Patents

Literature

58 results about "Sound energy density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sound energy density or sound density is the sound energy per unit volume. The SI unit of sound energy density is the pascal (Pa), that is the joule per cubic metre (J/m³) in SI based units.

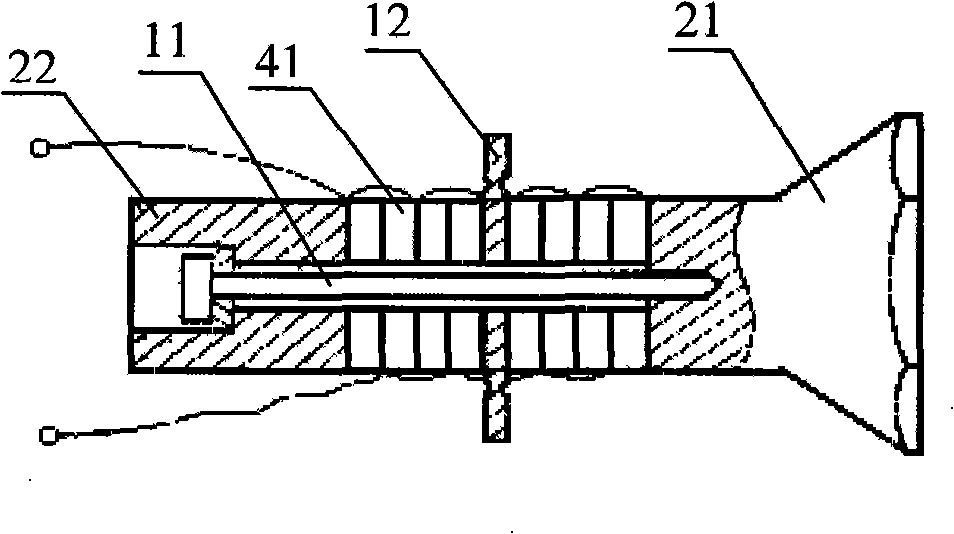

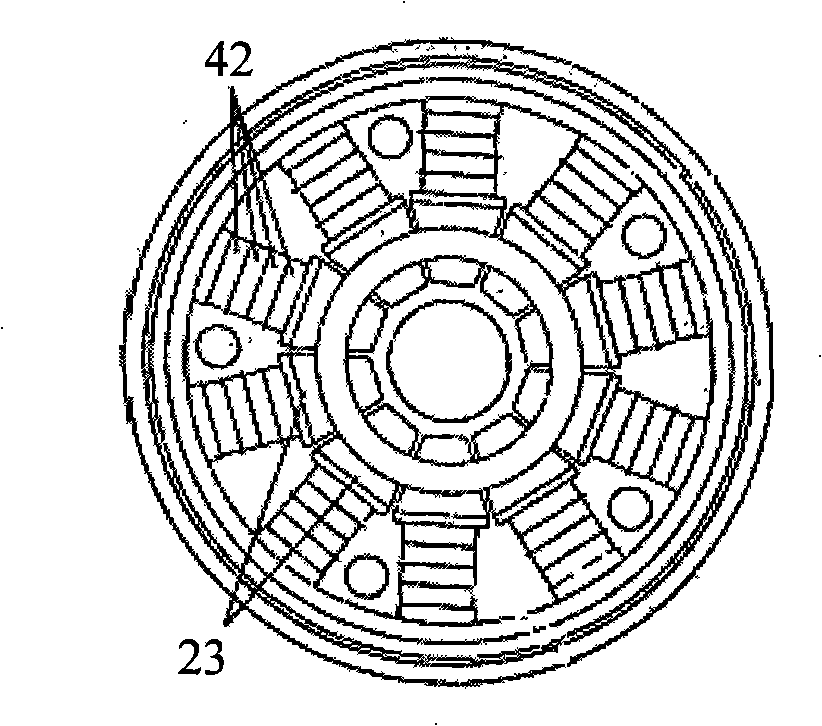

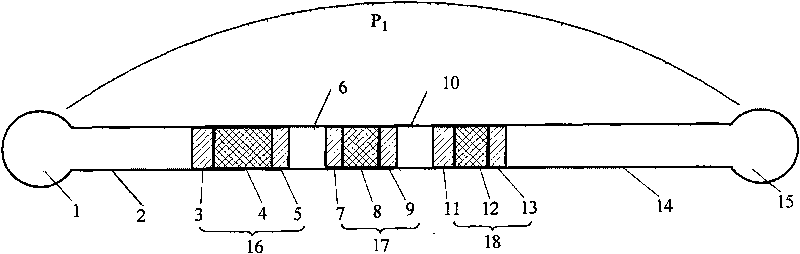

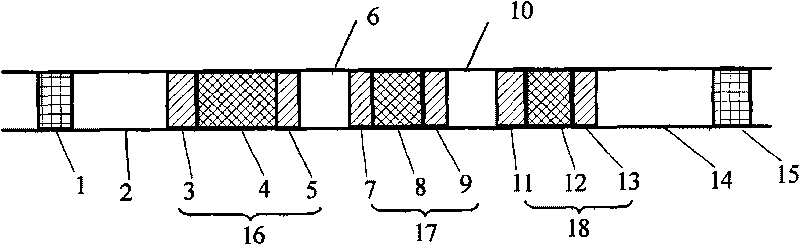

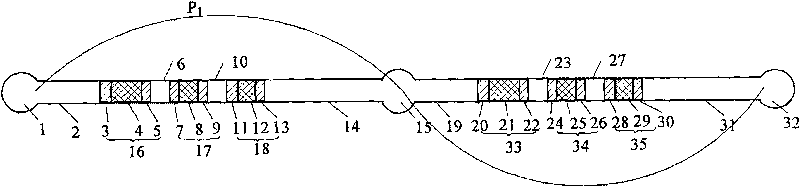

Cylindrical stack wafer underwater transducer

InactiveCN101321411AHigh sensitivityIncrease energy densityPiezoelectric/electrostrictive transducersTransducers for subaqueous useWaferingSound energy density

The invention provides an underwater acoustic transducer, comprising a piezoelectric ceramic wafer pack and metal cover plates on upper and lower ends thereof. The piezoelectric ceramic wafer pack is in a cylindrical shape and stacked by several circular piezoelectric ceramic wafers. Polarization direction of the piezoelectric ceramic wafers is along the thickness direction. 2 to 8 piezoelectric ceramic wafers form a group, and the wafer pack contains one or several groups of wafers, each is separated by a rubber chip. Metal sheets are clamped between adjacent wafers and between a wafer and a rubber chip. Contact conductors are welded on the metal sheets. The piezoelectric ceramic wafer pack and the upper and lower metal cover plates are further separated by the rubber chips. The cylindrical stacked wafer transducer of the invention is not only capable of maintaining characteristics of large transmitting sound energy density of traditional stacked wafer transducer and high sensitivity by reasonably designing diameter of piezoelectric stacked wafers, but capable of adjusting axial directivity open angle of the transducer by changing thickness of the piezoelectric wafer stack or adjusting the group number.

Owner:BEIJING INFORMATION SCI & TECH UNIV

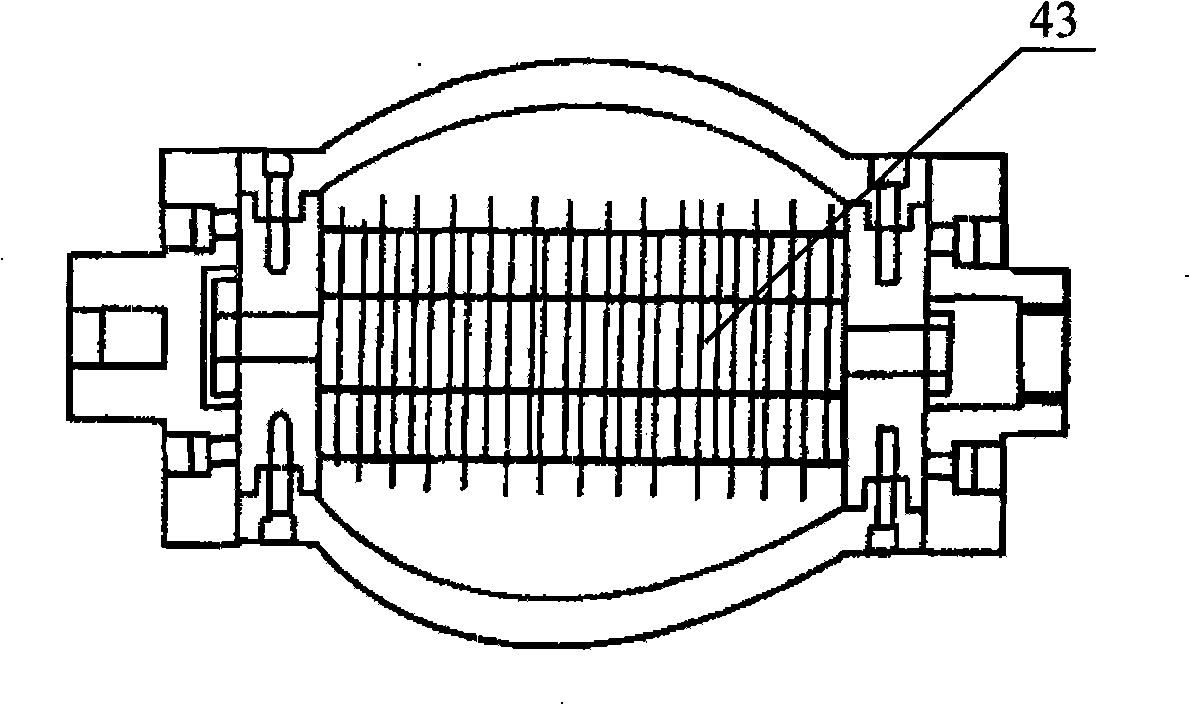

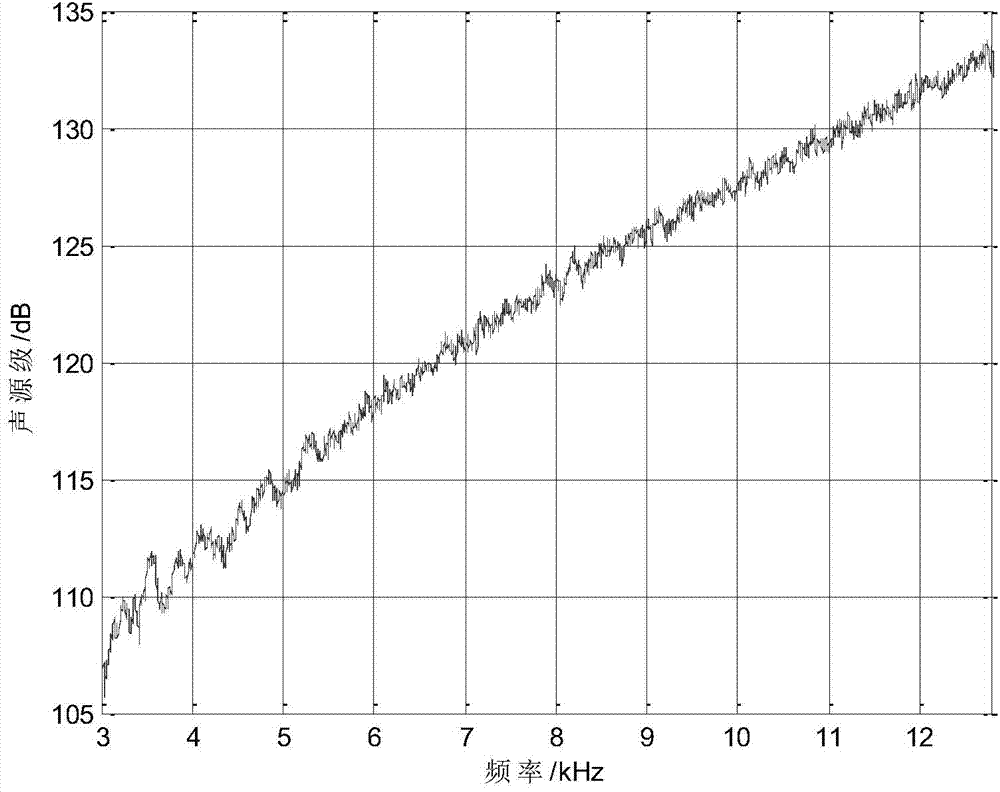

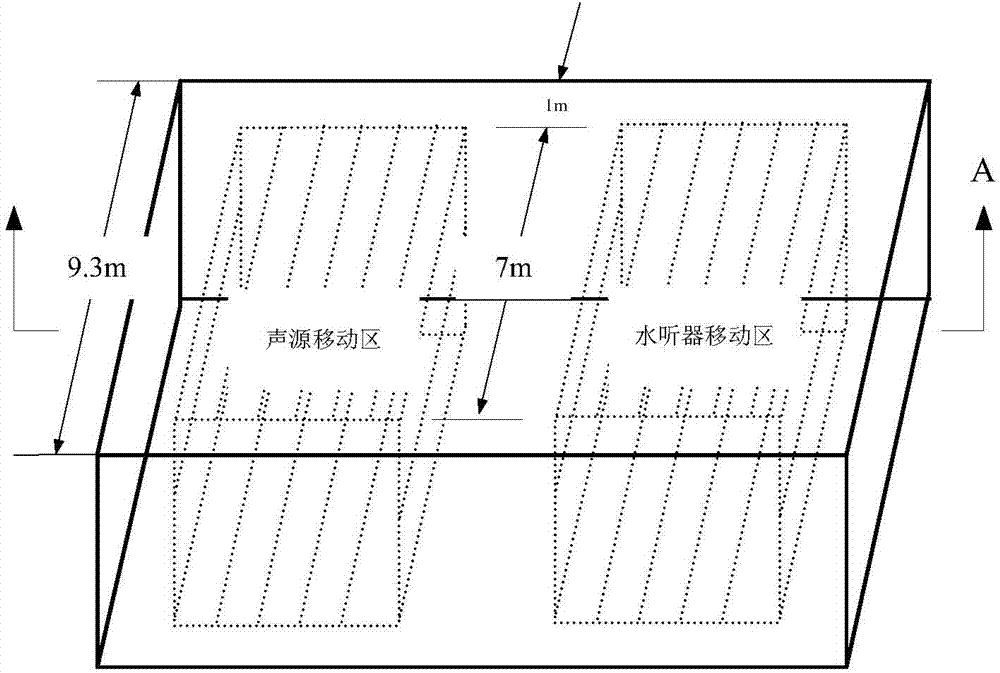

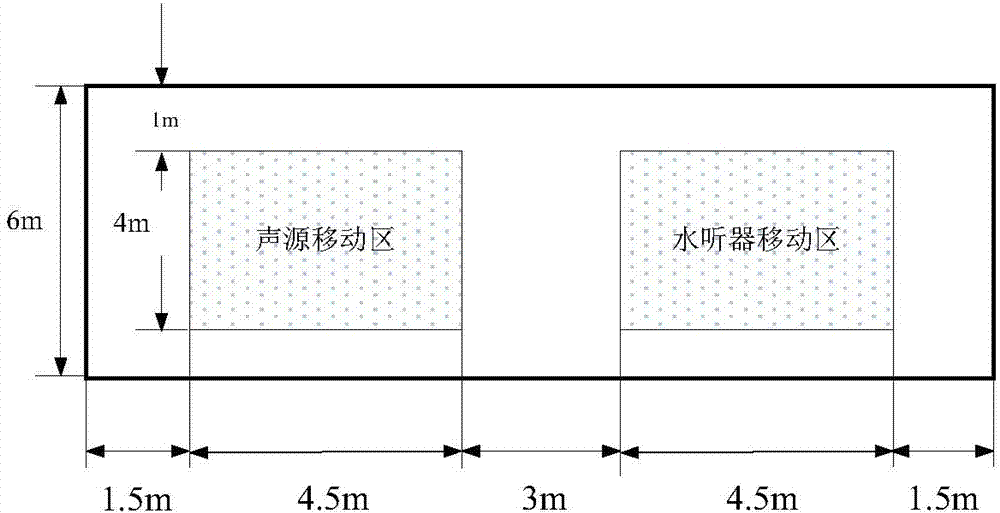

Inversion method utilizing single hydrophone to measure reverberation time of non-anechoic pool

ActiveCN104501939AEasy to measureEasy to operateReverberation timeVoltage amplitudeUltrasound attenuation

The invention relates to a reverberation time measurement method and particularly relates to an inversion method utilizing a single hydrophone to measure reverberation time of a non-anechoic pool. The method comprises steps that, a sound source level of a random non-directional sound source is measured in an anechoic pool by utilizing a calibrated hydrophone and is recorded and loaded to frequency and voltage amplitude on the sound source; the non-directional sound source and the hydrophone are put to a to-be-measured non-anechoic pool, frequency and voltage amplitude are recorded and are loaded to the non-directional sound source, the sound source and the hydrophone are simultaneously and slowly moved, and an average space sound pressure level is acquired by utilizing the hydrophone for measurement; the reverberation time of the non-anechoic pool can be acquired through inversion calculation according to the sound source level of the non-directional sound source in a free field and the measured average space sound pressure level of the sound source in the to-be-measured non-anechoic pool. The method has properties of high test efficiency and accurate result, and the average sound energy density attenuation time can be measured not on the basis of definition of the reverberation time.

Owner:HARBIN ENG UNIV

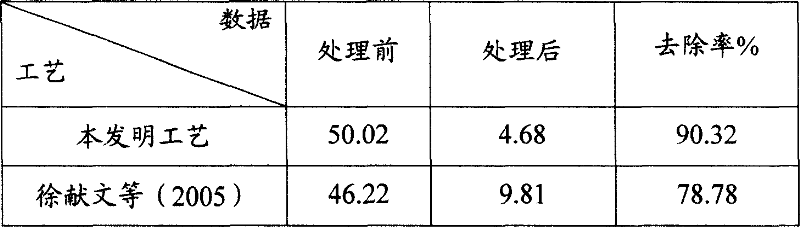

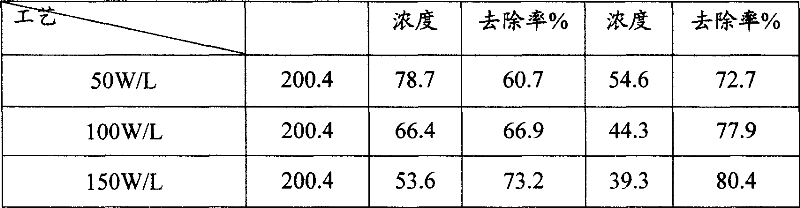

Ultrasonic ozone treating technique of chlorophenol-containing wastewater

ActiveCN101037249AImprove removal efficiencyReduce energy consumptionWater/sewage treatment with mechanical oscillationsWater contaminantsSound energy densityWastewater

The present invention provides a chlorophenol-containing wastewater treatment technology by ultrasonic ozonation, wherein a stainless steel ultrasonic wave reaction tank is adopted, the ozone contacts with the waste water through a pore diffuser fixed at the bottom of the reaction tank, the chlorophenol of the waste water is removed under the condition of a sound wave frequency of 40 kHz, a sound energy density of 50~150 W / L, a ozone amount of 10~30 mg / L.h, a pH value of 8.0~8.2 and a water power residence time in the tank of 60~90 min. In the present invention, by optimizing the technological parameters, the purpose of lower energy consumption, high removing efficiency is realized, and the technology is adapted to the practical chlorophenol-containing wastewater treatment and has excellent market development prospect.

Owner:ZHEJIANG UNIV OF TECH

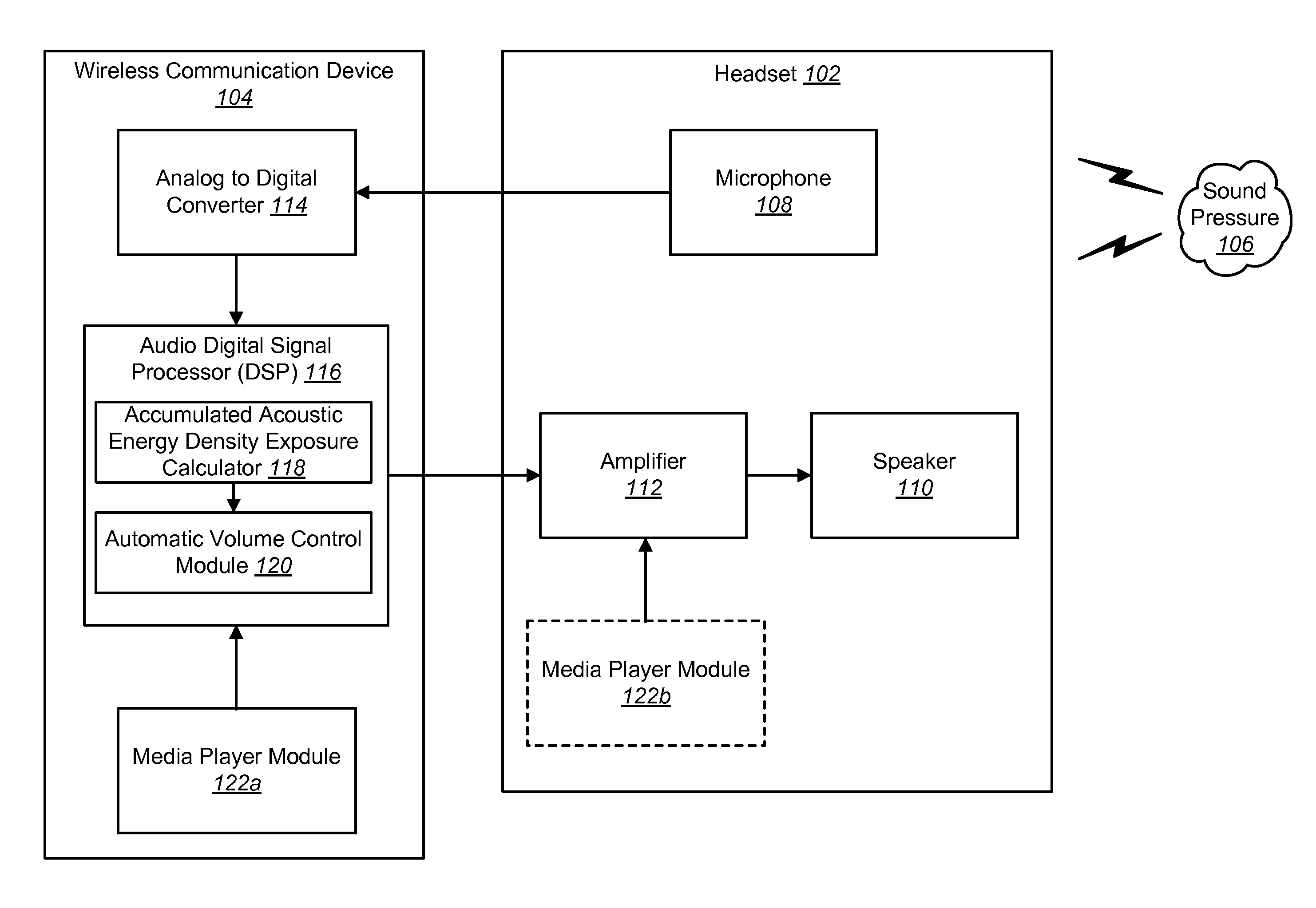

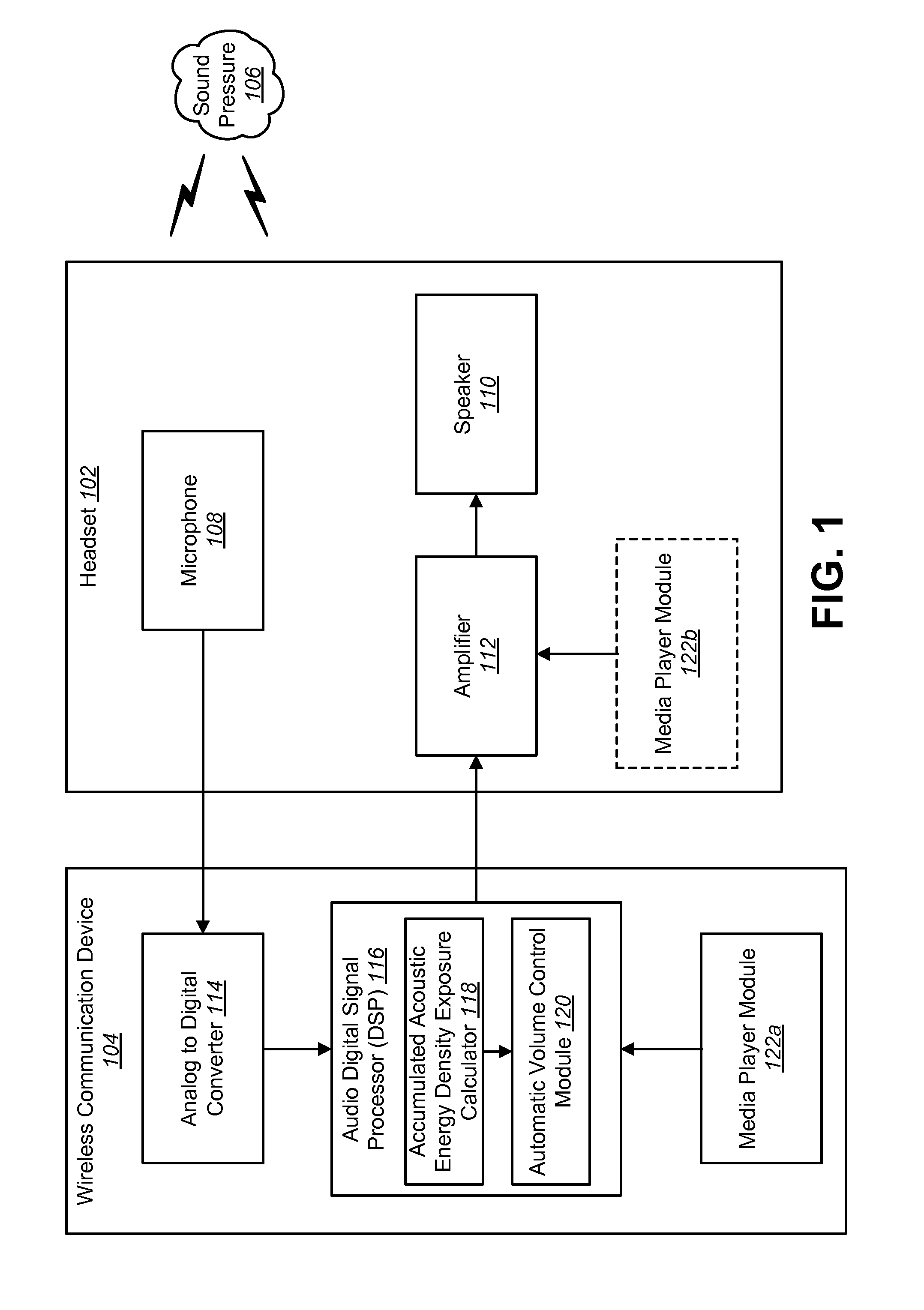

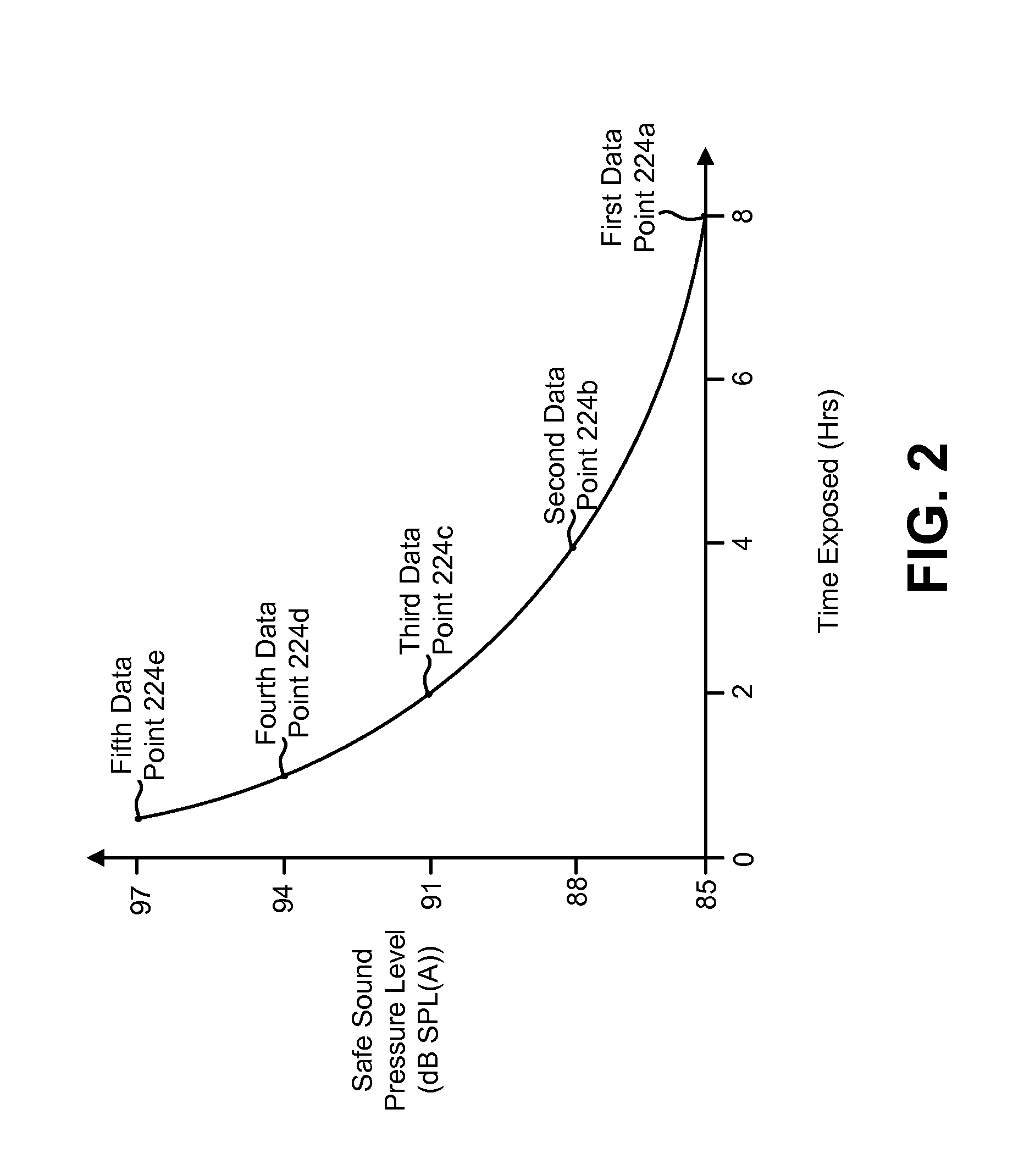

Automatic volume control based on acoustic energy exposure

InactiveUS20120051555A1Signal processingVibration measurement in fluidAutomatic controlAcoustic energy

A method for adjusting volume in a headset based on accumulated acoustic energy density exposure is disclosed. A sound pressure value of a microphone positioned in a user's ear canal is measured. A current accumulated acoustic energy density exposure is determined based on sound pressure values measured during the rolling window. The maximum volume in the headset is adjusted based on a comparison of the current accumulated energy density exposure to a predetermined threshold.

Owner:QUALCOMM INC

New ultrasound-assisted sludge dewatering system

InactiveCN102120682AShorten the timeLarge amount of processingSludge treatment by de-watering/drying/thickeningPipeline transportUltrasound assisted

The invention relates to a new ultrasound-assisted sludge dewatering system. The system comprises the following use steps: sludge is conveyed by a mud pump to a mixer connected with a sealed pipe, or the bottom sediment of a river course or lake reservoir is conveyed by an environmentally friendly dredging ship to a mixer connected with a sealed pipe, flocculant is added in the mixer through a metering pump, ultrasonic treatment is performed to the sludge with the flocculant and then sent to a geotech-Bag to dewater and solidify. The frequency of the ultrasonic treatment unit is 20kHz-41kHz, the energy density of sound is 0.15W / ml-0.50W / ml, and the ultrasonic treatment is performed for 10s-60s when the sound intensity is 400W / m<2>-600W / m<2>. In the pipeline transport process of sludge, the ultrasonic treatment unit is added in the system of the invention, thus the flocculation effect can be promoted, the dosage of the flocculant can be reduced and the dewatering and solidifying time of the geotech-Bag can be reduced. The new ultrasound-assisted sludge dewatering system can realize continuous operation, have high treatment capacity and efficiency and achieve high economic benefit.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION +1

Anaerobically digested sludge pyrohydrolysis-ultrasonic combined pretreatment method

ActiveCN102826730AIncrease the rate of hydrolysisBe harmlessSludge treatmentPretreatment methodSound energy density

The invention relates to an anaerobically digested sludge pyrohydrolysis-ultrasonic combined pretreatment method which comprises the following steps: (1) preheating concentrated sludge to 50-60 DEG C; (2) pumping the preheated sludge into a pyrohydrolysis reaction tank, continuously introducing hot steam generated by a steam generator into the pyrohydrolysis reaction tank, and keeping the temperature in the pyrohydrolysis reaction tank at 118-122 DEG C for 30 minutes, wherein the volume of the sludge does not exceed one half of the volume in the tank body; and (3) cooling the sludge subjected to pyrohydrolysis pretreatment to 50 DEG C with a heat exchanger, and carrying out ultrasonic treatment in an ultrasonic reactor for 30-60 minutes, wherein the ultrasonic frequency is 20-28 KHz, and the sound energy density is 0.33 W / mL. By adopting the pyrohydrolysis-ultrasonic combined pretreatment method, the invention can enhance the hydrolysis rate of the sludge, and lower the energy consumption for operation by using comprehensive allocation of heat.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method and equipment for processing industrial sludge through ultrasonic wave in combination with Fenton reaction and anaerobic digestion

InactiveCN103613262ASmall footprintReduce riskSludge treatment by oxidationWaste based fuelFenton reactionSound energy density

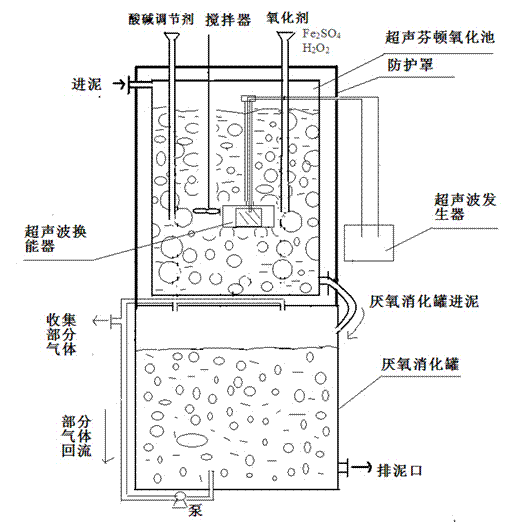

The invention discloses a method and equipment for processing industrial sludge through ultrasonic wave in combination with Fenton reaction and anaerobic digestion. The processing method comprises a pre-processing step and a post-processing step, wherein the pre-processing step is to simultaneously carry out Fenton reaction and ultrasonic breaking reaction on industrial sludge in same equipment, so as to break the industrial sludge and release a dissolved matter, wherein conditions of the Fenton reaction are as follows: pH is 1.5-3.5, H2O2 addition is 7-21g / L, Fe2+ addition is 0.1-3g / L, reaction duration is 0.5-2.0 hours, reaction temperature is 50-70 DEG C, sound energy density of the ultrasonic breaking is 0.1-3W / m<3>, and ultrasonic duration is 10-50min; and the post-processing step is to feed sludge after the Fenton reaction and the ultrasonic breaking to an anaerobic digestion tank, so as to carry out anaerobic digestion to produce marsh gas, wherein one part of the produced marsh gas is adopted as fuel and the other part circulates into the tank from the bottom of the tank, to form internal circulation, thus replacing a stirrer and avoiding maintenance of the stirrer.

Owner:GUANGXI UNIV

Method for cracking sludge through ultrasonic coupling Fenton oxidation

ActiveCN102503006AGood cracking effectIncrease concentrationMultistage water/sewage treatmentCapillary water absorptionSound energy density

The invention relates to a method for cracking sludge through ultrasonic coupling Fenton oxidation. Firstly, the pH value of a sludge system is regulated to 2.5 to 3.5 by diluted hydrochloric acid, then, ultrasonic waves and Fenton oxidation are adopted for simultaneously cracking a sludge system, the ultrasonic wave frequency is 20 to 40 kHz, and the ultrasonic sound energy density is 50 to 125 W / L; the simultaneous cracking time of the ultrasonic waves and Fenton oxidation on the sludge system is 0.25 to 1 hour, the sludge cracking effect is improved, and compared with non-enhanced Fenton oxidation treatment, the ultrasonic coupling Fenton oxidation has the advantages that the specific resistance of the sludge and the capillary water absorption time are greatly reduced. The method for cracking sludge through ultrasonic coupling Fenton oxidation has the advantages that the fetor control effect is obvious, and the Fe<2+> addition quantity and the H2O2 addition quantity are greatly reduced, so the treatment cost is greatly reduced.

Owner:TSINGHUA UNIV

Chlorine dioxide/ultrasonic wave-coupled excess sludge decrement pretreating method

ActiveCN102126818AMake up for the impactImprove processing efficiencySludge treatment by oxidationPretreatment methodChlorine dioxide

The invention discloses a chlorine dioxide / ultrasonic wave-coupled excess sludge decrement pretreating method. The method comprises the following steps of: performing chlorine dioxide treatment on excess sludge produced in the secondary biological sewage treatment process in advance, namely putting chlorine dioxide into sludge solution and stirring by using an electromagnetic stirrer at the rotating speed of 60 to 100r / min, wherein the addition amount of the chlorine dioxide in each gram of dry sludge is 2 to 6 mg and the treatment time is 60 to 90 minutes; and then performing ultrasonication, namely performing ultrasonic treatment on the sludge obtained after the chlorine dioxide treatment, wherein the sound energy density of ultrasound is 0.5 to 1.0W / mL, the action time of the ultrasound is 2 to 6 minutes, and the frequency of an ultrasonic wave is 20 to 40kHz. Compared with a treatment method in which the chlorine dioxide or the ultrasonic wave is independently used, the method hasthe advantages of improving the sludge treatment efficiency, reducing the energy consumption by 3 to 20 percent and reducing the treatment cost and is suitable for sludge decrement treatment in a sewage treatment plant.

Owner:SOUTH CHINA UNIV OF TECH

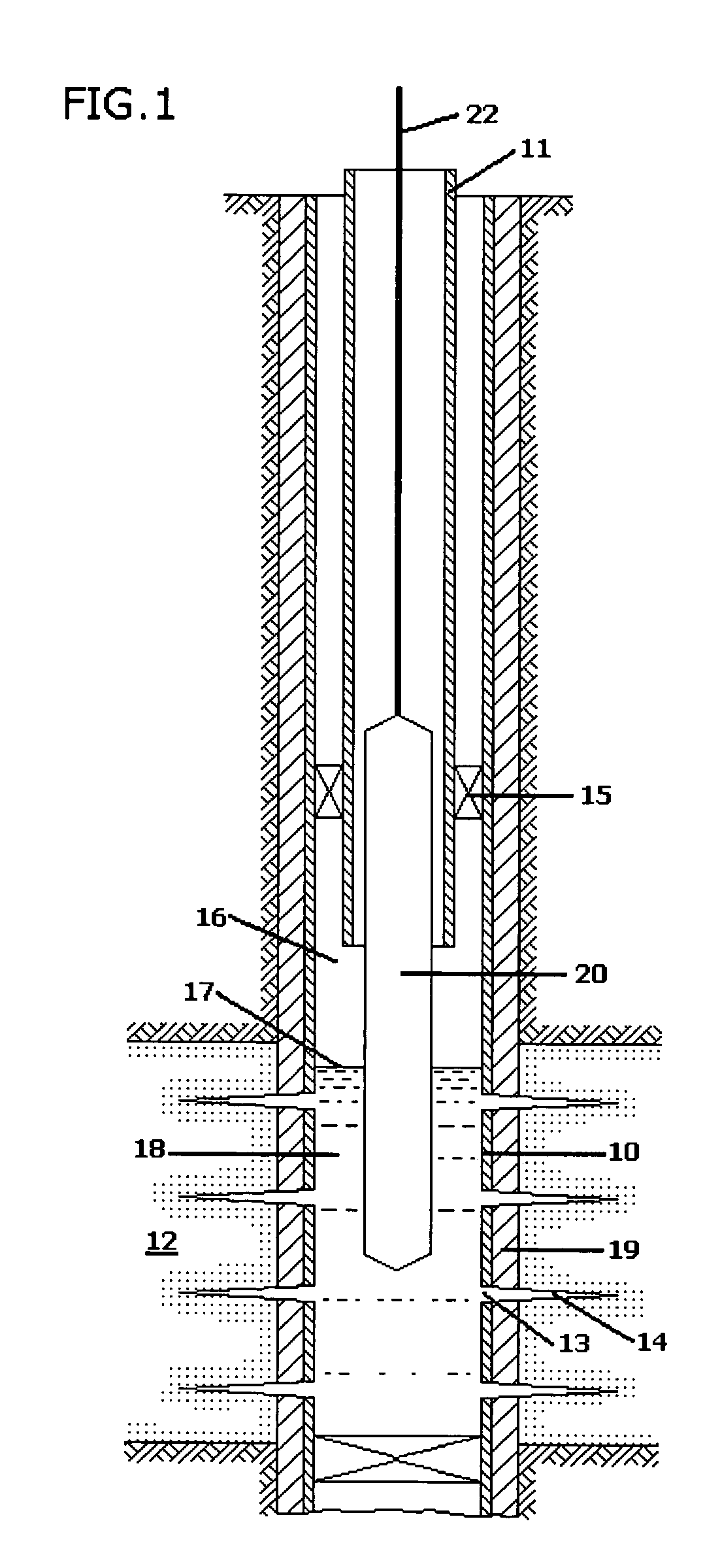

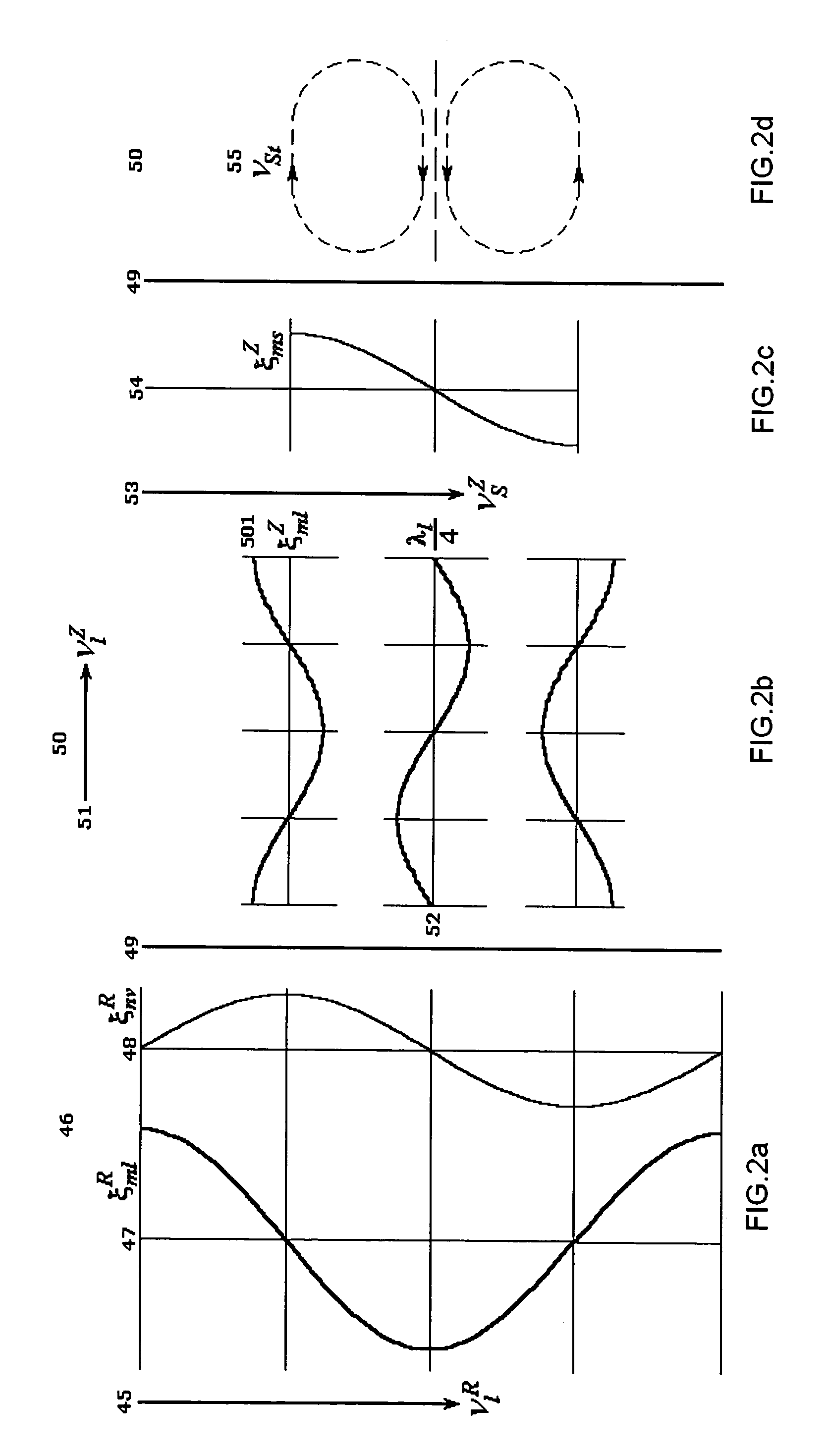

Electroacoustic method and device for stimulation of mass transfer processes for enhanced well recovery

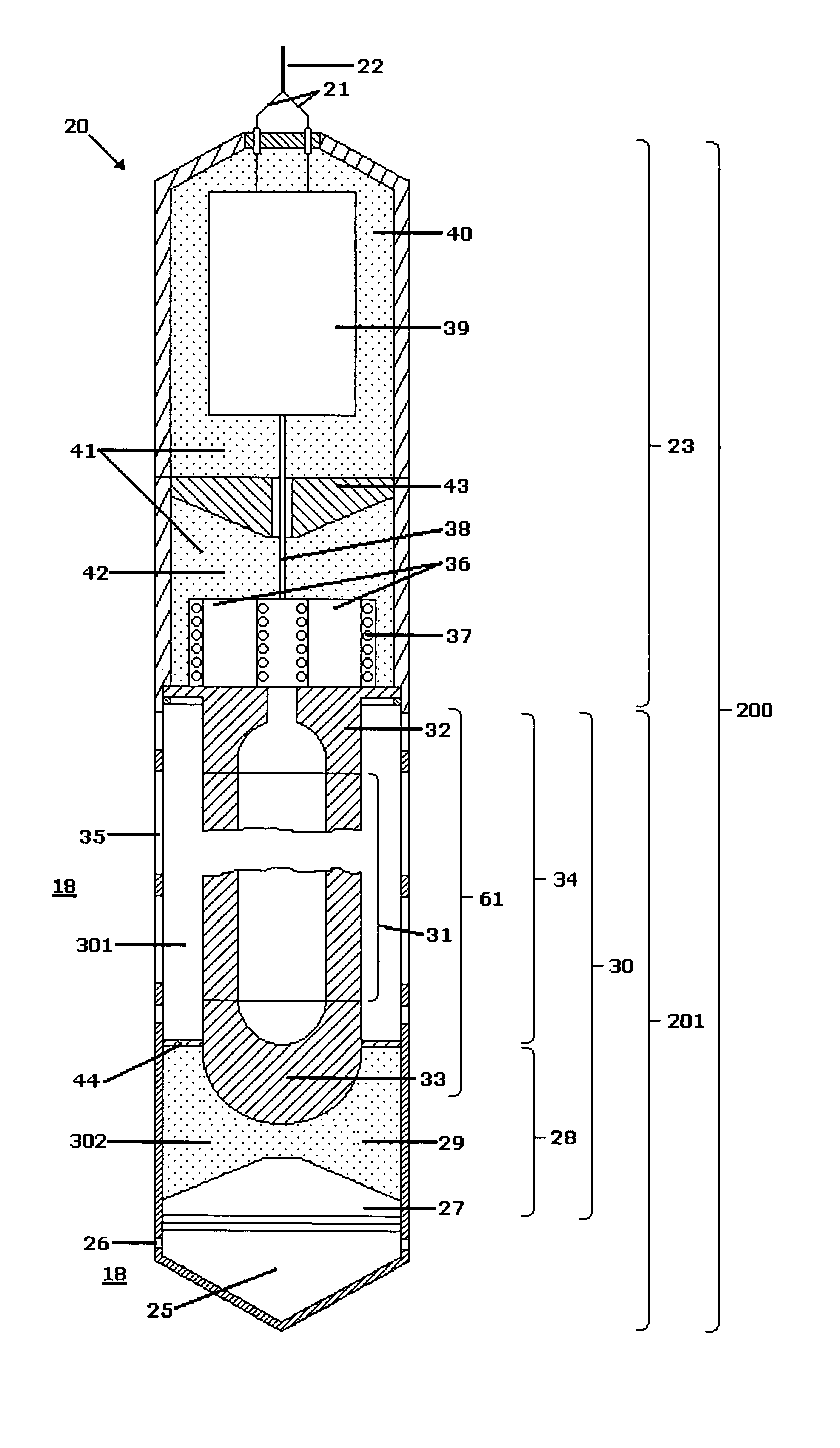

ActiveUS7059403B2Highly efficient acousticImprove liquidityFluid removalVibration devicesPorous mediumAcoustic energy

Owner:SONOPLUS

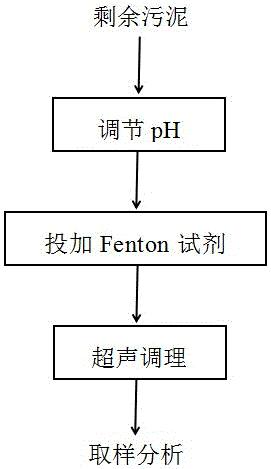

Method for conditioning urban sewage plant excess sludge through ultrasound and Fenton cooperation

InactiveCN106365412AReduce moisture contentIncreased proportion of free waterSludge treatment by de-watering/drying/thickeningWater treatment compoundsSound energy densityFenton reagent

The invention relates to a method for conditioning urban sewage plant excess sludge through ultrasound and Fenton cooperation. The method includes the following steps that S1, the pH value of excess sludge is adjusted to be 2.0-4.0; S2, a Fenton reagent is added into the excess sludge, wherein the Fenton reagents comprises ferrous sulfate with the saturation humidity ratio being 0.5-1.50 g / kgDS and hydrogen peroxide with the saturation humidity ratio being 15-30 g / kgDS; S3, the flow state of the excess sludge is kept through stirring, and an ultrasonic probe is immersed below the liquid level of the excess sludge; S4, ultrasonic frequency is adjusted to be 20-40 kHz, sound energy density is adjusted to be 0.07-0.10 W / mL, ultrasound time is set to be 20-240 s, and the ultrasonic probe is started for reaction; S5, after the ultrasound time is up, the ultrasonic probe is taken out from the excess sludge, the remaining sludge continues to react, and reaction time is 0.25-2 h; S6, after the reaction time is up, conditioning of the excess sludge is finished. The method reduces consumption of the Fenton reagent and ultrasonic conditioning consumption. Meanwhile, dewaterability of the excess sludge is further improved.

Owner:FUZHOU UNIV

Method for extracting plant selenoprotein from selenium-rich rice

ActiveCN107353321AThe extraction step facilitatesIncrease contentPeptide preparation methodsWater bathsSound energy density

The invention discloses a method for extracting plant selenoprotein from selenium-rich rice. The method comprises steps as follows: (1), pretreatment; (2), extraction treatment: slurry obtained after enzymolysis is mixed with an extract liquid, a mixture is subjected to far-infrared ray irradiation treatment as assistance, subjected to water bath oscillation for 1-6 h and centrifuged for 15-22 min at the temperature of 25 DEG C at the rotating speed of 3000-5000 r / min, and an obtained supernatant is a protein liquid; (3), deposition treatment: the protein liquid is enabled to be under the condition of ice bath, icy acetone 4 times the volume of the protein liquid is added, then a mixed liquid is put in an environment at the temperature of subzero 27 DEG C-subzero 17 DEG C and is placed for 3-5 h under the assistant treatment condition that sound energy density of ultrasonic waves is 10-18 W / mL for selenoprotein deposition, the mixed liquid is centrifuged for 10-15 min, precipitates are taken out and subjected to spray drying, and finally, finished selenoprotein products are obtained. The extracted plant selenoprotein has the advantages of small grain diameter and high extraction rate and the method has broad market popularization value.

Owner:AGRI RESOURCE & ENVIRONMENT RES INST GUANGXI ACADEMY OF AGRI SCI +2

Thermo-acoustic refrigerator device driven by cascade thermo-acoustic engine

InactiveCN101726133AAvoid lostImprove sound energy densityRefrigeration machinesResonant cavityThermoacoustics

The invention relates to a thermo-acoustic refrigerator device driven by a cascade thermo-acoustic engine, comprising an engine stage terminal resonant cavity, an engine stage resonatron, a standing wave stage engine unit, a standing wave section thermal buffer tube, a moving standing wave stage engine unit, a moving standing wave section thermal buffer tube, a moving standing wave stage refrigerator unit, a refrigerator stage resonatron and a refrigerator stage terminal resonant cavity. The invention comprehensively utilizes two mechanisms of thermo-acoustic conversion, so that the thermo-acoustic effects generated by both travelling wave component and standing wave component of sound wave in the moving standing wave stage engine unit are thermal acoustic effects and in the moving standing wave stage refrigerator are pumping thermal effect. The device uses linear arrangement to avoid acoustic circulation loss and simplify the system structure and adopts a two-stage or multistage engine unit to improve the sound energy density, effectively improve the cooling density and decrease the cooling temperature, thereby compacting the system structure.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for separating metal and non-metal in waste cable

ActiveCN101399098AGood control of cut lengthReduce wearBasic electric elementsElectronic waste recyclingSound energy densityWaste treatment

The invention discloses a method for stripping metal and nonmetal in a waste cable, belonging to the solid waste treatment and resource recycle field. In the method for stripping metal and nonmetal in the waste cable, sheared cable particles are put in a groove ultrasonic wave device with medium. The temperature range of water medium in the ultrasonic wave device is less than 100 DEG C, the working frequency of the ultrasonic wave is 9-40kHz, the sound energy density is 0.4W / cm<2>-0.8W / cm<2>, and the treatment time of the ultrasonic wave is 10s-10min. the method reduces losses of metal resources and ensures the complete stripping of the metal and the nonmetal in the cable. And the metal products are provided with high quality. Good conditions are provided for the categorized complete separation of various resources. The stripping efficiency of the metal and the nonmetal in the waste cable can be larger than 85 percent.

Owner:扬州宝泽电气有限公司

Method for treating waste water through Fenton oxidation by utilizing ultrasonic catalysis

InactiveCN104386868AReduce investmentImprove reaction efficiencyWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentActivated charcoal powderActivated carbon

The invention relates to a method for treating waste water through Fenton oxidation by utilizing ultrasonic catalysis. The method comprises the following specific steps: (1) adding an enough amount of activated carbon powder into the waste water, wherein the addition amount of the activated carbon powder is 0.7 weight percent of the weight of the waste water; (2) after the activated carbon powder adsorbs a great number of impurities in the water, filtering the waste water, and then injecting the waste water into an ultrasonic reactor; (3) performing ultrasonic crushing reaction, wherein the sound energy density of an ultrasonic wave is 0.1-0.3 w / m<3>; (4) after the reaction is performed for 20-40 minutes, adding ferrous ion salt and H2O2 into the ultrasonic reactor, adjusting the PH value to be 3-5, and performing stirring; (5) after the stirring is performed for 2-3 hours and performing sedimentation after the reaction is completed to separate the solid liquid and treat waste water. According to the method, ultrasonic water purification and Fenton oxidation water purification are combined, so that the water purification efficiency is improved, and the water purification cost is reduced.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

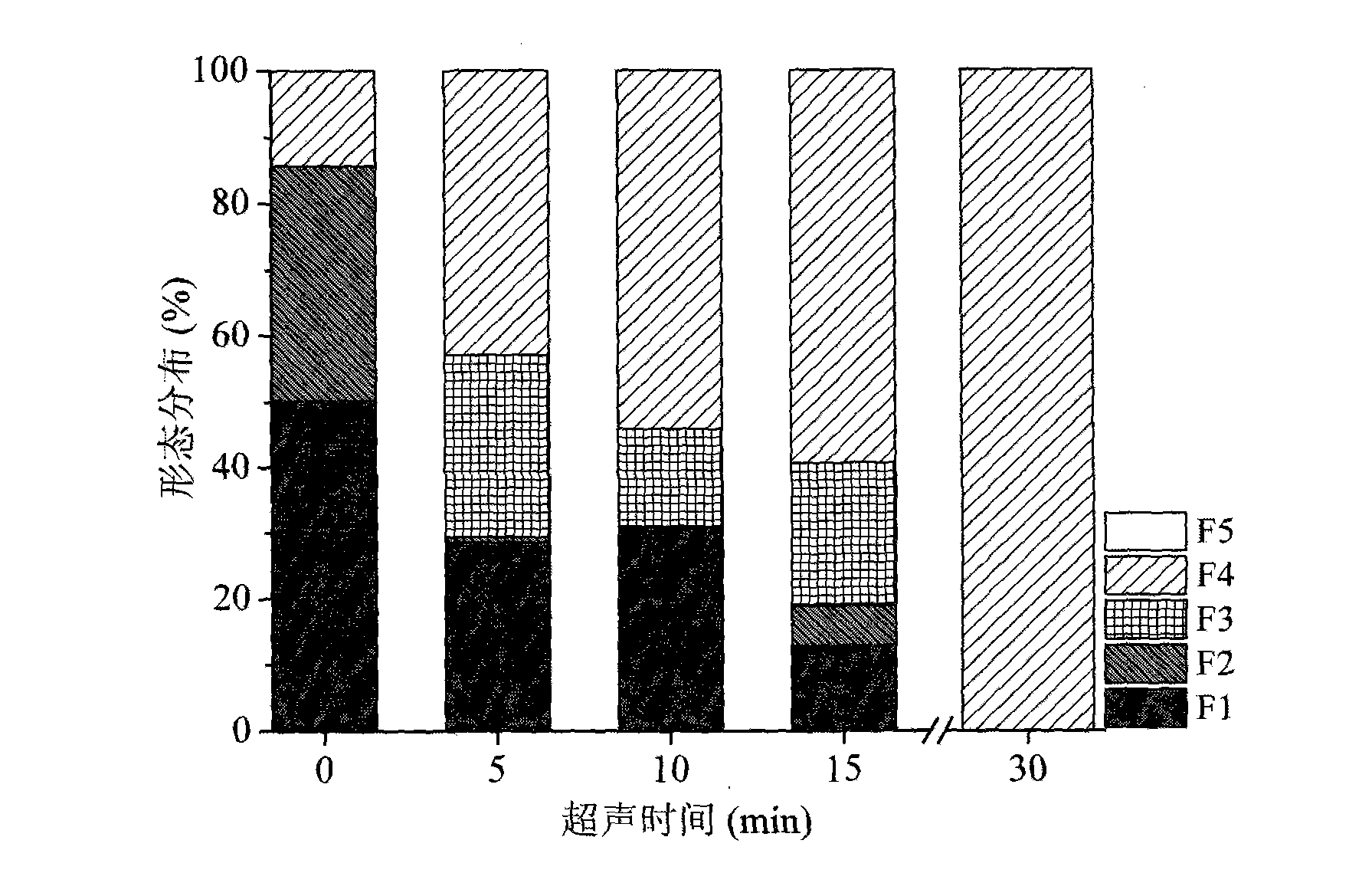

Method for leaching heavy metal contaminated soil by ultrasonic strengthening organic acid

InactiveCN104772329AImprove rinsing efficiencyShort rinse timeContaminated soil reclamationOrganic acidSound energy density

The invention relates to a method for leaching heavy metal contaminated soil by ultrasonic strengthening organic acid. The method comprises the steps of firstly, mixing organic acid and the heavy metal contaminated soil, and then leaching the heavy metal contaminated soil by the ultrasonic strengthening organic acid, wherein the ultrasonic frequency is 20-40kHz, the ultrasonic sound energy density is 20-50W / L, and the time for leaching the heavy metal contaminated soil by the ultrasonic strengthening organic acid is 5-20 minutes. After the method is used, the leaching effect of the heavy metal contaminated soil is improved, and the morphology distribution of the heavy metal is changed; the repair for leaching the heavy metal contaminated soil by the ultrasonic strengthening organic acid is an environment-friendly repair method; the method is simple in technology, short in leaching time and good in repairing effect.

Owner:TSINGHUA UNIV

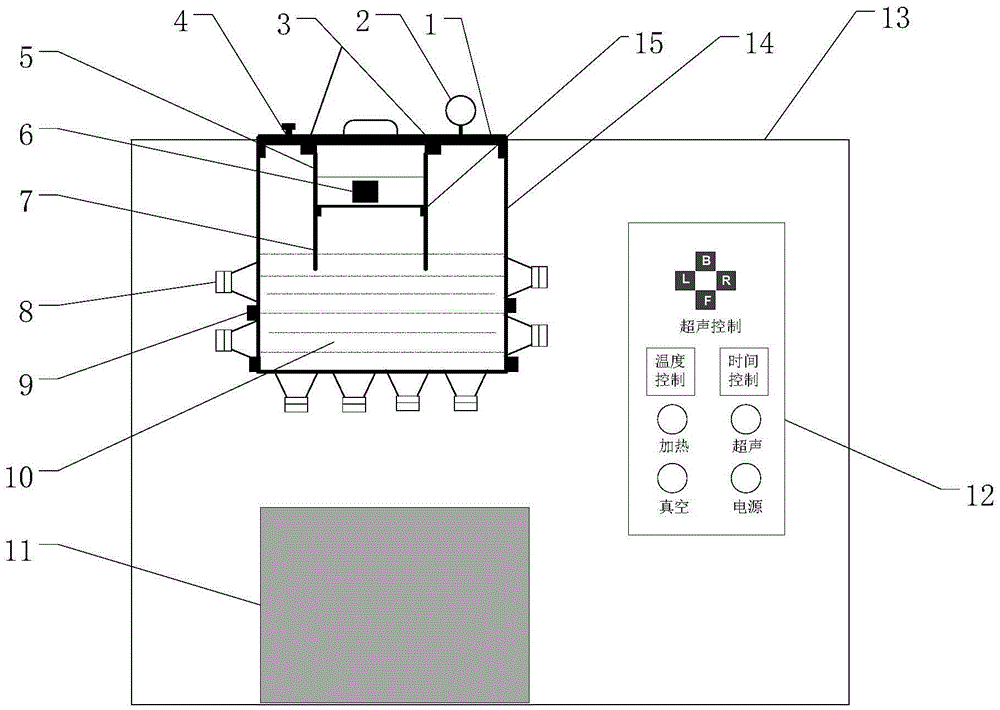

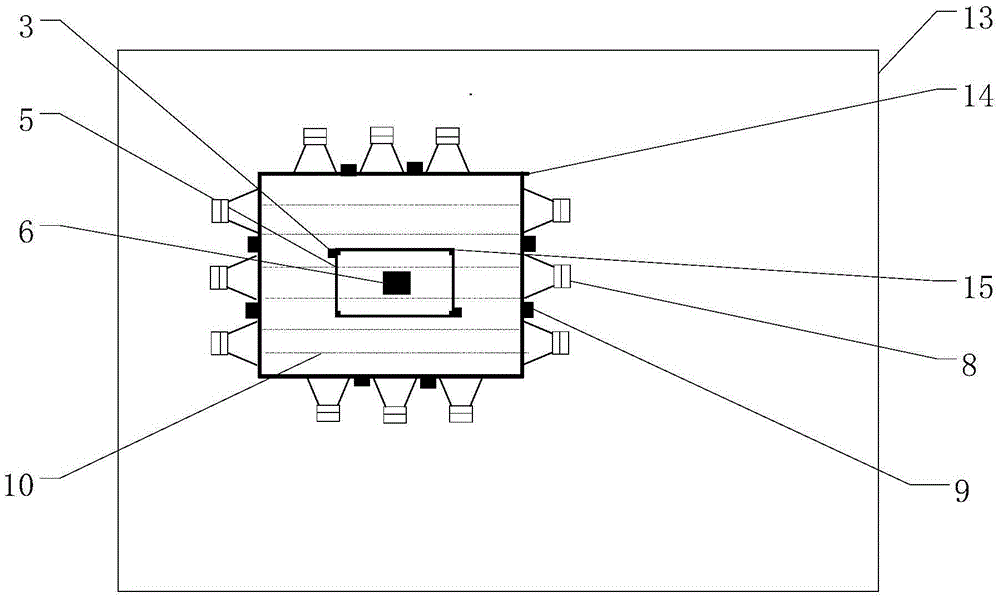

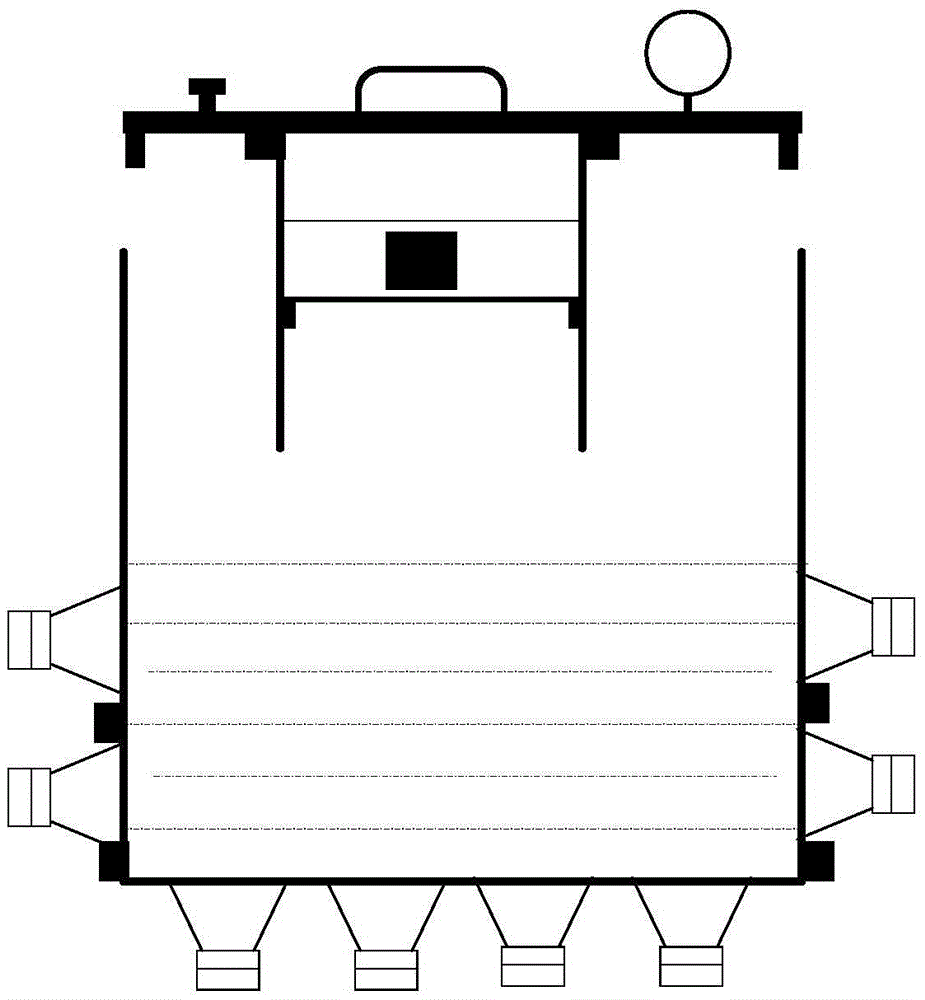

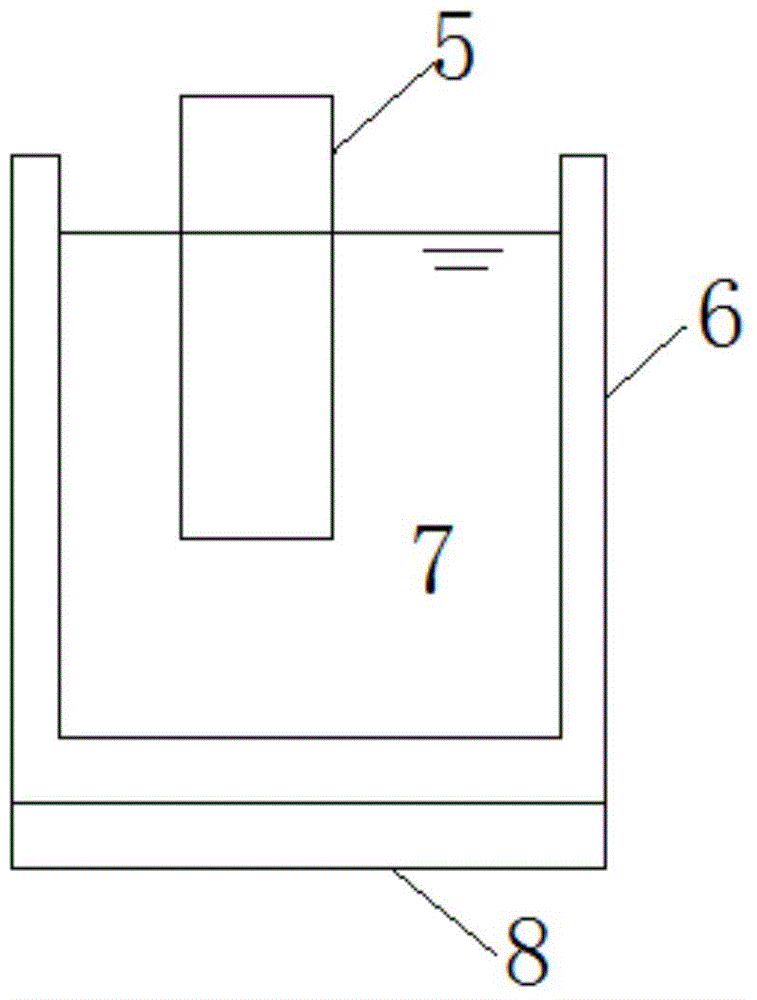

High-sound-energy-density single-slot vacuum frequency-mixing immersion type ultrasonic surface treatment device

The invention discloses a high-sound-energy-density single-slot vacuum frequency-mixing immersion type ultrasonic surface treatment device. The device is designed and manufactured according to an immersion type ultrasonic surface treatment method. The device is characterized in that the device is mainly composed of a machining pool, an ultrasonic generation and amplification device, a vacuum module and a temperature control system, the machining efficiency is further improved, and the loss of ultrasonic energy is reduced. An operation method comprises the steps that prepared machining liquid (10) is firstly added into the machining pool (14); a magnetically controlled switch (13) is turned on, and a machining basket (5) where a to-be-machined product (6) is fixed is adsorbed to a machining cover (1); the machining cover is closed, and vacuum treatment is carried out; after vacuum treatment is finished, a magnetic control system is utilized for controlling the machining basket to slide down along guide rails (7), and it is ensured that the to-be-machined product is immersed in the machining liquid; and the ultrasonic energy field intensity is set according to the material of the product for ultrasonic surface machining, and efficient treatment on the surface of the product is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Alkali-ultrasonic synergistic wastewater treatment method and device

InactiveCN104787996AIncrease organic matterSolve the problem of insufficient carbon sourcesSludge treatmentUltrasound - actionSound energy density

The invention relates to an alkali-ultrasonic synergistic wastewater treatment method and device. The alkali-ultrasonic synergistic wastewater treatment method comprises the following steps: precipitating and separating a mud-water mixture taken out of the outlet end of an aerobic biological treatment unit or an anoxic biological treatment unit, adding an alkali liquor into the separated sludge to regulate the pH value, and performing ultrasonic treatment; returning the sludge which is added with the alkali liquor and treated by ultrasonic to a wastewater biological treatment unit; adding an NaOH alkali liquor into the precipitated sludge to regulate the pH value to 10, and treating the sludge in an ultrasonic reactor, wherein the ultrasonic reactor is controlled to be 20 kHz in frequency, 8 W / mL in sound energy density and 50% in duty ratio of 50%, and under the condition that the ultrasonic treatment time is 30 min, floc destruction and cell cracking are performed on the sludge so as to release organic matters in floc cells of the sludge; returning the treated sludge to the biological treatment unit so as to increase the concentration of the organic matters in the biological treatment unit. Therefore, the problem that the biological treatment unit is short of a carbon source is solved.

Owner:TIANJIN UNIV

Method for preparing high-quality emulsified heavy oil

InactiveCN101837256ALow viscosityReduce interfacial tensionMixing methodsRefining by water treatmentEmulsionShear stress

The invention discloses a method for preparing high-quality emulsified heavy oil, which adopts a heavy oil emulsification technique of the combined emulsification of ultrasonic waves and mechanical stirring, and does not add any emulsifying agent in the emulsification process at all. In the method, the ultrasonic waves and the mechanical stirring synergistically act on a mixture of heavy oil and water to generate a larger shear stress to ensure that the heavy oil and the water are mixed together more sufficiently, and the particle size of a dispersed phase (water) is further thinned to form 'secondary emulsification' of an emulsion so as to form a micro-emulsion which is more stable, cannot be de-mixed easily and has thinner and more uniform emulsified particles. The method has the following main technical parameters that: the average sound energy density is 40 to 60 W / L, the ultrasonic frequency is 25 to 40 kHz, the stir speed is 100 to 300 r / min, the emulsifying temperature is 70 to80 DEG C, the emulsification time is 30 to 40 minutes, and the water mixing ratio is 1 to 25 percent. The method uses the synergistic action of the ultrasonic waves and the mechanical stirring to improve the emulsification effect and the stability of the emulsified heavy oil, and is a technique for preparing the high-quality emulsified heavy oil.

Owner:KUNMING UNIV OF SCI & TECH

Method for processing organic wastewater by electro-fenton

InactiveCN104326611AReduce investmentImprove reaction efficiencyWater contaminantsWater/sewage treatment with mechanical oscillationsActivated charcoal powderSound energy density

The invention relates to a method for processing an organic wastewater by electro-fenton. The method comprises the following specific steps: (1) adding enough activated carbon powder to the wastewater, wherein the adding amount of the activated carbon powder accounts for 0.7wt%-1.1wt% of the wastewater; (2) adsorbing a lot of impurities in water by the activated carbon powder, filtering the wastewater and injecting into an ultrasonic reactor; (3) carrying out ultrasonic crushing reaction, wherein the sound energy density of the ultrasonic wave is 0.1-0.3w / m<3>; (4) after reacting for 20-40 minutes, feeding the wastewater into an electrolytic cell, and adding mineralized refuse and an H2O2 solution to the electrolytic cell, wherein an anode electrode of the electrolytic cell is an iron electrode and a cathode electrode is a graphite electrode; connecting current of the electrolytic cell, and lastingly stirring in the overall process; and (5) after 2-4 hours, participating after reaction is ended, thus achieving solid-liquid separation, so as to finish wastewater treatment. The ultrasonic crushing reaction is utilized as earlier stage processing, and then the mineralized refuse is utilized to participate into electrolytic sewage purification, so that the defects that iron ions are difficult to remove and the removal efficiency of pollutants is low in an existing fenton technology are solved.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

A method for separating fungus extracellular polysaccharides by utilizing a three-phase system

InactiveCN108752487AImprove biological activityFast selective separationWater bathsSound energy density

The invention discloses a method for separating fungus extracellular polysaccharides by utilizing a three-phase system, belongs to the technical field of bioactive substance separation and purification, and particularly relates to selective separation of fungus extracellular polysaccharides by utilizing a system consisting of tert-butanol and an inorganic salt that is ammonium sulfate. The methodmainly includes steps of subjecting a fungus fermentation solution to treatment with ultrasonic waves having a sound energy density of 15 W / cm<3> for 10 min; adding the ammonium sulfate and the tert-butanol; performing vibration in a water bath at a constant temperature of 35 DEG C for 30 min; performing centrifugal separation; subjecting a lower inorganic salt phase to dialysis, concentration andspray drying to obtain fungus extracellular polysaccharide powder; and subjecting an upper organic phase to vacuum rotary evaporation to recover the tert-butanol. The three-phase system is suitable for industrial production of the fungus extracellular polysaccharides, and has rapid, efficient and environmentally friendly effects. The organic phase tert-butanol can be recycled and reutilized so that the method is safe, convenient and low in pollution, the production cost is reduced. The method can be widely applied for extracellular polysaccharide separation of various fungus fermentation solutions.

Owner:JIANGSU UNIV

Method for efficiently and fast treating high-content arsenic in surplus sludge

InactiveCN102701548AEffective passivationSmall particle sizeSludge treatment by oxidationWater contaminantsSound energy densityUltrasonic radiation

The invention relates to a method for efficiently and fast treating high-content arsenic in surplus sludge, belonging to the technical field of sludge treatment. With the adoption of the method, low-frequency ultrasonic wave is utilized to treat the surplus sludge and the high-content arsenic in the municipal sludge is stabilized by fully utilizing powerful shake waves generated by the cavatition of the ultrasonic wave, strong oxidant and high-temperature hot spot effect. The used low-frequency ultrasonic radiation device is a commercial device with frequency within 20-100KHz and sound energy density within 0.1-1.8w / ml. The retention time of the sludge is 1-30min. The method efficiently and fast treating the high-content arsenic in the surplus sludge has the characteristics of simple operation, convenient management, rapidness and high efficiency; stabilization rate of the high-content arsenic in the sludge can reach over 95%. The content of arsenic existing in a substitutable state, a combination state of carbonates and a oxidization state by iron and manganese in the treated sludge is remarkably reduced. The method is widely applied to treatment of the arsenic in the municipal sludge. The sludge treated by the method is widely applied to agriculture, garden green lands and roof greening, and is beneficial to full utilization of sludge resource, slowing or elimination of secondary pollution caused by the utilization of the sludge.

Owner:RENMIN UNIVERSITY OF CHINA

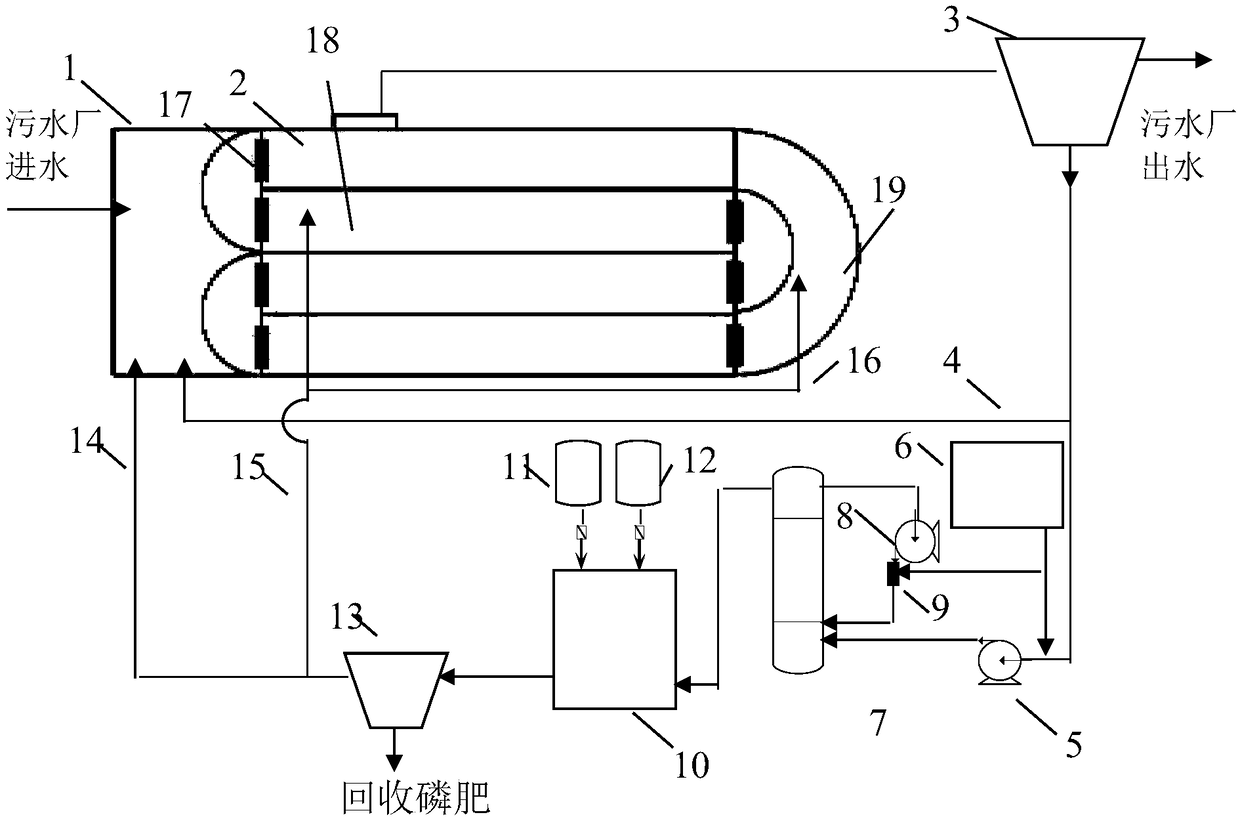

Ultrasonic ozone compound sludge reducing method coupled with Carrousel oxidation ditch and equipment thereof

ActiveCN108101332AIncrease profitEnhance the lysis effectSludge treatment by oxidationSpecific water treatment objectivesSound energy densityPhosphor

The invention provides an ultrasonic ozone compound sludge reducing method coupled with a Carrousel oxidation ditch and equipment thereof and belongs to the technical field of residual sludge treatment. The method comprises the following steps: 1) mixing residual sludge of the Carrousel oxidation ditch with ozone to obtain a gas-liquid mixture, wherein the ozone amount is 0.01 to 0.1gO3 / gTSS; 2) under ultrasonic treatment, performing pressurized sludge reduction on the gas-liquid mixture to obtain a reduced mixed solution, wherein the ultrasonic frequency is 50 to 100KHz, and the ultrasonic sound energy density is 0.2 to 0.3w / ml; 3) performing phosphorus recovery on the reduced mixed solution to obtain phosphorus-recovered material liquid, performing solid-liquid separation on the phosphor-recovered material liquid to obtain liquid supernatant and refluxing the liquid supernatant back to the Carrousel oxidation ditch. The method disclosed by the invention has the advantages of simpleness in operation, low cost and no secondary pollution.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing fertilizer by utilizing sludge left after sewage treatment and kitchen garbage

InactiveCN106966560ABio-organic fraction processingSewage/sludge fertilisersSound energy densityLitter

The invention relates to a method for preparing a fertilizer by utilizing sludge left after sewage treatment and kitchen garbage. The method comprises the following steps that 1, sludge from a sewage treatment plant is subject to ultrasonic wave radiation for 30-90 minutes, the sound energy density of ultrasonic waves is 0.5-3 w / mL; 2, the sludge obtained after ultrasonic wave radiation is mixed with the kitchen garbage and wood bits according to the volume ratio of 8 to 2 to 1; 3, the mixture obtained after ultrasonic wave radiation is piled on an open place, transverse water discharging bodies are laid on the surface of the sludge at intervals of preset heights, vertical water discharging bodies inserted into the sludge are arranged at intervals, and then earthworms are put on the surface of the sludge and are sequentially and upward piled, wherein the number of the earthworms put in per cubic meter of sludge is 3000-6000; 4, after 3-15 days, a layer of seal film is laid on the sludge after earthworm processing, then the seal film is connected with a vacuumizing apparatus, and vacuum preloading and solidification treatment is conducted on the sludge by using the vacuumizing apparatus. By adopting the method, the sludge obtained after urban municipal sewage treatment can be utilized and treated to obtain the organic fertilizer.

Owner:SUZHOU RUNHONG TRADING

Method for separating metals and nonmetals in waste cables through supersonic waves

ActiveCN103606424AImprove qualityImprove product qualityBasic electric elementsElectronic waste recyclingSound energy densitySupersonic waves

Disclosed is a method for separating metals and nonmetals in waste cables through use of supersonic waves. The method includes the following steps: 1) cleaning collected waste cables; 2)classifying the cleaned cables; 3) straightening the classified cables and putting the classified cables in order and feeding the cables into a cutting machine so that the cables are cut into sections; 4) feeding the sectioned cables into a grinding device for grinding processing; 5) feeding the ground cable sections into a refrigerating device so that the cables are refrigerated for 6 hours; 6) casting the refrigerated cable sections into an ultrasonic device, adding 10-20-time amount of water, immersing the cables at the temperature of 40-60 DEG C for 0.5 to 2 hours and carrying out ultrasonic processing twice at the temperature of 40-50 DEG C, ultrasonic power of 500W and sound energy density of 0.3W / cm<2> for an acoustic processing time of 5s to 5min; 7)putting the ultrasonic-processed cable sections into a separation device for separation until the metals and nonmetals are acquired. The method for separating the metals and nonmetals in the waste cables through use of the supersonic waves reduces the possibility that metals may be ground to be power-shaped so that loss of metal resources is reduced; the method is high in adaptability to the diameters of cut cables so that sufficient separation of the metals and the nonmetals in the cables is ensured; and the quality of metal products is high.

Owner:JIESHOU ZHENHANG PLASTIC MACHINERY

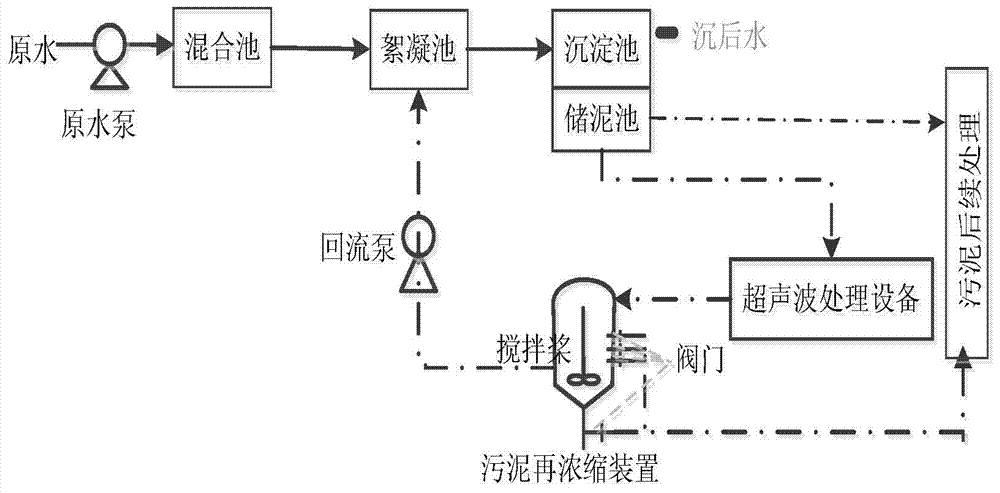

Method of improving quality of settled water from sludge return process by ultrasonic wave

InactiveCN103496832AAchieve reflowStrong resistance to shock loadsSludge treatmentSound energy densityWater source

The invention relates to a method of improving quality of settled water from the sludge return process by ultrasonic wave, belongs to the field of drinking water treatment and especially applies to enhanced coagulation in urban water treatment plants using lakes and reservoirs as water resources. Equipment comprises a mixing tank, a flocculating tank, a settling tank, a sludge storage tank, an ultrasonic treatment unit and a sludge re-thickening device, wherein all devices are connected in sequence. 10-15% of sludge in the sludge storage tank is used as return sludge entering the ultrasonic treatment unit and is treated with the ultrasonic wave under the ultrasonic frequency 25-160 KHz and sound energy density 23.3-30.0W / L for 15-30 minutes before being thickened by the sludge re-thickening device, under the re-thickening coefficient 0.6-0.8; the ultrasonically-re-thickened sludge 0.095-0.20w / w% in solid content is returned to the flocculating tank to enhance coagulating effect and improve the quality of settled water. The method has the advantages that organics and pathogenic microorganisms dissolved by ultrasonic cracking can be discharged out of a return system effectively; the method is significant to improving the quality of settled water, reducing treatment load of subsequent process, and guaranteeing water supply safety.

Owner:CHENGDU DUCHENG ENVIRONMENTAL PROTECTION CO LTD

Ultrasonic-wave-intensified hydrolytic treatment method for kitchen wastes

ActiveCN103253730AIncrease contentWater/sewage treatment with mechanical oscillationsChemical oxygen demandSound energy density

The invention relates to an ultrasonic-wave-intensified hydrolytic treatment method for kitchen wastes. The method comprises the following steps of: firstly selecting the kitchen wastes with the solid contents of 40-100 g / L; utilizing a trench type ultrasonic wave generator with the power of 9-960 W; putting 1 L of the kitchen wastes into the trench type ultrasonic wave generator, regulating the ultrasonic power at 0-960 W, and carrying out ultrasonic treatment for 150 minutes, wherein the ultrasonic sound energy density accepted by the kitchen wastes is 0-960 W / L; and centrifuging for 15 minutes at the revolving speed of 15000 rpm (revolutions per minute) after the ultrasonic treatment, measuring a COD (chemical oxygen demand) in supernate according to APHA-WPCF1998, measuring proteins according to Kjeldahl determination, and measuring the contents of polysaccharides by utilizing a spectrophotometric method, wherein the COD of the supernate is maximally increased by 1.7 times, the proteins are maximally increased by 7.9 times, and the polysaccharides are maximally increased by 4.5 times. The ultrasonic-wave-intensified hydrolytic treatment method can be used for improving the dissolution content of organic matters in the kitchen wastes.

Owner:TSINGHUA UNIV

Method for removing cyanide through basic Fenton reaction by utilizing ultrasonic catalysis

InactiveCN104386867AReduce investmentImprove reaction efficiencyMultistage water/sewage treatmentActivated charcoal powderActivated carbon

The invention relates to a method for removing cyanide through a basic Fenton reaction by utilizing ultrasonic catalysis. The method comprises the following specific steps: (1) adding an enough amount of activated carbon powder into waste water, wherein the addition amount of the activated carbon powder is 0.7 weight percent of the weight of the waste water; (2) after the activated carbon powder adsorbs a great number of impurities in the water, filtering the waste water, and then injecting the waste water into an ultrasonic reactor; (3) performing ultrasonic crushing reaction, wherein the sound energy density of an ultrasonic wave is 0.1-0.3 w / m<3>; (4) after the reaction is performed for 20-40 minutes, adding ferrous ion salt and H2O2 into the ultrasonic reactor, adjusting the PH value to be 8-10, adding a copper oxide as a catalyst, and performing stirring; (5) after the stirring is performed for 2-3 hours, performing sedimentation after the reaction is completed so as to separate the solid liquid and treat the waste water. The method has the advantage that the cyanide in sewage can be more effectively removed by performing ultrasonic treatment and then adding the copper oxide into the basic Fenton reaction.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

Method for making fertilizer from sludge in sewage treatment plant

InactiveCN106831025ASludge treatment by de-watering/drying/thickeningBio-organic fraction processingSound energy densityUltrasonic radiation

The invention relates to a method for making a fertilizer from sludge in a sewage treatment plant. The method comprises the following steps: 1) performing ultrasonic radiation on sludge in the sewage treatment plant for 30-90 minutes, wherein the sound energy density of the ultrasonic waves is 0.5-3w / mL; 2) mixing the sludge subjected to ultrasonic radiation and saw dust according to a volume ratio of 10:1; 3) putting earthworms into the surface of the mixed sludge, wherein the quantity of the earthworms put into the sludge per cubic meter is 3000-6000, and maintaining for 3-15 days; 4) airing the sludge treated by the earthworms until the moisture content is 40-50%; and 5) screening the aired sludge, and removing large particle impurities. According to the method, an organic fertilizer can be obtained by treating the sludge treated by municipal wastewater.

Owner:SUZHOU RUNHONG TRADING

Method for improving dewatering performance of concentrated sludge

InactiveCN110054394AAchieve stabilizationImprove dehydration effectSludge treatment by oxidationWater treatment compoundsParticulatesAcetic acid

The invention discloses a method for improving the dewatering performance of concentrated sludge, and relates to the technical field of sludge dewatering. The method includes the steps: a, feeding sulfuric acid into the sludge, adjusting the PH (potential of hydrogen) of the sludge to be 3-3.5, feeding flocculating agents into the sludge and flocculating sludge particulates; b, adding surfactants,performing low-speed stirring for 7-9 minutes, adding hydrogen peroxide mixed solution, performing oxidization for 34-36 minutes and finishing primary dewatering of the sludge by a vacuum filter; c,adding hydrolytic acidification bacteria into the sludge subjected to primary dewatering in the step b under the condition of 33-35 DEG C, increasing temperature to 53-55 DEG C, adding acetogenic bacteria and methanogenic bacteria, degrading organic substances in the sludge and then feeding calcined lime and walnut shells; d, treating the sludge in the step c by ultrasonic waves with the power of11.5-12W / L. Ultrasonic time is 125-130 seconds, sound energy density is 0.14-0.15W / mL, the regulated sludge to be dewatered is conveyed to a centrifugal dehydrator, secondary dewatering treatment is finished, and the sludge can be dewatered.

Owner:NANJING JIANGDAO INST OF ENVIRONMENT RES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com