Patents

Literature

4312 results about "Torque transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

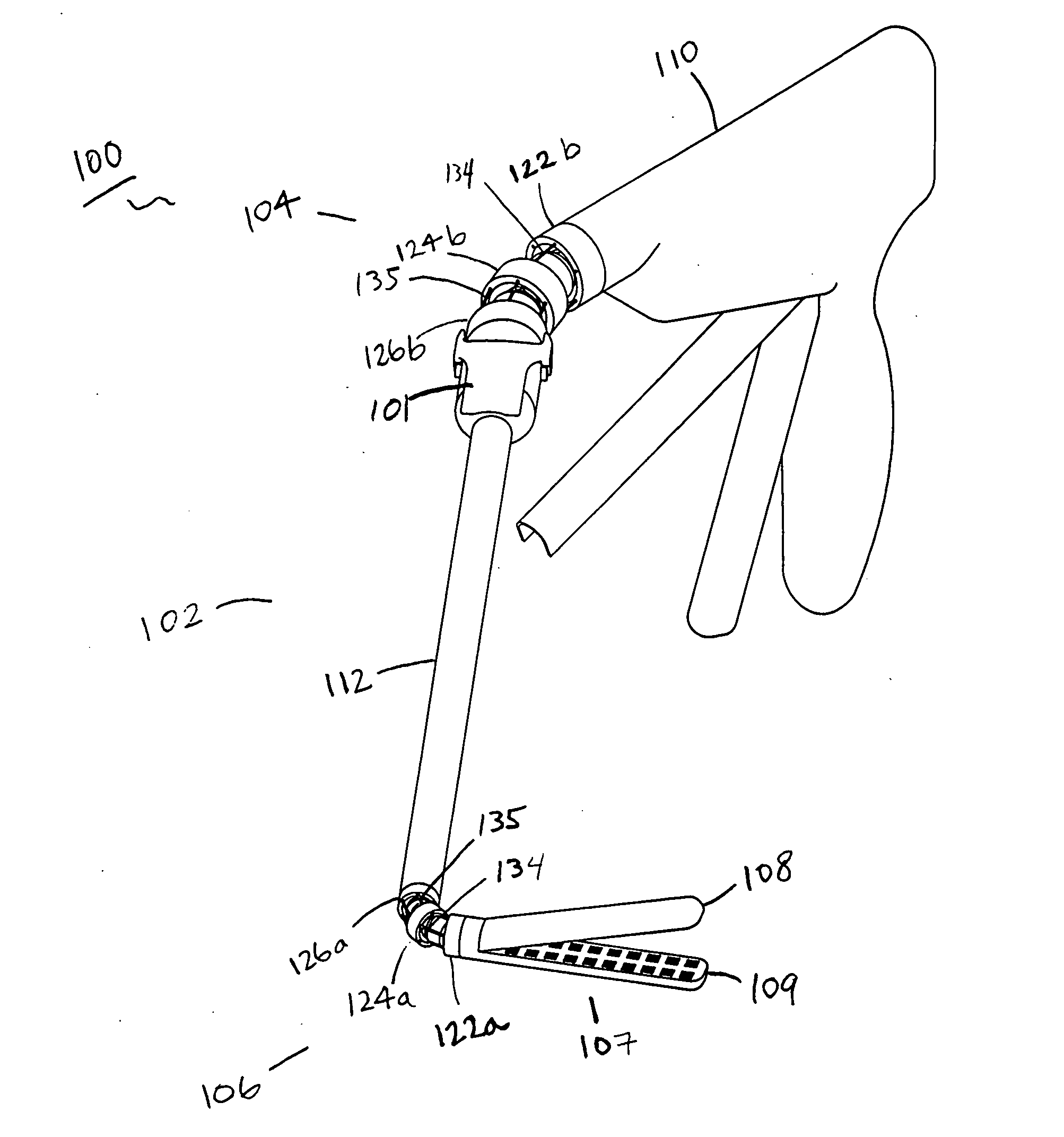

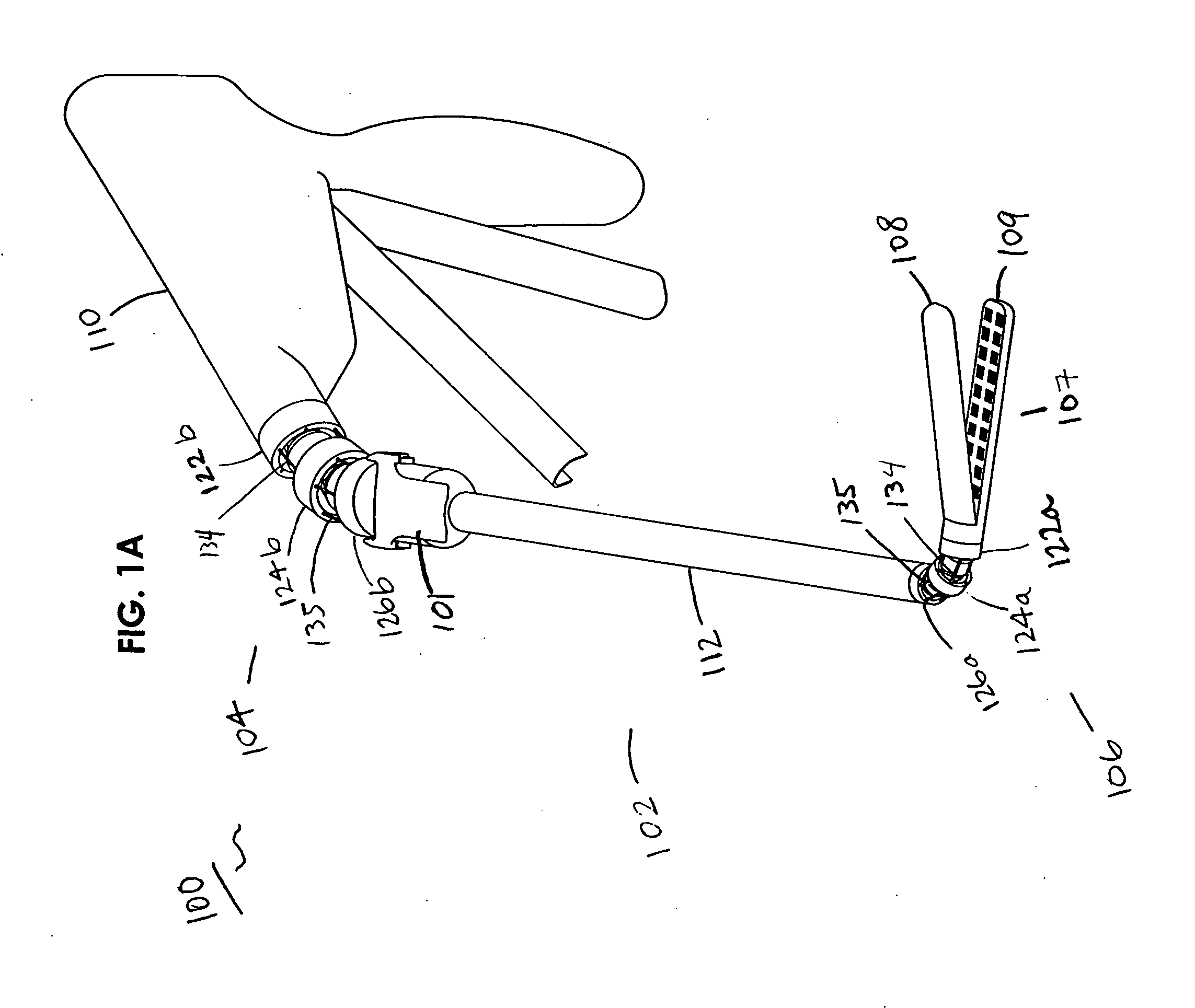

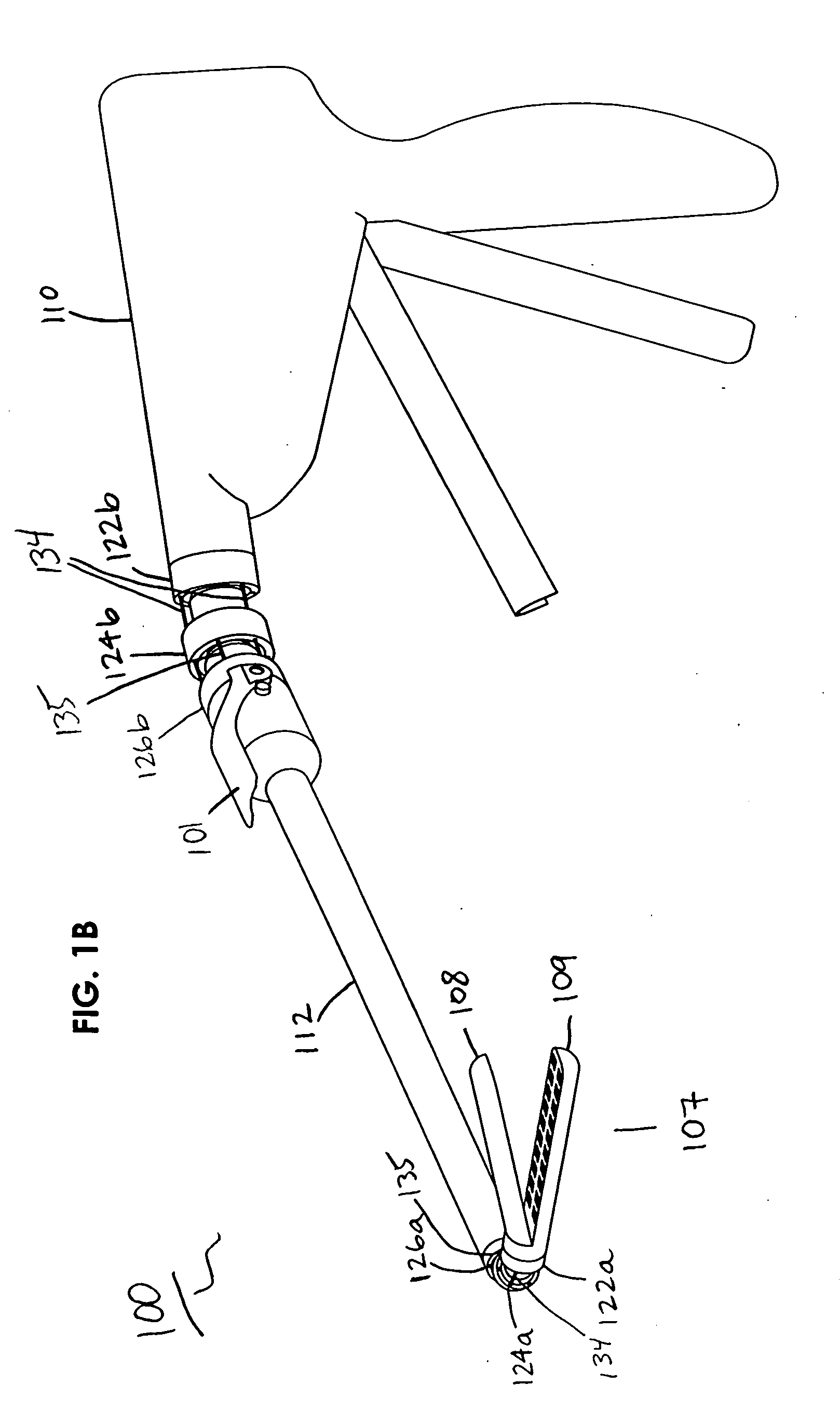

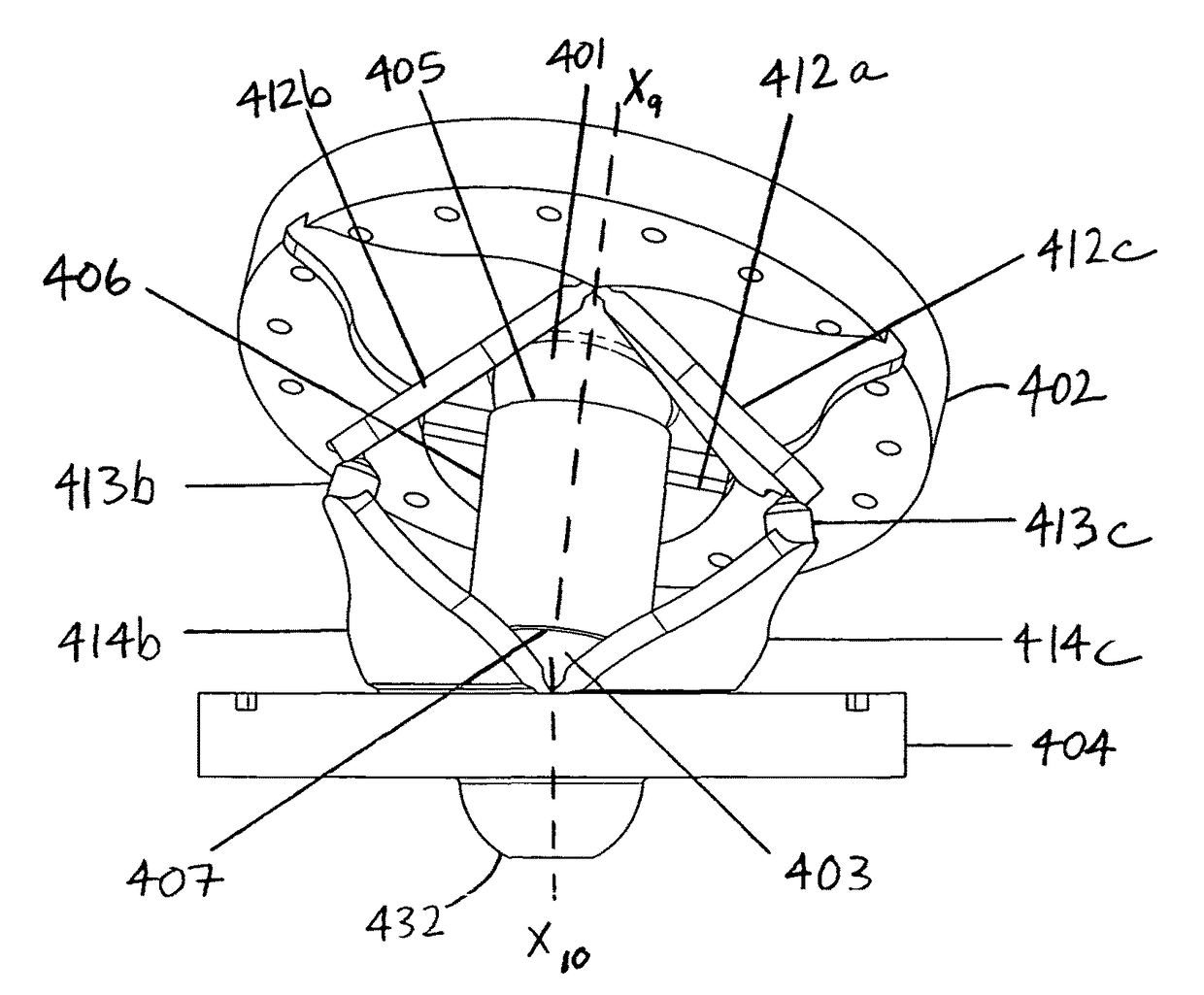

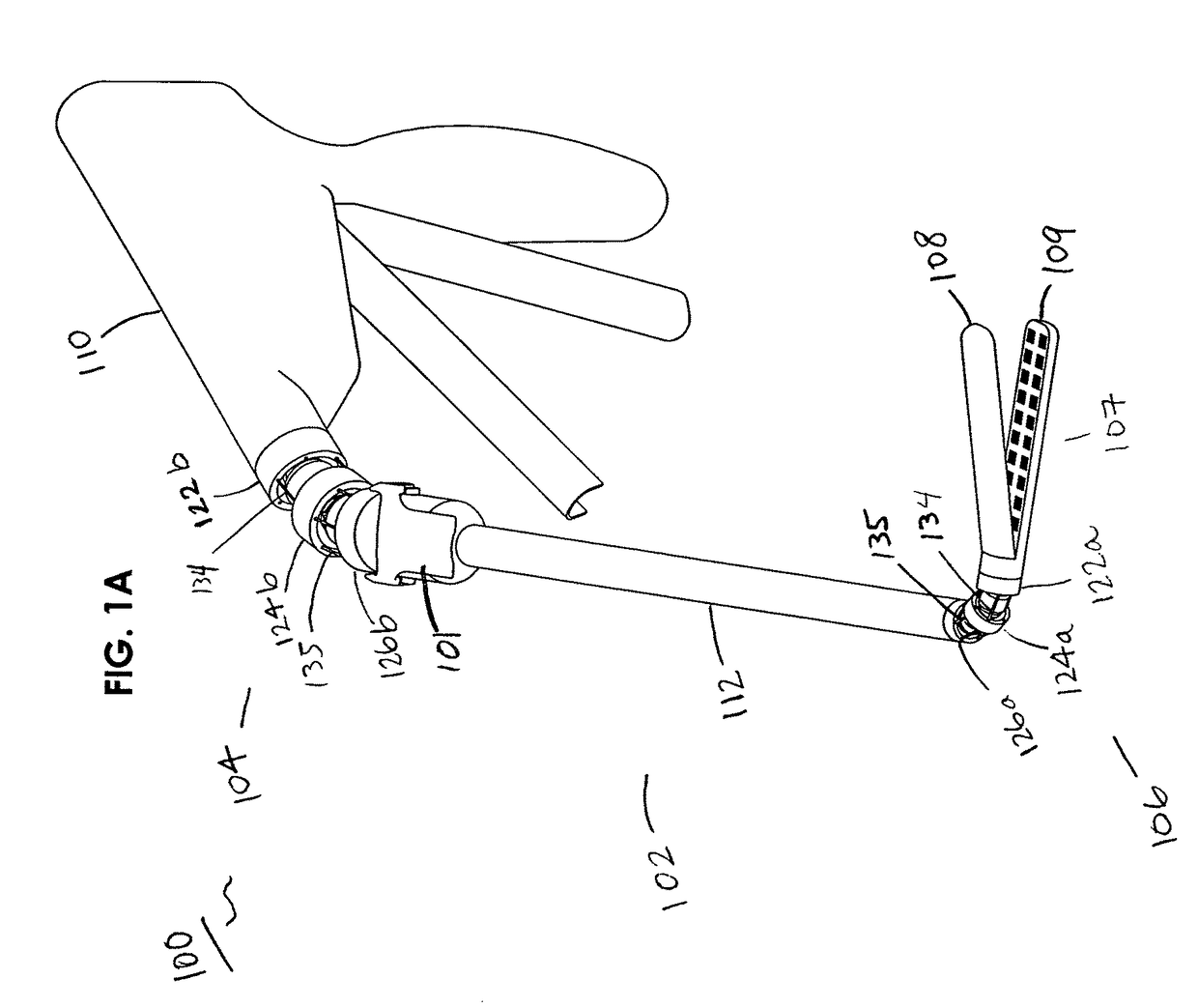

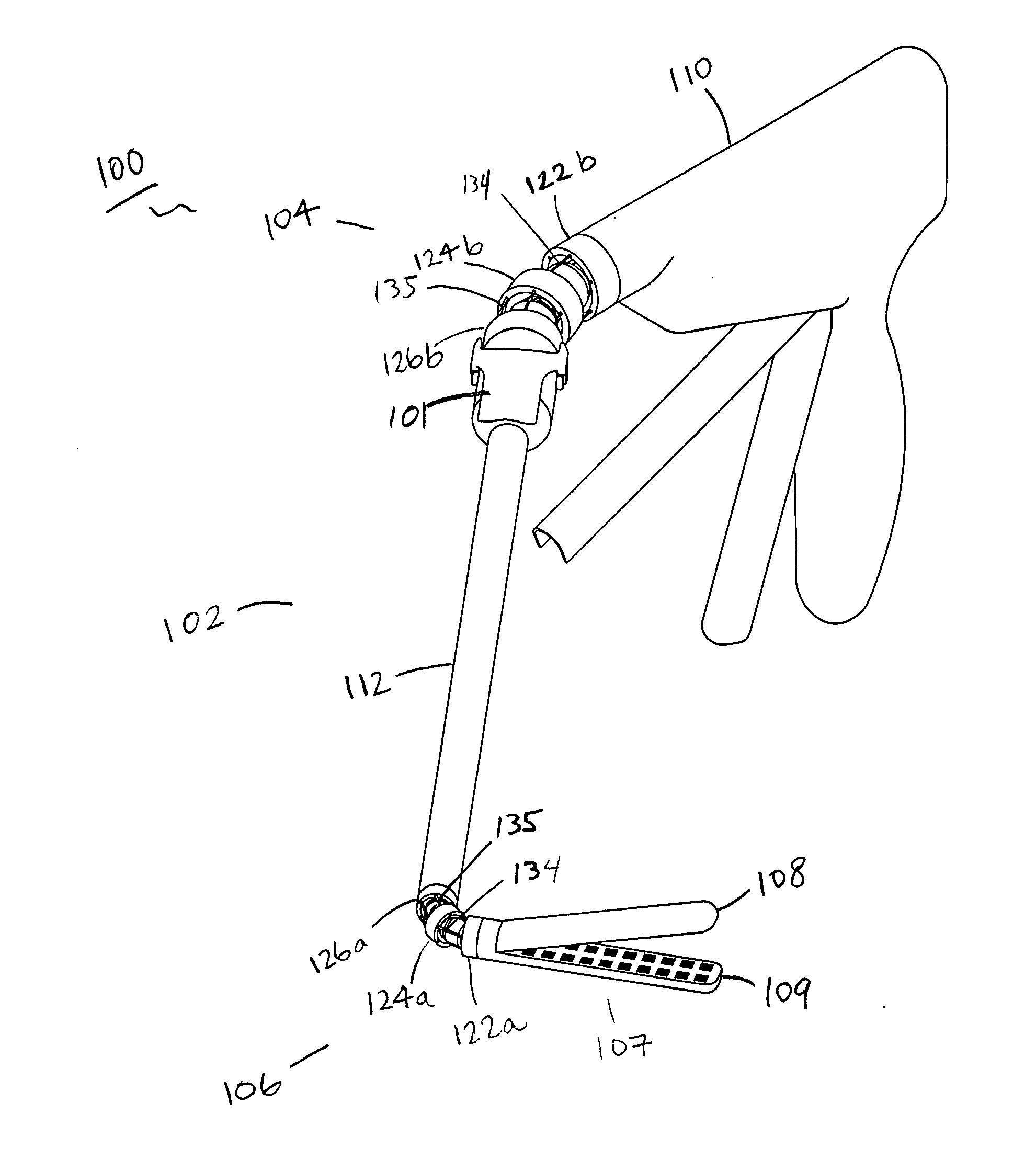

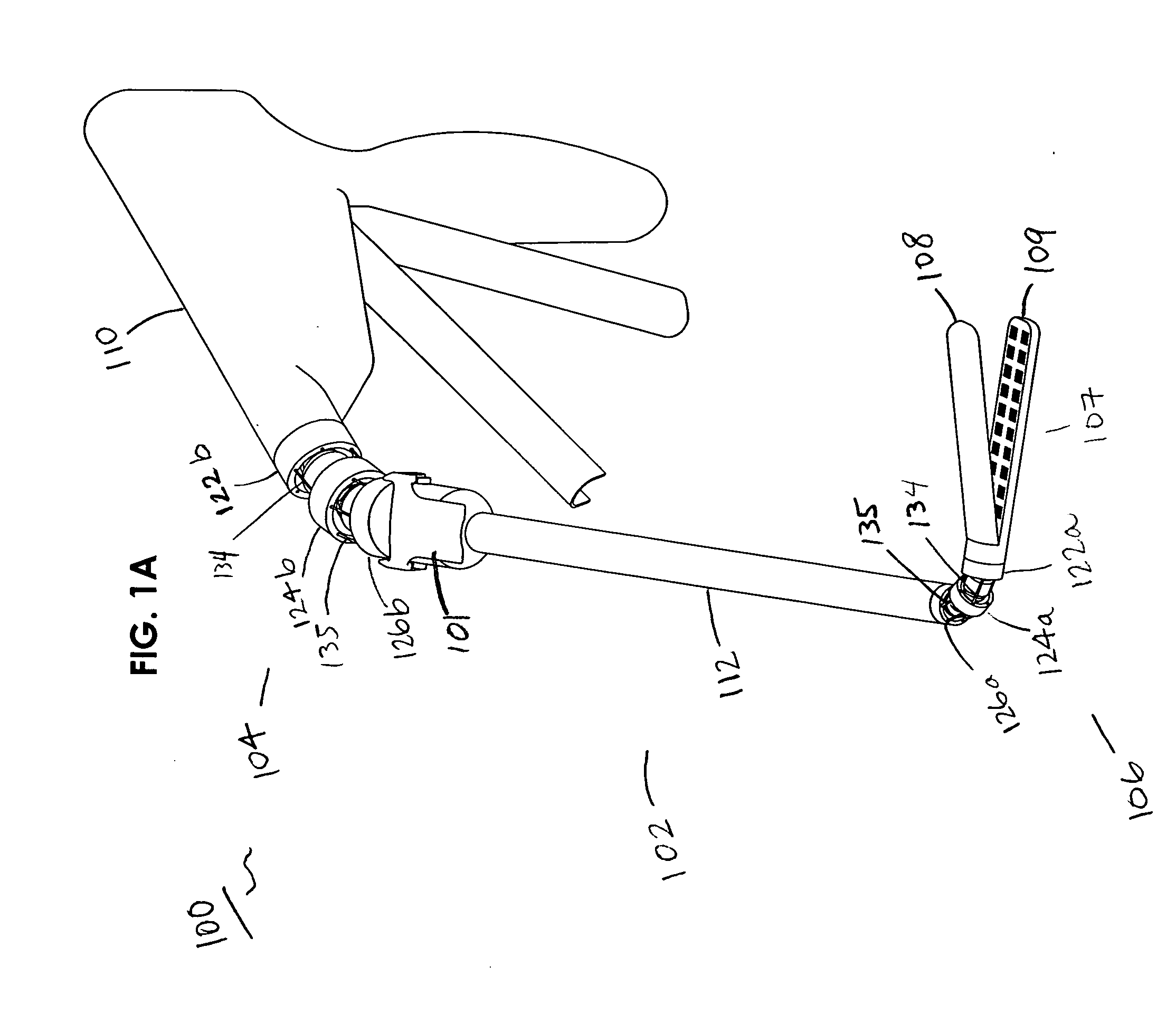

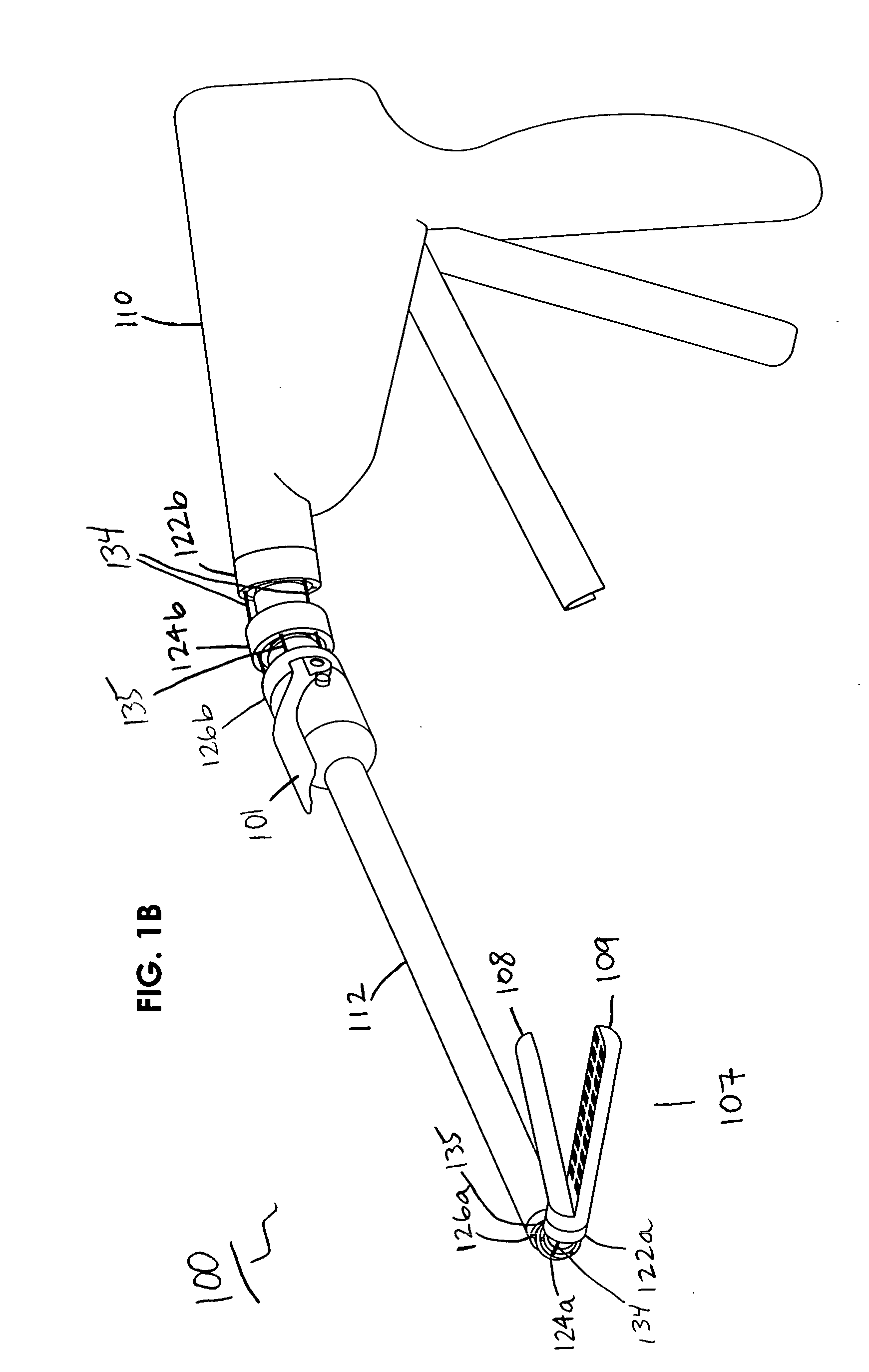

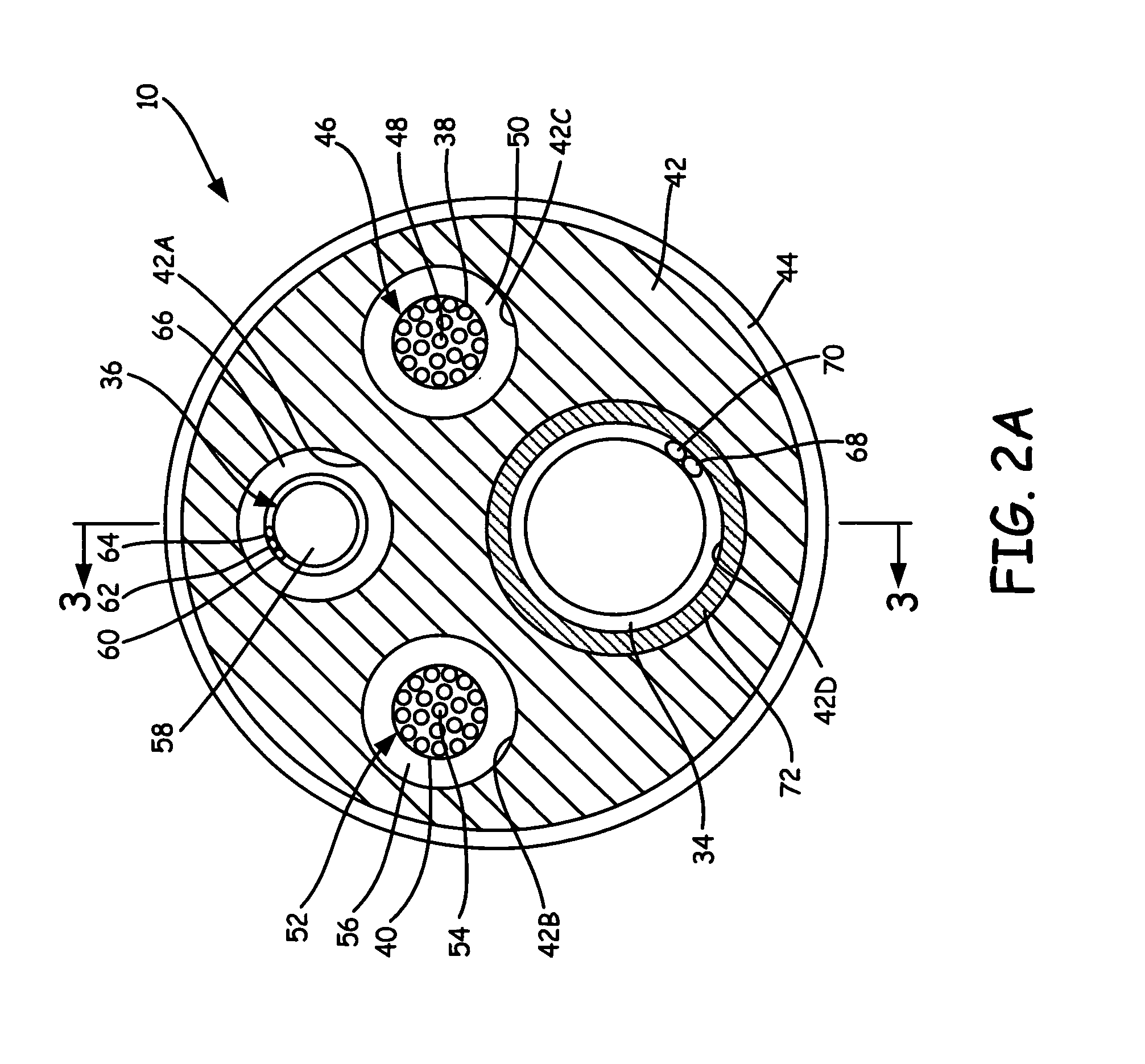

Articulating mechanisms and link systems with torque transmission in remote manipulation of instruments and tools

Articulating mechanisms, link systems, and components thereof, useful for a variety of purposes including, but not limited to, the remote manipulation of instruments such as surgical or diagnostic instruments or tools, are provided. The link systems include links wherein torque can be transferred between at least two adjacent links while allowing for pivoting motion between the links. Mechanisms for preventing undesired lateral movement of links relative to one another are also provided.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Articulating mechanisms and link systems with torque transmission in remote manipulation of instruments and tools

Articulating mechanisms, link systems, and components thereof, useful for a variety of purposes including, but not limited to, the remote manipulation of instruments such as surgical or diagnostic instruments or tools, are provided. The link systems include links wherein torque can be transferred between at least two adjacent links while allowing for pivoting motion between the links. Mechanisms for preventing undesired lateral movement of links relative to one another are also provided.

Owner:INTUITIVE SURGICAL OPERATIONS INC

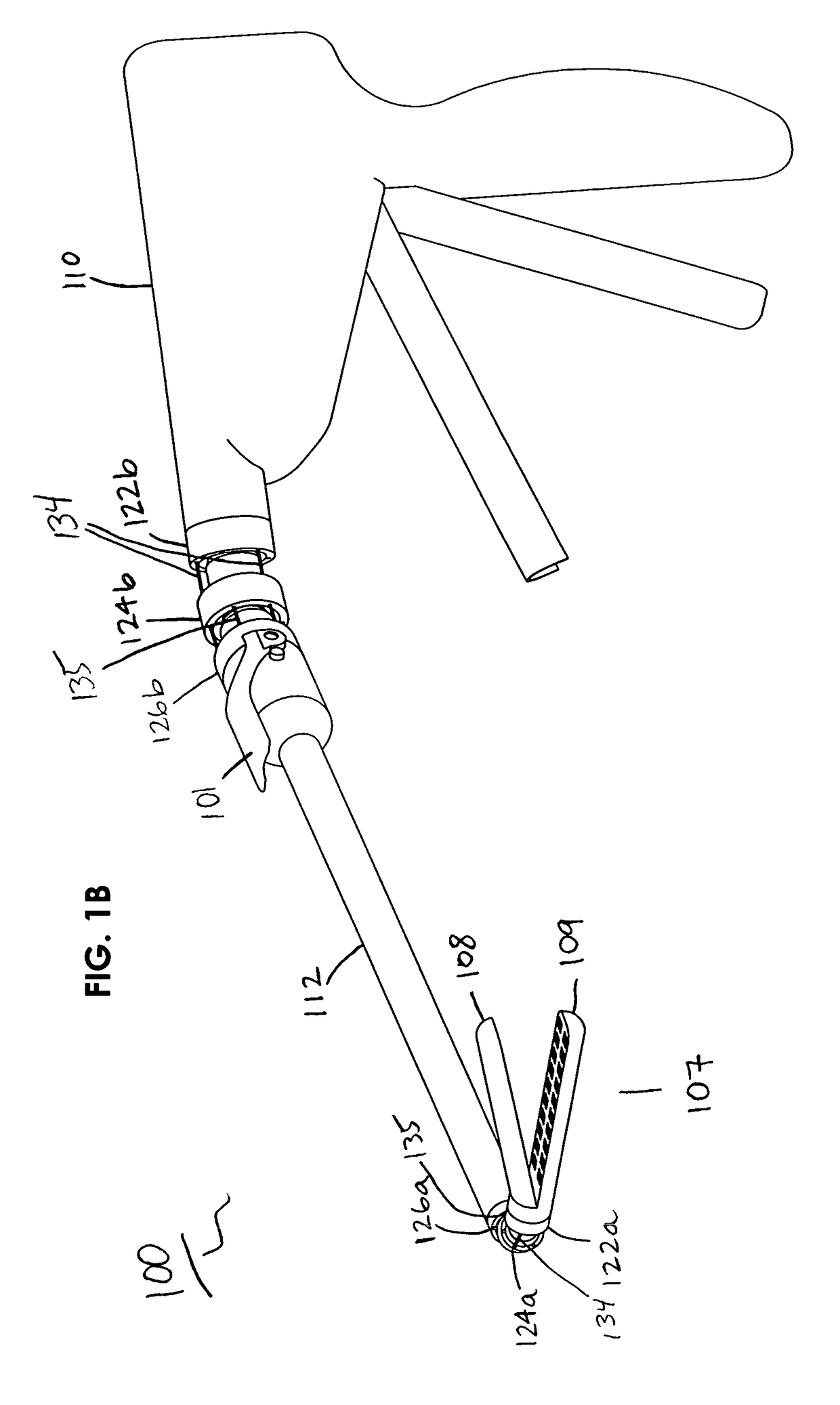

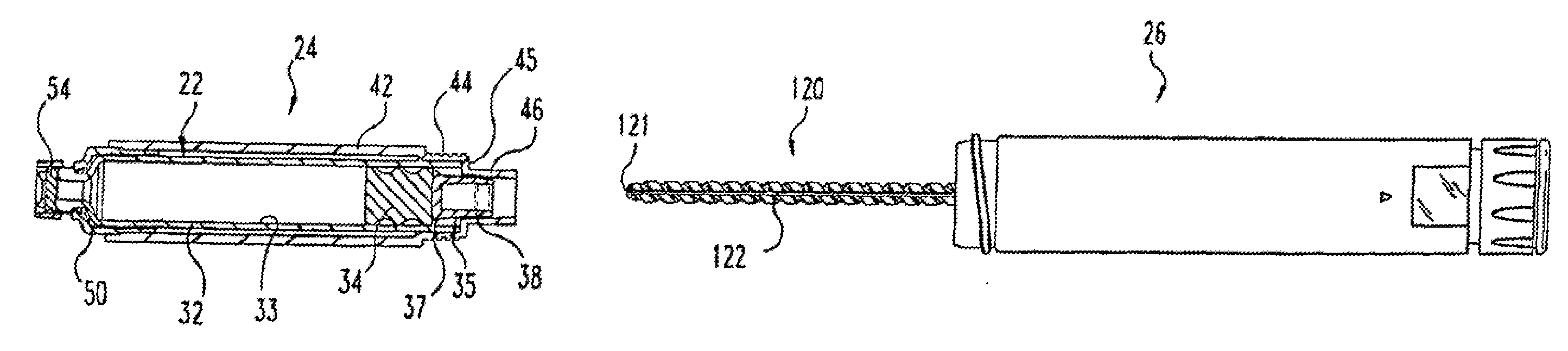

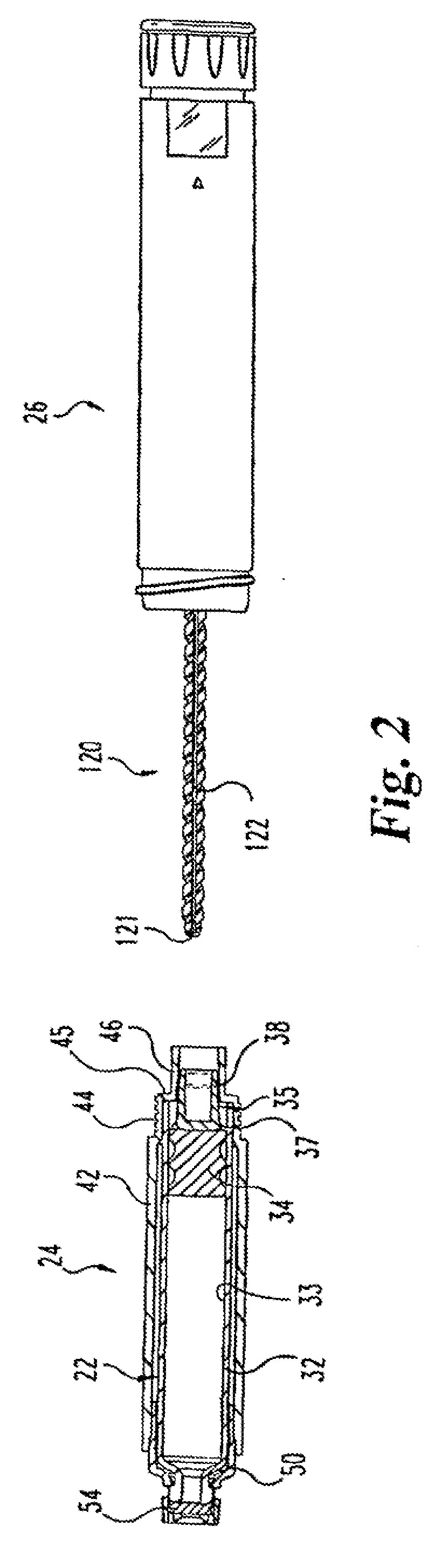

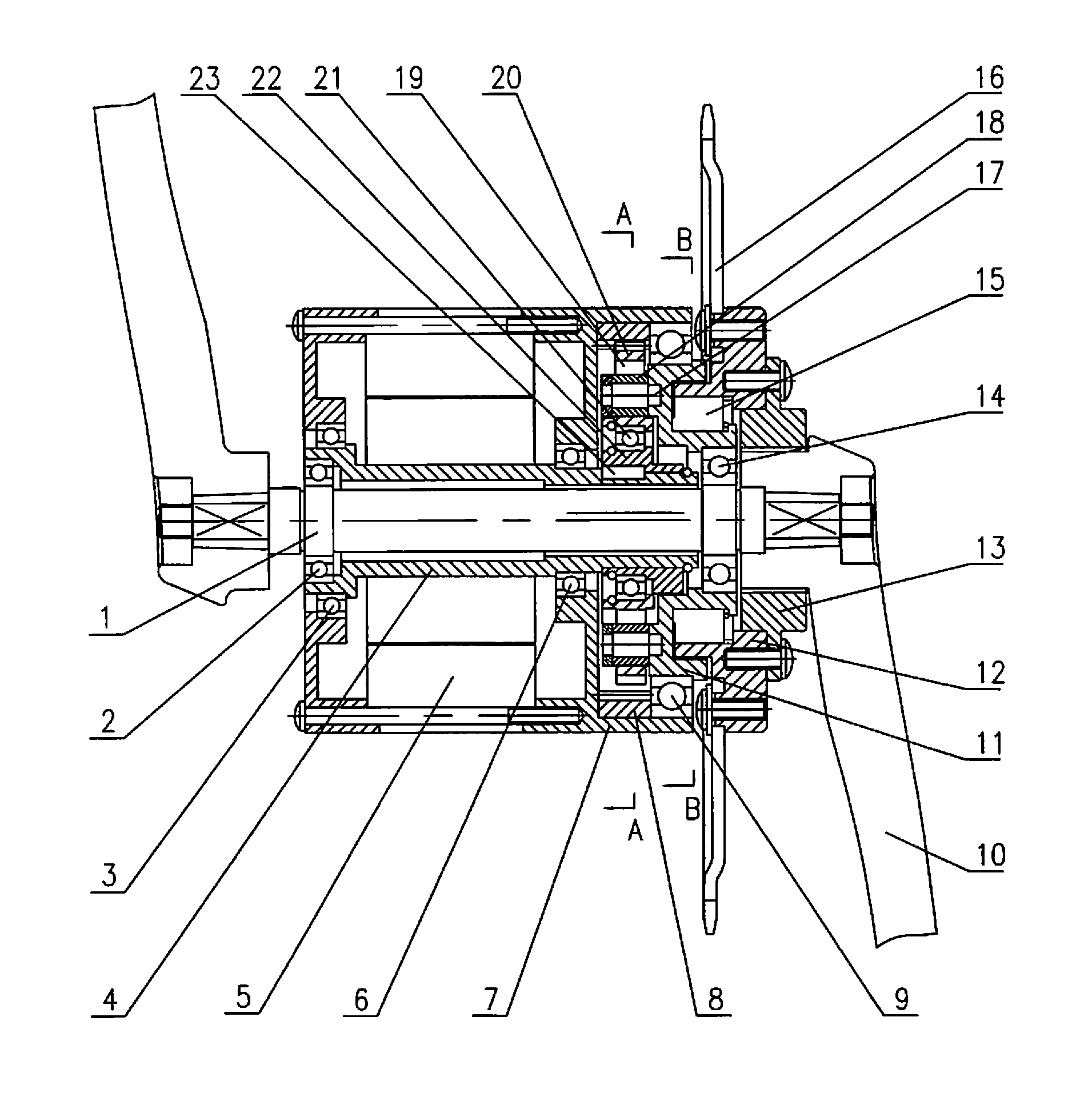

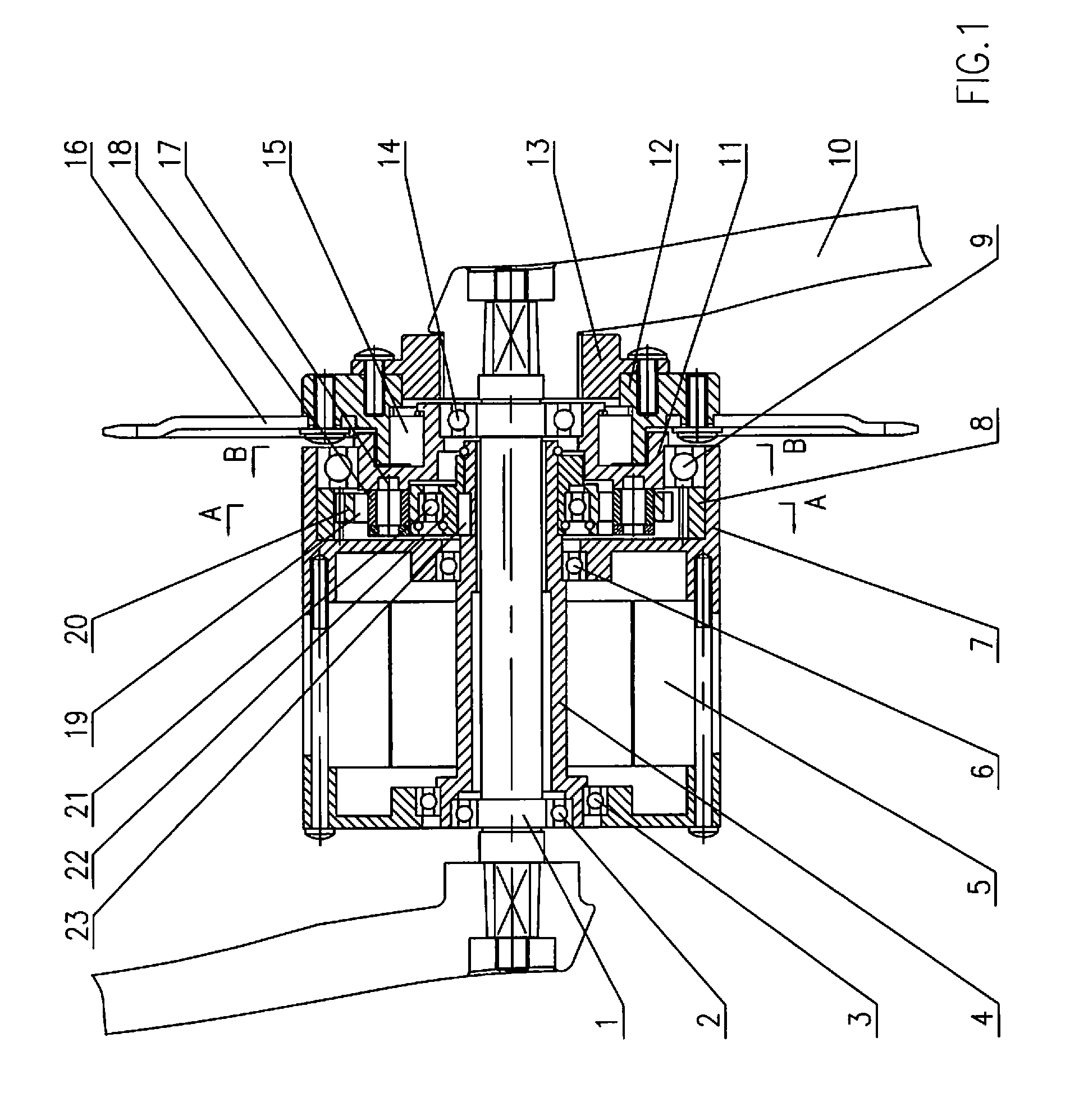

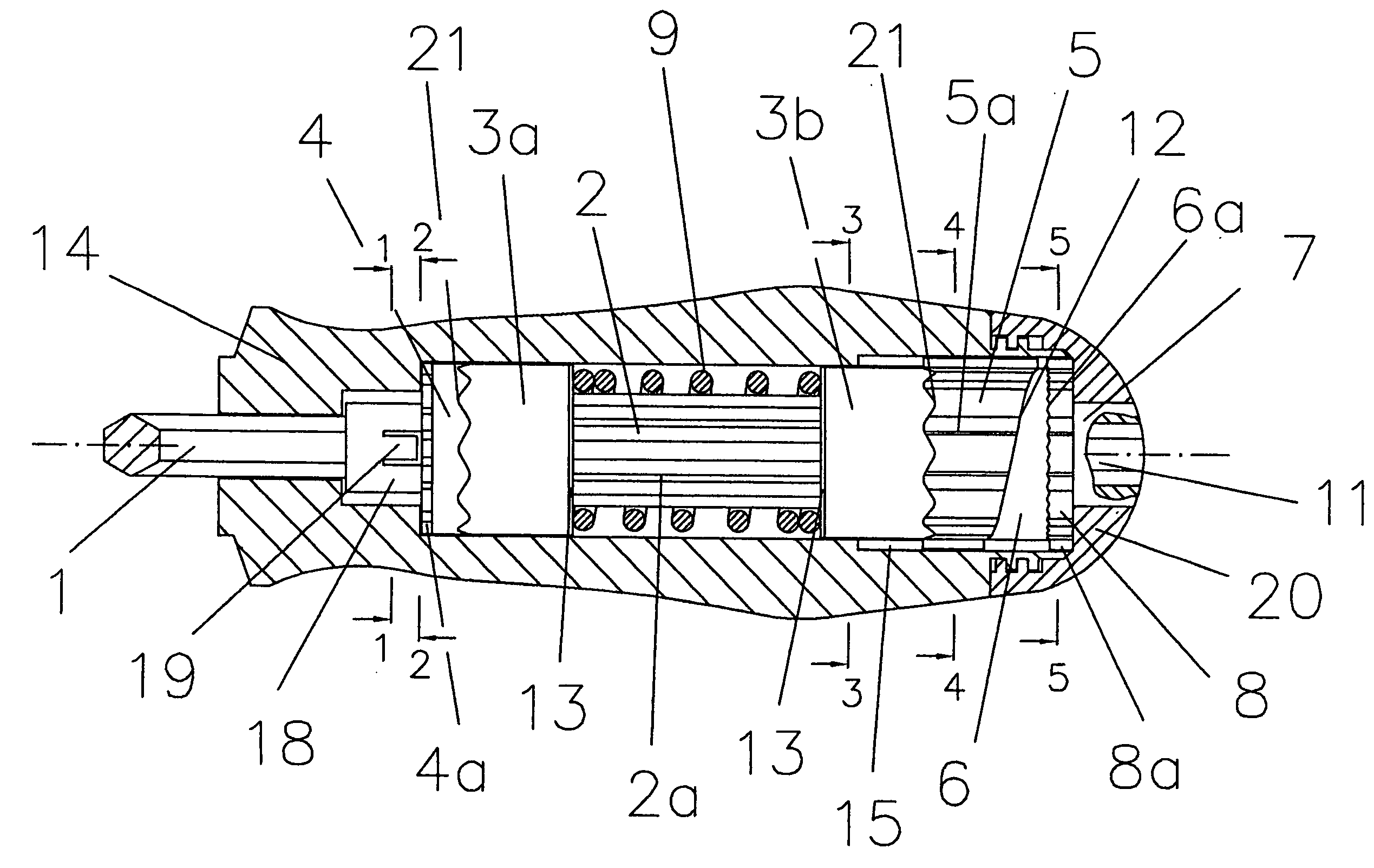

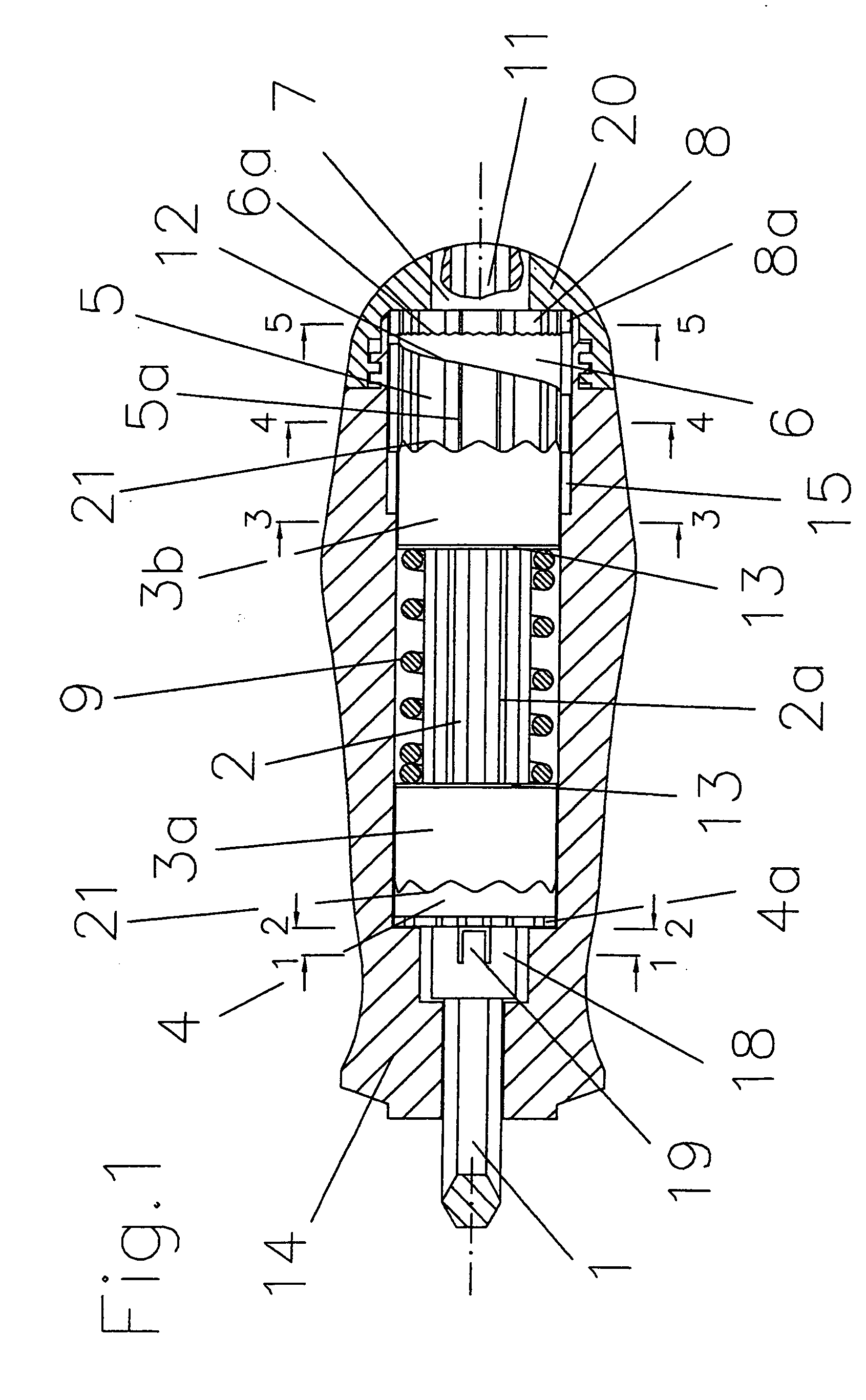

Medication injector apparatus with drive assembly that facilitates reset

A medication injector apparatus such as an injection pen. The injection pen includes a resettable, cartridge plunger drive assembly including an axially floating nut, a cartridge plunger engaging screw, and a drive clutch movable with the nut and which when rotated causes the screw to screw through the nut. When a cartridge assembly is mounted to the pen base, the floating nut and drive clutch are shifted proximally such that the drive clutch is in torque transmitting engagement with a rotatable drive member of the pen, such that rotation of that drive member results in drive screw advancement through the nut in the distal direction. When the cartridge assembly is not mounted to the pen base, the floating nut and drive clutch are biased distally to disengage the drive clutch from torque transmitting engagement with the rotatable drive member and to thereby allow the drive screw to be reset proximally through the nut to a position more retracted within the pen base. The injection pen also may include an injection clicker assembly having a collar arranged coaxially on a drive sleeve and which oscillates axially on the drive sleeve that rotates during medication dispensing to provide an audible clicking sound that indicates injecting use of the pen. The injection pen also may include a doseable quantity identifier that uses a rotational matrix and a sensor for electrically sensing the arrangement of the dose setting mechanism of the pen, which identifier may be part of a therapeutic dose indicating system that utilizes a cartridge recognizer to recognize a concentration of medication so as to allow an automatic determination of a therapeutic dose. The injection pen further may include an assembly for selectively rotating a drive sleeve of the pen, which assembly has a dial that rotates out during dose setting and which translates in without rotation during dose injecting.

Owner:ELI LILLY & CO

Articulating mechanisms and link systems with torque transmission in remote manipulation of instruments and tools

Articulating mechanisms, link systems, and components thereof, useful for a variety of purposes including, but not limited to, the remote manipulation of instruments such as surgical or diagnostic instruments or tools, are provided. The link systems include links wherein torque can be transferred between at least two adjacent links while allowing for pivoting motion between the links. Mechanisms for preventing undesired lateral movement of links relative to one another are also provided.

Owner:INTUITIVE SURGICAL OPERATIONS INC

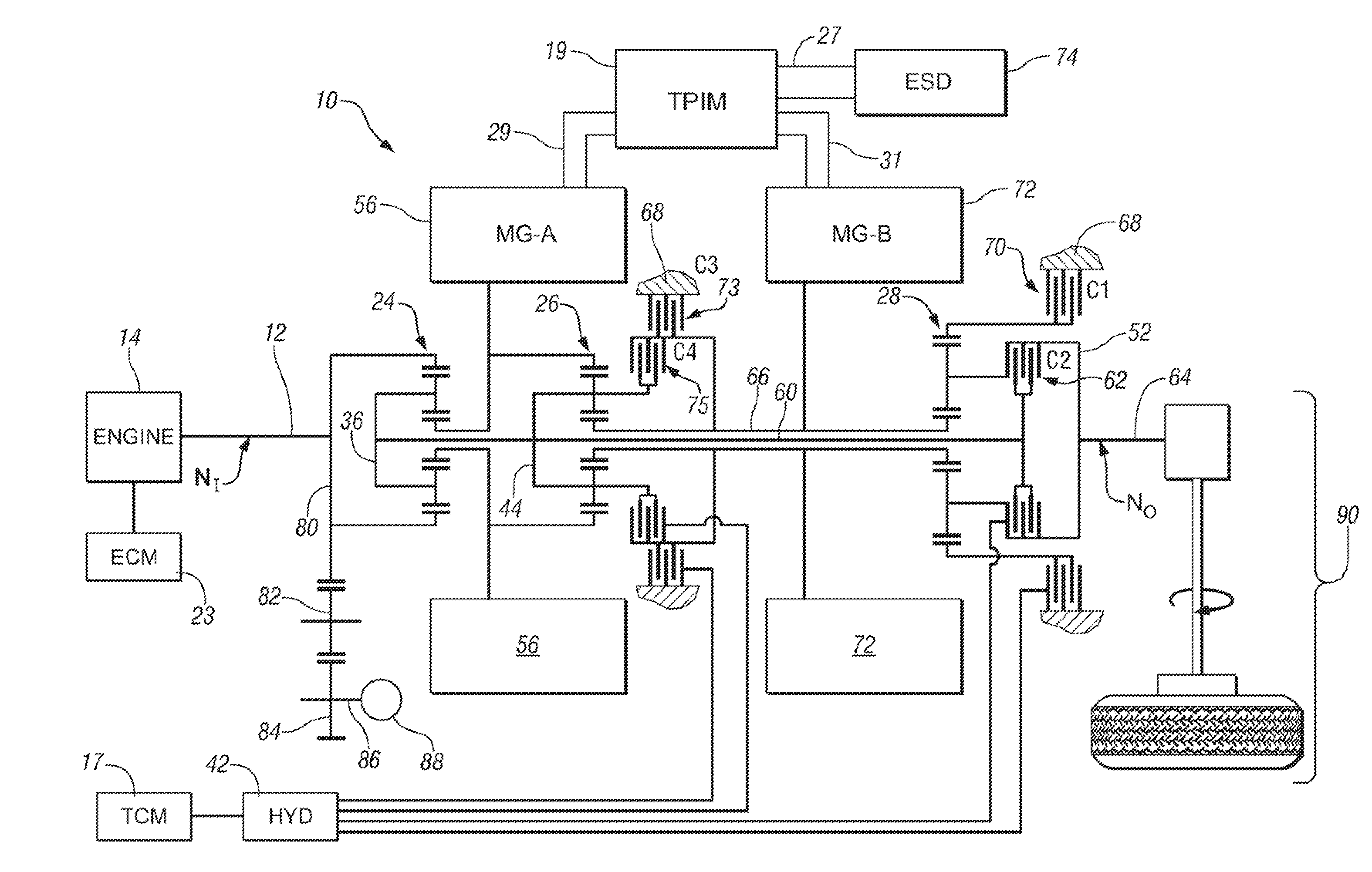

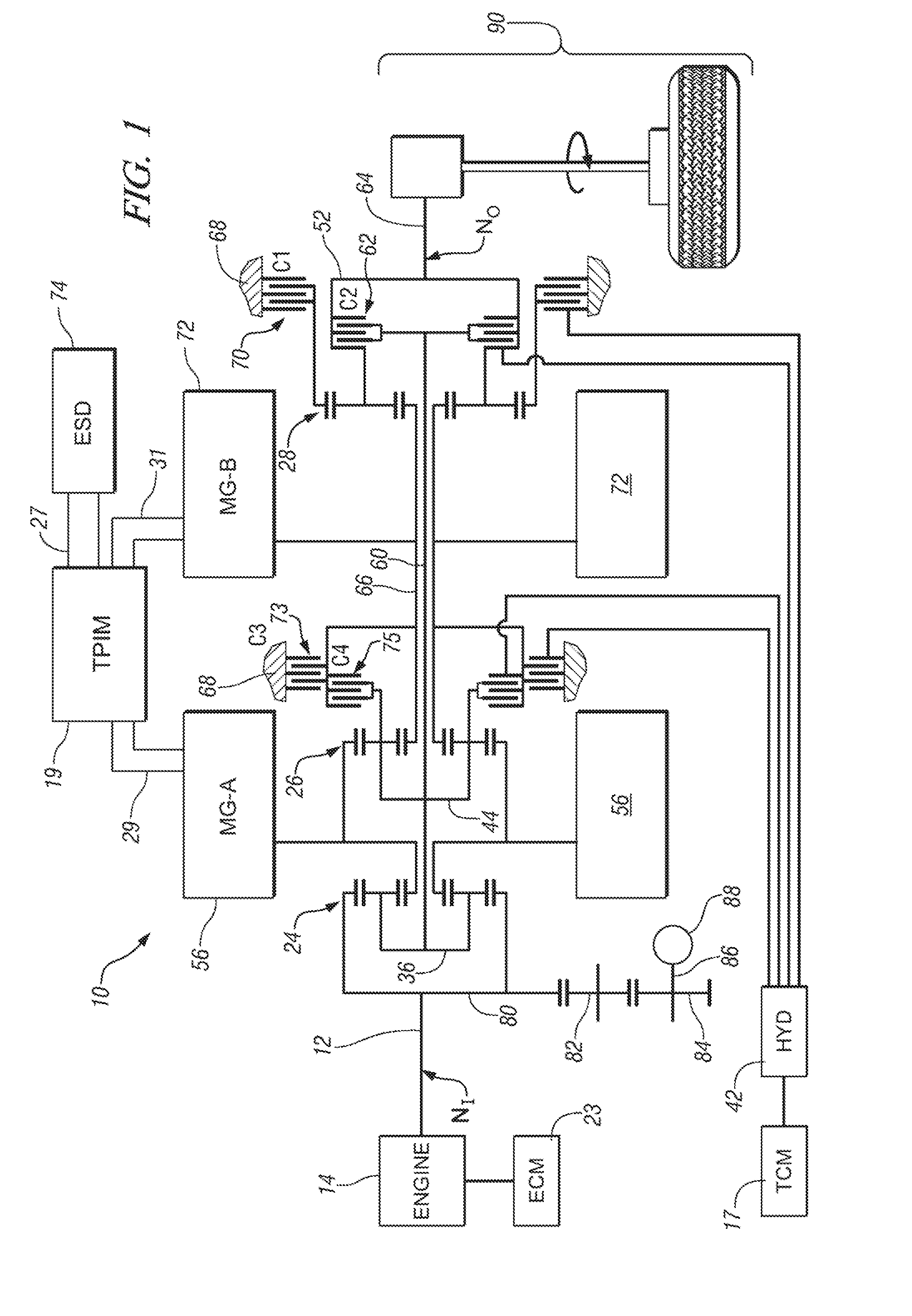

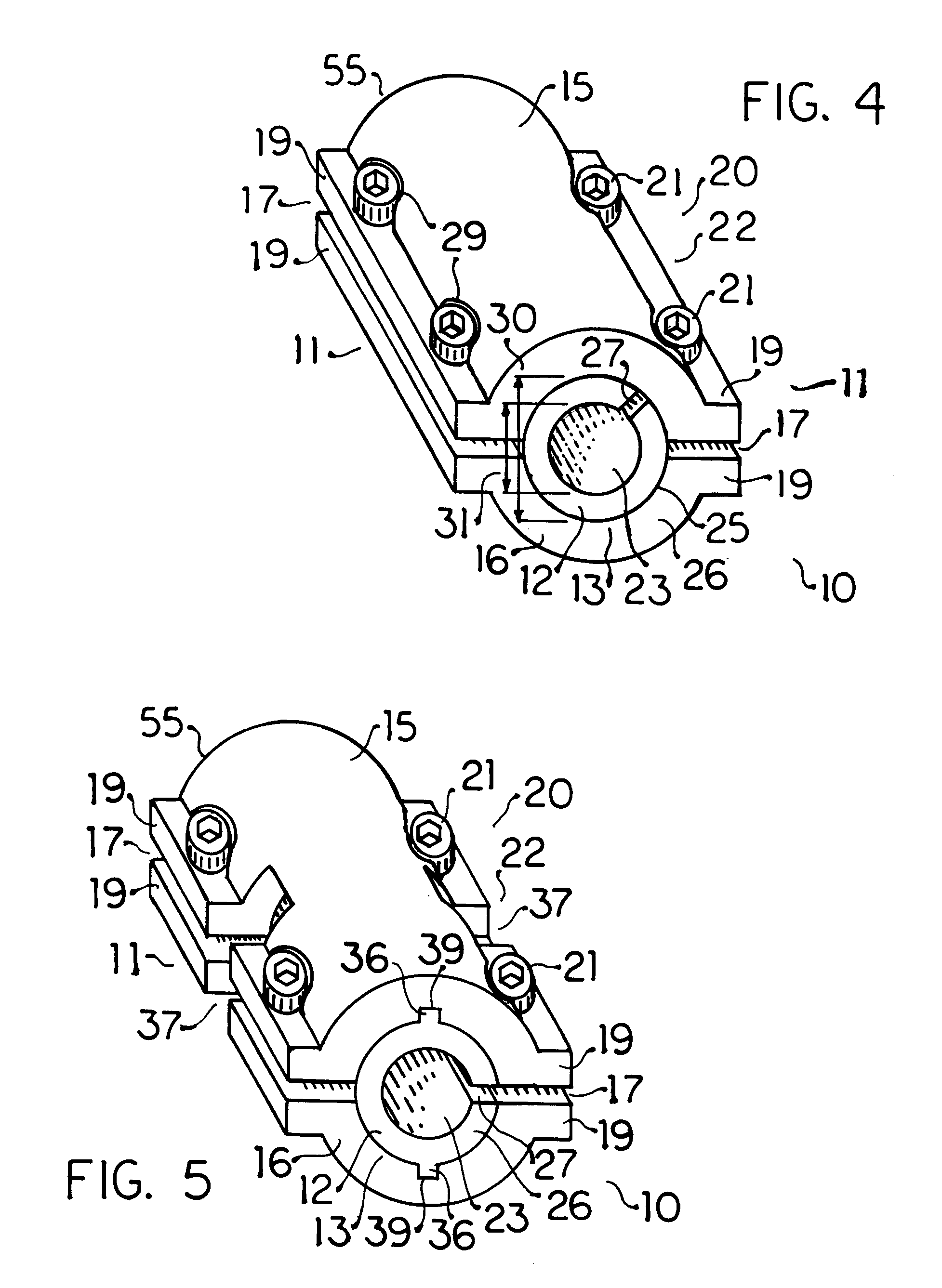

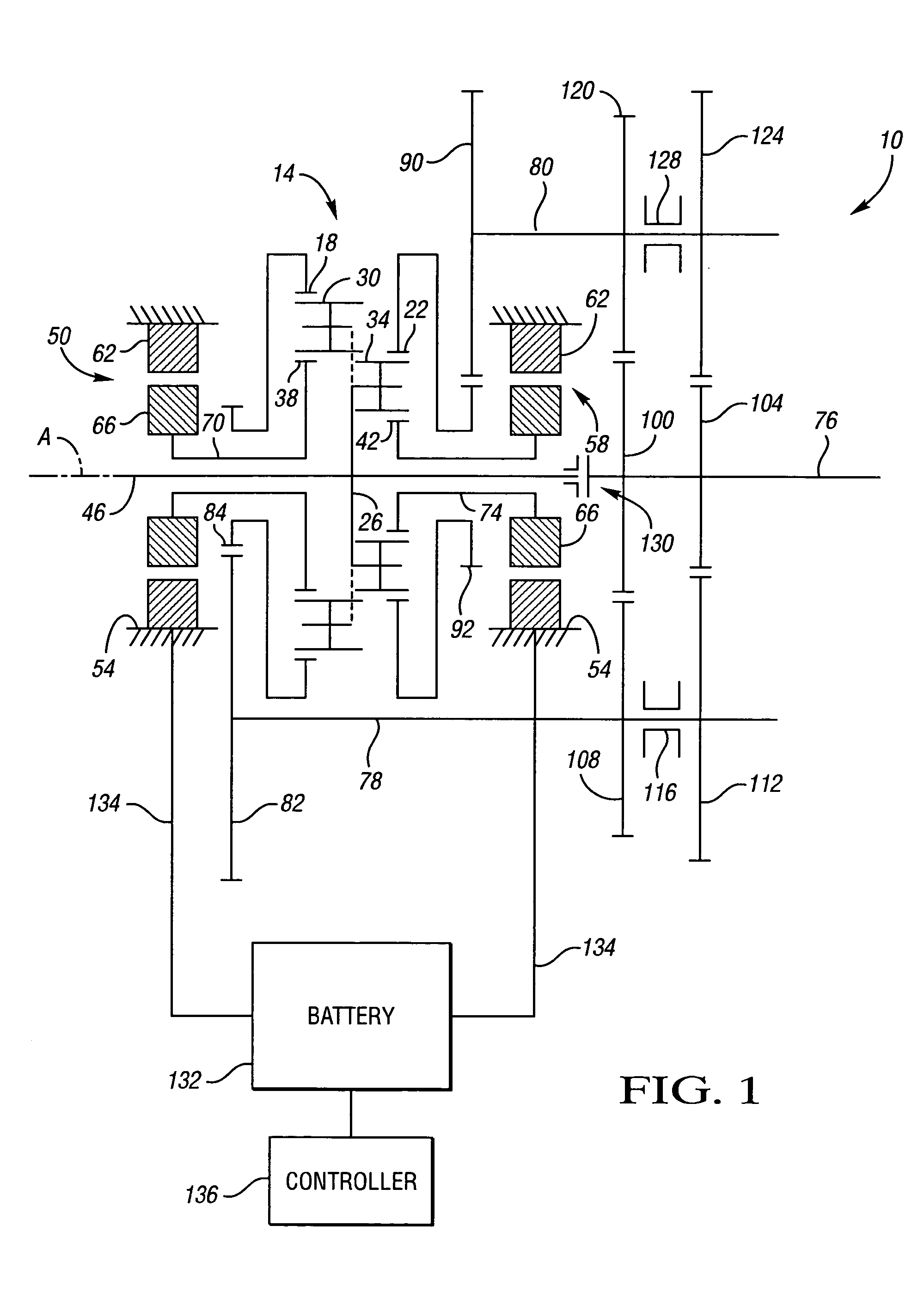

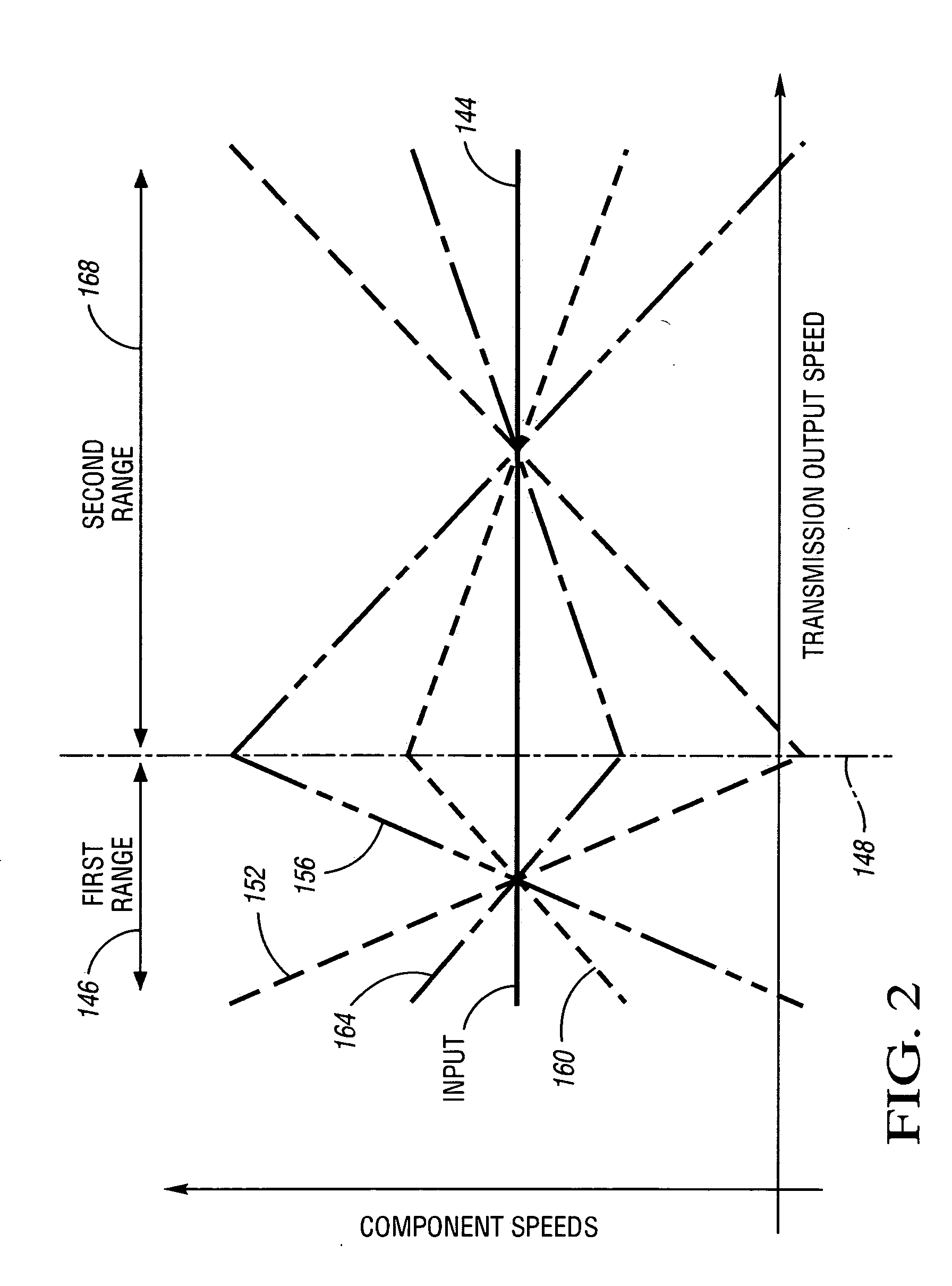

Method and apparatus for controlling an electro-mechanical transmission during a shift execution

InactiveUS20080119320A1Limit output torqueLimit in magnitude of outputElectric propulsion mountingGearing controlElectric machineClutch

A method and apparatus to control an electro-mechanical transmission during a shift event, including identifying a fault in an off-going clutch, is provided. The method includes deactivating an off-going torque-transfer clutch, monitoring slippage of the off-going torque-transfer clutch, and limiting a change in operation of an electrical machine operatively connected to the transmission until the slippage of the off-going torque-transfer clutch exceeds a threshold. Limiting a change in operation of the electrical machine comprises limiting an output torque of the electrical machine, comprising limiting a time-rate change in the output torque and limiting a magnitude of the output torque. The limit of the change Is discontinued when the slippage of the off-going torque-transfer clutch exceeds the threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

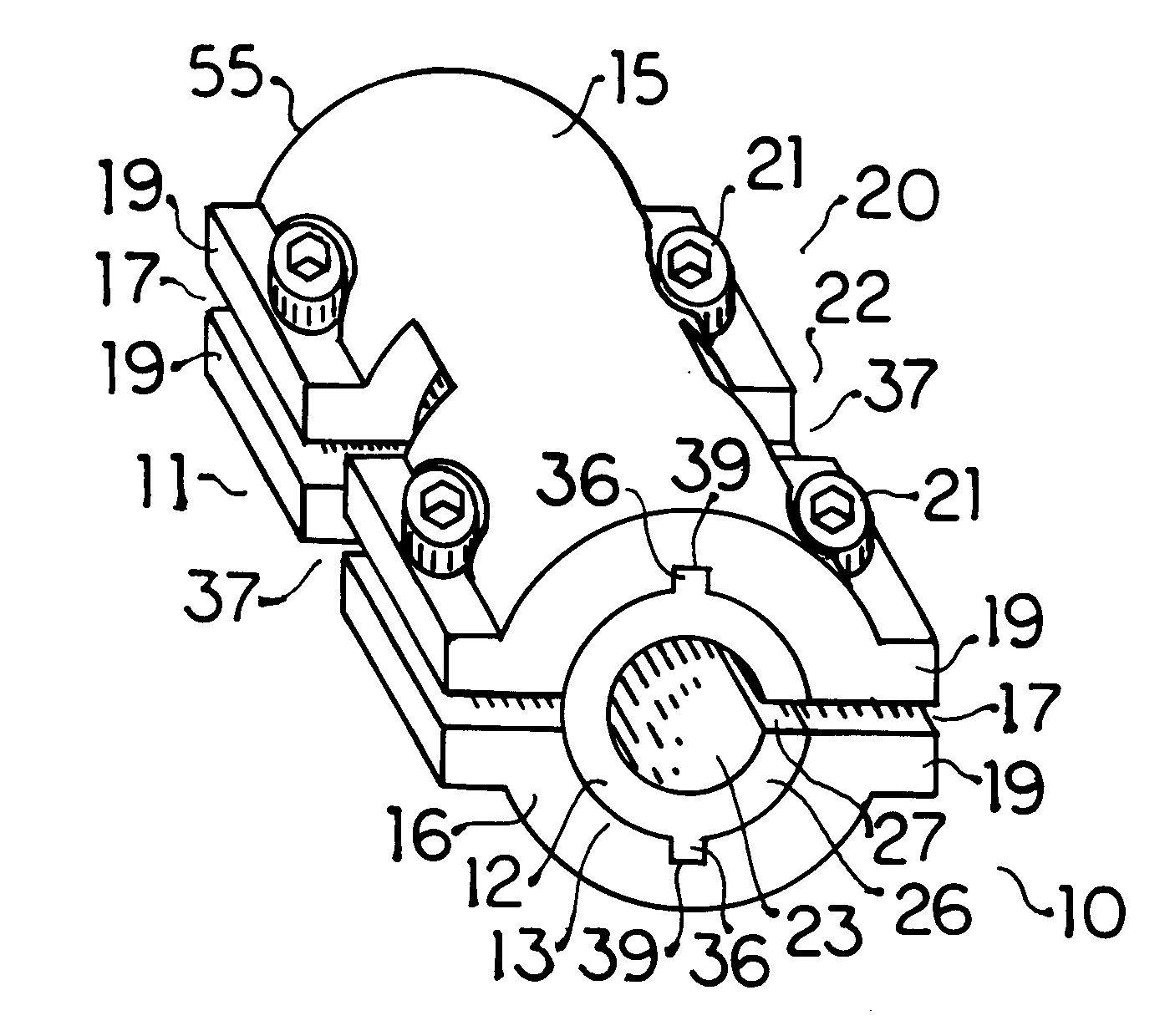

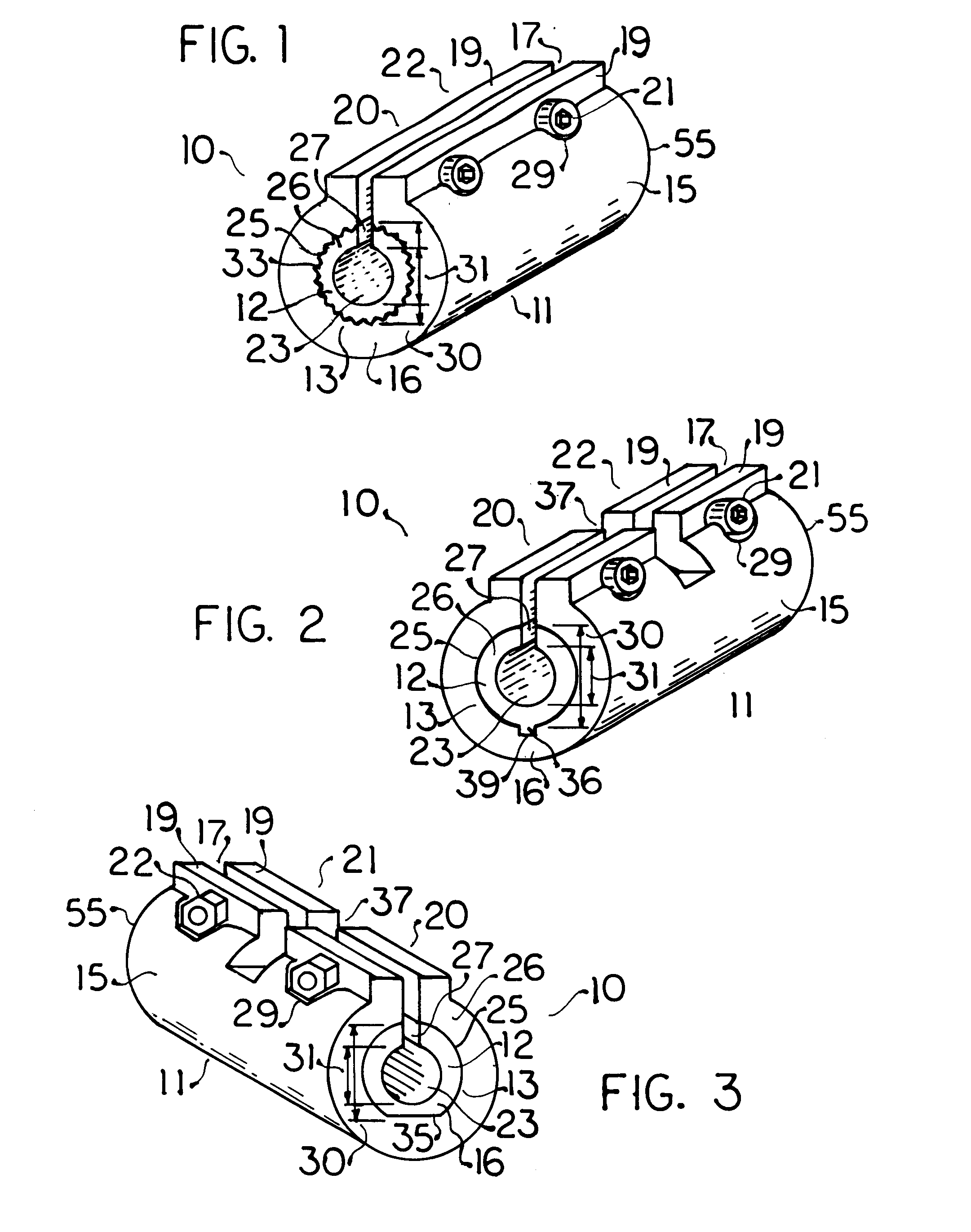

Multiple shaft diameter flexible coupling system

Compression exerted by a clamp collar integral to a molded plastic flexible shaft coupling accommodating angular shaft misalignment upon the circumferential outward surface of a radially compressible molded sleeve insert located in a shaft bore of the flexible coupling facilitates engagement of a reduced diameter shaft located within the sleeve insert. Use of a sleeve insert having a different internal diameter similarly accommodates flexible coupling to another diameter shaft. Utilization of sleeve inserts selected from a plurality of different reduced internal diameters and exterior diameters sized to fit either shaft bore enables flexible coupling of both multiple matched shaft diameters and an exponential number of differing opposed shaft diameter combinations within a range limited by the flexible coupling shaft bores. Radial compressibility of the sleeve insert is facilitated by the utilization of resilient material, interruption of the circumferential extension by a longitudinal slot, or both. Utilization of congruent longitudinally uniform, radially non-uniform, flexible coupling shaft bore and insert sleeve outward surfaces provides additional torque transmission capacity.

Owner:SHINOZUKA KINZOU

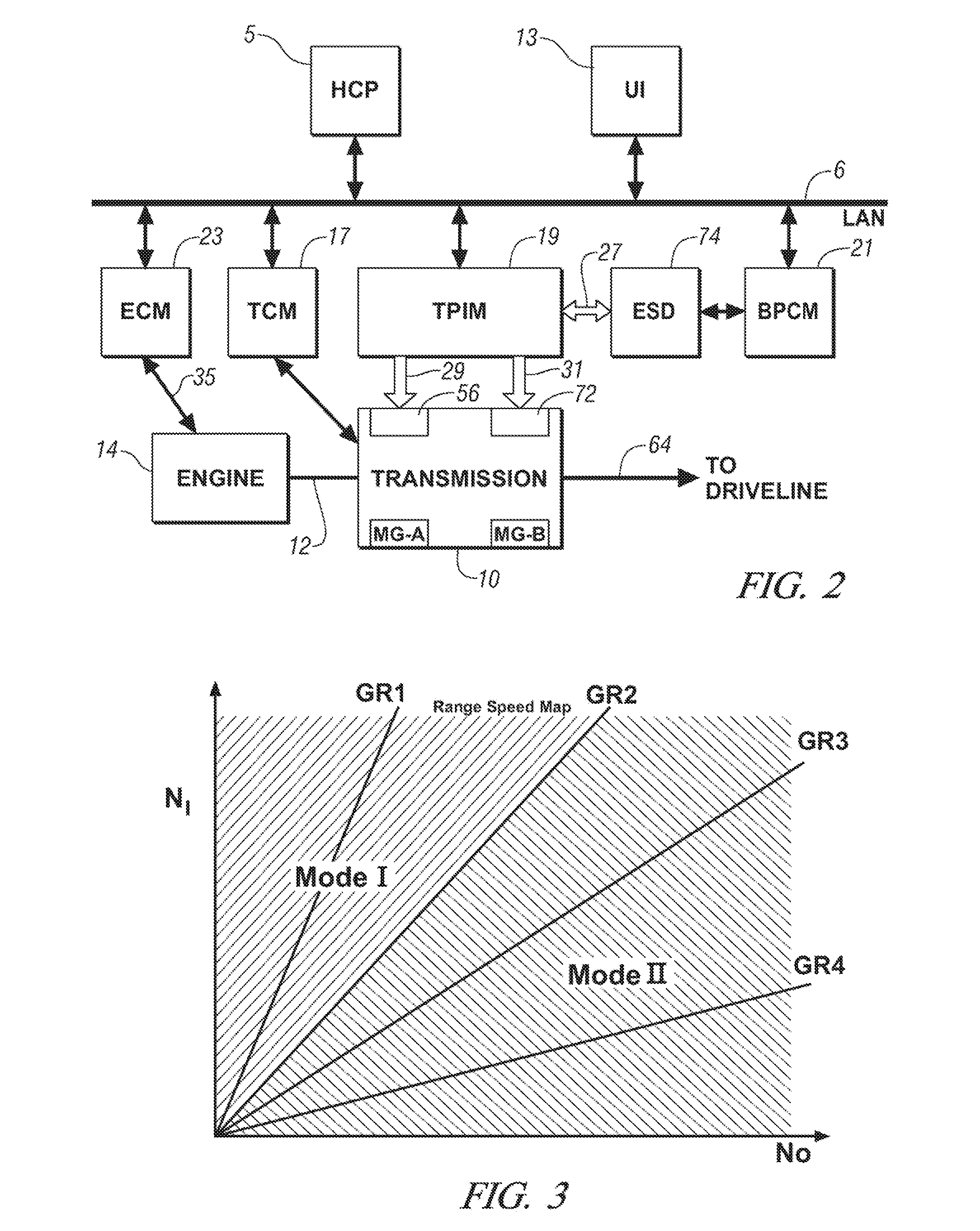

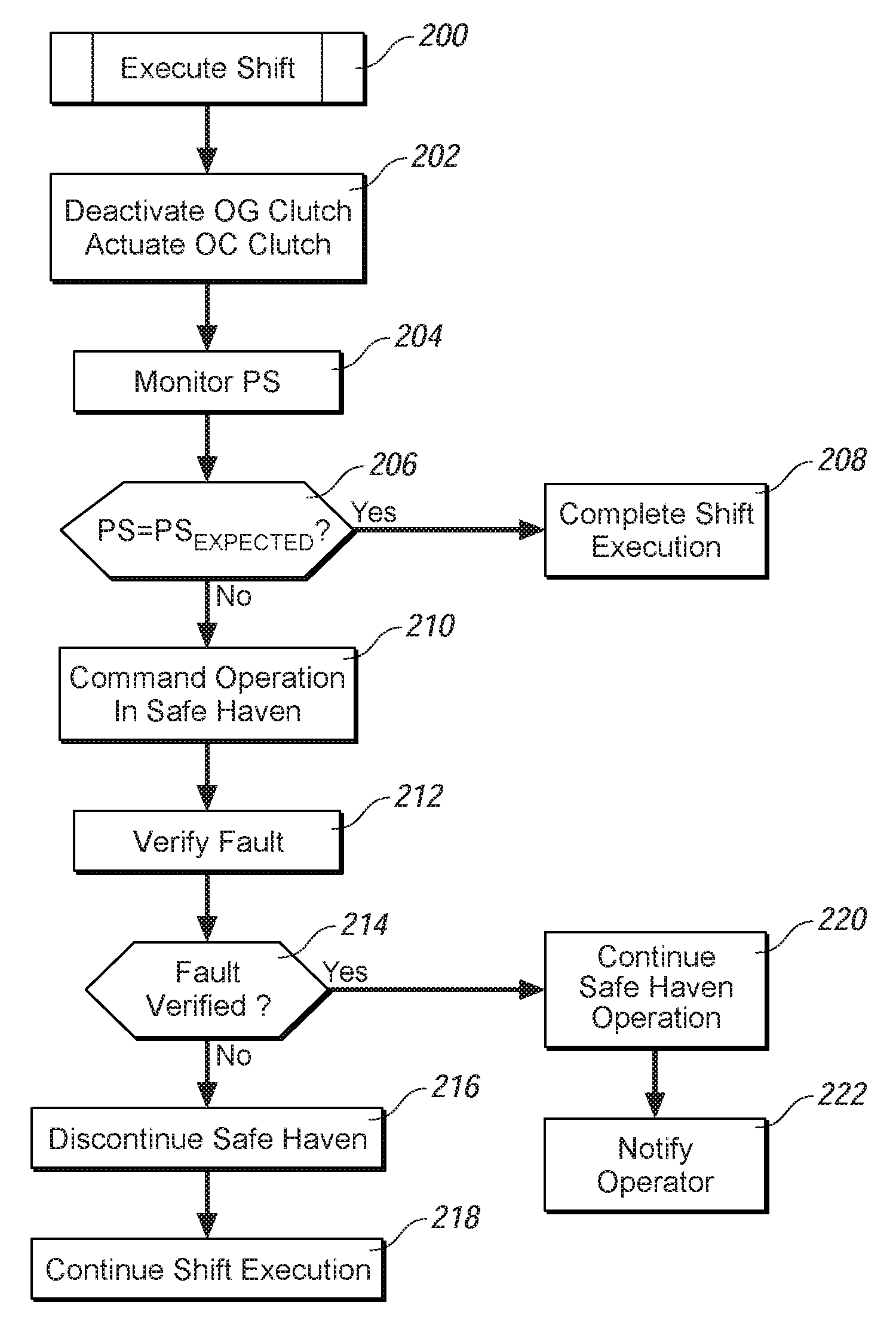

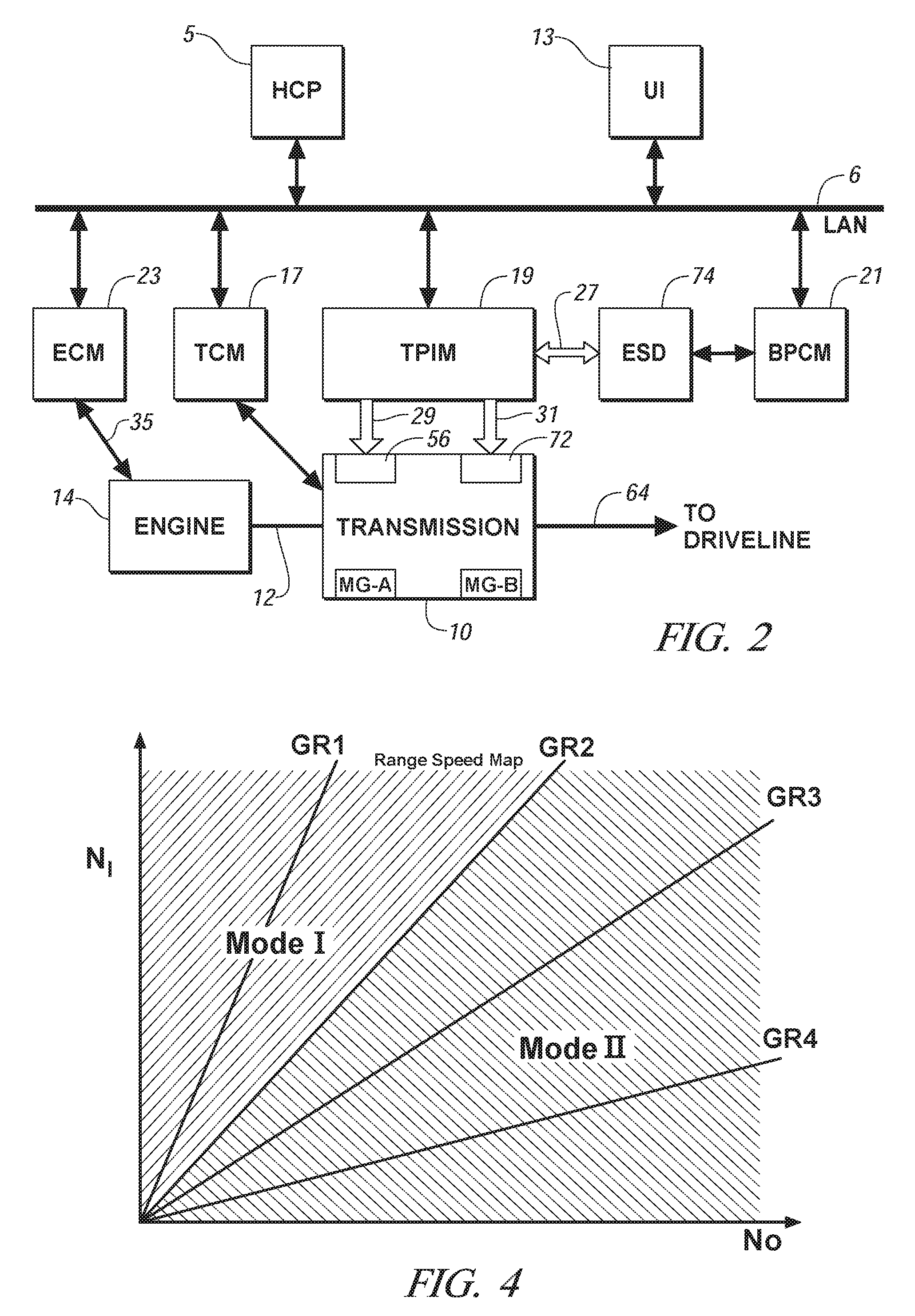

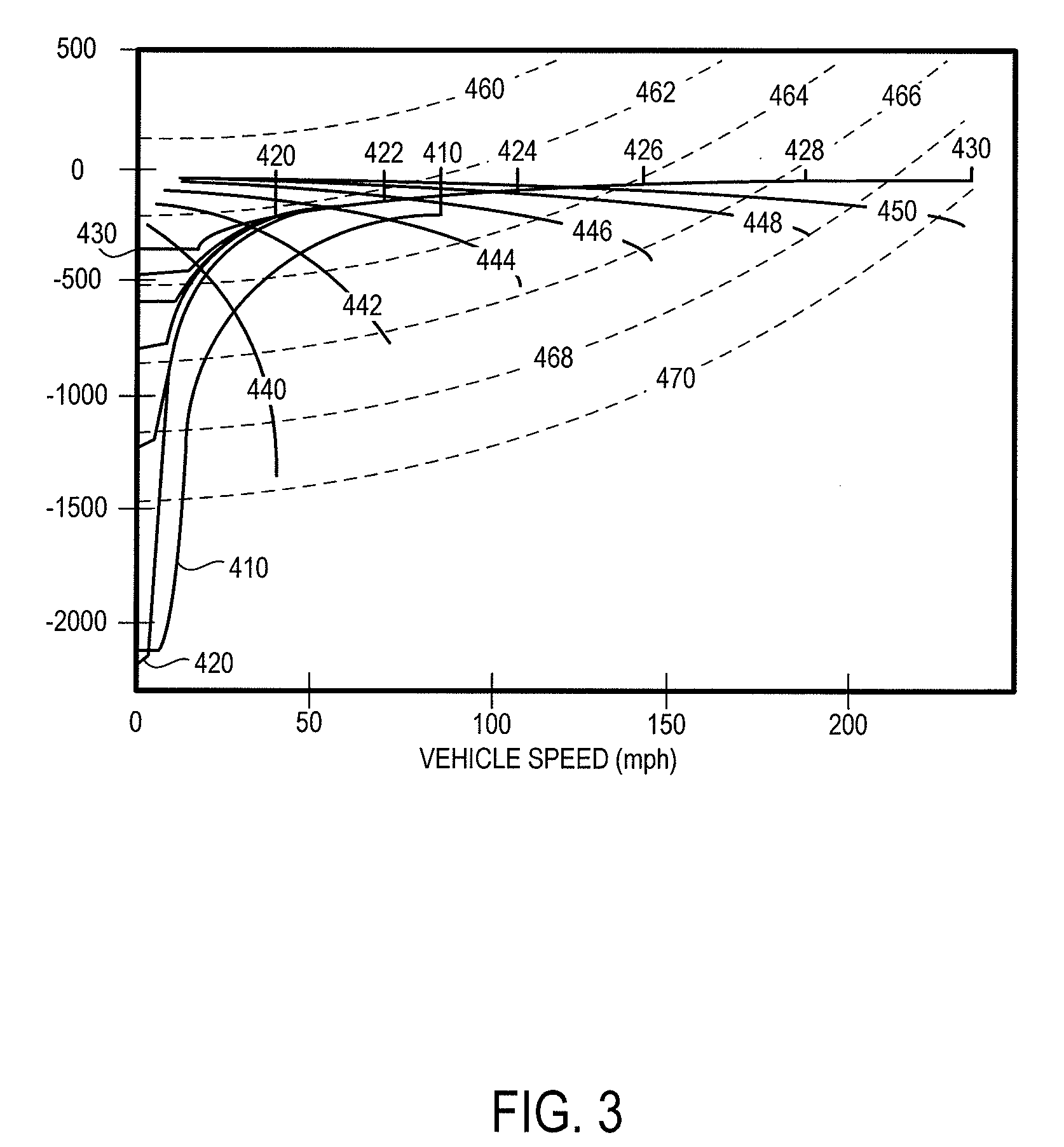

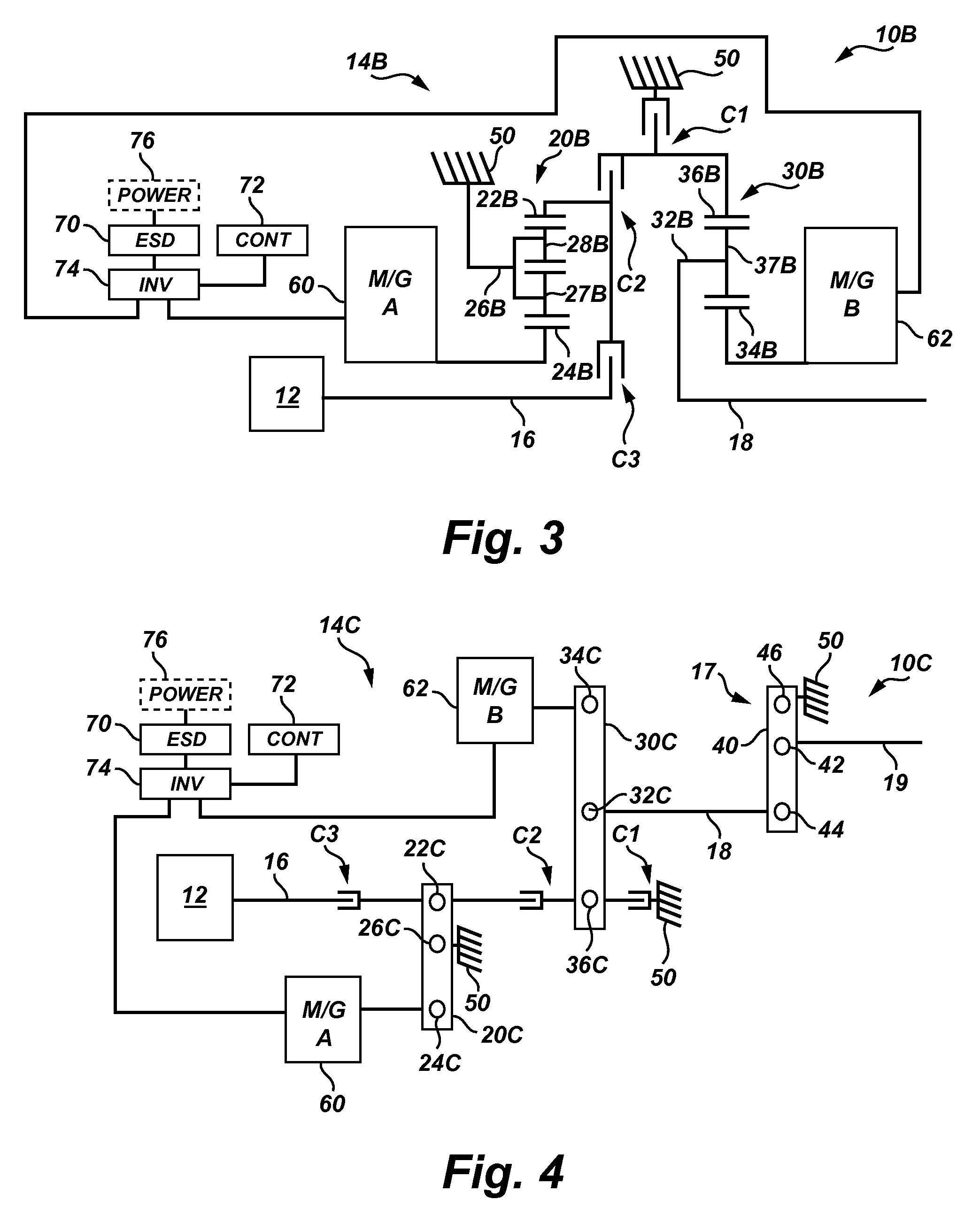

Method and apparatus to control operation of an electro-mechanical transmission

InactiveUS20080176706A1Hybrid vehiclesDigital data processing detailsTorque transmissionHydraulic circuit

A method and apparatus are provided to control operation of an electro-mechanical torque transmission device selectively operative in one of a plurality of fixed gear modes and two continuously variable modes, and operative to transmit torque input from a plurality of torque-generative devices. The transmission device includes a hydraulic circuit and is operative in one of a plurality of operating modes by selective actuation of a plurality of hydraulically-actuated torque-transfer clutches. The method comprises monitoring pressures in the hydraulic circuit, and restricting operation of the transmission when any one of the monitored hydraulic pressures does not correspond to an expected pressure thereat. Presence of a fault is verified during the restricted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

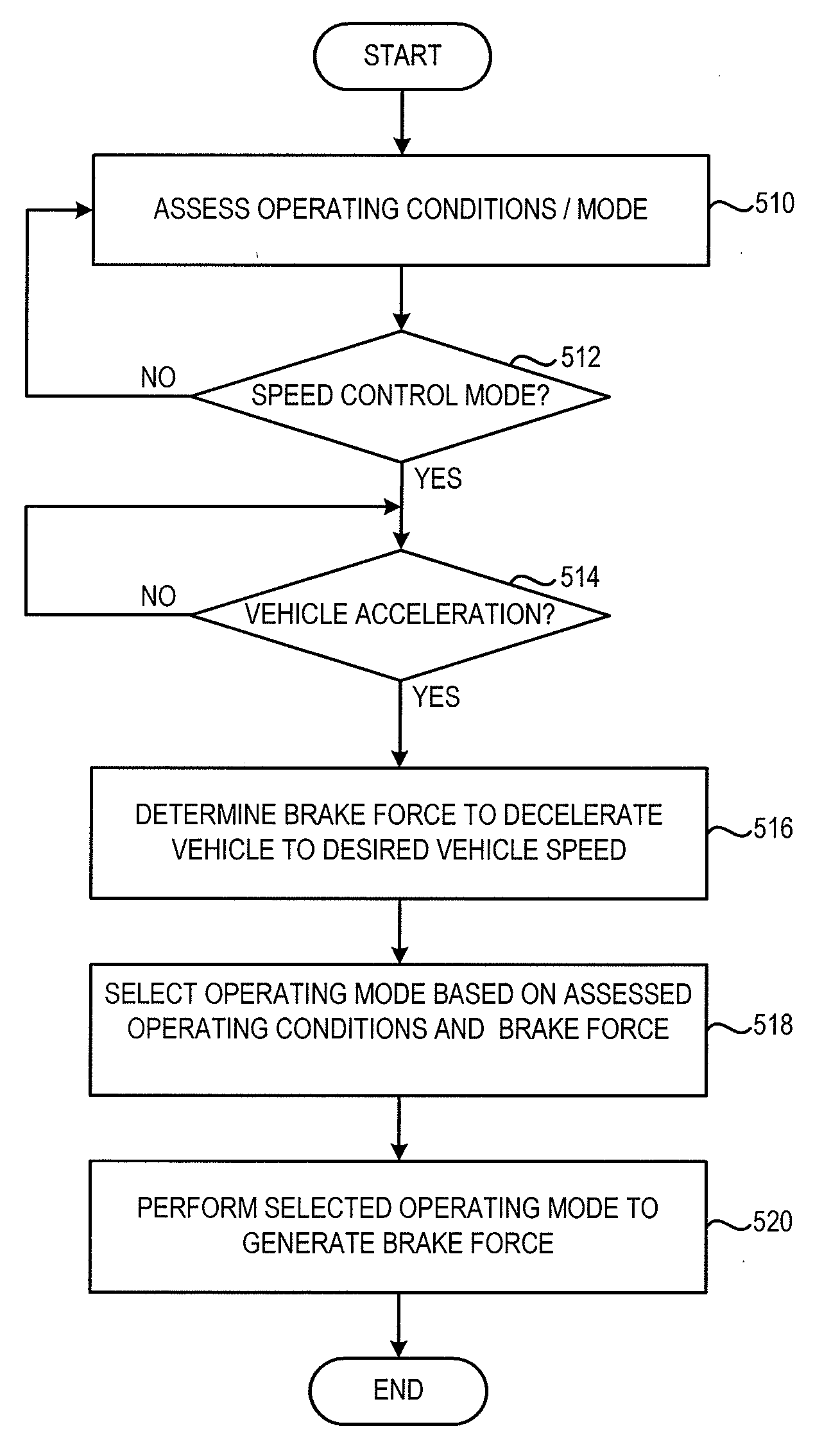

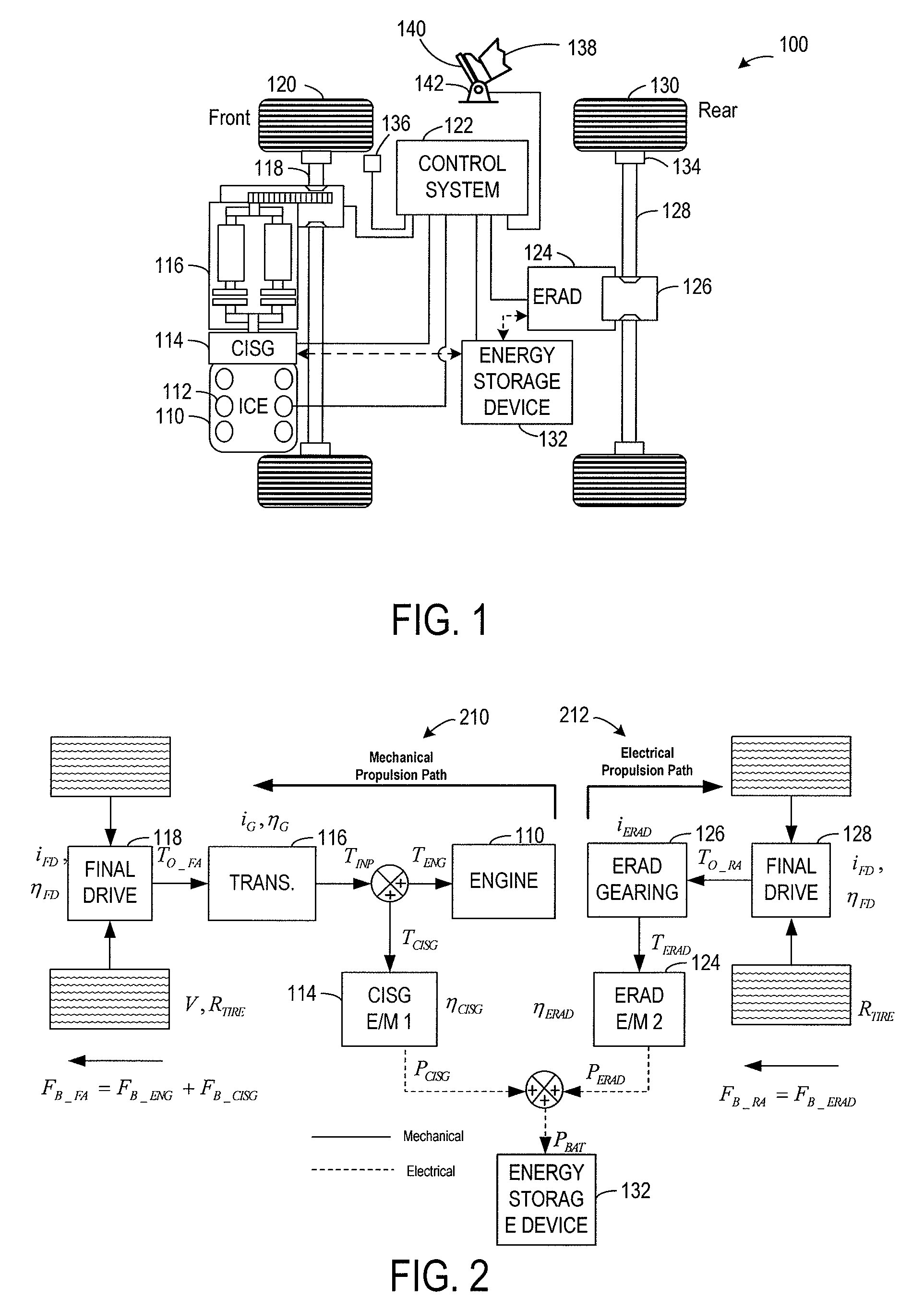

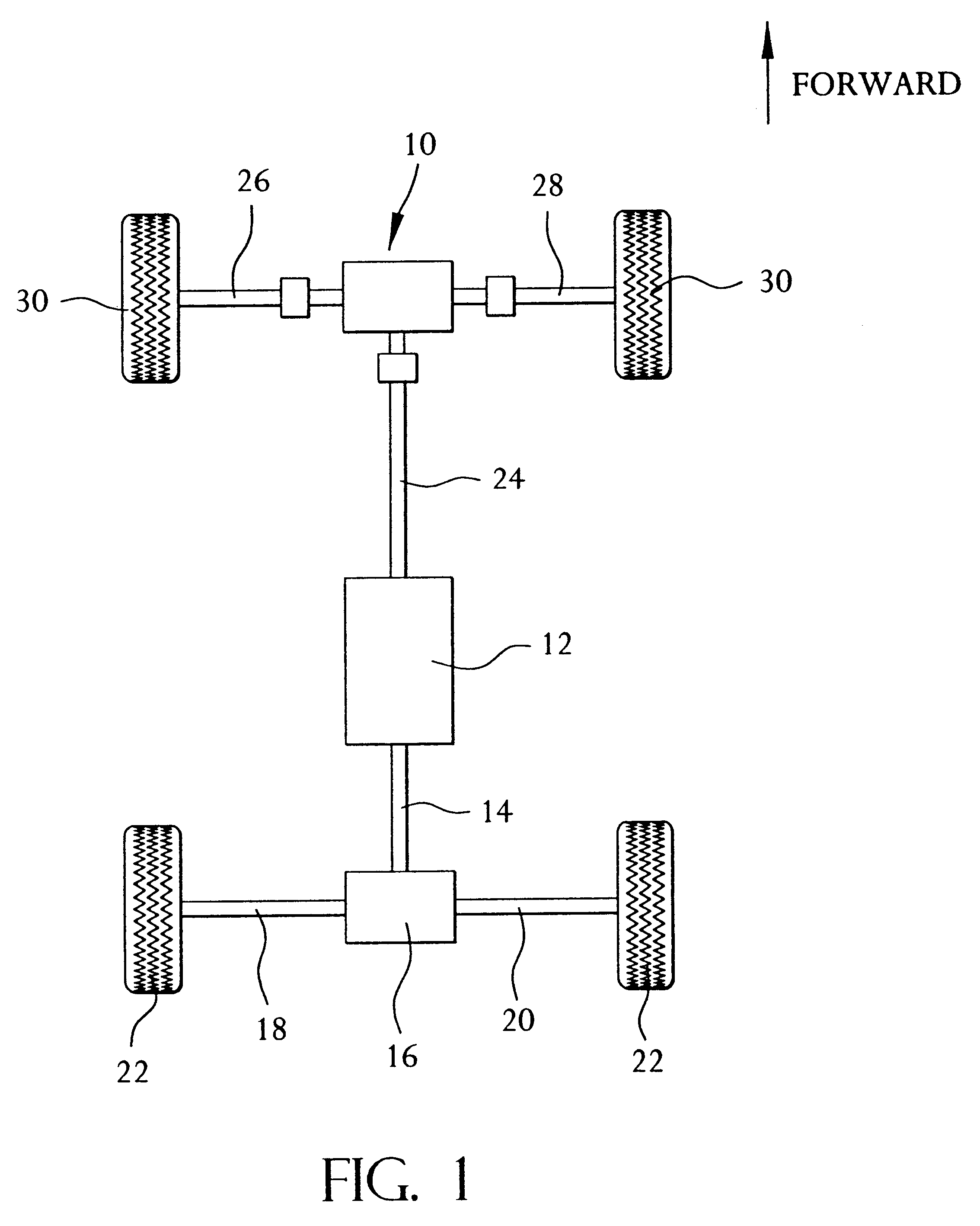

Torque Control for Hybrid Electric Vehicle Speed Control Operation

ActiveUS20090145673A1Improve vehicle efficiencyEasy to operateDigital data processing detailsElectric propulsion mountingBrake torqueDrive wheel

A hybrid propulsion system for a vehicle. The system including, a transmission device for transmitting torque to a first at least one drive wheel, a first electric energy conversion device coupled to an input of the transmission device, a second electric energy conversion device for transmitting torque to a second at least one drive wheel, and a control system, during a vehicle speed control operation where a speed of the vehicle is maintained at a desired speed, in response to acceleration resulting in vehicle speed beyond the desired speed, the acceleration not caused by vehicle operator input, the control system varying torque output of at least one of the first electric energy conversion device and the second electric energy conversion device to provide brake torque to at least one of the first at least one drive wheel and the second at least one drive wheel to decelerate the vehicle to the desired speed, selection of said one of the first and second electric energy conversion device based on an operating condition.

Owner:FORD GLOBAL TECH LLC

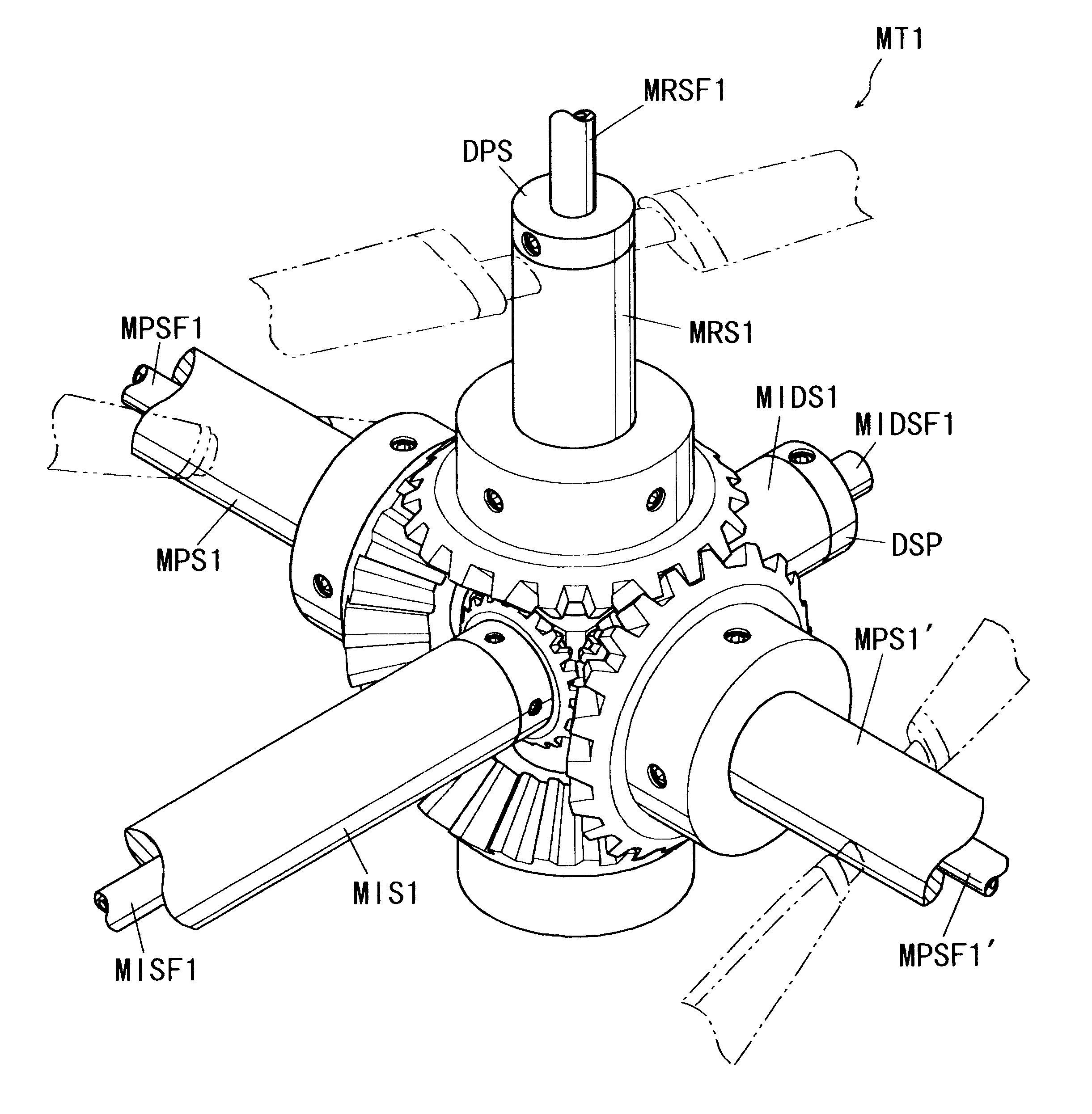

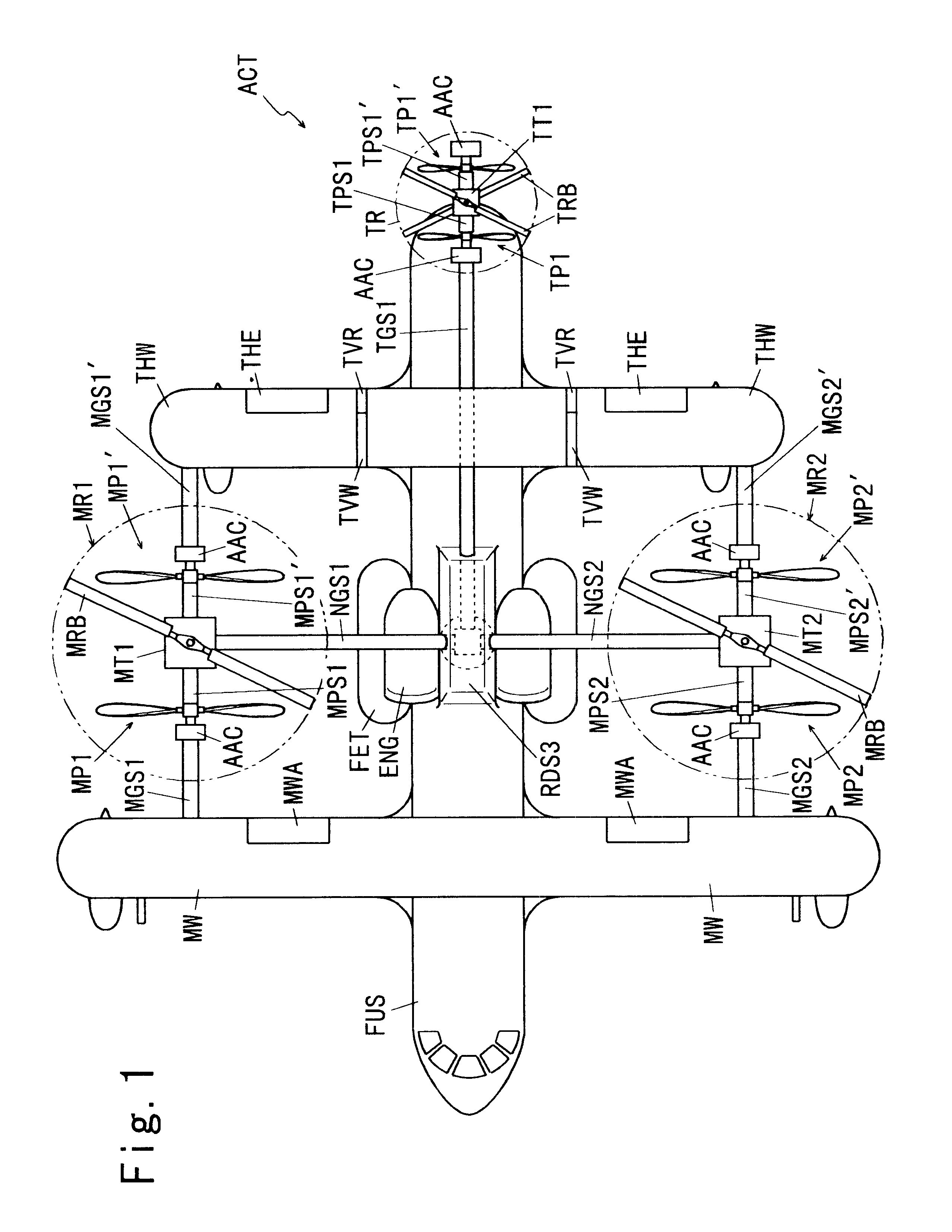

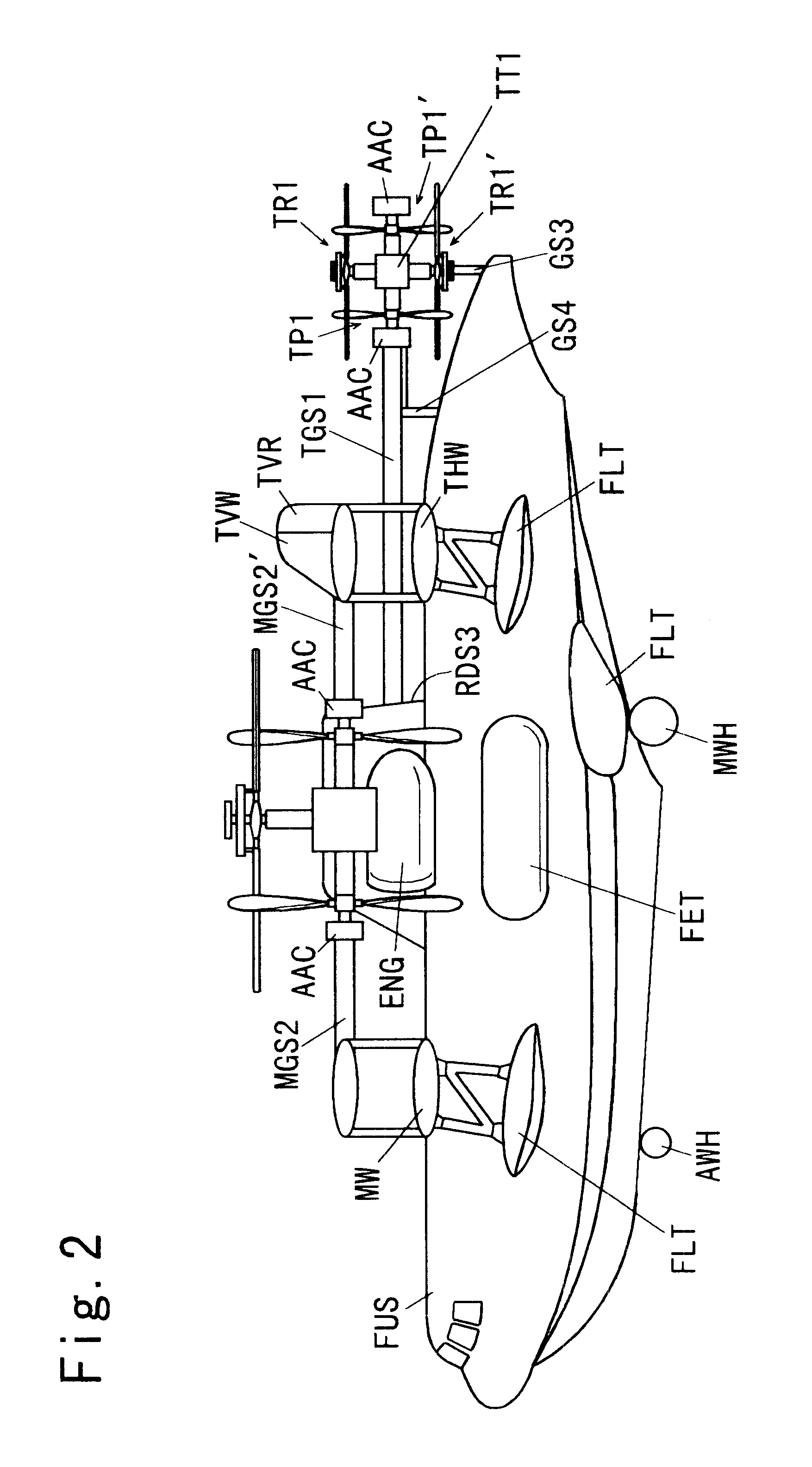

Aircraft and torque transmission

InactiveUS6467726B1Satisfactory stability and controllabilityReduce rotationAircraft navigation controlToothed gearingsFlight directionGear wheel

An aircraft including an airframe having a fuselage which extends longitudinally, and having fixed wings including a main wing, a horizontal tail wing and a vertical tail wing. A propeller-rotor torque transmission has a bevel gear which transmits the rotation of an input shaft simultaneously to a propeller shaft and to a rotor shaft. An engine gearbox supplies the above-mentioned input shaft with rotationalal motive power. The aircraft further includes a propeller collective pitch controller, a rotor collective pitch controller, an engine power controller which controls the output of the above-mentioned engine gearbox for the purpose of changing the rotational speed of the input shaft, and a flight control system having a directional (yaw) control system which controls the flight direction of the aircraft by controlling the positions of the above-mentioned control surfaces.

Owner:HOSODA ROKURO

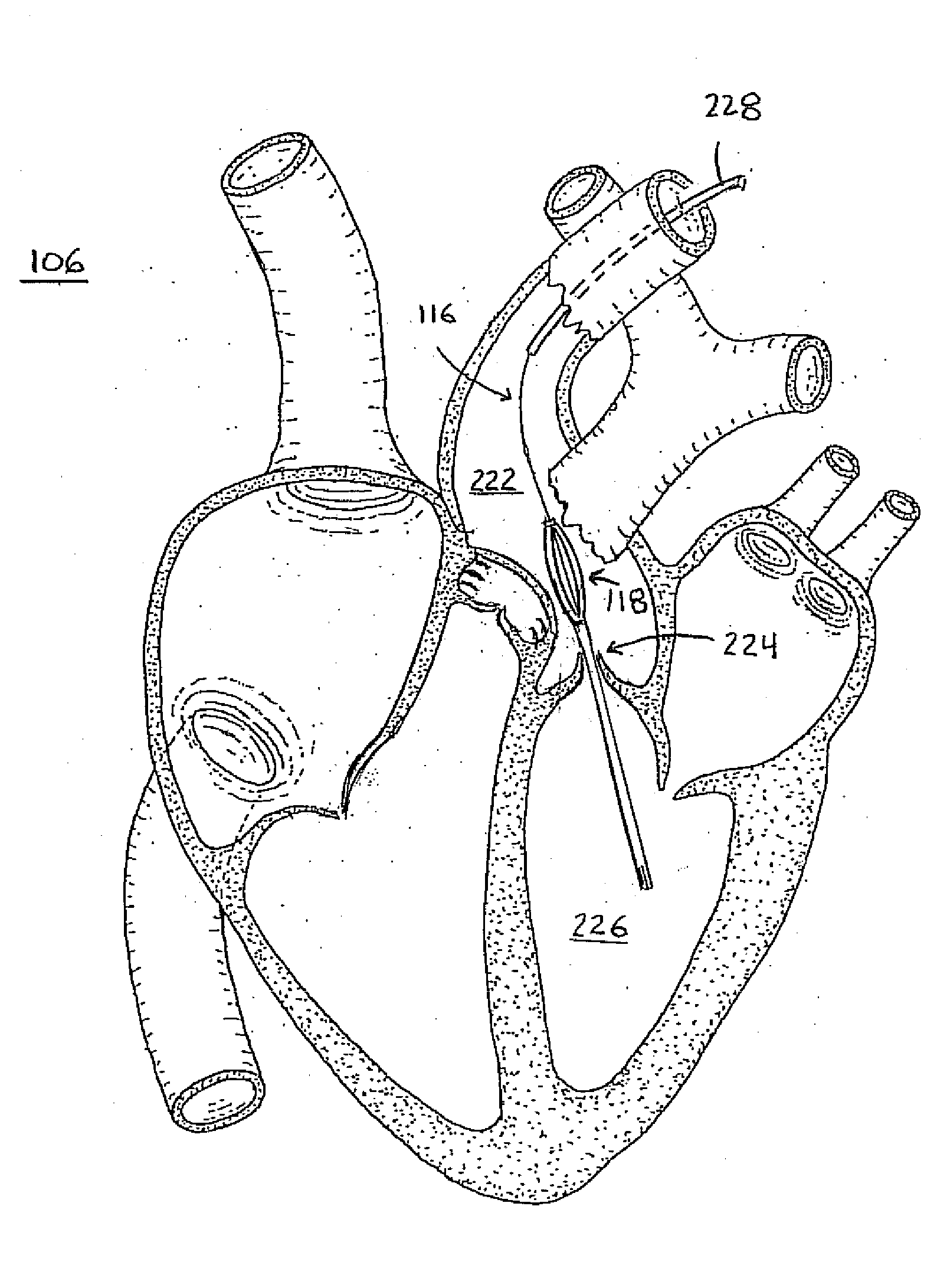

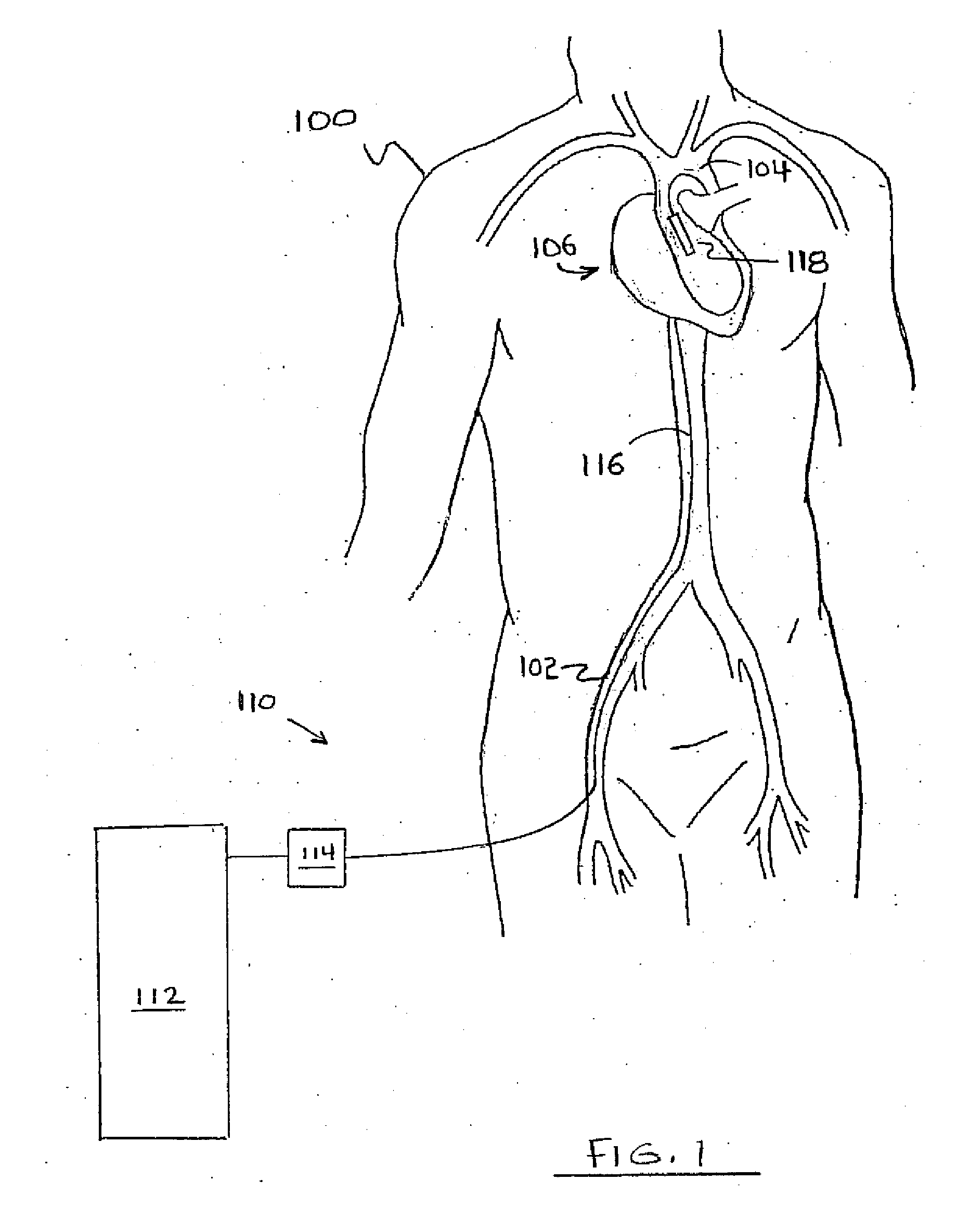

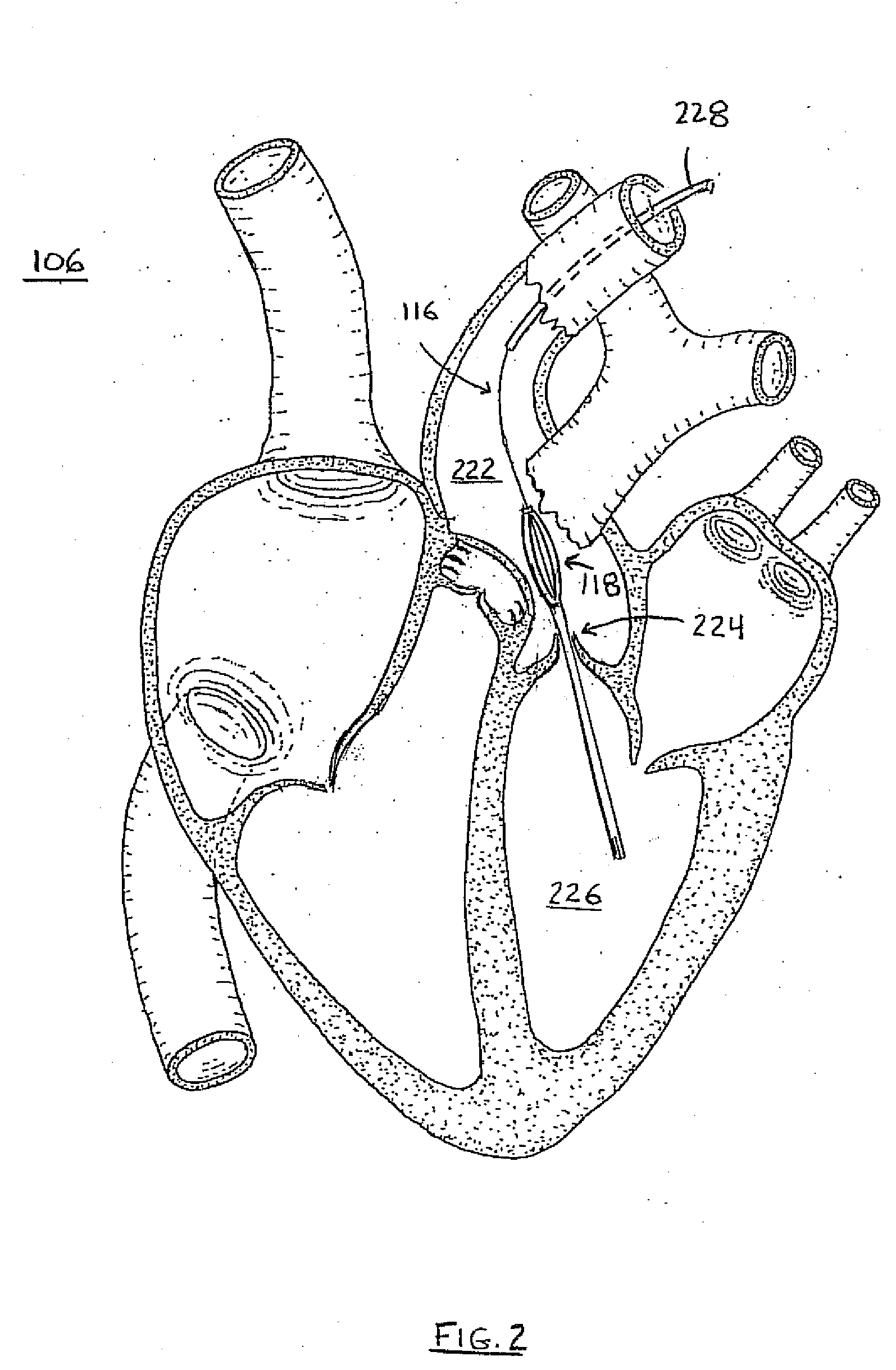

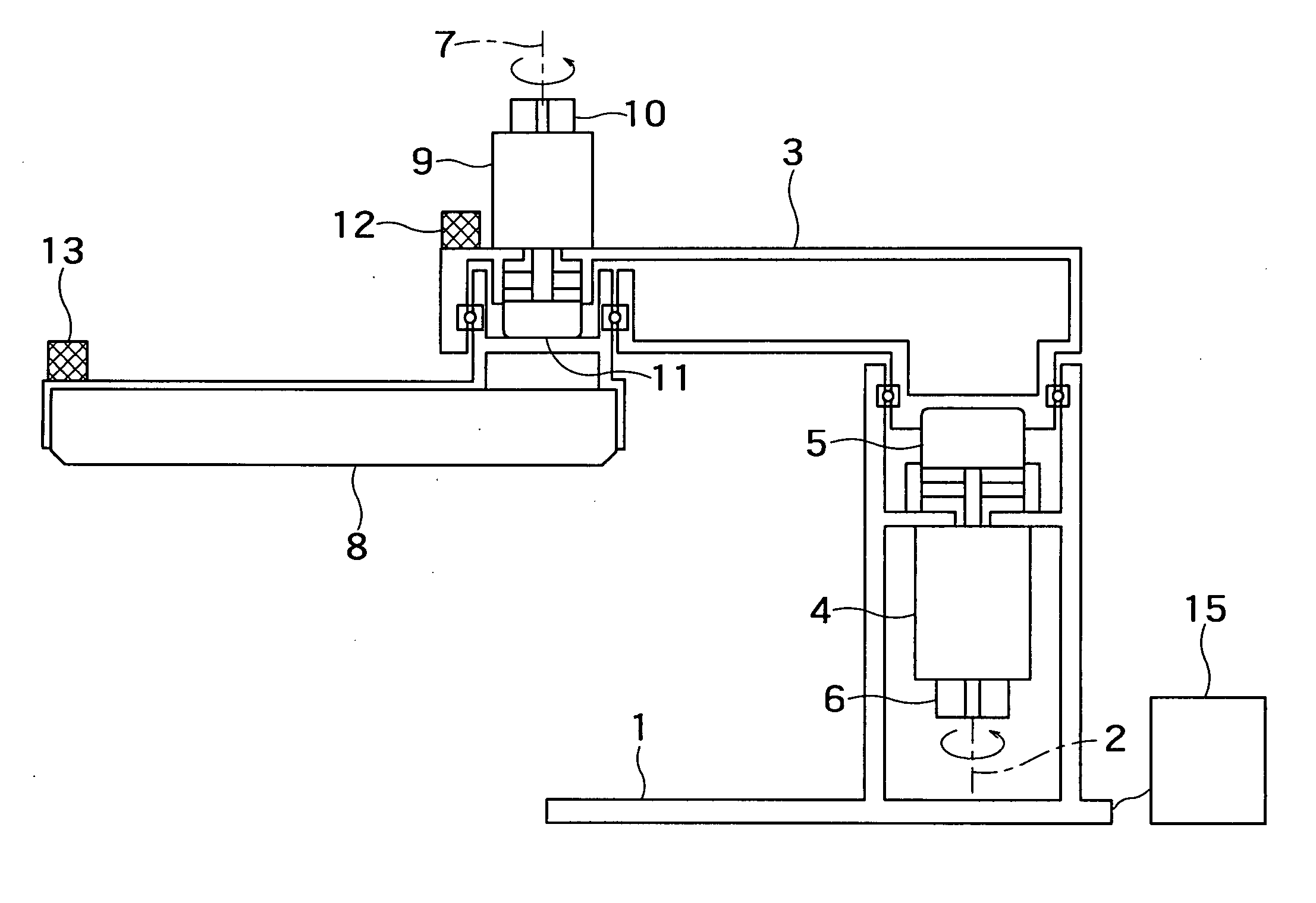

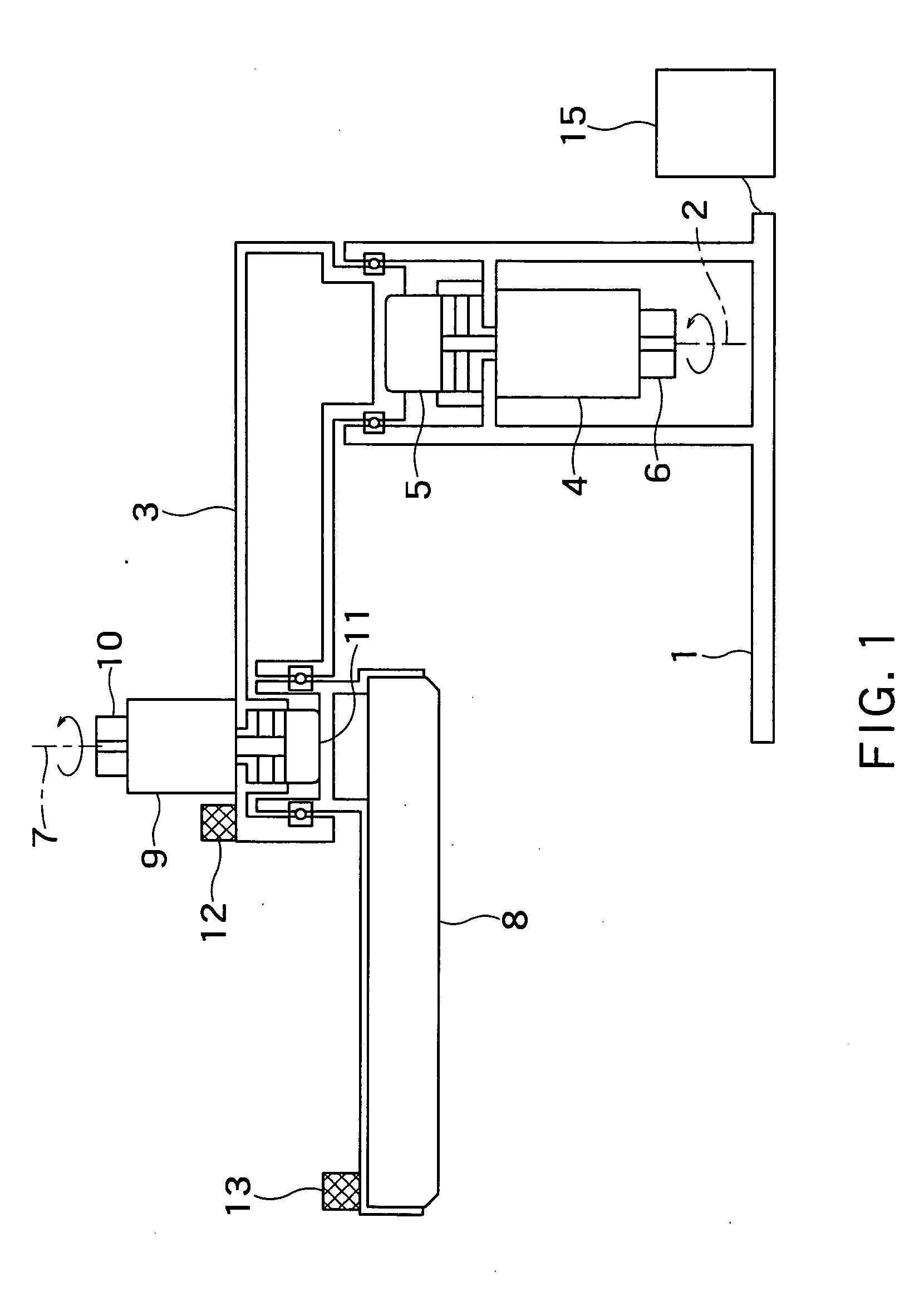

Medical Device

ActiveUS20080132747A1Reduce bending loadMinimizing contact pressureBlood pumpsIntravenous devicesAscending aortaImpeller

A temporary cardiac-assist device is disclosed. The device includes a pump assembly that is deployed in the ascending aorta or the heart. A torque transmission line couples the pump assembly to an external motor for driving impeller blades within the pump assembly. The pump assembly expands in size at its destination site for operation. In operation, neither the torque transmission line nor elements that support the impeller blades are under axial forces.

Owner:FBR MEDICAL INC

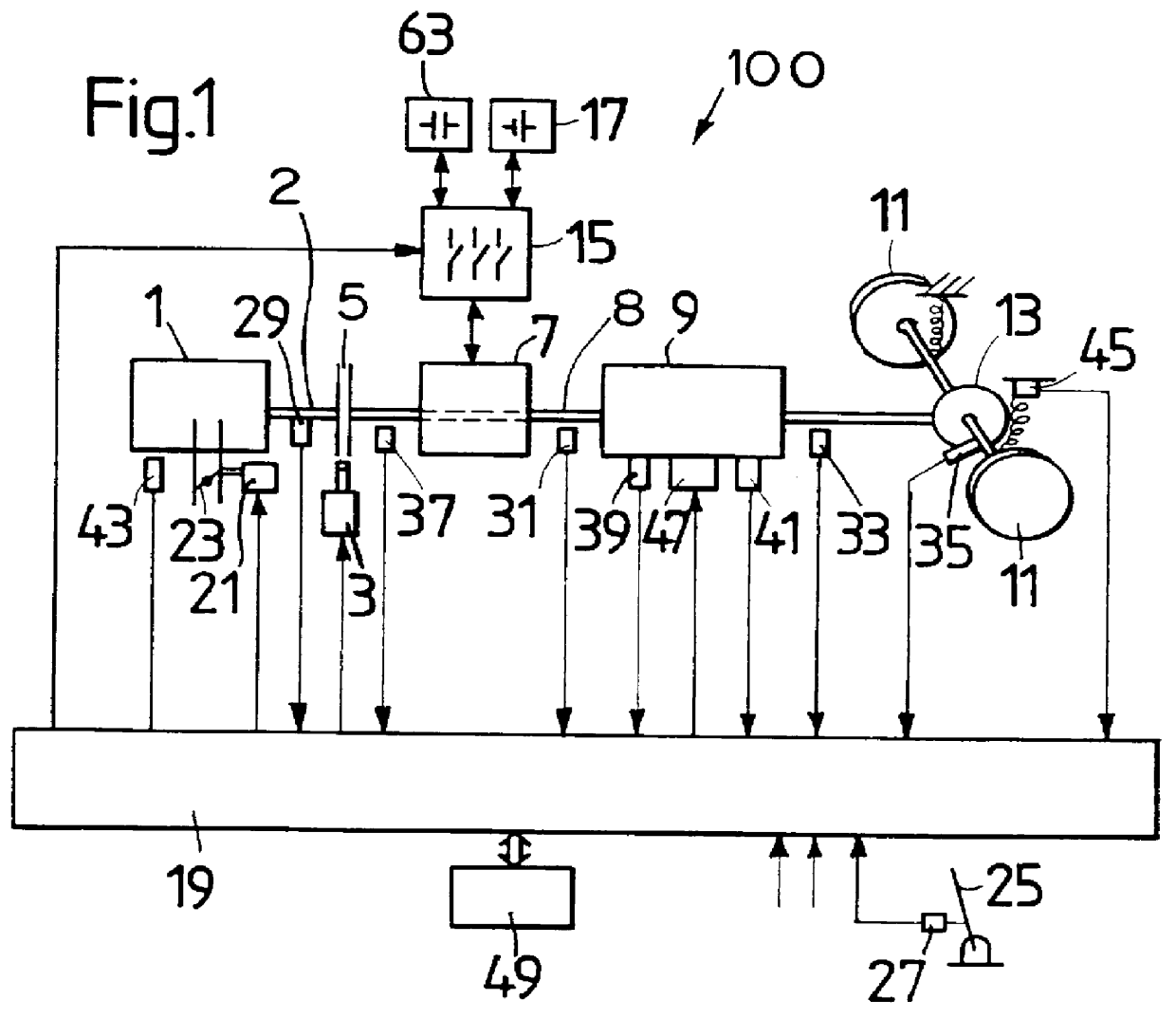

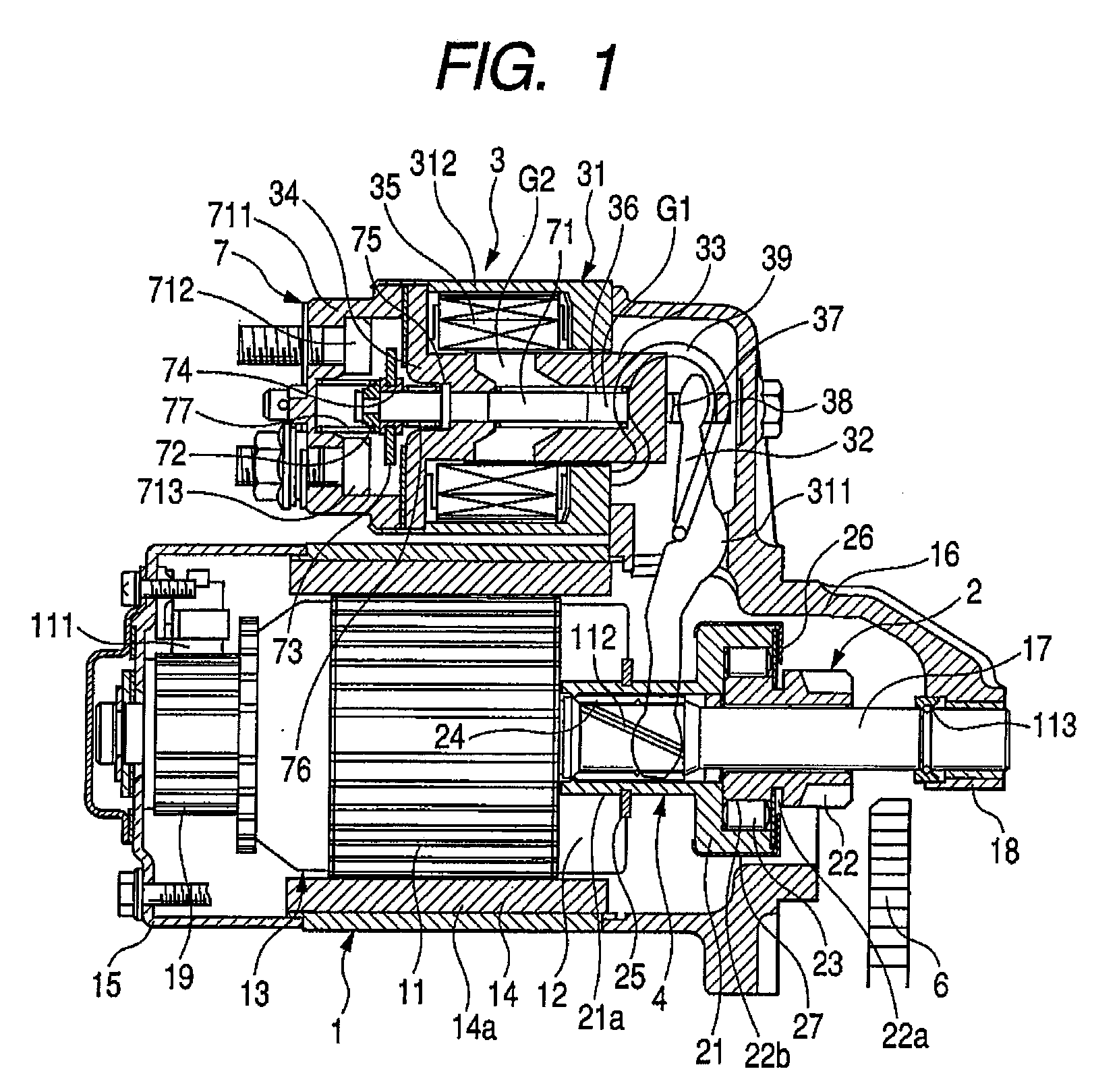

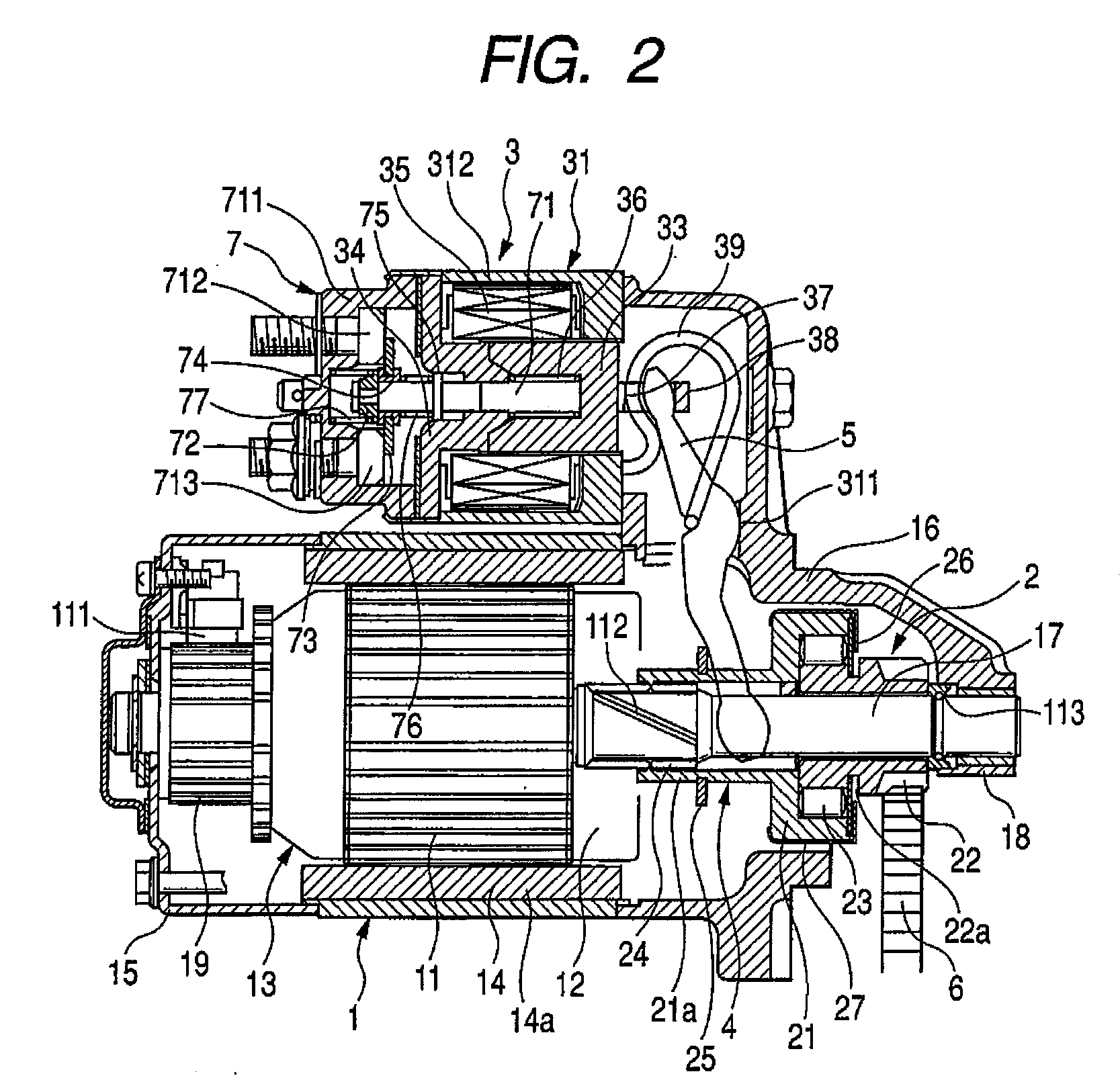

Hybrid vehicle drive for a motor vehicle

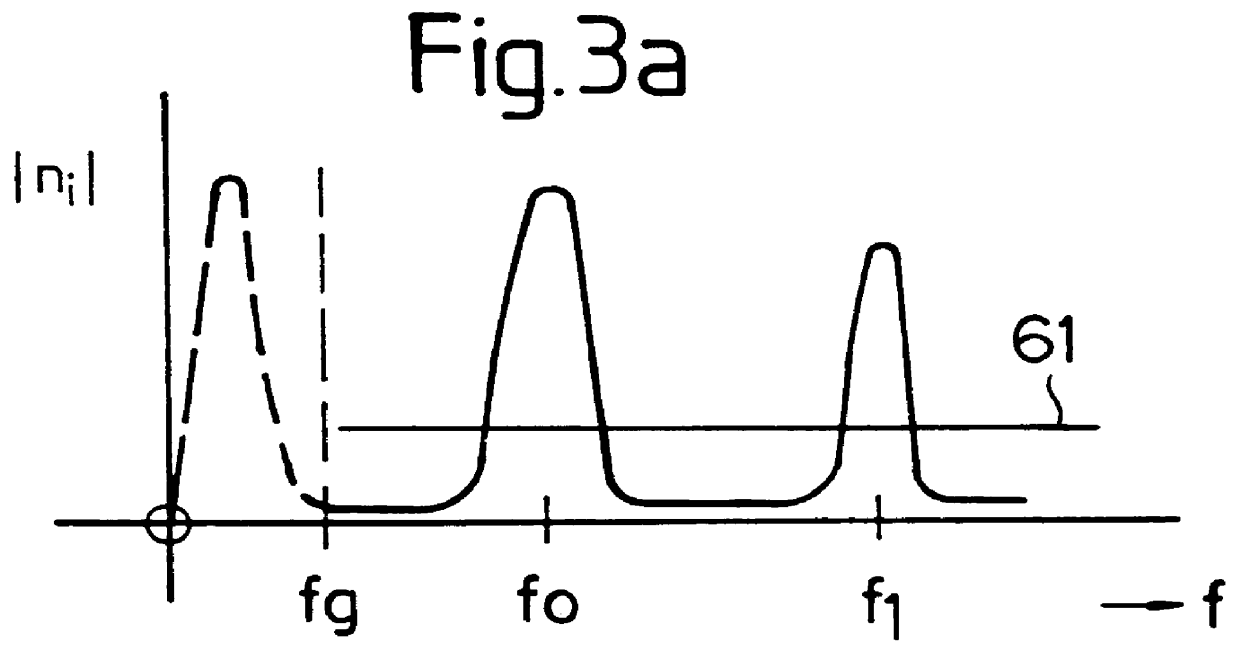

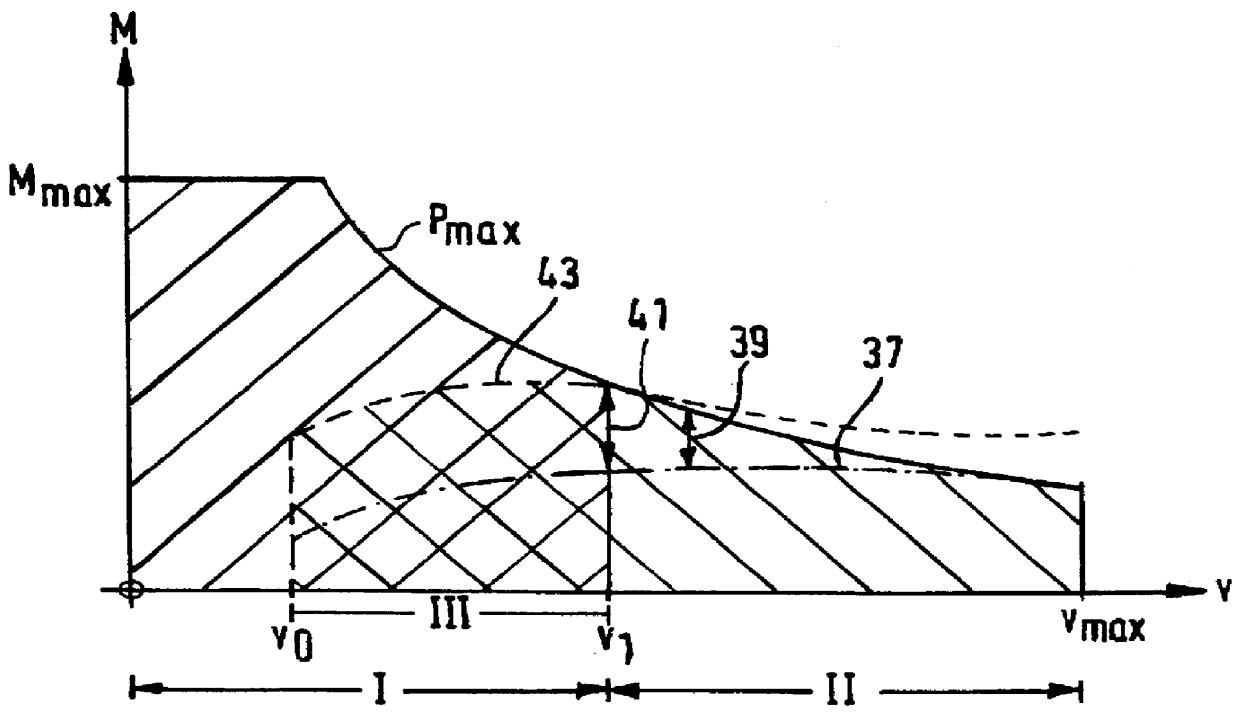

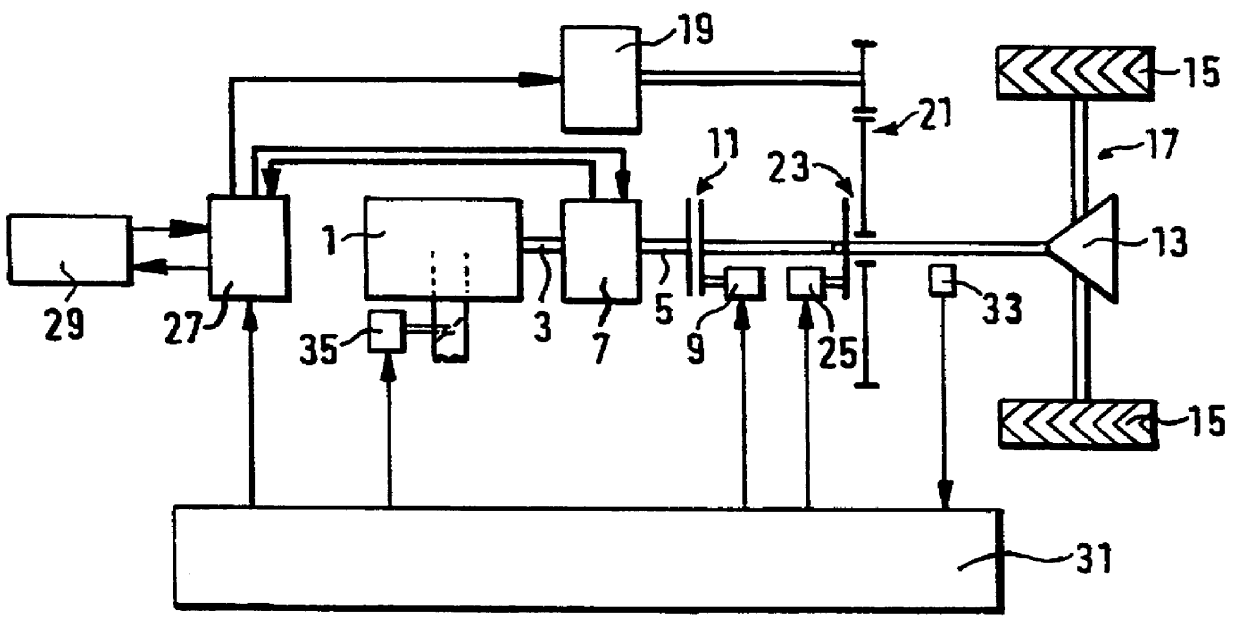

InactiveUS6102144AReducing and eliminating vibrationExcessive vibrationSuspensionsRotating vibration suppressionFrequency spectrumLoad torque

A hybrid vehicle drive for a motor vehicle includes an internal combustion engine and an electric machine which is selectively coupled with the internal combustion engine. The electric machine can be operated as a generator and as a motor. Regulation device which responds to a reference signal predetermined by a reference signal preset device are provided for the active damping of vibrations, especially torsional vibrations in the torque transmission path between the internal combustion engine and wheels of the motor vehicle driven by the latter. The regulation device also respond to sensing device which deliver an actual-value vibration signal containing vibration information about a rotating structural component of the motor vehicle and control the load torque exerted on the internal combustion engine by the electric machine for reducing or eliminating the vibrations of the structural component. An analysis device for determining a frequency spectrum of the actual-value vibration signal is associated with the regulation device. The reference signal preset device establishes a reference signal with predetermined frequency spectrum. The regulation device control the frequency spectrum of the load torque exerted on the internal combustion engine by the electric machine such that excessive spectral vibrations of the actual-value vibration signal are reduced or eliminated.

Owner:ZF FRIEDRICHSHAFEN AG

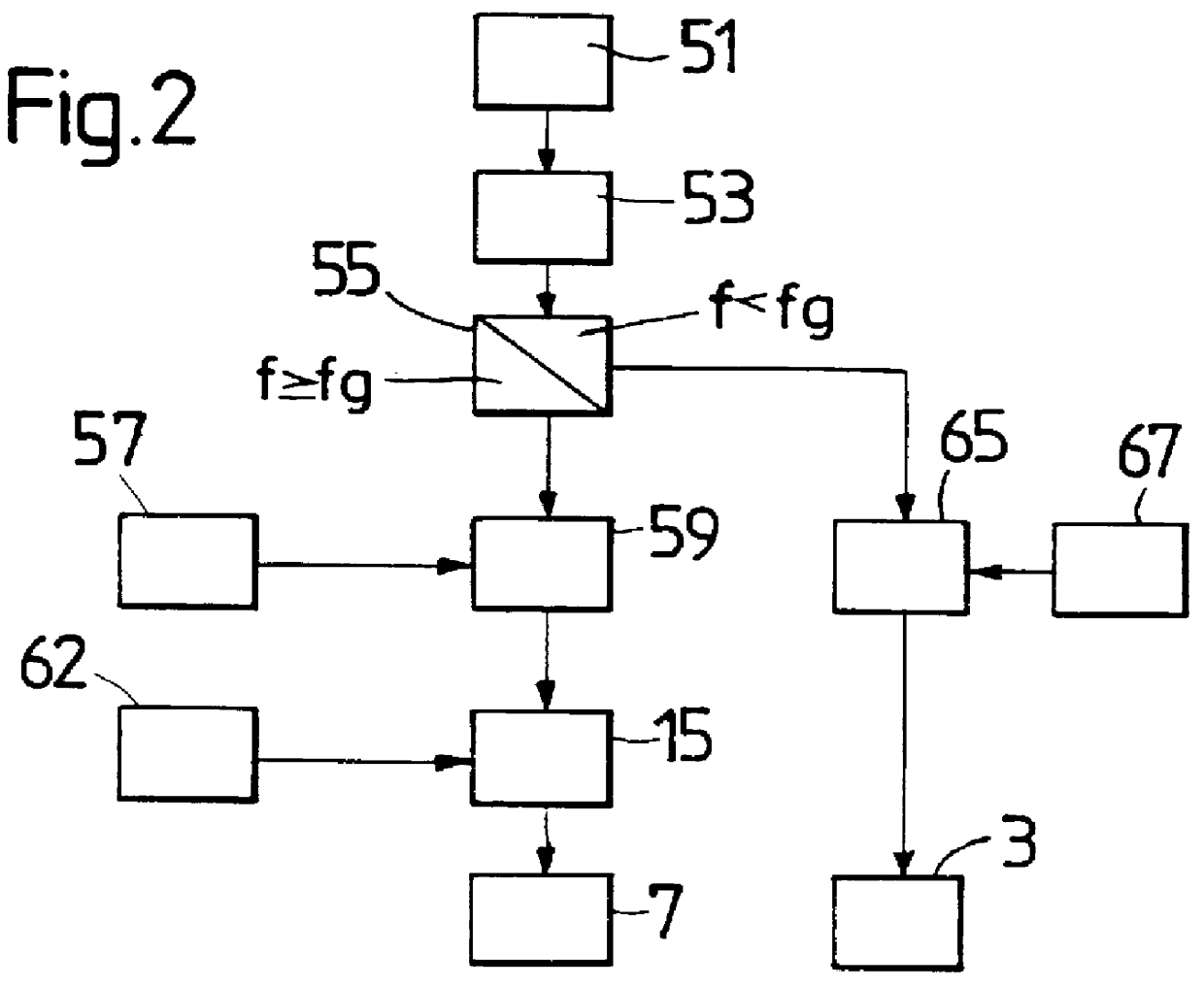

Drive arrangement for a motor vehicle

InactiveUS6059059AIncreases wheel-driving torqueReduce outputHybrid vehiclesDigital data processing detailsMobile vehicleDrive wheel

A hybrid drive arrangement for a motor vehicle including an internal combustion engine (1), which is connected or can be connected in a wheel-driving manner, via a first torque transmission path (11, 13), to a driving wheel (15) of the motor vehicle. An electric machine (19), which is operable at least as a motor, is fed from an electrical energy source (7, 29) of the motor vehicle and is connected or can be connected in a wheel-driving manner, via a second torque transmission path (21, 23, 13), to the driving wheel (15). Arranged in the first and / or the second torque transmission path are coupling elements (11, 23) which, in a first operating state, permit the driving of the motor vehicle by the wheel-driving torque of the electric machine (19), operated as a motor, without mechanical torque support from the internal combustion engine (1), and which, in a second operating state, permit the driving of the motor vehicle by the internal combustion engine (1), without mechanical torque support from the electric machine (19). Depending on the driving speed of the motor vehicle, an electronic driving control system (31) activates the first operating state, at least in a first range of driving speeds including standstill of the vehicle, if the driving speed is less than a predetermined speed limit, and activates the second operating state, at least in a second range including the maximum speed of the vehicle, if the driving speed is greater.

Owner:ZF FRIEDRICHSHAFEN AG

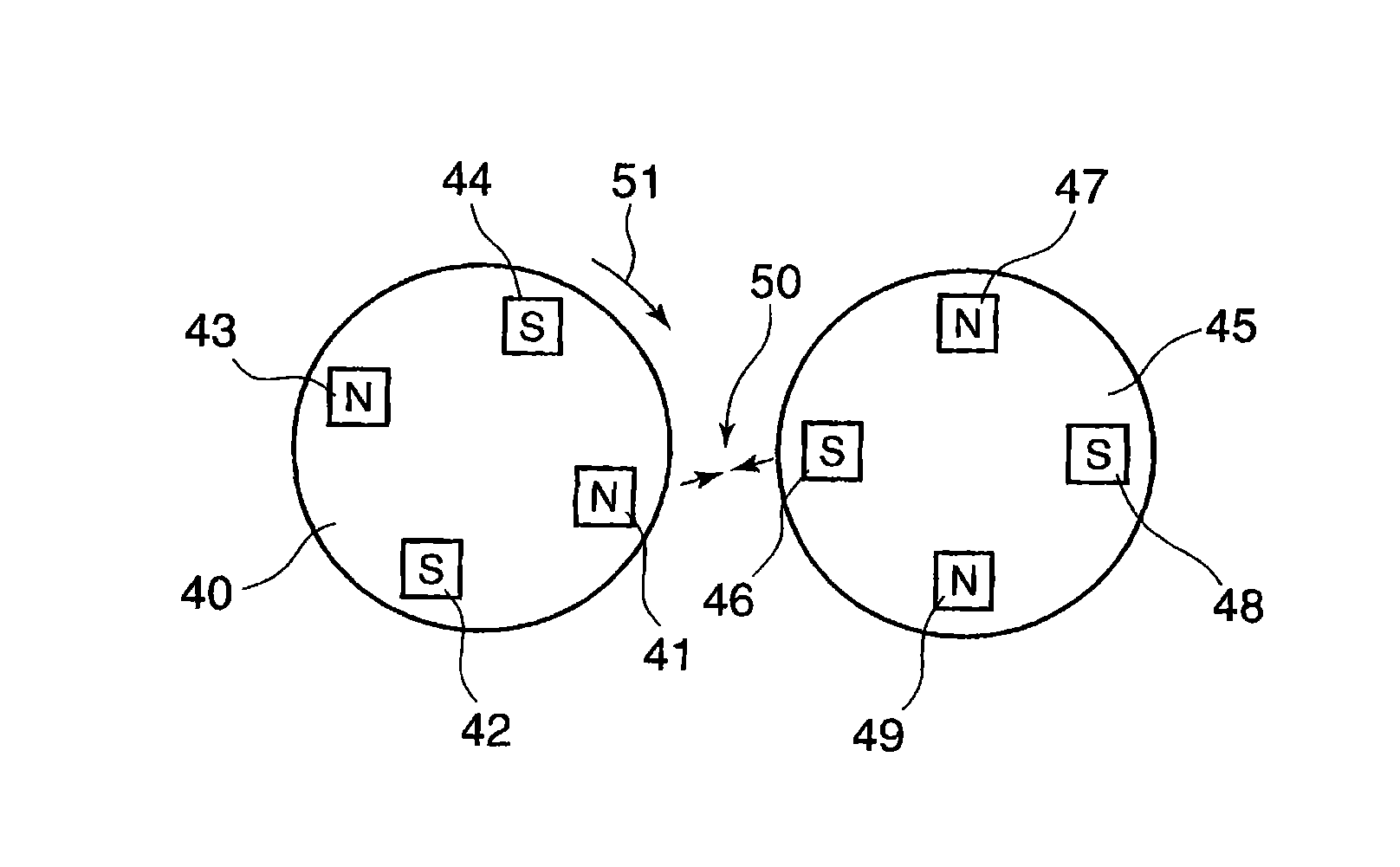

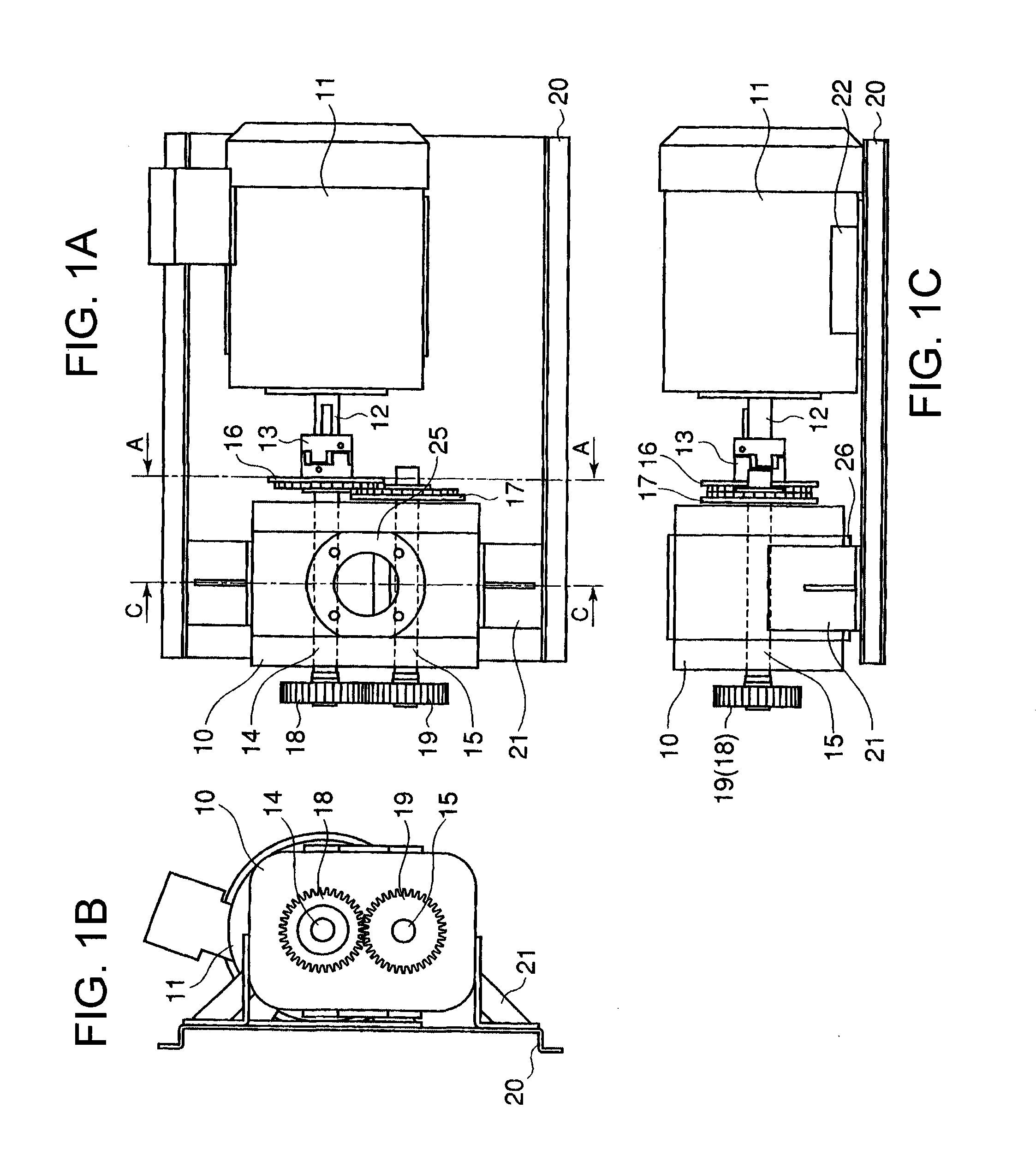

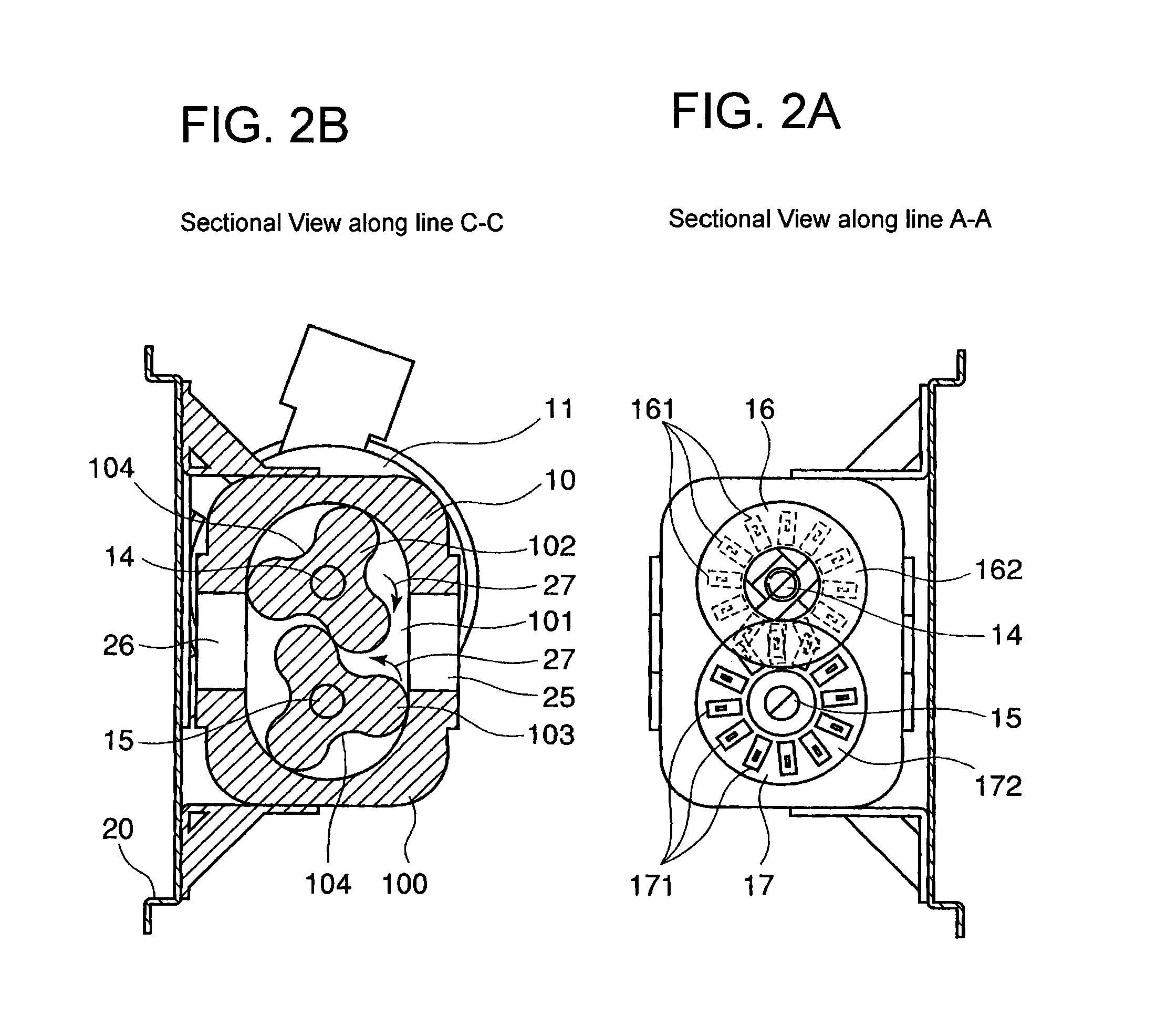

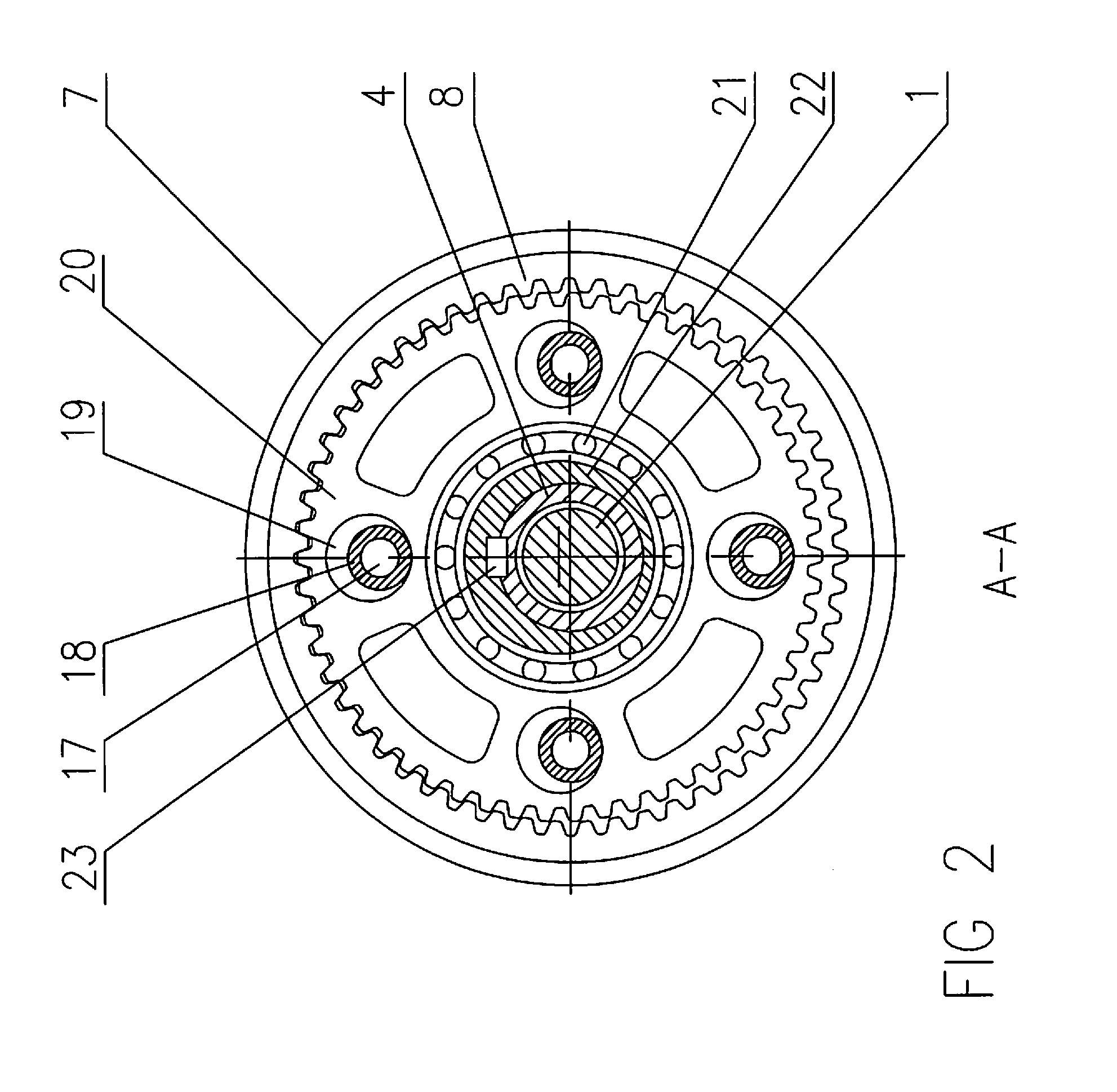

Drive transmission mechanism between two or more rotary shafts and oil-free fluid machine equipped with the mechanism

InactiveUS20080181804A1Reduced service lifeEliminate pollutionDynamo-electric brakes/clutchesEngine of counter-engagement typePlastic materialsOil free

A drive transmission mechanism for transmitting torque between two or more rotary shafts in synchronization with one another without need for lubrication thereby eliminating occurrence of oil contamination, and an oil-free fluid machine equipped with the mechanism, are provided. A magnetic drive disk 16 and a synchronization gear 18 are attached to a rotary shaft 14 connected to a drive motor 11, a magnetic drive disk 17 and a synchronization gear 19 is attached to a rotary shaft 15, torque transmission from the rotary shaft 14 to the rotary shaft 15 is carried out in two ways, via the magnetic drive disks 16, 17 and via the synchronization gears 18, 19, and at least one of the synchronization gears is made of plastic material. With the construction, torque transmit load between the rotary shafts via the synchronization gears is decreased, and a plastic gear or gears can be adopted for synchronization gears without reducing life of the gears without need for lubrication oil.

Owner:ANEST IWATA CORP

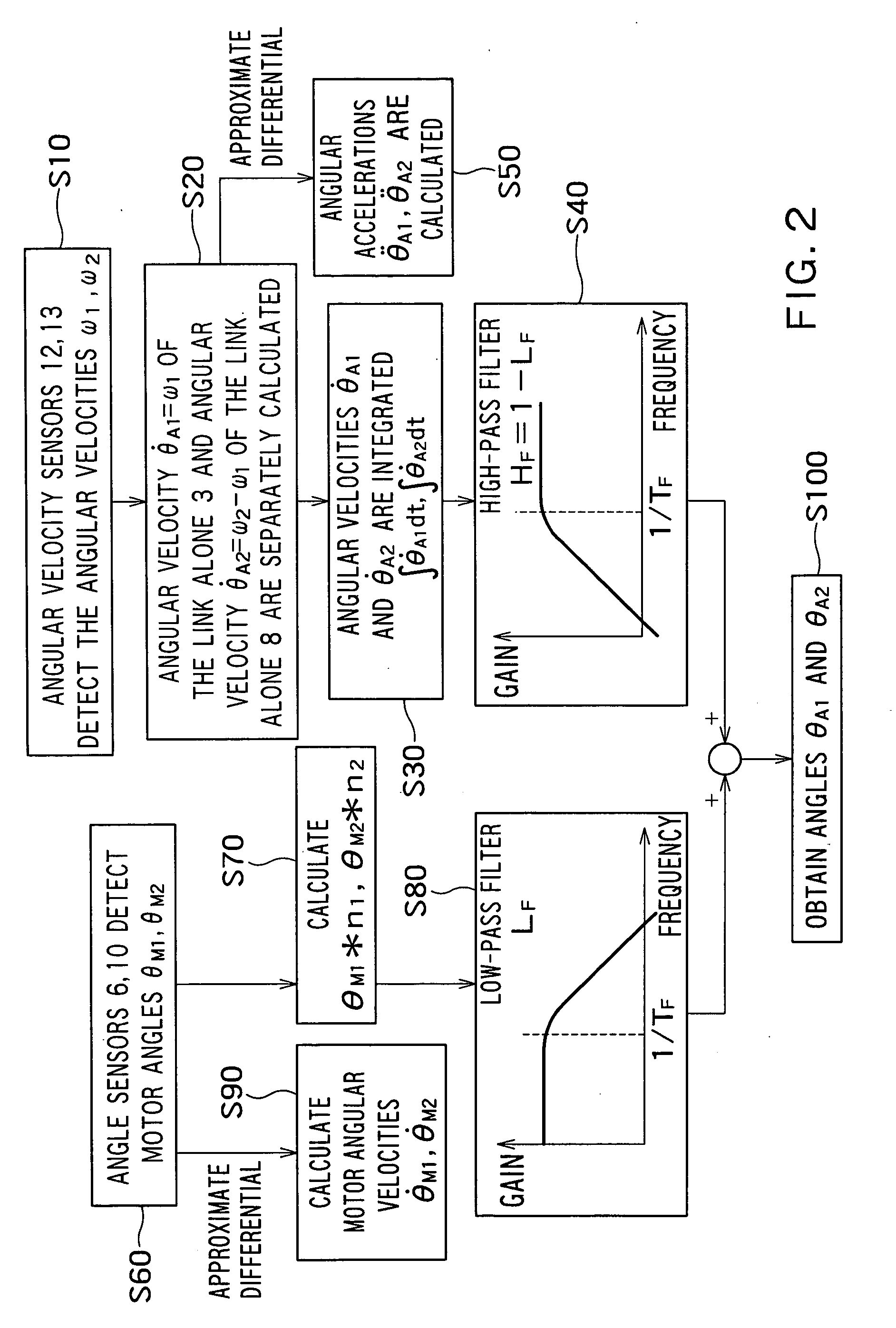

Robot controller and robot controlling method

InactiveUS20050246061A1Easy to controlProgramme-controlled manipulatorComputer controlAngular velocityTorque transmission

A robot controller according to an embodiment of the present invention comprises a base; a first link; a first actuator which drives to rotate the first link relative to the base; a first torque transmission mechanism which transmits the torque of the first actuator to the first link at a speed reducing ratio of N1; a first angular sensor which detects a rotating angle θM1 of the first actuator; a first angular velocity sensor which detects an angular velocity ωA1 of the first link rotating relatively to the base; and a processor which calculates an angle of the first link relatively to the base by using a high frequency content of an integrated value of ωA1 and a low frequency content of θM1*N1, the high frequency content being equal to a first frequency or higher and the low frequency content being equal to a first frequency or lower.

Owner:KK TOSHIBA

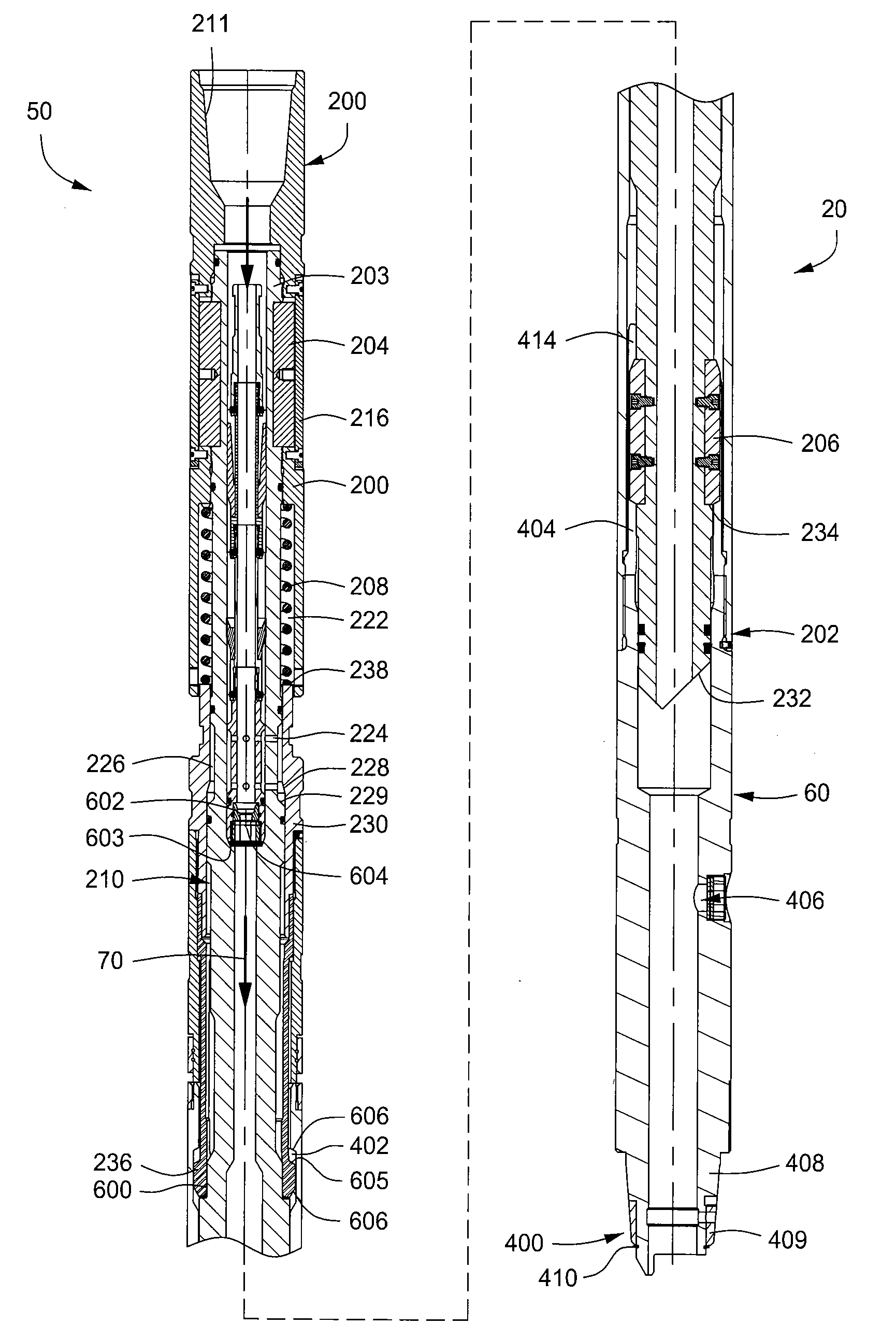

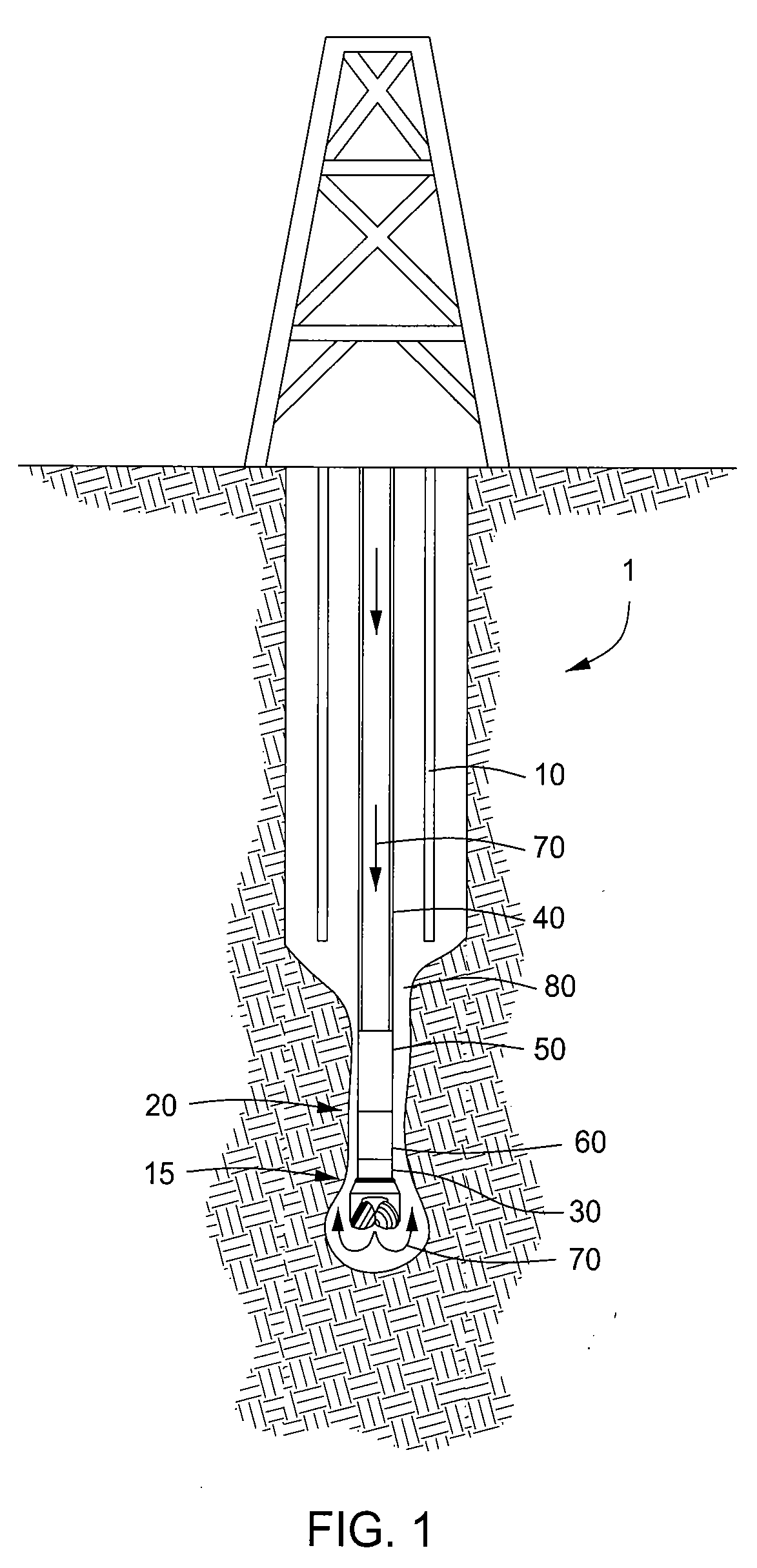

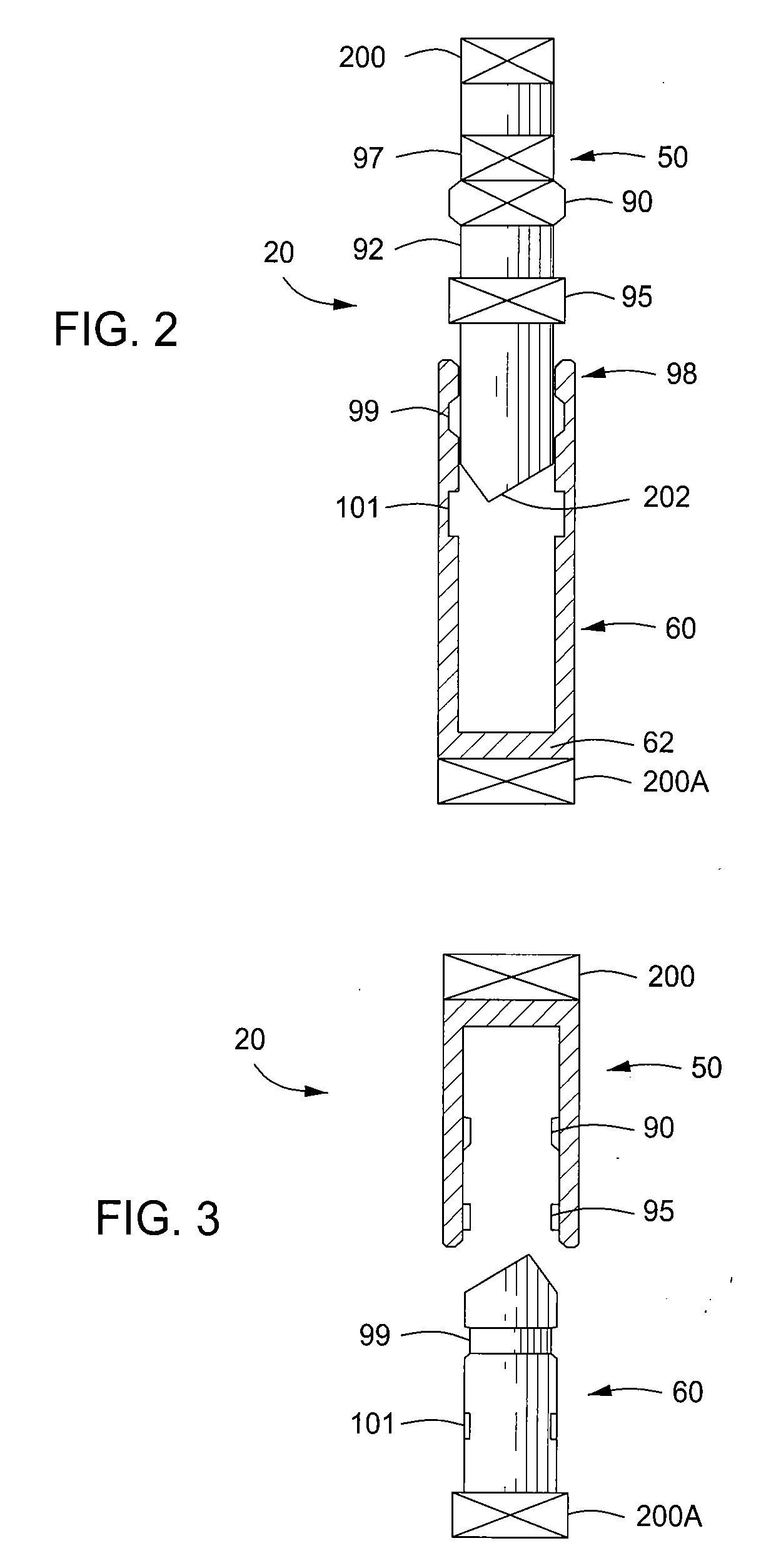

Releasing and recovering tool

Apparatus and methods for selectively releasing a first wellbore component to a second wellbore component using a disconnect device. In one embodiment, the method includes coupling a disconnect device to a workstring and a downhole tool; performing a downhole operation using the downhole tool, and selectively releasing an upper portion of the disconnect device from a lower portion of the disconnect device, thereby releasing the downhole tool from the workstring. The method may also include reconnecting the upper portion of the disconnect device to the lower portion of the disconnect device. In one embodiment, the disconnect device is capable of transferring torque to the wellbore component.

Owner:WEATHERFORD TECH HLDG LLC

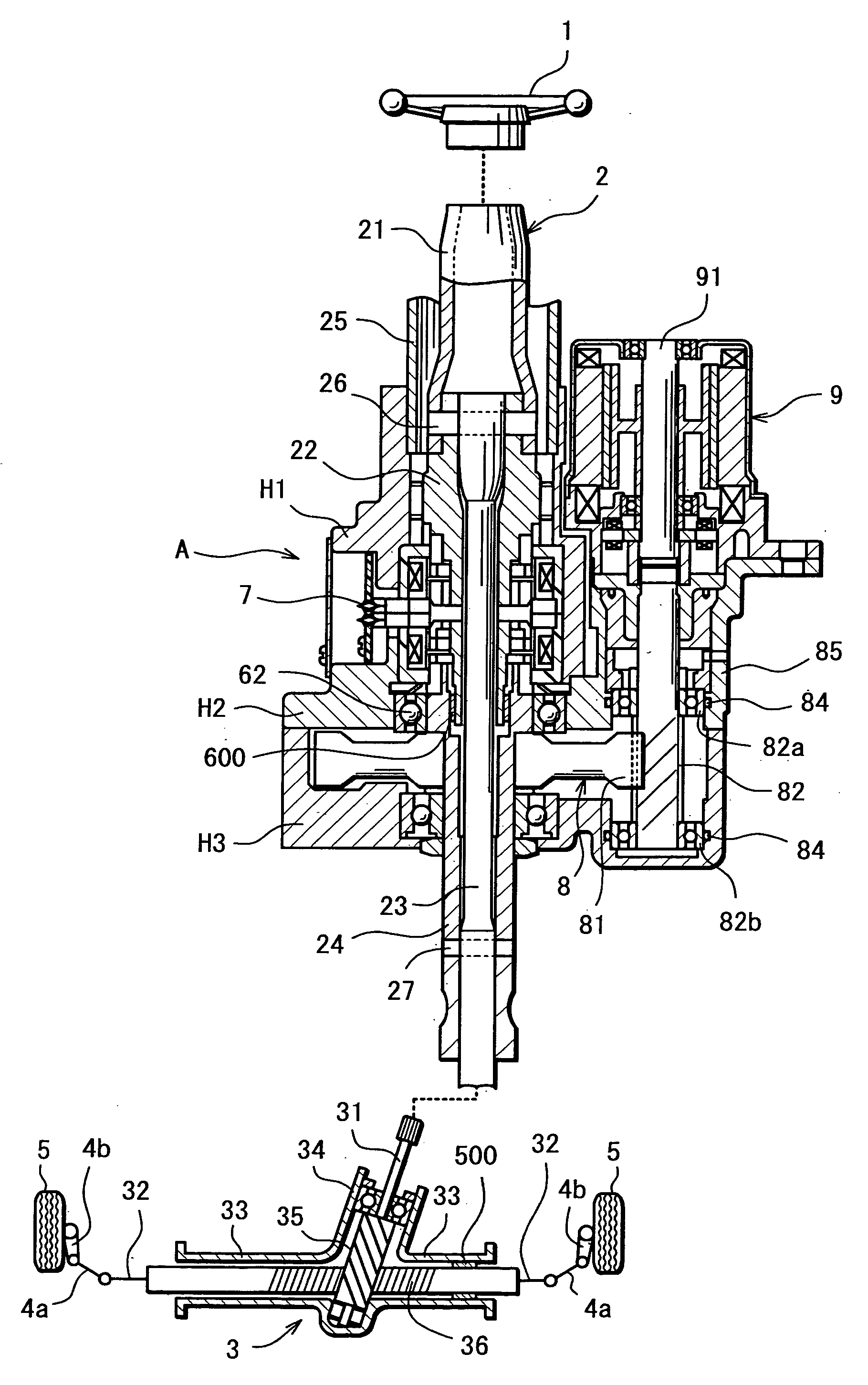

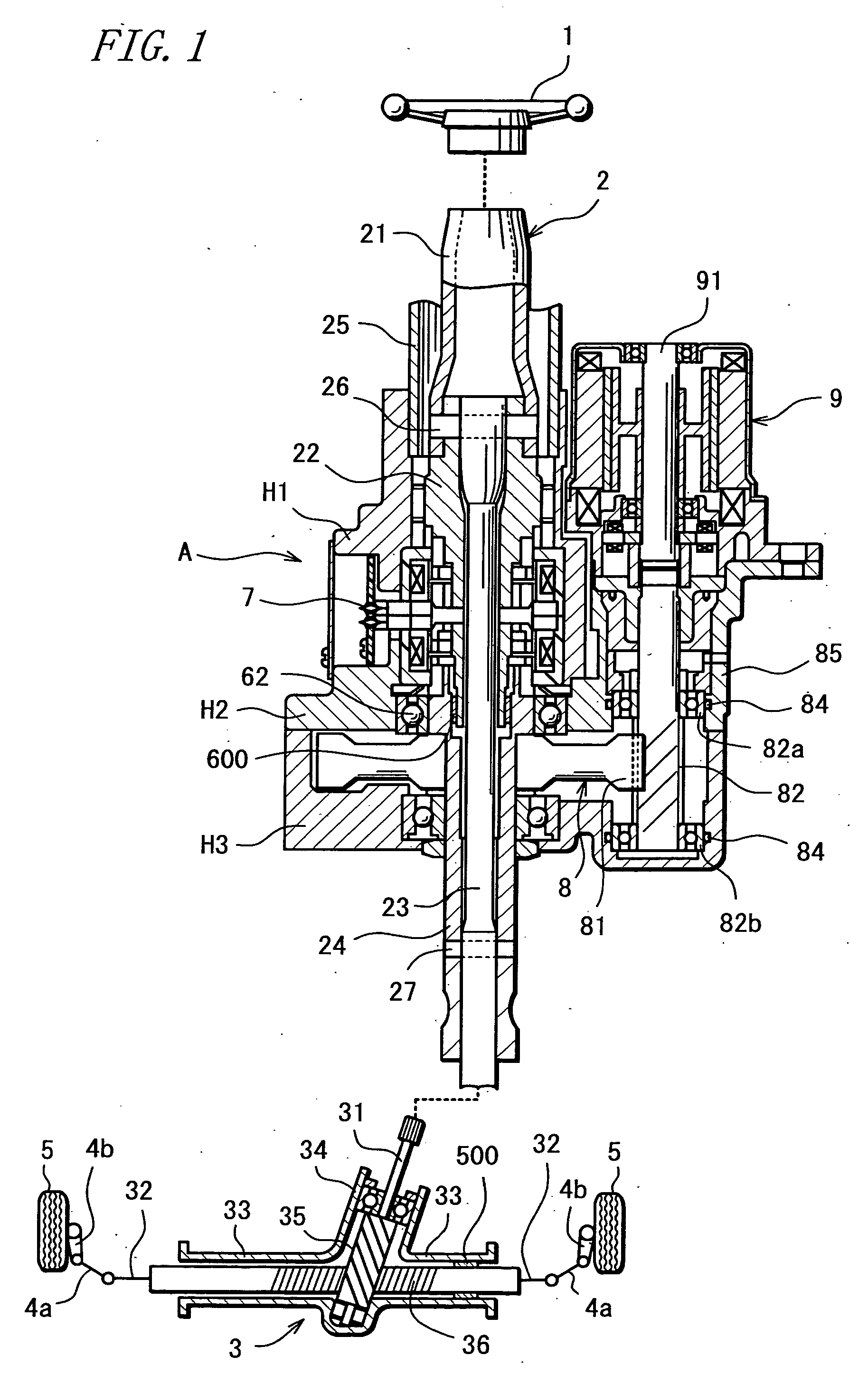

Electric Power Steering System

InactiveUS20070205041A1Favorable steering feelingLess inertia feelingSteering linkagesAutomatic steering controlElectric power steeringDamping torque

An electric power steering system is provided which is capable of providing a favorable steering feeling without using compensation logics such as of inertia compensation and friction compensation. The electric power steering system includes road-noise suppression control means (213) for controlling a steering assist motor (9) in a manner to damp torque transmission in a higher frequency region representing road noises than a frequency region representing road information. A friction value of a steering mechanism (A) is decreased enough to allow the intrinsic vibrations of the steering mechanism (A) to appear. Rotor inertia of the steering assist motor (9) is set to a value small enough to allow the frequencies of the intrinsic vibrations to be present in the frequency region where the torque transmission is damped by the road-noise suppression control means (213).

Owner:JTEKT CORP

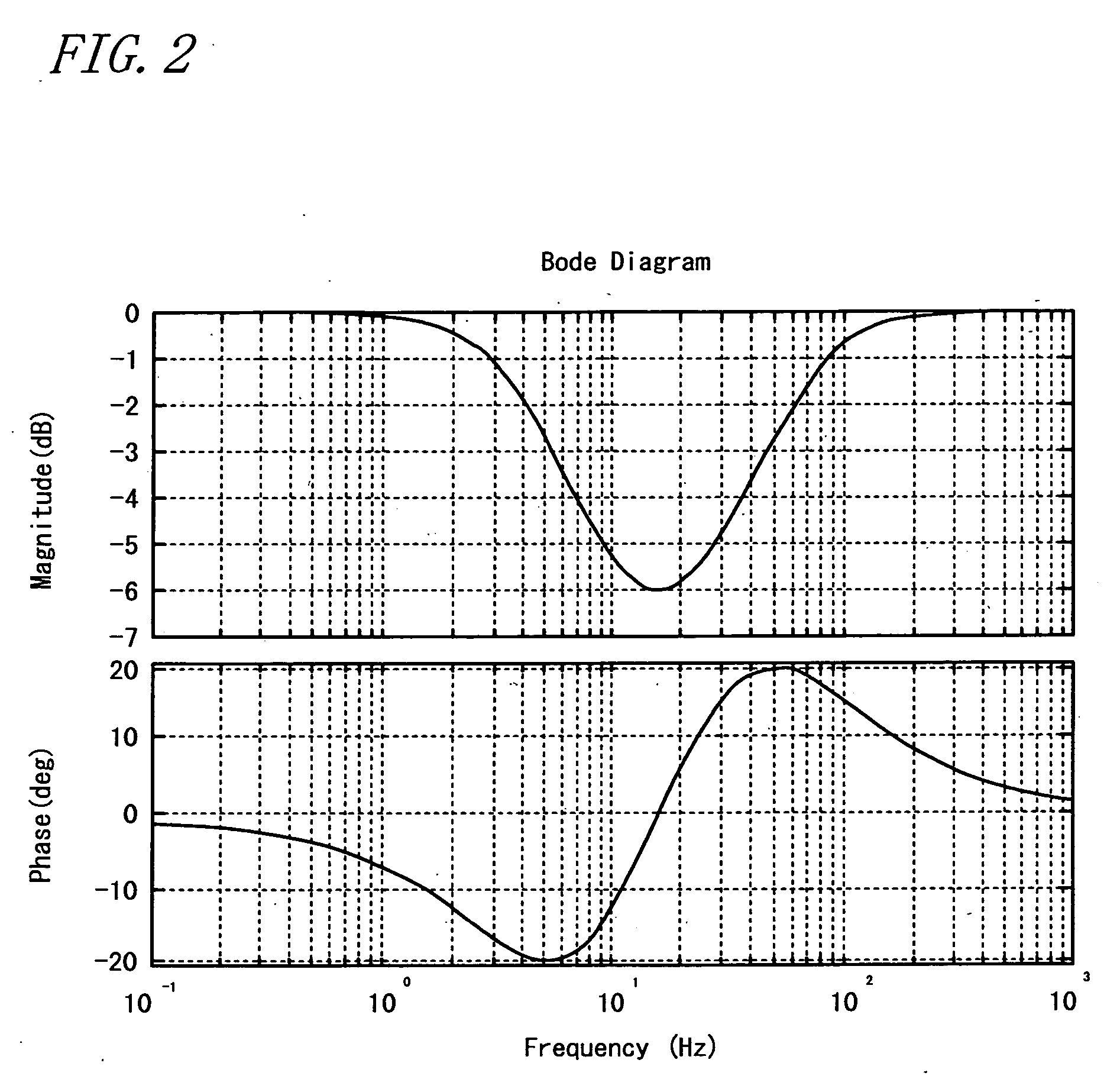

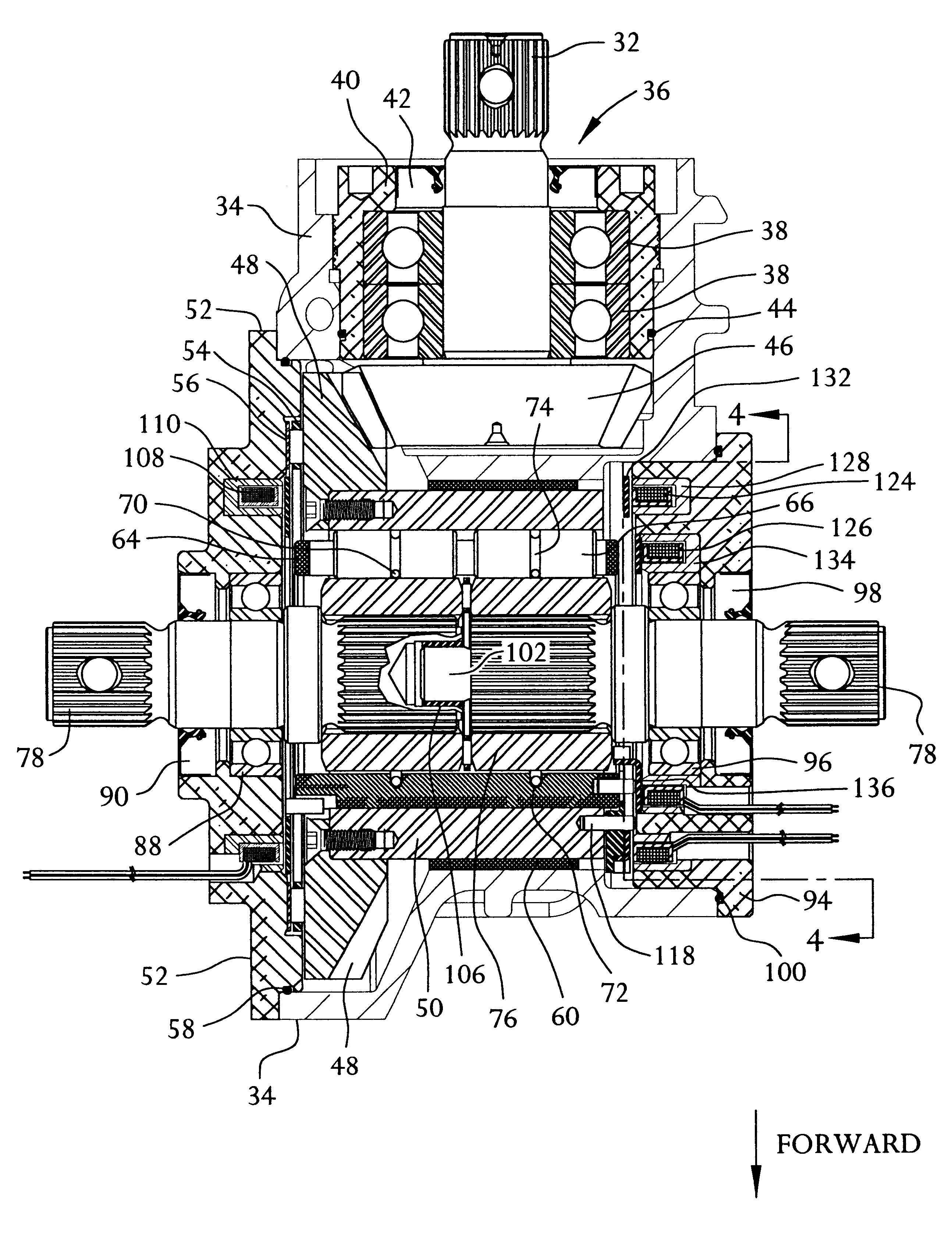

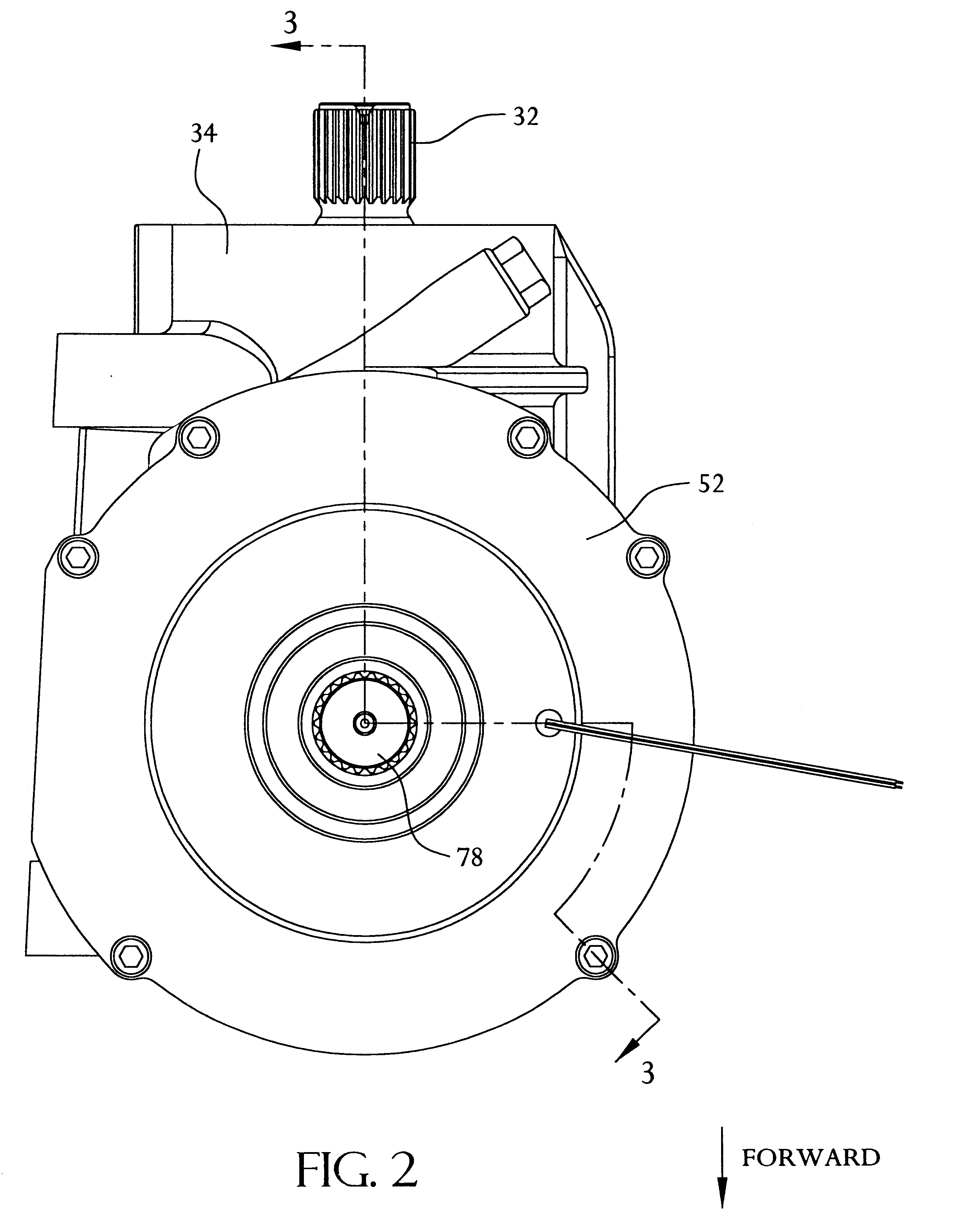

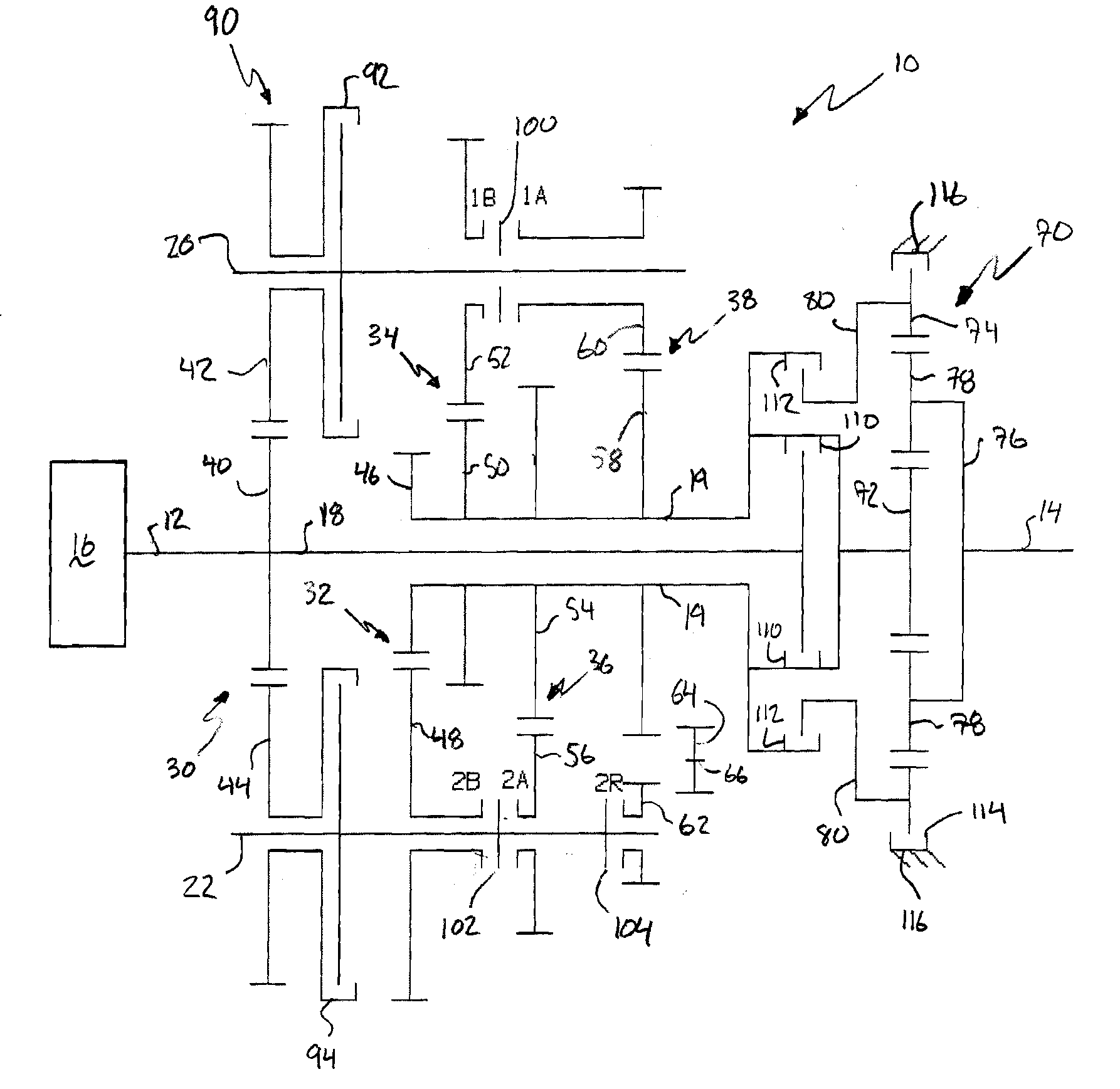

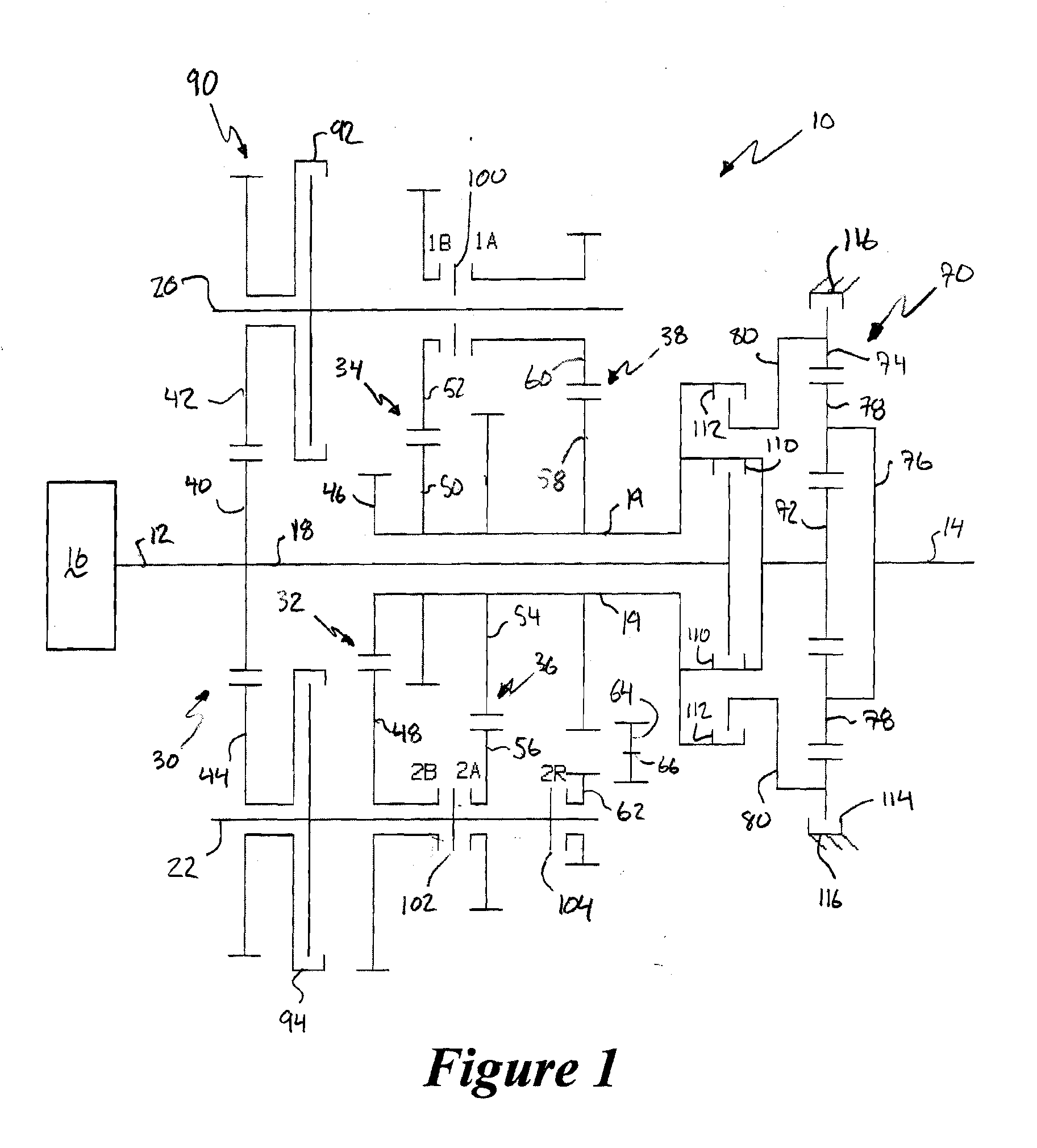

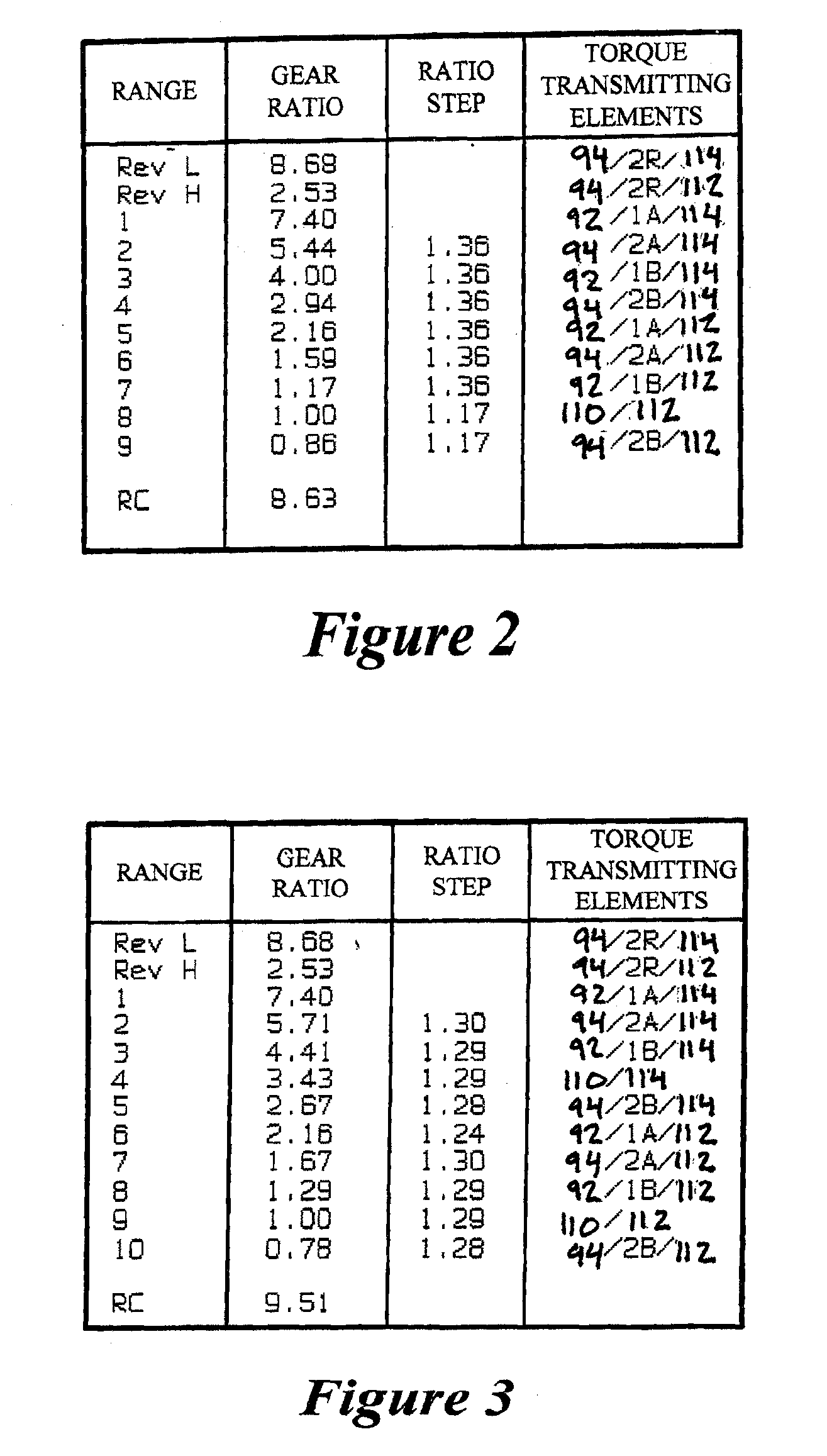

Compound differential dual power path transmission

InactiveUS20050227803A1Wider ratio spreadTransmission relatively inexpensive and efficientHybrid vehiclesElectric propulsion mountingGear wheelTorque transmission

A vehicle transmission includes a differential gearset having five coaxial gear elements and two output members. Two of the gear elements are controllable via torque-transmitting devices such as friction brakes or electric motors to establish a plurality of speed ratios between the input shaft and the two output members. The two output members are selectively operatively connectable to an output shaft via a gear arrangement that allows for a plurality of speed ratios between the output members and the output shaft. If the torque-transmitting devices are electric motors or hydraulic pumps, then a continuously variable speed ratio between the input shaft and the output shaft is achievable. The plurality of speed ratios between the two output members and the output shaft enable a plurality of compound split operating modes, facilitating smaller and less powerful motors or pumps compared to the prior art.

Owner:GM GLOBAL TECH OPERATIONS LLC

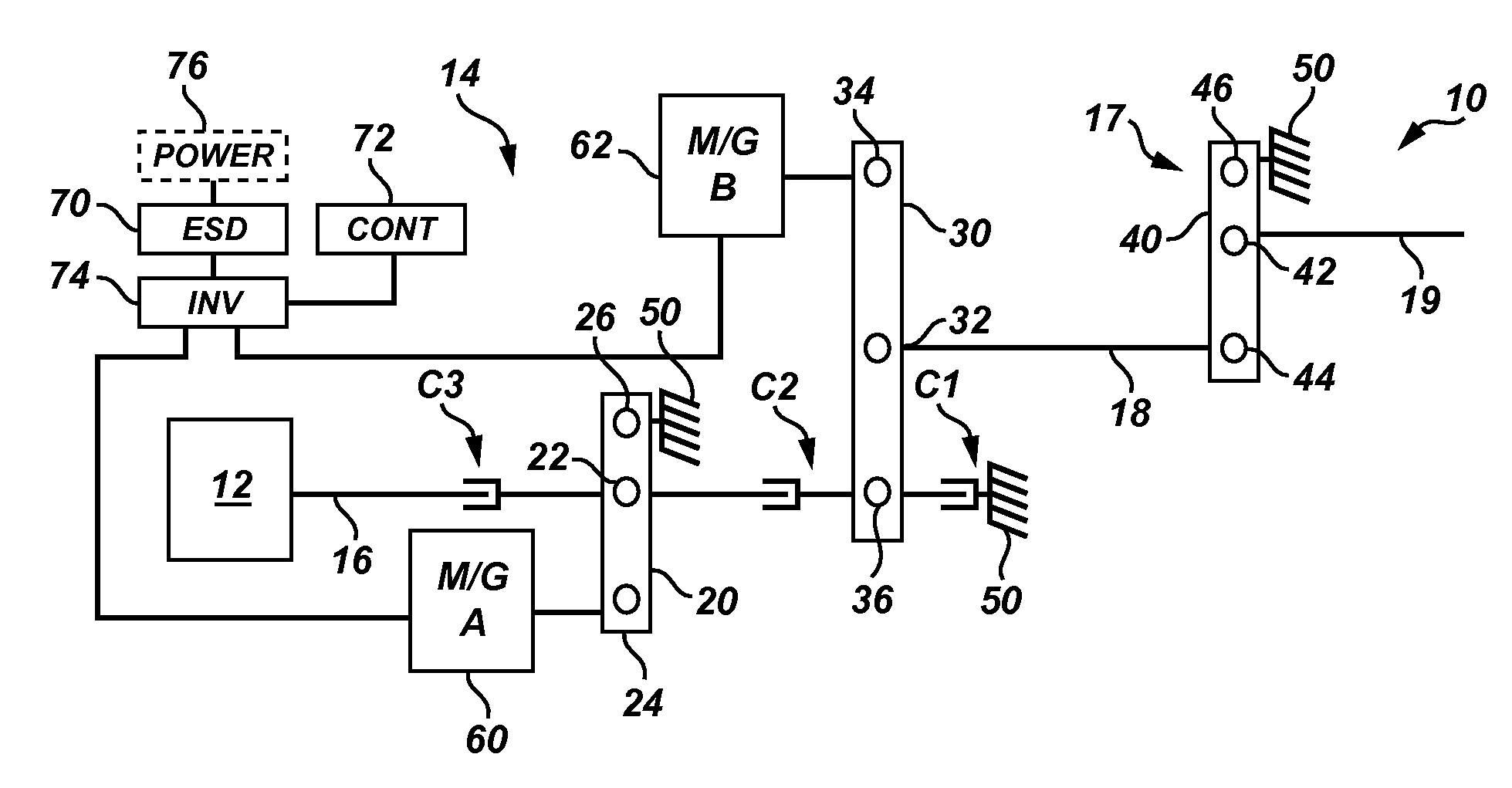

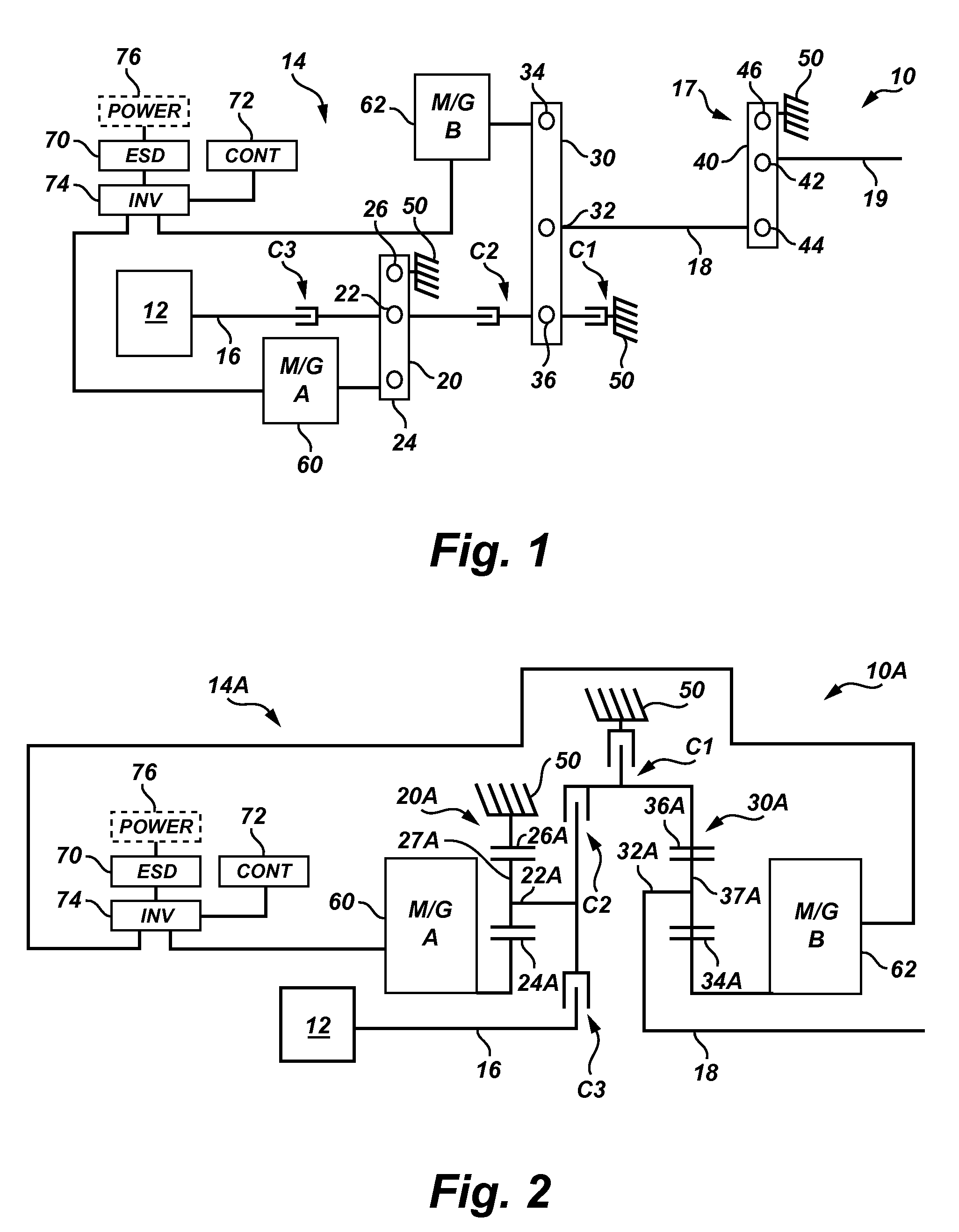

Output-split electrically-variable transmission with two planetary gear sets and two motor/generators

InactiveUS20100227722A1Improve cold start performanceImprove efficiencyHybrid vehiclesGas pressure propulsion mountingElectricityGear wheel

An electrically-variable transmission for use with an engine includes an input member configured for operative interconnection with the engine, an output member, and a stationary member. First and second motor / generators, a first and a second planetary gear set each having respective first, second, and third members are included. A first, a second, and a third selectively engagable torque-transmitting mechanism are included. The input member is connectable for common rotation with the first member of the first planetary gear set either continuously or selectively by engagement of the third torque-transmitting mechanism. The output member is connected for common rotation with the first member of the second planetary gear set. The motor / generators are controllable and the torque-transmitting mechanisms are selectively engagable to establish at least one electric-only mode, a series mode, an output-split mode, and at least one neutral mode.

Owner:GM GLOBAL TECH OPERATIONS LLC

Bi-directional overrunning clutch

InactiveUSRE38012E1Prevent rotationYielding couplingFluid couplingsElectronic control systemDrive shaft

A bi-directional overrunning clutch is disclosed for controlling torque transmission between a secondary drive shaft and secondary driven shafts. The overrunning clutch includes a pinion input shaft in a differential housing that engages with a clutch housing rotatably disposed within the differential housing. At least one race is located adjacent to the clutch housing and is engaged with an output shaft. A cage is located between the race and the clutch housing. The cage is movable with respect to the clutch housing. A <DEL-S DATE="20030304" ID="DEL-S-00001" / >first<DEL-E ID="DEL-S-00001" / > coil is mounted within the differential housing adjacent to the cage and is adapted to produce an electromagnetic field when energized which causes the cage to drag with respect to the clutch housing. The dragging of the cage with respect to the clutch housing positions <INS-S DATE="20030304" ID="INS-S-00001" / >rolls within <INS-E ID="INS-S-00001" / >the cage to engage the clutch housing with the race when wheels on a primary drive shaft lose traction. <DEL-S DATE="20030304" ID="DEL-S-00002" / >A<DEL-E ID="DEL-S-00002" / > <INS-S DATE="20030304" ID="INS-S-00002" / >If desired a <INS-E ID="INS-S-00002" / >second coil <DEL-S DATE="20030304" ID="DEL-S-00003" / >is<DEL-E ID="DEL-S-00003" / > <INS-S DATE="20030304" ID="INS-S-00003" / >may be <INS-E ID="INS-S-00003" / >mounted within the differential housing adjacent <DEL-S DATE="20030304" ID="DEL-S-00004" / >adjacent<DEL-E ID="DEL-S-00004" / > to the cage. The second coil is adapted to produce an electromagnetic field when energized which advances cage with respect to the clutch housing causing the clutch housing to engage with the races. When the second coil is activated, the output shaft drives the pinion input shaft producing engine braking. An electronic control system is utilized to control the energizing of the coils.

Owner:HILLIARD

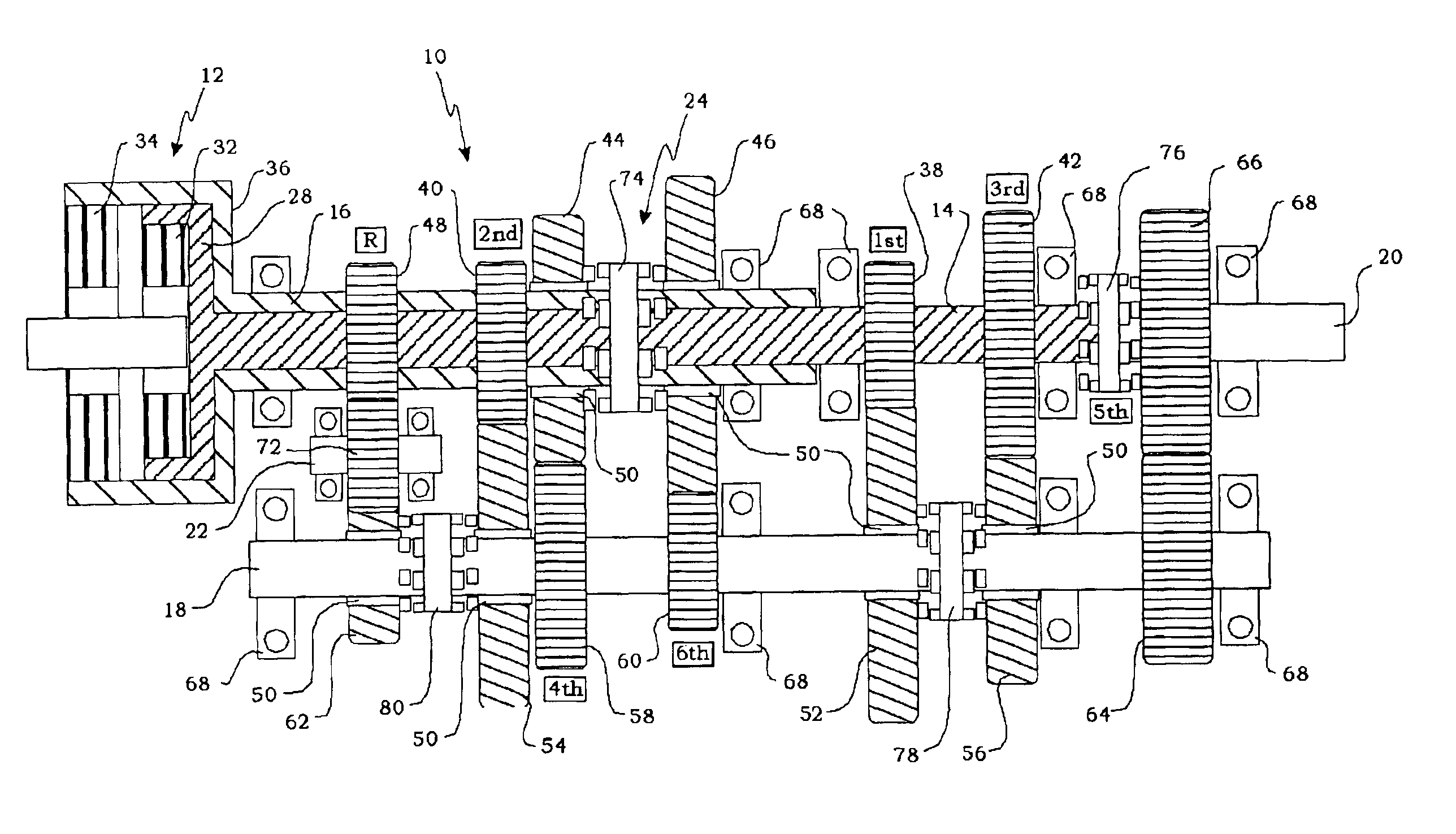

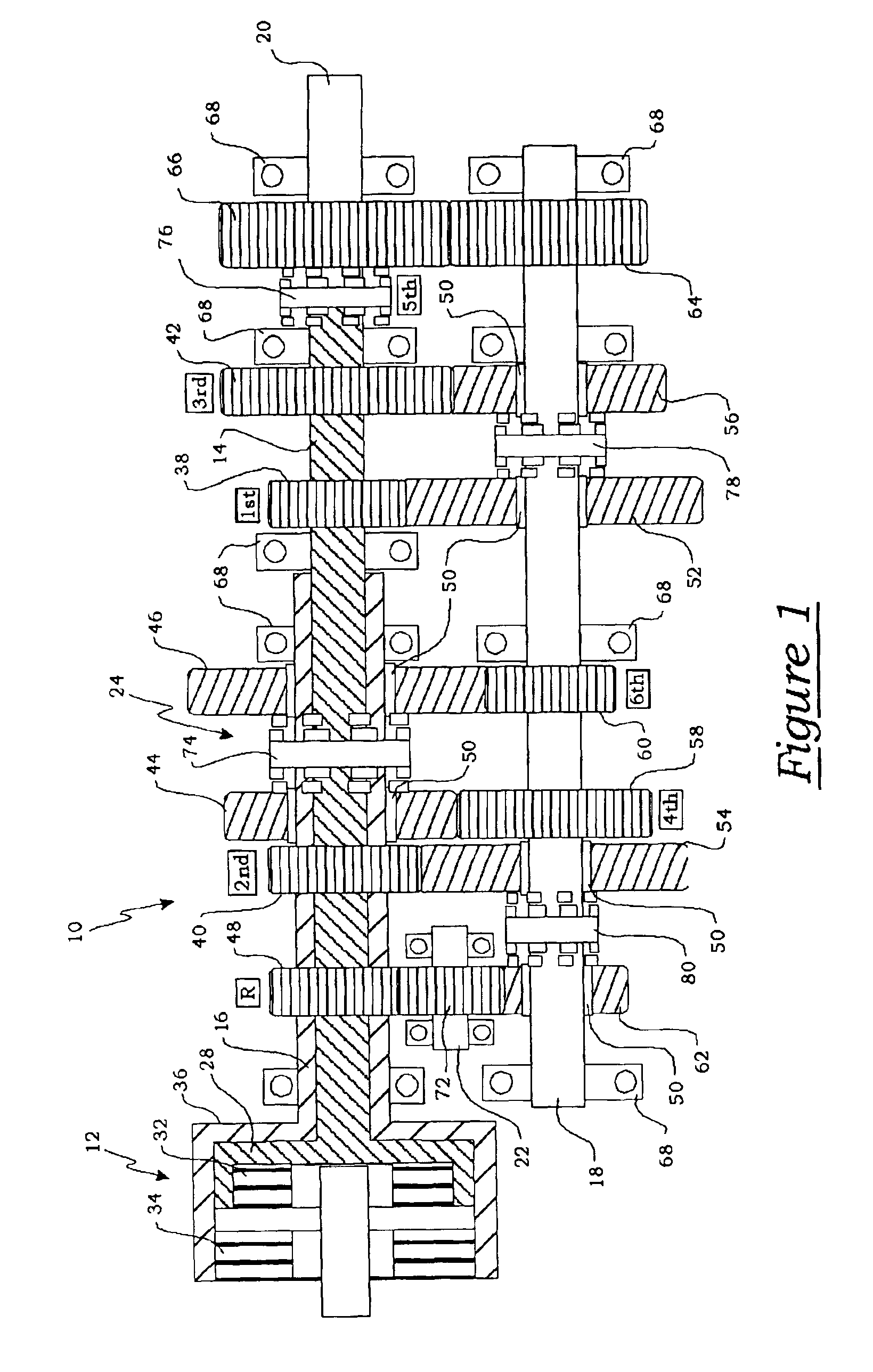

Electro-mechanical automatic transmission having dual input shafts

InactiveUS6044719APrevent rollbackImprove efficiencyRoad transportGear lubrication/coolingAutomatic transmissionEngineering

An electro-mechanical automatic transmission is provided including a first input shaft and a second input shaft concentric with the first input shaft. A plurality of drive gears are rotatably mounted to each input shaft and are provided with synchronizer devices for selectively engaging the drive gears to the input shafts. A driver shaft is provided with a plurality of driven gears in meshing engagement with the drive gears. The electro-mechanical automatic transmission is provided with a pair of electro-mechanical clutch actuators for selectively disengaging dual clutches which transmit engine torque to the input shafts, as well as an electro-mechanical shift actuator system which operatively engage the synchronizer devices for selectively engaging the drive gears.

Owner:FCA US

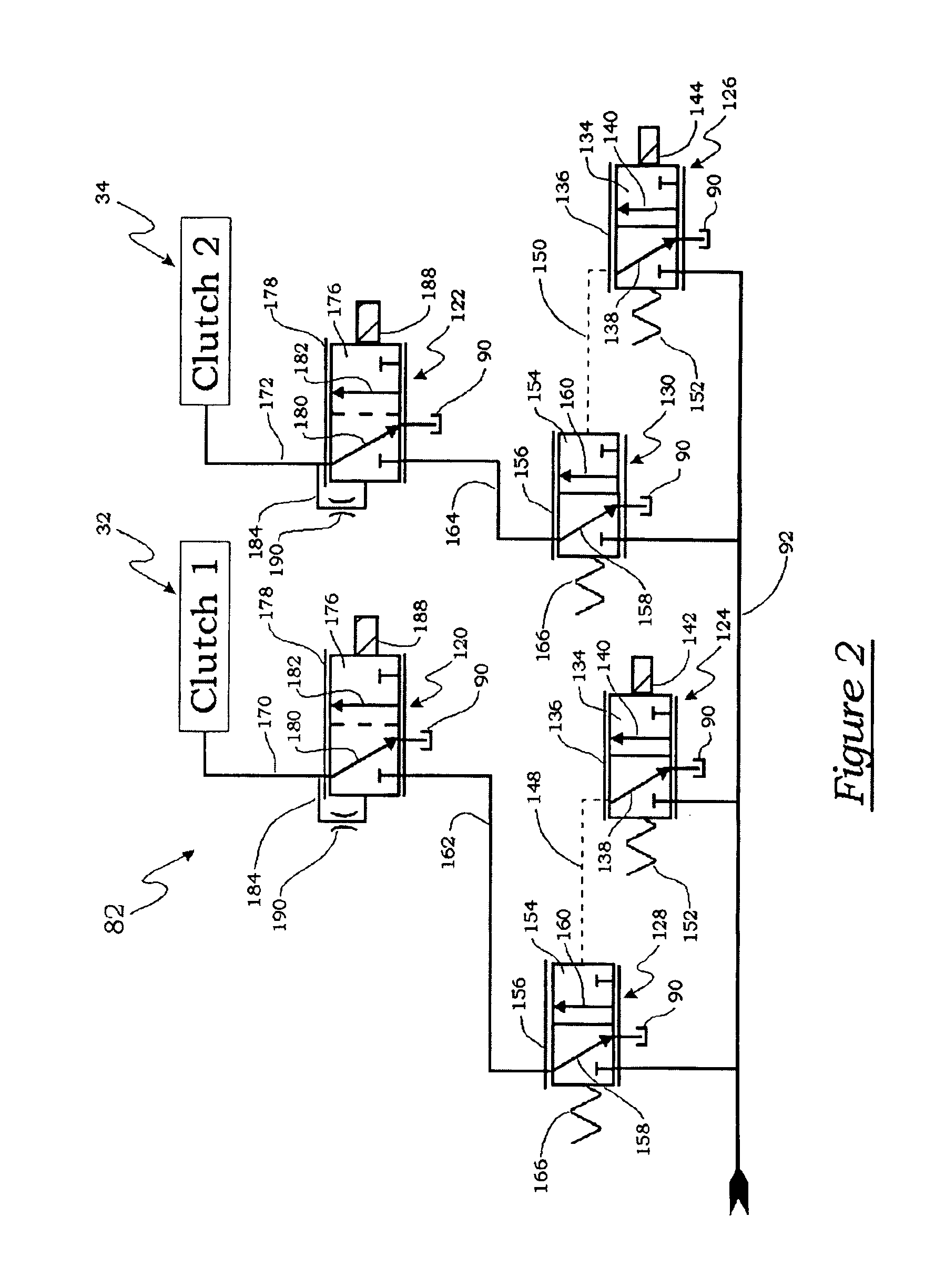

Method of controlling a dual clutch transmission

InactiveUS6887184B2Improving overall drivability and comfortClutchesDigital data processing detailsGear driveTorque transmission

A method of controlling the clutches of a dual clutch transmission during a two-gear positive downshift, wherein the first clutch drives an initial gear and the final gear and the second clutch drives an intermediate gear. The torque transfer across each clutch is controlled so that the torque output of the transmission will be linearly changed over from the first clutch to the second clutch to cause the engine to track a target engine speed profile. The method changes over the gears driven by the first clutch from the initial gear to the final gear as the engine continues to tracks the target speed. The torque transfer across each clutch is controlled so that the torque output will be linearly changed back from the second clutch to the first clutch in an inversely proportional rate to continue to cause the engine to track the target engine speed profile.

Owner:BORGWARNER INC

Starter

ActiveUS20080162007A1Improve installabilityAnalogue computers for vehiclesPower operated startersTorque transmissionEngineering

The present invention provides as tarter capable of keeping a state where a pinion and a ring gear maintain meshing with each other when an engine stops without providing a plunger stopper using a solenoid or the like. The state where the pinion and the ring gear maintain meshing with each other in the engine stop mode continues by movement resistance which occurs when a torque transmission member moves. Concretely, an inclination angle of a helical spline in a helical spline engagement part is set so that the above state continues. The helical spline engagement part is a part where a helical spline on the outer periphery of an output shaft of a starter motor and a helical spline on the inner periphery of the torque transmission member mesh with each. Consequently, the above state continues without a plunger stopper using a solenoid or the like.

Owner:HITACHI ASTEMO LTD

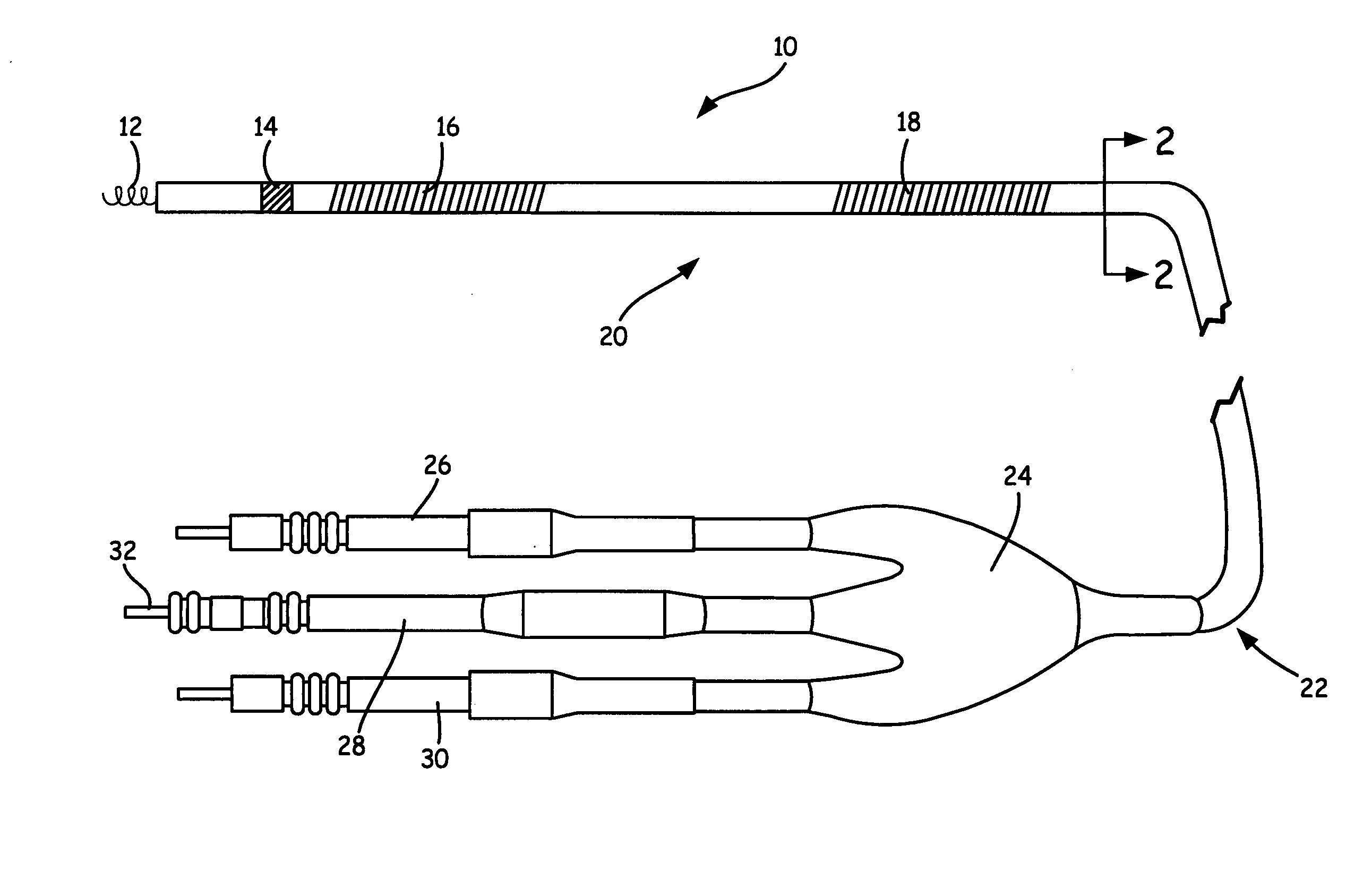

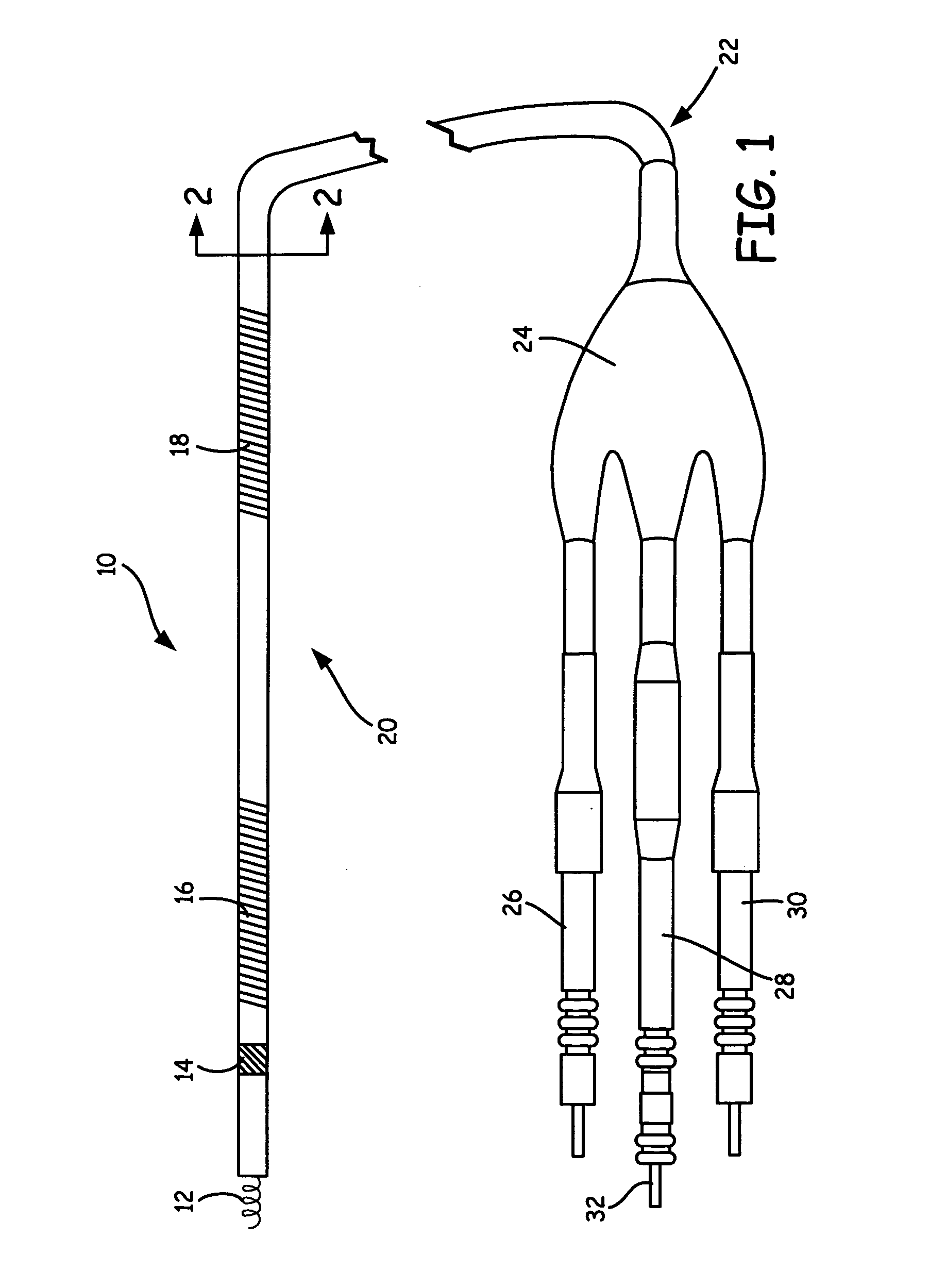

Polymer reinforced coil conductor for torque transmission

InactiveUS20070179582A1Increased torque transfer capabilityTransvascular endocardial electrodesExternal electrodesElectricityElectrical conductor

A coil conductor for connecting an electrode near a distal end of a medical electrical lead with an implantable medical device (IMD) connected with a proximal end of the medical electrical lead includes a multi-filar coil and a torque enhancing sheathing. The multi-filar coil comprises a co-radially wound, multi-filar coil that has an inductance of approximately 1.5 μH or greater. The sheathing is extruded over to enhance the torque transmitting properties of the coil conductor.

Owner:MEDTRONIC INC

Motor having an integrated torque sensor

A motor unit comprises a housing for containing a motor, a motor shaft for receiving a motor provided driving force, a torque sensor mechanism for detecting torque, and a controller for controlling power to the motor in response to a detected amount of torque. An actuator couples the torque sensor to a sensor of the controller. The actuator is configured to move relative to the controller sensor thereby causing the sensor to produce a signal indicative of the detected level of torque. The controller is contained within the housing of the motor. The motor unit may also have an auxiliary shaft for receiving an externally provided driving force with a first torque transmission path for transferring the externally provided driving force to a drive mechanism and a second torque transmission path for transferring the motor provided driving force to said drive mechanism. A first one way drive means is provided in the first torque transmission path between the auxiliary shaft and the drive mechanism such that when the drive mechanism is being driven by the motor provided driving force through the second torque transmission path, the auxiliary shaft is able to freewheel. The motor unit can drive any apparatus, but may be used in a pedal driven apparatus such as a bicycle where an externally provided driving force is provided by manually operable pedals of said apparatus which are fixed for rotation with the auxiliary shaft. In this case, the auxiliary shaft comprises a pedal spindle of the bicycle and the drive mechanism comprises a sprocket or belt drive.

Owner:FOSTER ASSETS CORPORATION

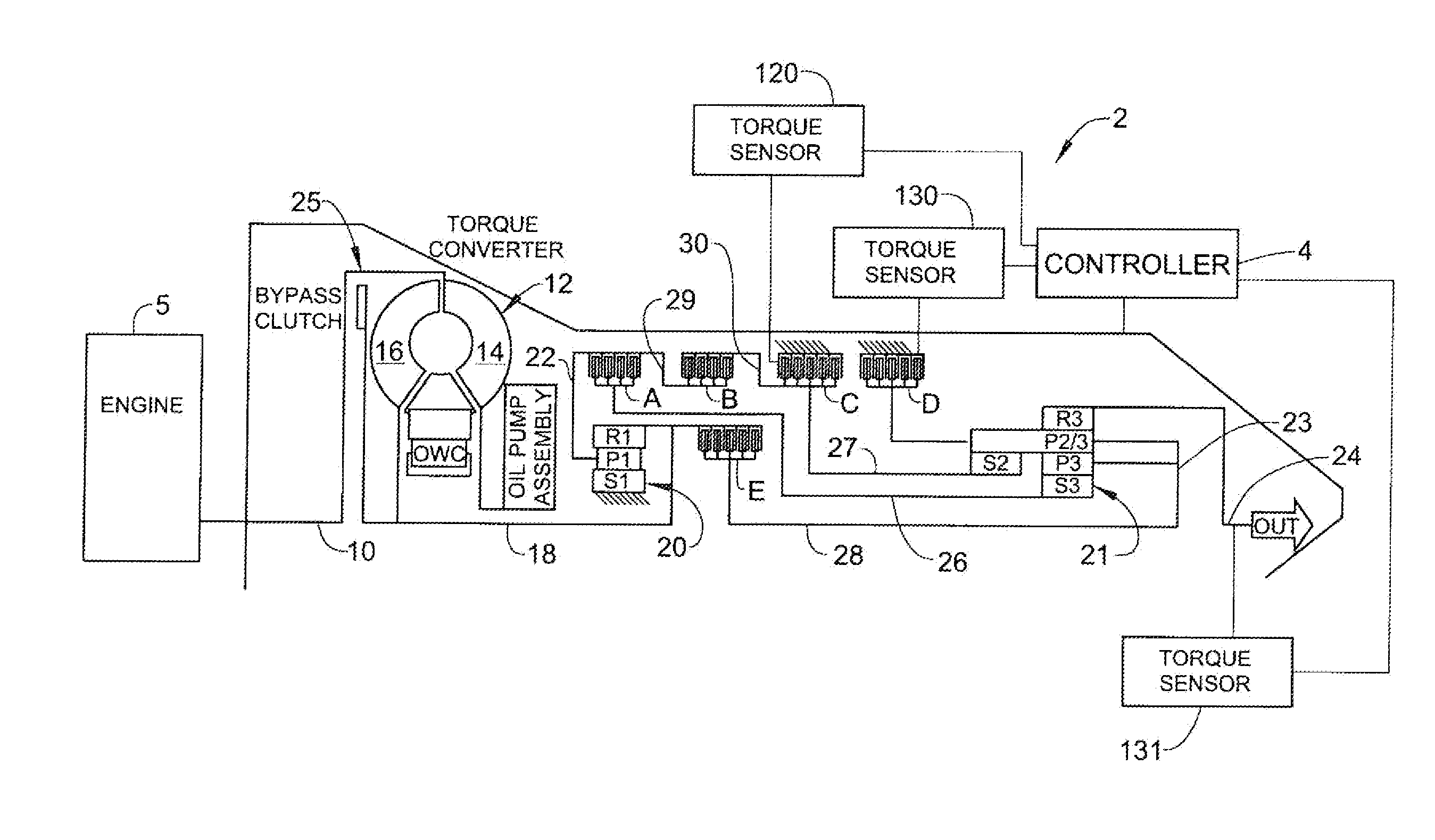

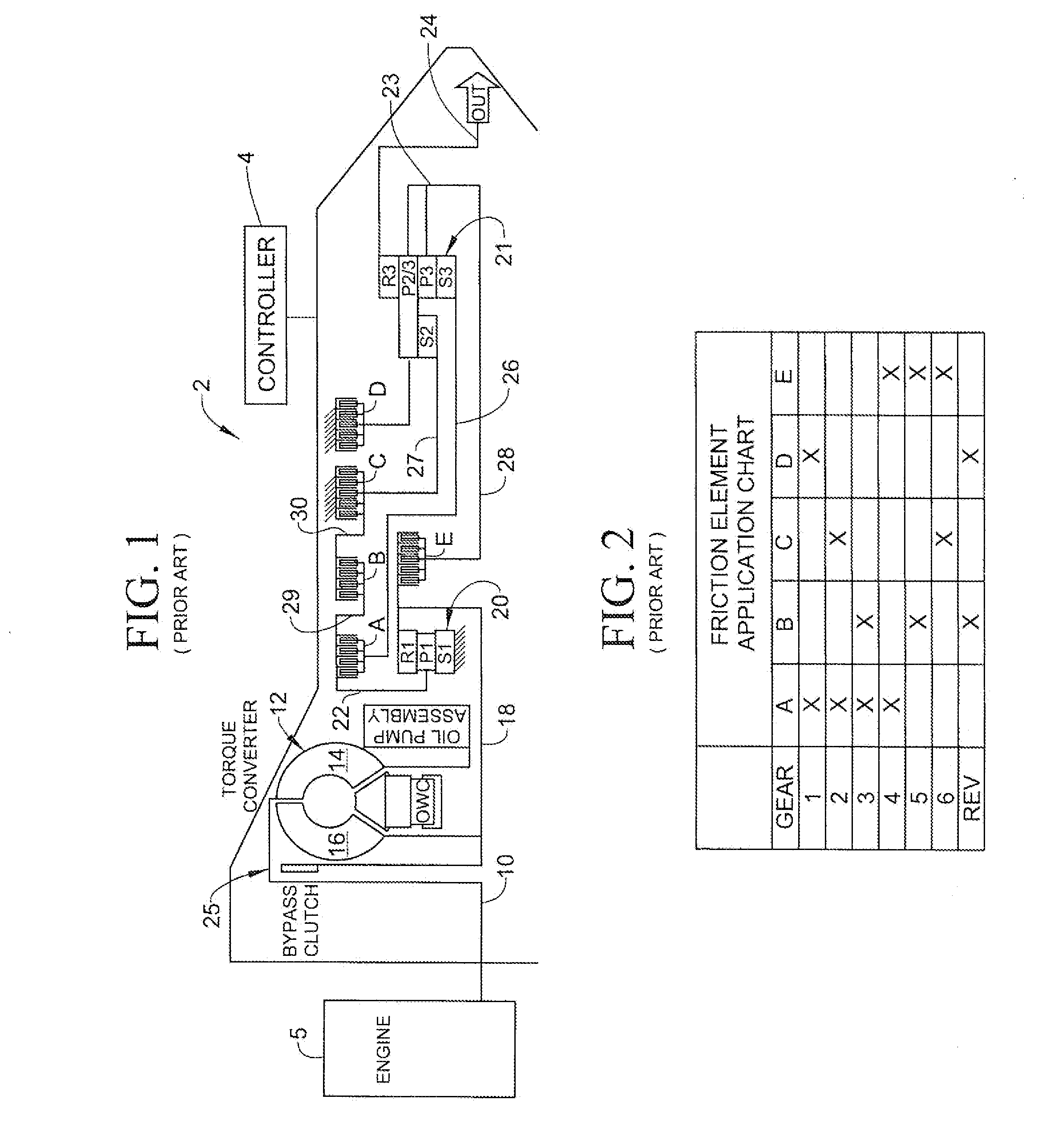

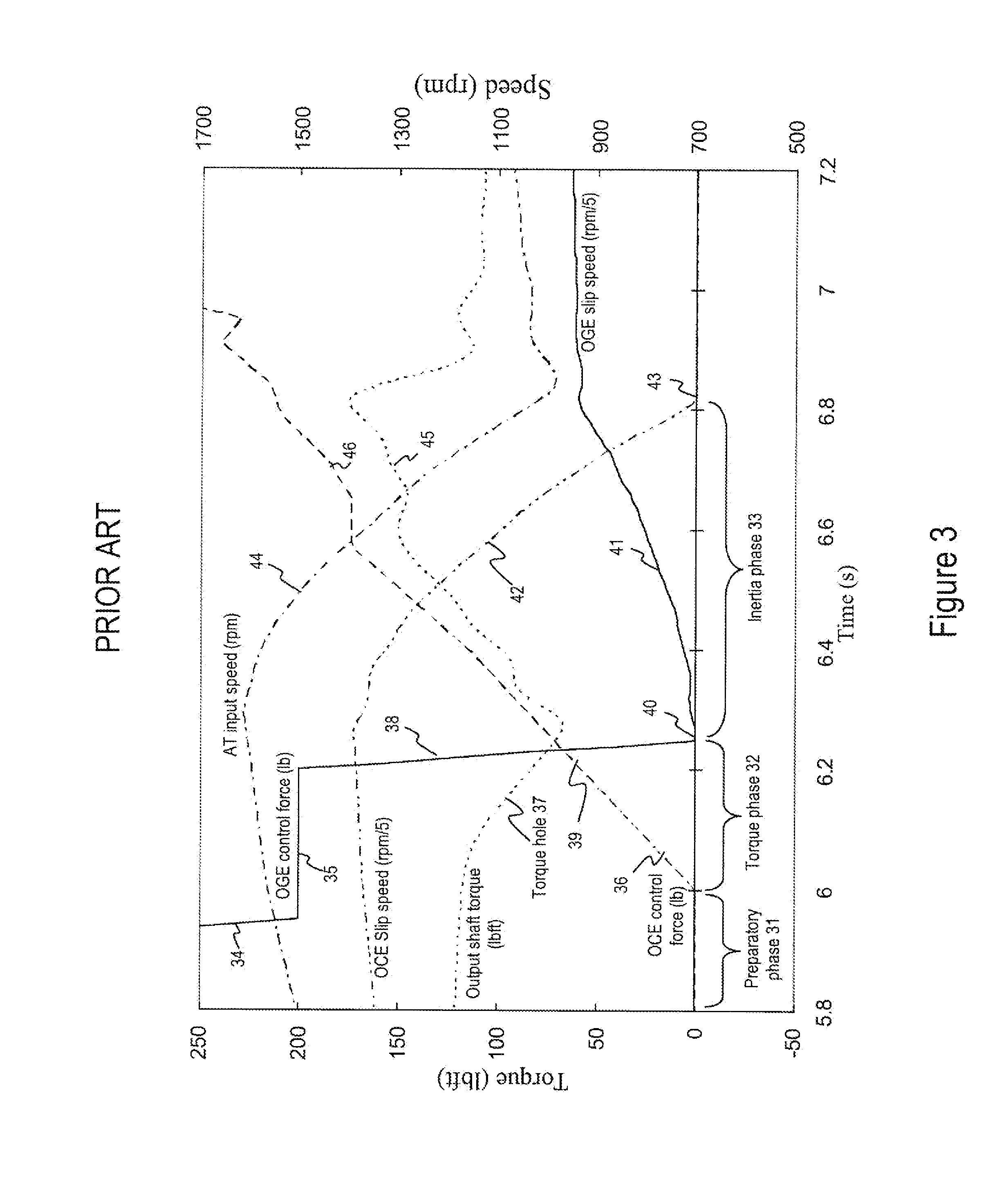

Closed-Loop Torque Phase Control for Shifting Automatic Transmission Gear Ratios Based on Friction Element Load Estimation

ActiveUS20100318269A1Increased torque capacityReducing torque capacityDigital data processing detailsGearing controlClosed loopTorque transmission

A closed loop shift control apparatus and method based on estimated torque in friction elements controls a torque transfer phase when shifting from a low gear configuration to a high gear configuration for an automatic transmission system. When pressure actuated friction elements are selectively engaged and released to establish torque flow paths in the transmission, estimates of torsional load exerted on the off-going friction element are used to predict the optimal off-going friction element release timing for achieving a consistent shift feel. The estimated torque is preferably calculated by using estimated torque signals generated as a function of speed measurements represented either the engine speed and turbine output speed or transmission output speed and wheel speed under dynamically changing conditions.

Owner:FORD GLOBAL TECH LLC

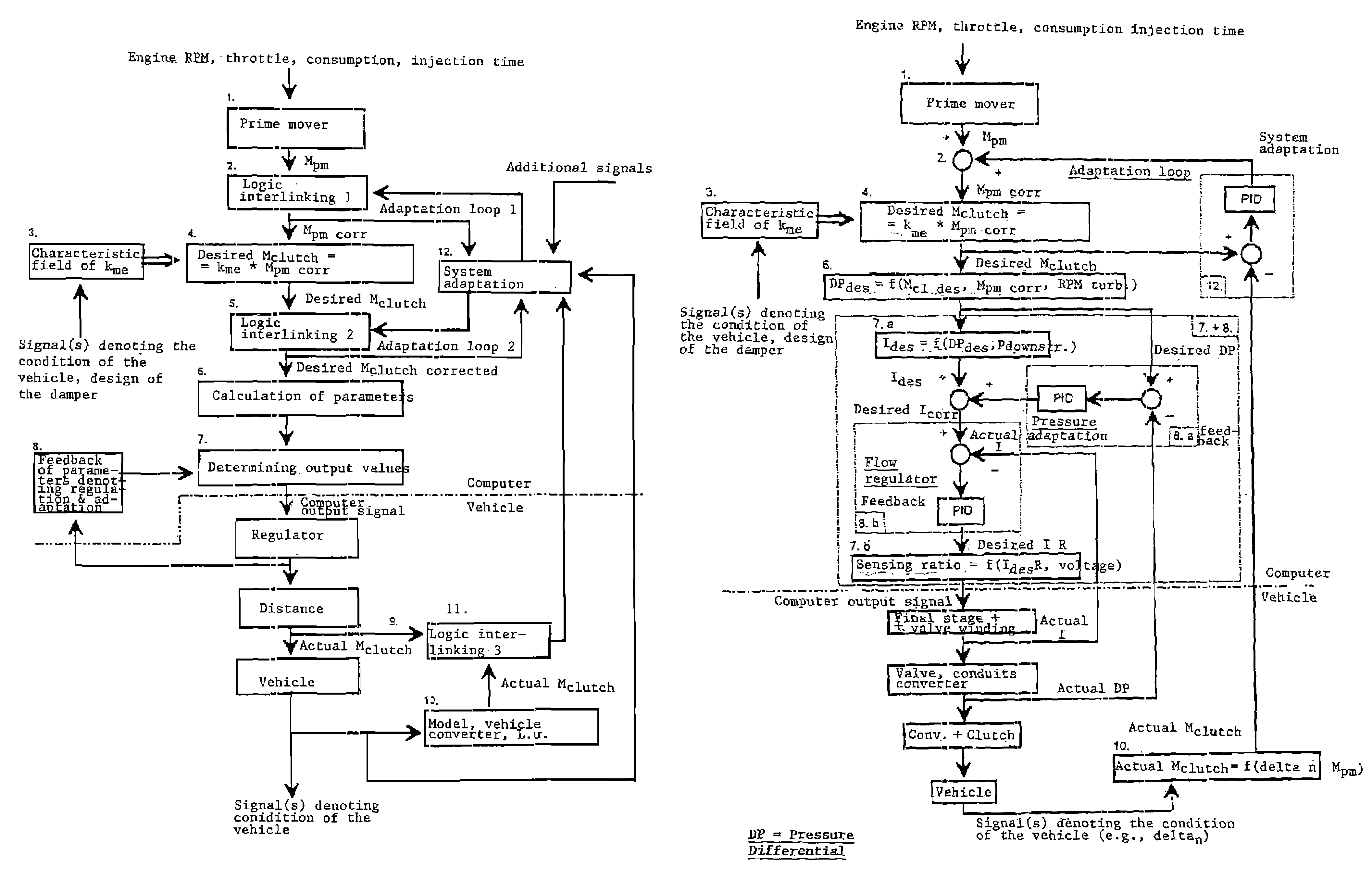

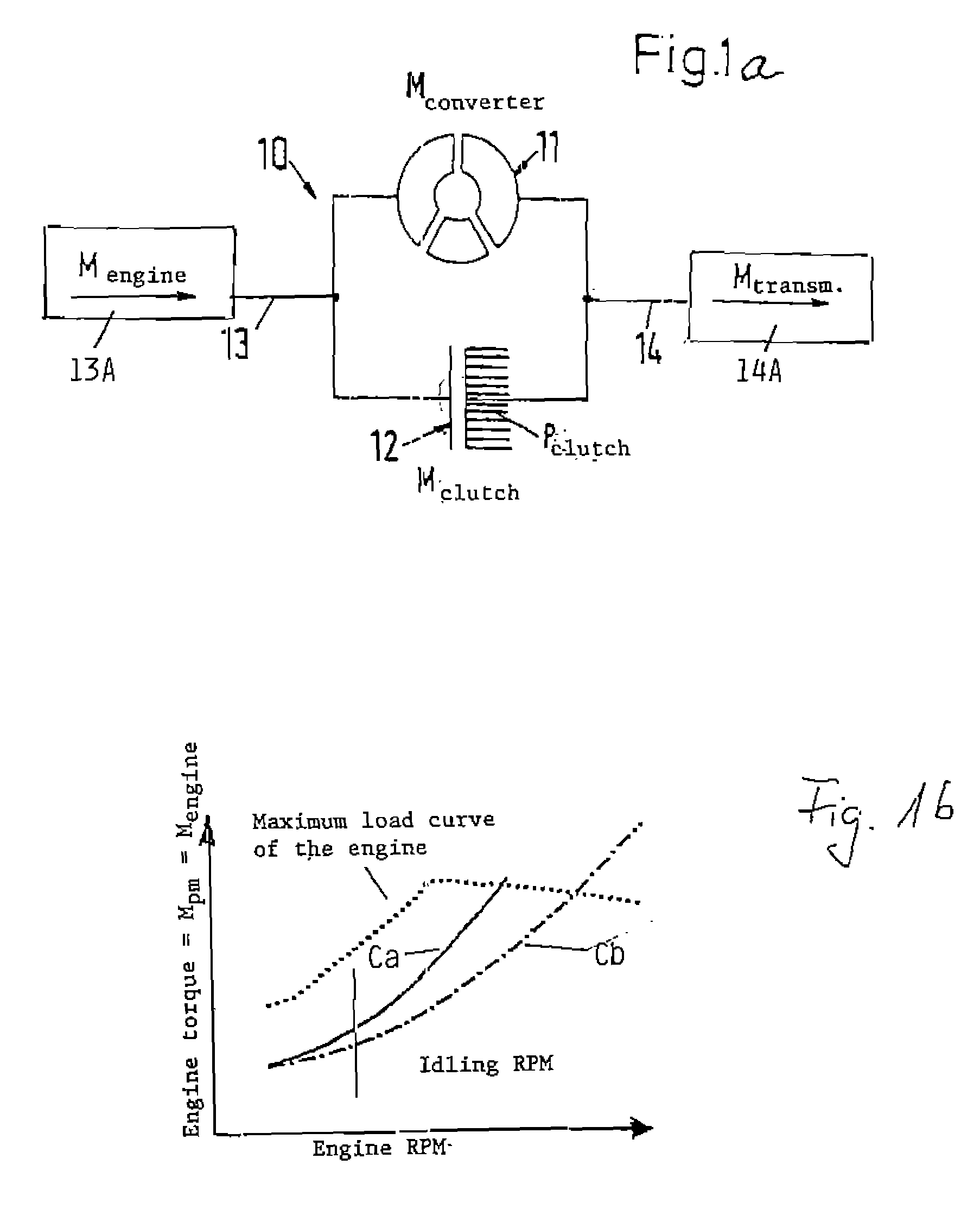

Method of and apparatus for transmitting torque in vehicular power trains

InactiveUS7286922B1Reduce capacityMechanical actuated clutchesDigital data processing detailsMobile vehicleAutomatic transmission

The magnitude of torque which can be transmitted by a bypass clutch between the housing and the turbine of a torque converter between a prime mover, such as an engine, and an automatic transmission in the power train of a motor vehicle is selectively regulatable by a computerized regulating unit. The regulation involves the transmission of torque by the clutch in dependency upon the magnitude of the torque being transmitted by the output element of the engine and ascertaining as well as adaptively applying to the clutch a variable force so that the clutch can transmit a predetermined torque. This entails automatic selection of a minimum slip between a torque receiving and a torque transmitting part of the power train. Compensation, particularly long-range compensation, is carried out for the existence of possible differences between the predetermined and actual torques being transmitted by the clutch.

Owner:LUK GETRIEBE SYST

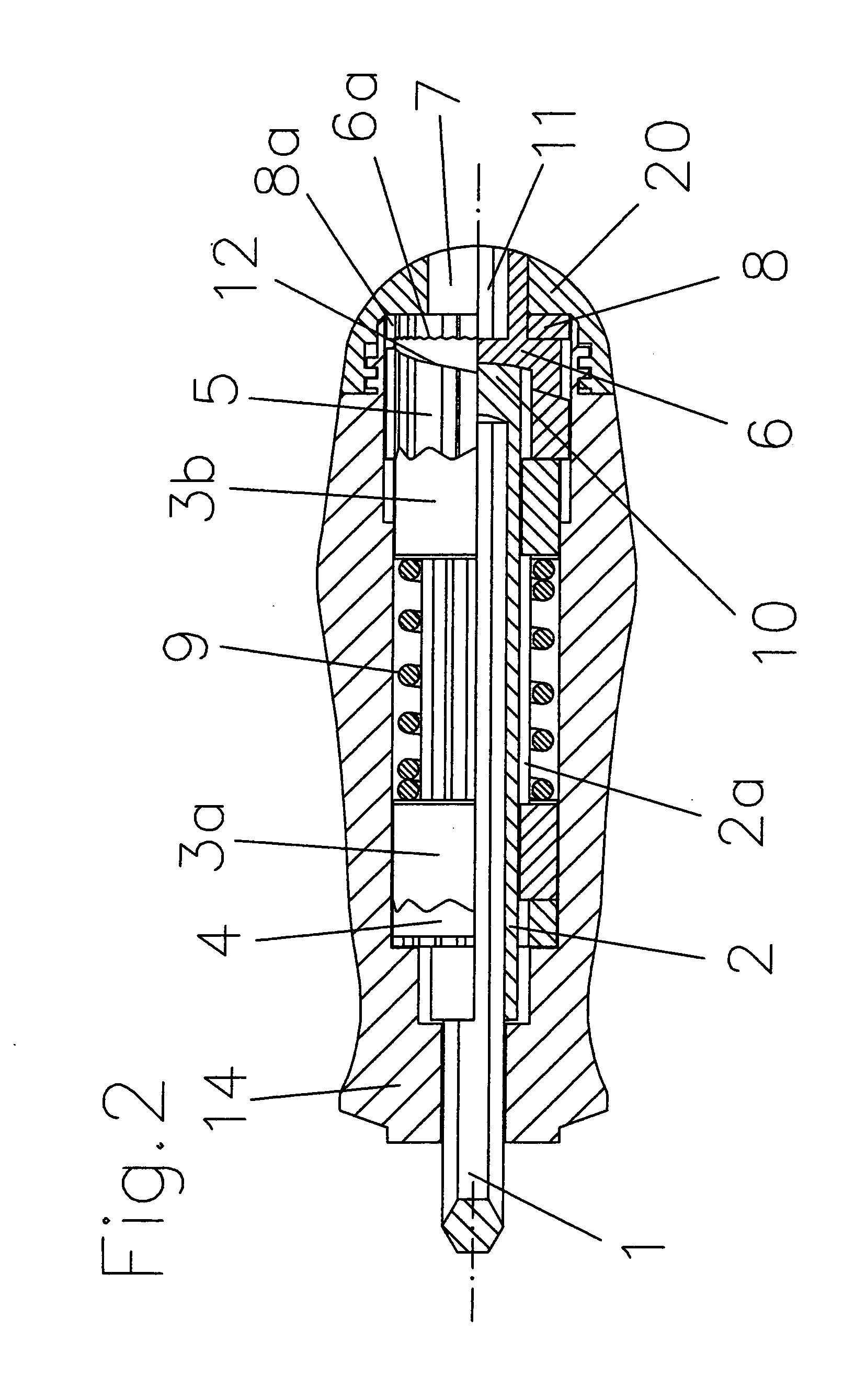

Screwdriver with adjustable device to limit transmitted torque

A screwing-tool with a device to adjust transmitted torque consists of a handle to introduce a torque to the device, which is borne in the hollow of the handle and a driver-shaft as outpout element of the torque. On the driver-shaft inside the handle two separate couplings are assembled, between them a compression spring exerting a spring force onto the two couplings. Each coupling consist of a first and second socket engaging each other by gearings at their opposing faces. The maximum torque at which the torque-transmission will be interrupted cab be adjusted in that way, that by an adjustment-element the distance between the couplings can be changed resulting in a change of the tension of the spring exerting a load on the couplings. The teeth of the gearings slide and the sockets rotate relatively to each other and interrupt the torque-transmission if a pre-adjusted torque is exceeded.

Owner:FELO WERKZEUGFAB HOLLAND LETZ

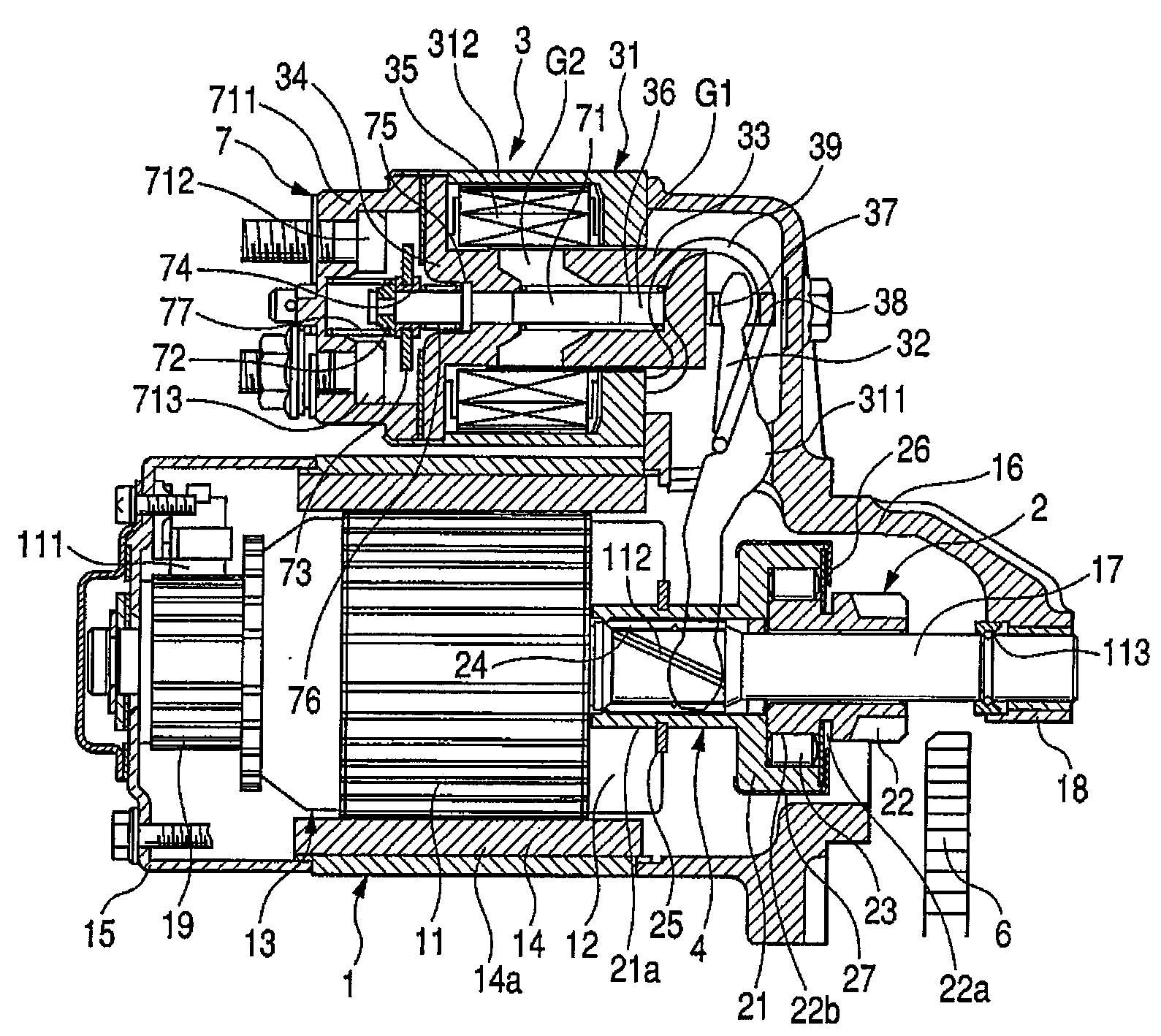

Multi-speed transmission

A transmission is provided having an input member, an output member, a dual clutch assembly, two countershaft gearing arrangements, one planetary gear set, a plurality of interconnecting members, and a plurality of torque transmitting devices. Each of the countershaft gearing arrangements includes a plurality of co-planar gear sets. The torque transmitting devices include a combination of clutches, brakes, and synchronizers.

Owner:GM GLOBAL TECH OPERATIONS LLC

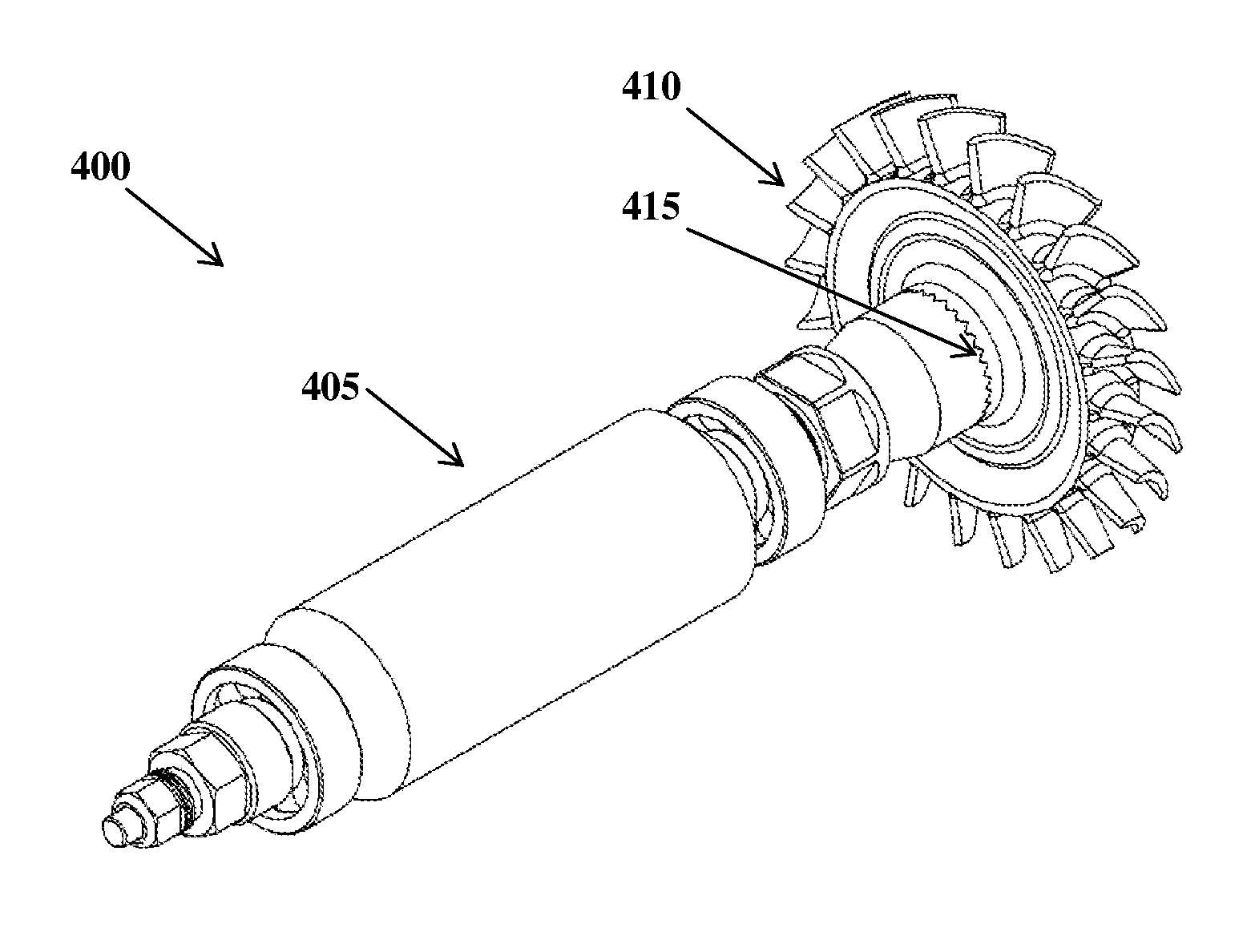

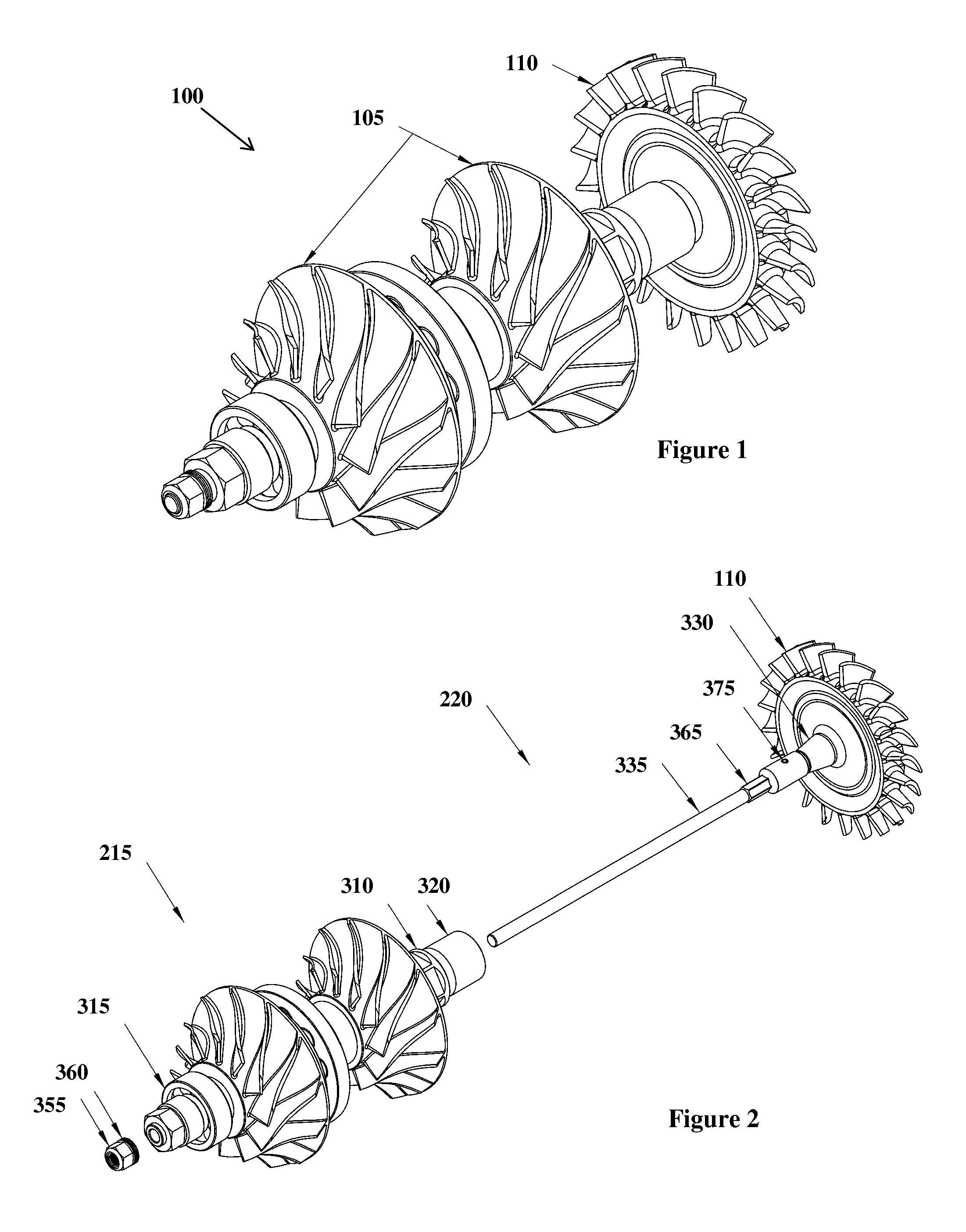

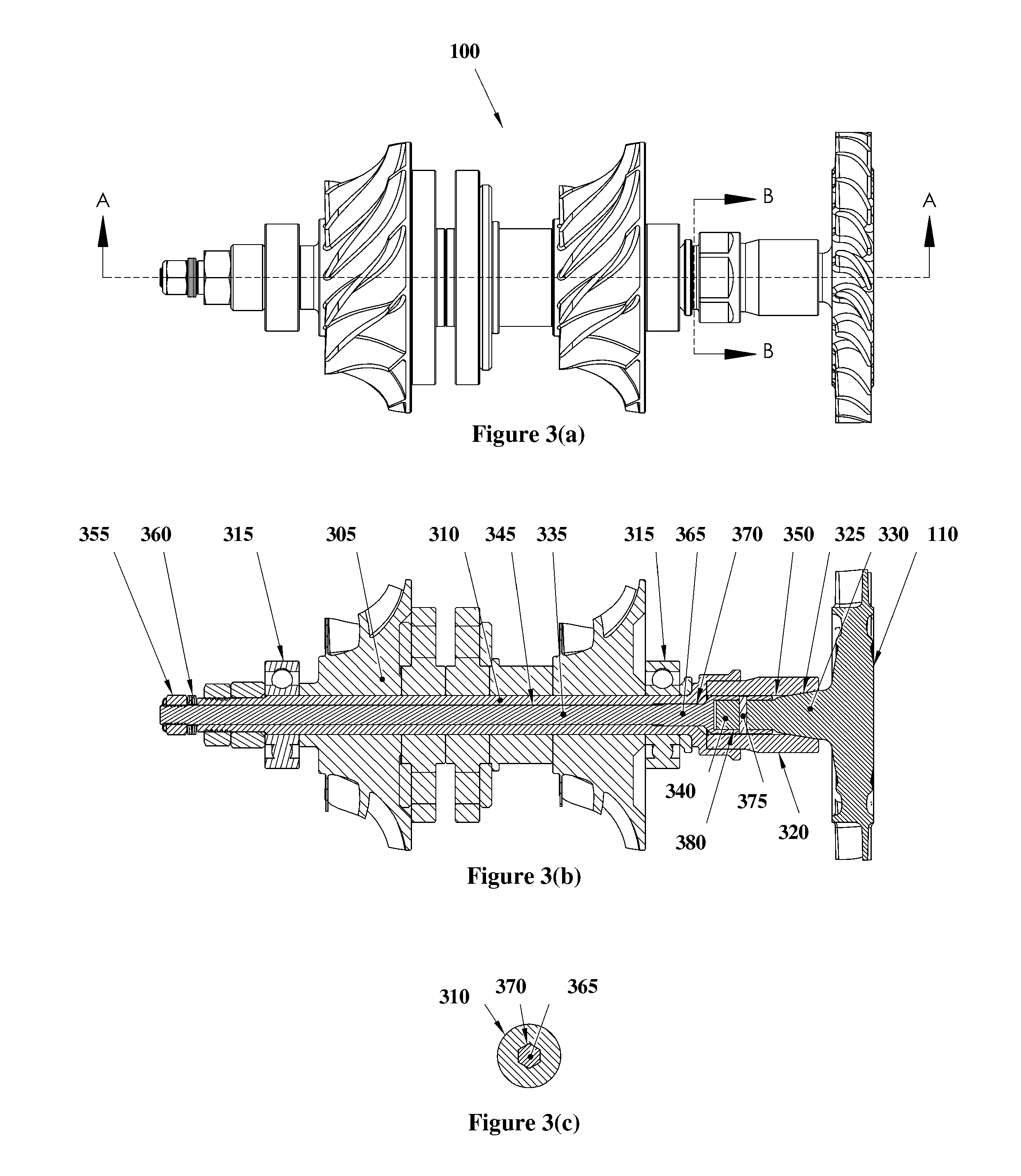

Thermally insulating turbine coupling

ActiveUS8840359B2Reduce heat transferPrevent rotationPump componentsEngine fuctionsCouplingTorque transmission

Owner:IMPERIAL INNOVATIONS LTD +1

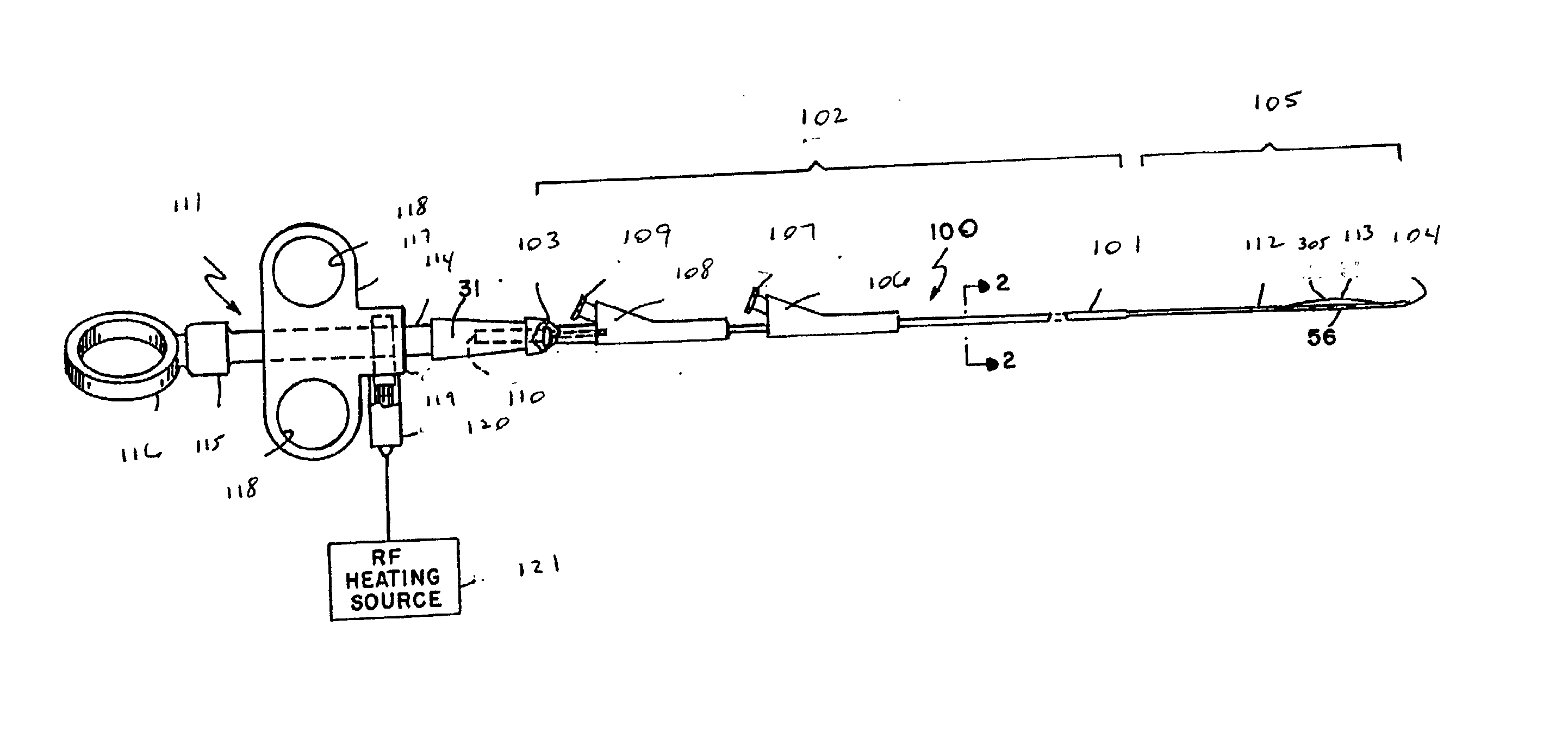

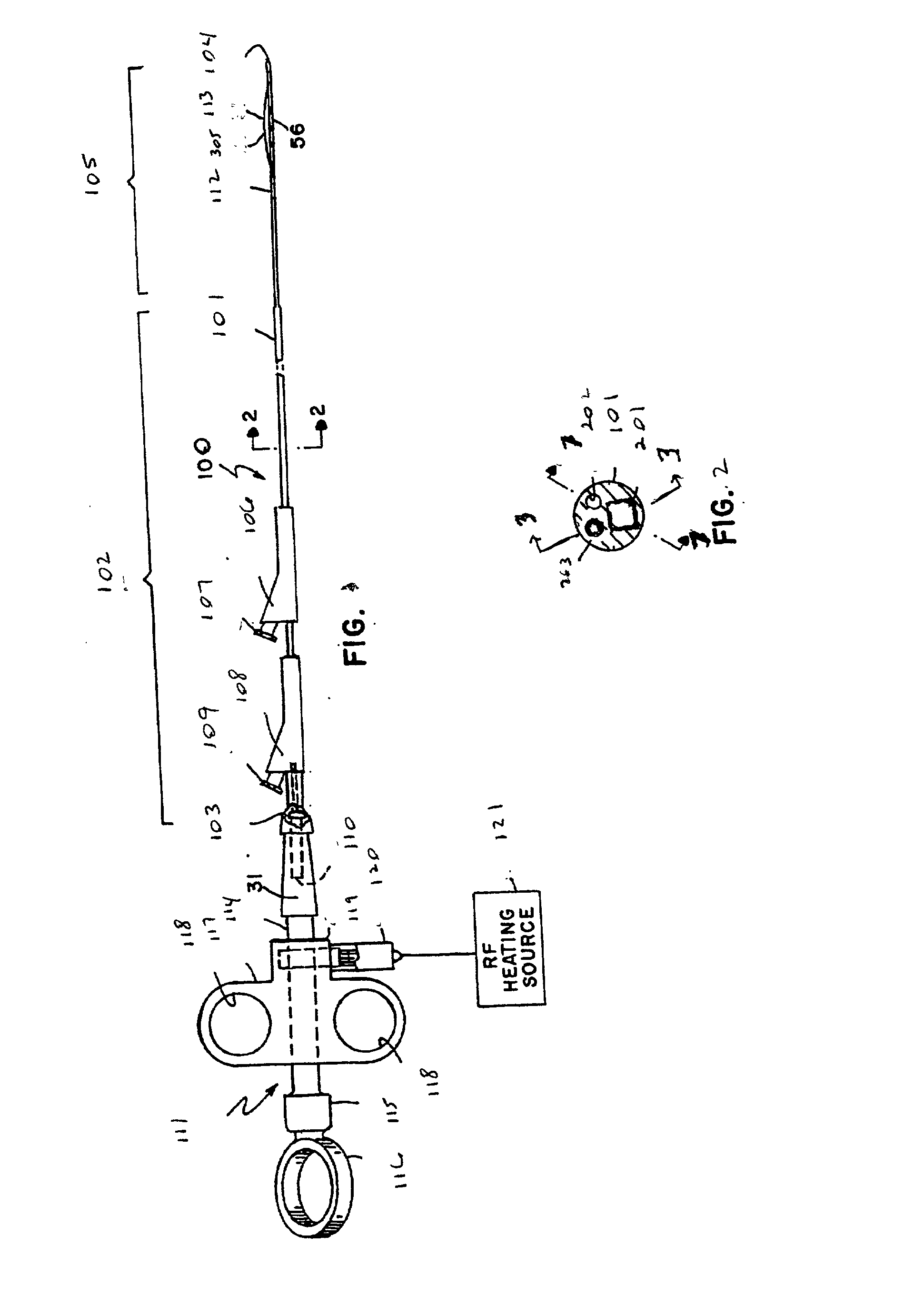

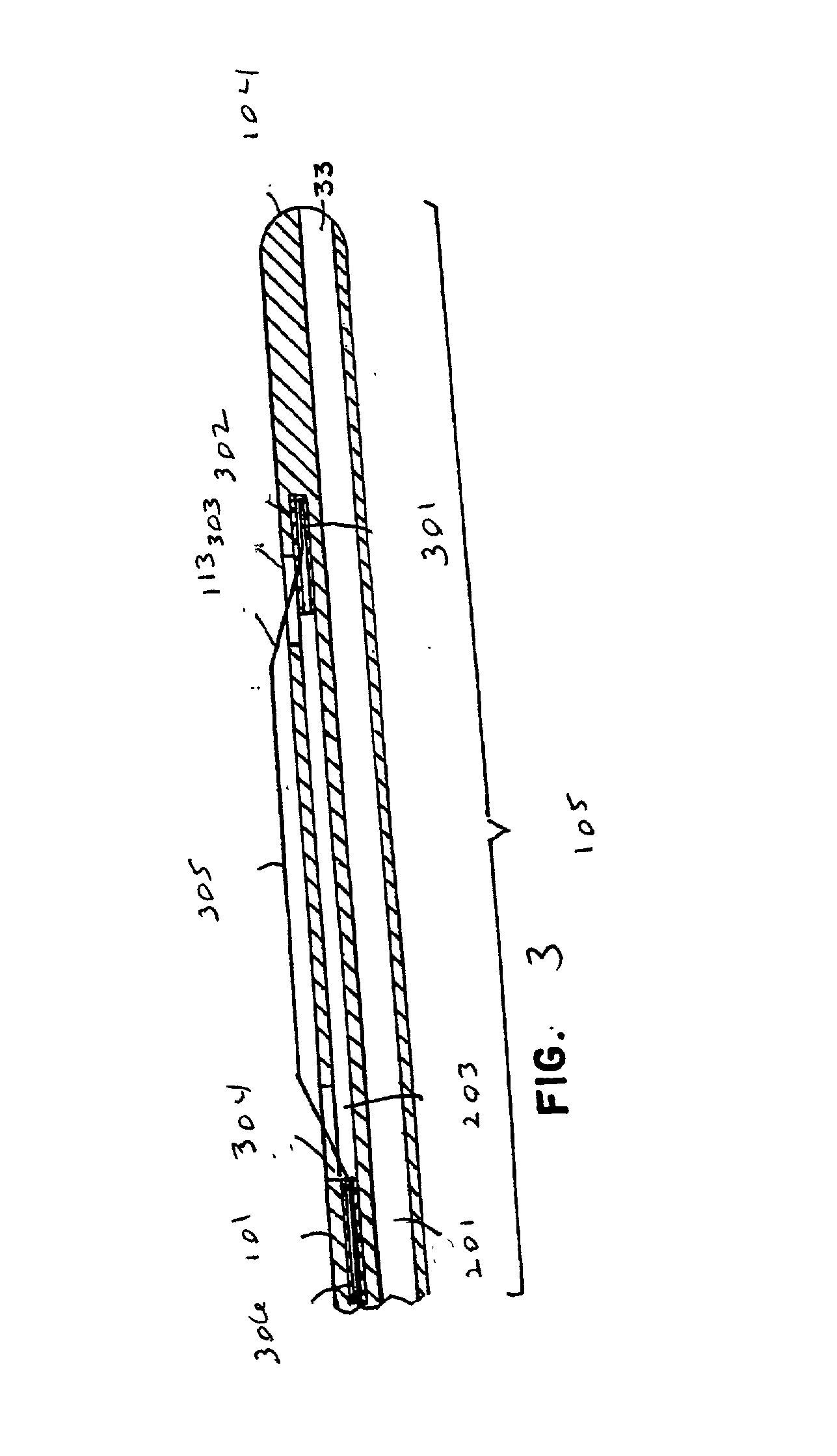

Steerable sphincterotome and methods for cannulation, papillotomy and sphincterotomy

The present invention relates to methodology of and apparatus for accurately positioning devices for performing endoscopic cannulation, papillotomy and sphincterotomy and similar procedures. The sphincterotome with a steerable or adjustable distal segment of the present invention allows the physician to control the position of the distal tip of the device independently of the endoscope and adjust for inconsistencies in the device and the anatomy. According to one embodiment of the present invention, a threaded portion of a cable assembly cooperates with a torque transmission element and a cog to enable the operator to rotate a cutting wire into a desired position relative to the catheter. Alternate embodiments allow the operator to fix the depth of a needle knife while allowing, if desired, accurate rotational positioning of the associated catheter. Threaded stabilizing elements, pivot elements and a steering wire may be used together or individually to accomplish these features. Presently available products that may be modified according to the present invention include, but are not limited to, Boston Scientific Sphincterotomes and Needle Knives.

Owner:BOSTON SCI SCIMED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com