Comprehensive recovery method of waste lithium battery positive electrode piece

A waste lithium battery and recycling method technology, which is applied in the field of comprehensive recycling of waste lithium battery positive plates, can solve problems such as difficulty in meeting the national standard requirements of ternary power batteries, affecting product purity and product performance, atmospheric environment, water environment pollution, etc. Achieve the effect of low processing cost, eliminate pollution, and eliminate three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

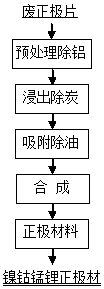

Image

Examples

Embodiment 1

[0035] Step A, pretreatment to remove aluminum: put the nickel-cobalt lithium manganese oxide positive electrode sheet into a vacuum furnace, control the vacuum degree to 0.7, and calcining at a temperature of 440°C, a heating rate of 10°C, and a calcining time of 5 hours. The calcined spent pole piece was put into a vibrating sieve with a particle size of 2 cm and a 5-mesh vibrating sieve for vibrating and sieving. The vibration frequency of the vibrating sieve was 30 rpm to obtain the positive electrode active material and aluminum foil. .

[0036] Step B, carbon removal by leaching: add the positive electrode active material into the sulfuric acid leaching solution for leaching, adopt two-stage leaching, the liquid-solid ratio of low-acid leaching = 4:1, leaching temperature 85 ° C, leaching time = 3 hours, the end point pH is 1.5 ; The liquid-solid ratio of high acid leaching=15:1, the leaching temperature is 95°C, the leaching time is 10 hours, and the leaching is strengt...

Embodiment 2

[0042] Step A, pretreatment to remove aluminum: put the nickel-cobalt lithium manganese oxide positive electrode into a vacuum furnace, control the vacuum degree to 0.8, and calcining under the conditions of 450°C, a heating rate of 12°C, and a calcination time of 4 hours. The calcined waste pole piece was put into a vibrating sieve with a particle size of 1 cm and a 15-mesh vibrating sieve for vibrating and sieving. The vibration frequency of the vibrating sieve was 40 rpm to obtain the positive electrode active material and aluminum foil. .

[0043] Step B, carbon removal by leaching: add the positive electrode active material into the sulfuric acid leaching solution for leaching, adopt two-stage leaching, the liquid-solid ratio of low-acid leaching = 5:1, leaching temperature 82 ° C, leaching time = 4 hours, the end point pH is 2.5 The liquid-solid ratio of high acid leaching=12:1, the leaching temperature is 92°C, the leaching time is 9 hours, and the leaching is strengthe...

Embodiment 3

[0049] Step A, pretreatment to remove aluminum: put the nickel-cobalt lithium manganese oxide positive electrode into a vacuum furnace, the vacuum degree is controlled to 0.9, the calcination temperature is 460°C, the heating rate is 15°C, and the calcination time is 3 hours. The calcined waste pole pieces were put into a vibrating sieve with 0.05 cm zirconia balls and a 30-mesh vibrating sieve with a particle size of 0.05 cm, and vibrated and sieved. The vibrating frequency of the vibrating sieve was 50 rpm to obtain the positive active material and aluminum foil.

[0050] Step B, carbon removal by leaching: add the positive electrode active material into the sulfuric acid leaching solution for leaching, adopt two-stage leaching, the liquid-solid ratio of low-acid leaching = 6:1, leaching temperature 80 ° C, leaching time = 5 hours, and the end point pH is 3.5 The liquid-solid ratio of high acid leaching=10:1, the leaching temperature is 90°C, the leaching time is 8 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com