Patents

Literature

2758 results about "Corn stover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corn stover consists of the leaves, stalks, and cobs of maize (corn) (Zea mays ssp. mays L.) plants left in a field after harvest. Such stover makes up about half of the yield of a corn crop and is similar to straw from other cereal grasses; in Britain it is sometimes called corn straw. Corn stover is a very common agricultural product in areas of large amounts of corn production. As well as the non-grain part of harvested corn, the stover can also contain other weeds and grasses. Field corn and sweet corn, two different types of maize, have relatively similar corn stover.

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

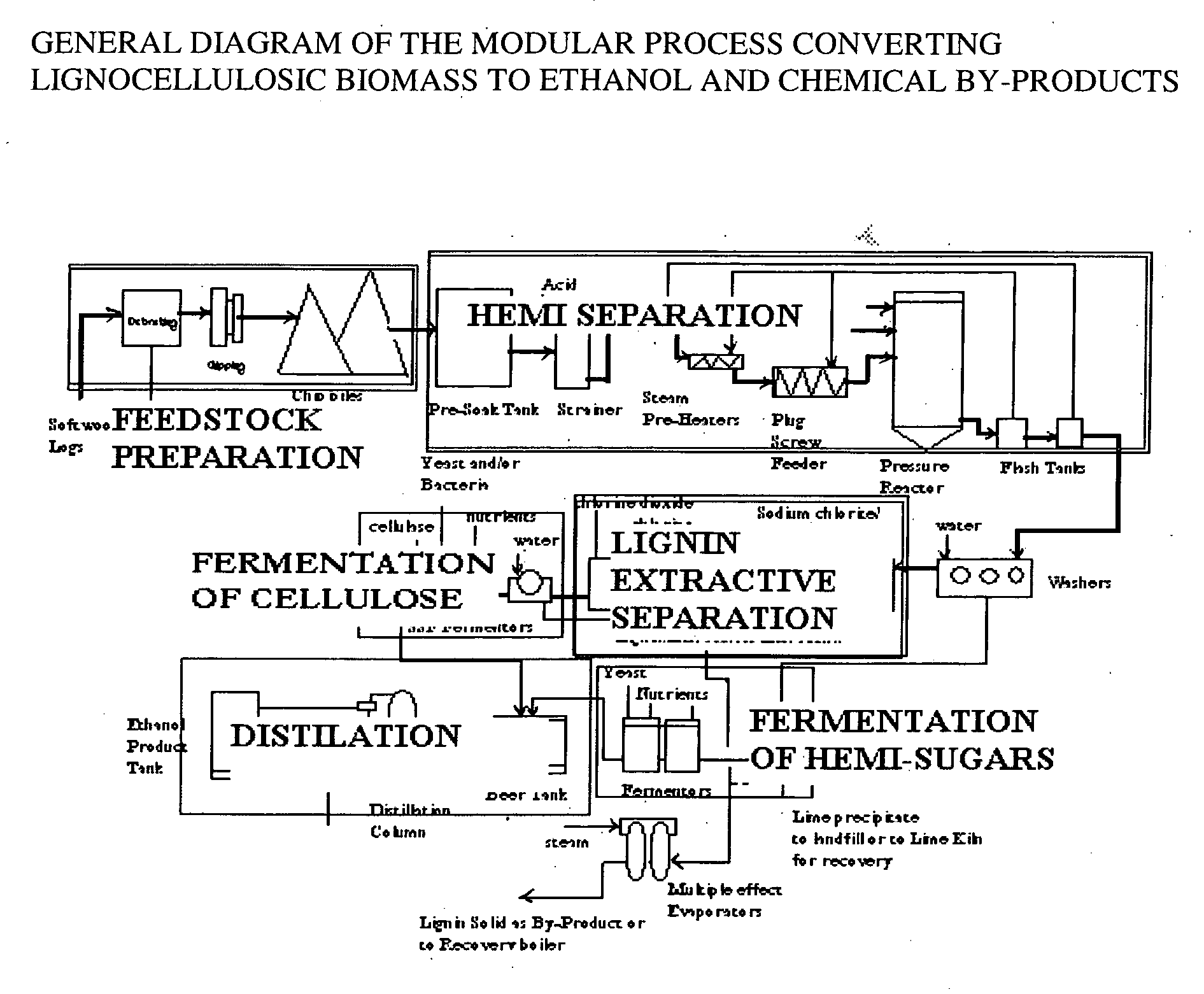

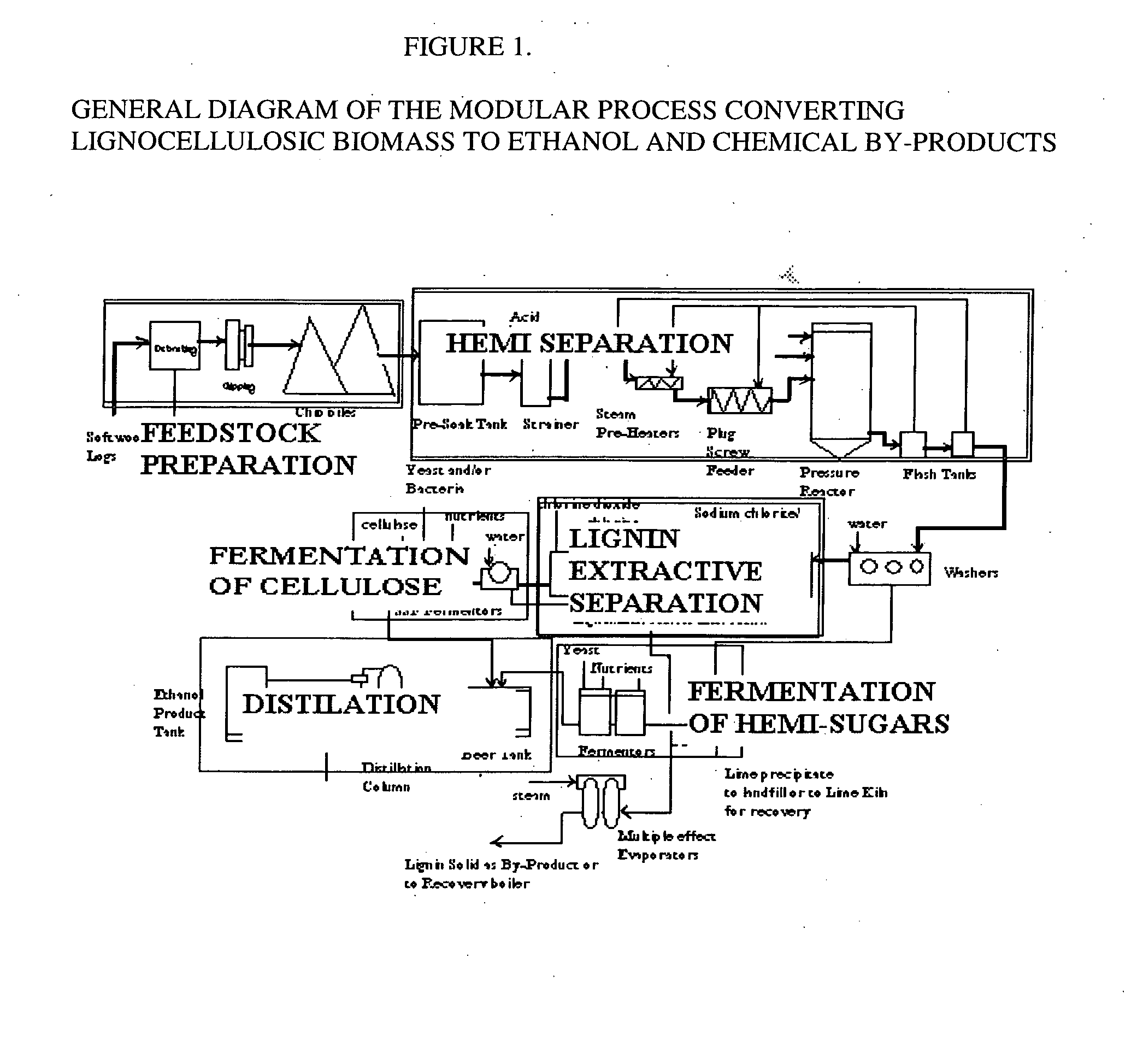

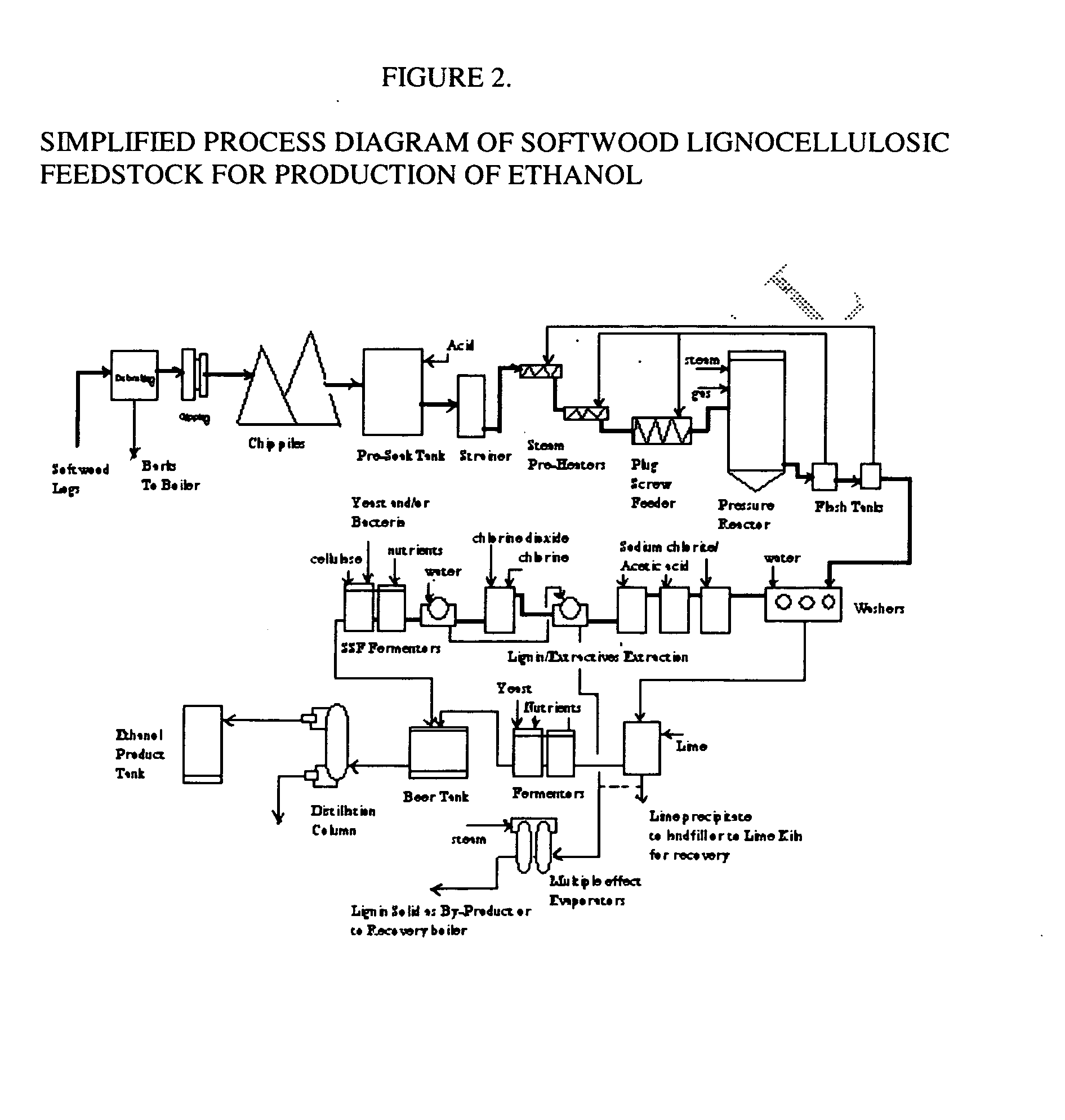

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

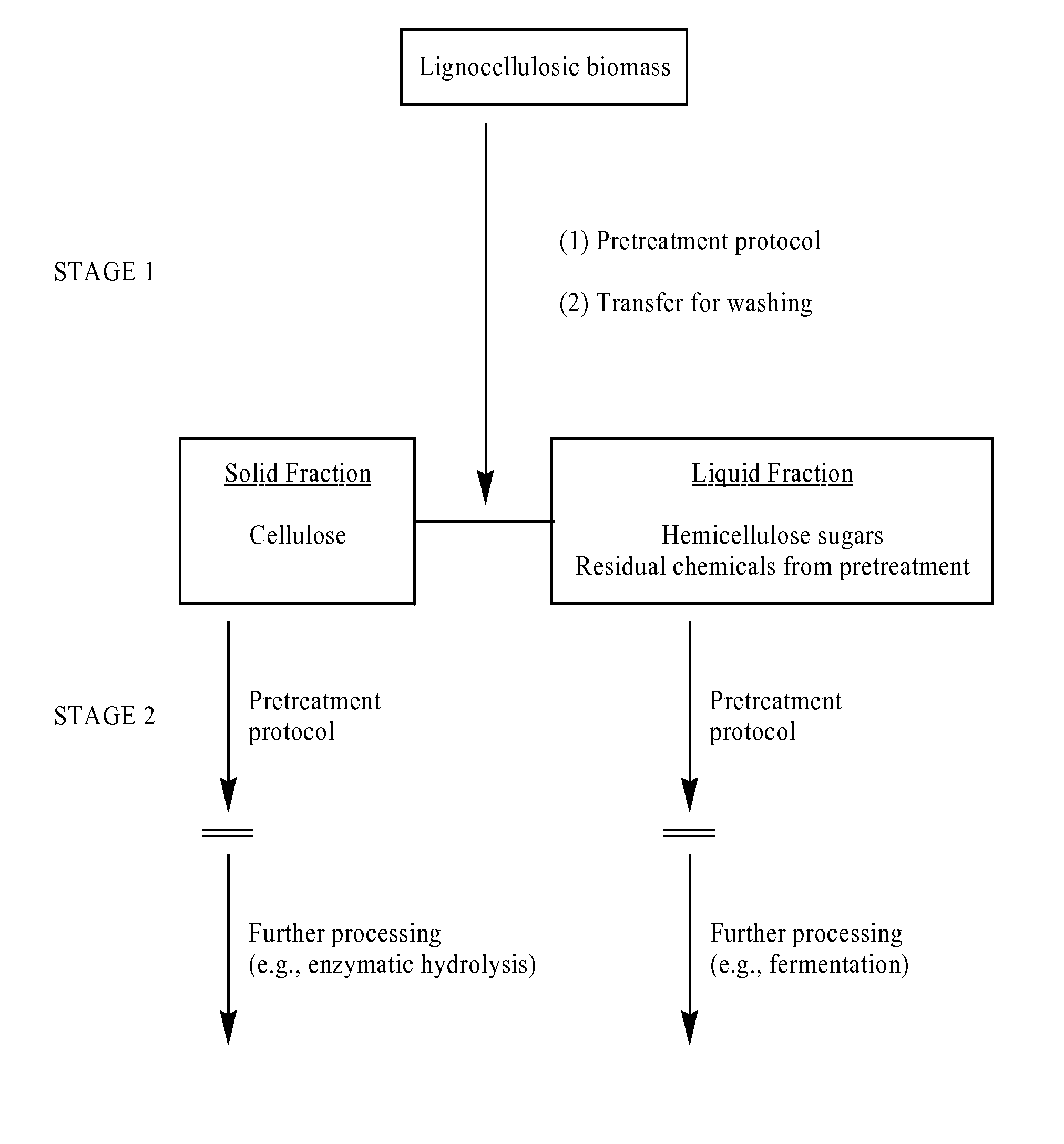

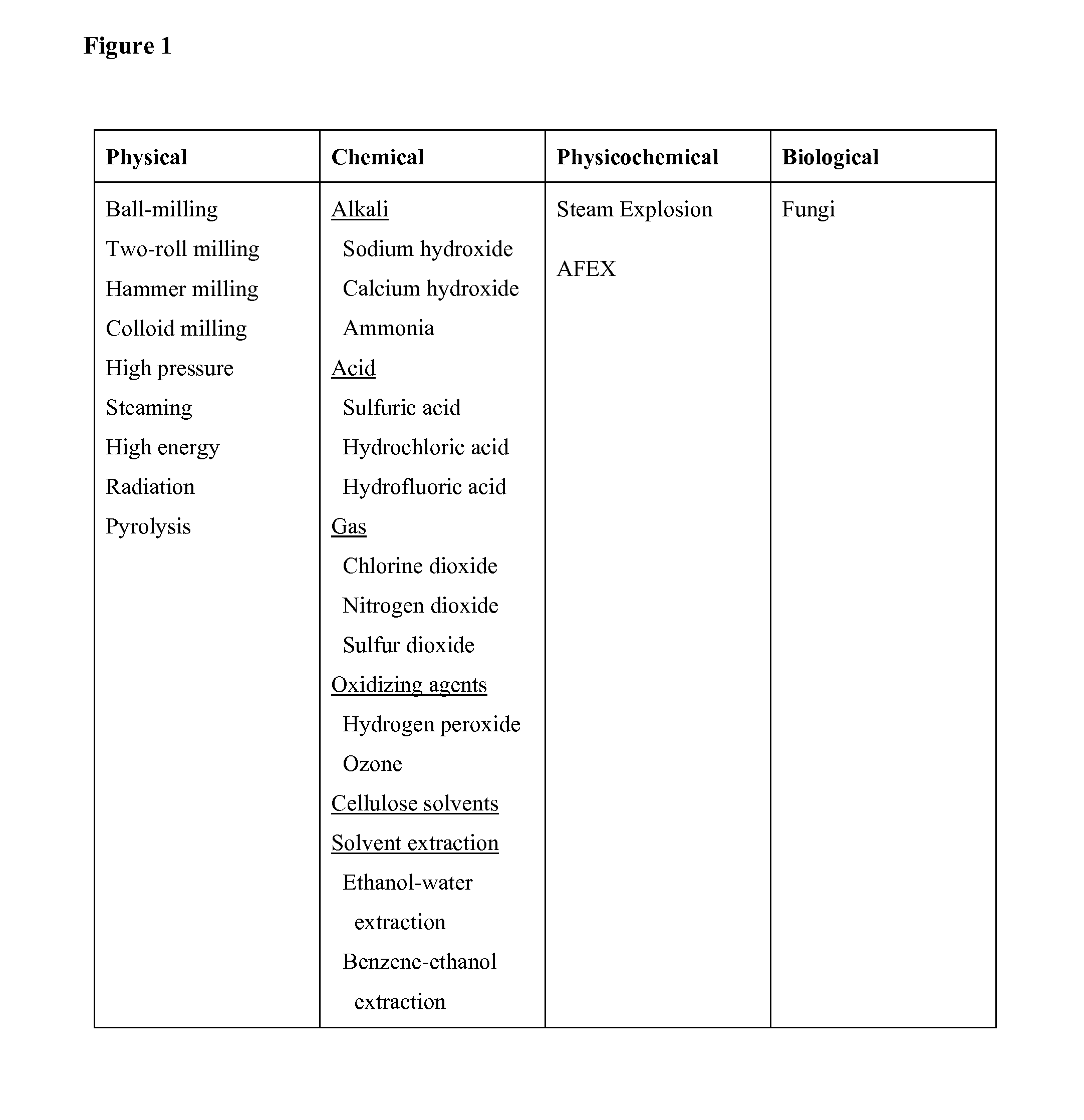

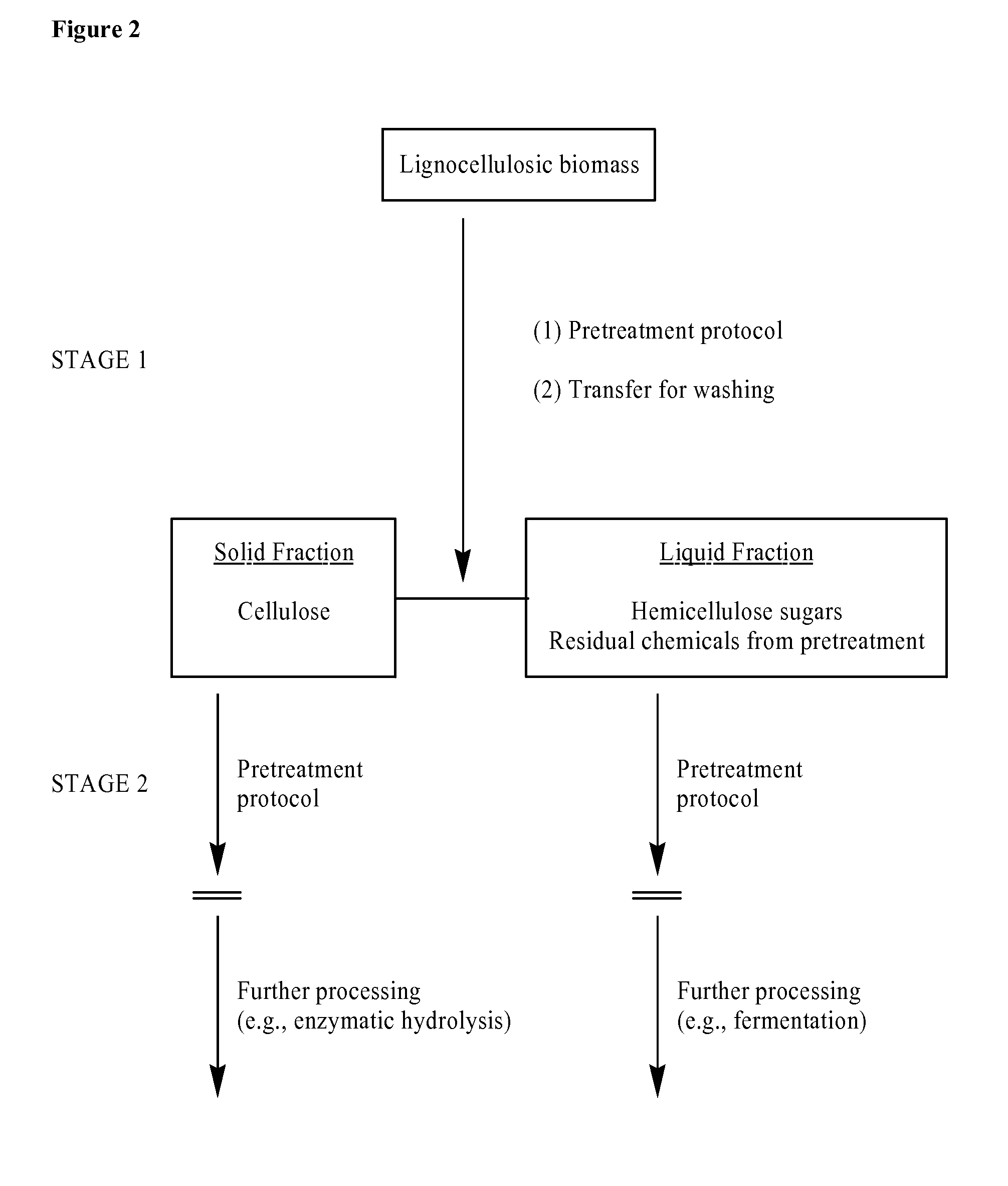

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

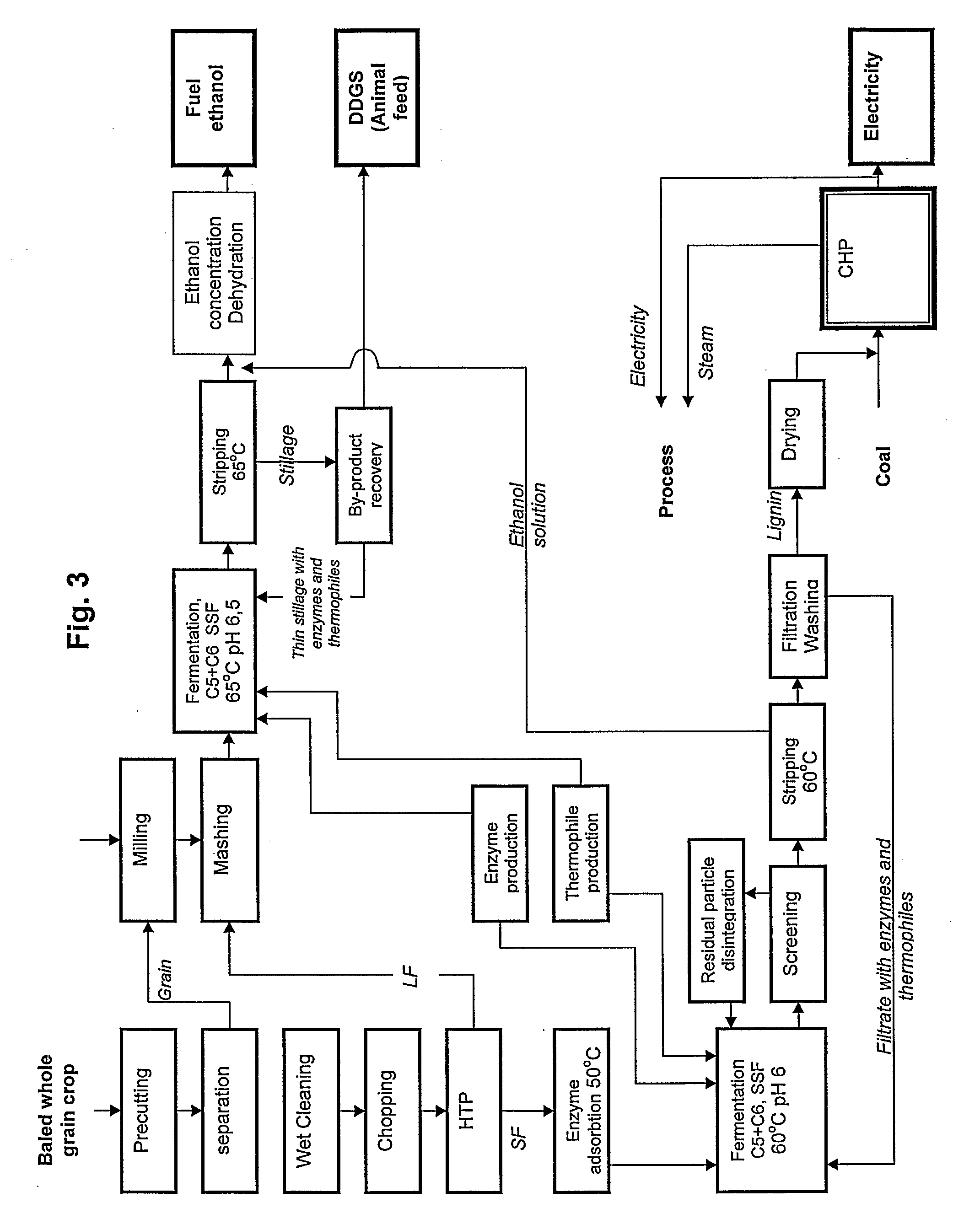

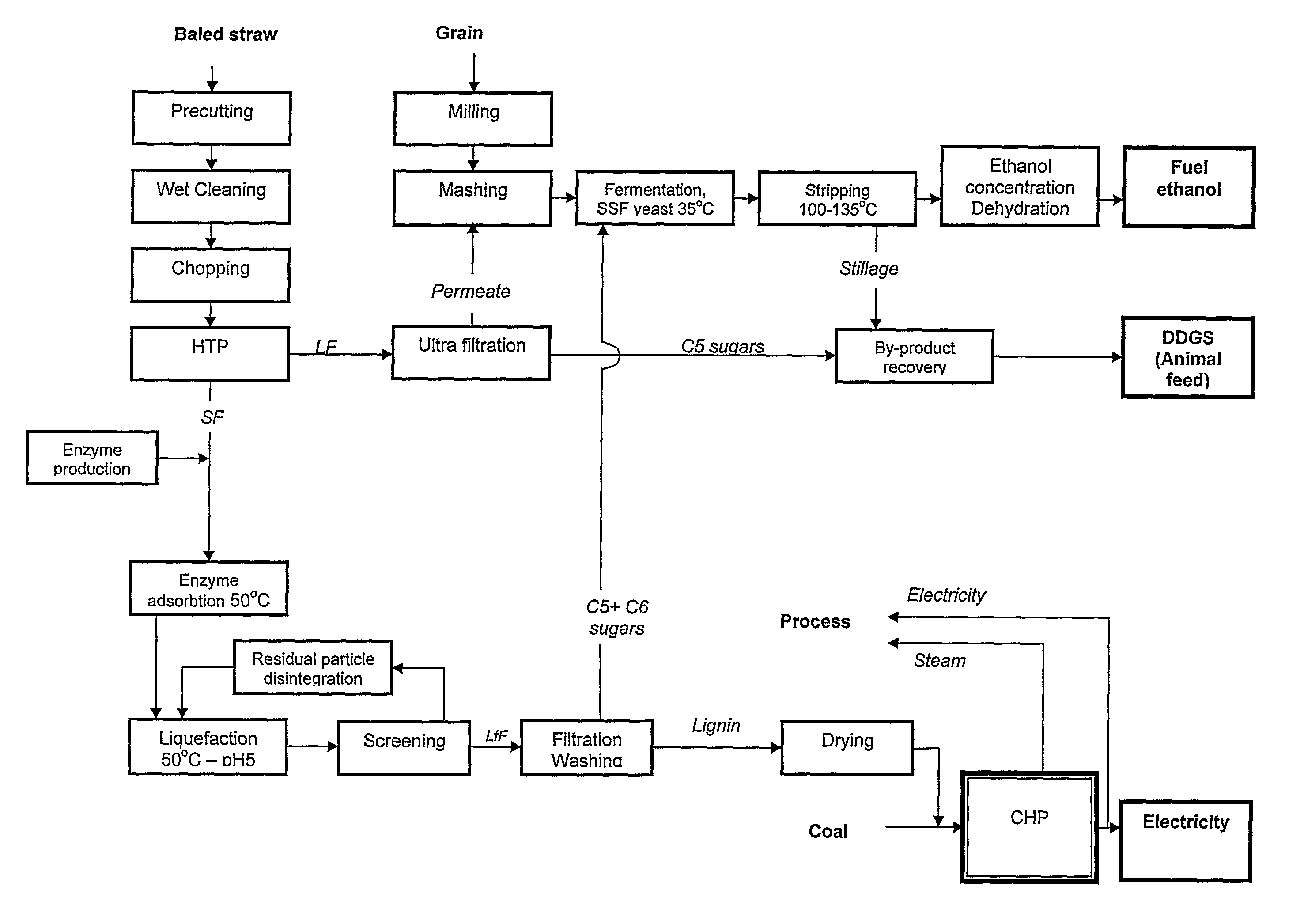

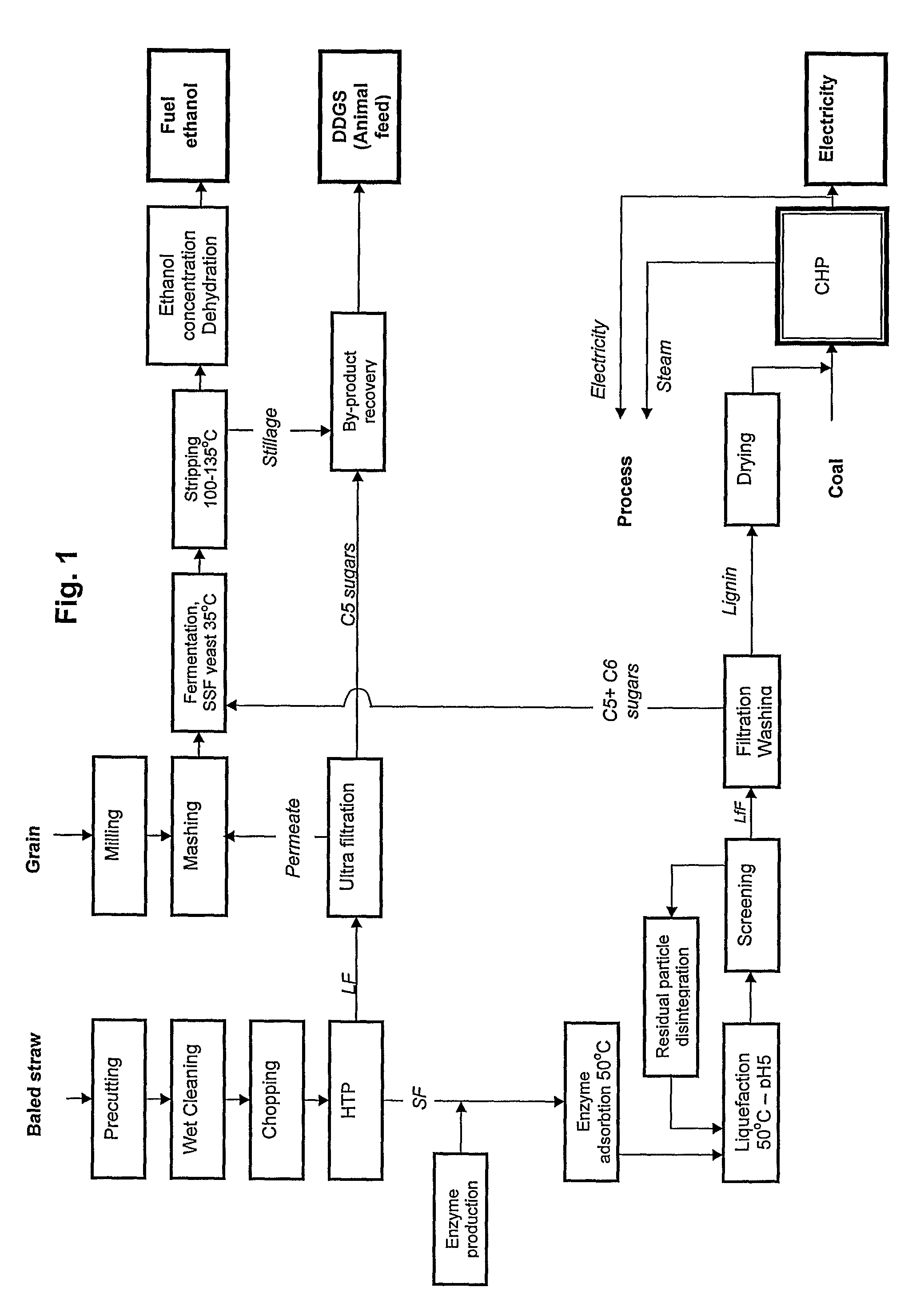

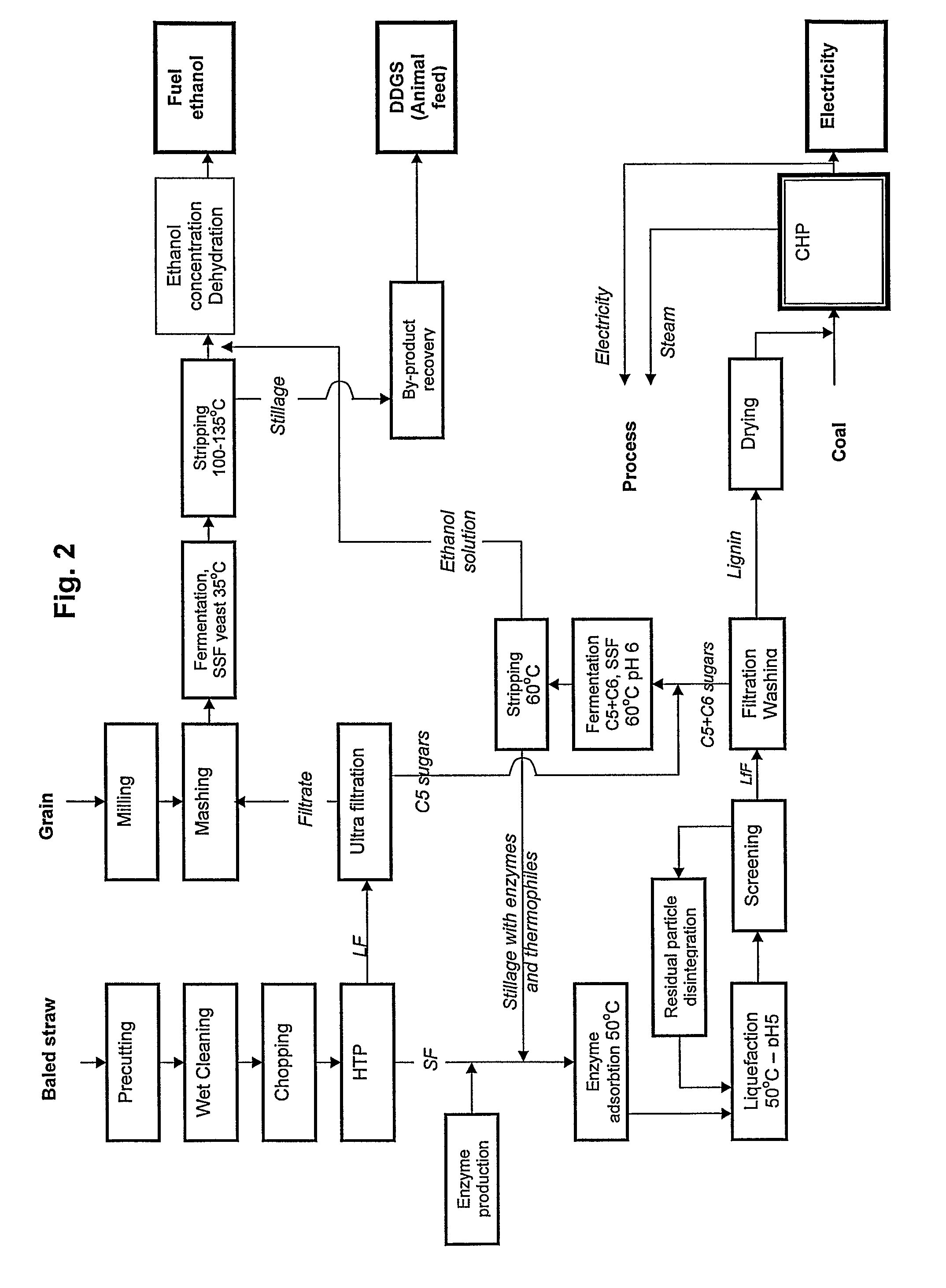

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS20100041119A1Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

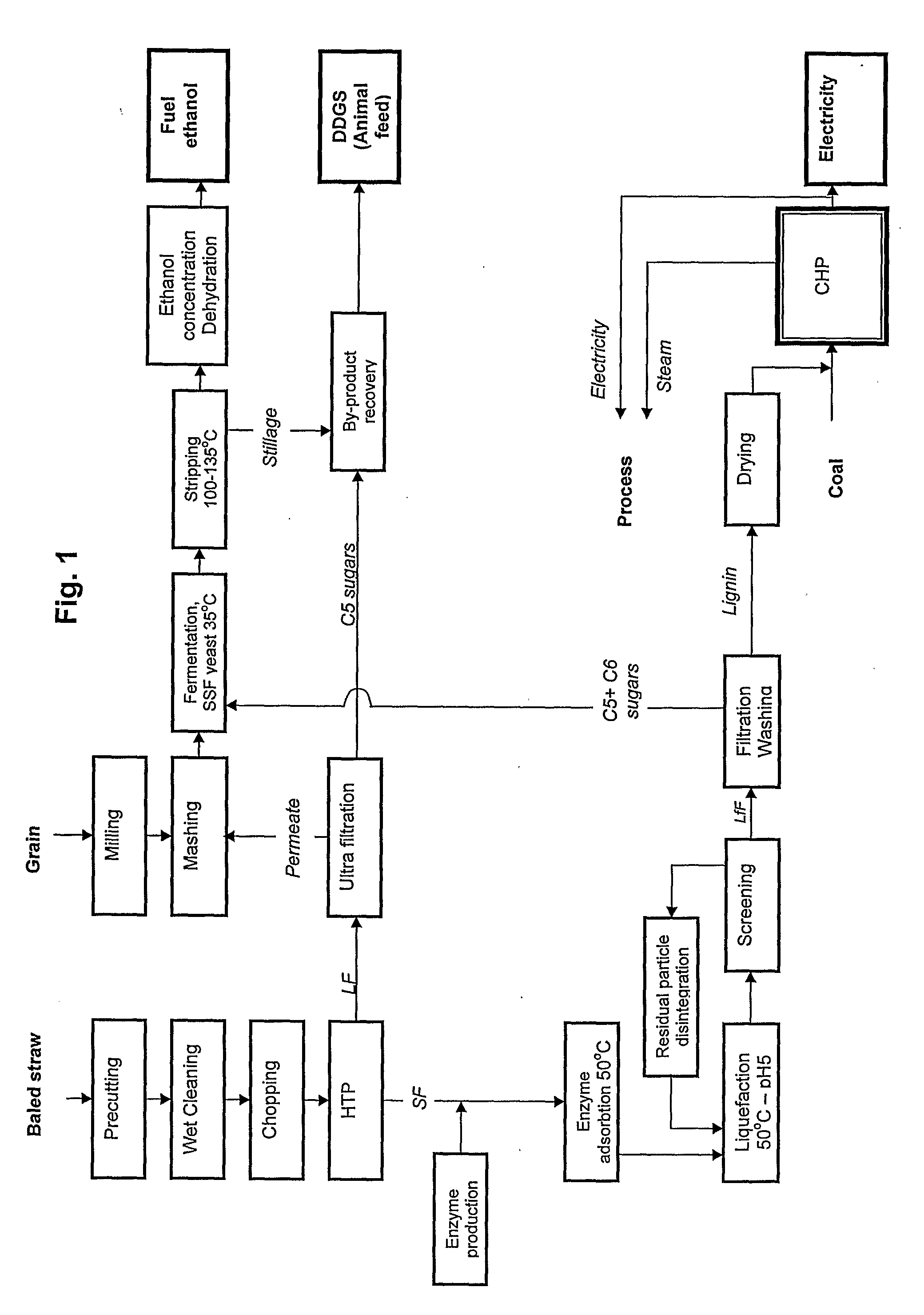

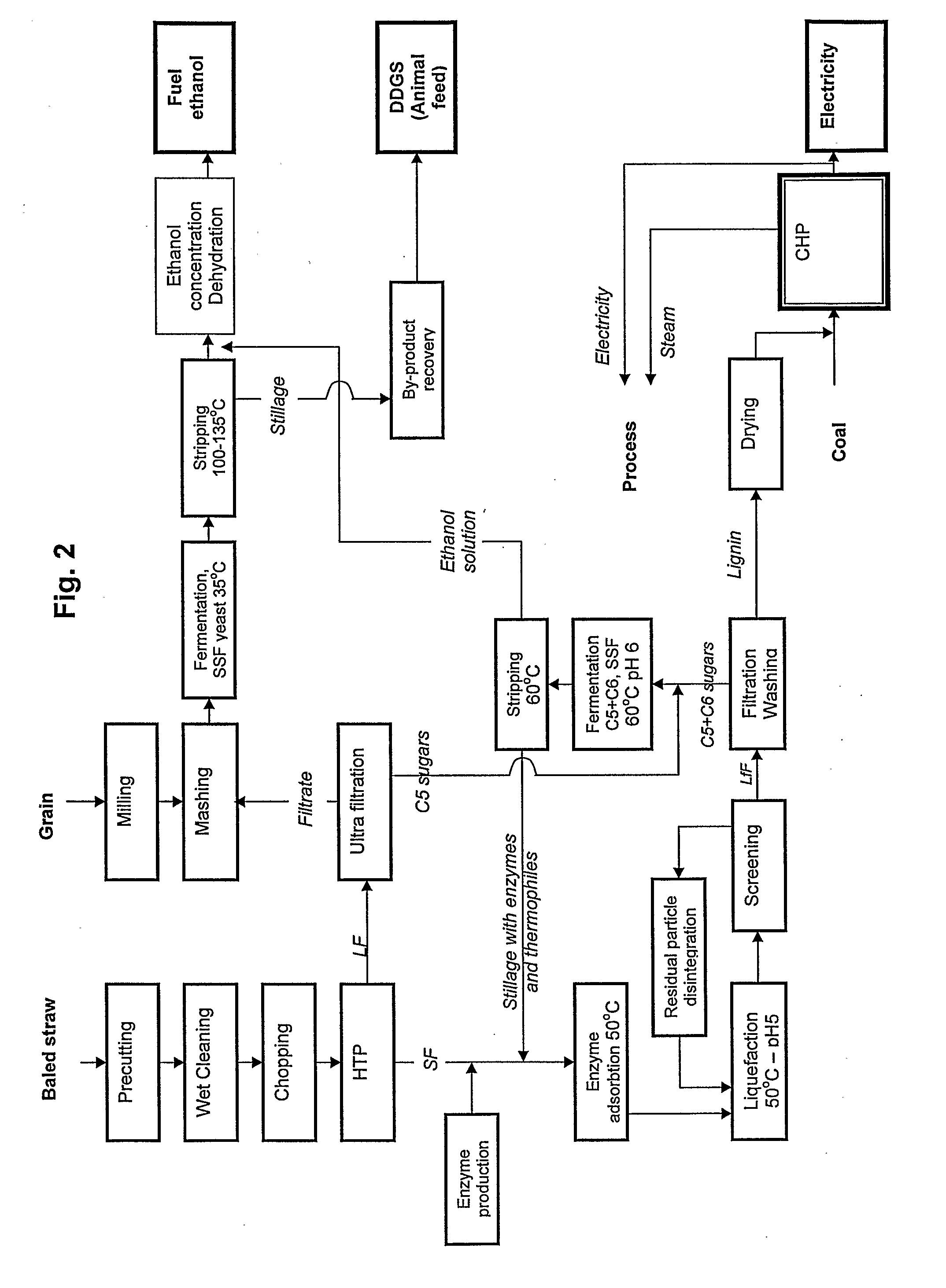

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fibre fraction are produced. The fibre fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurised reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fibre fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fibre fraction.

Owner:INBICON AS

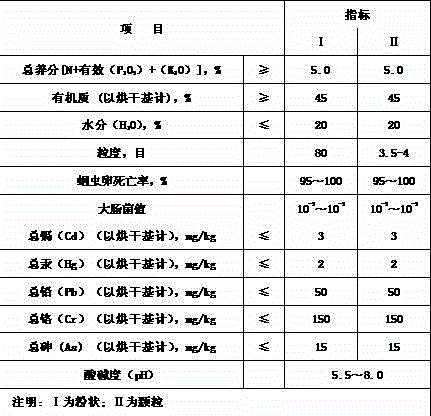

Organic fertilizer with livestock and poultry manure and preparation method thereof

InactiveCN103145463ANo pollution in the processImprove fertilizer efficiencyBio-organic fraction processingOrganic fertiliser preparationEffective microorganismMixed materials

The invention provides an organic fertilizer with livestock and poultry manure and a preparation method thereof. The organic fertilizer comprises cow manure, edible mushroom dregs, pig manure, chicken manure, maize straw powder and an Em (effective microorganisms) stock solution. The specific formula of the organic fertilizer comprises 19.7 percent of edible mushroom dregs, 10 percent of pig manure, 10 percent of chicken manure, 20 percent of maize straw powder, 0.3 percent of Em stock solution, and the balance of cow manure. The preparation method of the organic fertilizer is characterized in that a production technology of the organic fertilizer with the livestock and poultry manure mainly adopts a shallow pool type fermentation technology, namely the cow manure, the pig manure, the chicken manure, the edible mushroom dregs, the maize straw powder and the Em stock solution are poured into a mixer in proportion and are evenly mixed and stirred, the evenly mixed and stirred materials are sent into a shallow layer pool type fermentation pool, and the organic fertilizer fermentation environment temperature is controlled to be above 15 DEG C. Firstly, various raw materials including the livestock and poultry manure, the edible mushroom dregs, the straw powder and a fermentation bactericide are mixed, and then the mixed materials are put into a mixing and stirring machine to be evenly stirred, are sent into the material fermentation pool to be fermented for 8 days and are discharged from the pool to enter a secondary aerobic fermentation procedure. The organic fertilizer has the advantages of low cost and high yield and can improve the quality of crops.

Owner:郑晓华

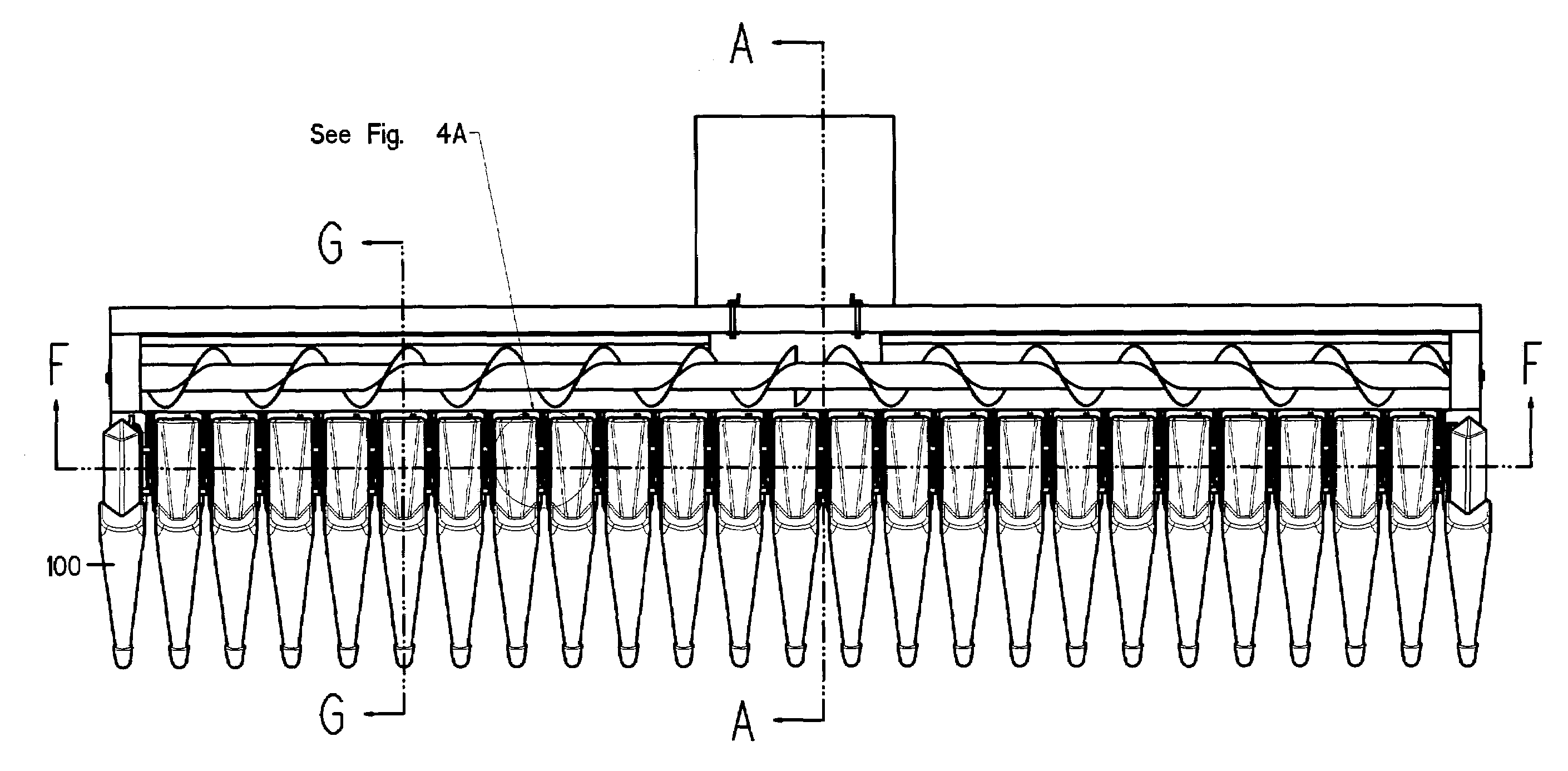

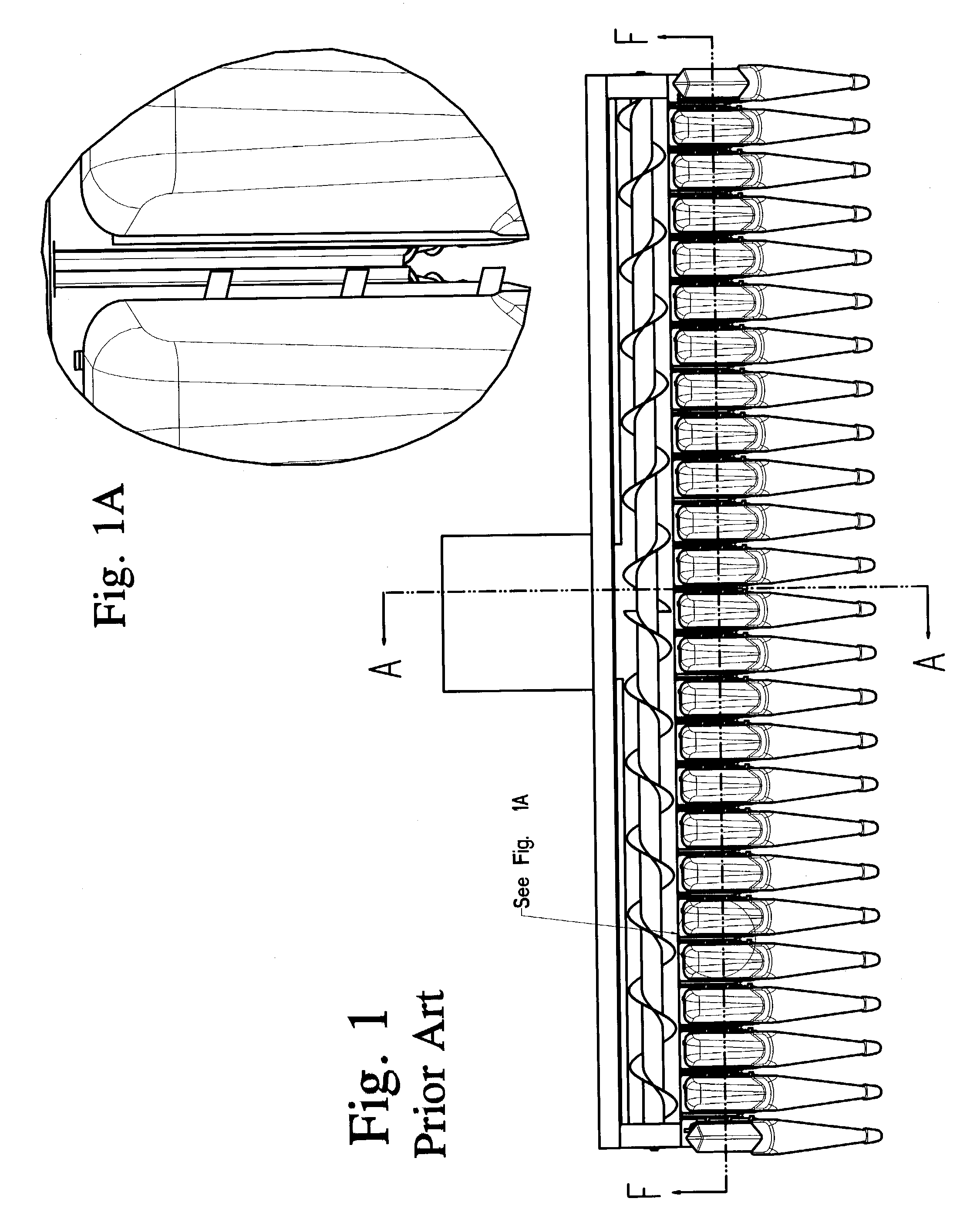

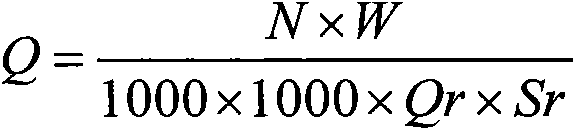

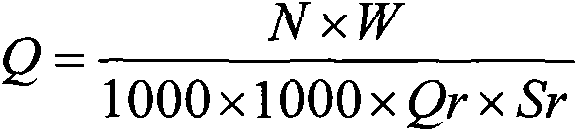

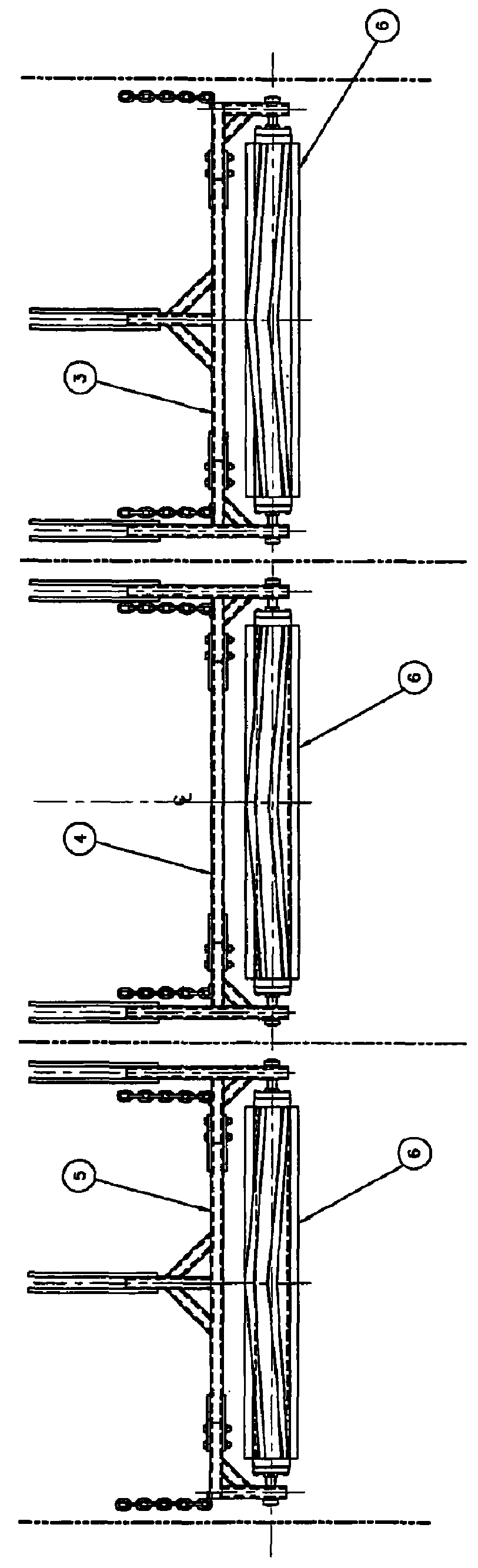

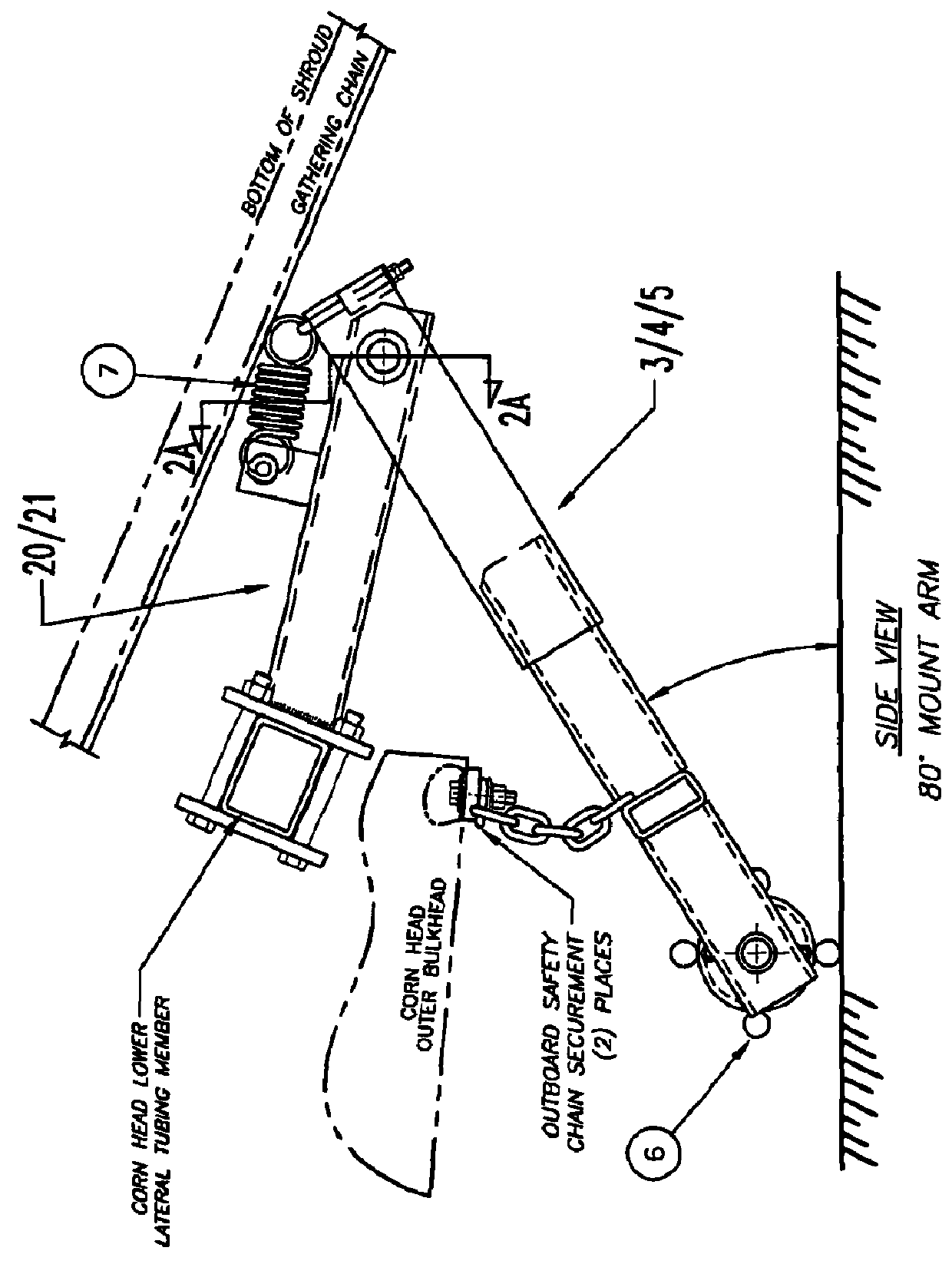

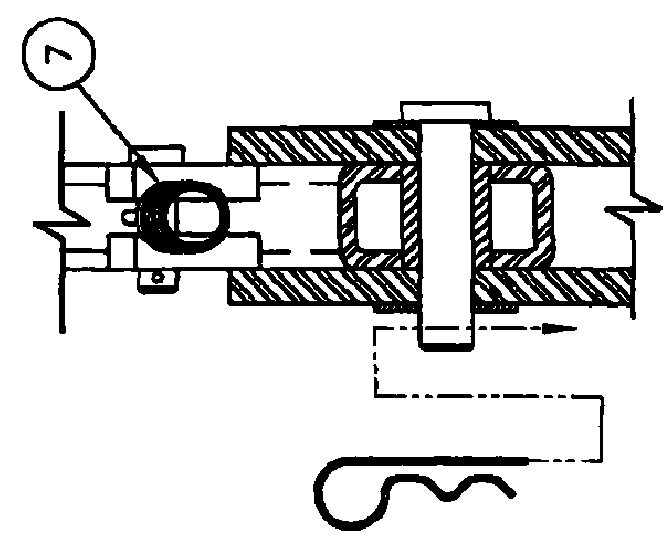

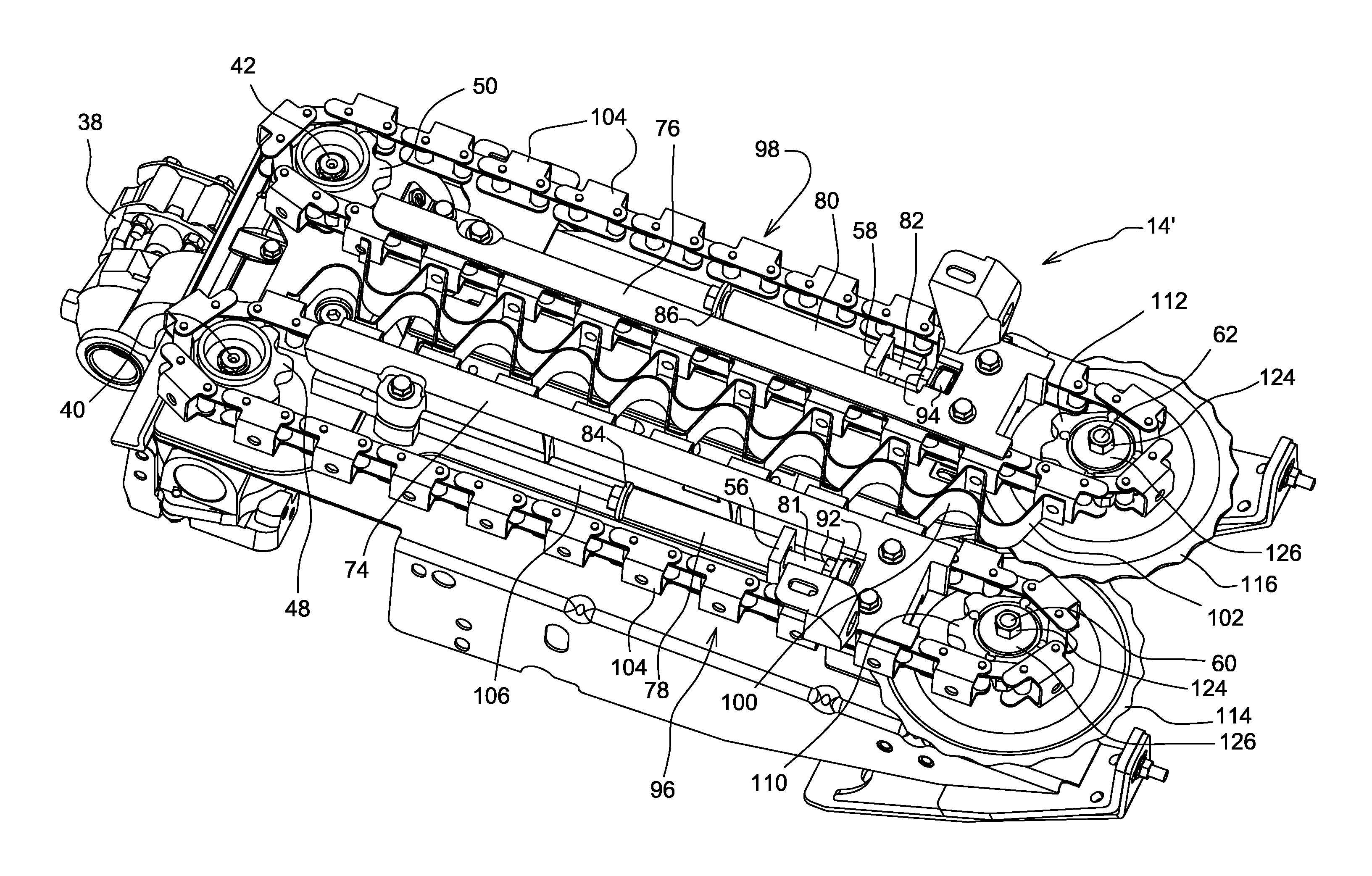

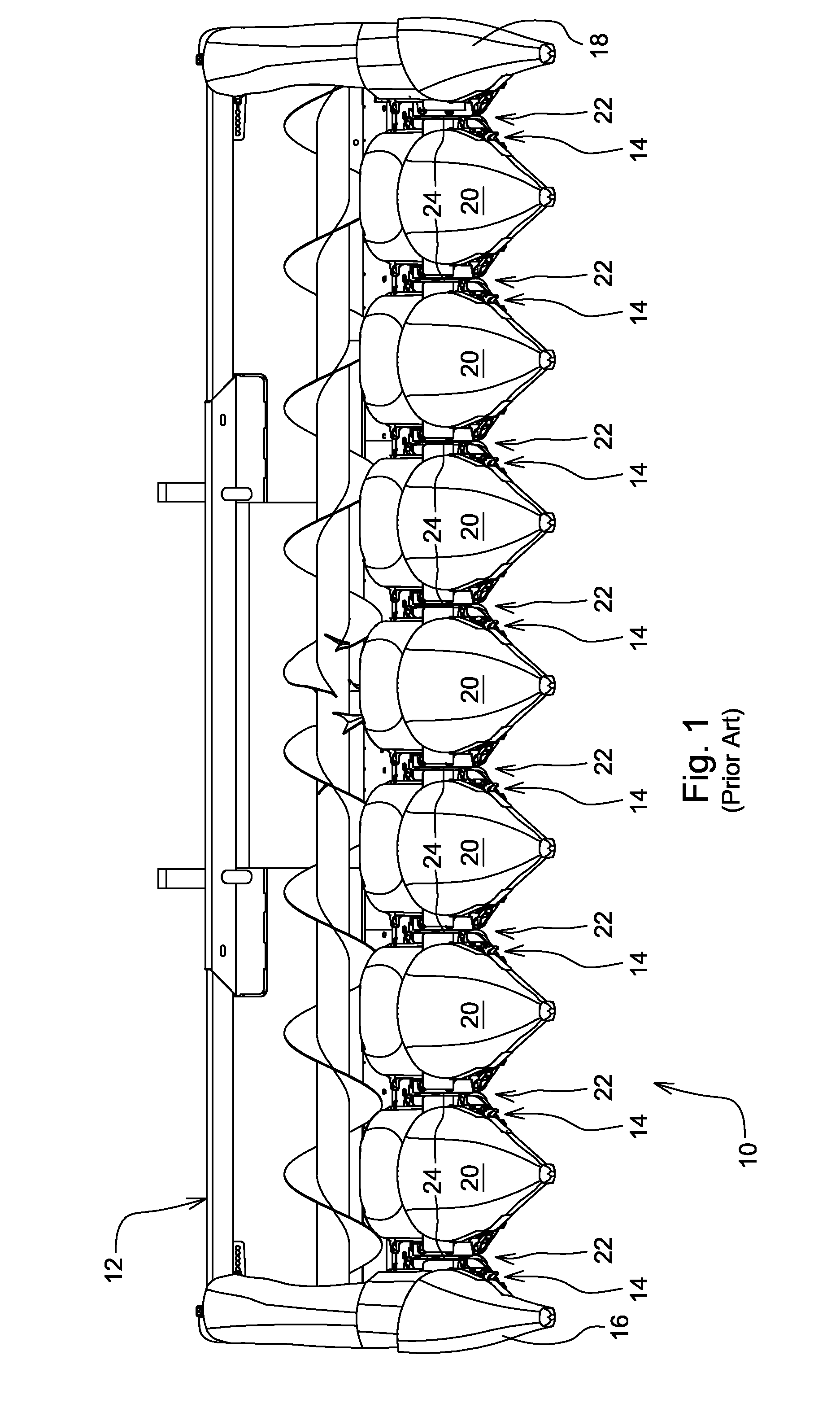

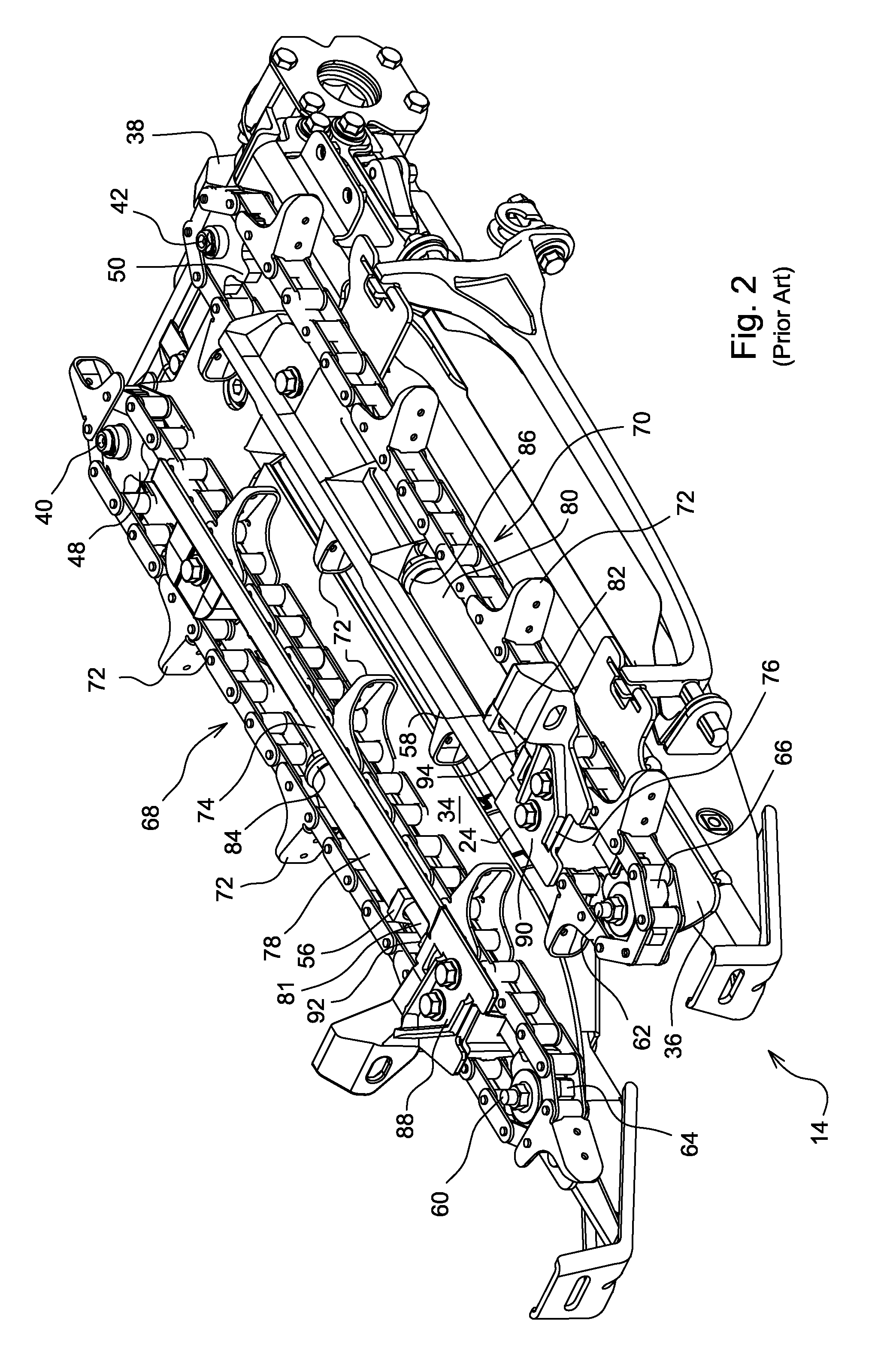

Corn head row unit

This row unit utilizes an improved multi-zone, multi-functional stalk roll, which contains a novel revolving entry window to improve entry and increase engagement of the fluted portion of the stalk roll flutes with the corn stalk. The stalk rolls described are multi-sectional and contain multi-length variable flutes. The number of flutes described for each zone may vary as well as whether the flutes are meshing or non-meshing and angled or non-angled. The stalk rolls described allow a constant speed drive shaft to create lower and / or higher effective circumferential contact speeds within each zone of the stalk roll. The invention provides that the rotating transport vanes located on the helical nose cone at the entry area to the stalk roll flutes lock the corn stalk into a revolving entry window. This novel row unit contains a multi-zone, multi-functional stripper plate that ensures minimal ear wedging and maximum discharge of material other than ears. This row unit utilizes a novel gathering / conveying chain(s), which reduces the number of and increases the angle and size of the paddles. This row unit design optimizes operation between the components imparting force to the corn plant and ears. The invention has a smooth uninterrupted improved flow of corn stalk material through the ear separation chamber and is the first row unit designed to be environmentally friendly by ensuring that the majority of the corn plant remains connected to its original root system which prevents it from rapidly decomposing, blowing or washing away. The row unit cover is spatially designed for improved flow in down, damp and tough harvesting conditions.

Owner:CALMER MARION

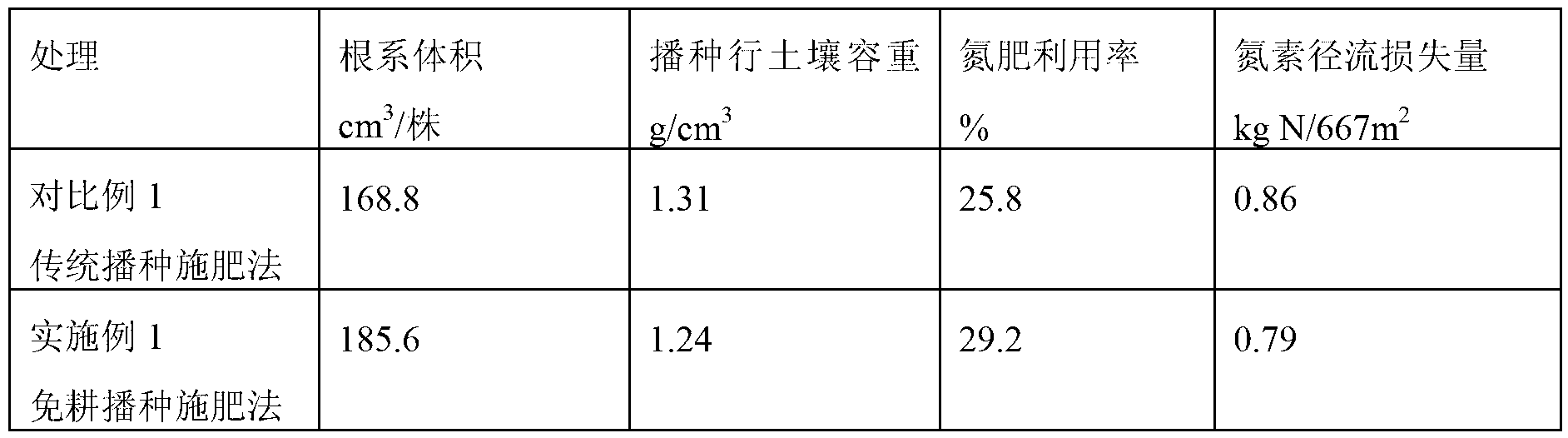

Water-saving fertilizer-saving method for crop rotation of winter wheat and summer maize

InactiveCN103518527AIncrease profitAchieve the effect of water saving, fertilizer saving and high yieldFertilising methodsAgriculture gas emission reductionWater savingPest control

The invention discloses a water-saving fertilizer-saving method for crop rotation of winter wheat and summer maize and belongs to the technical field of agriculture. The water-saving fertilizer-saving method comprises a wheat planting method and a maize planting method, wherein the wheat planting method and the maize planting method both comprise steps of seeding, fertilizing, irrigating, field management, chemical weeding, pest control, harvesting and the like, and all the wheat and maize straws are returned to the fields. By means of the water-saving fertilizer-saving method, the effect of water saving, fertilizer saving and high yield is improved, the fertilizer utilization rate is increased, and fertilizing labor intensity and cost are reduced.

Owner:MAIZE RES INST SHANDONG ACAD OF AGRI SCI

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS8123864B2Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fiber fraction are produced. The fiber fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurized reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fiber fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fiber fraction.

Owner:INBICON AS

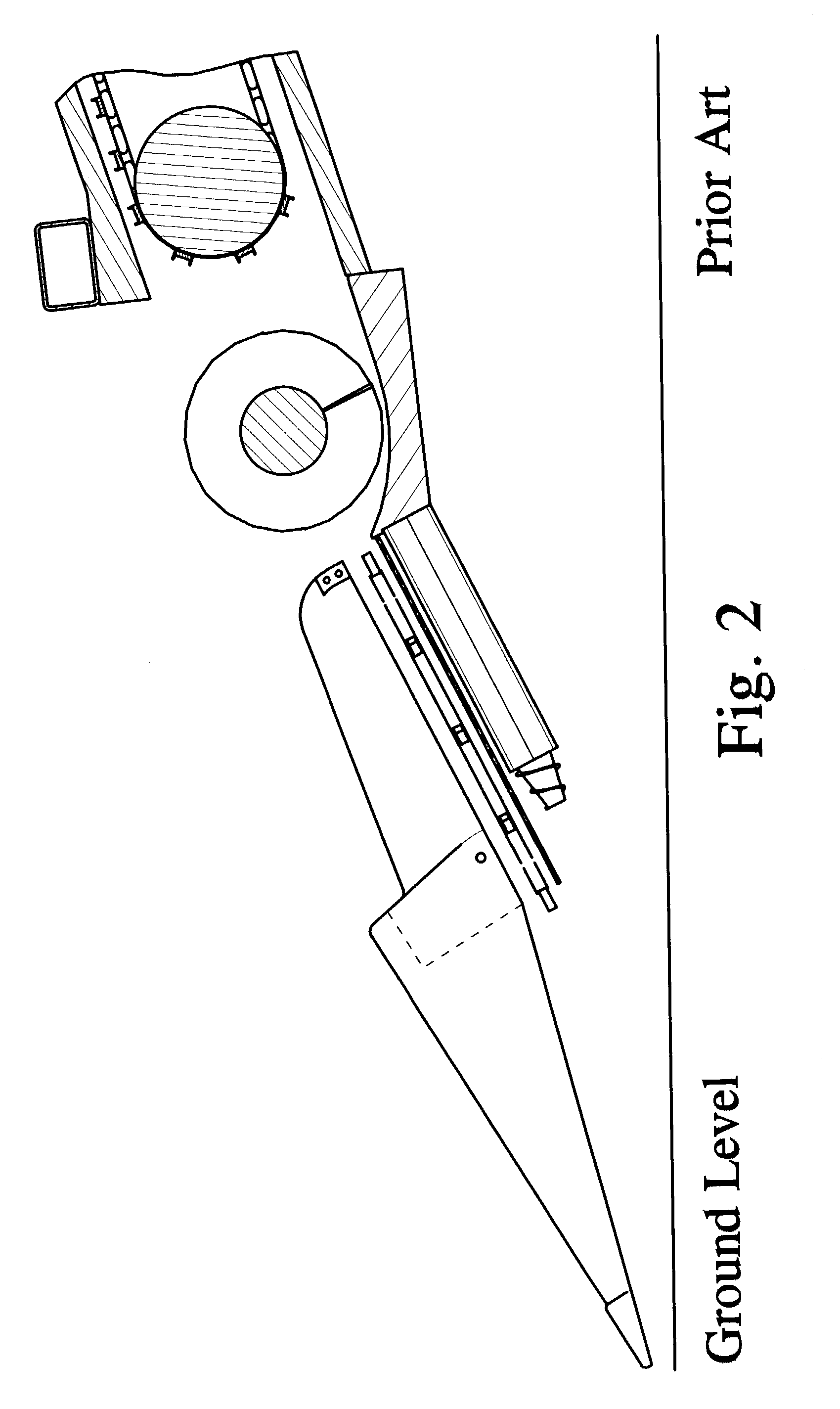

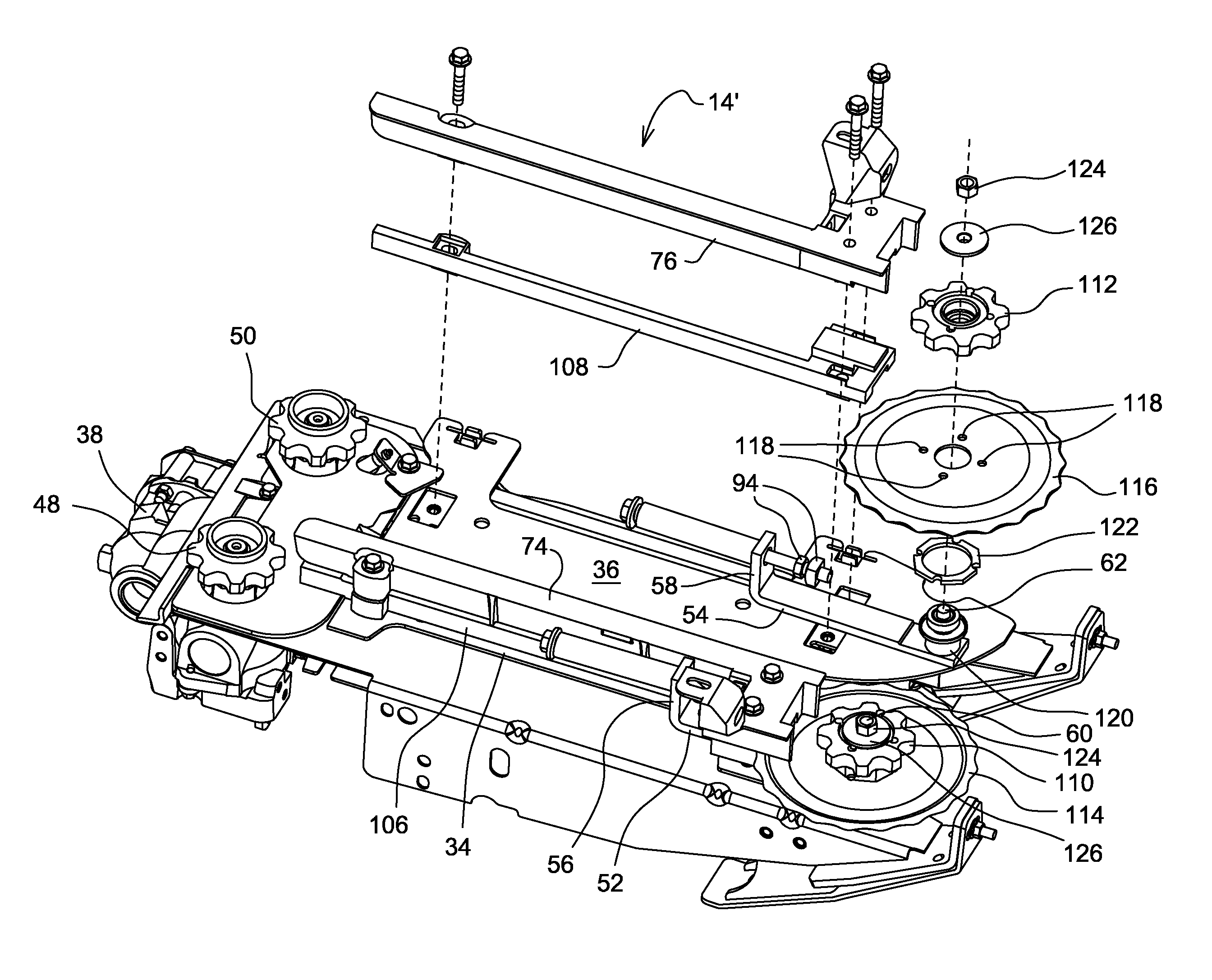

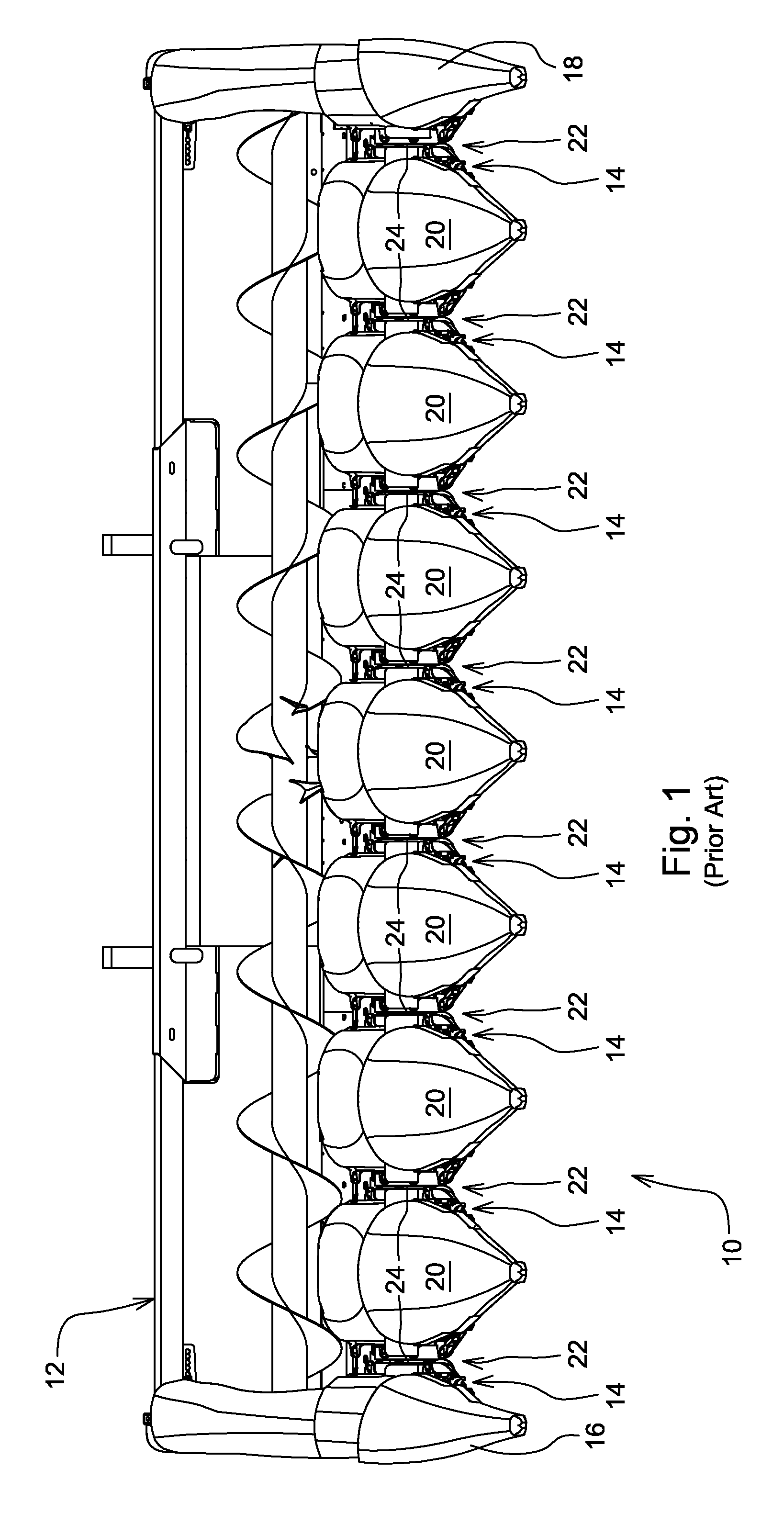

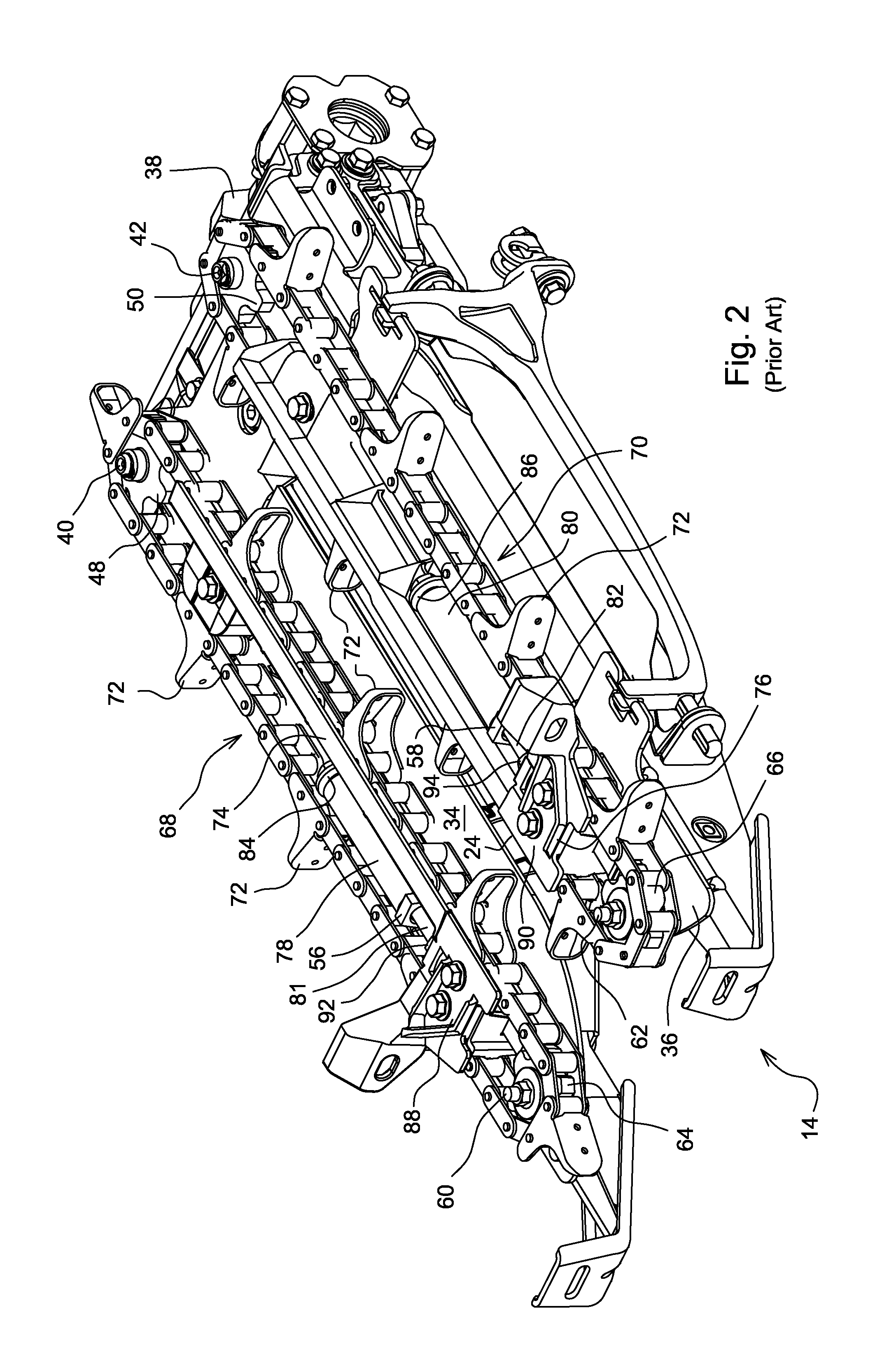

Converting a corn head row unit for harvesting corn stalks in addition to ears

Each row unit of a corn head can easily be converted between a first mode, wherein only ears are harvested, and a second mode, wherein ears together with stalks are harvested. In the first mode, a pair of snapping rolls is mounted for operation beneath each row unit frame for grasping corn stalks and pulling them downwardly through a narrow throat defined by a pair of laterally adjustable deck plates mounted to a top surface of the row unit frame. In the second mode, the snapping rolls are either removed or disabled and at least one stalk cutting disk is mounted on one of a pair of gathering chain drive idler shafts, mounted at the forward end of the row unit frame, for rotating above the frame. The snapping rolls are disabled by adjusting the deck plates toward each other to close the throat.

Owner:DEERE & CO

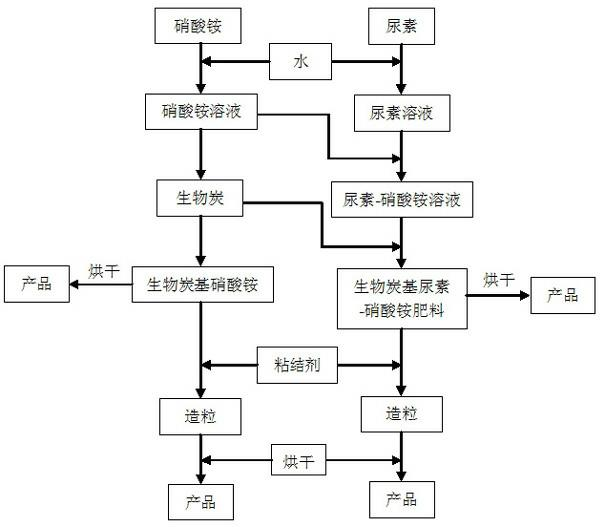

Method for producing biocarbon-based slow-release nitrogen fertilizer

InactiveCN102424642ASimple preparation processIncrease lossClimate change adaptationAgriculture gas emission reductionSoil scienceClimatic warming

The invention discloses a method for producing a biocarbon-based slow-release nitrogen fertilizer, which is characterized by comprising the following steps: thermal cracking or gasifying corn straw, or apple tree waste branch, trunk and wood chip to obtain the biocarbon; mixing the biocarbon and an ammonium nitrate solution, or urea and the ammonium nitrate solution, fully stirring and drying, or adding a binder with 1-3% of total amount and sending to a granulation system for granulation, then drying to obtain the biocarbon-based slow-release nitrogen fertilizer product. The fertilizer has the advantages of simple and easy preparation technology, and low cost. The biocarbon-based slow-release nitrogen fertilizer contains 10-12% of nitrogen, the biocarbon carrier material is stable in soil, and is a good soil amendment and a carbon sequestration agent, soil is applied for improving soil fertilization, the nitrogen element of the nitrogenous fertilizer loaded by the biocarbon has slow-release effect, so that the loss of the nitrogen element can be reduced, the nitrogenous fertilizer utilization rate can be enhanced; the biocarbon can retain in soil for long-term to play the effects of carbon sequestration and carbon emission reduction, the biocarbon is helpful for alleviating climate warming, and biocarbon-based slow-release nitrogen fertilizer is a green fertilizer.

Owner:NORTHWEST A & F UNIV

Bio-protein feed prepared by adopting cellulose raw material and preparation method thereof

InactiveCN102232466ASimple preparation processShort fermentation cycleFood processingAnimal feeding stuffDecompositionRapeseed

The invention relates to a bio-protein feed prepared by adopting a cellulose raw material, and the bio-protein feed provided by the invention comprises an organic material and complex bacteria, wherein the weight of the complex bacteria is 1-10% of that of the organic material; and the organic material comprises the cellulose raw material, rapeseed meal and bran; the cellulose raw material is one or more of corn stalks, corn cobs, straw, manioc waste and fruit residue; and the complex bacteria comprises bacillus subtilis, microzyme, lactobacillus and cellulose decomposition bacteria, and the cellulose decomposition bacteria is one or more of trichoderma harzianum and white-rot fungi. In the bio-protein feed, the content of probiotics is more than 108cfu / g, the bio-protein feed contains a variety of prolease, cellulase, amylase and the like, the preparation process is simple, and the fermentation period is short. The invention further discloses a preparation method of the feed.

Owner:洋浦慷民高科生物有限公司

Production method for biological organic fertilizer

InactiveCN102951950ASimple production processEasy to operateBio-organic fraction processingOrganic fertiliser preparationPhosphatePotassium

The invention discloses a production method for a biological organic fertilizer which belongs to the field of manufacturing of composite fertilizers. The production method comprises the following steps: with pig manure, cow dung, chicken manure, sheep manure, vinasse, vinegar residue, cassava residue, furfural residue, uncontaminated river mud, corn straw, peanut straw, rape straw, a cottonseed cake, plant ash, a deodorant, a biological nitrogen fixation bacterium, a phosphate solubilizing bacterium, a potassium solubilizing bacterium, a nodule bacterium and a phosphorus activator used as raw materials, carrying out tank continuous fermentation to allow the raw materials become thoroughly decomposed; carrying out deodorizing and removing water; and carrying out granulation to obtain the granular biological organic fertilizer. The fertilizer has the following advantages: a complete range of nutrient elements, capacity of improving physical and chemical properties of soil and enhancing water retention, fertilizer retention and fertility supplying capacity of the soil, no corrosion and damage to roots and seedlings and capacity of substantially improving the quality of an agricultural product.

Owner:訾然

Corn stalk rollers

Owner:KITCHEL ENTERPRISES

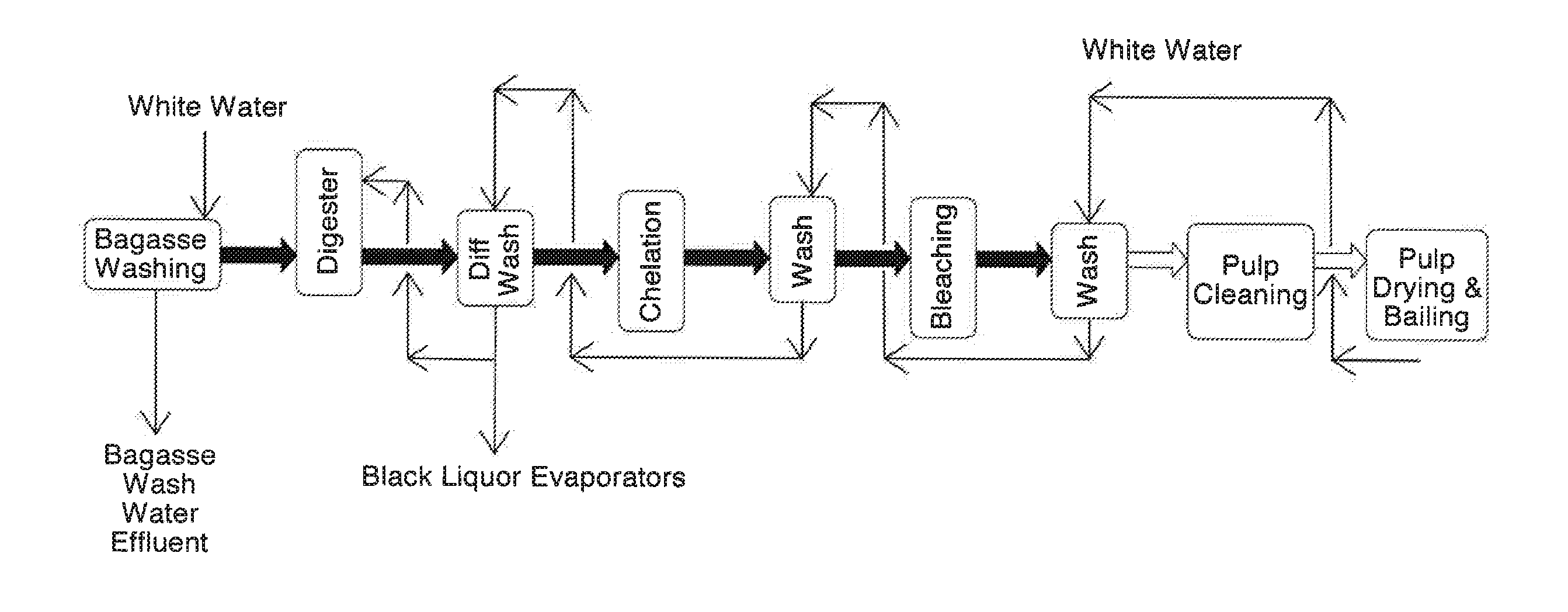

Pulping processes

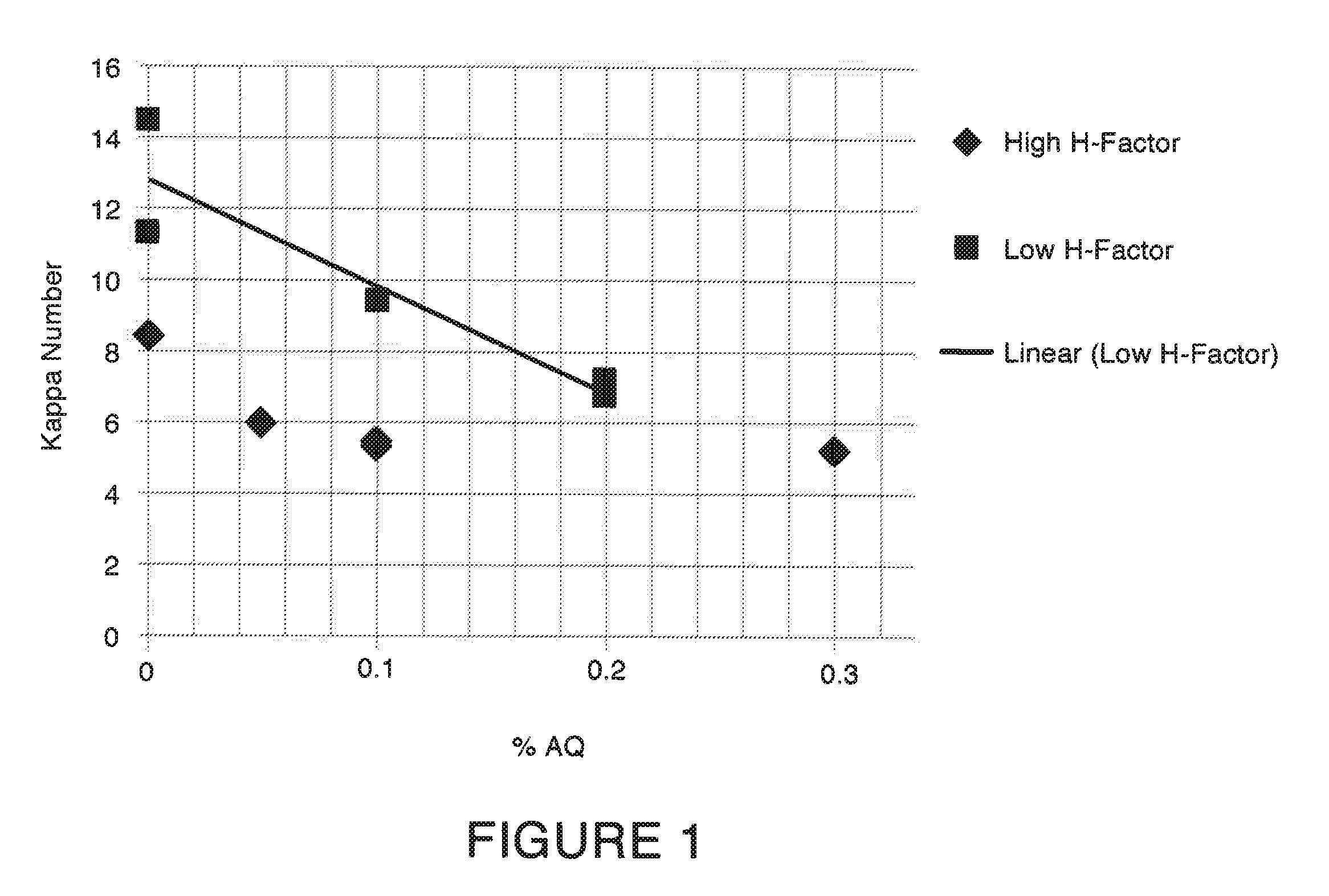

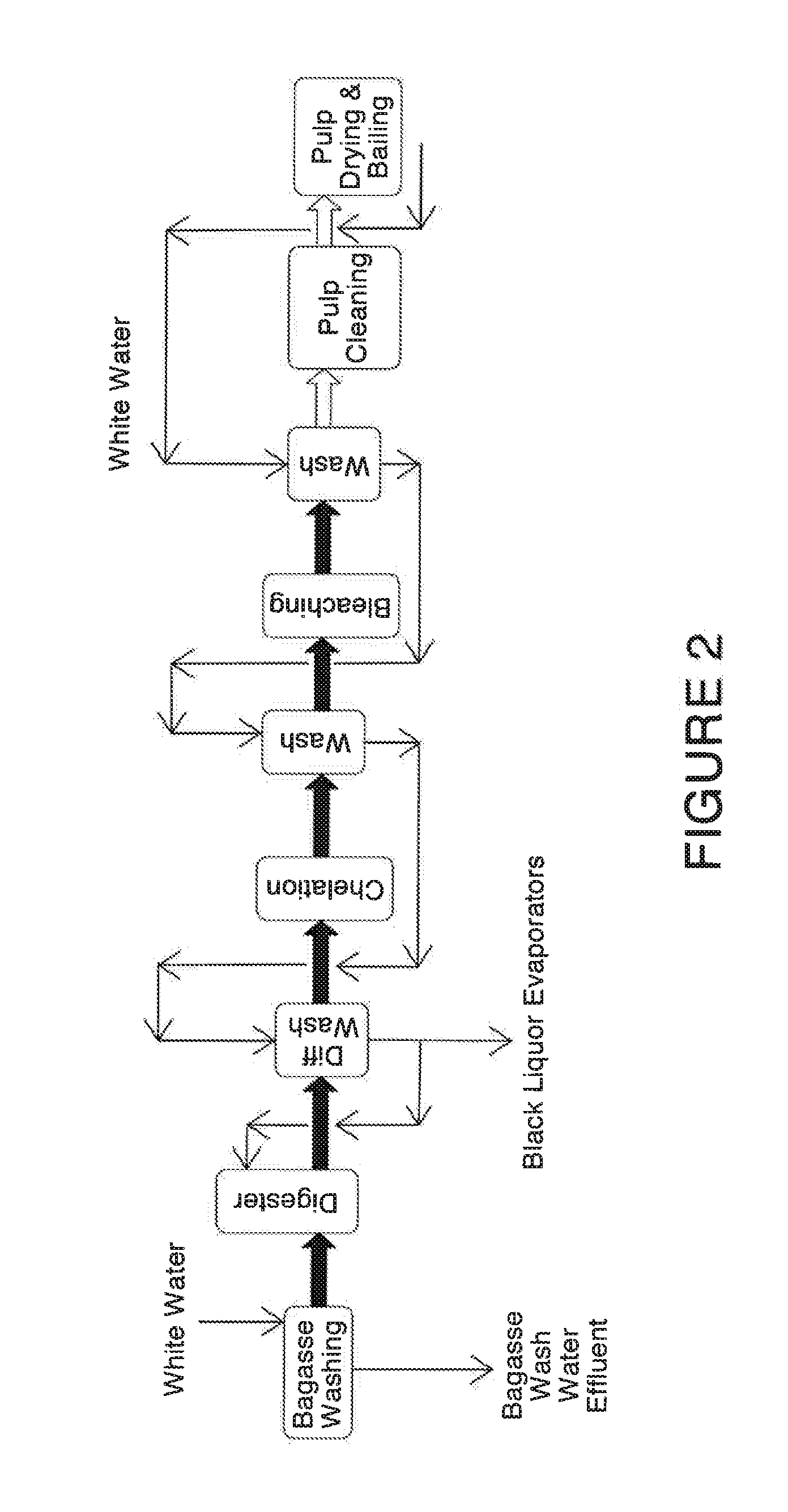

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

Few-no-tillage-soil seeding and fertilizing method for wheat and corns under complete straw mulching condition

The invention relates to a few-no-tillage-soil seeding and fertilizing method for wheat and corns under a complete straw mulching condition. The seeding and fertilizing method comprises the following steps of: after wheat is harvested by a combined wheat harvester, covering straws on the surface of soil in a strip manner basically, and implementing subsoiling, shallow and deep fertilization and seeding of corns in one step in seeding lines by a no-tillage corn seeding and fertilizing machine; and after the corns are harvested by a combined corn harvester, cutting up corn straws by rotary blades of the combined corn harvester, uniformly covering the corn straws on the surface of the ground, and implementing subsoiling, rotary tillage of wheat seeding belts, seeding of wheat and shallow and deep fertilization in one step by a no-tillage wheat seeding and fertilizing machine. The few-no-tillage-soil seeding and fertilizing method has the advantages of alleviating disturbance on soil, ensuring the variety and stable quantity of microorganisms in surface soil, being beneficial to benign growth of roots of crops and eliminating the influence of crop straw mulching on the quality of seeding and seedling emergence of wheat and corns.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

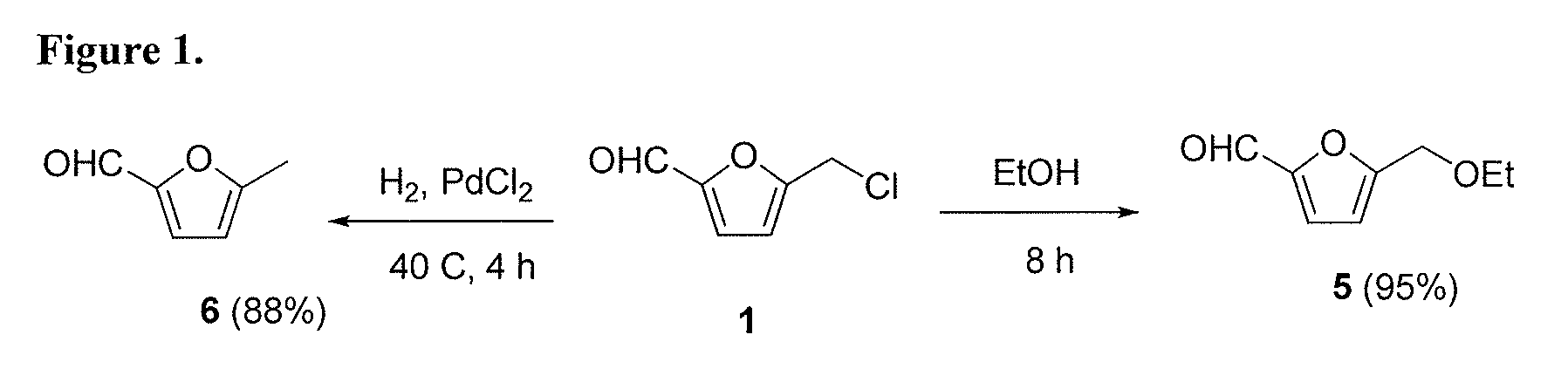

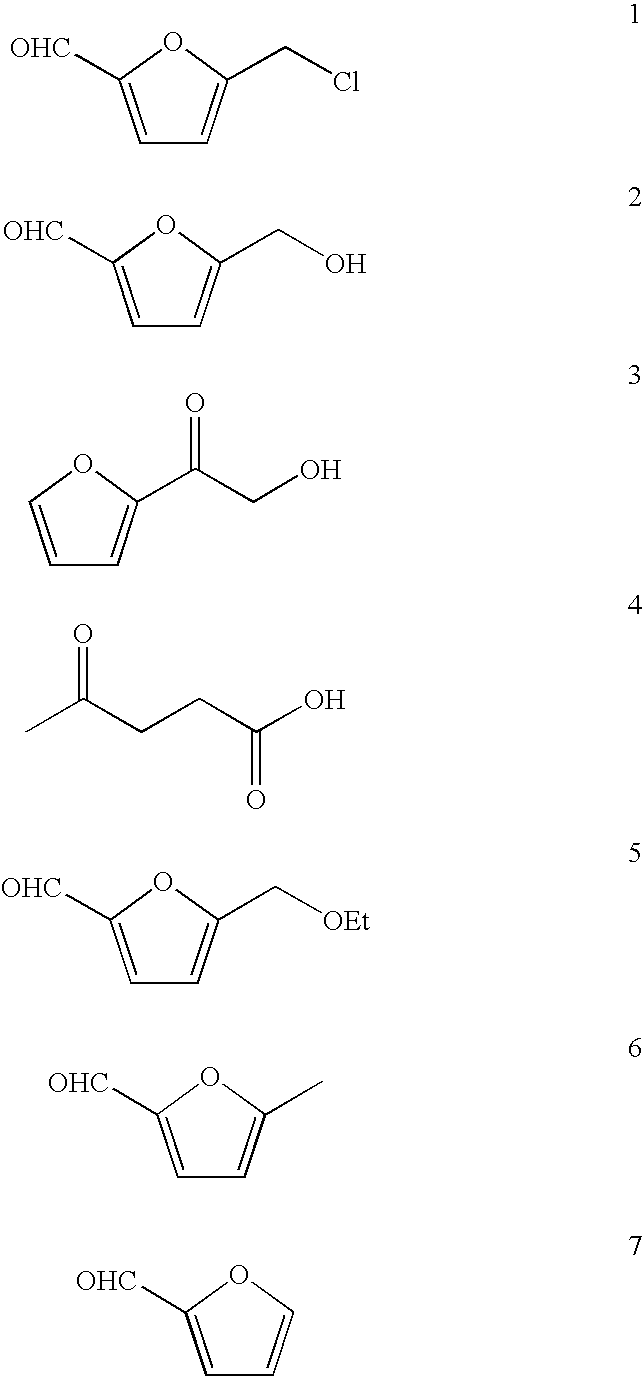

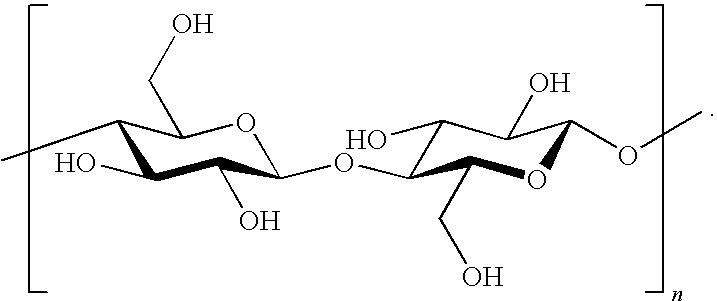

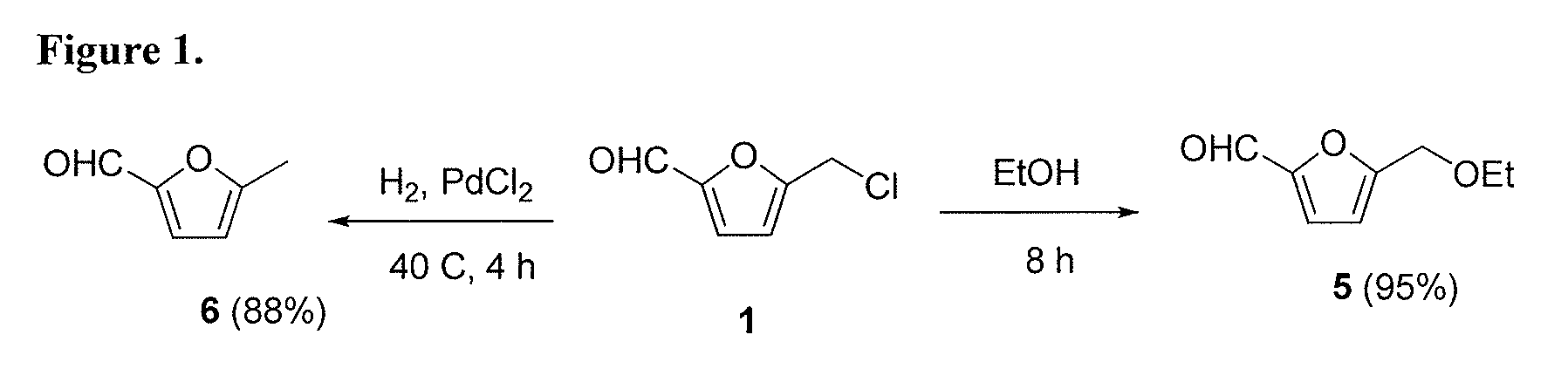

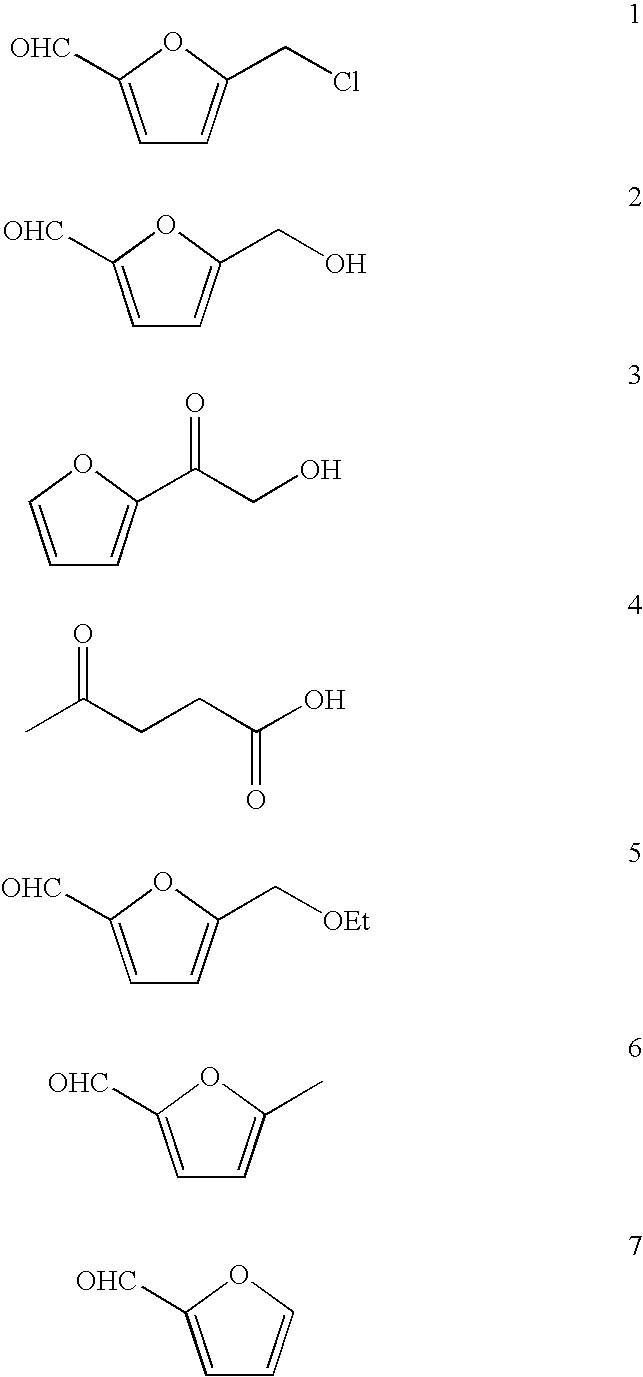

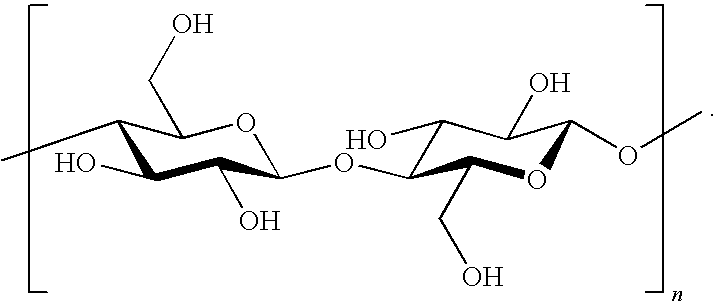

High-yield conversion of cellulosic biomass into furanic biofuels and value-added products

Paper, cotton, corn stover, straw, and wood are converted into furanic products in high yields (based on their cellulose content) using a simple, inexpensive process involving concurrent hydrolysis, dehydration, and substitution reactions coupled with continuous extraction into an organic phase. In a simultaneous process, the hemicellulose fraction of these substrates is converted into furfural, and together these constitute an efficient means for the total exploitation of the carbohydrate content of biomass.

Owner:RGT UNIV OF CALIFORNIA

High-yield conversion of cellulosic biomass into furanic biofuels and value-added products

Paper, cotton, corn stover, straw, and wood are converted into furanic products in high yields (based on their cellulose content) using a simple, inexpensive process involving concurrent hydrolysis, dehydration, and substitution reactions coupled with continuous extraction into an organic phase. In a simultaneous process, the hemicellulose fraction of these substrates is converted into furfural, and together these constitute an efficient means for the total exploitation of the carbohydrate content of biomass.

Owner:RGT UNIV OF CALIFORNIA

Pleurotus eryngii cultivation method and cultivation material thereof

InactiveCN101717298AHigh biological conversion ratePromote the process of industrializationHorticultureFertilizer mixturesBiologyGypsum

The invention discloses a pleurotus eryngii cultivation method and a cultivation material thereof. The cultivation material comprises the following components in parts by weight: 30 to 40 parts of corncobs or cornstalk, 0 to 60 parts of cotton seed shells, 8 to 10 parts of wheat bran, 5 to 8 parts of kapok seed powder, 5 to 8 parts of cornmeal, 1 to 2 parts of plaster powder and 1 to 3 parts of lime powder. The traditional formula using pure cotton seed shells as the mail materials is changed, and the optimized high-yield formula using the corncobs or cornstalk, kapok seed shells and the like is developed. The invention reduces the production cost, further standardizes the fore treatment of the cultivation material and the reasonable and scientific formula, provides the functions of sterilization and disinfection and obtains high yield and good quality of rare mushrooms through cultivation by using the stalk of crops.

Owner:SHANDONG FANGLV AGRI SCI & TECH

Converting a corn head row unit for harvesting corn stalks in addition to ears

A conventional corn head comprises side-by-side row units, each including a frame supporting a pair of snapping rolls below a pair of gathering chains for guiding corn stalks to the snapping rolls which operate to detach corn ears from the stalks, which remain attached to the ground. The row units are each designed such that they can be easily converted for harvesting the entire corn plant by adding one or more cutting disks for being driven together with idler sprockets of the gathering chain arrangement so as to sever the corn stalks from the ground. The gathering chains can also be replaced by chains including stalk grasping arrangements so as to better convey the stalks to a cross conveyor located behind the row units. The snapping rolls can be removed and their drive shafts shielded by deck plates located below the cutting disks when the row units are converted for harvesting entire corn plants. The cutting disks and gathering chains having a stalk grasping characteristic can be provided as part of a kit that is supplied for converting the row units of a conventional corn head into row units for harvesting entire corn plants.

Owner:DEERE & CO

Weaned lamb forage and preparation method thereof

The invention discloses a weaned lamb forage and a preparation method thereof. The weaned lamb forage is composed of the following raw materials, by weight, 45-55 parts of corn straw, 30-40 parts of Pennisetum sinese Roxb, 15-25 parts of Black Locust leaf, 5-10 parts of Herba Leonuri, 10-20 parts of sweet potato residue, 10-15 parts of brewer's grain, 20-30 parts of peanut hull powder, 1-2 parts of a starter, 40-50 parts of corn flour, 20-25 parts of wheat bran, 10-15 parts of soybean meal, 4-6 parts of a lyophilized powder additive, 3-5 parts of fried rice flour, 5-8 parts of MaiFan stone, 2-4 parts of mandarin oil, 3-6 parts of sodium alginate, 0.2-0.3 parts of calcium carbonate, 0.3-0.4 parts of potassium hydrogen phosphate and 0.3-0.5 parts of salt. The forage contains all nutrition required by the growth of weaned lambs, guarantees the healthy production of the weaned lambs, provides healthcare values, and raises the growth speed of the weaned lambs.

Owner:BENGBU DACHENG FOOD

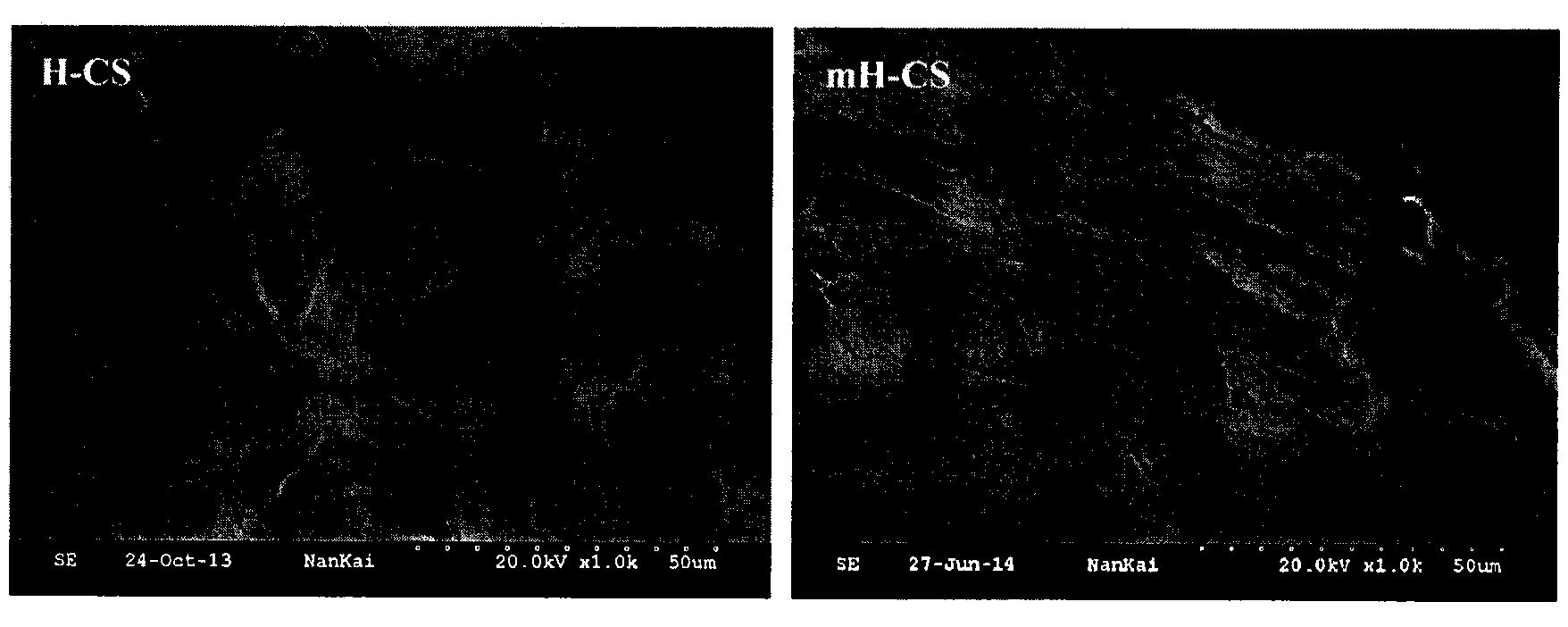

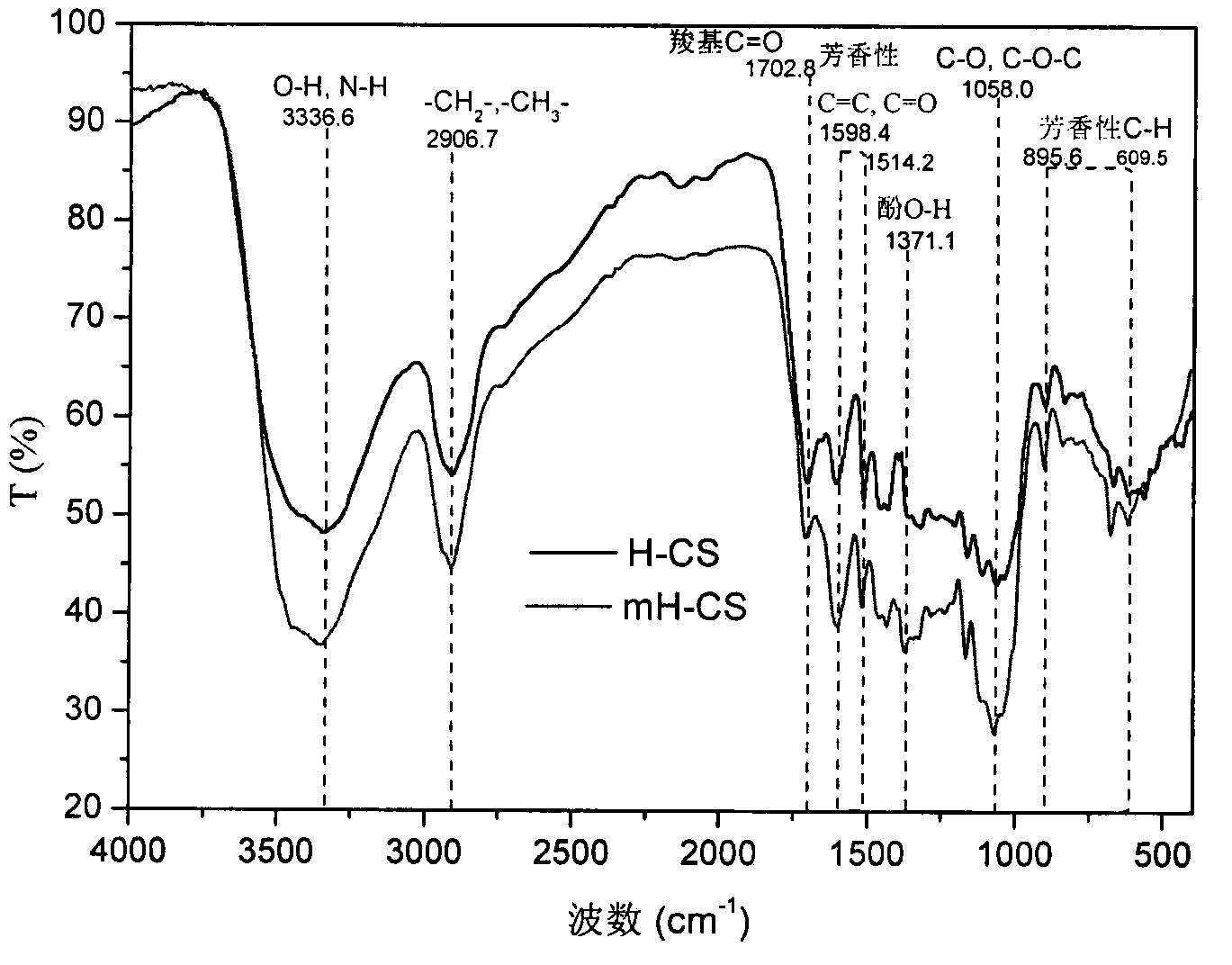

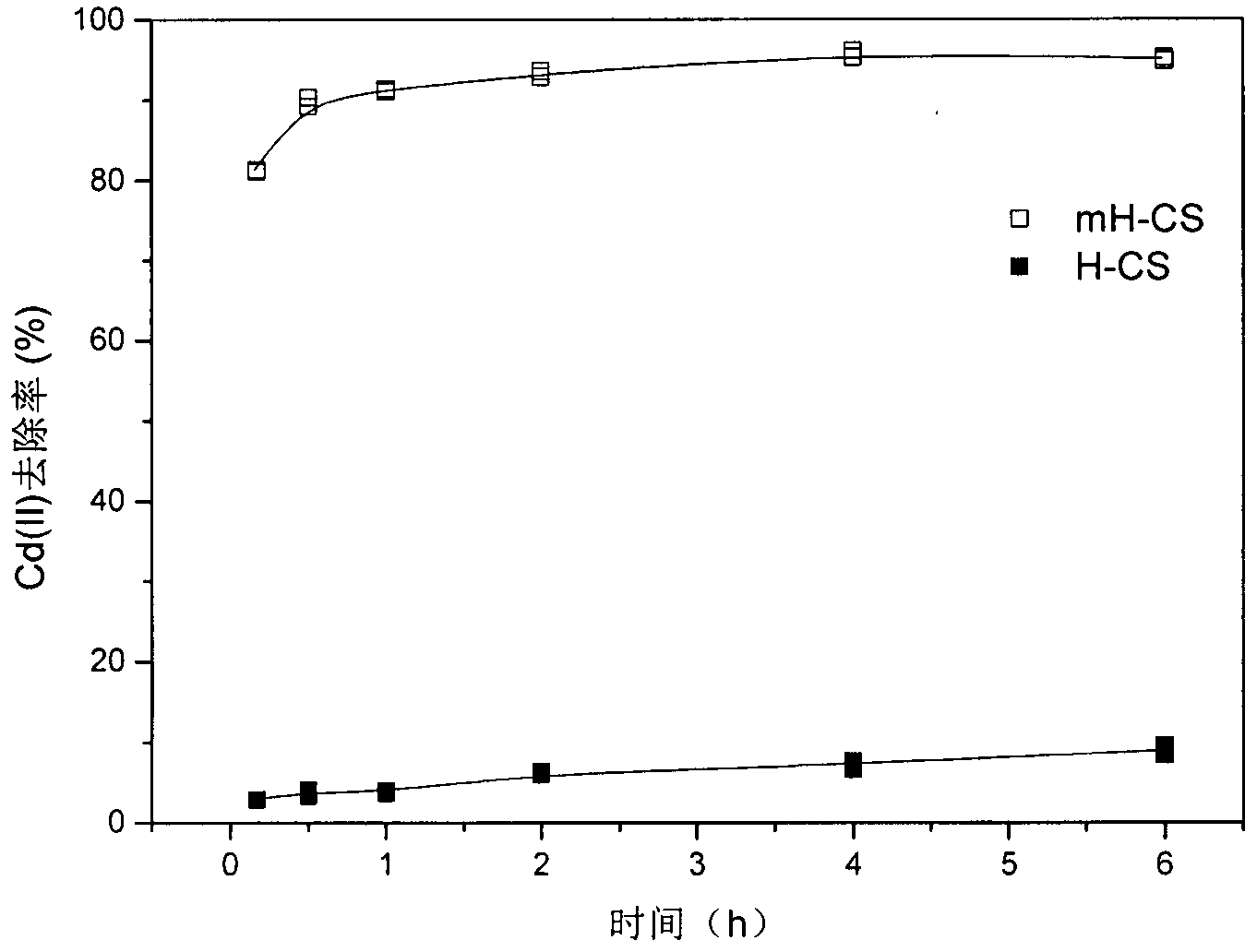

Method for preparing modified maize straw hydrothermal charcoal by adopting KOH

InactiveCN104069812AEfficient repairImprove removal efficiencyOther chemical processesWater contaminantsDistilled waterBiochar

A method for preparing modified maize straw hydrothermal charcoal by adopting KOH comprises the following steps: smashing the maize straw into powder; taking proper amount of maize straw powder, mixing with a distilled water,and conducting hydrothermal reaction in a reaction kettle so as to prepare the maize straw hydrothermal charcoal; mixing the obtained hydrothermal charcoal and a KOH solution, stirring for a period of time, and then conducting filtering, water washing and stoving so as to obtain the modified maize straw hydrothermal charcoal. The method is simple, and facilitates industrialized production; comparing the effect of the prepared modified hydrothermal charcoal with that of the conventional charcoal or a conventional similar charcoal adsorbent, the adsorptivity on heavy metal is greatly improved, and the stability is considerable.

Owner:NANKAI UNIV

Biomass carbon catalyst and preparation method and application thereof

The invention discloses a biomass carbon catalyst and a preparation method and application thereof. The precursor of the catalyst comprises biomass and metal salts, wherein the biomass includes one or more of maize straw, corncob, rice straw, cotton straw, peanut straw, peanut shell, wheat hull, rice hull, wood, sawdust, bamboo wood and weed. Through controlling addition of metal salts in different amounts, adjusting impregnation concentration of the precursor and reaction ambient and carbonization and nitriding treatment temperatures, the biomass carbon catalyst with controllable and adjustable pore structure and specific surface area can be prepared. When used as a fuel battery cathode catalyst, the biomass carbon catalyst shows excellent oxygen reduction reaction activity and stability. The preparation process is simple in flow, short in period and free of environment, provides a novel high-value-added resource recycling way for waste biomass and has dual effects of biomass disposal and energy and power generation.

Owner:SHENYANG AGRI UNIV

Production method of biotic straw feedstuff

InactiveCN1698457AHigh in proteinImprove digestion utilizationFood processingAnimal feeding stuffBiotechnologyMicroorganism

The invention relates to the production method of biotic straw feedstuff, wherein the bacterial employed includes fungus, saccharomycete, bacillus and lactic acid bacteria, the stalk comes from rice straw and corn stems, the auxiliary materials include bran and urea, the stalk fermentation procedure comprises aerobic solid fermentation. The process requires no acid, alkali or ammonification preparatory treatment.

Owner:HUNAN AGRICULTURAL UNIV

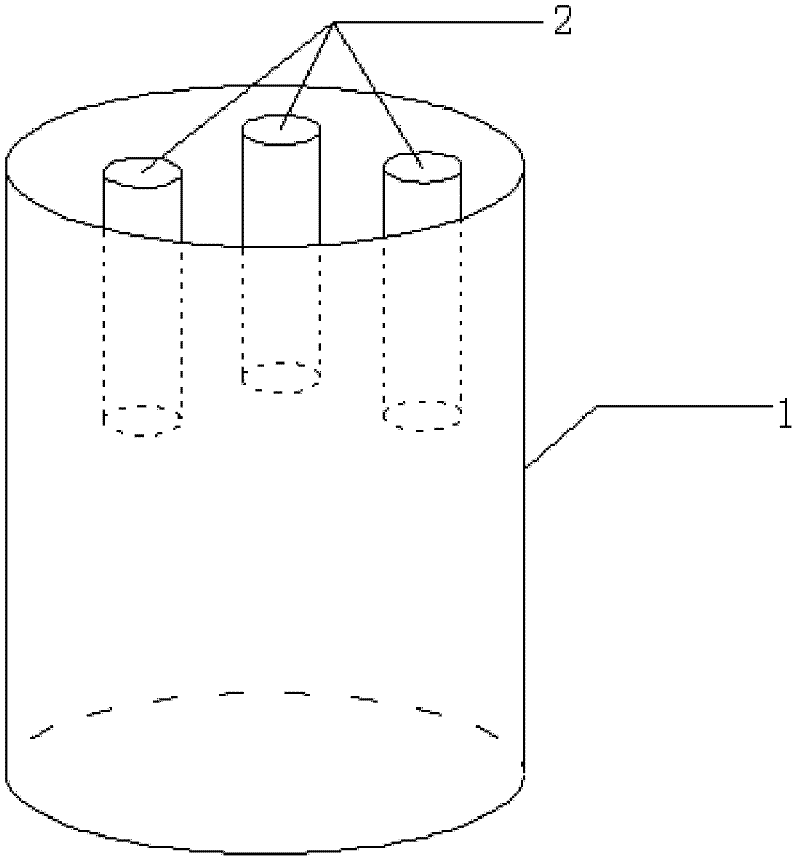

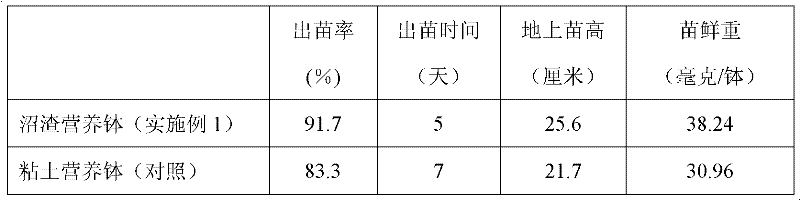

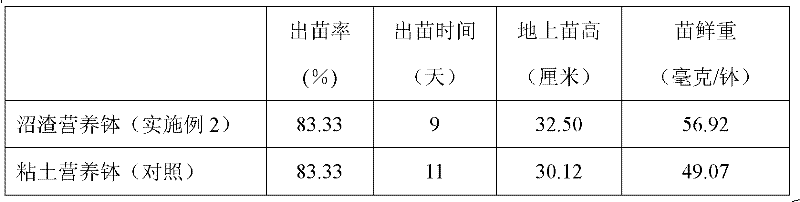

Biogas residue humus pot, and preparation method and application of biogas residue humus pot

InactiveCN102440158AFull of nutritionComplete ingredientsClimate change adaptationCultivating equipmentsActive enzymeOrganic content

The invention discloses a biogas residue humus pot and a preparation method thereof. The biogas residue humus pot is made of 62.5-186.5 parts of fresh biogas residue, 50-150 parts of clay and 0.5-5 parts of cotton seed hulls or 1-18 parts of wheat straws or corn straws. The fresh biogas residue, the clay and the cotton seed hulls (or wheat / corn straws) are proportionally mixed well to obtain a mixture, the mixture is fed into a mould to be manually or mechanically pressed into an object with a rectangular or disc-shaped seeding hole in the middle, and the object is then stripped and naturally aired for 2-8 days or dried so as to obtain a biogas residue humus pot or seedling raising tray. The biogas residue humus pot is full of nutrients and high in organic content, further contains vitamins B, gibberellin, heteroauxin, amino acid and active enzymes, has fine chemical and biological properties, and meets conditions of compost. The biogas residue humus pot has the advantages of no environmental pollution, natural degradability, no need of stripping, simplicity in preparation, low cost, fastness in seedling raising speed, capability of enhancing seedlings, effectiveness and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

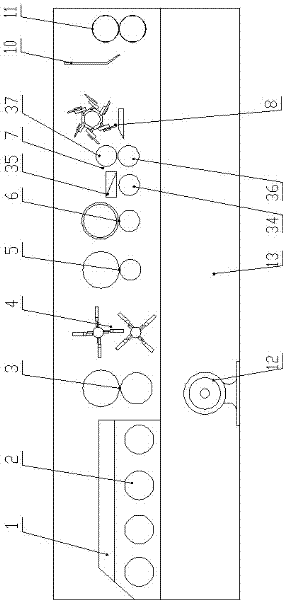

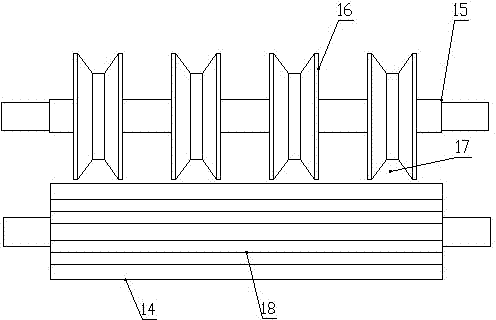

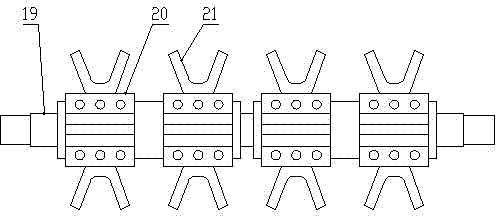

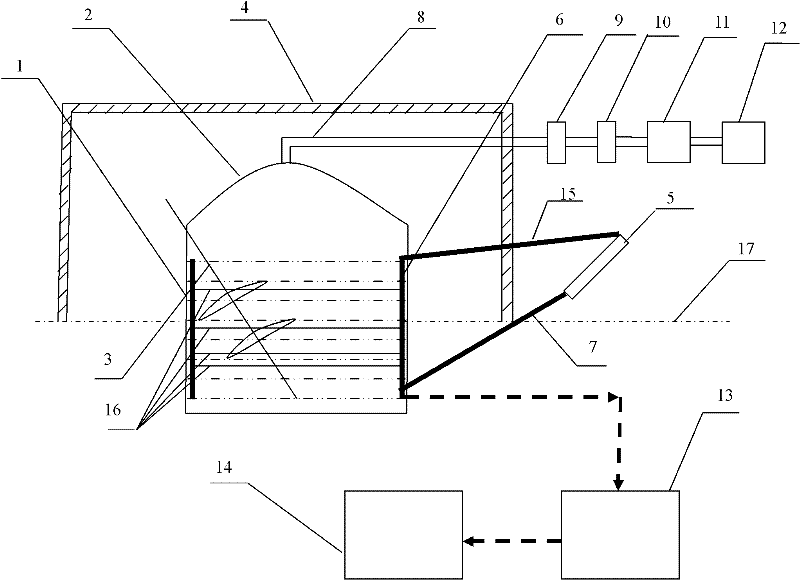

Peel-pith-leaf separator of maize straw

InactiveCN102528865AAchieve separationTake advantage ofCane mechanical workingEngineeringEnergy consumption

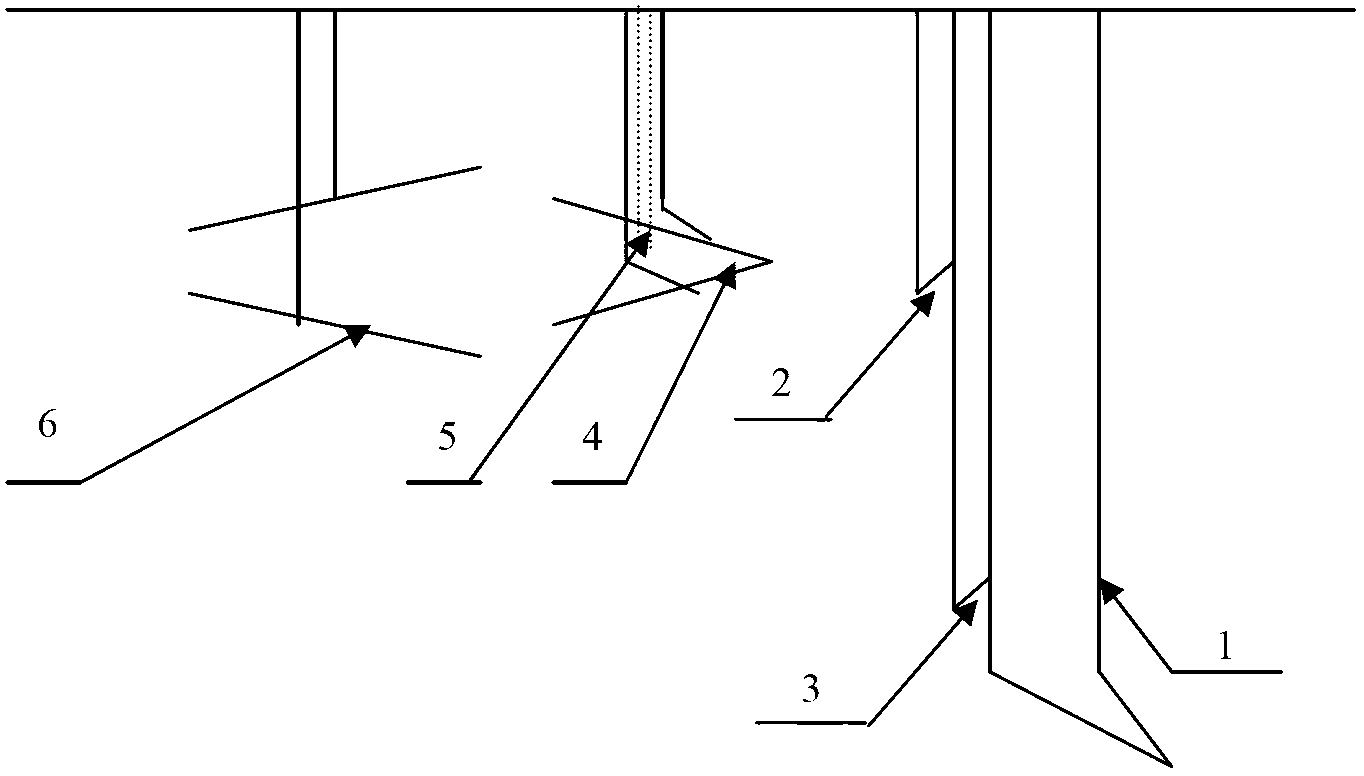

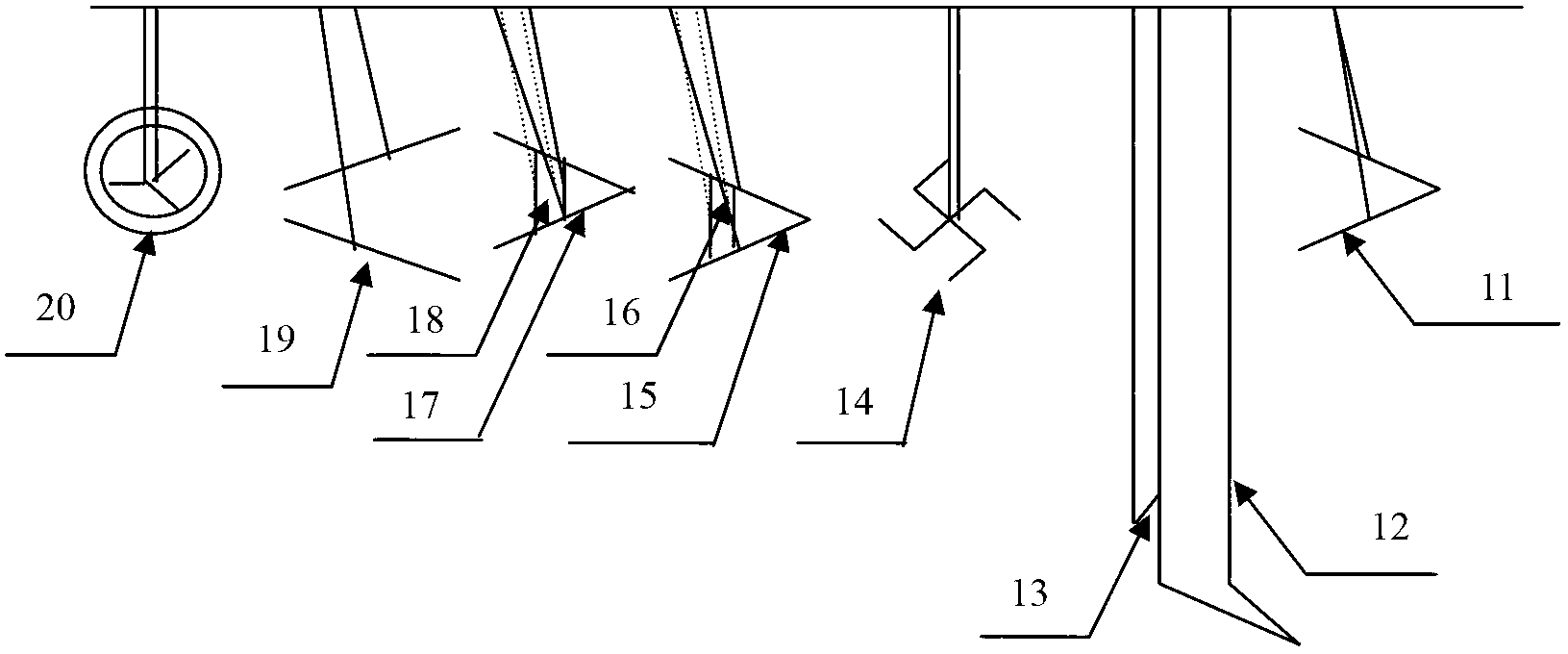

The invention discloses a peel-pith-leaf separator of a maize straw. The separator comprises a rack (13) and a power mechanism (12) arranged on the rack and is characterized in that a guiding conveying mechanism, a leaf removing mechanism, a peel-stripping mechanism and an output mechanism are arranged on the rack (13) from front to back and are all in transmission connection with the power mechanism (12). The separator disclosed by the invention specially aims at leaf-removing and pith-stripping works so as to realize the function of peel-pith-leaf thorough separation, and further the peel, the pith and the leaf of the maize straw can be respectively and effectively utilized; besides, the separator disclosed by the invention has the advantages of small mechanical vibration, low noise, less energy consumption, strong practicability, good market prospect and worthy of popularization and application.

Owner:HENAN AGRICULTURAL UNIVERSITY

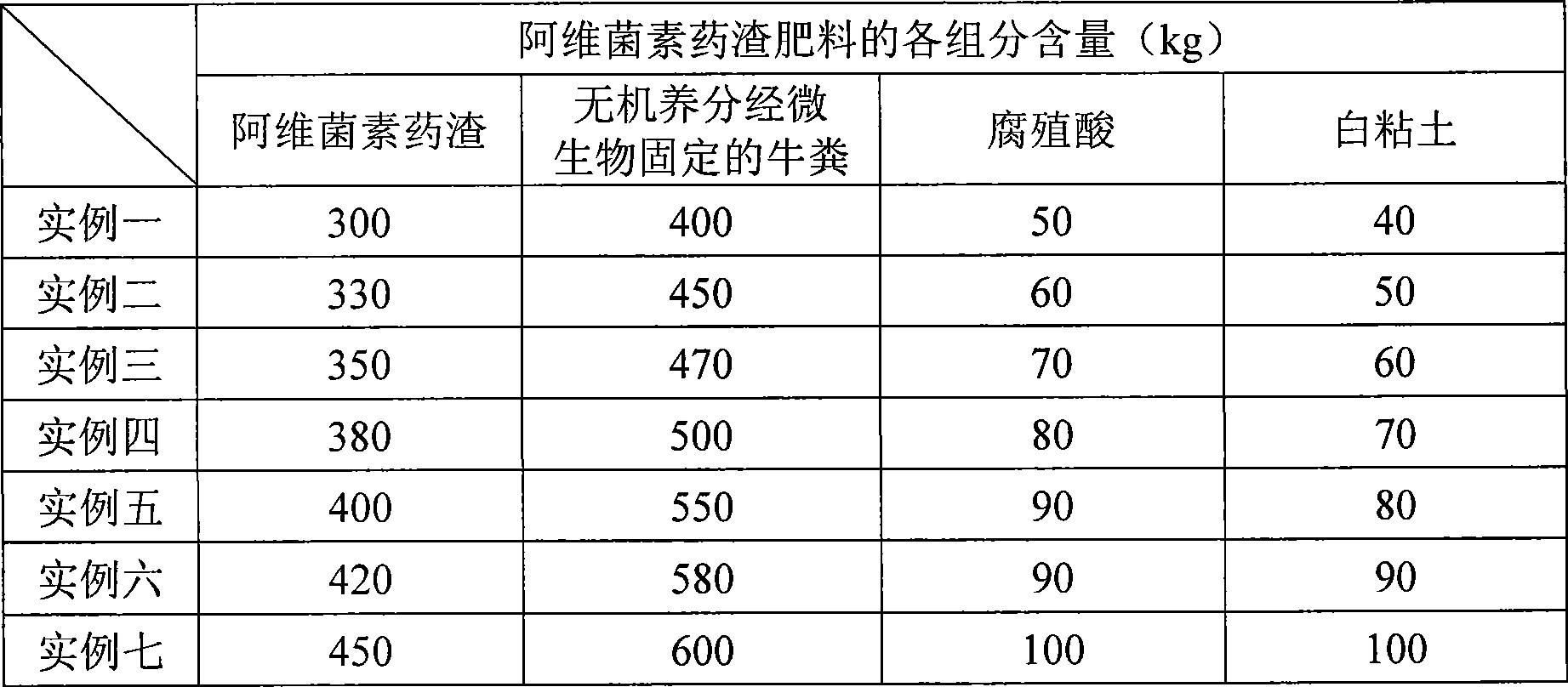

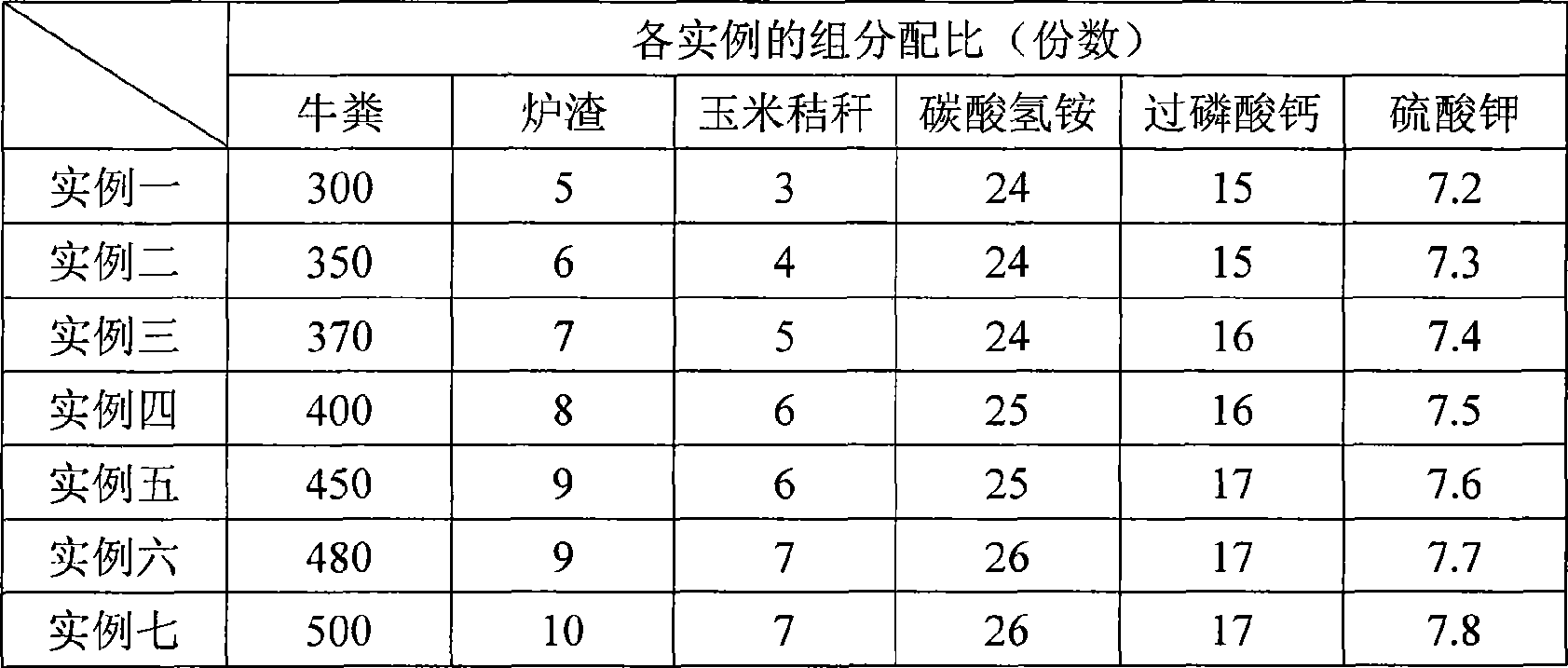

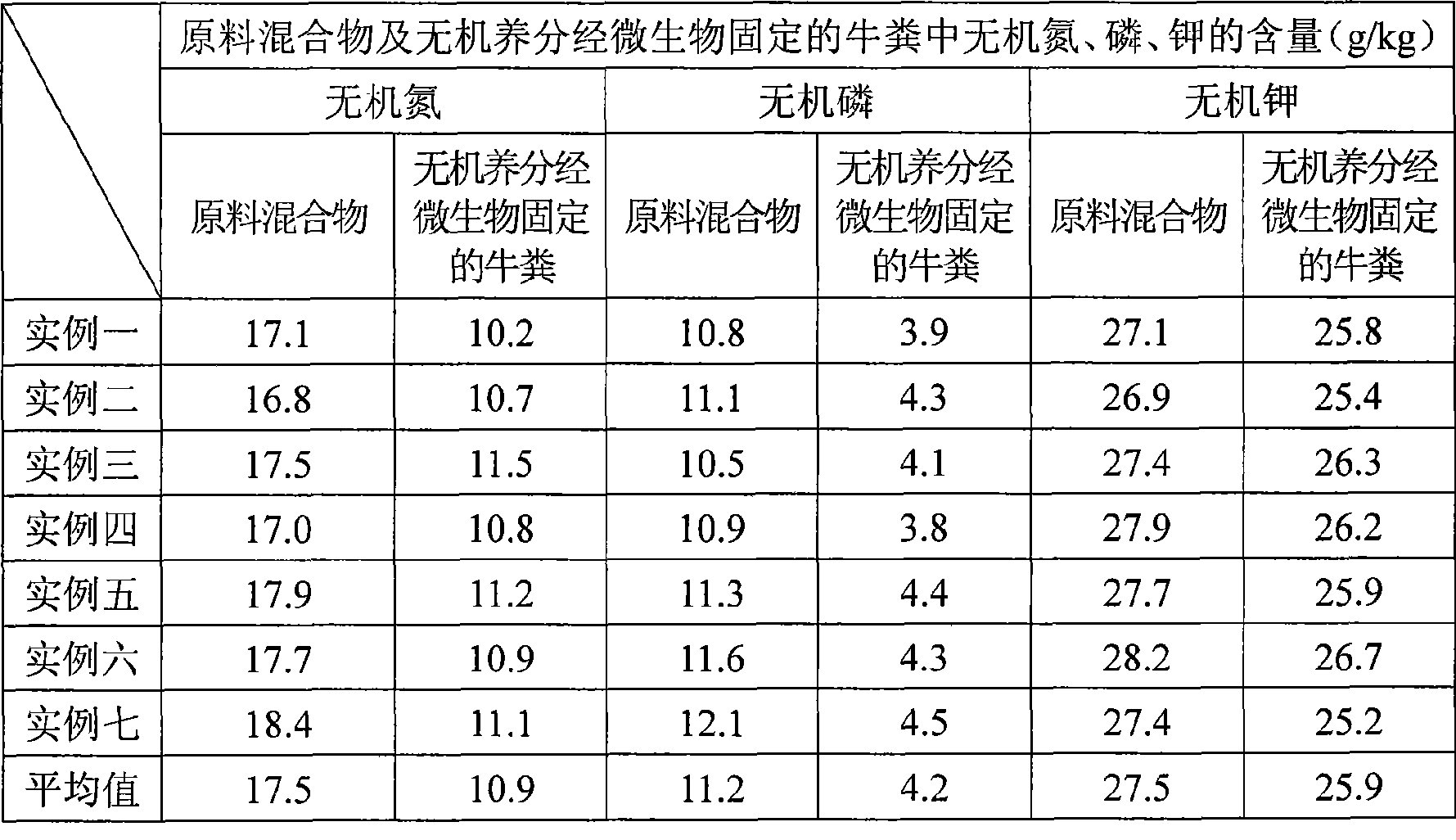

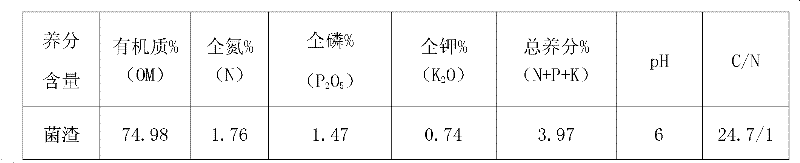

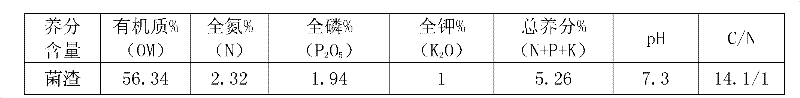

Preparation of avermectin slag fertilizer

InactiveCN101462909AIncrease contentReduce contentBio-organic fraction processingOrganic fertiliser preparationSlagPotassium

The invention relates to a preparation method of abamectin dreg fertilizer; the method solves the problem that: the existing preparation method of the organic fertilizer affects the content of total nitrogen, total phosphorus and total potassium when reducing the content of inorganic nitrogen, phosphorus and potassium in the fertilizer. The preparation method is characterized in that: the preparation method comprises the following steps: (1) dairy manure, slag, maize straw, ammonium hydrogen carbonate and potassium sulphate are uniformly mixed, composted and fermented; after the fermentation is finished, the dairy manure, the inorganic nutrients of which are fixed by microorganisms is obtained; (2) the abamectin dreg is dried to have 40-55% of the water content; (3) the dairy manure, the inorganic nutrients of which are fixed by microorganisms, the abamectin dreg, humic acid and argil are uniformly mixed and are made into particles, thus obtaining the abamectin dreg fertilizer. The method not only can improve the content of total nitrogen, total phosphorus and total potassium in the organic fertilizer, but also can effectively reduce the content of inorganic nitrogen, phosphorus and potassium in the fertilizer simultaneously; therefore, the produced fertilizer has high content of the total nitrogen, the total phosphorus, the total potassium and organic matters.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Biomass particle fuel and preparation method thereof

InactiveCN104927961AQuality improvementImprove qualitySolid fuelsWaste based fuelOrganic matterCow dung

The invention relates to the technical field of biomass fuel, in particular to biomass particle fuel and a preparation method thereof. The biomass particle fuel and the preparation method are characterized in that cow dung, biogas residues, sawdust, yellow mud and corn straw are pre-fermented to change the structure layer of the biomass raw materials and form a compact structure, high-content organic matter is formed, and organic matter components are increased; drainage oil is poured into the organic matter, high-speed stirring is used to allow microscopic biochemical reaction between the drainage oil and the fermented materials, and organic matter mass and quality are increased; the stirred mixture is fermented to further convert the organic matter so as to increase the combustible substances in the organic matter and improve the quality of the organic matter; combustion improver is added and extrusion forming is performed to allow the prepared biomass particle fuel to be good in quality.

Owner:广西稳德福能源科技有限公司

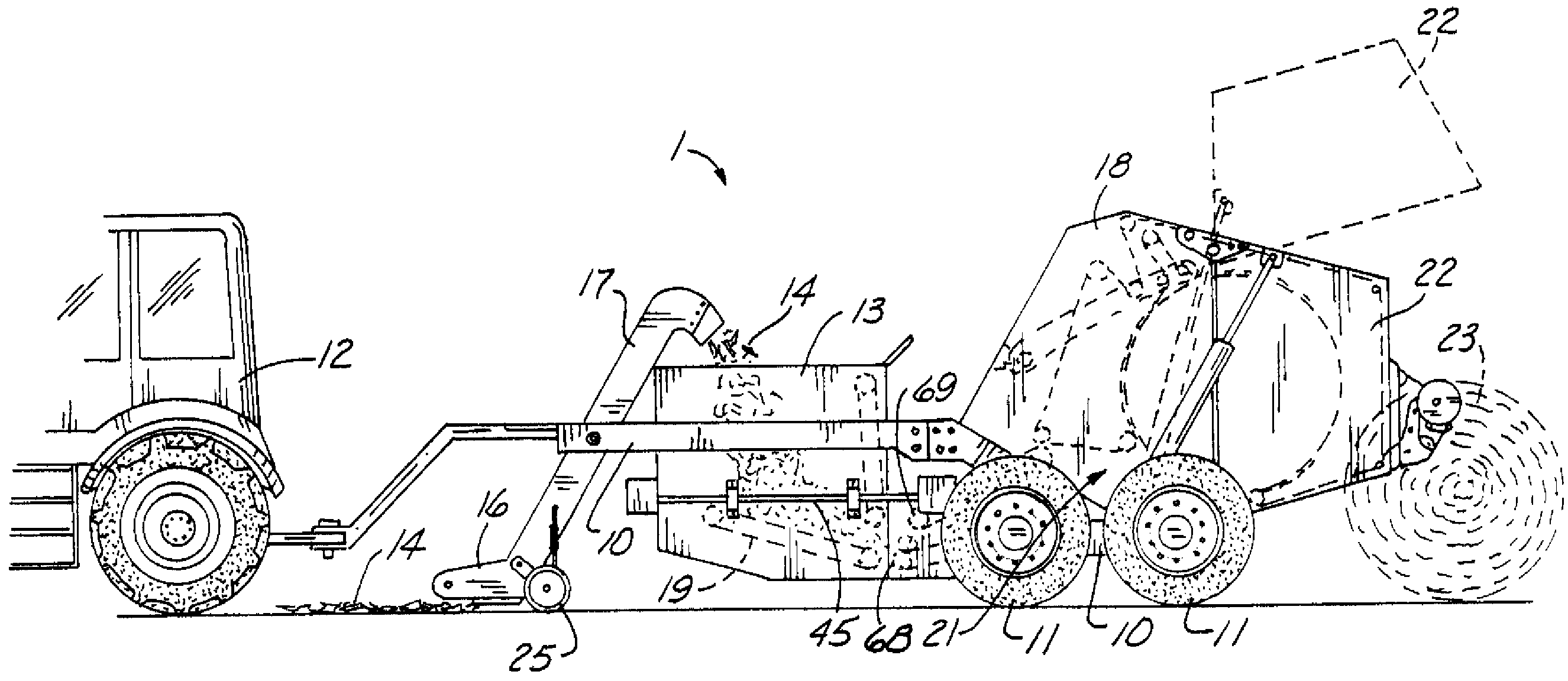

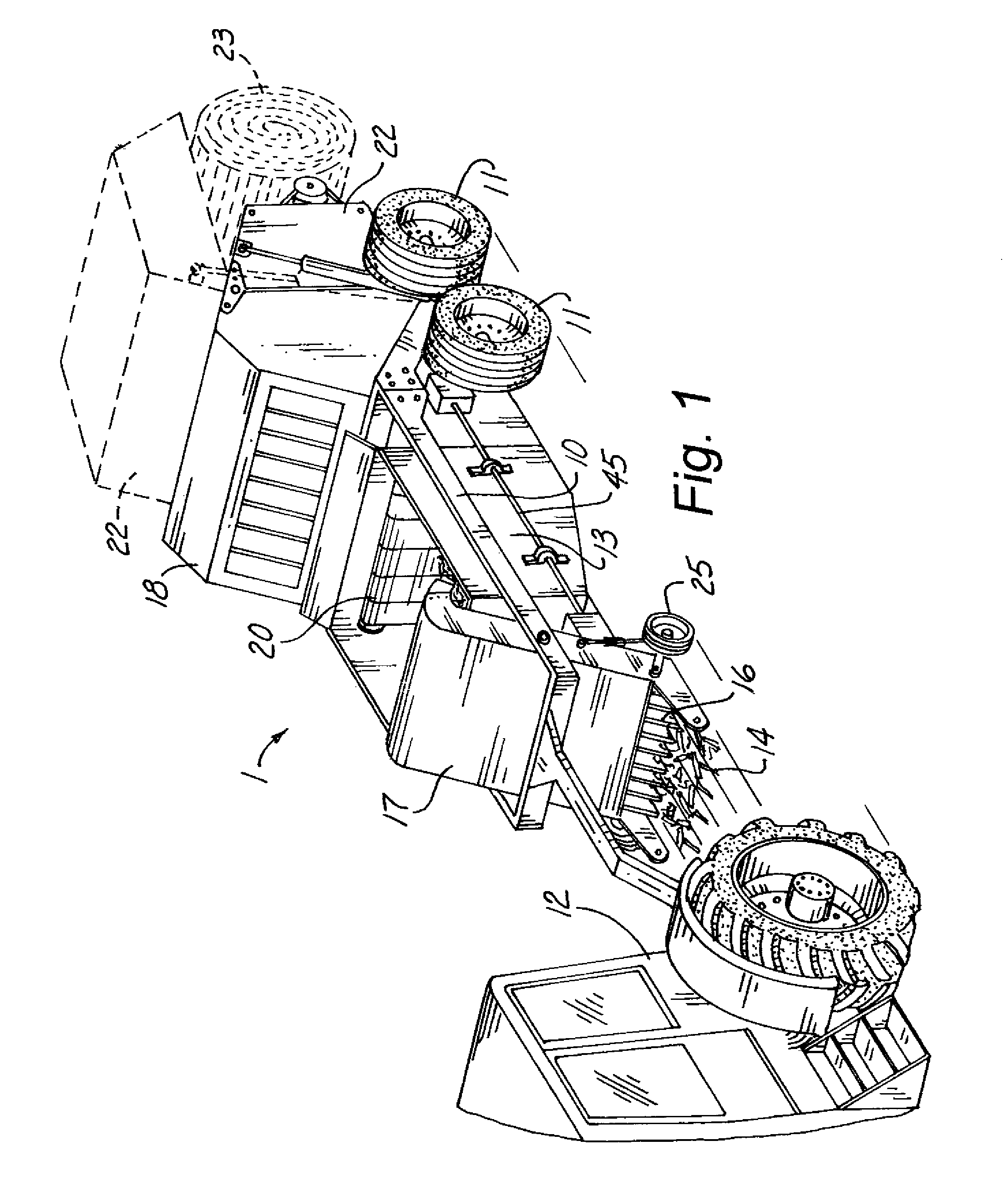

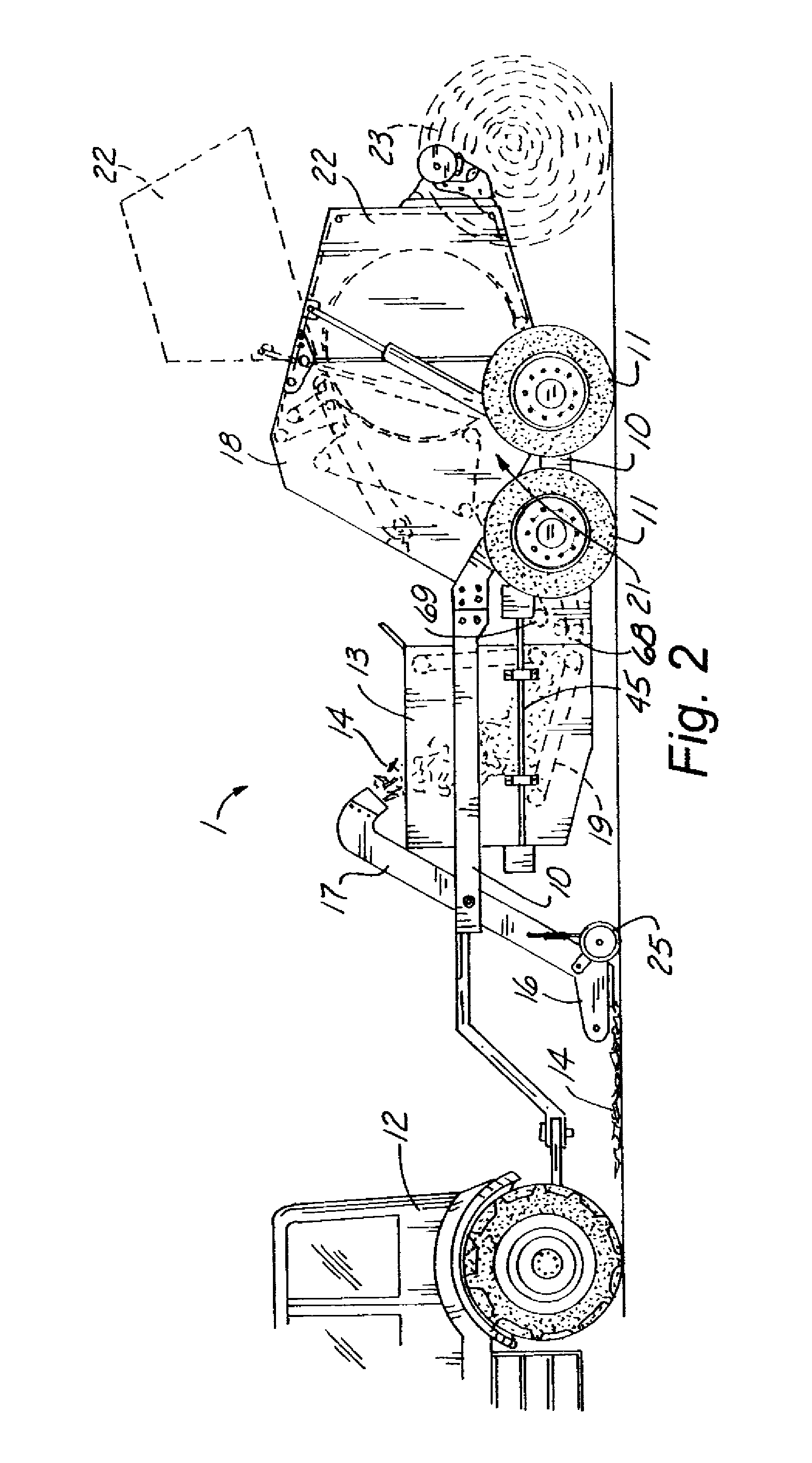

Corn stalk baling method and apparatus

Owner:VERMEER MFG CO

Method and device for recycling edible mushroom residues

ActiveCN102174586AImprove filtration efficiencyIncrease gas productionBioreactor/fermenter combinationsBiological substance pretreatmentsRed mudNew energy

The invention relates to a method and device for recycling edible mushroom residues. The method mainly comprises the steps of placing waste mushroom residues and maize straws or excrements from a cattle farm into an anaerobic reactor for united fermentation to produce biogas, and covering a red-mud plastic head cover on the anaerobic reactor, wherein an inclined stirrer is arranged and is beneficial to feeding / discharging of mushroom residue raw materials and avoidance of crusting. The produced biogas is used for power generation and agriculture, biogas residues are used for manufacturing organic fertilizers, biogas slurry is prepared into foliar fertilizer for fruits or vegetables, and thus, new energy sources, namely the biogas and the organic fertilizers, are obtained while the mushroom residues are treated. The method and the device in the invention are mainly used in major edible mushroom producing areas, a solar-panel greenhouse and a solar heat supply device are assorted for the device, a composite microbial inoculum is assorted for the method, and the anaerobic reactor can be normally used all the year round.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Rice seedling raising medium and rice seedling production method

InactiveCN101828491AReduce enclosed herbicide useReduce the use effectCultivating equipmentsSlagLactarius

The invention relates to a rice seedling raising medium and a rice seedling production method and belongs to a rice seedling raising medium and a rice seedling production method. The medium is prepared by a formula comprising 60 to 80 percent of 40 to 60 mesh crushed coin straw, 15 to 25 percent of industrial paper pulp processing waste slag liquid and 5 to 15 percent of 40 to 60 mesh industrial fluidized bed furnace ground slag and by a method comprising material preparation, raw material crushing and fermentation, wherein the fermentation is to add 0.5 kilogram of mixed solution of saccharomycetes and lactic acid bacteria in a ratio of 0.35:0.65 into each 1,000 kilograms of the crushed corn straw, mix the solution, dry the mixture and stir the mixture. In the invention, the problem of damaging vegetation during soil digging for raising seedlings and the problem of difficult soil digging are solved, the production processes of soil digging, soil sieving, acid regulation, fertilizer mixing, medicament mixing and the like are avoided, and the labor intensity of rice farmers is relieved. In the invention, a new approach is provided for utilizing straw resource, realizing energy conservation, emission reduction and agricultural circular economy.

Owner:吉林省农业科学院植物保护研究所

Culture medium for edible fungus and preparation method thereof

InactiveCN104844349AFast growthBio-organic fraction processingOrganic fertiliser preparationNutritive valuesCulture fungus

The invention discloses a culture medium for edible fungus and a preparation method thereof. The culture medium comprises the following raw materials: 10 to 20 parts of weed tree sawdust, 35 to 40 parts of corncob, 10 to 20 parts of bagasse, 15 to 25 parts of wheat bran, 3 to 8 parts of corn flour, 2 to 7 parts of bean pulp, 30 to 40 parts of pleurotus eryngii fungus residues, 8 to 12 parts of cow manure, 9 to 12 parts of corn stalk, 1 to 5 parts of calcium carbonate, 1 to 5 parts of lime, 2 to 3 parts of gypsum, 1 to 5 parts of a compound fertilizer, 2 to 6 parts of calcium superphosphate and 11 to 20 parts of bentonite. The culture medium has a pH value of 7.5 to 8 and water content of 65 to 68%. The culture medium for the edible fungus and the preparation method designed by the invention can ensure the growth rate and color of the edible fungus, improve the nutritional value of the edible fungus, reduce cost and improve yield of the edible fungus.

Owner:吴中区胥口精益生物医药研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com