Patents

Literature

838 results about "Myristic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Myristic acid (IUPAC systematic name: 1-tetradecanoic acid) is a common saturated fatty acid with the molecular formula CH₃(CH₂)₁₂COOH. Its salts and esters are commonly referred to as myristates or tetradecanoates. It is named after the binomial name for nutmeg (Myristica fragrans), from which it was first isolated in 1841 by Lyon Playfair.

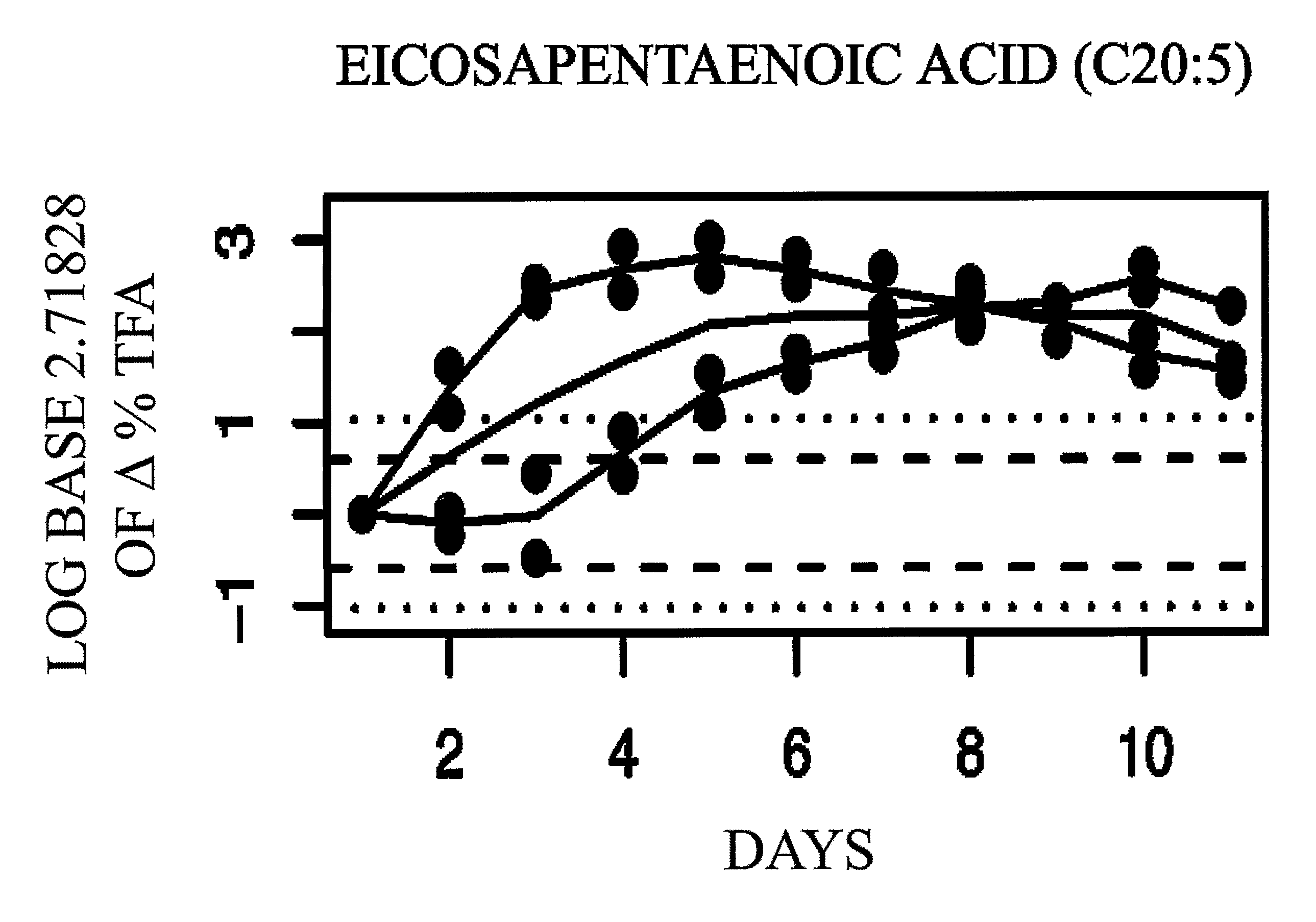

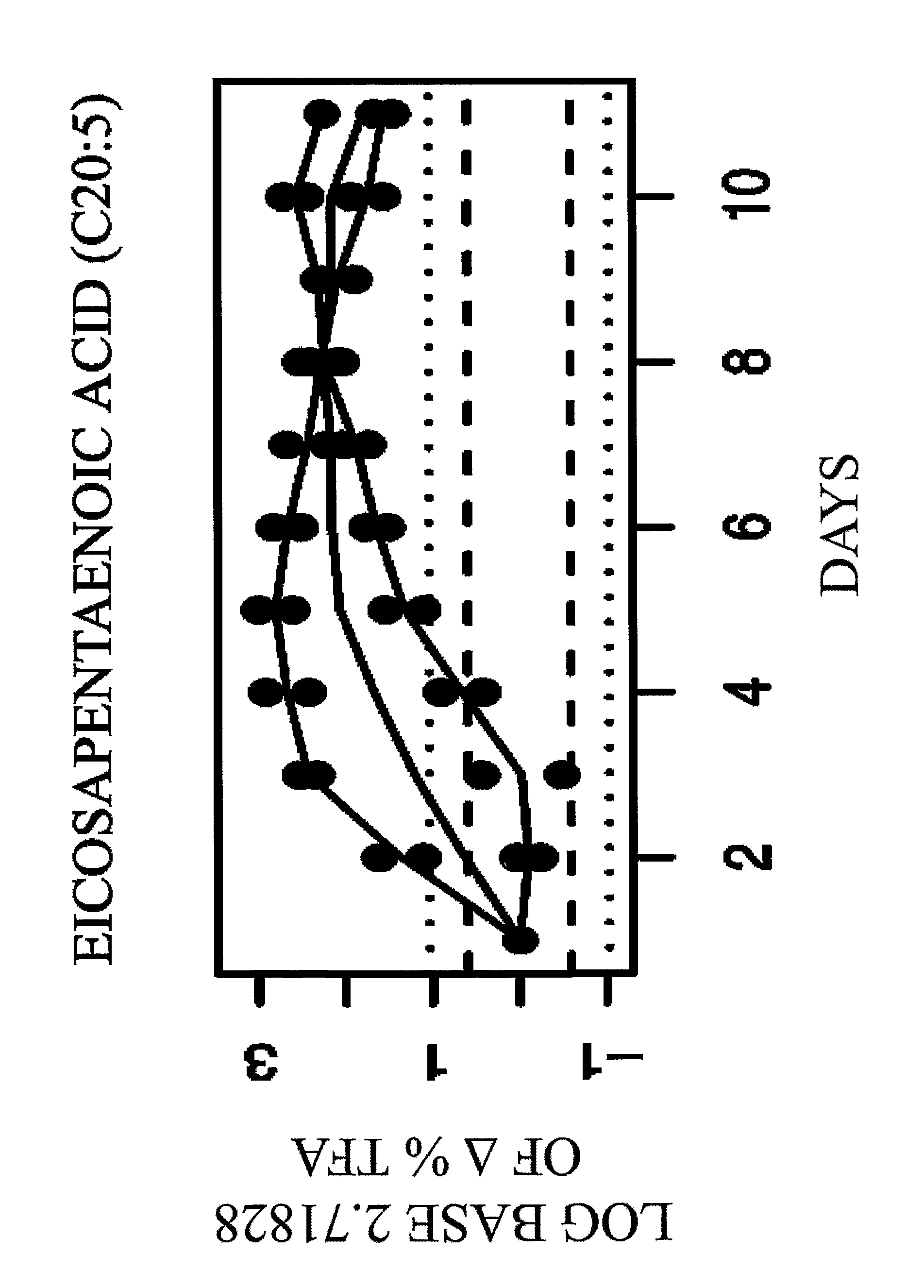

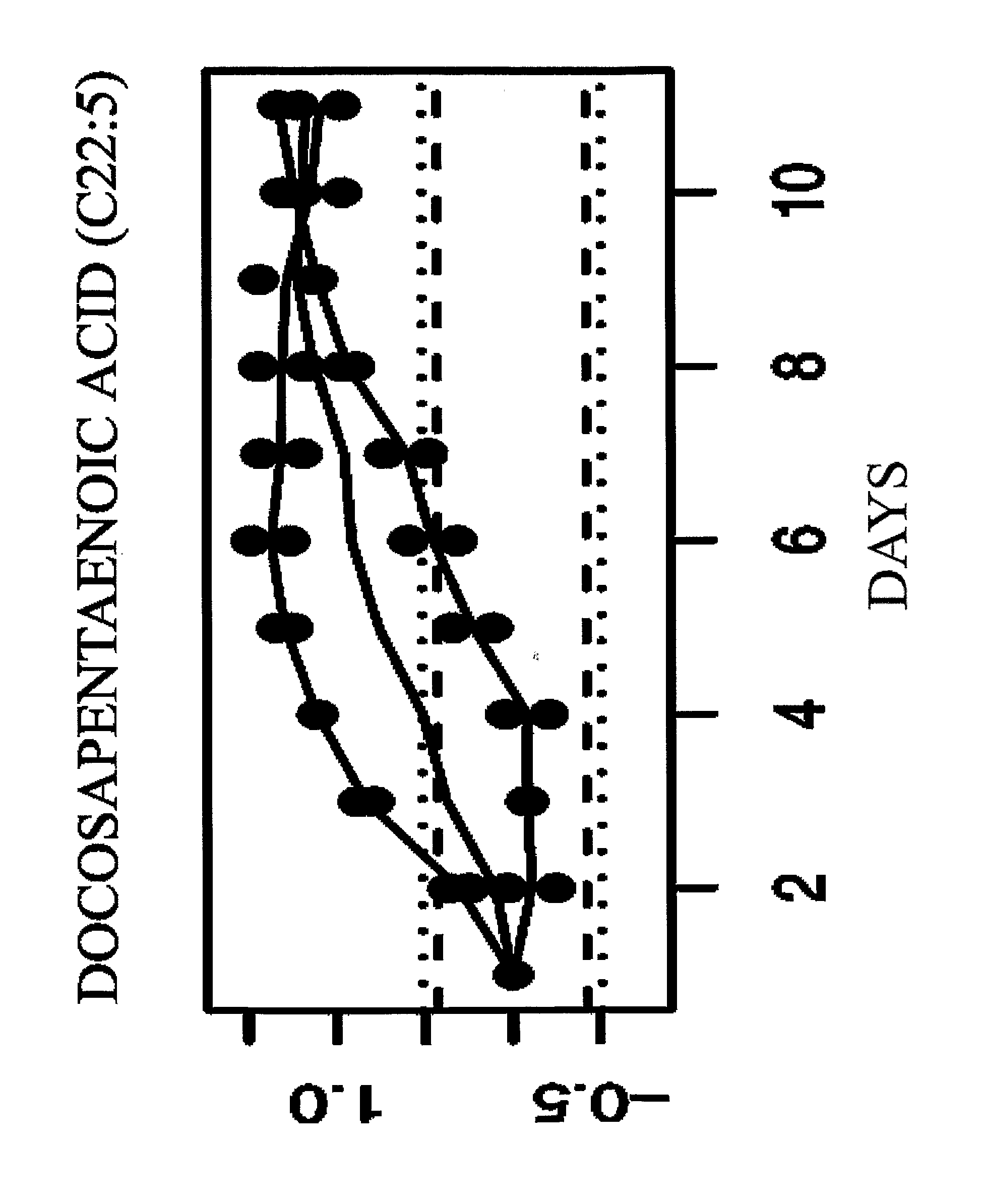

Compositions containing high omega-3 and low saturated fatty acid levels

Food products and supplements comprising the essential unsaturated fatty acids EPA or DHA at high concentrations relative to other n-3 HUFAs and with relatively low levels of saturated fatty acids (myristic and palmitic acids) are provided. These compositions can be made in commercial quantities in a cost effective manner by culture of selected microorganisms. The food products and supplements are suited to human health needs which are unable to be met from fish oil origins. Also provided are EPA containing food products obtained from animals.

Owner:PHOTONZ CORP

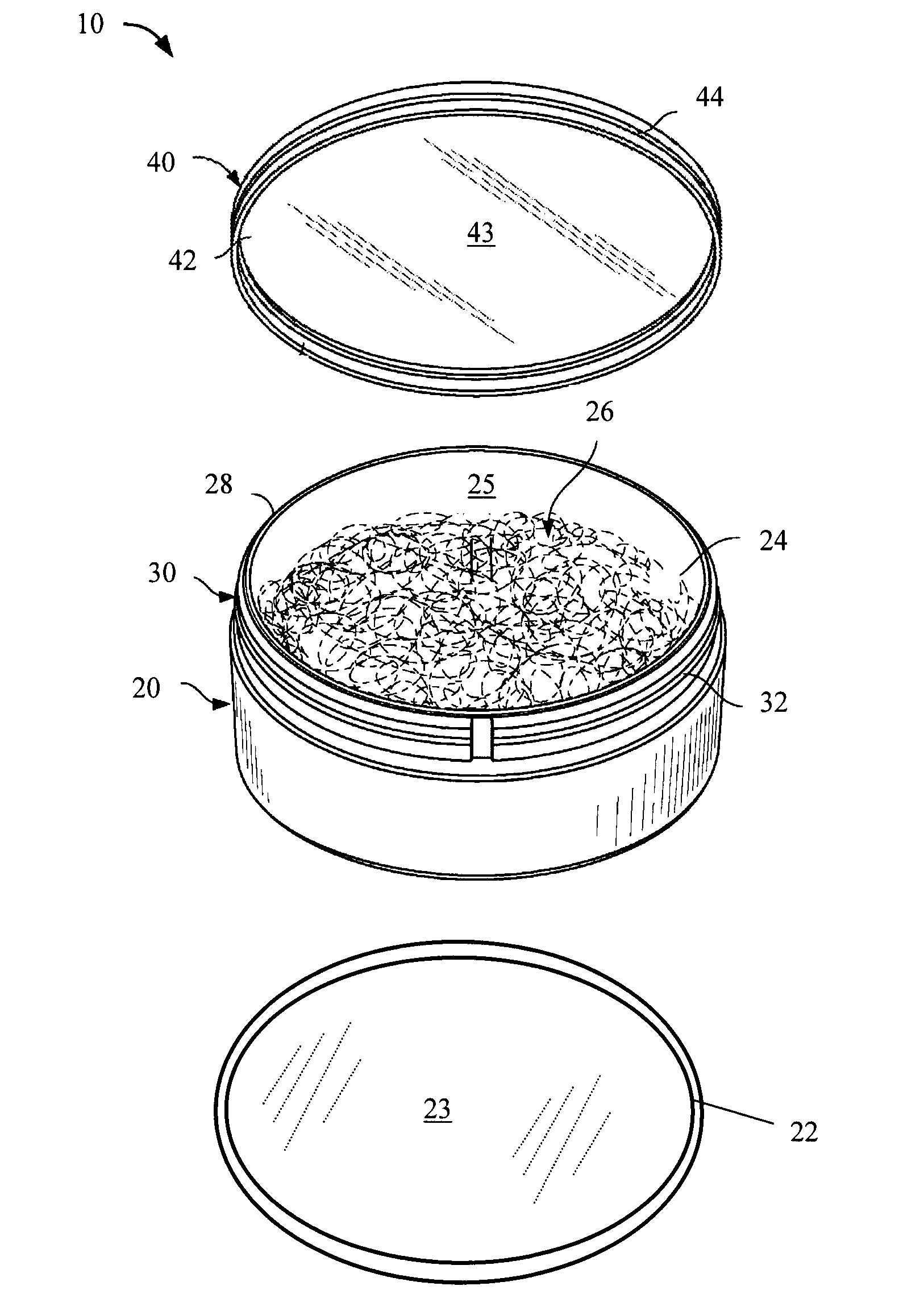

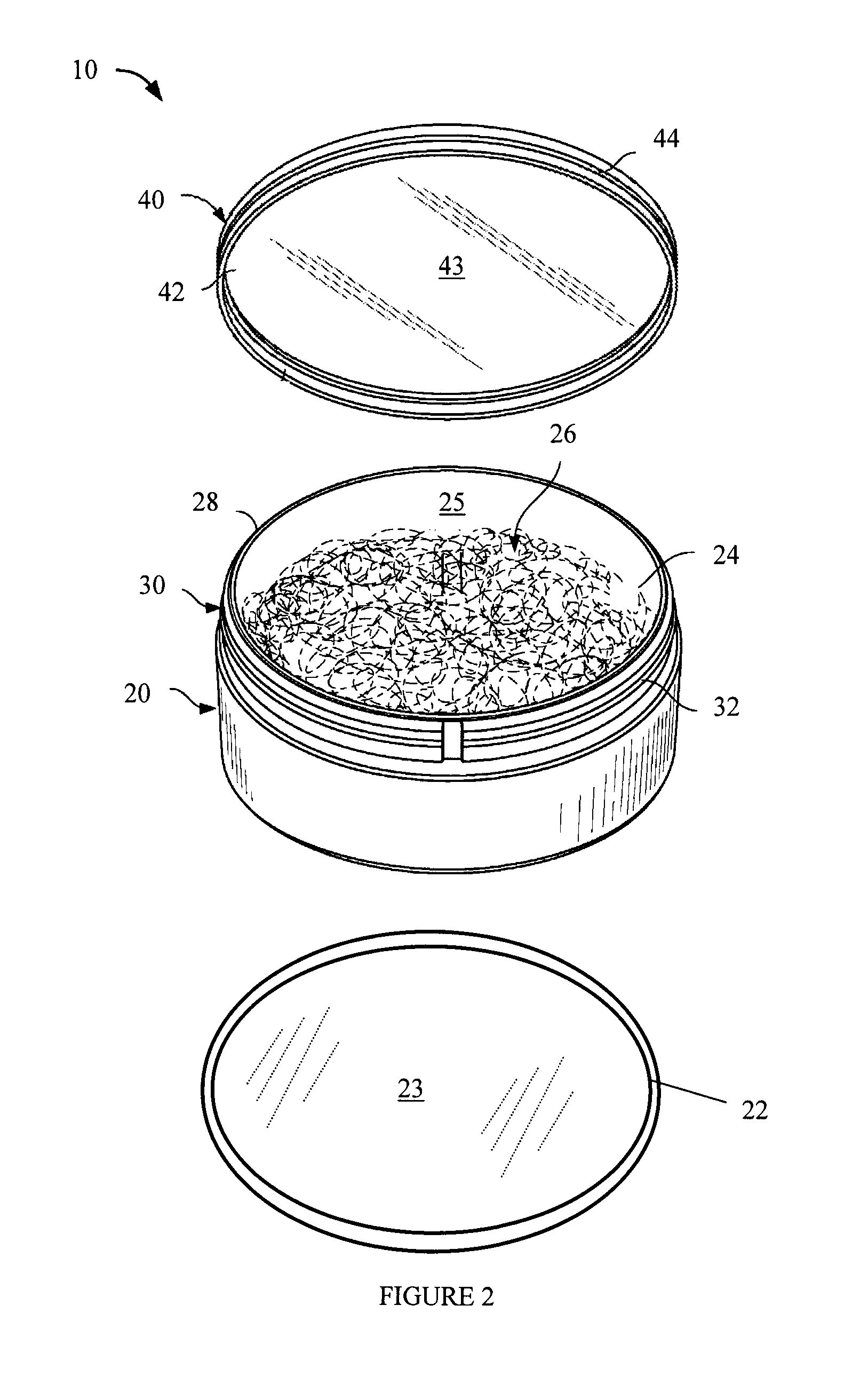

Transparent moisture barrier coatings for containers

Containers for smokeless tobacco products and other consumer and food products are provided. The containers include a layer of fibrous material, wherein the layer of fibrous material includes a moisture barrier layer imbedded within the layer of fibrous material or carried on an outer surface of the layer of fibrous material as a coating, the moisture barrier layer incorporating at least one of: (i) a triazine-containing compound; (ii) a nano-cellulose material; (iii) a nanoclay material; (iv) a polymer composition comprising one or more of a salt of one or more of myristic, palmitic and stearic acid, polyvinyl alcohol, and a C9-C18 fatty acid complex of a metal ion having an oxidation state of at least three; and (v) an inorganic oxide material.

Owner:R J REYNOLDS TOBACCO COMPANY

Preparation method of grease with humanized structure

ActiveCN102776077AHuge market potentialHigh number of reusesMilk preparationFatty acid esterificationVegetable oilMolecular rearrangement

The invention discloses a preparation method of grease with a humanized structure. The preparation method comprises the following steps: carrying out intra-molecular rearrangement reaction to palm oil with palmitic acid content of higher than 50% under the action of catalyst to obtain Sn-2 locus triglyceride with palmitic acid content of higher than 50%; and carrying out ester exchange reaction to the Sn-2 locus triglyceride with palmitic acid content of higher than 50% with mixed fatty acid or non-glyceride under the action of 1,3 locus Specificity lipase, and then subjecting the reaction product to after treatment, so as to obtain the grease with humanized structure, wherein the mixed fatty acid is mixture of at least two selected from the group consisting of decanoic acid, lauric acid,myristic acid, palmitoleic acid, stearic acid, oleic acid, linoleic acid and linolenic acid. The vegetable oils are used as the raw material according to the method, so the safety is high; the preparation process is simple, the reaction time is short, the enzyme dosage is low, and the cost is low; and the prepared grease with the humanized structure is very similar to the beast milk fat in the composition of fatty acid and the structural distribution of triglyceride, so the grease can be added in infant formula or formula foods and used as breast milk fat substitute.

Owner:ZANYU TECH GRP CO LTD

Long chain fatty acids for reducing off-taste of non-nutritive sweeteners

InactiveUS20080226790A1Food ingredient as taste affecting agentFood preparationArachidic acidAdipic acid

Aspects of the invention relate to beverage compositions, including, for example, concentrated and ready-to-drink formulations sweetened with at least one non-nutritive sweetener and further including a long chain fatty acid compound in an amount sufficient to reduce the off-note taste of the non-nutritive sweetener. In certain embodiments, the long chain fatty acid may be one or more of the following: lauric acid, myristic acid, palmitic acid, stearic acid, arachidic acid, behenic acid, oleic acid, linoleic acid, alpha-linolenic acid, arachidonic acid, eicosapentaenoic acid, docosahexaenoic acid, erucic acid, adipic acid, and palmitic acid. In certain exemplary embodiments, a plurality of different long chain fatty acids are utilized. In another embodiments, the long chain fatty acids comprise both natural and synthetic fatty acids.

Owner:CONCENTRATE MFG OF IRELAND

Balanced sn-2 myristate-containing edible oil

A nutritional fat or oil-based composition for increasing HDL cholesterol, decreasing LDL cholesterol and decreasing the LDL / HDL cholesterol ratio in human plasma is described. The composition typically includes at least 1% by weight myristic acid esterified at the sn-2 position in triglyceride molecules, includes between 10% and 40% by weight linoleic acid, and further includes between 30% and 65% by weight oleic acid and between 15% and 40% by weight total saturated fatty acids. The ratio of sn-2 myristic acid to sn-2 palmitic acid is typically greater than 1:1 and the sum of weight percentages for saturated, monounsaturated and polyunsaturated fatty acids equals 100%. In desirable cases, the composition is substantially cholesterol-free.

Owner:BRANDEIS UNIV

Nutritional blend oil with balanced fatty acid component and active component for middle and old aged

The invention relates to a nutritional blend oil with balanced fatty acid components and active components for the middle and old aged, which is prepared by a plurality of plant oils selected from flaxseed oil, walnut oil, double-low rapeseed oil, soybean oil, wheat germ oil, corn oil, teal oil, peanut oil, grape seed oil, rice bran oil, camellia oil, evening primrose seed oil, sunflower seed oil and the like, wherein, Omega 6 serial polyunsaturated fatty acids (PUFA) and Omega 3 serial PUFA are contained to enable the ratio of saturated fatty acid (SFA) to monounsaturated fatty acid (MUFA) to PUFA to be 0.6-0.8:1:1, the ratio of Omega 6 to Omega 3 to be 4:1 in the comprehensive evaluation of the blend oil absorbed by the middle and old aged and the fat from other sources, thereby meeting the recommended value of Chinese Nutrition Society; the nutritional blend oil contains 2% of gama-linolenic acid, thereby beneficial to improving the contents of DH-gama-linolenic acid and arachidonic acid; the total content of lauric acid, myristic acid and palmitic acid contained in the nutritional blend oil is below 8.5% in order to avoid over rising the level of Low density lipoprotein (LDL) in the plasm of the middle and old aged; in addition, the nutritional blend oil also comprises a plurality of active components with oxidation resistant property, so other antioxidants do not need to be added in the blend oil.The blend oil provided by the invention is characterized by low cost, balanced fatty acid nutrition, a plurality of abundant active components and higher security, thereby better improving the health and intelligence of eaters, preventing cardiovascular and cerebrovascular diseases, and avoiding fatness, hyperlipidemia, thrombotic diseases and the like caused by unbalanced fatty nutrition.

Owner:ZHEJIANG OIL MASTER

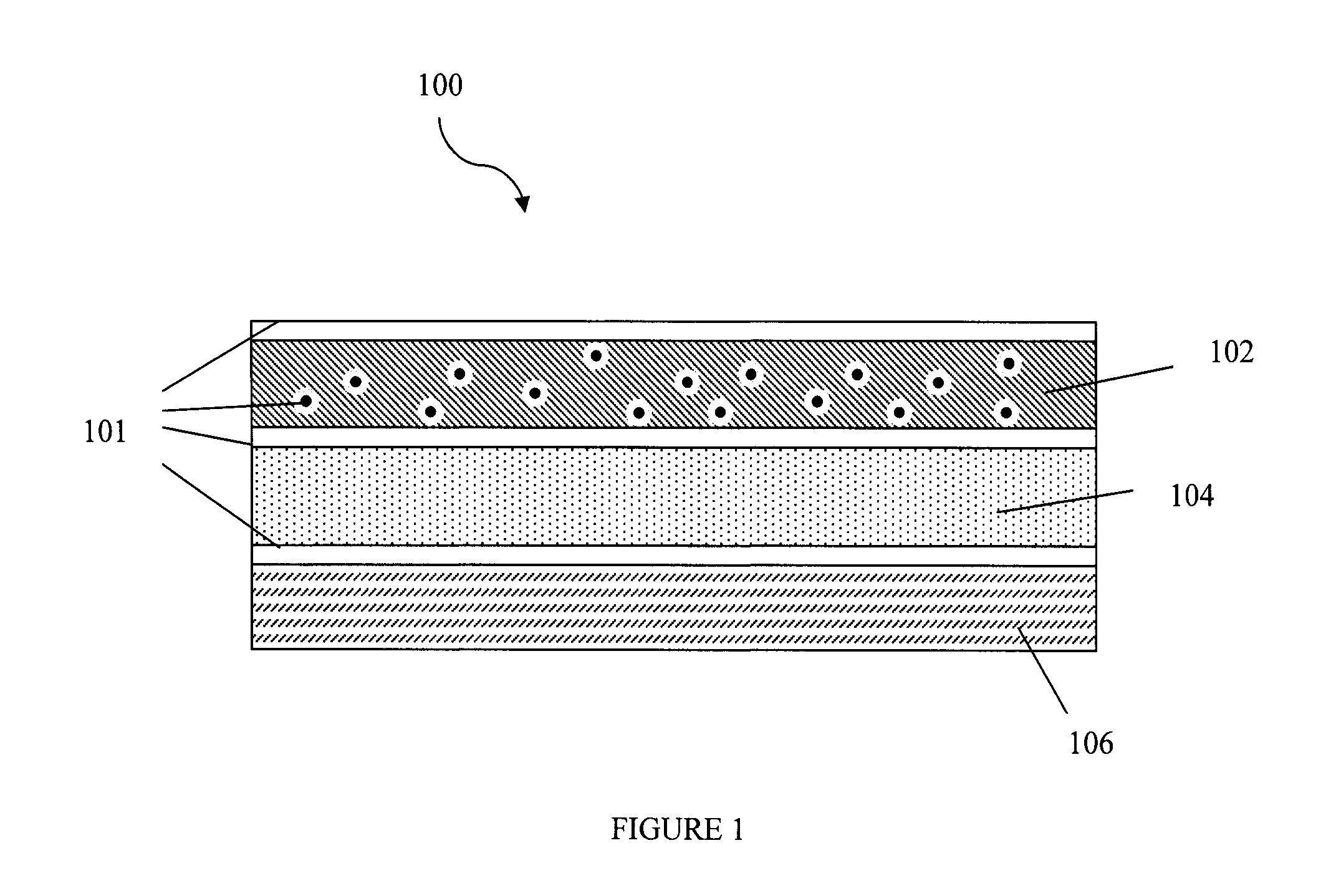

Constructional phase change energy storage plate and manufacturing method thereof

InactiveCN103015540APrevent leakageNo overflowLaminationLamination apparatusEnvironmental resistanceAlcohol

The invention discloses a constructional phase change energy storage plate, consisting of an upper cover plate, a lower bottom plate and a phase change material, wherein the phase change material is a mixture of fatty acid and high carbon alcohols; the fatty acid is n-decylic acid, lauric acid, myristic acid, palmitic acid and stearic acid; the alcohols are dodecanol, tetradecanol, hexadecanol and octadecanol; and the mass percent of the fatty acid to the mass percent of the high carbon alcohols is 46.4%: 53.6% to 97.5%: 2.5%. With the adoption of the constructional phase change energy storage plate and a manufacturing method thereof, the problems such as damages to mechanical performances, environmental protection, safety and the like are fundamentally solved, and meanwhile, the risks existing in actual application are prevented; the constructional phase change energy storage plate is stable in structure; the phase change material is not easy to leak; no irritant gas overflows; the appearance is attractive; and therefore, besides application onto constructed walls, the constructional phase change energy storage plate also can be used as an interior decoration, a suspended ceiling and a laid floor board.

Owner:TIANJIN UNIV

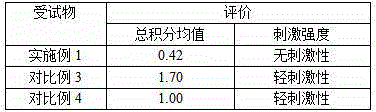

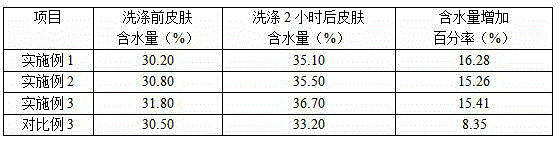

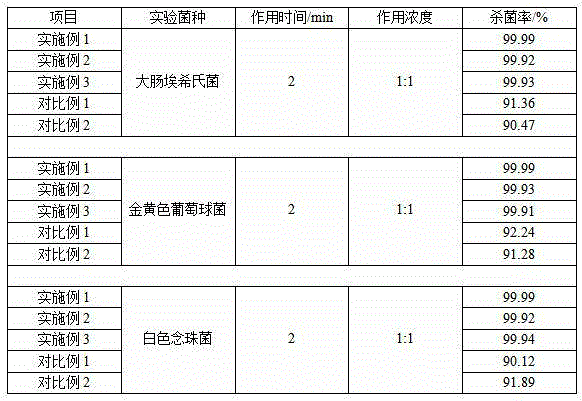

Antibacterial soap-based shower gel and preparation method thereof

ActiveCN104800123AImprove antibacterial propertiesGood moisturizing effectCosmetic preparationsToilet preparationsShower gelGlycerol

The invention discloses an antibacterial soap-based shower gel and a preparation method thereof. The shower gel comprises the following ingredients: thymol, salicylic acid, plants extracts, ethyl alcohol, propylene glycol, erythritol, lauric acid, myristic acid, palmitic acid, potassium hydroxide, glycol distearate, dihexyl sodium sulfosuccinate, cocamidopropyl betaine, sodium cocoyl glycinate, polyquaternium-7, polyglyceryl fatty acid ester composition, ethylene diamine tetraacetic acid tetrasodium, sodium chloride, citric acid, essence, a preservative and water. The antibacterial soap-based shower gel is soft and friendly to skin, can effectively resist bacteria and moisturize skin and is particularly applicable to people with thicker cuticle, high grease secretion, skin pruritus and tinea corporis.

Owner:WALCH GUANGZHOU COMMODITY

Method for production of preserved flower, and processing solution for use in the method

InactiveCN101861092AKeep natural colorReduce processDead plant preservationNatural resinVegetable oil

Disclosed is a method for producing a preserved flower, which enables to keep the original color of a real flower, particularly the subtle gradation in color of the real flower. Also disclosed is a processing solution for use in the method. Specifically disclosed is a method for producing a preserved flower, which comprises immersing a real flower in a processing solution and drying the flower, wherein the processing solution comprises a solution or dispersion containing at least one component selected from a natural oil material oil, a natural resin material, a siloxane, a synthetic resin, a water-addition-reaction-type urethane, a fatty acid ester and a surfactant, wherein the natural oil material is terpin oil, stand oil, whale oil, boiled oil, linseed oil, camellia oil, olive oil, rapeseed oil, a salad oil (a purified plant oil), sesame oil, camphor oil or the like, wherein the natural resin material is rosin, glue, wax, bees wax, rubber, rhus lacquer or the like, and wherein the fatty acid ester is an ester of a saturated or unsaturated fatty acid such as lauric acid, palmitic acid, stearic acid and myristic acid and a lower or polyhydric alcohol.

Owner:坂本好央

Transparent perfumed soap and preparation thereof

ActiveCN101497849AHigh transparencyHigh Fatty Acid Soap ContentSoap detergent compositionsPotassium hydroxideMyristic acid

The invention discloses transparent soap and a preparation method thereof. The composite of the transparent soap is prepared and compounded by adopting a plurality of natural fatty acids, such as dodecanoic acid, hexadecanoic acid, myristic acid, stearic acid, and the like. The compound fatty acid and alkali such as sodium hydroxide or potassium hydroxide performs neutralization reaction, and then compound natural clarifier is added to prepare the natural transparent soap with high transparency. The pH value of the prepared transparent soap is controlled within 6.8-7.5; the transparent soap is neutral and soft, does not hurt the skin, has high transparency, high fatty acid content, better inoxidizability, durability, exquisite and rich foam, and very smoothness without greasy of the skin after use, can keep the skin naturally smooth and soft and resilient, and has remarkable skin protecting effect.

Owner:FOSHAN BEAUTY & HEALTH CARE PRODS

Compositions and methods for hair growth

A composition that promotes hair growth includes a lipophilic compound, such as a fatty acid, an allantoin, and a therapeutically effective amount of a biologically active substance. The fatty acid can be a palmitic, palmitoleic, stearic, oleic, linoleic, linolenic, arachidic, eicosenoic, behenic, erucic, myristic acid, and lignoderic fatty acid. The composition also includes jojoba oil, tea tree oil and wild carrot seed oil. A method for promoting hair growth using such composition.

Owner:DAVIS ROSE

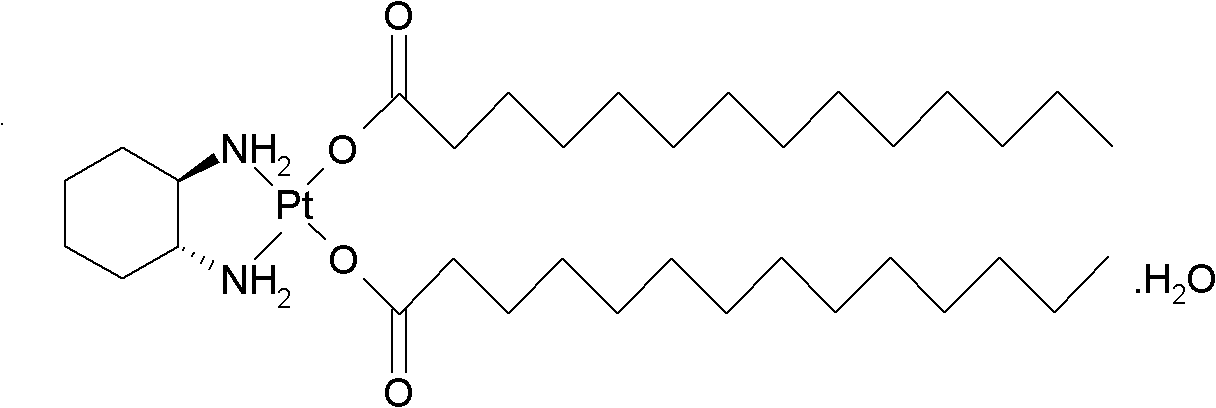

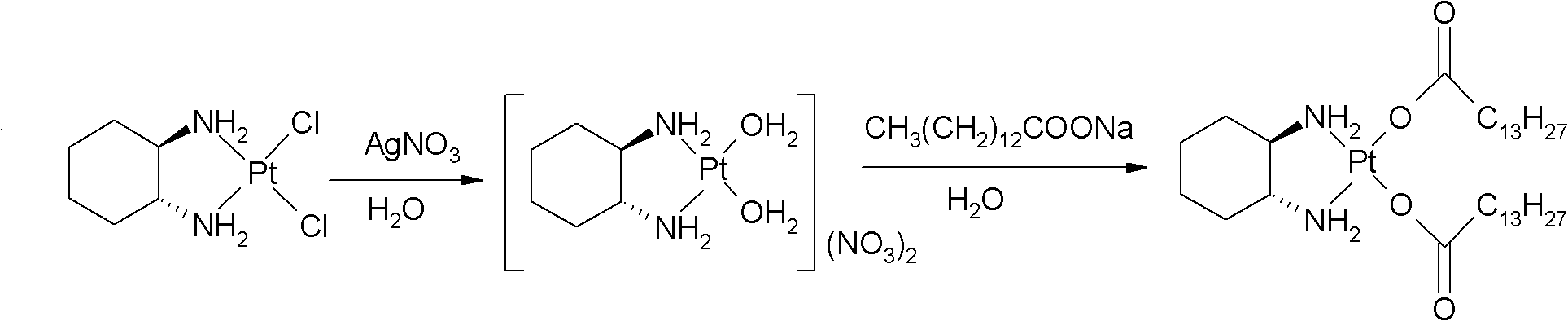

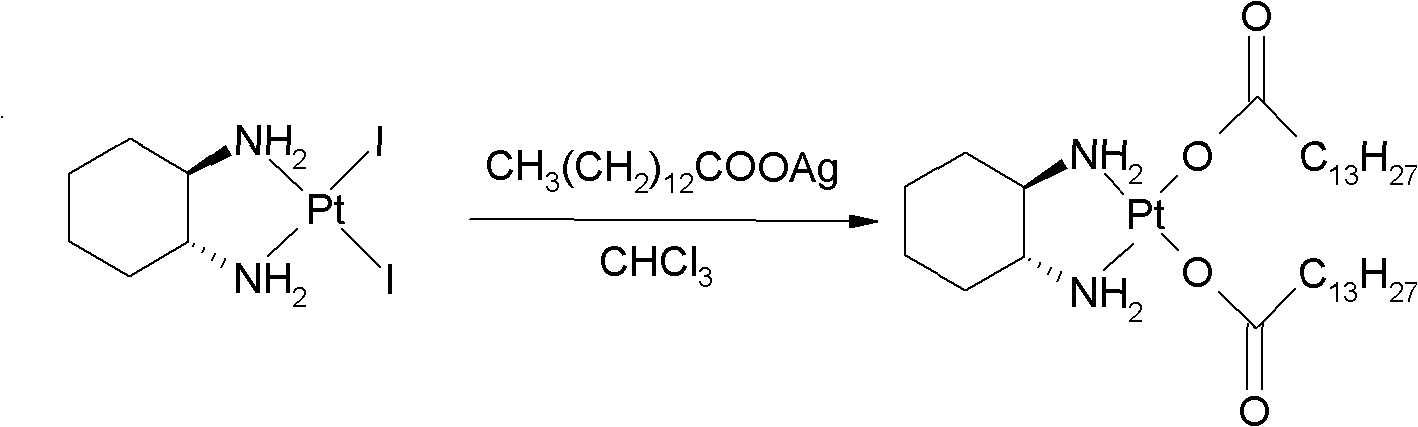

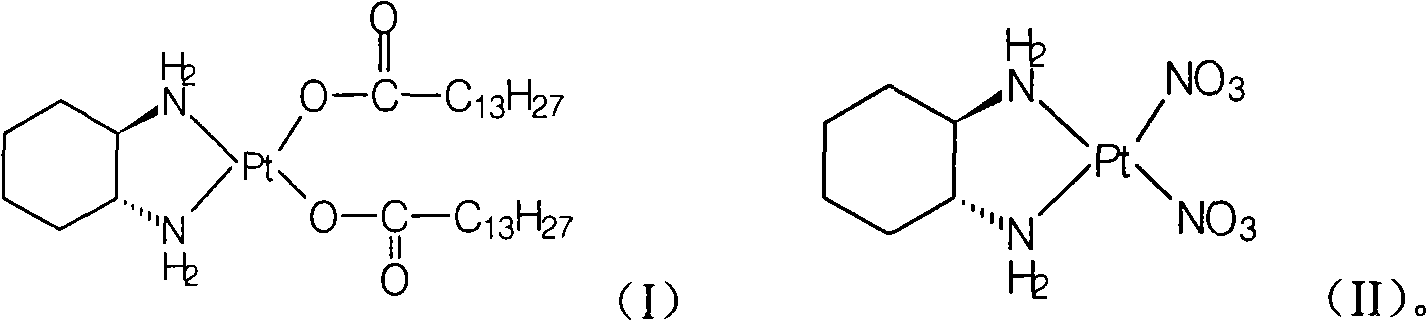

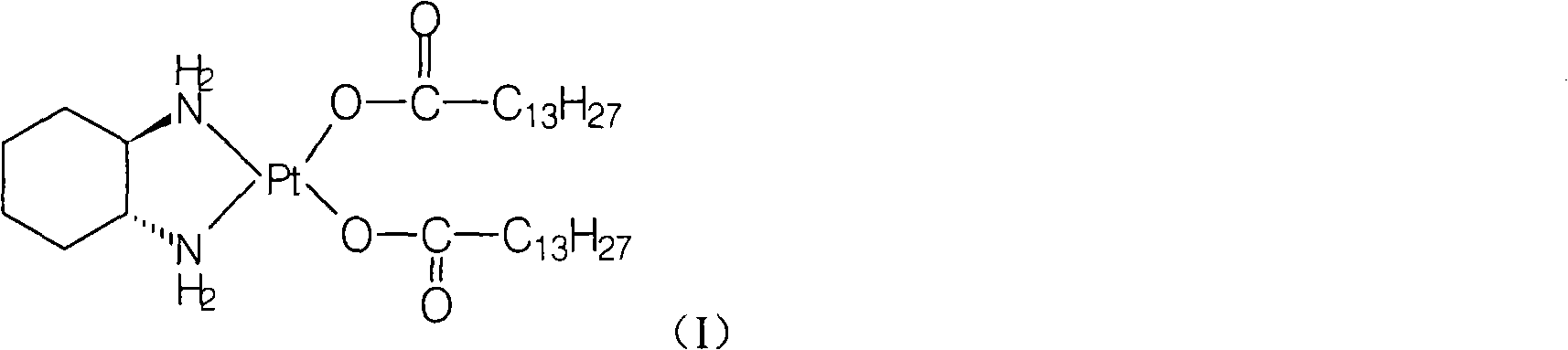

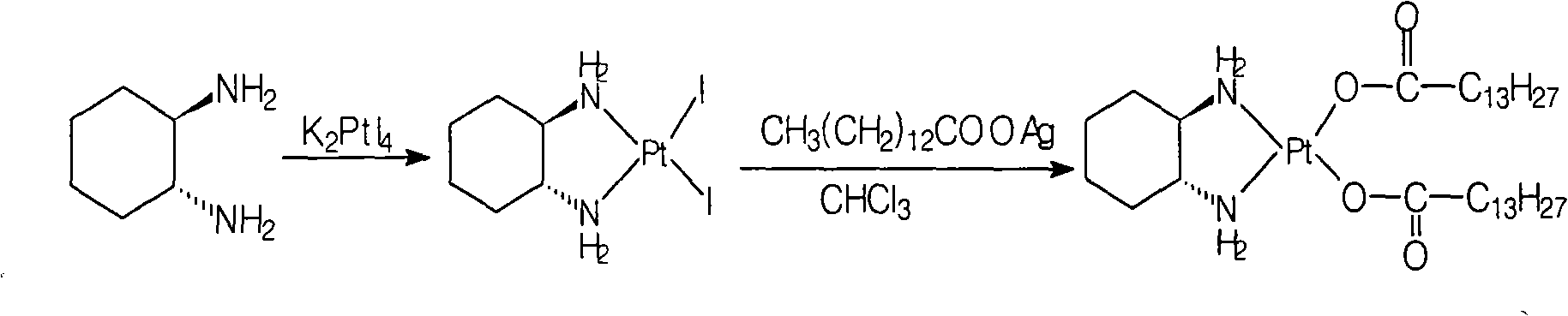

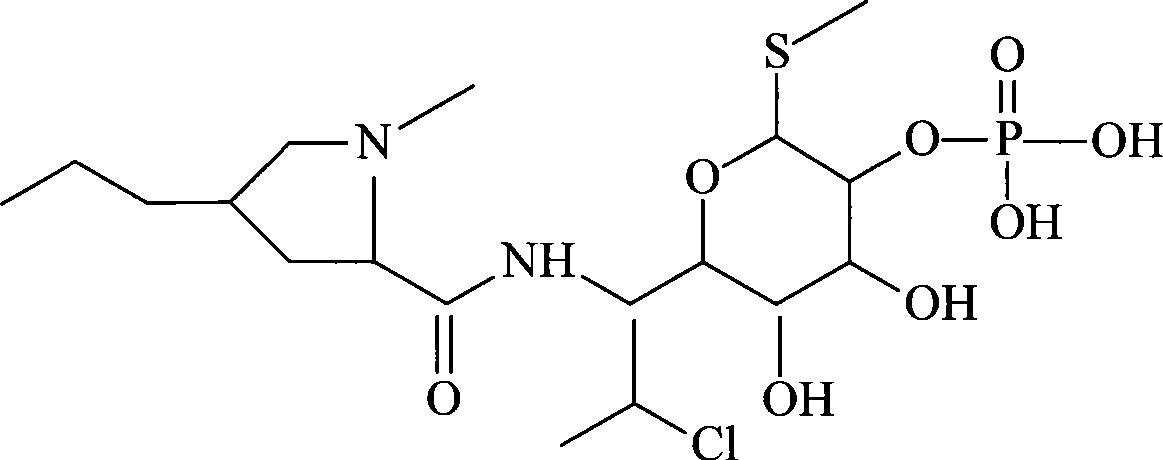

Preparation method of meter platinum

The invention relates to a preparation method of meter platinum, including that dinitric acid cis-((1R, 2R)-1, 2-diaminocyclohexane-dihydrate) platinum (II) and myristate react in solvent; wherein the solvent is composed of alkyl alcohol and water, the alkyl alcohol is methyl alcohol, ethyl alcohol, propyl alcohol or isopropyl alcohol, the myristate is sodium salt, kali salt or ammonium salt of myristic acid, reaction temperature is 20-80 DEG C, and the mass ratio of dinitric acid cis-((1R, 2R)-1, 2-diaminocyclohexane-dihydrate) platinum (II) and water is 1: 10-100. The volume ratio of water and alkyl alcohol is 1: 0.5-2 preferentially, and 1:1 more preferentially. The preparation method has simple steps, reaction medium can dissolve myristate, thus reaction can be effectively carried out and the method can be applied to industrialized production.

Owner:SOUTHEAST UNIV

Process for producing platinum

InactiveCN101402655ASimple and fast operationImprove product qualityGroup 8/9/10/18 element organic compoundsAntineoplastic agentsPlatinumRoom temperature

The invention relates to a preparation method of Miboplatin. In the preparation method, Cis-dinitrate ((1R, 2R)-1, 2-cyclohexanediamine)platinum (II) is taken as starting materials and added with purified water to react with myristate with a general chemical formula of CH3(CH2)12COOM (M refers to Na, K and NH4) for 0.5h to 8h, and then cooled to the room temperature, filtrated and dried to obtain the Miboplation, wherein, the reaction temperature is 10 DEG C to 80 DEG C; the purified water added is 5 times to 50 times the weight of the Cis-dinitrate ((1R, 2R)-1, 2-cyclohexanediamine)platinum (II); and the mol ratio of the Cis-dinitrate ((1R, 2R)-1, 2-cyclohexanediamine)platinum (II) and the myristate is 1:2.0 to 3.0. The preparation method uses no toxic solvent such as chloroform and the like and is simple in operation, high in quality of products prepared and yield and low in cost. Simultaneously, the preparation method is applicable to commercial production.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

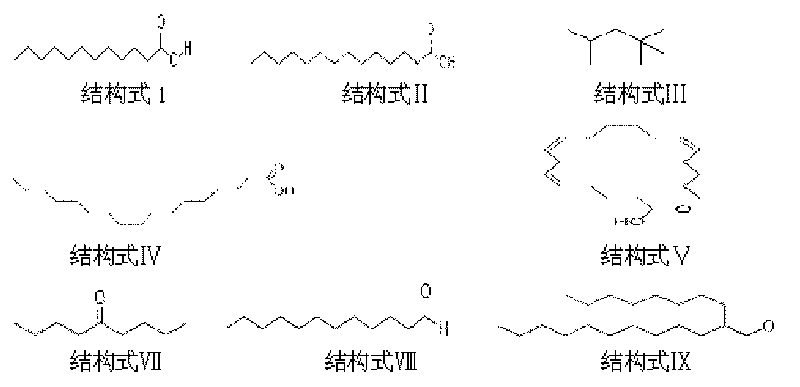

Tungsten ore floatation collecting agent and application thereof

ActiveCN101757983AIncreased critical micelle concentrationImprove surface activityFlotationAdditive ingredientPhosphoric acid

The invention relates to a tungsten ore floatation collecting agent and application thereof. The collecting agent is prepared from the following ingredients in mass percent: 15 to 20 percent of lauric acid, 15 to 20 percent of myristic acid, 10 to 15 percent of isooctane, 20 to 30 percent of oleic acid, 10 to 15 percent of arachidonic acid, 5 to 10 percent of 5-nonanone, 5 to 10 percent of dodecyl aldehyde and 5 to 10 percent of isomer 20 ether. The floatation collecting agent is applicable for wolframine and scheelite floatation. When being used, the floatation collecting agent is added intoraw ore according to the proportion of 200 to 500g / ton. The organic mixture improves the selective collecting capability of fatty acid type medicine agents to the tungsten ore. Compared with oxidizedore collecting agents of alkyl sulfonic acid (alkyl sulfonate), phosphoric acid and swelling acid, the invention can not cause environment pollution. Compared with hydroximic acid, the invention has the advantages that the cost is low, and the pipeline can not be blocked for causing the operation difficulty and the mineral dressing index influence. When being used in the scheelite floatation, theinvention has the predominant collecting performance, and belongs to the high-efficient floatation collecting agent for the wolframine and the scheelite.

Owner:CENT SOUTH UNIV

Skin externally-applied liquid state and solid state kreotoxin (liushengtai) composite nano emulsion and preparation thereof

InactiveCN101214200AAnti aging goodImprove scienceCosmetic preparationsToilet preparationsPolyethylene glycolExternal Liquid

The present invention relates to external liquid and solid kreotoxin (argireline) composite nanometer latex for skin and a preparation method thereof. The weight proportion of each raw material of liquid nanometer latex is 10g of isopropyl myristate, 2g of vitamin E, 0.8g of vitelline lecithin, 0.2g of ginseng saponin, 0.01g of rhodiola element, 0.005g of the argireline, 0.001g of superoxide dismutase, 0.5g of reduction type glutathione, 5g of fetal calf serum, 0.05g of hyaluronic acid, 0.05g of ceramide, 40g of distilled water, 36g of polyethylene glyceride glycol caprylic decanoate and 12g of polyglycerol fatty acid ester; the weight proportion of each raw material of solid nanometer latex is 10g of the isopropyl myristate, 2g of the vitamin E, 0.8g of the vitelline lecithin, 0.2g of the ginseng saponin, 0.01g of the rhodiola element, 0.005g of the argireline, 0.001g of the superoxide dismutase, 0.5g of the reduction type glutathione, 5g of the fetal calf serum, 0.05g of the hyaluronic acid, 0.05g of the ceramide, 40g of the distilled water, 36g of the polyethylene glyceride glycol caprylic decanoate, 12g of the polyglycerol fatty acid ester, 22g of mannitol and 3g of glycin.

Owner:丁克祥

Grease composition, breast milk fat substitute, and preparation methods of grease composition and breast milk fat substitute

InactiveCN106916631ALow costMilk preparationFatty acid esterificationTransesterificationMyristic acid

The present invention relates to a grease composition, a breast milk fat substitute, and preparation methods of the grease composition and the breast milk fat substitute. The preparation method of the grease composition or the breast milk fat substitute comprises: (1) carrying out random transesterification on a grease containing palmitic acid and a grease containing lauric acid and / or myristic acid to obtain a transesterified grease; and (2) carrying out a reaction on the transesterified grease obtained in the step (1) and a unsaturated-fatty-acid-containing mixture of fatty acid or an ester thereof in the presence of a lipase. With the preparation method of the present invention, the grease composition or the breast milk fat substitute having the fatty acid composition or the position distribution thereof more completely close to the breast fat can be obtained.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Fatty acid component balanced children type nutrition blended oil containing multiple active ingredients

The invention relates to fatty acid component balanced children type nutrition blended oil containing multiple active ingredients. The nutrition blended oil prepared from a plurality kinds of vegetable oils contains omega-6 polyunsaturated fatty acid (PUFA), and omega-3 PUFA, so that when the blended oil eaten by children and the fat of other dietary sources are comprehensive evaluated, the ratio of omega-6 to omega-3 is (4-6):1, and the recommended value of Chinese Nutrition Society is met. The nutrition blended oil contains 2 percent of gamma-linolenic acid, and the content sum of lauric acid, myristic acid and palmitic acid is less than 4.5 percent. In addition, the nutrition blended oil also contains multiple active ingredients without antioxidants. The nutrition blended oil has the advantages of contributing to improvement on body constitution and intelligence of users, preventing the occurrence of cardiovascular and cerebrovascular diseases, reducing the occurrence of obesity, hyperlipidemia and thrombosis, and the like caused by fat nutrition unbalance, along with low cost, balanced fatty acid nutrition, multiple active ingredients and higher safety.

Owner:ZHEJIANG OIL MASTER

Cleansing oil and preparation method thereof

ActiveCN108014031AGood emulsificationRemoves makeup wellCosmetic preparationsMake-upPlant SourcesRice Bran Extract

The invention discloses cleansing oil. The cleansing oil is prepared from the following components in percentage by weight: 11 to 31 percent of plant-sourced light oil, 30 to 60 percent of ethylhexylpalmitate / ethylhexyl stearate, 10 to 25 percent of isopropyl myristate, 3 to 10 percent of isohexadecane, 0.01 to 3 percent of water and 8 to 30 percent of polyglycerol emulsifier. By adopting the plant-sourced light oil, in particular to plant-extracted rice bran oil and sun-flower oil, the cleansing oil has a smooth touch feel and brings a fresh feel to a human after the cleansing oil is used; by adopting the polyglycerol emulsifier, optimizing the compound and reasonably adding an amount of the isohexadecane with polarity, the cleansing oil also has a more ideal cleansing effect when a handis wet and makeup is wet; moreover, an emulsification effect of the cleansing oil is excellent, and a makeup removal effect is good.

Owner:HUAANTANG BIOTECH GRP CO LTD

Antimicrobial nano-silver transparent soap and preparation method thereof

InactiveCN102978034APure textureMild in natureSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsCelluloseGlycerol

The invention relates to a skin-care and washing product, and specifically relates to an antimicrobial nano-silver transparent soap and a preparation method thereof. The antimicrobial nano-silver transparent soap comprises a modified nano-silver solution, a surfactant and a cellulose thickening amendment and is prepared according to the following weight parts: 5-15 parts of glycerol, 5-10 parts of propylene glycol, 10-25 parts of sodium palmitoleate, 8-12 parts of sodium cocoate, 5-12 parts of sodium stearate, 10-20 parts of sodium myristate, 8-15 parts of stearic acid, 2-6 parts of EDTA-4Na, 10.5-26.5 parts of a mixed soluble surfactant, 4-12 parts of the modified nano-silver solution, 6-18 parts of the cellulose thickening amendment and 1-5 parts of essence. The soap has pure quality, mild property, rich and meticulous foam and strong decontamination capability, has the function of antisepsis and anti-inflammation, and has very good moistening and protecting effects for human skins.

Owner:YANCHENG CITY HUZHENG NANO MATERIAL SCI & TECH

Liquid essential oil soap

InactiveCN104611163AStay hydratedImprove repair effectSurface-active non-soap compounds and soap mixture detergentsSkin careGlycerolPotassium hydroxide

The invention discloses liquid essential oil soap which comprises the following components: glycerin, sodium lauroyl glutamate, myristic acid, lauric acid, tocopheryl acetate, a plant origin extract and / or an animal origin extract, essential oil, lauramidopropyl hydroxy sulfobetaine, potassium hydroxide, cocoanut fatty acid diethanolamide, hydroxyethyl cellulose, allantoin, disodium EDTA, a preservative and water. The liquid oil soap has the advantages that on the basis of original soap, a large amount of glycerin, skin-care grease and pure essential oil or compound essential oil are added through technology improvement, so that effects of cleansing skin and caring skin are achieved, and the skin is maintained moisturized; since the essential oil has permeability in skin cells, the skin recovery effect is better; the essential oil is well fused with substances such as the glycerin and the skin-care grease, so that not only are the effects of controlling oil and shrinking pores as well as repairing damaged skin achieved, but also the skin is tender and silky, and the skin has no tight and dry feeling after being cleaned.

Owner:刘静涛

Triglyceride fat

ActiveUS7223435B2Promote formationFatty acid esterificationEdible oils/fats with aqeous phaseVegetable oilTriglyceride

Preparation of a fat phase suited for the preparation of food compositions which contain liquid or solid particles stably dispersed in the fat phase, which preparation comprises mixing 0.25–20 wt. % of a structuring triglyceride fat A with 0–19.75 wt. % of a triglyceride fat C and admixing a vegetable oil up to 100%, which fat A is characterized in that the fat is non-hydrogenated and thatits content of fully saturated triglycerides is 20–100 wt. %,80–100 wt. % of its saturated fatty acid residues are palmitic acid or stearic acid residues,0–5 wt. % of its saturated fatty acid residues are lauric acid or myristic acid residues,<50 wt. % of its saturated triglycerides are monoacyl triglycerides and that fat C having a solid fat content at 20° C. (N20) being at least 5 contains less than 20 wt. % of H2M fatty acid residues, where H denotes saturated fatty acid residues having chain lengths larger than 15 carbon atoms and where M denotes saturated fatty acid residues having chain lengths of either 12 or 14 carbon atoms.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

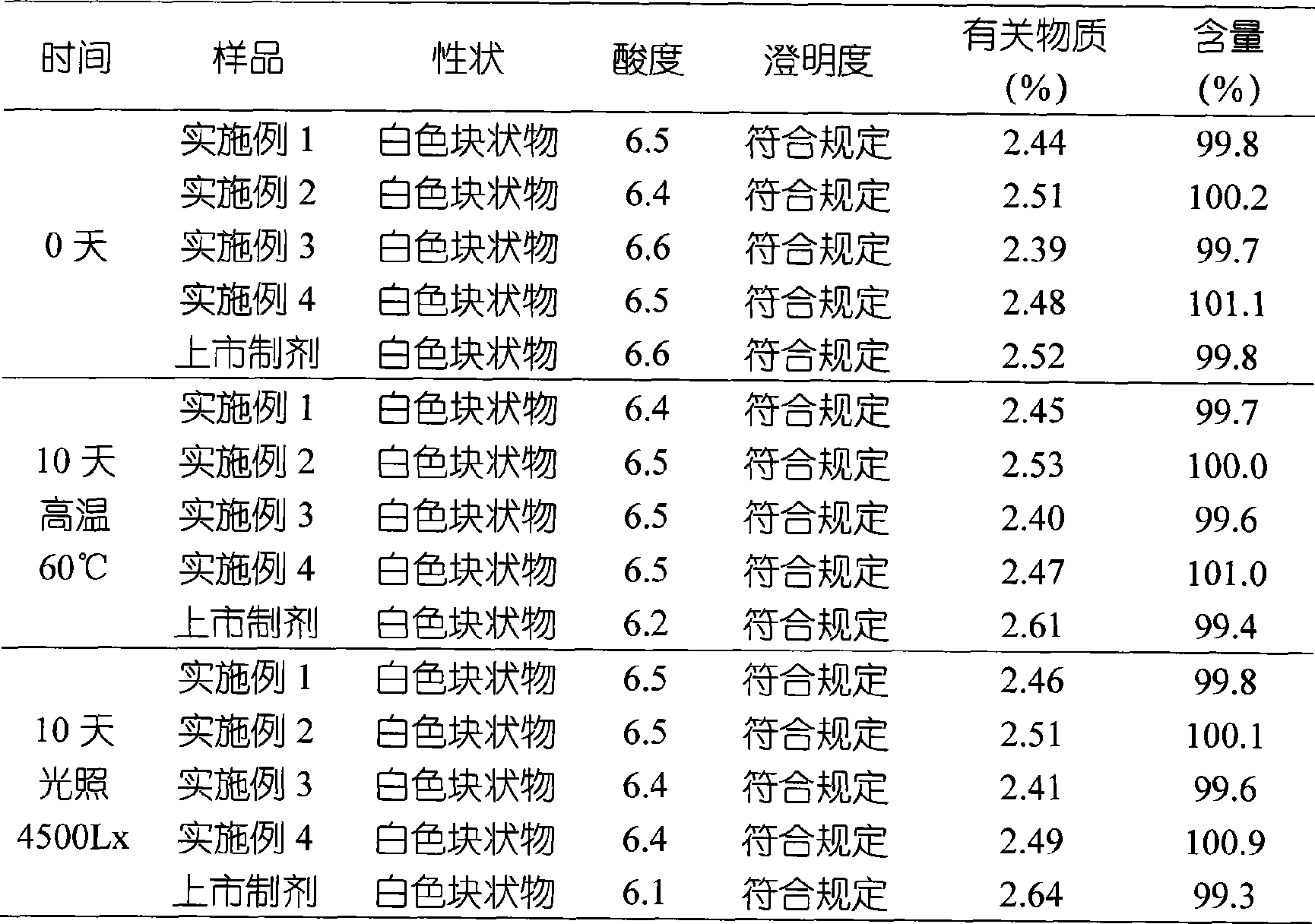

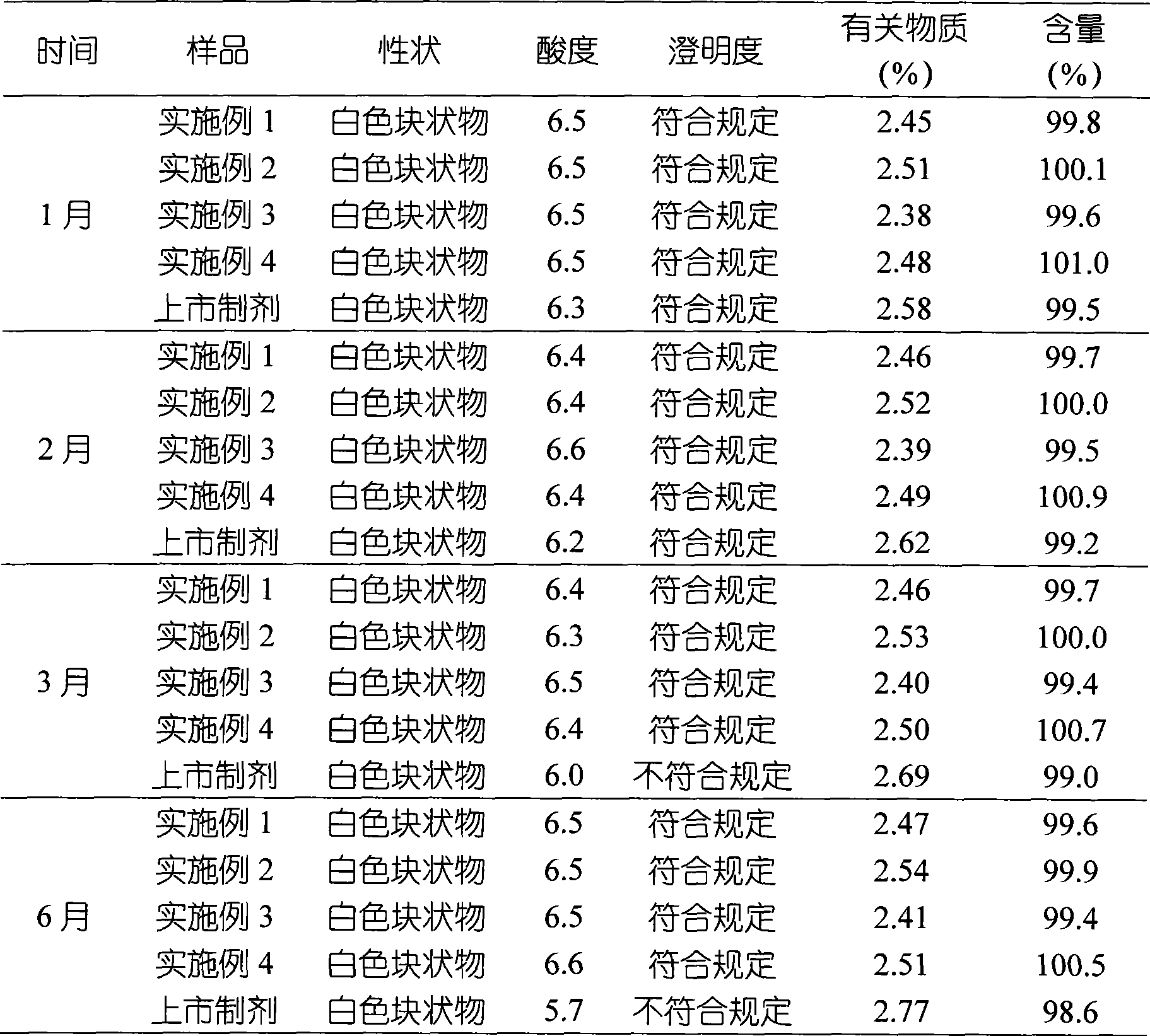

Clindamycin phosphate lipidosome freeze-dried preparation and preparation method thereof

InactiveCN101530393AAchieve vitrificationAvoid damageAntibacterial agentsOrganic active ingredientsFreeze-dryingCholesterol

The invention relates to a clindamycin phosphate lipidosome freeze-dried preparation and a preparation method thereof. The clindamycin phosphate lipidosome freeze-dried preparation is characterized by comprising the following components in portion by weight: 15 to 25 portions of clindamycin phosphate, 10 to 40 portions of dimyristyl acid lecithin, 1 to 10 portions of cholesterol, 1 to 5 portions of antioxidant, and 5 to 25 portions of cryoprotectant.

Owner:HAINAN LINGKANG PHARMA CO LTD

Anti-freezing anti-cracking hand lotion and preparation method thereof

InactiveCN101797216AImprove immunityReduce inflammationCosmetic preparationsToilet preparationsCAPRYLIC TRIGLYCERIDEGlycerol

The invention relates to an anti-freezing anti-cracking hand lotion and a preparation method thereof. The anti-freezing anti-cracking hand lotion comprises the following components: cetearyl glucoside, myristic acid and myristate, sodium cetearyl sulfate, Crodaderm S, shea butter, jojoba oil, capric / caprylic triglyceride, polydimethylsiloxane, lecithin, vitamin B3, trehalose, modified maize starch, glycerol, allantoin, carbomer, methylparaben, deionized water, triethanolamine and beta-glucan. By using the hand lotion, the fibrocyte of hand skin can avoid of dehydration damage, the natural structure of skin can be maintained, the damages caused by dry environment, high temperature and severe cold can be reduced, the skin immunity is enhanced, skin inflammation and erythema can be reduced, the ability of resisting environmental stimulations of cells can be increased, and the skin tolerance can be enhanced.

Owner:ZHEJIANG JIUDING PLASTICS & CHEM TECH

Antioxidant network efficacy nanoemulsion externally used for skin and preparation method thereof

ActiveCN101664372AFormulated ingredients streamlinedFormulated with fine ingredientsCosmetic preparationsToilet preparationsAdditive ingredientPolyethylene glycol

The invention relates to an antioxidant network efficacy nanoemulsion externally used for skin and a preparation method thereof. The nanoemulsion consists of the following raw materials according to weight mixture ratio: 1.0-1.5 of vitamin E, 2.0-3.0 of glutathione, 2.0-2.5 of L-ascorbic acid-2-heteroside, 1.0-1.8 of seabuckthorn oil, 1.0-1.6 of coenzyme Q10, 0.5-0.6 of alpha-lipoic acid, 8.0-10 of isopropyl myristate, 20-25 of caprylic acid capric acid polyethylene glycol glyceride, 7.0-9.0 of polyglyceryl fatty acid ester, 0.5-1.0 of azone, 46-50 of triple distilled water, 0.05-0.25 of citric acid and 1.0-1.6 of sodium citrate. The functional ingredients in the formula can form an antioxidant network system with cooperative interaction, synergy and regeneration, and the penetrating function of a nanoemulsion carrier system greatly enhances the antioxidant function and effect of the functional ingredients. The preparation method can enhance the stability and effectiveness of antioxidant, is simple in preparation technology and easy for scale production, needs no extra energy, saves time, energy and raw materials and is beneficial to environment protection.

Owner:董萍 +1

Insect repellent surface composition

Embodiments of the invention relate to a pest-control composition comprising at least one active ingredient and at least two other ingredients; wherein the at least one active ingredient is selected from the group consisting of geraniol, nootketone, amyl cinnamaldehyde, catnip, wintergreen, carvacrol, d-limonene, orange oil, lauric acid, alpha pinene, mint, cornmint oil, lemon oil, eucalyptus, eugenol, peppermint, lemongrass oil, and terpenes; and wherein the at least two other ingredients are selected from the group consisting of 2-propanol, alcohol, ethanol, monobutyl ether, ethylene glycol, terpenes, ethoxylated alcohol, dodecanol, ammonia, soap, lauryl polyglucose, polyethylene glycol, sodium lauryl sulfate, sodium olefin sulfonate, cocamidapropyl betaine, alkylbenzene sulfonate, polyoxyethelene alkylphenol sulfate, sodium dodecyl benzene sulfonate, sodium sterate, potassium sterate, potassium myristate, tomadol, polyglyceryl sterate, glycol monosterate, potassium oleate, polyglyceryl oleate, tween, polymers, acrylic polymers, ethyl cellulous, carboxymethyl cellulose, sodium hydroxide, ammonium hydroxide, polyacrylate polymer, polyvinyl pyrolidane, lauric diethanolamine, dimethyldodecylamine oxide, aspartic acid tetrasodium salt, and sodium citrate.

Owner:ENVANCE TECH LLC

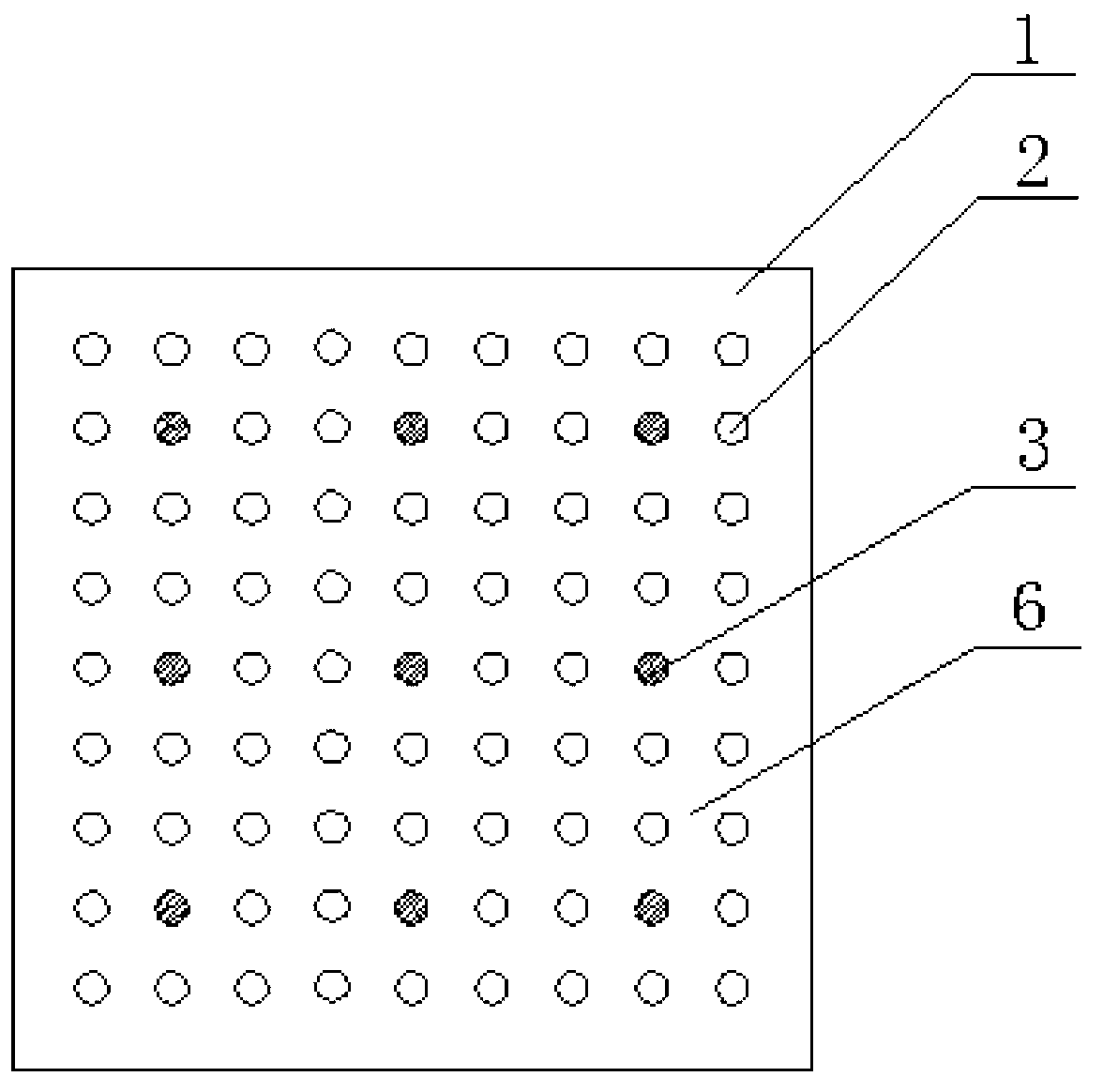

Preparation method of gypsum and clay composite phase-change energy storing material

ActiveCN104152114AHigh strengthImprove thermal performanceHeat-exchange elementsSodium BentoniteCalcite

The invention discloses a preparation method of a gypsum and clay composite phase-change energy storing material. The composite phase-change energy storing material is characterized by being prepared from a composite phase-change precursor and a gypsum cementing material, wherein the composite phase-change precursor is prepared through the steps of adsorbing an organic phase-change agent by using an inorganic porous clay material through a solution intercalation method, then, binding by using a binder, granulating and drying; and then, the product is mixed with hemi-hydrated gypsum, and the mixture is molded to prepare the gypsum and clay composite phase-change energy storing material. The phase-change agent is selected from decanoic acid, lauric acid, myristic acid, palmitic acid, stearic acid, dodecanol, tridecanol, tetradecanol, pentadecanol, methyl palmitate, methyl heptadecanoate, ethyl heptadecanoate, methyl octadecanoate and paraffin. The inorganic porous clay material is selected from attapulgite, sepiolite, montmorillonite, bentonite, diatomite, zeolite, silica, dolomite, calcite and illite. The molding binder is selected from water glass, hydroxymethyl cellulose, silica sol and aluminum sol. The prepared composite phase-change energy storing material is wide in phase change temperature range, high phase-change latent heat, favorable in mechanical property and high in thermal stability.

Owner:BEIJING UNIV OF CHEM TECH +1

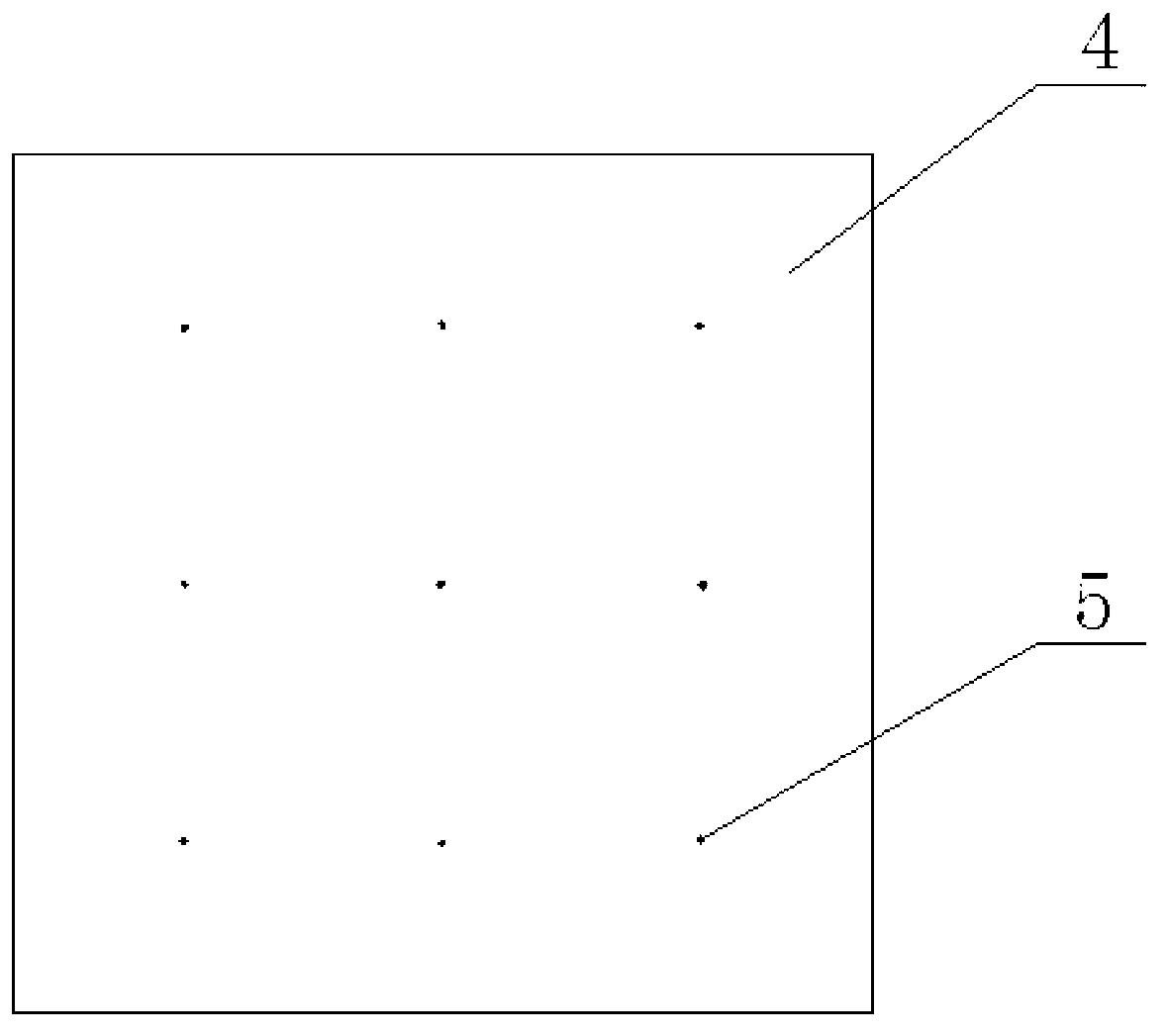

Method for manufacturing powder through neodymium iron boron alloy

ActiveCN103521758ASmooth rotationAvoid contactMagnetic materialsDiethylene glycol monobutyl etherZinc borate

The invention provides a method for manufacturing powder through neodymium iron boron alloy and belongs to the technical field of neodymium iron boron alloy preparation. The method is characterized by including the steps of adding an anti-oxygen lubricant accounting for 0.05-0.5% of neodymium iron boron coarse powder by mass after the neodymium iron boron coarse powder is placed into a powder mixing tank, obtaining fine powder through a jet milling process, then adding a lubricant accounting for 0.05-0.5% of the fine powder by mass, and performing mixing, molding and sintering to obtain the powder. The anti-oxygen lubricant is formed by mixing zinc stearate, diethylene glycol monobutyl ether, myristic acid and megilp according to the mass ratio of (1-50): (1-50): (1-70): (1-70), and the lubricant is formed by mixing isopropyl alcohol, zinc stearate, zinc borate ester and megilp according to the mass ratio of (1-50): (1-50): (1-70): (1-70). According to the method, in the process for manufacturing the powder through the neodymium iron boron alloy, corrosivity of the additives can be eliminated, meanwhile orientation in the compression process is improved, and the powder outgoing velocity in the jet milling process is increased.

Owner:ARCFL TECHNOLOGY LIMITED

Oil-controlling facial cleanser and preparation method thereof

ActiveCN104257567AReduce secretionServes the purpose of deep cleaning of the surfaceCosmetic preparationsToilet preparationsPotassium hydroxideGlycerol

The invention provides an oil-controlling facial cleanser. The oil-controlling facial cleanser in the formula comprises the following components in percentage by weight: 5-10 percent of lauric acid, 5-10 percent of myristic acid, 15-25 percent of stearic acid, 5-15 percent of potassium cocoyl glycinate, 5-7 percent of potassium hydroxide, 0-0.6 percent of preservative, 15-25 percent of glycerol, 0.01-0.1 percent of sodium hyaluronate, 0-0.3 percent of essence, 0.1-1 percent of yellowish sophora root, 0.1-1 percent of herba violae extract, 0.1-1 percent of agrimonia eupatoria extract and the balance of water. The oil-controlling facial cleanser provided by the invention can be used for deeply cleaning skin and has good oil controlling effect.

Owner:H&B COSMETICS

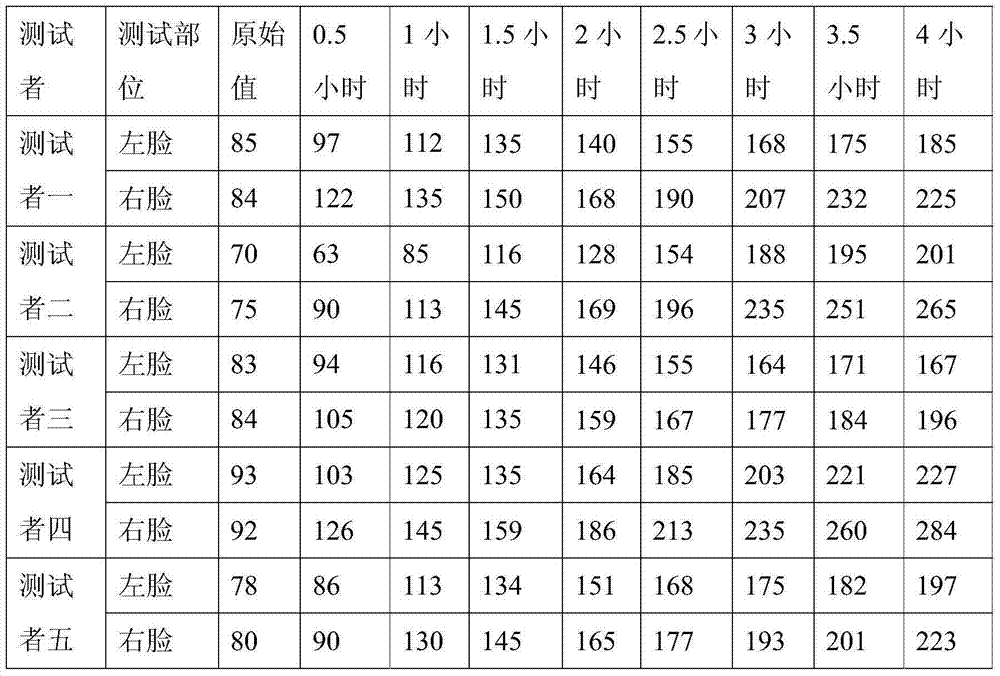

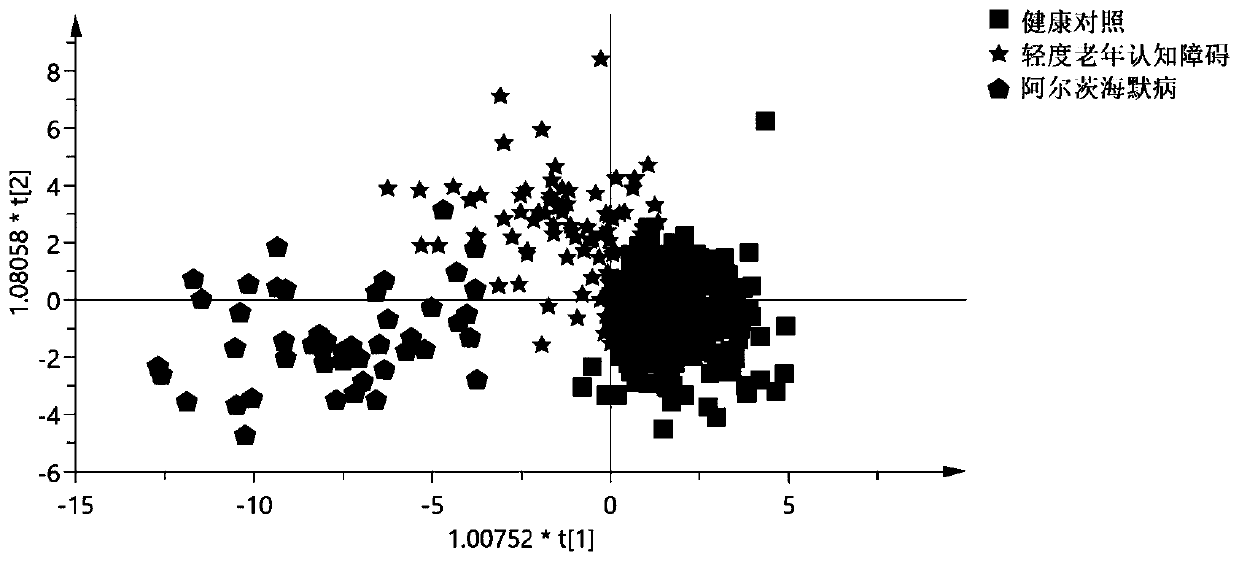

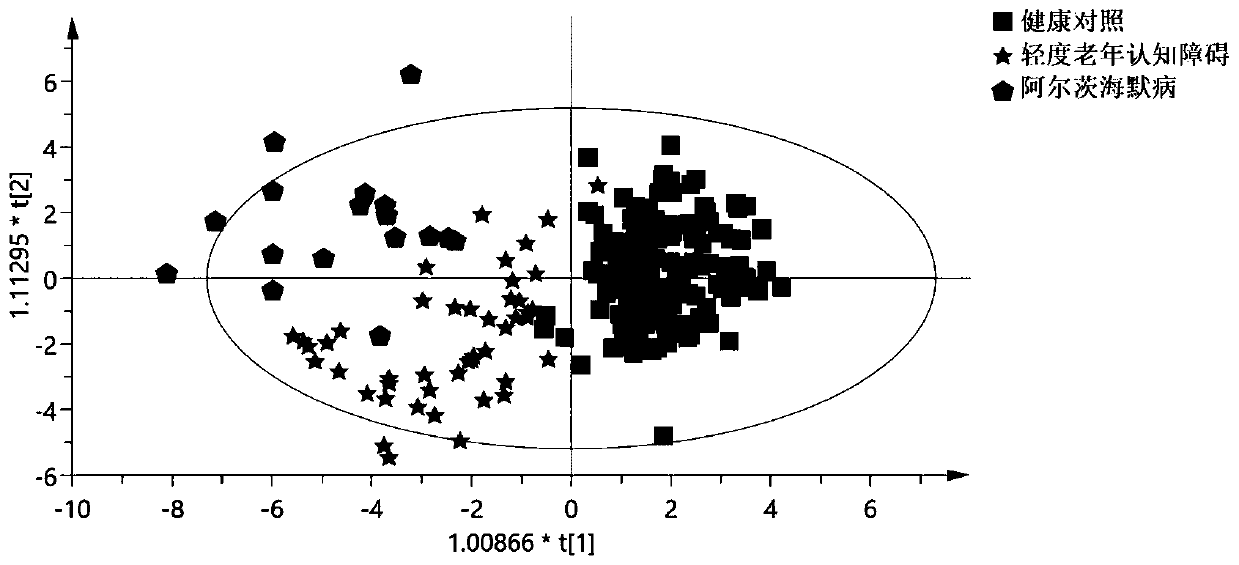

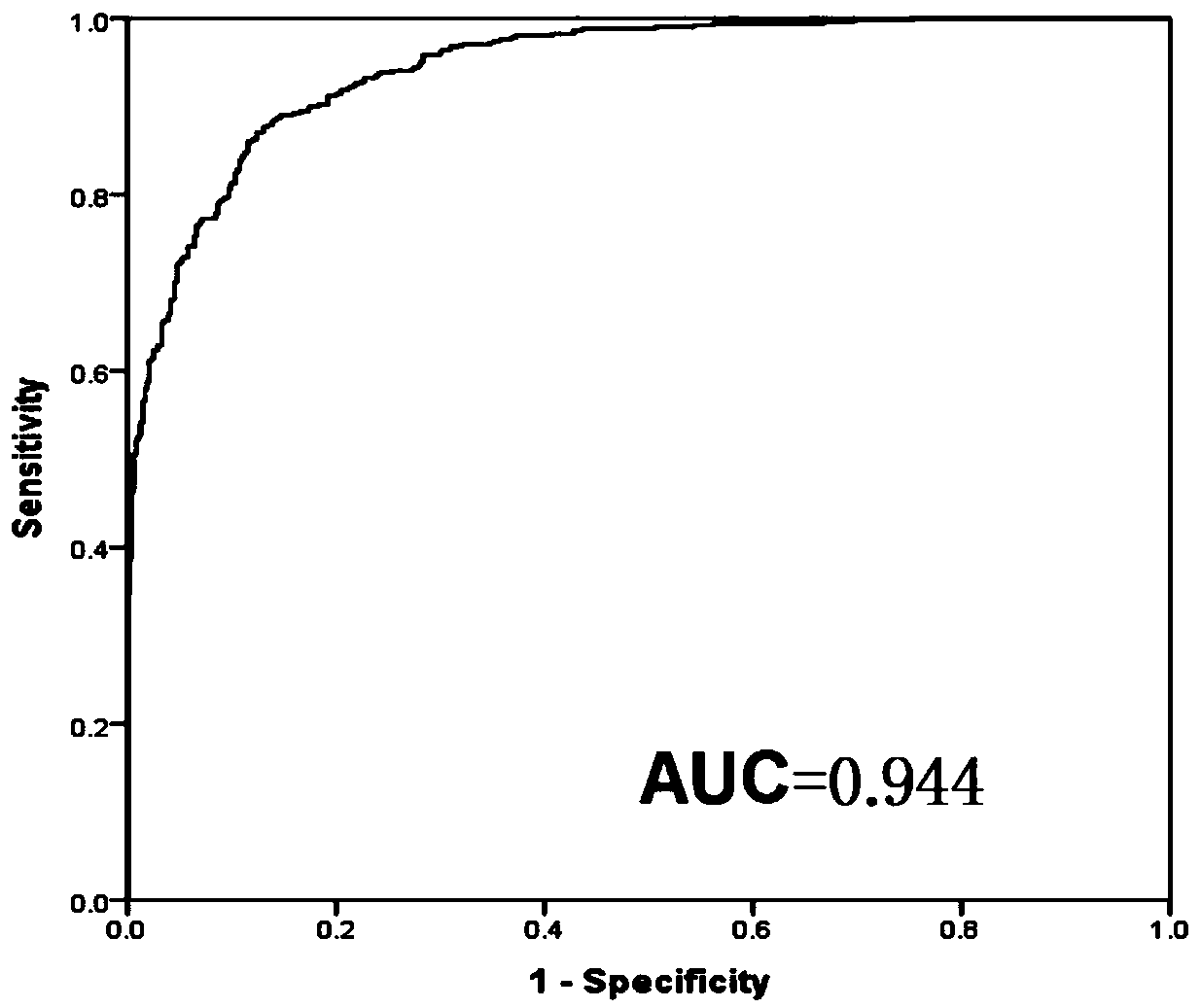

Biomarker combination for early diagnosis and prediction for Alzheimer's disease or mild cognitive impairement for the old, and application and measuring method thereof

InactiveCN109709235AEffective access to treatmentImprove clinical efficacyComponent separationBiological testingDiseaseOld patients

The invention discloses a biomarker combination for early diagnosis and prediction for Alzheimer's disease or mild cognitive impairement for the old, and application and measuring method thereof. Thebiomarker combination comprises one or combination of arachidonic acid, thymine, linoleic acid, palmitic acid, palmitoleic acid, myristic acid, petroselinic acid, GLCA, CA, and DCA and the like. According to the invention, the serum or plasma of an old patient with the Alzheimer's disease or mild cognitive impairement is processed by a liquid / gas chromatography mass spectrometry analysis method. The diagnosis marker can be used for preparing a kit; the detection method has characteristics of high sensitivity and high specificity and has the high sensitivity and specificity in mild cognitive impairement diagnosis for the old.

Owner:马红华

Balanced myristate- and laurate-containing edible oil

InactiveUS20110166227A1Increase percentageQuality improvementBiocideSpread compositionsTG - TriglycerideHDL/cholesterol ratio

Nutritional fat or oil-based compositions for increasing HDL cholesterol, decreasing total cholesterol (TC), LDL cholesterol and decreasing the LDL / HDL cholesterol ratio in human plasma are described. The compositions can advantageously include at least 10% of myristic acid and / or lauric acid in which at least 3% of said fatty acid composition is myristic acid and at least 3% is lauric acid; in some cases at least 1% by weight myristic acid and / or lauric acid is esterified at the sn-2 position in triglyceride molecules. The compositions also include between 5% and 40% by weight linoleic acid, and typically further include at least 10% by weight monounsaturated fatty acids and between 15% and 55% by weight total saturated fatty acids. The sum of weight percentages for saturated, monounsaturated and polyunsaturated fatty acids equals 100%. In desirable cases, the composition is substantially cholesterol-free. Also described are fat compositions and diets which are adapted to limit increases in blood triglycerides, total cholesterol, LDL, and VLDL, even in the presence of dietary cholesterol.

Owner:BRANDEIS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com