Natural-like multifunctional color batch and use thereof

A natural imitation and multi-functional technology, applied in the field of imitation natural multi-functional color masterbatch, can solve the problems of complex production process route, restrain the application development of plastic products, increase production equipment and cost, etc., so as to improve the appearance quality and grade, improve Self-value and profit, and the effect of reducing investment in machinery and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

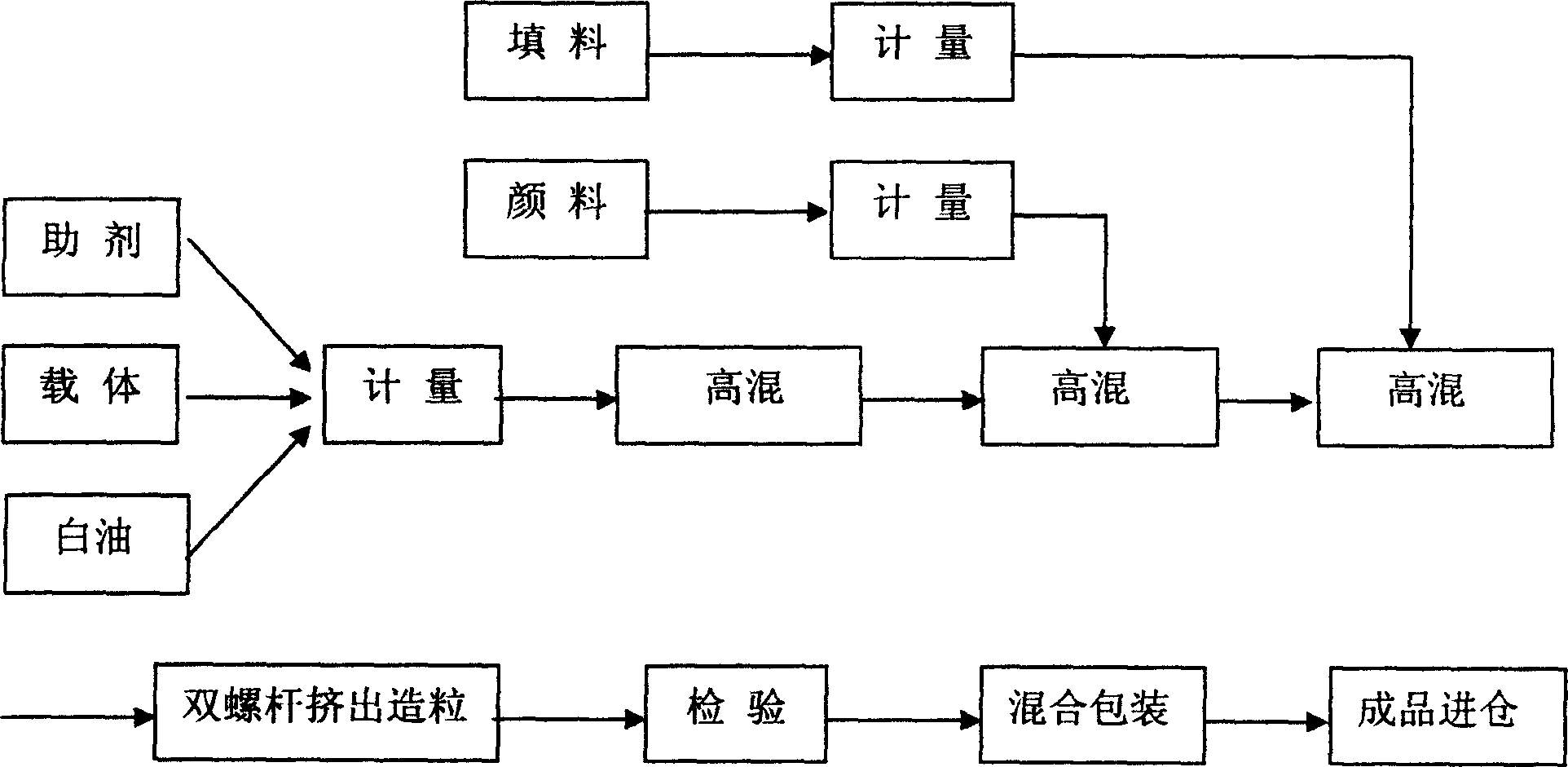

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the selection of polyolefin imitation natural multifunctional color masterbatch carrier resin

[0033] The basic resin (B) selects polypropylene as the research object, that is, determines that polypropylene is the B resin. According to the characteristic performance parameters of polypropylene B, polypropylene resin A is selected, and the best resin X is selected among resin varieties that can be alloyed with PP, such as polyester PBT, PET, polycarbonate PC and nylon PA. Black and white stripes are selected as the research objects for the color stripes, and the raw materials and content percentages of the screening experiments are shown in Table 2.

[0034] Table 2: Screening Example Formulations for Resin X (PP)

[0035]

[0036] According to the selected raw materials, the best resin X is screened with the examples, and the formula of the screening examples is shown in Table 2. According to the formula shown in Table 2, two kinds of bla...

Embodiment 2

[0041] Embodiment 2: the selection of the imitation natural multifunctional color masterbatch carrier resin of ABS

[0042] In ABS plastic products, ABS resin is first selected as A resin. According to the characteristic performance parameters of the two kinds of ABS resins A and B, it is planned to screen the best resin X among resin varieties such as polycarbonate (PC) and polyester PET that can be alloyed with ABS. Black and white stripes were selected as the research objects for color stripes, and the screening experimental formula is shown in Table 4.

[0043] Table 4: Screening Formulation for Resin X (ABS)

[0044]

[0045] According to the formula shown in Table 4, two black masterbatches and two white masterbatches were successively prepared. Add the four kinds of masterbatches to ABS resin (B resin) at a ratio of 1%, adjust the injection molding temperature to 210-235°C, and reasonably adjust the injection molding process and back pressure to obta...

Embodiment 4

[0063] Embodiment 4: the production of monochrome masterbatch

[0064] In view of the multi-color pattern structure and multi-functional requirements of the six swatches formulated, several single-color masterbatches must be manufactured in advance. Six kinds of single-color masterbatch production formulas shown in Table 8:

[0065] Table 8: Six single-color masterbatch formulations:

[0066]

[0067] According to the formula shown in Table 8, six kinds of single-color masterbatches were successively prepared. Taking polypropylene and ABS products as an example, add six kinds of masterbatches to polypropylene PP700 or ABS757 (B resin) at a ratio of about 1%, and adjust the injection temperature to 190-210°C for polypropylene and 210-235°C for ABS. Six kinds of cloud (grain) products were obtained by injection molding process and back pressure. The characteristic properties and swatch effects of the six monochrome masterbatches are shown in Table 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com