Constructional phase change energy storage plate and manufacturing method thereof

A technology of phase change energy storage and manufacturing method, which is applied in building structures, buildings, building components, etc., can solve the problem that the latent heat storage effect of phase change materials cannot be maximized, the rate of heat absorption and release is affected, and the phase change process is slow. and other problems to achieve the effect of maintaining indoor comfort, increasing thermal inertia, and reducing the number of starts and stops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

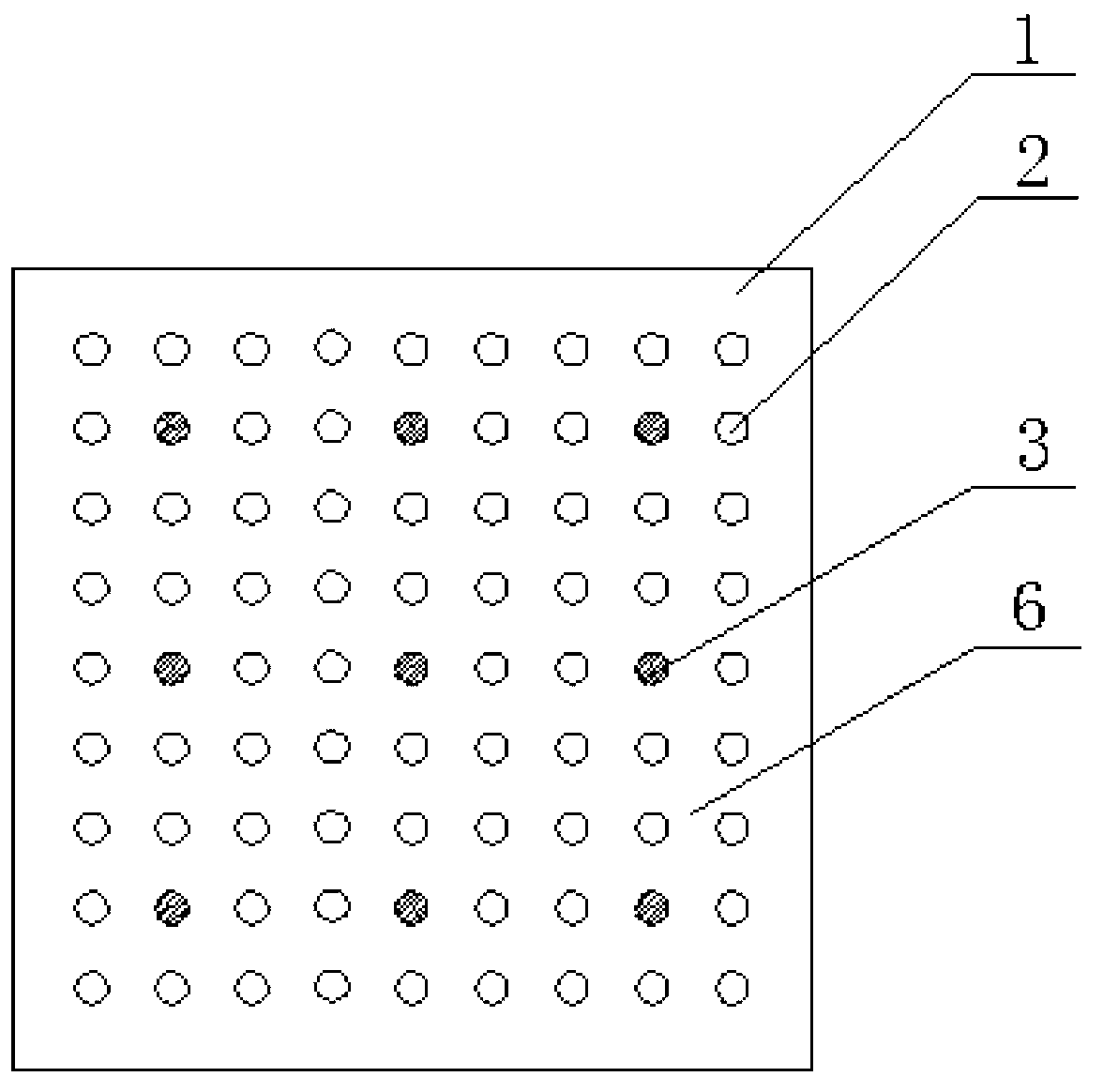

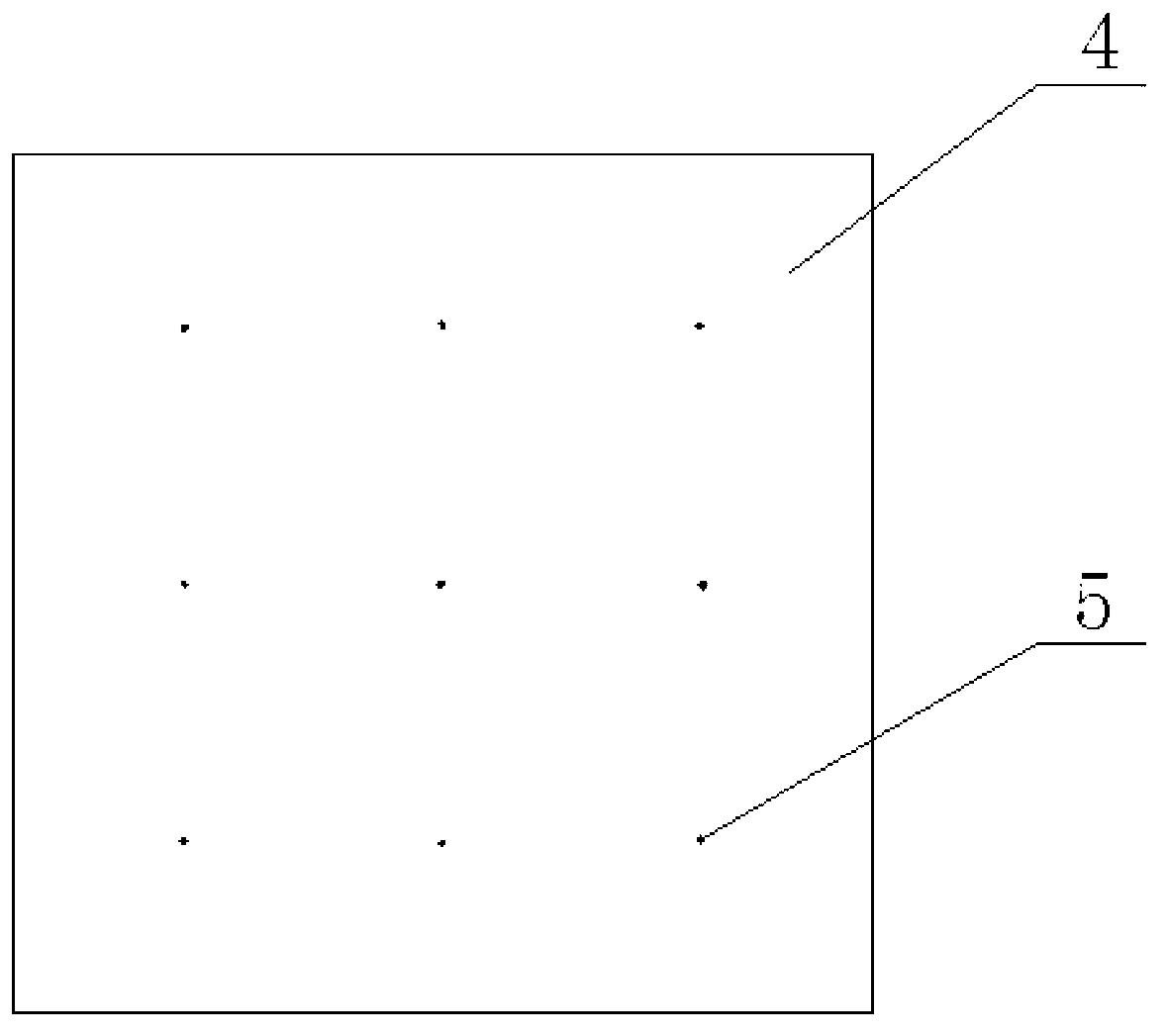

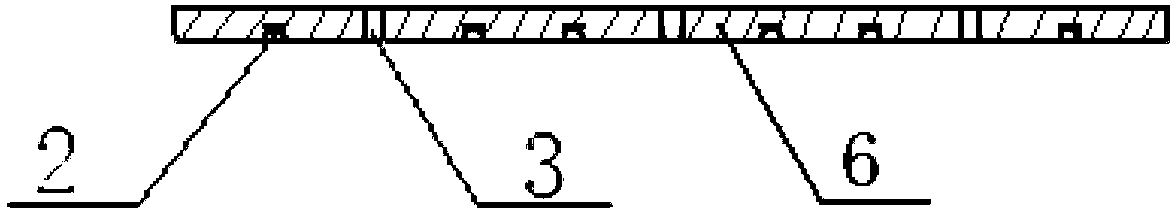

[0030] Both the upper cover plate 4 and the lower base plate 1 are made of an aluminum plate with a thickness of 1 mm. The lower base plate 1 is processed into an aluminum box shape with an inner height of 10 mm. It is made by argon arc welding of a bending machine or stretched by a lathe. 0.25m 2 ~1m 2 , can also be customized according to the actual application, and the upper cover plate 4 can be closely matched after covering the lower base plate 1. Make a sufficient number of cylinders I3 and II2, both with a diameter of 10mm, and the material of both cylinders is aluminum. Both cylinder I and cylinder II can enhance heat transfer. The thermal conductivity of aluminum is second only to copper but much cheaper than copper. The thermal conductivity of the phase change material itself is poor, but the existence of the cylinder increases the heat exchange area between the phase change material and the external heat. Therefore, the cylinder and the upper and lower plates join...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com