Patents

Literature

96results about How to "Fully stripped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

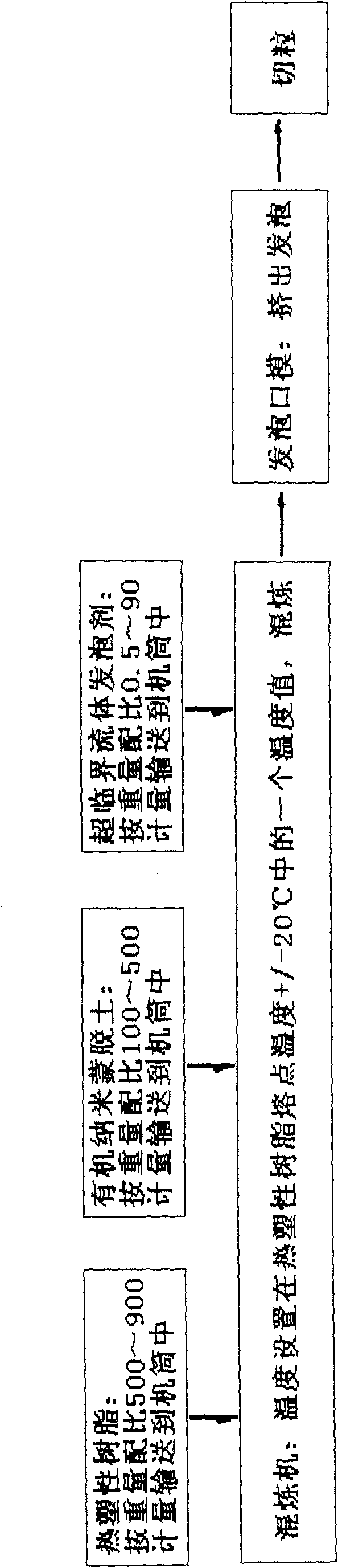

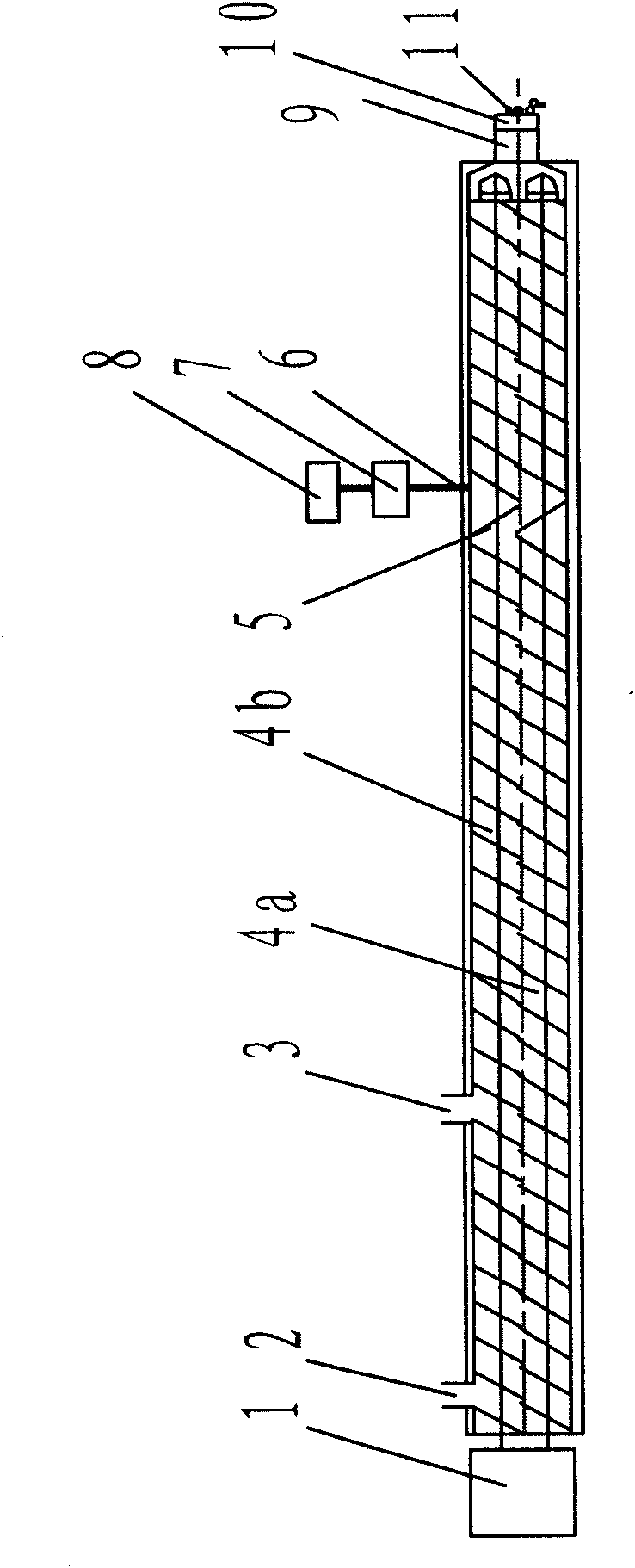

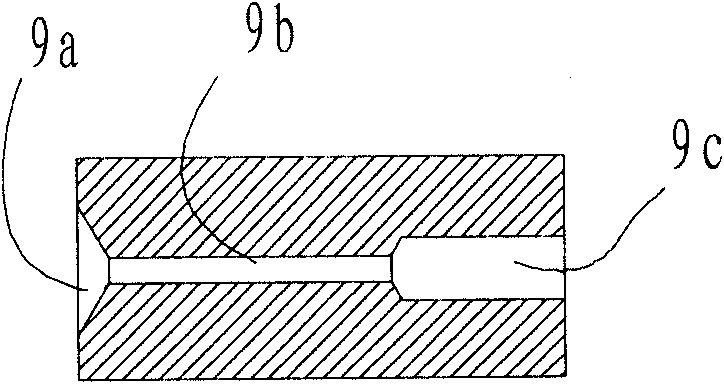

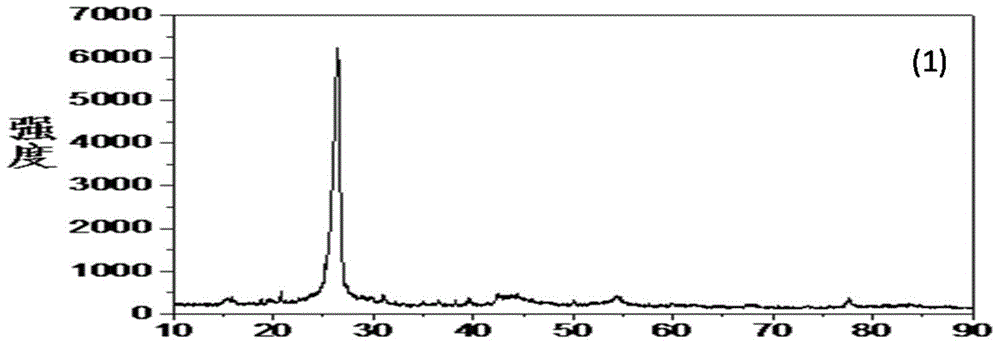

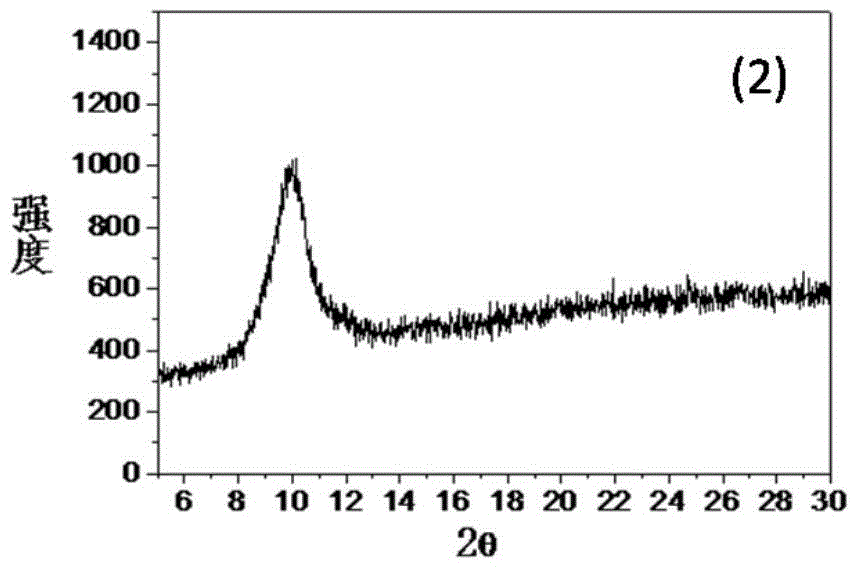

Nucleating agent master batches used for foaming of thermoplastic resin

ActiveCN101565550AConvenient injection foam moldingEasy extrusionVolumetric Mass DensityNitrogen gas

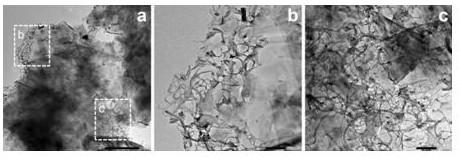

The invention relates to a nucleating agent and a method for preparing the nucleating agent, wherein the nucleating agent is used for reducing the dimension of the foaming hole and improving the density of the foaming hole when a supercritical fluid foaming agent (such as carbon dioxide or nitrogen) is used for producing thermoplastic foaming products. The raw materials of the nucleating agent mainly consists of an organic montmorillonite, a thermoplastic resin and a supercritical fluid foaming agent; the specific weight of the nucleating agent master batches is controlled within 100+ / -5% of that of the thermoplastic resin. The method has the advantages that a supercritical fluid foaming method is adopted to prepare the nucleating agent master batches which have approximate specific weights to the resin material adopted by the subsequent foam forming, thus facilitating the subsequent injection foam forming and extrusion foam forming; and the carbon dioxide or nitrogen in supercritical state is used for reducing the viscosity of the carrier resin during the mixing process, the dispersion uniformity of the peeled sandwich montmorillonite in the carrier resin is reinforced, the process temperature is reduced, the layer spacing of the sandwich nano-montmorillonite which may be not peeled is increased and the sufficient peeling is realized.

Owner:BEIJING CHN TOP MACHINERY

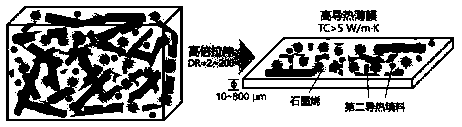

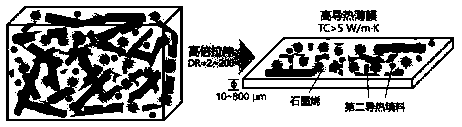

Polymer thermal conductive film containing uniformly dispersed and highly oriented graphene and preparation method thereof

InactiveCN110343315AGuaranteed cleanlinessGuaranteed continuityHeat-exchange elementsFlat articlesPolymer scienceProcedure Agents

The invention relates to the technical field of performance enhancing and functionalization of carbon nanocomposite materials, in particular to a polymer thermal conductive film containing uniformly dispersed and highly oriented graphene and a preparation method thereof. The thermal conductive film material is composed of the following components: a polymer matrix, graphene, second thermal conductive filler, a surface treatment agent, a filler coating agent and a processing aid. A technical route combining "high shear melting dispersion" and "high stretching" is employed to promote the uniformdispersion of graphene nanosheets and other thermal conductive filler in the polymer matrix and the acquisition of high orientation, graphene itself is utilized to construct a long-range continuous and three-dimensional hybrid thermal conductive network structure, thus overcoming the anisotropy of graphene, and constructing a stable and effective thermal conductive network.

Owner:江苏新奥碳纳米材料应用技术研究院有限公司 +1

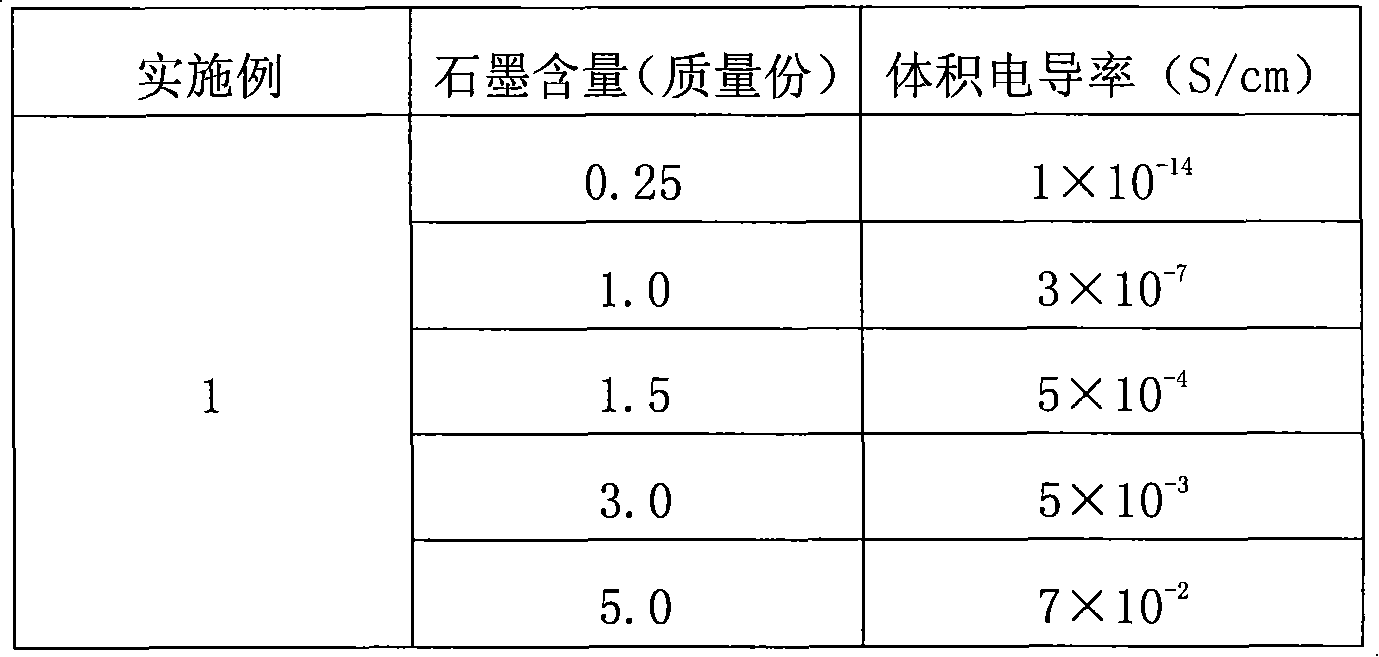

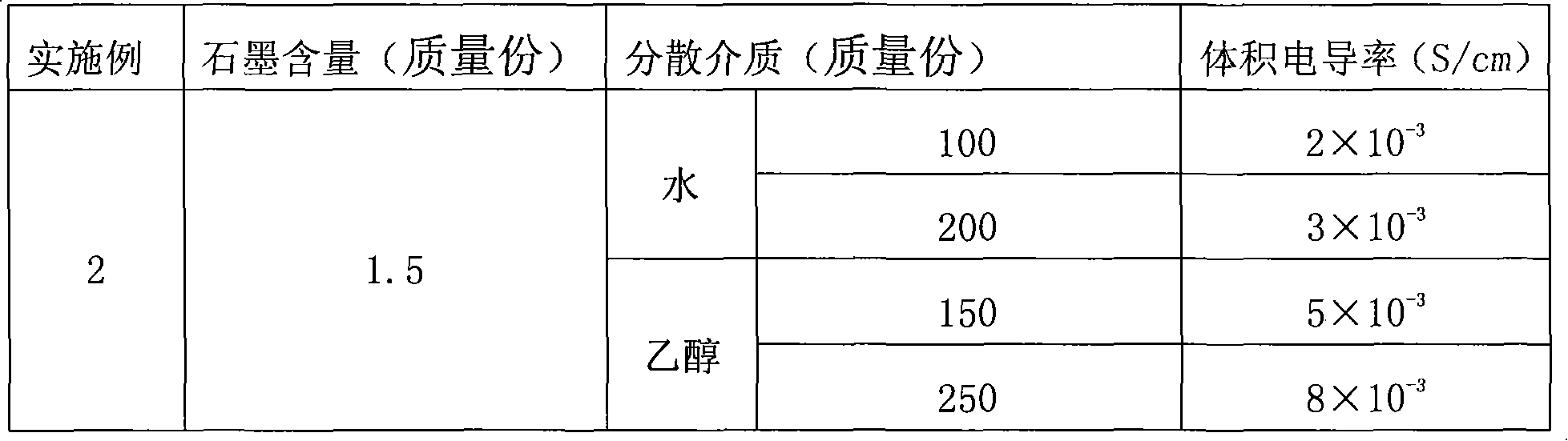

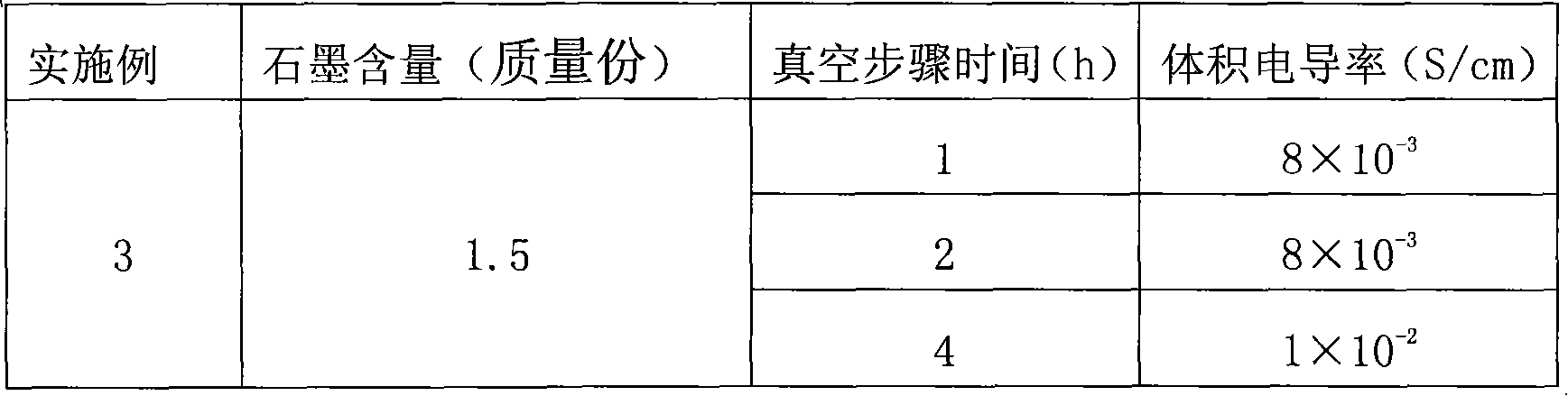

Polyamide/oxidized graphite composite material with high conduction performance and preparation method thereof

InactiveCN101608061AImprove conductivityReduce the amount of fillerIn situ polymerizationConductive polymer

The invention discloses a polyamide / graphite composite material with high conduction performance and a preparation method thereof. The composite material consists of a polyamide substrate and nanometer graphite and is prepared through in-situ polymerization. The nanometer graphite has high diameter-to-thickness ratio; and an effective conduction network can be formed in a polymer by using little nanometer graphite. With the low content of a conduction filling of the nanometer graphite, a conduction polymer material keeps original good mechanical performance. The volume conductivity of the polyamide / graphite composite material with high conduction performance can reach 8*10S / cm; and compared with a conventional natural graphite and expanded graphite conductive composite material, the polyamide / graphite composite material has excellent properties of low filling amount and high conductivity.

Owner:TORAY IND INC

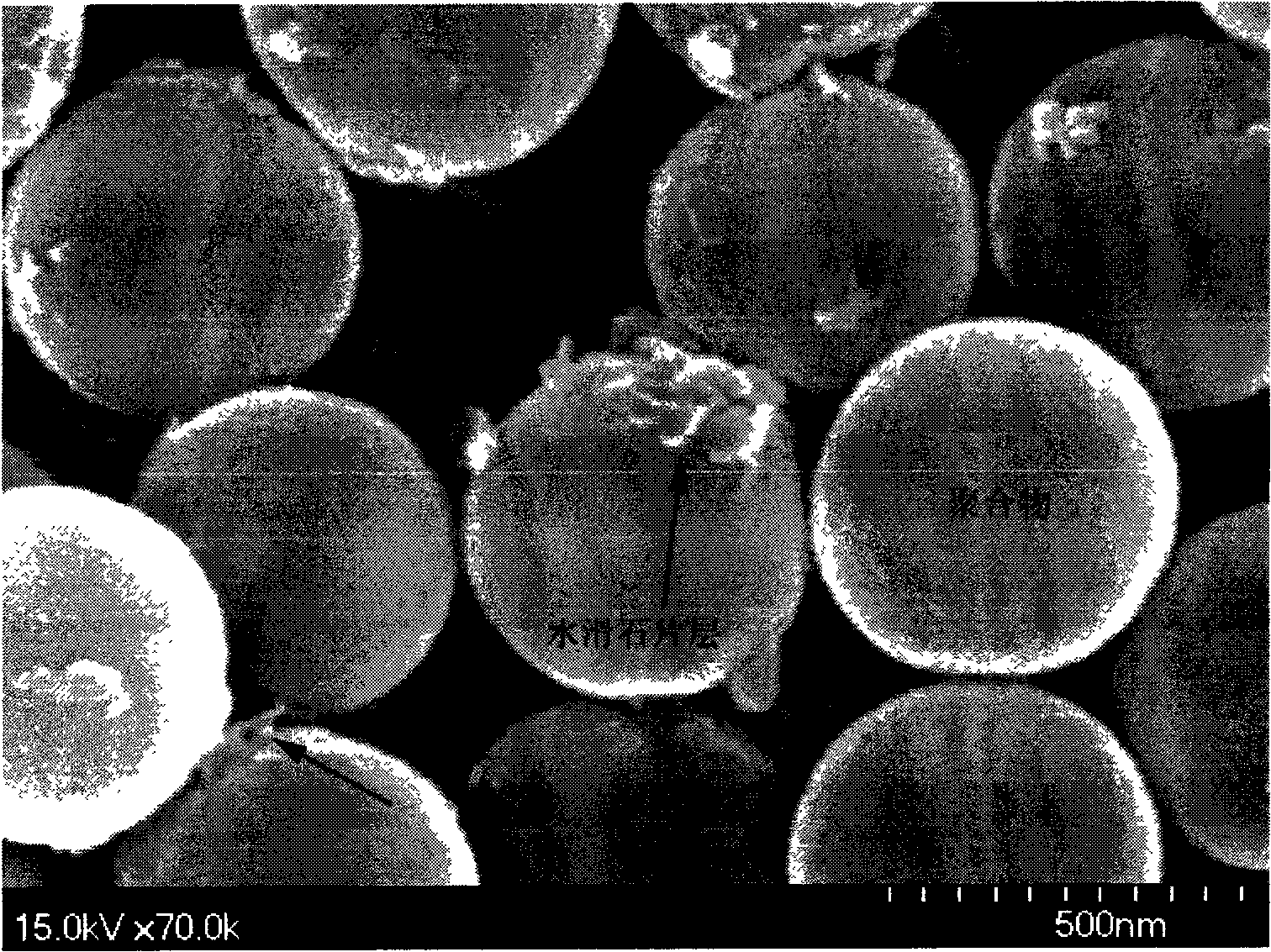

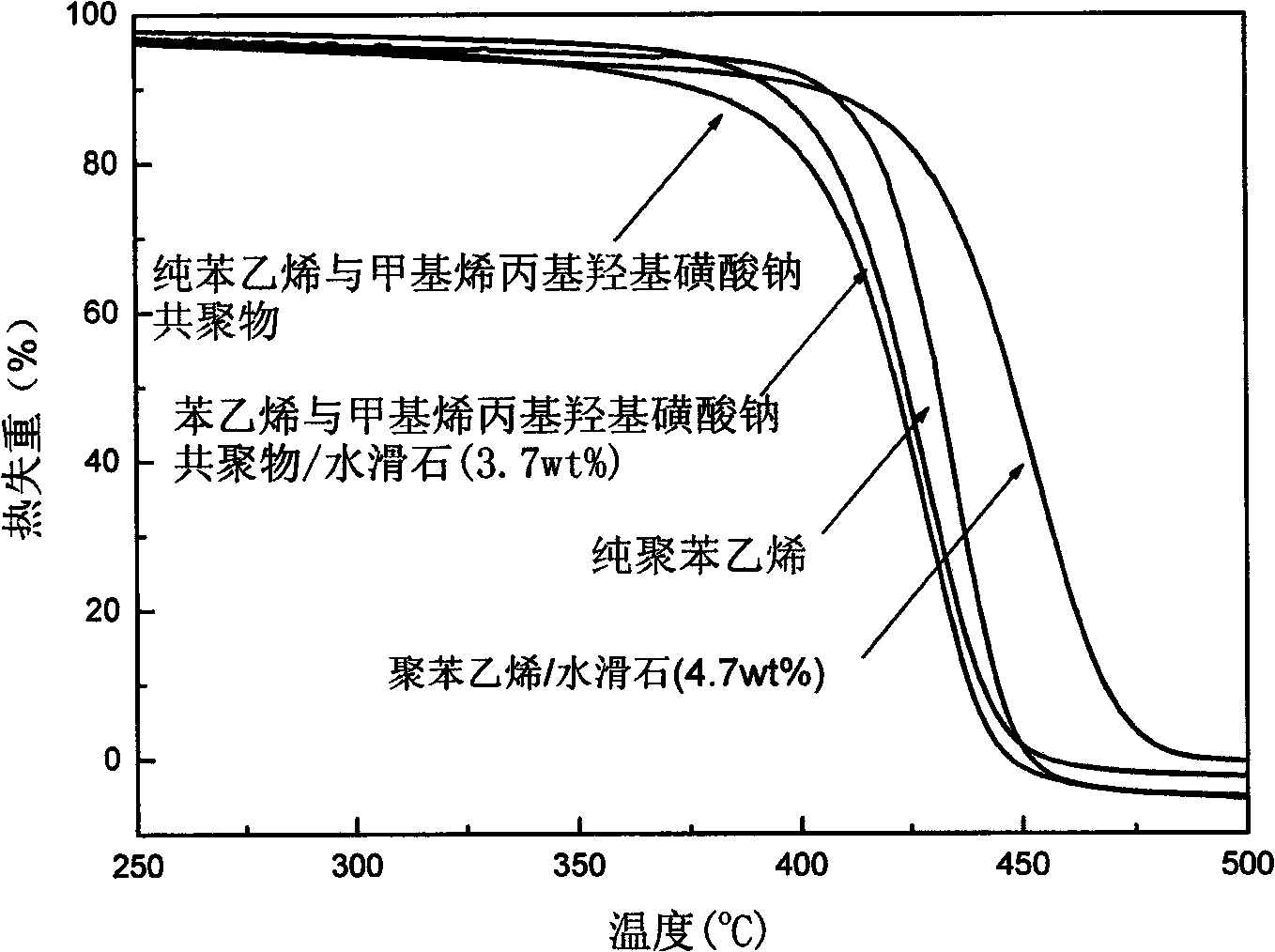

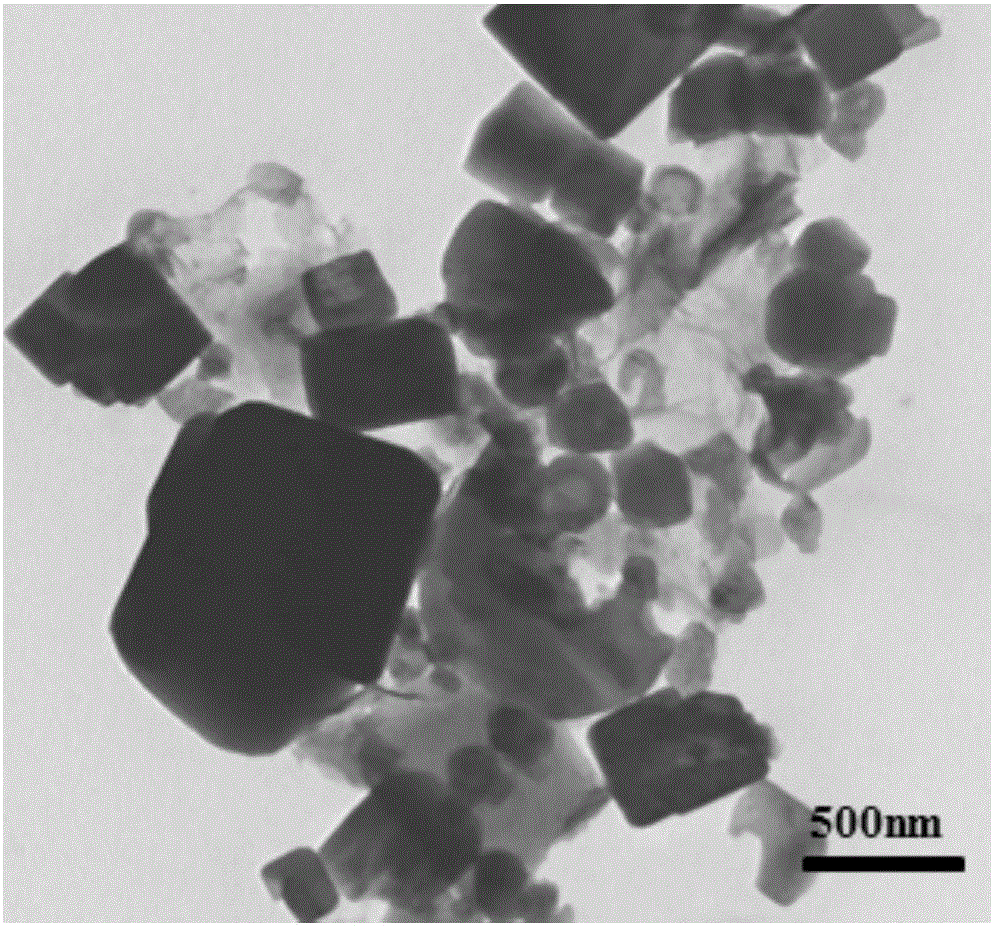

Method for preparing polymer/houghite nano composite material

The invention provides a method for preparing a polymer / houghite nano composite material, and the method comprises the following steps: 1) houghite is added to de-ionized water, and houghite suspension is obtained under the conditions of stirring and ultrasound; 2) a monomer, an anionic surfactant, an initiator and the de-ionized water are added into a polymer reactor, polymerization reaction is executed after the mixture is stirred uniformly, and polymer emulsion is obtained after cooling; and 3) the houghite suspension and the polymer emulsion are mixed and stirred to ensure houghite lamella and emulsion particles to form composite particles by electrostatic adherence, then the stirring is stopped, the composite particle suspension is filtered, washed and dried, and the polymer / houghite nano composite material is obtained. The method can realize organic modification of the houghite and the nano composition with the polymer in one step and has the advantages of low cost, simple operation and the like. In the prepared nano composite material, the houghite has good stripping dispersivity, and the interaction between the lamella and the polymer matrix can be regulated.

Owner:ZHEJIANG UNIV OF TECH

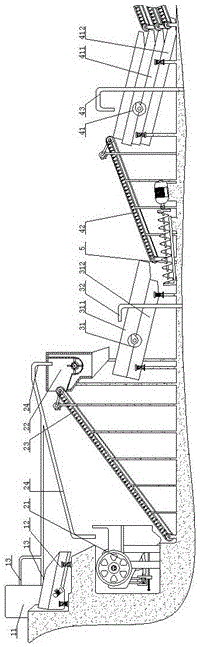

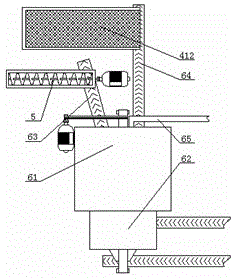

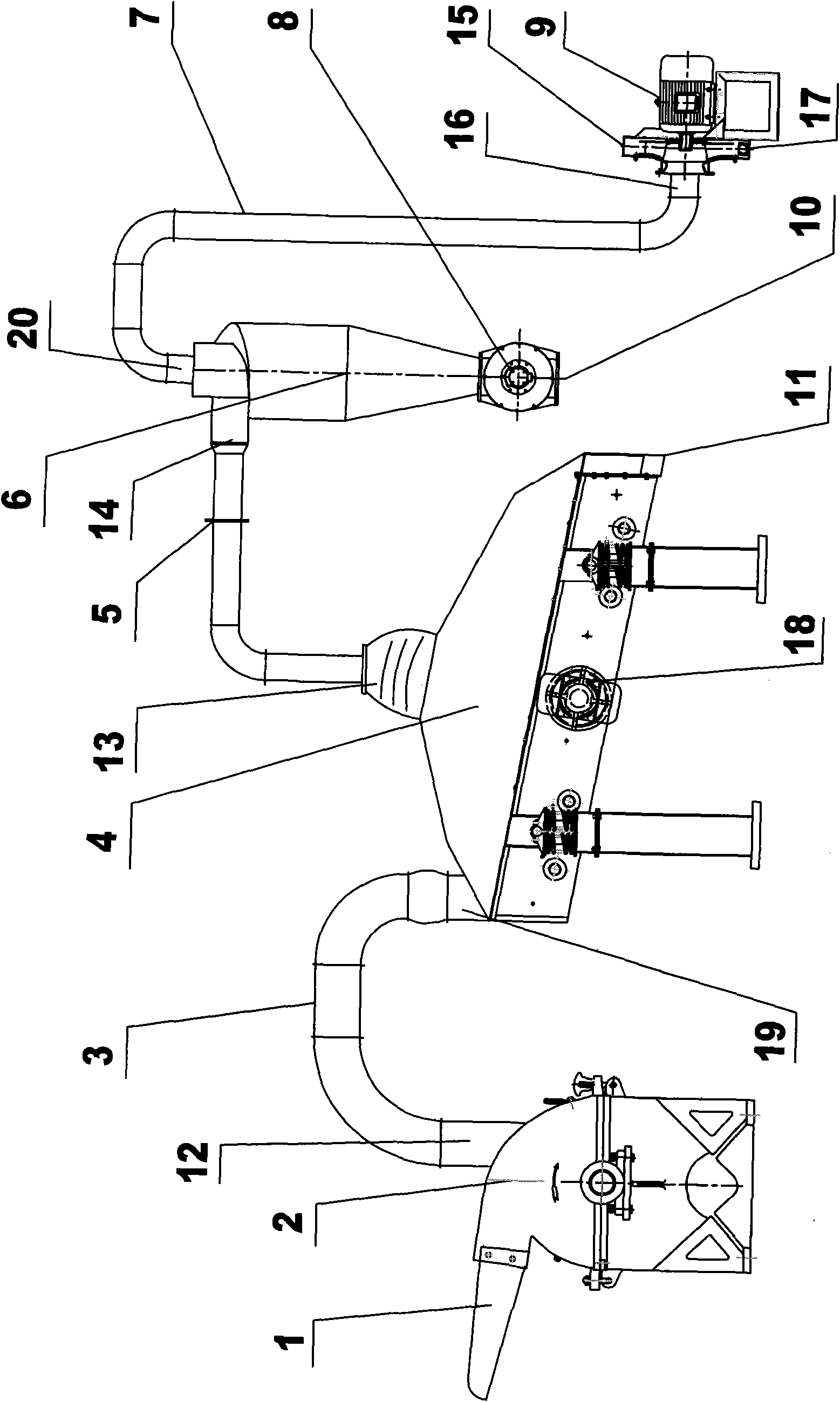

Mudstone environmental protection regeneration system

The invention discloses a mudstone environmental protection regeneration system. The mudstone environmental protection regeneration system comprises a feeding mechanism; the feeding mechanism comprises a stock bin, a vibrating feeding machine, a crushing mechanism which comprises a jaw type rough crushing machine and a hammer type fine crushing machine, a sand and gravel separating mechanism, a gravel fine separating mechanism and a mud and sand water passing mechanism; the sand and gravel separating mechanism comprises a rough separating vibrating screen; the rough separating vibrating screen comprises a gravel layer and a mud and sand layer; the gravel fine separating mechanism comprises a fine separating vibrating screen; the fine separating vibrating screen comprises a multi-layer finished product layer and a fine sand layer; the mud and sand water passing mechanism comprises a spiral conveyer; other devices except the spiral conveyer is provided with a spraying water pipe respectively. The mudstone environmental protection regeneration system can crush and clean gravel residues containing soil to enable the gravel residues to be recycled and has huge economic benefits and a remarkable environmental friendly effect.

Owner:魏根友

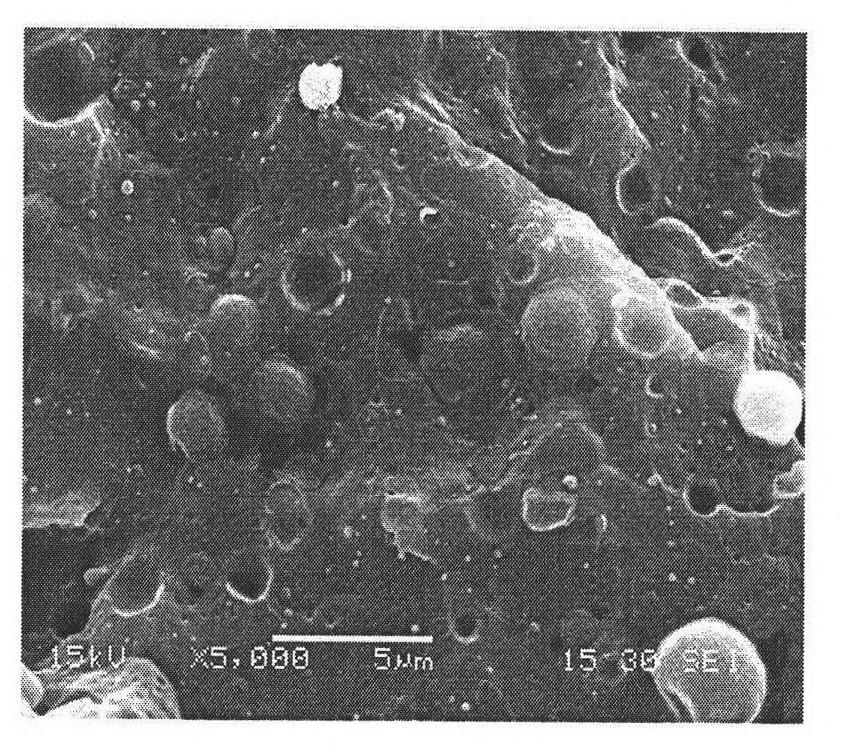

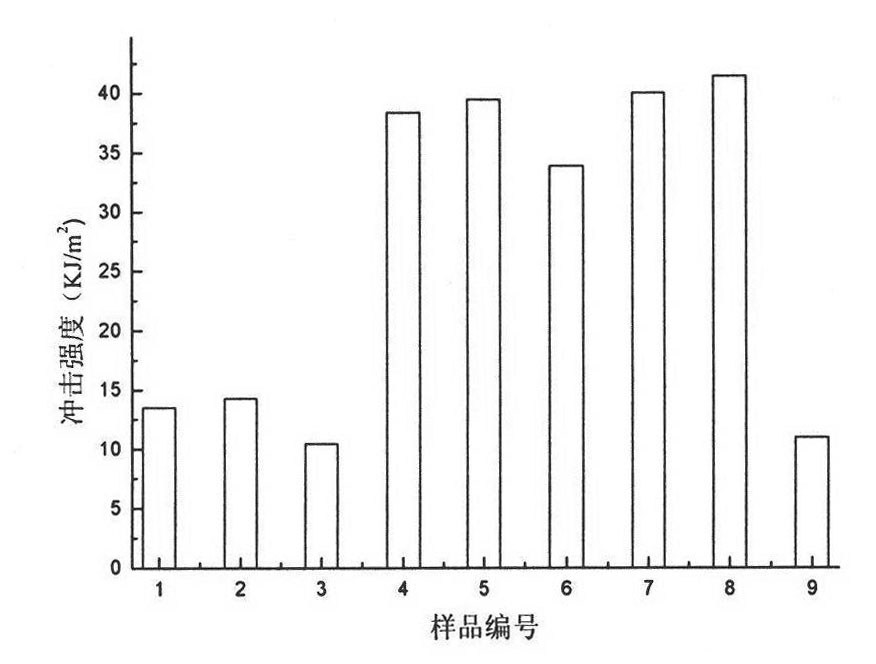

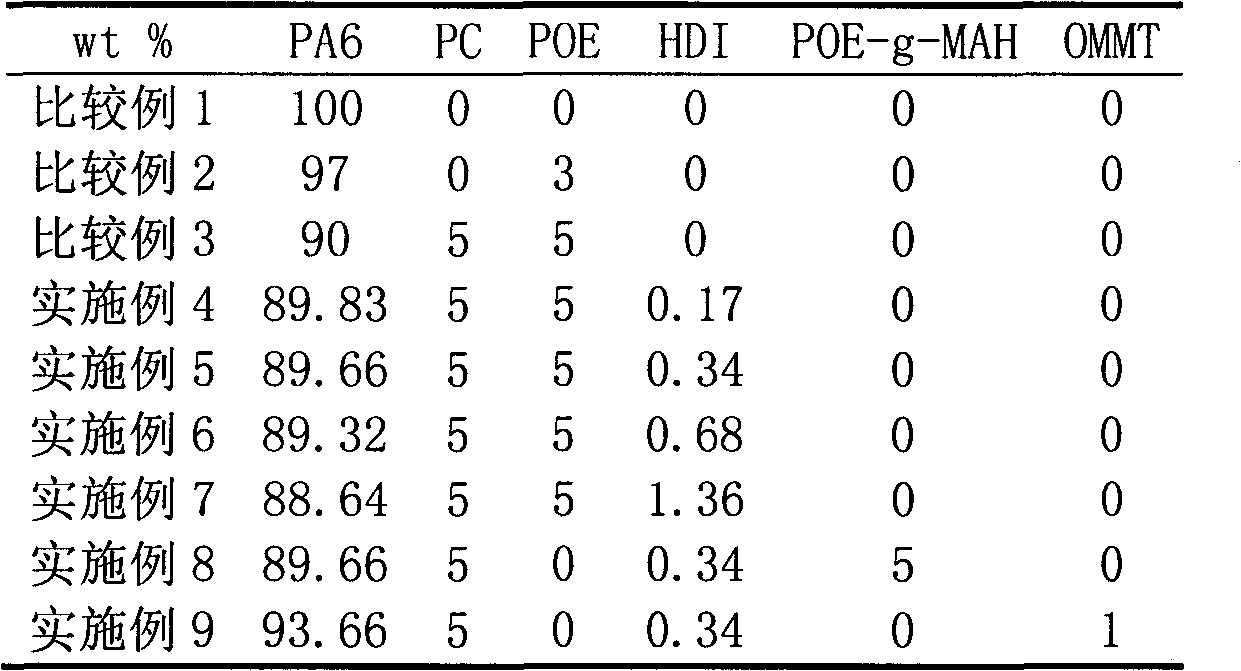

Production method of super-toughness engineering plastic of nylon 6/ polycarbonate/ elastomer/ HDI

The invention discloses a production method of a super-toughness engineering plastic of nylon 6 / polycarbonate / elastomer / HDI, comprising the following steps: 1) 100 parts by mass of nylon 6 (PA6), 5-15 parts by mass of polycarbonate (PC) and 5-15 parts by mass of maleic anhydride graft ethylene-octene copolymer elastomer (POE-g-MAH) are added, 100 parts by mass of PA6, 5-15 parts by mass of PC and 0-5 parts by mass of organ-montmorillonite (OMMT) are added and 0-1.36 wt% of HDI is respectively added to be evenly mixed at a ratio; and 2) the mixture is fused and extruded by a screw extruder for granulation at the extruding temperature of 230-260 DEG C, the rotating speed of the screw is 50-80 r / min, and the cooling mode of extrudate is characterized in water cooling. Compared with the prior art, the invention obtains super-toughness nylon 6 engineering plastic with high modulus.

Owner:EAST CHINA UNIV OF SCI & TECH

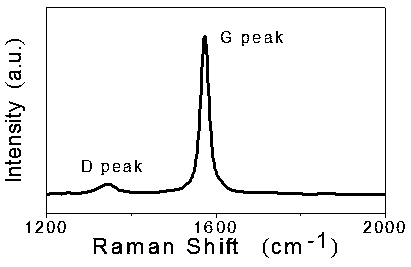

Preparation method of graphene sheet

The invention discloses a preparation method of a graphene sheet. The graphene sheet is prepared from graphite and alkali metal through electrochemical reduction exfoliation of the graphite in a short-circuit-resembling environment under the condition of a nonaqueous electrolyte as an intercalation agent. The preparation method has the benefits as follows: oxidizing raw materials such as strong acid and the like are not used, the graphite is mixed with the alkali metal directly in the electrolyte and exfoliated in an short-circuit-resembling electrochemical environment, the operation is simple, an exfoliation product is in the electrochemical environment all along, and the graphene sheet material with sufficient exfoliation is obtained more easily; further, the method is amplified easily for macroscopic preparation, and the prepared graphene sheet have complete structure, fewer defects, good homogeneity and good electrical conductivity.

Owner:HEFEI UNIV OF TECH

A method for low-temperature integrated recycle of waste lithium ion batteries

InactiveCN108933307AEfficient separationFully strippedWaste accumulators reclaimingBattery recyclingEngineeringPre treatment

A method for low-temperature integrated recycle of waste lithium ion batteries is disclosed. The method includes (1) subjecting the waste lithium ion batteries to be recycled to discharging and air drying; (2) pre-freezing the pretreated batteries; (3) subjecting the pre-frozen batteries to freezing and cutting for coarse crushing; (4) subjecting the coarsely crushed batteries to freezing and impacting for fine crushing; and (5) sieving the sample after fine crushing, with an oversize product being battery shells and current collector materials and an undersize product being powder containingpositive and negative electrode materials. Through freeze crushing and sieving separation, electrode materials are efficiently separated from the shell material and current collector materials of thelithium ion batteries, low-temperature crushing does not generate heat accumulation so as to avoid the risk of explosion, and does not generate toxic or harmful gas so that the method is energy-saving, environmentally friendly and high in efficiency. Recovered products are good in quality, can be conveniently recycled, and have promotion value.

Owner:CHINA UNIV OF MINING & TECH

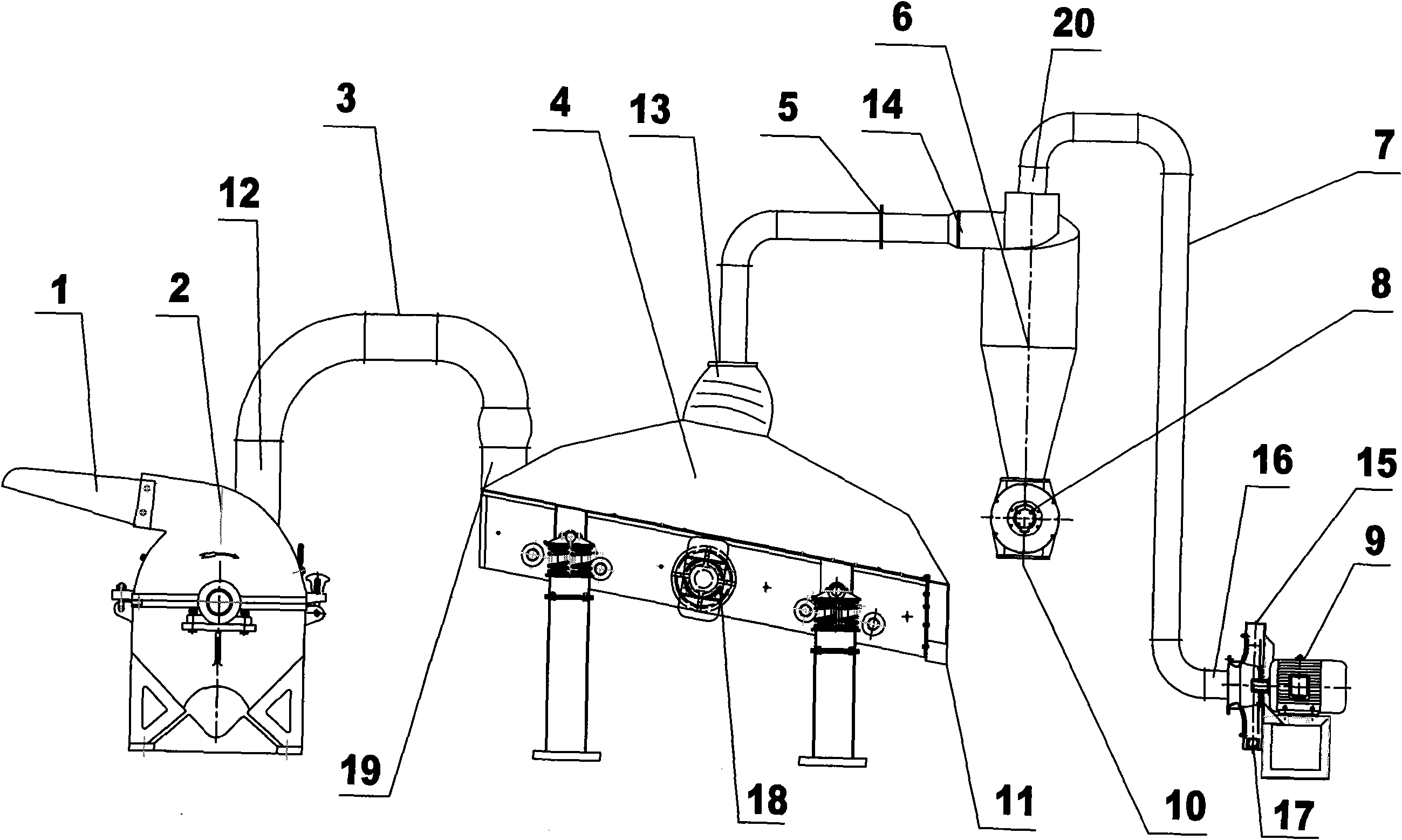

Method and device for separating corn stalk bark and corn pith

InactiveCN102092064AFully strippedImprove separation ratePlant material mechanical workingCrusherCentrifugal fan

The invention discloses a method for separating corn stalk bark and corn pith, which comprises the steps of: (1) crushing corn stalks, (2) separating crushed stalk barks from other light parts; (3) separating light parts of corns from air flow and dusts. The invention further discloses a device for realizing the method for separating corn stalk bark and corn pith, which comprises a crusher, a high-speed oscillating sieve, a cyclone separator and a centrifugal fan, and all the parts are connected by pipes. The device is mainly used for separating corn stalks without leaves and corn pith, or directly dividing the whole corn stalks into two parts, i.e. stalk barks and a mixture of stalk leaves and corn pith. Because the stalk barks, leaves and pith of the corns are different in components, the separation of all the parts is helpful for high-efficiency utilization, and lays a foundation for commercialized high-efficiency utilization of stalks of corns and the like.

Owner:NORTHWEST A & F UNIV

Method for preparing high-purity small oxidized graphene

The invention belongs to the technical field of oxidized graphene, and particularly relates to a method for preparing small oxidized graphene from cryptocrystalline graphite.The method mainly solves the problems of existing oxidized graphene preparing methods that purity is low, toxicity is high, technology is complicated and cost is high.According to the method, purified cryptocrystalline graphite, concentrated acid and strong oxidant are evenly mixed for reaction in an airtight environment at the temperature of 80-120 DEG C, a reaction mixture is slowly poured into an excessive amount of deionized water, uniform stirring is conducted, then an aqueous hydrogen peroxide solution with the mass concentration of 25% is added till turbid liquid becomes brown or luminous yellow, acid pickling and washing are conducted till pH value becomes 6-7, and then centrifugal separation is conducted to generate the small oxidized graphene.The ratio of the mass of purified cryptocrystalline graphite to the volume of concentrated acid is 1 : (20-80), and the mass ratio of purified cryptocrystalline graphite to purified cryptocrystalline graphite is 1 : (3-10).

Owner:SHANXI UNIV

Polymer heat-conducting film containing uniformly-dispersed and highly-oriented graphene, and preparation method thereof

InactiveCN110591209AGuaranteed cleanlinessGuaranteed continuityHeat-exchange elementsFlat articlesPolymer scienceProcedure Agents

The invention relates to the technical field of high performance and functionalization of carbon nanometer composite materials, particular to a polymer heat-conducting film containing uniformly-dispersed and highly-oriented graphene, and a preparation method thereof, wherein the heat-conducting film material comprises: a polymer matrix, graphene, a second heat-conducting filler, a surface treatingagent, a filler coating agent and a processing aid. According to the invention, by using the high-shear melt dispersion and high-power stretching combined technical route, the graphene nano-sheets and other heat-conducting fillers are uniformly dispersed in the polymer matrix, the high orientation is obtained, the long-range continuous three-dimensional hybrid heat-conducting network structure isconstructed by utilizing graphene, the anisotropy of the graphene is overcome, and the stable and effective heat-conducting network is constructed.

Owner:江苏新奥碳纳米材料应用技术研究院有限公司 +1

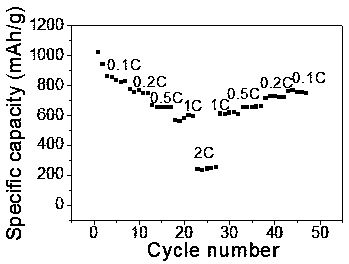

Small-size graphene positive electrode material for lithium-sulfur battery, lithium-sulfur battery prepared by small-size graphene positive electrode material and preparation method

ActiveCN107611395AImproved magnification performanceImprove wettabilityCell electrodesFinal product manufactureElectrolysisLithium sulfur

The invention discloses a small-size graphene positive electrode material for a lithium-sulfur battery, the lithium-sulfur battery prepared by the small-size graphene positive electrode material and apreparation method and belongs to the field of battery materials. The preparation method comprises the steps of preparing small-size graphene through electrolyzing microcrystalline graphite powder; compounding the small-size graphene or surface-modified small-size graphene, such as the small-size graphene-modified by sodium carboxymethyl cellulose, sulfate, silicate, metal ions, a metal oxide, anon-metallic element or a high polymer material and sulfur at the mass ratio of 2:(1-9) to prepare the positive electrode material for the lithium-sulfur battery; and then preparing the lithium-sulfurbattery by adopting metal lithium as a negative electrode. The prepared lithium-sulfur battery is a real sense of graphene lithium-sulfur battery, the graphene is only used as an additive in the other lithium-sulfur batteries, and the prepared lithium-sulfur battery is fundamentally different from the other lithium-sulfur batteries. The positive electrode material for the lithium-sulfur battery is high in specific capacity, good in cycle performance, high in security, high in conductivity and low in cost, and has a very broad market prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

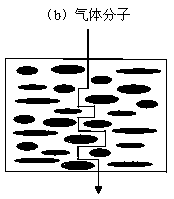

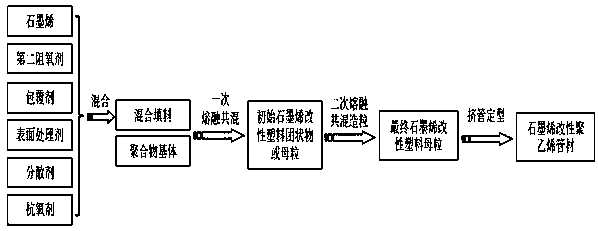

Graphene modified oxygen-resistant polyethylene master batch and preparation method and application thereof

InactiveCN111117041AEvenly dispersedGood oxygen barrierBulk chemical productionPolymer chemistryChemistry

The invention relates to the technical field of functionalization and high performance of plastic pipes, in particular to a graphene modified oxygen-resistant polyethylene master batch and a preparation method and application thereof. The modified plastic master batch is composed of the following components: a polyethylene matrix, graphene, a second oxygen inhibitor, a coating agent, a surface treating agent, a dispersing agent and an antioxidant. According to the three-step production process, the mixing, dispersing and stripping effects of graphene in a polyethylene matrix are improved, thefilling proportion of graphene in the composite material is increased through organic combination of a new material, a new technology and a new method, and formation of a perfect network structure inthe composite material matrix is promoted. The oxygen barrier property of the composite material can be remarkably improved through good construction of a network, so that the application potential ofgraphene in the oxygen barrier pipe is brought into full play, and the pipe filled with the high-barrier graphene nanosheet layer structure is obtained.

Owner:江苏新奥碳纳米材料应用技术研究院有限公司 +1

Aseptic paper packing material separation method based on ultrasonic pretreatment

ActiveCN103215832AEasy to peelFully strippedPaper recyclingRaw material divisionEconomic benefitsPulp and paper industry

The invention discloses an aseptic paper packing material separation method based on ultrasonic pretreatment. The method comprises the following steps that an aseptic paper packing material is cut into small pieces, then the small pieces are immersed in a container with water solution, and the solid material is completely immersed below the liquid level; the ultrasonic treatment is carried out, the time lasts 2-8 hours, the power of an ultrasonic generator is 200-2700W, and the ultrasonic frequency is 25-100KHz; after waste paper is torn up, the waste paper and a mixture of the aseptic paper packing material subjected to the ultrasonic pretreatment and water are put in a pulper together to be repulped for 15-40 minutes; the repulped size is put in a pulp screen to be screened, and the aluminum plastic part is screened out; and good size after screening is collected. Through the ultrasonic pretreatment, under the conditions of the same repulping strength and time, the method can significantly increase the separation efficiency of each part of the aseptic paper packing material, fully recycles paper, aluminum and plastic, increases the quality of recycled materials, and further increases the economic benefits of recycling.

Owner:SOUTH CHINA UNIV OF TECH

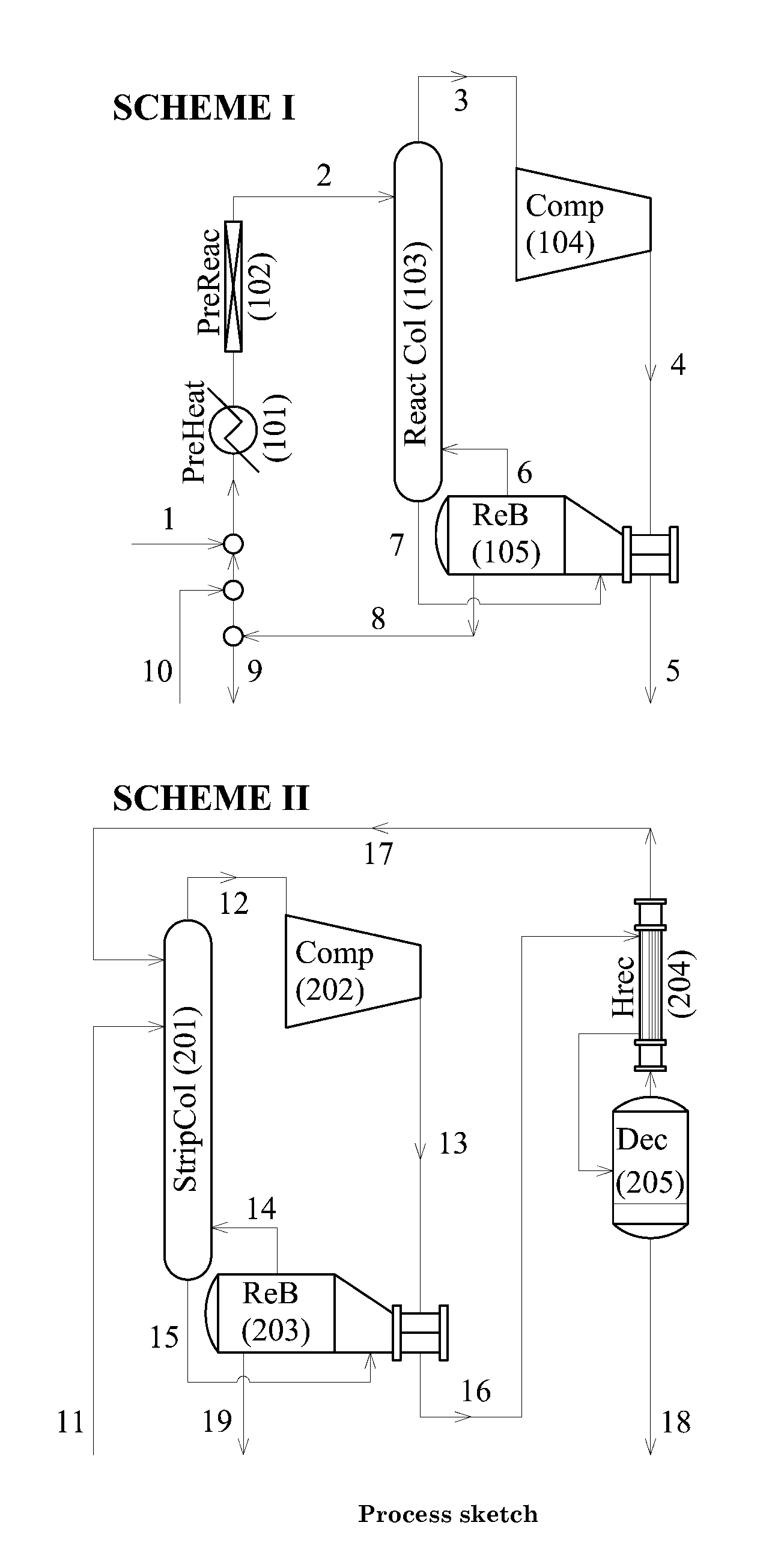

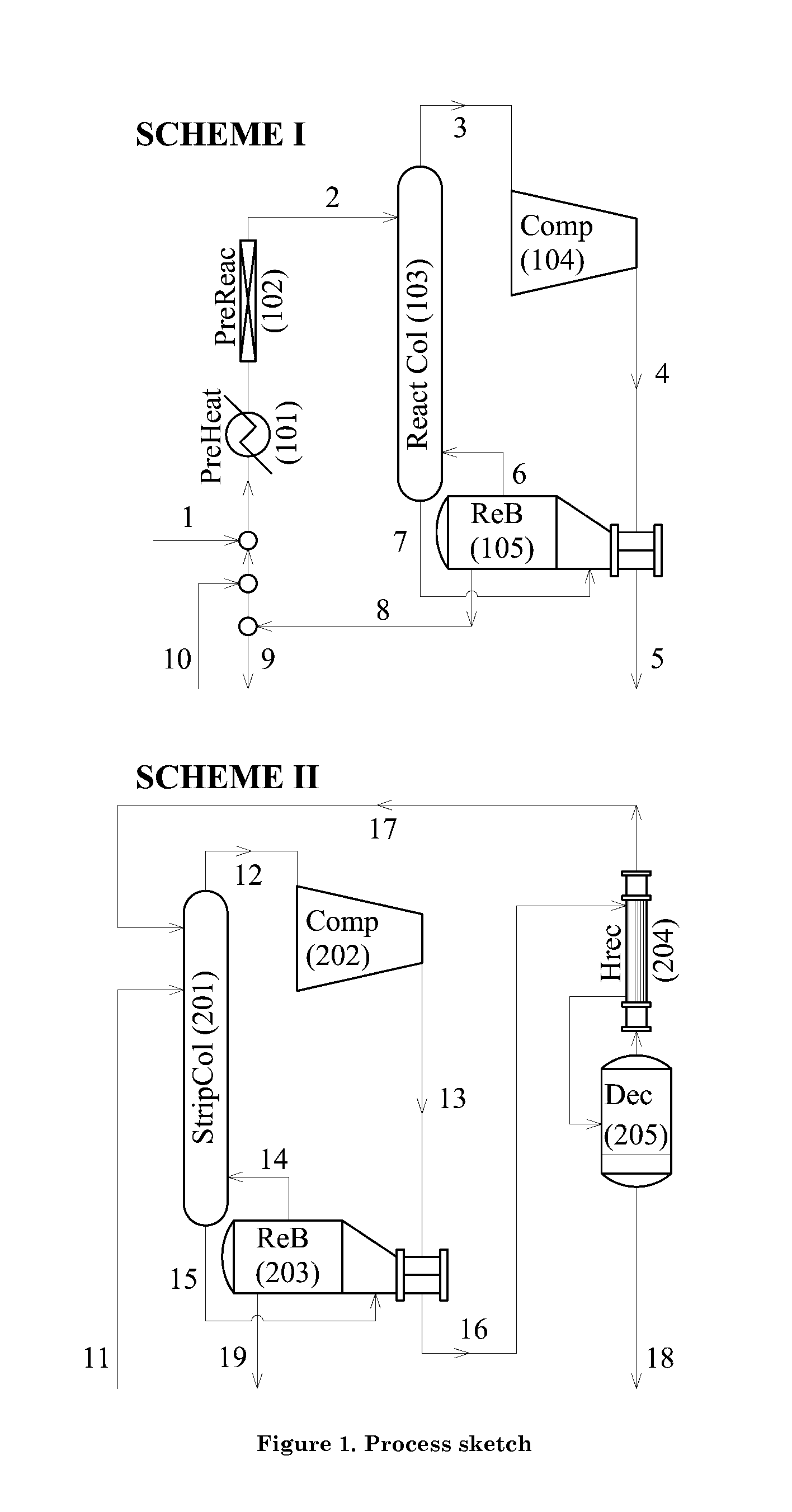

Process for the production of furfural from pentoses and/or water soluble pentosans

InactiveUS20120149924A1Less energyFully strippedOrganic chemistryChemical industryReboilerWater soluble

The invention is directed to a process for production of furfural from pentoses and / or water-soluble pentosans, said process comprising converting said pentoses and / or water soluble pentosans in aqueous solution in a first step to furfural and in a second step feeding the aqueous solution containing furfural obtained in step one to the top of a distillation column to produce an aqueous, liquid downflow, which column is heated at the bottom part thereof, using at least one reboiler to produce an upflow steam flow, recovering a water and furfural containing vapor product stream from the top of said column, compressing said vapor flow and condensing it on the hot side of the reboiler at the bottom of said column to produce sufficient steam in said bottom part of the column to produce said upflow steam flow, and to recover an aqueous furfural containing solution as the condensate in the reboiler.

Owner:TECH UNIV DELFT

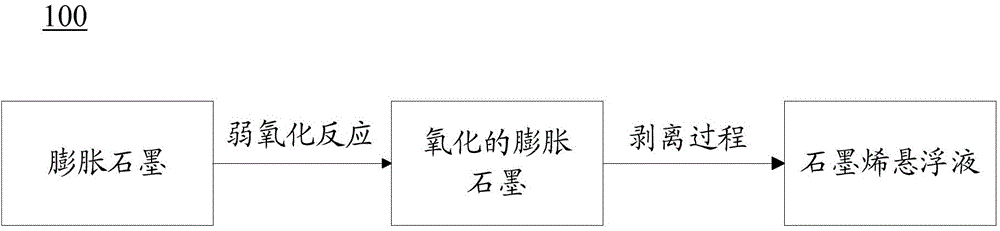

Graphene preparation method and graphene prepared through graphene preparation method

Embodiments of the present invention provide a graphene preparation method and graphene prepared through the graphene preparation method. The graphene preparation method comprises: (1) preparing expanded graphite; (b) mixing the expanded graphite obtained in the step (a) and an oxidizing agent, and initiating a weak oxidation reaction to obtain expanded graphite oxide; and (c) peeling the expanded graphite oxide obtained in the step (b) in a peeling reagent to obtain a graphene suspension. According to the embodiments of the present invention, the surface layer portion of the expanded graphite is oxidized with the oxidizing agent to obtain the expanded graphite oxide, and then the expanded graphite oxide is placed into the peeling reagent to be peeled so as to obtain the graphene suspension; and with the method, the surface layer portion of the expanded graphite is oxidized with the oxidizing agent to open the edge of the expanded graphite, such that the peeling reagent easily enters the internal of the expanded graphite so as to completely peel and improve the yield of the single-layer graphene.

Owner:HUAWEI TECH CO LTD +1

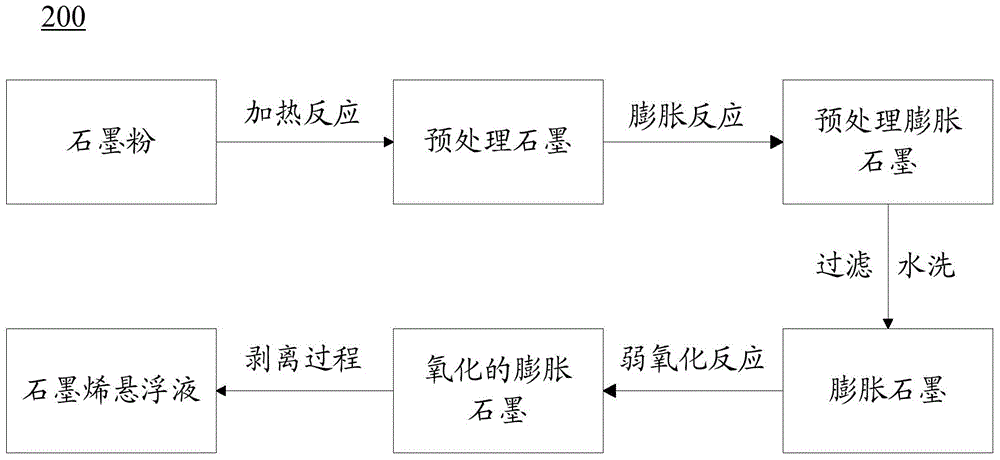

Preparation method of graphene

InactiveCN109319771AIncrease layer spacingLess peeling layersGrapheneBulk chemical productionGraphiteGraphene

The invention discloses a preparation method of graphene. The preparation method comprises the following steps that S1, hydrogen peroxide with the mass fraction being 35-40% is added into a reaction kettle, and the amount of the added hydrogen peroxide accounts for 55-60% of the volume of the reaction kettle; S2, expanded graphite is added into the reaction kettle, the mass ratio of the expanded graphite to the hydrogen peroxide is 1:(0.01-0.02), the temperature is raised to 200-280 DEG C under the normal pressure, and a reaction is conducted at the temperature of 200-280 DEG C for 10-20 minutes; S3, supercritical carbon dioxide is introduced into the reaction kettle for pressurizing, thus the pressure is increased to 8-15 MPa, and the pressure is maintained for 5-8 hours; S4, objects obtained in the reaction kettle is discharged and put into a homogenizer to be homogenized; and S5, the homogenized objects are dried, and then the graphene is prepared after drying. The preparation method has the advantages that stripping of graphene sheet layers is more thorough, the stripping layer number is less and more even, and environmental protection is achieved.

Owner:青岛岩海碳材料有限公司

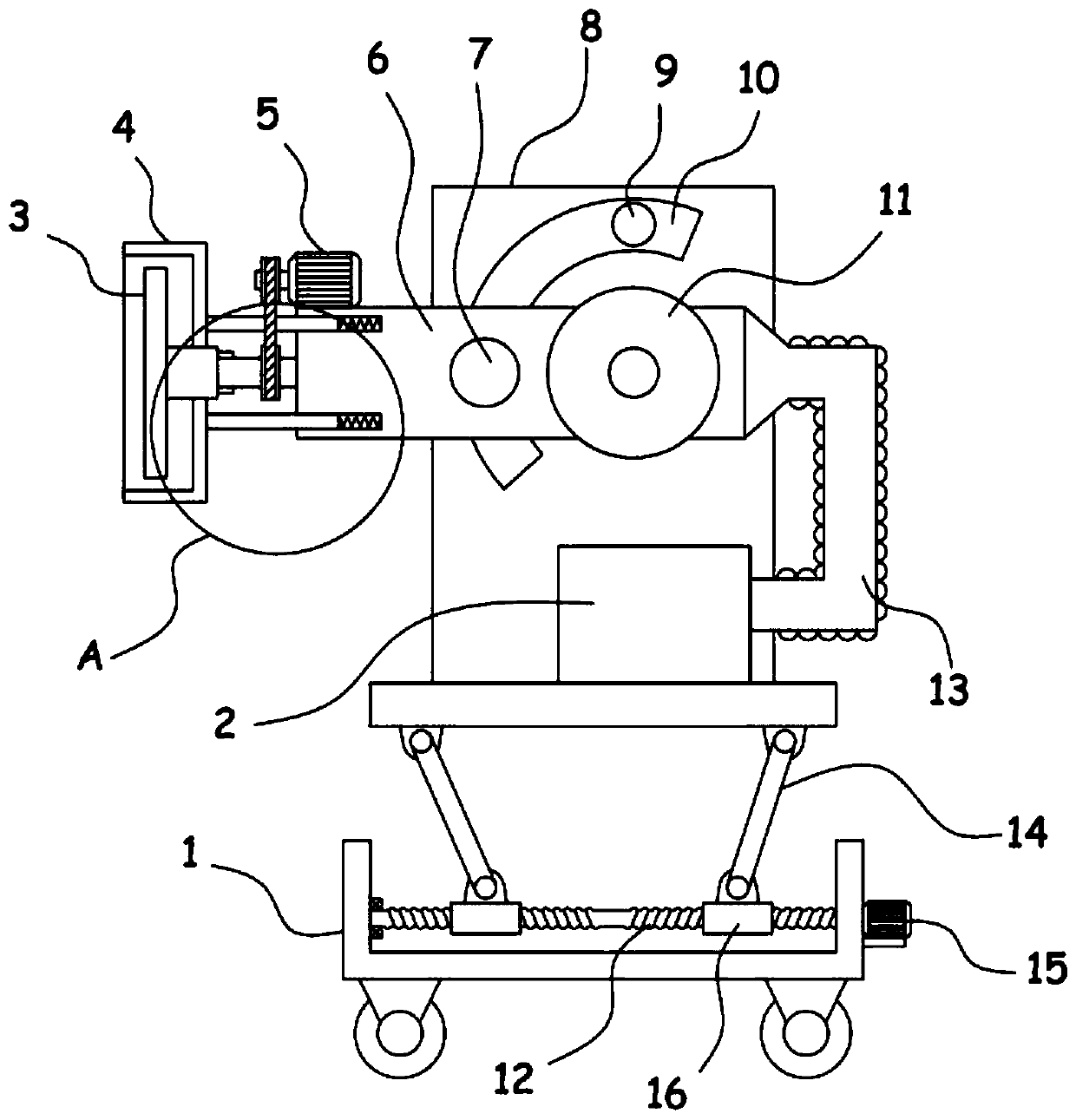

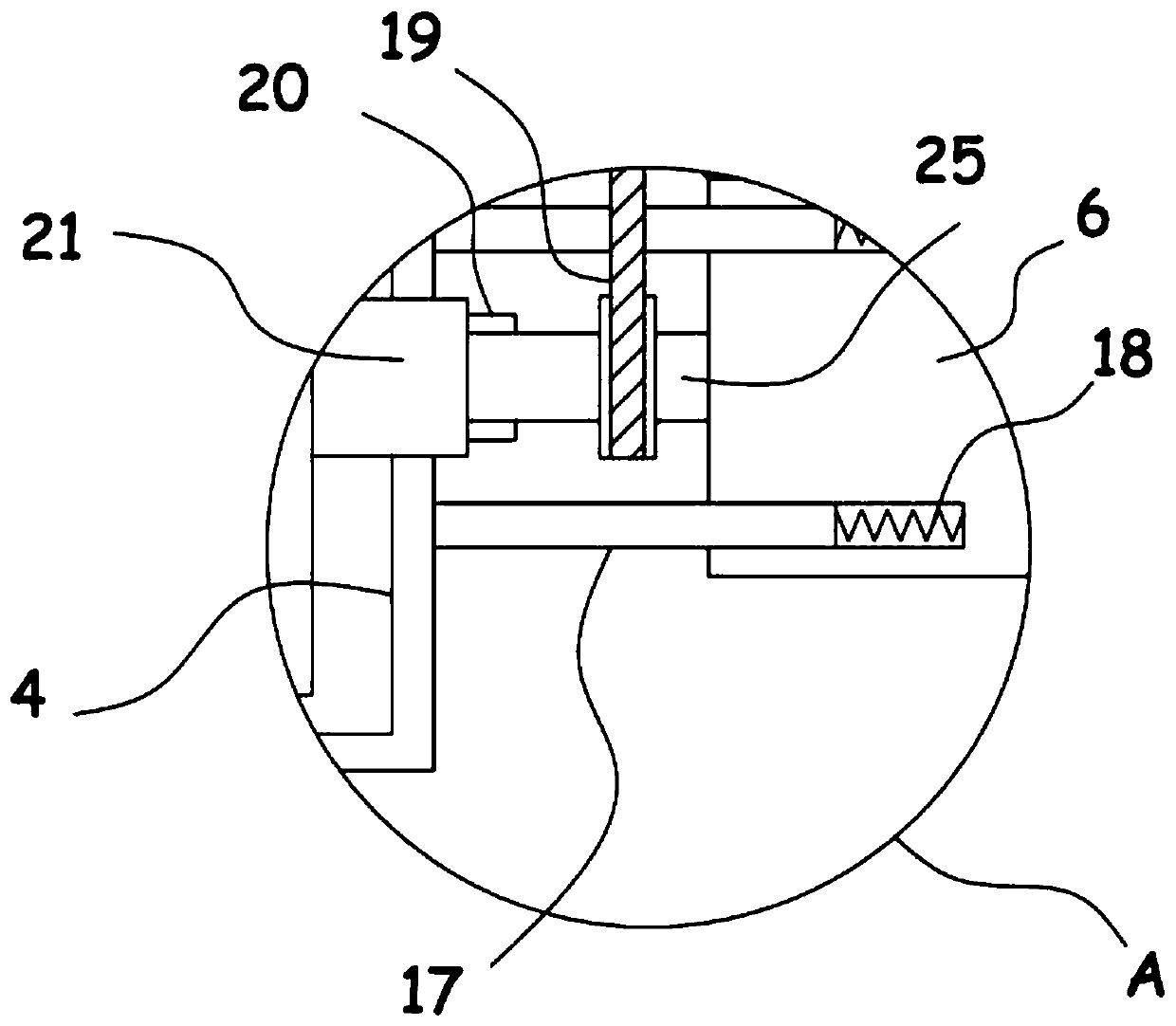

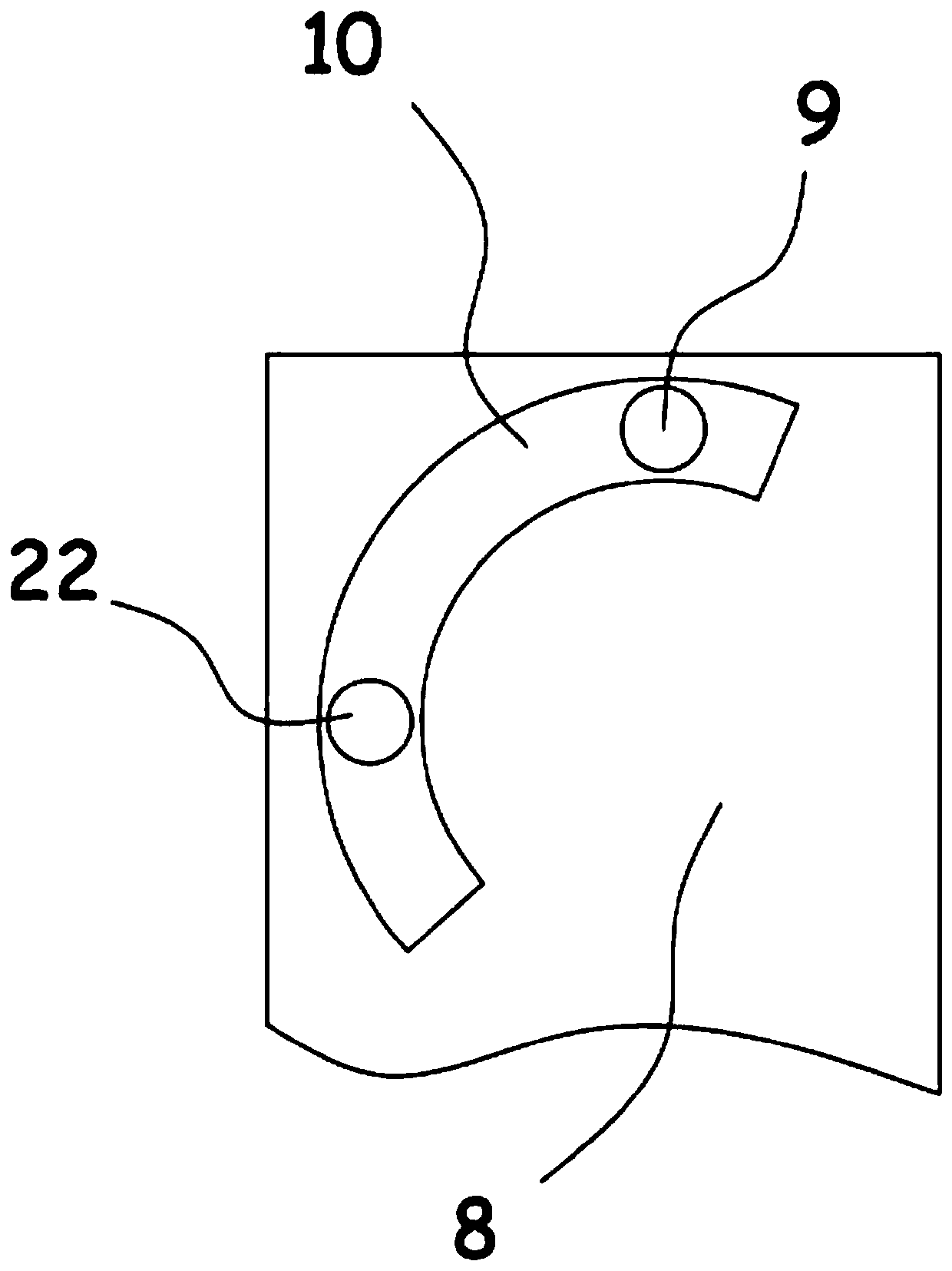

Dust-free stripping device for environment-friendly coating

ActiveCN110685450AFully strippedGood peeling effectBuilding repairsDirt cleaningFixed frameDust control

The invention discloses a dust-free stripping device for an environment-friendly coating, and relates to the technical field of decoration construction. The dust-free stripping device for the environment-friendly coating comprises a moving seat, wherein a fixing frame is supported on the moving seat through a lifting mechanism, a stripping mechanism used for stripping the coating is arranged at the end part of a gas collecting box, a coating accumulating used for accumulating the coating sleeves the stripping mechanism, and a reversing mechanism used for adjusting the rotating of the gas collecting box is arranged on the fixing frame. According to the dust-free stripping device for the environment-friendly coating, the horizontal and vertical orientation flexible conversion can be carriedout on the stripping mechanism used for stripping the coating through the arranged reversing mechanism, so that the coating of the wall surface and the wall top is subjected to sufficient stripping treatment; meanwhile, dust generated in the stripping process can be collected through an arranged collecting mechanism and timely sucked through a dust removal mechanism, so that dust removal operationis carried out while effective coating stripping is performed, and dust diffusion is greatly reduced; and finally, an arranged scraping disc can elastically slide relative to a hollow shaft, so thatpressing between the scraping disc and a wall coating layer is guaranteed, and the coating stripping effect is greatly improved.

Owner:瑞金市同富果业科技有限公司

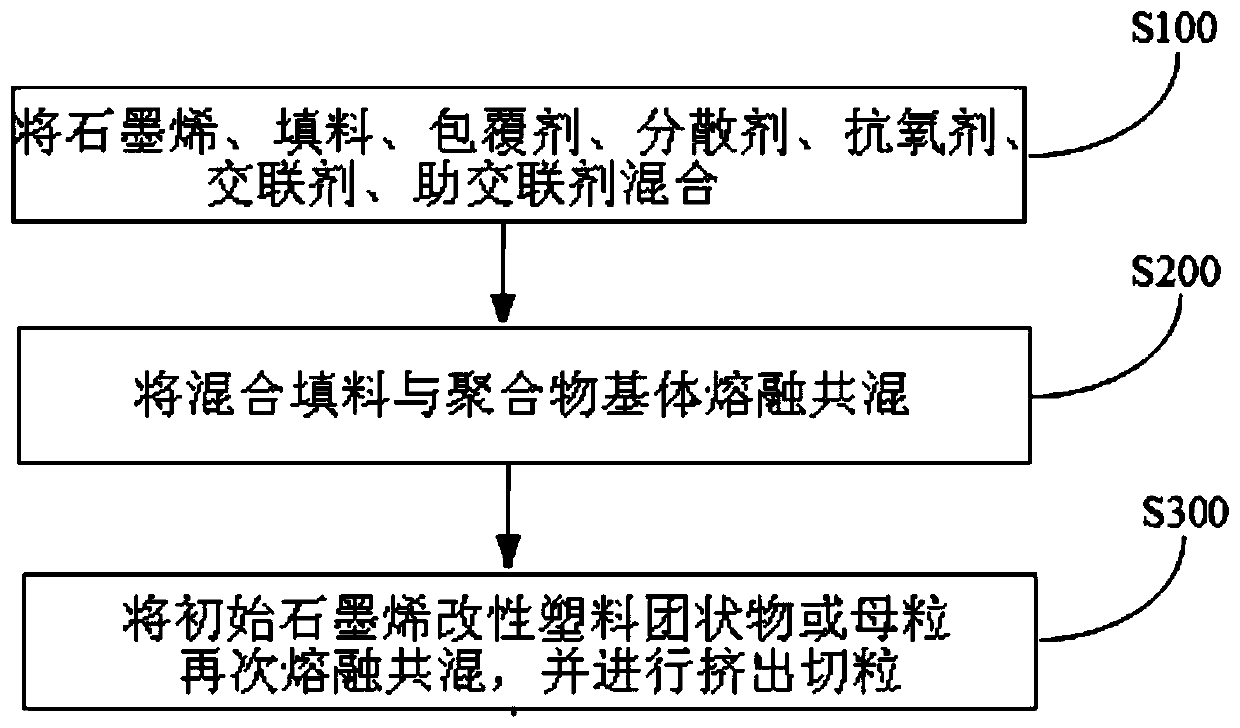

Plastic master batch and preparation method and application thereof

PendingCN111234386AFully strippedImprove performanceMechanical apparatusFluid circulation arrangementCapillary networkAntioxidant

The invention discloses a plastic master batch, and a preparation method and application thereof. The plastic master batch comprises a polymer matrix, graphene, a filling material, a coating agent, adispersant, an antioxidant, a crosslinking agent and an assistant crosslinking agent. Therefore, the plastic master batch has the characteristics of high thermal conductivity, high oxygen resistance,easiness in welding and uniform dispersion of graphene; and therefore, a capillary network prepared from the plastic master batch has the advantages of high thermal conductivity, high oxygen resistance and easiness in welding, so that cold and heat in a system are quickly transferred to the outside, efficient circulation of a medium is realized, energy waste is avoided, and popularization and application of a capillary network air conditioning system are facilitated.

Owner:新奥(内蒙古)石墨烯材料有限公司

Method for separating metal and non-metal in waste cable

ActiveCN101399098AGood control of cut lengthReduce wearBasic electric elementsElectronic waste recyclingSound energy densityWaste treatment

The invention discloses a method for stripping metal and nonmetal in a waste cable, belonging to the solid waste treatment and resource recycle field. In the method for stripping metal and nonmetal in the waste cable, sheared cable particles are put in a groove ultrasonic wave device with medium. The temperature range of water medium in the ultrasonic wave device is less than 100 DEG C, the working frequency of the ultrasonic wave is 9-40kHz, the sound energy density is 0.4W / cm<2>-0.8W / cm<2>, and the treatment time of the ultrasonic wave is 10s-10min. the method reduces losses of metal resources and ensures the complete stripping of the metal and the nonmetal in the cable. And the metal products are provided with high quality. Good conditions are provided for the categorized complete separation of various resources. The stripping efficiency of the metal and the nonmetal in the waste cable can be larger than 85 percent.

Owner:扬州宝泽电气有限公司

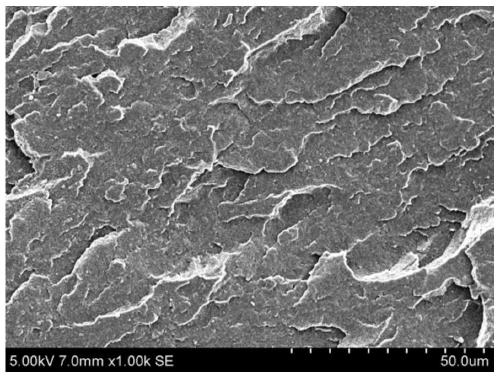

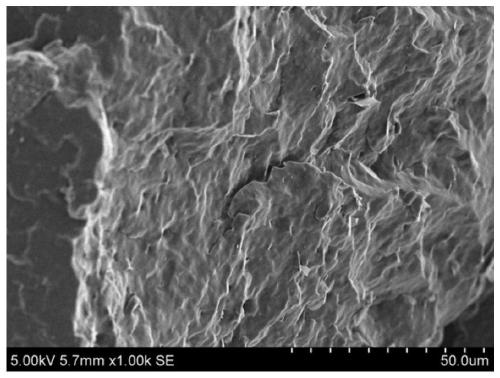

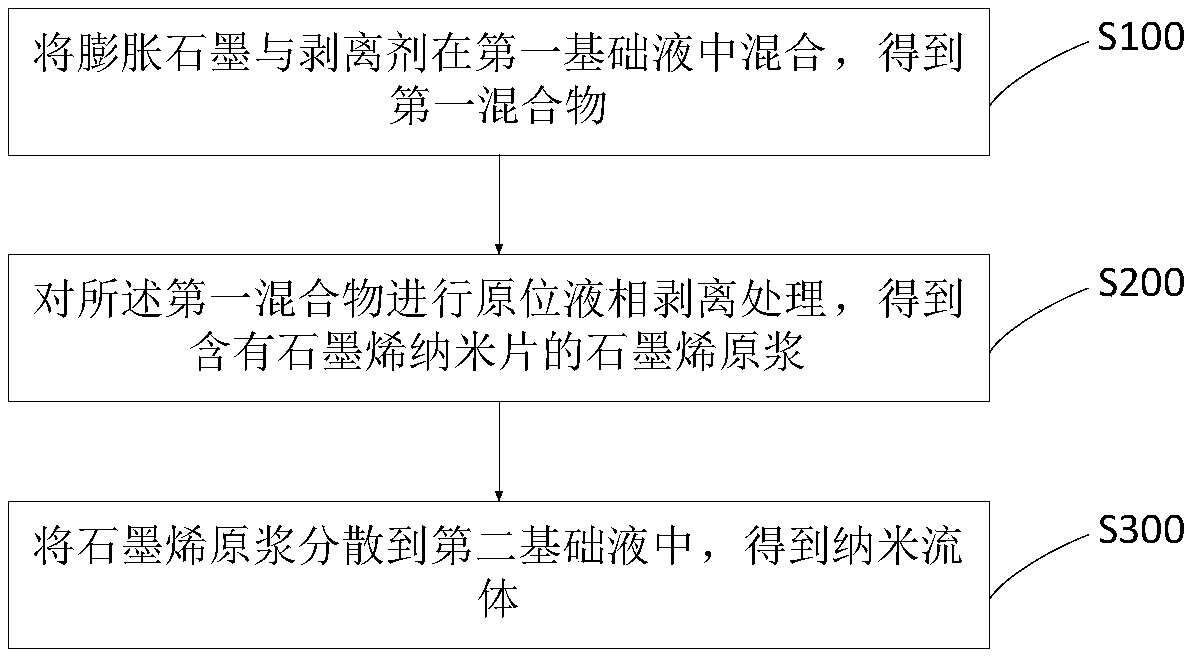

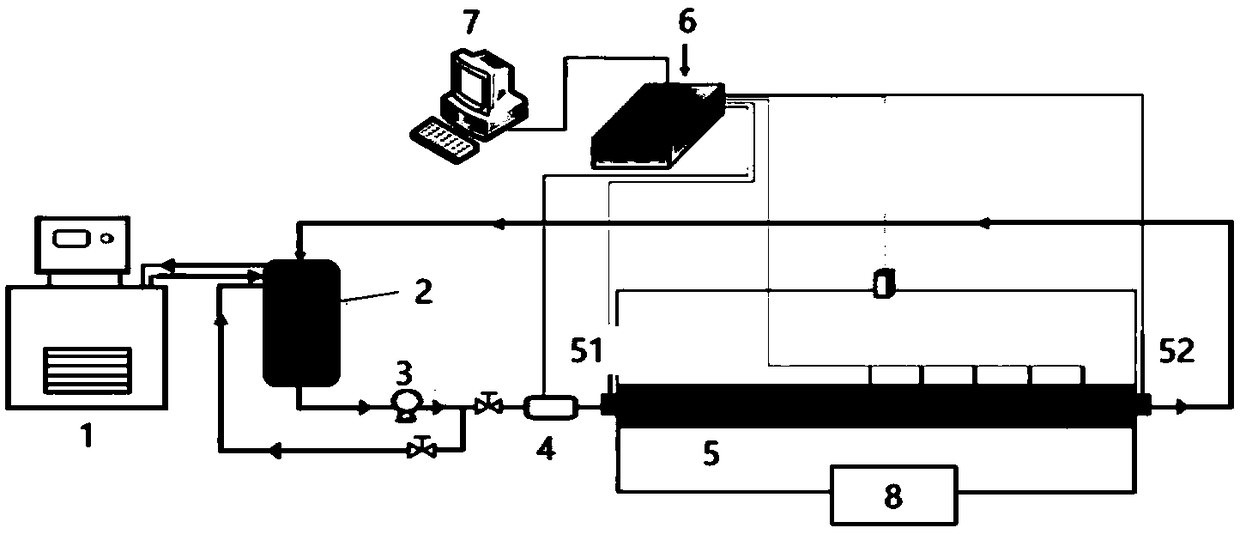

Nano-fluid for efficient heat transfer fluid, preparation method thereof and heat exchange device

The invention provides a nano-fluid, a preparation method thereof and a heat exchange device. The preparation method of the nano-fluid comprises the following steps: mixing expanded graphite with a stripping agent in a first base fluid to obtain a first mixture, and performing in-situ liquid phase stripping treatment on the first mixture to obtain a raw graphene stock containing graphene nano-sheets; and uniformly dispersing the raw graphene stock into a second base fluid to obtain the nano-fluid. The inventors have found that the method is simple and convenient to operate, facilitates large-scale production, is safe and environment-friendly, and can obtain the nano-fluid with high heat transfer coefficient, high thermal conductivity, low flow resistance and long-term stable dispersion.

Owner:ENN GRAPHENE TECH CO LTD

Terylene reduction cleaning agent and preparation method thereof

ActiveCN106638054AImprove stabilityImprove reliabilityDyeing processSpontaneous combustionCleansing Agents

The invention discloses a reduction cleaning agent for terylene. The reduction cleaning agent for the terylene is characterized by comprising deionized water, an unsaturated reduction system, a surfactant system and a pH value buffering system, in parts by mass: 84 to 35 parts of the deionized water, 10 to 50 parts of the unsaturated reduction system, 5 to 10 parts of the surfactant system and 1 to 5 parts of the pH value buffering system. The reduction cleaning agent for the terylene is stable in state, avoids heating and spontaneous combustion conditions, does not have pungent smell, is convenient to transport and store, and has an excellent cleaning effect.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

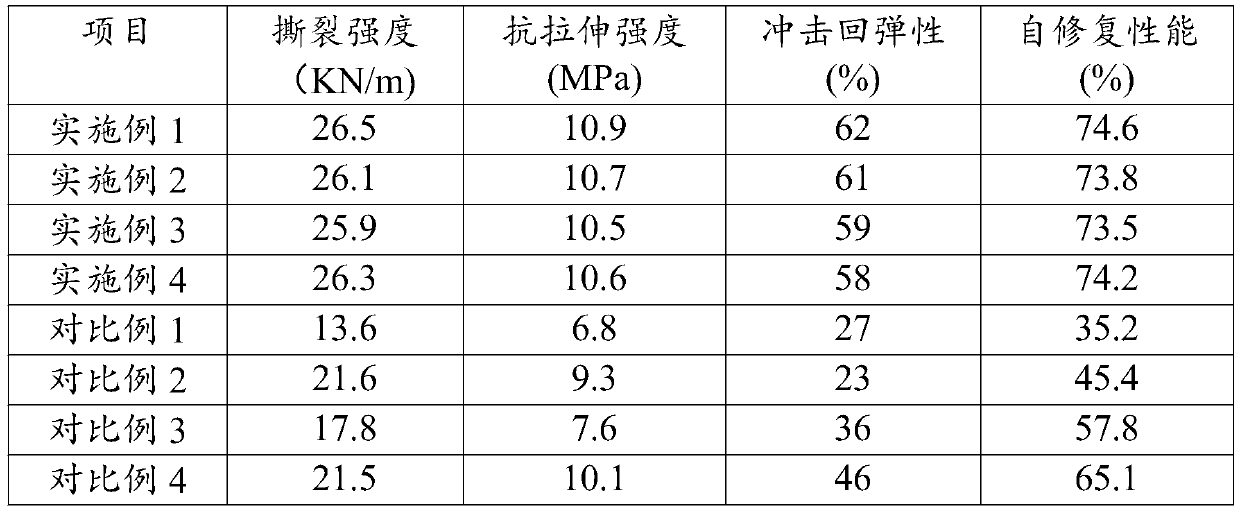

Self-repairing environmentally-friendly rubber material and preparation method thereof

The invention discloses a self-repairing environmentally-friendly rubber material and a preparation method thereof, and relates to the field of self-repairing rubber. The self-repairing environmentally-friendly rubber material comprises the following components: a butyl rubber substrate, a self-repairing filler, a toughening anti-stretching filler, and a vulcanization auxiliary agent dispersion, wherein the vulcanization auxiliary agent dispersion is composed of zinc oxide, bentonite, sodium carboxymethylcellulose, accelerator TMTD and expanded graphite. The preparation method comprises the following steps: performing ball milling to obtain the vulcanization auxiliary agent dispersion, performing mixing, and performing vulcanization to obtain the rubber material. The preparation method provided by the invention does not requires harsh conditions and is simple and controllable, and the finished rubber material produced by vulcanization can achieve a good repairing effect in air atmosphere without adding other repairing systems and thermoplastic components; and the rubber material has tear strength of 26.5 KN / m, tensile strength of 10.9 MPa, impact resilience of 62%, and self-repairing property of 74.6%.

Owner:GUANGDONG BANGGU CHEM TECH

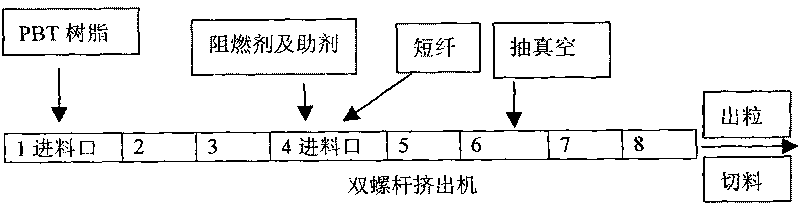

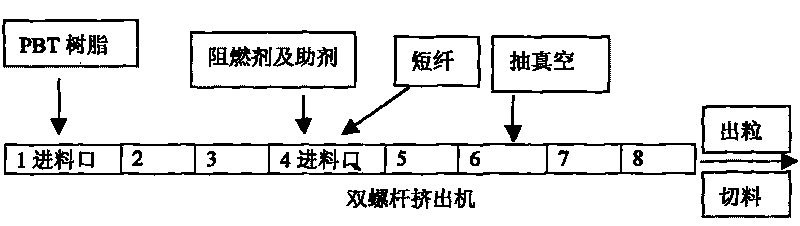

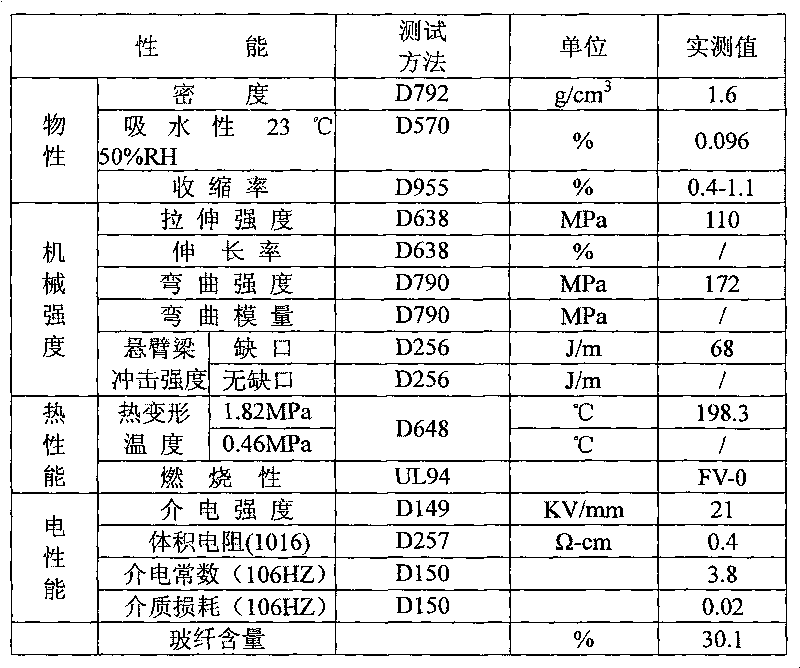

Tin-soldering resistant polybutylece terephthalate (PBT) engineering plastic and method for preparing same

InactiveCN101717559AEnhanced flame retardant modificationFully strippedPropanoic acidEngineering plastic

The invention relates to tin-soldering resistant polybutylece terephthalate (PBT) engineering plastic and a method for preparing the same. The PBT engineering plastic comprises the following raw material by weight percent: 40-45 percent of PBT, 9-16 percent of flame retardant of decabromodiphenyl ethane, 3-6 percent of antimony trioxide, 1-5 percent of plasticizer of ethylene-butyl acrylate-glycidyl ester terpolymer, 0.1-0.5 percent of compound anti-aging agent of Belta-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid octadecanol ester, 0.1-0.5 percent of pentaerythritol bis-phosphite ester (2, 4-di-tert-butyl-phenyl), 25-35 percent of short glass fiber, 3-6 percent of modified polytetrafluoroethylene TN3500 and 1-4 percent of release agent of polyethylenewax. The total weight percent of the raw materials is 100. The tin-soldering resistant PBT engineering plastic has low price and low requirement for the mold injecting and molding equipment.

Owner:JIANGYIN JIHUA NEW MATERIAL

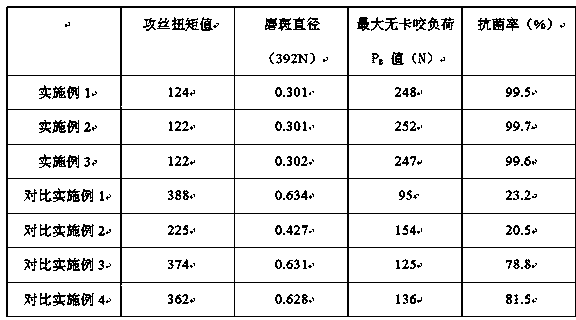

Metal cutting fluid containing nanometer titania of different particle sizes and preparation method of metal cutting fluid

InactiveCN109370717ALow tapping torque valueImprove the lubrication effectLubricant compositionVegetable oilSubstance.toxic

The invention discloses metal cutting fluid containing nanometer titania of different particle sizes and a preparation method of the metal cutting fluid. The prepared metal cutting fluid has low tapping torque and is excellent in lubricating property and low in grinding spot diameter, the wear resistance of the metal cutting fluid is excellent, the maximum non-seizure load PB value is great, the extreme pressure resistance is obvious, and the antibacterial property is outstanding. The metal cutting fluid does not contain sodium nitrite or any other substance toxic and harmful to the environment, takes vegetable oil as a main ingredient, is added with some high-efficiency additives, and is green, environmental-friendly, high-efficiency, simple in formula, excellent in antibacterial propertyand difficult to deteriorate. Due to the addition of silver-loaded graphene, silver particles are loaded among graphene sheet layers, so that the dispersion property of the graphene is further enhanced, the sheet stripping is full, and the anti-wear and friction reducing properties of the prepared cutting fluid are enhanced. Meanwhile, the cutting fluid is endowed with an antibacterial effect, the cutting fluid is difficult to deteriorate, and the storage period is prolonged.

Owner:五河富强鑫金属制品有限公司

Preparation method of epoxy resin grafted montmorillonite filler

ActiveCN102532954AReduce defectsReduce porosityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPolymer science

The invention relates to a preparation method of an epoxy resin grafted montmorillonite filler. The montmorillonite filler is prepared from the following raw materials: 100 of montmorillonite, 1-45 of organic amine, protonating agent same molar equivalent with organic amine, 0.5-300 of epoxy resin, 100-10000 of dispersant, and 10-5000 of solvent. The preparation method comprises the following steps of: firstly preparing organized montmorillonite; then adding epoxy resin to the organic montmorillonite, adding the solvent to regulate the viscosity of the reaction system, reacting at the temperature range of 15-140 DEG C for 1-24 hours, introducing epoxy resin molecules to the nano laminar surface of montmorillonite, and remaining the rest epoxide group; and stripping the nano lamella of montmorillonite to obtain the epoxy resin grafted montmorillonite filler. The obtained filler has few defects and pores, and can form a densified protective layer in an anti-corrosion coating, thereby significantly improving anticorrosion effect and service life of the anti-corrosion coating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

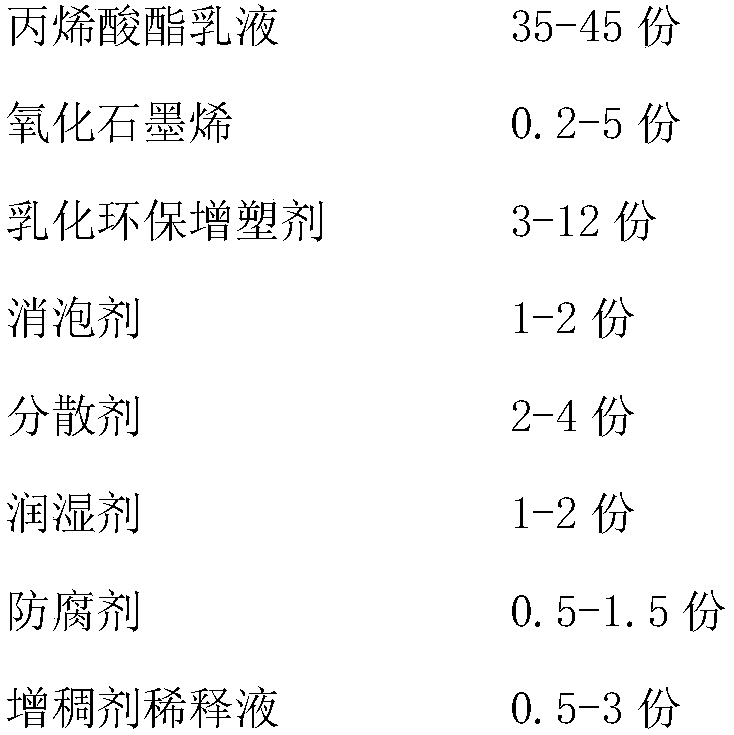

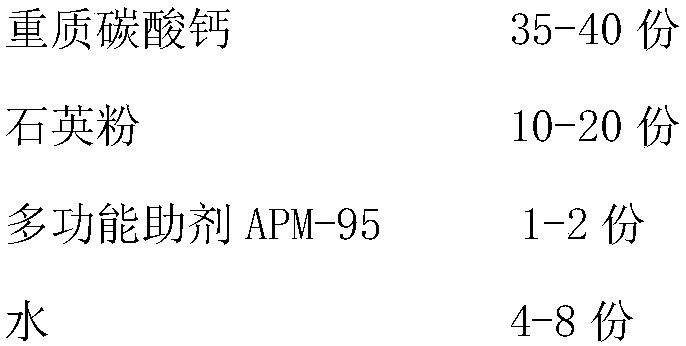

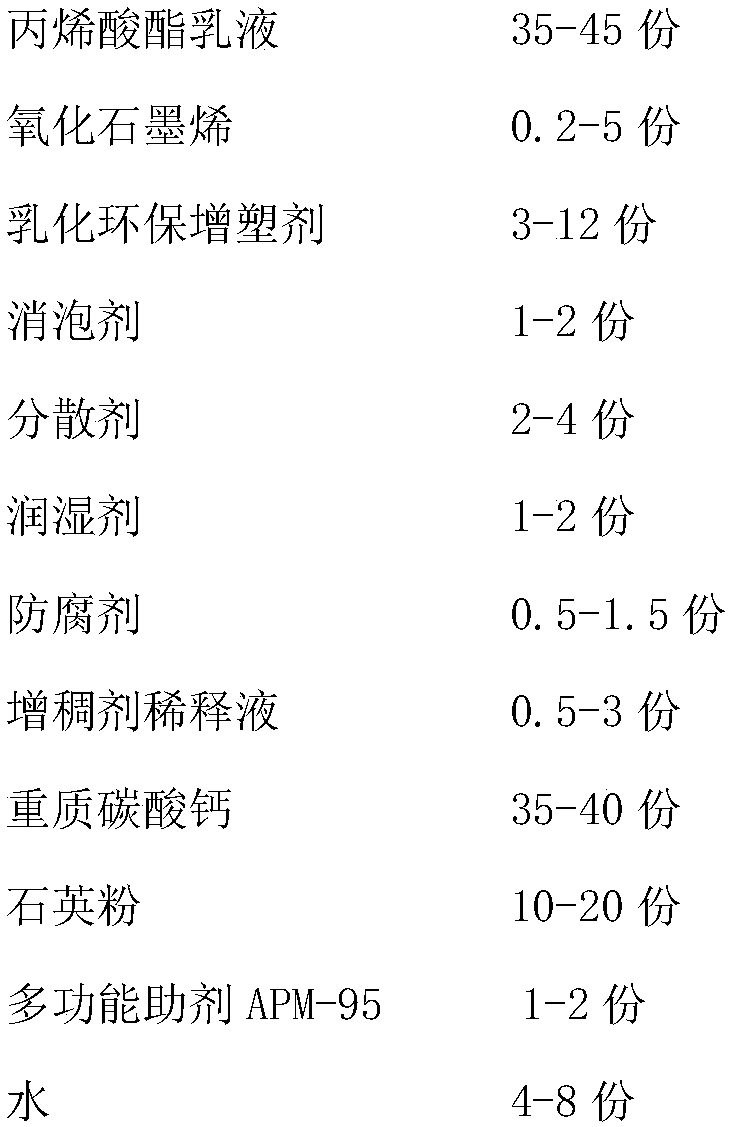

Aqueous antistatic acrylate waterproof coating and preparation method thereof

InactiveCN108129934AGood electrical conductivityImprove mechanical propertiesElectrically-conductive paintsEmulsionCalcium carbonate

The invention relates to the field of building waterproof materials and particularly relates to an aqueous antistatic acrylate waterproof coating and a preparation method thereof. The aqueous antistatic acrylate waterproof coating comprises, by mass, 35 to 45 parts of an acrylate emulsion, 0.2 to 5 parts of graphene oxide, 3 to 12 parts of an emulsified eco-friendly plasticizer, 1 to 2 parts of adefoamer, 2 to 4 parts of a dispersant, 1 to 2 parts of a wetting agent, 0.5 to 1.5 parts of a preservative, 0.5 to 3 parts of a thickener diluent, 35 to 40 parts of heavy calcium carbonate, 10 to 20parts of quartz powder, 1 to 2 parts of a multifunctional aid APM-95 and 4 to 8 parts of water. The aqueous antistatic acrylate waterproof coating significantly improves the antistatic performances ofa waterborne acrylic waterproof coating and has tensile strength of greater than or equal to 1.22MPa and the elongation at break of greater than or equal to 359%.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

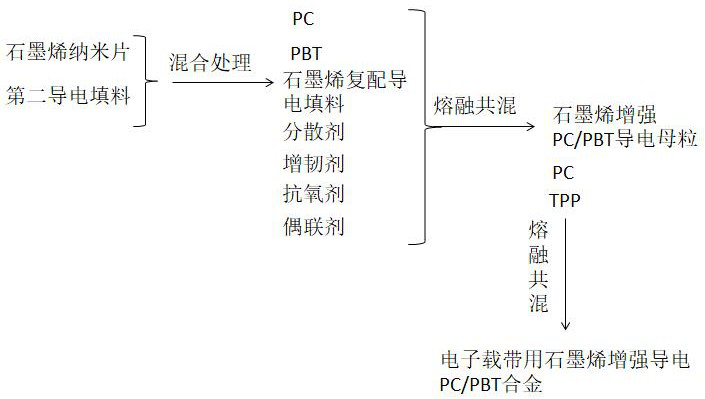

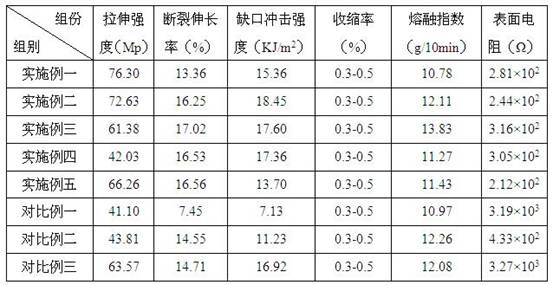

Graphene reinforced conductive PC/PBT alloy for electronic carrier tape

PendingCN111808412AImprove performanceCoordinating and balancing mechanical propertiesPtru catalystEngineering plastic

The invention relates to the technical field of engineering plastic alloys, in particular to a graphene reinforced conductive PC / PBT alloy for an electronic carrier tape. The alloy comprises the following components: 42 to 66 parts of PC; 20 to 43 parts of PBT; 0.1 to 5 parts of graphene; 0.1 to 10 parts of a second conductive filler; 0.5 to 3 parts of a toughening agent; 0.5 to 3 parts of a dispersant; 0.1 to 0.6 part of an antioxidant; 0.05 to 0.2 part of a coupling agent; 0.001 to 0.2 part of a catalyst; 0.01 to 0.2 part of TPP; the invention aims to innovatively develop an industrialized and clean production process of the graphene reinforced conductive PC / PBT alloy for the electronic carrier tape. The graphene nanosheets which are uniformly dispersed are promoted to form network distribution in a matrix, and the PC / PBT alloy can be endowed with relatively high conductivity under the condition of relatively low additive amount so that the efficiency of the graphene nanosheets for constructing a conductive network in the PC / PBT alloy is fully exerted.

Owner:江苏新奥碳纳米材料应用技术研究院有限公司 +1

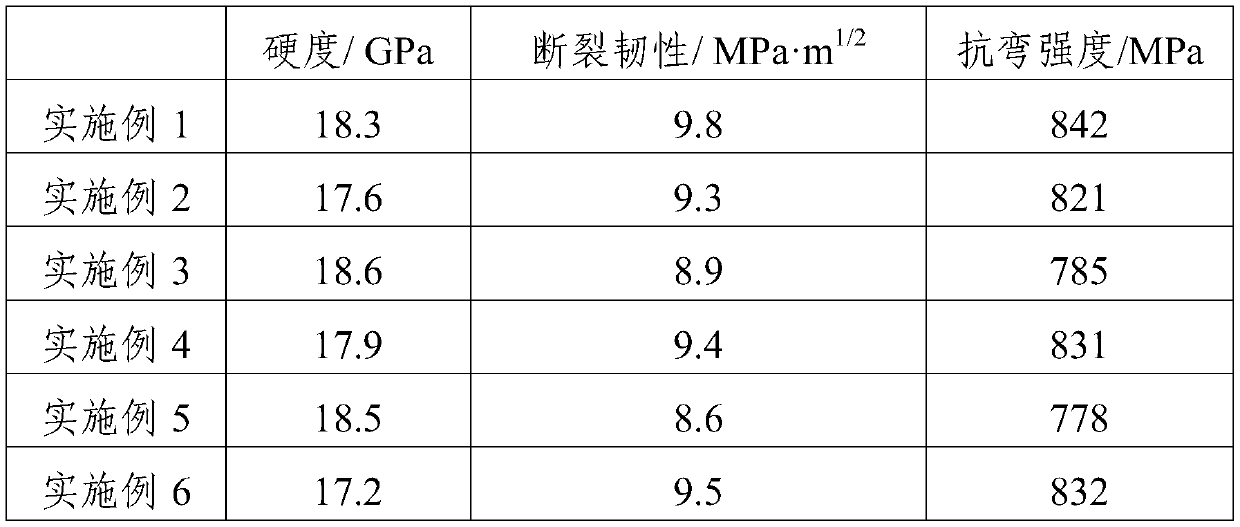

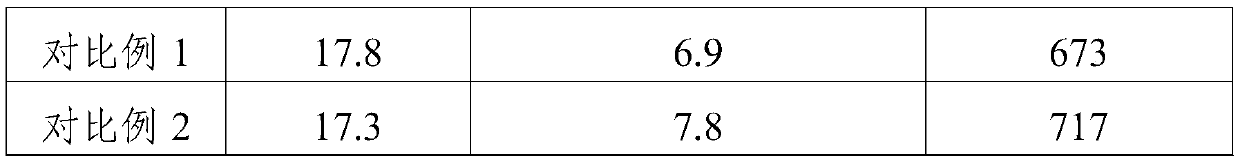

Preparation technology of graphene oxide toughened alumina-based ceramic cutter

The invention provides a preparation technology of a graphene oxide toughened alumina-based ceramic cutter, and relates to the technical field of ceramic cutters. The preparation technology comprisesthe following steps: (1) adding graphene oxide into anhydrous ethanol, and adding polyethylene glycol and alumina powder to obtain a powder slurry I; (2) mixing anhydrous ethanol with polyethylene glycol, and adding beta-SiC nanoparticles, TiC whiskers and a sintering aid to obtain a powder slurry II; (3) performing ball milling to obtain a composite slurry; (4) drying and sieving the composite slurry to obtain a composite powder; (5) carrying out pre-pressing forming; and (6) carrying out vacuum hot-pressing sintering on the obtained pre-pressed green body. The graphene, TiC whiskers and beta-SiC nano-particles have synergistic effects, so the reinforcing and toughening effects are good, the dispersity of all the raw materials in the preparation process is high, and the prepared ceramic cutter has excellent mechanical properties, high toughness and strength and good wear resistance.

Owner:安徽予初网络科技有限公司

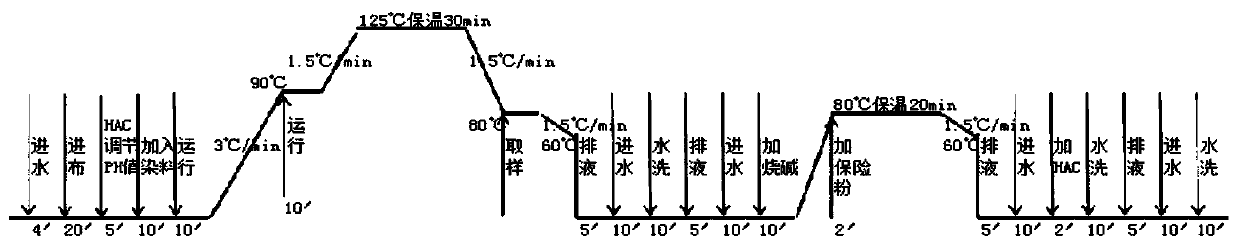

Method for dyeing cotton and viscose-polyester fabrics by combining overflow dyeing and continuous dyeing

InactiveCN110699977AAvoid damageLittle elastic damageSucessive textile treatmentsDyeing processDisperse dyePolymer science

The invention discloses a method for dyeing cotton and viscose polyester fabrics by combining overflow dyeing and continuous dyeing, which comprises the steps of A, invert-sewing cotton and viscose-polyester grey fabrics to obtain a product A; B, performing alkaline-oxygen pretreatment on the product A and then performing cold stacking to obtain a product B; C, tightly desizing and bleaching the product B to obtain a product C; D, singeing the product C to obtain a product D; E, presetting the product D to obtain a product E; F, performing high-temperature high-pressure overflow dyeing on theproduct E with disperse dyes to obtain a product F; G, stripping and washing the product F to obtain a product G; H, drying the product G to obtain a product H; I, carrying out continuous dyeing on the product H with reactive dyes to obtain a product I; J, post-finishing the product I to obtain a product J; K, preshrinking the product J to obtain a product K; and L, inspecting and packaging the product K to obtain a finished product. According to the invention, the dyeing efficiency is high, the vat difference is small, the fastness is good, the gram weight reduction is small, and the elasticity of the dyed stretch fabrics is good.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com