Patents

Literature

459 results about "White mineral oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Also called “liquid petroleum,” “paraffin oil,” and “white mineral oil,” mineral oil has long been used in a number of industries, including biomedicine, veterinary medicine, mechanical, electrical, and industrial.

Method for preparing trimeric high-strength and high-toughness energy-saving fishing net

ActiveCN102251303AMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer sciencePolyamide

The invention discloses a method for preparing a trimeric high-strength and high-toughness energy-saving fishing net, which is implemented by carrying out synthesis on polyethylene (1), polypropylene (2), polyamides (3), Nano silicon dioxide (4), polyethylene wax (5), a coupling / bulking agent (6), a UV (ultraviolet) resistant agent 173 (7), a coloring agent (8) and white mineral oil (9) accordingto five steps (namely, a step A, a step B, a step C, a step D and a step E).

Owner:HUNAN XINHAI CO LTD

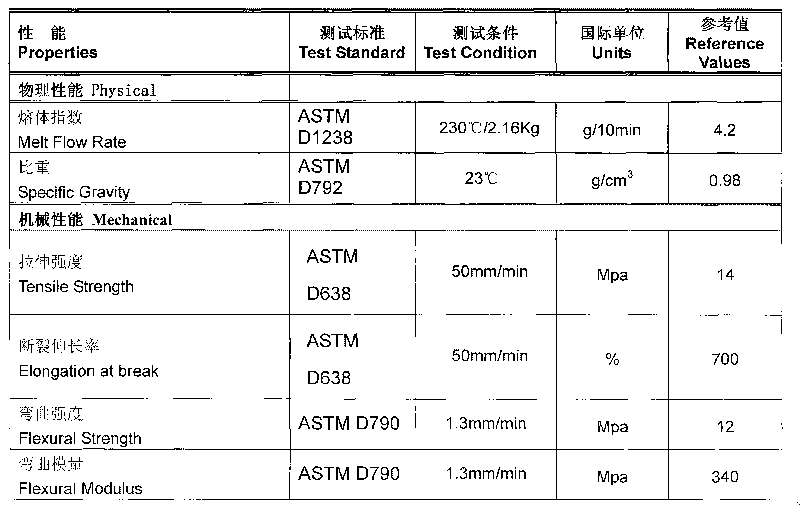

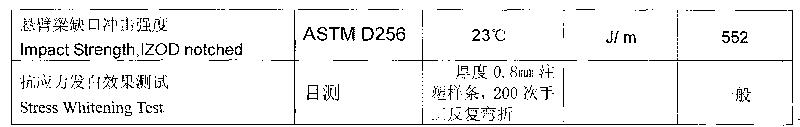

Anti-folding stress whitening resistant polypropylene (PP) material and preparation method thereof

The invention discloses an anti-folding stress whitening resistant polypropylene (PP) material and a preparation method thereof. The material is prepared from the following raw materials in part by weight: 55 to 75 parts of co-polypropylene, 5 to 20 parts of POE Lc670, 10 to 30 parts of stress whitening resistant master batch, 0.05 to 0.15 part of white mineral oil, 0.1 to 0.3 part of hindered phenol antioxidant 1010, 0.1 to 0.3 part of phosphite ester antioxidant 1680 and 0.1 to 0.3 part of calcium stearate. The stress whitening resistant master batch comprises the following components in part by weight: 40 to 65 parts of EPDM or EPR or POE, 30 to 50 parts of nano active light CaCO3, and 0.5 to 2 parts of sodium polyethylene with low molecular weight. The polypropylene (PP) material is prepared by using a double-screw extruder with 9 temperature control areas according to the specific process conditions. The material has the advantages of good repeated bending resistance and stress whitening resistance, simple preparation process and low preparation cost.

Owner:重庆启蓝塑料有限公司

Special material for modification and regeneration of polyethylene anticorrosive pipeline and preparation method thereof

The invention relates to a special material for modification and regeneration of a polyethylene anticorrosive pipeline and a preparation method thereof, belonging to the technical field of waste polyethylene recycling. The special material for modification and regeneration is prepared from the raw materials of polyethylene, recycled polyethylene, a toughening agent, glass beads, carbon black, an antioxidant 300, a secondary antioxidant DLTP, an ultraviolet absorbent UV-531 and white mineral oil by working procedures such as mixing and extruding. The special material effectively reduces the production cost of the polyethylene anticorrosive pipeline, solves the problems that the increasing amount of existing polyethylene waste causes pollution to the environment, and forms great waste of resources, and has positive significance for saving the resources, reducing the production cost, protecting the environment and the like.

Owner:HUBEI JIN KE ENVIRONMENT PROTECTION TECH

High-gloss polypropylene material containing carbon black colorant and preparation method thereof

The invention discloses a high-gloss polypropylene material containing carbon black colorant which is formed by processing granular homo-polypropylene, homo-polypropylene powder, an inorganic filler, carbon black, a lubricant, white mineral oil and other auxiliary agents, wherein the granular homo-polypropylene is granulated homo-polypropylene, the homo-polypropylene powder is un-granulated homo-polypropylene, and the inorganic filler is one of barium sulfate, calcium carbonate and French chalk, or a mixture of more than one type thereof. The preparation method comprises the following steps: firstly, pre-dispersing the carbon black, then pre-mixing all components, and finally utilizing a double-screw extruder for conducting extrusion granulation at temperature of 170-230 DEG C. The invention resolves the problem that the modified polypropylene added with the carbon black colorant can not meet the requirements of household electrical appliances on appearance gloss and color, and realizes uniform mixing of the carbon black and all components to the highest degree; and the surface glossiness of the prepared high-gloss polypropylene material containing the carbon black colorant is up to 85.

Owner:SHANGHAI KINGFA SCI & TECH +1

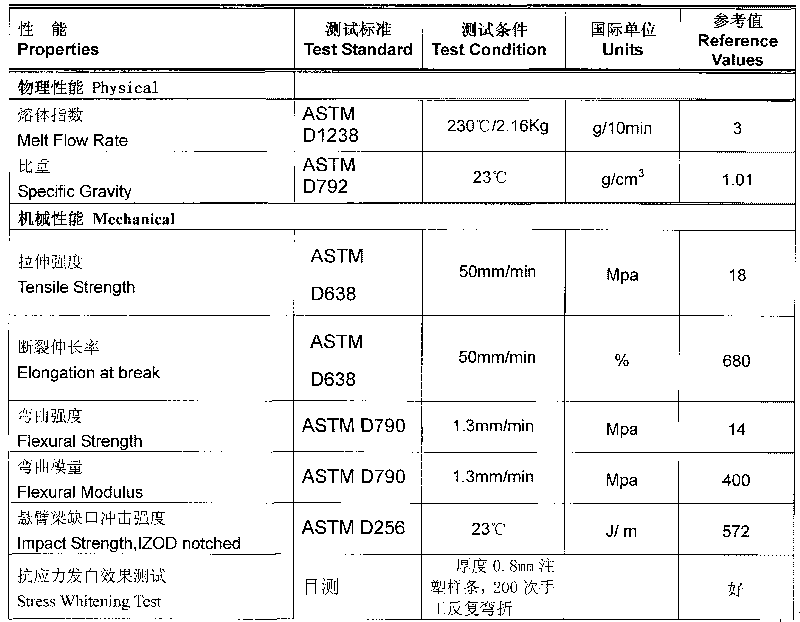

Face mask containing plant material residues

ActiveCN103432043ATake advantage ofIncrease profitCosmetic preparationsToilet preparationsMonoglyceridePolyethylene glycol

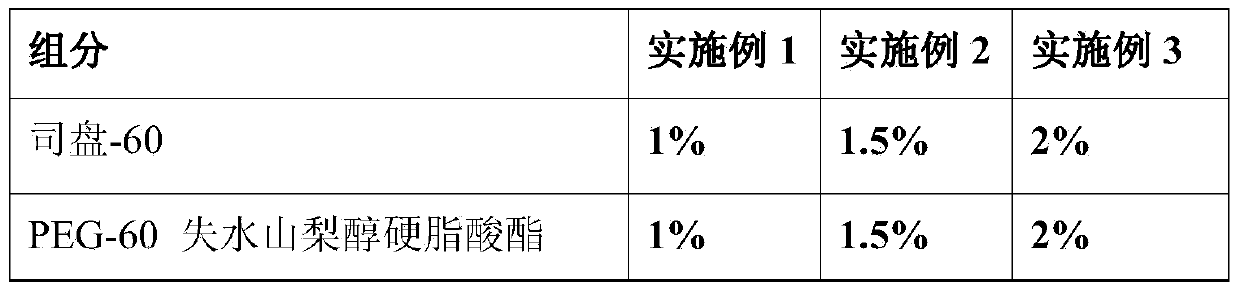

The invention provides a face mask containing plant material residues. A formula of the face mask comprises the following components in percentage by weight: 1%-2% of span 60, 1%-2% of PEG-60 (polyethylene glycol-60) sorbitan stearate, 2%-3% of stearic acid, 1%-2.5% of monoglyceride, 1%-3% of 16 / 18 alcohol, 3%-6% of 26# white mineral oil, 2%-6% of isopropyl myristate, 2%-6% of isooctyl palmitate, 1%-3% of polydimethylsiloxane, 3%-5% of glycerinum, 0.05-0.15% of xanthan gum, 0.1-10% of the plant material residues, 0.1%-0.2% of polyacrylate-13 (and) polyisobutene (and) polysorbate-20, 0.2%-0.4% of preservative and the balance of water. According to the face mask provided by the invention, the material residues after plant materials are extracted and utilized are turned into wealth, the production cost is reduced, and the utilization rate of the plant materials is increased.

Owner:广州市千纤草化妆品有限公司

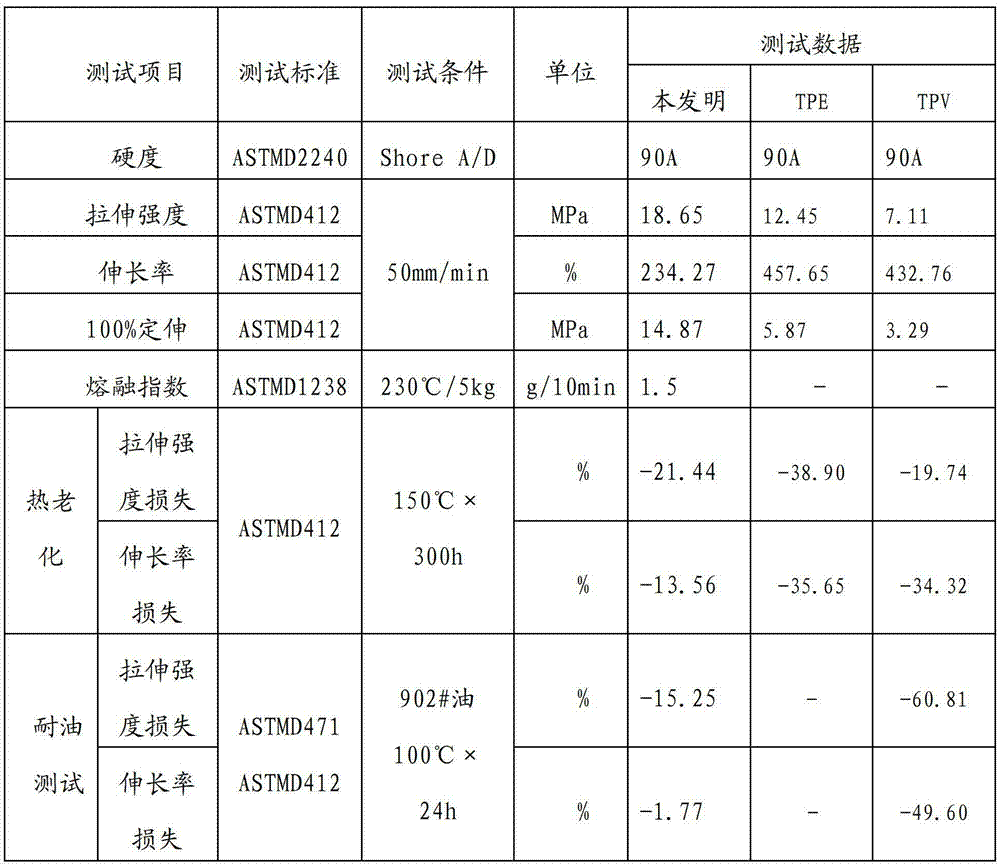

Thermoplastic polyurethane elastomer (TPE) door seal for refrigerator and freezer and preparation method thereof

InactiveCN102532778AGood weather resistanceImprove aging resistancePolymer sciencePolyvinyl chloride

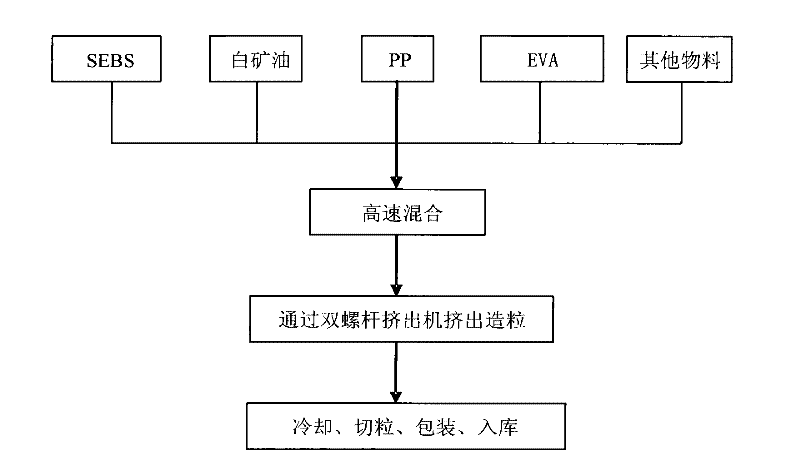

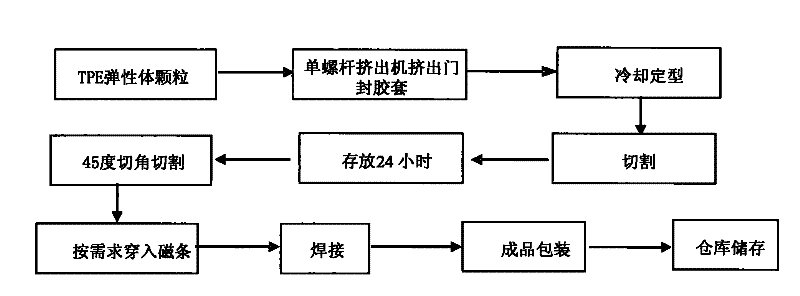

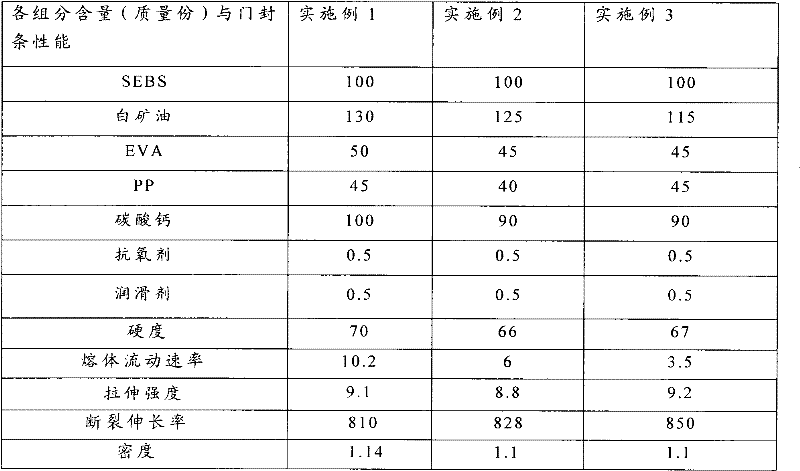

The invention discloses a thermoplastic polyurethane elastomer (TPE) door seal for a refrigerator and a freezer and a preparation method thereof. The TPE door seal is a TPE door seal rubber sleeve which is manufactured by adopting the following raw materials by mass: 15% to 50% of SEBS, 20% to 50% of white mineral oil, 10% to 48% of polypropylene, 10% to 45% of ethylene vinyl acetate (EVA), 5% to 25% of calcium carbonate, 0.1% to 0.6% of antioxygen and 0.1% to 0.6% of lubricant. The EVA material is introduced into a TPE door seal formula system, so that weather resistance, aging resistance and adhesiveness of the materials can be improved. The EVA material is added into a blending system of SEBS, white mineral oil, propene polymer and calcium carbonate, and low temperature resistance of products can be improved by utilizing good low temperature resistance of the EVA material. Compared with the polyvinyl chloride (PVC) material, the TPE material of the blending system of the SEBS, the white mineral oil, the propene polymer (PP), the EVA and the calcium carbonate has better low temperature resistance, and the problems of gap lighting, dropping and damage of the seal of the refrigerator and the freezer caused by the fact that the PVC material is poor in cold resistance and low temperature impact strength and the like can be resolved.

Owner:HAIER GRP CORP +1

Material special for corrugated pipe for high-density polyethylene prestressed concrete and production method thereof

The invention discloses a material special for a corrugated pipe for high-density polyethylene (PE) prestressed concrete and a production method thereof. According to a raw material formula, the material comprises the following components in part by weight: 100 parts of recycled high-density polyethylene, 5 to 20 parts of mica powder, 0.1 to 0.5 part of silane coupling agent KH570, 1 to 6 parts of maleic anhydride grafted polyethylene, 1 to 3 parts of PE wax, 0. 3 to 1.5 parts of white mineral oil and 0.2 to 0.5 part of color master batch, and is prepared by the following steps of: adding the mica powder, the silane coupling agent and the PE wax into a high-speed mixer; mixing at the rotation speed of between 800 and 1,200r / min and the temperature of between 100 and 130 DEG C for 2 to 5 minutes to activate the surface of the mica powder so as to obtain uniformly dispersed powdery mixture; and adding the recycled high-density polyethylene and the like in turn. The material special for the corrugated pipe for the high-density polyethylene prestressed concrete is low in cost, has high strength and stable performance, and can meet the operating requirements of the fields of capital construction of concrete, such as bridges, long-span building and the like.

Owner:广东致顺化工环保设备有限公司

Boiled bamboo shoots biological preserving method and biological preservative thereof

ActiveCN101507448ASatisfy taste needsTo achieve the effect of energy saving and emission reductionFruits/vegetable preservation by heatingSteam pressurePreservative

The invention discloses a method for biologically preserving water-cooked bamboo shoots, which comprises the following steps of: (1) selection of raw materials; (2) cooking and cooling; (3) peeling and reshaping; (4) rinsing and canning; (5) sterilization and can sealing; and (6) warehousing, wherein the sterilization and the can sealing in the step (5) comprise the following steps: adding a biological antistaling agent into bamboo shoot cans, and injecting boiled clear water into the bamboo shoot cans; placing the bamboo shoot cans into a pressure tank with a steam pressure of 2 kg / cm for cooking and sterilizing for 2 hours, and opening the pressure tank to inject the boiled clear water into the bamboo shoot cans for 3 to 4 times in the cooking and sterilizing process, wherein the injection interval time is 2 to 3 minutes per time; and sealing the bamboo shoot cans, cooling the bamboo shoot cans, washing the outer surfaces of the bamboo shoot cans to be clean, and smearing white mineral oil on sealing positions. The invention also discloses the biological antistaling agent applied to the method for making the water-cooked bamboo shoots. The biological antistaling agent comprises the following compositions: chitosan, phytic acid, ethanol, and the balance being water. The biological antistaling agent has the advantages of energy conservation and emission reduction, consolidated sterilization function, and guarantee of fresh mouthfeel and color and luster of the bamboo shoots.

Owner:ZHEJIANG ANJIJIAXIANG FOOD

Antibacterial functional ink as well as preparation method and application thereof

The invention provides antibacterial functional ink as well as a preparation method and an application thereof. The antibacterial functional ink is prepared by the steps: mixing and dispersing an antibacterial material, a solvent and a hyperdispersant according to a mass ratio of (10-40):(50-85):(3-10), grinding, removing iron, regulating the surface tension and viscosity, filtering, thereby obtaining the product. The antibacterial material is any one or a mixture of more than one of nano TiO2 powder, nano ZnO powder and nano Ag2O powder; the solvent is any one or a mixture of more than one of white mineral oil, isopropyl diphenyl and isoparaffin; and the hyperdispersant is a polyacrylate dispersing agent. The antibacterial functional ink is used for preparing antibacterial ceramic bricks. The antibacterial functional ink provided by the invention has the advantages of high dispersity, high stability, low production cost and the like, the usage amount of the antibacterial material can be adjusted at any time when the antibacterial material is printed on the ceramic bricks, and the cost of the material is saved.

Owner:佛山市帆思科材料技术有限公司

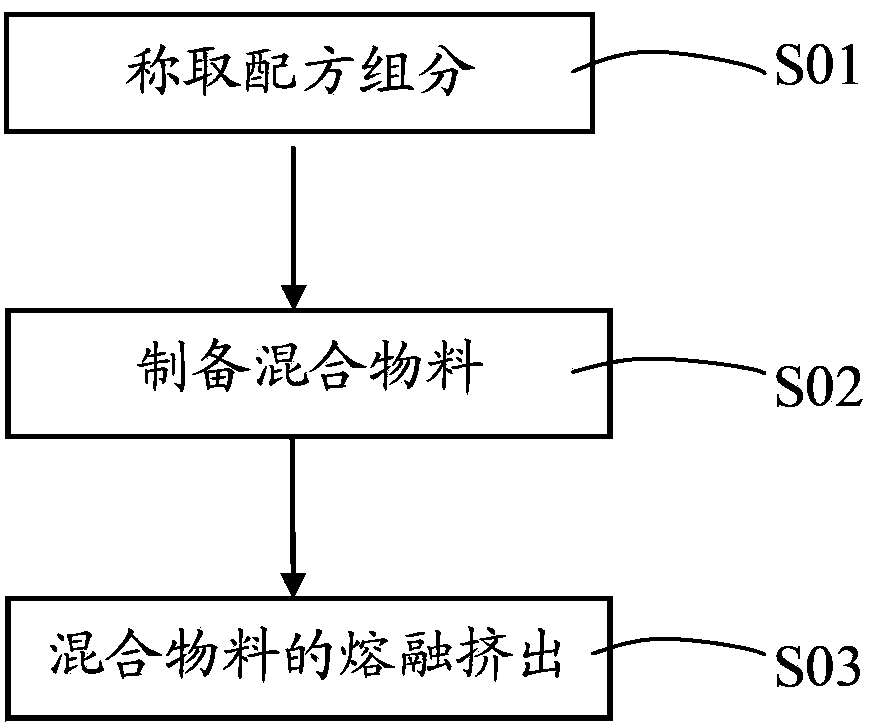

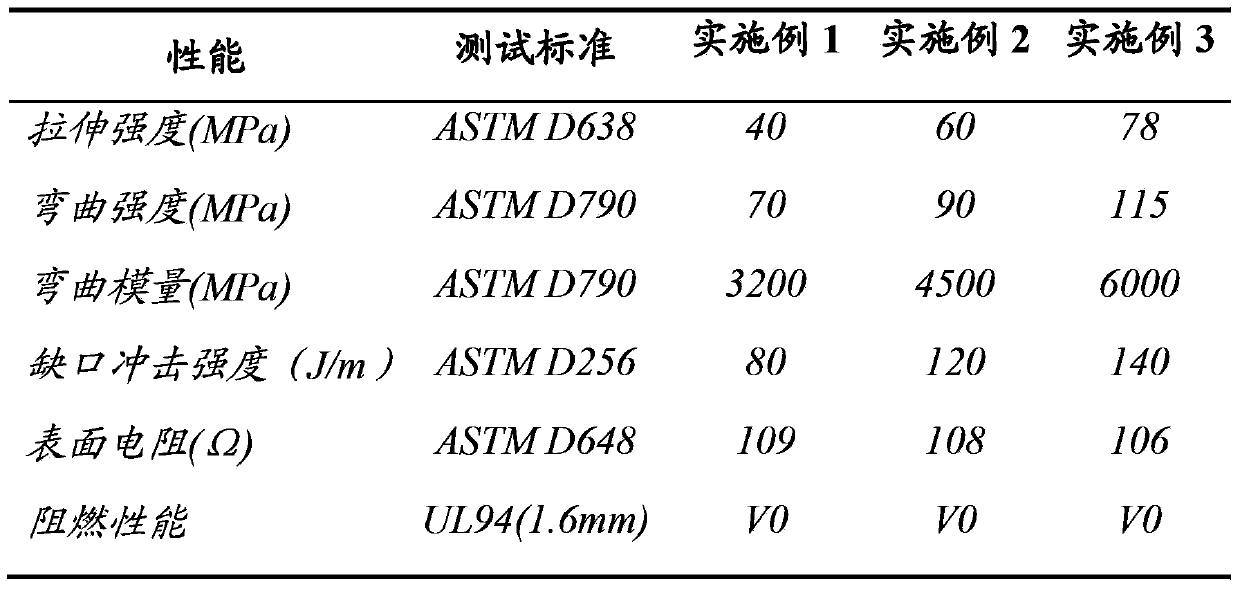

Flame-retardant and reinforced antistatic PP composite material and preparation method thereof

The invention discloses a flame-retardant and reinforced antistatic PP composite material and a preparation method thereof, wherein the Flame-retardant and reinforced antistatic PP composite material comprises the following formula components: polypropylene, a compatilizer, a white mineral oil, a coupling agent, glass fiber, a flame retardant, a synergetic flame retardant, an antistatic agent, a composite lubricant, and other auxiliary agents. The flame-retardant and reinforced antistatic PP composite material uses polypropylene as a matrix resin, uses a self-prepared compatilizer matched to the coupling agent, so as to make excellent combination force exist between the antistatic agent and the glass fiber, and the matrix resin, overcome a wick effect of the glass fiber-reinforced and flame retardant material, and have good flame retardant. Simultaneously, the glass fiber and conductive carbon black have obvious conductive synergism, so as to make the material have excellent conductivity. The preparation has advantages of simple operation, low cost and high production benefit, and is suitable for industrialization production.

Owner:ANHUI KEJU NEW MATERIALS

Mico-crosslinking thermoplastic elastomer and preparation method thereof

ActiveCN104356582AKeep for recyclingLower vulcanization temperatureFoaming agentThermoplastic elastomer

The invention relates to the technical field of high-molecular materials, and provides a mico-crosslinking thermoplastic elastomer and a preparation method thereof. The mico-crosslinking thermoplastic elastomer comprises the following components: a styrene type thermoplastic elastomer, synthetic rubber, white mineral oil, a foaming agent, a crosslinking agent, an antioxidant, a light stabilizer, zinc oxide, zinc stearate, abrasion-resistant agent and nano calcium carbonate. The preparation method comprises the following steps: placing the component materials into an internal mixer, and carrying out internal mixing for 10-15 minutes; controlling discharge temperature at 130-135 DEG C; then pressing into a uniform flaky shape by virtue of a double-roller open mill for discharge; finally cutting a material into a specified dimension, placing into a large-flake vulcanizing machine, carrying out vulcanizing forming, and controlling vulcanizing temperature at 170-175 DEG C and vulcanizing time at 180-350 seconds so as to obtain the mico-crosslinking thermoplastic elastomer. The mico-crosslinking thermoplastic elastomer disclosed by the invention has the characteristics of low density, high abrasion resistance, uniformity in froth, good low temperature flexibility, dimensional stability and the like.

Owner:MAOTAI FUJIAN SOLES CO LTD

Bactericidal mildew-proof wicker treatment agent and preparation method thereof

InactiveCN105291221AGood film formingImprove water resistanceBiocideReed/straw treatmentHigh resistancePotassium persulfate

The invention discloses a bactericidal mildew-proof wicker treatment agent. The treatment agent is prepared from the following raw materials in parts by weight: 3-5 parts of beewax, 3-5 parts of nano-silver, 4-6 parts of styrene, 6-8 parts of butyl acrylate, 0.5-1 part of litseacubeba oil, 0.3-0.5 part of cinnamon oil, 1-2 parts of white mineral oil, 0.5-1 part of potassium persulfate, 0.3-0.5 part of peregal O-25, 4-6 parts of beta-cyclodextrin, 10-15 parts of a coalescing agent, 0.3-0.5 part of sodium alginate and 40-50 parts of water. The wicker treatment agent disclosed by the invention has good film-forming property, is high in binding force with a base material, can form a uniform and dense coating on the surface of a wicker product, has the characteristics of high adhesive force, high water resistance, high air and moisture permeability, adhesion resistance, high stability and the like, has bactericidal mildew-proof effects and is clean, sanitary, environmentally friendly and high in practical value.

Owner:FUNAN YONGXING ARTS & CRAFTS

Lubricant For Conveyor Chains For Packaged Products

A lubricant for conveyor chains of bottled products, set for lubricating through direct application without dilution and in a discontinual way, in prolonged intervals, leaving a layer or film on the surface of the conveyor chain. The lubricant is composed of an homogeneous mixture of one or more fluids of silicon such as emulsified polydimethylsiloxane; one or more fatty acids such as the oleic acid; one or more amines such as the tensoactive product derived from an ethoxylated amine; one or more hydrocarbons such as the white mineral oils; one or more emulsifiers such as the sorbitan monooleate; and one or more polyglycols such as the polyalkylene-glycol, and alternatively a microbicide.

Owner:QUIMIPROD S A DE

Rubber composite for wear-resistant tire treads

The invention provides a rubber composite for wear-resistant tire treads. The rubber composite is prepared from, by weight, 4-30 parts of natural rubber, 4-40 parts of butadiene rubber, 4-40 parts of styrene butadiene rubber, 35-75 parts of high-dispersion white carbon black, 3-10 parts of white mineral oil, 1.0-2.5 parts of indirect zinc oxide, 1.0-2.0 parts of stearic acid, 1.0-2.0 parts of rubber protecting wax, 1.0-2.8 parts of silane coupling agent, 1.0-2.0 parts of anti-aging agent, 1.0-2.0 parts of tackifying resin, 1.0-2.0 parts of dispersing agent, 1.0-2.8 parts of common sulphur, 0.5-2.0 parts of accelerant CZ, 1.0-2.0 parts of accelerant DPG and 0.1-1.0 part of accelerant DM, by proportioning according to the formula prior to mixing via an internal mixer. The rubber composite is mixed via the internal mixer by means of blending the natural rubber and the synthetic rubber as main materials which are matched with the high-dispersion white carbon black as a reinforcing agent and through unique anti-aging system design, and accordingly tire treads produced by the rubber composite are excellent in wear-resisting property, good in tear resistance and high in tensile strength, and service lives of tires for taxies, family cars and the like can be prolonged.

Owner:双星东风轮胎有限公司

Alcohol-free fountain solution and preparation method thereof

ActiveCN104149514ALow costControl over emulsificationPrinting pre-treatmentAlcohol freeGallic acid ester

The invention discloses an alcohol-free fountain solution. The alcohol-free fountain solution is characterized by comprising the following raw materials of, by weight, 2-8 parts of water-soluble wool fat, 2-8 parts of sulfobutyl ether-beta-cyclodextrin, 1-4 parts of glucose, 1-3 parts of galactose, 1-3 parts of melitose, 1-4 parts of cetostearyl alcohol, 1-3 parts of gallic acid, 0.5-1.5 parts of tea saponin, 1-3 parts of white mineral oil, 1-4 parts of caprylic / capric triglyceride, 1-3 parts of sodium nitrate, 0.2-1 part of methylisothiazolinone, 5-10 parts of auxiliaries and 30-50 parts of water. The alcohol-free fountain solution is simple in technology, avoids use of alcohol, is gentle and harmless to human bodies and the environment, reduces cost, and meets the requirements for energy conservation and environmental protection; the raw materials of the alcohol-free fountain solution are easy to obtain.

Owner:合肥新意境材料有限责任公司

Light-emitting shoe material and preparation method thereof

The invention discloses a light-emitting shoe material and a preparation method thereof. The light-emitting shoe material comprises styrene type thermoplastic elastomer, 1,2-polybutadiene, styrene-butadiene copolymer (K adhesive), white mineral oil, a photo-thermal stabilizer, a lubricant and nano silicon dioxide. The preparation method comprises the following steps: premixing the components in a high-speed mixer, carrying out melt extrusion on the premixture at 120-130 through a double screw extruder, cooling, granulating, and finally, carrying out injection molding at 137-145 DEG C to obtain the light-emitting shoe material. The light-emitting shoe material has the characteristics of uniform light scattering, uniform brightness, soft light rays, favorable toughness, high anti-skid property, stable dimension and the like.

Owner:MAOTAI FUJIAN SOLES CO LTD

Thermoplastic elastomer foam material and preparation method thereof

The invention relates to the technical field of a foam material, in particular to a thermoplastic elastomer foam material and a preparation method thereof. The thermoplastic elastomer foam material consists of following raw materials in parts by weight: 20 to 30 parts of styrene-ethylene butylene-styrene (SEBS), 20 to 30 parts of white mineral oil, 25 to 35 parts of calcium carbonate, 3 to 8 parts of ethylene vinyl acetate (EVA), 1 to 5 parts of polyolefin elastomer (POE) and 0.1 to 0.5 parts of zinc stearate. Multiple raw materials such as calcium carbonate, EVA and POE are selected to be matched with the SEBS to use, so that the prepared foam material is not only low in cost and good in abradability and compression deformation, but also other physical indexes such as hardness, elasticity and the like are improved. The preparation method is simple in process and low in cost.

Owner:东莞市鑫塑源塑胶科技有限公司

Method for preparing anti-aging and anti-bacterial plastic granules and method for preparing double-layer PPR (Polypropylene Random) pipe by using anti-aging and anti-bacterial plastic granules

InactiveCN103980598AImprove antibacterial propertiesImprove anti-aging propertiesRigid pipesPolymer sciencePolypropylene

The invention discloses a method for preparing natural anti-aging and anti-bacterial plastic granules and a method for preparing a double-layer PPR (Polypropylene Random) pipe by using the anti-aging and anti-bacterial plastic granules. The method for preparing plastic granules comprise the steps of adding 0.1-5 part of white mineral oil No.10, 2-8 parts of polyethylene wax, 0.1-5 part of silane coupling agent, 20-40 parts of polyethylene resin, 5-10 parts of shell powder of which the granule size is 80-100 meshes, and 3-6 parts of silver-carried charcoal powder of which the granule size is 80-200 meshes into a high-speed mixer, mixing uniformly, extruding and granulating by a twin-screw extruder. The invention also discloses a method for preparing a bactericidal, anti-UV, anti-static and flame retardant double-layer PPR pipe by using the natural anti-aging and anti-bacterial plastic granules. The method disclosed by the invention has the advantages of simple operation, strong practicality, low-cost and environment friendliness; the obtained natural anti-aging and anti-bacterial plastic granules have the advantages of good dispersity and stable performance and the obtained PPR pipe has excellent anti-aging and antibacterial performances and high cost-performance ratio and has relatively strong practical application value and market development prospects.

Owner:GUANGXI JIALI IND & TRADE

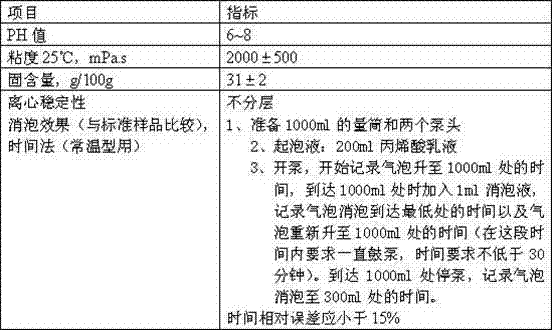

Low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and preparation method thereof

InactiveCN106833503AImprove adhesionImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationALUMINUM STEARATES

The invention discloses a low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and a preparation method thereof. The silicon sealant is prepared from hydroxyl end-blocked dimethylsiloxane, a plasticizer, white mineral oil, gas phase method silica aerogel, a reinforcing filler, aluminum stearate, pigment, a crosslinking agent, a vulcanization accelerator, a silane coupling agent and a catalyst. The preparation method comprises the following steps: 1) uniformly mixing the hydroxyl end-blocked dimethylsiloxane, the plasticizer, the white mineral oil, the gas phase method silica aerogel, the reinforcing filler, the aluminum stearate and the pigment, and drying the mixture fully to obtain a premix compound; 2) performing vacuum full kneading on the premix compound to obtain base; 3) adding the crosslinking agent, the vulcanization accelerator and the silane coupling agent into the base, performing vacuum stirring uniformly;4) adding the catalyst into the base, performing vacuum stirring uniformly, discharging the mixture, and performing filling and sealing. The low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant provided by the invention has the advantages of neutral solidification, strong bonding power, excellent mechanical property, and good heat resistance and oil resistance.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

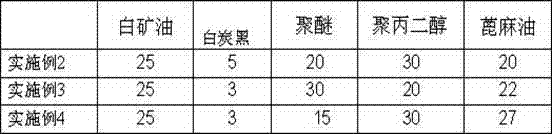

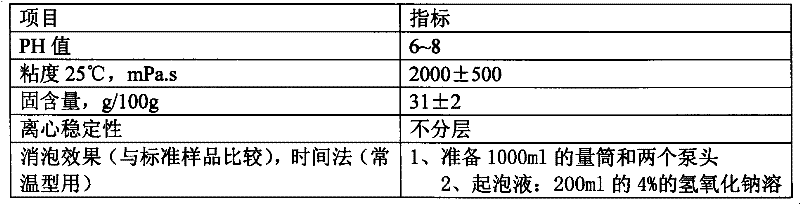

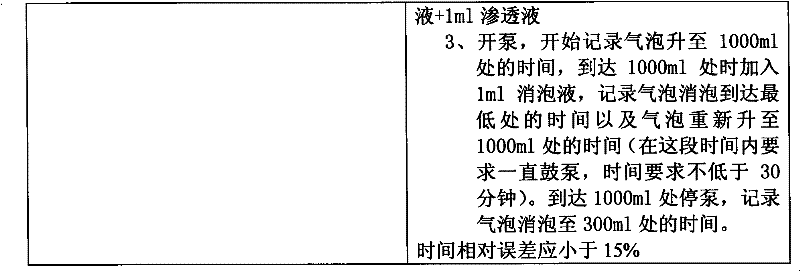

Preparation method of non-silicon defoaming agent

The invention discloses a preparation method of a non-silicon defoaming agent. The method is characterized in that the method comprises the steps that: first, a factice is prepared, wherein materials are blended according to a weight ratio that white mineral oil to white carbon black to polyether to polyether polyol to castor oil is 10-25:2-5:15-25:10-20:10-25; the materials are added into a reaction vessel provided with stirring blades, a motor and a heating system, and are well mixed under a room temperature; discharging can be carried out after 1h of stirring; 80 parts of the prepared factice, 20 parts of self-emulsifying silicone oil, 20 parts of tributyl phosphate, and 10 parts of a mixed emulsifier are well mixed by stirring; 280 parts of water is added such that the mixture is subjected to phase inversion; after phase inversion is completed, 16 parts of a thickening agent is added for regulating the viscosity to 1500-2000CS; and discharging and packaging are carried out. The preparation method is simple, production cost is low, and produced product is environment-friendly and has no pollution. Various performance indicators of the product are good. The non-silicon defoaming agent is suitable to be used in defoaming and foaming-inhibiting of water-based acrylic paints.

Owner:佛山市华联有机硅有限公司

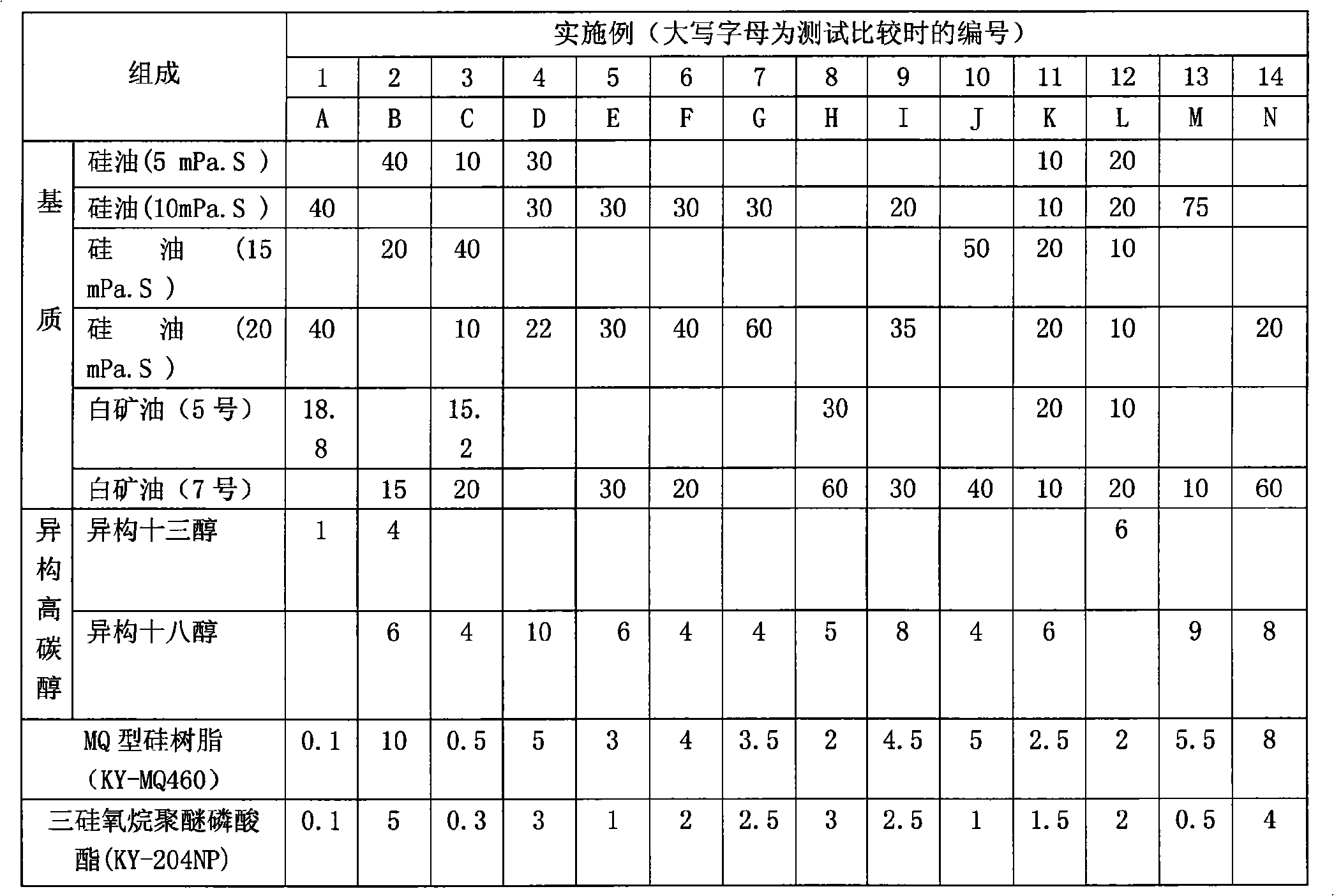

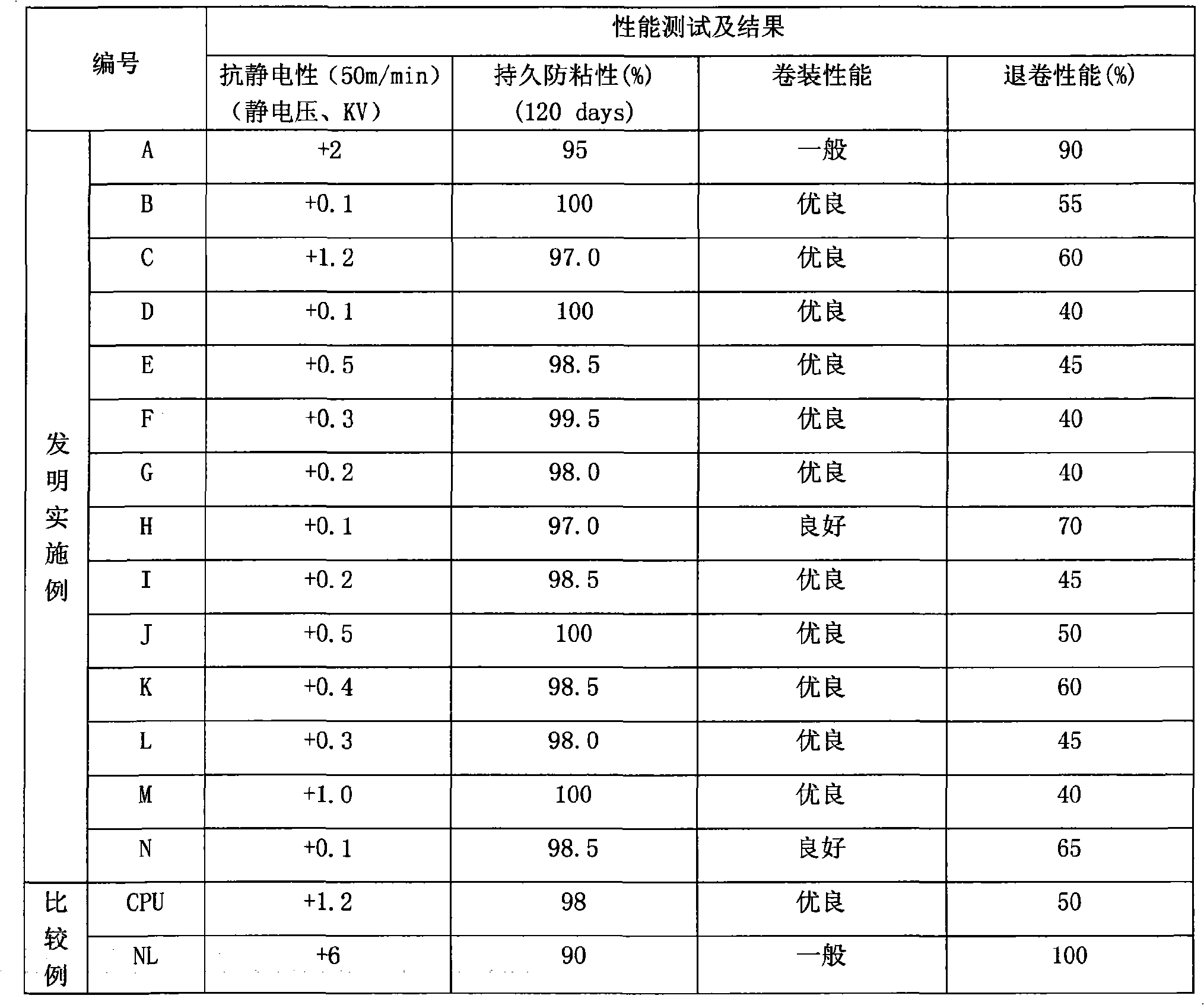

Polyurethane elastic fiber finishing agent

InactiveCN101666040AGood sealing and anti-sticking effectUniform sealing and anti-stick effectFibre typesAlcoholPhosphate

The invention discloses a polyurethane elastic fiber finishing agent, comprising the following components in parts by weight: 75.0-98.8 parts of at least one substrate selected from silicon oil and white mineral oil, 1.0-10.0 parts of isomerous high-carbon alcohol, 0.1-10.0 parts of MQ silicon resin of which the pour point is smaller than or equal to 100 DEG C and 0.1-5.0 parts of trisiloxane polyether organic phosphate. The finishing agent enables the polyurethane elastic fiber to have favorable antistatic property, lubricating property and grating balancing property in the filament reeling process, so that the polyurethane elastic fibers reeling at high speed have stable tension and do not skid or cause the filament roller to mess up, thereby endowing the polyurethane elastic fibers withfavorable reeling property. The finishing agent also enables the polyurethane elastic fibers rolled on the roller to have enduring anti-adhesion insulation property, so that the polyurethane elasticfibers have favorable cocoon reelability and thorough root unreeling property in the downstream unreeling process, thereby endowing the polyurethane elastic fibers with favorable unreeling property.

Owner:HUAIAN KAIYUE TECH DEV

Nylon-66 modified elastomer and preparation method thereof

ActiveCN103113740AImprove toughnessLight weightPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneElastomer

The invention belongs to the technical field of thermoplastic elastomers and discloses a nylon-66 modified elastomer and a preparation method thereof. The nylon-66 modified elastomer comprises the following components in parts by weight: 15-70 parts of PA66, 5-15 parts of nylon toughening compatilizer, 10-70 parts of SEBS, 15-75 parts of ultra-low density polyethylene, 1-15 parts of calcium stearate and 1-2 parts of white mineral oil. The nylon-66 modified elastomer has the characteristics of high temperature resistance and oil resistance, has the characteristics of SEBS, low specific gravity of ultra-low density polyethylene and high toughness and has high compatibility, proper product hardness and low cost.

Owner:广东明聚新材料科技有限公司

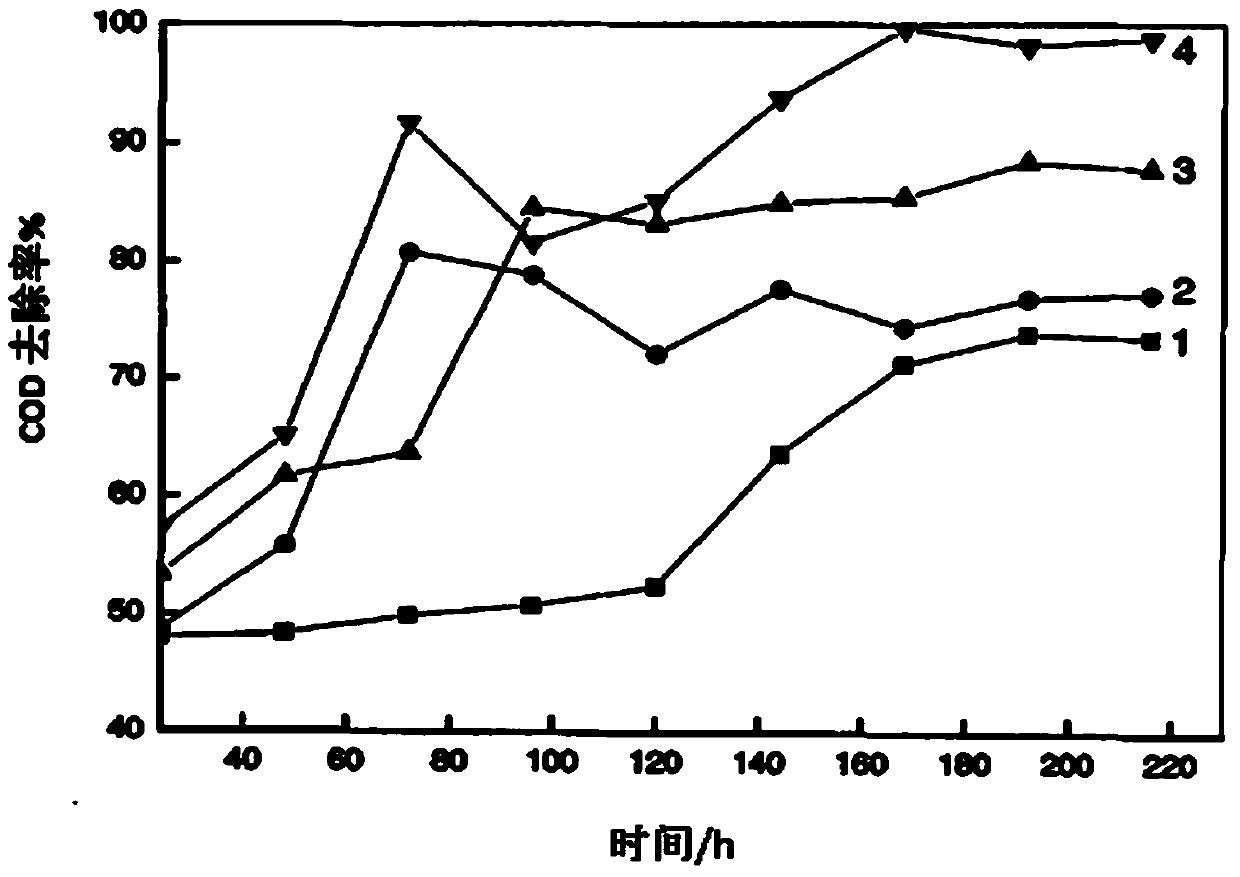

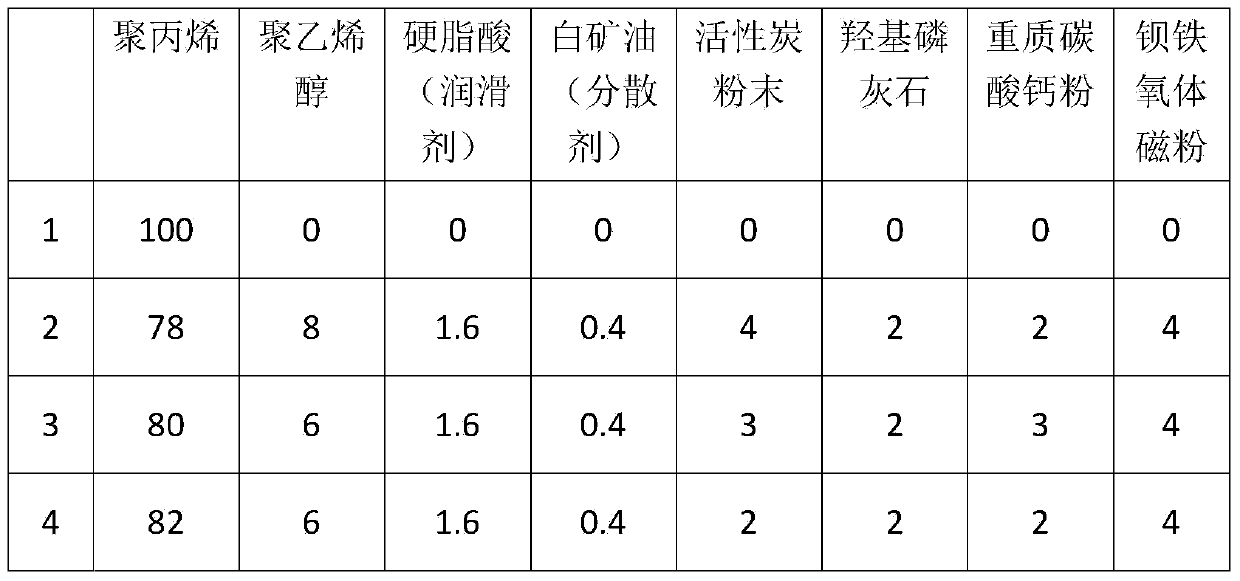

Biological affinitive hydrophilic modified magnetic filler

InactiveCN104192993AImprove hydrophilicityIncrease chance of contactSustainable biological treatmentBiological water/sewage treatmentPolyvinyl alcoholStearic acid

The invention relates to biological affinitive hydrophilic modified magnetic filler applied in the field of wastewater treatment. The biological affinitive hydrophilic modified magnetic filler comprises the following raw materials: 78%-82% of polypropylene, 6%-8% of polyvinyl alcohol, 2%-4% of active carbon powder, 2%-3% of modified heavy calcium carbonate powder, 2% of hydroxyapatite, 1.6% of stearic acid, 0.4% of white mineral oil and 4% of modified barium ferrite magnetic powder. According to the biological affinitive hydrophilic modified magnetic filler, a biological hydrophilic macromolecular material-polyvinyl alcohol is mainly introduced, so that the pollutant adsorption performance can be improved; the hydroxyapatite is introduced, so that the bioactivity can be improved, a proper nutritional source is provided for microorganisms, the hydrophilicity of the filler is improved, the biofilm formation starting speed is increased, and the wastewater treatment efficiency is improved; the modified barium ferrite magnetic powder containing rare metal is introduced, so that a microscopic high-intensity magnetic field and a macroscopic low-intensity magnetic field are formed, the adsorption effect of degradation bacteria on the surface of the filler is enhanced, and then the biofilm formation speed and the wastewater degradation speed of the filler in wastewater treatment are increased.

Owner:王伟

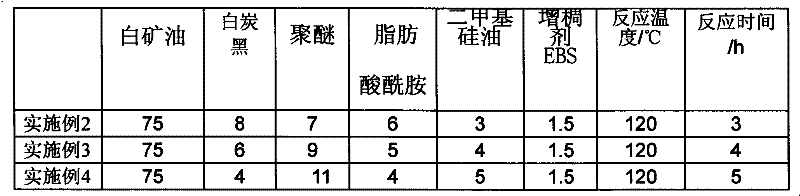

Preparation method for non-silicon antifoaming agent

InactiveCN102350098AEasy to useGood dispersionFoam dispersion/preventionAdditive ingredientPhosphate

The invention discloses a preparation method for a non-silicon antifoaming agent, comprising the following steps: firstly, preparing ingredients according to the following proportion: 60-80 weight portions of white mineral oil, 5-10 weight portions of white carbon black, 5-10 weight portions of polyether, 3-7 weight portions of dimethicone, 2-4 weight portions of fatty amide, and 1-3 weight portions of thickening agent EBS; then, adding the ingredients in a reaction vessel providing with a stainless steel stirrer, a motor and a heating system, uniformly mixing the ingredients at normal temperature, heating up to 120 DEG C and keeping the constant temperature of 120 DEG C for 3-5 h, and finally continuously stirring, cooling to room temperature, and discharging to obtain an ointment; taking 80 weight portions of the ointment, adding 20 weight portions of self-emulsifying silicone oil and 20 weight portions of phosphate ester, 5 weight portions of emulsifier XP-50, and 5 weight portions of emulsifier XP-80 in the ointment and uniformly stirring, then adding 280 weight portions of water for phase inversion, adding 16 weight portions of thickening agent for thickening and regulating the viscosity, and discharging and packaging. The method has the advantages of simple preparation and low cost, the prepared non-silicon antifoaming agent has no pollution to the environment, and all performance indexes of the non-silicon antifoaming agent are good.

Owner:佛山市华联有机硅有限公司

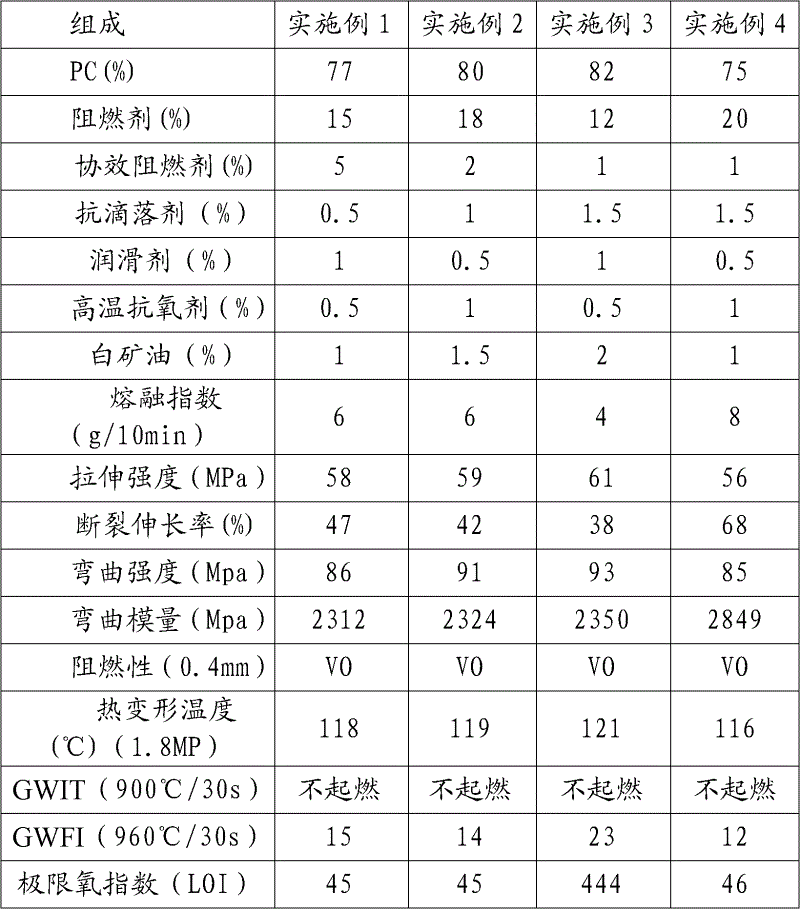

PC (Polycarbonate) film material and preparation method thereof

The invention discloses a PC (Polycarbonate) film material and a preparation method thereof. The PC film material comprises the following components by weight percentage: 70-85% of PC, 5-10% of flame retardant, 1-5% of flame retardant synergist, 0.1-1% of anti-dripping agent, 0.1-1% of high temperature antioxidant, 0.1-1% of lubricant, and 1-2% of white mineral oil. The PC film material provided by the invention has the advantages of good film-forming properties, environment friendliness and flame retardance, low smoke and low toxicity, high glow-wire ignition temperature (GWIT is more than or equal to 900 DEG C), high glow-wire flammability temperature (GWFI is more than or equal to 960 DEG C), and high oxygen index ( LOI is more than or equal to 44), and is suitable for the fields of electrical and electronic appliances of keyboard insulation, TV / monitor insulation, computer motherboard insulation and the like.

Owner:SHENZHEN KEJU NEW MATERIAL

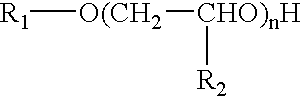

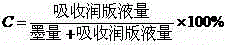

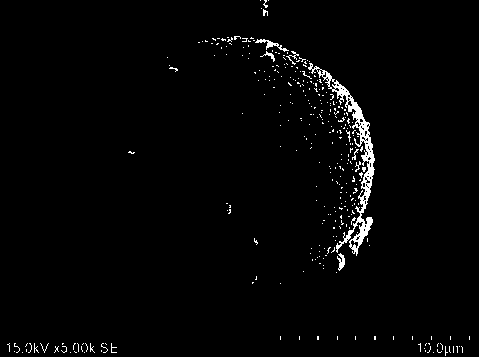

Novel high-strength uniform-strength cellulose microsphere preparation method

InactiveCN108745219AEasy to operateRaw materials are easy to getMicroballoon preparationMicrocapsule preparationCelluloseCross-link

The invention relates to a novel high-strength uniform-strength cellulose microsphere preparation method, and belongs to the technical field of materials. The preparation method includes first dissolving cellulose in an alkaline solvent; then placing the cellulose in an ice bath, adding a crosslinking agent dropwise, premixing the crosslinking agent with a cellulose solution to enable crosslinkingagent molecules to be evenly dispersed among cellulose molecules; utilizing the solution as a dispersed phase and white mineral oil as a continuous phase to prepare cellulose emulsion; after emulsification for a period, enabling the uniformly mixed crosslinking agent molecules and the cellulose molecules to have cross-linking reaction to form a stable cellulose gel sphere through auto polymerization in drops and then regenerate a cellulose microsphere. The results show that the cellulose microsphere prepared by the preparation method has high strength and uniform strength. The above results indicate that the microsphere prepared by the method has high uniform strength, is simple in process, wide in raw material source, easy to degrade, free of toxicity and good in biocompatibility, and greatly expands the application range of cellulose base materials.

Owner:SICHUAN UNIV

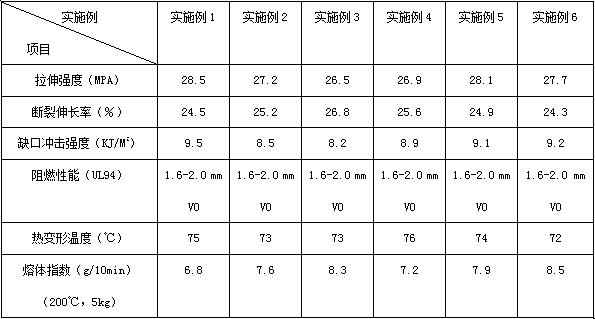

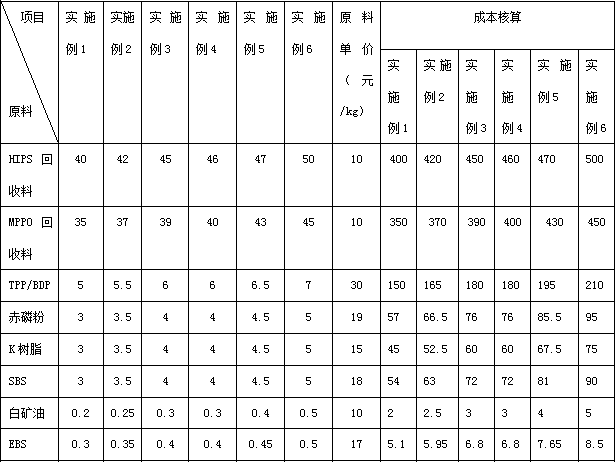

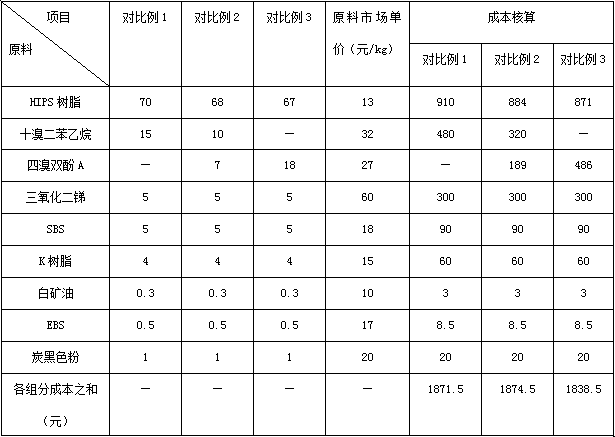

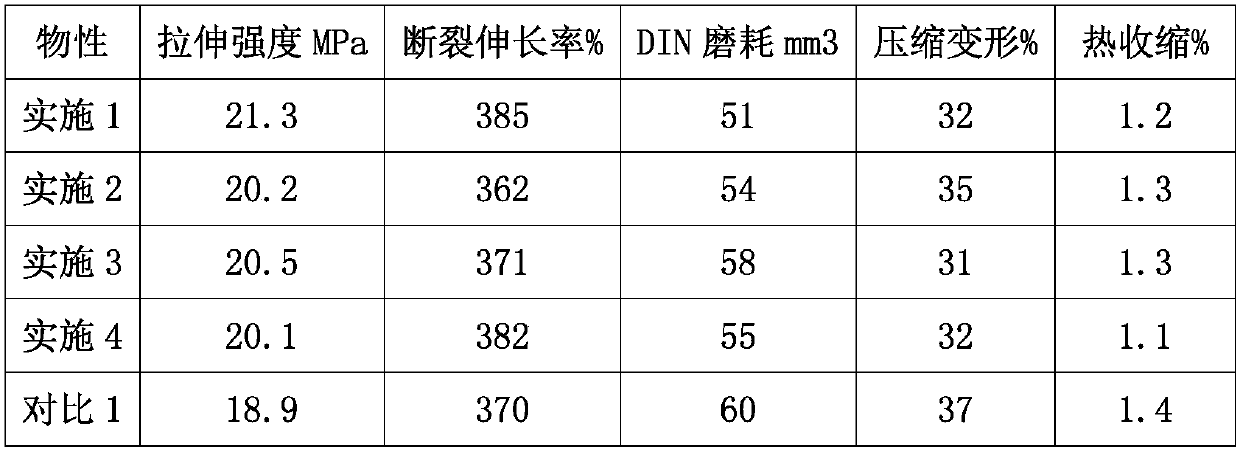

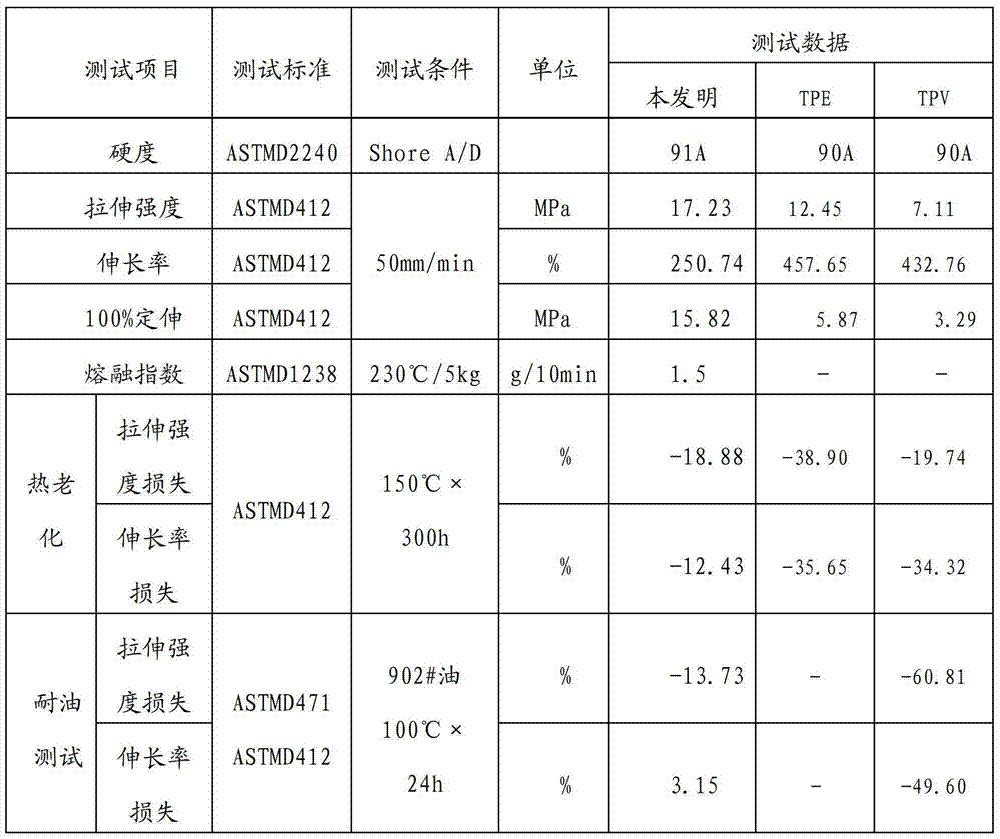

Halogen-free flame retardant HIPS (High Impact Polystyrene) plastic modified material and preparation method thereof

ActiveCN103242614AImprove flame retardant performanceImprove securityPlastic materialsUltimate tensile strength

The invention relates to a halogen-free flame retardant HIPS (High Impact Polystyrene) plastic modified material and a preparation method thereof. The halogen-free flame retardant HIPS plastic modified material comprises the following materials in parts by weight: 40-45 parts of HIPS, 35-40 parts of MPPO (Modified Polyphenylene Oxide), 5-7 parts of halogen-free flame retardant, 3-5 parts of red phosphorus powder, 3-5 parts of K resin, 3-5 parts of SBS (Styrene Butadiene Styrene), 0.3-0.5 part of lubricating agent, 0.2-0.5 part of white mineral oil and 0.5-2 parts of carbon black powder. The halogen-free flame retardant HIPS plastic modified material not only has good flame retardation and strong safety, but also has good mechanical performances including tensile strength and the like; a television enclosure, which is manufactured by the halogen-free flame retardant HIPS plastic modified material, has stronger impact resistance and a long service life, and can be recycled. The processing materials MPPO and HIPS are mainly reclaimed materials, so that the cost of the modified HIPS plastic material is greatly lowered. The halogen-free flame retardant HIPS plastic modified material is free of halogen, environment-friendly and capable of generating great environment-friendly benefits. Besides, the preparation method of the halogen-free flame retardant HIPS plastic modified material is simple to operate, less in needed equipment and low in production cost.

Owner:东莞国立高分子材料有限公司

Graphene regenerated rubber and plastic foamed colloidal particle for soles and preparation method thereof

The invention relates to a graphene regenerated rubber and plastic foamed colloidal particle for soles. The graphene regenerated rubber and plastic foamed colloidal particle for soles is prepared fromthe following ingredients in parts by weight: 60 to 65 parts of EVA (Ethylene-vinyl acetate copolymer) waste materials, 23 to 25 parts of natural rubber, 4 to 6 parts of POE (Polyolefin elastomers),1 to 2 parts of modified graphene, 0.1 to 0.2 part of poly N-vinylacetamide, 2.0 to 2.3 parts of white mineral oil, 1.0 to 1.2 parts of silicone oil, 1.4 to 1.5 parts of active zinc oxide, 0.8 to 1.0part of zinc stearate, 0.8 to 1.0 part of stearic acid, 0.8 to 1.0 part of crosslinking agents, 2.0 to 3.0 parts of flow additives and 1.5 to 1.8 parts of foaming agents. According to the invention, the existing EVA waste materials are sufficiently utilized; resources are regenerated; and the foamed colloidal particle with the physical properties reaching a standard and the heat-shrinkage-resistant performance capable of being enhanced is obtained.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Modified elastomer of nylon 6 and preparation method thereof

The invention relates to the technical field of a thermoplastic elastomer and discloses a modified elastomer of nylon 6 and a preparation method thereof. The modified elastomer comprises the following components in parts by weight: 15-70 parts of PA6 (Nylon 6), 5-15 parts of nylon toughening compatilizer, 10-70 parts of SEBS (thermoplastic elastomer), 15-75 parts of ultralow-density polyethylene, 1-15 parts of calcium stearate and 1-2 parts of white mineral oil. The modified elastomer disclosed by the invention has the high temperature resistance and oil resistance of PA6, has the characteristics of small specific gravity of SEBS and ultralow-density polyethylene and good toughness, and also has good compatibility, suitable product rigidity and low cost.

Owner:广东明聚新材料科技有限公司

Environment-friendly anti-aging automobile inner decorating glue and preparation method thereof

ActiveCN105602509ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSilanesAnti ageing

The invention discloses environment-friendly anti-aging automobile inner decorating glue. The glue is prepared from SBS, hydroxy-terminated hyperbranched polyurethane, HO-SBS, white mineral oil, dimethyl sulfoxide, antioxidant and silane modified hyperbranched polyimide, wherein the silane modified hyperbranched polyimide is prepared from raw materials including epoxy silane coupling agent and amino-terminated hyperbranched polyimide. The invention further discloses a preparation method of the environment-friendly anti-aging automobile inner decorating glue.

Owner:SHANGHAI JIAHAO ADHESIVE PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com