Patents

Literature

2571results about How to "Good anti-aging performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

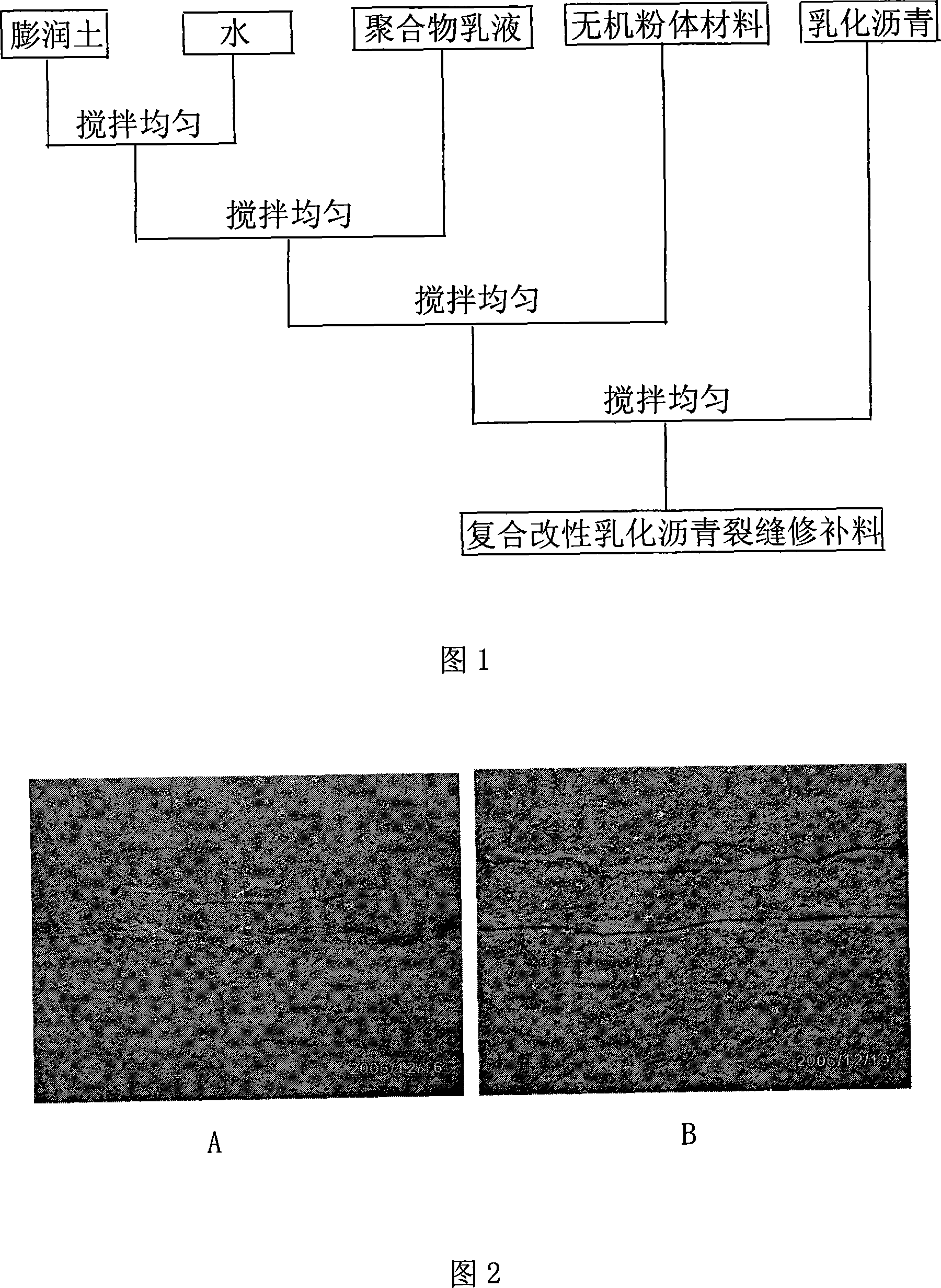

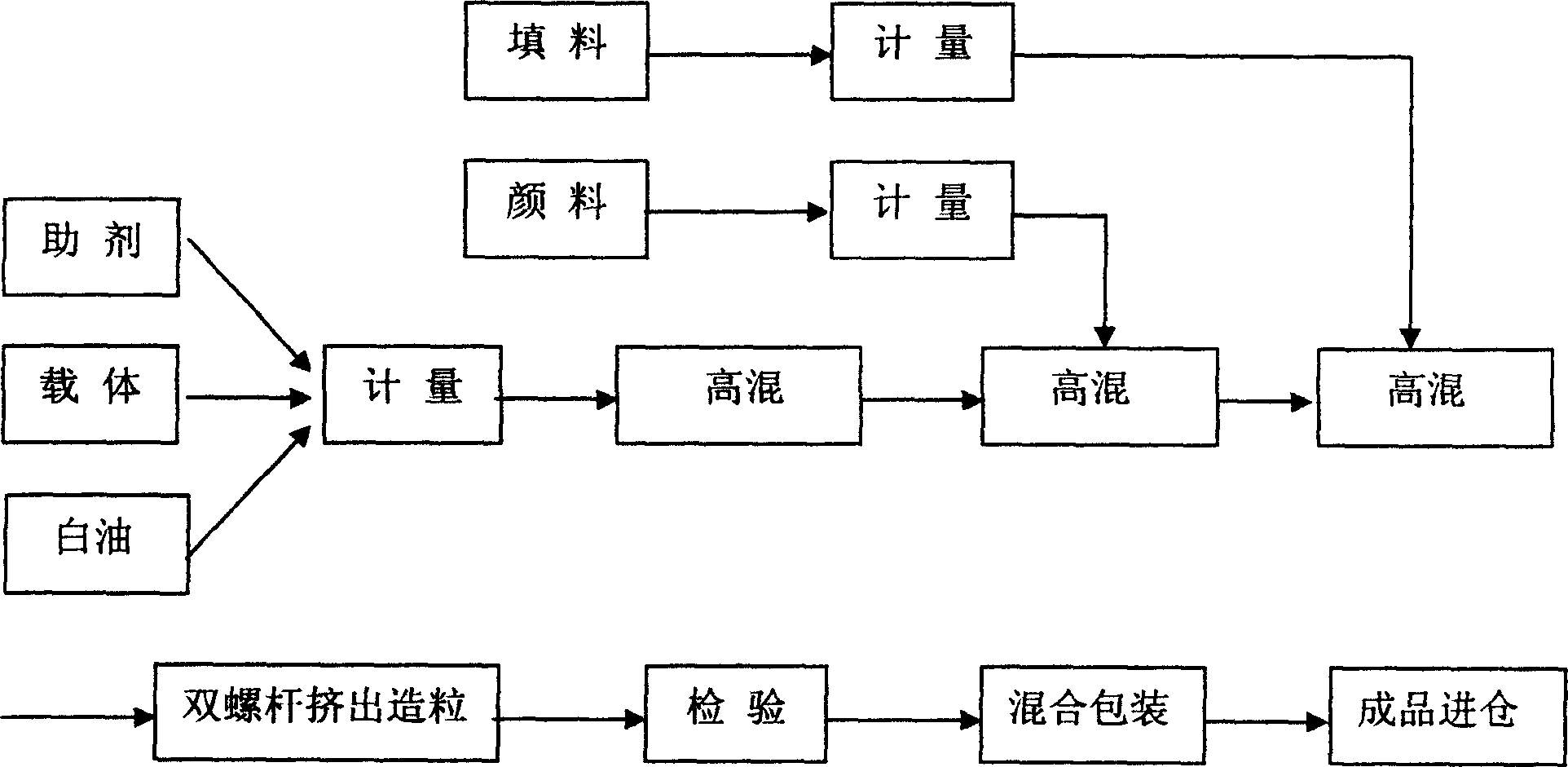

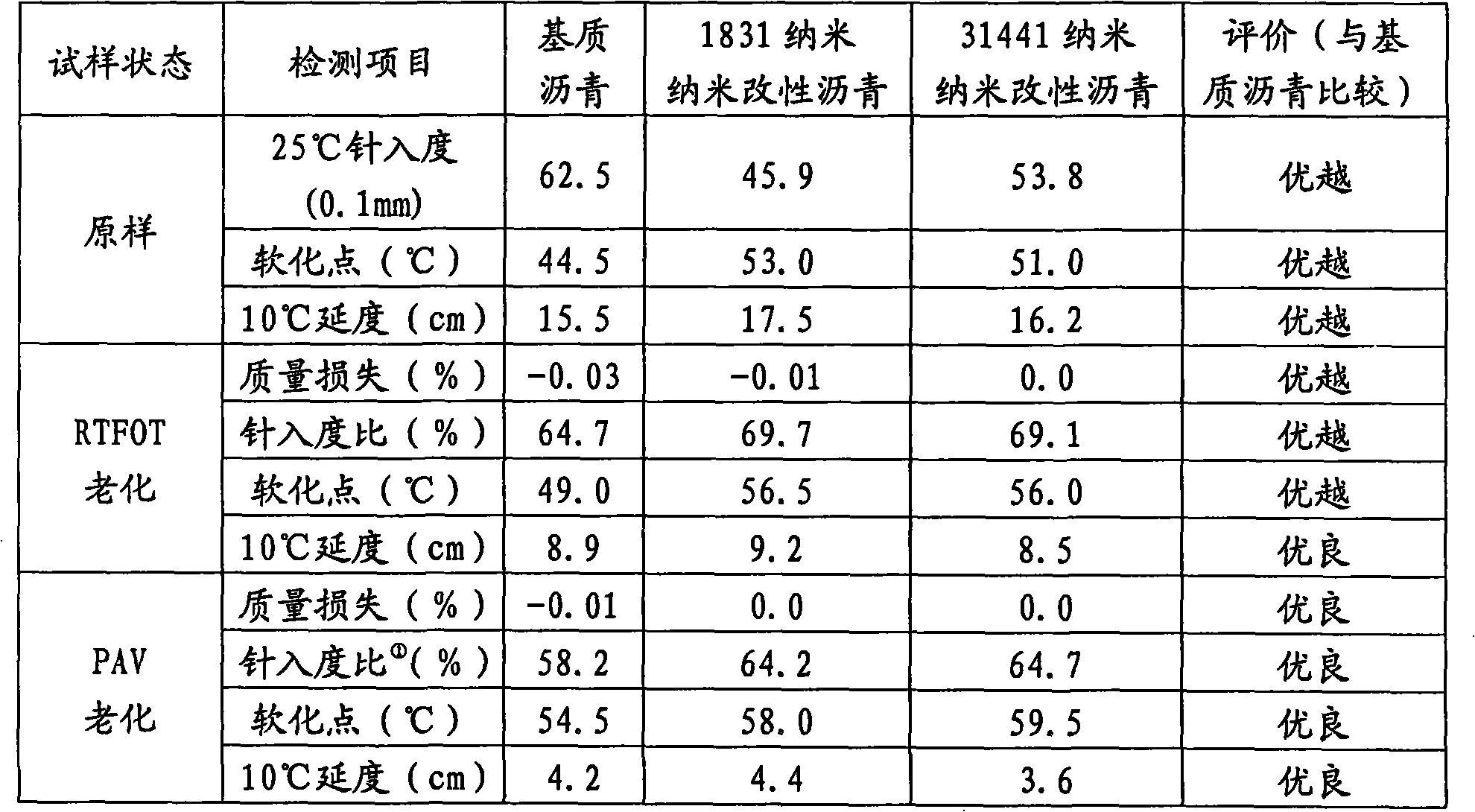

Environment-friendly type split mending material for polymer emulsion inorganic powder and nano material composite modified emulsified asphalt

InactiveCN101081933AImprove performanceImprove wear resistanceOther chemical processesSolid waste managementHigh wear resistanceInorganic materials

The present invention is one kind of environment friendly composite emulsified asphalt material for grouting and repairing cracks in highway and building. The composite emulsified asphalt material consists of emulsified asphalt40-90 weight portions, powdered inorganic material 50-90 weight portions, nanometer material 5-10 weight portions, polymer emulsion 20-40 weight portions and water 30-80 weight portions mainly. The composite emulsified asphalt material has nanometer particle component with unique surface effect, small size effect and tunnel effect, polymer emulsion component resulting in high interface combining force and high antiaging performance, and inorganic material powder component resulting in high wear resistance, high strength, etc., so that it has high comprehensive performance, good crack repairing effect and low cost.

Owner:HUNAN UNIV

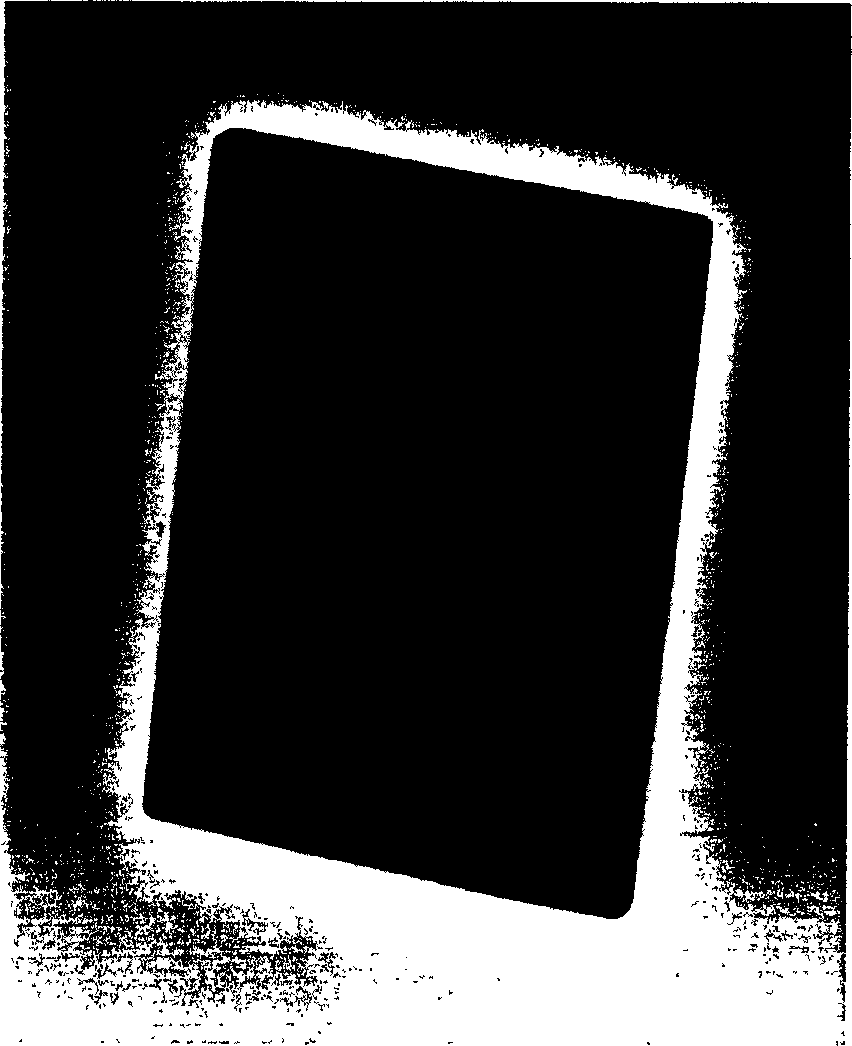

Natural-like multifunctional color batch and use thereof

The present invention features that the color concentrate is prepared with main carrier resin A, matched carrier resin X, compatizer, pigment, inorganic stuffing, antistatic agent, light stabilizer, antioxidant and pigment lubricating dispersant. The main carrier resin an and the matched carrier resin X, which has obviously different compatibility and smelting behavior from that of the basic resin B in the product, may constitute alloy carrier resin. The said materials may be altered to result in various decoration effects.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

Nano composite photocatalytic coating

InactiveUS20070000407A1Good anti-aging performanceNot perishableBiocideSolid waste managementAir cycleFungal microorganisms

A photocatalytic coating composition and method of coating articles, the composition containing solvents for rapid evaporation at room temperature, polyalkylphenylsiloxane, xylene, nano densified hydrophilic fumed silica, nanostructured composite photocatalyst powder and nano inorganic anti-bacteria powder. The coating may be applied by conventional coating methods to organic or inorganic structured surfaces where photocatalytic activity is desired, such as in a forced air-circulating environment. Once applied, the coating quickly dries to leave an adherent, flexible, durable, and long-lasting photocatalytic coating having a large surface area and exhibiting high surface activity against pathogens and pollutants such as bacteria, viruses, mold, fungi, and volatile organic compounds.

Owner:YORK INT CORP

Edible starch-based food packaging film and preparation method thereof

ActiveCN101899173AAvoid environmental pollutionAbundant sources of raw materialsFlexible coversWrappersFood packagingPlasticizer

The invention relates to an edible starch-based food packaging film and a preparation method thereof. The edible starch-based packaging film with high mechanical strength, barrier property, ageing resistance and heat sealability is prepared from a main film-forming raw material stabilized crosslinking compound modified starch, and auxiliary materials such as food grade plasticizers, lubricants, reinforcers, stabilizers and the like through high speed stirring and mixing, twin-screw extrusion granulation and single-screw extrusion blow molding. The preparation method has the characteristics of low energy consumption, high production efficiency and suitability for continuous industrialized production. The film has the advantages of edibility, full-degradable property, wide application for inner packaging of foods and no environmental pollution caused by non-degradable food packages.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

Conductive adhesive added with short rod type nano silver powder and preparation method thereof

ActiveCN101215450AImprove conductivityImprove mechanical propertiesNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPlastic materials

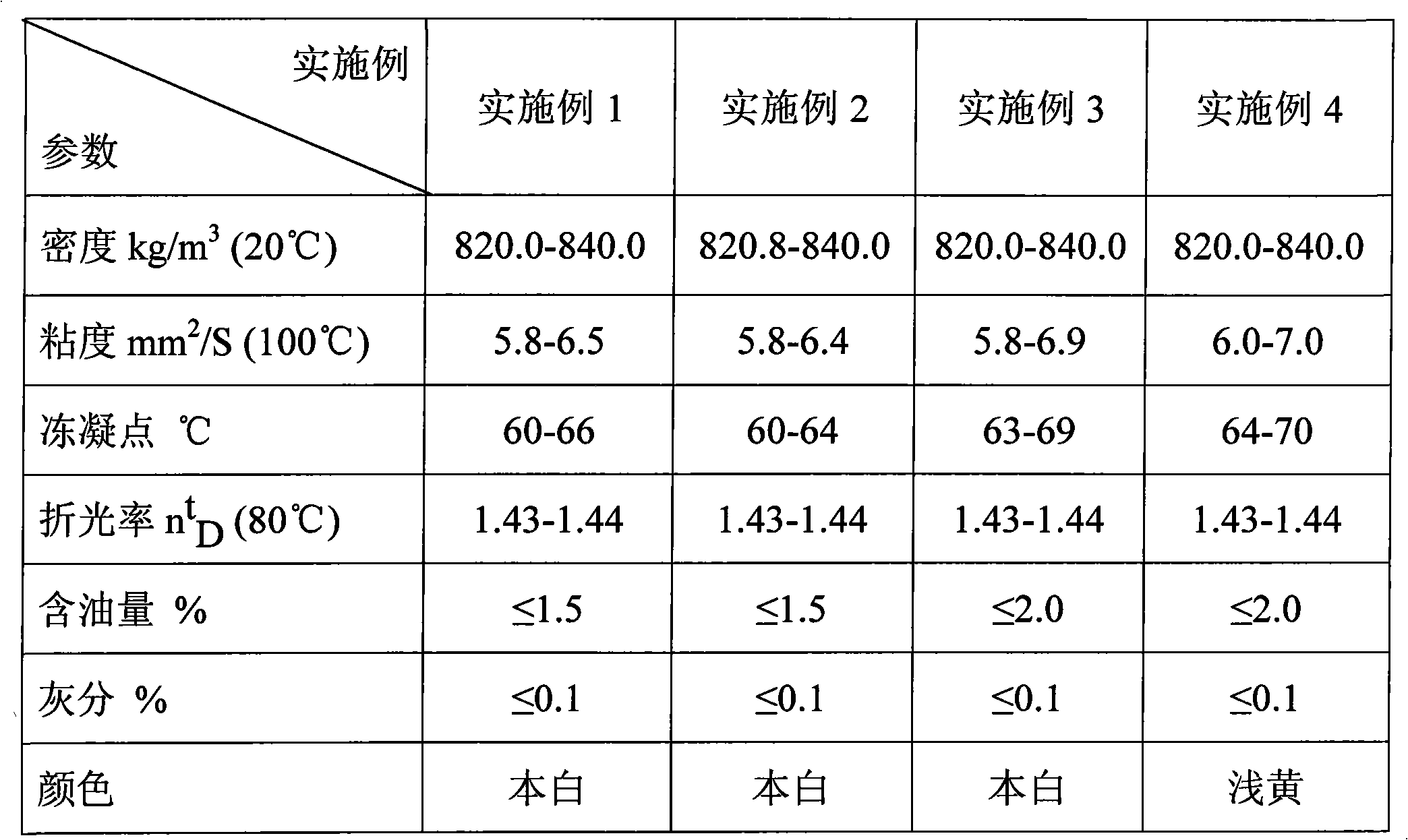

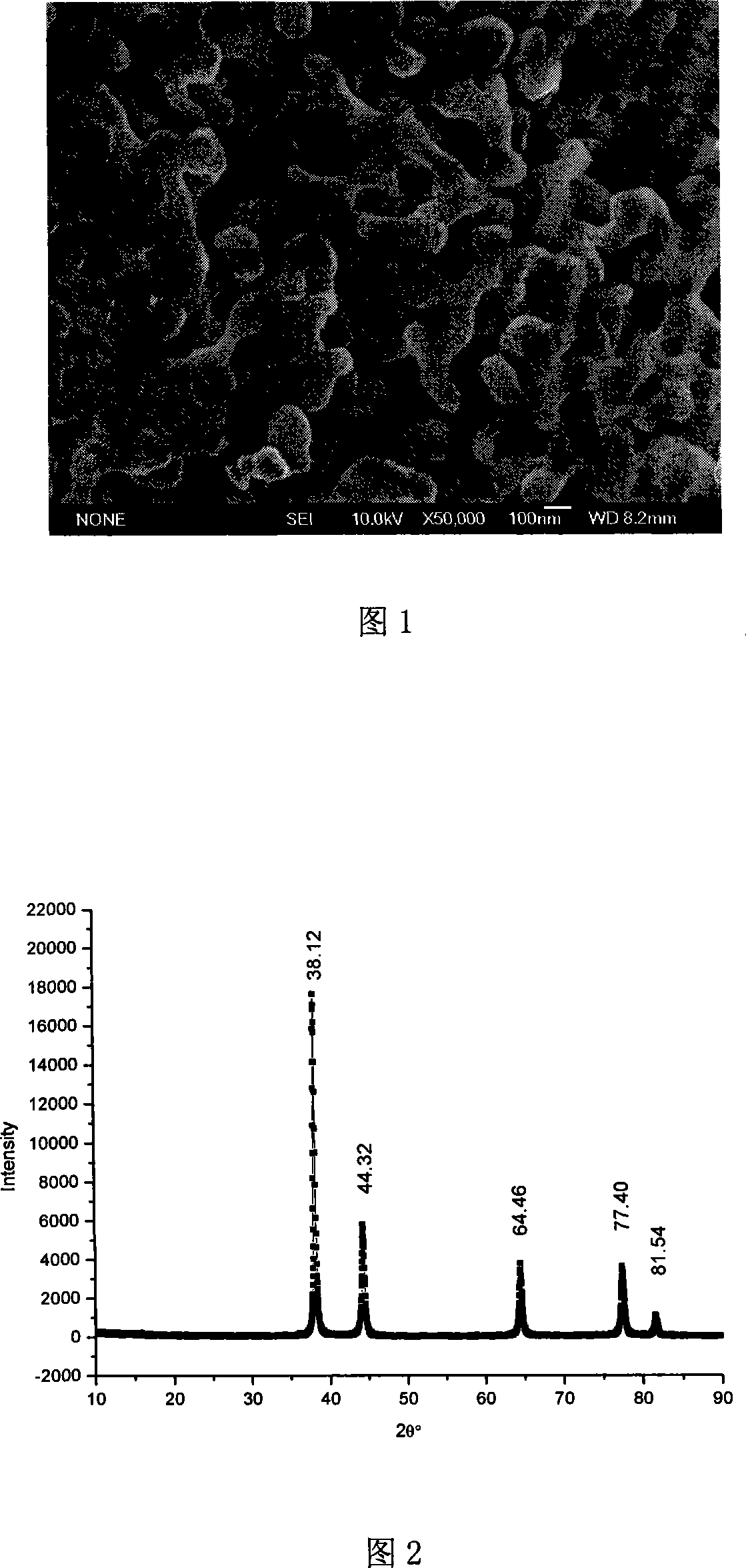

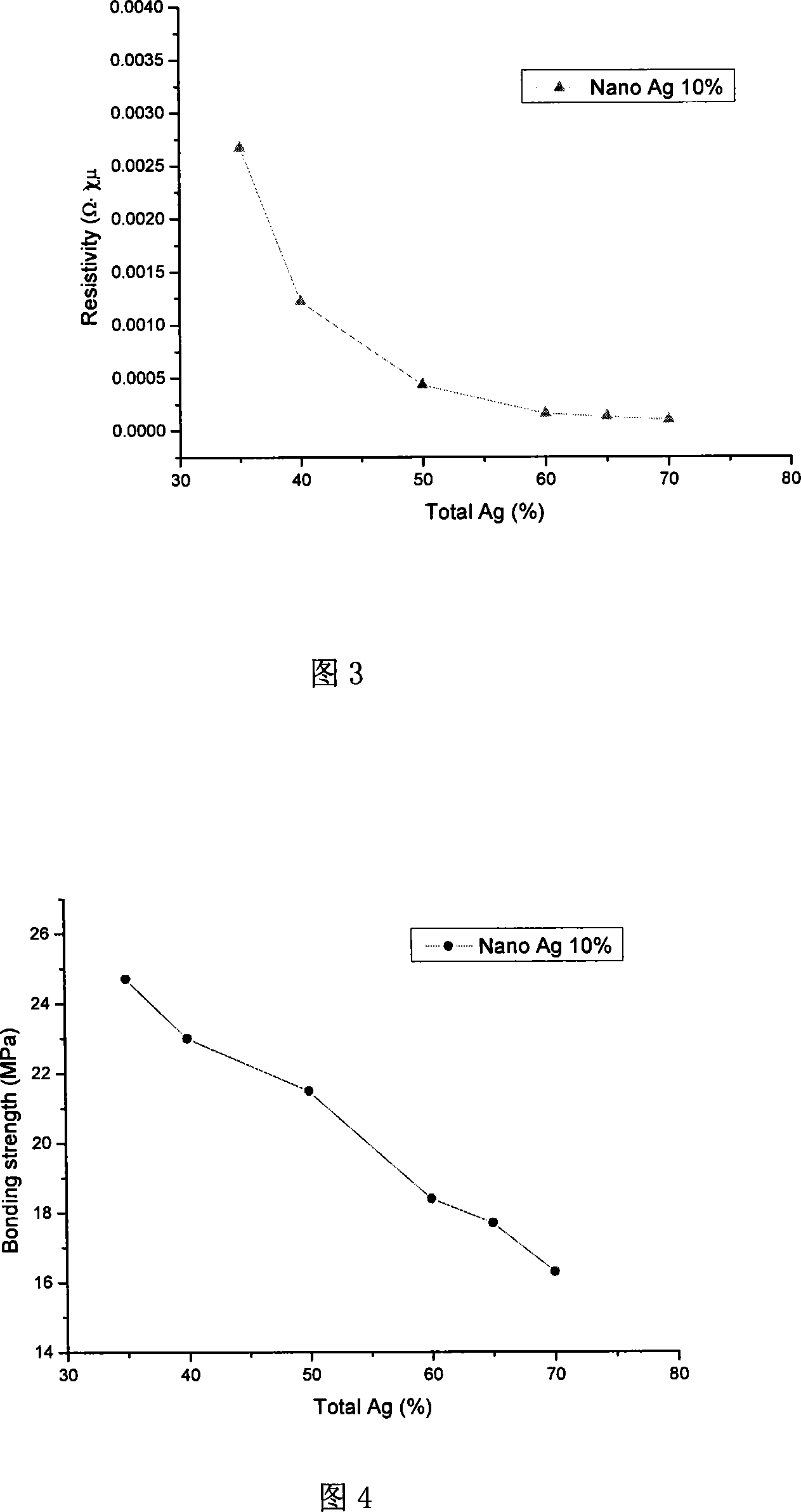

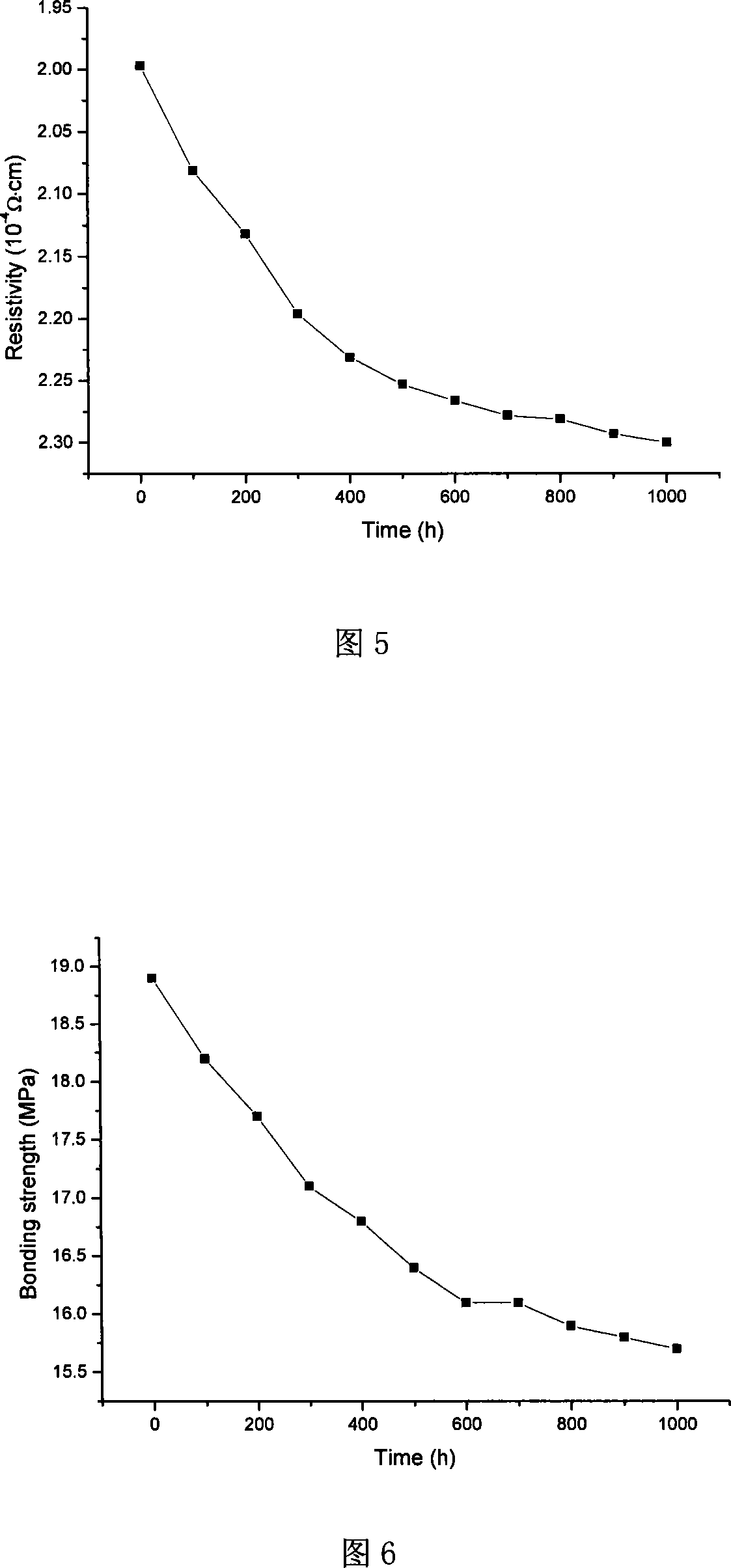

The invention relates to conductive adhesive which is added with short rod shaped silver powder and a process for preparation, which belong to the technical field of preparing technology for plastic material which is used to pack micro-electronics. The invention is characterized in that mixing silver powder of the short rod shaped silver powder and micrometer silver powder are taken as conductive filler and added into epoxide resin basal bodies to prepare utility conductive adhesive with high performance. The components and the percentage composition of the conductive adhesive are that polymeric matrix epoxide resin E-51 is 24-40%, conductive silver powder particles are 50-70%, wherein the short rod shaped silver powder is 10% and the micrometer silver powder is 40-60%, toughening agent dibutylphthalate is 2.4-4.0%, and curing agent triethanolamine is 3.6-6.0%. The preparation of the micrometer silver powder adopts silver nitrate, polyvinylpyrrolidone surface active agent and hydrazine hydrate reducing agent 5% as raw materials and prepared through liquid phase reducing reaction. The usage mass ratio of the silver nitrate and the polyvinylpyrrolidone is 1:1. Since the conductive adhesive which is prepared by the invention is added with the micrometer silver powder, thereby the electrical conductivity and the mechanical properties are increased, and the invention has better antiaging performance.

Owner:SHANGHAI UNIV

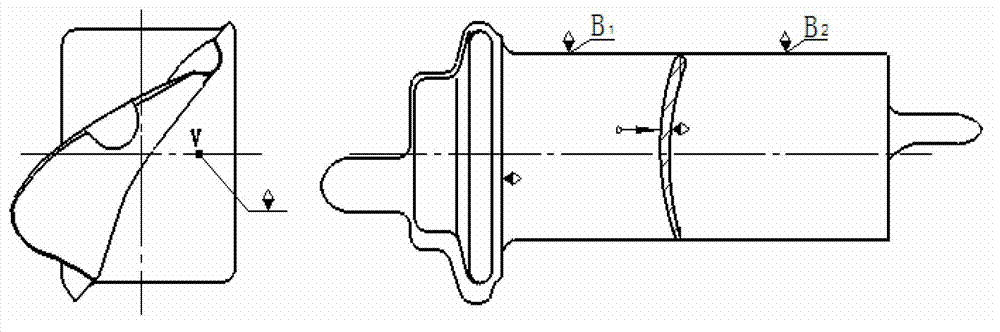

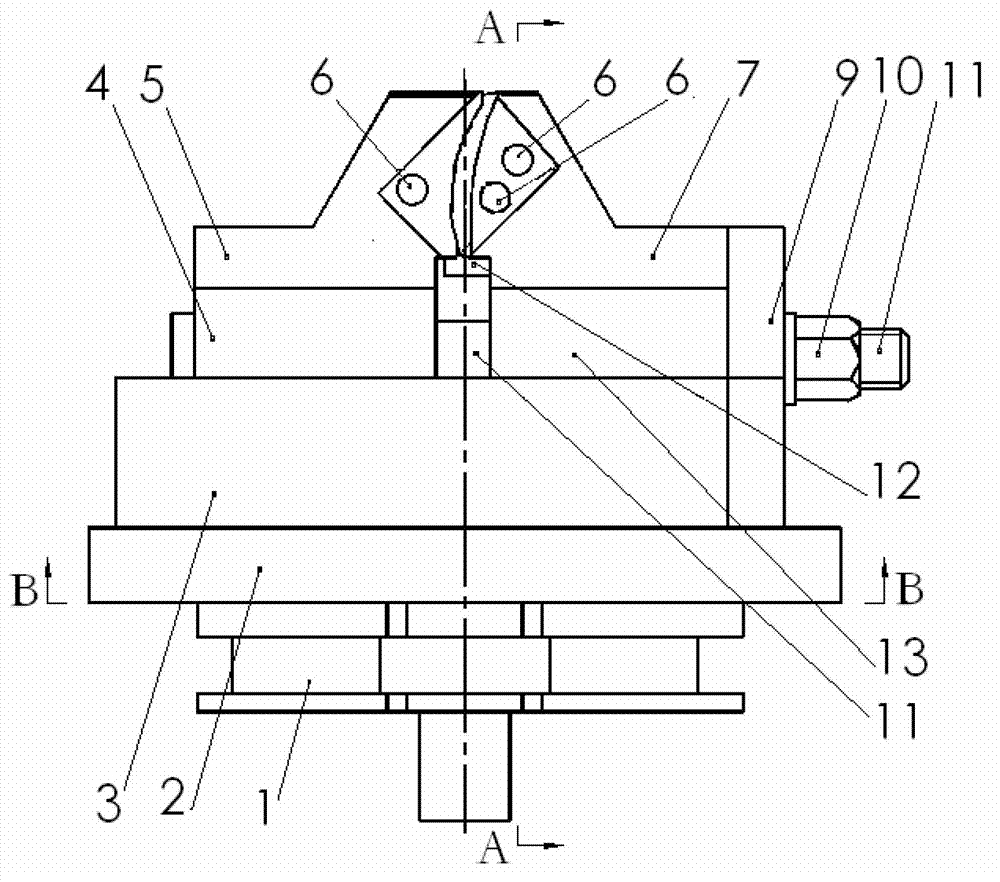

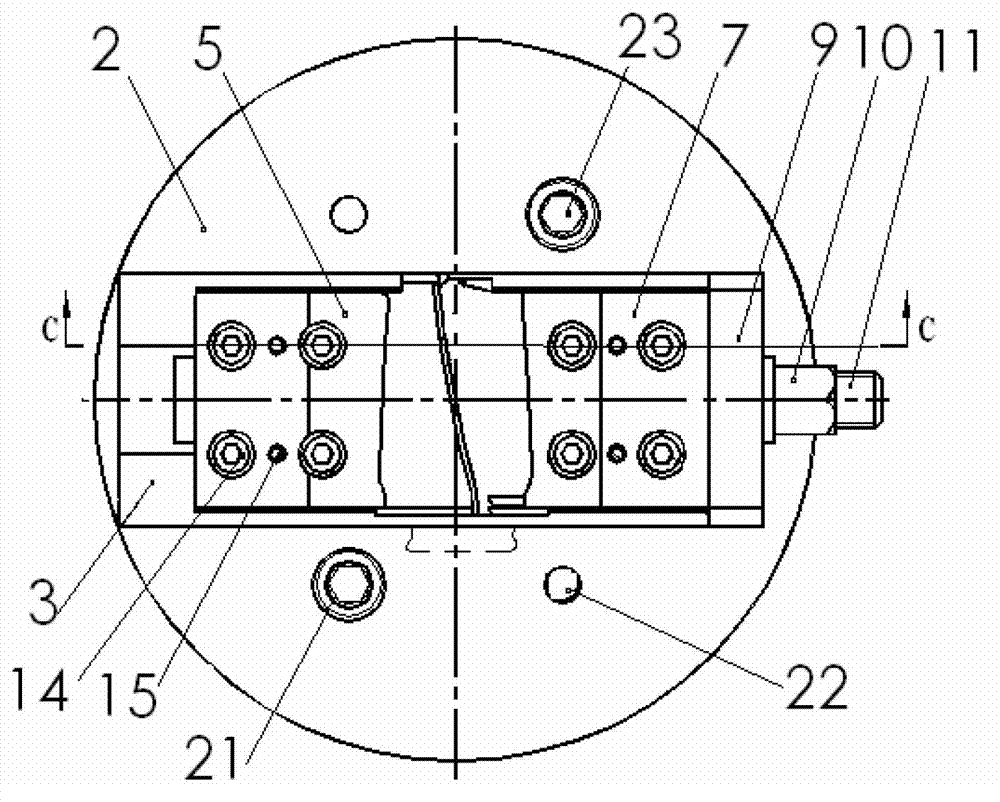

Method and clamp for moulding surface positioning clamping of finish forge blade

ActiveCN102773733AImprove rigidityImprove quality and efficiencyPositioning apparatusMetal-working holdersAdhesiveEngineering

The invention relates to a method and a clamp for moulding surface positioning clamping of a finish forge blade. According to the method, a vane is subjected to positioning clamping through a basin mounding surface of the blade, an inner side moulding surface of a blade root marginal plate, and a V point on the inner side mounting surface of the blade root marginal plate, by the positioning of an air inlet edge, and the clamping of a back mounding surface of the blade, as well as by using a high-accuracy positioning adhesive, and an adhesive coating method, and through a positioning block of the basin moulding surface of the blade and a clamping block of the back moulding surface of the blade. According to the method and the clamp, a satisfying contact area can be obtained by adoption of the high-accuracy adhesive, and the positioning rigidity of the blade is enhanced by adoption of the basin moulding surface of the blade, the inner side moulding surface of the blade root marginal plate and the V point on the inner side moulding surface of the blade root marginal plate for the positioning. According to the method and the device, the problems that the accurate positioning is difficult to realize and the moulding surface of the blade deforms or is damaged because the blade is thin, the blade body is small and the moulding surface is complex are solved. By the method and the device, the positioning accuracy of the mechanical processing of the blade is improved, and the technological process is optimized, so that the processing quality and the production efficiency of the blade are improved, the process is simple, the number of fixtures is reduced, the processing cycle is shortened, and the production cost is reduced.

Owner:AECC AVIATION POWER CO LTD

Nanometer conductive silver paste and preparing method thereof

InactiveCN104240793AGood silver powder solubilityModerate boiling pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePlasticizer

The invention relates to a nanometer conductive silver paste and a preparing method thereof. The nanometer conductive silver paste is characterized in that mass percentage content of the components are as follows: 20-90% of a silver powder, 0.01-5% of a high-molecular resin, 0.01-5% of an organic silicone oil, 0.01-10% of a thickening agent 1, 0.01-5% of a thickening agent 2, 0.01-5% of a plasticizer, 0.5-1% of a dispersant, 0.5-1% of a leveling agent, 5-20% of a solvent 1, and 5-20% of a solvent 2. The nanometer conductive silver paste of the invention has a remarkable low-temperature sintering property and saves energy. A formed circuit has advantages of high conductivity, high adhesiveness and high hardness. A selected Teslin substrate is degradable and environment-friendly. The nanometer conductive silver paste has wide application prospect in paste application fields of RFID electronic label, LED circuit board, touch screen circuit, etc.

Owner:NANO TOP ELECTRONICS TECH

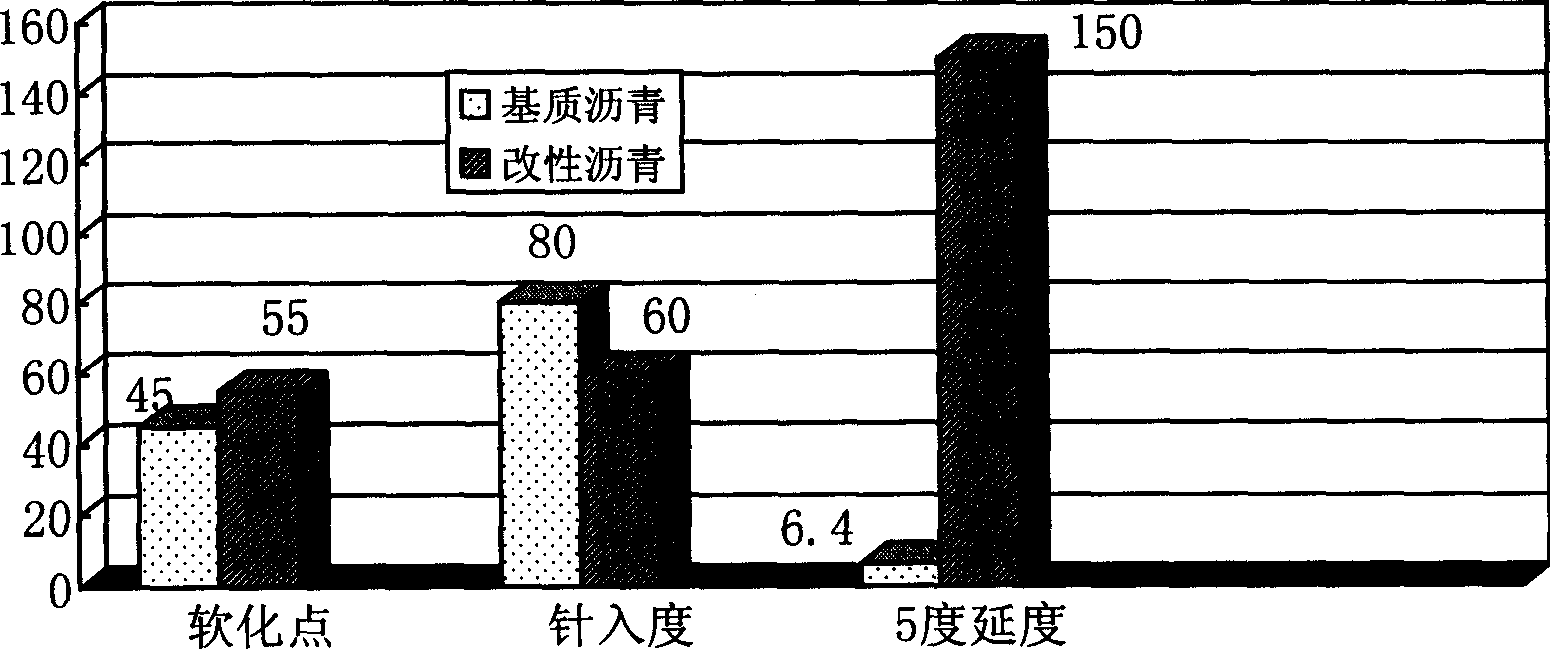

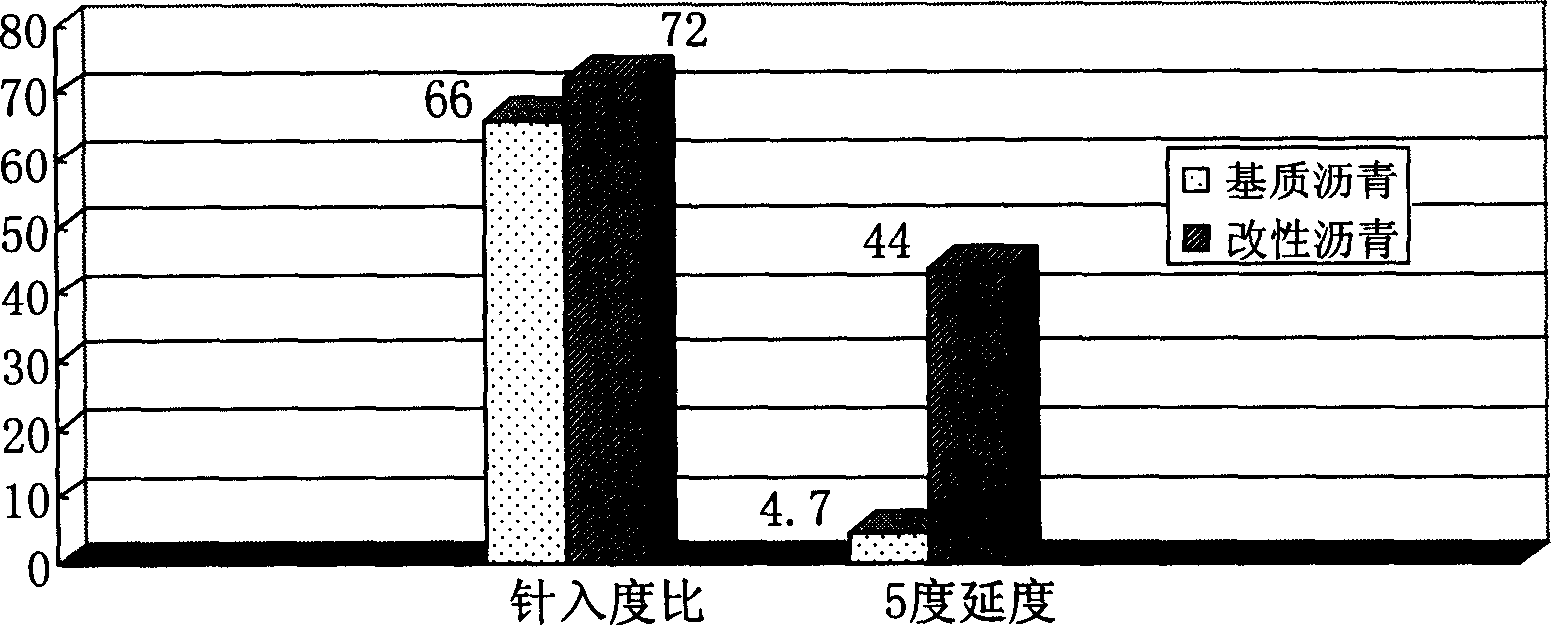

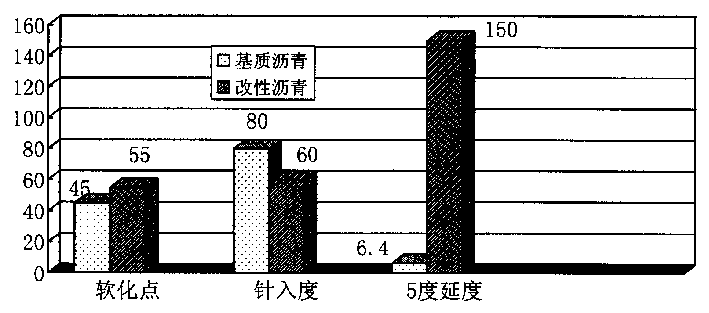

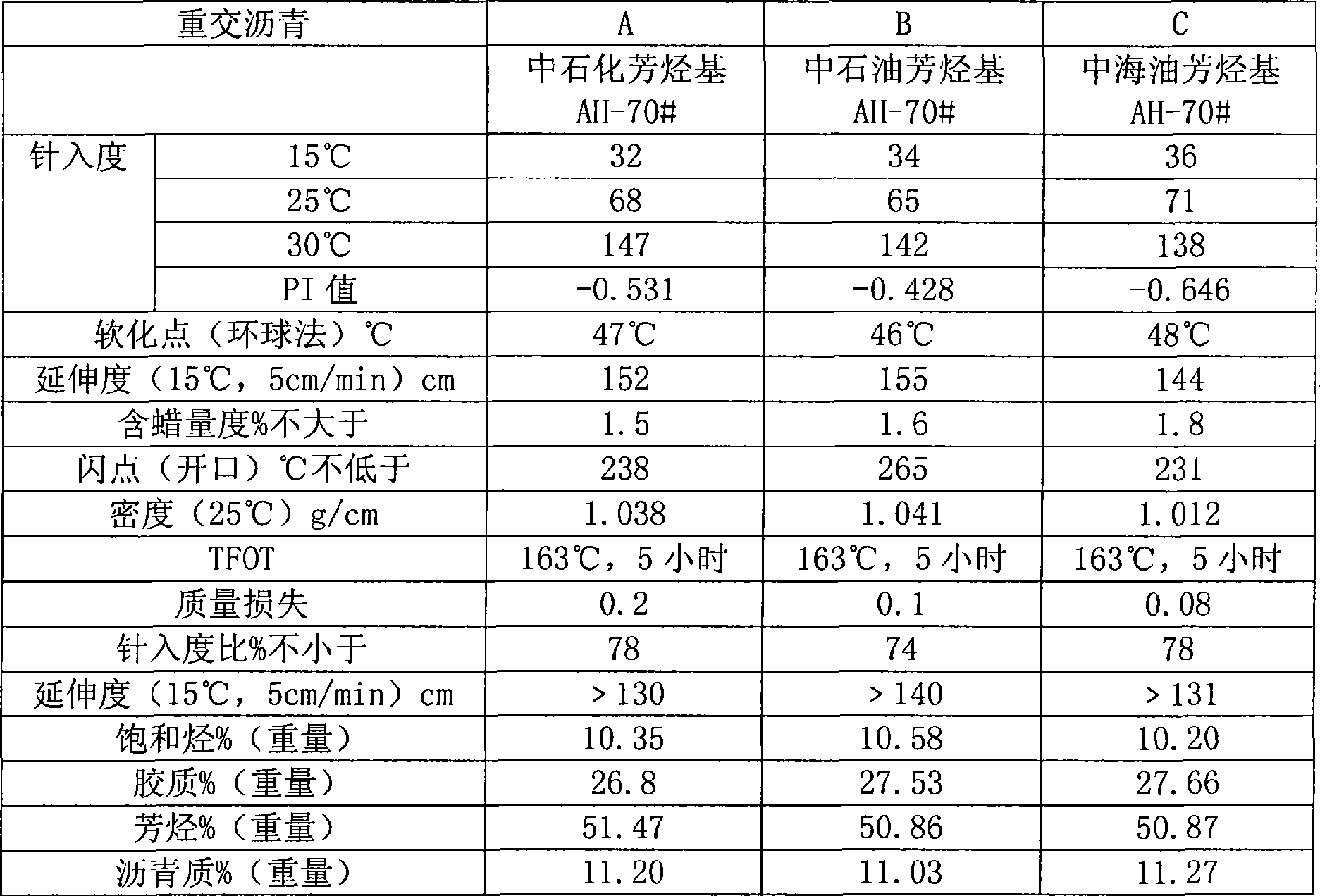

Bentonite composition modified asphalt and its preparing method

InactiveCN1587320AImprove high and low temperature performanceImprove road performanceBuilding insulationsWaxButadiene-styrene rubber

The bentonite composition modified asphalt consists of asphalt in 94-98 portions, bentonite in 1-3 portions and powdered styrene-butadiene rubber in 1-3 portions. The bentonite is at least one of calcium base bentonite, sodium bentonite and organic bentonite. The preparation process of the bentonite composition modified asphalt includes the following steps: eliminating sand in bentonite, drying, grinding and 325-mesh sieving bentonite; adding bentonite into the asphalt matrix; and adding powdered styrene-butadiene rubber while slowly stirring to mix homogeneously. The modified asphalt has the features of high temperature stability, low temperature cracking resistance, excellent anti-ageing performance, low cost, etc.

Owner:NORTHWEST NORMAL UNIVERSITY

Enzymolysis xylogen or its derivative modified asphalt composite material, and preparation method thereof

The present invention provides an enzymolysis lignin or enzymolysis derivant modified asphalt composite material and a preparation method. The raw materials include the enzymolysis lignin or the enzymolysis lignin derivant, the asphalt and other modification assistant agents. The preparation steps: the enzymolysis lignin or the enzymolysis lignin derivant, other modification assistant agents and filling agent are mixed in advance to the melted asphalt substrate to be uniformly mixed, and then the mixture is displaced for solidification. The present invention makes full use of the renewable living resource, and not only resolves the problem of the present polymer modified asphalt that depends on the synthesis of the petrochemical raw materials, but also can reduced the use cost of the polymer modified asphalt; appropriate enzymolysis additive can be selected according to different requirements of the modified asphalt product to substitute partial petrochemical raw materials, thus improving the anti-aging performance of the polymer asphalt product; moreover, the craftwork is simple and is easy to implement, thereby can reduce the production cost and improve the competition strength of the product.

Owner:FUZHOU UNIVERSITY

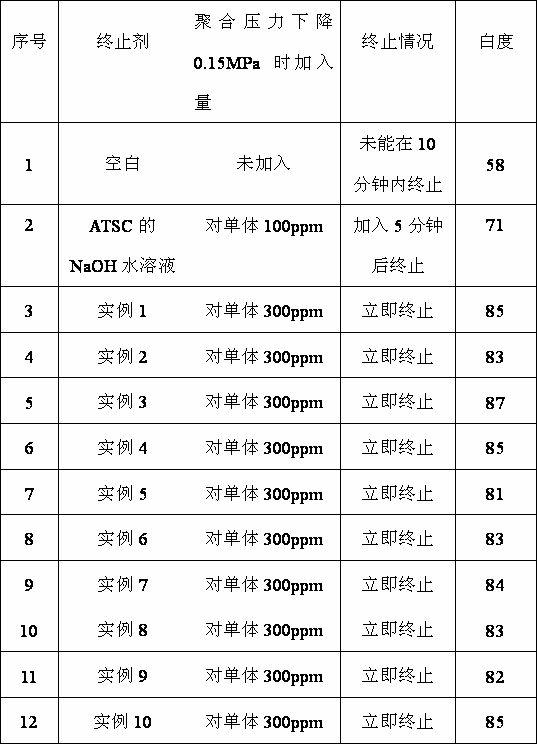

Water-emulsion-type high-efficiency terminator for polyvinyl chloride and preparation method thereof

InactiveCN102181000AStrong termination of polymerizationImprove thermal stabilityPolymer sciencePlasticizer

The invention relates to a water-emulsion-type high-efficiency terminator for polyvinyl chloride, which is prepared from the following raw materials in parts by mass: 10-16 parts of organic solvent or mixed solvent with a termination function, 15-22 parts of high-efficiency antiaging agent, 8-12 parts of plasticizer, 2-4 parts of thermal stabilizer, 2-5 parts of emulsifier and 0.2-1 part of emulsion stabilizer. The preparation method comprises the following steps: (1) organic phase dissolving and mixing; (2) water phase dissolving and mixing; (3) emulsifying by stirring; and (4) high-shear emulsifying. The terminator provided by the invention has a strong function on terminating polymerization, can enhance the thermal stability of resins, and can improve the whiteness and aging resistance of resins. Especially, the terminator provided by the invention is an environment-friendly terminator which is safe and convenient during production operation, and greatly enhances the use safety of the prepared polyvinyl chloride product. The terminator provided by the invention can be used in a food packaging material.

Owner:道尔达(西安)新材料有限公司

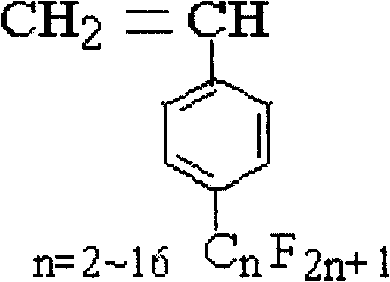

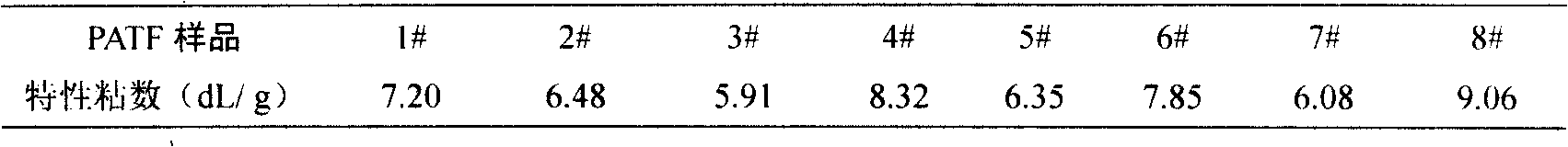

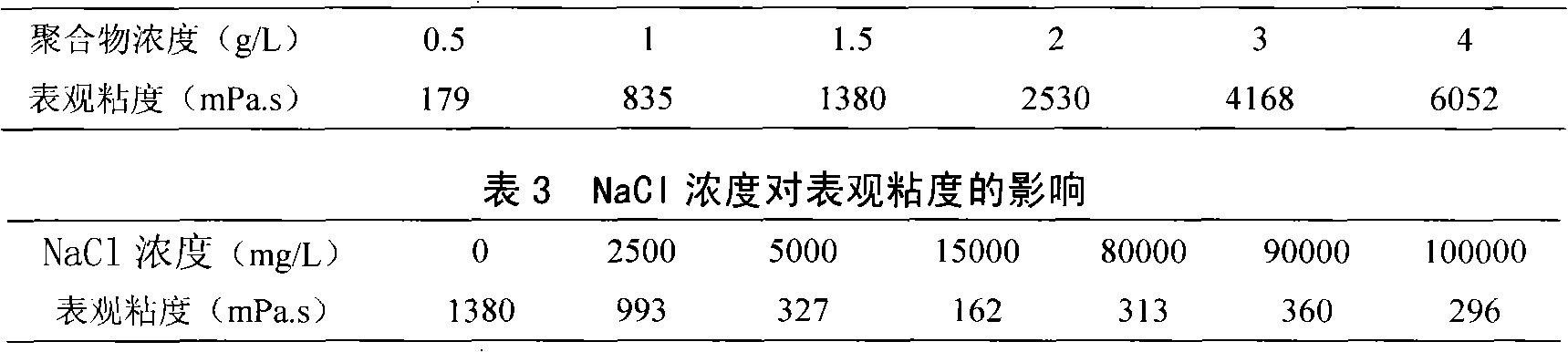

Temperature-resistant water-soluble copolymer, preparation and use thereof

InactiveCN101274974AImprove solution performanceImprove rigidityDrilling compositionSolubilityPersulfate

The invention discloses a copolymer with temperature resistance and water solubility and the preparation method and application thereof, which is characterized in that: 20 portions of acrylic amide, 0.1 to 10 portions of anion monomer or / and cation monomer, 0.05 to 3 portions of fluorine-containing styrene or / and perfluoroalkyl styrene hydrophobic monomer, 0.5 to 60 portions of surface active agent and 50 to 700 portions of deionized water are put into a three-necked reaction bulb; after the solution pH is regulated to be equal to 2.5 to 9 and N2 is connected for 30 minutes, 0.001 to 0.2 portion of an evocating agent of persulfate is added under temperature of 20 to 70 DEG C, reacting for 6 to 36 hours, and PATF is prepared. Then water is used for diluting so as to prepare PATF concentrated solution, thus obtaining a copolymer that has medium molecular weight and water solubility, is high-temperature resistant, has an ability of molecular association and can be used in high temperature and high salinity reservoir. The copolymer is prepared into aqueous solution with a mass concentration of 0.3 to 3g / L and a surface-active-agent concentration of 0.01 to 4mmol / L, which is put in a blending container with a dasher and is stirred even at room temperature to prepare a polymer oil-displacing agent which is high-temperature resistant, high tackifying and anti-sharing and has excellent aging resistance under high salinity and the temperature of 110 DEG C. The prepared oil-displacing polymer has excellent solution properties owing to the supermolecular structure formed by the association between molecules of fluorine-containing cinnamene or / and alkylbenzene hydrophobic groups, thus having favorable application prospects in high temperature and high salinity reservoir exploitation.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

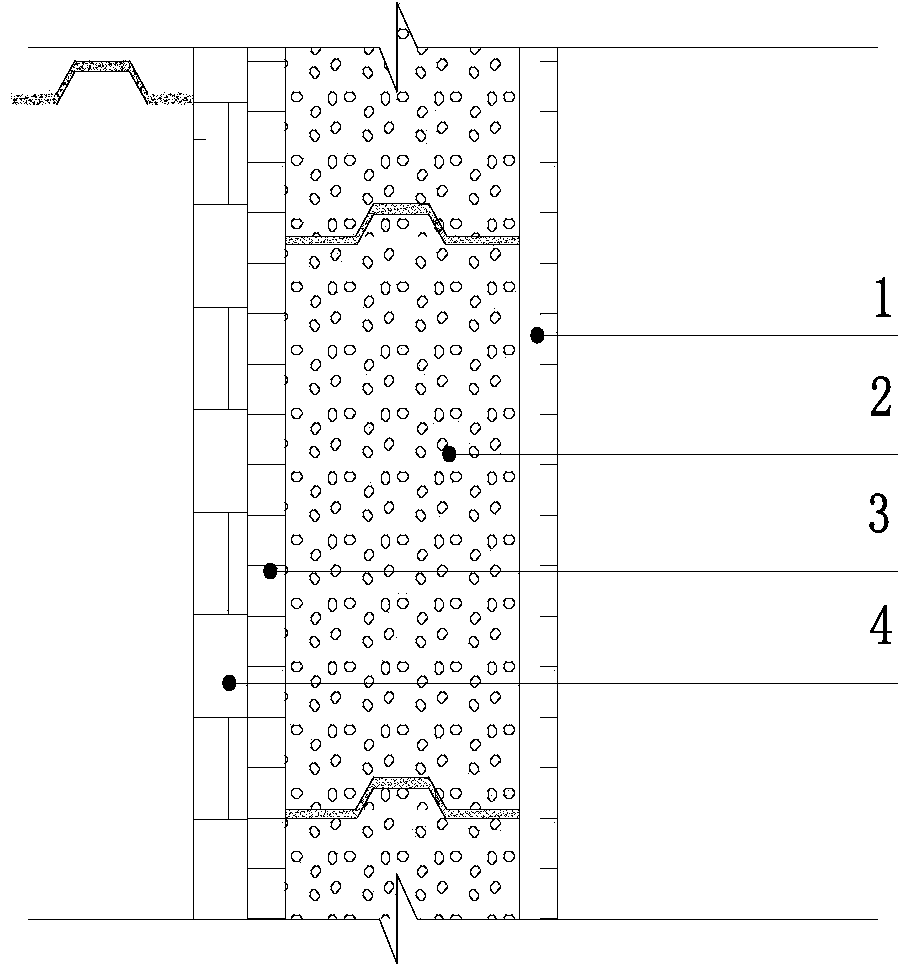

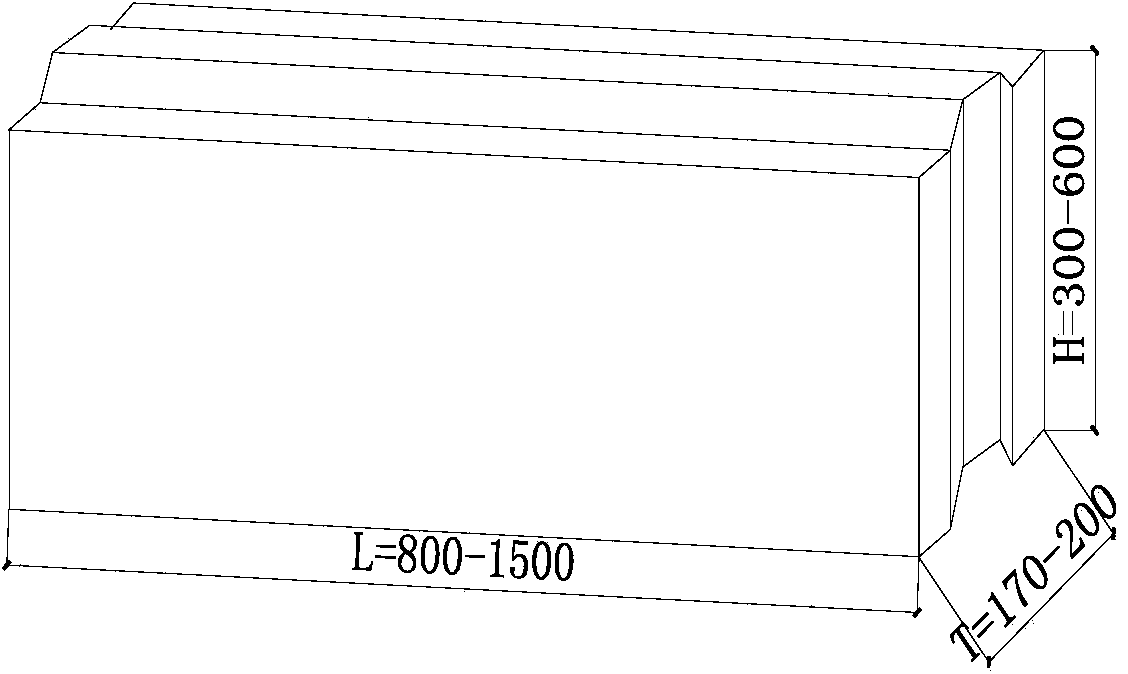

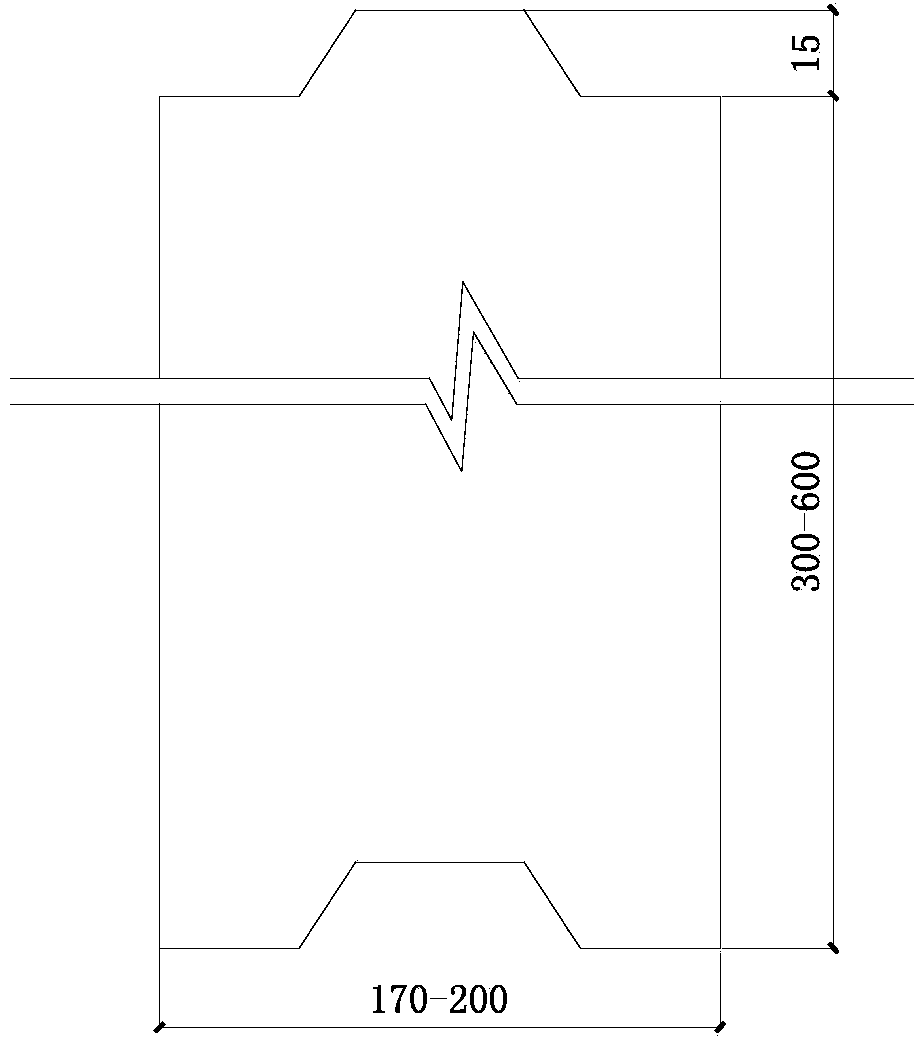

Outer wall structure and construction and installation method

InactiveCN104018598AComplete and reliable quality assuranceSolve common quality problemsCovering/liningsSolid waste managementWater leakageArchitectural engineering

The invention relates to a building outer wall structure, in particular to an outer wall structure and a construction and installation method. The outer wall structure is sequentially provided with an inner decorative layer, a structural layer, a waterproof layer and an outer decorative layer from inside to outside. The construction and installation method of the outer wall structure includes the steps that wall battens and doors and windows are installed; the waterproof layer is constructed; construction and installation method of the outer wall structure are finished after the inner wall face and the outer wall face are decorated. The common quality problems such as empty drums, deformation, cracks and water seepage caused by thermal insulation construction on the outer wall are solved by using a self-heat-preservation system for the outer wall, so that an integral and reliable quality guarantee is provided for an outer wall engineering system; all the adopted materials are common combinations with light inorganic materials as carriers and are good in cosolvency, usability, cohesiveness, ageing resistance and the like; the construction procedure of outer wall engineering is simplified, construction period is shortened, unified management on construction sites is facilitated, management cost is lowered, and project management efficiency is improved; the self-heat-preservation function of the wall is achieved, and the problem that the outer wall is prone to water seepage or water leakage is solved.

Owner:江西昌南建设集团有限公司

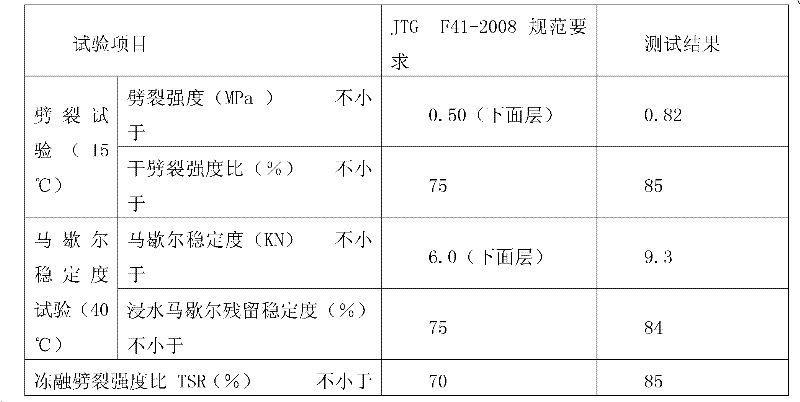

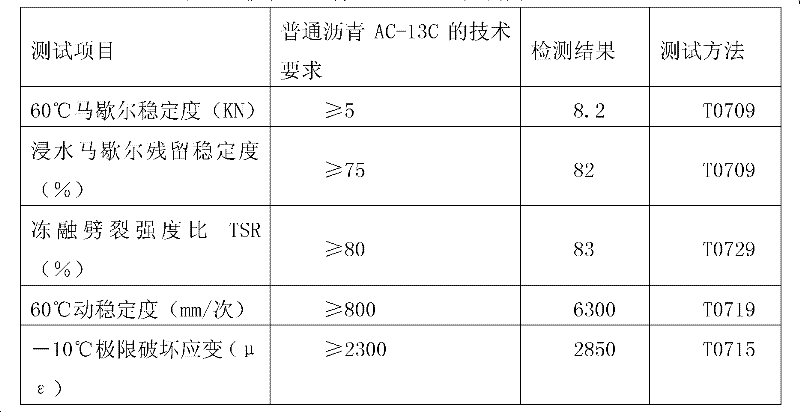

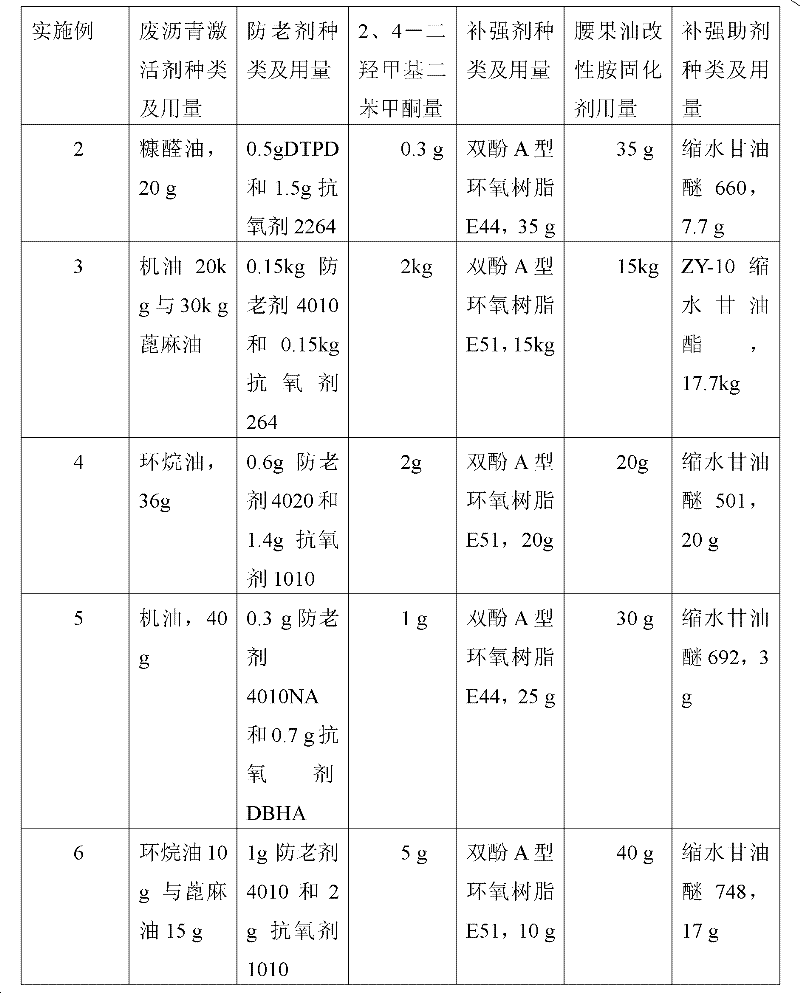

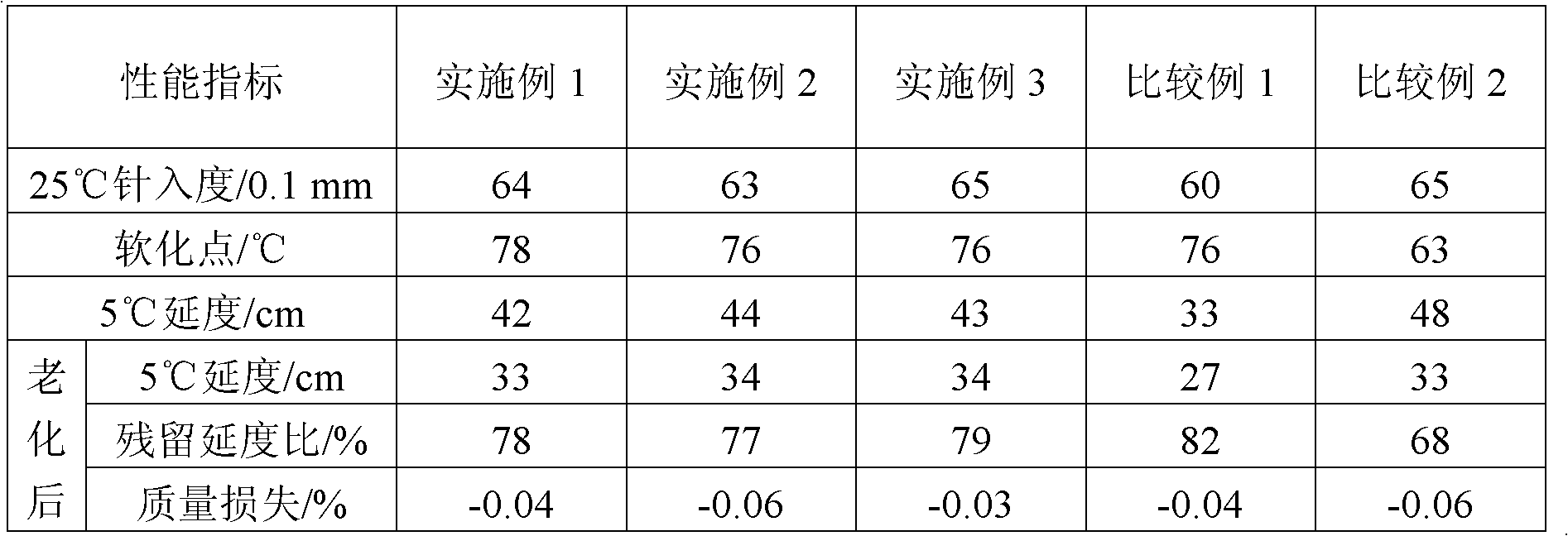

Asphalt cold recycling agent and preparation method thereof

ActiveCN102174267ANo pollution in the processImprove recycling ratesSolid waste managementBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt cold recycling agent, which is characterized by being prepared from a waste asphalt activator, an anti-aging agent, an ultraviolet absorbent, a reinforcing agent, a reinforcing curing agent and a reinforcing auxiliary agent serving as raw materials, wherein the waste asphalt activator consists of any one or more of engine oil, castor oil, naphthenic oil, aromatic hydrocarbon oil and furfural oil; the anti-aging agent is a mixture of an antioxidant and a p-phenylenediamine anti-aging agent; the ultraviolet absorbent is 2,4-dihydroxymethyl benzophenone; the reinforcing agent is bisphenol A epoxy resin E44 or E51; the reinforcing curing agent is a cashew nut oil modified amine curing agent; and the reinforcing auxiliary agent is a glycidyl ester epoxy active diluent. An asphalt recycled mixture prepared by adding the asphalt cold recycling agent into waste asphalt has high comprehensive performance, namely high bonding strength, high-temperature performance, low-temperature crack resistance and rheological performance, the actual service life of 8 years, and high aging resistance and weather resistance.

Owner:重庆市智翔铺道技术工程有限公司

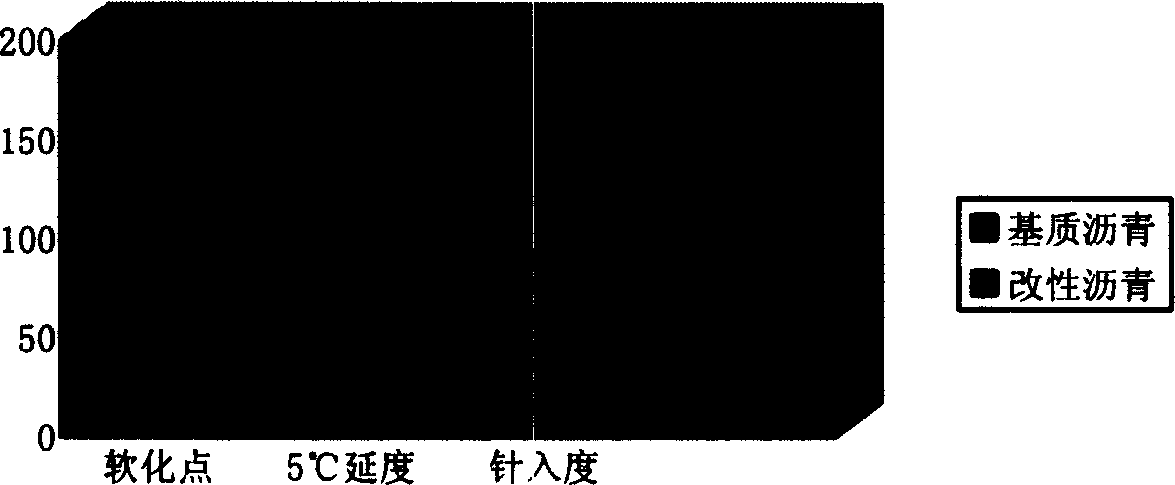

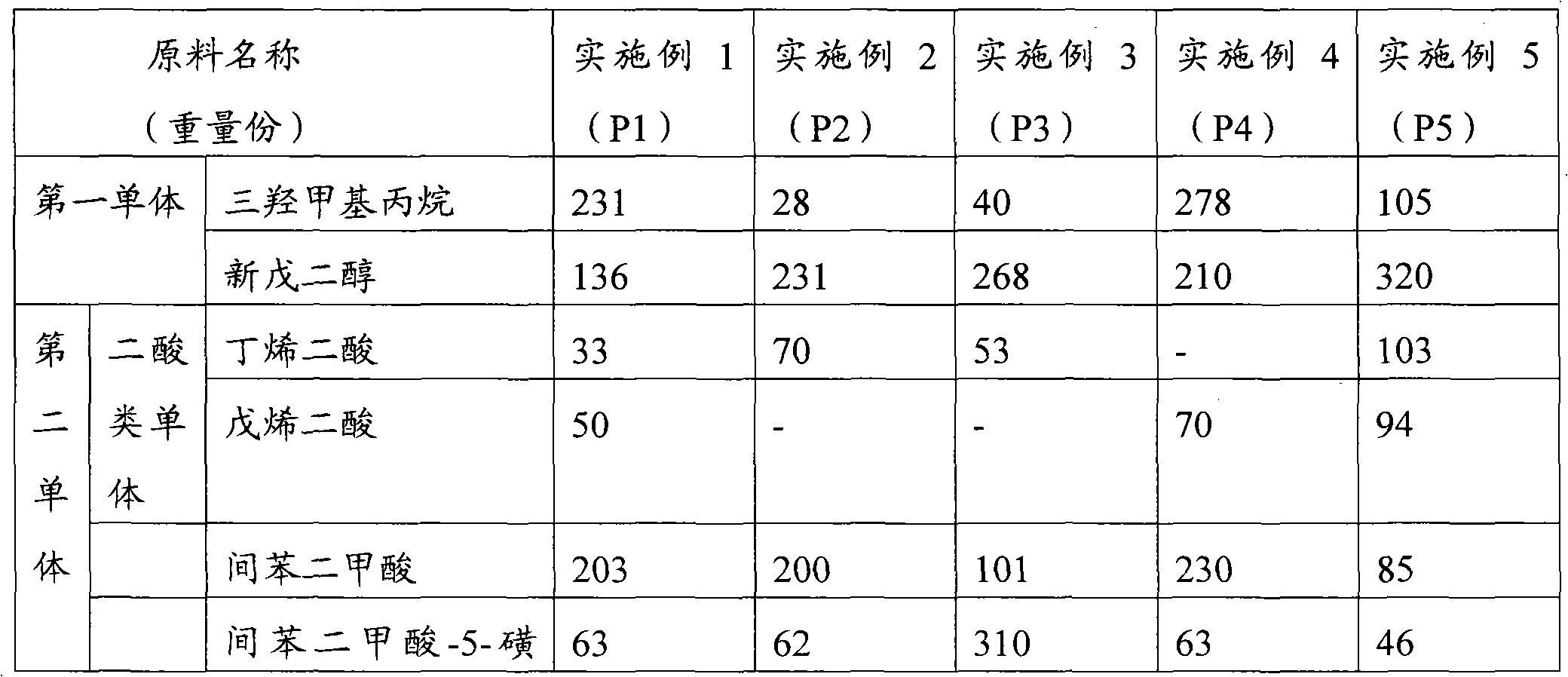

Composite modified asphalt and preparation method thereof

InactiveCN102153874AImprove low temperature performanceImprove anti-aging propertiesBuilding insulationsAging resistanceRoad surface

The invention discloses composite modified asphalt, which is prepared by mixing modifier and matrix asphalt, wherein the modifier consists of the following components in percentage by mass (based on 100 percent of the matrix asphalt): 1 to 10 percent of inorganic substance filler, 1 to 10 percent of polymer, 0.1 to 5 percent of stabilizer, and 0.1 to 5 percent of coupling agent. The prepared modified asphalt has good high and low temperature resistance and ageing resistance, can prolong the service life of roads and reduce the maintenance expense of pavements, and is suitable to be spread in the engineering of high-grade roads, airfield runways, parking lots, bridges and the like.

Owner:SHANDONG JIAOTONG UNIV

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

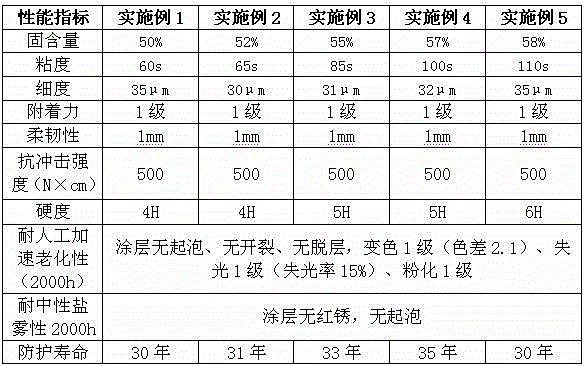

Preparation method of waterborne resin and water-based paint composite

ActiveCN102020759AImprove water resistanceImprove wear resistancePolyurea/polyurethane coatingsWater basedPolyester

The invention discloses a preparation method of waterborne resin and a water-based paint composite. The waterborne resin prepared with the preparation method of the invention contains various functional groups, such as a polyester group, a polypropylene resin group, an organic siloxane group, a polyurethane group and the like, and is acrylic ester graft modified polyester-type polyurethane water dispersion containing siloxane structure, and the siloxane structure can be hydrolyzed to form inorganic-organic crosslinking structure so as to improve the water resistance and the abrasive resistance of waterborne resin. The acrylic acid functional group structure improves the gloss and the weather fastness of a paint film; meanwhile, the polyester-type polyurethane structure ensures high hardness of the paint film because of larger cohesive energy. The water-based paint composite takes the waterborne resin as the main material for forming films, does not contain toxic and harmful substances of toluene and dimethylbenzene, has excellent gloss, good abrasive resistance, and excellent waterproof property and anti-ageing property and is an environmentally-friendly water-based paint with excellent comprehensive performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

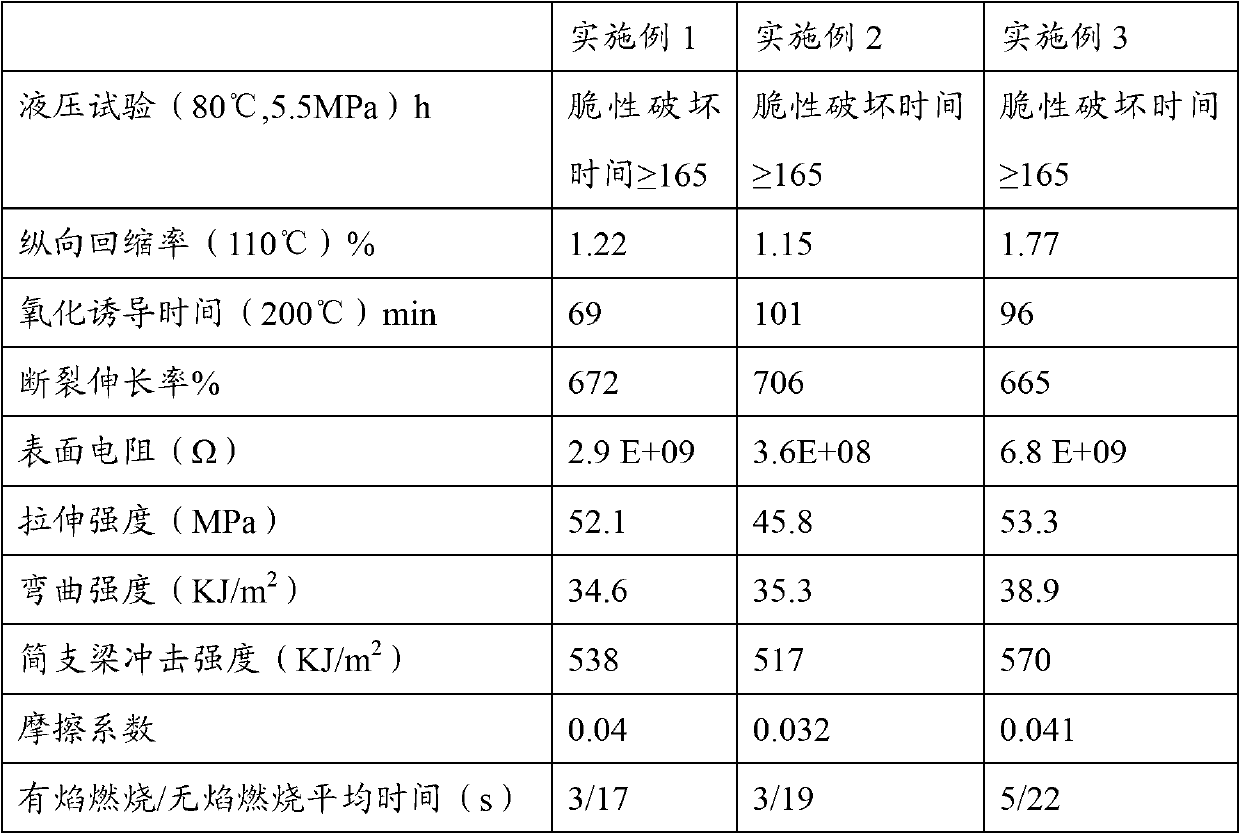

Mine polyethylene tube

ActiveCN102850629AImprove flame retardant performanceGood chemical resistanceRigid pipesLow-density polyethyleneSulfur

The invention relates to a mine polyethylene tube which comprises the following components in parts by weight: 55-85 parts of high-density polyethylene, 5-20 parts of ethylene-propylene rubber, 5-20 parts of polypropylene, 3-10 parts of low-density polyethylene, 3-8 parts of lubricant, 2-6 parts of compatilizer, 0.1-6.0 parts of vulcanizing agent, 5-10 parts of flame retardant, 10-20 parts of carbon black and 0-5 parts of sulfur. Compared with the existing mine polyethylene tube, the mine polyethylene tube provided by the invention has the advantages of excellent flame retardancy, favorable aging resistance, favorable corrosion resistance, high chemical stability, favorable wear resistance and strong shock resistance.

Owner:ZHEJIANG XINDA PLASTIC PIPE

Carbon nano tube composite carbon crystal paint and method for preparing carbon crystal electric heating material from same

InactiveCN101914347AStrong far infrared radiationHigh electrothermal conversion efficiencyChemical industryPolyurea/polyurethane coatingsFiberCarbon fibers

The invention discloses a carbon nano tube composite carbon crystal paint and a method for preparing a carbon crystal electric heating material from the same, wherein the carbon crystal composite paint is prepared from carbon nano tubes, modified ball milling short carbon fibers, resin paints, infrared emission powder and the like; and the carbon crystal electric heating material is prepared by spraying or scratching the paint into a film on a planar template (paper base template, plastic template and the like), and compositing with an aging proof high molecular material to obtain the planar electric heating material. The carbon crystal composite paint and the carbon crystal electric heating material have strong far-infrared radiation, high electric heating conversion efficiency, small surface temperature difference, good corrosion resistance, weather resistance and aging resistance and high safety, can be compatible with concrete, can be used as a heating product for buildings, and can also be processed into various electric heating products, such as an electric heating plate, an electric heating carpet, a dry wardrobe, a foot warmer, a food warmer and the like.

Owner:龚亮 +1

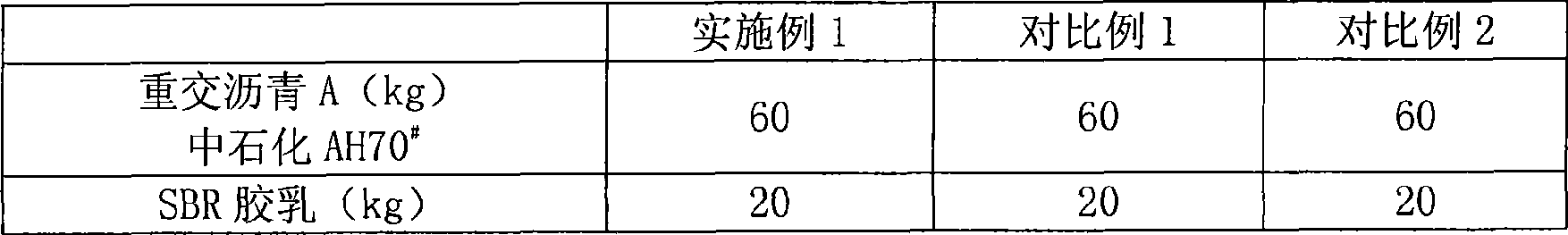

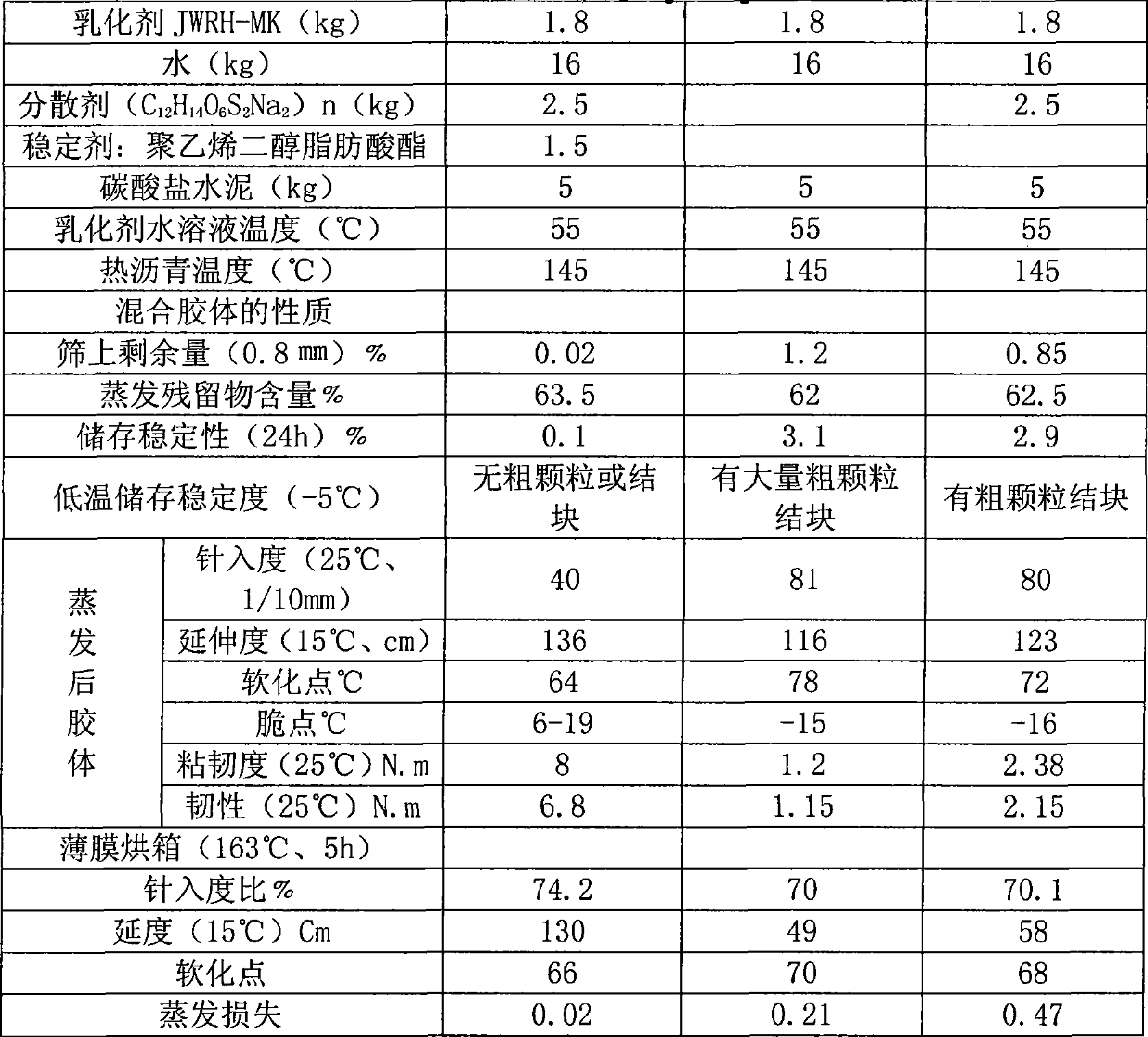

High strength cold state asphalt fissure cementation water-proof glue and preparation thereof

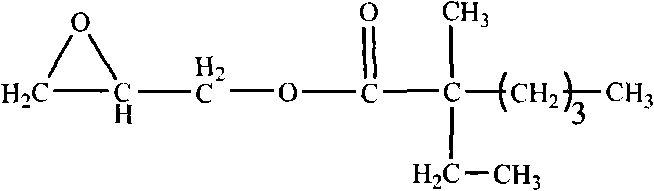

ActiveCN101475748AGood anti-aging performanceImprove high temperature performanceOther chemical processesBuilding insulationsTO-18Adhesive

The invention relates to high-strength cold asphalt crack-pouring waterproof adhesive and a preparation method thereof. The waterproof adhesive comprises the following components in portion by weight: 15 to 20 portions of modifier polymer, 2.0 to 3 portions of dispersant, 0.5 to 2.0 portions of stabilizing agent, 50 to 60 portions of heavy rubber asphalt, 1.5 to 2.0 portions of emulsifying agent, 15 to 18 portions of purified water, and 4 to 16 portions of curing agent. The waterproof adhesive has the advantages of simple preparation, reliability and excellent properties, can be widely applied to crack pouring for large traffics in cities and countryside, heavy loading high-grade roads, stress absorbing structural layers, waterproof and mist sealing layers or layer sealing mat coats and the like, and remarkably improves water proofing, skid resistance, flatness and abrasion resistances of the roads.

Owner:钦兰成

Anionic emulsified modified asphalt and preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating

ActiveCN109575310AGood dispersionHigh strengthConjugated diene hydrocarbon coatingsChloropene polymer coatingsFiberCarbon fibers

The invention discloses anionic emulsified modified asphalt and a preparation method thereof and anionic high-adhesiveness waterborne asphalt waterproof coating. The anionic emulsified modified asphalt is prepared from, by mass, 50-70 parts of matrix asphalt, 1-20 parts of a polymer modifier, 0.5-2 parts of nano carbon fibers, 2-5 parts of a surface modifier, 1-2 parts of an anionic surfactant, 0.1-0.8 part of a pH regulator and 20-40 parts of water. A film formed by the waterproof coating has excellent creep performance and extending performance and is capable of well sealing cracks of a baselayer to effectively resist cracking caused by base layer settlement, deformation and the like, water channeling is prevented, and reliability of an upper waterproof roll is improved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

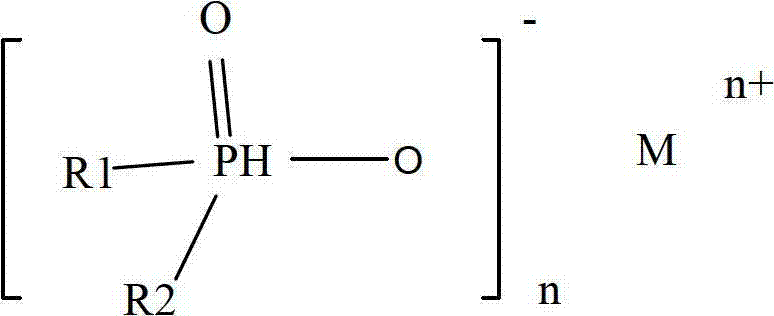

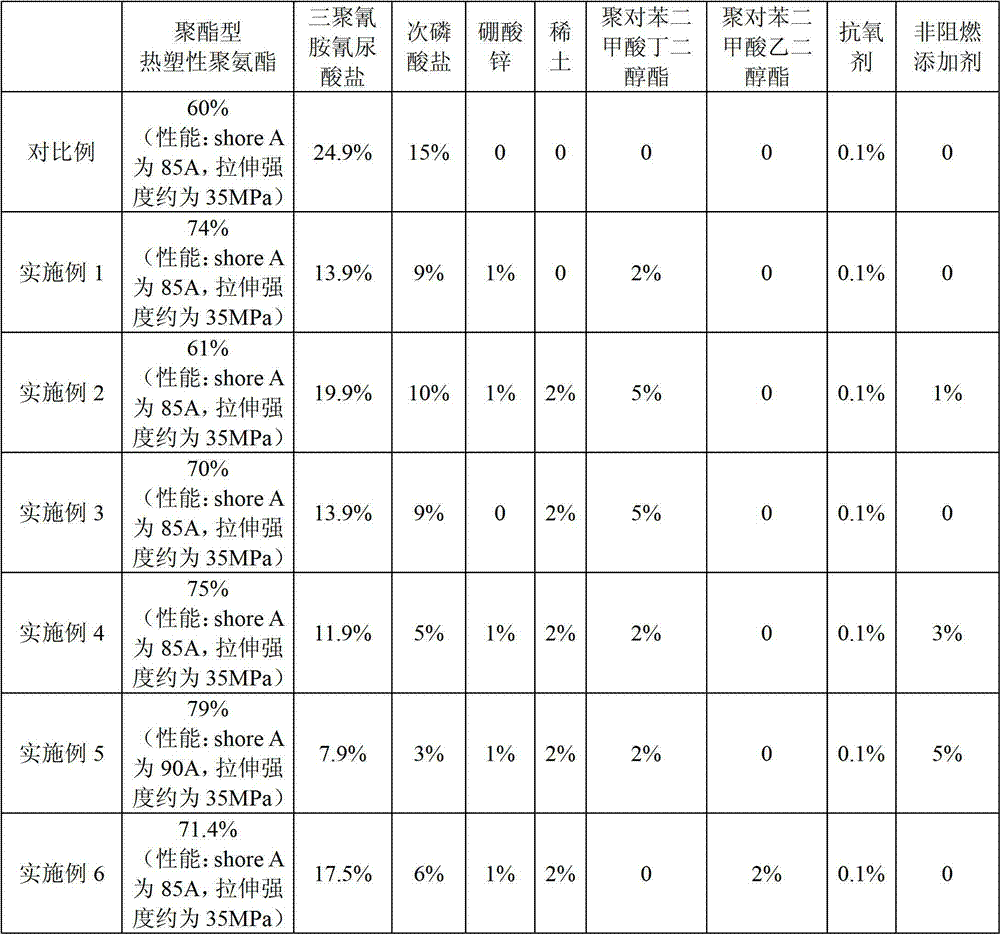

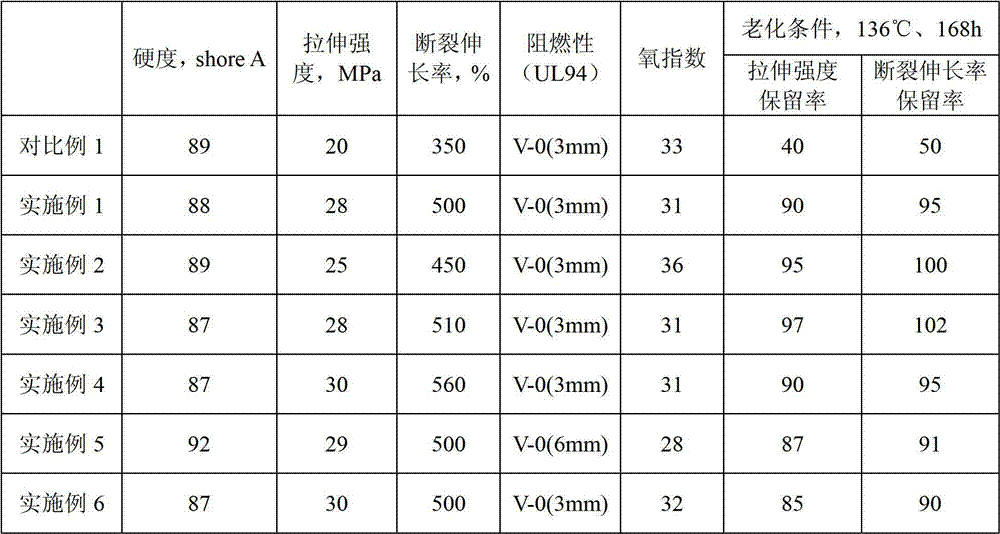

Inflaming retarding thermoplastic polyurethane elastic body

The invention discloses an inflaming retarding thermoplastic polyurethane elastic body which comprises the following components by weight percentage of: 60-80% of polyester thermoplastic polyurethane, 10-30% of halogen-free fire retardant, 1-10% of inflaming retarding synergist, 1-10% of chain extender, 0.1-2% of antioxidant and less than 5% of non-inflaming-retarding additive. According to the inflaming retarding thermoplastic polyurethane elastic body disclosed by the invention, the good inflaming retarding performance can be achieved and relatively good mechanical performances of previous high tensile strength, cracking elongation at break and the like of a TPU (Thermoplastic Polyurethane) raw material; the inflaming retarding thermoplastic polyurethane elastic body has the advantages of good wear resistance, tearing resistance, hydrolysis resistance and anti-ageing performance; and the inflaming retarding thermoplastic polyurethane elastic body does not contain halogens and heavy metal and particularly does not contain lead, cadmium, mercury, hexavalent chromium heavy metal, as well as poly-brominated diphenyl ether and poly-brominated biphenyls, so that the European Union RoH2.0 instruction requirements are met.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

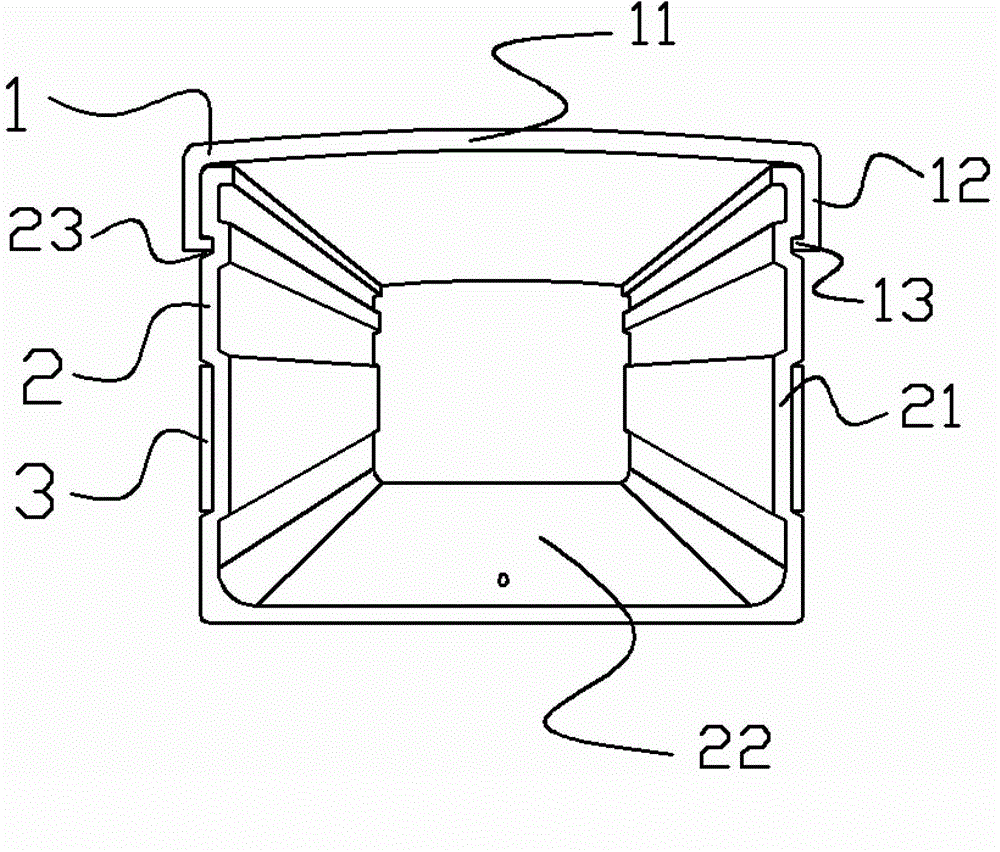

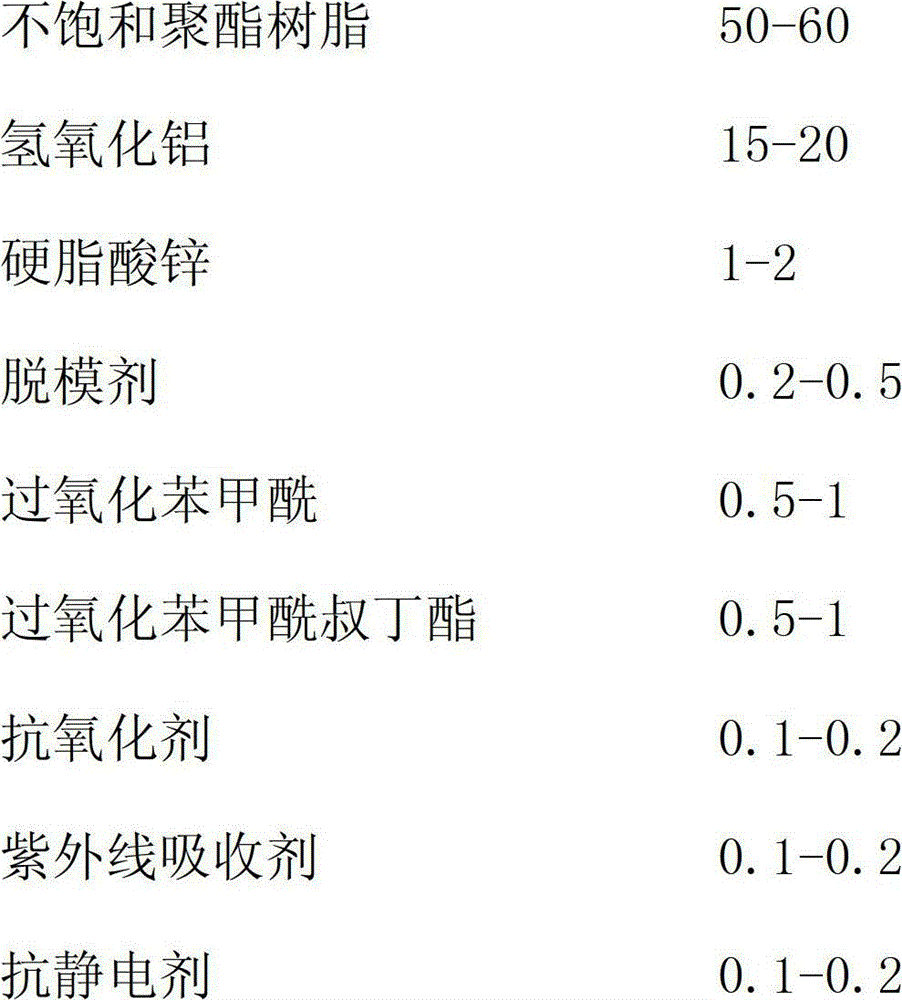

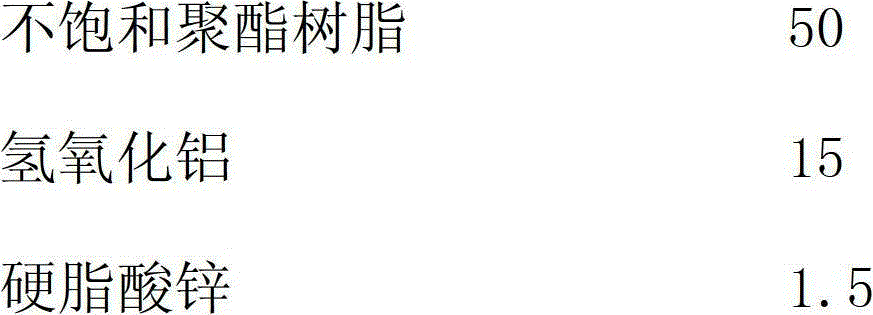

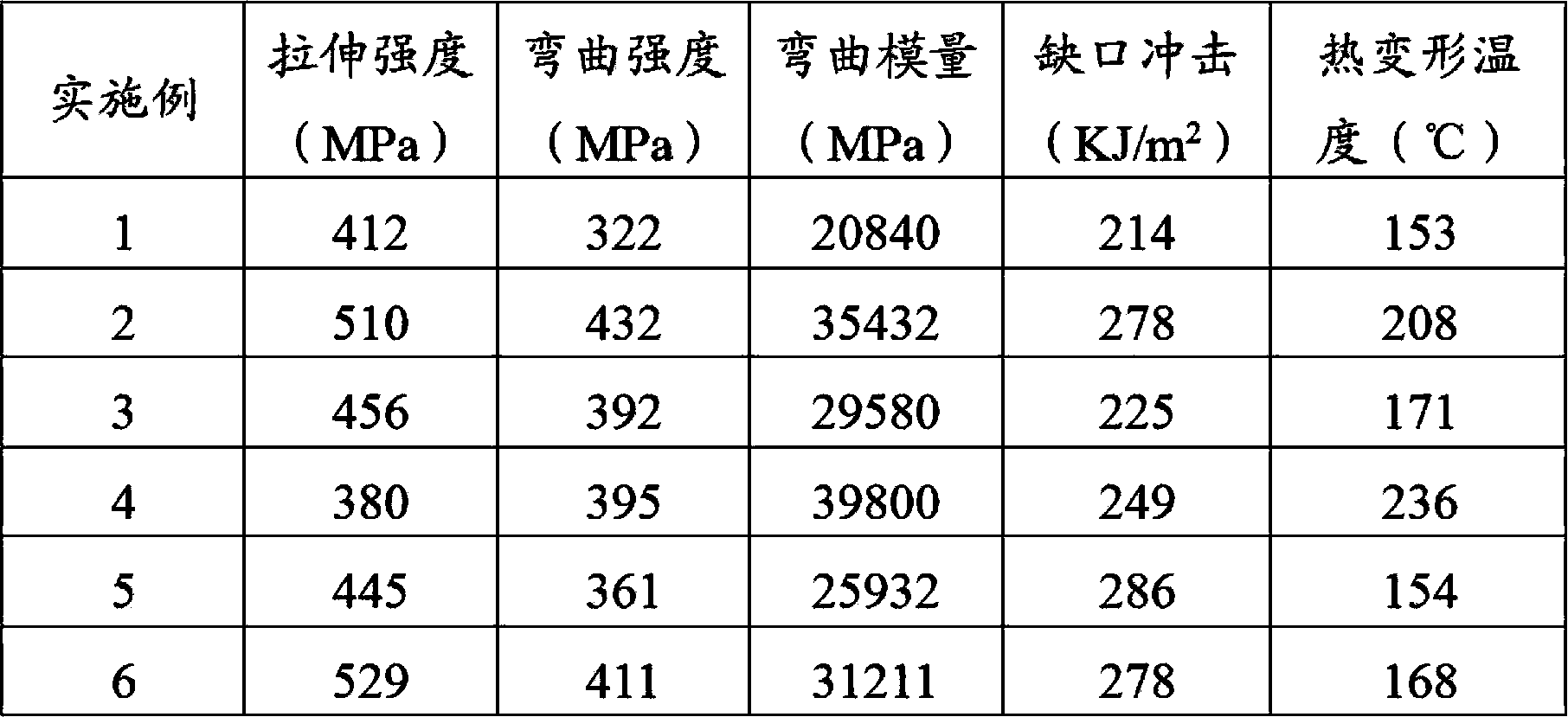

Glass fiber reinforced plastic curing agent composition and glass fiber reinforced plastic composite material prepared by same as well as cable trough

ActiveCN102977574AGood anti-aging performanceHigh strengthElectrical apparatusGlass fiberBenzoyl peroxide

The invention discloses a glass fiber reinforced plastic curing agent composition and a glass fiber reinforced plastic composite material prepared by the same as well as a cable trough. The glass fiber reinforced plastic curing agent composition is formed by the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 15-20 parts of aluminum hydroxide, 1-2 parts of zinc stearate, 0.2-0.5 part of de-molding agent, 0.5-1 part of benzoyl peroxide, 0.5-1 part of benzoyl peroxide tert-butyl ester, 0.1-0.2 part of antioxidant, 0.1-0.2 part of ultraviolet absorbent, and 0.1-0.2 part of antistatic agent. A glass fiber reinforced plastic material is prepared by an extruding and molding process. The glass fiber reinforced plastic material prepared by the curing agent composition disclosed by the invention is low in production cost, has light weight and high strength, and has good weather resistance even under an extreme hygrothermal environment.

Owner:ELECTRICITY AFFAIR ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP

Antirust paint with rust and preparation method thereof

InactiveCN103059699ALow viscosityStrong penetrationAnti-corrosive paintsEpoxy resin coatingsChemistryEmulsion

The invention relates to an antirust paint and a preparation method thereof. The antirust paint with rust disclosed by the invention comprises the following components in parts by weight: 28-42 parts of silicone acrylic emulsion, 0.1-0.7 parts of sodium hexametaphosphate, 1.4-2.2 parts of alcohol ester 12, 0.9-2.1 parts of triethanolamine, 2.5-4 parts of aluminum dihydrogen triphosphate, 5.6-8.2 parts of titanium dioxide, 5.6-8.2 parts of barium metaborate, 1.8-4.1 parts of silica sol, 1.6-4.3 parts of potassium metasilicate, 0.15-0.35 parts of anti-rust agent, and 20-30 parts of vinyl ester resin. The preparation method comprises the following steps of: firstly, preparing vinyl ester resin, and weighing each component; putting the other components except for the vinyl ester resin into a mixer to mix and stir for 15-40 minutes to obtain mixed material I; grinding the mixed material I until the fineness of the grain size of the mixture is 20-40 microns; adding the vinyl ester resin to stir for 30-50 minutes, and then filtering by 300-350 meshes of filter cloth. The antirust paint with rust provided by the invention has the characteristics of low cost, high thermal resistance, corrosion resistance, flame retardant properties and the like, and can be widely applied to production and construction equipment.

Owner:河北华强科技开发有限公司

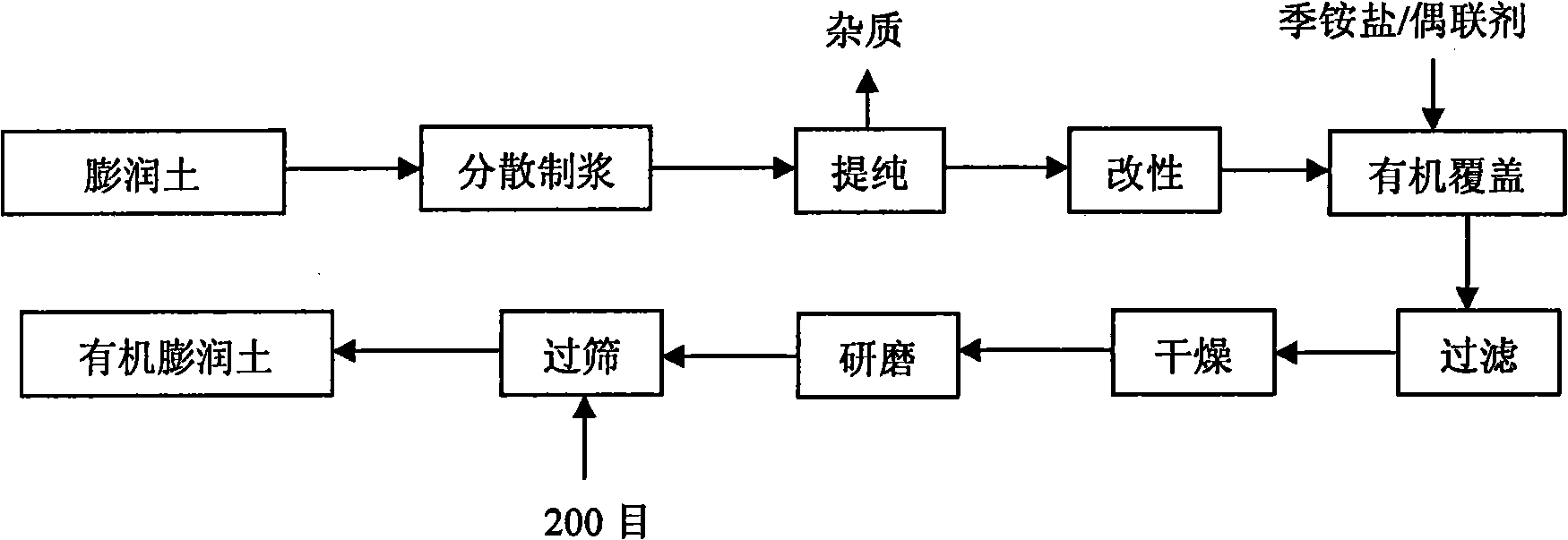

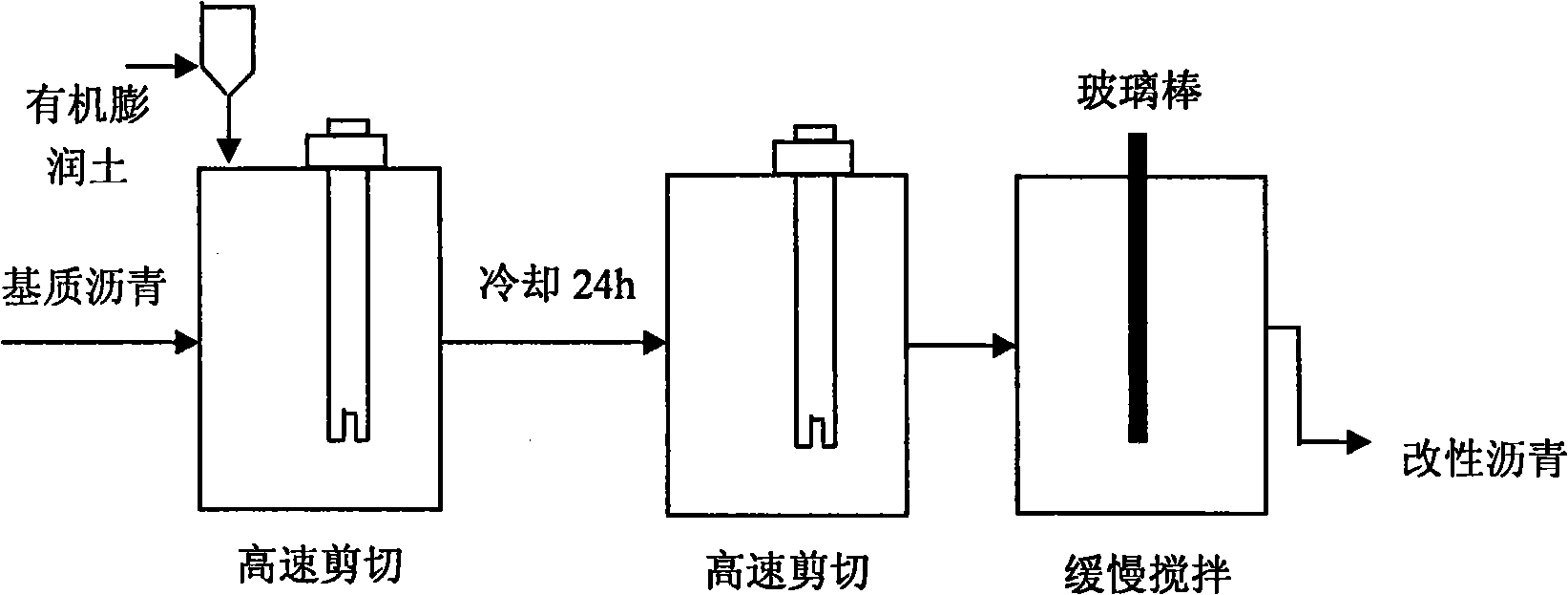

Phyllosilicate nano modified asphalt by dual processing of intercalation and coupling and preparation method thereof

InactiveCN101525492AImprove high temperature stabilityEnhanced toughening effectBuilding insulationsOrganificationCoupling

The invention adopts organic cation intercalator and coupling agent to carry out organification intercalation processing on laminated clay silicate, so as to prepare organification laminated clay silicate and mix the silicate with liquated road asphalt to form the modified asphalt. The invention also relates to the preparation process of the modified asphalt. The modified asphalt of the invention not only has better road performance than that of matrix asphalt but also prevents premature failure of asphalt road surface and lengthens service life of the road surface; in addition, the cost of materials and processing devices is far lower than the cost of polymer nano modified asphalt.

Owner:CHONGQING JIAOTONG UNIVERSITY

Novel preparation method for polyether amine composite material

The invention discloses a novel preparation method for a polyether amine composite material, which comprises the following preparation steps: (1) preparing refined polyether polyol; and (2) preparing polyether amine. In the invention, upstream raw materials are used as starting raw materials, various monomer raw materials are used to produce a hydroxyl polyol with a multi-functional group structure, a high-activity catalyst is combined, the activity of the catalyst is improved, many tests are carried out, the tested product has high comprehensive performance, production cost is reduced, and the product is suitable to be used in more industries. In the invention, new varieties of upstream raw materials of the polyether amine product are added, the polyether products are diversified, the application adaptability of the product in the composite material is improved, product quality is improved, product cost is reduced, reaction pressure and temperature are lowered, the production safety coefficient is high, equipment manufacturing cost is lowered, energy consumption is reduced, and continuous large-scale production is promoted.

Owner:东莞市科道玛电子复合材料有限公司

Integral fuel gas buring catalyst and process for preparing the same

InactiveCN1504260AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCatalytic functionHigh activity

The invention discloses an integral style gas, combustion catalyst and method for the making same, wherein the base material of the catalyst is integral ceramic honeycomb body or metallic honeycomb body, the catalyst coating layer coated on the base material surface comprises catalytic functional components and coating layer aiding agents, the catalytic functional components are classified into compound catalytic functional components having at least three different catalytic functions, each of which is prepared through corresponding predecessor physical process. The catalyst by the invention has high activity, high stability, high heat efficiency and low contaminant discharge.

Owner:SICHUAN TIANJIAN CATALYTIC COMBUSTION

Plastic-wood composite material and manufacturing method thereof

The invention relates to a plastic-wood composite material which is characterized by comprising a main material and an auxiliary material, wherein the main material comprises waste plastic and biomass fibers; the auxiliary material comprises a lubricant, a compatilizer, a stabilizer, a dispersant, a coupling agent and an antioxidant; the main material also comprises cement, fly ash and natural stone powder. The plastic-wood composite material has the advantages of high compression resistance, high impact resistance, favorable acid / alkali resistance, favorable high / low-temperature resistance, favorable heat-insulating property, favorable wear resistance, favorable elasticity, favorable aging resistance, long service life and the like, can comprehensively utilize waste materials, is environment-friendly, and can be used for making various articles or appliances instead of wood, plastic and stone. The invention also provides a manufacturing method of the plastic-wood composite material, which is scientific and reasonable in technique, and is easy for formation.

Owner:李胜刚

Ultra-high strength glass fiber reinforced thermoplastic resin composite plate and preparation method thereof

InactiveCN103571046AImprove mechanical propertiesImprove flame retardant performanceSynthetic resin layered productsLaminationGlass fiberAging resistance

The invention discloses an ultra-high strength glass fiber reinforced thermoplastic resin composite plate. The composite plate comprises the following components in parts by weight: 40-60 parts of thermoplastic resin, 40-60 parts of continuous ultra-high strength glass fiber and 0.2-0.5 parts of silane coupling agent. The invention further discloses a preparation method of the ultra-high strength glass fiber reinforced thermoplastic resin composite plate. The ultra-high strength glass fiber reinforced thermoplastic resin composite plate disclosed by the invention has the advantages of high mechanical properties, relatively good flame retardancy, aging resistance and high temperature resistance, excellent comprehensive performances, low price and relatively high performance-price ratio.

Owner:LIAONING LIAOJIE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com