Scheduling optimization method and device in semiconductor production line CPS environment

A production line scheduling and optimization device technology, applied in control/adjustment systems, comprehensive factory control, instruments, etc., can solve the problems of scarcity of CPS environment scheduling optimization applications, blank research results, etc., to achieve frequent and efficient interaction, and improve calculation accuracy , the effect of reducing information delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

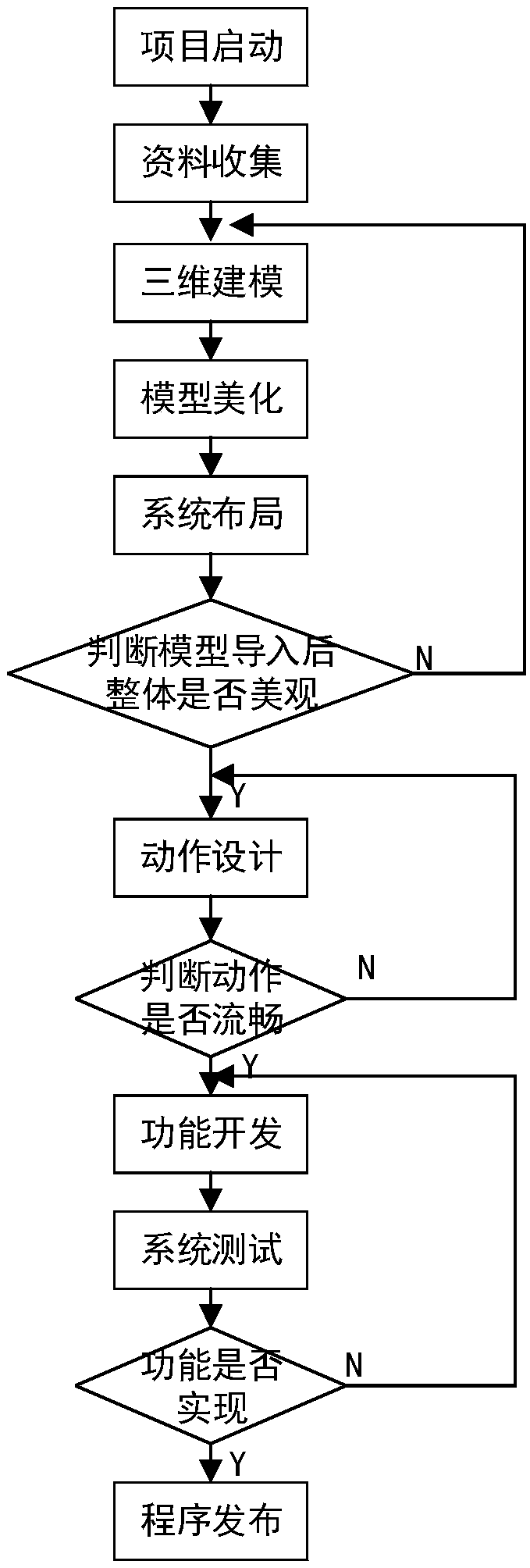

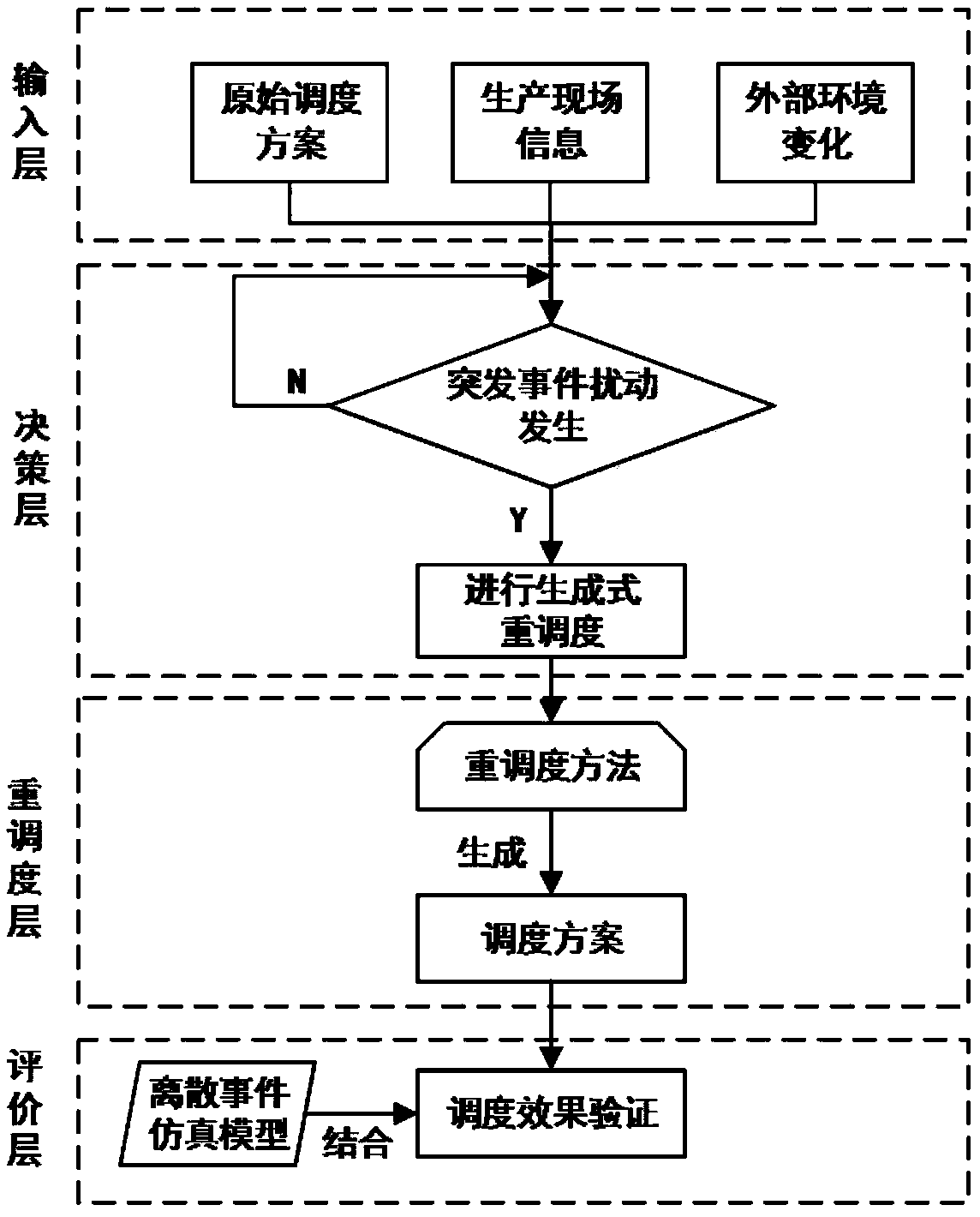

[0108] This embodiment uses python to realize the calculation logic of the designed scheduling method, and uses C# language to program the window interface, call the designed calculation model, integrate the scheduling module program with the CPS environment, and realize real-time scheduling in the semiconductor production process with control.

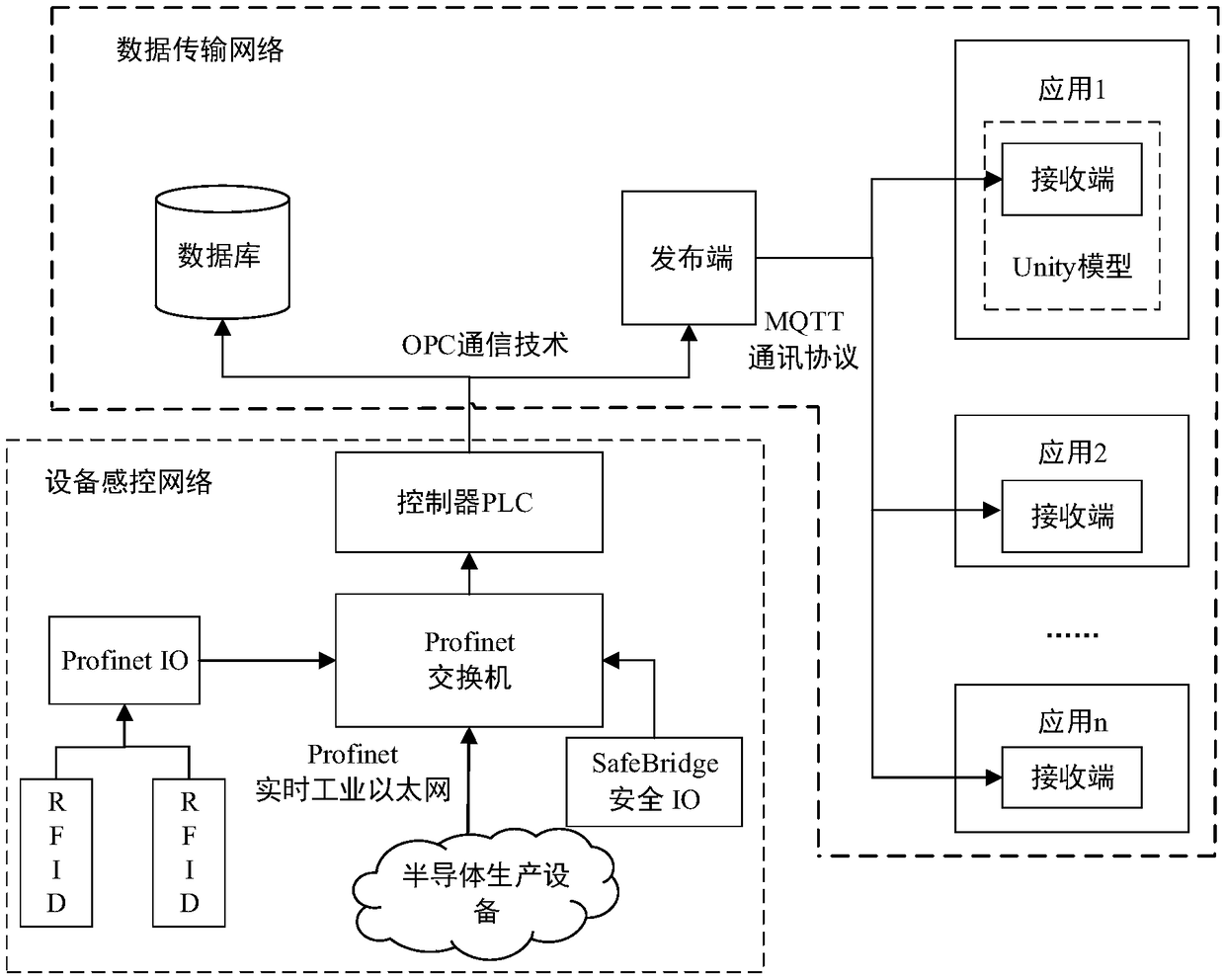

[0109] This embodiment is implemented in a smart manufacturing demonstration unit based on a semiconductor Minifab production line. The dispatching device of this embodiment realizes the simulation of the actual production process of the semiconductor MiniFab production line through technologies such as PROFINET, SafetyBridge, and RFID. The demonstration unit has one simulated lithography device, two simulated diffusion devices and two simulated ion implantation devices. In addition, the unit also includes a simulated storage location, which is composed of a raw material area and a finished product area, responsible for storing raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com