Patents

Literature

5300 results about "Structural component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Structural component Structural component means a component that supports non-variable forces or weights (dead loads) and variable forces or weights (live loads).

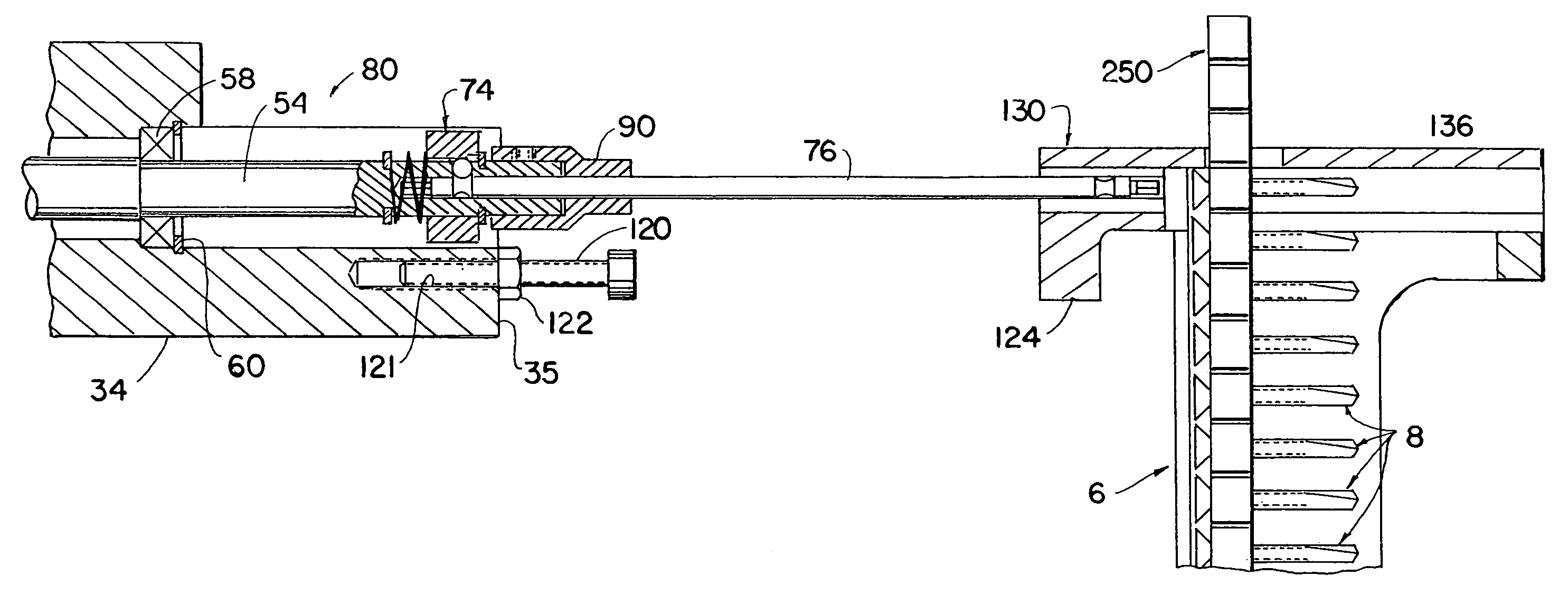

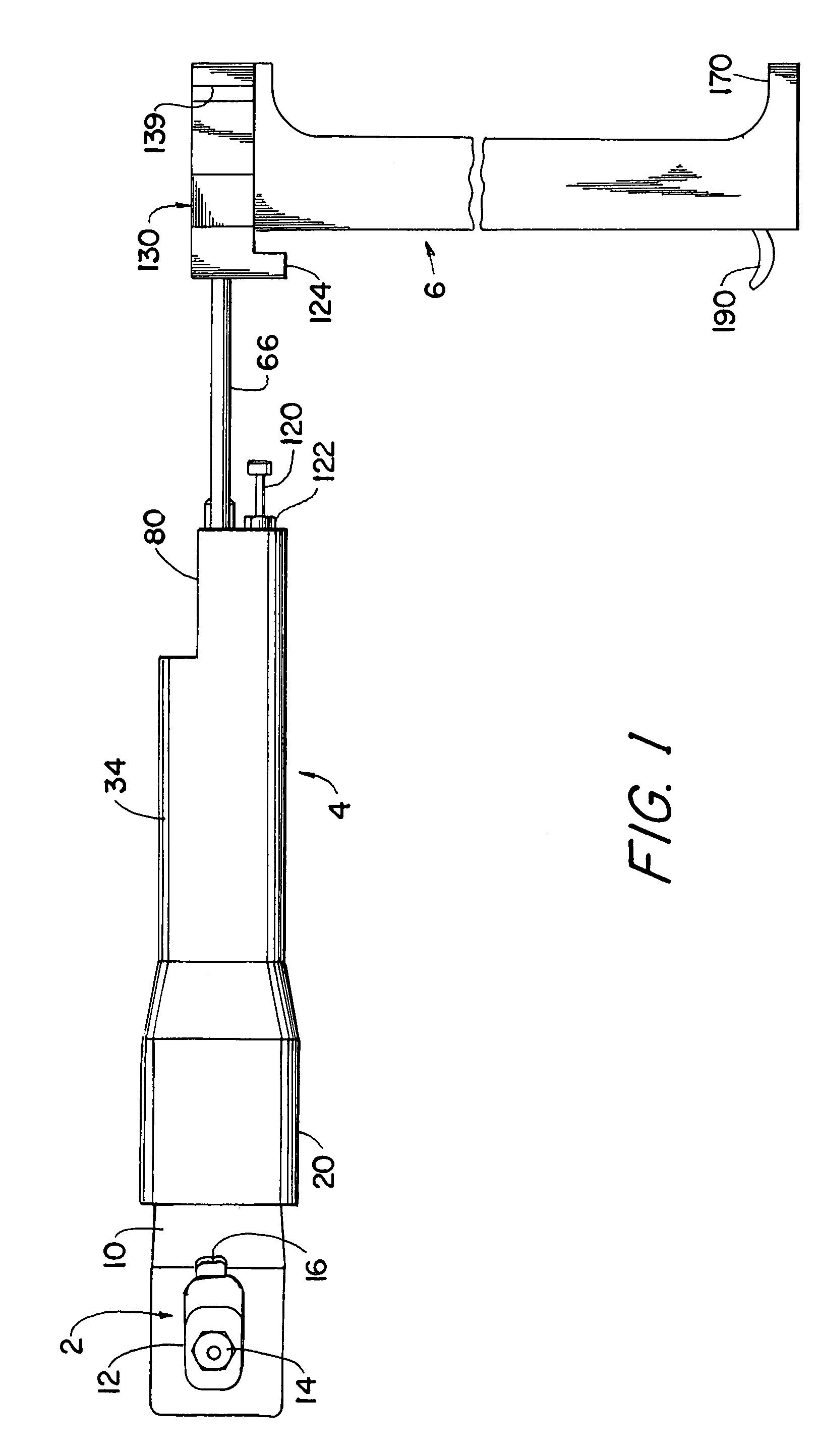

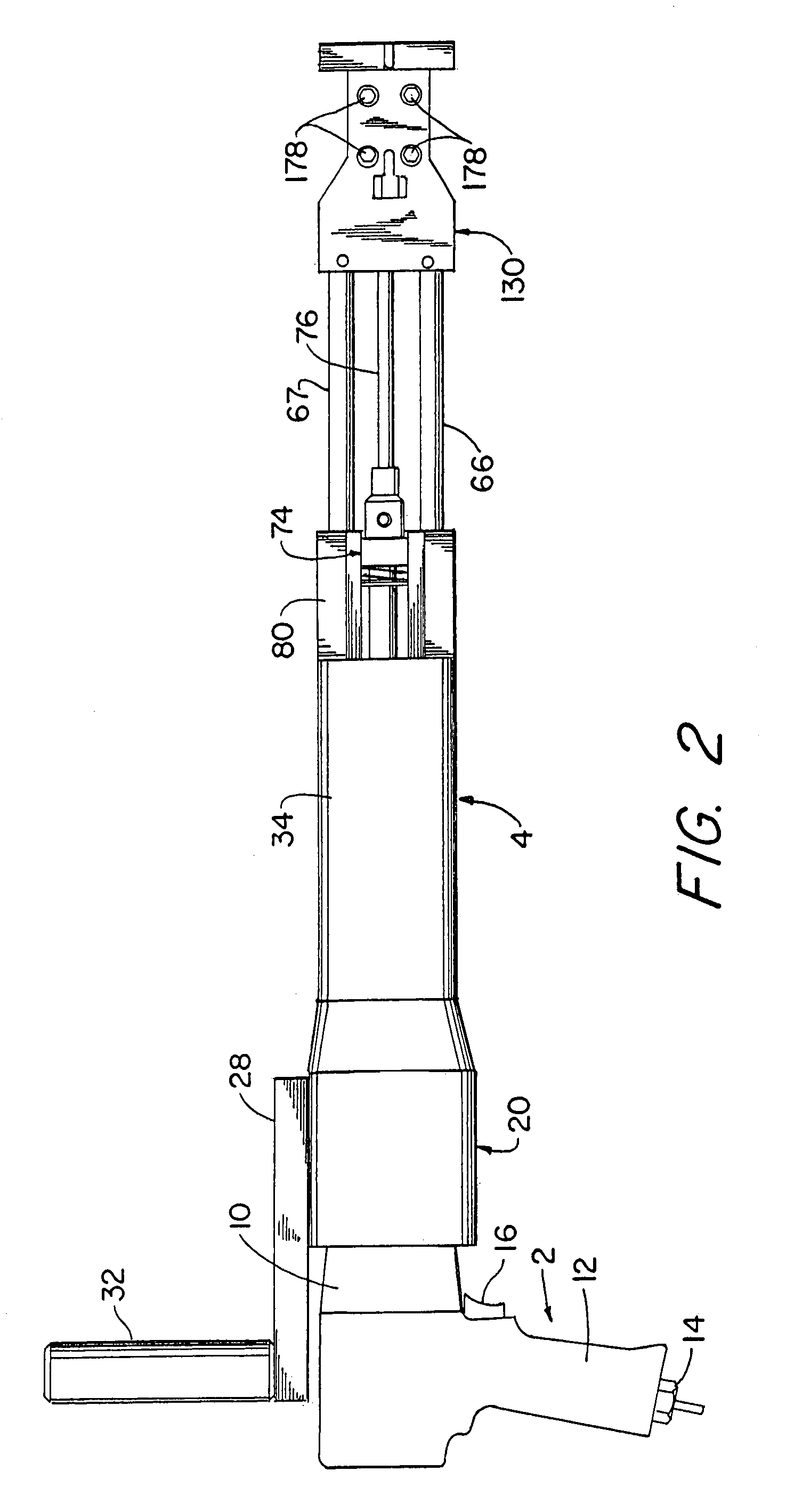

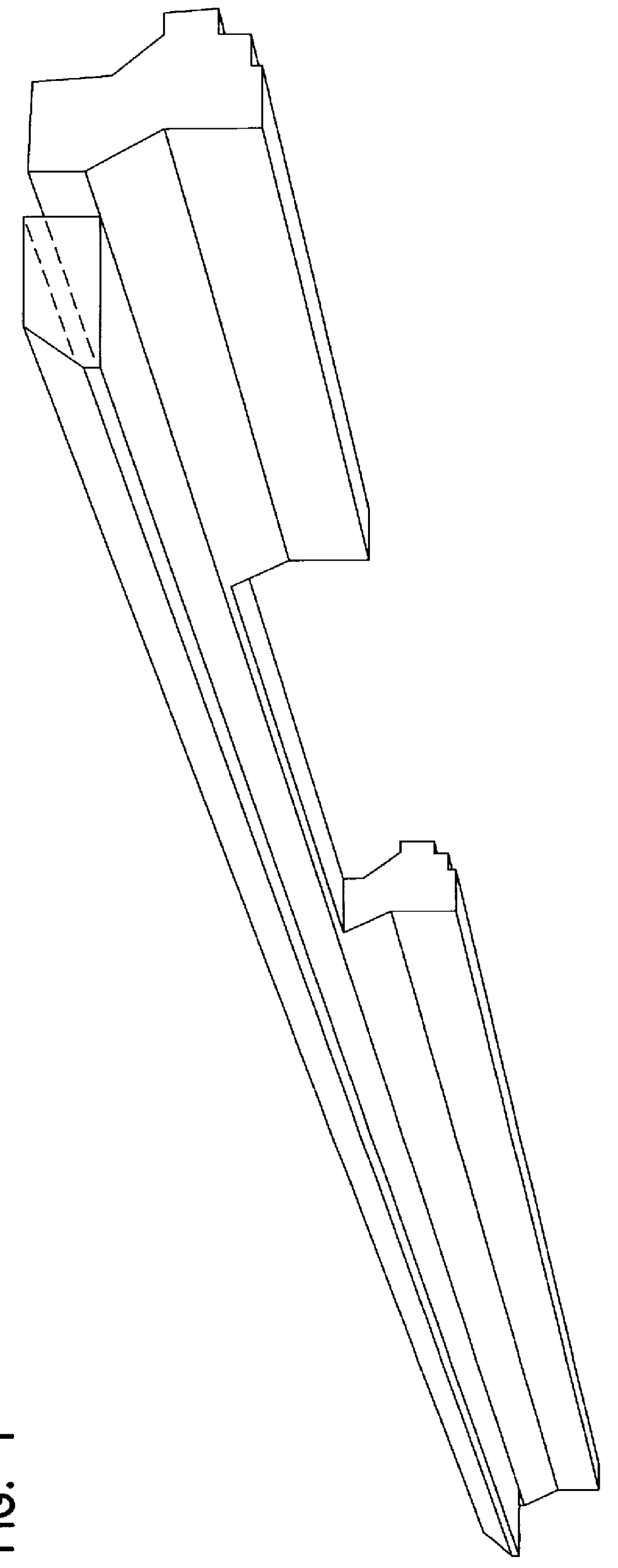

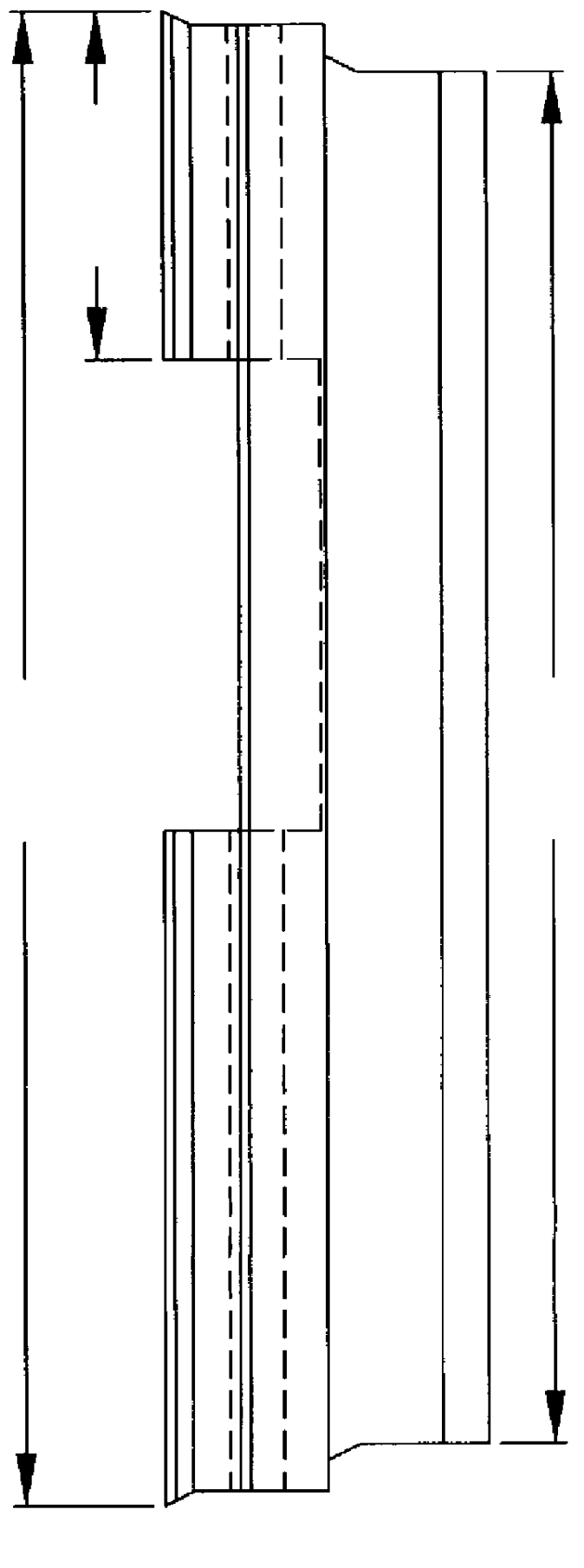

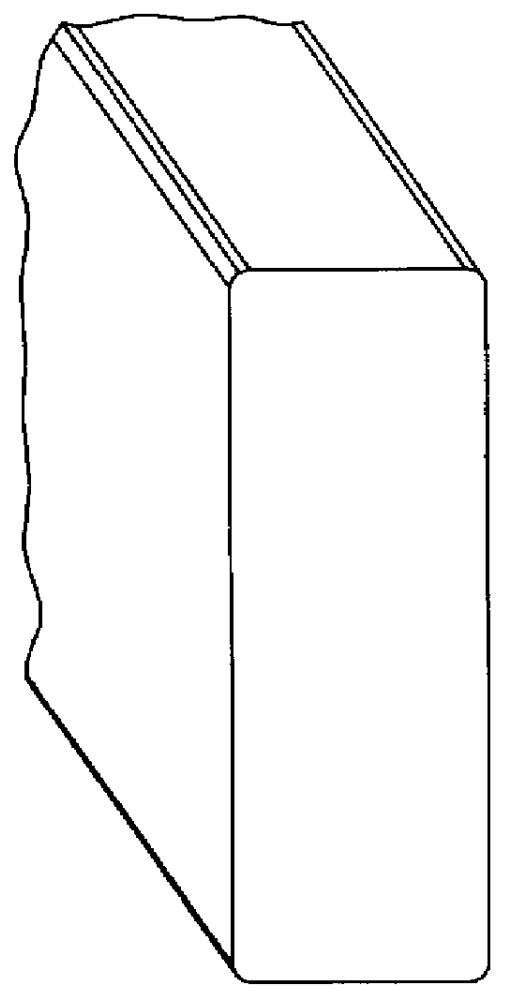

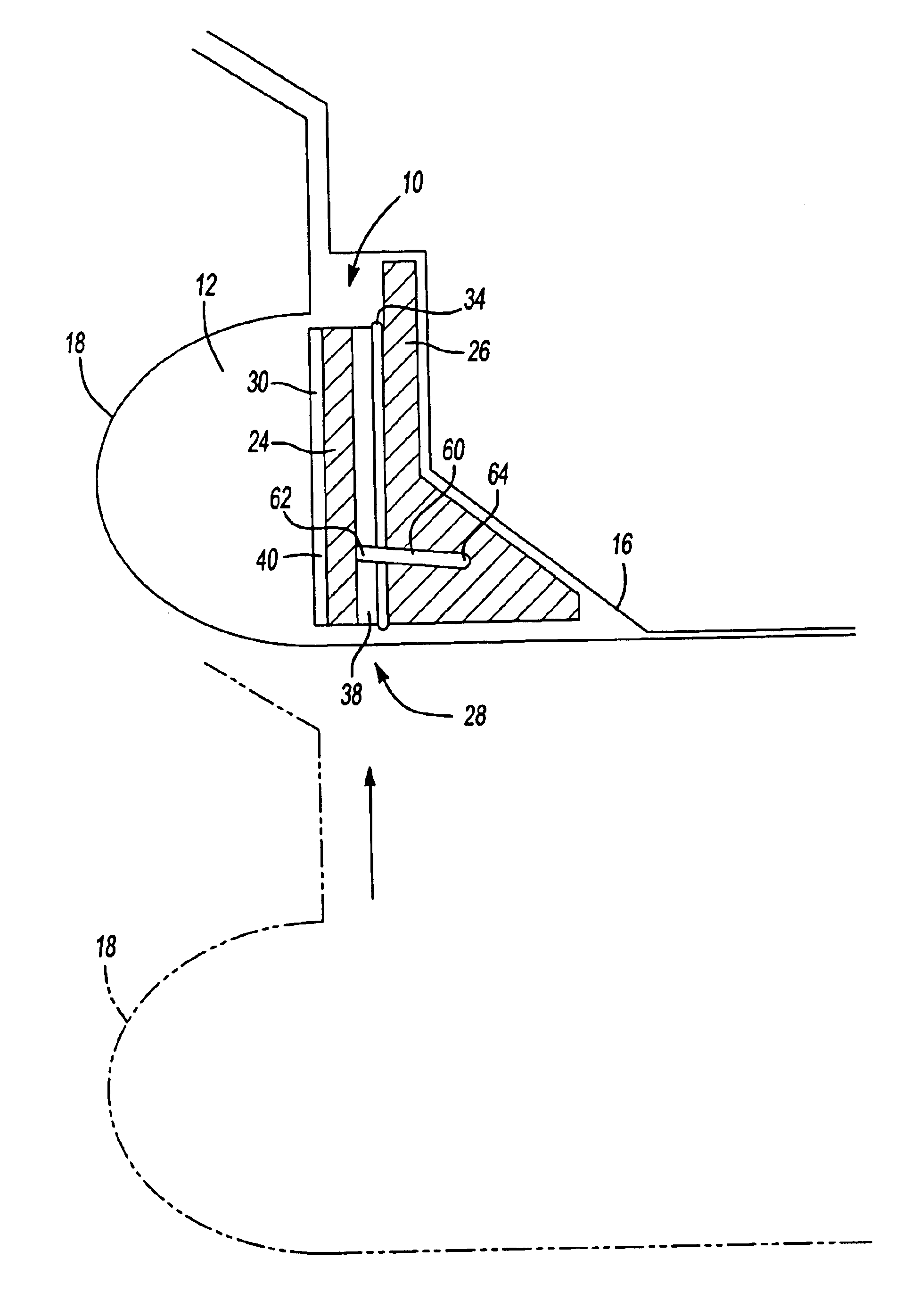

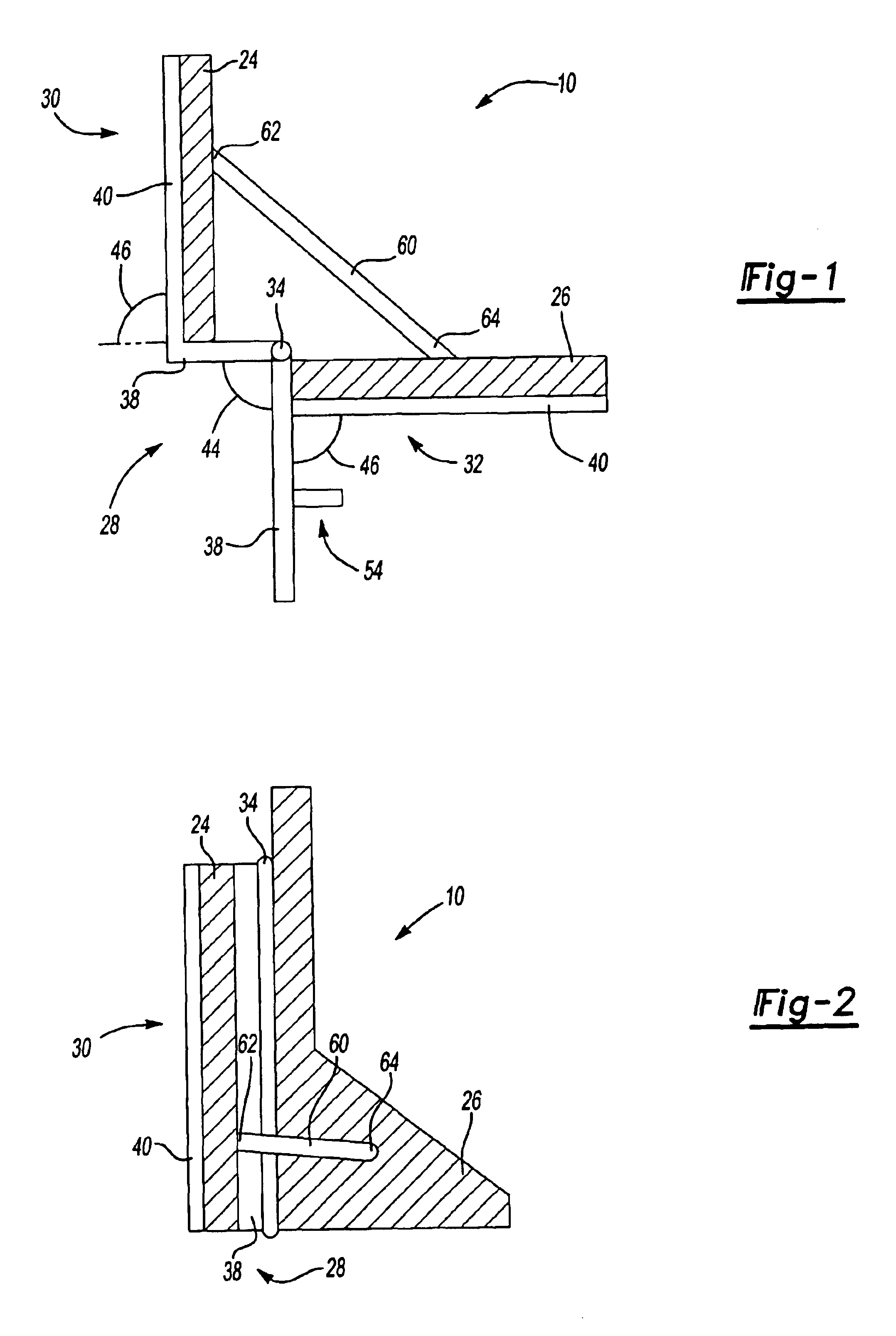

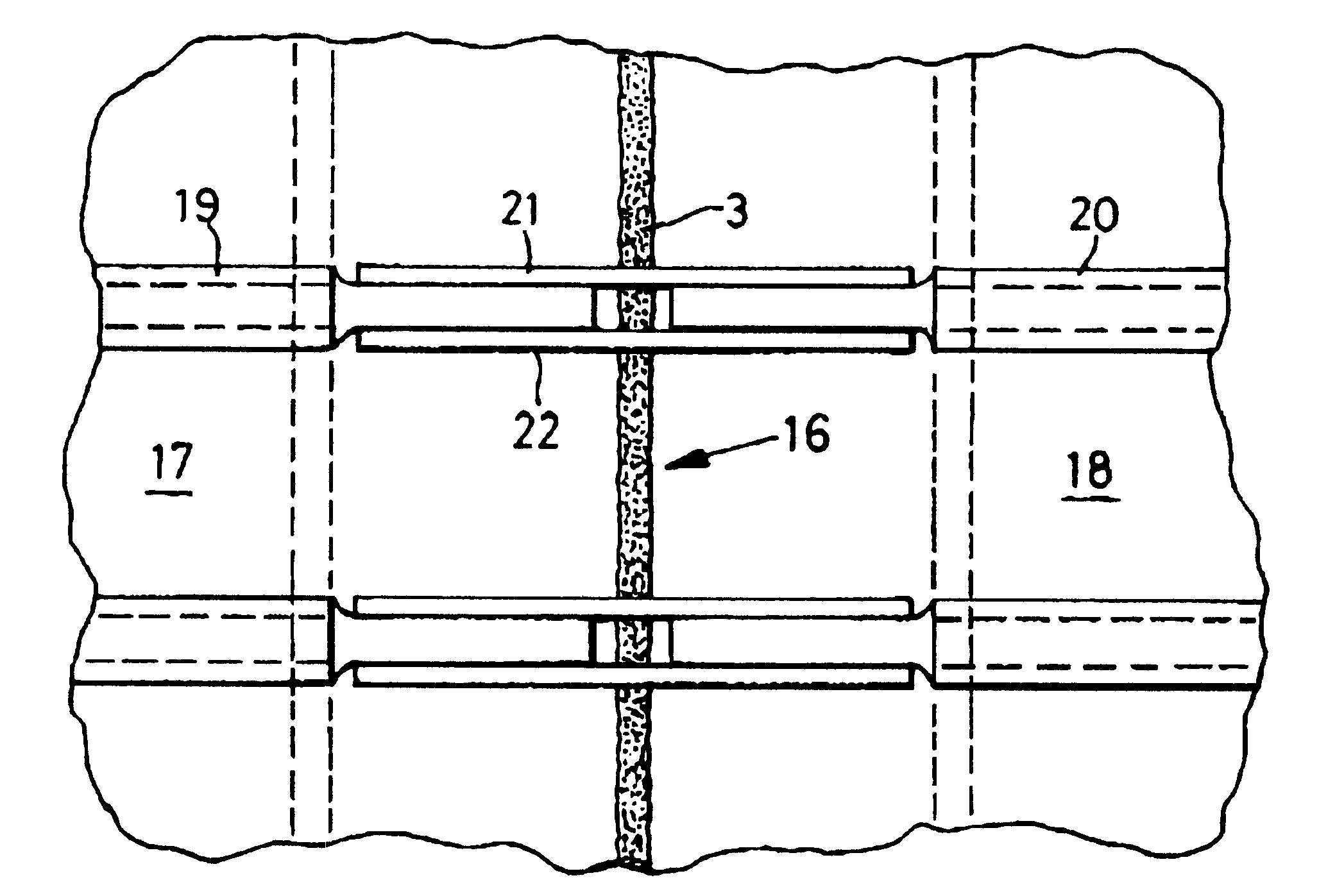

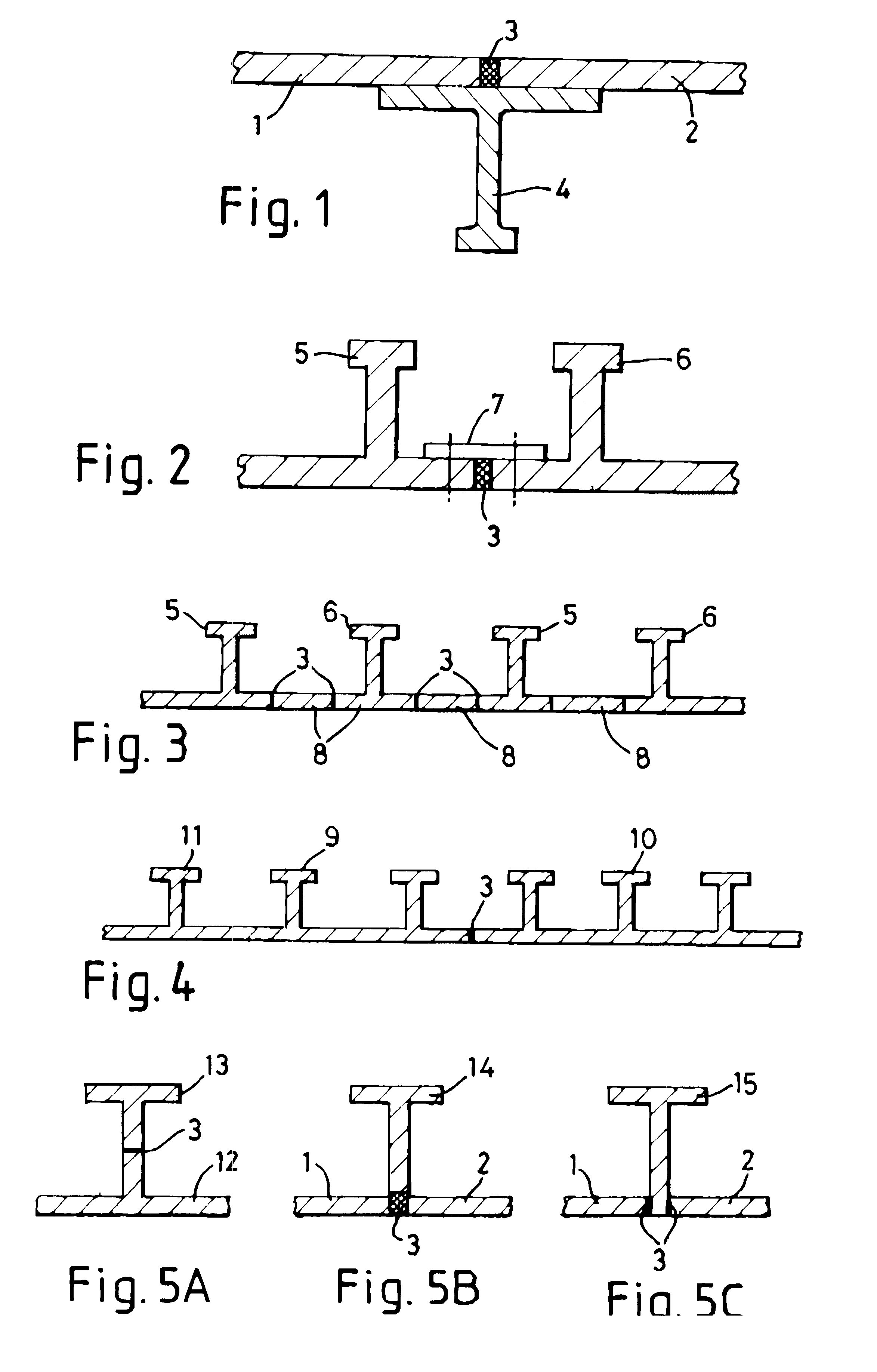

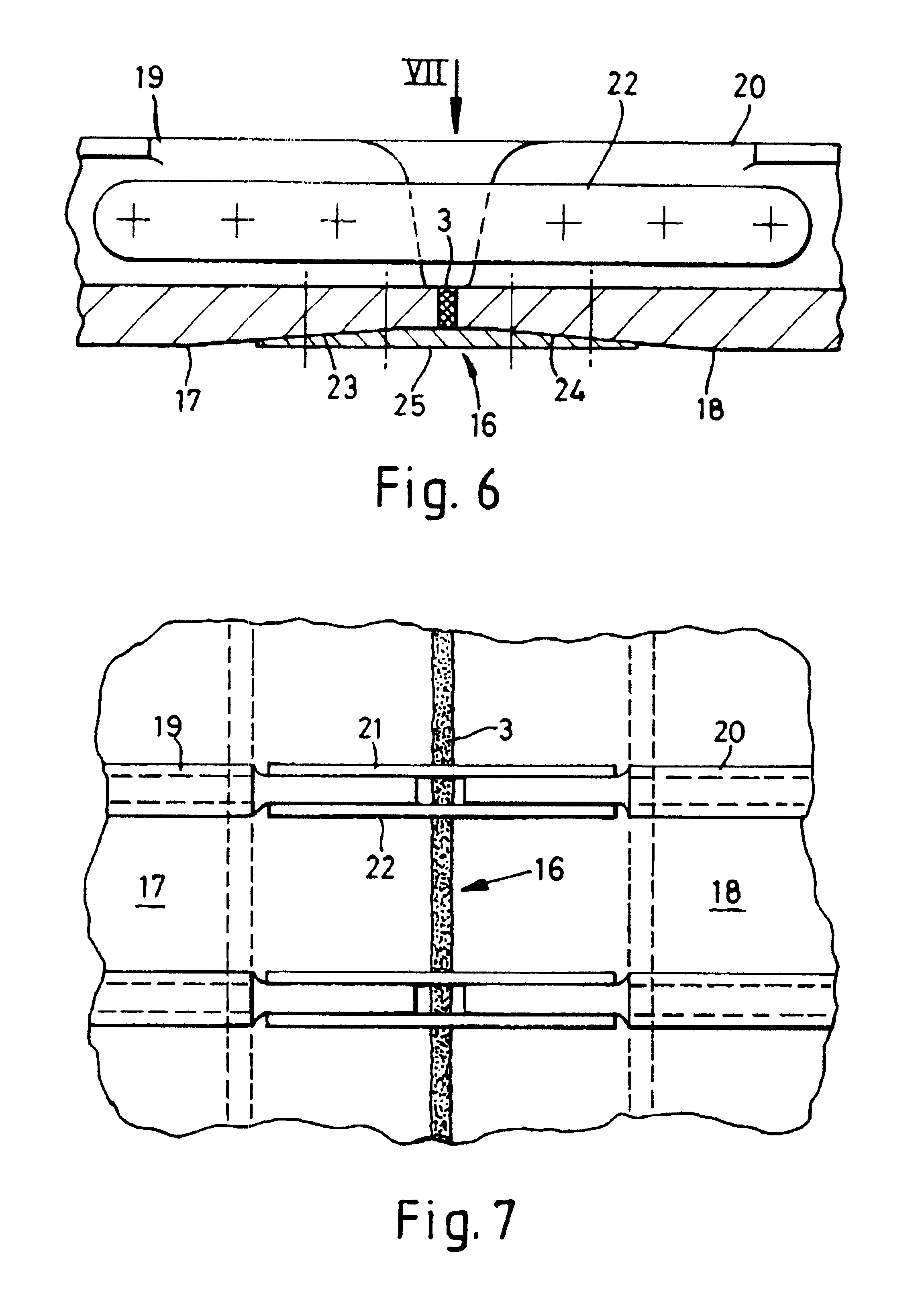

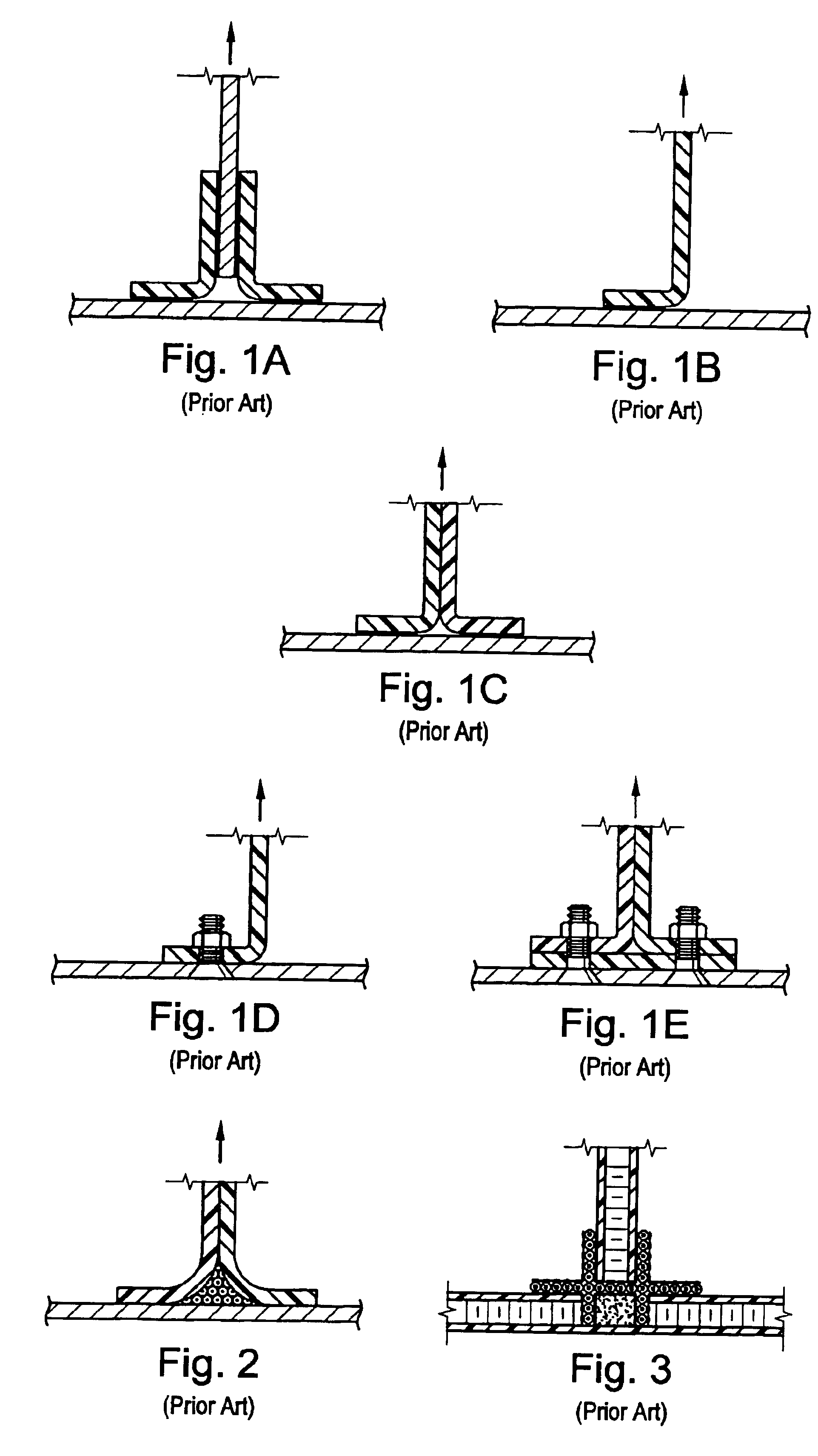

Method and apparatus for fastening together structural components

Owner:HAYTAYAN HARRY M

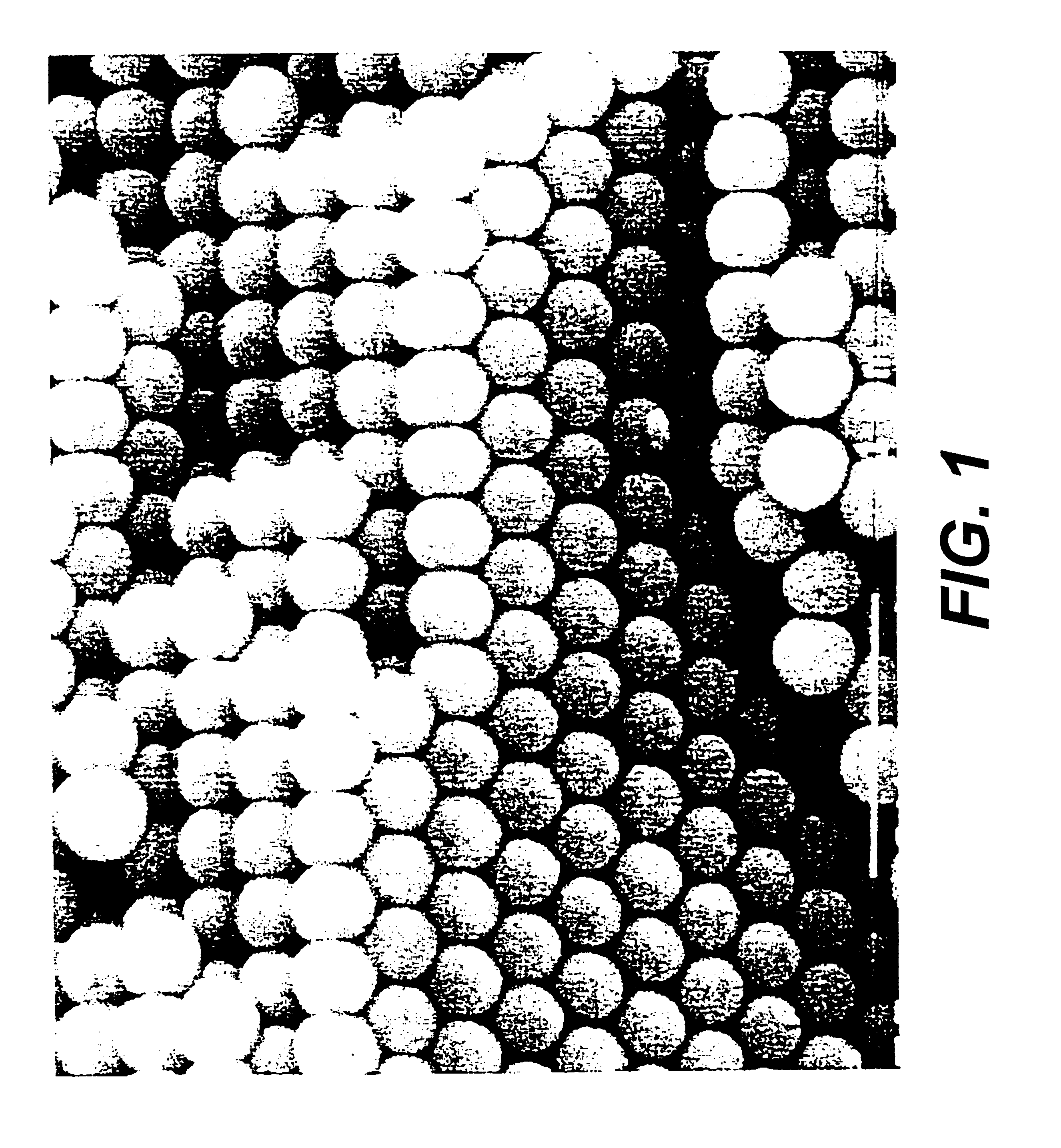

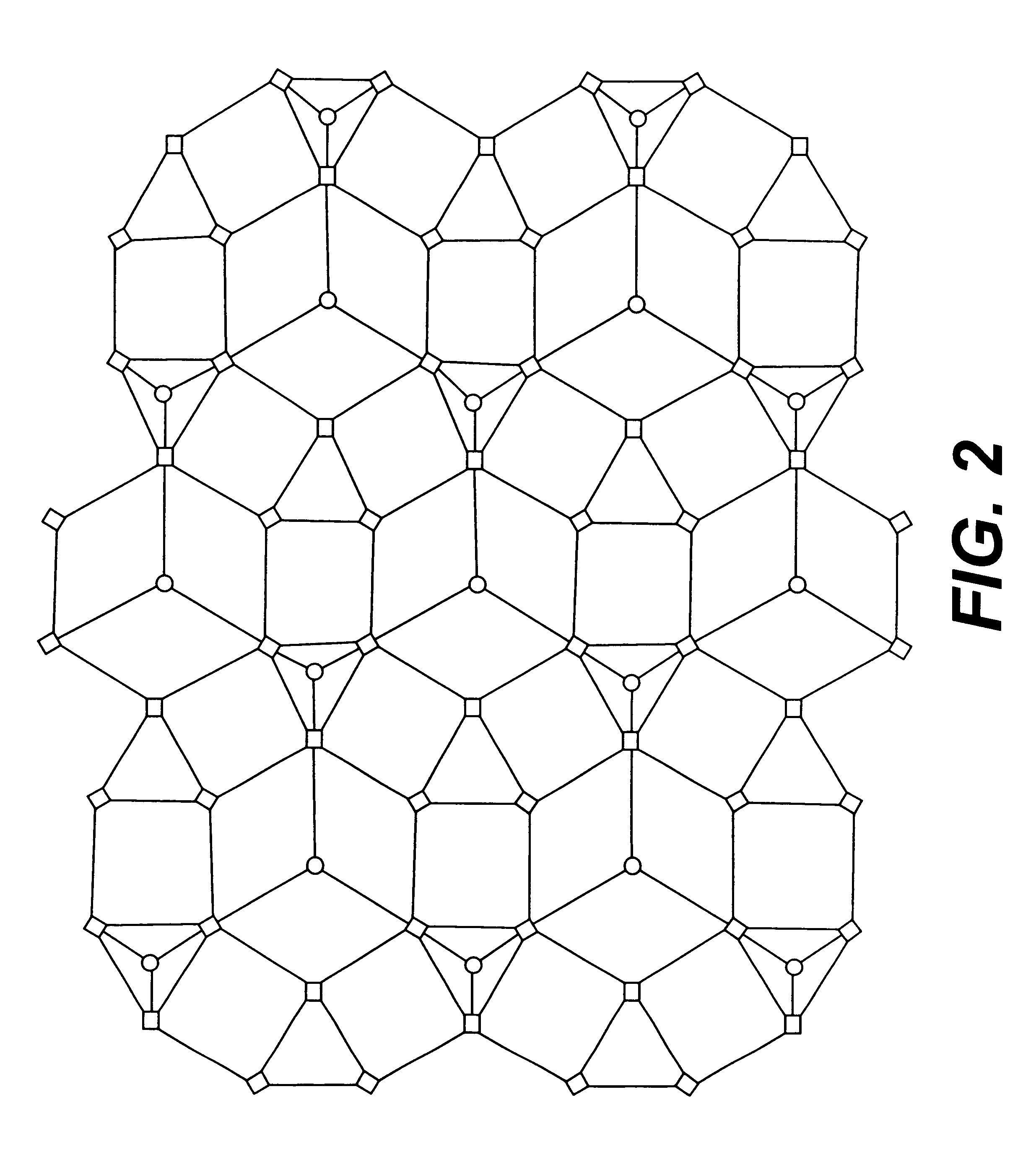

Three dimensionally periodic structural assemblies on nanometer and longer scales

InactiveUS6261469B1Low melting pointEasily de-infiltrateSilicaPaper/cardboard articlesChromatographic separationThermoelectric materials

This invention relates to processes for the assembly of three-dimensional structures having periodicities on the scale of optical wavelengths, and at both smaller and larger dimensions, as well as compositions and applications therefore. Invention embodiments involve the self assembly of three-dimensionally periodic arrays of spherical particles, the processing of these arrays so that both infiltration and extraction processes can occur, one or more infiltration steps for these periodic arrays, and, in some instances, extraction steps. The product articles are three-dimensionally periodic on a scale where conventional processing methods cannot be used. Articles and materials made by these processes are useful as thermoelectrics and thermionics, electrochromic display elements, low dielectric constant electronic substrate materials, electron emitters (particularly for displays), piezoelectric sensors and actuators, electrostrictive actuators, piezochromic rubbers, gas storage materials, chromatographic separation materials, catalyst support materials, photonic bandgap materials for optical circuitry, and opalescent colorants for the ultraviolet, visible, and infrared regions.

Owner:ALLIEDSIGNAL INC

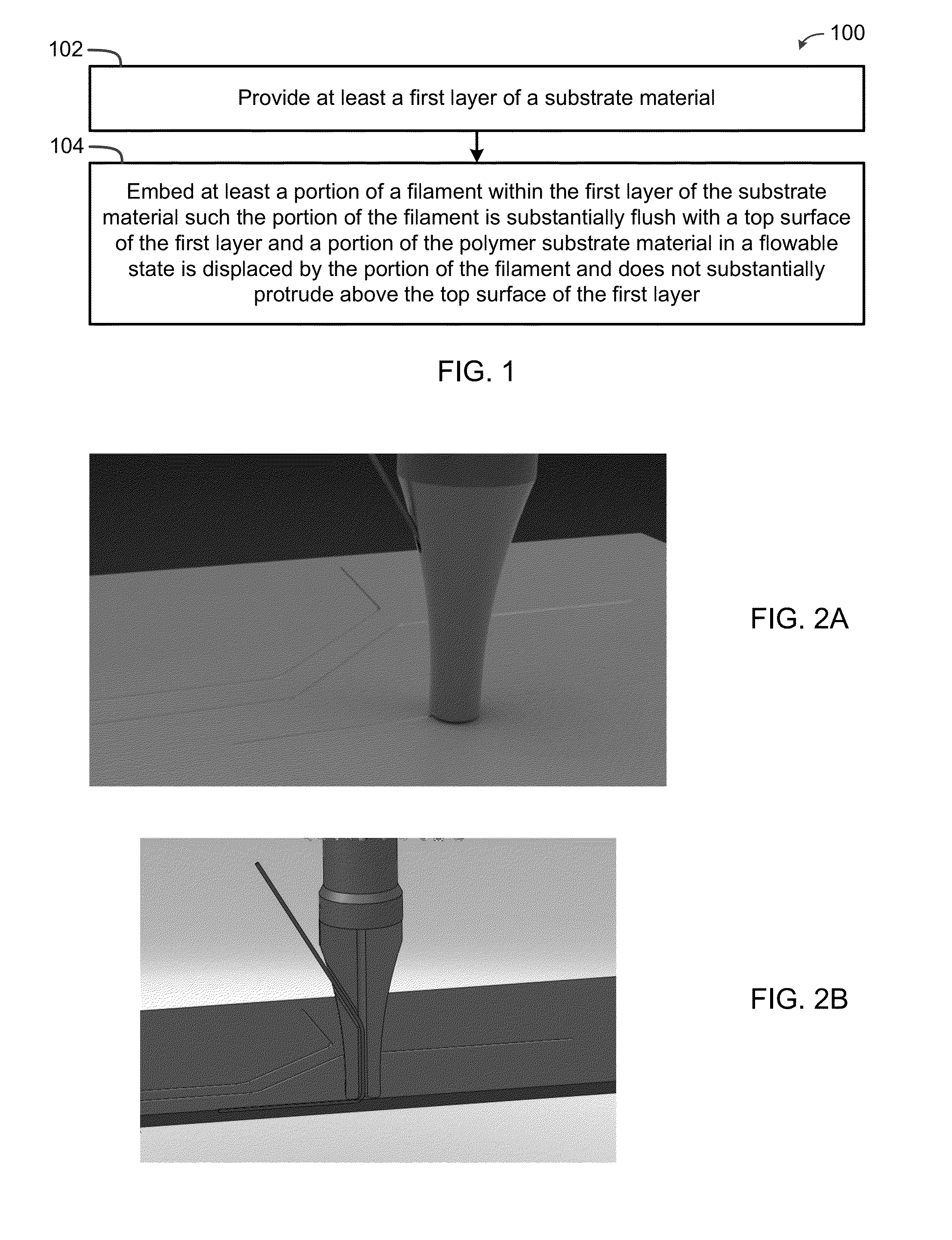

Methods and Systems For Embedding Filaments in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

ActiveUS20140268604A1High mechanical strengthElectric discharge heatingCeramic shaping apparatusElectricityEngineering

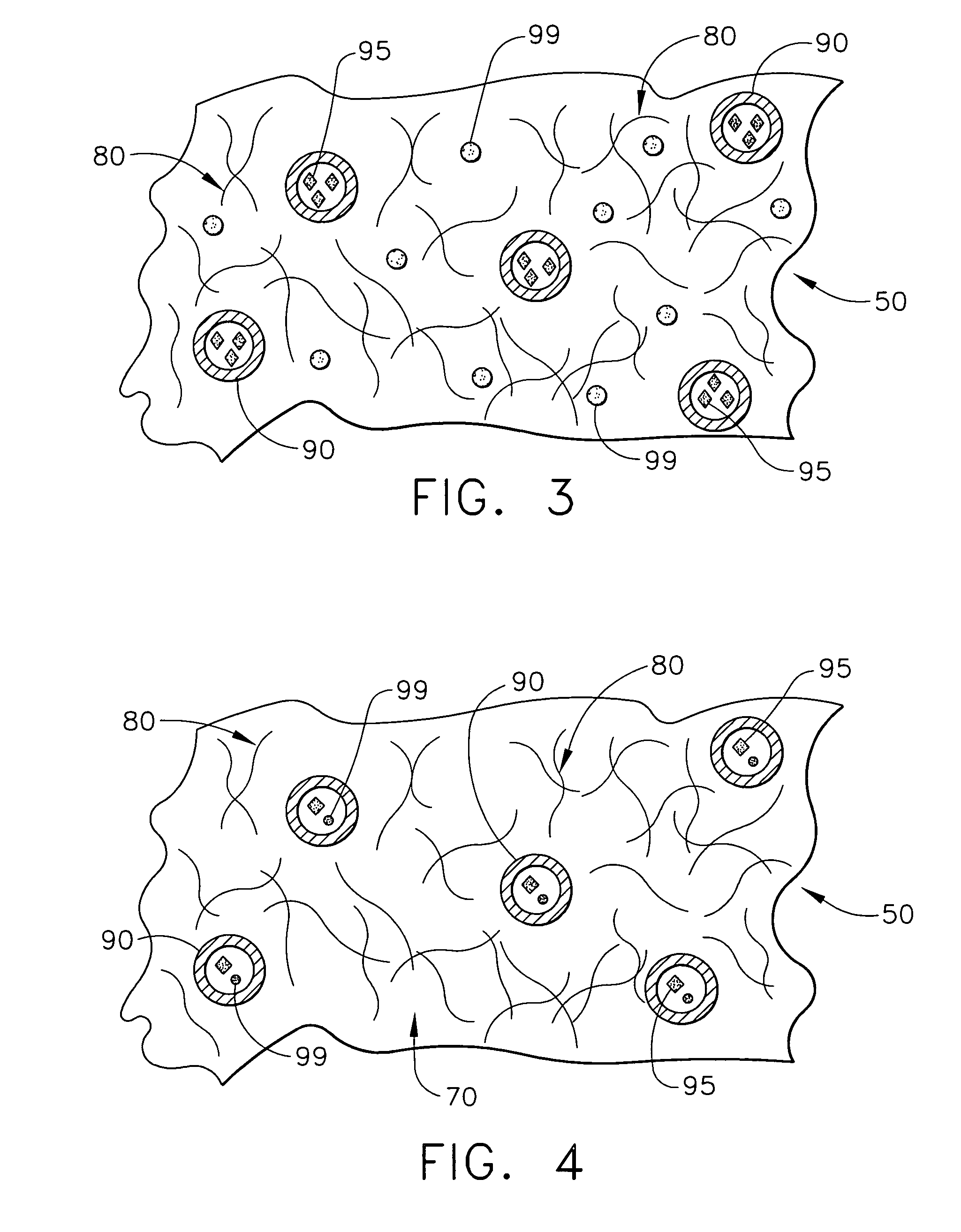

The present invention provides systems and methods for embedding a filament or filament mesh in a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device by providing at least a first layer of a substrate material, and embedding at least a portion of a filament or filament mesh within the first layer of the substrate material such the portion of the filament or filament mesh is substantially flush with a top surface of the first layer and a substrate material in a flowable state is displaced by the portion of the filament and does not substantially protrude above the top surface of the first layer, allowing the continuation of an additive manufacturing process above the embedded filament or filament mesh. A method is provided for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Electrode support structure assemblies

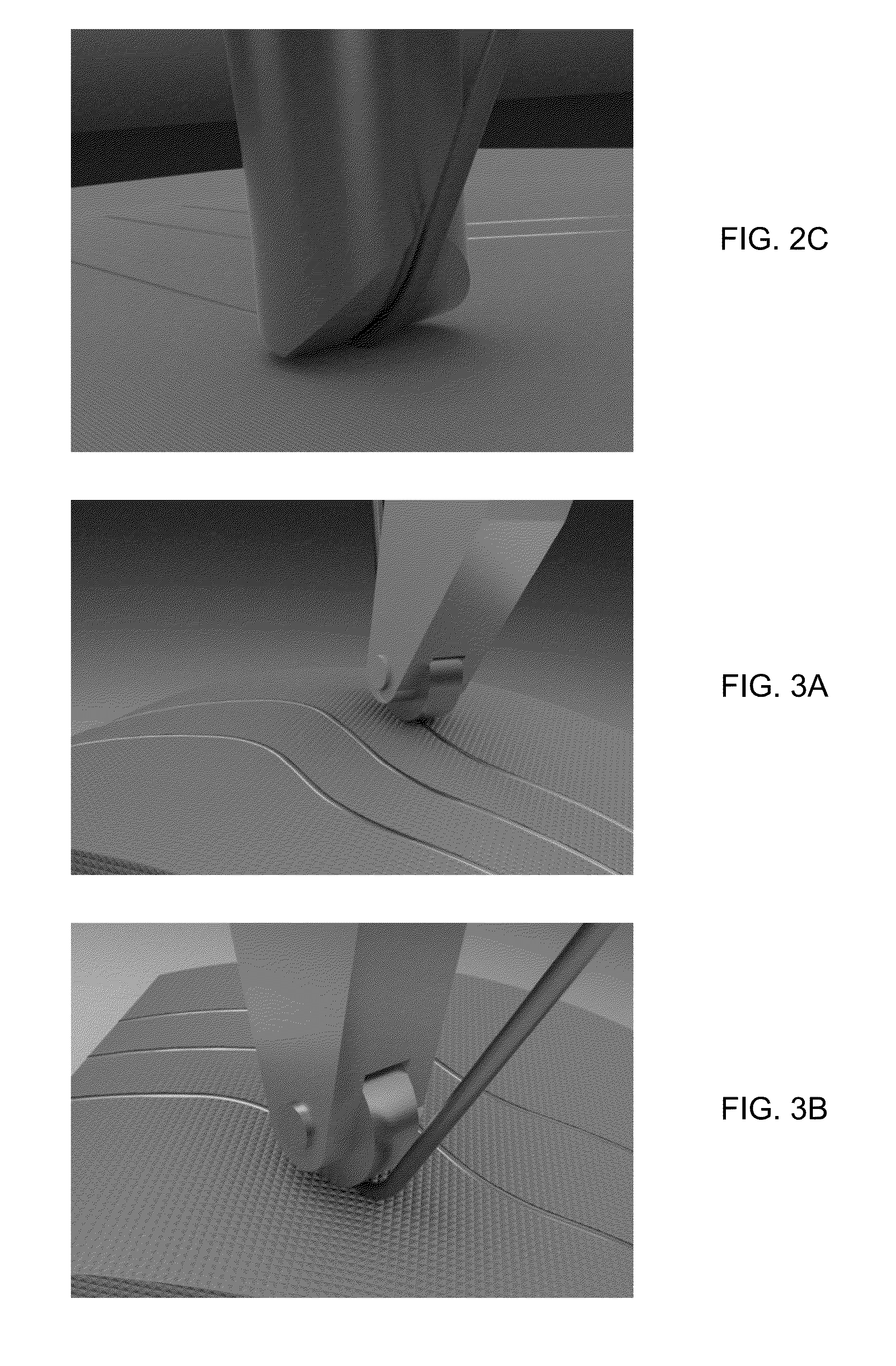

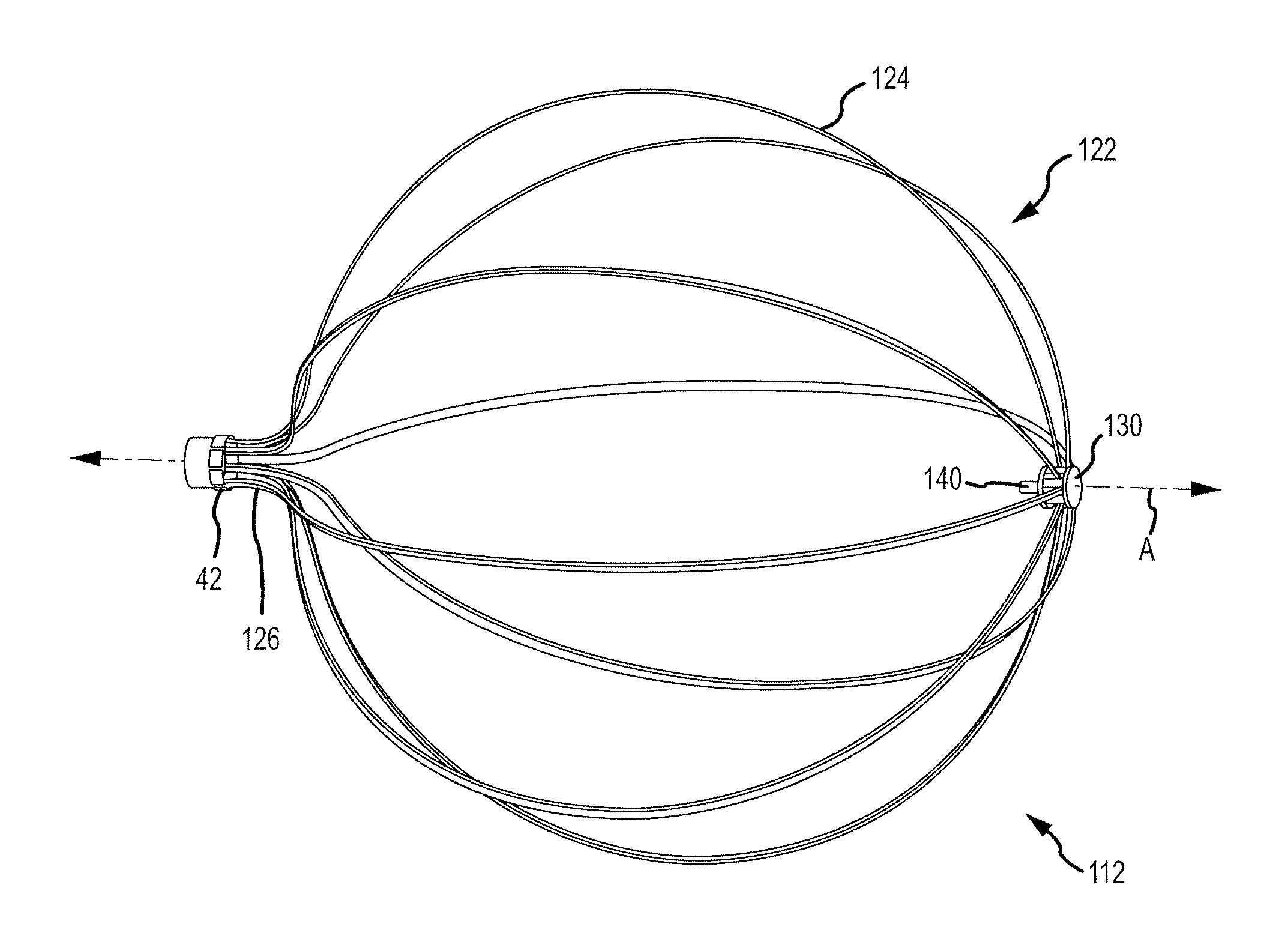

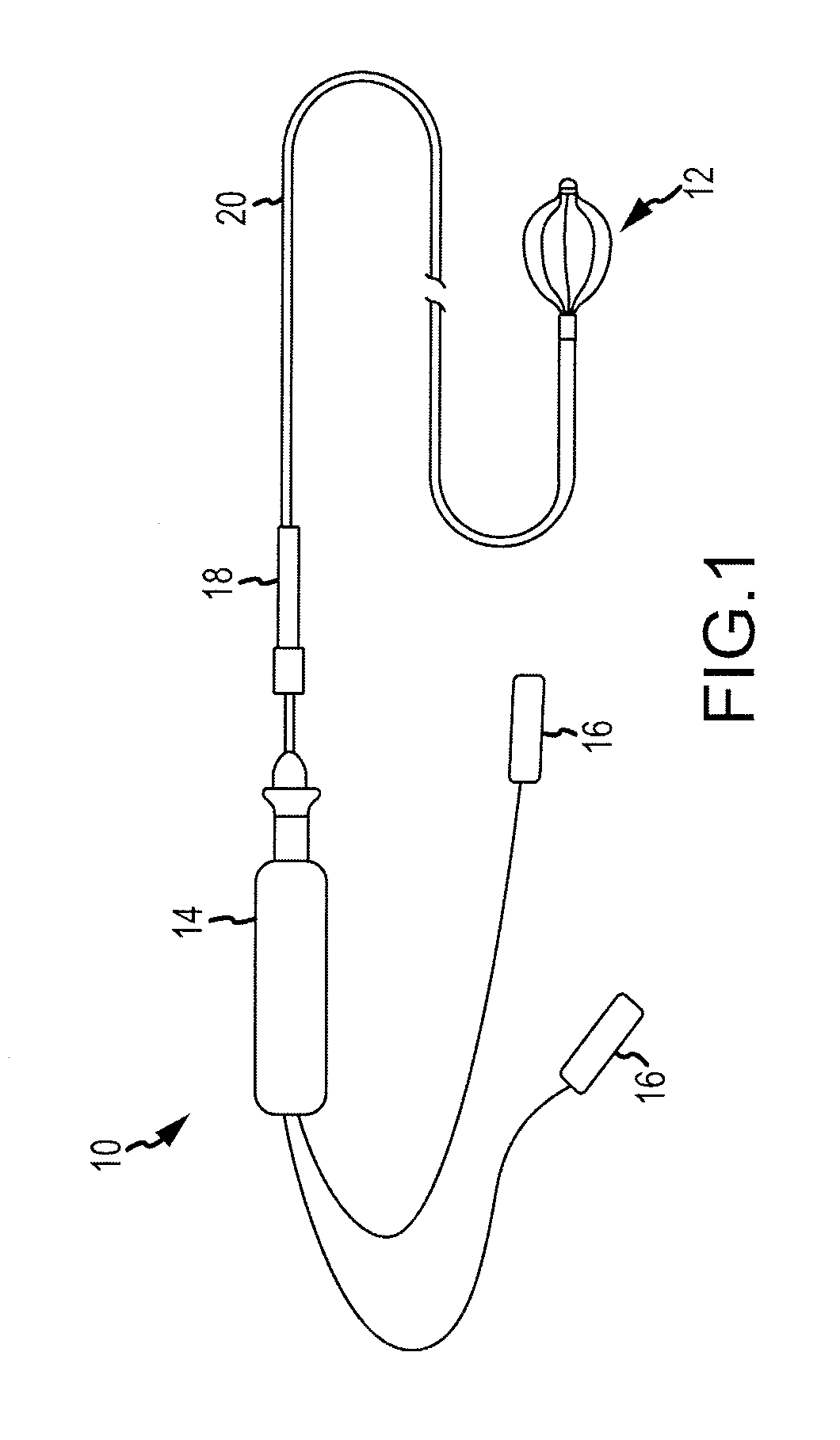

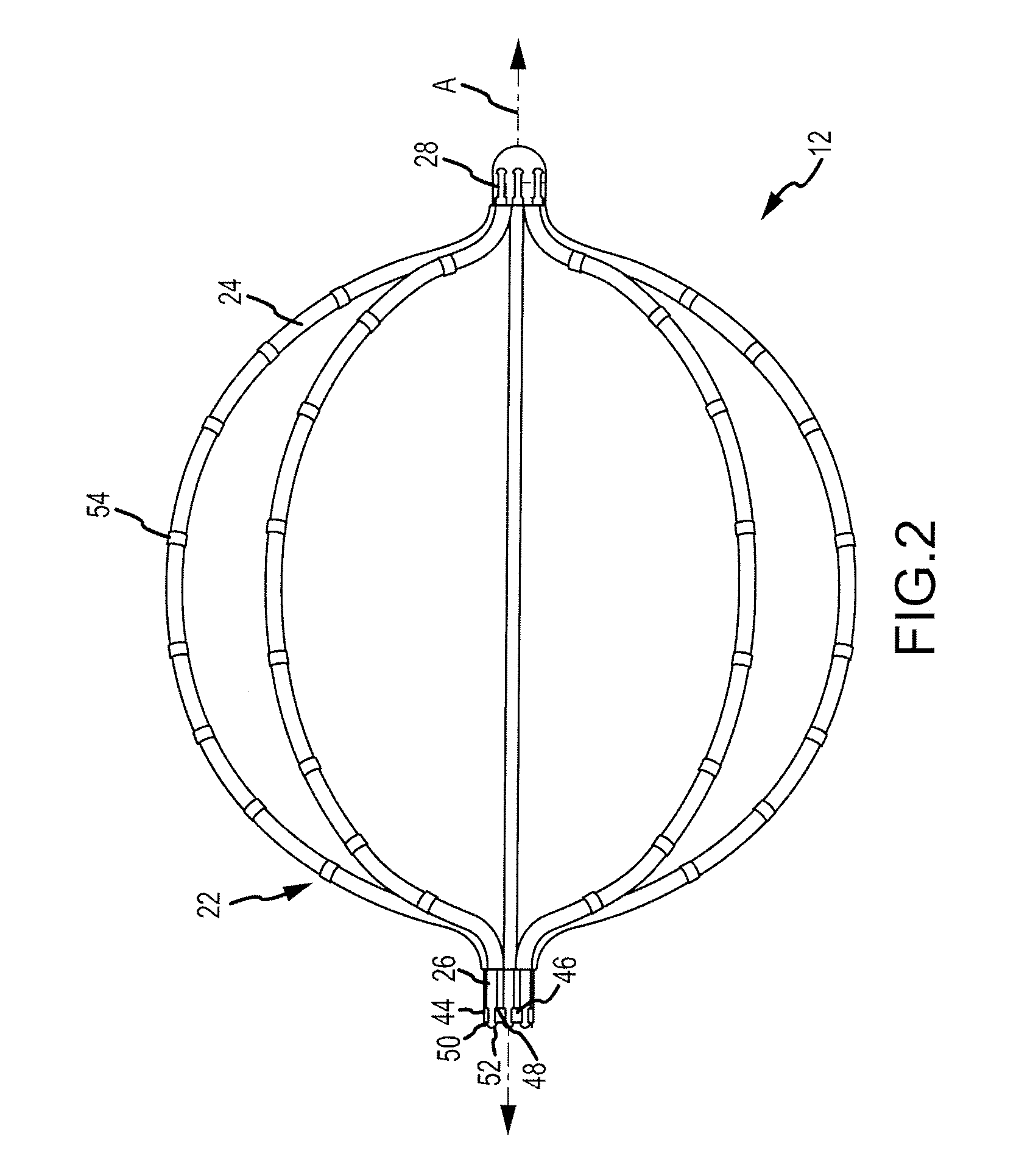

ActiveUS20130172715A1Stress minimizationEvenly distributedElectrocardiographyCatheterEngineeringElectrode

An electrode support structure assembly is provided comprising an electrode support structure including a plurality of splines. Each of the plurality of splines can have a proximal end portion and a distal end portion. The assembly further comprises a first element defining an axis and comprising an outer surface. The outer surface comprises a plurality of slots configured to receive the distal end portion of each of the plurality of splines. The first element is configured such that the distal end portion of each of the plurality of splines may move with respect to each slot. In accordance with some embodiments, the distal end portion of each of the plurality of splines comprises a section configured for engagement with the first element, wherein the section comprises a shoulder.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

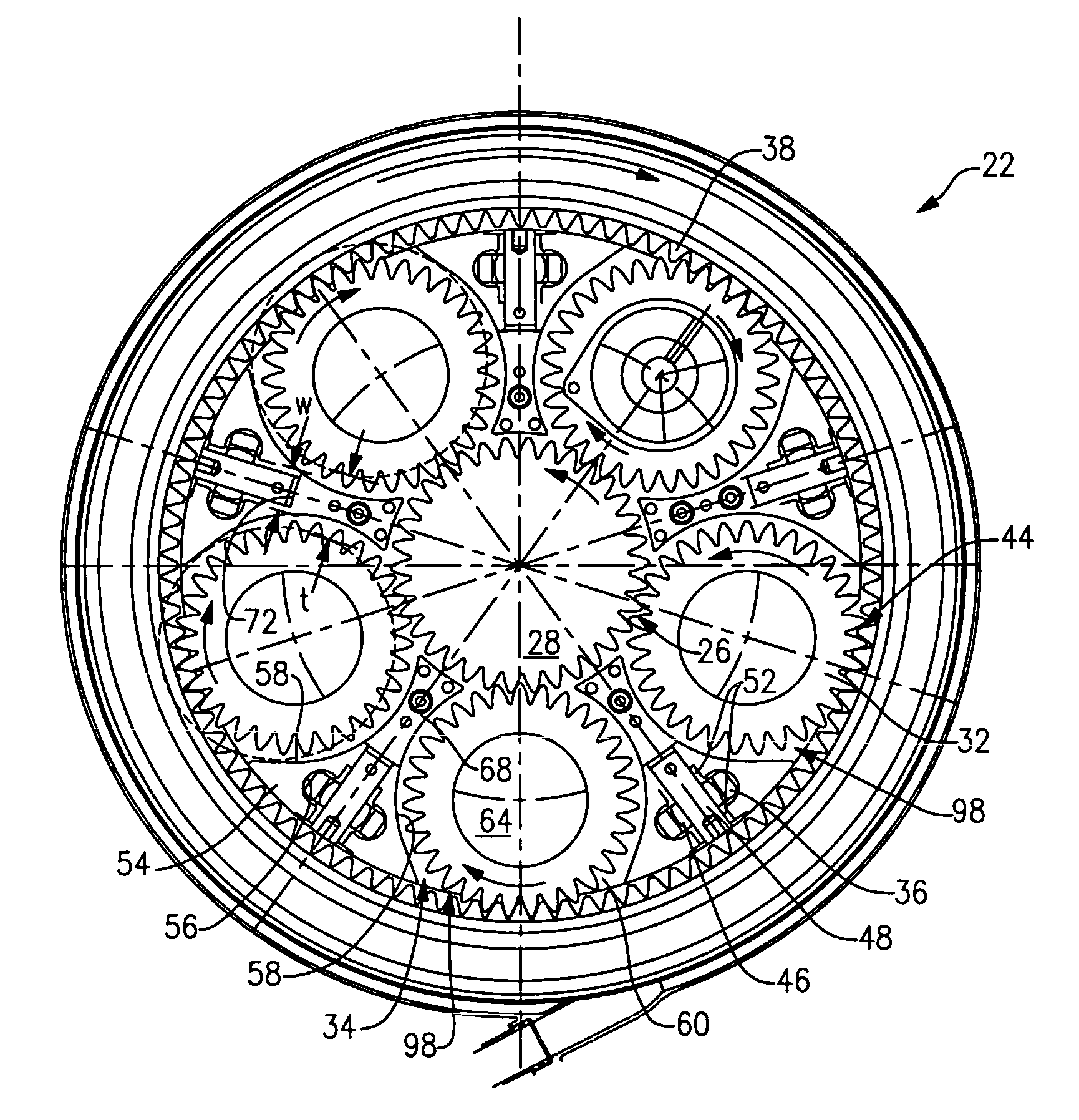

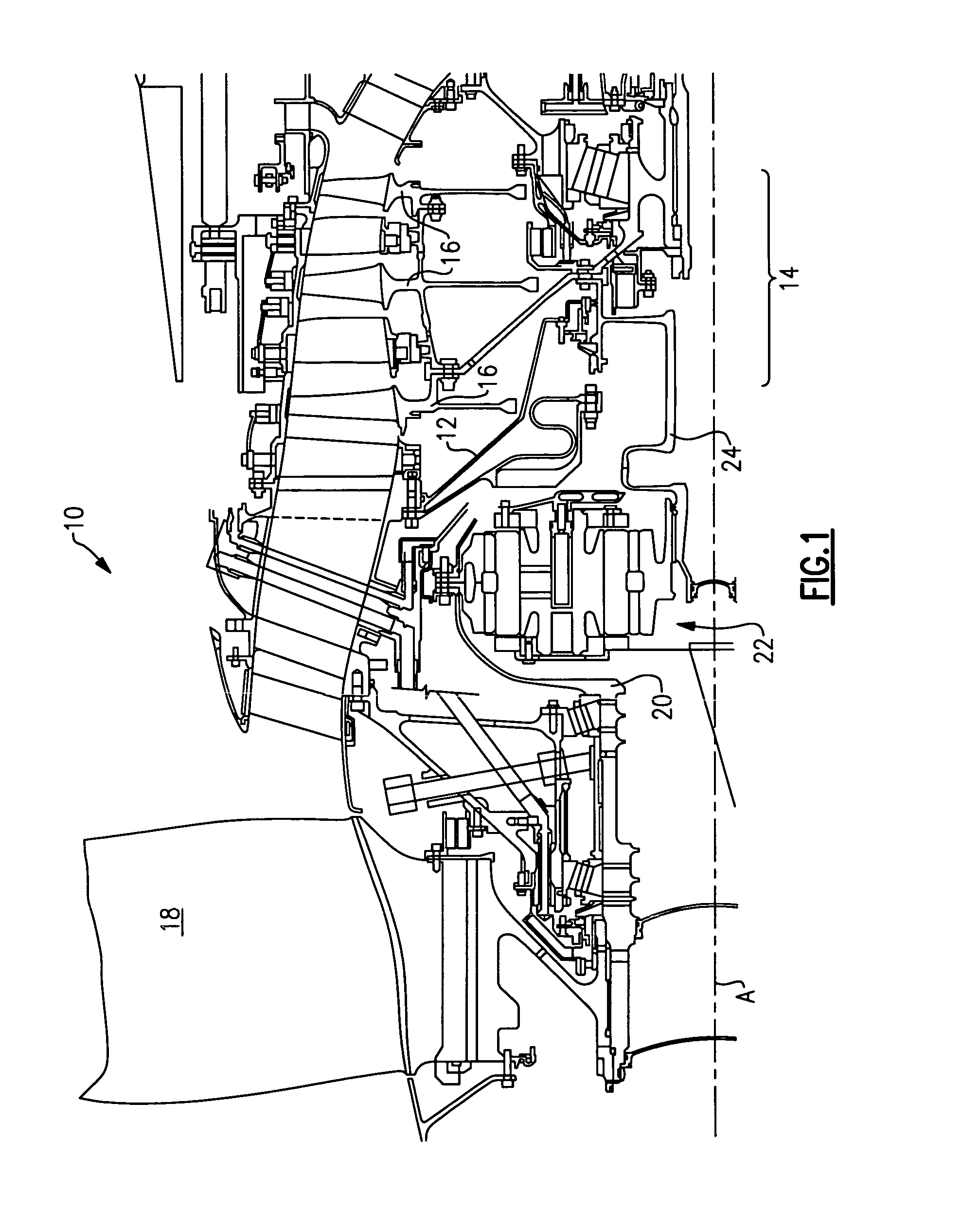

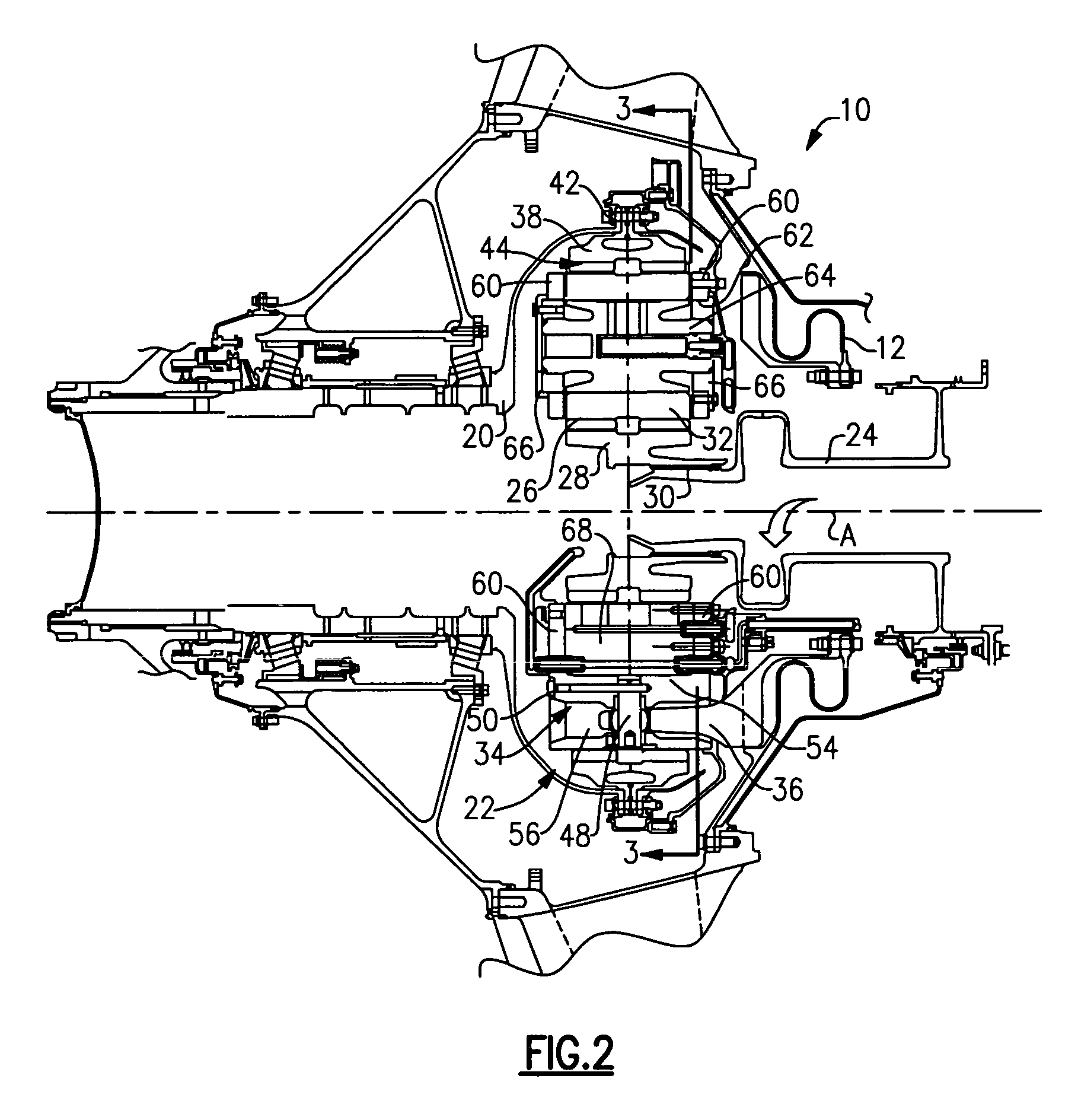

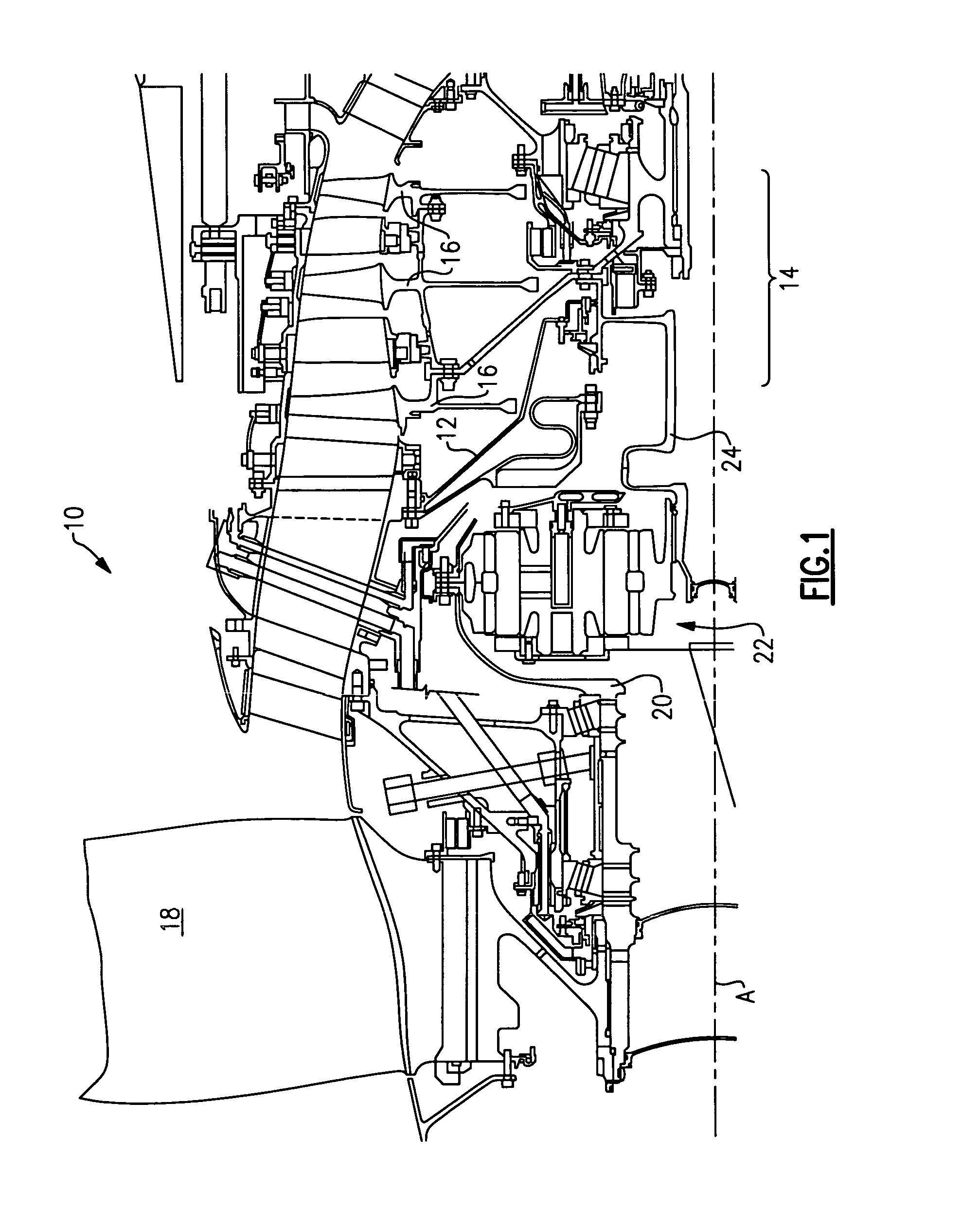

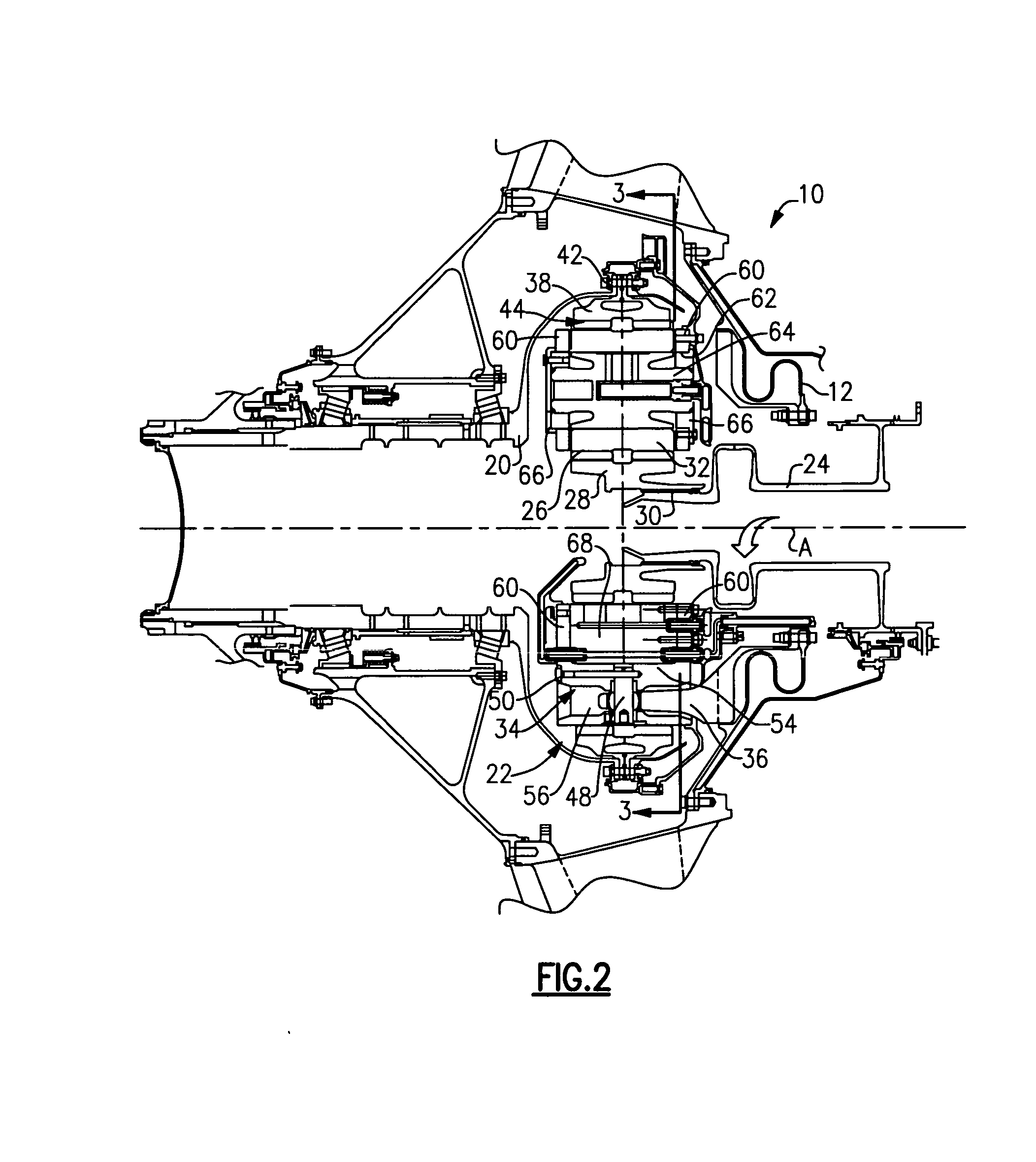

Oil baffle for gas turbine fan drive gear system

Owner:RTX CORP

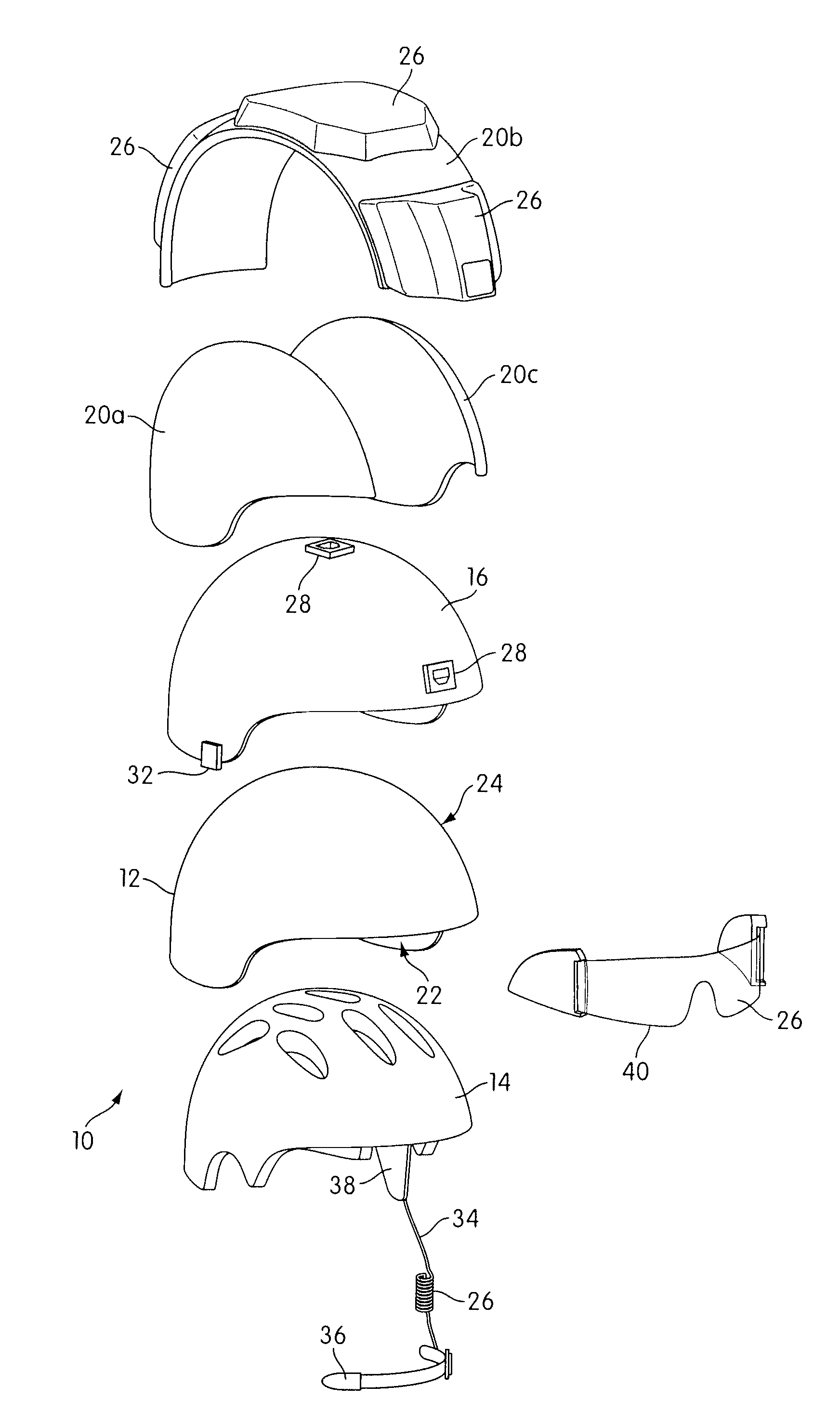

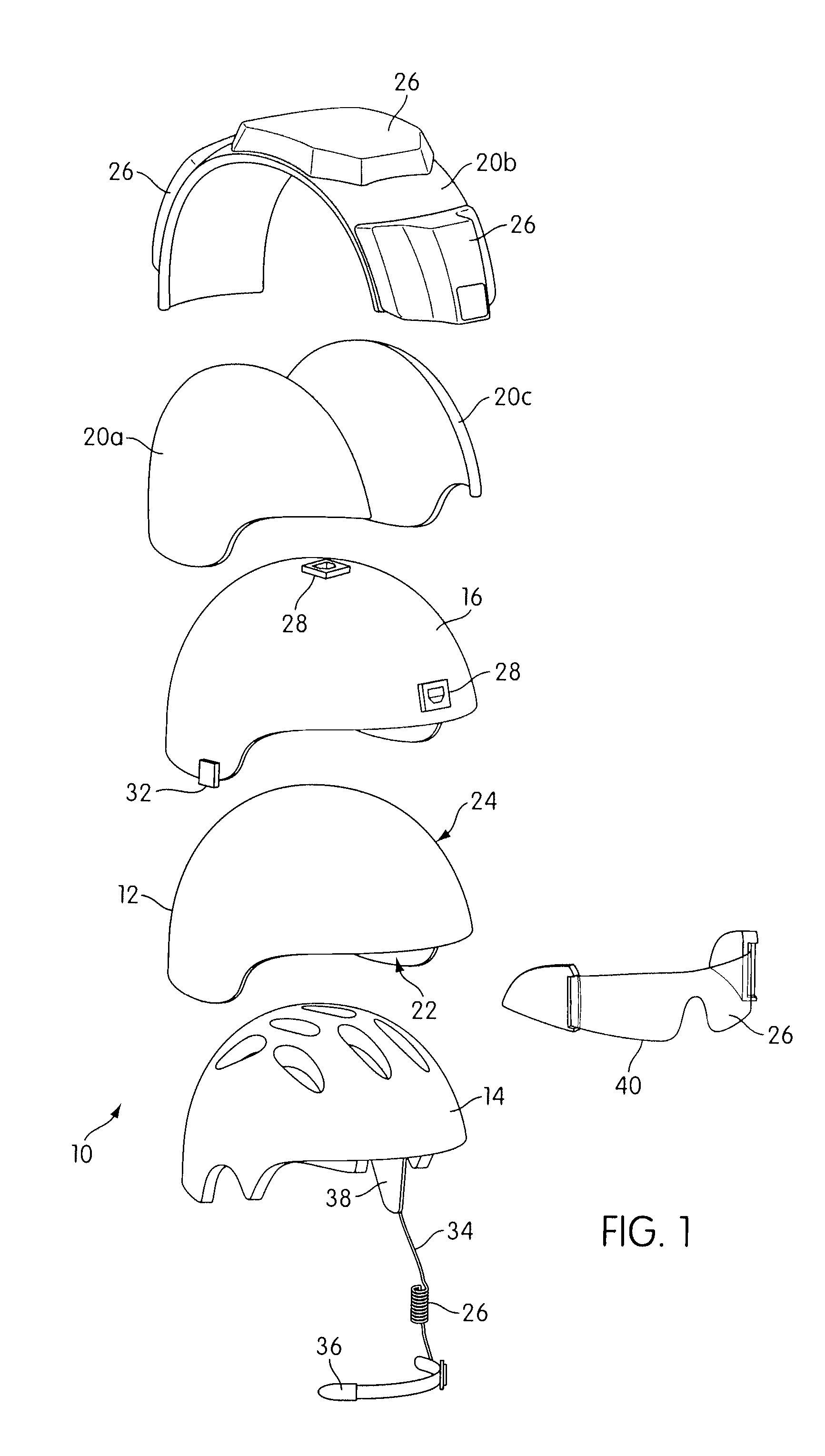

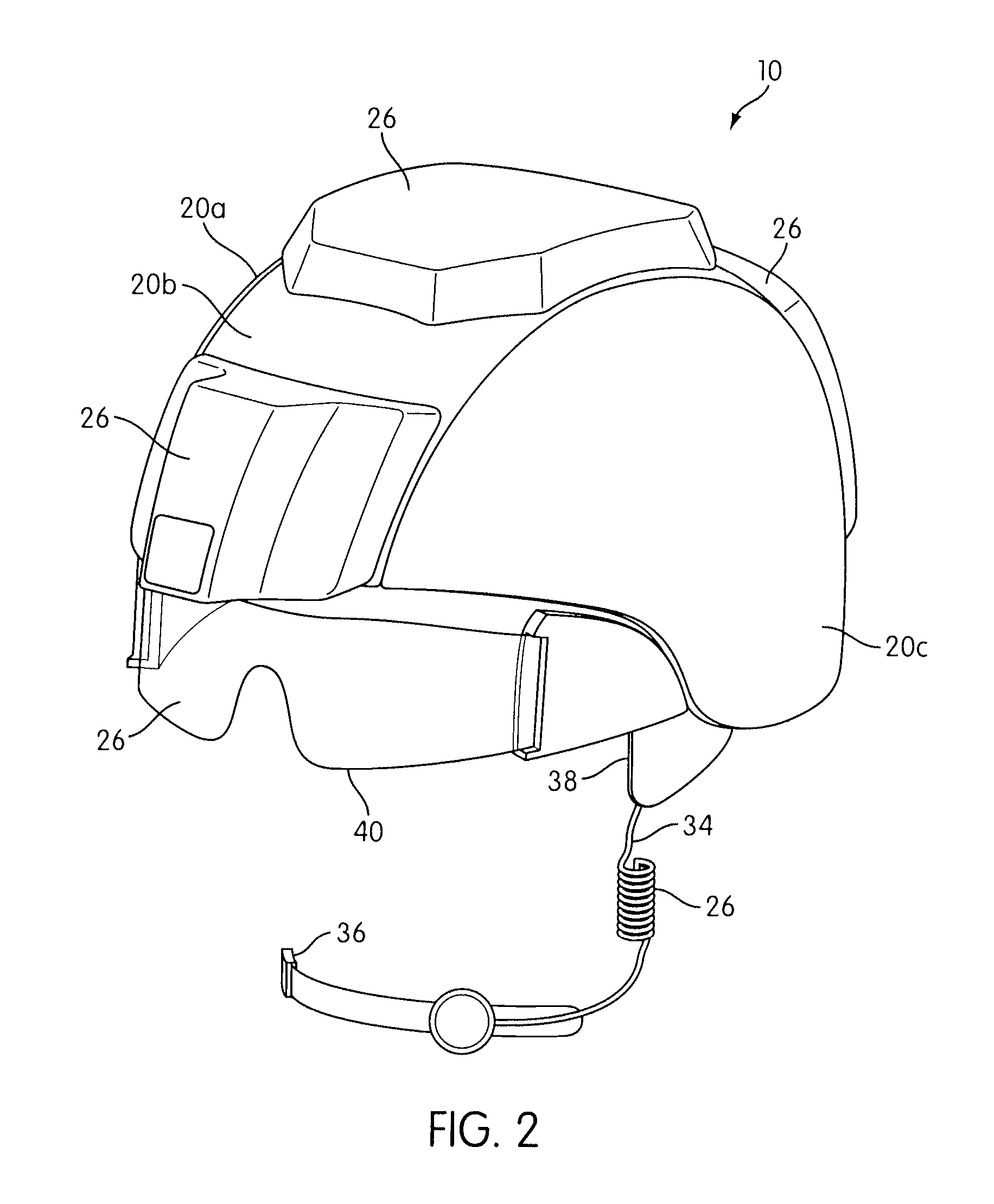

Customizable military helmet system

InactiveUS20110197327A1Easy to customizeImprove protectionVehicle seatsLayered productsInformation processingInformation transmission

A helmet system that enables a user of the helmet system to customize the helmet system according to personal taste, a task at hand, responsibilities within a tactical group (e.g., communications, command, etc.), and / or according to other parameters. The customization of the helmet system may include a customization of electronics modules carried on the helmet system that optionally provide communications, environment detection, health or biometrics monitoring, power, information transmission / reception, information processing, and / or other functionalities. The customization of the helmet system may include a customization of structural components that enable the user to balance the structural protection provided to the user against other considerations. The other considerations may include, for example, weight, form factor, comfort, and / or other considerations.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

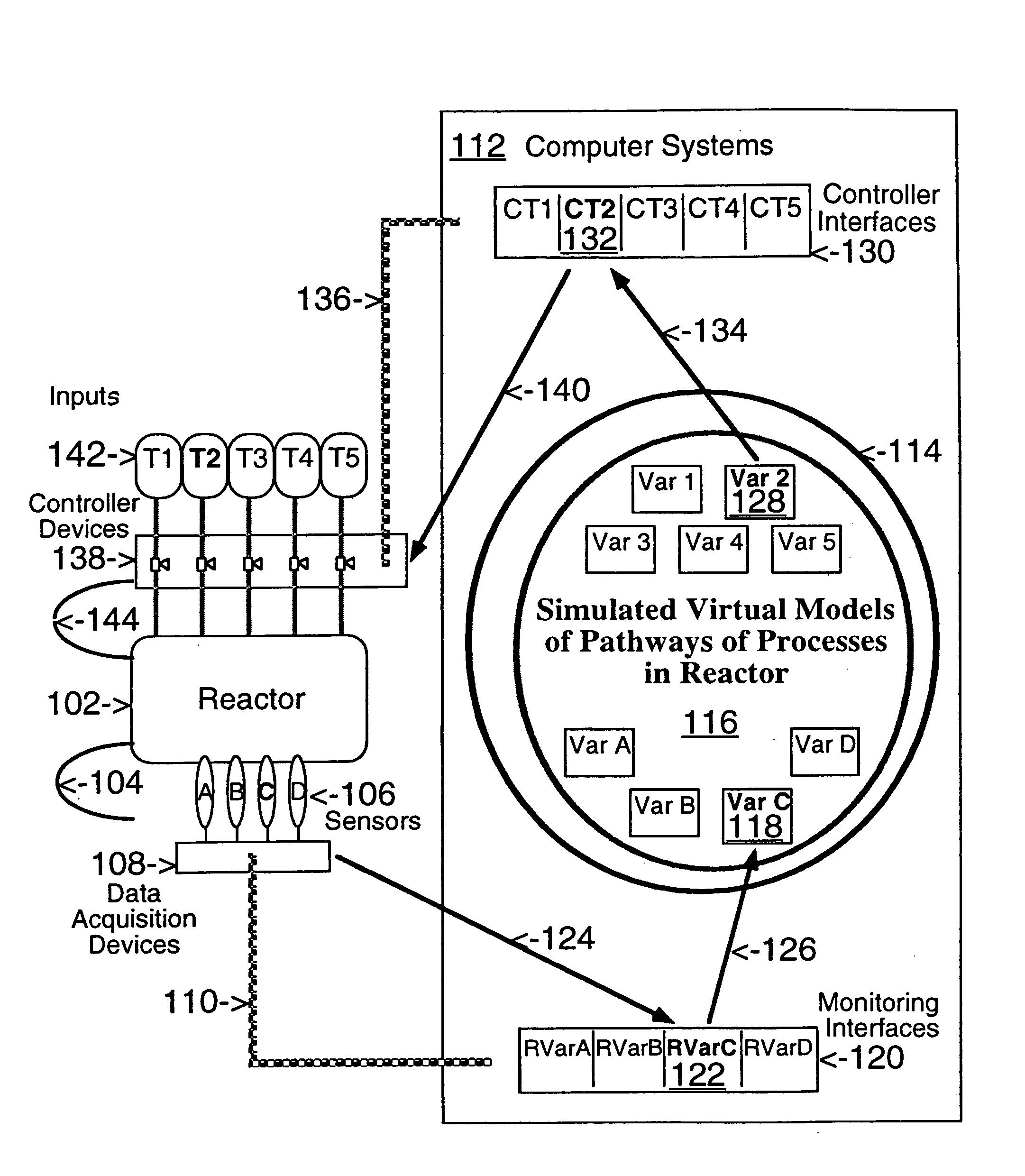

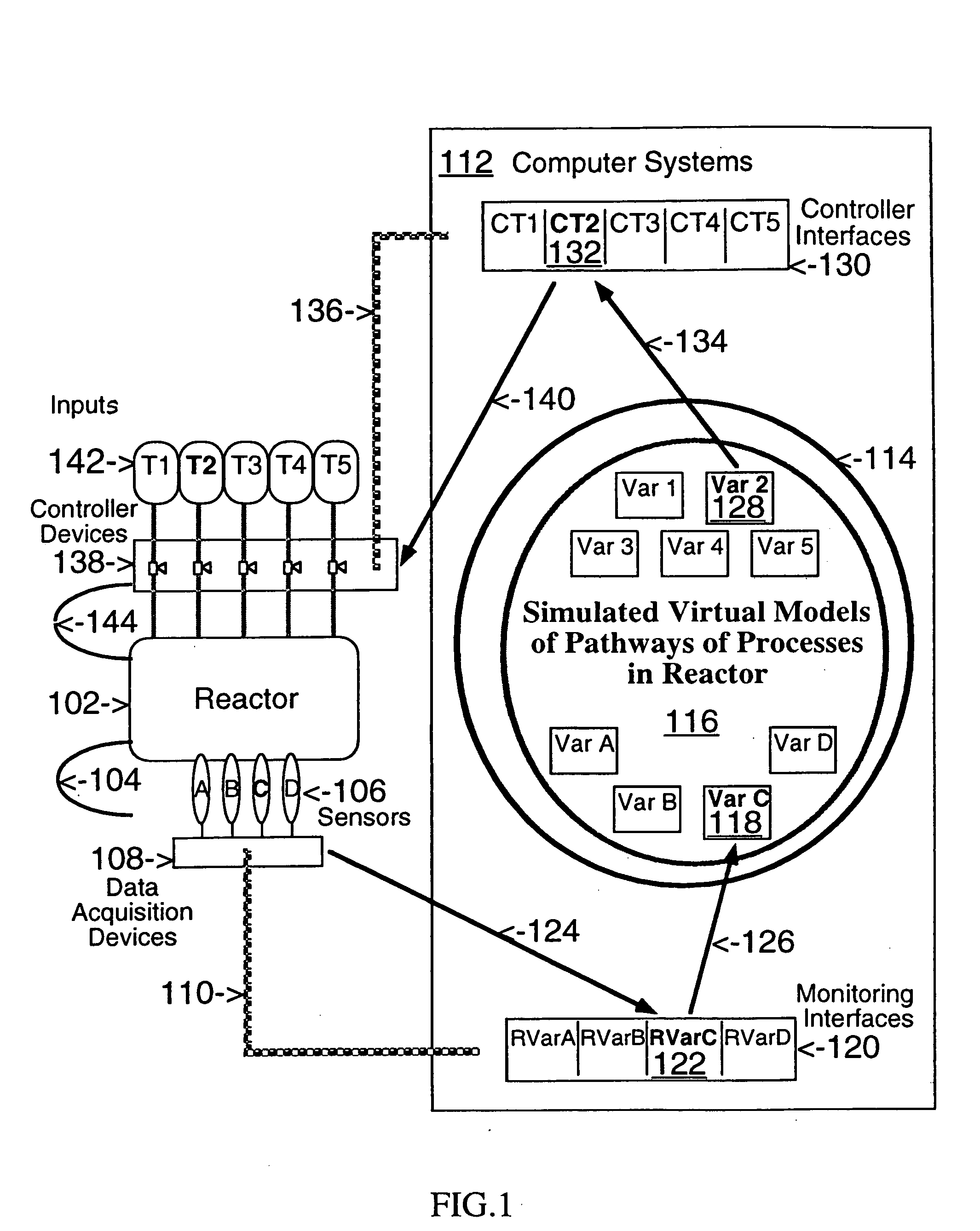

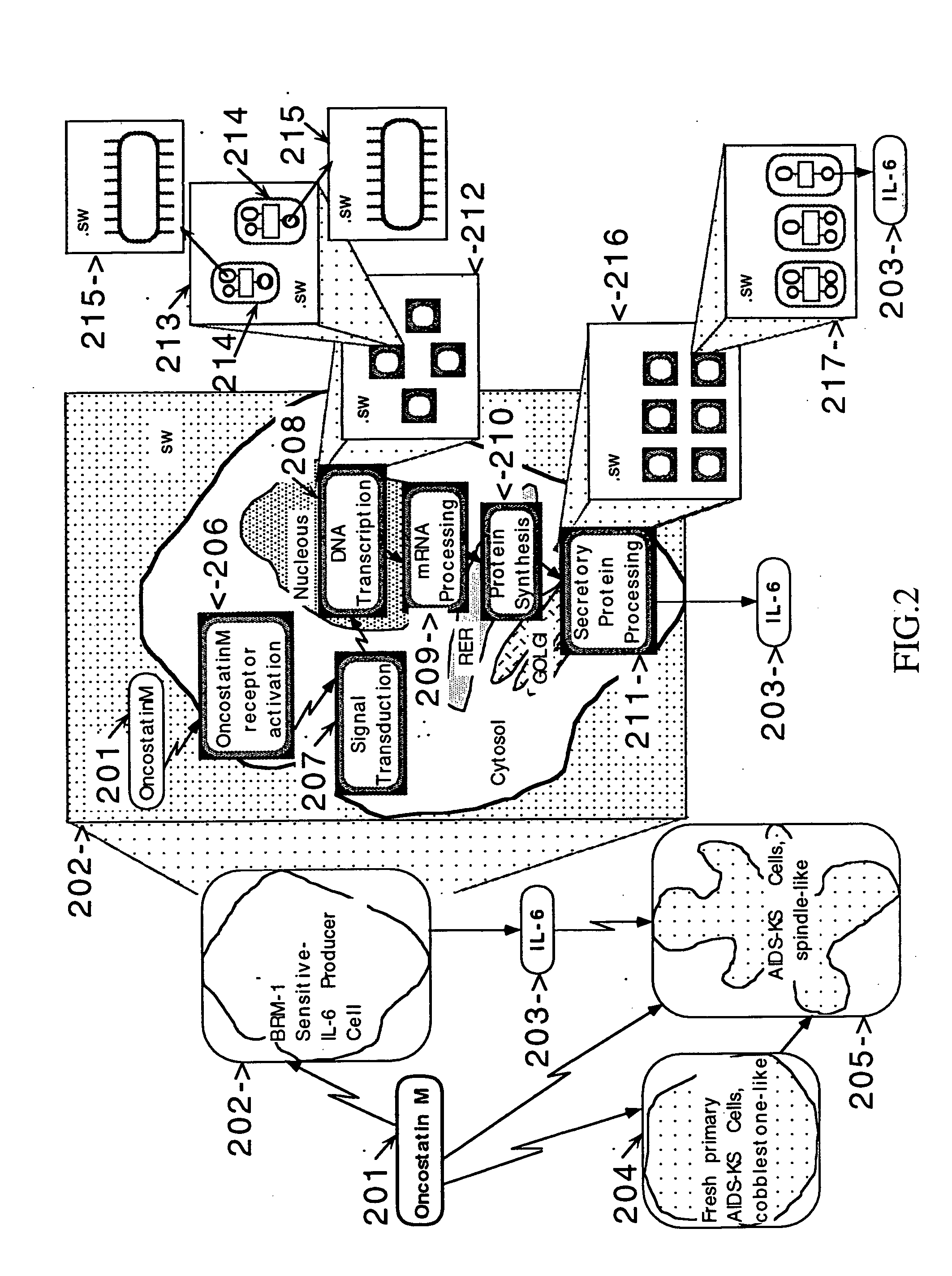

Network models of complex systems

This invention describes computer based virtual models of complex systems, together with integrated systems and methods providing a development and execution framework for visual modeling and dynamic simulation of said models. The virtual models can be used for analysis, monitoring, or control of the operation of the complex systems modeled, as well as for information retrieval. More particularly, the virtual models in the present implementation relate to biological complex systems. In the current implementation the virtual models comprise building blocks representing physical, chemical, or biological processes, the pools of entities that participate in those processes, a hierarchy of compartments representing time-intervals or the spatial and / or functional structure of the complex system in which said entities are located and said processes take place, and the description of the composition of those entities. The building blocks encapsulate in different layers the information, data, and mathematical models that characterize and define each virtual model, and a plurality of methods is associated with their components. The models are built by linking instances of the building blocks in a predefined way, which, when integrated by the methods provided in this invention, result in multidimensional networks of pathways. A number of functions and graphical interfaces can be selected for said instances of building blocks, to extract in various forms the information contained in said models. Those functions include: a) on-the-fly creation of displays of interactive multidimensional networks of pathways, according to user selections; b) dynamic quantitative simulations of selected networks; and c) complex predefined queries based on the relative position of pools of entities in the pathways, the role that the pools play in different processes, the location in selected compartments, and / or the structural components of the entities of those pools. The system integrates inferential control with quantitative and scaled simulation methods, and provides a variety of alternatives to deal with complex dynamic systems and with incomplete and constantly evolving information and data.

Owner:INTERTECH VENTURES

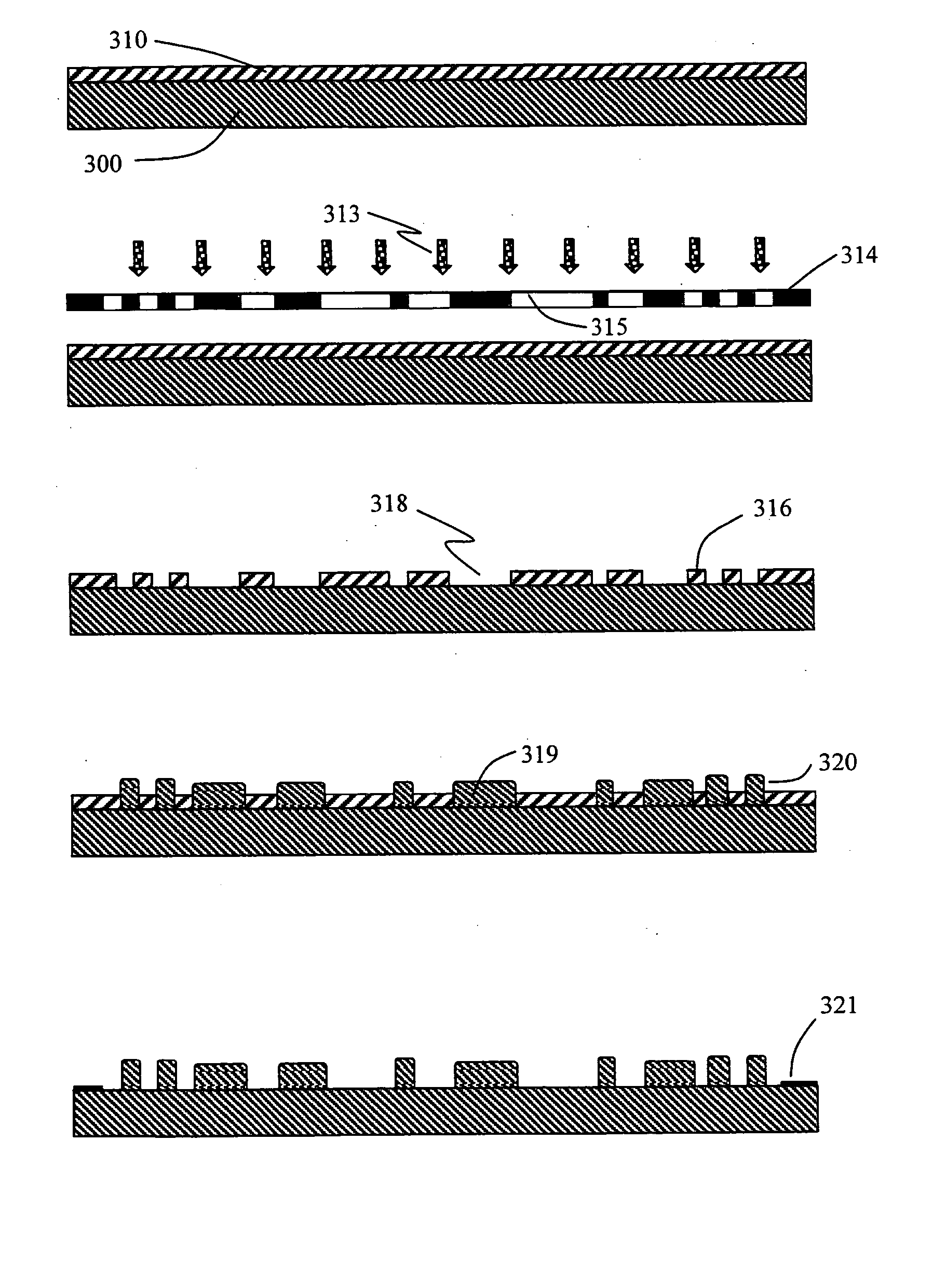

Microfabricated structures and processes for manufacturing same

InactiveUS20050067286A1Minimize surface roughnessEasy to controlElectroforming processesMicroelectromechanical systemsManufacturing technologyCompound (substance)

Various techniques for the fabrication of highly accurate master molds with precisely defined microstructures for use in plastic replication using injection molding, hot embossing, or casting techniques are disclosed herein. Three different fabrication processes used for master mold fabrication are disclosed wherein one of the processes is a combination of the other two processes. In an embodiment of the first process, a two-step electroplating approach is used wherein one of the metals forms the microstructures and the second metal is used as a sacrificial support layer. Following electroplating, the exact height of the microstructures is defined using a chemical mechanical polishing process. In an embodiment of the second process, a modified electroforming process is used for master mold fabrication. The specific modifications include the use of Nickel-Iron (80:20) as a structural component of the master mold, and the use of a higher saccharin concentration in the electroplating bath to reduce tensile stress during plating and electroforming on the top as well as sides of the dummy substrate to prevent peel off of the electroform. The electroforming process is also well suited towards the fabrication of microstructures with non-rectangular cross sectional profiles. Also disclosed is an embodiment of a simple fabrication process using direct deposition of a curable liquid molding material combined with the electroforming process. Finally, an embodiment of a third fabrication process combines the meritorious features of the first two approaches and is used to fabricate a master mold using a combination of the two-step electroplating plus chemical mechanical polishing approach and the electroforming approach to fabricate highly accurate master molds with precisely defined microstructures. The microstructures are an integral part of the master mold and hence the master mold is more robust and well suited for high volume production of plastic MEMS devices through replication techniques such as injection molding.

Owner:CINCINNATI UNIVERISITY OF THE

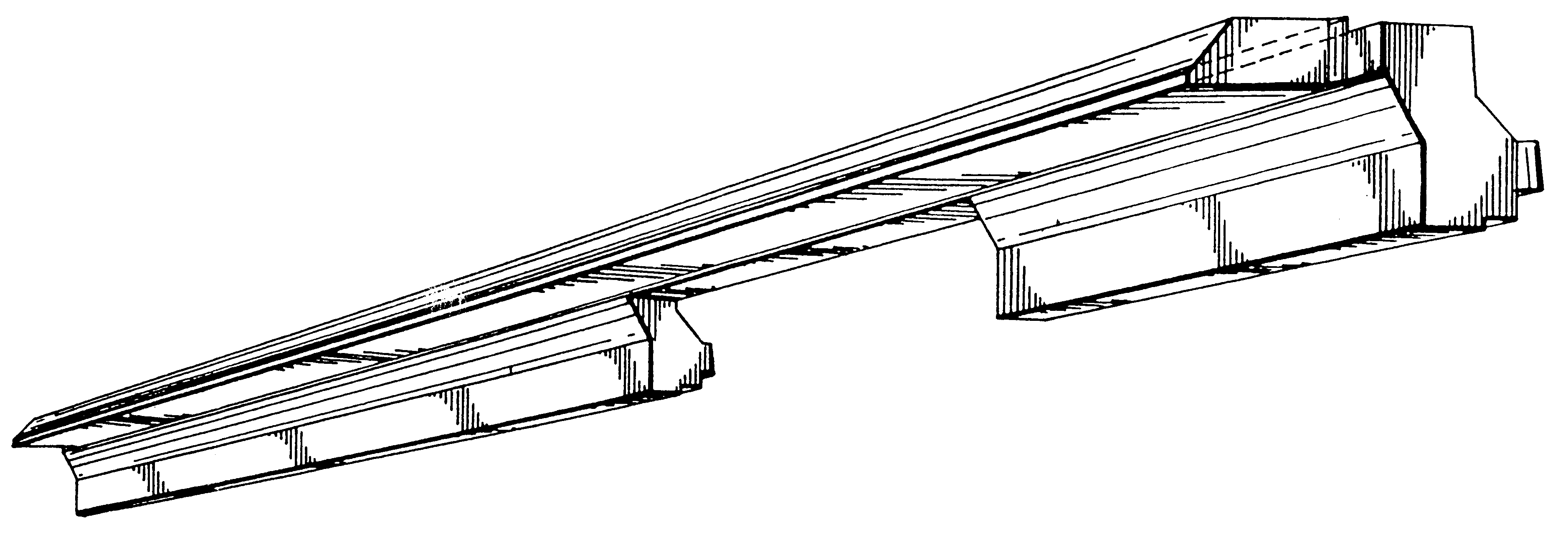

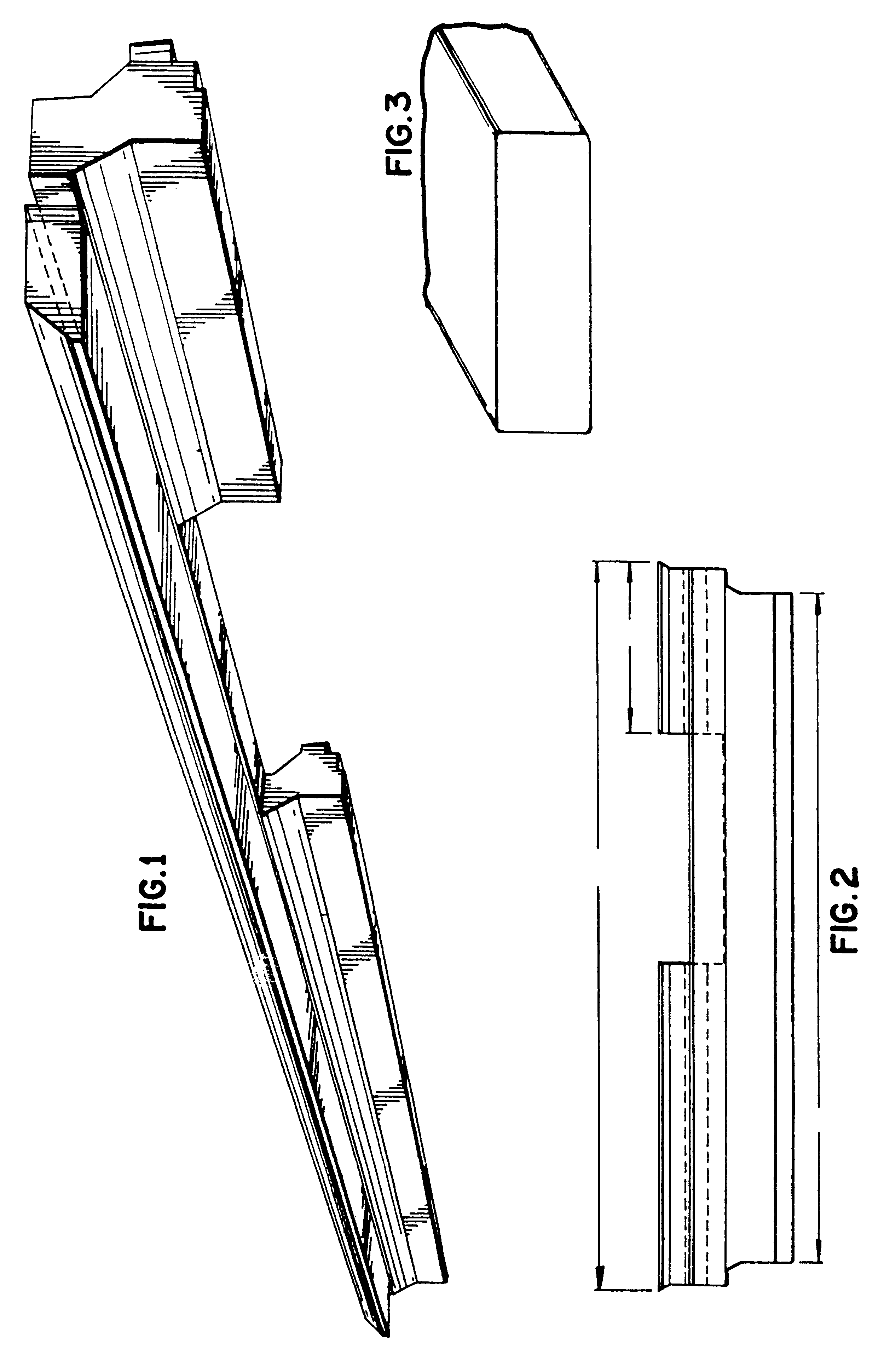

Foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6054207AHigh compressive strengthImproved fastener retentionConstruction materialLoad-supporting elementsComposite constructionThermoplastic

Advanced structural components comprising a foamed thermoplastic that can be used in virtually any application where wooden components have a use. Such structural components can comprise sized lumber, shaped trim, posts, beams or shaped structural members. An advanced profile composite structural component comprising an exterior capping layer with an interior comprising a foamed thermoplastic can be used in the assembly of fenestration units adapted to residential and commercial structures. Preferably the profile structural component can be used in a window or door assembly. The profile member is adapted for ease of construction of the fenestration units, can be easily installed in a rough opening to framing members, and can be trimmed and adjusted on site. The profile is structurally strong, thermally stable, shrink resistant and will accept and retain the insertion of fasteners such as staples, nails and screws permanently with substantial retention and little or no damage to the units. The profile structural components possess strength that permits the manufacture of a structurally sound fenestration unit from two or more foamed profile members or other conventional members.

Owner:ANDERSEN CORPORATION

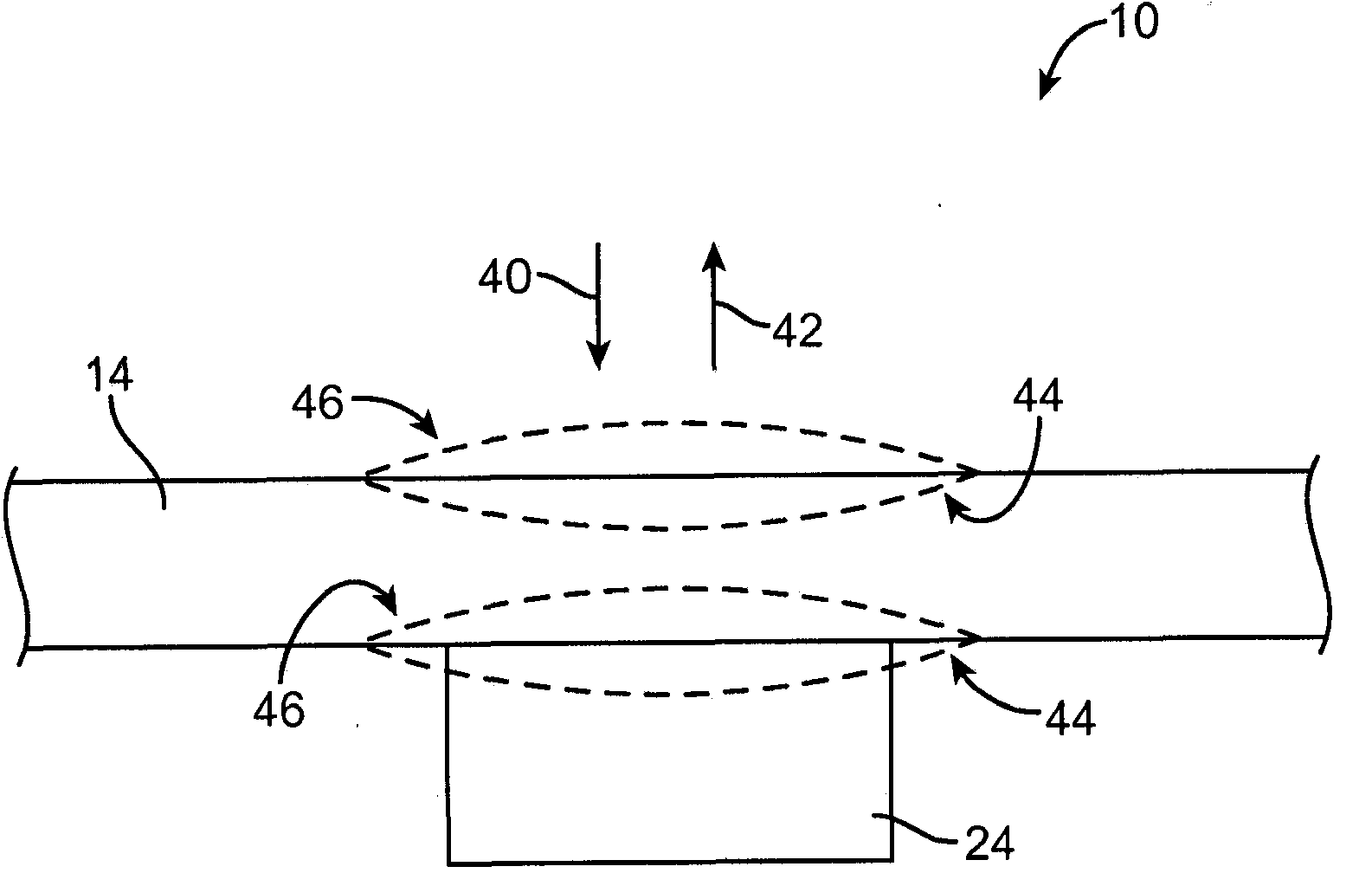

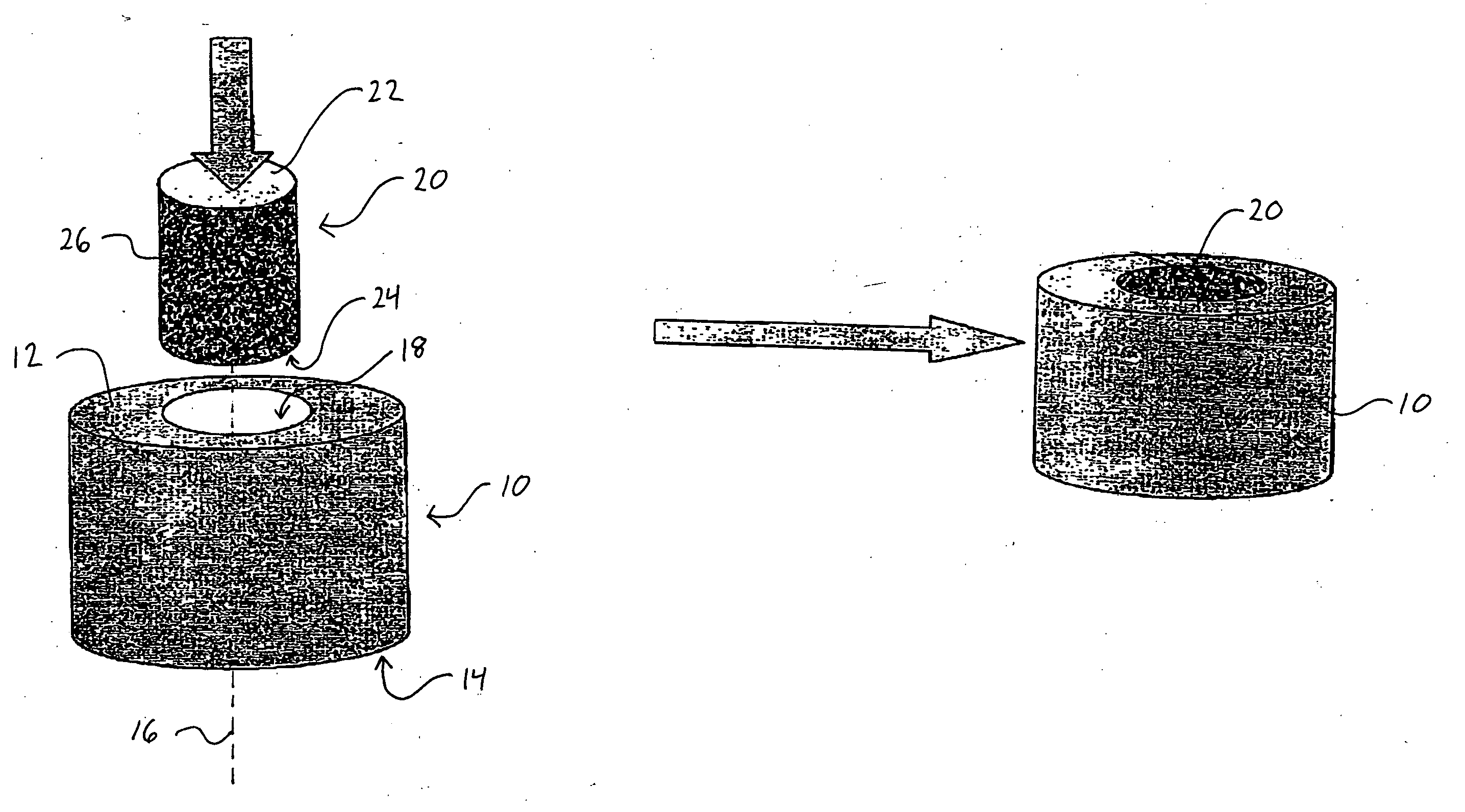

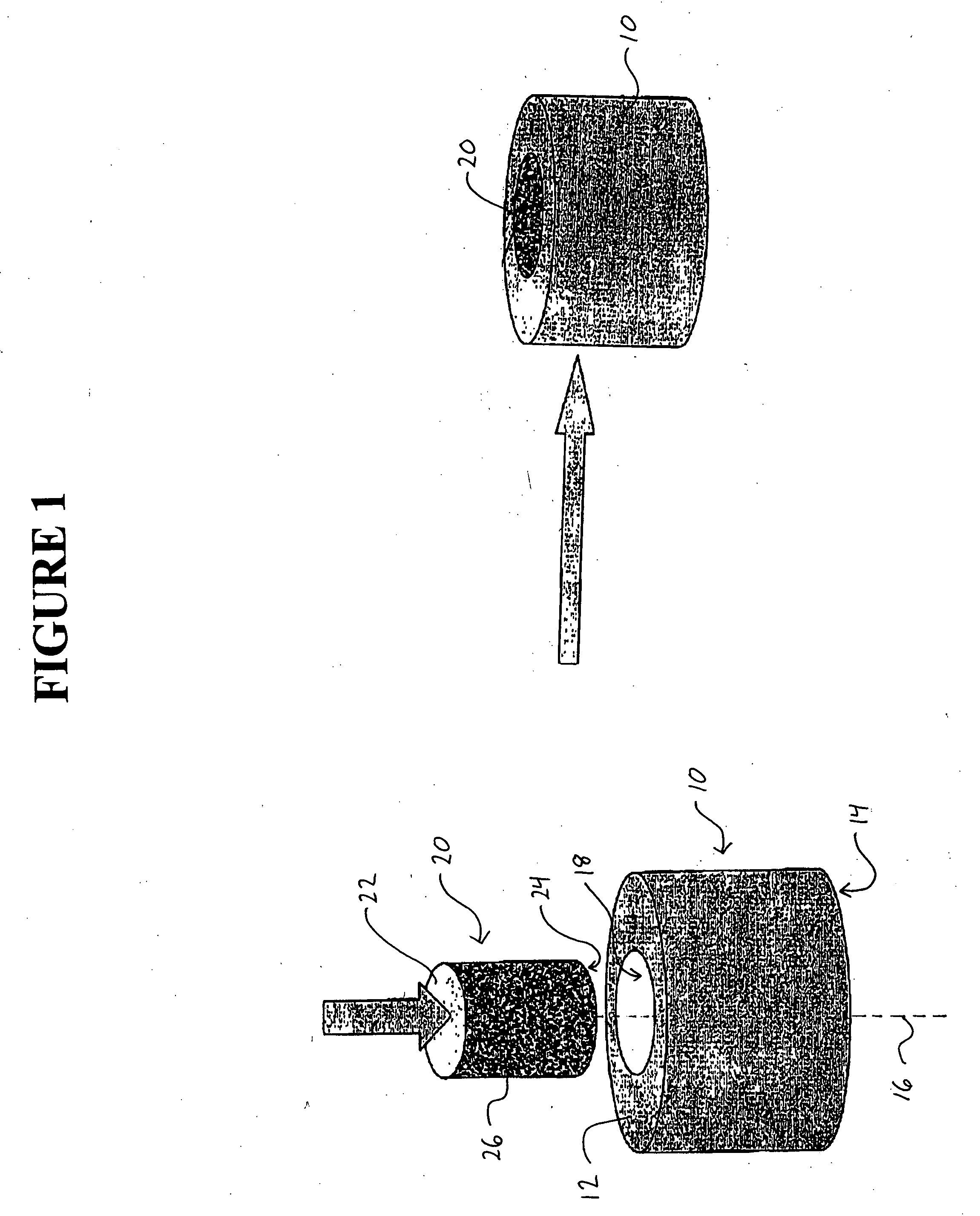

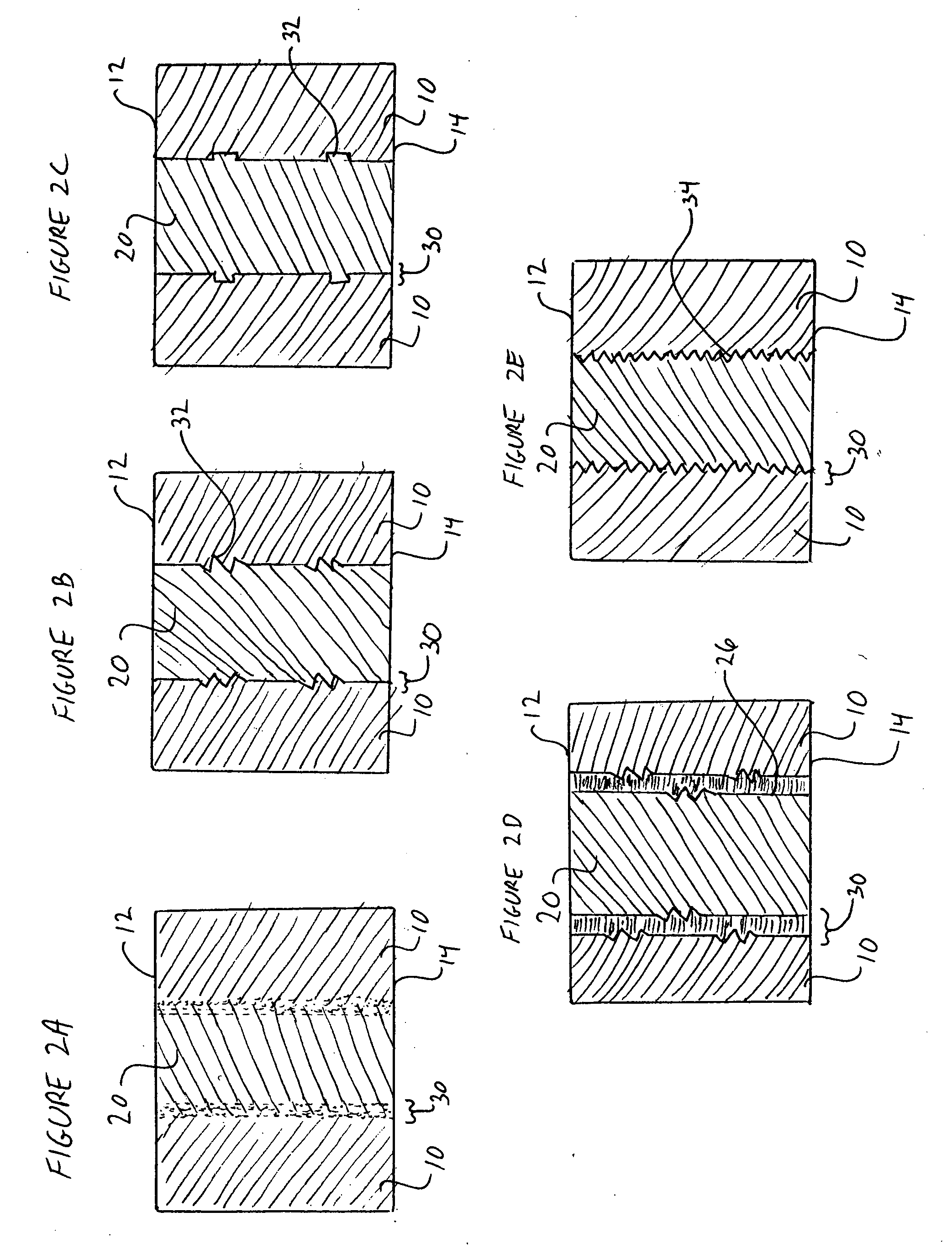

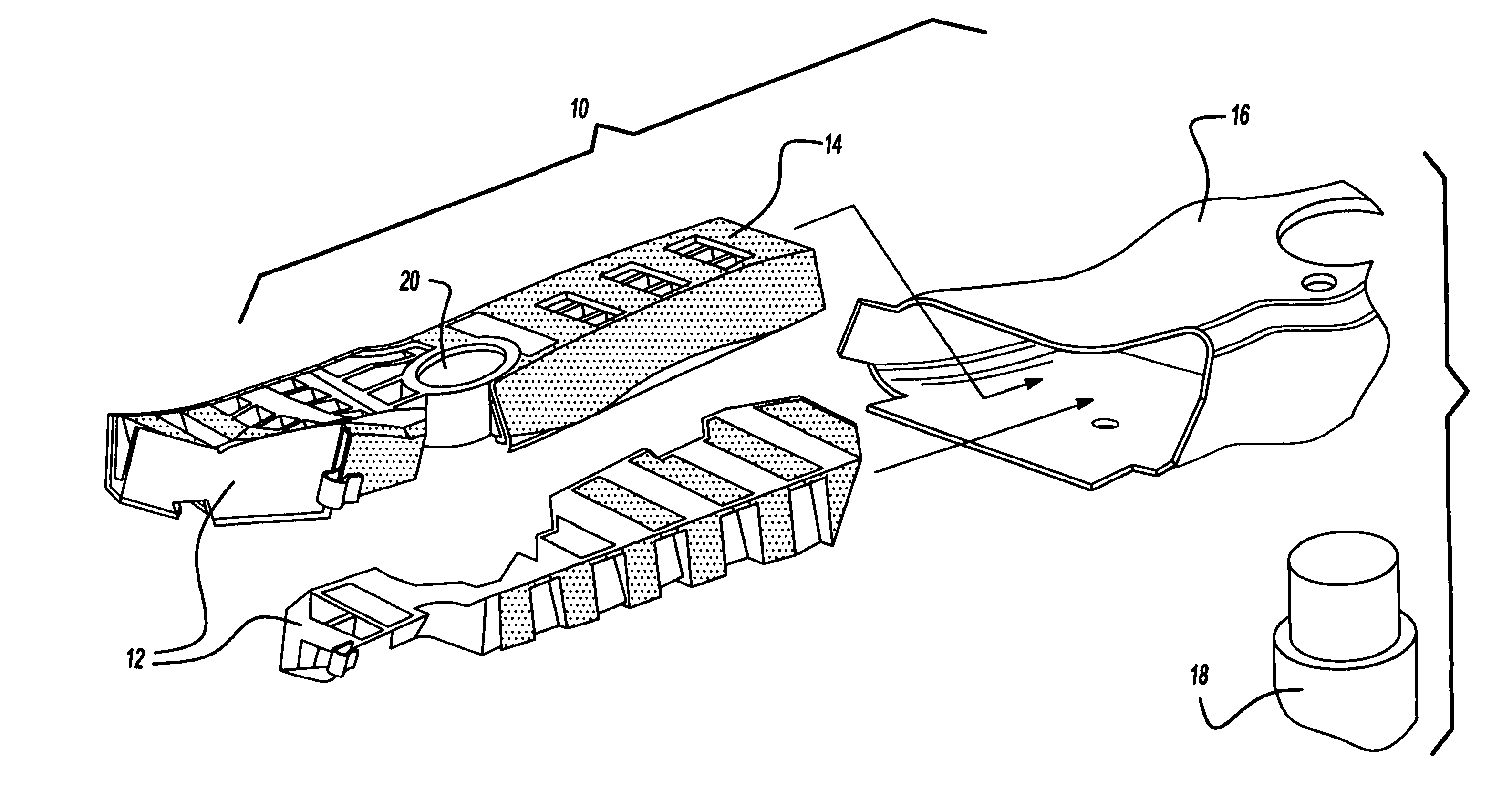

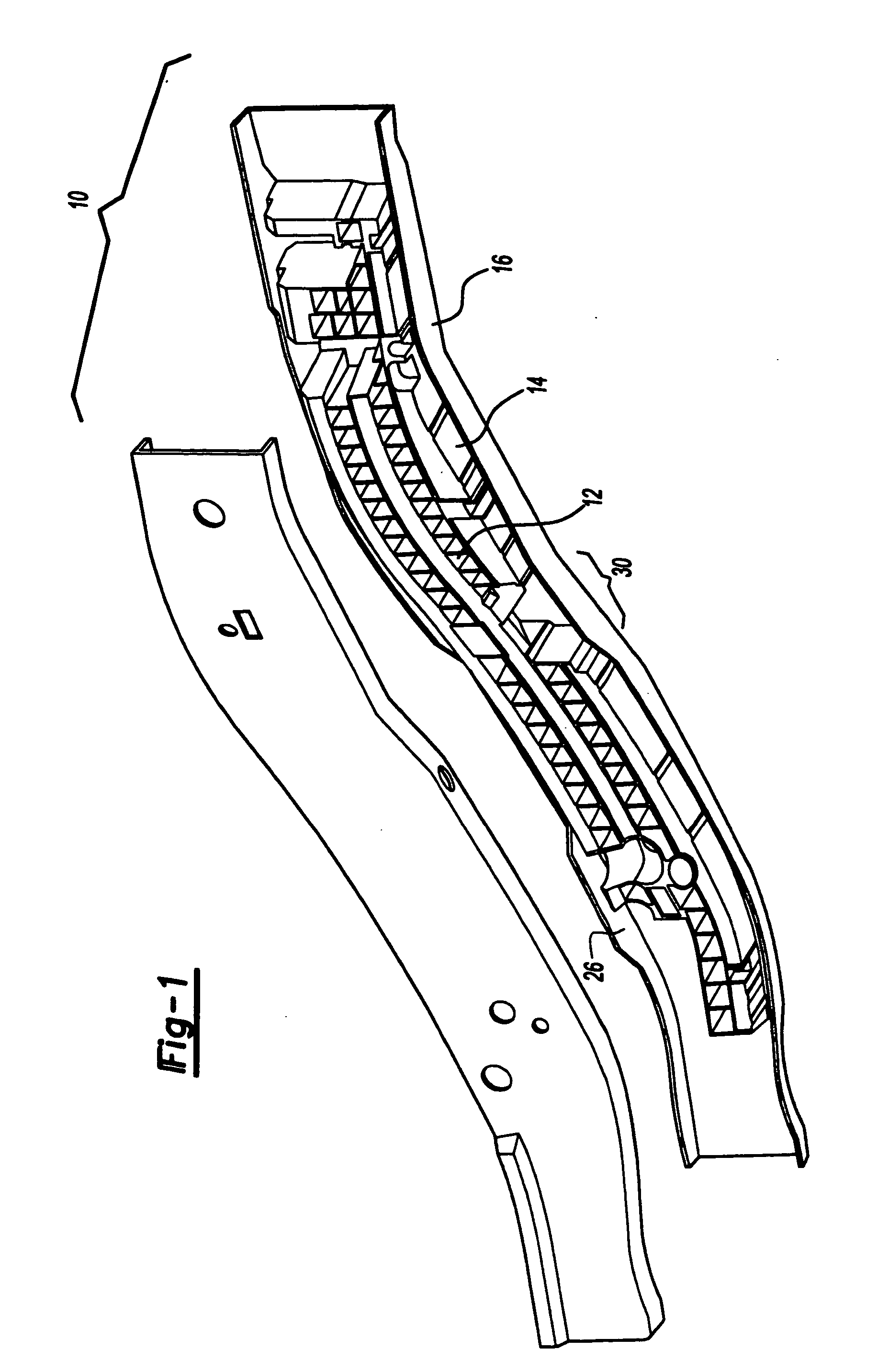

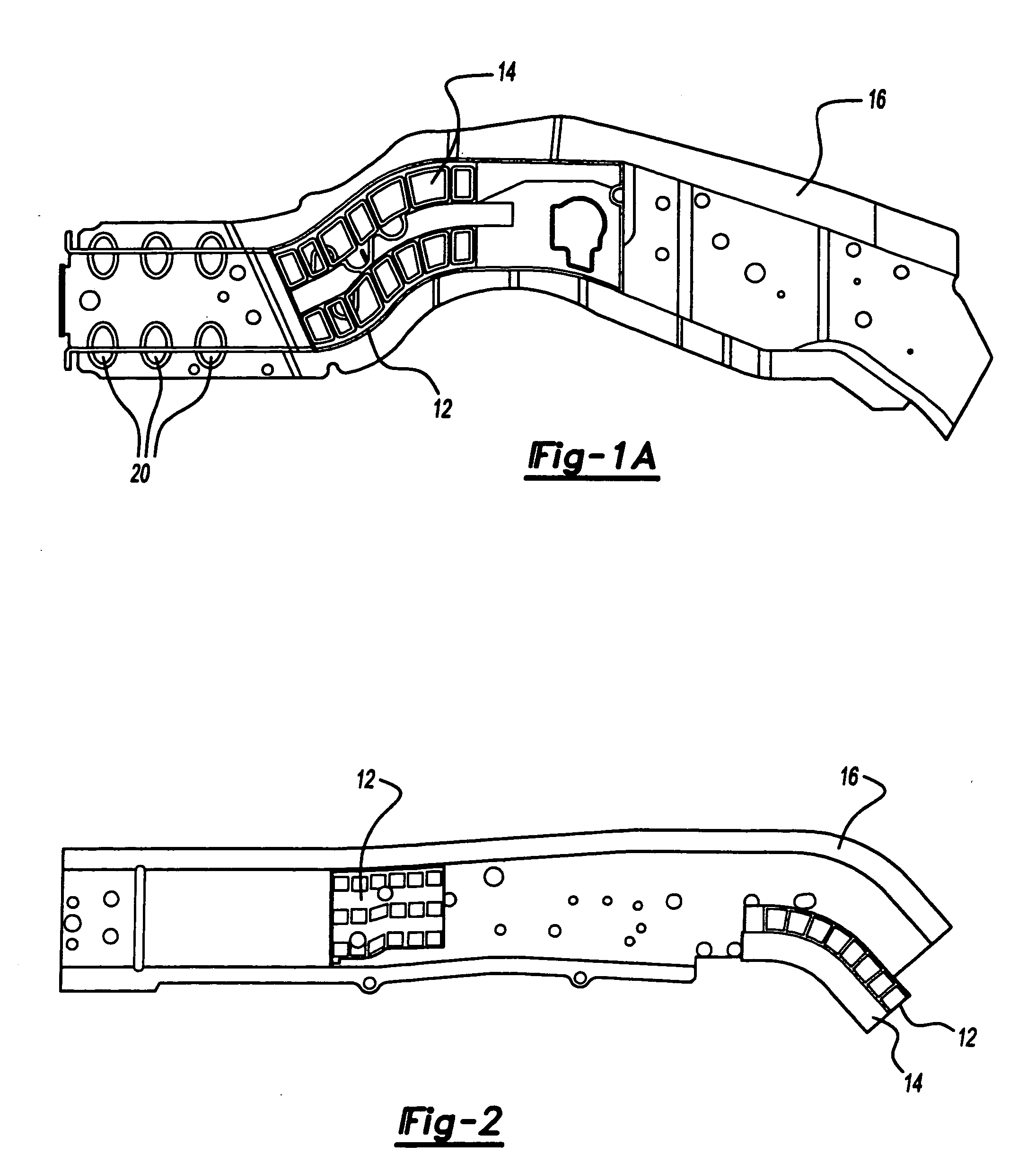

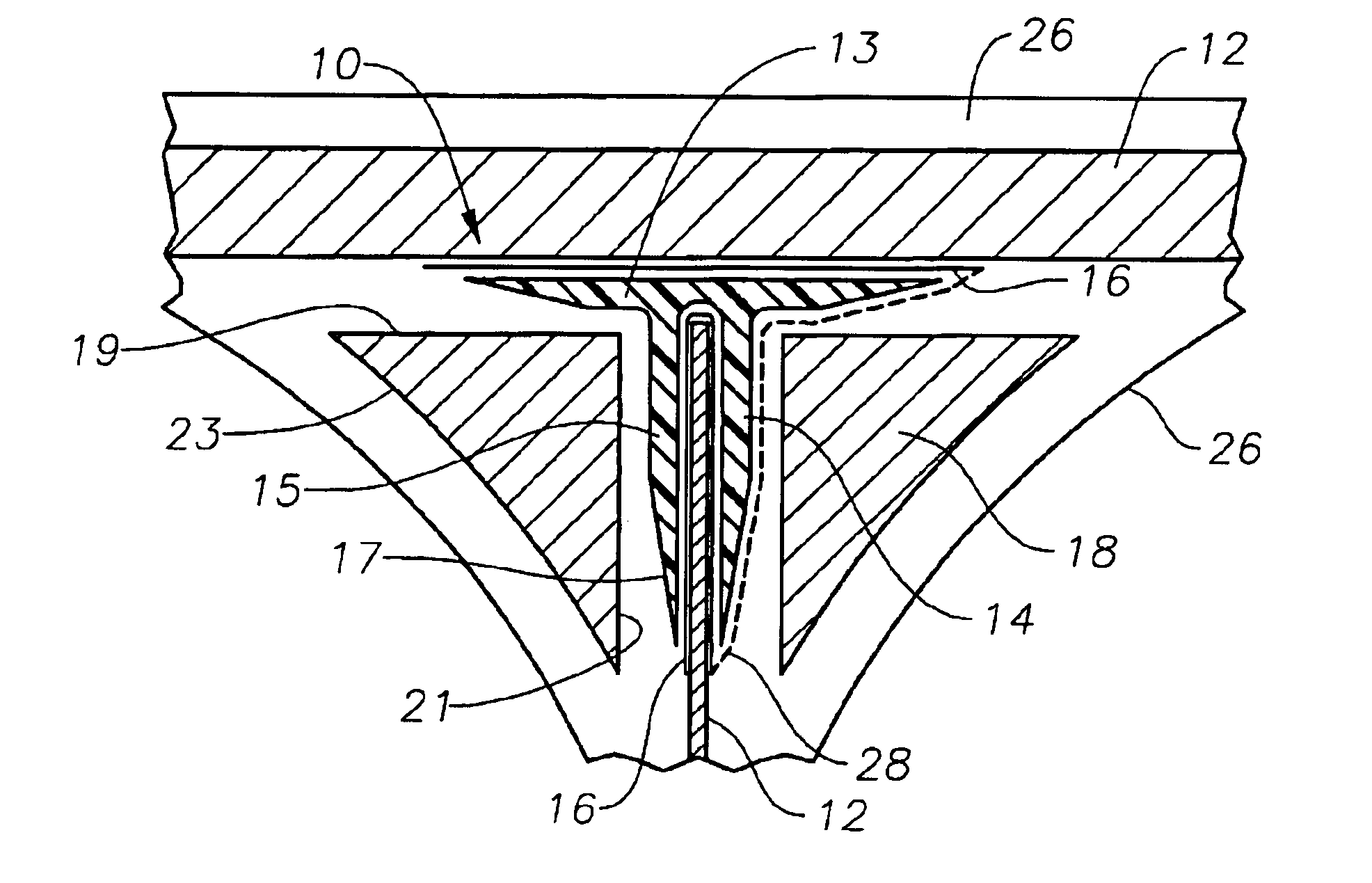

Dynamic self-adjusting assembly for sealing, baffling or structural reinforcement

There is disclosed a reinforced structural assembly and a method of using the assembly for sealing, baffling and / or reinforcing components of an automotive vehicle. The assembly generally includes at least a first mass of expandable material. Preferably, the first mass is movably (e.g., rotatably) connected to a second mass of material and / or another member. According to the method, the assembly is placed in a cavity of an automotive vehicle and the at least one mass is activated to expand. Preferably, upon activation, the first mass self adjusts by moving (e.g., rotating) relative to the second mass and / or the other member.

Owner:ZEPHYROS INC

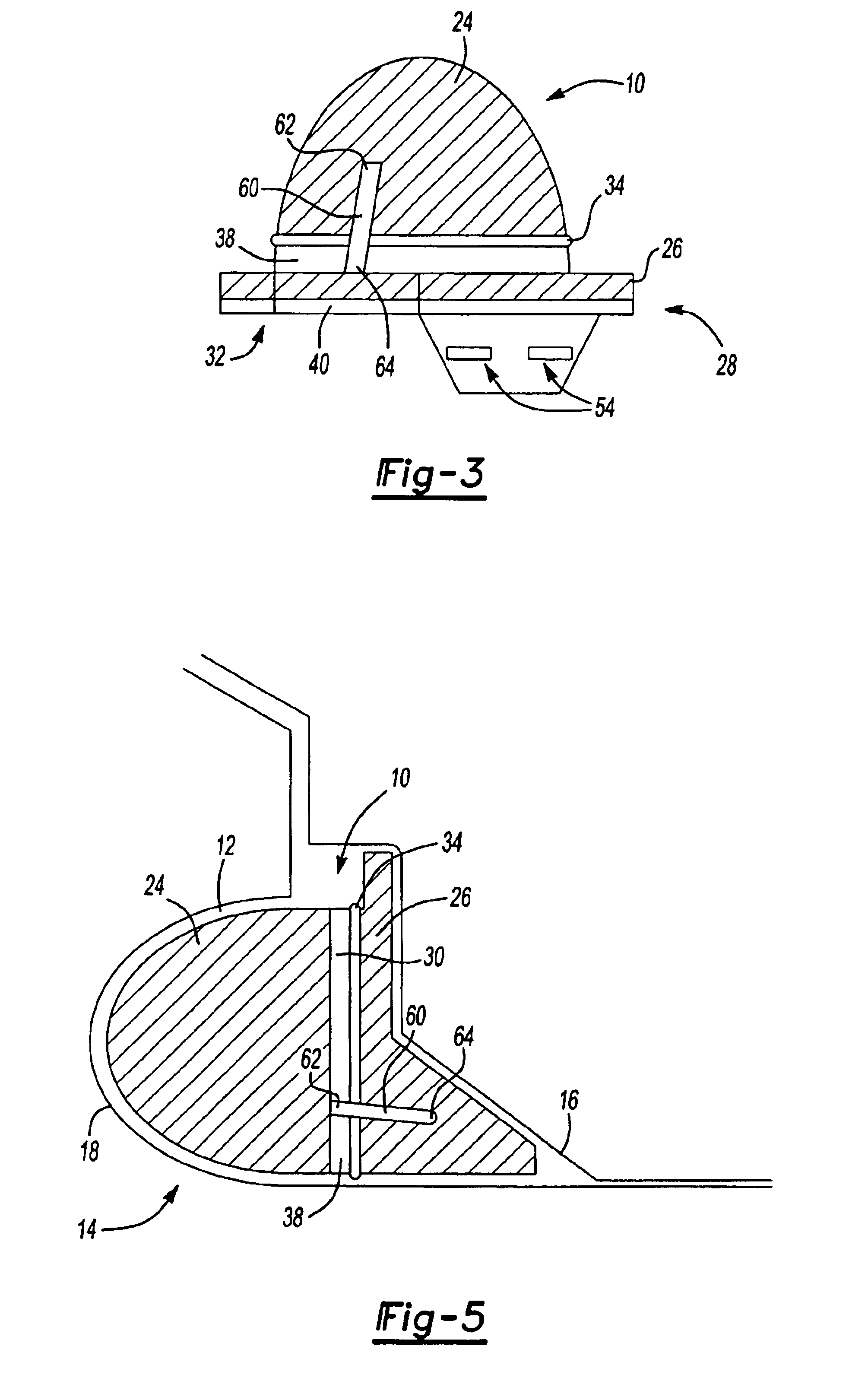

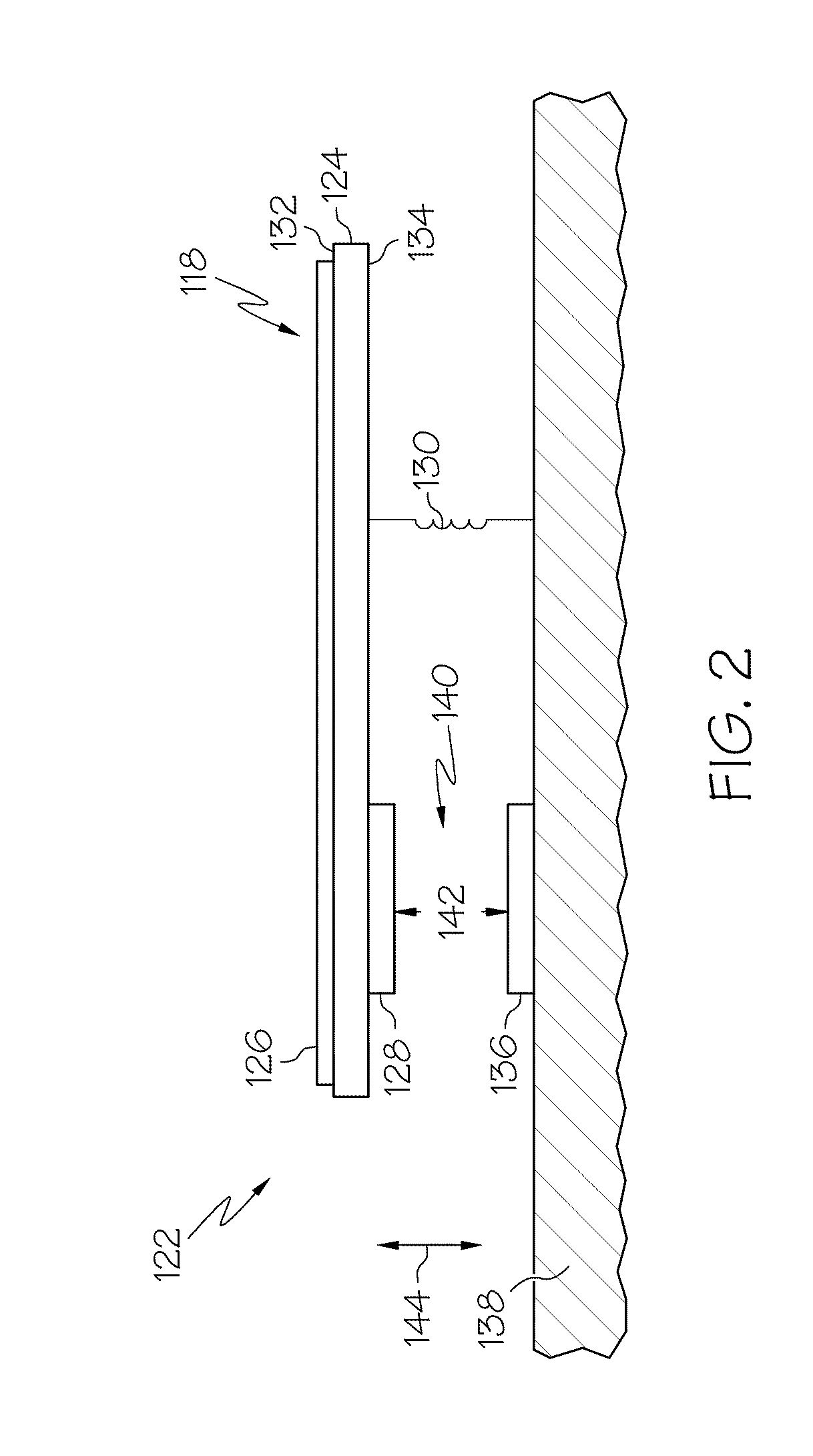

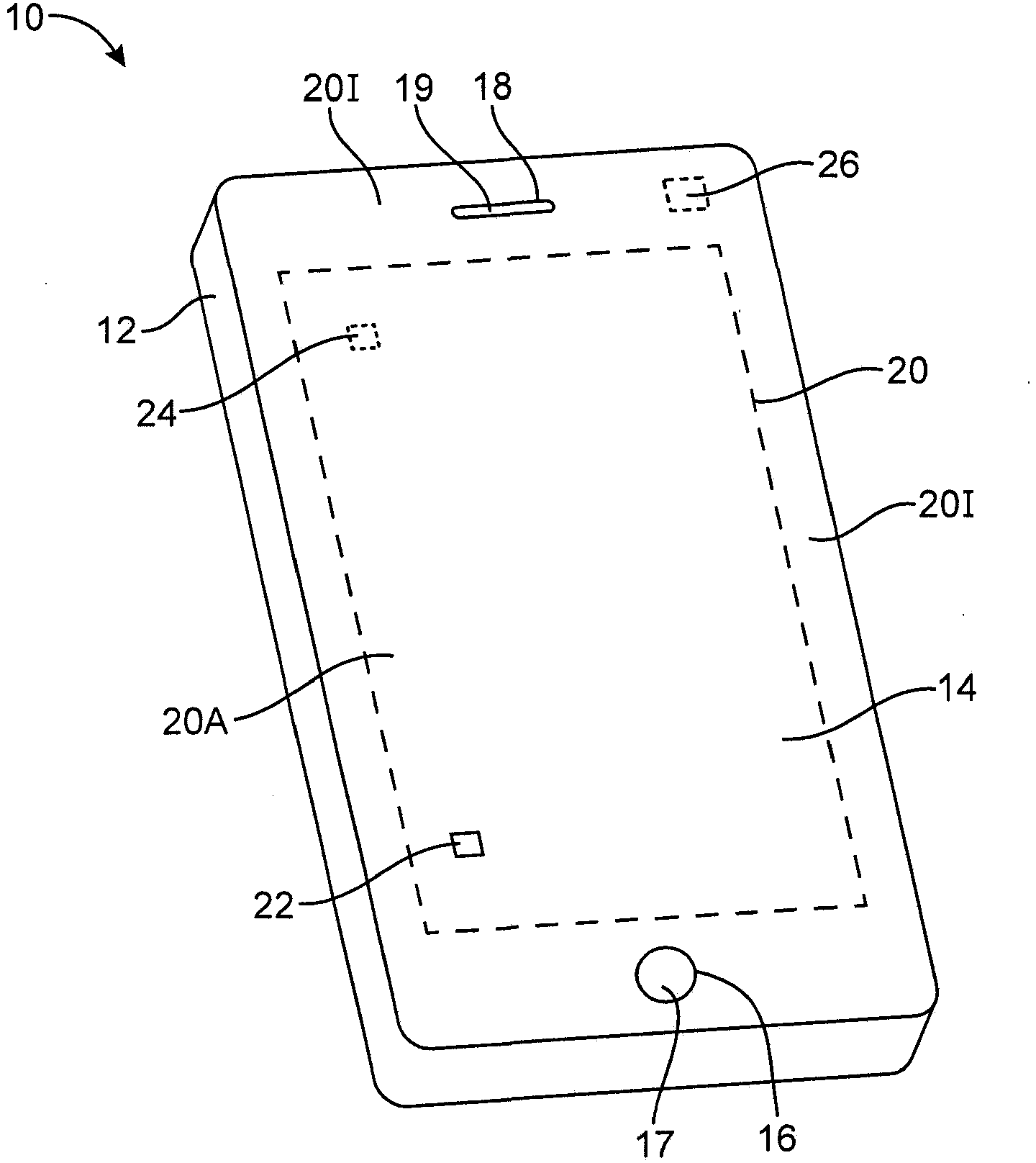

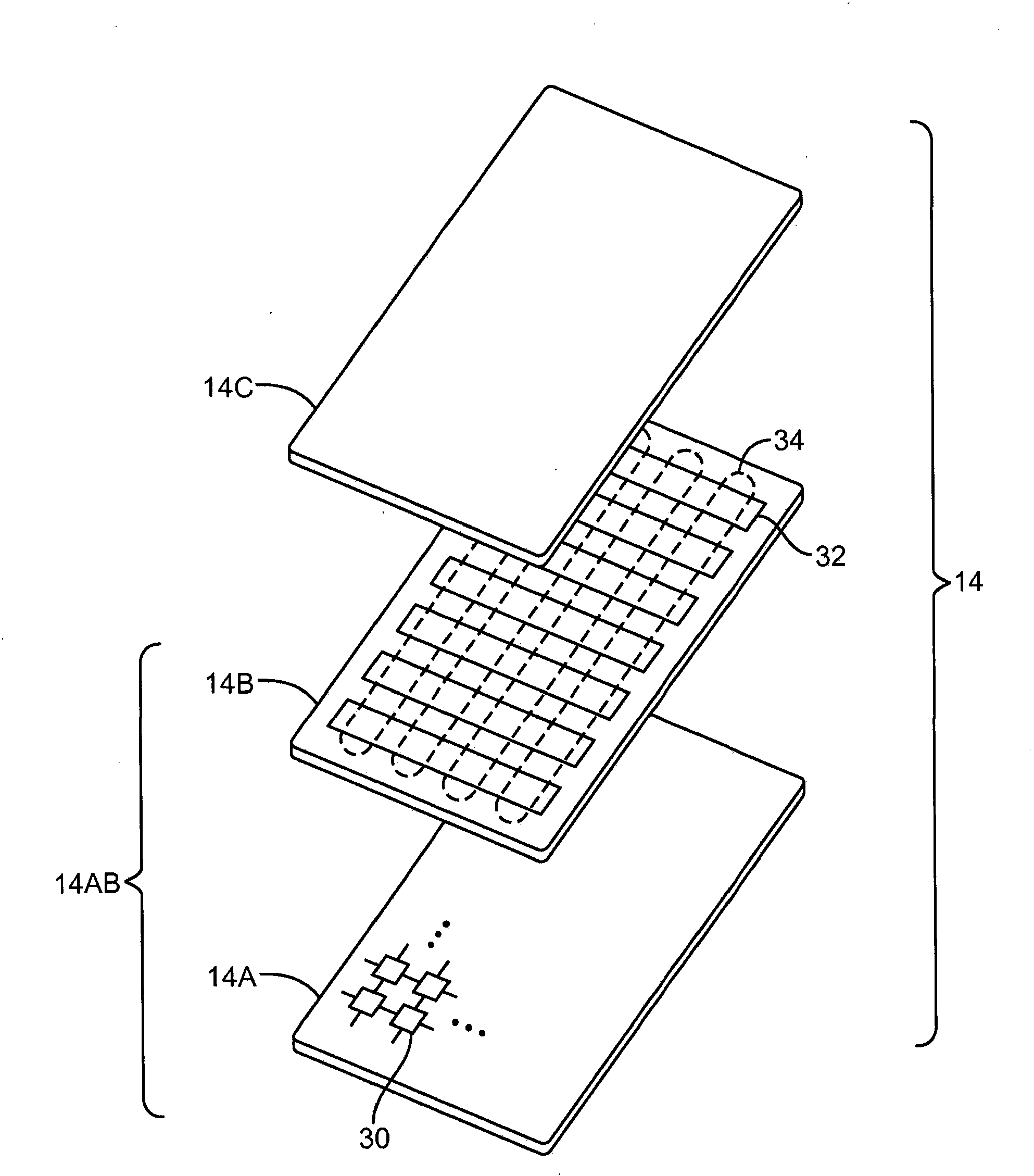

Input device with capacitive force sensor and method for constructing the same

Input devices which include a capacitive force sensor, along with methods of making and using such, are provided. The input device includes a structural component having first and second substantially opposing sides, a plurality of sensor electrodes located on the first side of the structural component, the plurality of sensor electrodes configured to capacitively sense positional information associated with user input in a sensing region, a first capacitive electrode located on the second side of the structural component, the first capacitive electrode being configured to capacitively couple to a second capacitive electrode that is separated from the first capacitive electrode by a gas and moveable relative to the first capacitive electrode, and a biasing member configured to be physically coupled to the structural component such that a force associated with the user input causes a change in a separation distance between the first and second capacitive electrodes based on the force.

Owner:SYNAPTICS INC

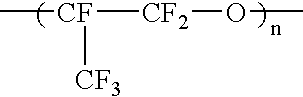

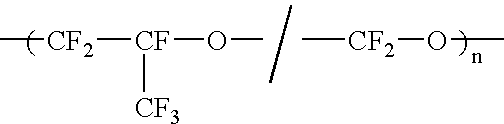

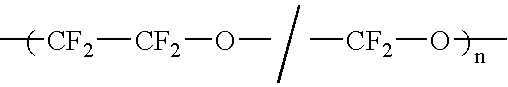

Liquid perfluoropolymers and medical applications incorporating same

InactiveUS20050142315A1Promote tissue growthImprove survivabilitySuture equipmentsElectrotherapyPerfluoropolyetherOxygen

Liquid curable perfluoropolyether (PFPE) materials are provided for use as coatings, sealants, flexible fillers, and structural parts for a wide variety of medical applications, particularly where silicone has been utilized conventionally. The PFPE material is oxygen permeable and bacterial impermeable and may contain one or more pharmacological agents elutably trapped therewithin for delivery within the body of a subject.

Owner:LIQUIDIA TECH

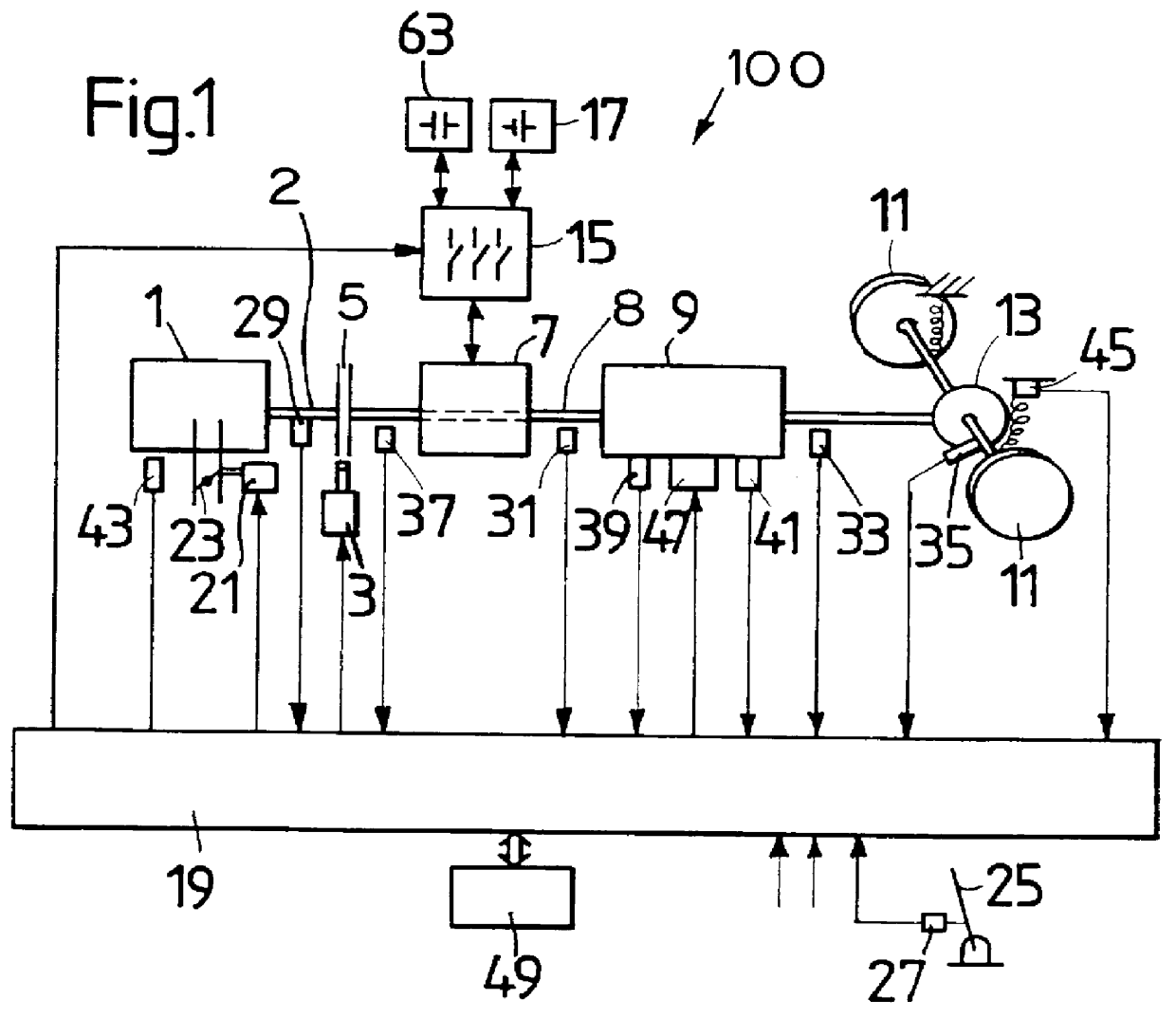

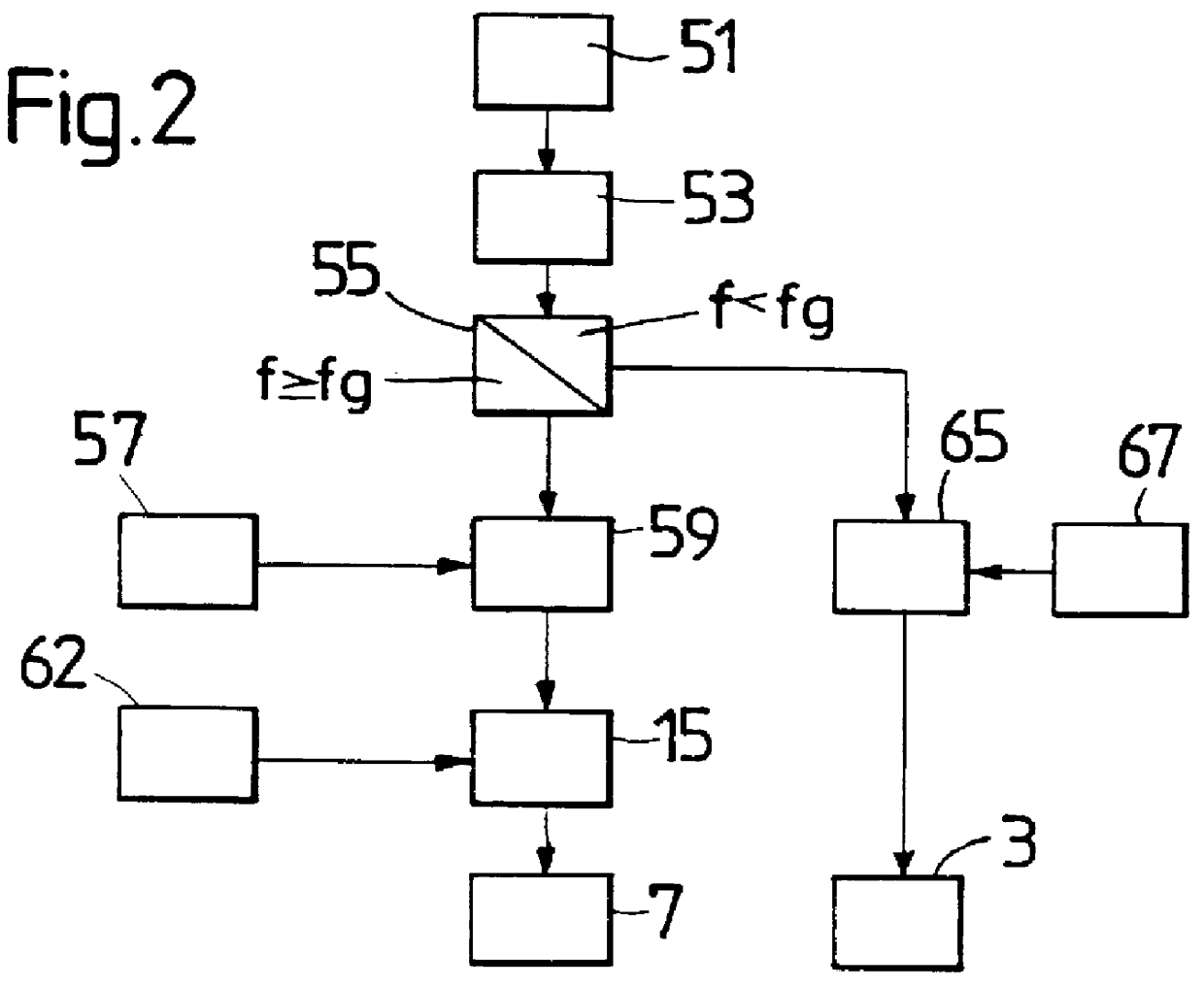

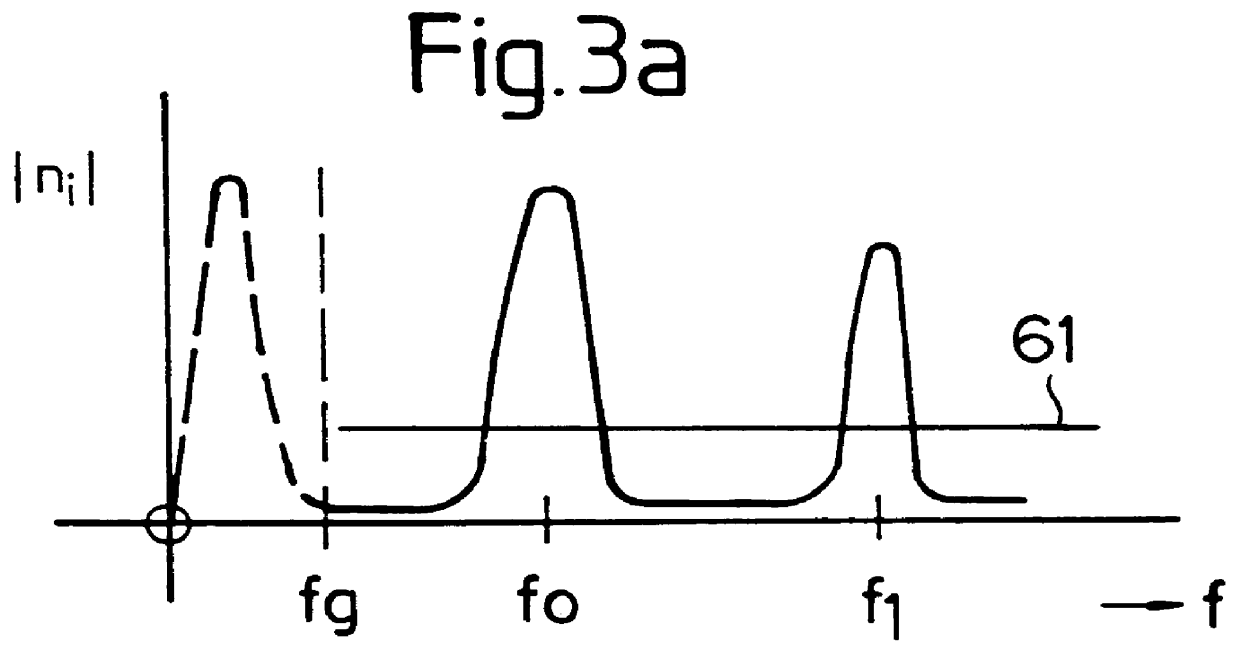

Hybrid vehicle drive for a motor vehicle

InactiveUS6102144AReducing and eliminating vibrationExcessive vibrationSuspensionsRotating vibration suppressionFrequency spectrumLoad torque

A hybrid vehicle drive for a motor vehicle includes an internal combustion engine and an electric machine which is selectively coupled with the internal combustion engine. The electric machine can be operated as a generator and as a motor. Regulation device which responds to a reference signal predetermined by a reference signal preset device are provided for the active damping of vibrations, especially torsional vibrations in the torque transmission path between the internal combustion engine and wheels of the motor vehicle driven by the latter. The regulation device also respond to sensing device which deliver an actual-value vibration signal containing vibration information about a rotating structural component of the motor vehicle and control the load torque exerted on the internal combustion engine by the electric machine for reducing or eliminating the vibrations of the structural component. An analysis device for determining a frequency spectrum of the actual-value vibration signal is associated with the regulation device. The reference signal preset device establishes a reference signal with predetermined frequency spectrum. The regulation device control the frequency spectrum of the load torque exerted on the internal combustion engine by the electric machine such that excessive spectral vibrations of the actual-value vibration signal are reduced or eliminated.

Owner:ZF FRIEDRICHSHAFEN AG

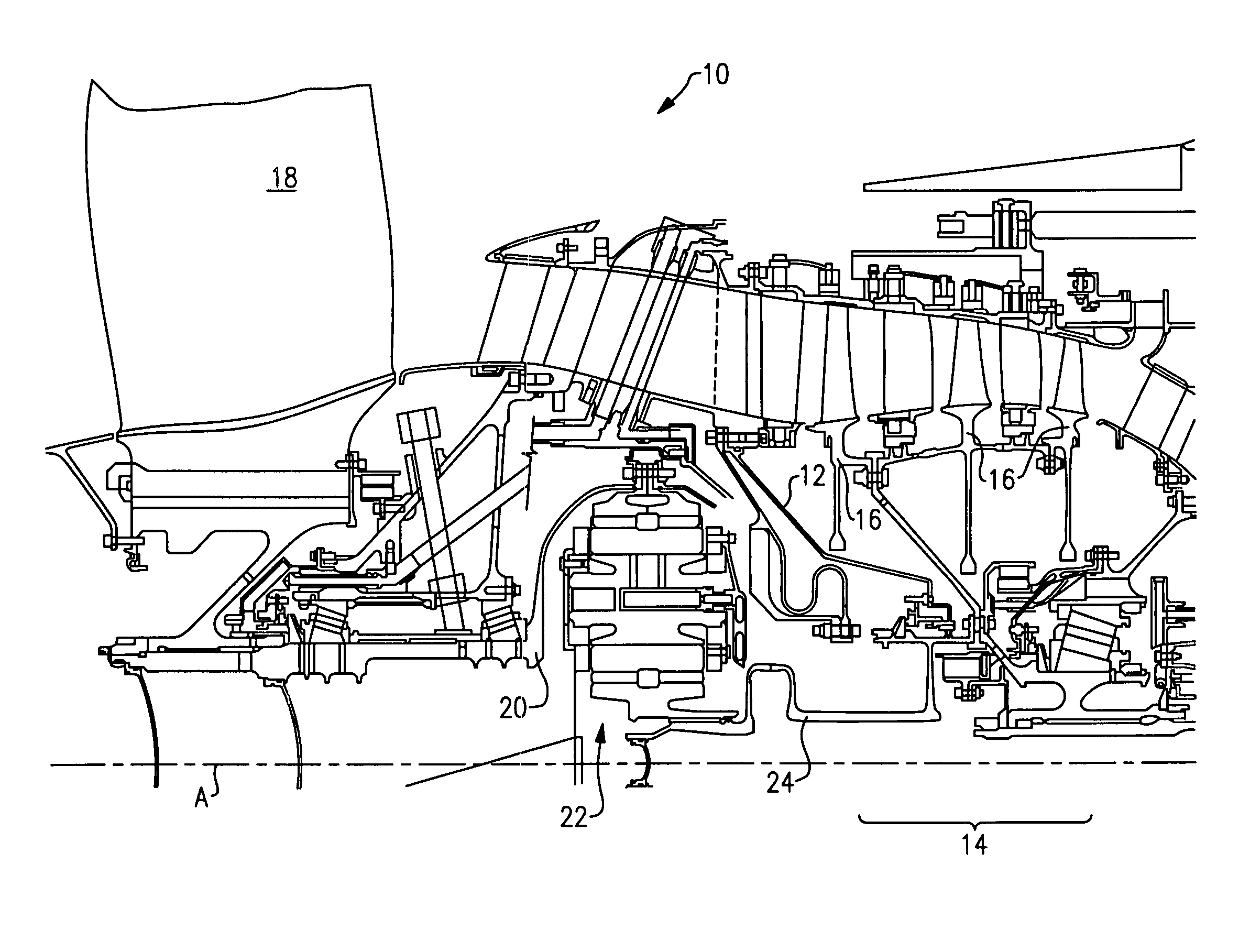

Oil baffle for gas turbine fan drive gear system

A gas turbine engine includes an epicyclic gear train that drives a turbo fan. The epicyclic gear train employs a one-piece carrier in which the spaced side walls are interconnected with circumferentially spaced apart mounts to form a unitary structure. Baffles are secured to the carrier near the mounts and provide lubrication passages that spray oil onto the sun gear and / or intermediate gears arranged between the baffles. The baffles can be constructed from a different material than the carrier since the baffles are not structural components in the gear train.

Owner:RAYTHEON TECH CORP

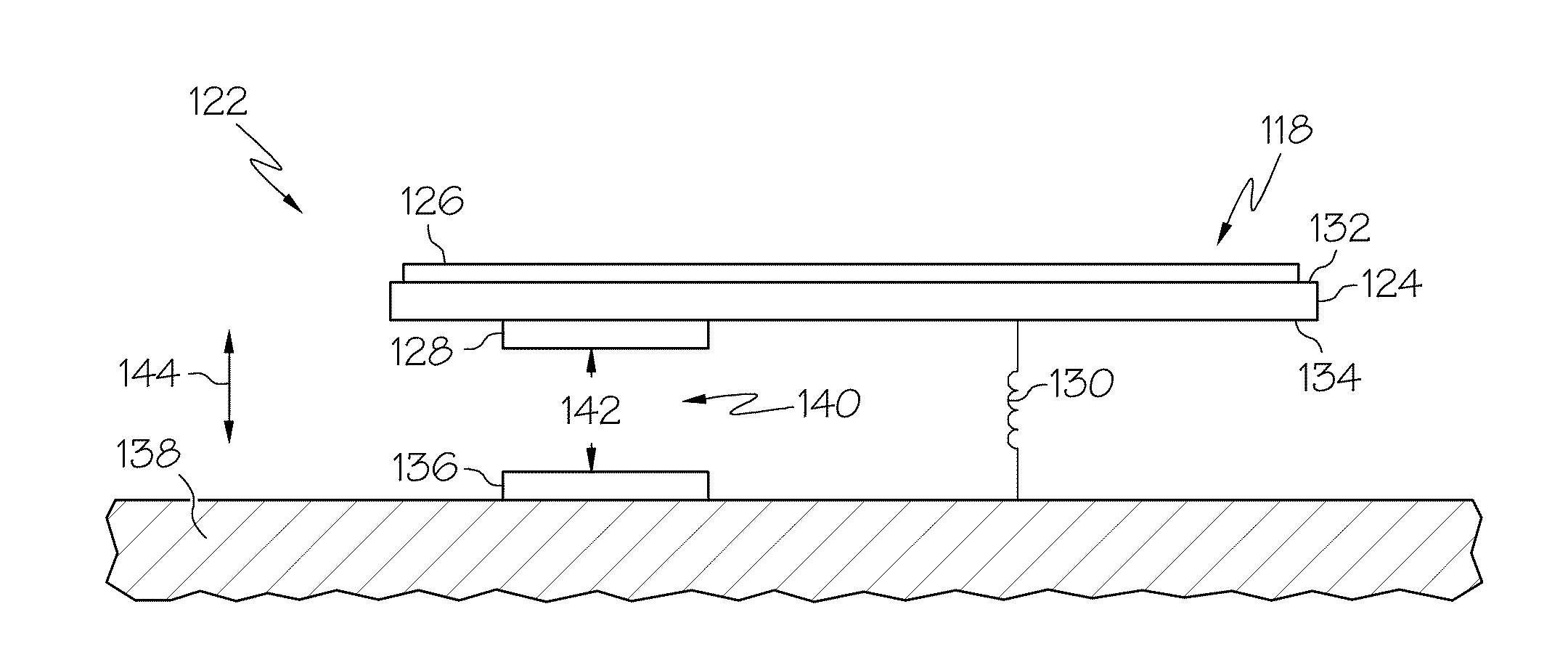

Electronic devices with flexible displays

Electronic devices may be provided that contain flexible displays and internal components. An internal component may be positioned under the flexible display. The internal component may be an output device such as a speaker that transmits sound through the flexible display or an actuator that deforms the display in a way that is sensed by a user. The internal component may also be a microphone or pressure sensor that receives sound or pressure information through the flexible display. Structural components may be used to permanently or temporarily deform the flexible display to provide tactile feedback to a user of the device. Electronic devices may be provided with concave displays or convex displays formed from one or more flexible layers including a flexible display layer. Portions of the flexible display may be used as speaker membranes for display-based speaker structures.

Owner:APPLE INC

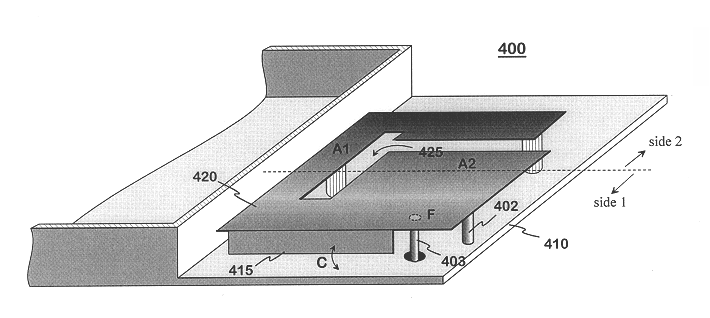

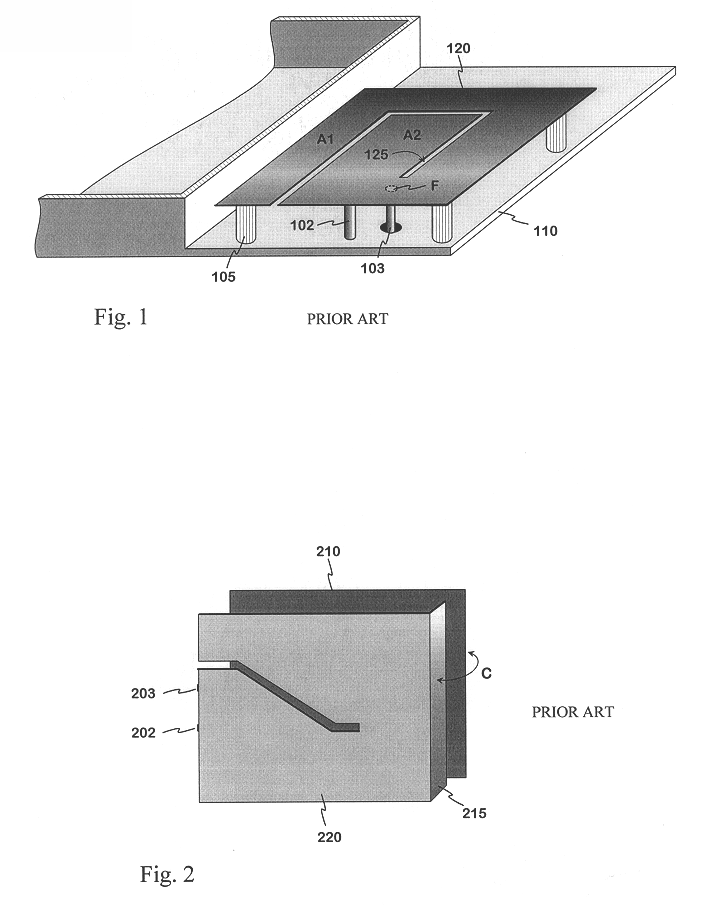

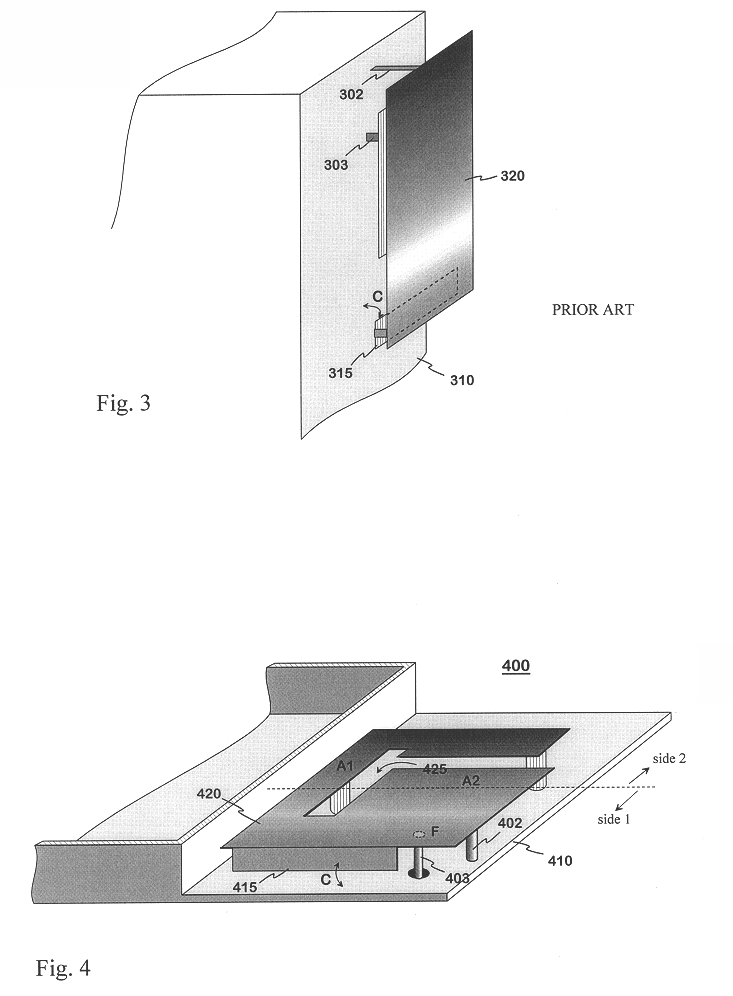

Planar antenna

InactiveUS6538604B1Small sizeSimple structureSimultaneous aerial operationsAntenna supports/mountingsCapacitanceAntenna bandwidth

The invention relates to an antenna structure (400) to be placed inside in particular small radio apparatus. A conventional PIFA-type structure is extended by arranging a structural part (415) adding to the capacitance between the radiating plane (420) and ground plane (410) relatively close to the feed point (F) of the antenna. The structural component may be a projection extending from the radiating plane towards the ground plane or vice versa. An advantage of the invention is that it achieves a significant increase in the antenna bandwidth without increasing the size of the antenna. Another advantage of the invention is that the structure according to it is simple and the increase in the manufacturing costs is relatively low.

Owner:PULSE FINLAND

Osteoconductive integrated spinal cage and method of making same

The spinal cage comprises a structural component having sufficient strength to withstand the compressive loading between vertebral bodies. The structural component is integrated with an osteoconductive component to facilitate bone growth between the vertebral bodies. The structural component may comprise any of PEEK, PEKK, or other structural material. The osteoconductive component may comprise any of allograft, natural bone, tricalcium phosphate, hydroxyapatite or a blend of calcium carbonate, calcium lactate and other calcium salts. A method for making the spinal cage involves molding polymers around an osteoconductive component, heat staking, and may further include ultrasonically welding, snap fit or mechanically assembling and / or adhesively bonding components.

Owner:SPINAL ELEMENTS INC

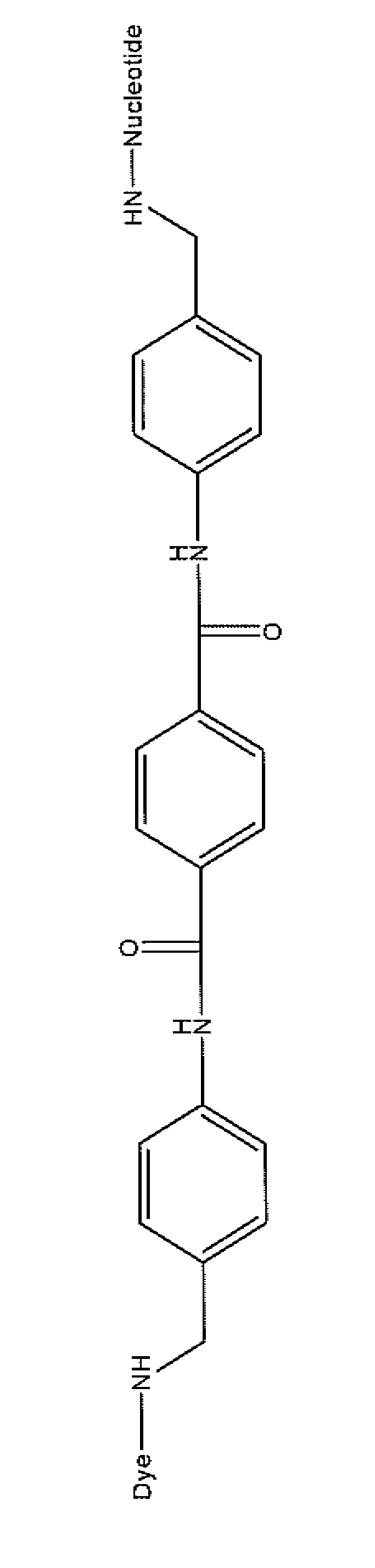

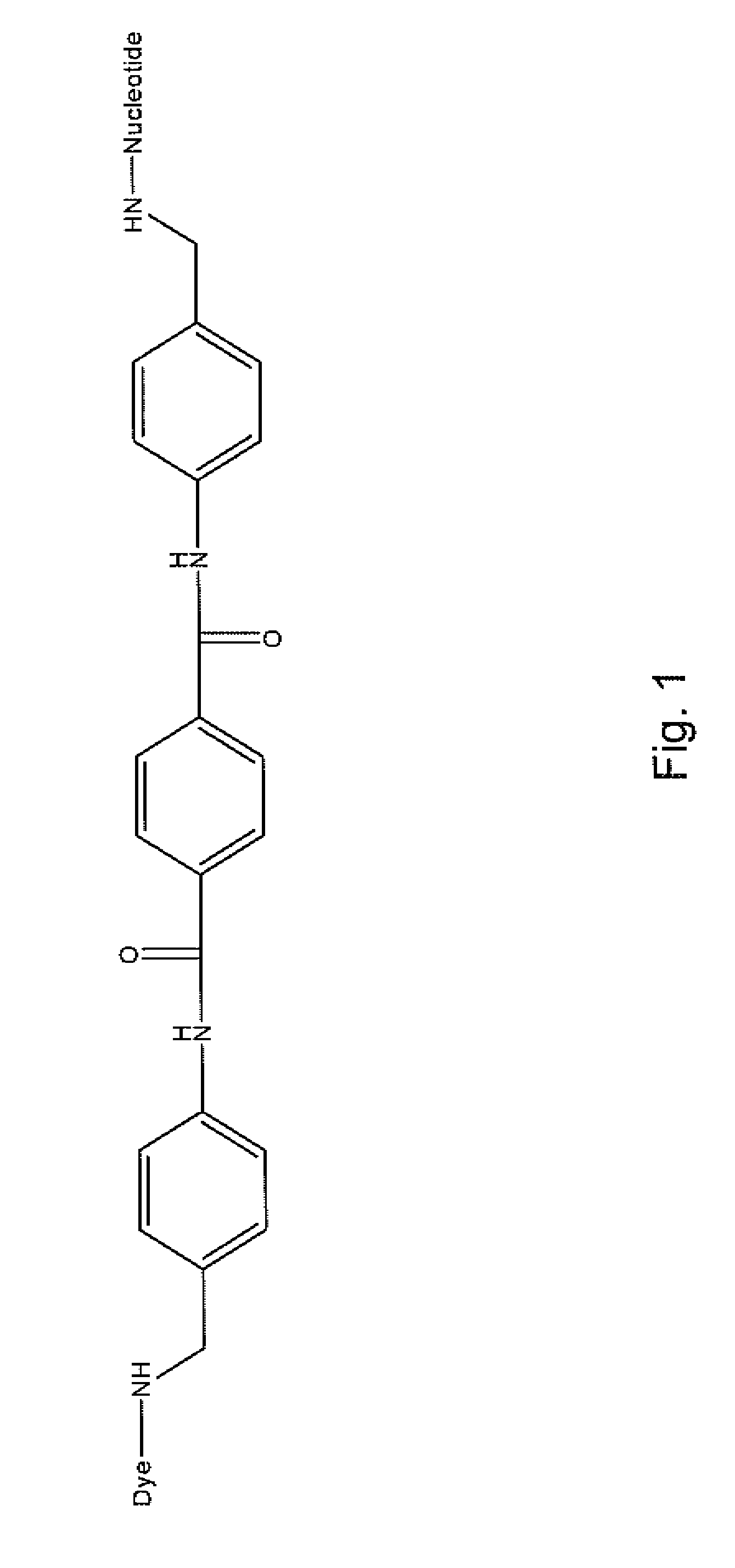

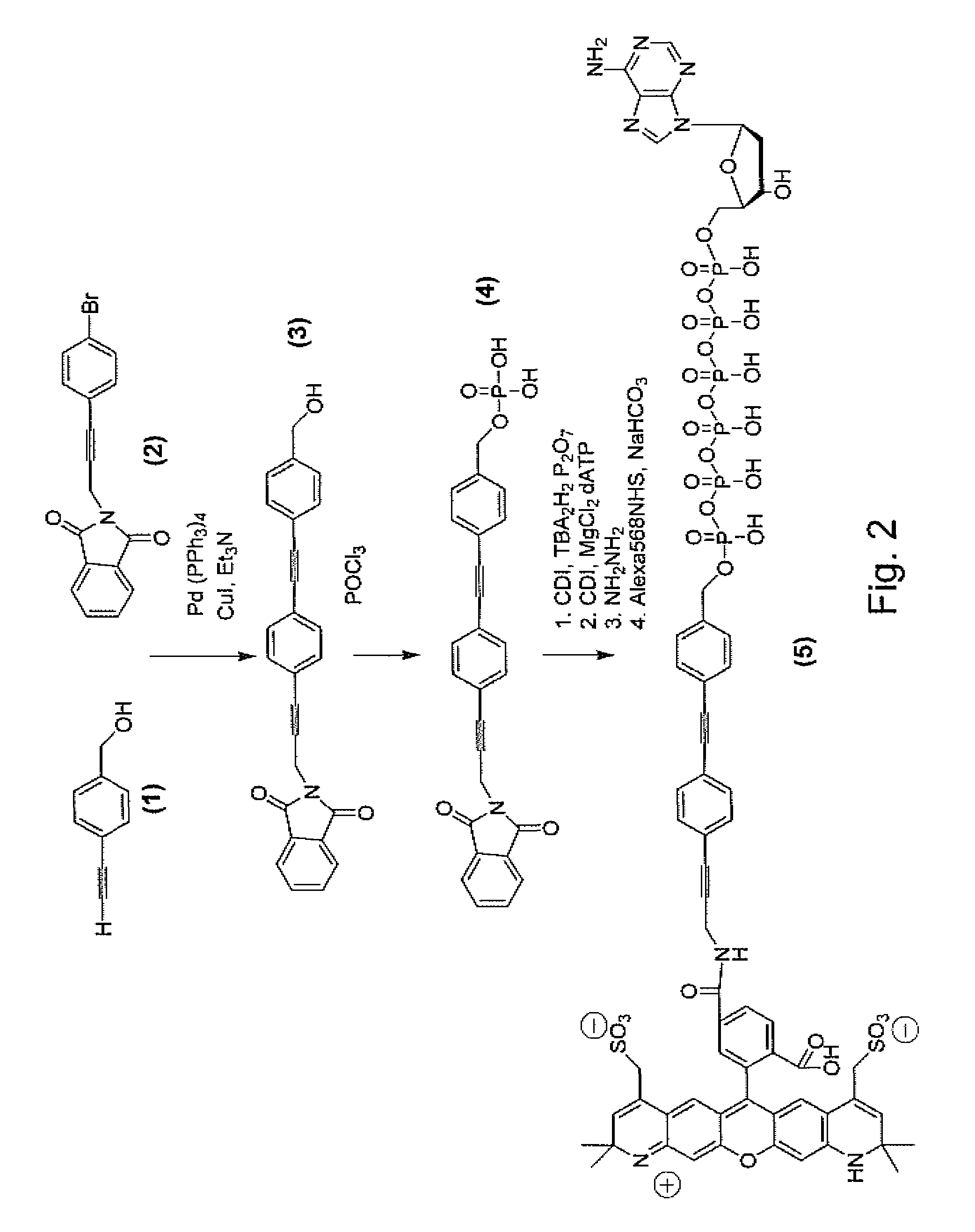

Labeled reactants and their uses

Labeled reactant compositions, and particularly labeled nucleic acid reaction compositions, that include structural components that maintain potentially damaging labeling components sufficiently distal from the reactant portion of the molecule such that damaging effects of the label group on other reaction components, such as enzymes, are reduced, minimized and / or eliminated.

Owner:PACIFIC BIOSCIENCES

Friction welding metal components

InactiveUS6328261B1Additions can be avoidedPrevent skinFuselage framesWingsFriction weldingButt welding

A method of forming a structural airframe component for an aircraft and an airframe structural component The method includes placing at least two components (1,2) in abutting relationship with each other and joining them together by friction stir butt welding (3), and the structural airframe component comprises a component manufactured according to the method of the invention.

Owner:AIRBUS OPERATIONS LTD

Method of forming a foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6342172B1Improved thermal and physical propertyImprove performanceSemi-permeable membranesLaminationComposite constructionThermoplastic

Owner:ANDERSEN CORPORATION

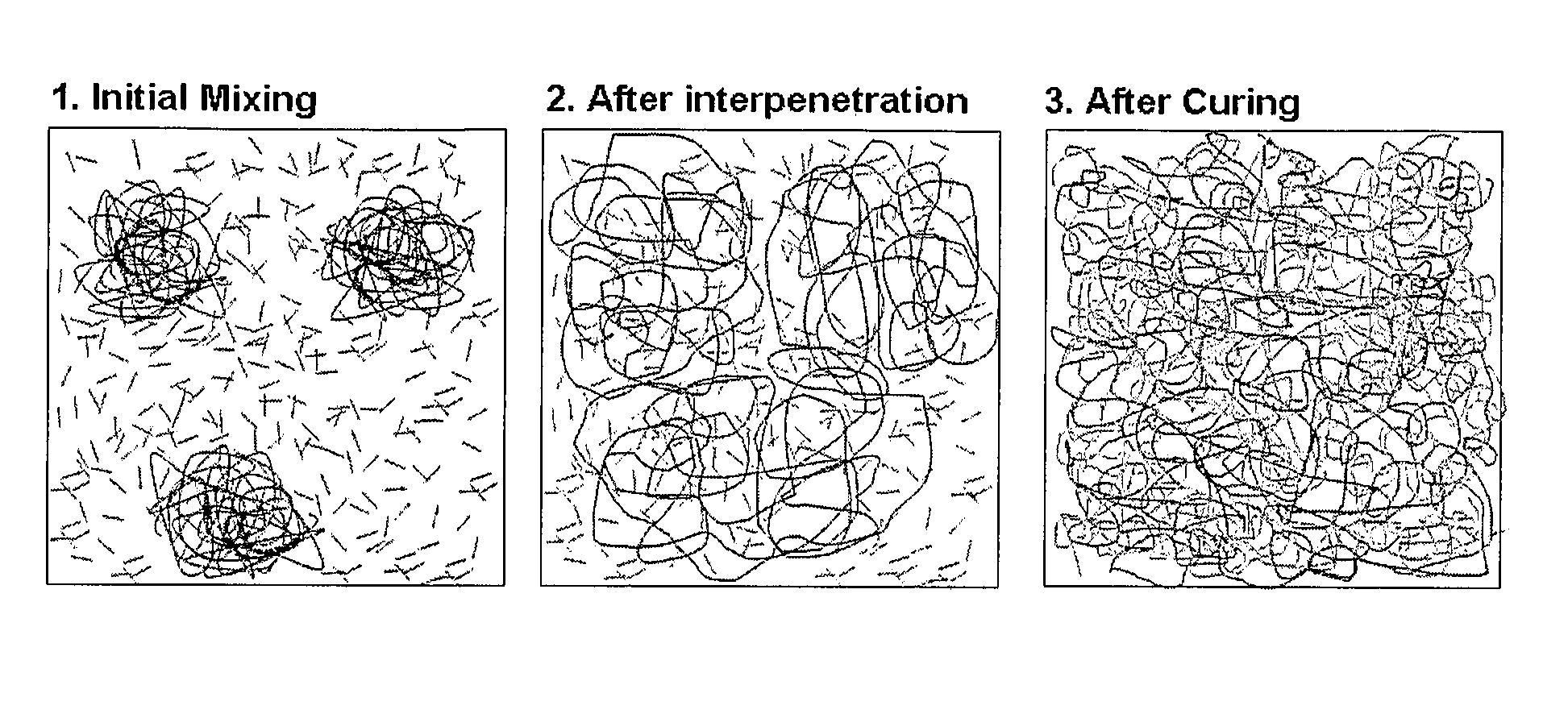

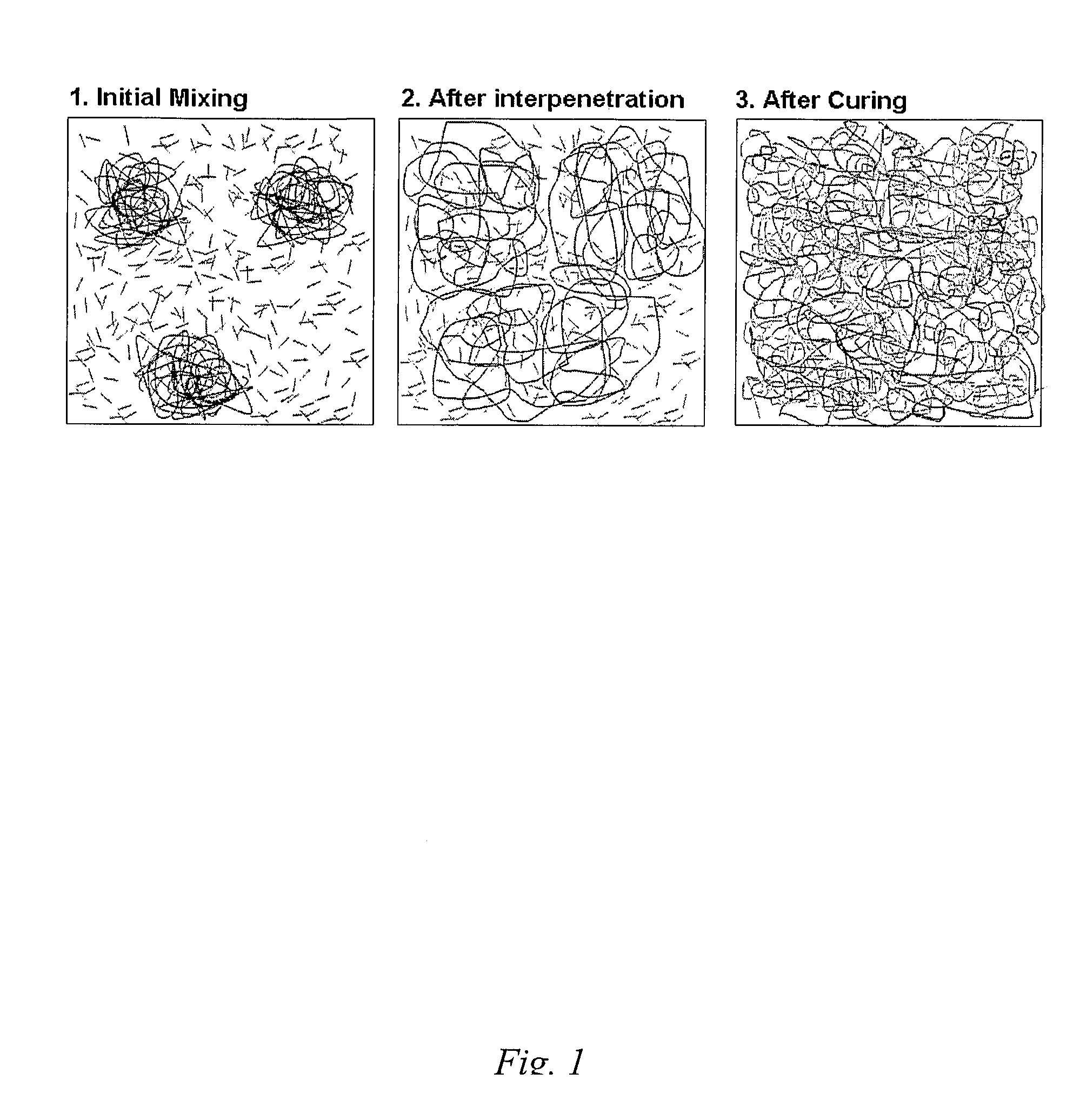

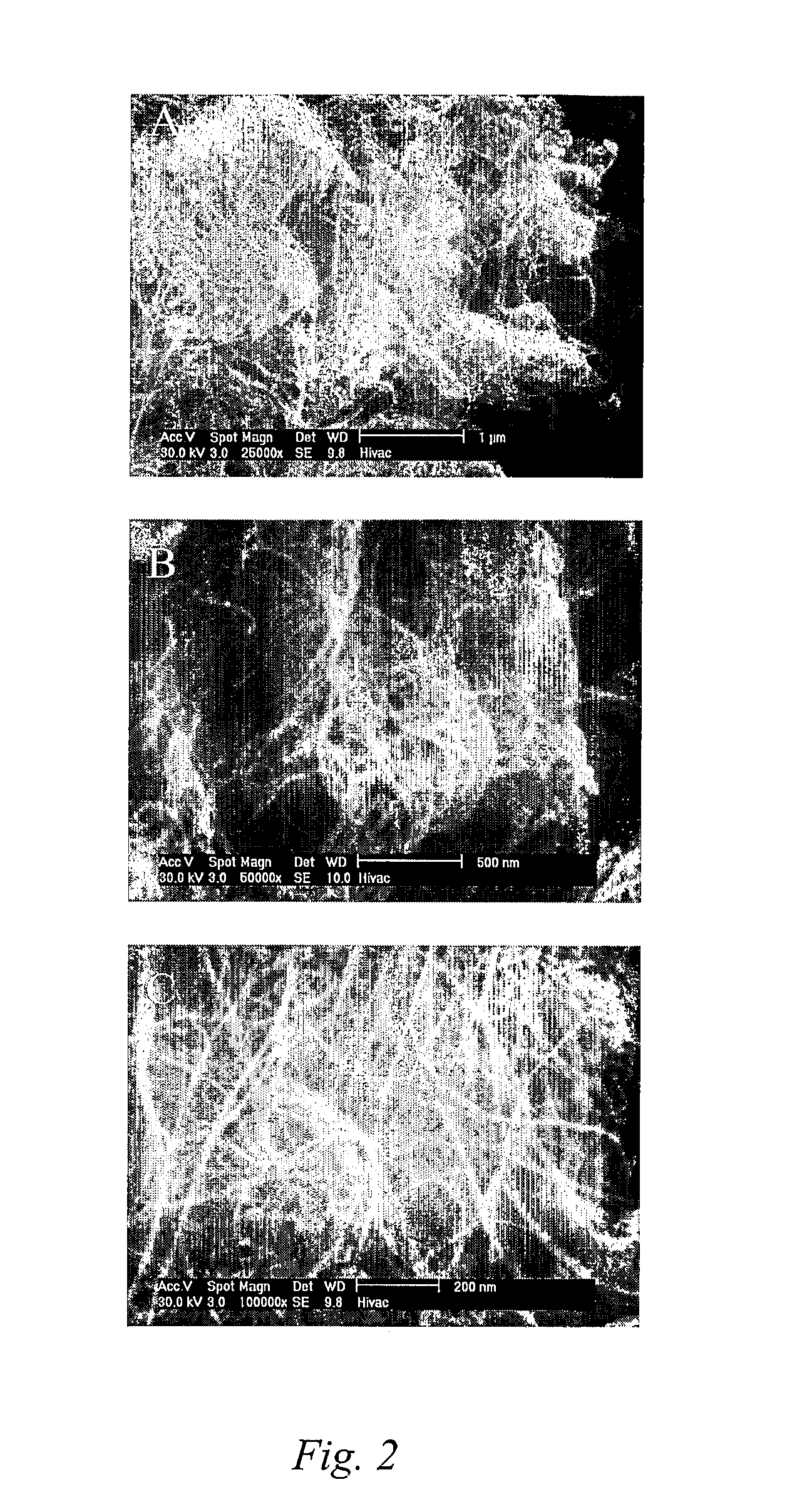

Polymer / Carbon-Nanotube Interpenetrating Networks and Process for Making Same

ActiveUS20080048364A1Improve propertiesHigh strengthPigmenting treatmentMaterial nanotechnologyCross-linkConductive polymer composite

The present invention is directed to new methods for combining, processing, and modifying existing materials, resulting in novel products with enhanced mechanical, electrical and electronic properties. The present invention provides for polymer / carbon nanotube composites with increased strength and toughness; beneficial for lighter and / or stronger structural components for terrestrial and aerospace applications, electrically and thermally conductive polymer composites, and electrostatic dissipative materials. Such composites rely on a molecular interpenetration between entangled single-wall carbon nanotubes (SWNTs) and cross-linked polymers to a degree not possible with previous processes.

Owner:RICE UNIV

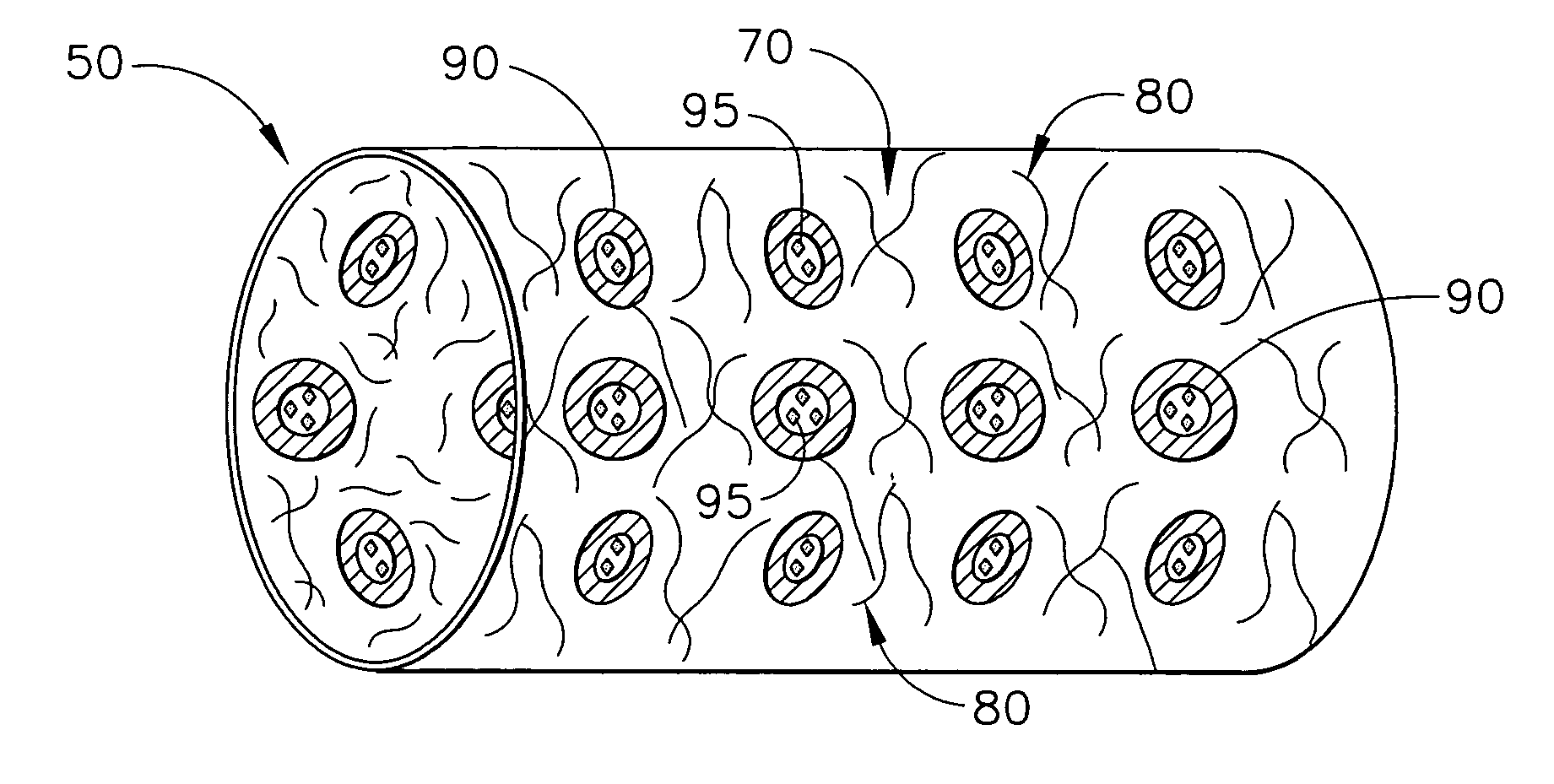

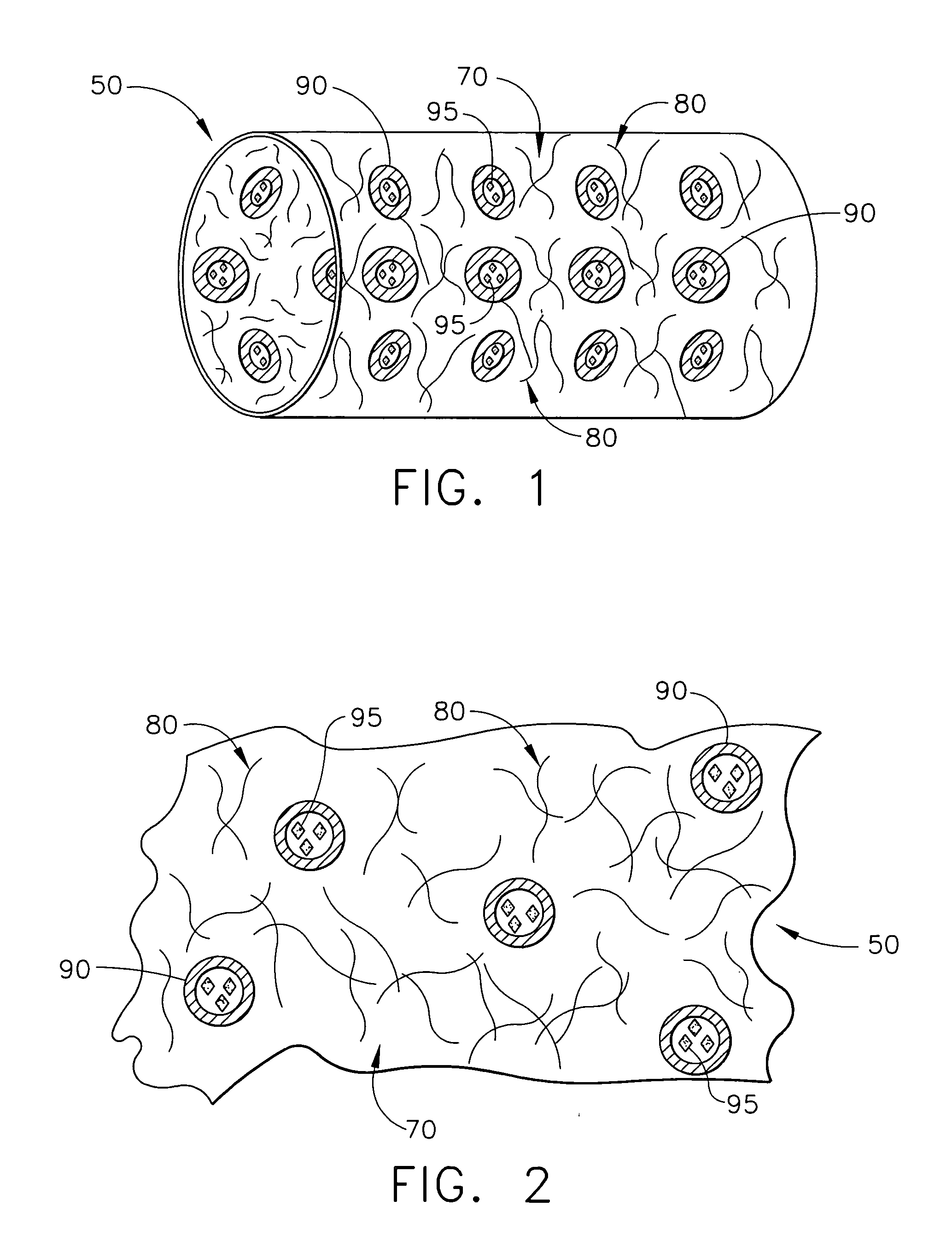

Biodegradable medical implant with encapsulated buffering agent

ActiveUS20050267565A1Control acidic effectEliminate the effects ofStentsBiocideBuffering agentMedical device

A medical device for placement at a site in a patient's body and for controlling pH levels at the site in the patient's body includes one or more structural components made of a first biodegradable and / or bioabsorbable material or, alternatively, one or more structural components having a coating thereon made of a first biodegradable and / or bioabsorbable material. The device also includes a buffering agent and at least one second biodegradable and / or bioabsorbable material on or in the one or more structural components, or alternatively, on or in the coating on the one or more structural components. The at least one second biodegradable and / or bioabsorbable material encapsulates the buffering agent and the buffering agent is dispersed from the at least one second biodegradable and / or bioabsorbable material in response to hydrolysis of the first biodegradable and / or bioabsorbable material. Additionally, the device can include a drug that is either also encapsulated by the at least one second biodegradable and / or bioabsorbable material or is included with the first biodegradable and / or bioabsorbable material.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Occlusive Device

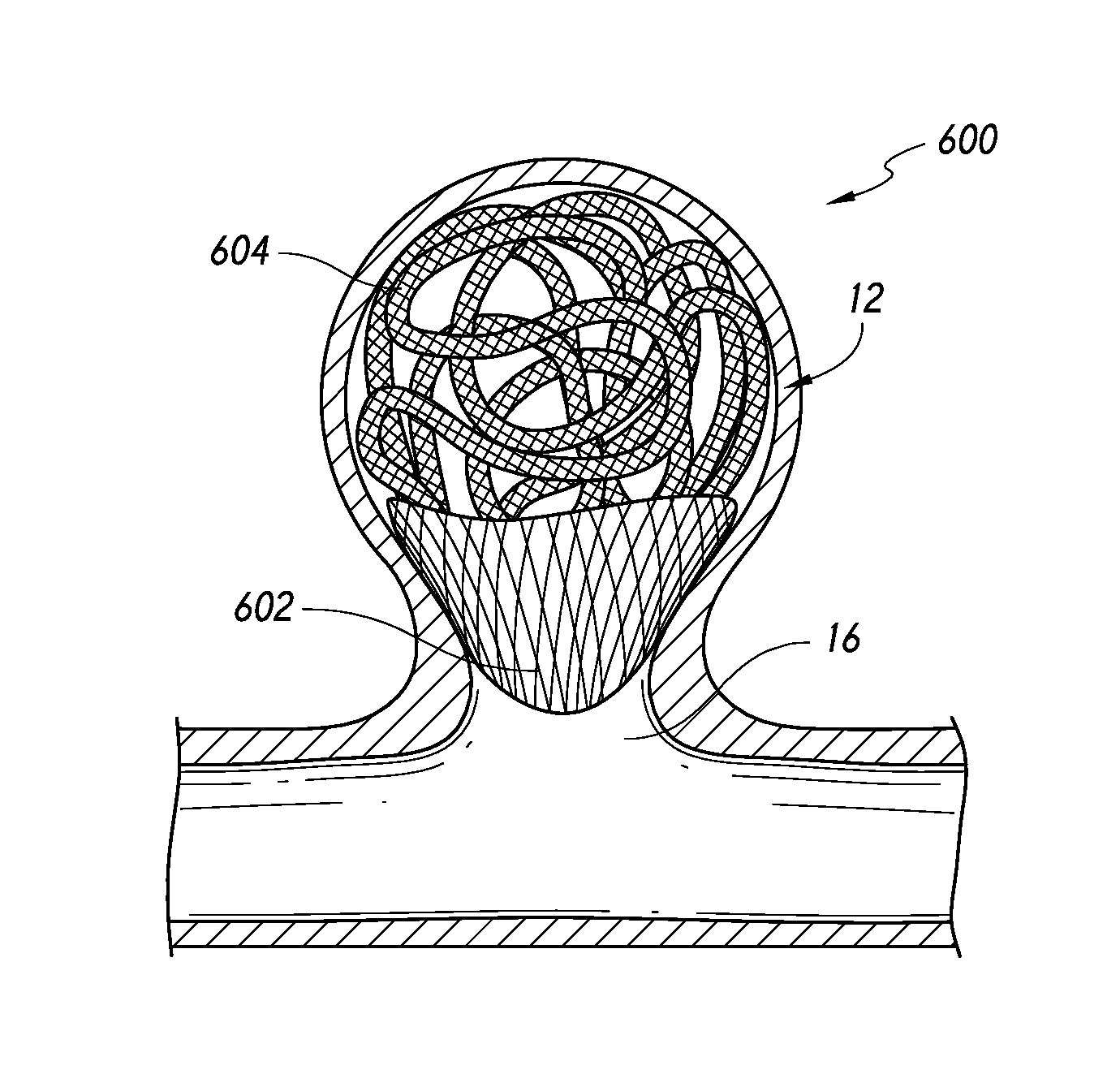

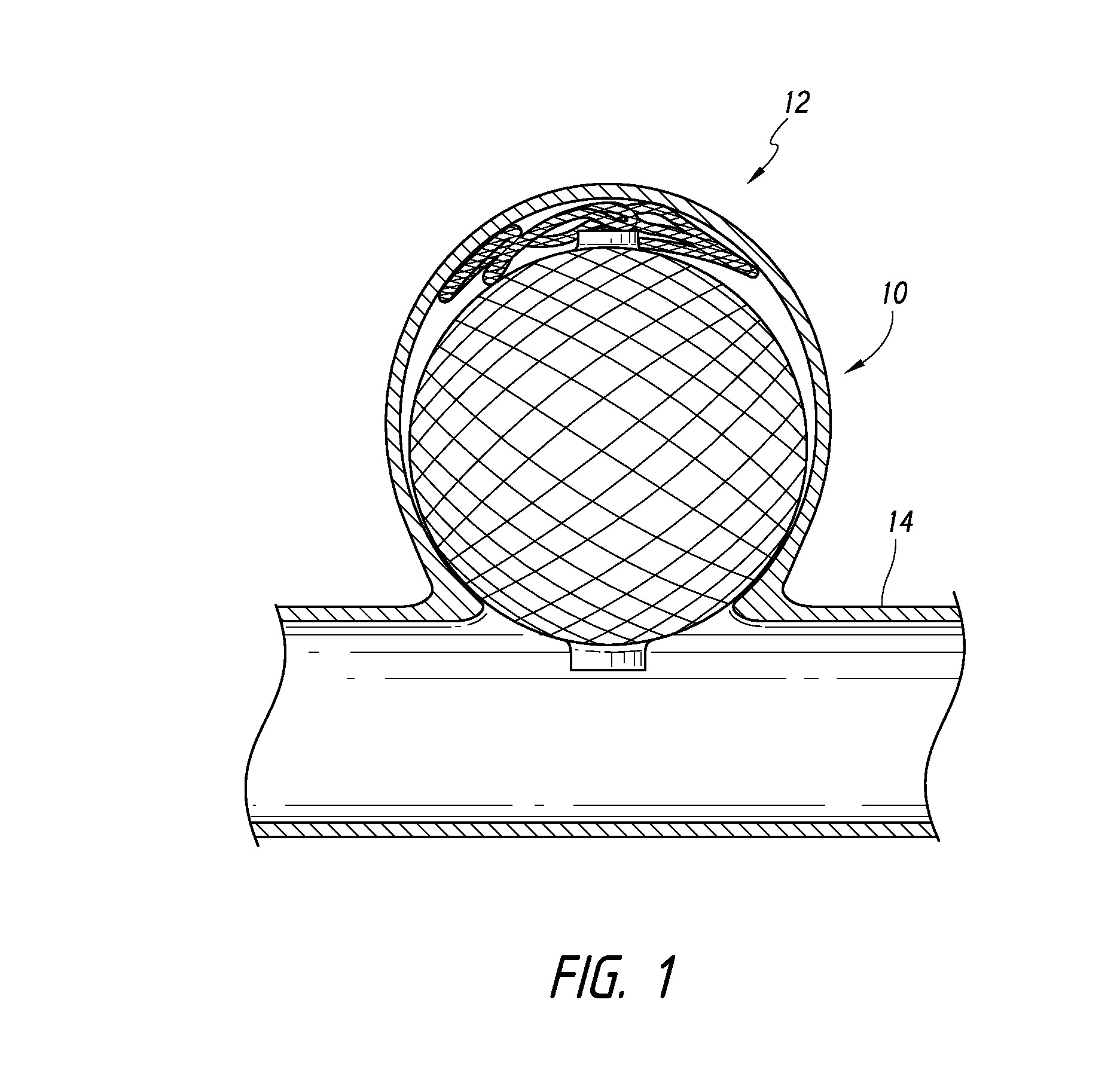

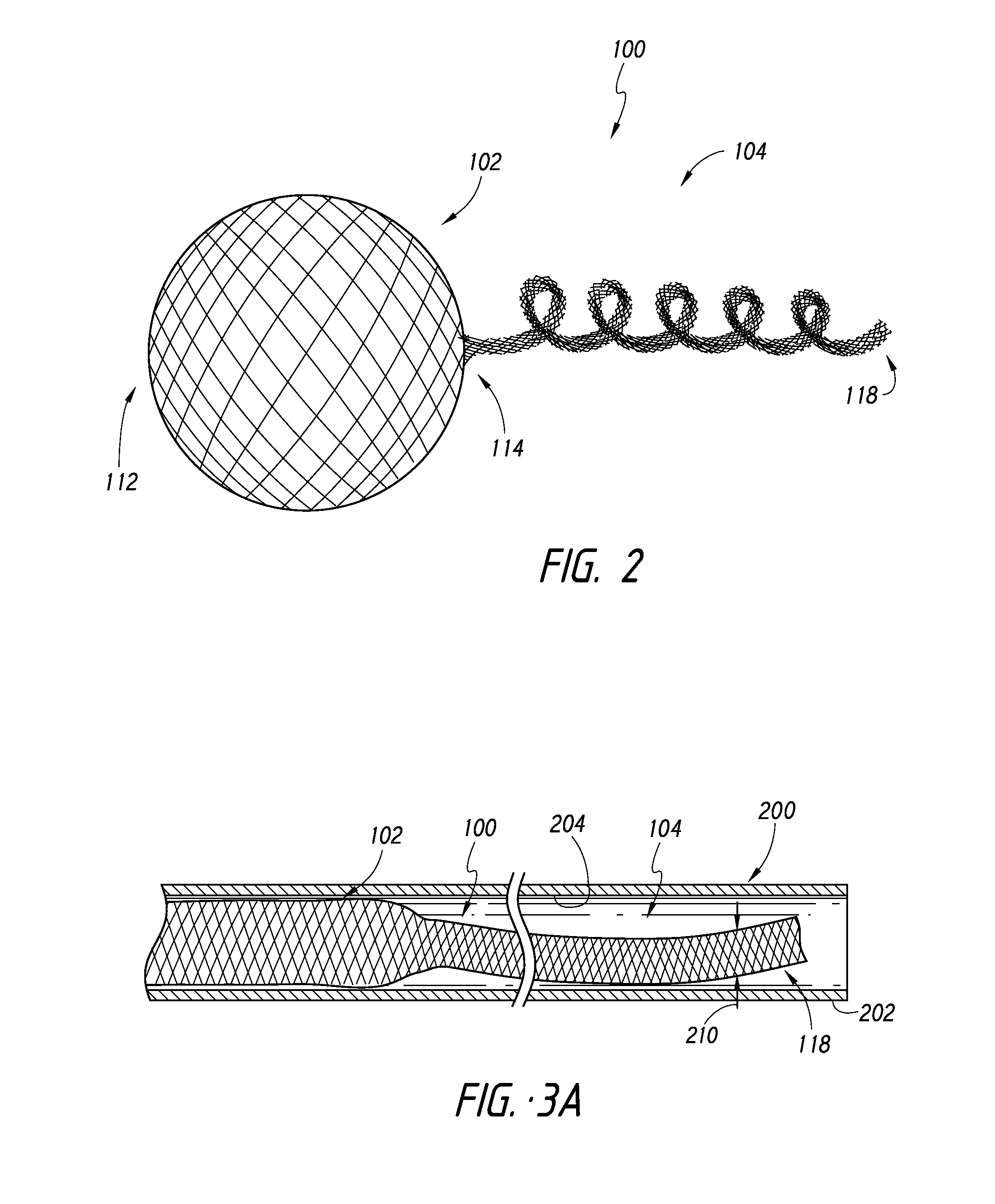

An aneurysm embolization device can include a body having a single, continuous piece of material that is shape set into a plurality of distinct structural components. For example, the device can have an expandable component and an atraumatic tip portion extending therefrom. Further, the tip portion can be configured to enable the device to be implanted within the aneurysm while tending to mitigate risk of puncturing the aneurysm dome or otherwise assist in framing the aneurysm in advance of placement of additional embolic material.

Owner:TYCO HEALTHCARE GRP LP

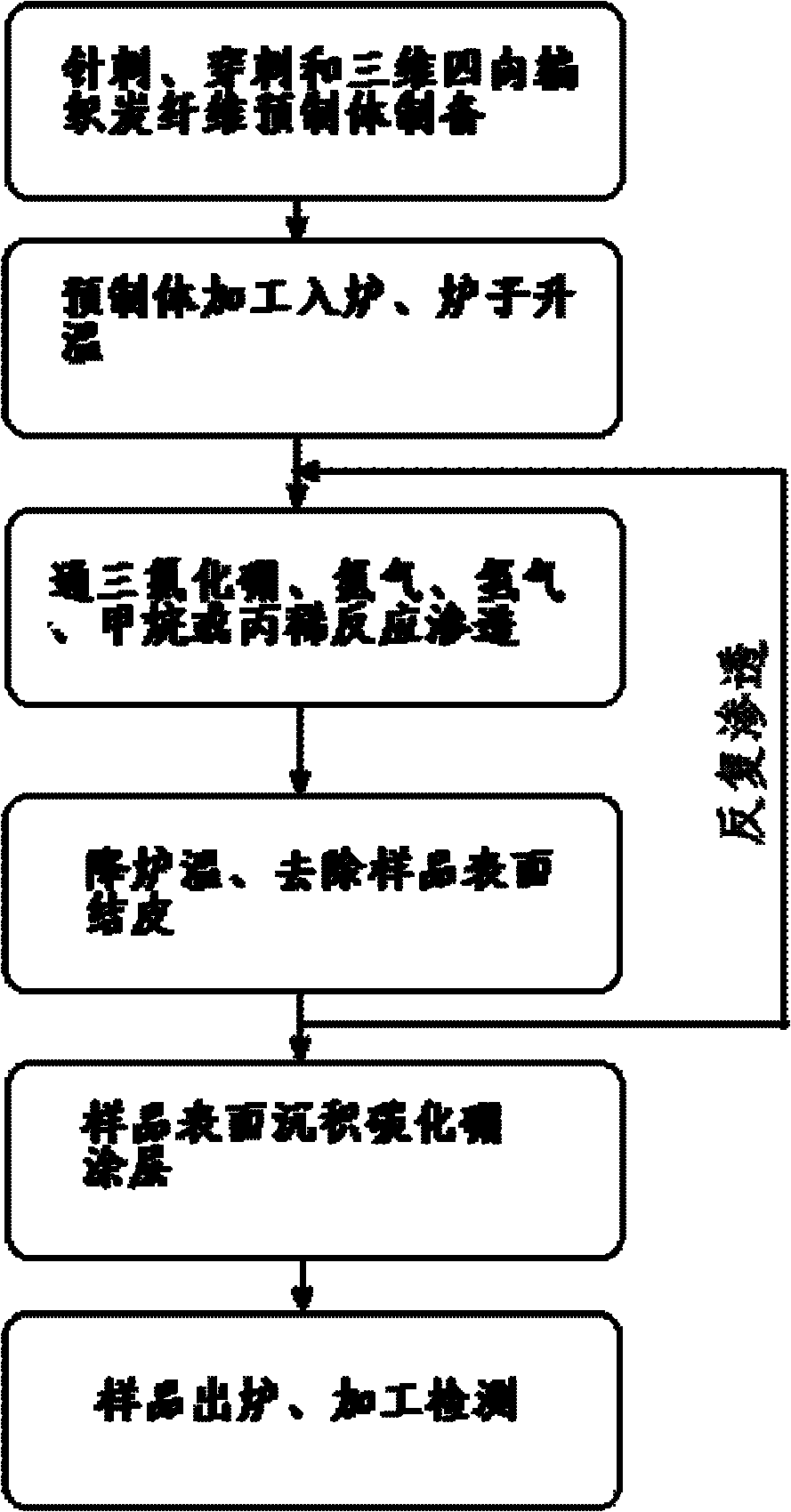

Automotive rail/frame energy management system

InactiveUS20050017543A1Reduce laborReduced capitol expenseVehicle seatsUnderstructuresVehicle frameAbsorbed energy

An energy management system and device for use in an automotive frame, rail, or other structural component of an automotive vehicle. The frame or rail having a cavity or exposed surface capable of supporting at least one member. The member having an interior portion and an exterior portion with the interior portion being defined by at least one trigger or step change to the geometry of the inner portion to target and direct axial bending of the system. A reinforcing material, such as a polymer-based expandable material, is disposed along the exterior portion of a member prior to final assembly of the vehicle by the vehicle manufacturer. The system is activated as the vehicle undergoes the final vehicle assembly process and paint operation which activates and transforms the reinforcing material to expand, bond and structurally adhere the frame rail to mange, direct, and / or absorb energy in the event of an impact to the vehicle from an applied load or an external force.

Owner:ZEPHYROS INC +1

System and method of forming structural assemblies with 3-D woven joint pre-forms

InactiveUS6849150B1Improve structural strengthEliminate needFuselage framesCylinder headsAdhesiveEngineering

A system and method for forming structural assemblies with 3-D woven joint pre-forms. The method of the present invention forms complex structural assemblies with pre-formed structures. Adhesive is applied between the preformed structures and uncured 3-D woven textile pre-forms. Then together the preformed structures and uncured resin impregnated 3-D woven textile are cured with heat and / or pressure to form the larger complex structural assemblies.

Owner:LOCKHEED MARTIN CORP

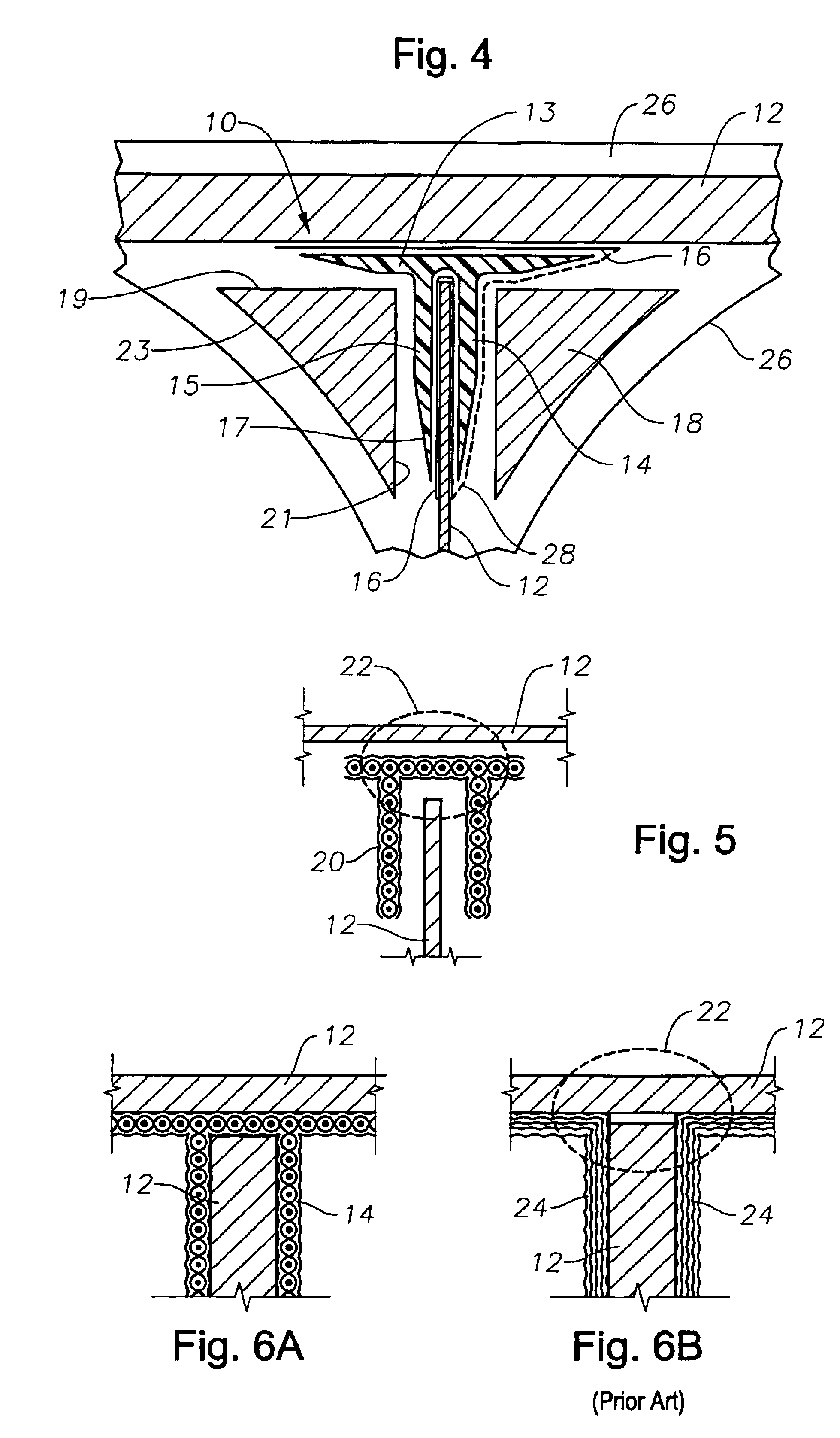

Carbon fiber reinforced boron carbide composite material and preparation method thereof

The invention relates to a carbon fiber reinforced boron carbide composite material and a preparation method thereof. The preparation method comprises the following steps of: preparing a carbon fiber preform by adopting a needling, puncturing or three-dimensional weaving process; and depositing boron carbide matrix in the porous carbon fiber preform by osmosis to form the compact carbon fiber reinforced boron carbide composite material. Aiming at a certain specific application environment, a boron carbide coat can be deposited on the surface of a sample by adopting the same chemical vapor osmosis process. The carbon fiber reinforced boron carbide-based composite material manufactured by the method has the characteristics of good mechanical property, toughness superior to that of the traditional sintered boron carbide, compact structure, light weight, abrasion resistance and high hardness, and is suitable to be applied to a high-temperature light structural component.

Owner:CENT SOUTH UNIV

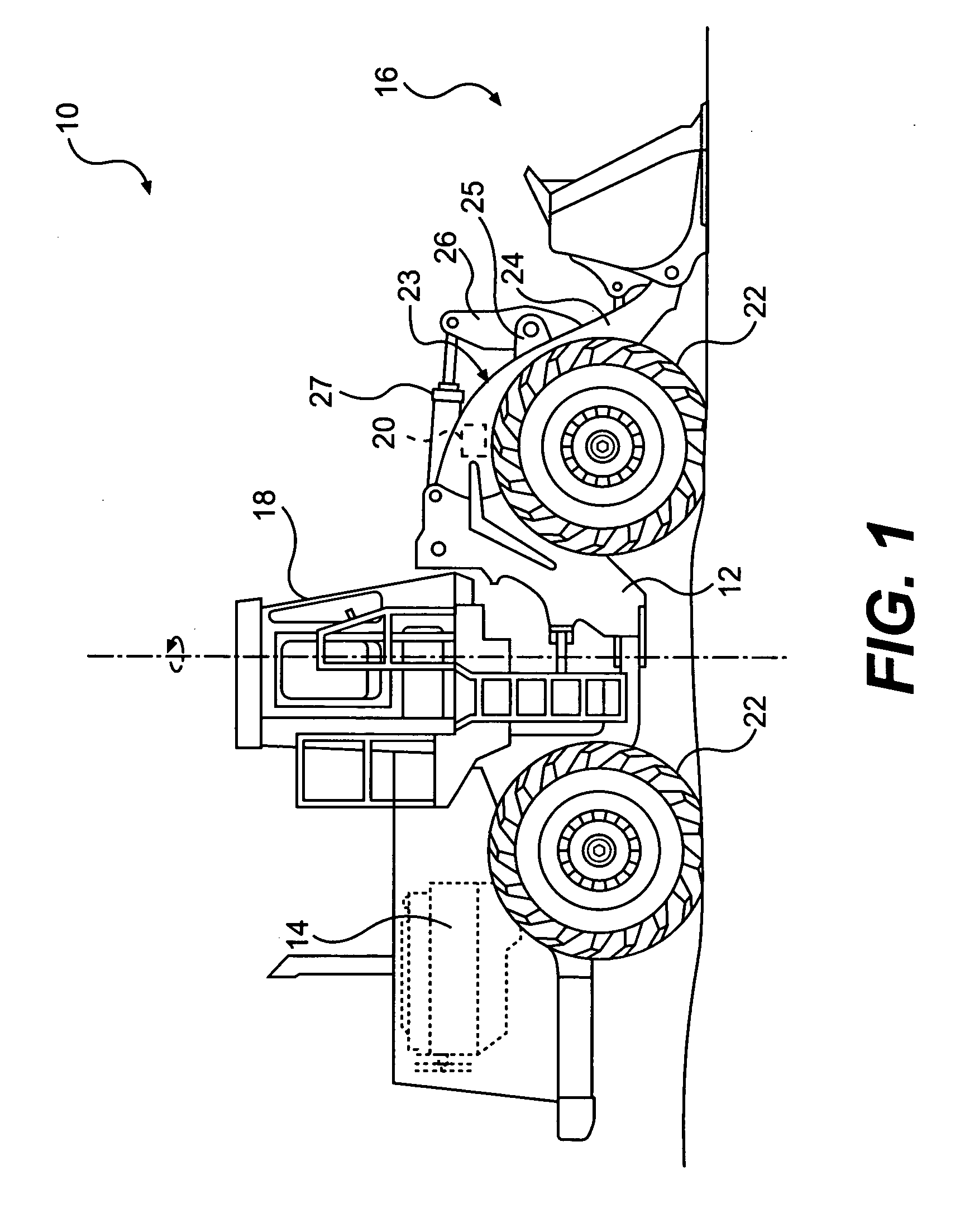

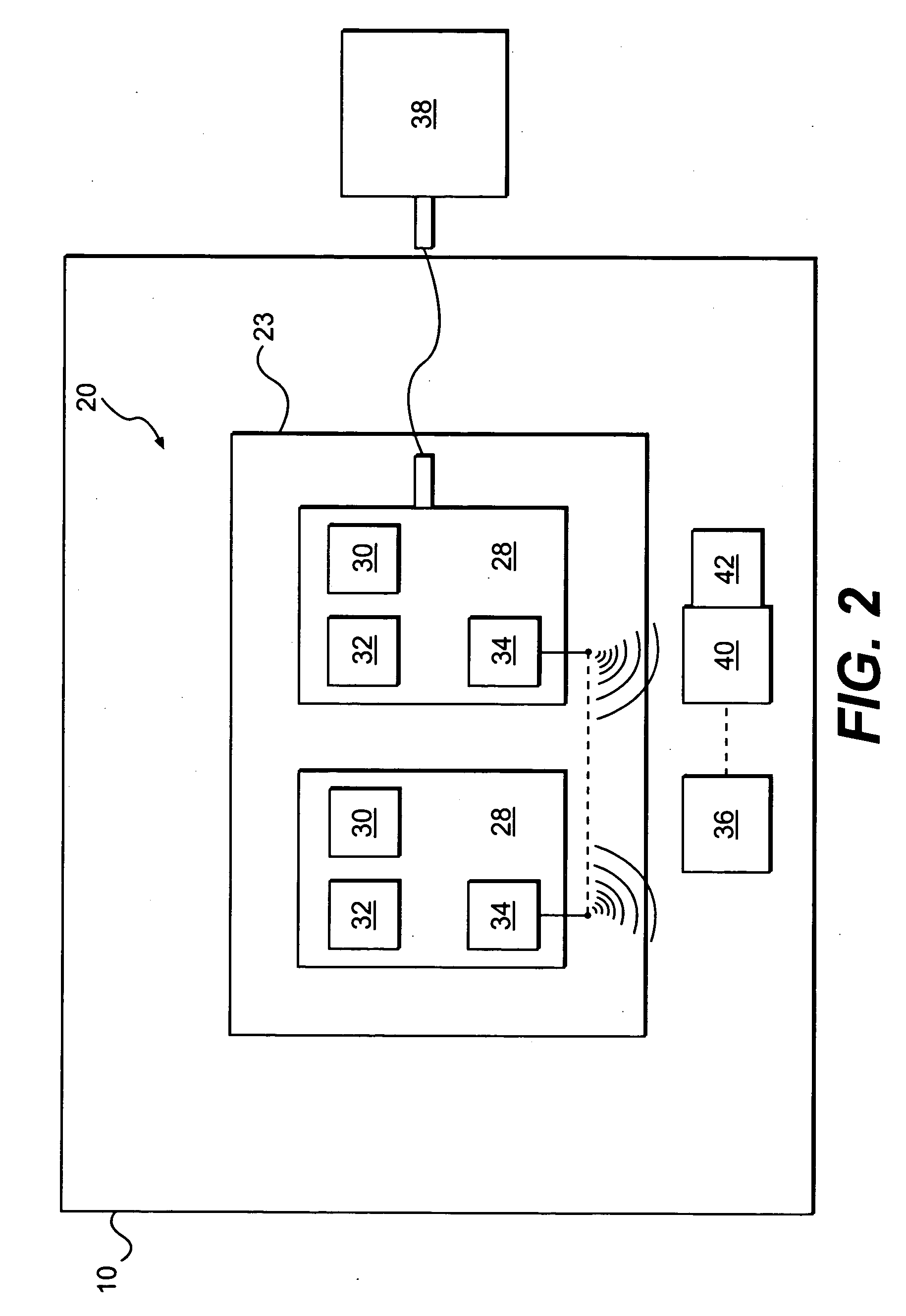

Monitoring system

A monitoring system is provided, which may include a structural component configured to undergo mechanical loading and a wireless node attached to the structural component. The node may include a strain sensing device configured to measure strain experienced by the structural component at the location of the node. The node may also include a processor configured to predict, based on the strain measurements, fatigue life of the structural component.

Owner:CATERPILLAR INC

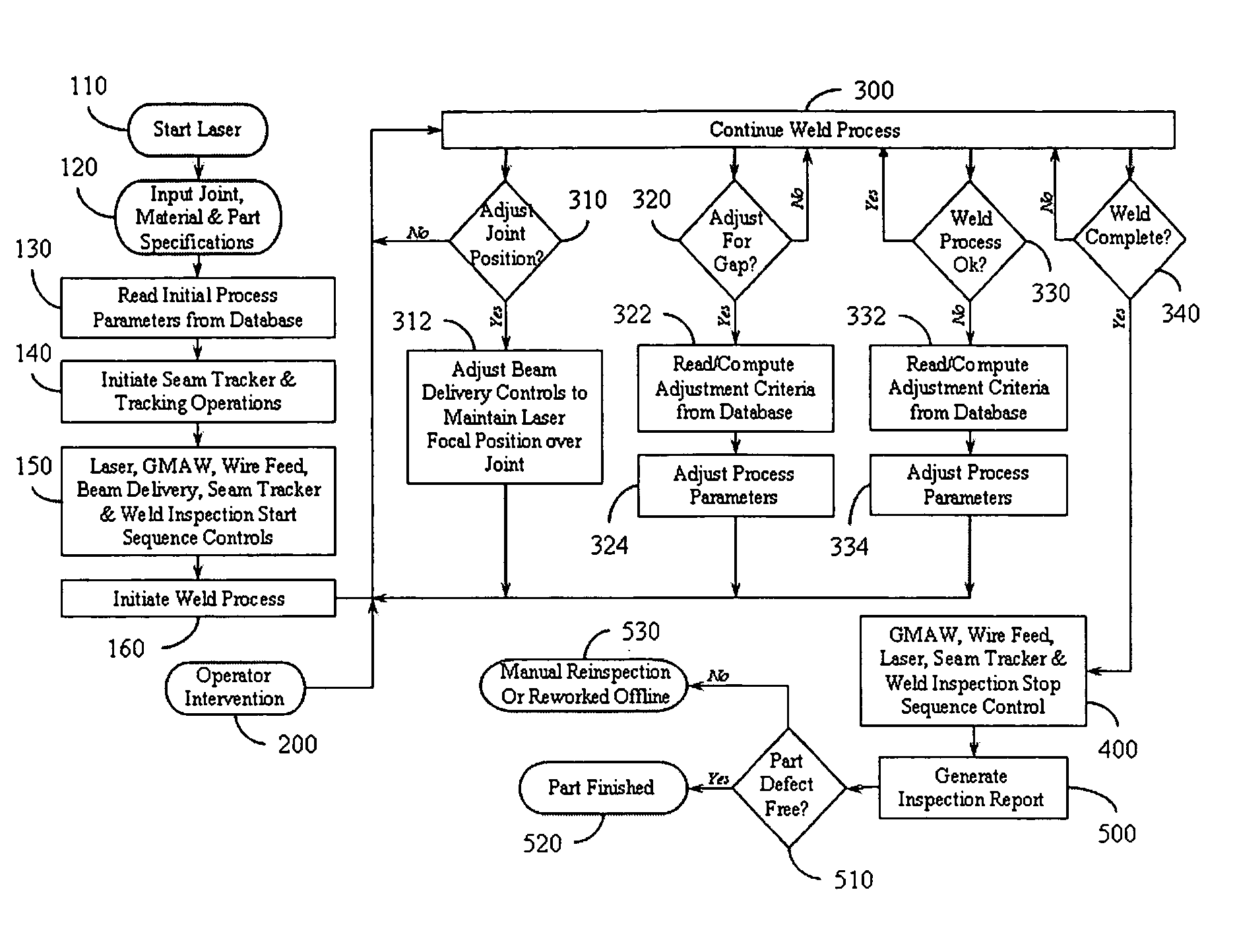

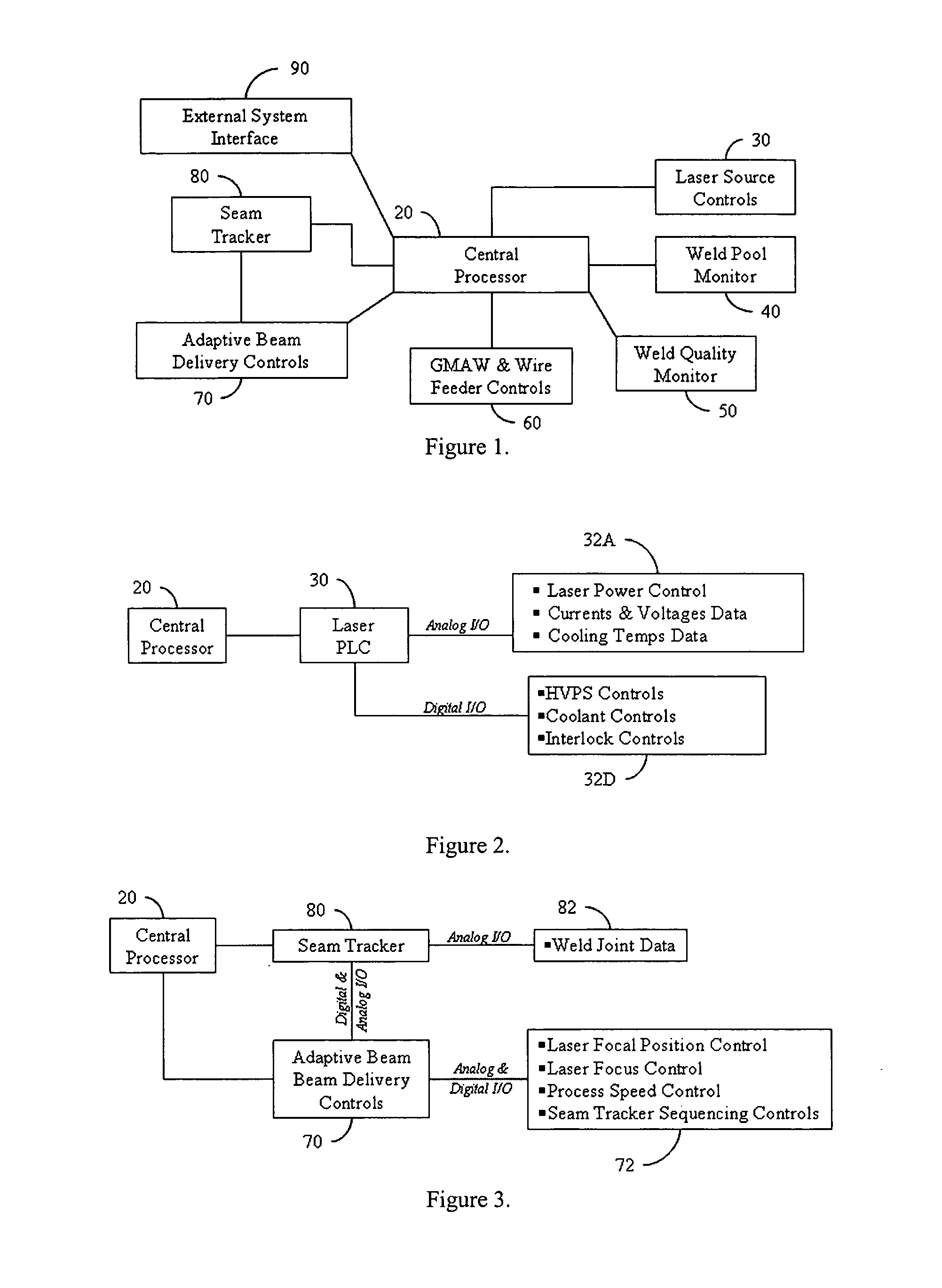

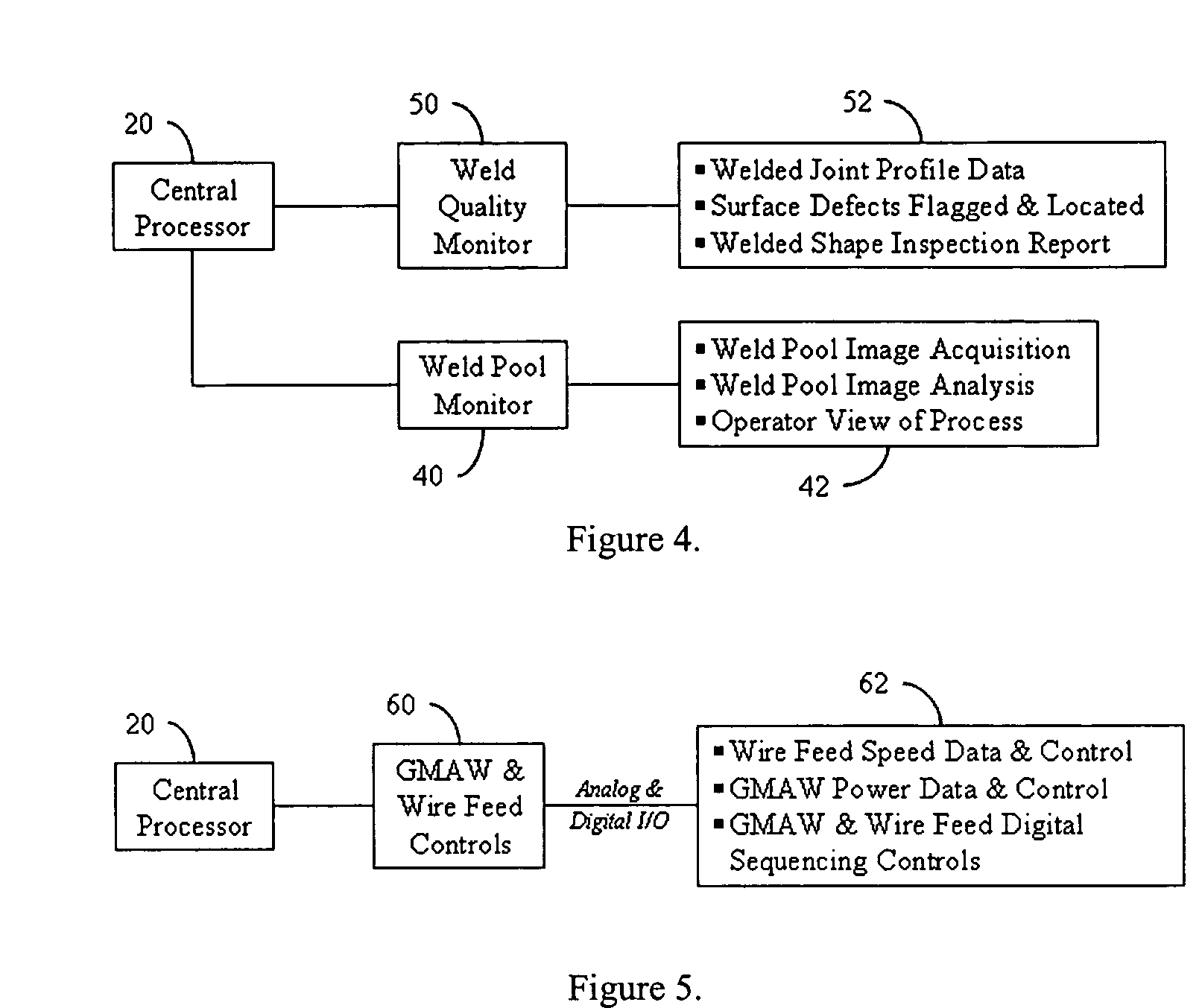

Laser welding control system

ActiveUS7107118B2Improve reliabilityReduce the amount requiredProgramme controlElectrical apparatusClosed loopVision based

A fully integrated automated laser weld process control system (LWPCS) and method of controlling the fabrication of structural parts, particularly for shipbuilding and other industries. The LWPCS defines joint and weld quality attributes as process control variables and integrates these weld quality variables, along with the more traditional process parameters such as laser power, wire feed, GMAW voltage and active seam tracking, into a closed-loop monitoring and control system. The LWPCS includes a central processor and a plurality of subsystems that control laser beam positioning, vision-based monitoring and image processing, active weld-quality monitoring and inspection, adaptive beam delivery, and seam tracking. Cross-communication between subsystems is managed by the central processor. In addition to process control, the system extracts weld quality attributes during the weld process and provides immediate documentation of the weld quality.

Owner:ESAB AB

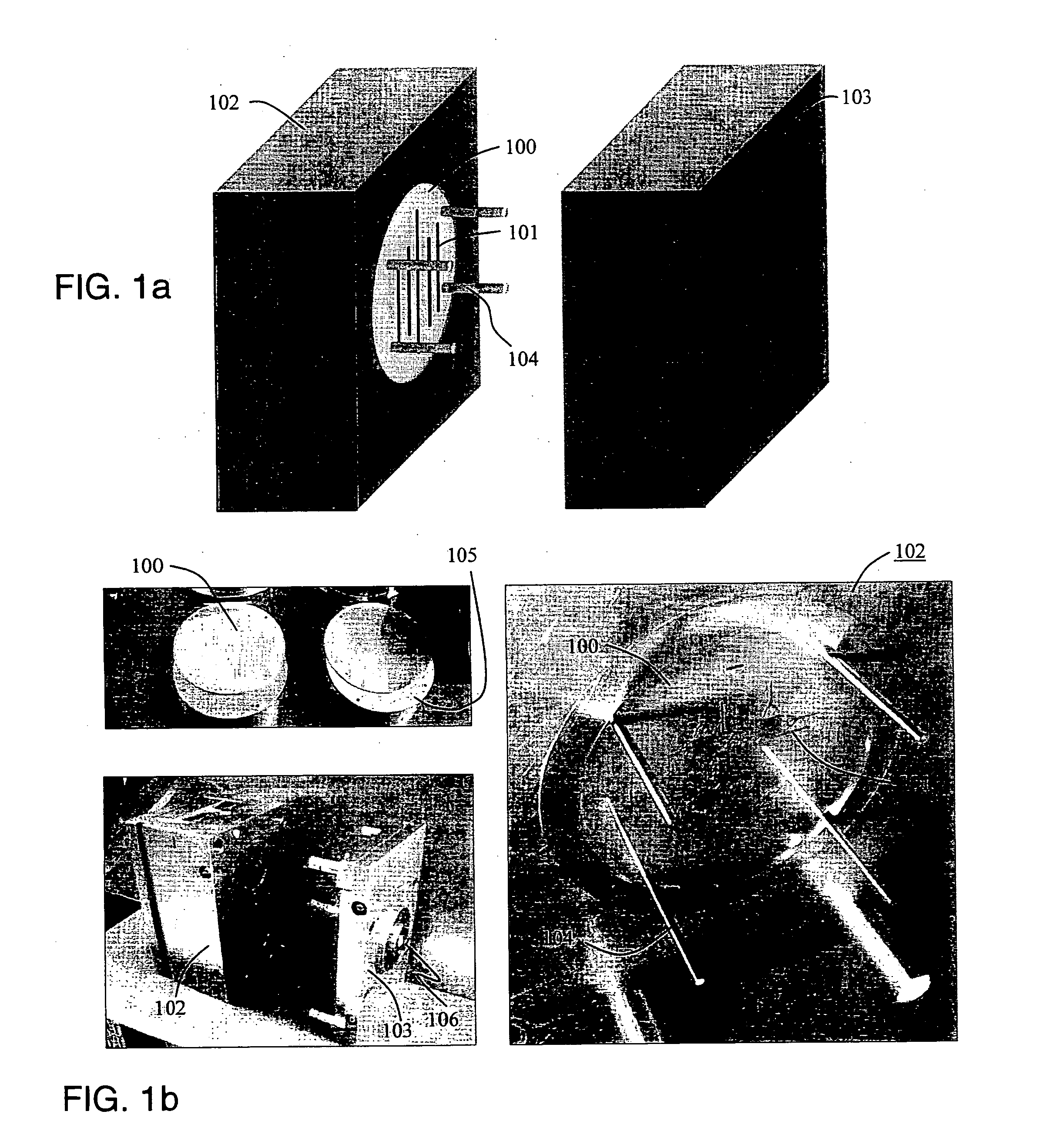

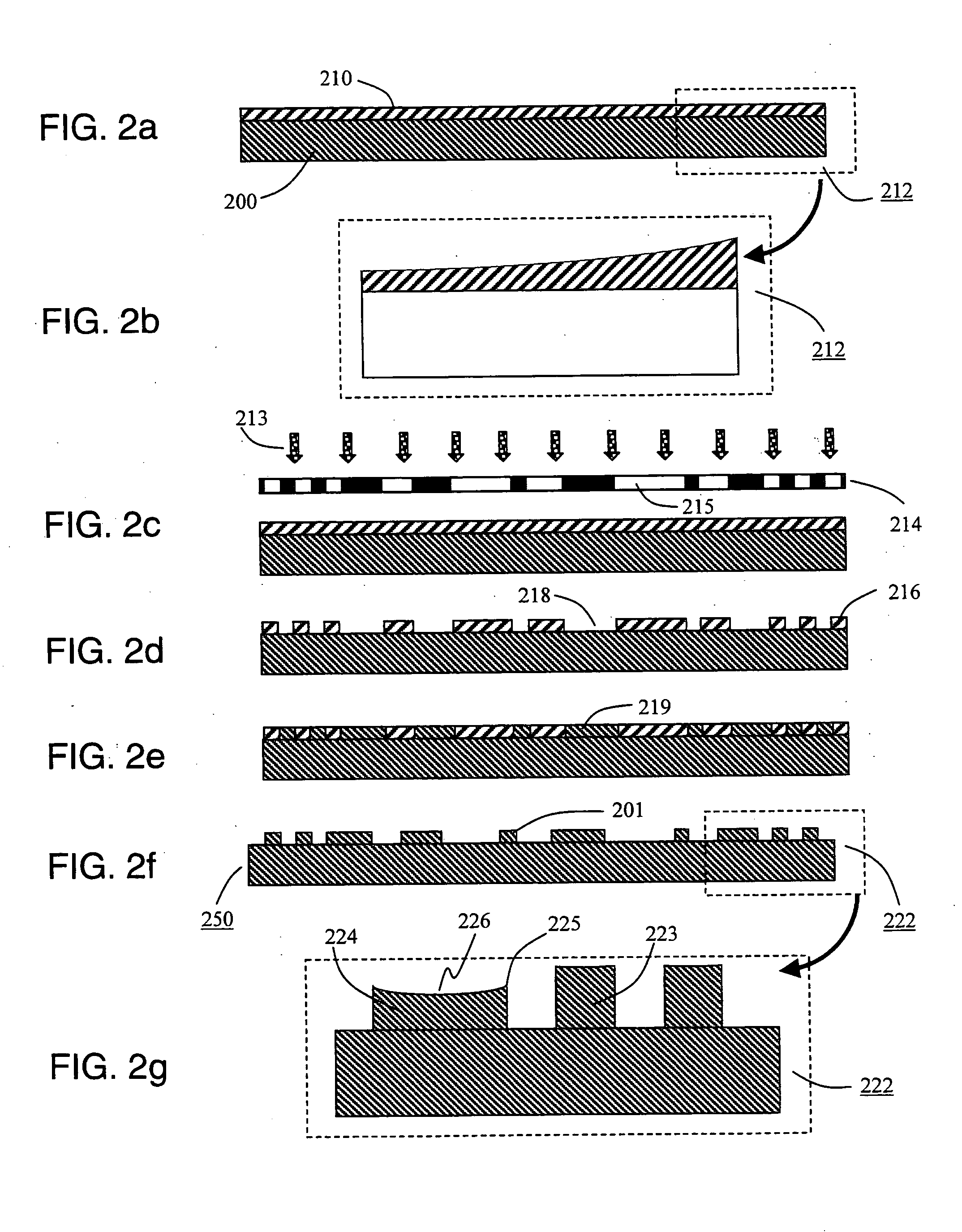

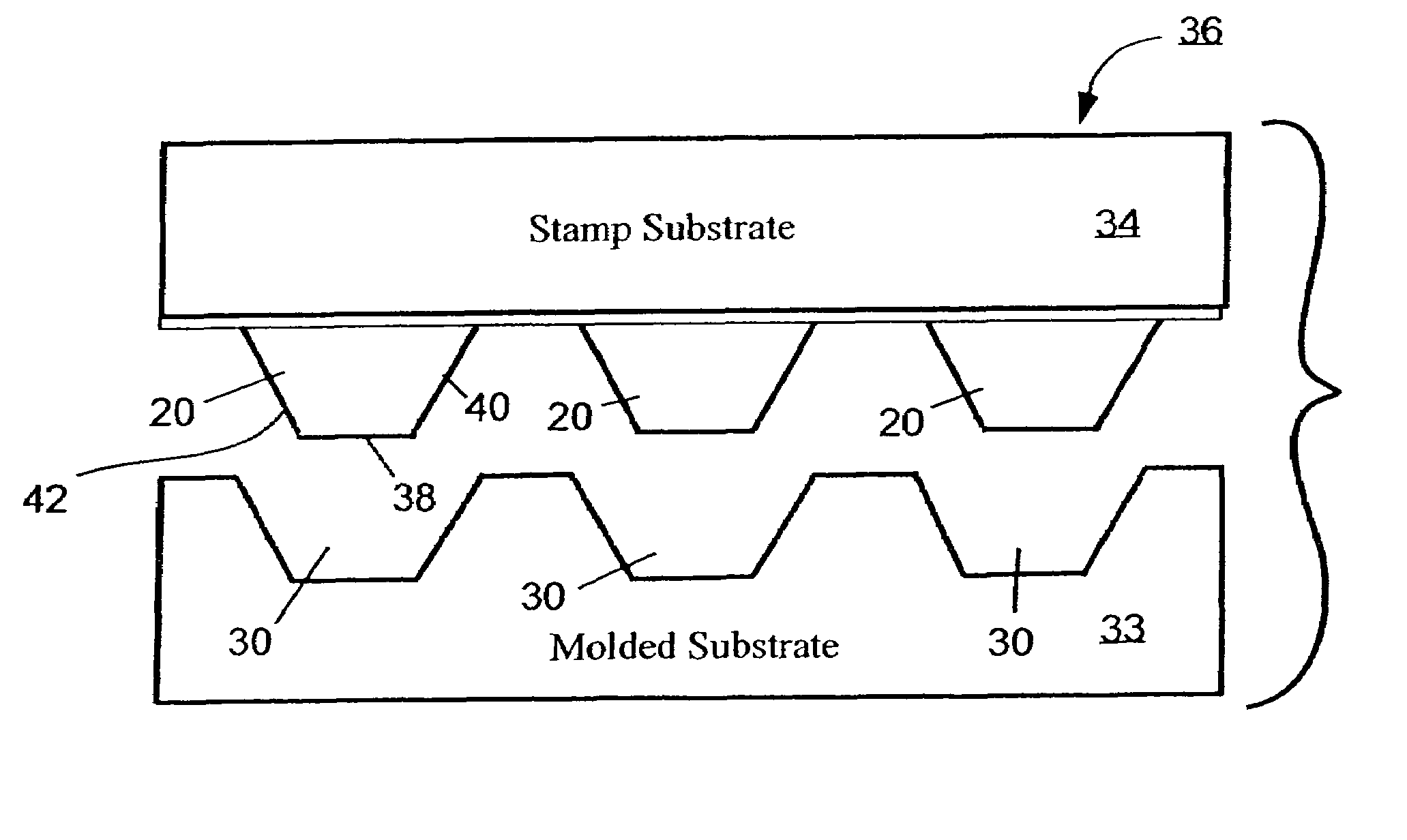

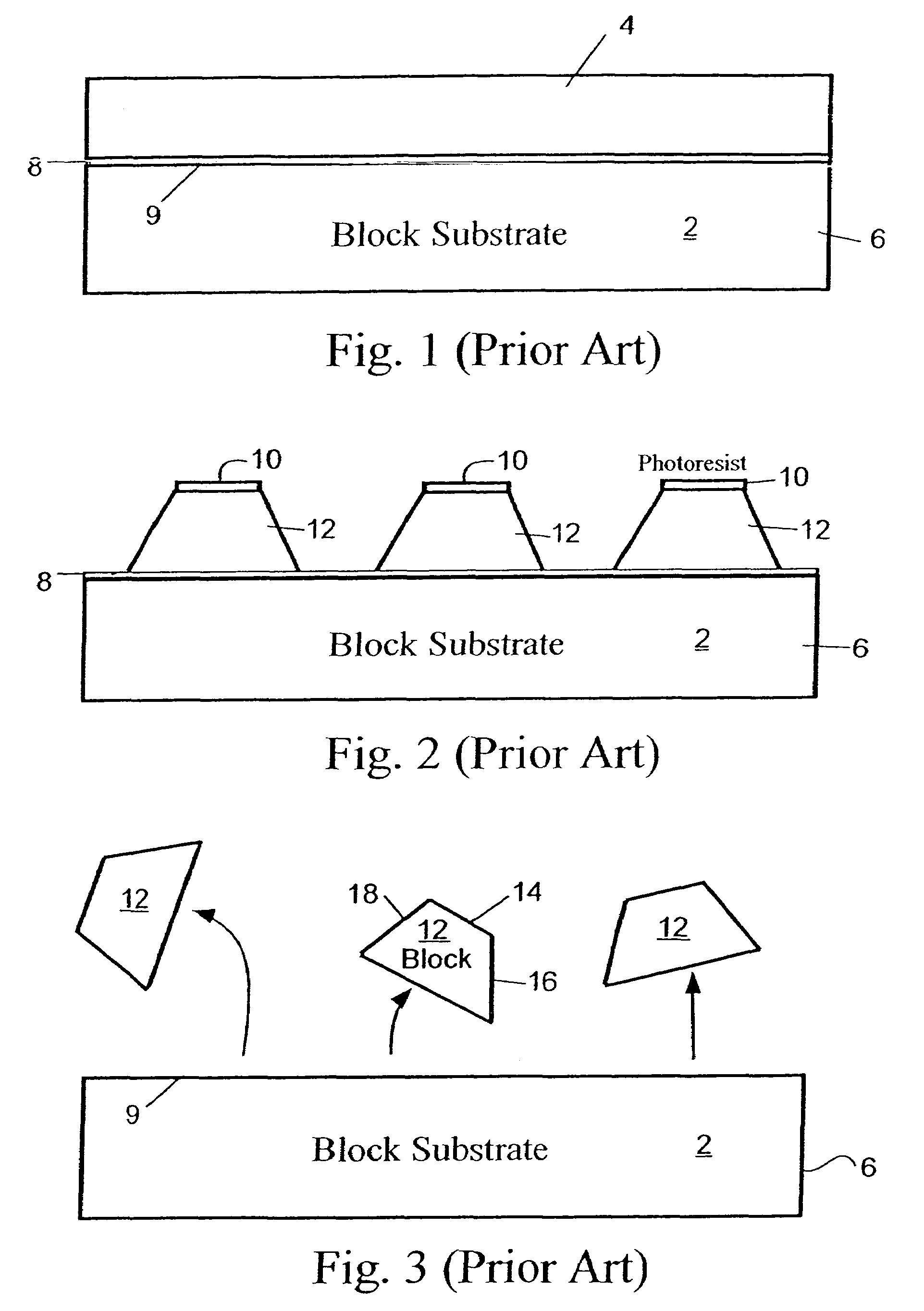

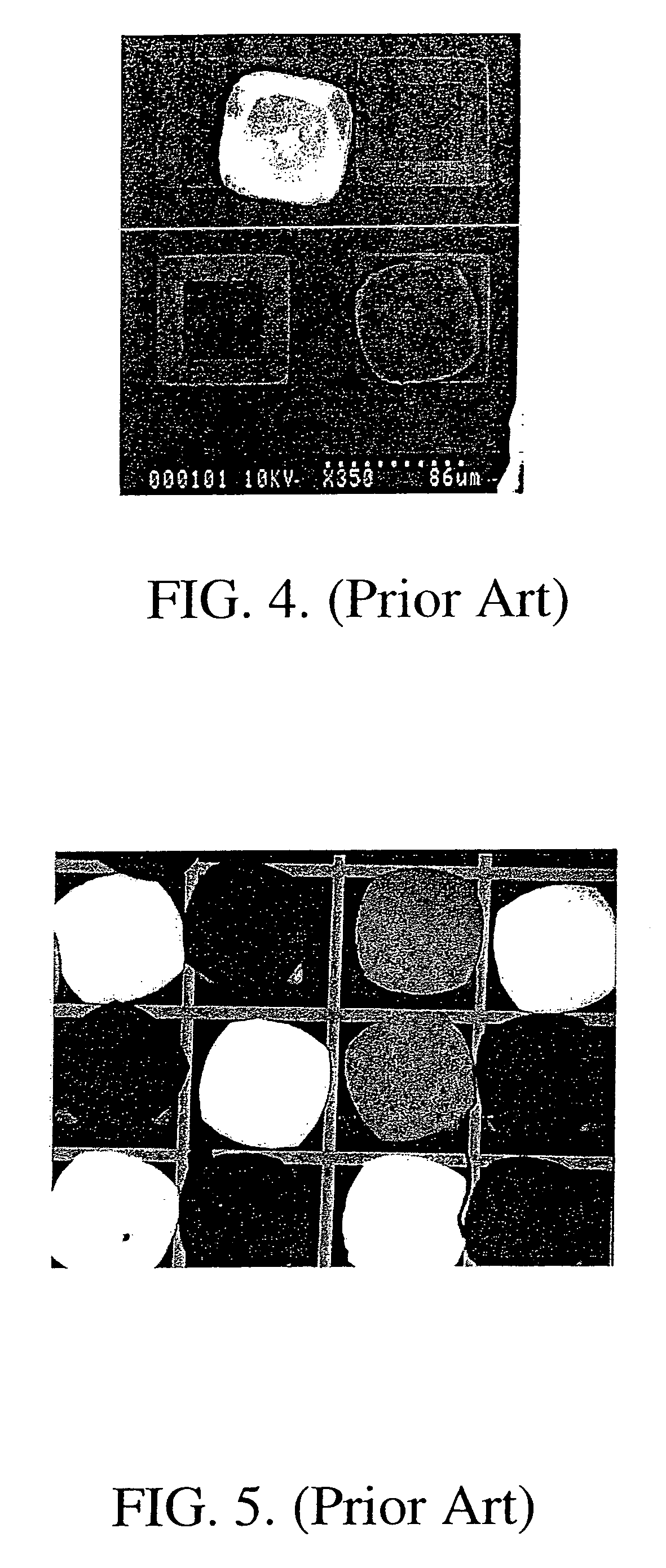

Method for assembly of complementary-shaped receptacle site and device microstructures

InactiveUS7018575B2Material nanotechnologySemiconductor/solid-state device detailsShell moldingThree dimensional shape

A method for assembly including the steps of:(a) providing a plurality of microstructure components with each of the components having a bottom with the same three dimensional shape;(b) forming a mold with at least one protuberance from a surface thereof so that the at least one protuberance has the same shape;(c) molding a moldable substrate with the mold to form a molded substrate having a surface with at least one recess having the same shape; and(d) positioning a first of the plurality of microstructure components into said at least one recess. Each of the microstructure components may be formed by a masking and etching process, with the mold being formed by the same masking and etching process. The positioning step may consist of mixing the microstructure components with a fluid to form a slurry; and depositing the slurry on the surface of the molded substrate to cause the first of the plurality of microstructure components to self-align in the recess.

Owner:HRL LAB

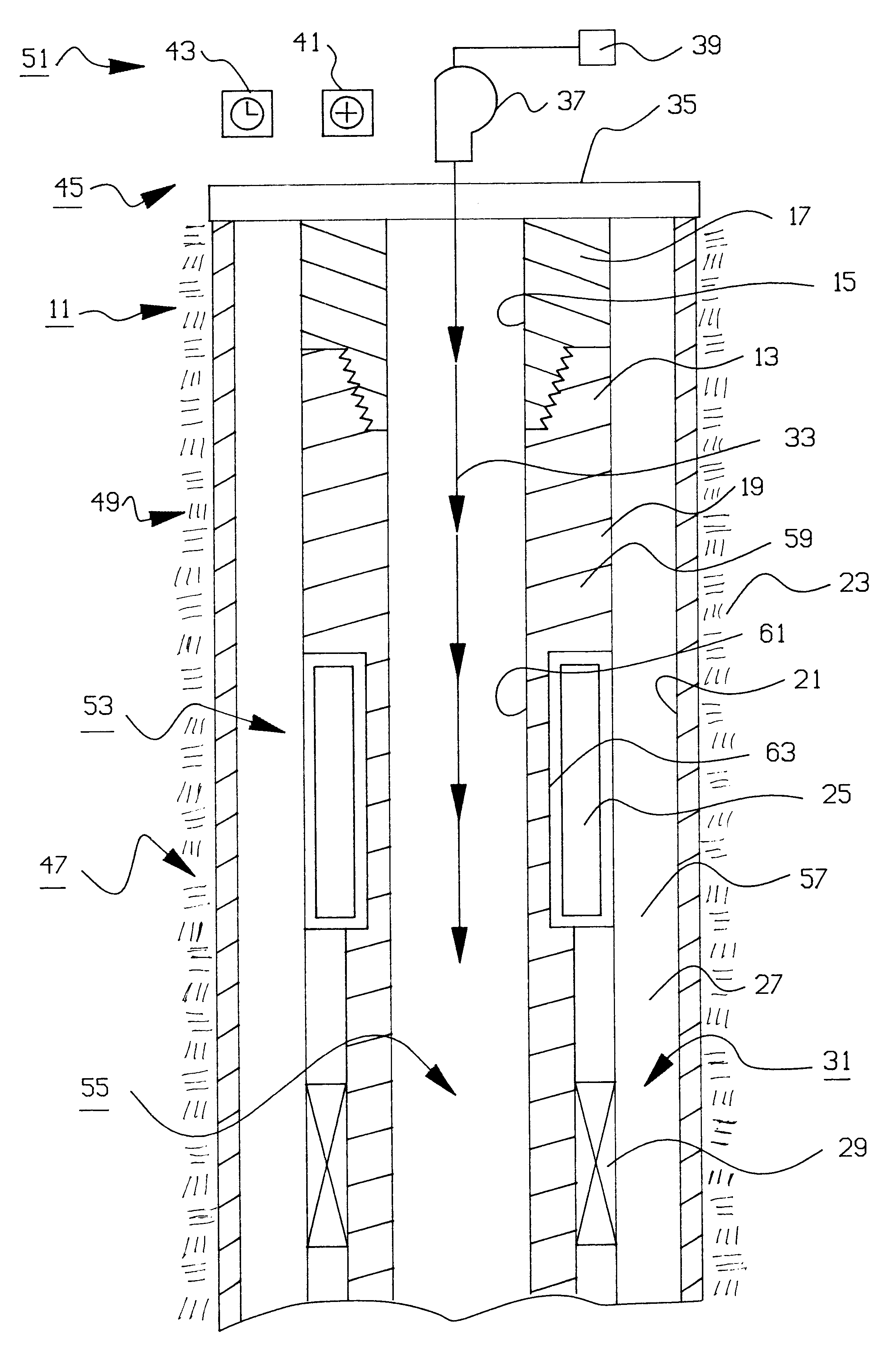

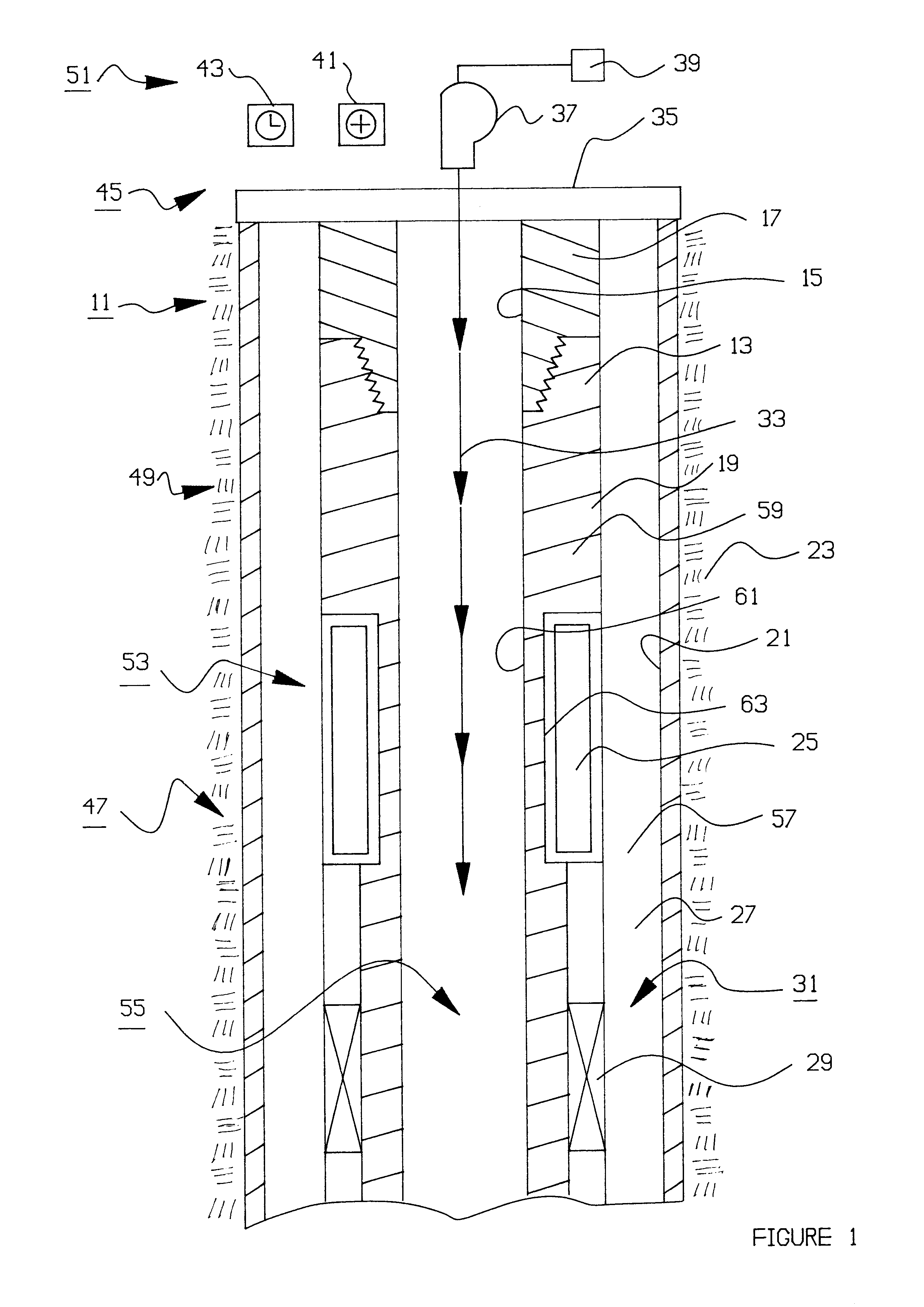

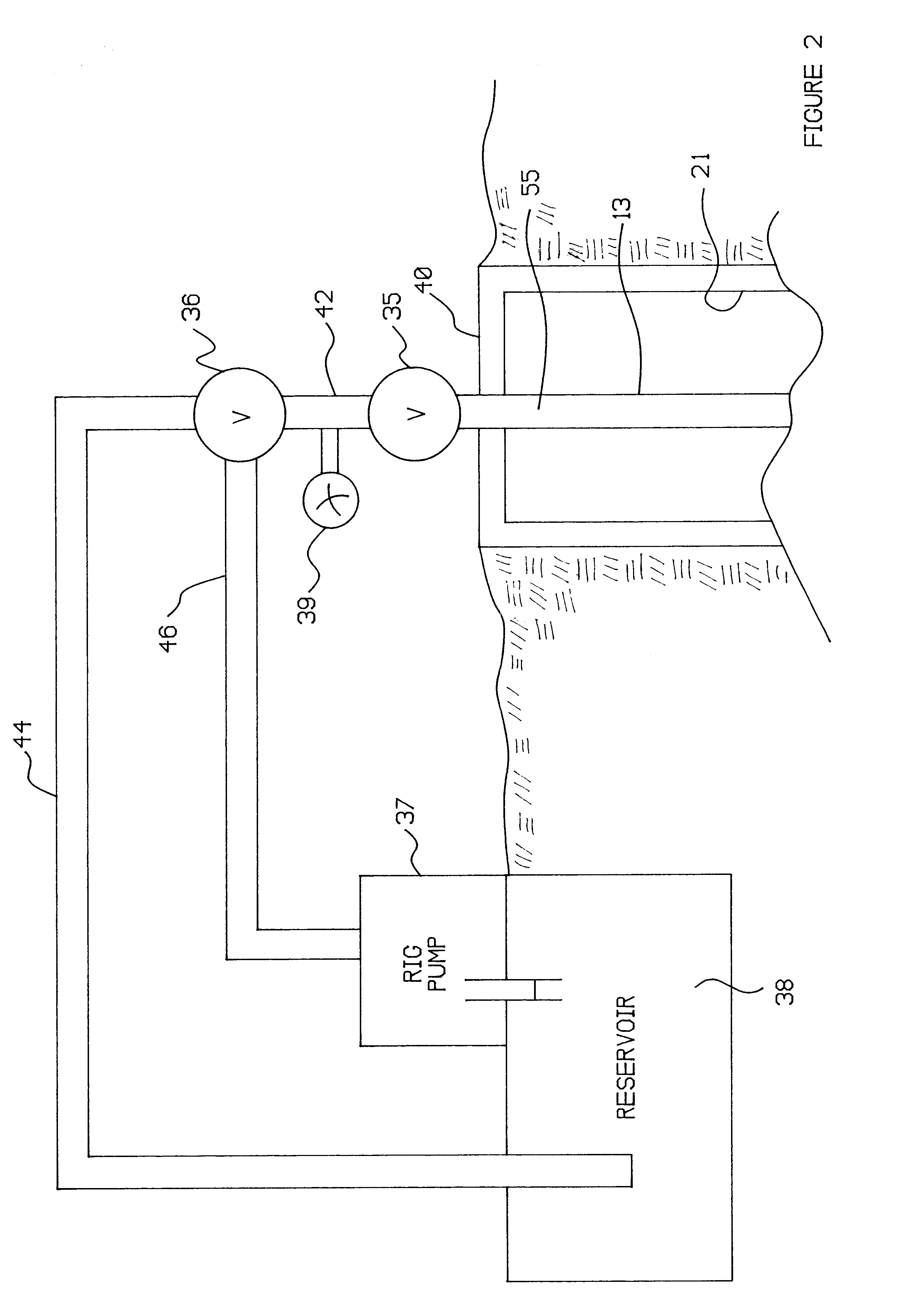

Method and apparatus for communicating coded messages in a wellbore

A method and apparatus for communicating coded messages in a wellbore between a transmission node and a reception node is provided. The coded messages are messages are impressed upon a fluid column which extends between the transmission node and the reception node. A transmission apparatus is provided at the transmission node which is in communication with the fluid column, for altering pressure of the fluid column to generate at least a portion of the coded message. A reception apparatus is provided at the reception node. The reception apparatus includes a rigid structural component with an exterior surface which is in direct contact with fluid column and an interior surface which is not in contact with the fluid column, and a sensor assembly which detects elastic deformation of the rigid structural component. The transmission apparatus is utilized to alter pressure of the fluid column in a predetermined pattern to generate at least one coded message. The reception apparatus is utilized to detect the coded message in the fluid column through changes in elastic deformation of the rigid structural component.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com