an amine or an amine / polyol composition deposited on a nano-structured support such as nanosilica. The sorbent provides structural integrity, as well as high selectivity and increased capacity for efficiently capturing carbon dioxide from gas mixtures, including the air. The sorbent is regenerative, and can be used through multiple operations of absorption-desorption cycles.

Owner:UNIV OF SOUTHERN CALIFORNIA

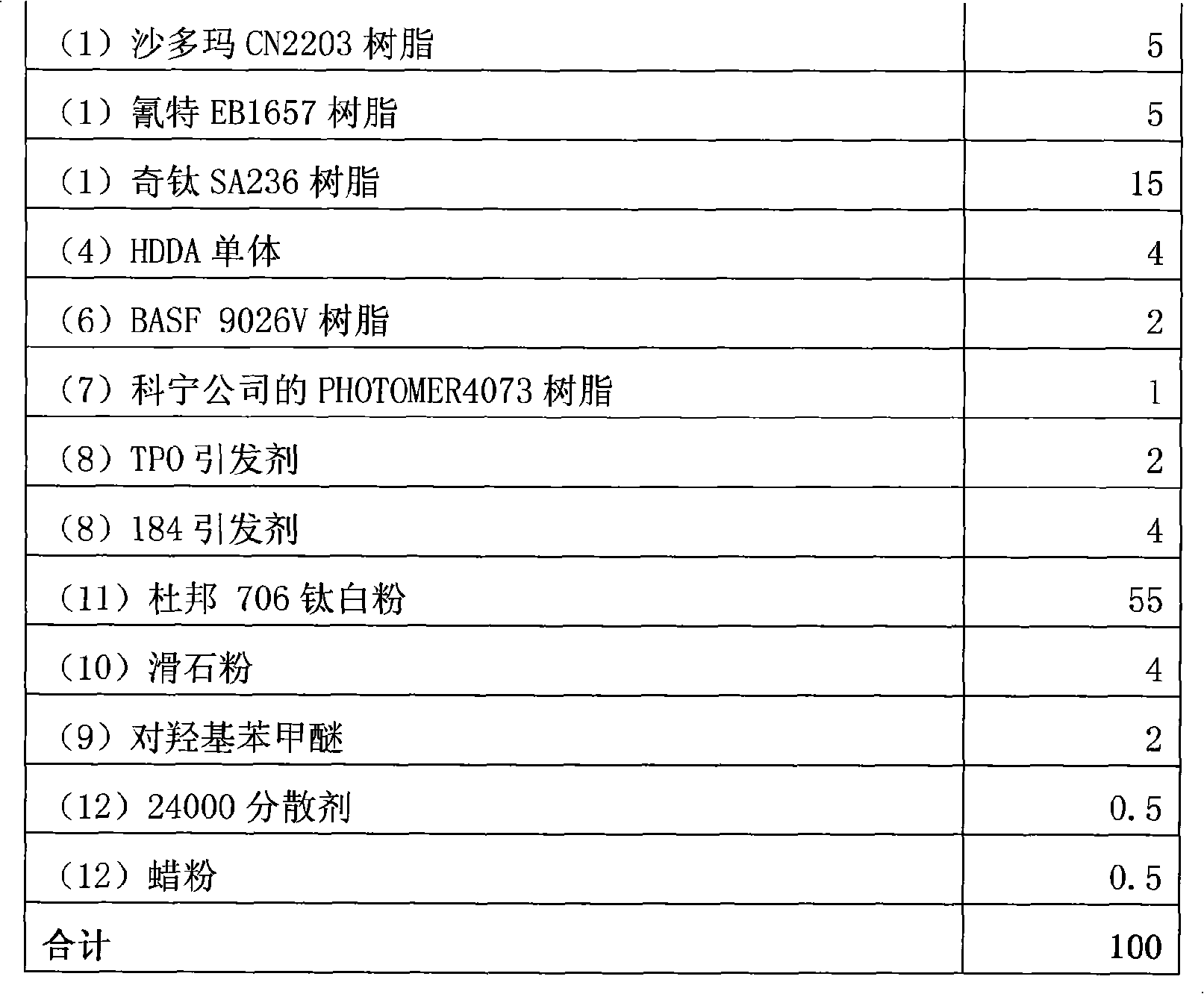

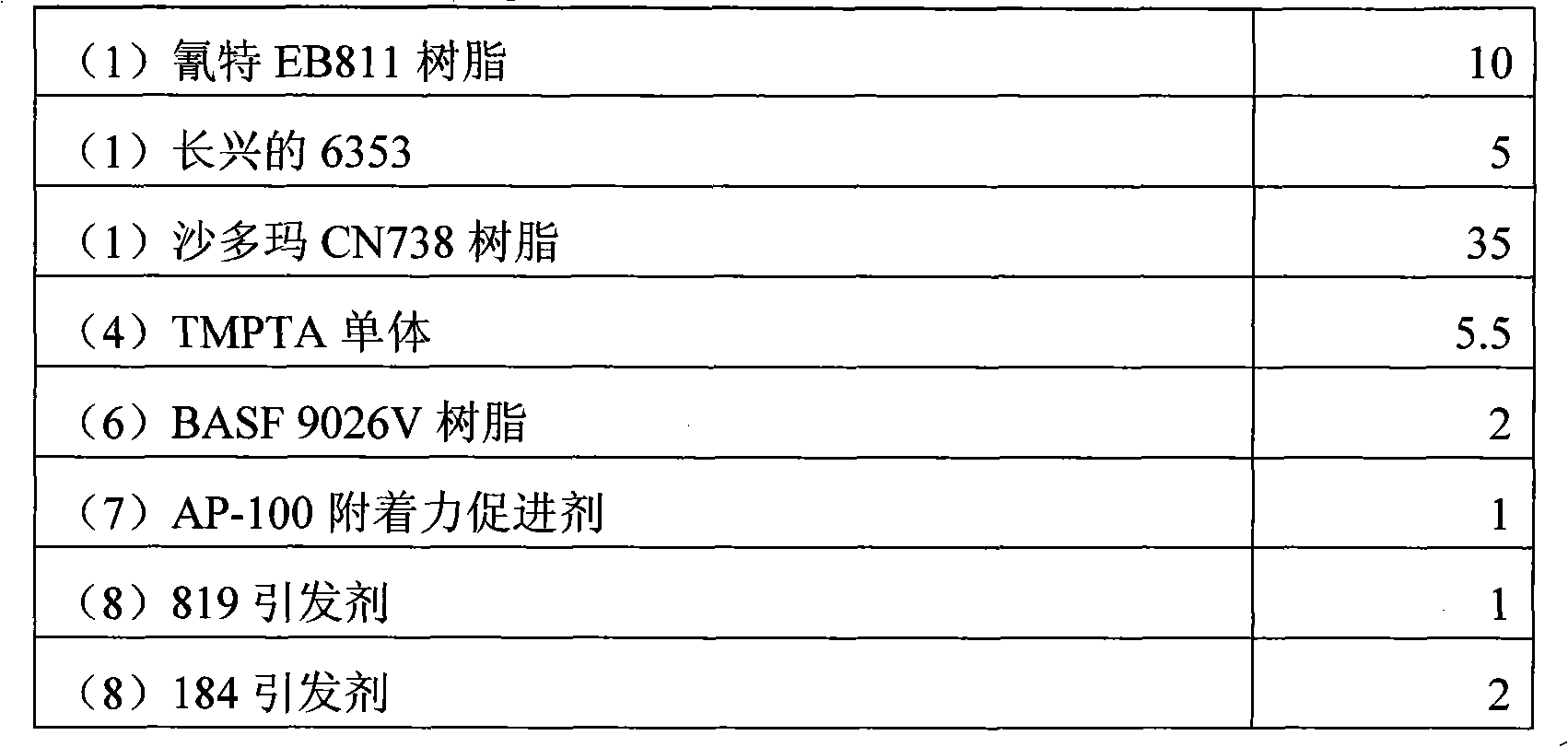

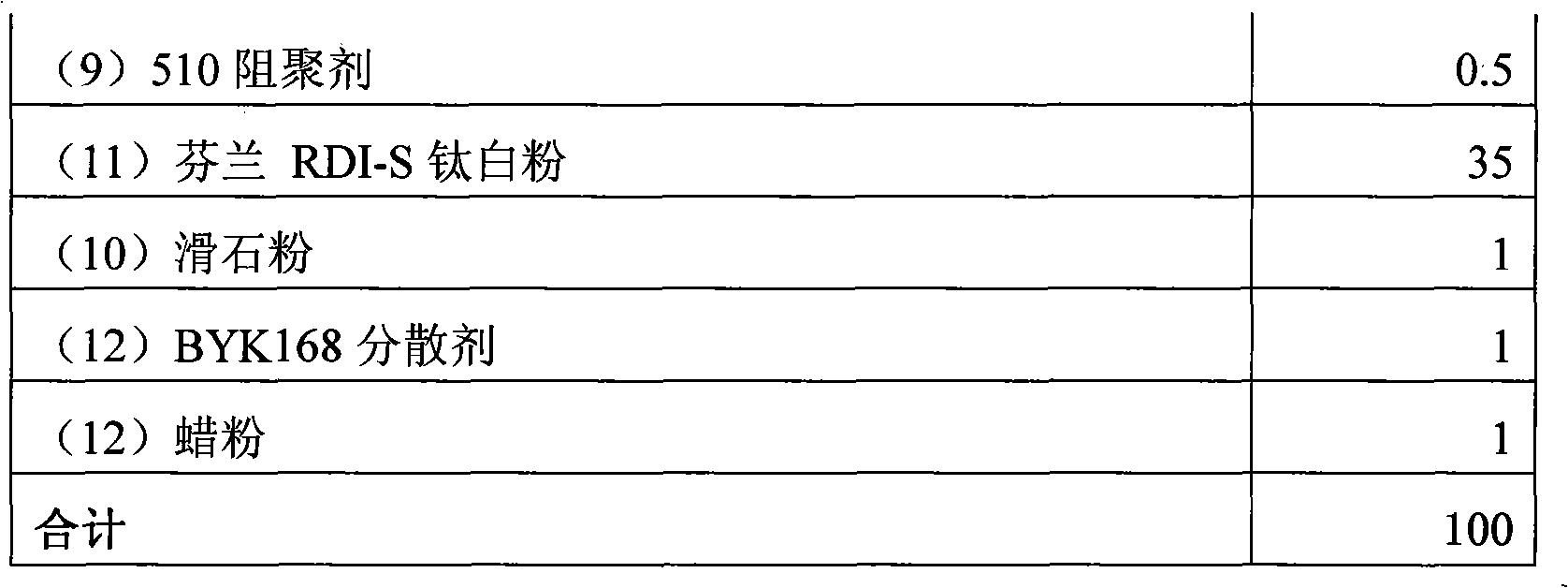

Ultraviolet light curing offset printing ink and preparation method thereof

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Nano-structure supported solid regenerative polyamine and polyamine polyol absorbents for the separation of carbon dioxide from gas mixtures including the air

The invention relates to regenerative, supported amine sorbents that includes an amine or an amine / polyol composition deposited on a nano-structured support such as nanosilica. The sorbent provides structural integrity, as well as high selectivity and increased capacity for efficiently capturing carbon dioxide from gas mixtures, including the air. The sorbent is regenerative, and can be used through multiple operations of absorption-desorption cycles.

Owner:UNIV OF SOUTHERN CALIFORNIA

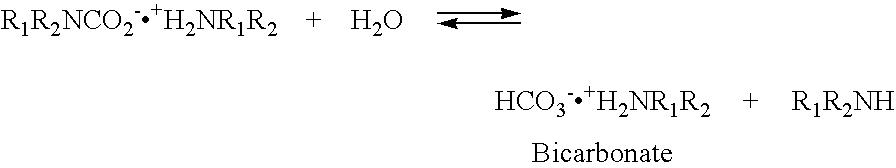

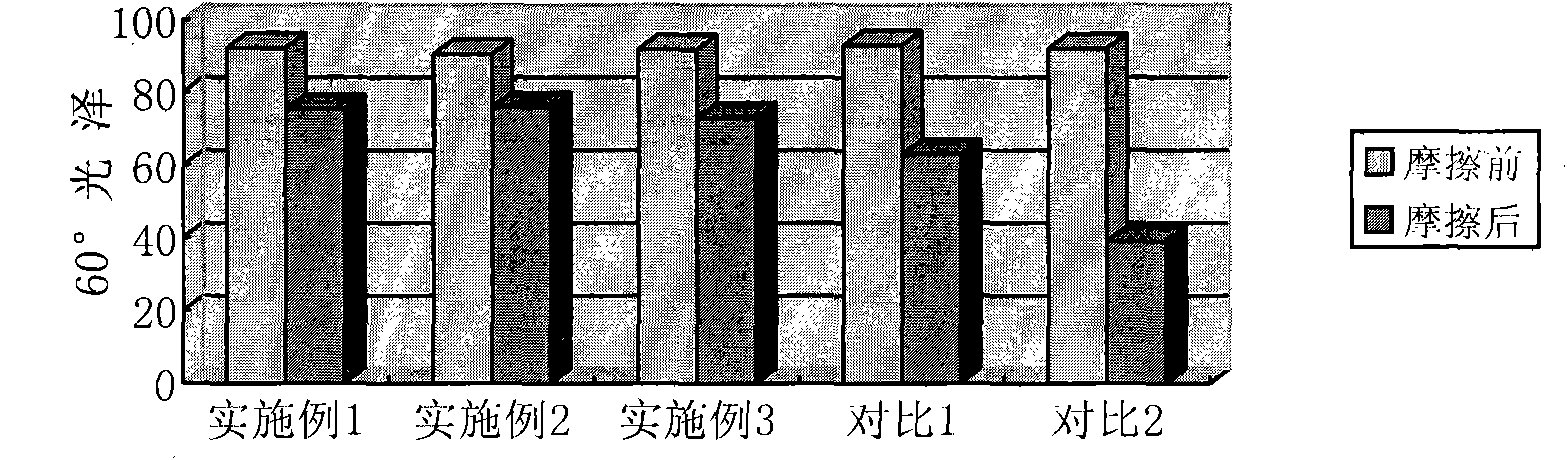

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

Nano-structure supported solid regenerative polyamine and polyamine polyol absorbents for the separation of carbon dioxide from gas mixtures including the air

Owner:UNIV OF SOUTHERN CALIFORNIA

Catalyst for production of 1,4-butynediol and preparation method of catalyst

ActiveCN102950014AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationBASIC CUPRIC CARBONATESlurry reactor

The invention discloses a catalyst for production of 1,4-butynediol and a preparation method of the catalyst, belongs to the field of catalyst research, more particularly relates to a load type catalyst for production of 1,4-butynediol in a slurry reactor and a preparation method of the catalyst. According to the method, nanosilicon dioxide which has a larger external specific surface is used as a carrier, copper and bismuth are attached to the carrier by adopting a settling and depositing method, the active components of the catalyst exist in a form of basic cupric carbonate, and the catalyst comprises the following components in percentage by mass: 20-50 percent of carrier, 35-70 percent of basic cupric carbonate and 2-15 percent of bismuth subcarbonate. The prepared catalyst has the characteristics of good activity and high selectivity and is easy to activate.

Owner:大连瑞克科技股份有限公司

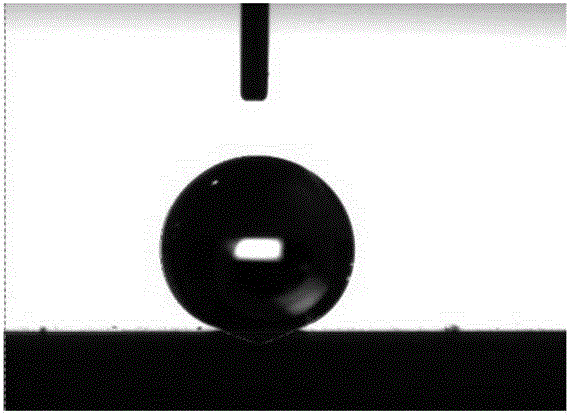

Fluorosilicone material for super-hydrophobic coating and its preparation method and use method

InactiveCN103224719ALower surface energyReduce usageCoatingsSpecial surfacesSilicon oxideSilicon dioxide

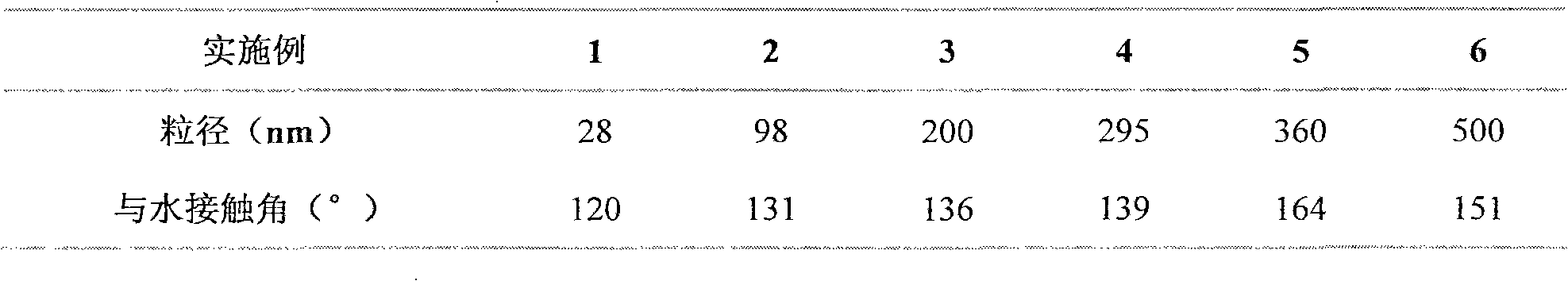

The invention relates to a fluorosilicone material for a super-hydrophobic coating and its preparation method and use method. The fluorosilicone material is prepared from fluorinated nano-silica and / or nano-titanium dioxide sol having two particle sizes. The fluorinated nano-silica or nano-titanium dioxide sol having the small particle size has the average particle size of 10 to 150nm. The fluorinated nano-silica or nano-titanium dioxide sol having the large particle size has the average particle size of 200 to 500nm. Through utilization of fluorine-containing siloxane in silica and / or titanium dioxide preparation, surface energy of the fluorosilicone material as a coating is effectively reduced. Through utilization of non-fluorinated dichlorodialkylsilane, coating surface hydrophily is partly reduced and a fluorine-containing silane use amount and a cost are reduced.

Owner:HUBEI UNIV

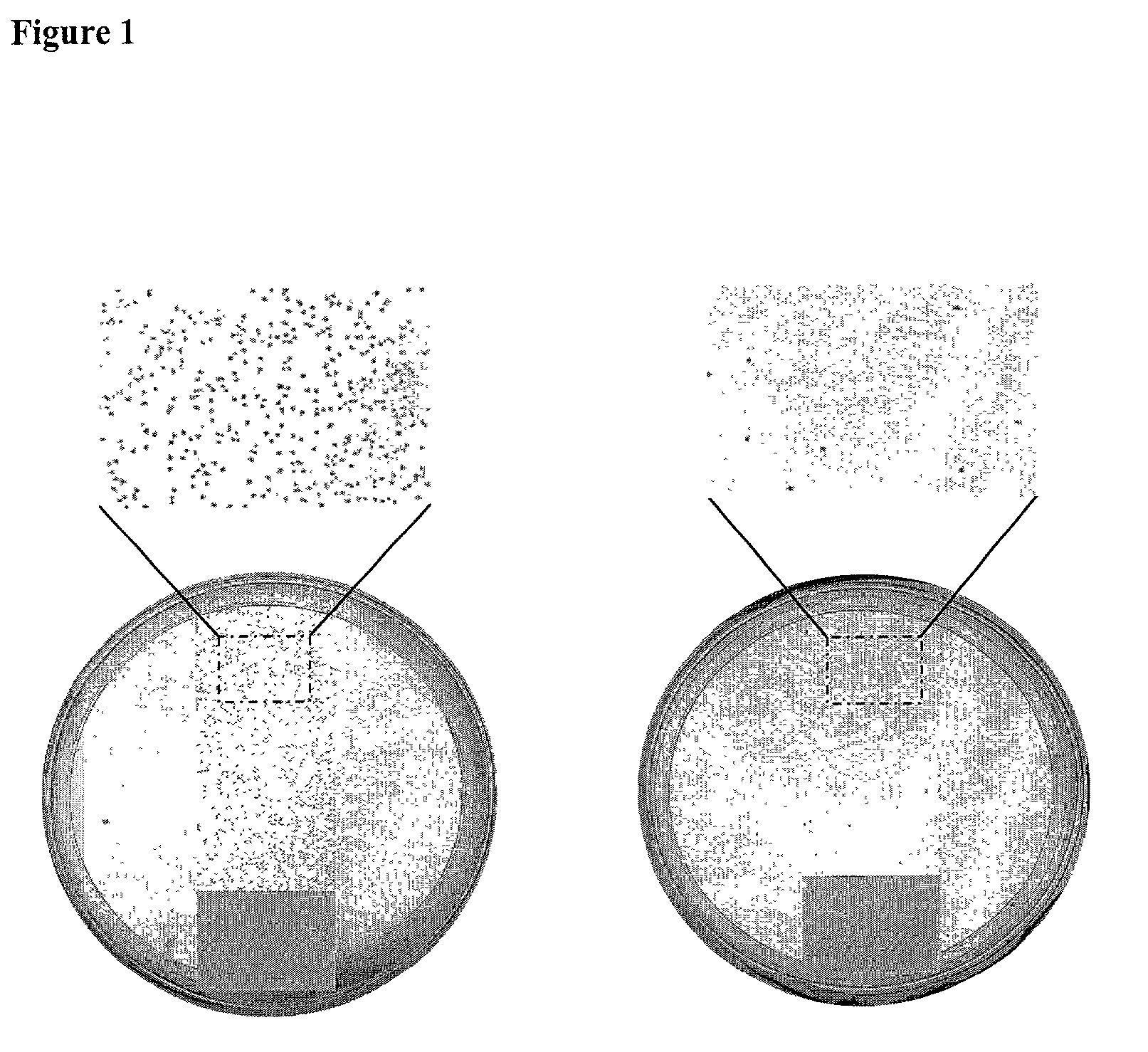

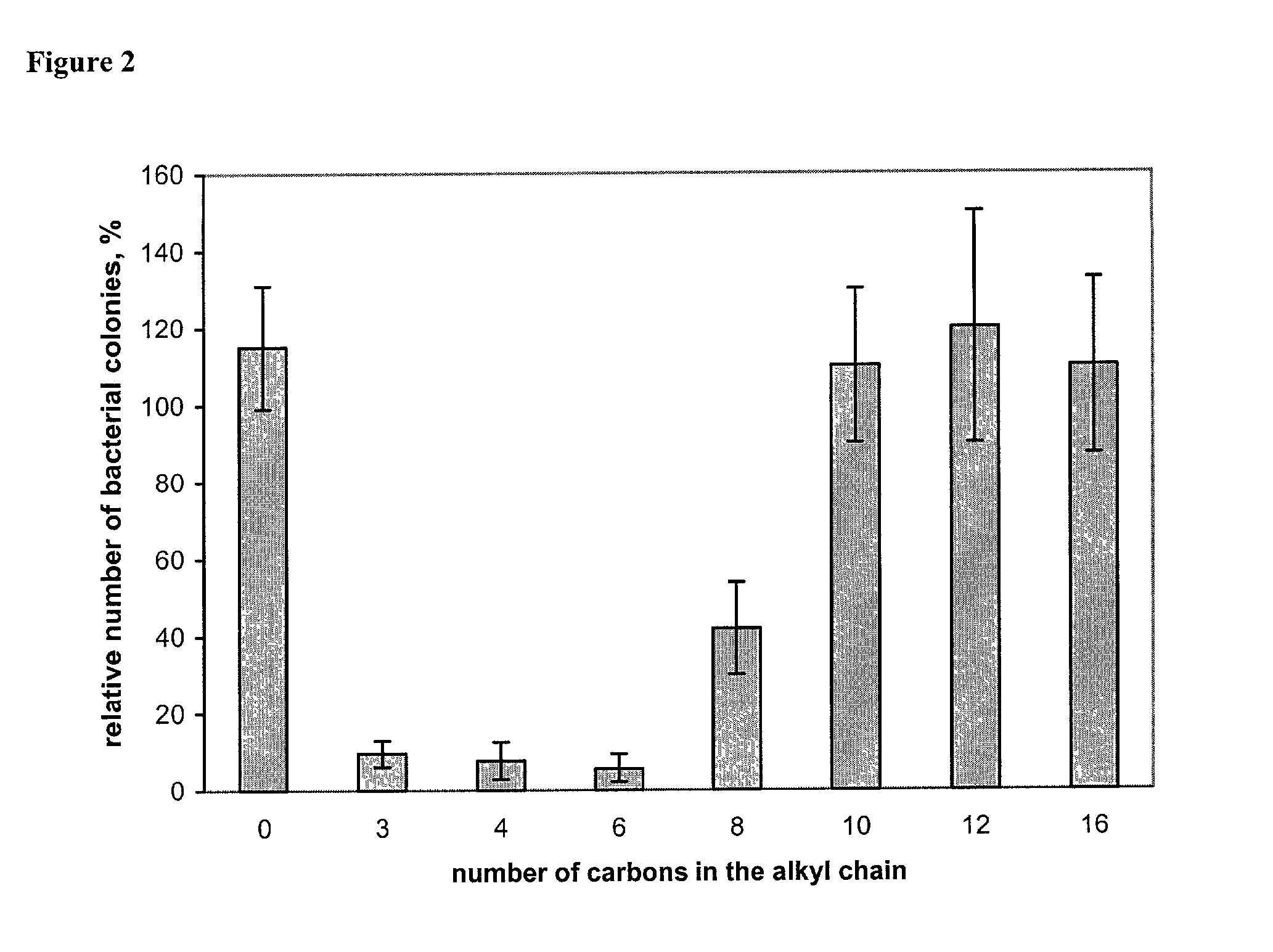

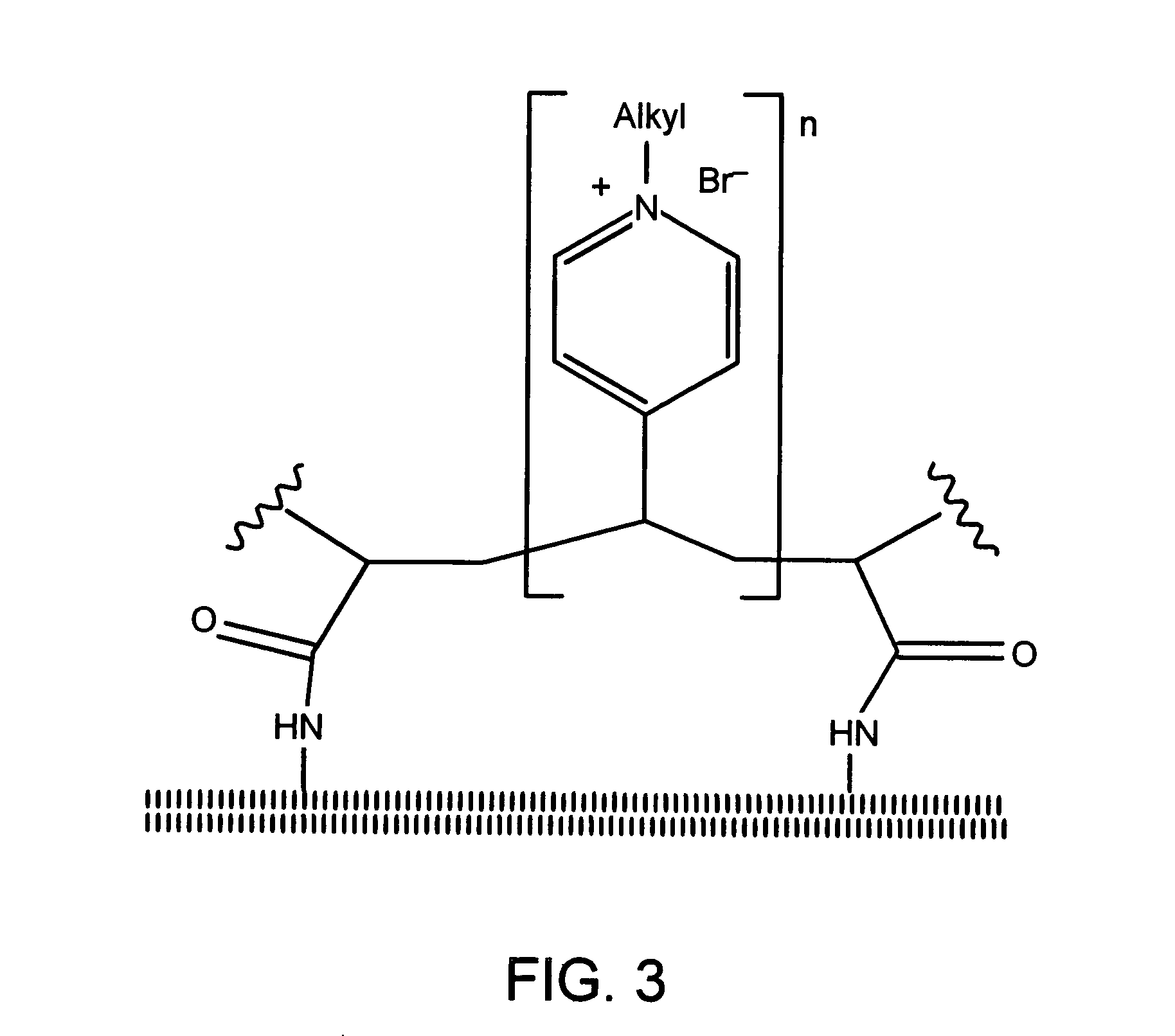

Antimicrobial polymeric surfaces

Bactericidal compositions are disclosed that comprise a polymeric compound immobilized on a material. Medical devices are also disclosed which comprise such a bactericidal composition. Methods are disclosed for covalently derivatizing the surfaces of common materials with an antibacterial polycation, e.g., poly(vinyl-N-pyridinium bromide); the first step of the methods involves coating the surface with a nanolayer of silica. Various commercial synthetic polymers derivatized in this manner are bactericidal, i.e., they kill on contact up to 99% of deposited Gram-positive and Gram-negative bacteria, whether deposited through air or water.

Owner:TRUSTEES OF TUFTS COLLEGE +1

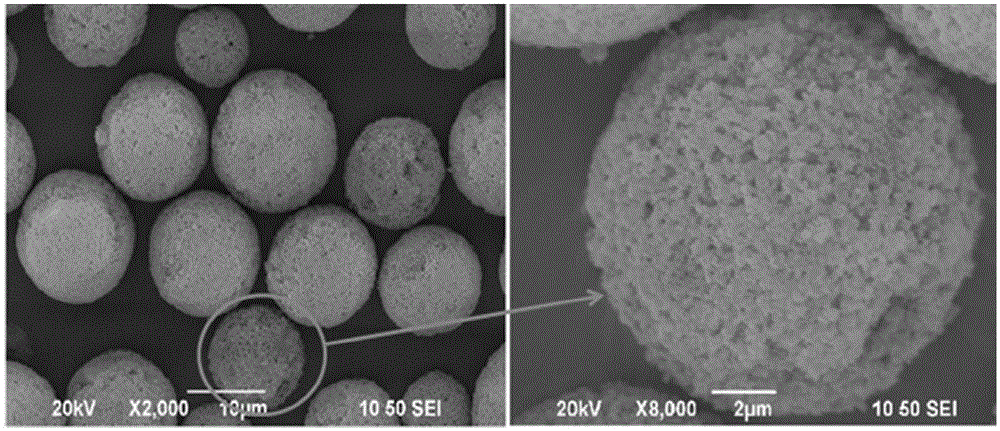

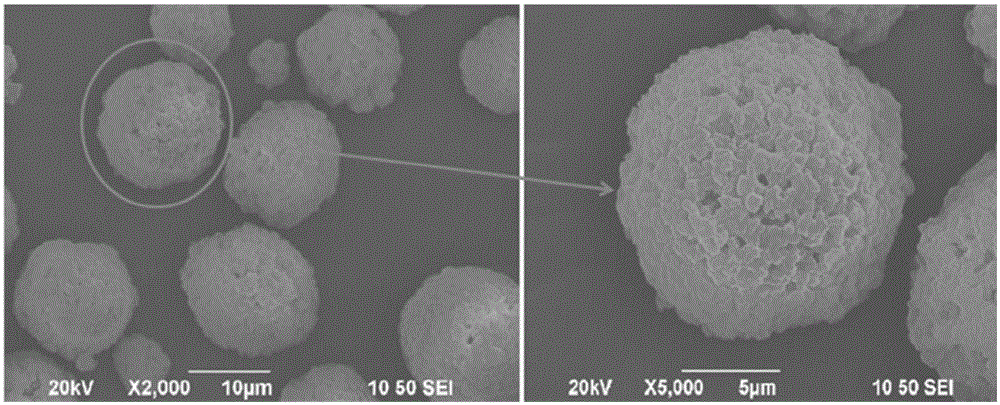

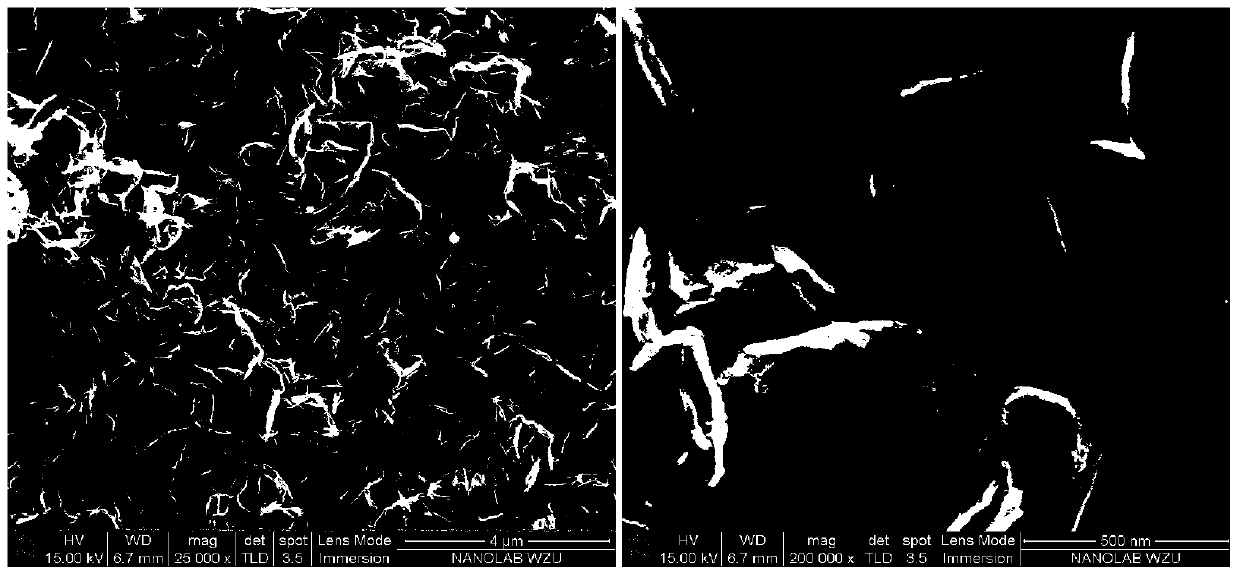

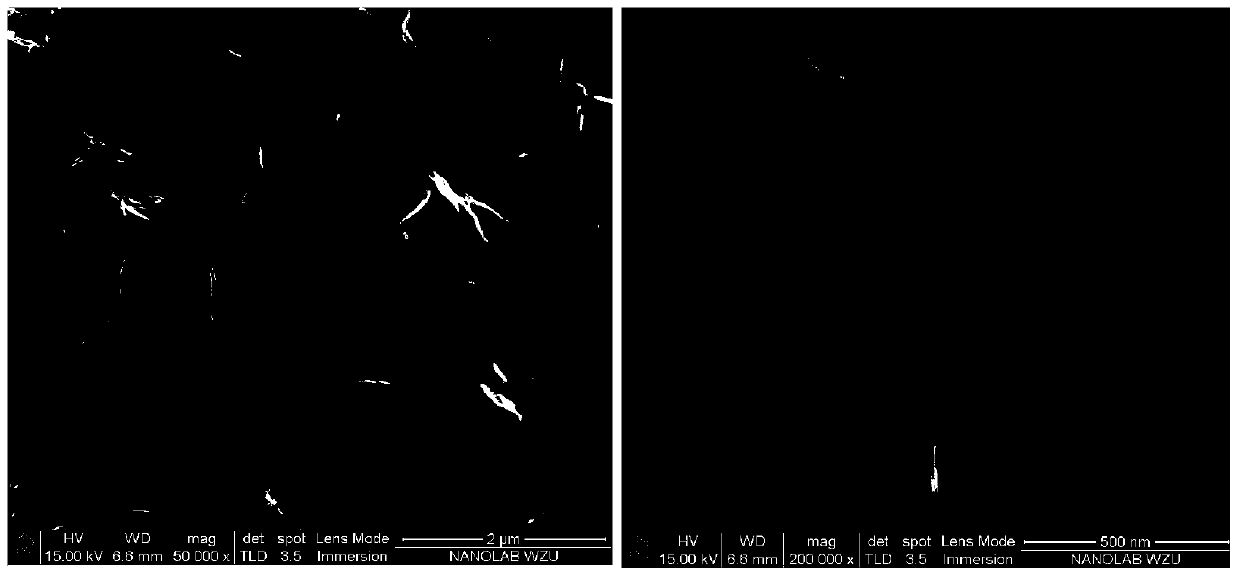

Preparation method for super-hydrophobic silica particle and super-hydrophobic coating

InactiveCN106587075ASimple manufacturing processExcellent superhydrophobic propertiesSilicaPolyurea/polyurethane coatingsHydrophobic silicaUltrasonic nebulization

The invention provides a preparation method for super-hydrophobic silica particles and super-hydrophobic coatings. The method includes the following steps that in step S1, nanometer silica particles and silane modifiers are dispersed in a solvent to form a mixed solution, wherein weight ratio for nanometer silica particles and silane modifiers and the solvent is 1:0.05-0.5:3-20; the PH value of the mixed solution is adjusted to 2.0-5.0 by hydrochloric acid, and then the mixed solution is stirred for 2 to 24 hours at the temperature from 0 DEG C to 50 DEG C; the PH value of the mixed solution is adjusted to 6.0-7.5 by ammonia water, and then the mixed solution is stirred for 0.5 to 3 hours; a dispersion solution of modified nanometer silica particles is achieved; in step S2 the dispersion solution is dispersed into droplets by an ultrasonic nebulization technology and is dried at the temperature from 80 DEG C to 120 DEG C; the super-hydrophobic silica particles are achieved. With the preparation method for super-hydrophobic silica particles and super-hydrophobic coatings, the super-hydrophobic silica particles and the super-hydrophobic coatings are achieved, and have the advantages of being good in super-hydrophobic effect and simple in manufacturing process.

Owner:THE HONG KONG POLYTECHNIC UNIV

Super hydrophobic cotton fabric and preparation method thereof

The invention belongs to the fabric water-repellent finishing and processing field, in particular relates a super hydrophobic cotton fabric and a preparation method thereof. The preparation method of the super hydrophobic cotton fabric is characterized in that the epoxy-functionalized modification is performed to the cotton fiber of fabric, then aminated nano-SiO2 and epoxy-functionalized nano-SiO2 are used to impregnate the cotton fabric in turn so as to increase the surface roughness of the fabric, finally a low-surface-energy material is adopted to perform hydrophobization treatment to the fabric; the contact angle between the prepared cotton fabric and water drops is more than 150 degrees; the method utilizes the covalent reaction of epoxy groups of cotton fabric, amino groups of nano-SiO2 and epoxy groups of nano-SiO2 to ensure the built rough surface to have good fastness; and the built surface has a large number of Si-OHs and epoxy groups so as to facilitate the chemical combination of the low-surface-energy material and the surface, thus the superhydrophobic property of the prepared fabric has excellent stability.

Owner:SHAANXI UNIV OF SCI & TECH

Catalyst for preparing 1, 4-butynediol and preparation method thereof

InactiveCN103480382ALarge external specific surfaceHigh activityMetal/metal-oxides/metal-hydroxide catalystsDeposition precipitationCopper oxide

The invention discloses a catalyst for preparing 1, 4-butynediol and a preparation method of the catalyst for preparing 1, 4-butynediol. According to the method, acidized nano-silica is adopted as a carrier, the adopted nano-silica has a large outer specific surface, a dipping method and a deposition-precipitation method are used for adsorbing copper and bismuth on the carrier, so that the catalyst comprises 35-65% of copper oxide by mass, and meanwhile silica sol is added, so that the catalyst is more stable and abrasion resistant. The prepared catalyst is good in activity, high in selectivity and strength, not prone to pulverizing in the process of using and capable of keeping high activity.

Owner:大连瑞克科技股份有限公司

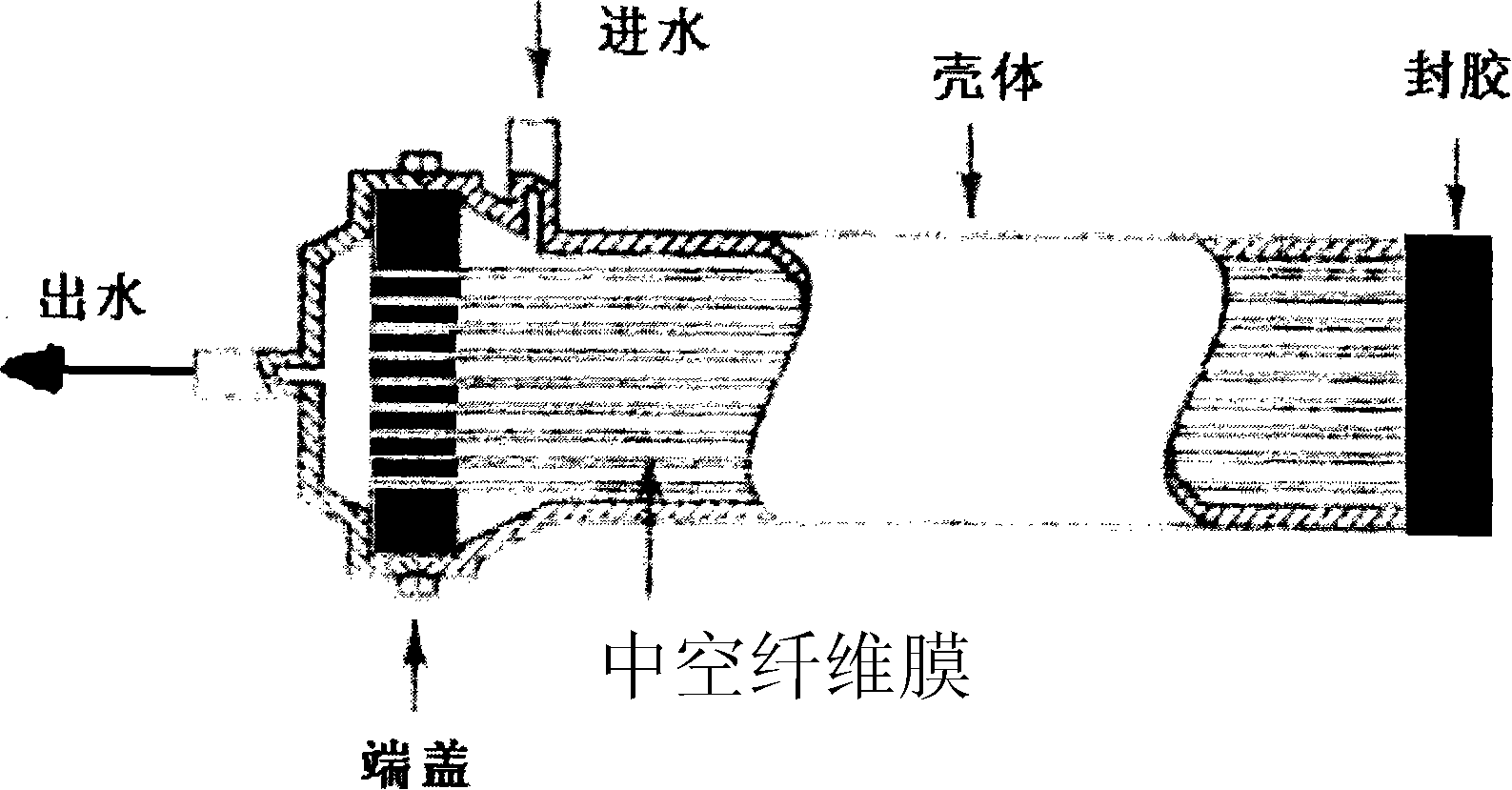

Hydrophilicity kynoar hollow fiber microporous membrane and preparation method thereof

ActiveCN101190401AImprove anti-pollution performanceAvoid adsorptionSemi-permeable membranesHollow fibrePorosity

The invention discloses a hydrophilic polyvinylidene fluoride hollow fiber microporous membrane and the preparation method thereof. The main composition and the mass content of the membrane are 70% to 90% of polyvinylidene fluoride, amphiphilic poly-(propylene oxide-oxirane), 5% to 29% of poly-(methacrylic acid- acrylic acid) or poly-(methacrylic acid methyl ester-vinyl alcohol) copolymer and 1% to 5% of nano-silicon dioxide. The membrane preparation method is that all the components are mixed and dissolved with aperture regulator, thickener and solvent to obtain the membrane preparation liquid; after that, the hollow fiber forming is carried out through a dry-wet spinning technique, and finally cleaning and drying are implemented. The obtained membrane has adjustable internal diameter and external diameter, 60% to 80% of porosity and the aperture ranging from 0.01micron to 0.2micron. As a water disposal separating membrane material with excellent performance, the invention has the advantages of being able to be fully humid, organic adsorption resistance and great water flux, etc.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

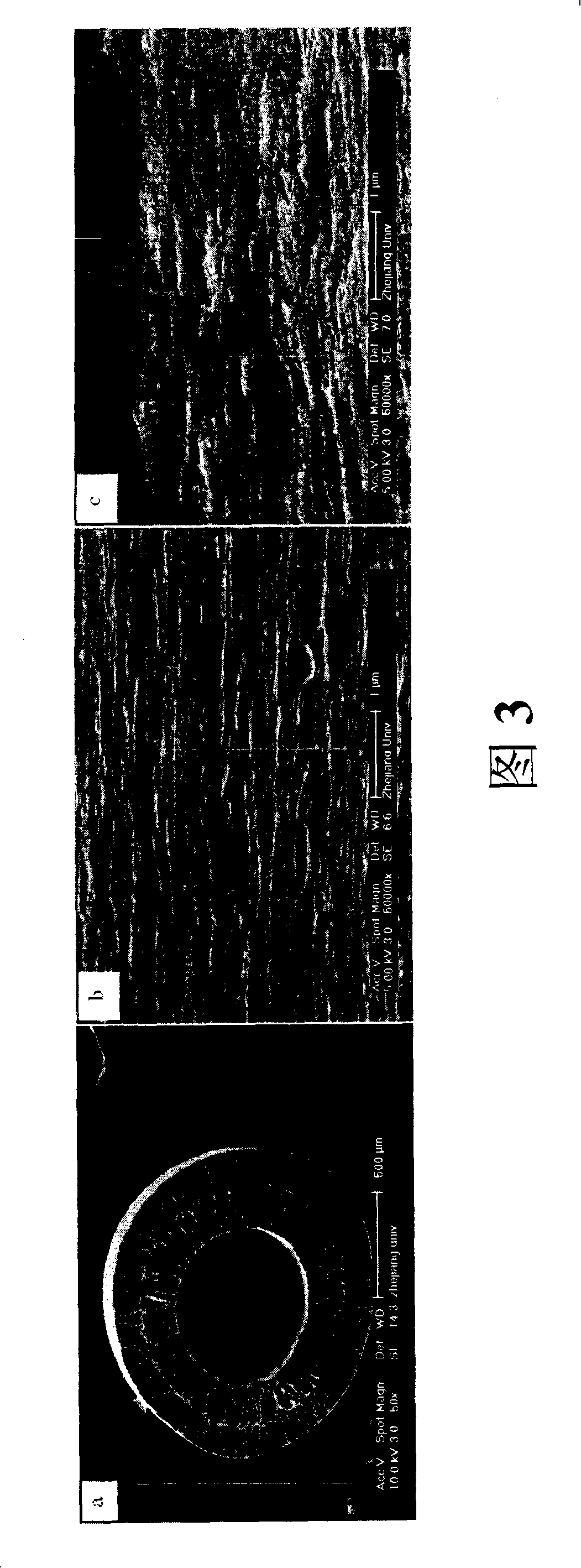

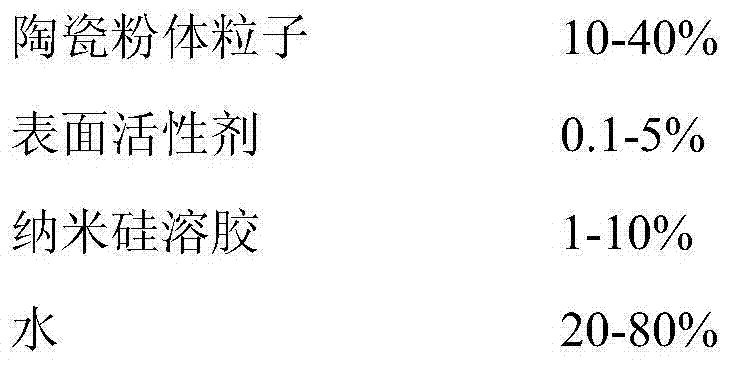

Preparation method of large-size thin-wall hollow flat-plate ceramic film

ActiveCN104258737ALower sintering temperatureReduce production energy consumptionSemi-permeable membranesLarge sizeEnergy consumption

The invention belongs to the technical field of ceramic films, and in particular relates to a preparation method of a large-size thin-wall hollow flat-plate ceramic film. The preparation method comprises preparation of a flat-plate ceramic supporting body and preparation of a separation film layer. According to the preparation method, an alpha-Al2O3 powder body is coated by nano silicon dioxide dispersing liquid, so that the sintering temperature of the flat-plate film supporting body is greatly lowered, and the production energy consumption of a product is reduced; furthermore, chemical components of the supporting body are relatively high in purity, and the acid-alkali corrosion resistance is high; in a process of preparing a large-size thin-wall flat-plate film, deformation of a flat-plate film blank in extrusion, drying and sintering processes can be greatly reduced, and the yield of the flat-plate film is increased; the separation film layer adopts ceramic powder body particles modified by nano-silica sol; the surfaces of the particles are rounded and spheroidized; a duct of the prepared separation film layer is smooth and is low in filtering resistance; the water flux can be increased by over 30 percent.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

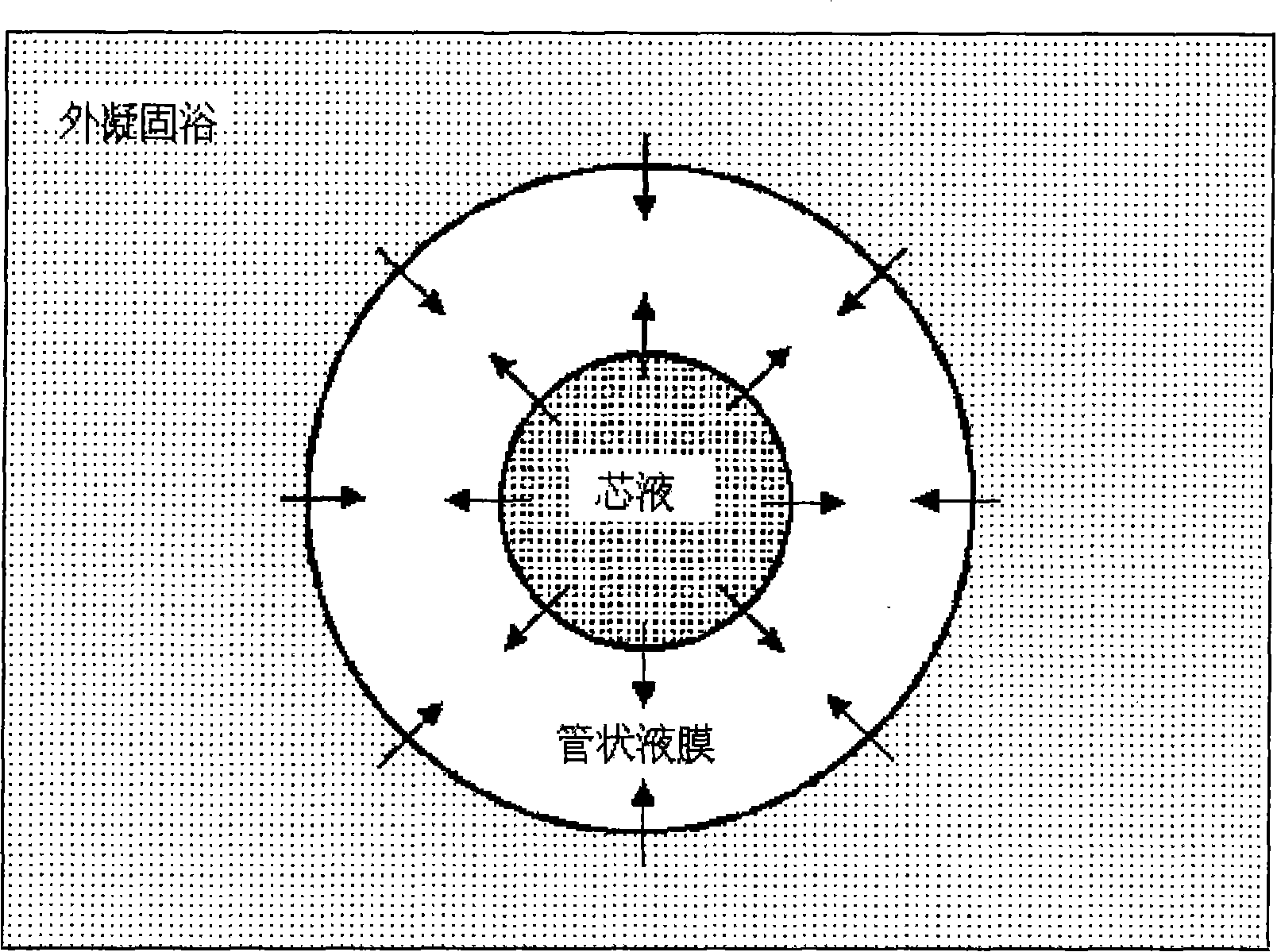

Method for preparing amphiphilic nano silica powder and method for preparing Pickering emulsion using same

InactiveCN101704529AEasy hard reunionHard reunion noNanostructure manufactureSilicaNano sio2Room temperature

The invention discloses a method for preparing amphiphilic nano silica powder and is used for preparing nano silica powder with about 90 degrees of a tri-phase contact angle. The method uses ultrasonic preparation, thus having short preparation process; the invention adopts liquid phase modification, thus avoiding processing means such as grinding, calcining and the like which are easy to cause the powder to generate hard particle agglomeration; the invention can prepare better amphiphilic surface (about 90 degrees of tri-phase contact angle) nano silica powder. The invention also discloses a method for preparing Pickering emulsion by using the amphiphilic nano silica powder under the action of ultrasound or cutting, the nano silica powder stably exists in oil-water interface, thus preventing diffused oil (water) droplets to re-agglomerate into big droplets to split phase and stabilizing emulsion. The prepared emulsion can be stored at room temperature without occurrence of demulsification in three months.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

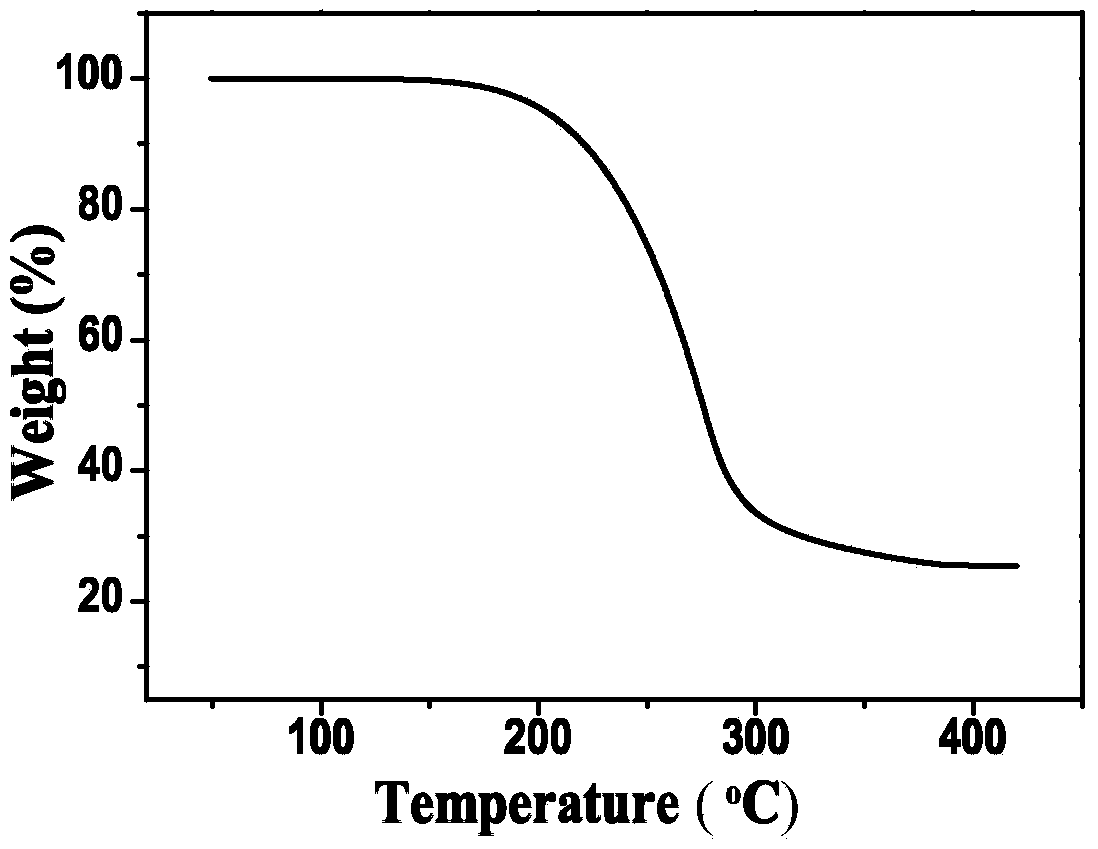

Preparation method of high elasticity super hydrophobic high temperature nano silicon dioxide fibrous membrane

InactiveCN101603245AGood flexibilityBend freelyFilament/thread formingNon-woven fabricsElectrospinningSolvent

The invention provides a preparation method of high elasticity super hydrophobic high temperature silicon dioxide fibrous membrane. The invention is characterized in that the method includes the following steps: template polymer is stirred in solvent at 60 DEG C to obtain template solution with mass concentration of 5-30%; organic silicon or nano silicon dioxide are mixed with water and inorganic acid at normal temperature to obtain silicon source solution; the template solution and the silicon source solution are mixed to be uniform at normal temperature to obtain electro spun solution; the electro spun solution is subject to electrostatic spinning at normal temperature to obtain composite fibrous membrane; the compound fibrous membrane is placed into a muffle furnace to be forged, so as to obtain a nano silicon dioxide fibrous membrane; the nano silicon dioxide fibrous membrane is placed into organic silicon hydrocarbon compound solution to be soaked for 6-30h and then is dried in vacuum, thus obtaining the high elasticity super hydrophobic high temperature nano silicon dioxide fibrous membrane. The material is antifouling and self-cleaning under high temperature high pressure severe environment.

Owner:DONGHUA UNIV

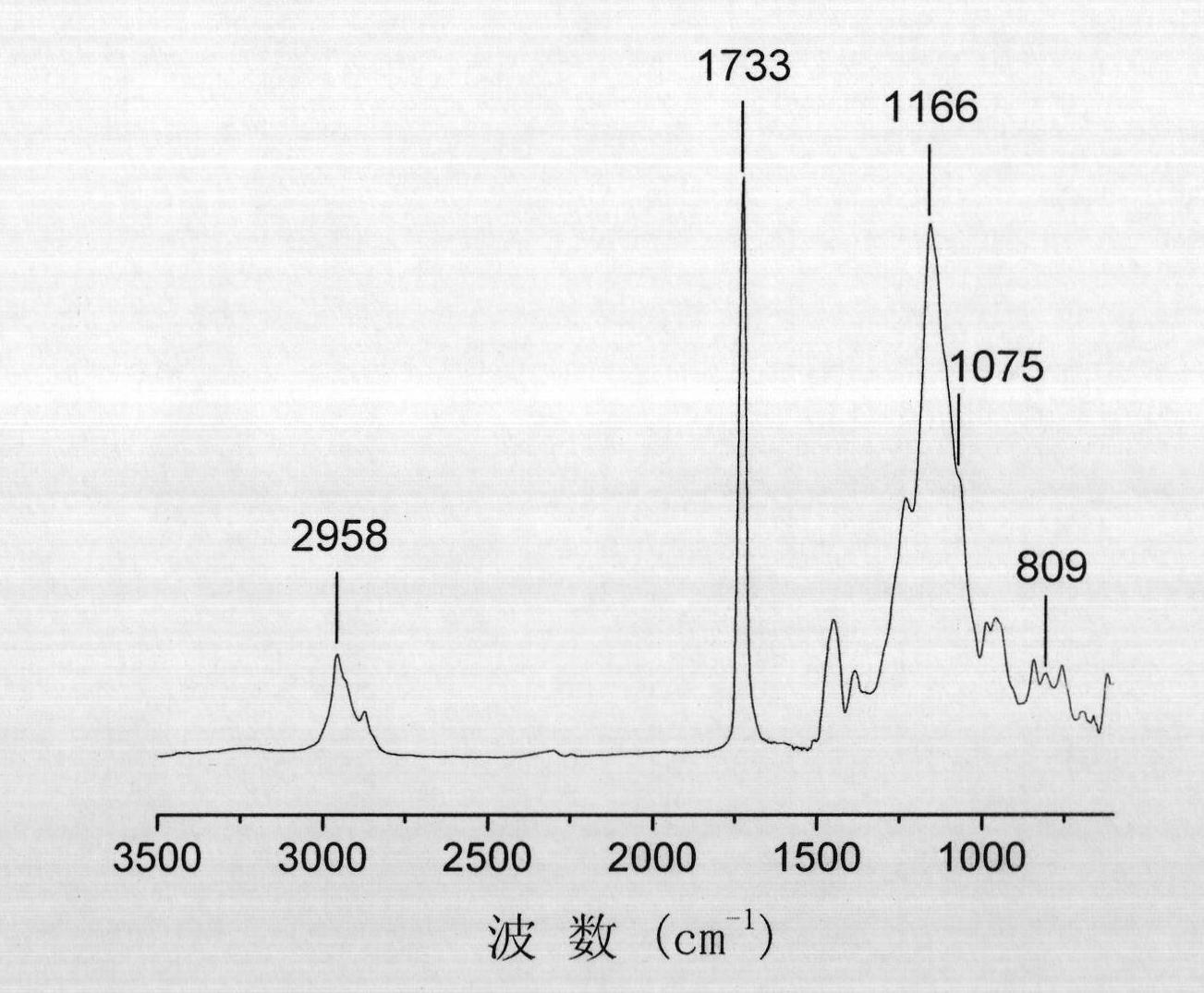

Method for preparing nano silicon/polyacrylate composite emulsion

InactiveCN102030873AAvoid the problem of "secondary reunion"Good dispersionCoatingsSilanesCombined method

The invention discloses a method for preparing nano silicon / polyacrylate composite emulsion. The method comprises the following steps of: adding the adding hydrochloric solution and an emulsifier into de-ionized water, mixing the mixed solution and tetraethoxysilane, a silane coupling agent and acrylate monomers and pre-emulsifying to obtain modified nano silicon pre-emulsion; heating, adding an initiator, and preparing the nano silicon / polyacrylate composite emulsion by adopting an in-situ emulsion polymerization and seed emulsion polymerization combined method. The method has a simple process, solves the problem of 'secondary aggregation' of the traditional nano silicon during emulsion polymerization and effectively guarantees the stable proceeding of a polymerization reaction, the prepared nano silicon / polyacrylate composite emulsion has high stability, and the film of the nano silicon / polyacrylate composite emulsion has high heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

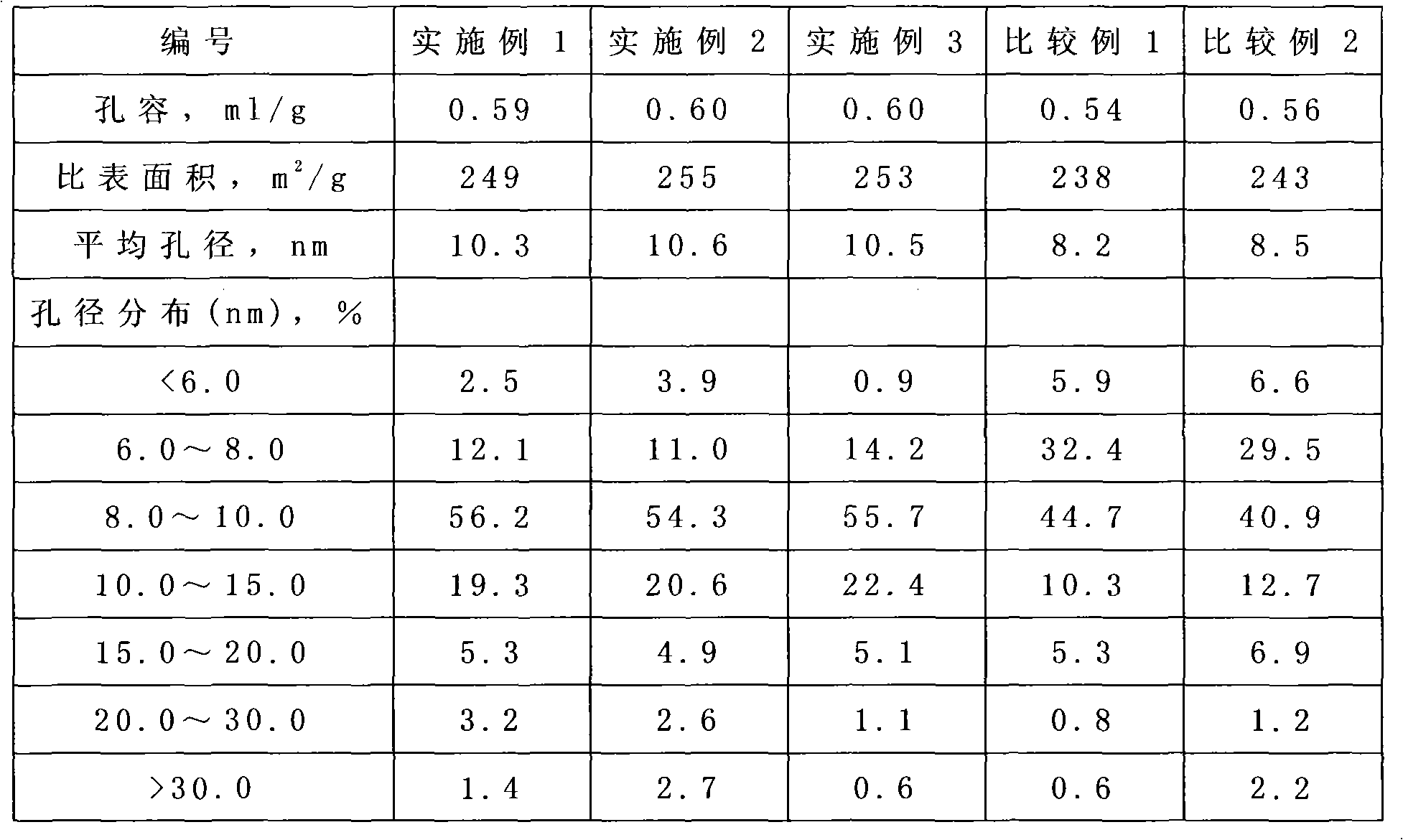

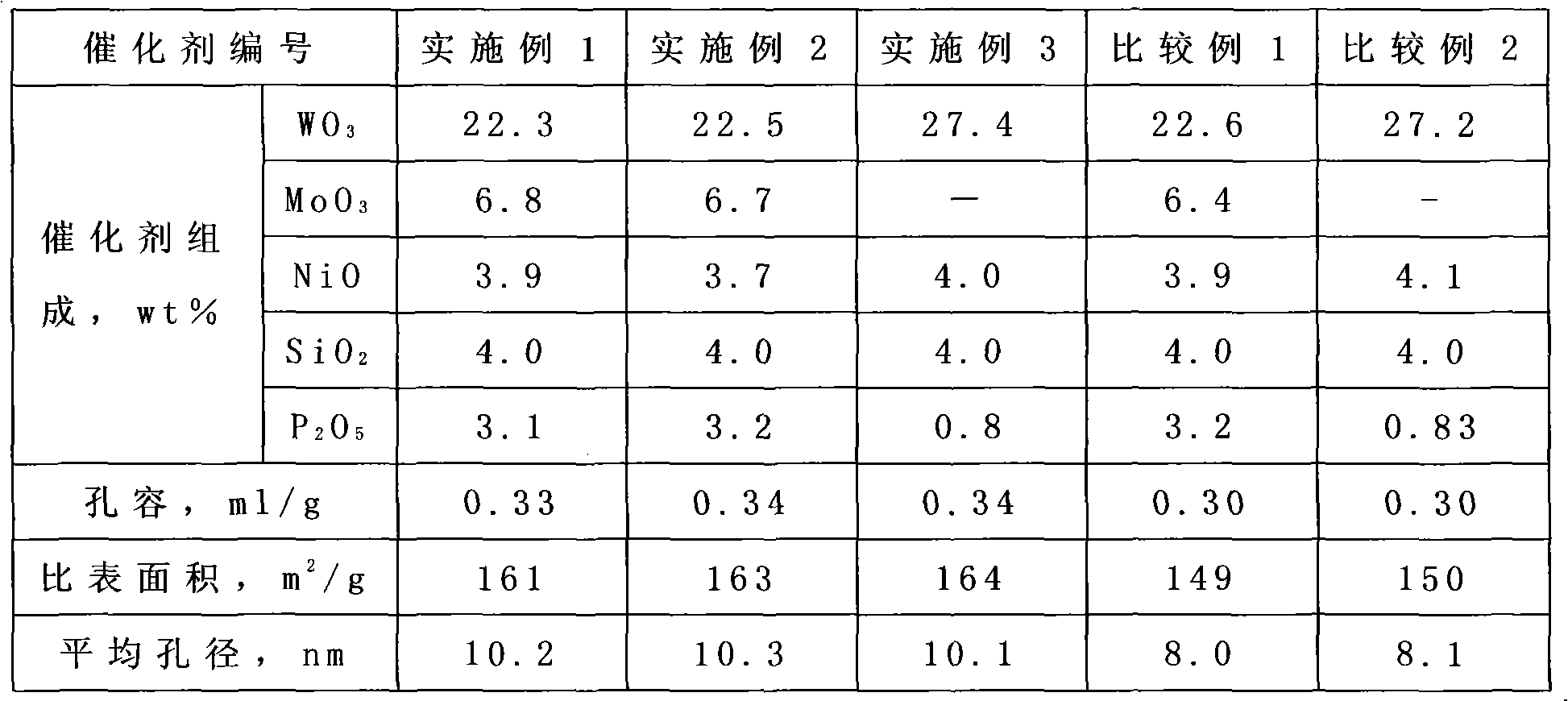

Method for preparing petroleum wax hydrofining catalyst

ActiveCN102039148AIncreased dispersionPore Structure ModulationCatalyst carriersPetroleum wax refiningCooking & bakingWax

The invention relates to a method for preparing a petroleum wax hydrofining catalyst. The method comprises the following steps of: weighing boehmite, adding a silicon-containing compound in an amount which is 6 to 17 percent based on the weight of the boehmite and phosphorus-containing organic compound solution in an amount which is 2 to 20 percent based on the weight of the boehmite, and extruding and forming on an extruder; drying at the temperature of between 100 and 120 DEG C; baking at the temperature of between 500 and 700 DEG C to obtain a gamma-Al2O3 carrier containing silicon and phosphorus, wherein the silicon-containing compound is silica solution of which SiO2 accounts for 30 percent based on the weight of the silica solution, or nano-silica; the active ingredients are one or two of NiO and Moo3, and WO3; NiO accounts for 2 to 7 percent based on the total mass of the catalyst, and MoO3 and / or WO3 account for 28 to 32 percent based on the total mass of the catalyst; the prepared catalyst has intensively distributed pores and appropriate surface acidity and still has high hydrogenation activity at a low reaction temperature and under a low reaction pressure.

Owner:PETROCHINA CO LTD

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

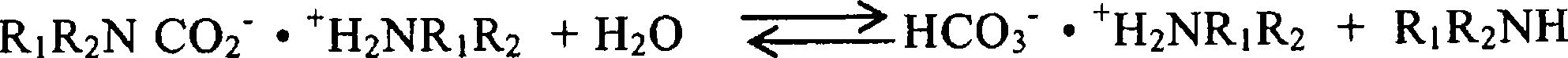

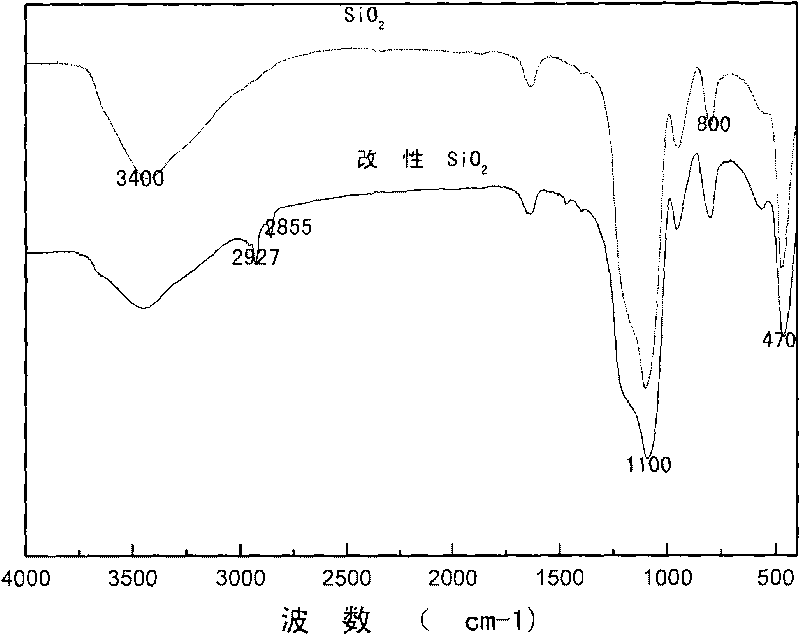

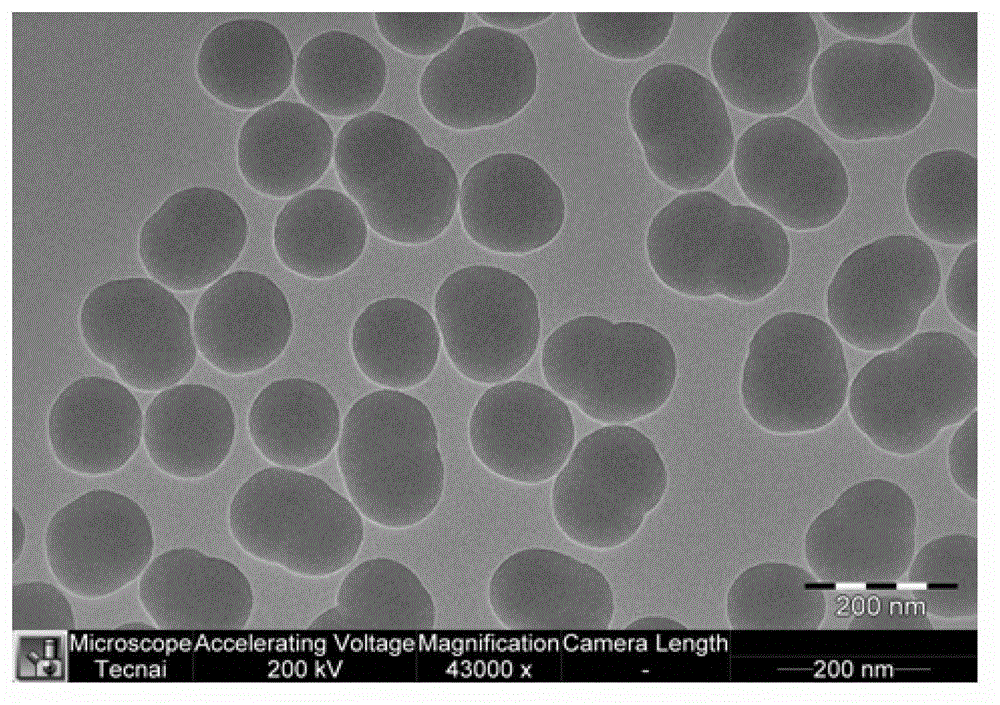

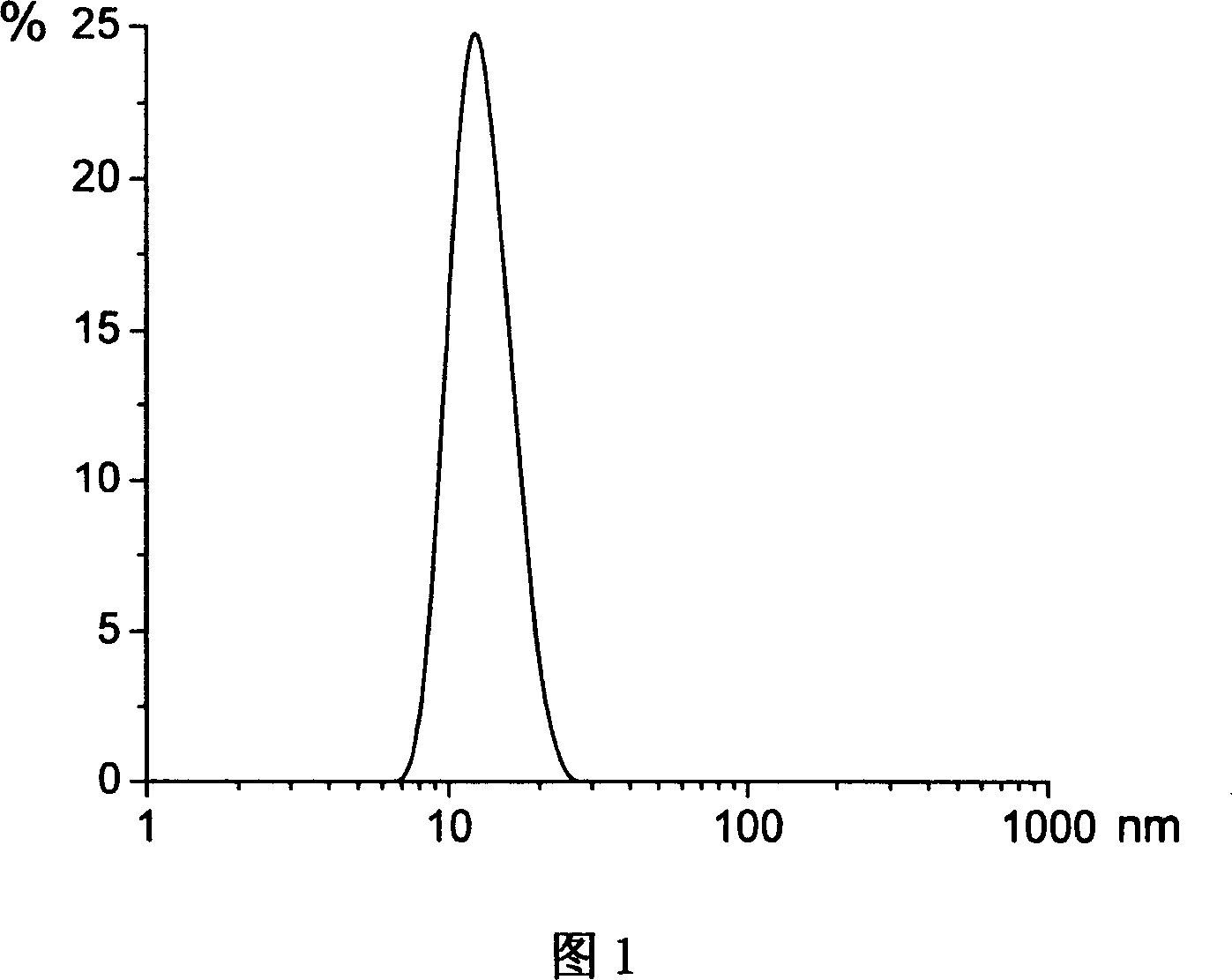

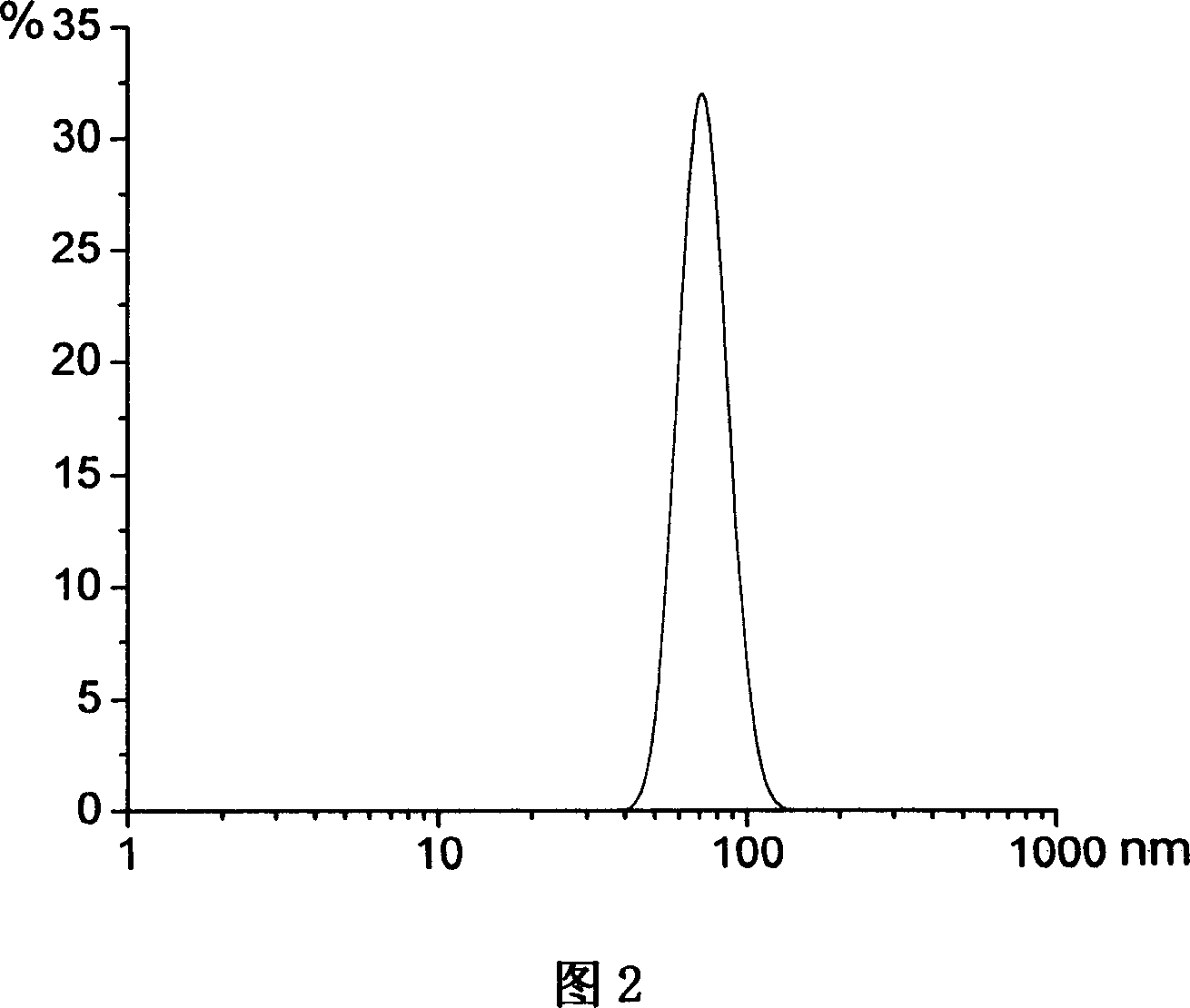

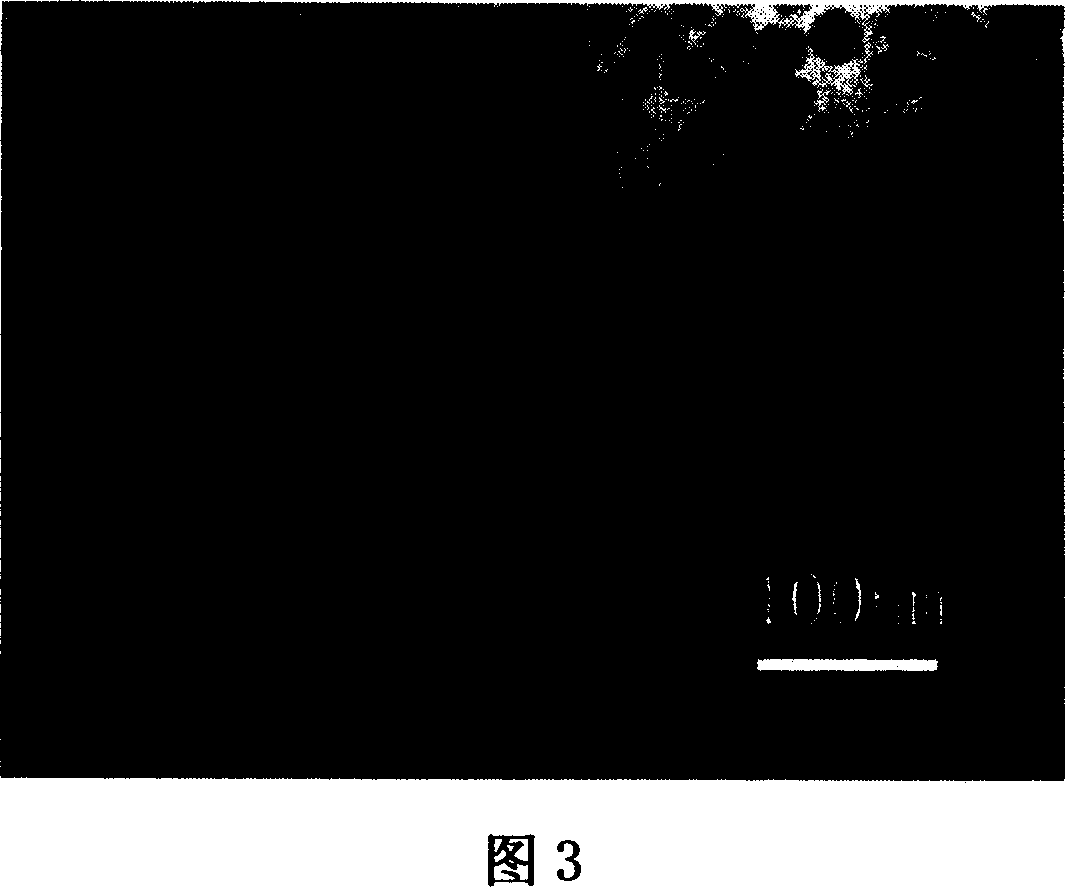

Preparation method capable of realizing chemical blending of modified nano silicon dioxide particles in acrylate monomer

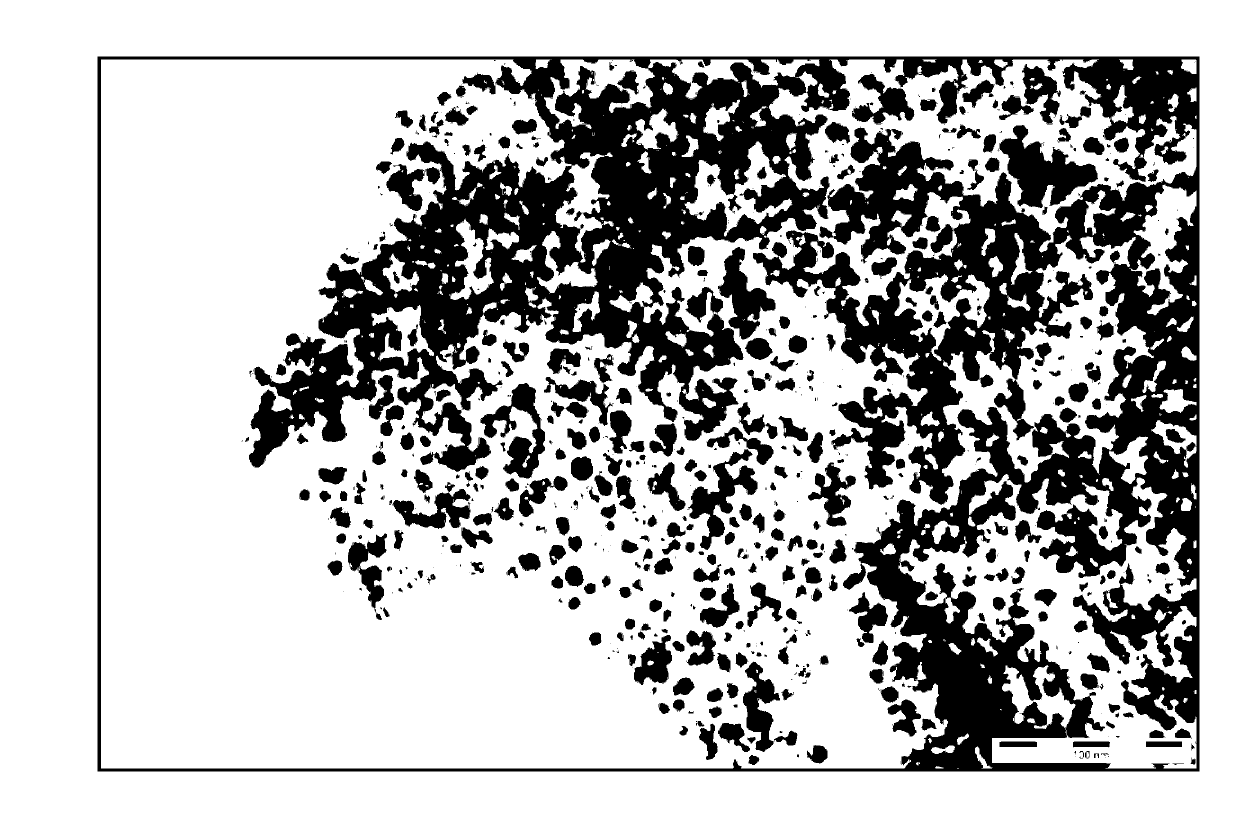

A preparation method capable of realizing chemical blending of modified nano silicon dioxide particles in an acrylate monomer relates to the field of the application of uniform dispersity of acryloyl oxygen radical contained silane couplint agent modified nano silicon dioxide particles in the acrylate monomer and the application of photocuring products in coating material. According to the method, the modified silicon dioxide is formed in a way that alkoxy on silane couplint agent and hydroxy on the surfaces of the nano silicon dioxide particles are reacted to form firm silicon-oxygen-silicon bonds; the double-bond silane couplint agent modified nano silicon dioxide is mixed in the monomer; during the photopolymerization process of the product, the acryloyl oxygen radical contained silane couplint agent modified nano silicon dioxide and the monomer are polymerized through the chemical bonds, so as to allow the nano silicon dioxide to be more uniformly distributed in the polymer; and the acryloyl oxygen radical contained silane couplint agent modified nano silicon dioxide particles are subjected to laser size analysis and transmission electron microscopy. The purpose of improving the application of the nano silicon dioxide composite acrylate monomer in the coating material field is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Silicon-titanium mixed oxide powder prepared by flame hydrolysis, which is surface-enriched with silicon dioxide, and the preparation and the use thereof

InactiveUS7083769B2Reduce photocatalytic activitySimple preparation processPowder deliveryCosmetic preparationsHydrolysisSilicon dioxide

Owner:EVONIK DEGUSSA GMBH

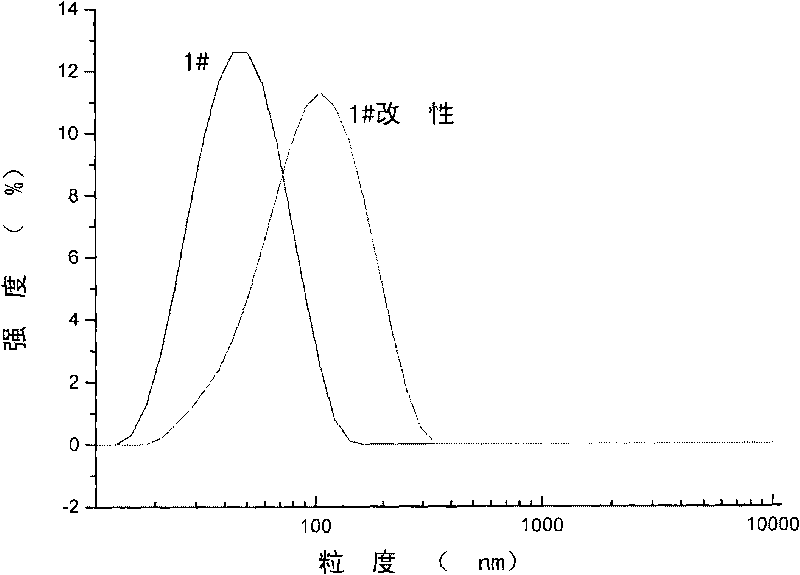

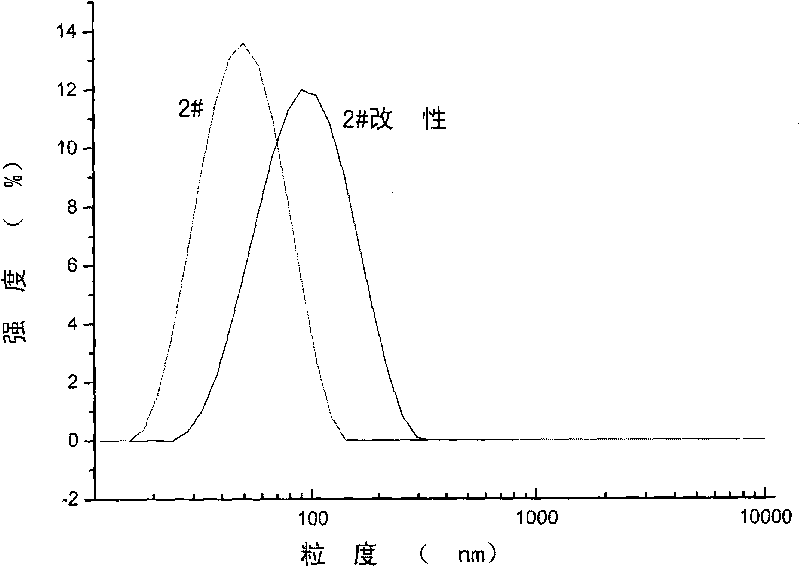

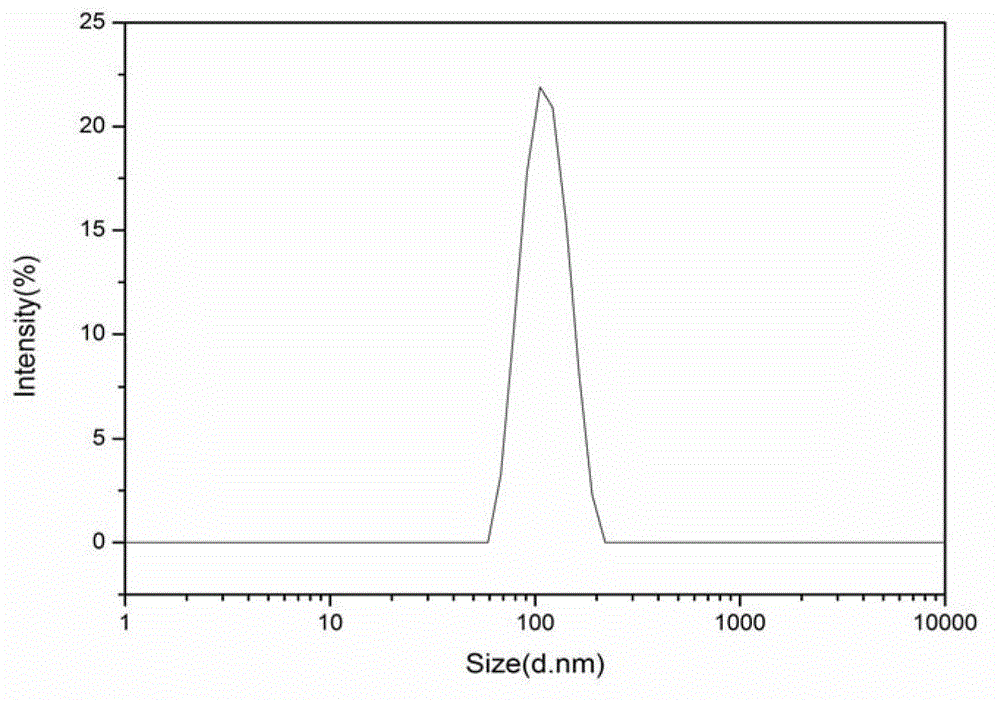

Method for preparing hydrophobic nano-silica with controllable grain diameter

InactiveCN101880478AGood dispersionHydrophobicPigment treatment with organosilicon compoundsSal ammoniacReaction temperature

The invention discloses a method for preparing hydrophobic nano-silica with a controllable grain diameter. The method comprises the following steps of: adding ammonia water and water into absolute ethanol and stirring the mixture for 0.5 to 1 hour at the temperature of between 20 and 70 DEG C; under an alkali condition, performing hydrolytic polycondensation to obtain nano-silica by using the absolute ethanol as solvent and tetraethoxysilane as a raw material; and preparing the hydrophobic nano-silica with the grain diameter in the range of between 20 and 500 nm by using a silane coupling agent as a hydrophobic modifier, wherein the using amount of ammonia water is 40 to 100 percent of the weight of the tetraethoxysilane; the using amount of the absolute ethanol is 12 to 25 times the weight of the tetraethoxysilane; and the using amount of the water is 30 to 150 percent of the weight of the tetraethoxysilane. The preparation method has the advantages of simpleness, easy operation and mild reaction condition. The hydrophobic nano-silica with the controllable grain diameter can be prepared by adjusting proportion and technological parameters of the materials.

Owner:SOUTH CHINA UNIV OF TECH

Graphene-based nitrogen-doped hierachical-pore carbon nanosheet/sulfur composite material for cathode of lithium sulfur battery, as well as preparation method and application of graphene-based nitrogen-doped hierachical-pore carbon nanosheet/sulfur composite material

ActiveCN103700859AIncrease loadNovel structureNon-aqueous electrolyte accumulator electrodesLi-accumulatorsElectrolytic agentElectrical battery

The invention discloses a graphene-based nitrogen-doped hierachical-pore carbon nanosheet / sulfur composite material for a cathode of a lithium sulfur battery, as well as a preparation method and application of the graphene-based nitrogen-doped hierachical-pore carbon nanosheet / sulfur composite material. The carbon nanosheet is a graphene-based nitrogen-doped hierachical-pore carbon nanosheet, and is prepared by the steps of growing poly-pyrrole on graphene oxide in situ, performing carbonization at high temperature, activating by using potassium hydroxide and forming pores, wherein the graphene oxide and nano-silicon dioxide serve as double templates; the thickness of the carbon nanosheet is 10 to 25 nm; the specific surface area is 800 to 1,600 m<2> / g; the pore diameter of the carbon nanosheet is distributed into the range of 0.8 to 6 nm in a concentrated way; the structure of the carbon nanosheet is a sandwich-like type which adopts graphene as the interlayer of the carbon nanosheet. The carbon nanosheet with abundant micro-pores, meso-pores and large specific surface area can load more sulfur active substances and can effectively inhibit dissolution of polysulfide. The ultrathin nanosheet, and the micro-pores and meso-pores guarantee diffusion of electrolyte and transmission of ions. According to the structure, the capacity, the cycling stability, the coulombic efficiency and the rate performance of the carbon nanosheet / sulfur composition material applied to the lithium sulfur battery are improved synergistically.

Owner:WENZHOU UNIVERSITY

Anti-soiling aging-resisting stainless steel paint and preparation method thereof

ActiveCN101215438AImprove aging resistanceImproves UV resistanceLiquid surface applicatorsAntifouling/underwater paintsEpoxyWater based

The invention relates to anti-pollution anti-aging rustless steel coating material and a process for preparation, and coating material comprises acroleic acid resin, film forming matter, filling material, dissolvent and auxiliary agent which are mixed, the film forming matter comprises fluoro containing resin, water-based polyurethane and epoxide resin, the filling material comprises nanometer silicon oxide. The process comprises dissolving acroleic acid resin in dissolvent, further adding film forming matter, filling material, and auxiliary agent, balling to evenly mix. The rustless steel coating material of the invention adopts nanometer silicon oxide and fluoro containing resin to modify acroleic acid coating material, utilizes the ultraviolet screening performance of nanometer silicon oxide, the particle diameter of nanometer-grade particle and low surface tension of fluoro containing resin to lead the anti-aging capability and anti-ultraviolet performance of acroleic acid resin which is prepared to be greatly enhanced, the invention has longer life span than the existing normal acroleic acid resin coating material, which has better fingerprint resisting effect, and the quality and the level are greatly improved, the scope of application is further enlarged.

Owner:HAIMEN SENDA DECORATION MATERIAL CO LTD +1

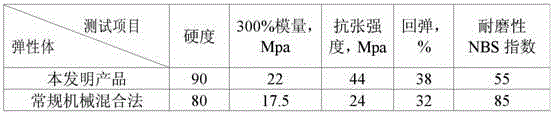

Nanosilicon dioxide modified polyurethane elastomer and preparation method thereof

The invention discloses a nanosilicon dioxide modified polyurethane elastomer and a preparation method thereof. The preparation method comprises the steps of enabling polyether glycol, isocyanate and micromolecular dihydroxy alcohol to be subjected to addition polymerization reaction to prepare a polyurethane prepolymer as a component A; uniformly mixing a chain extender, ethyl silicate and a silane coupling agent, carrying out in-situ hydrolysis on ethyl silicate to form nanosilicon dioxide particles, performing surface hydrophobicity modification on the nanosilicon dioxide particles by using the silane coupling agent, and removing a solvent in the mixture to obtain a component B; uniformly mixing the component A and the component B according to a certain ratio, degassing, pouring and carrying out vulcanization molding to obtain the nano-modified polyurethane elastomer. By using the preparation method, the uniform dispersion of silicon dioxide particles in polyurethane is realized, the enhancement effect of nanoparticles is sufficiently taken, the prepared polyurethane elastomer is obtained by crosslinking the nanosilicon dioxide particles, and the heat resistance and chemical stability of the polyurethane elastomer can be remarkably improved; in addition, the nanosilicon dioxide modified polyurethane elastomer can meet the requirements of a sealing element for mechanical strength, wear resistance, high elasticity and oil resistance and has a wide market prospect.

Owner:安徽嘉明新材料科技有限公司

Prepn process of monodispersive silica sol

ActiveCN1974385ASolve the shortcomings of small particle sizeImprove controllabilitySilicaReaction temperatureSilica gel

The present invention discloses one kind of nanometer monodispersive silica sol prepared with metal silicon powder and through reaction with water under the catalysis of certain amount of alkali catalyst at temperature of 50-95 deg.c. During the preparation, alkali solution adding speed is so controlled that the newly produced silicon sol precursor concentration is in the new nucleus forming concentration. Compared with available silica sol preparing process, the present invention has the advantages of homogeneous size distribution of nanometer silica sol, capacity of designing the sol size, simple preparation process, low cost and easy precise control.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

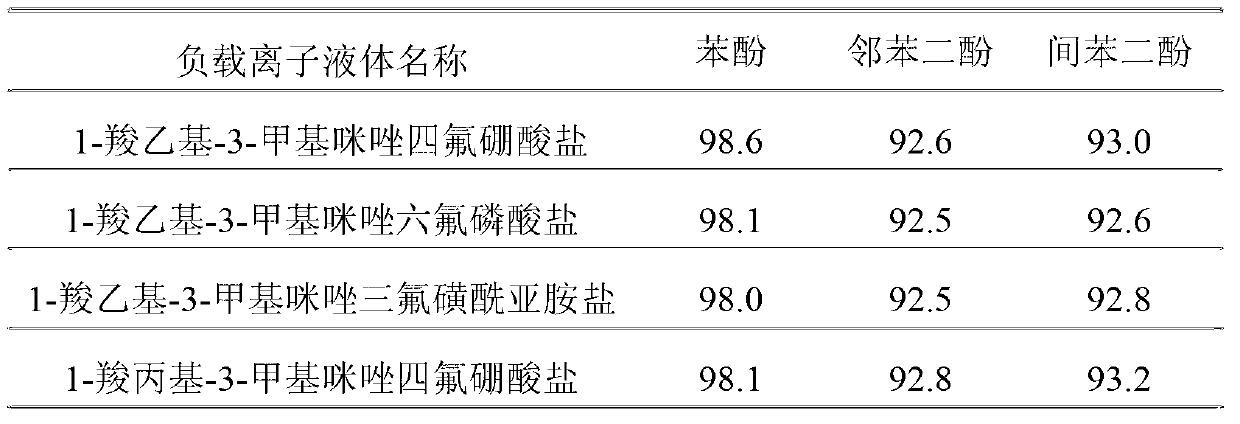

Magnetic nanometer ion liquid composite particles as well as preparation method and application thereof

InactiveCN103100358ASimple and fast operationLow costMicroballoon preparationWater/sewage treatment by extractionCarboxyl radicalSilicic acid

The invention discloses magnetic nanometer ion liquid composite particles as well as a preparation method and application of the magnetic nanometer ion liquid composite particles in removing pollutants in water bodies. The preparation method of the magnetic nanometer ion liquid composite particle comprises the following steps of: firstly synthesizing ferric oleate into magnetic Fe3O4 nanometer particles by taking ferric oleate as an iron source and adopting a chemical precipitation method; preparing nanometer nuclear shell type magnetic silicon dioxide with surface amino-functionalization by utilizing the nanometer magnetic particles as a kern, taking ethyl orthosilicate and a silane coupling agent as silicon sources, and utilizing a colloidal sol-gel method; and synthesizing a functionalized ion liquid by utilizing reaction between N, N-carbonyldimidazole (CDI) and an ion liquid containing carboxyl, and thus preparing the magnetic nanometer ion liquid composite particle by utilizing reaction between the functionalized ion liquid and amino on the surface of the magnetic nanometer silicon dioxide; and the method is used for removing pollutants in the water bodies. The method provided by the invention has the advantages that the operation is simple and convenient, the cost is low, the treatment process is simple, and the removal efficiency is high.

Owner:SOUTH CHINA UNIV OF TECH

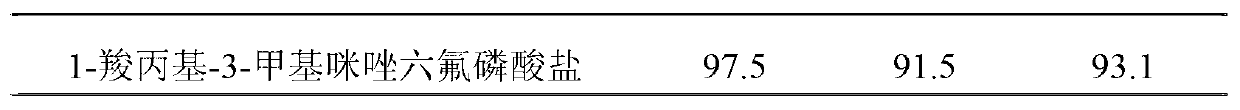

Nano composite aqueous epoxide resin coating material and preparation method

The nano composite water-base epoxy resin coating material comprises: epoxy constituent composed of epoxy resin, active diluent, nano SiO2 particle, and silane coupling agent; and water-base amic curing agent constituent composed of water-base amic curing agent, wet dispersant, defamer, paint, filler, film-forming adjuvant, thickener, and water. This invention also discloses opposite preparation method, improves greatly product properties, and has no pollution.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and manufacturing method thereof

InactiveCN107083579AWith far infrared heating performanceAntibacterial and anti-mite effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to negative-ion, far-infrared, antibacterial and anti-mite compound polyester fibers and a manufacturing method thereof. The compound polyester fibers are added with a negative-ion additive, a far-infrared additive and an antibacterial and anti-mite additive, wherein the negative-ion additive, the far-infrared additive and the antibacterial and anti-mite additive respectively account for 2%, 5% and 6% by mass in the compound polyester fibers; the negative-ion additive comprises an additive carrier and tourmaline negative-ion powder; the far-infrared additive comprises an additive carrier, Tai Chi stone powder, ZrO2 nano-powder, nano-silicon dioxide, nano-aluminum oxide, nano-manganese oxide and nano-calcium oxide; the antibacterial and anti-mite additive comprises an additive carrier, nano-Cu-ZnO compound particles, nano-titanium dioxide, nano-zinc oxide and nano-silicon dioxide; and the additive carrier is TiO2 hollow spheres.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

Method for preparing trimeric high-strength and high-toughness energy-saving fishing net

ActiveCN102251303AMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer sciencePolyamide

The invention discloses a method for preparing a trimeric high-strength and high-toughness energy-saving fishing net, which is implemented by carrying out synthesis on polyethylene (1), polypropylene (2), polyamides (3), Nano silicon dioxide (4), polyethylene wax (5), a coupling / bulking agent (6), a UV (ultraviolet) resistant agent 173 (7), a coloring agent (8) and white mineral oil (9) accordingto five steps (namely, a step A, a step B, a step C, a step D and a step E).

Owner:HUNAN XINHAI CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com