Automatic shielding performance testing system

A technology for automatic testing and shielding performance, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

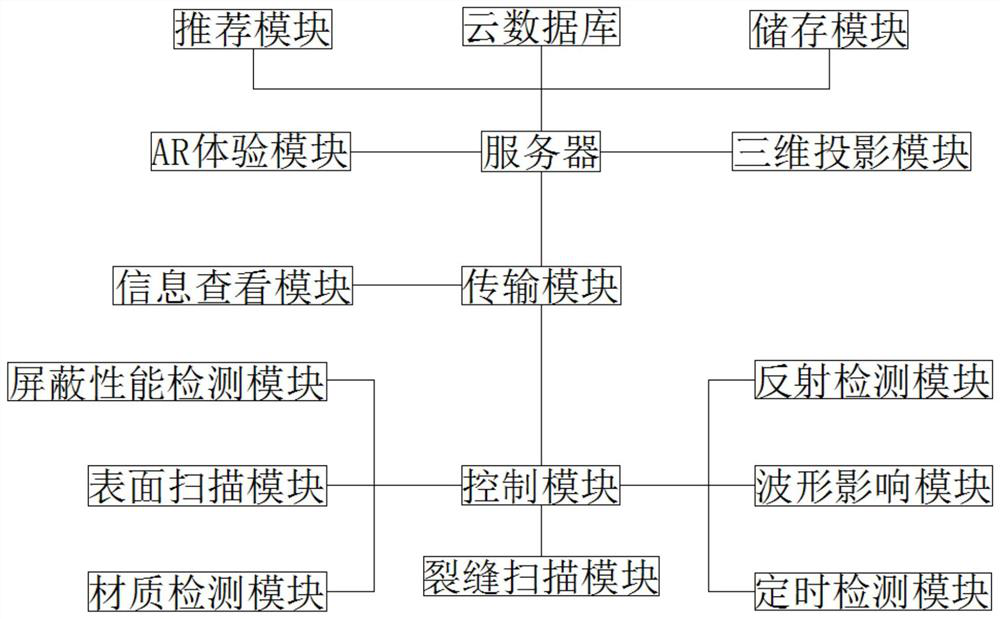

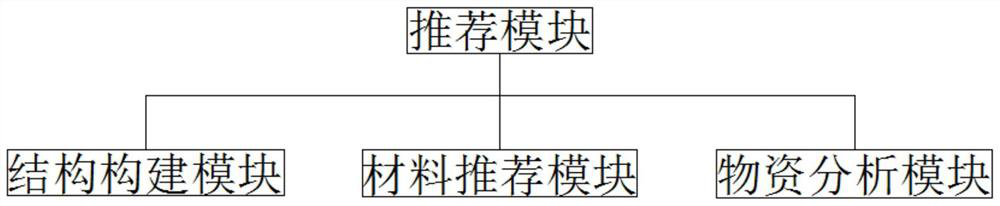

[0030] see figure 1 , 2 , an automated test shielding performance system, including a server, a recommendation module, a cloud database, a storage module, an AR experience module, a three-dimensional projection module, a transmission module, an information viewing module and a control module, and the server is respectively connected to the recommendation module through cables, networks and wireless , cloud database, storage module, three-dimensional projection module, AR experience module and transmission module, the transmission module is respectively connected to the information viewing module and the control module through cables and the network, and the control module is connected to the shielding performance detection module, surface scanning module, Material detection module, crack scanning module, reflection detection module, waveform influence module and timing detection module, recommendation module includes structural component module, material recommendation module ...

Embodiment 2

[0041] see figure 1 , an automated test shielding performance system, including a server, a recommendation module, a cloud database, a storage module, an AR experience module, a three-dimensional projection module, a transmission module, an information viewing module and a control module, and the server is respectively connected to the recommendation module through cables, networks and wireless , cloud database, storage module, three-dimensional projection module, AR experience module and transmission module, the transmission module is respectively connected to the information viewing module and the control module through cables and the network, and the control module is connected to the shielding performance detection module, surface scanning module, Material detection module, crack scanning module, reflection detection module, waveform influence module and timing detection module. The recommendation module includes structural component module, material recommendation module a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com