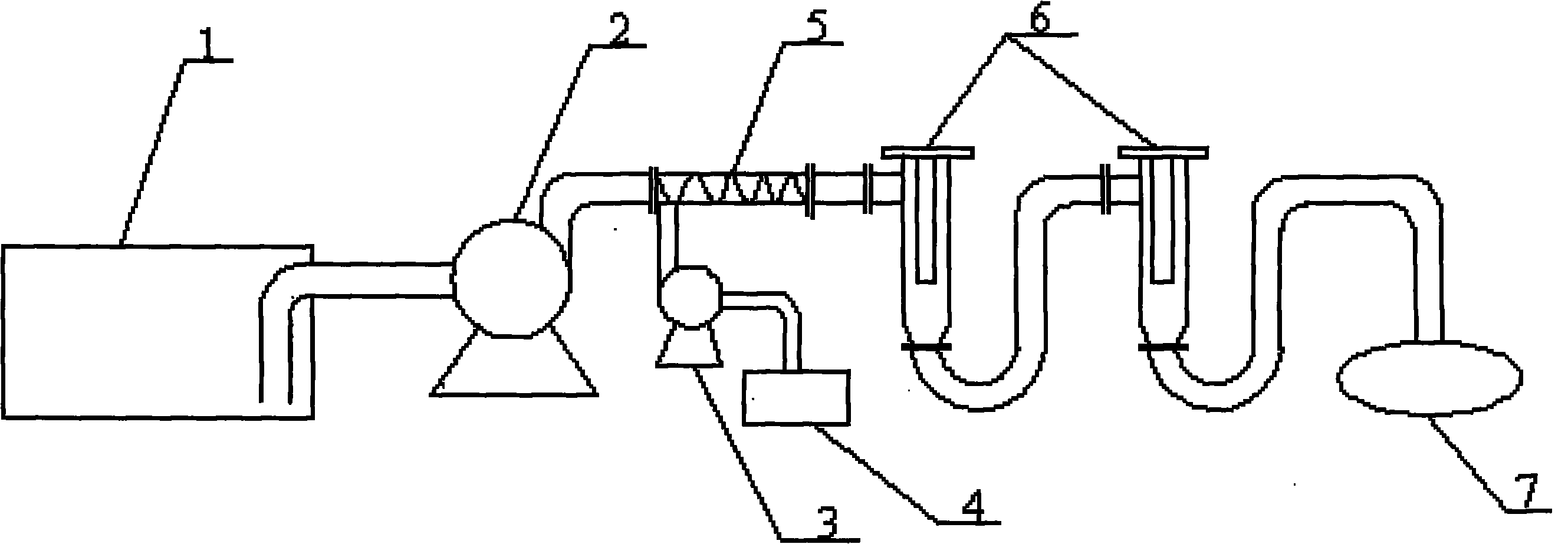

New ultrasound-assisted sludge dewatering system

A sludge dewatering and ultrasonic technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of difficult sludge dehydration, low efficiency, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The remaining sludge of a sewage treatment plant in Tianjin has a water content of 98.1%. The sludge is transported to the sealed pipeline by a mud pump with a flow rate of 200m 3 / h, use a metering pump to add a cationic polyacrylamide flocculant solution with a concentration of 5‰ (weight ratio) to the mixture, the ultrasonic generating device will not start, that is, no ultrasonic action will be applied, and the geotechnical tube bag will be dehydrated and consolidated for 10 days after it is filled. , The average moisture content of the sludge is 56%.

Embodiment 2

[0021] The dosage of flocculant is changed to 4‰ (weight ratio), and the ultrasonic generator is turned on. After the sludge is added with flocculant, the frequency is 20kHz and the sound intensity is 400W / m 3 , the ultrasonic action of sound energy density 0.3W / ml, other conditions are the same as embodiment 1, geotechnical tube bag is dewatered and consolidated for 10 days, and the moisture content of sludge is 48%. The reduction without sonication was 8%.

Embodiment 3

[0023] The amount of flocculant dosage and ultrasonic conditions are the same as in Example 2, and the dehydration and consolidation time of the geotube bag is changed to 7 days, the moisture content of the sludge is 53%, the consolidation time is reduced by three days, and the amount of flocculant used is reduced by 1‰ , the moisture content was reduced by 3% compared with that without ultrasonic treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com