Method for producing biocarbon-based slow-release nitrogen fertilizer

A production method and biochar technology, applied in fertilization devices, fertilizer mixtures, agricultural gas emission reduction, etc., can solve the problems of no market, easy loss of ammonium nitrate, etc., to reduce nutrient loss, facilitate fertilization, and reduce greenhouse gas emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

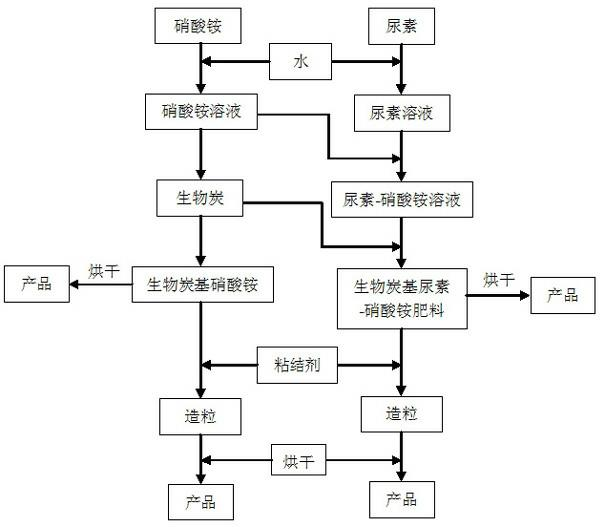

Method used

Image

Examples

Embodiment 1

[0031] 1) Or the solid by-products of waste biomass thermal cracking or gasification plant thermal cracking or gasification of apple tree waste branches and wood chips or corn stalks - biochar or biochar, the physical form is black powdery particles, if it is in the form of rods or Lumpy, use a pulverizer to crush it into particles that pass through a 3mm sieve.

[0032] 2) Agricultural ammonium nitrate fertilizer, containing at least 34% nitrogen, add 200 parts of agricultural ammonium nitrate to every 100 parts of 80 ℃ hot water, stir while heating (intermittent process or continuous process) to completely dissolve ammonium nitrate in water, form 22.67% N ammonium nitrate solution, the ammonium nitrate solution is stored for later use or enters the next process.

[0033] 3) Add 63-82 parts of the ammonium nitrate solution in process 2 to every 100 parts of apple tree waste wood chip charcoal or corn stalk biochar in process 1, and add while stirring. In the batch production...

Embodiment 2

[0038]1) Solid by-products from thermal cracking of biomass or waste biomass or gasification plant pyrolysis or gasification of waste branches of apple trees or corn stalks - biochar or biochar, the physical form is black powdery particles , If it is in the form of a stick or block, use a pulverizer to crush it into particles that pass through a 2mm sieve.

[0039] 2) Ammonium nitrate and urea fertilizers come from commercial agricultural ammonium nitrate and urea in the market. The nitrogen content of ammonium nitrate is more than 34%, and the nitrogen content of urea is at least 46%. Add 40 parts of ammonium nitrate and 30 parts of urea to every 30 parts of hot water heated to 80°C, stir and dissolve to form a 28% N urea-ammonium nitrate solution, which is ready for use or transported to the next process.

[0040] 3) Mix 48 parts of the urea-ammonium nitrate solution in process 2 with 100 parts of apple tree waste wood chips or corn stalk biochar, and stir thoroughly. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com