Patents

Literature

4530results about How to "Eliminate pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

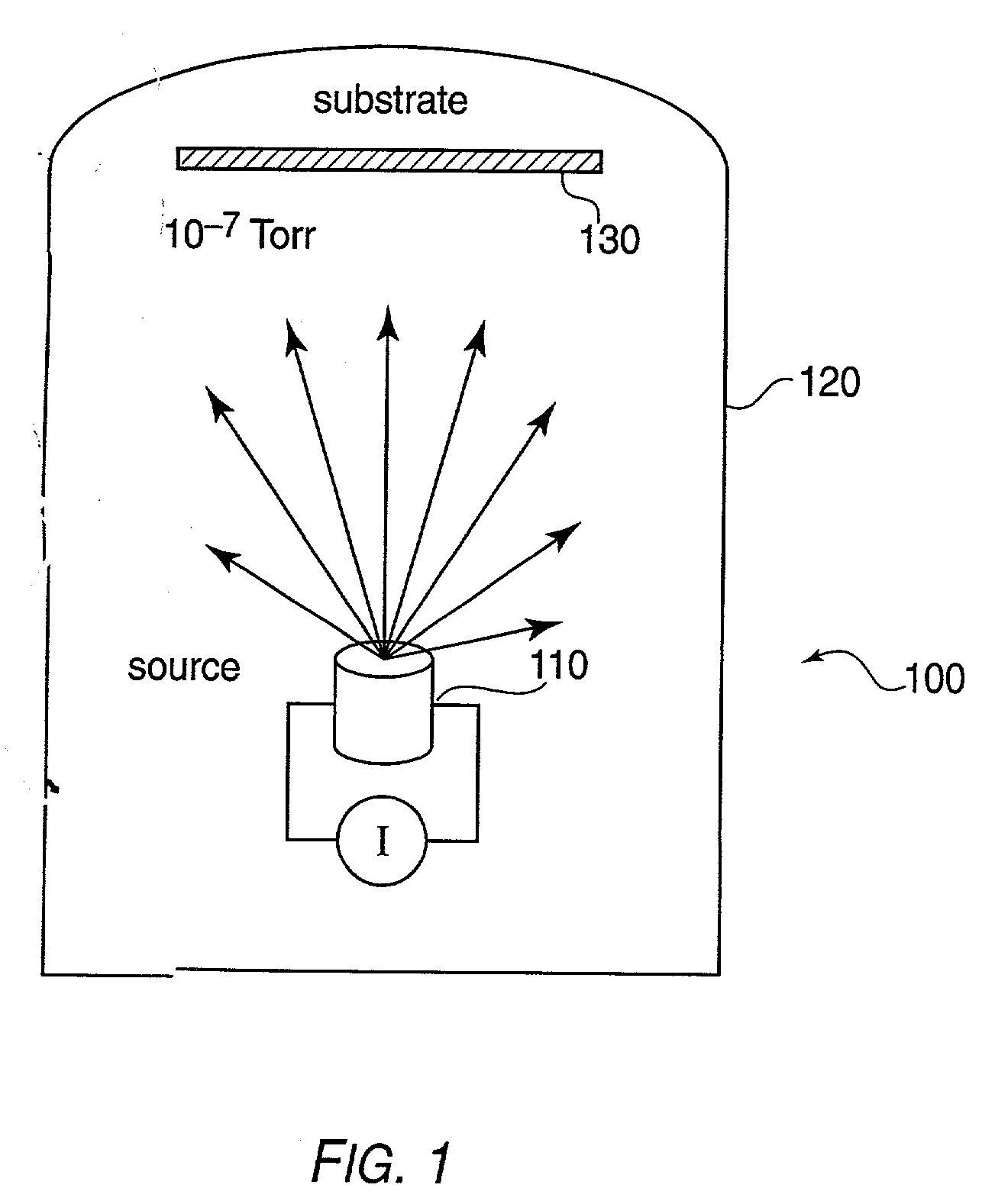

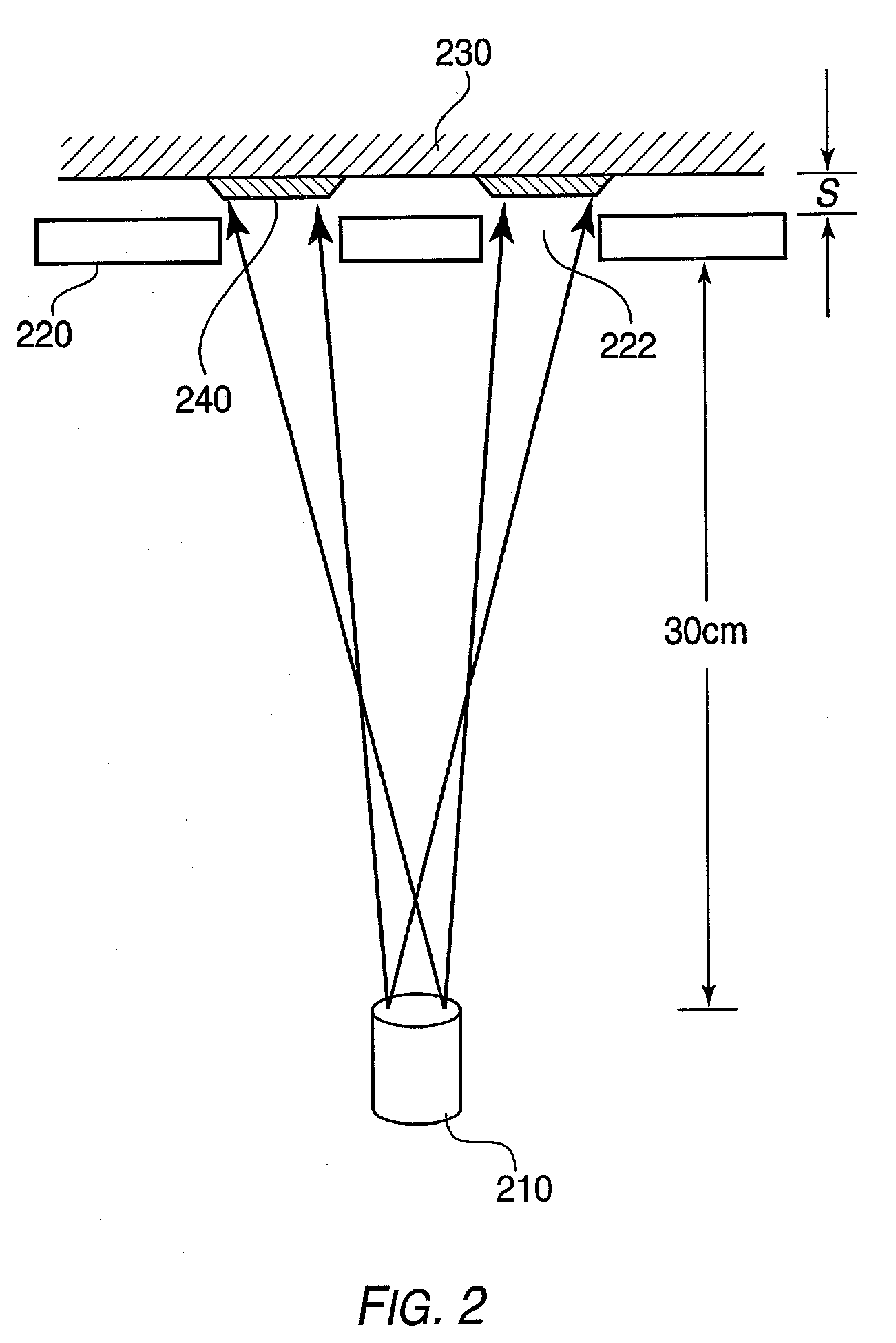

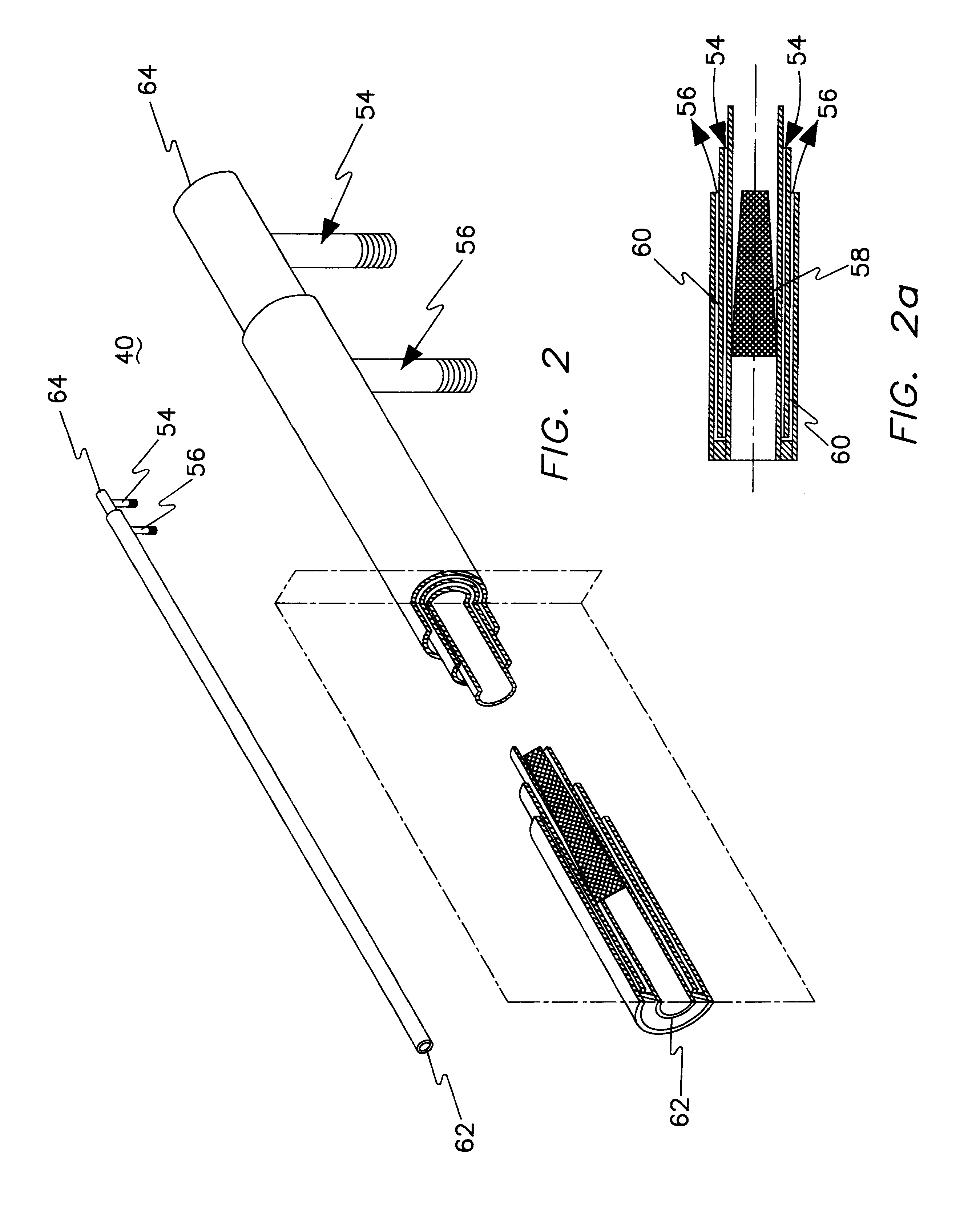

Process and apparatus for organic vapor jet deposition

ActiveUS7431968B1Good directionSharp pixelVacuum evaporation coatingSputtering coatingOrganic filmVacuum chamber

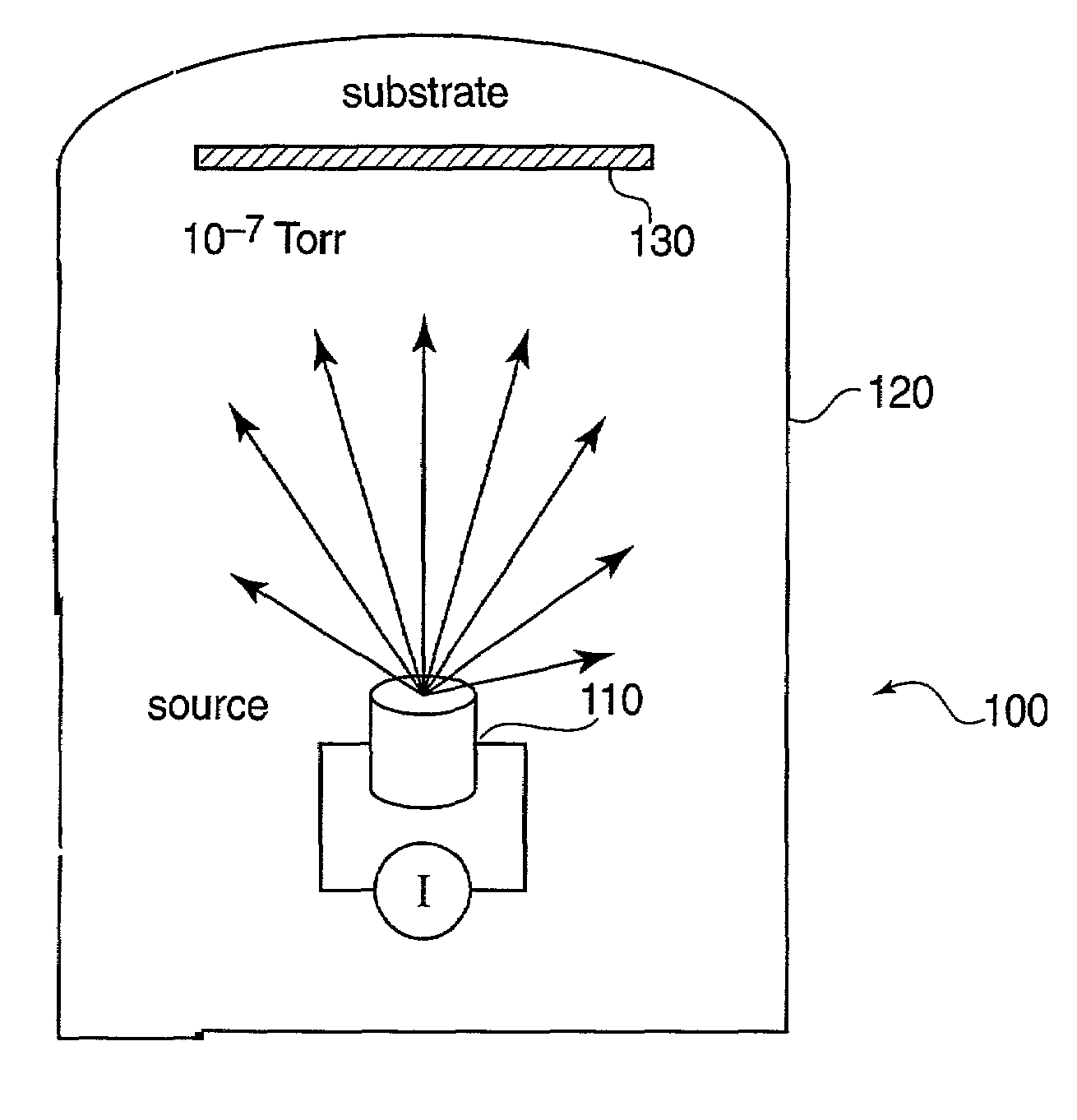

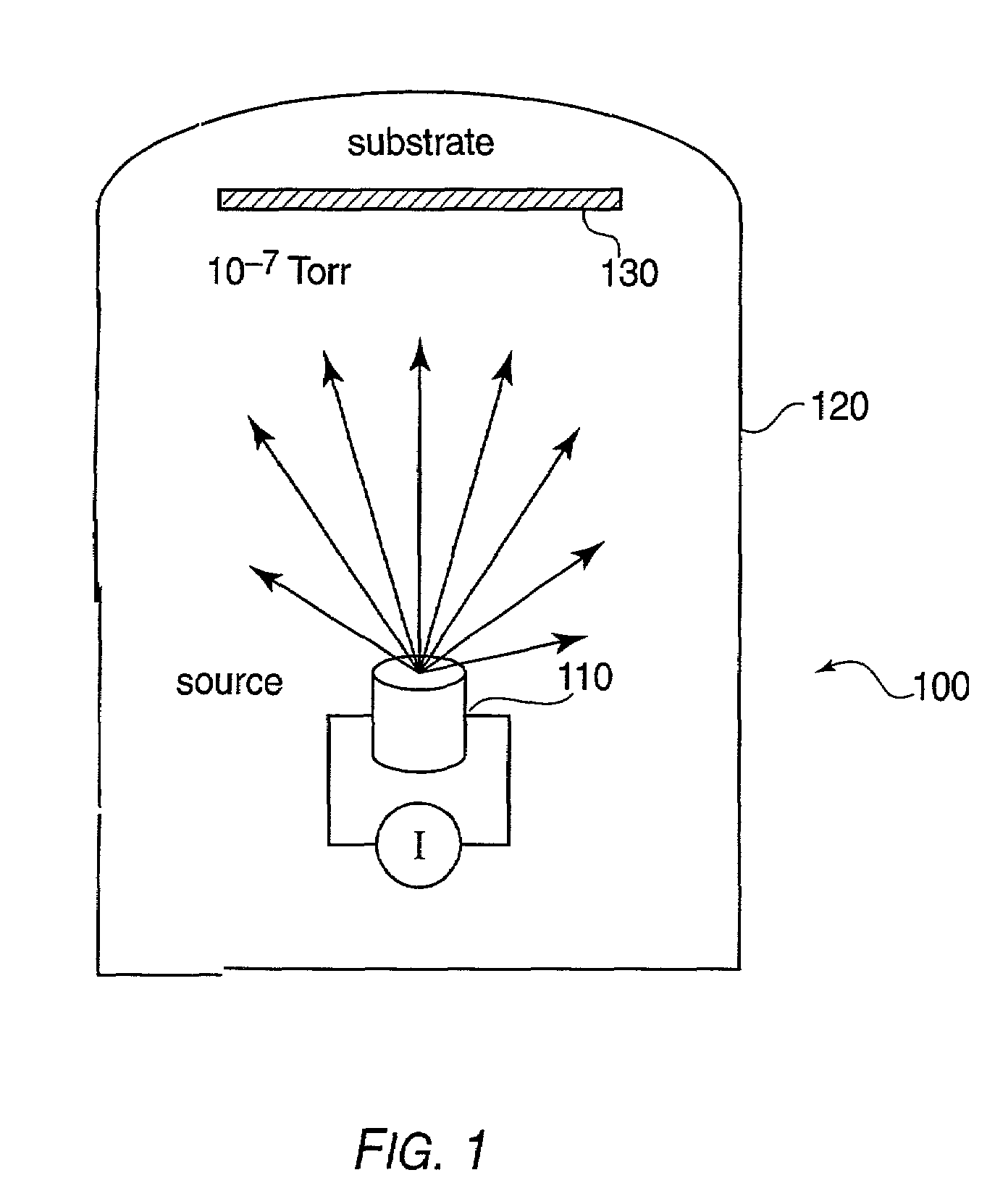

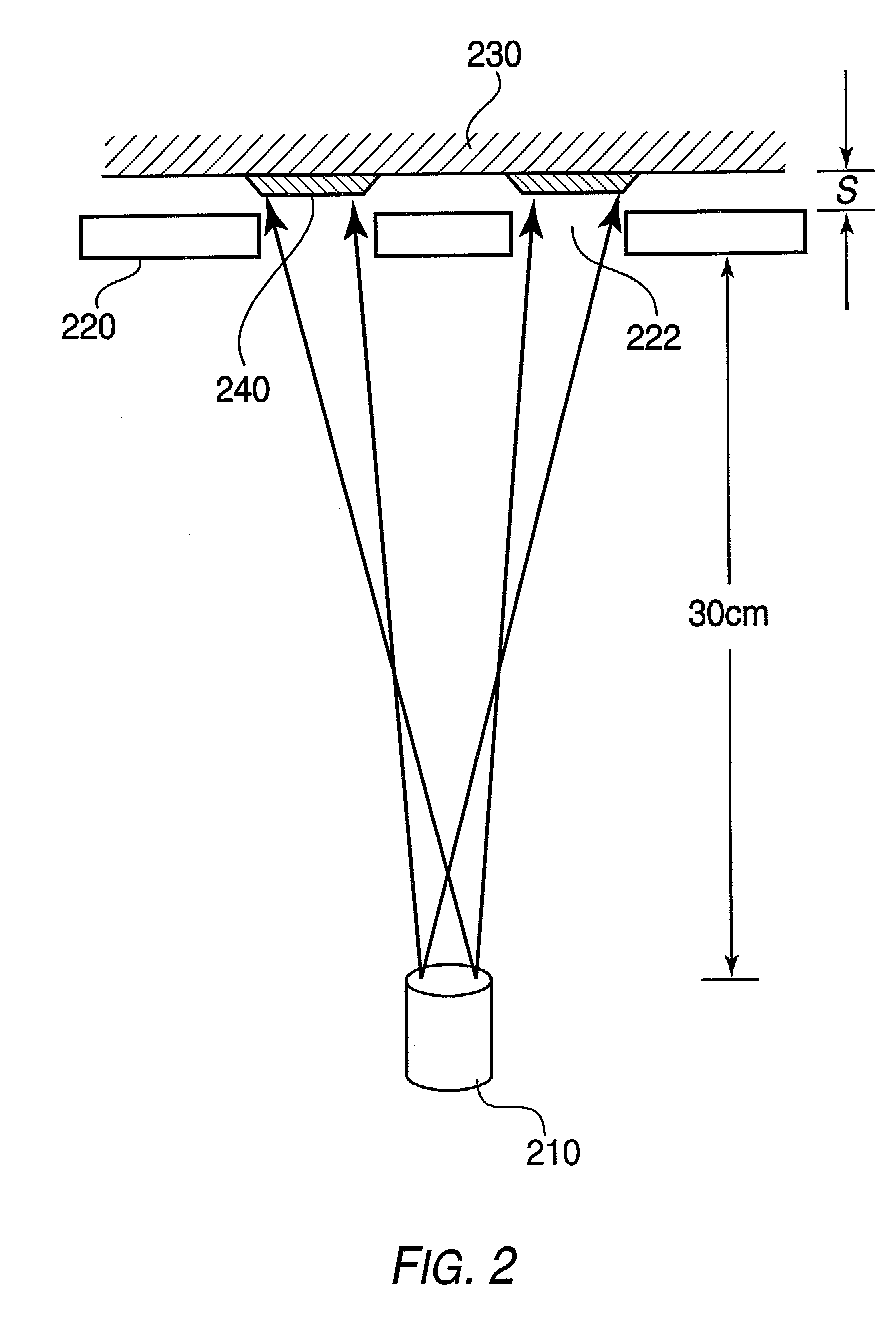

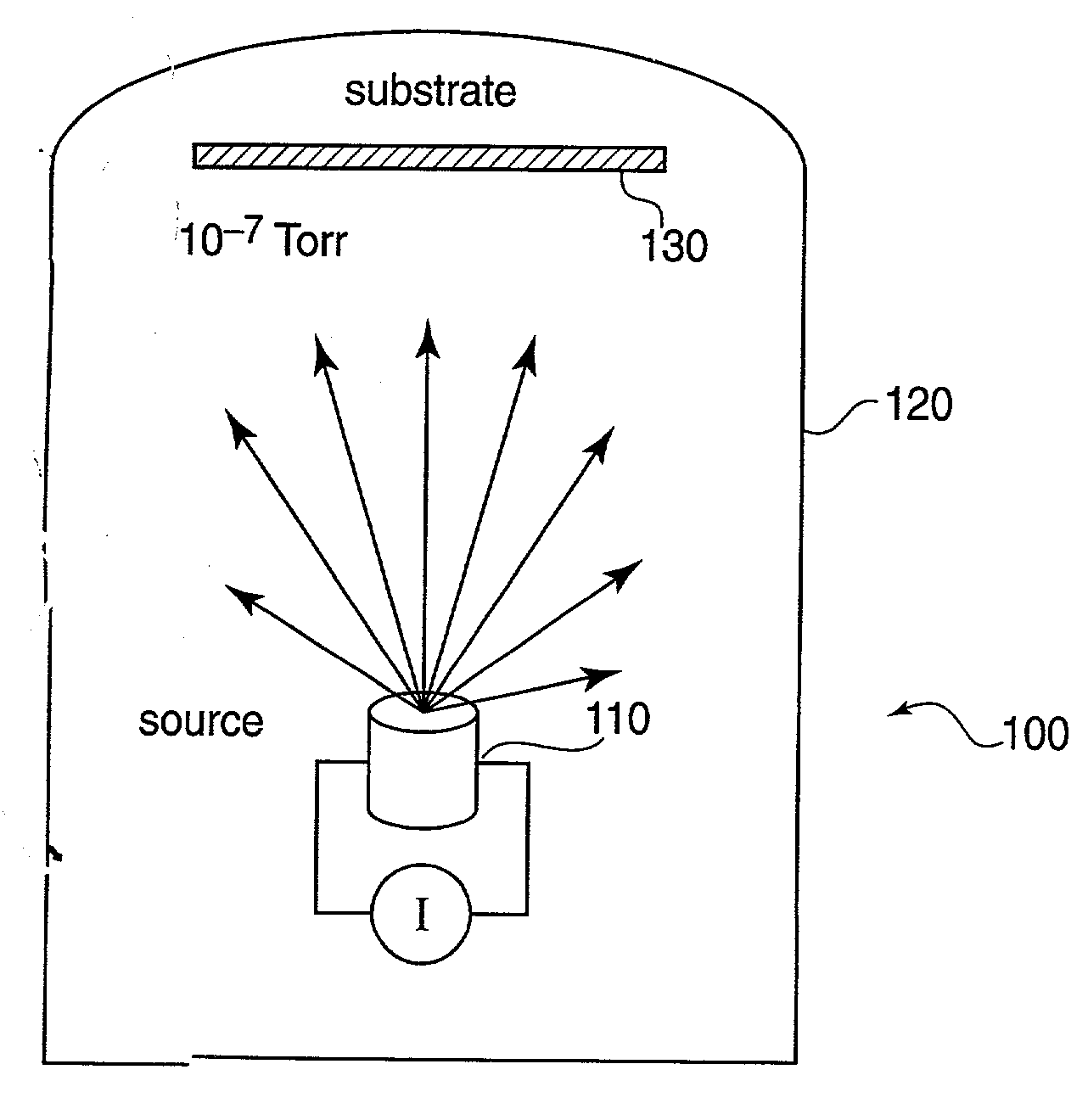

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

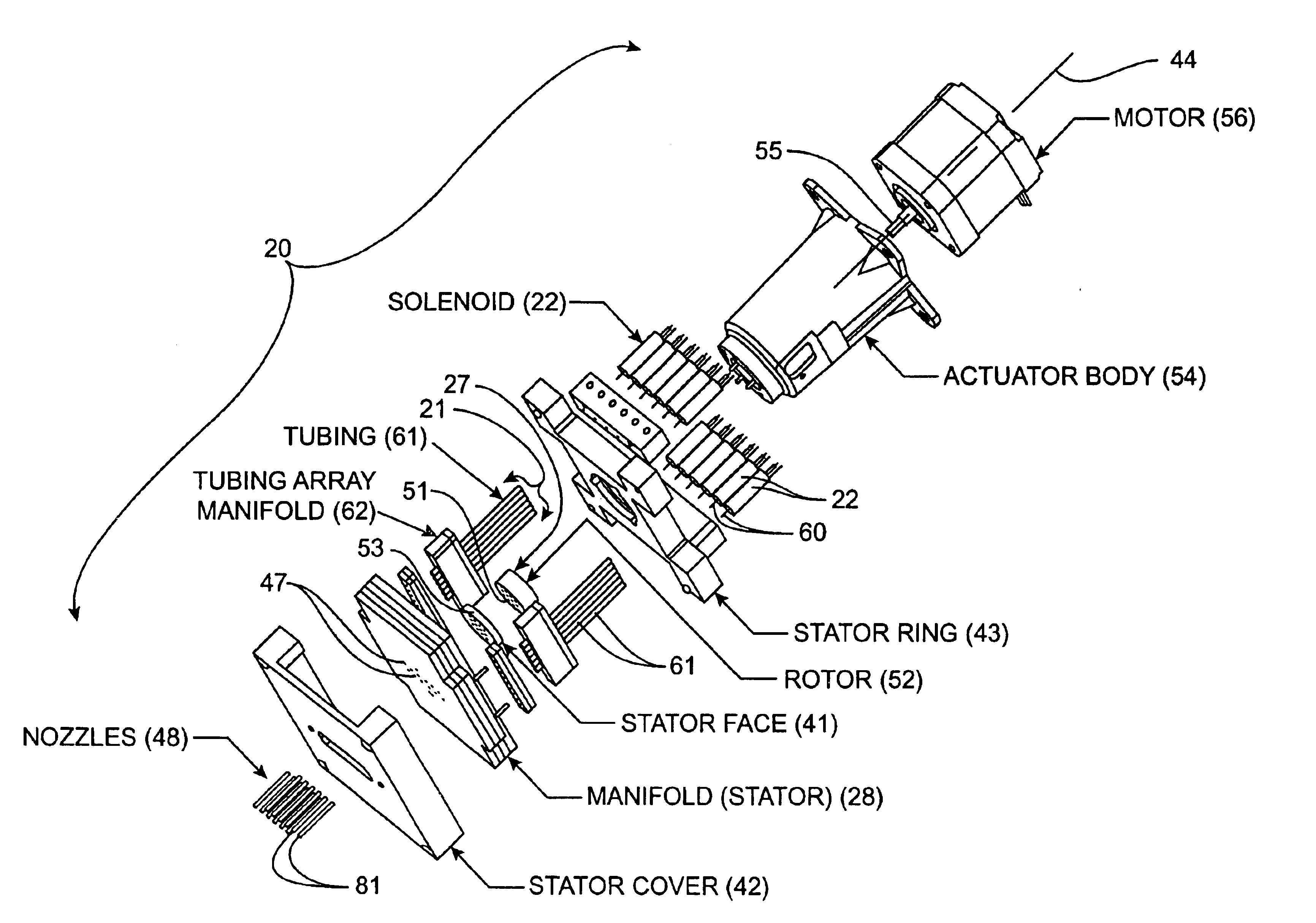

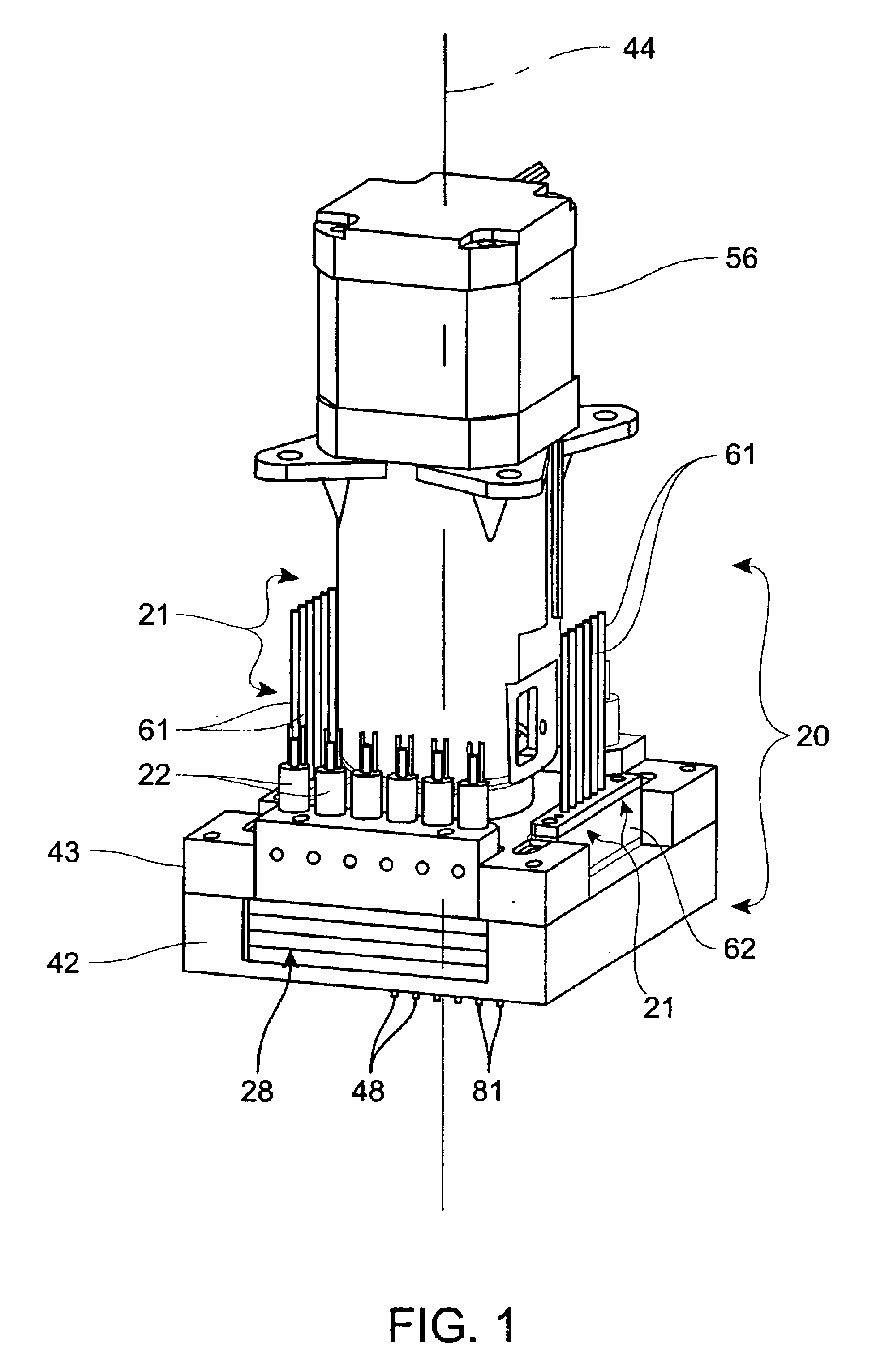

Process and apparatus for organic vapor jet deposition

ActiveUS20080233287A1Good directionalityMinimize material wasteVacuum evaporation coatingSputtering coatingOrganic vaporOrganic film

A method of fabricating an organic film is provided. A non-reactive carrier gas is used to transport an organic vapor. The organic vapor is ejected through a nozzle block onto a cooled substrate, to form a patterned organic film. A device for carrying out the method is also provided. The device includes a source of organic vapors, a source of carrier gas and a vacuum chamber. A heated nozzle block attached to the source of organic vapors and the source of carrier gas has at least one nozzle adapted to eject carrier gas and organic vapors onto a cooled substrate disposed within the vacuum chamber.

Owner:THE TRUSTEES FOR PRINCETON UNIV

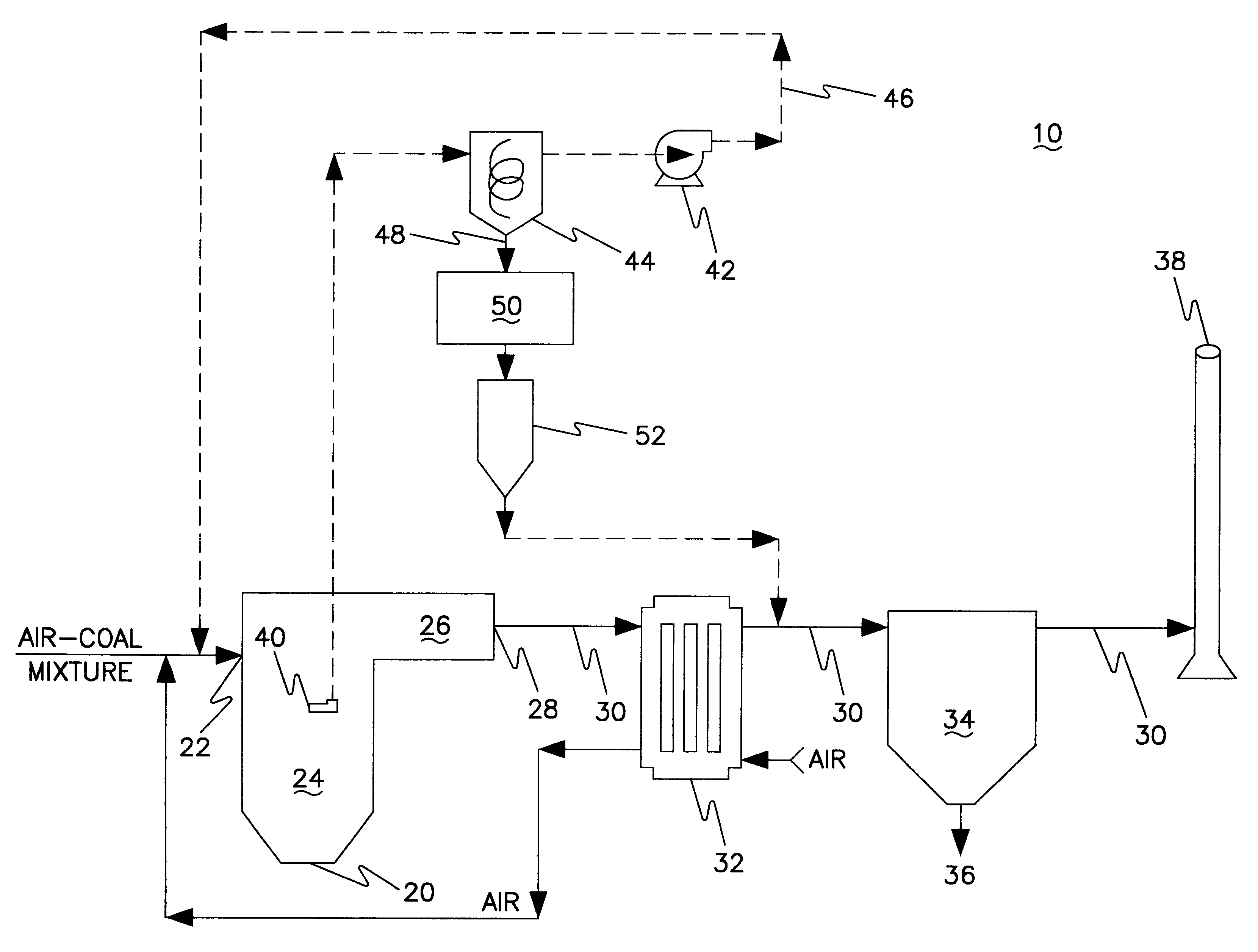

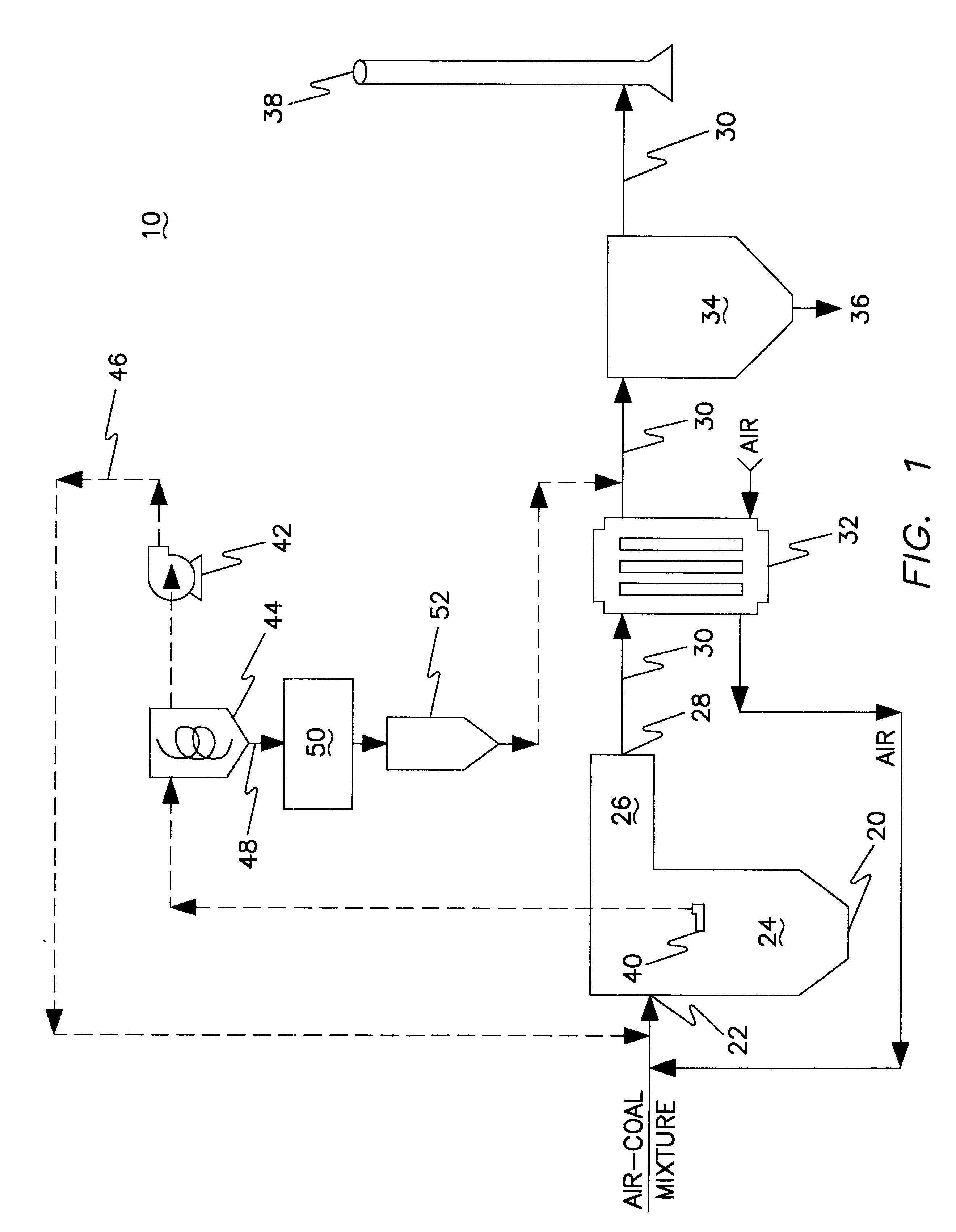

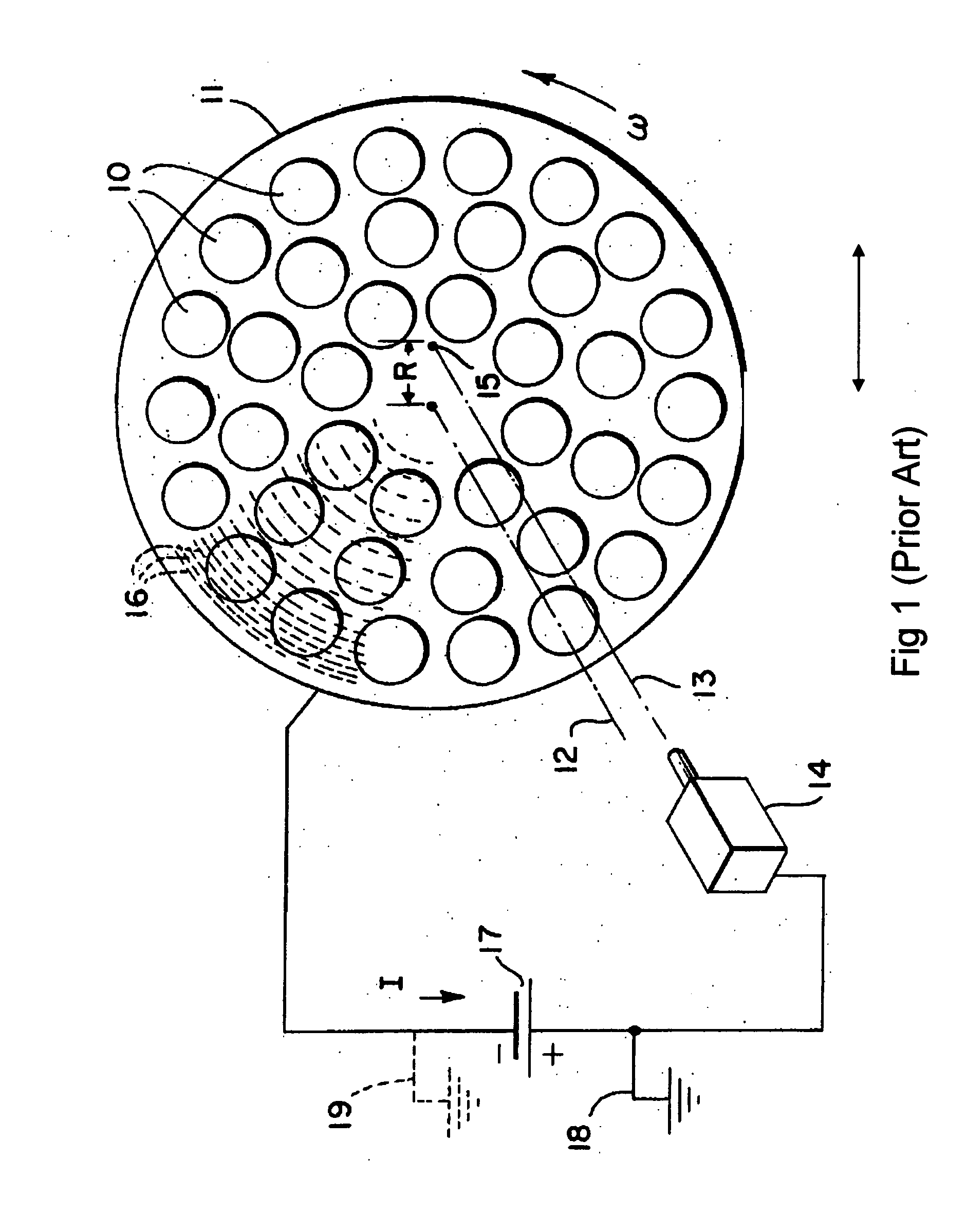

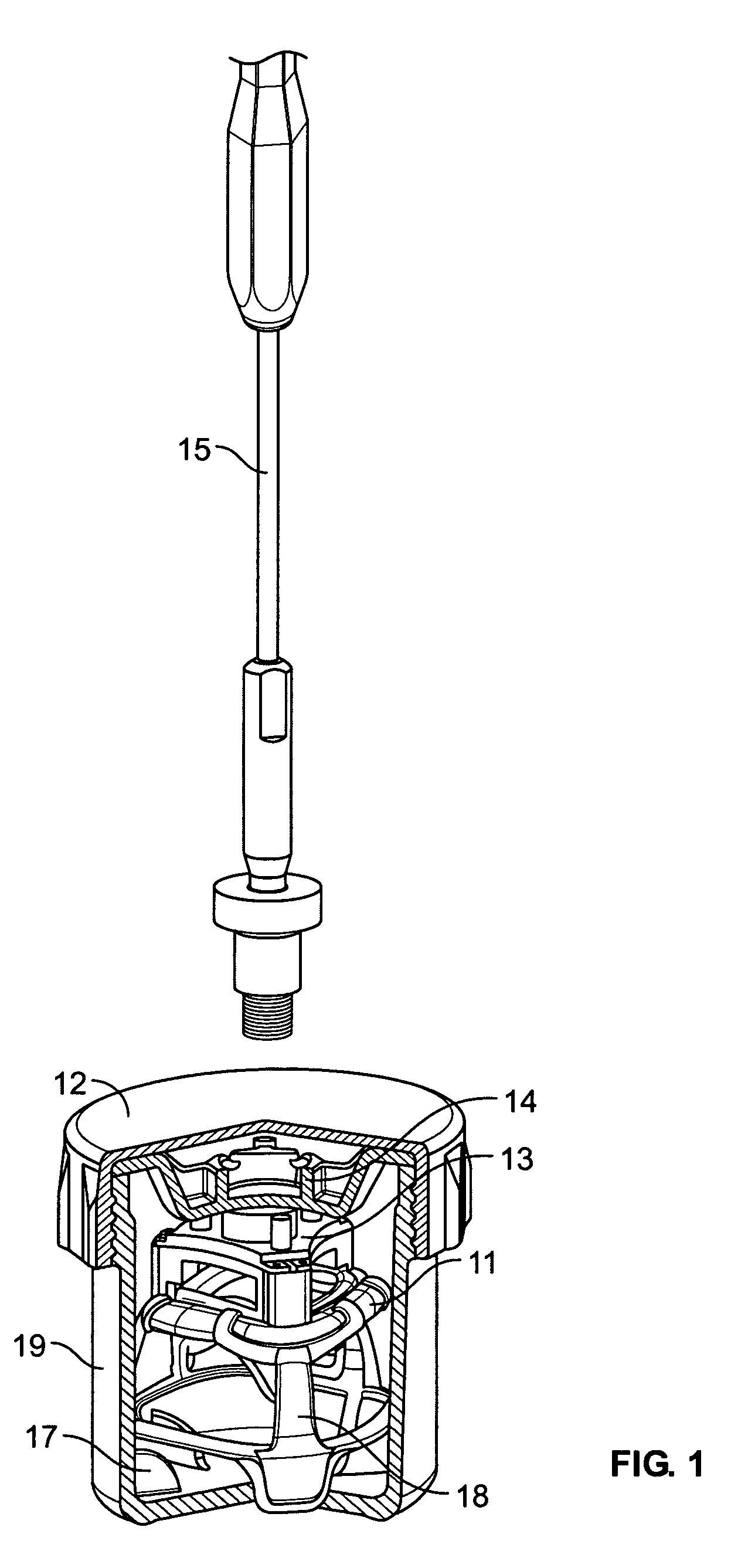

Thief process for the removal of mercury from flue gas

InactiveUS6521021B1Low costQuench oxidationGas treatmentUsing liquid separation agentParticulatesCombustion chamber

A system and method for removing mercury from the flue gas of a coal-fired power plant is described. Mercury removal is by adsorption onto a thermally activated sorbent produced in-situ at the power plant. To obtain the thermally activated sorbent, a lance (thief) is inserted into a location within the combustion zone of the combustion chamber and extracts a mixture of semi-combusted coal and gas. The semi-combusted coal has adsorptive properties suitable for the removal of elemental and oxidized mercury. The mixture of semi-combusted coal and gas is separated into a stream of gas and semi-combusted coal that has been converted to a stream of thermally activated sorbent. The separated stream of gas is recycled to the combustion chamber. The thermally activated sorbent is injected into the duct work of the power plant at a location downstream from the exit port of the combustion chamber. Mercury within the flue gas contacts and adsorbs onto the thermally activated sorbent. The sorbent-mercury combination is removed from the plant by a particulate collection system.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

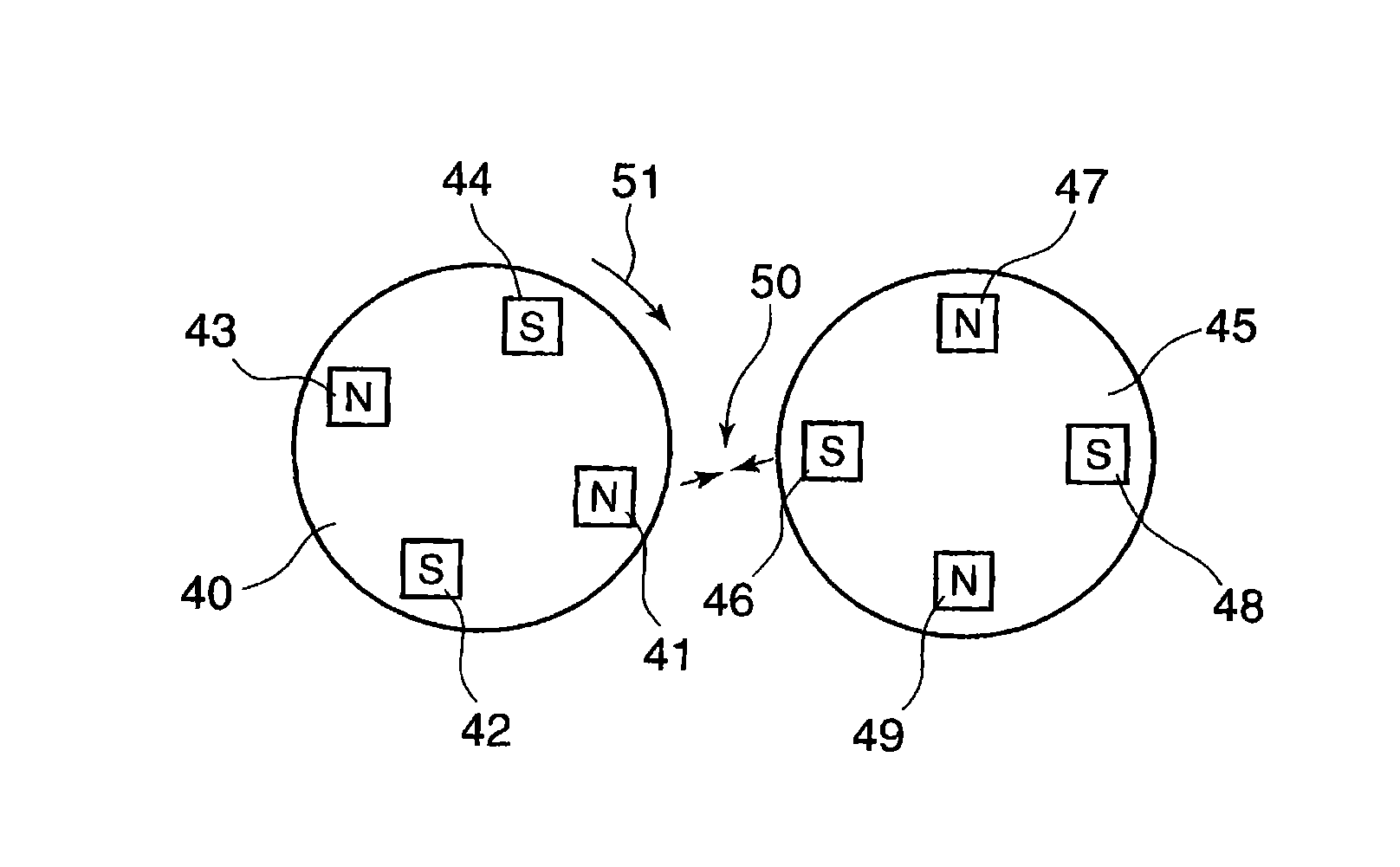

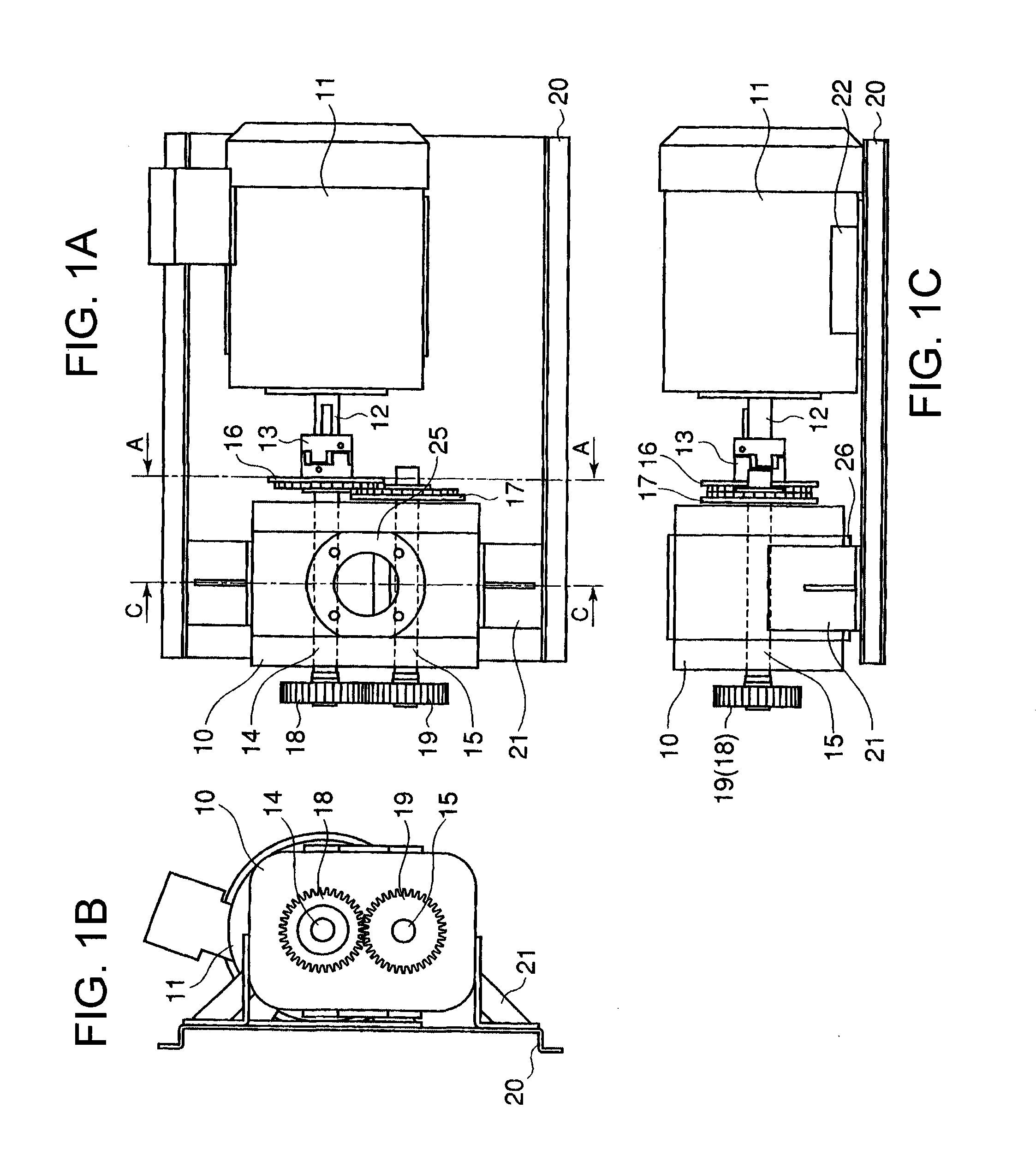

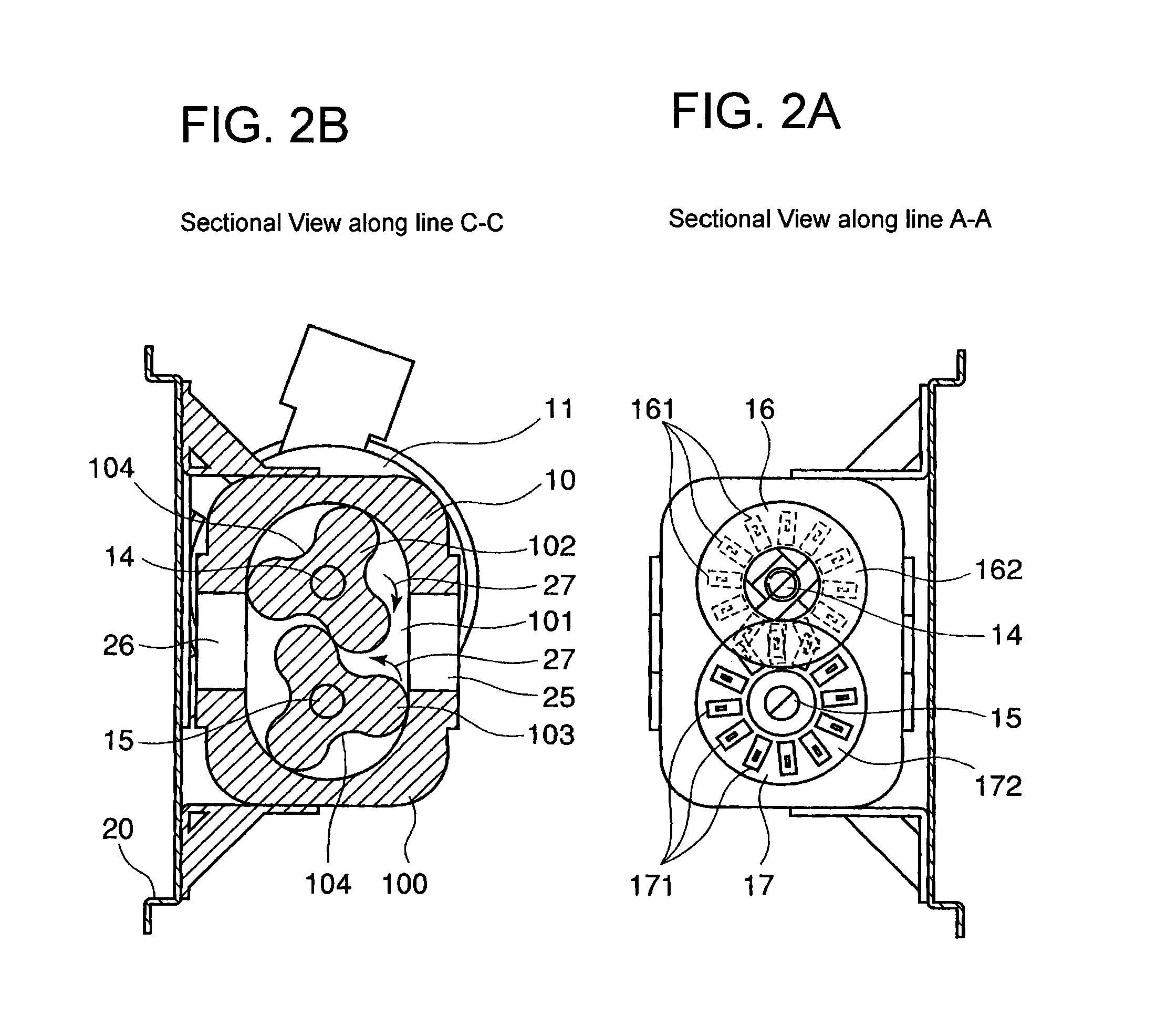

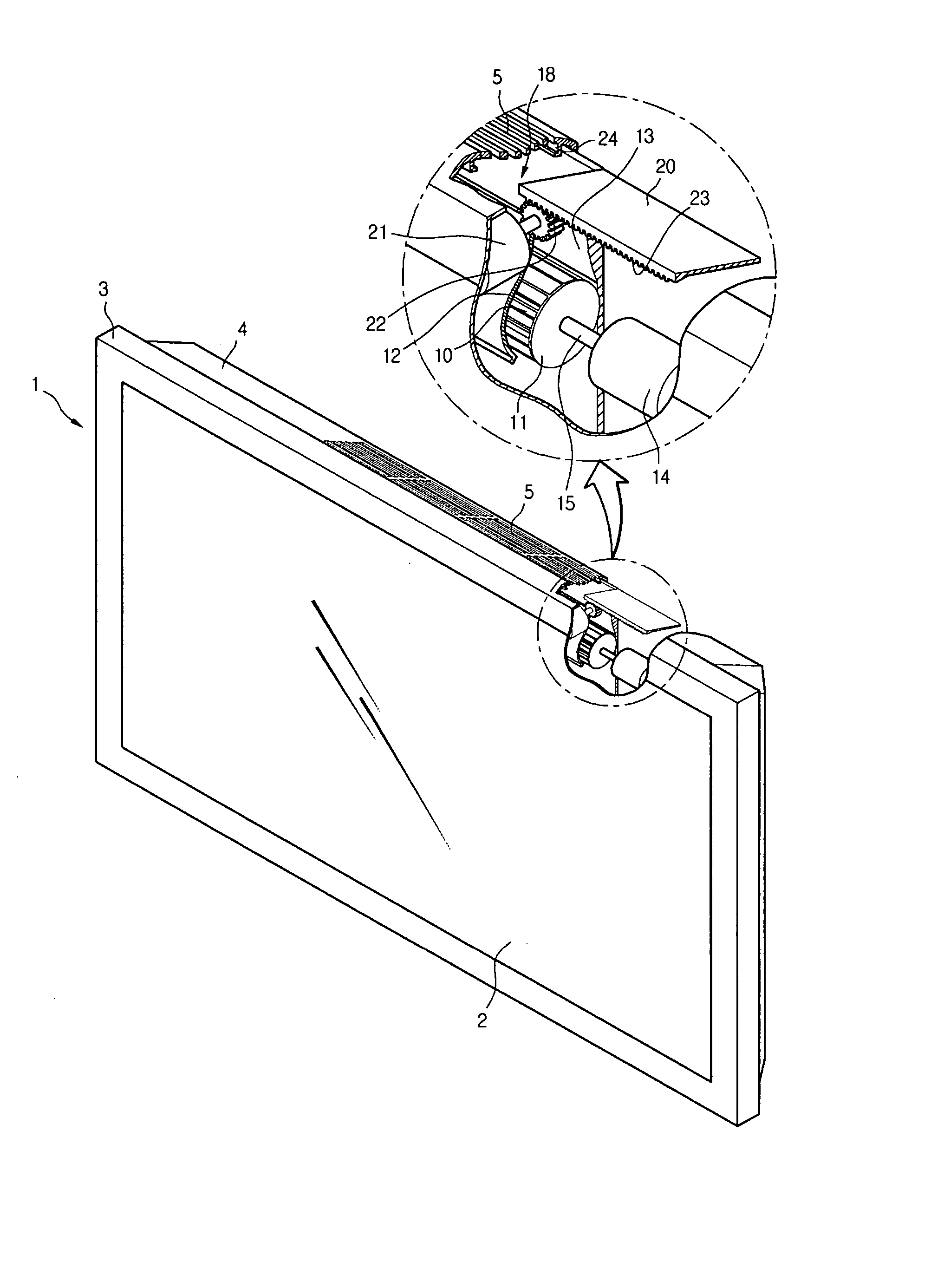

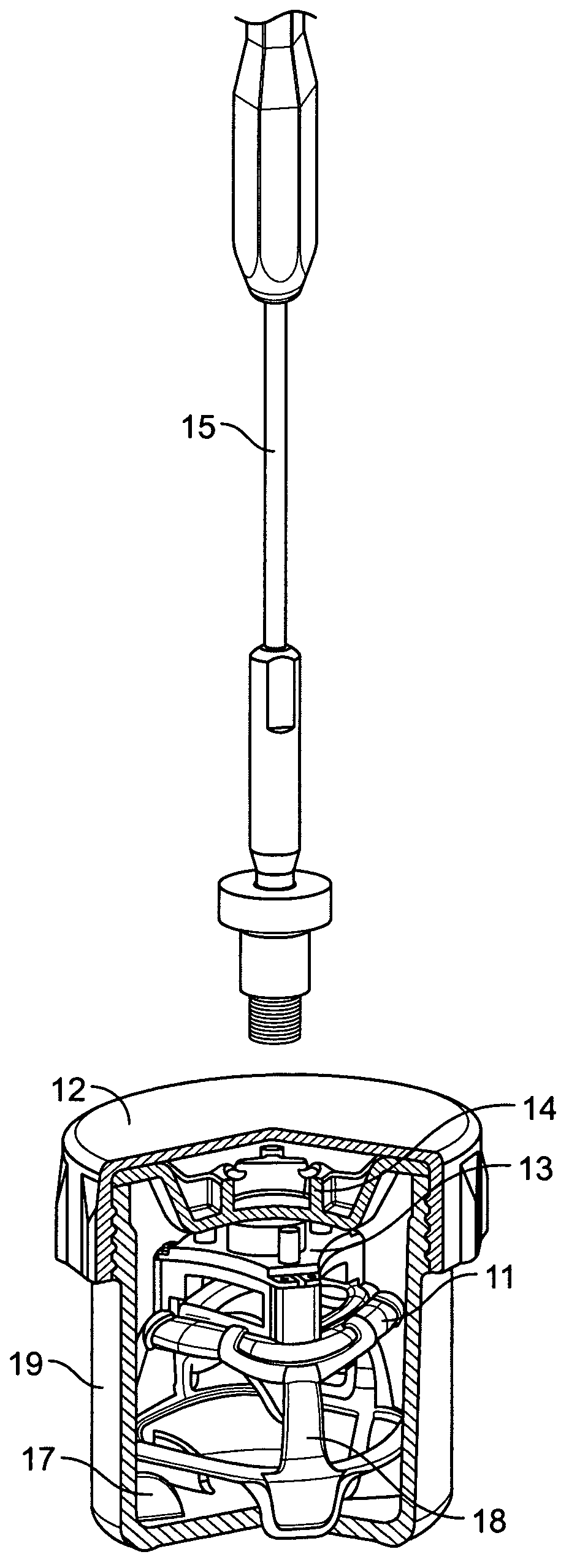

Drive transmission mechanism between two or more rotary shafts and oil-free fluid machine equipped with the mechanism

InactiveUS20080181804A1Reduced service lifeEliminate pollutionDynamo-electric brakes/clutchesEngine of counter-engagement typePlastic materialsOil free

A drive transmission mechanism for transmitting torque between two or more rotary shafts in synchronization with one another without need for lubrication thereby eliminating occurrence of oil contamination, and an oil-free fluid machine equipped with the mechanism, are provided. A magnetic drive disk 16 and a synchronization gear 18 are attached to a rotary shaft 14 connected to a drive motor 11, a magnetic drive disk 17 and a synchronization gear 19 is attached to a rotary shaft 15, torque transmission from the rotary shaft 14 to the rotary shaft 15 is carried out in two ways, via the magnetic drive disks 16, 17 and via the synchronization gears 18, 19, and at least one of the synchronization gears is made of plastic material. With the construction, torque transmit load between the rotary shafts via the synchronization gears is decreased, and a plastic gear or gears can be adopted for synchronization gears without reducing life of the gears without need for lubrication oil.

Owner:ANEST IWATA CORP

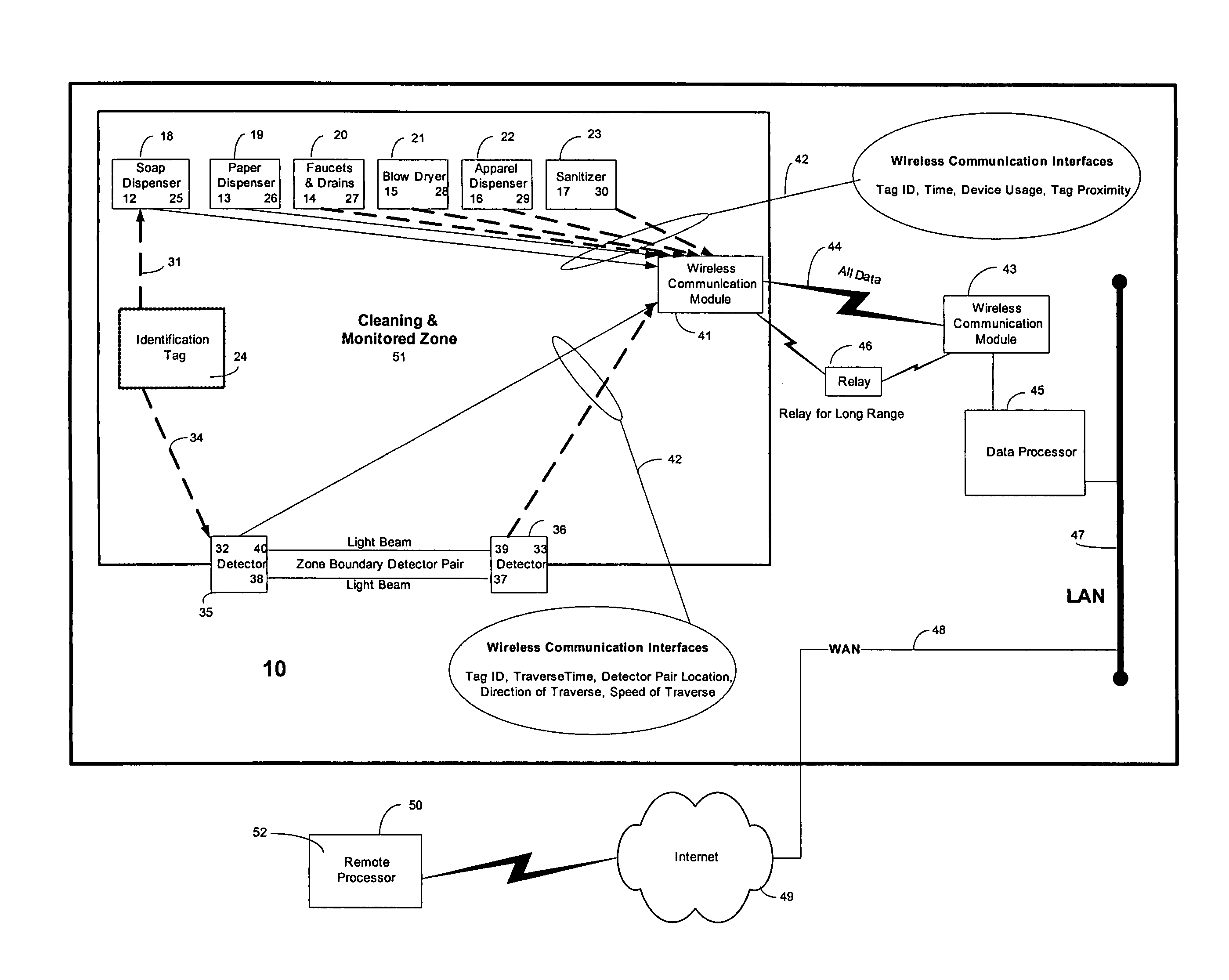

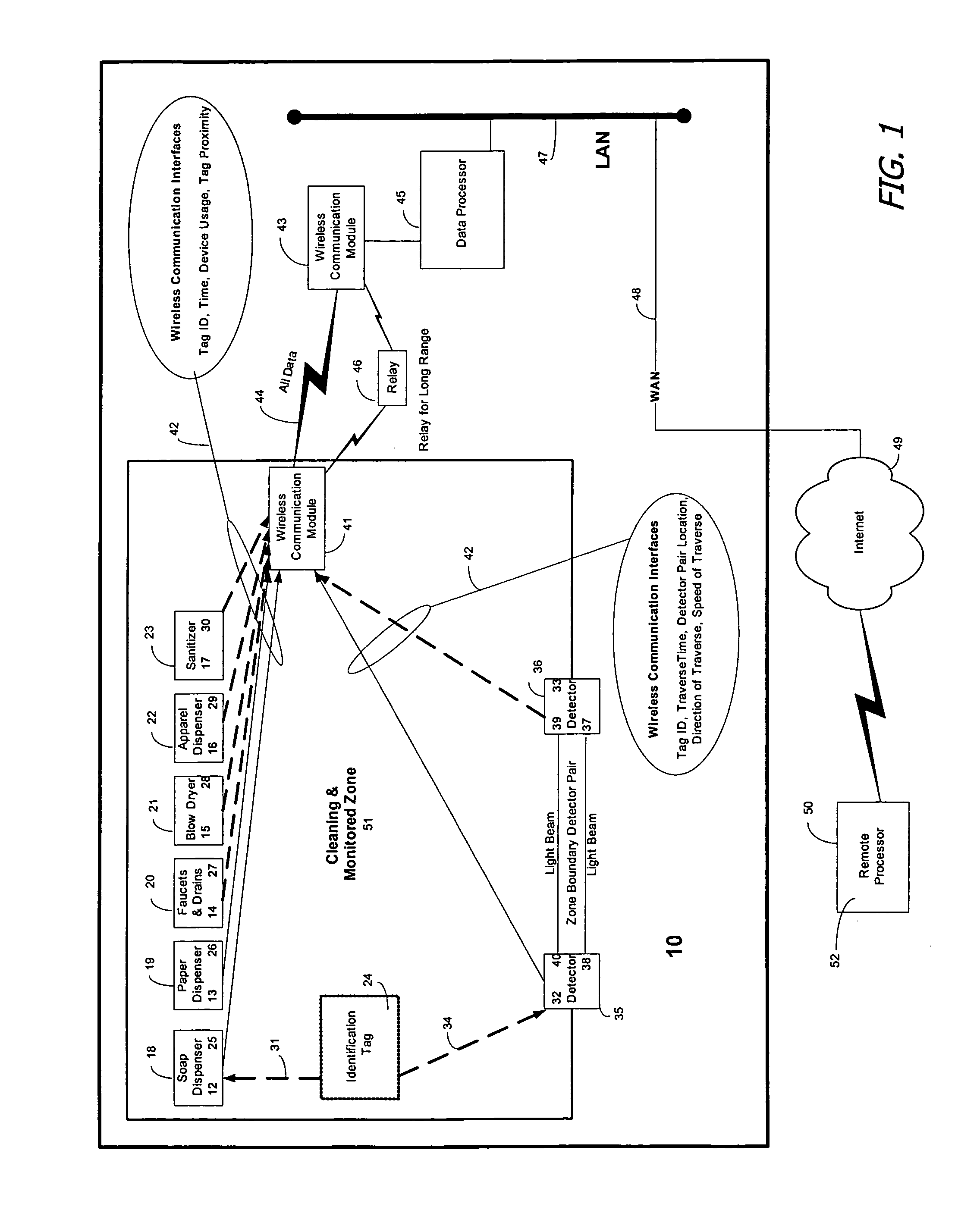

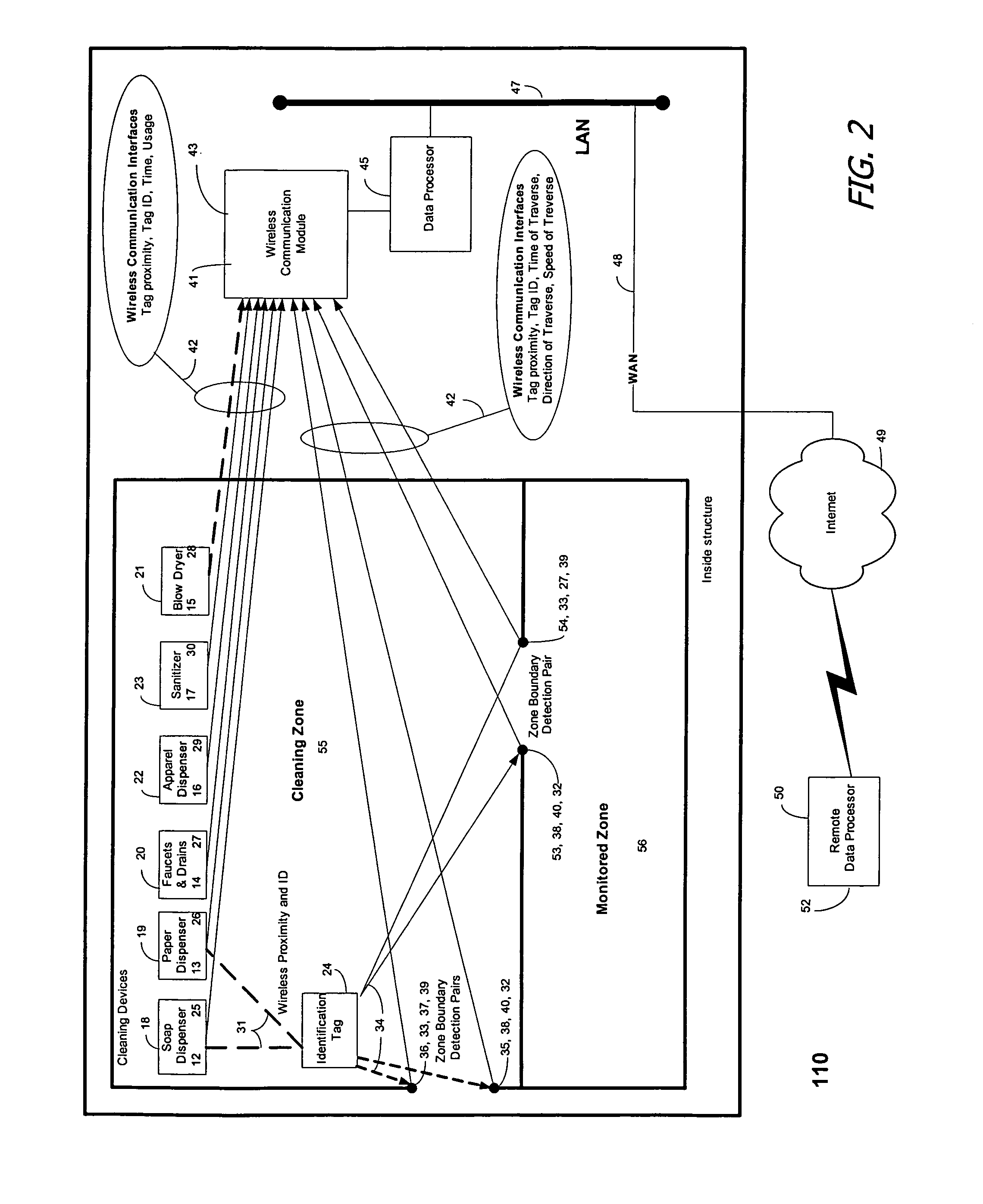

System for monitoring and recording cross-contamination events

ActiveUS7423533B1Eliminate pollutionBurglar alarm by hand-portable articles removalTelecommunicationsManagement system

A cross-contamination management system for remotely monitoring of personnel and objects and their use of sanitation facilities in adherence to a managed process with cleansing and sanitizing requirements generally includes a plurality of wireless communication devices with a first number of the wireless communication devices being disposed within or adjacent cleaning devices and operative for monitoring and reporting functional status and operation thereof. A second number of the wireless communication devices disposed in tags suitable for carrying by individuals or attaching to objects. A third number of wireless communication devices being configured to determine if a cleaning device associated with the one of the third number of wireless communication devices is to be ascribed to one of the tags and reporting thereon by an output signal. A fourth number of wireless communication devices being disposed at access points to determine if an object or person traversing access points associated with the fourth number of wireless communication devices is to be ascribed to one of the second wireless communication devices and reporting therein by an output signal.

Owner:COGNOS SYST

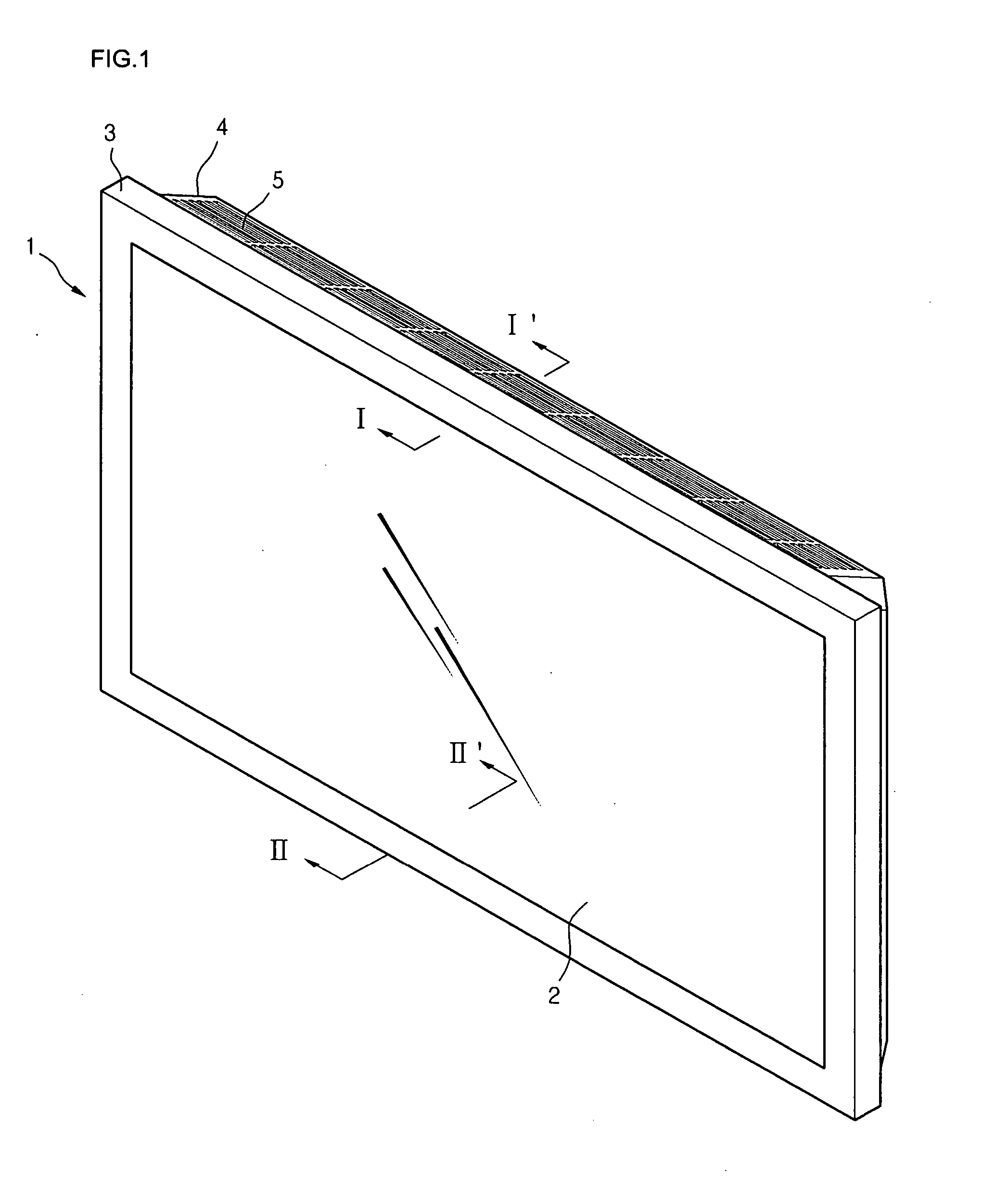

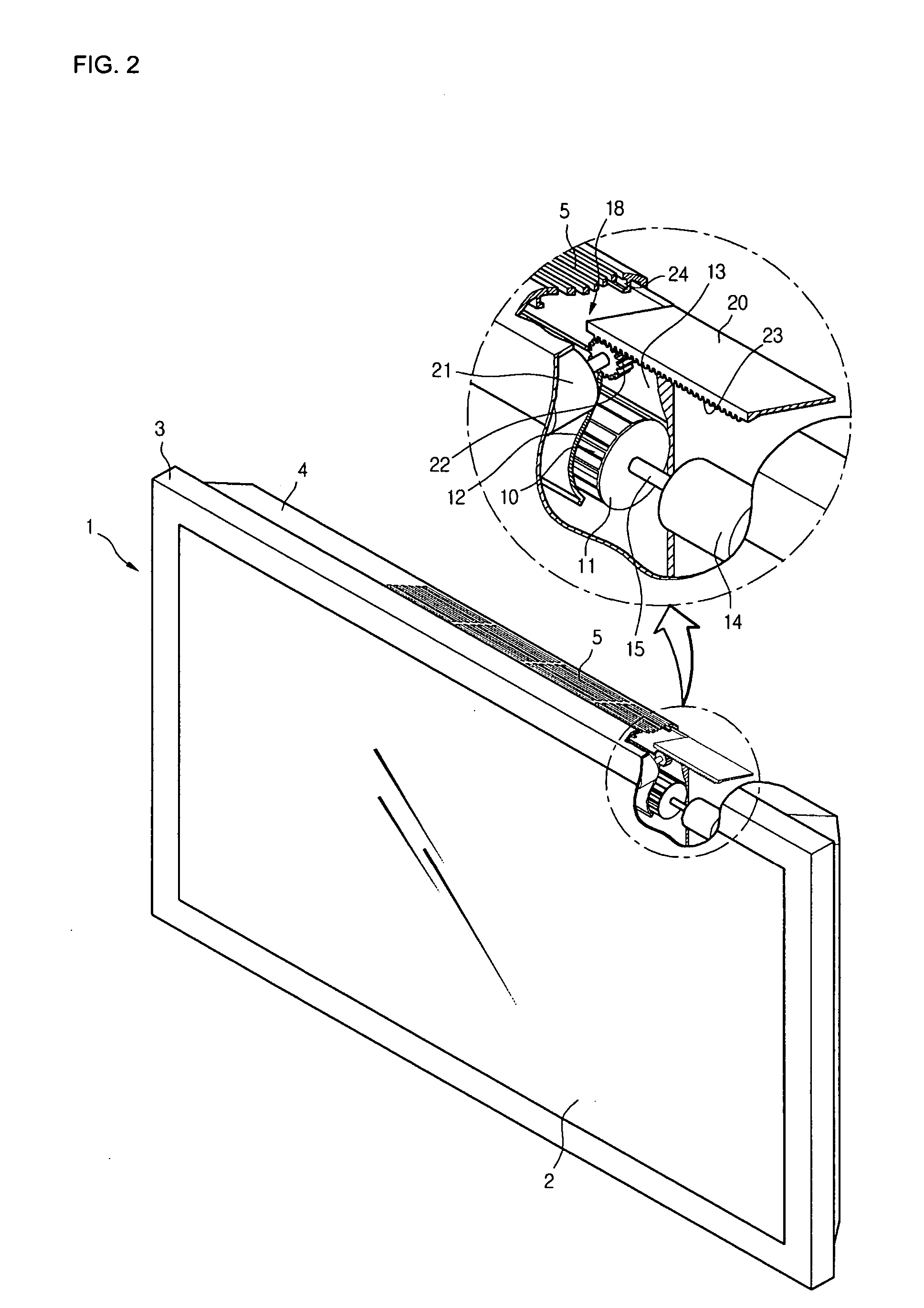

Flat display device and cooling apparatus for the same

ActiveUS20070103866A1Improve performanceEliminate dangerTelevision system detailsCircumferential flow pumpsDisplay deviceEngineering

There is provided a cooling apparatus for a flat display device. The cooling apparatus includes a flat display module, a cover for protecting an exterior of the flat display module, an air inlet formed on one side of the cover, for introducing external air, an air outlet formed in the other side of the cover, for discharging high temperature air contained inside the cover, and a shield for selectively closing the air outlet to prevent inflow of foreign substances.

Owner:LG ELECTRONICS INC

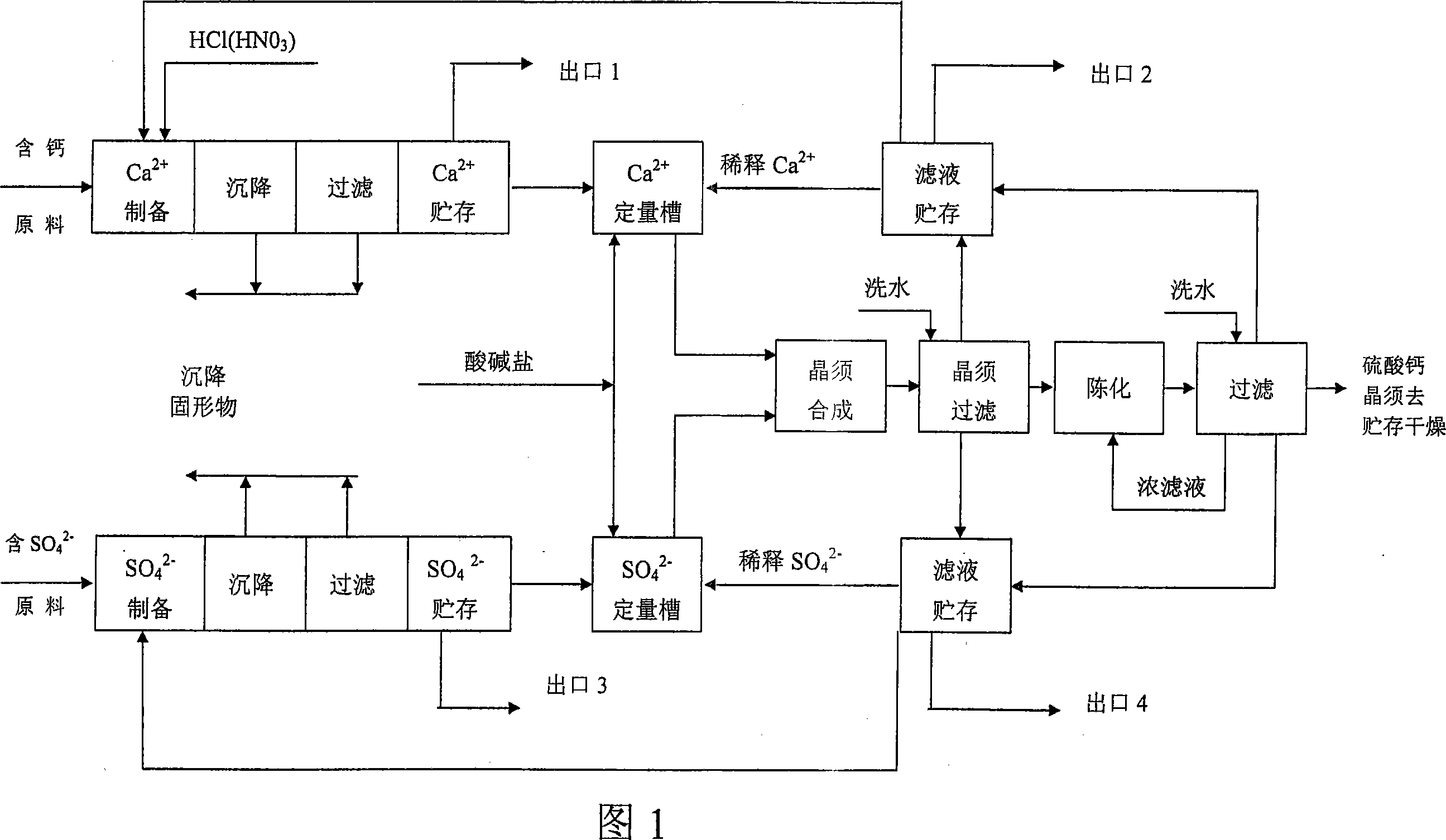

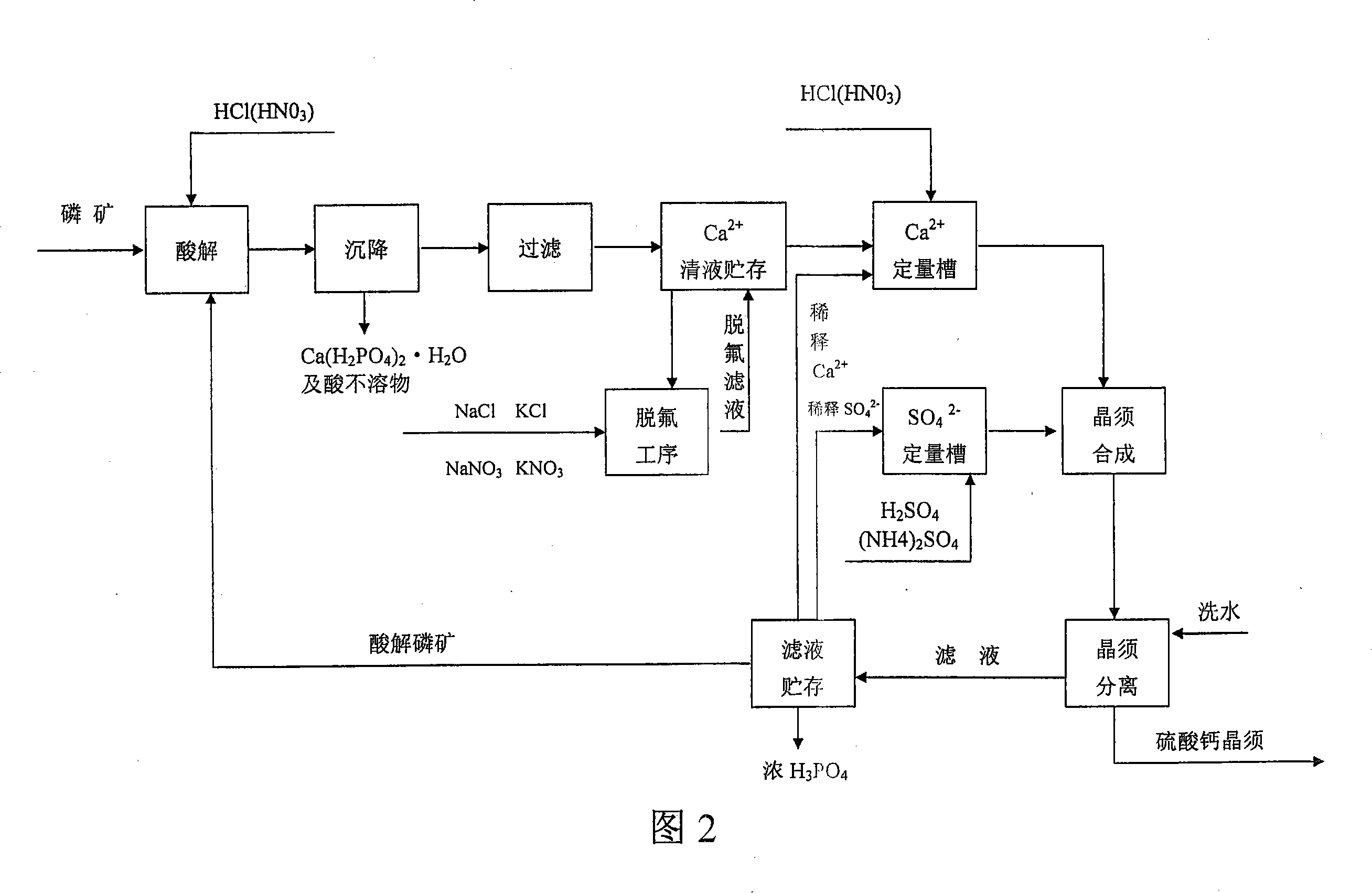

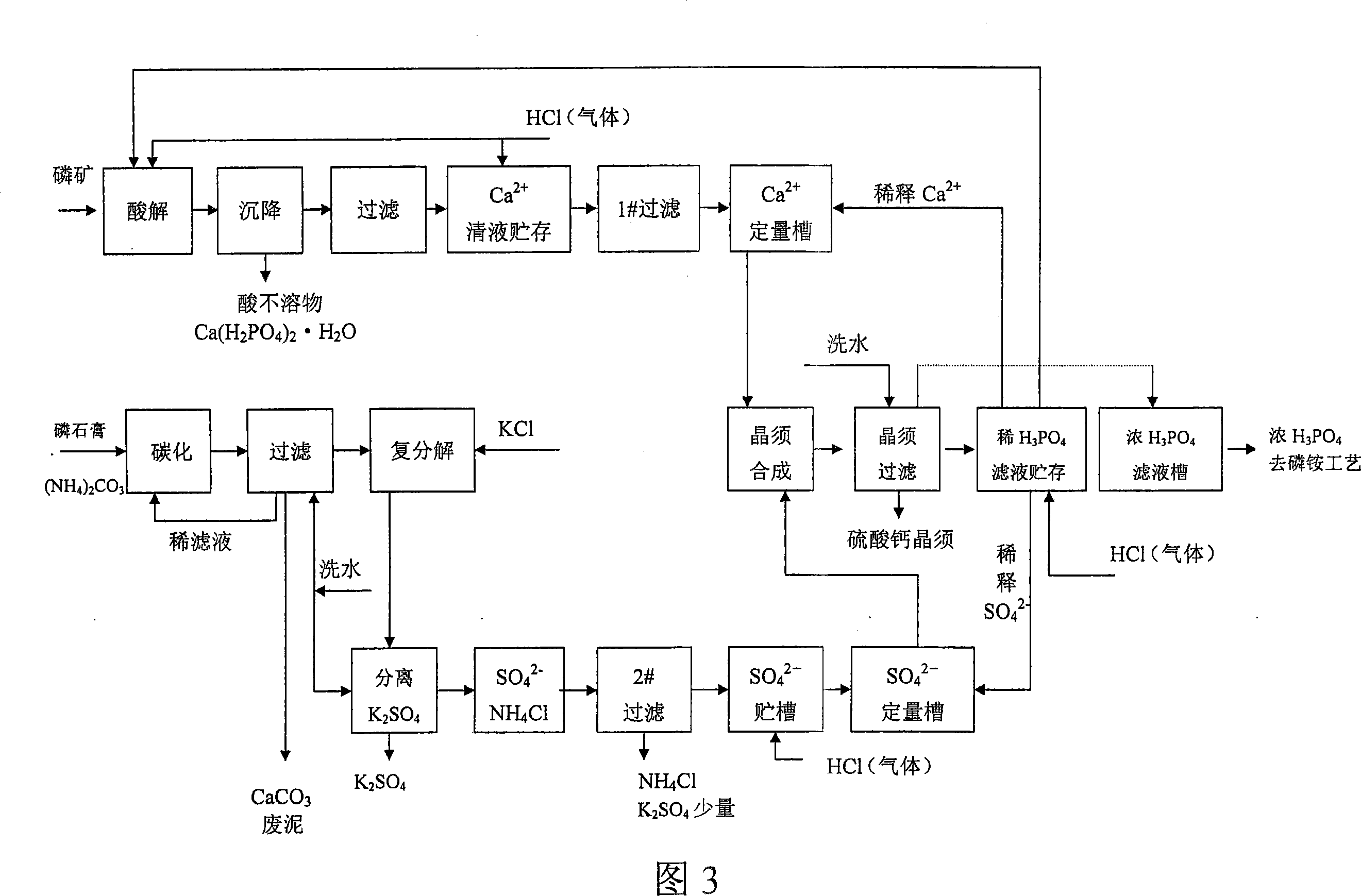

Mass production method for calcium sulfate whisker

ActiveCN101168852ALarge amount of preparationImprove environmental benefitsPolycrystalline material growthFrom normal temperature solutionsSulfateSludge

The invention discloses a new method for large-scale production of calcium sulfate whiskers, which is characterized in that a large number of cheap water-soluble Ca2+ and water-soluble SO42- ions are used at a certain pH, salt-containing impurities and whisker control agents and a certain synthesis Calcium sulfate whiskers were synthesized under conditions such as , aging, and temperature. The invention has the advantages of simple process, low investment, low cost and excellent products. It can be co-produced with various existing processes containing Ca2+ and SO42-, can eliminate the waste water and waste residue pollution of these processes, and can greatly improve these co-production processes. economic benefits.

Owner:武善东 +1

Bio-organic compound fertilizer

InactiveCN101781149AImprove fat retention capacityImprove buffering effectFertilizer mixturesPotassiumOrganic compound

The invention relates to a bio-organic compound fertilizer, which comprises the following components in part by weight: 10 to 30 parts of organic matter, 2 to 10 parts of compound microbial inoculants, 5 to 20 parts of humic acid, 5 to 20 parts of amino acid, 4 to 10 parts of chitin, 1 to 5 parts of polypeptide, 530 parts of nitrogen, phosphorus and potassium, 5 to 10 parts of secondary and trace elements, 5 to 15 parts of algae fertilizer, 5 to 10 parts of zeolite powder and 1 to 5 parts of synergistic agent. Through the scientific and rational formula, the bio-organic compound fertilizer achieves nutritive equilibrium and can satisfy the need of crop growth in nutrient. The microbial inoculants are added to quickly degrade natural macromolecular organic compounds into the organic fertilizer and decompose organic pollutants, which effectively improves the capacity of crops in the absorption of nutrient components, reduces the waste of the fertilizer and reduces the damage of the chemical fertilizer to soil to further achieve the nutritive equilibrium, satisfy the need of the crop growth in the nutrient, achieve the aims of low investment and high output value, improve the quality of the crops and improve the economic benefit brought by the crops.

Owner:张钧

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

Compound microbial agent for degrading antibiotic and pesticide residues as well as preparation and application thereof

InactiveCN106434430AEliminate pollutionAchieve biodegradableFungiBacteriaEcological environmentBacillus megaterium

The invention relates to a compound microbial agent for degrading antibiotic and pesticide residues as well as preparation and application thereof, and belongs to the field of biotechnology and environmental protection. Multi-thallus compound microbial powder is prepared from the compound microbial agent according to the weight percentage of living microbes to the total amount of compound microbial powder as follows: 10%-15% of bacillus subtilis, 10%-15% of aspergillus niger, 10%-15% of bacillus mucilaginosus, 10%-15% of enterococcus faecalis, 8%-12% of bacillus licheniformis, 8%-12% of bacillus megaterium, 8%-12% of pseudomonas fluorescens, 5%-8% of lactobacillus plantarum, 5%-8% of bacillus polymyxin and 6%-8% of streptococcus thermophiles. The compound microbial agent has the effects of degrading antibiotic and pesticide residues, fermenting and composting organic matter, acting as functional fertilizer and repairing the environment, and can solve the problems of secondary pollution caused by antibiotic residues in culture feces and resource utilization of organic waste and realizes biodegradation of the antibiotic and pesticide residues in soil when applied to the agricultural ecological environment, thereby being of great value and practical significance in restoration of agricultural ecological environment and protection of human health.

Owner:中山市润泽生物科技有限公司

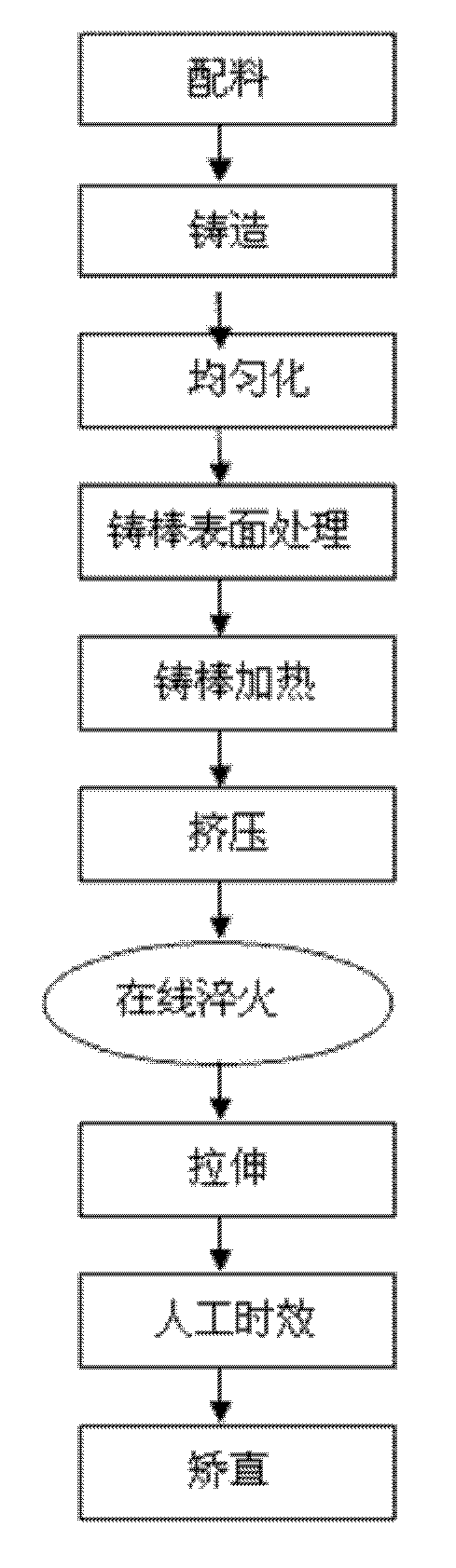

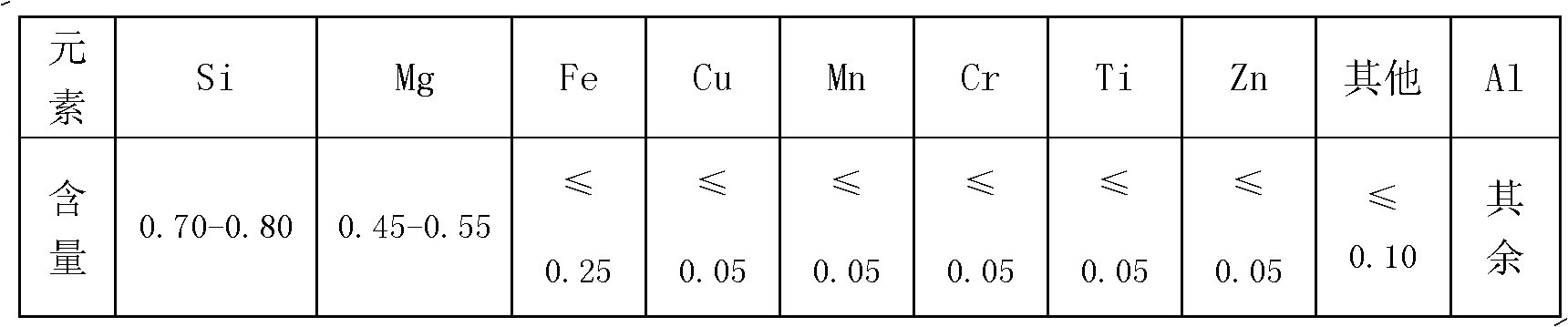

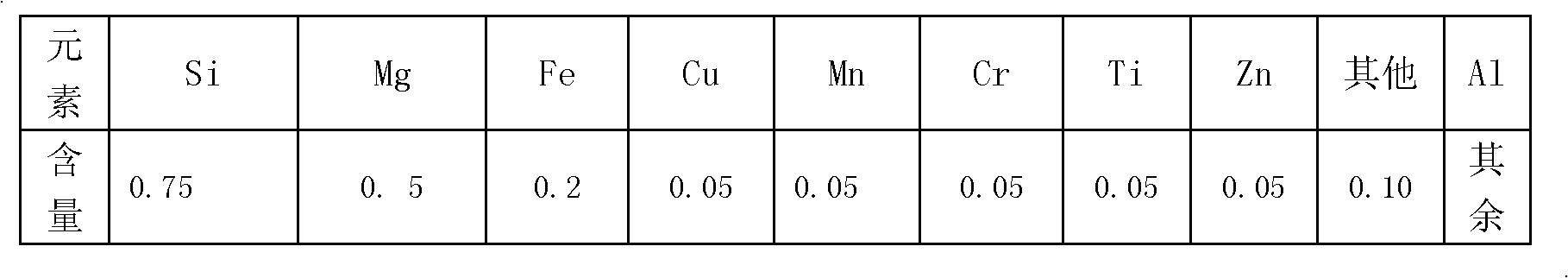

Extruding processing technology of aluminium alloy tubing with large diameter

InactiveCN102492877AReduce residual stressHigh strength propertiesExtrusion control devicesFailure rateHigh energy

The invention discloses an extruding processing technology of an aluminium alloy tubing with large diameter. The method comprises steps of a. proportioning, b. casting, c. uniformization, d. surface treatment on casting rod, e. casting rod heating, f. extrution, g. on-line quenching, h. stretching, i. artificial aging and j. straightening, etc. Strict control on each parameter can solve problems of extruding production of tubing with large diameter, eliminate disadvantages of long production period, low production efficiency, high energy consumption, huge environmental pollution and expensiveauxiliary equipment of rolling and drawing, save cost, simplify arrangement of auxiliary equipment and further reduce failure rate of an apparatus. The energy consumption of the present invention is merely 1 / 4 that of rolling and drawing, and water consumption is 1 / 8 that of a steam jet pump set; therefore, the invention brings obvious economic effects.

Owner:CHINA ZHONGWANG

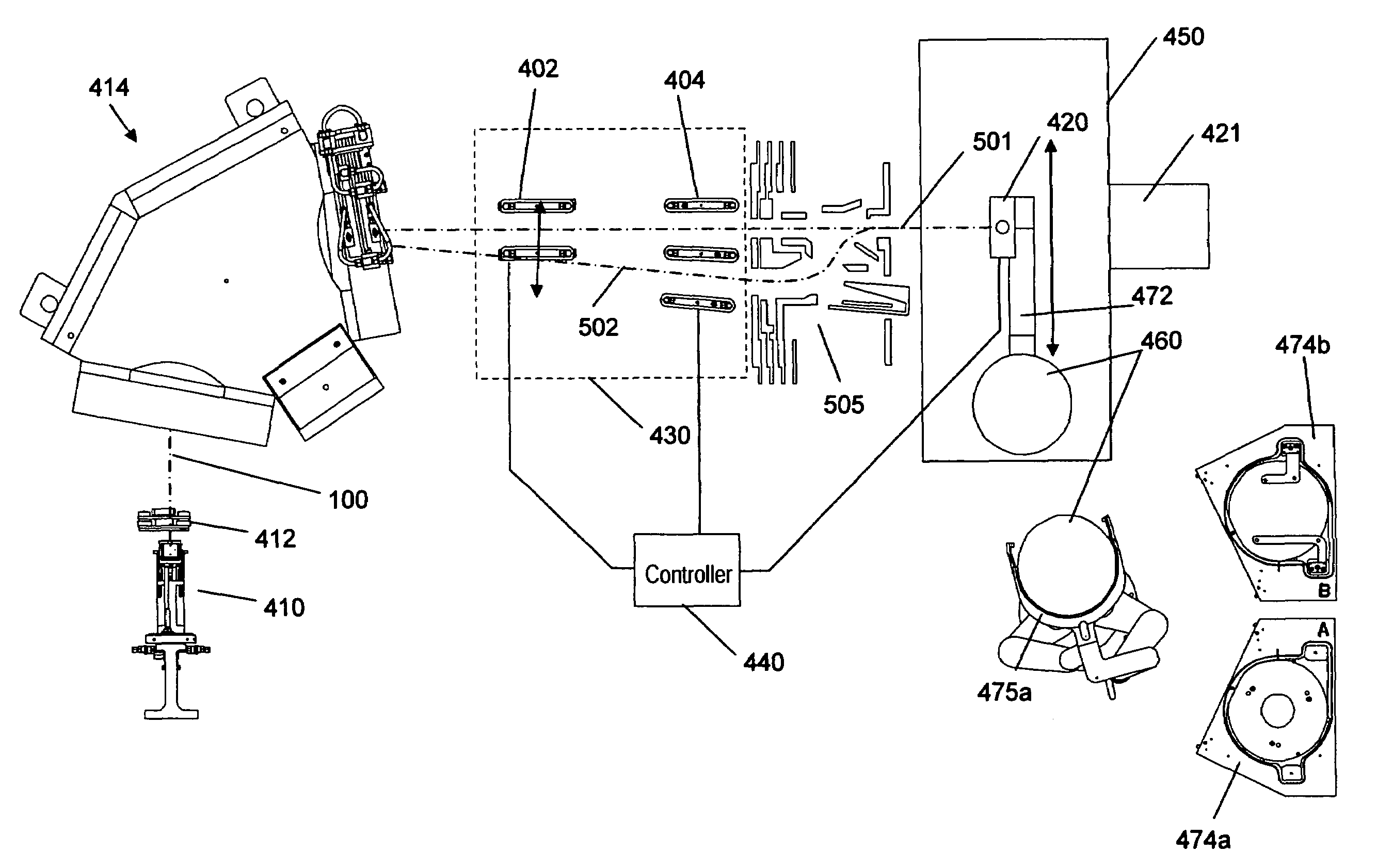

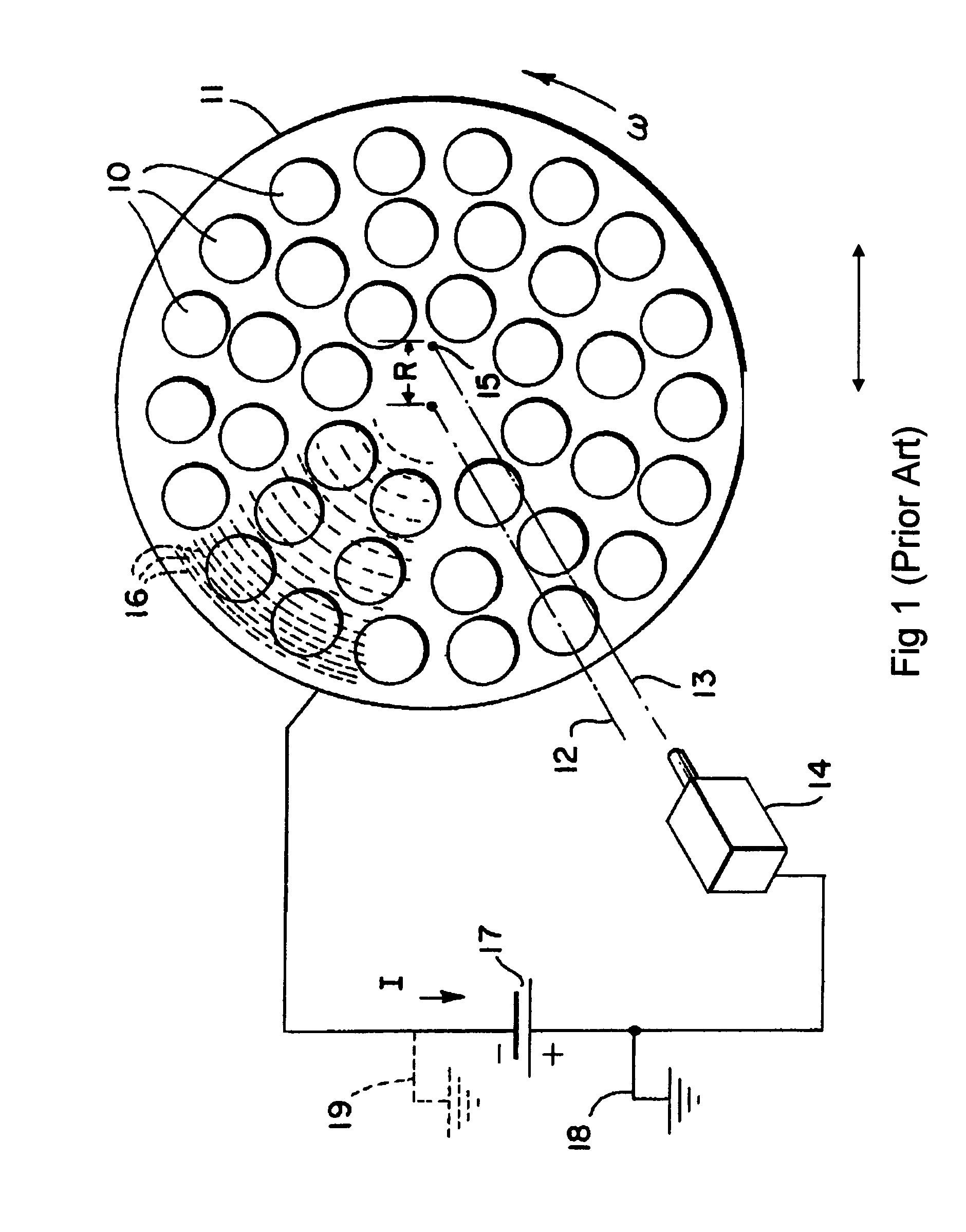

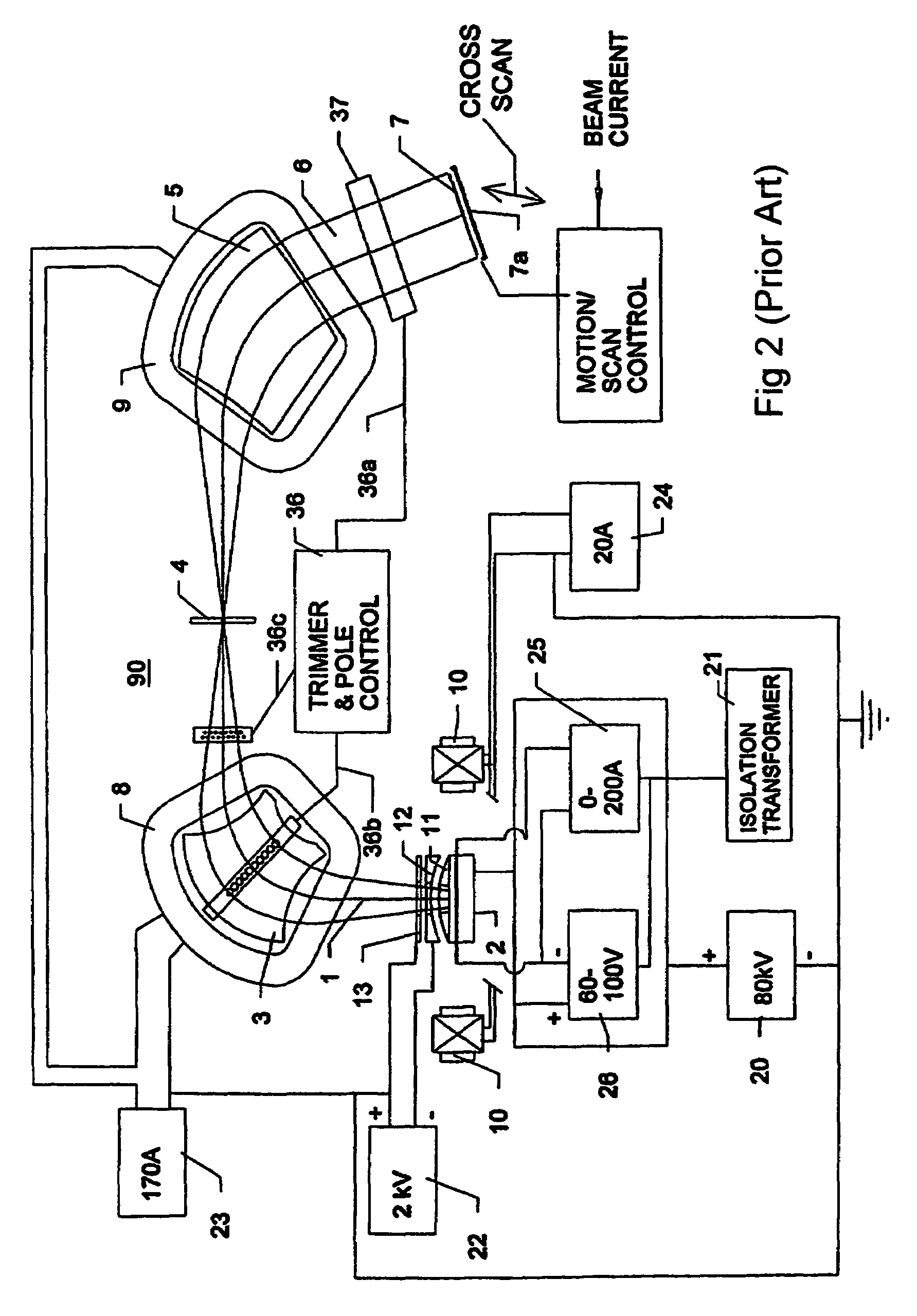

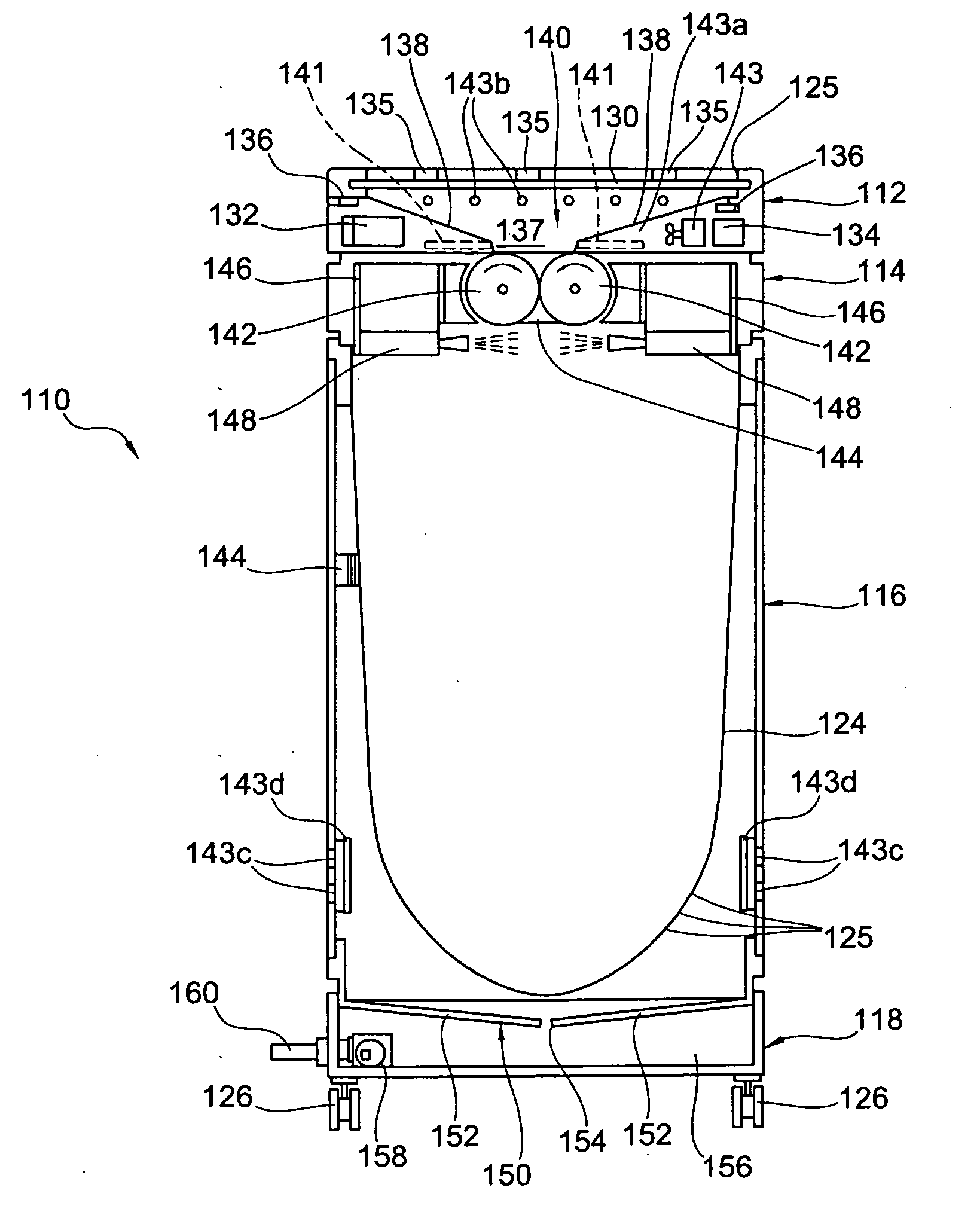

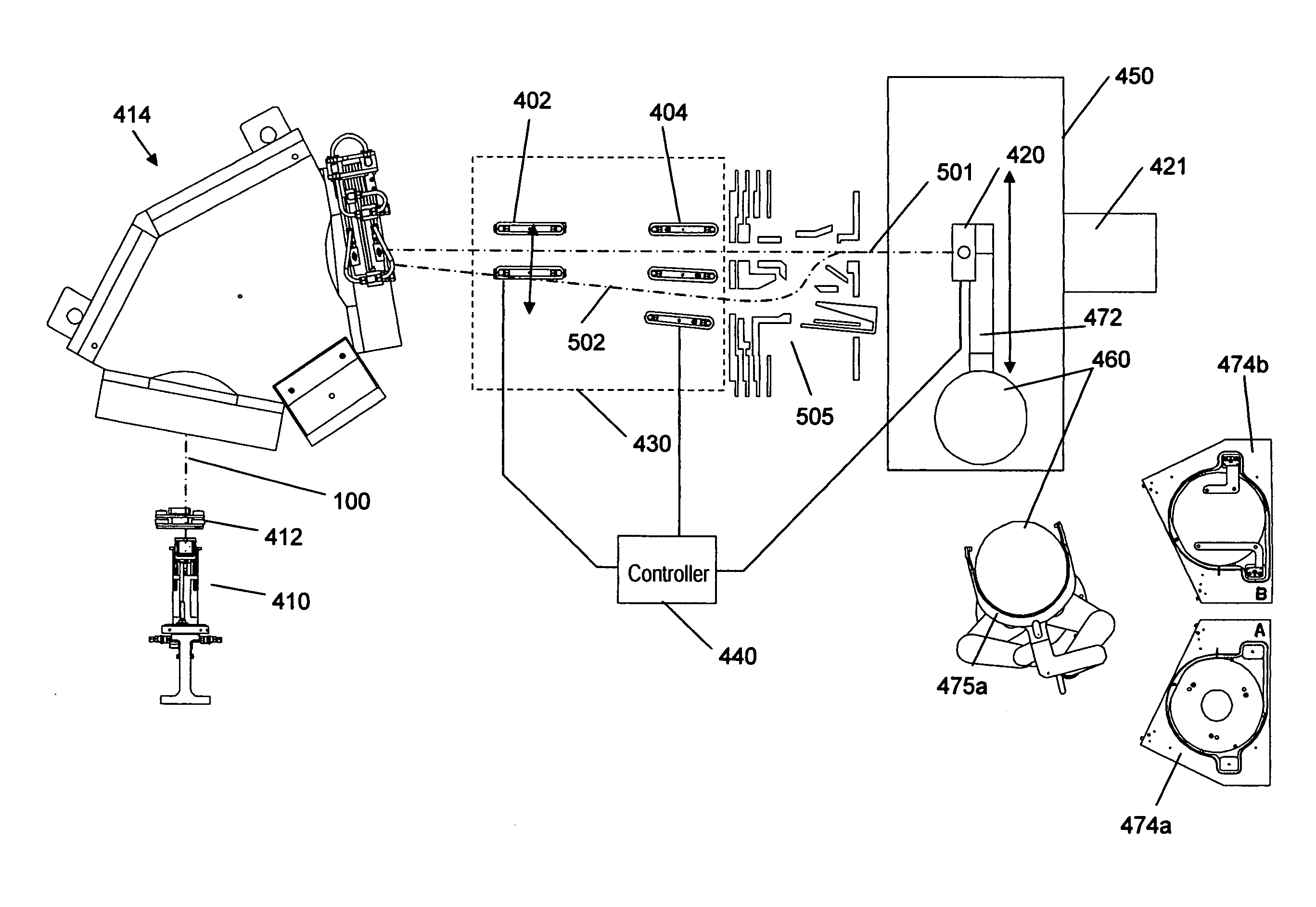

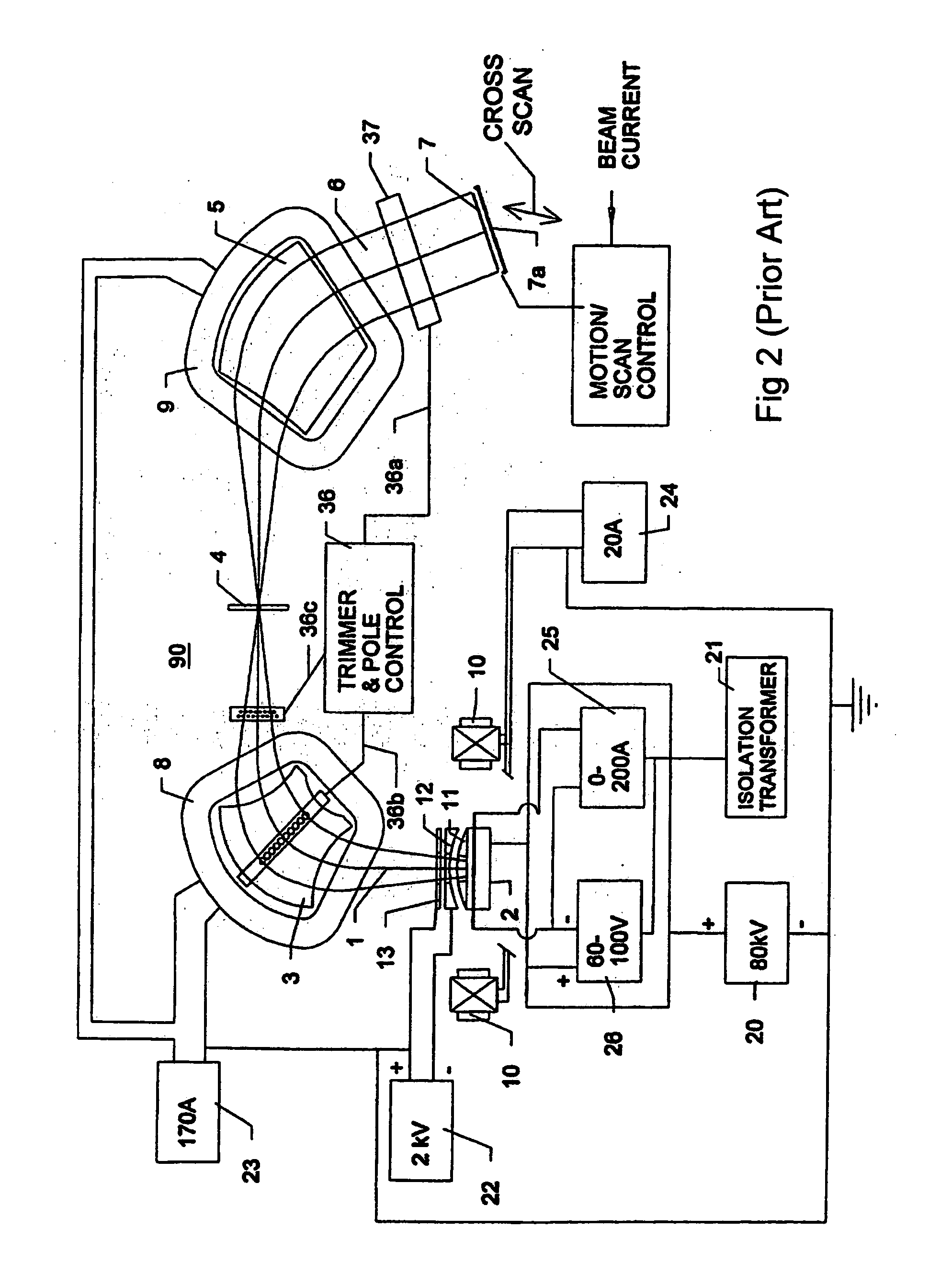

Apparatus and methods for ion beam implantation using ribbon and spot beams

ActiveUS7326941B2Difficult to controlIncrease throughputMagnetsMaterial analysis by optical meansBand shapeIon beam

This invention discloses an ion implantation apparatus with multiple operating modes. It has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. The invention further discloses a two-path beamline in which a second path incorporates a deceleration system incorporating energy filtering. The invention discloses methods of ion implantation in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning, and from a simple path to an s-shaped path with deceleration.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

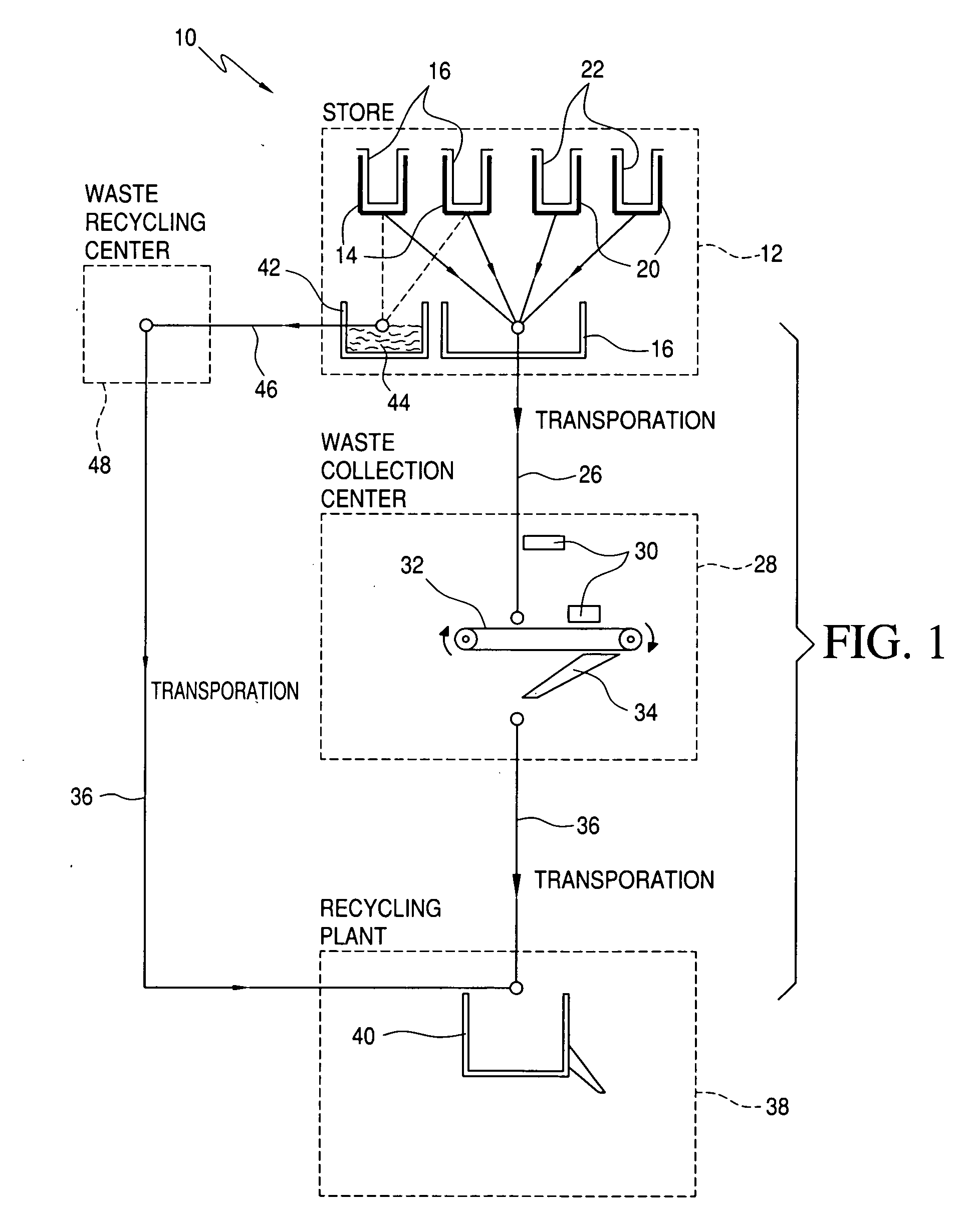

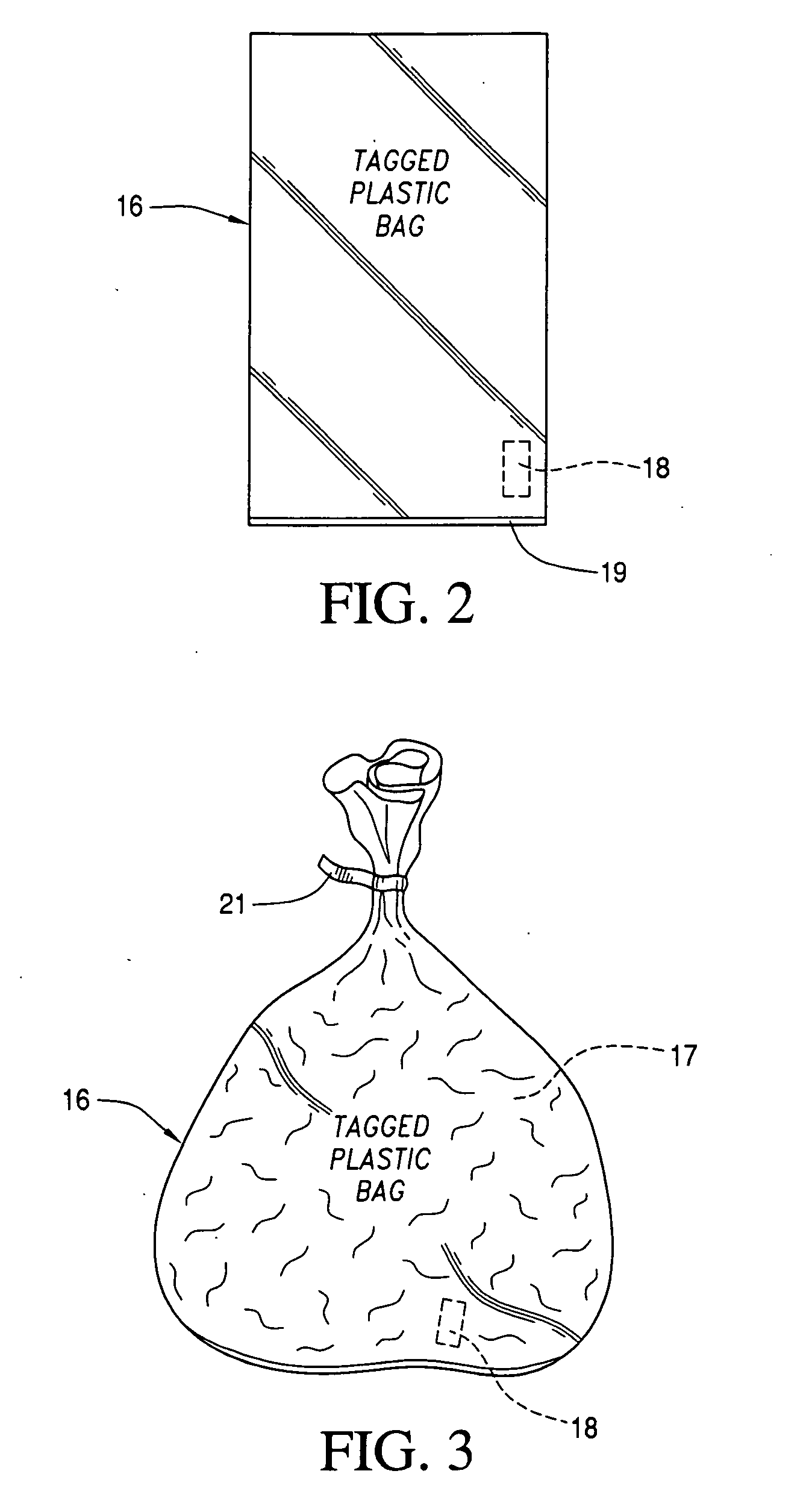

Waste Collection Device, and Waste Recycling System

InactiveUS20110056952A1Inhibit deteriorationEliminate pollutionBagsLarge containersDisinfectantWaste collection

A waste collection device configured to shred, treat waste with disinfectant, and / or remove water from the waste, and a waste recycling system.

Owner:BOROWSKI DAVID +2

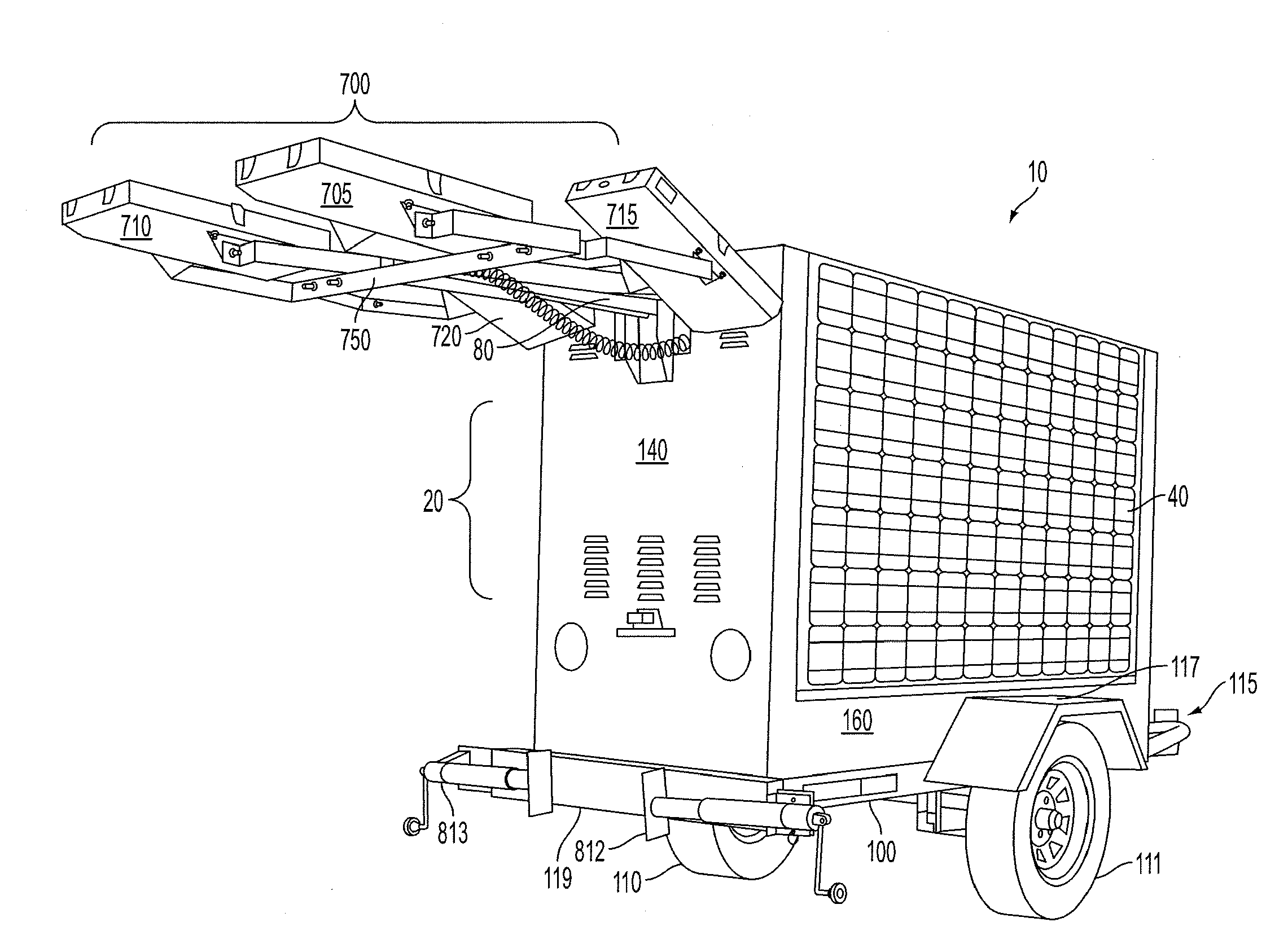

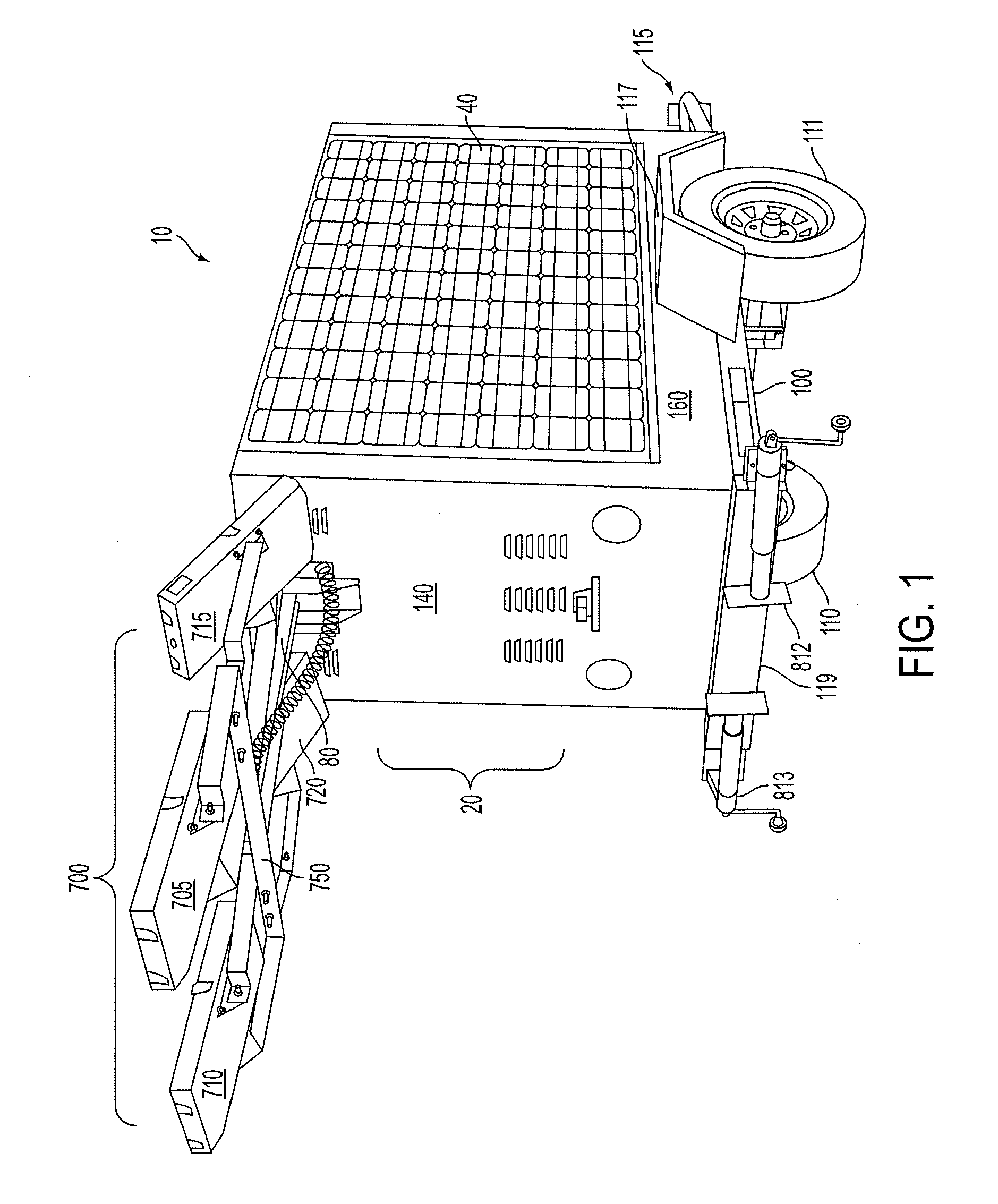

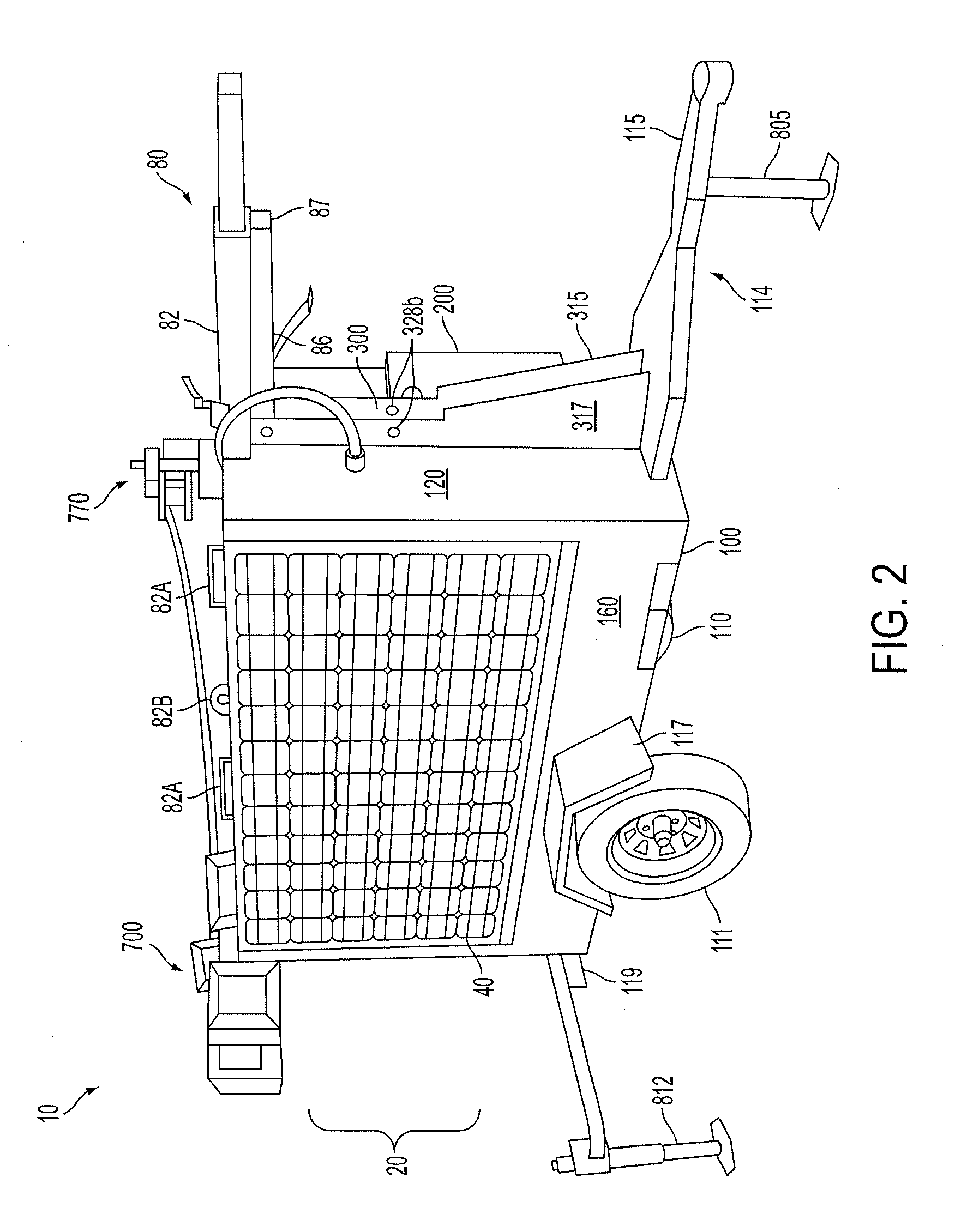

Mobile solar-powered light tower

ActiveUS20120201016A1Excellent and useful lightingRemove carbon emissionsMechanical apparatusLighting support devicesLight equipmentElectrical battery

Provided is a mobile lighting device that can derive power from a renewable energy source, such as solar power. The device can comprise a mobile base unit that can house one or more components of the device. The device further can comprise a solar power module associated with the mobile base unit that converts solar energy into electrical current. The device also can comprise a lighting module associated with the mobile base unit that is at least partially powered either directly or indirectly using the electrical current from the solar power module. The device further can comprise a solar power storage module, such as comprising one or more batteries, for storing energy and discharging as electrical current for powering the lighting module, which can be positioned atop a mast that can be extendable, pivotable, and / or rotatable. The invention also provides methods and systems for illuminating areas.

Owner:RENEWABLE ENERGY HLDG

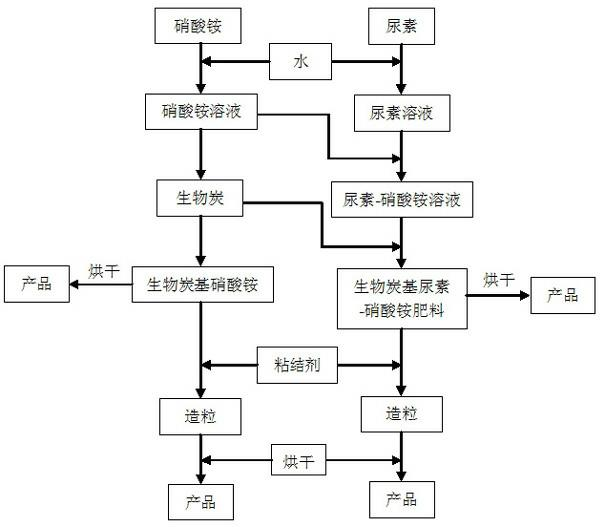

Method for producing biocarbon-based slow-release nitrogen fertilizer

InactiveCN102424642ASimple preparation processIncrease lossClimate change adaptationAgriculture gas emission reductionSoil scienceClimatic warming

The invention discloses a method for producing a biocarbon-based slow-release nitrogen fertilizer, which is characterized by comprising the following steps: thermal cracking or gasifying corn straw, or apple tree waste branch, trunk and wood chip to obtain the biocarbon; mixing the biocarbon and an ammonium nitrate solution, or urea and the ammonium nitrate solution, fully stirring and drying, or adding a binder with 1-3% of total amount and sending to a granulation system for granulation, then drying to obtain the biocarbon-based slow-release nitrogen fertilizer product. The fertilizer has the advantages of simple and easy preparation technology, and low cost. The biocarbon-based slow-release nitrogen fertilizer contains 10-12% of nitrogen, the biocarbon carrier material is stable in soil, and is a good soil amendment and a carbon sequestration agent, soil is applied for improving soil fertilization, the nitrogen element of the nitrogenous fertilizer loaded by the biocarbon has slow-release effect, so that the loss of the nitrogen element can be reduced, the nitrogenous fertilizer utilization rate can be enhanced; the biocarbon can retain in soil for long-term to play the effects of carbon sequestration and carbon emission reduction, the biocarbon is helpful for alleviating climate warming, and biocarbon-based slow-release nitrogen fertilizer is a green fertilizer.

Owner:NORTHWEST A & F UNIV

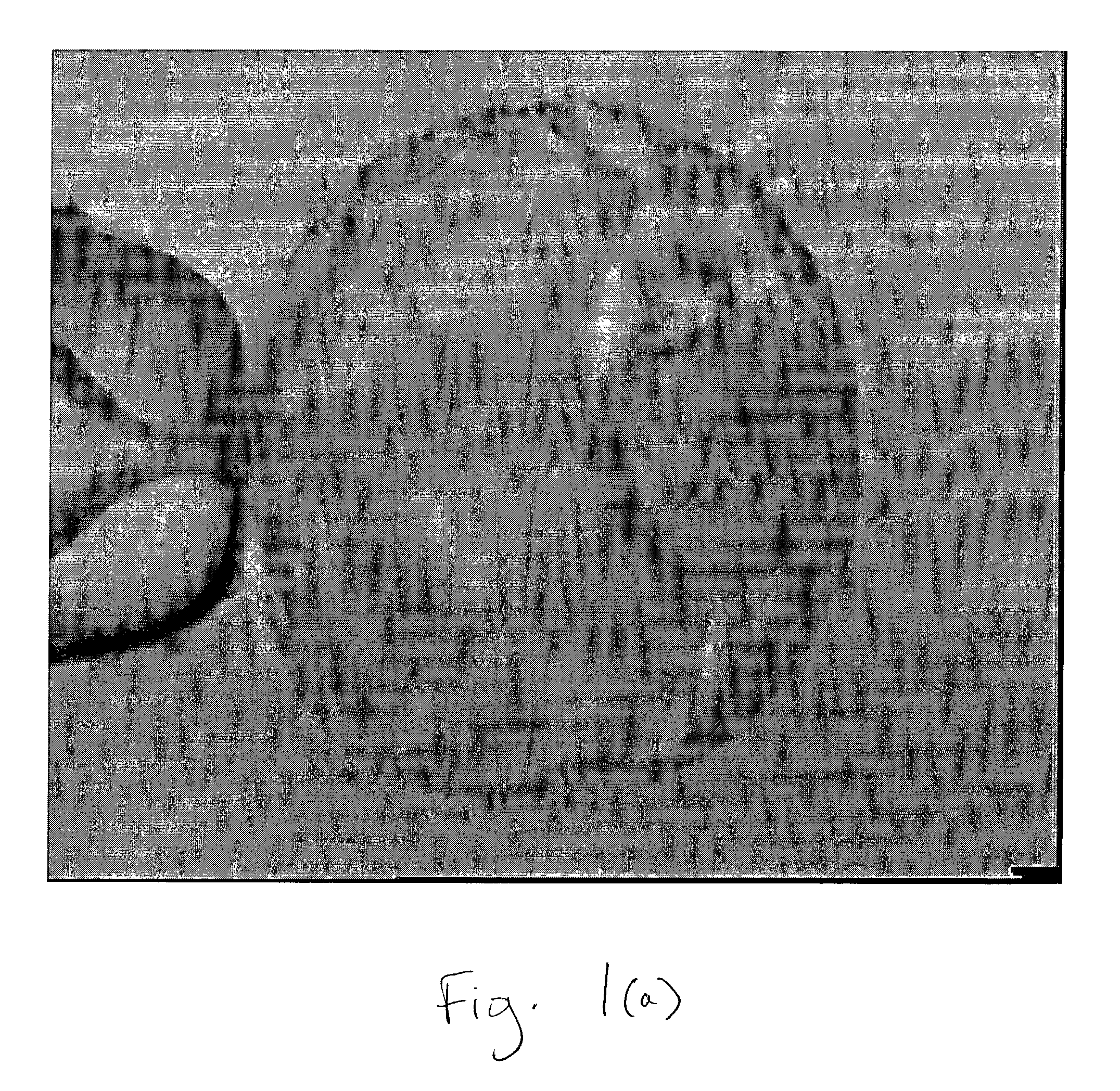

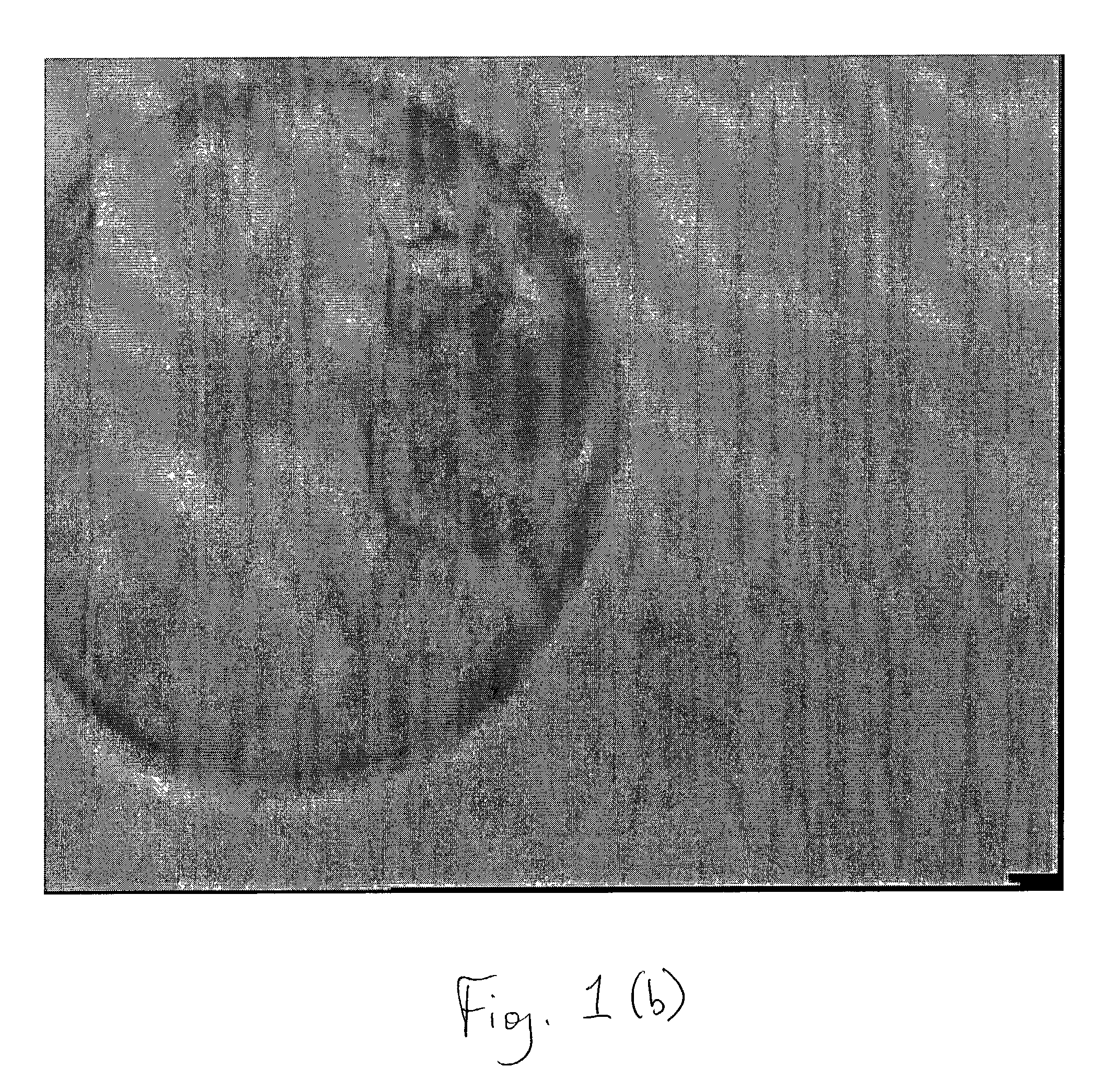

Isolation of inner cell mass for the establishment of human embryonic stem cell (hESC) lines

InactiveUS7294508B2Easy to useAvoid possibilityMammal material medical ingredientsDead animal preservationGerm layerHuman embryonic stem cell line

A method for isolating an inner cell mass comprising the steps of immobilizing a blastocyst stage embryo having a zona pellucida, trophectoderm, and inner cell mass, creating an aperture in the blastocyst stage embryo by laser ablation, and removing the inner cell mass from the blastocyst stage embryo through the aperture. The aperture is through the zona pellucida and the trophectoderm. The laser ablation is acheived using a non-contact diode laser. The inner cell mass removed from the blastocyst stage embryo is used to establish human Embryonic Stem Cell lines.

Owner:RELIANCE LIFE SCI PVT

Apparatus and methods for ion beam implantation using ribbon and spot beams

ActiveUS20060113494A1High resolve powerMass-analyzed efficientlyMagnetsMaterial analysis by optical meansBeamlineSpecific mass

This invention discloses an ion implantation apparatus with multiple operating modes. It has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. The invention further discloses a two-path beamline in which a second path incorporates a deceleration system incorporating energy filtering. The invention discloses methods of ion implantation in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning, and from a simple path to an s-shaped path with deceleration.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

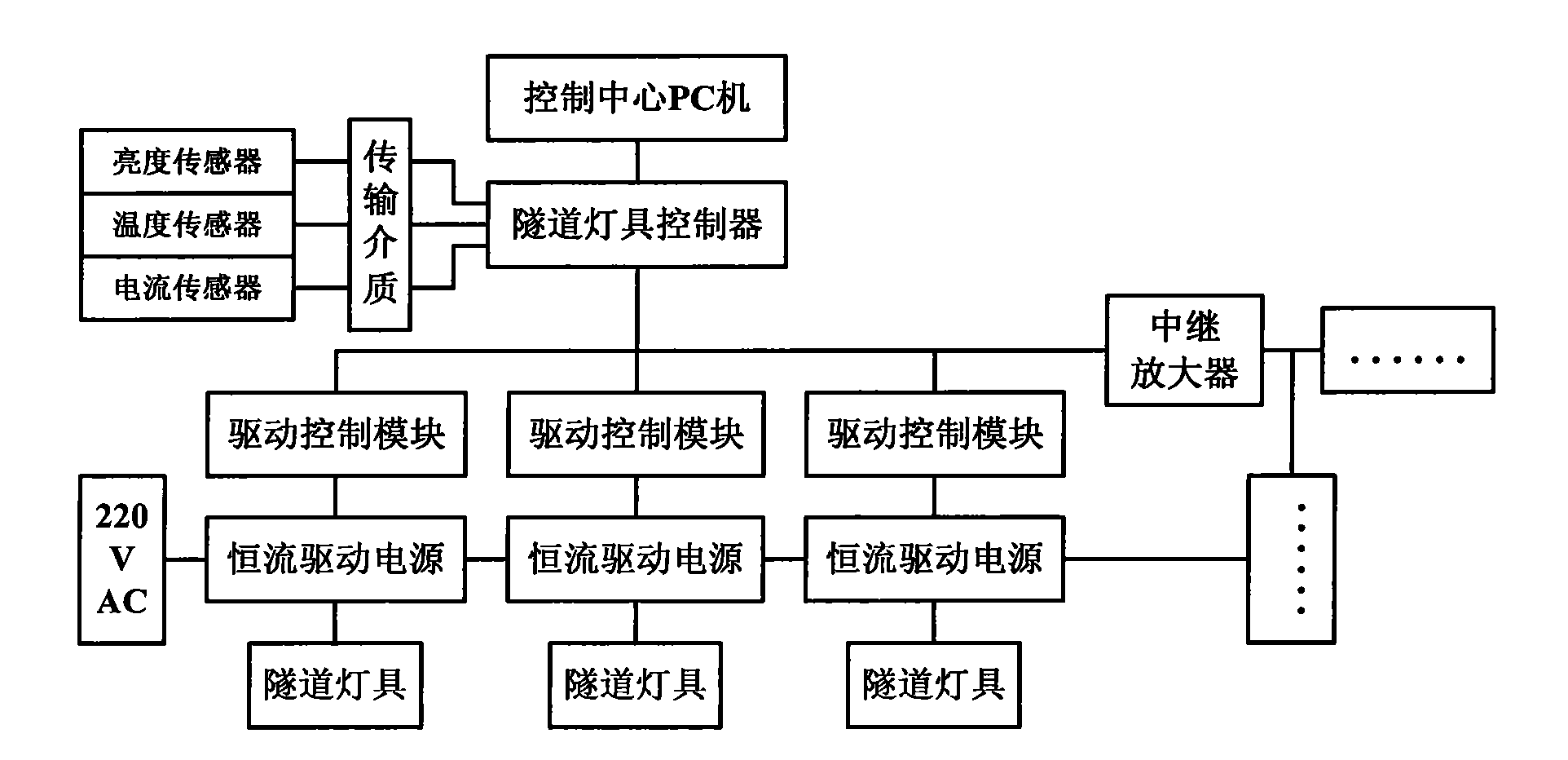

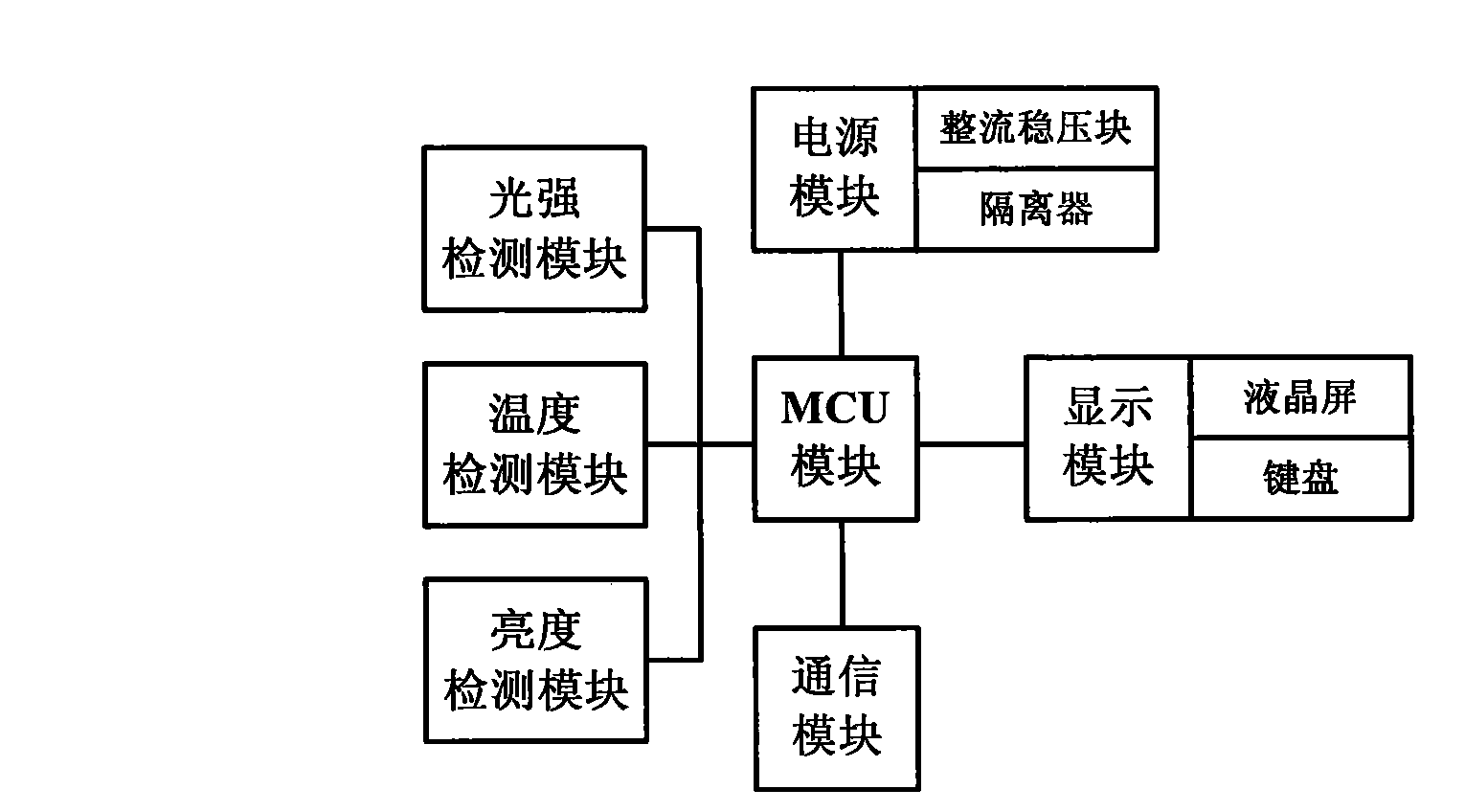

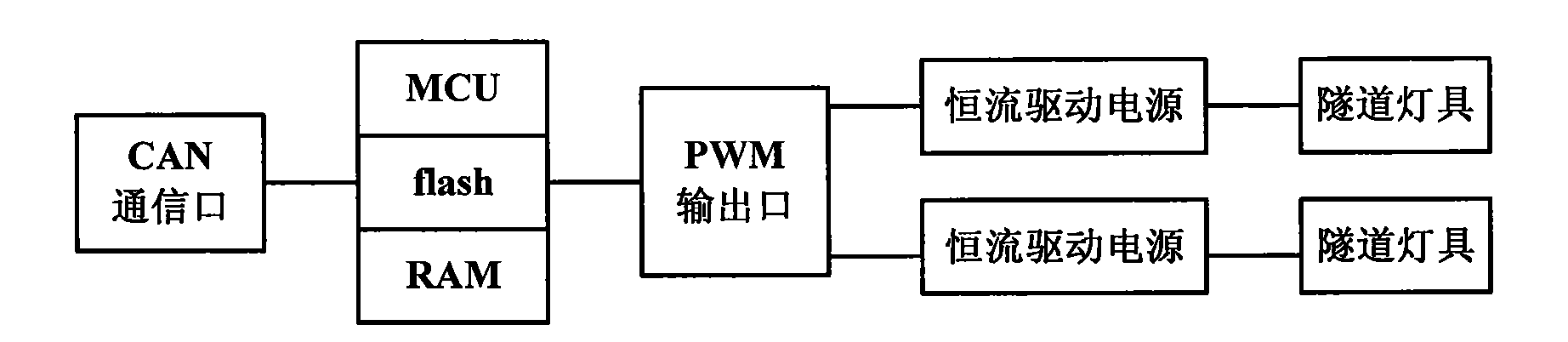

Intelligent control system for LED tunnel lamps and method for controlling LED tunnel lamps

InactiveCN101662863ARealize stepless intelligent controlOptimal control methodElectronic switchingElectric light circuit arrangementCurrent sensorEngineering

The invention provides an intelligent control system for LED tunnel lamps and a method for controlling the LED tunnel lamps. The system comprises a control center PC computer, a tunnel lamp controllerand lamps, wherein a brightness / temperature / current sensor is connected with the controller via a transmission medium; the control center PC computer is connected with a plurality of drive control modules via the controller and a bus structure; and each drive control module is connected with a constant-current driving power supply of each LED tunnel lamp. Therefore, the system detects the intensity and weakness of light at the entrance and exit of a tunnel in real time via optical detectors distributed in the tunnel by applying highly accurate intelligent detection measure based on an advanced RISC microprocessor, and feeds processed data back to a control center; the control center processes the data and controls various tunnel lamps at different positions so as to control the brightnessof the LED tunnel lamps at different positions and finally achieve the aim of saving energy source.

Owner:NANJING HANDSON SCI & TECH CORP

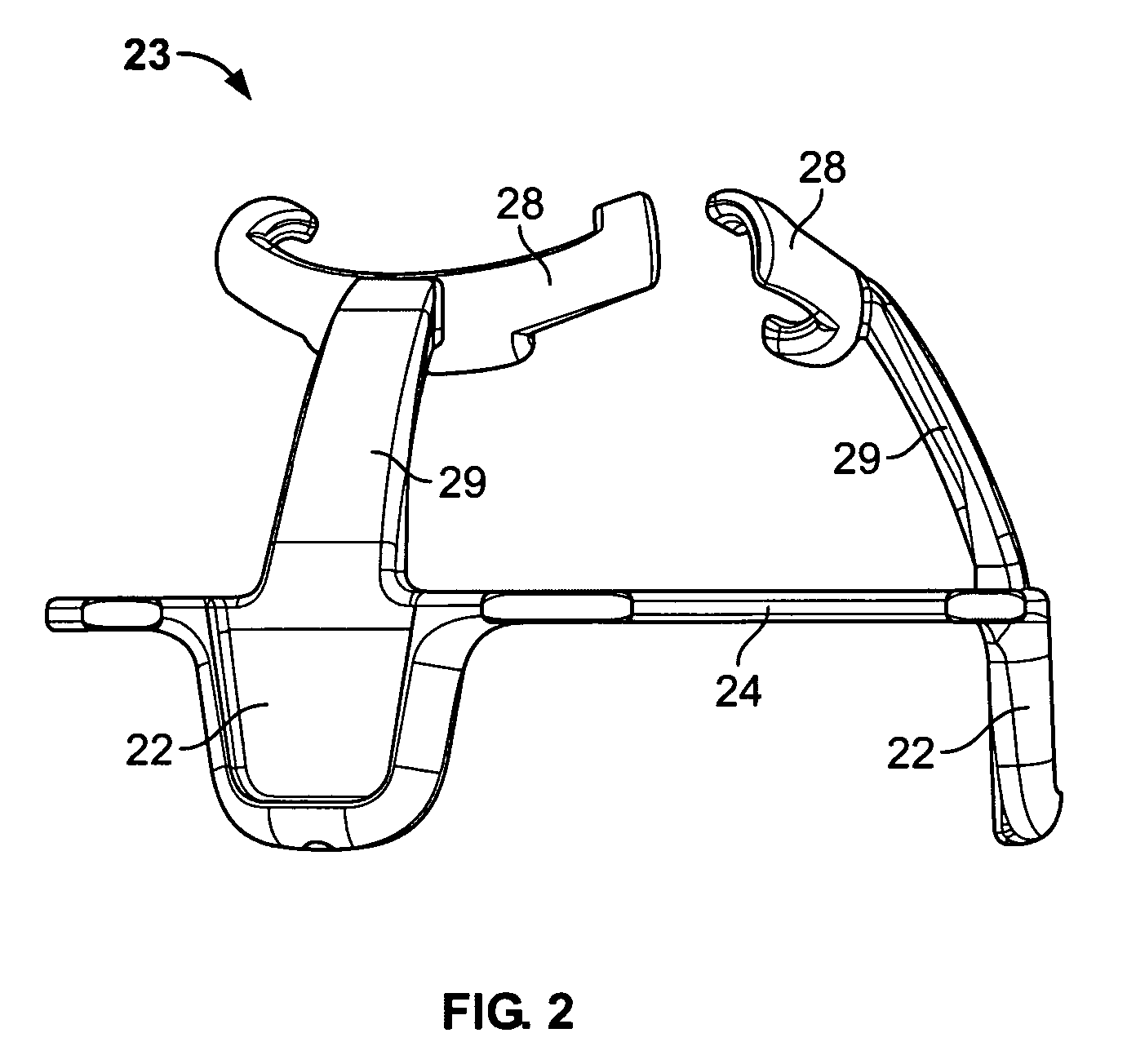

Heart valve support and storing lid system and methods associated therewith

ActiveUS7389874B2Eliminate pollutionEliminate contaminationDispensing apparatusDiagnosticsProsthesisBiomedical engineering

Systems and methods for supporting a replacement heart valve are presented herein. A bioprosthesis may be stored in a storage container by suspending the bioprosthesis from a support structure. The volume of storage solution may be reduced by using a lid with a boss extending therefrom to displace some of the volume of the storage container. The support structure may rest on the base of the storage container. Additionally, there may be a holder attached to the bioprosthesis above the support structure. The holder-bioprosthesis-support structure may be constrained between the lid and base of the storage container.

Owner:ST JUDE MEDICAL

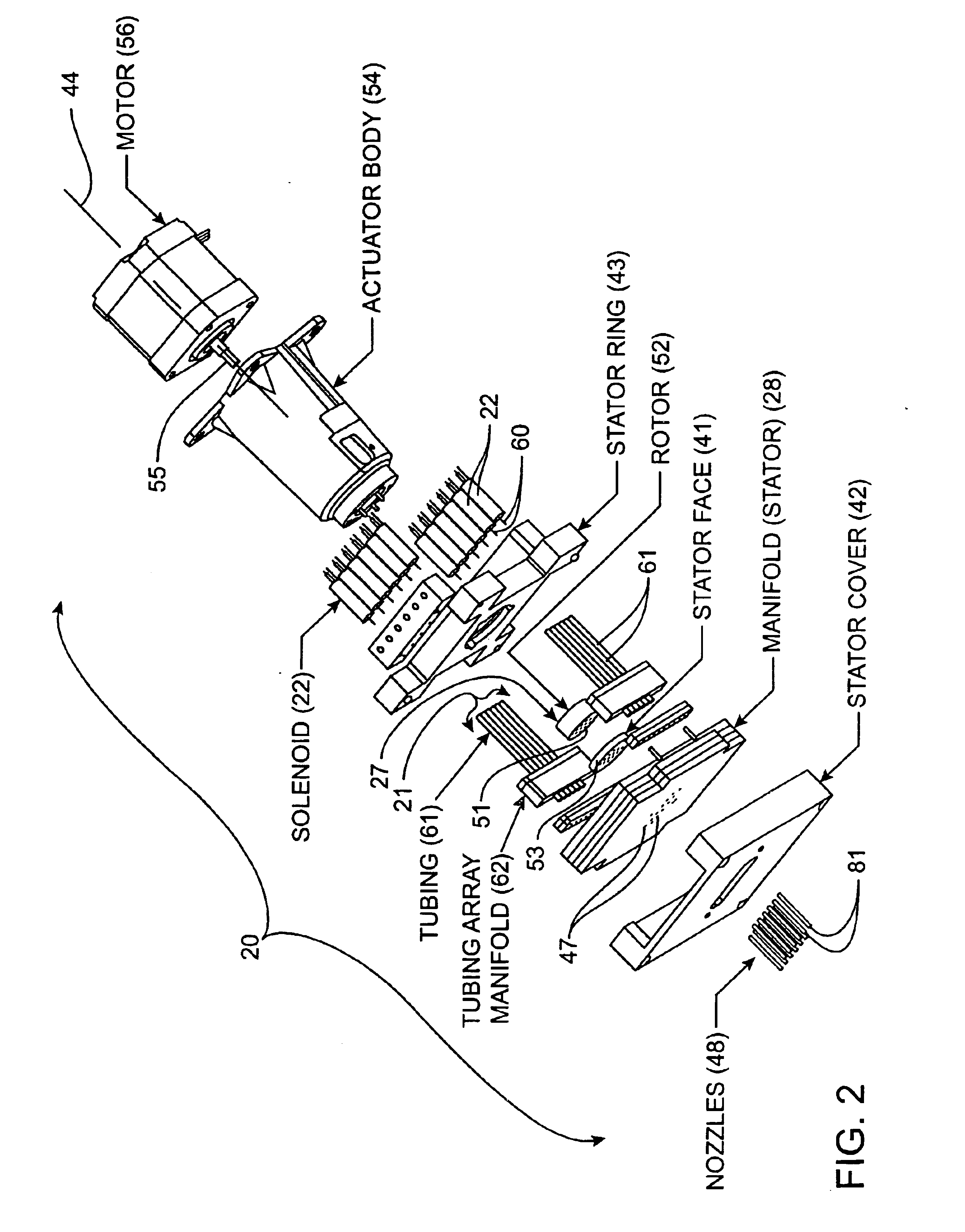

Hybrid valve apparatus and method for fluid handling

InactiveUS6852291B1Eliminate pollutionBioreactor/fermenter combinationsSequential/parallel process reactionsBiomedical engineeringSubstrate surface

A hybrid valve apparatus for use with an aspiration actuator and a dispensing actuator to transfer fluid from a reservoir to a test site on a substrate surface. The hybrid valve includes a valve assembly movable between an aspiration condition and a dispensing condition, and a manifold device coupled to the valve assembly. The manifold device includes a fluid aspiration conduit having a first aspiration port in fluid communication with the aspiration actuator. On an opposite end of the aspiration conduit is a second aspiration port in selective fluid communication with the valve assembly to selectively aspirate a liquid sample slug from the reservoir into a discrete sample path when the valve assembly is in the aspiration condition. The manifold device further includes a fluid dispensing conduit having a first dispensing port in fluid communication with the dispensing actuator, and a second dispensing port in selective fluid communication with the valve assembly. When the valve assembly is in the dispensing condition, the sample path is fluidly coupled to the dispensing actuator to selectively dispense at least one droplet of the liquid sample slug therefrom, while simultaneously being out of fluid communication with the aspiration actuator. In contrast, in the aspiration condition, the sample path is in fluid communication with the aspiration actuator, while being out of fluid communication with the dispensing actuator.

Owner:UT BATTELLE LLC +1

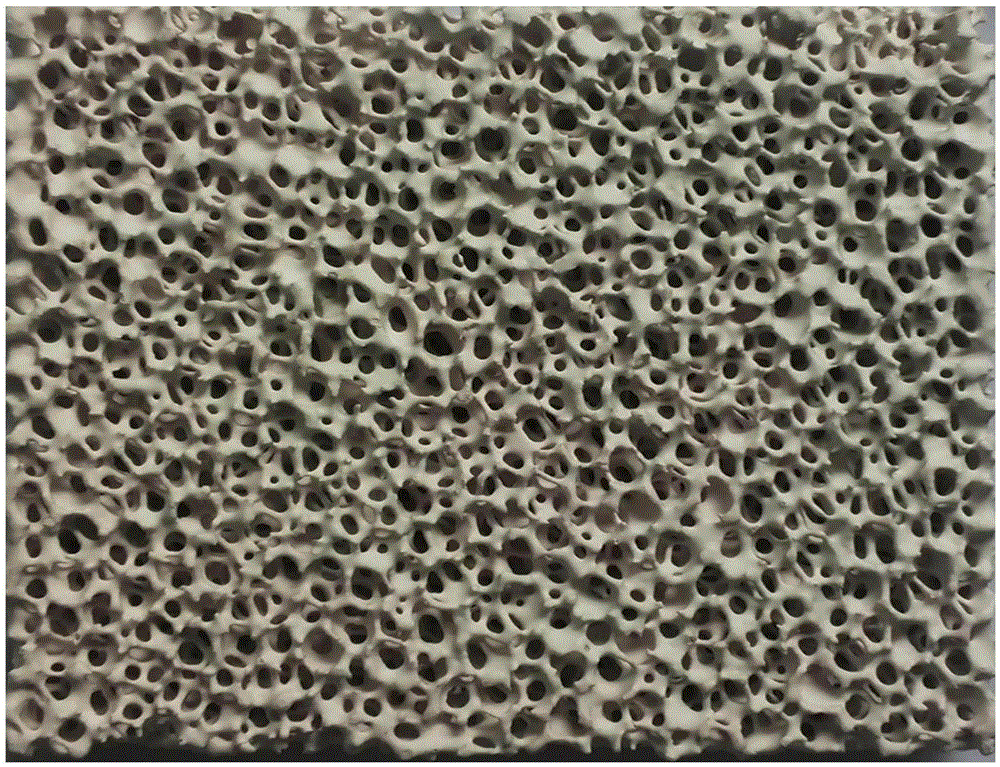

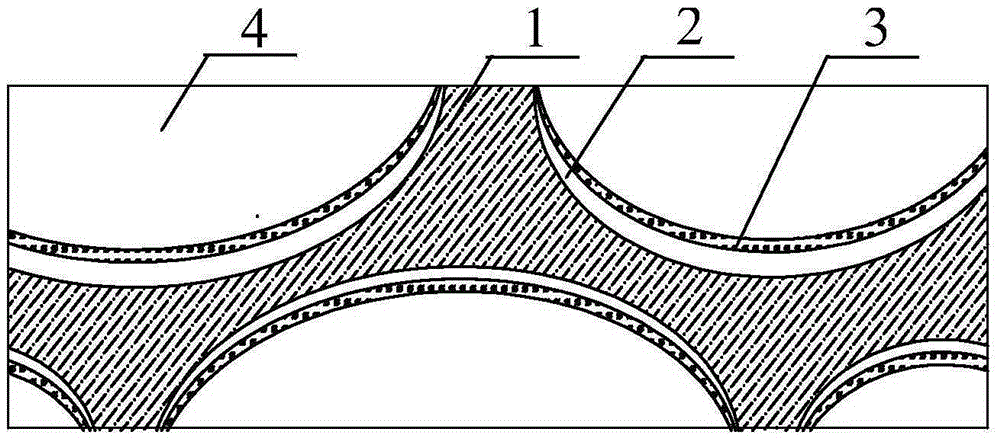

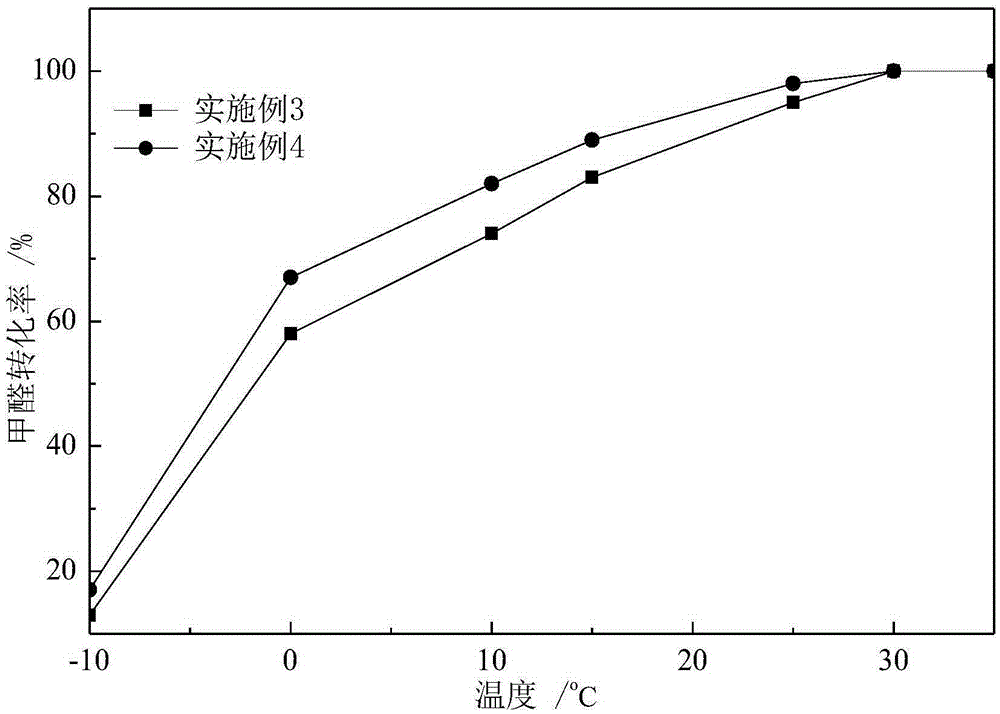

Catalytic module capable of removing formaldehyde at room temperature and preparation method thereof

ActiveCN105289298AImprove catalytic activity and purification efficiencyExcellent low temperature activity and removal efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChemistryLight source

The invention discloses a catalytic module capable of removing formaldehyde at room temperature and a preparation method thereof. The catalytic module comprises a skeleton carrier, coatings and catalyst layers, the skeleton carrier is a foam ceramic structure with three-dimensional pore channels, and the foam ceramic structure is internally provided with multiple pore channels which are interwoven into a net-shaped structure and arranged in any one of the X direction, the Y direction and the Z direction; the coatings are evenly coated on the surfaces of the pore channels in the foam ceramic structure and the other surface of the foam ceramic structure, and the catalyst layers are highly dispersed on the coatings. By means of the catalytic module capable of removing the formaldehyde at the room temperature and the preparation method thereof, at the room temperature and environment humidity, low-concentration formaldehyde can be oxidized into H2O and CO2, excellent low-temperature activity and removing efficiency are achieved, and the formaldehyde removing efficiency can be kept above 98 percent at the airspeed SV equal to 50,000 h<-1>. The preparation process is simple, the precious metal load is low, and accessory equipment such as light sources and heating are not needed. The catalytic module is suitable for air purification of closed and semi-closed spaces such as living rooms, office buildings, schools, dormitories, shopping malls, furniture markets and automobiles.

Owner:展宗城

Preparation method of water-based polyurethane/nano-silicon dioxide composite emulsion

InactiveCN101845217AEliminate pollutionAddress pollution and damagePolyurea/polyurethane coatingsPrepolymerSolvent

The invention relates to a preparation method of a water-based polyurethane / nano-silicon dioxide composite emulsion, which comprises the following steps: uniformly mixing and stirring ethyl orthosilicate, absolute ethyl alcohol and octadecyl trimethyl ammonium chloride for reacting to obtain nano-silicon dioxide sol; heating polyglycol, and then, adding diisocyanate and dibutyltin dilaurate for reacting to form polyurethane prepolymer; adding a hydrophilic chain extender and a cross-linking agent into the polyurethane prepolymer for carrying out chain extending reaction, adding organic base for regulating the pH value to be 7.0-8.0, and then, adding deionized water to obtain 30% of water-based polyurethane emulsion; and mixing the nano-silicon dioxide sol and the water-based polyurethane emulsion in a water bath, and carrying out ultrasonic treatment to obtain the water-based polyurethane / nano-silicon dioxide composite emulsion. Harmful solvents and emulsifying agents do not need to be added in the preparation process of the invention, thereby solving the problems of polluting environment and injuring operators.

Owner:SHAANXI UNIV OF SCI & TECH

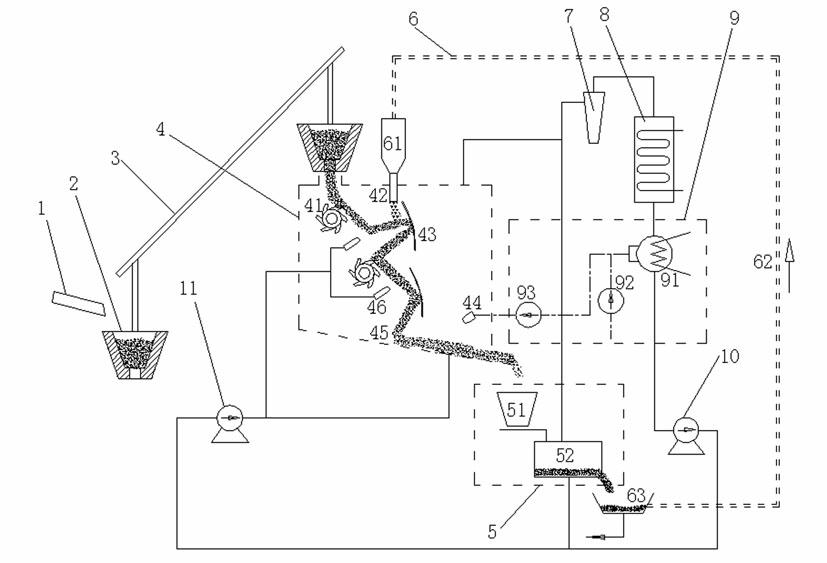

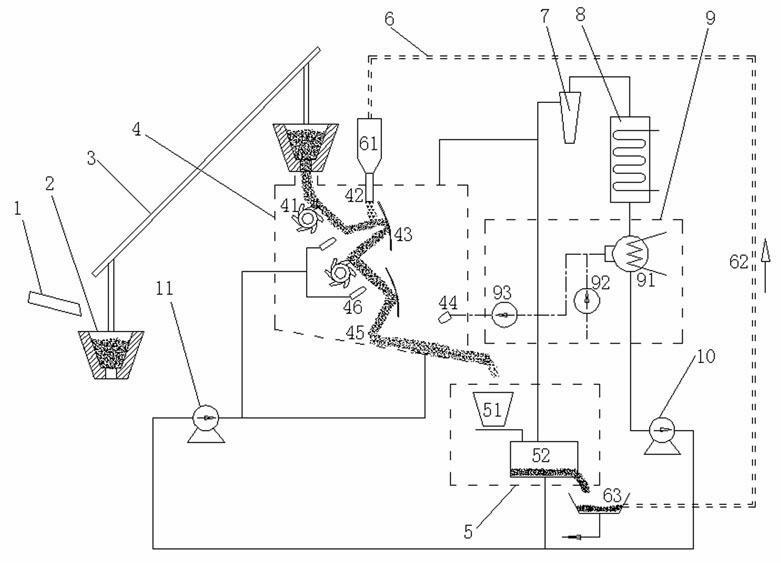

Method and system for recovering high-temperature sensible heat of molten blast furnace slag

ActiveCN102162016ADoes not affect activityImprove waste heat qualityIncreasing energy efficiencyDischarge devicesSlagSlow cooling

The invention discloses a method and a system for recovering high-temperature sensible heat of molten blast furnace slag. The system comprises a blast furnace slag runner, a slag hopper, a slag hopper lifting mechanism, a quenching unit, a slow cooling unit, a cold slag particle circulation unit, a cyclone dust collector, a waste heat boiler, a condensing unit, a circulating fan, and a booster fan. The method for recovering waste heat comprises the following steps of: crushing and quickly cooling the molten blast furnace slag in the quenching unit in a composite way of a rotary crushing wheel, high-pressure cold air, a slag trap, cold slag particles and cooling water, and fully exchanging heat with solidified blast furnace slag in the slow cooling unit by using cooling air; and allowing high-temperature air which comes out of the quenching unit and the slow cooling unit to enter the waste heat boiler and performing heat exchange, transforming into steam or electric power and then outputting. The subsequent utilization of blast furnace slag and the waste heat recovery efficiency are synchronously considered, condensed water is recycled, finished slag does not contain water or only contains a small amount of water, the granulation effect of the slag is better, and the contradiction between intermittent slagging and continuous heat production of blast-furnace ironmaking is resolved.

Owner:HANGZHOU BOILER GRP CO LTD

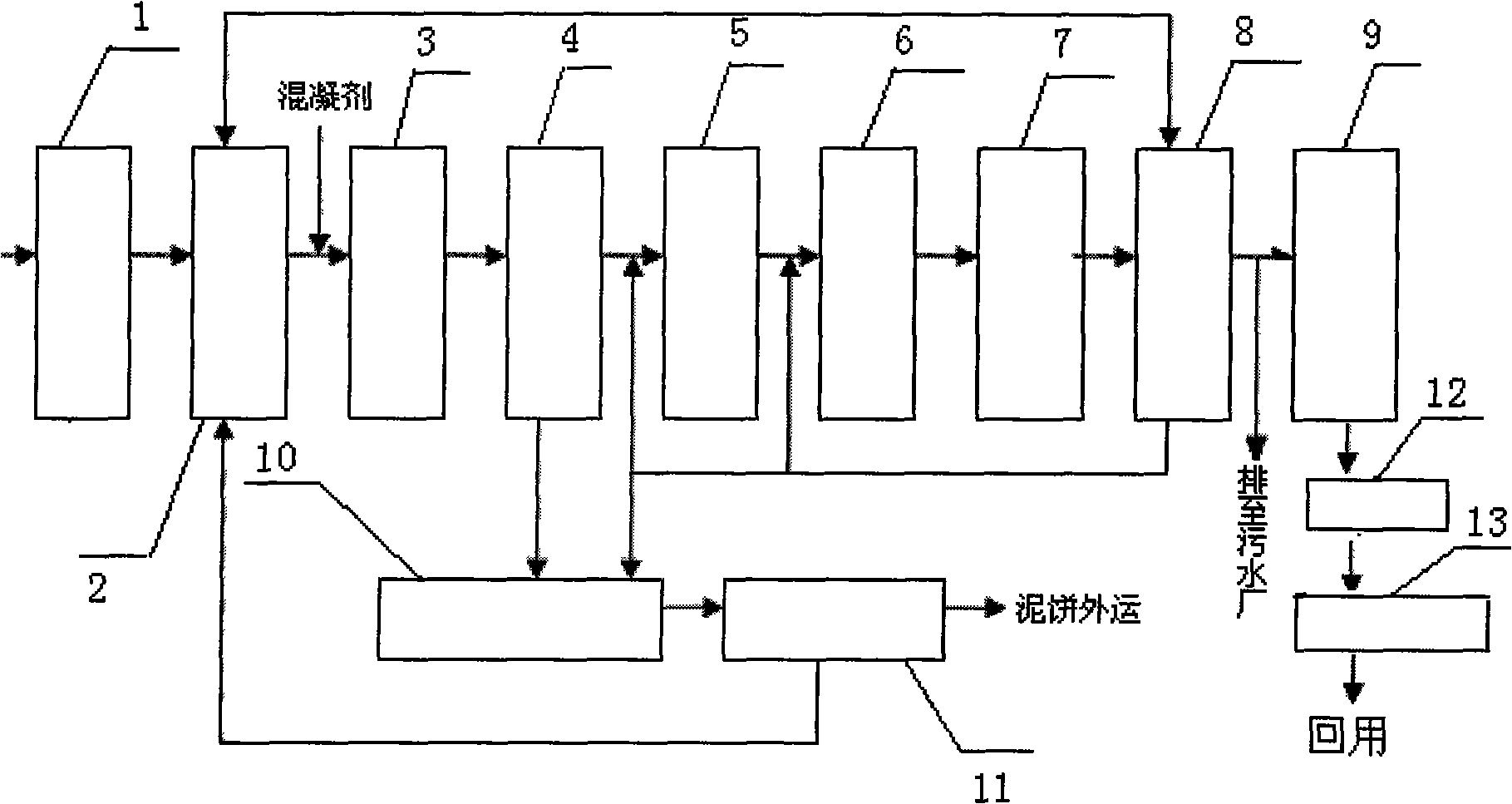

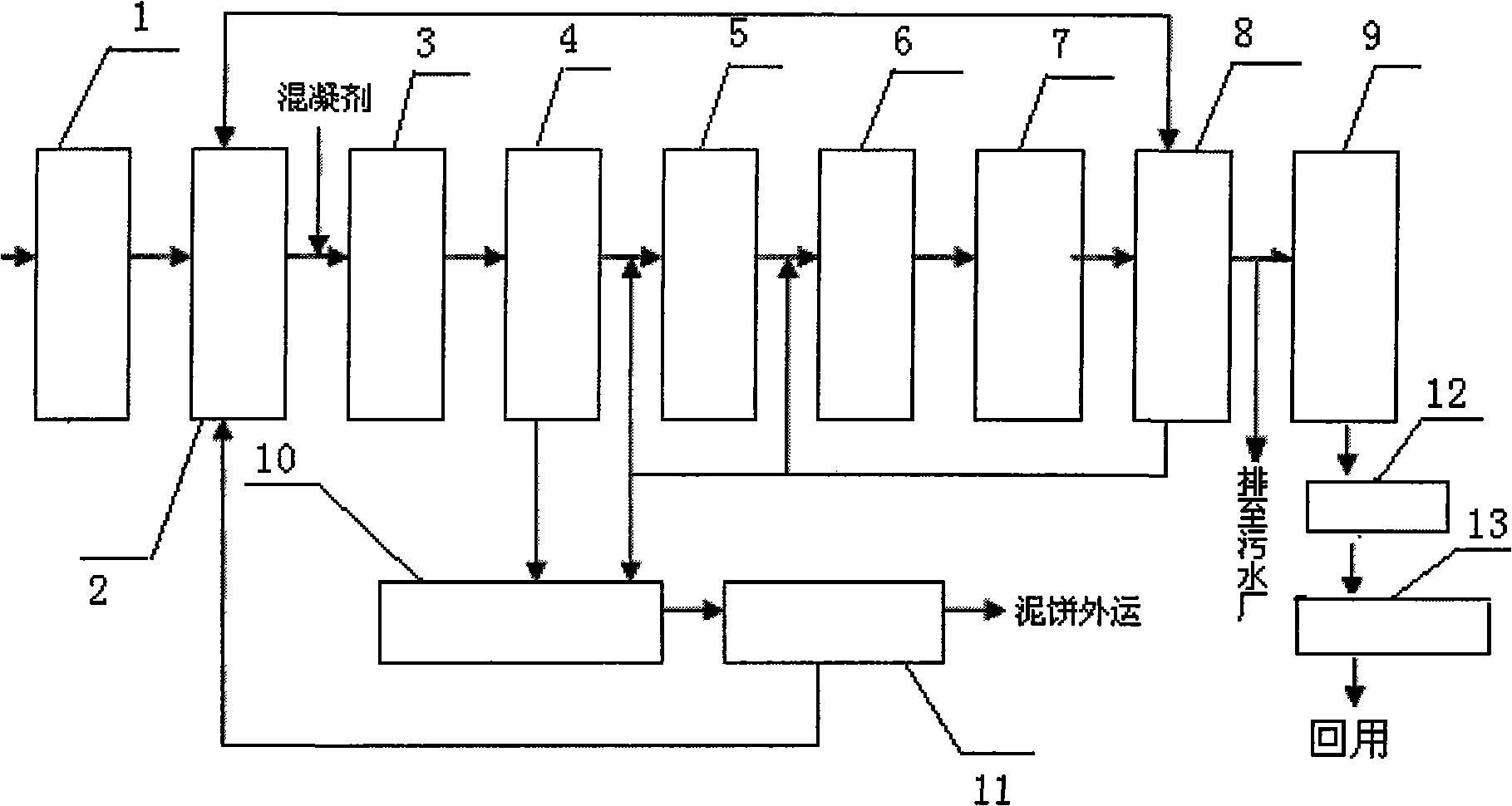

Advanced dyeing wastewater treatment and reclaimed water reuse system and method thereof

InactiveCN101525202ASimple processLow running costSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesBiological activated carbonReclaimed water

The invention relates to an advanced dyeing wastewater treatment and reclaimed water reuse system and a method thereof. The system consists of a regulating tank (2), a coagulation tank (3), a preliminary sedimentation tank (4), an acidification hydrolysis tank (5), a deep well (6), a deaeration tank (7), a secondary sedimentation tank (8), a biological activated carbon tank (9), a sludge concentration tank (10), a sludge dewatering tank (11), a filter tank (12) and an ozone oxidation tank (13). The method comprises the following steps: wastewater is sent to the regulating tank, the coagulation tank and the preliminary sedimentation tank, then sludge is returned to the coagulation tank, excess sludge is discharged to the sludge concentration tank, clarified water flows to the acidification hydrolysis tank, is sent to a deep well aeration tank and then sent to the secondary sedimentation tank; and the obtained clarified water is discharged after meeting the standard, or flows to the biological activated carbon tank and is treated for production. The system and the method have the advantages of simple process, low operating cost, high stability and reliability, convenient operation, and realization of automation control. Most of the wastewater discharged is reused in production after the treated wastewater meets the standard, thus reducing emission of pollutants, being capable of eliminating environmental pollution resulting from the wastewater and protecting environment.

Owner:常州市东霞房地产代理有限公司 +2

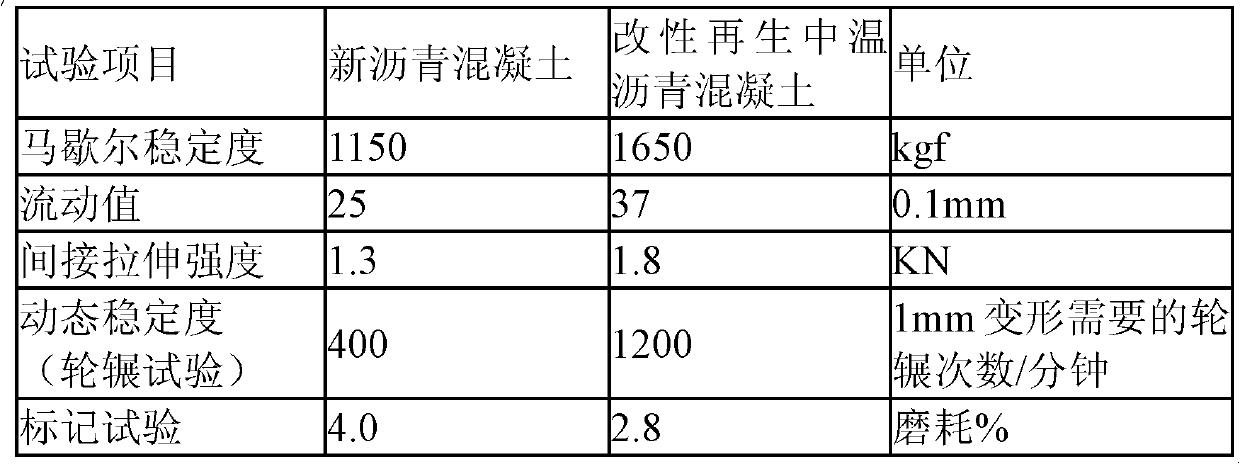

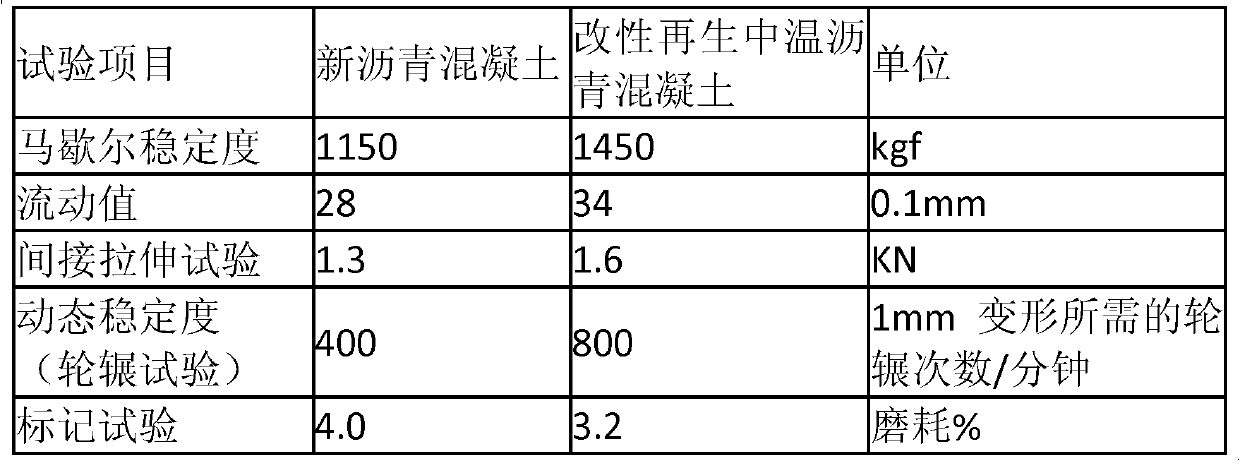

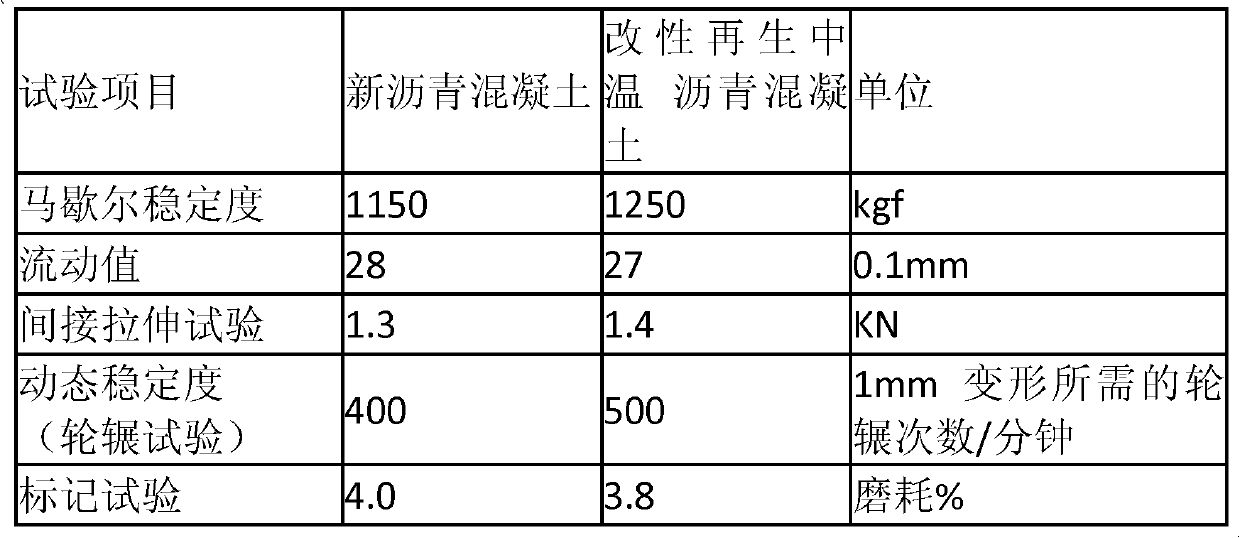

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

Non-glue diatom ooze building material

The invention discloses non-glue diatom ooze building material, which is used for wall decoration, surface dressing of boards and intermediate sandwich of the boards, and comprises the following components in parts by weight: 4-90 parts of kieselguhr below 10000 mesh, 20-60 parts of bentonite below 2000 mesh, 10-40 parts of kaolin below 2000 mesh, 5-30 parts of activated clay below 2000 mesh, 10-60 parts of quartz sand below 200 mesh, 5-40 parts of sepiolite below 800 mesh, 5-40 parts of calcium carbonate below 800 mesh, 5-30 parts of medical stone powder below 800 mesh, 2-20 parts of nanosized titania powder below 20000 mesh, 0.1-3 parts of fiber with the length being 5mm or below, 4.5-40 parts of attapulgite below 800 mesh, 2-20 parts of hydroxypropyl methyl cellulose, and 1-20 parts ofpigment. According to the non-glue diatom ooze building material, the kieselguhr and other porous natural materials with adsorption capacity are selected to manufacture interior building materials, the proportion is reasonable, chemical adhesive agents are not needed, and adhesive forming is realized through characteristics of the natural materials, so that porous structures of the natural materials can be maintained, indoor pollution can be eliminated, indoor humidity can be adjusted, odor can be removed, noise can be isolated, and flame retardant is realized.

Owner:青岛泉佳美硅藻泥科技有限公司

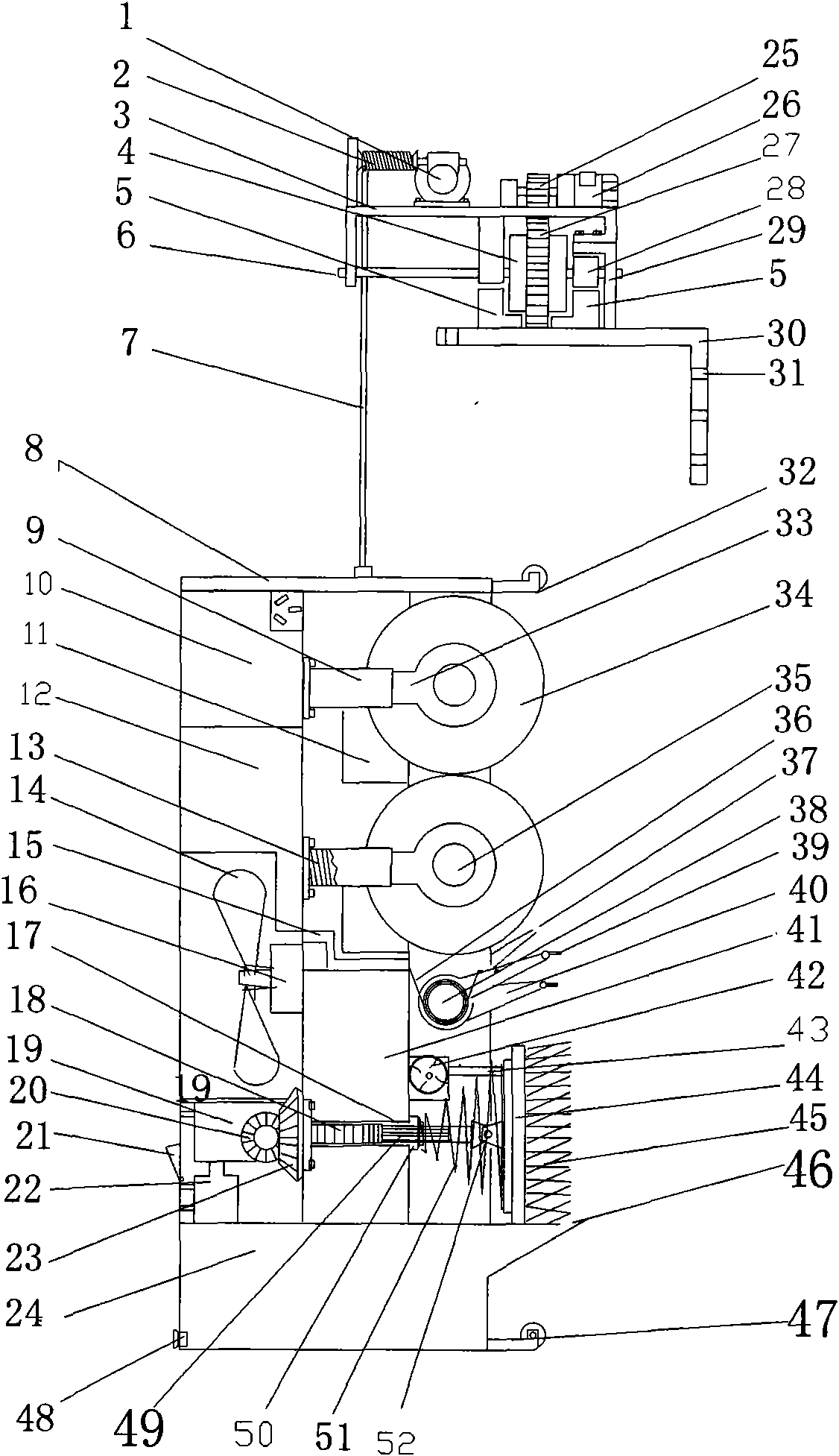

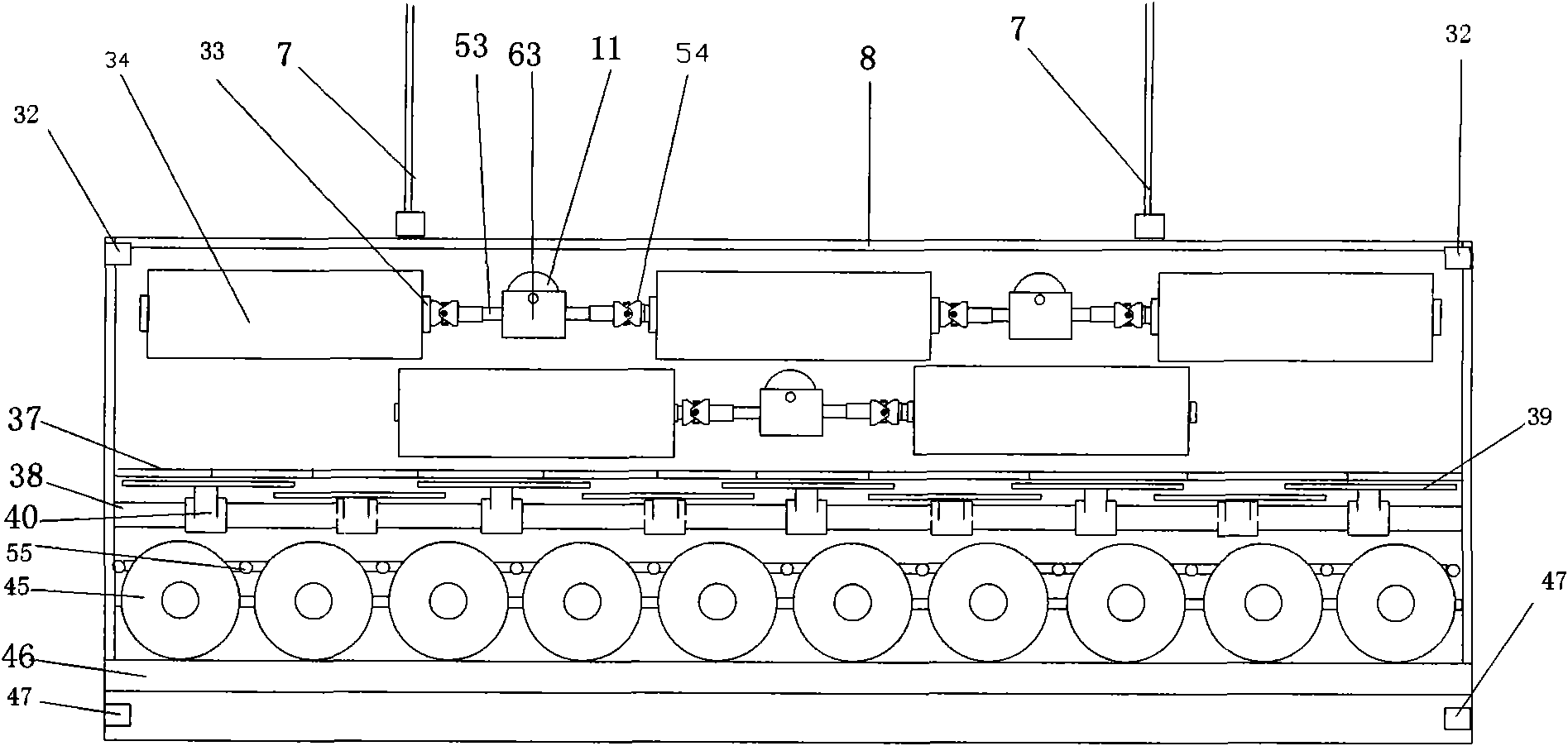

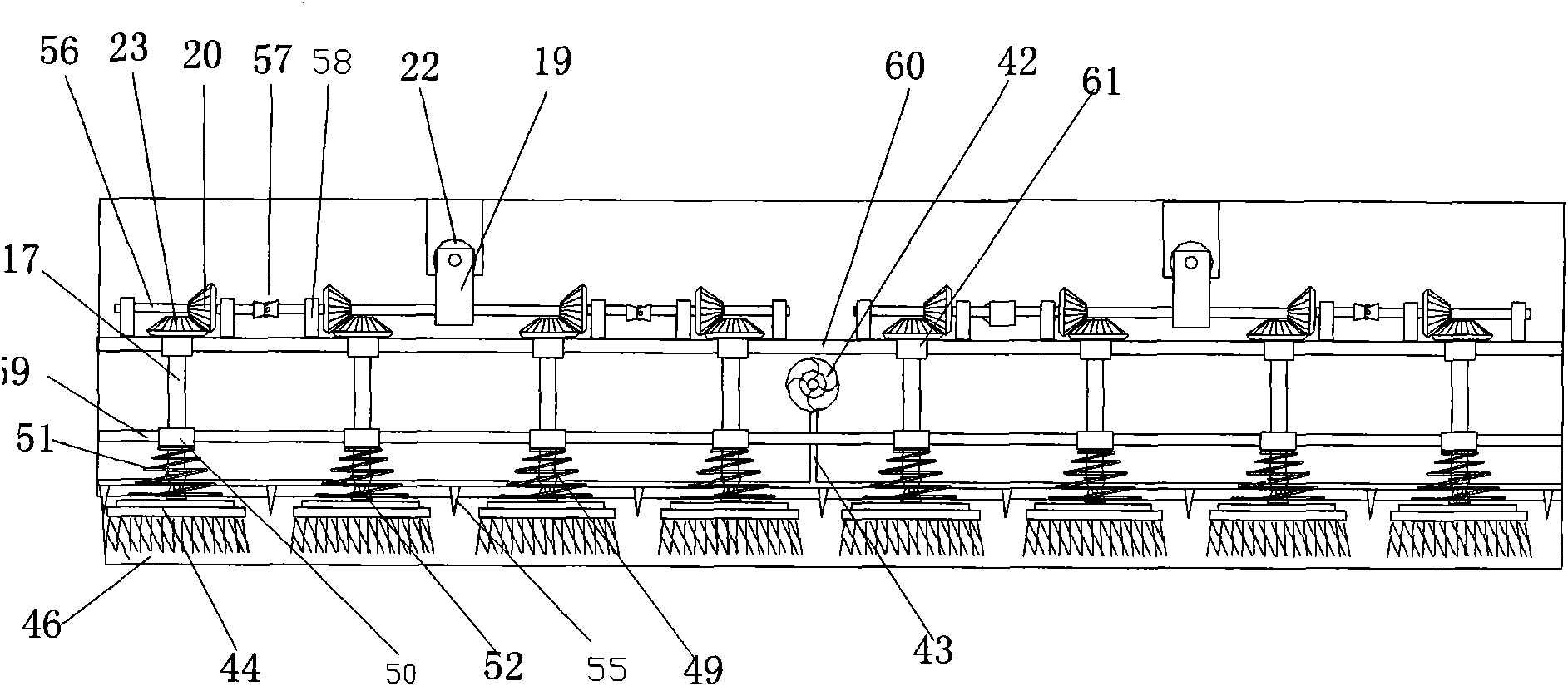

Full automatic glass curtain wall cleaning machine

ActiveCN101589936AReduce labor intensityEliminate pollutionCarpet cleanersFloor cleanersElectricityQuality of work

The invention relates to a full automatic glass curtain wall cleaning machine, and solves the problems that the speed for cleaning a building bit by bit by using a brush when a person is hoisted to slide vertically by using a rope from a roof is low, the cleaning is unclean and the risk is big, the casualty is easily caused, the cleaning sewage falling around from the high position causes secondary pollution to the environment, and the like of the prior art. In order to solve the technical problems, the invention adopts the technical proposal key that the full automatic glass curtain wall cleaning machine consists of devices of hanging and walking, lifting, brushing, scraping, electric baking and drying, and the like. The full automatic glass curtain wall cleaning machine can clean automatically and does not use manpower to operate so as to remarkably reduce the labor intensity of workers and effectively prevent accidents of personal injury. The full automatic glass curtain wall cleaning machine has high automation degree, greatly improves the working efficiency and working quality, avoids environment pollution caused by manpower cleaning, and saves the cost.

Owner:宋树建

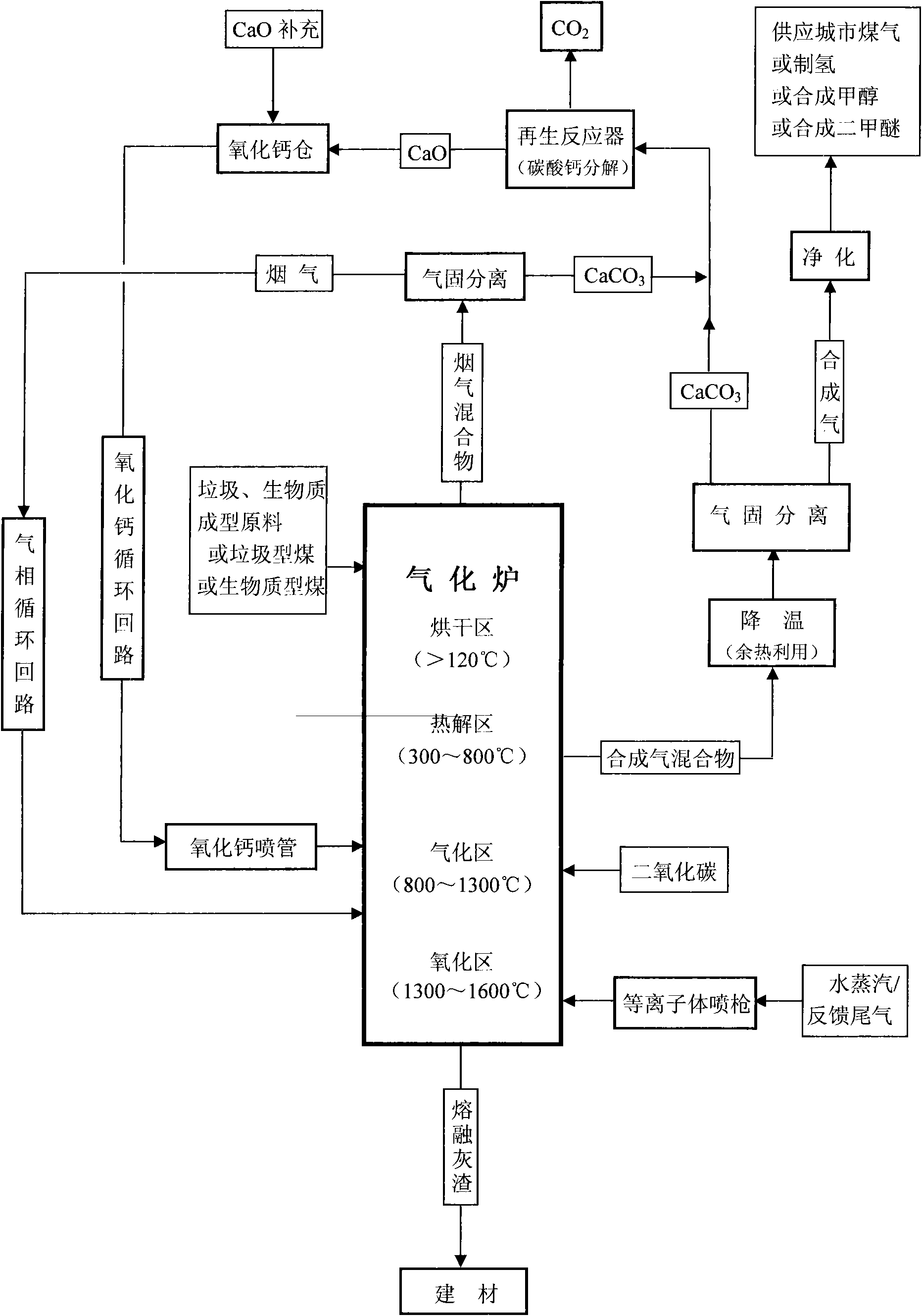

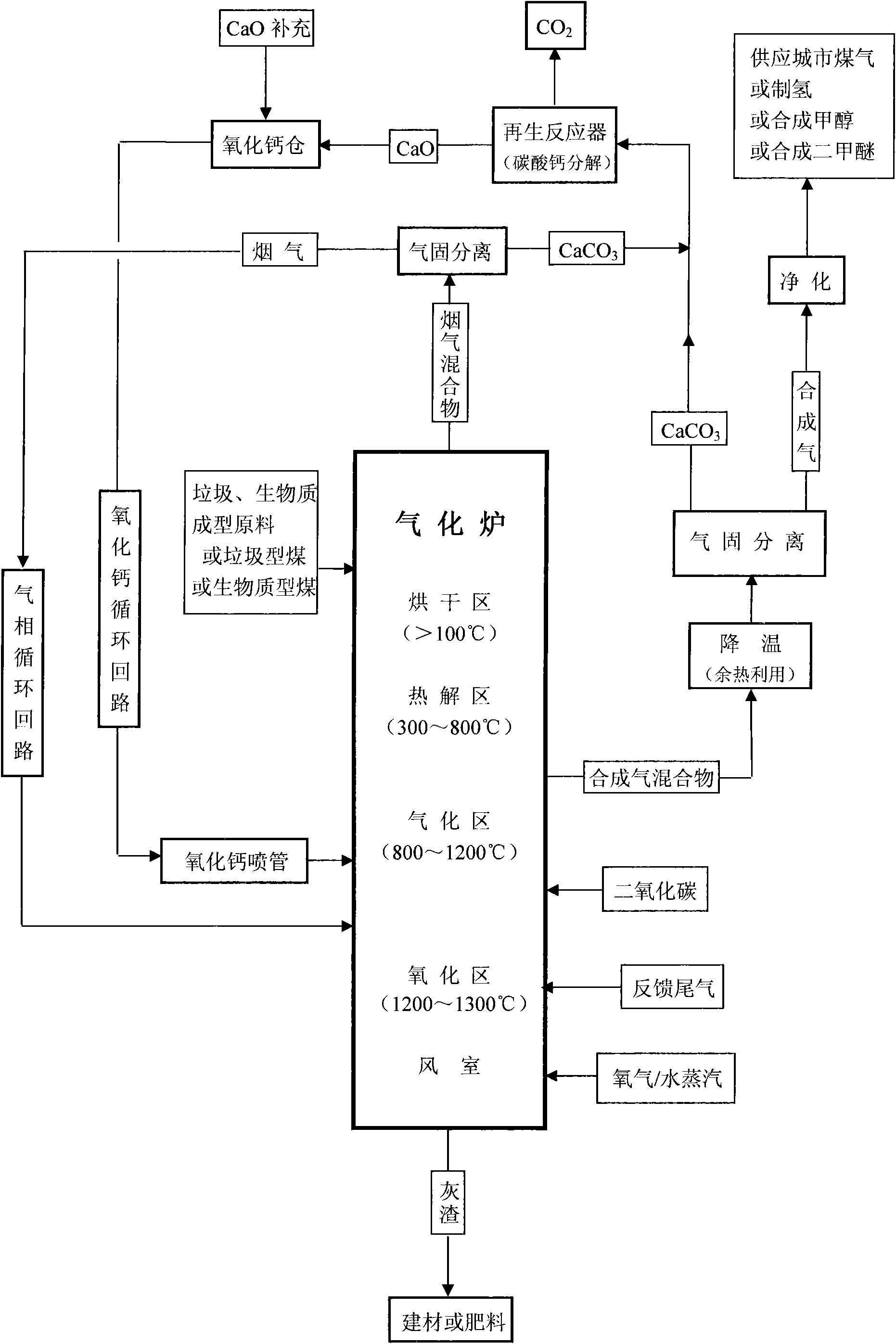

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

Method for cultivating earthworm by cattle manure and corps stalks

InactiveCN101233835ASolve processing problemsAchieve recyclingFood processingAnimal feeding stuffAgricultural scienceFeces

The invention discloses a method for raising earthworm by taking advantage of dairy manure and straws and stalks of crop, which applies fresh dairy manure and straws and stalks of crop to raise earthworm. The invention adopts fresh dairy manure and straws and stalks of crop as raw materials, which can not only solve the treatment problem of dairy manure in large-scale cattle farms and reduce environment pollution, but also obtain earthworm with high economic value as well as odourless, clean and natural organic manure with high quality, thus realizing the regeneration and utilization of dairy manure, reducing treatment cost for dairy manure on cattle farms, and greatly improving economic benefits of enterprises.

Owner:GUIZHOU JILONG ECOLOGICAL TECH

Energy utilization method of carbon dioxide zero-emission type organic waste

ActiveCN101914572AReduce the cost of trainingAvoid emissionsBio-organic fraction processingInternal combustion piston enginesNew energySludge

The invention provides an energy utilization method of carbon dioxide zero-emission type organic wastes, comprising the following steps of: (1) collecting and pretreating raw materials; (2) preparing hydrogen by anaerobic fermentation and purifying hydrogen; (3) fermenting methane and generating power by the methane; (4) treating biogas slurry and fixing carbon dioxide with microalgae; (5) processing biogas residues and planting energy grass; and (6) recycling afterheat. The method is suitable for treating various types of organic wastes, can be used for treating agricultural organic wastes, industrial organic wastes, domestic organic garbage, mud, and the like and the industries of developing new energy, and the like. The method can carry out a concrete application example of cyclic economy, eliminates environmental pollution, obtains clean energy at the same time, has no greenhouse gas emission in the process and can realize three effects of treating wastes, generating renewable clean energy and reducing carbon dioxide emission.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com