Patents

Literature

302 results about "Rapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapping is "spoken or chanted rhyming lyrics". The components of rapping include "content", "flow", and "delivery". Rapping is distinct from spoken word poetry in that it is performed in time to a beat. Rapping is often associated with and a primary ingredient of hip hop music, but the origins of the phenomenon can be said to predate hip hop culture by centuries. It can also be found in alternative rock such as that of Cake and the Red Hot Chili Peppers. Rapping is also used in Kwaito music, a genre that originated in Johannesburg, South Africa and is composed of hip hop elements. Since the early 21st century, it has been possible to hear rap in every major language of the world. Rapping can be delivered over a beat or without accompaniment. Stylistically, rap occupies a gray area between speech, prose, poetry, and singing. The word as used to describe quick speech or repartee predates the musical form. The word had been used in British English since the 16th century, and specifically meaning "to say" since the 18th.

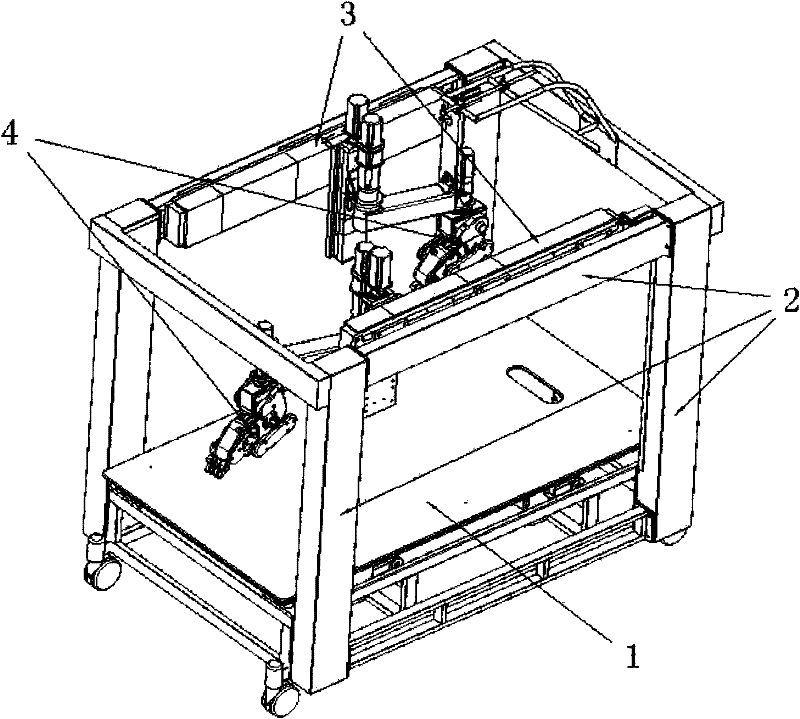

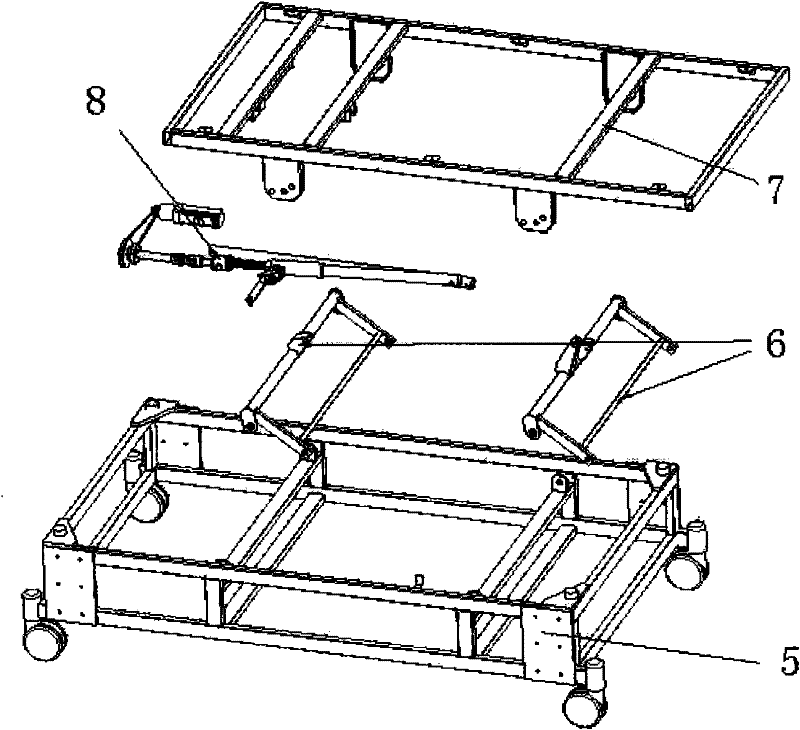

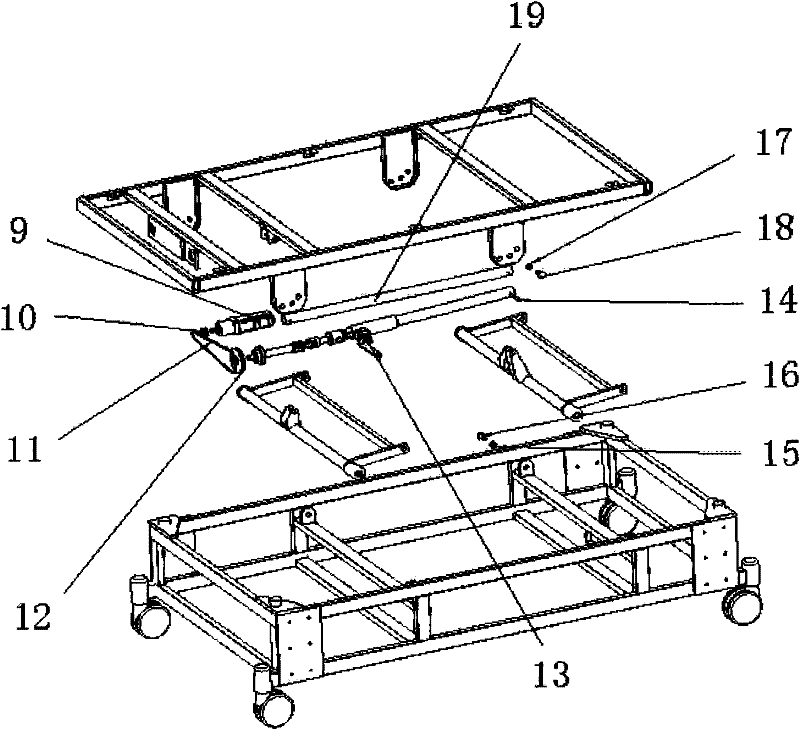

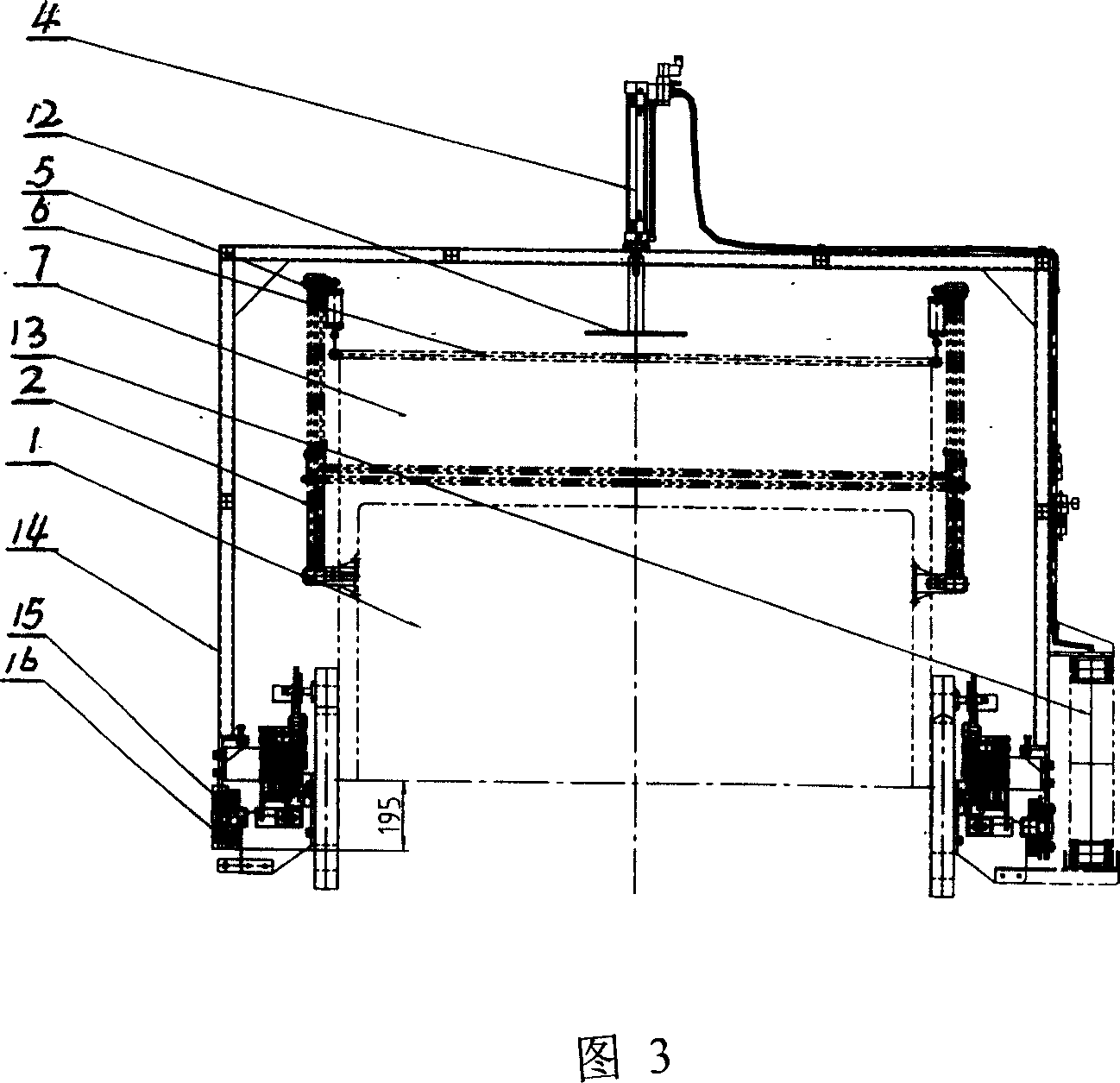

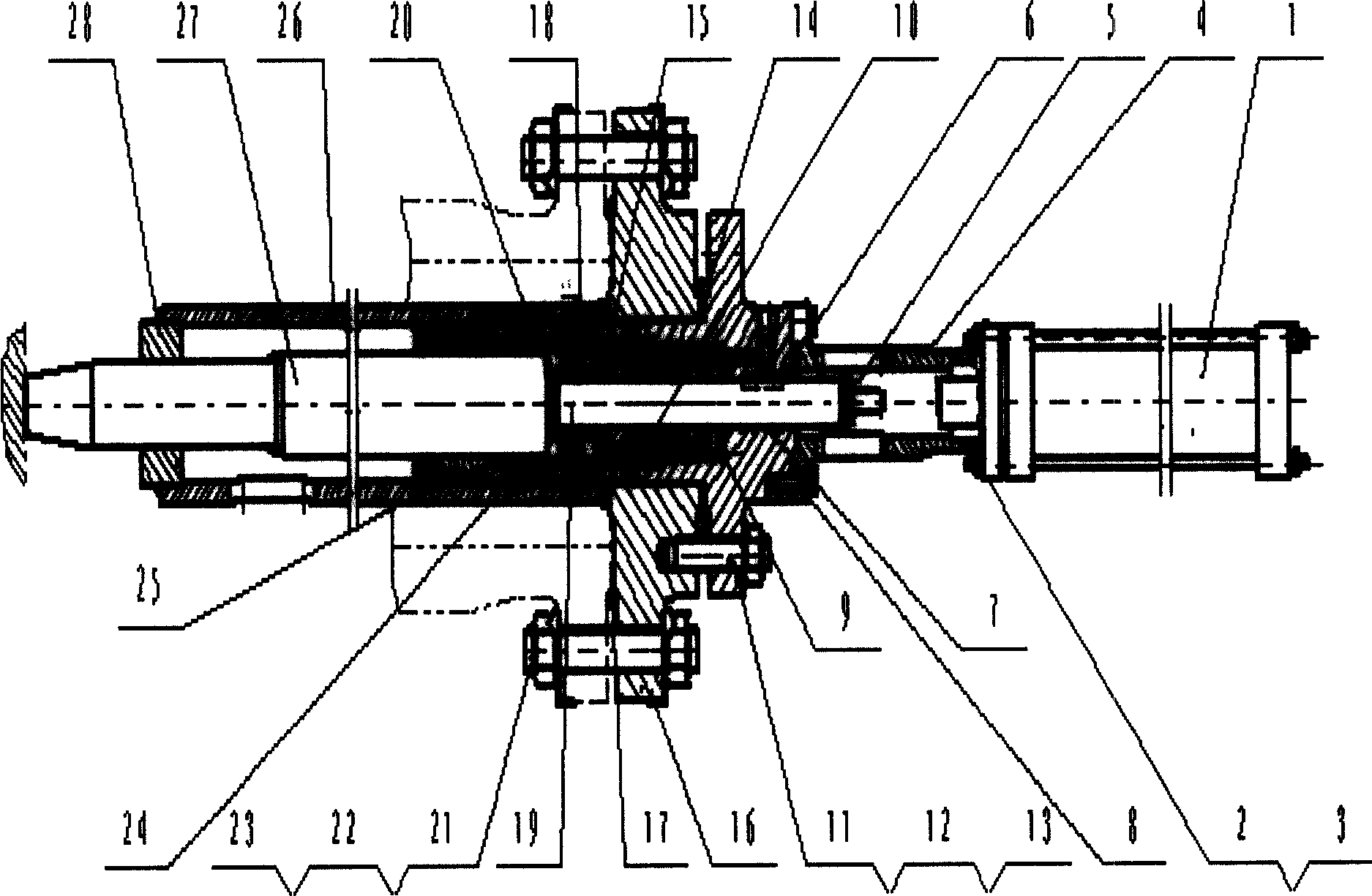

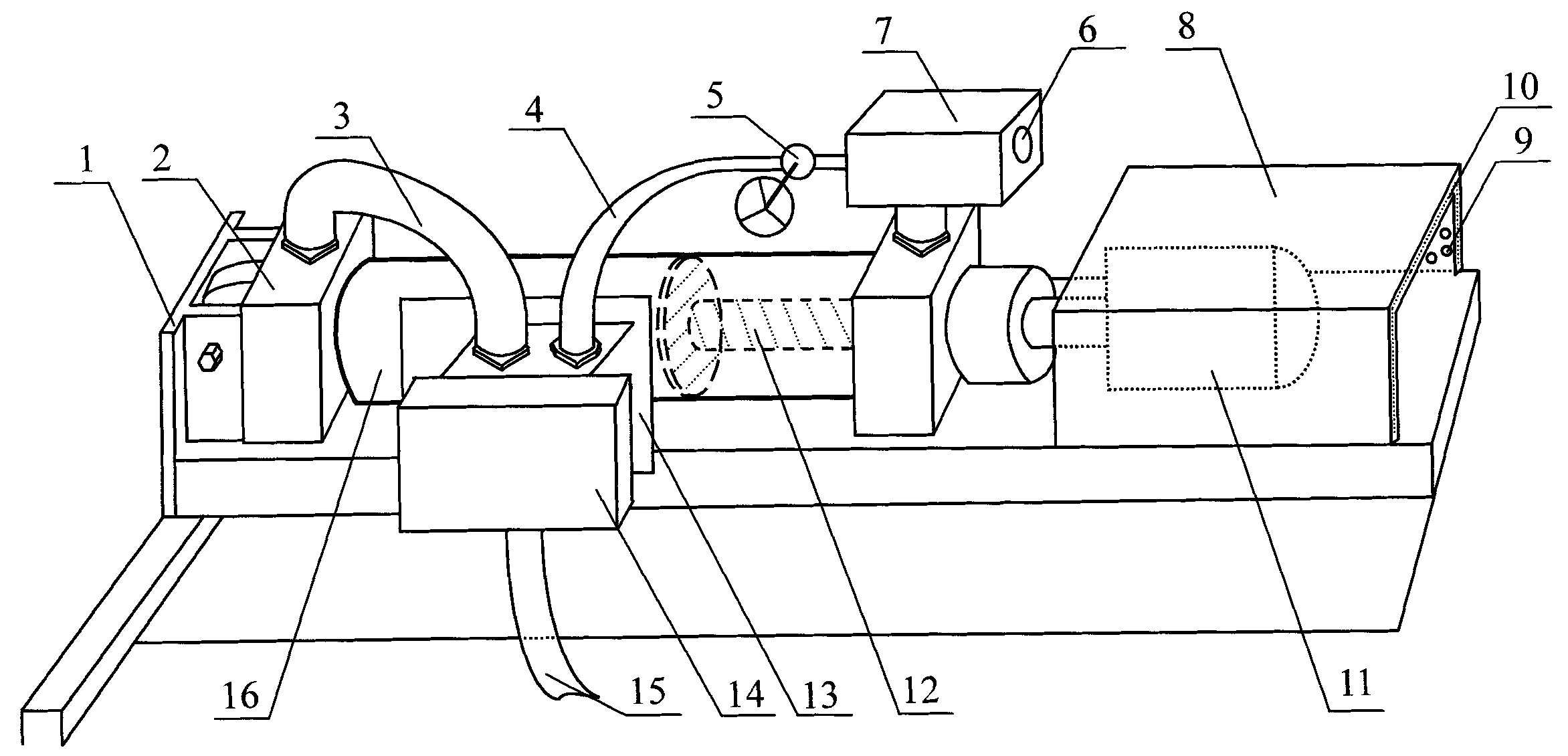

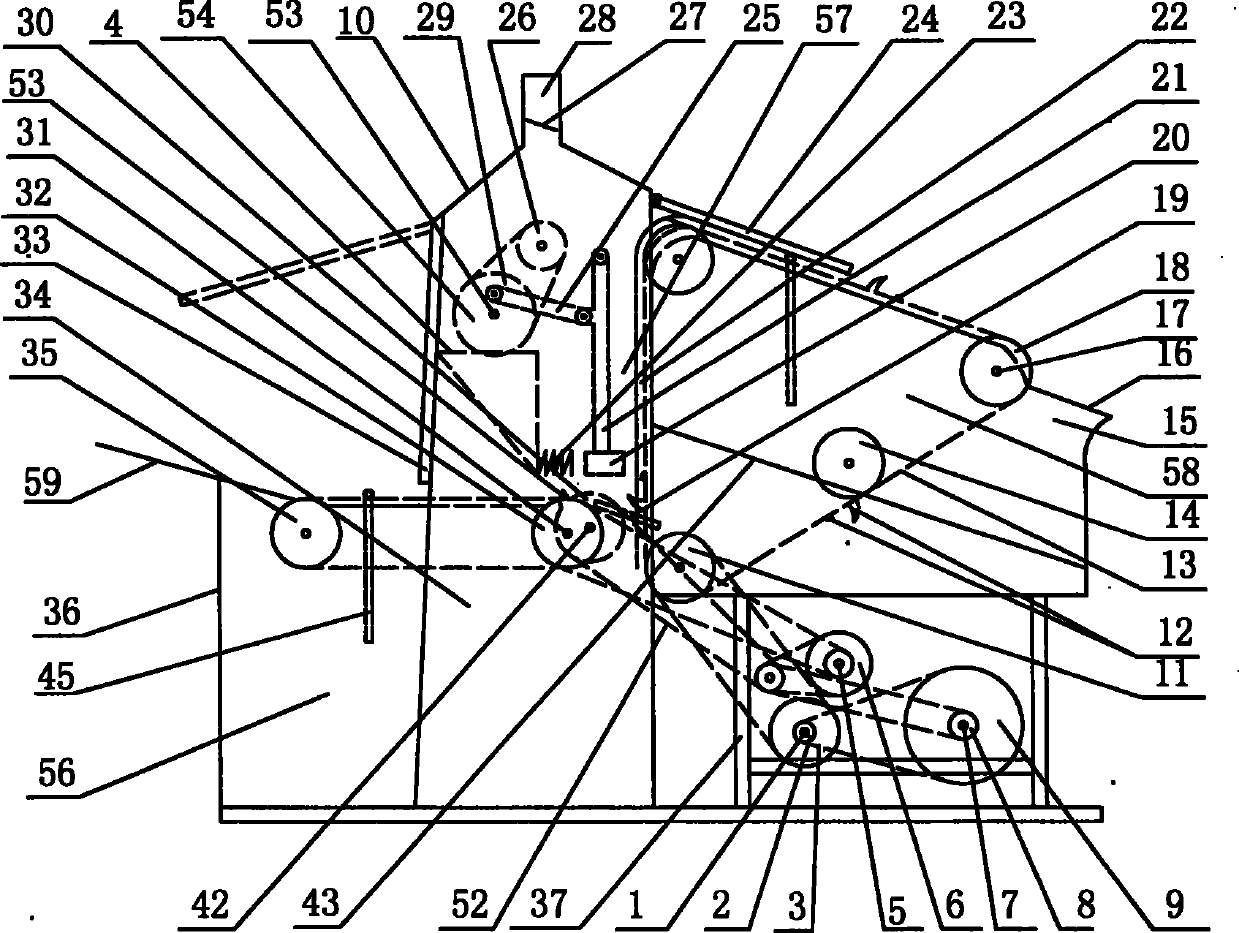

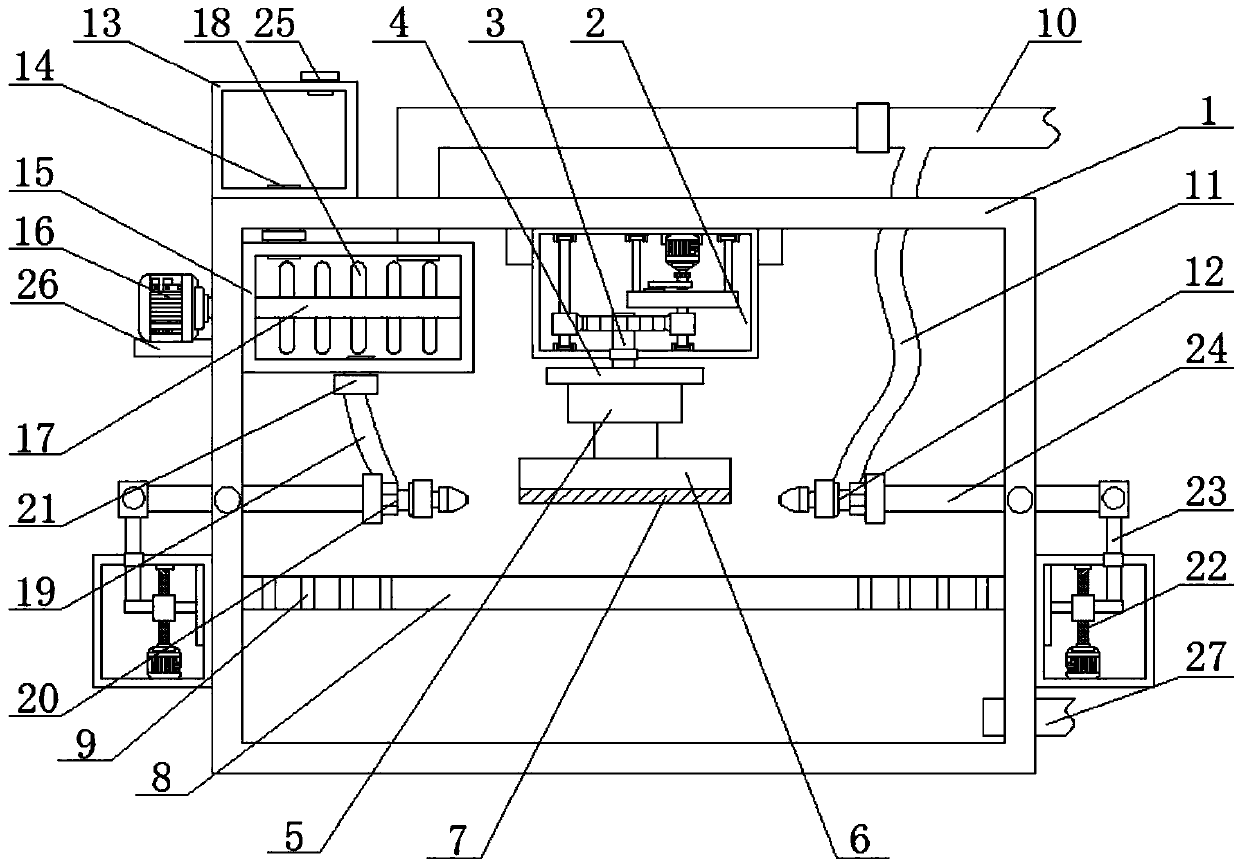

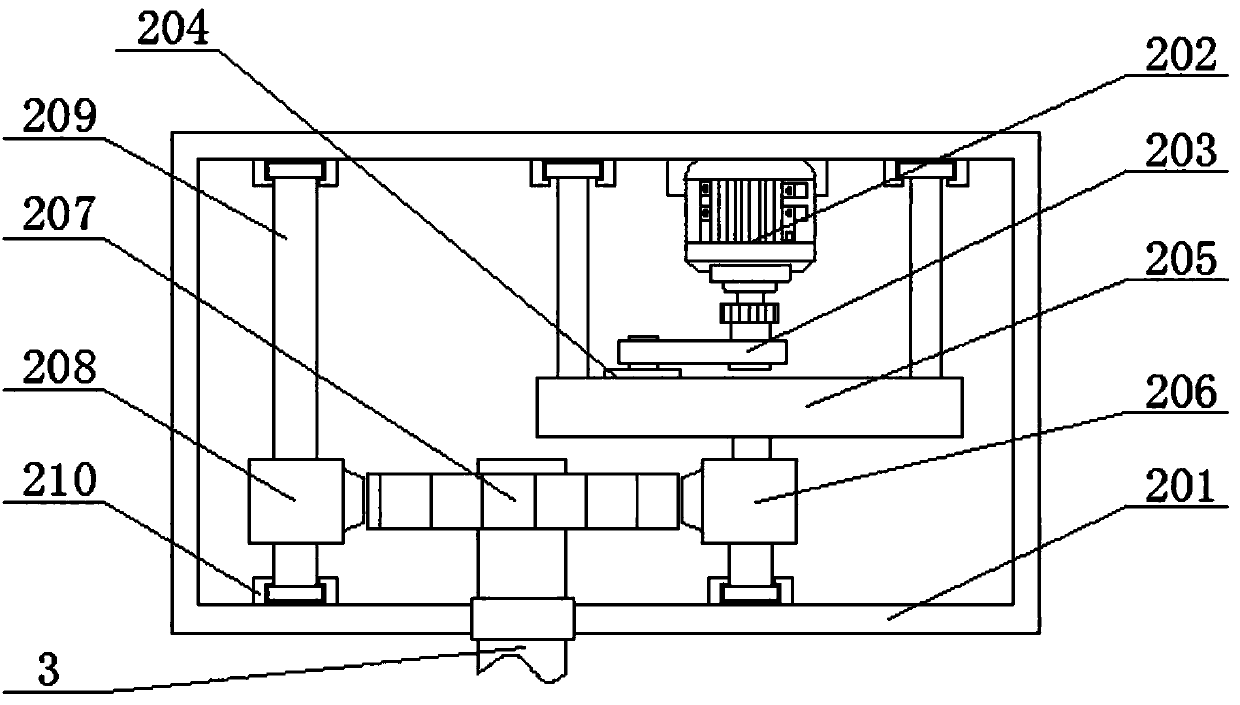

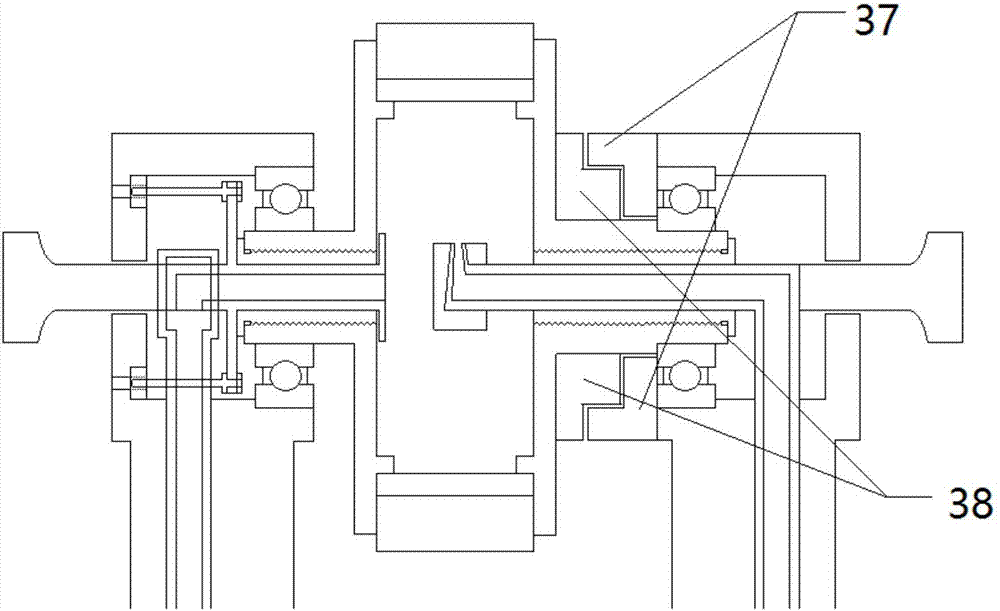

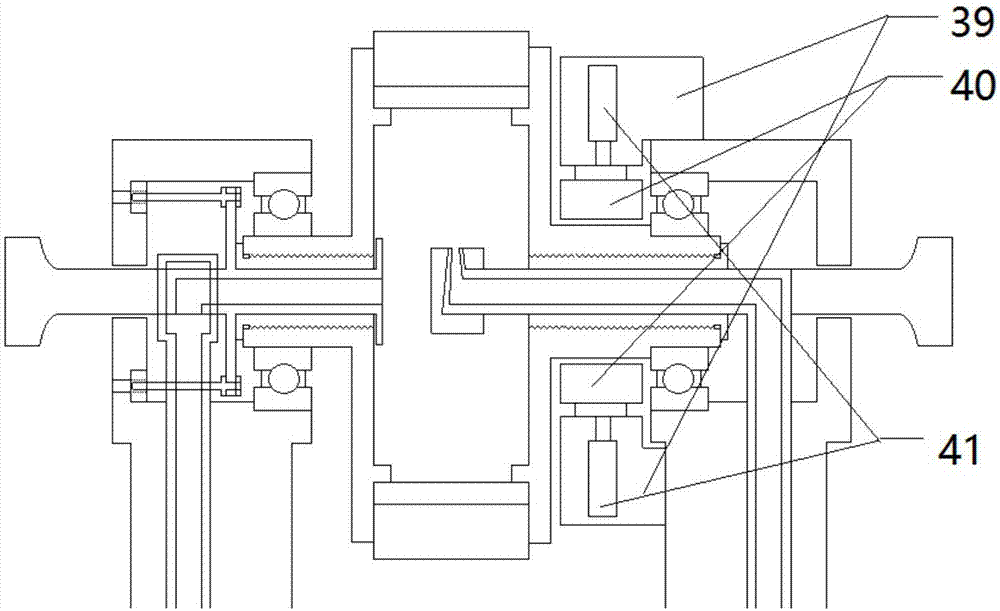

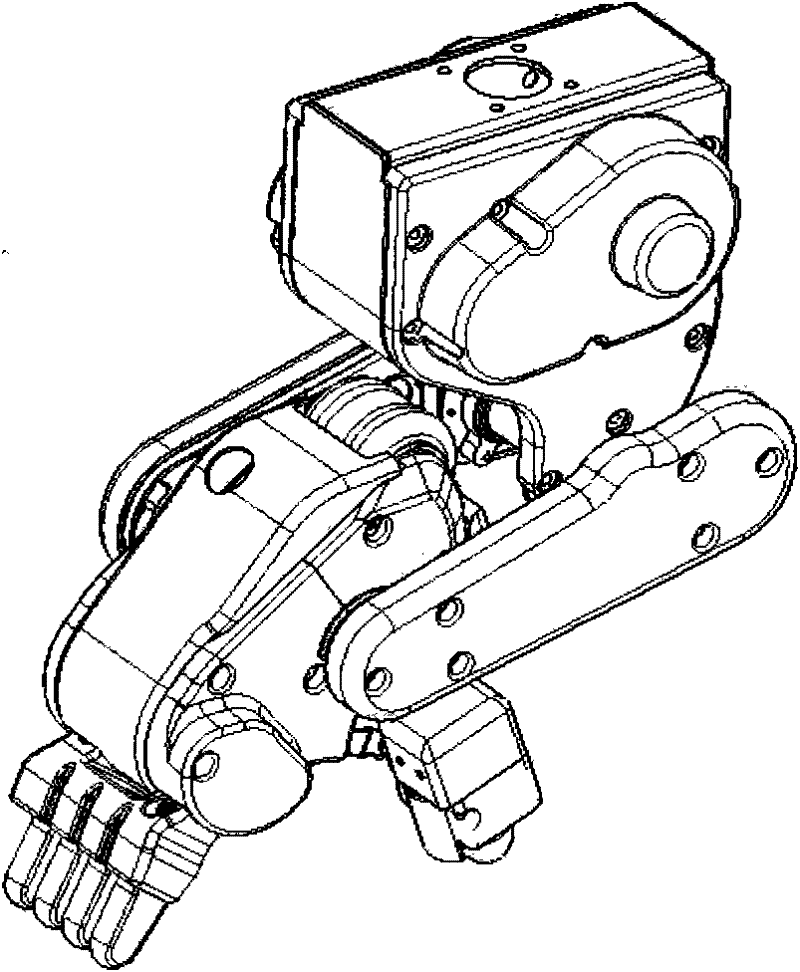

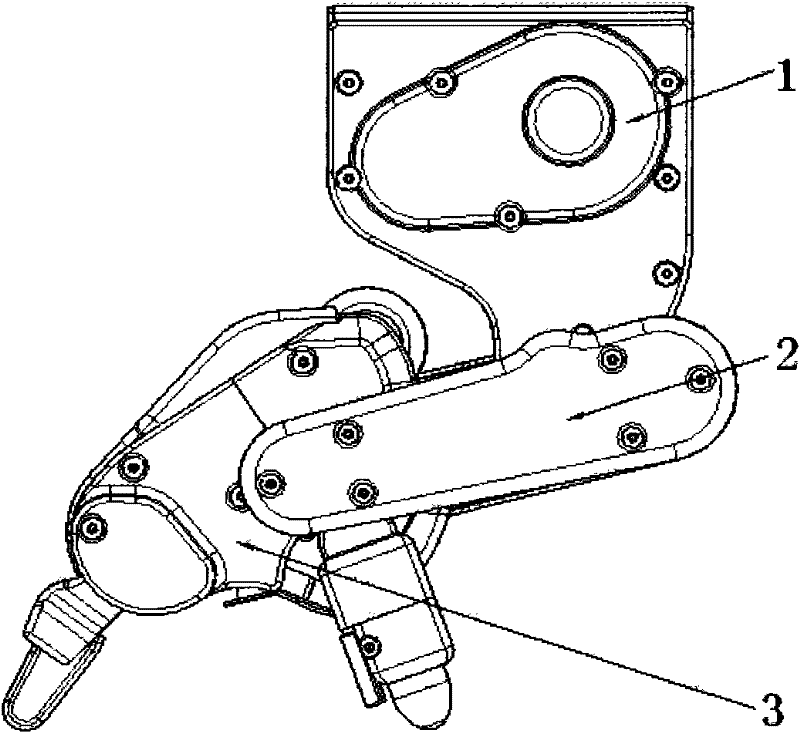

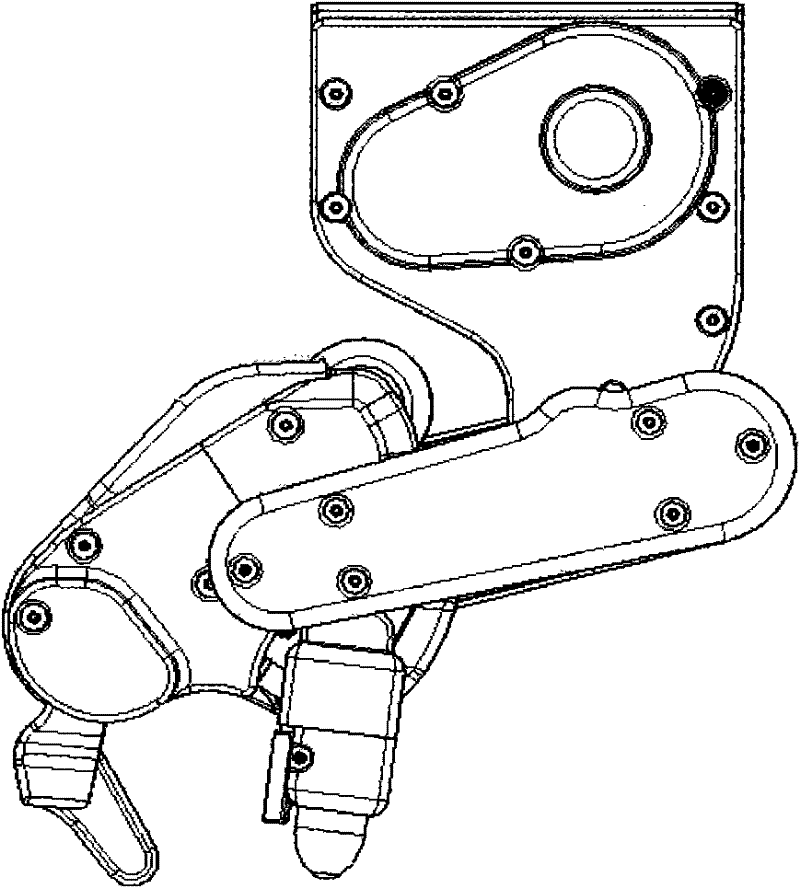

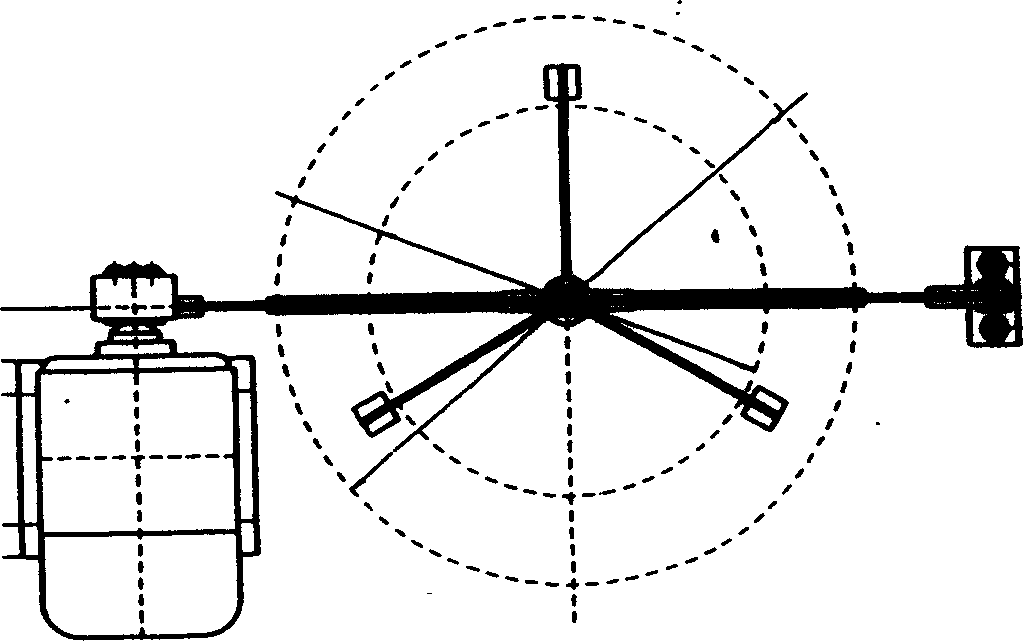

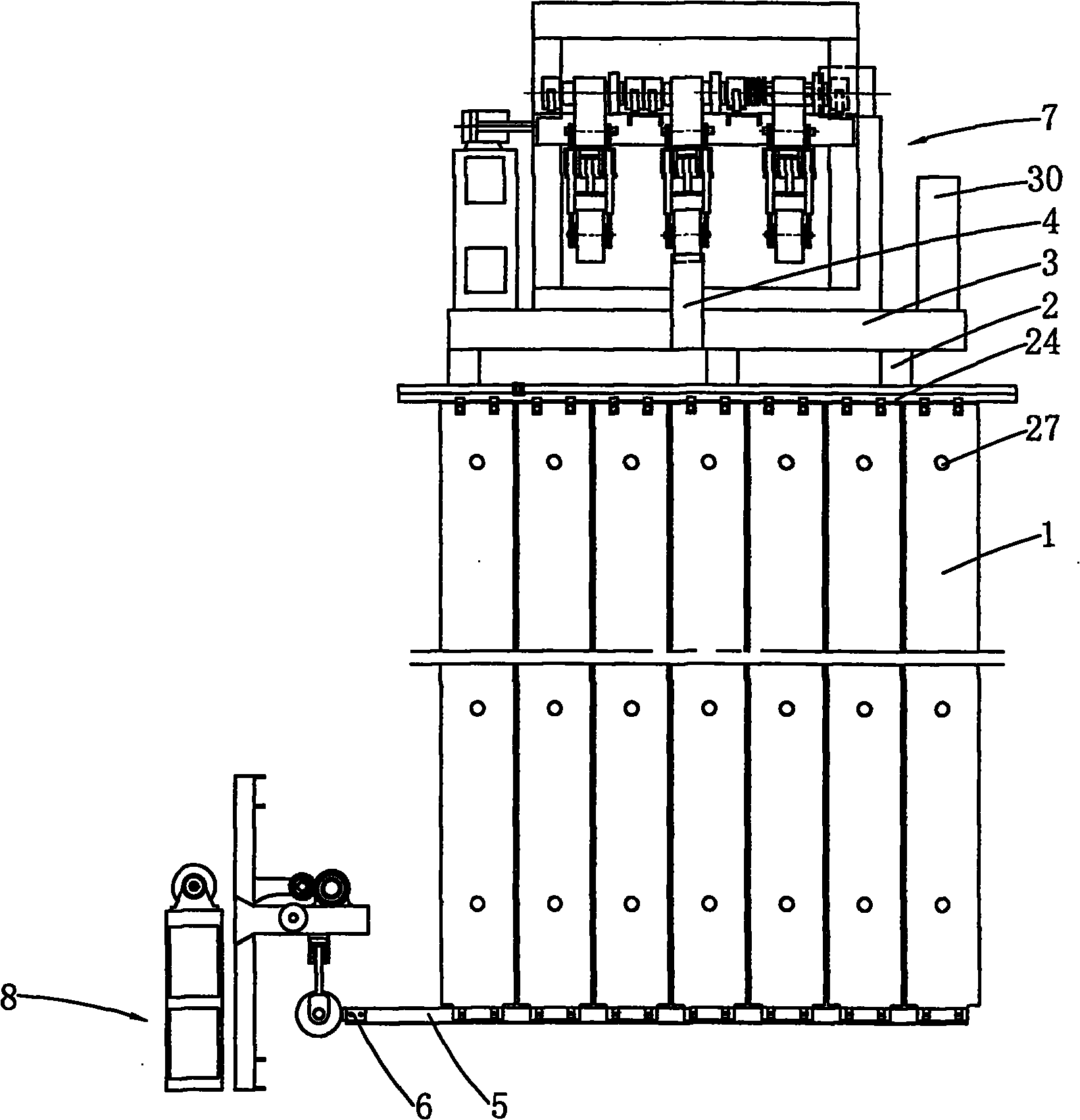

A traditional Chinese medicine massage robot combining rectangular coordinates and joints

ActiveCN102283765AImprove rigidityHigh positioning accuracyDevices for locating reflex pointsVibration massagePhysical medicine and rehabilitationRectangular coordinates

The invention relates to a rectangular coordinate and joint type combined traditional Chinese massage robot which is characterized by comprising a bed body provided with a support frame, wherein a mechanical arm is arranged on the support frame; and a massage device comprising a thumb rubber assembly, a metacarpus massage assembly and a roller is arranged at the tail end of the mechanical arm. The mechanical arm in the rectangular coordinate and joint type combined traditional Chinese massage robot is a rectangular coordinate and joint type combined mechanical device and has the characteristics of favorable rigidity and high positioning precision endowed by a rectangular coordinate type mechanical device as well as the characteristic of flexible action endowed by a joint type mechanical device; and the massage device is arranged at the tail end of the mechanical arm. The massage device can be used for realizing various traditional Chinese massage methods such as kneading, finger rolling, finger pressing, palm pushing, palm kneading, palm pressing, vibrating, rolling, rapping and the like under the matching of the mechanical arm.

Owner:SHANDONG KANGTAI INDAL

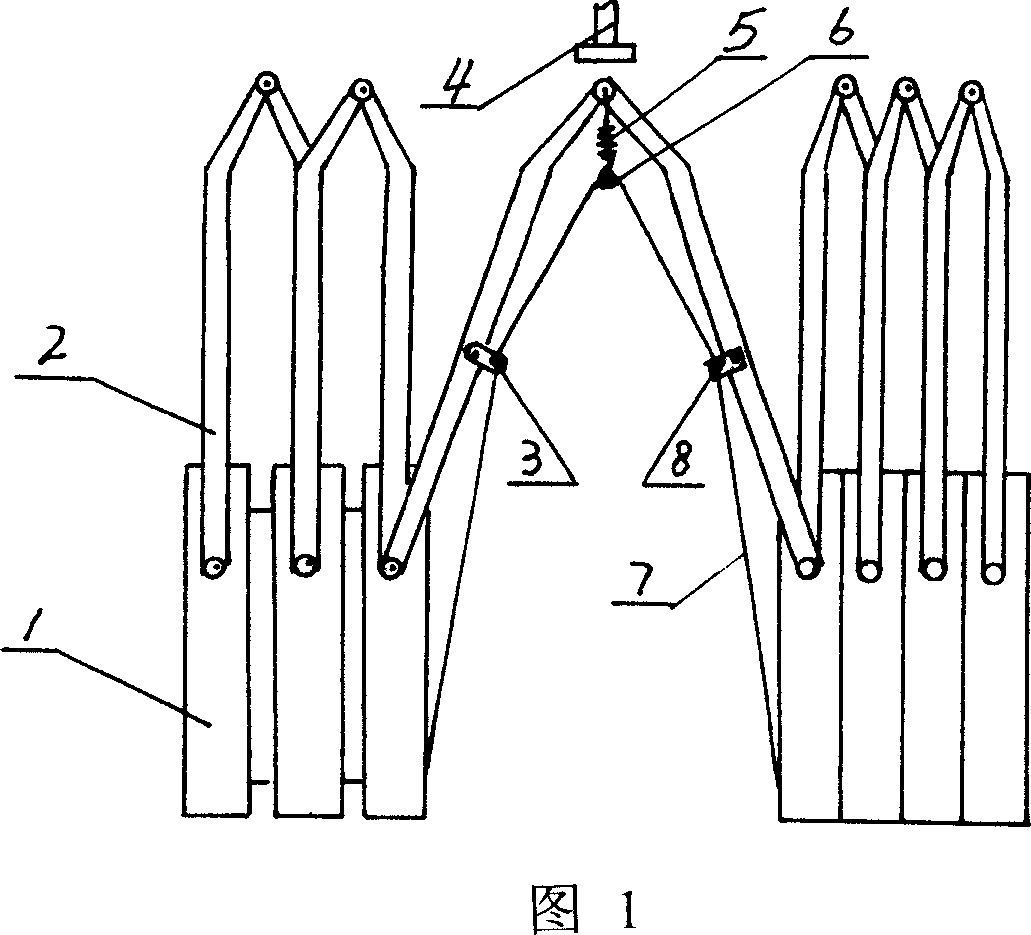

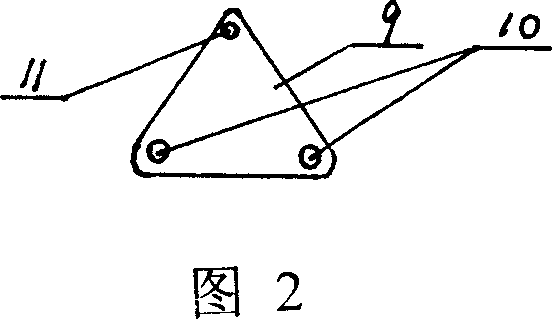

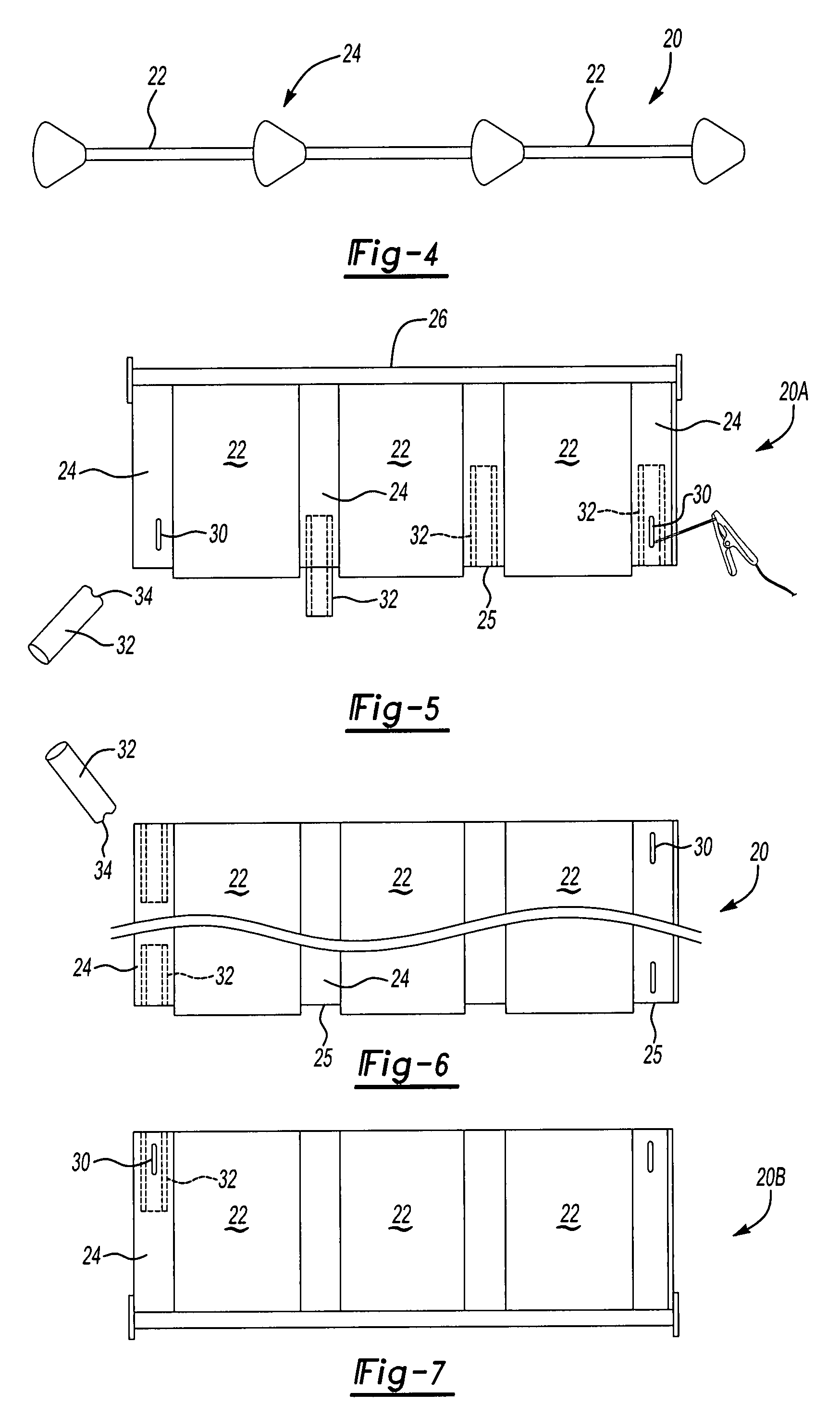

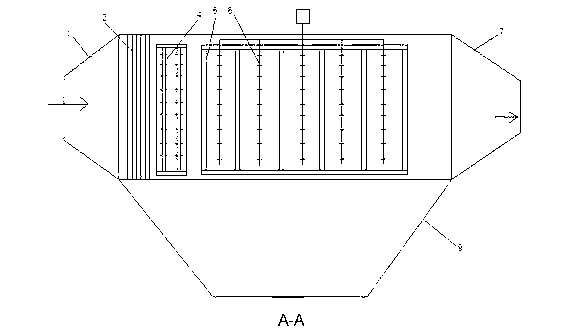

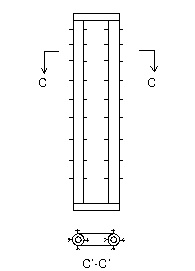

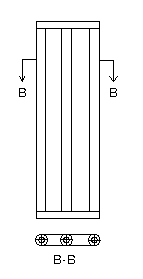

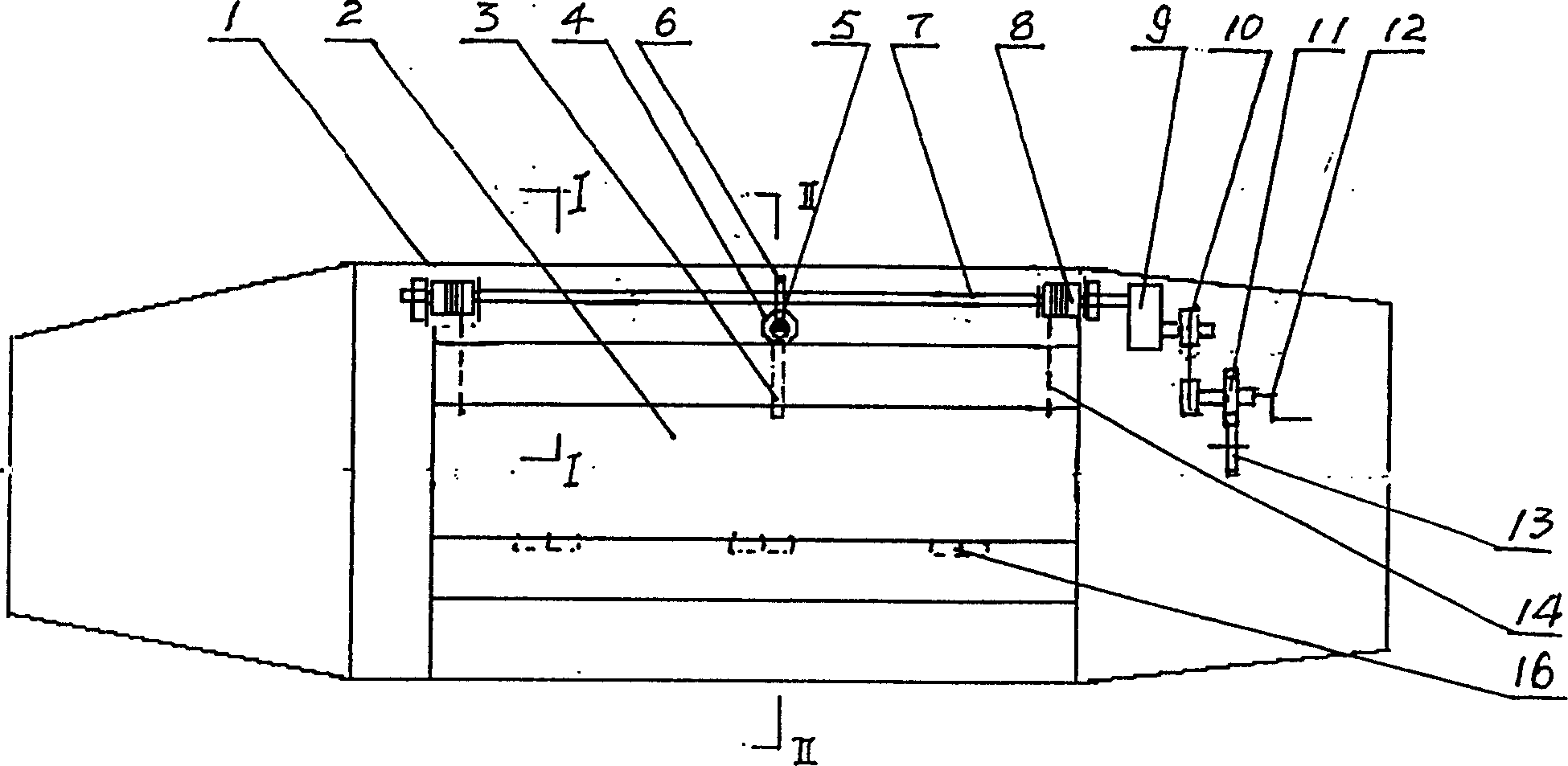

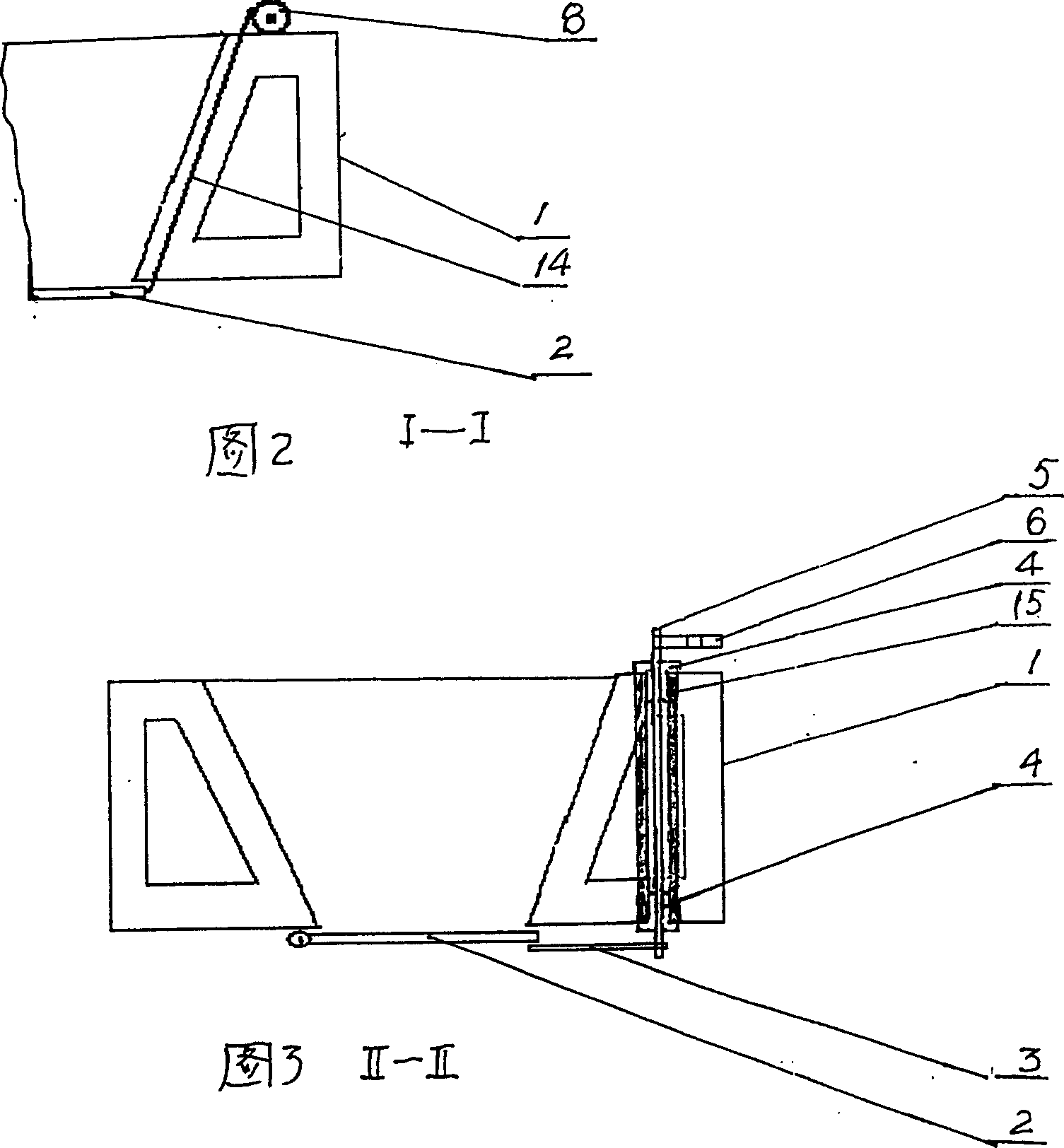

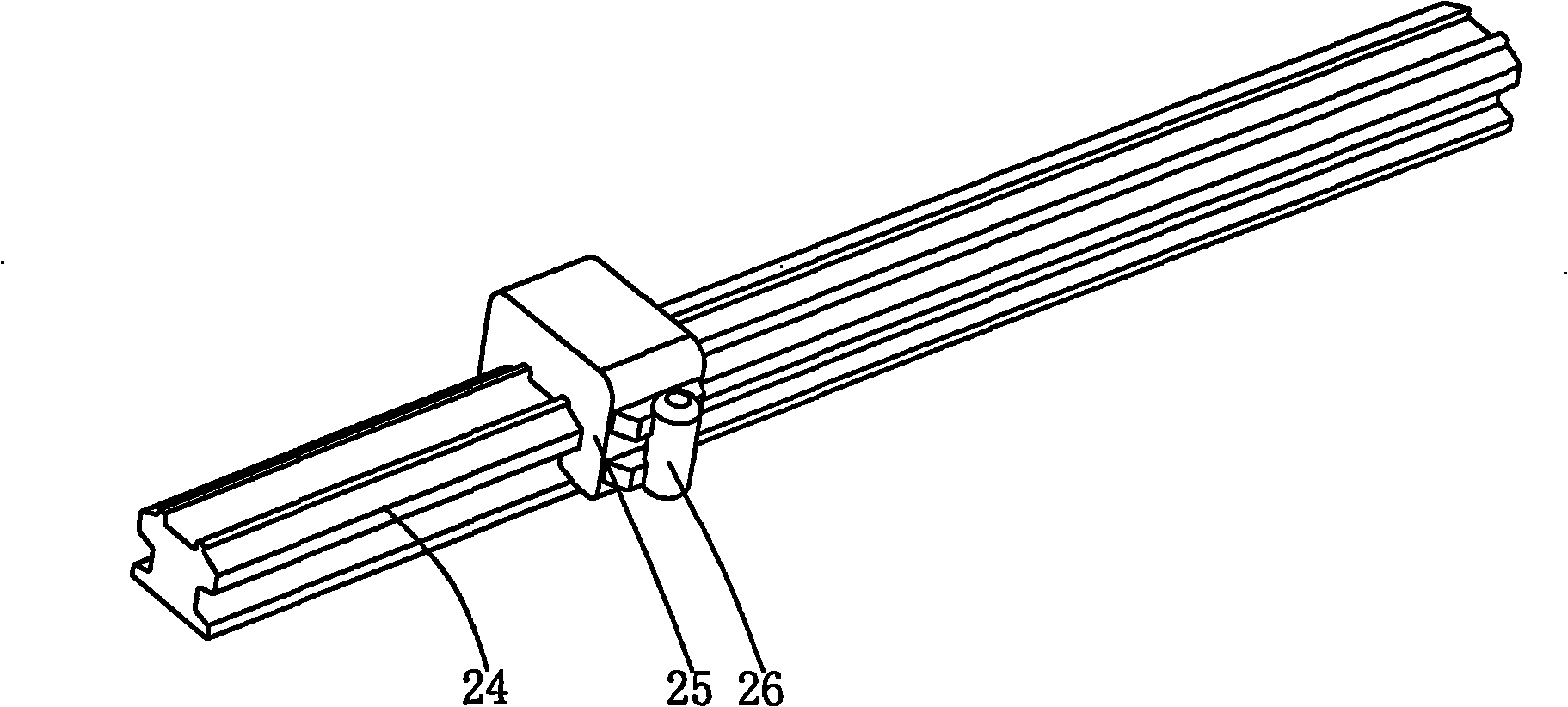

Filter-cloth curved-stretching rapping mechanism of pressure filter and rapping method

ActiveCN101073722AAvoid unclean shavingAvoid the disadvantages of fragileFiltration separationFilter pressFilter cake

The invention is concerned with the framework and the method that cleans up the filtering cloth mud of the filter cake on the filtering cloth of the pressure filter by the fluctuating shaking hit framework and the method, it is: the armtie framework pulls the filtering pad, the shaking hit framework located on the filtering pad hits filtering cloth bar on the top of the fluctuating bar directly when the filtering pad opens with each other, the filtering bar moves downwards by the shake and drives the filtering cloth shake strongly assorting by the filtering cloth bracing assembly, puts the filtering cake drop that is located on the filtering cloth, the filtering cloth resets by the fluctuating spring effect after the drop of the filtering cake, the filtering cloth resets with the filtering cloth bar, by analogy, the filtering cake in the fluctuating shaking hit framework can drop.

Owner:杭州兴源环保设备有限公司

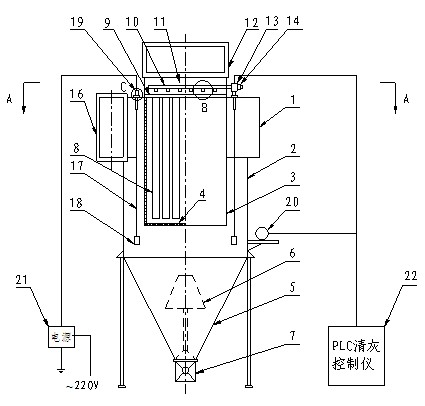

Cyclone electric-bag pulse filter cylinder separator

InactiveCN102366700AEasy to useCombination devicesDispersed particle filtrationHigh concentrationCyclone

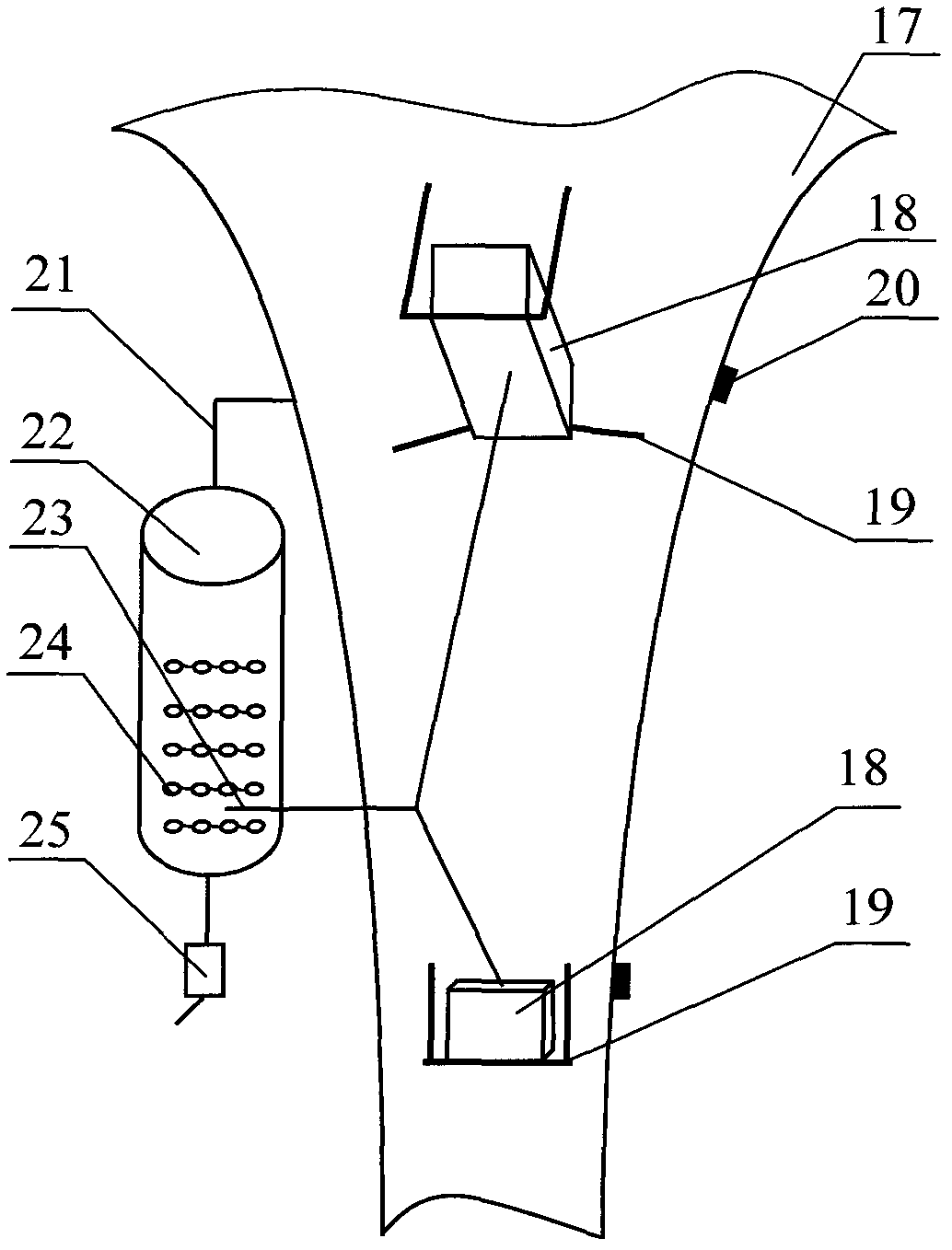

The invention relates to a cyclone electric-bag pulse filter cylinder separator. The separator comprises components of, from top to bottom: an upper spiral case, a lower outer cylinder, a lower ash hopper, and a dumper. The upper spiral case is positioned on the upper end of the separator. The lower outer cylinder is arranged on the lower part of the upper spiral case. An inner cylinder is arranged in the lower outer cylinder. Filter bags are arranged in the inner cylinder. A grate plate is arranged on the lower end of the inner cylinder. A rapping device is arranged on the outer side of the lower part of the lower outer cylinder. The lower ash hopper is arranged on the lower part of the lower outer cylinder. The dumper is arranged on the bottom of the lower ash hopper. Emitter wires are distributed on the peripheral of the upper spiral case. Porcelain bushings are sleeved on the emitter wires. An air outlet is arranged above the upper spiral case. A plurality of gas storing packs are arranged on the outer side of the air outlet. A pulse valve is arranged on the gas storing packs. The pulse valve is connected to an injection pipe. The actions of the pulse valve are controlled by an ash removing controlling apparatus. The cyclone electric-bag pulse filter cylinder separator provided by the invention is suitable to be used for treating flue gas with a relatively high concentration, and provides a separation efficiency reaching 99.99%. The gas obtained after separation can be directly discharged into the atmosphere. The actual application effect of the separator is good.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

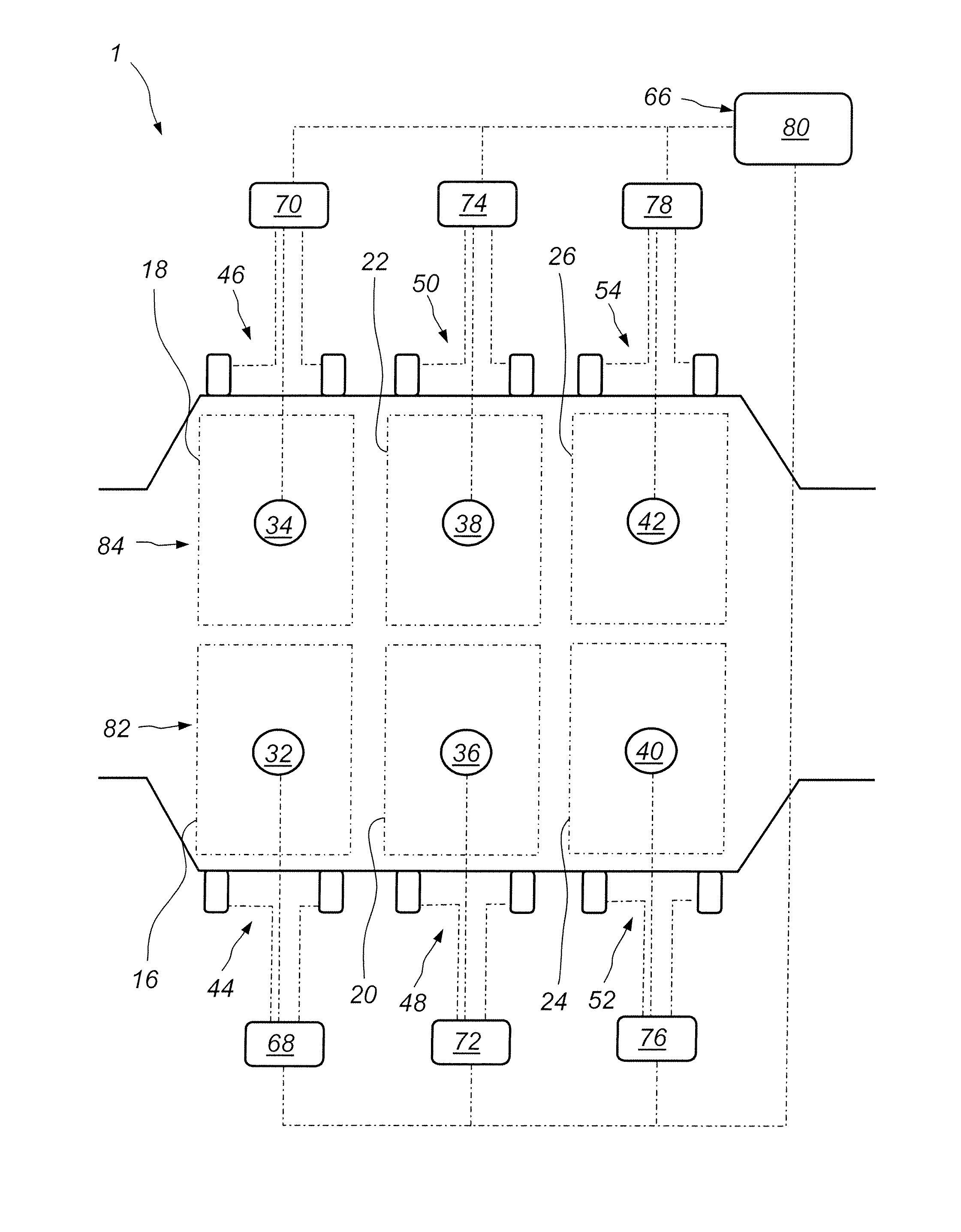

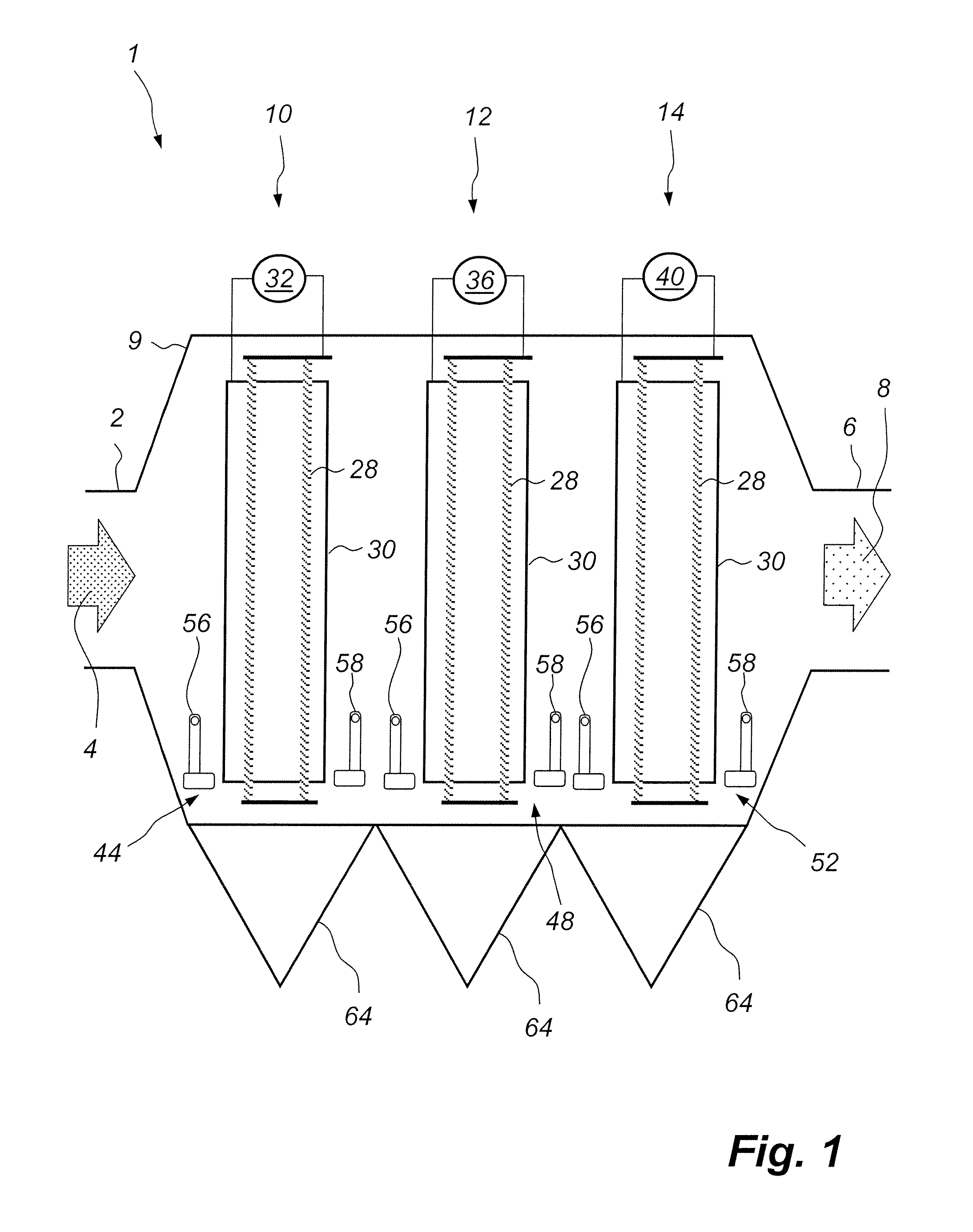

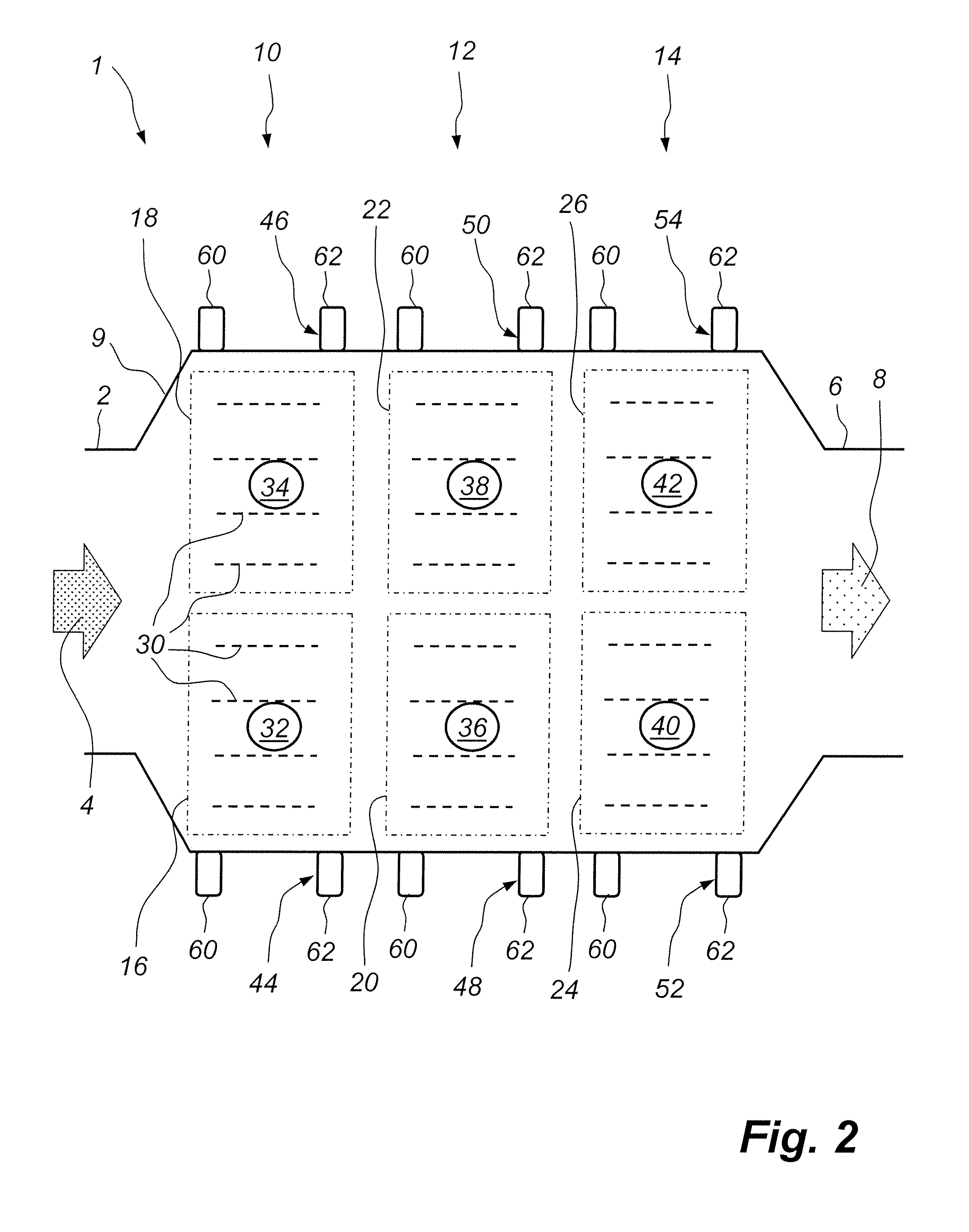

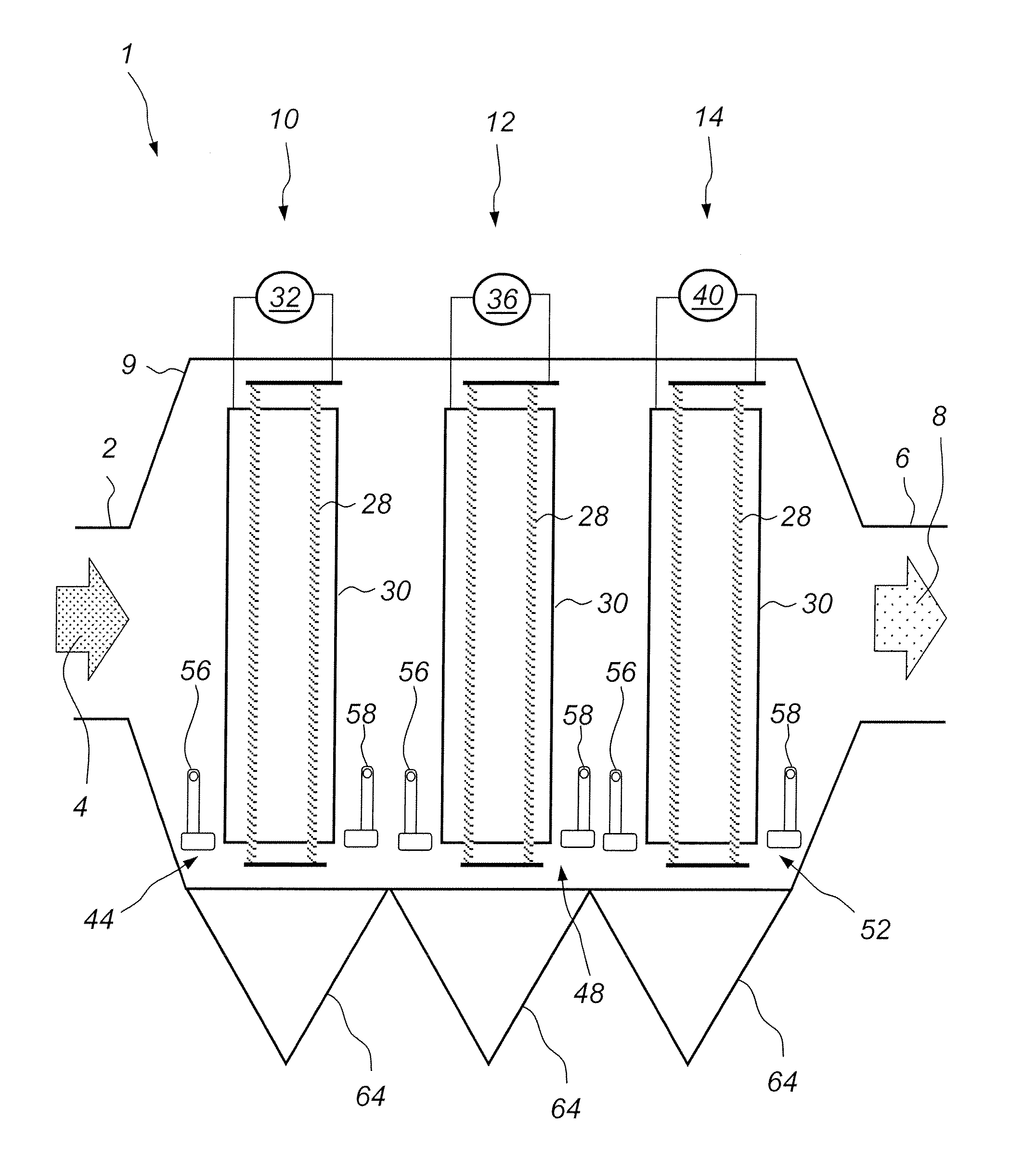

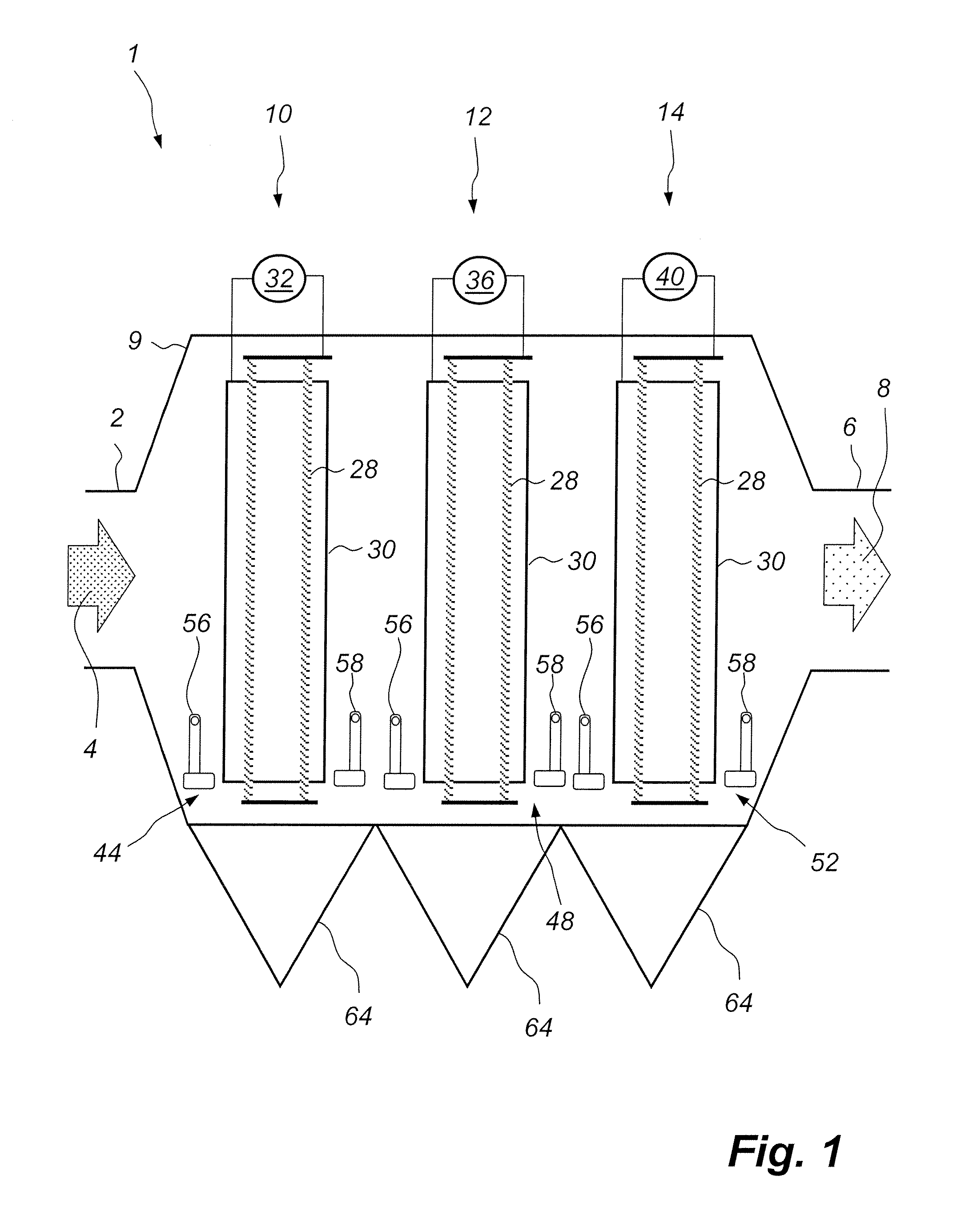

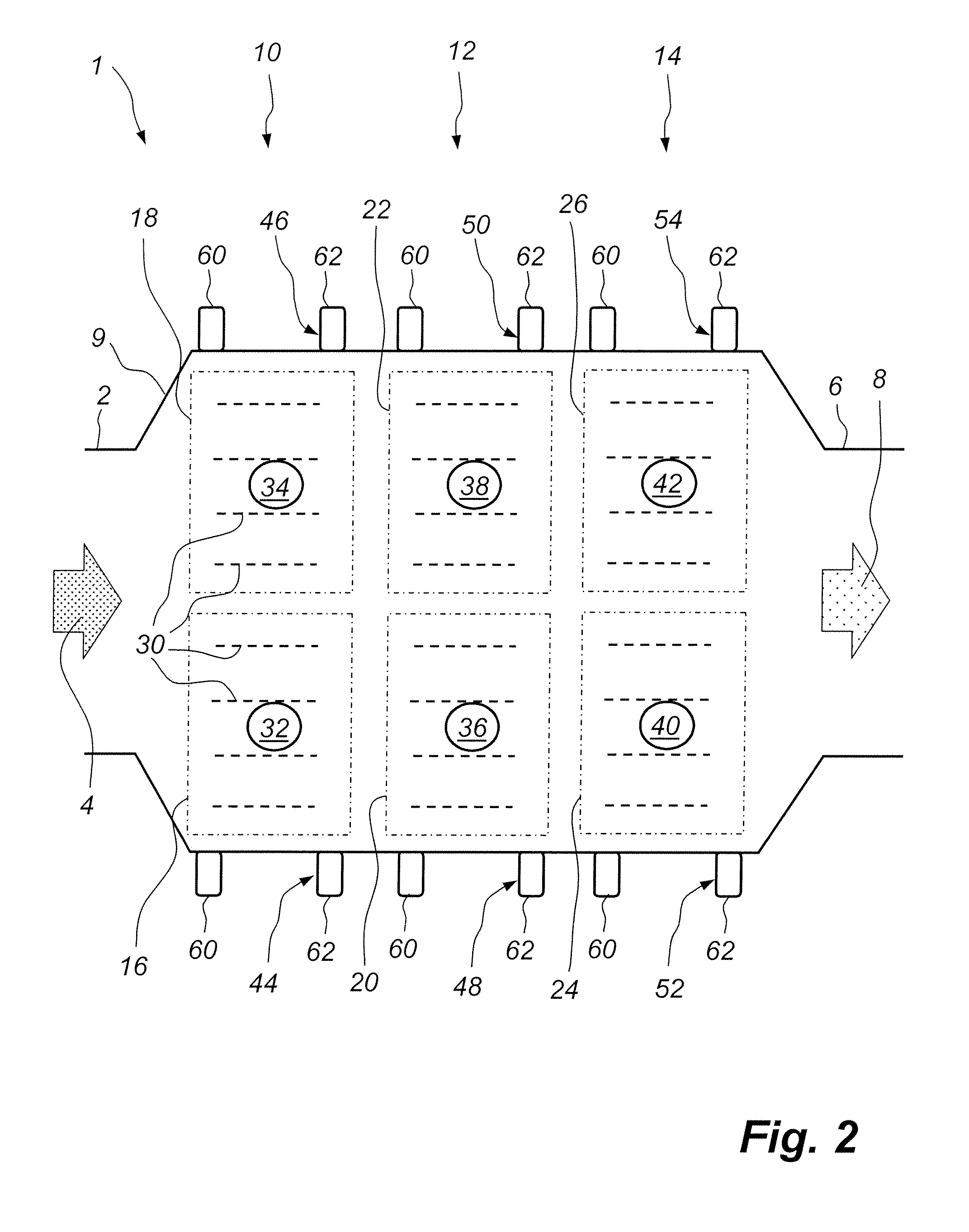

Method of estimating the dust load of an ESP, and a method and a device of controlling the rapping of an ESP

ActiveUS8328902B2Good removal effectImprove dust removal efficiencyElectrode carrying meansDispersed particle filtrationEngineeringVoltage

A device and method for controlling the rapping of at least one collecting electrode plate (30) of an electrostatic precipitator (1) is provided. The device controls such rapping by applying, by means of a power source (32), a voltage between at least one collecting electrode plate (30) and at least one discharge electrode (28). The sparking rate between the at least one collecting electrode plate (30) and at least one discharge electrode (28) is then measured, with the rapping of the at least one collecting electrode plate (30) controlled using the measured present sparking rate.

Owner:ANDRITZ AB

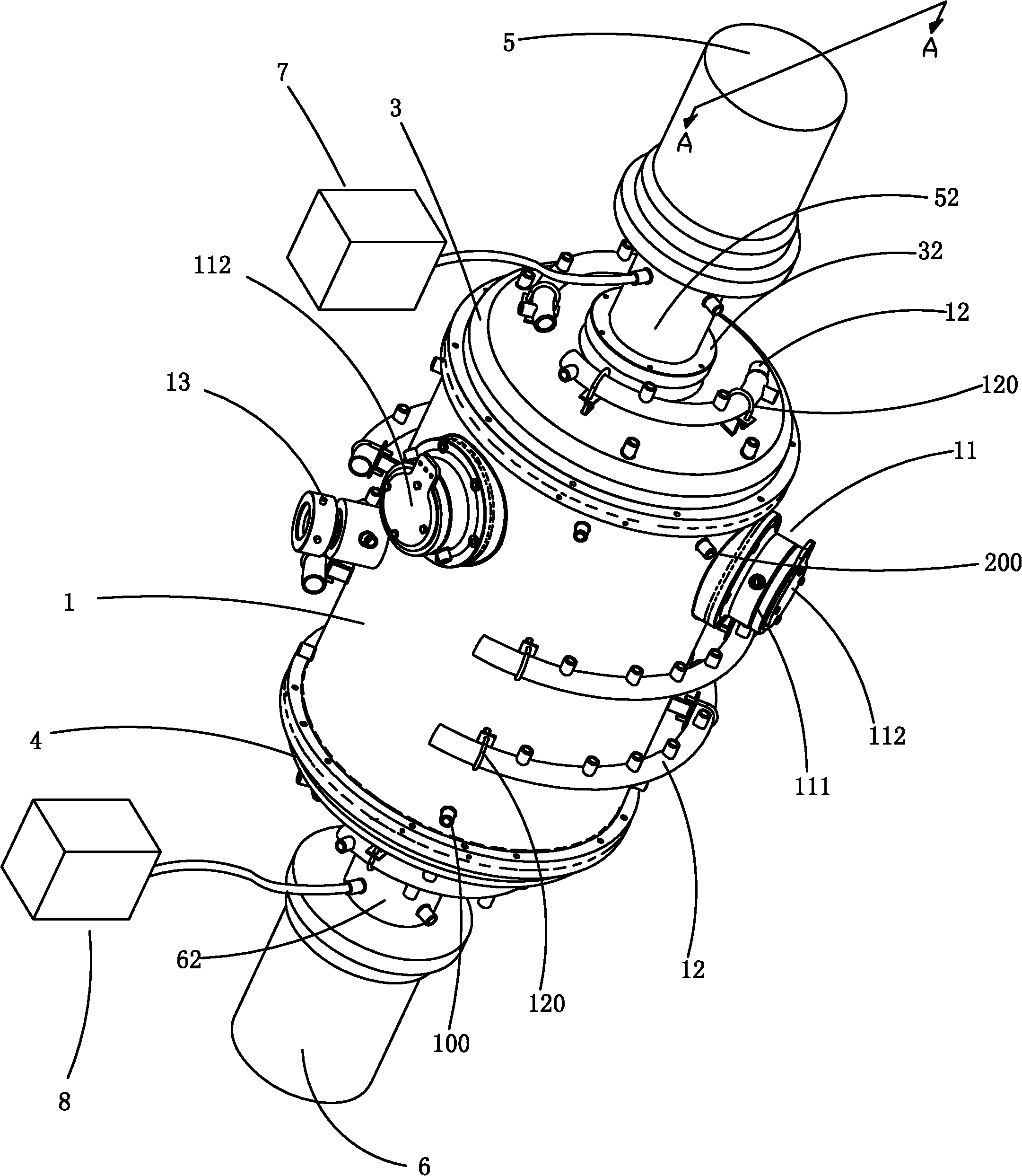

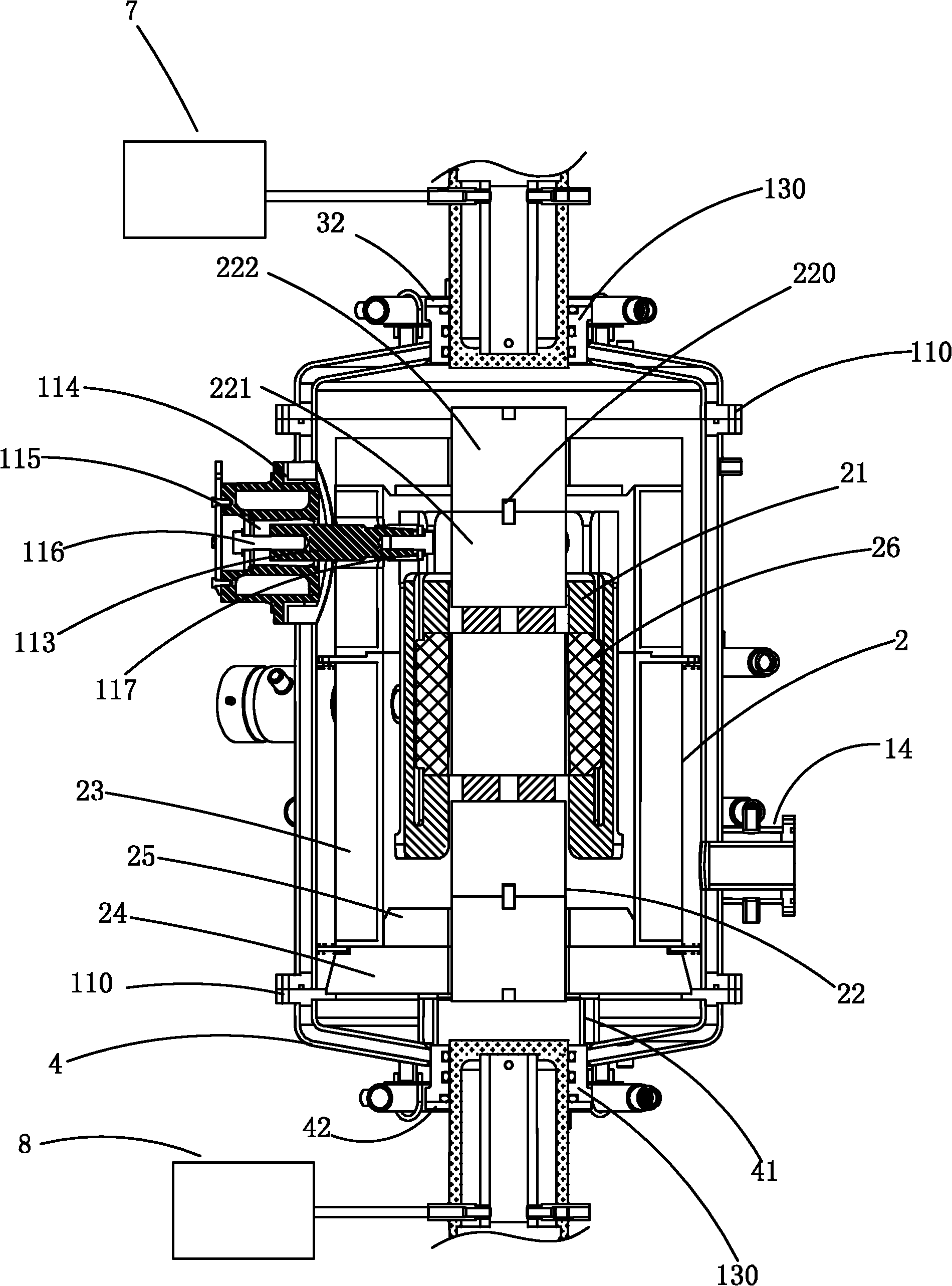

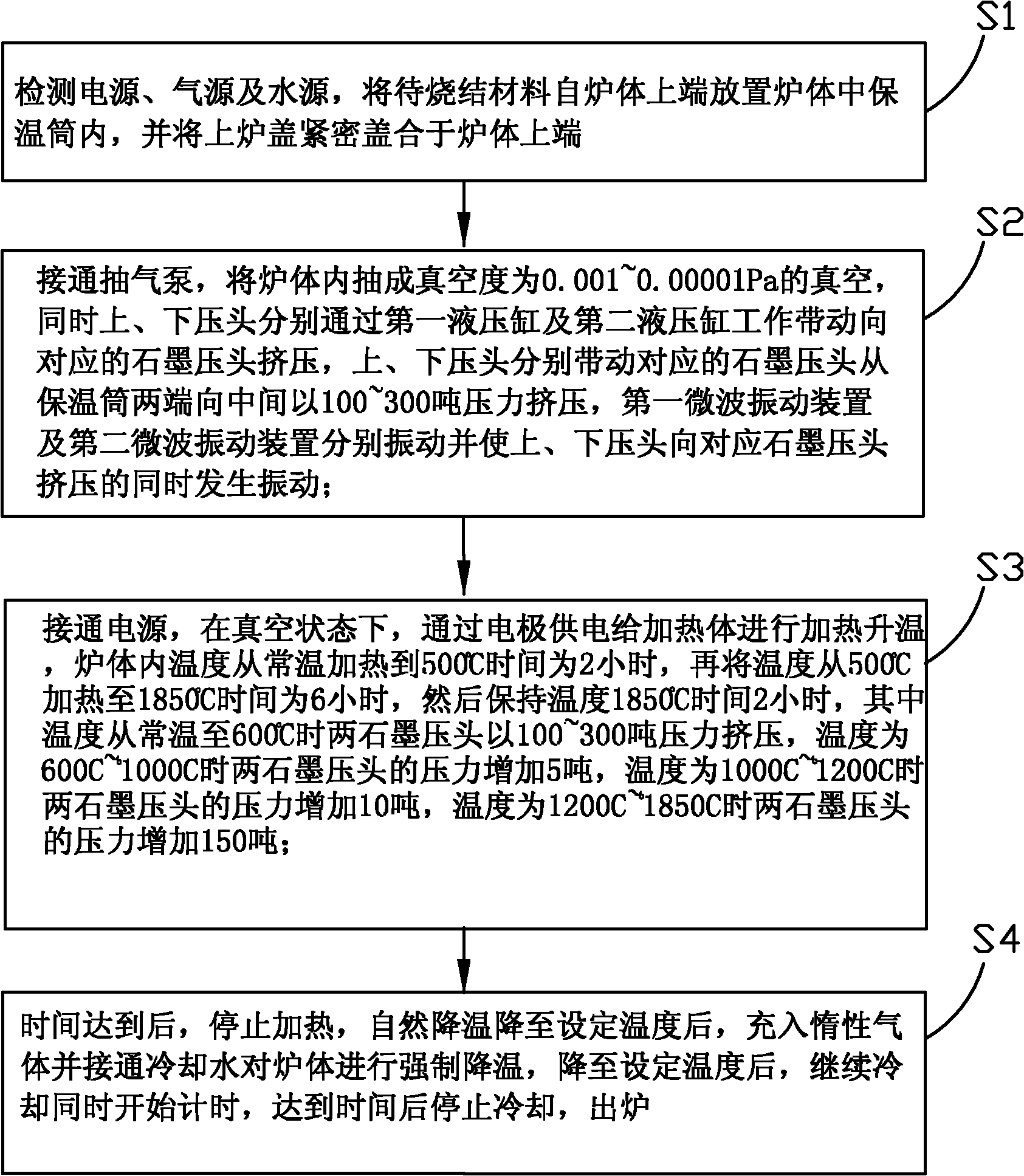

Bidirectional hot-pressing high-temperature oscillation sintering furnace and working method thereof

InactiveCN102072638AUniform pressure distributionHigh strengthMuffle furnacesRetort furnacesHydraulic cylinderMicrowave

The invention discloses a bidirectional hot-pressing high-temperature oscillation sintering furnace and a working method thereof. The sintering furnace provided by the invention comprises a first hydraulic cylinder, a second hydraulic cylinder, a furnace body, a thermal-insulation barrel, an upper furnace cover, a lower furnace cover, an upper pressure head, a lower pressure head, a first microwave rapping device and a second microwave rapping device, wherein the first hydraulic cylinder is provided with a first moving bar; the second hydraulic cylinder is provided with a second moving bar; the thermal-insulation barrel is arranged in the furnace body; the upper furnace cover and the lower furnace cover are respectively covered on the upper end and the lower end of the furnace body in a sealing mode by a flange plate; the upper pressure head integrally extends from the first moving bar of the first hydraulic cylinder and is arranged on the upper furnace cover; the lower pressure head integrally extends from the second moving bar of the second hydraulic cylinder and is arranged on the lower furnace cover; the first microwave rapping device and the second microwave rapping device are respectively connected with the upper pressure head and the lower pressure head; the furnace body is provided with a plurality of electrodes and a plurality of water pipes fixed on the furnace body via drivepipes; a gap is formed between the thermal-insulation barrel and the inner surface of the furnace body; a heating body and two graphite pressure heads are arranged in the thermal-insulation barrel, wherein two graphite pressure heads are oppositely arranged up and down by corresponding to the upper pressure head and the lower pressure head; and the plurality of electrodes respectively andsuccessively pass through electrode through holes on the furnace body and the thermal-insulation barrel to enter into the furnace body, and are connected with the heating body.

Owner:邓湘凌

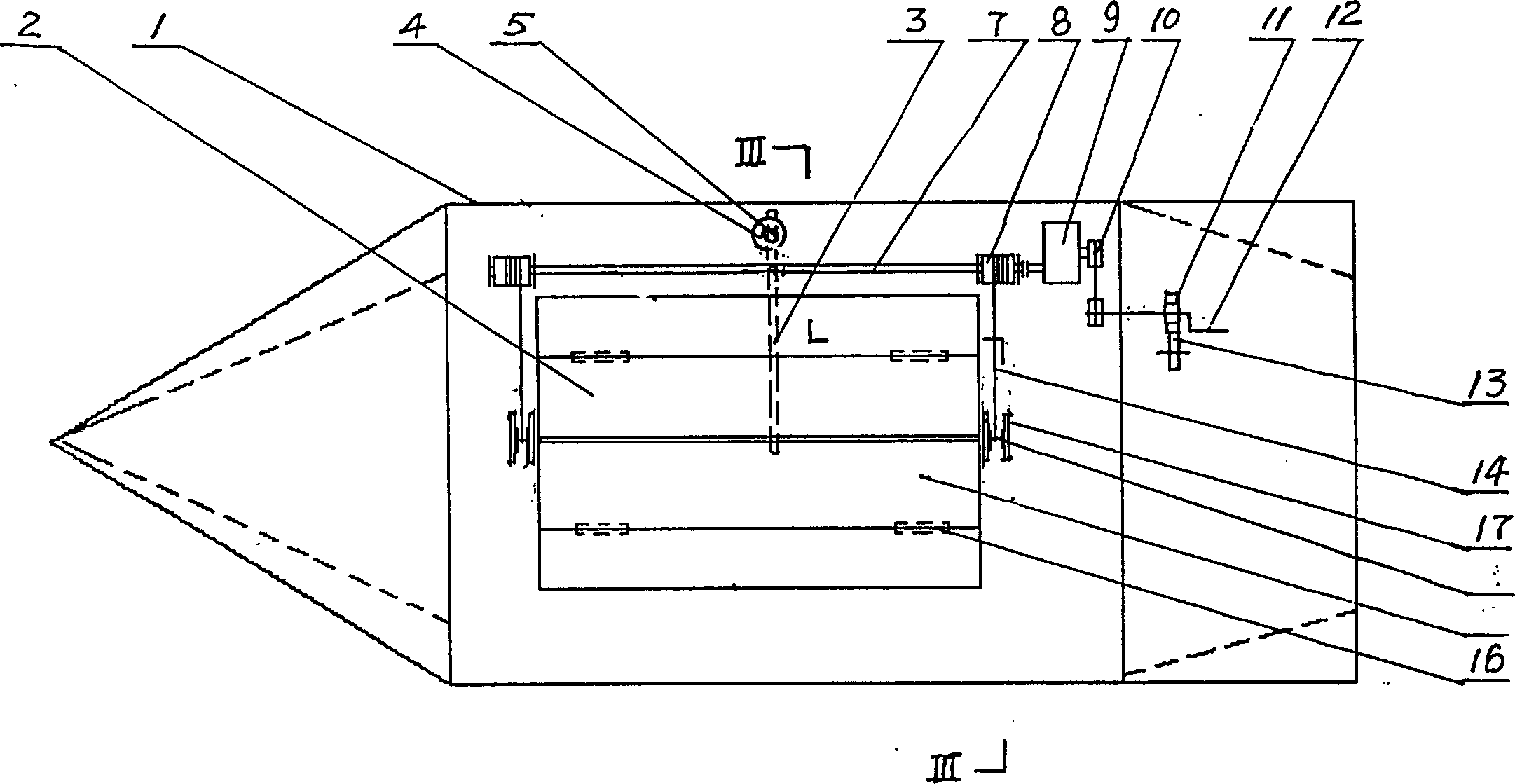

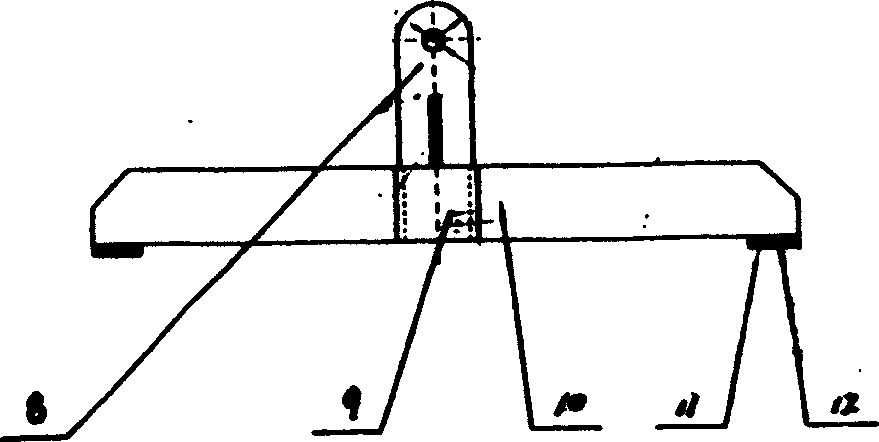

Mechanical rapping apparatus

ActiveCN1686616AAchieve removalGuaranteed continuityElectrodes cleaningEngineeringHeat transfer efficiency

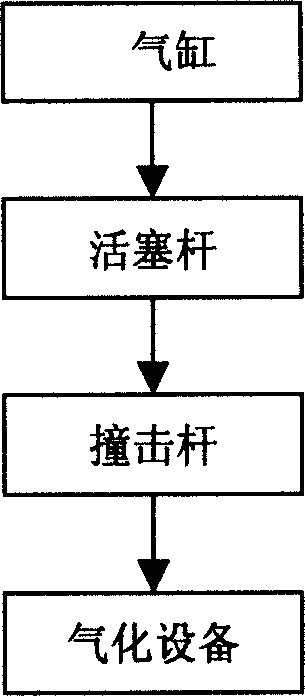

A mechanical shaker is composed of vibrating unit, sealing part, filtering and supporting-connecting unit. The piston rod is impacted by the kinetic energy generated from cylinder. The kinetic energy is then transferred to the impacting rod for impacting against the gasifying apparatus to remove the dust deposit and increase heat transfer efficiency.

Owner:WUHAN JEHOO HIGH TECH

Automated foam concrete producing method

InactiveCN104416678AReal-time monitoring of process flowAccurate measurementCement mixing apparatusCeramicwareFoam concreteSlurry

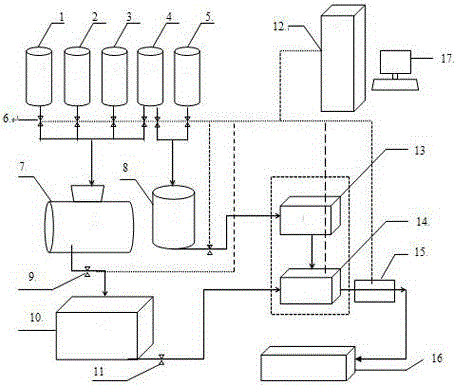

The invention discloses an automated foam concrete producing method. A device mainly consists of following units: a material bin, a frequency-variable speed regulator, a rapping machine, a gas circuit electromagnetic valve, a pneumatic valve, a liquid level meter, a liquid buffer chamber, an electromagnetic valve, a vacuum centrifugal pump, a material slurry feeding pump, a water-reagent mixing chamber, a stirrer, a foaming machine, an air compressor, a manual gate valve, a stirring slurry-making machine, a material slurry storage pot, a foam mixing apparatus, a density meter, a control cabinet, a project control system, a computer and a client software platform. The method for prepare the foam concrete in various specifications includes steps of automatically feeding materials according to preset parameters, automatically stirring the materials, performing an automatically foaming process and an automatically foam mixing process, automatically measuring a density, wherein the processes are fully-automatically (or manually) controlled and integrates technologies of material blending, slurry making, foam generating and foam mixing during preparation of the foam concrete. The method allow each process to be detected, the materials to be weighed automatically and accurately, the processes to be monitored in real time and product quality of the foam concrete to be controlled strictly.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Silo wall rapping air hammer

The invention discloses a bunker wall vibration air hammer, which solves the problem of lower hopper-plugging dredging efficiency at present and is characterized by comprising an electromagnetic reversing valve, an air cylinder, a hammer head, a quick exhaust valve and the like, wherein the electromagnetic reversing valve is connected with an air outlet pipeline of an air storage tank through an air inlet pipeline, connected to one end of the air cylinder through a front air pipe and connected to the other end of the air cylinder through a rear air pipe and the quick exhaust valve; an adjustment valve is arranged between the rear air pipe and the quick exhaust valve; the air cylinder is fixed on a base; and a piston rod of the air cylinder is connected with the hammer head. The bunker wall vibration air hammer has a simple structure and low manufacturing cost; the whole device is arranged outside the wall of a hopper, so openings are not required to be formed on the hopper, the dredging capability is higher and the bunker wall vibration air hammer is quick and convenient to install and maintain; due to an electric control system, regular and continuous vibration can be realized and the vibration frequency can be set randomly; furthermore, the vibration strength is higher, can be adjusted and much higher than manual strength; the vibration is uniform and an effect is outstanding, so the working efficiency can be improved by multiple times; and the bunker wall vibration air hammer is particularly applicable to dredging of raw coal bunkers of thermal power plants.

Owner:ANHUI KANGDI ELECTRIC POWER SCI & TECH

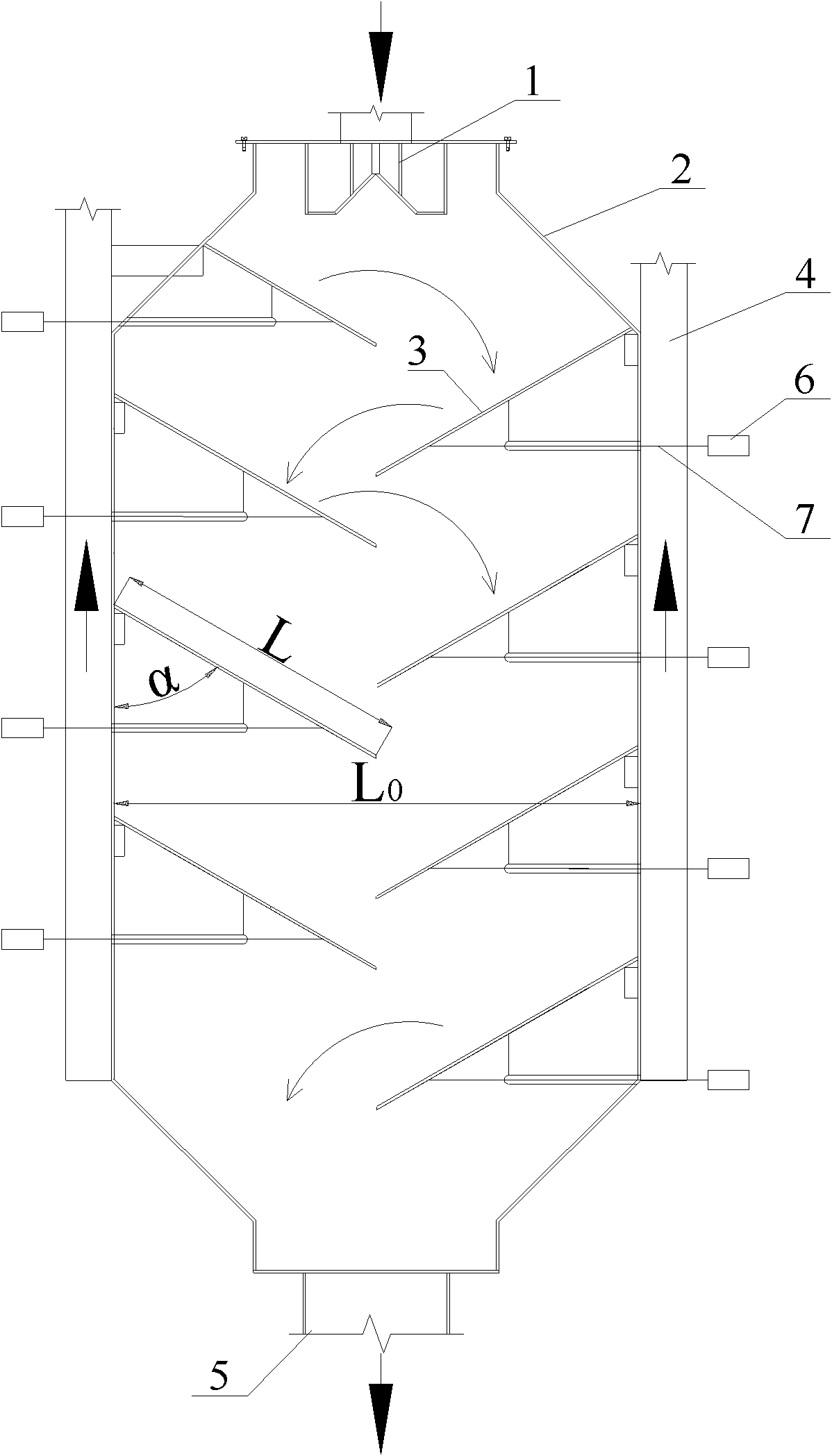

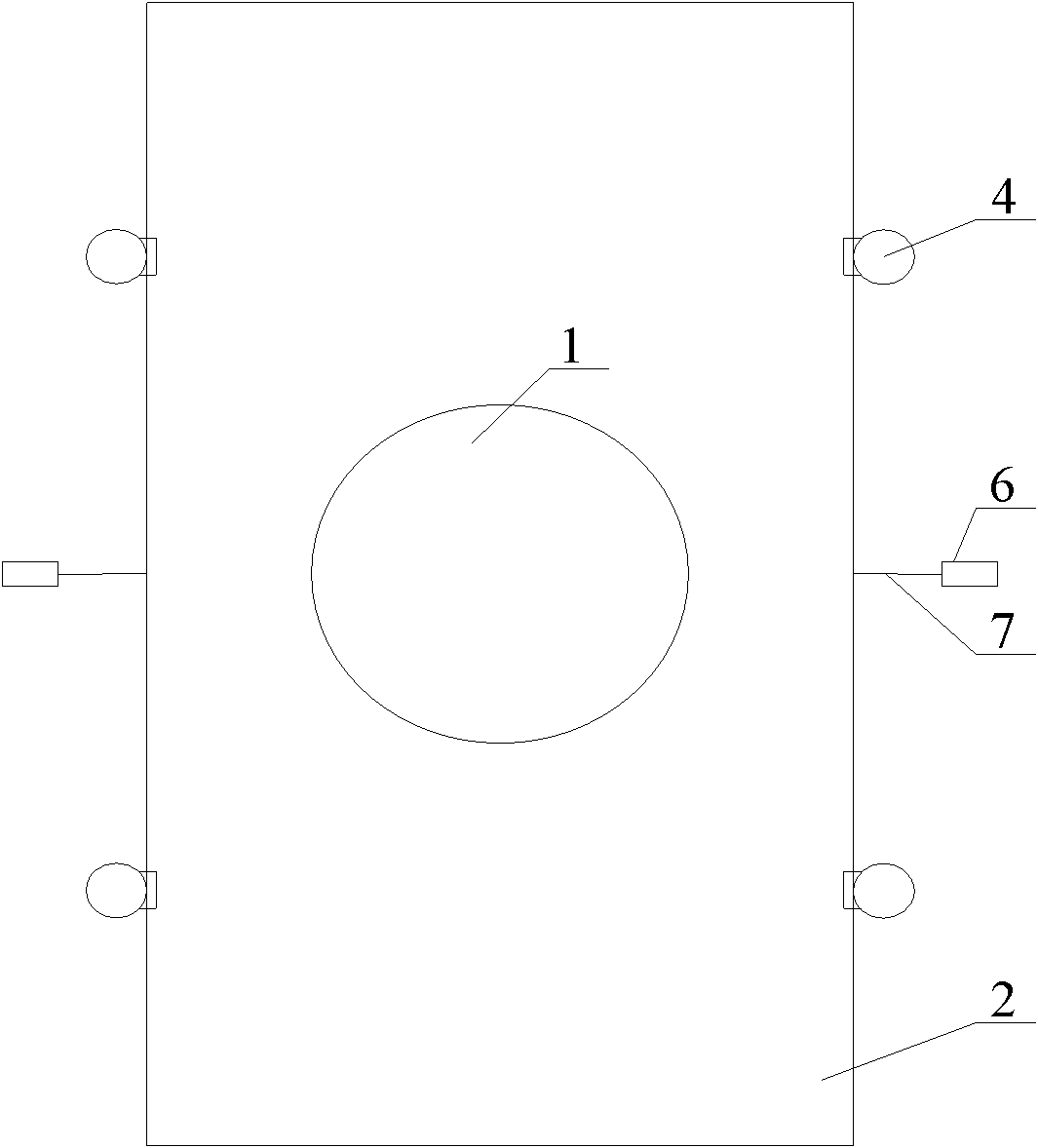

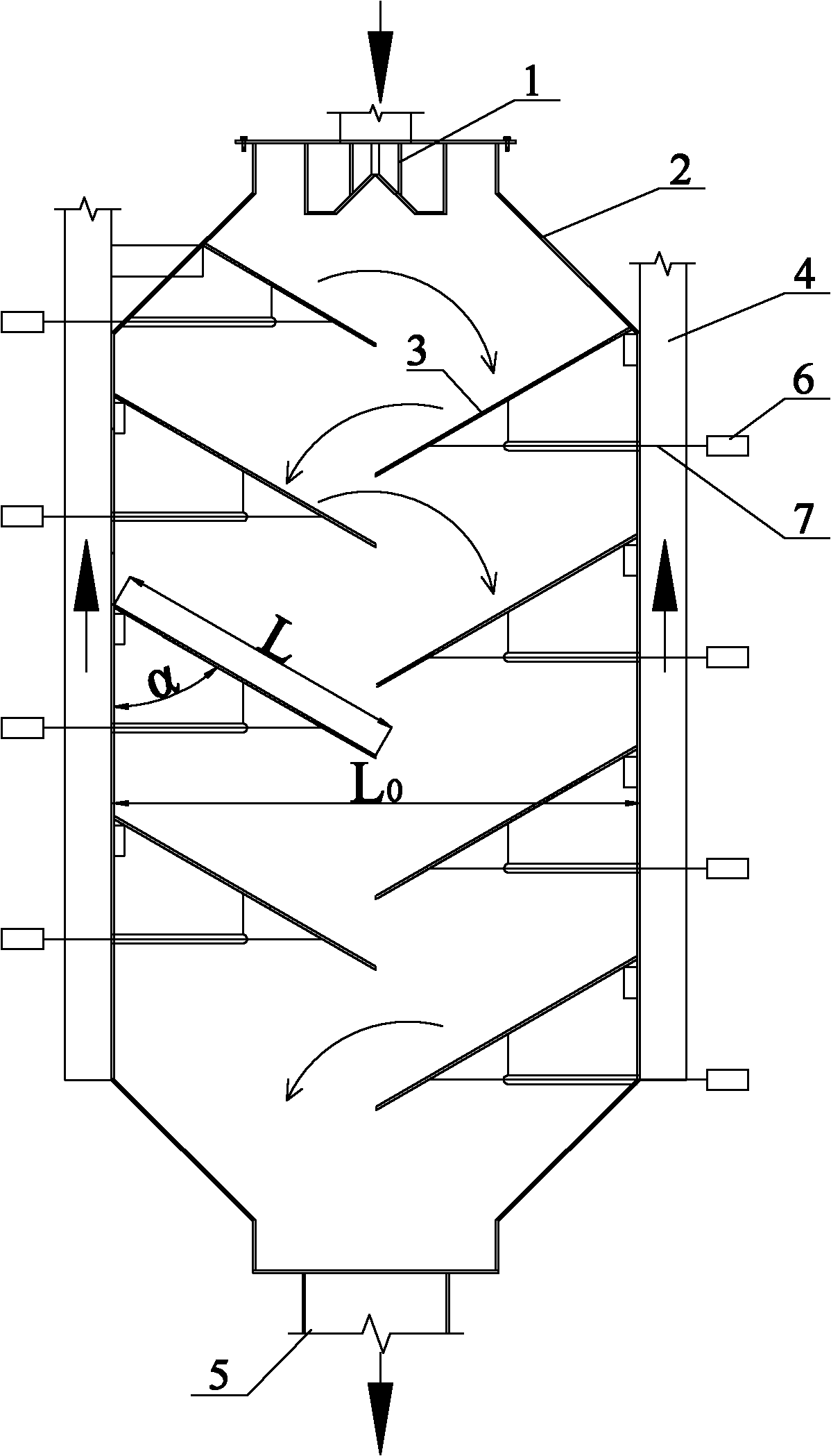

Moving bed reactor for medium temperature dry distillation

InactiveCN102102022AImprove heat transfer efficiencyEasy to moveDirect heating destructive distillationSpecial form destructive distillationHeat carrierNuclear engineering

A moving bed reactor for the medium temperature dry distillation is used in the lignite dry distillation and deep processing based on solid heat-carrying. The moving bed reactor mainly contains a feeder, a shell, baffle plates, a gas pipe, a material outlet and a rapping device. When the moving bed reactor is used, the treated lignite and heat carrier enter the moving bed reactor through the feeder, the feeder and the baffle plates are used to mix the solid material repeatedly, heat carrier and lignite or semicoke perform continuous heat transfer in the moving bed and stay for a certain time,the dry distillation of lignite or semicoke is performed, the generated oil and gas are led out through the gas pipe to an oil-gas separation system, and the solid material is led out through the material outlet to be used as the product or heated again to be used as heat carrrier. The moving bed reactor has the advantages of novel equipment, uniform heat transfer, low heat consumption, safety, economy and the like.

Owner:TSINGHUA UNIV +1

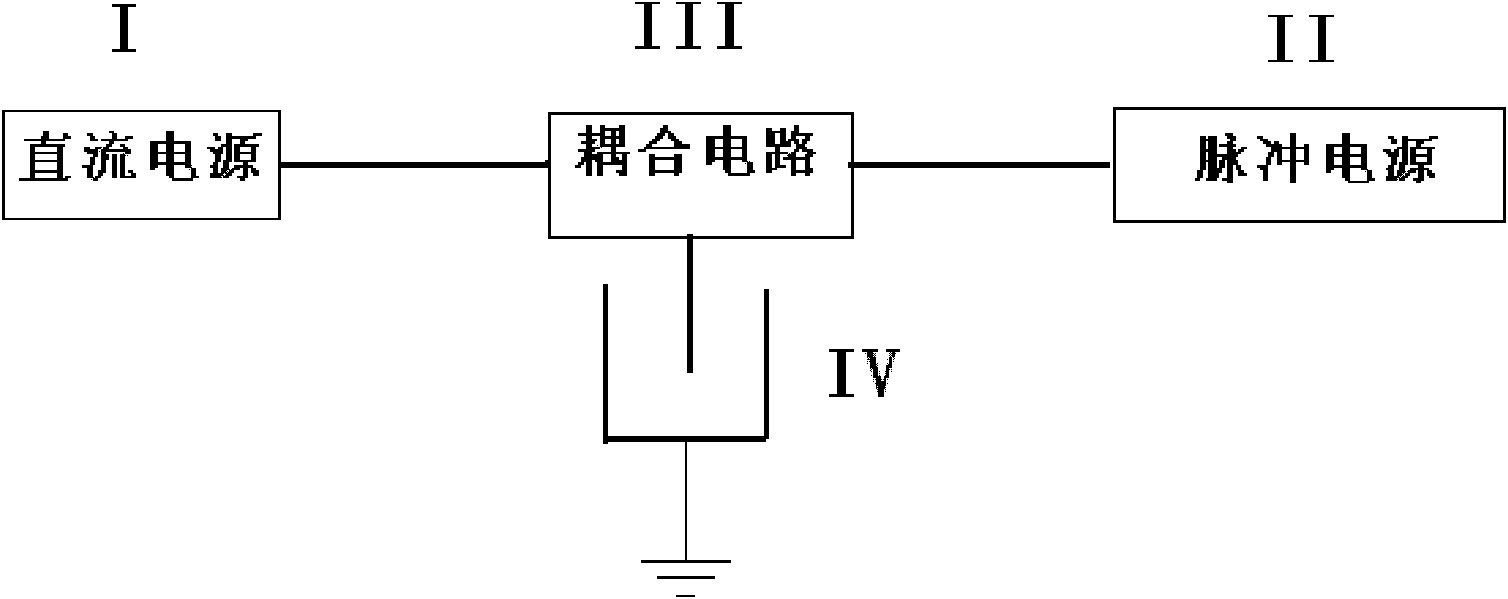

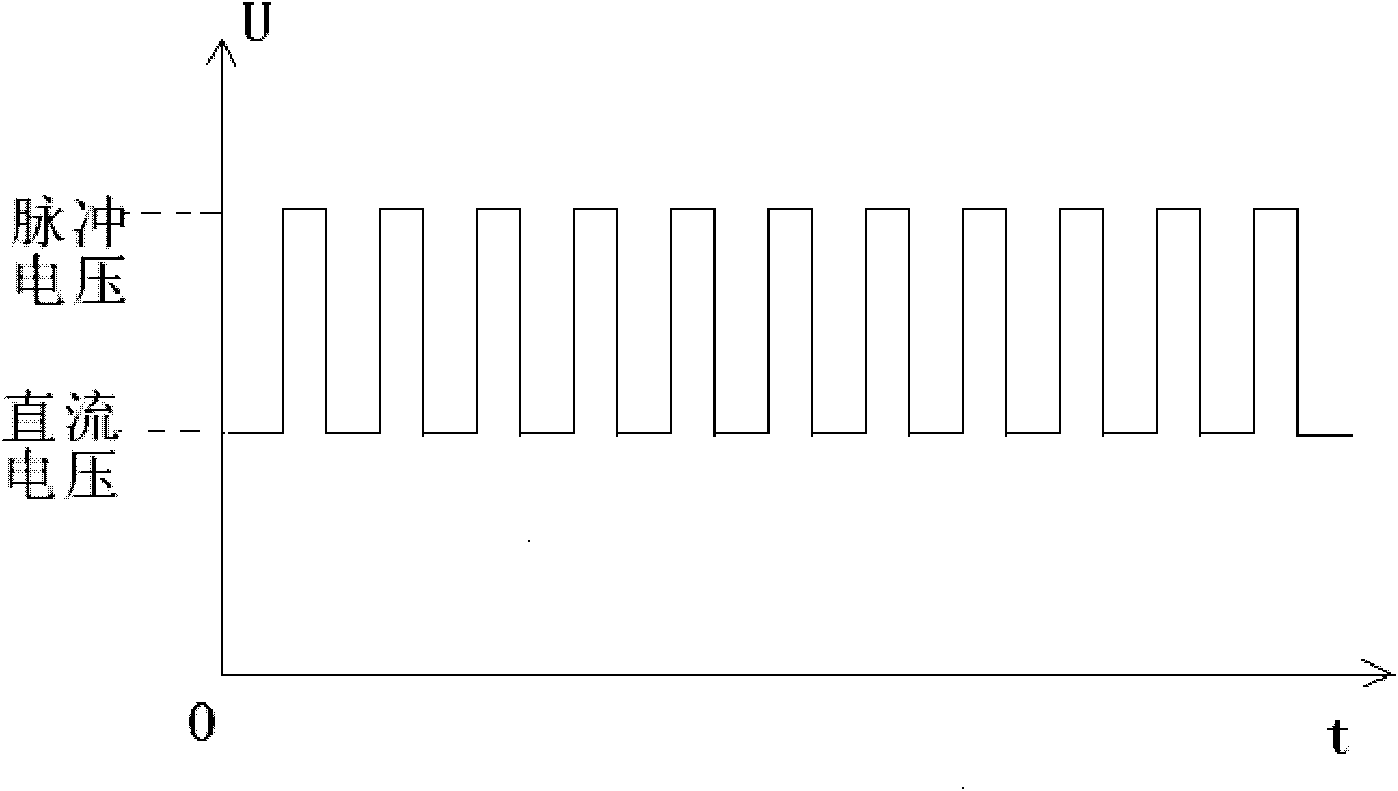

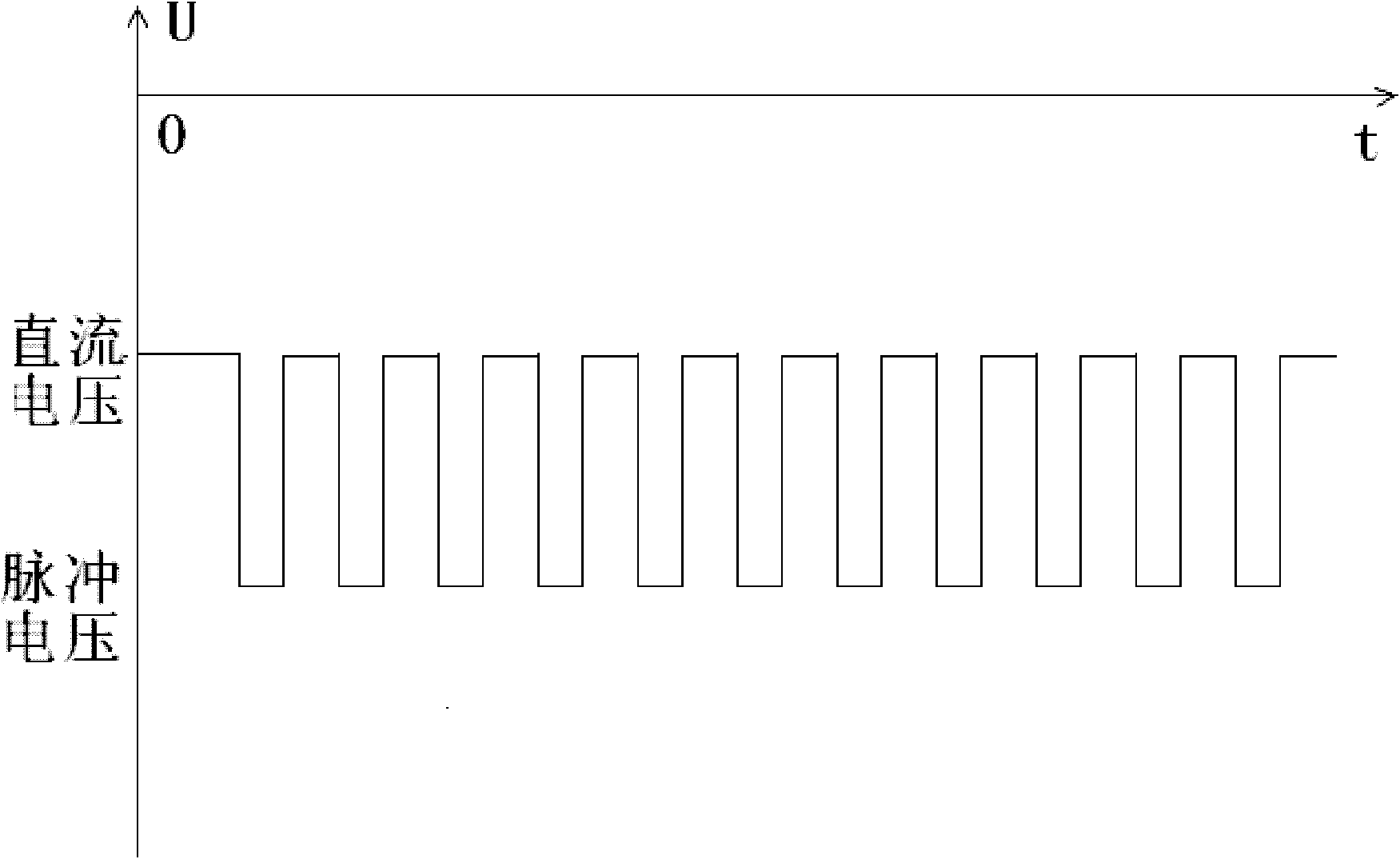

DC superposed pulse electric precipitation method

InactiveCN101850301AImprove bindingImprove power efficiencyElectric supply techniquesEngineeringHigh pressure

The invention discloses a DC superposed pulse electric precipitation method. High-voltage current is generated by a DC power circuit, pulse waveforms are generated by a pulse power supply and have rise time in a range of millisecond to nanosecond, and then the high-voltage current and the pulse waveforms are superposed by a coupling circuit to act together on a dedusting reactor. The method has the advantages of overcoming the defect that conventional electric precipitators are supplied with power only by a DC power supply, reducing power consumption, reducing secondary rise caused by rapping, improving the efficiency of high specific resistance dust and reducing dust collection areas of the precipitators, and is more suitable for the industrial application of the purification and treatment of a great amount of smoke.

Owner:BEIJING BODXY ENERGY CONSERVATION TECH & RES

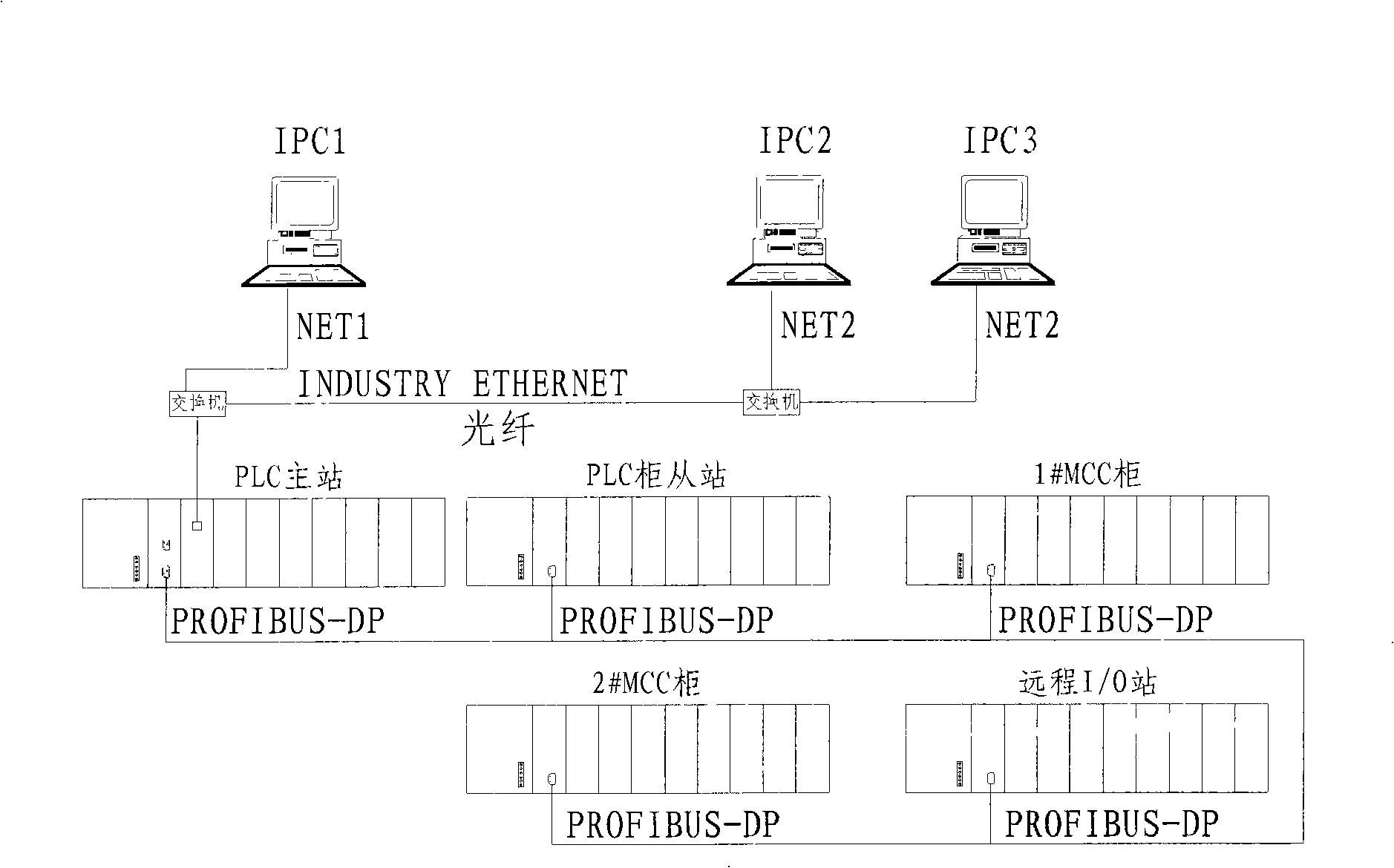

Electric dust removal control system and control method thereof

InactiveCN101303586AHigh degree of automationLess power consumptionEnergy industryElectrostatic separation detailsChemical industryElectric power system

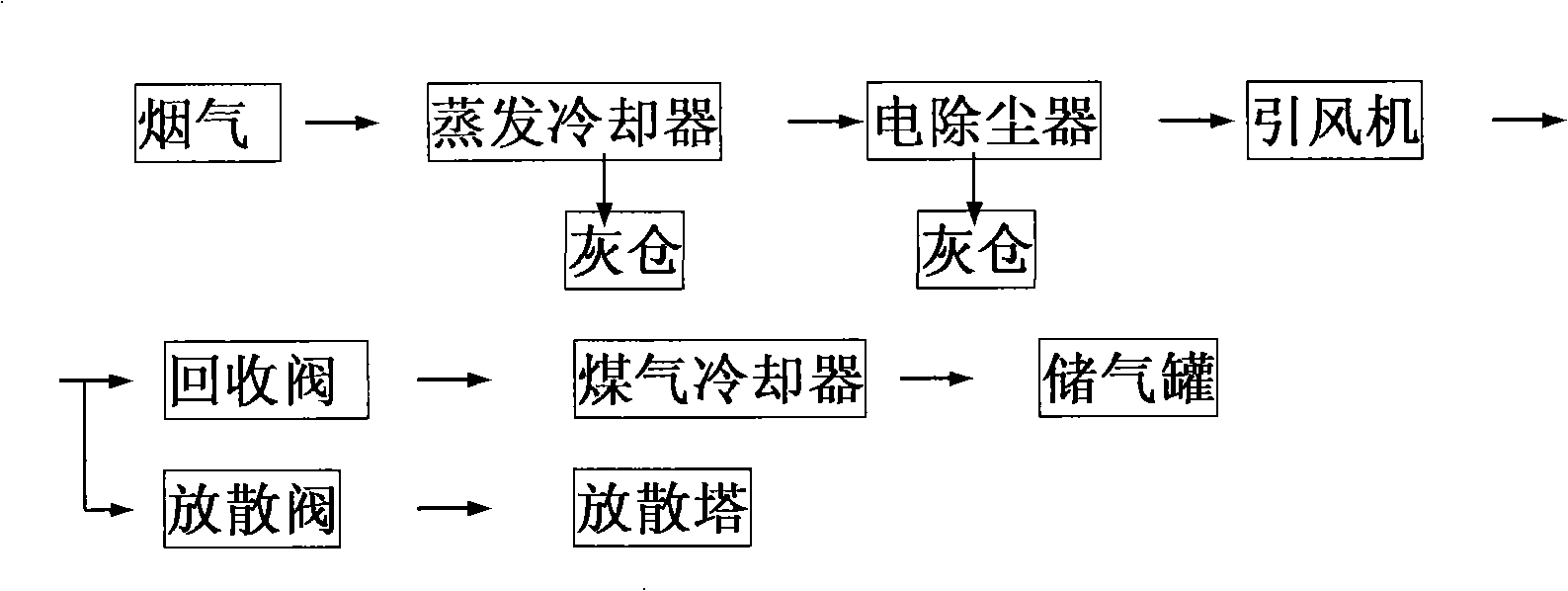

The invention belongs to the field of an environment protective control, which particularly relates to an electric dedusting control system and a control method thereof; the invention is essentially applicable to the fields such as the power supply system, cement, metallurgy, nonferrous metals and chemical industries, including a central control system, an upper machine set and a lower machine set; the industrial Ethernet based on the TCP / IP protocol is adopted among upper computers in the upper machine set and between the upper computers and lower computers, the lower machine set is connected with the central control system by a switch software Ethernet, the central control system is taken as a monitoring control terminal to design, alter and debug the operation of the system in the upper computer image monitoring control terminal software; the electric dedusting control method includes a fan control, an evaporation low temperature control, an electric field control, a rapping control, a changing-over station control and a gas cold control. The environment protective control of the invention has high degree of automation, low operation cost, small electric energy consumption, convenient maintenance and management and relatively high dedusting efficiency.

Owner:沈阳创思达自动化系统有限公司

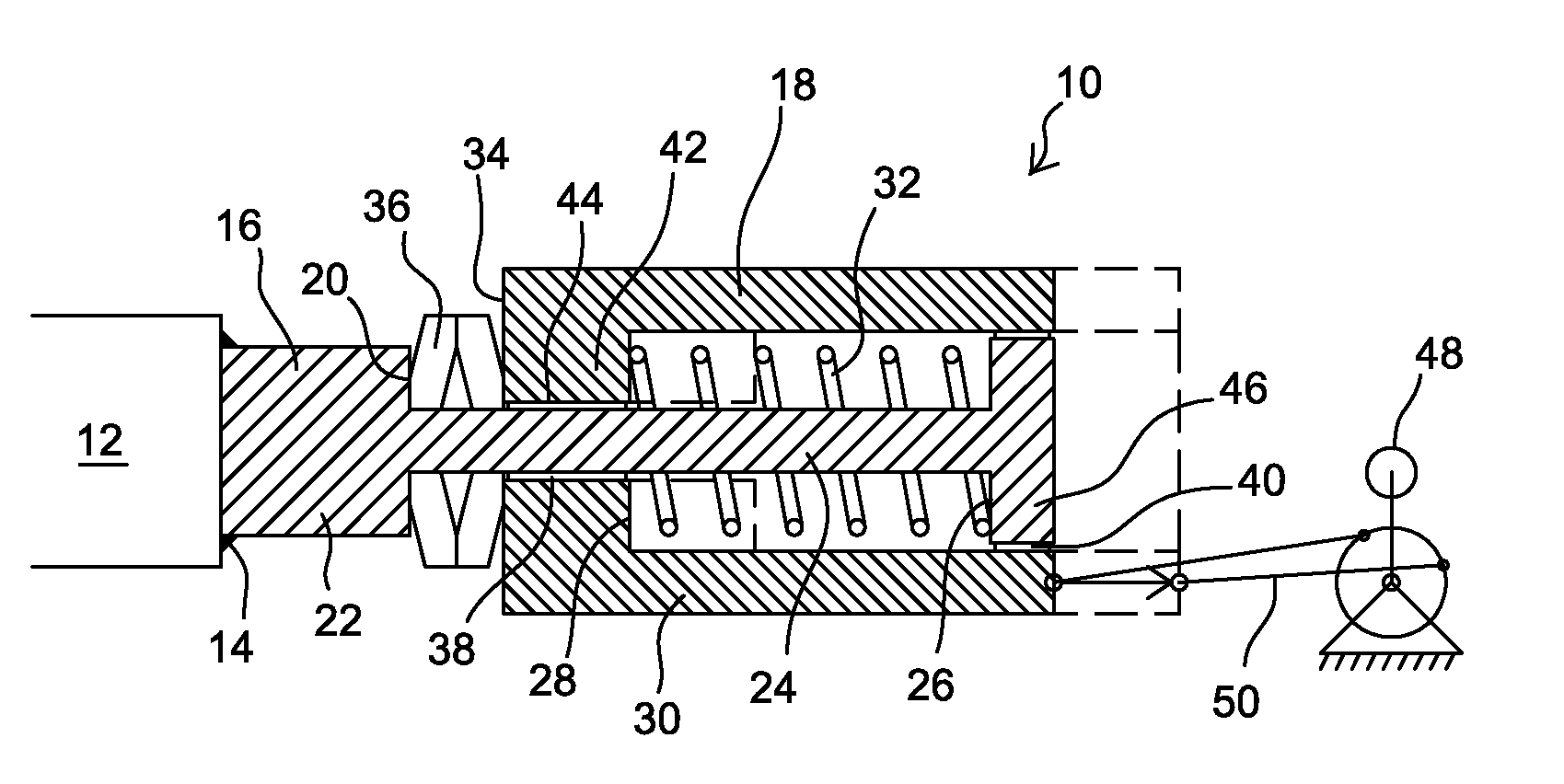

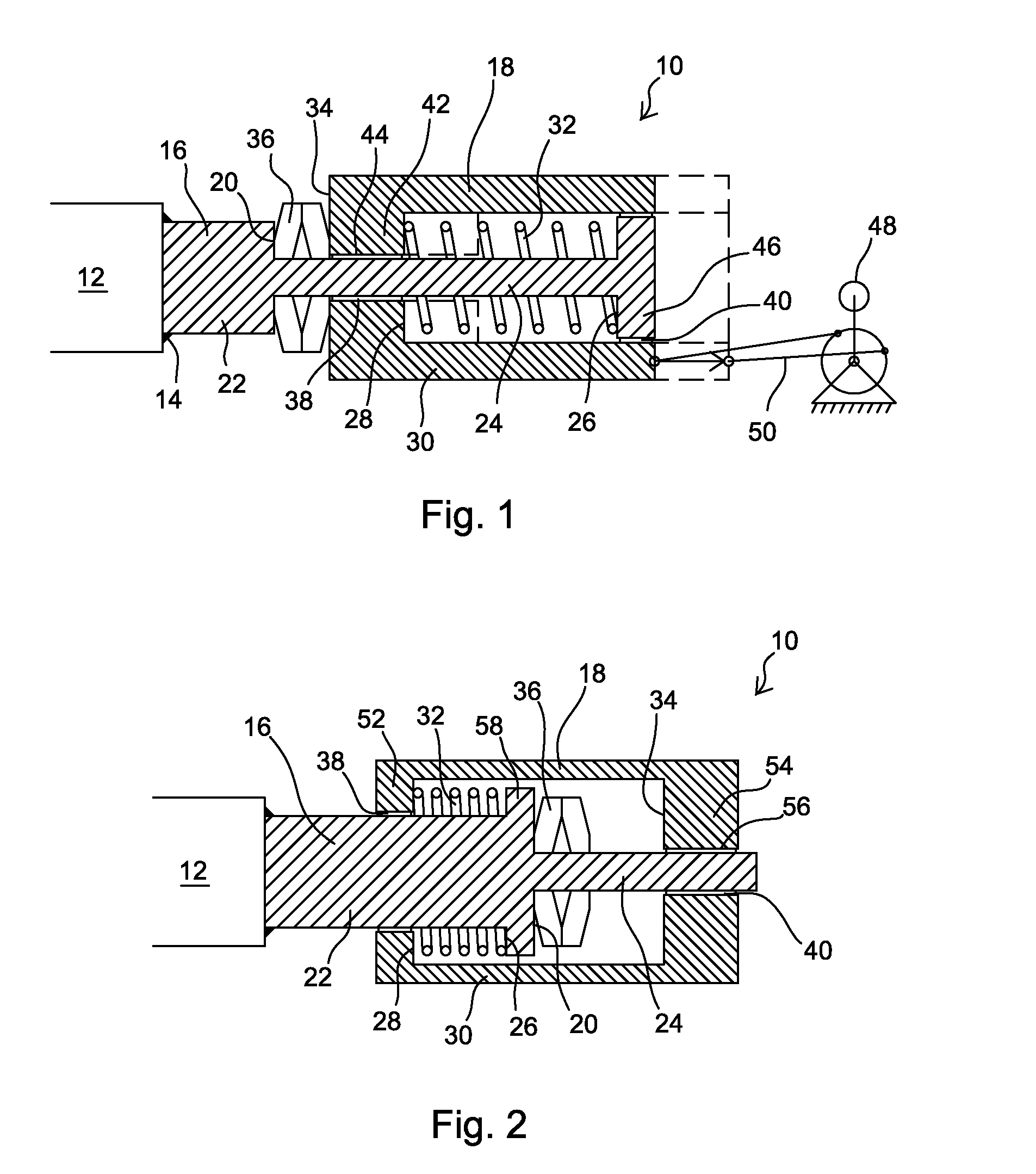

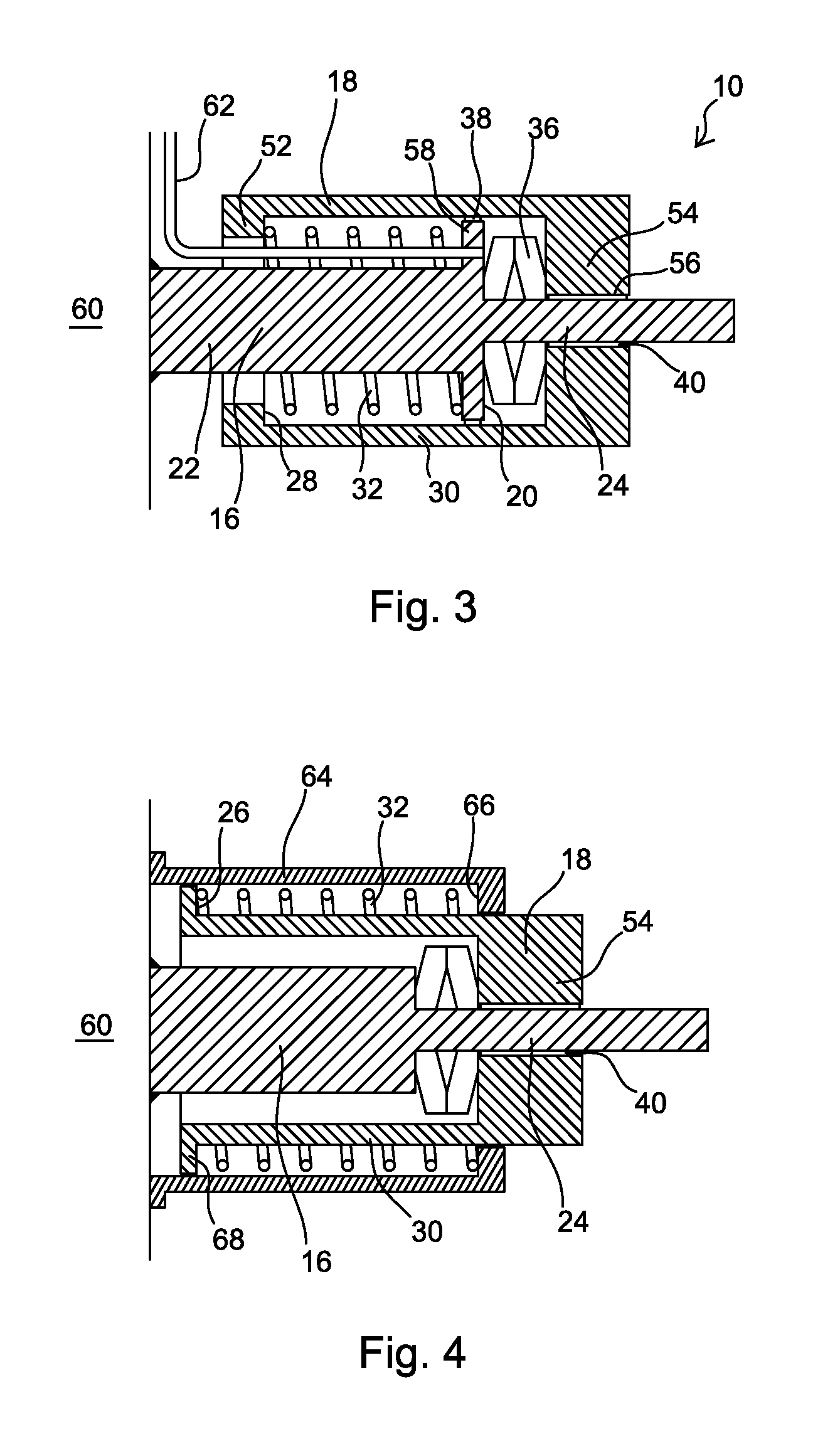

Impact Rapping Device

ActiveUS20100108340A1Prevent movementSimple structureReciprocating drilling machinesConstructionsPhysicsRapping

An impact rapping device includes a stationary anvil integrated with a surface to be rapped, the anvil having a hammering axis perpendicular to the surface to rapped, a hammer arranged to move coaxially with the hammering axis, to hit an impact surface of the anvil, and a device for moving the hammer. The anvil and the hammer form a compact unit, which can be assembled in any position. The hammer is supported to lean on the anvil in such a way that the position of the hammer automatically follows changes of place or position of the anvil, and so that the hammer can move only parallel to the hammering axis.

Owner:FOSTER WHEELER ENERGIA OY

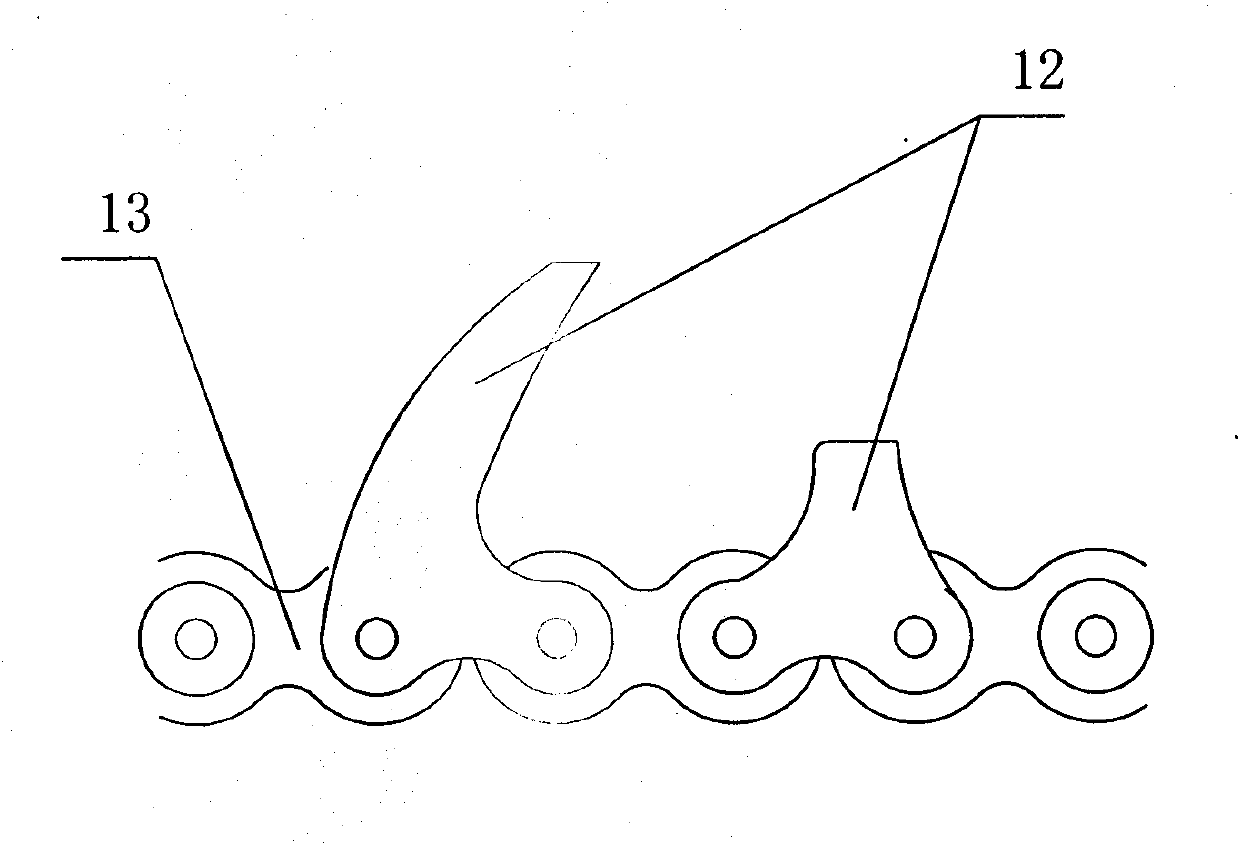

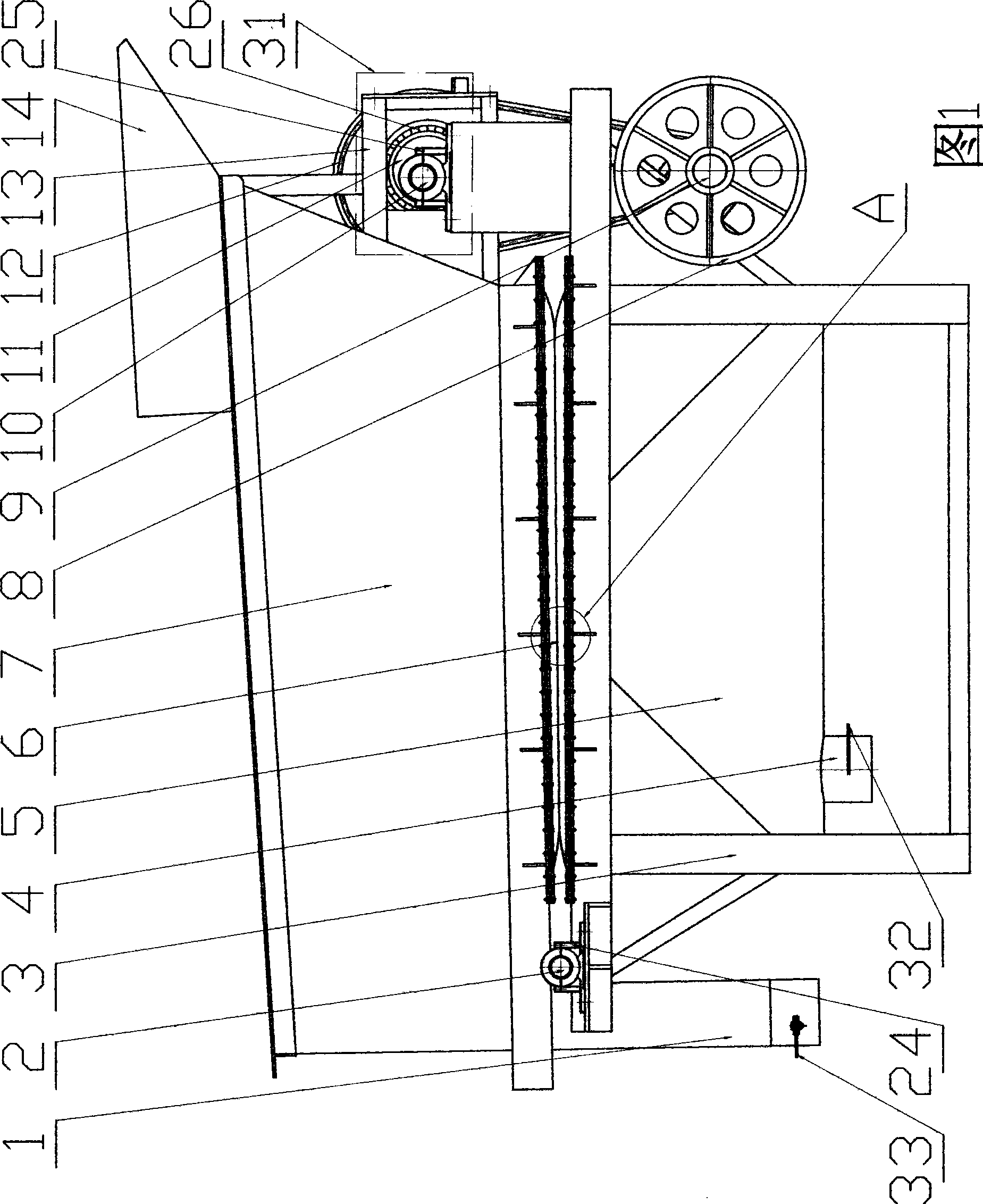

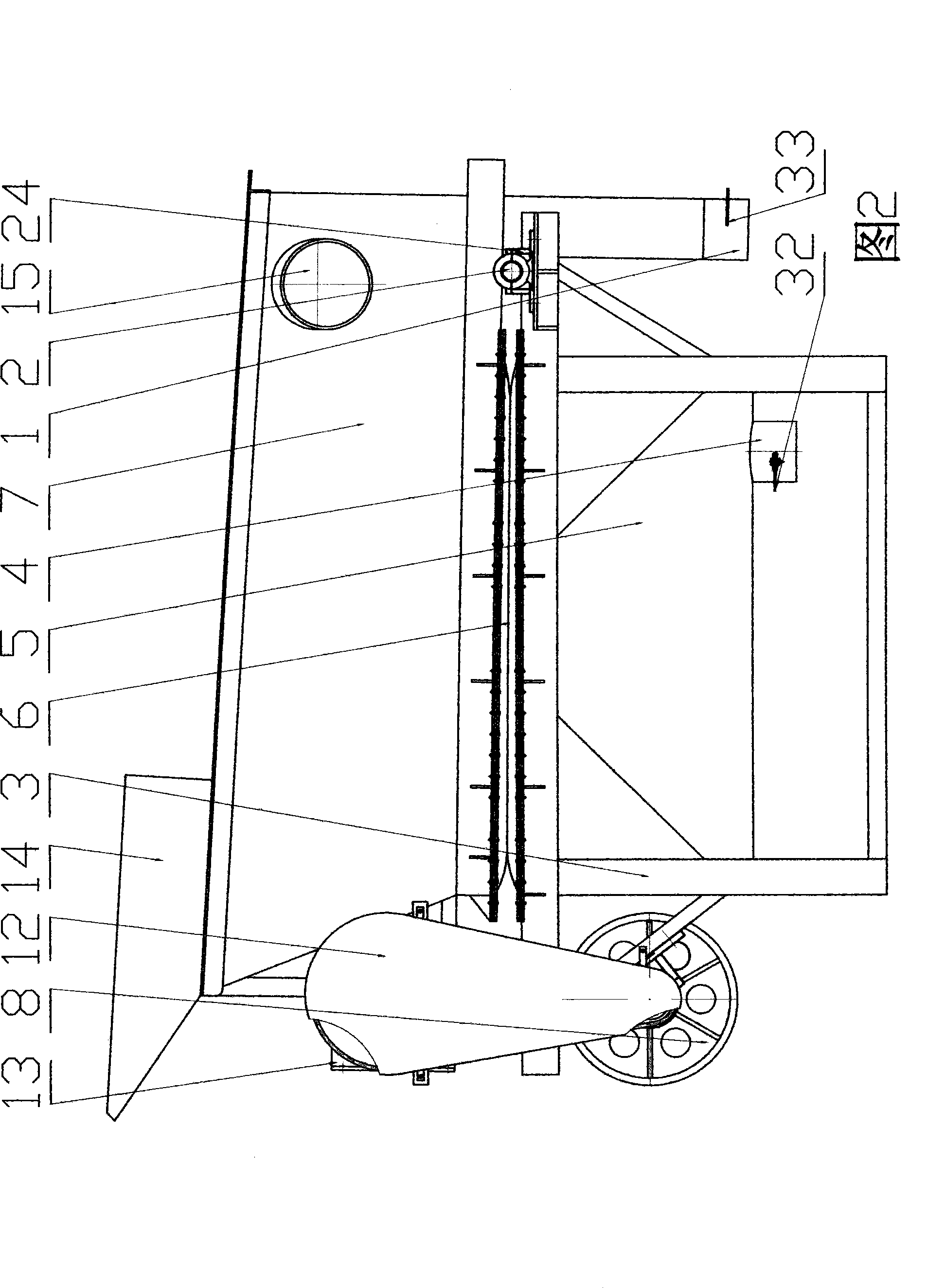

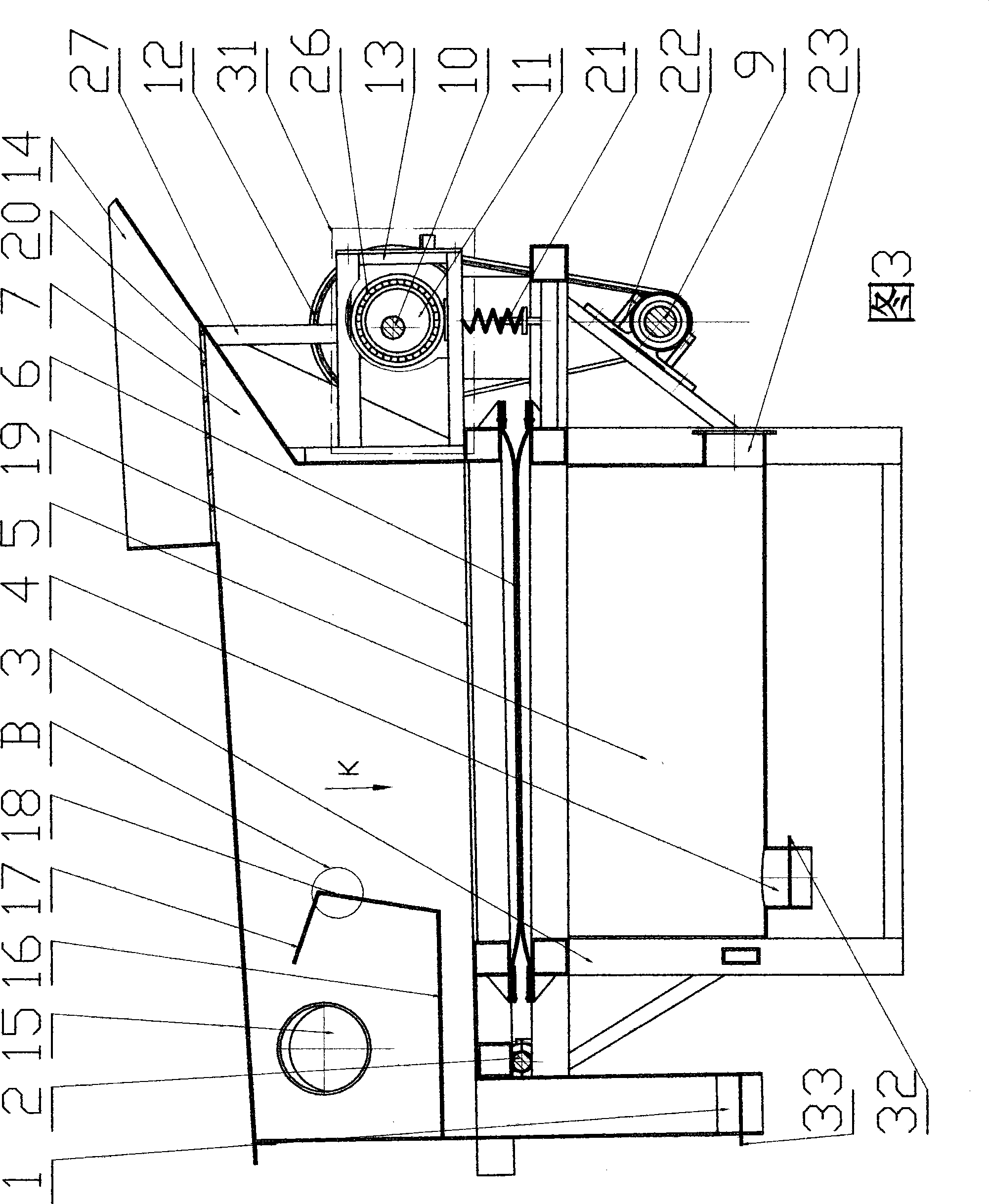

Deposited manganese sheet automatic detachment machine on electrolytic manganese metal negative plate

InactiveCN101906647AEasy Guaranteed KnockbackGuaranteed KnockbackElectrolysis componentsManganeseEngineering

The invention discloses an electrolytic manganese metal automatic detachment machine, which is provided with a plate feeding channel and a plate conveying channel, wherein a vertical plate lifting channel is formed between the plate feeding channel and the plate conveying channel; a knock rapping device is arranged above the plate feeding channel; plate conveying upright plates on two sides of the plate conveying channel are provided with plate conveying chains which are provided with polar plate hook groups; and a main frame below the plate conveying channel is provided with a transmission main shaft, an infrared sensing timing control driving device and a plate feeding and plate conveying driving device. The knock rapping device comprises an eccentric wheel, a tappet and a driving hammer; a kick spring is arranged in front of the driving hammer; a guide rail and a polar plate supporting block are arranged in the plate lifting channel; and a plate dividing wheel and a polar plate receiving and feeding block are arranged between the plate feeding channel and the plate lifting channel. The detachment machine has the advantages of long service life, steady running, environmental protection, flexible control, simple structure, convenient operation, does not damage a plate, has a plate correcting function, and can greatly reduce the production cost of manganese metal and improve the production efficiency.

Owner:HUNAN HONGYANG TECH

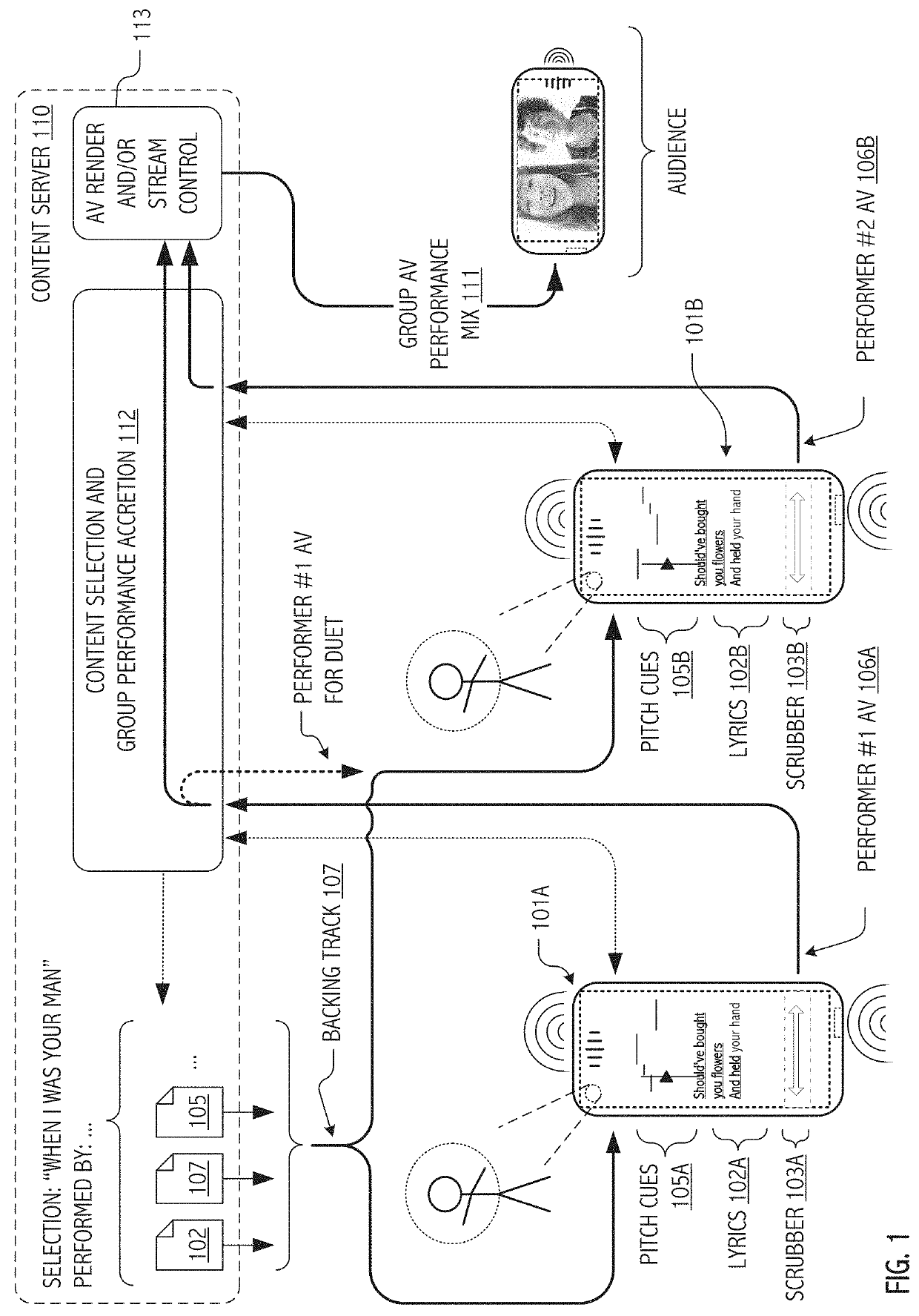

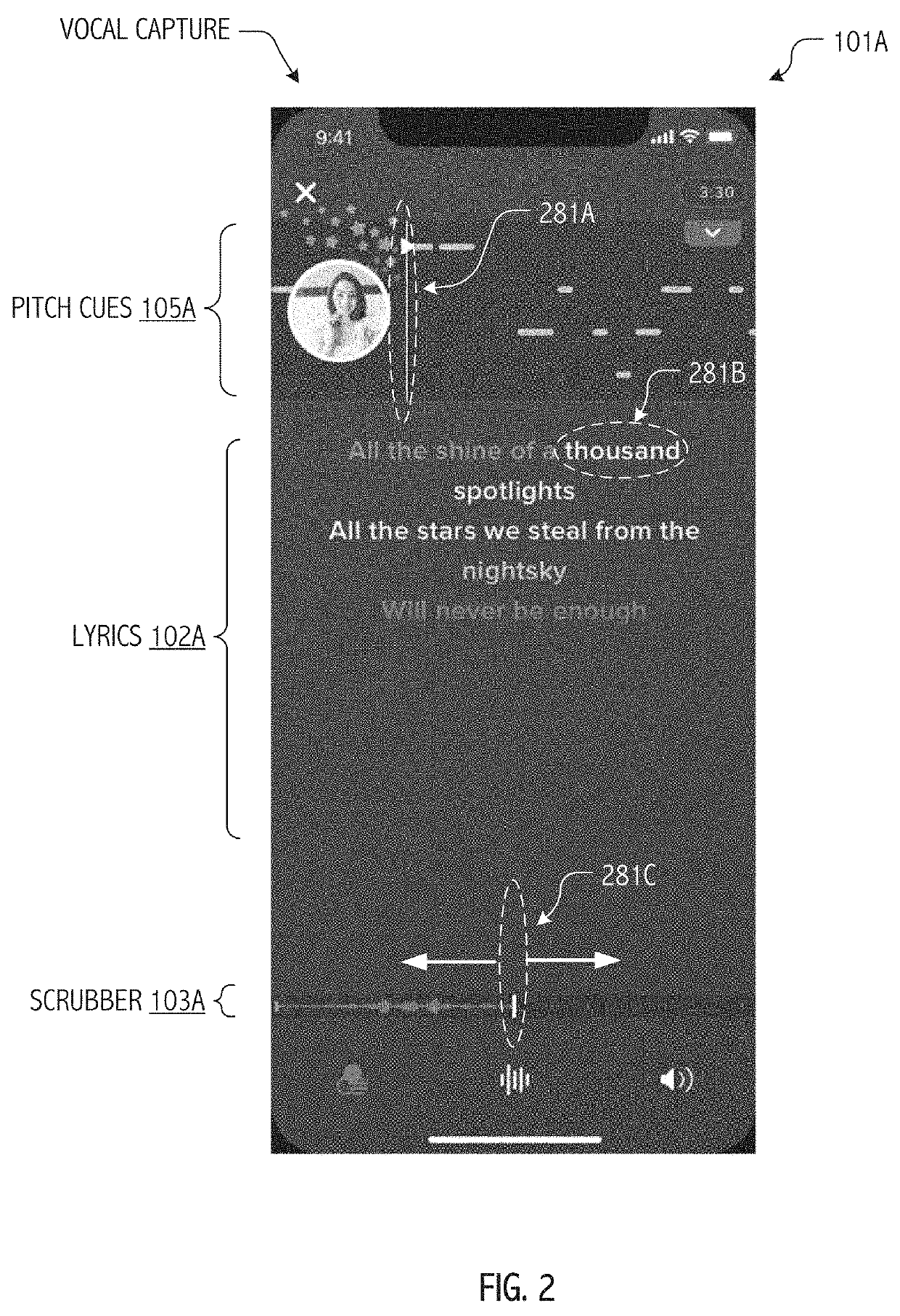

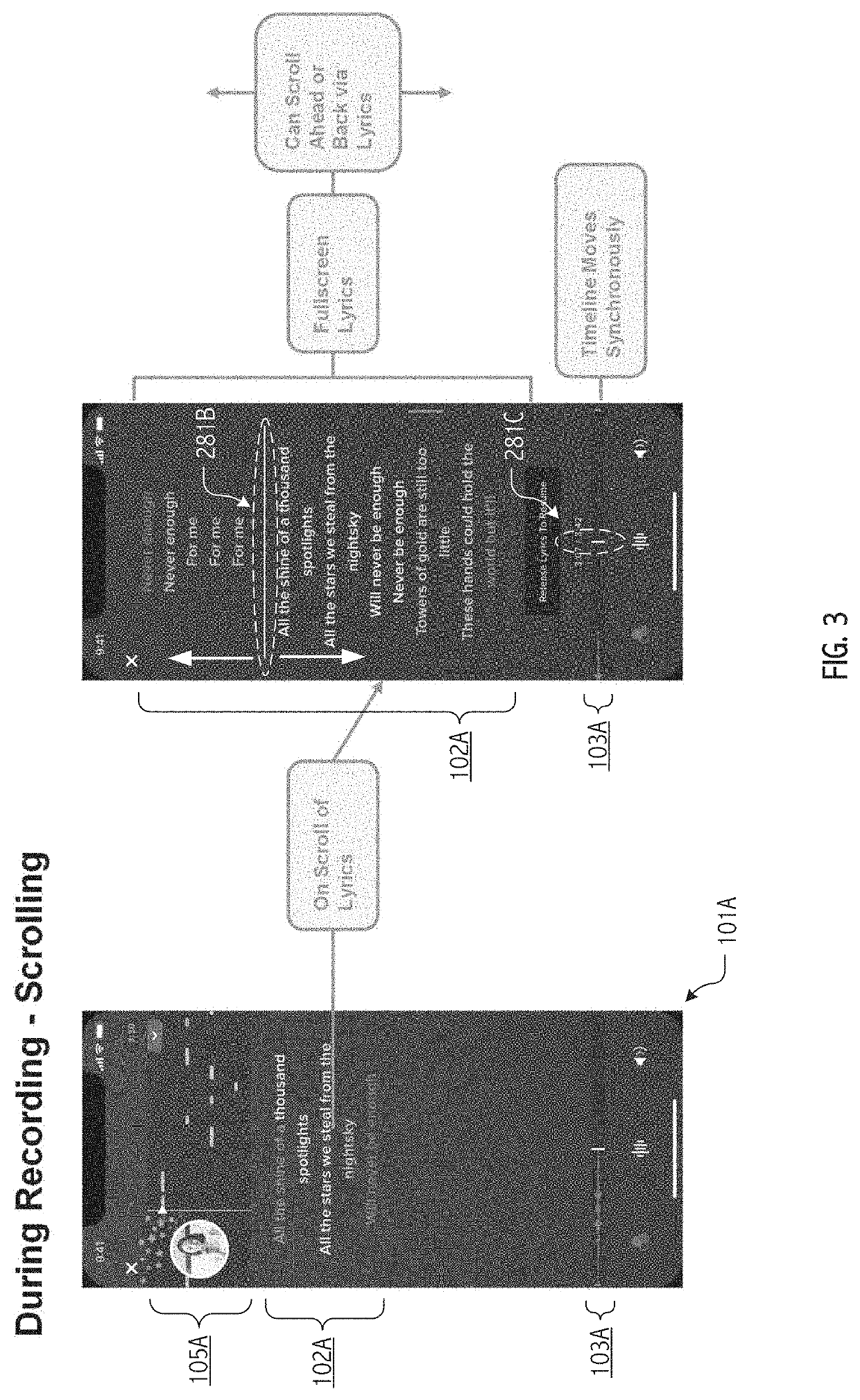

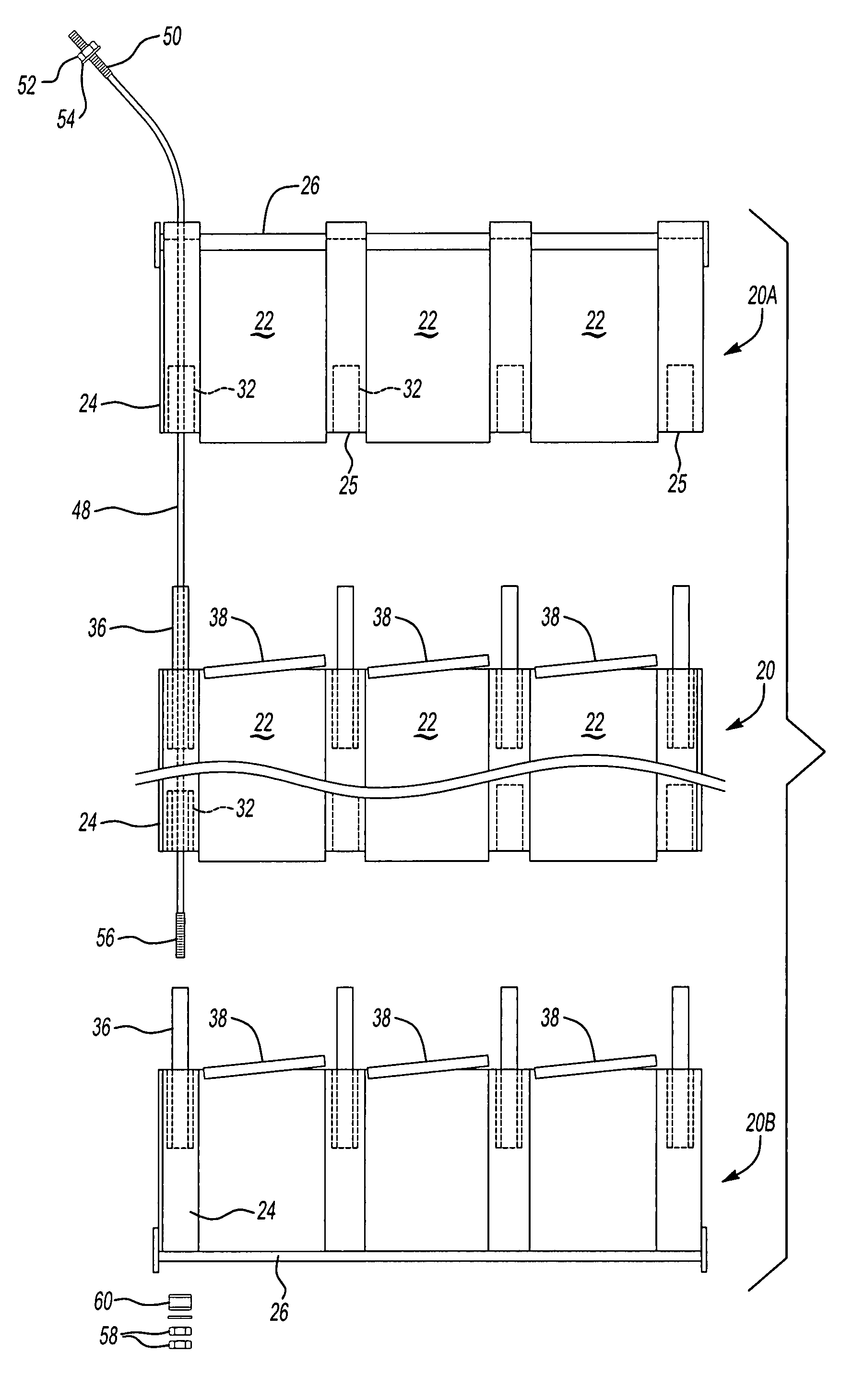

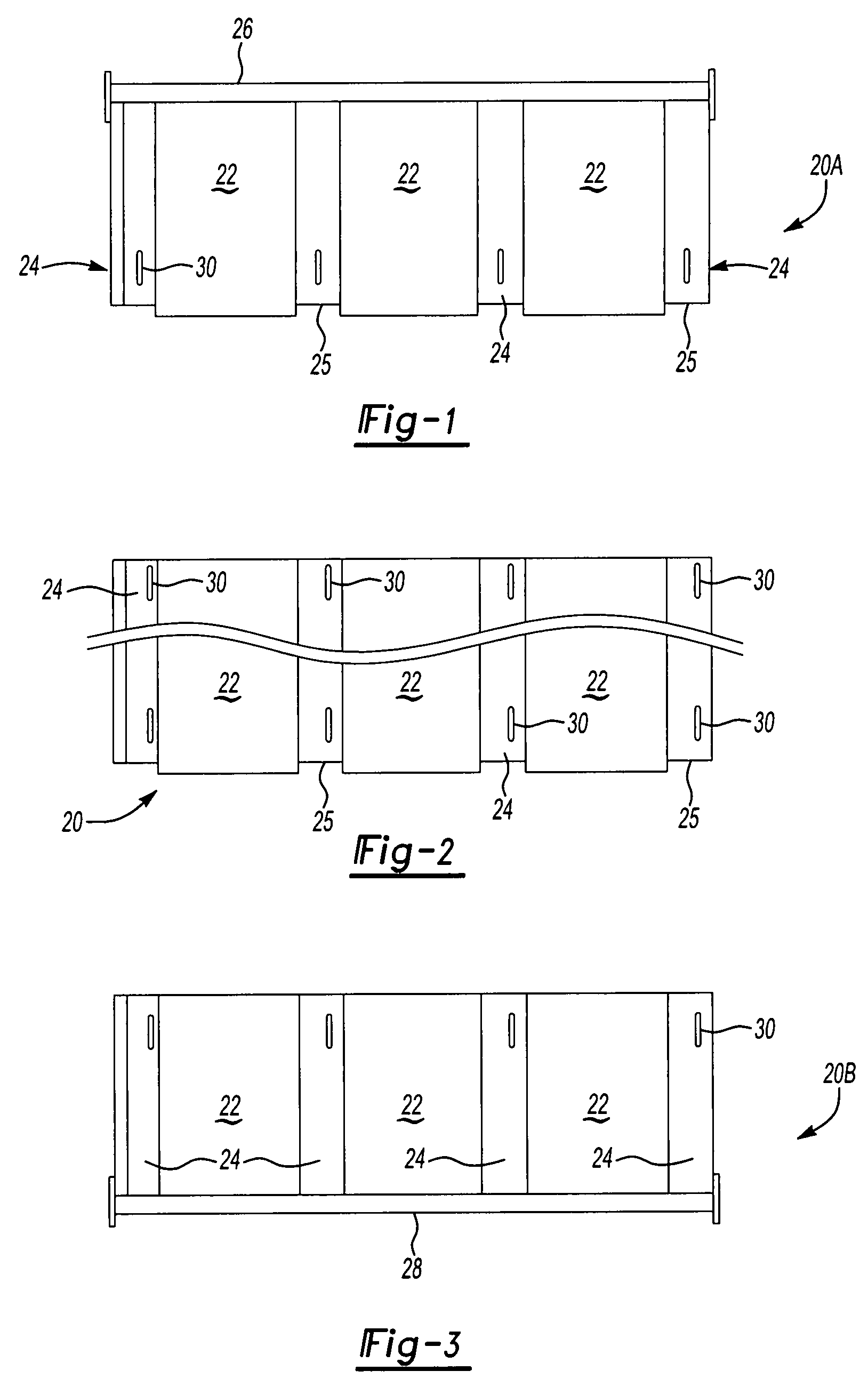

Audiovisual collaboration system and method with seed/join mechanic

ActiveUS20190355336A1Facilitate animationFacilitate display artifactSpecial service provision for substationElectrophonic musical instrumentsSocial mediaSocial network

User interface techniques provide user vocalists with mechanisms for seeding subsequent performances by other users (e.g., joiners). A seed may be a full-length seed spanning much or all of a pre-existing audio (or audiovisual) work and mixing, to seed further contributions of one or more joiners, a user's captured media content for at least some portions of the audio (or audiovisual) work. A short seed may span less than all (and in some cases, much less than all) of the audio (or audiovisual) work. For example, a verse, chorus, refrain, hook or other limited “chunk” of an audio (or audiovisual) work may constitute a seed. A seeding user's call invites other users to join the full-length or short-form seed by singing along, singing a particular vocal part or musical section, singing harmony or other duet part, rapping, talking, clapping, recording video, adding a video clip from camera roll, etc. The resulting group performance, whether full-length or just a chunk, may be posted, livestreamed, or otherwise disseminated in a social network.

Owner:SMULE

Method of estimating the dust load of an esp, and a method and a device of controlling the rapping of an esp

ActiveUS20100037767A1Good removal effectImprove dust removal efficiencyElectrode carrying meansDispersed particle filtrationEngineeringVoltage

A method of controlling the rapping of at least one collecting electrode plate (30) of an electrostatic precipitator (1) comprises applying, by means of a power source (32), a voltage between said at least one collecting electrode plate (30) and at least one discharge electrode (28), measuring the sparking rate between said at least one collecting electrode plate (30) and said at least one discharge electrode (28), and controlling, using the measured present sparking rate, the rapping of said at least one collecting electrode plate (30).

Owner:ANDRITZ AB

Combined type electric deduster

InactiveCN102343308AElimination of Heteropolar Pitch VariationsAvoid falling accidentsElectrode carrying meansElectrostatic separation housingCorona dischargeEngineering

The existing electric deduster at home and abroad has the defects that a design structure is reasonable; faults are produced frequently; and especially, heteropole separation distance errors are difficult to be controlled in installation construction and thus the heteropole separation distance errors largely exceed the standard frequently so that applied secondary voltage is greatly insufficient and it is influenced that dedusting efficiency reaches the standard. Aiming at the defects, the invention provides a combined type electric deduster. The combined type electric deduster is a combined type dust collecting device. A corona discharging pole wire and an anode plate are assembled accurately outside a box body of the combined type electric deduster and then internal parts of the combined type electric deduster are installed. Therefore, assembling errors can be limited to a minimal value; an anode plate dust collecting area is greatly improved simultaneously; a complex cathode wire framework suspension installation system and a complex cathode rapping ash removal device are left out so that sources of faults produced frequently are eliminated; and smoke dust emission concentration of the combined type electric deduster is reduced a value of 1 to 0mg / Nm<3>. The technology of the combined type electric deduster is suitable for large, middle and small electric dedusters.

Owner:SHENYANG LONGDA ENVIRONMENTAL PROTECTION

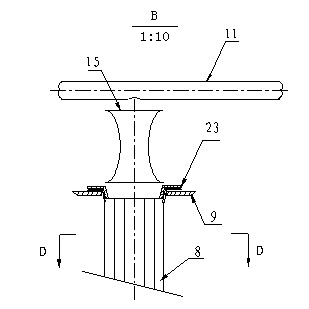

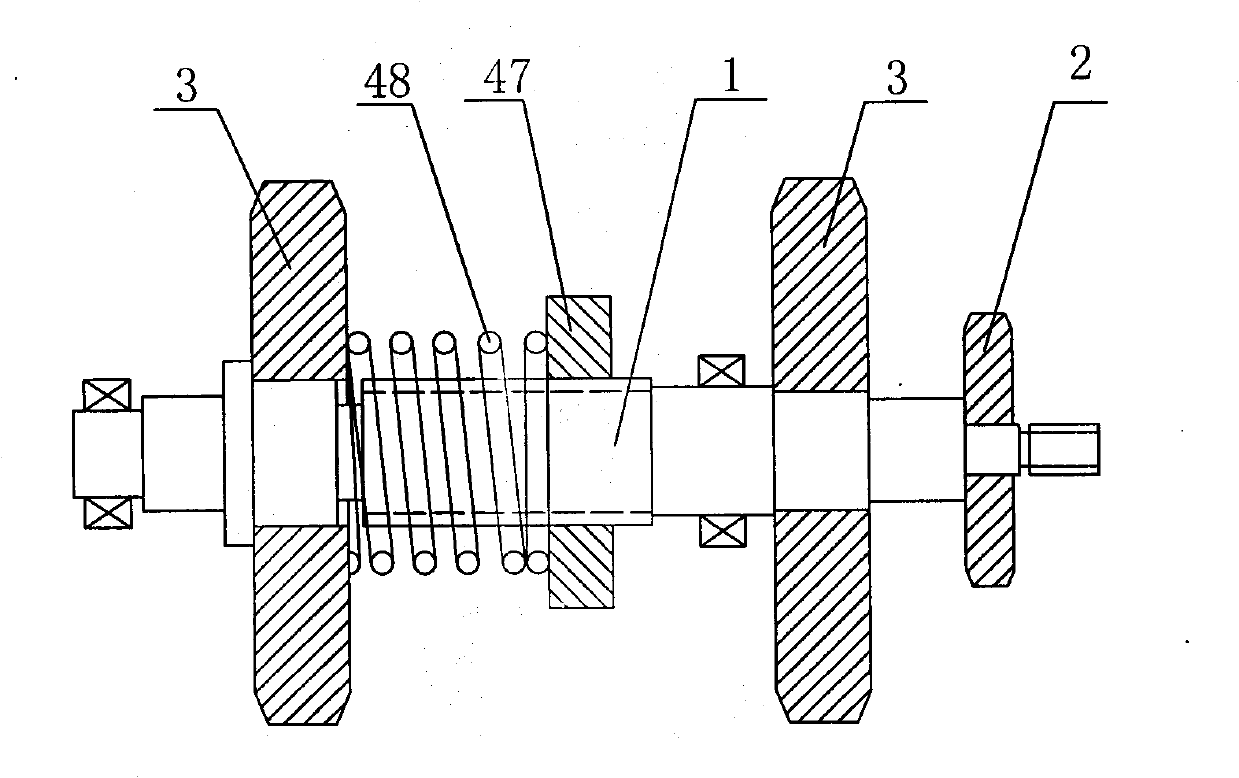

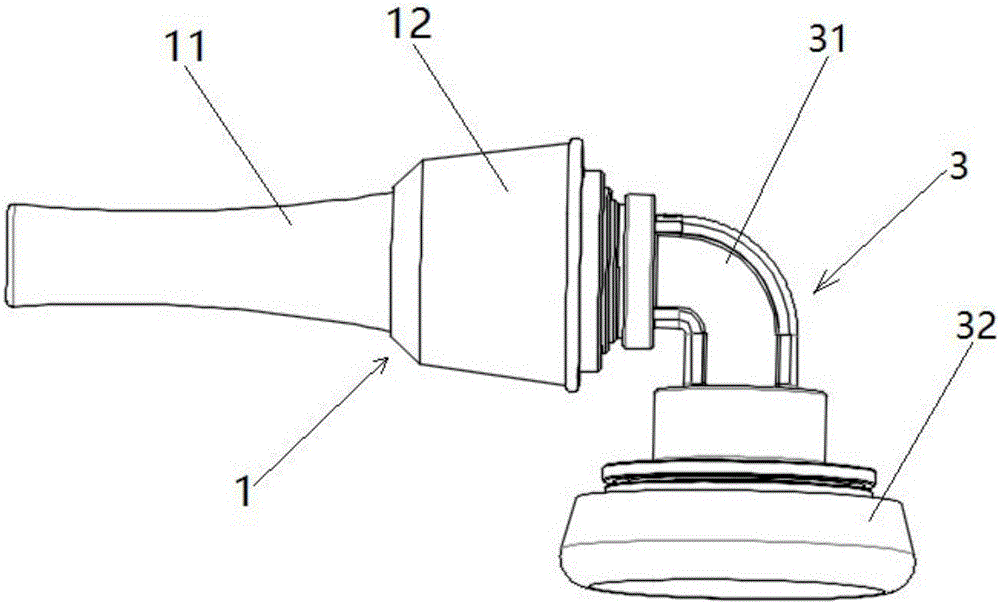

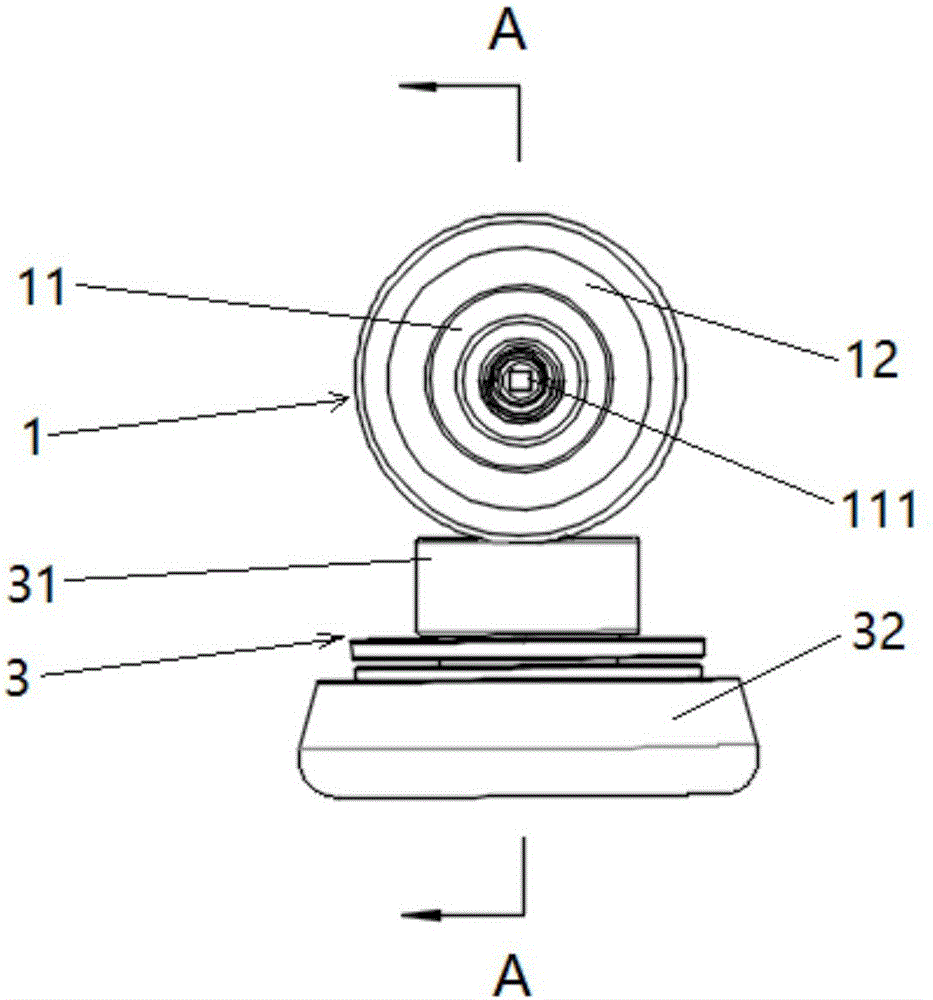

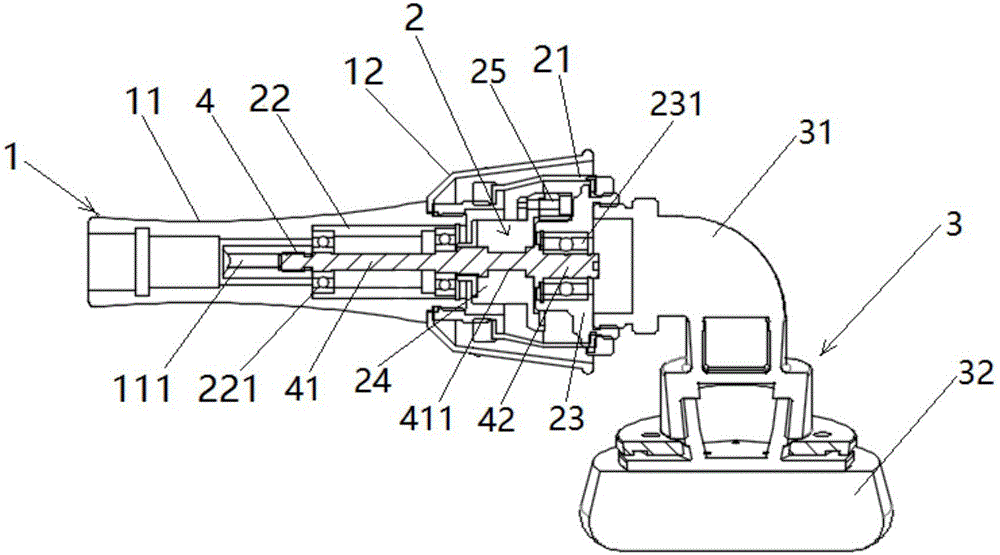

Treatment head of vibration sputum elimination machine

The invention relates to a treatment head of a vibration sputum elimination machine. The treatment head comprises a handle, a transmission assembly and a treatment head body, wherein the transmission assembly is arranged inside the handle; the treatment head body is rotationally connected with one end of the transmission assembly; the transmission assembly comprises a sleeve, a bearing seat, a first bearing arranged in the sleeve, a second bearing arranged on the bearing seat and an eccentric shaft; the eccentric shaft comprises a connecting rod and an eccentric rod arranged at one end of the connecting rod; the first bearing is arranged on the connecting rod in a sleeving way; the second bearing is arranged on the eccentric rod in a sleeving way; the treatment head body is of a bent structure; one end of the treatment head body is fixedly connected with the bearing seat. The treatment head of the vibration sputum elimination machine has the advantages that through the eccentric shaft, the rotation of a motor is transferred to the treatment head body, so that the treatment head body generates eccentric movement; the eccentric movement in the horizontal direction is converted into rapping in the vertical direction through a bent head; the structure is simple; the use is convenient; a better treatment effect is achieved.

Owner:NANJING LEJI MEDICAL EQUIP CO LTD

Cleaning device for automobile spare part manufacturing mold

InactiveCN108015032AEasy to cleanImprove work efficiencyTransportation and packagingRotary stirring mixersEngineeringMaterial resources

The invention discloses a cleaning device for an automobile spare part manufacturing mold, and relates to the technical field of automobile spare parts. The cleaning device comprises a box body. A transmission device is arranged at the top of an inner cavity of the box body. A rotating rod penetrates through the bottom of the transmission device. A supporting plate is arranged at the bottom end ofthe rotating rod. An electric telescopic rod is arranged at the bottom of the supporting plate. A connecting plate is arranged at the bottom end of the electric telescopic rod. According to the cleaning device for the automobile spare part manufacturing mold, the transmission device is arranged, the cleaning effect of the cleaning device is greatly improved, and therefore working efficiency of the cleaning device is also improved and manpower and material resources are saved; due to arrangement of a rapping device and the electric telescopic rod, molds of any specification can be cleaned, andthe using effect requirements of users are met; and due to arrangement of a first motor, a stirring shaft, mixing rods, a material pipe, a second water spraying head and timing valves, unnecessary economic losses are avoided, and the working efficiency of the cleaning device is improved indirectly.

Owner:曹诗晴

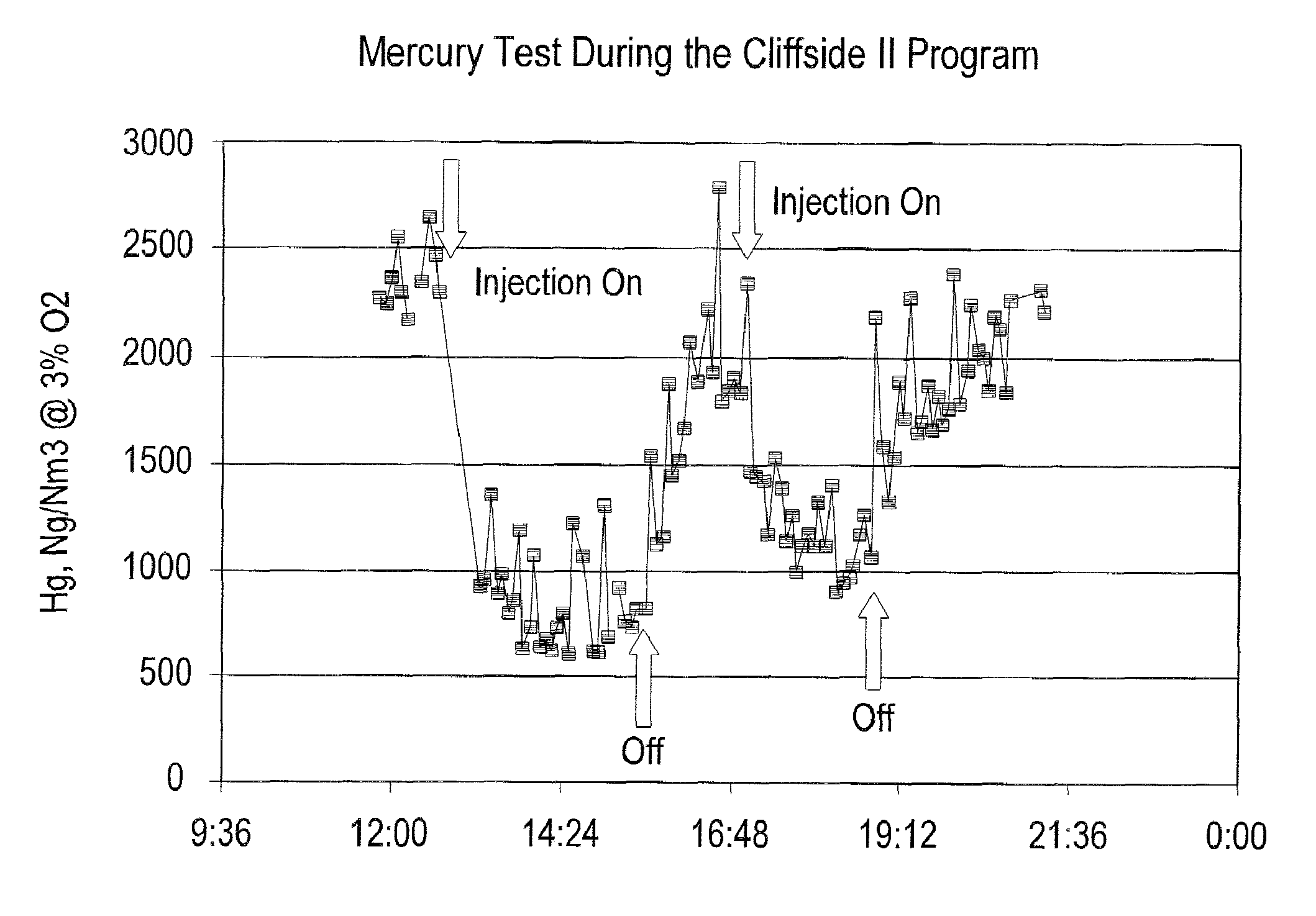

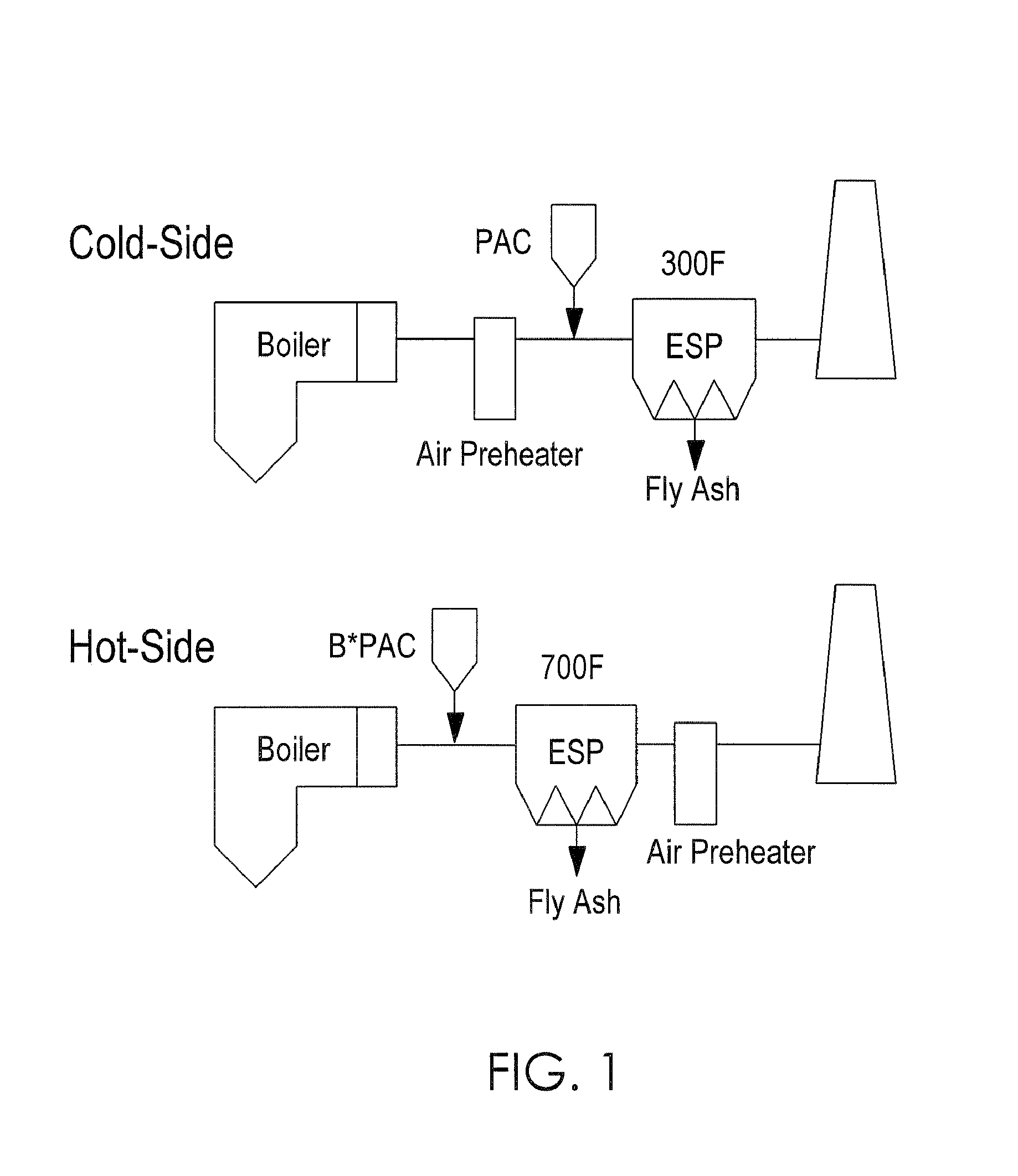

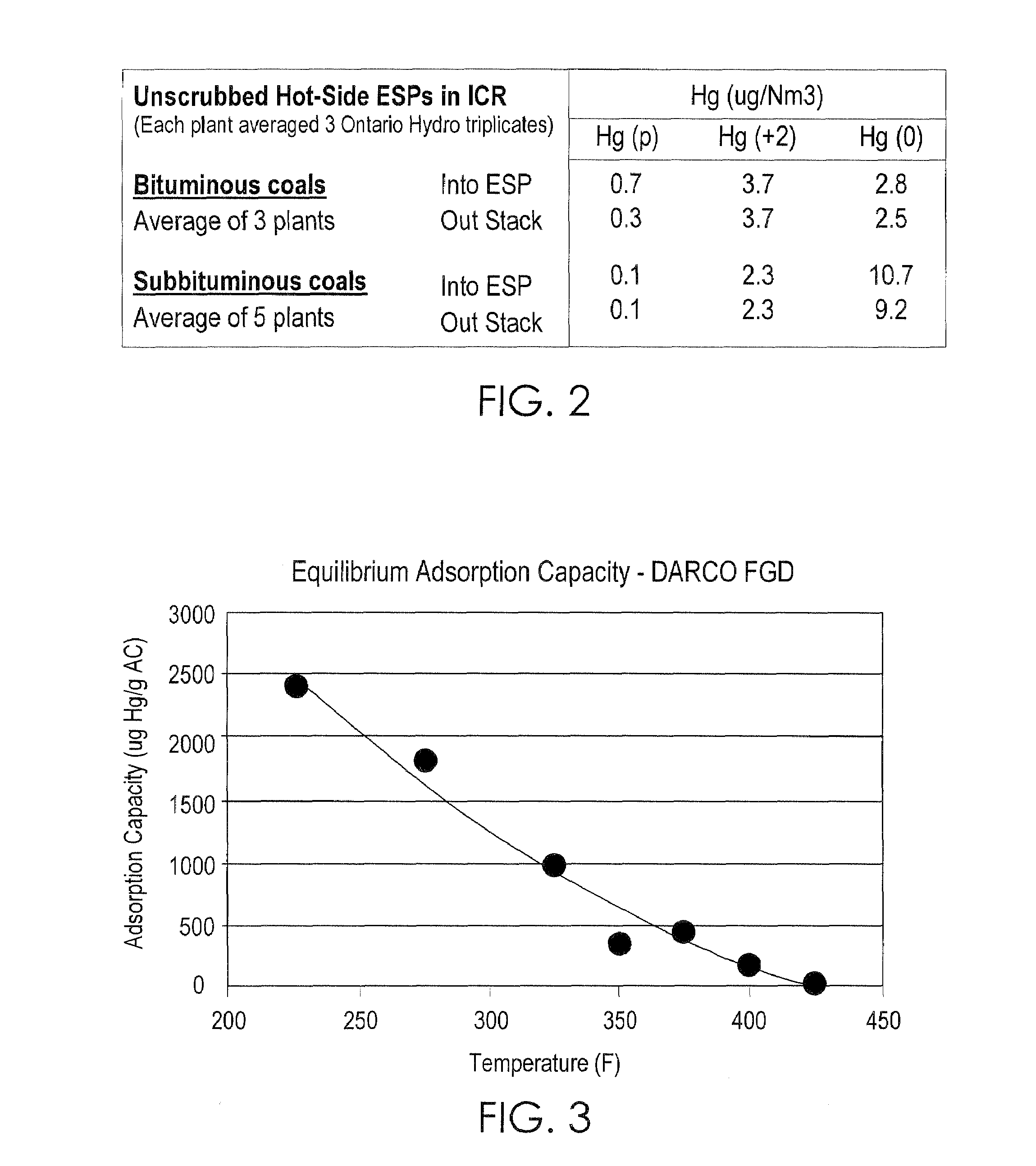

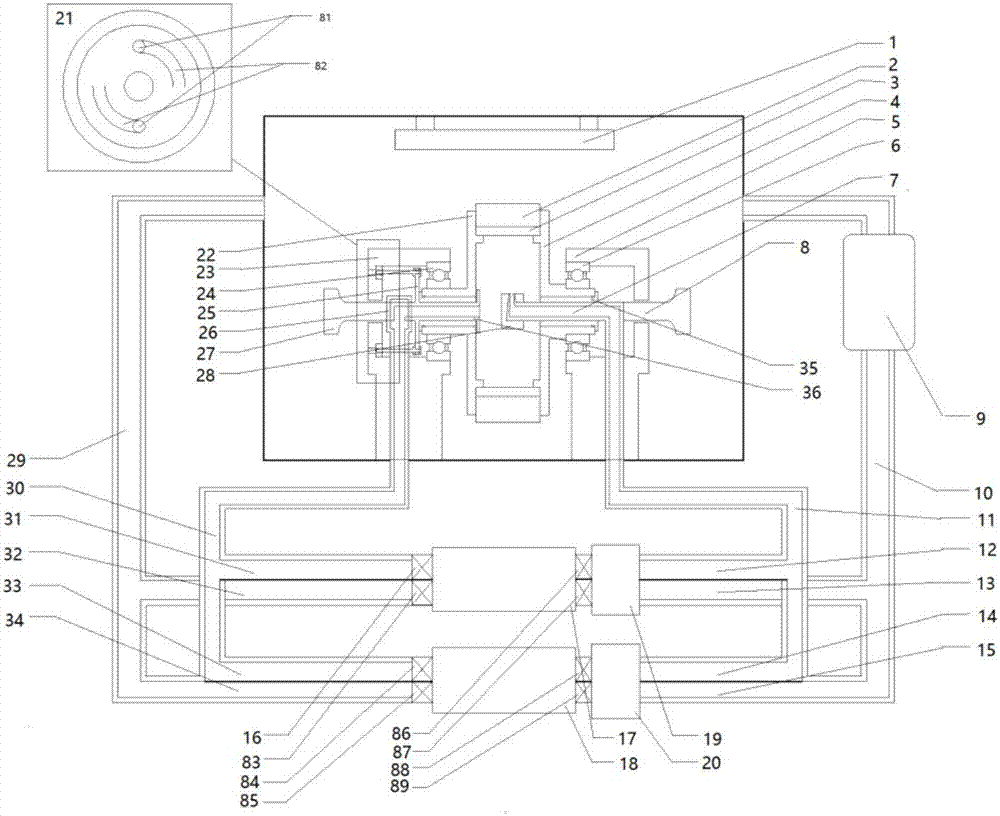

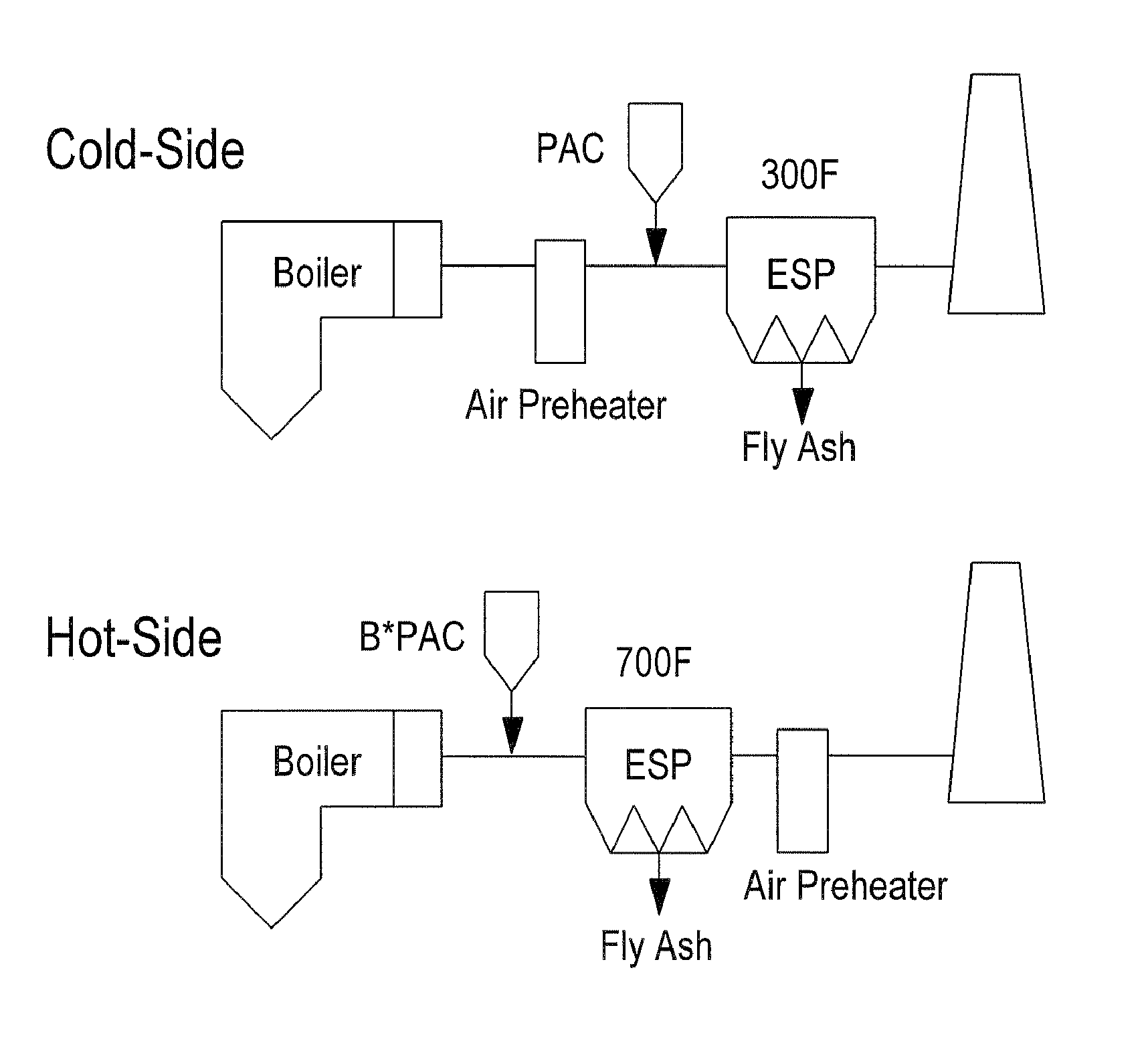

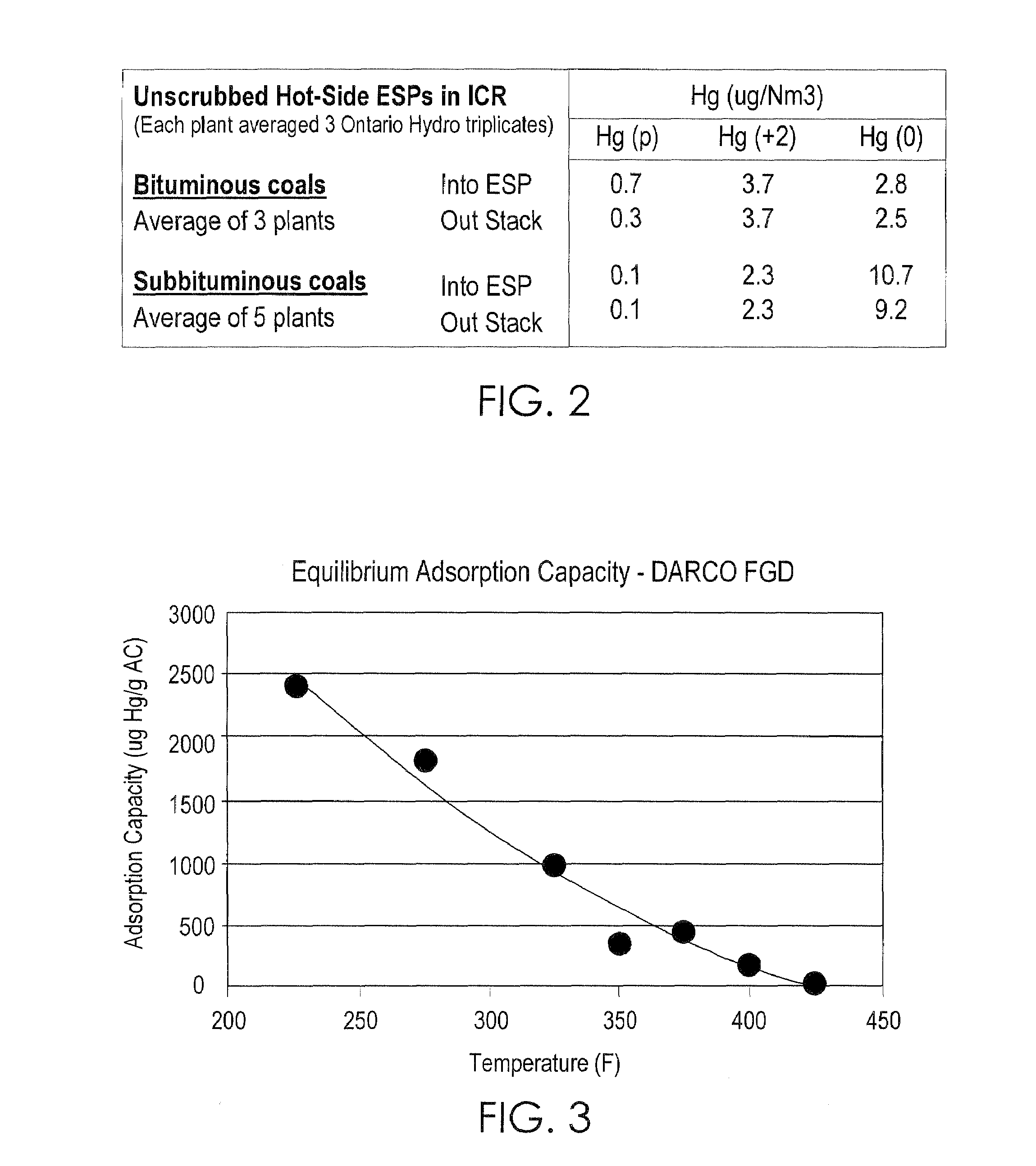

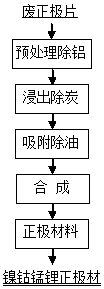

Methods and sorbents for utilizing a hot-side electrostatic precipitator for removal of mercury from combustion gases

Methods are provided for reducing emission of mercury from a gas stream by treating the gas with carbonaceous mercury sorbent particles to reduce the mercury content of the gas; collecting the carbonaceous mercury sorbent particles on collection plates of a hot-side ESP; periodically rapping the collection plates to release a substantial portion of the collected carbonaceous mercury sorbent particles into hoppers; and periodically emptying the hoppers, wherein such rapping and emptying are done at rates such that less than 70% of mercury adsorbed onto the mercury sorbent desorbs from the collected mercury sorbent into the gas stream.

Owner:ALBEMARLE AMENDMENTS LLC

Novel rubber abrasion test machine

ActiveCN107505187AReach the braking effectPrecise regulation of braking forceInvestigating abrasion/wear resistancePositive pressureEngineering

The invention provides a novel rubber abrasion test machine for detecting abrasion performance of rubber. The novel rubber abrasion machine adopts a vertical structure and mainly comprises a base, a chassis, a heat transfer rotating hub, a sand belt, a belt pulley, a friction anvil, a shaft and machine system and a corresponding cooperation device, wherein the cooperation device comprises an aging test system, a chassis internal drying apparatus, a brake system, a control panel, a rapping apparatus, a damping apparatus, a circuit and a temperature control assembly. A rubber wheel test sample is fixed on the heat transfer rotating hub, and the test temperature is controlled by virtue of a refrigerating and heating system and the temperature control assembly; the shaft and machine system control test friction positive pressure and a friction deflection angle; the rapping apparatus realizes silt-free chippings removal; and the damping apparatus, the aging test apparatus, the chassis internal drying apparatus and the brake system are used for more accurately simulating and testing the aging abrasion and the abrasion of the rubber under an actual brake condition.

Owner:QINGDAO UNIV OF SCI & TECH

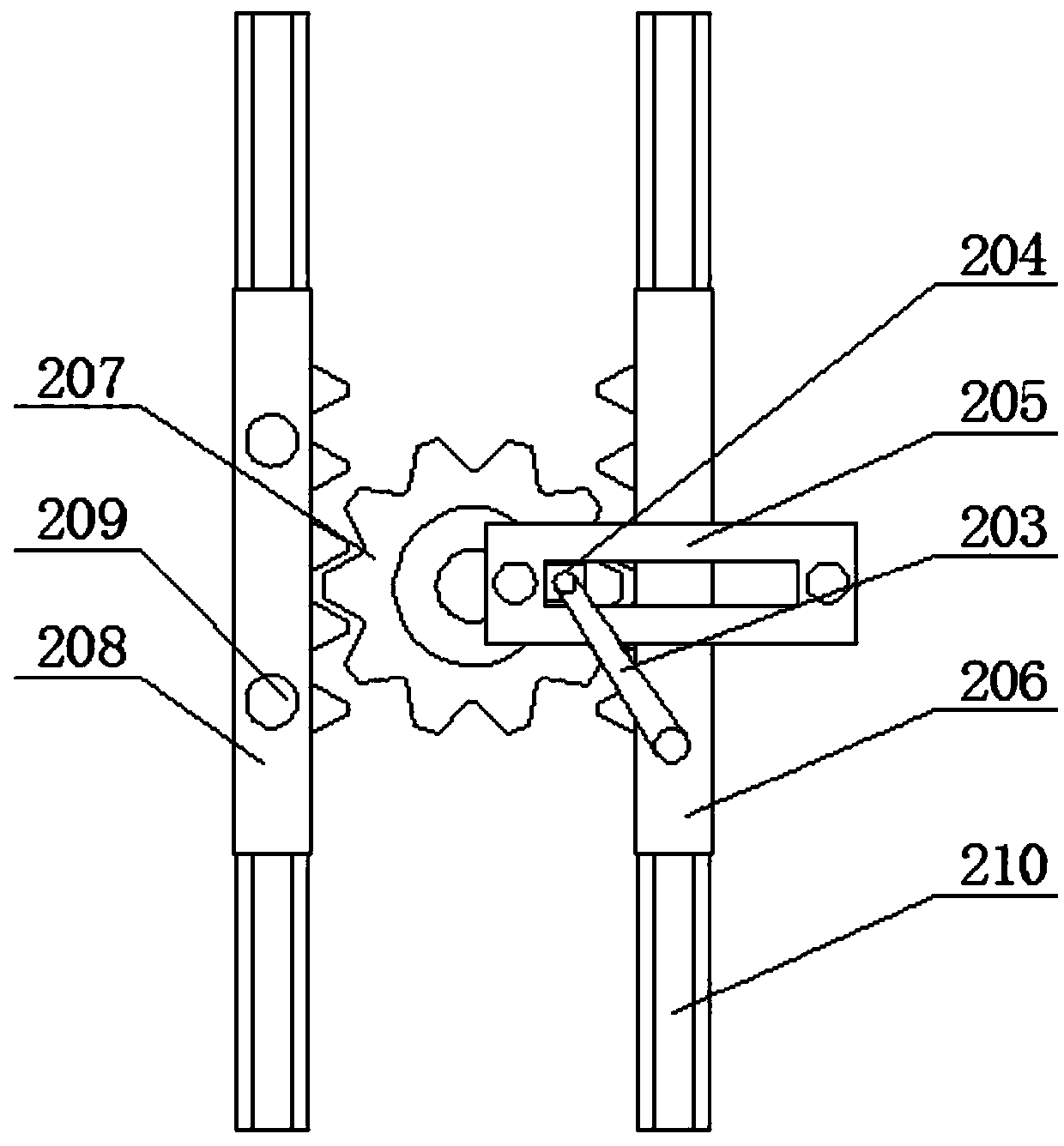

A massage device with multiple professional massage techniques

The invention relates to a massage device, in particular to the massage device with various traditional Chinese massage manipulations, such as kneading, finger rolling, finger pressing, palm kneading, palm pushing, palm pressing, rapping, rolling, vibrating and the like, which belongs to the technical field of massage device structures. The massage device with various traditional Chinese massage manipulations is characterized by mainly comprising a fixed supporting mechanism, a connecting mechanism and a massage execution mechanism and can be used for realizing free conversion between the various traditional Chinese massage manipulations, such as the kneading, the finger rolling, the finger pressing, the palm kneading, the palm pushing, the palm pressing, the rapping, the rolling, the vibrating and the like and various massage manipulations. The various massage manipulations in the invention are realized according to the requirements for the traditional Chinese massage manipulations and meet the requirements for a traditional Chinese massage theory matched with the various massage manipulations.

Owner:SHANDONG KANGTAI INDAL

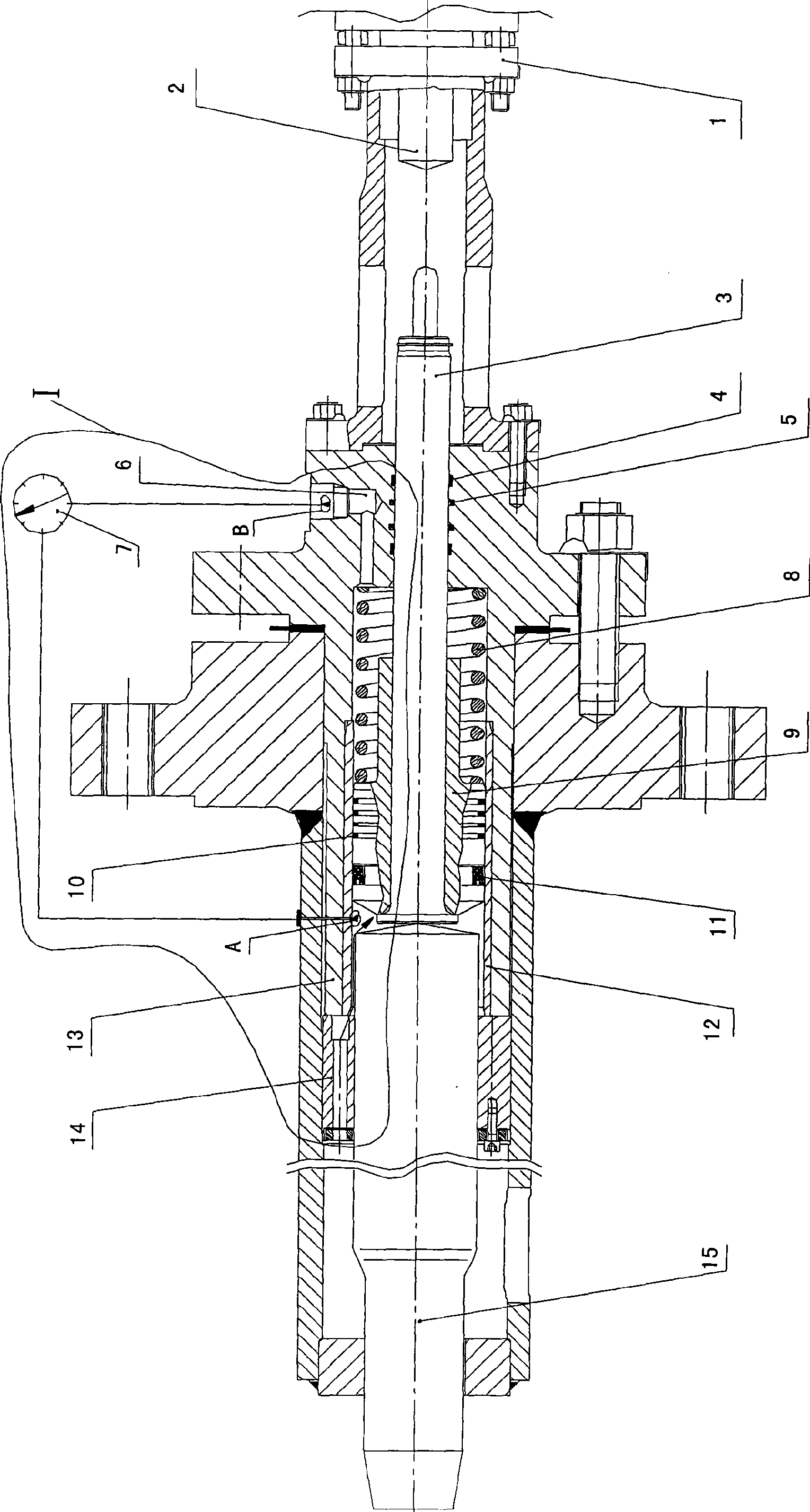

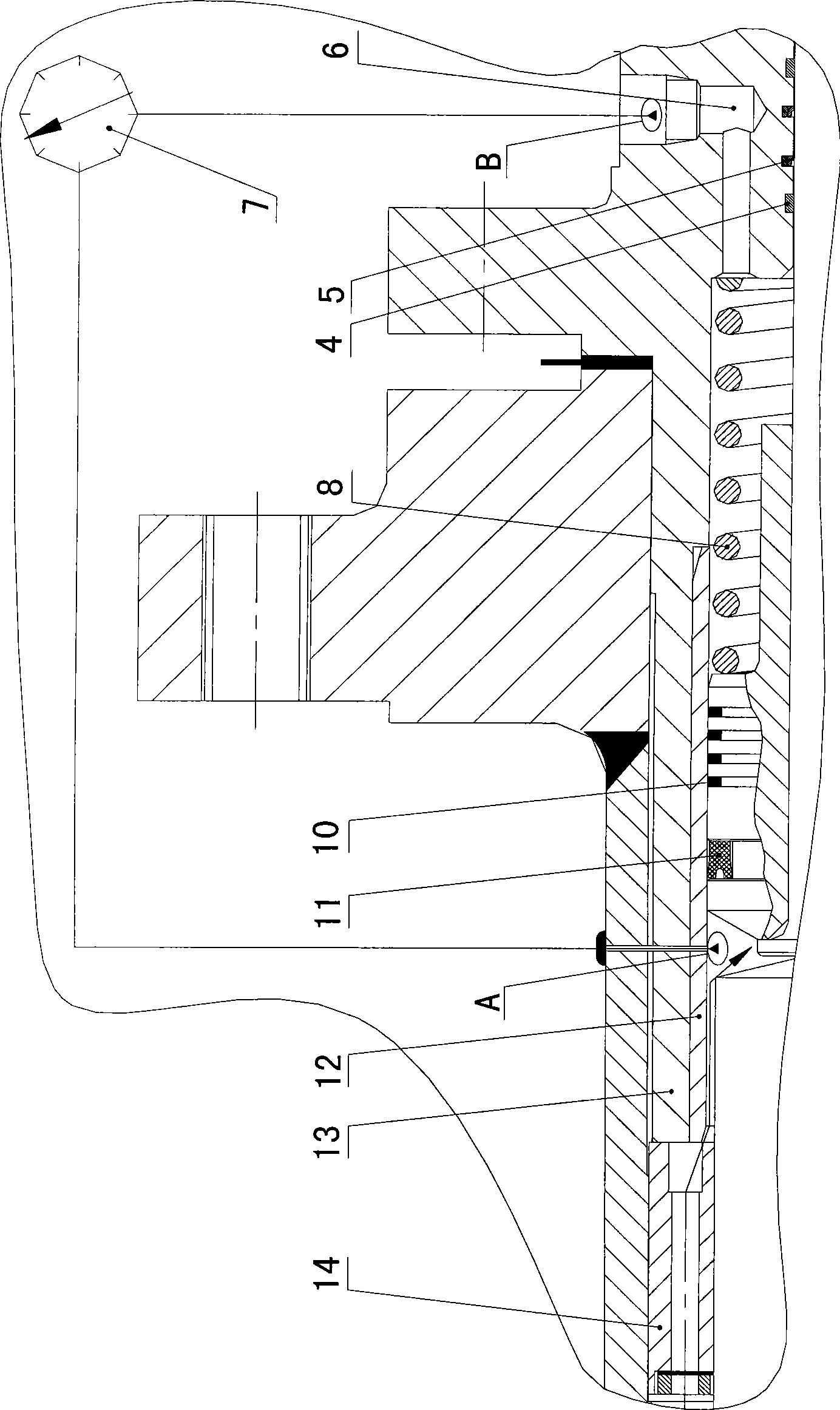

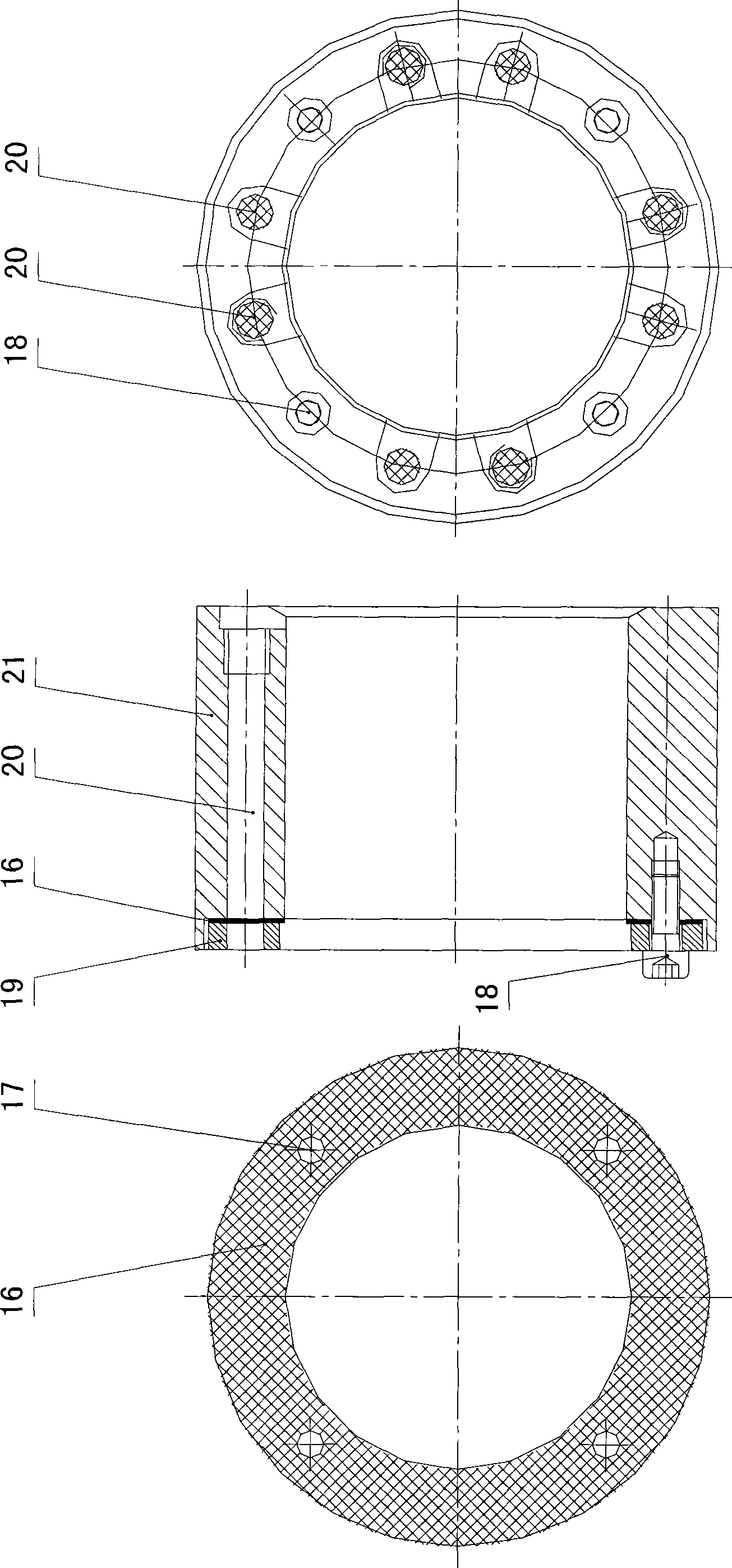

Sealing system of mechanical rapping apparatus

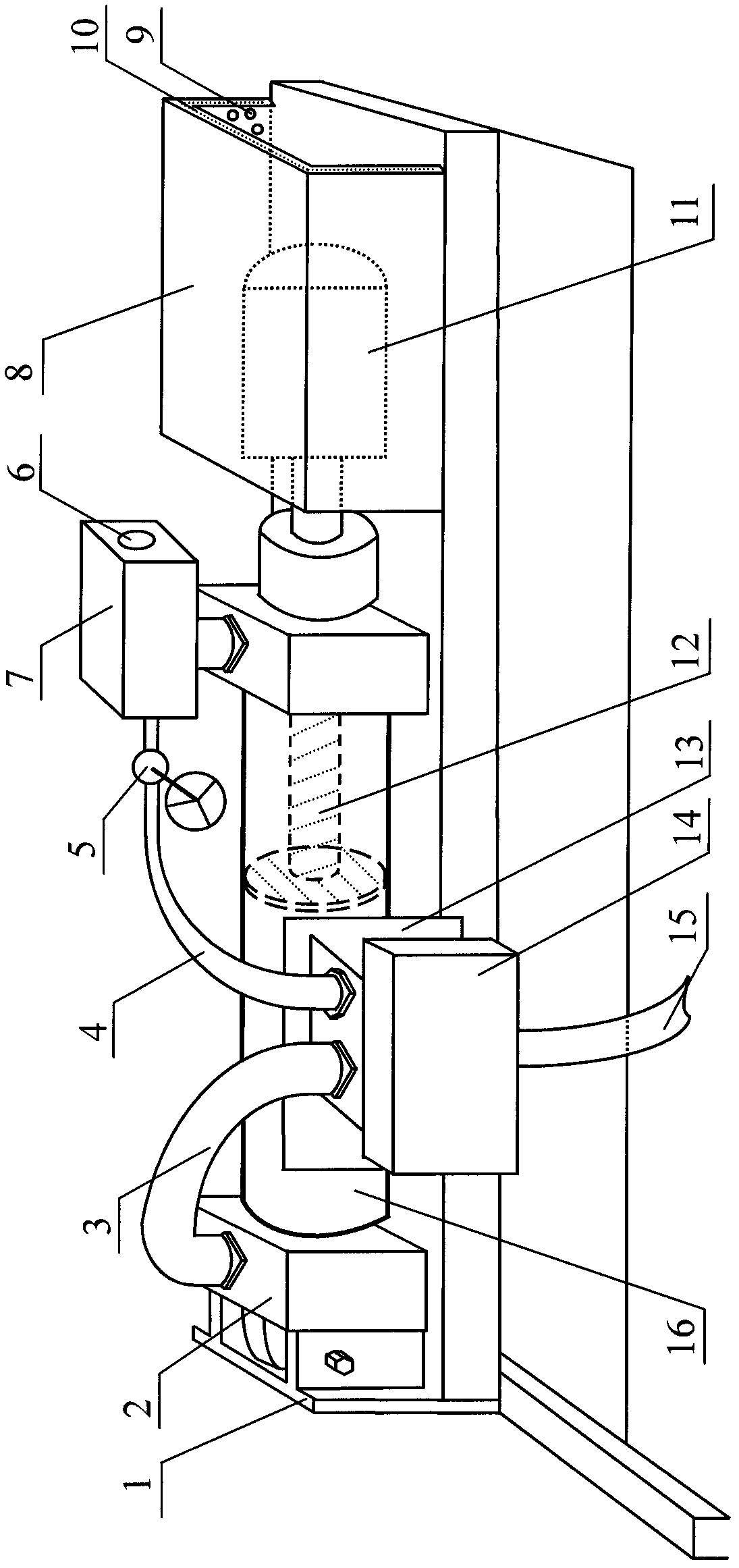

InactiveCN101502828AExtend your lifeImprove reliabilityEngine sealsMechanical vibrations separationPiston ringPiston Guide

The invention discloses a sealing system of a mechanical vibrator, comprising a filter, a sealing ring mounted on a piston close to one end of a trip rod, a piston ring sleeved on the piston, and guide rings mounted on a piston rod close to one end of a cylinder in a piston guide barrel. A gasket is mounted on the piston guide barrel between two guide rings, the piston guide barrel close to a spring base and a guide ring end is provided with a hole. The hole communicates with exterior of the mechanical vibrator and the interior of the piston guide barrel to form an air inlet communicating with an air source. The advantages of the invention are that the working pressure of a sealing element is reduced and frication between the piston rod and the piston position is reduced, as the sealing system of the mechanical vibrator brings in gas sealing; synchronously, the invention further brings in a gas leakage alarm device and monitors the sealing system of the mechanical vibrator in real time. The integral sealing structure of the system is rationally designed and has low cost. The service life of the sealing element is long and the sealing system is used in the working condition that the mechanical vibrator works at high temperature, under high pressure and with dusty medium.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Method of making replacement collecting electrodes for an electrostatic precipitator

InactiveUS7438743B2Improve performanceImprove rigidityElectrode carrying meansGas separationElectrodeRapping

A method of forming a modular collecting electrode for an electrostatic precipitator, including forming a plurality of horizontal collecting electrode sections, each section having vertical planar portions separated by vertical tubular portions, and wherein the method includes inserting interconnecting support elements into the tubular portions of adjacent collector electrode sections and compressing the interconnected electrode sections to form a rigid modular assembly. In one preferred embodiment, the method includes applying stiffening members across the ends of the planar portions of adjacent electrode sections for transmitting rapping forces through the assembled sections.

Owner:HAMON RES COTTRELL

Ore-washing ore processing equipment

InactiveCN101362115ADrum powerEasy to useMechanical vibrations separationWet separationEngineeringEnergy storage

The invention discloses an ore washing and beneficiating machine, which pertains to the field of mining machinery and comprises a frame 3, a water tank 5, a movable washing and beneficiating chamber 7, a power transmitting device 12, a flexible connection device 6, a rapping device 31 and an energy storage device 21. The ore washing and beneficiating machine is characterized by convenient use, high producing efficiency, saving energy, beneficiating coarse ore and fine ore simultaneously, integrating washing and beneficiating and the like; the ore washing and beneficiating machine is applicable to beneficiating various ores in gravity beneficiation and can be widely applied in various mine and operation enterprises as well as smelting enterprises.

Owner:苏乐建

Double-region electrostatic dust collector

ActiveCN103056029AIncrease driving speedThe number of electric fields is smallExternal electric electrostatic seperatorVapor flow controlParticulatesHigh frequency power

The invention discloses a double-region electrostatic dust collector. The double-region electrostatic dust collector comprises a smoke gas inlet part, a labyrinth type gas flow uniform-distribution device, a charged plate, a charged region discharging corona electrode, an I-shaped dust collecting polar plate, a dust collecting corona, a smoke gas outlet part, a shell, an ash bucket, a rapping device, a high-voltage dust collecting power supply and a charged high-voltage and high-frequency power supply, wherein a dust collecting chamber is divided into a charged region and a dust collecting region; a gas flow containing smoke gas enters the charged region via the inlet part and the labyrinth type gas flow uniform-distribution device and then enters the dust collecting region; and after being purified, the smoke gas flow is fed into a smoke window for exhaustion via the outlet part; after the charged region and the dust collecting region are respectively supplied with high voltages, a large amount of ions and electrons are generated through corona discharge of the charged region, so that the passed particles are substantially provided with saturated charges; in the dust collecting region, the transverse I-shaped polar plate is used for depositing the charged particles on the polar plate by means of comprehensive action of an electrostatic force and an inertia force; and through rapping dust into the ash bucket, the smoke gas containing dust is purified.

Owner:浙江欧托电气有限公司

Cabin storage discharging device for riprap boat

InactiveCN1775621AEasy to unload stoneReduce labor intensityCargo handling apparatusPassenger handling apparatusLocking mechanismShallow sea

The invention relates to a cabin stored stone unloading device for a stone rip-rapping ship, especially applied to carrying stones to fill the sea to compose seafood breeding reefs in deep and shallow sea area, characterized in arranging a square open stone storage cabin whose stone outlet is small and top mouth is big, the cabin bottom is provided with stone outlet, the cabin bottom under the stone outlet is hinged with single-fan or double-fan outlet door through loose-leaf, corresponding to the opening position of the outlet door, symmetrically arranging an outlet door opening and closing mechanism on deck, which is composed of steel wire rope, drum, through shaft, reduction box, chain drive, notch wheel, pawl, and clutch rocking handle (or additional sliding steel wire rope and pulley block), corresponding to the middle under the outlet door, arranging an outlet door locking mechanism on deck, which is composed of locking plate, trapezoidal threaded rod, upper and lower nut sleeves, protective sleeve and crank. The invention replaces human labor with mechanisms to discharge stones, saving labor and time, safe and largely reducing labor strength and remarkably raising productivity and increasing economic benefits.

Owner:王心斌

Methods and sorbents for utilizing a hot-side electrostatic precipitator for removal of mercury from combustion gases

Methods are provided for reducing emission of mercury from a gas stream by treating the gas with carbonaceous mercury sorbent particles to reduce the mercury content of the gas; collecting the carbonaceous mercury sorbent particles on collection plates of a hot-side ESP; periodically rapping the collection plates to release a substantial portion of the collected carbonaceous mercury sorbent particles into hoppers; and periodically emptying the hoppers, wherein such rapping and emptying are done at rates such that less than 70% of mercury adsorbed onto the mercury sorbent desorbs from the collected mercury sorbent into the gas stream.

Owner:ALBEMARLE AMENDMENTS LLC

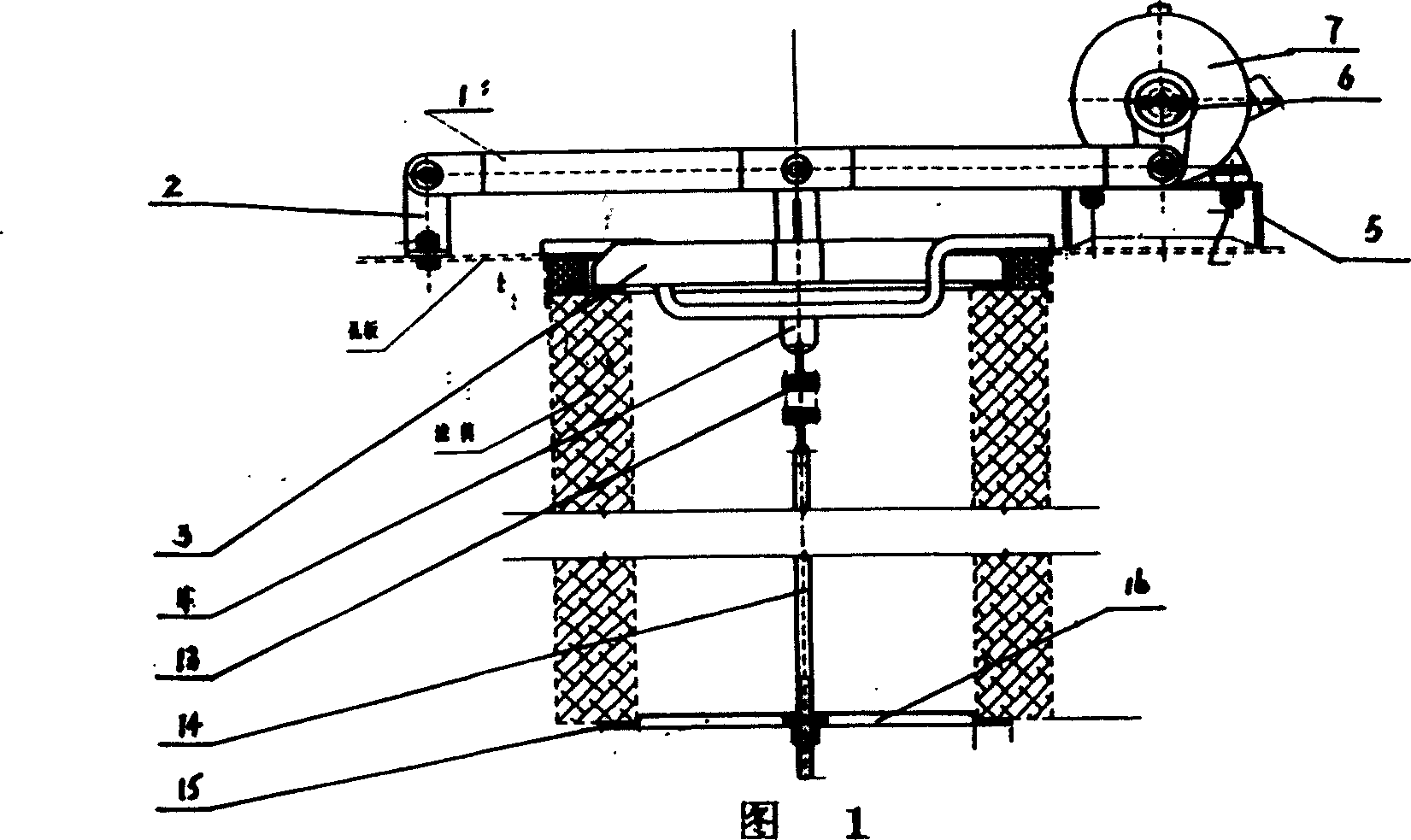

Comprehensive recovery method of waste lithium battery positive electrode piece

InactiveCN110144461AEasy to recycleAvoid pollutionCell electrodesWaste accumulators reclaimingRecovery methodSlag

The invention discloses a comprehensive recovery method of a waste lithium battery positive electrode piece. The method comprises the steps that a positive electrode leftover material and a wasted positive electrode piece are placed into a vacuum furnace to be calcinated, rapping and screening are conducted to obtain a positive active substance, the positive electrode active material is added to asulphuric acid leaching solution, second-stage leaching is conducted, and leached slag carbon and the leaching solution containing nickel, cobalt, manganese and lithium; activated carbon is added tothe leaching solution to perform adsorption deoiling and silica removing, nickel carbonate, cobalt carbonate, manganese carbonate or lithium carbonate is replenished to the filtered residue to obtainprecursors, ball milling, sintering, pulverizing, grinding and mesh screening are conducted on the precursors, and a nickel-cobalt-manganese-acid-lithium positive electrode material is obtained. The method has the advantages that the technology is reasonable, the separation cost is low, and there exists no pollution, toxin or harm.

Owner:ZHUZHOU SMELTER GRP

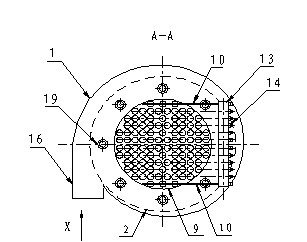

Shaking and deashing mechanism special for filtering cartridge type dedusting and purifying equipment

InactiveCN1544121AGuaranteed instant reproducibilityExtended service lifeDispersed particle filtrationEngineeringElectric motor

The invention relates to a special rapping dust-cleaning mechanism for filter tube dust-cleaning purification device, composed of positioning pin, link rod, eccentric mechanism, rapping press frame and electric motor, where the eccentric mechanism is driven by the electric motor, one end of the link rod is pinned with the drive plate in the eccentric mechanism and the other one with the positioning pin, and the straight plate in the rapping press frame cooperates with the rapping block in the middle part of the link rod by intermittently colliding. Its advantages: 1, adopting eccentric mechanism as the kernel of rapping dust-cleaning mechanism, so that not only the structure is novel, particular and simple but also the rapping effect completely remarkable, ensuring the instantaneous reappearance of the filter tube; 2, not only having dust-cleaning effect and long service life of the filter tube, but also reducing working noise.

Owner:NANFANG ENVIRONMENT PURIFYING EQUIP HANGZHOU

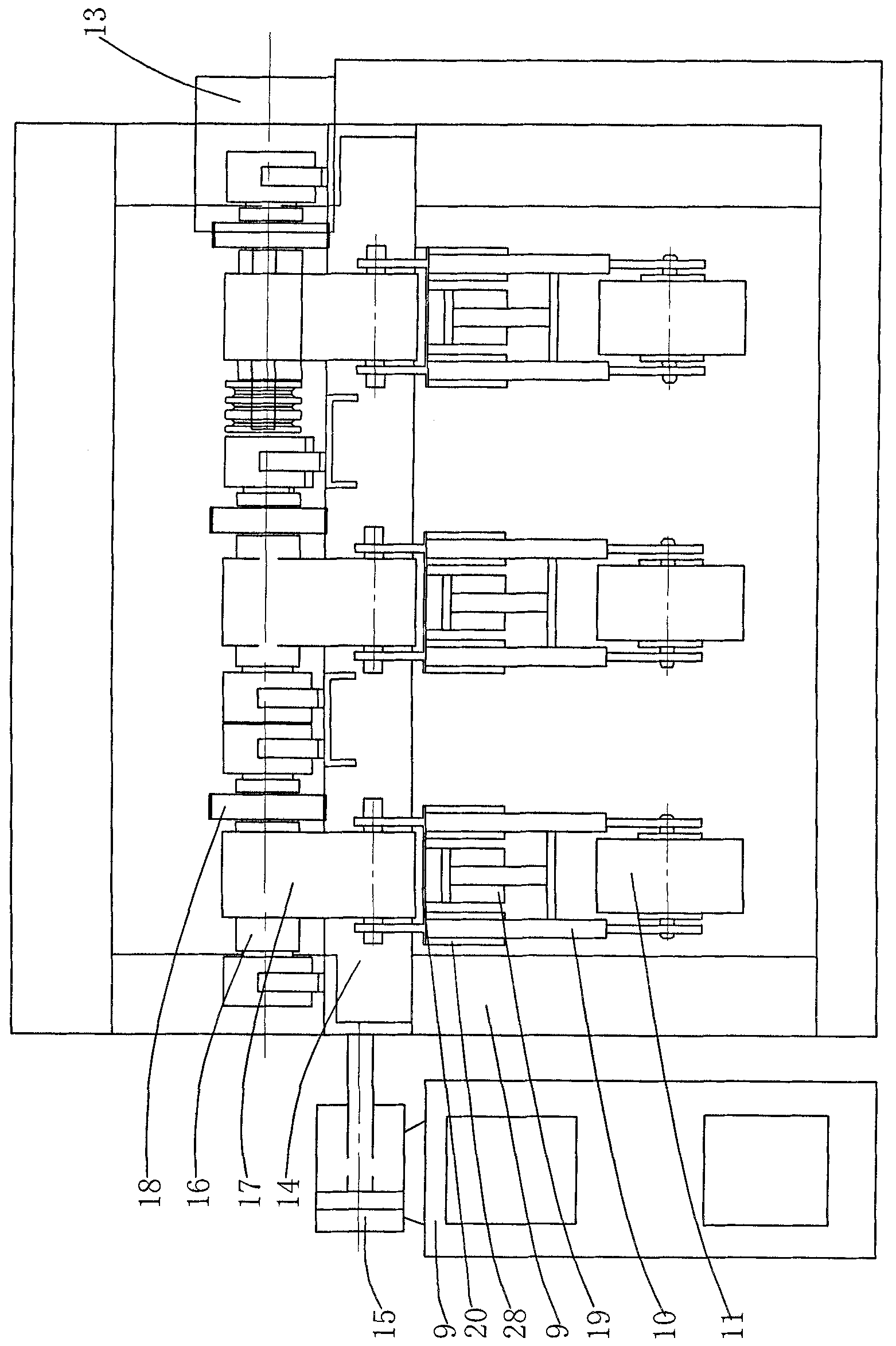

Top and bottom composite rapping electric dust collector with variable rapping strength

InactiveCN101829632AAppropriate rapping forceWill not cause secondary dustExternal electric electrostatic seperatorElectrodes cleaningHydraulic cylinderEngineering

The invention discloses a top and bottom composite rapping electric dust collector with variable rapping strength, comprising an anode plate, wherein a first rapping device and a computer system are arranged at the top of the anode plate, a second rapping device is arranged at the bottom of the anode plate, has the same structure with the first rapping device and comprises a base, wherein a core shaft, a motor, a mounting seat and a driving hydraulic cylinder are arranged on the base, and a piston rod extension end of the driving hydraulic cylinder is fixed with the mounting seat; rapping units are arranged on the mounting seat side by side, wherein each rapping unit comprises a crank arm shaft, a crank arm, a driven gear, a hydraulic cylinder, a mounting plate, hammer arms and a hammer head, wherein the crank arm and the driven gear are sleeved on the crank arm shaft, the piston rod extension end of the hydraulic cylinder is fixed with the hammer arms, and the hammer head is arrangedbetween the two hammer arms; each rapping unit has the same number with driven gears, and the weights of the hammers are different, wherein one driven gear is engaged. The invention has smart design and simple structure, can regulate the rapping strength according to factors of dust formation thickness, and the like, and can be used for cleaning dust thoroughly without causing secondary dust raise.

Owner:CHONGQING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com