Patents

Literature

205 results about "Aluminum Stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The aluminum salt of the fatty acid, stearic acid.

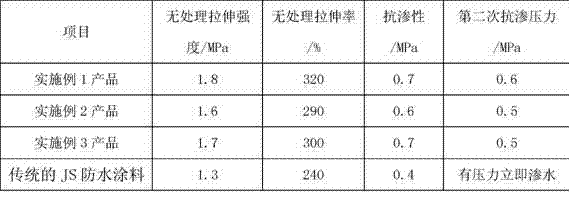

Polymer cement waterproof coating

The invention discloses a polymer cement waterproof coating which is formed by mixing a liquid material and an inorganic powder material based on a mass ratio of 1:1, wherein the liquid material comprises the following components: 60-80% of polymer emulsion, 0.5-1% of wetting dispersant, 0.05-0.1% of antifoaming agent, 1-5.0% of anti-settling agent, 1-5.0% of coalescing agent, 0.5-1% of mildew-proof preservative, 1-2% of leveling agent and the balance of water; and the inorganic powder material comprises the following components: 35-50% of cement with strength grade of 42.5, 10-15% of admixture, 5-10% of calcium carbonate, 0.1-0.5% of water reducing agent, 1-5% of instant sodium silicate, 1-% of aluminum stearate, 0.05-0.1% of thickening agent, 0.05-0.1% of triethanolamine and the balance of quartz sand. Compared with the traditional JS waterproof coating, the tensile strength, stretch rate, impermeability and secondary impermeability pressure of a film of the polymer cement waterproof coating disclosed by the invention are greatly improved.

Owner:CHENGDU JIAXIN TECH

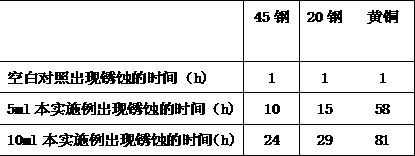

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

Biological degradable thin film material for transfusion bag and its preparing method

InactiveCN1821303AAdjustable degradation rateLower glass transition temperaturePharmaceutical containersMedical packagingPolyethylene glycolAluminum Stearate

The present invention relates to a kind one biodegradable film material for transfusion bag and its preparation process. The new type of medical film is prepared with polylactic acid as main material; proper amount of polyepsilon-caprolactone and lactic acid-epsilon-caprolactone copolymer; medical plasticizer tributyl acetylcitrate, tributyl citrate, triethyl citrate or polyglycol; defoaming agent methyl silicon oil or tributyl phosphate; lubricant aluminum stearate or calcium stearate; heat stabilizer maleic anhydride or EOS; and strengthening agent MMT. The biodegradable film material for transfusion bag has excellent flexibility, physical and chemical performance, and biological performance, and is expected to replace non-degradable film to avoid í‹white pollutioníŒ.

Owner:SHANGHAI UNIV

Polyurethane composite material regenerated from waste polyurethane soles and preparation process thereof

InactiveCN104448775ASolving Recycling ProblemsRaw materials are easy to getAmmonium polyphosphateChemistry

The invention discloses a polyurethane composite material regenerated from waste polyurethane soles and a preparation process thereof. The polyurethane composite material is prepared from the following raw materials in parts by weight: 170-180 parts of waste polyurethane soles, 10-14 parts of a compatibilizer, 5-7 parts of toluene diisocynate, 2-4 parts of tri(2,4-di-tert-butylphenol) phosphite ester, 4-6 parts of medical stone powder, 6-8 parts of organic silicon, 2-3 parts of ammonium polyphosphate, 12-18 parts of polyisocyanate, 3-5 parts of hybrid polyester polyol, 5-7 parts of dibutyltin dilaurate, 6-8 parts of alkanolamide, 4-5 parts of nano-alumina powder, 2-3 parts of antioxidant TNP, 7-9 parts of aluminum stearate, 8-10 parts of isocyanate, 4-6 parts of zirconium oxide, 9-11 parts of nano montmorillonite and 10-12 parts of additives. According to the invention, on one hand, the recovery problem of the waste polyurethane soles is solved, on the other hand, the raw materials are easy to obtain, the cost is low, the operation is simple, and emission of three wastes is avoided in the production, so as to protect the environment and reduce the production cost, and ensure that the economic benefit and the social benefit are considerable.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

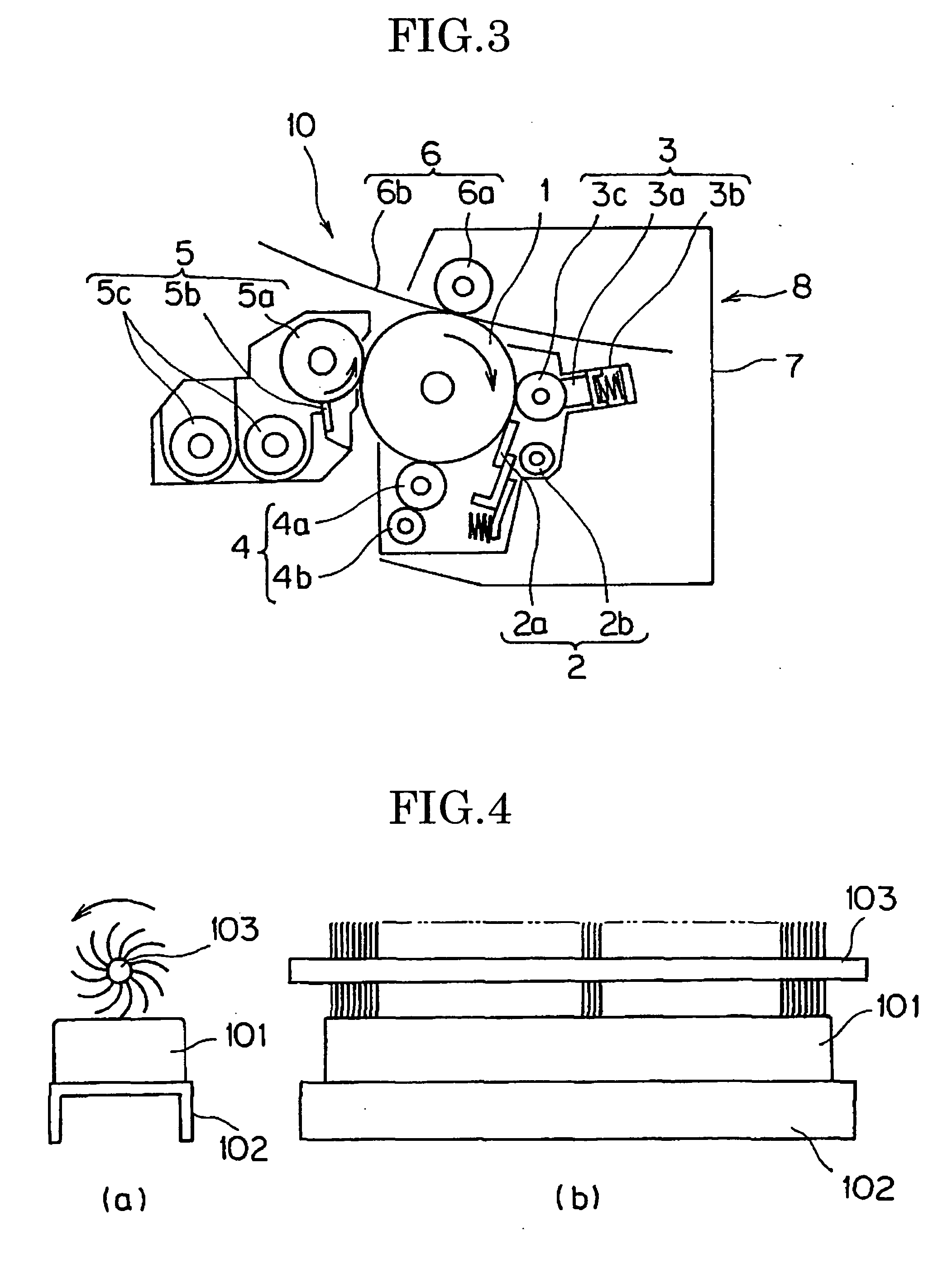

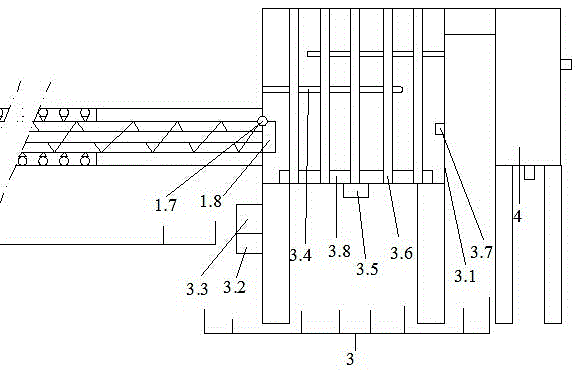

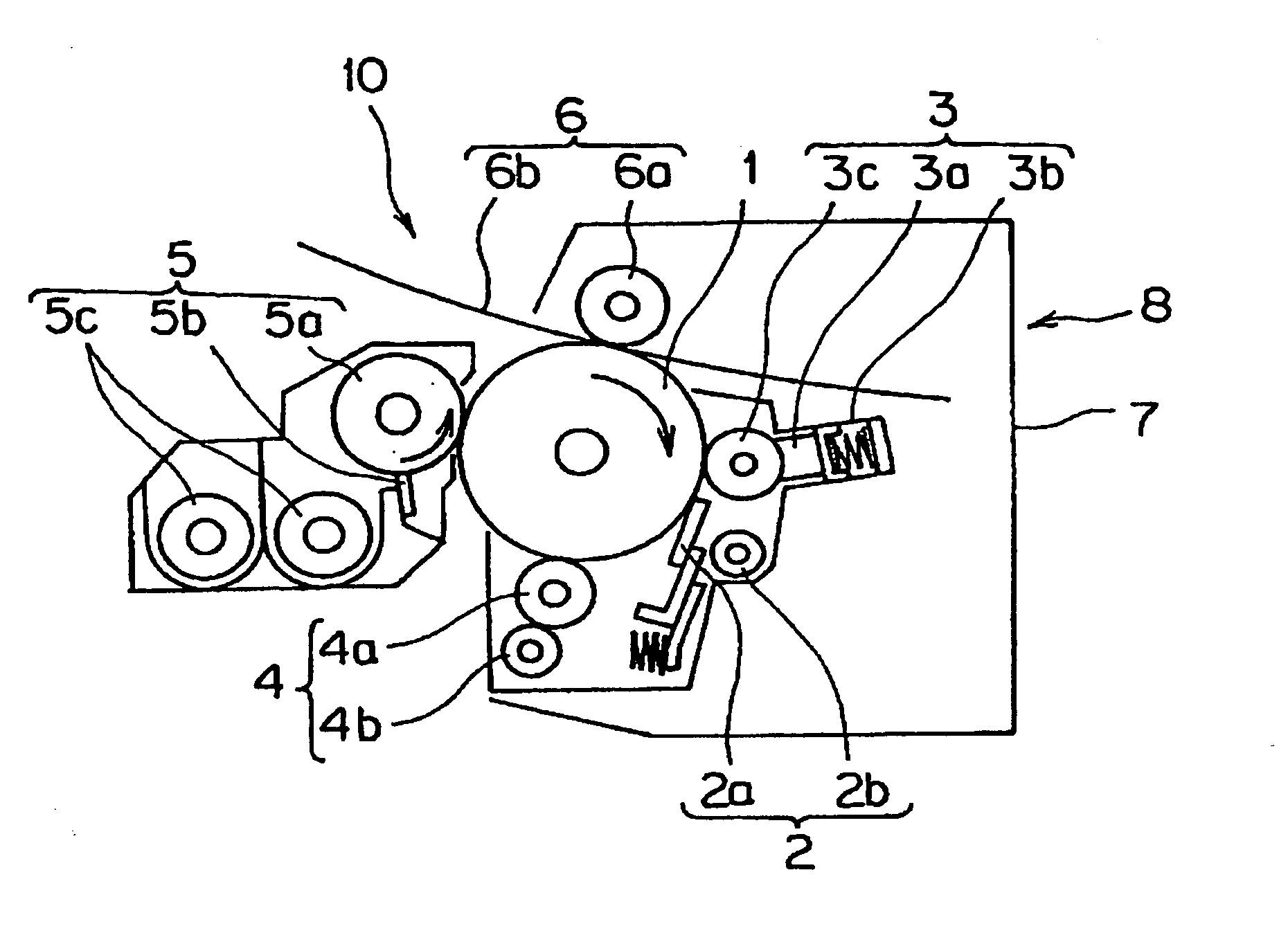

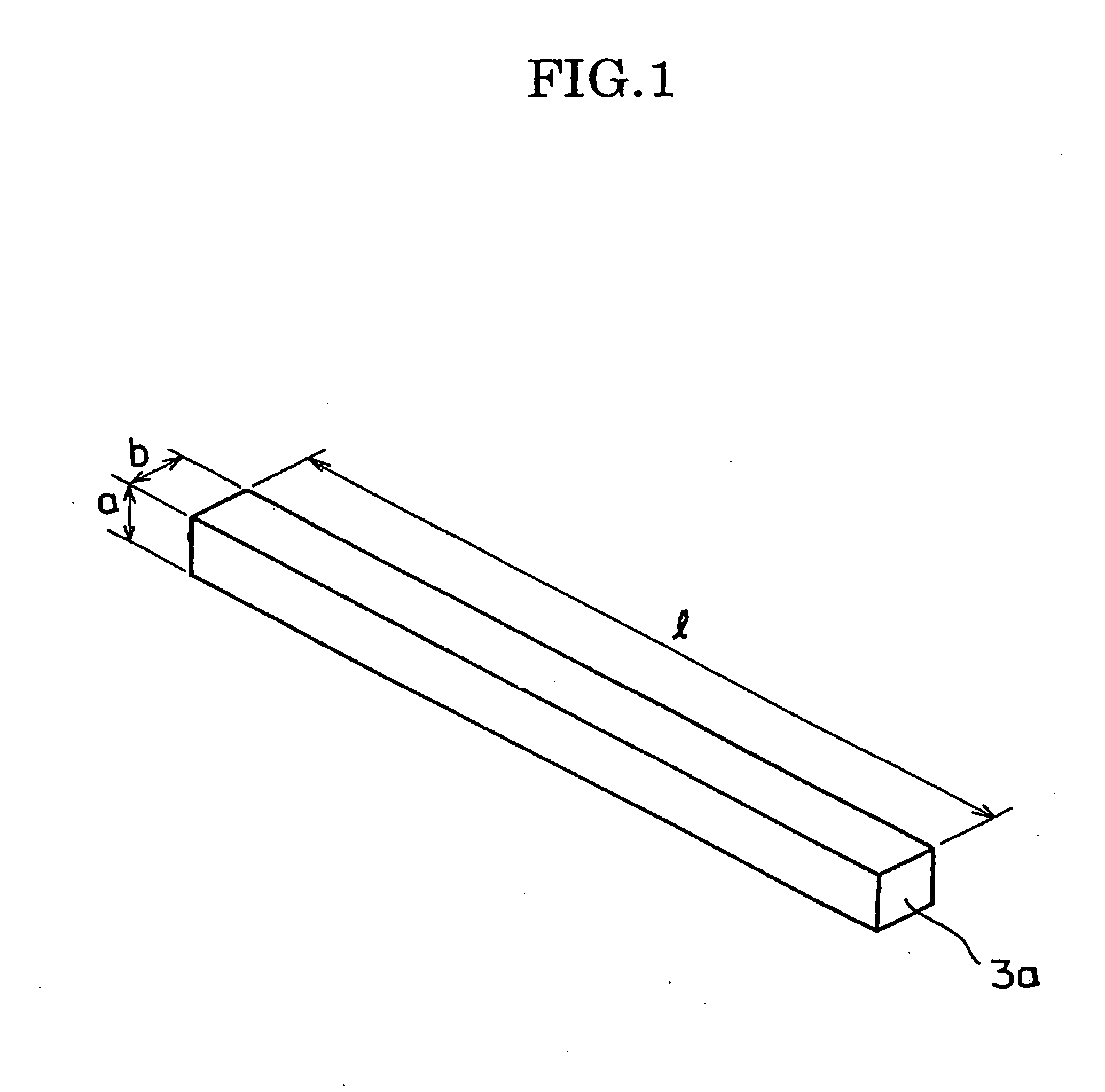

Lubricant molded body, lubricant application apparatus, process cartridge, and image forming apparatus

ActiveUS20070123435A1Low costFew cracking and cuttingFibre treatmentSynthetic resin layered productsCarbon numberAluminum Stearate

A lubricant molded body, which is to be applied to a surface of a photosensitive layer for electrophotography in an image forming apparatus, for example, is composed of at least two kinds of higher fatty acid metallic salts having respectively different carbon numbers. As the higher fatty acid metallic salt that forms lubricant molded body, compounds such as zinc stearate, calcium stearate, barium stearate, aluminum stearate, zinc laurate, calcium laurate, etc. may be recited. The higher fatty acid metallic salts may contain at least one kind of fillers selected from the group consisting of silica, alumina, tungsten disulfide, molybdenum disulfide, graphite fluoride, graphite, boron nitride, polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and polyvinylidene fluoride (PVDF).

Owner:RICOH KK

Art oil paint containing nano-pigment and method for manufacturing same

InactiveCN101225253ABright and brightSaturated and IntenseWax coatingsArtist's paintsALUMINUM STEARATESCobalt

The invention relates to art oil paint with nano-pigment and the preparation method, which is characterized in that the beeswax is added into refined linseed oil and polly seed salad oil and blended evenly to make bond after heating and melting. The nano-pigment is added into the bond to blend evenly and then the pigment is added in and blended evenly. Then aluminum stearate, 2-ethyl hexanol cobalt (CAS No.13586-82-8), silicon dioxide hydrate, hydrafil, phenoxetol, butyl-p-cresol and lithopone are added in and then blended evenly. The product can be obtained after grinding. The preparation method first disperses the nano-pigment into the bond and drains most air on the surface of the common pigment grain, and then disaggregates the large grain and small gobbet of the sizing agent by the large shearing force, extrusion force and grinding force between the two rollers generated by the turn of the three-roller muller. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

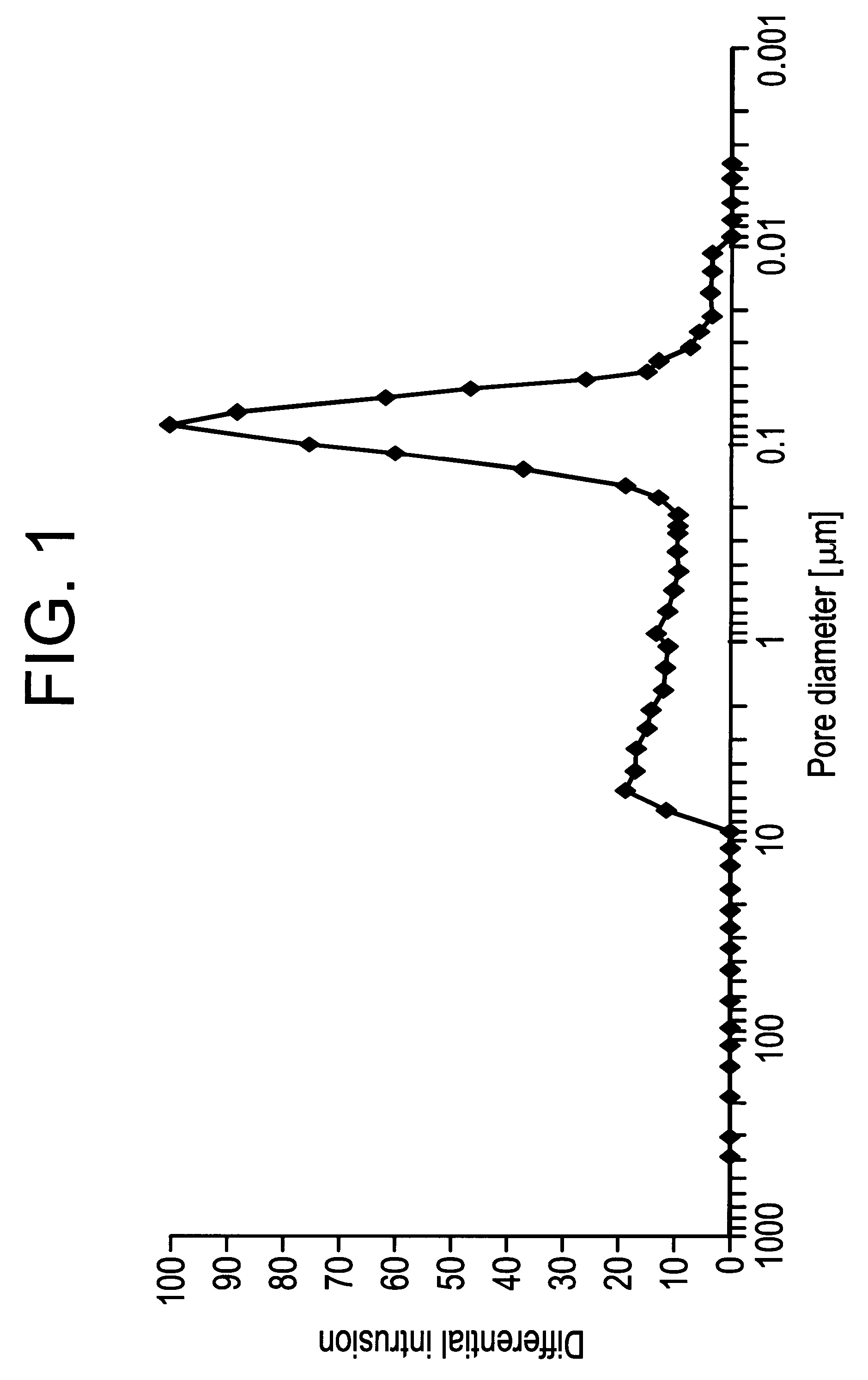

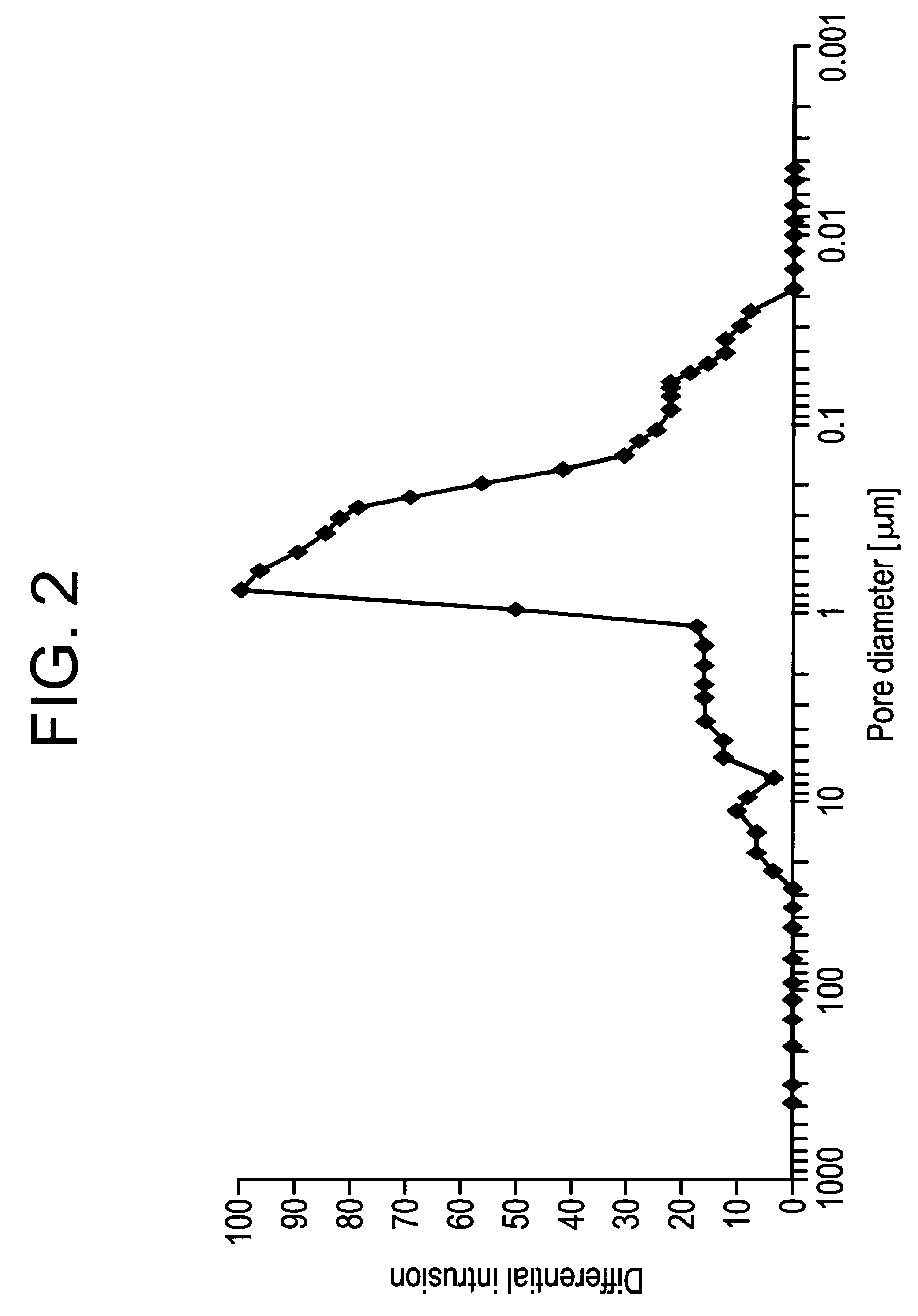

Moldings including pyrogenic mixed oxide and the use thereof

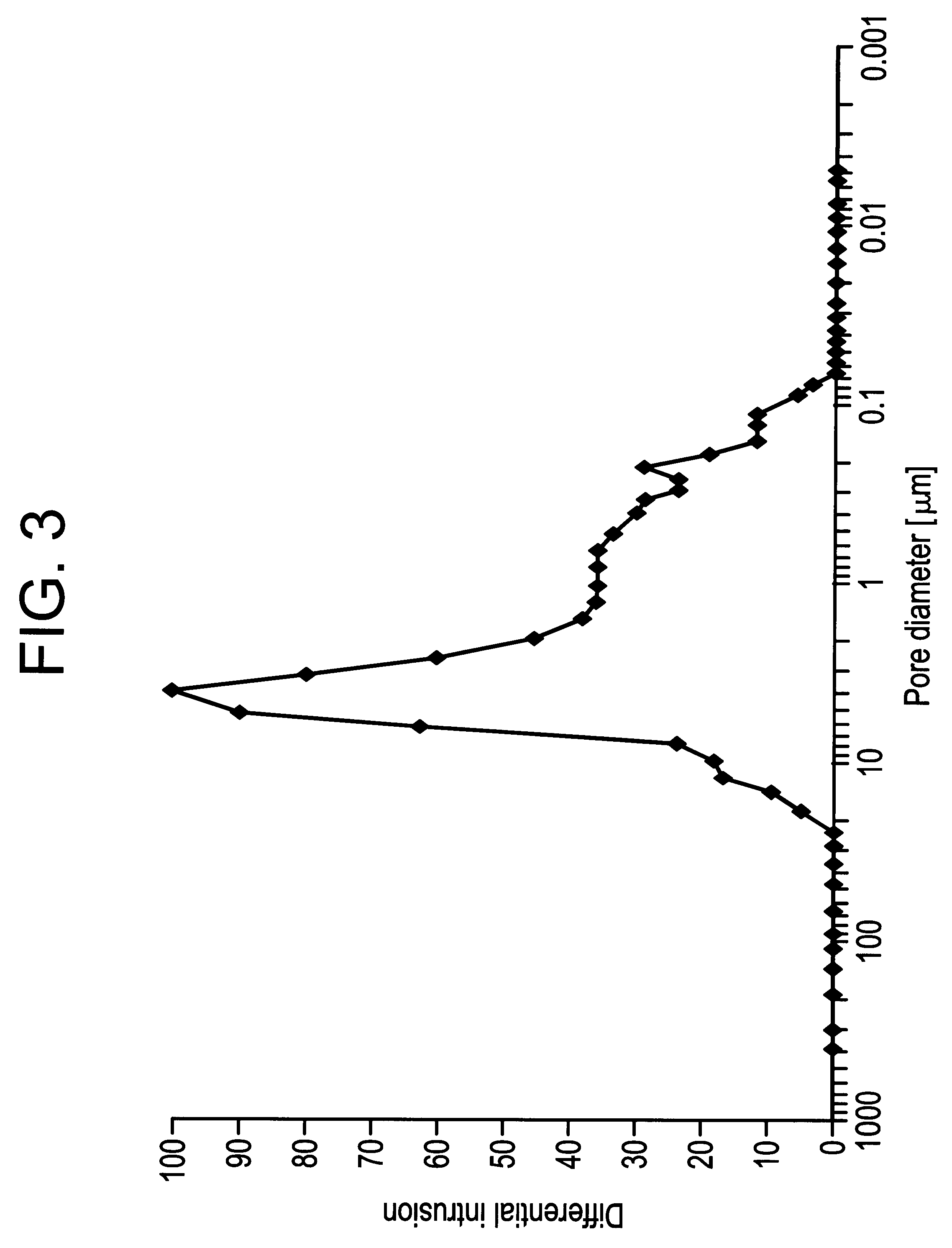

Moldings are disclosed for use as a catalyst or catalyst support for hydrating olefin, such as ethylene and propylene. The moldings are based on a pyrogenically produced mixed oxide having the following physicochemical parameters:The moldings are produced by homogenizing pyrogenically produced mixed oxide as desired with water and one or more compounds selected from the group of methylcellulose, methylhydroxyethylcellulose, wax, polyethylene glycol, magnesium stearate or aluminium stearate; drying the product at a temperature of 70-150° C.; optionally comminuting to yield a powder; optionally compression molding the powder to yield moldings; and performing heat treatment for a period of 0.5 to 10 hours at a temperature of 400 to 1200° C. Prior to drying, the mixture may also be subjected to kneading and / or shaping processes and extruded.

Owner:DEGUSSA AG

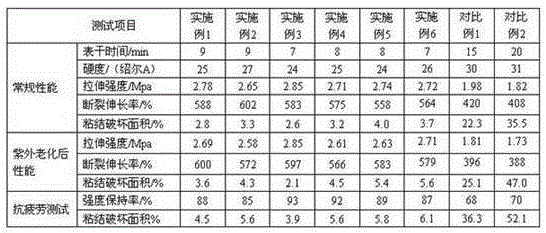

Fatigue-resistant ultraviolet-resistant one-component dealcoholization type silicone structure sealant and preparation method thereof

ActiveCN105385408AGood mechanical propertiesGood storage stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The present invention discloses a fatigue-resistant ultraviolet-resistant one-component dealcoholization type silicone structure sealant and a preparation method thereof, the sealant comprises the following raw materials in parts by weight: 100 parts of terminal hydroxyl polydimethylsiloxane, 60 to 120 parts of a reinforcing filler, 5 to 15 parts of a plasticizer, 3 to 8 parts of a crosslinking agent, 0.2 to 2 parts of a bi-metal aluminum-zirconium coupling agent, 0.5 to 3 parts of a catalyst and 0.5 to 2 parts of a deep layer curing agent. The bi-metal aluminum-zirconium coupling agent is one or more agents of aluminium adipate-zirconium coupling agent, aluminium itaconate-zirconium coupling agent and aluminium stearate-zirconium coupling agent. The fatigue-resistant ultraviolet-resistant one-component dealcoholization type silicone structure sealant has good mechanical properties and good storage stability, has the characteristics of being not easy to turn yellow and fast to cure, also has fatigue resistance, ultraviolet irradiation resistance and other performances, is suitable for being widely used in insulated cable and automotive industries, and has good economic and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

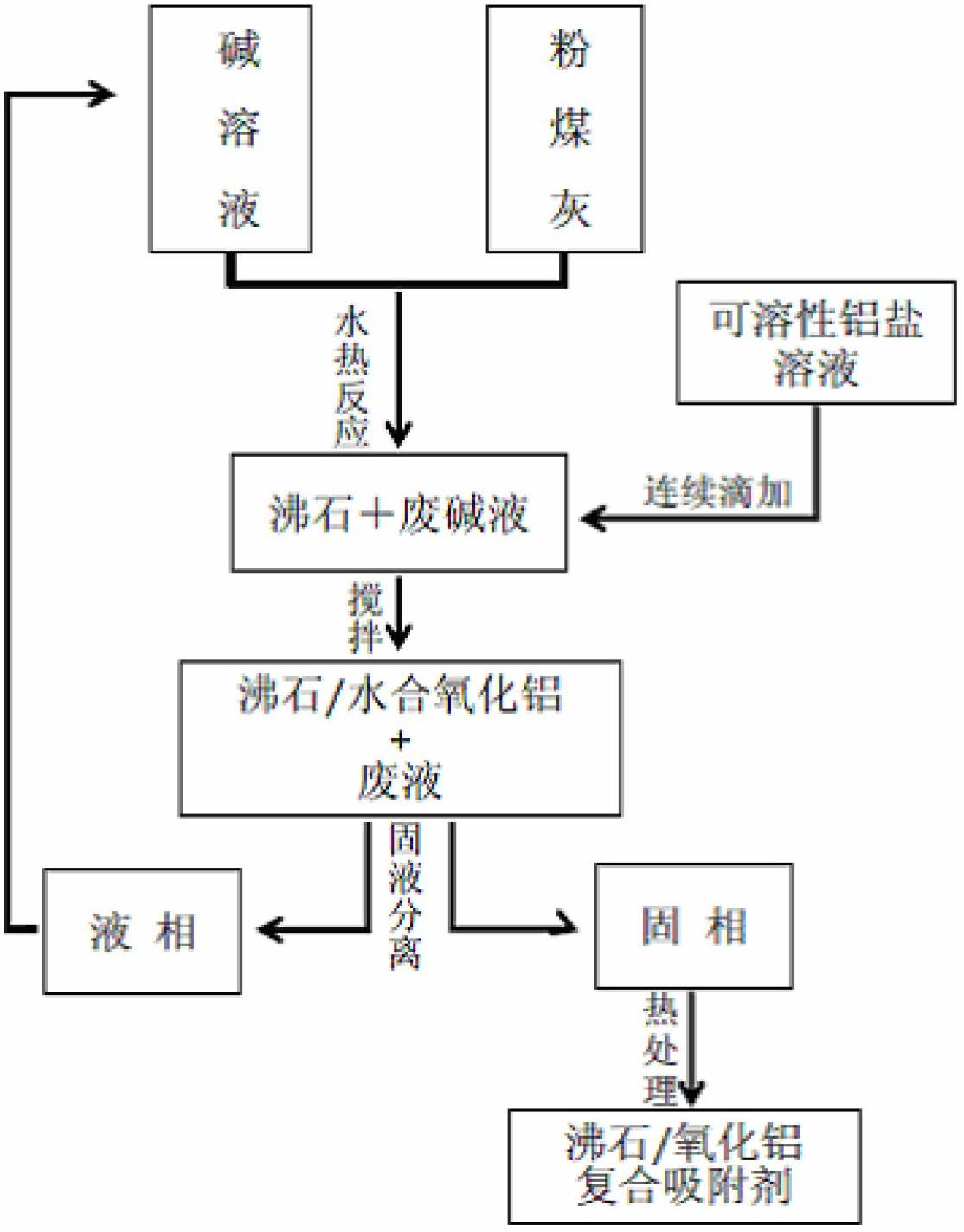

Preparation method of fly ash based zeolite / alumina composite adsorbing material

InactiveCN102671623ACause secondary pollutionHigh deamination and dephosphorization effectOther chemical processesAluminum StearateAlumina composite

The invention discloses a preparation method of fly ash based zeolite / alumina composite adsorbing material, which comprises the following steps: metal lye solution and fly ash are mixed to be subjected to hydrothermal synthesis reaction; soluble aluminum stearate solution is continuously added in the mixture of the synthetic zeolite and waste lye liquor under stirring drop by drop, after solid-liquid separation, the solid phase is subjected to heat treatment to obtain zeolite / alumina composite adsorbent material, and the remaining solution is used to the preparation of lye solution in the subsequent synthesis process. According to the preparation method of the fly ash based zeolite / alumina composite adsorbing material, the waste lye liquor generated during the zeolite synthetizing with fly ash is changed into alumina, so that the long-standing unsolved problems that waste lye produced when the fly ash is used as raw material to produce zeolite cannot be treated, and the zeolite product has strong basicity can be solved, and the prepared zeolite / alumina composite adsorbing material has more efficient adsorption effect on nitrogen and phosphorus nutrients in the water, so the treatment of wastes with processes of waster against one another can be achieved; and the synthesis process is simple, and the cost is low.

Owner:SHANGHAI JIAO TONG UNIV

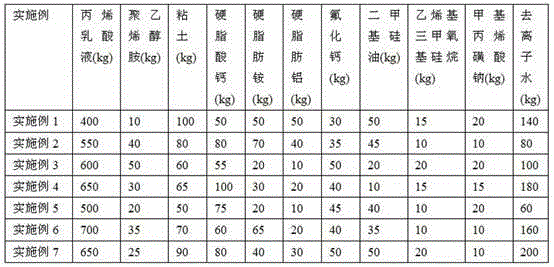

Building waterproof agent

The present invention provides a safe and non-toxic building waterproof agent, and belongs to the field of building additives. The building waterproof agent of the present invention comprises, by weight, 40-70 parts of an acrylic acid emulsion, 1-5 parts of polyvinyl alcohol amine, 5-10 parts of clay, 5-10 parts of calcium stearate, 2-7 parts of ammonium stearate, 1-5 parts of aluminum stearate, 3-5 parts of calcium fluoride, 1-5 parts of dimethyl silicone oil, 1-2 parts of vinyltrimethoxysilane, 1-2 parts of sodium methyl acryl sulfonate, and 6-20 parts of deionized water. The preparation method comprises: uniformly mixingan an acrylic acid emulsion, polyvinyl alcohol amine, clay, calcium stearate, ammonium stearate, aluminum stearate, calcium fluoride and sodium methyl acryl sulfonate to obtain a mixture, heating to a temperature of 30-50 DEG C, stirring dimethyl silicone oil, vinyltrimethoxysilane and deionized water to obtain a mixed material, and slowly adding the mixed material to the mixture. The building waterproof agent of the present invention has characteristics of inexpensive raw materials, simple preparation method and significant waterproof effect.

Owner:QINGDAO WINCHANCE TECH

Impact resistant rigid vinyl chloride polymer composition and method of making the same

InactiveUS20090093577A1Synthetic resin layered productsLiquid carbonaceous fuelsAluminum StearateAlpha-olefin

The instant invention is an impact resistant rigid vinyl chloride polymer composition, and method of making the same. The impact resistant rigid vinyl chloride polymer composition, according to instant invention, includes a vinyl chloride polymer, an impact modifier, and a lubricant system. The impact modifier includes a chlorinated olefin polymer, and an ethylene / alpha-olefin copolymer. The lubricant system includes a first component, a second component, and a third component. The first component is a carboxylic acid selected from the group consisting of stearic acid, lauric acid, myristic acid, palmitic acid, blends thereof, and combinations thereof. The second component is a hydrocarbon wax selected from the group consisting of a paraffin wax, polyolefin wax, blends thereof, and combinations thereof. The third component is a metal soap selected from the group consisting of calcium stearate, aluminum stearate, copper stearate, lithium stearate, magnesium stearate, sodium stearate, zinc stearate, blends thereof, and combinations thereof. The process for preparing the impact resistant rigid vinyl chloride polymer composition of the instant invention includes the following steps: (1) providing a vinyl chloride polymer; (2) providing an impact modifier as described above; (3) providing a lubricant system as described above; (4) blending the vinyl chloride polymer, the impact modifier, and the lubricant system thereby forming the impact resistant rigid vinyl chloride polymer composition.

Owner:DOW GLOBAL TECH LLC

Reinforcing glass fiber reinforced plastics coating material and preparation method thereof

The invention discloses a reinforcing glass fiber reinforced plastics coating material. The material is characterized by being prepared by the following raw materials in parts by weight: 40-45 parts of phenolic resin, 6-8 parts of epoxy resin, 5-7 parts of amino resin, 5-8 parts of rosin, 10-13 parts of acrylic acid, 8-10 parts of tert-butyl peroxybenzoate, 9-13 parts of methyl methacrylate, 4-6 parts of paraffin, 3-4 parts of bentonite, 2-3 parts of dicyandiamide, 3-4 parts of aluminum stearate, 4-7 parts of zinc oxide, 2-3 parts of methyl trioctyl ammonium chloride, 28-33 parts of chopped glass fiber, and 1-2 parts of additive. Due to the addition of additive, the material has good physical property and mechanical property; zinc oxide is taken as a reinforcing agent, thus increasing the strength of the material; due to the flame-retardant effect of zinc oxide, the prepared material has long service life, is fireproof, has low cost, is tough, can be produced on a large scale, is applicable to popularization and application, and is suitable for manufacturing into different shapes.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Defoaming agent for water-based drilling fluid and preparation method thereof

The invention relates to a defoaming agent for a water-based drilling fluid and a preparation method thereof. Selected solvent oil, stearic acid, oleic acid, isooctyl alcohol and tributyl phosphate are compounded. The solvent oil is heated to swell aluminum distearate, so as to facilitate compound with other components to play synergistic effect. The method for producing the defoaming agent has simple preparation process; the defoaming agent displays excellent defoaming effect with a small amount; and the product has lubrication action.

Owner:SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

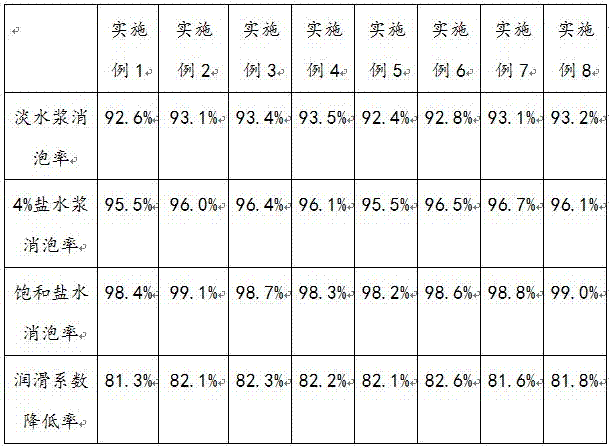

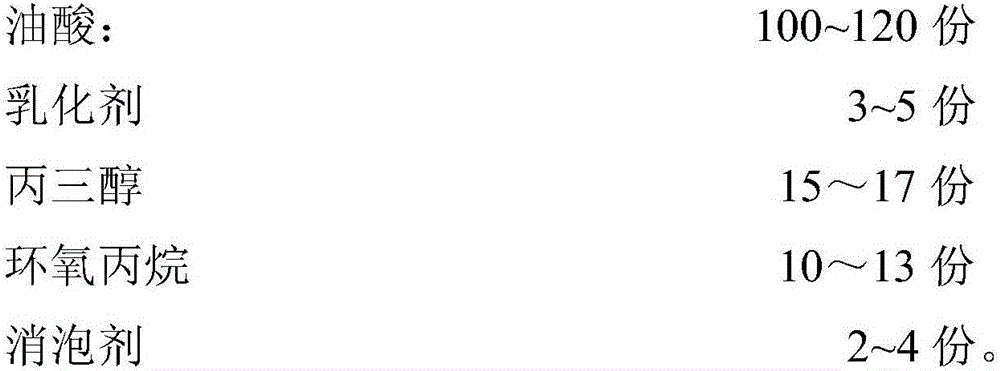

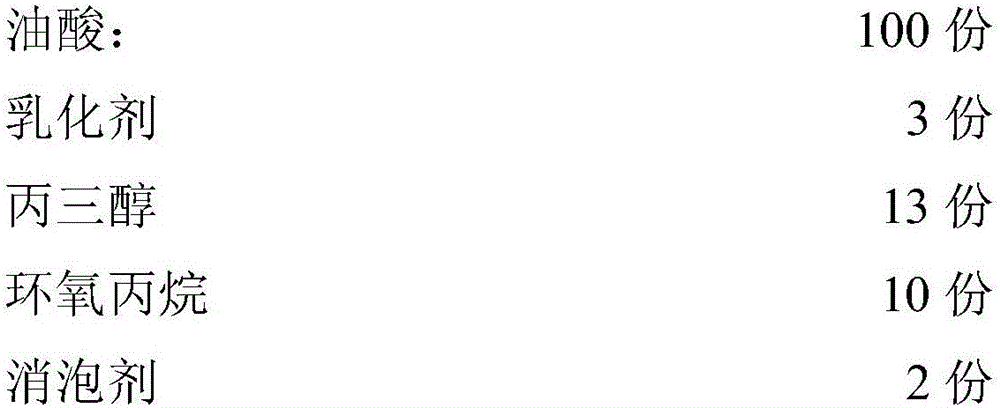

Biomimetic liquid lubricating agent for drilling fluid and preparation method thereof

The invention relates to a biomimetic liquid lubricating agent for drilling fluid and a preparation method thereof. The biomimetic liquid lubricating agent is prepared from the following raw materials including oleic acid, emulsifiers, glycerol, epoxy propane and antifoaming agents, wherein the emulsifiers are one or several materials selected from triethanolamine, aluminum stearate and span-80. The preparation method comprises the following technical steps of weight the raw materials of the oleic acid, the emulsifiers, the glycerol and the epoxy propane; adding the raw materials into a reaction kettle so that the raw materials are sufficiently mixed, and a mixed material is obtained; performing an esterification process on the mixed material at the esterification temperature of 200 to 250 DEG C for the esterification time being 1 to 3h; performing cooling to obtain an esterification product; performing an emulsification process on the esterification product at the emulsification temperature of 80 to 100 DEG C for the emulsification time being 1 to 2h; lowering the temperature of a product after completing the emulsification process; adding the antifoaming agents so that the materials are sufficiently and uniformly mixed; discharging the materials after the temperature is lowered to room temperature. The biomimetic liquid lubricating agent can resist high temperature being 200 DEG C or higher; the friction coefficient of the drilling fluid can be reduced; the adhesion coefficient of the drilling fluid can also be reduced; the fluorescence grade is low.

Owner:石家庄华莱鼎盛科技有限公司

Formula of building indoor wall surface coating and preparation method

InactiveCN106883711AGood for healthAnti-sheddingAntifouling/underwater paintsPaints with biocidesPolyvinyl chlorideAluminum Stearate

The invention discloses a formula of a building indoor wall surface coating and a preparation method. The formula consists of water, titanium dioxide, a wax emulsion, sorbitan monostearate, white oil, spermaceti wax, propylene glycol, a styrene-acrylic emulsion, dipropylene glycol butyl ether, propylene glycol monomethyl ether, polyurethane resin, broad spectrum bactericides, bamboo charcoal factors, PVC (Polyvinyl Chloride) resin powder, nano calcium carbonate, talcum powder, xylene, acrylic resin, calcium carbonate, aluminum stearate, and butanol. Compared with the prior art, a finished product of the formula is an aqueous wall coating, is capable of adsorbing harmful substances of self and harmful substances in the air due to the carbon charcoal factors, has effects of good viscosity, peeling resistance, dampness resistance and sterilization due to multiple resin materials, is environmentally friendly and scientific, is beneficial to human body health, is free of odor, and has popularization and application values.

Owner:SHAANXI SCI TECH UNIV

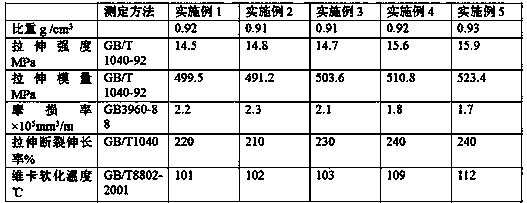

Preparation method of heat-resisting PVC (polyvinyl chloride)/ABS (acrylonitrile butadiene styrene)/PMMA (polymethyl methacrylate) alloy material

The invention relates to a preparation method of a heat-resisting PVC / ABS / PMMA alloy material and belongs to the technical field of high polymer materials. The method comprises the following steps of adding PVC, ABS, PMMA, fluororubber, white carbon black, dioctyl phthalate, aluminum stearate, stratiform silicon flagstone powder, argil, silica powder and zinc oxide into a mixer, increasing the temperature and performing temperature increasing, uniform mixing, discharging and cooling; extruding the obtained cooled materials through a double-screw extrusion granulator to obtain granules A; uniformly mixing and stirring the granules A, chlorinated polyethylene elastomer and trimerical isocyanate triene propyl ester; adding the mixture above into a single-screw extruder, and performing hot-melt extrusion to obtain the heat-resisting PVC / ABS / PMMA alloy material. The hot-melt extrusion to obtain the heat-resisting PVC / ABS / PMMA alloy material still obtains good wear-resisting performance under high-temperature testing.

Owner:NINGBO YOSUN AUTO PARTS

Permeation crystallizing waterproof dry powder coating for concrete and preparation method

The invention discloses a permeation crystallizing waterproof dry powder coating for concrete and a preparation method. The preparation method comprises the following steps of a, adding microcrystalline cellulose, bentonite, white alum and potassiam polyoxyethylene laurylether phosphate into water, mixing, grinding, and spray-drying, so as to obtain nanometer composite microspheres; b, mixing andstirring nanometer silicon micropowder, aluminum stearate, and a redispersible latex powder, so as to obtain the coated nanometer silicon micropowder; c, uniformly dispersing the nanometer composite microspheres, the coated nanometer silicon micropowder, a large-size mica powder, and methyl sodium silicate, so as to obtain the permeation crystallizing waterproof dry powder coating for the concrete. The preparation method has the beneficial effects that after the prepared permeation crystallizing waterproof dry powder coating is used, the permeation uniformity of the self-permeation material isgood, the crack crystals can be formed, the waterproof property is excellent, and the purpose of lasting waterproof property is realized; the repair function is realized on the strength and compactness of the concrete, and the slight cracks of the building elevations, underground tunnels and the like can be resisted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

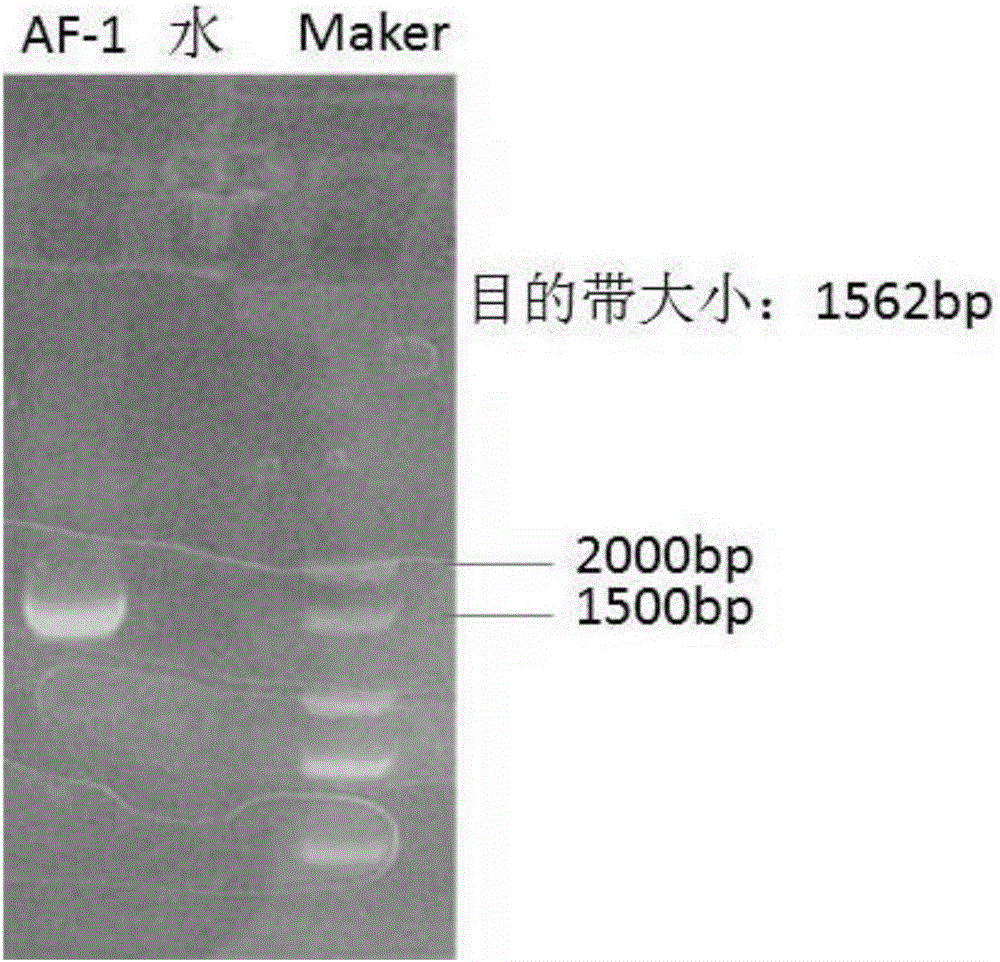

Pigeon paramyxovirus 1 strain AF-1 and application thereof

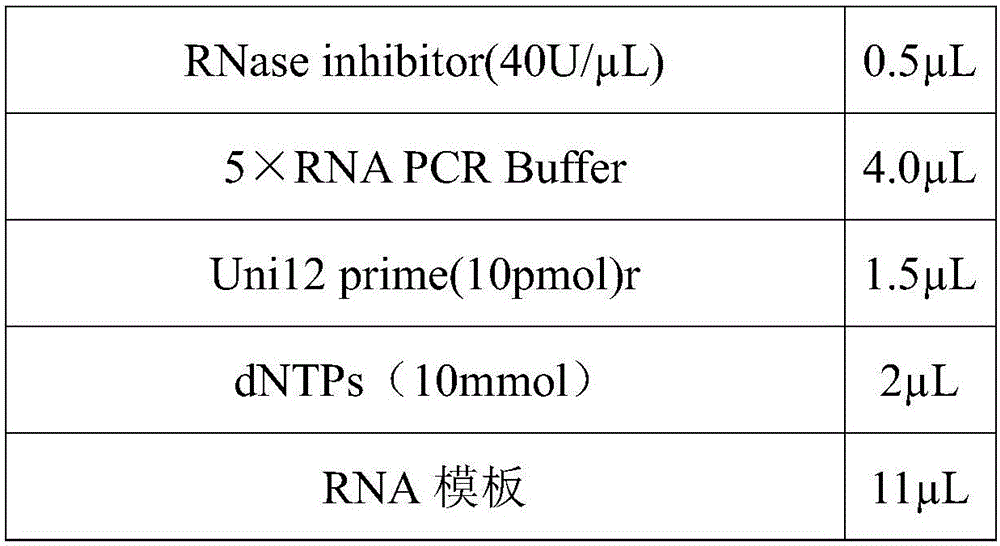

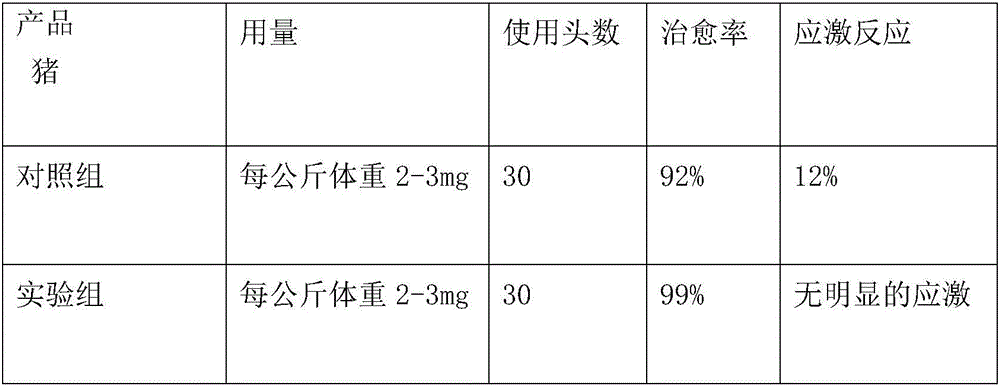

InactiveCN105936893AImproving immunogenicityHigh proliferative titerSsRNA viruses negative-senseViral antigen ingredientsAluminum StearateInfection induced

The invention discloses a pigeon paramyxovirus 1 strain AF-1 and an application thereof. The strain is a pigeon paramyxovirus 1 strain AF-1, and the preservation number of the strain is CCTCC NO:V 201613. A method for preparing an inactivated vaccine through using the pigeon paramyxovirus 1 strain AF-1 comprises the following steps: culturing the pigeon paramyxovirus 1 strain AF-1 to obtain an AF-1 strain virus solution, and adding beta-propiolactone to the AF-1 strain virus solution; inactivating the obtained virus solution to obtain a mixed solution; adding tween-80 to obtain an aqueous solution; adding aluminum stearate to white oil while stirring until the obtained oil is completely transparent, and adding tween-80 to obtain an oil solution; and slowly adding the aqueous solution to the oil solution, placing the obtained solution mixture in an emulsifying tank, and emulsifying the solution mixture to obtain the inactivated vaccine. The inactivated vaccine helps pigeons to effectively resist infection induced by pigeon paramyxovirus 1, greatly reduces the loss, promotes the development of the pigeon industry, is safe and effective, and can be applied to production practices.

Owner:武汉智健动物保健有限公司

Bamboo cane softener

InactiveCN104890071AImprove softening effectGood effectWood treatment detailsWood impregnation detailsIsobutanolMethyl carbamate

The invention discloses a bamboo cane softener. The bamboo cane softener comprises components of raw materials in parts as follows: 20-30 parts of epichlorohydrin, 30-40 parts of ethyl acetate, 20-25 parts of n-caprylic alcohol, 25-30 parts of isoamyl alcohol, 20-25 parts of isobutanol, 8-10 parts of castor oil polyoxyethylene ether, 6-8 parts of sodium dodecyl benzene sulfonate, 8-10 parts of dodecyl dimethyl amine oxide, 6-10 parts of zinc stearate, 8-10 parts of copper stearate, 8-10 parts of aluminum stearate, 6-10 parts of nickel stearate, 8-10 parts of butyl butyrate, 10-12 parts of methyl carbamate, 8-10 parts of ethyl methacrylate, 6-10 parts of petroleum ether, 10-15 parts of chlorinated paraffin and 150-200 parts of deionized water. The bamboo cane softener has a good softening effect, is non-corrosive and convenient to popularize and use and has a better effect on improvement of the strength and the toughness of a softened part.

Owner:陈新棠

Sealing anti-rust oil of tank engine and production method

InactiveCN102533414AExtended service lifeExtend the anti-rust period of storageAdditivesAluminum StearateSuccinic acid

The invention discloses sealing anti-rust oil of a tank engine. The sealing anti-rust oil of the tank engine comprises the following raw material components in percentages by weight: 1-6% of barium petroleum sulfonate, 1-4% of dinonyl naphthalenesulfonic acid, 0.1-0.8% of dodecene succinic acid, 1-4% of wool oil magnesium soap, 1-2% of zinc dialkyl dithiophosphate, 1-10% of aluminum stearate, 1-6% of polybutene, 0.1-0.6% of methyl silicone oil and the balance of aviation lubricating oil. The production method of the sealing anti-rust oil of the tank engine comprises the following steps of: adding the aviation lubricating oil into an oil product reaction kettle, heating to 60 degrees centigrade, starting a stirrer to control the rotating speed to 40 revolutions per minute, slowly adding barium petroleum sulfonate, dinonyl naphthalenesulfonic acid, wool oil magnesium soap, dodecene succinic acid, zinc dialkyl dithiophosphate, aluminum stearate, polybutene and methyl silicone oil into the reaction kettle in sequence, stirring for 30 min when each raw material is added, and keeping on stirring for 2-4 hours after the raw materials are added completely so as to obtain the sealing anti-rust oil of the tank engine.

Owner:DALIAN SANDAAOKE CHEM

Super temperature-difference resistant and salt-mist corrosion resistant asphalt varnish and preparation method thereof

InactiveCN104449393AMix and grind evenlyHas costAnti-corrosive paintsPolyether coatingsMeth-Microsphere

The invention discloses a super temperature-difference resistant and salt-mist corrosion resistant asphalt varnish prepared from the following raw materials in parts by weight: 20-24 parts of methyl organic silicon resin, 26-32 parts of vinyl resin, 4-6 parts of diaminodiphenyl-methane, 1-2 parts of benzotriazole, 4-5 parts of potassium polyacrylate, 3-5 parts of polyethylene glycol, 12-16 parts of modified asphalt, 7-9 parts of modified waste resin sand, 1-2 parts of sodium selenite, 0.5-1.0 part of an accelerant CMCM, 1-2 parts of cobalt naphthenate, 1-2 parts of triammonium citrate, 2-3 parts of aluminum stearate, 5-7 parts of polyacrylate, 1-2 parts of a silane coupling agent, 0.5-1.0 part of magnesium ammonium sulfate, 3-4 parts of floating beads, 2-3 parts of hollow microspheres, 6-9 parts of methylbenzene, 5-8 parts of dimethylbenzene and 6-9 parts of butanol acetate. By adopting the asphalt varnish disclosed by the invention, harms of the waste resin sand to the environment are solved, the production cost of the varnish is reduced, and the quality of the varnish is improved.

Owner:TIANCHANG YINHU PAINT

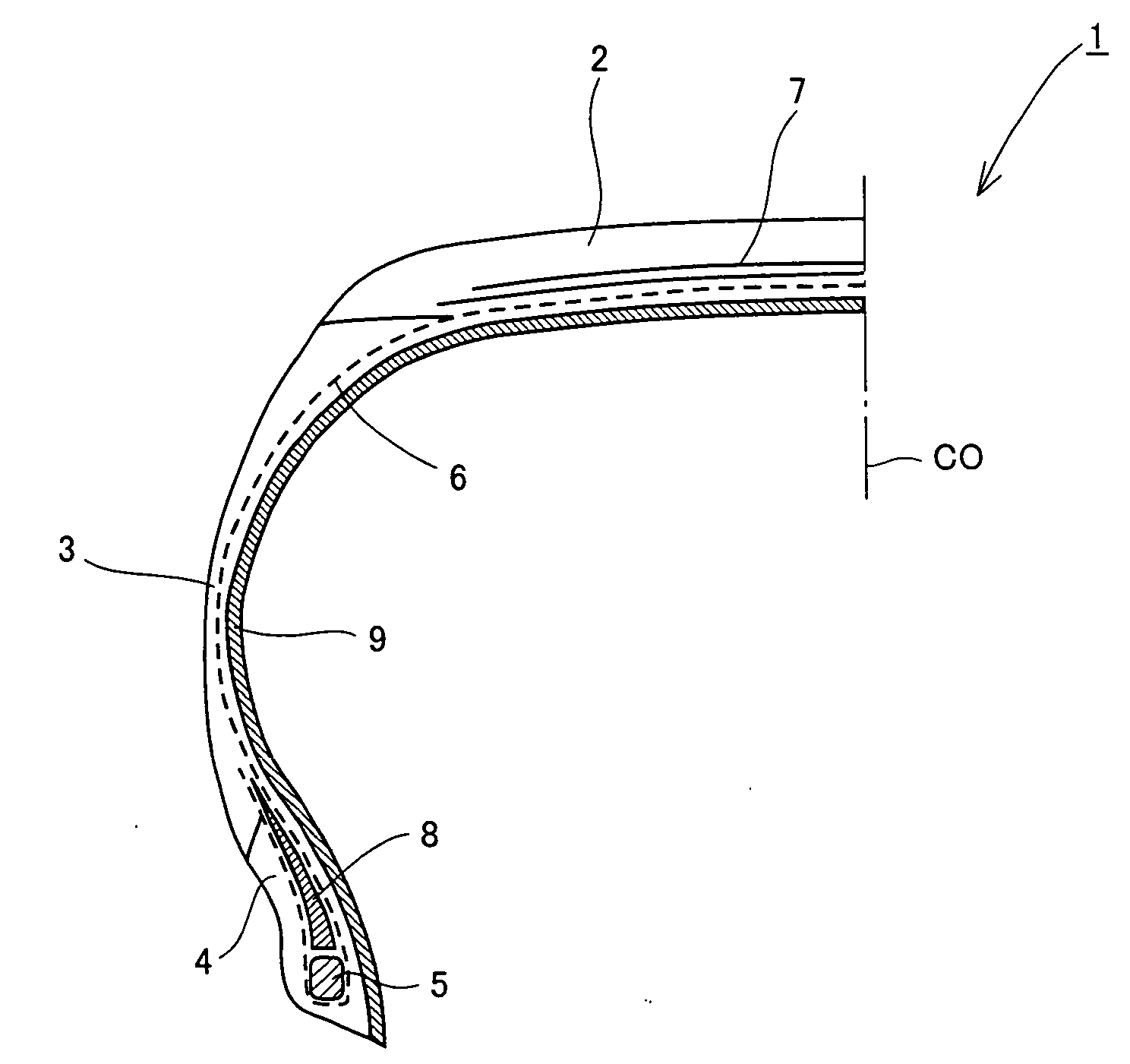

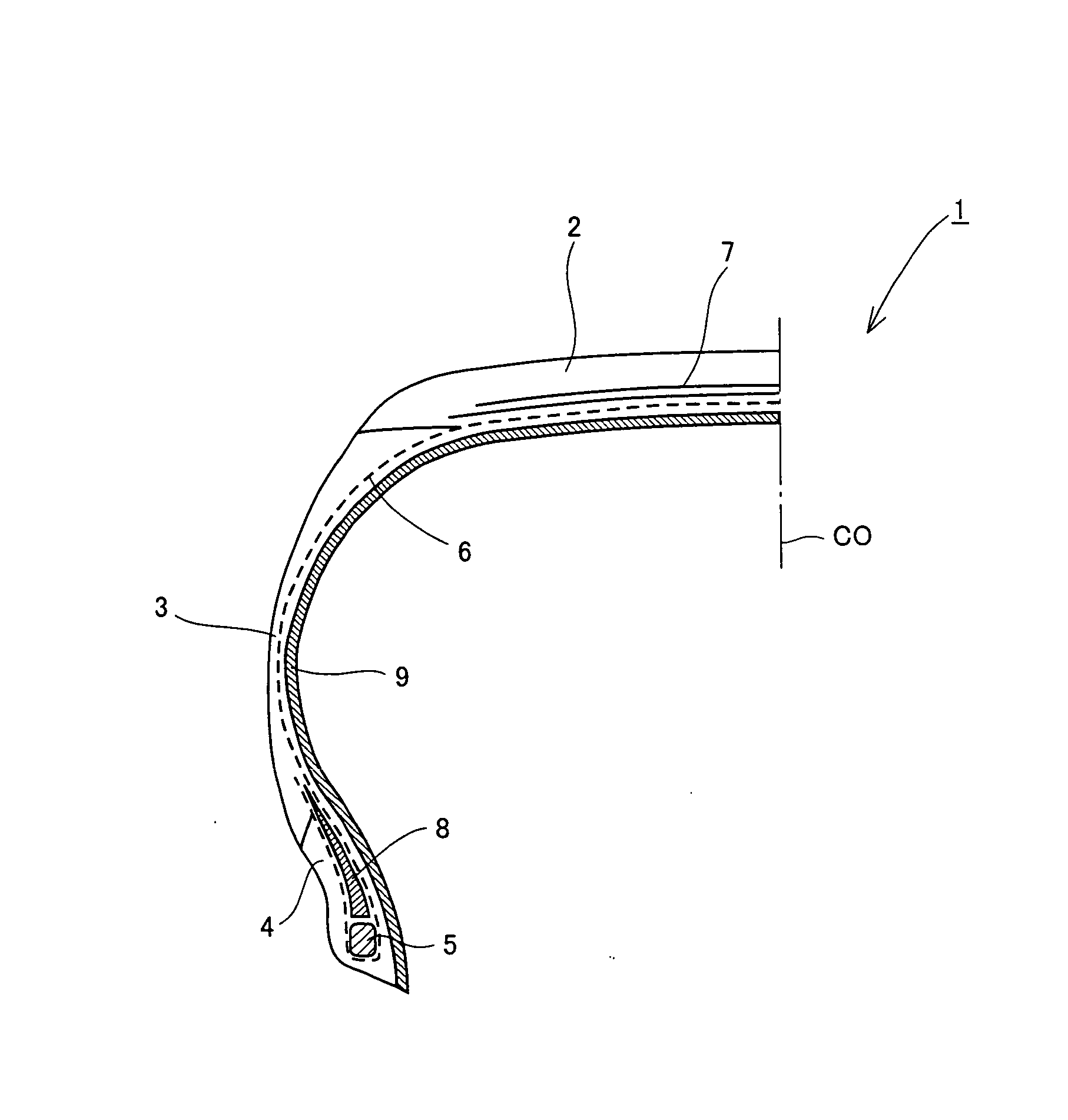

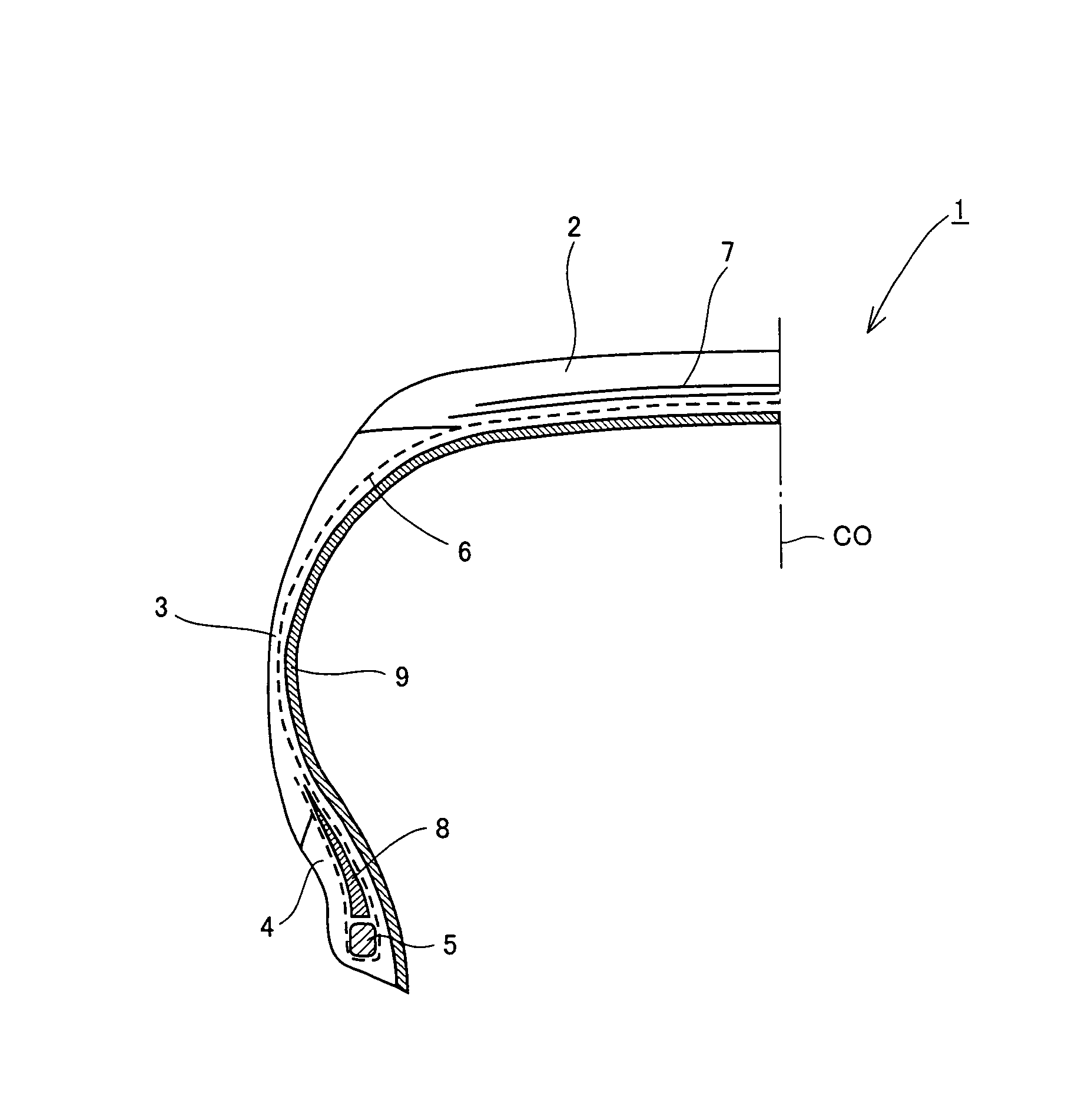

Rubber composition for tire, and tire

InactiveUS20080306199A1Improve rubber strengthPrevent reversalFibre treatmentSpecial tyresSulfurAluminum Stearate

The present invention provides a rubber composition for a tire containing an epoxidized natural rubber, sulfur and a fatty acid metal salt, in which the metal of the fatty acid metal salt is a metal belonging to Group 12, 13 or 14 of the periodic table. Here, the fatty acid metal salt is preferably at least one kind selected from the group consisting of zinc stearate, aluminum stearate and tin stearate. Also, the present invention provides a tire manufactured by using the foregoing rubber composition for a tire.

Owner:SUMITOMO RUBBER IND LTD

Anethol trithione soft capsule and preparation method thereof

ActiveCN101204393AClinical application safetyOrganic active ingredientsDigestive systemVegetable oilAluminum monostearate

The invention provides a soft capsule containing an anethol trithione. The soft capsule contains the anethol trithione, a substrate, a suspending agent and a surface active agent, wherein, the weight proportion of the three matters is as follows: the anethol trithione: the substrate: the suspending agent: the surface agent is equal to 1: 2 through 75: 0.1 through 10: 0.3 through 15. The substrate can be a sesame oil, a groundnut oil, a corn oil, an olive oil, a sunflower seed oil, a soybean oil, a salad oil, a cotton oil, or a colza oil or a mixture made from a plurality of these oils. The suspending agent can be a beeswax, a yellow wax, a white wax, a mixed wax, a palm oil, a hydrogenated vegetable oil, a sterin, an aluminum monostearate, a glycerin monostearate, a fatty glyceride, a fatty glyceride mixed, an aerosil, or a silicon dioxide or a mixture made from a plurality of these matters. The surface active agent is tween. The soft capsule can strengthen the beneficial effect of the anethol trithione in human body, and meanwhile shows a relativity in and out of the human body.

Owner:江苏万高药业股份有限公司

Cefquinome sulfate injection and preparation process

InactiveCN106491532ANot easy to layerNot easy to settleAntibacterial agentsOrganic active ingredientsALUMINUM STEARATESAntioxidant

The invention belongs to the field of the animal medicine, and particularly relates to cefquinome sulfate injection and a preparation process. The formula comprises the following components by weight: 2.5 parts of cefquinome sulfate, 1.8-2.2 parts of aluminum stearate, 0.8-1.2 parts of lecithin, 1.8-2.2 parts of span E, 0.08-0.12 parts of phenol, 0.08-0.12 parts of vitamin E, and 100 parts of ethyl oleate. After the cefquinome sulfate is superfine-grinded, the prepared suspension preparation is not easy to layering and settling, the sedimentation rate is reduced above 50%. The preparation is easy to shake uniformly in use, the needle cleaning property is better, the injection is easy, and the stress after the injection is smaller. A specific pure natural antioxidant is added, so the stability is better, and the content descent rate is reduced by 18%.

Owner:SICHUAN MEIJIALONG BIOTECH

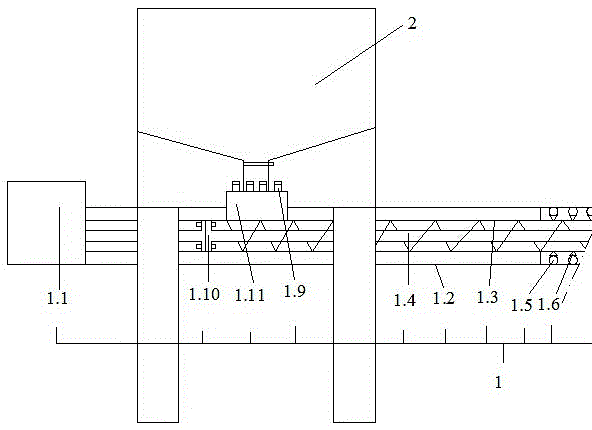

Modification method and device for heavy calcium carbonate special for wires and cables

ActiveCN105566951AShort modification timeThoroughly modifiedPigment treatment with macromolecular organic compoundsPigment physical treatmentPolyesterPhysical chemistry

The invention relates to a modification method for heavy calcium carbonate special for wires and cables. The modification method is characterized by including the following steps that heavy calcium carbonate is added into a grinding device and ground into fine powder with the average particle size being 1500-2000 meshes; water, stearic acid, an aluminate coupling agent and polyester type hyperdispersant are added into the powder through four feeding pipes respectively and are stirred to form a mixture, wherein the water, stearic acid, the aluminate coupling agent and the polyester type hyperdispersant account for 0.4-0.5%, 0.9-1.1%, 1-1.2% and 0.5-0.8% of the total weight of the mixture respectively. The modification method has the advantages that the time for modifying heavy calcium carbonate is shorter due to the function from inside to outside, modification is more sufficient, modified heavy calcium carbonate has heat resistance and dispersity, and can be compatible with a resin organic carrier and a high polymer material, so that toughness, brightness, plastic thermal hysteresis performance and bending strength of wires and cables are improved, and light resistance and ageing resistance are enhanced.

Owner:HUNAN LEIXIN NEW MATERIAL TECH

Lubricant molded body, lubricant application apparatus, process cartridge, and image forming apparatus

InactiveUS20100150627A1Low costFew cracking and cuttingElectrography/magnetographyBase-materialsCarbon numberPolymer science

A lubricant molded body, which is to be applied to a surface of a photosensitive layer for electrophotography in an image forming apparatus, for example, is composed of at least two kinds of higher fatty acid metallic salts having respectively different carbon numbers. As the higher fatty acid metallic salt that forms lubricant molded body, compounds such as zinc stearate, calcium stearate, barium stearate, aluminum stearate, zinc laurate, calcium laurate, etc. may be recited. The higher fatty acid metallic salts may contain at least one kind of fillers selected from the group consisting of silica, alumina, tungsten disulfide, molybdenum disulfide, graphite fluoride, graphite, boron nitride, polytetrafluoroethylene (PTFE), ethylene tetrafluoroethylene (ETFE), and polyvinylidene fluoride (PVDF).

Owner:USAMI JOE

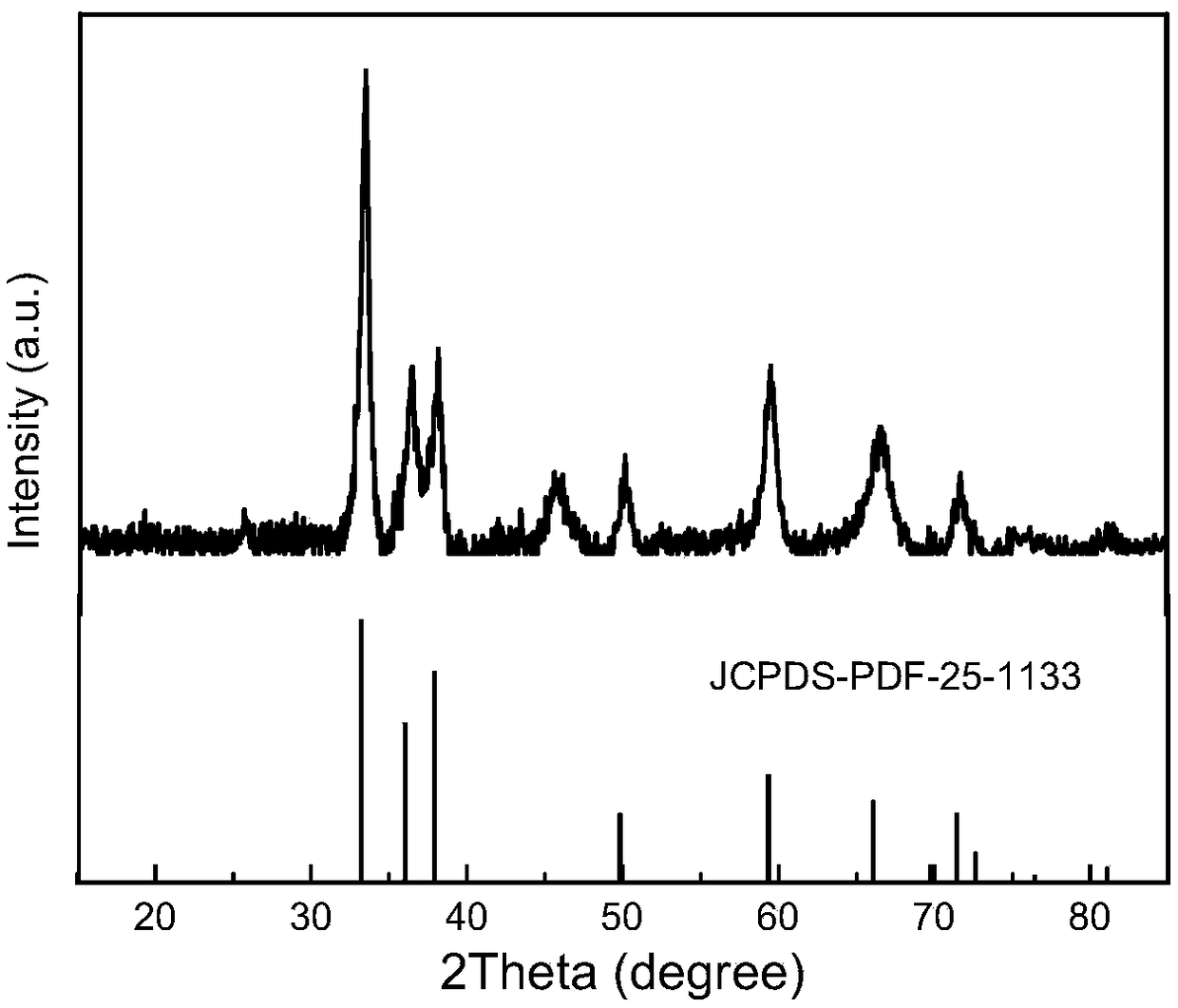

Method for preparing AlN powder

InactiveCN109264679AHigh purity powderHigh purityMaterial nanotechnologyNitrogen compoundsAir atmospherePhenanthroline

The invention discloses a method for preparing AlN powder. The method includes first dissolving an aluminum source and a nitrogen source completely in a solvent according to the Al:N molar ratio of 1:1-1:35, mixing evenly, drying the solvent by evaporating, roasting an obtained solid mixture at 500-1000 DEG C for 1-9h in a roasting atmosphere, and then decarburizing the mixture at 200-750 DEG C for 1 to 5h in an air atmosphere to obtain the high-purity AlN powder. The aluminum source is aluminum chloride hydrate, aluminum lactate, aluminum glycinate, aluminum stearate and the like; the nitrogen source is guanidine hydrochloride, guanidine acetate, chitosan, 1,10-phenanthroline; the solvent is any one of deionized water, methanol, ethanol, ethyl acetate, acetone, diethyl ether, benzene andtoluene; the roasting atmosphere is one or two of nitrogen, ammonia, argon and helium. Compared with the conventional AlN preparation method, the method has the advantages of wide reactant range, environmentally-friendly process, simple operation, high product purity and low cost.

Owner:SHAANXI UNIV OF SCI & TECH +1

Cleaning type lubricating oil

InactiveCN104830500AImprove antioxidant capacityEasy to cleanLubricant compositionBenzoic acidAluminum Stearate

The invention relates to a cleaning type lubricating oil, which is prepared from the following raw materials by weight: 20-32 parts of base oil, 4-6 parts of stearic acid, 3-5 parts of an additive, 3-4 parts of methyl silicone oil, 1-2 parts of chloroform, 2-6 parts of calcium petroleum sulfonate, 4-9 parts of barium hydroxide, 5-8 parts of aluminum stearate soap, 2-6 parts of high carbonic acid, 5-7 parts of boric acid, 1-3 parts of oleic acid butyl diester, 2-4 parts of antioxidant 1076, 6-7 parts of benzoic acid, 3-5 parts of 1H-benzotriazole, and 10-17 parts of water. The cleaning type lubricating oil of the present invention has beneficial effects of strong anti-oxidation property, dirt cleaning enhancing, and no pollution.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

Rubber composition for tire, and tire

The present invention provides a rubber composition for a tire containing an epoxidized natural rubber, sulfur and a fatty acid metal salt, in which the metal of the fatty acid metal salt is a metal belonging to Group 12, 13 or 14 of the periodic table. Here, the fatty acid metal salt is preferably at least one kind selected from the group consisting of zinc stearate, aluminum stearate and tin stearate. Also, the present invention provides a tire manufactured by using the foregoing rubber composition for a tire.

Owner:SUMITOMO RUBBER IND LTD

Moisture barrier material of asphalt

InactiveCN103773027AHigh bonding strengthHigh tensile strengthBuilding insulationsXylyleneMethacrylate methyl

The invention relates to a moisture barrier material of asphalt. The moisture barrier material of asphalt is prepared from the following components in parts by weight: 100 parts of petroleum asphalt, 30-45 parts of zinc yellow, 10-15 parts of heavy diesel fuel, 5-8 parts of xylene, 10-14 parts of asbestos wools, 6-8 parts of mica iron oxide, 10-20 parts of tung oil, 30-35 parts of vinyl acetate, 5-8 parts of aluminum stearate, 10-15 parts of butyl acrylate, 2-5 parts of butanol, 4-10 parts of methyl methacrylate and 2-3 parts of a curing agent. The material is good in bonding strength and free from toxicity, and the time for surface dry is 2-3 hours and the time for hard dry is 8-10 hours. The tensile strength of the product is 200-300MPa, and the product is good in water resistance and stability, waterproof and moistureproof. The material is impermeable at 0.3MPa and no leakage is available within 1 hour. The elongation at break of the product is 500%, and the material is flawless at -30 DEG C and can be widely produced and continuously replace existing materials.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com