Making process of horizontal polyethylene storage tank with integral support

A manufacturing process, polyethylene technology, applied in applications, coatings, household appliances, etc., can solve the problems that affect the chemical resistance and service life of the storage tank, the overall structure of the storage tank is discontinuous, and the cement support is not easy to move, etc., to achieve Light weight, smooth and beautiful appearance, strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

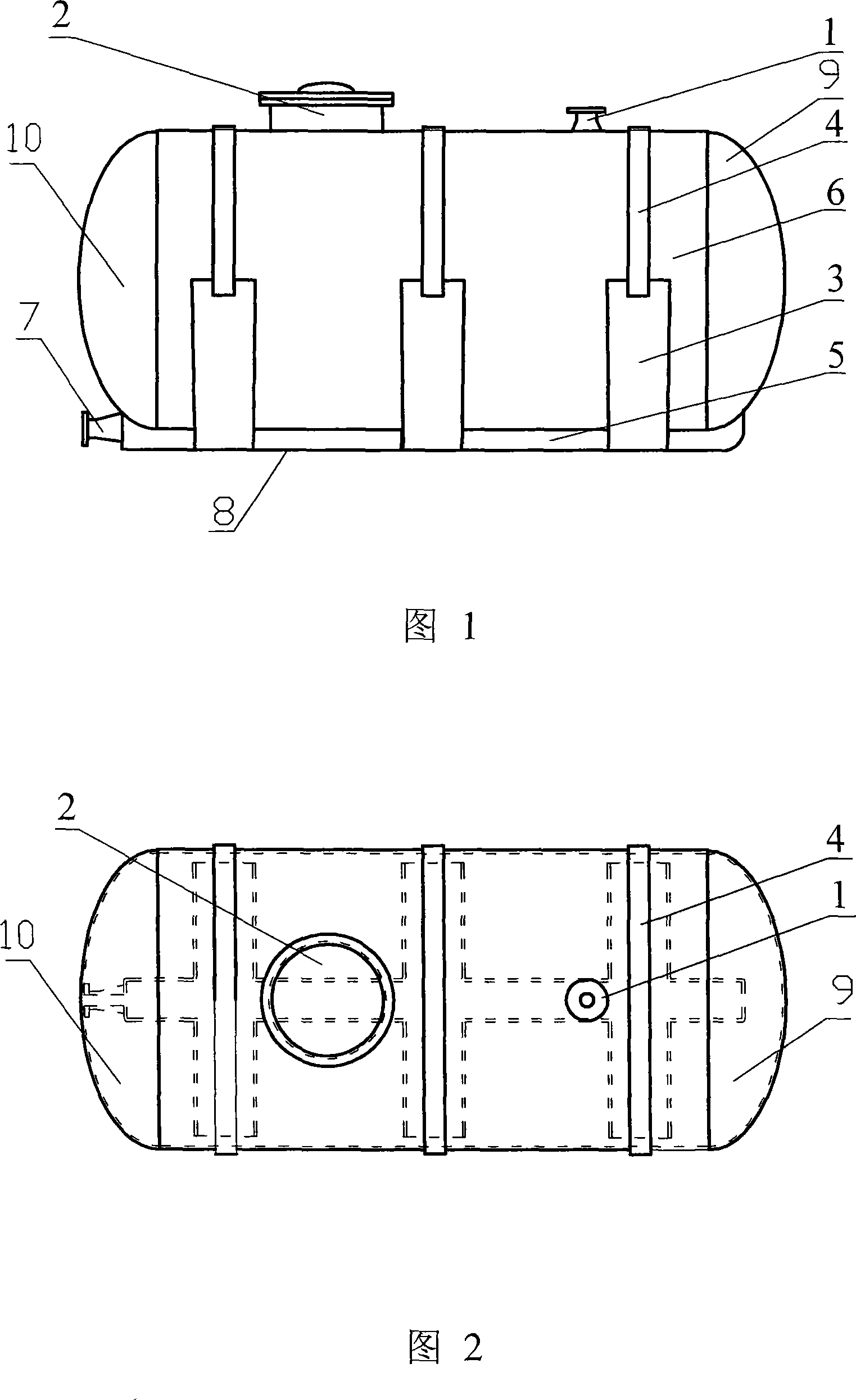

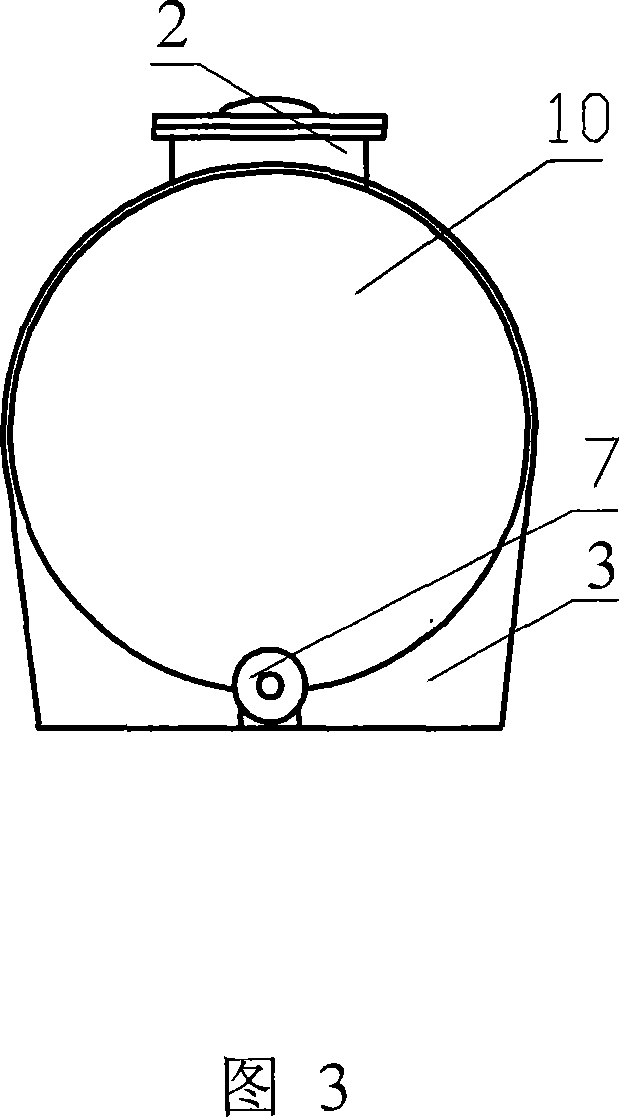

[0017] As shown in the figure: the process method of the horizontal polyethylene integrated support storage tank includes the following steps:

[0018] 1. Raw material preparation: The required raw materials linear low-density polyethylene (LLDPE) and high-density polyethylene (HDPE) are tested according to production standards to check the quality, and then sieved to control the fineness of raw materials and prevent the impact of raw materials from agglomeration The quality of rotomolding and the anti-chemical material are then mixed in parts by weight of 100:10-20.

[0019] 2. Production of steel lined tank body:

[0020] a. Select the steel plate profiles that meet the required specifications and externally processed components such as the head 9 and the back cover 10, and roll the tank body of the specified size with a plate rolling machine according to the requirements of the production design drawings.

[0021] b. According to the requirements of JB / T 4735-1997 "Steel W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com