Patents

Literature

91results about How to "Retain toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exogenous cornea substrate without cells and its preparation method and use

The invention provides a cell-less heterogenetic cornea material and manufacturing method and use, the manufacturing method for the product is: acquires the fresh animals' cornea at first; eliminates the cell membrane of the cornea material and nucleic acid with chemical method and enzyme method; carries on dehydration process to the cell-less heterogenetic cornea material; stores for backup. The method eliminates the antigenicity of the heterogenetic cornea material through eliminating the cell elements in the cornea material. At the same time, it reserves the integrity of glue fiber and transparency of the cornea. The material can be applied to construction of manmade cornea or used as the medical material for cornea transplantation, and cornea refraction operation directly.

Owner:THE AFFILIATED SIR RUN RUN SHAW HOSPITAL OF SCHOOL OF MEDICINE ZHEJIANG UNIV

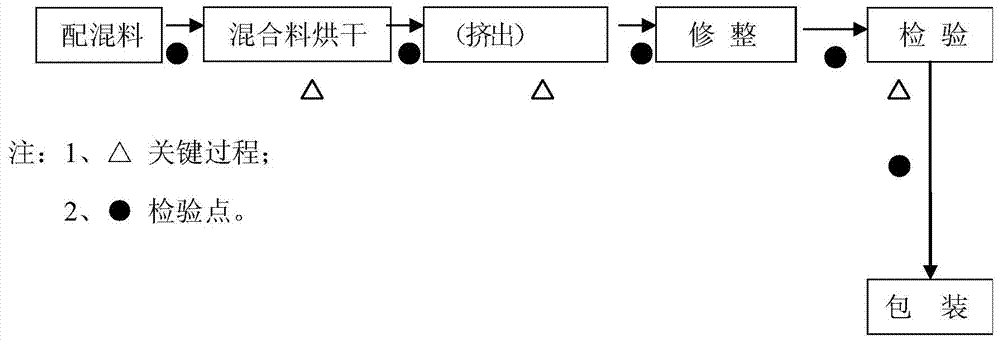

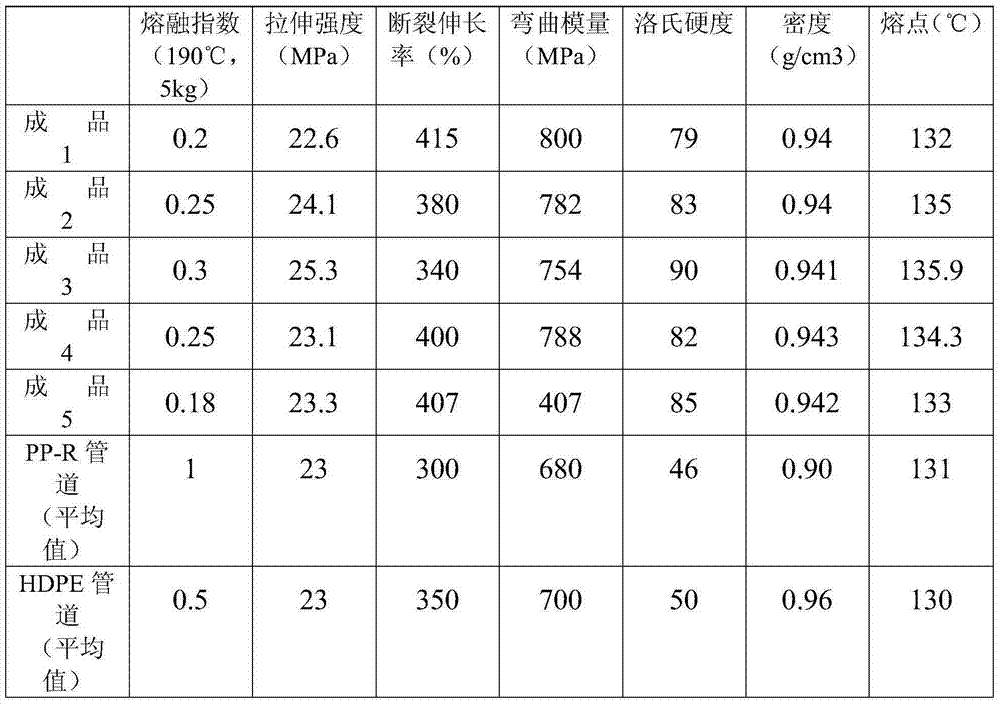

High-temperature, temperature-resisting and wear-resisting polyethylene pipe

The invention discloses a high-temperature, temperature-resisting and wear-resisting polyethylene pipe. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe sequentially comprises a micron-grade modified ultra-high molecular weight polyethylene layer, a high molecular weight modified material layer of high density polyethylene and inorganic minerals and a polyethylene felt layer from inside to outside. The polyethylene felt layer is composed of the following raw materials: 100 parts of the polyethylene, 10-20 parts of nano materials, 1-3 parts of a compatilizer, 1-3 parts of a toughening agent, 1-2 parts of a coupling agent, 1-1.5 parts of a processing lubricant and 1-1.5 parts of an antioxidant. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe has the advantages that nano particles are sufficiently dispersed in plastic resin so that the heat resistance, the weather resistance, the wear resistance and the like of the plastic are effectively improved.

Owner:NINGBO BOER PIPE IND DEV

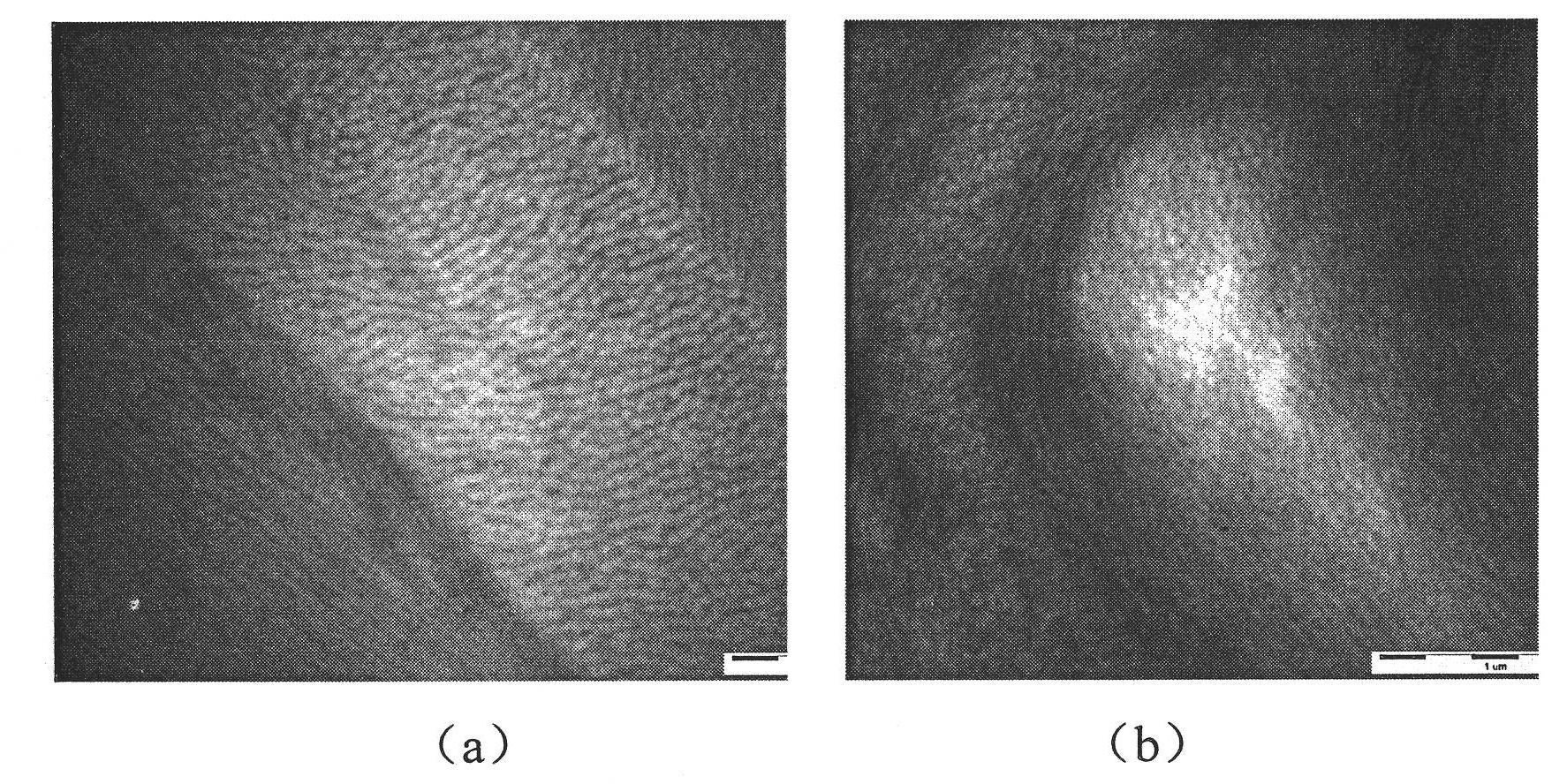

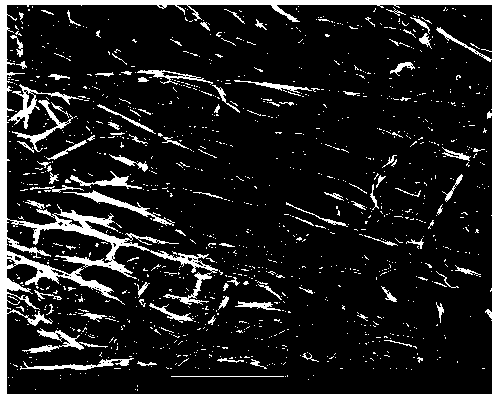

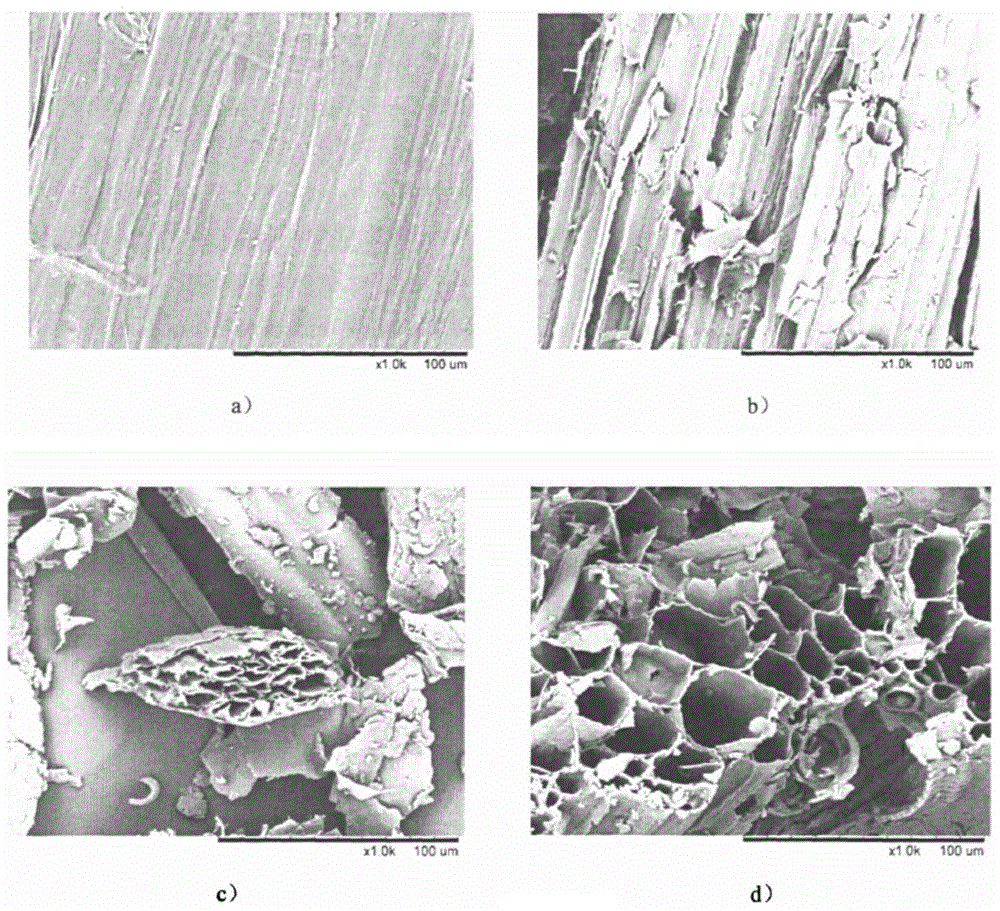

Acellular cornea or acellular corneal stroma, preparation method and application thereof

InactiveCN101985051ARetain toughnessLow immunogenicityProsthesisFreeze thawingVaccine Immunogenicity

The invention discloses acellular cornea or acellular corneal stroma, a preparation method and application thereof. The method comprises the following steps of: (1) obtaining fresh animal full-thickness cornea or corneal stroma; (2) removing corneal epithelium, corneal endothelium and stroma cells, namely 1, soaking the full-thickness cornea or the corneal stroma in pure water at room temperature; 2, placing the soaked full-thickness cornea or corneal stroma into enzyme solution, digesting with oscillating, and washing with balanced salt solution with oscillating; and 3, repeating freeze-thaw processes of the full-thickness cornea or the corneal stroma for 4 to 8 times and washing with balanced salt solution with oscillating to obtain the acellular cornea or the acellular corneal stroma; (3) dehydrating; and (4) sterilizing and storing. In the method, the decellularization processing time of the cornea is short; the influence on the structure and the physiological property of the cornea is small; and the processed cornea has very low immunogenicity which is similar to the property of natural cornea. The acellular cornea or the acellular corneal stroma can be applied to artificial cornea construction of tissue engineering and also can serve as a medical material applied to corneal transplantation and refraction surgery.

Owner:JINAN UNIVERSITY

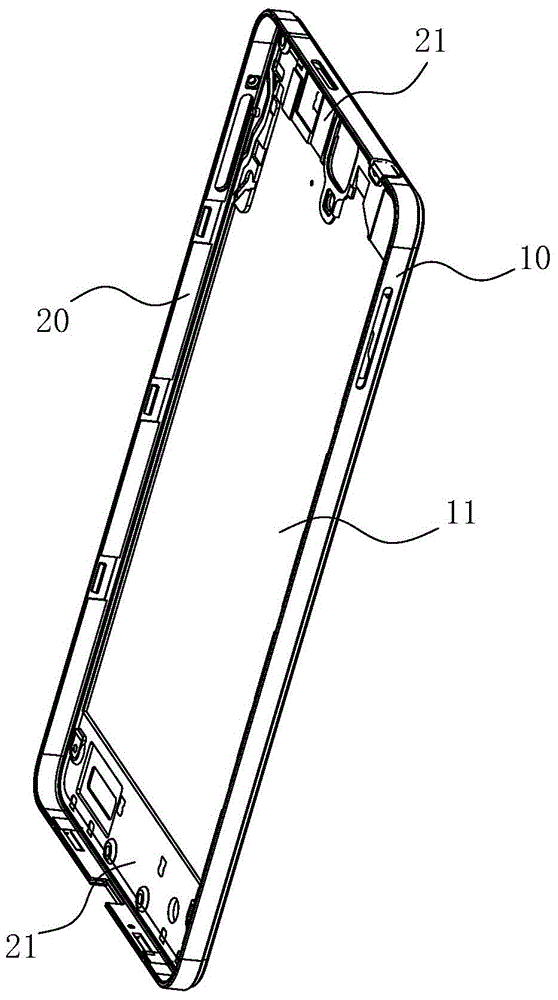

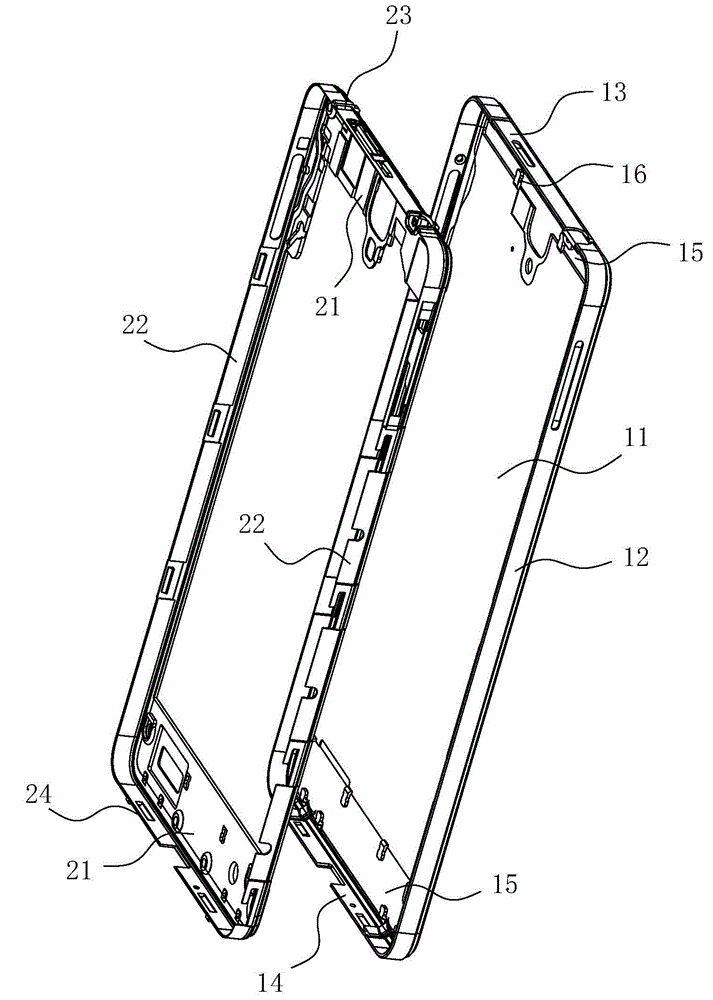

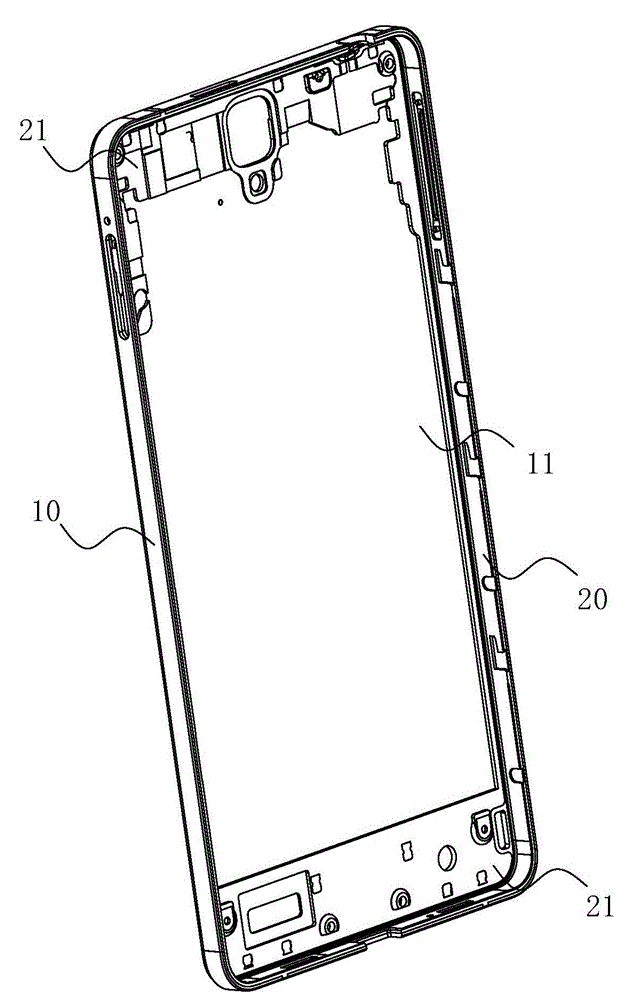

Mobile phone battery case and forming process thereof

InactiveCN104539753ARetain toughnessReduce processing timeTelephone set constructionsElectrical batteryMobile phone

The invention discloses a mobile phone battery case. The mobile phone battery case comprises a metal case and plastic parts fixedly connected to the metal case, wherein the metal case comprises a metal frame and a metal cover board, the metal cover board and the metal frame form an integrated structure, and a partial hollow structure is formed at a position where the metal cover board is connected with the metal frame; the plastic parts consist of a plastic frame and a plastic filling part, the plastic frame and the plastic filling part form an integrated structure, the plastic frame is in tight contact with the metal frame at the inner side of the metal frame, and the hollow structure is filled with the plastic filling part. The invention also discloses a forming process of the mobile phone battery case. By adopting the mobile phone battery case, the appearance expression of the mobile phone product is guaranteed, the structure of the metal case is simplified, the thickness of the metal case is reduced, the processing difficulty and the product cost are reduced, and the product productivity is improved; by adopting the process, the production efficiency is improved while the production quality of the product is guaranteed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for peeling off walnut kernel pellicle by ultrasonic waves

InactiveCN101961130AHigh peeling efficiencyGuaranteed qualityHuskingHullingWrinkleUltrasonic generator

The invention discloses a method for peeling off walnut kernel pellicle by ultrasonic waves, which is characterized by comprising: firstly, placing walnut meat in 50 to 75 DEG C hot water and completely immersing the walnut meat in the hot water for 5 to 20 minutes; secondly, placing the heated walnut meat in a cold water container, and immersing the walnut meat in the water completely; thirdly, applying ultrasonic waves at a frequency of 1 to 10KHz and a sound intensity of 0.2 to 10W / cm<2> to the cold water for performing ultrasonic treatment for 4 to 20 minutes by using a piezoelectric ultrasonic generator to remove the pellicle on the surface of the walnut meat; and finally, manually removing the residual pellicle in the wrinkles of the walnut meat and obtaining clean hulled walnut meat. The method of the invention is efficiency, pollution-free, economic and practical, is applicable to almonds, ginkgo nut pip, pine nut pip, hazelnut pip, pea nut pip and other nut pips and suitable for industrial production and has very high promotion value.

Owner:HEFEI UNIV OF TECH

Fiber-reinforced sludge curing agent

InactiveCN103880378ARetain toughnessGive full play to the role of micro-reinforcementSludge treatment by de-watering/drying/thickeningSlagShock resistance

The invention discloses a fiber-reinforced sludge curing agent, which mainly comprises 99%-99.9% by weight of curing material and 0.1%-1% by weight of fiber material, wherein the curing material comprises the following components in percentage by weight: 10-30% of mineral slag, 15%-45% of pulverized ash, 10%-25% of cement, 20%-30% of lime and 0.5%-5% of exciter. Aiming at the problems of the existing sludge curing material, such as high addition quantity, poor mechanical performance, poor tensile toughness and poor bending toughness, the sludge curing agent is reinforced by the fiber material, and therefore the comprehensive mechanical performances of the sludge curing soil, such as compressive strength, splitting tensile strength and toughness, as well as shock resistance property, can be effectively enhanced; moreover, the addition of fibers is small, the fiber-reinforced sludge curing agent is convenient to produce and wide in application range.

Owner:JIANGSU NATURE WAY TECH

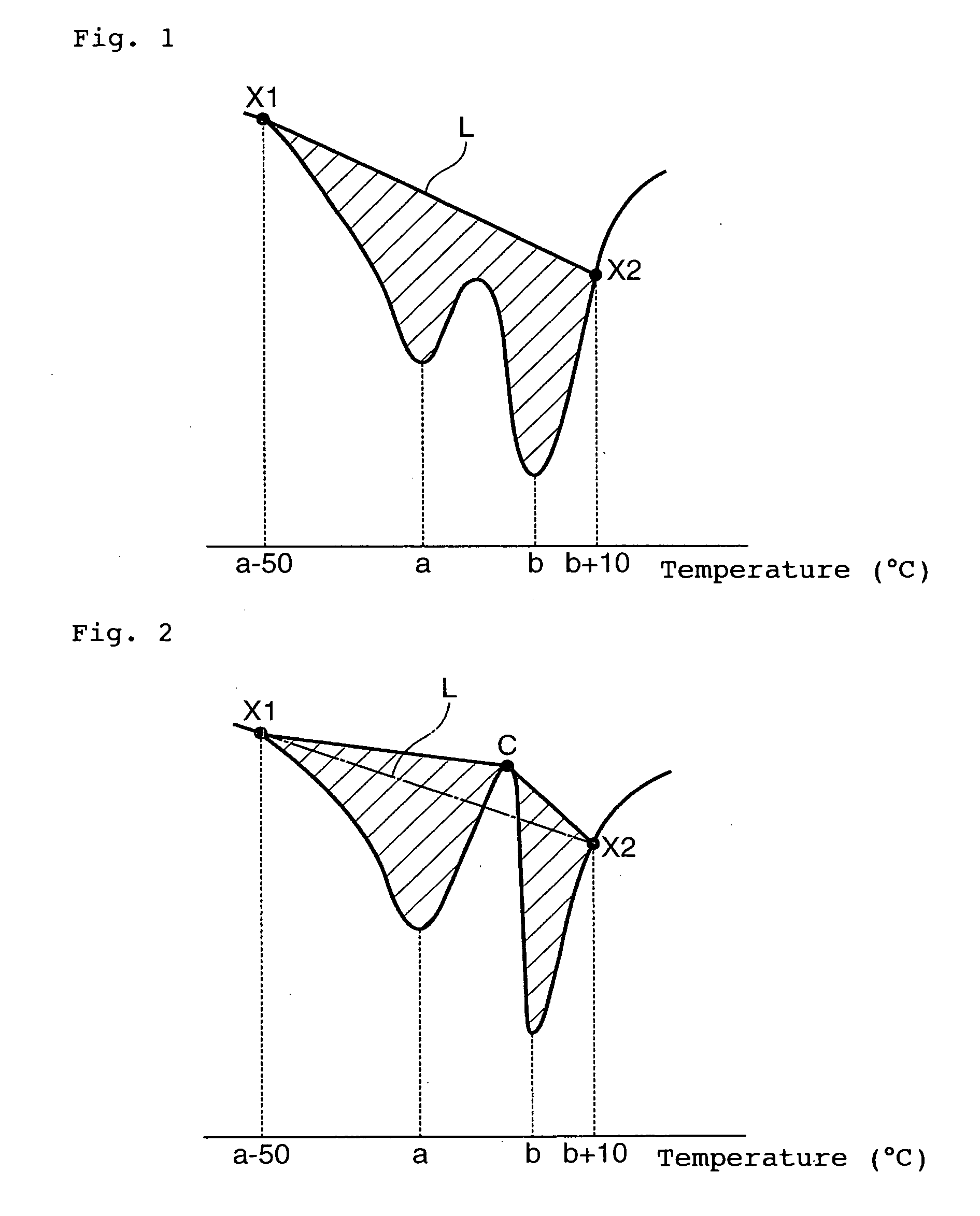

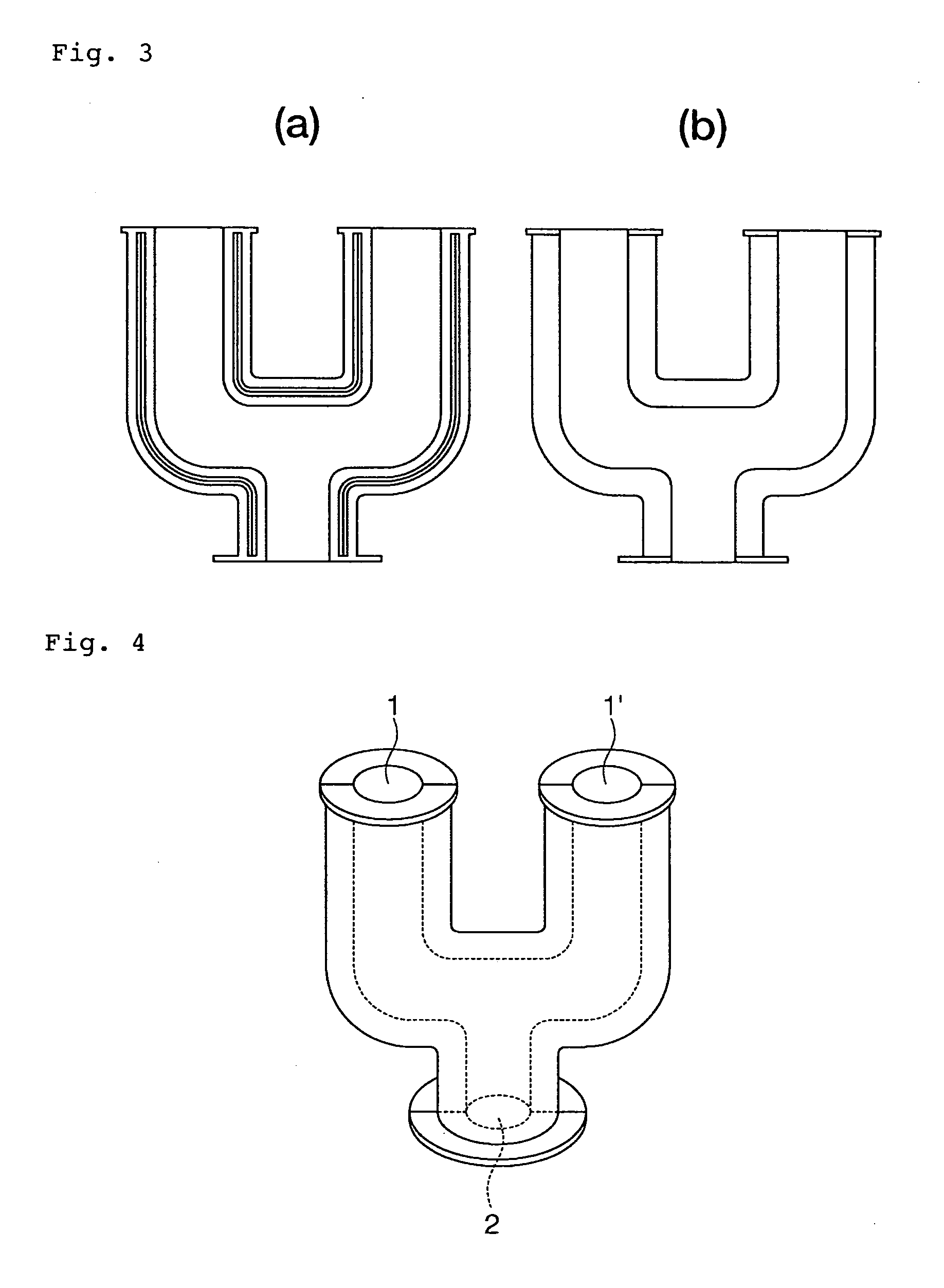

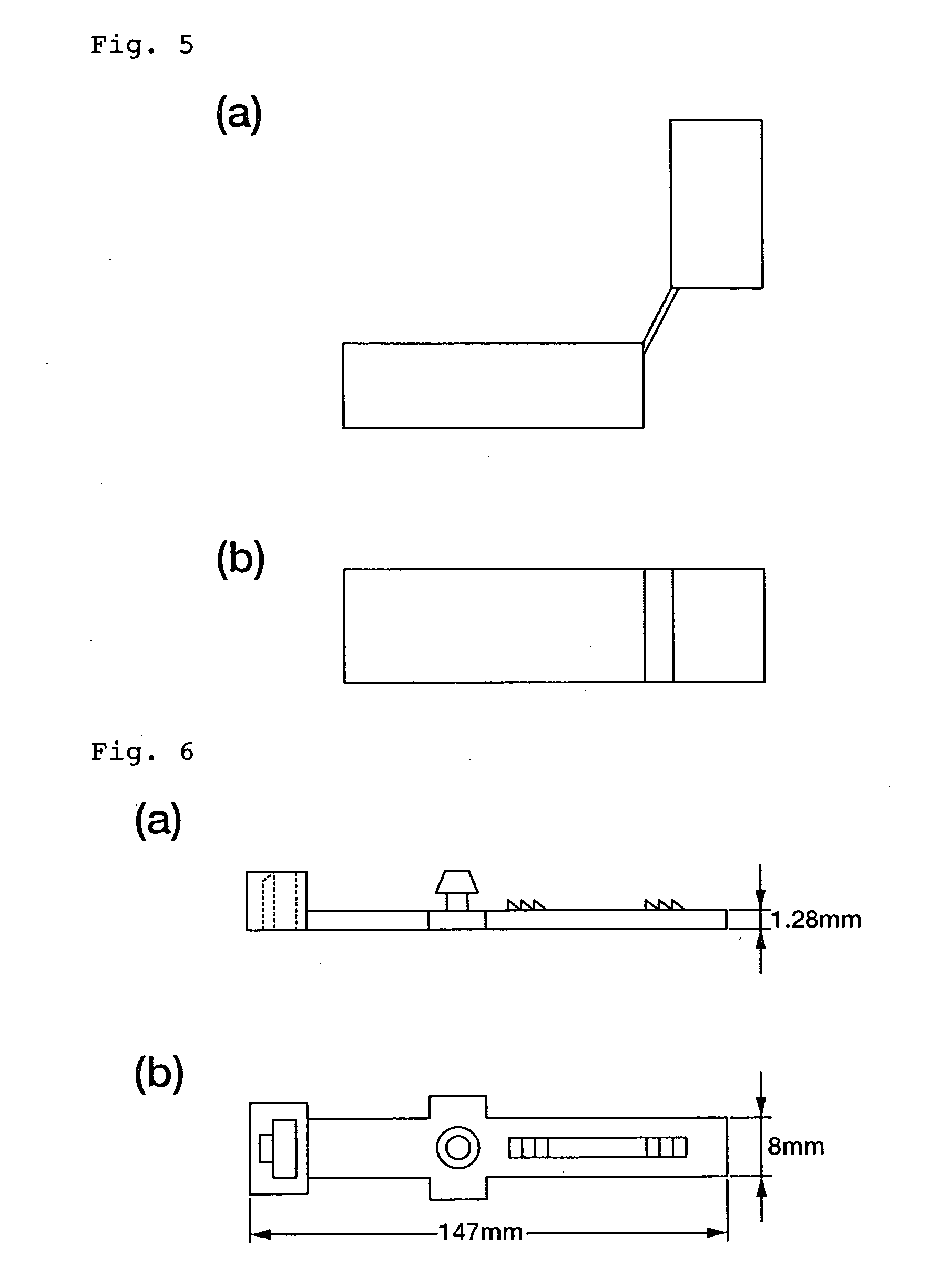

Polyamide Resin and Hinged Molded Product

InactiveUS20070249783A1Excellent vibration welding strengthHigh hinge propertyNon-fibrous pulp additionMonocomponent copolyamides artificial filamentHexamethyldiamineHexamethylenediamine

A polyamide resin comprising a dicarboxylic acid constitutional unit comprising an adipic acid unit and a diamine constitutional unit comprising a pentamethylenediamine unit and a hexamethylenediamine unit wherein a weight ratio of the pentamethylenediamine unit to the hexamethylenediamine unit being in the range of 95:5 to 60:40; a vibration-welded molded product having an excellent vibration welding strength, a hinged molded product and a binding band having an excellent low-temperature toughness, and a filament having an excellent transparency which are obtained from the polyamide resin; and a hinged molded product comprising a polyamide resin constituted of an adipic acid unit and a pentamethylenediamine unit.

Owner:MITSUBISHI CHEM CORP

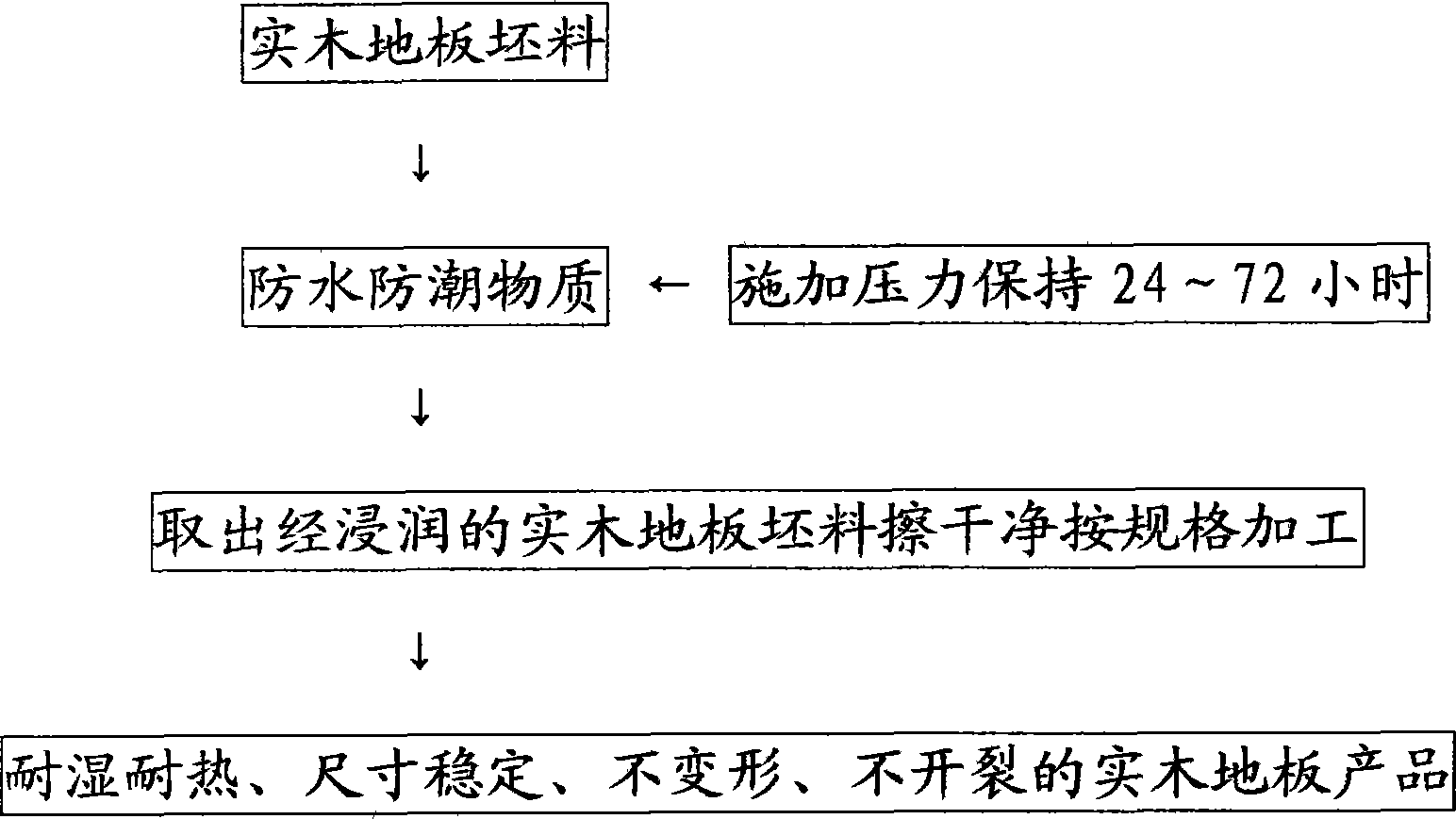

Moisture-proof, heatproof, size-stable, deformation-free and anti-cracking solid wood floor processing method

InactiveCN103223686ADimensionally stableNot deformedPressure impregnationWood impregnation detailsSolid woodWax

A moisture-proof, heatproof, size-stable, deformation-free and anti-cracking solid wood floor processing method provided by the invention relates to the technical field of building materials. By the adoption of a wet-heat resistant, anti-deformation and anti-cracking key technology, a solid wood floor blank is completely immersed in a container filled with a waterproof moisture-proof substance in a liquid state of 35-95 DEG C, and simultaneously a pressure of 0.2-1.5Mpa is applied for 24-72 hours so as to make the waterproof moisture-proof substance to be permeated into the inside of the solid wood floor blank; and after the solid wood floor blank is taken out and infiltrated, the solid wood floor blank is dried and processed according to specification requirements so as to manufacture the moisture-proof, heatproof, size-stable, deformation-free and anti-cracking solid wood floor product. The waterproof moisture-proof substance comprises, by weight, 0-100% of wax and 0-100% of dry plant oil, is used in wet-heat resistant, anti-deformation and anti-cracking processing of wood floor, and can be used to make solid wood floor moisture-proof, heatproof, size-stable, deformation-free, anti-cracking and durable.

Owner:王永洁

Ligament support and preparation method thereof

InactiveCN104043148AEliminate biocompatibilityAdjustable widthNon-woven fabricsProsthesisFiberNanofiber

The invention relates to a ligament support containing silk fibroin compound oriented nanofiber and a preparation method thereof, and belongs to the technical field of medical apparatus and instruments. The ligament support is prepared from oriented fiber combining silk fibroin with a medical high molecular synthetic material and has a porous three dimensional structure, the mass ratio of the silk fibroin and medical high molecular synthetic material in the compound oriented fiber is (1-20):(1-1), the diameter of the compound oriented fiber is 500nm-10000nm, the thickness of the ligament is 1mm-10mm, and the width of the ligament is 1mm-15mm. The ligament support has a uniform microstructure and good biocompatibility, provides a matrix structure for growing of ligament cells, and can be used for increasing the tensile strength of the ligament due to the compound fiber orientated structure. The ligament support is simple in preparation method and convenient to operate, the preparation process is controllable, and the preparation method is suitable for preparing the ligament supports of various sections and lengths.

Owner:WUHAN TEXTILE UNIV

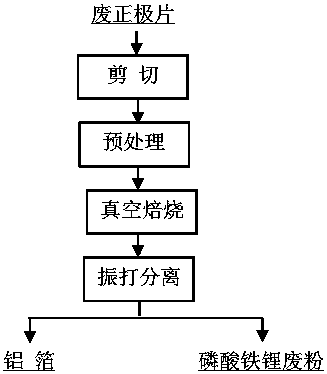

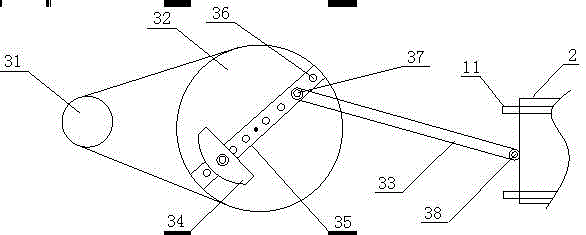

Vacuum separation method of waste lithium iron phosphate battery positive plate

ActiveCN110148801AAvoid pollutionEasy to recycleWaste accumulators reclaimingBattery recyclingLithium iron phosphateSteel ball

A vacuum separation method of a waste lithium iron phosphate battery positive plate comprises the following steps: cutting the waste lithium iron phosphate battery positive plate into loose sheets, and putting the loose pole plates into a vacuum furnace for vacuum roasting at the temperature of 350-450 DEG C for 1-6 hours; putting the calcined waste pole sheets into a vibrating screen in batches;adding steel balls with different particle sizes at the same time; and vibrating and screening to obtain aluminum foils on the vibrating screen and lithium iron phosphate waste powder under the vibrating screen. According to the method, the situation that aluminum foils are damaged and enters the lithium iron phosphate waste powder in the vibrating and screening process is reduced; and meanwhile,lithium is activated, and a foundation is laid for direct repair and recovery of a lithium iron phosphate pyrogenic process.

Owner:ZHUZHOU SMELTER GRP

Low antigen hetero stroma of cornea treated by frozen, and its prepn. method

Owner:THE AFFILIATED SIR RUN RUN SHAW HOSPITAL OF SCHOOL OF MEDICINE ZHEJIANG UNIV

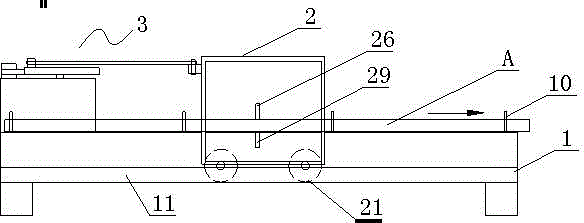

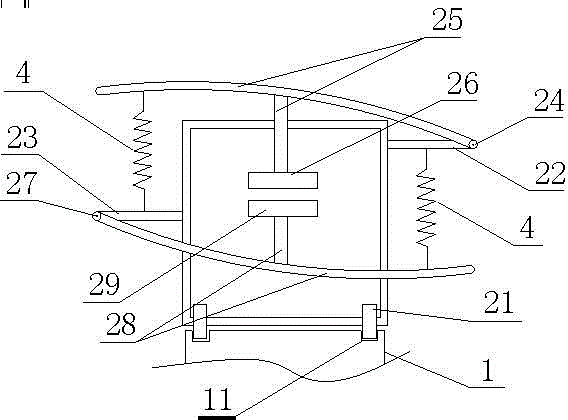

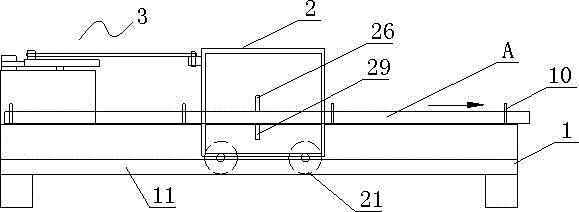

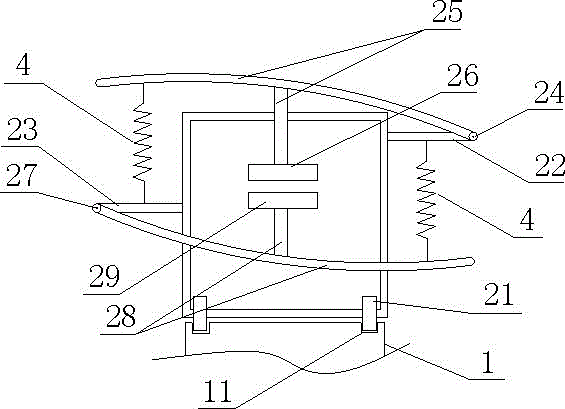

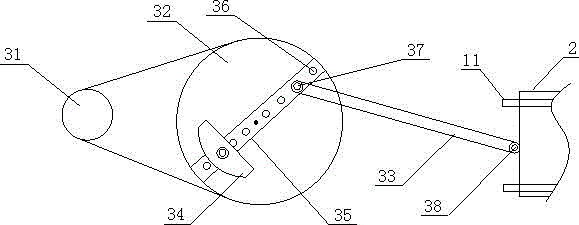

Reciprocating scrape type bamboo outer skin removing device

InactiveCN104385398ARetain toughnessImprove work efficiencyCane mechanical workingPlant material mechanical workingKnife bladesBiomedical engineering

The invention aims at providing a reciprocating scrape type bamboo outer skin removing device, comprising a rack, a knife rest and a knife rest driving mechanism, wherein the knife rest is connected with the knife rest driving mechanism, and mutually matched guide mechanisms are arranged between the knife rest and the rack so as to make the knife rest move up and down on the rack; at least one set of blade group is arranged on the knife rest, the blade group internally comprises two opposite blades which are connected with the knife rest through an elastic pressing mechanism so as to make the two blades in the same blade group able to clamp the bamboo passing between the two blades; the rack is further provided with a position limiting mechanism for limiting the position of the bamboo. The reciprocating scrape type bamboo outer skin removing device changes the working manner of a bamboo outer skin removing machine in the prior art, uses the reciprocating blades to simulate manual bamboo outer skin scraping, is able to improve the working efficiency greatly, lowers the manual labor intensity, and can keep the bamboo tenacity to the maximum extent.

Owner:李静

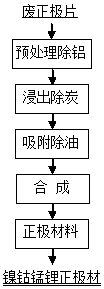

Comprehensive recovery method of waste lithium battery positive electrode piece

InactiveCN110144461AEasy to recycleAvoid pollutionCell electrodesWaste accumulators reclaimingRecovery methodSlag

The invention discloses a comprehensive recovery method of a waste lithium battery positive electrode piece. The method comprises the steps that a positive electrode leftover material and a wasted positive electrode piece are placed into a vacuum furnace to be calcinated, rapping and screening are conducted to obtain a positive active substance, the positive electrode active material is added to asulphuric acid leaching solution, second-stage leaching is conducted, and leached slag carbon and the leaching solution containing nickel, cobalt, manganese and lithium; activated carbon is added tothe leaching solution to perform adsorption deoiling and silica removing, nickel carbonate, cobalt carbonate, manganese carbonate or lithium carbonate is replenished to the filtered residue to obtainprecursors, ball milling, sintering, pulverizing, grinding and mesh screening are conducted on the precursors, and a nickel-cobalt-manganese-acid-lithium positive electrode material is obtained. The method has the advantages that the technology is reasonable, the separation cost is low, and there exists no pollution, toxin or harm.

Owner:ZHUZHOU SMELTER GRP

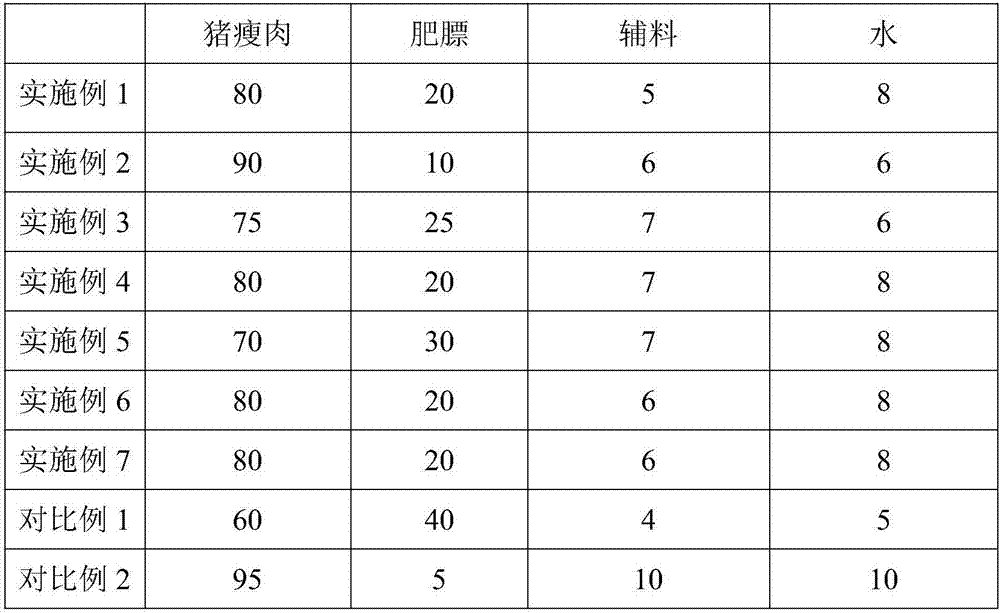

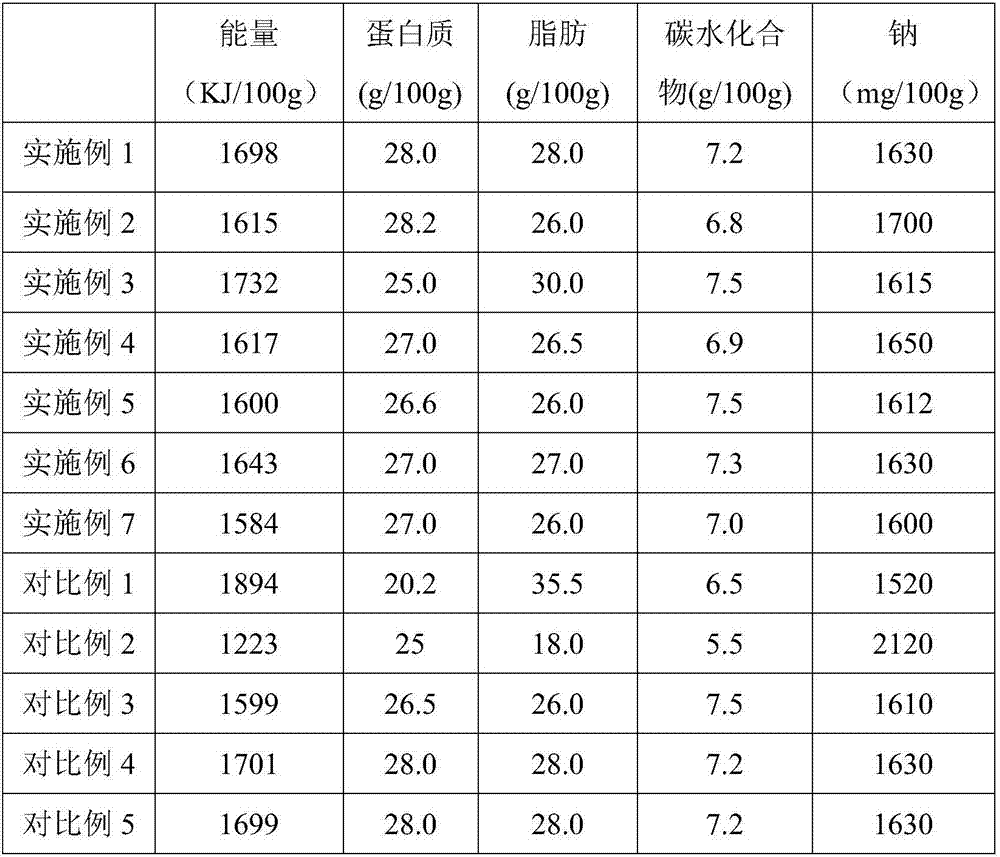

Handmade sausage and making method thereof

The invention discloses a handmade sausage and a making method thereof. The handmade sausage is made by stirring and mixing pork lean meat, fat, auxiliary materials and water and performing vacuum rolling rubbing, casting filling and fumigation and baking, wherein the weight part ratio of the pork lean meat to fat is 9:1 to 7:3, the ratio of the total weight of the pork lean meat and fat to the mass of the auxiliary materials is 100 to 5-7, the ratio of the total weight of the pork lean meat and fat to the mass of the water is 100 to 6-8, and the grain size ratio of the pork lean meat to fat is 1:1 to 4:1. Fresh rear leg pork is carefully selected as the raw material for the handmade sausage, naturally casings are adopted for filling, manual cutting and stirring are performed, the taste and toughness of the sausage are retained to the most degree, the big sectional meat grains of the product are clear and visible, the protein content is high, the nutritive value is high, and a special fermentation flavor is produced in the special salting and backing technology process. Required devices are common devices, the cost is lower, the operability is strong, large-scale production is easy, and especially the product has a special flavor characteristic and has a wide market prospect.

Owner:湖南唐人神肉制品有限公司

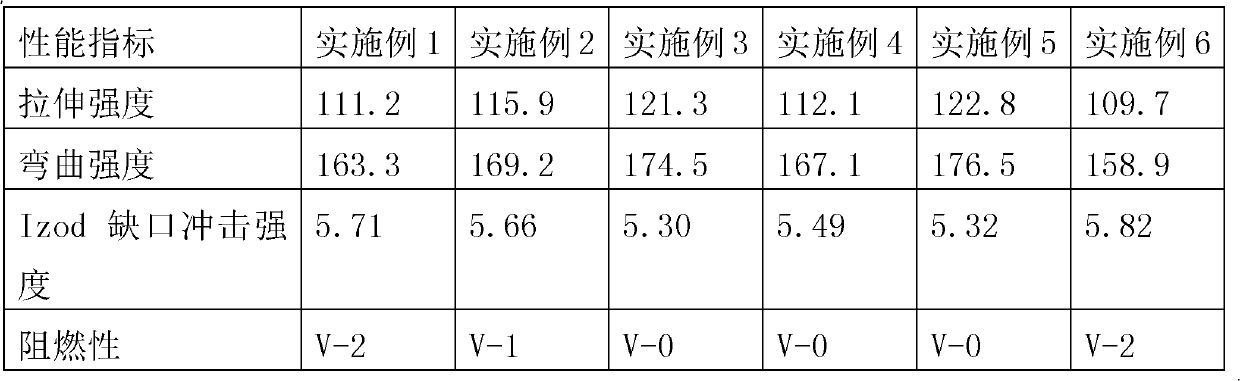

Hydrotalcite-intercalated flame-retarding-enhanced polypropylene material and preparing method thereof

The invention provides a hydrotalcite-intercalated flame-retarding-enhanced polypropylene material and a preparing method thereof, and relates to the technical field of polymeric composite materials. The hydrotalcite-intercalated flame-retarding-enhanced polypropylene material is prepared from polypropylene, a light stabilizer, a lubricating agent, modified hydrotalcite, a compatilizer, an antioxidant and an assistant. The hydrotalcite-intercalated flame-retarding-enhanced polypropylene material has the high strength, the heat stability and the flame-retarding performance.

Owner:ORINKO NEW MATERIAL CO LTD

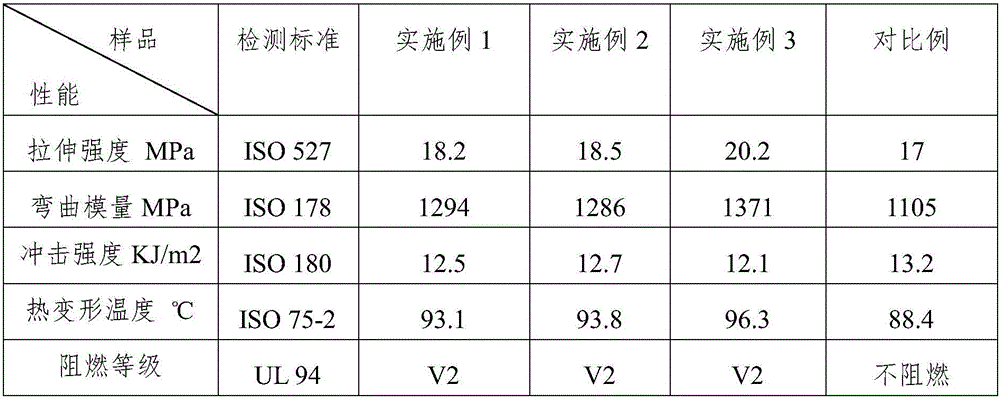

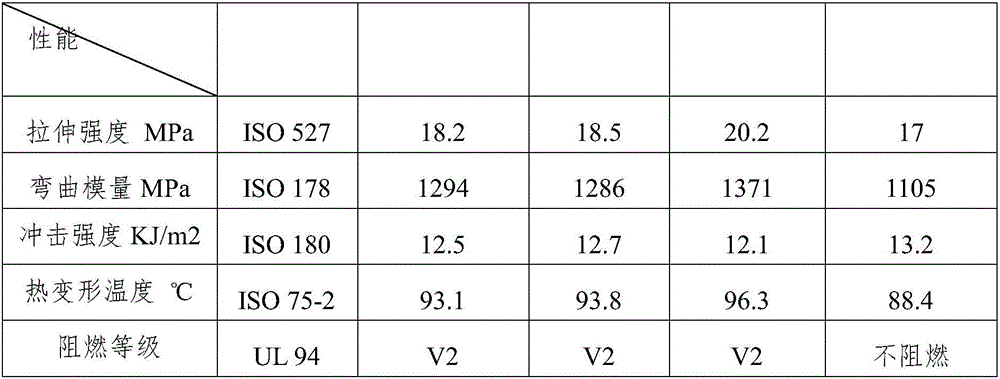

Glass fiber reinforced flame-retardant styrene-acrylonitrile copolymer/ polybutylene terephthalate (AS/ PBT) material and preparation method thereof

The invention relates to a glass fiber reinforced flame-retardant resin, in particular to a glass fiber reinforced flame-retardant styrene-acrylonitrile copolymer / polybutylene terephthalate (AS / PBT) material and a preparation method thereof, and belongs to the field of polymers. The material comprises the following components in percentage by weight: 25 to 65 percent of AS, 5 to 25 percent of PBT, 10 to 30 percent of glass fiber, 5 to 20 percent of bromine-based flame retardant, 2 to 15 percent of antimony-based flame retardant, 0.1 to 1.4 percent of drip-proof additive, 0.3 to 1 percent of antioxidant, and 3 to 10 percent of compatilizer. Compared with the prior art, the invention has the advantages that: the glass fiber reinforced flame-retardant AS / PBT modified resin material keeps the strength of glass fiber reinforced flame-retardant AS / PBT resin, has good flame-retardant performance, can be widely applied in the field of electronic-electrical equipment and the like with flame-retardant, climate-resistant and heat-resistant requirements, and has a broad application prospect.

Owner:SHANGHAI KINGFA SCI & TECH

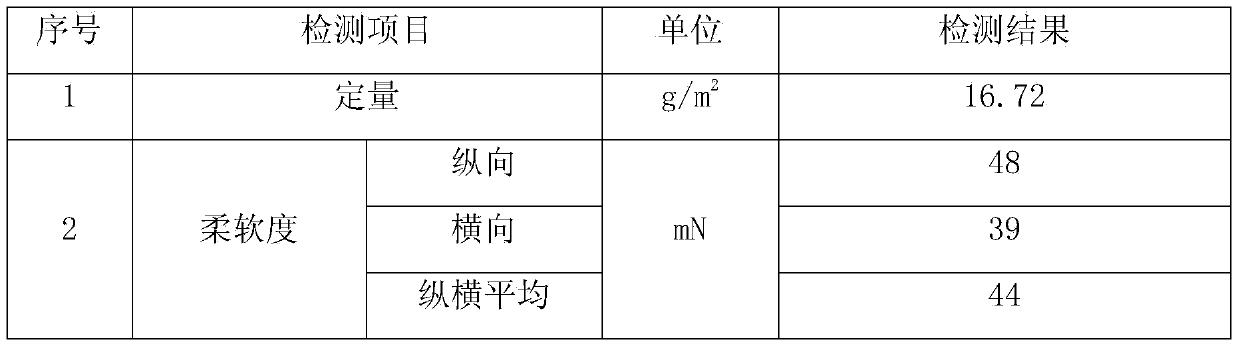

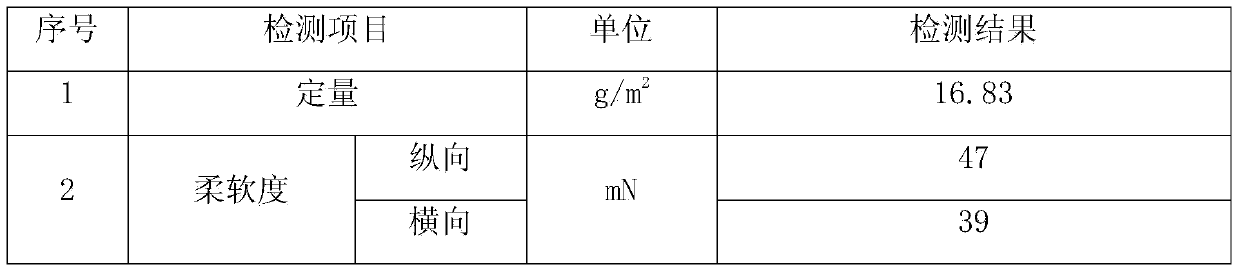

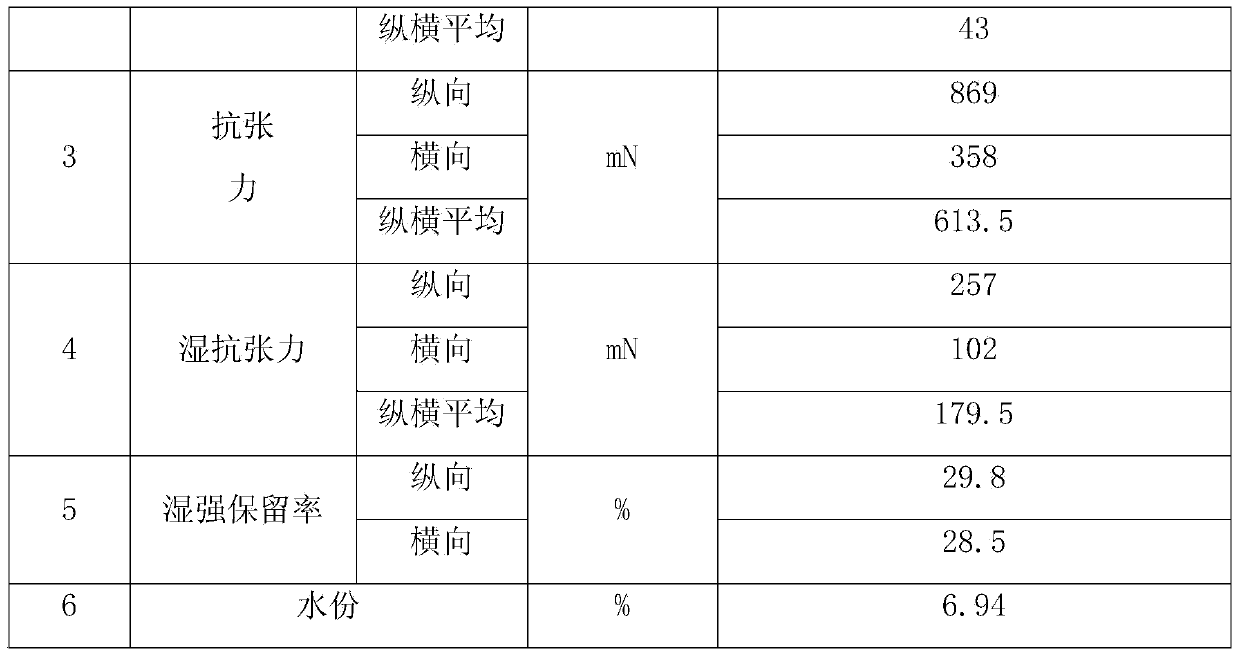

Highly quantitative soft facial tissues and production method thereof

ActiveCN103628347ASuper softHigh quantitativeNatural cellulose pulp/paperDomestic applicationsToughnessSizing

The invention discloses a method for producing highly quantitative soft facial tissues. The production process comprises the following steps: (1) pulping, wherein a ratio of needlebush to broadleaf wood is (20-40 percent):(60-80 percent), the beating degree of the pulped needlebush is 22-300 SR, the broadleaf wood is not pulped, intermediate concentration repulping is adopted, and 10-25kg of softening agents are added into the pulp per ton during repulping; (2) sizing; (3) dehydrating and drying; (4) wrinkling and coiling; and (5) slitting and packing. By virtue of the technical scheme, the highly quantitative soft facial tissue has a super-soft feeling and is highly quantitative, high tension stress can be kept on the basis of super-softening, and the toughness and absorption property of the facial tissues are kept.

Owner:VINDA PAPER (CHINA) CO LTD

Modified straw fertilizer capable of improving soil structure and preparation method thereof

InactiveCN104945083APromote decompositionIncrease softnessBio-organic fraction processingOrganic fertiliser preparationFermentationMicrobial inoculant

The invention discloses a modified straw fertilizer capable of improving soil structure and a preparation method thereof. The modified straw fertilizer is prepared from the following raw materials in parts by weight: rice straw, wheat bran, rice hull, peat soil, ammonium bicarbonate, a microbial fermentation inoculant, sodium dihydrogen phosphate, potassium permanganate, humic acid, magnesium sulfate, additives and a proper amount of water. The preparation method comprises the following steps: carrying out ammonification treatment on the rice straw, carrying out microwave radiation for some time, fermenting for a short time, and mixing with the basic carriers and chemical fertilizers. The straw can not be easily decomposed itself, but can be easily decomposed in soil; the microbial inoculant fermentation time is slightly shortened, so that the straw is not fermented too completely, and maintains certain toughness, thereby being beneficial to enhancing the looseness of the soil; and thus, the modified straw fertilizer is very useful in air permeability enhancement and pest control.

Owner:FEIXI AGRI TECH PROMOTION CENT

Glass gluing material for architectural decoration

The invention discloses a glass gluing material for architectural decoration, and belongs to the technical field of building materials. The glass gluing material consists of the following raw materials in percentage by weight: 10 to 20 percent of cement, 25 to 40 percent of styrene-acrylate emulsion, 40 to 60 percent of quartz sand with 20 to 25 meshes, and 1 to 5 percent of other filler. When glass is glued, the styrene-acrylate emulsion, the cement, the quartz sand and the other filler are mixed uniformly, or coated to the back of the glass, cured and then is glued to a roughcast wall with cement mortar, or directly coated between the glass and the newly constructed cement mortar, so the gluing material and the cement mortar are cured together. The glass gluing material has the advantages of low cost of raw materials, simple manufacturing process, good acid-alkali resistance and water resistance, no pollution, non-combustibility, and convenient storage and transportation. The styrene-acrylate emulsion and the cement are compounded, so the glass gluing material has strong gluing force, is particularly suitable for gluing the glass and the cement surface, saves labor and materials, can greatly reduces the construction cost of the decorative glass, and improves decorative aesthetics.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

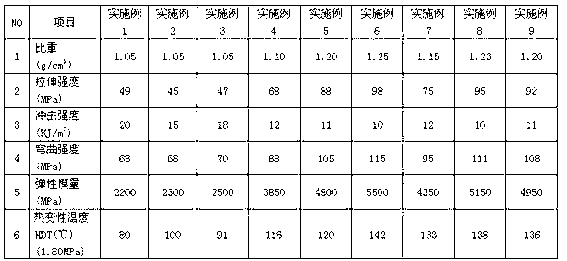

Glass fiber reinforced ABS (Acrylonitrile Butadiene Styrene) material with high heat resistance

The invention discloses a glass fiber reinforced ABS (Acrylonitrile Butadiene Styrene) material with high heat resistance and belongs to the technical field of high molecular materials. The ABS material consists of the following components: ABS, glass fibers, a compatilizer, a toughening agent, a heat resisting agent, an antioxidant and a processing aid. Compared with the prior art, the ABS material has the following advantages and beneficial effects: (1) the high-efficiency ABS heat resisting agent is adopted, the effect of compatibility with an ABS base material is good, the properties are enhanced remarkably, the heat-resisting temperature of the unmodified ABS material is about 80 DEG C and the heat-resisting temperature of the modified ABS material achieves over 100 DEG C; (2) by the composition of the glass fibers, the heat resistance of the ABS material is enhanced further, so that the heat-resisting temperature of the modified ABS material achieves over 150 DEG C, also, the strength of the material is enhanced and the application field of products is expanded; and (3) the ABS material with high heat resistance and high strength has high rigidity and meanwhile retains certain toughness, so that the application field is expanded further; and the ABS material conforms to national environment protection requirements.

Owner:杭州金州高分子科技有限公司

Carotenoid reinforced nutrition vermicelli loaded with sporidiobolus pararoseus y7 powder interlayer, and preparation method thereof

InactiveCN105166675APromote absorptionIncrease elasticityFood ingredient functionsFood preparationSporidiobolus pararoseusAbsorption capacity

The present invention discloses a carotenoid reinforced nutrition vermicelli loaded with a sporidiobolus pararoseus y7 powder interlayer, wherein the components comprise, by weight, 60-80 parts of middle-gluten flour, 40-60 parts of low-gluten flour, 10-12 parts of corn acetate starch, 1-2 parts of compound phosphate, 6-8 parts of ginkgo leaf, 10-20 parts of wheat germ, 20-30 parts of purple sweet potato powder, 2-3 parts of sporidiobolus pararoseus y7 powder, 0.01-0.12 part of sodium alginate, 0.001-0.0012 part of glucose oxidase, 8-10 parts of edible salt, and a proper amount of water. According to the present invention, the corn acetate starch is mixed into the high-gluten flour and the low-gluten flour so as to significantly reduce the cooking loss of the vermicelli, and the compound phosphate is used to increase the absorption capacity of the flour, ensure the complete expansion of the gluten protein, promote the formation of the gluten network, and increase the flexibility and the toughness of the vermicelli.

Owner:安徽昊晨食品股份有限公司

Nano-tungsten alloy material and preparing method thereof

The invention discloses a nano-tungsten alloy material and a preparing method thereof. The nano-tungsten alloy material is mainly composed of metal tungsten and further comprises, by weight percent, 3.8 to 4.55% of Ni, 1.2 to 1.95% of Fe and 0.23 to 0.5% of Co, burdening, ball milling, mixing, pressing and sintering are adopted to make the nano-tungsten alloy. The prepared nano-tungsten alloy hasthe high density of 16.5 to 19.0g / cm<3>, the large proportion of 16.5 to 18.75 g / cm<3> and high strength, the tensile strength is 700 to 1000 MPa, and the alloy can be widely applied to the industriesof aerospace, aviation, military, medicine and the like.

Owner:江西澳科新材料科技股份有限公司

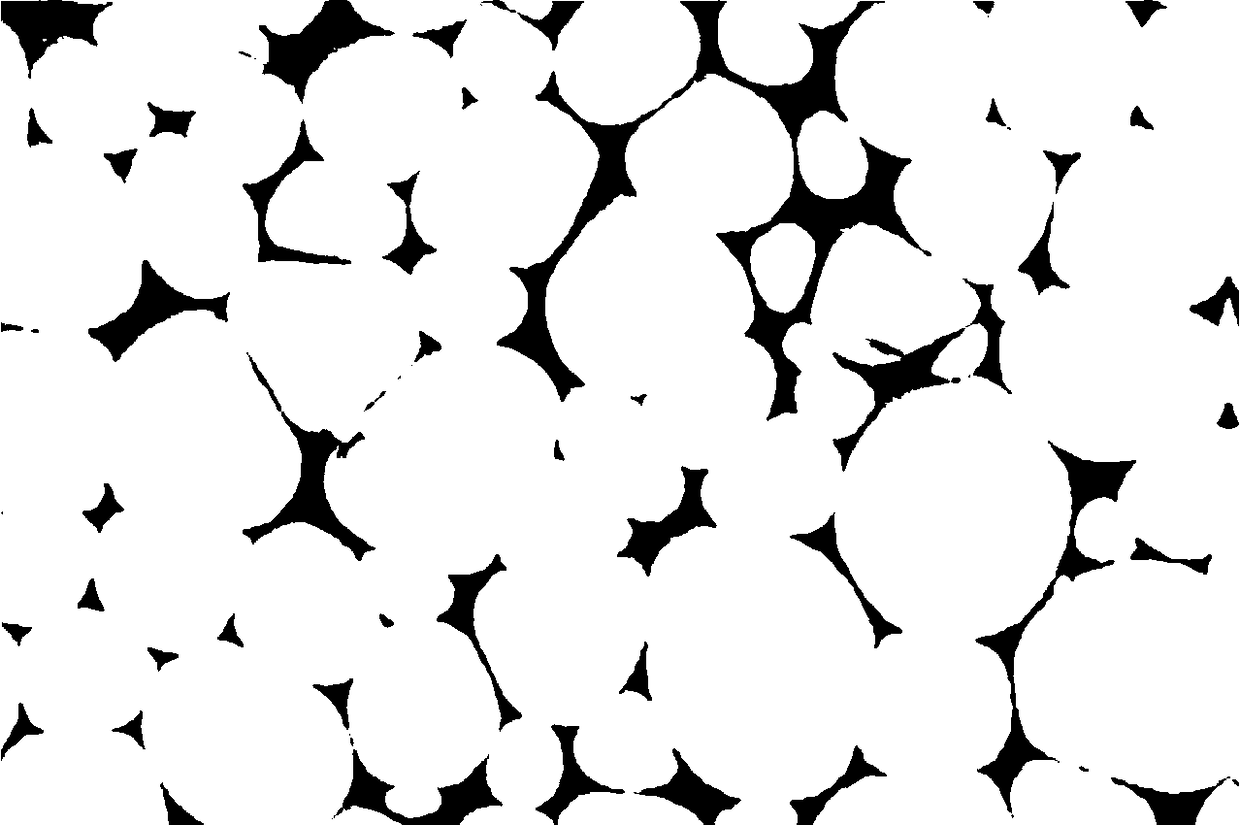

Preparation method of carbon nanotube nanosilica co-modified polyvinyl alcohol composite ultra-filtration membrane

InactiveCN103120902ARetain hydrophilicityImprove anti-pollution performanceSemi-permeable membranesFiltration membranePolyvinyl alcohol

The invention discloses a preparation method of a carbon nanotube nanosilica co-modified polyvinyl alcohol composite ultra-filtration membrane. The preparation method comprises the following steps of: adding a certain amount of carboxylated carbon nanotubes and nanosilica which are dispersed by a surfactant, to a casting membrane solution by adopting polyvinyl alcohol as a membrane substrate material; and preparing the membrane by adopting polyethylene glycol as a pore-foaming agent through an immersion-precipitation phase transformation process. The prepared membrane not only has the hydrophily of the polyvinyl alcohol to achieve strong anti-pollution capacity, but also keeps the strength and toughness of inorganic materials to make up the defects of low strength and inability of resisting pressure of the polyvinyl alcohol wet membrane. The composite ultra-filtration membrane has strong anti-pollution capacity, high water flux and better retaining characteristic, can be repeatedly used and is long in service life.

Owner:高润宝

Anti-cracking stone-like coating and preparation method thereof

The invention discloses an anti-cracking stone-like coating and a preparation method thereof, belonging to the field of building exterior wall coatings. According to technical key points in the invention, the anti-cracking stone-like coating is prepared from the following raw materials in parts by weight: 100-120 parts of water, 1 to 2 parts of hydroxyethyl cellulose, 2.5 to 3.5 parts of a dispersing agent, 0.6-1 part of a wetting agent, 0.8 to 1.2 parts of a de-foaming agent, 8 to 12 parts of rutile titanium dioxide, 40 to 60 parts of heavy calcium carbonate, 160 to 180 parts of an acrylic emulsion, 7-9 parts of ethylene glycol, 1.2 to 1.6 parts of a multifunctional amine auxiliary agent, 1.8 to 2 parts of a coalescing agent, 40 to 120 parts of sand, 2-2.5 parts of a preservative, 2-3 parts of a thickening agent, and 2.5 to 3.5 parts of semi-carbonized fiber. The stone-like coating provided by the invention has the advantage of crack resistance.

Owner:泾川县新裕新型建材有限公司

DNA immunoadsorbent, and preparation method thereof

ActiveCN108246264AHigh strengthReduce sheddingOther blood circulation devicesOther chemical processesImmunosorbentsPolystyrene

The invention discloses a DNA immunoadsorbent and a preparation method thereof. The preparation method comprises the following steps: 1) preparation of polystyrene-based macroporous adsorption resin containing aldehyde groups; and 2) grafting and immobilization of DNA ligand. The DNA immunosorbent prepared by using the method directly adopts the macroporous adsorption resin as a carrier and replaces activated carbon or carbonized resin with the macroporous adsorption resin; and the toughness of a resin skeleton is retained and the risk of falling of particles is greatly reduced due to the omitting of carbonization and activation procedures during production. In addition, a chemical grafting method is employed to directly immobilize the DNA ligand to the macroporous adsorption resin, and the DNA ligand linked by a chemical bond is firmly immobilized and hardly falls off; moreover, without embedding and covering of coating materials like collodion, DNAs immobilized on the surface of theresin and inside the pores of the resin can exert maximum adsorption effect.

Owner:JAFRON BIOMEDICAL

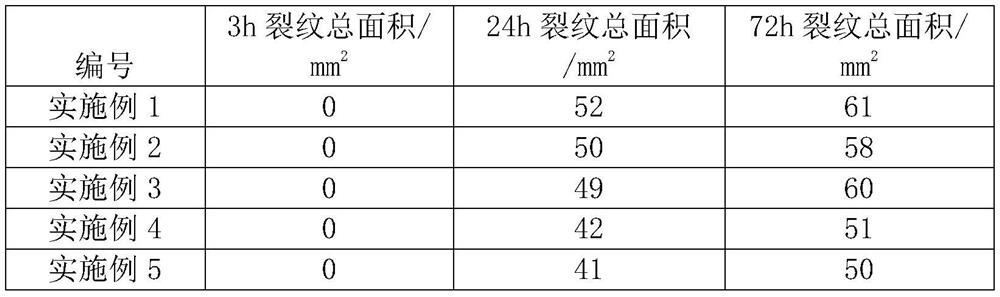

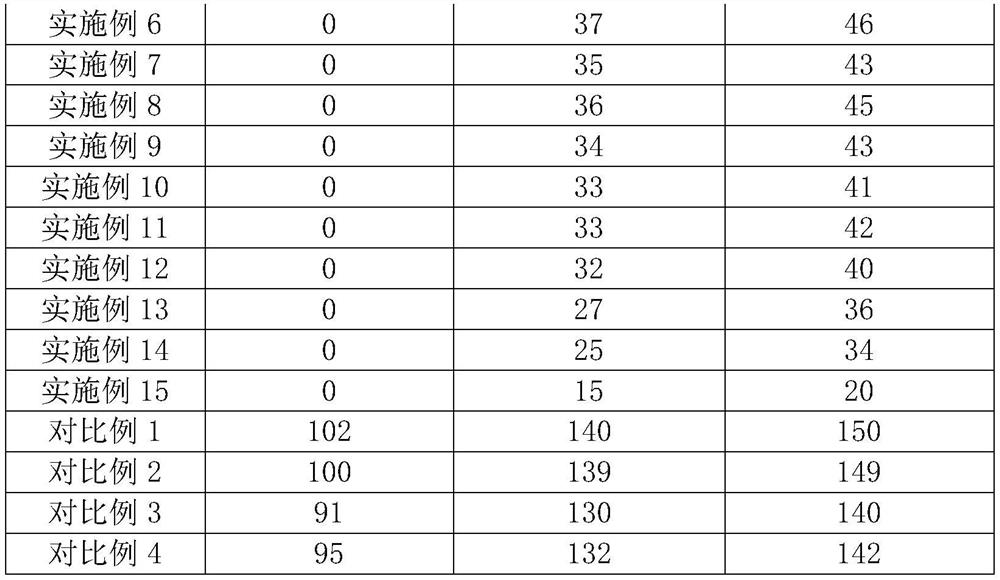

Production process of ball pin

ActiveCN109483177AAvoid crackingHigh surface hardnessFurnace typesPivotal connectionsStress concentrationFatigue damage

The invention discloses a production process of a ball pin, and relates to machining technologies. The production process of the ball pin is used for solving the problem that a common ball pin is prone to breakage. The production process comprises the following steps that (1) material selection and blanking are carried out; (2) forging and strengthening are carried out, and specifically a metal raw material in the step (1) is heated to 700-750 DEG C and then undergoes hot forging; (3) rough blank shaping is carried out, and specifically the forged metal is heated to 850-890 DEG C again, and then undergoes rolling shaping by using a die; (4) rough blank grinding is carried out; (5) heat treatment is carried out; and (6) post-processing is carried out. The production process of the ball pinhas the following advantages and effects that the ball pin formed through hot forging and rolling is not prone to crack due to the technological problem in the manufacturing process, then the ball pinis not prone to breakage due to stress concentration at the cracking position in the using process, moreover, the ball pin has relatively high surface hardness while the toughness of the core part isreserved by adopting the forming mode, then the fatigue damage is not prone to occurrence in the using process of the ball pin, and then the breakage is further not prone to occurrence.

Owner:ZHEJIANG TONGSHI AUTO PARTS

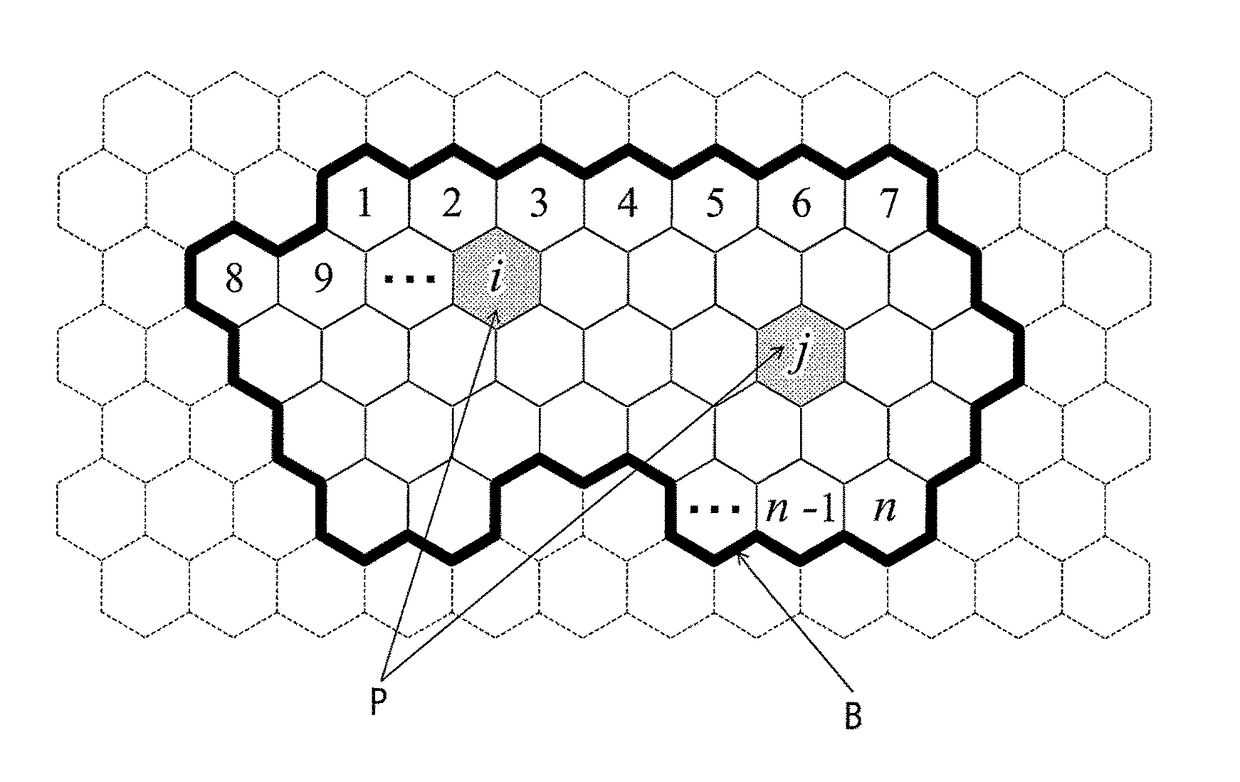

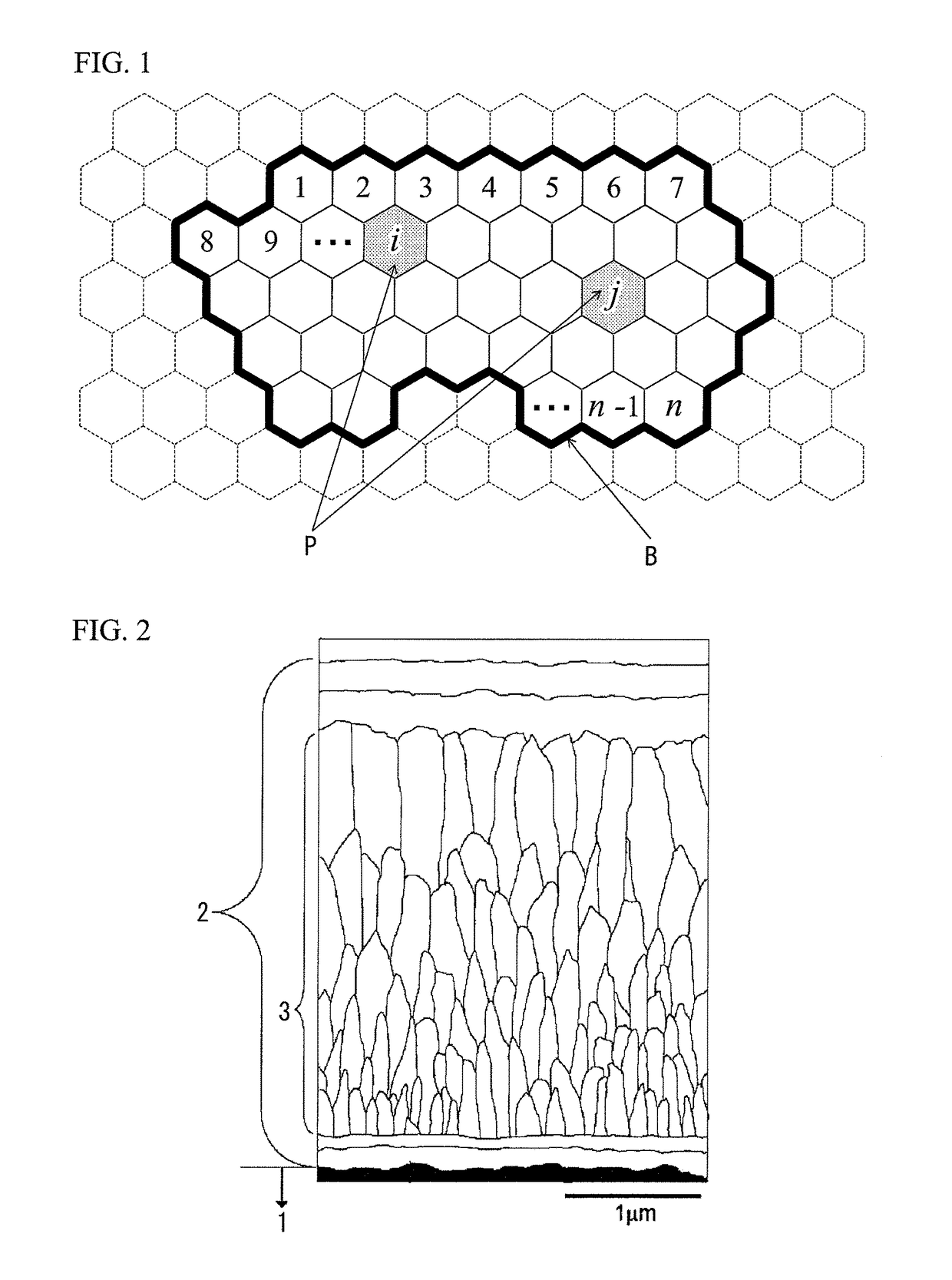

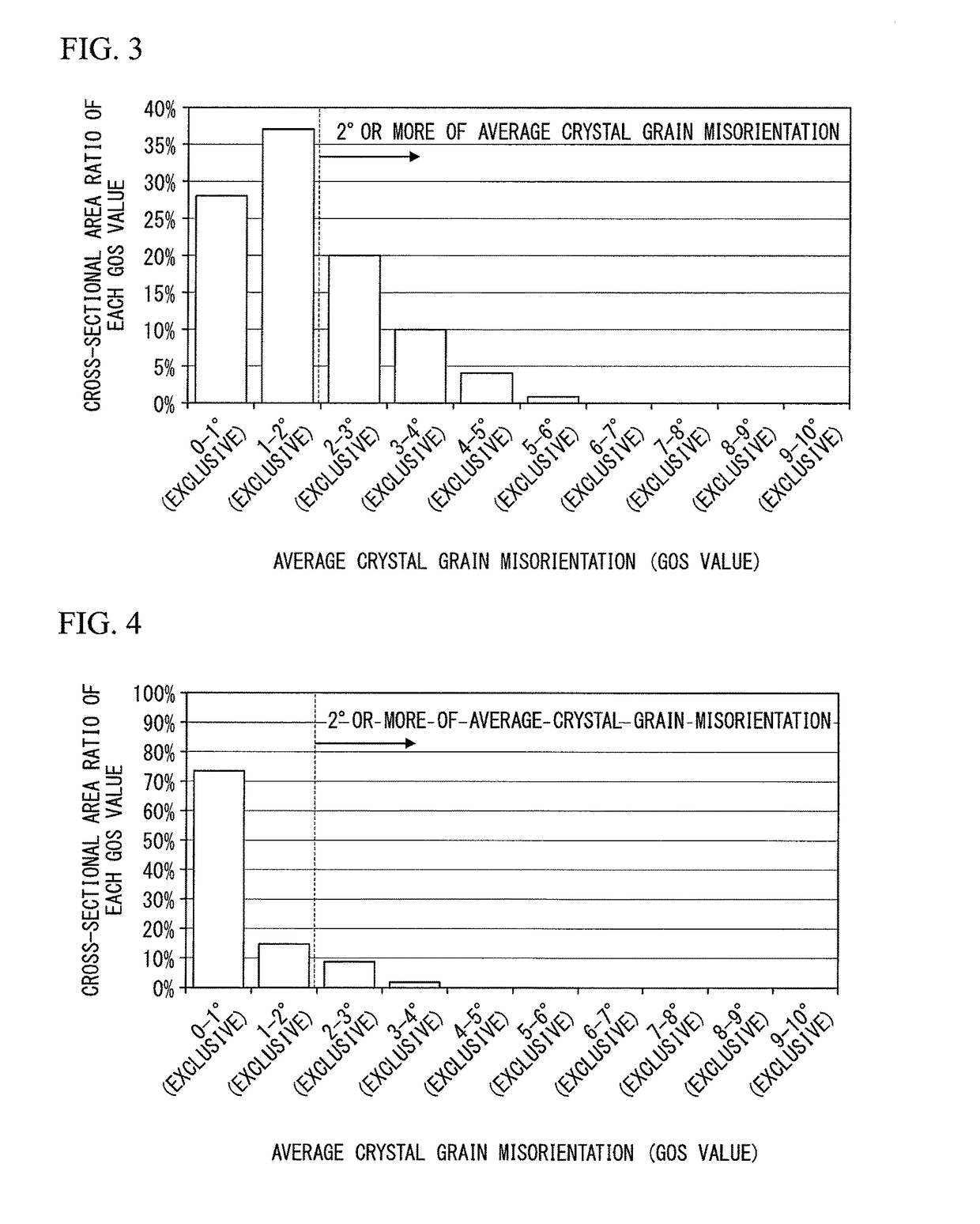

Surface-coated cutting tool having hard coating layer that exhibits excellent chipping resistance

ActiveUS20170198400A1Reduce resistanceImprove cutting performanceTurning toolsChemical vapor deposition coatingNitrideMaterials science

The hard coating layer includes at least a complex nitride or complex carbonitride layer expressed by the composition formula (Ti1-xAlx)(CyN1-y). The average Al content ratio xavg the average C content ratio yavg satisfy 0.60≦xavg≦0.95 and 0≦yavg≦0.005, respectively, each of the xavg and yavg is in atomic ratio. The crystal grains constituting the complex nitride or complex carbonitride layer include a crystal grain having the cubic structure. Predetermined average crystal grain misorientation and inclined angle distribution exist in the crystal grains having the cubic structure.

Owner:MITSUBISHI MATERIALS CORP

Extrusion process of ultra-thin aluminum alloy profile

ActiveCN109821914BHigh strengthPrevent shrinkageExtrusion control devicesIngotUltimate tensile strength

The invention relates to an ultra-thin aluminum alloy profile extrusion process. The process comprises the following steps that aluminum alloy cast ingots are heated, extruded, subjected to heat preservation, quenched, straightened and subjected to heat preservation, ultra-thin aluminum alloy profile is obtained, the extrusion discharge temperature is 490-510 DEG C, air-cooling is adopted for cooling at first, then water mist is adopted for rapid cooling, artificial aging treatment is conducted after straightening, a two-stage forced quenching scheme is adopted for rapid cooling, the problem that water is directly used for cooling, the cooling speed is too high, and consequently metal is fractured is solved, meanwhile, air is used for cooling at first, then water is used for cooling quenching, a certain degree of toughness can be maintained while the strength is improved, a heat insulation box is used for heat preservation, the situation that water is splashed on a mold in the quenching process is avoided, the usage safety is improved, and the service life of the mold is prolonged.

Owner:FUJIAN MINFA ALUMINUM

Reciprocating scraping type bamboo green removal device

InactiveCN104385398BRetain toughnessImprove work efficiencyCane mechanical workingPlant material mechanical workingEngineering

The invention aims at providing a reciprocating scrape type bamboo outer skin removing device, comprising a rack, a knife rest and a knife rest driving mechanism, wherein the knife rest is connected with the knife rest driving mechanism, and mutually matched guide mechanisms are arranged between the knife rest and the rack so as to make the knife rest move up and down on the rack; at least one set of blade group is arranged on the knife rest, the blade group internally comprises two opposite blades which are connected with the knife rest through an elastic pressing mechanism so as to make the two blades in the same blade group able to clamp the bamboo passing between the two blades; the rack is further provided with a position limiting mechanism for limiting the position of the bamboo. The reciprocating scrape type bamboo outer skin removing device changes the working manner of a bamboo outer skin removing machine in the prior art, uses the reciprocating blades to simulate manual bamboo outer skin scraping, is able to improve the working efficiency greatly, lowers the manual labor intensity, and can keep the bamboo tenacity to the maximum extent.

Owner:李静

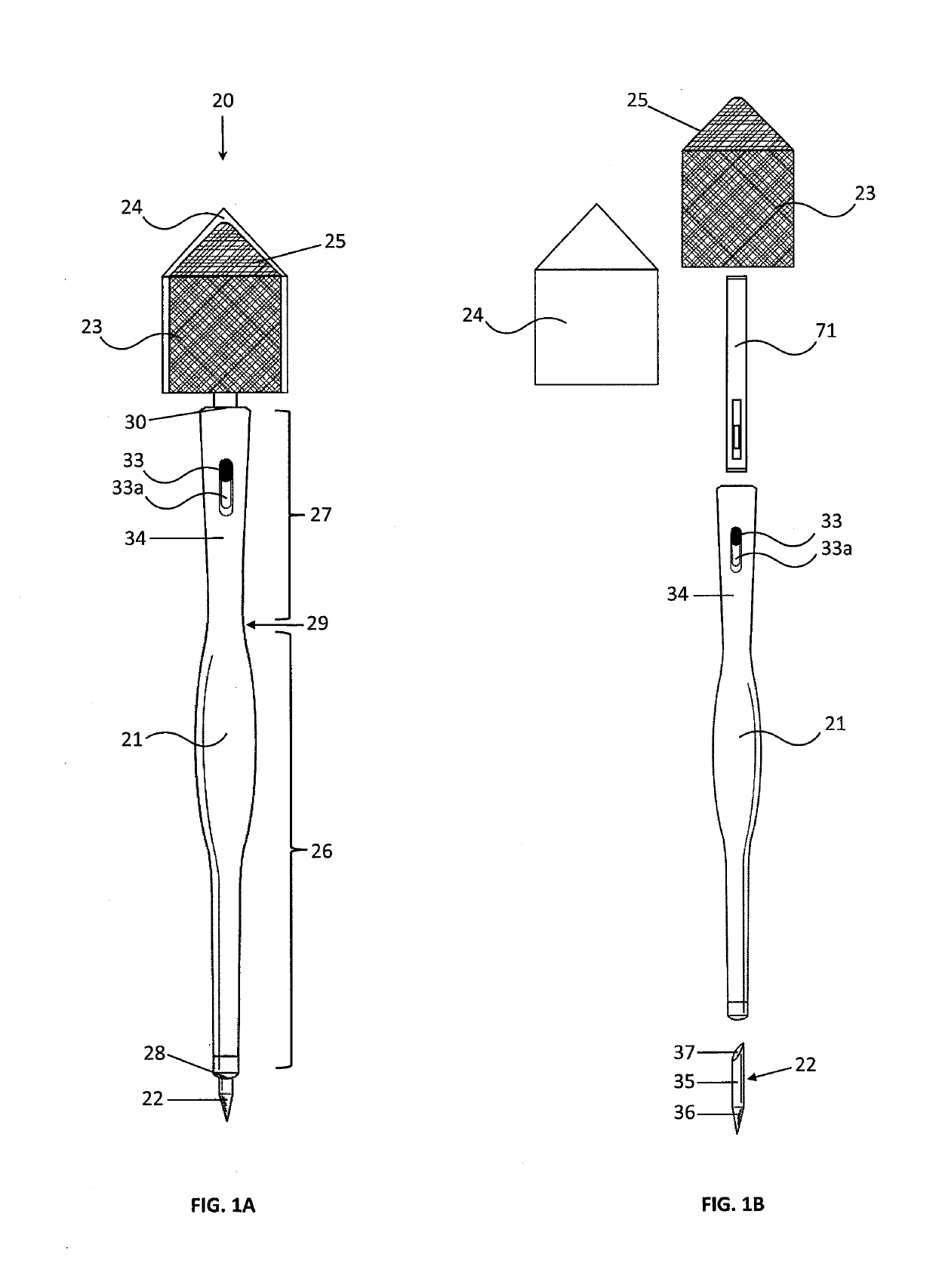

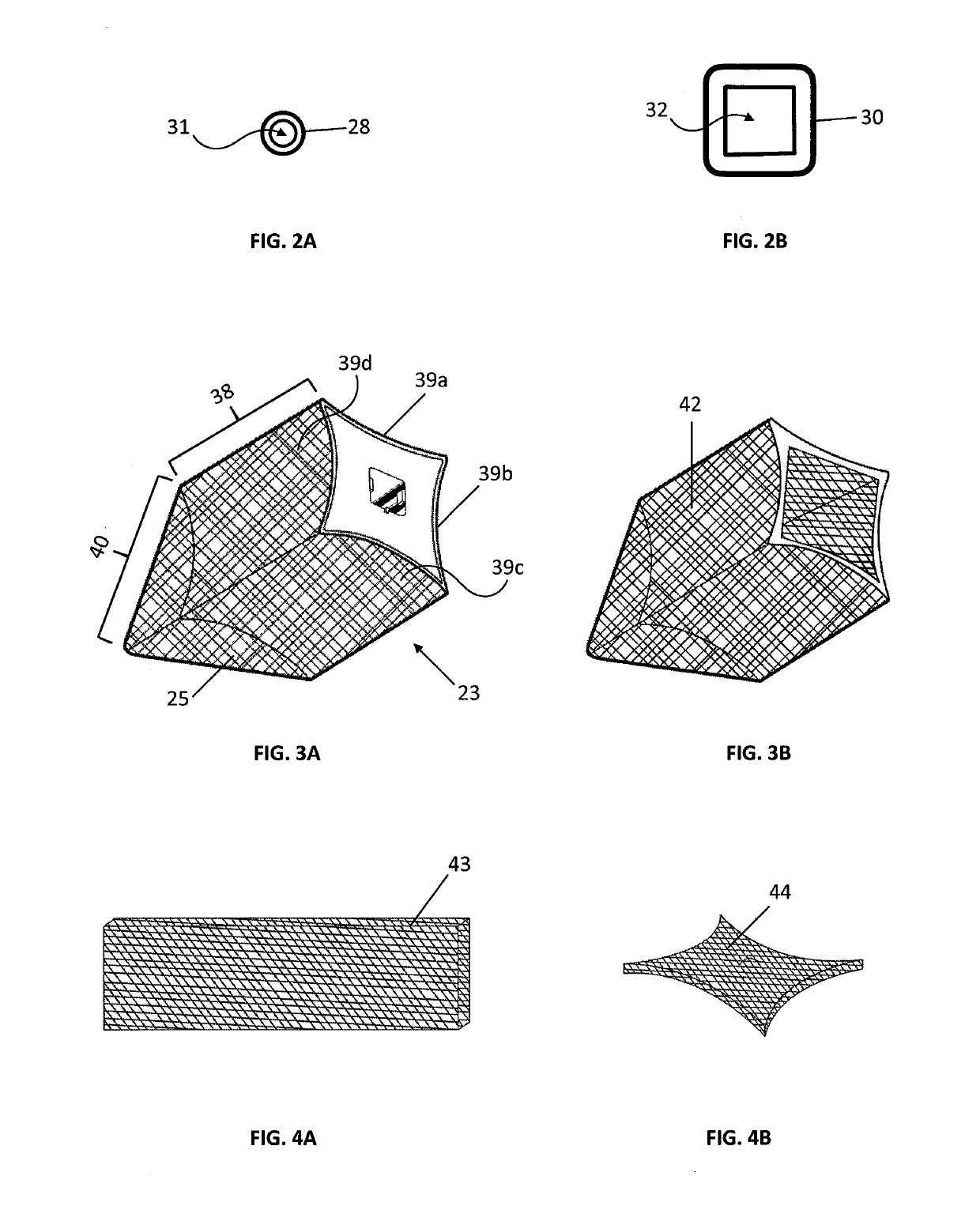

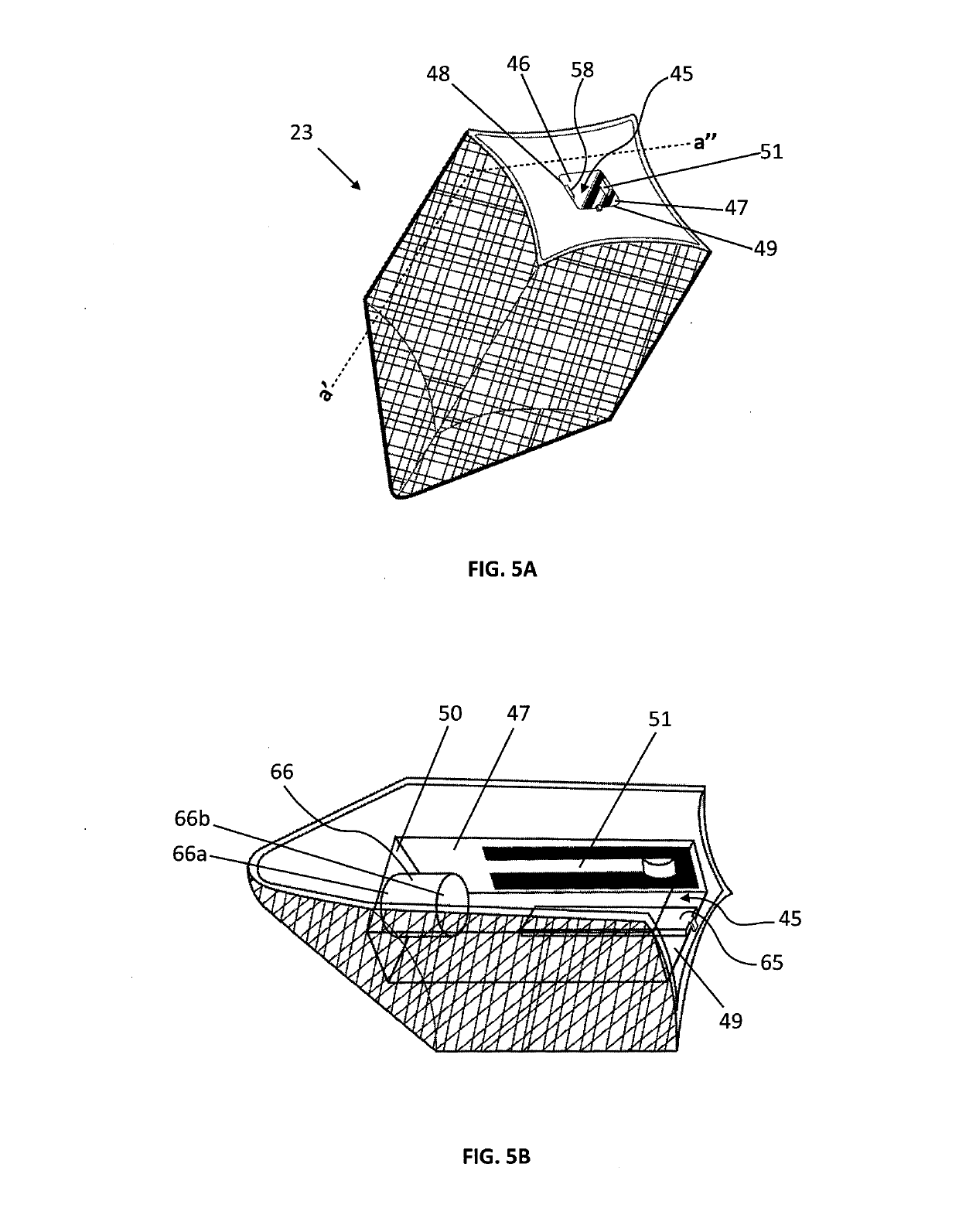

Tool for removing nail polish and buffing nails

A nail care tool having an ergonomic elongated handle and a removable operational head attached to the handle is presented. The tool also has a removable scraper or end tip inserted in one of the ends of the handle, useful in cleaning critical cuticle areas. The operational head has adhered to it a lining of material commonly used in the nail care and maintenance processes; for instance, it may be a nail polish removal material or a nail buffing material. In some embodiments of the invention, the ergonomic handle and the head are interconnected in a nonpermanent manner by a male / female system; in such embodiments, the head may be engage or connected to the handle by screwing the head to the handle and, it may be disengaged or disconnected, by simply unscrewing it from the handle. In other embodiments of the invention, the handle is connected to the head by a hold / release system, allowing the User to connect the head and the handle by inserting an already assembled cartridge inside the handle into a rectangular internal cavity on the head. In order to disconnect the head from the handle, the User slides backwardly a button on the ergonomic handle without even having to touch the head. The hold / release system allows the User to easily attach or detach heads to the handle. The operational removable head required for any of the embodiments may have different shapes and operational lining materials, in order for the User to use the tool as an applicator—meaning being able to remove most of the nail polishes—or as a nail buffer.

Owner:ALICEA GARCIA JOHANNA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com