Patents

Literature

52 results about "Vacuum ceramic filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

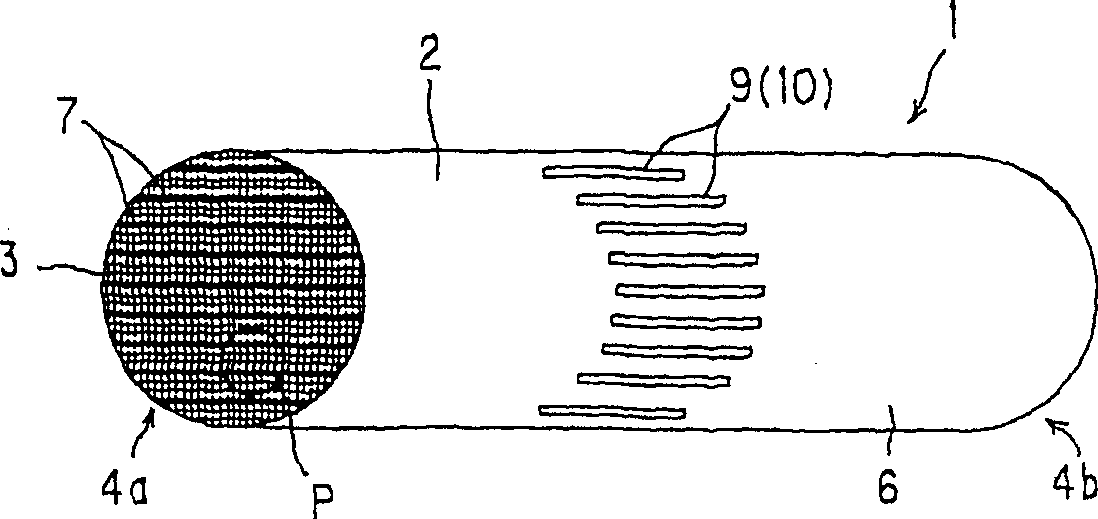

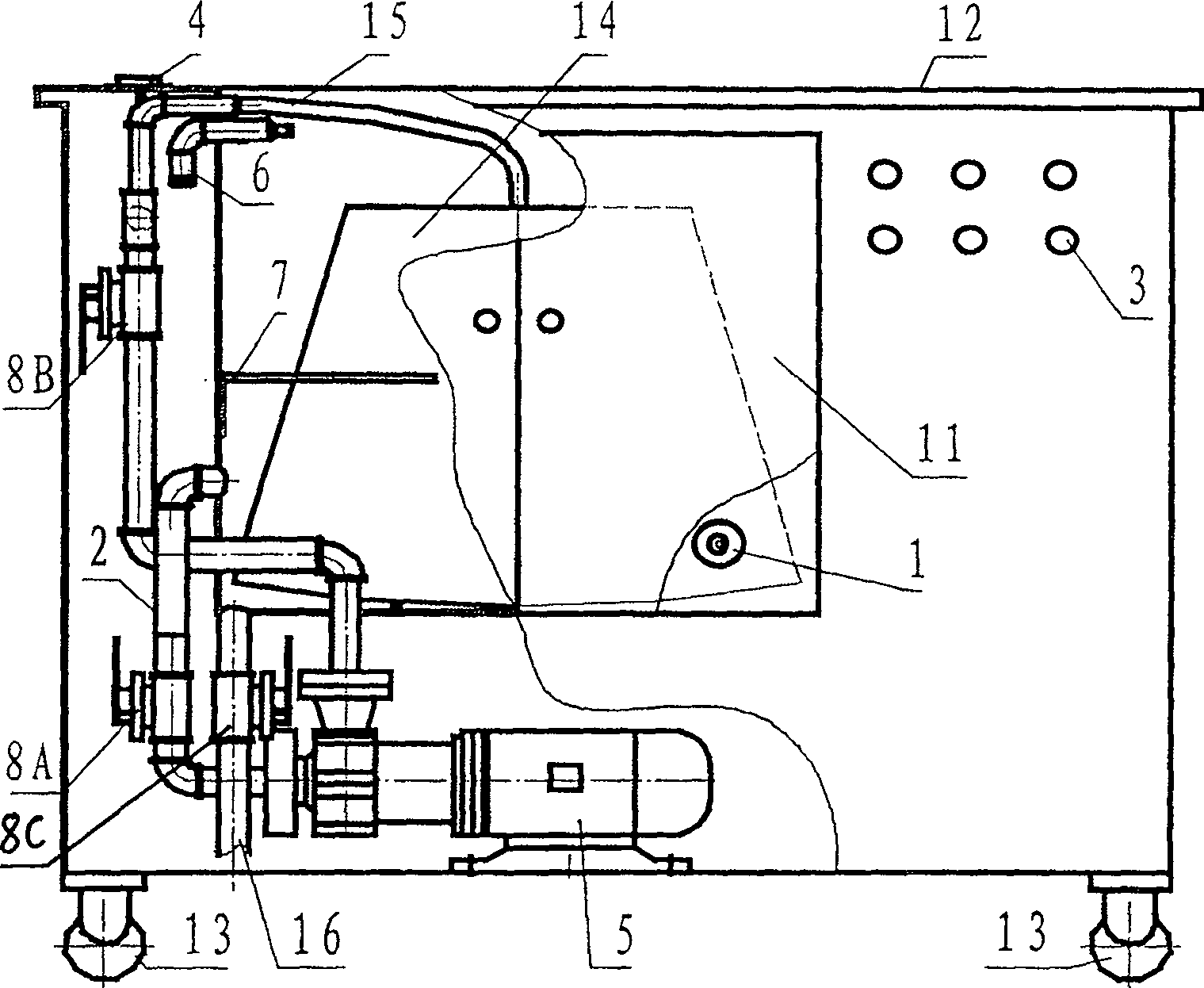

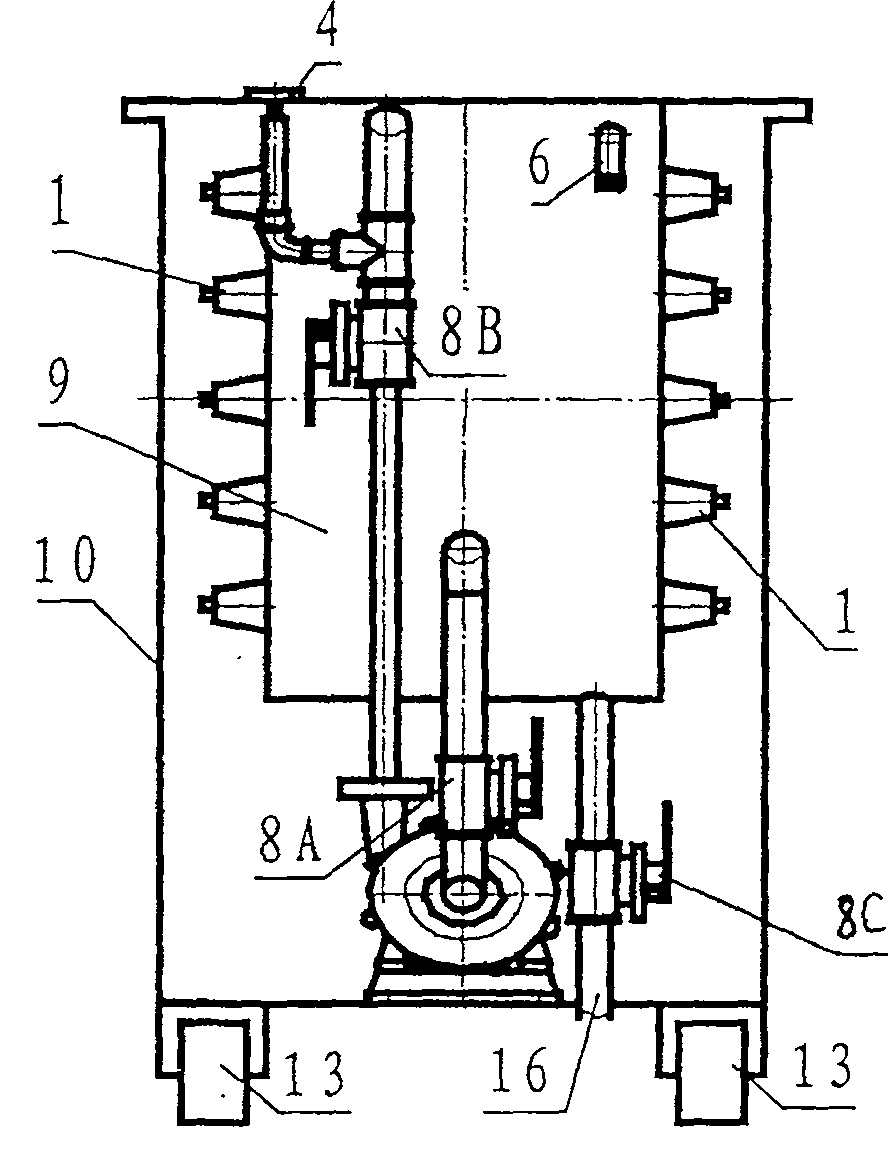

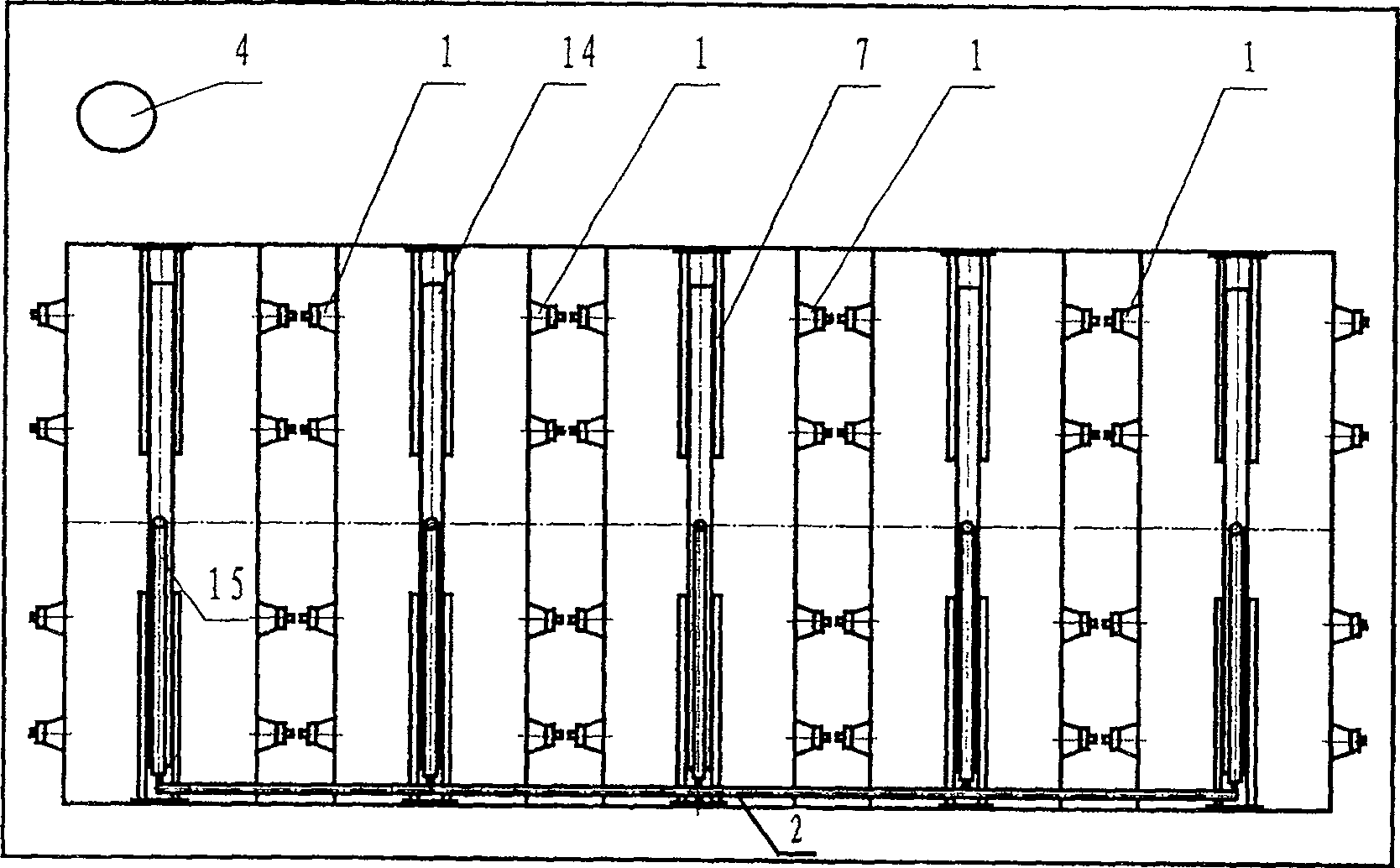

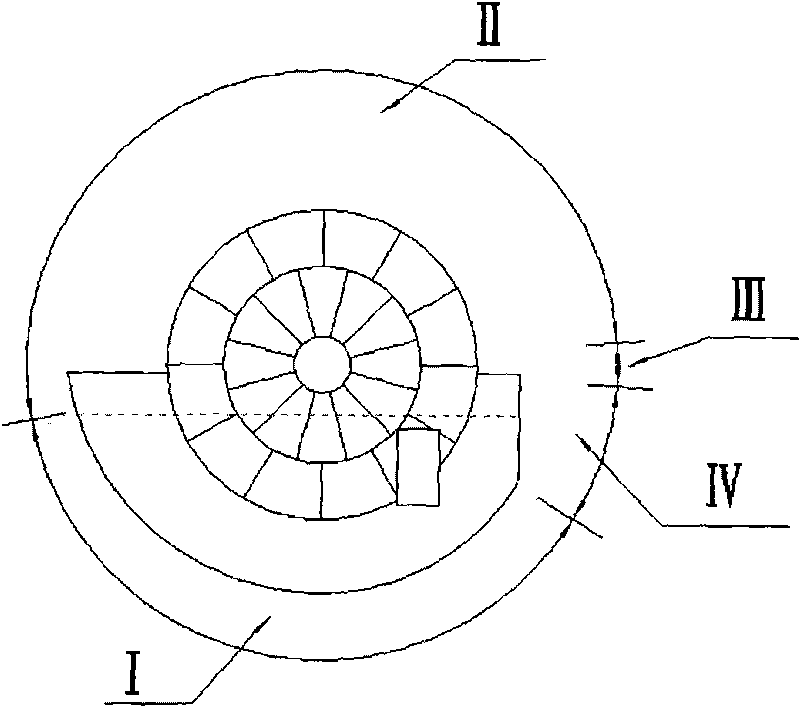

A vacuum ceramic filter is designed to separate liquids from solids for dewatering purposes. The device consists of a rotator, slurry tank, ceramic filter plate, distributor, discharge scraper, cleaning device, frame, agitating device, pipe system, vacuum system, automatic acid dosing system, automatic lubricating system, valve and discharge chute. The operation and construction principle of vacuum ceramic filter resemble those of a conventional disc filter, but the filter medium is replaced by a finely porous ceramic disc. The disc material is inert, has a long operational life and is resistant to almost all chemicals. Performance can be optimized by taking into account all those factors which affect the overall efficiency of the separation process. Some of the variables affecting the performance of a vacuum ceramic filter include the solid concentration, speed rotation of the disc, slurry level in the feed basin, temperature of the feed slurry, and the pressure during dewatering stages and filter cake formation.

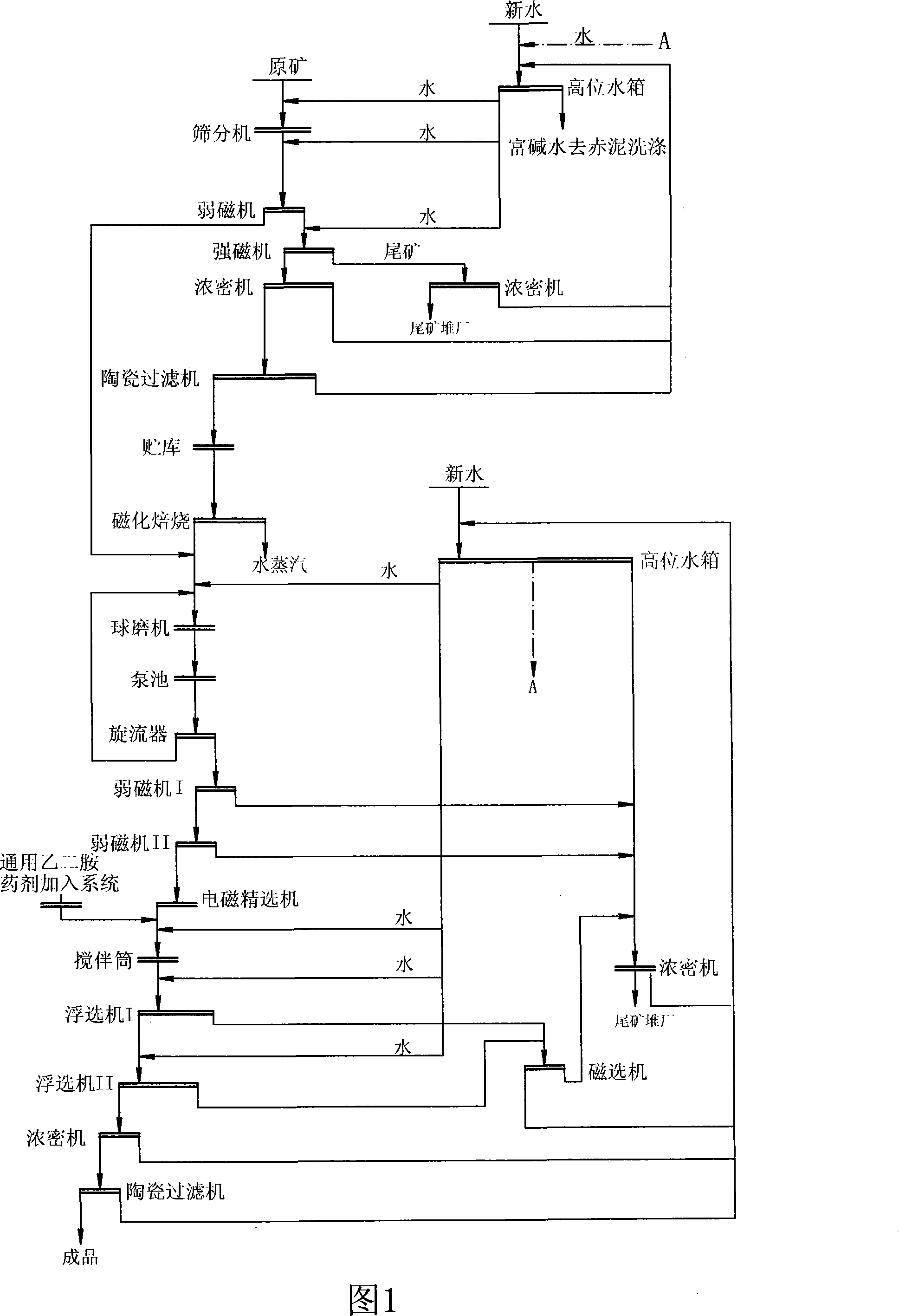

Method of refining iron ore from alkaline red mud and making gangue neutral

The invention relates to a method to select refined iron ore from alkaline red mud and neutralize mine tailings. The method consists of red mud pretreatment and technological process of preparing refined iron ore. The red mud pretreatment is that water is added into the red mud slurry discharged from aluminum factory; the red mud slurry is diluted to the solid concentration of 30 to 40 percent and then is screened and put into a low intensity magnetic separator for selecting ferromagnetic substance. The ferromagnetic substance is dehydrated and directly selected as the product. The remaining red mud is watered down to 30 percent solid concentration and put into a high intensity magnetic separator for magnetic separation and desliming. The obtained coarse ore is washed to a coarse ore settling tank or a thickener to be concentrated while the undercurrent is sent into a vacuum ceramic filter and a filter cake is roasted in a suspended magnetic roasting furnace. The roasted materials are crushed into a ball mill and then are milled. The water is overflown until 95 percent of the solid material granularities are less than 75m and then is treated by the third stage magnetic separation and the second flotation. The undercurrent is filtered by the ceramic filter, and then the refined iron ore with a purity of 58 to 65 percent is obtained. The refined iron ore is recycled from the red mud by the invention so as to fully employ aluminum ore, save resources and energy consumption and neutralize the whole red mud. The invention reduces environmental pollution and has good economic and social benefits.

Owner:SHENYANG XINBO IND TECH

Ceramic filter and filter device

InactiveUS20020157358A1Increase pressure dropMechanical strengthCombination devicesAuxillary pretreatmentTemperature treatmentVacuum ceramic filter

Owner:NGK INSULATORS LTD

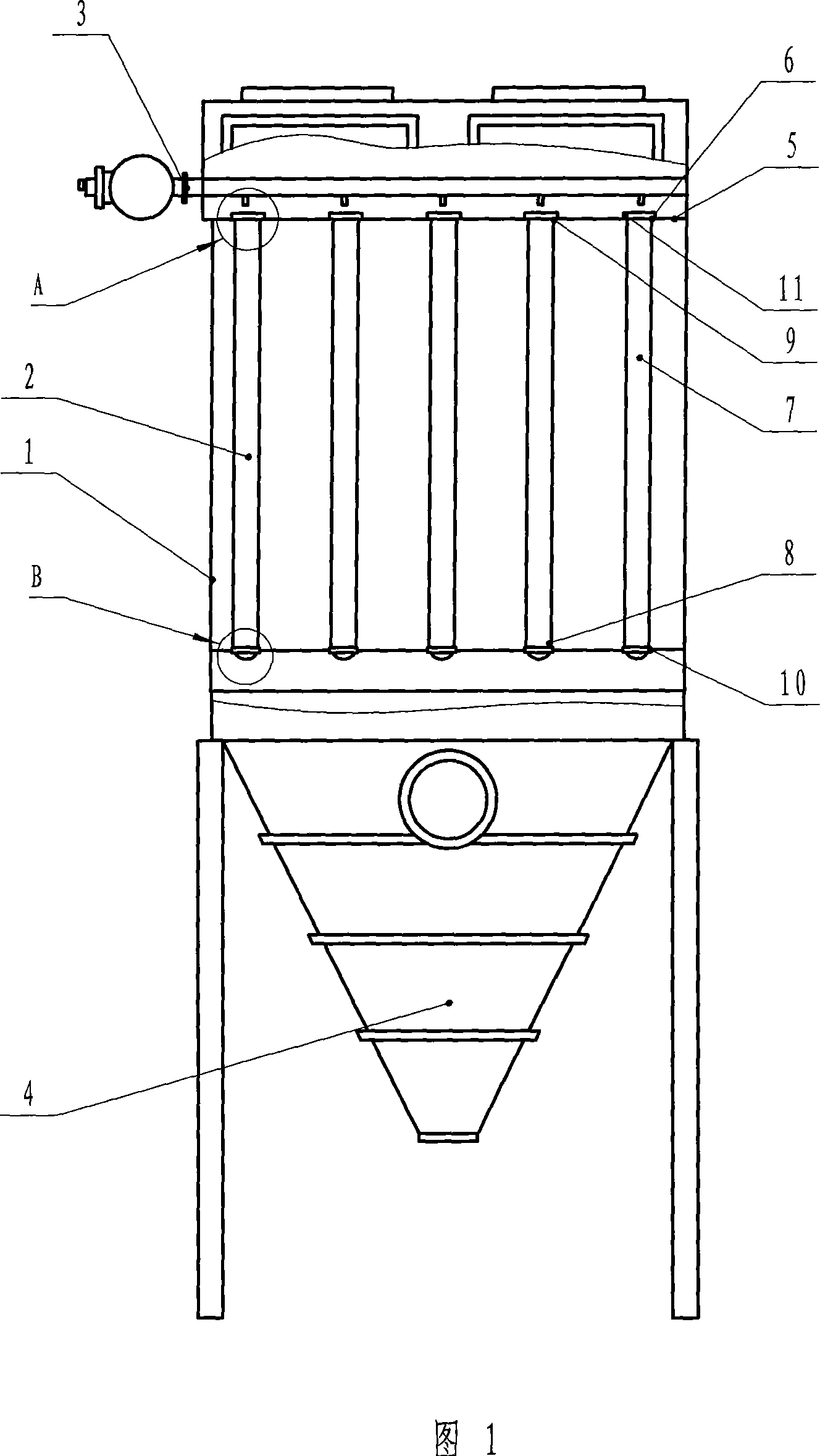

Ceramic filter-element dust collector

InactiveCN101073734AImprove work efficiencyFast filteringDispersed particle filtrationVacuum ceramic filterMetallurgy

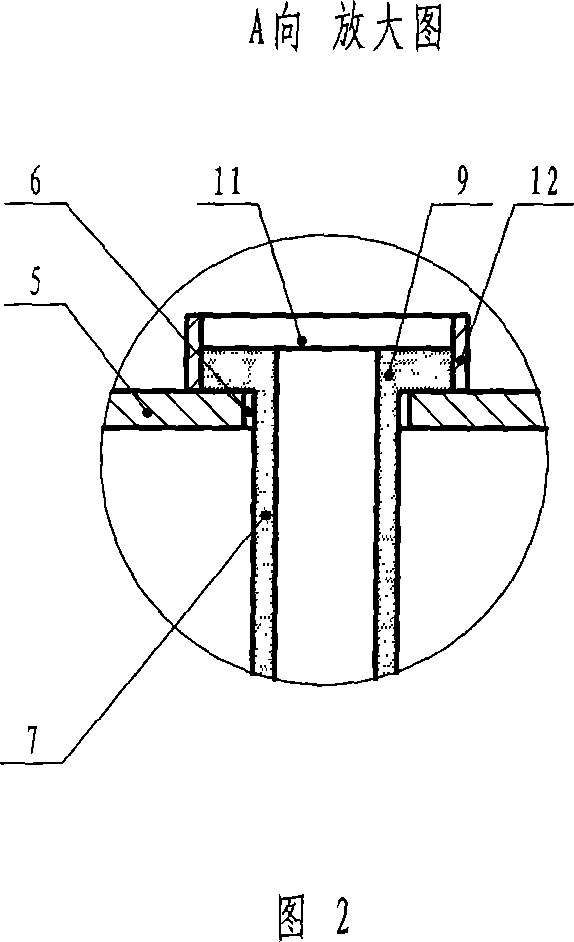

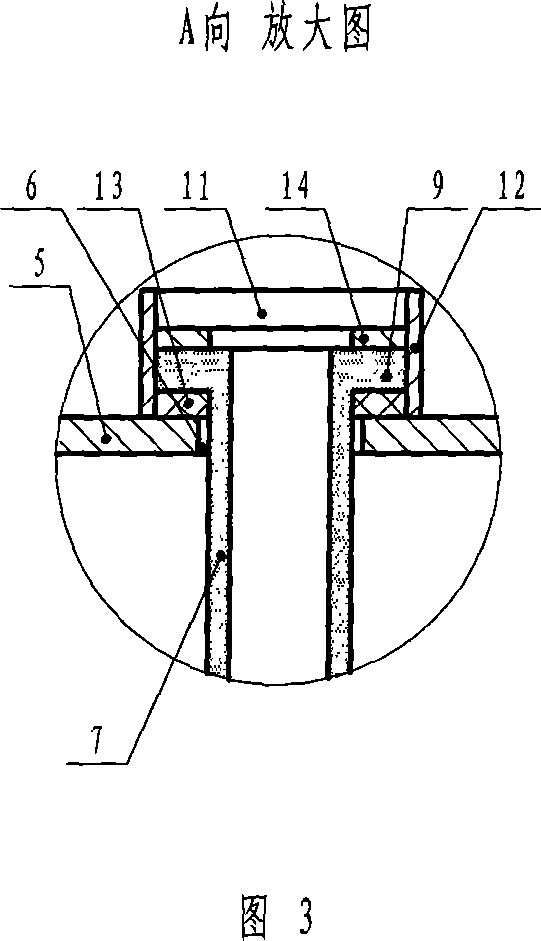

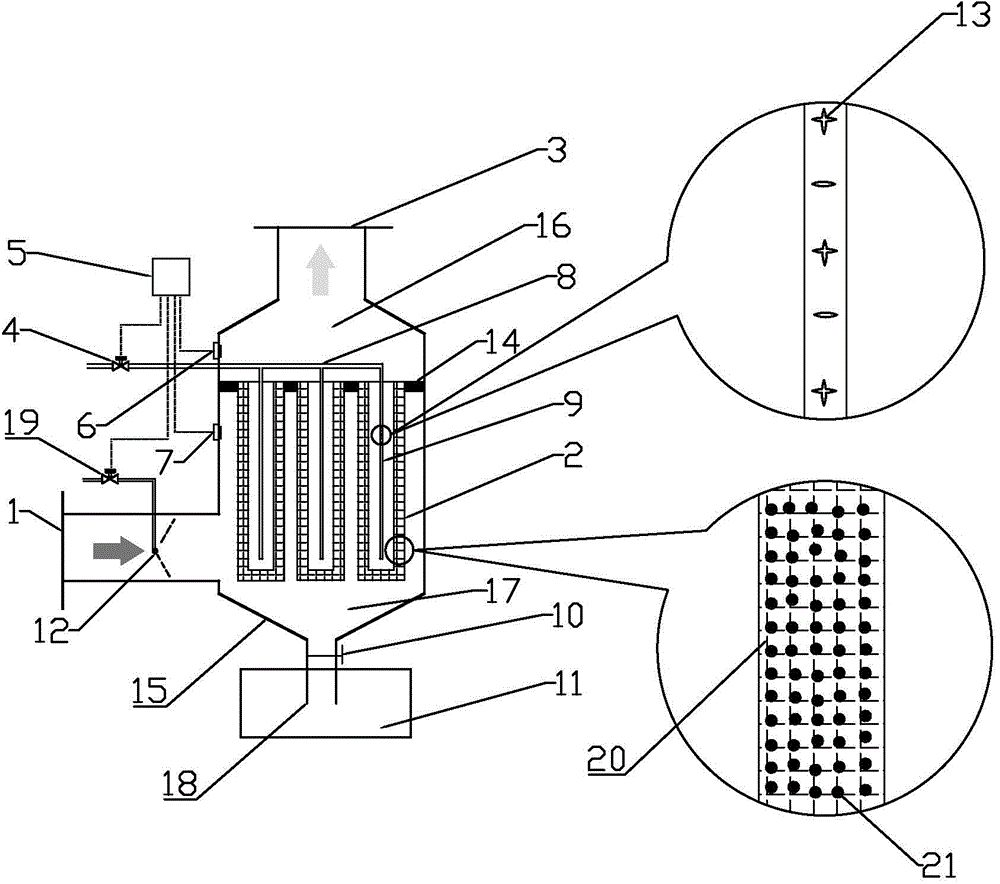

The invention is concerned with removing dust equipment for high temperature gas with solid impurity belonging to dust removing equipment technology field. This ceramic filter core dust catcher affords a kind of high effect dust catcher with anti-high-temperature and anti- causticity. The ceramic filter core dust catcher relates to shell, ceramic filter equipment, pulse anti-blow system and cleanout system. The ceramic filter equipment is the match-board with hole fixed on the inner side of shell, and the below head of ceramic filter core enters into the shell from the hole of match board and is fixed with shell through below fixation equipment. The upper head of ceramic filter core connects with match-board and is fixed with match board with upper fixation equipment. The ceramic filter equipment with different specifications fit for dust removing of some kinds of high temperature gas with wide application future.

Owner:山西金色阳光环保工程有限公司

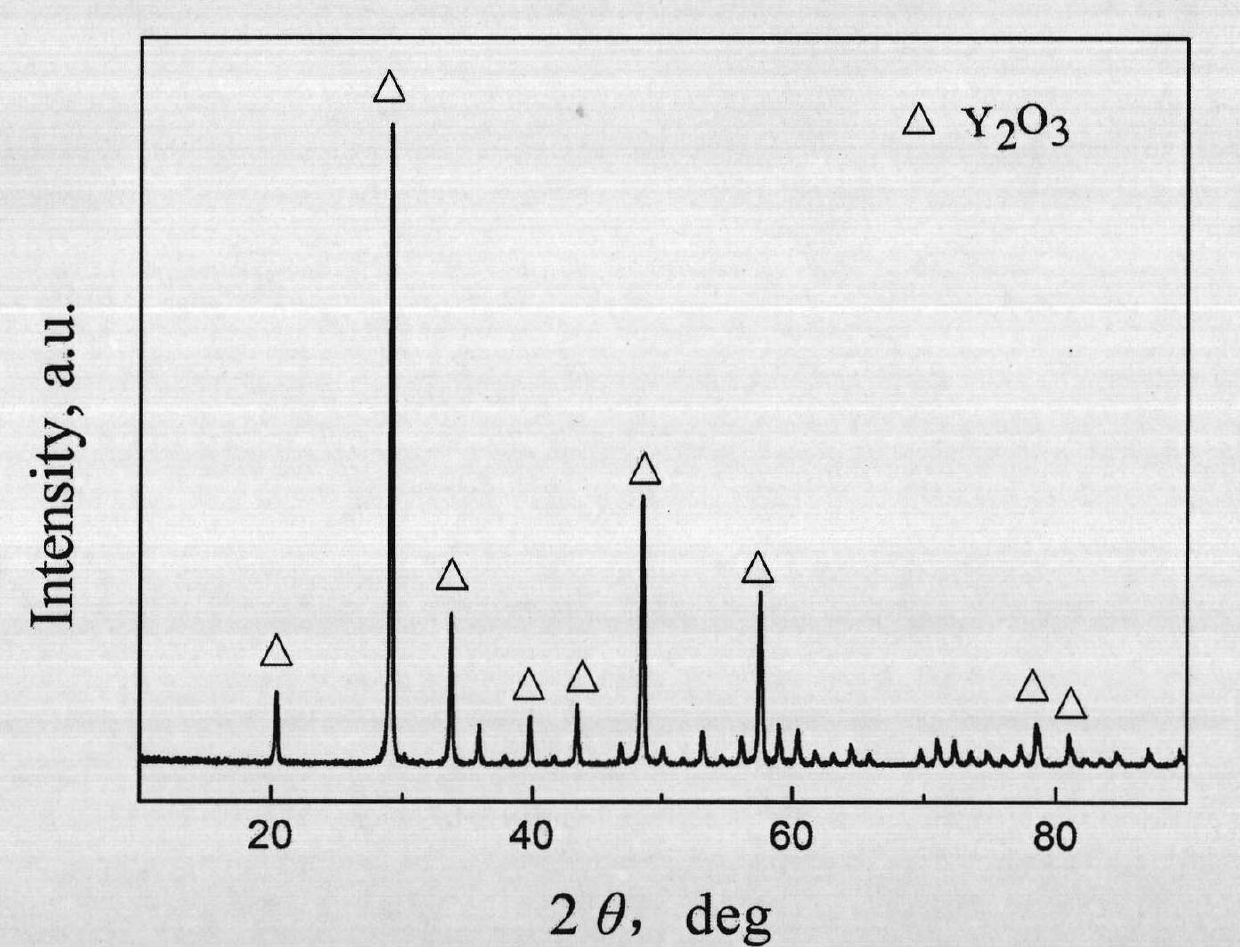

Yttria foamed ceramic filter and preparation method thereof

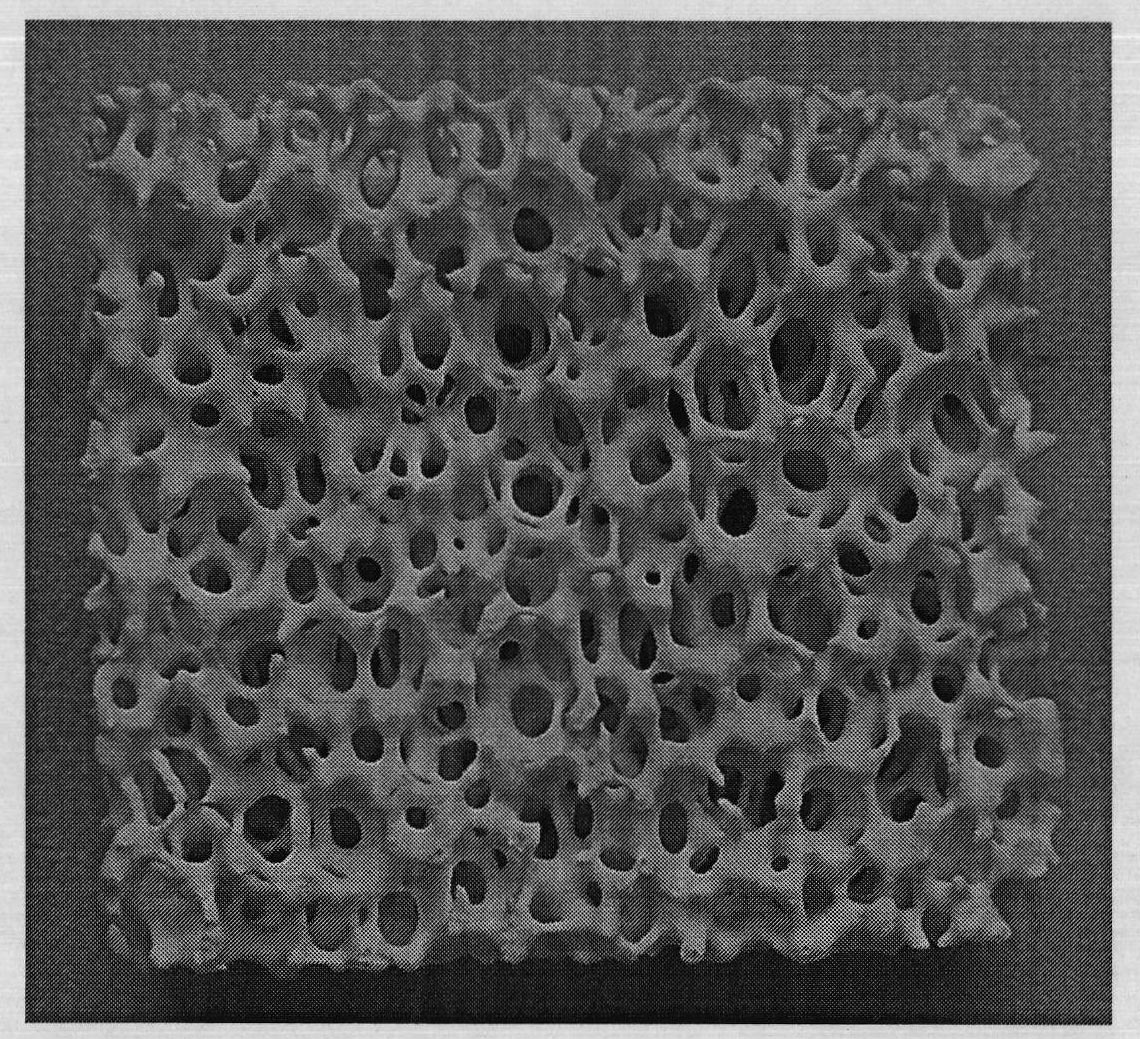

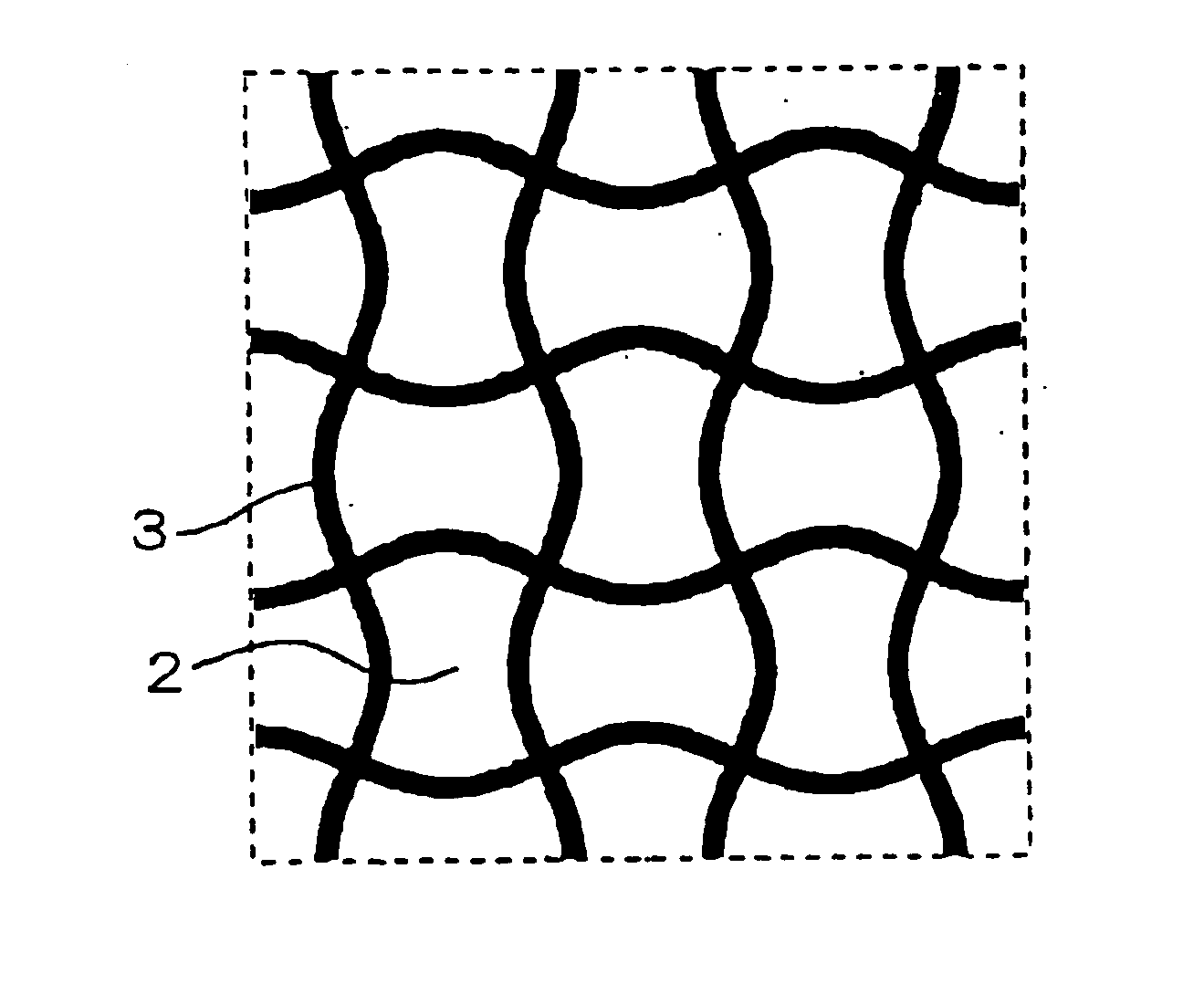

InactiveCN102000458AImprove high temperature strengthImprove heat resistanceFiltration separationCeramicwareAdhesiveSlurry

The invention discloses an yttria foamed ceramic filter and a preparation method thereof. The principal crystalline phase of the filter is yttria. The preparation process of the filter comprises the following steps of: mixing yttria or yttria and additives which are used as raw material with an adhesive, a dispersant and deionized water to prepare slurry; soaking the slurry with soft polyurethane foam which is used as a carrier, extruding and centrifuging to prepare a plain blank; and drying and sintering to obtain a finished product. The yttria foamed ceramic filter of the invention can be used for filtering a high-temperature high-activity alloy and has favorable high-temperature strength, thermal stability, thermal shock resistance and high-temperature chemical stability without alloy pollution, favorable capability of filtering impurities in a high-temperature high-activity alloy solution and good filtering and purifying effects.

Owner:BEIHANG UNIV

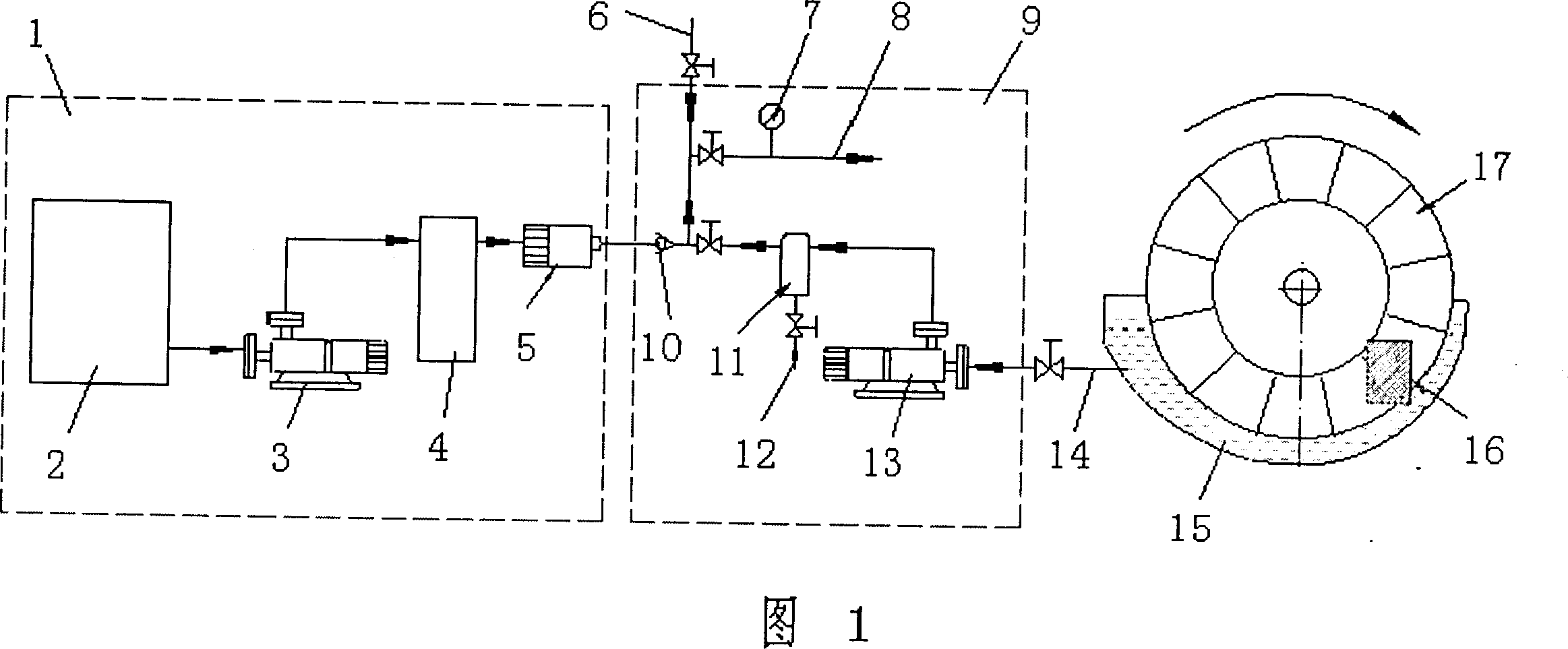

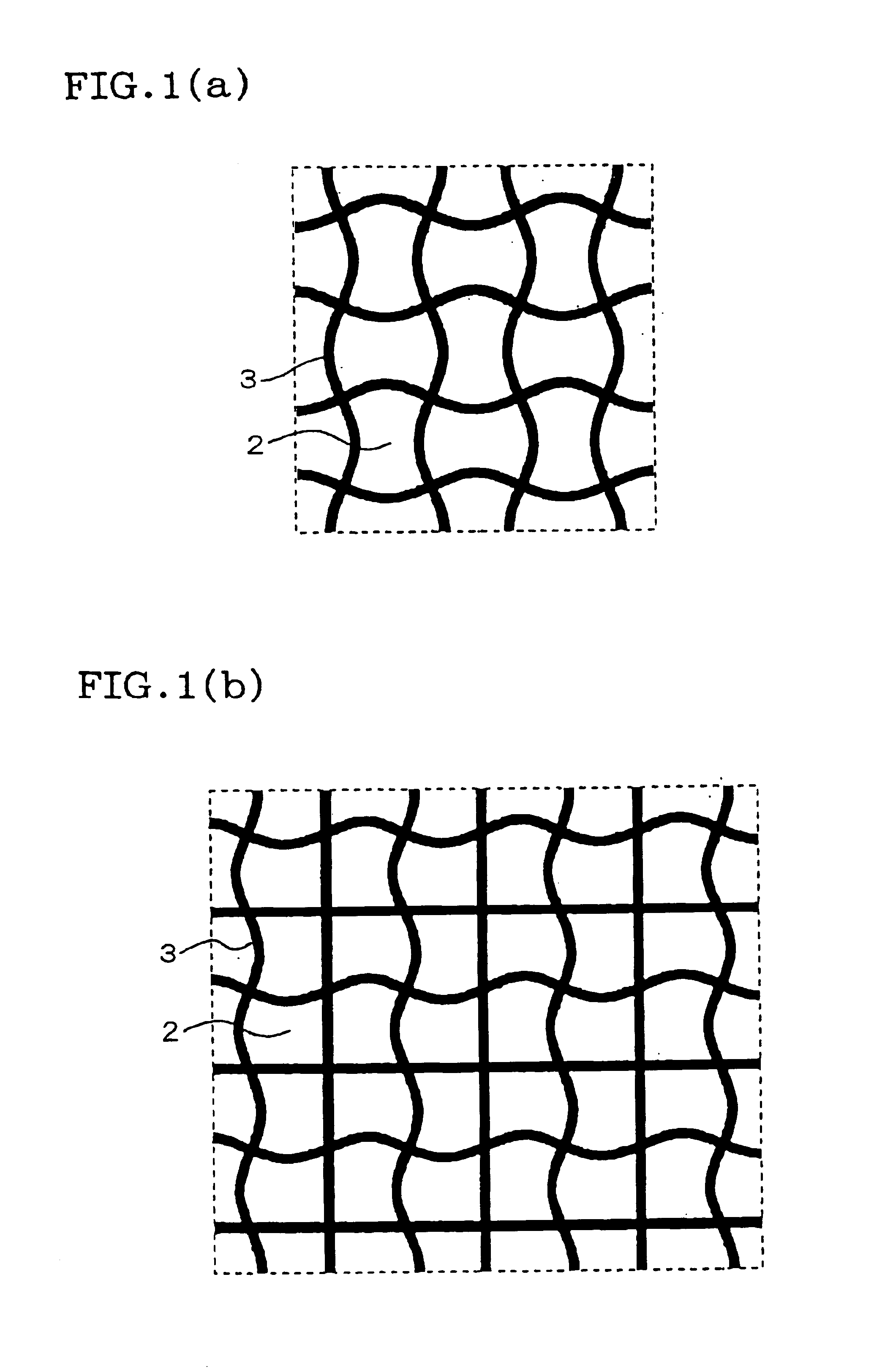

On-line washing method of ceramic filter and apparatus therefor

InactiveCN1978028AIncrease pressureExtended service lifeMoving filtering element filtersVacuum ceramic filterMegasonic cleaning

The present invention relates to a n on-line recycle cleaning method of ceramic filter and its equipment. Said method includes the following steps: (1), stopping ceramic filter, discharging slurry and cleaning with water; (2), adopting acid pickling mode to make the cleaning fluid be fed into ceramic filtering plate by means of reverse-washing pipeline; (3), intervally starting ultrasonic cleaning device to make cleaning operation, at the same time using circulating pump to pump out the cleaning fluid from the filtering channel body interior, filtering said cleaning fluid and making the filtered cleaning fluid be returned into filtering plate by means of reverse-washing pipeline; and (4), stopping cleaning operation and removing residual cleaning fluid from filtering plate interior.

Owner:ANHUI TONGGUAN MACHINERY

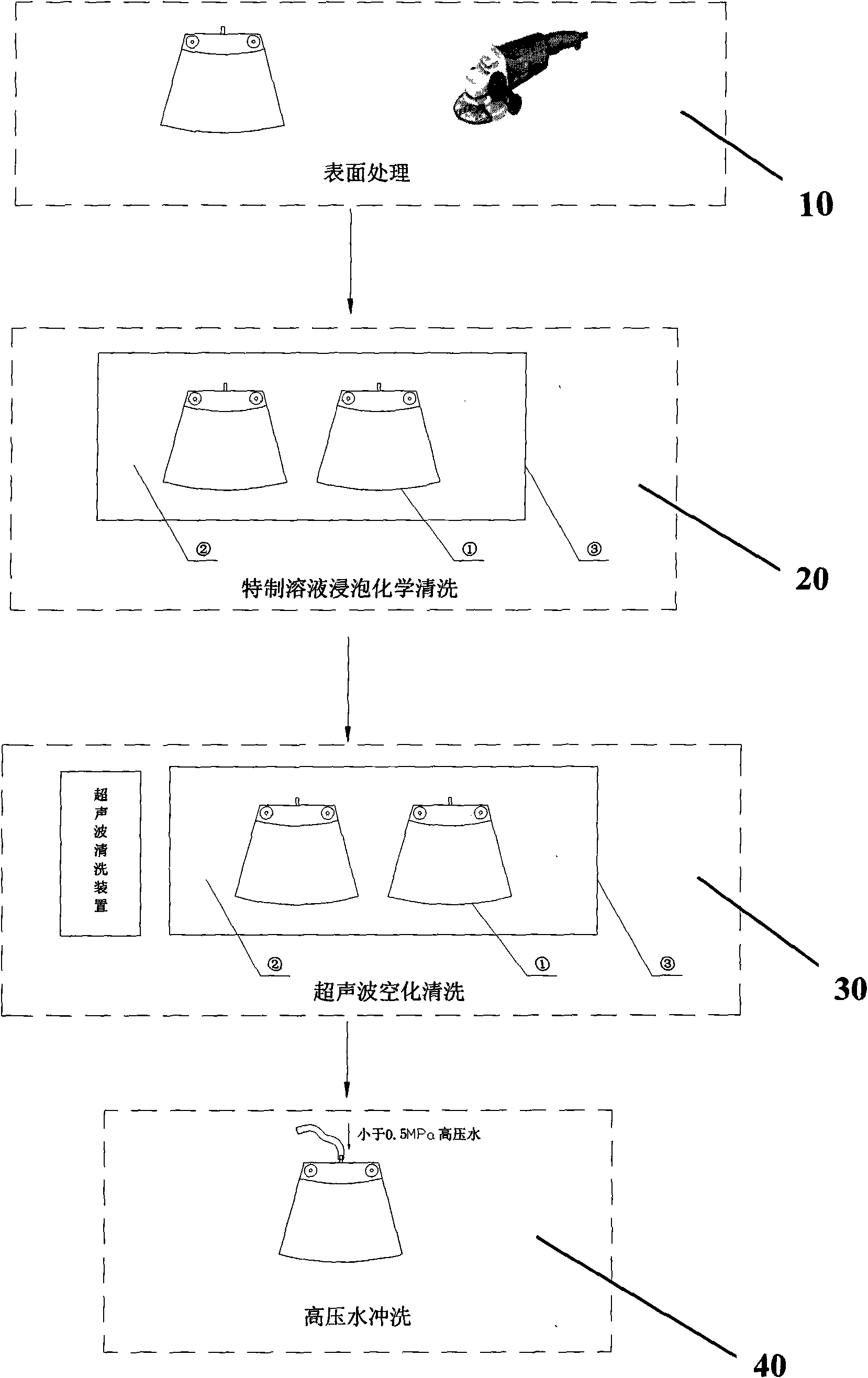

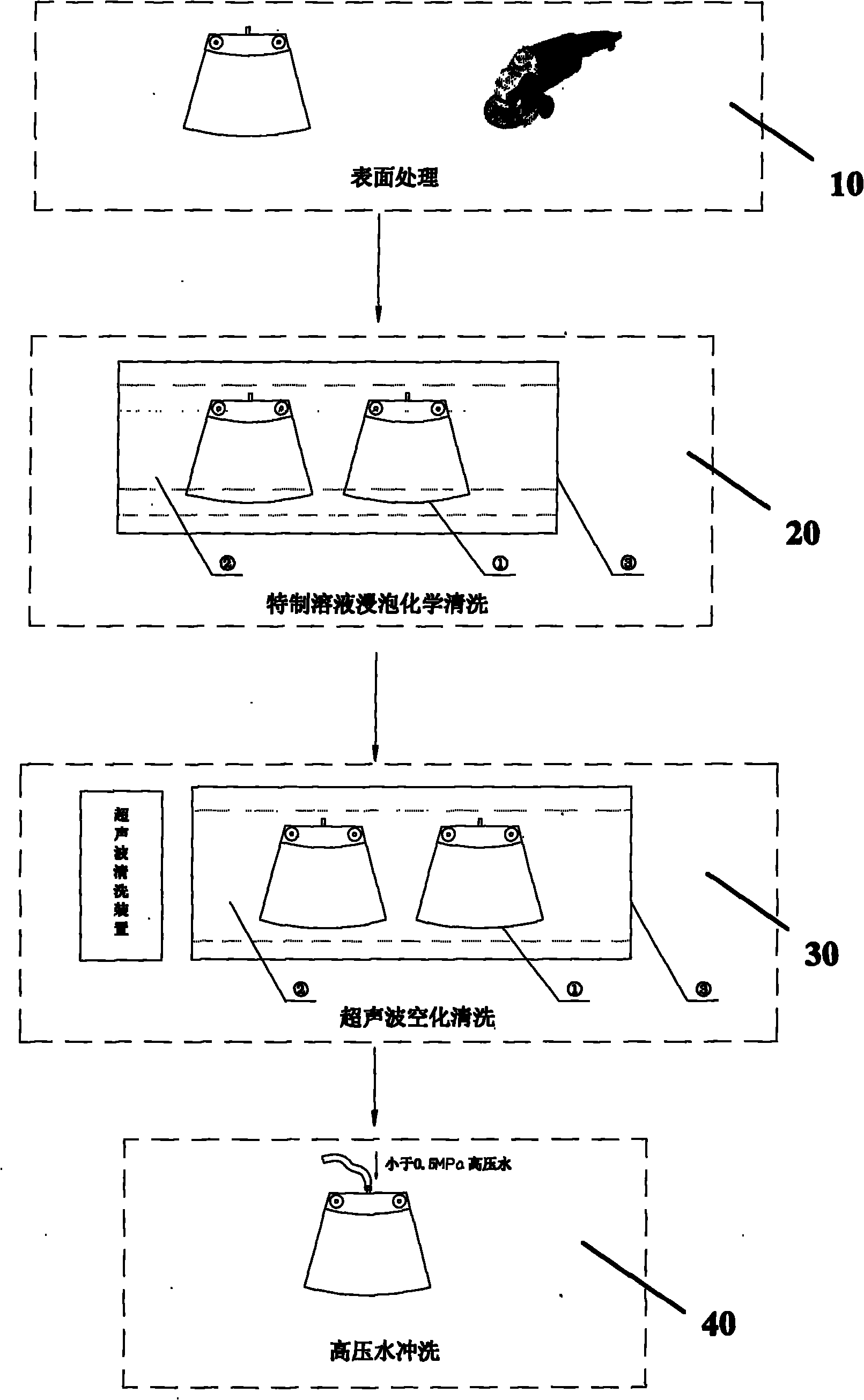

Method for cleaning ceramic filter plate of ceramic filter

InactiveCN101954226ASolve dirty cleaningExtended service lifeFilter regenerationVacuum ceramic filterMegasonic cleaning

The invention relates to a method for cleaning a ceramic filter plate of a ceramic filter. The cleaning method comprises a surface treatment step of the ceramic filter plate, wherein the surface treatment is surface polishing treatment of the ceramic filter plate. The cleaning method also comprises a chemical cleaning step, an ultrasonic cleaning step and a high-pressure water flushing step. The method has the advantages of simpleness in operation of the four steps and low cost, and greatly prolongs the service life of the ceramic filter plate; and the cleaning method can be reused, greatly reduces the operation cost of the ceramic filter, and can be popularized and applied to the filter plate of the ceramic filter.

Owner:宝钢集团上海梅山有限公司

Ceramic filter and filter device

The present invention provides a ceramic filter to be used at a high temperature, and it contains a substance having preferential reactivity with an ash component contained in materials captured by the ceramic filter and not removed by a high temperature treatment such as combustion over the principal component of the ceramic filter; the reaction between the ash component being not removed by a high temperature treatment such as combustion of the filter and remaining accumulated and the filter component to cause melting of the filter being suppressed to attain a long period of service.

Owner:NGK INSULATORS LTD

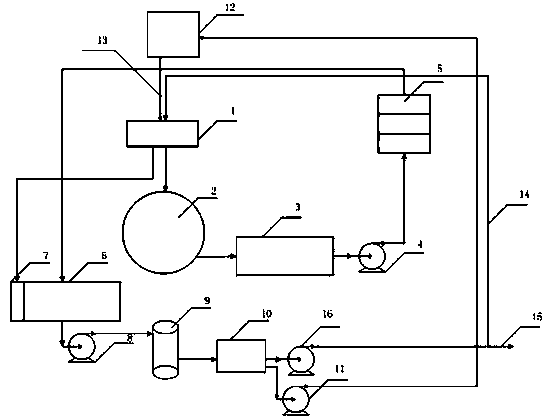

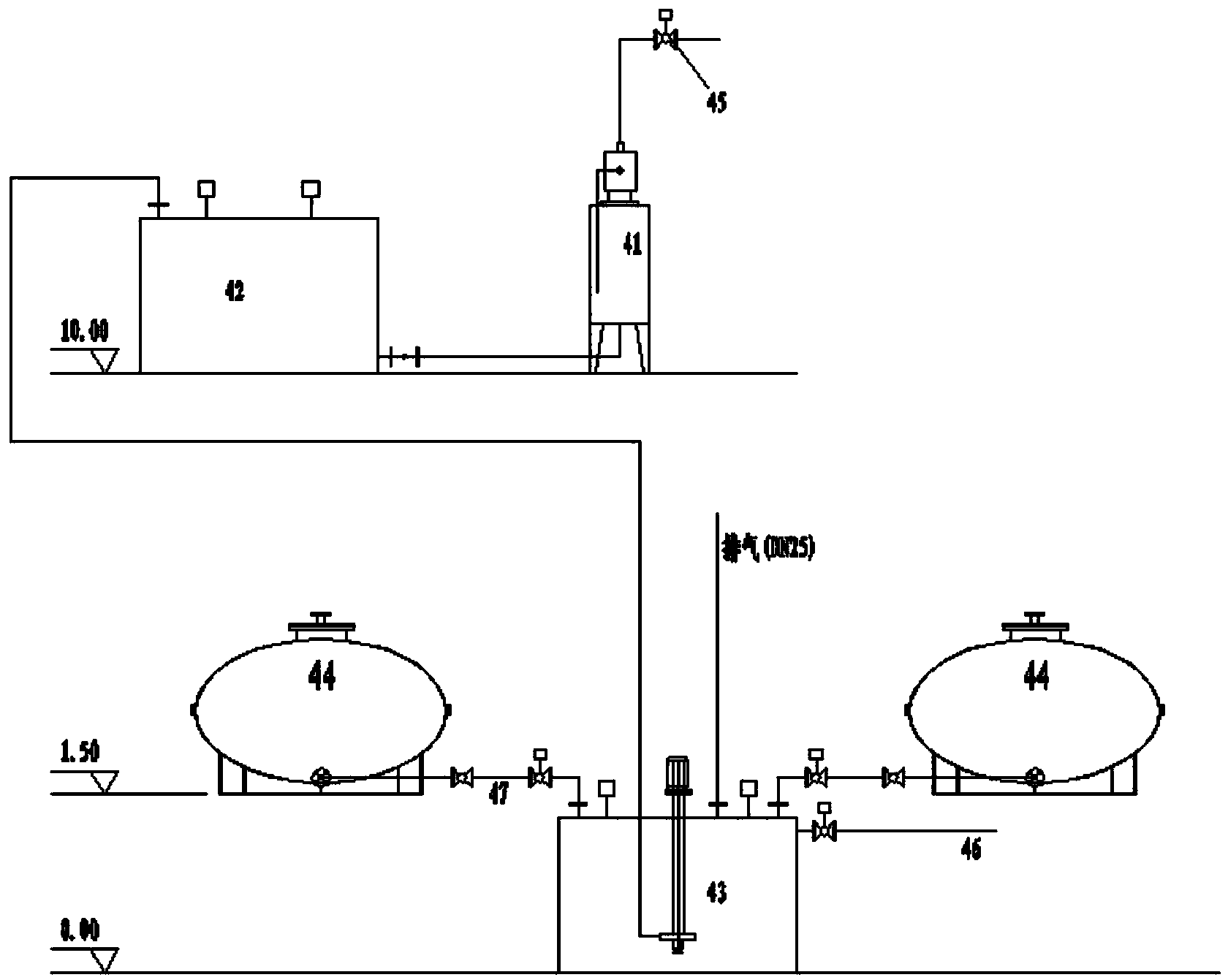

Reverse cleaning system and reverse cleaning method of ceramic filter in iron ore dehydration

ActiveCN103432813AImprove efficiencyReduce circulationMultistage water/sewage treatmentFiltration separationVacuum ceramic filterWater quality

The invention provides a reverse cleaning system and a reverse cleaning method which are applicable to reverse cleaning of a ceramic filter in a concentrated iron ore slurry dehydration process. The reverse cleaning system comprises a filtrate pool, a sewage treatment unit, a pipeline switching unit and a cleaning pump, wherein the filtrate pool is connected with the sewage treatment unit and the cleaning pump by the pipeline switching unit respectively; when filtrate water meets a preset cleaning water quality requirement, the pipeline switching unit controls the filtrate pool to be communicated with the cleaning pump; and when the filtrate water does not meet the preset cleaning water quality requirement, the pipeline switching unit controls the filtrate pool to be communicated with the sewage treatment unit. According to the reverse cleaning system and the reverse cleaning method, the filtrate water of the ceramic filter is recycled, so that the filtrate water pumped by the ceramic filter is used effectively; an industrial water demand is reduced; the quality of the cleaning water is ensured by detecting the water quality of the filtrate water in real time; and the purification cost of industrial sewage is lowered.

Owner:YUNNAN DAHONGSHAN PIPELINE

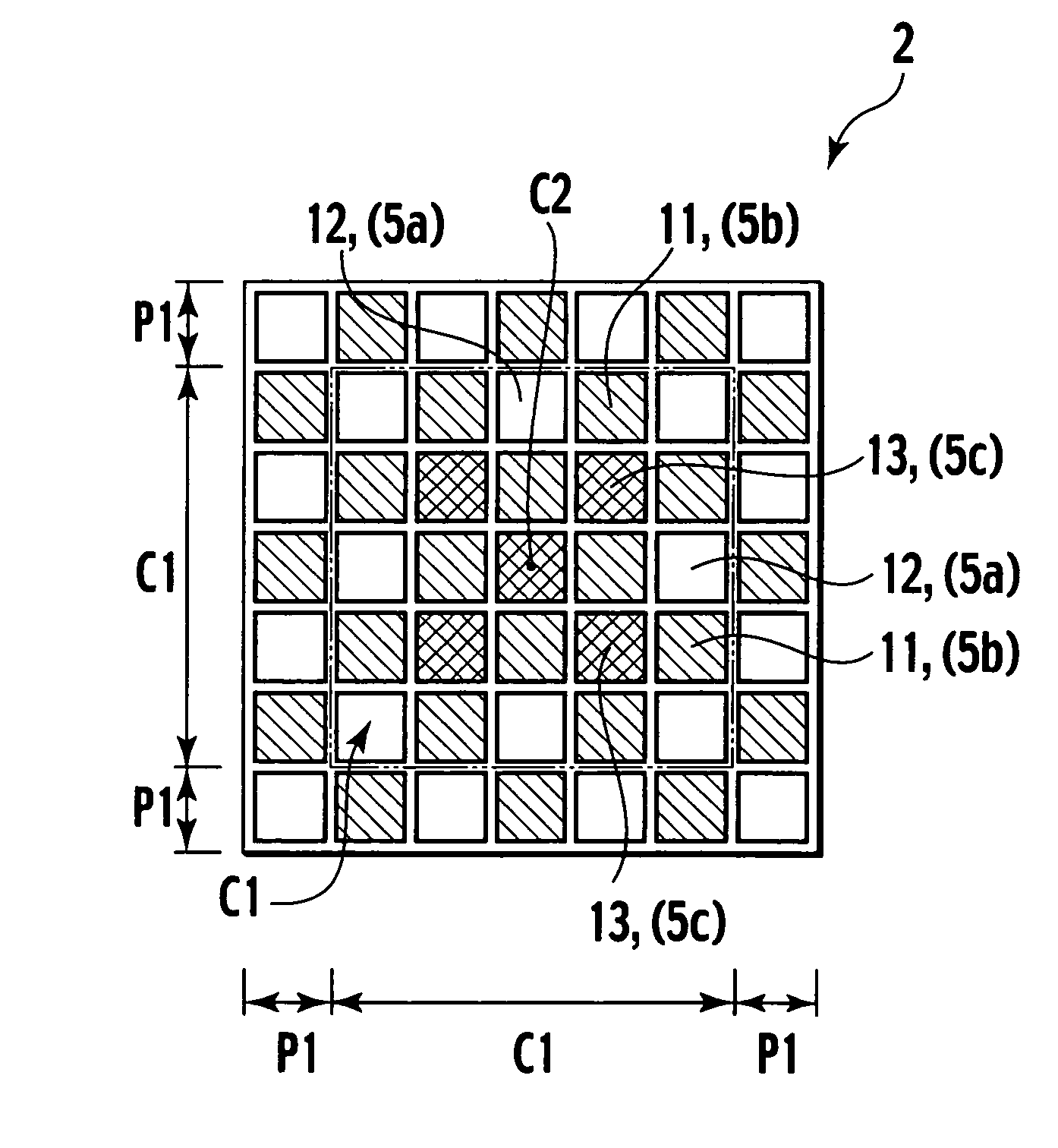

Ceramic filter

ActiveUS7892308B2Small amount of heatReduce temperature riseCombination devicesGas treatmentVacuum ceramic filterMetallurgy

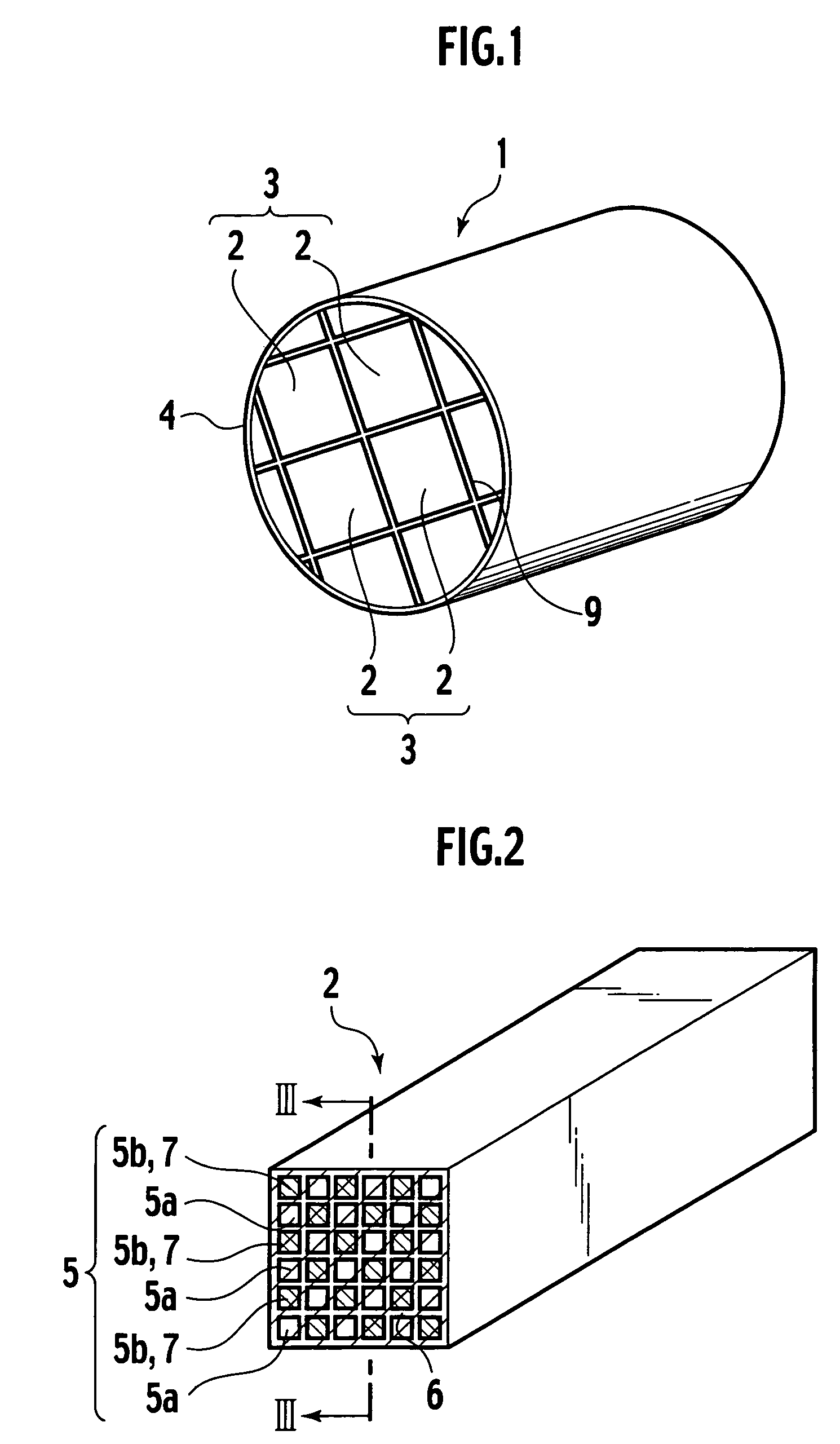

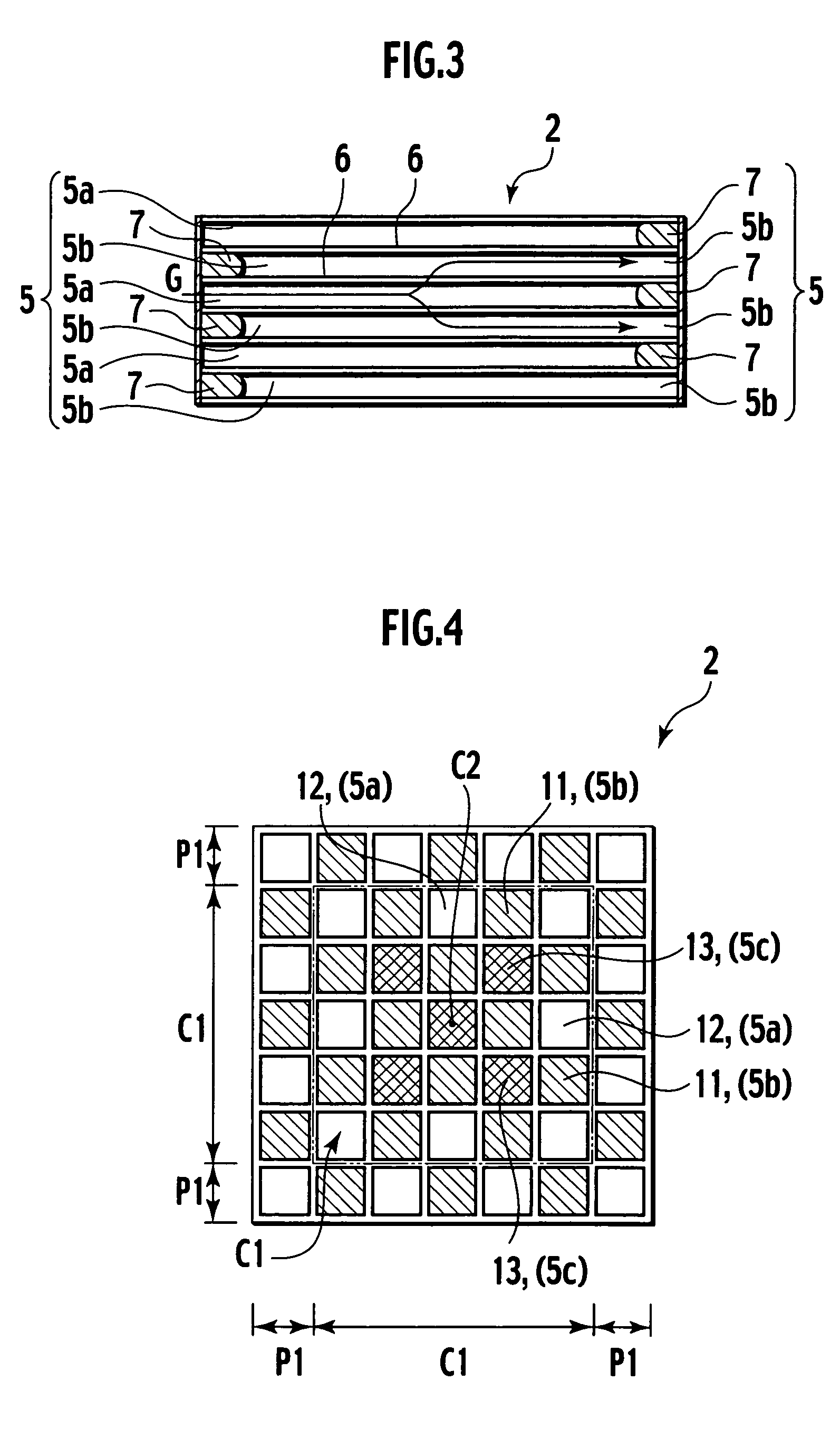

A filling percentage of a central portion is larger than that of a peripheral portion at the inlet end surface of an exhaust gas of a honeycomb segment (2) constituting a ceramic filter due to additional filling (13). Thus, an amount of soot accumulated in vents (5) in the central portion of each honeycomb segment (2) is less relative to that in the peripheral portion. This decreases a quantity of heat generated by burning of soot in the central portion, and reduces temperature rise during recycling, thus limiting the maximum temperature of the ceramic filter (1).

Owner:NGK INSULATORS LTD

Automatic backwashing filter

InactiveCN104083961ASolve the trouble of cleaningAvoid poisoningDispersed particle filtrationDust controlDenitrification

The invention discloses an automatic backwashing filter. The automatic backwashing filter comprises a shell, ceramic filters, filter fixing plates, a control unit, a compressed air header pipe and backwashing pipes, wherein a dust discharge opening controlled by a dust control valve is arranged below the shell; a dust-contained gas chamber is internally provided with a dust-contained gas pressure sensor; a clean gas chamber is internally provided with a clean gas pressure sensor; a compressed air control valve, the dust-contained gas pressure sensor and the clean gas pressure sensor are all connected with the control unit. According to the invention, the trouble of cleaning the filter by taking down is prevented, and the filter can be automatically backwashed; the ceramic filters act as catalyst carriers for denitrification reaction, and catalysts can be prevented from being poisoned because of attachment of dust by backwashing; the pressure monitoring is timely and accurate; the service life of a filter element can be prolonged.

Owner:DALIAN MARITIME UNIVERSITY

Cleaning method of ceramic filter

ActiveCN104307241AAccelerated obsolescenceIncrease productivityMoving filtering element filtersUltrasonic sensorVacuum ceramic filter

The invention discloses a cleaning method of a ceramic filter, which comprises the following steps in sequence: (1) stopping production, keeping idle running of the ceramic filter, cleaning the surface of a ceramic filter plate and a groove body, (2) inputting alkaline liquor at a mass fraction of 10-20% and clear water into a back flushing pipeline for mixing, adjusting water pressure of the back flushing pipeline to be stabilized at 0.15-0.2MPa for back flushing for 45-50min, (3) carrying out the back flushing for 5min with the clear water, flushing the groove body for 5min with circulation production water at the same time, and (4) filling the groove body with the circulation production water, turning on an ultrasonic transducer, inputting concentrated nitric acid at a mass fraction of 50-60% and the clear water for mixing, and adjusting the water pressure of the back flushing pipeline to be stabilized at 0.15-0.2MPa for back flushing for 30min. The method has a good cleaning effect, the ceramic filter can be cleaned every other 24h of continuous operation, the production cost of an enterprise is greatly saved, and the production efficiency is improved.

Owner:HUANGSHI HAOYUN MINING EQUIP ENERGY SAVING DEV CO LTD

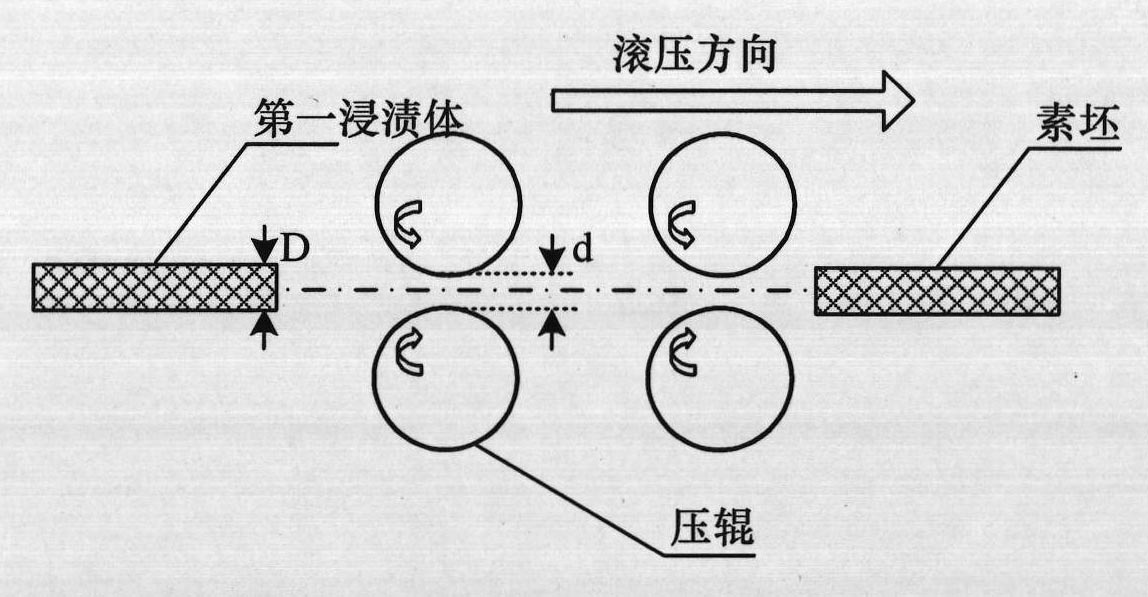

Preparation method of rare earth ceramic foam filter

ActiveCN105272351AImprove filtering effectEfficient purificationCeramicwareVacuum ceramic filterAdhesive

The invention belongs to the technical field of a preparation method of a ceramic filter for casting and relates to a preparation method of a rare earth ceramic foam filter. The preparation method comprises the following steps of preparing ceramic pulp: mixing rare earth, ceramic aggregate and an adhesive in parts by weight to prepare ceramic pulp A and ceramic pulp B; preparing a blank: dipping a polyurethane foam carrier into the ceramic pulp A, sufficiently absorbing the ceramic pulp A, carrying out roll forming via roll forming equipment to prepare the blank, reinforcing the upper surface, the lower surface and a core of the blank twice via glazing equipment after drying the blank; and carrying out high-temperature sintering: putting the blank after twice reinforcing and drying into a high-temperature sintering furnace for sintering to form the rare earth ceramic foam filter. A sintering period is short; the energy is saved; the breakage of the blank is avoided; at the same time, the pulp is adhered more uniformly; the blank is reinforced twice via glazing; the internal pulp is distributed uniformly and has low possibility of falling-off; and the property of a sintered product is stable.

Owner:青岛铸英特陶科技有限公司

Method and device for cleaning ceramic filter

ActiveCN102614705AReduce dosageExtended service lifeMoving filtering element filtersVacuum ceramic filterEngineering

The invention belongs to the technical field of filters and in particular relates to a method and a device for cleaning a ceramic filter by recycling cleaning fluid. The cleaning method is characterized in that clear water in the previous steps is replaced by the cleaning fluid in a cleaning fluid pool from the second-time washing to the last-time washing. The device is characterized in that one end of a cleaning fluid pipeline is connected with the cleaning fluid pool through a circulating pump, and the other end of the cleaning fluid pipeline is connected with the upper part of a tank body; one end of a drainage pipeline is connected with the cleaning fluid pool, and the other end of the drainage pipeline is respectively connected with the bottom and top of the tank body through a bottom flow valve and an overflow valve. Compared with the prior art, the invention has the advantages that the using amount of cleaning water can be reduced by over 60 percent, the service life of a ceramic plate is prolonged, the productivity of a filter is improved, the using amount of chemical agents is reduced, the production cost is reduced, and the device has low sewage discharge amount and is energy-saving and environment-friendly.

Owner:YANTAI HEJING CERAMIC NEW MATERIALS

Method for improving normal temperature strength of foamed ceramic filter

ActiveCN101108777AHigh bulk densityImprove toughnessCasting cleaning apparatusFiltration separationVacuum ceramic filterAtmospheric temperature

The invention discloses a method capable of improving the atmospheric temperature strength of the foamed ceramics filter. Through spraying and coating a layer of organic or inorganic materials on the surface of the sintered foamed ceramics filter and through natural drying or drying, the invention can greatly improve the atmospheric temperature strength of the filter and does not affect the service performance of the filter, which is beneficial for the filter to overcome the defects caused in transport and use, thereby ensuring the further increase of the casting quality.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

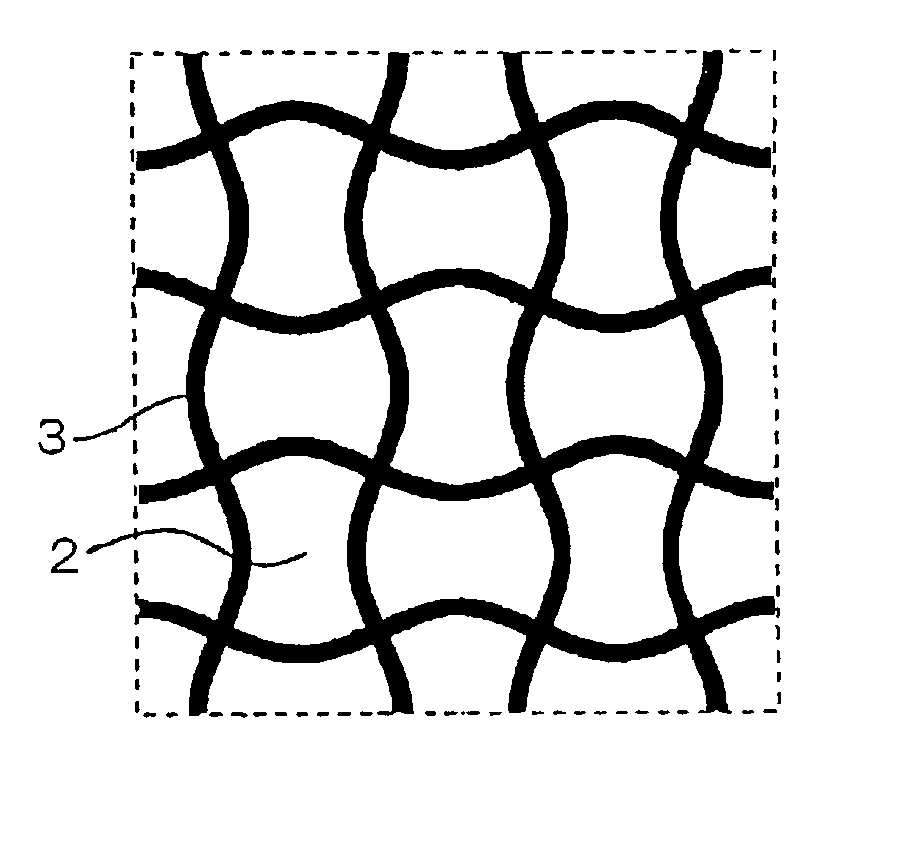

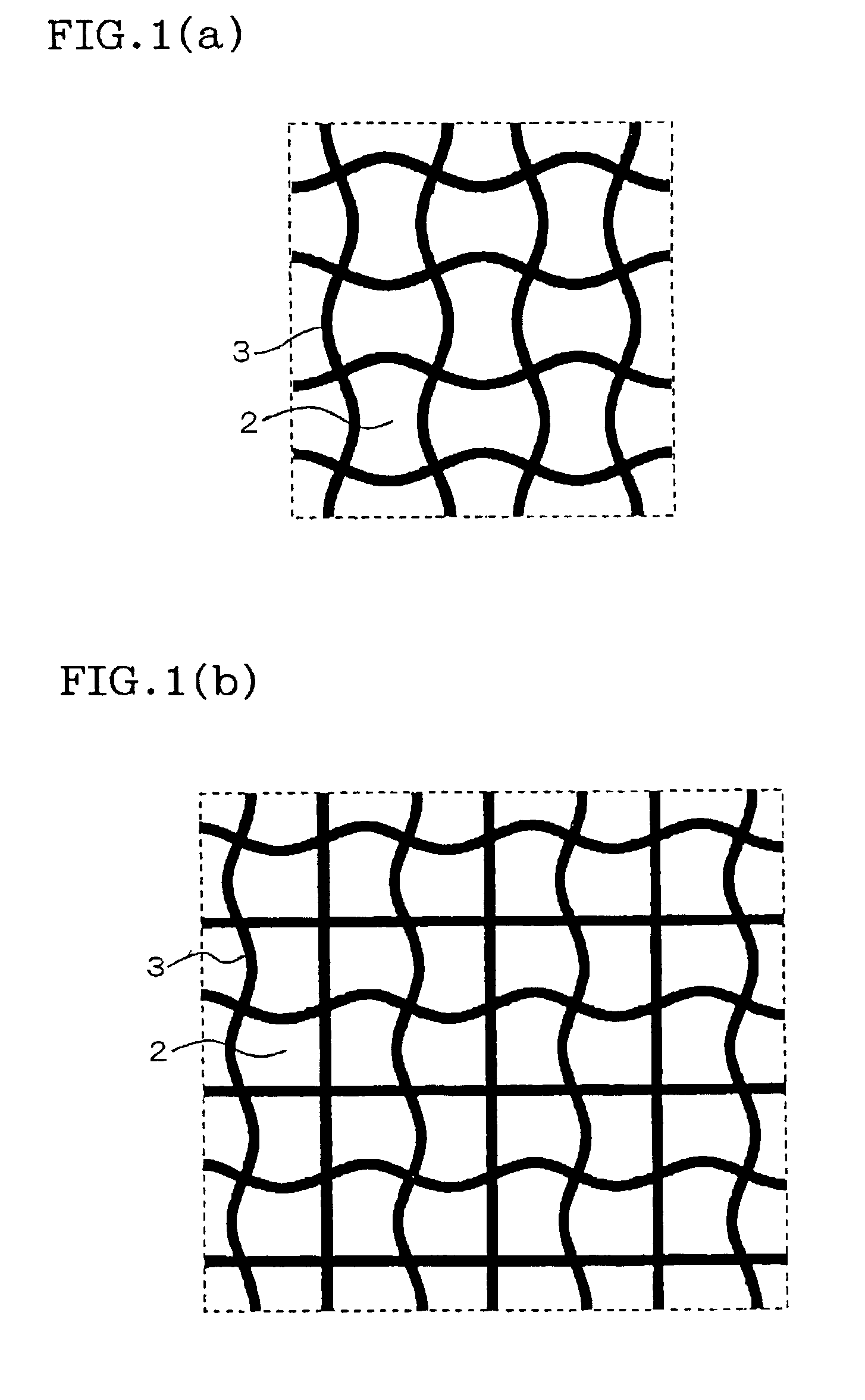

Polyester type large-aperture filtration sponge for ceramic filter and preparation method of large-aperture filtration sponge

The invention provides polyester type large-aperture filtration sponge for a ceramic filter sheets and a preparation method of the large-aperture filtration sponge, belongs to the technical field of polyester sponge, and solves the technical problems of relatively small aperture of the conventional polyester sponge and the like. The preparation method of the polyester sponge comprises the following steps: conveying polyester polyol, isocyanate, water, silicone oil and a catalyst to a foaming machine head through a metering pump; adjusting a machine head pressure and a raw material spraying pressure; respectively vacuuming the various raw materials; mixing the various raw materials in a reaction kettle; after the raw materials are stirred at a high speed, uniformly distributing the materials on a conveyor belt of a foaming production line; performing gel reaction in a conveying process of the continuous foaming production line, solidifying and molding the materials to obtain polyurethane flexible foam plastic, and then cutting the plastic into a specified size on line; performing meshing treatment on the cut polyester sponge to obtain the polyester sponge having a PPI value between7 and 15. The preparation method has the advantage of obtaining the large-aperture polyester sponge.

Owner:湖北世丰新材料有限公司

Automatic fail preventing device for ceramic filter

InactiveCN104436918AImprove economyLow costDispersed particle filtrationMetallurgyVacuum ceramic filter

The invention provides an automatic fail preventing device for a ceramic filter. The automatic fail preventing device for the ceramic filter comprises a porous metal protection pipe and a fixing seat, wherein the porous metal protection pipe is fixed at the upper part of a main pipe plate of the filter through the fixing seat, and the position of the porous metal protection pipe corresponds to that of a ceramic filtering pipe up and down; an injecting and blowing pipe is arranged in the porous metal protection pipe, the upper end of the injecting and blowing pipe extends out of the top of the porous metal protection pipe and is communicated with a back flushing distribution pipe, and a spiral drain pump is arranged at the lower end of the injecting and blowing pipe. According to the automatic fail preventing device for the ceramic filter, the pressure drop is relatively low when the ceramic filter safely runs, cleaning gas can smoothly enter an air purification room through the wall of the protection pipe; when a filtering element has failure, large-particle dust can be quickly sealed so as to prevent an integral system from stopping caused by the damage of few of filtering elements. The automatic fail preventing device for the ceramic filter automatically seal damaged filtering elements, and a precise online monitoring device and a corresponding probe for locating the damaged filtering elements do not need to be installed, so that the operation and the installation are convenient, and the error stopping caused by error judgment is also avoided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

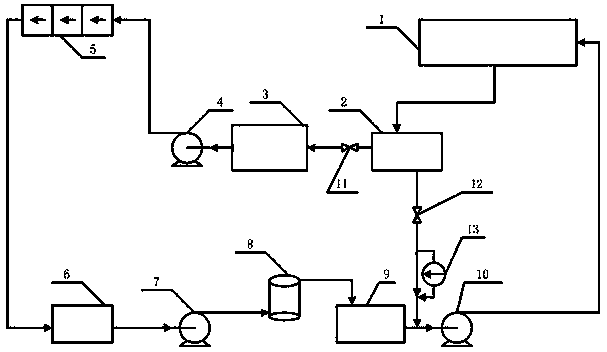

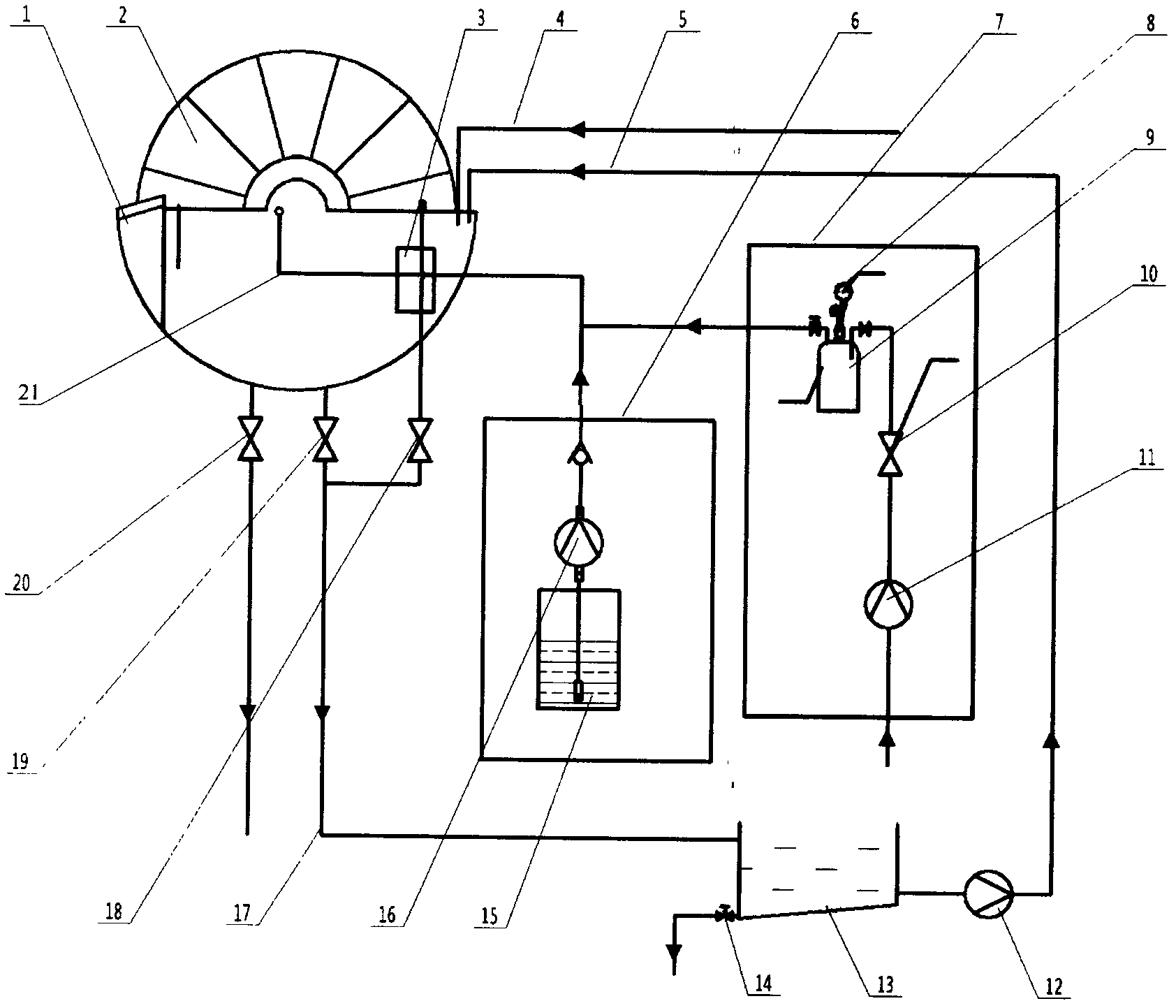

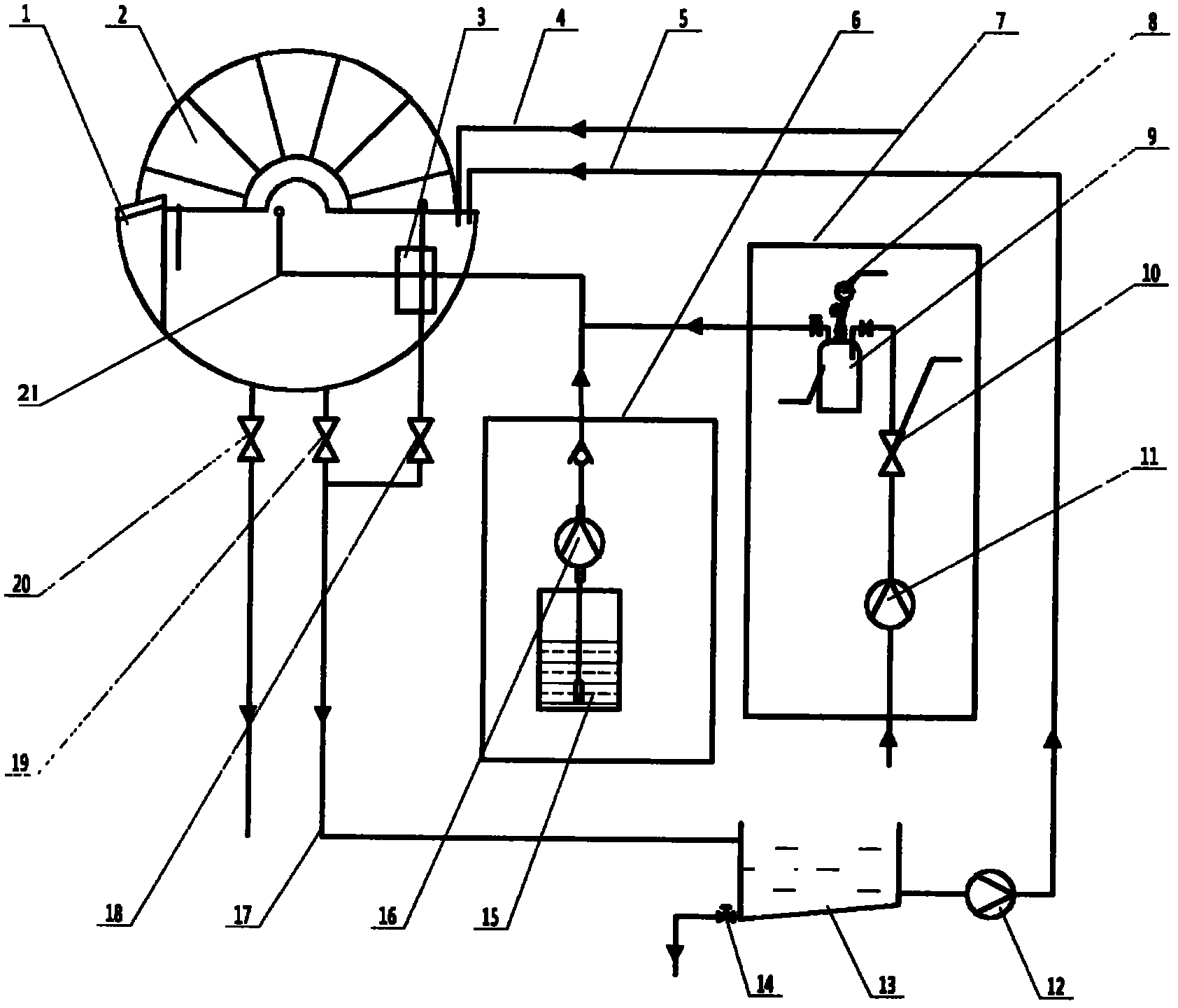

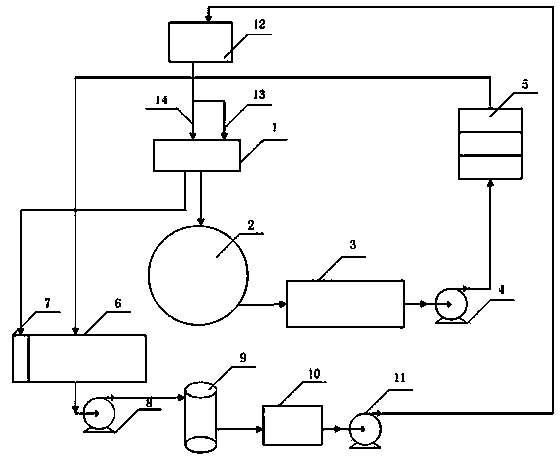

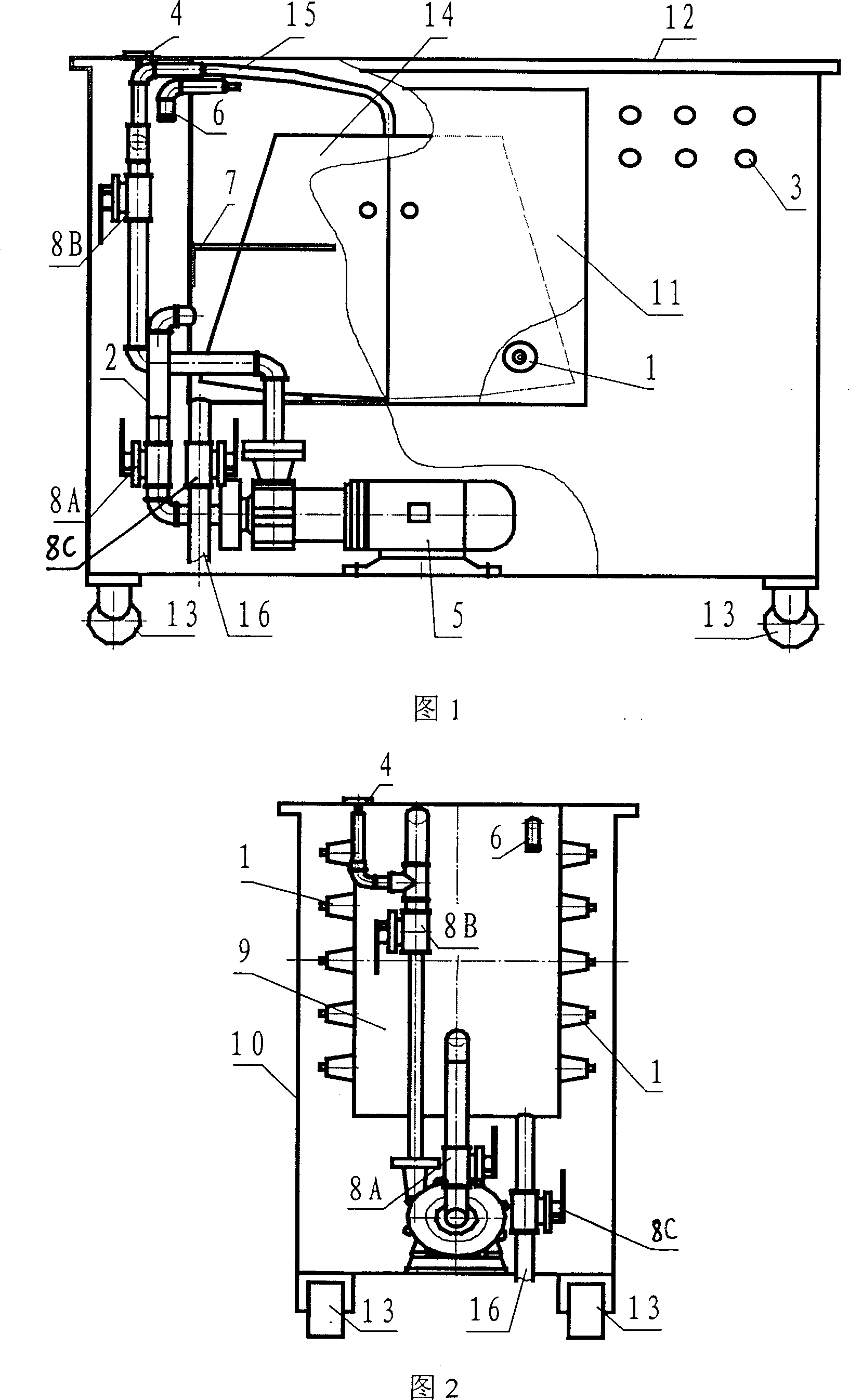

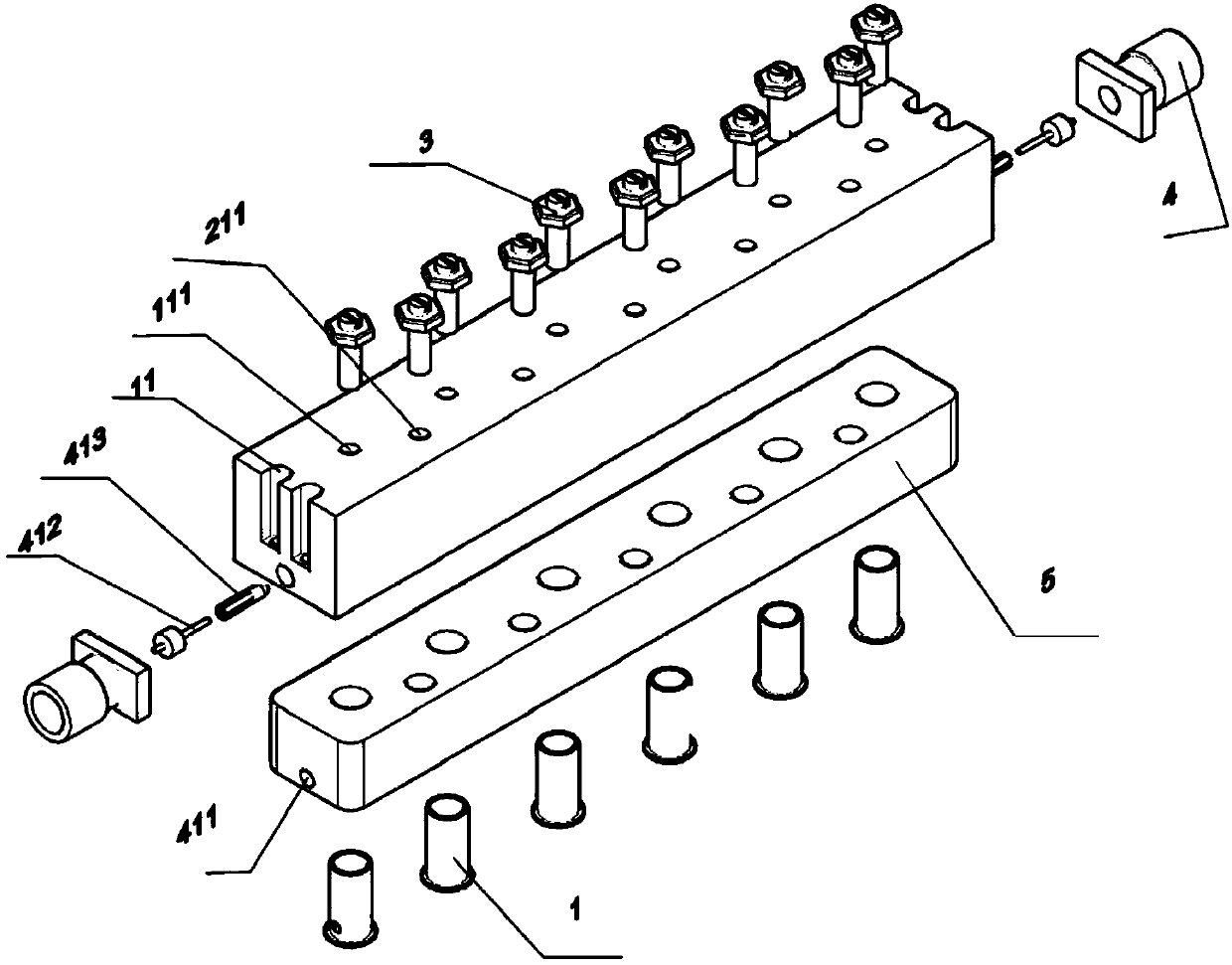

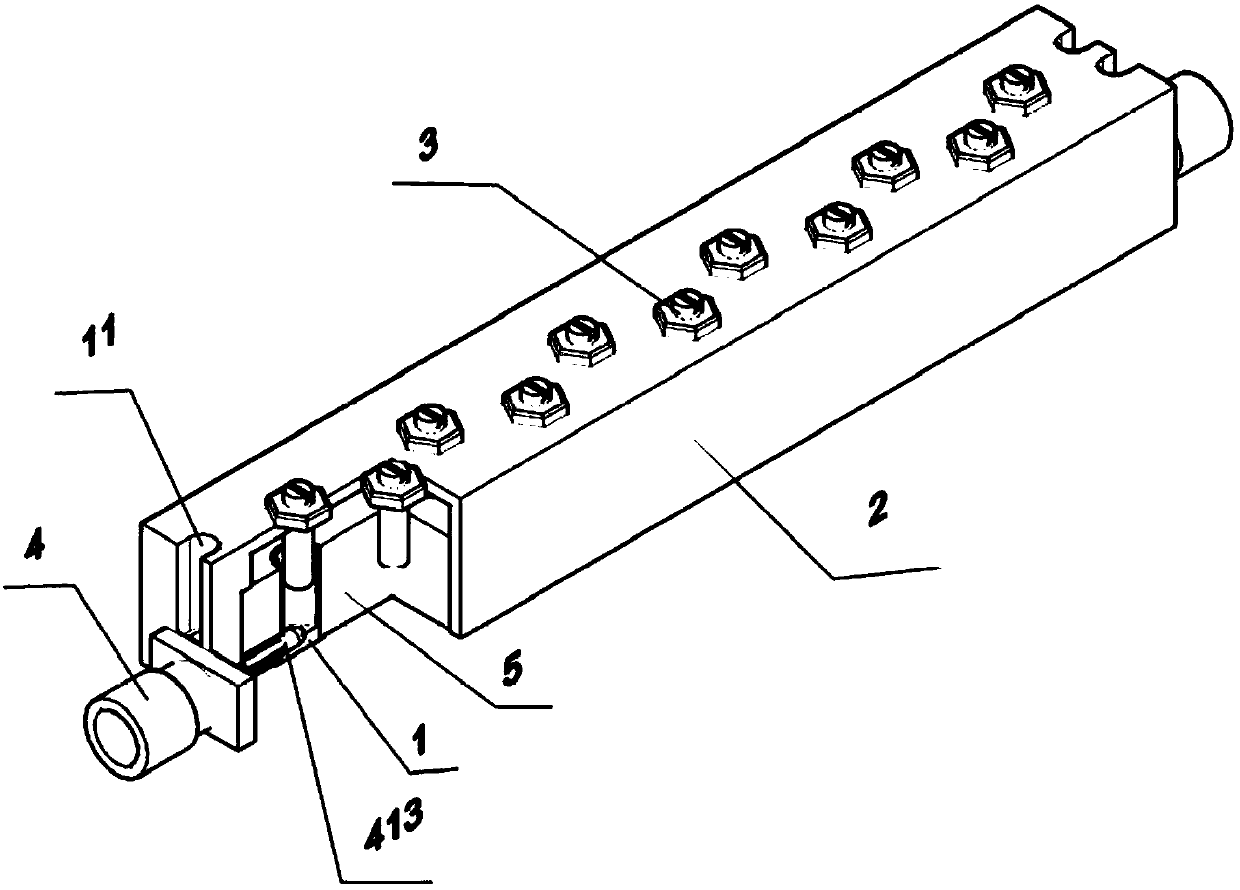

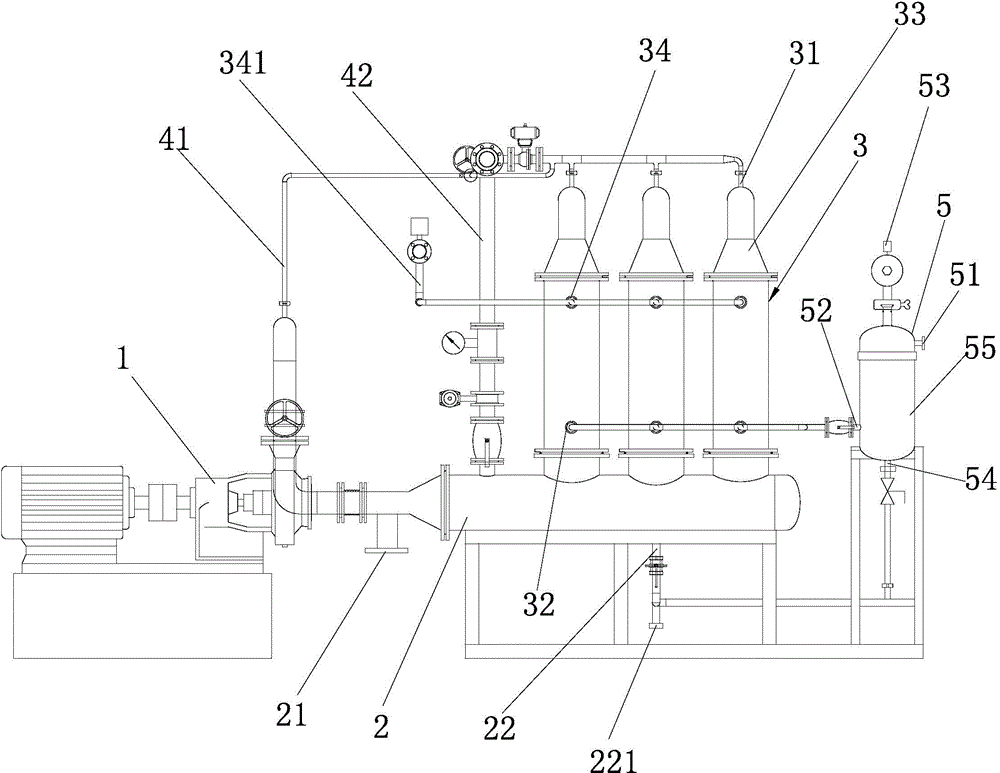

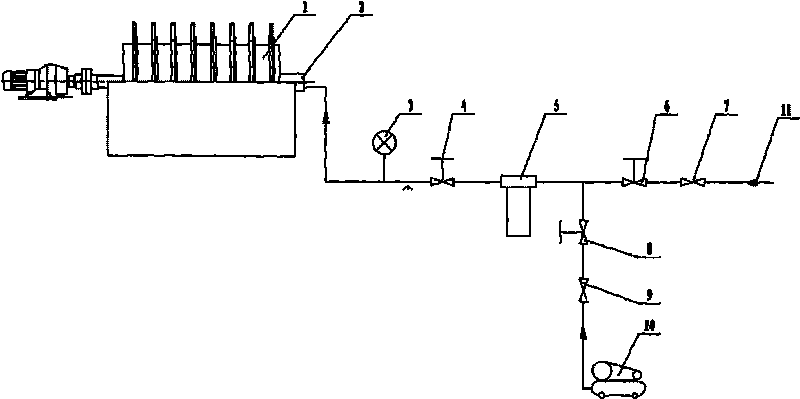

Optimizing system and method for shaft seal water of vacuum pump of ceramic filter

ActiveCN103463865AAvoid low water pressureReverse flushing water quantity guaranteeFiltration circuitsVacuum ceramic filterVacuum pump

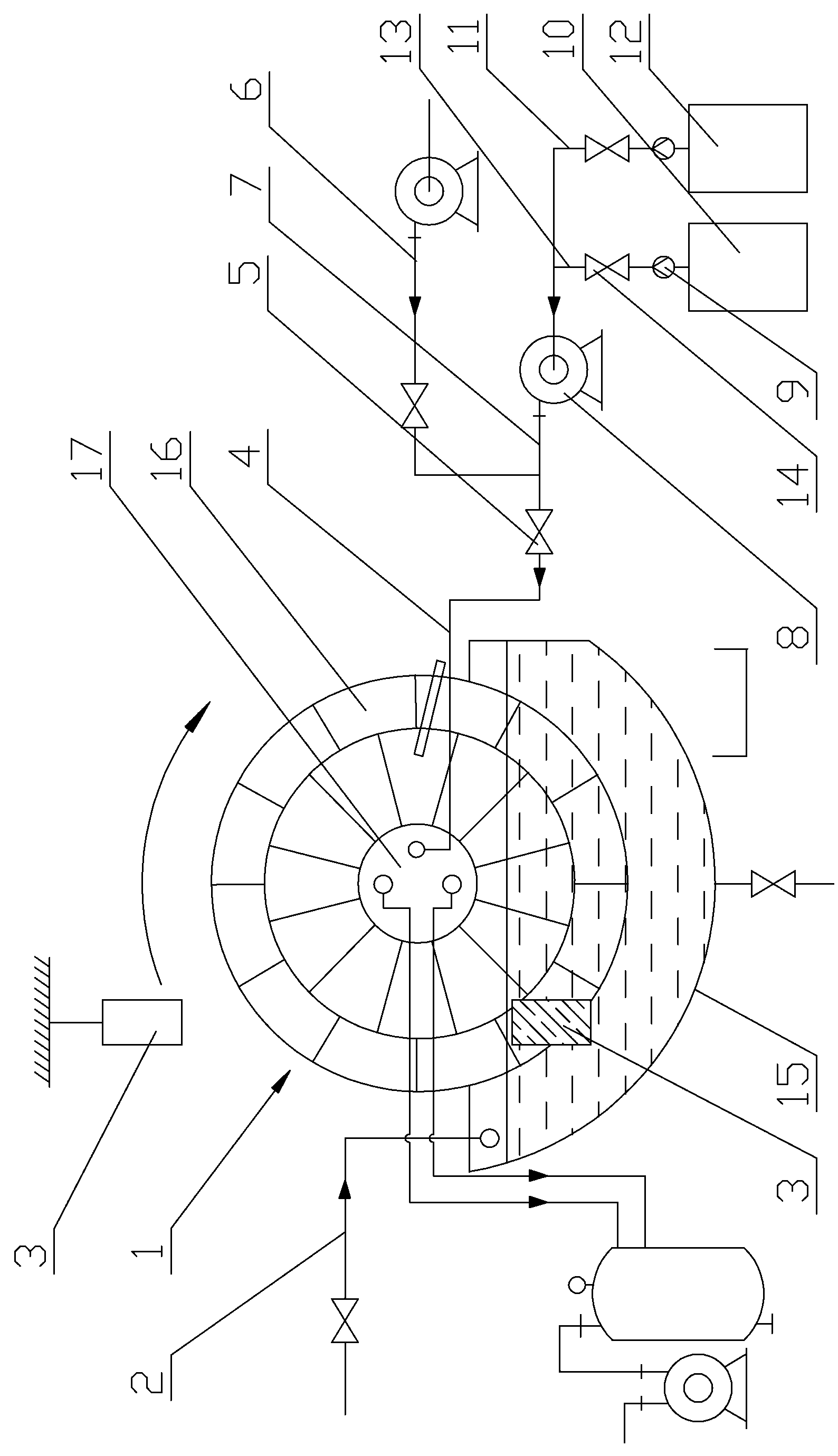

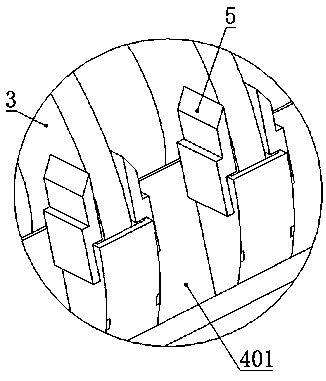

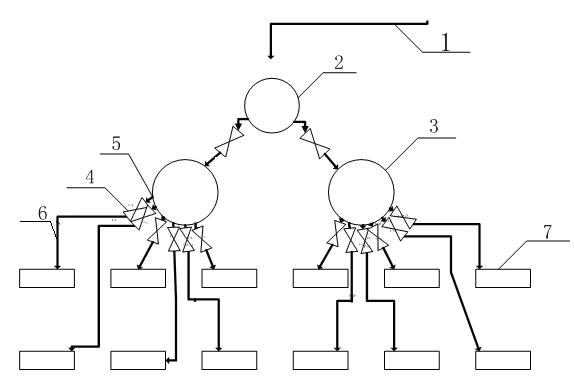

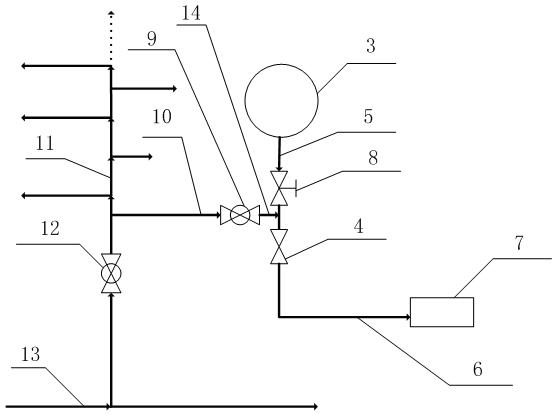

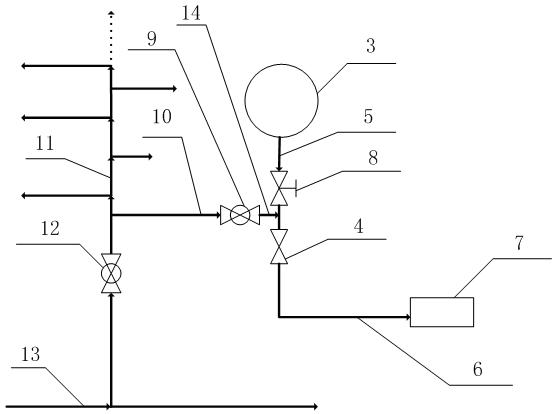

The invention relates to an optimizing system and method for shaft seal water of a vacuum pump of a ceramic filter. Clear water in a clear water pool (10) is pumped to a high position water tank (12) by a first output pipeline and a first clear water pump (11), water in the high position water tank (12) serves as backflushing water of a ceramic filter (1) by a ceramic filter backflushing pipeline (13), a second output pipeline of the clear water pool (10) is connected with one end of a vacuum pump shaft seal water pipeline (14), the other end of the vacuum pump shaft seal water pipeline (14) is directly connected with a vacuum pump of the ceramic filter (1), and a second clear water pump (16) is arranged on the second output pipeline. According to the invention, water supply for the vacuum pump shaft seal water and water supply for ceramic filter backflushing water are separated and do not affect each other, thereby effectively avoiding the problem of low pressure of the ceramic filter backflushing water, and guaranteeing the volumes of the shaft seal water of the ceramic filter vacuum pump and the backflushing water of the ceramic filter.

Owner:YUNNAN DAHONGSHAN PIPELINE

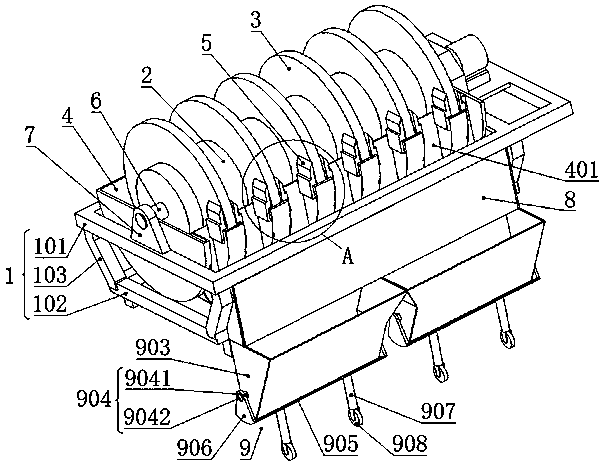

Ceramic filter

InactiveCN108993010APrevent splashReduced transit timeMoving filtering element filtersVacuum ceramic filterParticle scattering

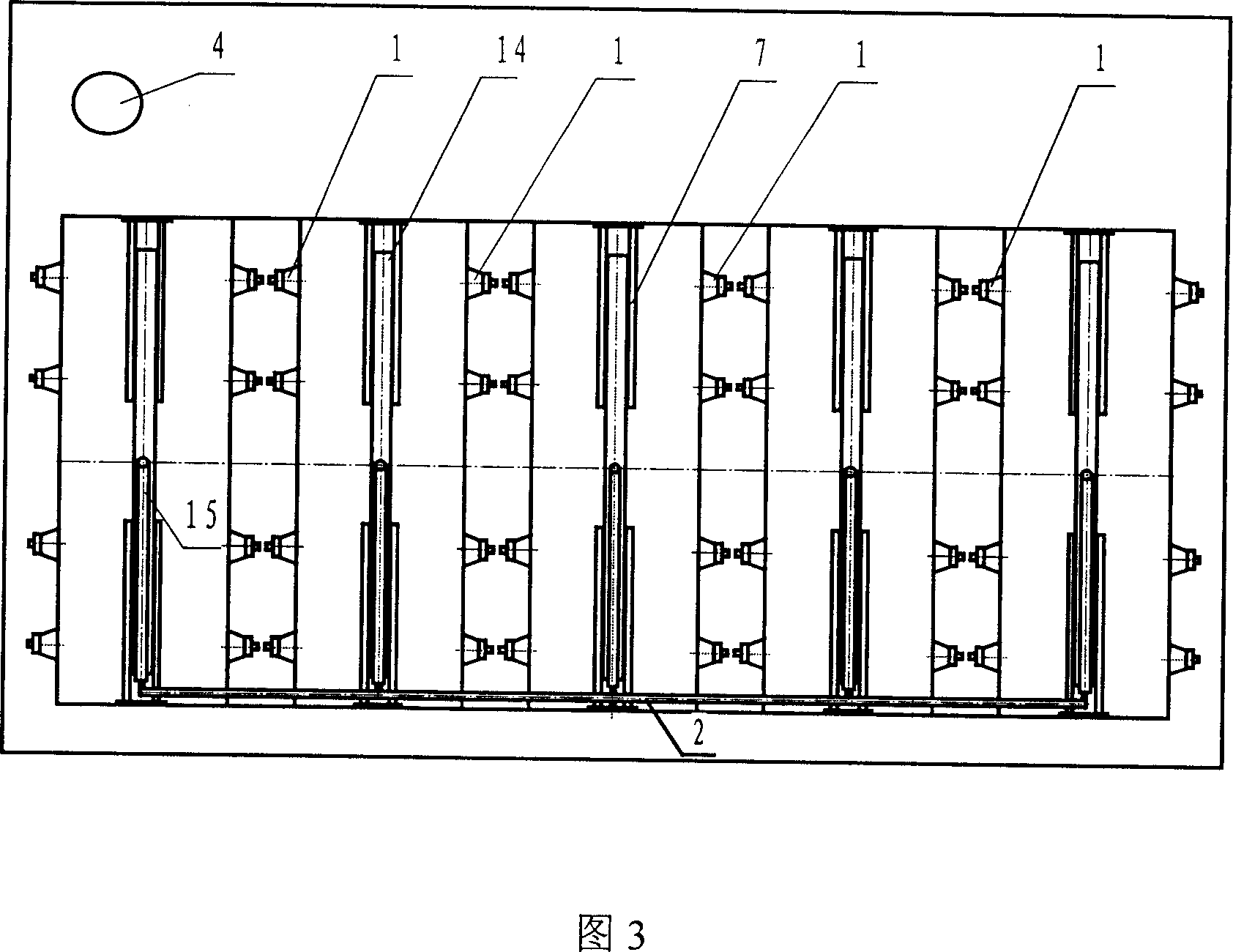

The invention discloses a ceramic filter. The ceramic filter is capable of solving problems in the prior art that filtered particle scattering is easily caused by a blanking conveying platform, and conveying vehicle waiting time is too long. The ceramic filter comprises a machine frame, pressure chambers, ceramic filter plates, a sludge groove, and scrapers; a plurality of opening blanking groovesare arranged on one external side of the slurry groove at intervals; the scrappers are fixedly arranged on the two side groove walls of the opening blanking grooves, and are pressed against the ceramic filter plates; a material guide groove is arranged between the sludge groove and the machine frame; a plurality of material collecting hoppers are fixedly arranged on the machine frame below the material guide groove; each material collecting hopper is connected with a material hopper door used for sealing a material collecting hopper material outlet using a rotating part; and each material hopper door is fixedly provided with a hopper opening push rod. According to the ceramic filter, mud is introduced into the material collecting hoppers through the material guide groove, so that mud scattering is avoided; the hopper opening push rod is pushed by a transport vehicle to open the corresponding material hopper door for blanking, so that long blanking waiting time is shortened, and the transportation time is shortened.

Owner:王卓

Device and method for preventing feeding valve of ceramic filter from being blocked

ActiveCN102489068AIncrease productivityWith backwash functionFiltration separationVacuum ceramic filterBlocked valves

The invention relates to a device and a method for preventing a feeding valve of a ceramic filter from being blocked, which comprises a main pulp pipeline, a distribution barrel, a mixing barrel, the feeding valve and the ceramic filter. Pulp of the main pulp pipeline enters the distribution barrel which distributes the pulp to one or a plurality of mixing barrels, and each mixing barrel is connected with each ceramic filter through a pipeline. The feeding valve is disposed on the pipeline and divides the pipeline into a feeding valve front section pipeline and a feeding valve rear end pipeline. Mineral powder accumulated in the feeding valve, the feeding valve front section pipeline and the feeding valve rear end pipeline is washed and dredged through a backwash device. Due to the fact that after the backwash device and the method are arranged, the blocked valve pipeline of the ceramic filter can be directly washed without stopping other ceramic filters and mixing barrels, productionefficiency is greatly improved.

Owner:YUNNAN DAHONGSHAN PIPELINE

Ceramic filter

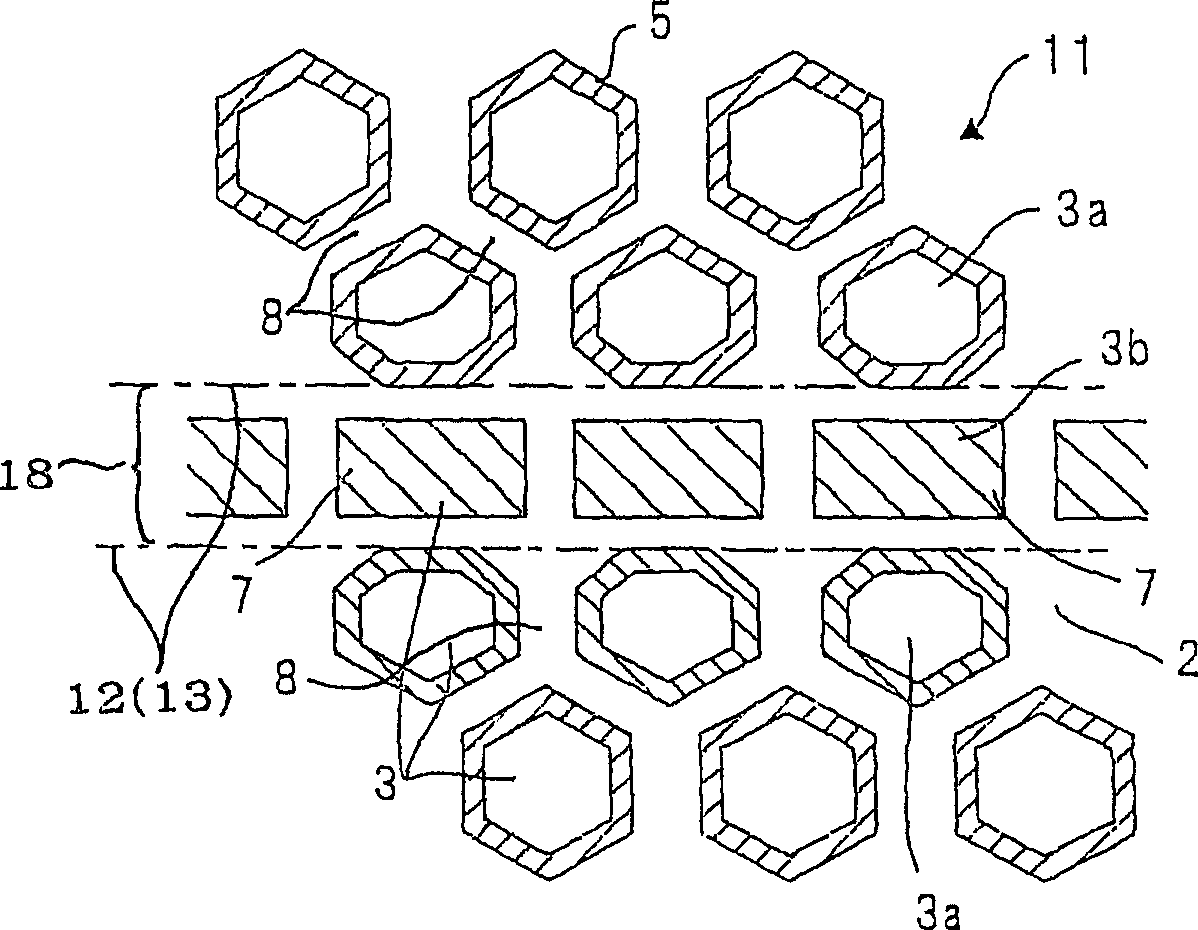

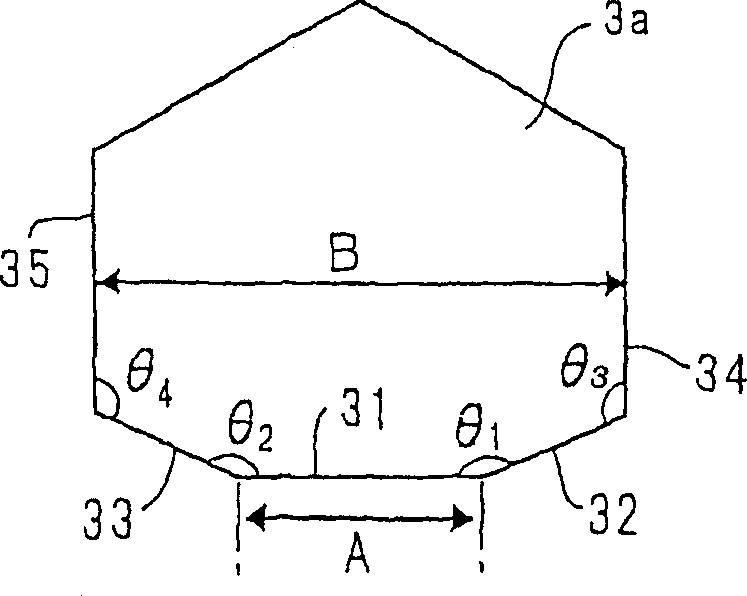

ActiveCN1764496ADispersed particle filtrationFiltration separationVacuum ceramic filterMaterials science

The invention relates to a ceramic filter used for filtering liquid, gas and other fluids. The ceramic filter of the present invention is a ceramic filter (1) composed of a porous body (2) and a filter membrane (5). The cross-sectional shape is arranged in a row in a predetermined pattern, and the cross-sectional shape of the specific partition (18) perpendicular to the direction of the fluid to be purified or the flow path of the purified fluid is surrounded by a shape formed by two parallel straight lines separated by a predetermined interval. The shape of the first specific main flow path (3a) perpendicular to the flow path direction of the purified fluid or purified fluid is a heptagonal or polygonal shape configured in a predetermined state, and θ1, θ2, θ3, θ4 In the range of 110° to 160°, A and B satisfy the relationship of 0.3B≤A≤0.7B, no defects such as cracks occur on the filter membrane, and the output rate is improved.

Owner:NGK INSULATORS LTD

Washing machine special for porous ceramic filtering plate of ceramic filter

InactiveCN1978031AEasy to cleanExtended service lifeFilter regenerationMoving filtering element filtersUltrasonic sensorMetallurgy

The present invention relates to a special-purpose cleaning machine for microporous ceramic filtering plate of ceramic filter. It includes shell body, cleaning channel set on said shell body, ultrasonic transducers and washing device. In the cleaning channel interior a ceramic filtering plate positioning frame is set, its bottom portion is equipped with fluid-discharging tube, the ultrasonic transducers are respectively mounted at two sides of said cleaning channel. The washing device is formed from internal circulating pipeline and circulating pump mounted on the internal circulating pipeline. Said invention utilizes ultrasonic wave and chemical cleaning agent to clean filtering plate, so that it can prolong the service life of ceramic filtering plate.

Owner:ANHUI TONGGUAN MACHINERY

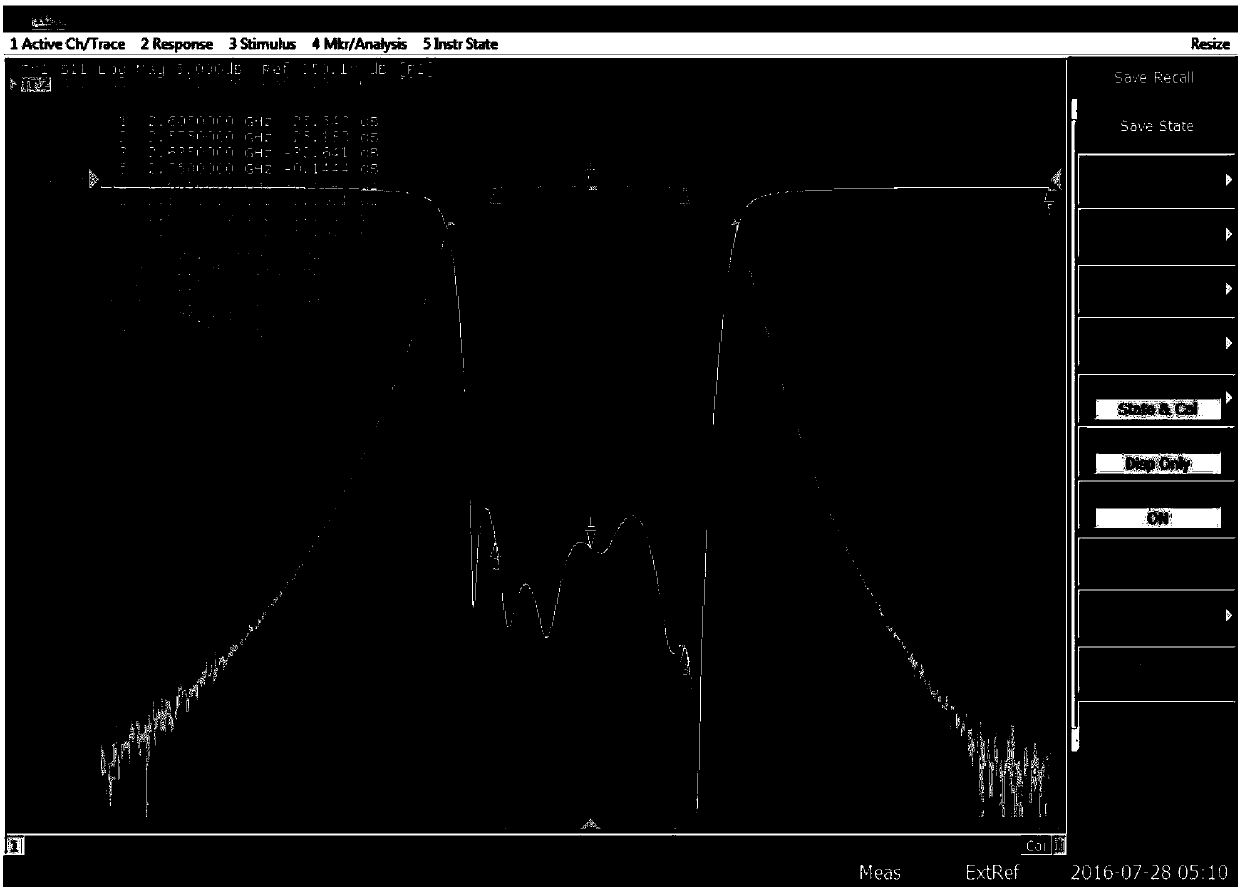

Embedded ceramic cavity filter

The invention discloses an embedded ceramic cavity filter comprising n resonators, a ceramic block and a metal cavity, wherein n is not less than 2. The resonator is accommodated in the metal cavity by being embedded in the ceramic block; the filter is provided with n resonance holes and n-1 coupling holes. Each resonator hole penetrates the ceramic block from the top surface of the metal cavity and extends into the corresponding resonator; each coupling hole extends into the ceramic block from the top surface of the metal cavity and is located between two adjacent resonators. The invention can adjust the frequency and has a closed cavity structure to be embodied by using a resonator, so as to improve the problem that the conventional ceramic filter cannot achieve the suppression difference, mutual interference between signals, and large loss. The invention uses the form of resonator insertion to minimize the loss and improve the performance, and the Qu value is 1.5 to 2 times higher than the ceramic filter; at the same time, the cavity filter has the features of miniaturization and light weight.

Owner:SUZHOU RF TOP ELECTRONICS COMM +2

Ceramic filtering system

InactiveCN104801184AFully filteredImprove filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisVacuum ceramic filterEngineering

The invention discloses a ceramic filtering system. The ceramic filtering system comprises a circulation pump, a material conveying pipe and filters; a slurry inlet is formed in the material conveying pipe; the circulation pump is connected with the material conveying pipe; the material conveying pipe is communicated with the filters; the filters are provided with purified liquor outlets and material outlets; the material outlets of the filters are provided with regulating pipelines; the filters are connected with the material conveying pipe by the regulating pipelines; the filters are internally provided with a ceramic membrane filtering pipe. The ceramic filtering system provided by the invention filters slurry fully by adopting an operating mode of circulation filtration, is good in filtering effect, is favorable in abrasion resistance by adopting the ceramic membrane filtering pipe, is high in firmness, and has long service life.

Owner:宜兴市科创环保有限公司

Method for cleaning ceramic filter

InactiveCN101810961AExtended service lifeLow failure rateStationary filtering element filtersMoving filtering element filtersUltrasonic sensorMotor drive

The invention relates to a method for cleaning a ceramic filter, which can facilitate maintenance of an ultrasonic transducer and has better cleaning effect. The invention adopts a technical scheme that: a filter plate of the ceramic filter is cleaned through the ultrasonic transducer. The method is characterized in that: a motor drives an ultrasonic transducer box to move up and down; the ultrasonic transducer box is positioned at different positions by controlling start or stop of the motor; and the filter plate is cleaned.

Owner:YUNNAN DAHONGSHAN PIPELINE

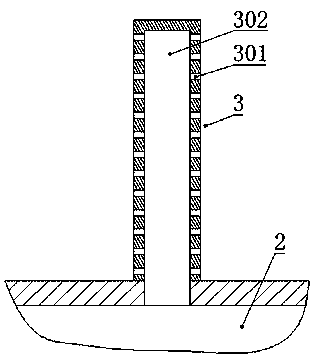

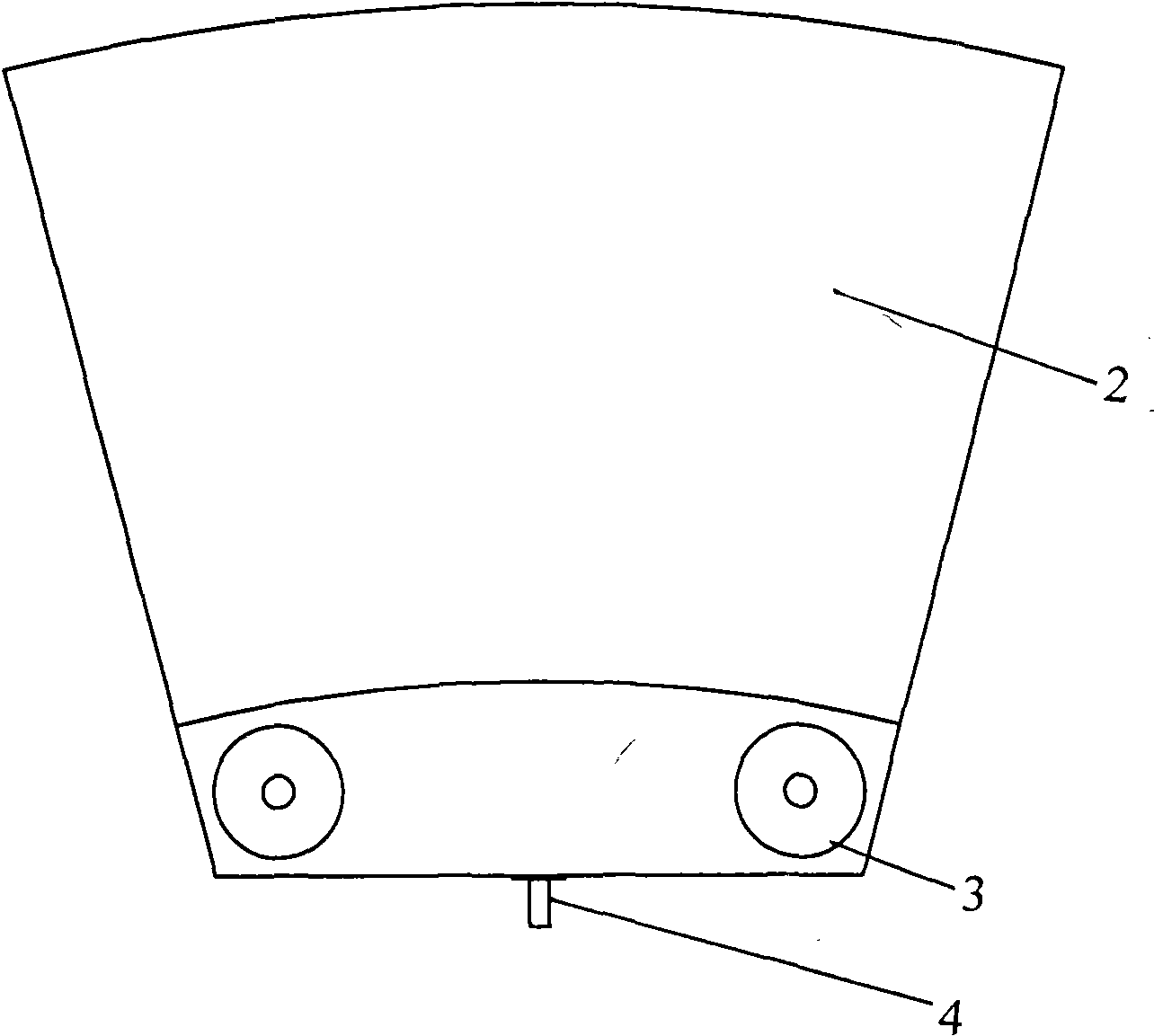

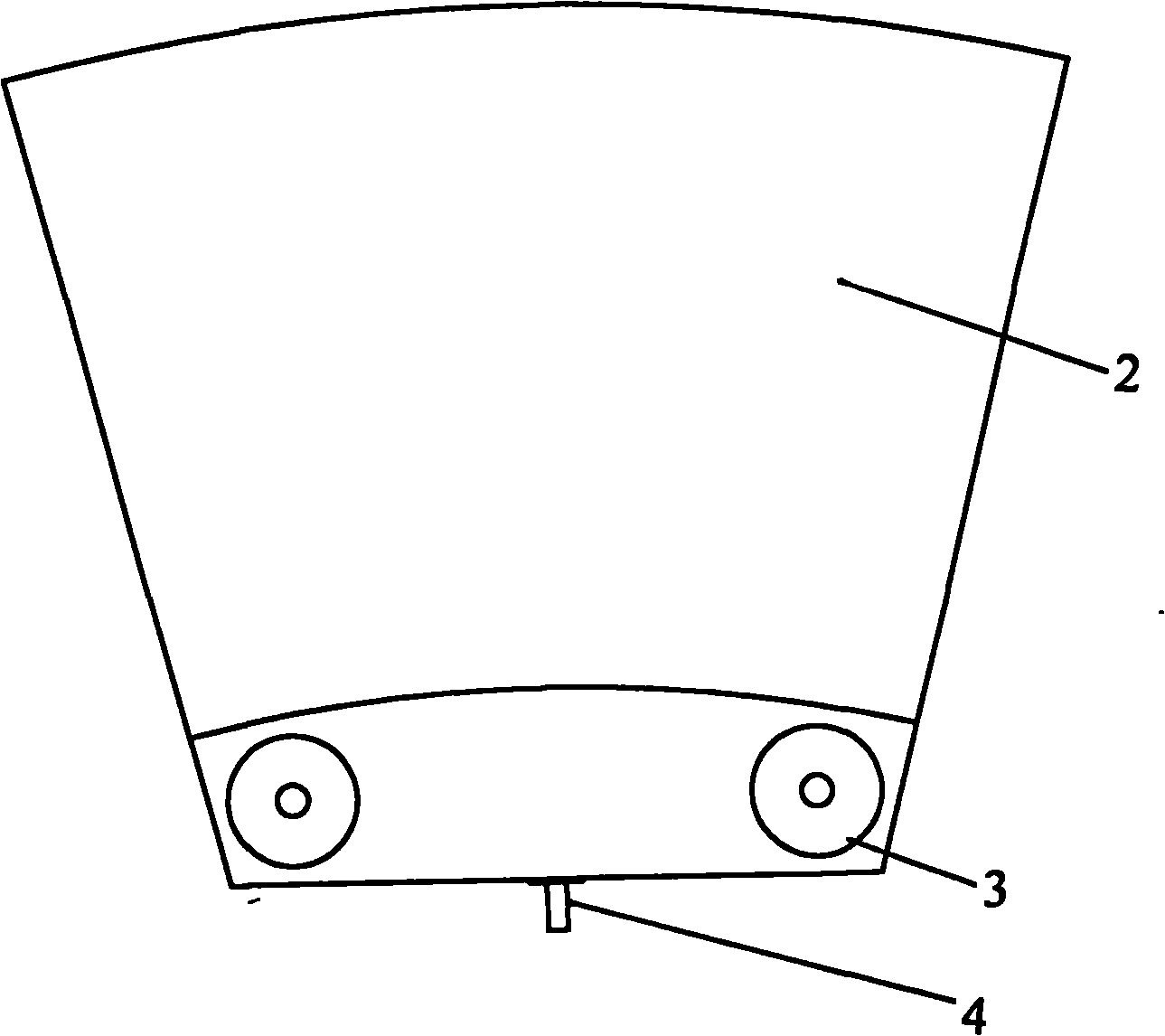

Vacuum ceramic filter plate and manufacture method thereof

InactiveCN101773746AReduce purchasing costsImprove performanceStationary filtering element filtersMoving filtering element filtersAir compressionVacuum ceramic filter

The invention relates to a vacuum ceramic filter plate and a manufacture method thereof. The vacuum ceramic filter plate is structurally characterized in that a film hole is formed on the film surface of the vacuum ceramic filter plate, the film hole is in a step shape and is in the reverse conical shape, and the thickness of the film surface is between 0.2 and 0.7 mm. The manufacture method comprises the following steps: base plate bonding agent preparation; material mixing, forming and drying; primary sintering, grinding processing and soaking flushing; staged film spraying process; secondary drying; secondary sintering and gluing; assembly hole manufacture and installation; edge sealing and painting; and checking and storage. The invention has the advantages that the procurement cost of users is saved, the frequency and times for replacing the filter plate are reduced, the shutdown time loss caused by unexpected plate bursting in the production is reduced, the production efficiency is improved, the generation of solid waste materials is reduced, and the invention has good environment protection valve and good social economic benefits. The integral structural intensity (in a wet state) reaches the effect that the plate bursting does not occur in the 0.6 MPa air compression test, and the abrasion resistance intensity is more than one time higher than that of a conventional film surface. The rejection rate of the filter plate is reduced by more than 50 percent, and the generation of solid waste materials is reduced.

Owner:江苏势坤研磨新材料有限公司

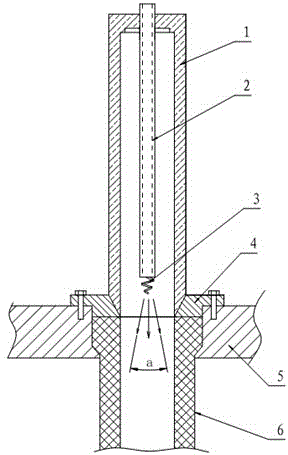

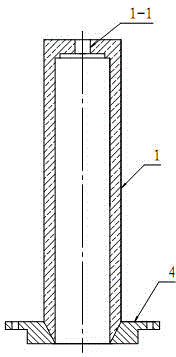

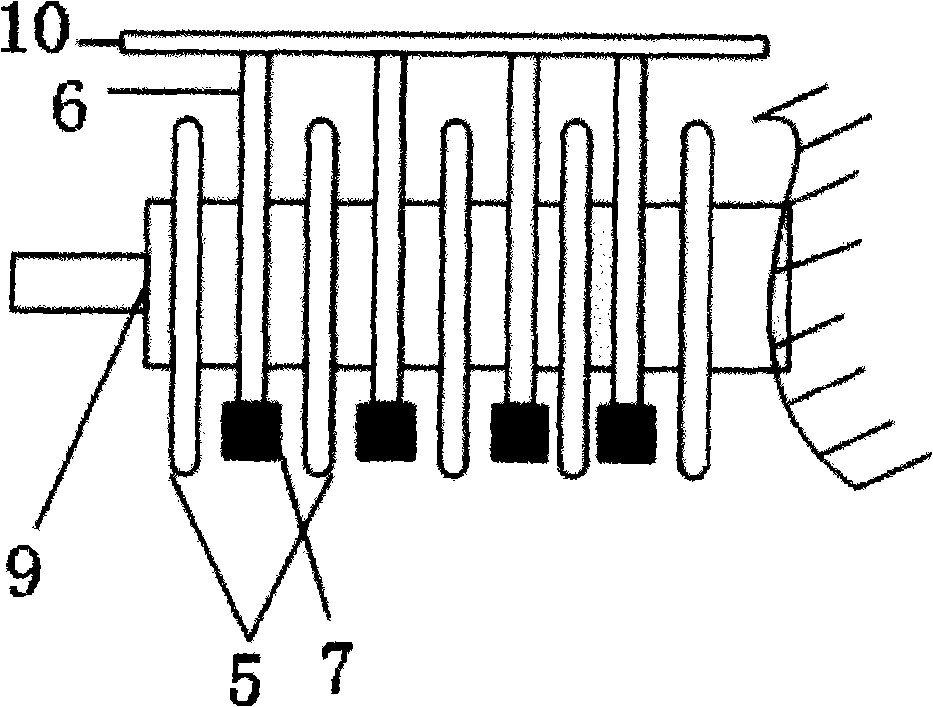

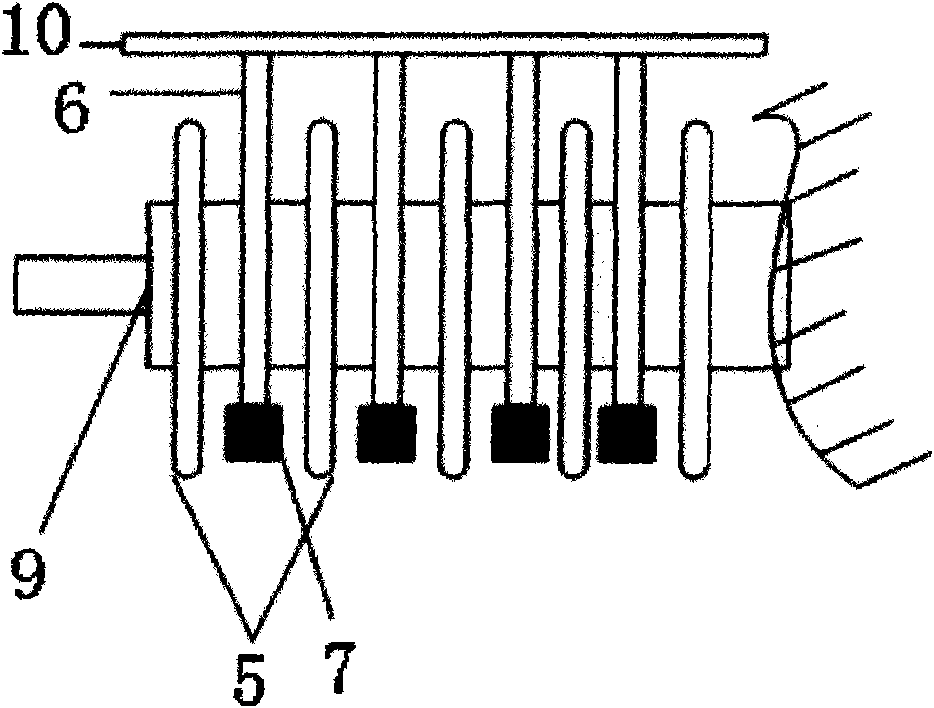

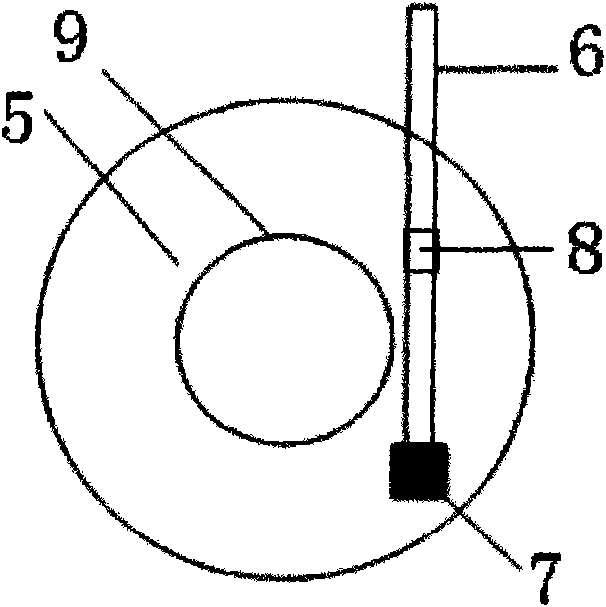

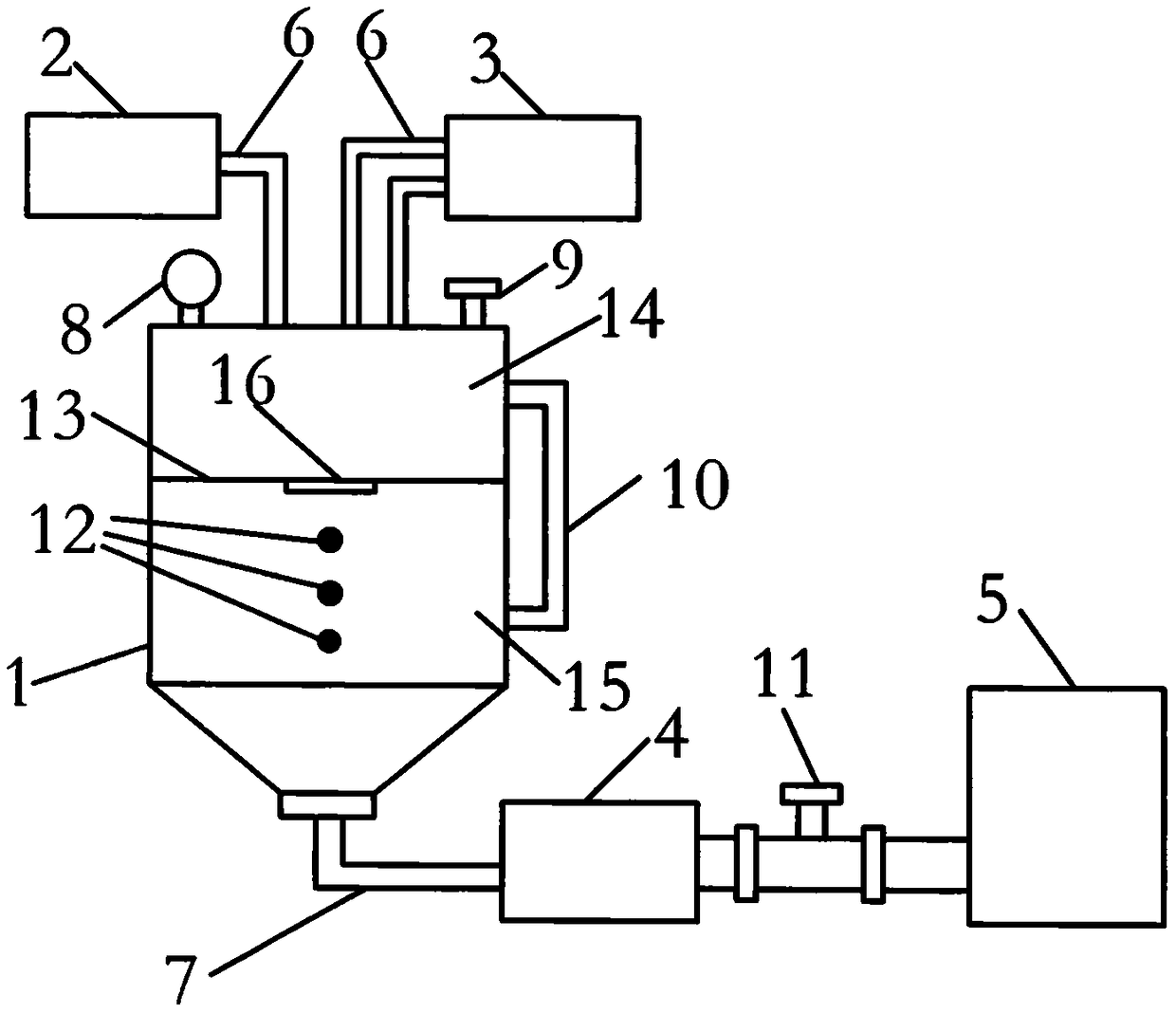

Automatic liquid discharging device for vacuum ceramic filter

InactiveCN109499160AIncrease productionImprove drainage efficiencyFiltration separationDischarge efficiencyAutomatic control

The invention relates to the field of liquid discharging equipment, and discloses an automatic liquid discharging device for a vacuum ceramic filter. The device comprises a vacuum tank (1); the top end of the vacuum tank (1) is connected with a vacuum pump (2) through a vacuum tube (6); the other end of the vacuum tank (1) is connected with a ceramic filter liquid distributor (3) through the vacuum tube (6); the bottom of the vacuum tank (1) is connected with a drain pump (4) through an iron wire hose (7); the drain pump (4) is connected with a liquid storage barrel (5) through a pneumatic valve (11); three liquid level sensors (12) are uniformly arranged on the inner side wall of the vacuum tank (1) from bottom to top; and a liquid level tube (10) for measuring water level is arranged onthe side surface of the vacuum tank (1). The device is good in liquid discharging efficiency and is capable of improving the overall output of the vacuum ceramic filter, and the overall output is 2-3times of that of other liquid discharging systems; and the device is automatically controlled by a computer and is simple to operate.

Owner:于伟

Washing machine special for porous ceramic filtering plate of ceramic filter

InactiveCN100496670CExtended service lifeSolving Recycling ProblemsFilter regenerationMoving filtering element filtersUltrasonic sensorMetallurgy

The present invention relates to a special-purpose cleaning machine for microporous ceramic filtering plate of ceramic filter. It includes shell body, cleaning channel set on said shell body, ultrasonic transducers and washing device. In the cleaning channel interior a ceramic filtering plate positioning frame is set, its bottom portion is equipped with fluid-discharging tube, the ultrasonic transducers are respectively mounted at two sides of said cleaning channel. The washing device is formed from internal circulating pipeline and circulating pump mounted on the internal circulating pipeline. Said invention utilizes ultrasonic wave and chemical cleaning agent to clean filtering plate, so that it can prolong the service life of ceramic filtering plate.

Owner:ANHUI TONGGUAN MACHINERY

On-line gas cleaning method for ceramic filter

InactiveCN101757811AImprove work performanceEasy to cleanMoving filtering element filtersUltrasound attenuationMetallurgy

The invention discloses an on-line gas cleaning method for a ceramic filter. A medium for on-line cleaning is a compressed gas. The on-line gas cleaning system for the ceramic filter adopts the compressed gas as the cleaning medium, has no impurities in the cleaning process, has small resistance in the pipeline, high speed and small pressure oscillation, and has obvious cleaning effect on the ceramic plate so that the attenuation of the ceramic plate can be slower. The working efficiency of the ceramic filter can be improved by 20 to 30 percent. And everyday a mass of cleaning water can be saved.

Owner:ANHUI TONGGUAN MACHINERY

Ceramic filter cleaning system

InactiveCN103657233AEasy to handleReduce the moisture content of mineral powderFiltration separationVacuum ceramic filterMaterials science

The invention provides a ceramic filter cleaning system including an ore separation box, a ceramic filter, a high level water tank and an acid regulation system; a pipeline below the ore separation box is connected with the ceramic filter; the high level water tank is arranged above the ceramic filter and is connected with a pipeline of the ceramic filter; the acid regulation system is arranged at a position no higher than the ceramic filter, and the acid regulation system is connected with the pipeline of the ceramic filter; by arrangement of the high level water tank, position regulation of different parts of the acid regulation system, and other improvement of the whole-set equipment structure, the processing ability of the ceramic filter is effectively improved, meanwhile water in ore powder can be greatly reduced, and equipment corrosion situation can be reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

Ceramic filter and preparation method and application thereof

InactiveCN109650938ASolve problems such as wasteImprove plasticityDispersed particle filtrationFiltration separationMicrometerMetallurgy

The invention belongs to the technical field of ceramic filter parts, and particularly relates to a ceramic filter. The filter is composed of several ceramic particles. Several micro pores are formedin the insides of ceramic particles and between adjacent ceramic particles, the size of the pores inside the ceramic particles is 0.5-10.5 micrometers, and the diameter of the ceramic particles is 0.02-2.5 mm; the average of the pores between the adjacent ceramic particles is 10-60 micrometers. Compared with the prior art, the plasticity is high, products of any size and specifications can be prepared, no any chemical additives are added, the ceramic filter is more environmentally friendly, the food grade of utensils can be achieved, the filtering speed is high, pressure from other equipment is not required, flowing gravitational force of liquid can be used for fully separating solid and liquid, meanwhile cleaning is convenient, solid stays on the surface of a microporous filtration element, and the ceramic filter can be cleaned by direct flushing.

Owner:赵志刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com