Patents

Literature

3479 results about "Red mud" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bauxite tailings, also known as bauxite residue, red mud, red sludge, or alumina refinery residues (ARR), is a highly alkaline waste product composed mainly of iron oxide that is generated in the industrial production of alumina (aluminium oxide, the principal raw material used in the manufacture of aluminium metal and also widely used in the manufacture of ceramics, abrasives and refractories). It is important to differentiate between the alkaline waste generated in the Bayer process and the tailings generated during the mining of bauxite. This article specifically covers the alkaline waste generated when operating the Bayer process. The scale of production makes the waste product an important one, and issues with its storage are reviewed and every opportunity is explored to find uses for it.

High-strength compress supporting agent for coarse oil and preparation method thereof

ActiveCN101575503AGood effectHas high strengthFluid removalDrilling compositionChemical compositionRed mud

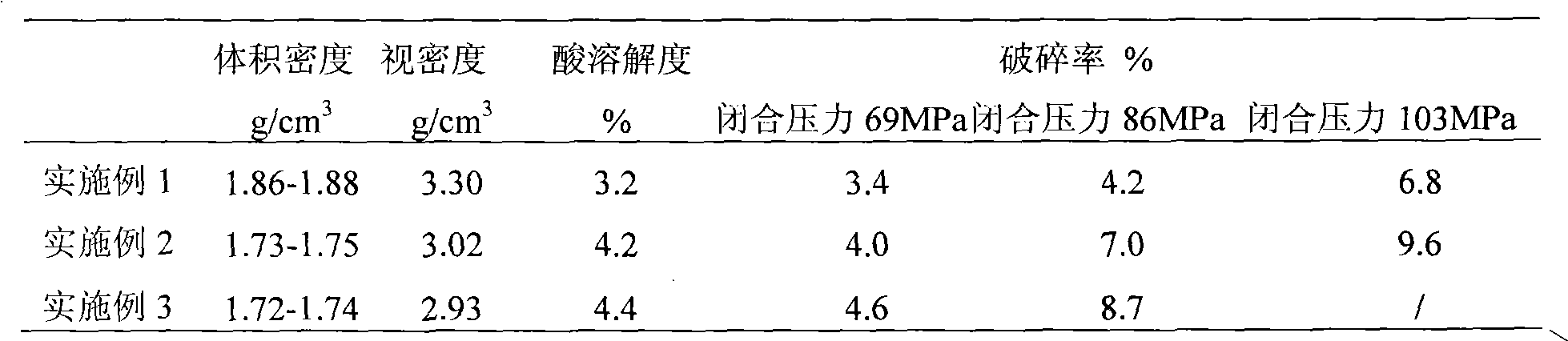

The invention relates to a high-strength compress supporting agent for coarse oil and a preparation method thereof. The high-strength compress supporting agent for the coarse oil is prepared from the following raw materials by mass portion: 60 to 85 portions of ceramic roller waste, 1 to 20 portions of red mud, 0 to 20 portions of fly ash, 0 to 5 portions of manganese oxide or barium carbonate, 0 to 3 portions of dolomite and 5 to 10 portions of ceramic clay. The ceramic roller waste refers to corner waste or / and damaged and broken ceramic roller waste in the processing process of ceramic roller manufactures, and Al2O3 content of chemical compositions of the ceramic roller waste is not less than 68 percent. The high-strength compress supporting agent for the coarse oil prepared from the ceramic roller waste with high alumina content has the characteristics of high strength and acid resistance, and is used for oil fracturing in medium-deep wells; and the preparation method is simple and feasible, and is suitable for batch production.

Owner:JINGANG NEW MATERIALS

Sintered heat insulating hollow building block

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Supported noble metal catalyst for low-temperature catalytic oxidation benzene series and preparation method thereof

The invention discloses a supported noble metal catalyst for low-temperature catalytically oxidizing benzene series (benzene, methylbenzene and dimethylbenzene) gas to CO2 and H2O. Active components of the noble metal catalyst are: at least one of Pd, Pt, Ag, Au and Rh; carrier is at least one of active carbon, red mud, molecular sieve, aluminum sesquioxide, titanium dioxide, manganese dioxide, zirconium dioxide, silicon dioxide, cerium dioxide, lanthanum sesquioxide, cobalt oxide, magnesium oxide, zinc oxide, calcium oxide and cupric oxide. Under general pressure, in atmosphere ambient, in fixed bed reactor, with a space velocity range from 10,000 to 100,000h<-1> and at a temperature range from 110 to 210 DEG C, the catalyst can be used for directly oxidizing 100 to 800ppm benzene series gas to CO2 and H2O without byproduct, which shows good low-temperature catalytic activity. The catalyst of the invention has the advantages of simple preparation, lower complete oxidation temperature, immunity to H2O, good stability and high practical value.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

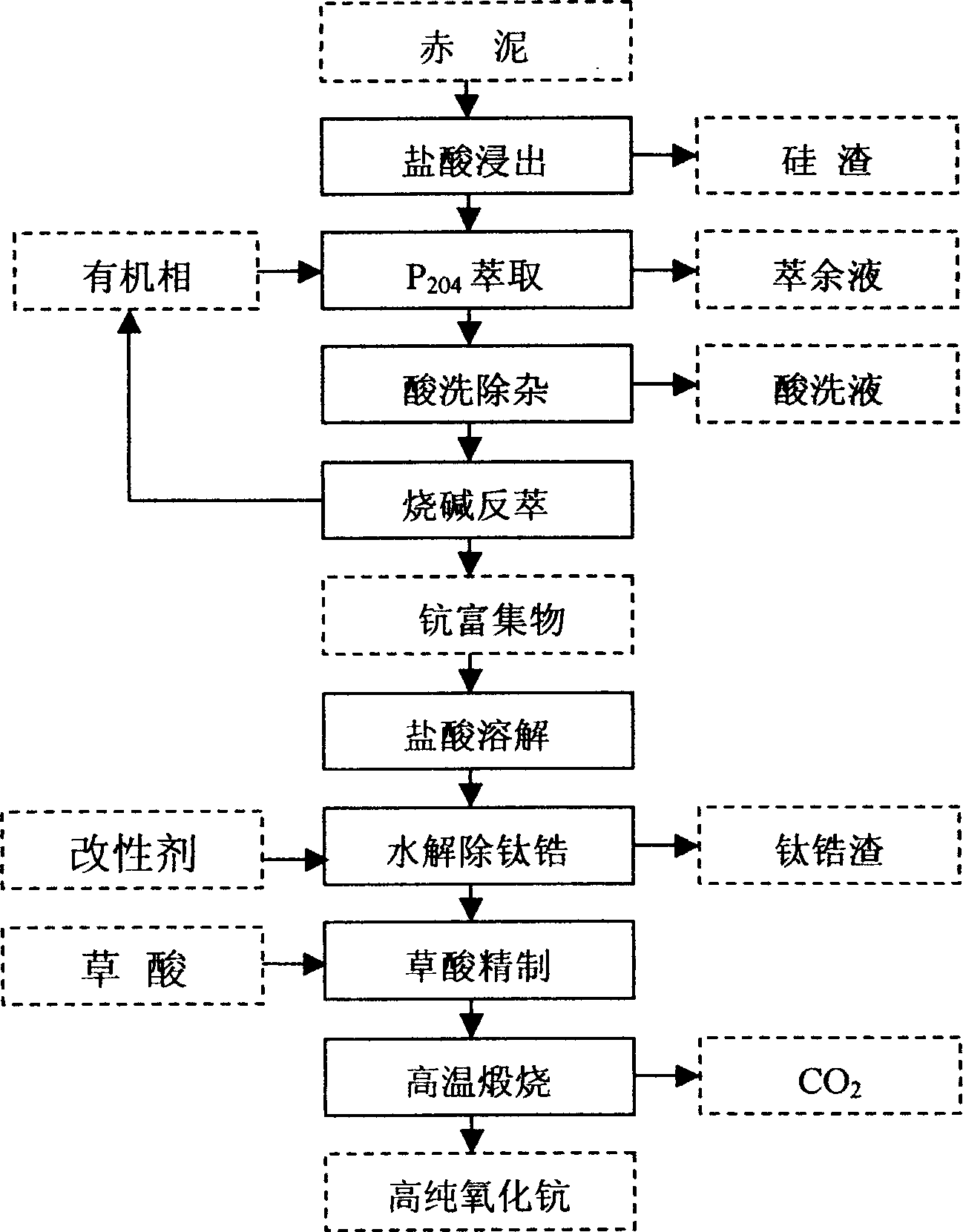

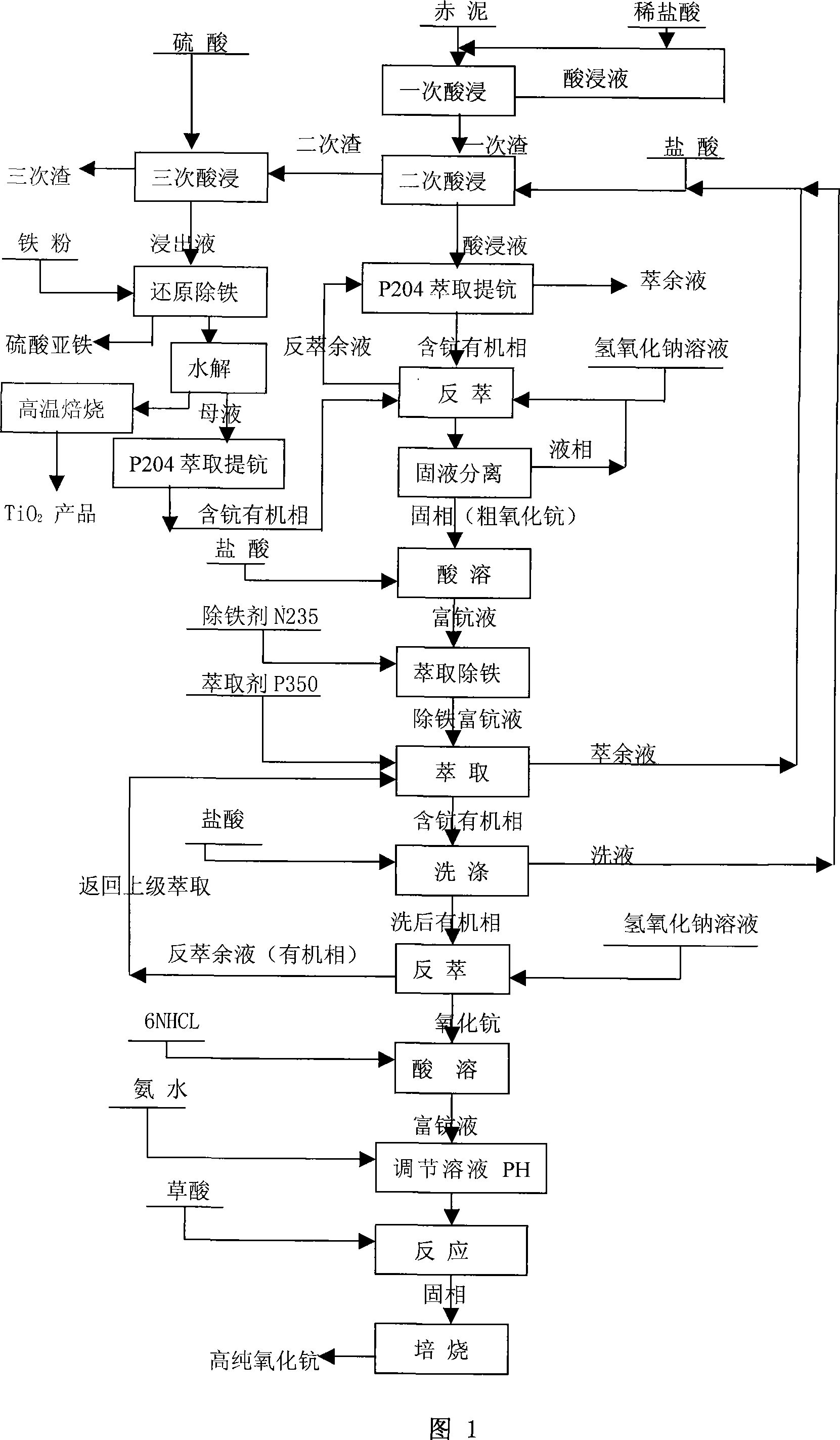

Method for extracting scandium from red mud

InactiveCN1844421AImprove protectionSimple processProcess efficiency improvementRed mudDecomposition

The invention relate to a method of extracting scandium from red mud, the method utilize the red mud that come from the process of producing aluminum oxide from alumyte, in accordance with specific characteristics of red mud, applying hydrochloric acid leach, P204 abstraction, acid-washing edulcoration, sodium-hydroxide back extraction, ammonia modifier hydrolytic decomposition zirconium and titanate in hydrochloric acid solution, oxalic acid precipitating scandium and medium temperature calcining technique, the purity of final production Sc2O3 is 99.9%. Extracting scandium from red mud change refuse into available material, save mineral resources, benefiting environmental conservation. The invention also fills up the study vacant of isolation technique in high-strength zirconium titanate and scandium.

Owner:汪友华

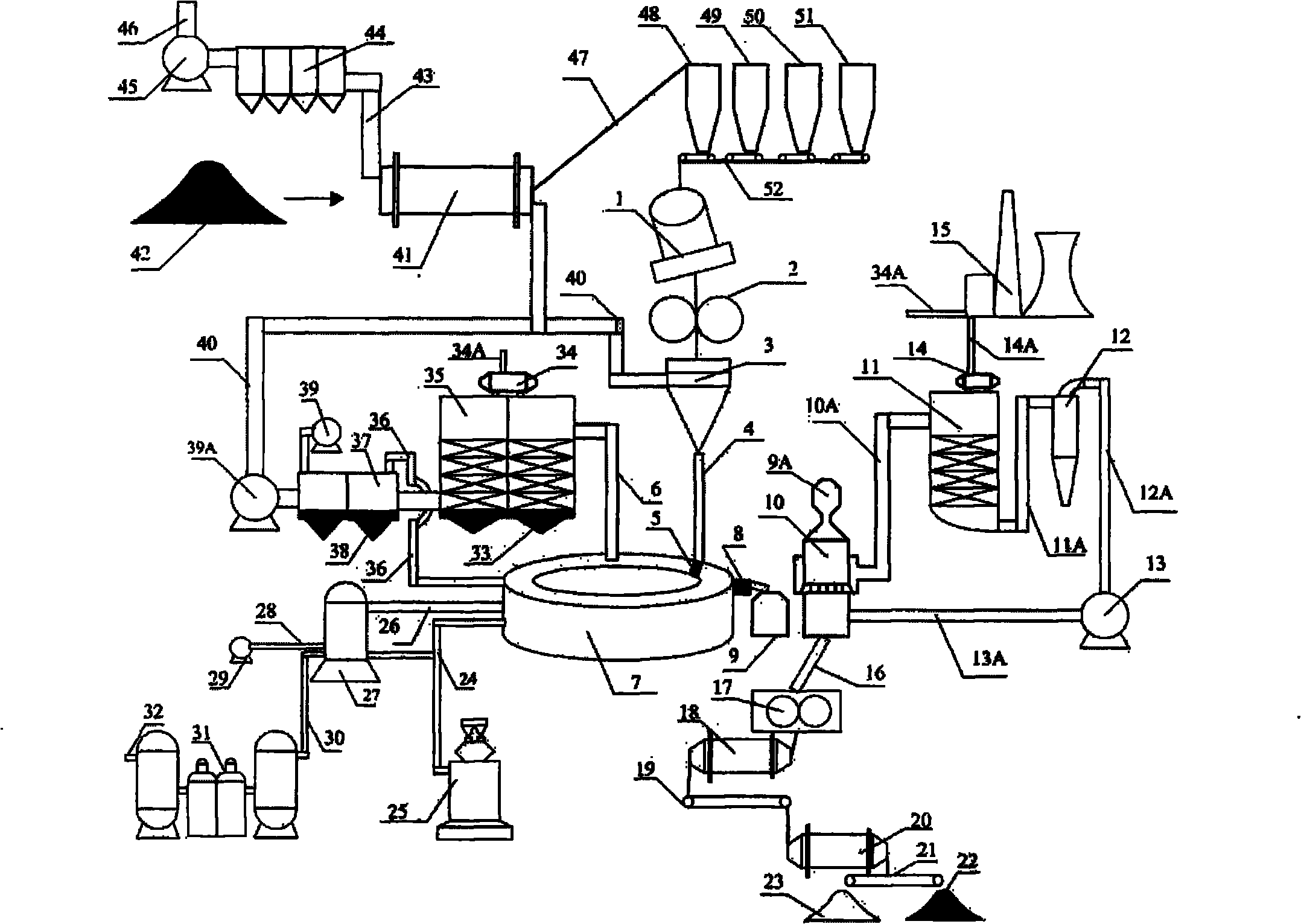

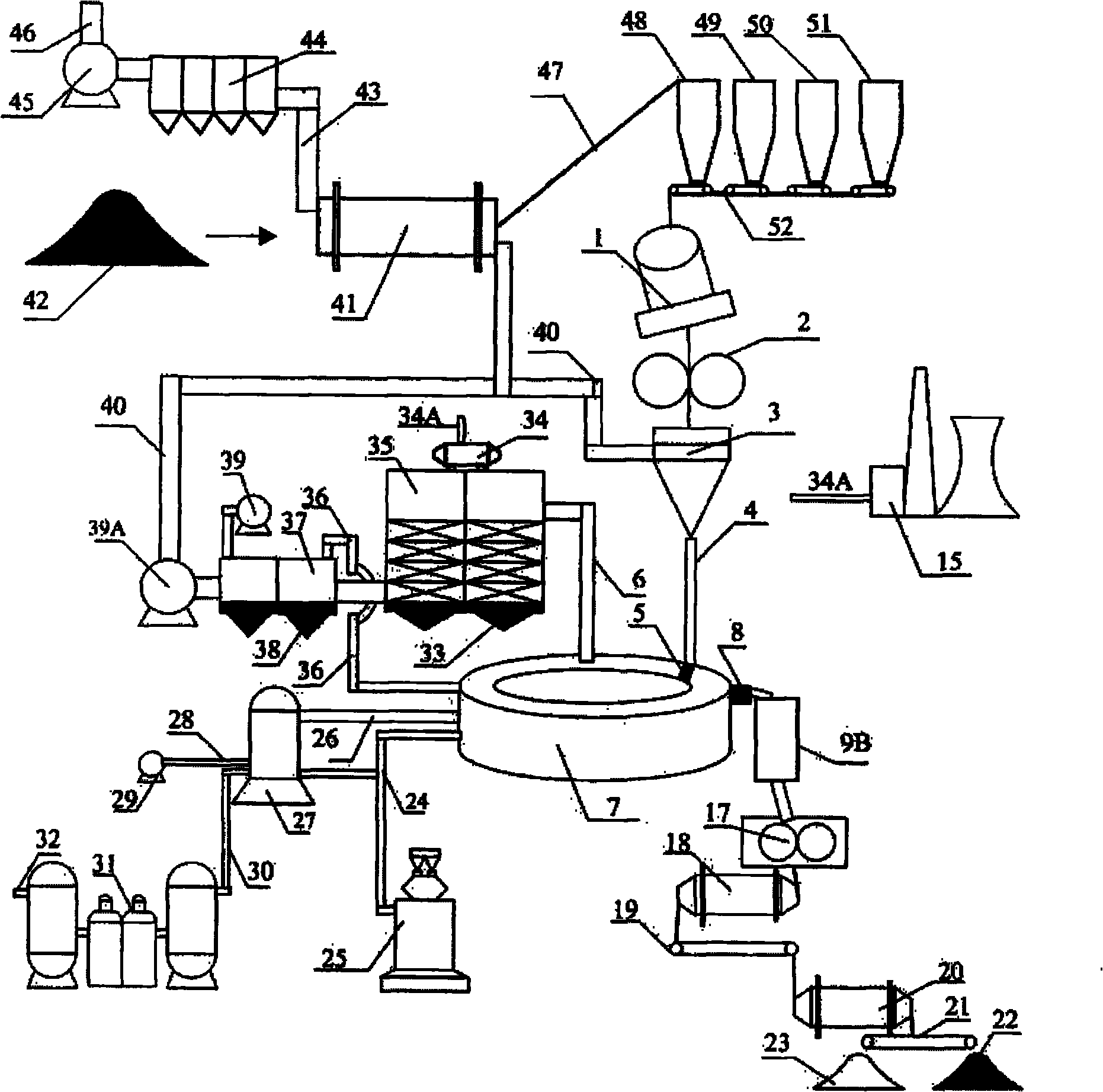

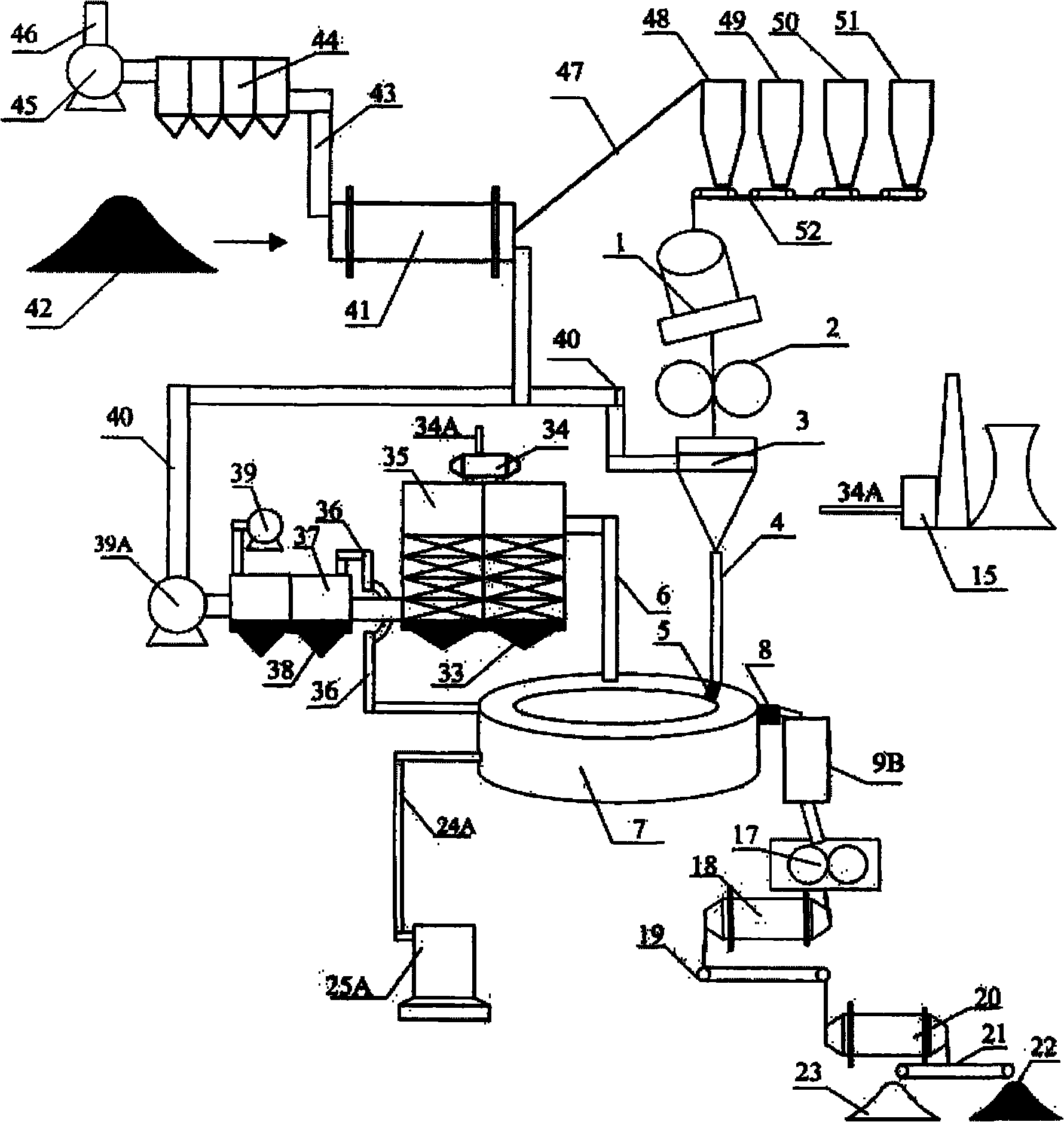

Short-process comprehensive red mud utilization method and equipment

The invention relates to a short-process environmentally-friendly comprehensive red mud utilization method and equipment for comprehensively utilizing energy, which can be used for refining iron in high-pollution red mud difficult to treat, with high efficiency, high quality and high benefits, and applying the iron to electric furnace steel making or steel casting and the like, without using coke, so as to realize the large-scale comprehensive utilization of the red mud. High-temperature smoke of a revolving bed is used for waste heat generation, secondary-combustion hot wind preheating, pellets preheating and red mud drying, a dry quenching pellet technology is used for applying the heat of high-temperature pellets to waste heat generation so that waste heat is fully utilized, a low-cost pressure swing adsorption oxygen generation technology is utilized, and therefore, the comprehensive energy consumption and the production cost are low. Aluminum silica residues are used for producing high-grade cement or used as the raw material for refractory materials; and Na2O and K2O and other alkaline metallic oxide powder are used for refining metal Na and K, or used for producing the raw materials of fertilizers, or used as chemical raw materials. Accordingly, the problems on environmental pollution, land occupation for stacking and safety due to the red mud are thoroughly solved, and the economic and social benefits are obvious.

Owner:董亚飞

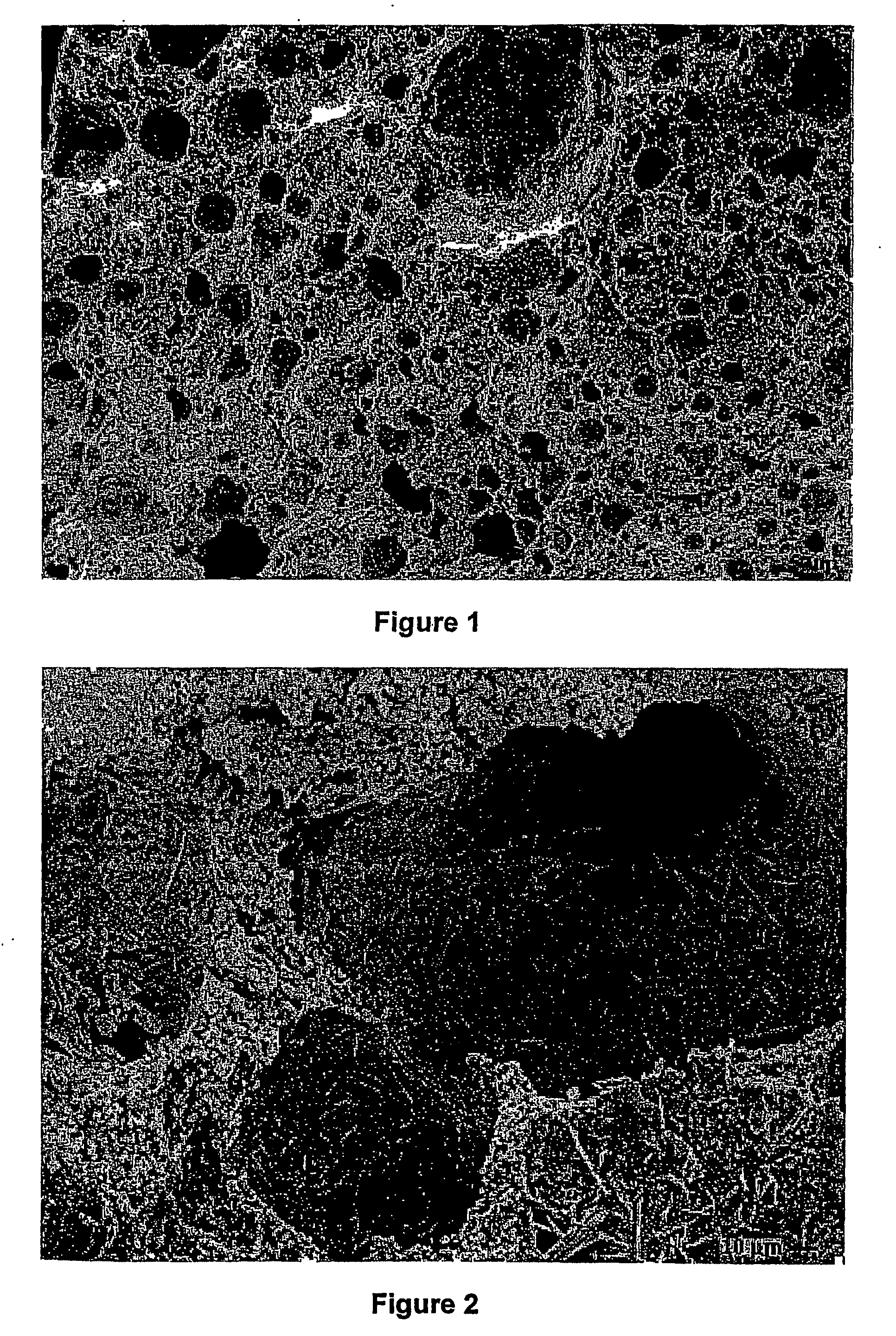

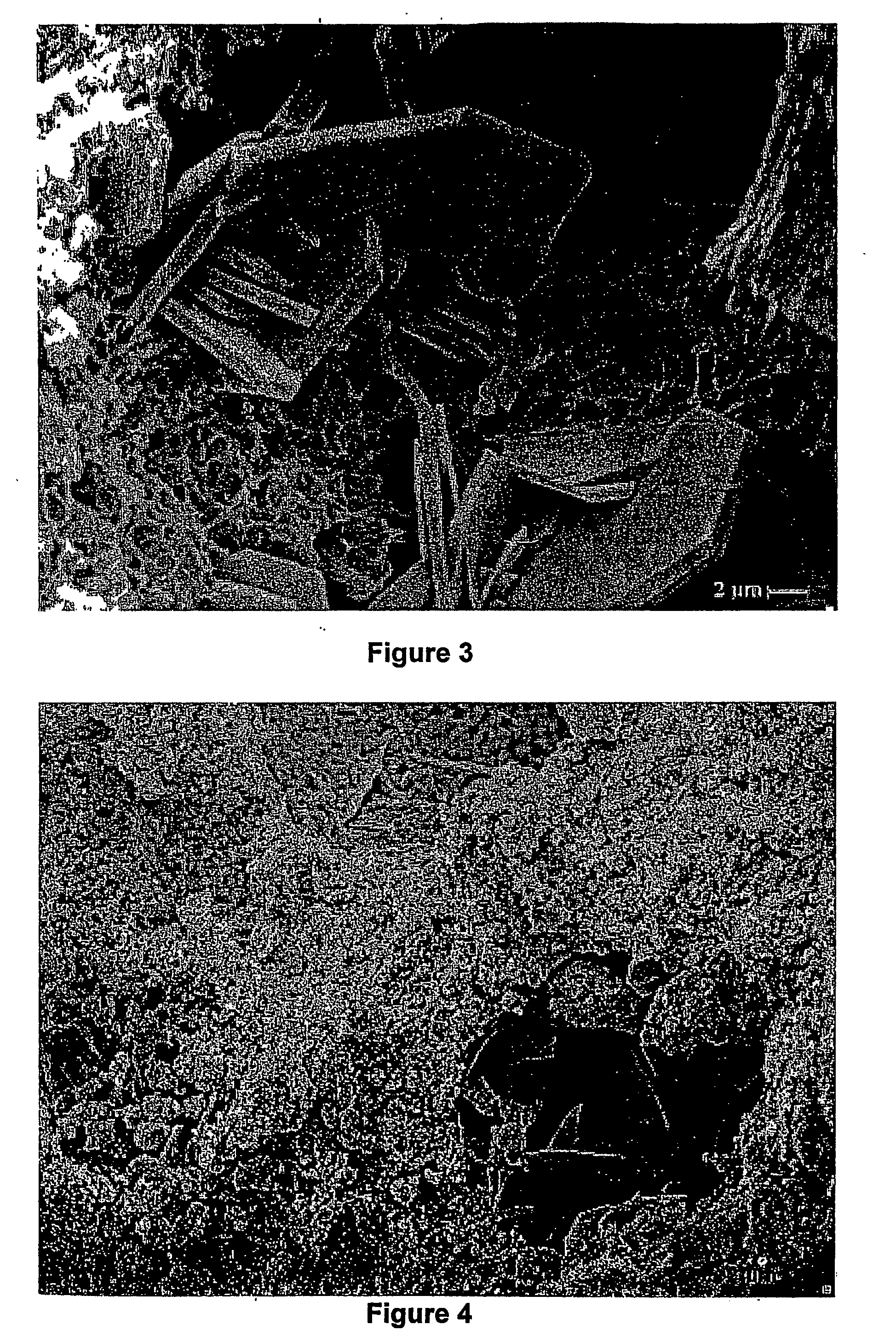

Porous Particulate Material For Fluid Treatment, Cementitious Composition and Method of Manufacture Thereof

InactiveUS20080179253A1Improve machinabilityInhibit initial setting timePhysical/chemical process catalystsOther chemical processesRed mudPorous particle

A porous particulate material for treating a fluid containing a contaminant is disclosed. The particulate material comprises a cementitious matrix or binder and treated bauxite refinery residue or red mud. At least a portion of the pores in the particulate material is open cell or interconnected pores. The invention also relates to the use of a reactive permeable barrier comprising porous material, for treating a contaminated fluid. Also disclosed is a method for producing porous particulate material for treating a contaminated fluid and a method for treating a contaminated fluid, in which the porous material is used. The invention furthermore relates to a cementitious composition comprising partially neutralised red mud and cement, wherein the partially neutralised red mud has been pre-treated by contacting it with water having a total hardness supplied by calcium, magnesium or a combination thereof, of at least 3.5 millimoles per litre calcium carbonate equivalent. The cementitious composition is useful as a building and construction material.

Owner:MT ASPIRING GEOCHEMISTRY CONSULTANTS PTY LTD

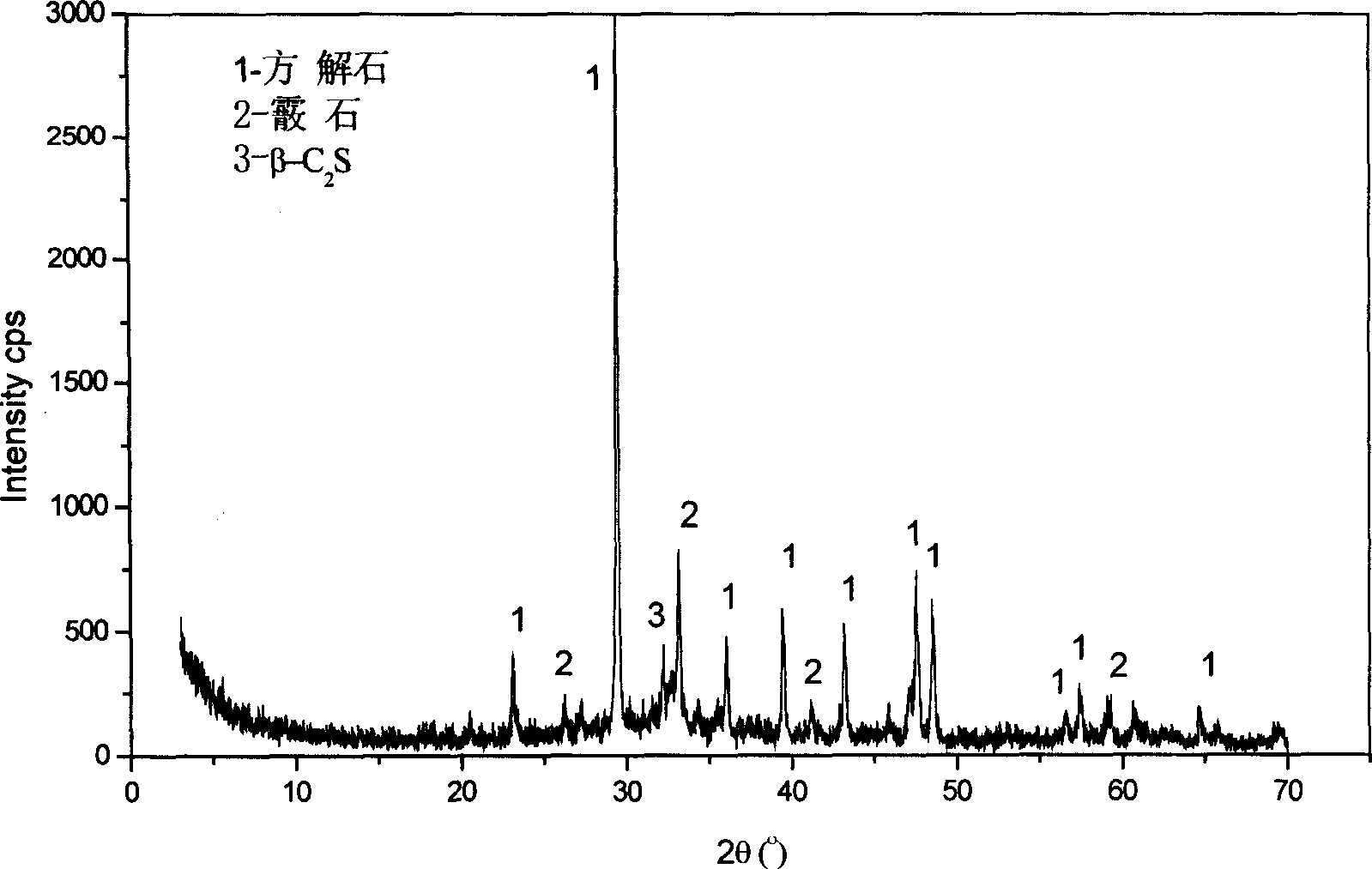

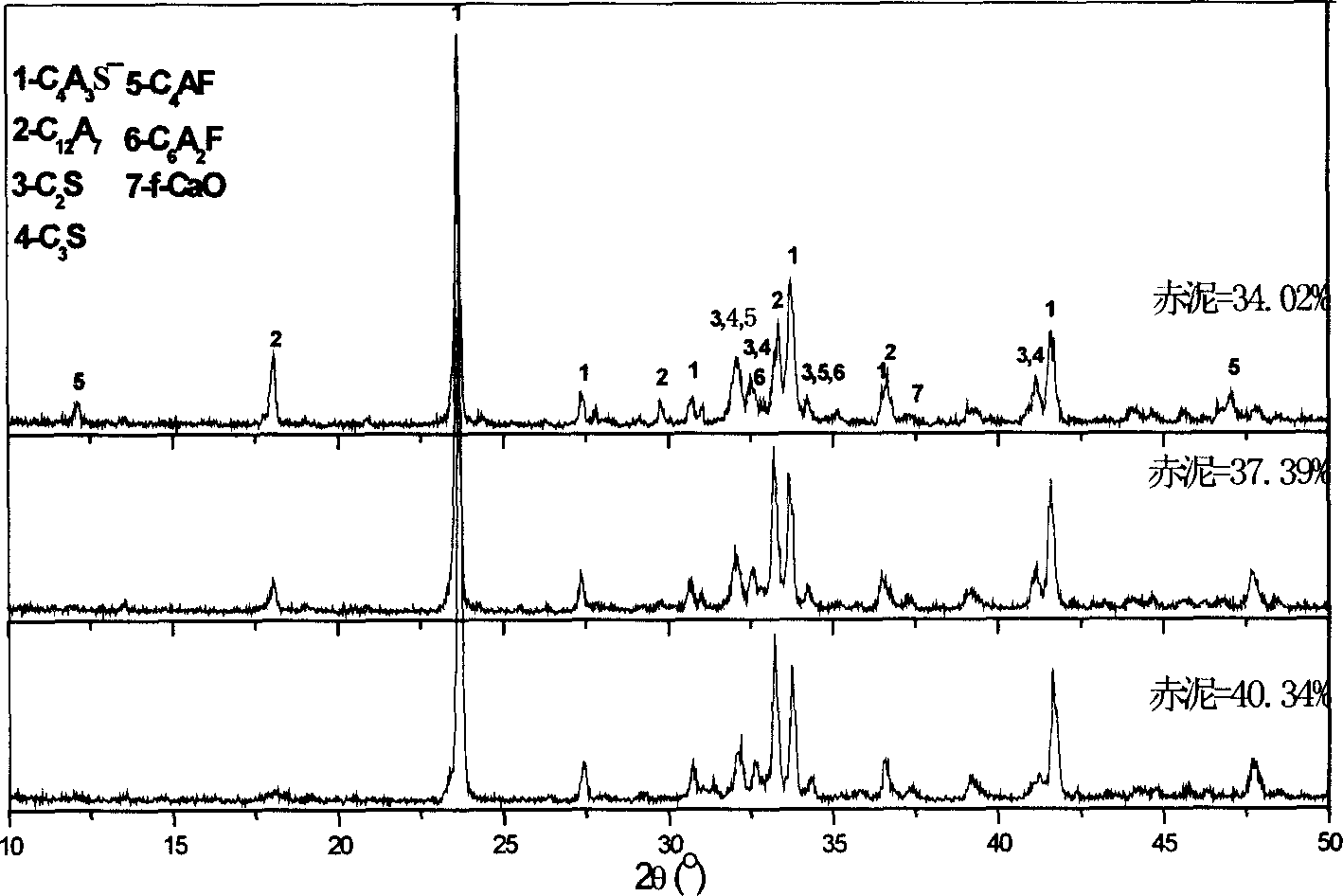

Method for preparing sulphate aluminium cement by red mud

InactiveCN1837121AImprove developmentDevelopmental enhancement and stabilityCinker content reductionCalcium in biologyRed mud

The invention discloses a red mud preparing sulpho-aluminate cement, which is characterized by the following: using 26%-41% red mud to take place of part of aluminium and calcium raw material and whole silica and irony raw material of regular sulpho-aluminate cement production; grinding for certain fineness; desining the C4A3S,C2S,C4AF and main mineral of cement clinker; Preparing sulpho-aluminate cement by alumina, lime carbonate, calcium sulfate and other burdens. The sulpho-aluminate cement has quick induration speed and high early strength.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for extracting metal scandium and titanium from red mud

ActiveCN101182601AReduce processing costsEfficient use ofProcess efficiency improvementRed mudHydrolysate

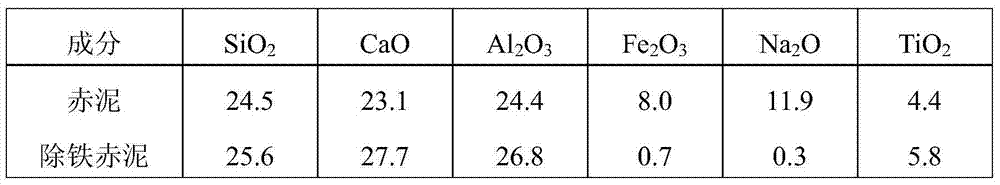

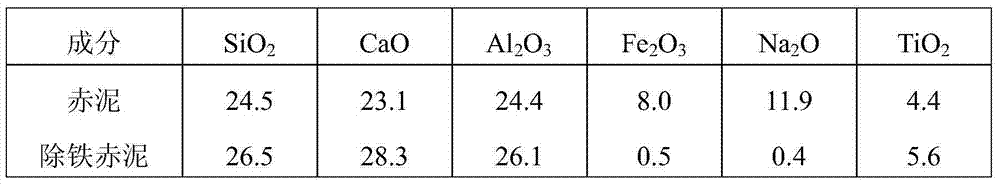

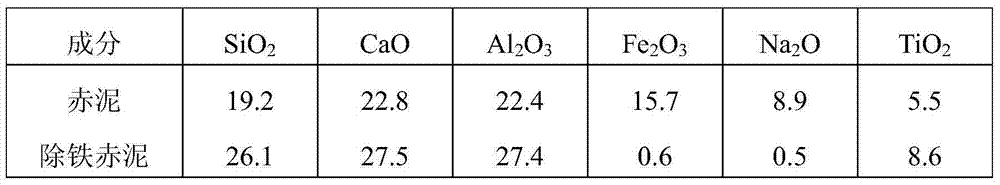

The invention relates to a method for extracting metal scandium and titanium from red mud; the method is used for extracting scandium and titanium from the red mud; the method takes the red mud which is produced through the sinter process of the high-grade ore two portion of clinker in alumina plant as the raw material; the hydrochloric acid with a concentration of 2 percent to 6 percent is used for leaching the calcium and sodium from the red mud to increase the content of the scandium and titanium in the red mud; and then the hydrochloric acid with a concentration of 16 percent to 22 percent is used for a second acid dipping of the red mud and the product of scandium oxide is obtained after the leaching liquid passes the processes of extraction, reverse extraction and baking; the hydrochloric acid with a concentration of 80 percent to 90 percent is used for a third acid dipping of the red mud after the second one and the leaching liquid is added with iron powder for reduction and then the temperature is reduced to crystallize and separate out iron in the pattern of FeSO<4>.7H<2>O; the acid liquid which contains titanium after the iron is removed is added with alkali and heated for hydrolysis; the product of titanium oxide is obtained after the hydrolysate is baked. The method is simple and easy to be carried out and most metal elements in the red mud can be recovered and the cost for processing the red mud is low, all of which are beneficial to the comprehensive utilization of the red mud.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Heavy metal contaminated soil conditioner and plant and chemistry combined remediation method

ActiveCN101724404AImprove stabilityImprove bindingContaminated soil reclamationOrganic fertilisersSoil propertiesSoil remediation

The invention discloses a heavy metal contaminated soil conditioner and a plant and chemistry combined remediation method. The heavy metal contaminated soil conditioner is a mixture of red mud and slaked lime. In the invention, the plant and chemistry combined remediation method is used, the pH of the soil is regulated by a chemical method, and heavy metals in the soil are absorbed by planting energy crops, hyperaccumulative plants and the like, thereby improving the soil properties, gradually reducing the content of heavy metals in the soil, finally achieving the purpose of soil remediation, improving the plant remediation efficiency, and being favorable to large-scale commercial application.

Owner:广东华农大城市规划设计院有限公司

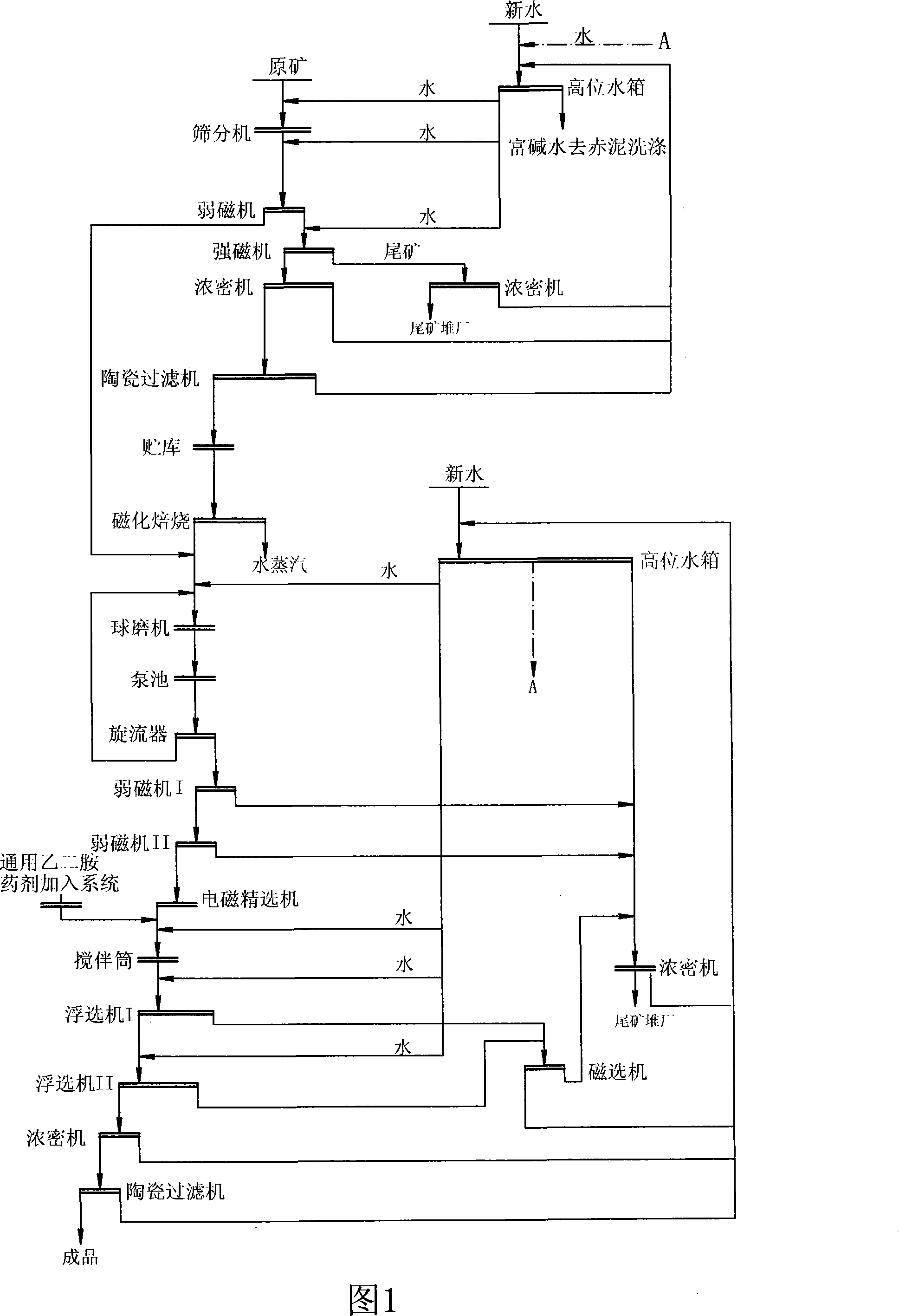

Method of refining iron ore from alkaline red mud and making gangue neutral

The invention relates to a method to select refined iron ore from alkaline red mud and neutralize mine tailings. The method consists of red mud pretreatment and technological process of preparing refined iron ore. The red mud pretreatment is that water is added into the red mud slurry discharged from aluminum factory; the red mud slurry is diluted to the solid concentration of 30 to 40 percent and then is screened and put into a low intensity magnetic separator for selecting ferromagnetic substance. The ferromagnetic substance is dehydrated and directly selected as the product. The remaining red mud is watered down to 30 percent solid concentration and put into a high intensity magnetic separator for magnetic separation and desliming. The obtained coarse ore is washed to a coarse ore settling tank or a thickener to be concentrated while the undercurrent is sent into a vacuum ceramic filter and a filter cake is roasted in a suspended magnetic roasting furnace. The roasted materials are crushed into a ball mill and then are milled. The water is overflown until 95 percent of the solid material granularities are less than 75m and then is treated by the third stage magnetic separation and the second flotation. The undercurrent is filtered by the ceramic filter, and then the refined iron ore with a purity of 58 to 65 percent is obtained. The refined iron ore is recycled from the red mud by the invention so as to fully employ aluminum ore, save resources and energy consumption and neutralize the whole red mud. The invention reduces environmental pollution and has good economic and social benefits.

Owner:SHENYANG XINBO IND TECH

Method for preparing acid-resistant pressing crack supporting agent from red mud

The invention discloses a method for preparing acid- proof fracturing propping agent with red mud. The comprised raw materials and their weight proportion are as follows: red mud 20- 60%, aluminium-containing substance 20- 60%, barium- containing substance 5- 35%, plasticizing agent 5- 15%. The method comprises following steps: (1) putting red mud and aluminium- containing substance into ball grinding tank for grinding respectively; (2) adding barium- containing substance and plasticizing agent into material got in steps (1), feeding it into ball grinding tank for grinding; (3) preparing material got in step (2) into semi- product particle; (4) calcinating material got in step (3) for 1- 3 hours, getting acid- proof crack propping product. The invention develops new way for red mud application, and provides effective method for increasing acid- proof performance for crack propping agent.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Novel red-mud-based grouting material and preparation method thereof

InactiveCN103896503ALow grade requirementsHigh strengthClinker productionRed mudUltimate tensile strength

The invention discloses a novel red-mud-based grouting material and a preparation method thereof. The grouting material comprises the following components in percentage by weight: 70-80% of red mud, 20-30% of a mineral admixture, and an additionally-admixed composite alkali activator of which the modulus is 1.2-1.6, and the appropriate admixing amount is 8-12%. The novel red-mud-based grouting material prepared by using the red mud and the mineral admixture has good liquidity and relatively high early strength, can be used for reducing the influence on the environment by reasonably adopting industrial waste residues, and is simple in ingredients and low in manufacturing cost.

Owner:焦作丁豪科技股份有限公司

Burning-free geology polymer material of red mud coal ash and preparation method thereof

InactiveCN101708983AGood strength performanceHigh strengthSolid waste managementCeramic shaping apparatusRed mudCrushed stone

The invention relates to a burning-free geology polymer material of red mud coal ash and a preparation method thereof, belonging to the technical field of recycling inorganic nonmetal material and industrial solid waste. Kawazu mud powder and coal ash are taken as main substrate raw materials, building fine sands and building crushed stones are taken as aggregate, solid water glass powder is taken as alkali activator to prepare the burning-free geology polymer material of red mud coal ash. The raw materials comprise the following components based on parts by weight percent: 5-98% of the kawazu mud powder, 1-65% of the coal ash, 1-96% of the building fine sands and the building crushed stones, and 1-20% of the solid water glass powder. Counting the red mud+the coal ash+the building fine sands and the building crushed stones as 100%, the raw materials further comprise the following components based on parts by weight percent: 5-45% of water and 0.1-10% of calcium lignosulphonate. The preparation method comprises the steps of: dosing, mixing, aging, shaping, maintaining and drying, etc. The invention has the advantages of the high use ratio of industrial solid waste, the less pollution, the low energy composition and the simple operation of the preparation technology, and embodies the important meanings of environment protection, energy conservation and emission reduction.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

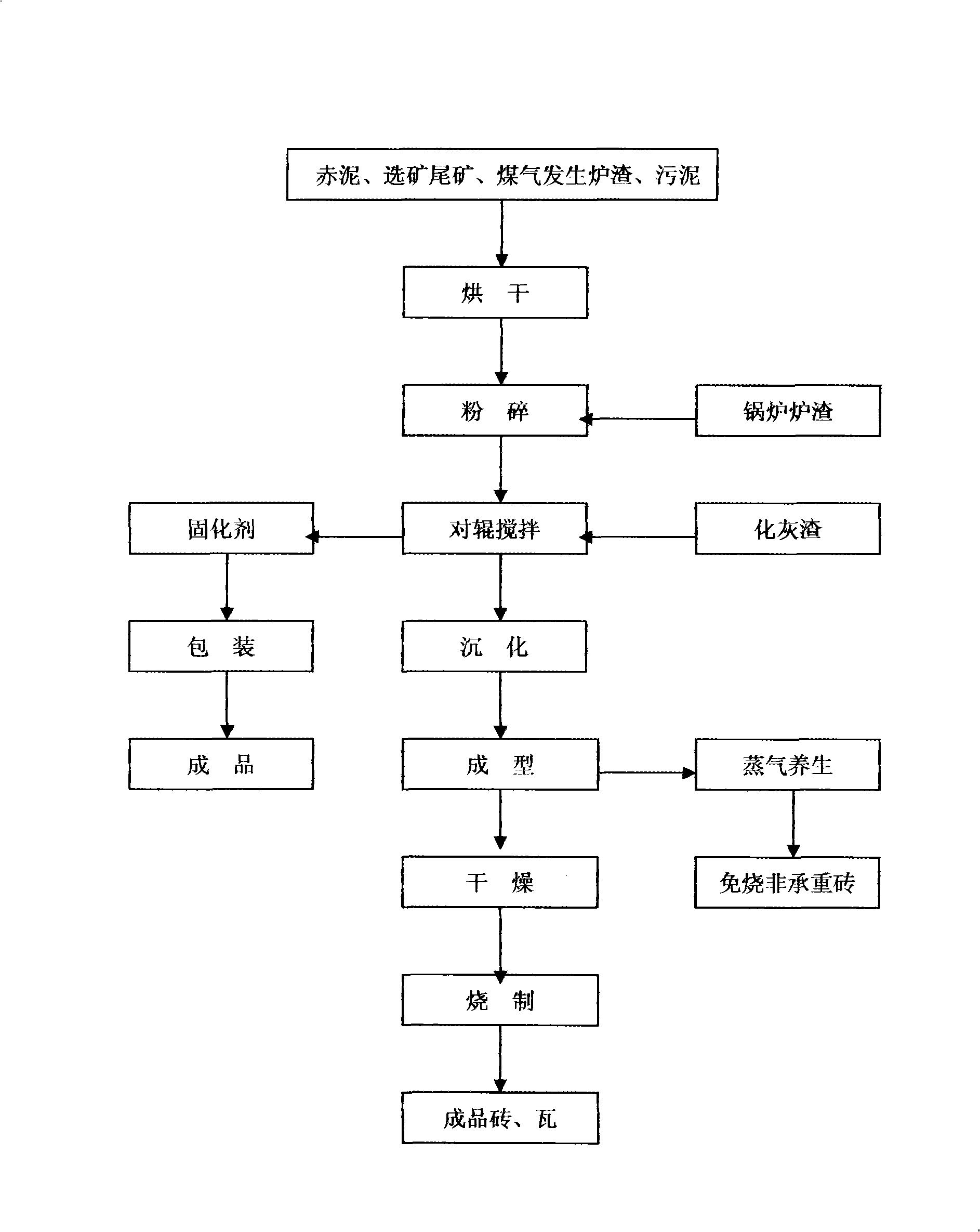

Process and method for converting waste slag wholly of aluminum industry into ecological building material

The invention belongs to a method for utilizing resources. The method utilizes the matter characteristics of solid wastes (six kinds of waste residues) such as red mud(the sintered method and the Bayer method), boiler slag, ore dressing tailings, ash and gas generation slag, which are generated during the manufacturing process in aluminum industry, and converts the solid wastes into a novel road material and construction walling material by the processes such as drying, crushing, reasonable proportioning, machine shaping(grinding and extrusion) and consolidation or sintering. The method is characterized in that the utilization ratio of the waste residues is 100 percent. The waste residues comprise the following compositions: (1) the produced road material-curing agent, which can be used to reinforce a highway subgrade and bases of road surface substrates(substrate and subbase) and buildings and completely replace cement, lime and sandstone materials, and the road material can meet prior national(industrial) standards and environmental protection standards in performance; and (2) the produced construction walling materials-non supporting brick, supporting brick, air brick, hollow building block, common tile, glazed roof tile and andorful tile, which are superior to the prior national standards in performance. The material obtained by the invention has the characteristics of energy conservation, thermal insulation, high strength, corrosion resistance, efflorescence resistance and no pollution.

Owner:王文举

Method for high-efficiency separation and comprehensive utilization of iron, aluminum and sodium in high-iron red mud

ActiveCN102851425AWon't breakReasonable useCombustible gas chemical modificationProcess efficiency improvementRed mudSlag

The invention provides a method for high-efficiency separation and comprehensive utilization of iron, aluminum and sodium in high-iron red mud. The method comprises the following steps of adding iron ore concentrate and coke powder into high-iron red mud as a raw material, pressing the mixture into red mud pellets, drying, pre-heating, directly reducing metallic oxides of iron and sodium by a rotary hearth furnace, feeding the reduced metalized pellets into an iron bath-type oxy-coal smelting reduction furnace, carrying out high-temperature melting separation, using separated iron for steel-making, recovering alumina from the modified high-aluminum slag, recovering the metallic oxide of sodium from smoke dust carried by exhaust gas, improving quality of mixed gas produced by the iron bath-type oxy-coal smelting reduction furnace, and feeding back the treated mixed gas to the rotary hearth furnace for use. The method provided by the invention can effectively realize high efficiency recovery and large-scale industrial comprehensive utilization of a red mud resource.

Owner:NORTHEASTERN UNIV

Anti-crack alkalis excited ecological cement

The invention relates to anti-cracking alkali exciting ecological cement, which consists of A, B and C, and solid-phase mass ratio of the A to the B to the C is 5-10:75-90:5-15. The A is exciting agent, which comprises the following components by mass percentage: more than or equal to 80 percent of water glass of which modulus is 0.7 to 1.4, and less than or equal to 20 percent of one or a plurality of sodium sulfate, sodium phosphate, sodium carbonate, sodium chloride and magnesium chloride; and the A is prepared into solution containing more than or equal to 40 percent of solid for use. The B is a mineral additive, which comprises the following components by mass percentage: 30 to 70 percent of slag powder, and 30 to 70 percent of other additives, wherein the other additives comprise one or a plurality of siliceous dust, coal ash, metakaolin, red mud, burnt shale, colliery waste, steel slag and alloy slag, and is grinded to powder of which specific surface is 350 to 800m<2> / g. The C is active magnesium oxide, wherein mass content of MgO is more than or equal to 70 percent. The active magnesium oxide is calcined at a temperature of between 700 and 1,000 DEG C and then mixed and grinded with the B to become powder. The cement is the low-carbon discharge ecological cement with the advantages of high-early strength, durability, permeability resistance, corrosion resistance, freezing and thawing resistance, low heat of hydration, good cracking resistance, economy and environmental protection, and is used for civil construction, water conservancy, national defense, and oil well and mine passage support engineering.

Owner:WUHAN UNIV OF TECH

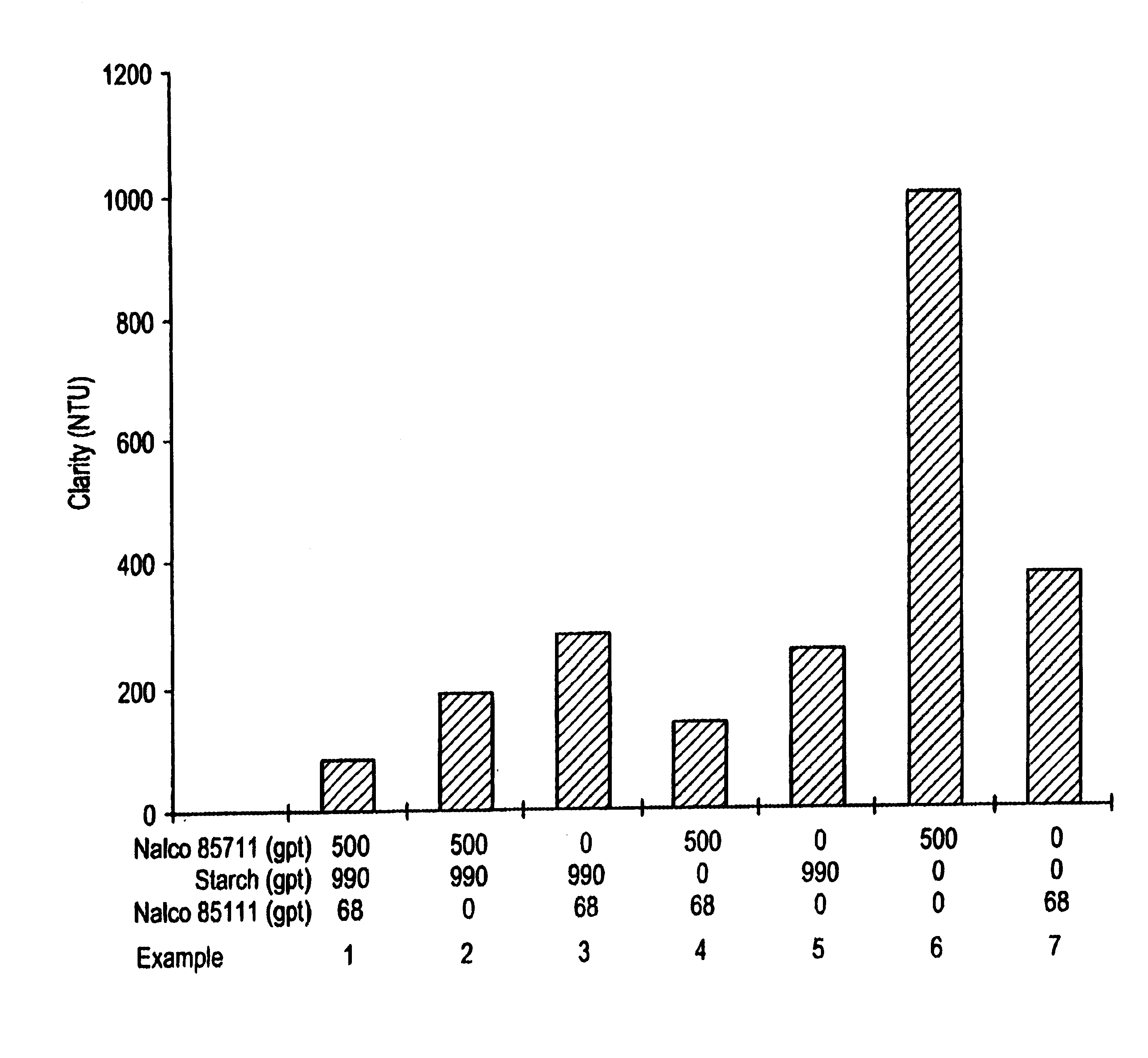

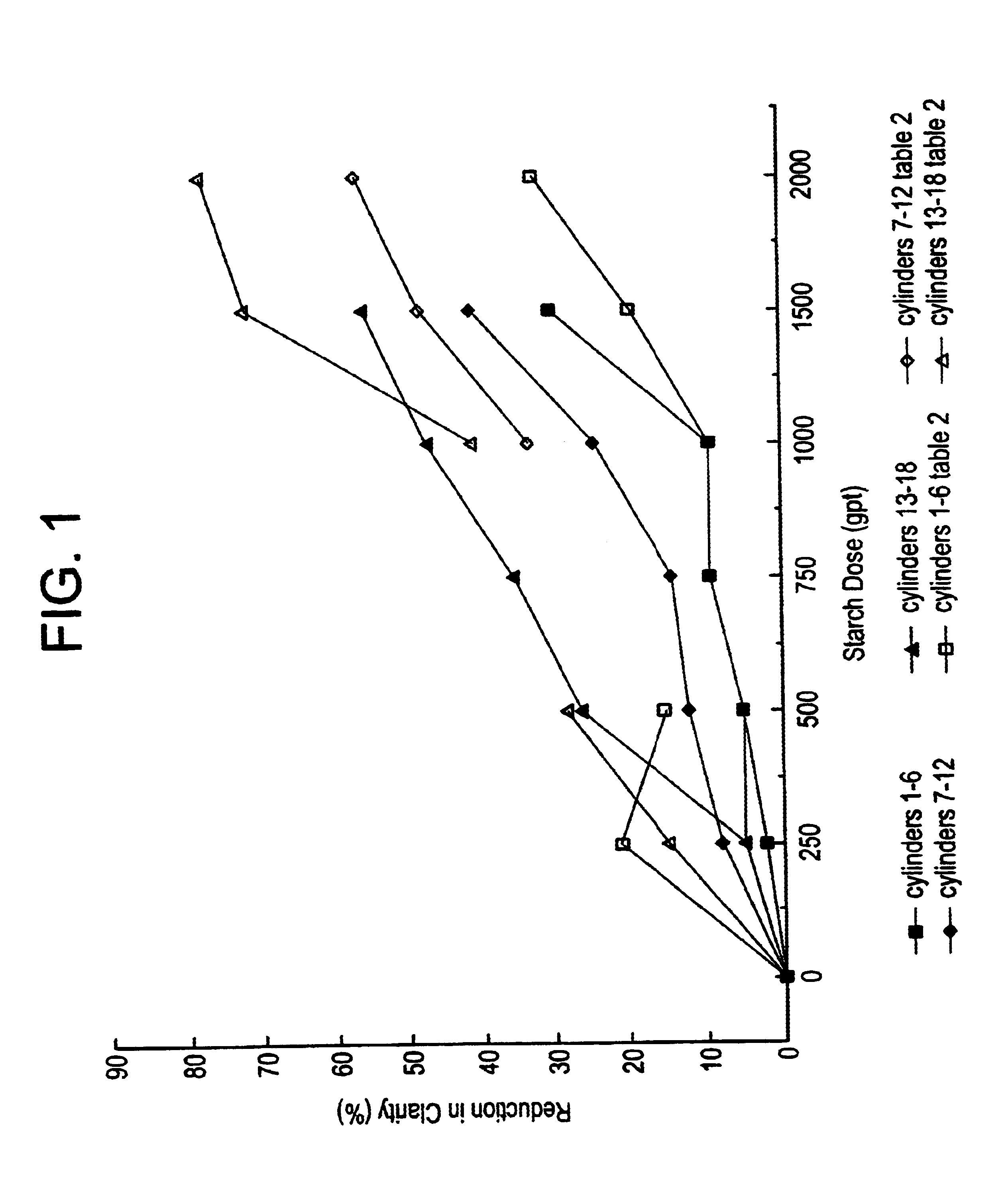

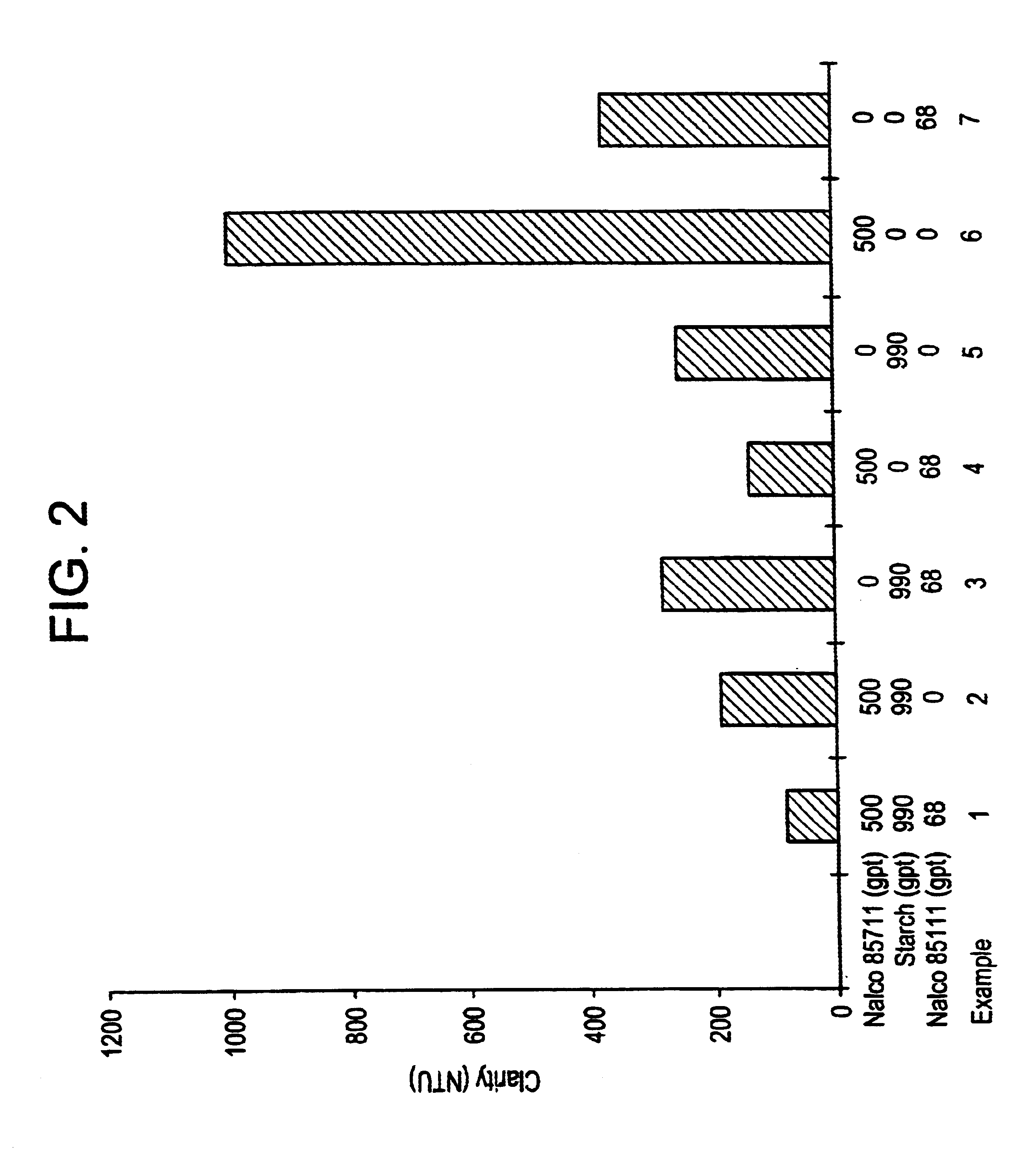

Dextran starch and flocculant combination for improving red mud clarification

InactiveUS6726845B1Easy to separateGallium/indium/thallium compoundsCentrifugal force sediment separationFiltrationCentrifugation

The claimed invention is a method for separating Bayer process red mud from a Bayer process liquor which comprises adding to a Bayer process liquor containing red mud an effective amount of a water soluble synthetic flocculant, dextran and starch combination. The flocculant is added anywhere in the slurry containing the red mud suspended in Bayer process liquor, or in a liquor slurry containing bauxite prior to or during digestion. Once the flocculant combination is added, it is mixed sequentially with the Bayer process liquor and the red mud contained in the Bayer process liquor is removed by sedimentation, centrifugation or filtration.

Owner:ECOLAB USA INC

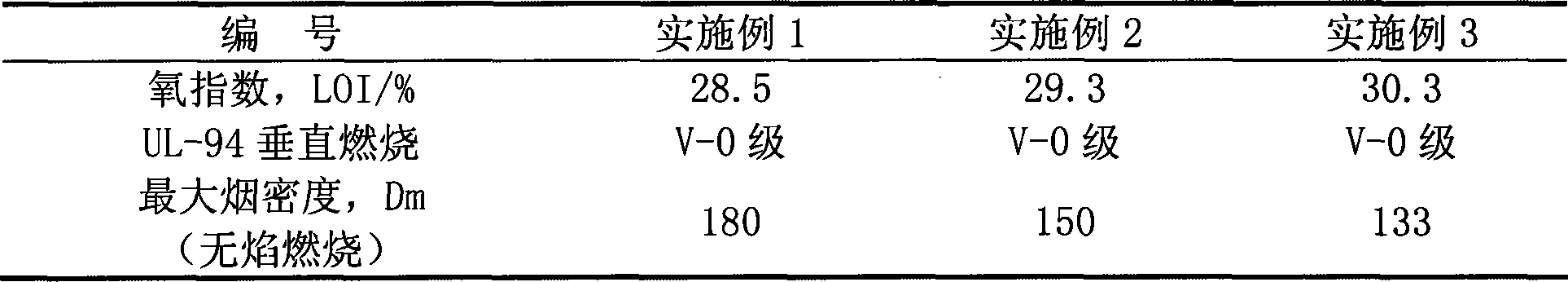

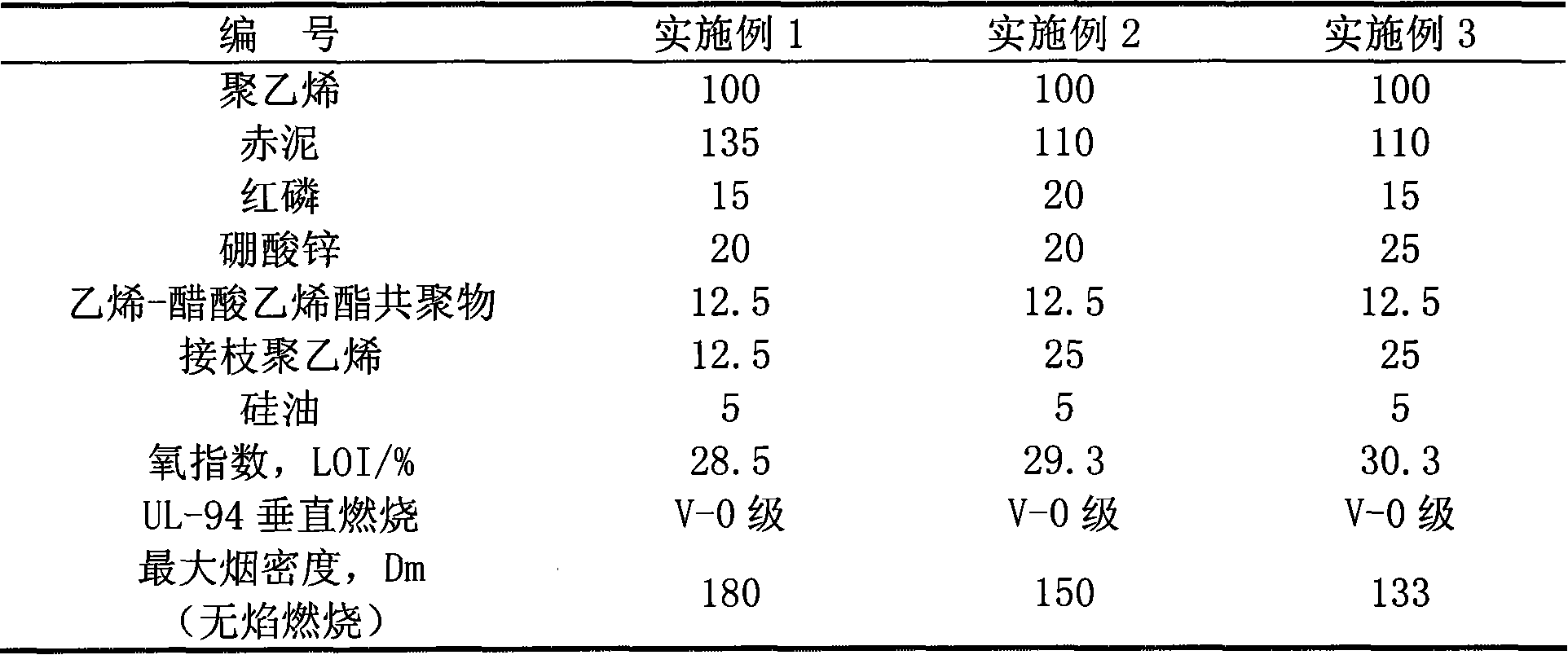

Environmental protection based red mud combination modification synergism fire-retardant polyethylene

InactiveCN101624457AIncrease added valueMeet environmental protection requirementsRed mudCarvacryl acetate

The invention relates to an environmental protection based red mud combination modification synergism fire-retardant polyethylene, and belongs to the technical field of compressive utilization and fire-retardant plastics. The fire-retardant polyethylene is suitable for fire safety protection in important public places in the fields of electric products, building materials and transportation. The fire-retardant polyethylene consists of the following components in percentage by weight: 30 to 35 percent of polyethylene, 34 to 39 percent of red mud, 6 to 13 percent of red phosphorus, 5 to 17 percent of zinc borate, 3 to 8 percent of ethylene-vinyl acetate copolymer, 2 to 7 percent of grafted polyethylene, and 2 to 8 percent of silicone oil. The preparation process comprises the following steps of: grinding and drying the red mud; blending the ground red mud with other raw materials according to the blending ratio; mixing the mixture with polyethylene resin by fully stirring at a high speed; fusing, co-mixing and processing the mixture; and preparing a sample. The processing conditions comprise that: the roll temperature of a double-roller mixing mill is between 140 and 150 DEG C; and the forming temperature of the flat vulcanizing machine sample is between 120 and 130 DEG C, the heating time is between 4 and 8 minutes, and the pressure is between 10 and 20MPa. The fire-retardant system meets the requirements of industrial application on mechanical property, and simultaneously has comprehensive properties such as good fire-retardant effect, low cost, environmental protection and the like; moreover, the application field of the red mud is widened, and the red mud product with high added value is prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Acidified zeolite

The invention discloses an acidified zeolite. The technical scheme is as follows: the acidified zeolite is composed of zeolite, attapulgite clay, magnesia, hydrochloric acid, instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate. The acidified zeolite materials are input into a mill and milled, and the milled powder is the acidified zeolite. The production method of acidified red mud adopts acidification before composite proportioning, thereby avoiding the chemical reaction between the sulfuric acid and the instant sodium silicate, polyvinyl alcohol, hydroxypropyl methylcellulose and sodium carbonate; and the acidified zeolite can effectively remove ammonia, iron, fluorine, phosphides and micro pollutants in domestic sewage, and can be used for removing or recovering heavy metal ions and treating radioactive waste. The acidified rear has the characteristics of favorable thixotropy, favorable heat stability, favorable plasticity and favorable binding property, and is suitable for producing drying agents, adsorptive separation agents, molecular sieves, catalysts, defluorination soil improvers, deodorizers and firefighting products.

Owner:江苏世澳非金属应用科技有限公司

Grouting material employing red mud as raw material

The invention discloses a grouting material employing red mud as a raw material. The grouting material used in grouting engineering is a cement-based material, and the cement-based material is poor in stability, low in stone effect and low in binding power. The red mud is an industrial solid waste discharged from aluminum-making industry, so that the utilization rate is low, and the environment is polluted. The grouting material employing the red mud as the raw material comprises the following main components in parts by weight: 50-65 parts of red mud, 4-8 parts of an excitant, 20-40 parts of an active initiator, 1-5 parts of silica fume, 0.5-1 part of a retarder, 0.5-1 part of a surfactant and 0.5-1 part of a water-retaining agent. The grouting material has the advantages of good liquidity, high consolidation strength and wide grouting range, and the slurry is high in binding force with cement concrete and soil in the solidification process. The strength, stone rate and liquidity of the grouting material are improved; the liquidity of the prepared slurry is greater than 15s; the liquidity is still greater than 15s after the slurry is placed for 30 minutes; the stone rate is 99%; the 3d compressive strength is 3.2MPa; and the 28d compressive strength is greater than 12MPa.

Owner:广西启利新材料科技股份有限公司

Method for preparing magnetic sludge-based biochar material from sludge and application of magnetic sludge-based biochar material

ActiveCN112354516AEasy to separateLarge specific surface areaOther chemical processesSludge treatment by pyrolysisSludgeRed mud

The invention discloses a method for preparing a magnetic sludge-based biochar material from sludge and the application of the magnetic sludge-based biochar material, and belongs to the technical field of sludge resource utilization. The invention aims to fully utilize municipal and industrial wastes such as sewage sludge, hematite, rust, Bayer process red mud, high-iron-content fly ash, picklingwastewater and the like, and prepare magnetic sludge-based biochar from a solid waste iron source: dried sludge with the water content of less than 15% and a solid iron source are mechanically crushedand uniformly mixed; continuous pyrolysis is carried out, the pyrolysis temperature is 400-800 DEG C, the solid material stays in the device for 20-120 min, and fine ball milling and smashing are carried out until the particle size is 100 [mu] m or below; in the nano Fe3O4 / magnetic sludge-based biochar core-shell material prepared by the method, both the material core and the shell have magnetism, so that efficient recycling can be realized.

Owner:SHANGHAI FUTING TECH CO LTD

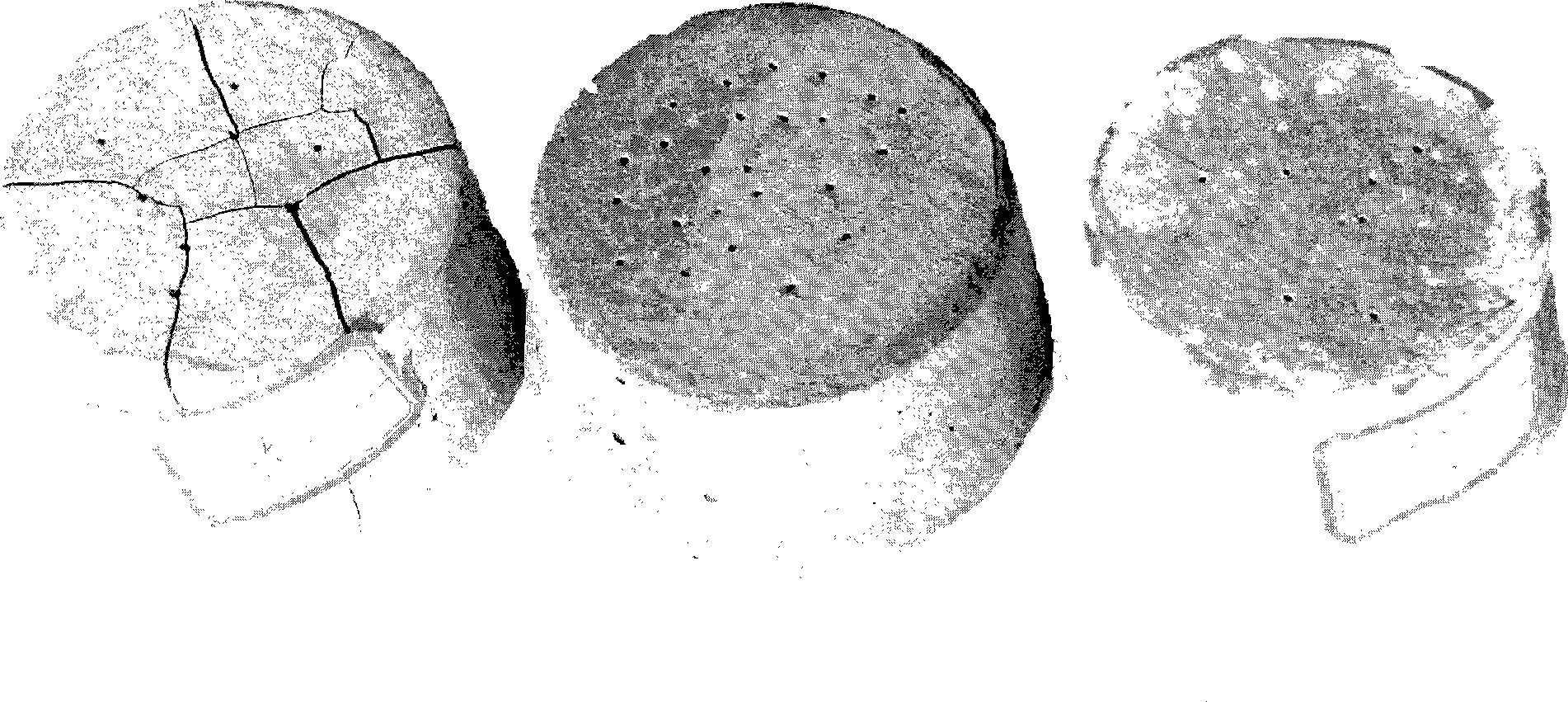

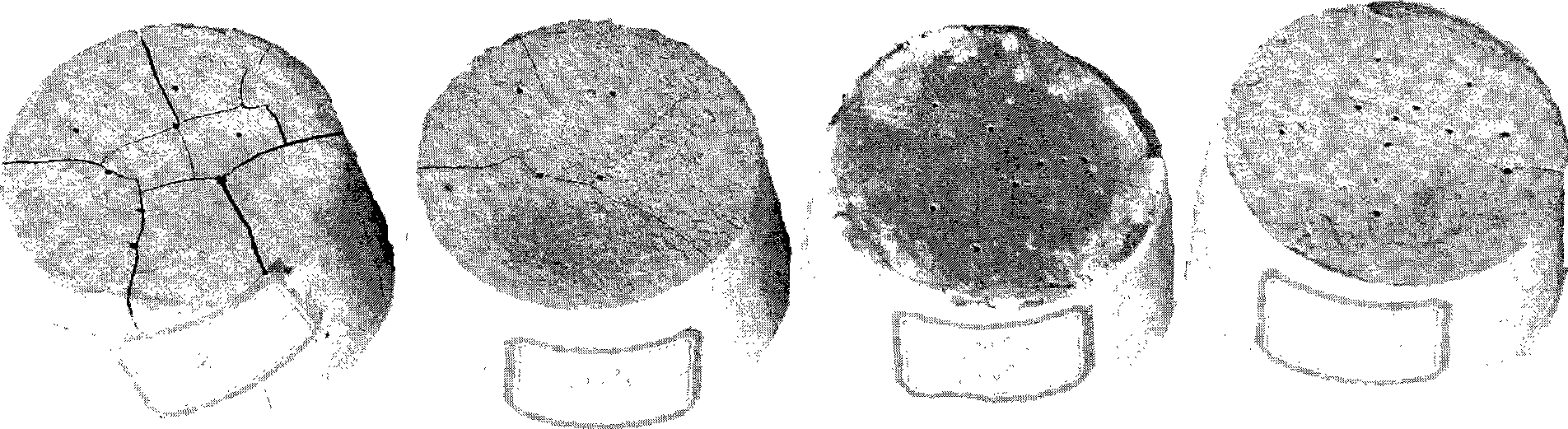

Method for producing high-performance haydite from red mud

The invention discloses a method for producing high-performance haydite from red mud, which comprises the following steps: taking 40-70 parts by weight of Bayer-process red mud, 0-30 parts by weight of sintering-process red mud, 5-20 parts by weight of fly ash and 5-30 parts by weight of clay material on dry basis as raw materials; evenly mixing the raw materials with 5-20 parts by weight of water, and putting the mixture on a pelletization plate to carry out pelletization, thereby obtaining the haydite fresh pellets; sintering the haydite fresh pellets, of which the diameters are 0.5-20mm, in a rotary kiln or sintering machine at 1050-1200 DEG C for 15-60 minutes; and quenching the sintered haydite to obtain the high-performance haydite product, of which the density level is 600-900, the water absorptivity is lower than 12%, the cylindrical compressive strength is higher than 7.5MPa and the strength grade is higher than 50MPa. The invention can effectively and massively utilize red mud as the raw material to produce the high-performance haydite, has the advantages of simple manufacturing technique and high product quality, and changes wastes into valuable substances.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

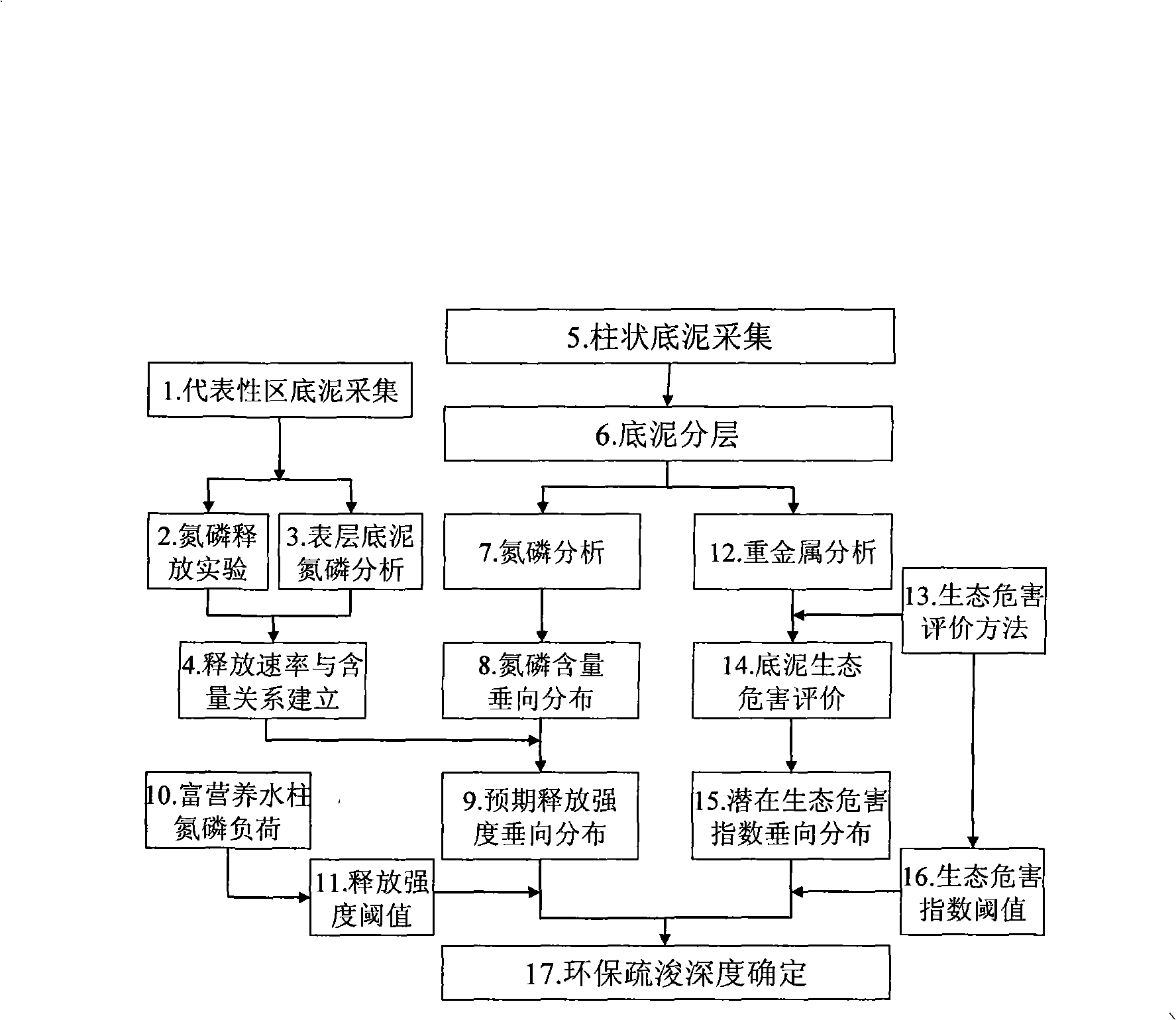

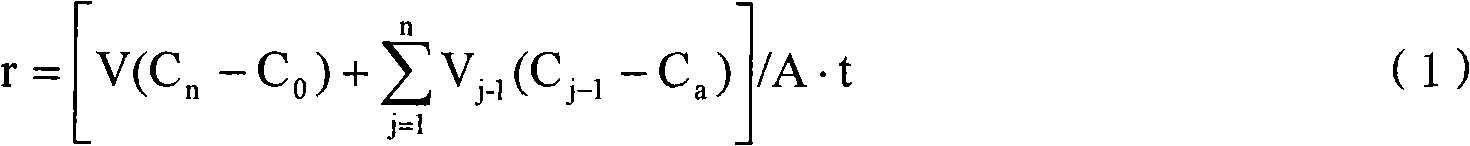

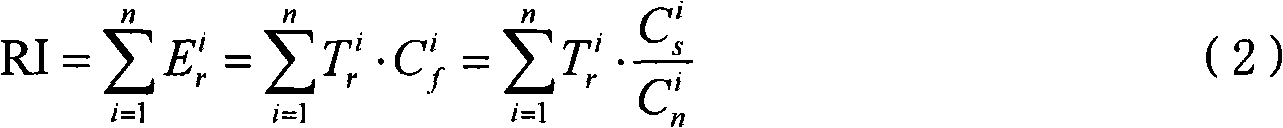

Polluted water body deposit environment-friendly dredging depth determination method

InactiveCN101266235APollution suppressionReduce ecological riskMaterial analysisSurface layerRed mud

The invention provides a determining method for polluted water bed mud environmental protection dredging depth, comprising analyzing and evaluating the releasing risk and ecological hazard risk of the pollutant at different layer side of the mud based on the vertical distribution of the pollutant in the bed mud by researching the relation of the releasing of bed mud pollutant nitrogen, phosphor or the like and the corresponding pollutant content and the ecological hazard evaluation corresponding with the content of the bed mud pollutant containing heavy metal; and determining the bed mud dredging depth based on the divided corresponding risk grade. After dredging, the anticipated release rate of the key pollutant such as nitrogen, phosphor at the new surface layer of bed mud-hydrosphere achieves or exceeds a release intensity threshold and the latent ecological hazard index of the heavy metal at the new surface layer of bed mud achieves or exceeds a hazard threshold, therefore the basis of the dredging depth is determined.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Method for separating and recovering iron from red mud

The invention relates to a method for separating and recovering iron from red mud. The method is characterized by comprising the steps: of leaching out and removing iron from the red mud by using an oxalic acid solution, and filtering to obtain iron-free red mud and an iron oxalate-containing leaching solution, wherein the obtained iron-free red mud can be used as a raw material for producing cement and fireproof bricks; iron oxalate in the obtained leaching solution is reduced to ferrous oxalate through membrane electrolysis or adding a reducing agent and ferrous oxalate is precipitated out, or iron in the solution is separated by directly neutralizing and precipitating an iron hydroxide and oxalate mixture; obtained ferrous oxalate is decomposed to obtain oxalic acid and an iron-containing compound; the obtained iron hydroxide and oxalate mixture is selectively leached out, separated and recovered to obtain oxalic acid and an iron-containing compound; the process of returning recovered oxalic acid to the red mud to leach out and remove iron is cyclically used. The method has the characteristics of short technological process, good iron separation effect, simplicity and convenience in operation, environmental friendliness and the like, and is suitable for large-scale industrialized application.

Owner:CENT SOUTH UNIV

Phosphogypsum-based gelling material and its application in mine tailing filling

ActiveCN104211313ARealize high-quality utilizationWide variety of sourcesMaterial fill-upRed mudPhosphogypsum

The invention relates to a gelling material for mine tailing filling. The gelling material for mine tailing filling used for improving the early stage strength of a filler and having good water segregation performance is obtained through the steps of respectively milling phosphogypsum, red mud, phosphorus residues and clinker to 800m<2> / kg, 700m<2> / kg, 300m<2> / kg and above 300m<2> / kg respectively, uniformly mixing the above milled raw materials, and adding an exciting agent. The gelling material is used to carry out mine tailing filling, and the raw materials are from various industrial waste residues, so the gelling material has the advantages of low cost, simple technology, strong maneuverability, low filling cost, effective utilization of various industrial waste residues of the metallurgy industry, energy saving, emission reduction and environmental protection.

Owner:CHINA THREE GORGES UNIV

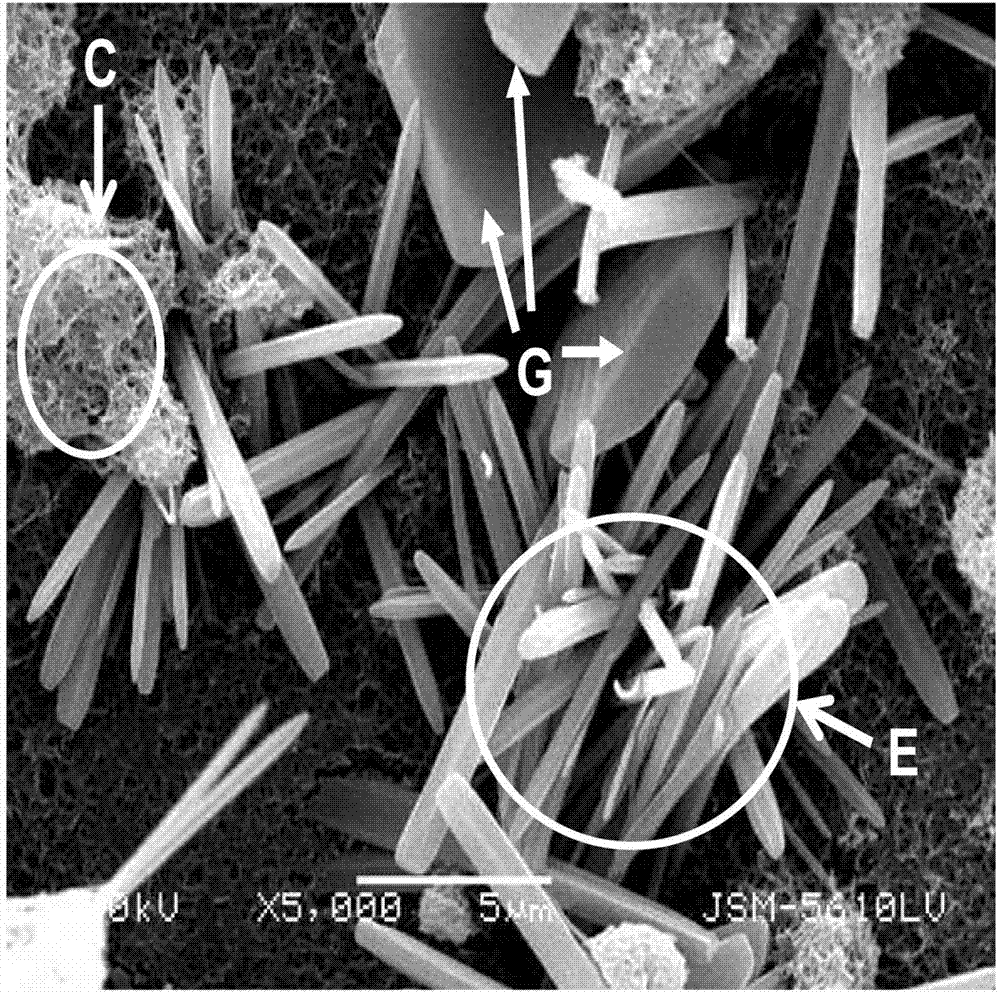

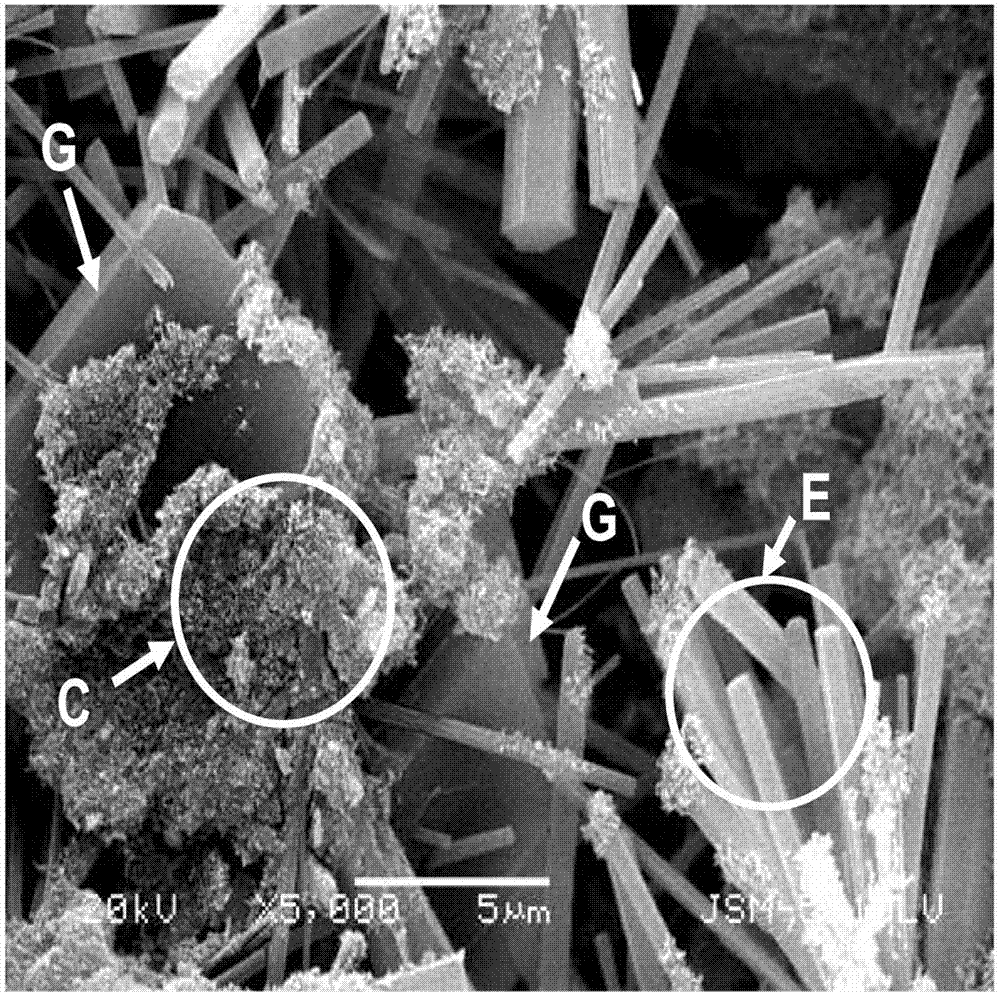

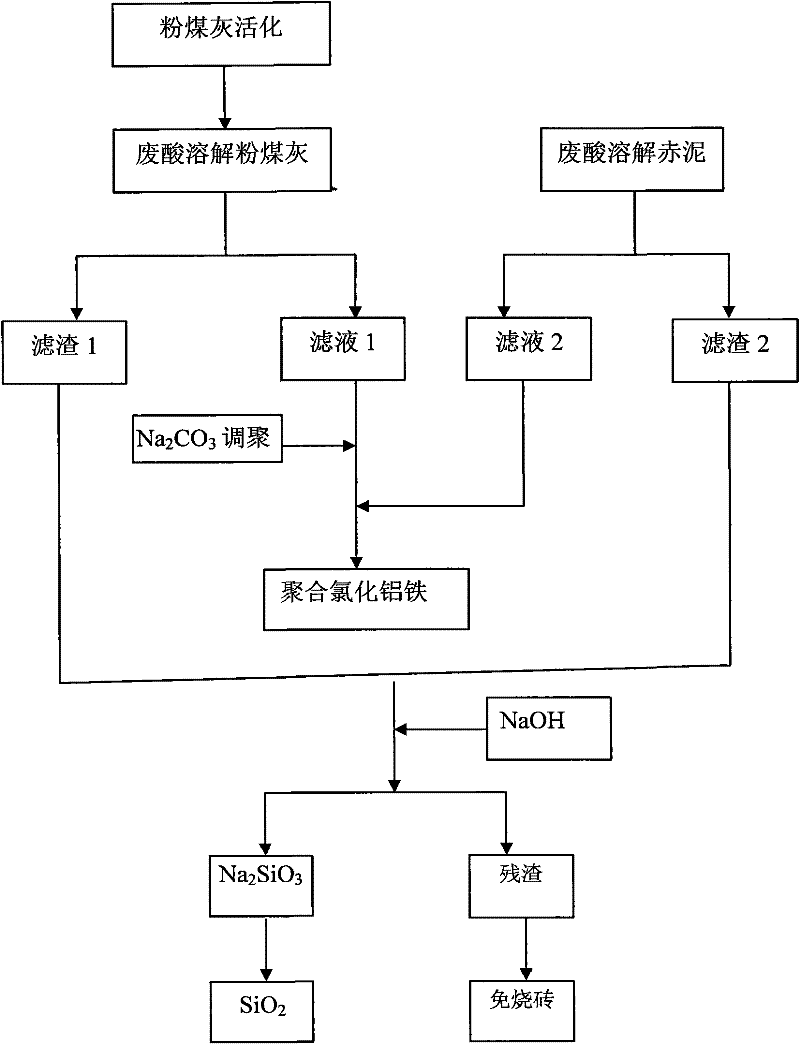

New method for resource comprehensive utilization of red mud and fly ash

InactiveCN102344171AAchieve recyclingAchieve near-zero emissionsSilicaSolid waste disposalAluminium chlorideRed mud

The invention discloses a new method for resource comprehensive utilization of red mud and fly ash, and relates to a comprehensive utilization of industrial waste, specifically to a preparation method for a flocculating agent of aluminum ferric chloride and white carbon black. The method comprises the following steps: (1) acid leaching: the red mud and the activated fly ash are adopted as raw materials, and react with HCl, wherein the leaching temperature is 70-90 DEG C, a solid-liquid ratio is 10:1-10:3, the HCl concentration is 3-6 mol.L<-1>, the leaching time is 4-10 hours; (2) polymerization: Na2CO3 is added to a dissolution solution 1 to carry out telomerization, a dissolution solution 2 is added to the dissolution solution 1 until the dissolution solution 1 is stable, then the polymerization reaction is performed to obtain the polyaluminum ferric chloride, wherein the temperature is 60-70 DEG C, the pH value is 2.5-3.0, the aging time is 12-24 hours; (3) white carbon black preparing: a NaOH solution is adopted to carry out alkali dissolution to dissolve the filter residue, then treatments of acidification and calcination are performed to obtain the powder SiO2, wherein the alkali dissolution temperature is 80-100 DEG C, the time is 4-8 hours.

Owner:孙建之

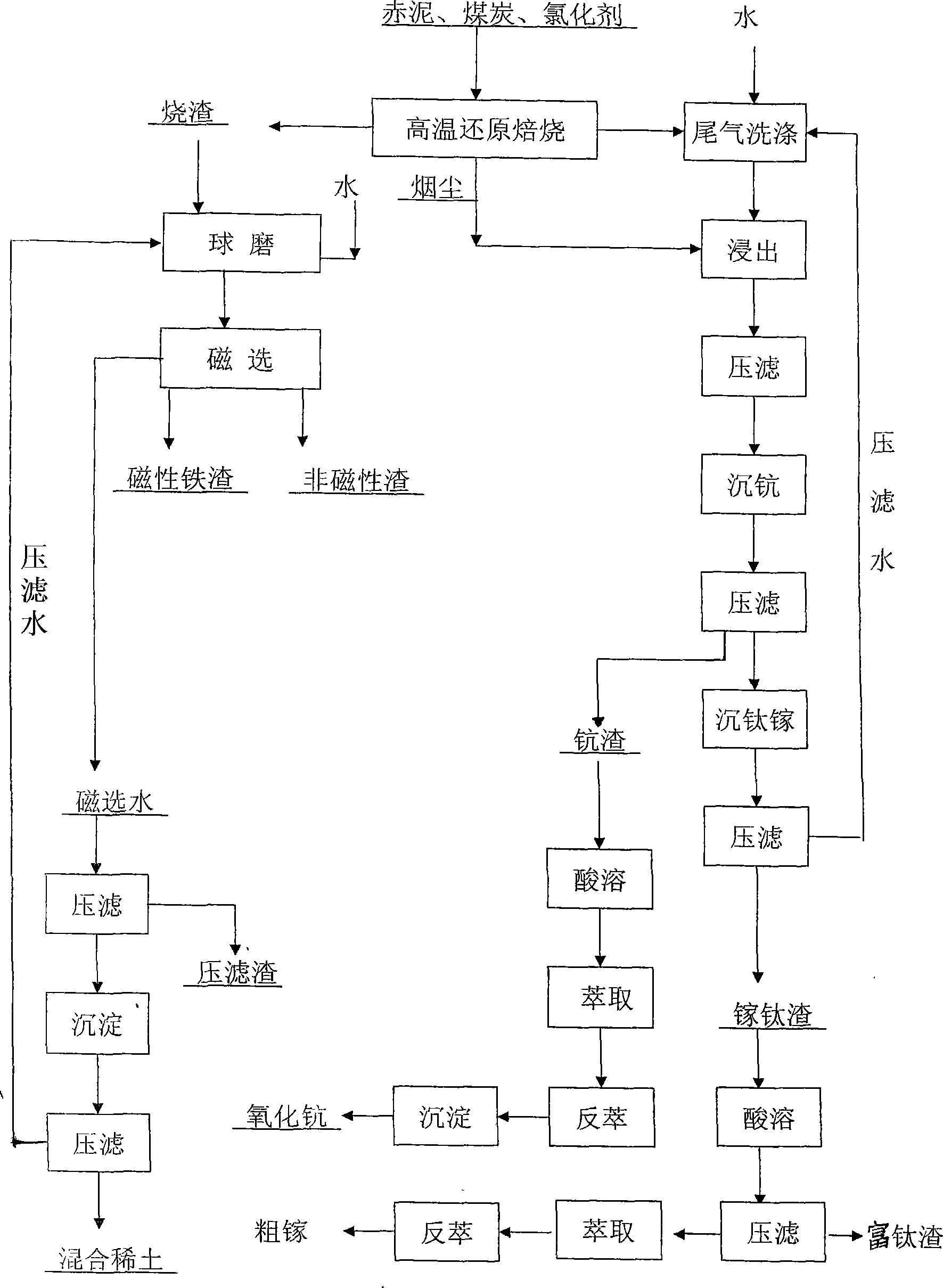

Comprehensive utilization method for red mud

InactiveCN101463426APromote environmental protectionGood benefitSolid waste managementProcess efficiency improvementWash waterRed mud

The invention discloses a method for comprehensively utilizing red mud, comprising the following steps: chloridizing roasting, namely roasting the mixture of the red mud, coal and calcium chloride; cinder treatment, namely obtaining magnetic iron slag and non-magnetic slag after magnetic separation is carried out to levigated cinder, and then separating the magnetic iron slag and non-magnetic slag; adding calcined soda or oxalic acid after levigation liquid and wash water are rich in mischmetal due to cyclic use, and then precipitating mischmetal slag; treatment of dry dust and circulation liquid, namely, after dry powder for roasting dust collection is collected, mixing the dry powder with scouring water which is used for tail gas circulation and then leaching soluble ScCl3 and GaCl3; after filter pressing, precipitating scandium by adding oxalic acid crystal in filtrate; carrying out filter pressing again, precipitating gallium and Ti(OH)4 by adding ammonia into the filtrate, dissolving obtained gallium-titanium slag with acid and then using P2O4 extractant to extract the gallium; and using extractant to extract the scandium after scandium precipitate is dissolved by acid, carrying out precipitation again by adopting back-extraction acid dissolving, and obtaining Sc2O3 by means of roasting. The method can realize recovery of valuable metals from the red mud, and secondary residual slag is totally used for building material production; and the method has environment protection effects and economic benefits, plays an important role in the development of recycling economy and is applicable to enterprises generating red mud.

Owner:张钦

Ironmaking and aluminum extraction comprehensive utilization method of high-iron red mud

ActiveCN102816880ASolve wasteAvoid Condensation RefluxBlast furnace detailsIncreasing energy efficiencyAluminateSlag

The invention provides an ironmaking and aluminum extraction comprehensive utilization method of high-iron red mud. The method is characterized in that a blast furnace is used as main equipment; red mud is utilized to prepare micropellet composite sinter or pellet; micropellet composite sinter or pellet and coke are then treated with hot charging into the furnace layer by layer at no less than 400 DEG C; rich oxygen to full oxygen blast is employed; and tuyeres on the furnace body are increased, and reducing gas rich in hydrogen is blown into the furnace, so as to realize red mud ironmaking. At the same, calcium oxide is added during a deslagging process; the slag is treated with temperature control cooling to obtain self-pulverization calcium aluminate slag, which is leached and extracted with alumina; and sodium element is synchronously recovered from high temperature exhaust of the furnace top, so as to complete efficient separation and recycling of aluminum, iron and sodium in the red mud.

Owner:NORTHEASTERN UNIV

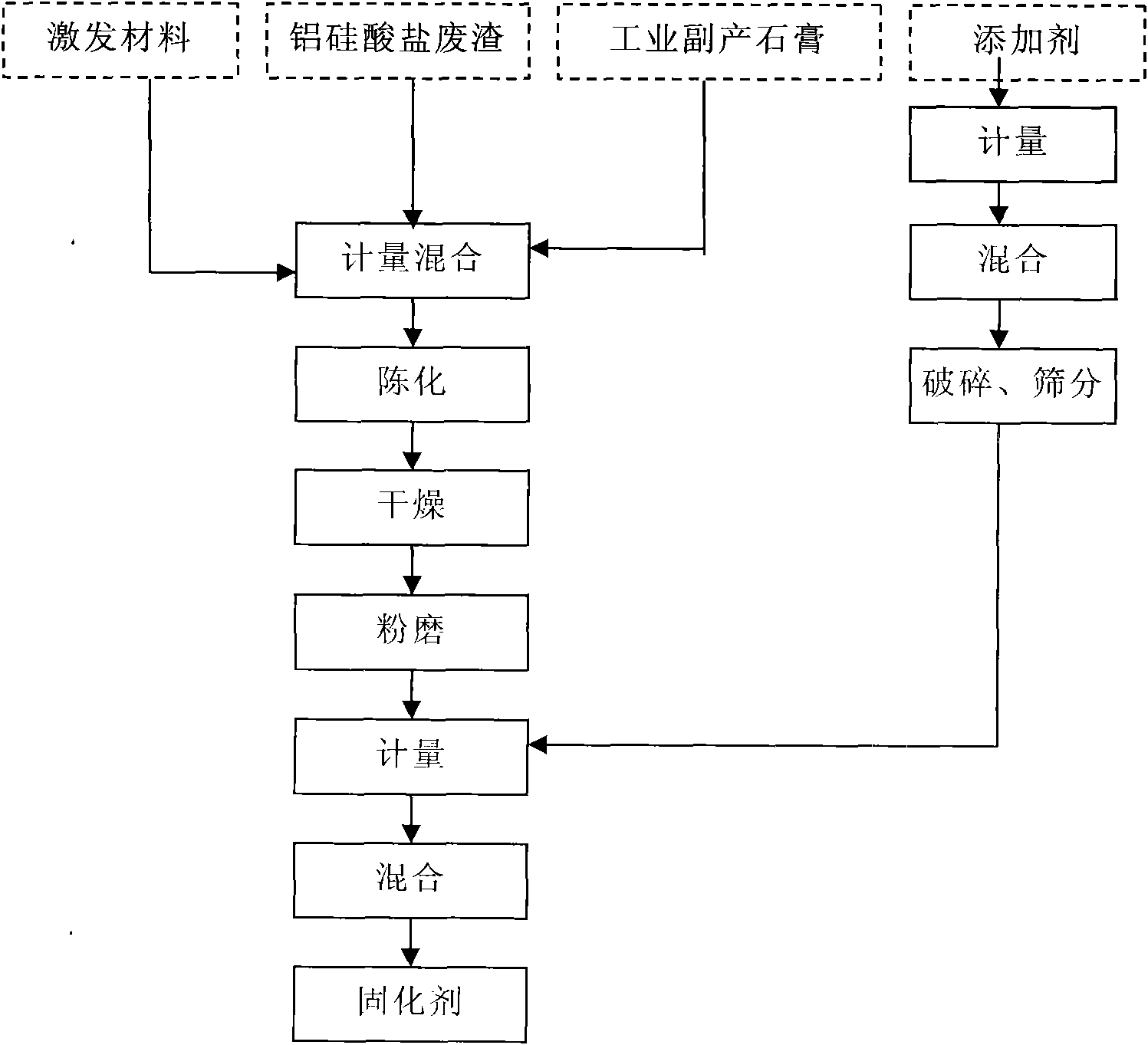

Low-temperature ceramic curing agent of red mud from Bayer process

The invention relates to a low-temperature ceramic curing agent of red mud from a Bayer process. The low-temperature ceramic curing agent is prepared by the following raw materials by weight parts: 100 aluminosilicate residues, 20-150 industrial by-product gypsum, 50-200 excited materials, 0-3.0 water-reducing agent, 0-5.0 flocculating agent and 0-5.0 retarder. The production method thereof comprises the following steps: (1) processing main raw materials; (2) preparing additives; and (3) preparing a curing agent. The invention has the beneficial effects that (1) all components of the curing agent can irreversibly react with the red mud; compared with the prior gelled material, the invention does not use cement, base excited materials and expensive high molecular polymers, thereby achieving low cost; (2) the invention uses the industrial residues as the raw materials to cure the red mud so as to achieve the aim of treating a waste with another waste; no secondary waste is exhausted in a production process and an application process so as to benefit environmental protection; and (3) the invention can thoroughly solve the safety problem of a red mud library after curing the red mud.

Owner:山西鑫秀工矿废渣利用有限公司 +1

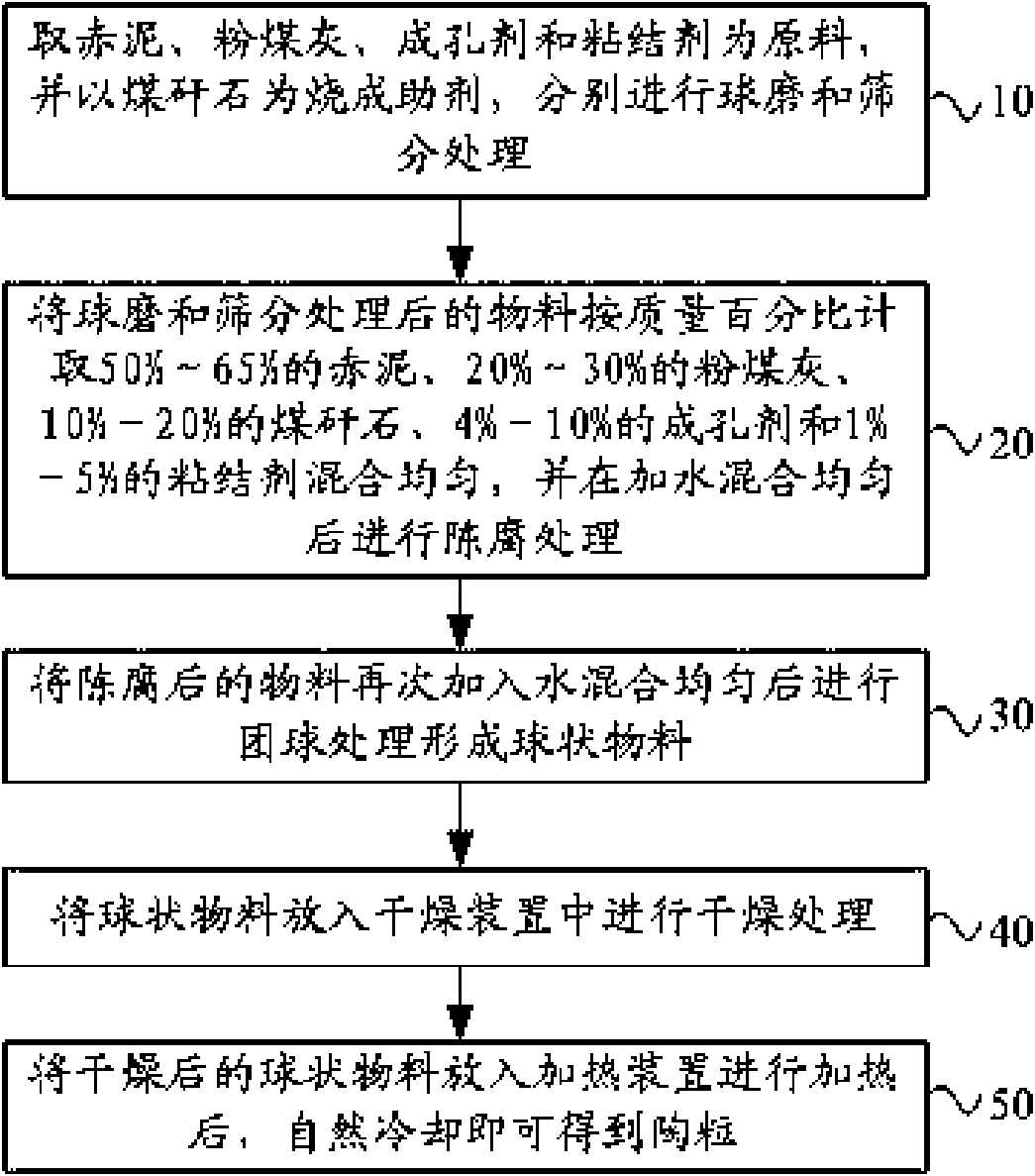

Porcelain granule and preparation method thereof

InactiveCN101624294ARich stomataImprove surface propertiesSolid waste disposalCeramicwareRed mudMaterials science

The invention relates to a preparation method of porcelain granule, comprising the following steps: carrying out ball milling and screening process on red mud, flyash, coal gangue, pore former and binding agent; taking 50-65 percent of red mud, 20-30 percent of flyash, 10-20 percent of coal gangue, 4-10 percent of pore former and 1-5 percent of binding agent by weight percent to be uniformly mixed, adding water, uniformly mixing and carrying out staleness treatment; adding water again and uniformly mixing to carry out agglomerating treatment to form globular material; placing the globular material into a drying device for drying process; and placing the dried globular material into a heating device to heat and naturally cooling to obtain the porcelain granule. In the invention, industrial solid waste red mud is utilized as the main material, the flyash and the coal gangue are utilized as sintering aid, and proper pore former and binding agent are added as ingredients, thereby porous porcelain granules which have rich air outlets, favorable surface characteristic and high strength and meet the requirement of waste water treatment application are prepared through selecting preparation process and controlling sintering temperature.

Owner:准格尔旗粉煤灰煤矸石研发中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com