Method and device for separating corn stalk bark and corn pith

A technology of corn stalk and separation method, which is applied in the direction of plant material mechanical processing, mechanical equipment, etc., can solve the problems of corn stalk pith separation technology and imperfect equipment, and achieve the effect of simple structure, high separation rate and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

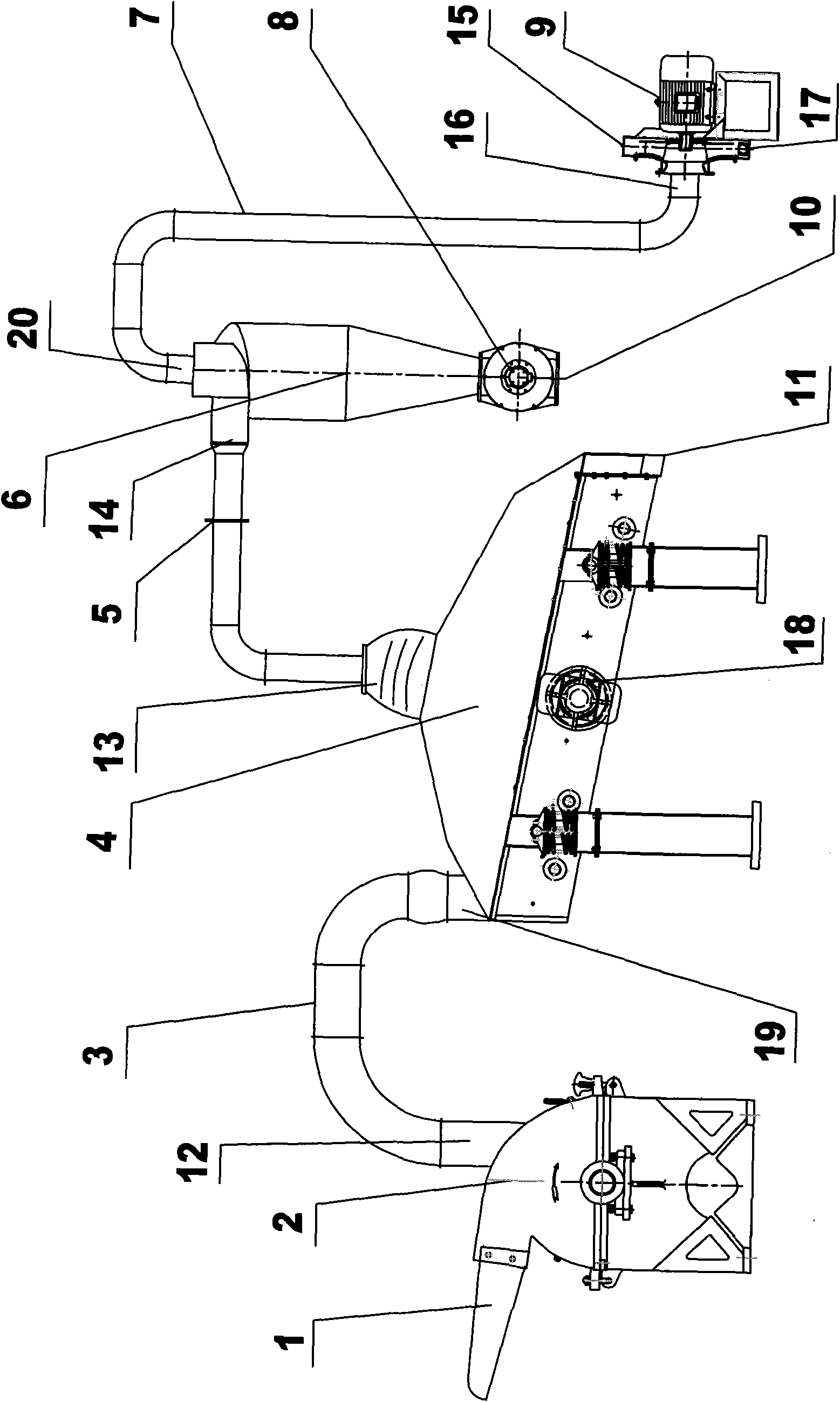

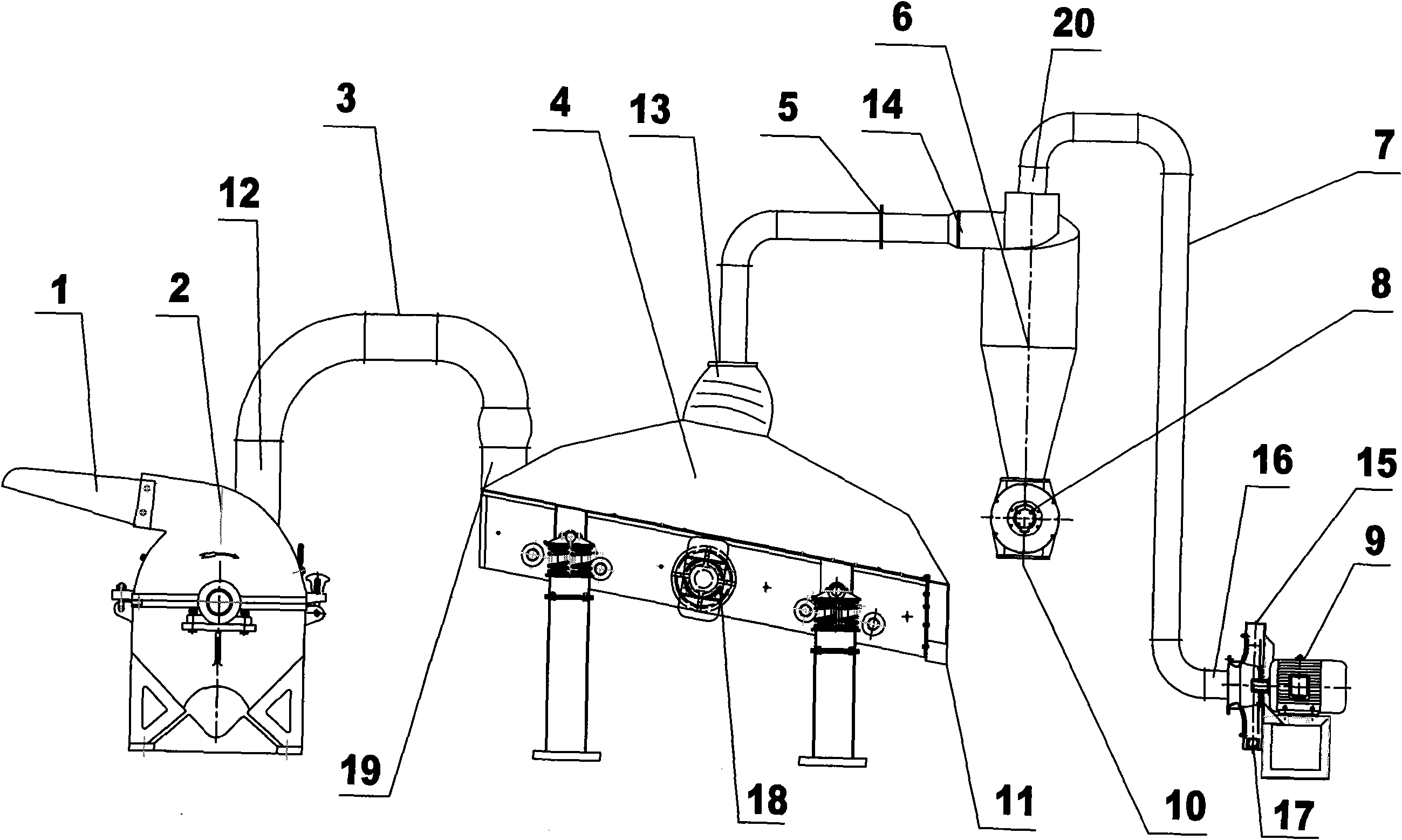

[0026] The corn stalks are peeled off from the husk and pith under the impact and shear of the crushing parts of the grinder, and are crushed into a certain particle size and passed through the screen surface. The airflow formed by the grinder itself and the suction effect of the centrifugal fan The bottom enters through the connecting pipe I from the feed inlet on the upper left of the high-speed vibration separation device, and is evenly paved along the width direction of the high-speed vibration separation device to form a material layer with a certain thickness. The material is thrown up along the vibration direction under the action of vibration, and at the same time , under the action of the bottom-up sieving uniform airflow, the material is in a suspended or semi-suspended state. At this time, the light material with a small suspension speed follows the airflow from the light material outlet above the high-speed vibration separation device through the connecting pipe II ...

Embodiment 2

[0028] figure 1 The first embodiment of the corn stalk husk and pith separation device of the present invention is given, including a vertical vane pulverizer 1, a high-speed vibrating screen 4, a cyclone separator 6, an air locker 8, and a centrifugal fan 15. The vertical vane type The discharge port 2 of the pulverizer 1 is connected to the feed port 9 on the upper left of the high-speed vibrating screen 4 through the connecting pipe I3, and the light material outlet 13 above the high-speed vibrating screen 4 is fed to the cyclone separator 6 through the connecting pipe II5. The port 14 is connected, the lower right side of the high-speed vibrating screen 4 is provided with a heavy material outlet 11, the lower part of the cyclone separator 6 is equipped with an air locker 8, the bottom of the air locker 8 is the separated light material outlet 10, and the cyclone separator 6 The air flow at the top and the dust outlet 12 are connected with one end of the connecting pipe III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com