Patents

Literature

494 results about "Industrial setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

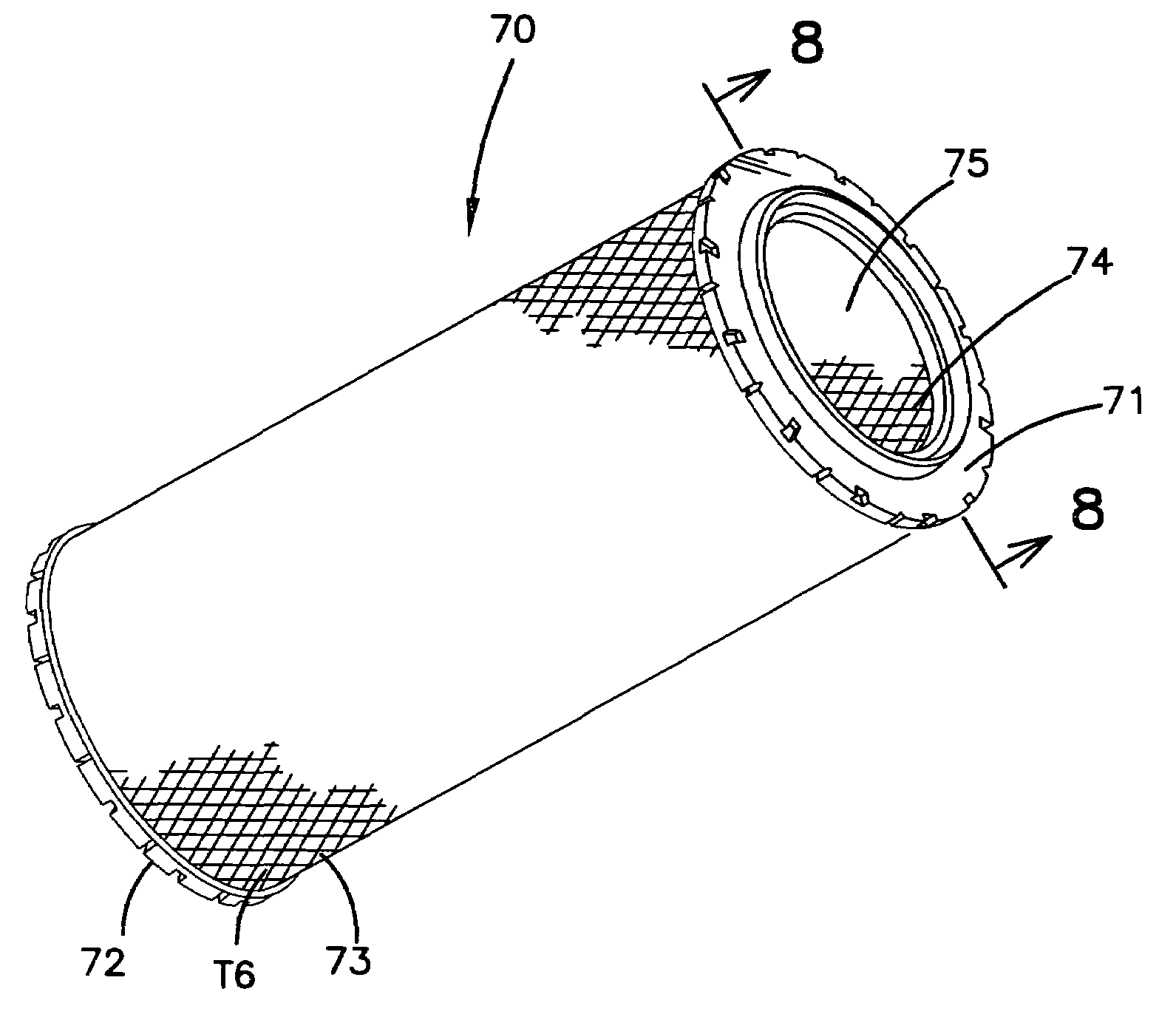

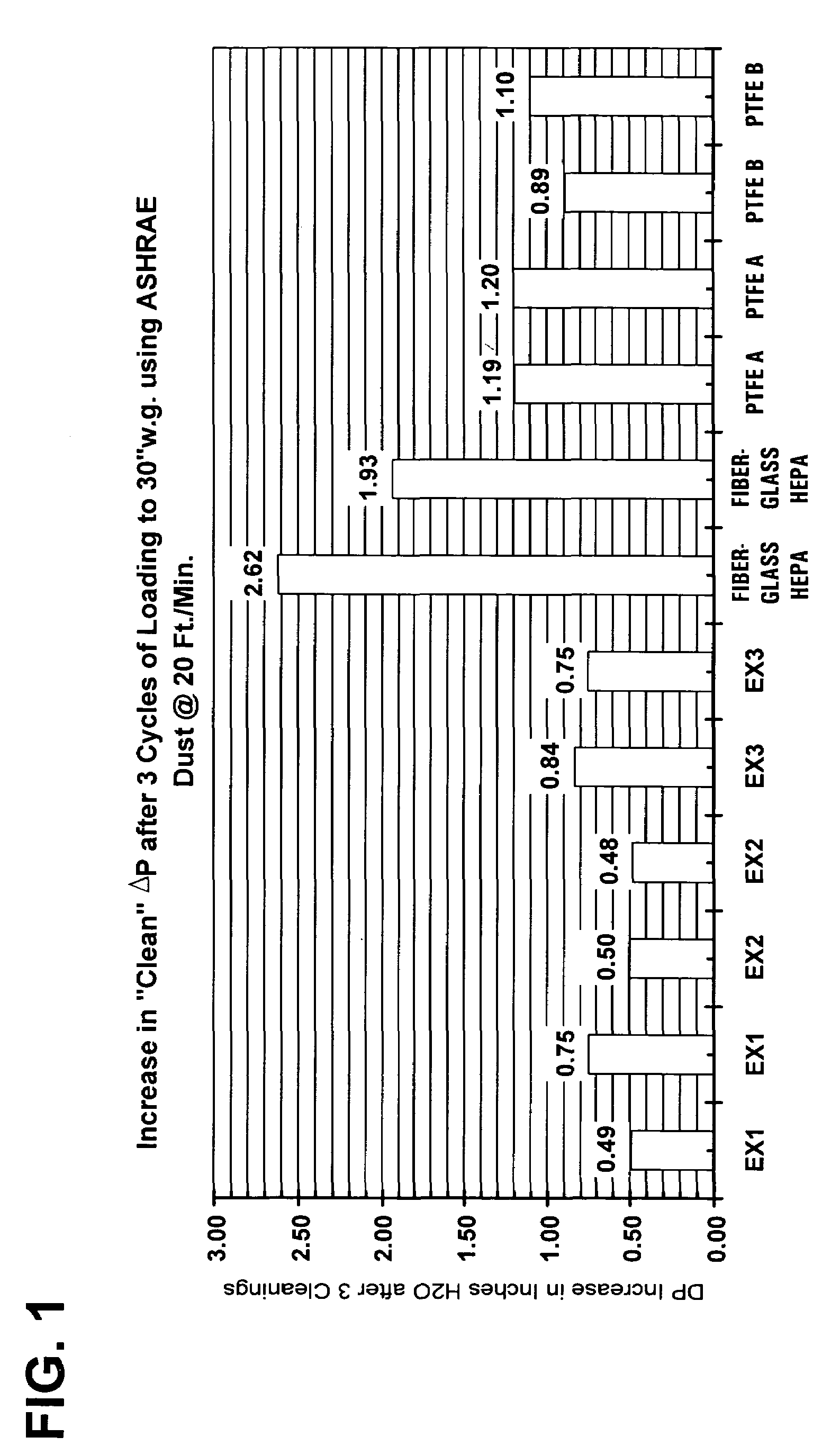

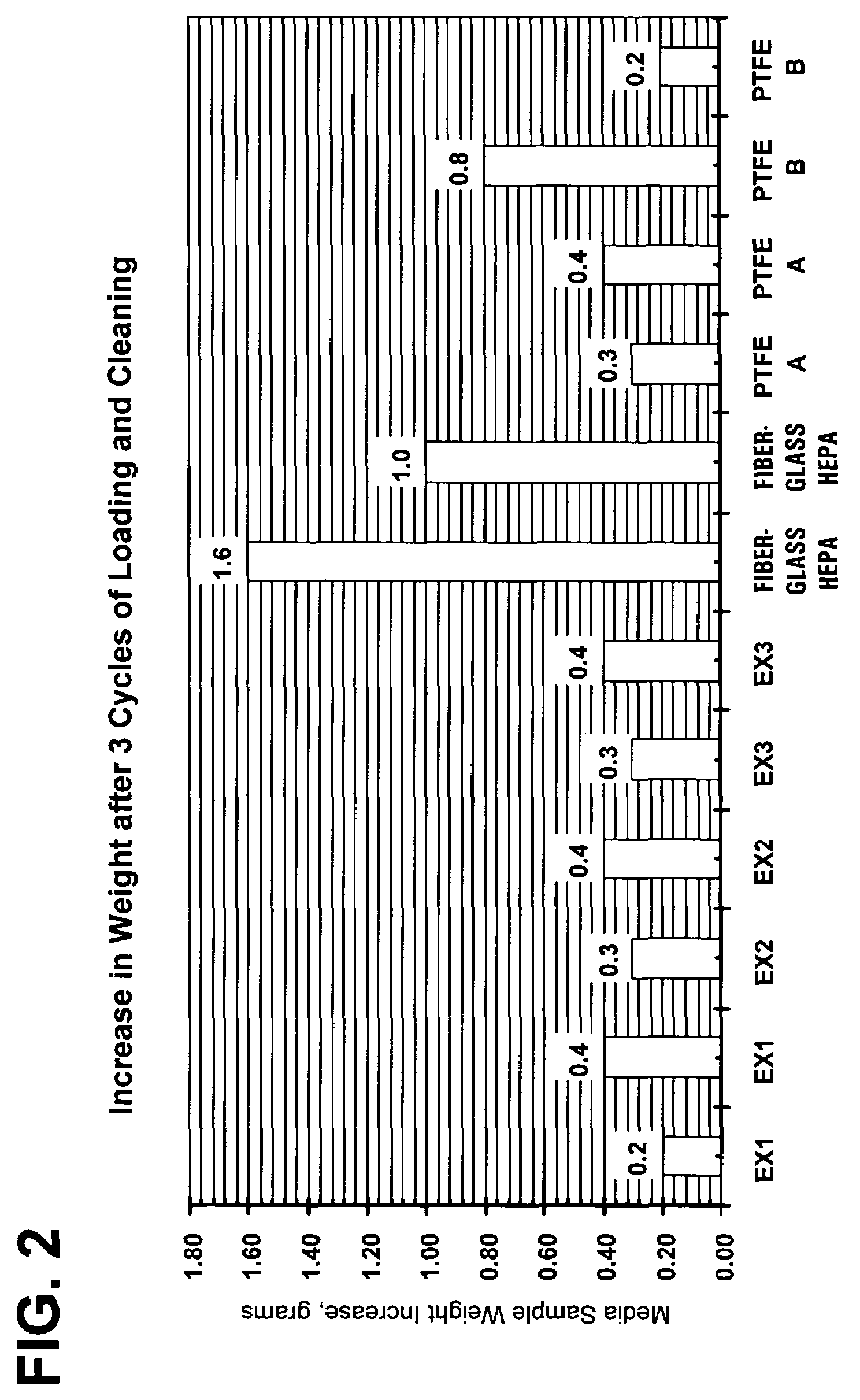

Cleanable high efficiency filter media structure and applications for use

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

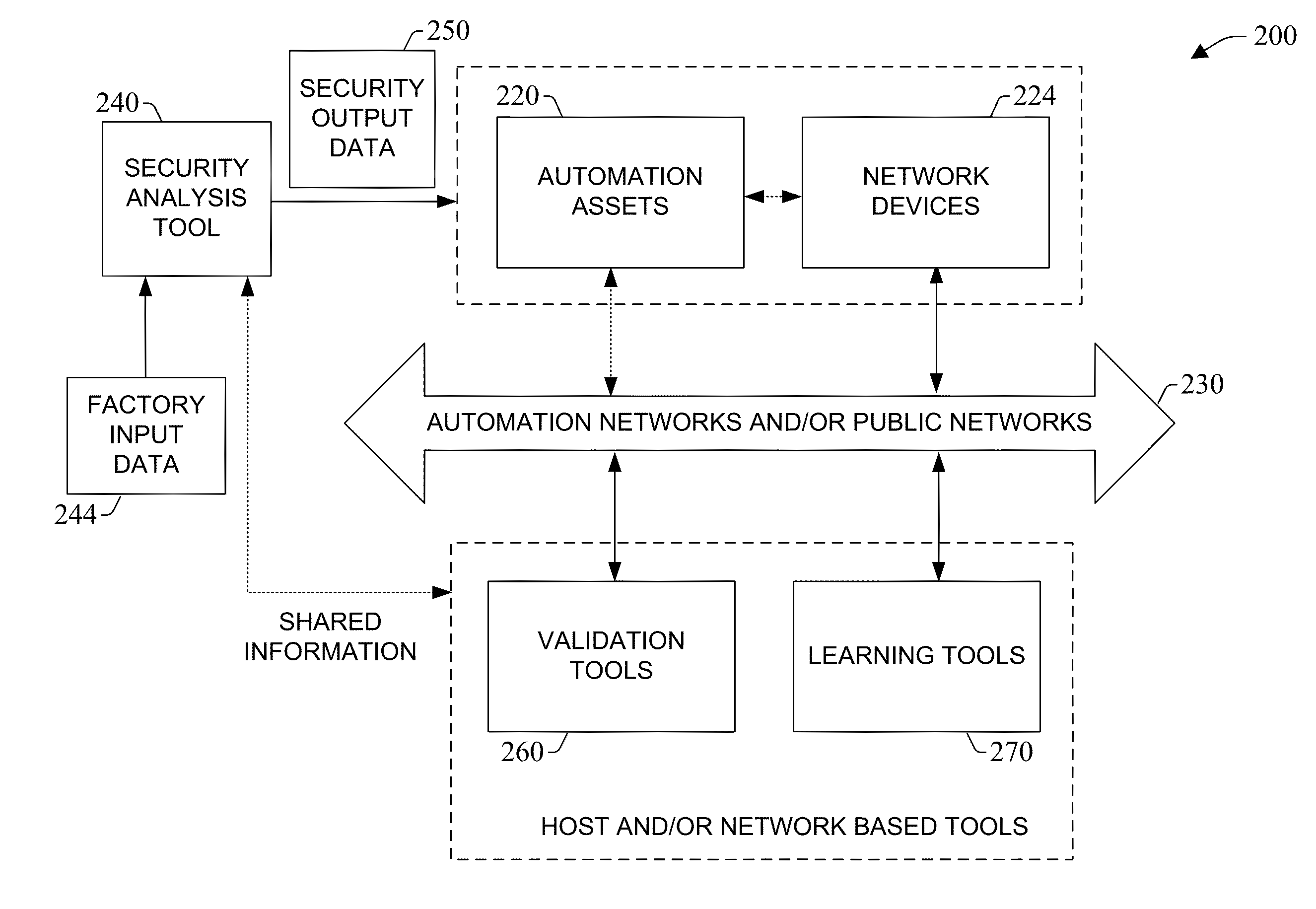

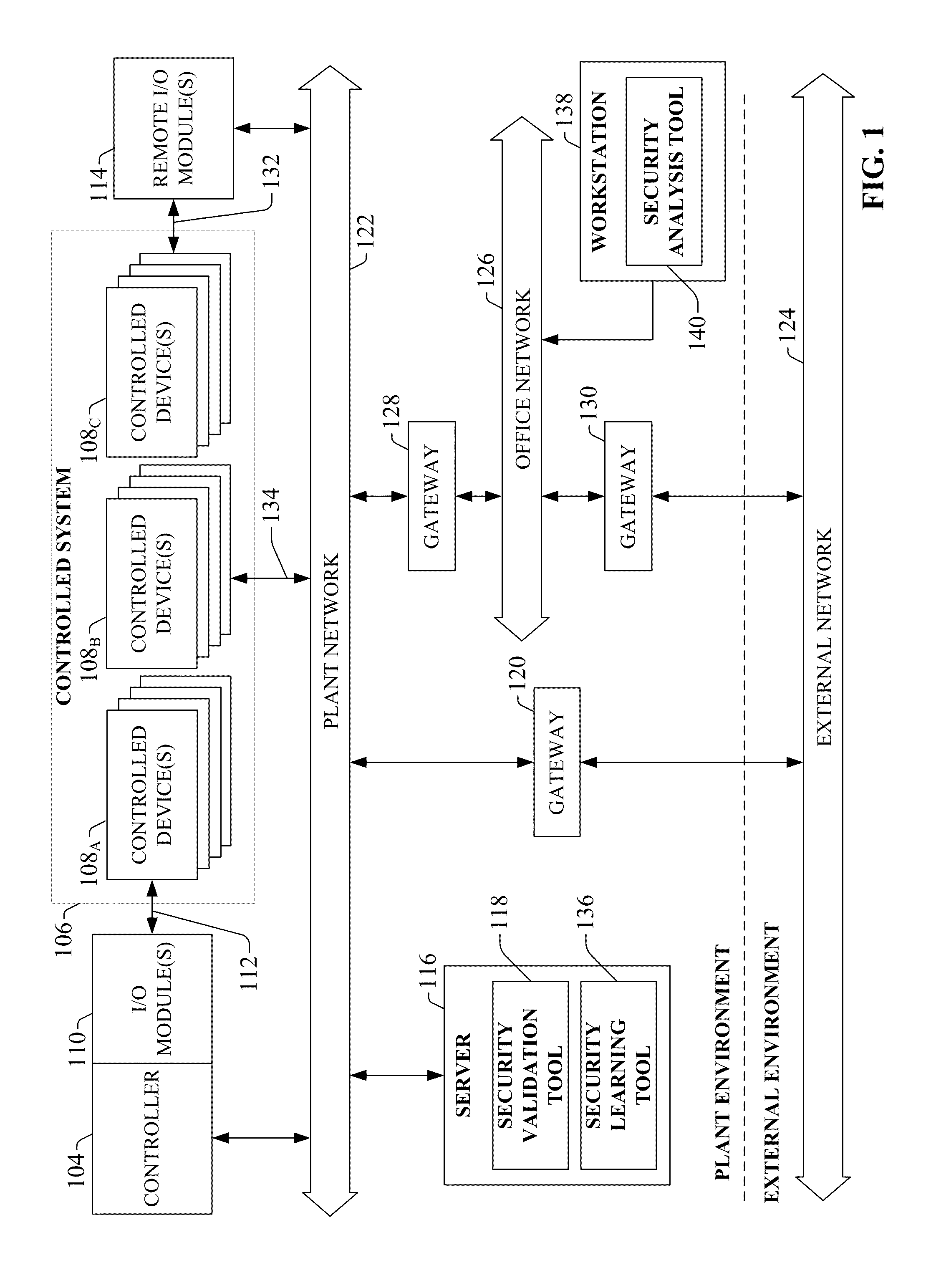

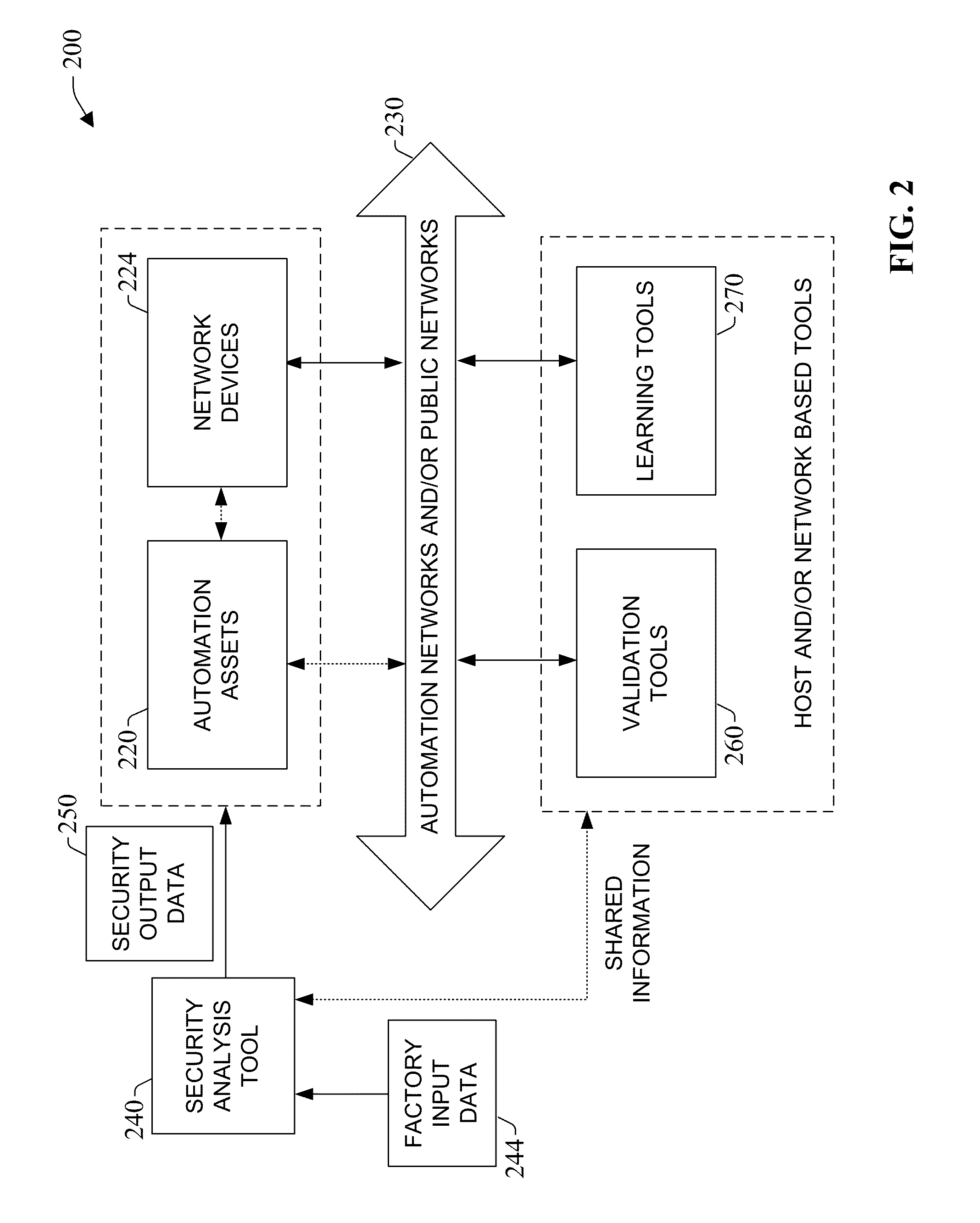

System and methodology providing automation security analysis and network intrusion protection in an industrial environment

ActiveUS20130031037A1Improve integrityFacilitate privacyProgramme controlComputer controlGuidelineEngineering

The present invention relates to a system and methodology facilitating automation security in a networked-based industrial controller environment. Various components, systems and methodologies are provided to facilitate varying levels of automation security in accordance with security analysis tools, security validation tools and / or security learning systems. The security analysis tool receives abstract factory models or descriptions for input and generates an output that can include security guidelines, components, topologies, procedures, rules, policies, and the like for deployment in an automation security network. The validation tools are operative in the automation security network, wherein the tools perform security checking and / or auditing functions, for example, to determine if security components are in place and / or in suitable working order. The security learning system monitors / learns network traffic patterns during a learning phase, fires alarms or events based upon detected deviations from the learned patterns, and / or causes other automated actions to occur.

Owner:ROCKWELL AUTOMATION TECH

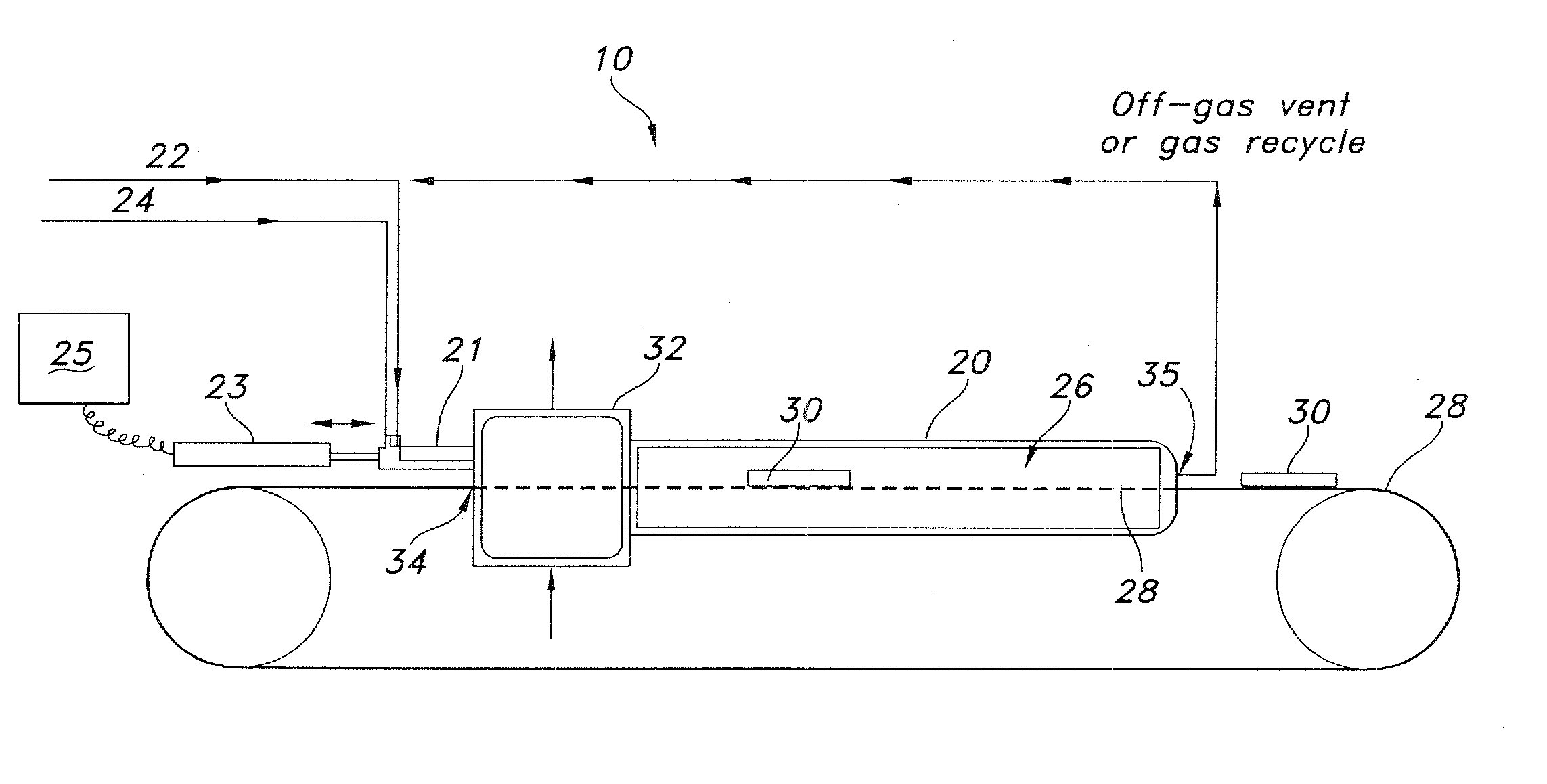

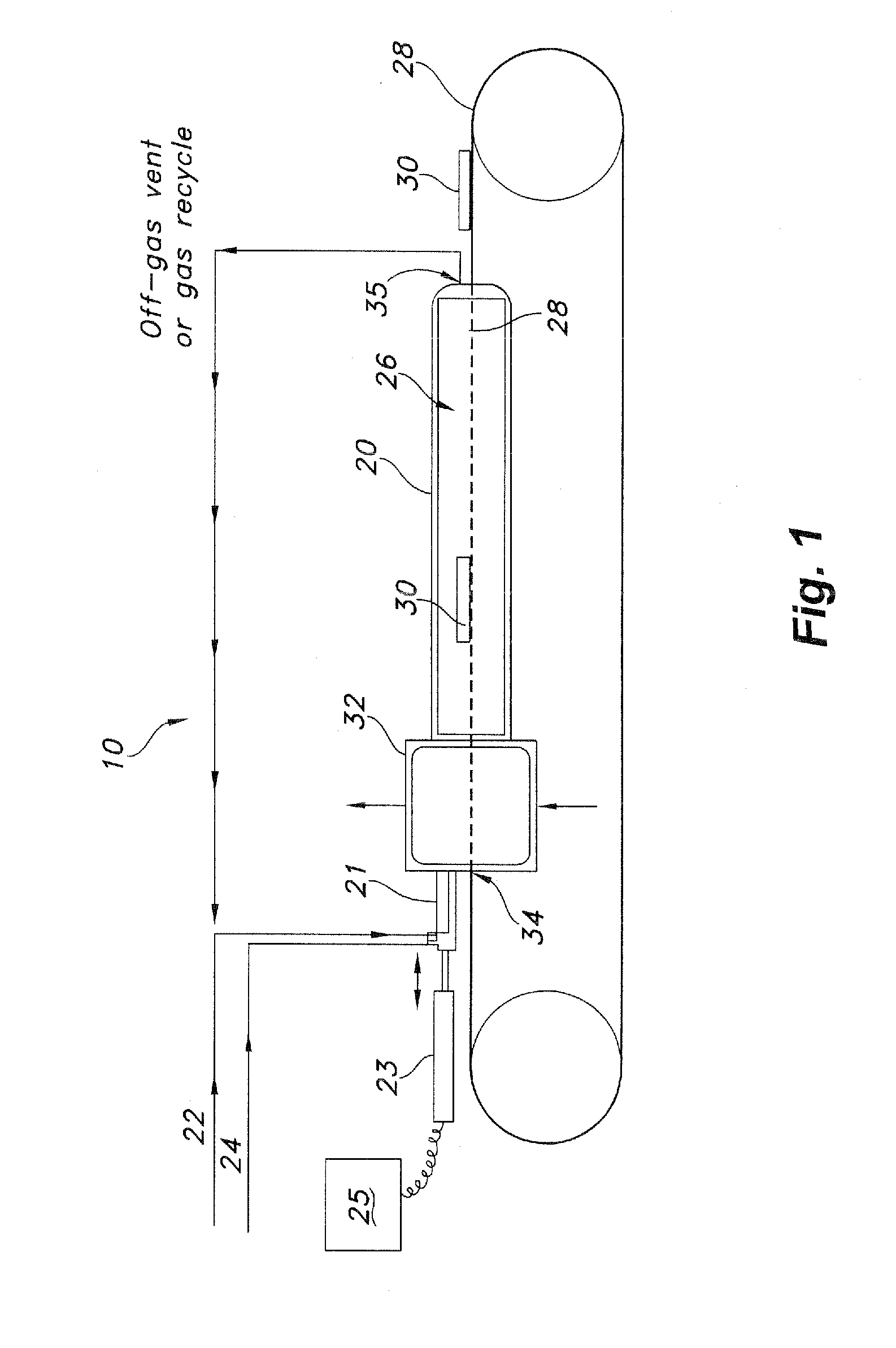

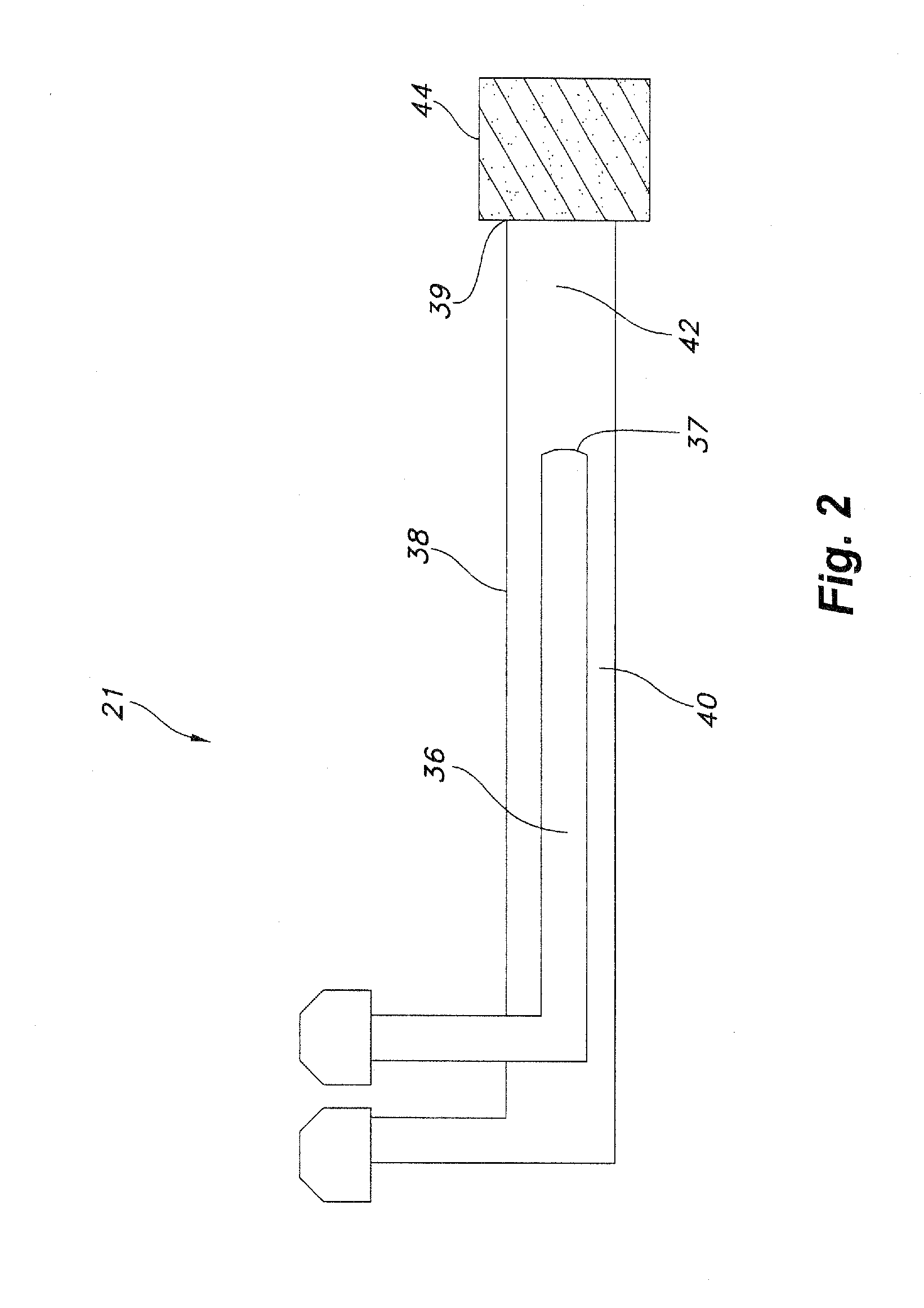

Process for the continuous production of aligned carbon nanotubes

ActiveUS7160531B1Improve flow characteristicsMaterial nanotechnologyCarbon compoundsMetal catalystPorous medium

Novel methods and apparati for continuous production of aligned carbon nanotubes are disclosed. In one aspect, the method comprises dispersion of a metal catalyst in a liquid hydrocarbon to form a feed solution, and volatilizing the feed solution in a reactor through which a substrate is continuously passed to allow growth of nanotubes thereon. In another aspect, the apparatus comprises a reactor, a tube-within-a-tube injector, and a conveyor belt for passing a substrate through the reactor. The present invention further discloses a method for restricting the external diameter of carbon nanotubes produced thereby comprising passing the feed solution through injector tubing of a specified diameter, followed by passing the feed solution through an inert, porous medium. The method and apparati of this invention provide a means for producing aligned carbon nanotubes of a particular external diameter which is suitable for large scale production in an industrial setting.

Owner:UNIV OF KENTUCKY RES FOUND

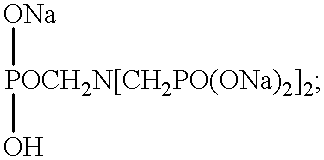

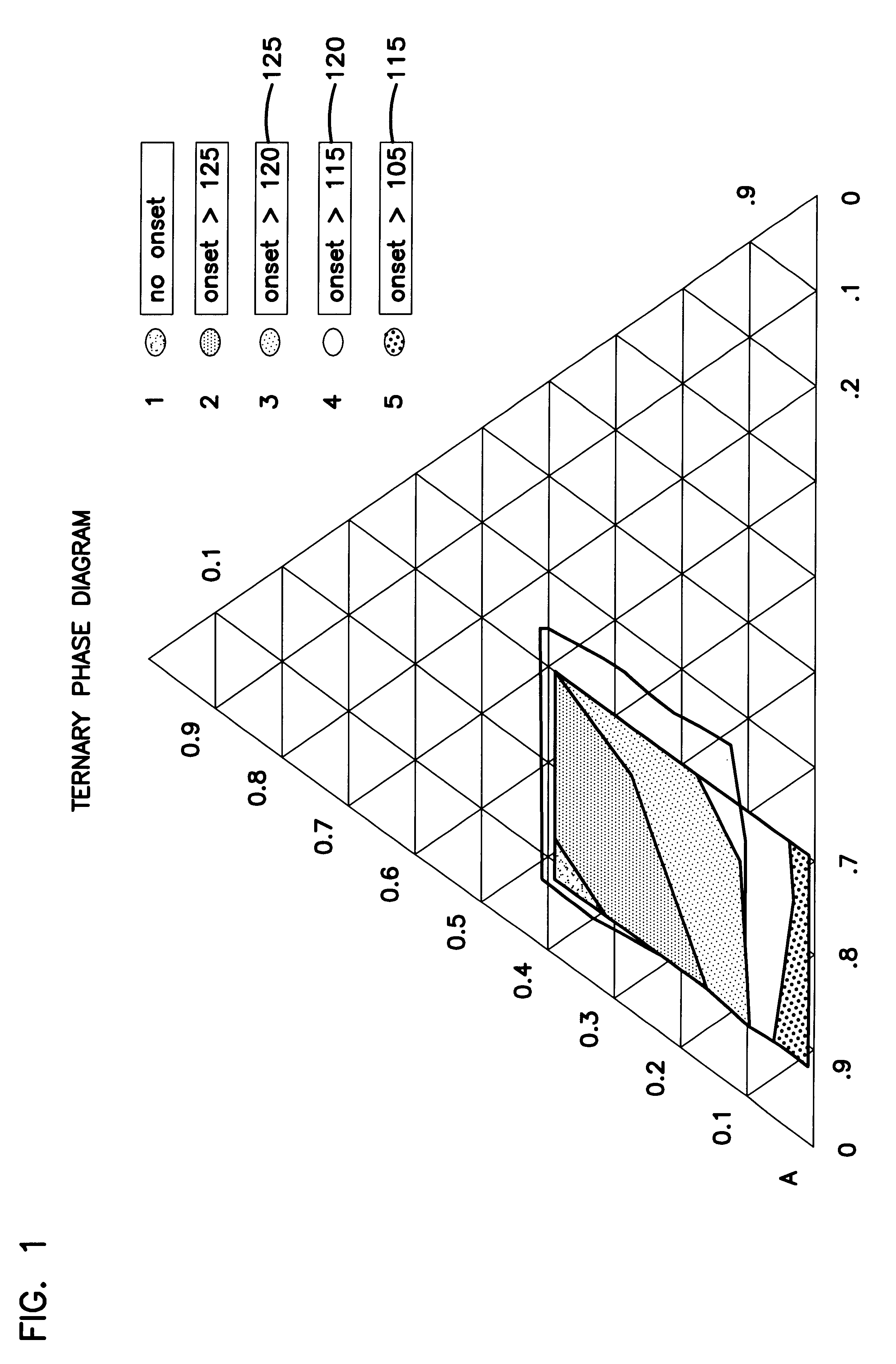

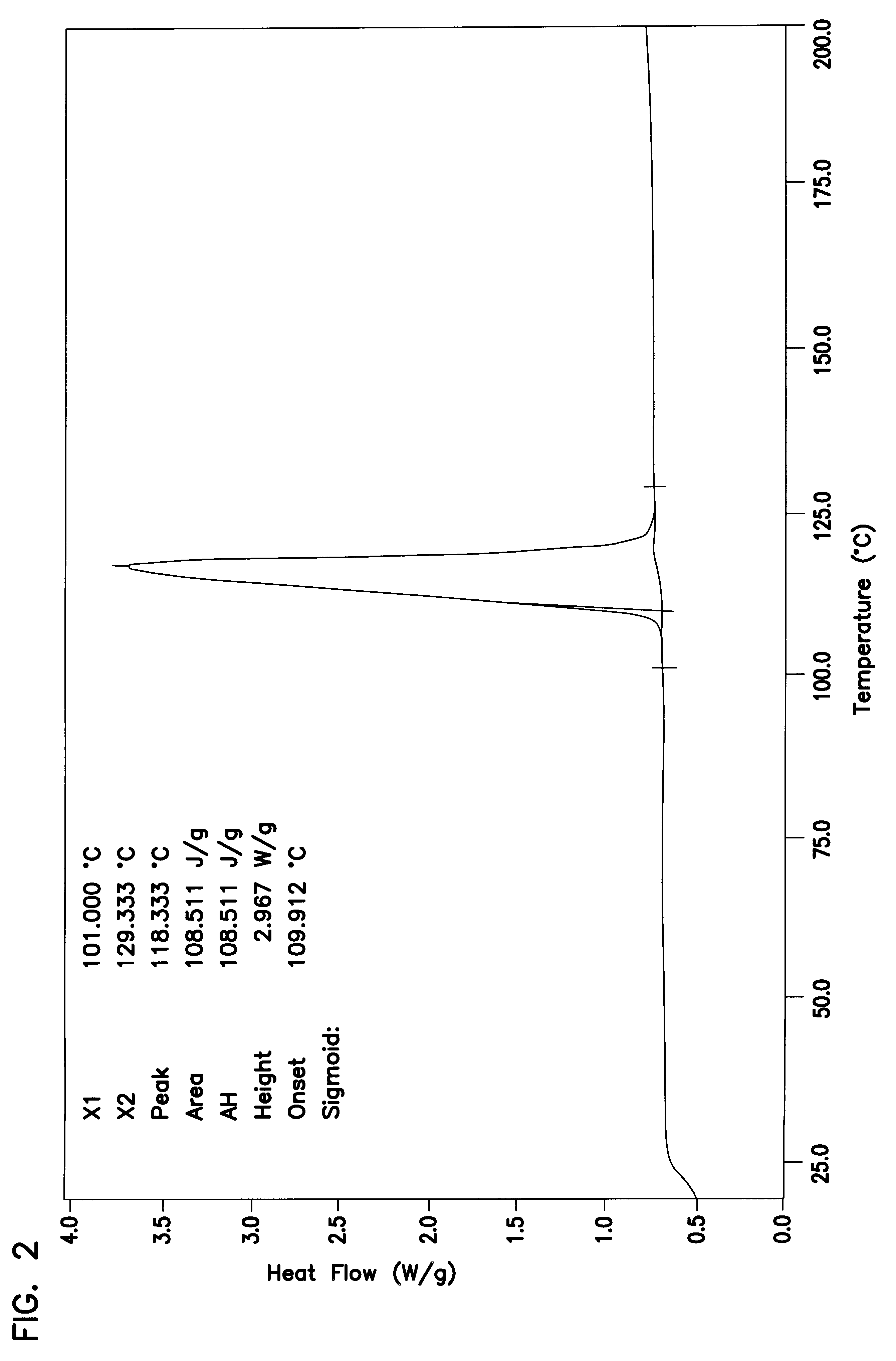

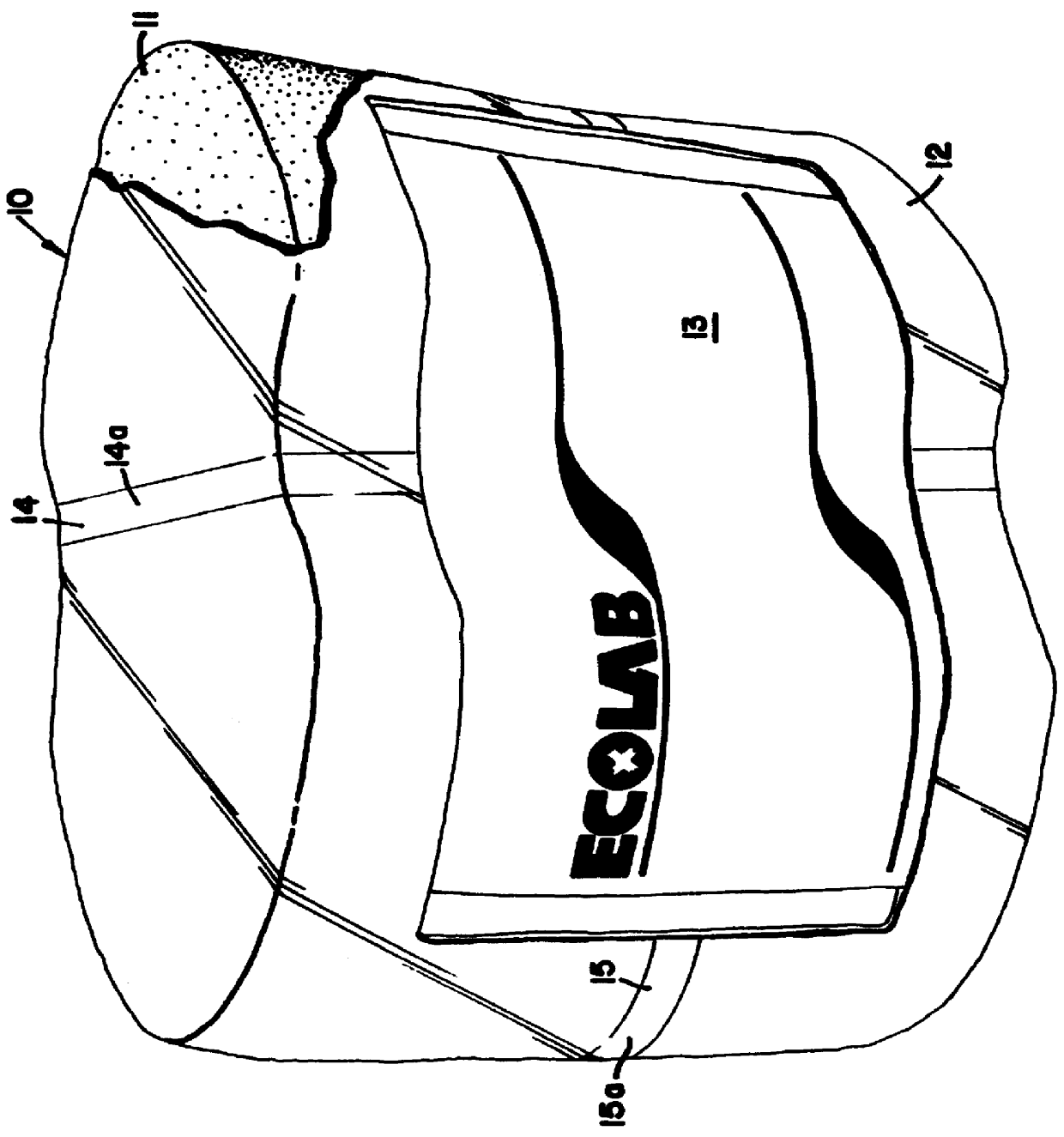

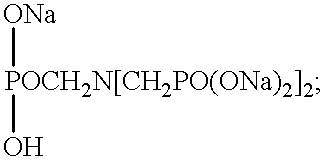

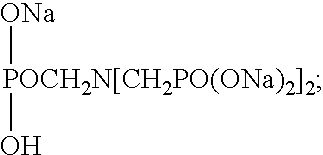

Stable solid block detergent composition

InactiveUS6177392B1Fit tightlyEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

The dimensionally stable alkaline solid block warewashing detergent uses an E-form binder forming a solid comprising a sodium carbonate source of alkalinity, a sequestrant, a surfactant package and other optional material. The solid block is dimensionally stable and highly effective in removing soil from the surfaces of dishware in the institutional and industrial environment. The E-form hydrate comprises an organic phosphonate and a hydrated carbonate.

Owner:ECOLAB USA INC

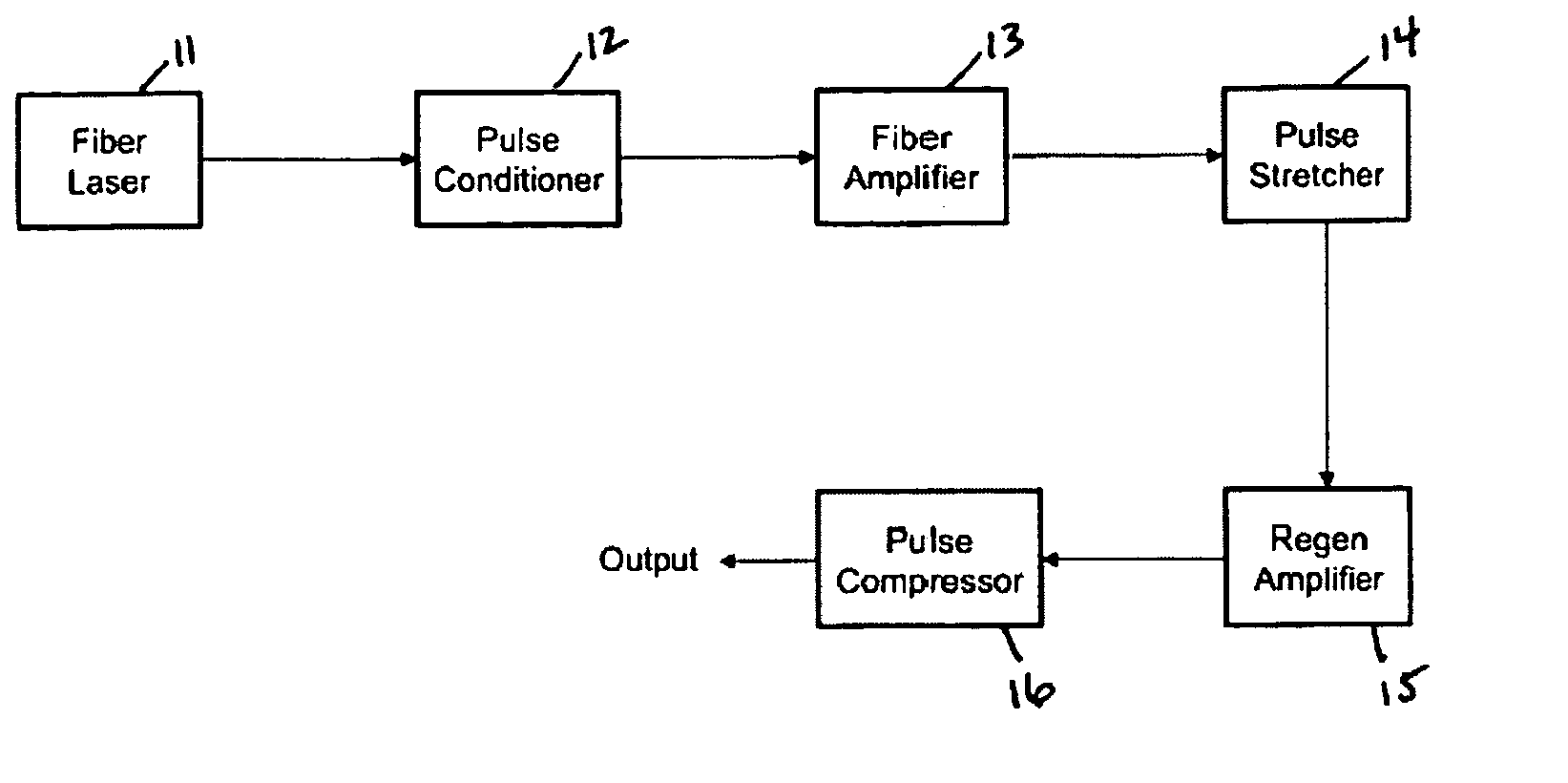

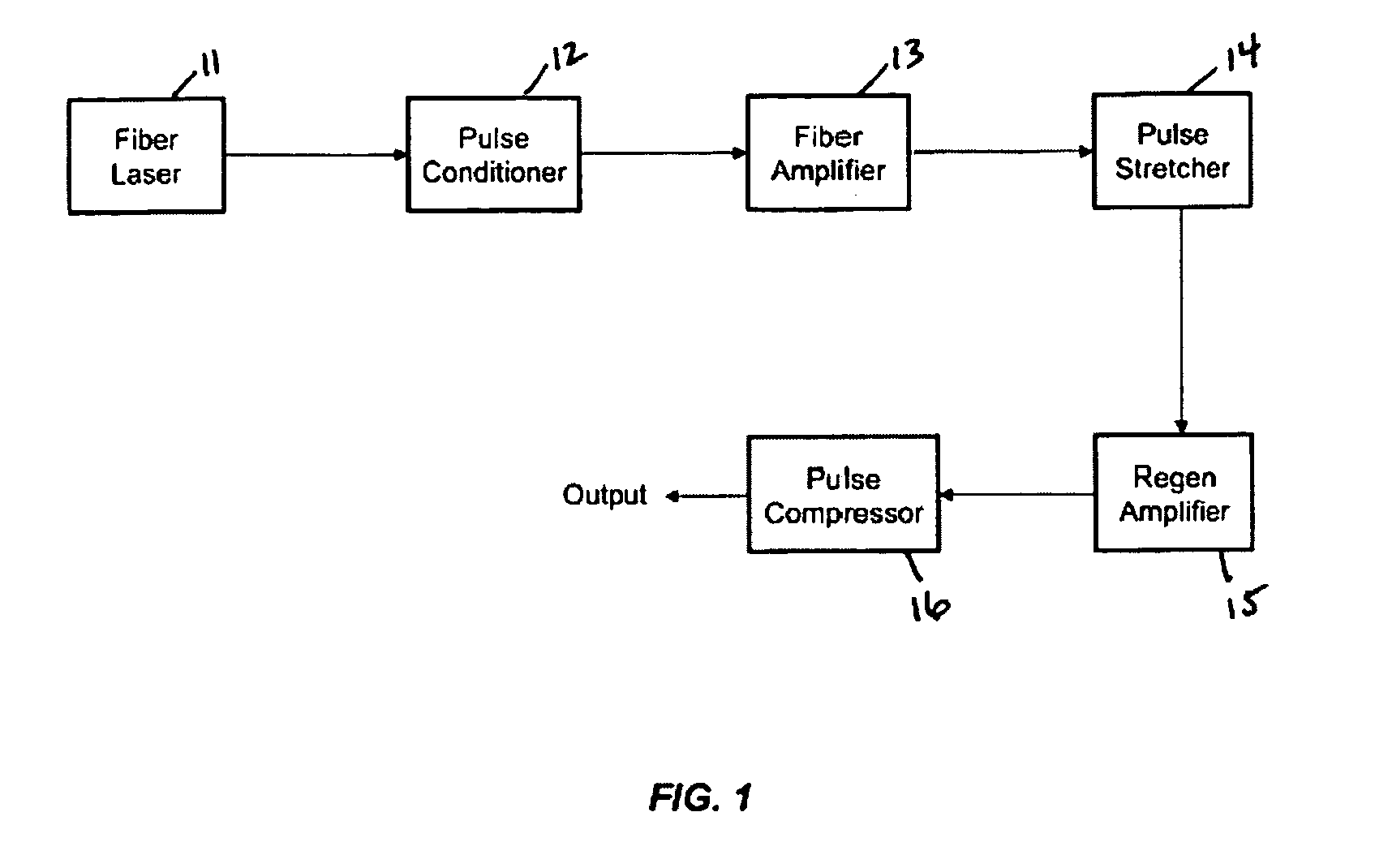

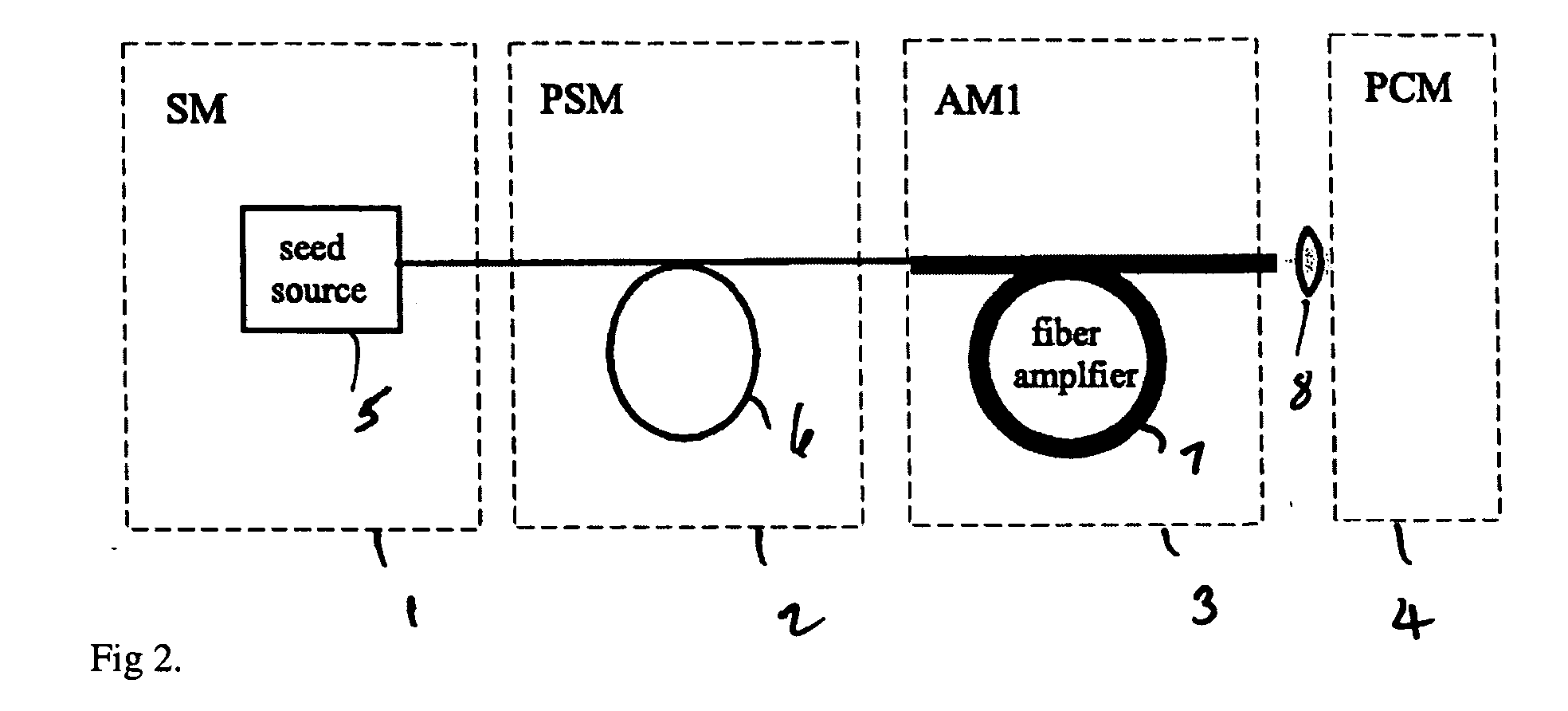

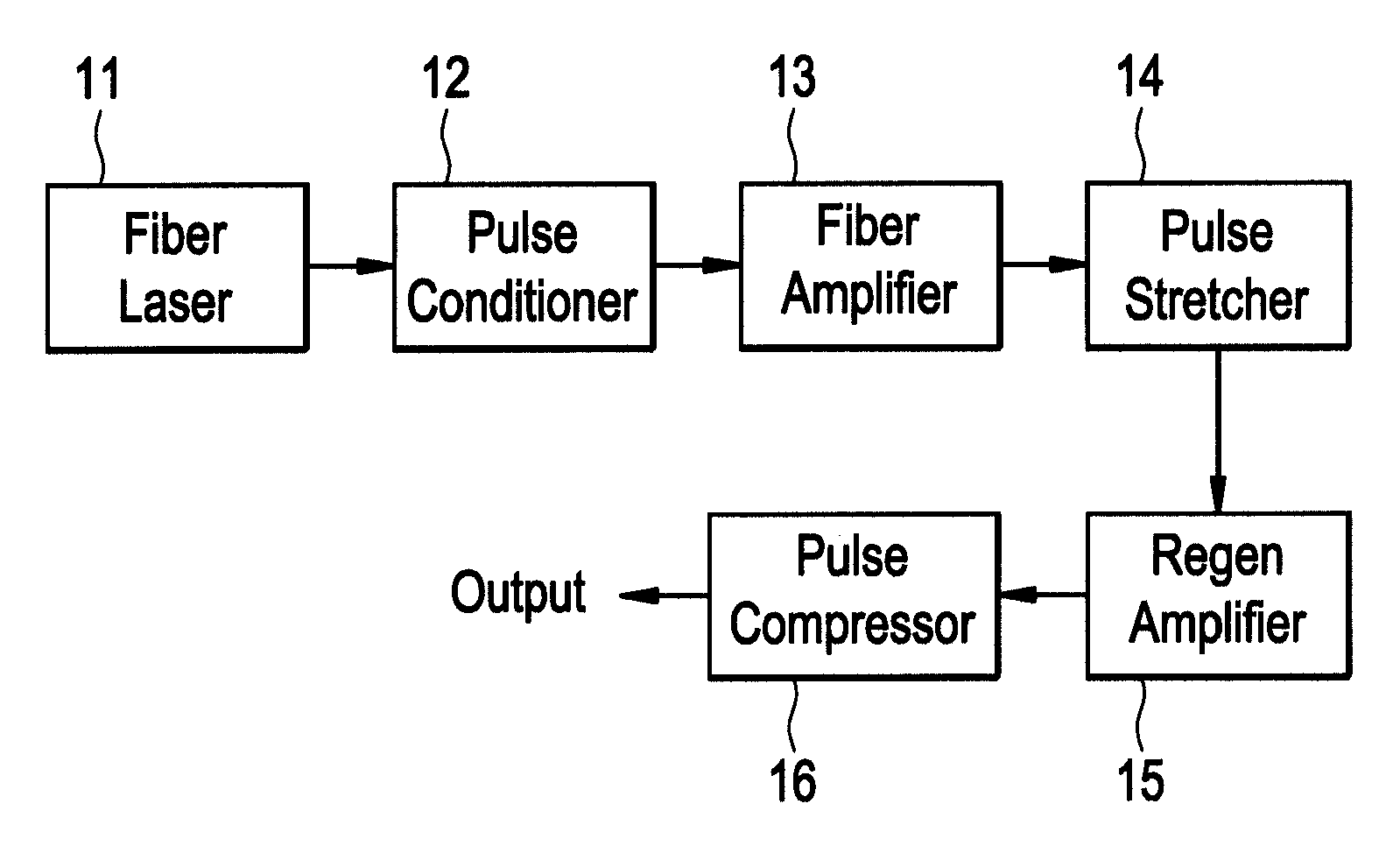

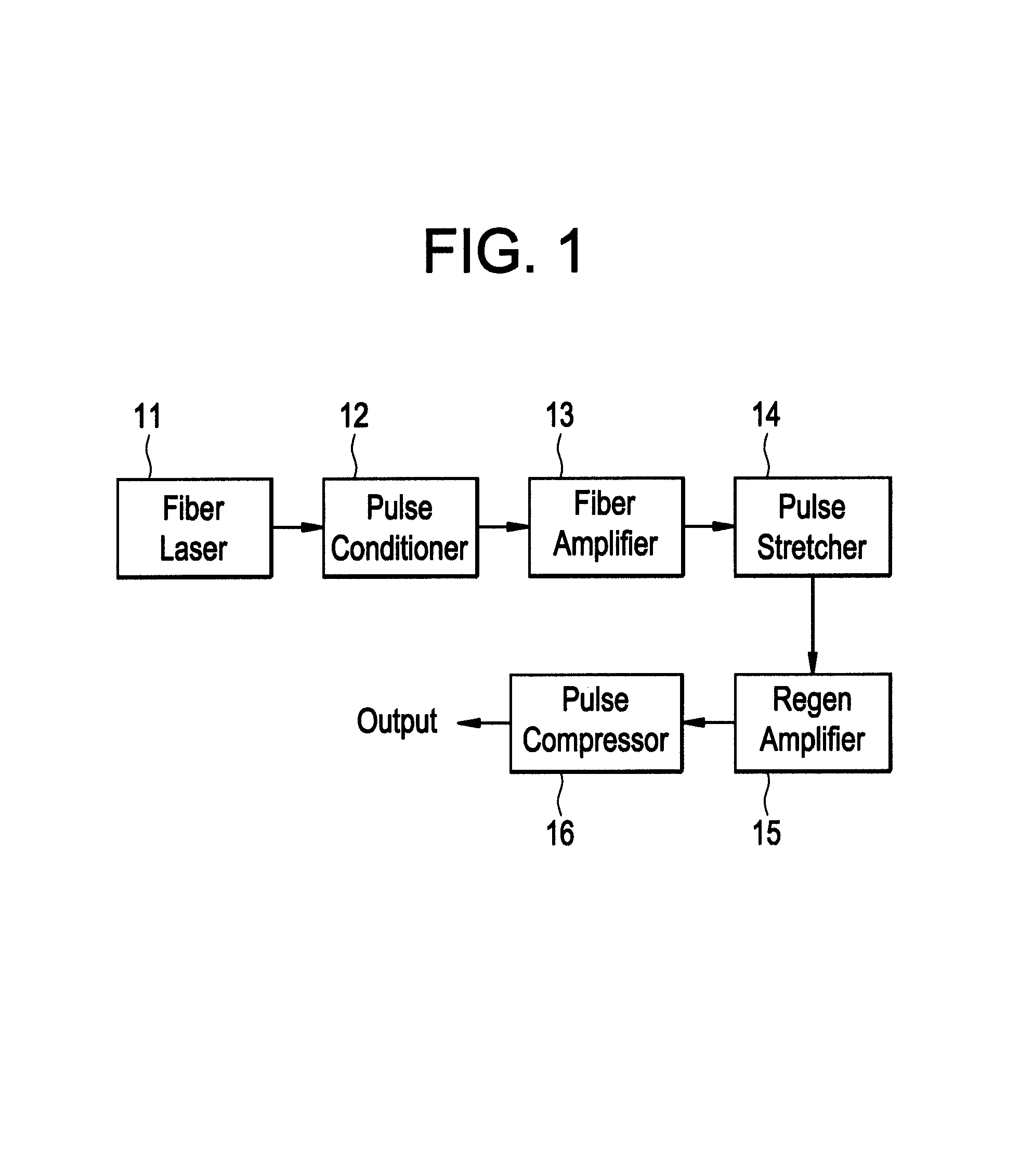

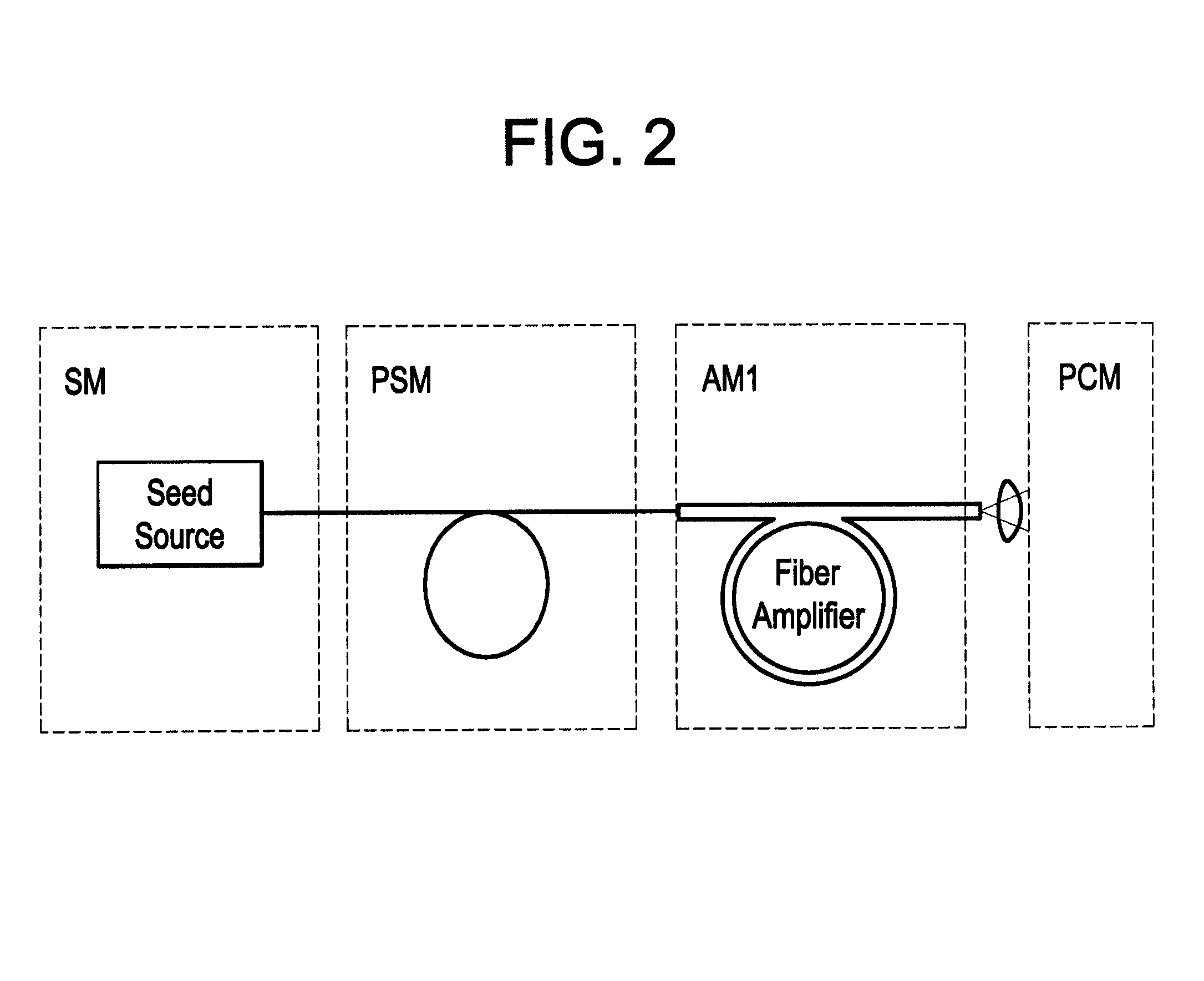

Yb: and Nd: mode-locked oscillators and fiber systems incorporated in solid-state short pulse laser systems

InactiveUS20060120418A1Increase flexibilityMaximize positive effectOptical devices for laserAudio power amplifierEngineering

The invention describes classes of robust fiber laser systems usable as pulse sources for Nd: or Yb: based regenerative amplifiers intended for industrial settings. The invention modifies adapts and incorporates several recent advances in FCPA systems to use as the input source for this new class of regenerative amplifier.

Owner:IMRA AMERICA

Stable solid block metal protecting warewashing detergent composition

InactiveUS6156715AFit tightlyEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

The dimensionally stable alkaline solid block warewashing detergent uses an E-form binder forming a solid comprising a sodium carbonate source of alkalinity, a metal corrosion protecting alkali metal silicate composition, a sequestrant, a surfactant package and other optional material. The solid block is dimensionally stable and highly effective in removing soil from the surfaces of dishware in the institutional and industrial environment. The E-form hydrate comprises an organic phosphonate and a hydrated carbonate.

Owner:ECOLAB USA INC

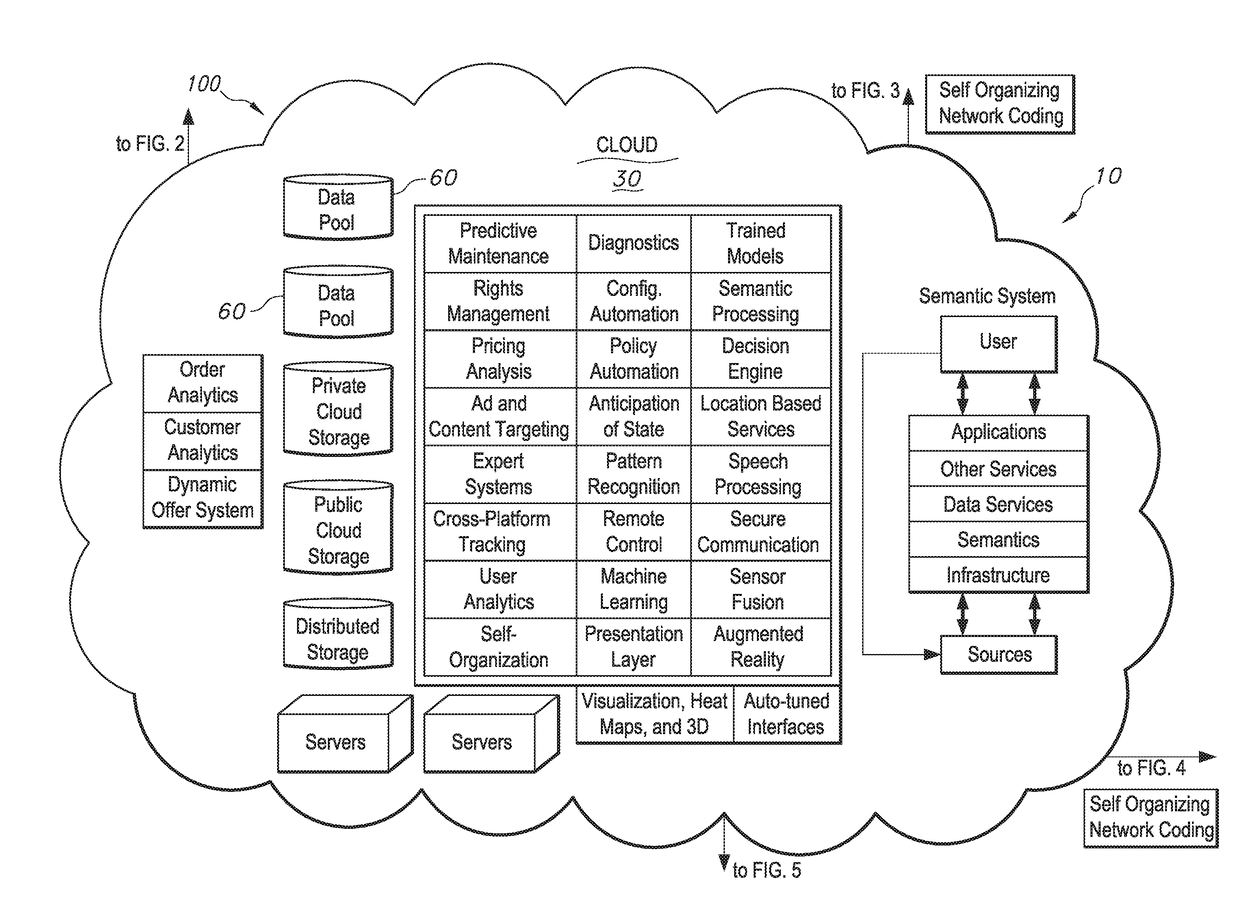

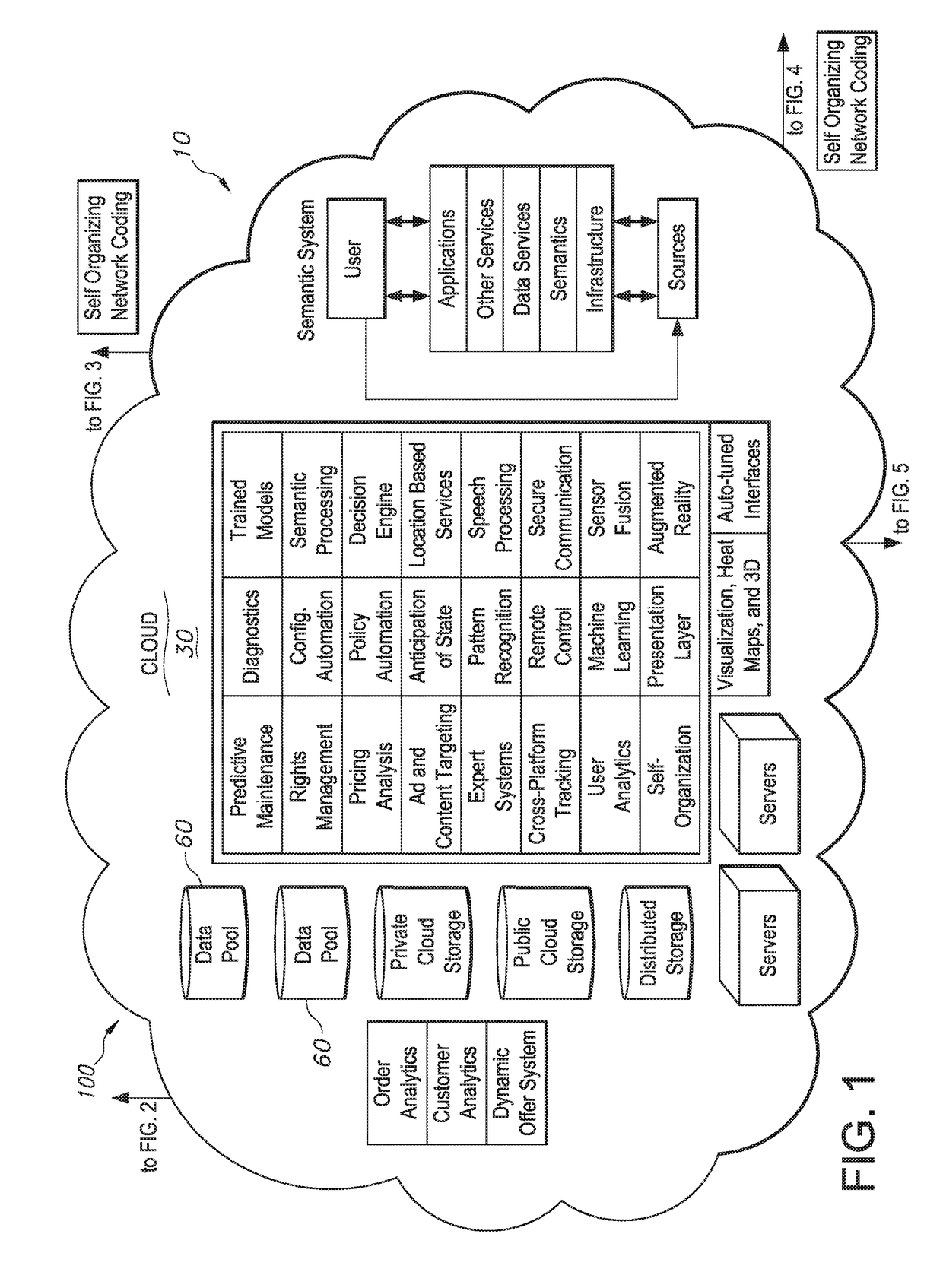

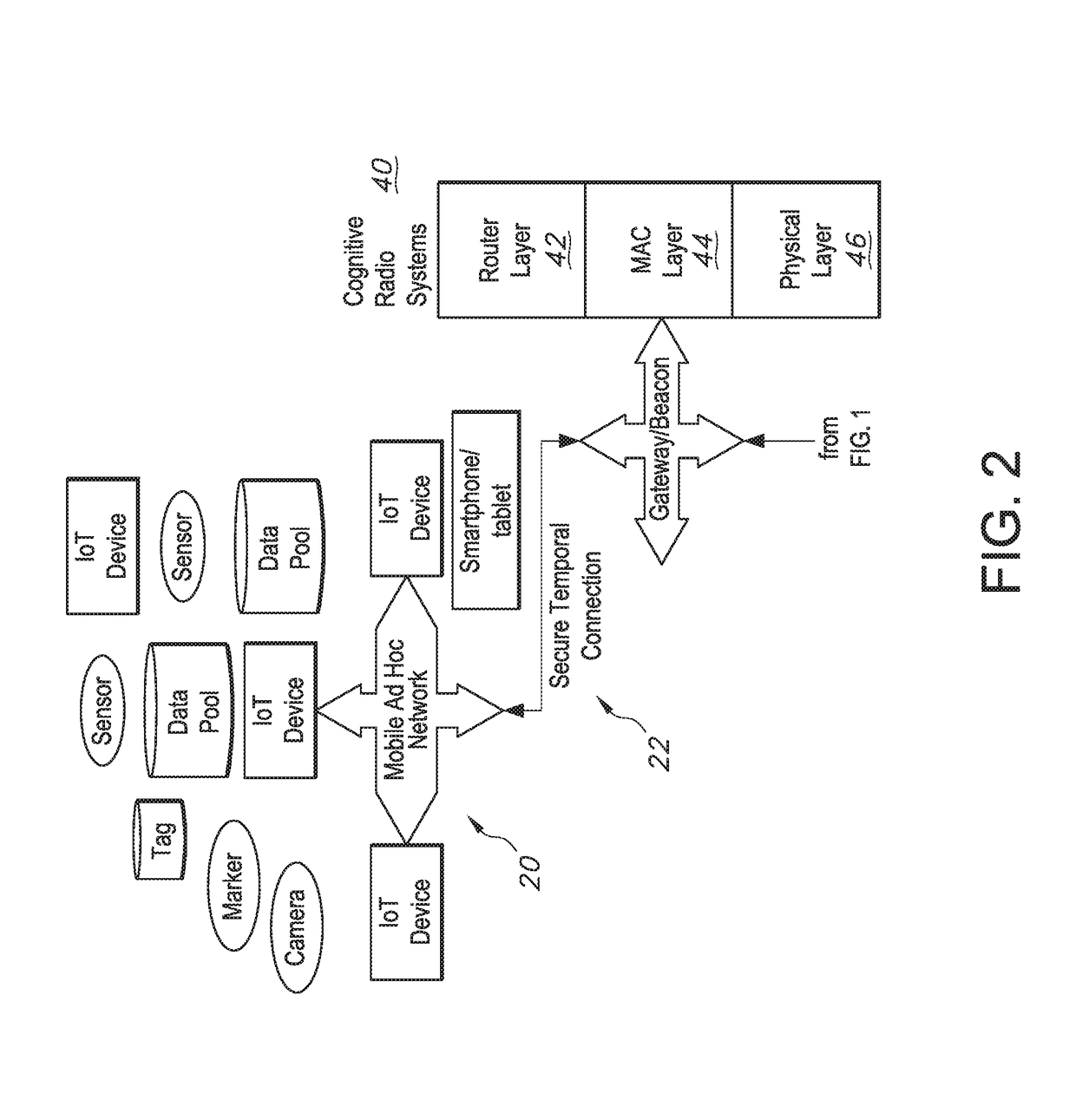

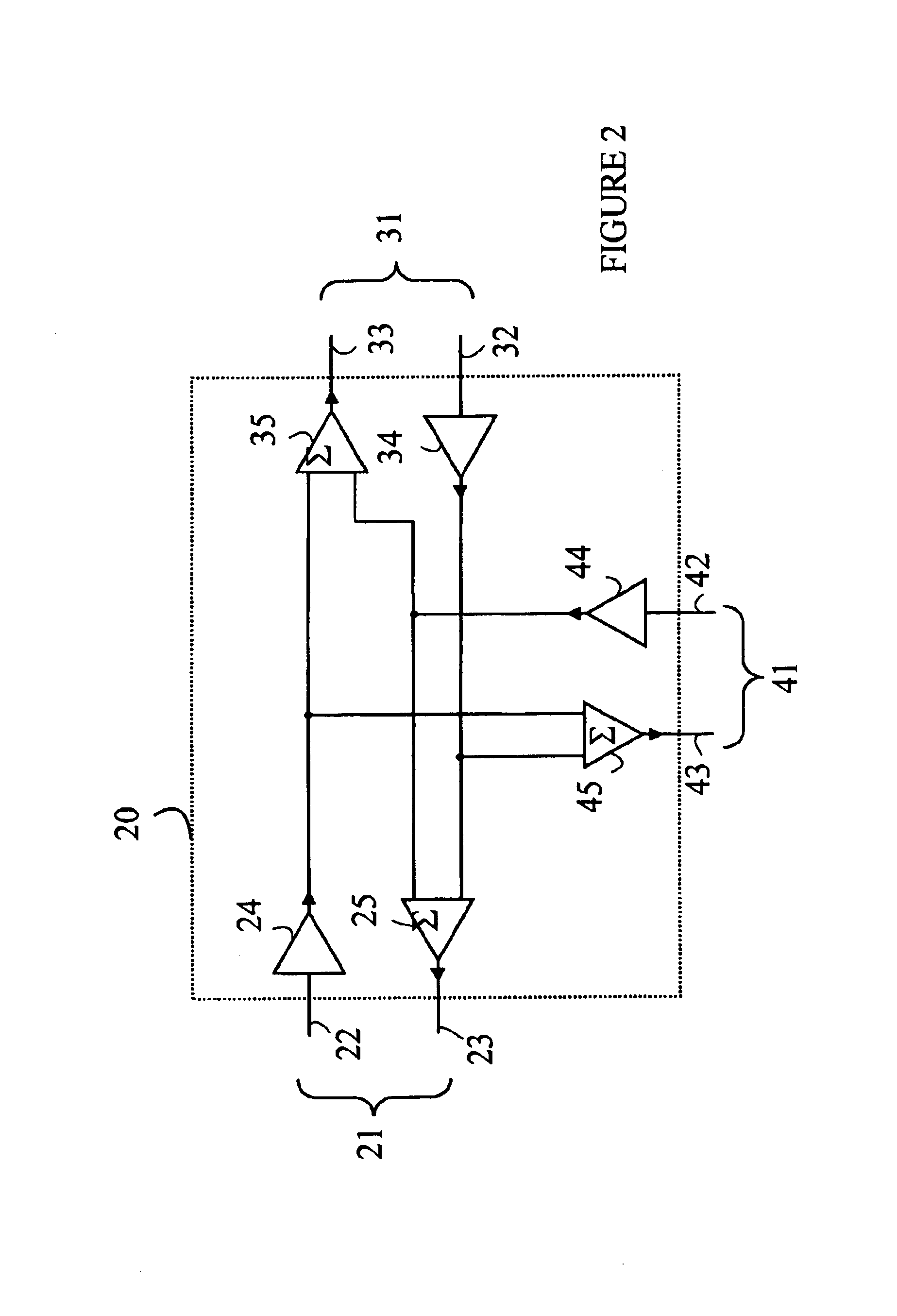

Methods and systems for the industrial internet of things

ActiveUS20180188704A1Improve signal-to-noise ratioLow sampling rateVibration measurement in solidsMachine part testingData streamData acquisition

The system generally includes a crosspoint switch in the local data collection system having multiple inputs and multiple outputs including a first input connected to the first sensor and a second input connected to the second sensor. The multiple outputs include a first output and a second output configured to be switchable between a condition in which the first output is configured to switch between delivery of the first sensor signal and the second sensor signal and a condition in which there is simultaneous delivery of the first sensor signal from the first output and the second sensor signal from the second output. Each of multiple inputs is configured to be individually assigned to any of the multiple outputs. Unassigned outputs are configured to be switched off producing a high-impedance state. The local data collection system includes multiple multiplexing units and multiple data acquisition units receiving multiple data streams from multiple machines in the industrial environment. The local data collection system includes distributed complex programmable hardware device (CPLD) chips each dedicated to a data bus for logic control of the multiple multiplexing units and the multiple data acquisition units that receive the multiple data streams from the multiple machines in the industrial environment. The local data collection system is configured to manage data collection bands.

Owner:STRONG FORCE IOT

Stable solid block metal protecting warewashing detergent composition

InactiveUS6410495B1Easy to cleanImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

Owner:ECOLAB USA INC

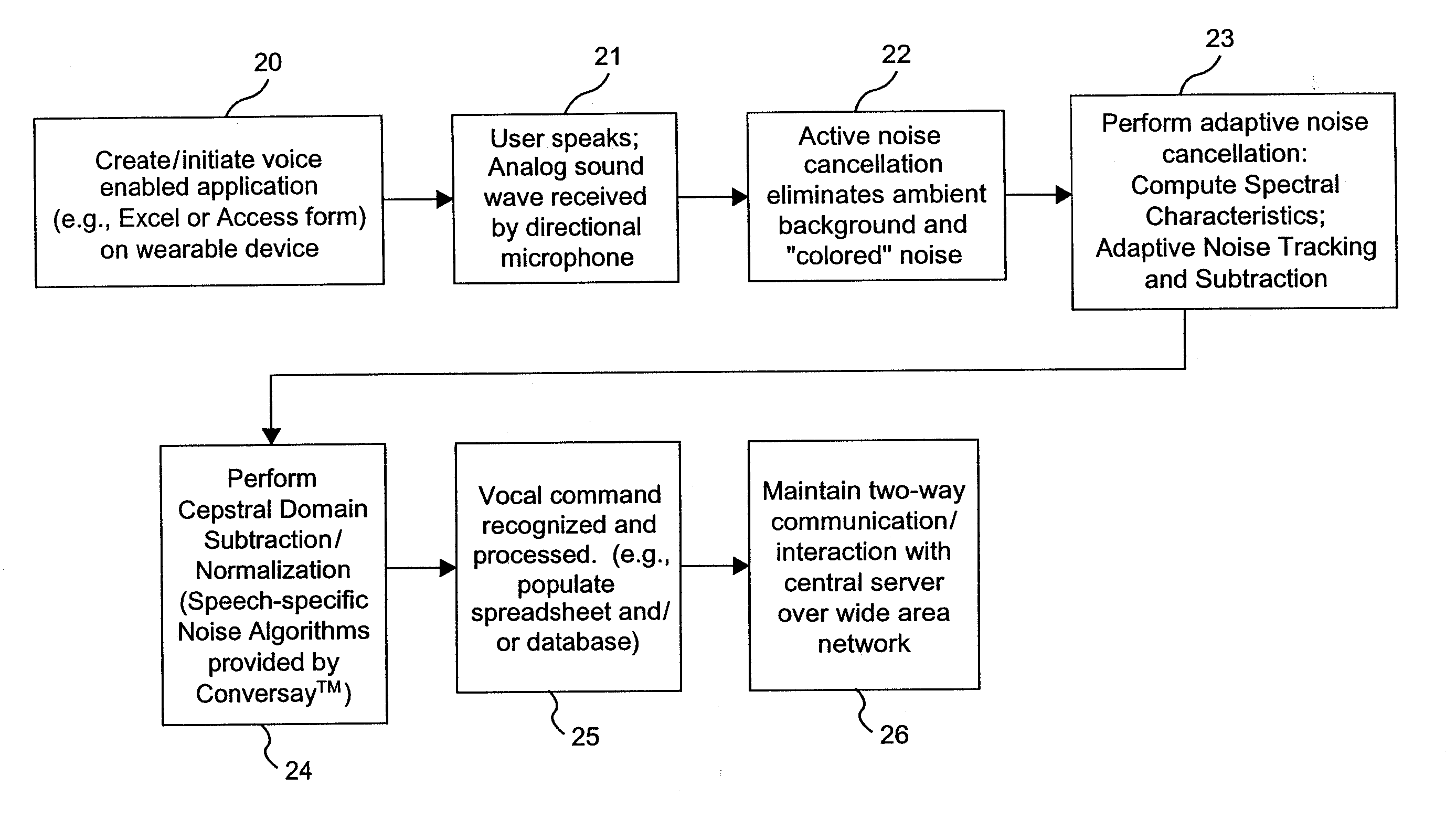

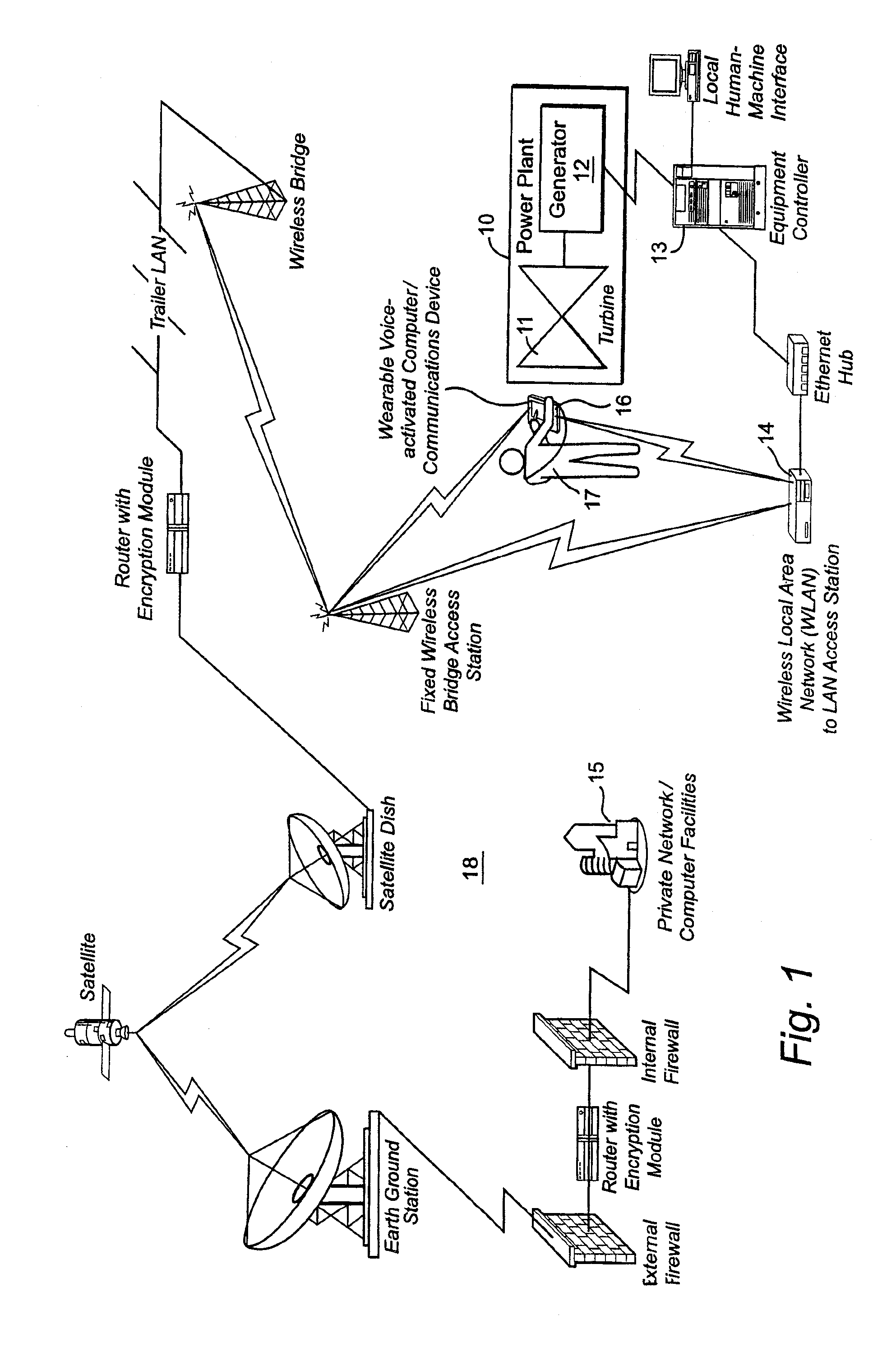

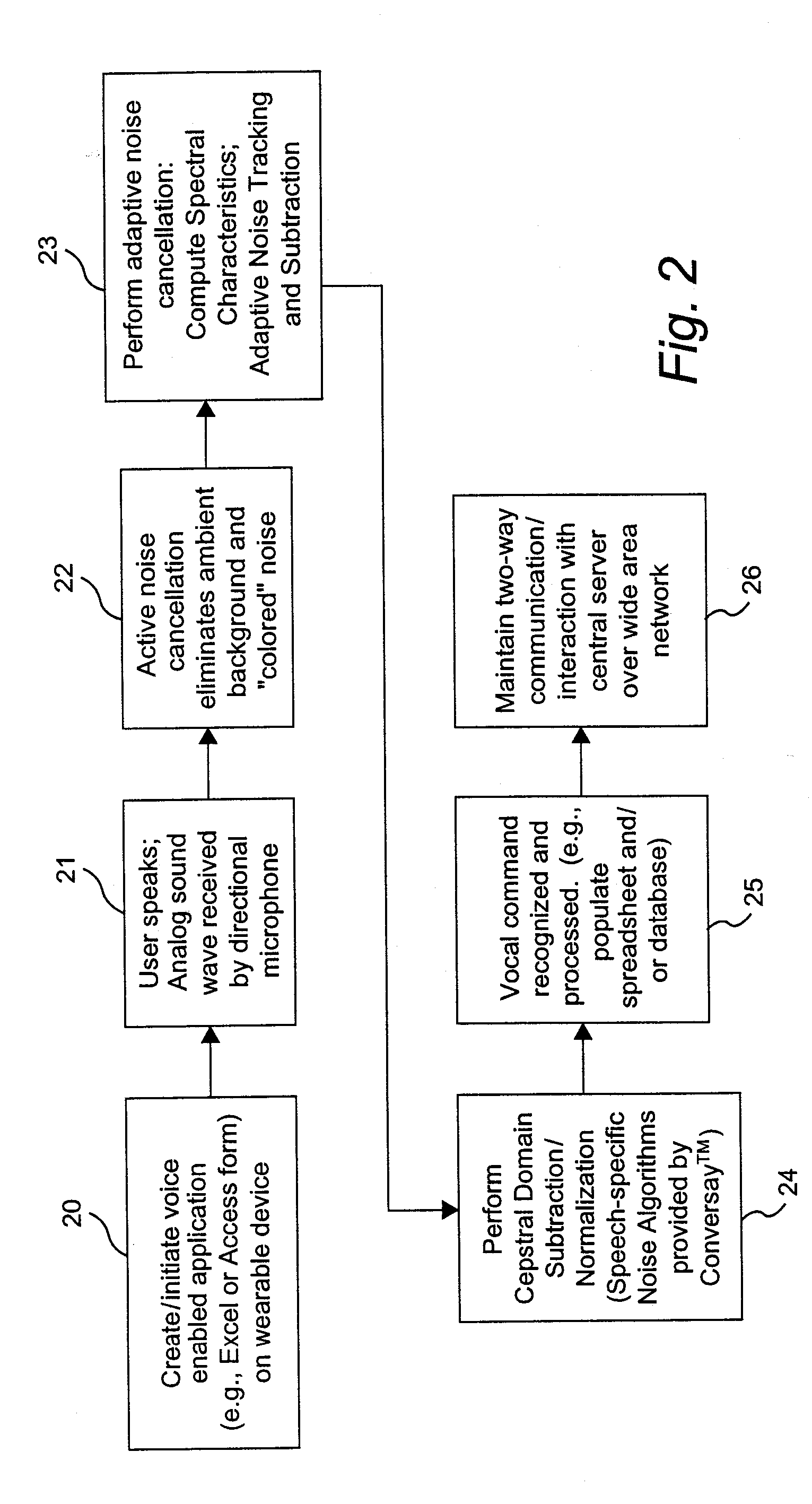

Digitization of work processes using wearable wireless devices capable of vocal command recognition in noisy environments

InactiveUS20050080620A1High bandwidth connectivityImprove productivitySpeech analysisInformation processingFrequency spectrum

In an information processing system having an equipment controller for enabling the digitization of complex work processes conducted during testing and / or operation of machinery and equipment, a local wireless communications network is implemented using at least one fixed point wireless communications access station and one or more voice-responsive wireless mobile computing / communications devices that are capable of accurate vocal command recognition in noisy industrial environments. The computing / communications device determines spectral characteristics of ambient non-speech background noises and provides active noise cancellation through the use of a directional microphone and an adaptive noise tracking and subtraction process. The device is carried by a user and is responsive to one or more vocal utterances of the user for communicating data to the information processing system and / or generating operational control commands to provide to the equipment controller for controlling the machinery or equipment.

Owner:GENERAL ELECTRIC CO

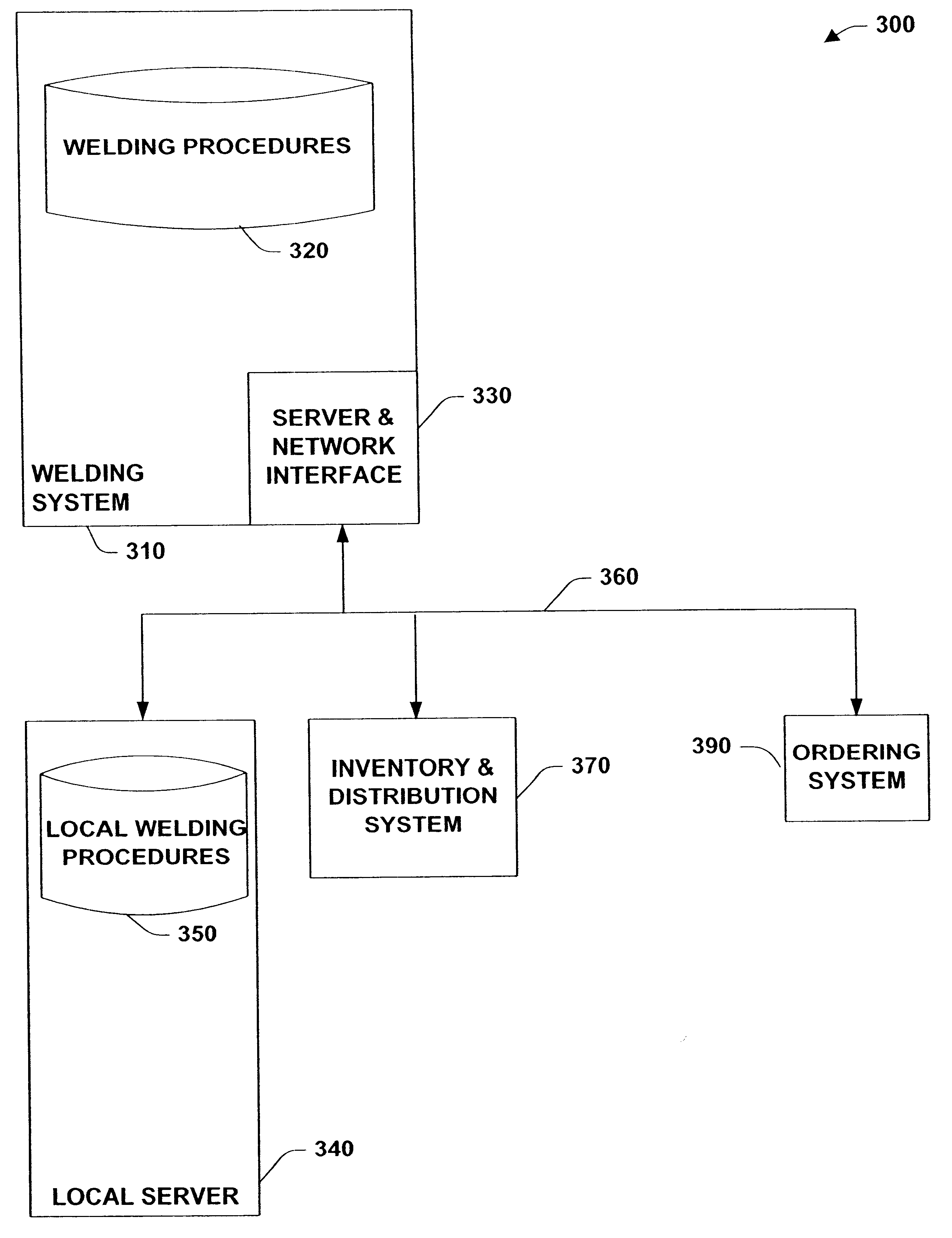

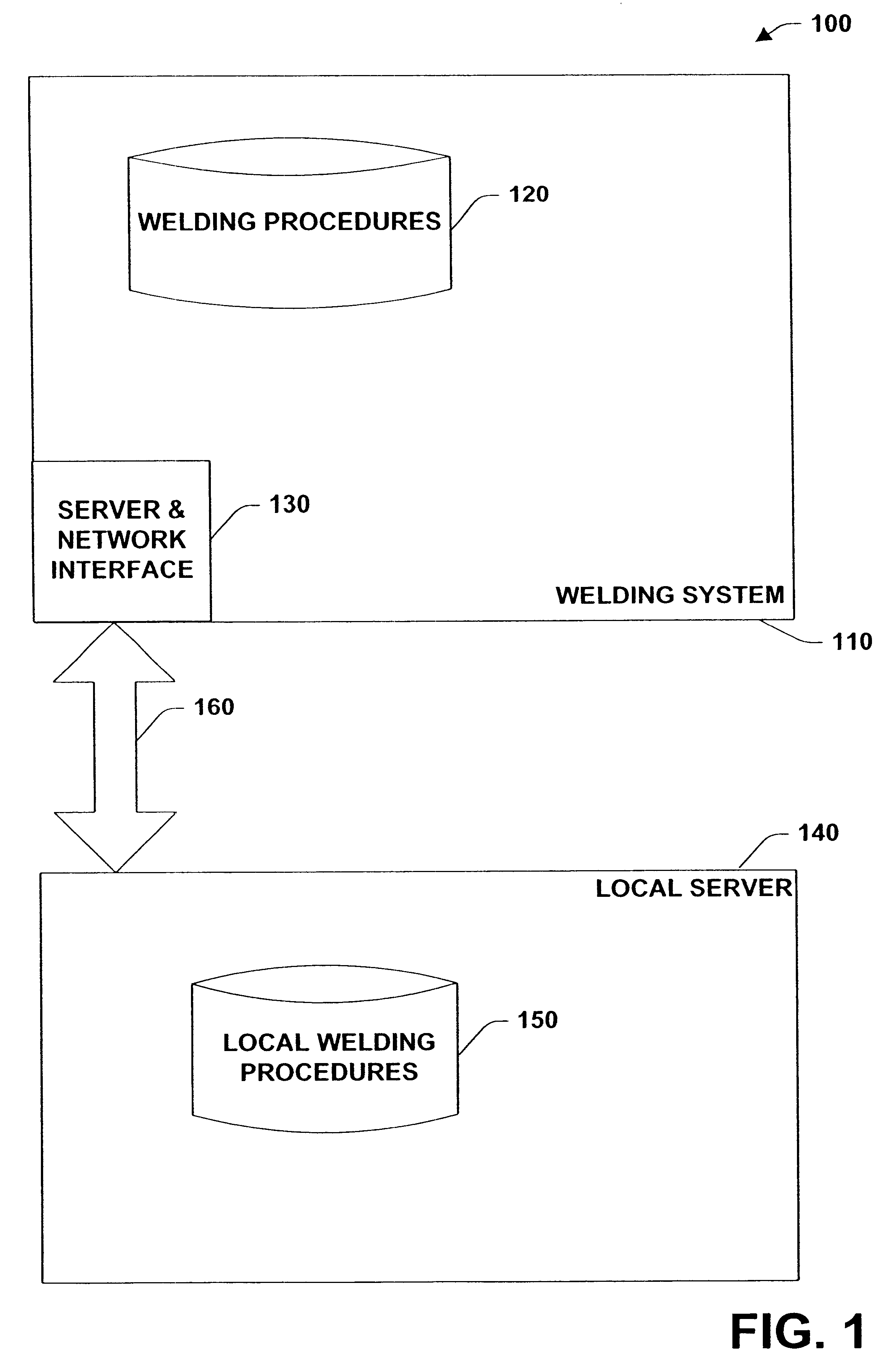

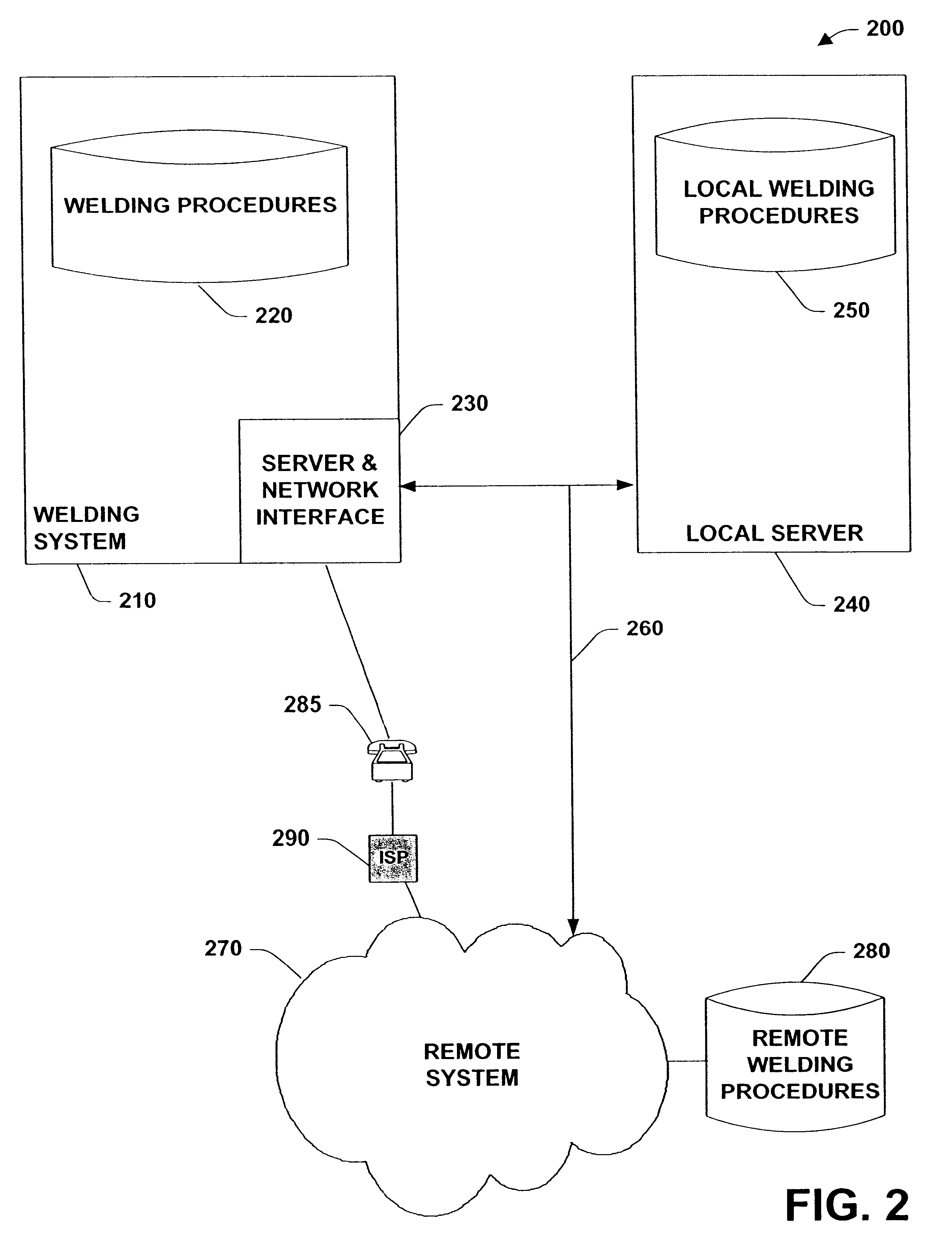

System and method for managing welding procedures and welding resources

InactiveUS6636776B1Well formedElectric discharge heatingWelding electric supplyRemote systemUser input

A system and method for managing welding procedures is provided. The invention includes a welding system, a local server and / or a remote system. The invention further provides for searching of the welding system, local server and / or remote system for potentially suitable welding procedure(s). The invention further provides for dynamic creation of welding procedure(s) based upon user input, information stored on the welding system, a local area network and / or a remote system. The invention also includes filtering of the search results based at least in part upon commonality of consumables. The invention further includes calculation of weld costs for potentially suitable welding procedure(s). The invention further provides for communication with an inventory & distribution system and / or ordering system in order to facilitate further automation of the industrial environment.

Owner:LINCOLN GLOBAL INC

Stable solid block detergent composition

InactiveUS6583094B1Easy to cleanImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkalinityIndustrial setting

The dimensionally stable alkaline solid block warewashing detergent uses an E-form binder forming a solid comprising a sodium carbonate source of alkalinity, a sequestrant, a surfactant package and other optional material. The solid block is dimensionally stable and highly effective in removing soil from the surfaces of dishware in the institutional and industrial environment. The E-form hydrate comprises an organic phosphonate and a hydrated carbonate.

Owner:ECOLAB USA INC

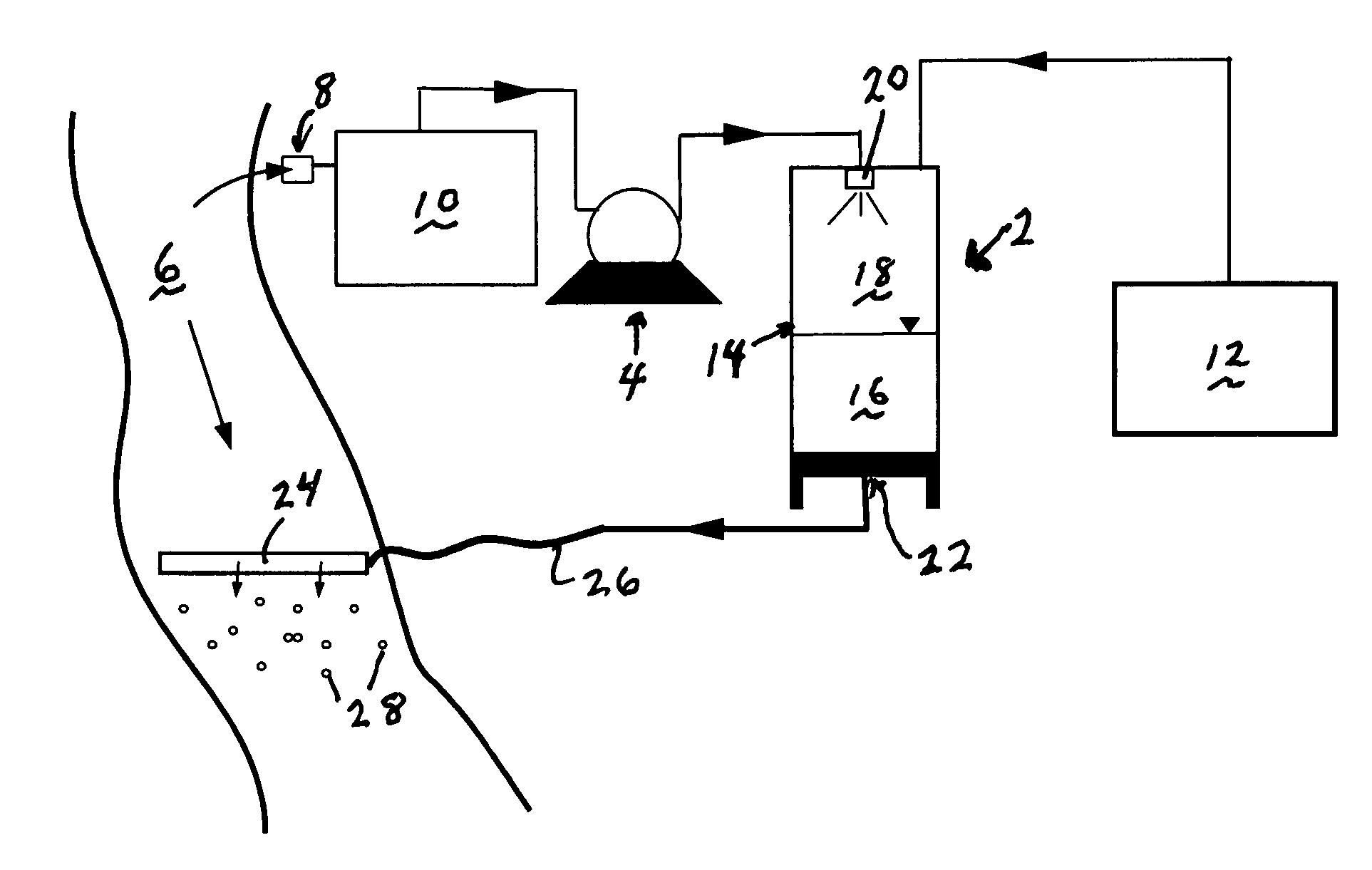

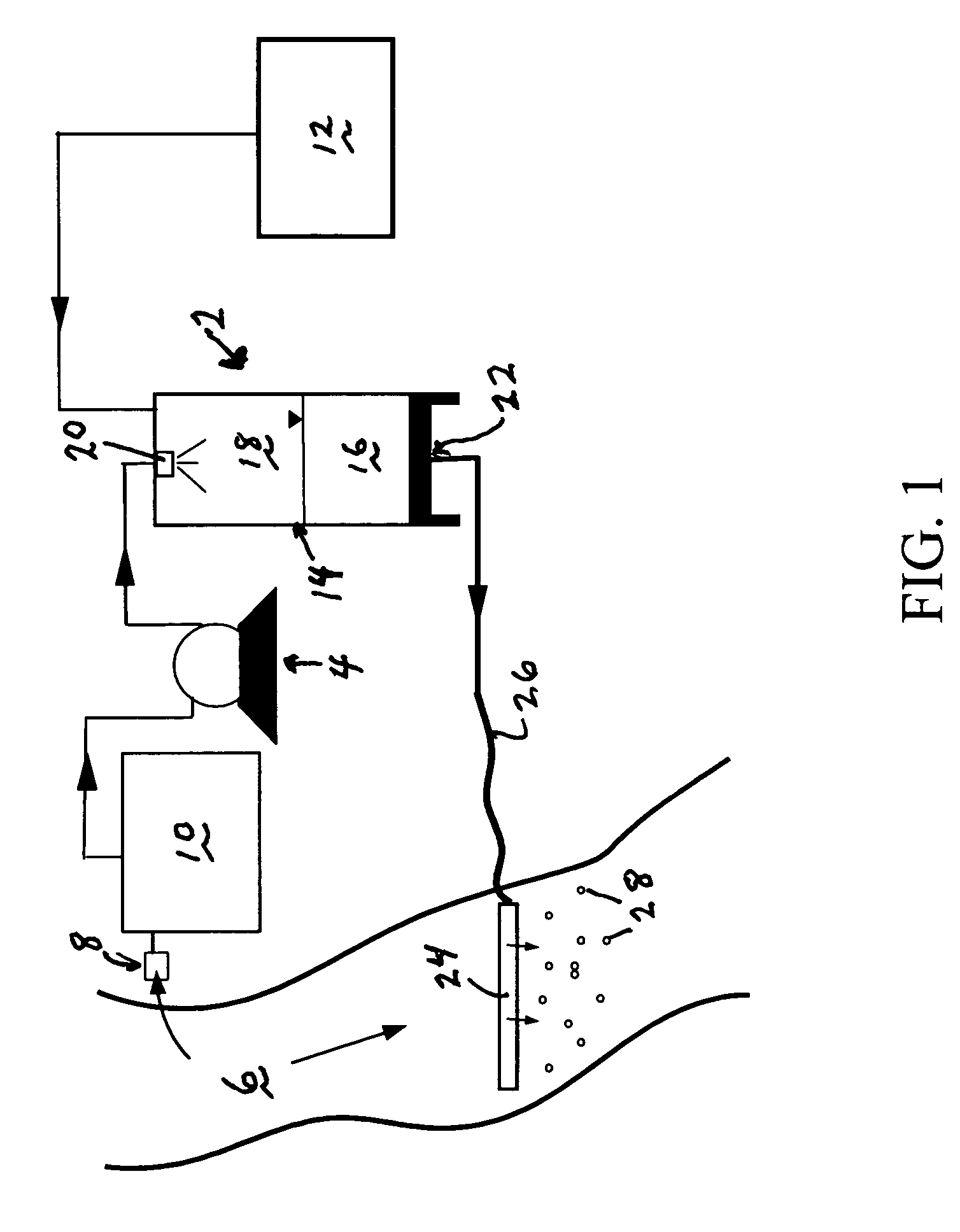

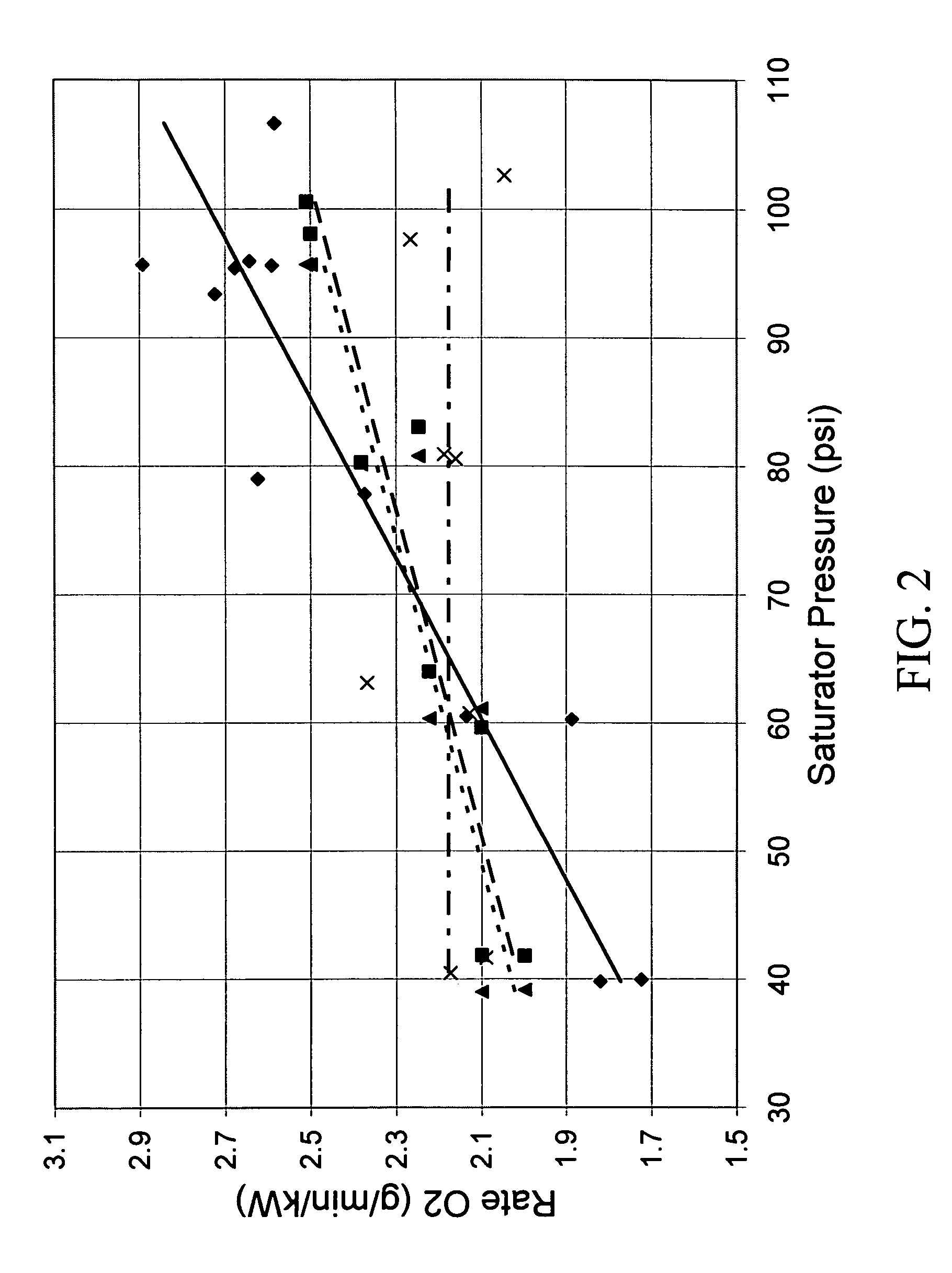

System and method for dissolving gases in liquids

ActiveUS7255332B2Improve solubilityFlow mixersTransportation and packagingSuspended particlesDissolution

Apparatus and methods for dissolving a gas into a liquid comprises a saturation tank, a high pressure liquid pump in fluid communication with the tank, and a pressurized gas source in communication with a regulated gas head space of the saturation tank. The saturation tank comprises a pressure vessel for containing the liquid and has a regulated gas head space above the liquid, contains at least one liquid spray nozzle that permits passage of liquid into the pressure vessel, and an outlet for the liquid containing dissolved gas. Upon passing the gas-containing liquid into a second fluid, the gas is released in the form of microbubbles. The microbubbles aid in flocculation of suspended particles and promote dissolution of the gas in the second fluid. Preferred gases for use with the apparatus are oxygen, air, and ozone. Anticipated uses include treatment of rivers, streams, and ponds in natural or industrial settings, as well as smaller scale applications.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

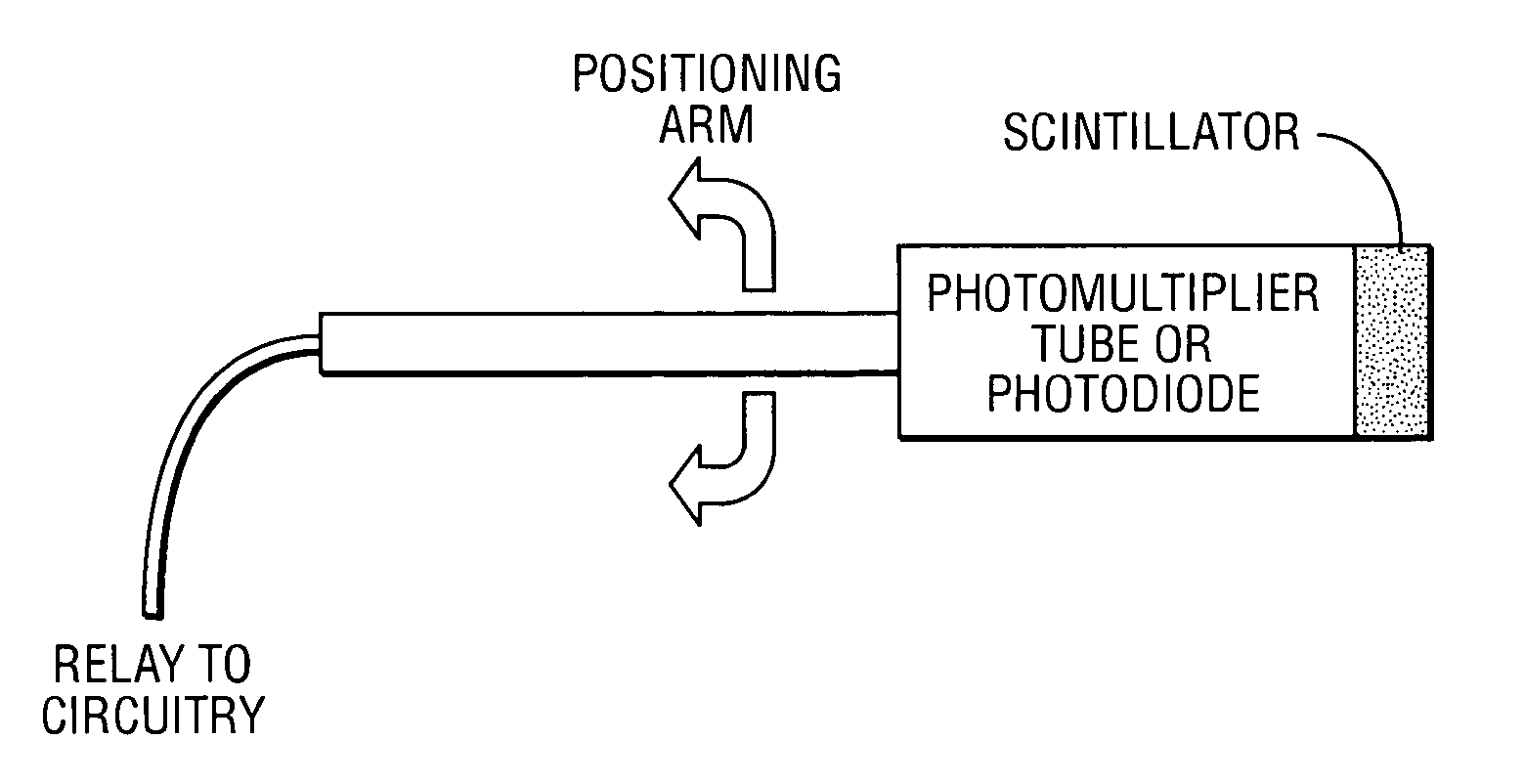

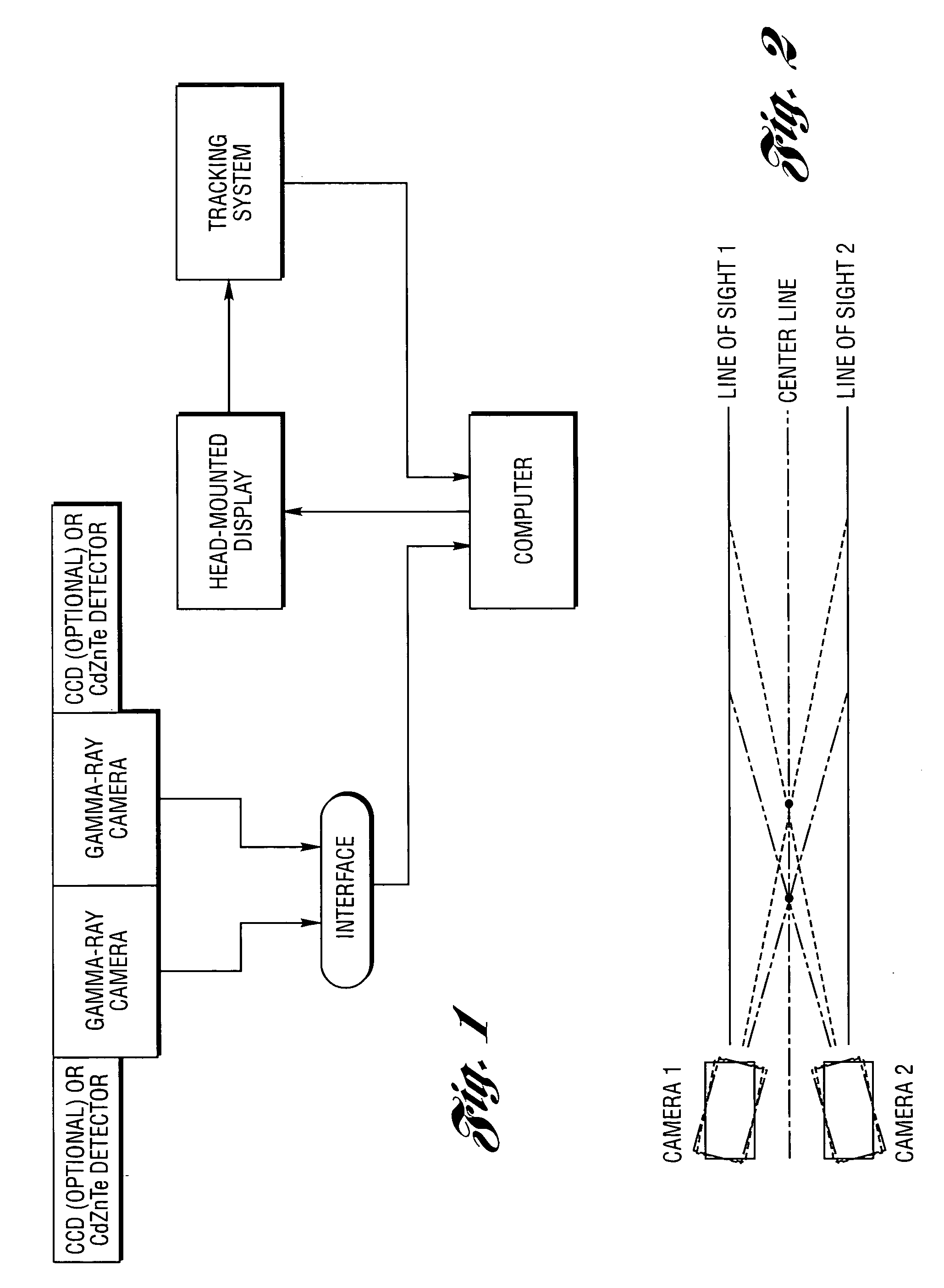

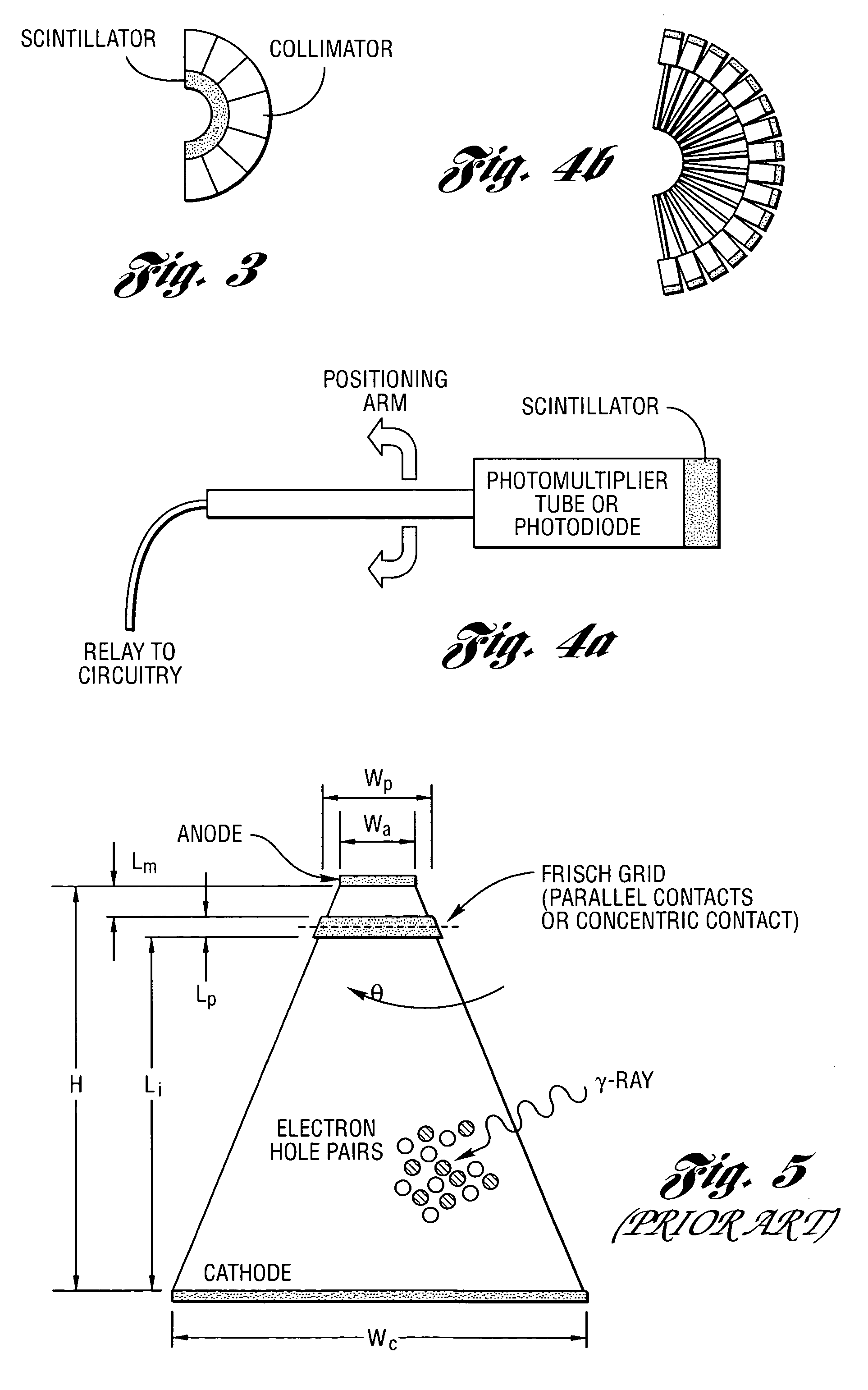

Method and system for high-speed, 3D imaging of optically-invisible radiation and detector and array of such detectors for use therein

InactiveUS20050017181A1Reduce exposureStrong applicationElectric discharge tubesSolid-state devicesHuman exposureSpectroscopy

A high-speed, three-dimensional, gamma-ray imaging method and system as well as a detector and array of such detectors for use therein are provided which characterize radioactivity distributions in nuclear and radioactive waste and materials facilities by superimposing radiation images on a view of the environment using see-through display screens or shields to provide a stereoscopic view of the radiation. The method and system provide real-time visual feedback about the locations and relative strengths of radioactive sources. The method and system dynamically provide continuous updates to the displayed image illustrating changes, such as source movement. A pair of spaced gamma-ray cameras of a detector subsystem function like “gamma eyes”. A pair of CCD cameras may be coupled to the detector subsystem to obtain information about the physical architecture of the environment. A motion tracking subsystem is used to generate information on the user's position and head orientation to determine what a user “sees”. The invention exploits the human brain's ability to naturally reconstruct a 3D, stereoscopic image from 2D images generated by two “imagers” separated by a known angle(s) without the need for 3D mathematical image reconstruction. The method and system are not only tools for minimizing human exposure to radiation thus assisting in ALARA (As Low As Reasonably Achievable) planning, but also are helpful for identifying contamination in, for example, laboratory or industrial settings. Other optically-invisible radiation such as infrared radiation caused by smoldering fires may also be imaged. Detectors are manufactured or configured in curvilinear geometries (such as hemispheres, spheres, circles, arcs, or other arrangements) to enable sampling of the ionizing radiation field for determination of positional activity (absolute or relative amounts of ionizing radiation) or spectroscopy (energy distributions of photons). More than one detector system may be used to obtain three-dimensional information. The detector systems are specifically suitable for direct visualization of radiation fields.

Owner:RGT UNIV OF MICHIGAN

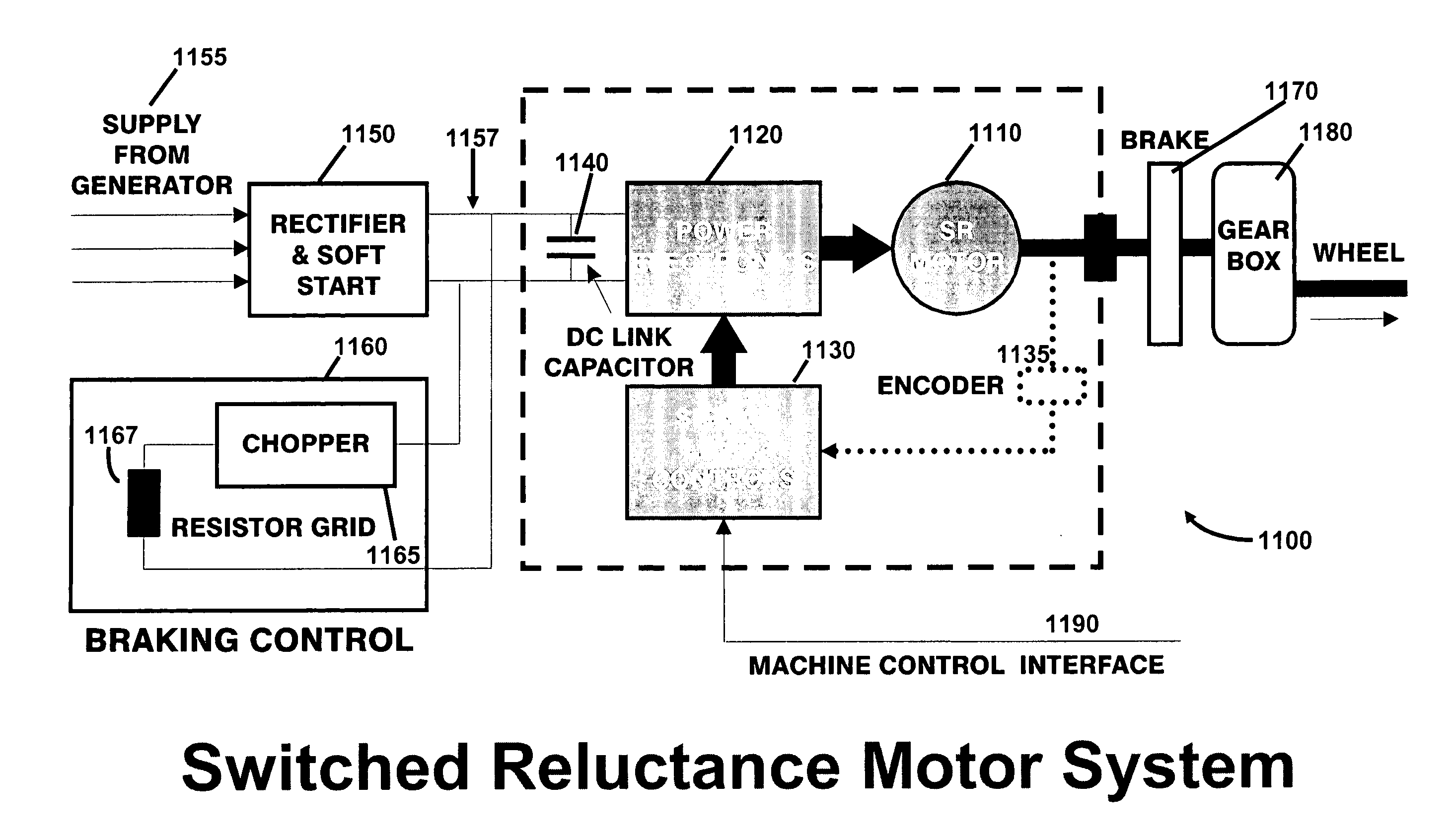

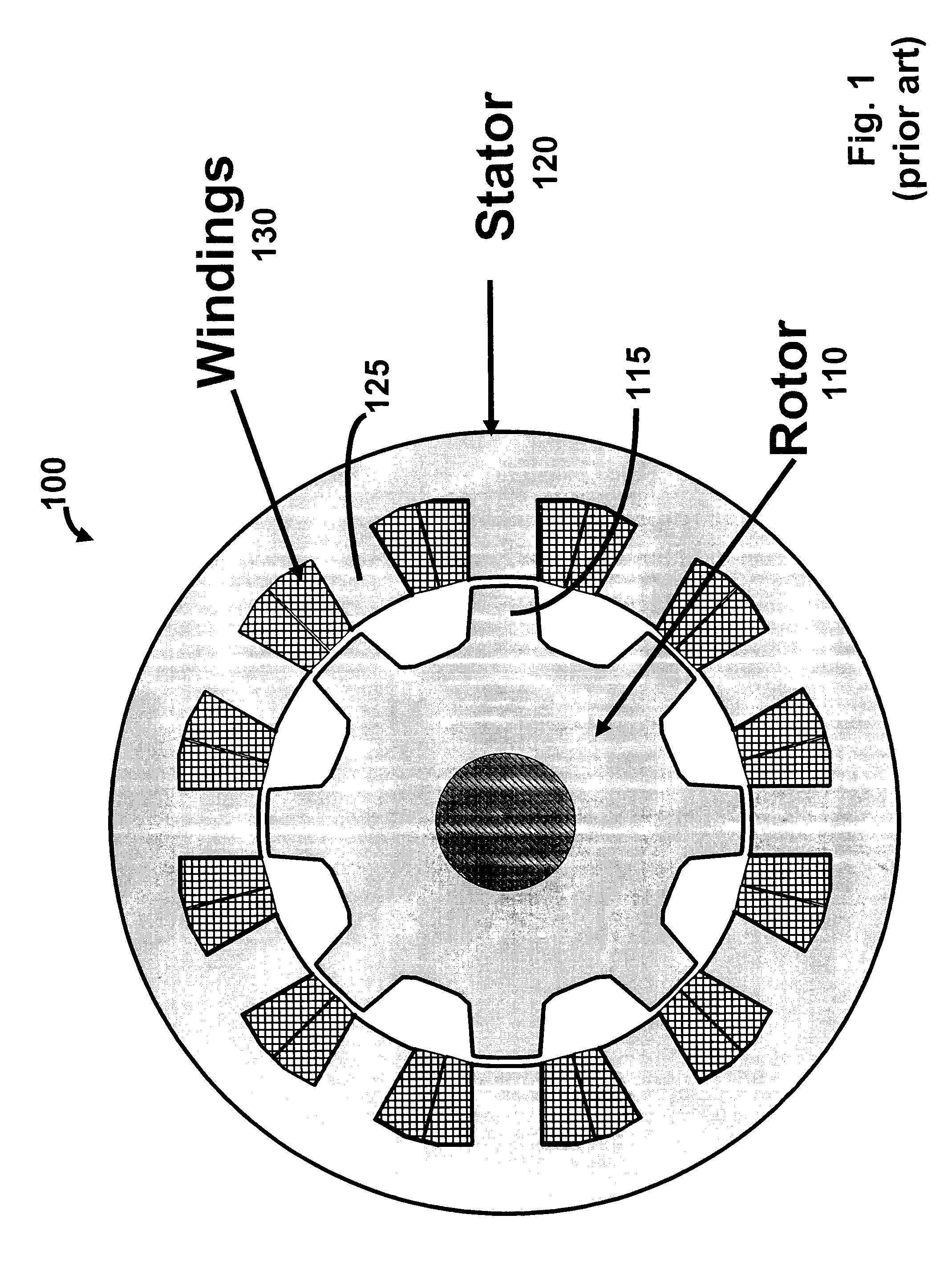

Vehicle for materials handling and other industrial uses

A heavy duty wheeled vehicle for an industrial environment is electrically driven by one or more switched reluctance motor traction drive system connected to the wheels. The switched reluctance motors are powered by an electrical generator that is driven by an engine, such as a diesel engine, which may run at a substantially constant RPM. A digital control system provides operator displays and controls power conversion from the generator, as well as providing maintenance and control functions for the switched reluctance motors. A heavy-duty hoisting apparatus electrically drives a hoisting mechanism using an SR motor, providing power for lifting a load. The heavy-duty hoisting apparatus may include an engine and generator or provide power to the SR motor from an external source.

Owner:R G LE TOURNEAU

Method for observation of a person in an industrial environment

Manufacturing processes profit greatly from a close collaboration between human and machine. Whereas a human behaves flexibly and adaptively but is inclined to make mistakes during repetitive work operations, machines operate quickly and exactly but are static and not very flexible. In order to enable an improved hazard protection in the context of a safe human-machine interaction, a spatial- and time-dependent variable degree of hazard is allocated to monitored spatial areas as a function of the current position and the current movement state of a machine or a machine element, as well as of the observed person. For this purpose, a multicamera system is used to acquire image data of the person in order to obtain the most detailed information possible about the position and alignment of a person, in particular also with reference to the body parts thereof, in an industrial environment. These image data are then examined with regard to the imaging of a person so that whenever a person has been detected in the image data, an articulated virtual 3D model of the human body is matched to this person hypothesis. Subsequently, this virtual body model is continuously matched to the movement behavior of the person detected in the image data. A hazard potential is determined using knowledge of the position and the movement behavior of the virtual body model in space. The hazard potential thus determined is subjected to a threshold value comparison in order to act upon the movement control of the machine or the machine part in the event of this threshold value being exceeded.

Owner:PILZ (COMPANY)

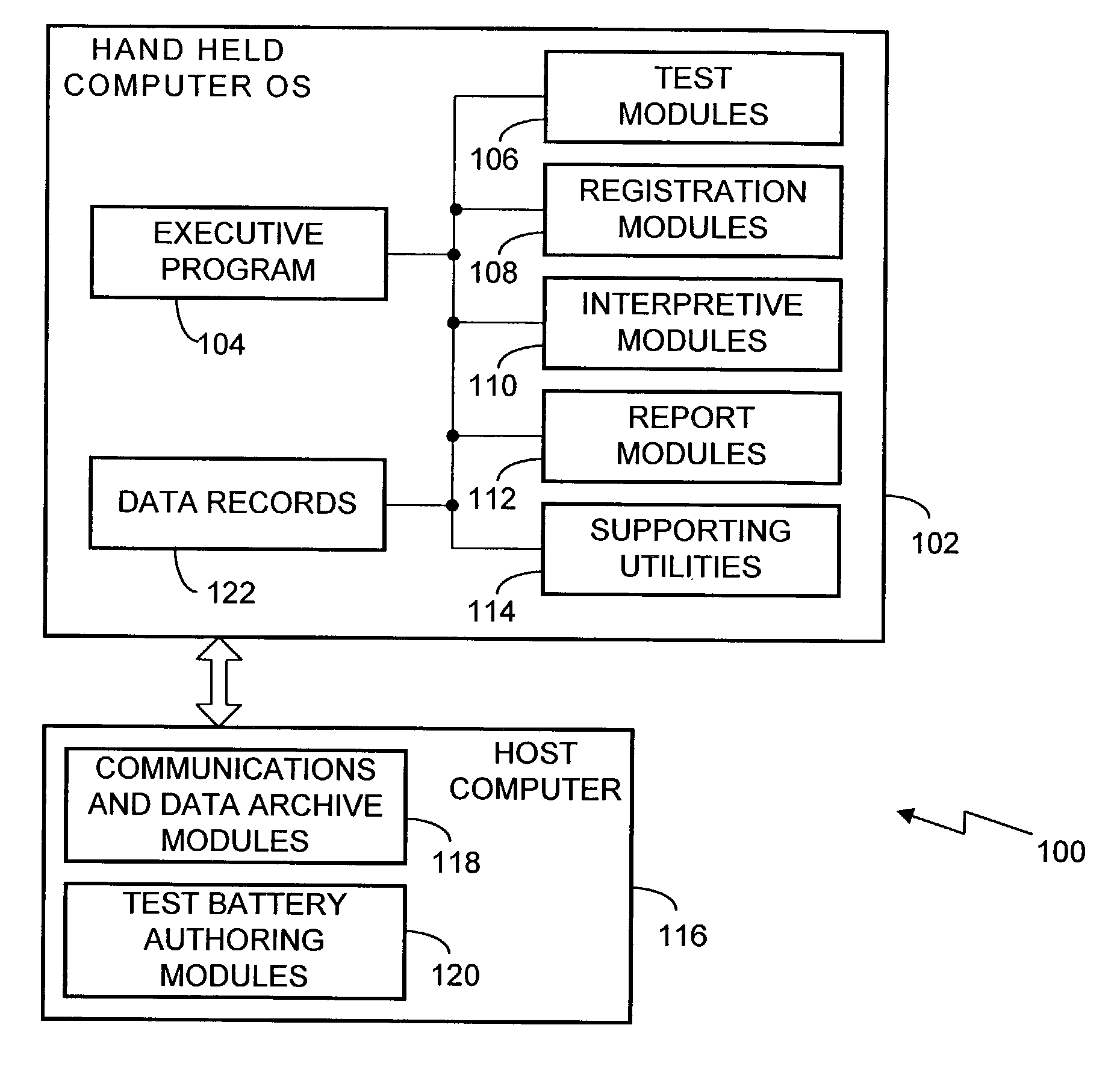

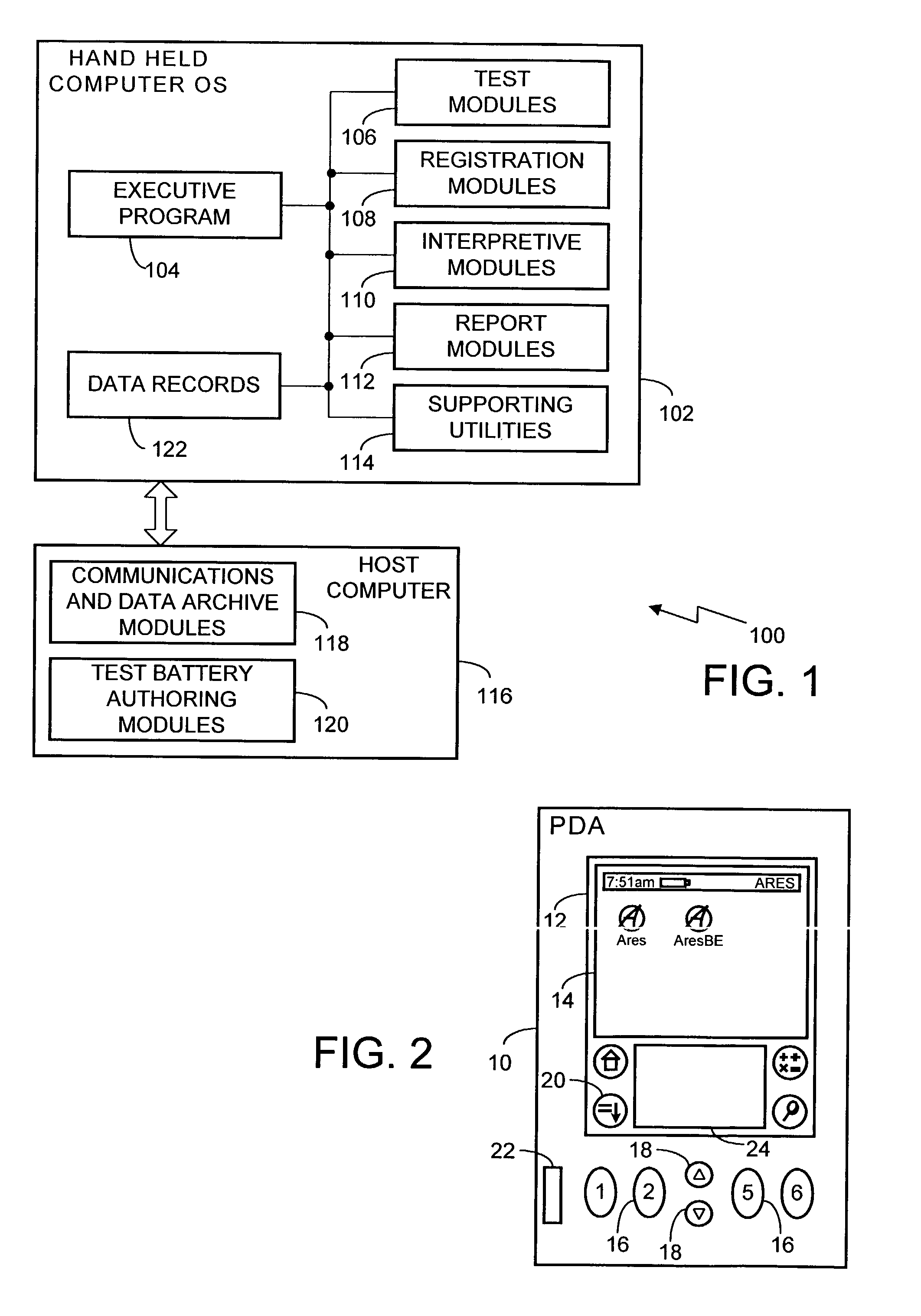

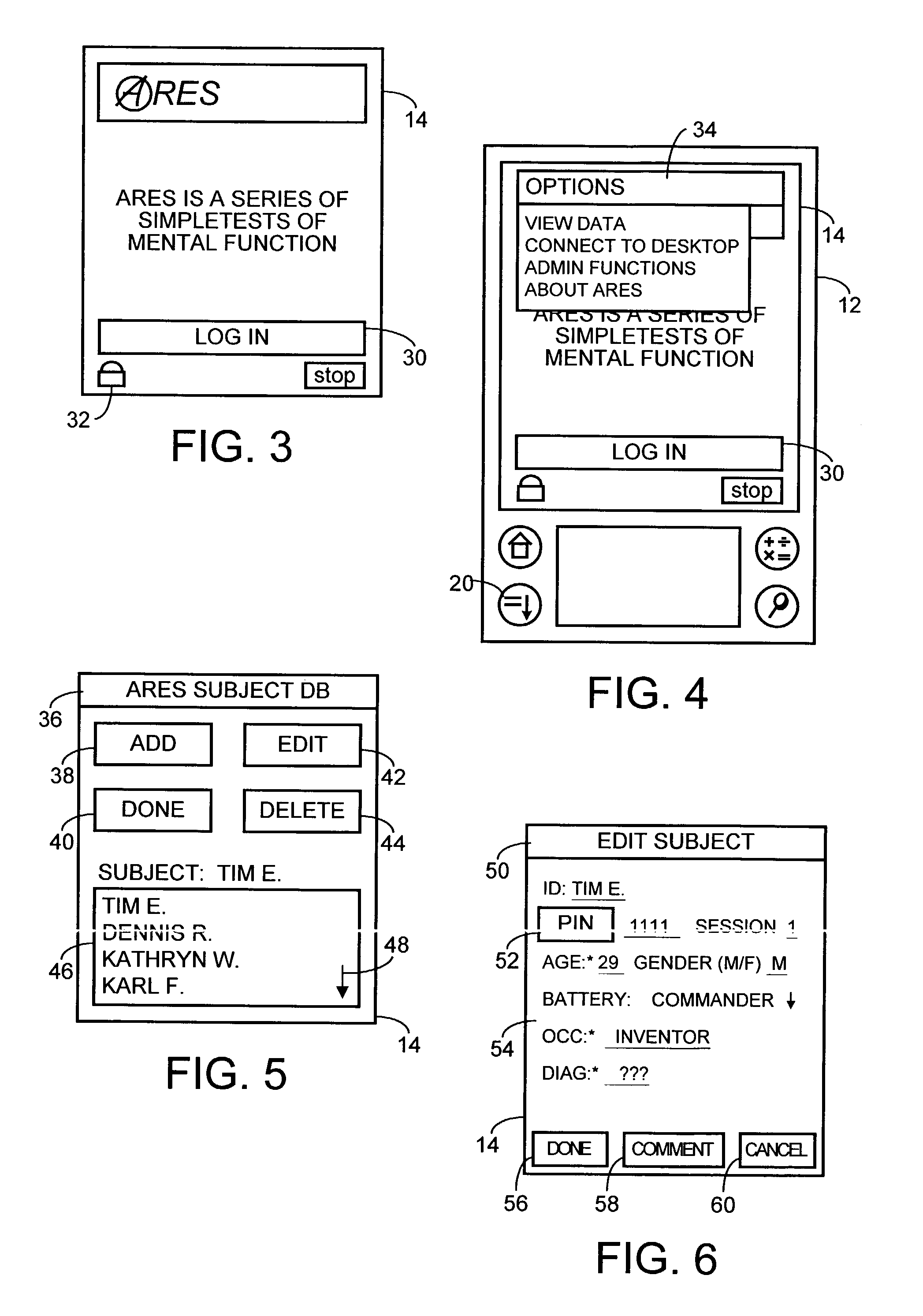

Neurocognitive and psychomotor performance assessment and rehabilitation system

InactiveUS7837472B1Highly attractiveCost efficientComputer-assisted medical data acquisitionMedical automated diagnosisClinical settingsSystems design

A computerized Neuropsychological / NeuroCognitive and Psychomotor Performance Assessment and Rehabilitation system is designed for use on handheld computer systems. Components of the system include an executive program, test modules, interpretive and report modules, and supporting utilities. The system provides point-of-use interpretations and result reports. The system is designed for use in clinical settings, occupational medicine, and research. Medical applications include use as a diagnostic, evaluation, and treatment instrument. In industrial settings it can be used as a fitness / readiness for work assessment. The assessment and rehabilitation system also contains modules for use in forensic mental competency, mental and emotional status examinations.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

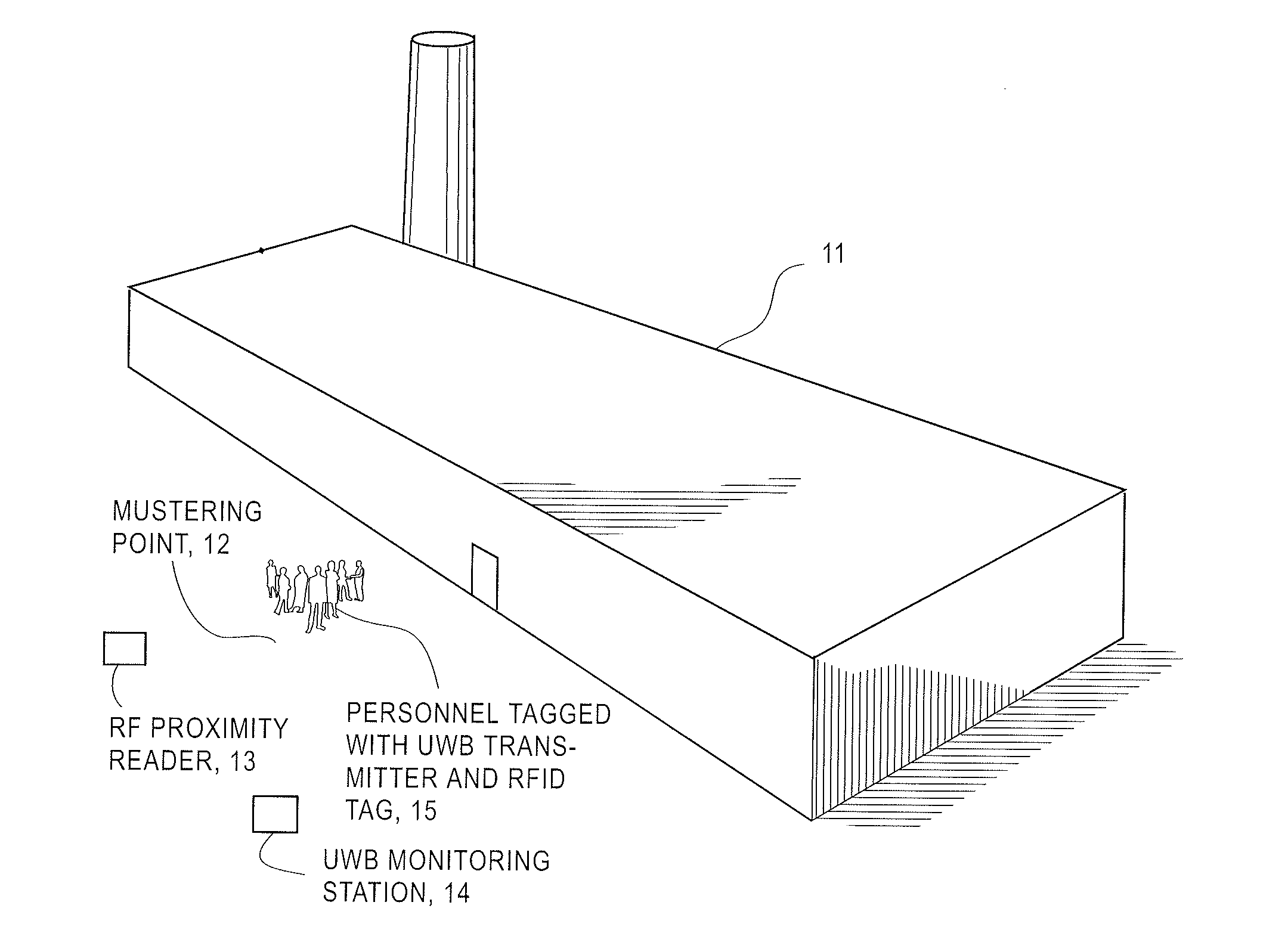

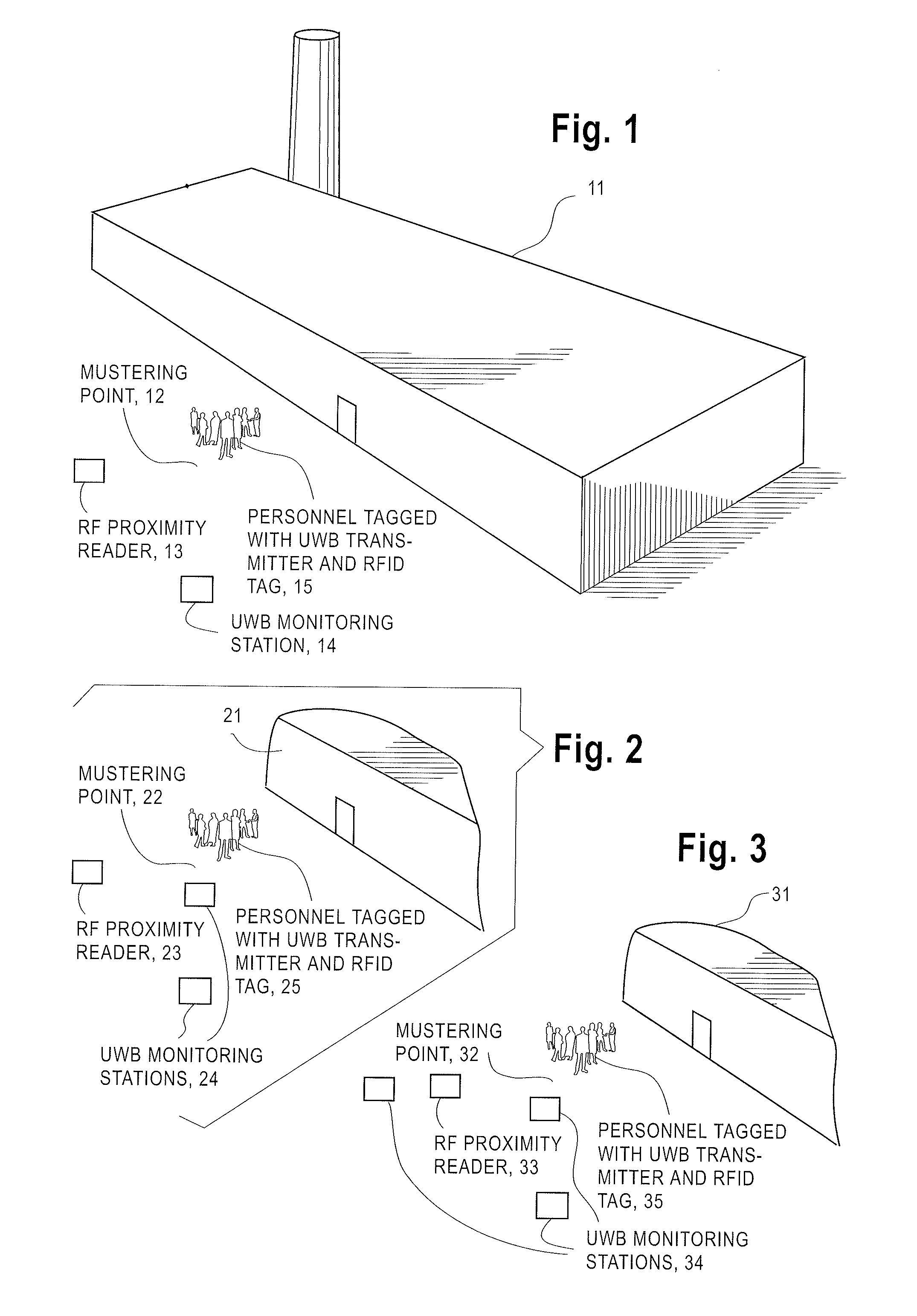

Method for accounting for people in emergencies in industrial settings

A method for accounting for individuals in an emergency at industrial facilities utilizing Ultra-Wideband (UWB) transmitters associated with individuals or objects and UWB monitoring stations. Identification information received from the UWB transmitters by UWB monitoring stations are communicated along with time of arrival information to a computer which calculates the location of the UWB transmitter. The system can be used despite severe multi-path effects and can provide location information in 3 dimensions. The system can optionally include proximity-based RF equipment for access control or otherwise for identification in specific locations. Information from the proximity-based RF equipment is also sent to the computer which also receives information from the UWB monitoring stations.

Owner:BP CORP NORTH AMERICA INC +1

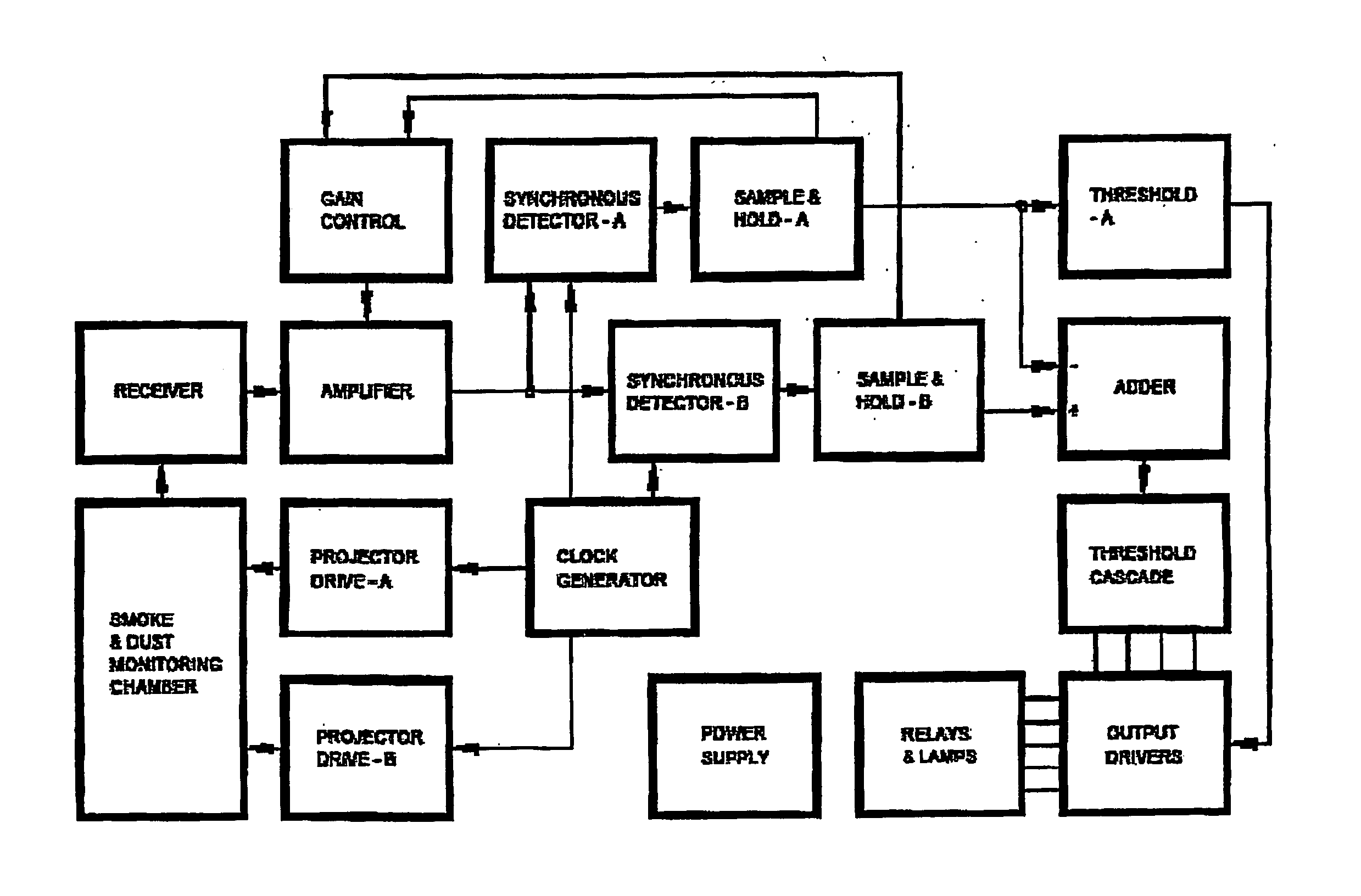

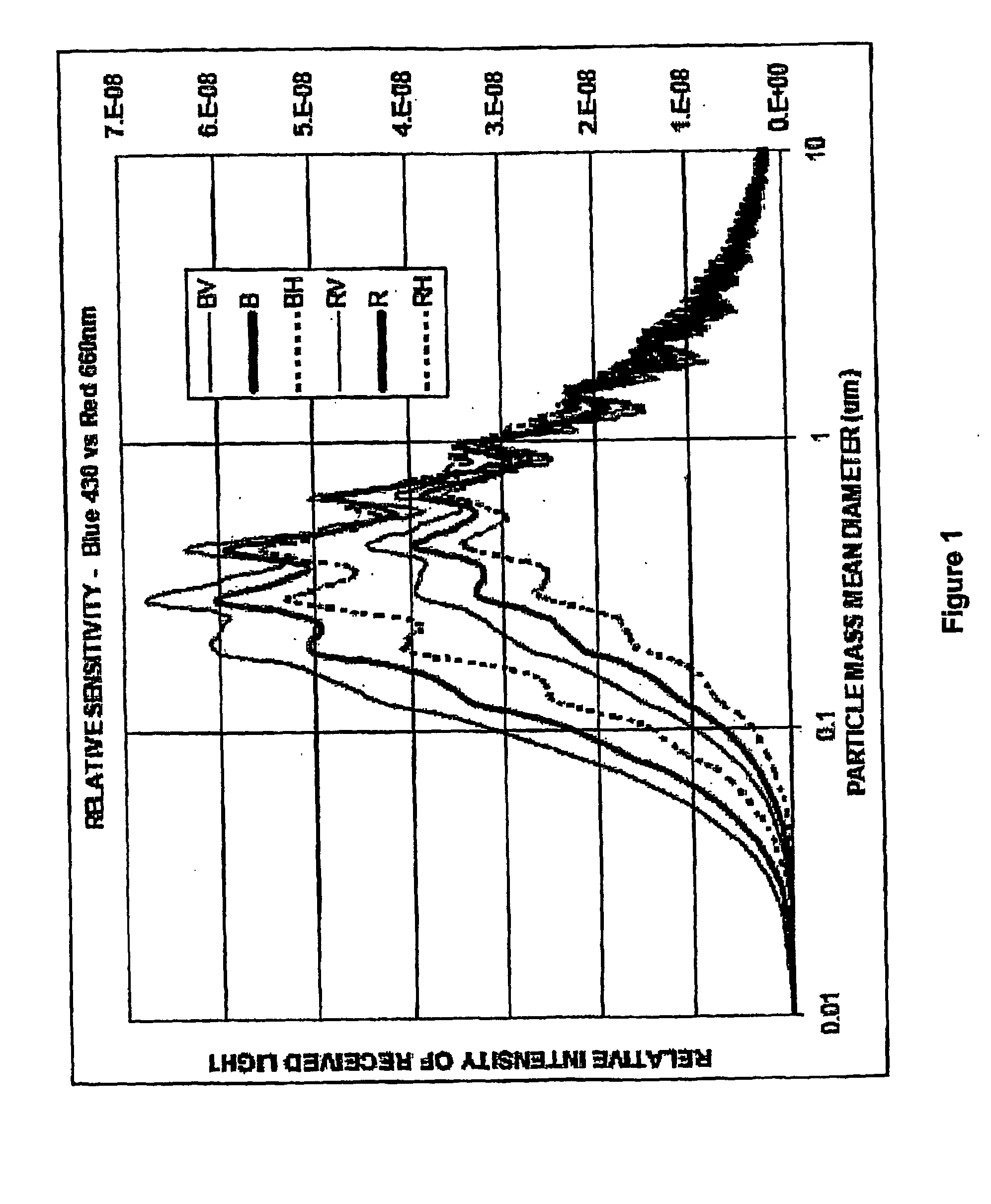

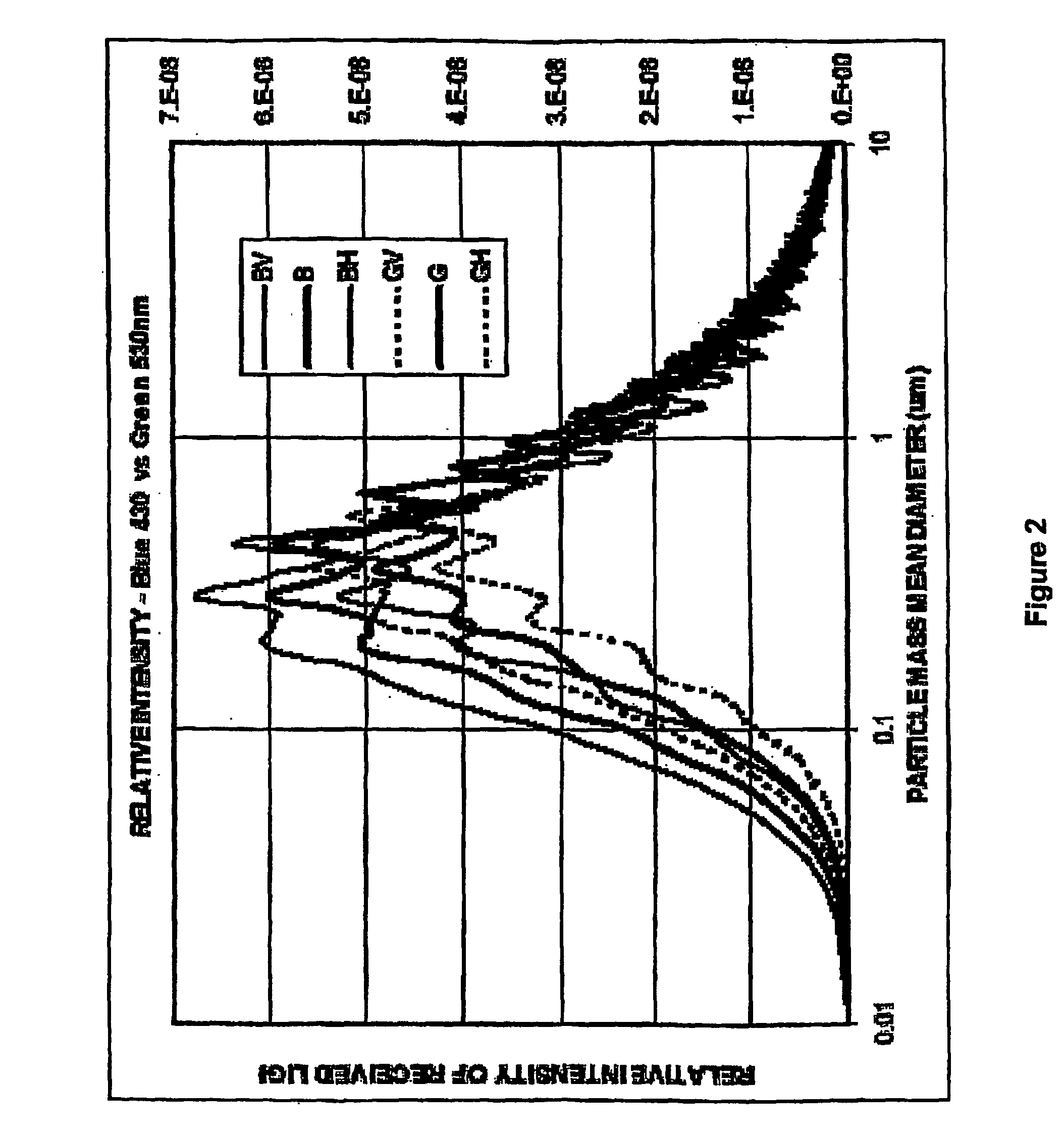

Particle monitors and method(s) therefor

InactiveUS20070024459A1Low costWeaken energyVolume/mass flow measurementScattering properties measurementsSmoke detectorsCombustion

The present invention relates to the field of the detection, analysis and / or determination of matter or particles suspended in fluid. In one particular form, the present invention relates to smoke detectors, which detect unwanted pyrolysis or combustion of material. In another form, the present Invention relates to smoke detectors of the early detection type, and which may be applied to ventilation, air-conditioning or duct monitoring of a particular area. In yet another form, the present invention relates to surveillance monitoring, such as building, fire or security monitoring. in still another form, the present invention relates to environment monitoring, such as monitoring, detection and / or analysis of a fluid, zone, area and / or ambient environment, including commercial and Industrial environments.

Owner:SIEMENS SWITZERLAND

Yb: and Nd: mode-locked oscillators and fiber systems incorporated in solid-state short pulse laser systems

InactiveUS7508853B2Increase flexibilityMaximize positive effectLaser using scattering effectsOptical devices for laserAudio power amplifierEngineering

The invention describes classes of robust fiber laser systems usable as pulse sources for Nd: or Yb: based regenerative amplifiers intended for industrial settings. The invention modifies adapts and incorporates several recent advances in FCPA systems to use as the input source for this new class of regenerative amplifier.

Owner:IMRA AMERICA

Method for observation of a person in an industrial environment

A method for observing a person in an industrial environment using a multicamera system to acquire image data about the position and alignment of a person, including a person's body parts. These image data are then examined with regard to the imaging of a person so that whenever a person has been detected in the image data, an articulated virtual 3D model of the human body is matched to this person hypothesis. Subsequently, this virtual body model is continuously matched to the movement behavior of the person detected in the image data. A hazard potential is determined using knowledge of the position and the movement behavior of the virtual body model in space. The hazard potential thus determined is subjected to a threshold value comparison in order to act upon the movement control of the machine or the machine part in the event of this threshold value being exceeded.

Owner:PILZ (COMPANY)

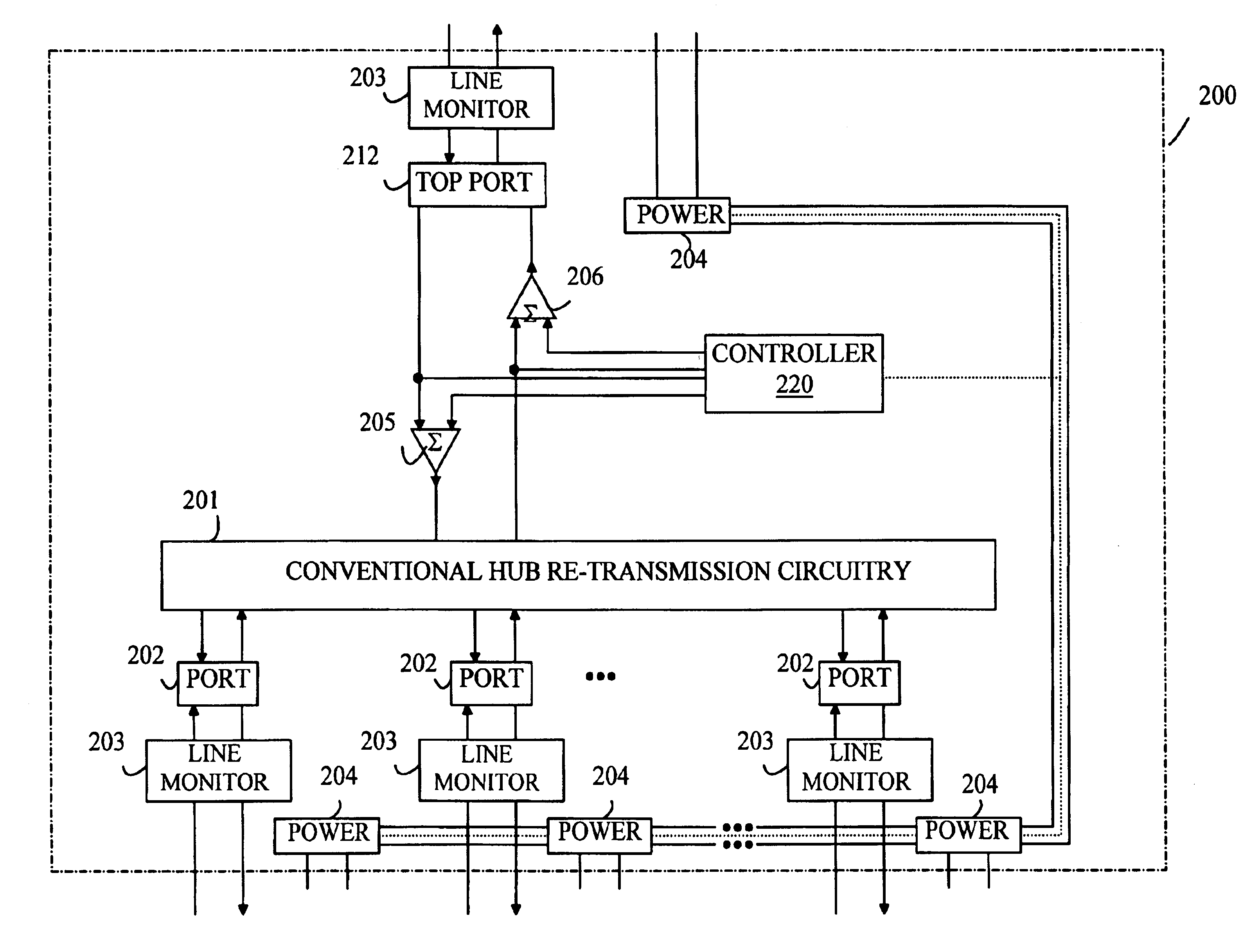

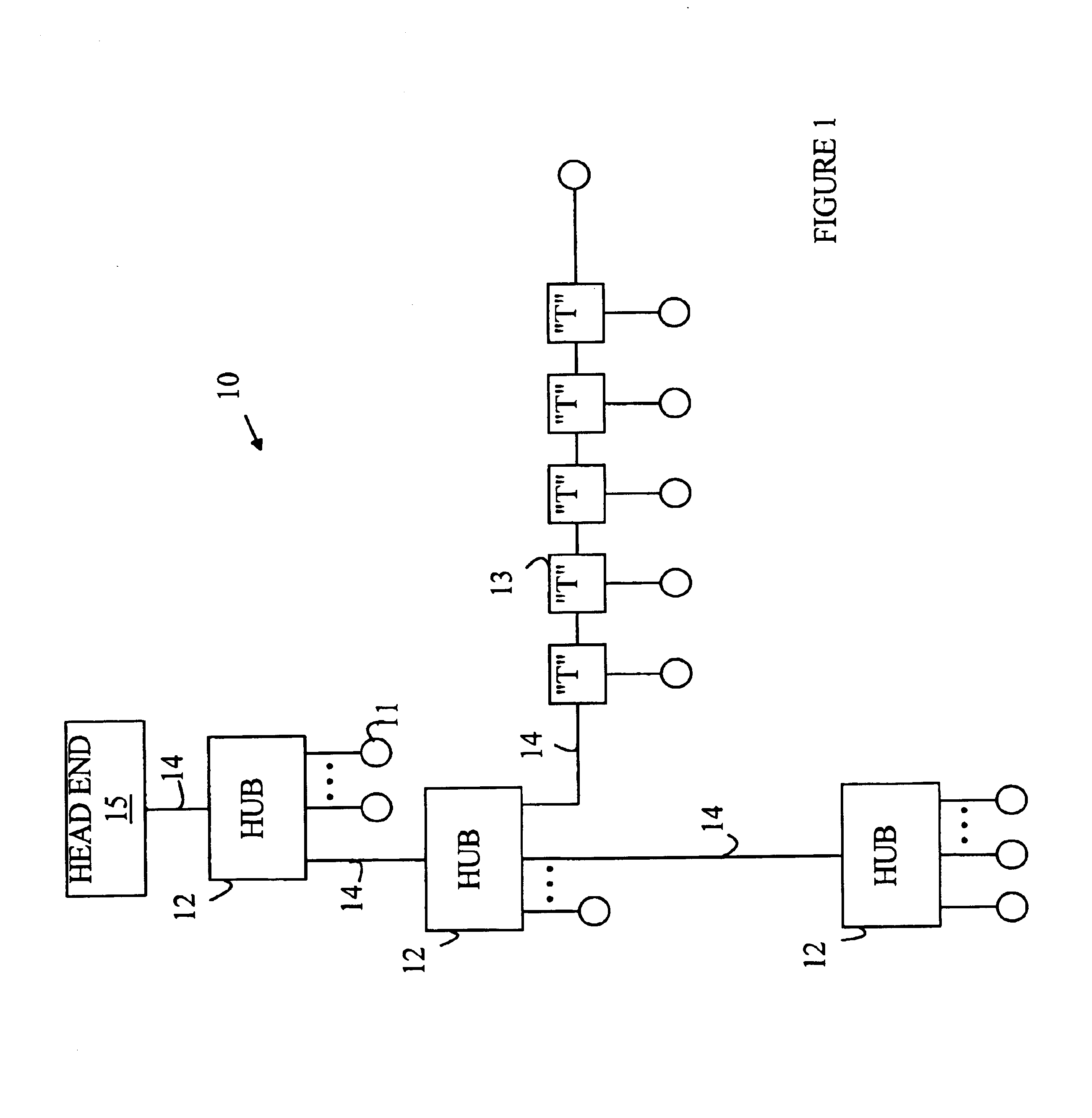

Computer network adapted for industrial environments

InactiveUS6889095B1Thermoelectric device with peltier/seeback effectElectric controllersControl storeSignal on

A network for connecting a plurality of devices and the components used in constructing the network. The network includes at least one fan-out device for connecting the devices to each other. The fan-out device includes a controller, a top port and a plurality of downstream ports. The controller monitors messages received by the ports and generates messages that are sent via the ports. The network also includes a plurality of network cables, one per port. The network preferably utilizes a cabling system that includes twisted pairs for communicating the messages via the Ethernet protocol and power conductors for distributing power to the various network devices. The fan-out device includes one power component associated with each of the ports. Each power component provides connections between the power lines in the network capble and the ports of the fan-out device. The power components are used to power the devices on the network and to monitor the power lines for problems. Switching circuitry in the power components allows the fan-out device to isolate cable runs connected thereto that have shorts or other problems. The fan-out device preferably stores a device identification number that the controller transmits on all of the ports in response to a message received on one of the downstream ports. The controller also generates a signal on the top port that causes any device connected to the fan-out device via the top port to ignore the message. One embodiment of the fan-out device provides a hub that is transparent to Ethernet protocols while not introducing the jitter into the signals associated with the re-transmission and synchronization functions performed by conventional hubs.

Owner:AGILENT TECH INC

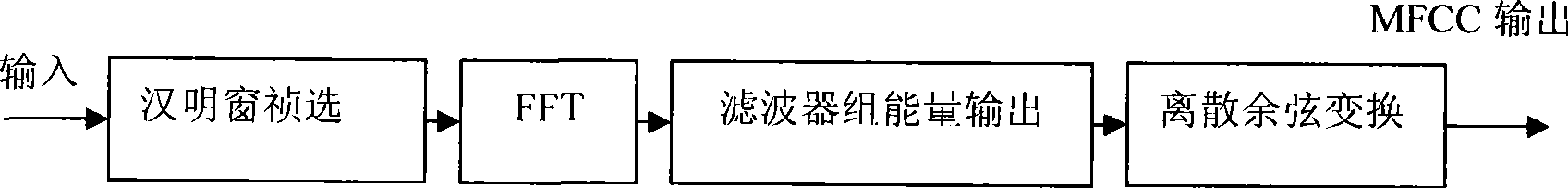

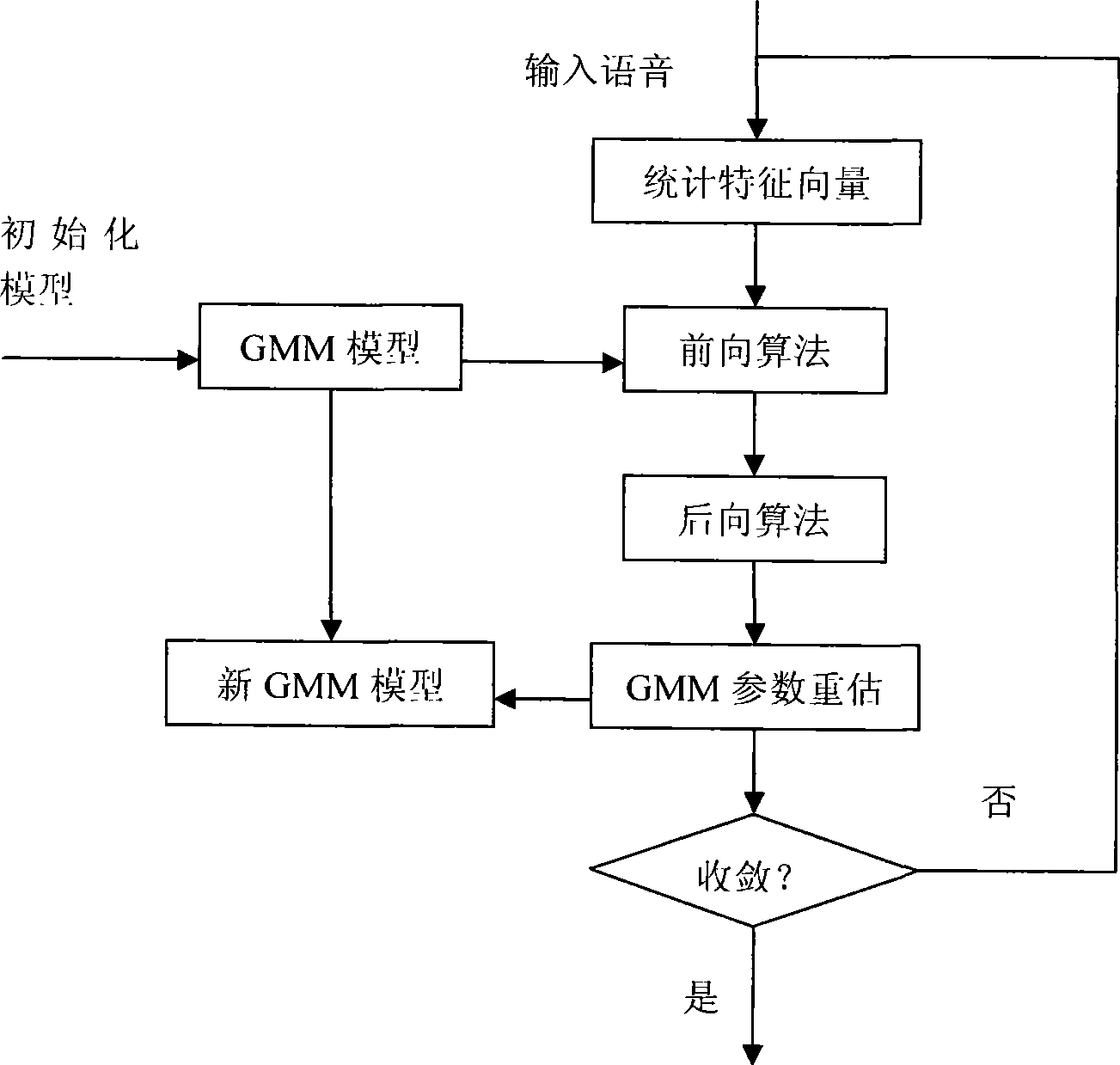

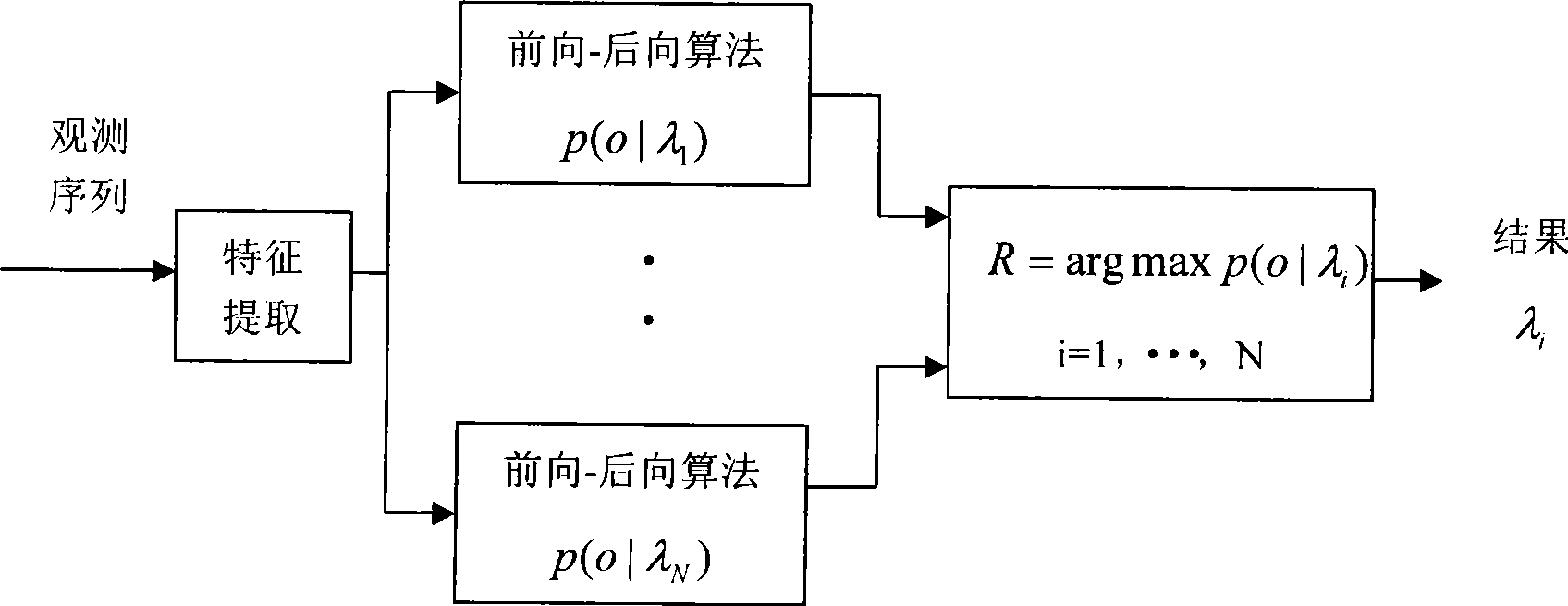

Sound image combined monitoring method and system

InactiveCN101364408AReduce re-developmentClosed circuit television systemsSpeech recognitionVideo monitoringSound image

The invention particularly relates to an audio / video combined monitoring method and a system thereof, belongs to the technical field of industrial environment monitoring, and aims to solve the problems in the prior art, for example, the monitoring is only conducted by video monitoring operators on duty, who are easy to be fatigue and hardly identify places with potential safety hazards, moreover, video monitoring is limited by functions and viewing angles, so that the potential hazard cannot be found in time, thereby missing rescue opportunities. The audio / video combined monitoring method uses audio signals and video signals at the same time to conduct environmental monitoring, and guides the operators on duty to selectively observe video windows by using the identification results of the audio signals. The processing method of the audio signals comprises the following steps: (1) feature extraction, (2) model training, (3) sound classification, (4) online study, and (5) hazard rating evaluation.

Owner:XI AN CHENGFENG TECH CO LTD

Method for accounting for people in emergencies in industrial settings

ActiveUS20080030359A1Accurate locationPosition fixationSatellite radio beaconingUltra-widebandMulti path

A method for accounting for individuals in an emergency at industrial facilities utilizing Ultra-Wideband (UWB) transmitters associated with individuals or objects and UWB monitoring stations. Identification information received from the UWB transmitters by UWB monitoring stations are communicated along with time of arrival information to a computer which calculates the location of the UWB transmitter. The system can be used despite severe multi-path effects and can provide location information in 3 dimensions. The system can optionally include proximity-based RF equipment for access control or otherwise for identification in specific locations. Information from the proximity-based RF equipment is also sent to the computer which also receives information from the UWB monitoring stations.

Owner:BP CORP NORTH AMERICA INC +1

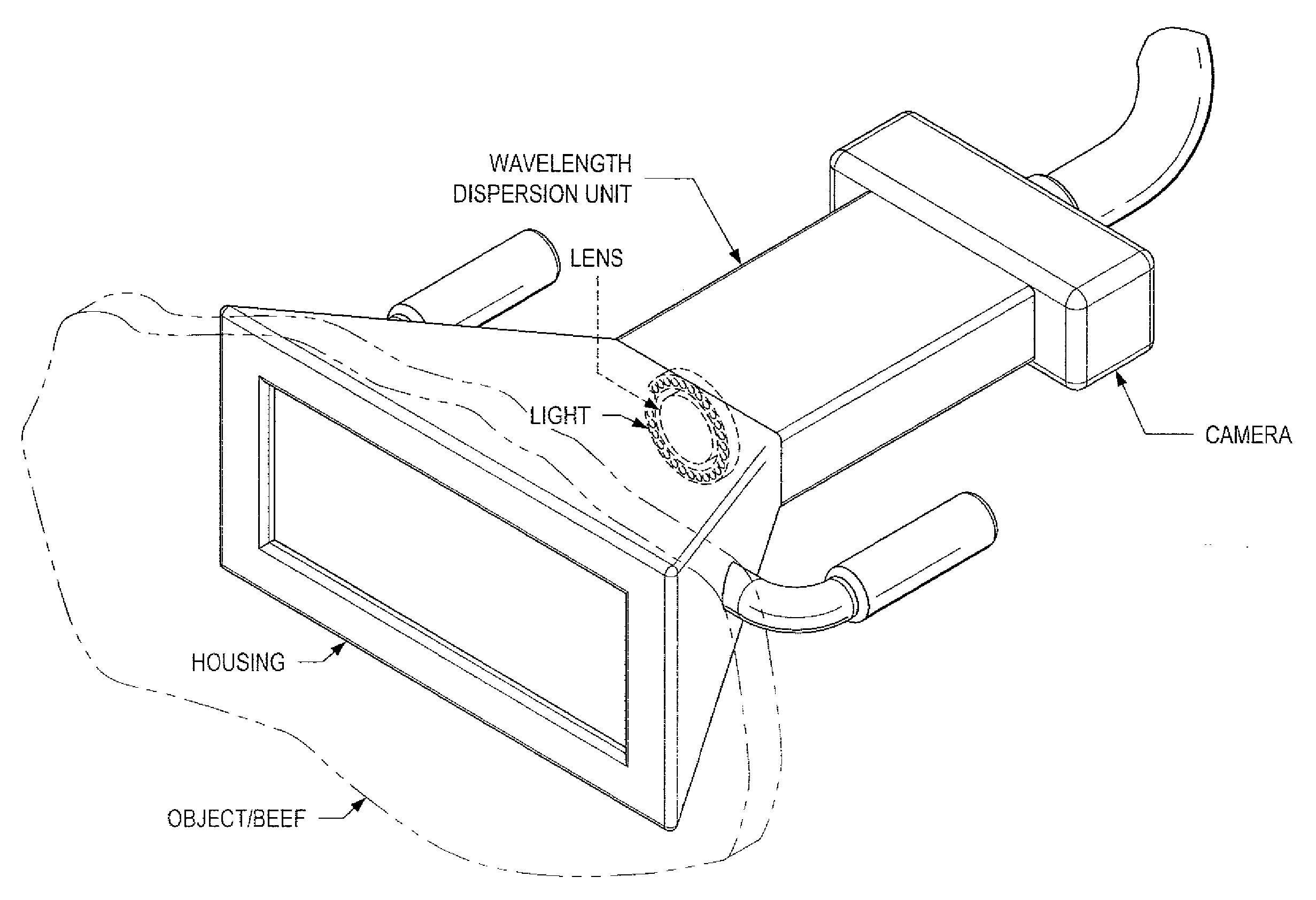

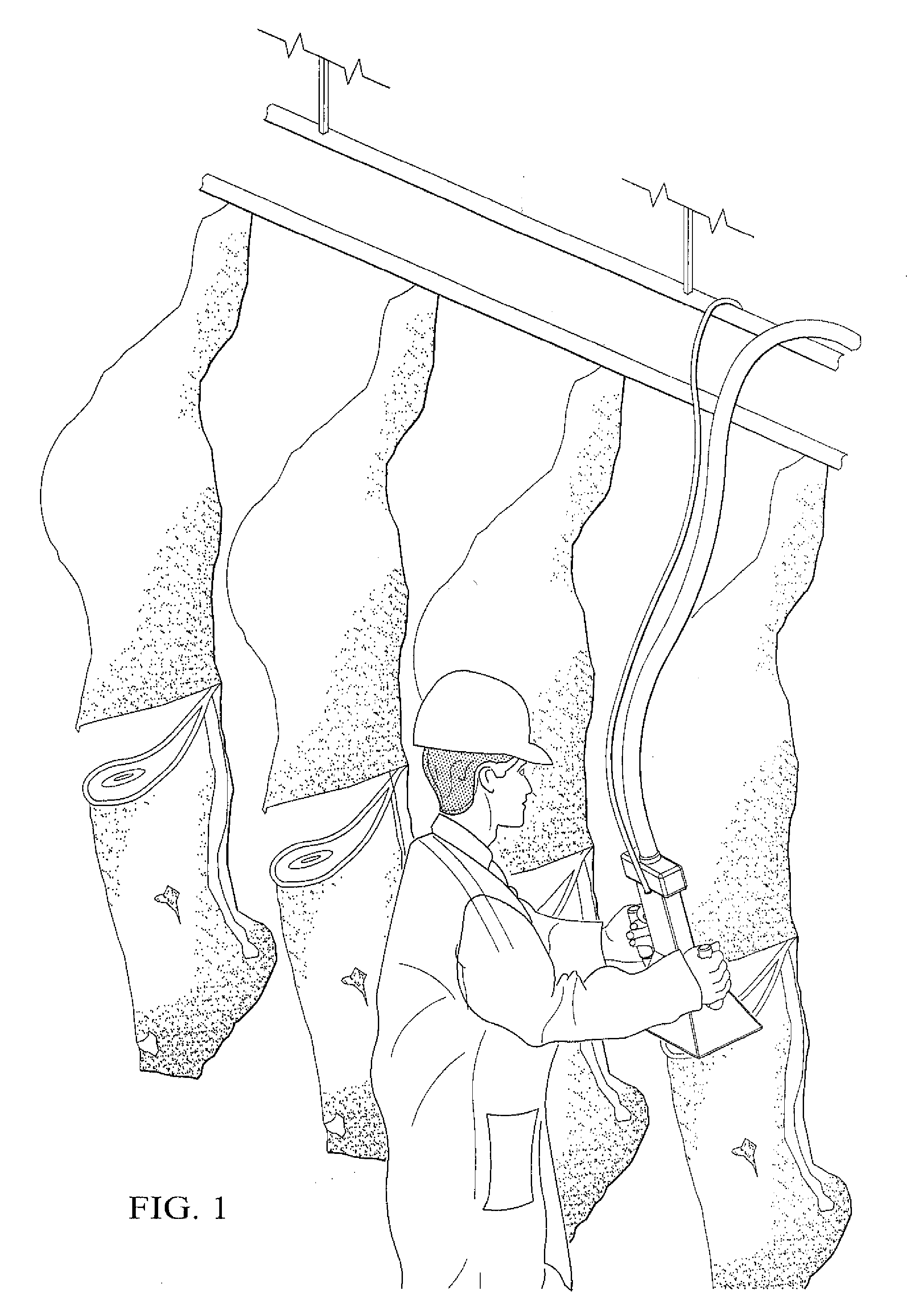

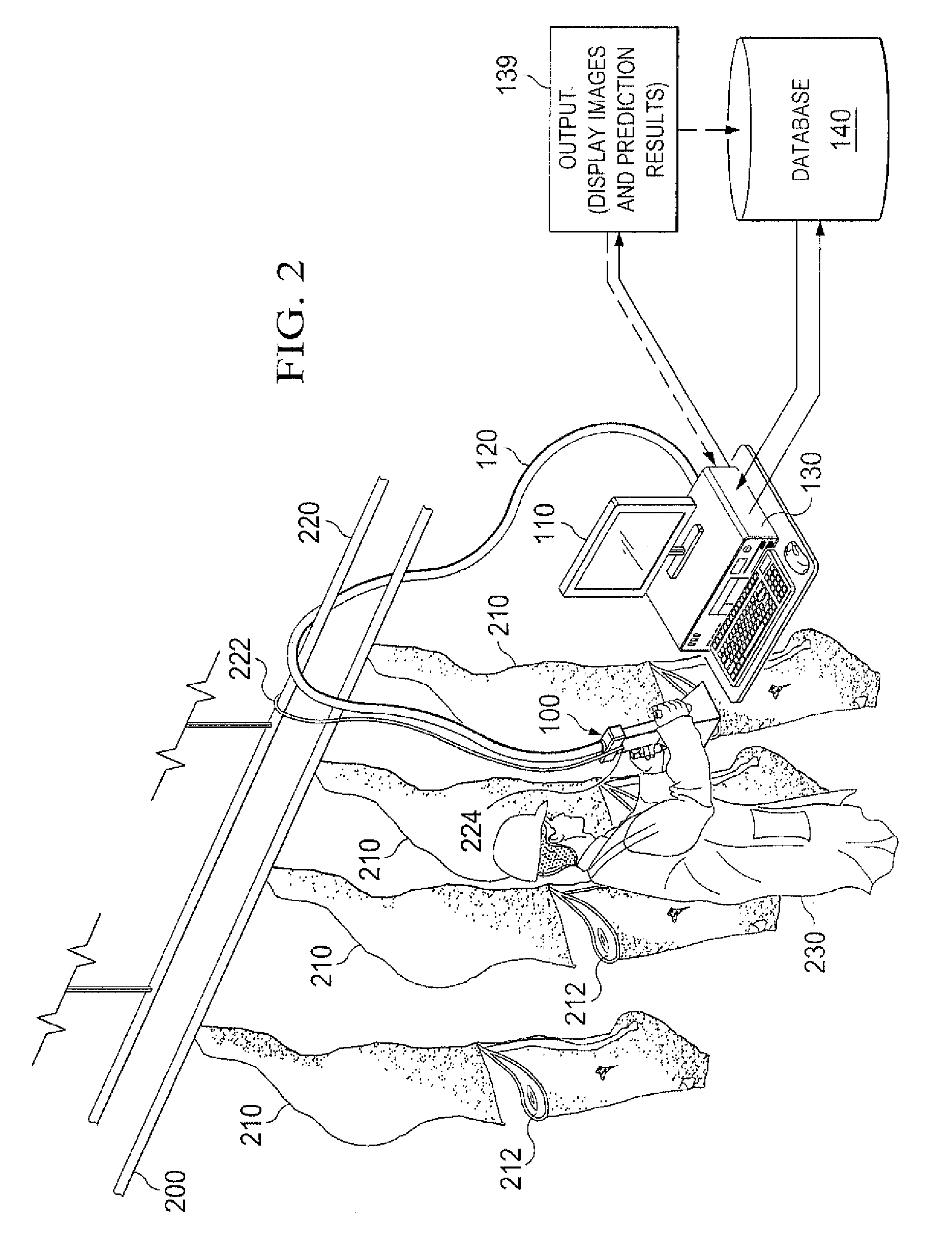

System and Method for Analyzing Properties of Meat Using Multispectral Imaging

ActiveUS20110273558A1Eliminates lag and delayRapid and objective determinationImage enhancementImage analysisMeat tendernessIndustrial setting

A system and method for obtaining multispectral images of fresh meat at predetermined wavelength bands at a first time, subjecting the images to analysis in an image analysis system comprising a computer programmed to perform such analysis, and outputting a forecast of meat tenderness at a later point in time. Predetermined key wavelength bands are precorrelated with a high degree of prediction of meat tenderness and / or other properties of meat and are used in the multispectral system and method. A system and method for determining the key wavelengths is also disclosed. The multispectral imaging system and method is suitable for use in an industrial setting, such as a meat processing plant. The system and method is useful in a method for determining quality and yield grades at or near the time of imaging in lieu of visual inspection with the unaided human eye, increasing efficiency and objectivity.

Owner:CARNE TENDER LLC

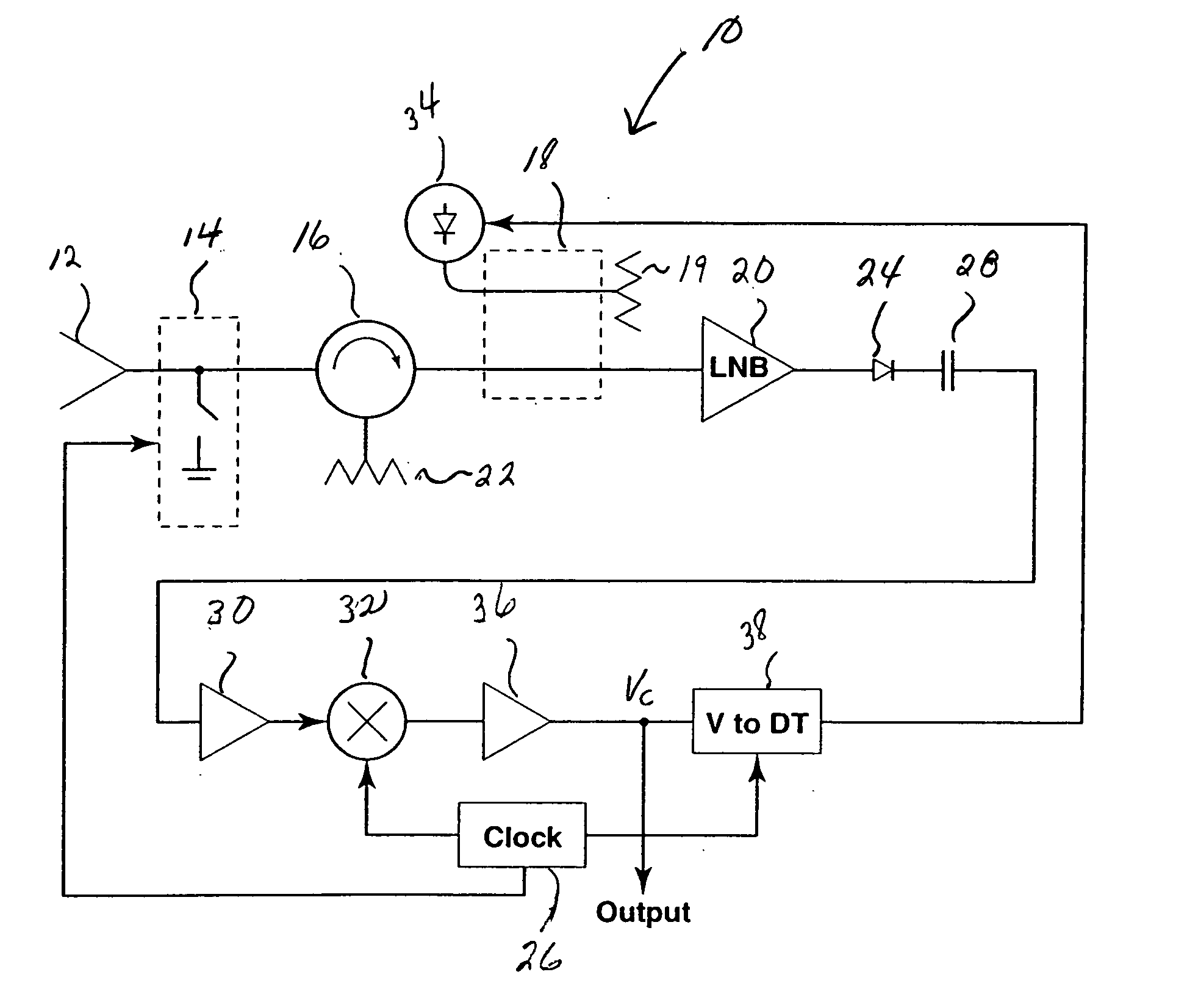

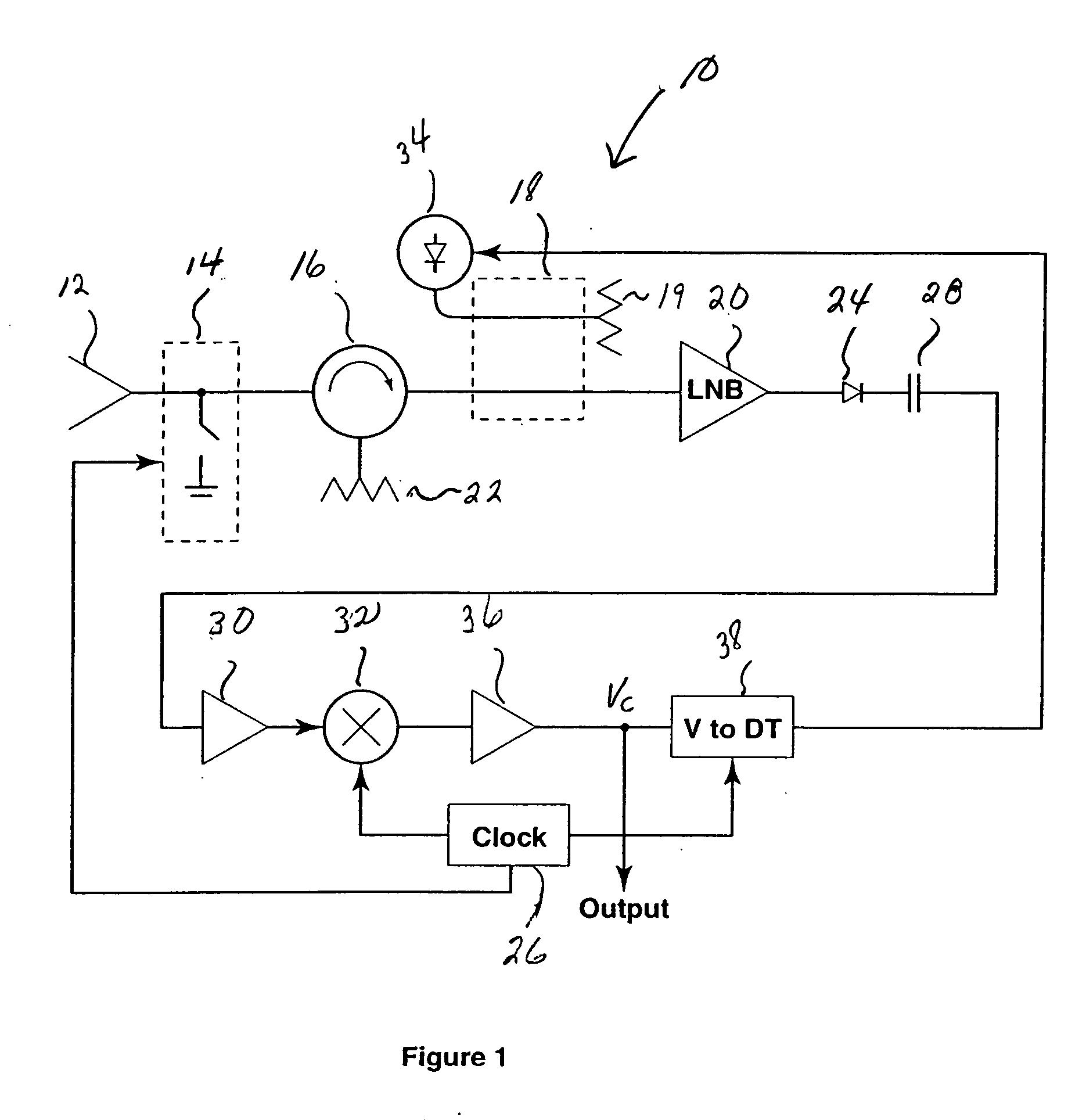

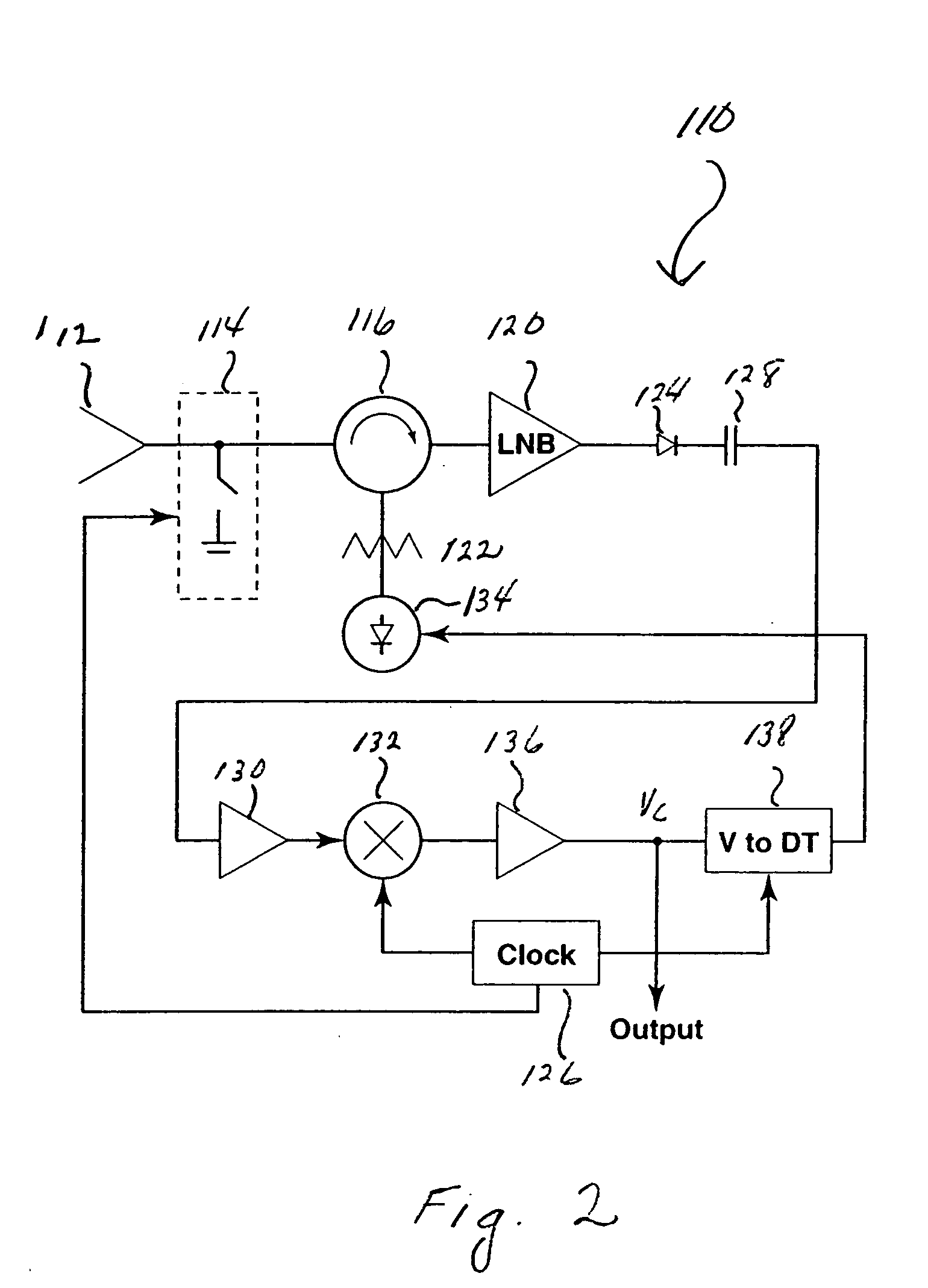

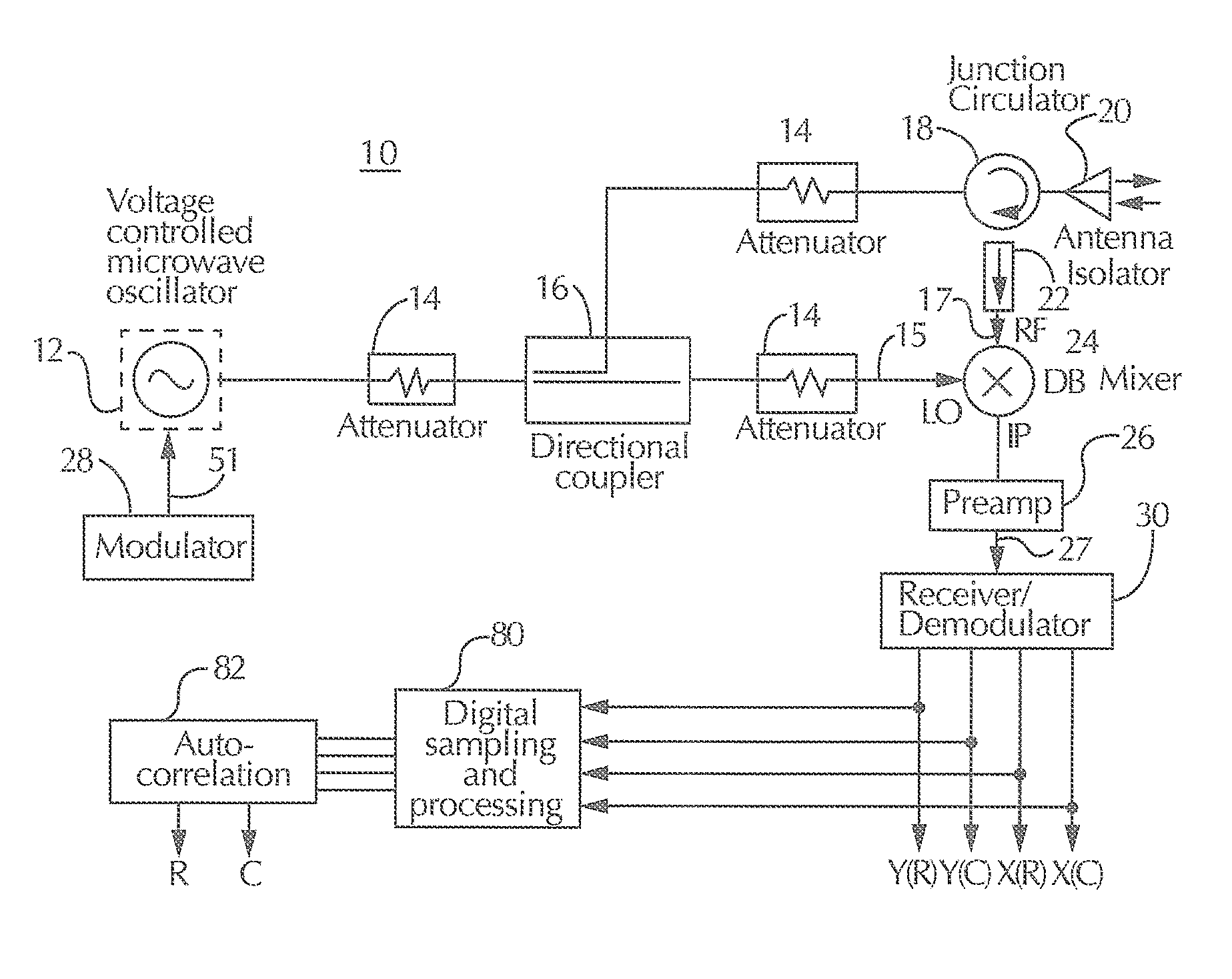

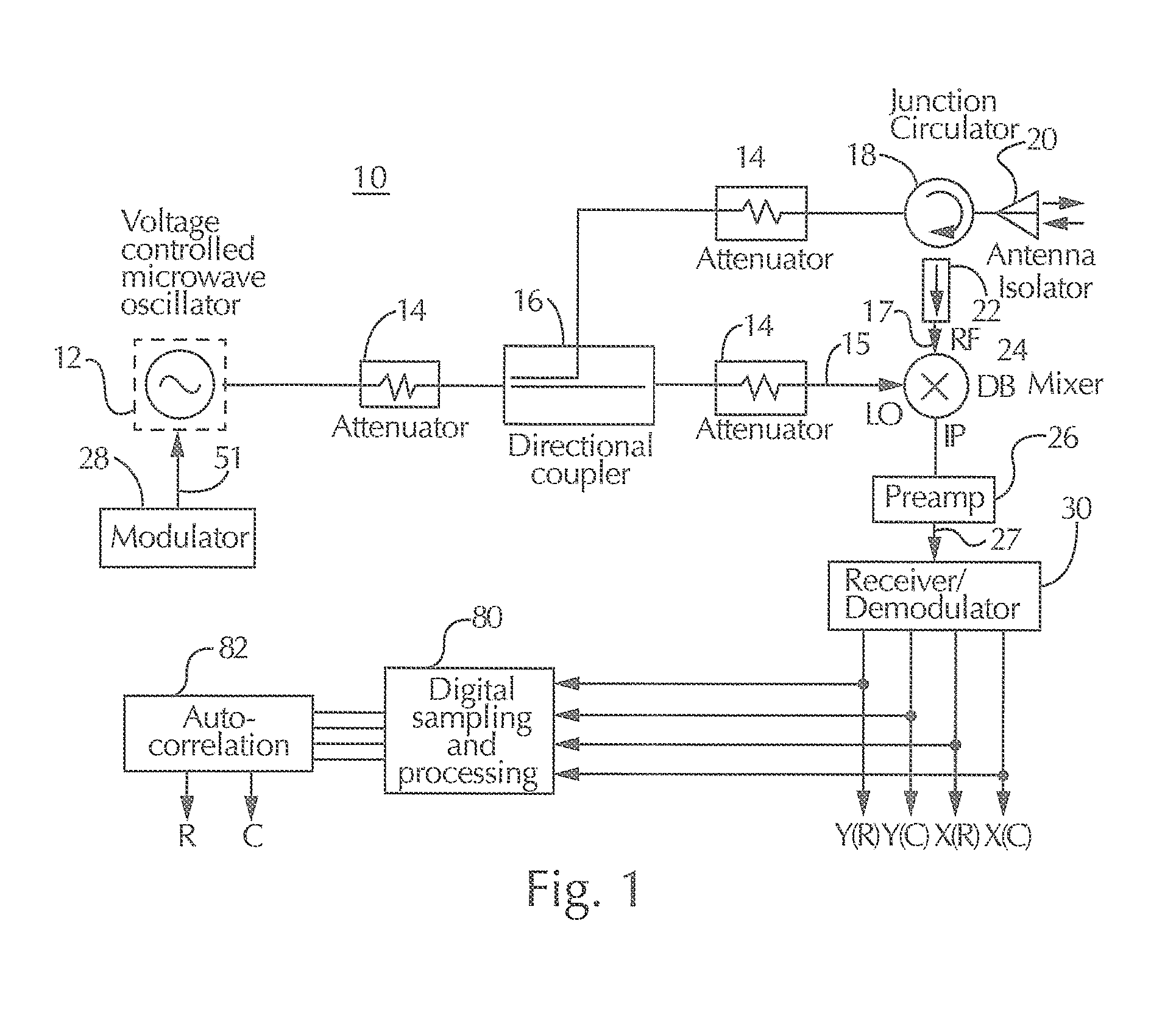

Remote temperature measuring system for hostile industrial environments using microwave radiometry

ActiveUS20050053118A1Increase temperatureThermometer detailsRadiation pyrometryMicrowave radiometryLow noise

A system and method for remotely measuring the temperature of an object using microwave radiometry that may be used in hostile environments. A single pole-single throw reflective PIN diode switch is operable in a PASS mode and a BLOCK mode. In the PASS mode, the switch passes the power received from the object to a low-noise block converter (“LNB”) for amplification. In the BLOCK mode, the switch blocks the object power and reflects the load noise power of an ambient temperature load to the LNB. A detector diode detects the amplified power output during both the BLOCK and PASS mode and the AC signal from the detector is converted to an output signal proportional to the difference in the noise powers detected in the PASS and BLOCK modes. A servo loop uses the output signal to generate a feedback signal to a noise injection diode that causes the diode to inject sufficient power into the LNB to automatically maintain a balance between noise power measured in the PASS mode and the combined noise powers measured in the BLOCK mode. The output signal is then used to compute the temperature of the object.

Owner:THE UNIV OF TEXAS SYST +1

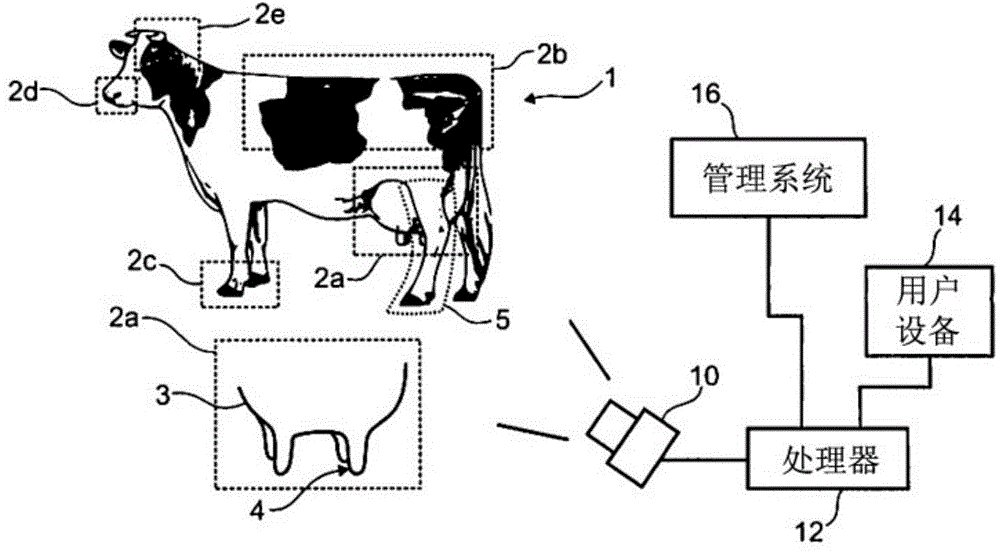

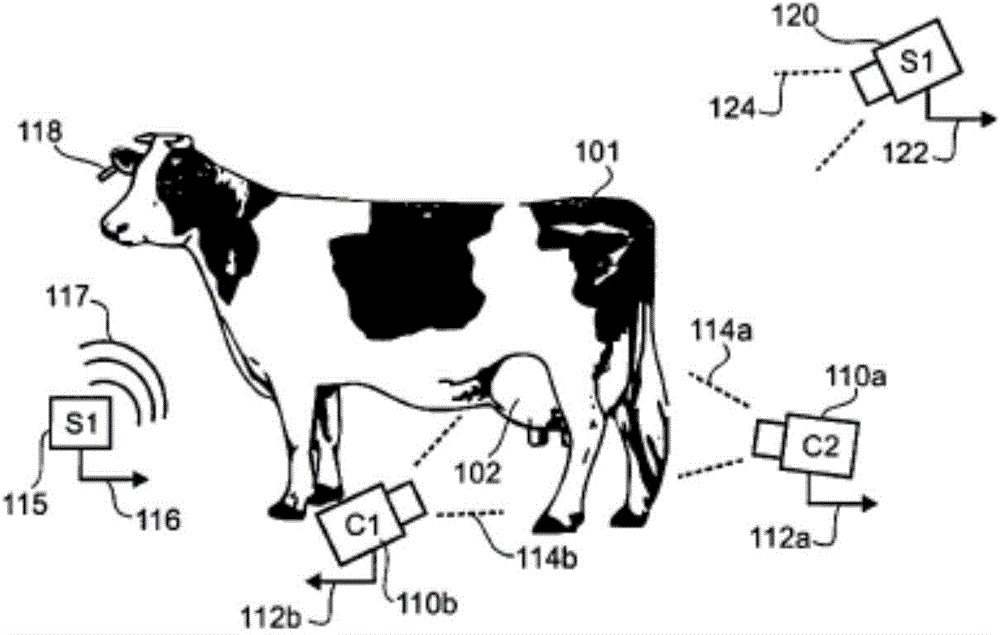

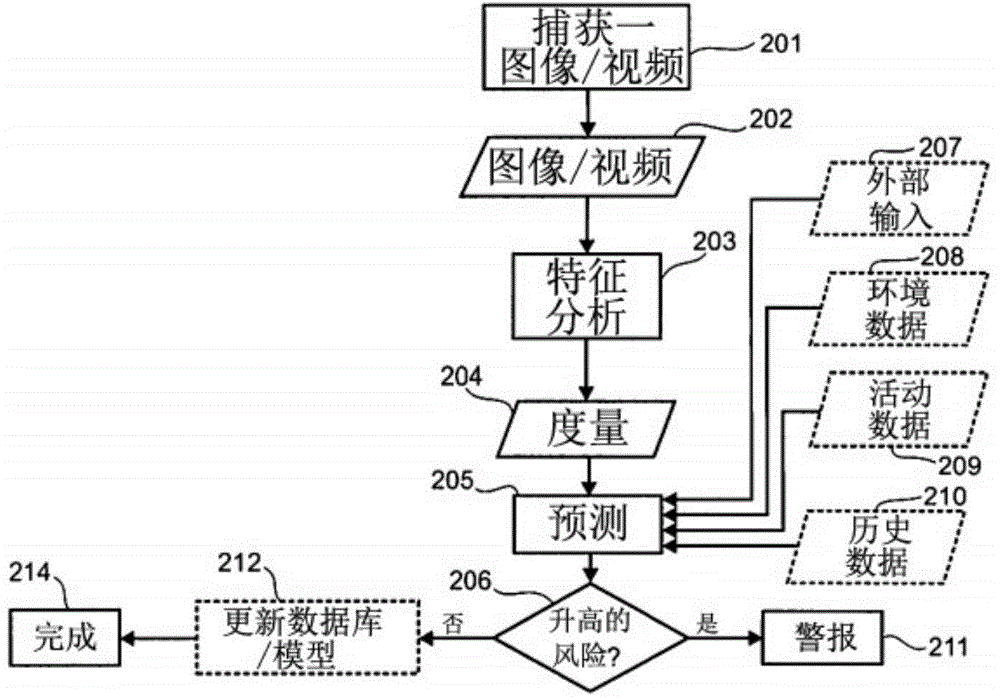

Systems and methods for predicting the outcome of a state of a subject

Systems and methods for improving the health and wellbeing of subjects in an industrial setting are disclosed. The systems may include a camera arranged so as to observe one or more features of a subject, and a processor, coupled to the camera, the processor configured to analyze one or more images obtained therefrom, to extract one or more features from the image(s) of the subject, and to analyze one or more of the features, or sub features nested therein to predict an outcome of a state of the subject. In particular the system may be configured to generate a diagnostic signal (e.g. an outcome, fever, mastitis, virus, bacterial infection, rut, etc.) based upon the analysis.

Owner:AGRICAM

Apparatus And Method For Monitoring The Condition Of A Living Subject

InactiveUS20130001422A1Radiation pyrometryRadio wave direction/deviation determination systemsBiological bodyIndustrial setting

A method and apparatus for monitoring the condition of a living subject may be self-adjusting or adjustable to accommodate different end uses. Adjustments might be made, for example, based on characteristics of the subject to be monitored (such as species, age, health, etc.), environment (such as home or industrial setting, room size, room contents, spurious signals in the environment), and set-up conditions (such as distance between the apparatus and living subject, alignment of the apparatus with the subject, etc.).

Owner:THE PROCTER & GAMBLE COMPANY

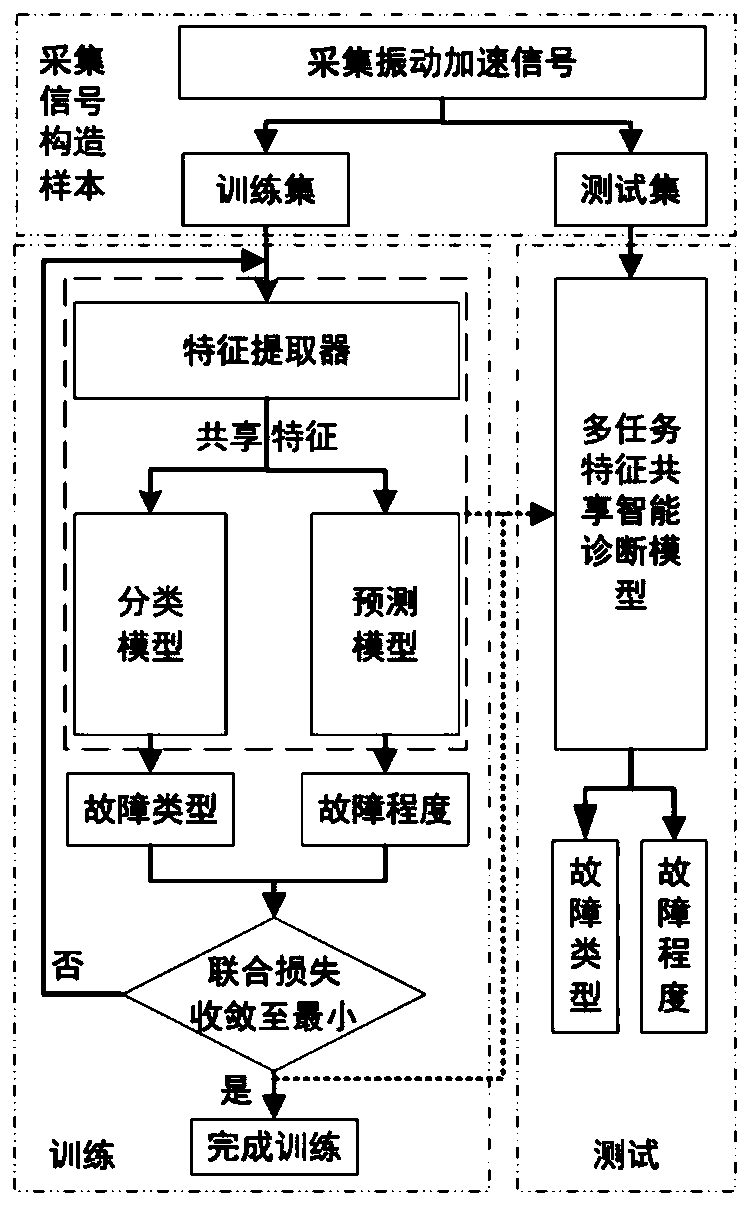

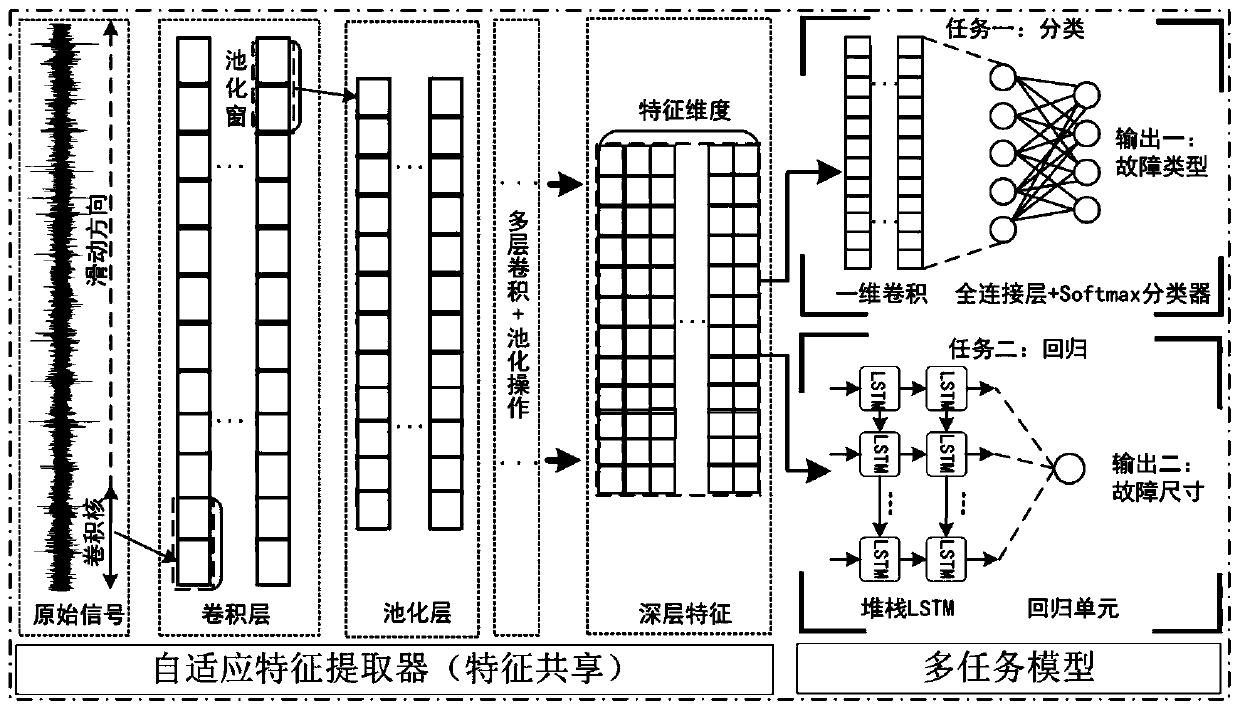

Intelligent fault diagnosis method based on multi-task feature sharing neural network

ActiveCN110361176AIncrease diversityReduce time complexityMachine bearings testingNeural architecturesFeature extractionVibration acceleration

The invention discloses an intelligent fault diagnosis method based on a multi-task feature sharing neural network. The intelligent fault diagnosis method comprises the steps of: (1) separately acquiring original vibration acceleration signals of a rotating machine under different experimental conditions, constructing a sample by intercepting a certain length of signal data, and labeling the sample; (2) constructing the multi-task feature sharing neural network, which comprises an input layer, a feature extractor, a classification model and a prediction model; (3) adopting multi-task joint training, and simultaneously training the classification model and the prediction model; (4) and inputting a vibration acceleration signal acquired in an actual industrial environment into the trained models to obtain a multi-task diagnosis result. The intelligent fault diagnosis method can simultaneously realize the classification of fault types and the prediction of the fault degrees, and has highpractical application value.

Owner:SOUTH CHINA UNIV OF TECH

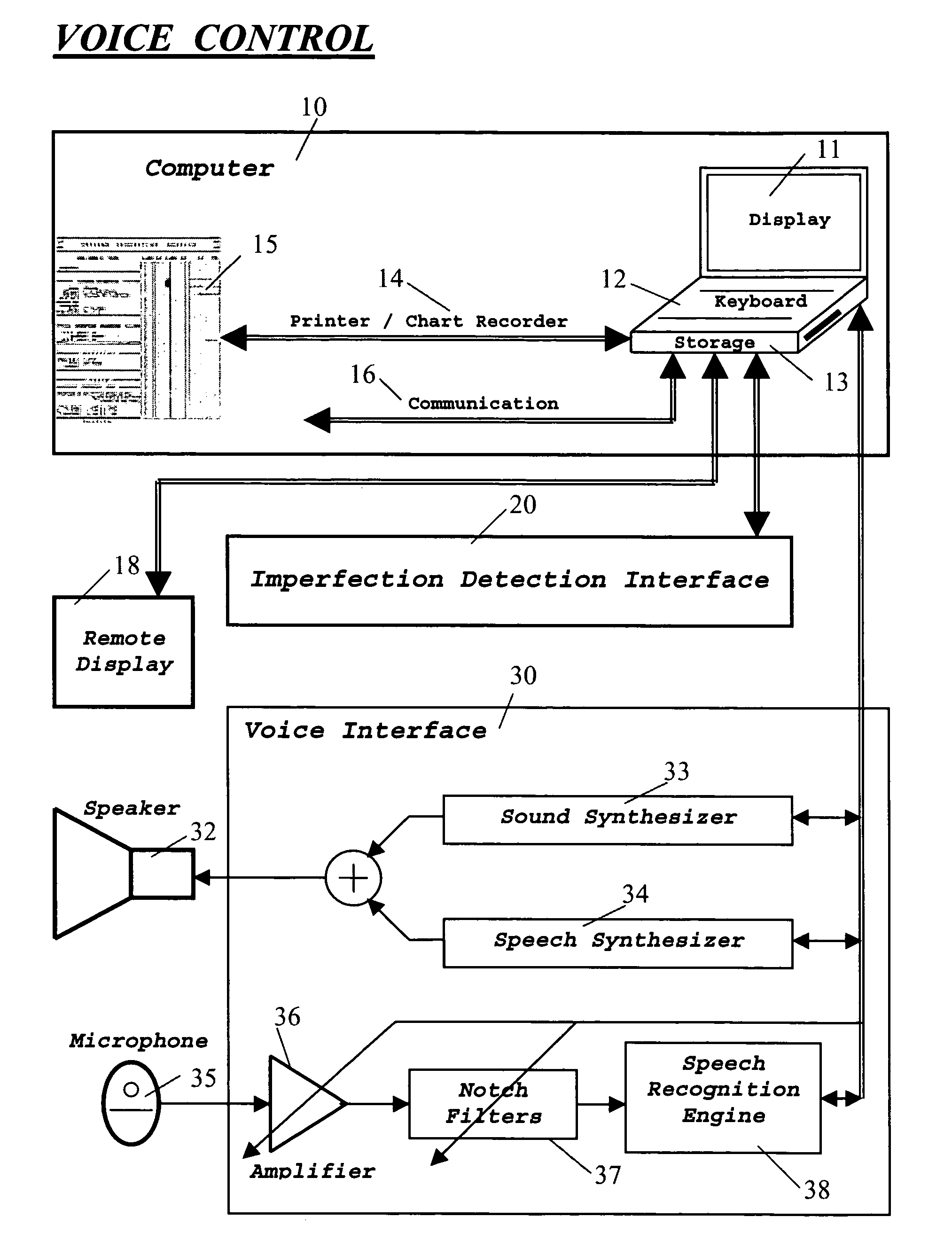

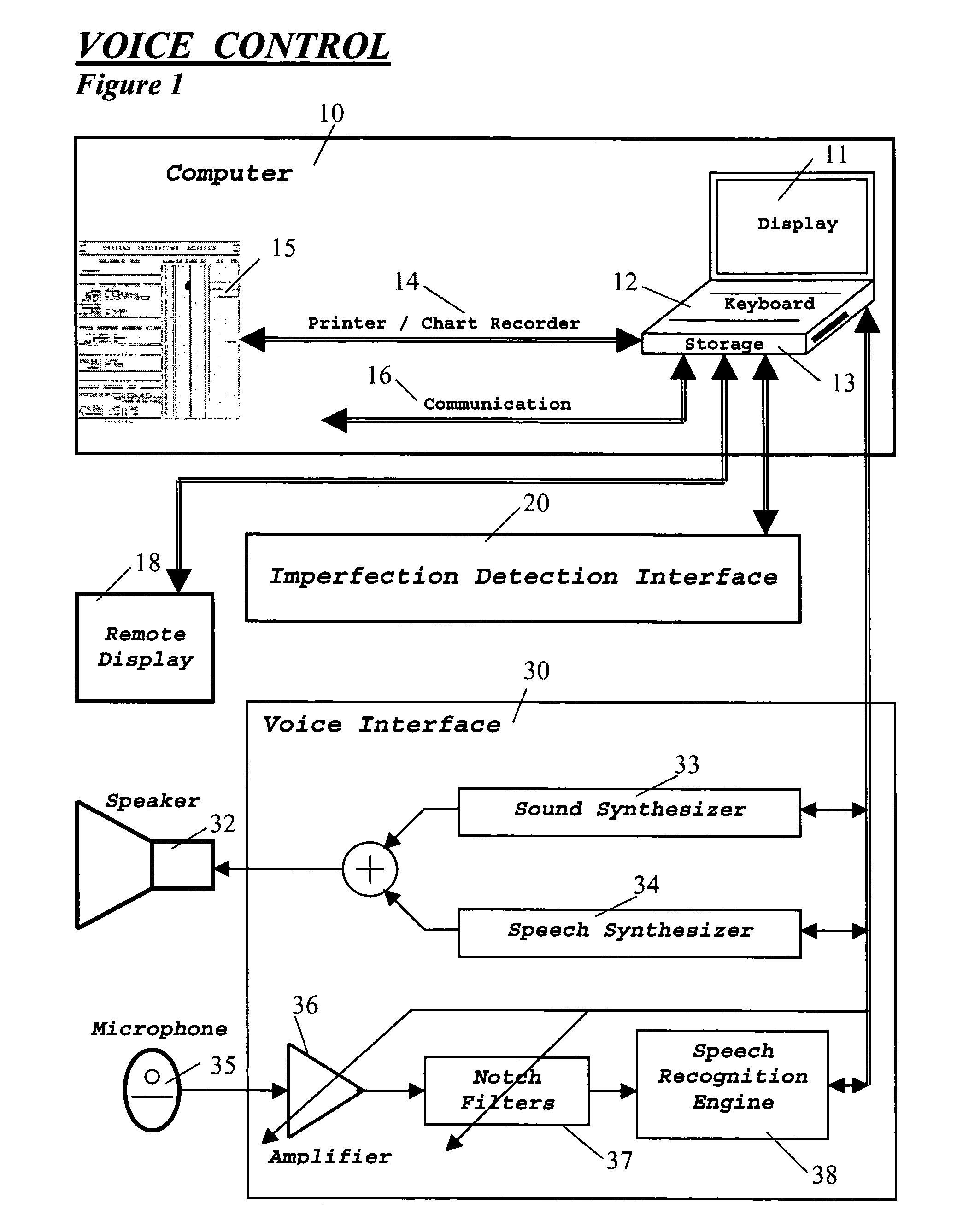

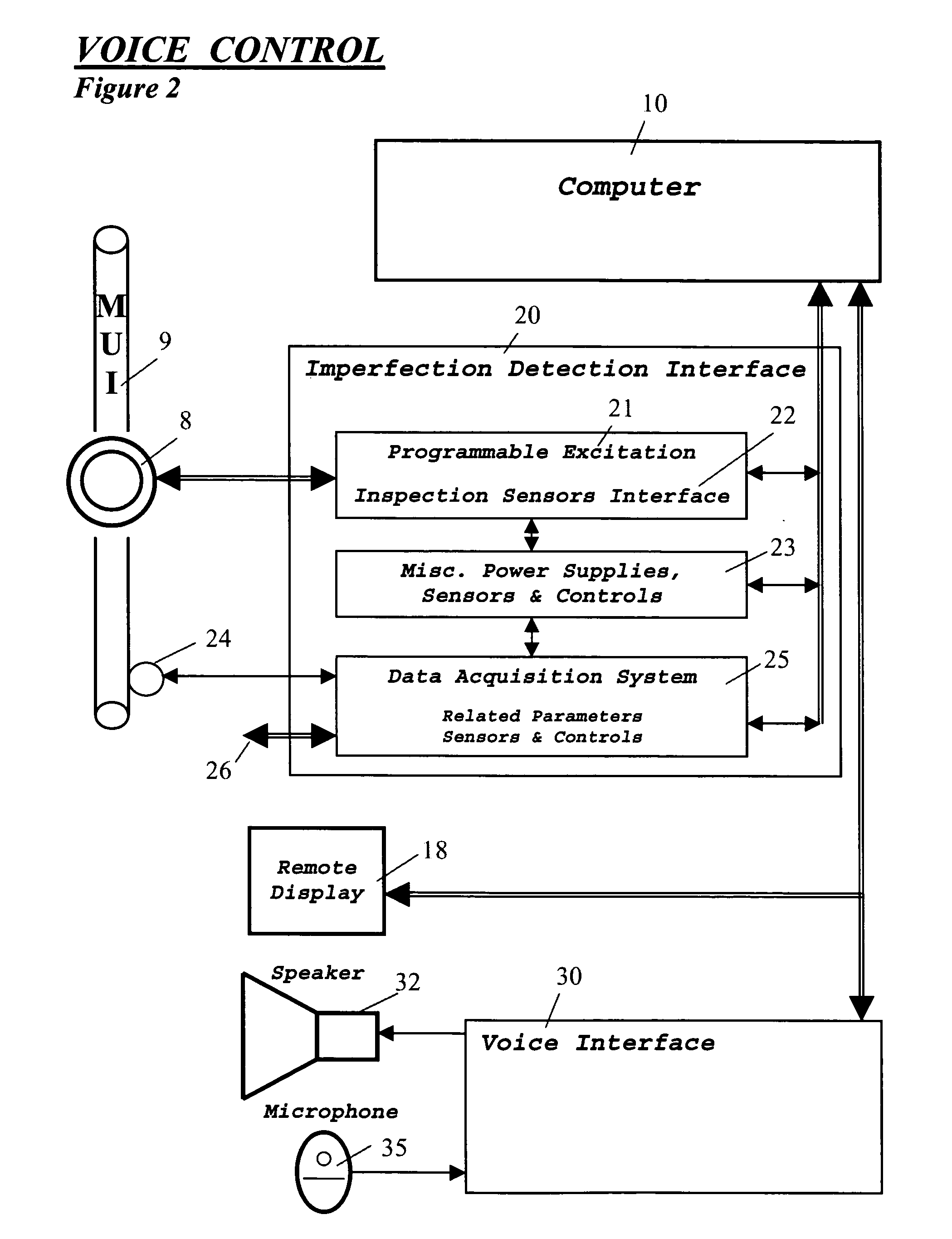

Voice interaction with and control of inspection equipment

The non-destructive inspection equipment is provided with voice interaction to interface with the inspector and / or operator who preferably controls the inspection equipment and the inspection process, at least in part, through the use of voice control and by receiving audio and / or video feedback from the inspection equipment. The overall inspection quality is preferably substantially improved when the inspector and / or operator can focus entirely on the material under inspection while maintaining full control of the inspection equipment and the inspection process. The inspection equipment and its interfaces are adapted and fine-tuned for interaction with humans, particularly in a harsh noise industrial environment. Further, the voice interaction preferably allows the inspector and / or operator to operate the inspection equipment while wearing gloves or with dirty hands as he / she will not need to constantly physically manipulate the inspection equipment.

Owner:STYLWAN IP HLDG LLC

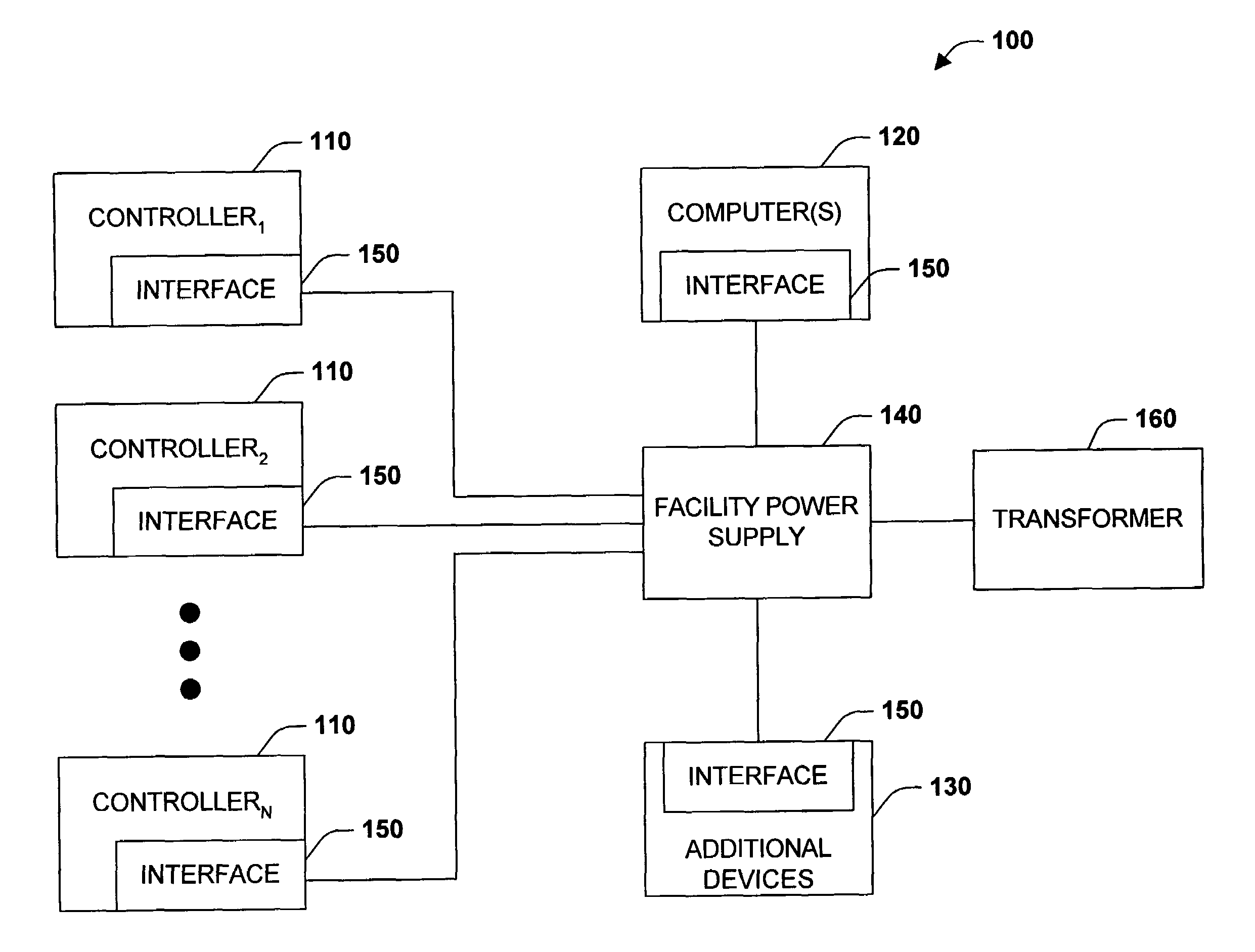

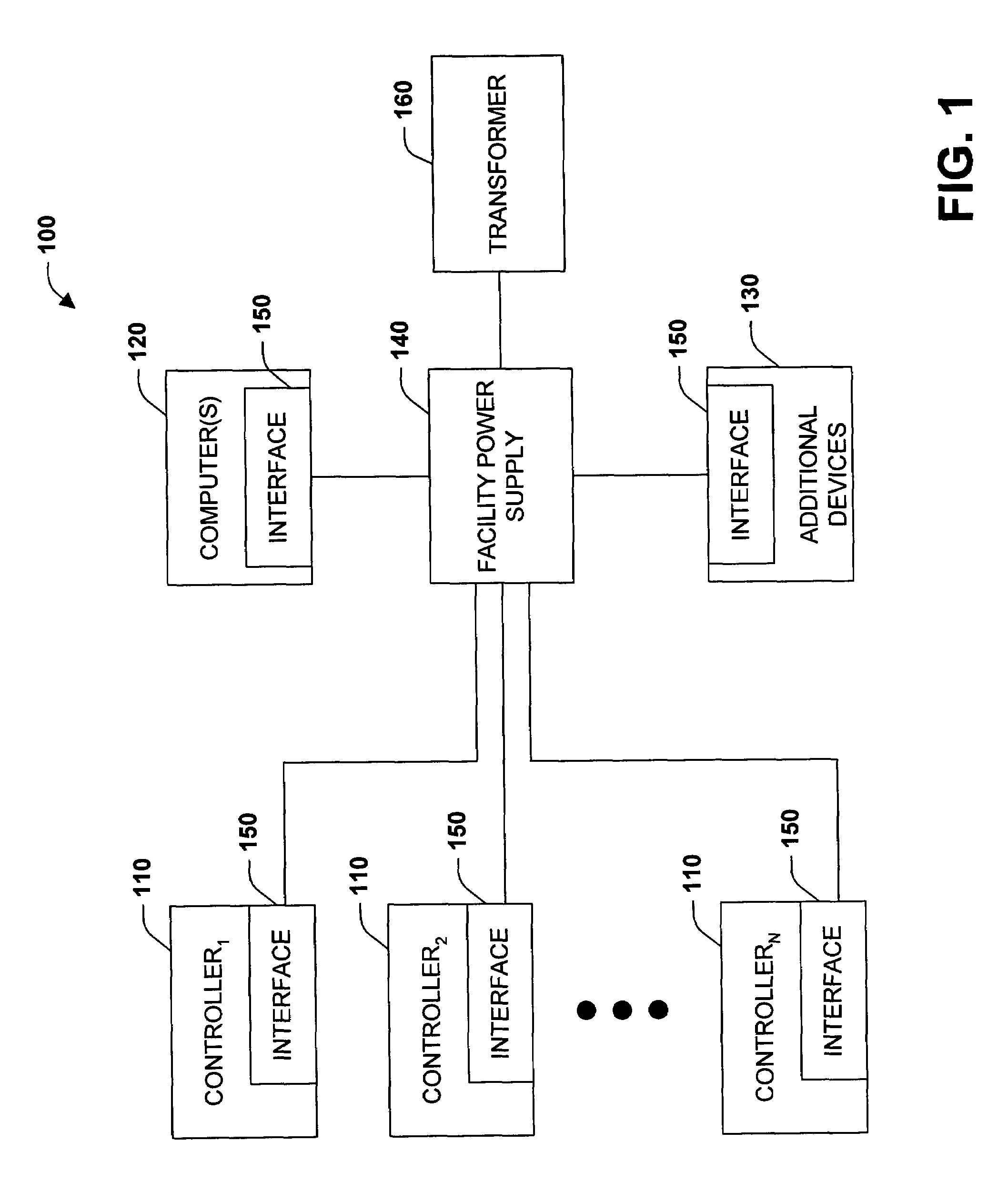

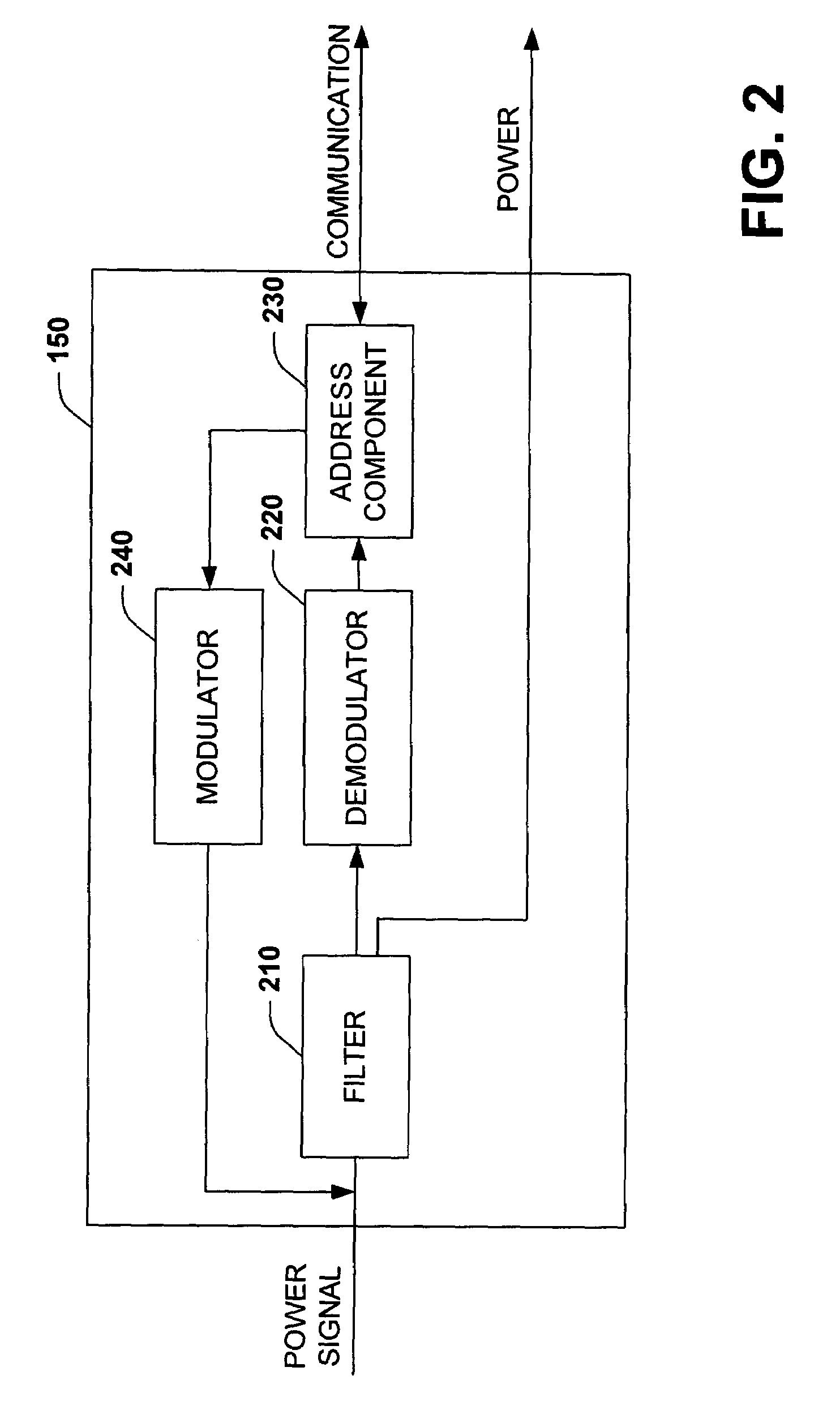

Power supply communication system and method

ActiveUS7327221B1Facilitate network communicationElectric signal transmission systemsFrequency-division multiplex detailsCommunications systemPower line network

A system and method for configuring and monitoring devices utilizing a power line network is provided herein. Each network device (e.g., programmable logic controller, machine, or sensor) contains a power line interface to facilitate communication over a power line network. The power line interfaces contain at least one unique identifier to distinguish the interface and its associated network device from other devices on the same network and thereby enable device message exchange. The ubiquity of power lines in an industrial environment or any environment for that matter provides an accommodating medium of communication, which the subject invention exploits to set-up, configure, and program industrial control devices connected thereto. Furthermore, the subject invention can utilizes power lines after configuration, during system operation, or upon device failure to monitor, diagnose, and / or predict the health of a system device.

Owner:ROCKWELL AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com