Washing machine special for porous ceramic filtering plate of ceramic filter

A ceramic filter and microporous ceramic technology, which is applied in the direction of mobile filter element filter, filter separation, filter regeneration, etc., can solve the problem of shortened service life of microporous ceramic filter plate, affecting the use efficiency of filter plate, limited cleaning effect, etc. problem, to achieve the effect of high ultrasonic conversion efficiency, beautiful appearance, and perfect protection circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

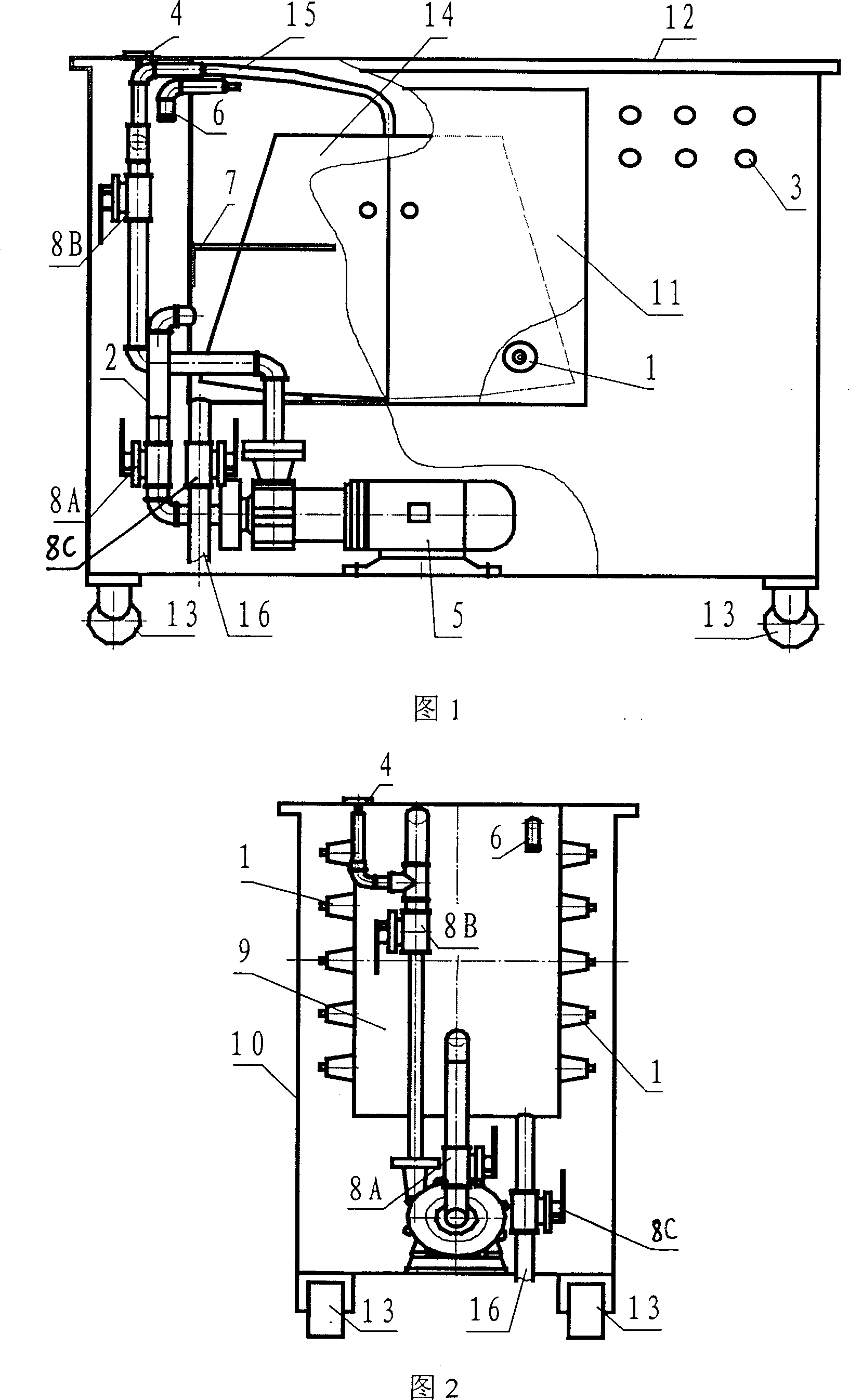

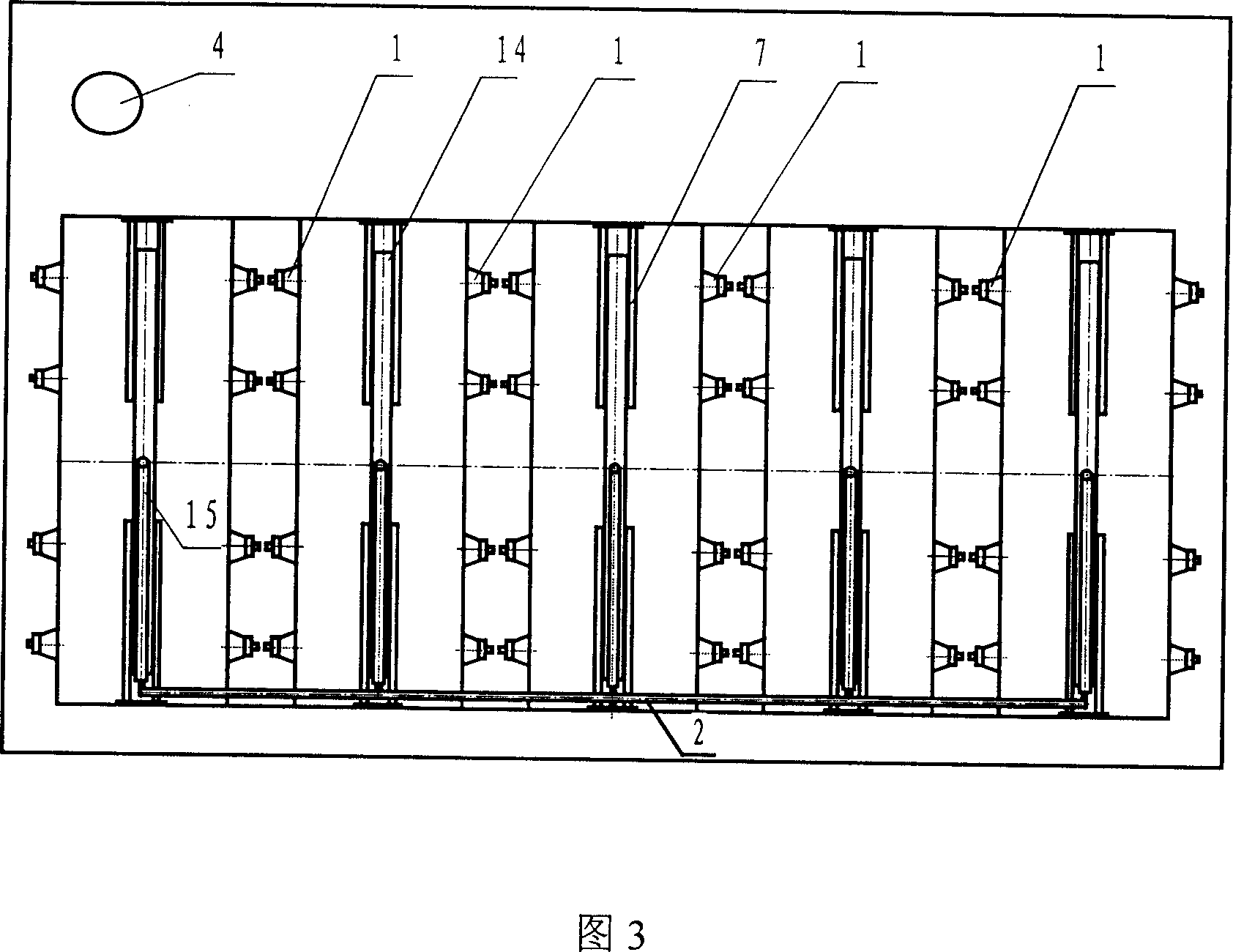

[0013] As shown in Fig. 1 and Fig. 2, the ceramic filter microporous ceramic filter plate cleaning machine of the present invention comprises a housing 10, a cleaning tank 9 arranged on the housing, an ultrasonic transducer 1 and an internal circulation pipeline 2 and A flushing device composed of a circulating pump 5 installed on the internal circulation pipeline, a liquid inlet 6 for delivering cleaning liquid to the cleaning tank is arranged on the left side wall of the upper part of the housing; a positioning frame 7 for placing a ceramic filter plate 14 is provided in the cleaning tank , the bottom is provided with a drain pipe 16 leading to the outside of the housing; the ultrasonic transducer 1 is installed on the outer wall of the cleaning tank 9 facing the two working end faces of the ceramic filter plate 14, and multiple can be installed to improve its power; the inner circulation pipe The liquid inlet of road 2 communicates with the lower part of the cleaning tank 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com