Patents

Literature

164results about How to "Smooth and beautiful appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

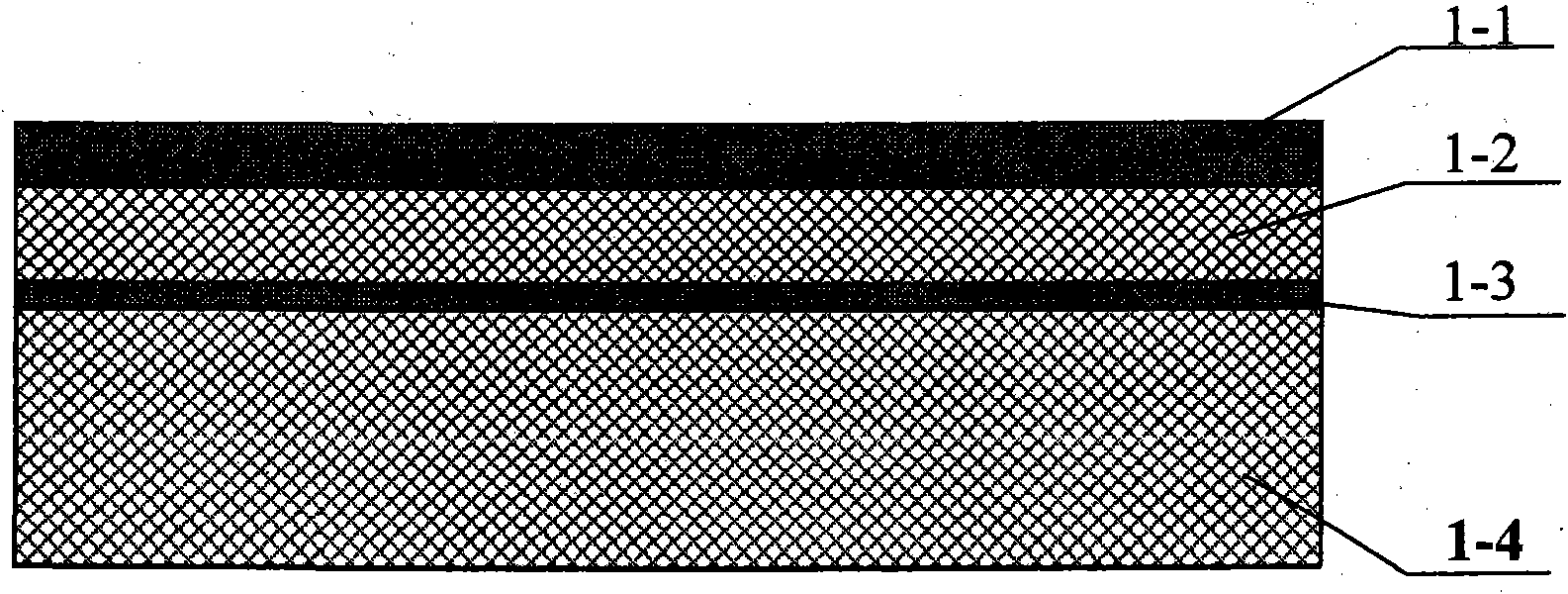

Constructional phase change energy storage plate and manufacturing method thereof

InactiveCN103015540APrevent leakageNo overflowLaminationLamination apparatusEnvironmental resistanceAlcohol

The invention discloses a constructional phase change energy storage plate, consisting of an upper cover plate, a lower bottom plate and a phase change material, wherein the phase change material is a mixture of fatty acid and high carbon alcohols; the fatty acid is n-decylic acid, lauric acid, myristic acid, palmitic acid and stearic acid; the alcohols are dodecanol, tetradecanol, hexadecanol and octadecanol; and the mass percent of the fatty acid to the mass percent of the high carbon alcohols is 46.4%: 53.6% to 97.5%: 2.5%. With the adoption of the constructional phase change energy storage plate and a manufacturing method thereof, the problems such as damages to mechanical performances, environmental protection, safety and the like are fundamentally solved, and meanwhile, the risks existing in actual application are prevented; the constructional phase change energy storage plate is stable in structure; the phase change material is not easy to leak; no irritant gas overflows; the appearance is attractive; and therefore, besides application onto constructed walls, the constructional phase change energy storage plate also can be used as an interior decoration, a suspended ceiling and a laid floor board.

Owner:TIANJIN UNIV

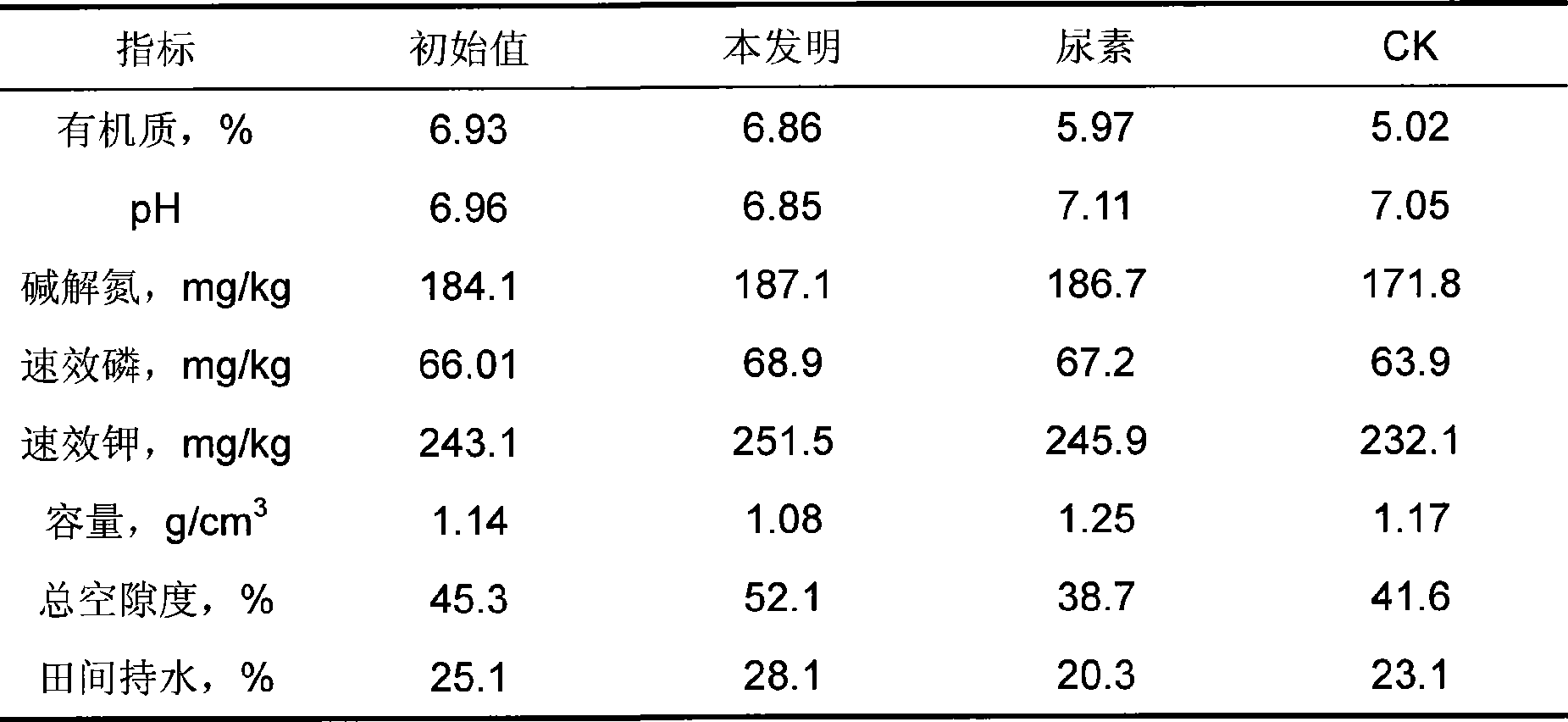

Humic acid urea and method for producing the same

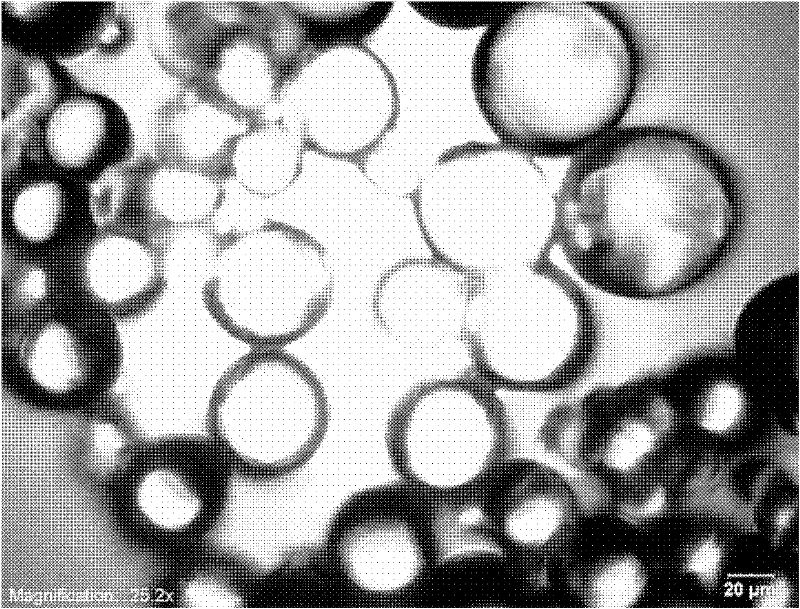

InactiveCN101429063ACrystal clear white particlesSmooth and beautiful appearanceOrganic fertilisersUrea compound fertilisersHumic acidUrea

The invention provides humic acid urea. At a temperature of between 70 and 150 DEG C, the urea is heated and melted to be liquid state, sprayed on the surface of humic acid particles rotating in a rotating drum at a pressure of between 0.4 and 0.6MPa, and cooled down to be prepared into the urea-coated humic acid type humic acid urea. The outer part of the humic acid urea is hard shell formed by the urea or the mixture mainly comprising the urea, and the nutritive substance which is humic acid is coated in the middle part of the humic acid urea, so that the humic acid urea has crystal-clear and pure white particle as well as smooth and beautiful appearance; moreover, no powder is existed in the humic acid urea, the nutritive substance does not fall off because the nutritive substance is embedded in the humic acid urea, and the appearance of the humic acid urea is beautiful.

Owner:王矛

Processing method for stabilized recombined quick-cooking brown rice

InactiveCN102067968ASmooth and beautiful appearanceYellowish colorFood preparationAgricultural engineeringRice grain

The invention discloses a processing method for stabilized recombined quick-cooking brown rice, comprising the following steps: (1) taking paddy as a raw material, drying, cleaning, grading, removing stones, ridging paddy, and separating paddy from brown rice to obtain the brown rice; (2) smashing the brown rice, and regulating the moisture of the material to 15-30%; (3) adding or adding no food ingredients; (4) feeding the material obtained from the above step into an extruder for extruding, restructuring and prilling; and (5) drying, packaging and the like. In the processing method, the problems of short shelf life, long cooking time, rough taste, inconvenient eating and the like of the brown rice are solved. The brown rice processed with the method has the grain shape similar to natural brown rice, keeps the nutrient components of the natural brown rice, improves storage stability, improves processing and eating quality of the brown rice and improves the utilization and the added value benefit of the paddy.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

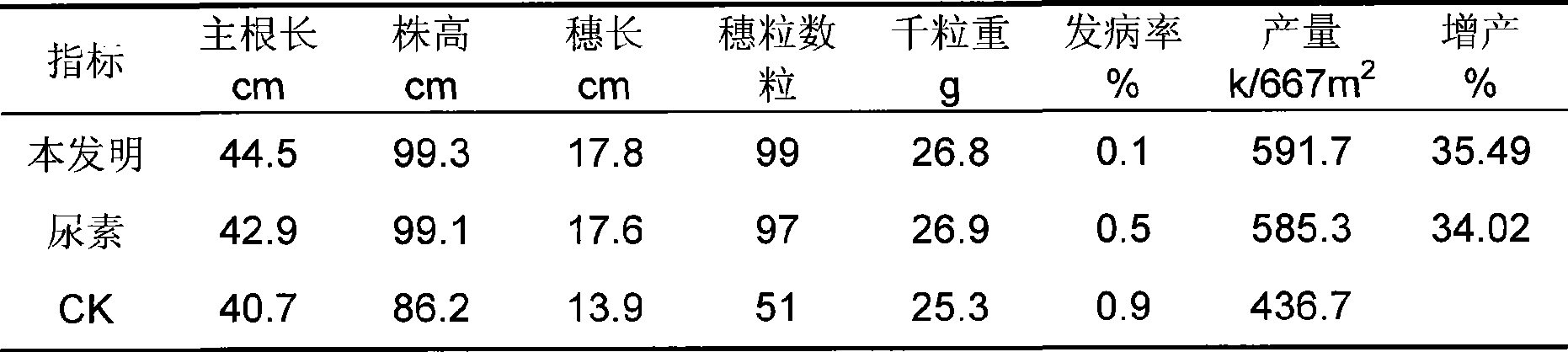

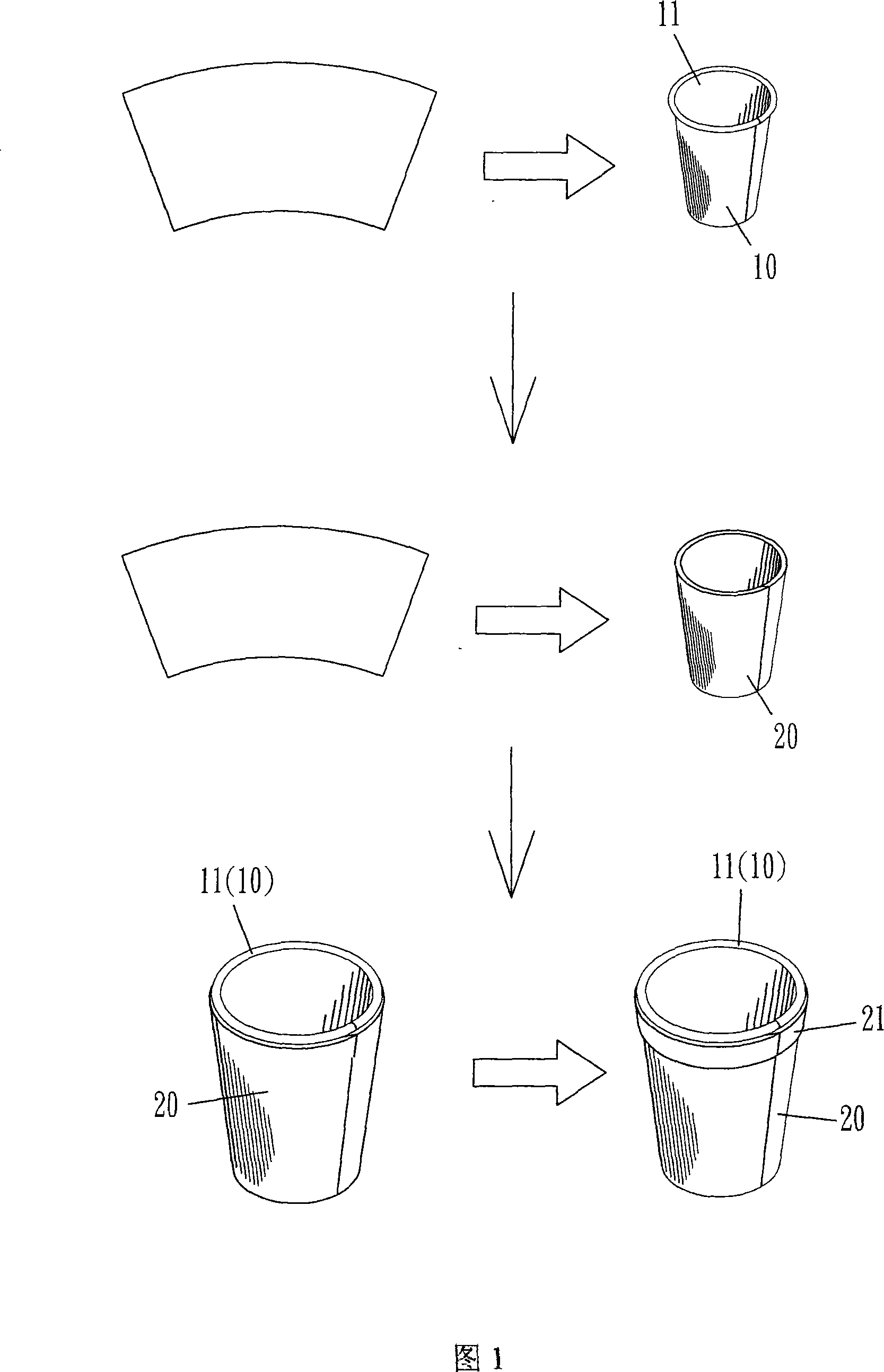

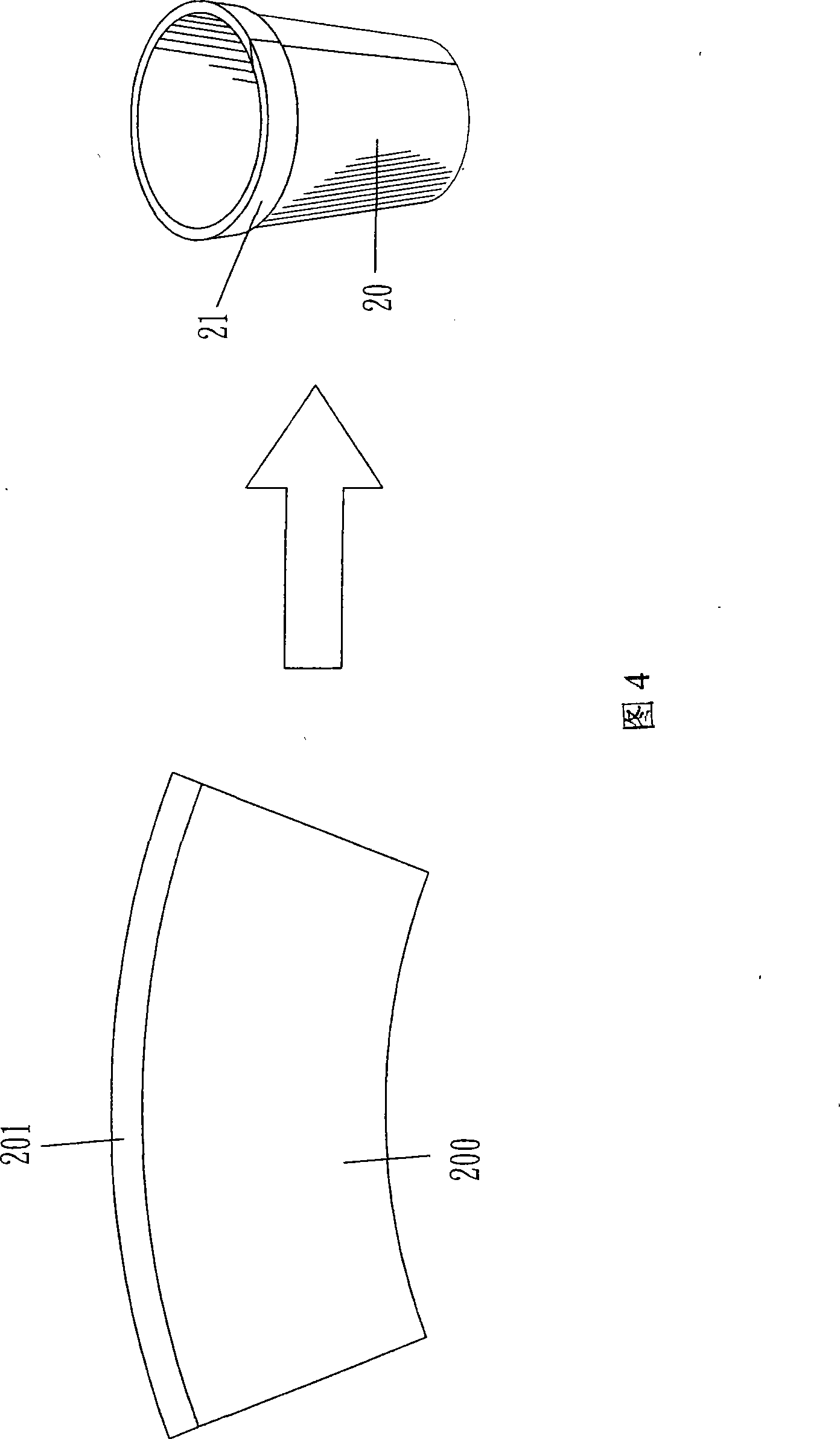

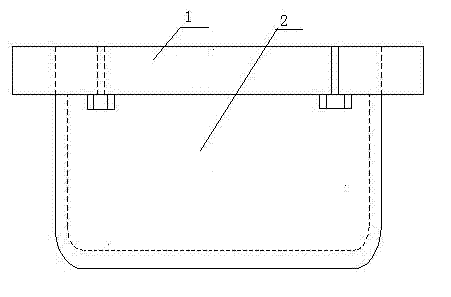

Method for making container cup and structure thereof

InactiveCN101249732APrevent tight fittingEasy to take outBoxes/cartons making machineryThermal insulationPulp and paper industry

The invention relates to a manufacturing method of a container cup and a structure thereof, which belongs to the daily article class. The invention comprises a paper cup and a cup-shaped electronic bridging foaming body, wherein the inner surface or the outer surface of the paper cup is sprinkled and covered with a film layer, and is pressed into the paper cup through shape cutting; the cup-shaped electronic bridging foaming body is formed by being bonded in a hot pressing way after an electronic bridging foaming plate is manufactured into a sector body through printing, shape cutting and stripe pinching, the inner peripheral of the cup-shaped electronic bridging foaming body is ensured to produce softening viscosity in the hot pressing way, then the paper cup is directly covered on and bonded with the inside of the cup-shaped electronic bridging foaming body, and meanwhile a convex ring with a oversize diameter is formed at the outer part of the paper cup lip where the cup-shaped electronic bridging foaming body is positioned. The structure has the advantages that the protective effect is good, the thermal insulation function is good, the water absorbability is low, the appearance is smooth and artistic, the structure is not easy to be metamorphic, the drug fastness is good, the processing is easy, etc.

Owner:张锡卿

PU shoe sole laminating and forming process

InactiveCN106313409ASmooth and beautiful appearanceNo manual patchingDomestic articlesVacuum pumpingEngineering

The invention provides a PU shoe sole laminating and forming process which comprises the following steps of: flatly putting film paper on a bottom mould of a mould, and pressing a middle frame to cover the bottom mould, and fixing by tensioning hand fasteners; carrying out vacuum-pumping on an inner cavity of the mould and enabling the film paper to completely fit to the bottom mould; heating the mould for increasing the mould temperature to 60-70 DEG C; and finally, pouring a polyurethane foaming stock solution into the mould cavity for foaming and forming the polyurethane foaming stock solution in a mould cavity, and cooling and de-molding, thereby obtaining the laminated PU foamed shoe sole. The PU shoe sole laminating and forming process can effectively solve the problems of bubbles, material deficiency, foamed grains, pits and pores generated in a PU foamed shoe sole production process, so that bright effect of products is improved.

Owner:佛山市创意新材料科技有限公司

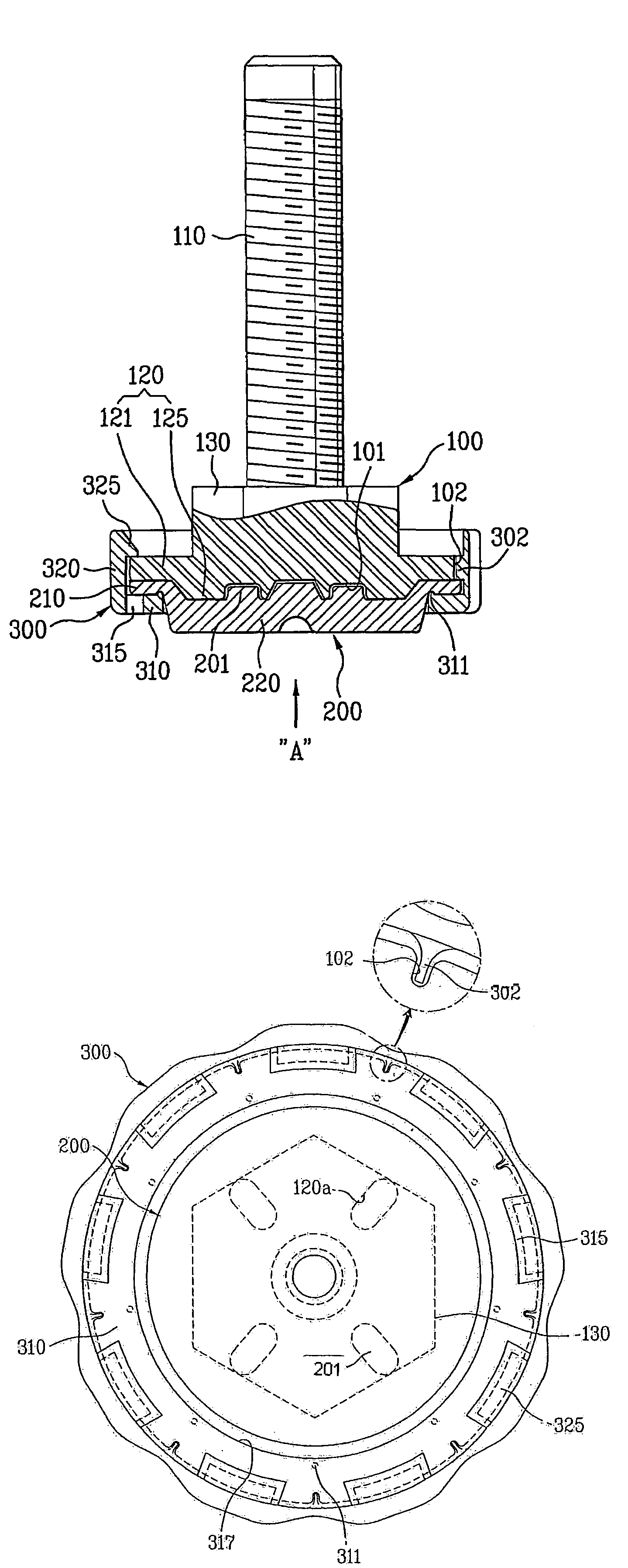

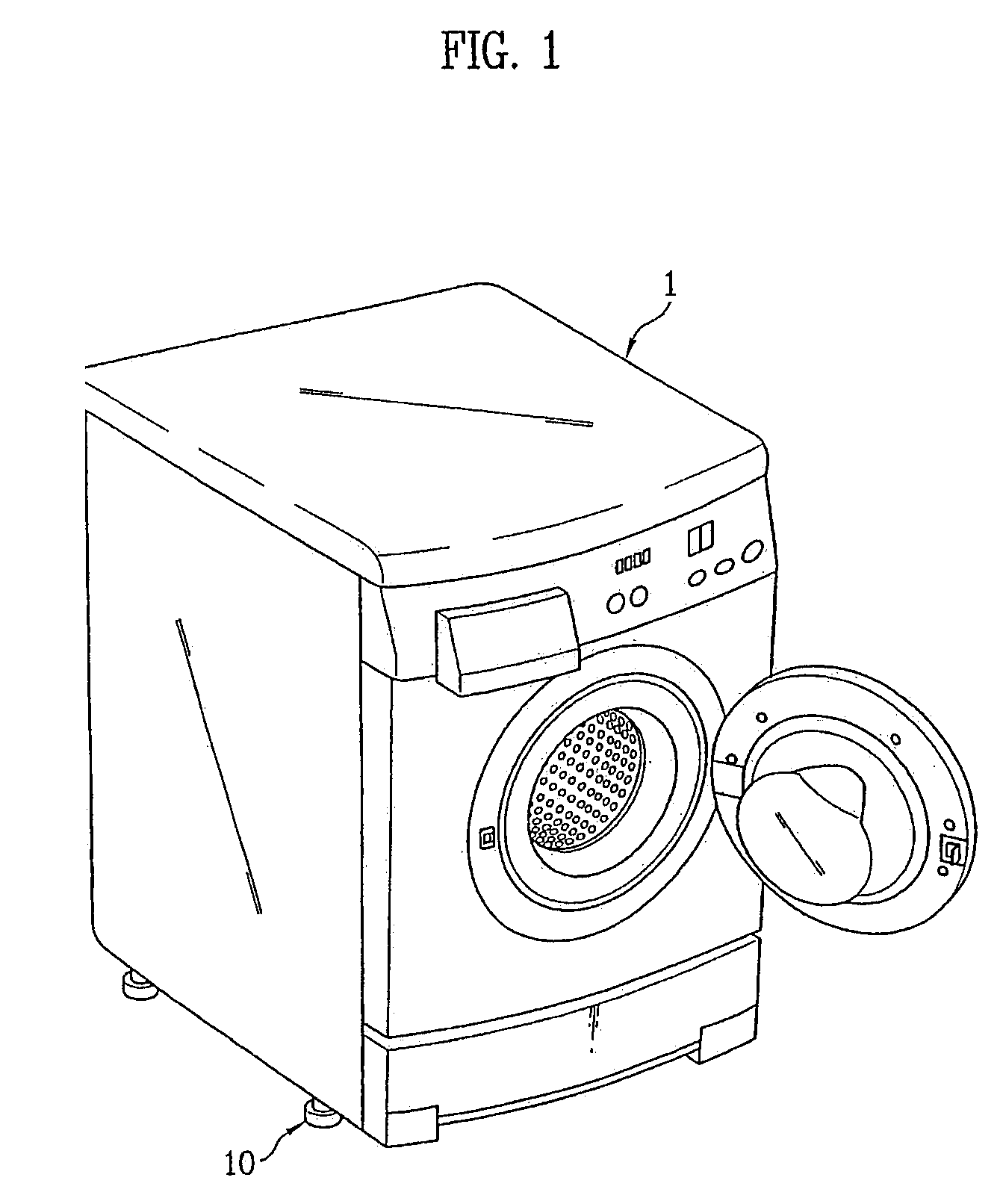

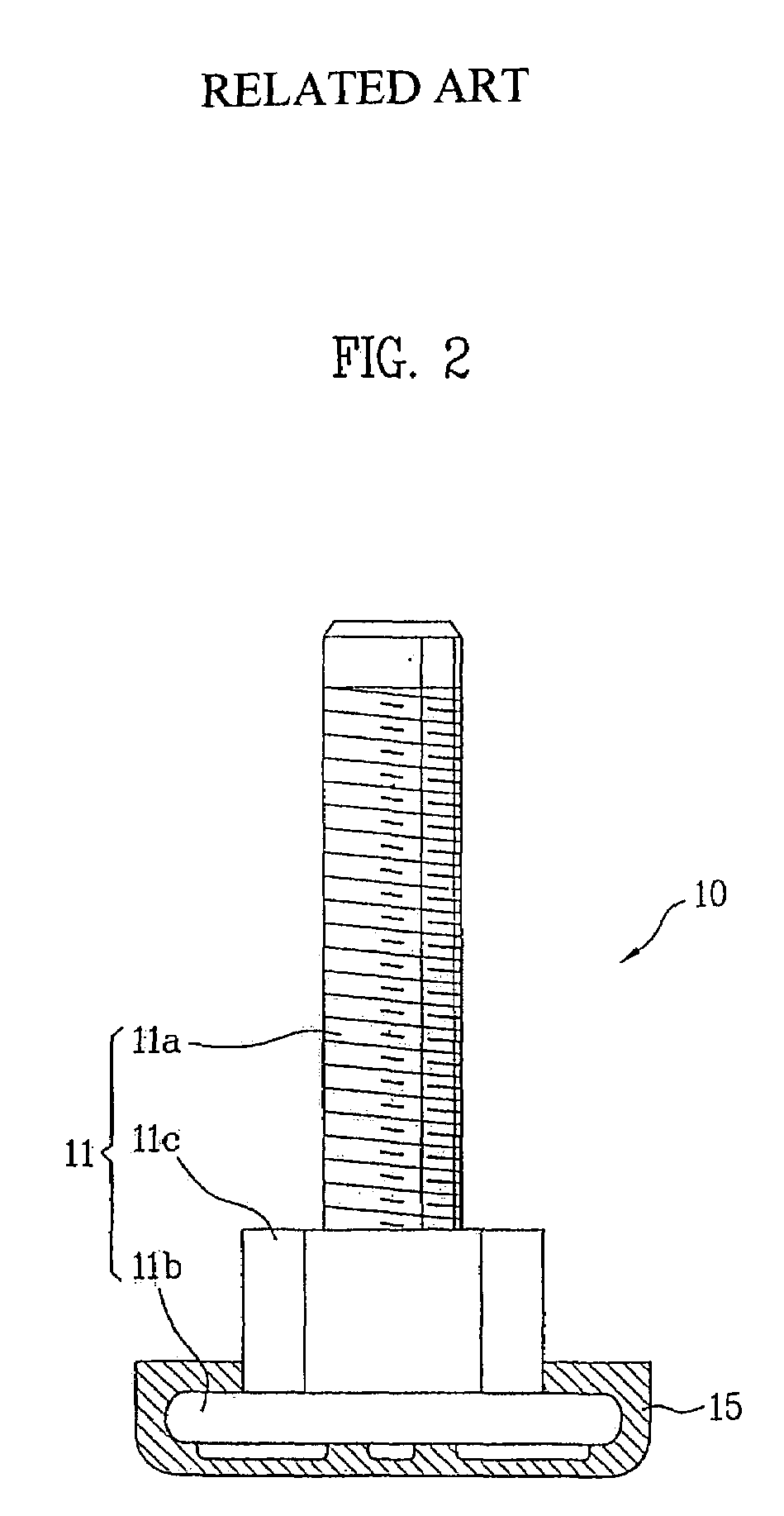

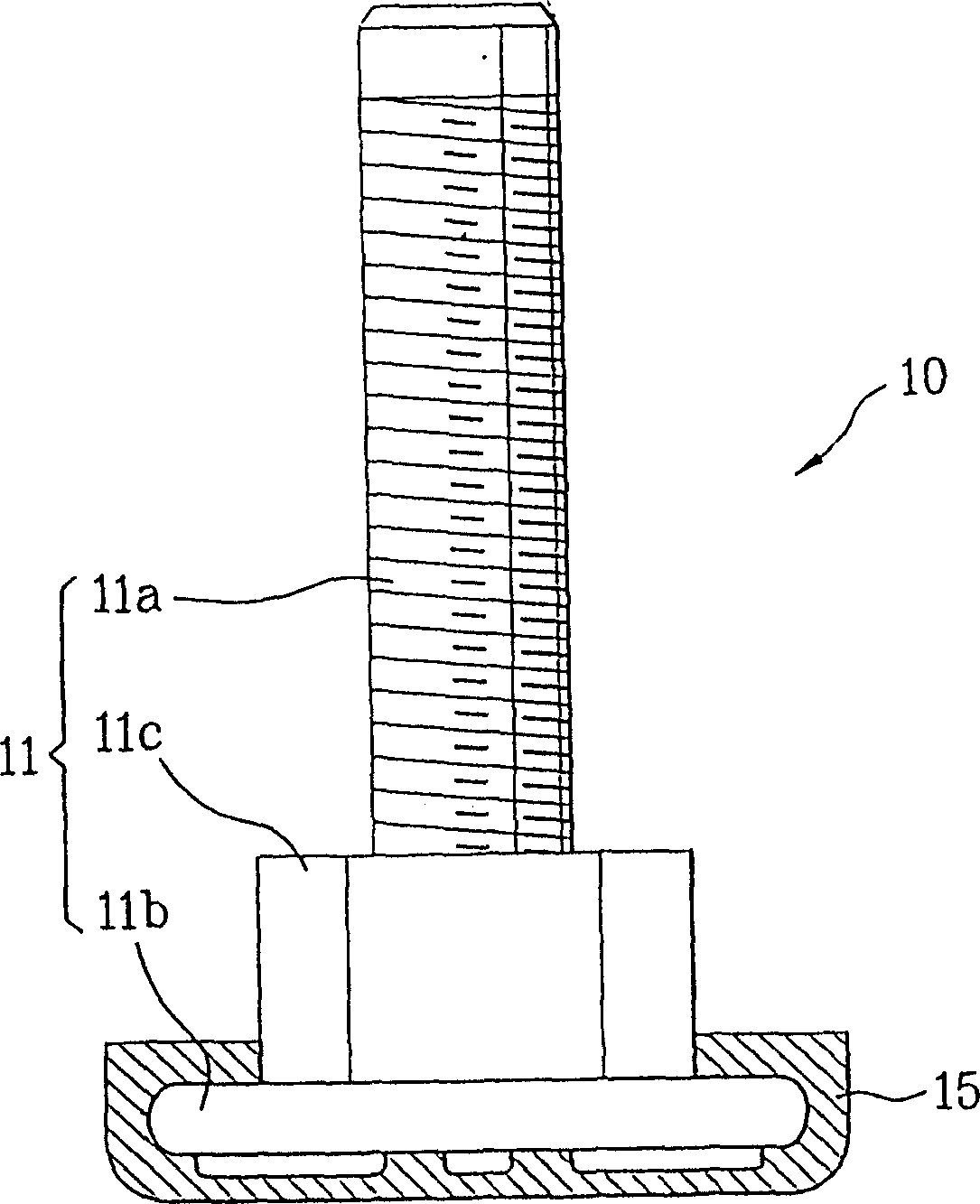

Leg assembly for home appliance

ActiveUS7427052B2Simple structureImprove efficiencyPortable framesOther washing machinesEngineeringHome appliance

Disclosed is a leg assembly for electric home appliances for supporting an electric home appliance such as a washing machine and a clothes dryer. The leg assembly in accordance with the present invention includes, a leg bolt (100) having a screw (110) coupled with the electric home appliance and a head (120) provided at an end of a screw (110) a pad made of a soft material and closely adhered to the head (120) an being in contact with a floor; and at least one holder (300) being coupled with the head (120) for fixing the head (120) and the pad (200) by pressing the pad (200) toward the head (120).

Owner:LG ELECTRONICS INC

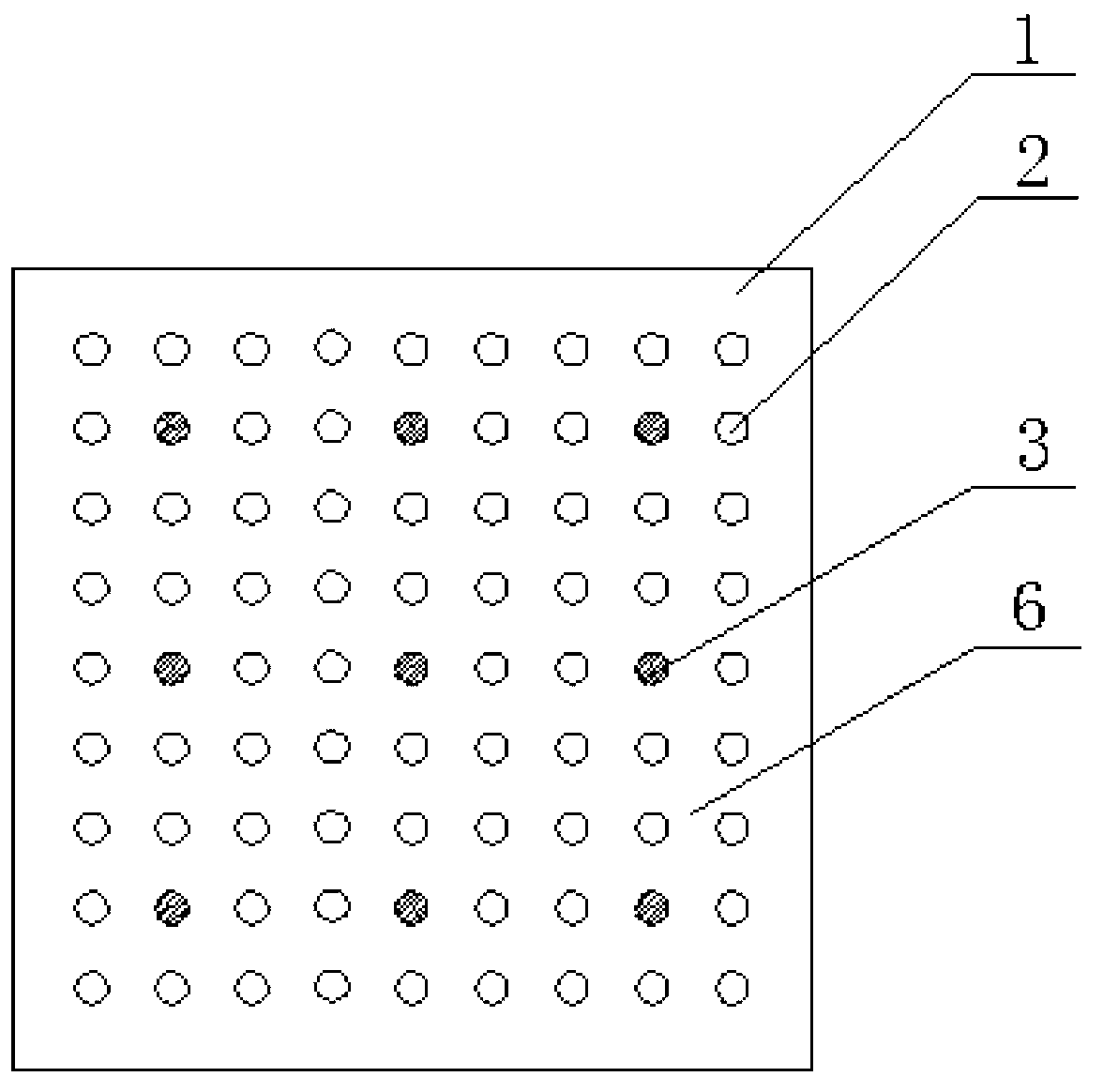

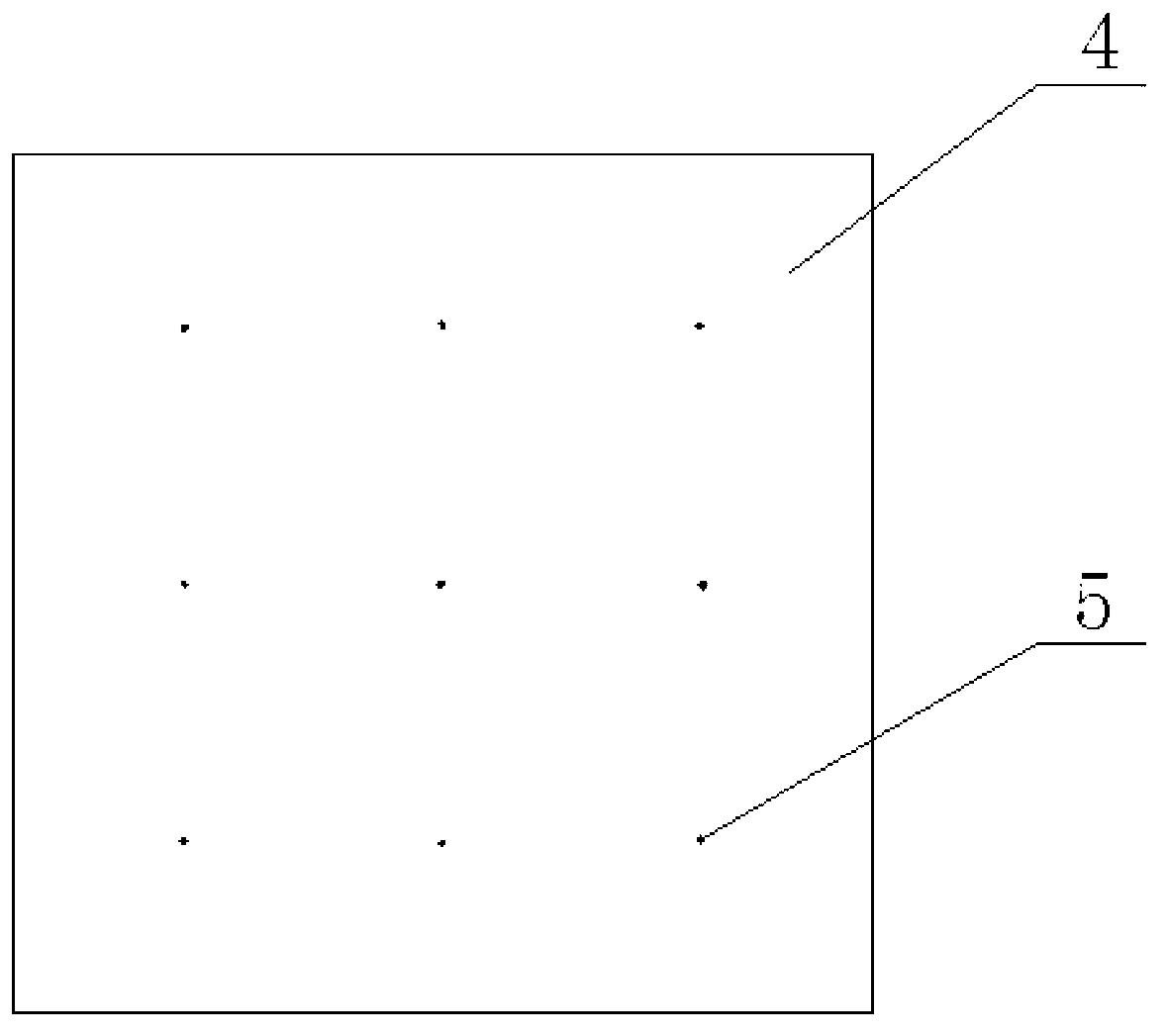

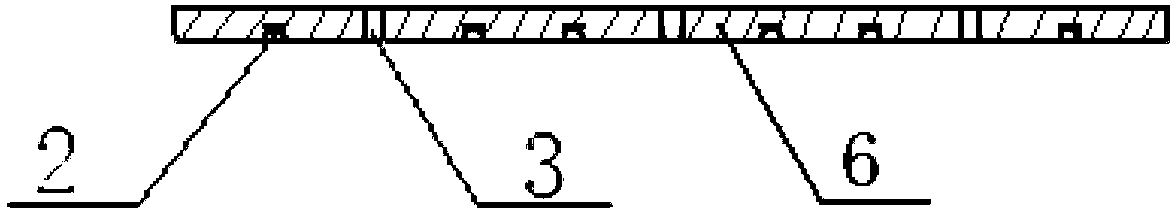

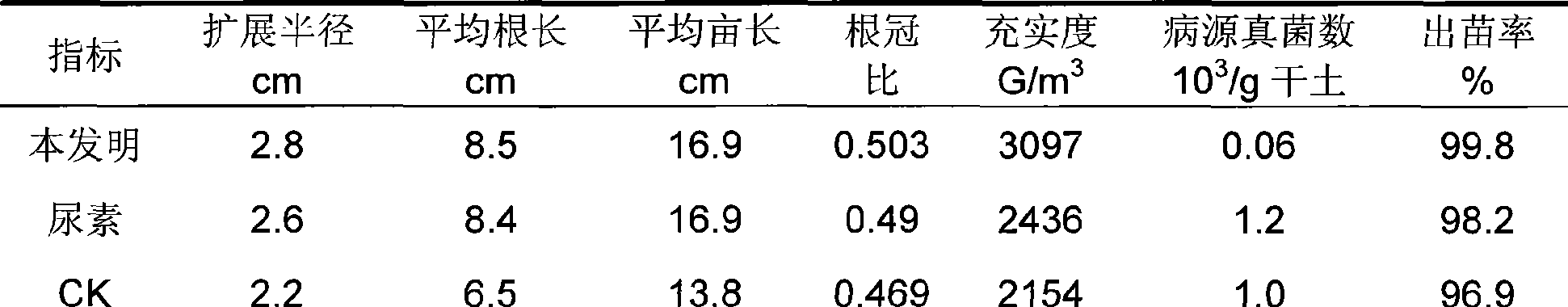

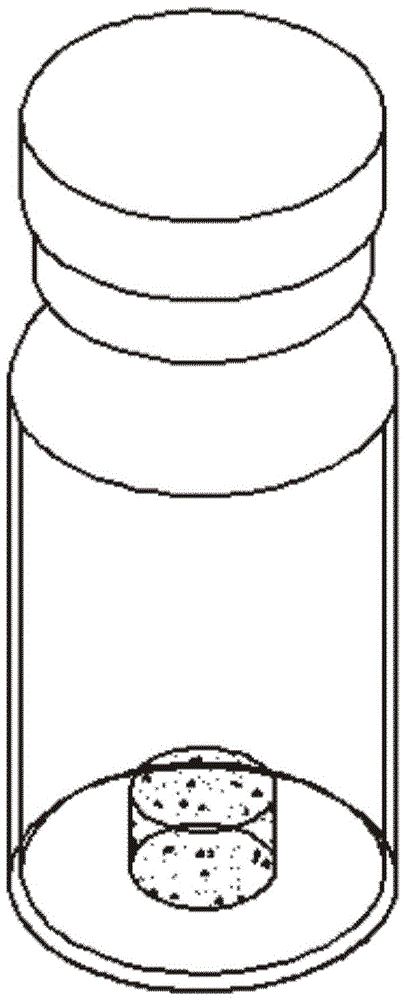

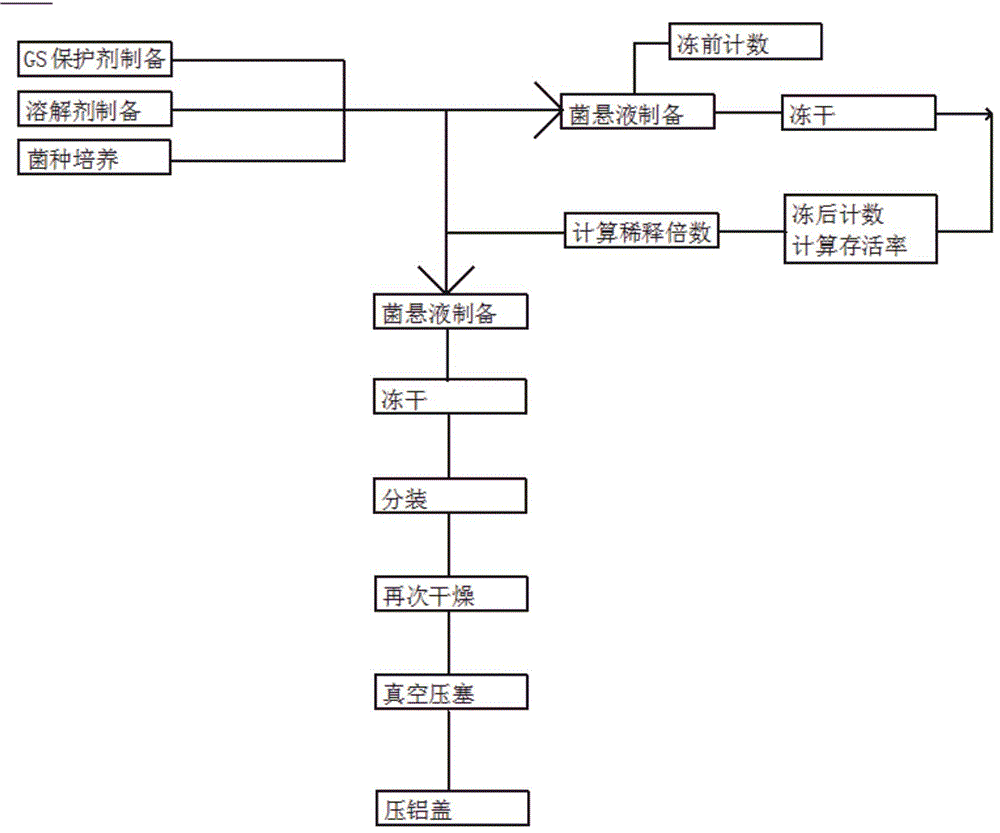

Solid-state freeze-dried product of quantitative strain and preparation method and using method thereof

The invention discloses a solid-state freeze-dried product of a quantitative strain and a preparation method and a using method thereof. 0.1% to 0.5% of glucose, 5% to 10% of sucrose, 0.5% to 1.5% of gelatin, 1% to 2% of tryptone, 0.5% to 1% of soy peptone, 0.5% to 1% of sodium chloride, 0.2% to 0.5% of yeast powder and 0.2% to 0.5% of activated carbon are prepared into solution serving as a protective agent, and after the solution and diluted bacteria suspension are uniformly mixed according to a certain proportion, the mixture is prepared into the dried product by freezing-drying; the product is excellent in solubility and can be completely dissolved in a dissolving agent in 1 to 2 seconds. The cylindrical freeze-dried product has an amount of bacteria of 100cfu to 1,000cfu or can customize bacterium content in a specific range. One single freeze-dried product is taken and dissolved into N ml of dissolving agent, and the bacterium content per N tenths ml is smaller than 100cfu, so that the solid-state freeze-dried product is accurate and convenient. Use of the protective agent can greatly reduce a damage degree of the strain in the freeze-drying process; the proper protective agent provides an excellent shape and freeze-drying environment for the product so as to guarantee activity of the strain to be protected to the greatest degree. The dissolving agent provides an excellent pH value, an excellent osmotic pressure and proper nutrient substances to the strain so as to guarantee the strain to obtain the optimal recovery conditions after the strain is dissolved.

Owner:浙江泰林生命科学有限公司

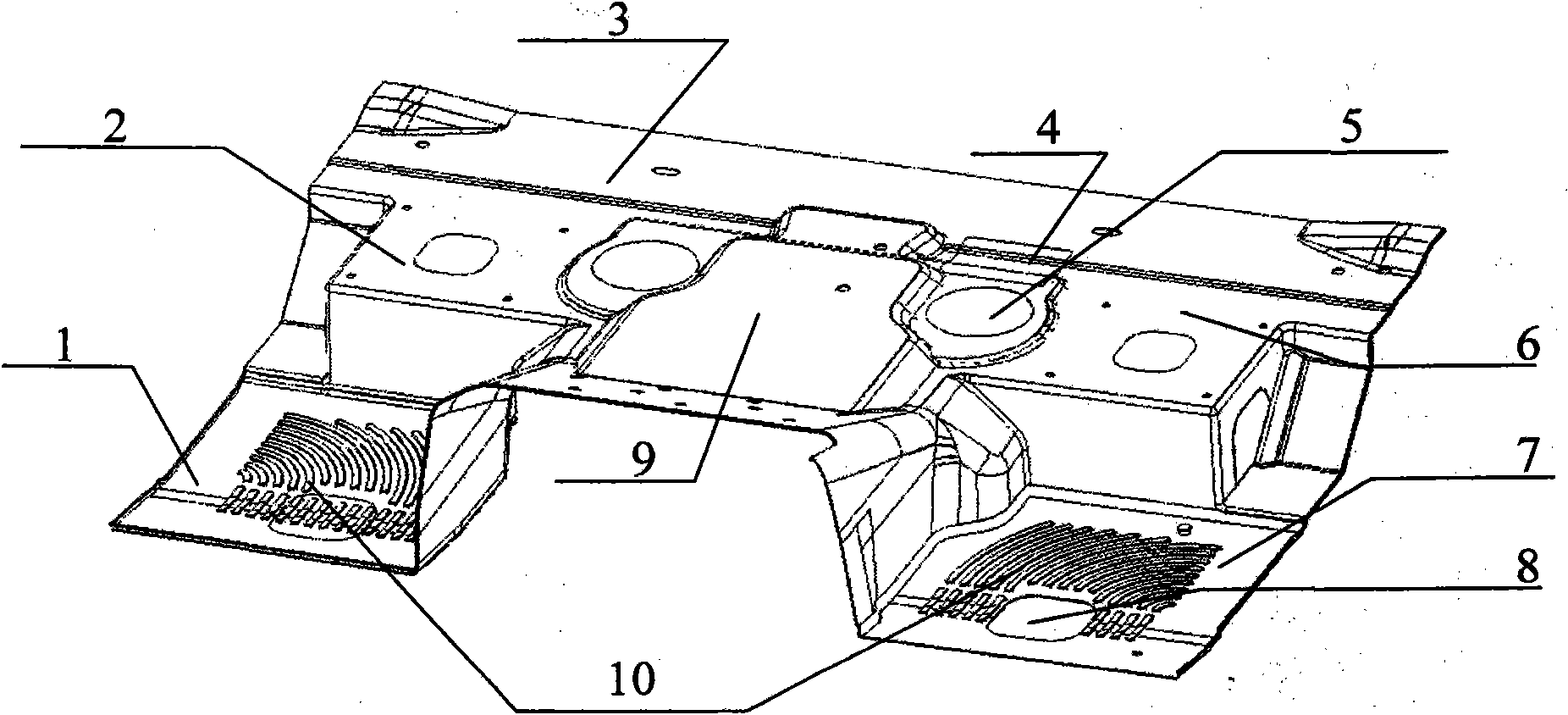

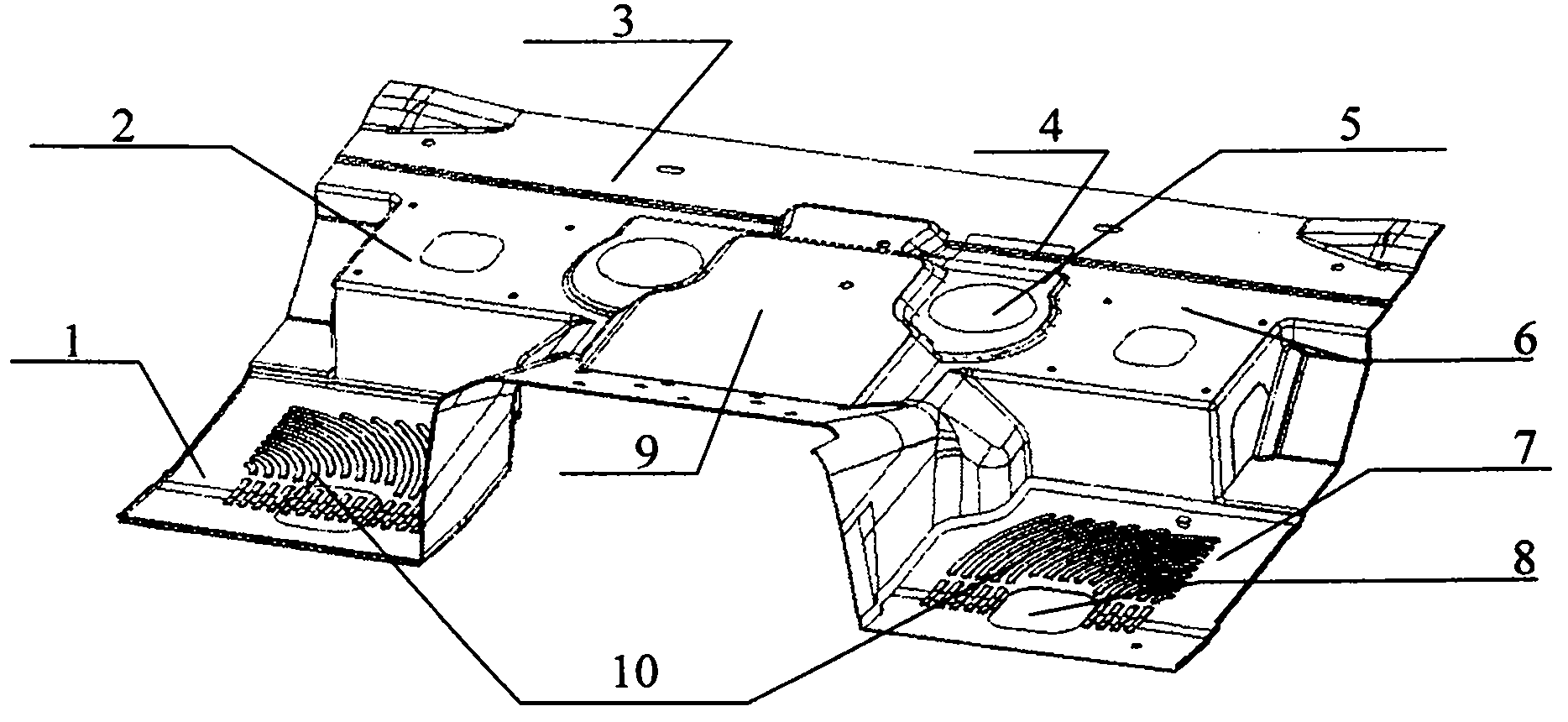

Method for producing automotive sound-absorption and heat-insulation integrated carpet

ActiveCN101830188ASolve sound absorption and heat insulationAddress personalizationVehicle arrangementsLayered productsPunchingHazardous substance

The invention relates to a method for producing an automotive sound-absorption and heat-insulation integrated carpet and belongs to the technical field of automotive interior decorations. In the method, an environmentally-friendly 3.5 millimeter (including 0.8 millimeters of a toughening layer, 2.5 millimeters of a foaming layer and 0.2 millimeter of a bottom film protective layer) PVC foamed leather is mainly used and subjected to heating, baking, vacuum forming, cooling forming, 8 millimeter cotton-based sound-absorption and heat-insulation carpet compression and lamination, shearing, hole making, punching and inspection to produce a finished product. The method solves and improves the indexes, such as sound absorption, heat insulation, dust prevention, attractive appearance and easy cleaning, of the automotive carpet and makes the automotive carpet reach international advanced level-III and meet the design requirements on environmental protection, attractive appearance, comfortableness, sound absorption and heat insulation of an automotive cab. In a plastic absorption process, a pneumatic pre-feeding device is used to ensure the thickness of the foamed leather on the highly-stretched part of the large section of the product, so the overall quality of the product is improved, the quality consistency of the product is guaranteed, the production efficiency is improved greatly and the labor intensity is relieved greatly. The compression and lamination of the sound-absorption and heat-insulation carpet improve the sound and heat insulation performance of the product and make the appearance of the product smooth and elegant and touch comfortable. In the while production process of the product, no harmful matter is produced, and the product is an environmentally-friendly product.

Owner:XIAN TIANRUI AUTOMOBILE INTERIORS

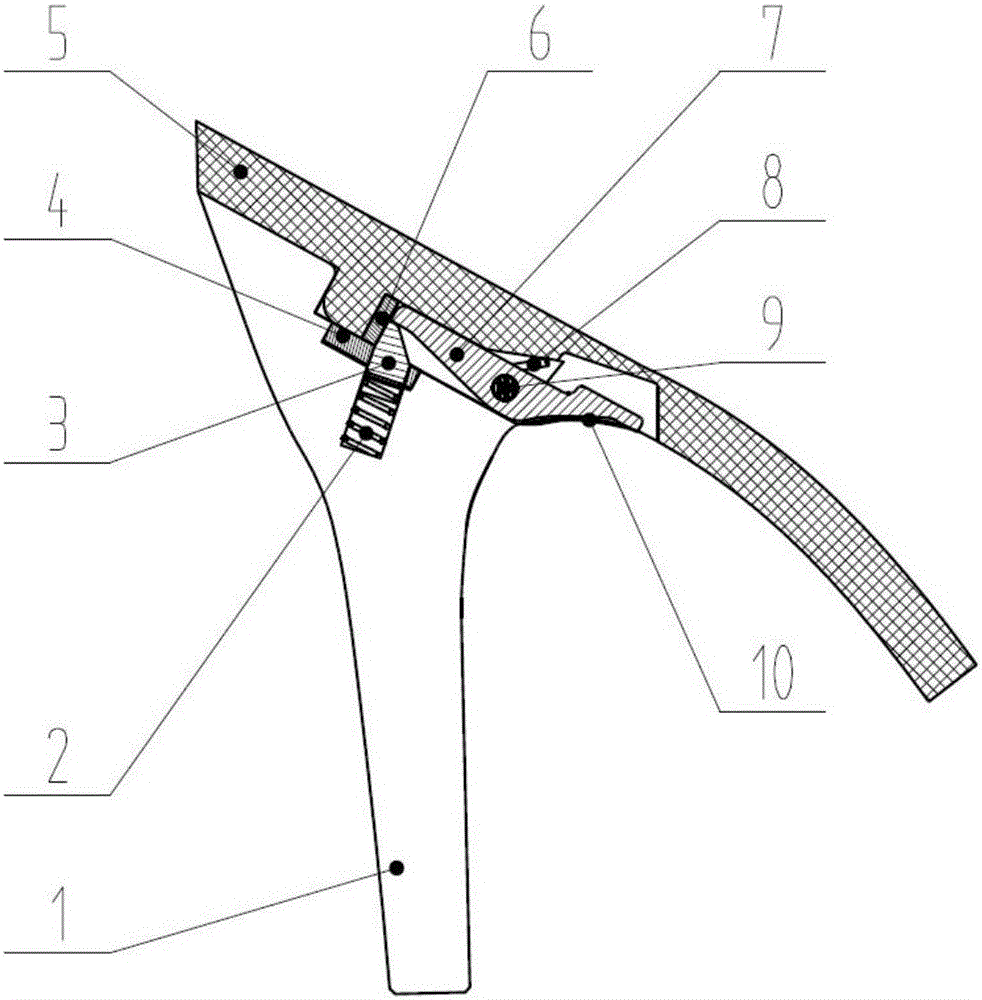

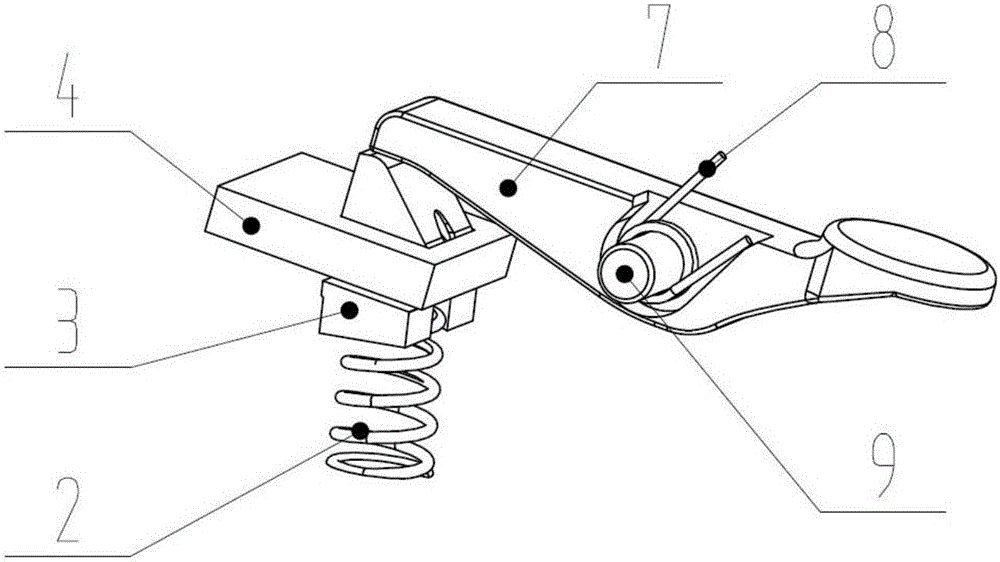

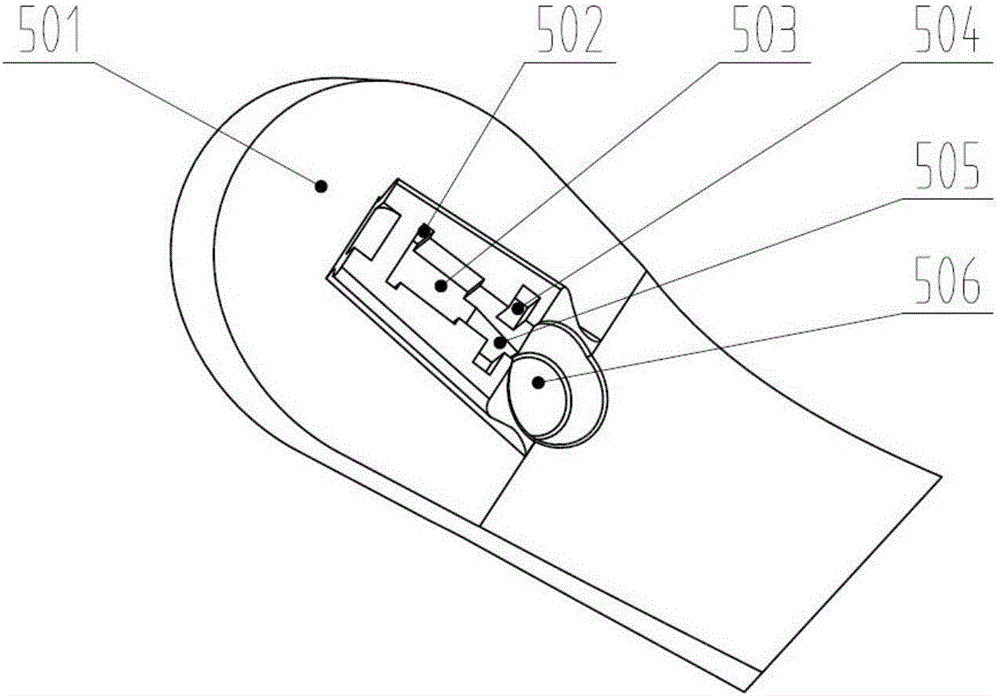

High-heeled shoes with replaceable heels

ActiveCN105831884AHigh material utilizationHigh material strengthHeelsTop-piecesButt jointEngineering

The invention discloses a pair of high-heeled shoes with replaceable heels. Each high-heeled shoe comprises a shoe sole and a heel, wherein a heel butt joint device is arranged between the shoe sole and the heel; the heel butt joint device comprises a clamping structure, an elastic ejection rod which is fixed on the heel and is used for clamping the shoe sole, and a pressing rod structure which is fixed on the shoe sole and drives the elastic ejection rod to be released from the shoe sole. The pressing rod structure and the elastic ejection rod are separately designed, and parts are convenient to replace; space utilization ratios of the shoe sole and the heel are proper, the loss cost of the parts is reduced and pressing saves more power; a press button is located on the surface of a shoe body and the pressing is convenient; the high-heeled shoe is simple and convenient to replace; the press button is arranged on the shoe sole and is hidden at an engaged part of the heel and the shoe sole; the appearance line of the high-heeled shoe is smoother and more beautiful, the wearing comfort is improved and the service life of the high-heeled shoe is prolonged.

Owner:HANGZHOU JIUBA HONGTU TECH CO LTD

Filtrate reducer for oil well cement and preparation method thereof

InactiveCN102220115AStable in natureConvenient for long-term storage and long-distance transportationDrilling compositionOil wellMaterials science

Owner:CHINA NAT OFFSHORE OIL CORP +2

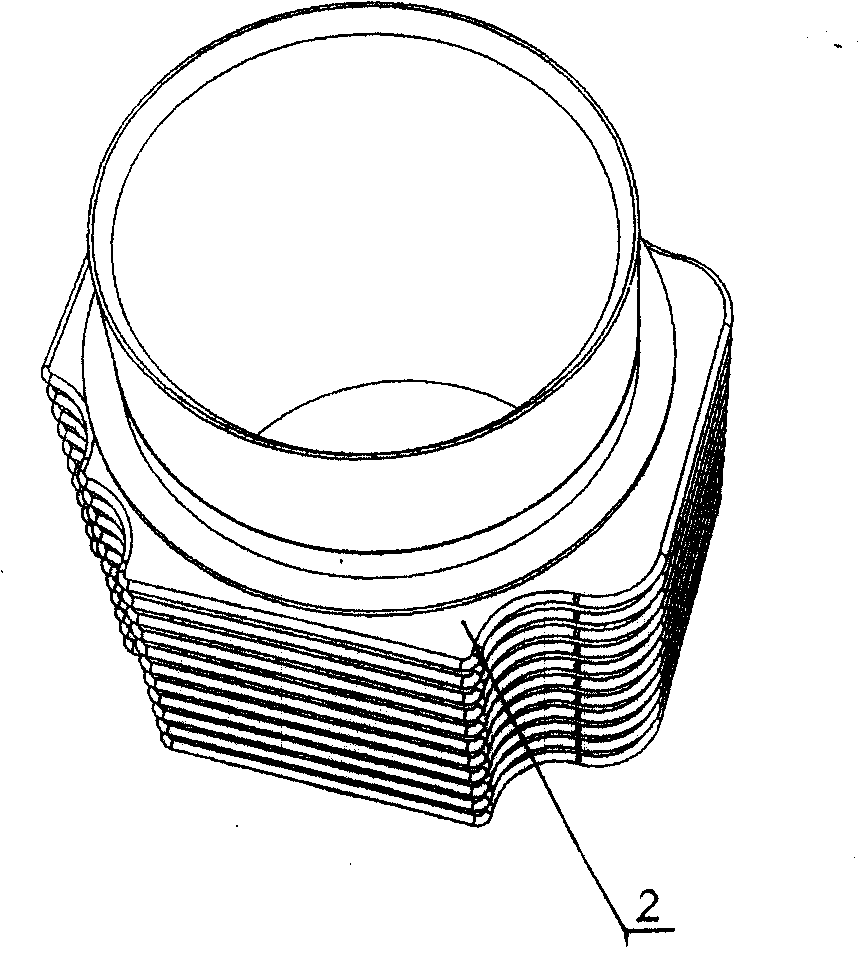

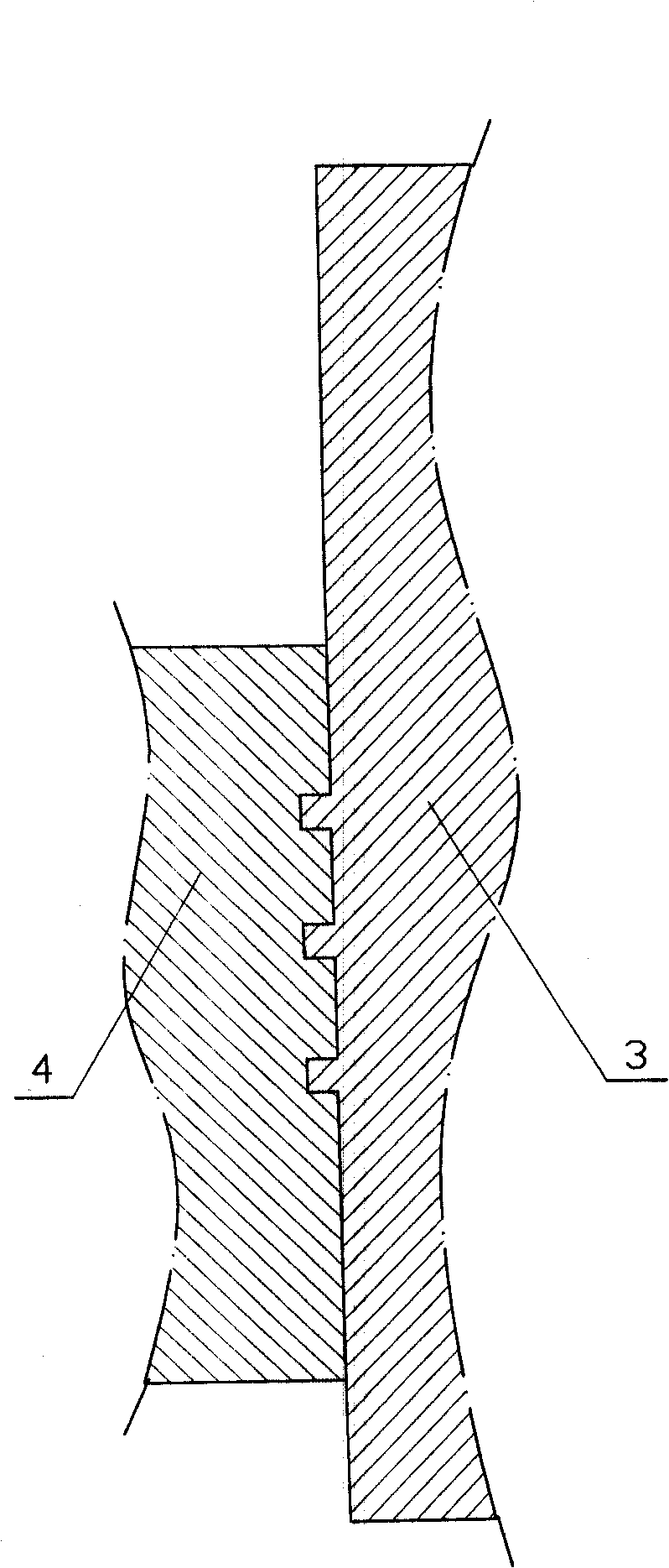

Dual-alloy compound cylinder body and manufacture method thereof

InactiveCN101526044ASmooth and beautiful appearanceImprove heat transfer efficiencyCylinder headsCylindersFree coolingTitanium

The invention discloses a dual-alloy compound cylinder body and a manufacture method thereof. The cylinder body consists of a cylinder sleeve manufactured by chromium, vanadium, titanium and cast iron alloy as well as a cylinder sleeve cover cast by aluminum alloy; the position of the cylinder sleeve and the position of the cylinder sleeve cover are fixed as a whole by an embedding ring to facilitate the cylinder sleeve and the cylinder sleeve cover to cooperate intimately. The manufacture method comprises: using chromium, vanadium, titanium and cast iron alloy to manufacture the cylinder sleeve; processing the embedding ring; preheating the cylinder sleeve, fixing the cylinder sleeve in a die, and folding the left and right split dies; melting and refining the aluminum alloy twice in a well type furnace, casting the aluminum alloy solution in the dies after passing the test and cooling naturally; after cooling and passing test, cutting out a dead head and a pouring head, removing burrs, and carrying out quench hot treatment to obtain the cylinder body flan; fine processing the cylinder body flan and polishing the inner wall of the cylinder body to finally obtain the cylinder body product. The cylinder body of the invention has smooth and beautiful appearance, high heat transference efficiency, light weight, and is capable of reducing engine power consumption and suitable for engine manufacturers.

Owner:GUIZHOU JINTAI SCI & TECH DEV

A kind of preparation method of humic acid coated urea

ActiveCN102260124AAbundant resourcesEase of continuous industrial operationFertilizer mixturesCoated ureaPhosphate

The invention provides a method for preparing humic acid coated urea, which comprises the following steps of: dissolving 20 to 400 parts of urea in 40 to 200 parts of water at the temperature of between 20 and 60 DEG C, reacting with 40 to 200 parts of humic acid feed coal at the temperature of between 40 and 100 DEG C for 5 to 30 minutes, adding 10 to 100 parts of phosphate, continuously stirring for reacting for 30 to 120 minutes, performing solid-liquid separation, and evaporating and concentrating to obtain a humic acid-urea complex concentrated liquor, or drying to obtain a solid humic acid-urea complex; and spraying, infiltrating and drying by using coat drying equipment to obtain the humic acid coated urea. The humic acid feed coal has rich resources, and is cheap and readily available; a process flow is short, equipment is easy and convenient to operate, reaction conditions are mild, and the method is easy for production control; the production process is environment-friendly,pollution emission is avoided, and the method is suitable for large-scale industrial production and promotion and application; and the product has good water solubility and attractive appearance, caneffectively inhibit urease from decomposing the urea and improve the fertilizer efficiency of the urea and the utilization rate of nitrogen.

Owner:谭钧

Chinese chestnut flavored composite health care rice and preparation method thereof

InactiveCN103494085ASmooth and beautiful appearanceSoft tasteNatural extract food ingredientsFood preparationPEARBalsam

The invention discloses Chinese chestnut flavored composite health care rice and a preparation method thereof. The Chinese chestnut flavored composite health care rice comprises the following raw materials of polished round-grained rice, Chinese chestnut, yam, balsam pear, burdock, radix rehmanniae recen, cassia seed, Chinese wolfberry fruit, glossy privet fruit, fructus alpiniae oxyphyllae, rhizoma alismatis and polygonum multiflorum. The Chinese chestnut flavored composite health care rice has the beneficial effects that finished products are smooth and attractive in appearance and soft and glutinous in taste after being cooked, have special fresh scent of the Chinese chestnut, are delicious and nutritious, and are suitable for being eaten by people for a long time.

Owner:迁西县生产力促进中心

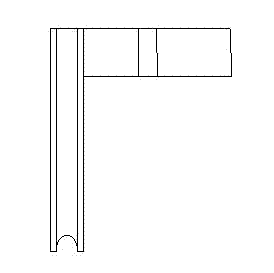

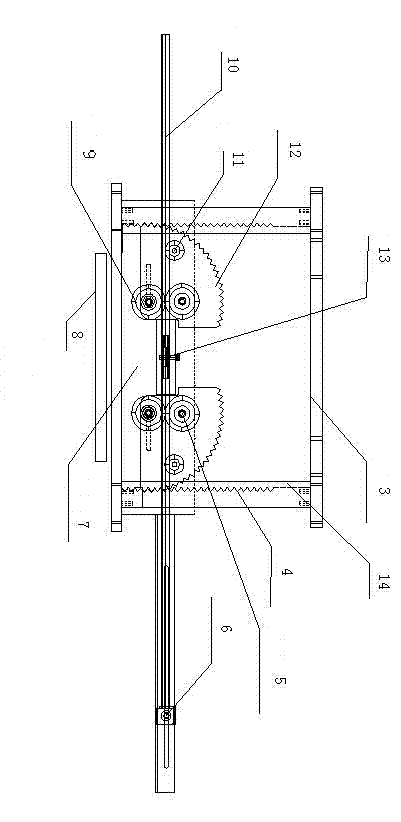

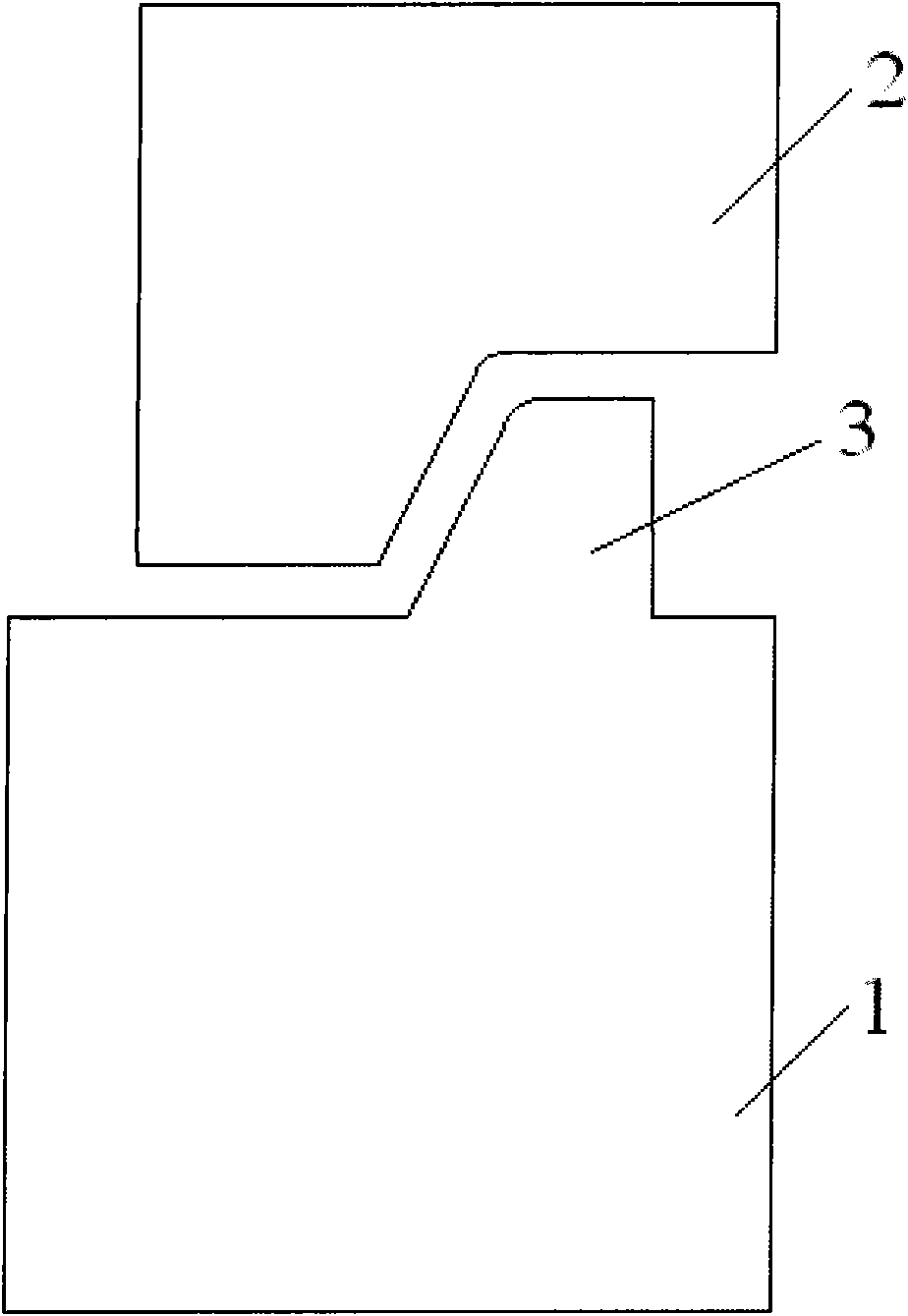

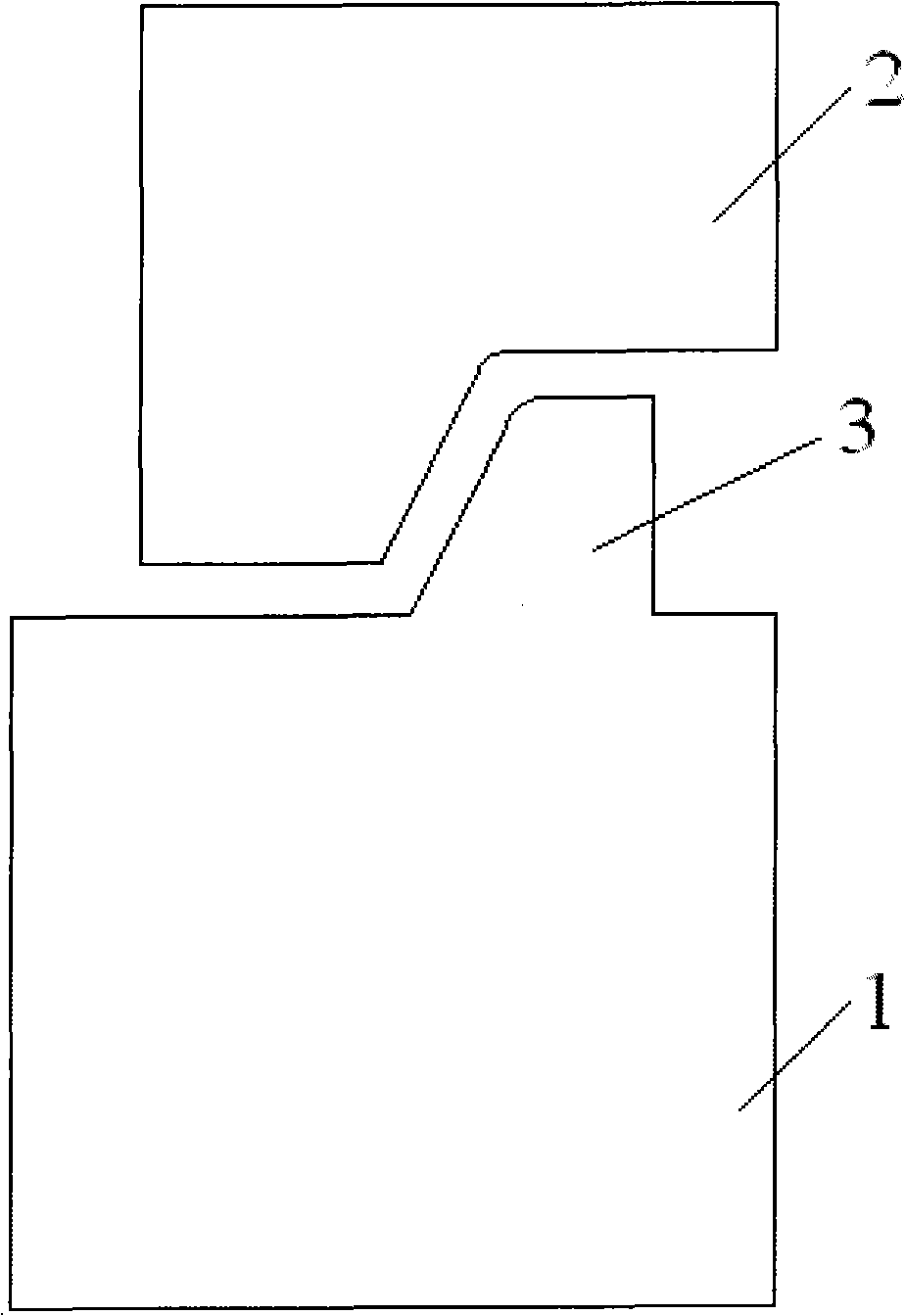

Precise U-shaped bending die for magnesium alloy sectional materials

ActiveCN102950207AGuaranteed uniform speedEnsure balanceShaping toolsMaterials scienceMagnesium alloy

A precise U-shaped bending die for magnesium alloy sectional materials is mainly used for processing the magnesium alloy sectional materials. The die comprises an upper die frame and a lower die plate and is characterized in that the rectangular upper die frame consists of an upper crossbeam plate, a lower crossbeam steel pad and two precisely feeding racks, wherein the upper crossbeam plate and the lower crossbeam steel pad are horizontally arranged, the precisely feeding racks are vertically arranged as vertical sides, and the precisely feeding racks are connected to the upper crossbeam plate and the lower crossbeam steel pad; retaining plates are embedded on the outer sides of the precisely feeding racks, grooves are formed between the precisely feeding racks and the retaining plates, and rotating gear discs can slide in the grooves and are meshed with the precisely feeding racks; and two adjustable support wheels, the rotating gear discs and a retainer are arranged on the lower die plate, and a guide wheel and a molding wheel are arranged on each rotating gear disc. The deformation and breakage problems of magnesium alloy are basically solved. Through the fine adjustment of a wheel gap, the gap accuracy of the sectional materials is increased by 50%, and the defective rate is reduced by 80%.

Owner:山西东银实业有限公司

Production method of precursor pueraria rice flour and product thereof

InactiveCN103385427AAvoid lossGuaranteed healthcare valueFood preparationLimited componentMaterials science

The invention discloses a production method of precursor pueraria rice flour and a product thereof. The production method comprises the following steps of: stacking pueraria collected in winter for 14-24hours at the temperature of 18 DEG C, cleaning by water, peeling, standing for 10-14hours, slicing, crushing the pueraria into small particles, drying at the temperature of 45-60 DEG C, crushing into pueraria powder at the temperature of 50-60 DEG C, mixing with rice powder, evenly blending with a precursor pueraria liquid or precursor pueraria water, extruding into precursor pueraria rice flour at the temperature of 50-60 DEG C, ageing, loosening rice flour and drying to obtain the product. The production method disclosed by the invention can effectively prevent limited components in the pueraria from being lost, and the product is smooth and beautiful in appearance, good in adhesive property, soft and lubricated in taste and rich in fresh scent of precursor pueraria, and is a daily food which is naturally green, organic and environment-friendly and health-care.

Owner:李时令

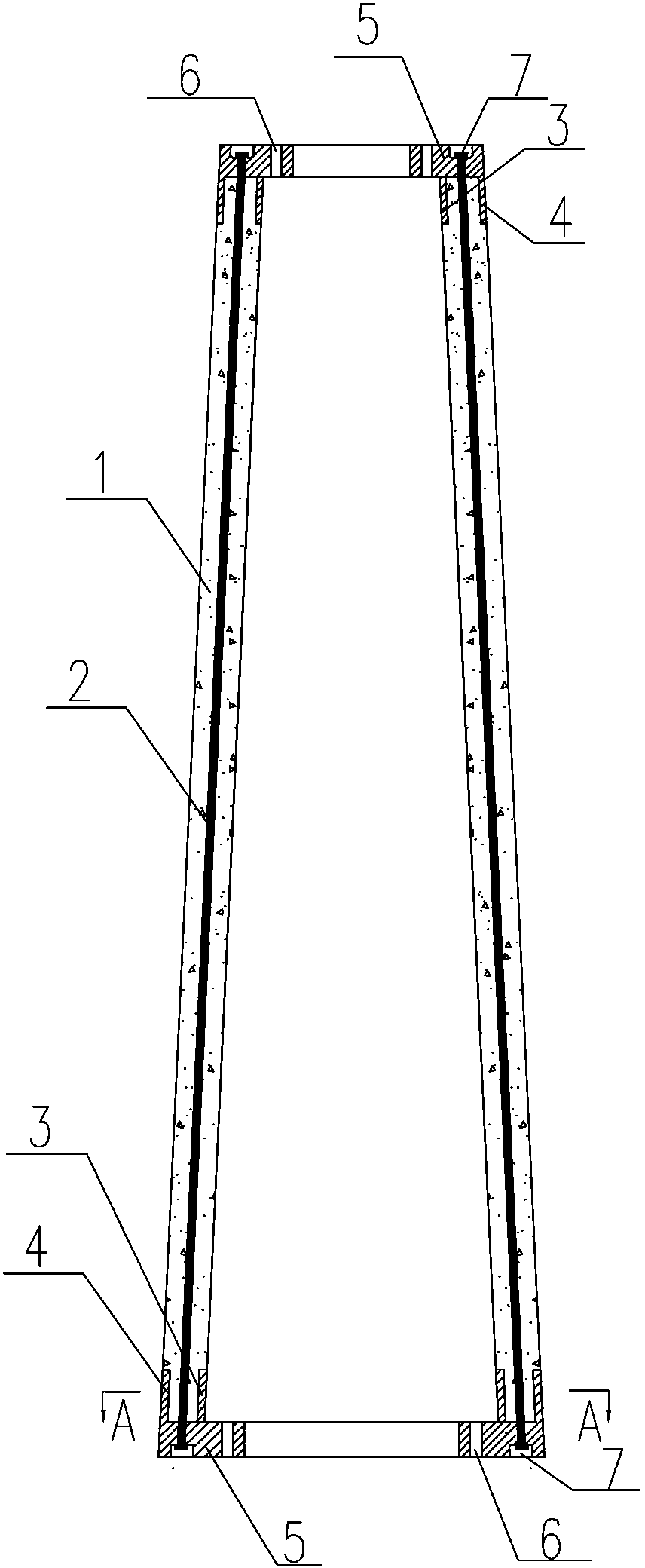

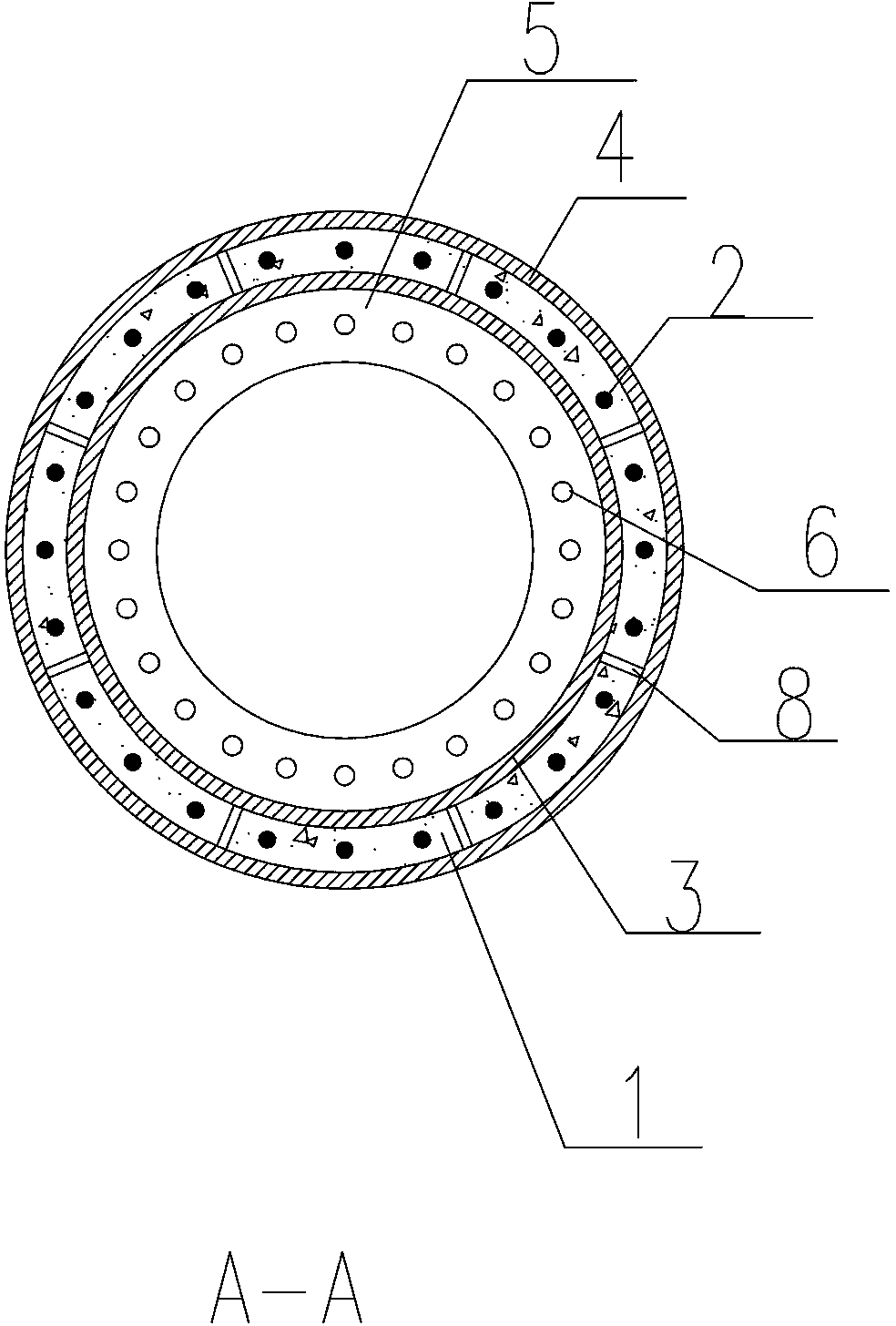

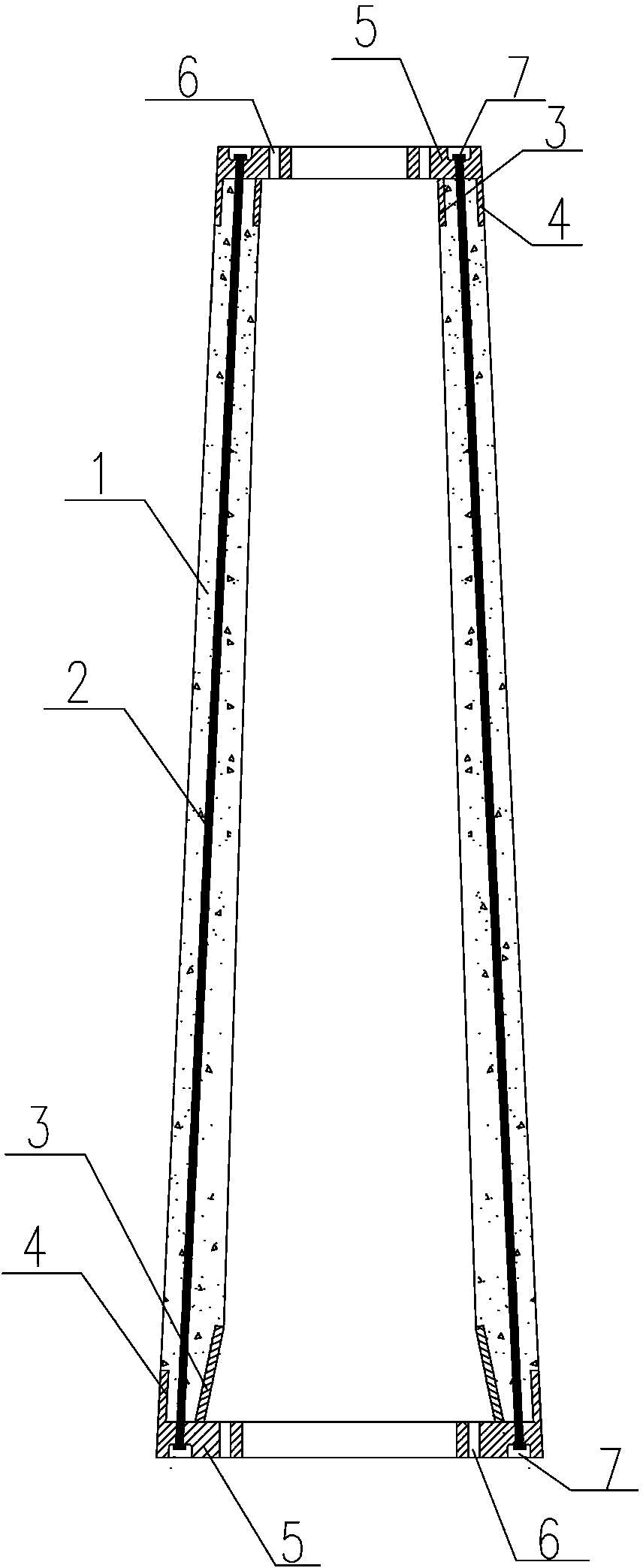

Prestressed concrete rod section with two ends in inner flange connection

InactiveCN103422702ASmooth and beautiful appearanceFirmly connectedTowersPre stressArchitectural engineering

The invention relates to a prestressed concrete rod section with the two ends in inner flange connection. The prestressed concrete rod section comprises a prestressed concrete rod body and connecting flanges which are arranged at the two ends portions of the prestressed concrete rod body. The prestressed concrete rod section is characterized in that the connecting flanges which are arranged at the two ends portions of the prestressed concrete rod body are respectively steel inner flanges which are provided with an inner protection ring and an outer protection ring, connecting bolt holes and step holes are evenly formed in the periphery directions of the steel inner flanges provided with the inner protection ring and the outer protection ring, the inner protection ring and the outer protection ring are connected through a rib plate or a steel rib and are pre-buried at the two ends of the prestressed concrete rod body, the outer protection ring is arranged flush with the outer surface of the prestressed concrete rod body, and the two end heads of a prestressed main rib are directly anchored in the step holes of the inner flanges. The prestressed concrete rod section has the advantages that the rob body which is connected through the steel inner flanges is smooth and attractive in appearance, bumping cannot not happen easily, and the steel inner flanges with the inner protection ring and the outer protection ring are firmly connected with the prestressed concrete rod body.

Owner:祁锦明

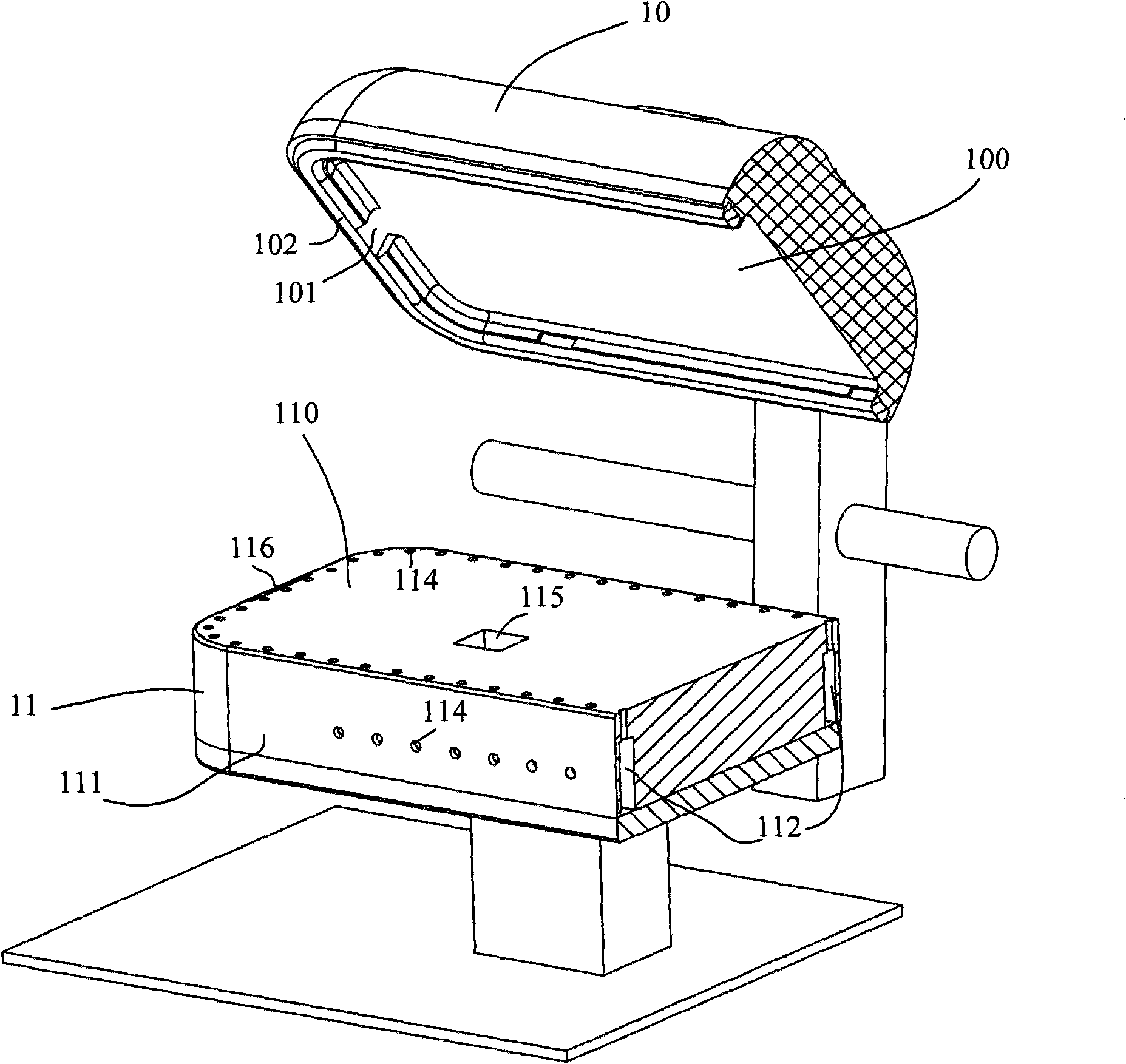

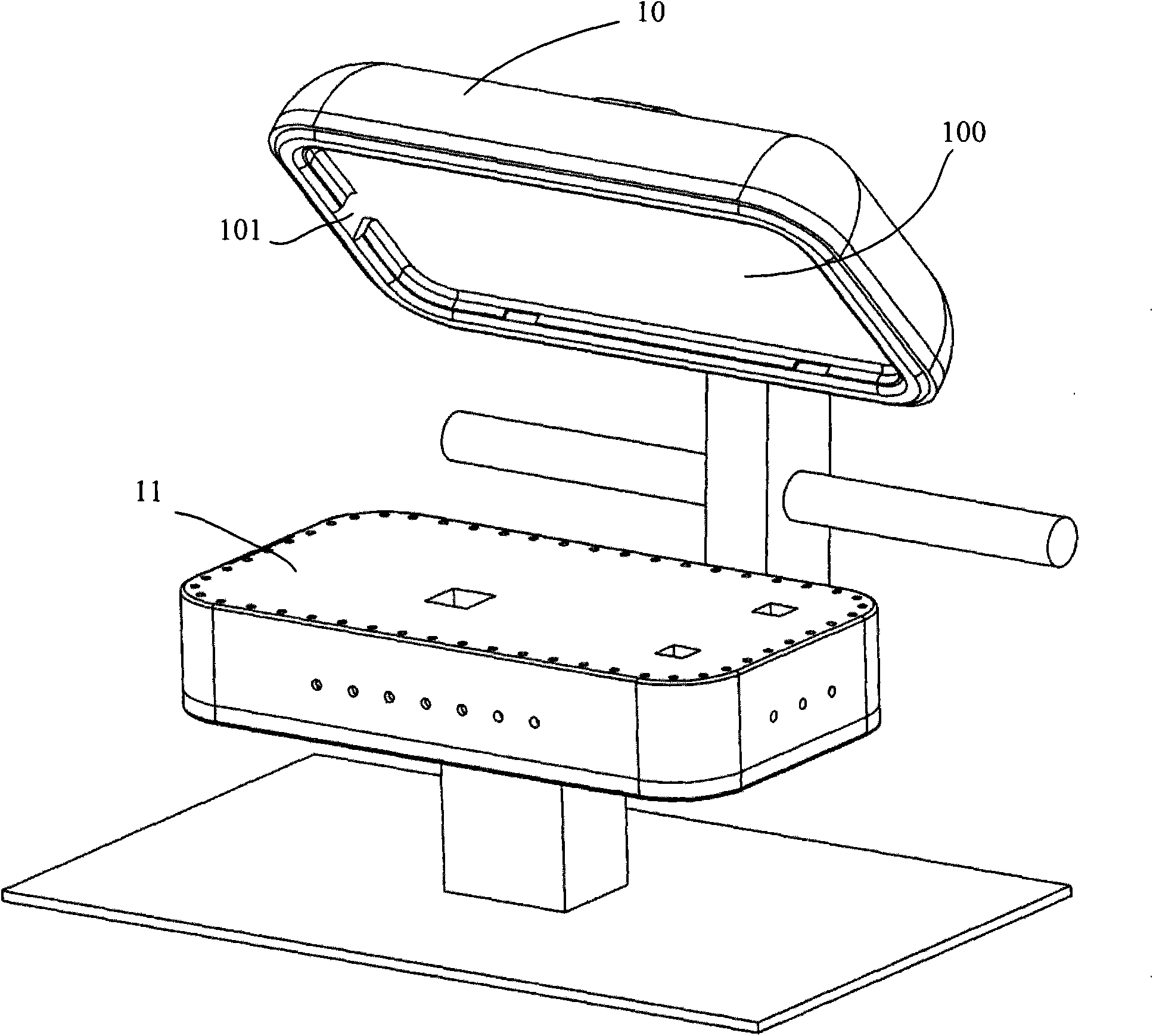

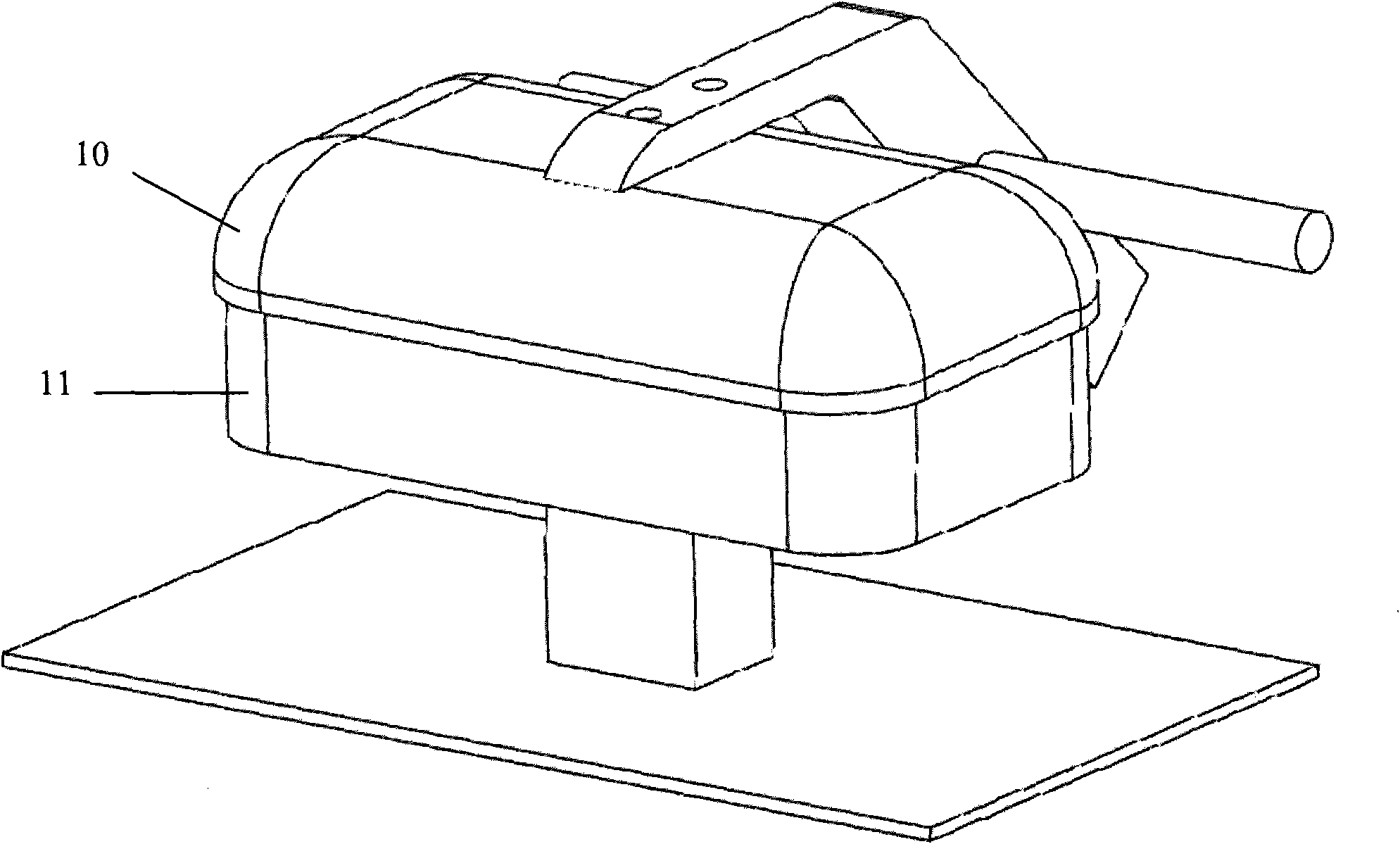

Hot press molding process, molding system and mould group thereof

The invention relates to a hot press molding process, a molding system and a mould group thereof, which can replace the conventional stitching manufacture manner. A first mould is provided with an annular hot press part, a second mould is provided with a hot press surface, a plurality of air absorbing holes are formed in an outer ring of the hot press surface, an air duct is internally arranged in the second mould and is used for connecting an air source, the air absorbing holes are communicated with the air duct, an outer ring cutting sheet is sleeved on the sidewall of the second mould so that a flange of the outer ring cutting sheet faces the hot press surface of the second mould, an air absorbing system is used for absorbing air in the air duct of the second mould so that the flange of the outer ring cutting sheet is smoothly located on the outer ring of the hot press surface depending on the air absorbing holes, the hot press part of the first mould is heated, and the flange of the outer ring cutting sheet is pressed in a hot state by the hot press part so as to enable the flange to be molded; in addition, a central cutting sheet is arranged on the outer ring cutting sheet, and the central cutting sheet and the flange of the outer ring cutting sheet are melted by utilizing the hot press part of the first mould.

Owner:上海华培胶带有限公司 +1

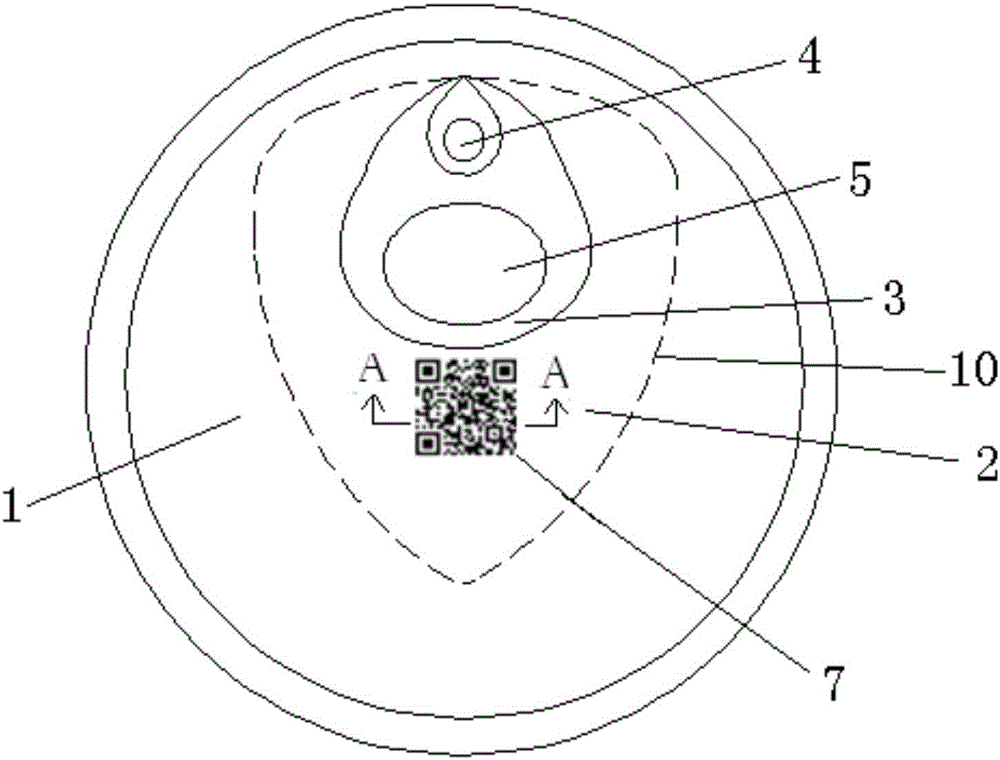

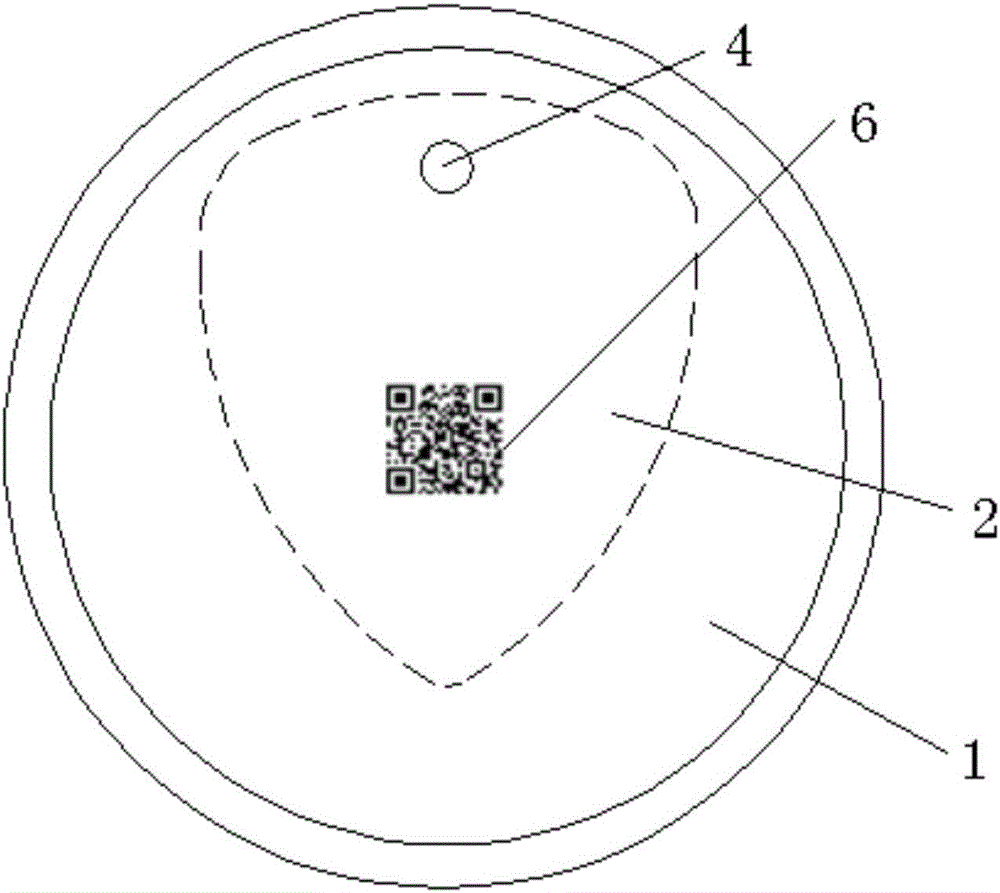

Large-opening ring-pull can top cover with gray scale identification code

InactiveCN106240998ASimplify manufacturing difficultyGuaranteed setting integrityContainer decorationsLevel indicationsEngineeringPhoton

The invention discloses a large-opening ring-pull can top cover with a gray scale identification code. The large-opening ring-pull can top cover comprises a cover body and a pull ring, wherein the cover body at least comprises a base material and a photon sensitive ink layer arranged on the inner side of the base material; the photon sensitive ink layer is exposed to form a first gray scale identification code, or after forming the first gray scale identification code, the photon sensitive ink layer is covered by an inner coating layer; the first gray scale identification code is an image formed by the appearance change of part of a photon active material in the photon sensitive ink layer; the surface of the first gray scale identification code is smooth, and has a gray scale difference from the surrounding region; and the first gray scale identification code is arranged on the back surface of the opening region and is located at the central position of the cover body. By the arrangement of the opening region with a relatively large area at the central position of the cover body and the arrangement of the first gray scale identification code with the smooth and attractive surface at the central position in the cover body, the large-opening ring-pull can top cover guarantees the arrangement completeness of the first gray scale identification code on the inner side of the opening region, and the difficulty in manufacturing the ring-pull can top cover is simplified.

Owner:SIGMATRIX TECH CO LTD

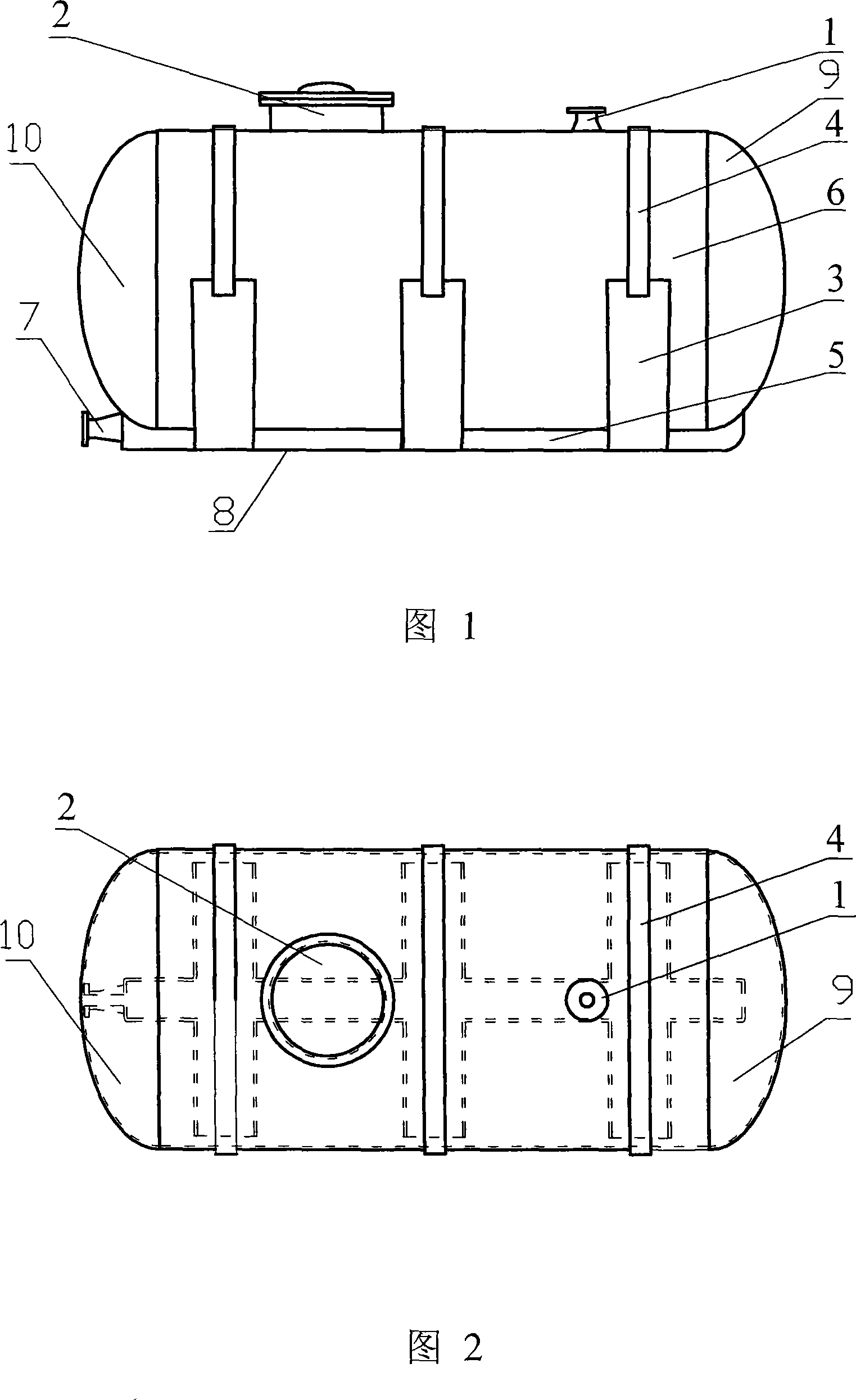

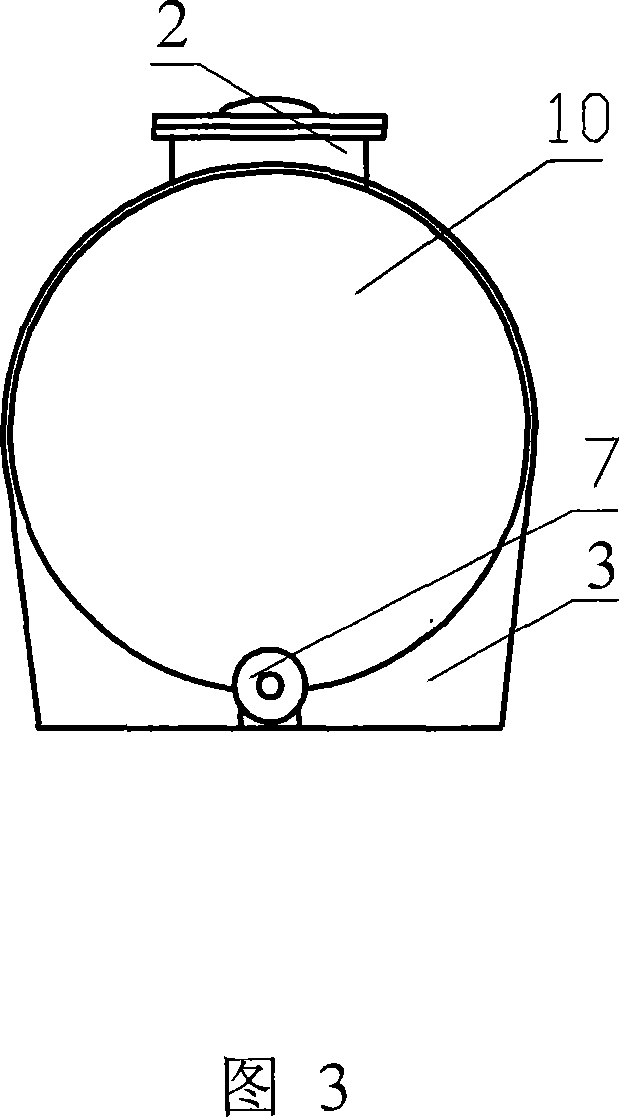

Making process of horizontal polyethylene storage tank with integral support

InactiveCN101020350AImprove integrityExtended service lifeCoatingsHollow articlesLow-density polyethyleneLinear low-density polyethylene

The technological process of making horizontal polyethylene storage tank integral support includes the following steps: 1. preparing material through mixing linear low-density polyethylene and linear high-density polyethylene in the weight ratio of 100 to 10-20; 2. making tank steel lining; 3. preparing mold; 4. assembling mold and clamping mold; 5. rolling plastic to form the tank through rolling in roller rotation speed of 30-40 rpm, baking at tank wall temperature of 170-250 deg.c for 40-350 min and curing for the plastic to be attached to the surface of the steel lining; and 6. cooling and demolding. The storage tank thus produced has the advantages of once integral formation, no seam, high impact strength, ageing resistance, light weight, acid and alkali resistance, long service life, etc.

Owner:杭新华

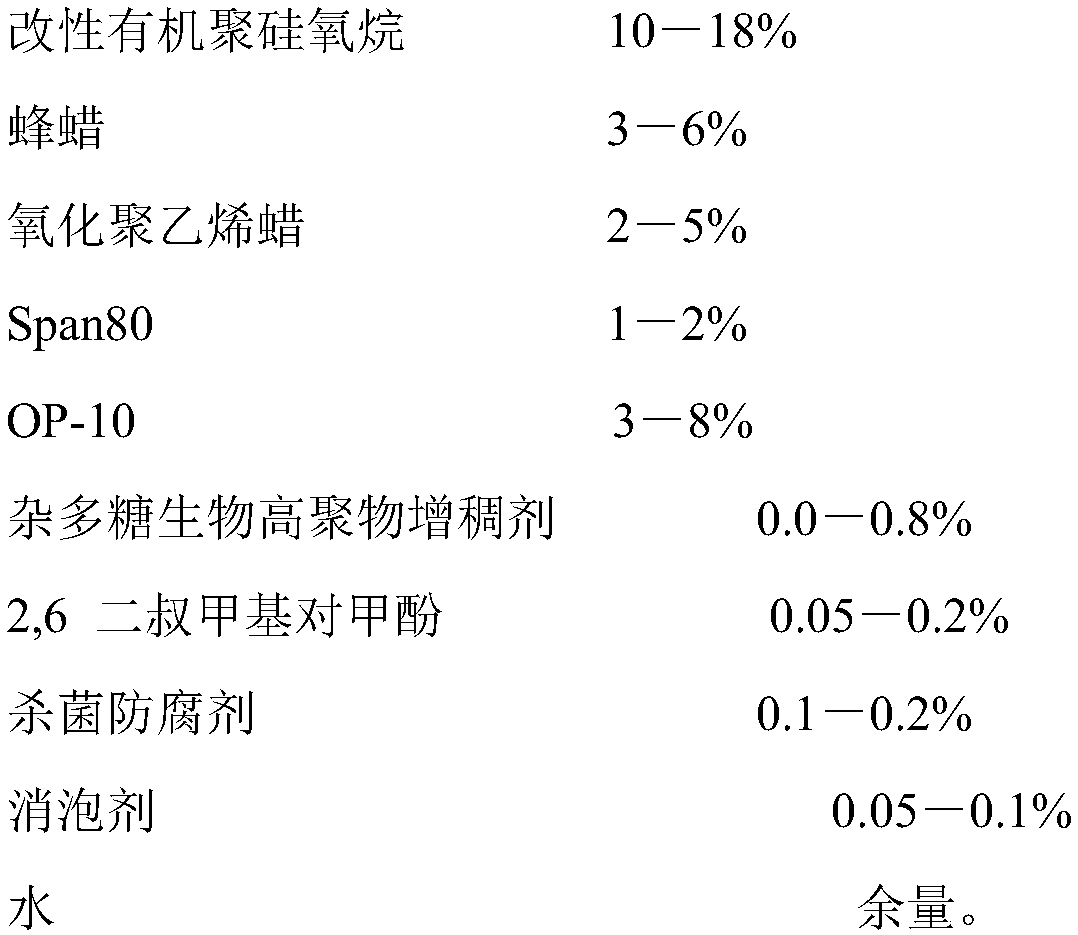

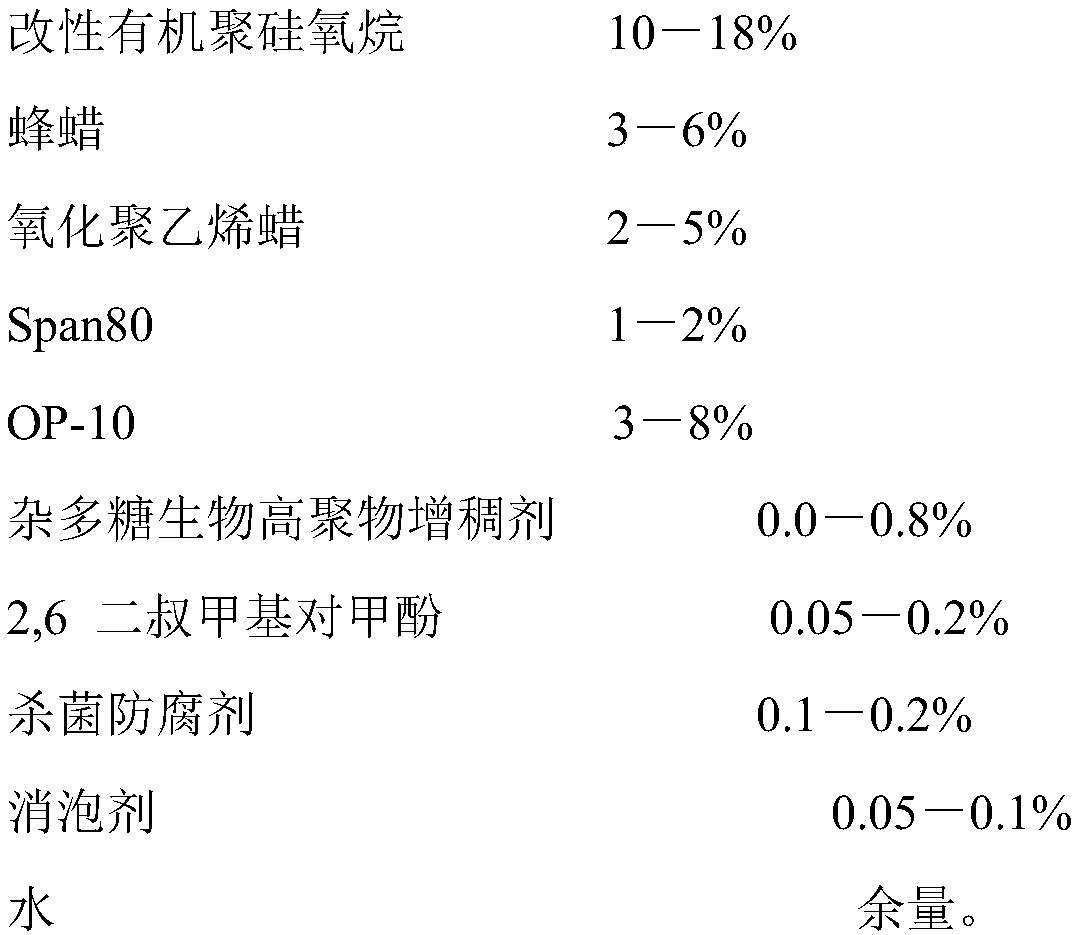

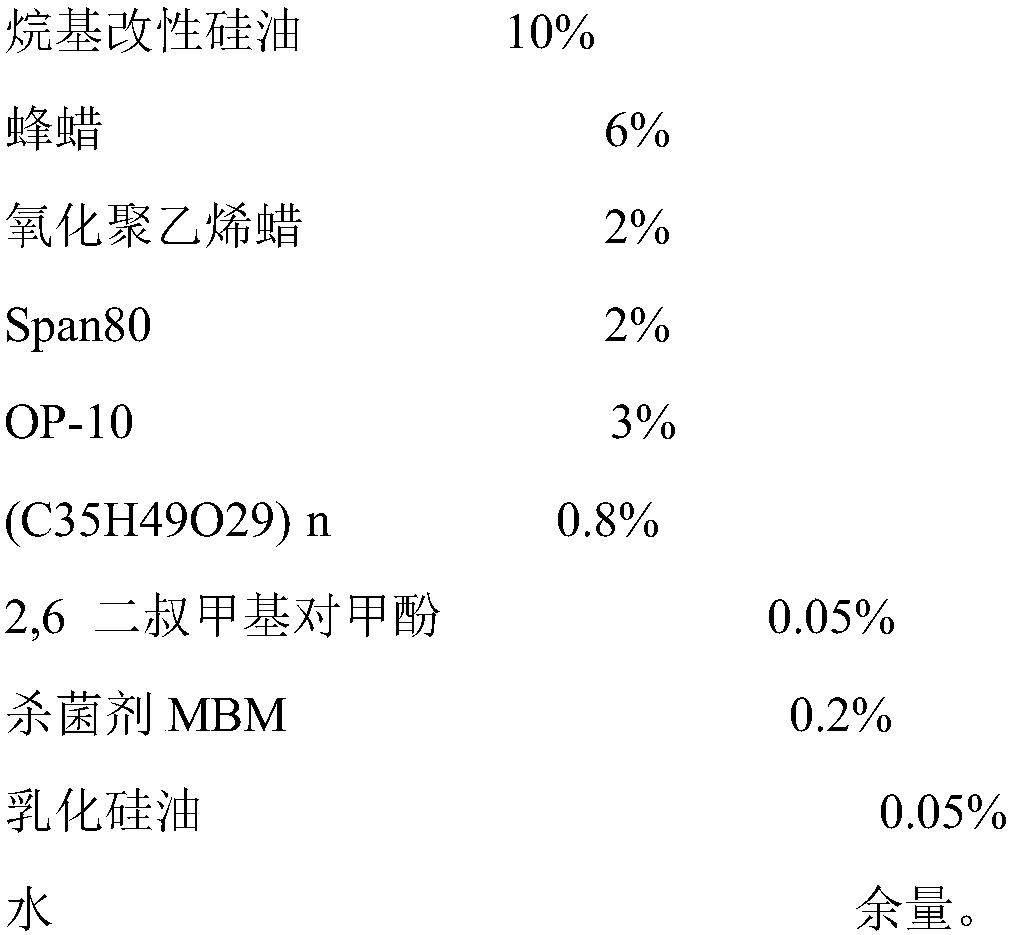

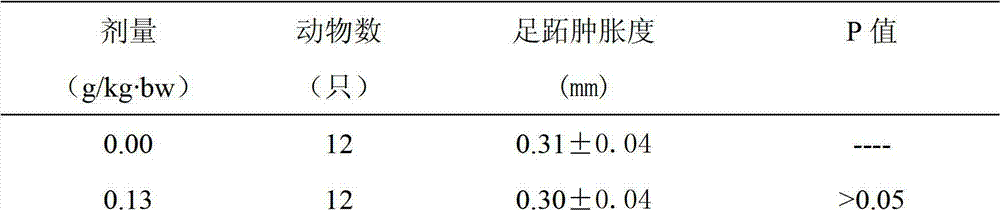

Efficient water-based mold release agent for aluminum alloy die casting

InactiveCN107617717AEasy to cleanExtended service lifeFoundry mouldsFoundry coresWater basedBiopolymer

The invention relates to an efficient water-based mold release agent for aluminum alloy die casting. The efficient water-based mold release agent for aluminum alloy die casting comprises, by mass, 10%-18% of modified organic polysiloxane, 3%-6% of bee wax, 2%-5% of oxidized polyethylene wax, 1%-2% of Span80, 3%-8% of OP-10, 0-0.8% of heteropolysaccharide biopolymer thickening agent, 0.05%-0.2% of2,6-di-tert-butyl-4-methylphenol, 0.1%-0.2% of sterilizing preservative, 0.05%-0.1% of antifoaming agent and the balance water. The water-based emulsion mold release agent is high in stability, the high-temperature wetting temperature is 320 DEG C, and the film forming property is good, the efficient water-based mold release agent can easily form a uniform lubricating film having a certain strength on the surface of metal, and effective lubricating agents achieve stable and continuous gas formation at high temperature; trial application to complicated aluminum alloy die casting production shows that the mold release effect is good, and the surface of the casting is smooth and clean.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

VE (Vitamin E) coenzyme Q10 composition for assisting to reduce blood fat and boosting immunity and preparation method thereof

The invention discloses a VE (Vitamin E) coenzyme Q10 composition for assisting to reduce blood fat and boosting immunity and a preparation method of the composition. The VE coenzyme Q10 composition comprises the following components in parts by weight: 0.5-5 part(s) of coenzyme Q10, 0.7-21 part(s) of vitamin E and 25-300 parts of granulesten. The preparation method for the composition comprises the following steps of: adding the materials to matrix which is mixed and dissolved with soybean oil and beewax; stirring and dissolving the materials in the matrix at about 50 DEG C; putting the mixture to a colloid mill for grinding and circulating until the mixture is uniform; and obtaining soft capsule preparation by carrying out the processes such as pelleting, shaping, pill-washing, drying in the air, drying, picking and the like. According to the VE coenzyme Q10 composition provided by the invention, the bioavailability and stability of the coenzyme Q10 are greatly increased; and the dual effects of assisting to reduce blood fat and boosting immunity are achieved.

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD

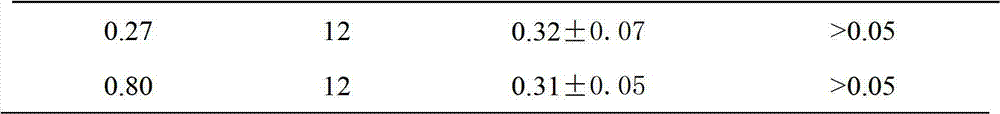

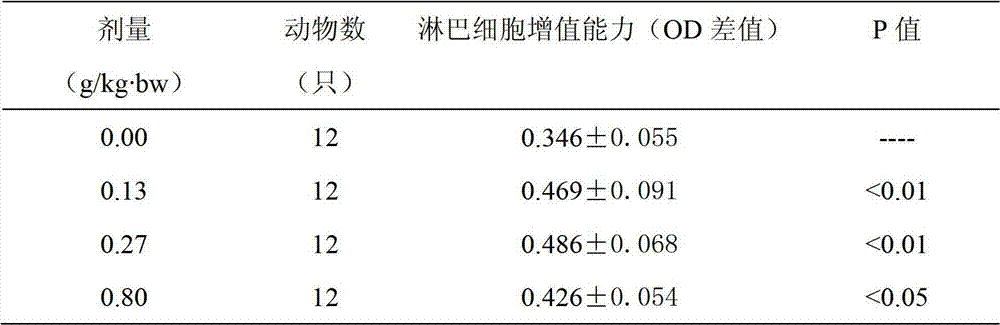

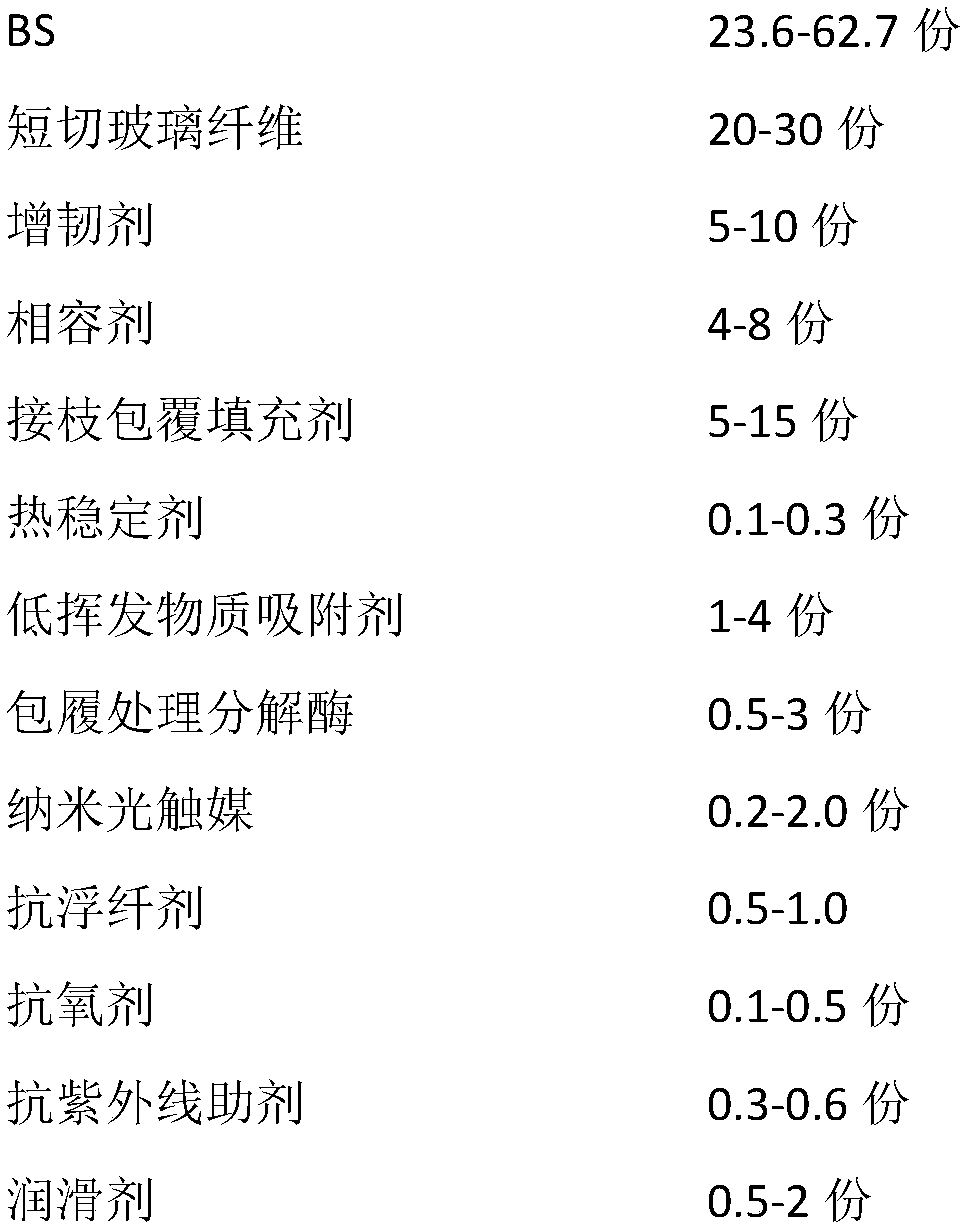

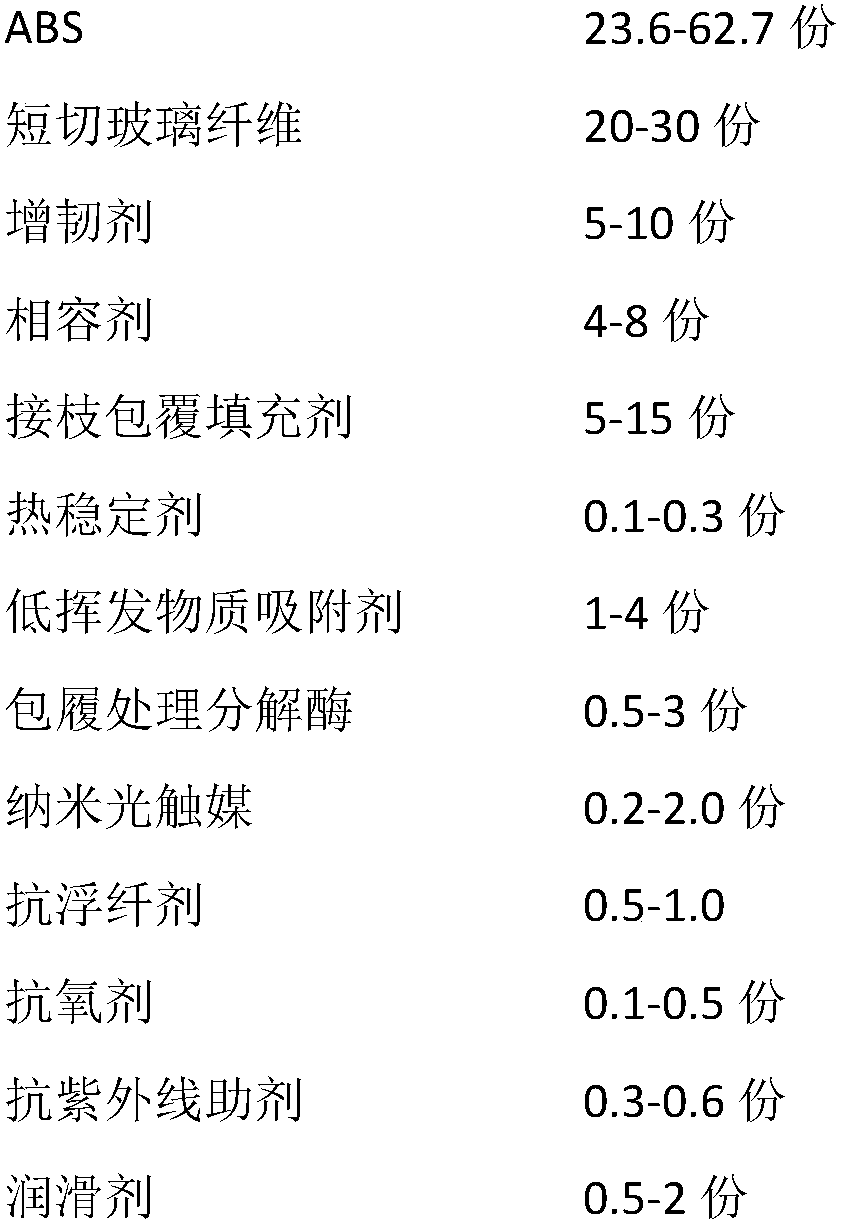

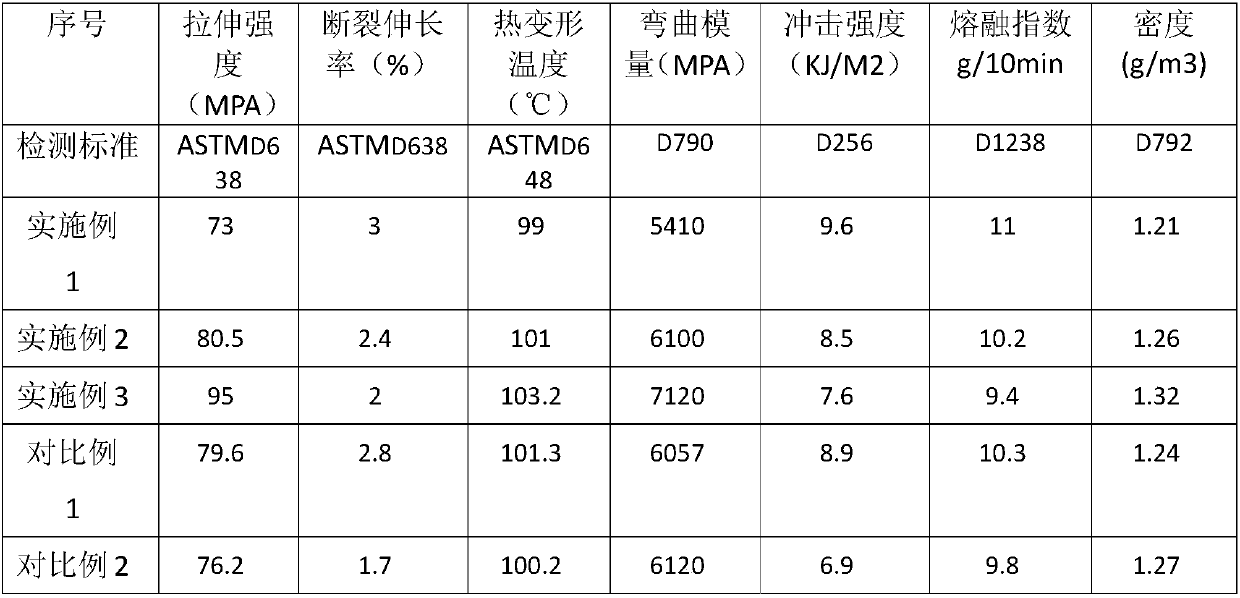

Low-odor sterilization reinforced ABS (acrylonitrile butadiene styrene) automobile rearview mirror frame material and method for preparing same

The invention discloses a low-odor sterilization reinforced ABS (acrylonitrile butadiene styrene) automobile rearview mirror frame material and a method for preparing the same. The low-odor sterilization reinforced ABS automobile rearview mirror frame material comprises, by weight, ABS, chopped glass fibers, toughening agents, compatilizers, grafting and coating fillers, heat stabilizers, low-volatility matter adsorbents, coating treatment clastic enzymes, nano-photocatalysts, antioxidants, anti-ultraviolet absorbents, anti-floating cellosolve and lubricants. The low-odor sterilization reinforced ABS automobile rearview mirror frame material and the method have the advantages that the low-volatility matter adsorbents are extremely high in adsorption capacity, and low-volatility harmful gasgenerated by components formed from composite materials can be effectively prevented from being outwardly diffused; generated trace low-volatility harmful gas can be decomposed by the coating treatment clastic enzymes and the nano-photocatalysts to obtain carbon dioxide and water which are harmless, and the low-odor sterilization reinforced ABS automobile rearview mirror frame material is excellent in physical and mechanical property, heat aging resistance and weather resistance and low in odor and TVOC (total volatile organic compound) content, is stress-crack-resistant, corrosion-resistant,shock-resistant and scratch-resistant and can be used for producing automobile rearview mirror frames.

Owner:DONGGUAN JISU PLASTIC TECH

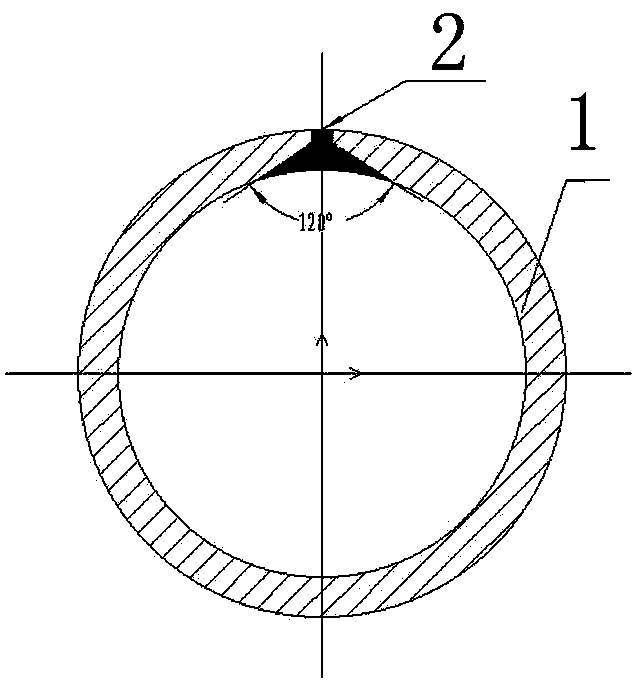

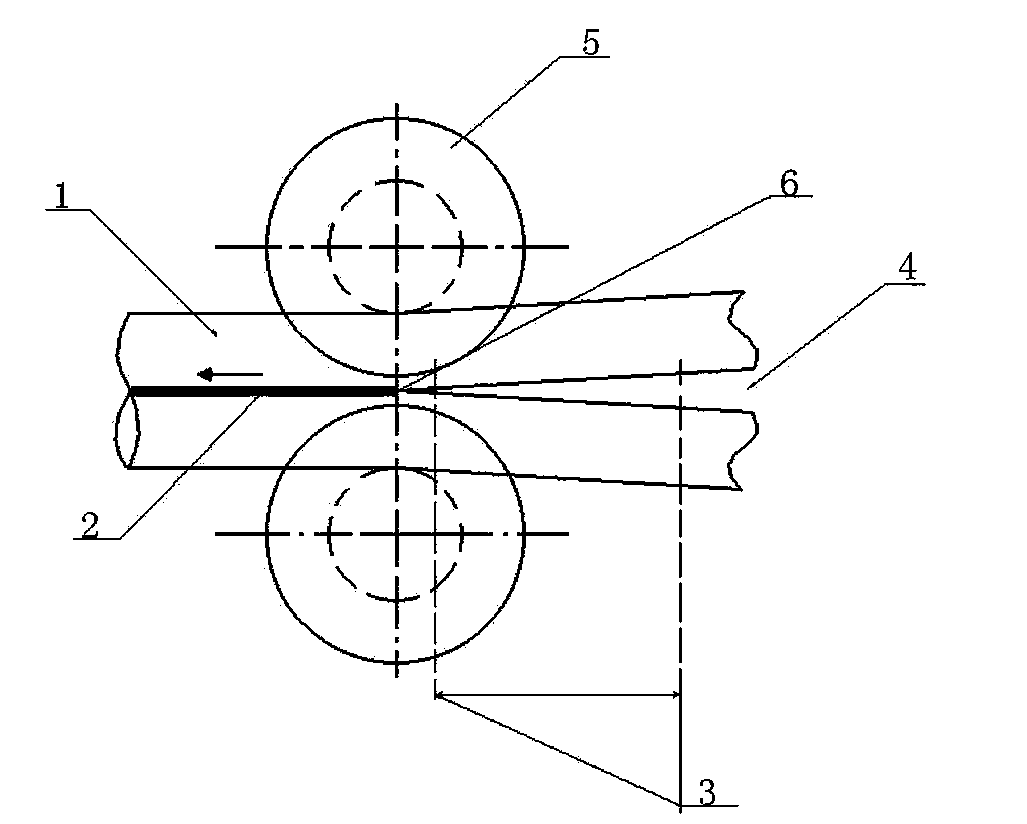

Special steel pipe for CO2 (carbon dioxide) air conditioner compressor casing and processing process of special steel pipe

The invention relates to a special steel pipe for a CO2 (carbon dioxide) air conditioner compressor casing and a processing process of the special steel pipe. The processing method comprises the following process steps that steel coils are sheared into required steel belts according to specifications; the steel belts are subjected to leveling through a leveling machine after entering a machine unit production line, the smoothness is + / -0.30mm, and the two sides of the steel belts are respectively subjected to 60-degree planing and shaping; the welding current is regulated, and the current is controlled to be between 550A and 650A; the welding speed is controlled to be 30meter / minute to 35meter / minute; a heat affecting region is lengthened, and a welding opening angle is enlarged; the steel belts are formed into steel pipes by adopting a multi-roller extruding device; welding seams are formed at the welding points; the steel pipes are naturally cooled through air and are cooled through water after the welding, the steel pipes enter a correcting region, the roundness of the special steel pipes can be ensured, and the appearance dimension requirements are met. The special steel pipe and the processing process have the advantages that the roundness of the welding steel pipe casing and the tightness of the welding seams can be ensured, the welding seams can bear the maximum intensity pressure greater than or equal to 30Mpa, the production process is simple, the productivity can be improved, the manufacturing finished product rate is high, raw materials can be saved, the appearance is smooth and attractive, the quality can be improved, and the cost can also be reduced.

Owner:无锡天龙钢管有限公司

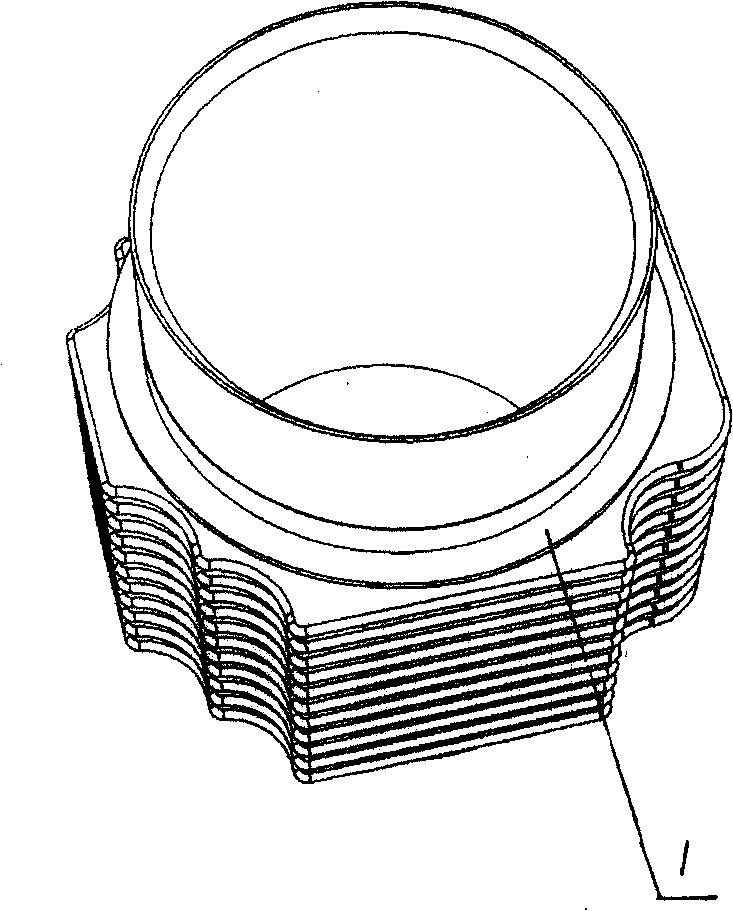

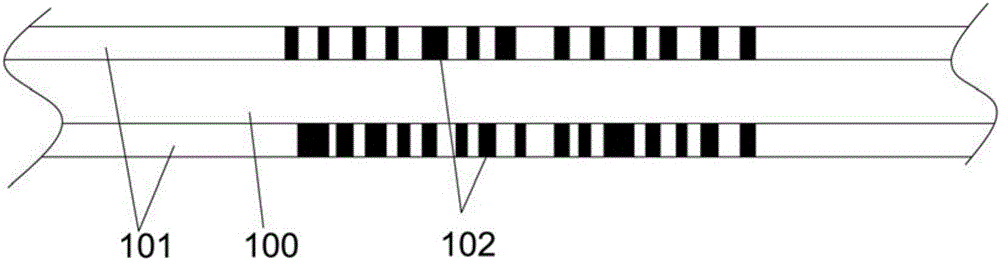

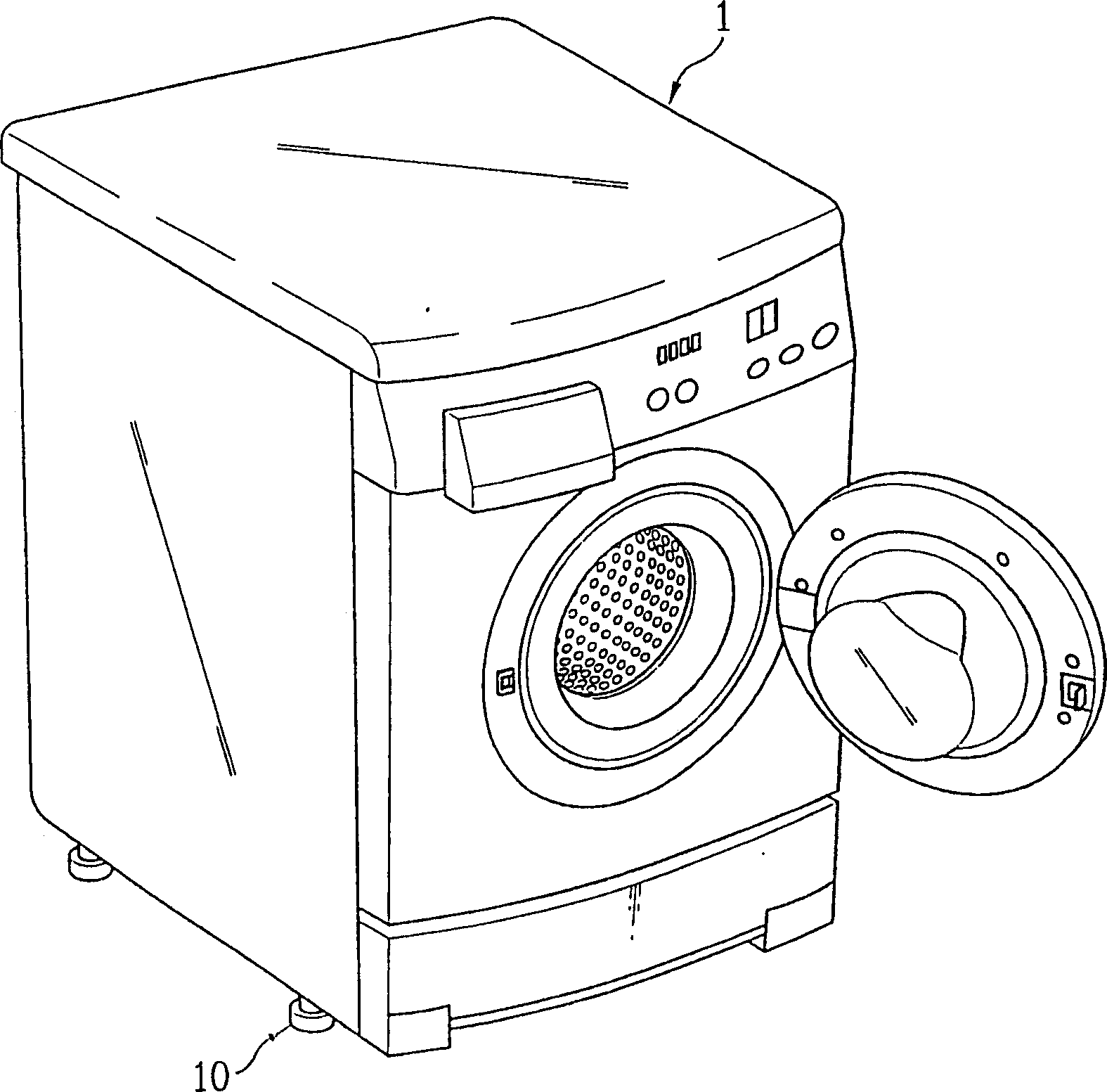

Leg assembly for home appliance

InactiveCN1701197AImprove efficiencyImprove productivityMachine framesOther washing machinesGround contactSoft materials

Disclosed is a leg assembly for electric home appliances for supporting an electric home appliance such as a washing machine and a clothes dryer. The leg assembly in accordance with the present invention includes, a leg bolt ( 100 ) having a screw ( 110 ) coupled with the electric home appliance and a head ( 120 ) provided at an end of a screw ( 110 ) a pad made of a soft material and closely adhered to the head ( 120 ) an being in contact with a floor; and at least one holder ( 300 ) being coupled with the head ( 120 ) for fixing the head ( 120 ) and the pad ( 200 ) by pressing the pad ( 200 ) toward the head ( 120 ).

Owner:LG ELECTRONICS INC

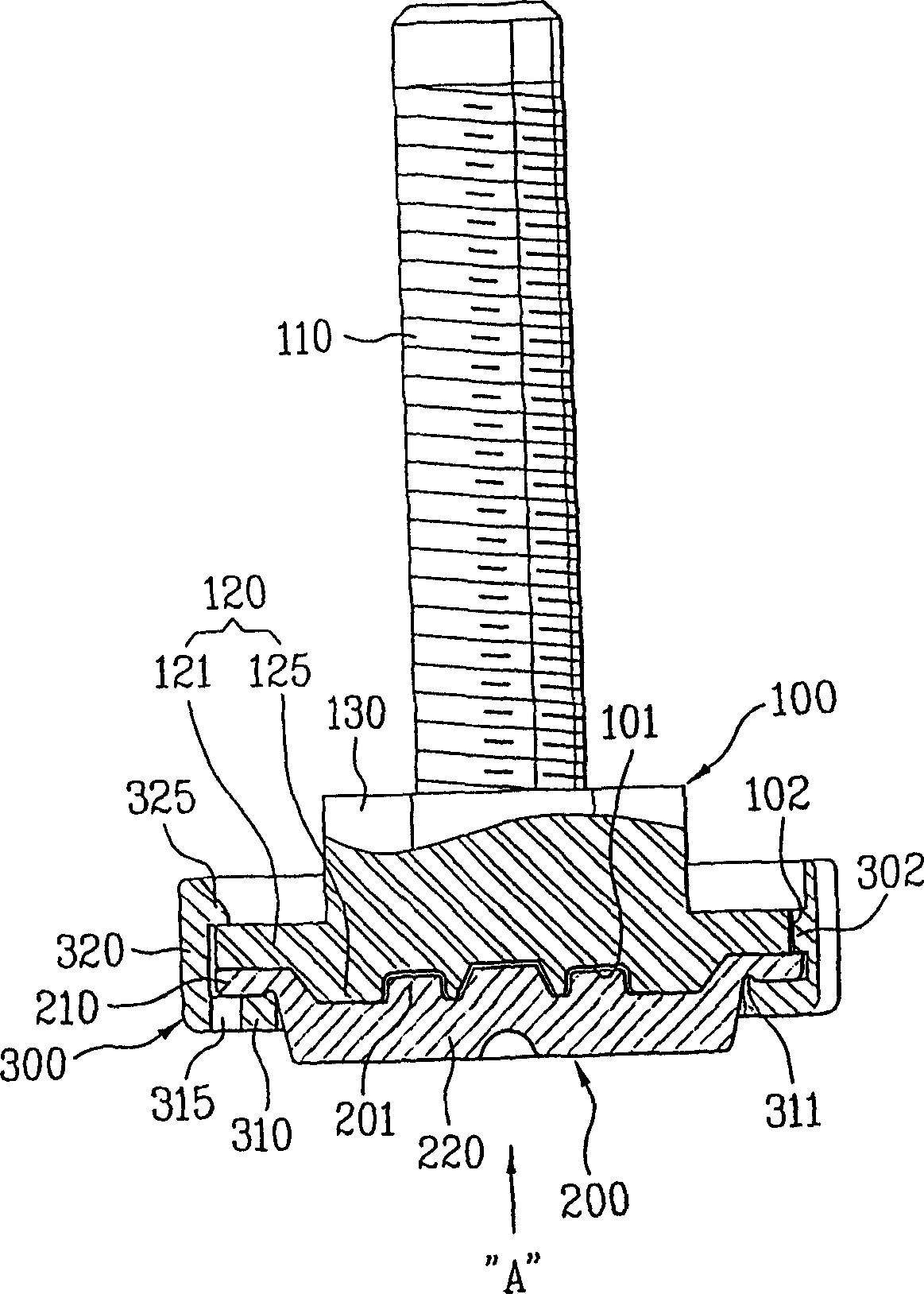

Staircase anti-biting bar and forming technology thereof

The invention discloses an anti-clip strip for an escalator and a moulding technique thereof. The anti-clip strip comprises a base and an anti-clip component which are arranged on a skirt panel of the escalator, wherein, the anti-clip component is provided with an anti-clip fixing strip which can be tabled with the upper opening of the base and an anti-clip blocking strip which protrudes outwards and extends along one edge of the anti-clip fixing strip; at least one metal green plate which is capable of controlling the contraction of the anti-clip strip component passes through the inner part of the anti-clip fixing strip. The moulding technique comprises steps of mixing granulation, plastic modification, base moulding and the extrusion molding forming, the component and the products finishing of the anti-clip strip component. Both the base and the anti-clip strip component of the invention adopt the moulding technique of plastic extrusion and have low production cost and convenient production; the metal green plate is embedded into the anti-clip fixed strip, thereby further controlling the contraction distortion of the anti-clip strip component in the extrusion process and having higher moulding quality of the extruded anti-clip strip component; both the base and the anti-clip strip component adopt flexible plastic materials, thereby having better bending property and being convenient for the operation of a dismantlement process.

Owner:余惠江

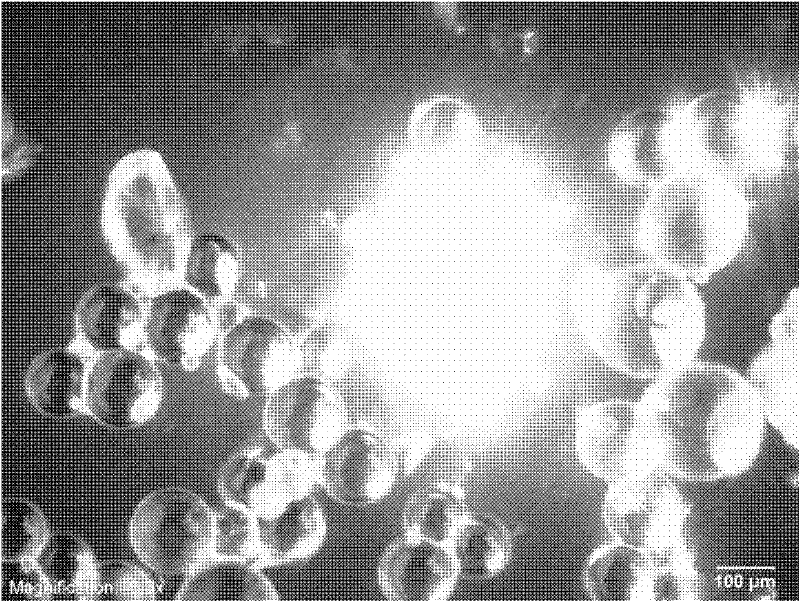

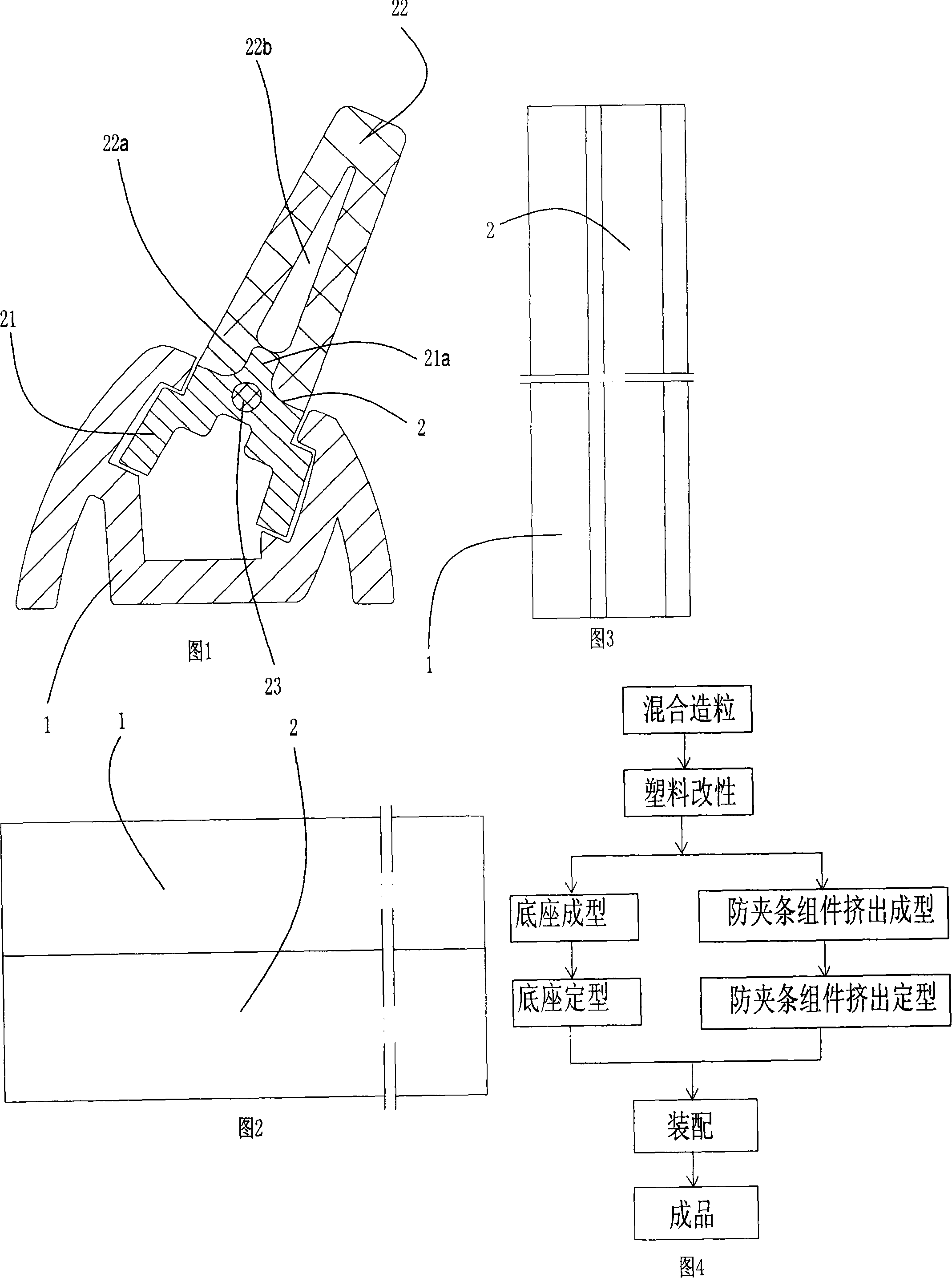

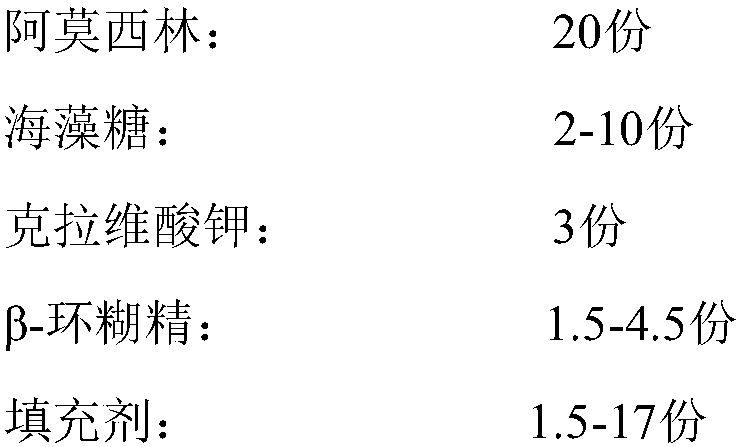

Amoxicillin and clavulanate potassium preparation and preparation method thereof

ActiveCN109248150AGood dispersionGood hygroscopicityAntibacterial agentsPharmaceutical non-active ingredientsMedicineCLAVULANATE POTASSIUM

The invention belongs to the technical field medicines, and provides an amoxicillin and clavulanate potassium preparation and a preparation method thereof. According to the dispersed tablet (the preparation) prepared by the technology, the amoxicillin and clavulanate potassium is high in stability, relatively good in dissolution effect and relatively low in related materials. The method provided by the invention can effectively shorten a technological process, reduce a production cycle and explosion time of medicines in time, guarantee stability of medicines and further improve quality of thefinished product (the amoxicillin and clavulanate potassium preparation).

Owner:LUNAN PHARMA GROUP CORPORATION

Production method and product of plasmod-radix puerariae electuary

ActiveCN103431492AEffective controlSmooth and beautiful appearanceFood shapingFood preparationWater contentFood science

The invention relates to a production method and a product of a plasmod-radix puerariae electuary. The production method comprises the steps of stacking radix puerariae collected in a winter for 24h at 18 DEG C, washing with water, peeling, placing for 10-14h, slicing, crushing into radix puerariae granules, drying below 50 DEG C, crushing into plasmod-radix puerariae powder at 50-60 DEG C, adding plasmod-radix puerariae liquid or radix puerariae juice obtained by collecting, stirring till the water content is 35-40%, extruding into electuary granules at 50-60 DEG C, drying till the water content is below 13.5%, cooling, and packaging. According to the preparation method and the product, the temperature is controlled strictly in a production process according to a physicochemical property of the radix puerariae; the water is discharged gradually time after time; a half-cooked extrusion method is adopted, so that the radix puerariae can be effectively controlled to contain about 12% of flavonoid compound, and the flavonoid compound is not lost; the original property of the radix puerariae is kept; and the product is smooth, attractive, good in bonding property, and soft and smooth in taste, has a delicate fragrance of the plasmod-radix puerariae, and is a natural, green, organic and environment-friendly daily edible electuary beverage.

Owner:李时令

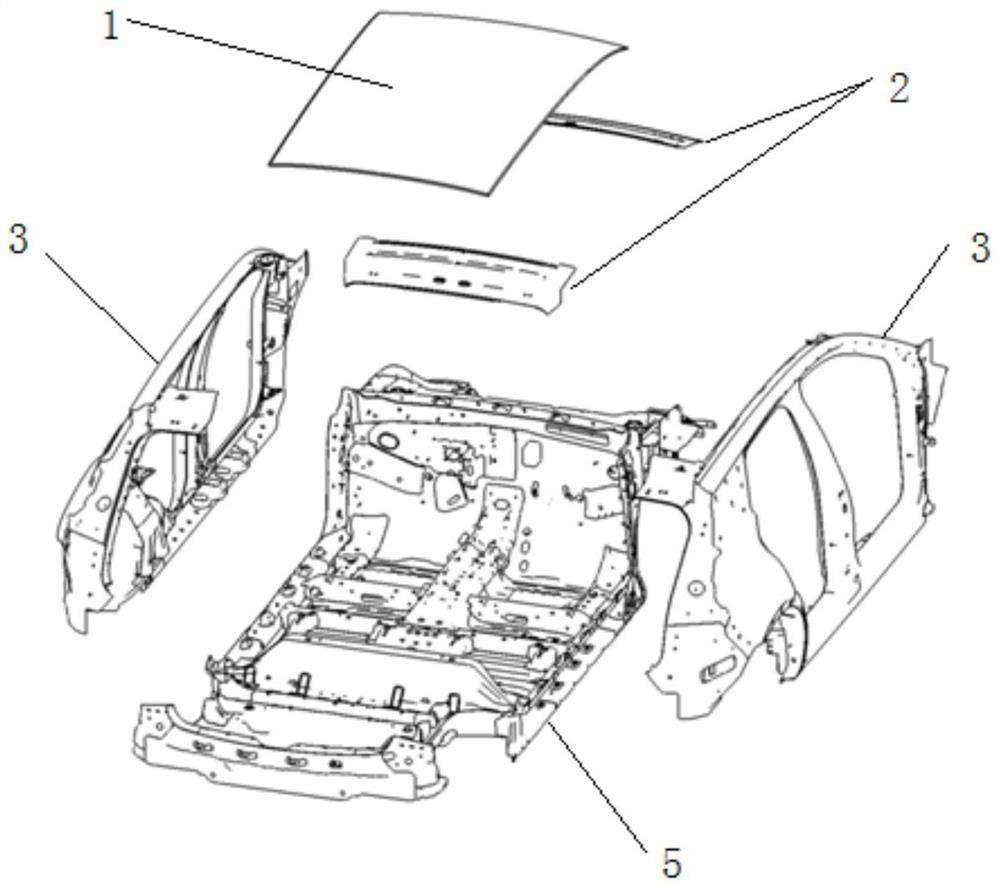

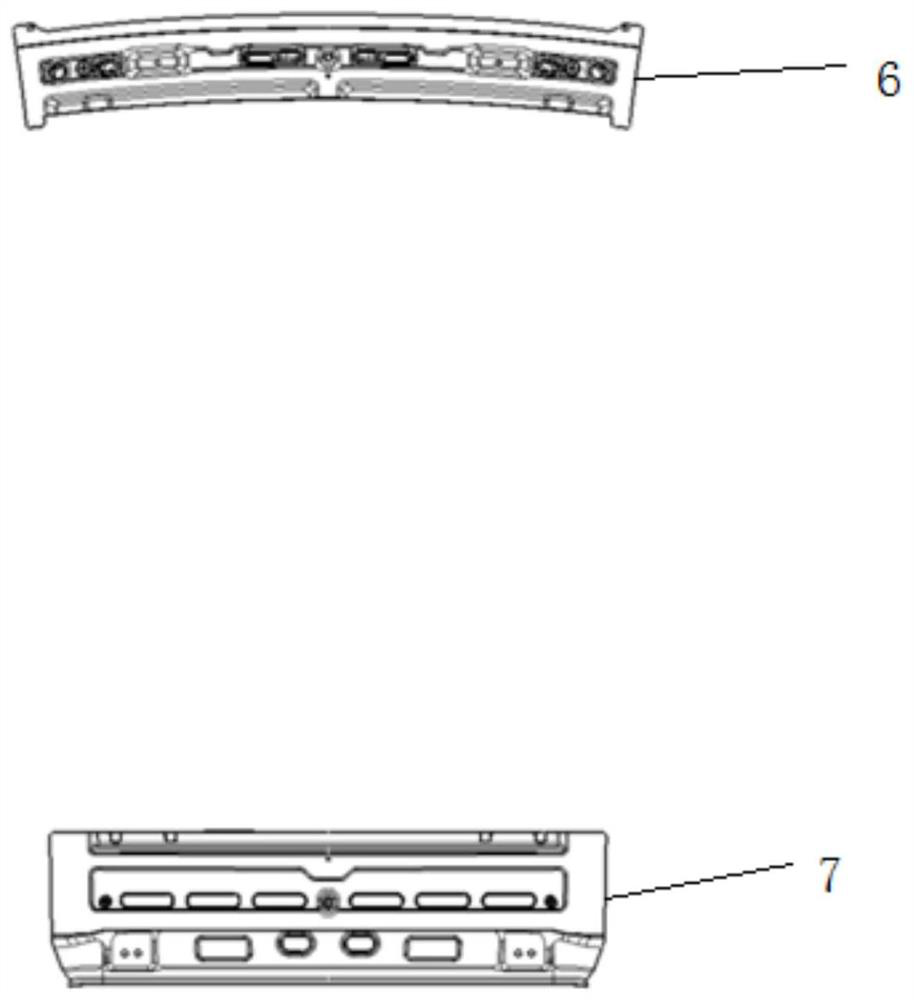

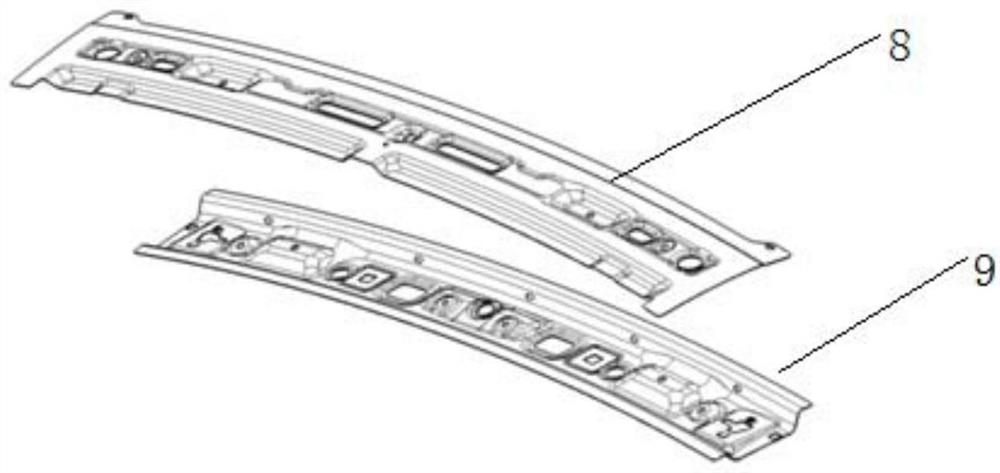

Front cross beam for panoramic backdrop automobile roof

The invention discloses a front cross beam for a panoramic backdrop automobile roof. The front cross beam comprises a front cross beam lower plate which is groove-shaped and comprises a bottom plate and side plates connected with the front end and the rear end of the bottom plate, and turnups are arranged at the tops of the side plates and are turned over towards one sides, far away from the bottom plate, of the side plates; a front cross beam upper plate covers the front cross beam lower plate, and the turnups of the front cross beam lower plate are connected with the bottom surface of the front cross beam upper plate, so that a cavity is formed between the front cross beam upper plate and the front cross beam lower plate; and a front windshield glass mounting surface and a canopy glass mounting surface are arranged on the top surface of the front cross beam upper plate. According to the scheme, the front cross beam is used for installing panoramic backdrop tempered glass, parts suchas a stiffening beam and a ceiling can be omitted, the weight of an automobile body is reduced, the rigidity of the automobile roof is improved, the concave resistance of the roof is improved, the space in the automobile is larger, transparent and bright, the view field is wide, lighting is good, and the ergonomics is improved.

Owner:BAIC MOTOR CORP LTD

Kudzuvine root rice and production method thereof

The invention provides kudzuvine root rice and a production method thereof. The production method comprises the steps of peeling washed kudzuvine root, washing the kudzuvine root by using mountain spring water at the temperature of below 10 DEG C while peeling, collecting washing liquor to obtain raw kudzuvine liquor, standing the peeled kudzuvine root for about 12 hours at the temperature of below 10 DEG C, cutting the kudzuvine root into kudzuvine root pieces, drying the kudzuvine root pieces till the water content is below 13%, smashing and sieving by a 40-mesh sieve, smashing again and sieving by a 70-mesh sieve to obtain raw kudzuvine fiber powder, fermenting the raw kudzuvine fiber powder and coarse food grain powder, preparing the mixture to be of rice grain shape, steaming, drying, and packing to obtain an end product. The production method provided by the invention has the advantages that the health care components and medicinal components of the kudzuvine root are blended into the product; and the end product is smooth and attractive in appearance, good in adhesive property, soft is mouthfeel, strong in kudzuvine aroma and difficult to age, has edible, health care and medicinal comprehensive values and can be directly eaten and eaten after being processed by people according to the characteristics of rice.

Owner:李时令

Bending die of double metal bracket stamping part

The invention discloses a bending die of a double metal bracket stamping part, which comprises a lower mold plate and is characterized in that: a boss is formed on one side of the upper surface of the lower mold plate; the inner side of the boss is a slope surface; a punch head is arranged above the lower mold plate; and one side of the lower surface of the punch head is provided with a slope surface which is matched with the boss of the lower mold plate. The bending die of the double metal bracket stamping part has the advantages that: the structure is simple, and the bend stamping part has light weight, high rigidity, high strength, relatively high surface quality and a smooth and attractive appearance; and dimension precision is relatively high, and the identical modules have a uniform and homogeneous dimension and relatively high exchangeability, and the general assembling and can meet the general assembling and using requirements without further machining.

Owner:ANHUI HUIJING MOLD R & D TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com