Patents

Literature

420 results about "New production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In biological oceanography, new production is supported by nutrient inputs from outside the euphotic zone, especially upwelling of nutrients from deep water, but also from terrestrial and atmosphere sources (as opposite to regenerated production, which is supported by recycling of nutrients in the euphotic zone). New production depends on mixing and vertical advective processes associated with the circulation.

Method of modelling the production of an oil reservoir

InactiveUS20060047489A1Risk minimizationSimple and inexpensiveElectric/magnetic detection for well-loggingFluid removalGeomorphologyReservoir modelling

The invention stimulates the production of an oil reservoir by carrying out a sequence of steps of constructing a flow simulator from physical data measured in the oil reservoir; determining a first analytical model relating the production of the reservoir as a function of time by taking account of parameters having an influence on the production of the reservoir, the first model best adjusting to a finite number of production values obtained by the reservoir simulator; selecting at least one new production value, this new value being obtained by the reservoir simulator; and determining a second model by adjusting the first model so that the second model interpolates the new production value.

Owner:INST FR DU PETROLE

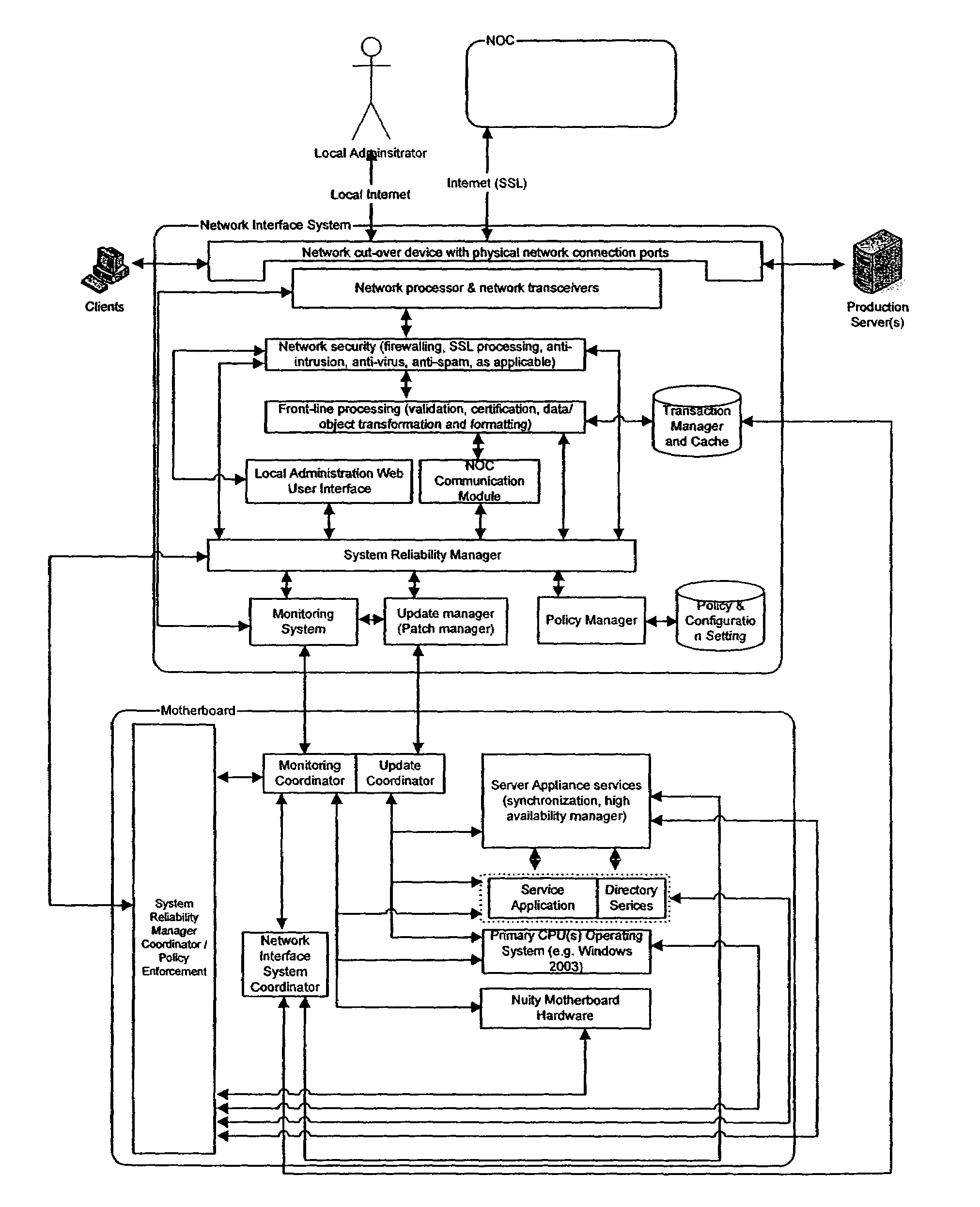

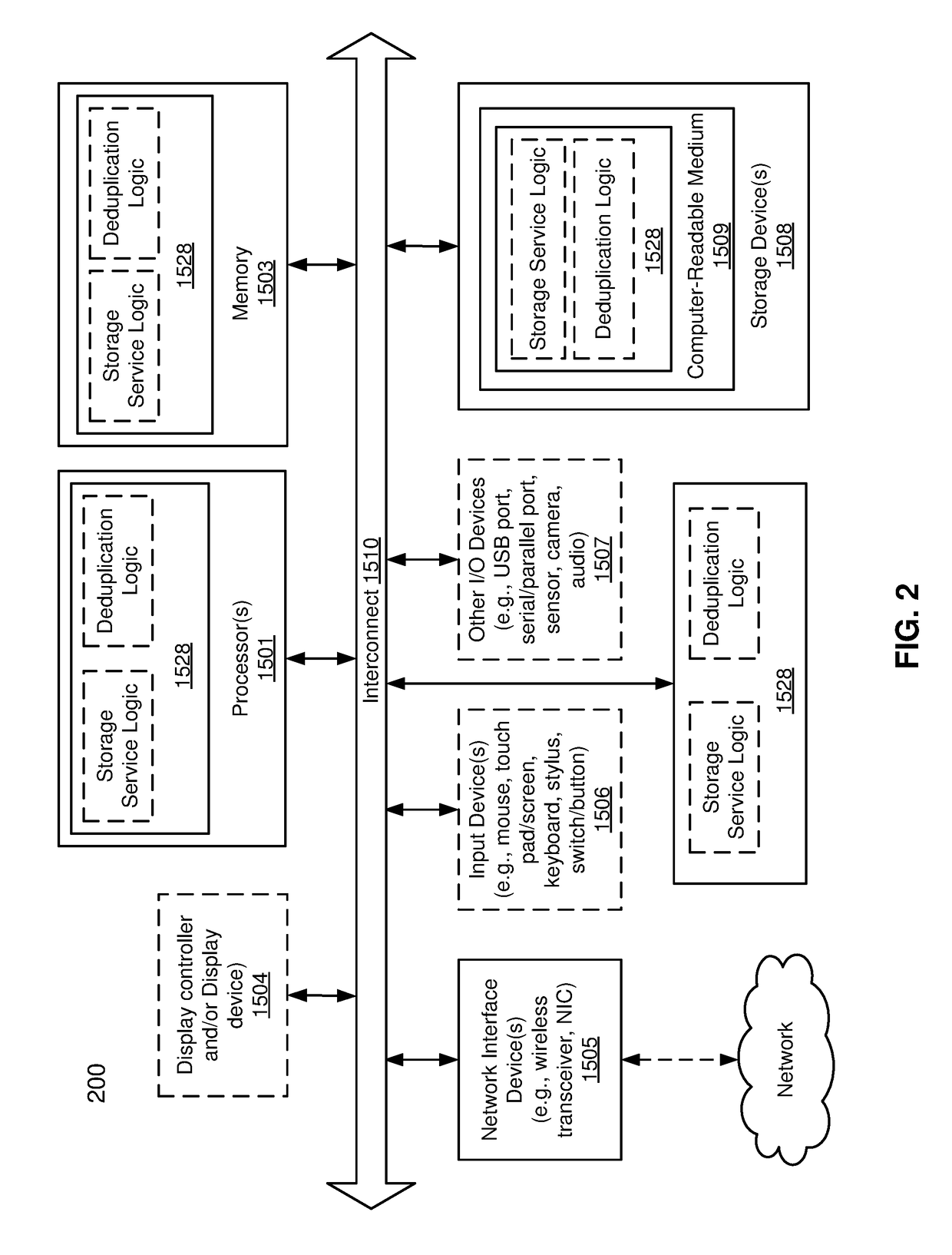

Autonomous service backup and migration

ActiveUS7363365B2Error detection/correctionMultiple digital computer combinationsApplication softwareService user

Owner:ONGOING OPERATIONS

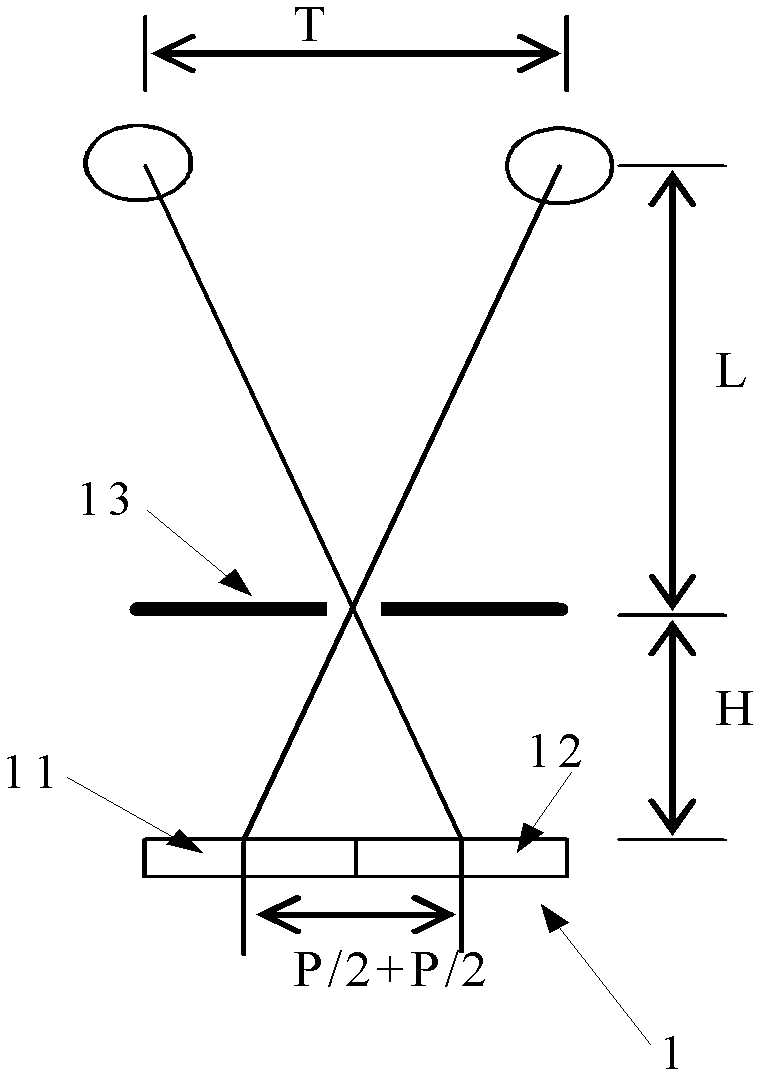

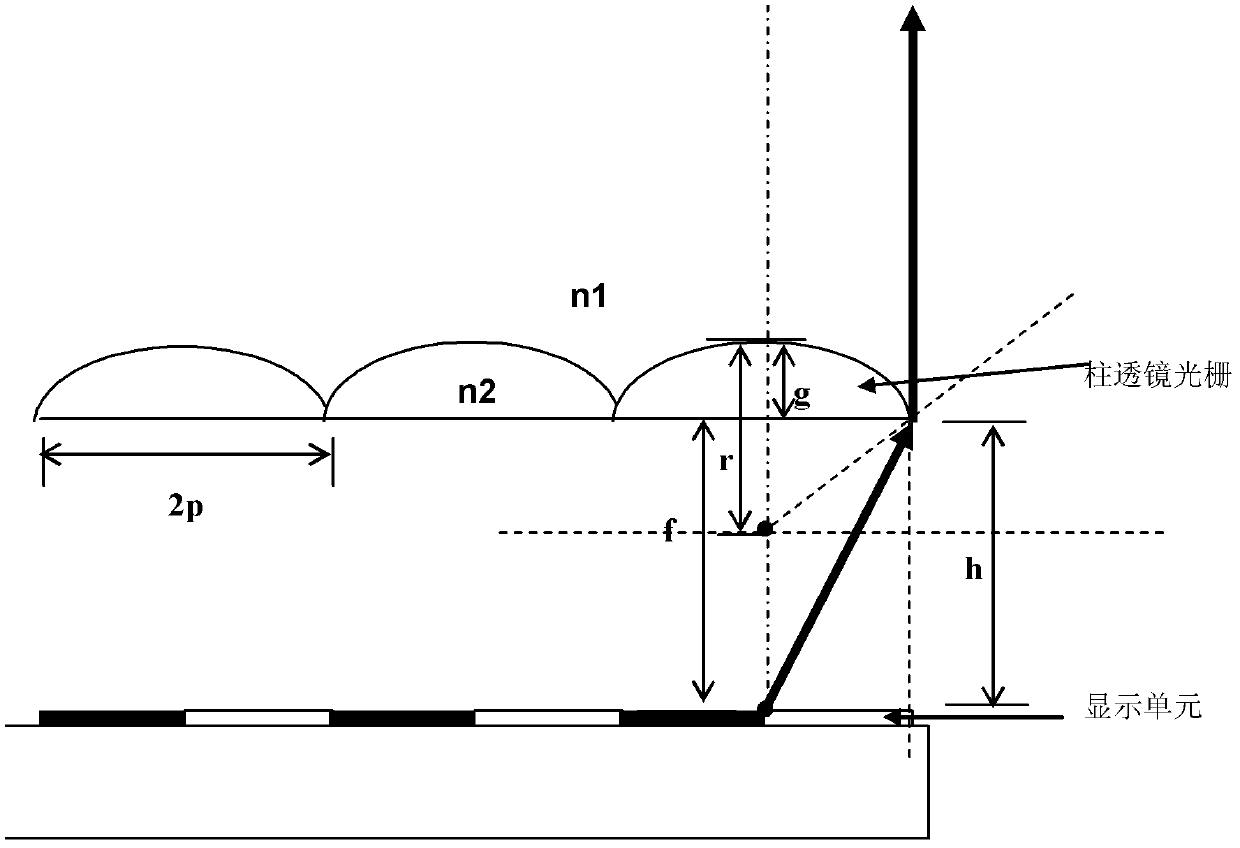

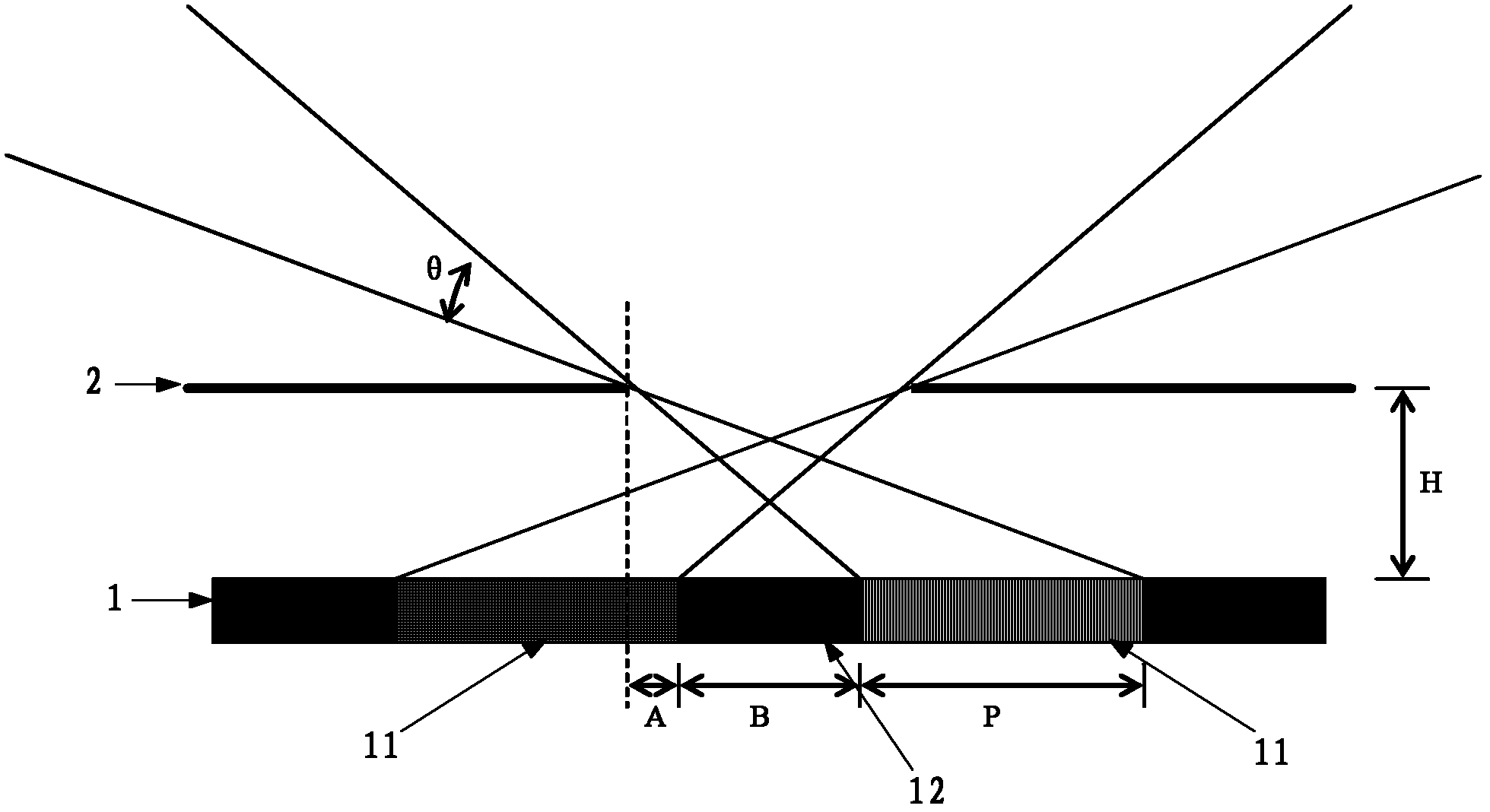

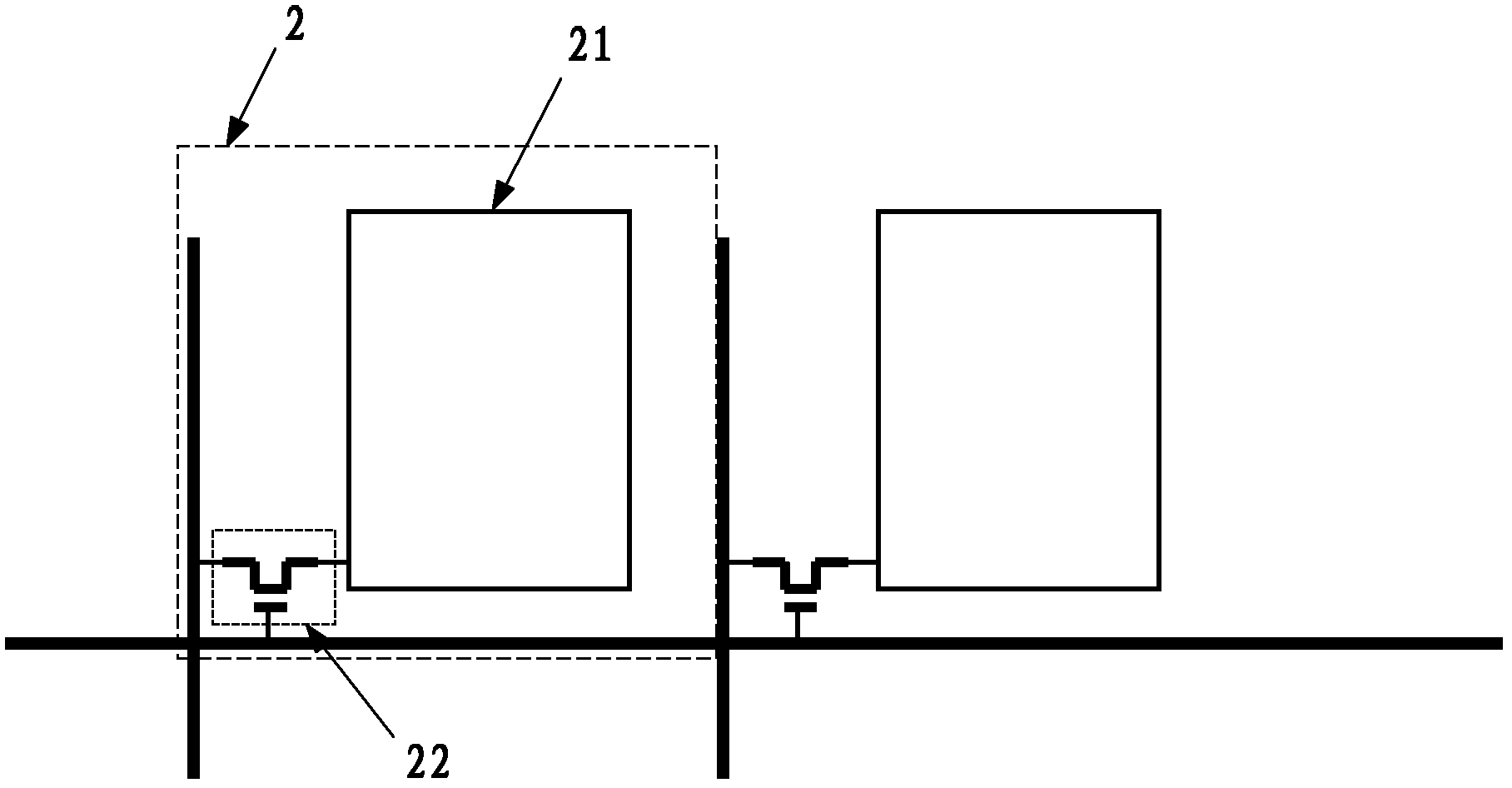

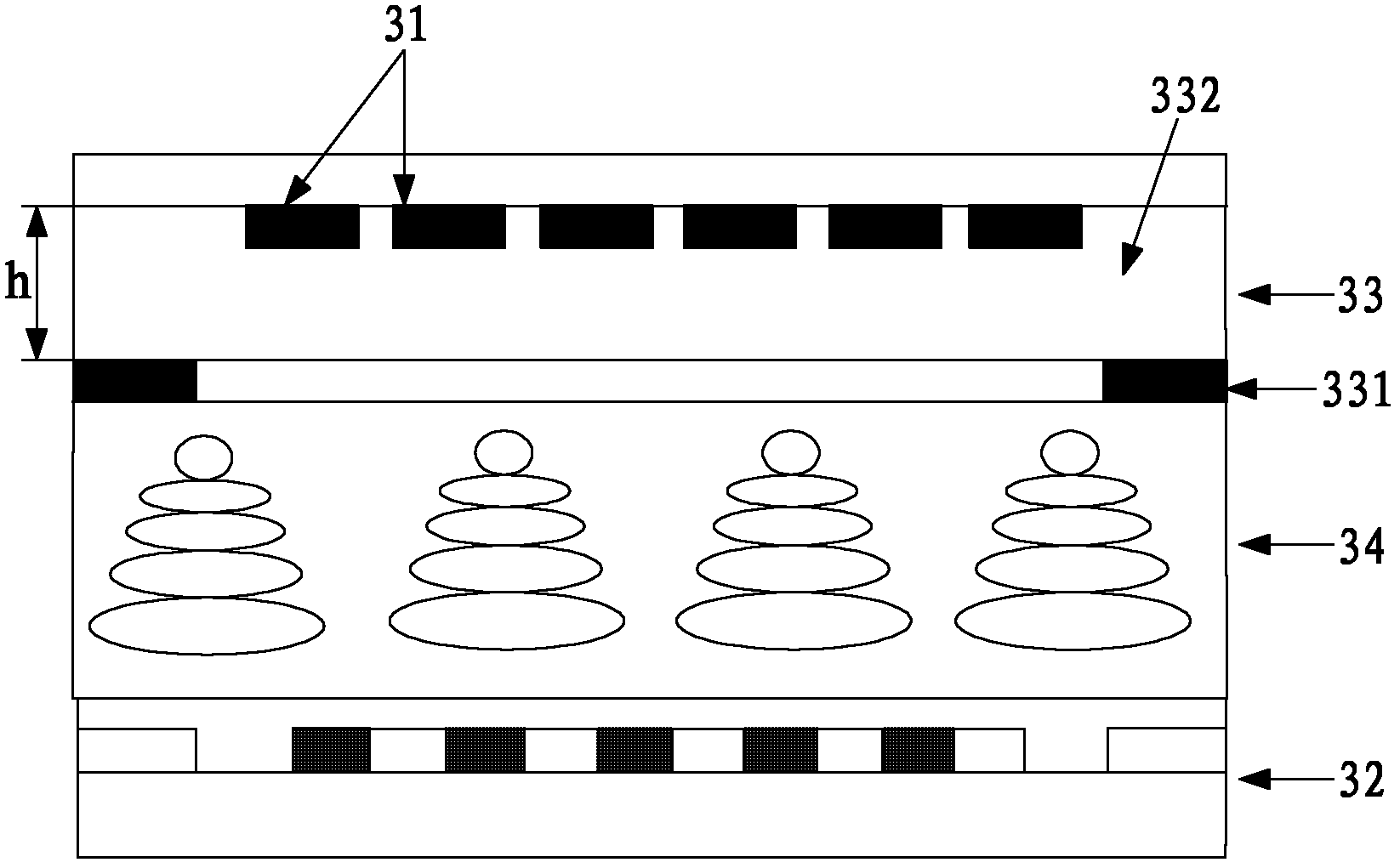

Three-dimensional (3D) display device and manufacture method thereof

ActiveCN102629041AReduce widthReduce thicknessDiffraction gratingsSteroscopic systemsParallaxGrating

An embodiment of the invention provides a three-dimensional (3D) display device and a manufacture method thereof, which relate to the technical field of 3D display. A parallax retaining board can be manufactured in a display device box molded through opposite boxes, arch height of a lens is reduced, increasing of new processes or adoption of new production devices is avoided, and production cost is reduced. A 3D liquid crystal display device comprises a grating layer, a thin film transistor (TFT) array substrate molded through opposite boxes and a color film substrate. The TFT array substrate comprises a plurality of pixel units divided through grating lines and data lines crossing transversely and vertically. Each pixel unit comprises a pixel electrode and a TFT circuit. Each pixel electrode of each pixel unit comprises at least two left view field pixel electrodes and at least two right view field pixel electrodes, and the left view field pixel electrodes and the right view field electrodes are at interval. The TFT circuit of each pixel unit comprises a first sub TFT circuit connected with the left view field pixel electrodes and a second sub TFT circuit connected with the right view field pixel electrodes. The embodiment of the 3D display device and the manufacture method are used for manufacturing the 3D display device.

Owner:BOE TECH GRP CO LTD

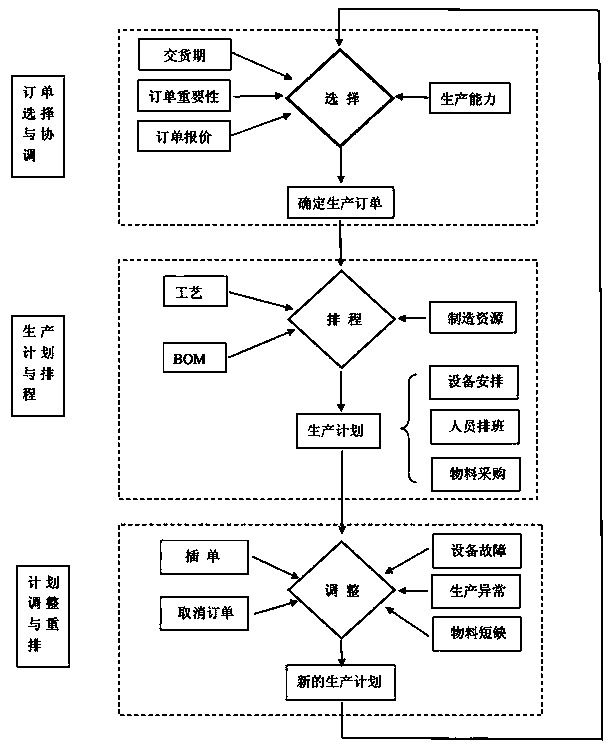

PCB enterprise order management and production planning system

InactiveCN104299107AReduce manufacturing costTake advantage ofResourcesProgram planningEnterprise data management

The invention provides a PCB enterprise order management and production planning system. According to the system, a production schedule in a period of time is automatically generated according to the production capacity of existing equipment, and the equipment, personnel and materials are arranged. The system is operated in coordination with a PCB enterprise product tracking query system and can master the processing progress of each order and the equipment utilization condition. If abnormal situations such as equipment failure and material shortage occur, or a customer inserts an order or withdraws an order, deviation between the actual production situation and the scheduled production plan occurs, the system can conduct calculation again and generates a new production plan and an order schedule according to the situations, and a new estimated product delivery time is provided.

Owner:叶校然

Method of modelling the production of an oil reservoir

InactiveUS7788074B2Simple and inexpensive to formRisk minimizationFluid removalAnalogue processes for specific applicationsProcess engineeringAnalysis models

The invention stimulates production of an oil reservoir by determining a flow simulator from physical data measured in the oil reservoir; determining a first analytical model relating the production of the reservoir as a function of time by accounting for parameters which provides adjustment to production values closest to the production of the reservoir, the first model providing adjustment to the production values closest to a production values provided from the flow simulator; selecting at least one new production value, which is obtained from the reservoir simulator; and determining a second model by adjusting the first model so that the second model interpolates the new production value.

Owner:INST FR DU PETROLE

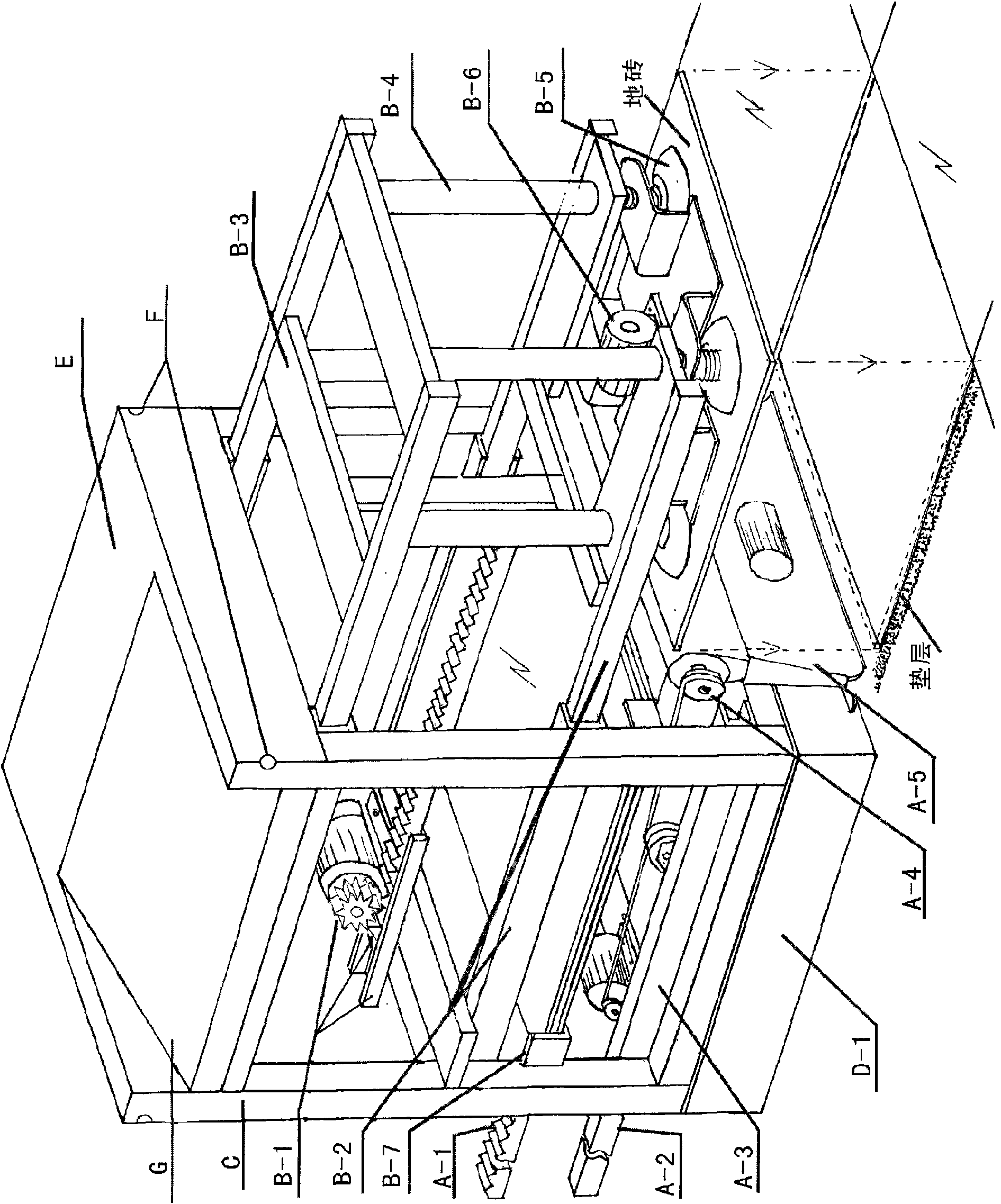

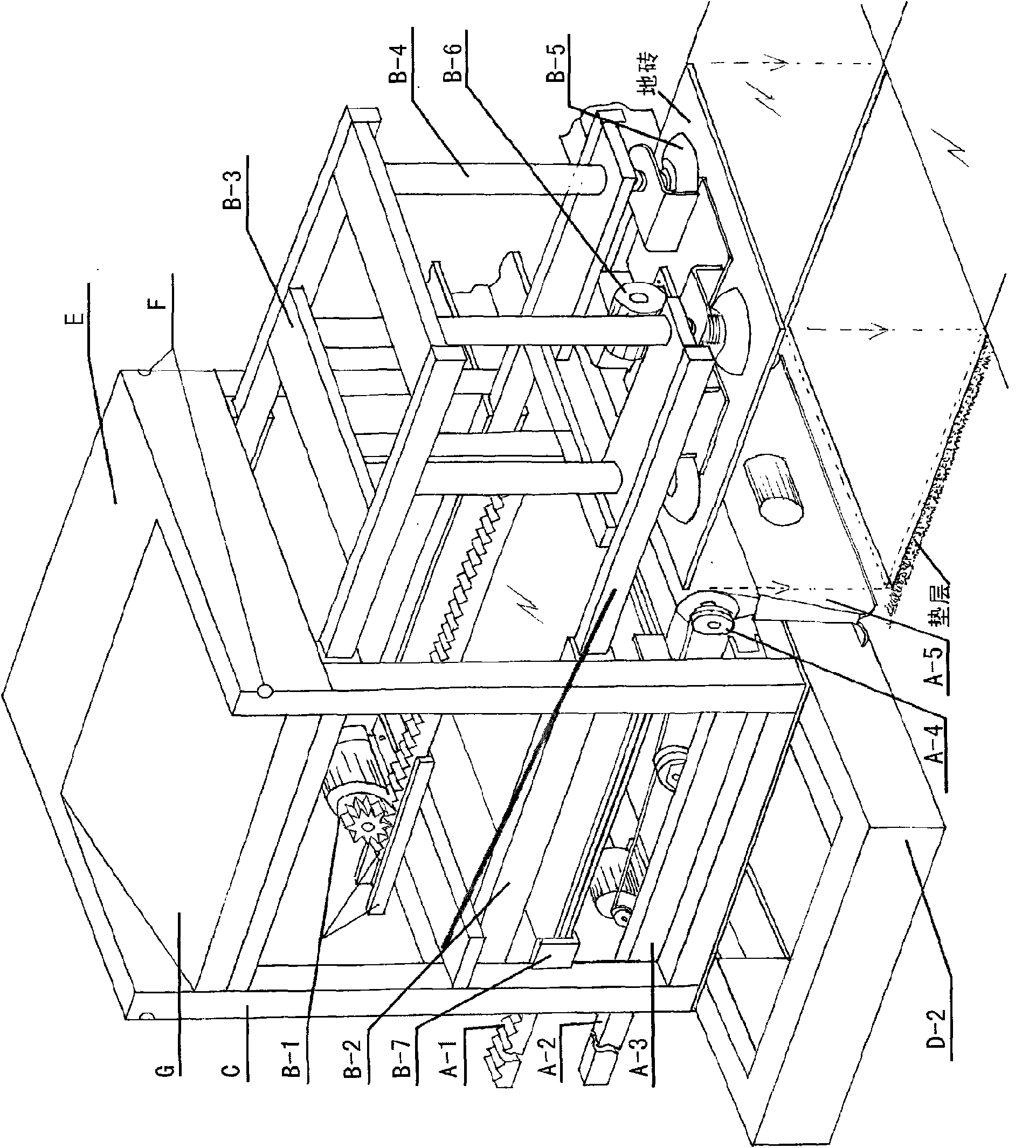

Intelligent paving machine

The invention relates to an intelligent paving machine and belongs to an intelligent machine integrated with machinery and electronics. Currently, floor bricks of a building are manually paved; and the manual paving has great disadvantages of poor quality, low efficiency, high labor cost and the like. The invention adopts a brand-new production process and the brand-new intelligent paving machine. The machine rapidly and accurately completes the paving work of the floor bricks under the program control of a detection device and specially-programmed computer application software; and the efficiency is ten times of that of manual operation. The paving machine substantially improves the paving quality, accelerates the engineering schedule and reduces the labor cost. The popularization and the application of the technology and a product effectively promote the modernized and industrialized production level of building decoration industry and create good economic and social effects for enterprises and society.

Owner:王怀成

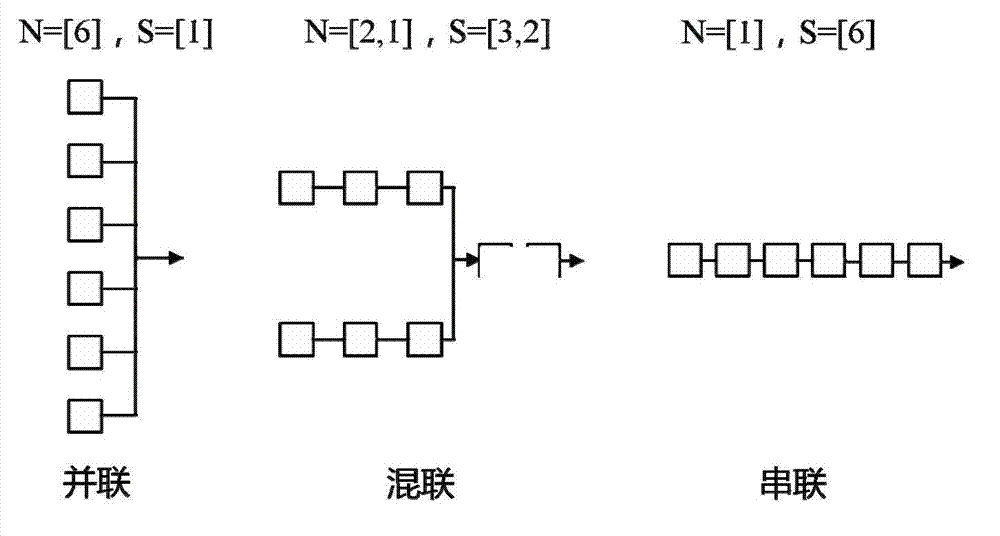

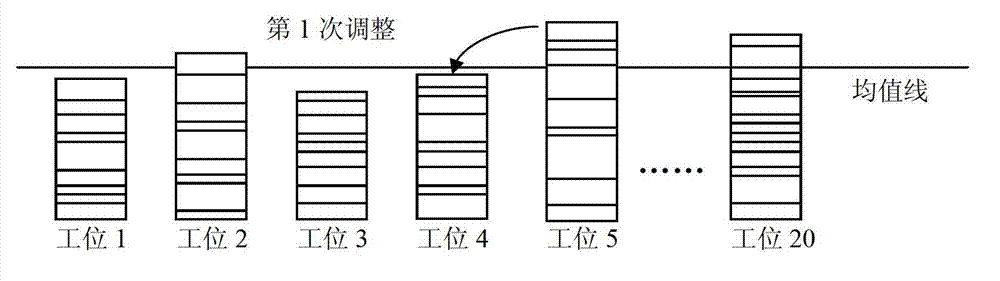

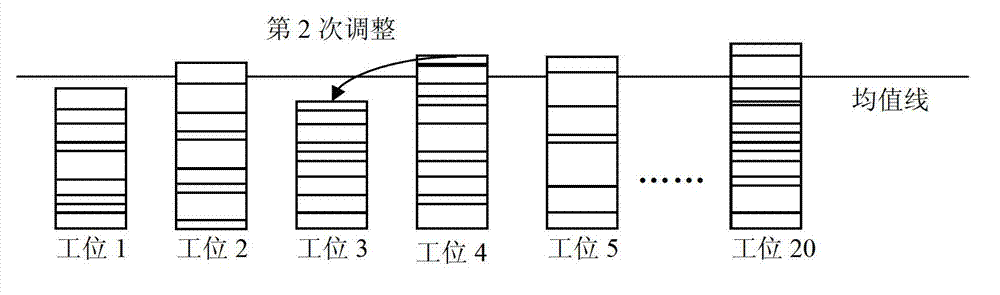

Optimal design method for production line layout

ActiveCN103049801AReduce the impact of volatilityIncrease production capacityForecastingProduction lineTotal investment

The invention relates to the field of engineering manufacture, in particular to an optimal design method for production line layout. The technical problem that the influence of production fluctuation on production efficiency cannot be reduced by the conventional method so as to reduce enterprise benefits is solved. According to the scheme, the optimal design method for new production line layout mainly comprises the following steps of: acquiring the labor house data of original sub-procedures; generating functional segments and a station number by adopting a line balancing planning method, so that the cycle time of a single line in each functional segment is shortest; when total investment C is determined, finding all N and S combinations consistent with a constraint condition by using an enumeration method; calculating the cycle time of each functional segment; calculating the overall cycle time of each [N, S] scheme; and performing calculation according to the steps, and when the total investment C is determined, determining a scheme with the shortest cycle time in all the [N, S] schemes as a target scheme. The method can be used for the design of the new production line layout and the modification of the conventional production line layout.

Owner:四川长虹智能制造技术有限公司

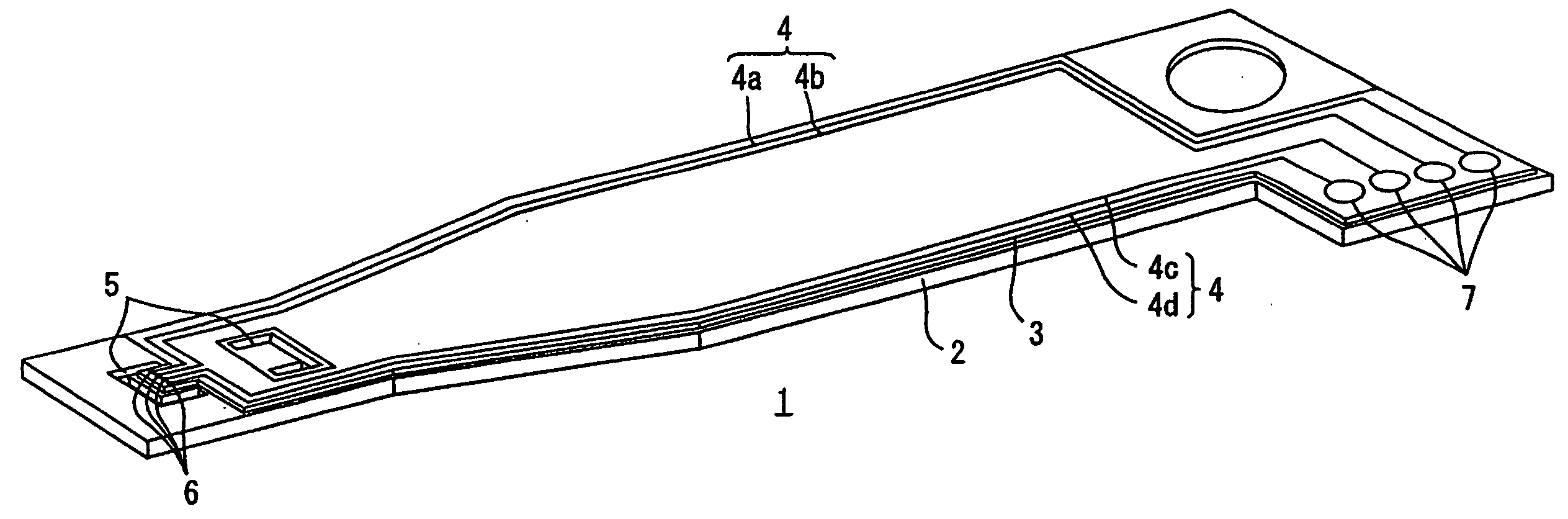

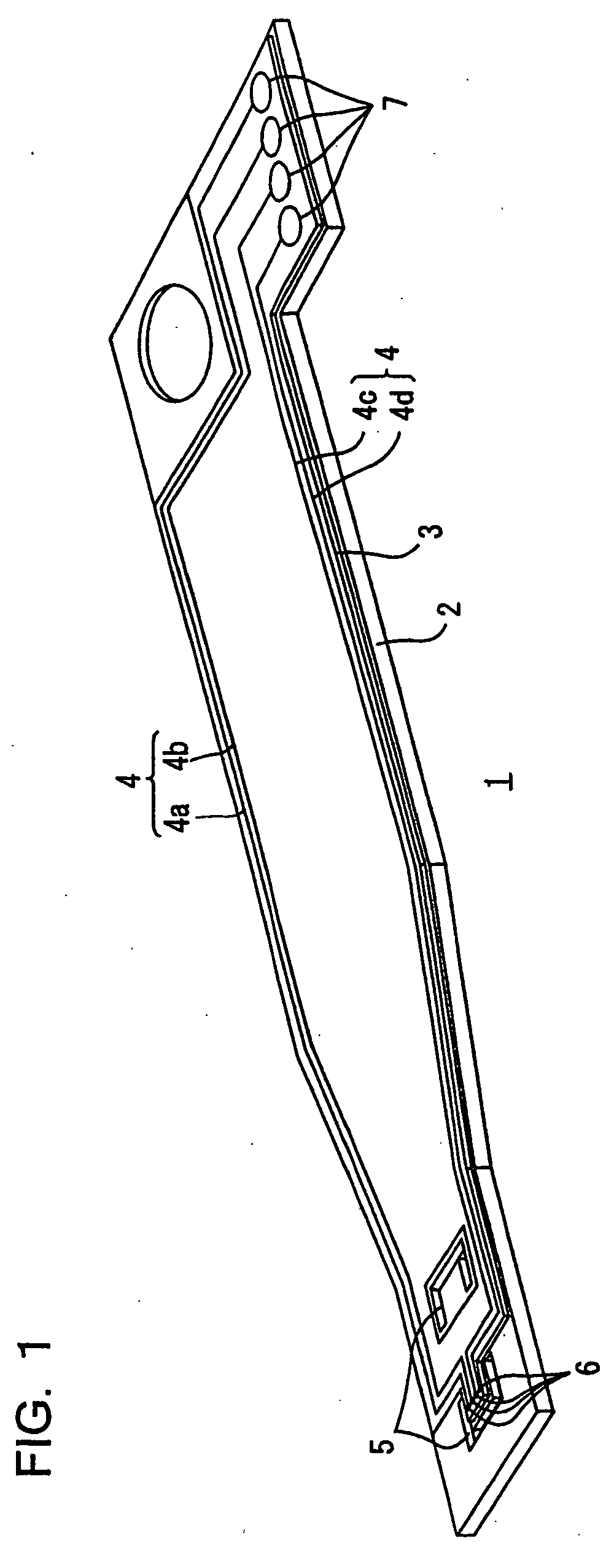

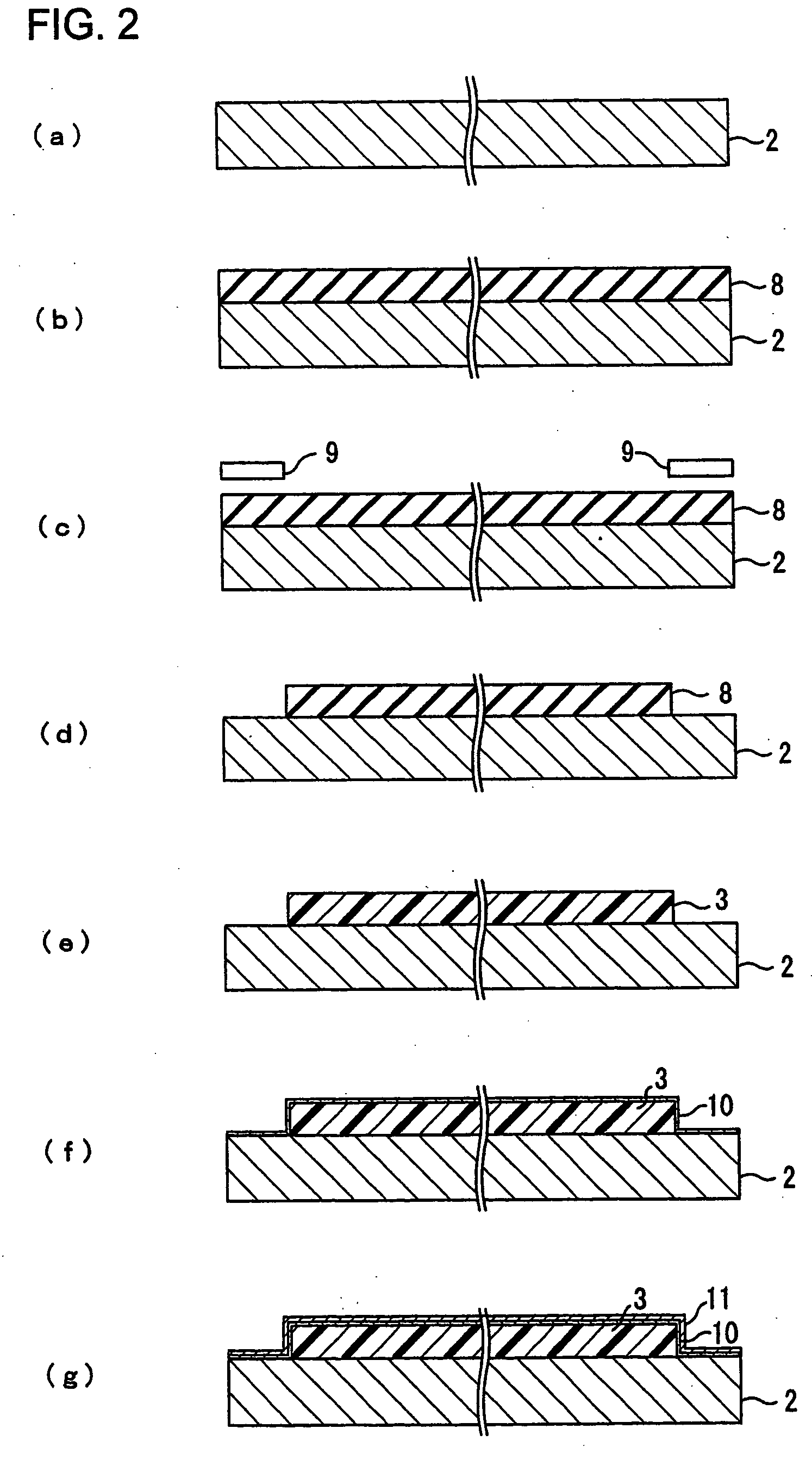

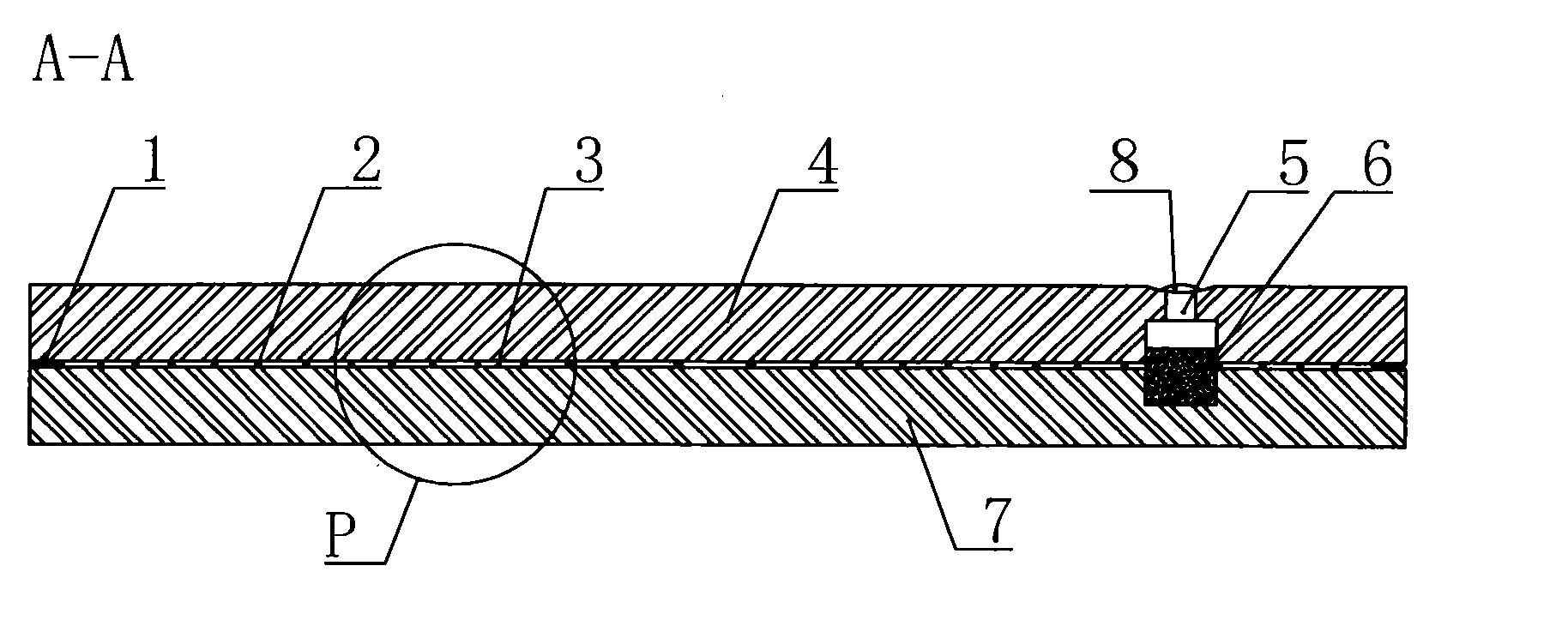

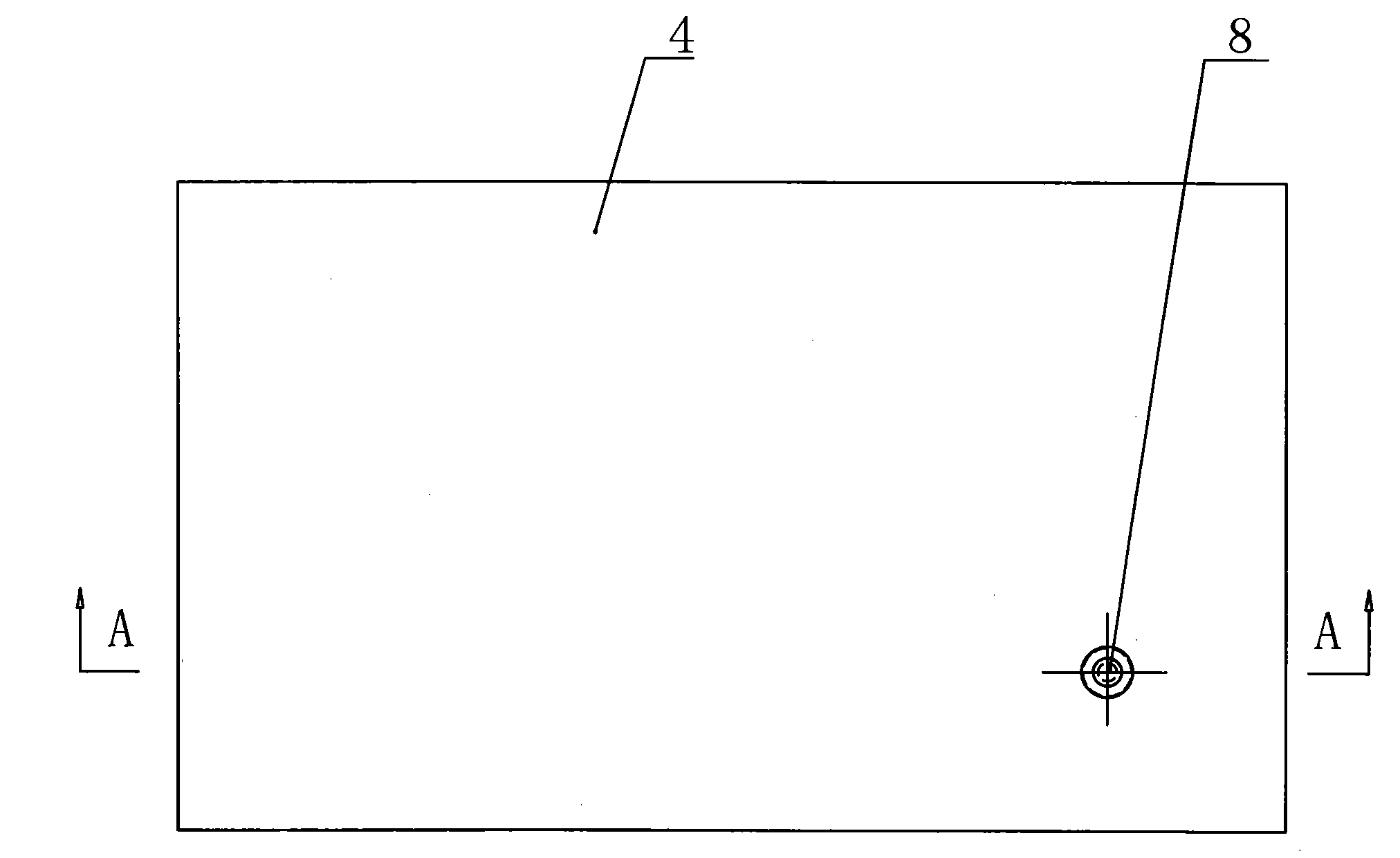

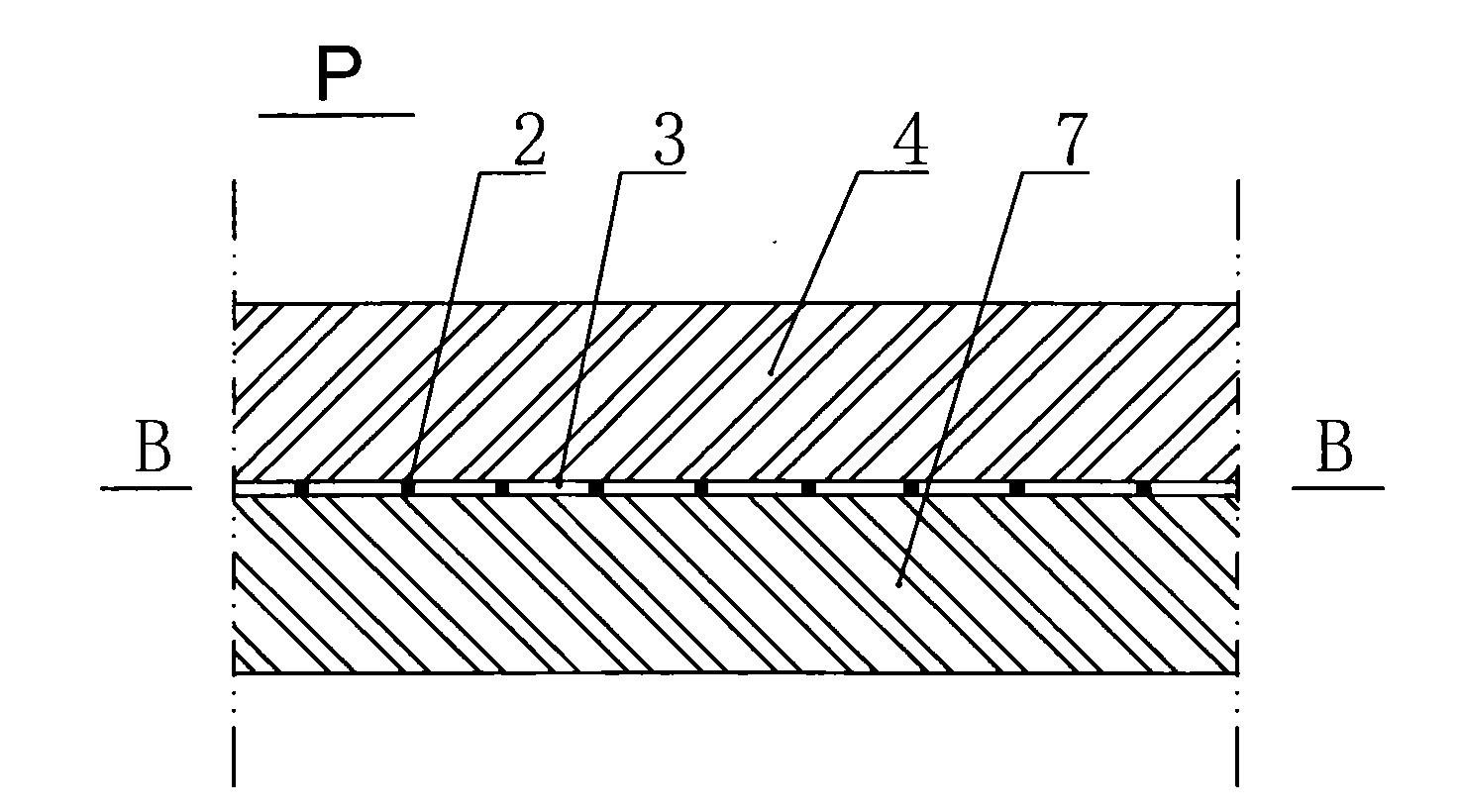

Production method of suspension board with circuit

InactiveUS20050186332A1Preventing deterioration of outward appearance and defectPrevent deterioration of outward appearance and defectFluid-dynamic spacing of headsRecord information storageResistElectrical conductor

In order to provide a new production method of a suspension board with circuit capable of preventing deterioration of the outward appearance and defects in products caused by a metal supporting layer, and further capable of forming an electroless nickel plating layer having an even thickness in a reliable manner, an insulating base layer is first formed on a supporting board, and a chromium thin film and a copper thin film are formed next sequentially on the surface of the supporting board exposed from the insulating base layer and on the entire surface of the insulating base layer. Subsequently, a plating resist is formed in a reversal pattern with respect to the wired circuit pattern on the surface of the copper thin film, and a conductor layer is formed on the surface of the copper thin film exposed from the plating resist by electrolytic plating. The plating resist is removed after an electroless nickel plating layer is formed on the conductor layer. Subsequently, the copper thin film and the chromium thin film are removed sequentially, and an insulating cover layer is formed next.

Owner:NITTO DENKO CORP

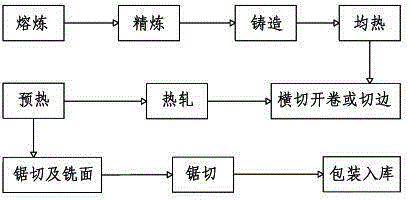

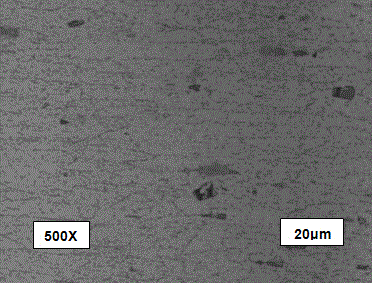

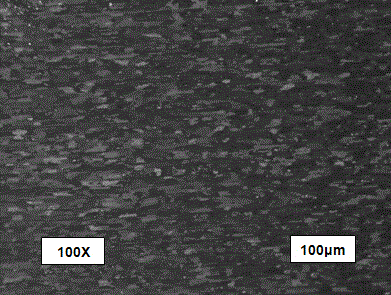

Preparation method for high-magnesium aluminum alloy O-state plate of 5XXX series

InactiveCN105177327AReduce the production process of annealingReduce production processHigh magnesiumAlloy

The invention relates to a preparation method for a high-magnesium aluminum alloy O-state plate of 5XXX series. The method comprises the steps of smelting, refining, casting, soaking, saw cutting, surface milling, preheating, hot rolling, cross-cutting and uncoiling or edge trimming, saw cutting, packaging and warehousing and the like. According to the preparation method, the high-magnesium aluminum alloy O-state plate of the 5XXX series is prepared through a new production process, under the condition that the performance and structure stability of high-magnesium aluminum alloy are maintained, the production procedures can be reduced, and surface quality defects of the high-magnesium aluminum alloy can be reduced; products can be directly produced after the aluminum alloy plate with the thickness being equal to or larger than 3 mm is subjected to hot rolling, the product yield can be substantially increased, and production efficiency can be improved sufficiently.

Owner:广西南南铝加工有限公司

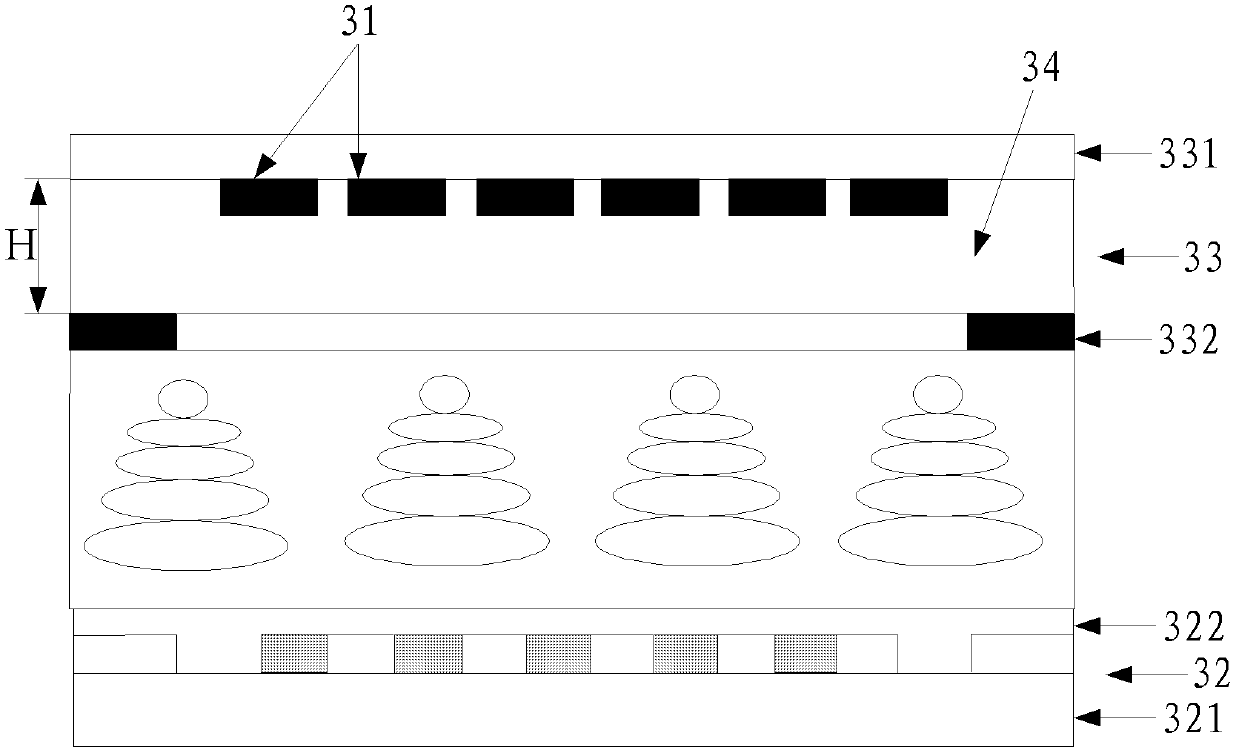

Array substrate, dual field of view display device and manufacturing method thereof

ActiveCN102629607AReduce manufacturing costIncrease visual rangeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The embodiment of the invention provides an array substrate, a dual field of view display device and a manufacturing method thereof, relating to the field of display technology. The array substrate comprises a plurality of pixel units divided by grid lines and data lines which are crossed vertically and horizontally. Each pixel unit comprises a pixel electrode and a TFT circuit, wherein the pixel electrode of each pixel unit comprises at least two first pixel electrodes and at least two second pixel electrodes which are mutually spaced, and the TFT circuit of each pixel unit comprises a first sub TFT circuit connecting with the first pixel electrode and a second sub TFT circuit connecting with the second pixel electrode. The above array substrate is used by the dual field of view display device. Since the above array substrate is used, a double vision baffle can be made in the display device, adding a new working procedure or employing new production equipment is avoided, thus production cost is reduced. The embodiment of the invention is used for manufacturing the dual field of view display device.

Owner:BOE TECH GRP CO LTD

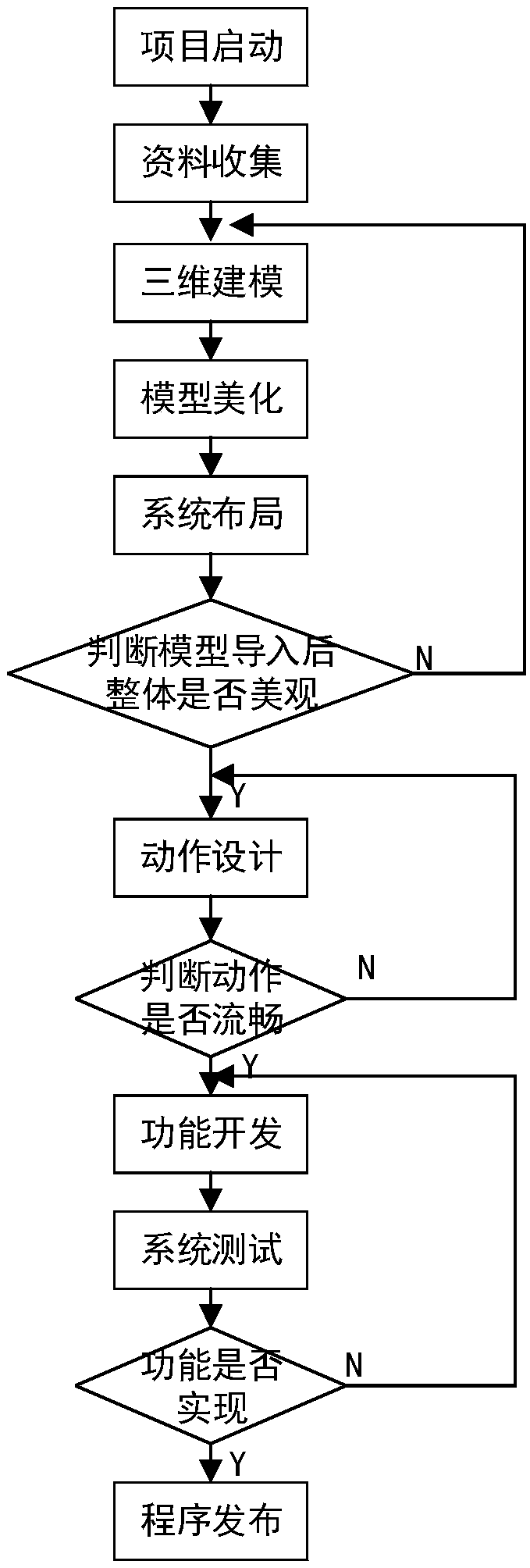

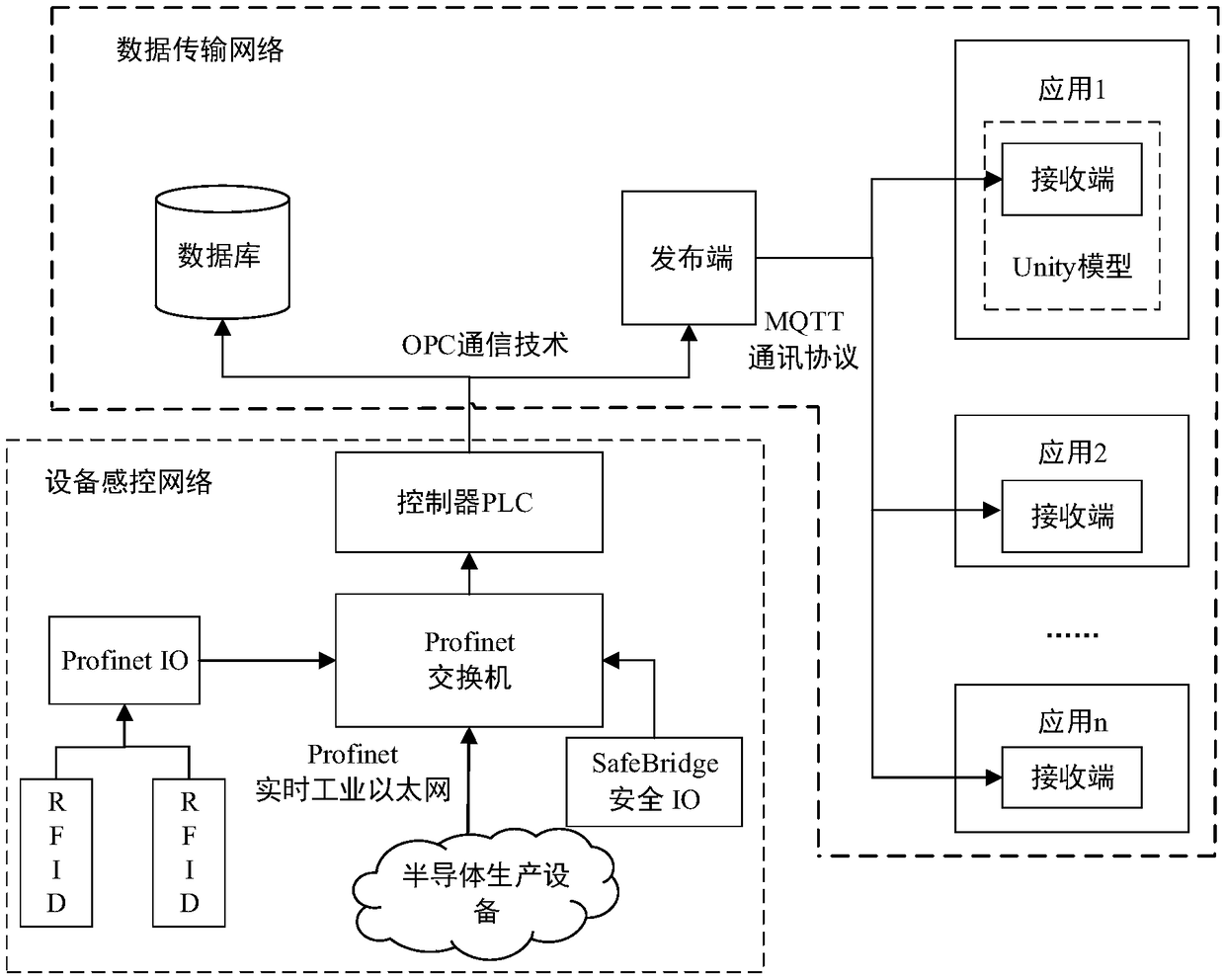

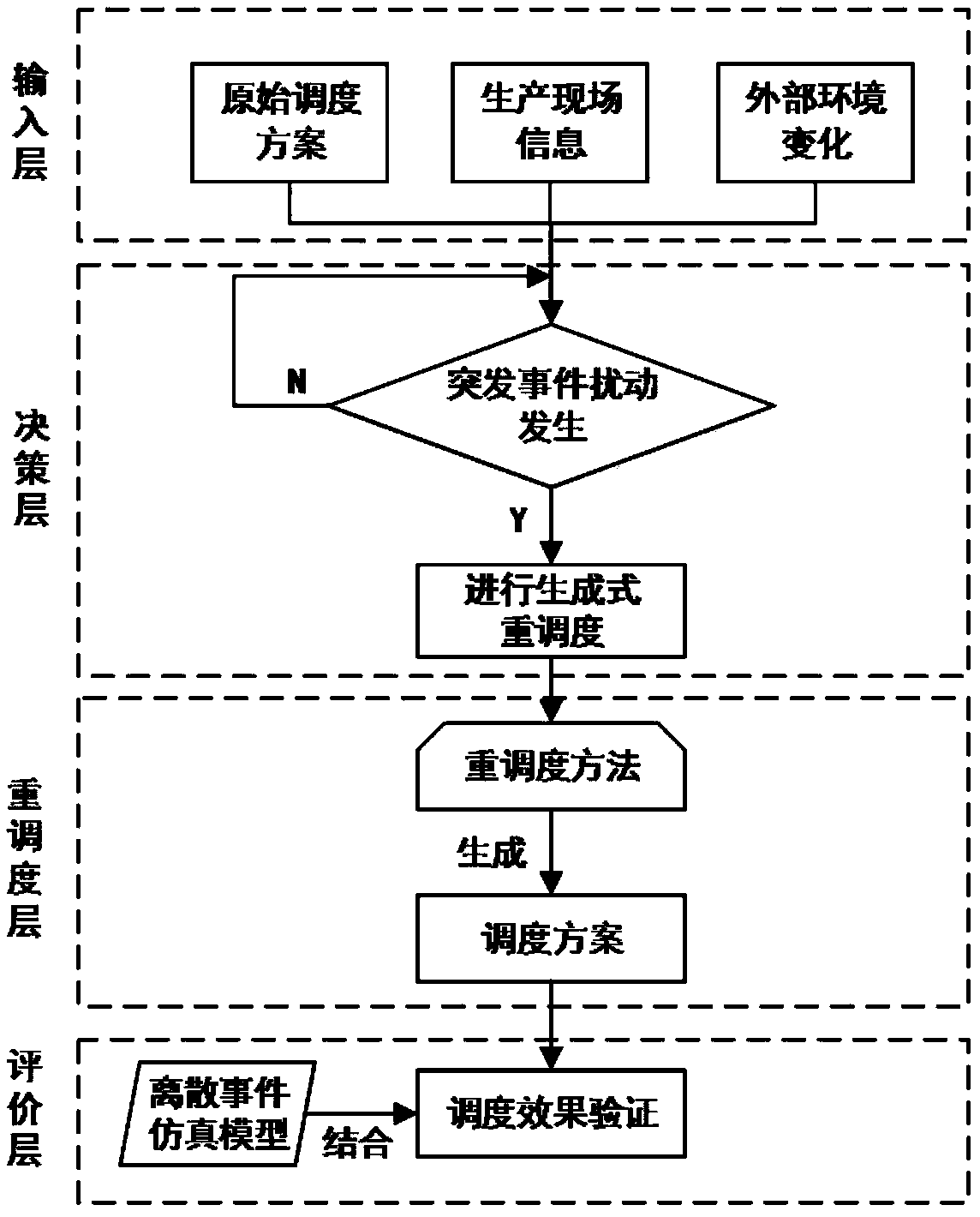

Scheduling optimization method and device in semiconductor production line CPS environment

InactiveCN108829052ARealize the digital modeling processStereoscopic displayTotal factory controlProgramme total factory controlProduction lineVariation of information

The invention relates to a scheduling optimization method and device in a semiconductor production line CPS environment, and the method specifically comprises the steps: constructing a semiconductor production line CPS environment for scheduling; sensing various types of sudden disturbances of a semiconductor production line in a production process; and performing the re-scheduling based on the dynamic information of the production line during the occurrence of the sudden disturbances. The device comprises a communication module which achieves the communication with an actual production line;a CPS environment constructing module which is used for constructing a digitalized three-dimensional model; a scheduling optimization design module which is used for sensing the production informationin real time, triggering the re-scheduling when the production information changes, generating a new production line scheduling scheme according to the dynamic information of the production line, andachieving the re-scheduling. Compared with the prior art, the method and device have the advantages that the method and device can be used for the semiconductor production line and other complex manufacturing systems, are high in timeliness, and are good in scheduling effect.

Owner:TONGJI UNIV

New production technique for fruit and vegetable canned food

InactiveCN1631181AFruits/vegetable preservation by irradiation/electric treatmentPackaging under vacuum/special atmosphereMicrowave ovenFluid replacement

Disclosed is a production technique for fruit and vegetable canned food which comprises, preprocessing the fruit and vegetable foodstuff, loading into container, carrying out tunnel type microwave oven sterilization, capping with fluid replacement or not, then cooling down, airing, coating plaster, and boxing.

Owner:广州果子食品厂有限公司

Novel technique for producing manioc waste ethanol

InactiveCN101195836ASolve the use problemImprove stabilityBiofuelsFermentationAlcohol productionSlurry

The invention discloses a new cassava dreg alcohol production technology. The new production technology is characterized in that cassava dregs are separated from raw cassava or cassava dry plates to be separately performed steam boiling and saccharification, the dregs and water separation is performed to the cassava dregs after being saccharified, solid dregs are directly pulled out to be used as forage or fertilizer, and the filtrate of the cassava dregs saccharifing is used as the slurry-adjusting liquid of the raw cassava or the cassava dry plates. The production cycle of the method is short, the energy consumption is low, the operation is simple, and the product stability is high. The problem that the energy consumption of producing the cassava dregs alcohol is high and the pollution is serious are effectively solved, the economic efficiency of the cassava dregs is enhanced, the problem of the utilizing of the present cassava dreg wastes is solved, and the economic efficiency of cassava grain distilleries is enhanced.

Owner:广西农垦明阳生化有限公司

Method for knitting high-strength rope from high-strength polyethylene fibers

The invention relates to a new production method for knitting a high-strength rope from high-strength polyethylene fibers, which is superior to the current production method for ropes. The method of the invention comprises the following concrete steps: selecting high-strength large-tow polyethylene fibers; by homogenizing tension by a fiber tension device, twisting and stranding multiple tows of fibers; homogenizing the tension of multiple strands of twisted fibers according to the specification requirements of the rope, combining the multiple strands of twisted fibers, and then homogenizing the tension of the combined single-strand tows; knitting 12 strands of ropes by a knitting machine; and coating resin on the surface, drying and shaping to form a high-strength polyethylene fiber rope. The rope produced by the invention has the advantages of convenient use, high strength, corrosion resistance, wear resistance, excellent toughness and flexibility, long service life and the like, and can be widely applied to the fields of industries, national defense, physical education, oceans and the like.

Owner:NINGBO DACHENG ADVANCED MATERIAL

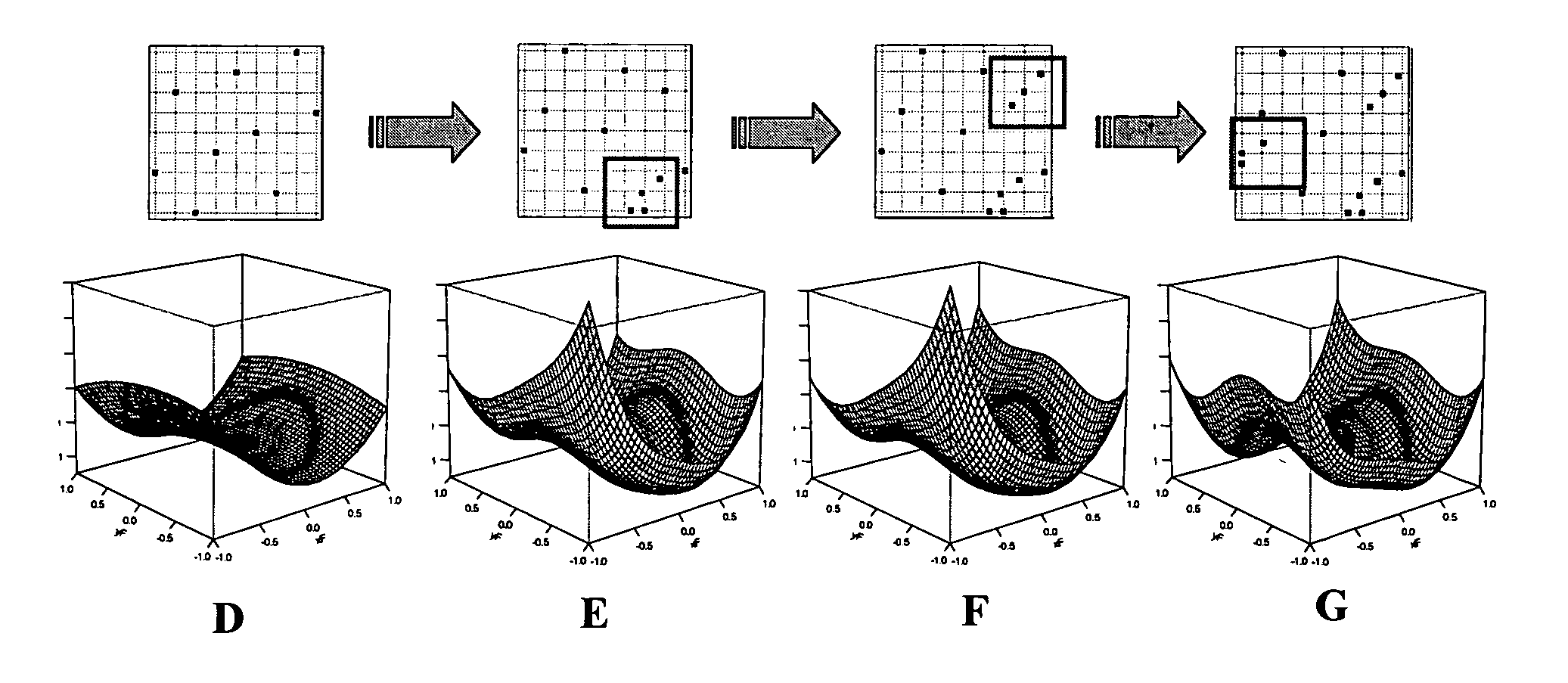

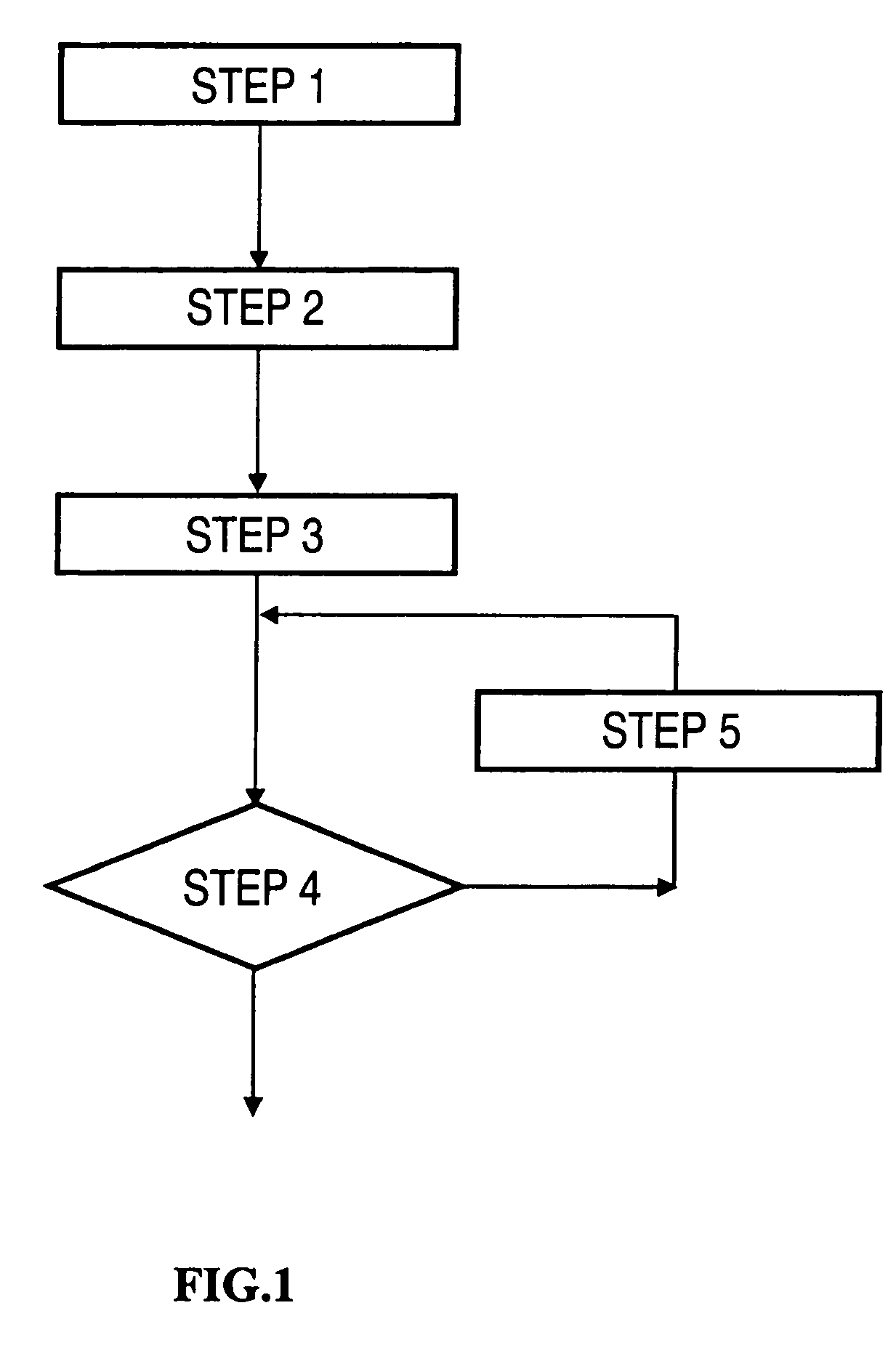

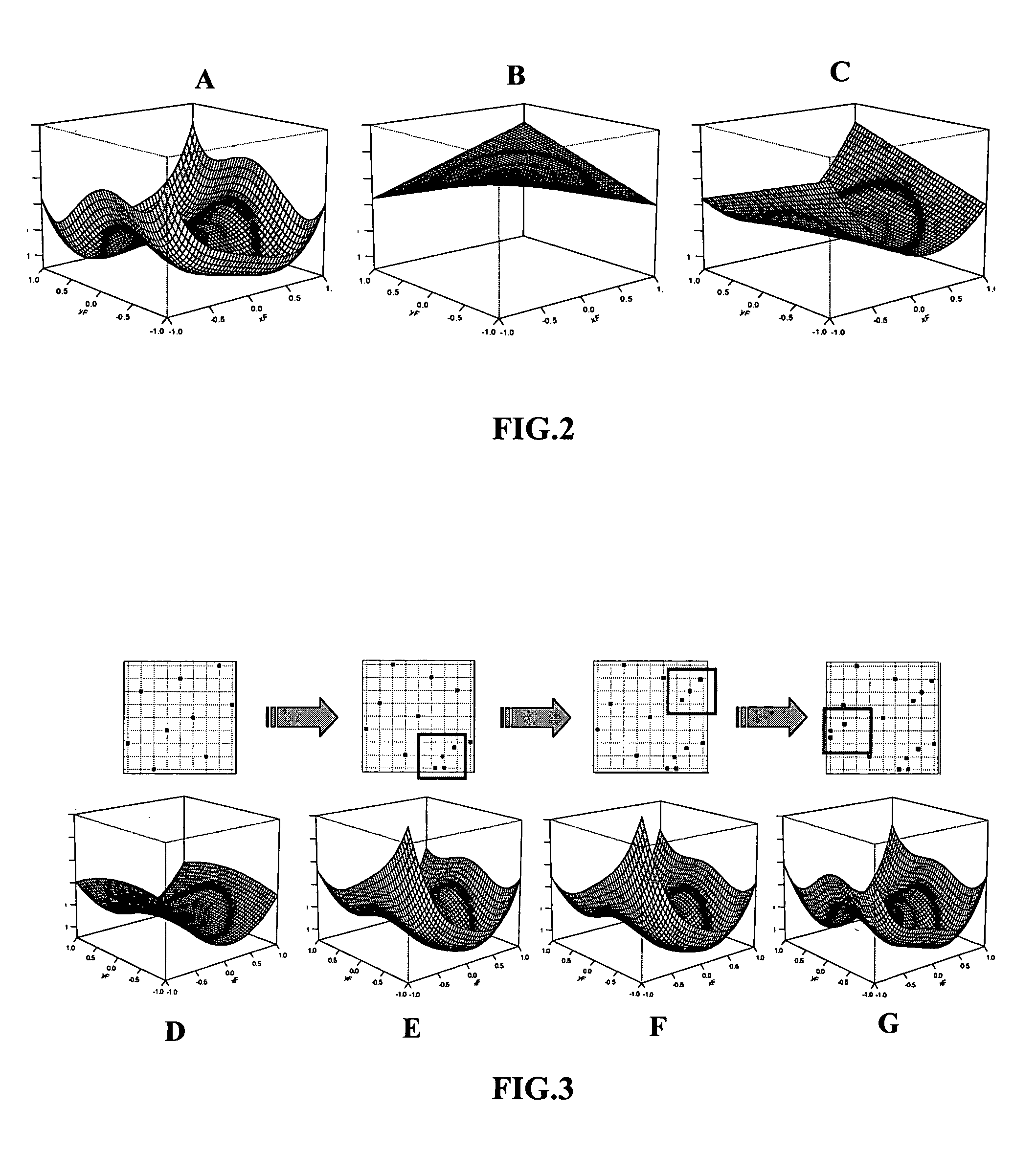

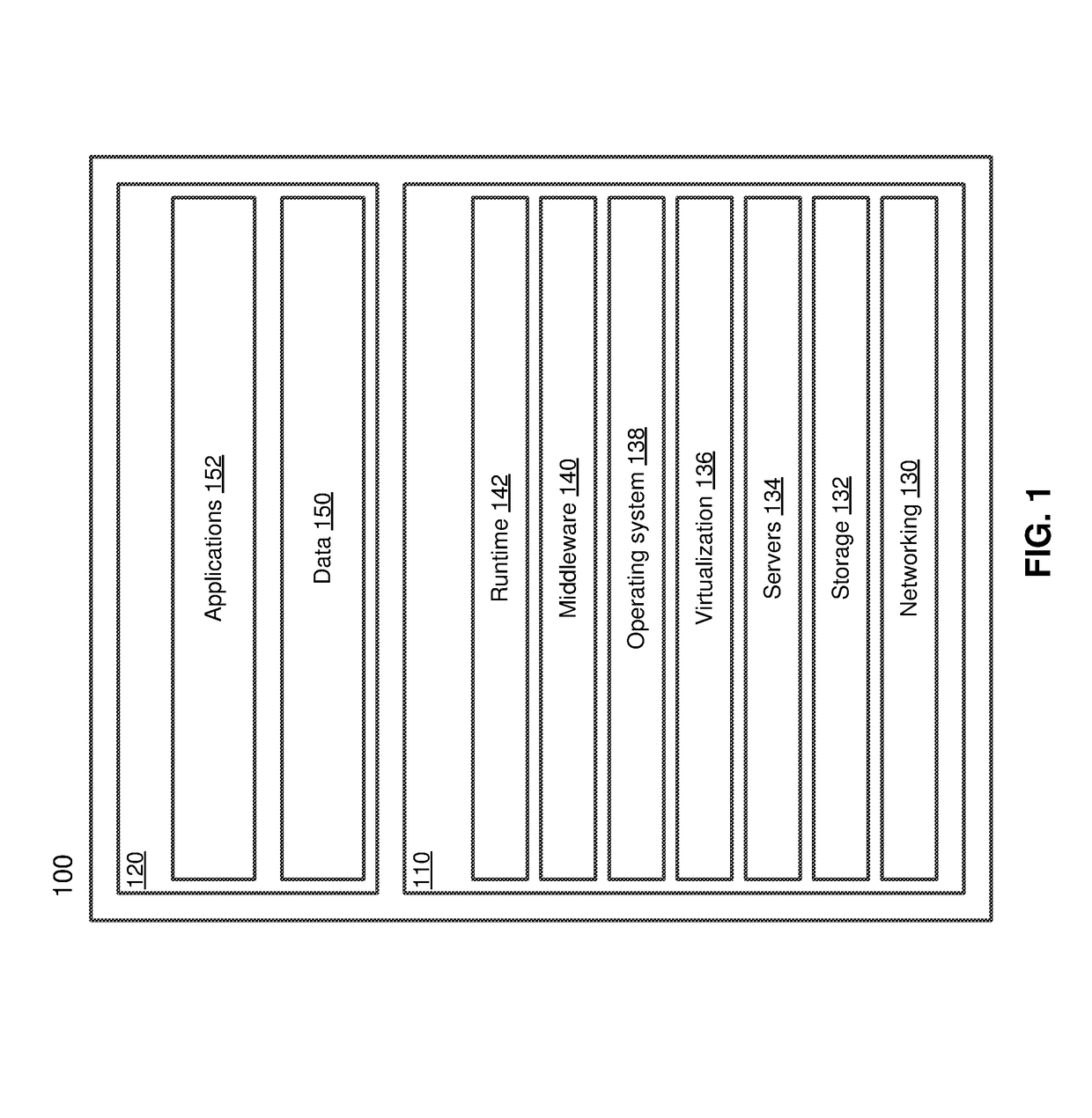

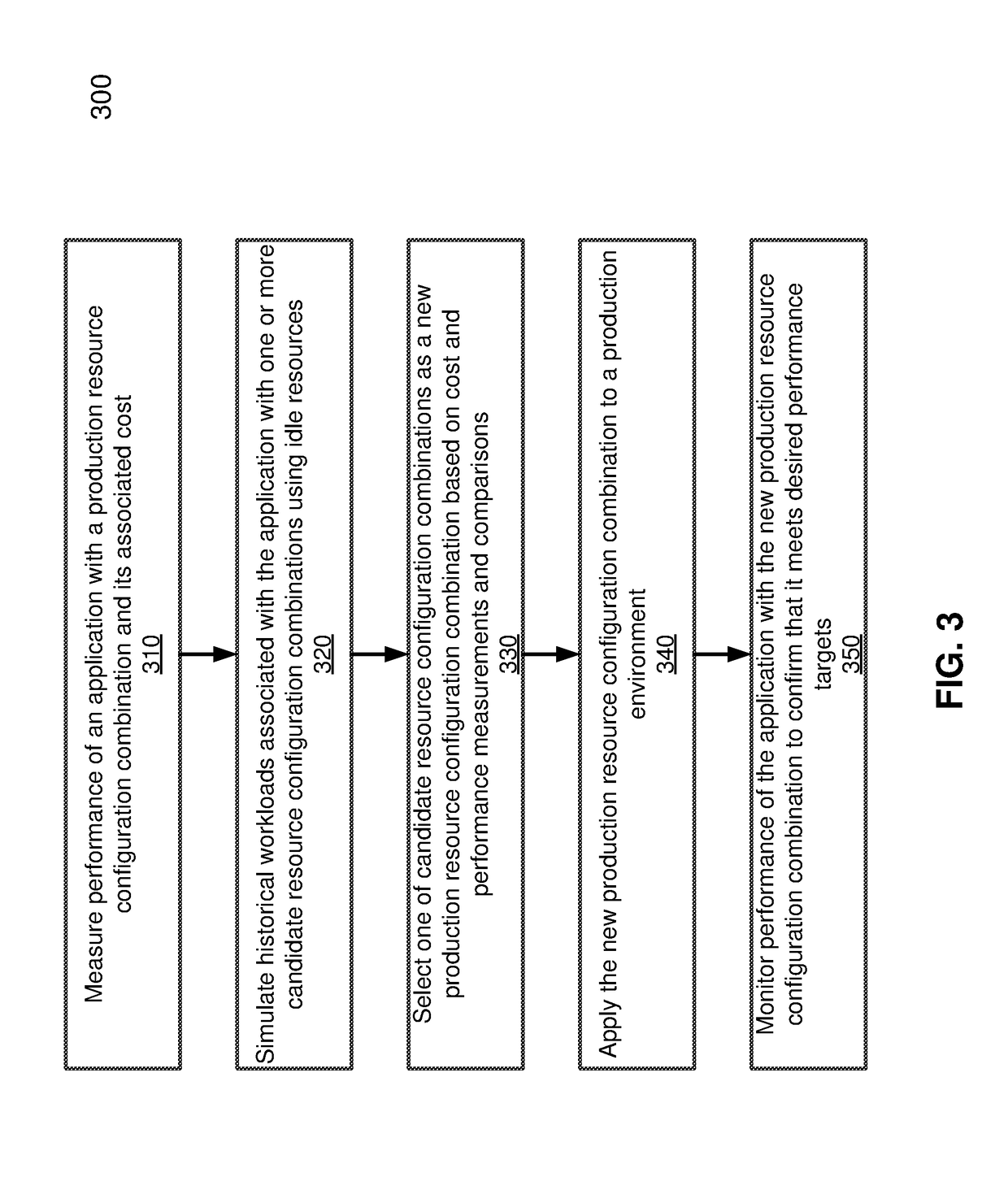

Implementing continues PaaS apps resource optimization using production workload replay with intelligent configuration permutations

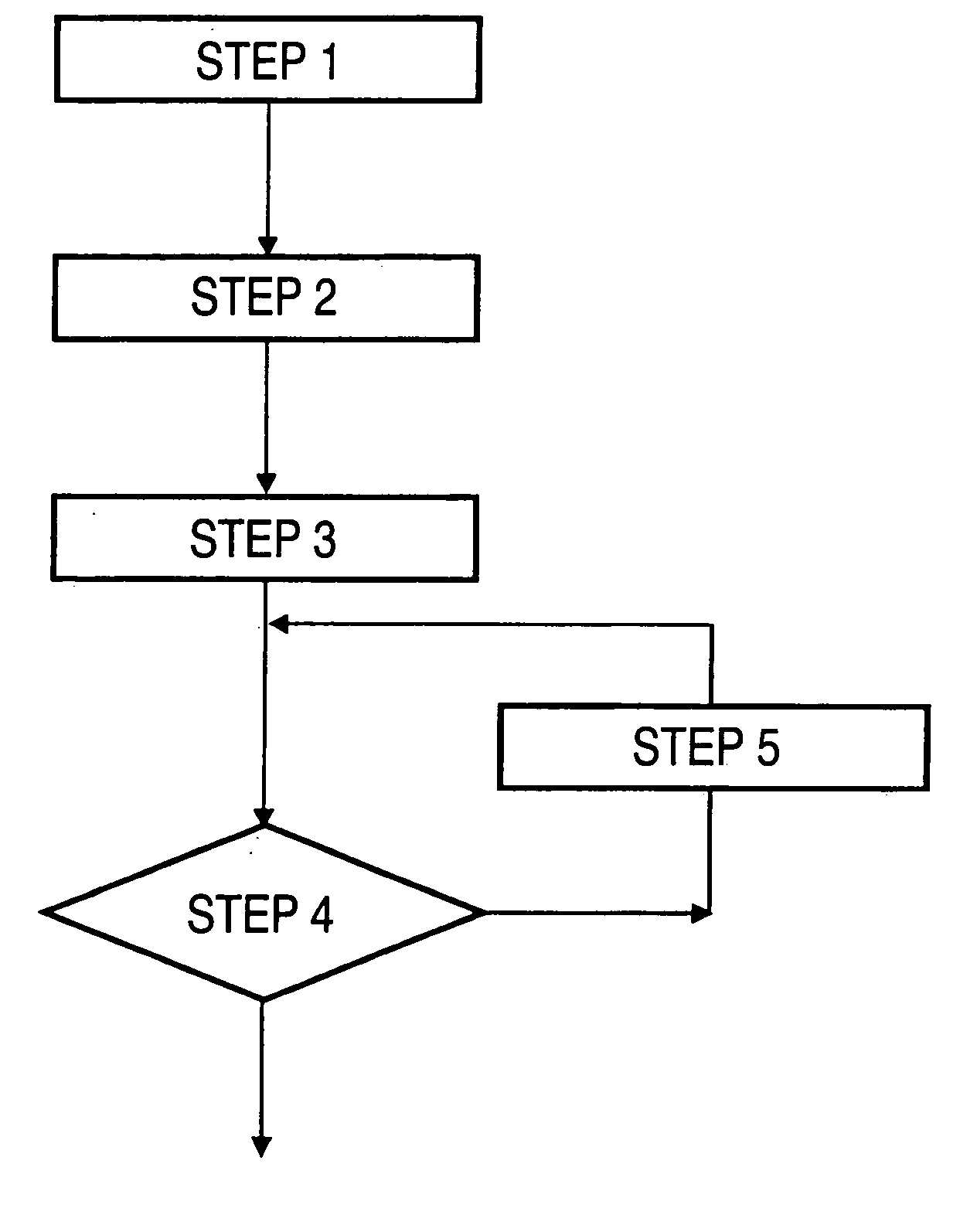

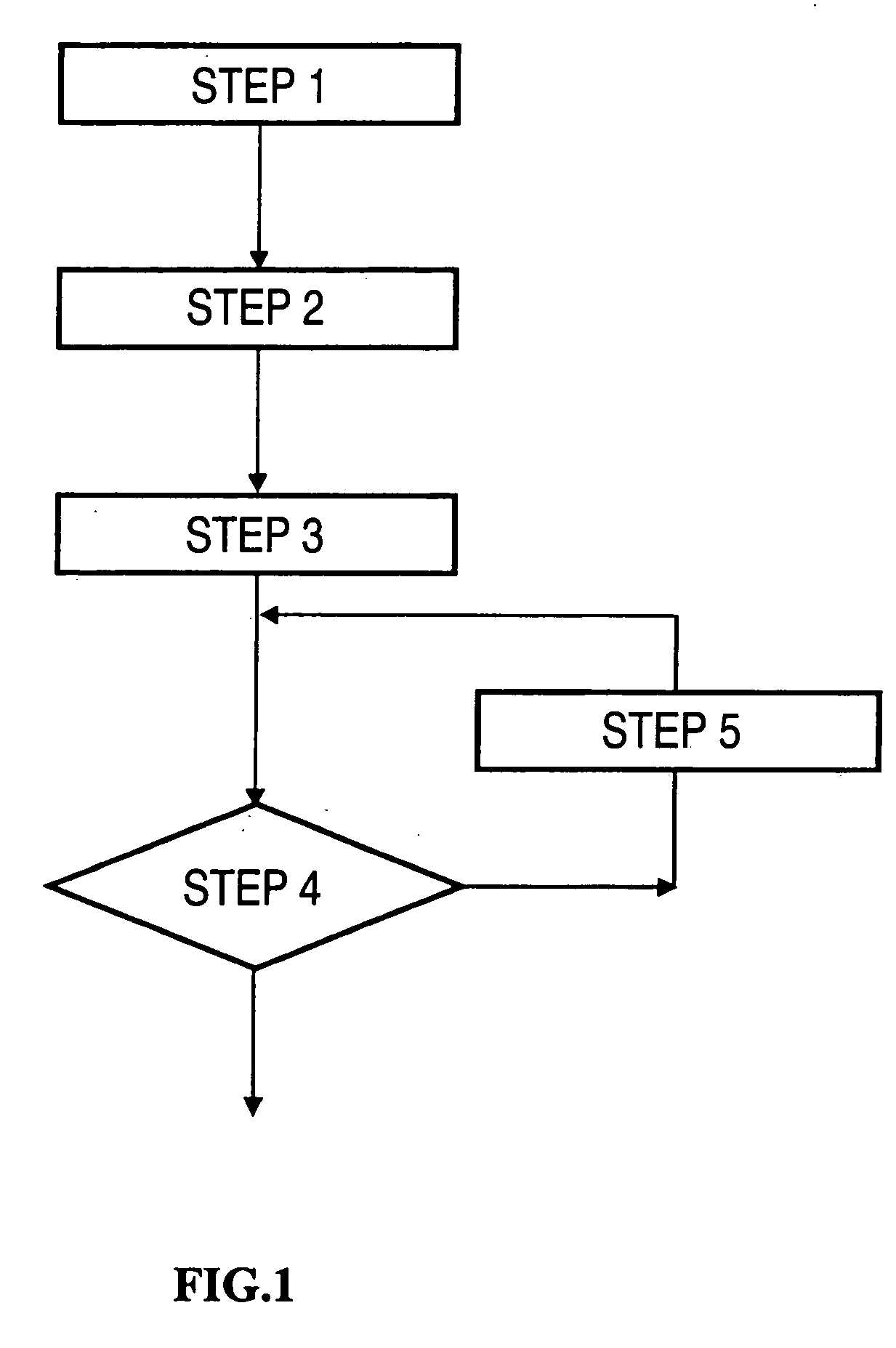

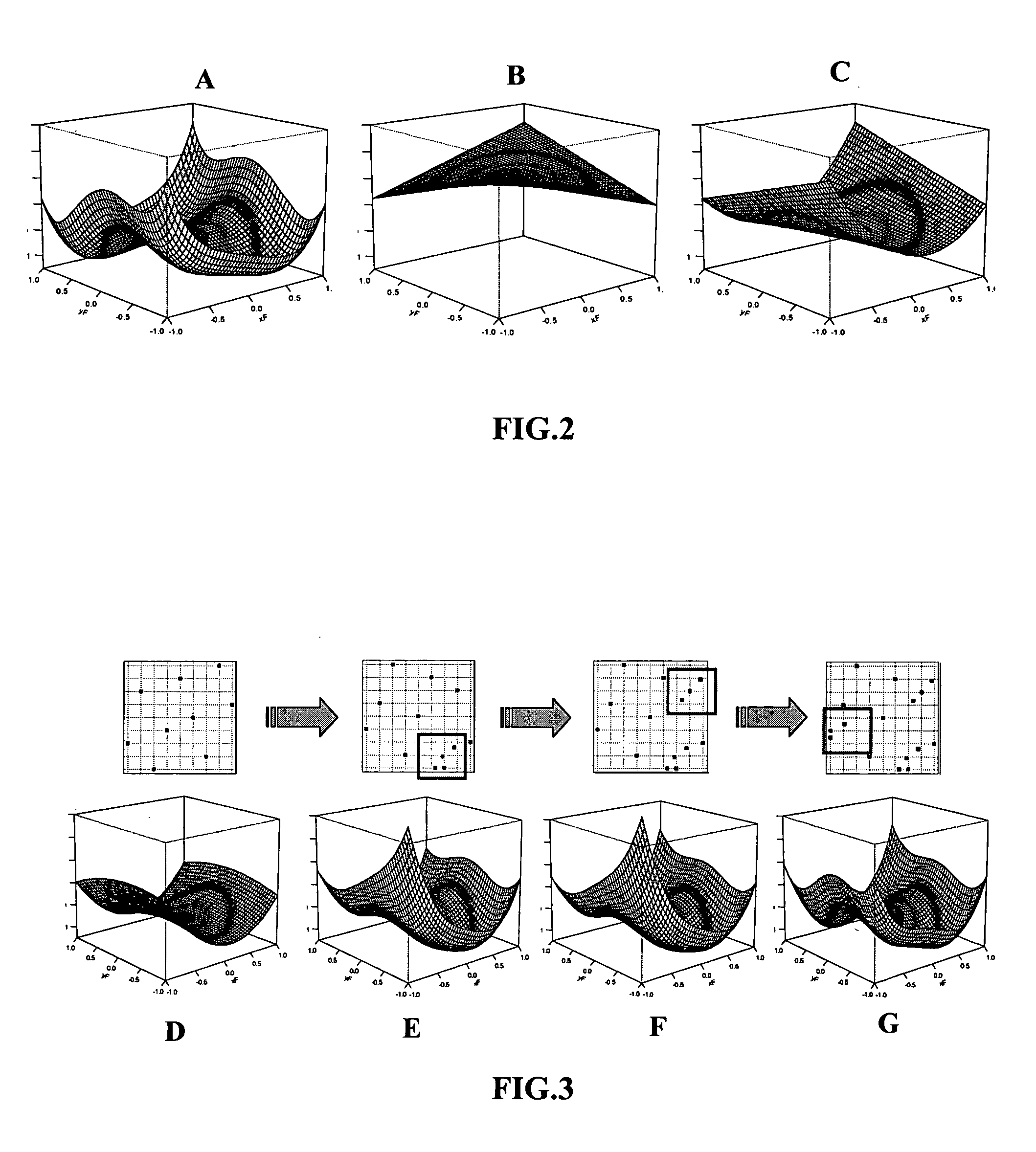

One embodiment is related to a method for determining an optimal resource configuration combination, comprising: (1) measuring performance of an application with a production resource configuration combination and its associated cost; (2) simulating historical workloads associated with the application with one or more candidate resource configuration combinations using idle resources; (3) selecting one of the candidate resource configuration combinations as a new production resource configuration combination based on cost and performance measurements and comparisons; (4) applying the new production resource configuration combination to a production environment; and (5) monitoring performance of the application with the new production resource configuration combination to confirm that it meets desired performance targets, wherein operations (1) to (5) are performed on a Platform as a Service (PaaS) platform.

Owner:EMC IP HLDG CO LLC

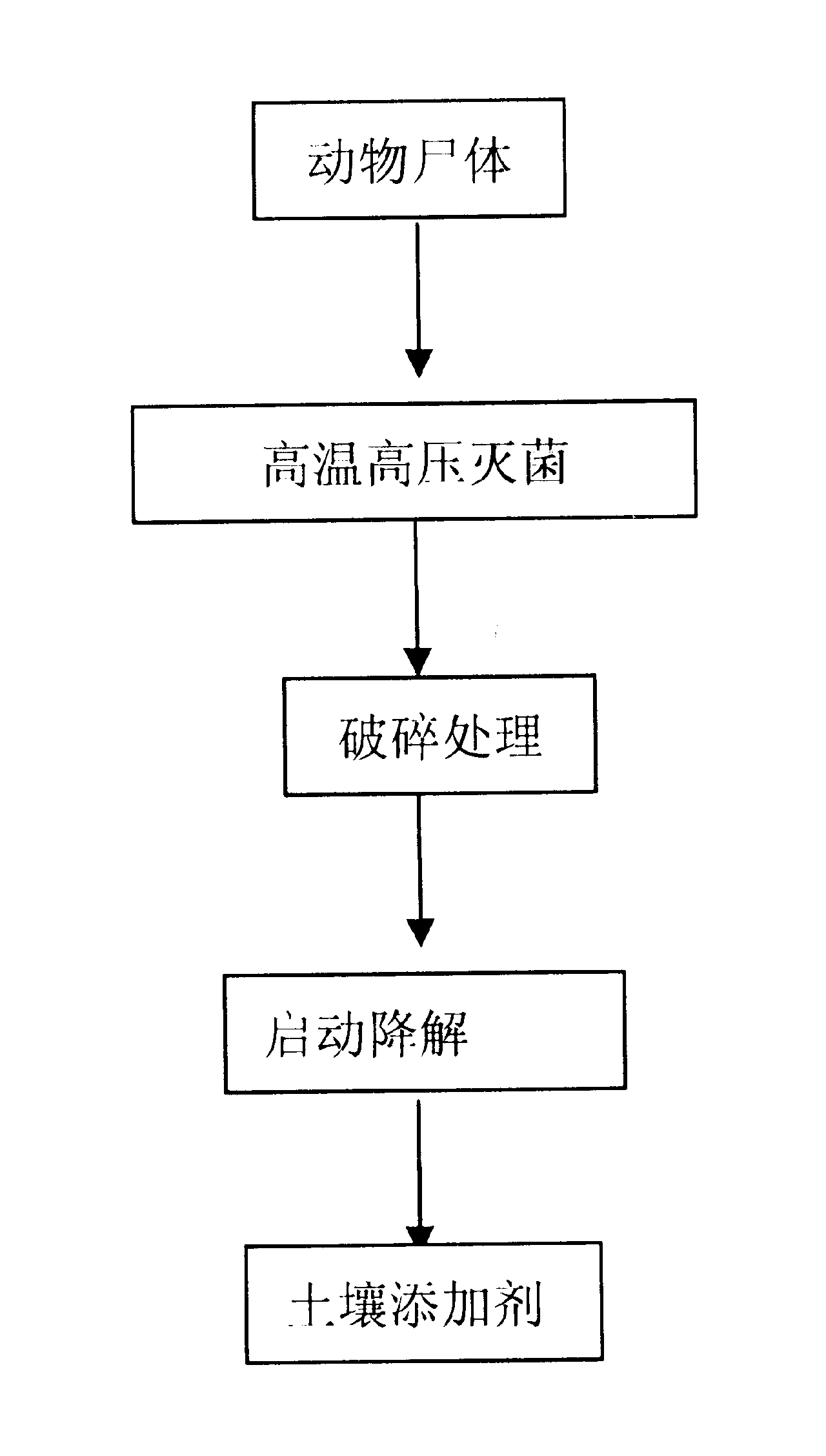

Method for performing innocent treatment on carcasses

InactiveCN103073336ARapid SterilizationBatch sterilizationBio-organic fraction processingAnimal corpse fertilisersPathogenic microorganismPlant disease

The invention discloses a method for quickly performing high temperature sterilization on carcasses in batches and degrading the carcasses into soil fertilizers. The method comprises the following steps: 1, sterilizing tissues of the carcasses; 2, crushing; and 3, starting degradation. According to the method, a brand new production technology is utilized to realize the quick and batch treatment on the ill carcasses; the pathogenic microorganism is effectively killed; and the purposes of recycling waste resources and protecting environment are achieved.

Owner:全勇

New production process of toughened vacuum glass

ActiveCN102040329AEnsure safetyThickness is easy to adjustGlass reforming apparatusGlass tempering apparatusScreen printingFlat glass

The invention discloses a production process of toughened vacuum glass. The process is characterized by comprising the following process steps of: making a supporting point, namely making the supporting point on the surface of flat plate glass by a screen printing method; curing, namely airing naturally or drying so as to form the supporting point; manufacturing toughened glass with the supporting point; compounding and sealing; and vacuumizing and sealing an exhaust hole. The process has the advantages that: vacuum glass can be toughened or semi-toughened, so that the safety performance of a product is ensured and the application range of the product is expanded; the glass supporting point is processed in a screen printing mode, so that production efficiency is improved, automatic level is raised, the process can be applied to mass production and the thickness of a vacuum layer is convenient to adjust; due to the application of lead-free glass powder, an environmentally-friendly and nontoxic product is obtained and the low energy consumption and high efficiency of production are ensured by the low melting point of the lead-free glass powder; and due to the application of an evapotranspiration getter, the service life of the product is prolonged effectively and the transparency of glass is enhanced effectively.

Owner:青岛新亨达真空玻璃技术有限公司

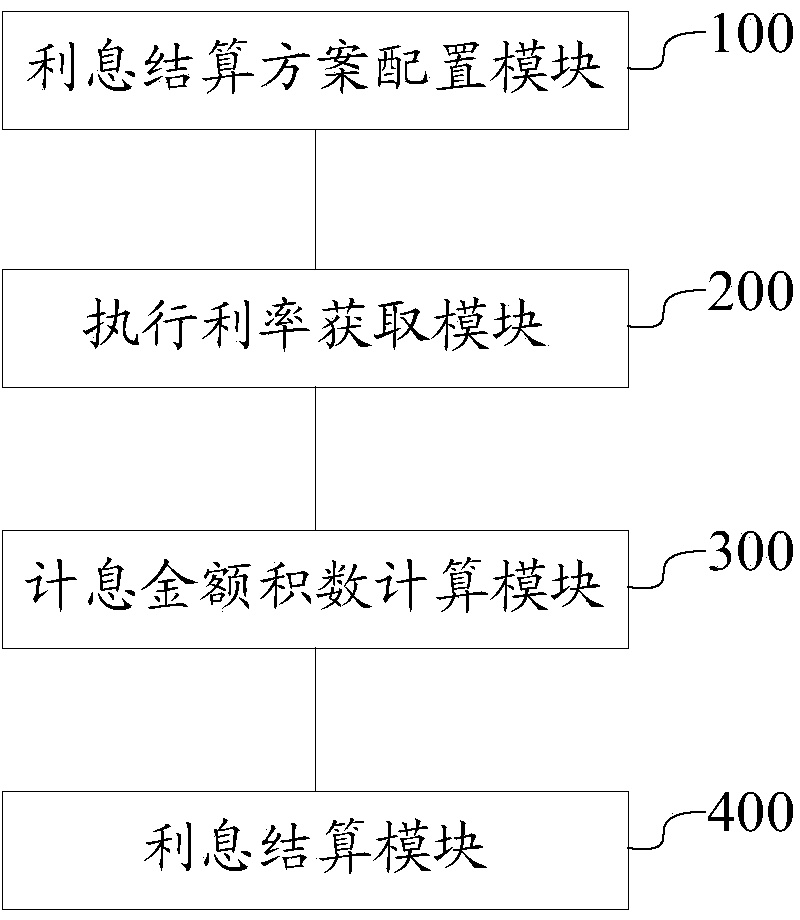

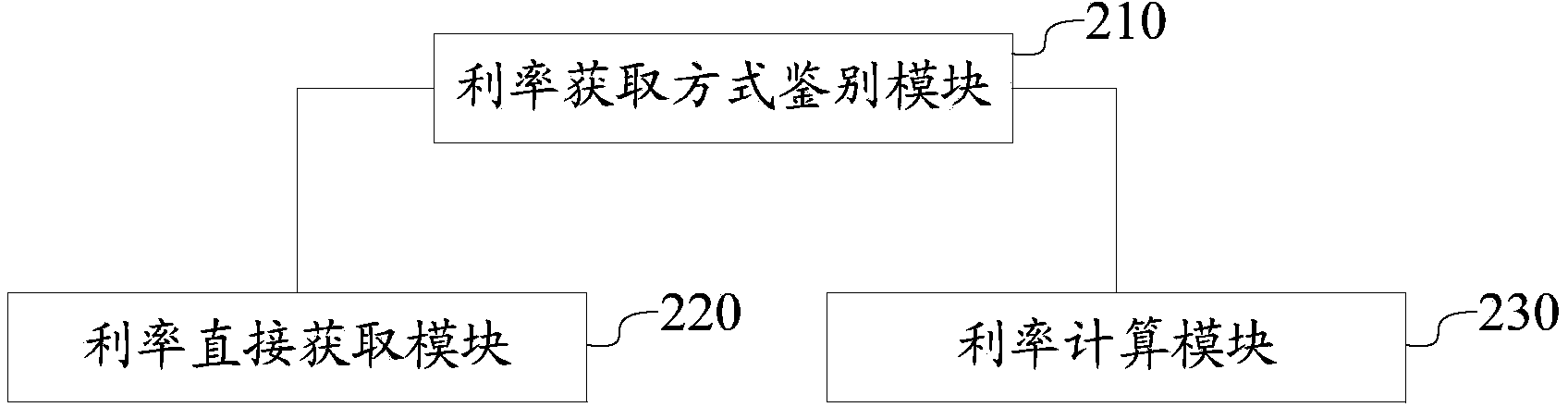

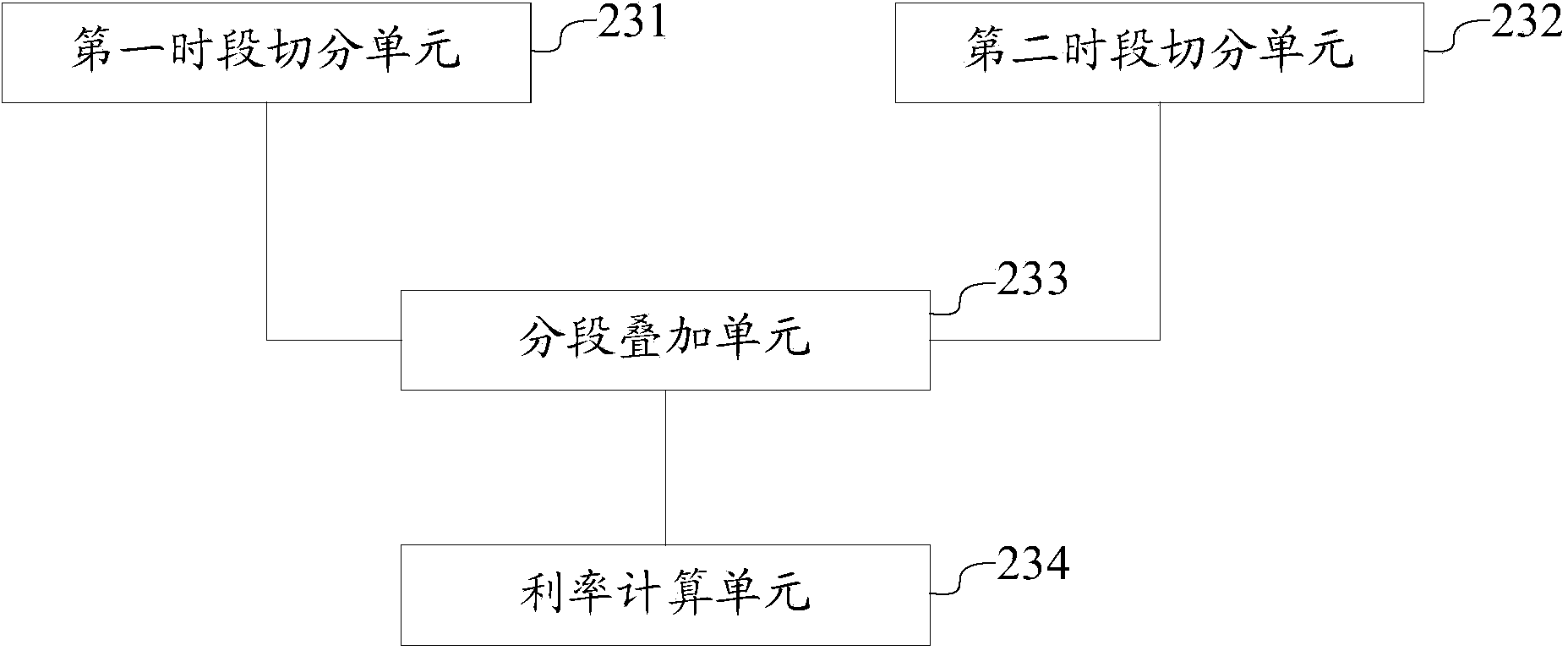

Interest settlement system and method

The invention discloses an interest settlement system and method. The system comprises an interest settlement scheme configuration module, a strike rate acquisition module, an interest accrual money accumulation calculation module and an interest settlement module. The method is based on a factorized design thought, a unified regulation of components of bank products is predefined, and then componentized and parameterized new production customization is achieved. Information used for interest settlement is derived from products, and therefore in the product establishment process, the interest settlement scheme configuration module can configure an interest settlement scheme according to the interest settlement requirement of products and based on componentized product information. The strike rate acquisition module and the interest accrual money accumulation calculation module acquire needed data from bank subsystems according to the interest settlement scheme, and eventually the interest settlement module calculates interest through the data. It can be seen that componentized and parameterized configuration of the interest settlement scheme is achieved, the interest settlement core process based on the product configuration is achieved, and the problems that in the prior art, the reuse degree is low, and the development workload is large are solved.

Owner:AGRICULTURAL BANK OF CHINA

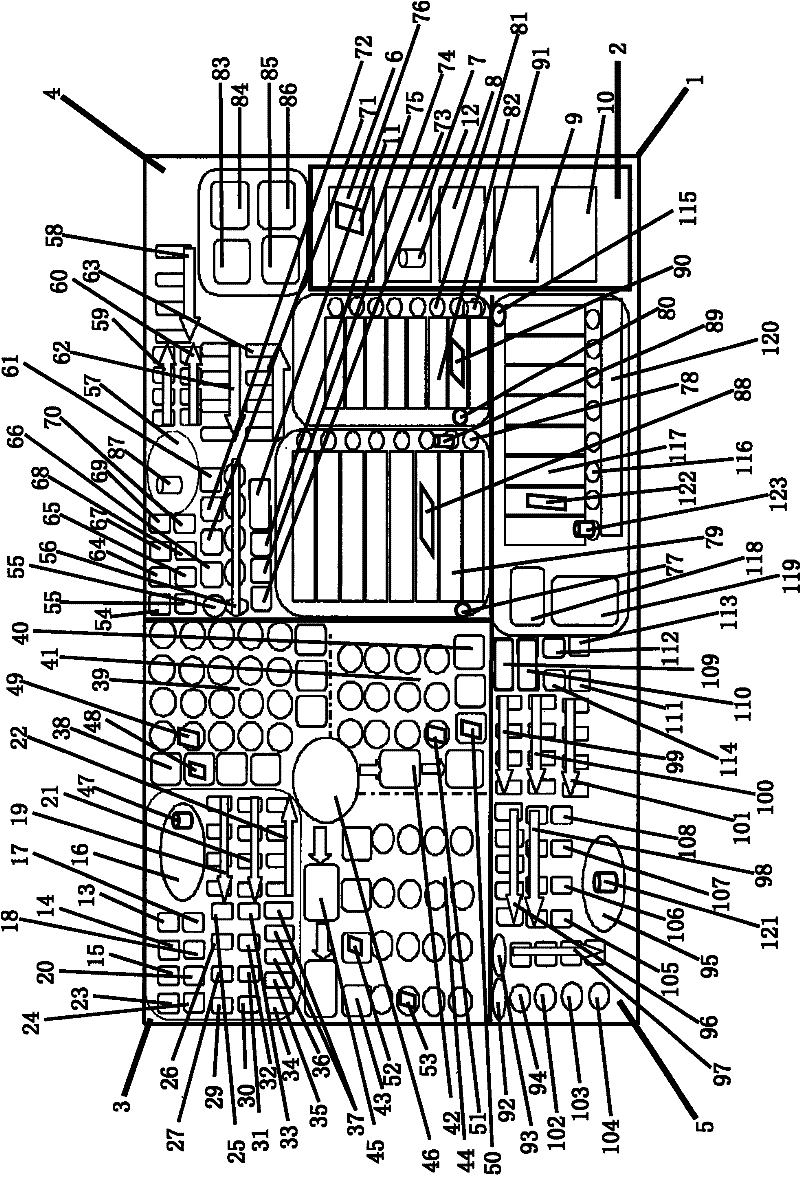

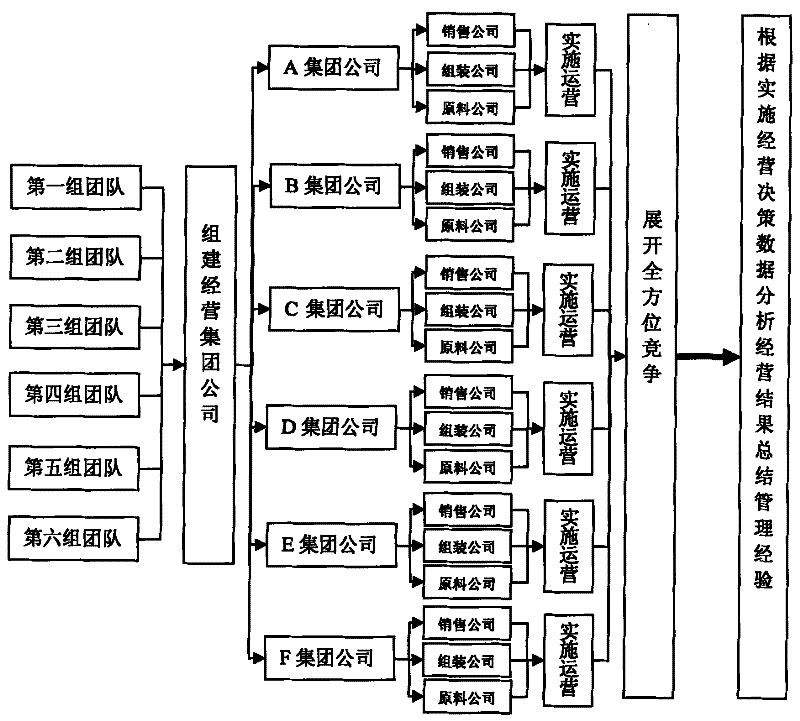

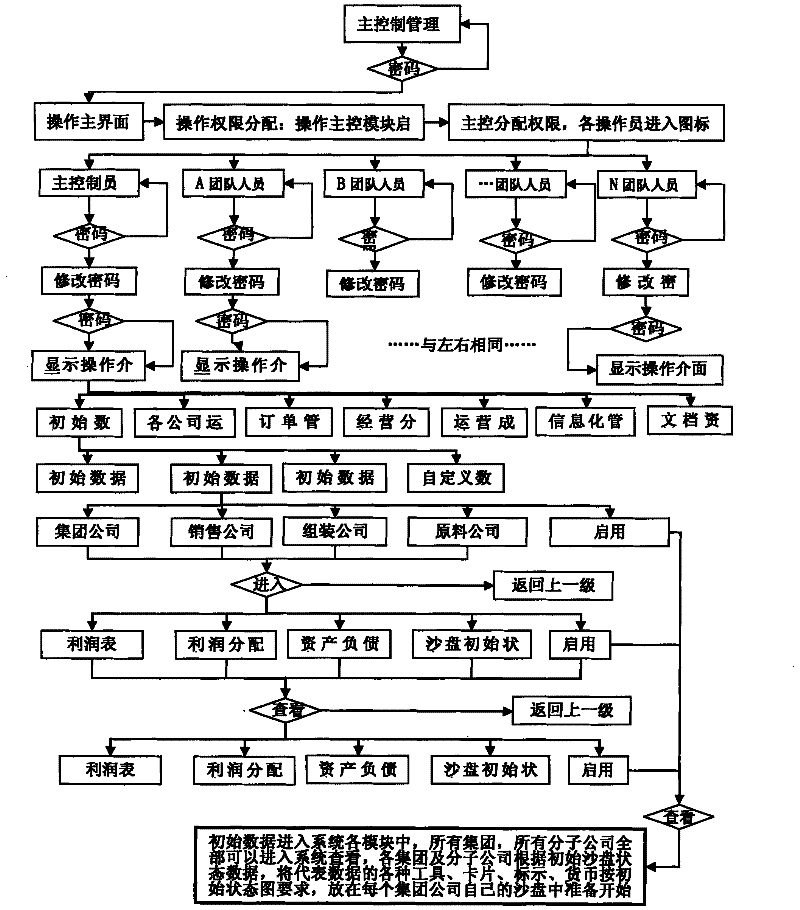

Enterprise resource planning multi-organization business operation sand table system

InactiveCN102184456AImprove management levelOptimize resource allocationTeaching apparatusDecision makerSoftware system

The invention discloses an enterprise resource planning (ERP) multi-organization business operation sand table system. A business operation simulation sand table and a business management software system based on characteristics of a discrete manufacturing industry, a currency industry and the like are exploited by a design; the business operation simulation sand table and the business management software system are combined to form a complete multi-organization operation simulation platform; no matter the system is used by a business decision maker or a business manager or applied to the field of teaching, by adoption of the ERP multi-organization business operation sand table system, changeable decision methods and decision results can be simulated. A set of complete management and decision platform is provided for the decision maker on the aspects of realizing a decision idea, finding out a new management method, researching a new production management flow, solving and searching the decision risk and the like.

Owner:詹亚辉

Ultrafine traditional Chinese medicinal granule piece and preparation process thereof

ActiveCN102727534AEvenly processedThoroughly concoctedPharmaceutical product form changeGranular deliveryMedicineSoft materials

The invention which belongs to the traditional Chinese medicinal piece field concretely relates to an ultrafine traditional Chinese medicinal granule piece and a preparation process thereof. The invention which aims at present granulation processes and devices, small viscosity of traditional Chinese medicines, and the defects of irregular shape, easy moisture absorbing and bad fluidity of prepared granules provides a new production process which allows the ultrafine traditional Chinese medicinal granule piece with regular shape and good fluidity to be prepared from the small viscosity traditional Chinese medicines. The preparation process comprises the following steps: crushing the traditional Chinese medicines until the crushed traditional Chinese medicines can pass a 80-100 mesh sieve, processing according to a routine method, and crushing the traditional Chinese medicines to 400-1200 meshes; preparing a soft material; granulating by adopting a compression granulator; and drying the granules. The granule piece of the invention, which is prepared through crushing, processing and re-crushing, allows the traditional Chinese medicines to be uniformly and thoroughly processed, and the granule piece obtained through granulating and shaping the small viscosity traditional Chinese medicines by strong extruding force of the compression granulator has the advantages of regular shape, good visibility, small specific surface area, difficult moisture absorbing, and good fluidity, and can satisfy clinical medicine demands.

Owner:SICHUAN JINSUIFANG PHARMA

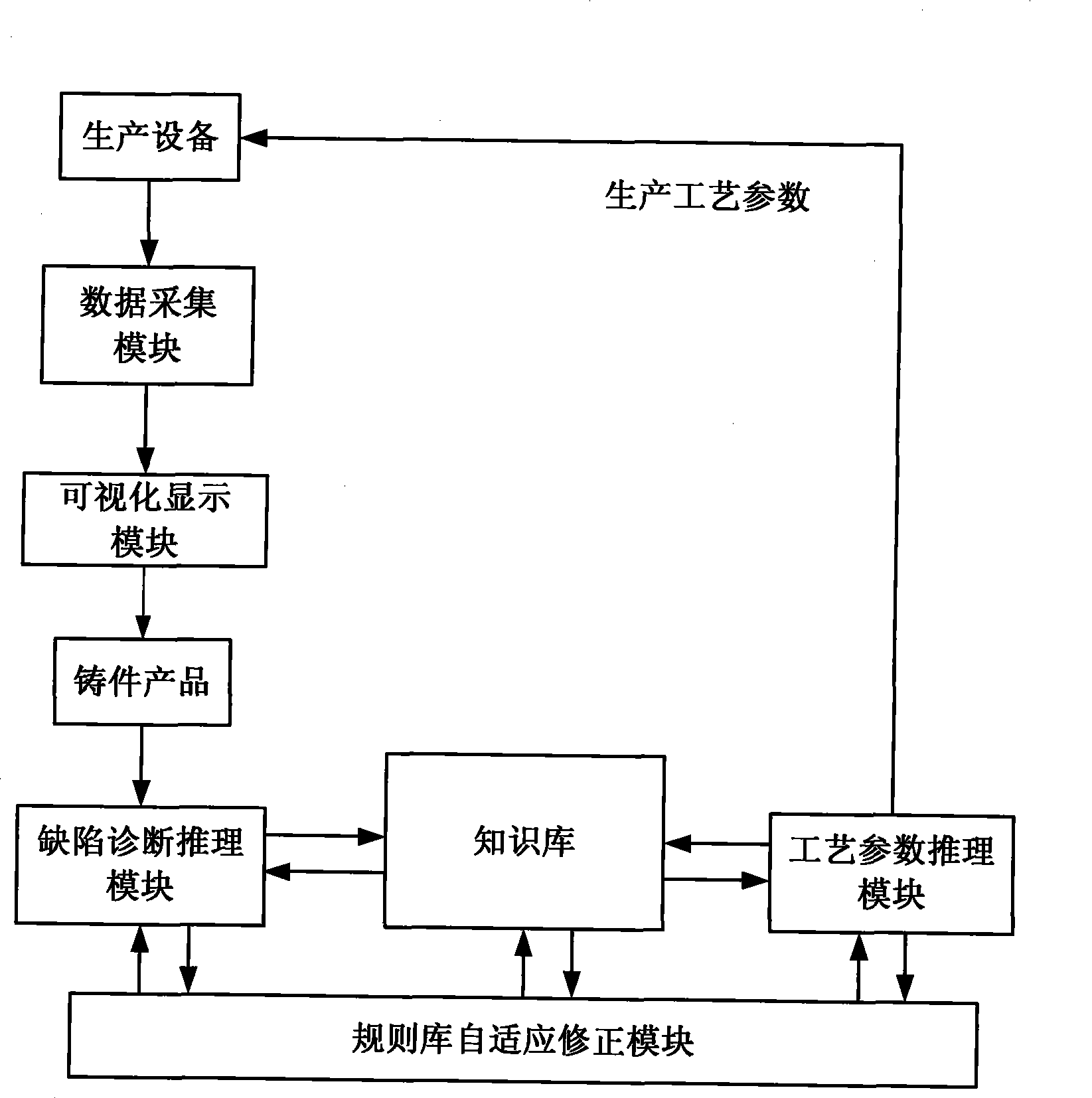

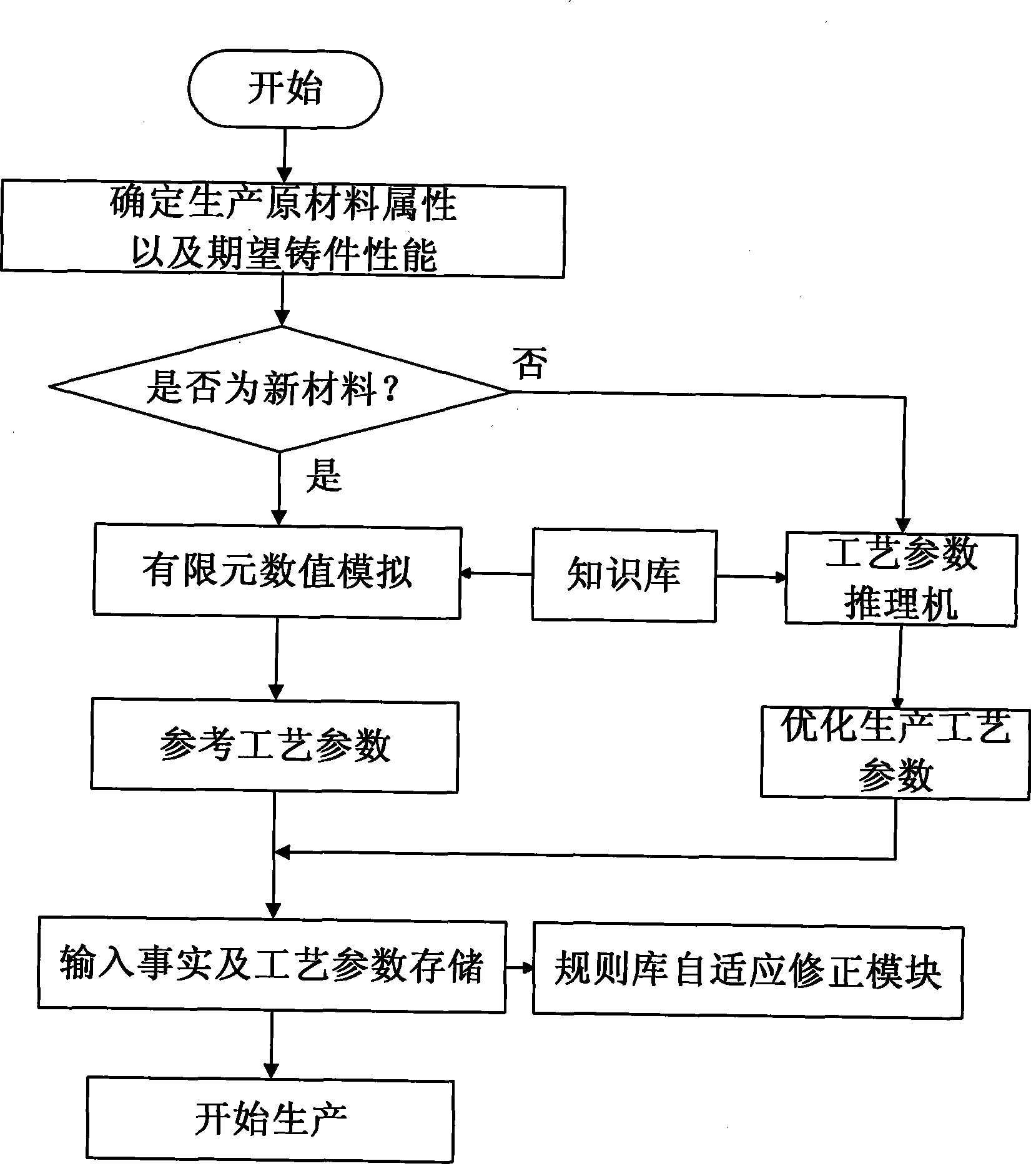

System and method suitable for quality control of reverse solidification technique

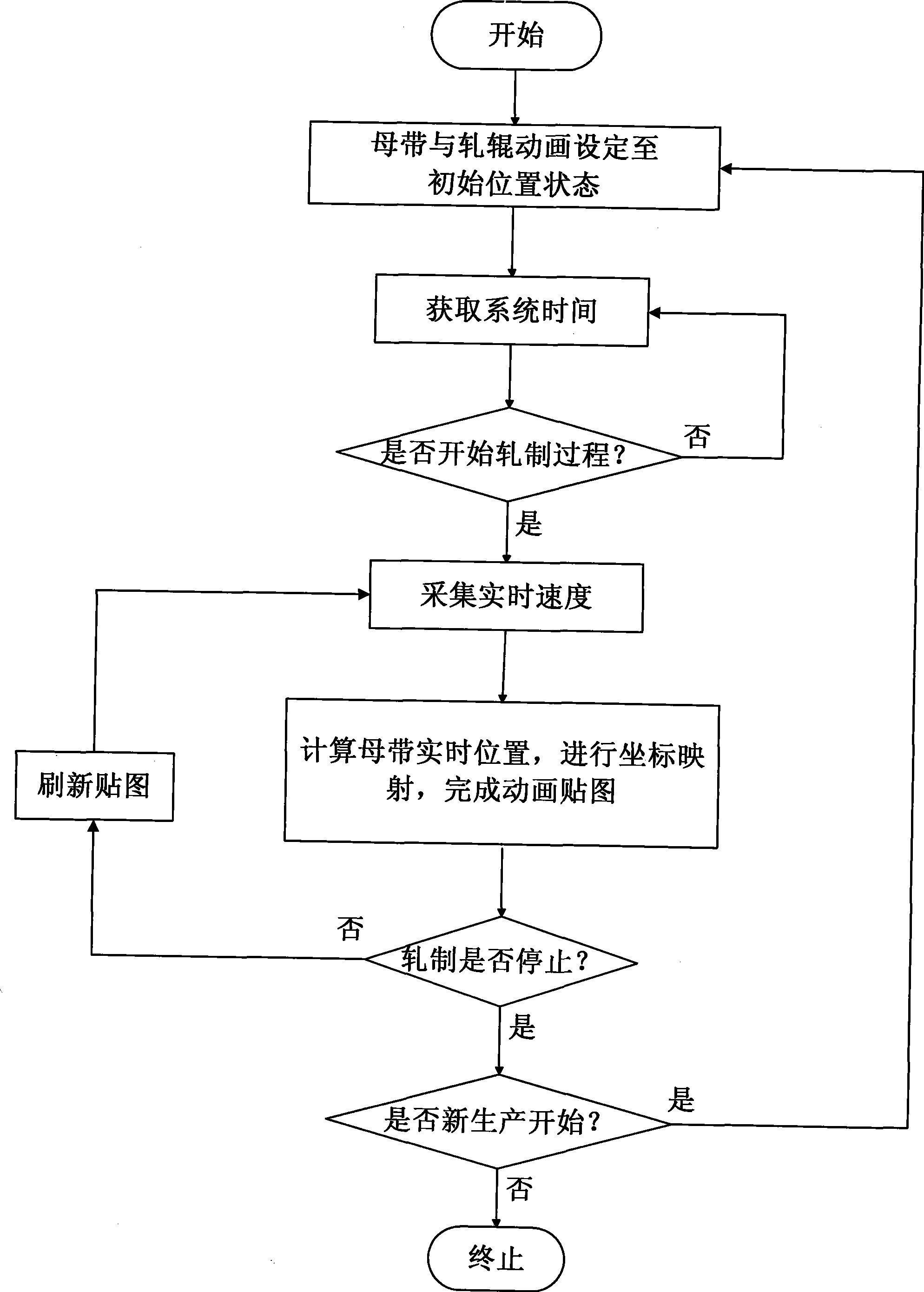

The invention discloses a system and a method suitable for quality control in an inverse solidification process. The system mainly comprises a data acquisition module, a visualized display module, and an adaptive expert system, wherein the adaptive expert system comprises a defect diagnostic reasoning module, a processing parameter reasoning module, an adaptive rule base correcting module, and a knowledge base. The processing parameter reasoning module reasons and provides optimized processing parameters before production, the data acquisition module and the visualized display module carry out data acquisition and visualized animation display on a detected production process, the defect diagnostic reasoning module analyzes performance and defects of products, and the adaptive rule base correcting module extracts defect analysis result of the products and the processing parameters re-correct rule to be fed back and applied to the processing parameter reasoning module so as to carry out a new production process. The system and the method can remarkably improve combination quality of a motherboard solidification layer in the inverse solidification process, accumulate processing experience, reduce defect, and save experiment expense.

Owner:BEIHANG UNIV

New technique for producing starch of octane succinate

InactiveCN1563096APromote safe productionProduct quality is easy to controlOctenyl succinateOCTENYLSUCCINIC ACID

The invention provides a new production process of octoalkenyl succinate starch, and adopts a method of thermal dextrinization to implement industrialization production of octoalkenyl succinate starch. Its step includes two processes of esterization raw material starch into starch milk, adding dilute alkali to regulate pH value to 8.0-9.0, then adding octoalkenyl succinyl oxide to make heating reaction, after the reaction is completed, adding dilute acid to regulate pH value to about 5.0, then washing and centrifugally-drying; and the dextrinization process includes the following steps: placing the above-mentioned esterized octoalkenyl succinate starch semifinished product in mixer, and adding dilute acid to regulate pH value to 2.4-2.5, predrying, feeding the above-mentioned material into double-cone reactor to make high-temp. vacuum reaction, then discharging material, cooling and packaging finished product.

Owner:BAISHIDA STARCH GUANGXI

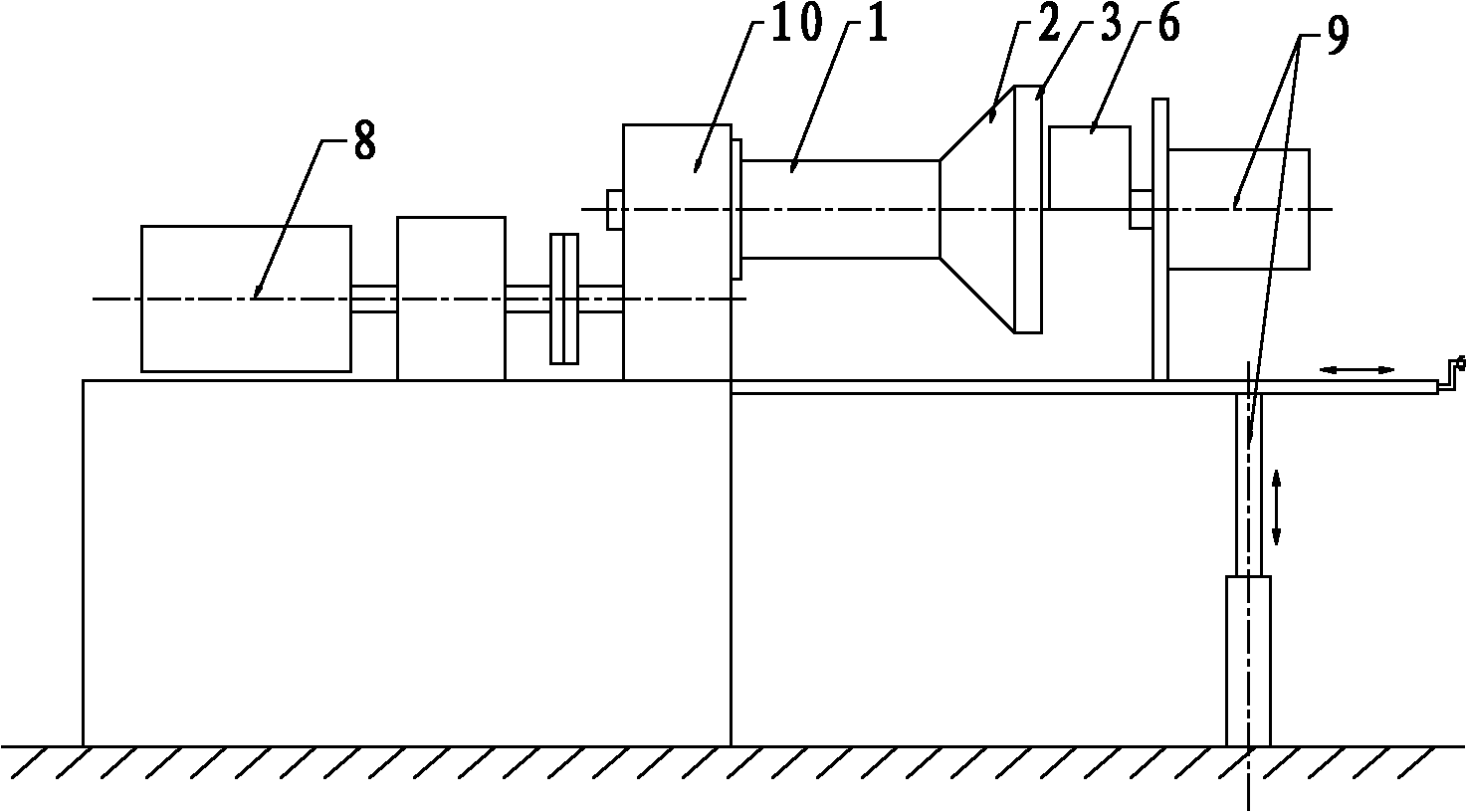

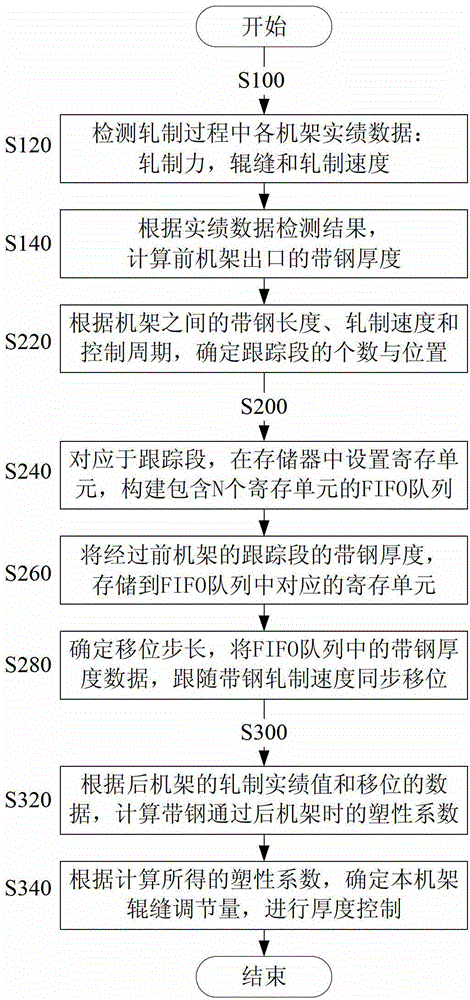

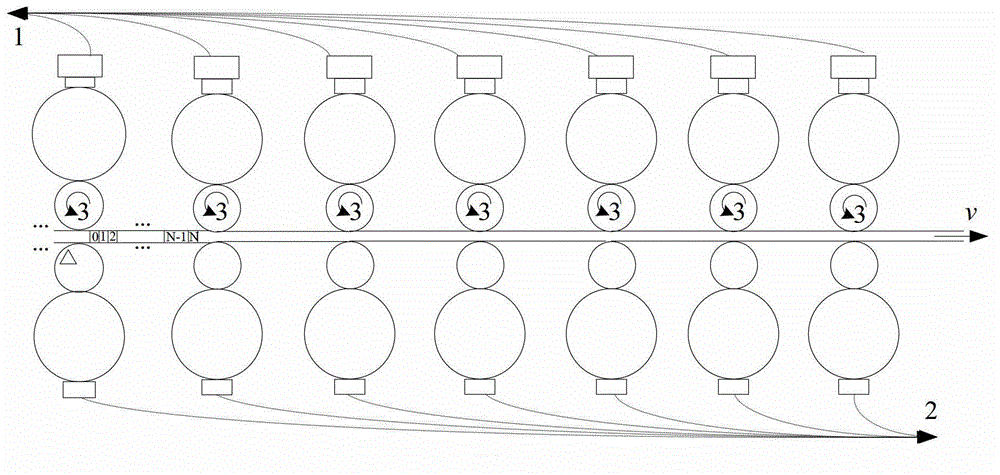

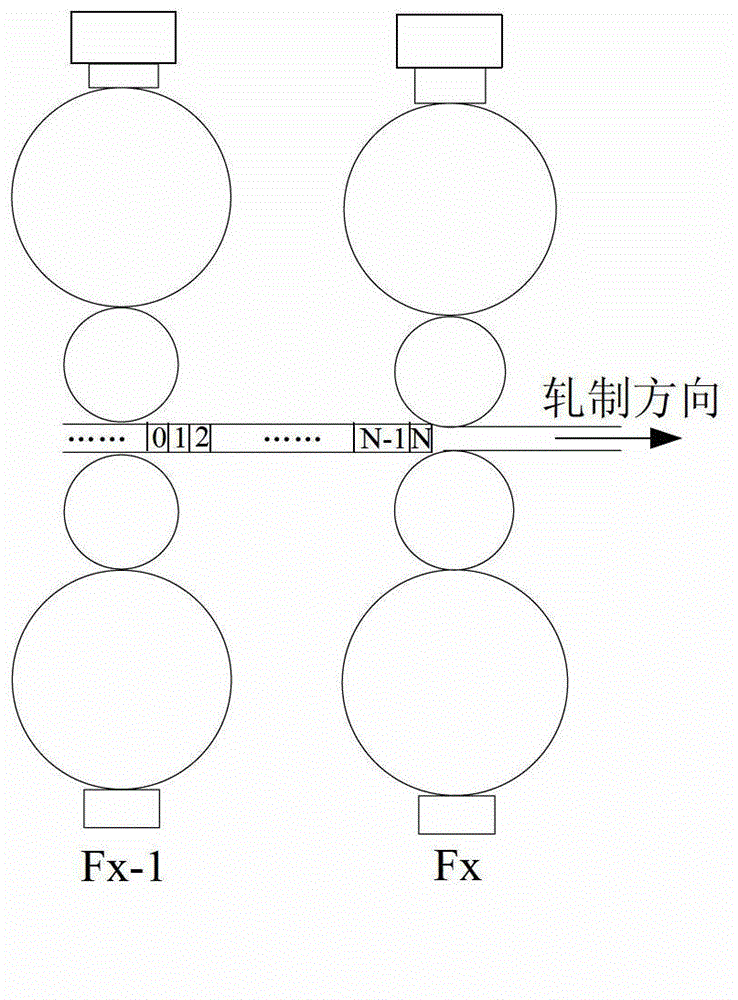

Hot-rolling and finish-rolling strip steel thickness control method

ActiveCN103934278AAccurately obtain the plasticity coefficientImprove thickness control accuracyRoll mill control devicesMetal rolling arrangementsProduction lineStrip mill

The invention provides a hot-rolling and finish-rolling strip steel thickness control method which is especially suitable for metal rolling mills or control devices for machining products, and particularly relates to a method for controlling the thickness of hot-rolling and finish-rolling strip steel through computer programs. According to the detection value of rolling actual performance value of a machine frame, the thickness of strip steel at the outlet of the machine frame is calculated; the moment the calculated strip steel thickness data reaching the machine frame is tracked and combined with the rolling actual performance value data, the plasticity coefficient of the strip steel passing through the machine frame is calculated in real time; according to the plasticity coefficient, which is obtained through real-time calculation, of the strip steel, the roll gap adjustment amount of the machine frame is determined, and feed-forward control is carried out on the thickness of the strip steel in real time. The control method can accurately obtain the plasticity coefficients of different sections of the strip steel, the plasticity coefficients are shown in roll gap adjustment amount of the different sections so as to be adaptive to hardness changes of the strip steel, control precision of the thickness of a finish rolling area is improved, a software programming control method is adopted, hardware investment is not needed, and the method is widely applied to new production lines and production line renovation projects.

Owner:BAOSHAN IRON & STEEL CO LTD

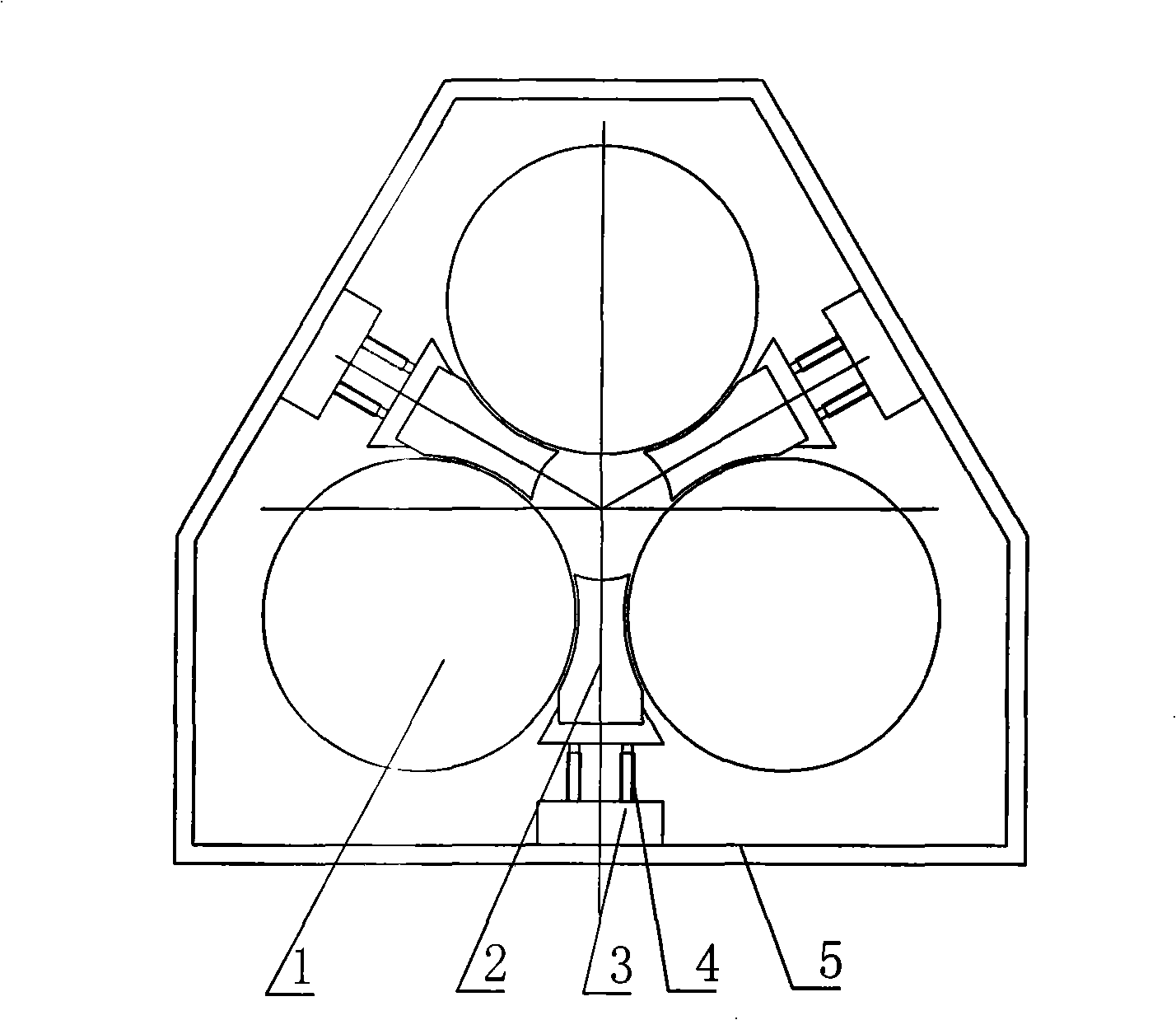

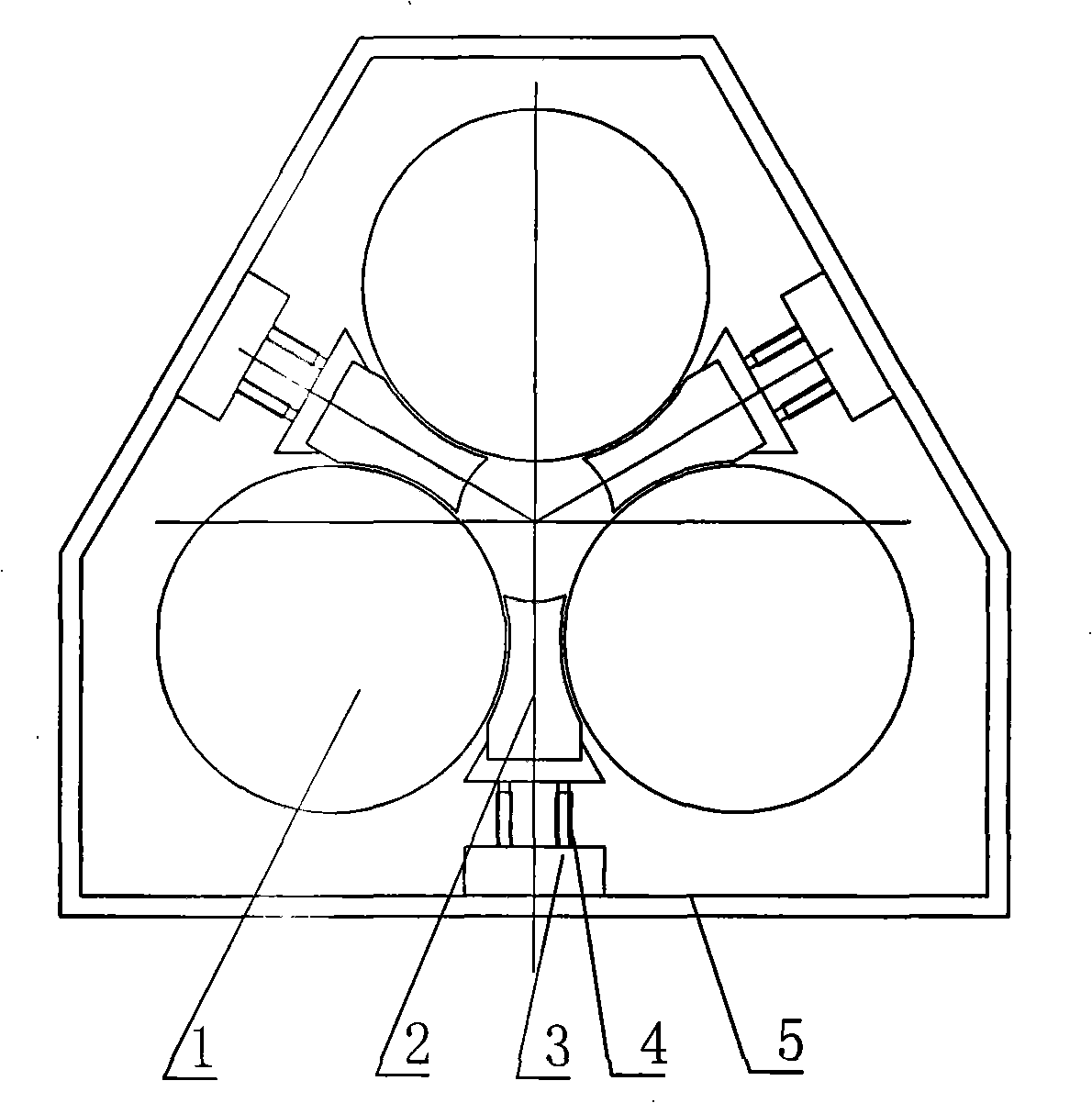

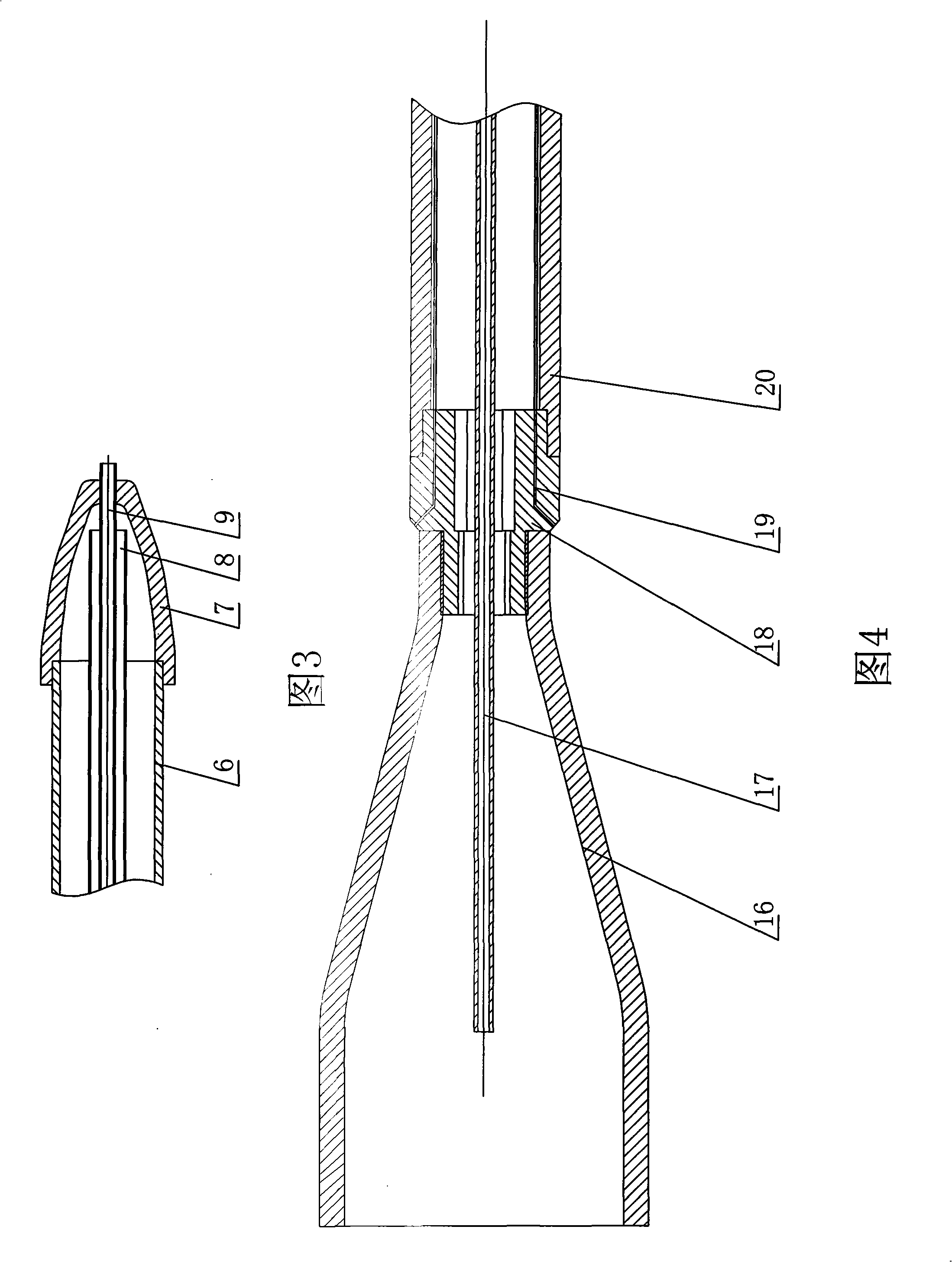

Novel technique for producing large-sized seamless steel pipe

InactiveCN101352728AExtended service lifeQuality improvementGuiding/positioning/aligning arrangementsWork treatment devicesHeating furnaceOrbit

The invention discloses a new production process of a large seamless steel pipe. The process comprises the following steps: pipe billets are preheated to the temperature of 1050-1290 DEG C by a heating furnace, and delivered to a three-roll skew rolling piercing mill for piercing by a skew roll table conveying mechanism to finish diameter expansion and wall reduction rolling, the maximal ratio of diameter to wall D / S is over 32, and hollow billets are produced; the hollow billets are delivered to a three-roll skew rolling elongating finishing mill by a shift oblique orbit conveying mechanism to finish diameter expansion and wall reduction rolling or diameter reduction and wall reduction rolling, and the pierced billets are rolled, straightened, cropped end, cut to length, defect are detected, and the finished products are obtained after passing inspections. The new production process also perfects and improves the conventional three-roll skew rolling seamless steel pipe process, solves the problems of not rolling thin walls and great extension in the three-roll skew rolling process, the diameter expansion and wall reduction rolling can be carried out, and the diameter reduction and wall reduction rolling can be carried out. The new production process is especially suitable for rolling large and oversized seamless steel pipes (Phi is 500-2000mm), the ratio of single reduced diameter and expanded diameter is more than 30%, the reduced wall diameter is more than 70%, and the reduced wall thickness is 5-7 times of that of a longitudinal pipe rolling mill.

Owner:沈阳东方钢铁有限公司

Method for producing magnesium hydroxide and calcium carbonate in manners of burning dolomite and dissolving into water to separate calcium and magnesium

ActiveCN103738986ASimple processLow costCalcium/strontium/barium carbonatesMagnesium hydroxideCalcium hydroxideCalcium carbonate precipitation

The invention provides a method for separating calcium and magnesium and preparing magnesium hydroxide by water dissolving and leaching of burnt dolomite. The method comprises the following operation steps: crushing the dolomite and burning into dolomite ashes; slaking the dolomite ashes by water to generate calcium hydroxide and magnesium hydroxide; filtering and separating an insoluble substance magnesium hydroxide; introducing carbon dioxide to leaching liquid to separate out calcium carbonate precipitate; separating again to obtain a calcium carbonate product, adding a purifying agent to filter residue to remove impurities such as iron, aluminum and the like, centrifuging and separating, and baking, so as to obtain the magnesium hydroxide product. The method has the characteristics of being low in cost, simple in process, and good in product quality, and a new production way is provided for preparation of magnesium hydroxide from dolomite.

Owner:贵州胜威化工新材料研究院有限公司

Production method of formula feed for meat geese

ActiveCN103431247AGood granulationEasy to solveFood processingAnimal feeding stuffFiberBiotechnology

The invention discloses a production method of a formula feed for meat geese and provides a new production process with optimal formulation according to the food and disease characteristics of meat geese. The method includes the steps of saccharifying corn straws and sweet potato seedlings, which are easily available, have wide sources and high fiber content, to convert hard crude fibers into soft materials containing xylitol, mixing the saccharified materials with green plants (such as cucumber, witloof and wild buckwheat) with nutritional and health-care functions and low production costs and processed potatoes, pumpkins, bone powder and the like, granulating and drying to produce the nutritional and health-care daily feed for geese, which is rich in dietary fiber, pectin, plant protein and vitamins, can promote appetite, meet the herbivorous habit of geese and promote goose growth, and has the functions of clearing away heat and toxic materials and relaxing bowel. The feed has a high return rate, is convenient in feeding, is high in palatability due to a high saccharified material proportion in a formula, and solves the annual supply problem of feeds in autumn and winter and for large-scale goose breeding.

Owner:东兰县科技情报研究所

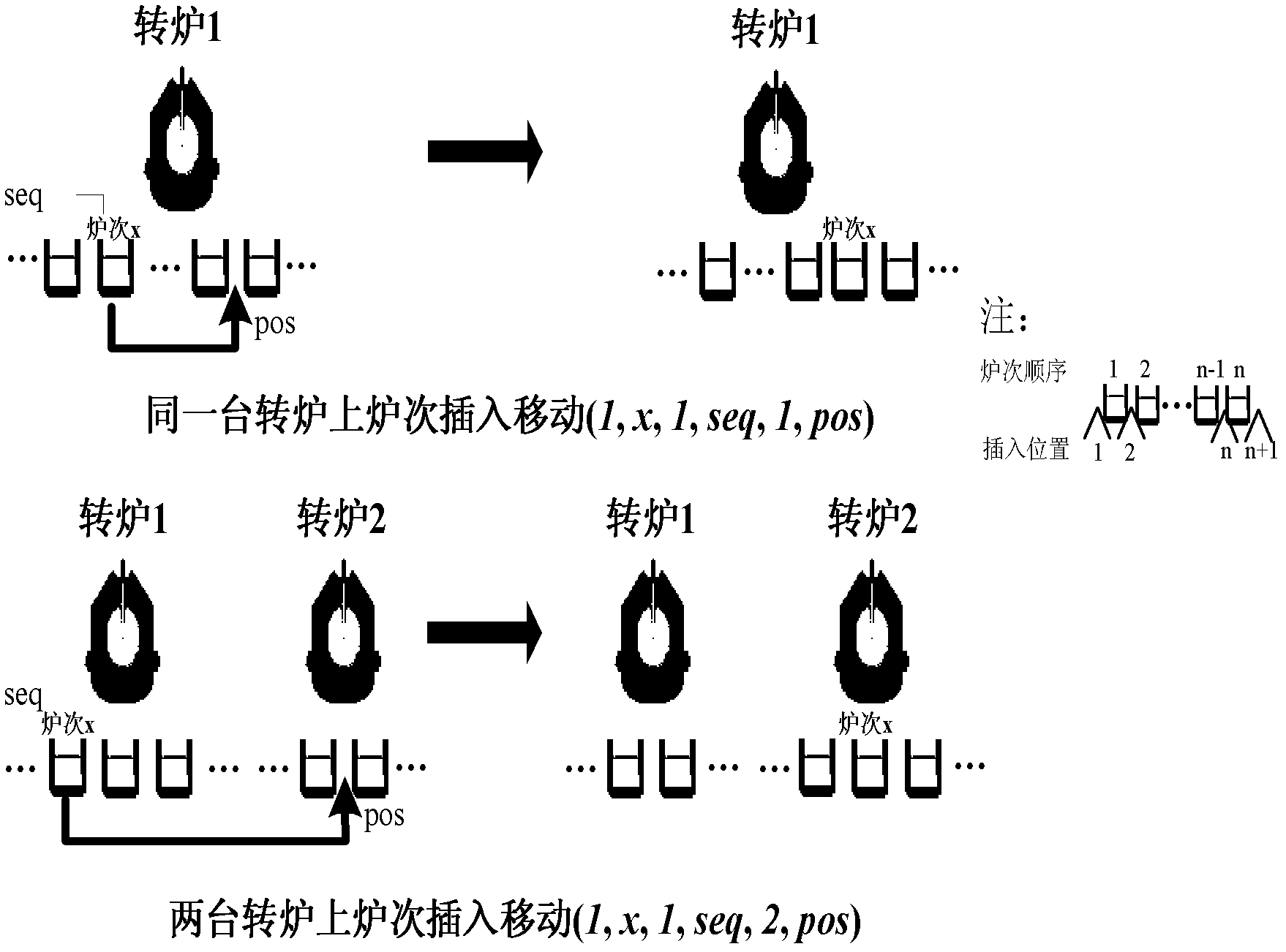

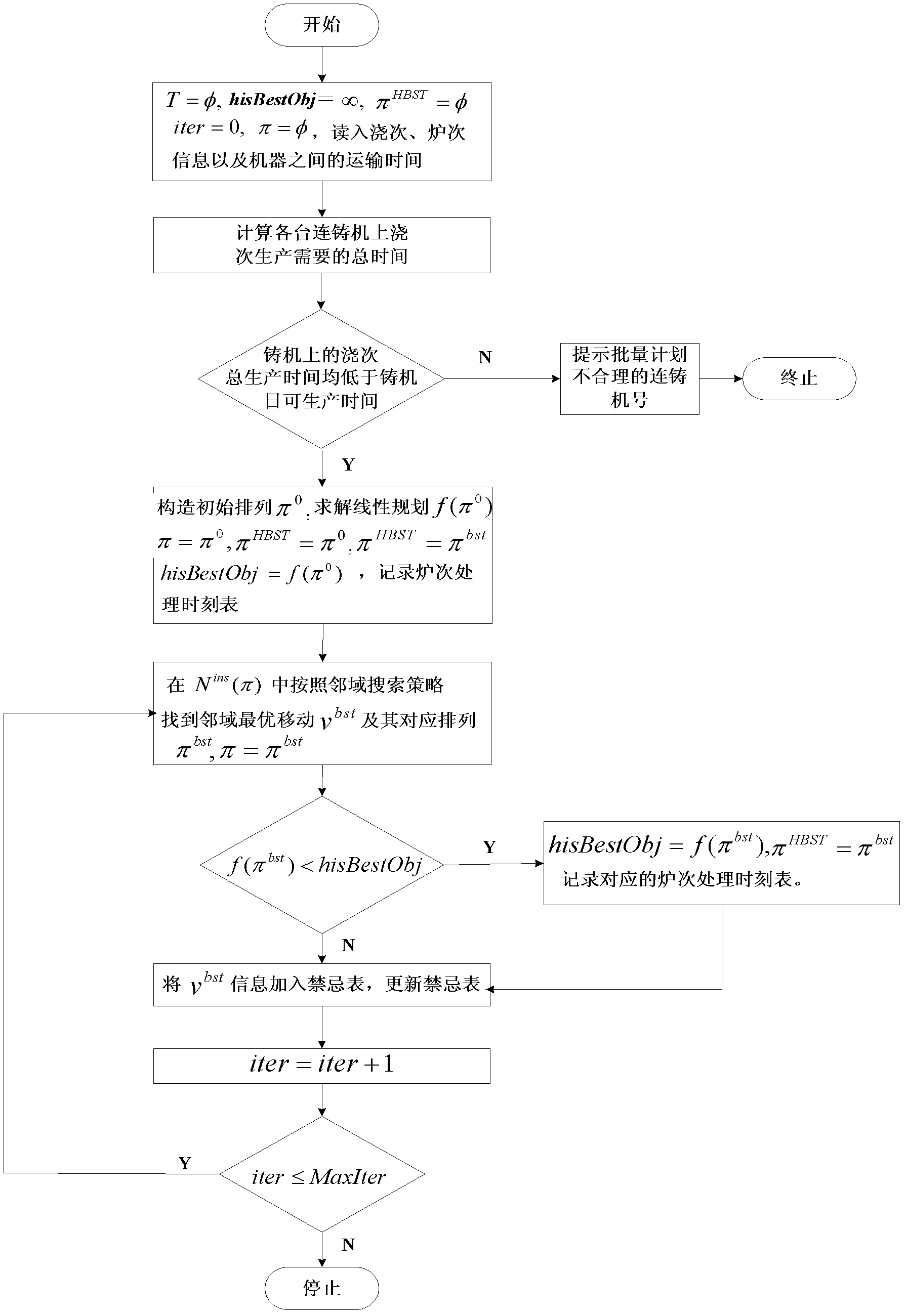

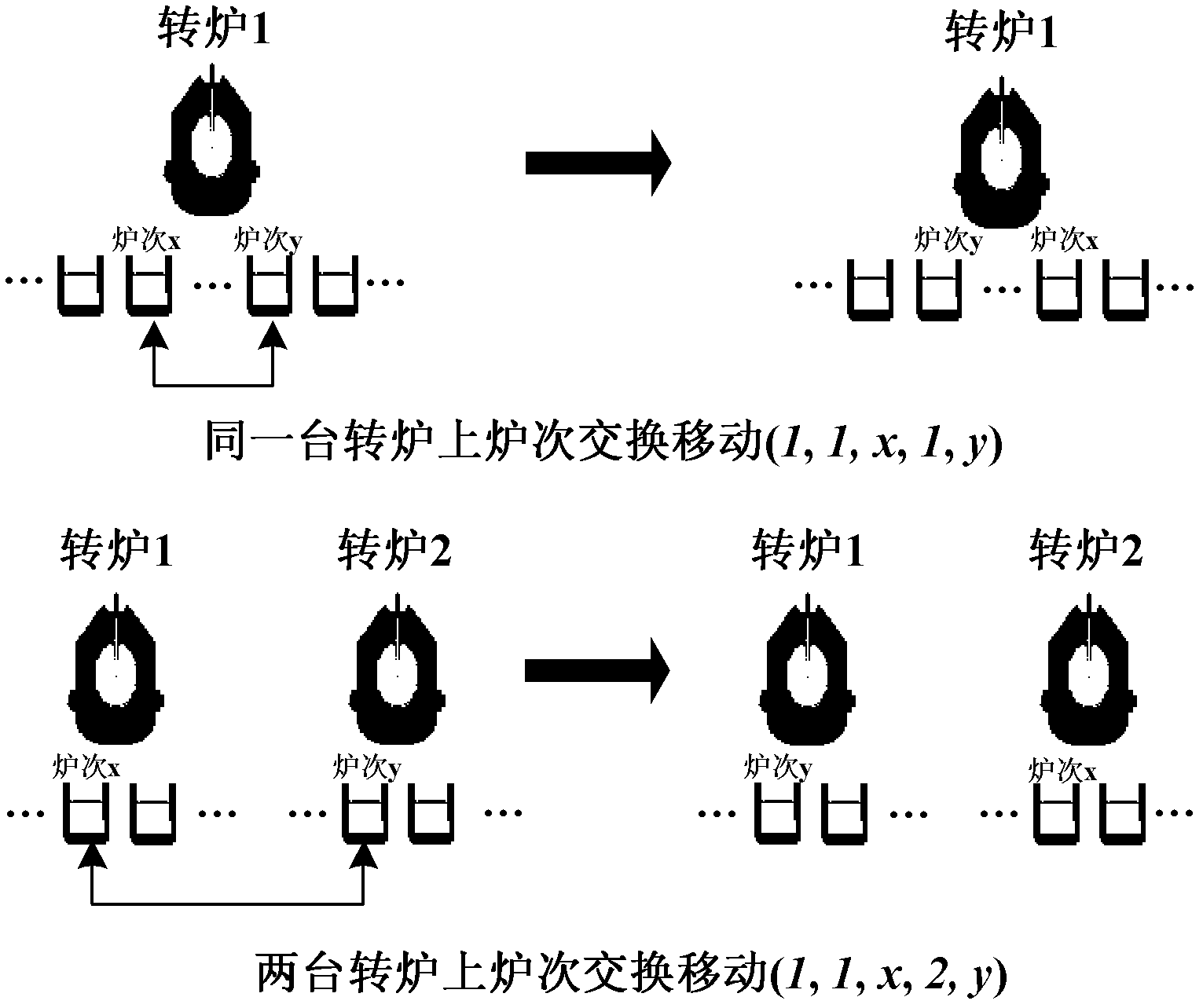

Method for controlling molten steel processing of steelmaking workshop

The invention relates to a method for controlling molten steel processing of a steelmaking workshop. Process constraints in actual production are taken into account to reduce heat losses of molten steel and obtain a process for controlling the molten steel processing of the steelmaking workshop. By adopting the method, prompt production can be achieved, the times of interruption to casting can bereduced, the rate of utilization of production equipment can be increased, the production of a steelmaking plant can be carried out according to the processing startup time of heat on each machine, and the heat can be promptly delivered to a continuous casting machine to ensure continuous casting. Meanwhile, the load on each refining device is uniform, the failure rate is low, and the productivity of the continuous casting machine and the steelmaking workshop can be improved. By adopting the method, new production schemes can be prepared in a short term according to new production environments so as to deal with unavoidable equipment faults and other unexpected accidents. Due to the reasonable and efficient control of the molten steel processing progress, the heat can be utilized on the reasonable machine, excessive heat delivery can be reduced, energy can be saved, the logistic cost can be decreased, the waiting time of molten steel in different procedures and heat losses of the molten steel can be reduced, and the effects of energy conservation and consumption reduction can be achieved.

Owner:NORTHEASTERN UNIV

Production method of zinc-rich rice

InactiveCN103766723AIntegrity guaranteedSimple production processFood preparationBiotechnologyOrganic liquids

The invention provides a production method of zinc-rich rice, belonging to a rice processing method. The production method specifically comprises the following steps: puffing, spraying, stirring, drying and packaging: (1) puffing the whole rice grains of the processed rice on the market to obtain multiple micropores through a hot-humid puffing machine; (2) spraying a zinc-rich nutrient solution into the puffed micropores; (3) drying the sprayed rice; (4) quantitatively sub-packaging as necessary to obtain finished products of zinc-rich rice. The zinc-rich nutrient solution is obtained by uniformly mixing all zinc-element organic liquids with pre-pasted starch, gelatin liquid, lysine and threonine according to the designed dosage. The invention provides a new production method of zinc-rich rice.

Owner:王国清

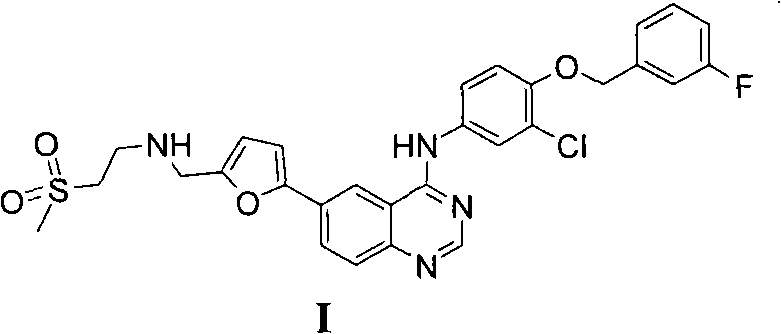

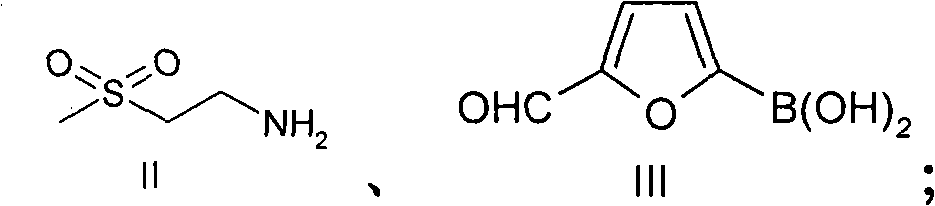

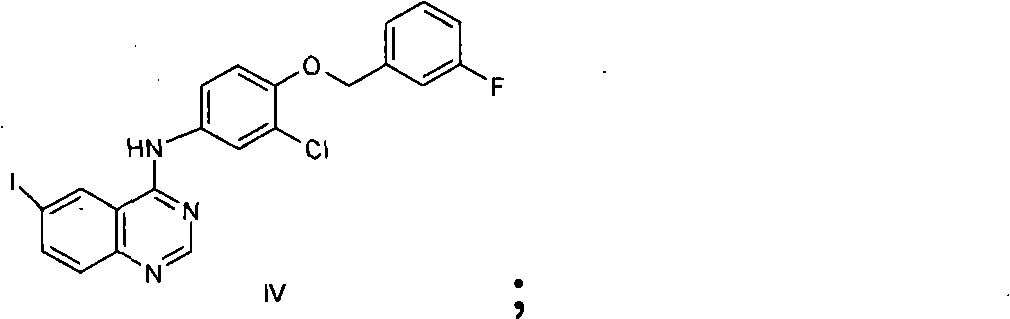

New preparation method of lapatinib

The invention provides a novel method for preparing lapatinib. Specifically, the method for preparing a compound shown in a formula I or medicinal salt thereof comprises the following steps of: (1) reacting a compound shown in a formula II or salt thereof and a compound shown in a formula III at the first temperature; (2) reacting a reaction product obtained in the step (1) and a compound shown in a formula IV in reaction liquid in the step (1) at the second temperature; (3) adding a reducing agent into reaction liquid in the step (2) to reduce the reaction product obtained in the step (2) to obtain the compound shown in the formula I; and optionally (4) reacting the compound shown in the formula I and obtained in the step (3) and acid to obtain medicinal salt of the compound shown in the formula I. The method is high in yield, and can overcome one or more disadvantages of the conventional method and the purity of a product is high.

Owner:QILU PHARMA +1

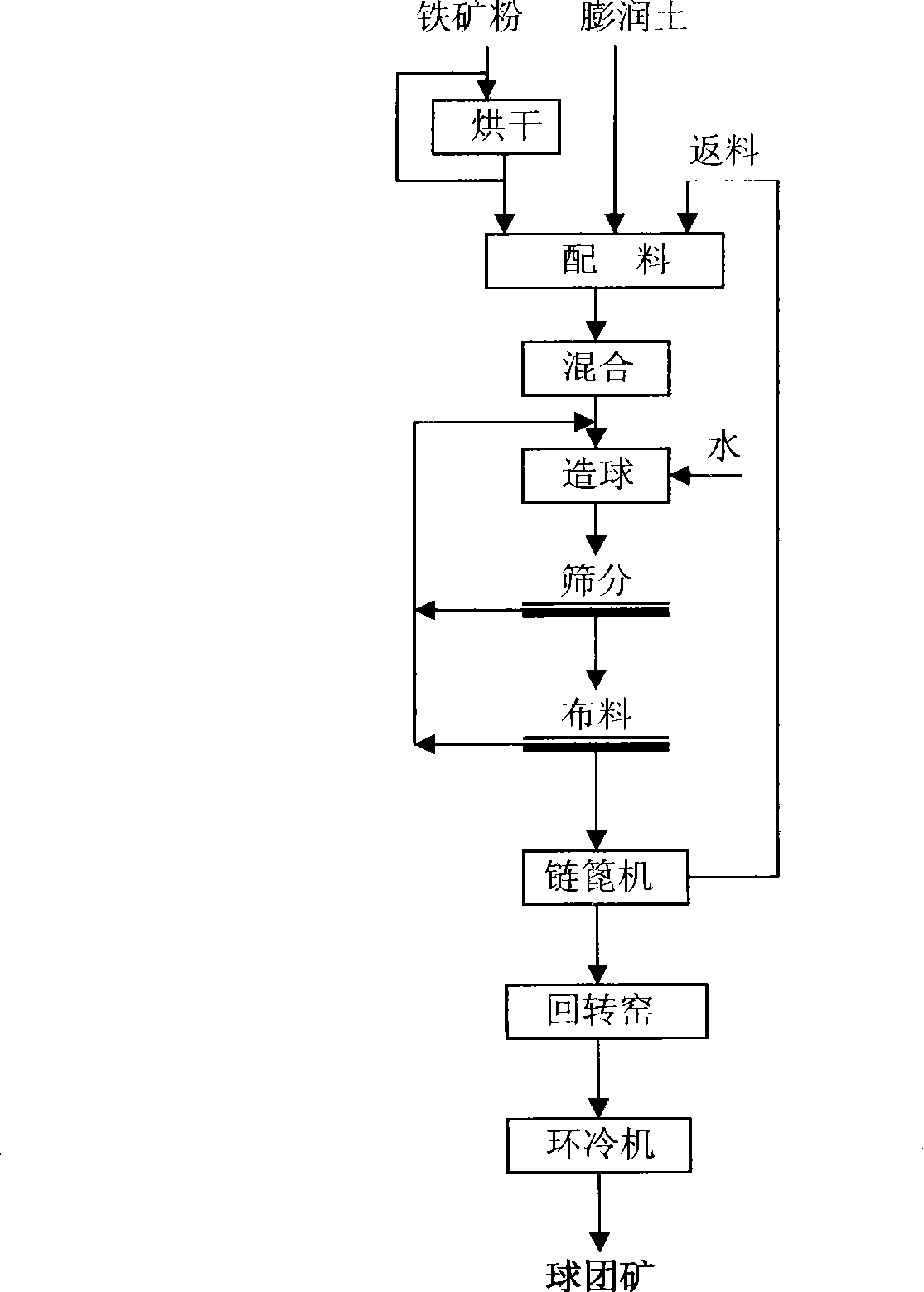

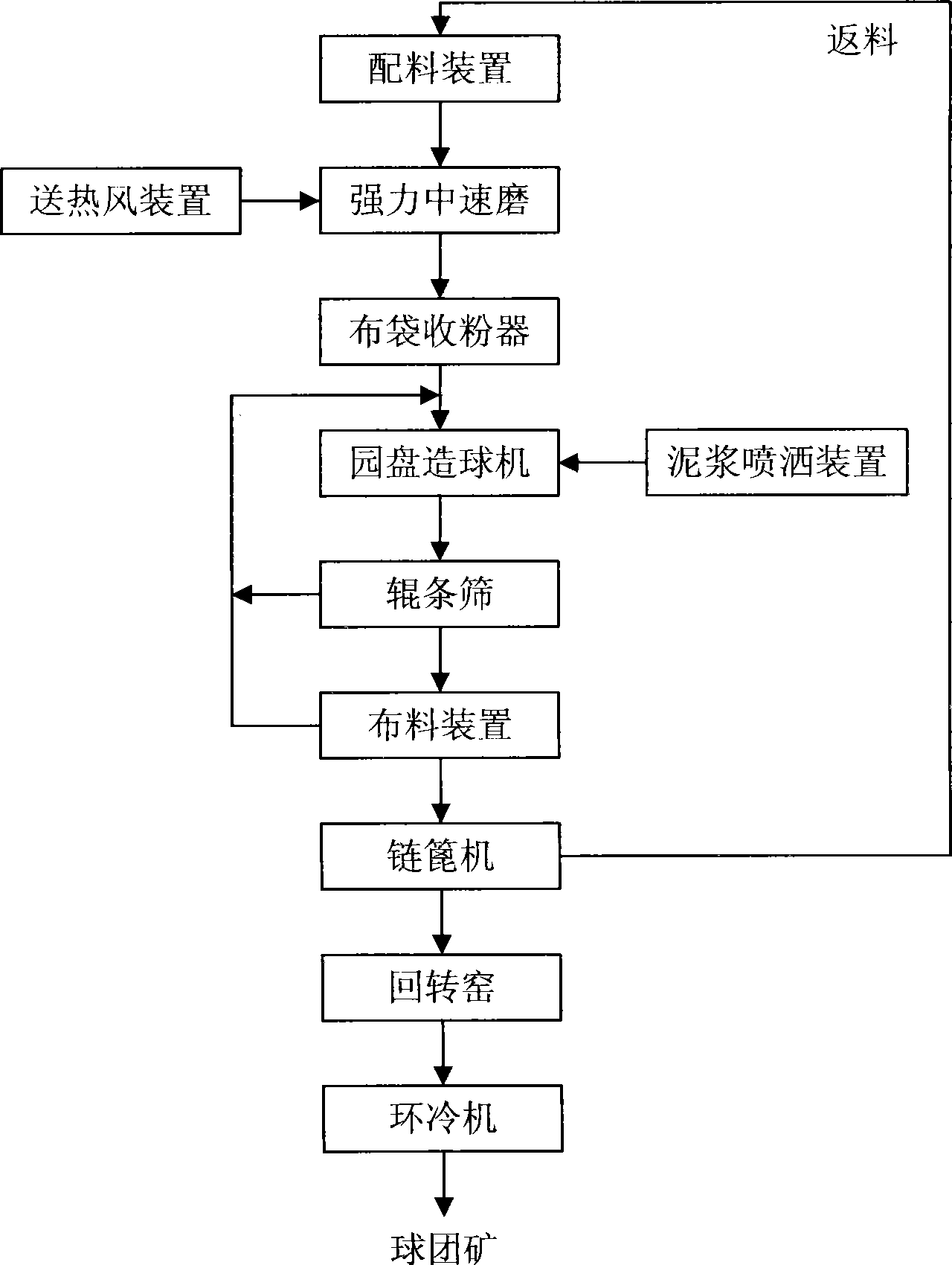

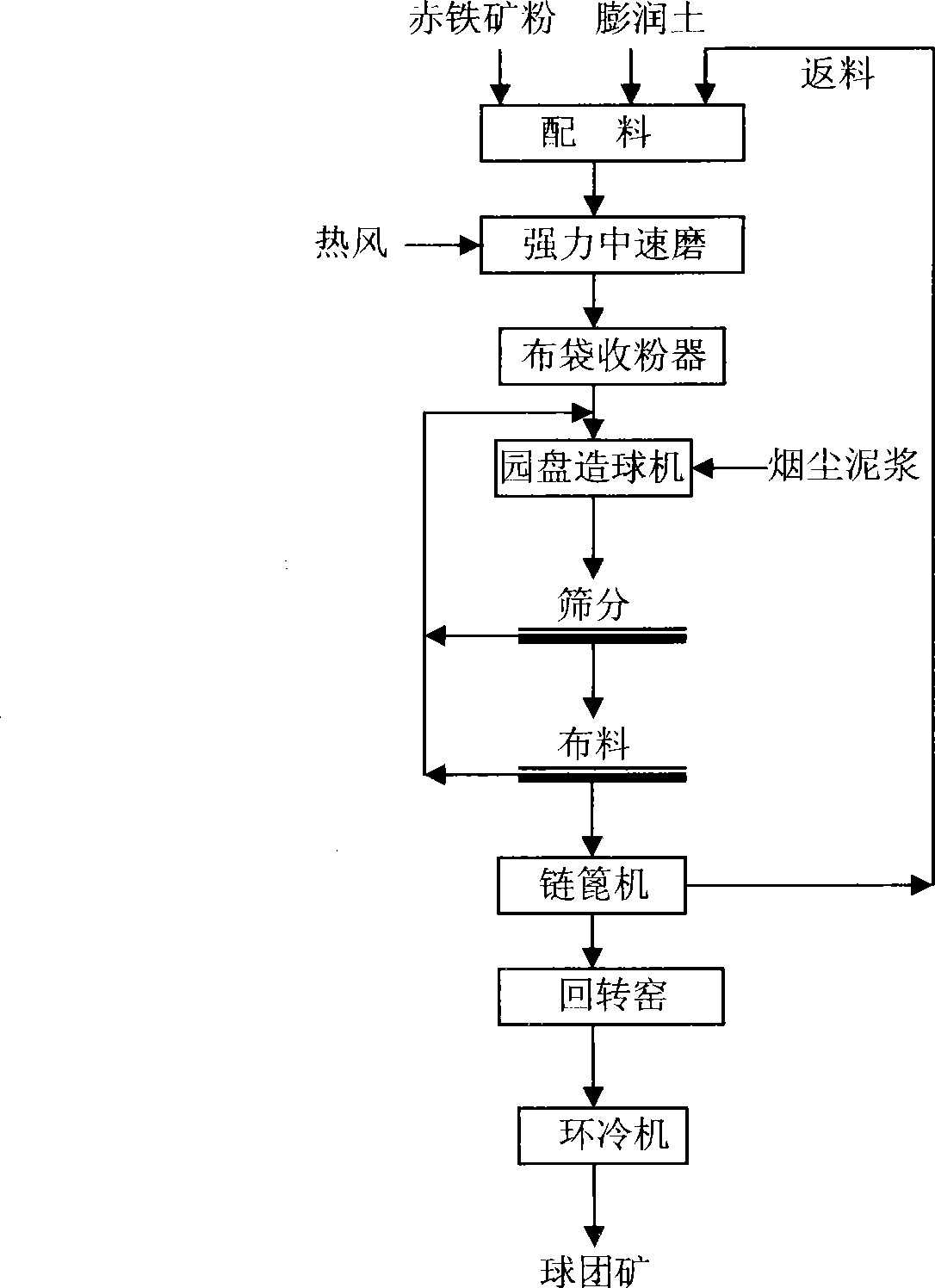

Equipment for producing oxidized pellet and method for producing oxidized pellet by using the same

The invention provides a device for producing oxidized pellets and a method for producing the oxidized pellets using the device. The device provides a new production plant used in a medium speed pulverizing-drying grate-rotary kiln for producing the oxidized pellets based on a traditional drying grate-rotary kiln. The method is added with a step of grinding a mixture of mineral powder and bentonite in a hot air condition based on a traditional process, dust slurry is sprayed during pelletizing to produce wet pellets, then the wet pellets is delivered to a drying grate-rotary kiln device for roasting, and then cooled. In the device and the method, over 80% of mineral powder is minums 200 meshes (0.074mm) fine powder after medium-speed pulverizing; a little converter dust slurry is sprayed during palletizing in a disc pelletizer so as to causes the addition amount of bentonite to be only 1.0-1.5% which is only the 1 / 2-1 / 4 of the common amount of domestic enterprises, thus effectively improving the iron grade of the pellets with the compressive strength of the final pellets larger than 2200N / P.

Owner:范英俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com