Mobile phone battery case and forming process thereof

A mobile phone battery and molding process technology, applied to the structure of telephones, etc., can solve the problems of increasing raw material costs, complicated processing technology, and long processing hours, and achieve the effects of improving the rigidity of mobile phones, enhancing the heat dissipation effect, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

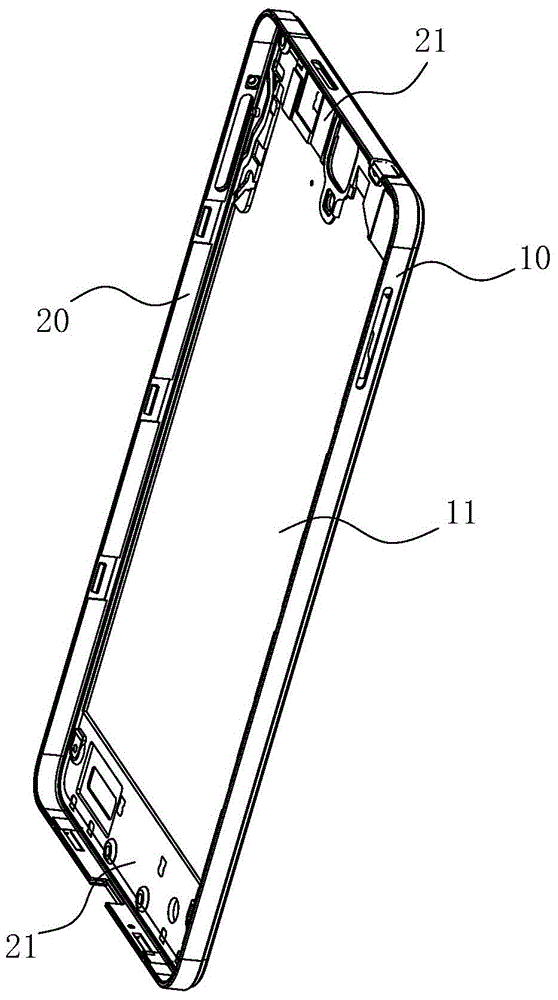

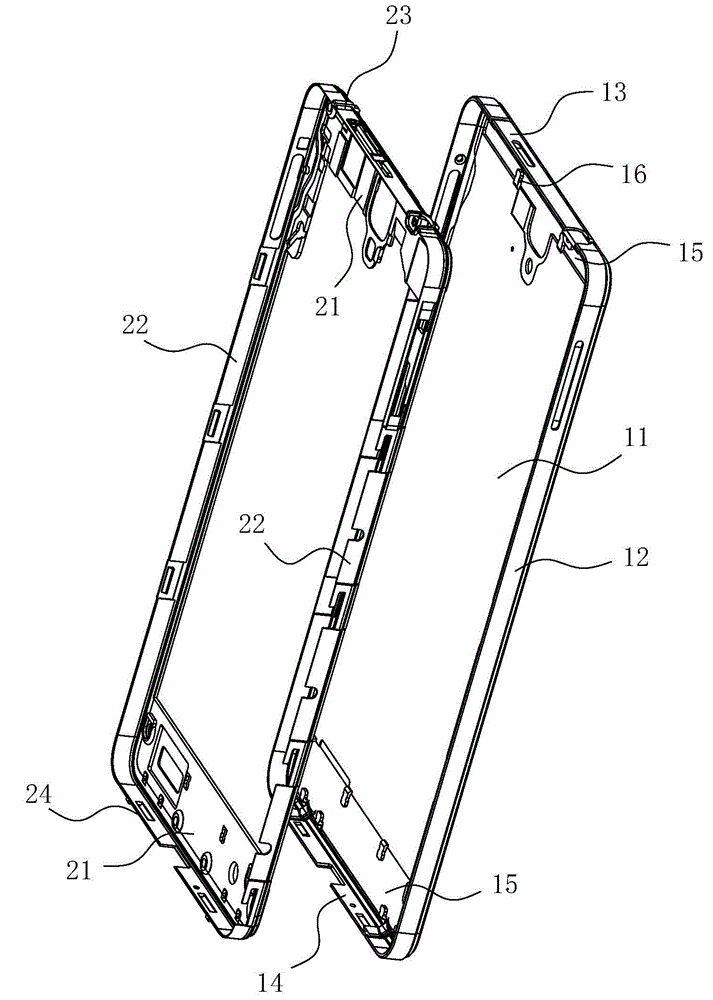

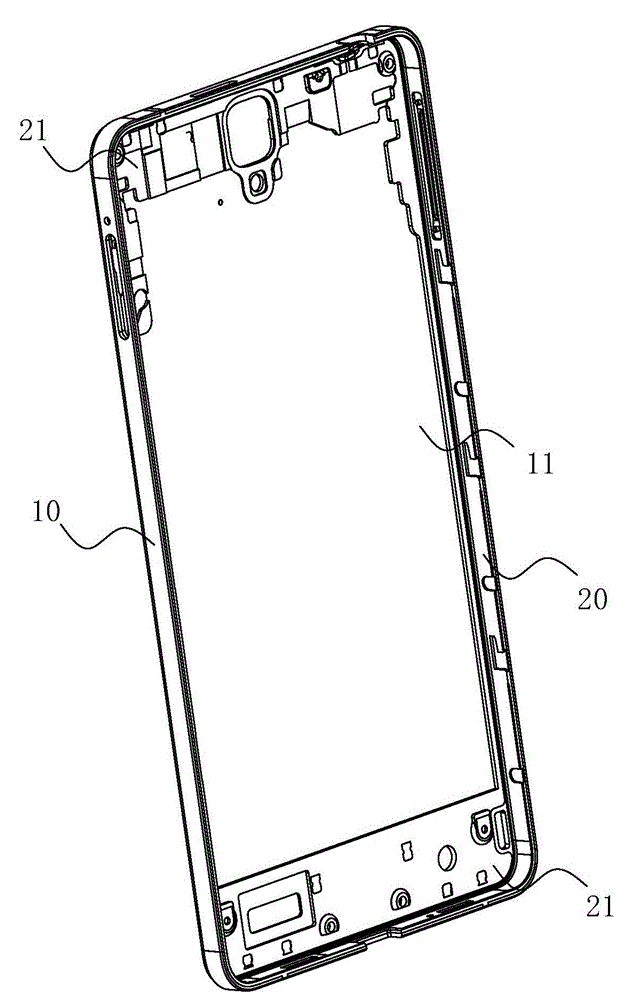

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0041] Such as Figure 1-8 As shown, in this embodiment, a mobile phone battery case according to the present invention includes a metal case 10 formed by punching a metal sheet and processed by CNC, and a metal case formed inside the metal case 10 by injection molding. The plastic part 20 forms a connection structure on the side of the plastic part 20 away from the metal housing 10 to connect with the electronic components inside the mobile phone.

[0042] Such as figure 2 As shown, the metal shell 10 includes a metal cover 11 and a metal frame arranged around the metal cover 11 . The metal frame includes two metal side frames 12 parallel to each other and equal in length, and a metal upper frame 13 and a metal lower frame 14 connecting the two metal side frames 12 at both ends. Chamfering stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com