Patents

Literature

330results about "Plant material mechanical working" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

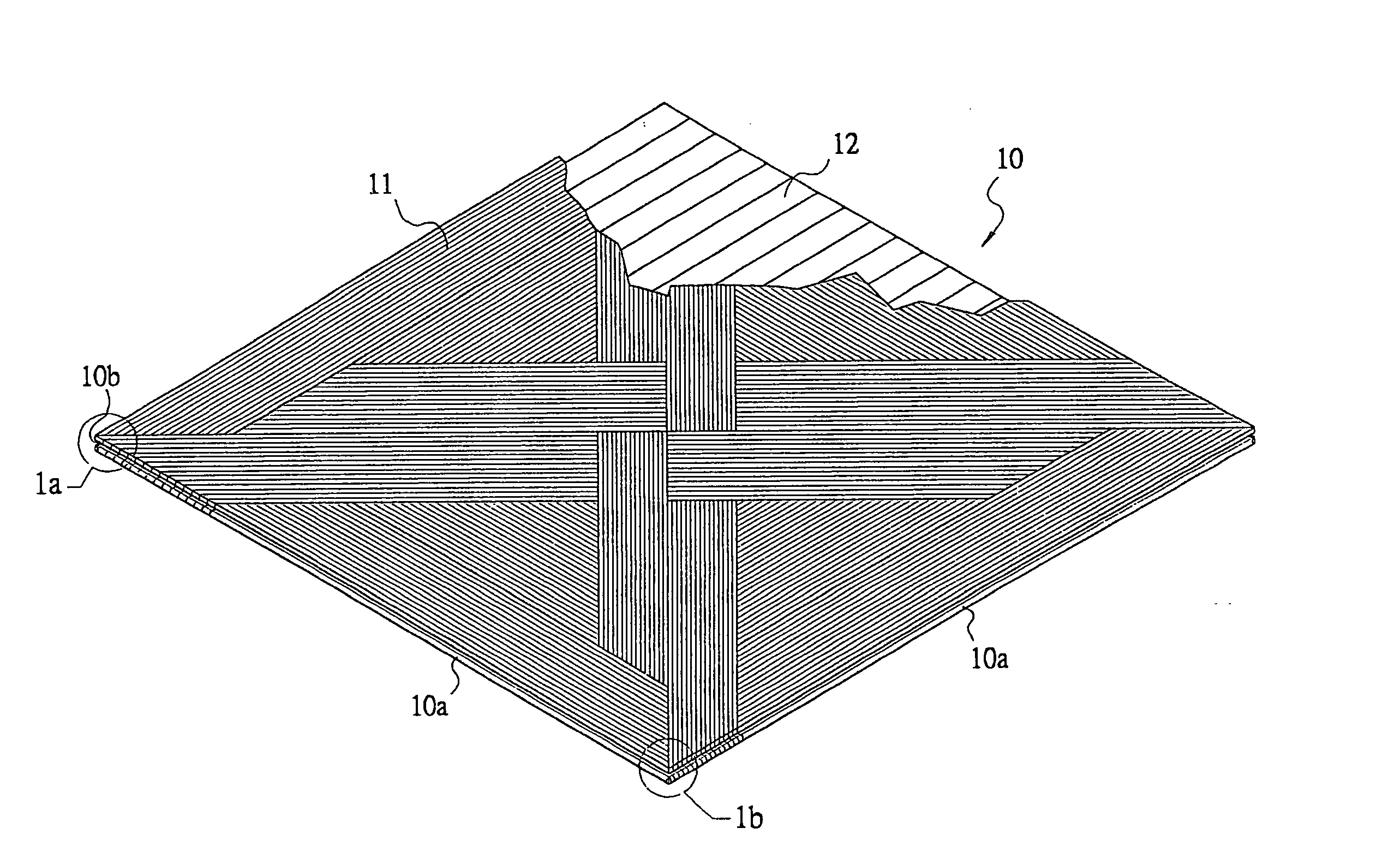

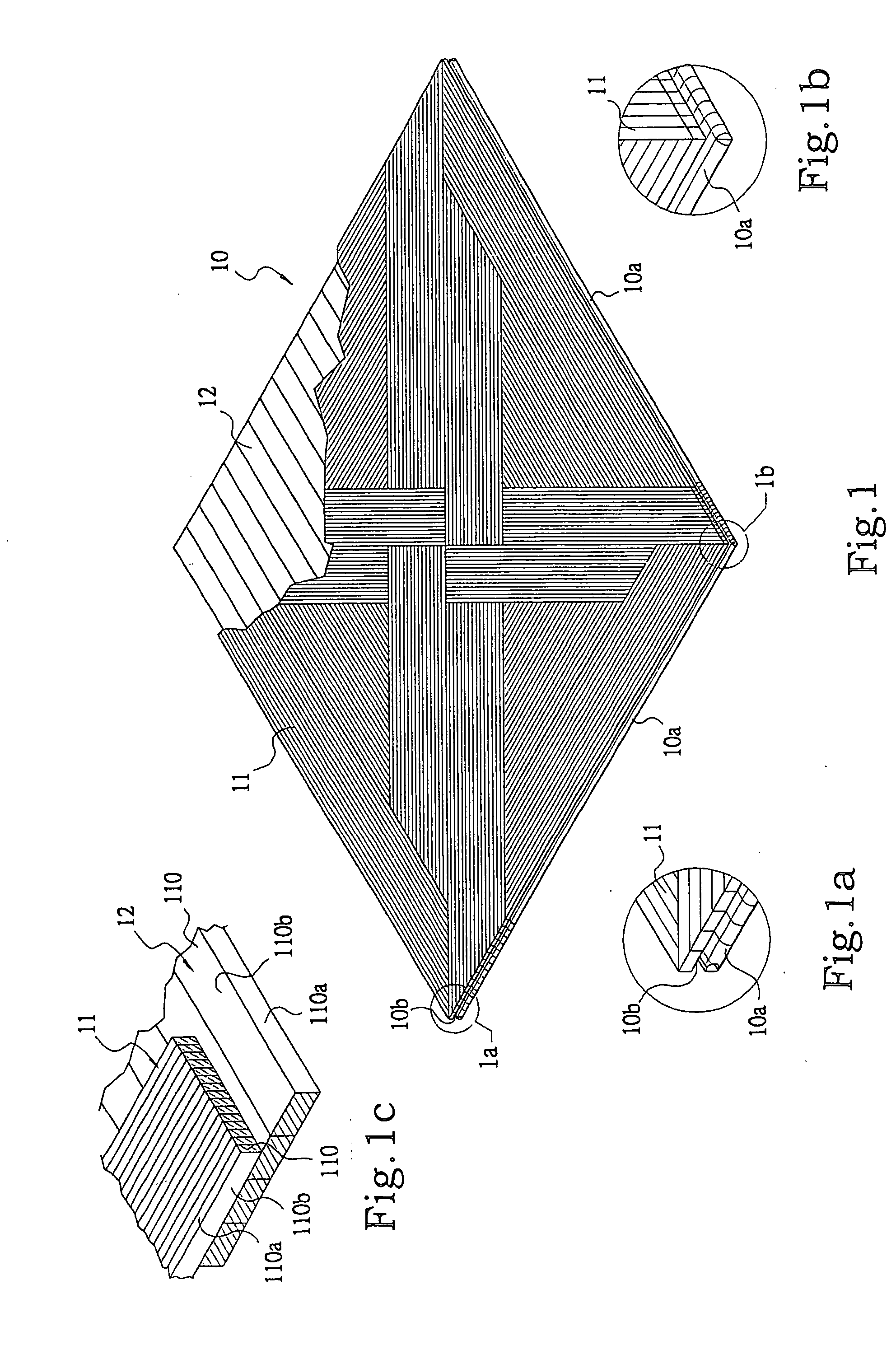

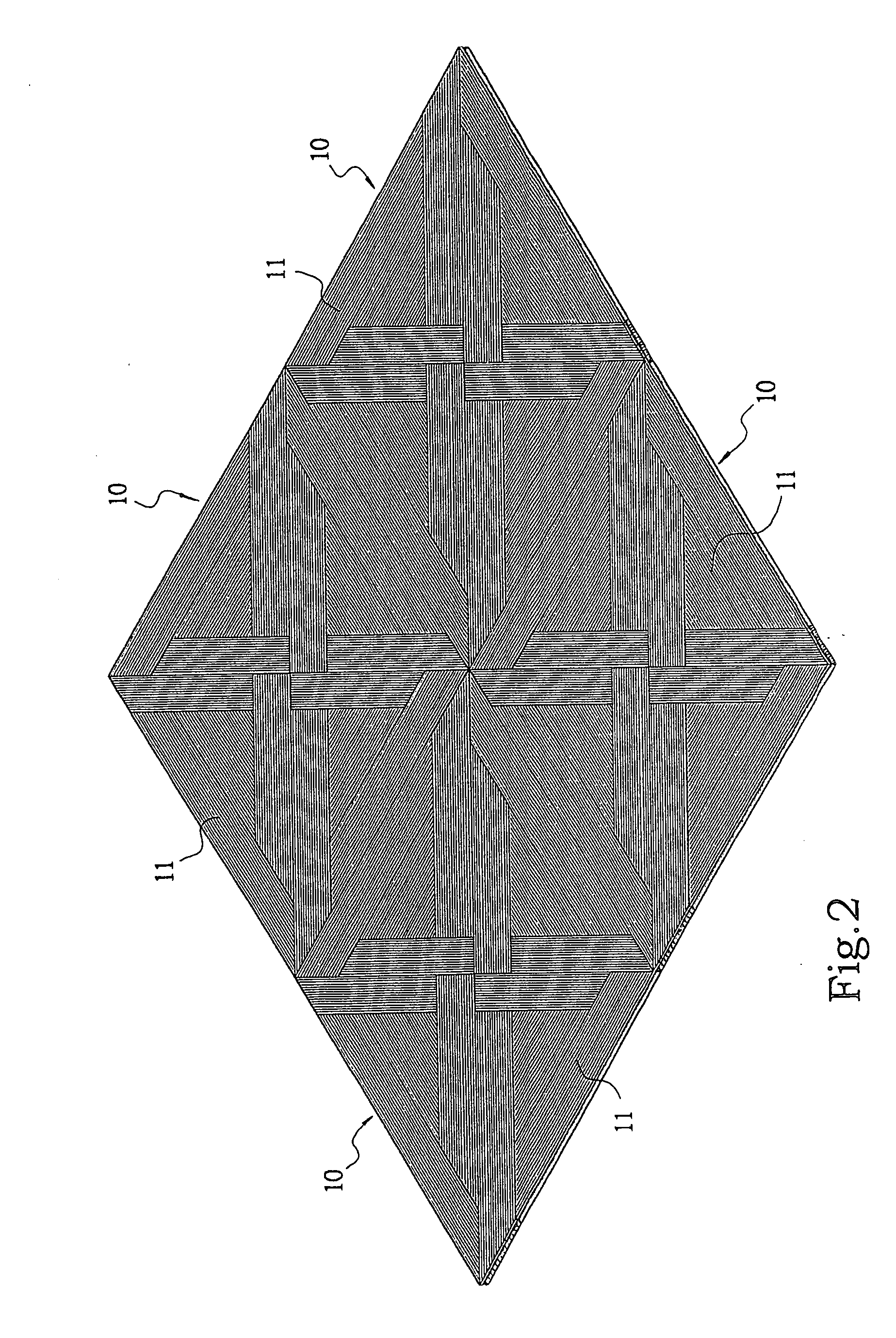

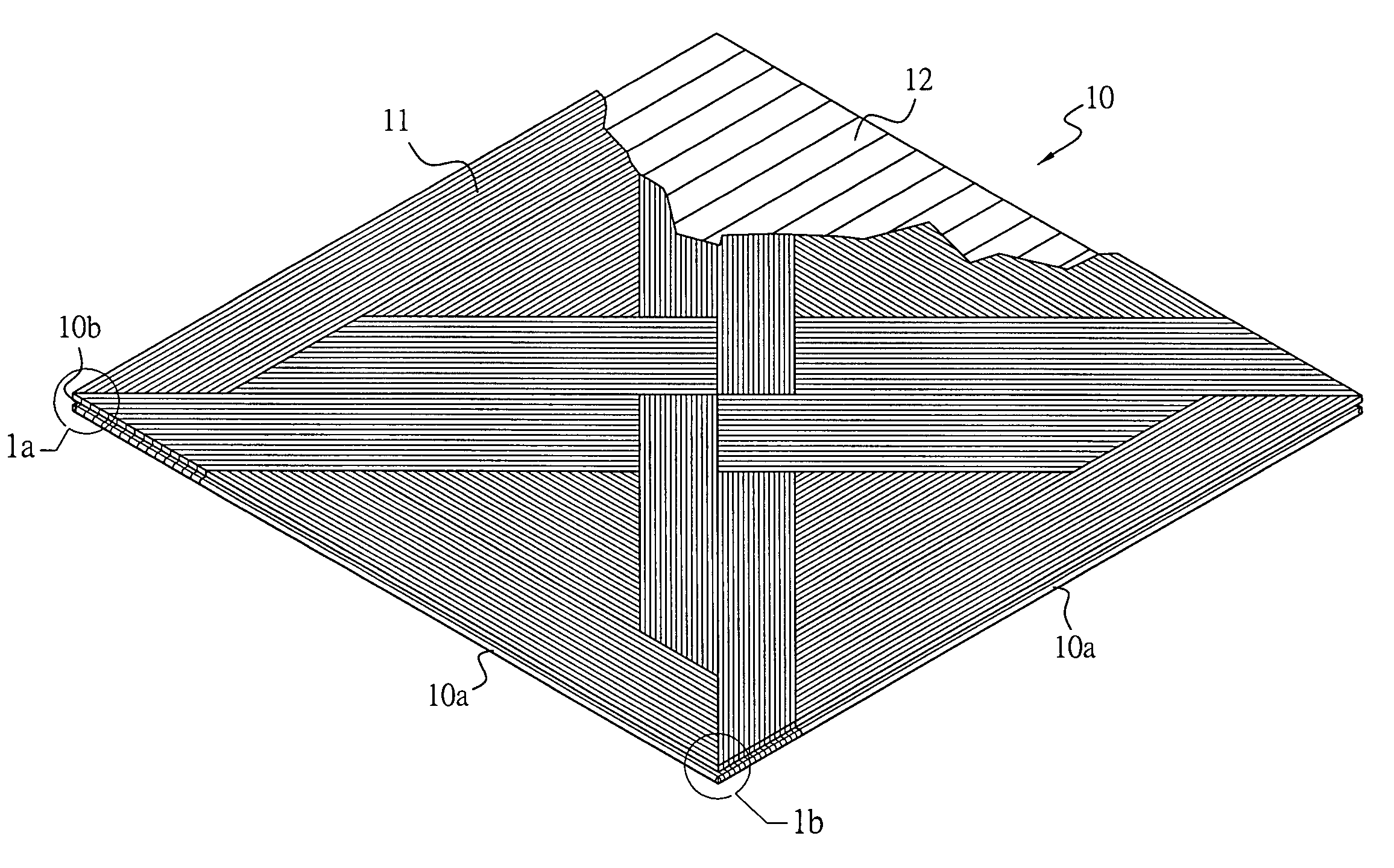

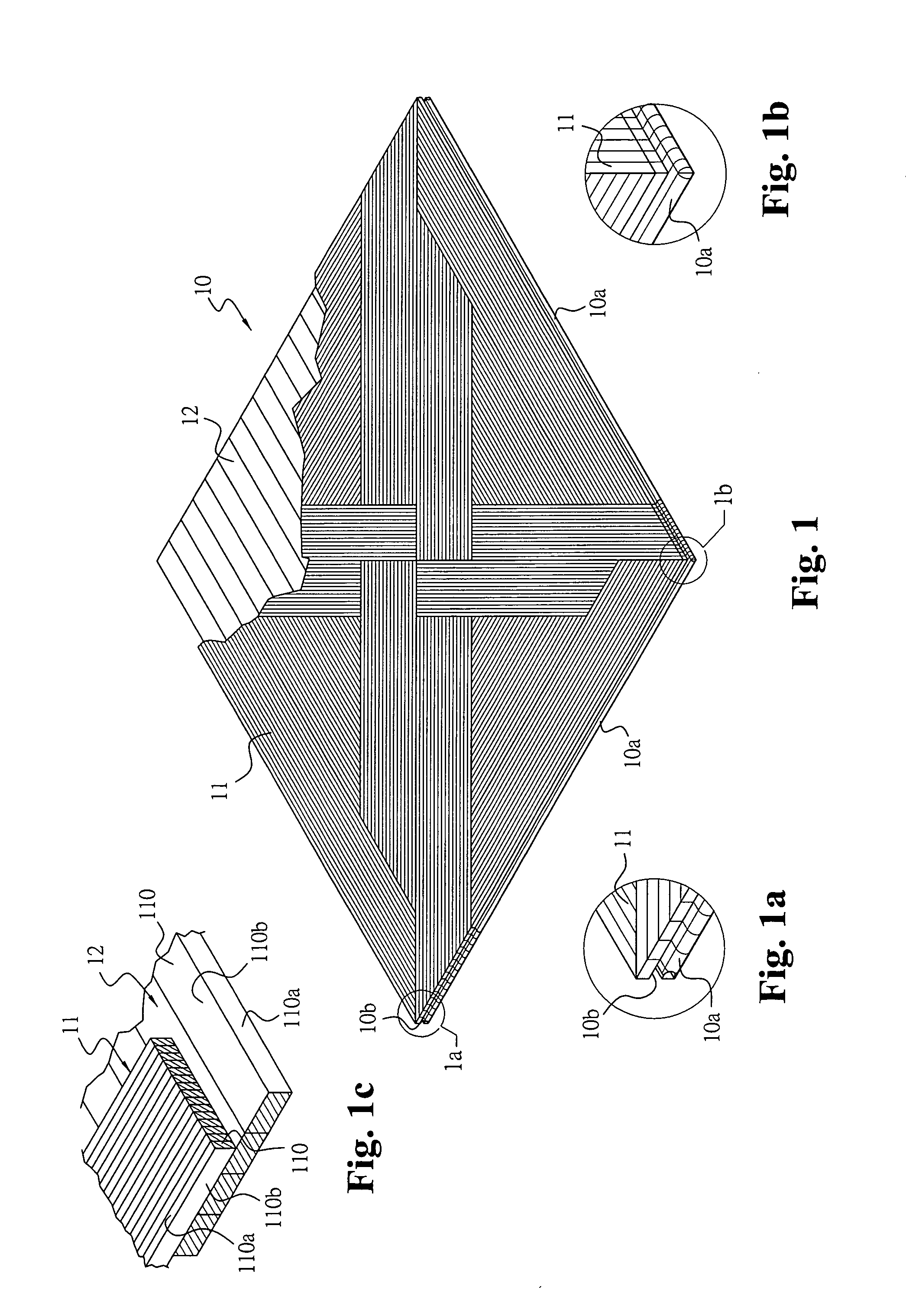

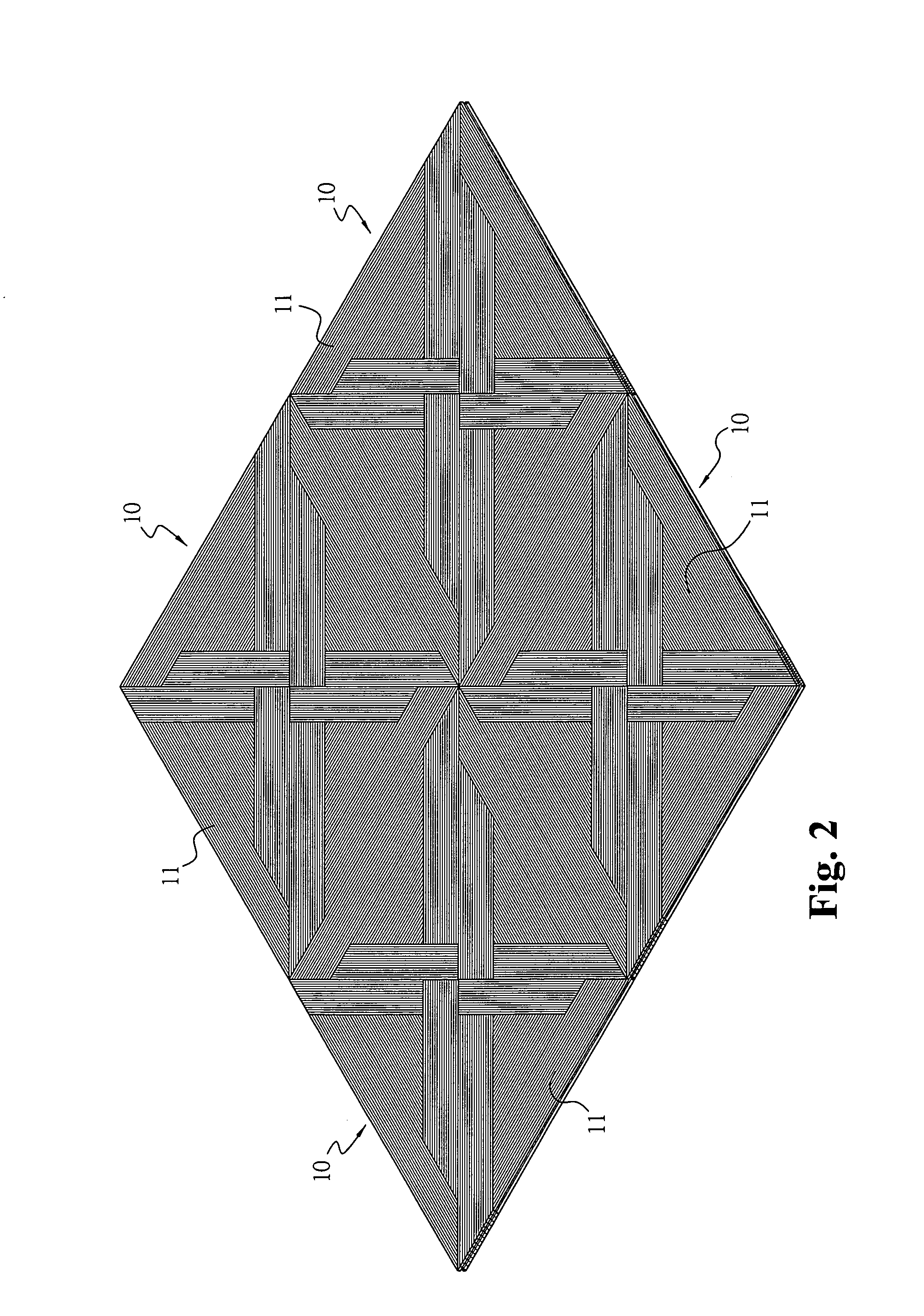

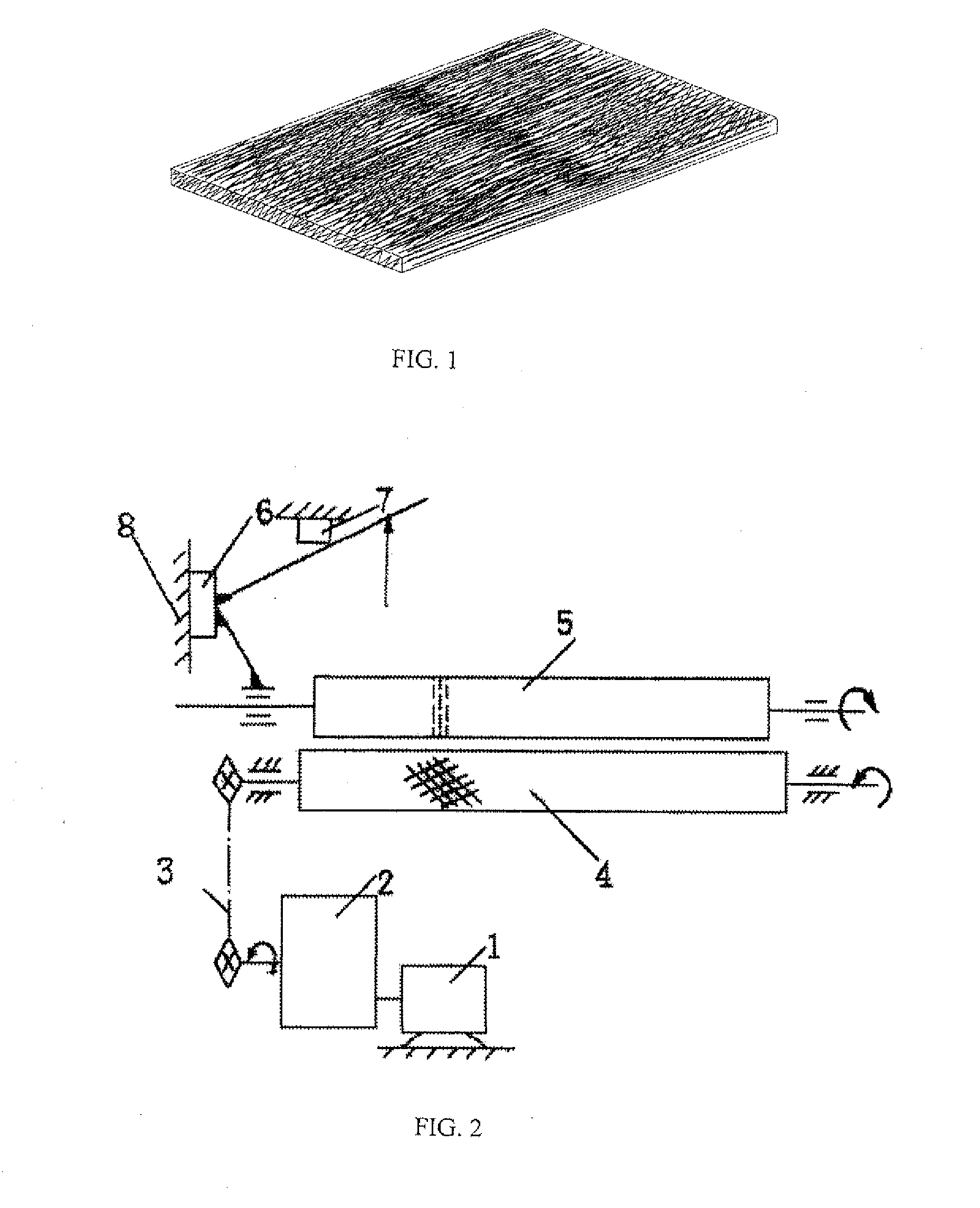

Bamboo mat board and method for producing the same

ActiveUS20050161116A1Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerEngineering

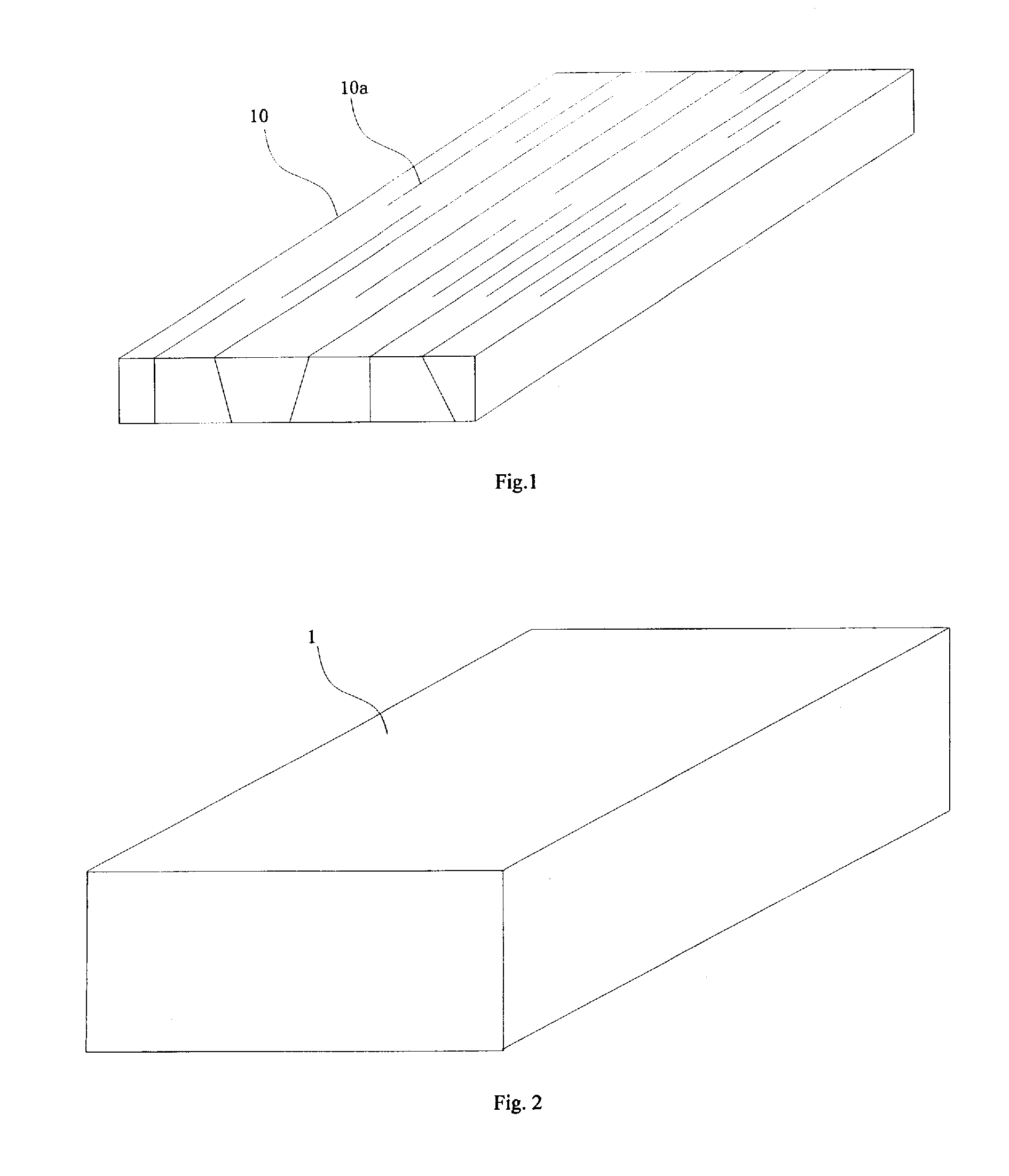

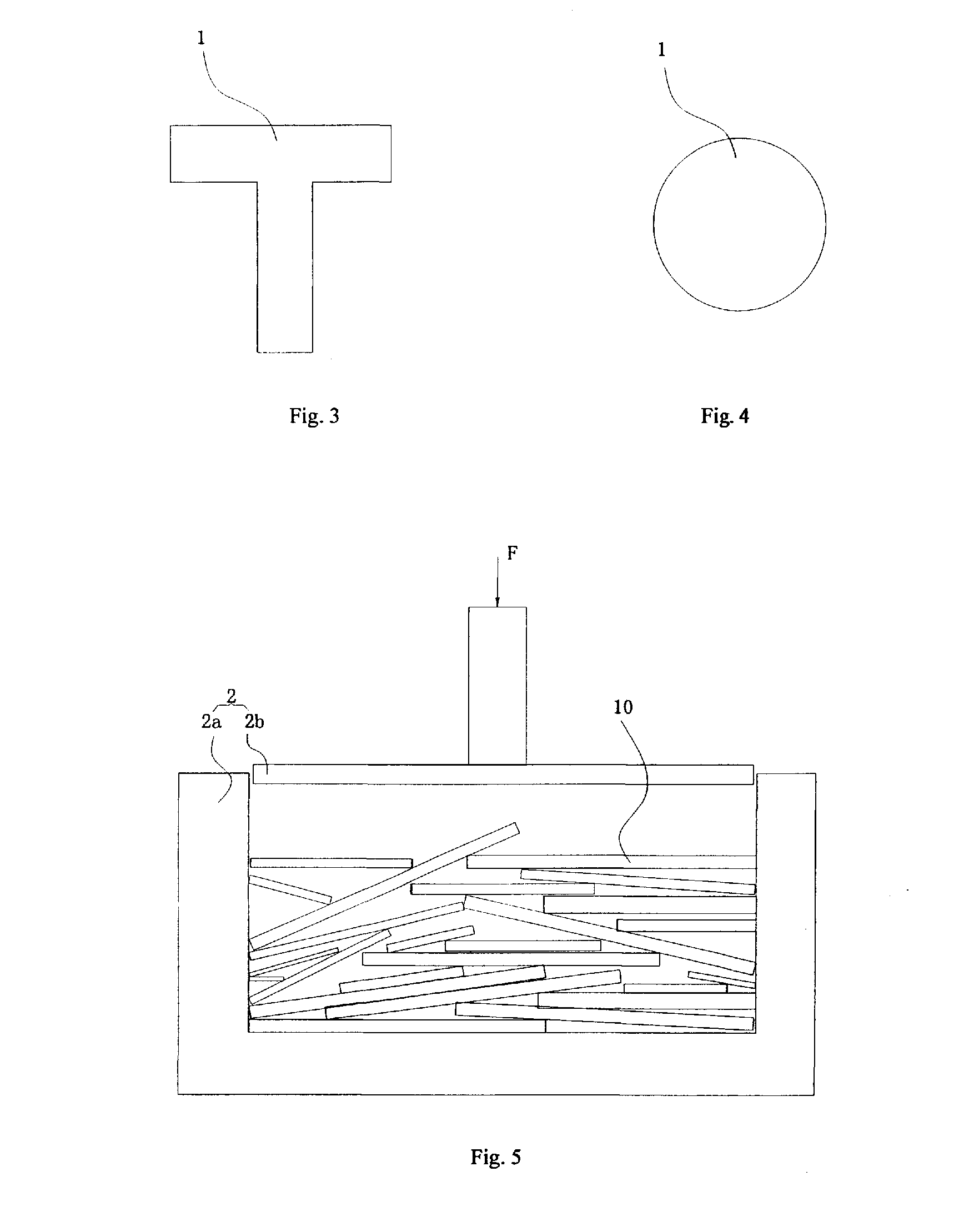

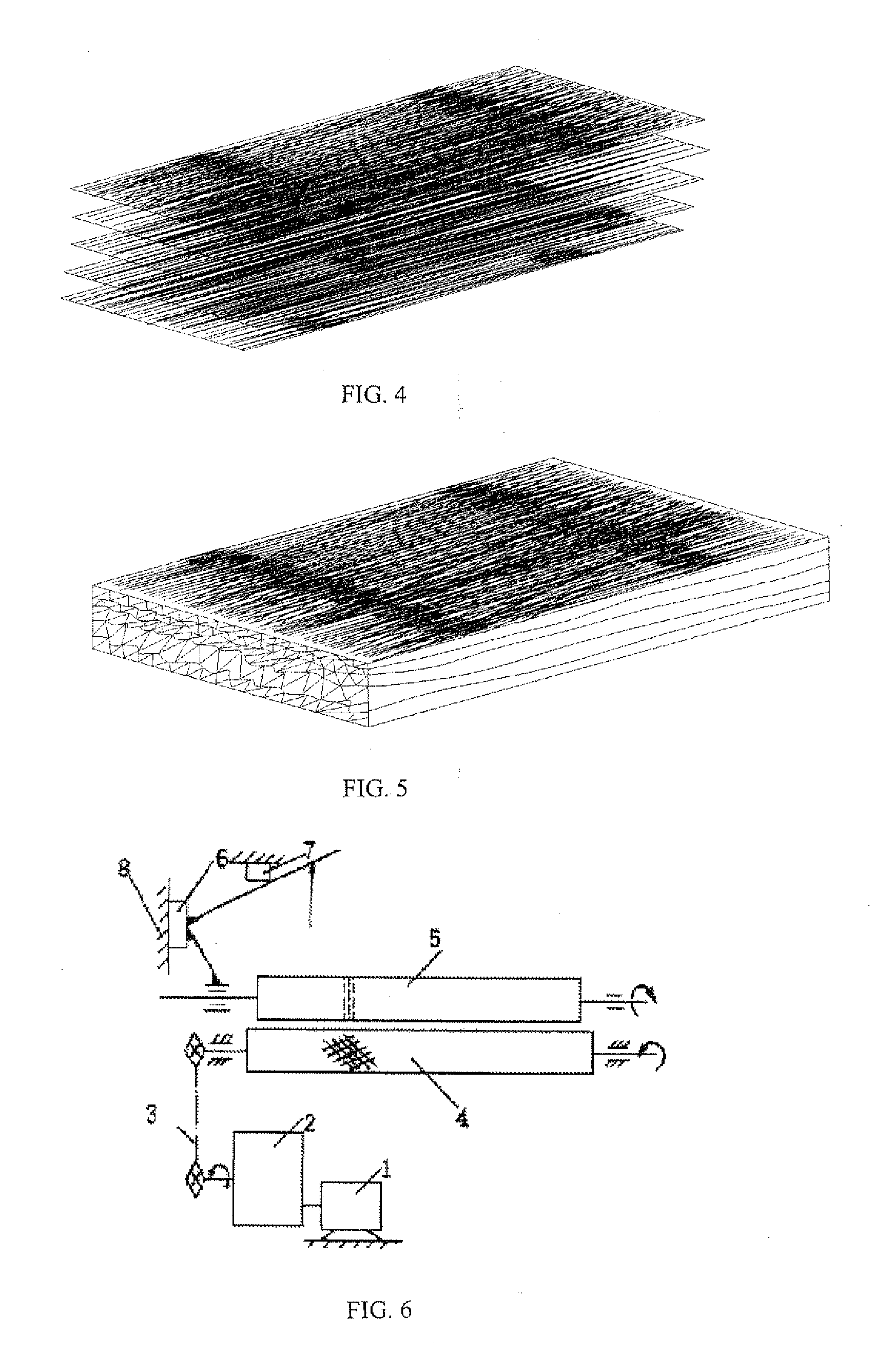

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

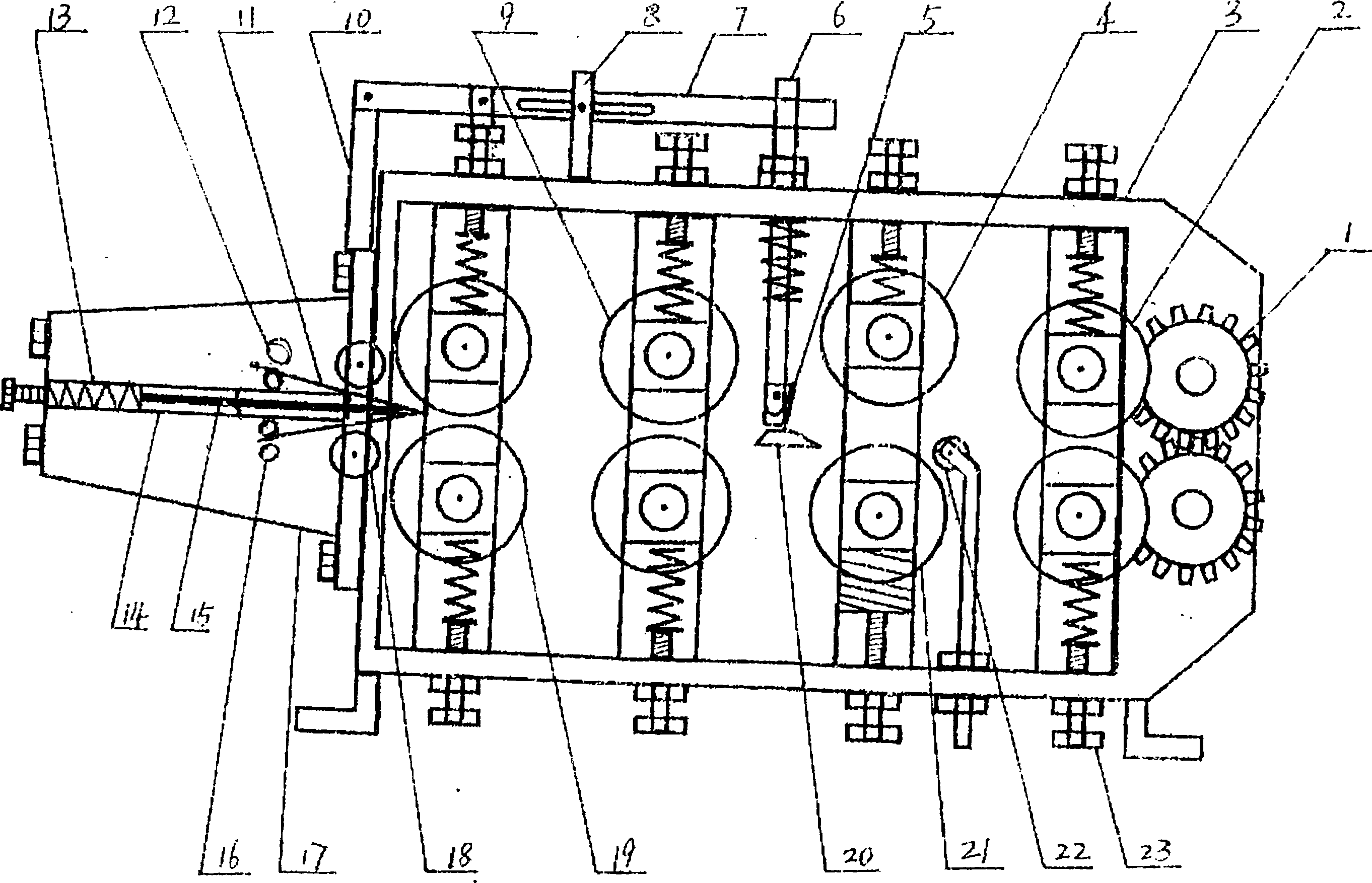

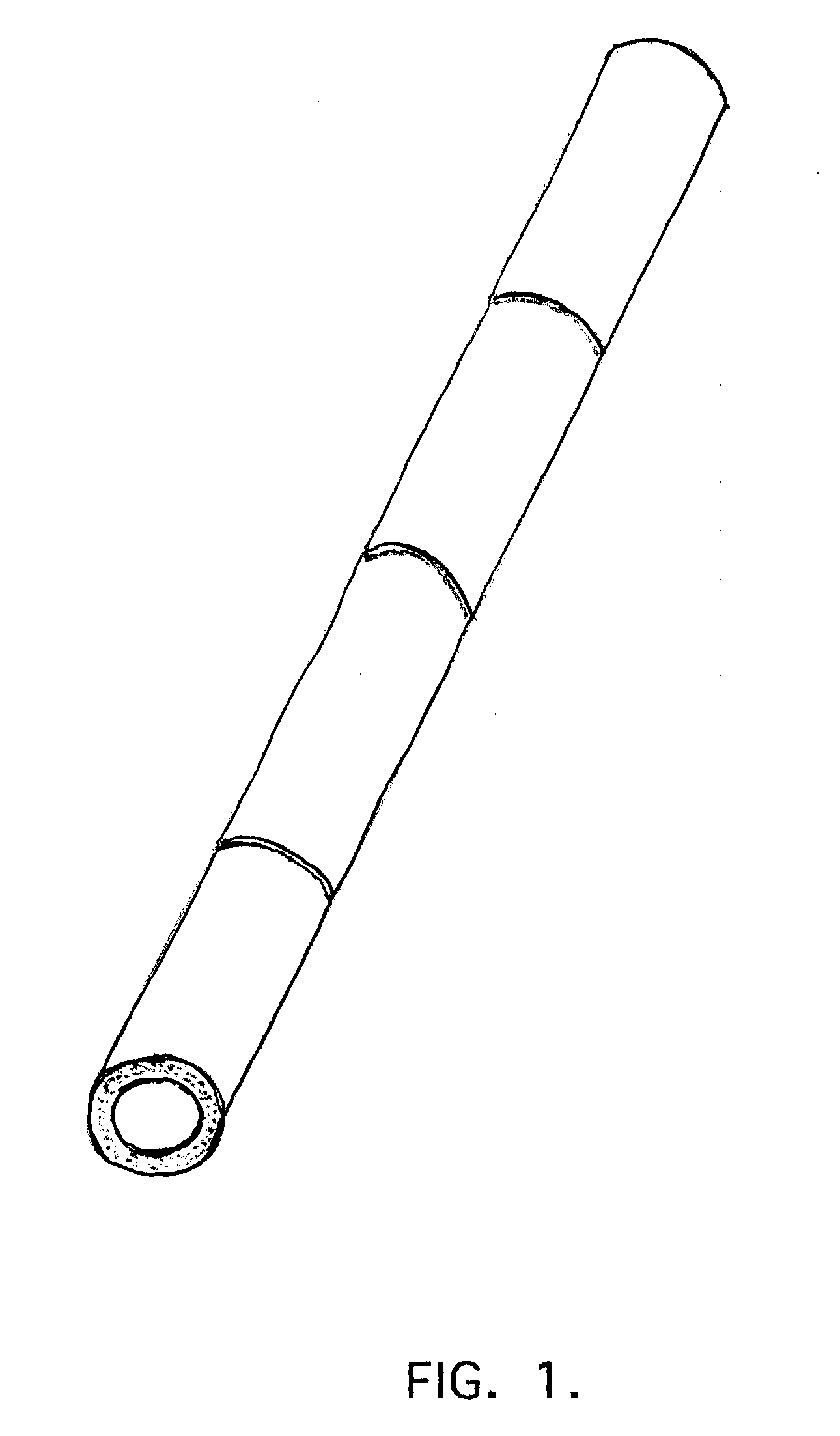

New type thin bamboo strip splitting machine

InactiveCN1785619AImprove quality requirementsControl uniformityCane mechanical workingVeneer manufactureMechanical engineering

A bamboo strip making machine is composed of plate-type machine frame, feeding gears, bamboo splitting plate, spring and regulating screw bolt, blade, movable rod, blade supporter, and bamboo strip driving gears. It features that the wheel attached to planer, green joint remover, auxiliary unit and operation regulator are additionally used.

Owner:周云龙

Bamboo mat board and method for producing the same

ActiveUS7021346B2Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerMechanical engineering

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

Method for Making Plywood and Dimensional Lumber from Arundo Donax L. or Bamboo

ActiveUS20070125446A1Reduce dependenceConstruction materialCane mechanical workingEngineeringFire retardant

A method of producing a virtually fireproof plywood from perennial grasses such as Arundo donax Ligneous, various bamboo strains, or a blend thereof, by first weaving the stalks of these plants into a mat and then layering these mats and binding each layer with any one of several commercial resins mixed with potash for the purpose of enhancing the board's fire retardant quality. The result is the formation of a finished product with structural board attributes and an exceptionally high flash point in relation to other manufactured board products made from forest materials.

Owner:ABDULNASER ABDULMALIK +1

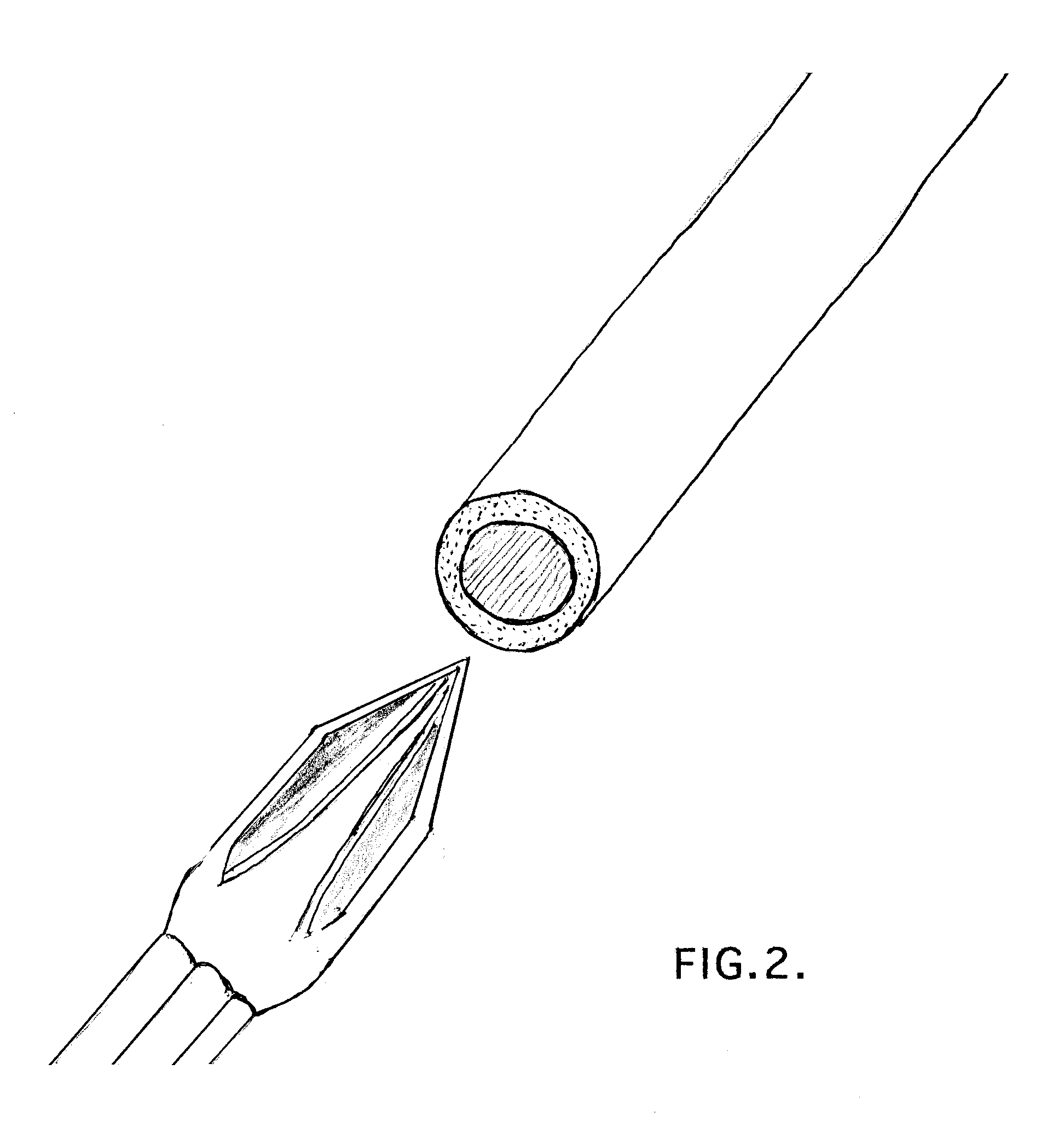

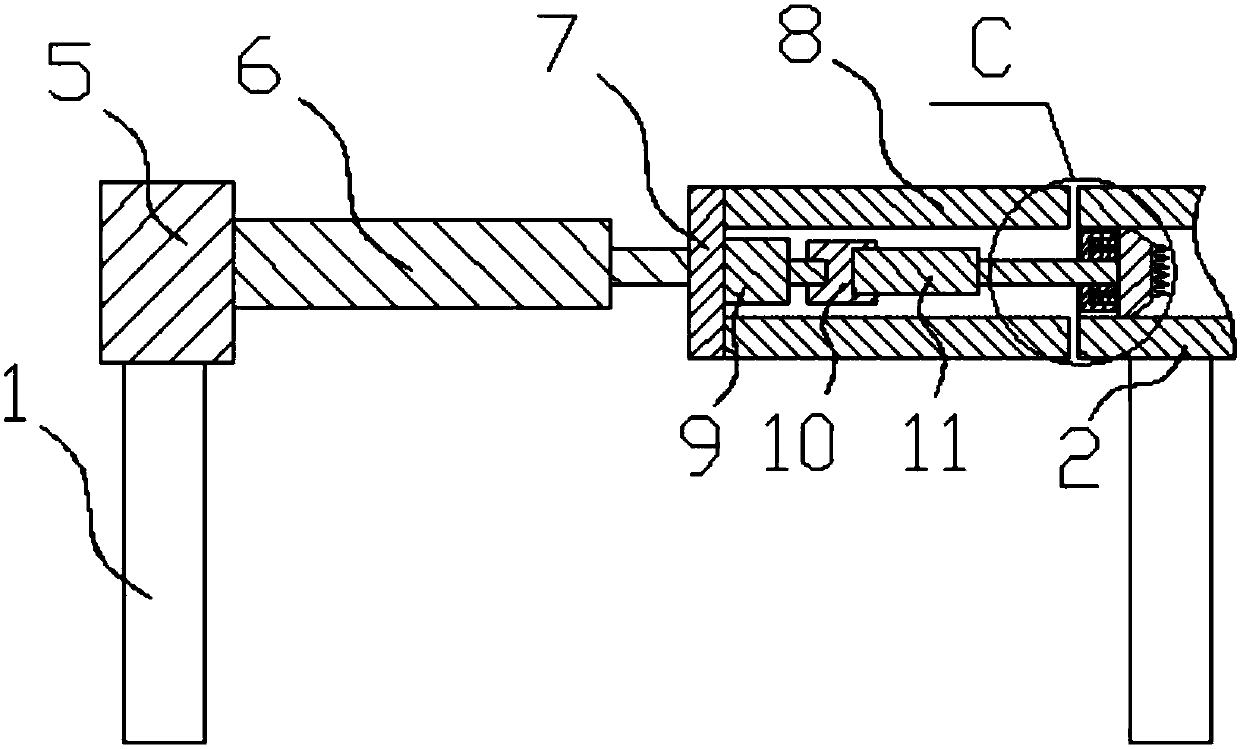

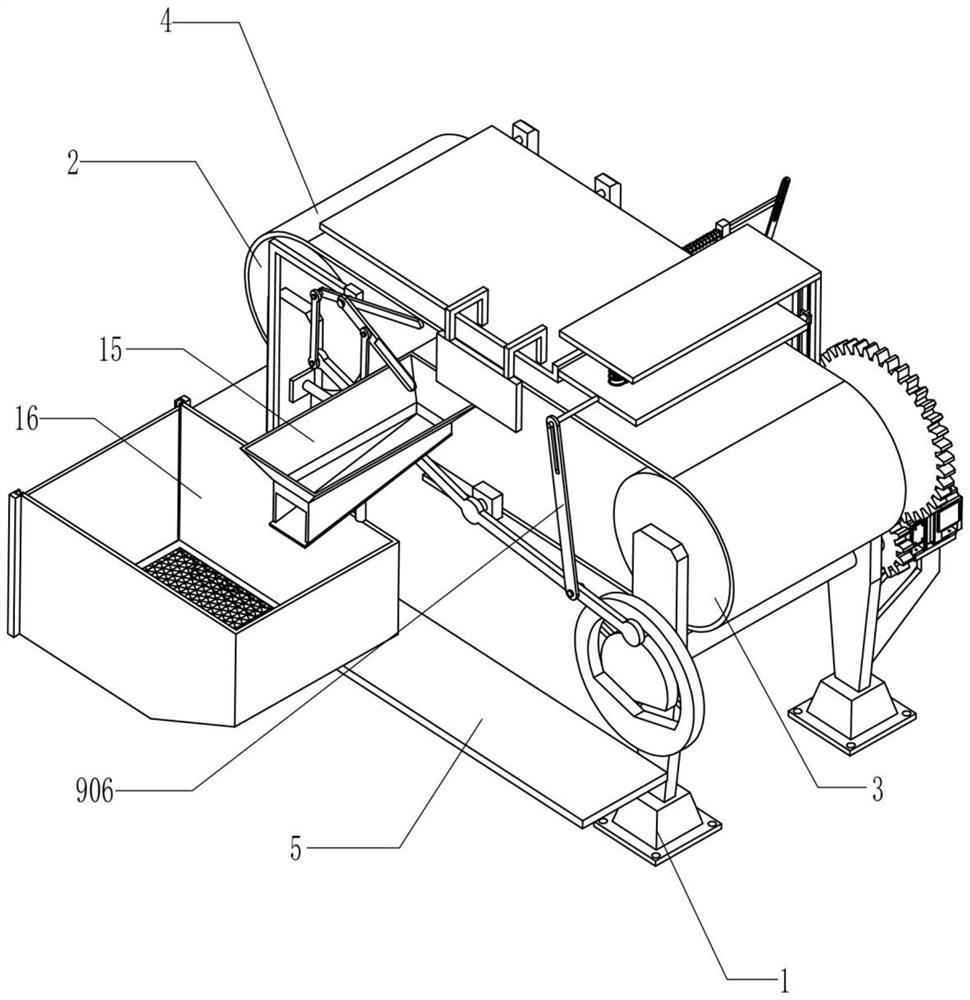

Inner segment removing machine

ActiveCN104942926AEasy to interveneAvoid scratchesCane mechanical workingPlant material mechanical workingEngineeringPunching

The invention discloses an inner segment removing machine. The machine comprises a rack, wherein an inner segment removing scraper assembly is erected on the rack and comprises a knife rest, a segment punching knife mounted at the front end of the knife rest, inner segment scrapers mounted on sides of the knife rest and located behind the segment punching knife, elastic propping pieces for driving the inner segment scrapers to get away from the sides of the knife rest as well as limiting pieces for preventing the inner segment scrapers from separating from the knife rest; blunt propping parts for propping are arranged at ends, far away from the knife rest, of the inner segment scrapers; the segment punching knife rotates and forms breaches in inner segments, and the inner segment scrapers rotate and grind and scrape the breached inner segments; the inner segment scrapers can be attached to the inner wall of a bamboo for grinding and scrape bamboo segment residues left after the segment punching knife passes; the blunt propping parts are propped against the inner wall of the bamboo to prevent the inner segment scrapers from excessively scraping the inner side of the bamboo under the action of the elastic propping pieces. The machine can be adapted to bamboos with different shapes and can fully scrape bamboo segments under the condition that no bamboo body is hurt.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

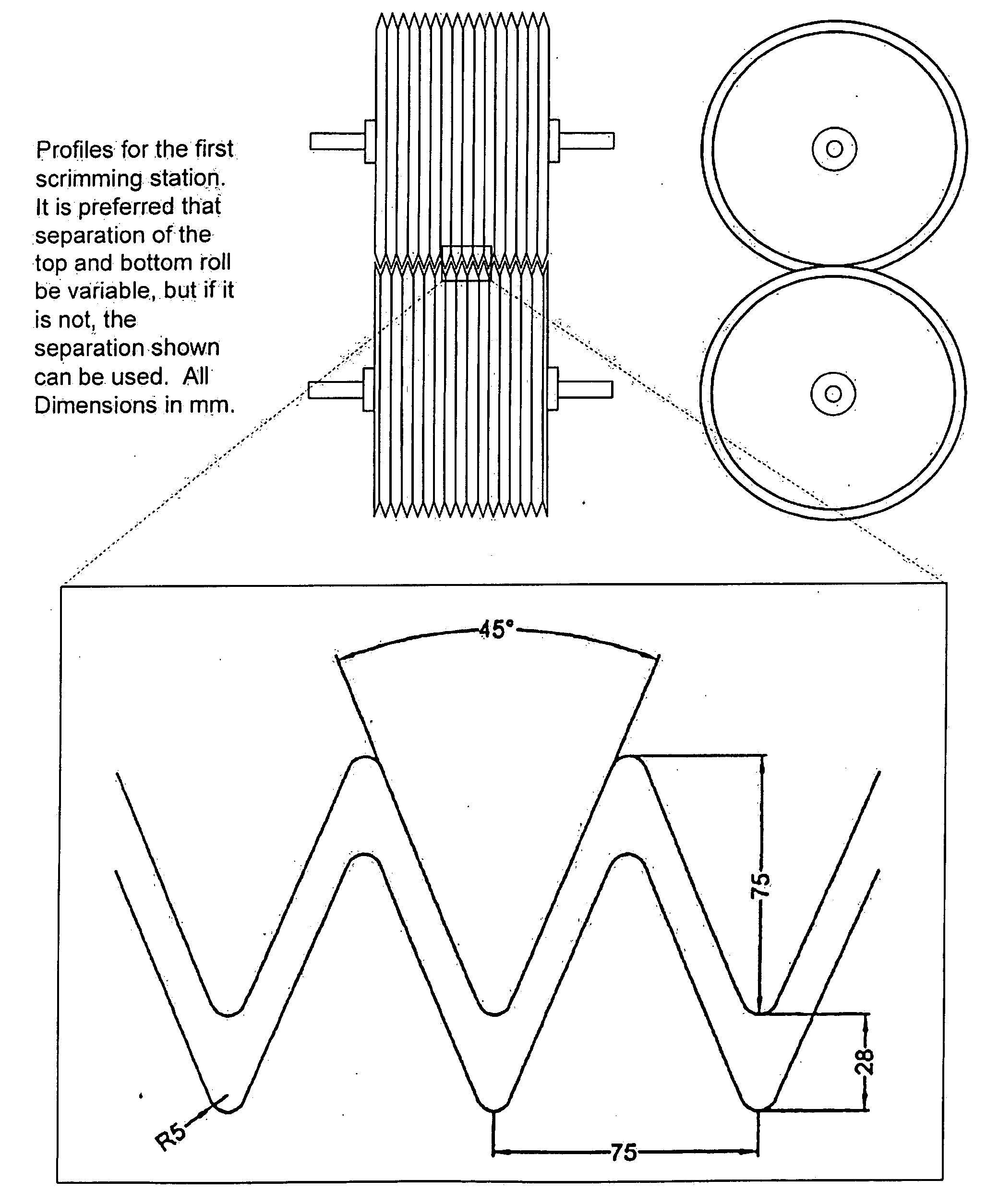

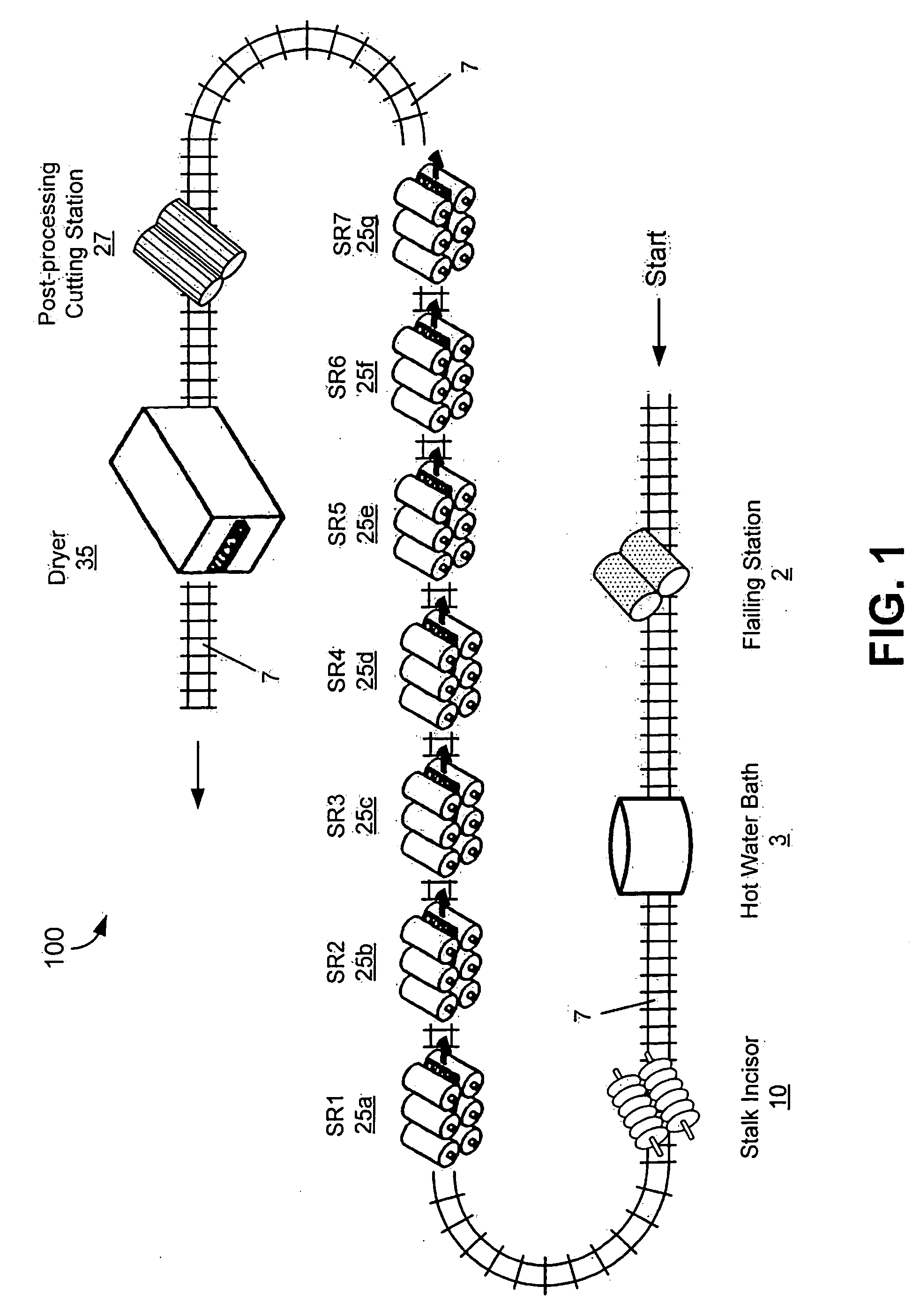

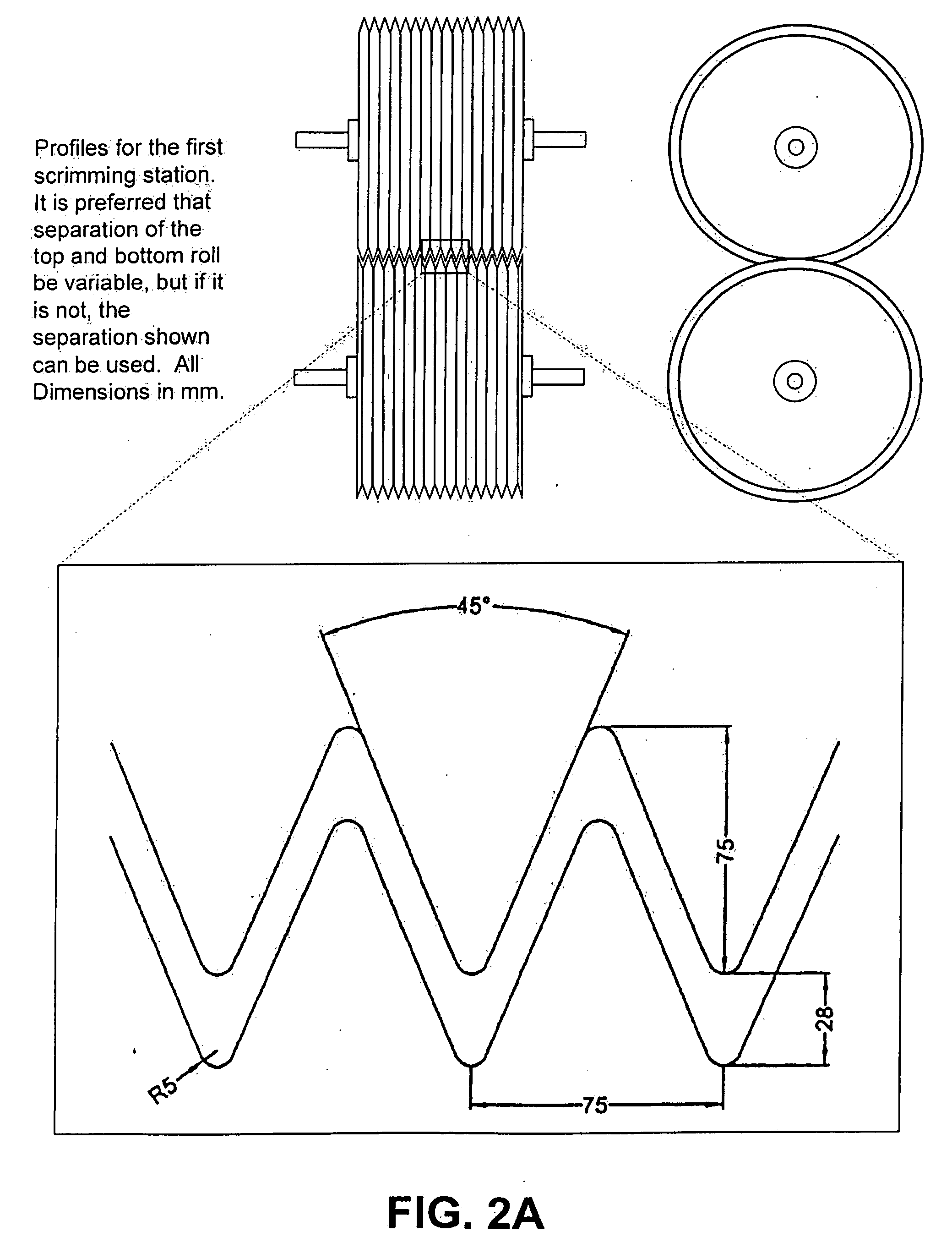

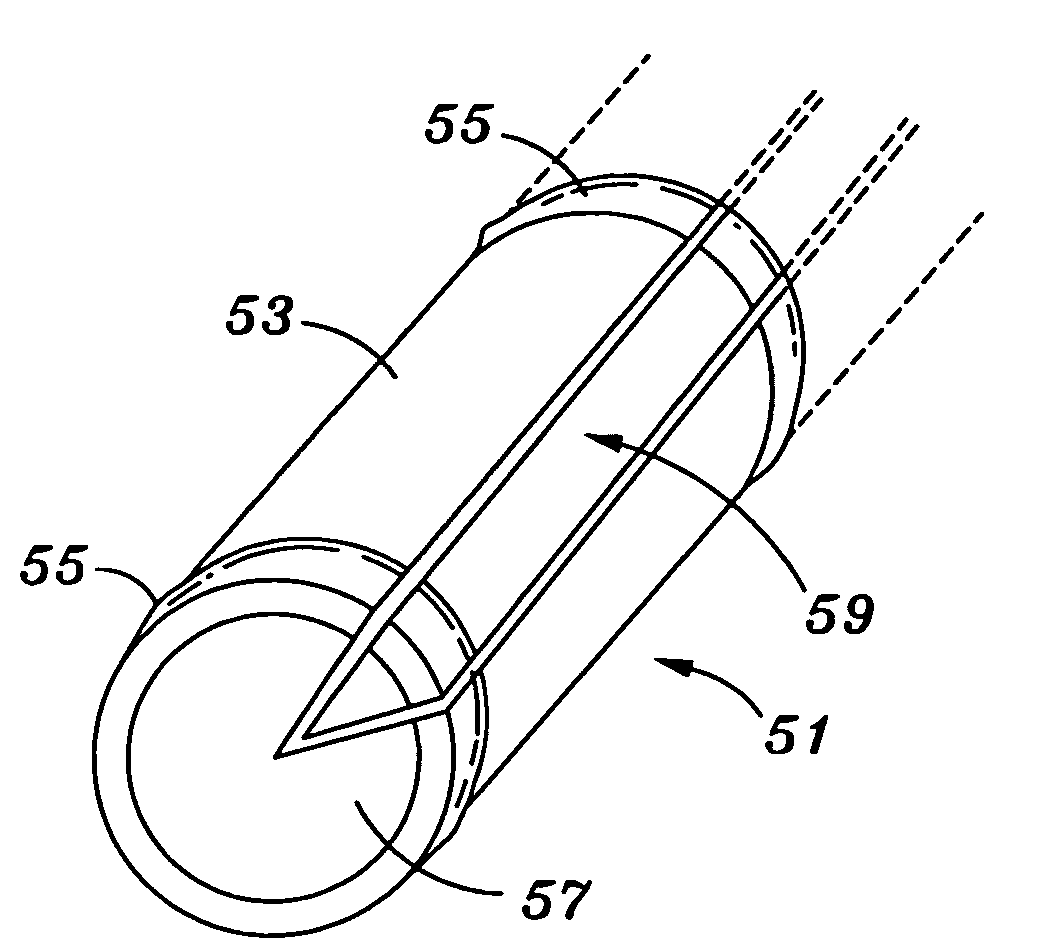

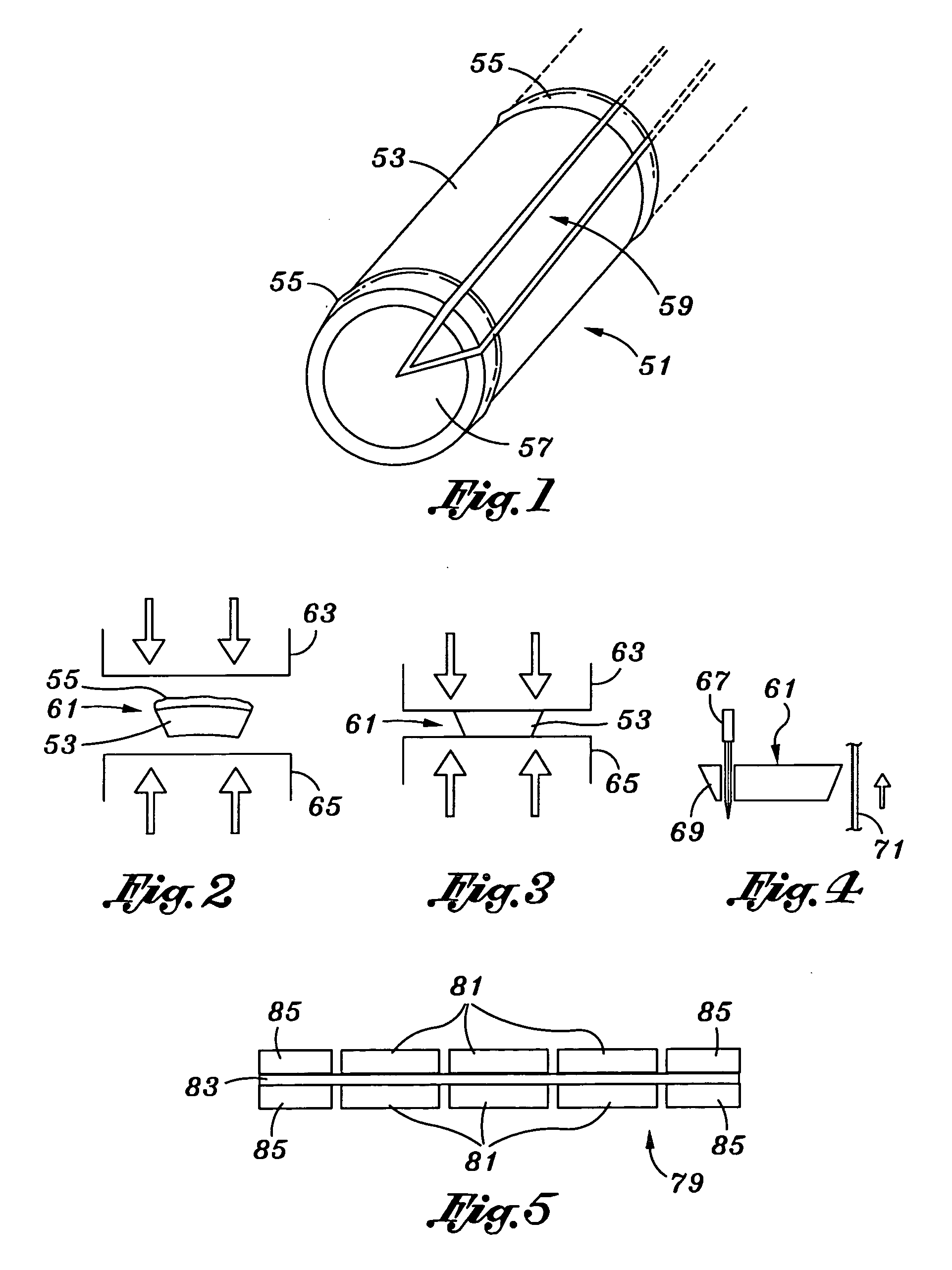

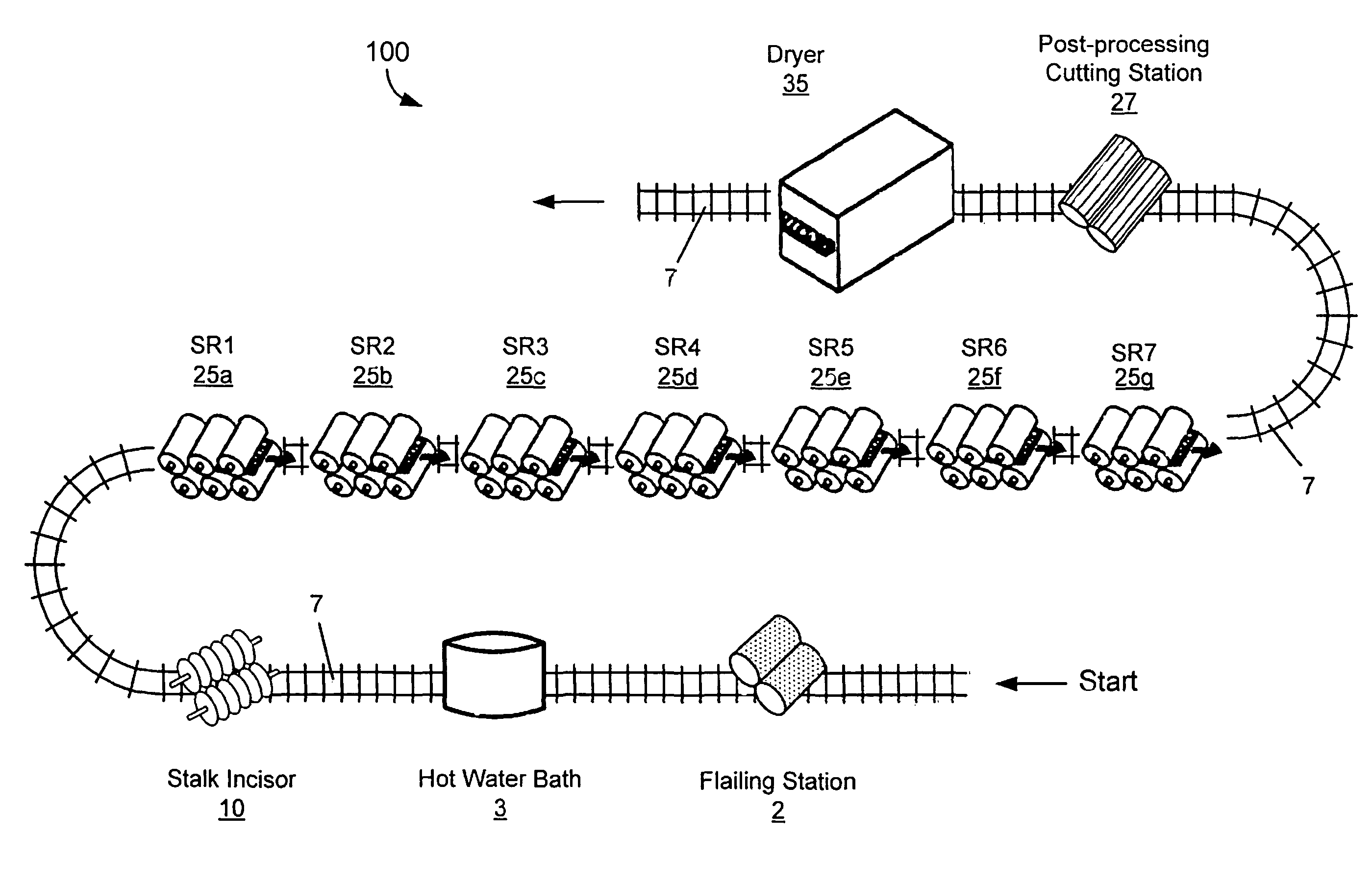

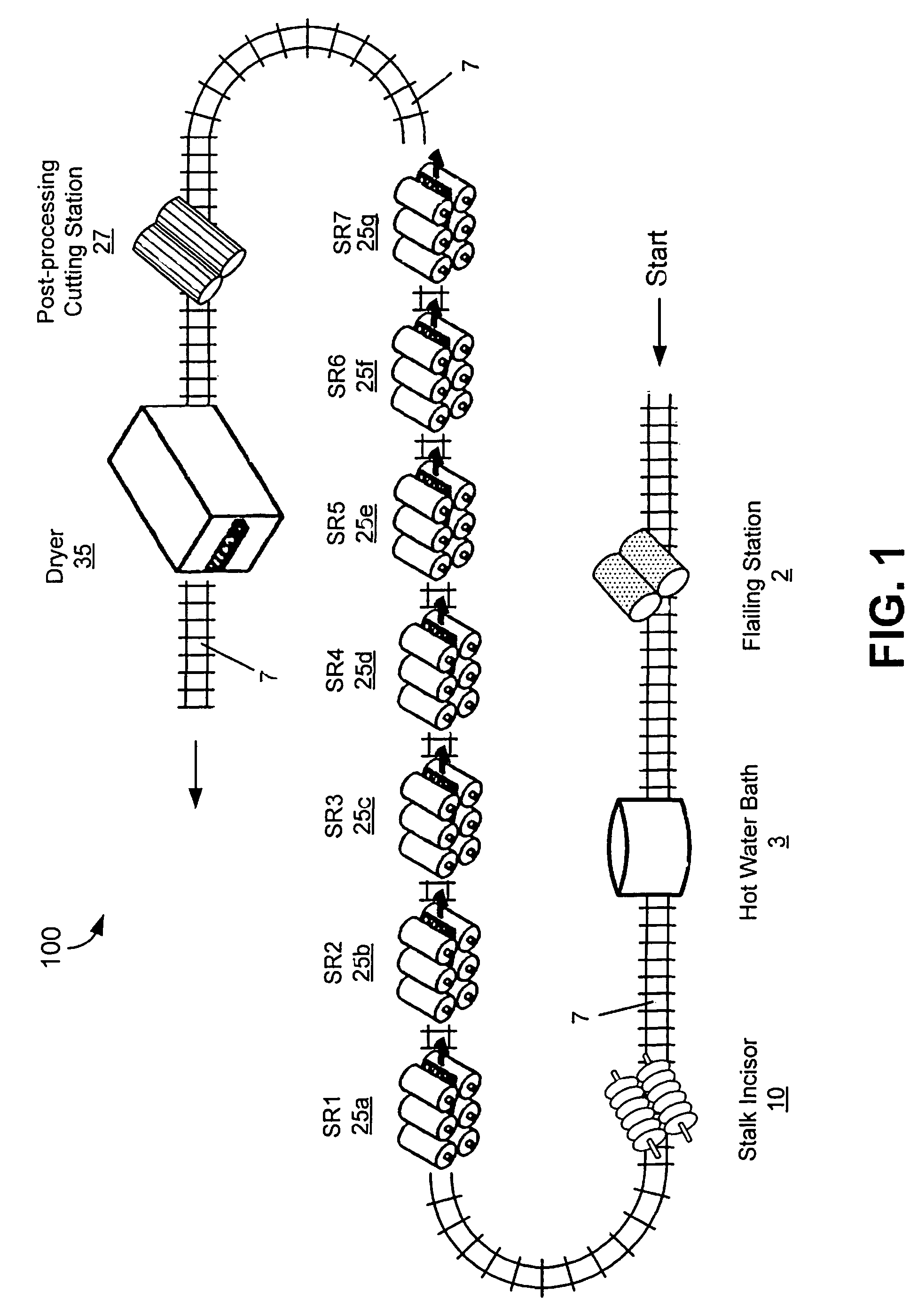

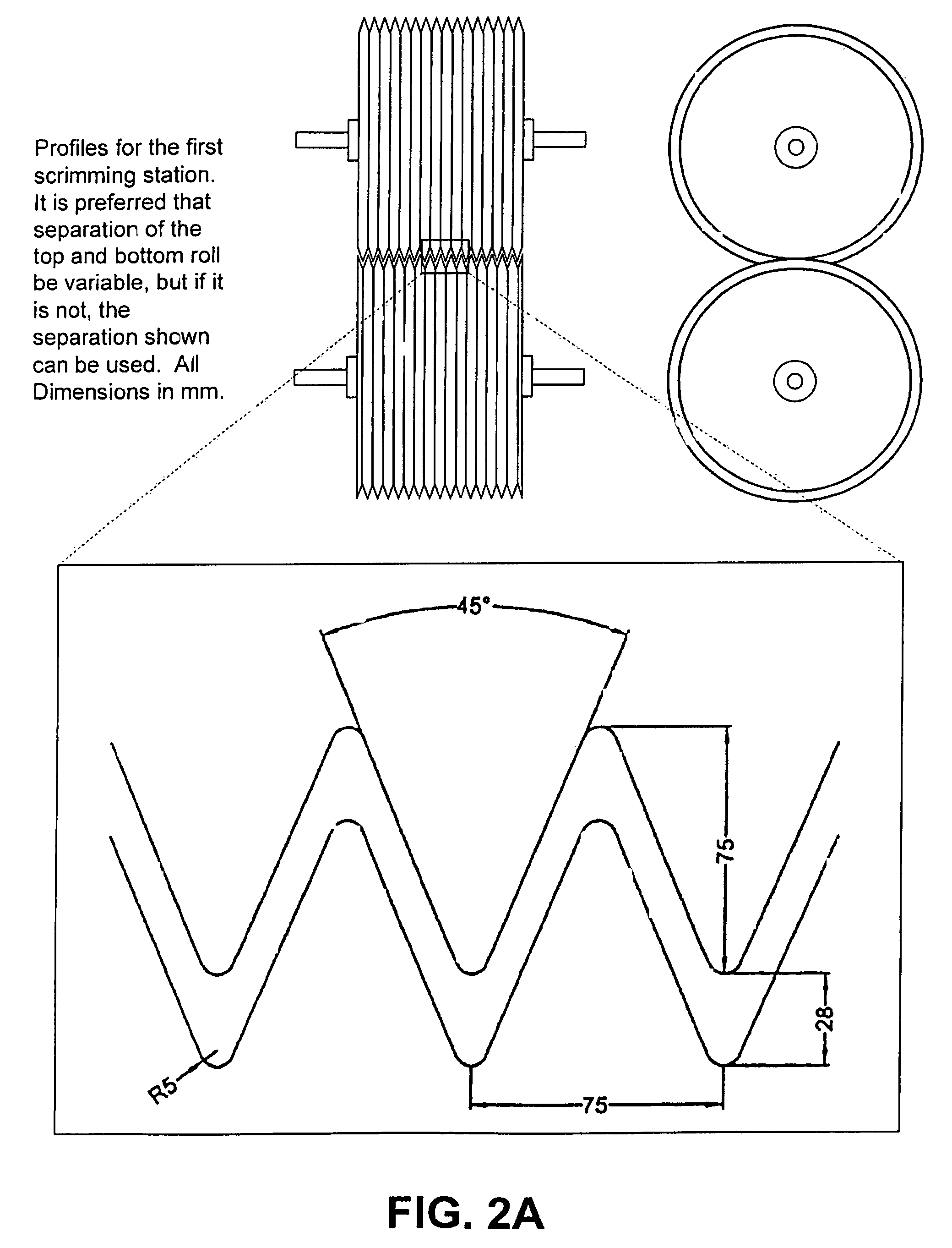

System and method for the separation of bast fibers

InactiveUS20090145563A1Quality improvementEfficient separationFibre cleaning/opening by toothed membersWood working apparatusEngineeringBast fibre

The present invention relates generally to the timber products industry, and particularly to methods and apparatus for the separation of bast fibers. More particularly, the present invention relates to methods and apparatus for use in the separation of inner core from outer bast of bast plants using soaking, cutting, and scrimming methods and apparatuses.

Owner:TIMTEK

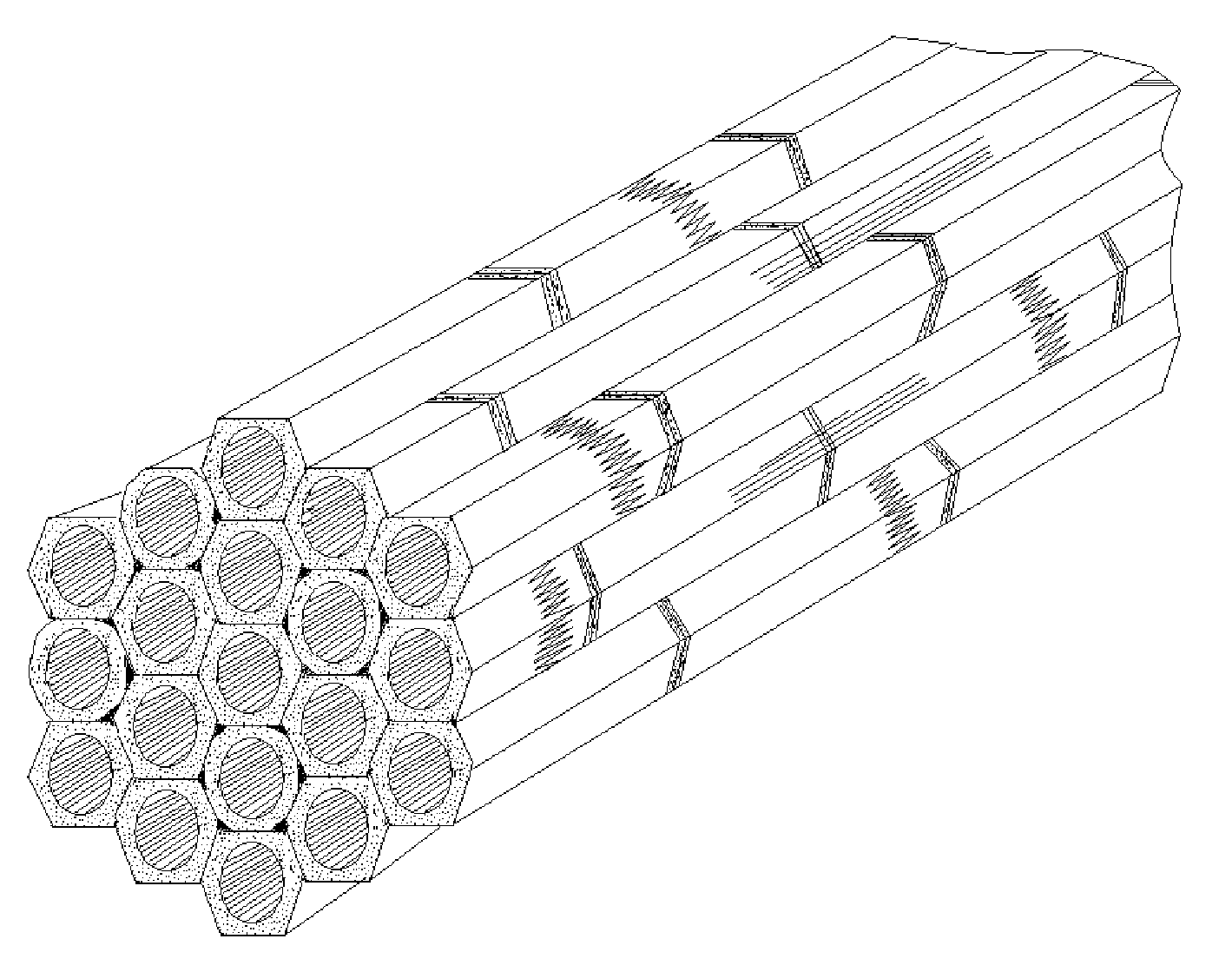

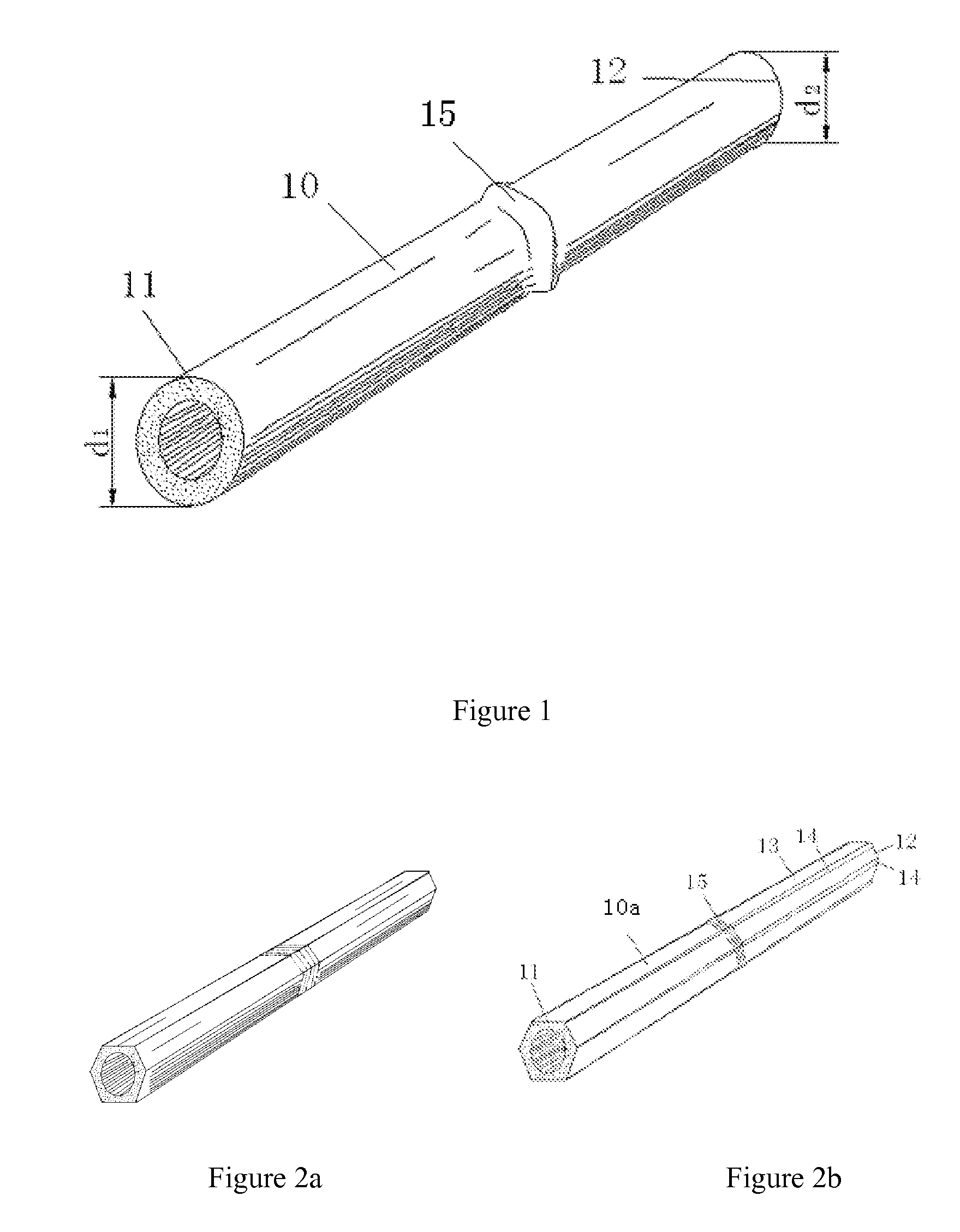

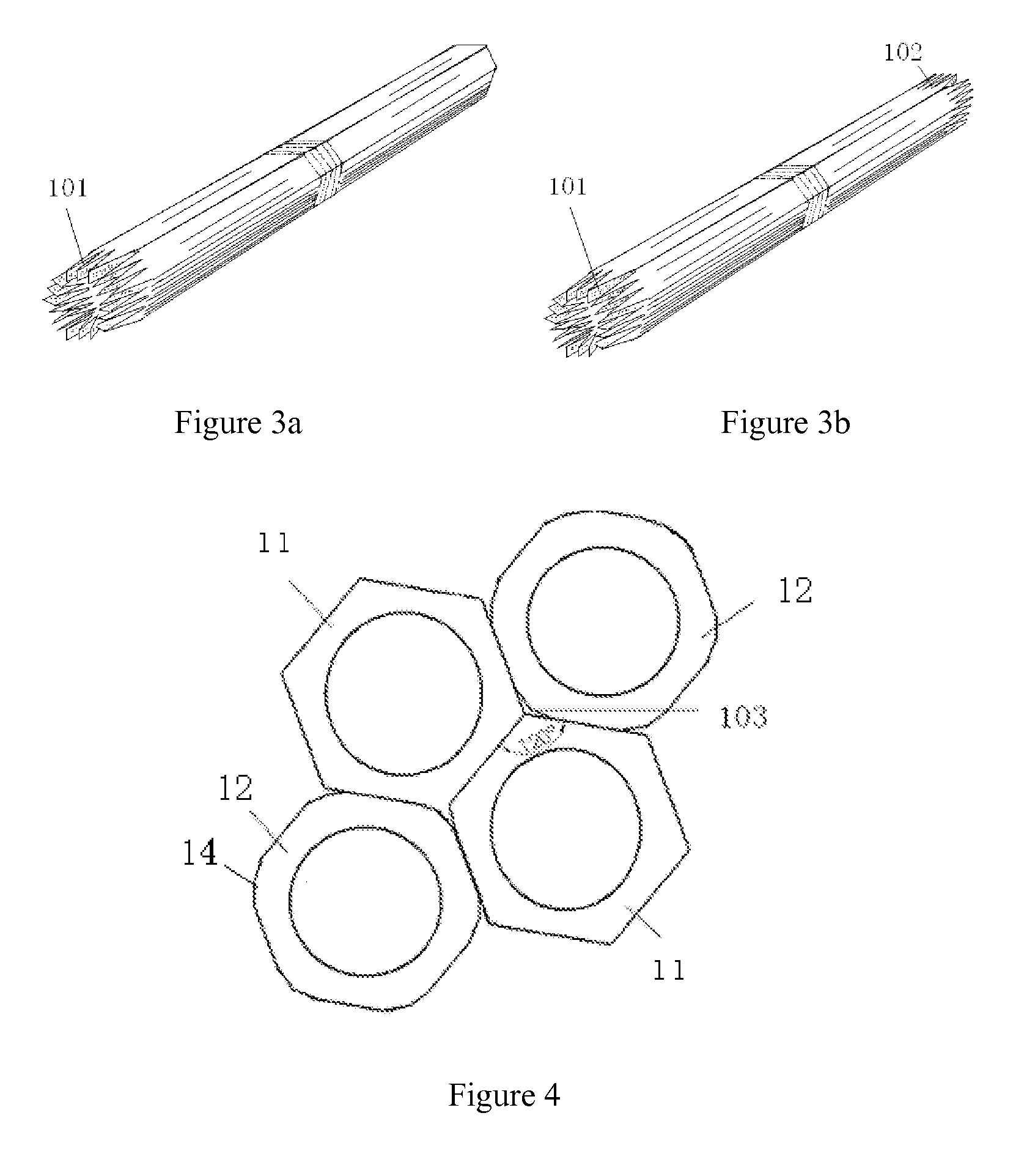

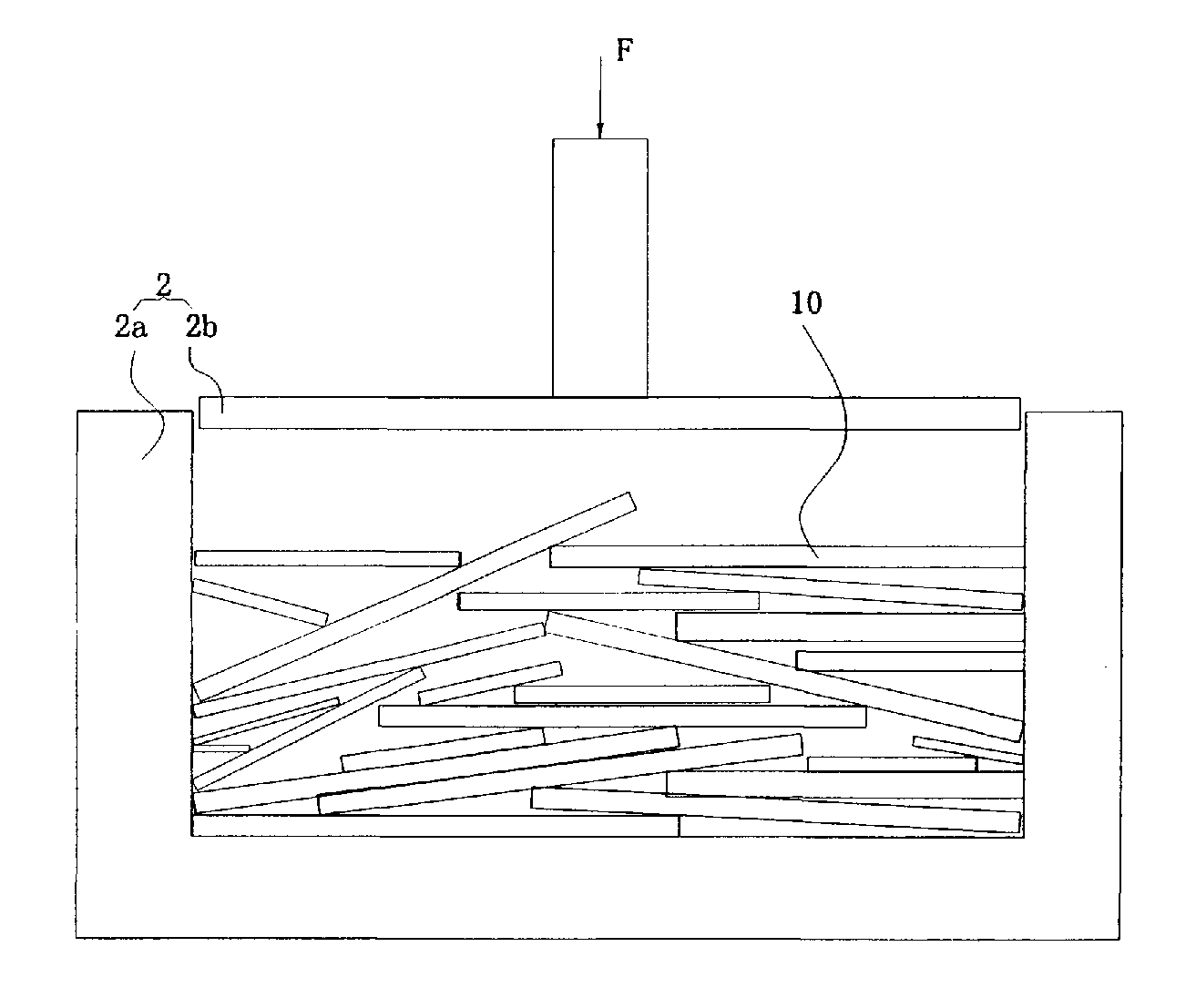

Prestress structural material formed by reorganization with polygonal original bamboo and the manufacturing method

InactiveUS20110151172A1Insufficient improvementHigh strengthLayered productsLoad-supporting elementsChemical solutionPre stress

The invention provides a prestress structural material formed by reorganization with polygonal bamboo units and the manufacturing method for it, the manufacturing method includes manufacturing substrate of prestress structural material formed by reorganization with polygonal bamboo units, and the adding of reinforcement material. Bamboo unit undergoes boiling with chemical solution, drying, and then milling the unit on its outer surface, in order to make it become polygonal bamboo segment, arranging abreast side by side in cross-section direction and longitudinally elongating by finger joints, after all, the substrate of prestress structural material formed by polygonal original bamboo units is formed; after those, extending the lacing wire through all or part of bamboo unit of substrate, and the high-strength baffles are disposed on both ends of substrate, fastening both ends of tautened substrate on baffles by anchors or nuts, allowing the lacing wire act as reinforcement material, then the prestress structural material is formed. The invention makes full use of the structure and physical characteristic of original bamboo, and the prestressed effect generated by lacing wire, the environmental friendly structural material with high-intensity, large span, low power, which effectively alleviates the contradiction between China's timber supply and demand, and partially substitutes for concrete and steel materials, it has broad development prospect.

Owner:BEIJING FORESTRY MACHINERY RES INST OF THE FORESTRY ADMINISTRATION

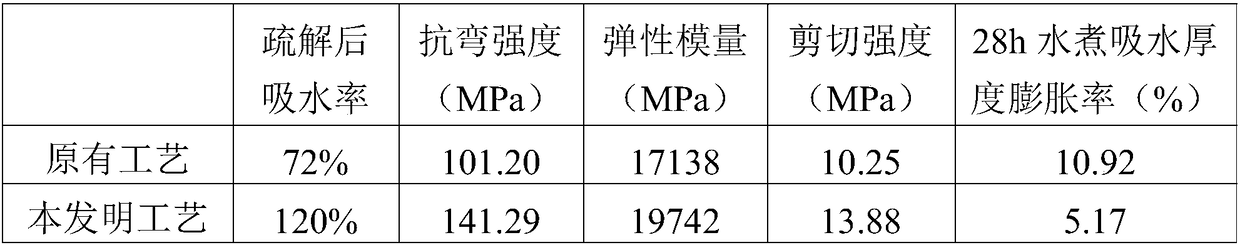

Method for using thin-wall bamboo materials to prepare bamboo scrimbers

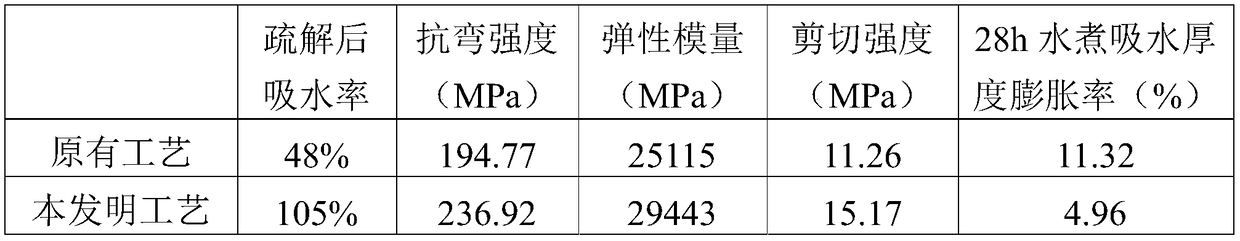

PendingCN108127753AEnhance the ability to defuseEffective chemical attackWood compressionReed/straw treatmentWaxLiquid waste

The invention discloses a method for using thin-wall bamboo materials to prepare bamboo scrimbers. The method includes the steps that alkali is adopted for stewing thin-wall bamboo sheets, and then defibering, gum dipping, laying and hot pressing are carried out in sequence; NaOH is used for stewing the bamboo sheets, and the bamboo sheets are processed by lipase and then subjected to defibering,wherein by means of the procedures above, the defibering effect of bamboo bundles is obviously improved by 35% or above, bamboo green and tabasheer on the surfaces of the bamboo materials are effectively subjected to chemical erosion, the purpose of breaking wax layers and silicon layers is achieved, and the effect of improving gluing is achieved. A waste liquid generated after stewing is used fordiluting a glum liquid, and the problem of discharging the waste liquid is solved; by adopting a vacuum pressurizing dipping mode, even permeation of an adhesive in the bamboo materials is achieved,consumption of the adhesive is reduced, the production cost is reduced, efficient utilization of the thin-wall bamboo materials is achieved, and the environment is protected. The physical and chemicalstrength of the scrimbers are obviously improved, the horizontal shearing strength is improved by 25% or above, the thickness swelling rate of water absorption is reduced by 100% or above, the bending strength is improved by 20% or above, and the elasticity modulus is increased by 15% or above.

Owner:GUANGDONG ACAD OF FORESTRY

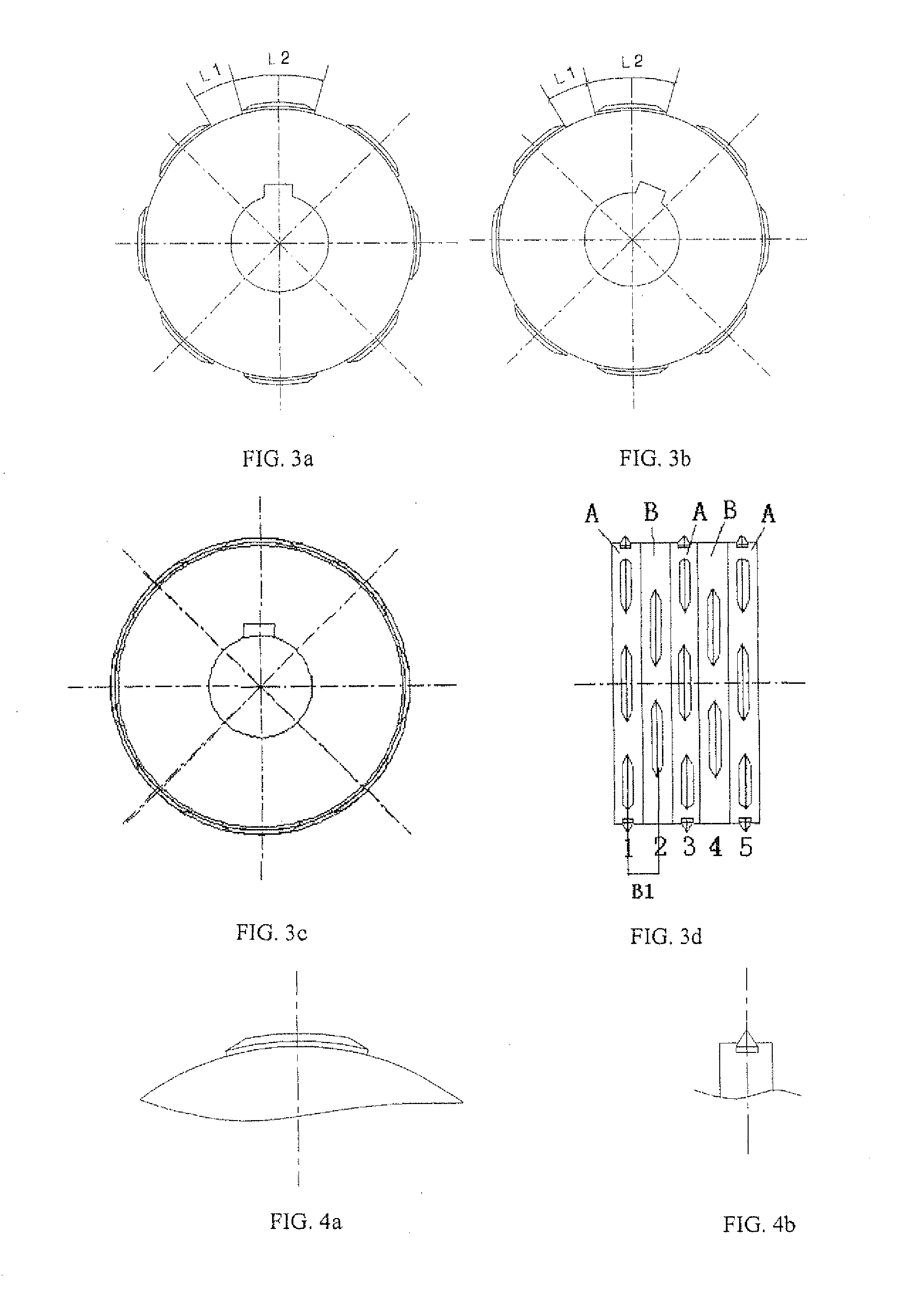

Production technology for natural bamboo fibers

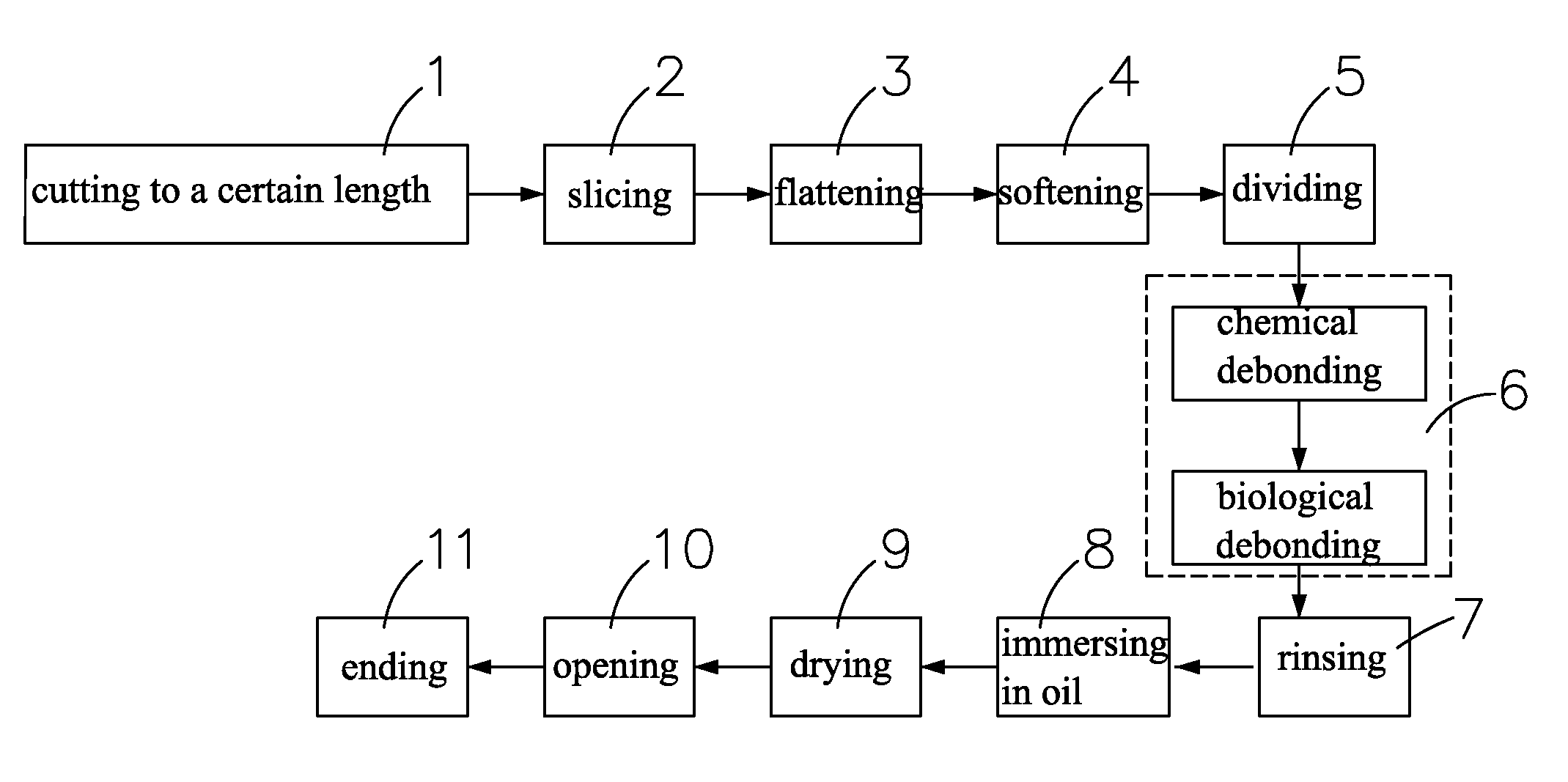

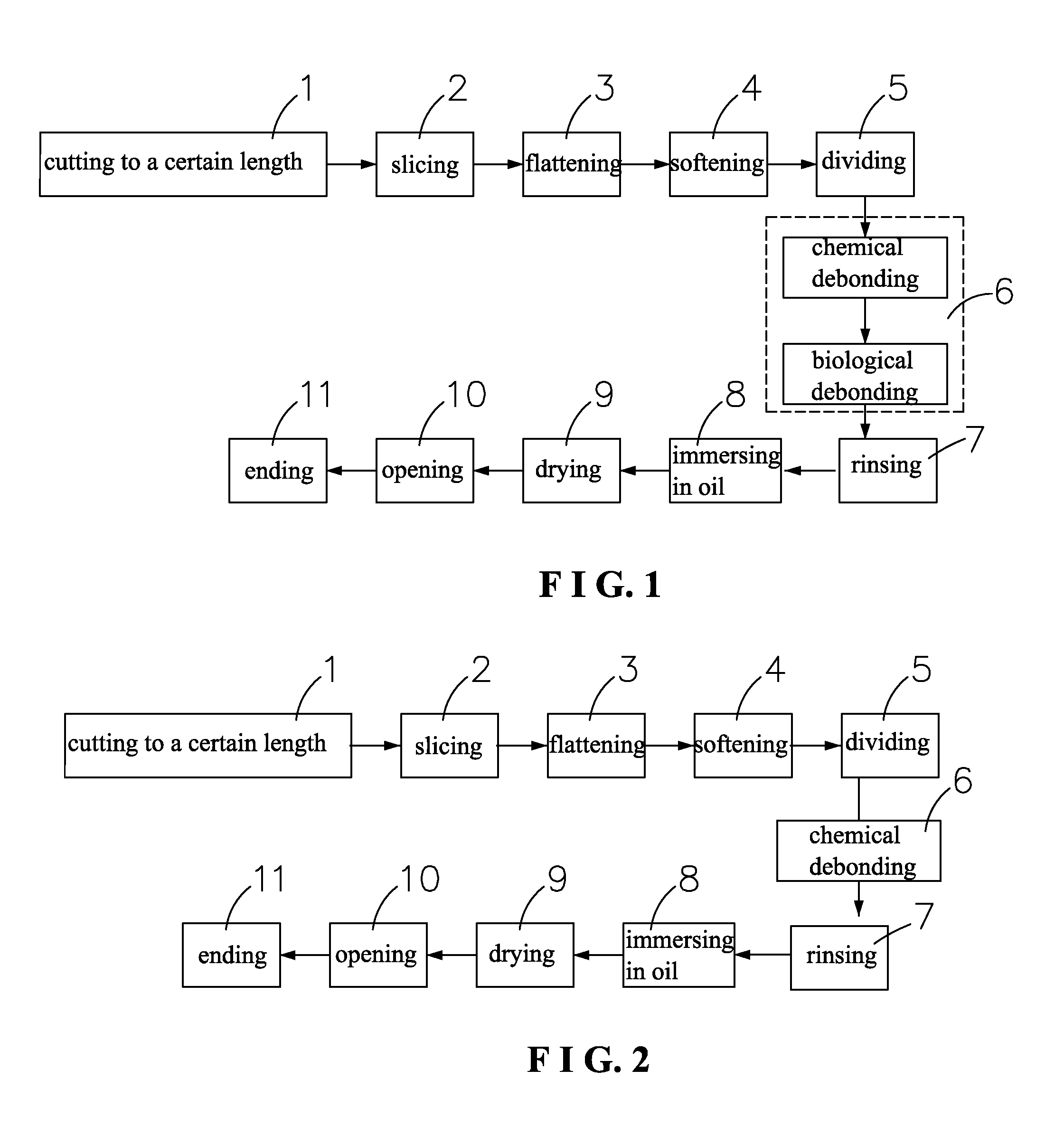

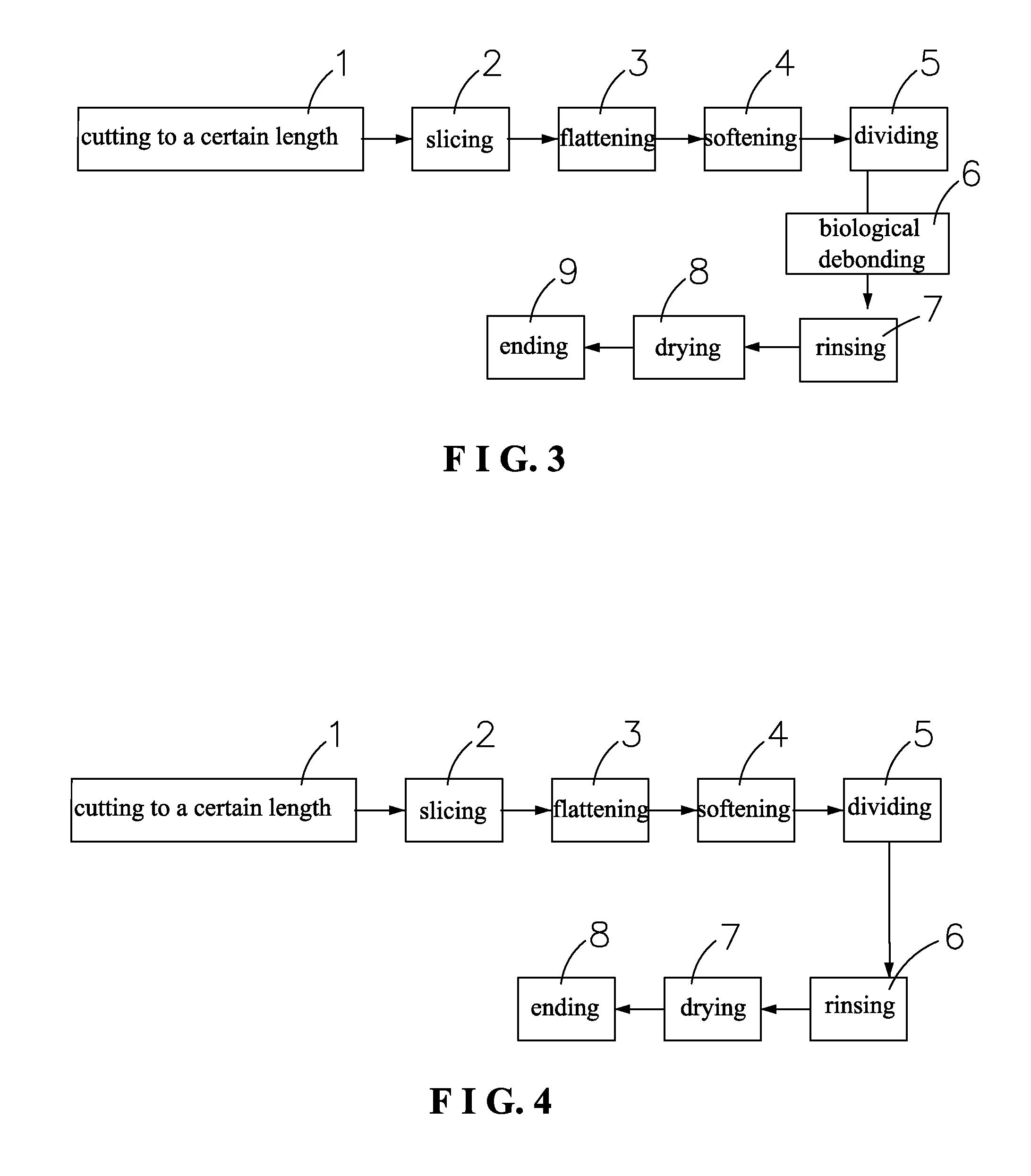

ActiveUS20140000761A1Simple and high-efficient producing methodImprove adaptabilityWood working apparatusPlant material mechanical workingFiberMaterials science

A production technology for natural bamboo fibers is applied in producing woven bamboo fibers, non-woven bamboo fibers, and reinforcing composite bamboo fibers. The woven bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding, rinsing, soaking in oil, drying, and opening. The non-woven bamboo fibers and the reinforcing composite bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding (optional), rinsing, and drying.

Owner:ZHANG YI

Method for making plywood and dimensional lumber from Arundo donax L. or bamboo

ActiveUS7647957B2Reduce dependenceConstruction materialCane mechanical workingEngineeringFire retardant

A method of producing a virtually fireproof plywood from perennial grasses such as Arundo donax Ligneous, various bamboo strains, or a blend thereof, by first weaving the stalks of these plants into a mat and then layering these mats and binding each layer with any one of several commercial resins mixed with potash for the purpose of enhancing the board's fire retardant quality. The result is the formation of a finished product with structural board attributes and an exceptionally high flash point in relation to other manufactured board products made from forest materials.

Owner:ABDULNASER ABDULMALIK +1

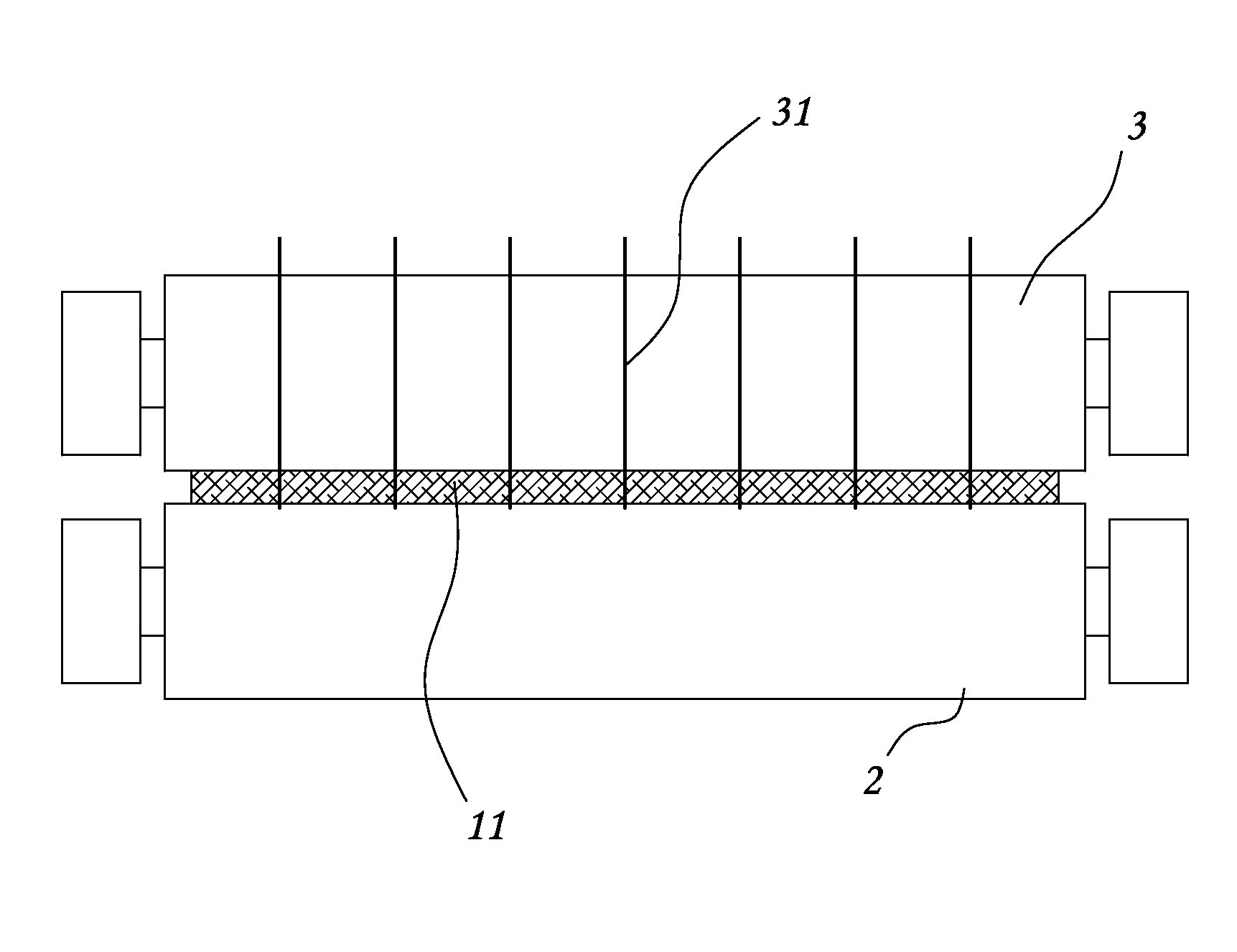

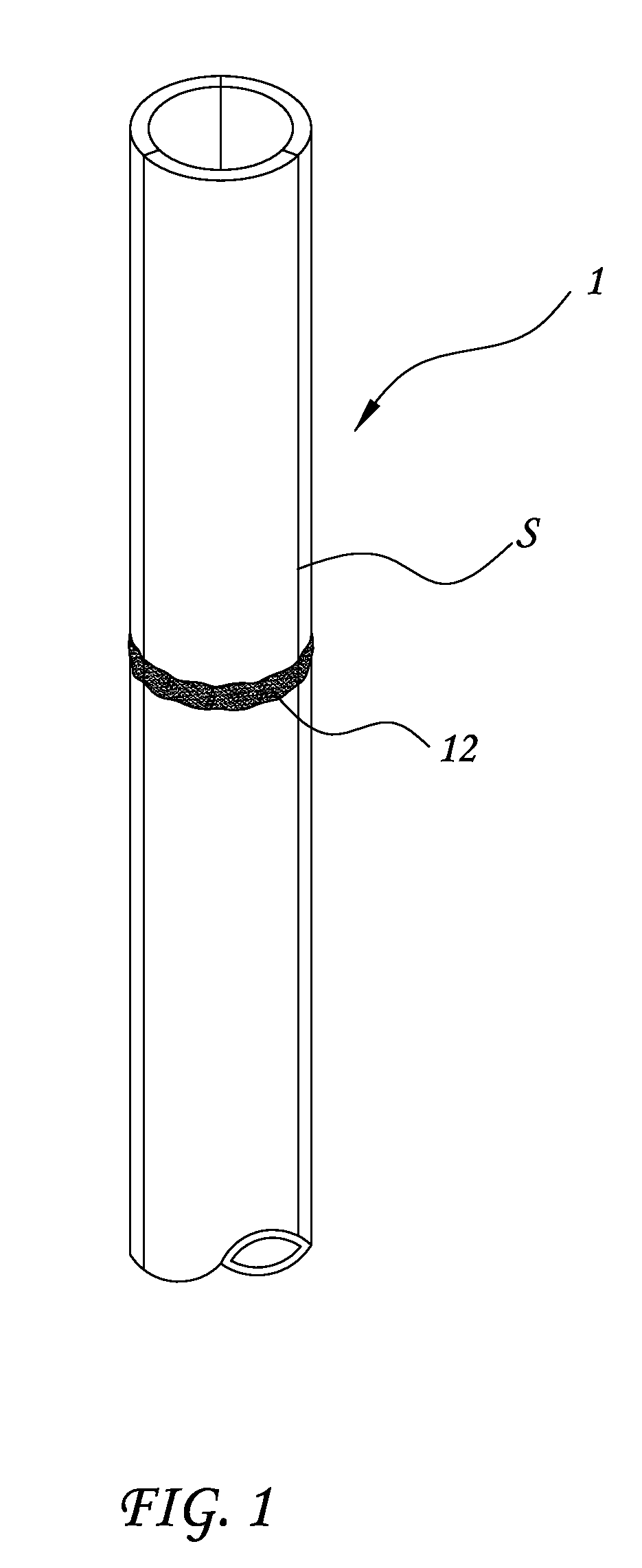

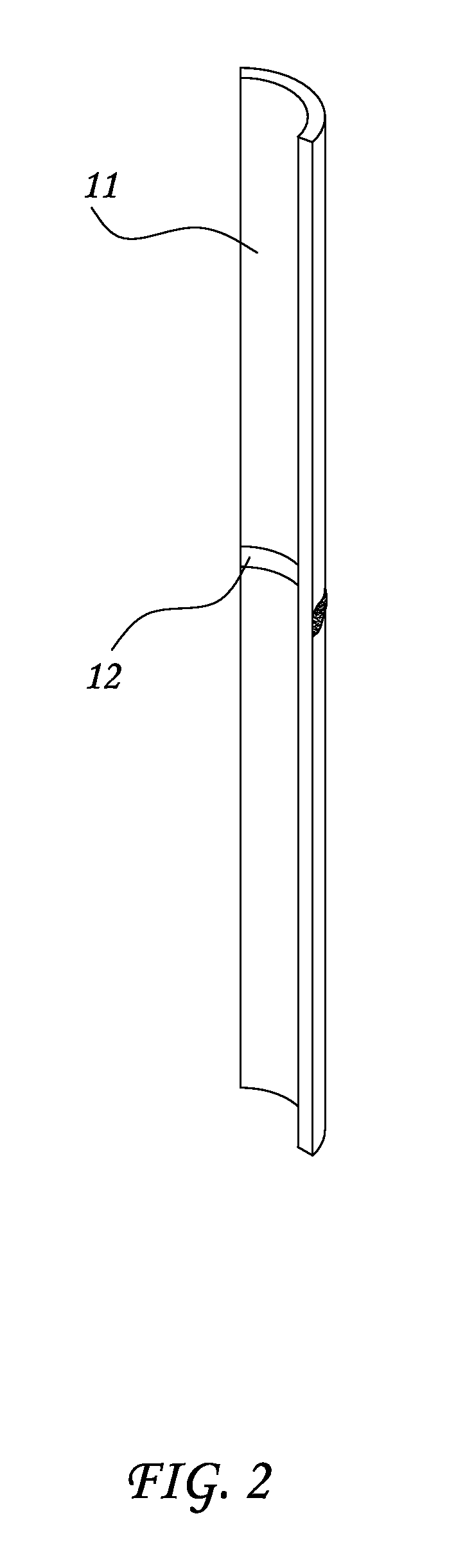

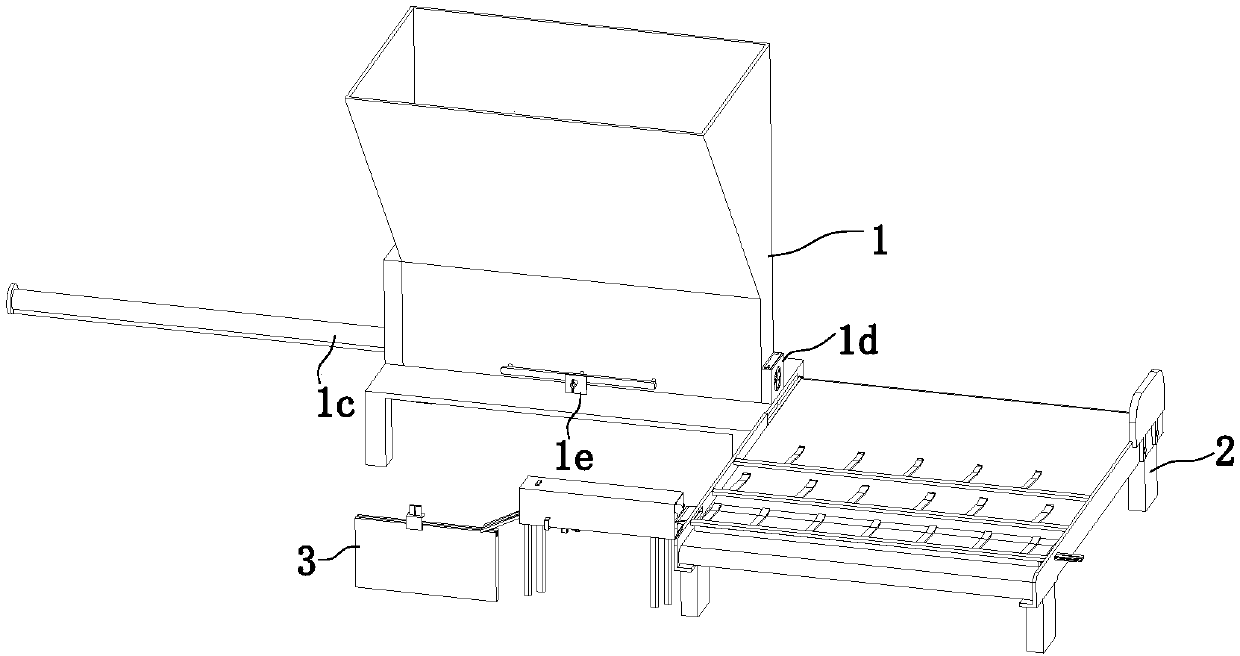

Bamboo scrimber and manufacturing method thereof

ActiveUS20110027529A1Increase surface areaReduce stiffnessWood working apparatusPlant material mechanical workingFiberAdhesive

A bamboo scrimber includes a plurality of pressure-pressed bamboo strips impregnated with an adhesive and modified through heat-treatment. Each of the bamboo strips is formed with a plurality of slots penetrating through the bamboo strip substantially in a direction of thickness defined by the bamboo strip. A substantially longitudinal direction defined by the slots is substantially consistent with a substantially longitudinal direction defined by fibers of the bamboo strip.

Owner:DASSO INT INC

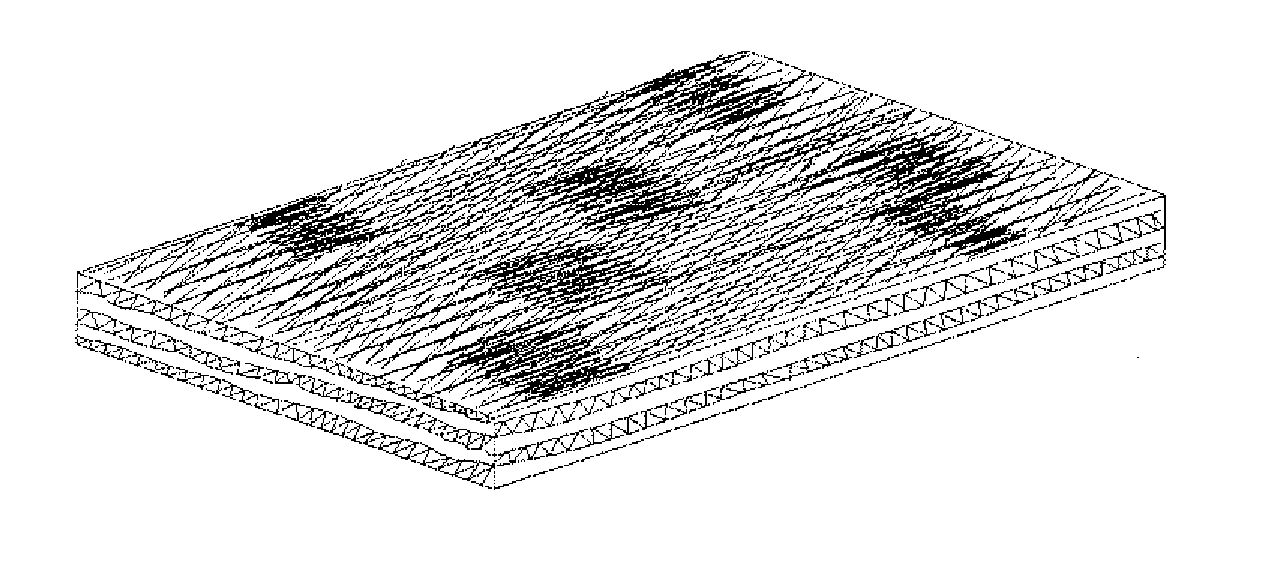

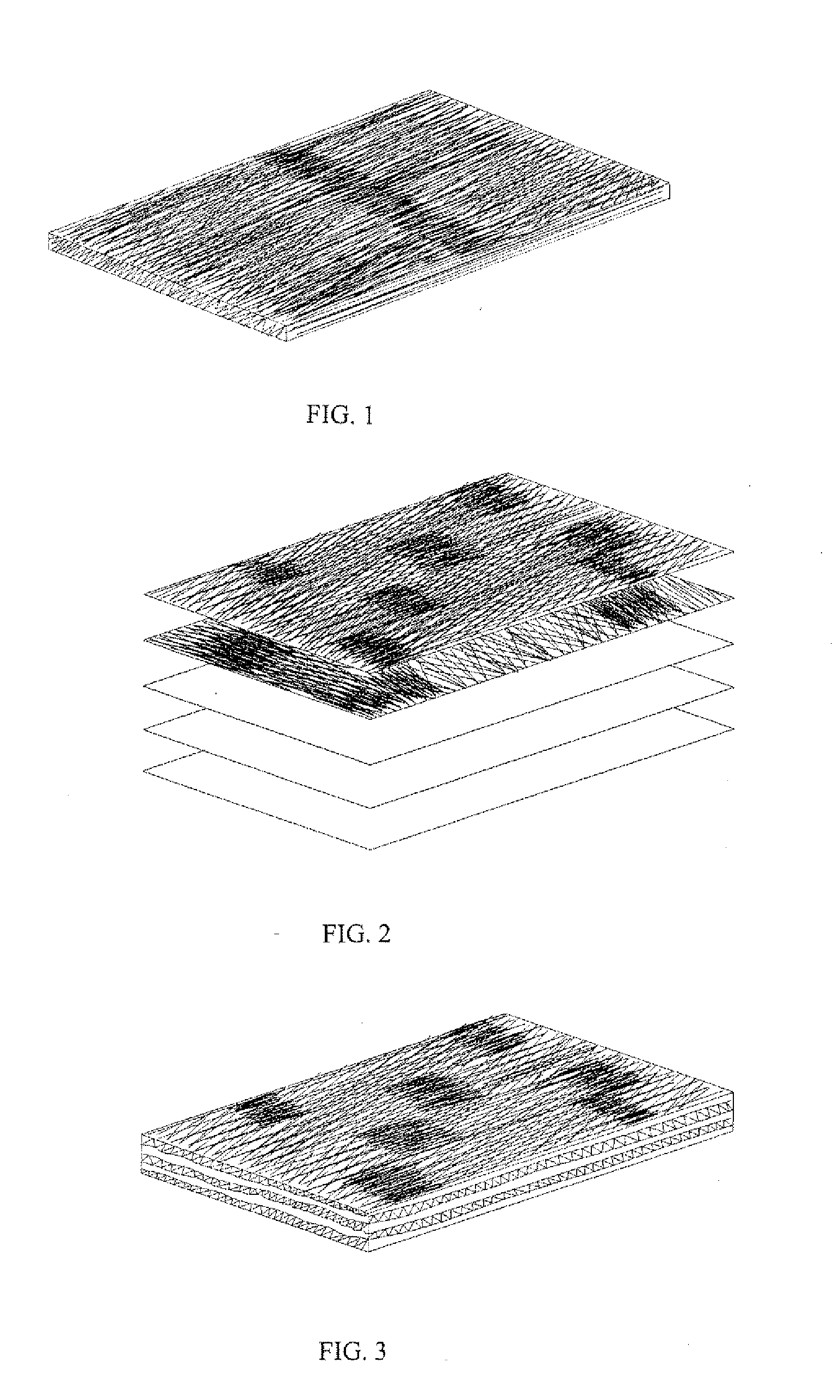

Bamboo artificial board and producing method thereof

InactiveUS20110293880A1Existing technologyImprove performanceConstruction materialCane mechanical workingEngineeringFiber-reinforced composite

The present invention provides a bamboo-based panel comprising a hunk bamboo bundle mat based panel and a bamboo fiber reinforced composite. The bamboo-based panel comprises several pieces of the hunk bamboo bundle mats or oriented bamboo fiber mats (OBFM) which are parallel or cross laid up with each other, the glue layer is arranged among them so as to make panels by gluing. The upper surface and the lower surface of said hunk bamboo bundle mat comprise the outer layer and inner layer of said bamboo, wherein, a waxy layer and a siliceous layer are respectively removed therefrom.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

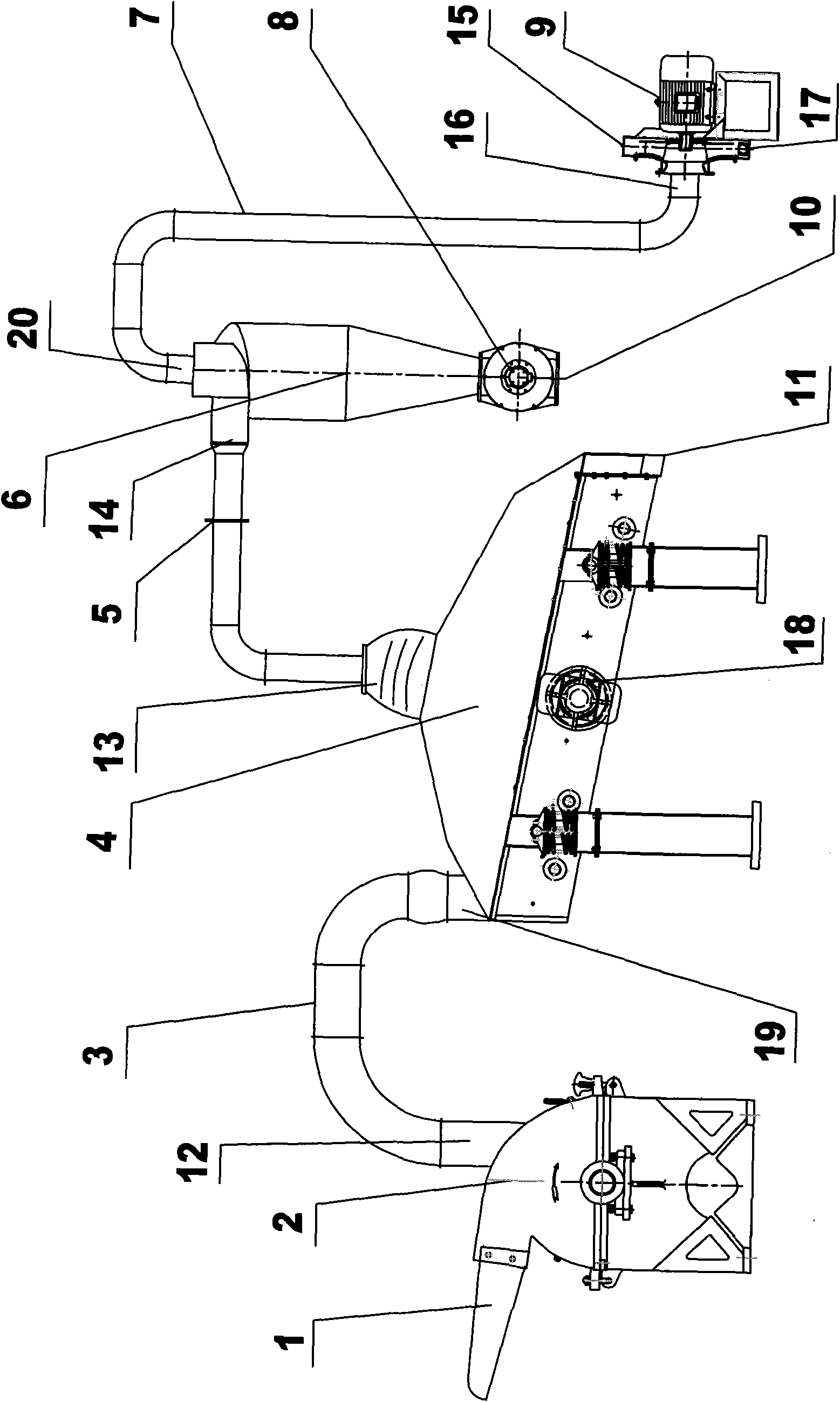

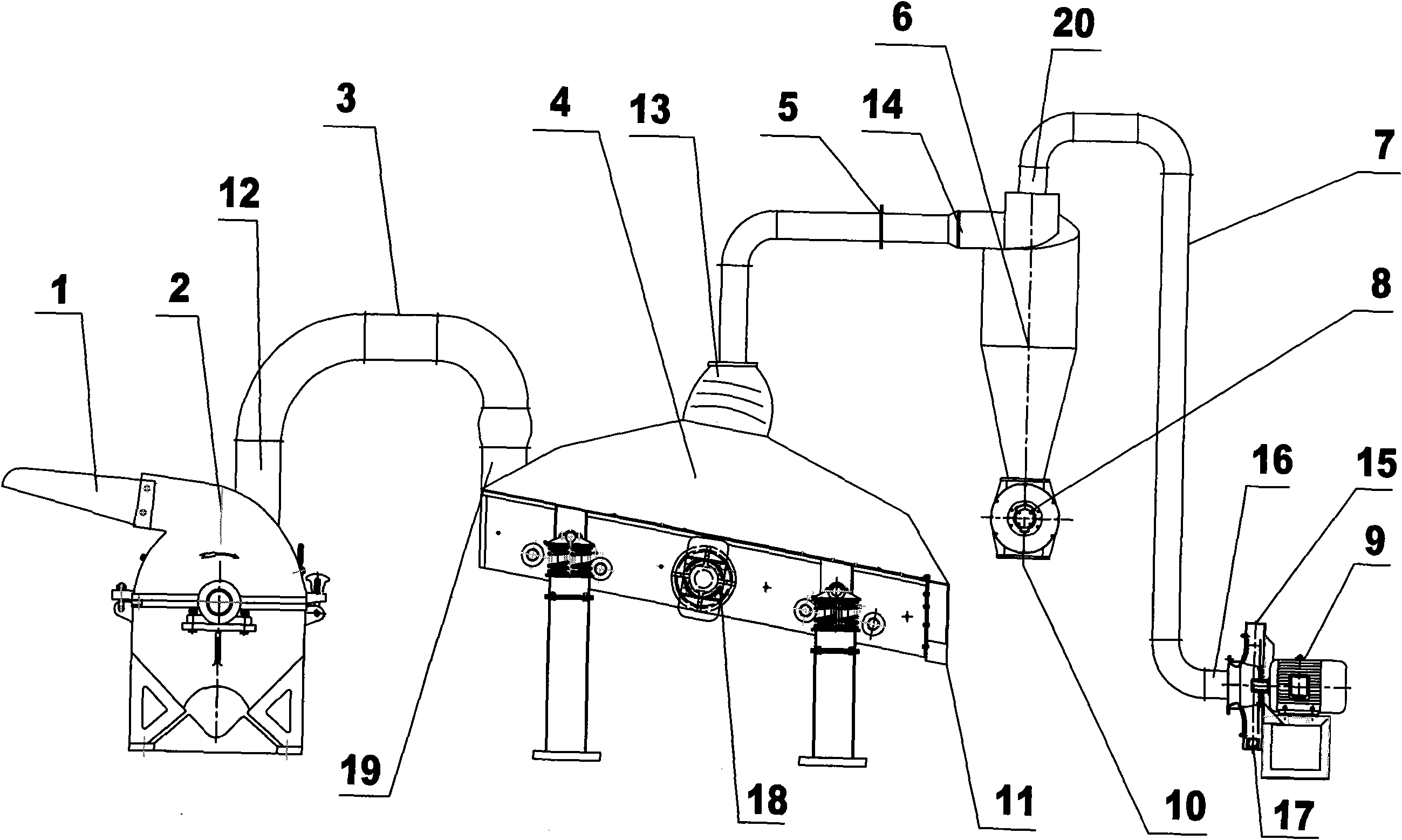

Method and device for separating corn stalk bark and corn pith

InactiveCN102092064AFully strippedImprove separation ratePlant material mechanical workingCrusherCentrifugal fan

The invention discloses a method for separating corn stalk bark and corn pith, which comprises the steps of: (1) crushing corn stalks, (2) separating crushed stalk barks from other light parts; (3) separating light parts of corns from air flow and dusts. The invention further discloses a device for realizing the method for separating corn stalk bark and corn pith, which comprises a crusher, a high-speed oscillating sieve, a cyclone separator and a centrifugal fan, and all the parts are connected by pipes. The device is mainly used for separating corn stalks without leaves and corn pith, or directly dividing the whole corn stalks into two parts, i.e. stalk barks and a mixture of stalk leaves and corn pith. Because the stalk barks, leaves and pith of the corns are different in components, the separation of all the parts is helpful for high-efficiency utilization, and lays a foundation for commercialized high-efficiency utilization of stalks of corns and the like.

Owner:NORTHWEST A & F UNIV

Flat bamboo element fabrication method

InactiveUS20090250141A1Eliminate useReduce energy consumptionCane mechanical workingPlant material mechanical workingEngineeringKnife blades

A flat bamboo element fabrication method for making flat bamboo elements by trimming prepared bamboo cane and cutting the trimmed bamboo cane into a number of bamboo bars of equal length and width and then delivering each bamboo bar through the gap in between the bottom ramming roller and upper ramming roller of a ramming machine for ramming into a flat bamboo element that has a crack pattern therein. In an alternate form, the upper ramming roller has parallel circular cutter blades for cutting each rammed flat bamboo bar into multiple flat bamboo elements.

Owner:WANG WEN TSAN

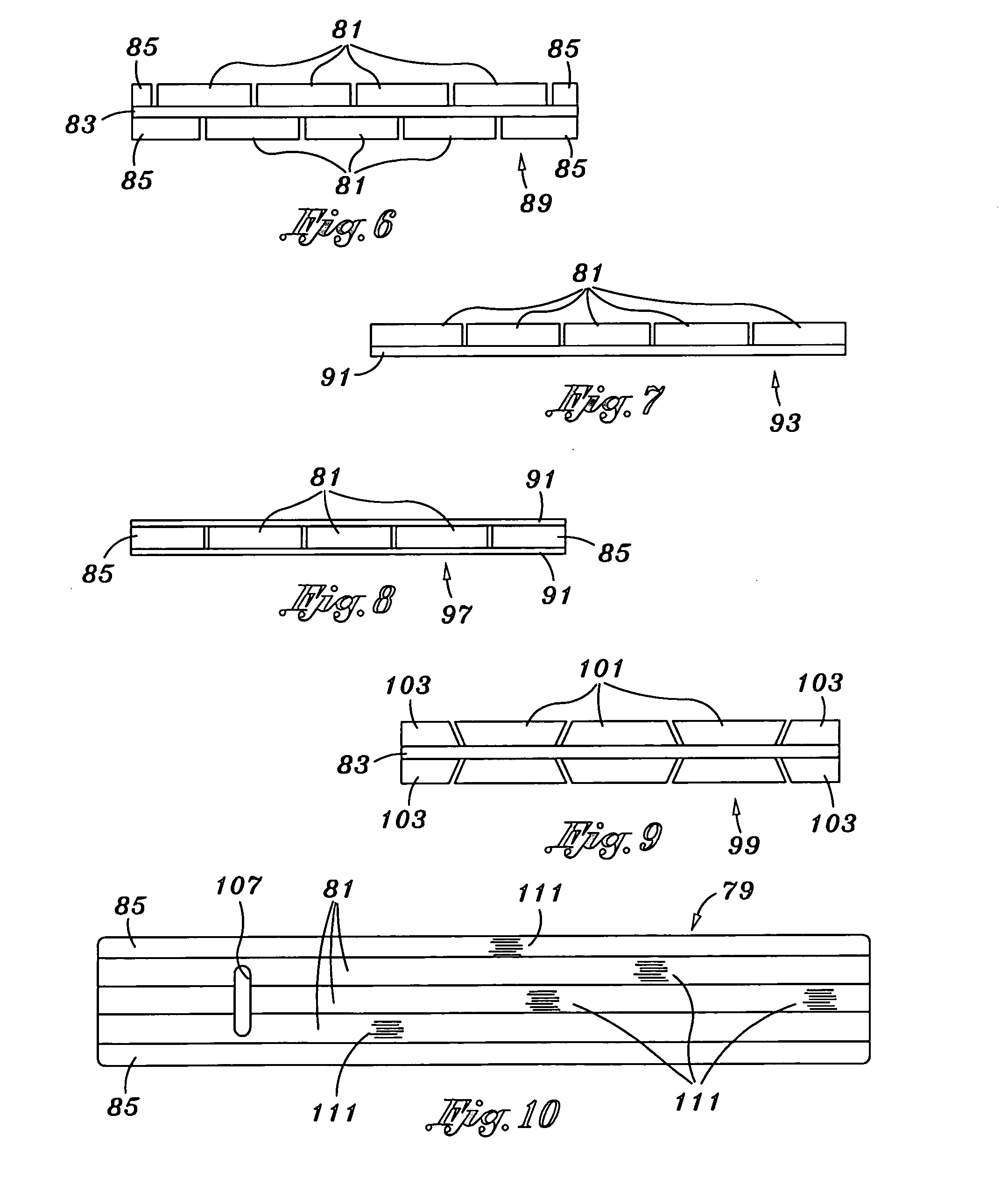

Bamboo composition slat system, covering and method

InactiveUS20080078469A1Extensive and efficientSheer strengthDoor/window protective devicesCane mechanical workingEngineeringLouver

A structures and process incorporates the efficient use of the annularly shaped bamboo plant to make planar shaped slats or louvers. Structures include a double rank of bamboo strips, an offset series of bamboo strips, an optional interstitial support, a single rank of bamboo strips attached to a thin wood expanse, a double thin wood expanse sandwiching a single rank of bamboo strips and a double rank of trapezoidal shaped series of bamboo strips. Steps for production include cutting a bamboo culm into strips, introduction to water for relaxing, pressing, drying, shaping, and attaching the strips adjacent each other to create a formed slat, and performing finishing shaping of the formed slat.

Owner:LEE HAN SEN

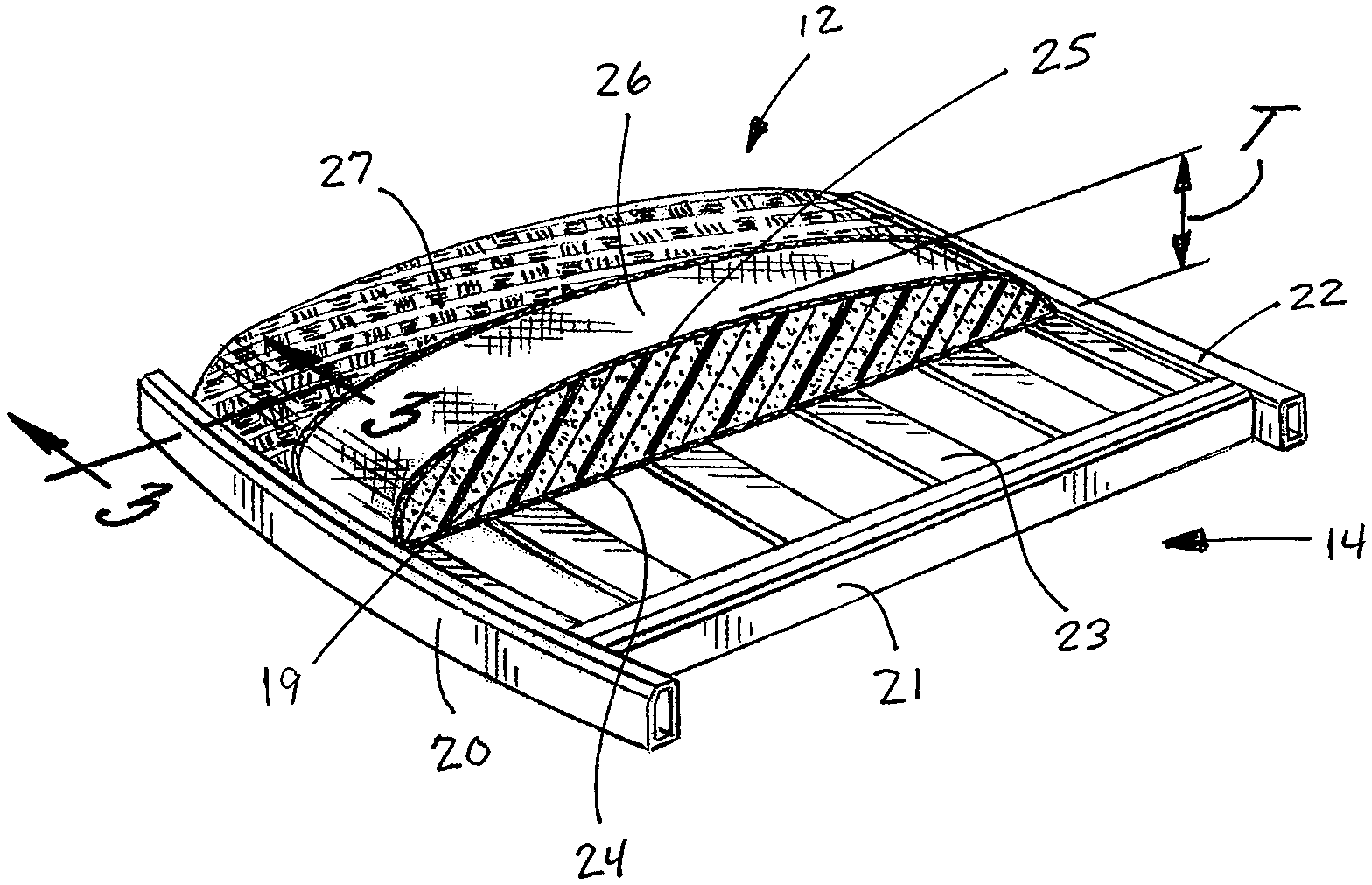

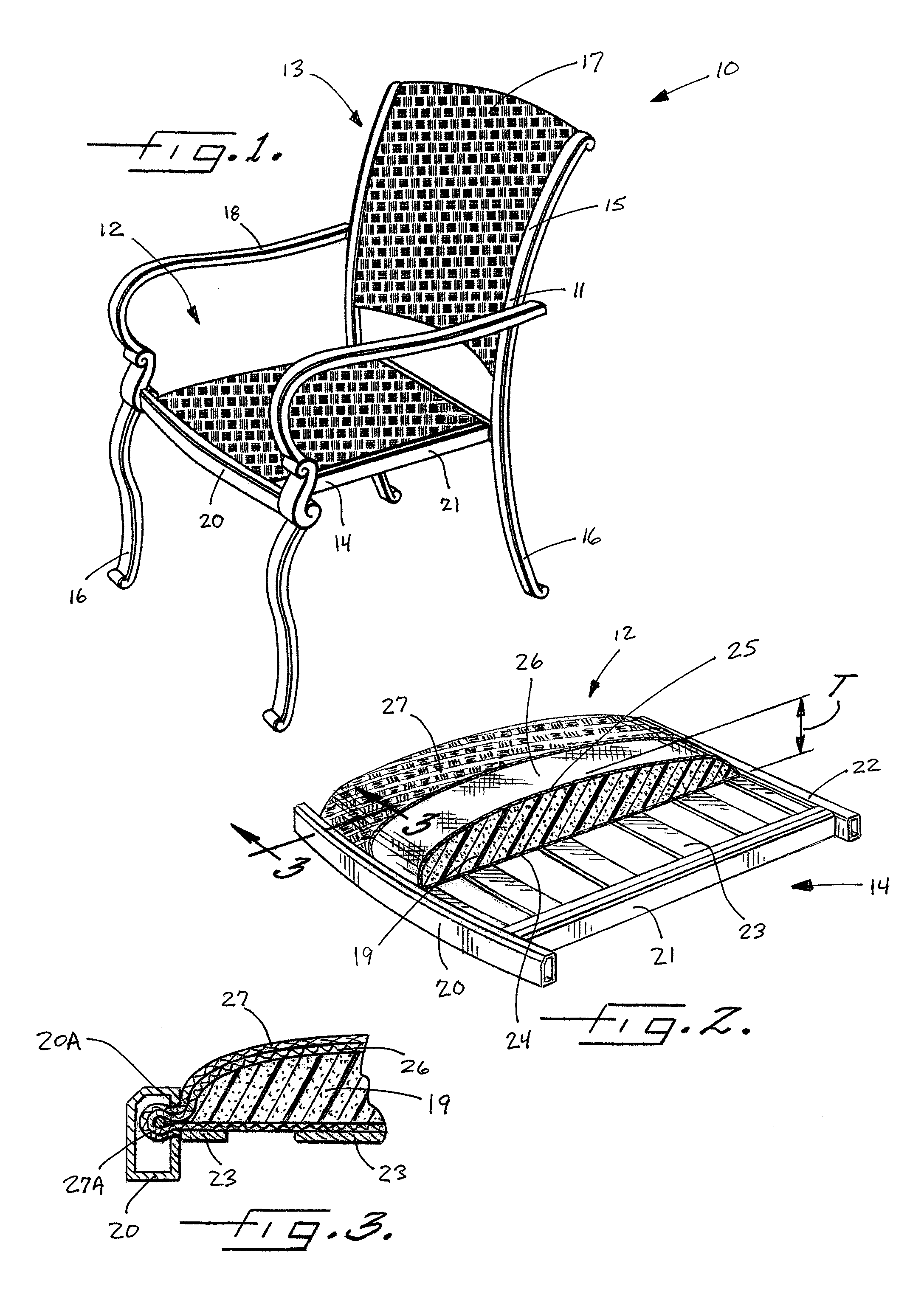

Article of rattan furniture having a seat support cushion

InactiveUS7267408B2Improve comfortMaintaining aesthetic appealStoolsPlant material mechanical workingEngineeringBack support

An improved support area for use with rattan furniture. The present invention provides a frame, a seat contact portion, and a back contact portion. In various embodiments, the chair includes a seat cushion that is supported by a seat support portion of the frame. The seat cushion is covered on its outside by a rattan outer layer that is attached to the seat support structure such that the rattan outer layer conforms to the shape of the seat cushion and the presence of the seat cushion is obscured by the rattan outer layer. In other embodiments, the back support portion may include a similarly configured back cushion. As a result, the present invention has the appearance and aesthetic appeal of a typical article of rattan furniture, having rattan seat and back surfaces, however the present invention provides a level of comfort that is not typically provided by rattan seat and / or back surfaces.

Owner:ZHEJIANG YOTRIO GRP CO LTD

Preparation method of corn stalk regenerated cellulose and nano activated carbon composite gel film

ActiveCN106117610ALow toxicityImprove adsorption capacityMaterial nanotechnologyPulping with inorganic basesThioureaLithium hydroxide

The present invention discloses a preparation method of corn stalk regenerated cellulose and nano activated carbon composite gel film, including: stripping air-dried corn stalks, cutting, grinding, screening to obtain shanks and leaves, and subjecting the shanks to oxygen, hydrogen peroxide, potassium hydroxide or anthraquinone treatment to obtain corn stalk cellulose; dissolving the cellulose by means of low-temperature lithium hydroxide (sodium hydroxide) or thiourea (urea) method; converting corn leaves into nano activated carbon by means of thermal carbonization, ball milling, ethanol activating and dispersing as well as centrifugal classifying; mixing the activated carbon with the stalk cellulose dissolved solution, shaping in a mold, neutralizing and shaping by sulfuric acid bath, washing, and drying to obtain the core stalk composite gel film. The gel film produced by the method is semitransparent and brown sheeting that has great ability to adsorb heavy metal ions such as Zn2+, Fe3+, Cd3+ and Cu2+.

Owner:KUNMING UNIV OF SCI & TECH

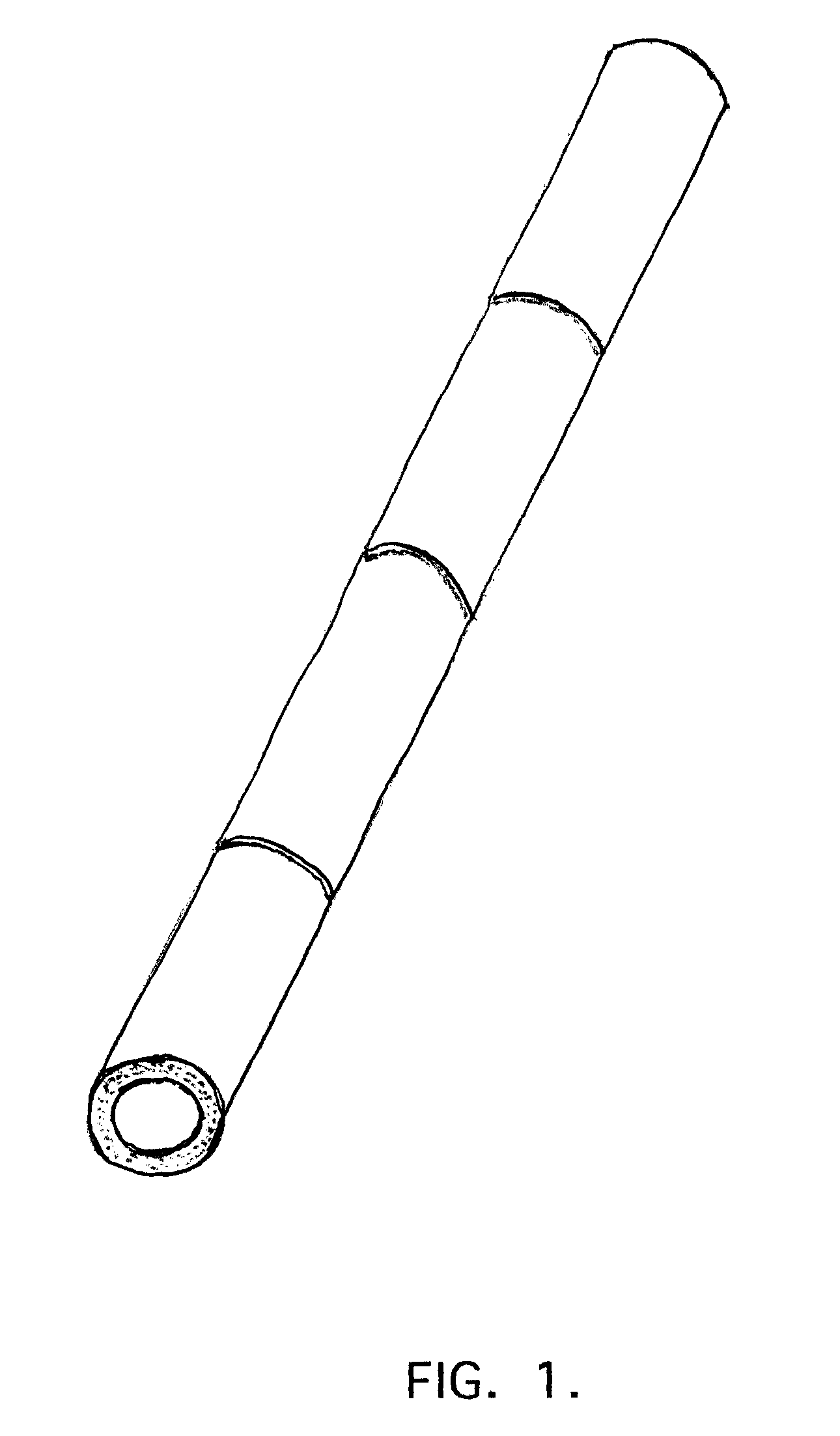

Bamboo artificial board unit, manufacturing method thereof and apparatus therefor

InactiveUS20110293885A1Easy to operateImprove production efficiencyWooden sticks manufactureMulti-purpose machinesFiberEngineering

The present invention provides a bamboo based panel unit comprising a hunk bamboo bundle mat and an oriented bamboo fiber mat (OBFM). Series of dotted and / or linear shaped cracks are formed on the cylinder wall of a semicircular bamboo tube which is split and whose inner nodes are removed. The upper surface and the lower surface of the bamboo based panel unit comprise an outer layer and an inner layer of said bamboo, wherein, a waxy layer and a siliceous layer are removed respectively therefrom.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Panel containing bamboo

InactiveUS20070049152A1Paper/cardboard layered productsPlant material mechanical workingSurface layerEngineering

Disclosed is a wood panel comprising: a composite wood component having upper and lower surface layers and a core layer; and one or more bamboo layers, the one or more bamboo layers having a thickness of about about 0.0625 inches to about 0.5, attached to the upper surface layer of the wood composite.

Owner:HUBER ENGINEERED WOODS

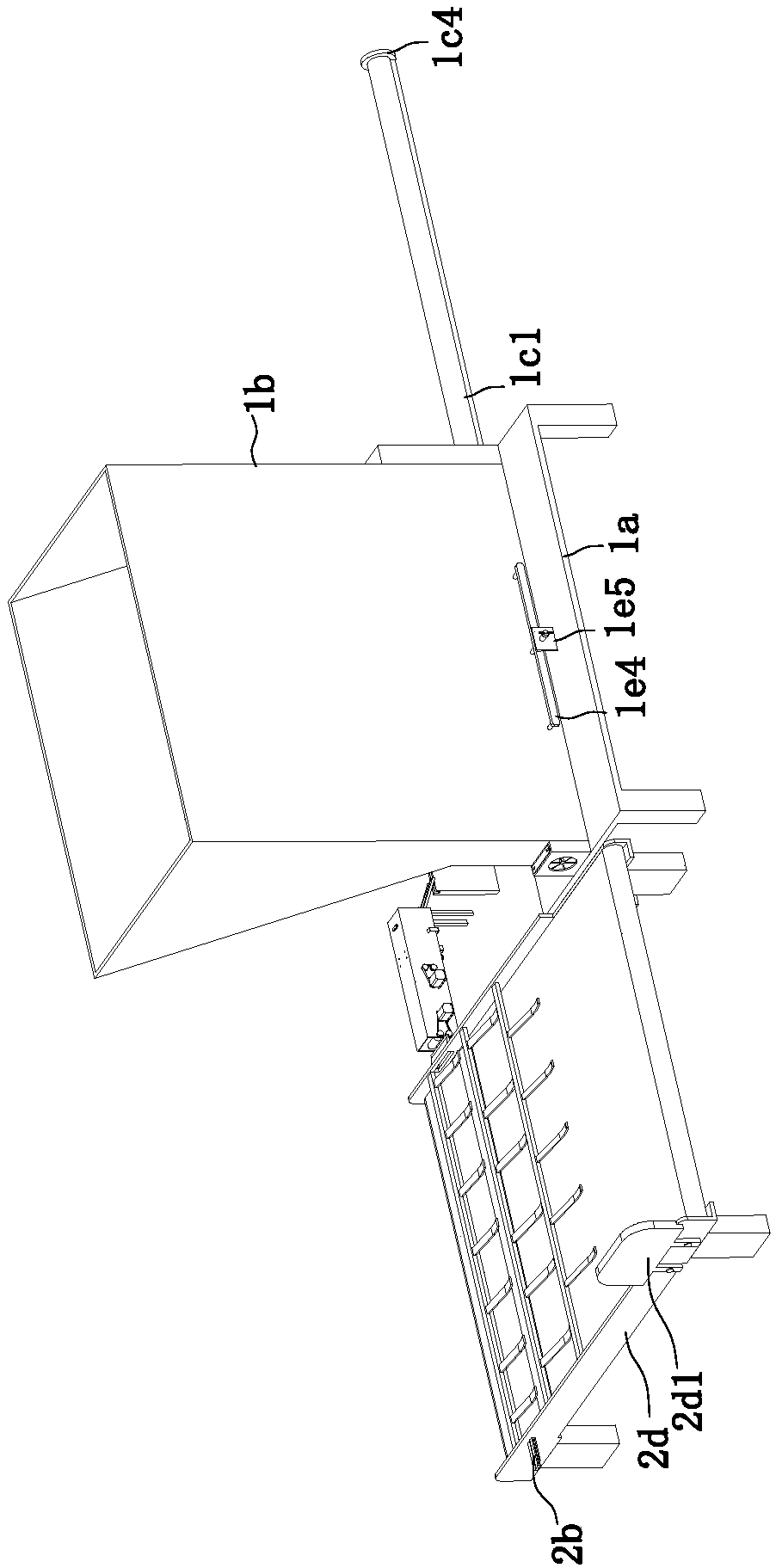

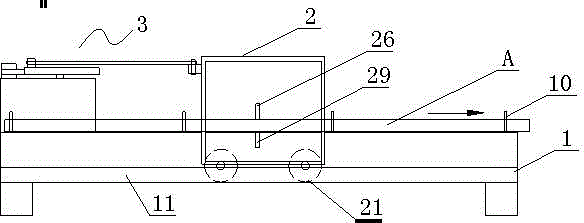

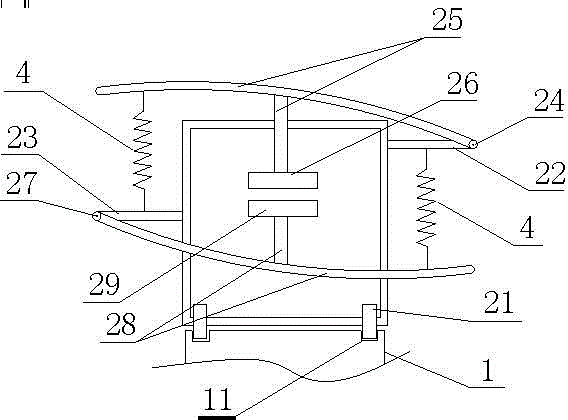

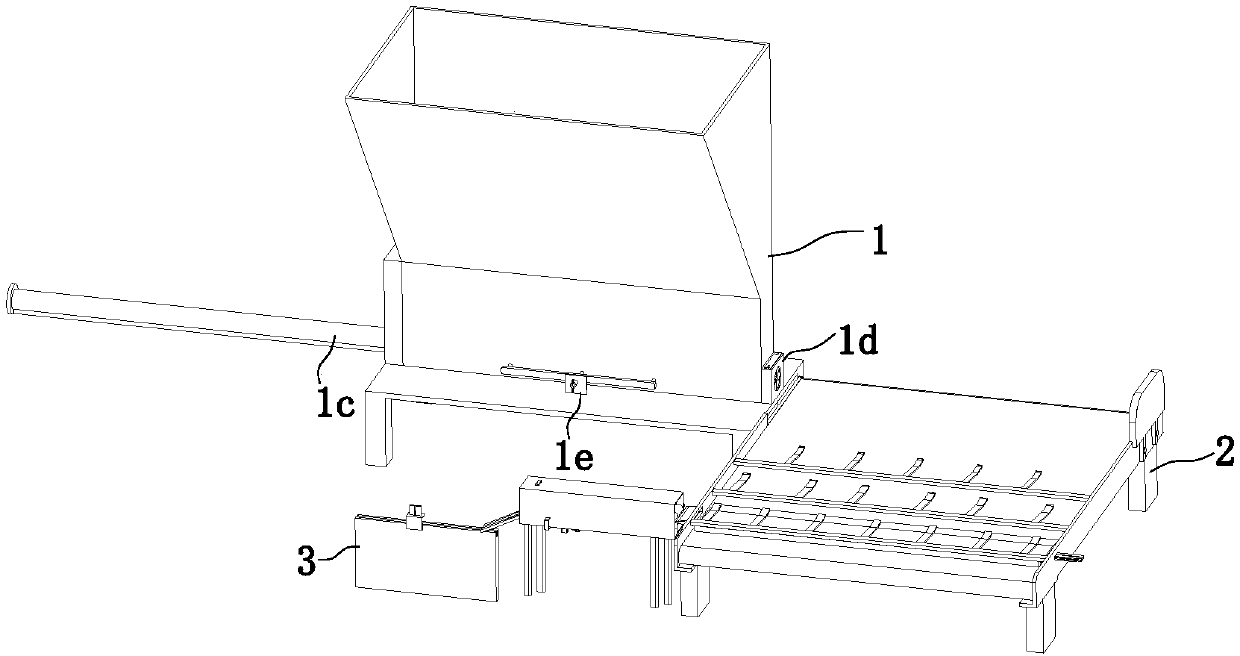

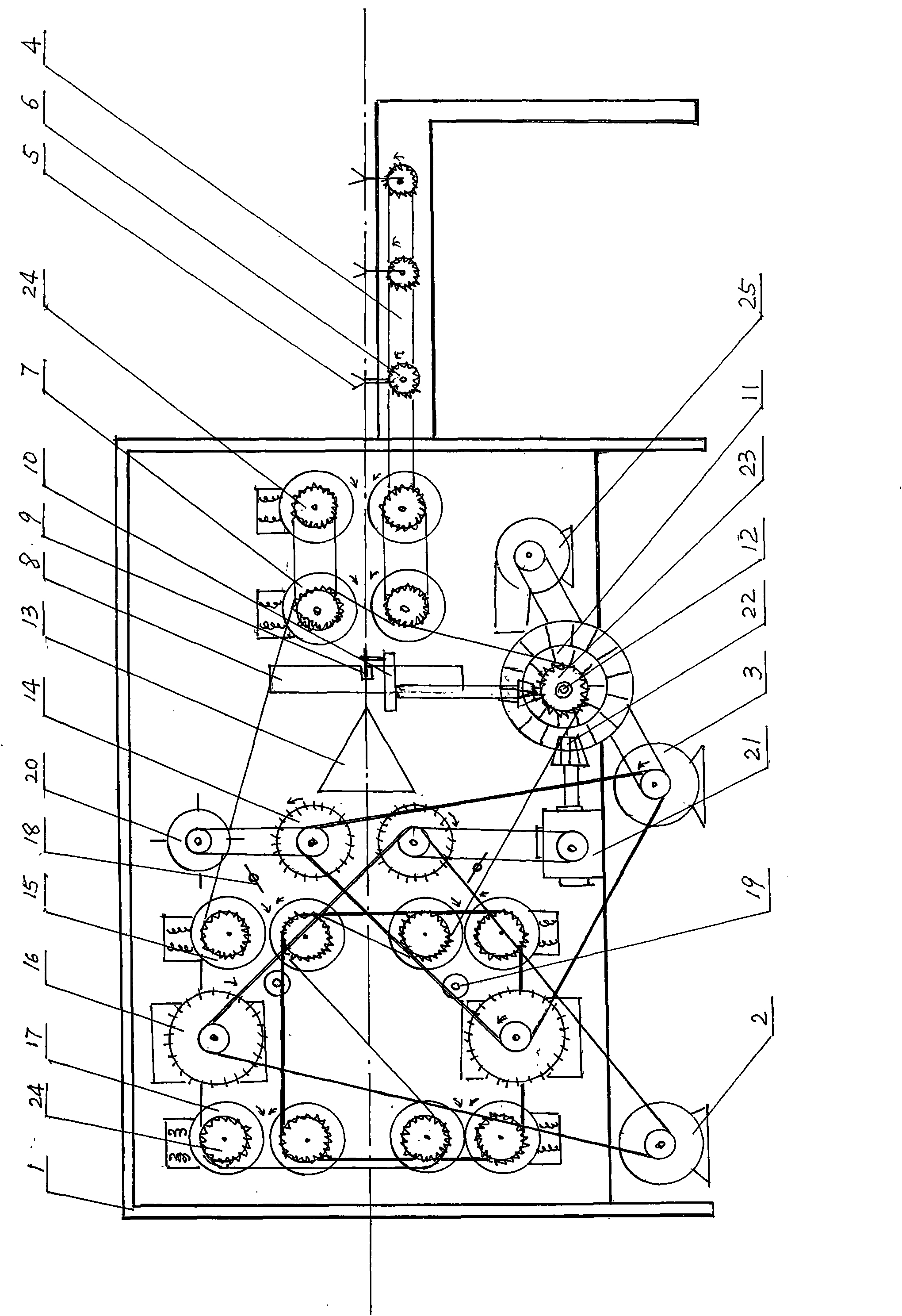

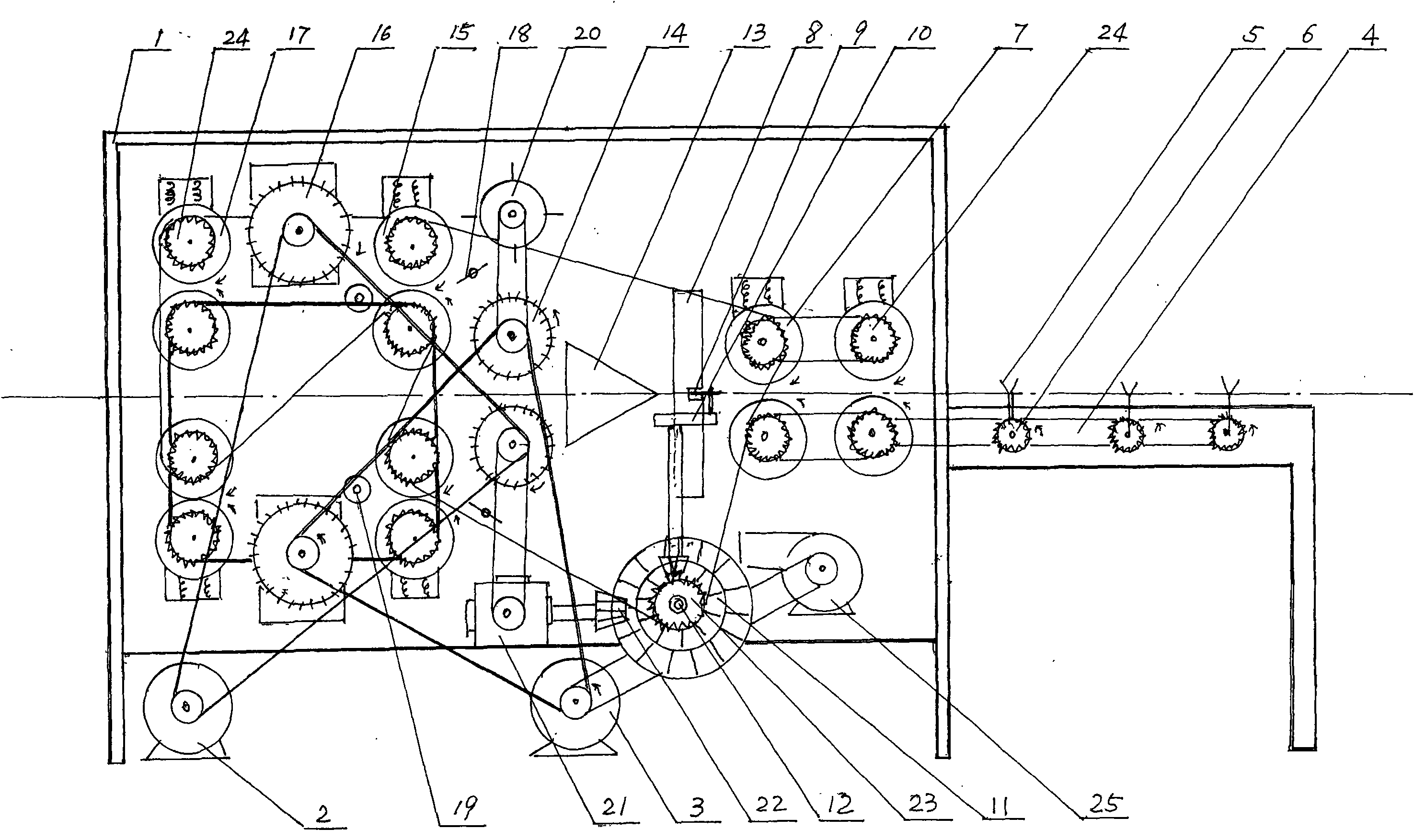

Automatic production line for bamboo chopsticks

ActiveCN107627428ARealize semi-automatic productionAvoid squeezingWooden sticks manufacturePlant material mechanical workingProduction lineSemi automatic

The invention relates to the field of mao bamboo processing, in particular to an automatic production line for bamboo chopsticks. The automatic production line comprises a loading device, a first conveyor belt and a grinding cutting device, wherein the loading device is positioned beside an input end of the first conveyor belt; the grinding cutting device is positioned beside the output end of thefirst conveyor belt; the loading device comprises a pedestal, a feeding assembly for supporting mao bamboos, a pushing assembly for moving the mao bamboos to the first conveyor belt from the feedingassembly, and a cutting part for cutting the mao bamboos into bamboo sheets; the feeding assembly, the pushing assembly and the cutting part are positioned on the top of the pedestal, and are fixedlyconnected with the pedestal; a limiting assembly for stacking bamboo sheets is arranged on the top of the first conveyor belt; one side, away from the grinding cutting device, of the first conveyor belt is equipped with a moving assembly for outputting the bamboo sheets on the top of the first conveyor belt to the grinding cutting device. The loading device, the first conveyor belt and the grinding cutting device realize semi-automatic production of bamboo chopsticks, and saves loss of human resources.

Owner:诸暨市景旺机械科技有限公司

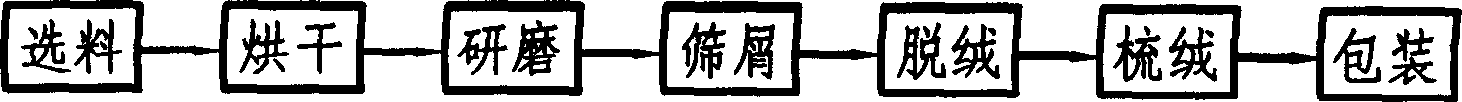

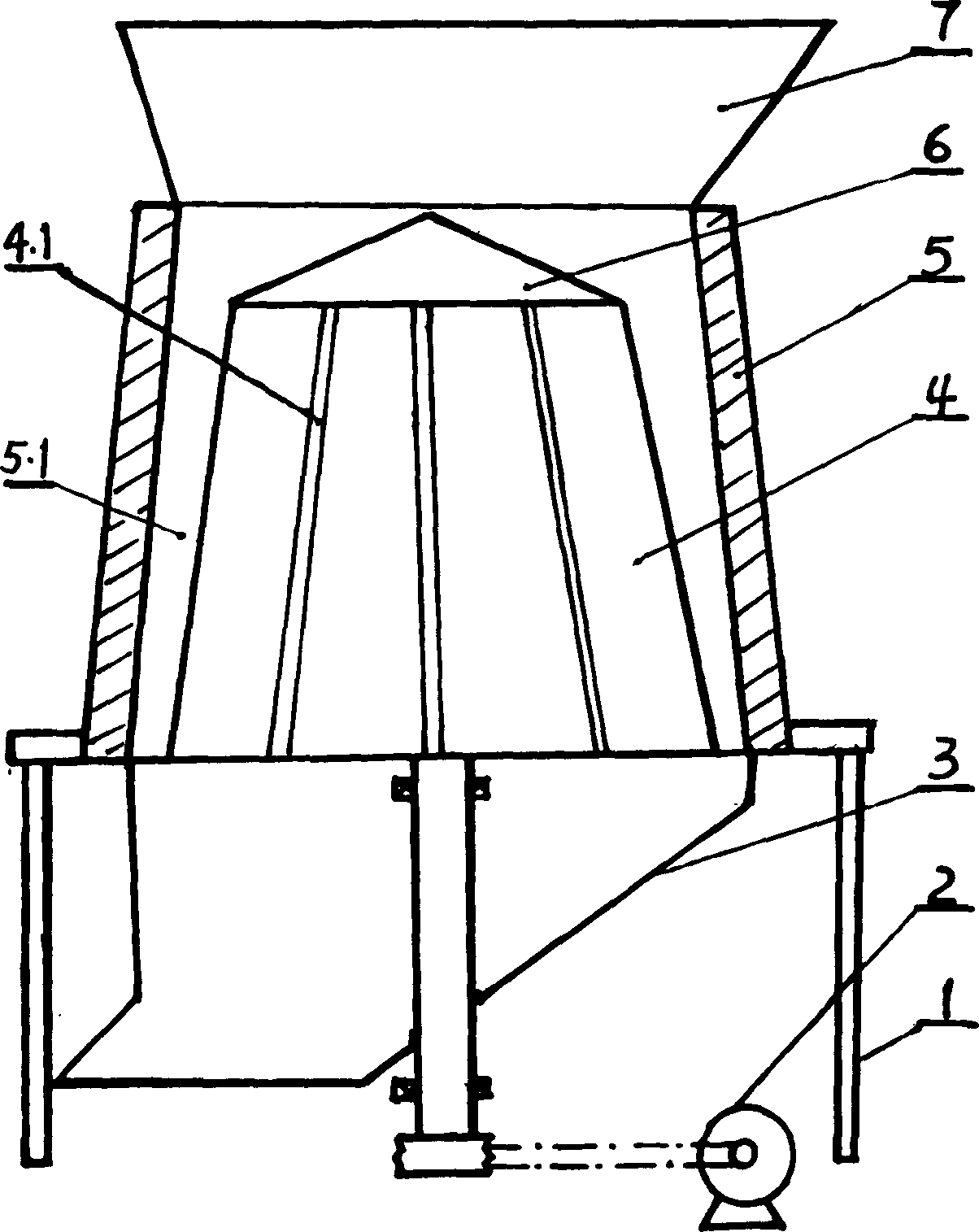

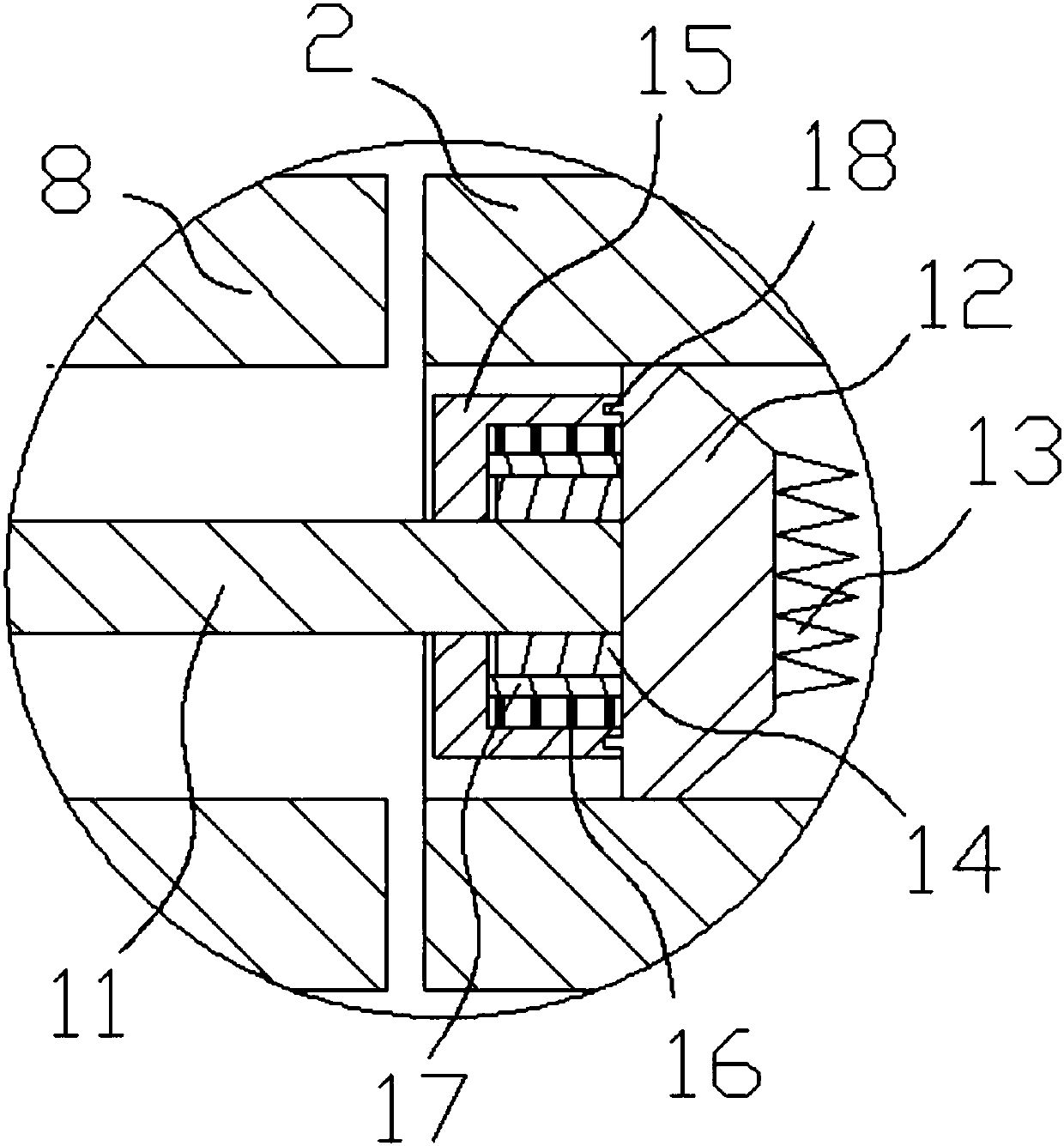

Moxa extraction process and grinder therefor

InactiveCN1864954AImprove crushing qualityImprove crushing effectVegetable fibres from other vegetable matterPlant material mechanical workingFiberEngineering

The invention relates to a method for extracting moxa from argyi leaf and relative grinder. It mainly comprises following steps that selecting material; drying; grinding; screening; removing hair; and combing moxa. Wherein. The invention uses taper grinder whose movable grinding element is a rotary table inside the cylinder fixed grinding element, while there is a grinding chamber between them; the upper end of movable grinding element is mounted with taper setting gauge. The invention can improve the quality of broken argyi leaf, to protect the natural length of moxa, improve the moxa extraction rate. And it uses eccentric moxa combing method, to improve the shape of moxa.

Owner:刘志宏

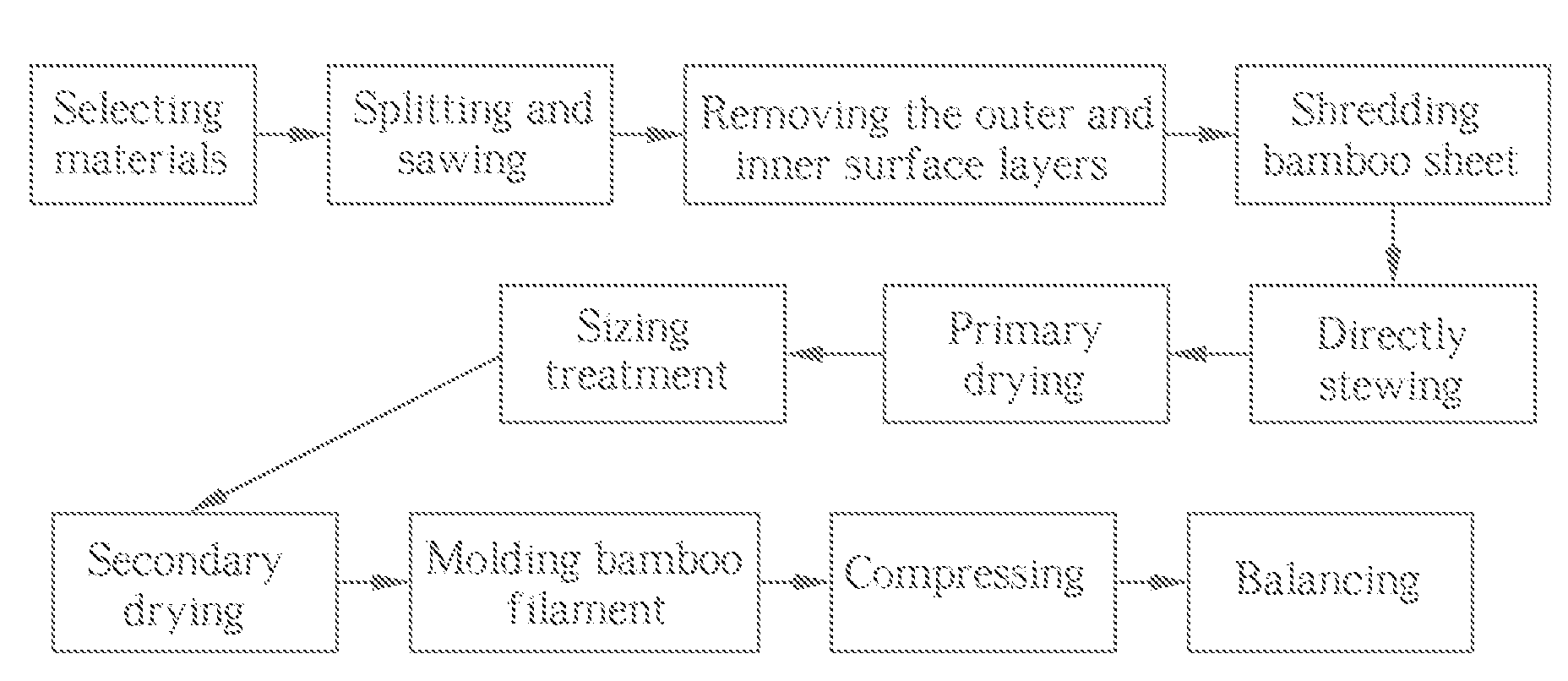

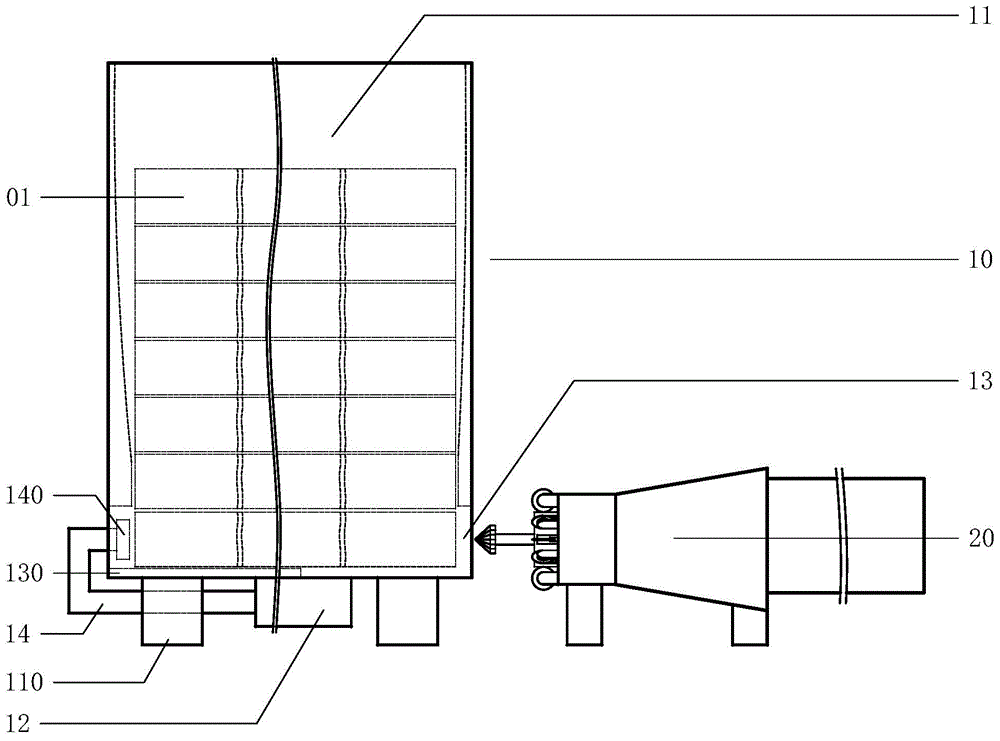

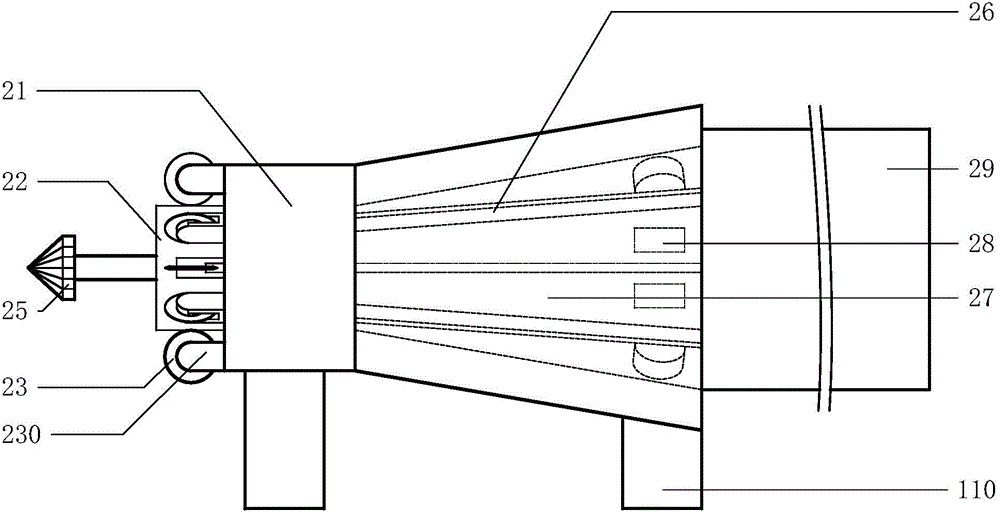

Process for making a bamboo filament slab floor by opposite directional hot pressing

InactiveUS7661450B2Easy to reboundEasy to expandStapling toolsWood compressionManufacturing technologyEngineering

Owner:WANG ZHENGFENG

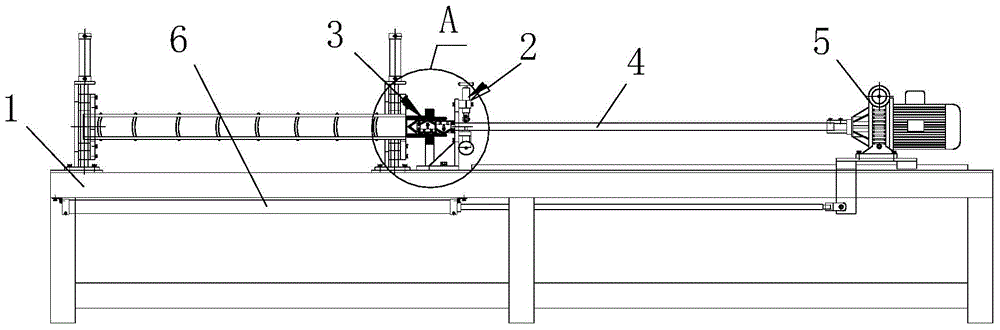

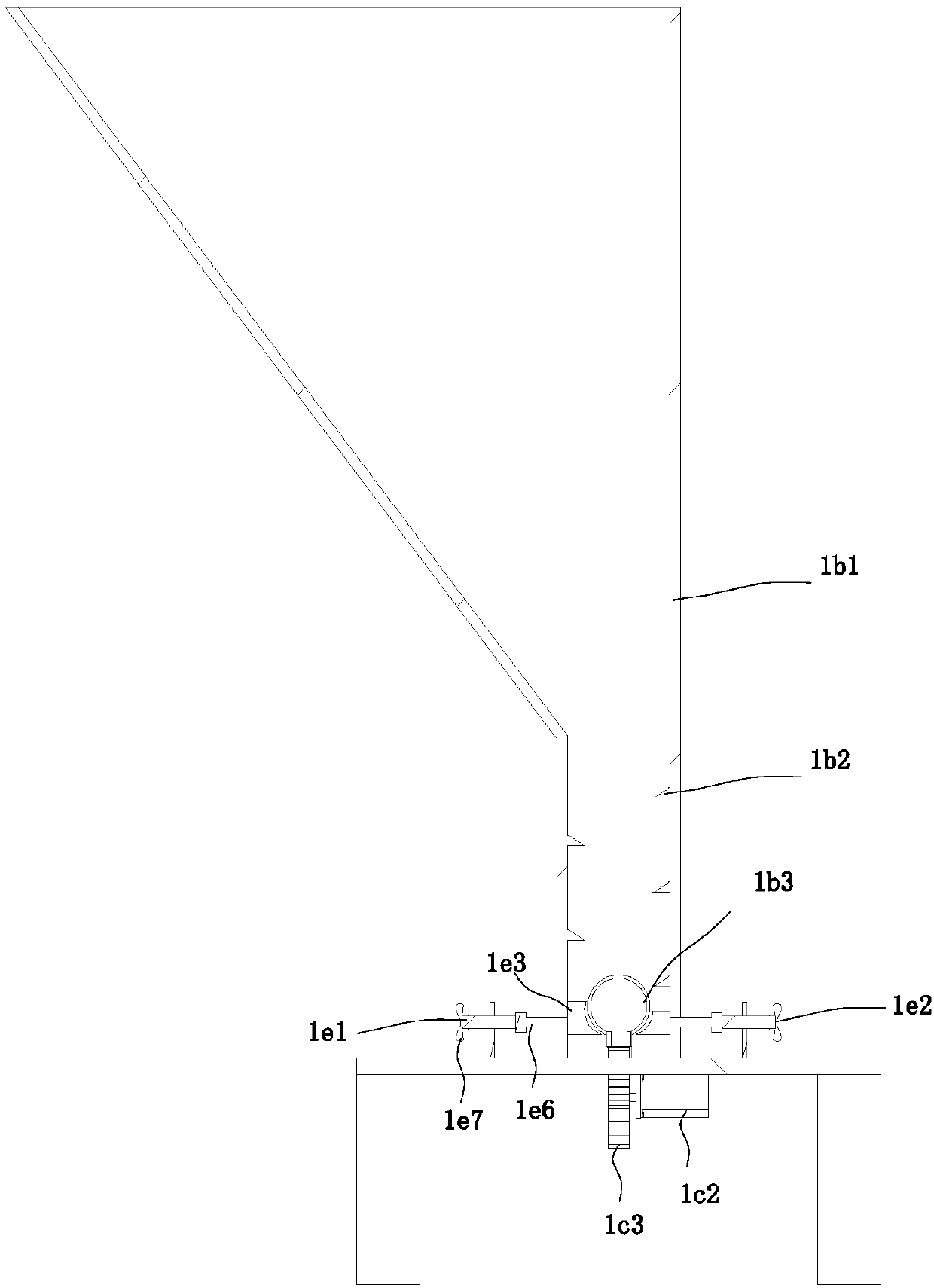

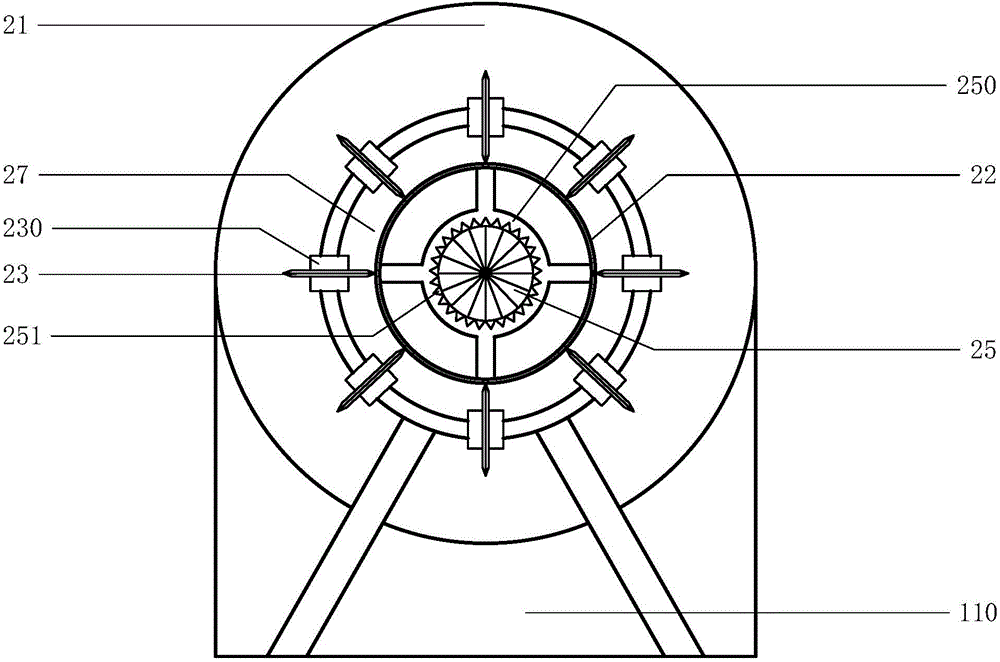

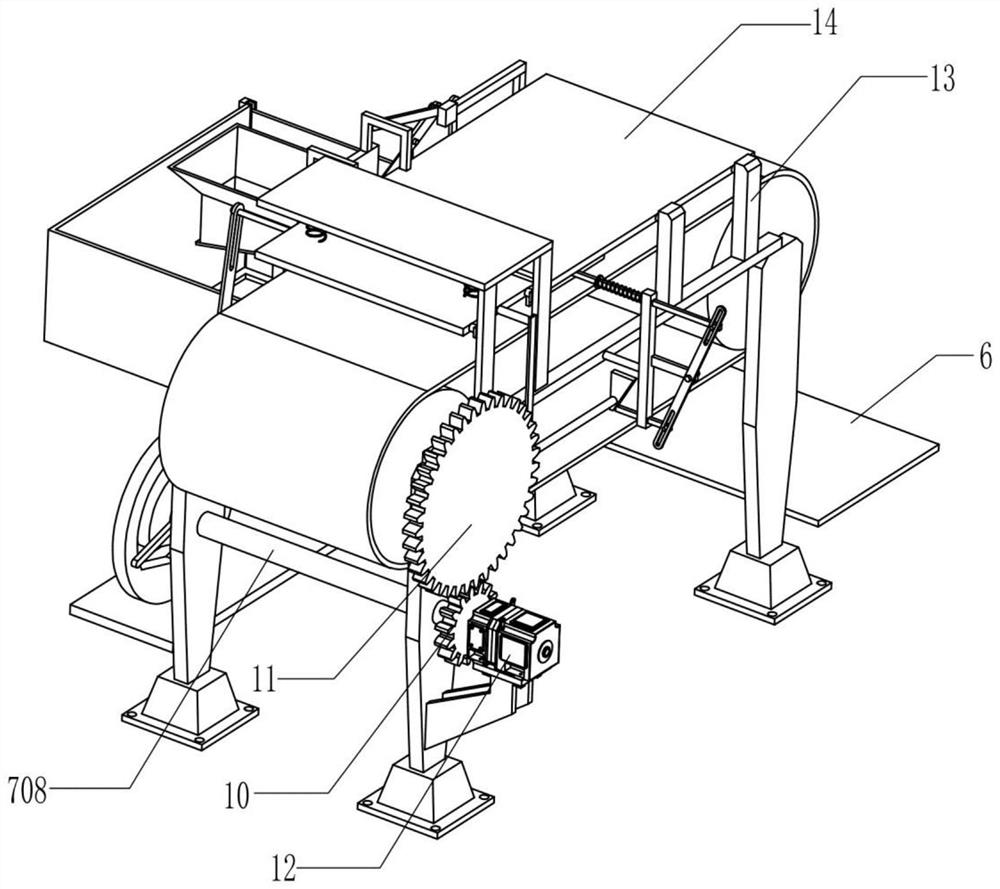

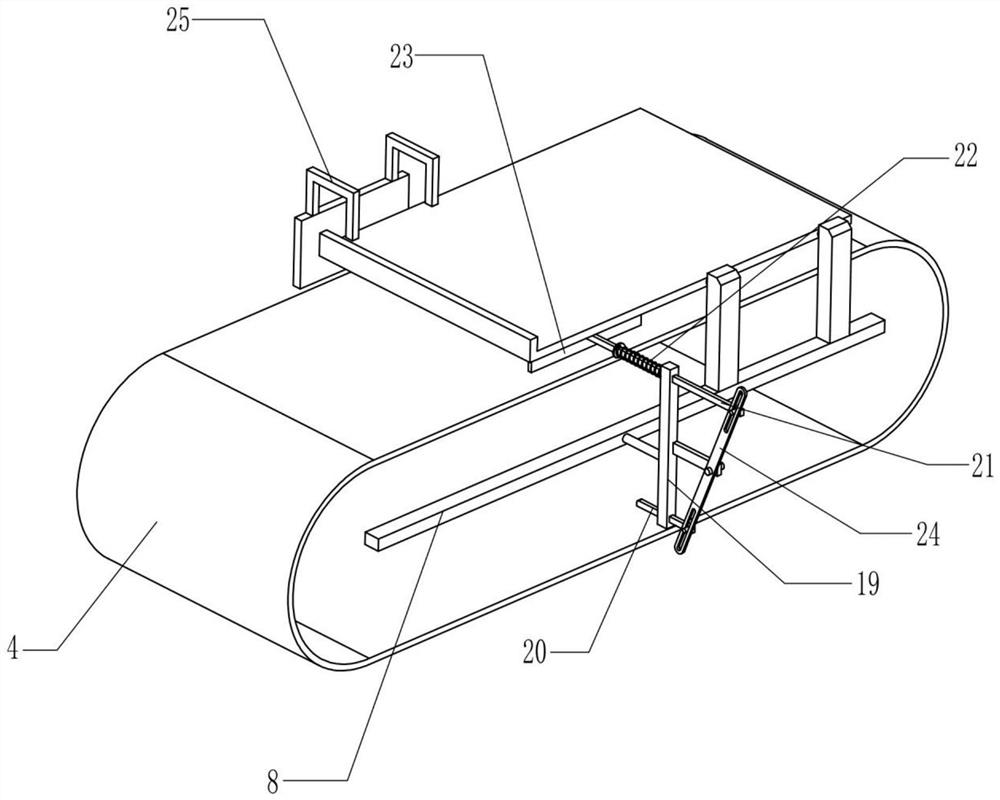

Moso bamboo slivering machine

InactiveCN104626311AIncrease profitReasonable structureWood splittingCane mechanical workingEngineering

The invention discloses a moso bamboo slivering machine which comprises a jacking feeder and a bamboo breaking tabasheer stripper, wherein the jacking feeder comprises an automatic feeding bin and a transverse jacking machine, the transverse jacking machine is arranged at the bottom of an automatic feeding bin and provided with a pushing moment arm; the bamboo breaking tabasheer stripper comprises an outer sleeve rack, an inner sleeve rack, a gear-shaped bamboo breaking wheel, a tabasheer stripping knife and a bamboo joint crushing head; the outer sleeve frame is arranged at the side surface of the jacking feeder, the inner sleeve rack is arranged at an inner cavity of the outer sleeve rack in a sleeving manner, and a plurality of bamboo tendon breaking plates and umbrella bamboo slides are arranged between the outer sleeve rack and the inner sleeve rack. According to the embodiment, moso bamboos are conveyed into the bamboo breaking tabasheer stripper one by one by virtue of the jacking feeder, the bamboo breaking tabasheer stripper is used for cutting the moso bamboos into bar-shaped materials which are uniform and equal to width; tabasheer of the moso bamboos are stripped and removed in a cutting process. Therefore, the moso bamboo slivering machine is reasonable in structure and convenient to operate and control; the comprehensive utilization rate of the moso bamboos can be improved, and the production procedures can be reduced and the production cost is lowered.

Owner:安徽青藤再生资源有限公司

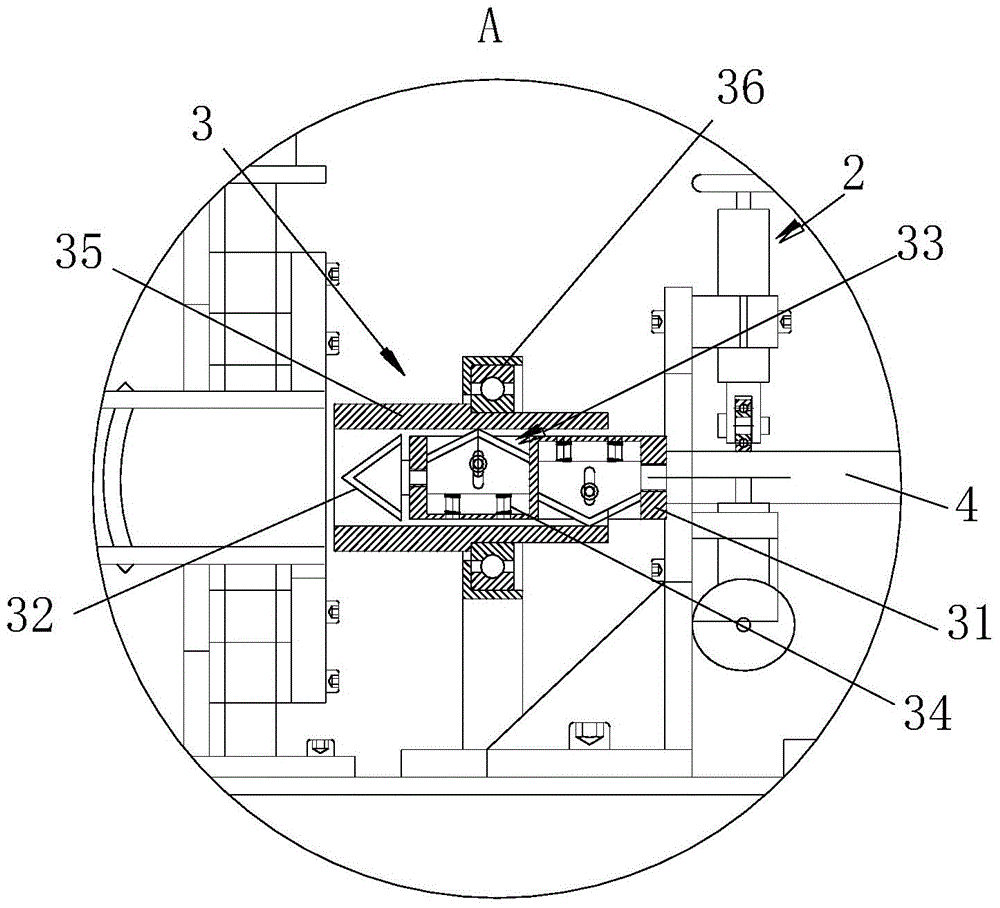

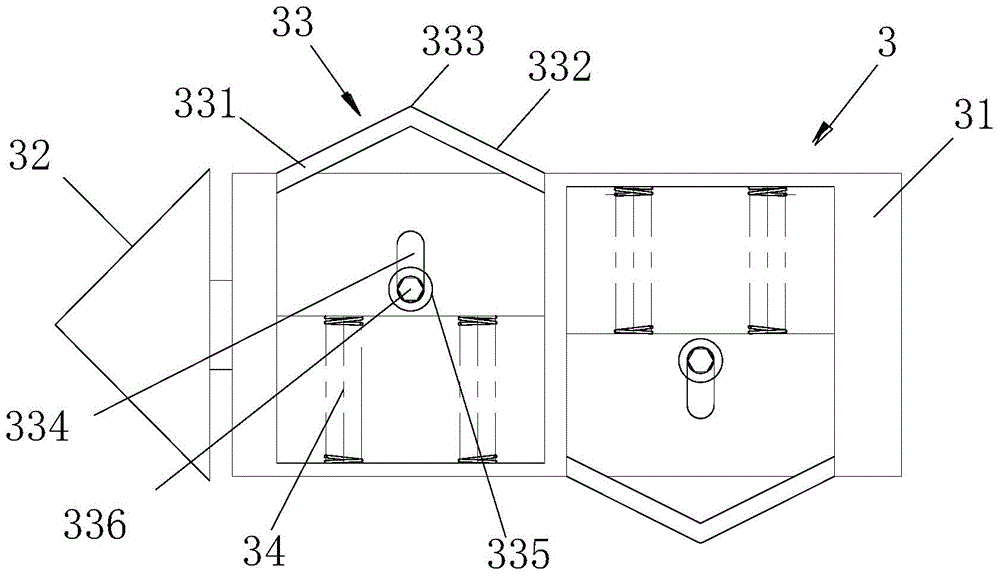

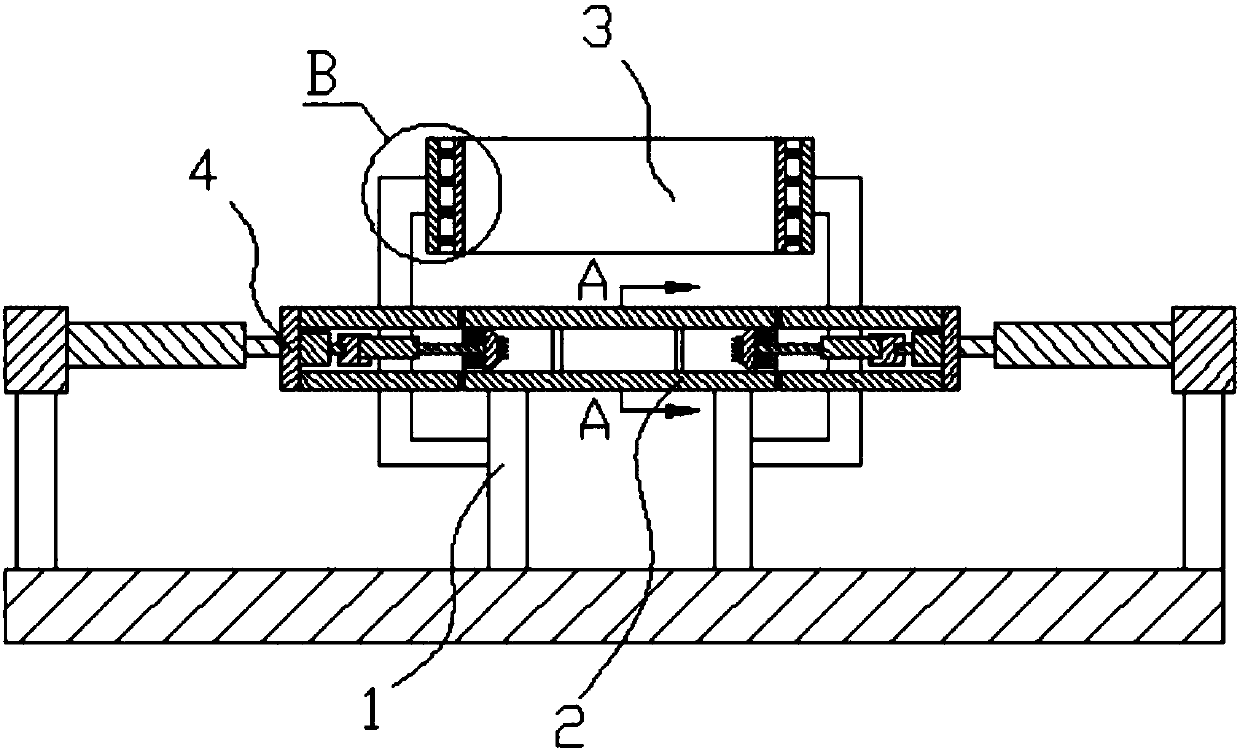

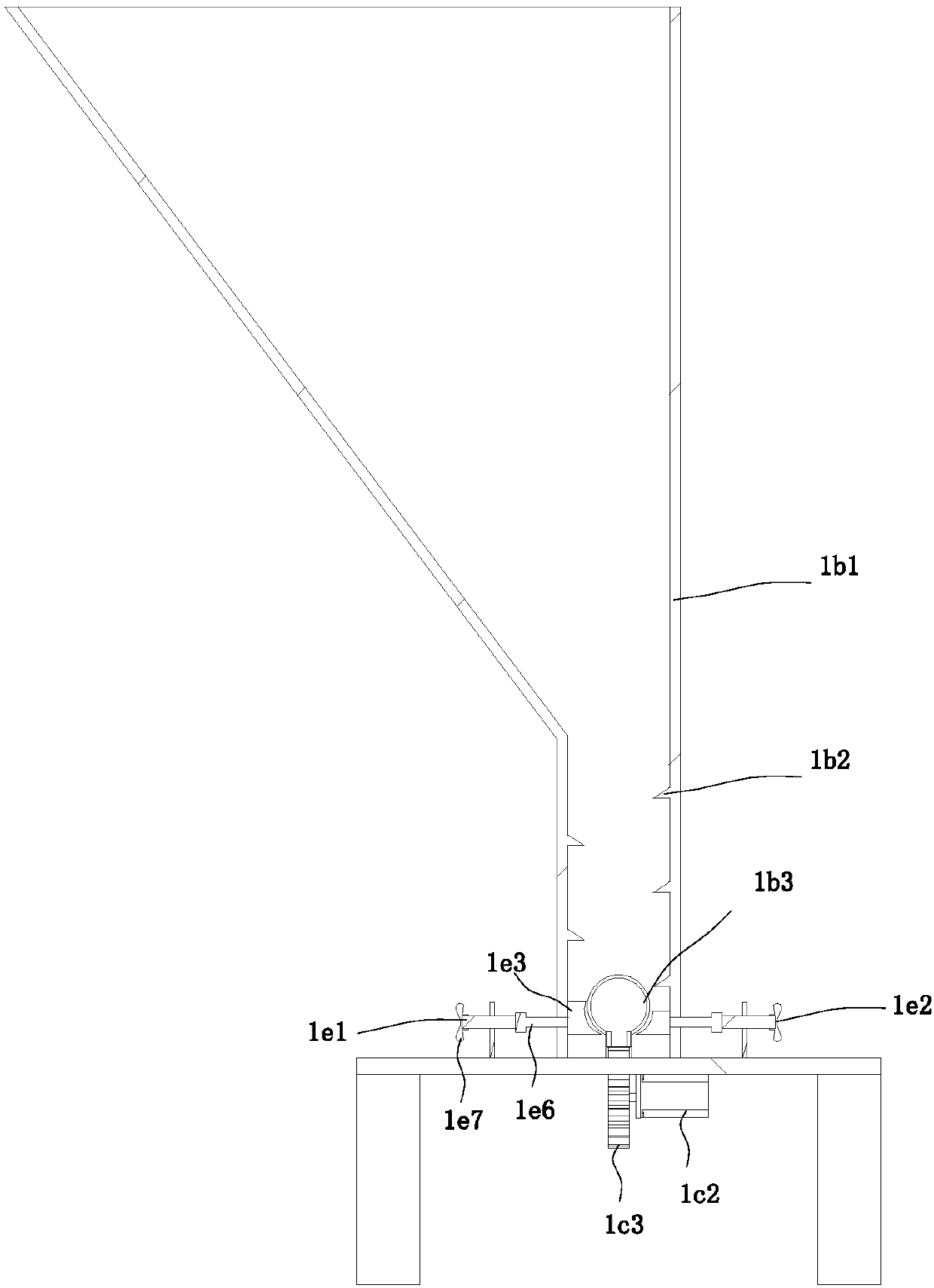

Bamboo splitting and inner joint removing all-in-one machine

InactiveCN107756578AGood sandingPlay a role of position restrictionWood splittingPlant material mechanical workingEngineering

The invention relates to an integrated machine for breaking bamboo and removing internal knots, which includes a frame and a clamping device. The two opening sides of the bamboo tube in the clamping device are equipped with a mechanism for breaking bamboo and removing internal knots. The bamboo-breaking seat is equipped with a bamboo-breaking propulsion cylinder that is consistent with the direction of the bamboo tube, and the bamboo-breaking propulsion cylinder is connected with a bamboo-breaking propulsion seat, and the outside of the bamboo-breaking propulsion seat is uniformly provided with a bamboo-breaking knife that matches the bamboo tube in the clamping device 1. The center is provided with a rotating motor for removing the inner section, and the rotating motor for removing the inner section is connected to the feeding cylinder for removing the inner section. The feed cylinder for inner section removal makes the inner section grinding column located on the feeding side of the bamboo cutter, so that the bamboo cutter penetrating into the bamboo tube plays a role in restricting the position of the bamboo, ensuring good grinding of the inner section grinding column Effect, the effect of breaking bamboo and removing internal joints is improved while realizing integration.

Owner:DONGGUAN UNIV OF TECH

Reciprocating scrape type bamboo outer skin removing device

InactiveCN104385398ARetain toughnessImprove work efficiencyCane mechanical workingPlant material mechanical workingKnife bladesBiomedical engineering

The invention aims at providing a reciprocating scrape type bamboo outer skin removing device, comprising a rack, a knife rest and a knife rest driving mechanism, wherein the knife rest is connected with the knife rest driving mechanism, and mutually matched guide mechanisms are arranged between the knife rest and the rack so as to make the knife rest move up and down on the rack; at least one set of blade group is arranged on the knife rest, the blade group internally comprises two opposite blades which are connected with the knife rest through an elastic pressing mechanism so as to make the two blades in the same blade group able to clamp the bamboo passing between the two blades; the rack is further provided with a position limiting mechanism for limiting the position of the bamboo. The reciprocating scrape type bamboo outer skin removing device changes the working manner of a bamboo outer skin removing machine in the prior art, uses the reciprocating blades to simulate manual bamboo outer skin scraping, is able to improve the working efficiency greatly, lowers the manual labor intensity, and can keep the bamboo tenacity to the maximum extent.

Owner:李静

Durable and efficient proliferating artificial fish reef and preparation method thereof

ActiveCN107021722ANo pollution in the processLow costClimate change adaptationWood treatment detailsBrickSlag

The invention discloses a durable and efficient proliferating artificial fish reef and a preparation method thereof. The artificial fish reef comprises a reinforced concrete material, aggregate and bamboo strips. The reinforced concrete material is prepared from the following components by weight: 10-20 parts of slag, 5-20 parts of steel slag, 5-12 parts of alkaline slag, 5-15 parts of desulfurized gypsum, 50-70 parts of fly ash, 1-7 parts of manganese-containing waste slag, 2-5 parts of quick lime, 0.1-1 part of glass fiber, 1-3 parts of silicon powder, and 0.5-5 parts of anhydrous gypsum. The aggregate is selected from one or more of waste glass, waste ceramics, waste brick and shell rejected materials, and the aggregate size is single-sized. The bamboo strips are used for enhancing the connection performance and firmness of the fish reef. The artificial fish reef provided by the invention has the characteristics of stable performance in seawater, strong corrosion resistance, and strength enhancement in a seawater environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

System and method for the separation of bast fibers

InactiveUS8075735B2Efficient separationSoftening of outer bastFibre cleaning/opening by toothed membersWood working apparatusFiberScreening method

The present invention relates generally to the timber products industry, and particularly to methods and apparatus for the separation of bast fibers. More particularly, the present invention relates to methods and apparatus for use in the separation of inner core from outer bast of bast plants using soaking, cutting, and scrimming methods and apparatuses.

Owner:TIMTEK

Coptis chinensis stem and leaf batched separation equipment of Chinese medicinal herb processing

The invention discloses coptis chinensis stem and leaf batched separation equipment of Chinese medicinal herb processing, and relates to the technical field of traditional chinese medicinal material processing. The aim is to provide coptis chinensis stem and leaf batched separation equipment of Chinese medicinal herb processing, wherein the equipment can automatically separate stems and leaves ofmass coptis chinensis and improve the coptis chinensis stem and leaf separation efficiency effectively and is high in function targeted performance. The coptis chinensis stem and leaf batched separation equipment of Chinese medicinal herb processing comprises a base, a first transmission roller, a second transmission roller, a conveying belt, a long plate, a containing plate, a coptis chinensis stem and leaf separation device, a first supporting rod, a coptis chinensis compaction device and the like. The first transmission roller and the second transmission roller are rotationally mounted on the base, and the conveying belt is connected between the first transmission roller and the second transmission roller. In the equipment, the coptis chinensis stem and leaf separation device and the coptis chinensis compaction device cooperatively work, coptis chinensis located on the conveying belt is firstly subjected to compaction operation, then stems and leaves of coptis chinensis are rapidlyseparated, and the coptis chinensis stem and leaf separation efficiency is high.

Owner:聊城市蓓智信息科技有限公司

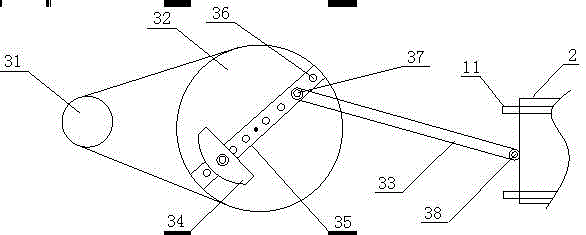

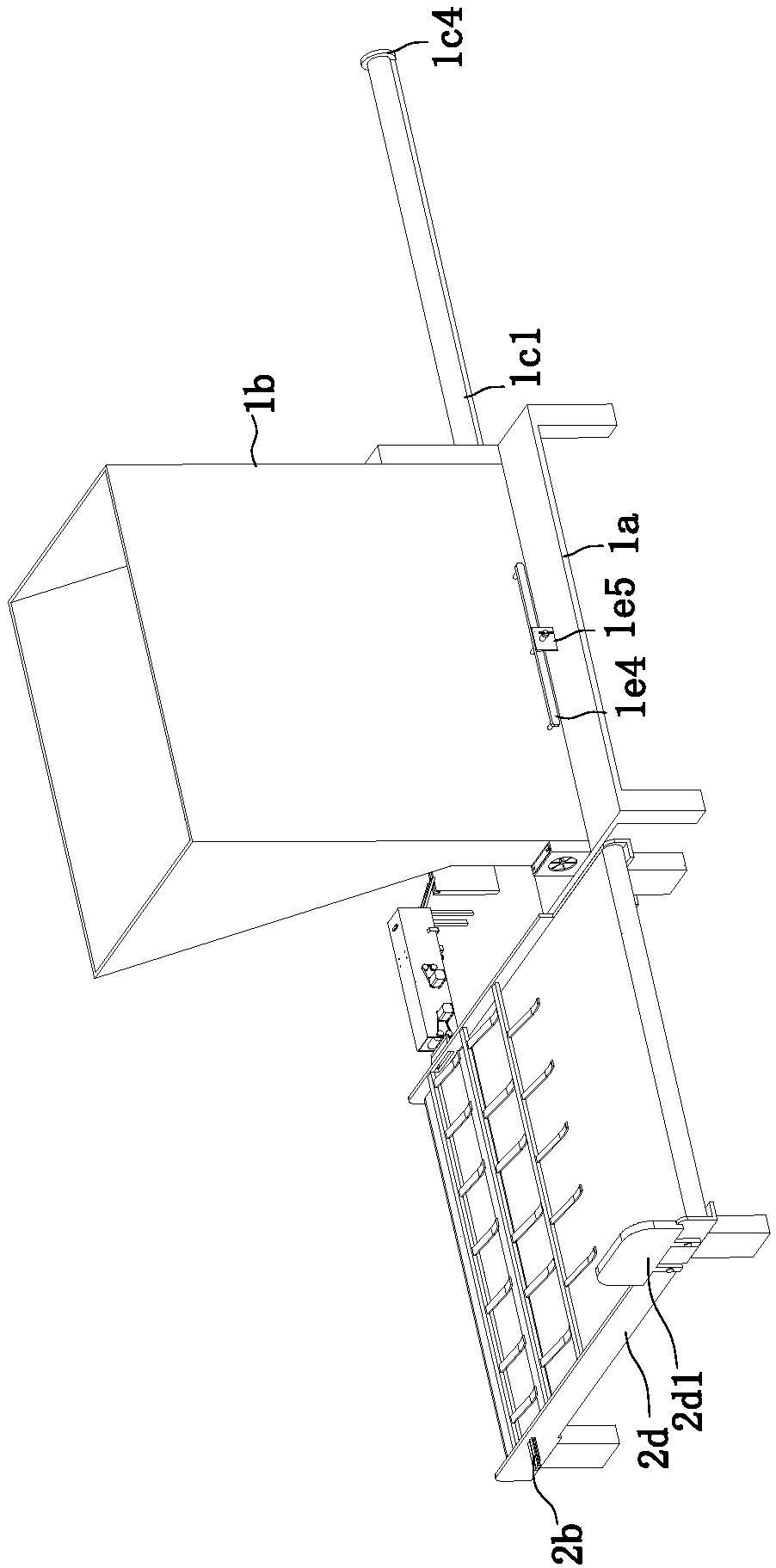

Grinding and cutting device of automatic bamboo chopstick production line

ActiveCN107900857ASimple structureProfiling/shaping machinesPlant material mechanical workingProduction lineEngineering

The invention relates to the field of moso bamboo processing, in particular to a grinding and cutting device of an automatic bamboo chopstick production line. The grinding and cutting device comprisesa material passing channel, a feeding assembly, a grinding assembly and a cutting assembly. The feeding assembly, the grinding assembly and the cutting assembly are sequentially arranged at intervalsin the feeding direction of the material passing channel and are fixedly connected with the material passing channel. The feeding assembly comprises a first roller and a second roller which are usedfor conveying bamboo chips. The grinding assembly comprises a first grinding piece for grinding the tops and the bottoms of the bamboo chips and a second grinding piece for grinding the left sides andthe right sides of the bamboo chips. The cutting device comprises a first cutting piece for rough cutting of the bamboo chips in the material passing channel, and a second cutting piece used for finecutting of the bamboo chips outside the material passing channel. The bamboo chips are ground into the early shape of the bamboo chopsticks through the first grinding piece and the second grinding piece, the bamboo chips are sequentially divided into segments through a first cutting saw web, and a second cutting sheet cuts the segmented bamboo chips obtained after cutting again so that the bamboochips can become finished bamboo chopsticks.

Owner:会同汇达竹业有限公司

Mechanical equipment for removing bark and kernel of sunflower stalk

InactiveCN102092065AEfficient removalIncrease productivityPlant material mechanical workingHigh volume manufacturingCuticle

The invention relates to mechanical equipment for removing bark and kernel of a sunflower stalk, belonging to the field of material manufacturing machinery. In the equipment, a saw blade is placed on a tool rest; cams are respectively arranged on two ends of the saw blade, and are connected with a group of bevel gears on a drive shaft through cam shafts; a drift is arranged on the front end of the tool rest, and is arranged on a frame; a bark removing and kernel removing devices are symmetrically arranged above and under the central line of the frame which is positioned on the front end of the drift; each bark and kernel removing device comprises a core removing steel wire wheel, a steel pipe feed roller, a bark removing steel wire wheel and a steel pipe discharger roller; a guide plate is arranged between the core removing steel wire wheel and the steel pipe feed roller; an adjusting roller is arranged between the steel pipe feed roller and the bark removing steel wire wheel; and springs are arranged above the steel pipe feed roller and steel pipe discharge roller respectively. The mechanical equipment can be used for effectively removing the bark and core of the sunflower stalk, and spreading the sunflower stalk without bark or core through the steel pipe discharge roller, providing powerful guarantee for batch production of a sunflower stalk artificial plate which is a novel variety of composite plates, and has the advantages of high production efficiency and low cost.

Owner:刘庆喜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com