Patents

Literature

904 results about "Sound energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, sound energy is a form of energy. Sound is a mechanical wave and as such consists physically in oscillatory elastic compression and in oscillatory displacement of a fluid. Therefore, the medium acts as storage for both potential and kinetic energy. Consequently, the sound energy in a volume of interest is defined as the sum of the potential and kinetic energy densities integrated over that volume: W=Wₚₒₜₑₙₜᵢₐₗ+Wₖᵢₙₑₜᵢc=∫Vp²/2ρ₀c² dV+∫Vρv²/2 dV, Here: V is the volume of interest; p is the sound pressure; v is the particle velocity; ρ₀ is the density of the medium without sound present; ρ is the local density of the medium; c is the speed of sound.

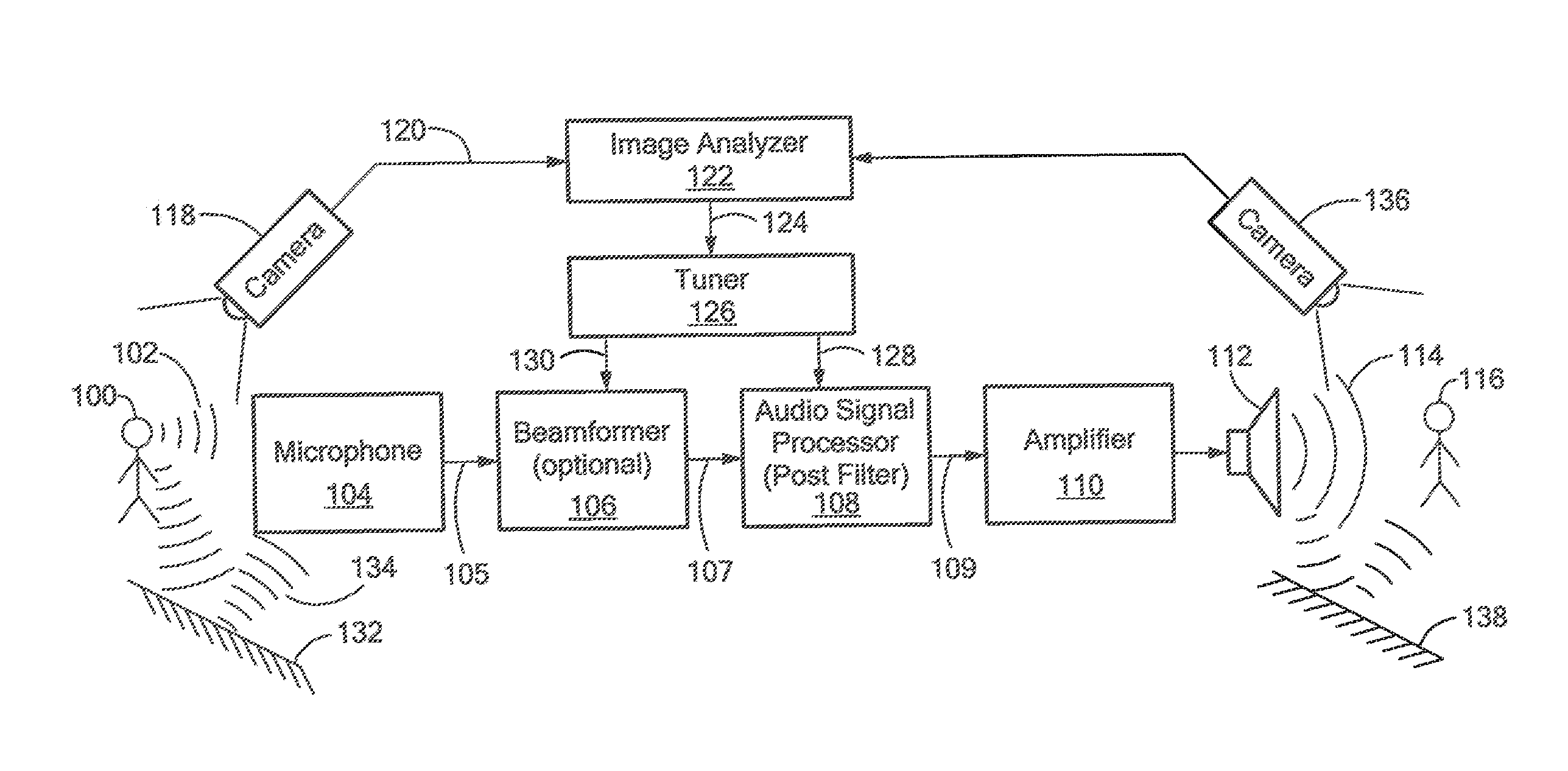

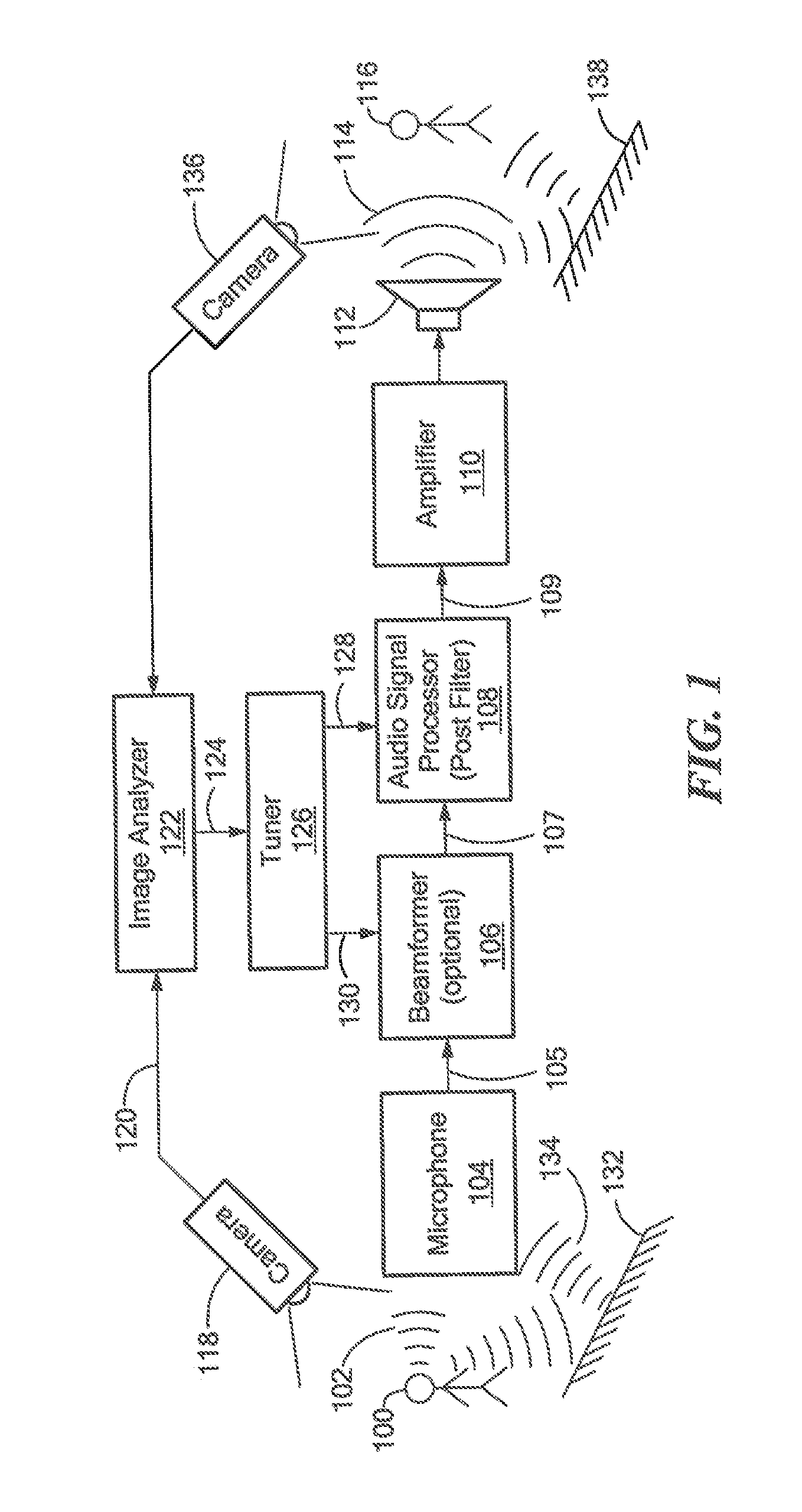

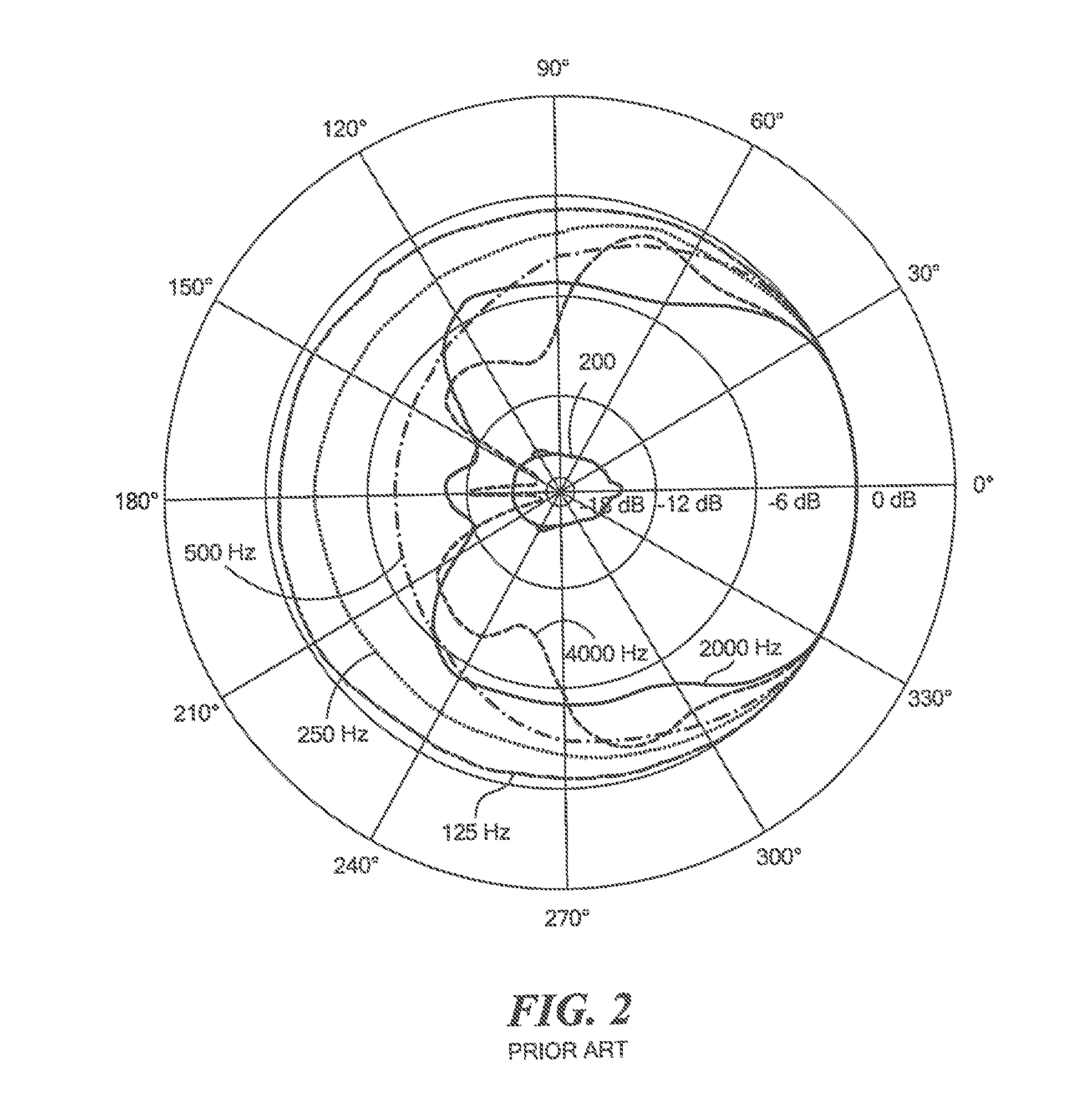

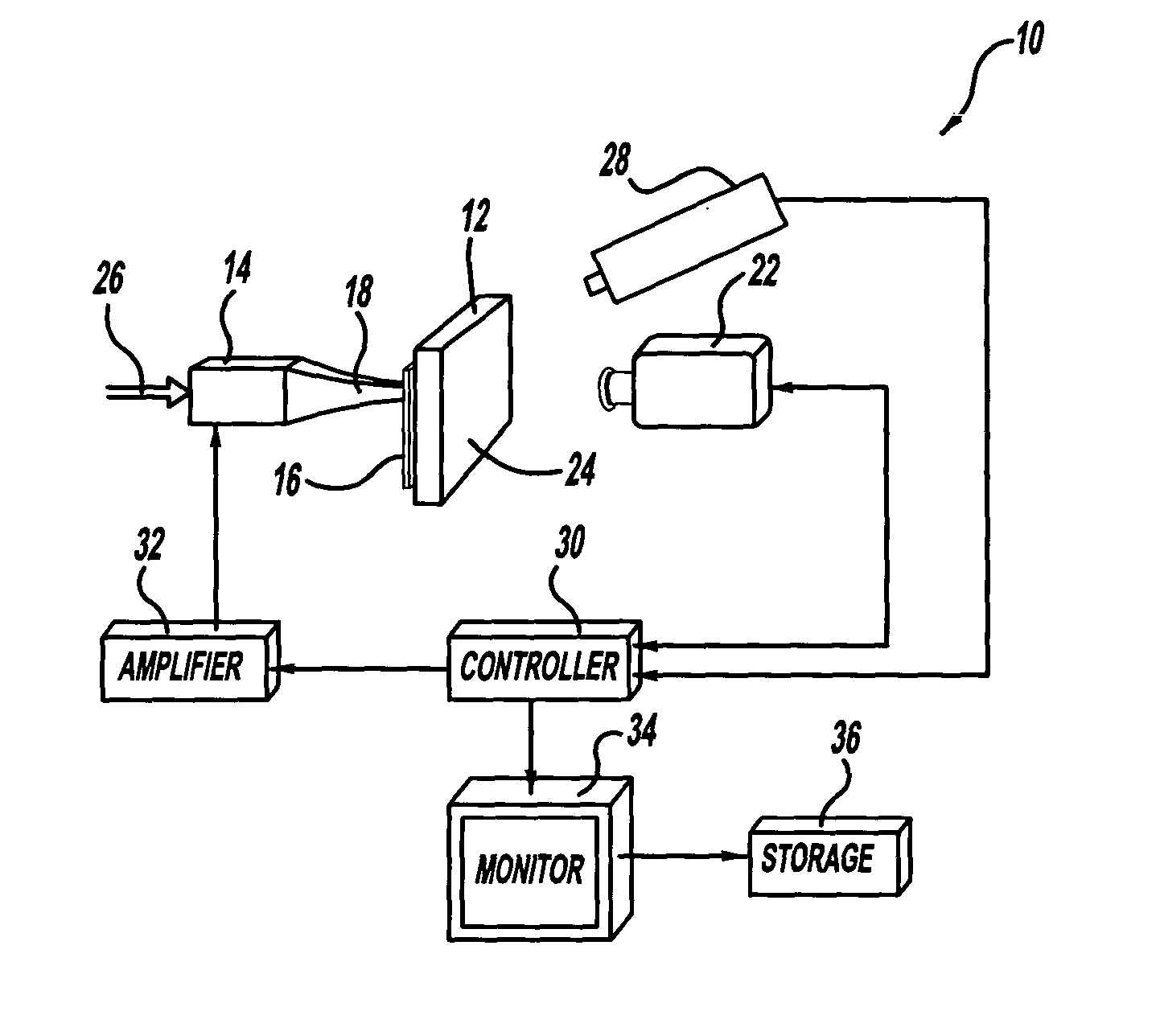

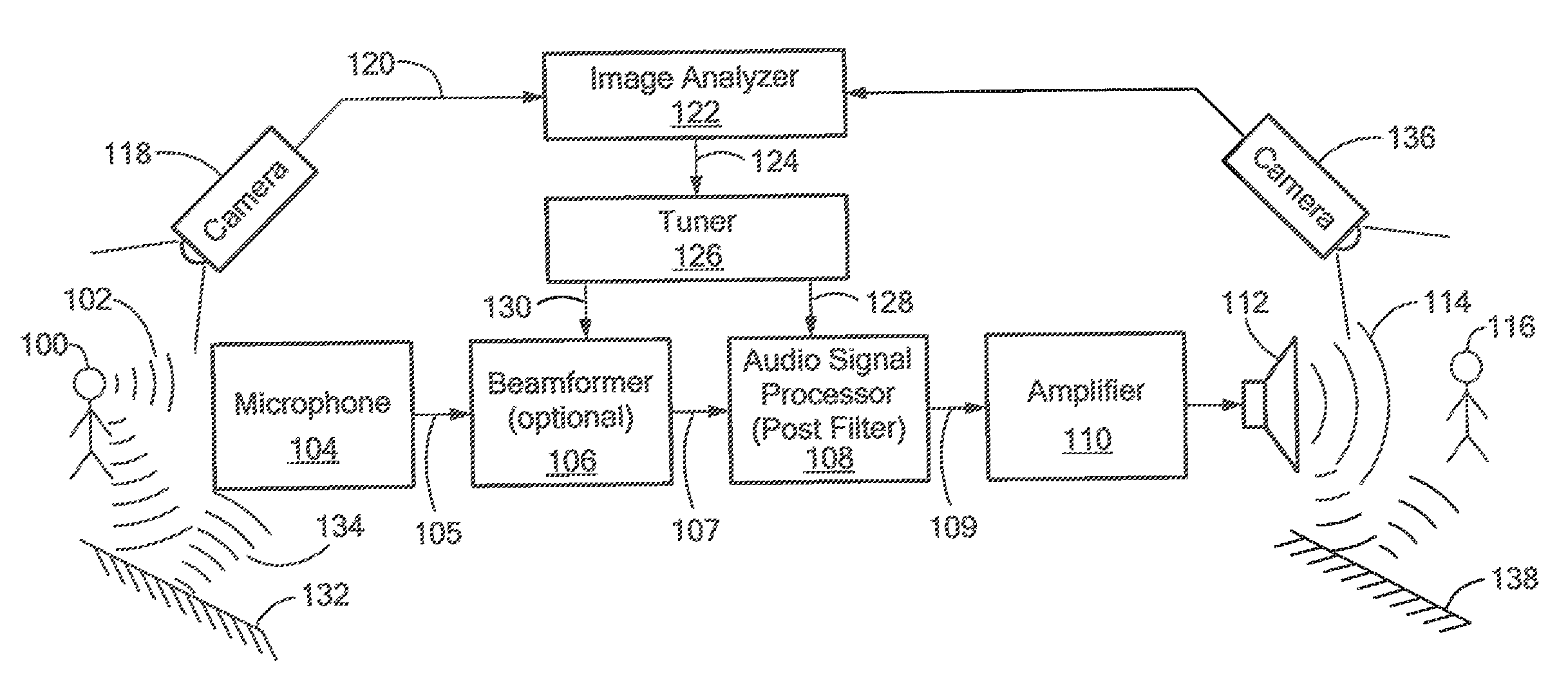

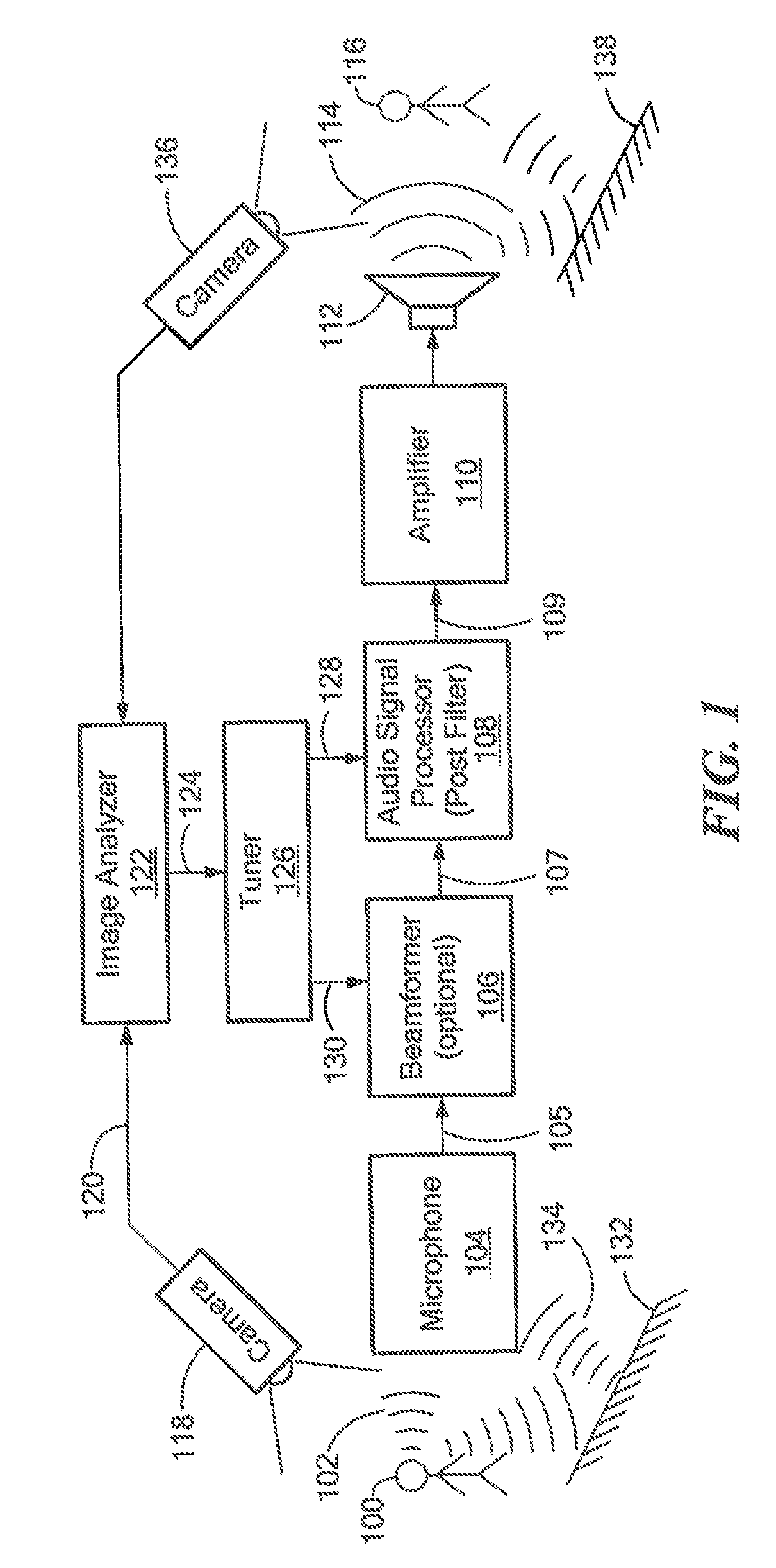

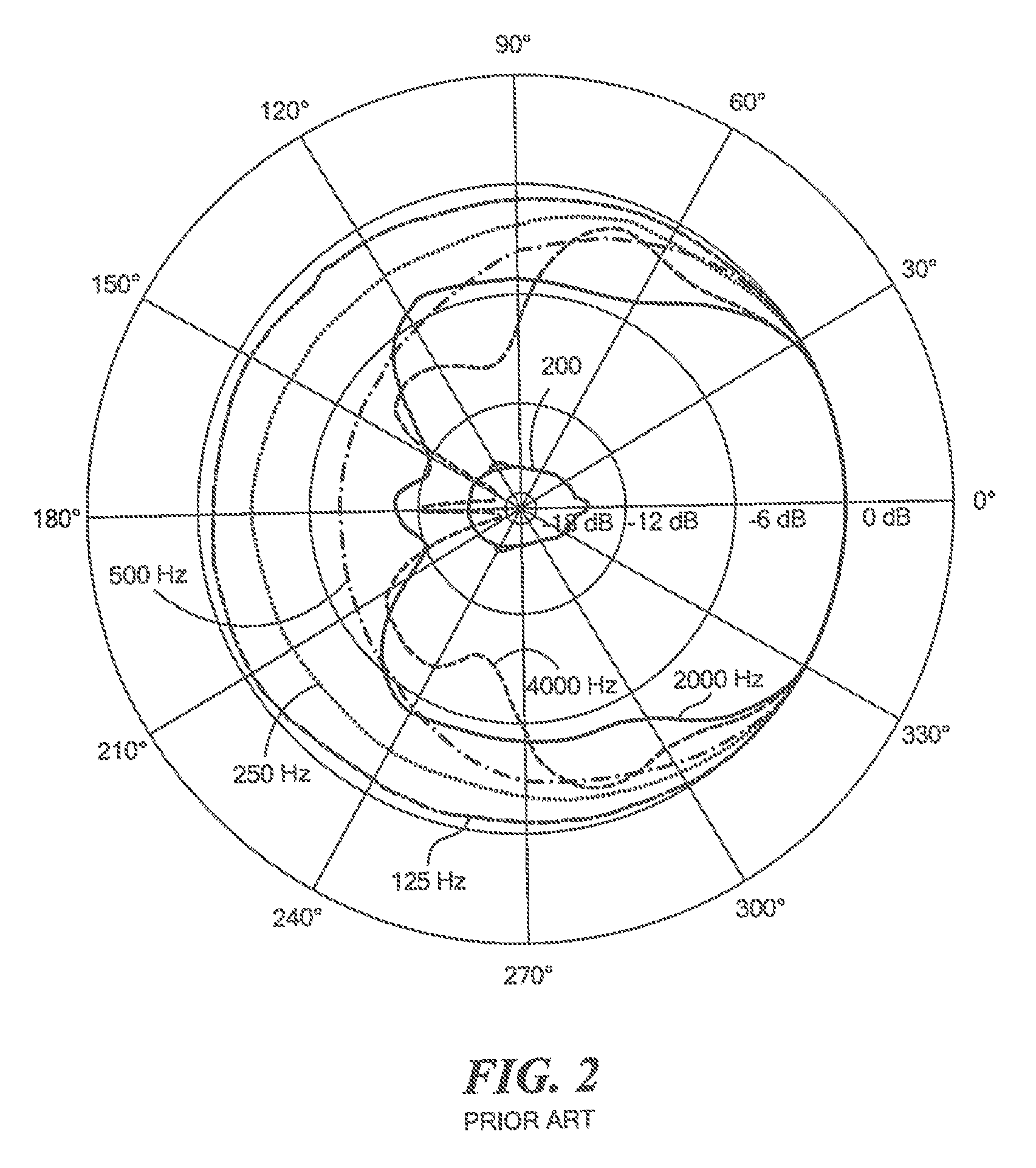

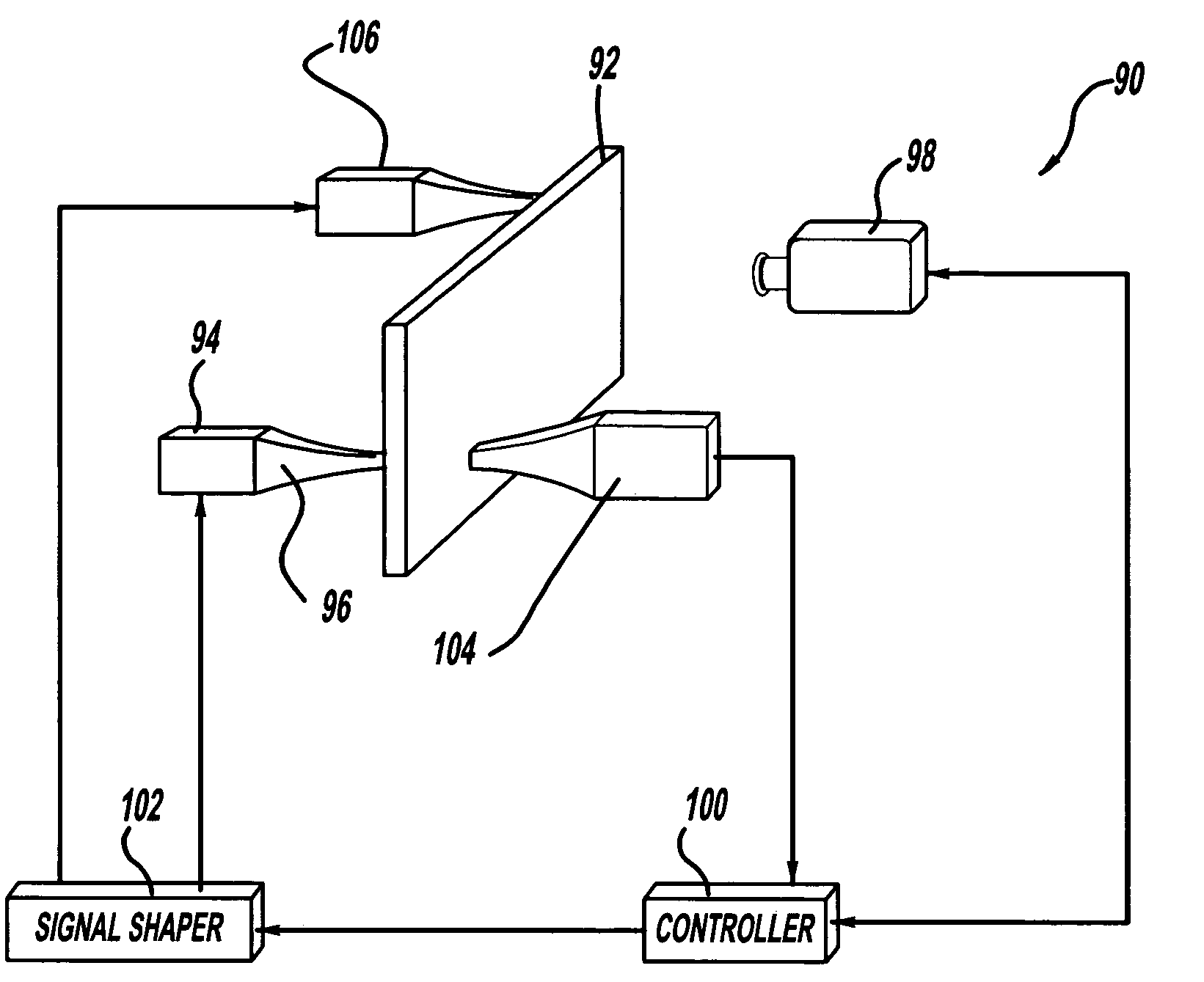

Speech Signal Enhancement Using Visual Information

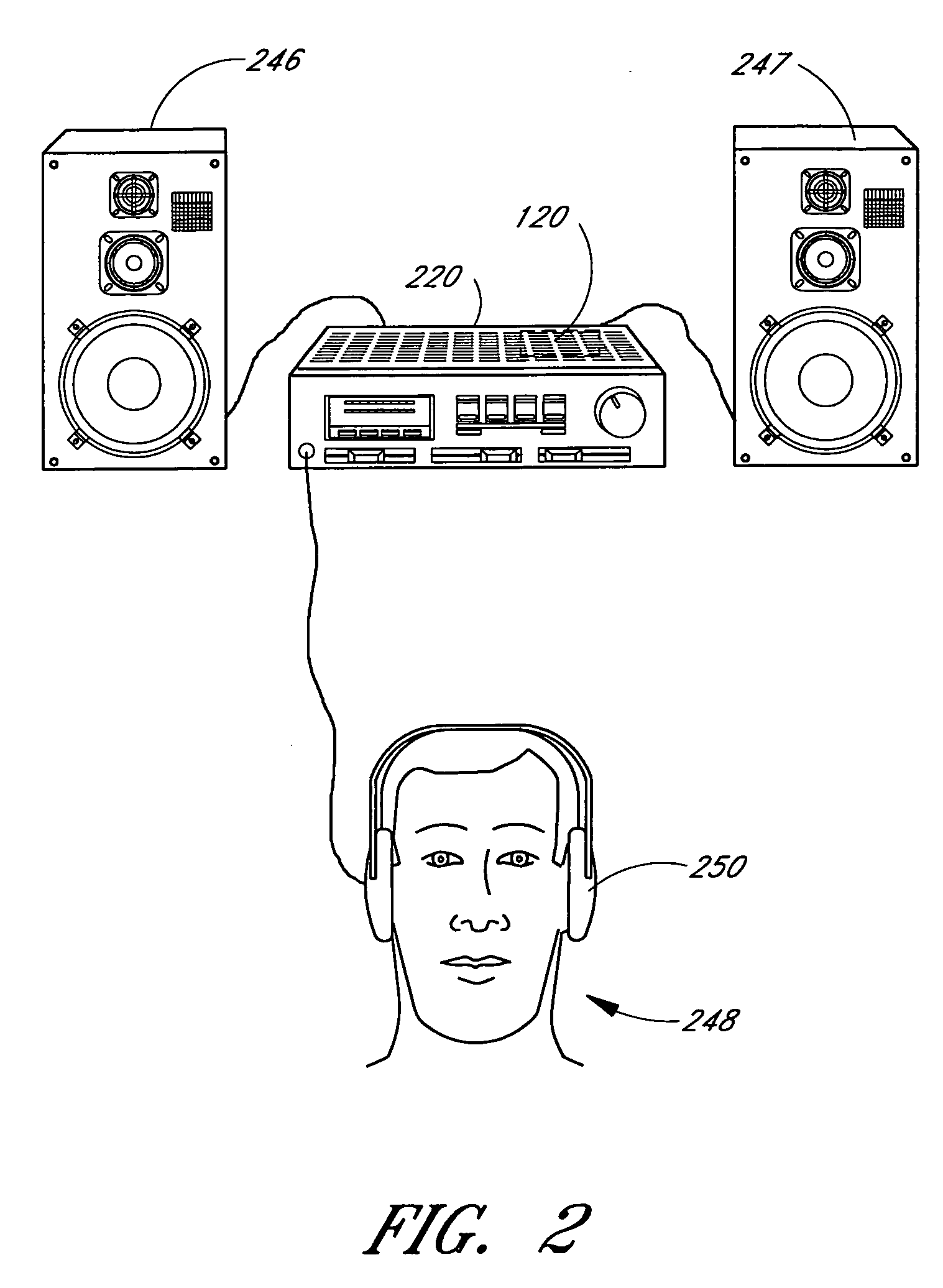

Visual information is used to alter or set an operating parameter of an audio signal processor, other than a beamformer. A digital camera captures visual information about a scene that includes a human speaker and / or a listener. The visual information is analyzed to ascertain information about acoustics of a room. A distance between the speaker and a microphone may be estimated, and this distance estimate may be used to adjust an overall gain of the system. Distances among, and locations of, the speaker, the listener, the microphone, a loudspeaker and / or a sound-reflecting surface may be estimated. These estimates may be used to estimate reverberations within the room and adjust aggressiveness of an anti-reverberation filter, based on an estimated ratio of direct to indirect (reverberated) sound energy expected to reach the microphone. In addition, orientation of the speaker or the listener, relative to the microphone or the loudspeaker, can also be estimated, and this estimate may be used to adjust frequency-dependent filter weights to compensate for uneven frequency propagation of acoustic signals from a mouth, or to a human ear, about a human head.

Owner:CERENCE OPERATING CO

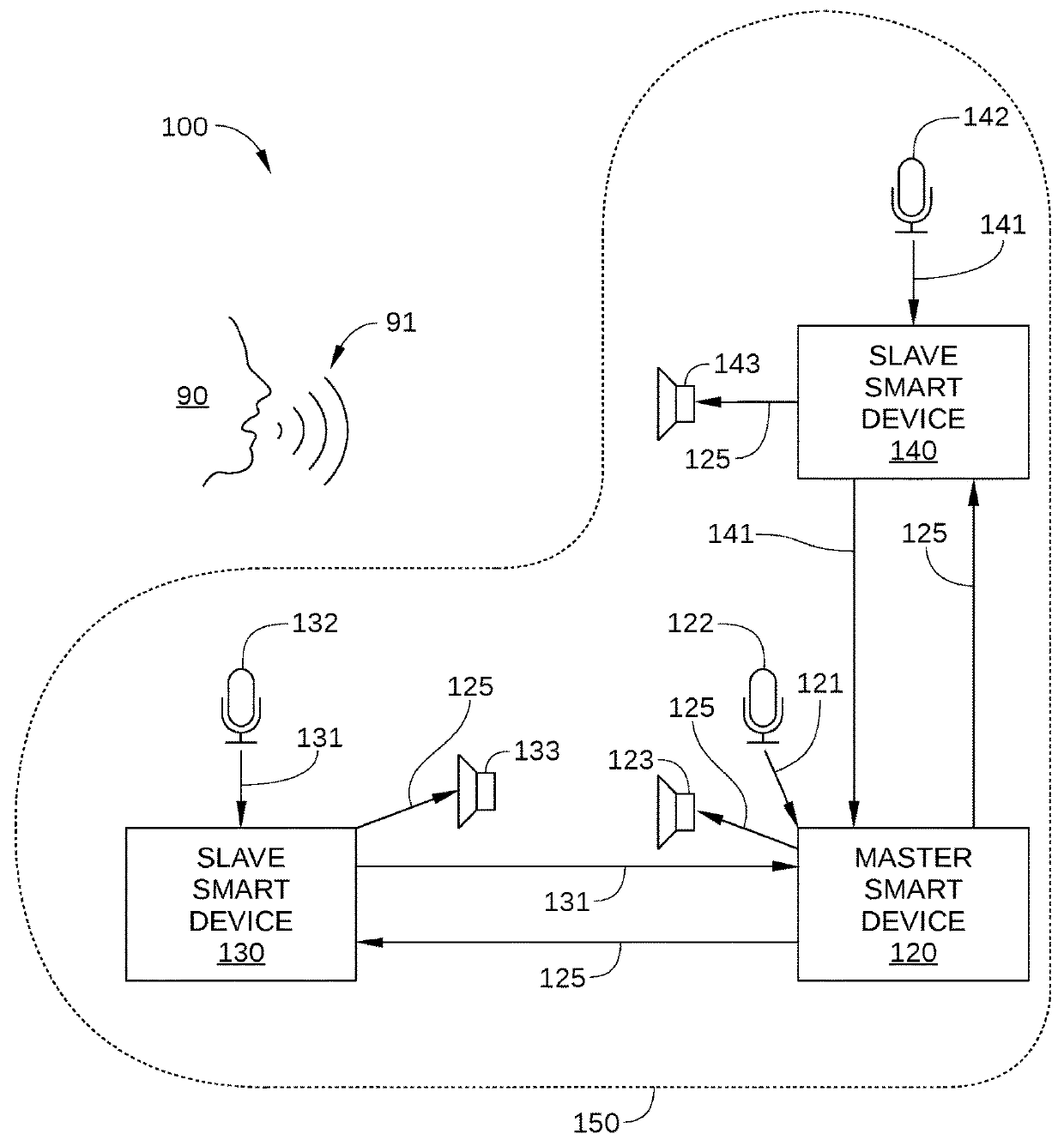

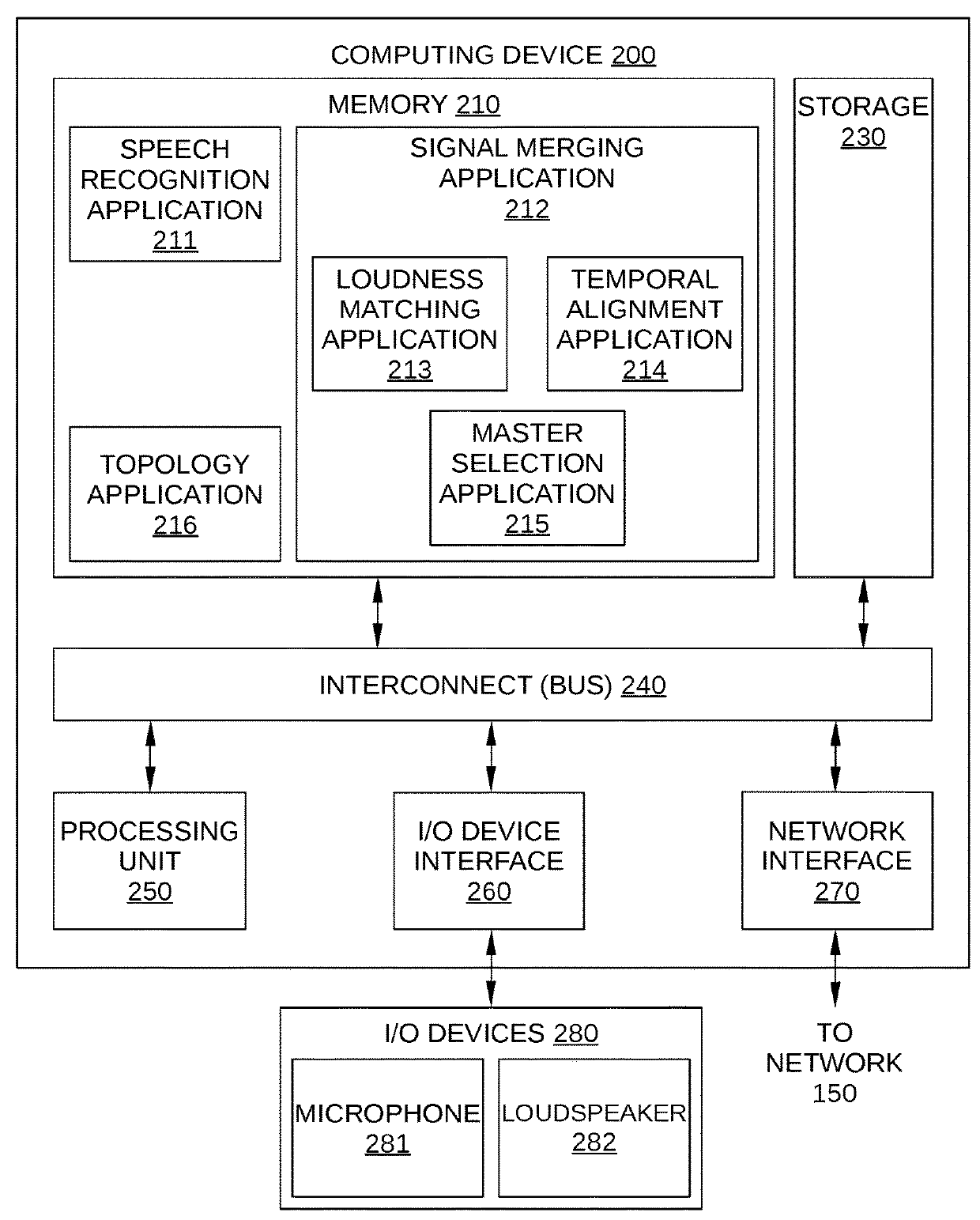

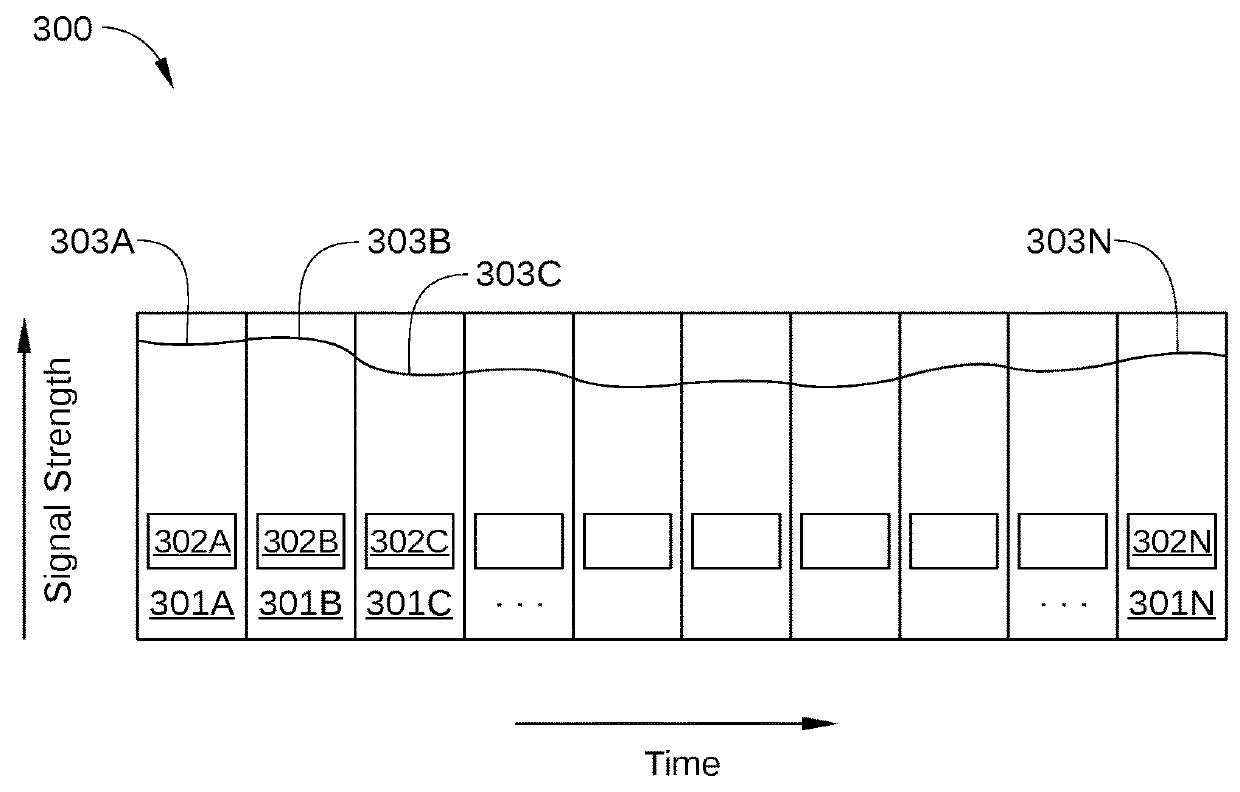

Execution of voice commands in a multi-device system

ActiveUS20180277107A1Speech recognitionInput/output processes for data processingSound energySpeech identification

Performing speech recognition in a multi-device system includes receiving a first audio signal that is generated by a first microphone in response to a verbal utterance, and a second audio signal that is generated by a second microphone in response to the verbal utterance; dividing the first audio signal into a first sequence of temporal segments; dividing the second audio signal into a second sequence of temporal segments; comparing a sound energy level associated with a first temporal segment of the first sequence to a sound energy level associated with a first temporal segment of the second sequence; based on the comparing, selecting, as a first temporal segment of a speech recognition audio signal, one of the first temporal segment of the first sequence and the first temporal segment of the second sequence; and performing speech recognition on the speech recognition audio signal.

Owner:HARMAN INT IND INC

Acoustic correction apparatus

InactiveUS20060126851A1Improve performanceIncrease in sizeHeadphones for stereophonic communicationFrequency response correctionSound imageSound energy

Owner:DTS

Vibration sensor assembly and method for bark controller

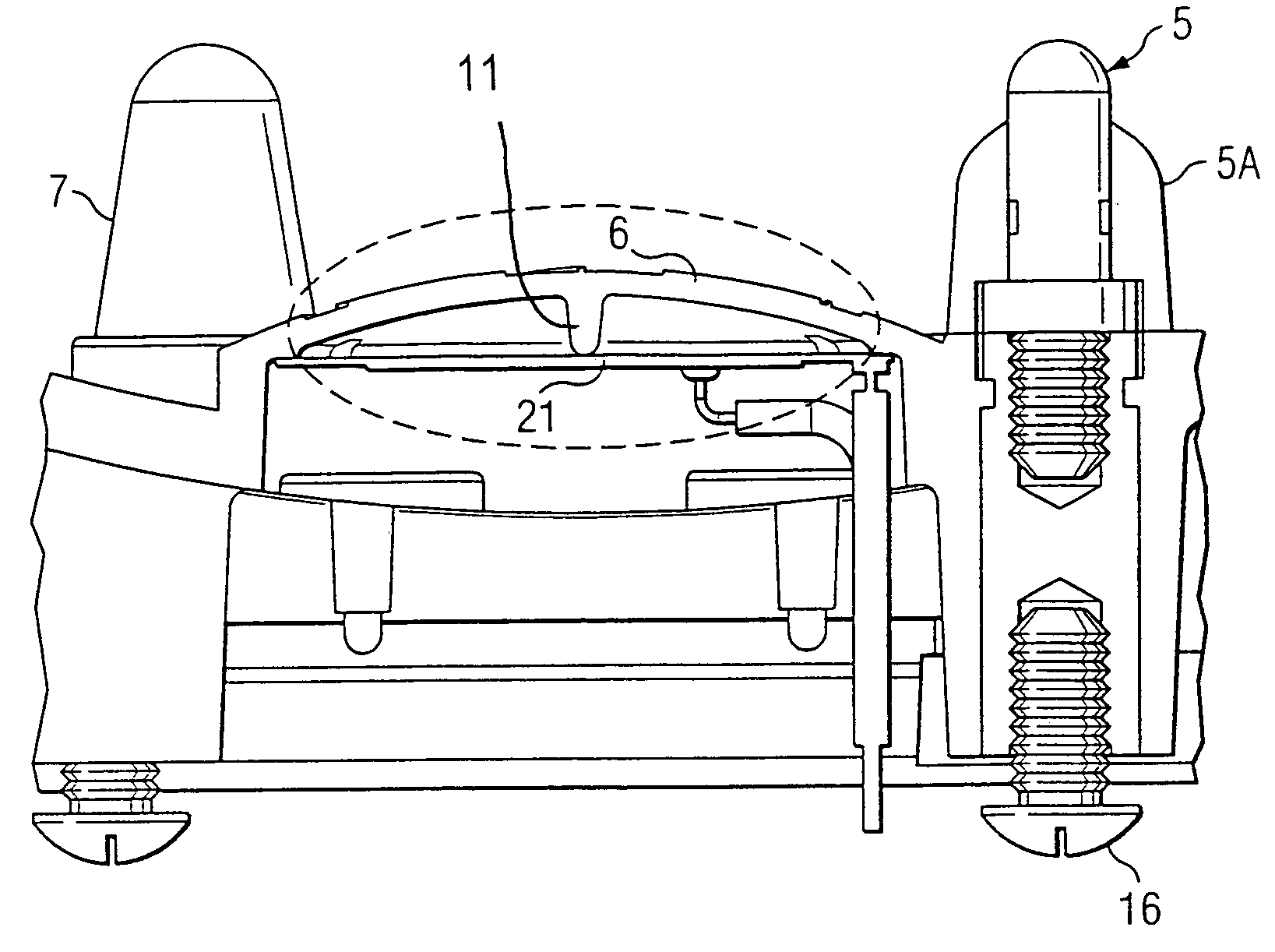

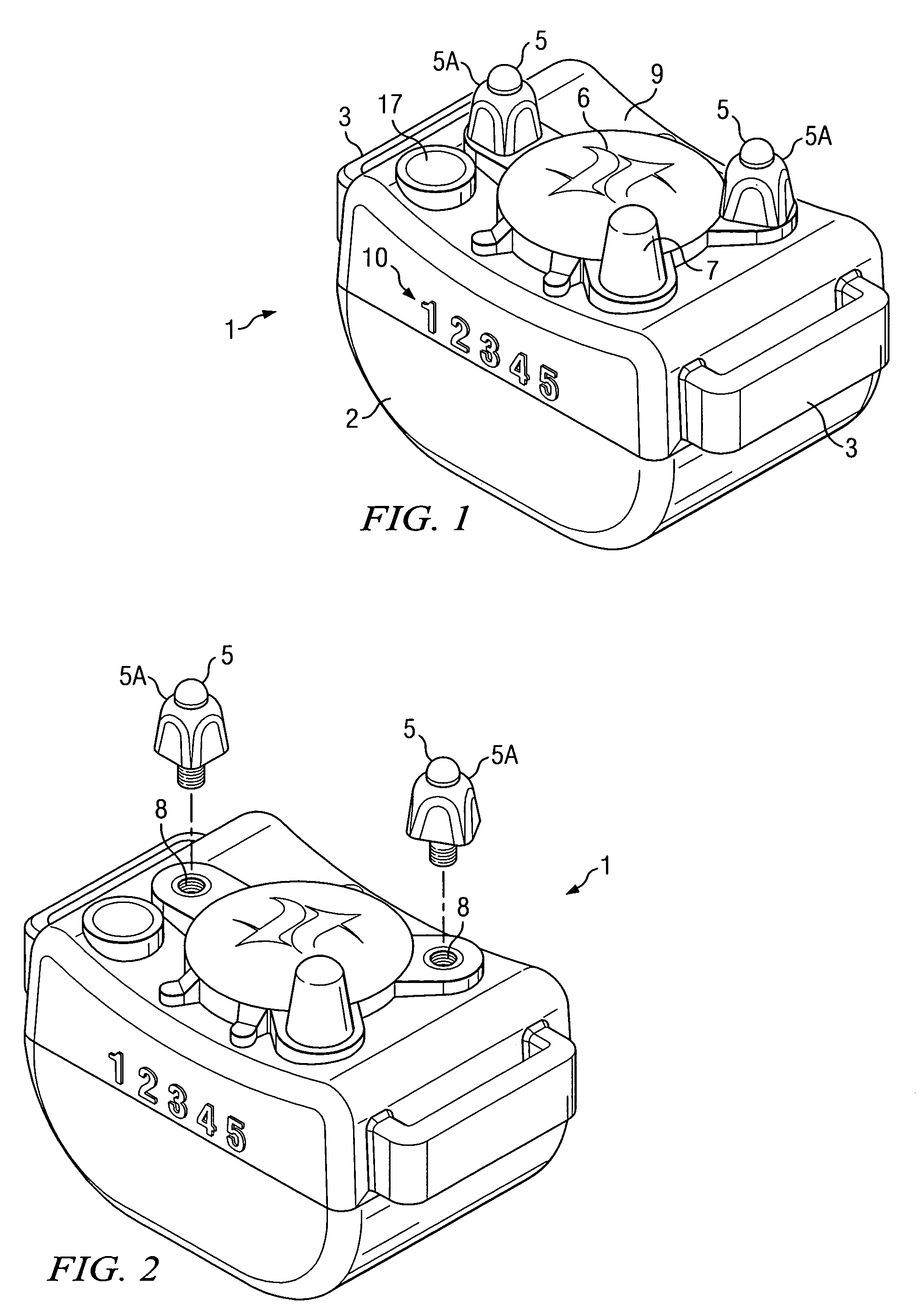

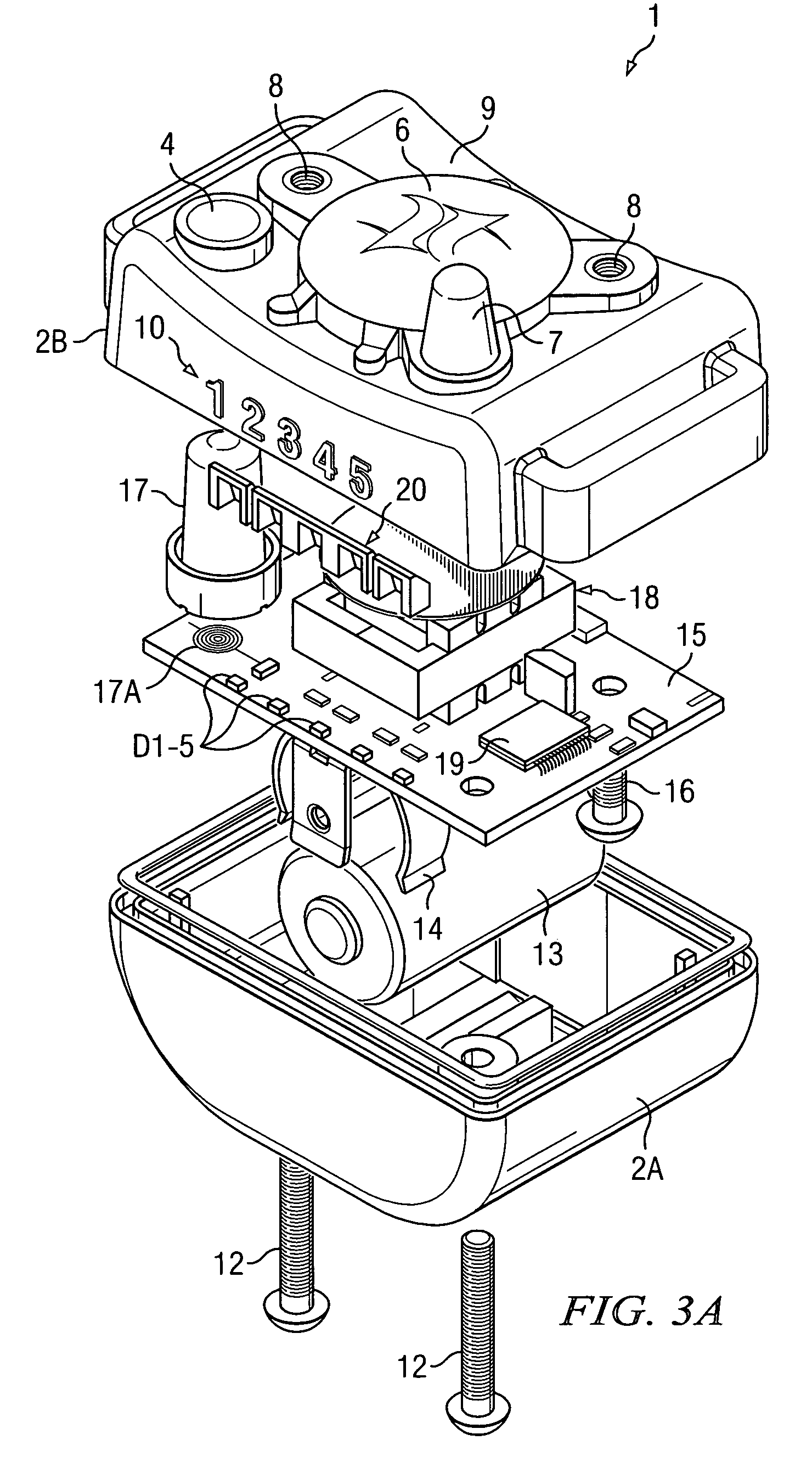

A dog bark limiter includes a housing (2) supported against the dog's skin by a strap, stimulus electrodes (5), and a sensor (6) for producing signals in response to vocalizing by the dog. The sensor includes a membrane (6) supported by the surface (9) for efficiently transmitting sound energy through the housing and a rigid nipple (11) engaging the membrane. Control circuitry in the housing has an input coupled to an output of the transducer and output terminals coupled to produce aversive stimulus signals between the first and second electrodes in response to the signals produced in response valid barking by the dog. A motion detector (40) produces a motion detection signal in response to a characteristic movement of the portion of dog that accompanies barking by the dog and aids in detecting a valid bark. A controller (33) executes a frequency capture routine to produce a frequency spectrum of the dog's vocalizations and compares it with a valid bark spectrum to determine if the vocalization constitutes a valid bark.

Owner:GARMIN

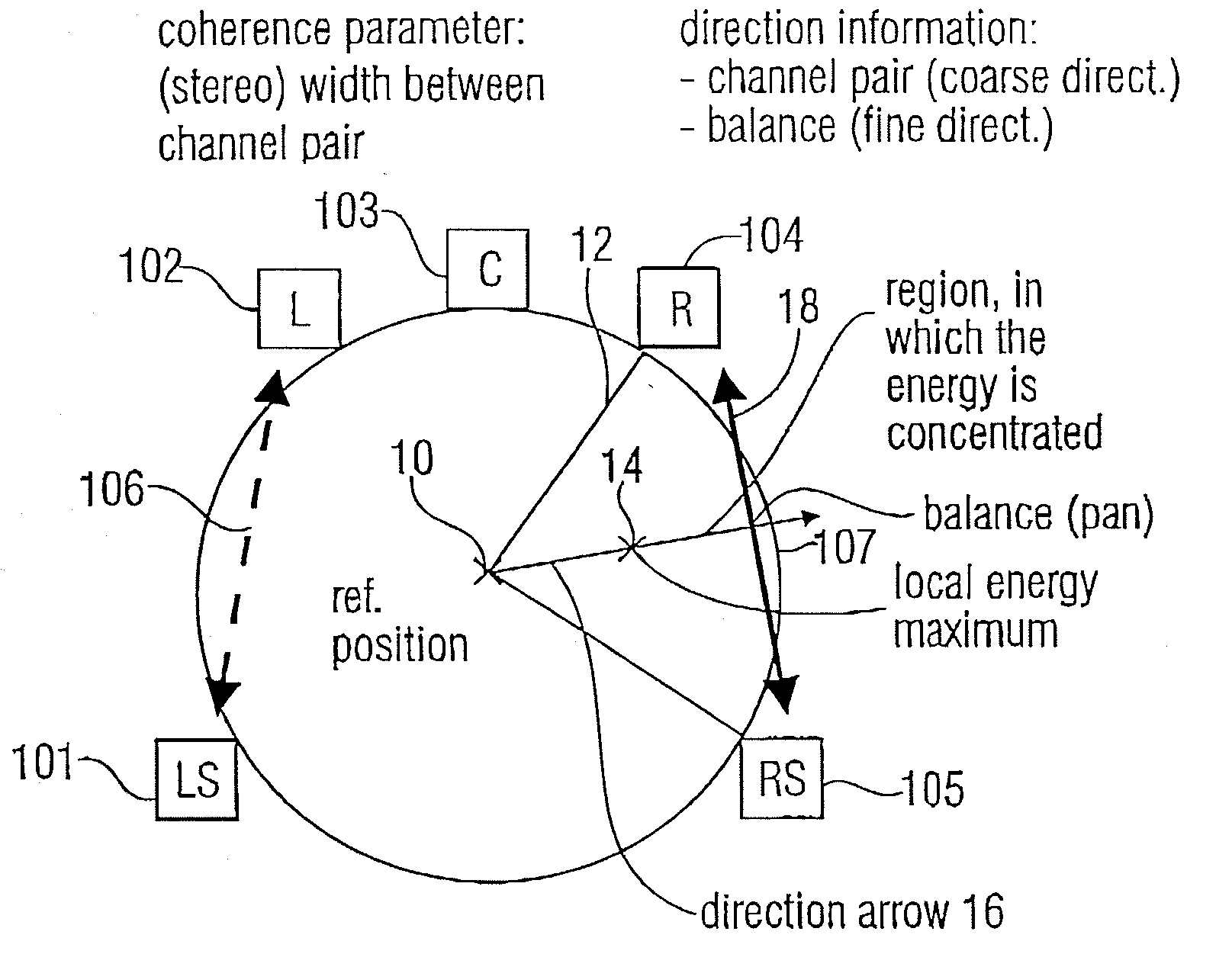

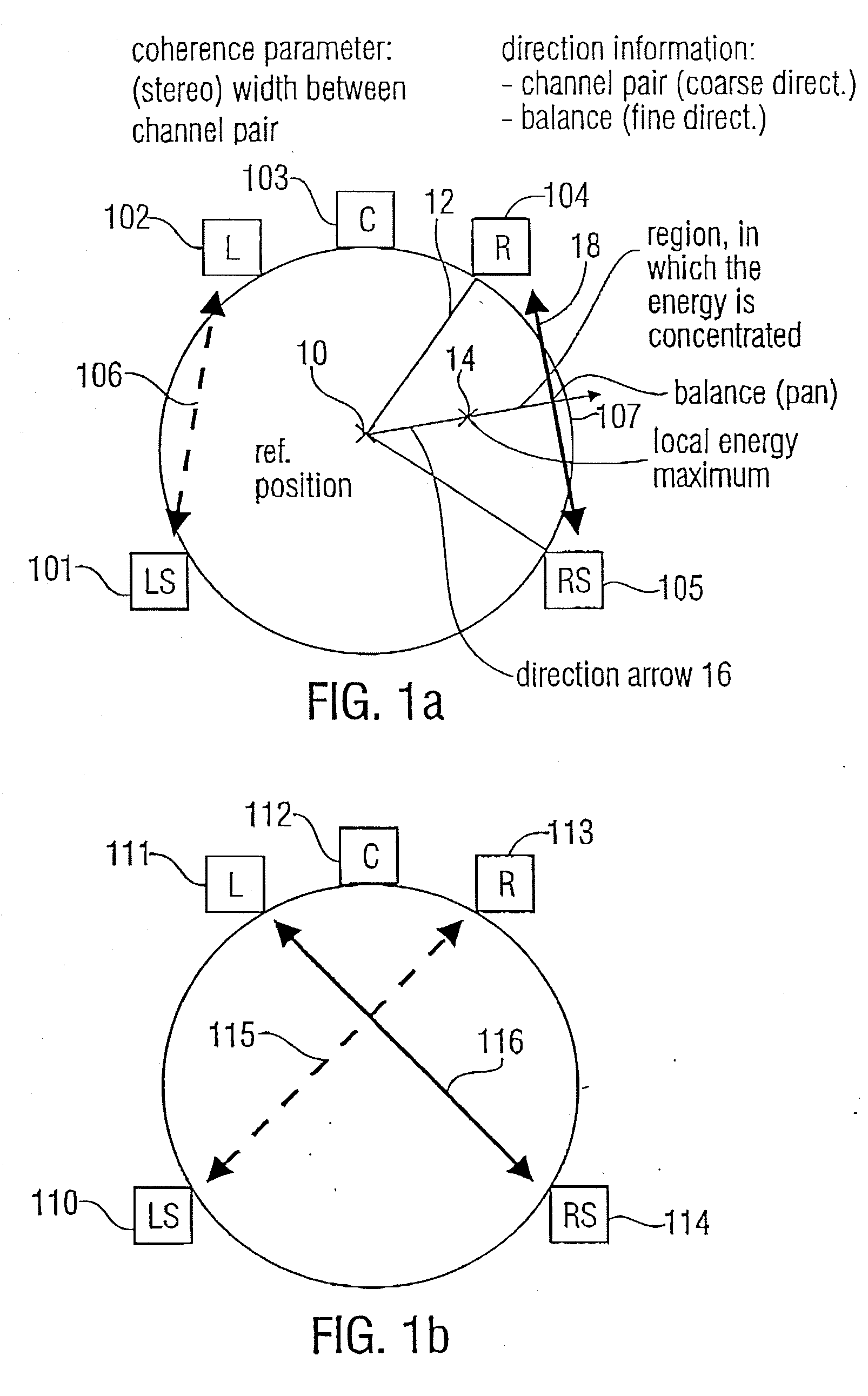

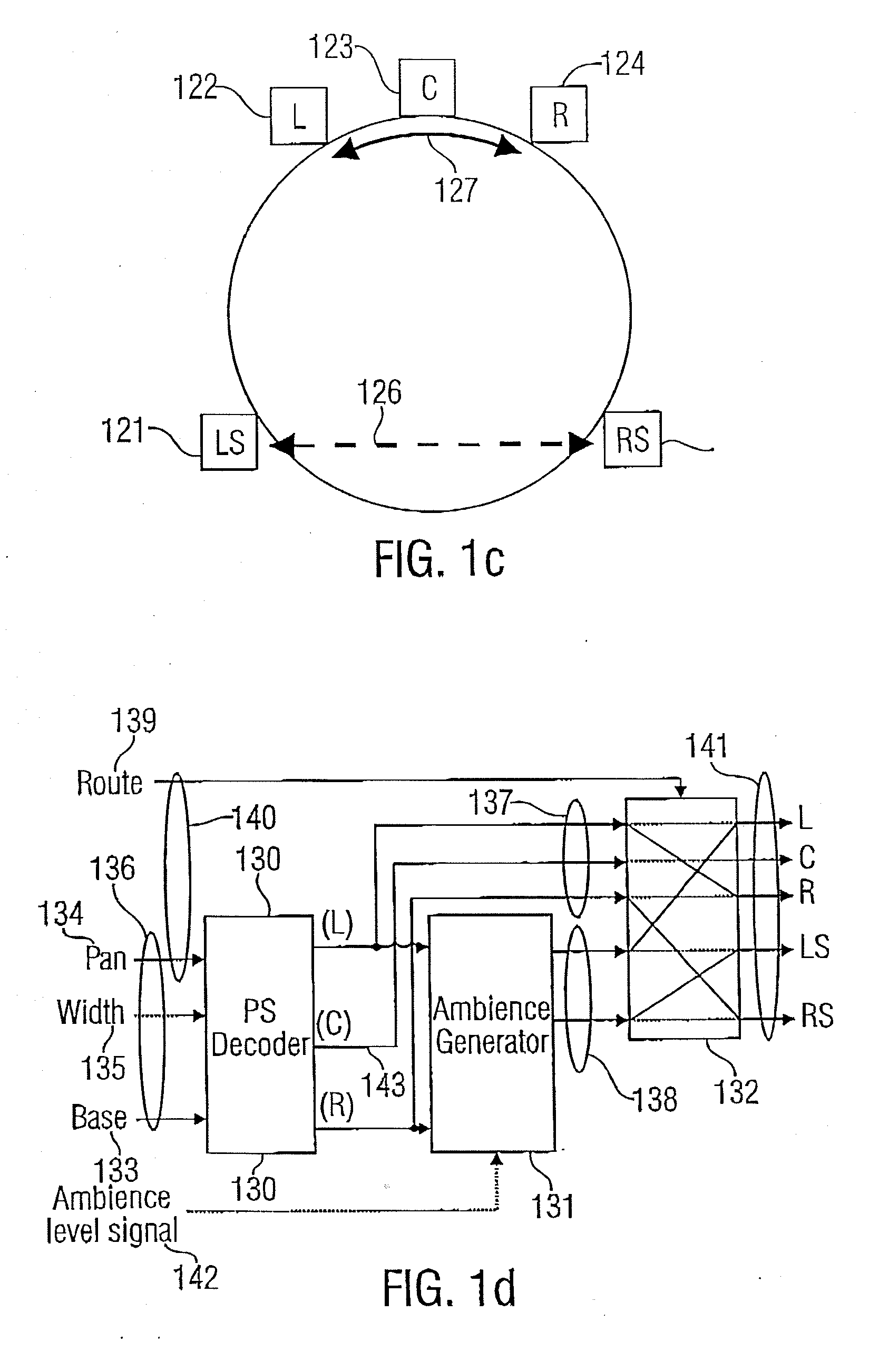

Scheme for Generating a Parametric Representation for Low-Bit Rate Applications

ActiveUS20070127733A1Little informationSpeech analysisBroadcast circuit arrangementsSound energyComputer science

For generating a parametric representation of a multi-channel signal especially suitable for low-bit rate applications, only the location of the maximum of the sound energy within a replay setup is encoded and transmitted using direction parameter information. For multi-channel reconstruction, the energy distribution of the output channels identified by the direction parameter information is controlled by the direction parameter information, while the energy distribution in the remaining ambience channels is not controlled by the direction parameter information.

Owner:DOLBY INT AB

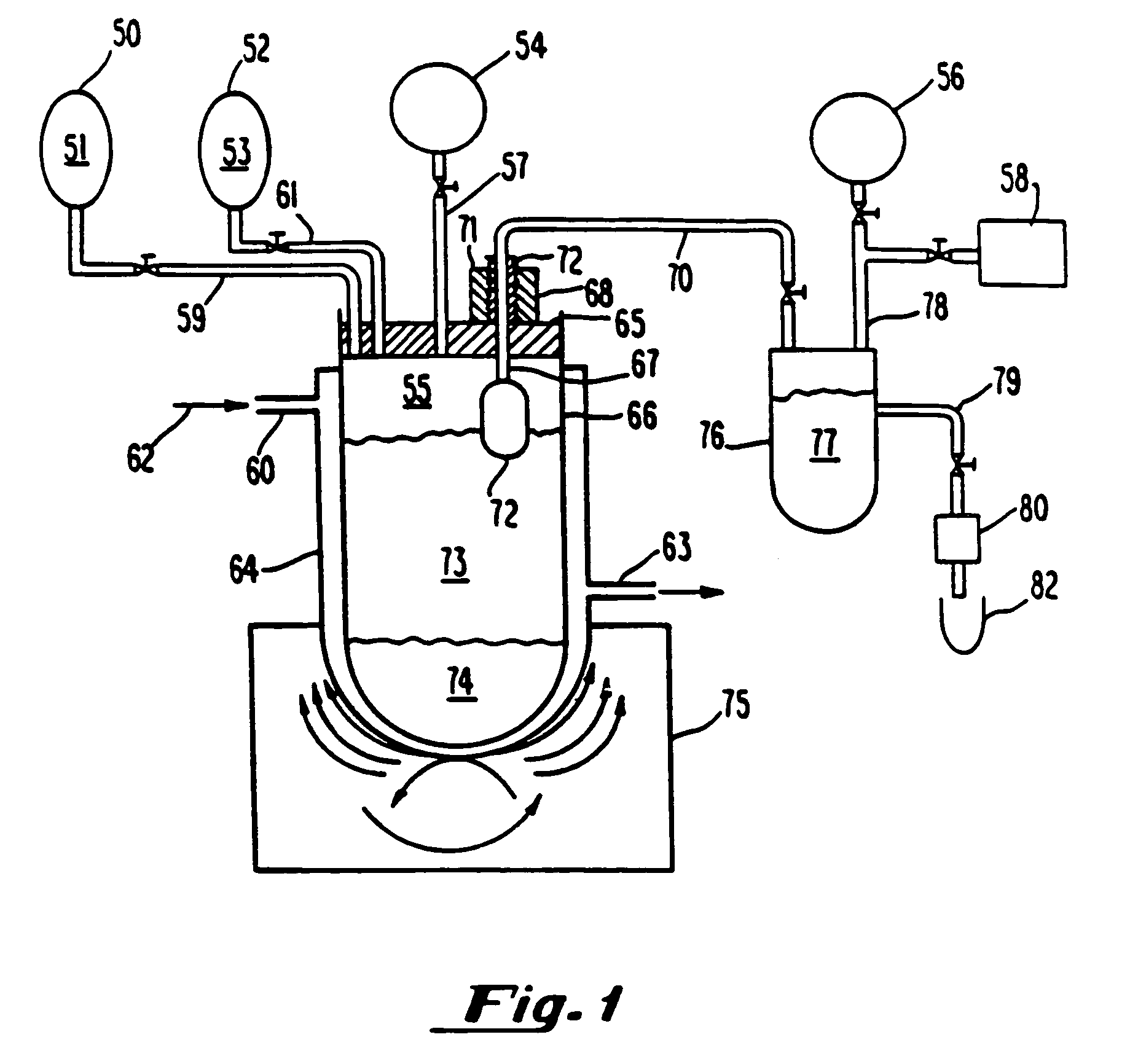

Ultrasound imaging and treatment

InactiveUS7078015B2Low costSuitable for useUltrasonic/sonic/infrasonic diagnosticsCosmetic preparationsSound energyUltrasonic imaging

Methods of and apparatus for preparing temperature activated gaseous precursor-filled liposomes are described. Gaseous precursor-filled liposomes prepared by these methods are particularly usefull for example, in ultrasonic imaging applications and in therapeutic drug delivery systems.Gas, gaseous precursors and perfluorocarbons are presented as novel potentiators for ultrasonic hyper-thermia. The gas, gaseous precursors and perfluorocarbons which may be administered into the vasculature, interstitially or into any body cavity are designed to accumulate in cancerous and diseased tissues. When therapeutic ultrasonic energy is applied to the diseased region heating is increased because of the greater effectiveness of sound energy absorption caused by these agents.

Owner:IMARX THERAPEUTICS

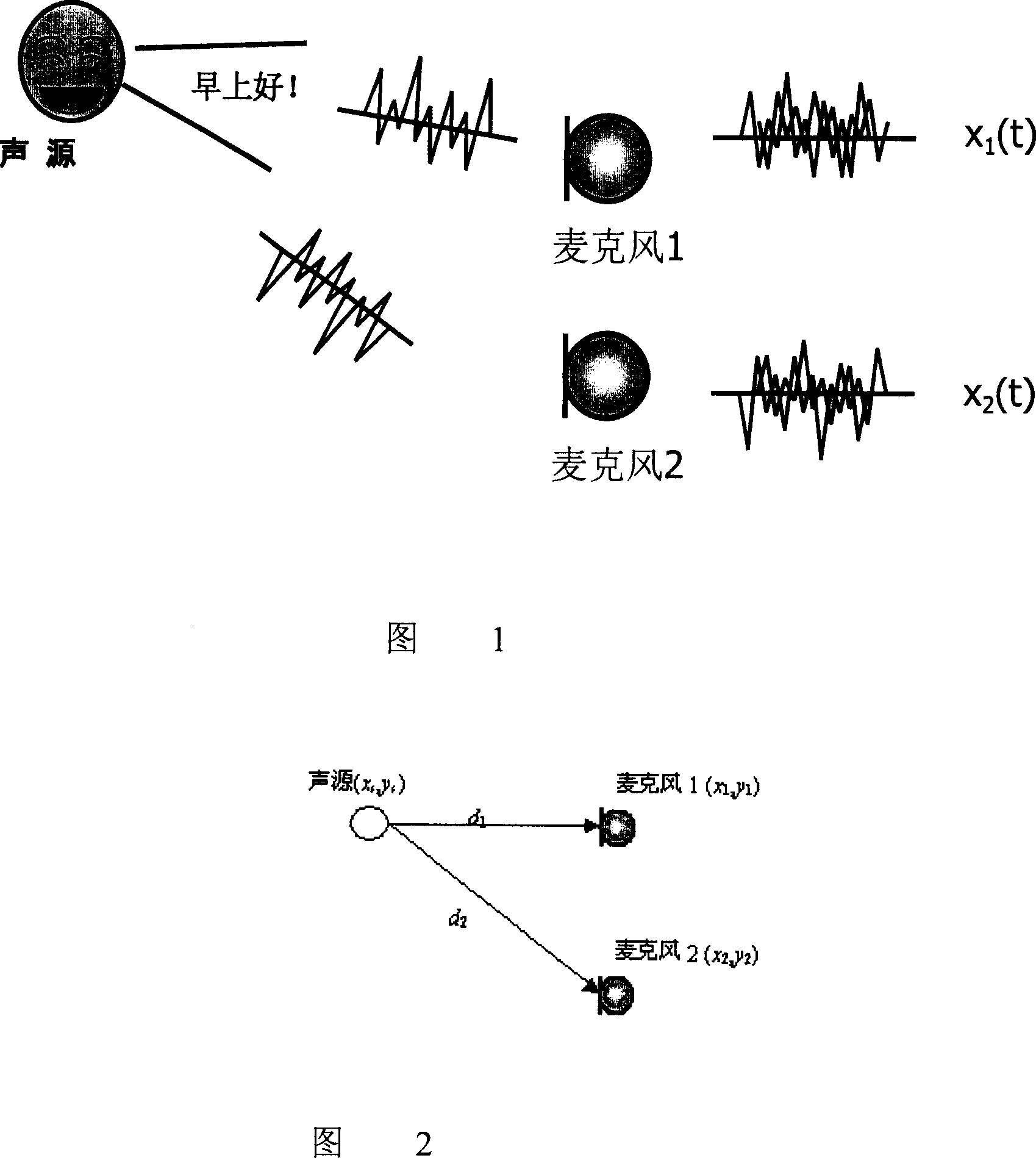

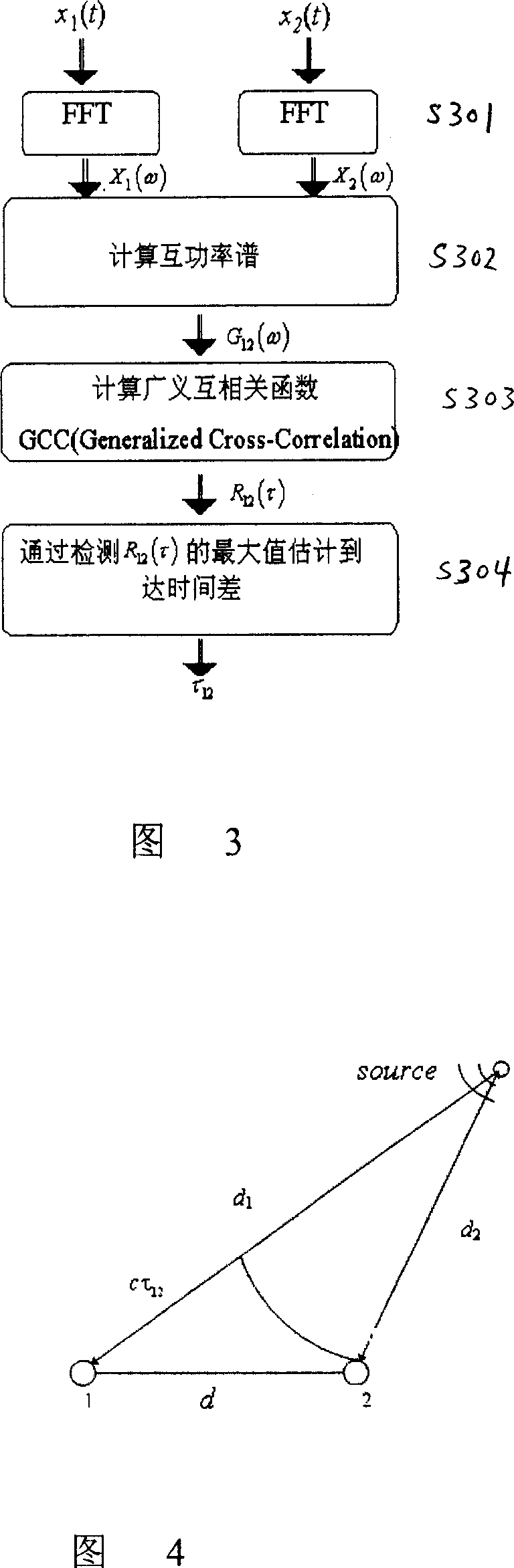

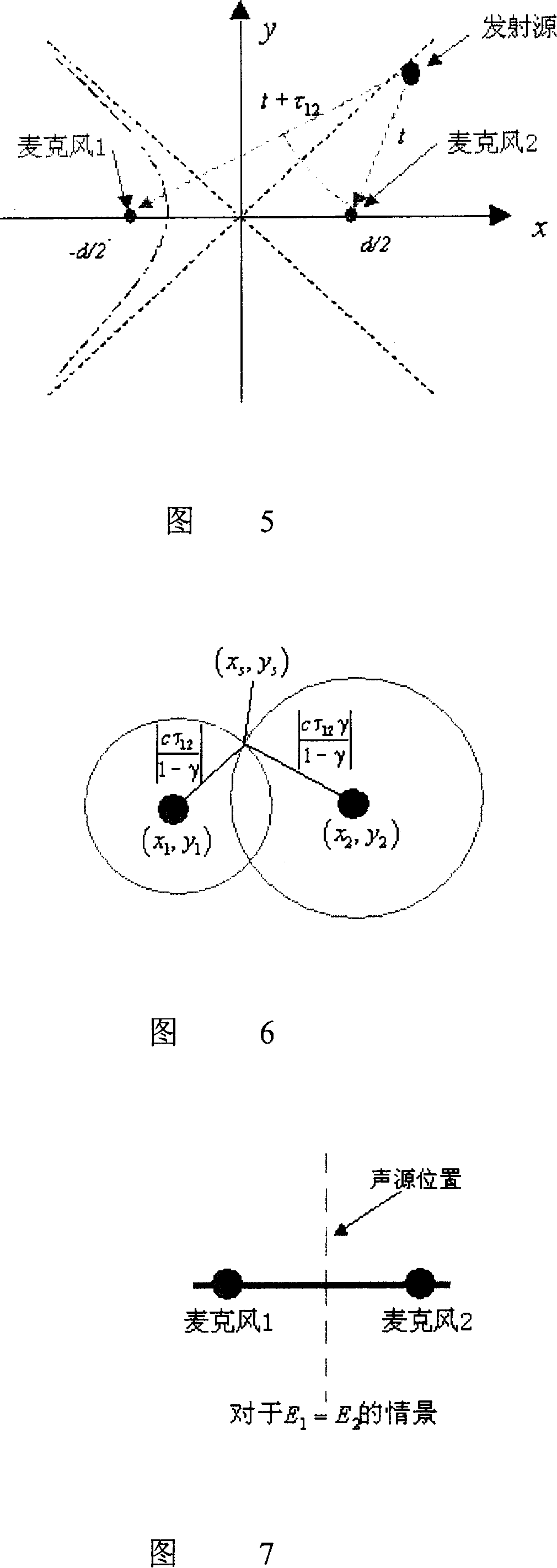

Method and device for localization of sound source by microphone

A method for positioning the location of sound source is disclosed that includes steps: the receiving device receives the sound signal generated by the sound source; provisional estimates the time difference of said sound signals reaching the receiving device; provisional estimates the receiving device separately receives the energy ratio of said sound signals; ascertains the location of the sound source by the time difference and the energy ratio. The method of double micro sound localization is compared to people's double ears position mechanism; the position is located by the sound energy and the time-delay information simultaneously, it can reach the aim of reducing the number of matrix element, and doesn't need to send and receive the type-specific reference signal.

Owner:PANASONIC CORP

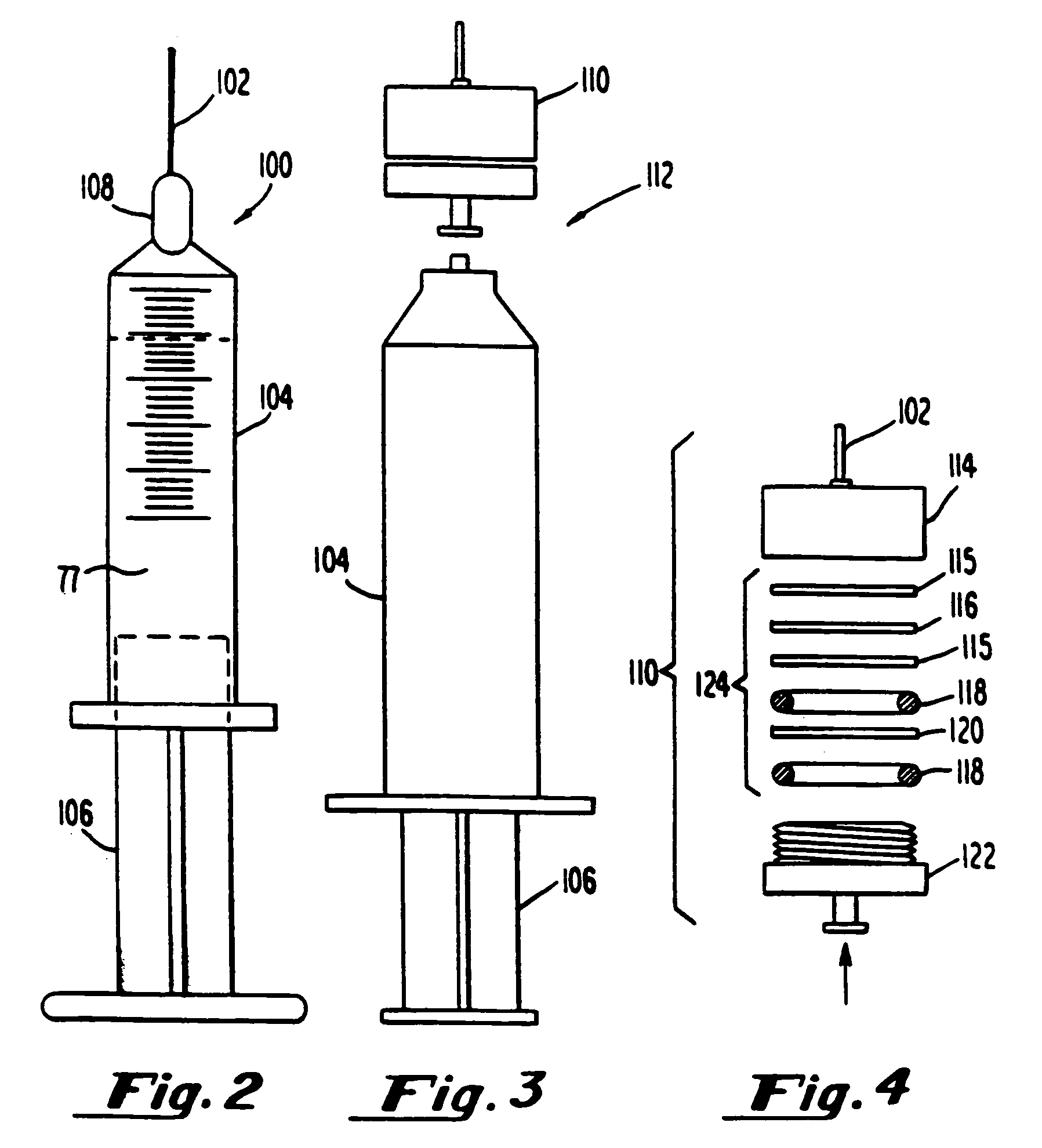

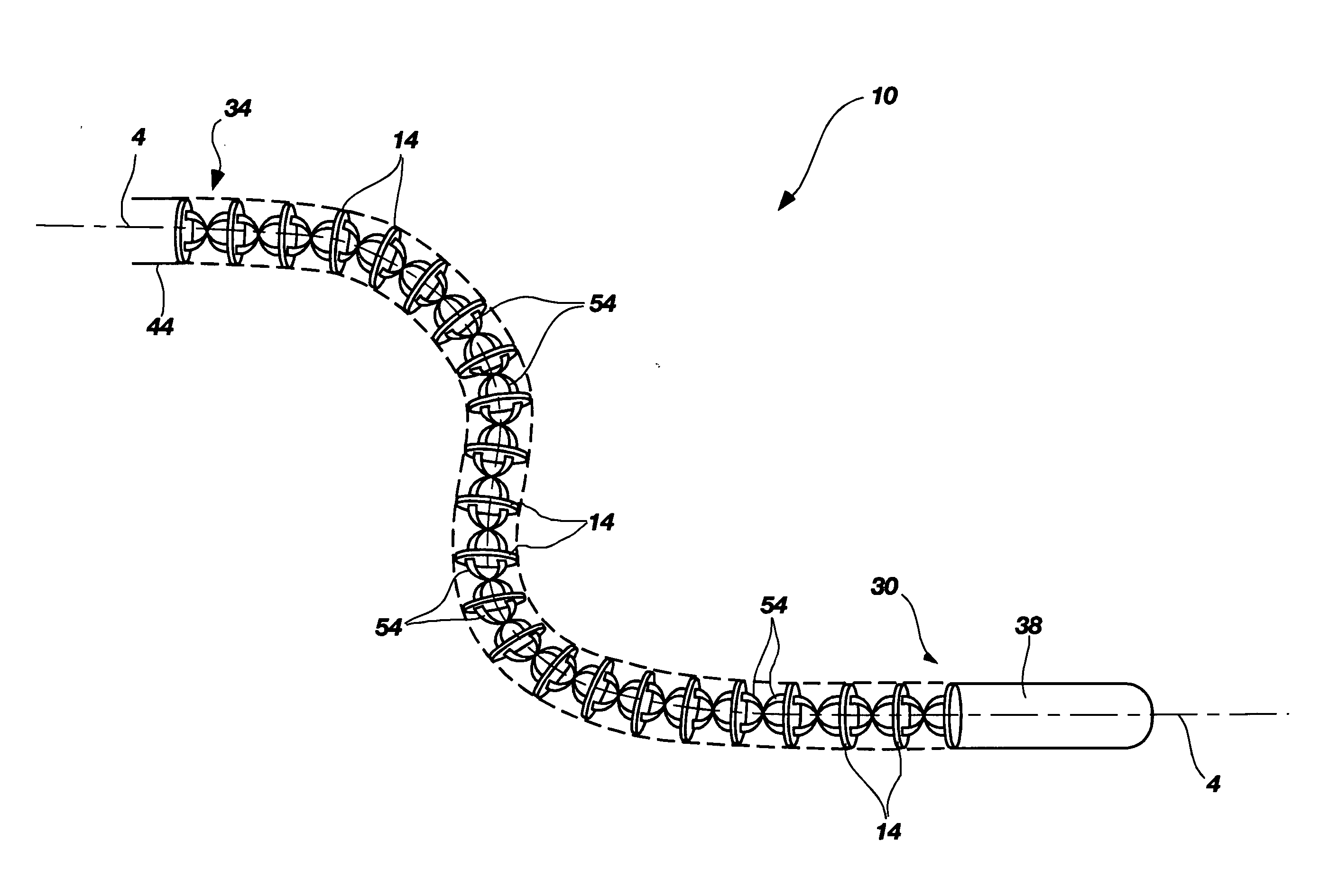

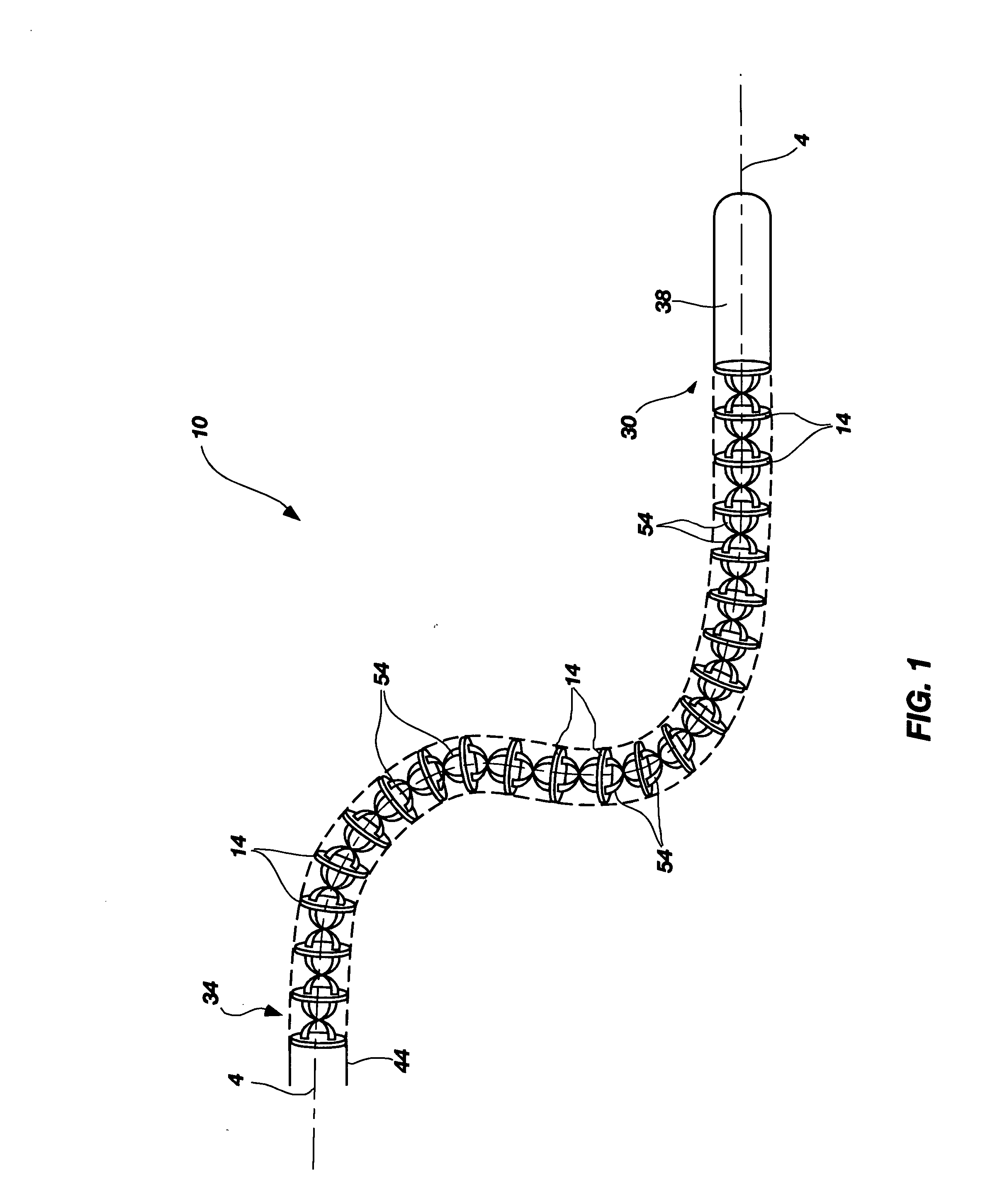

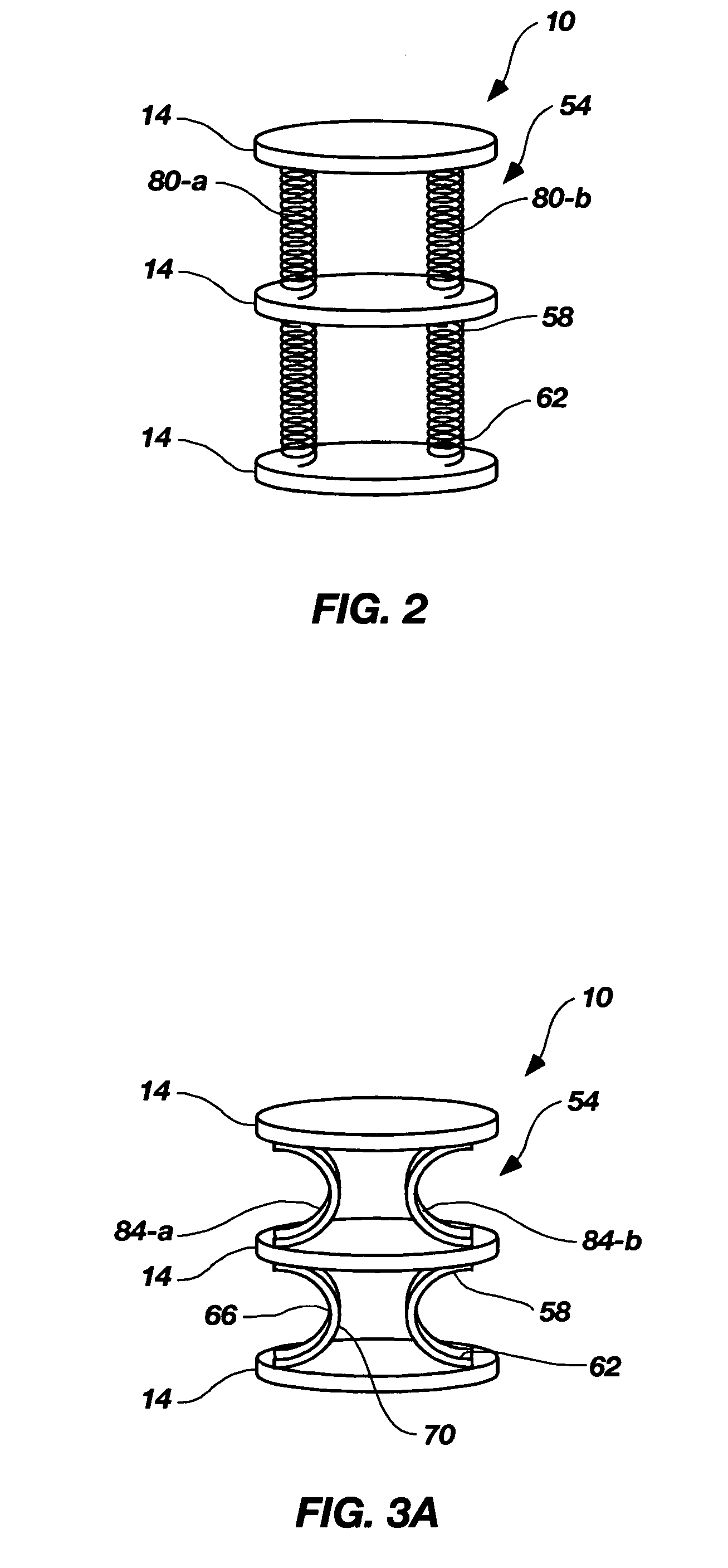

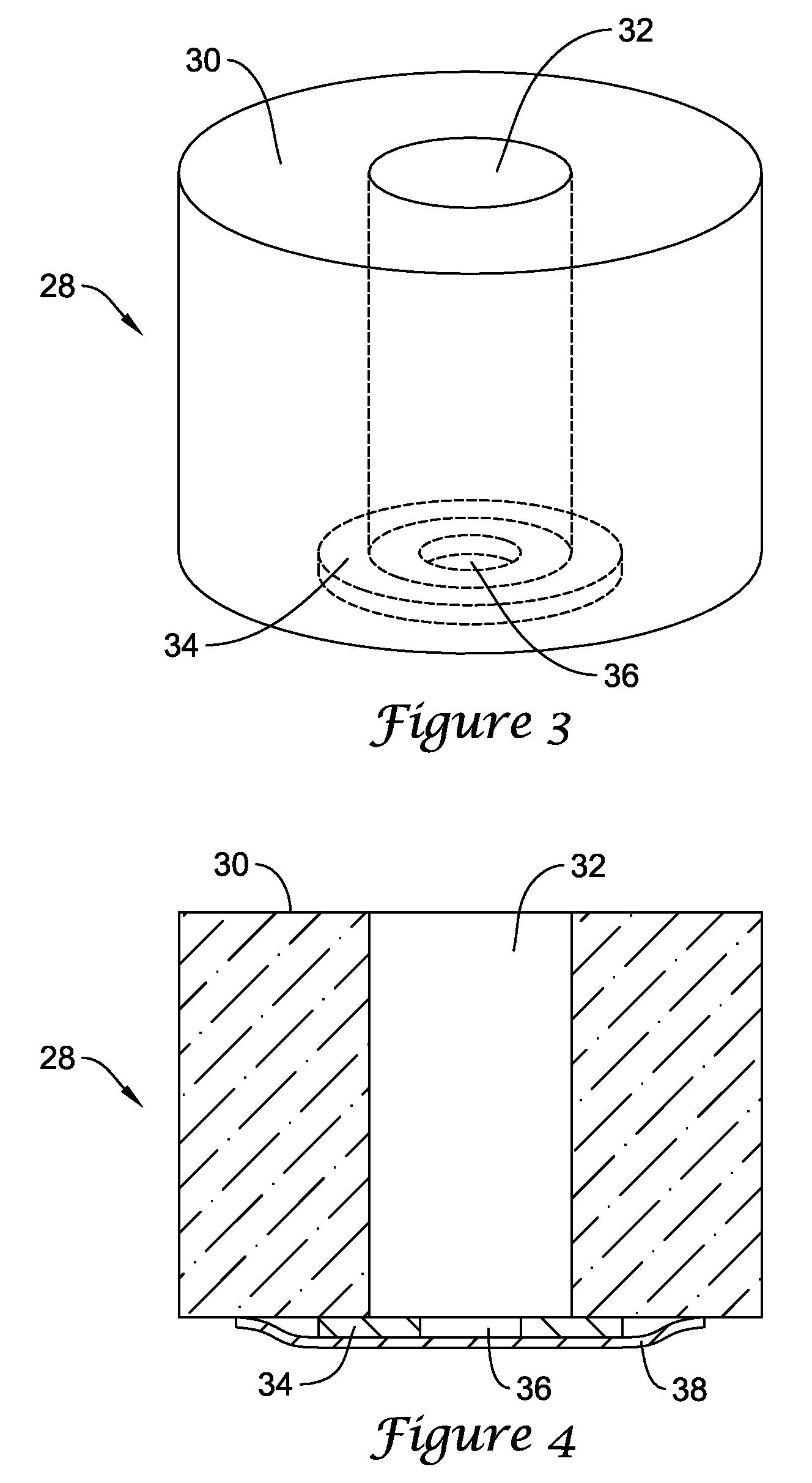

Mechanical serpentine device

InactiveUS20060156851A1Improve operating characteristicsEasy alignmentMechanical apparatusJointsElectricityCircular disc

A serpentine device having a proximal end and a distal end comprising a series of discs arrayed in succession and on center along a common, neutral axis, wherein the discs comprise a first and second surface; and at least one flexible interconnect extending between and connecting each disc to any succeeding disc according to a pre-determined connection configuration, wherein the interconnects are indirectly connected to one another through the discs and configured to provide torsional and bending support to each of the discs connected thereto under an applied load, thus achieving a continuum of flexibility along an entire length of the serpentine device, as well as to facilitate the torquability of the serpentine device. The serpentine device may further comprise a bendable member and at least one transfer element configured to perform one or more transfer functions, namely the transfer of energy, work, fluid, electricity, light energy, sound energy, matter, etc. from one location to another location, and particularly from a source to one or more of the discs of the serpentine device. An actuation system is also featured, which is configured to selectively actuate the discs in a pre-determined direction in three-dimensional space.

Owner:RAYTHEON SARCOS LLC

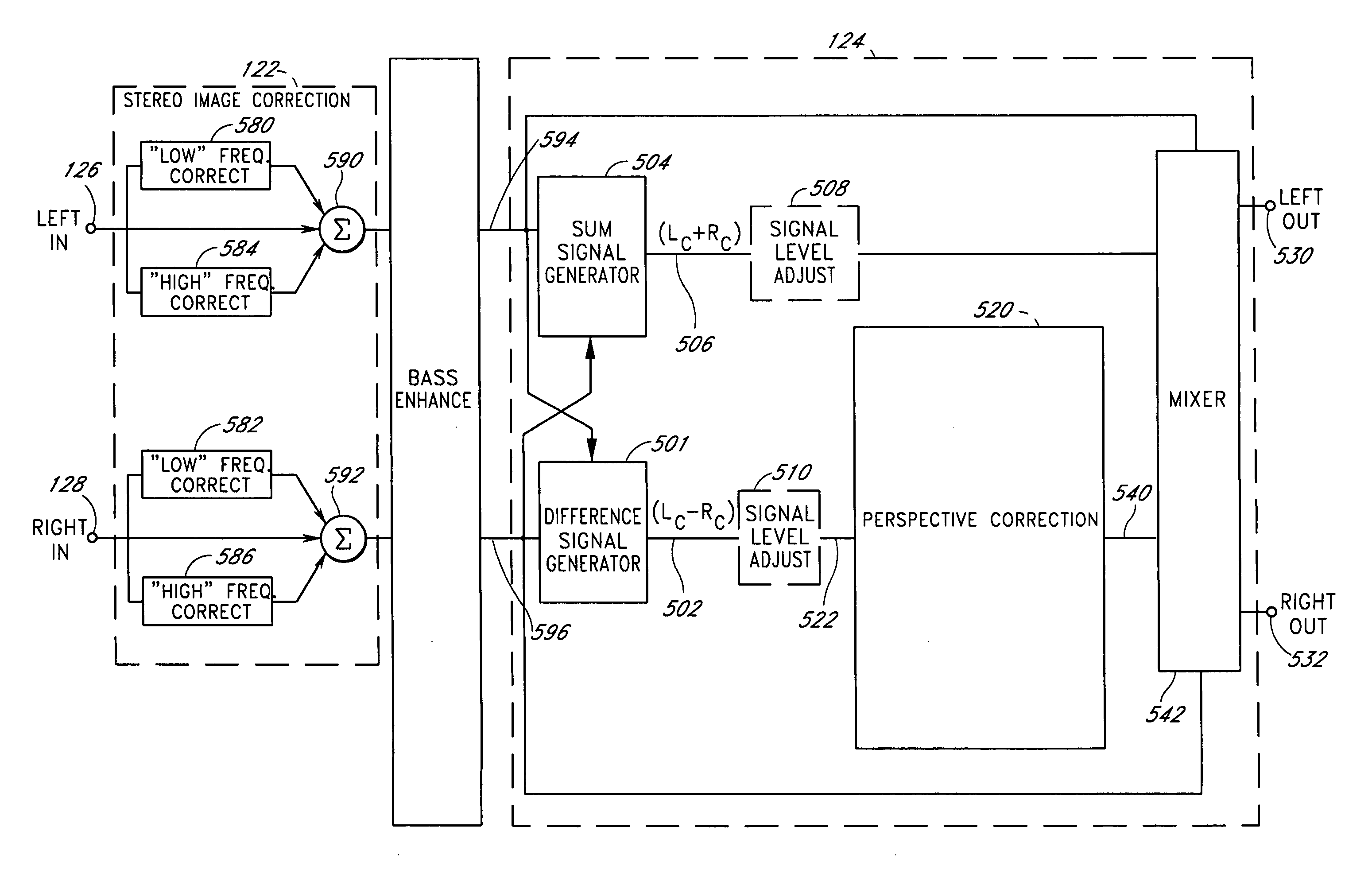

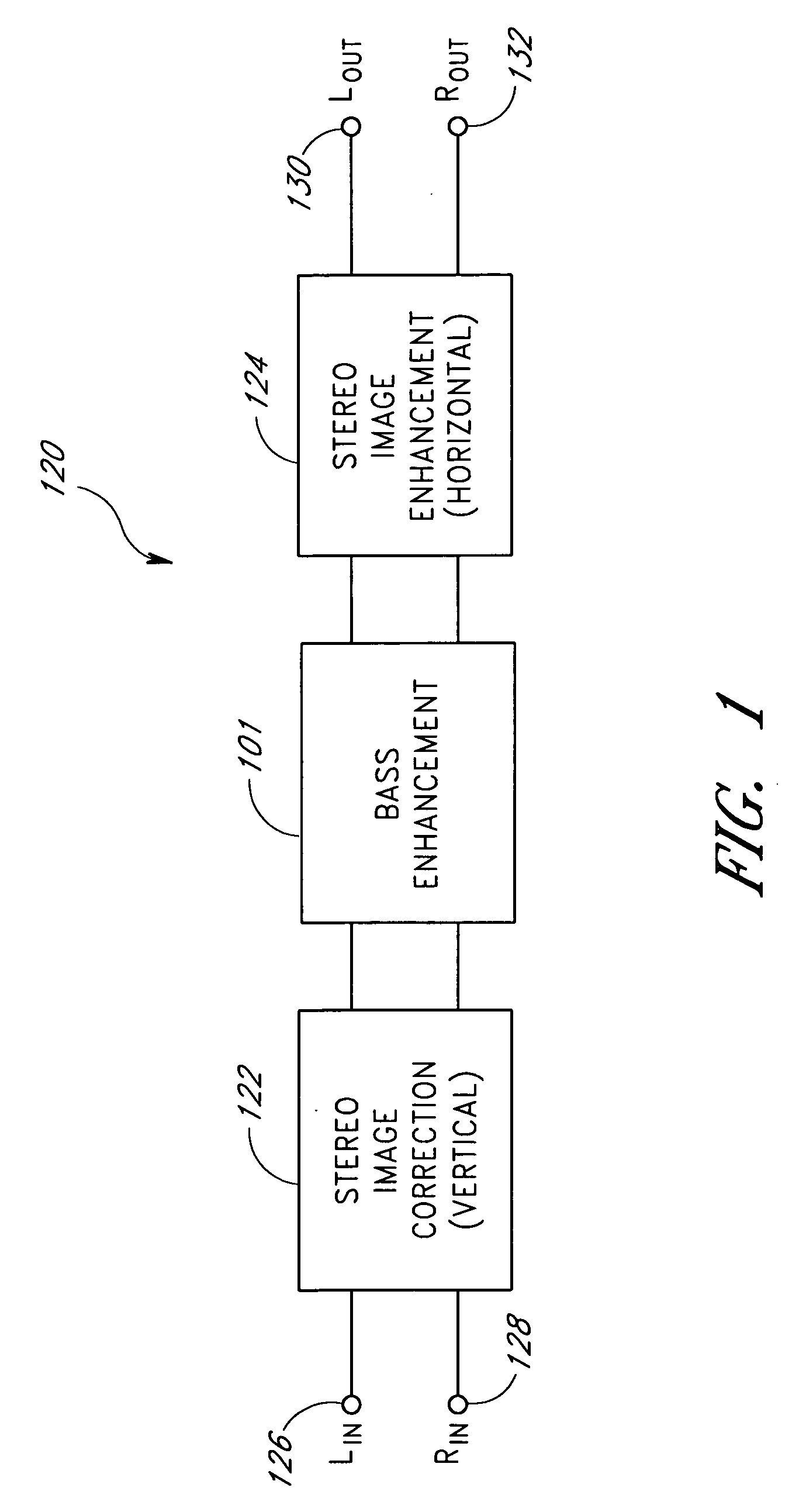

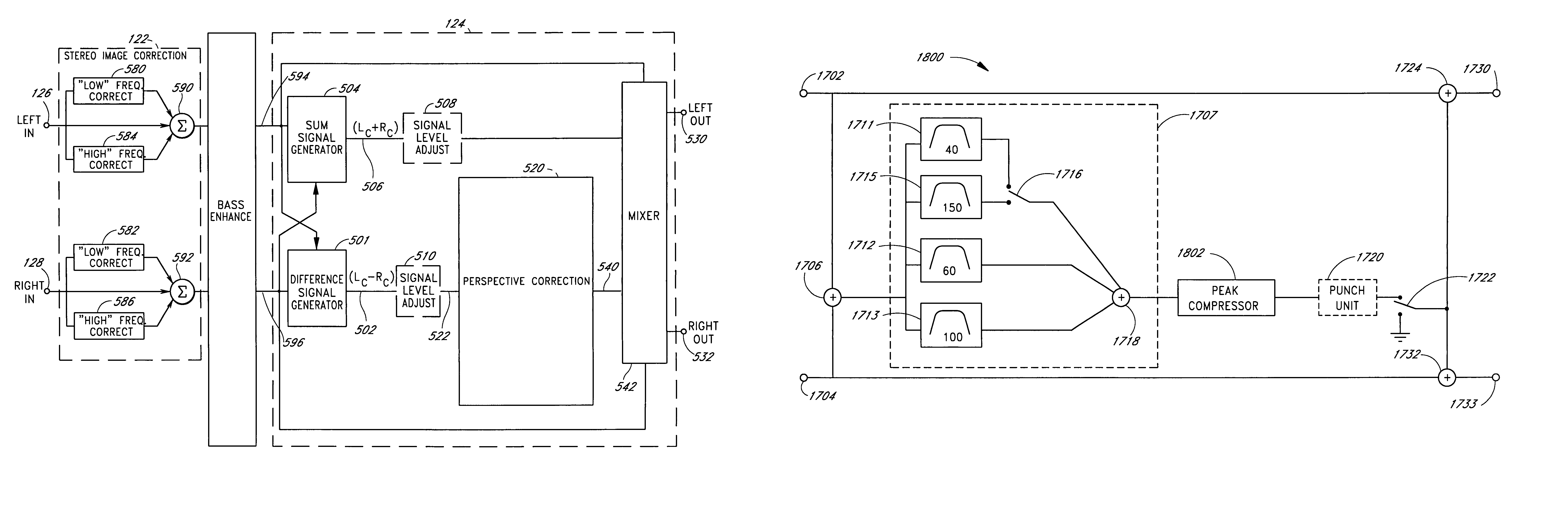

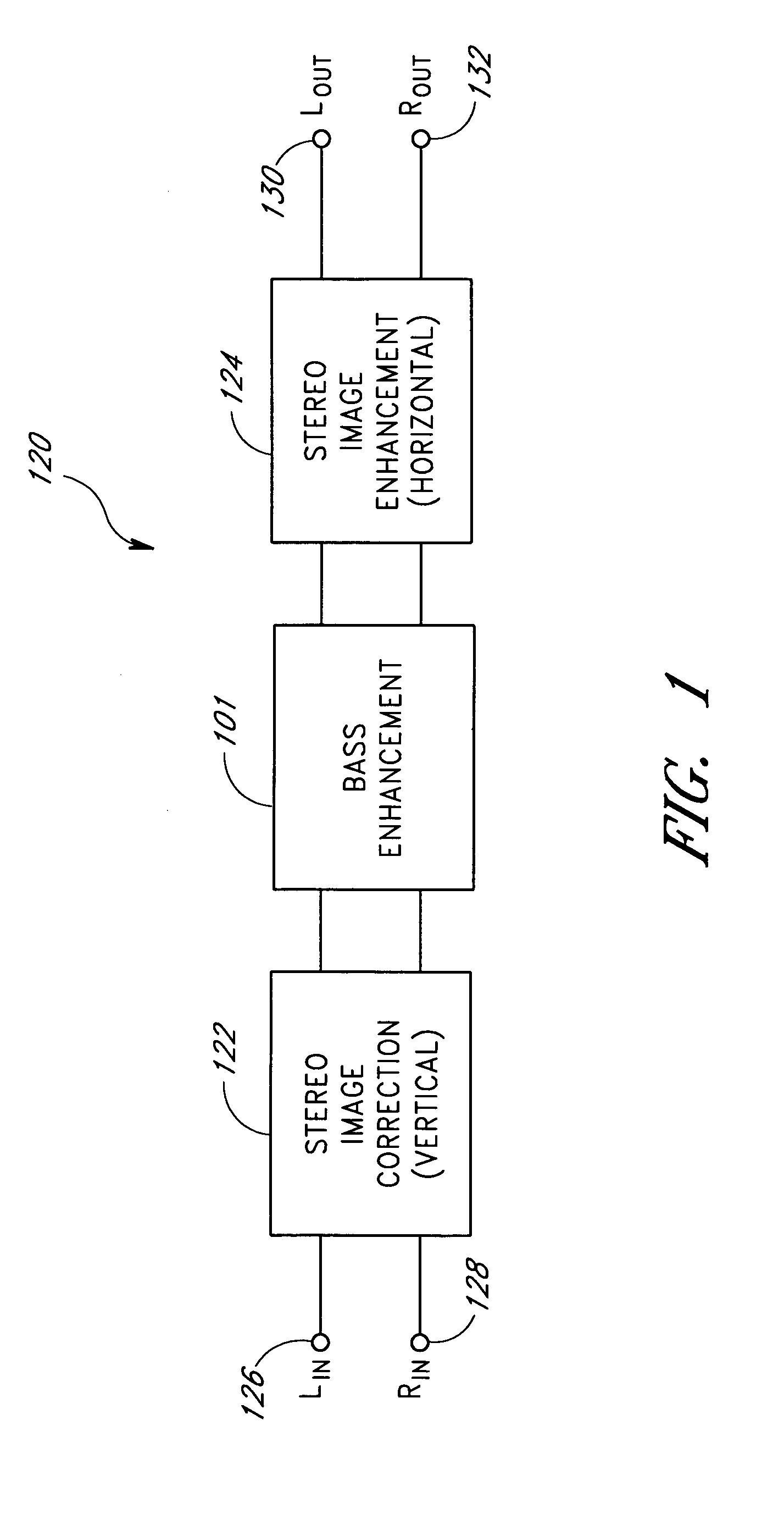

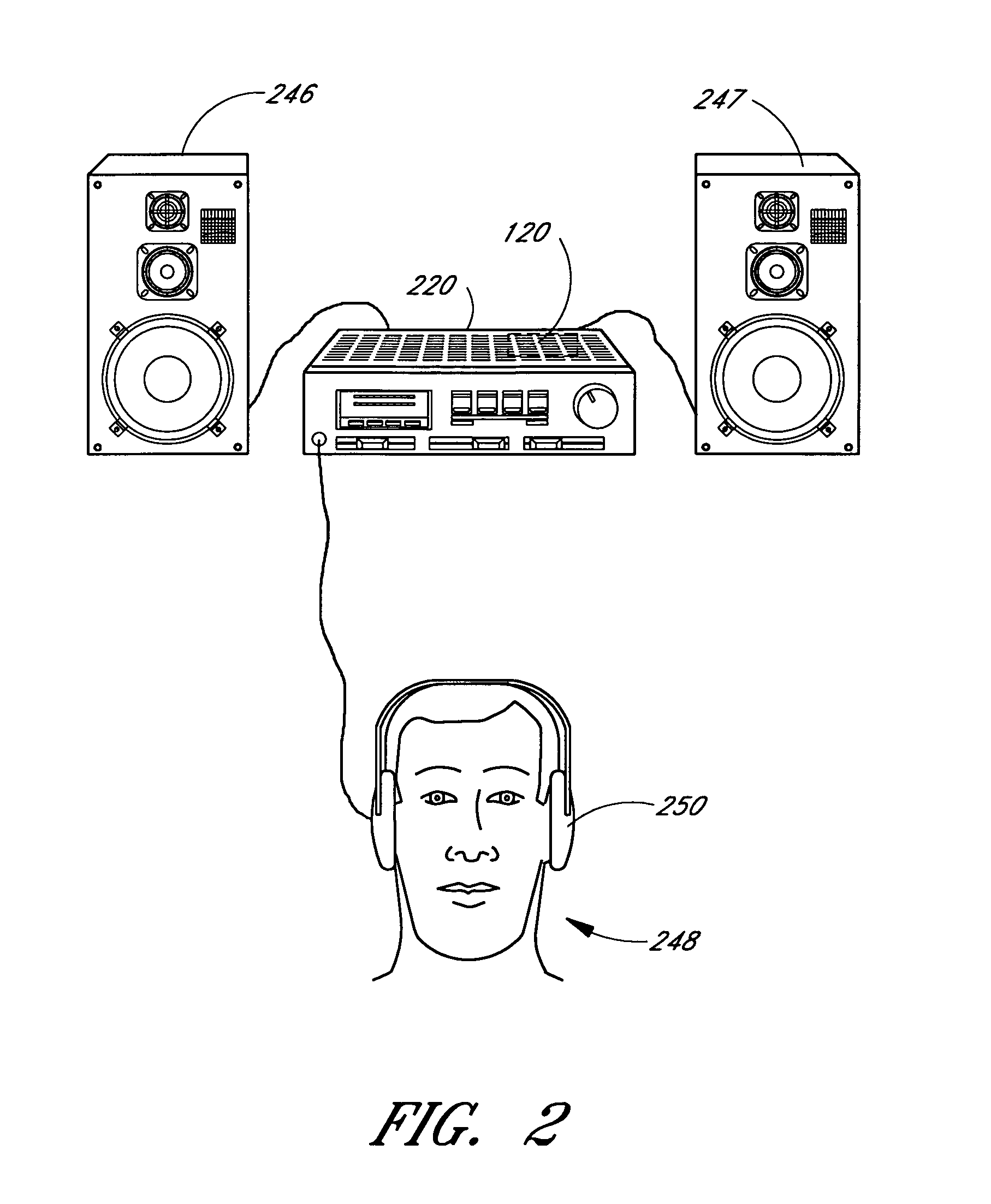

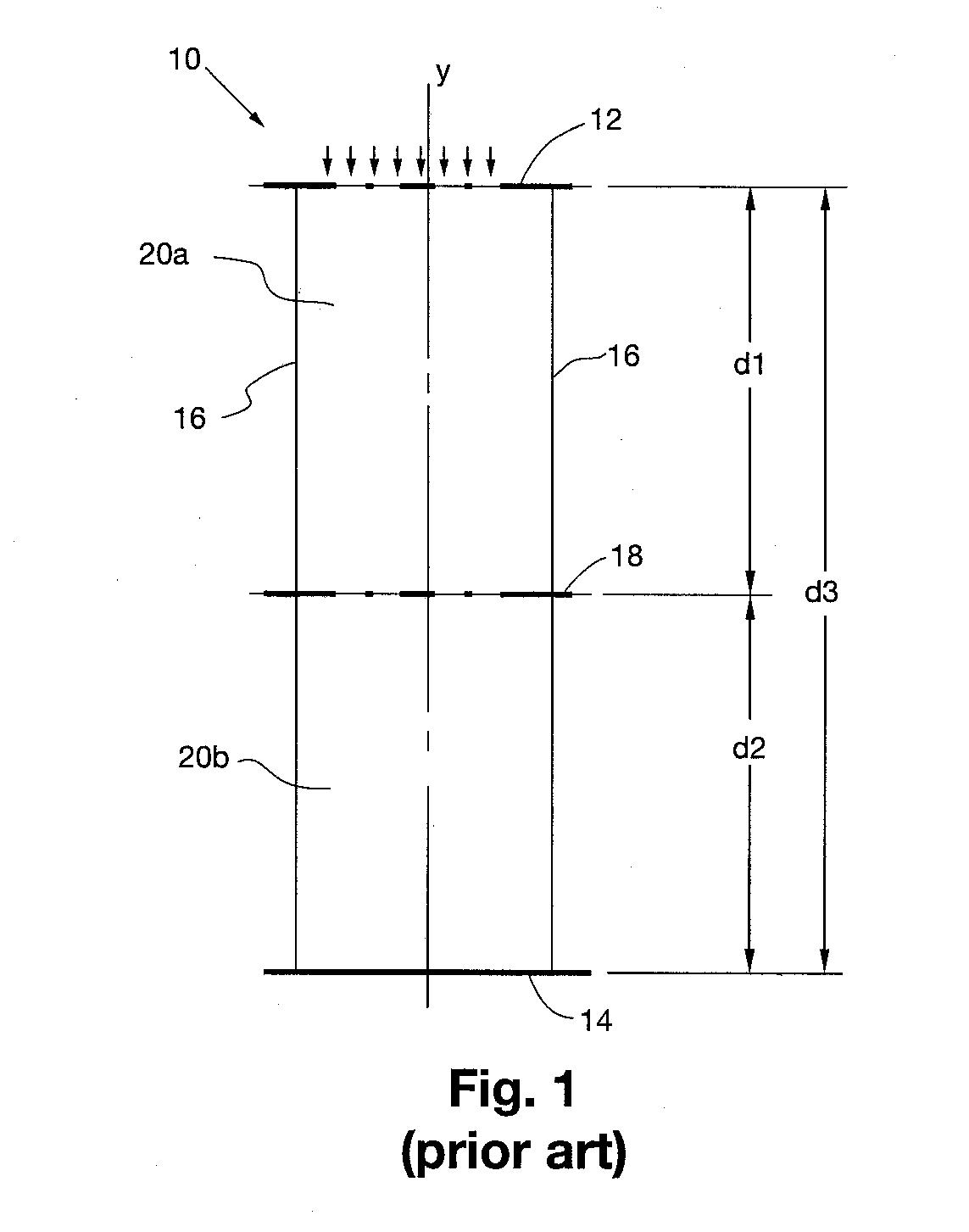

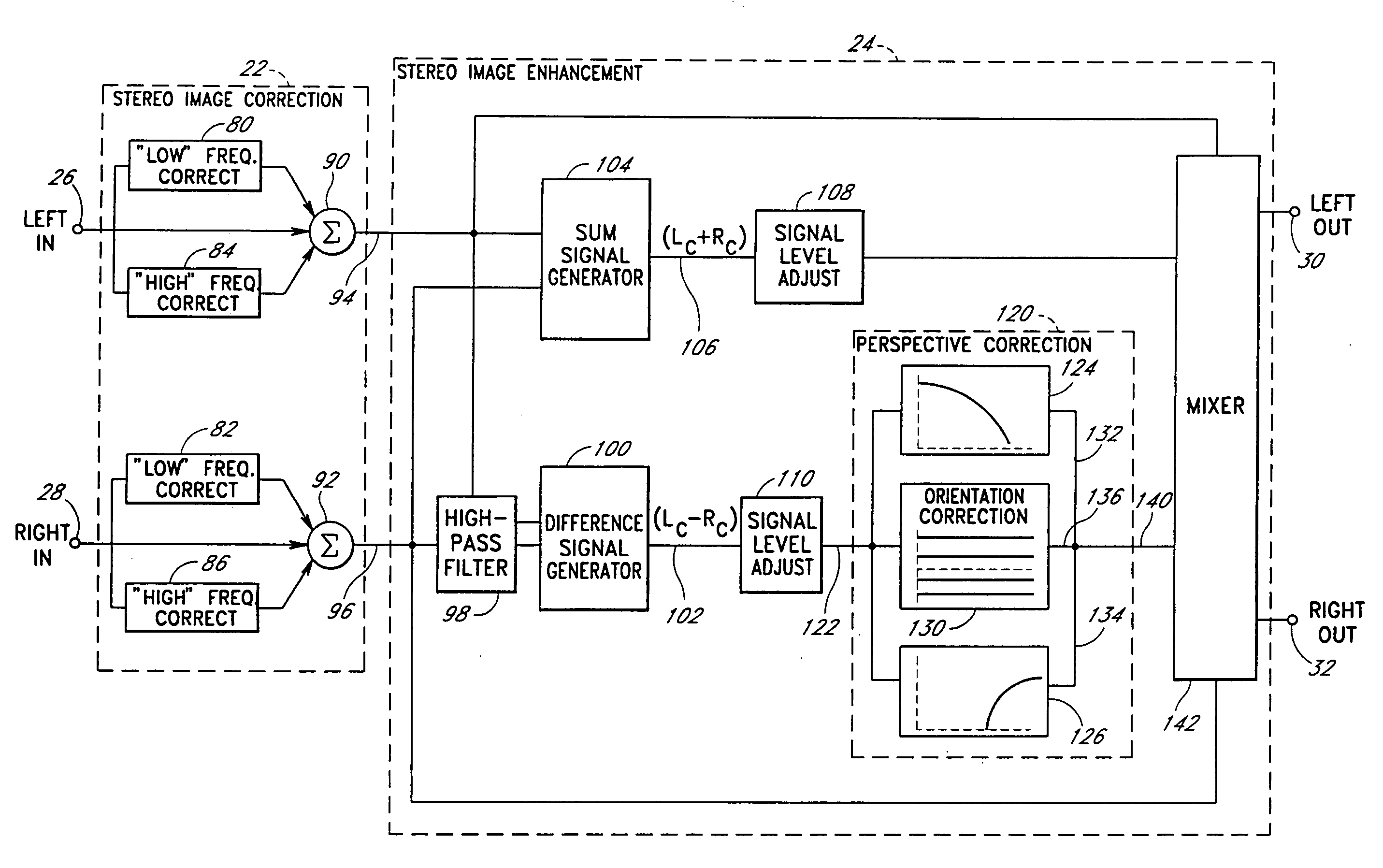

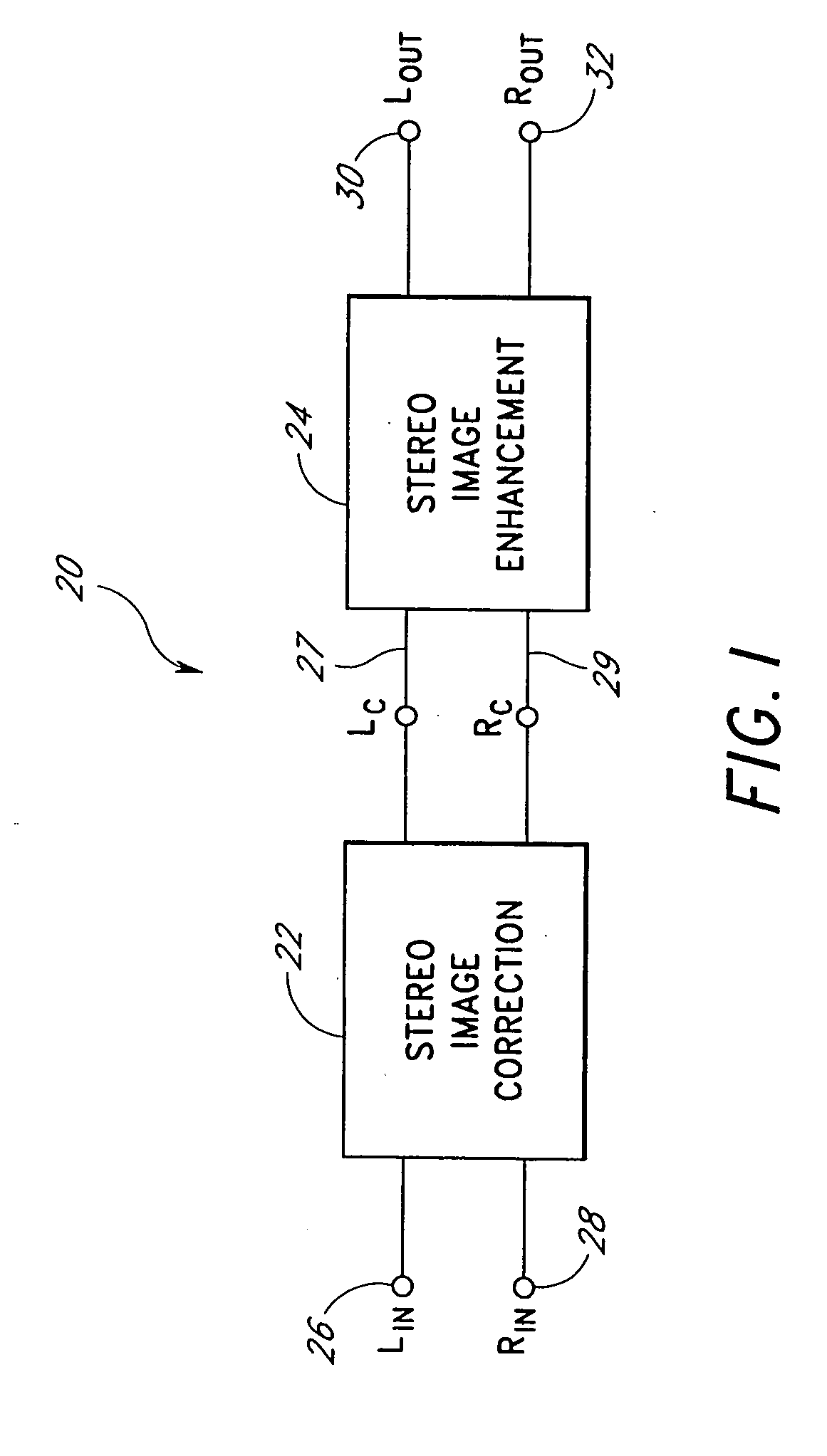

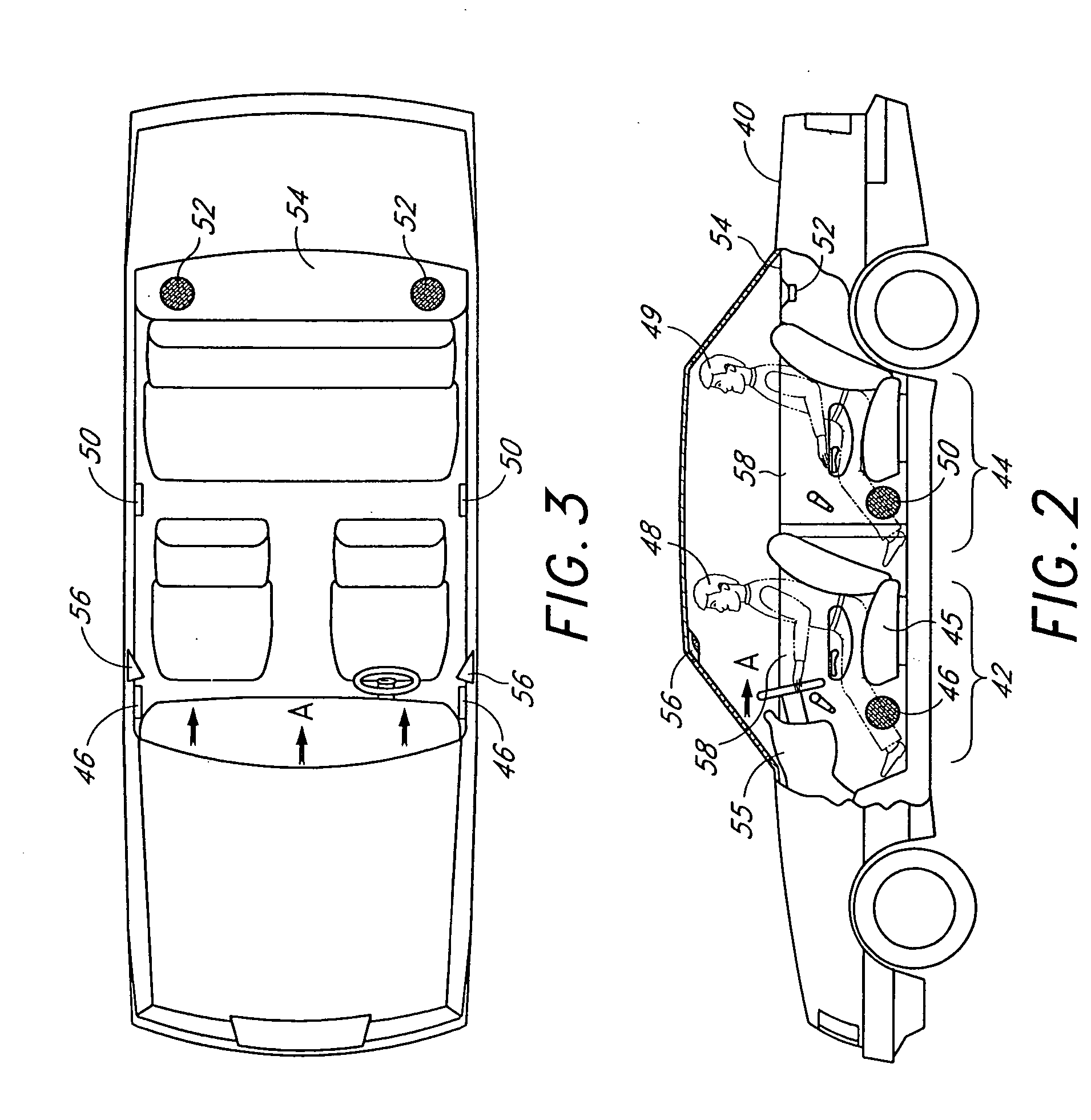

Acoustic correction apparatus

InactiveUS7031474B1Improve performanceIncrease in sizeHeadphones for stereophonic communicationFrequency response correctionSound imageSound energy

An acoustic correction apparatus processes a pair of left and right input signals to compensate for spatial distortion as a function of frequency when said input signals are reproduced through loudspeakers in a sound system. The sound-energy of the left and right input signals is separated and corrected in a first low-frequency range and a second high-frequency range. The resultant signals are recombined to create image-corrected audio signals having a desired sound-pressure response when reproduced by the loudspeakers in the sound system. The desired sound-pressure response creates an apparent sound image location with respect to a listener. The image-corrected signals can also be spatially-enhanced to broaden the apparent sound image and improve the low frequency characteristics of the sound when played on small loudspeakers.

Owner:DTS

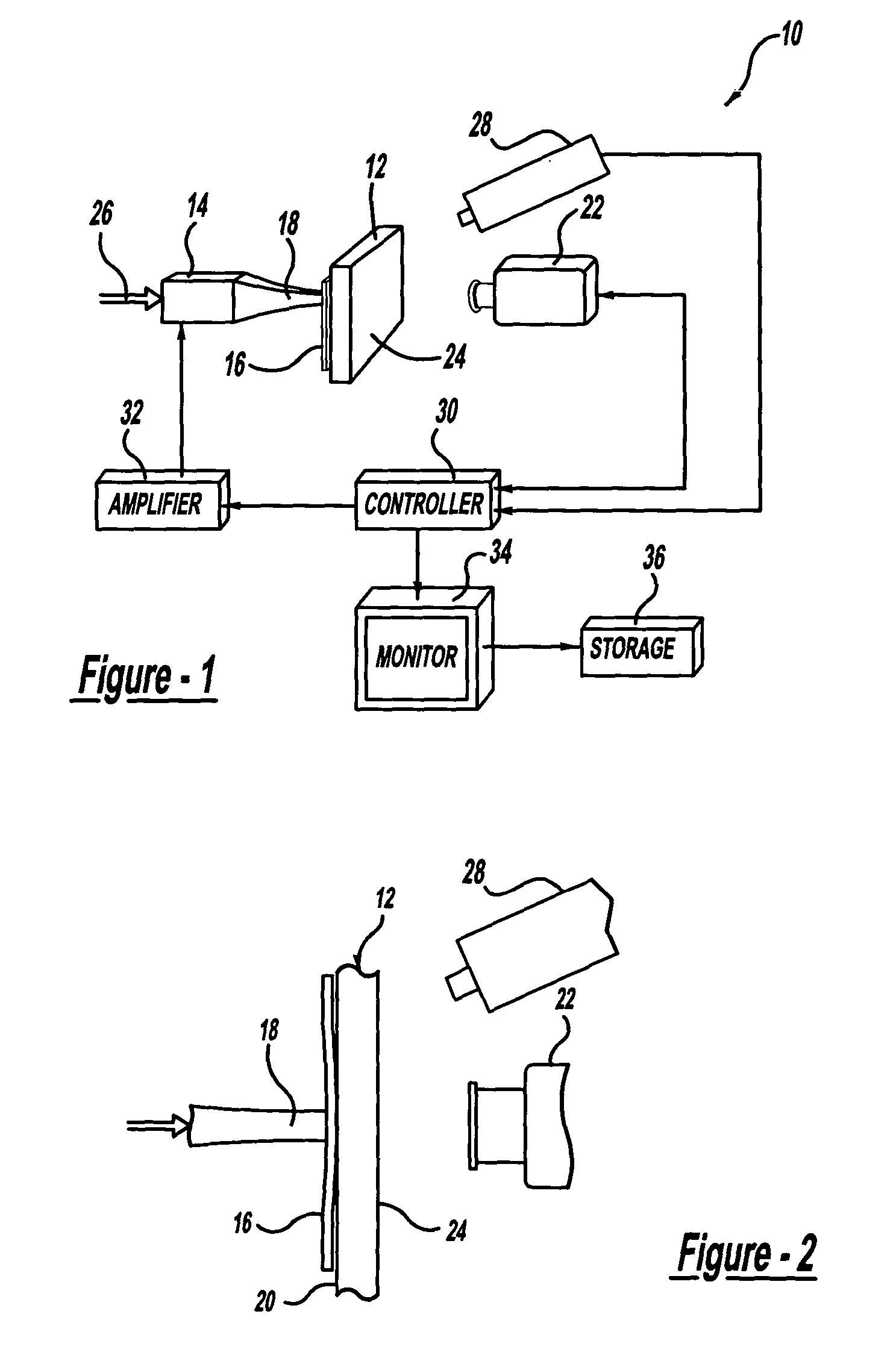

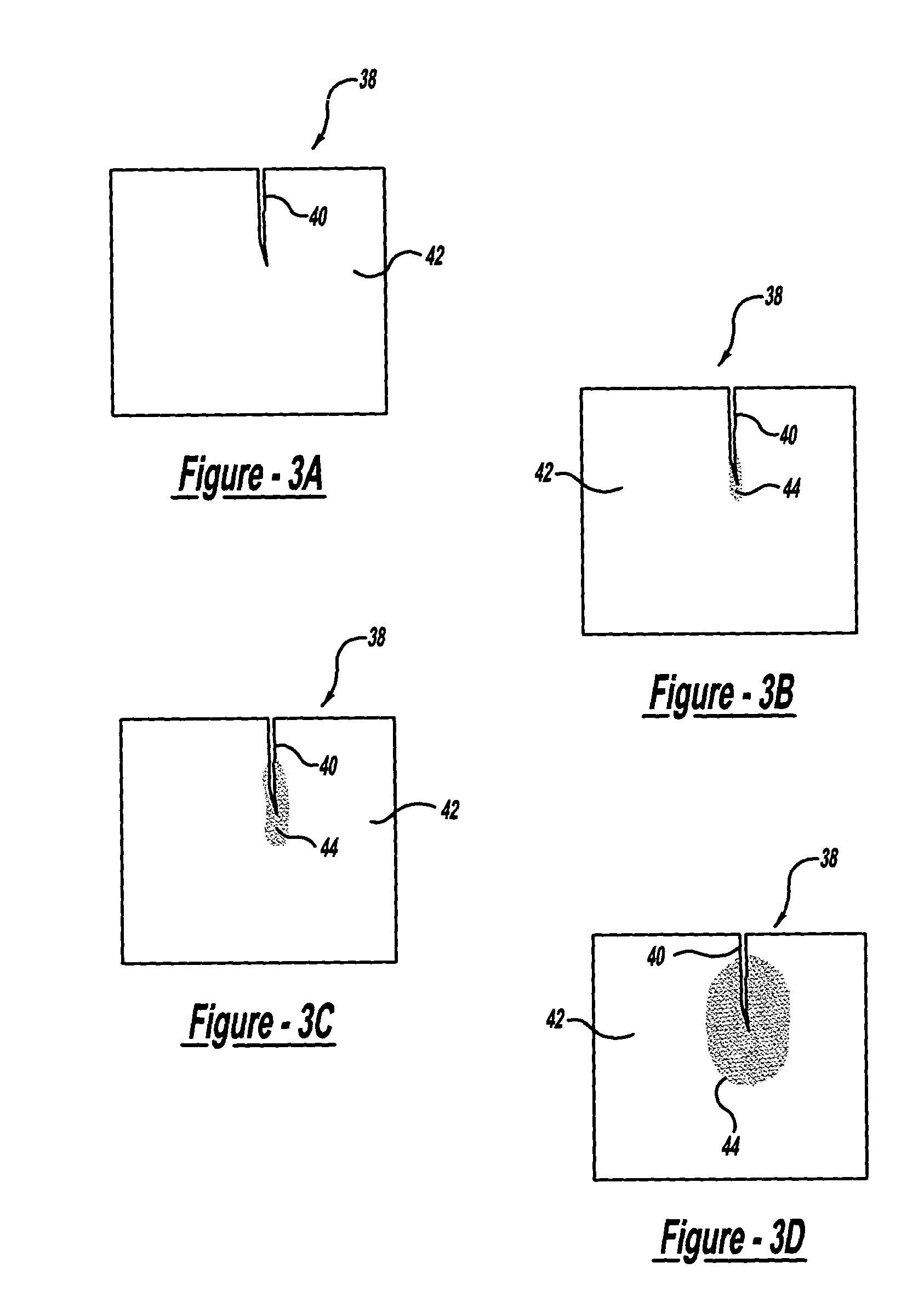

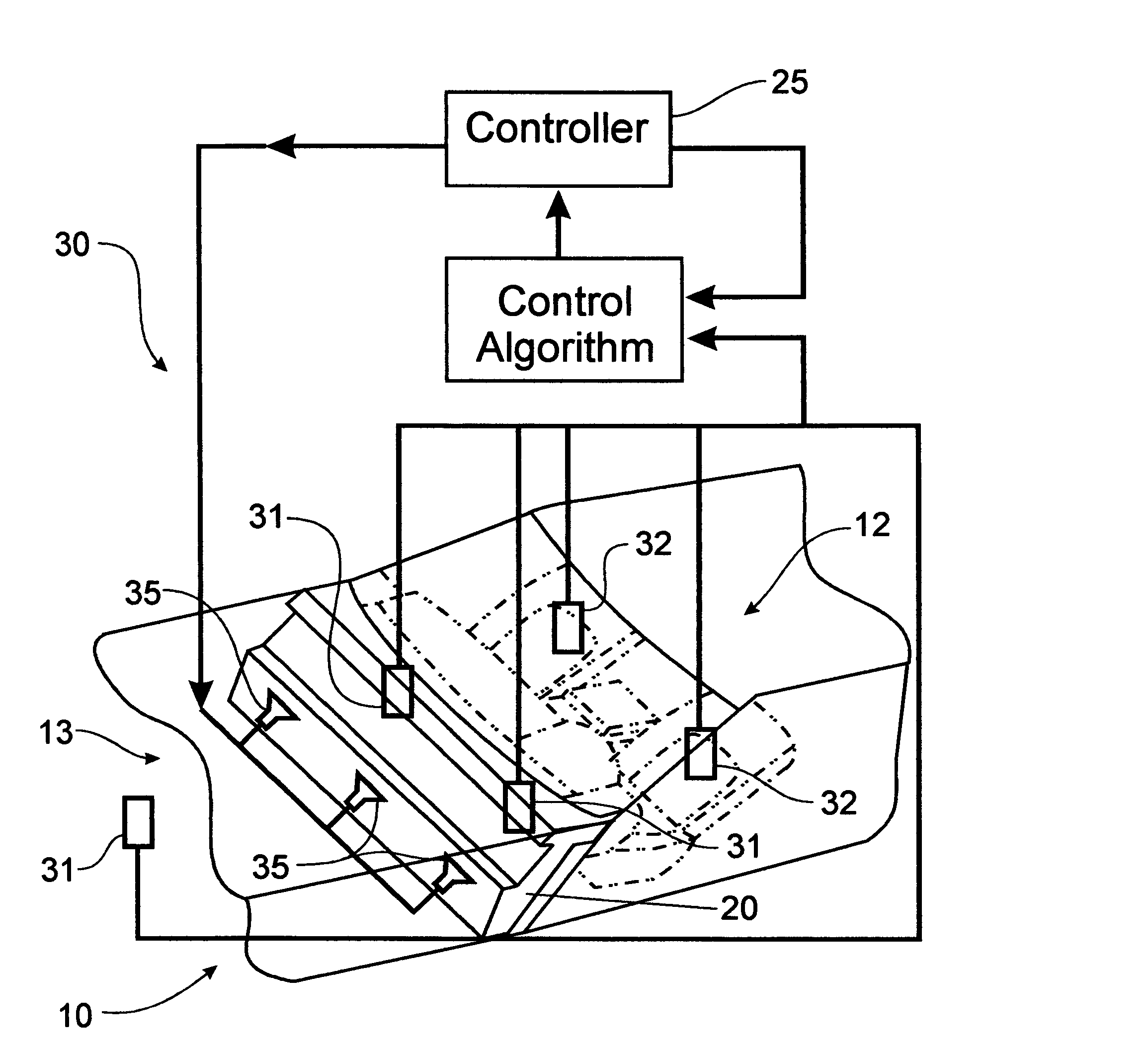

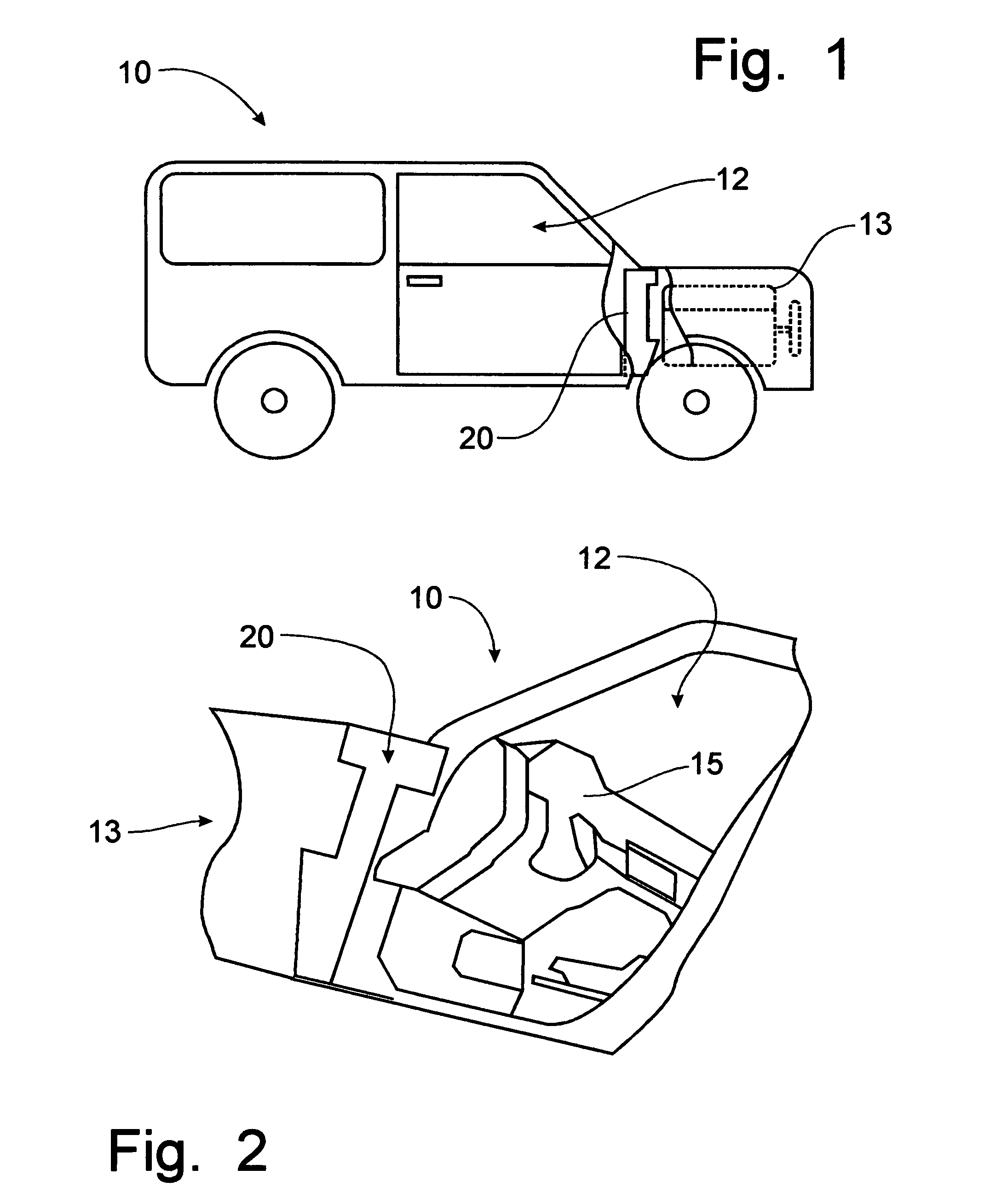

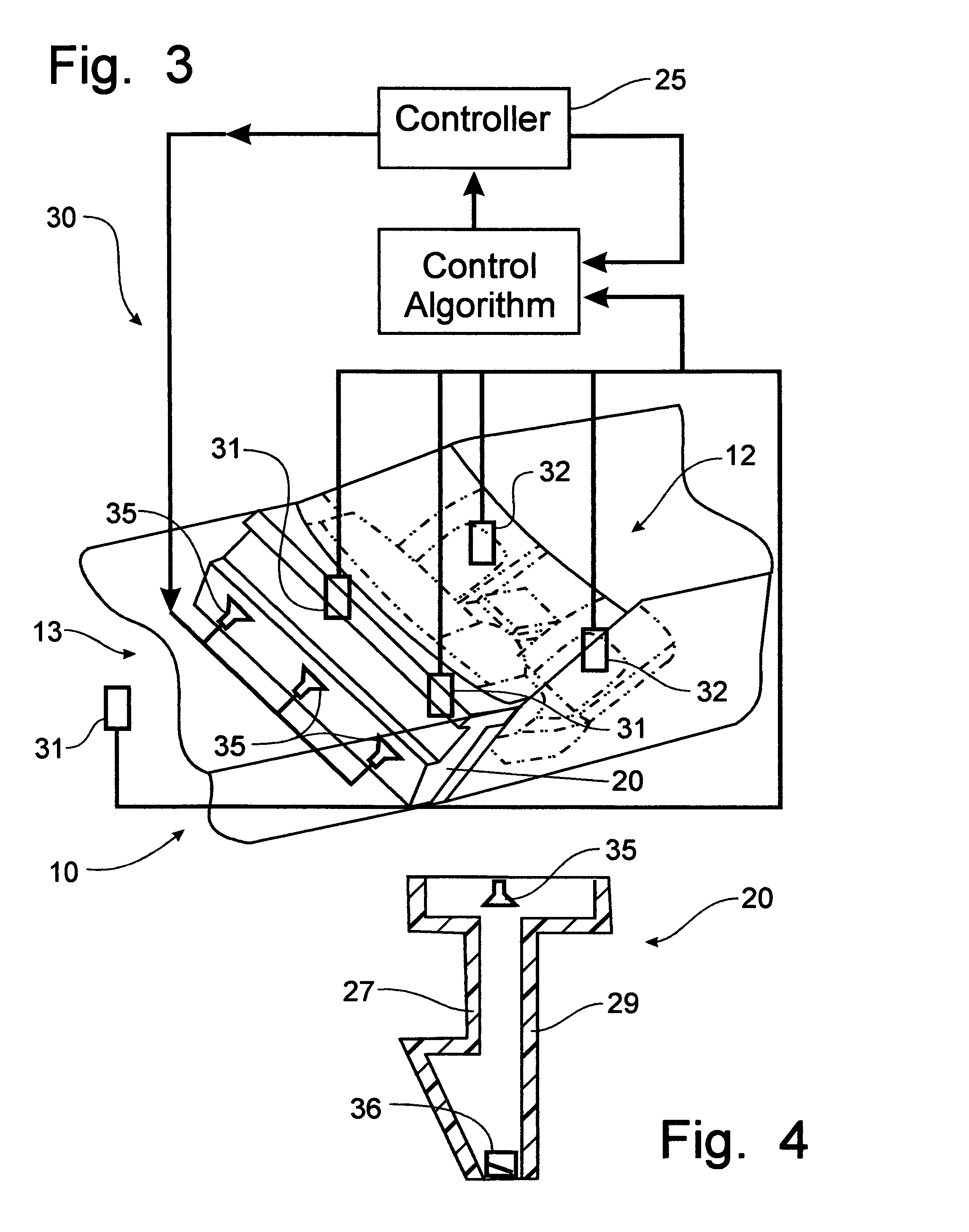

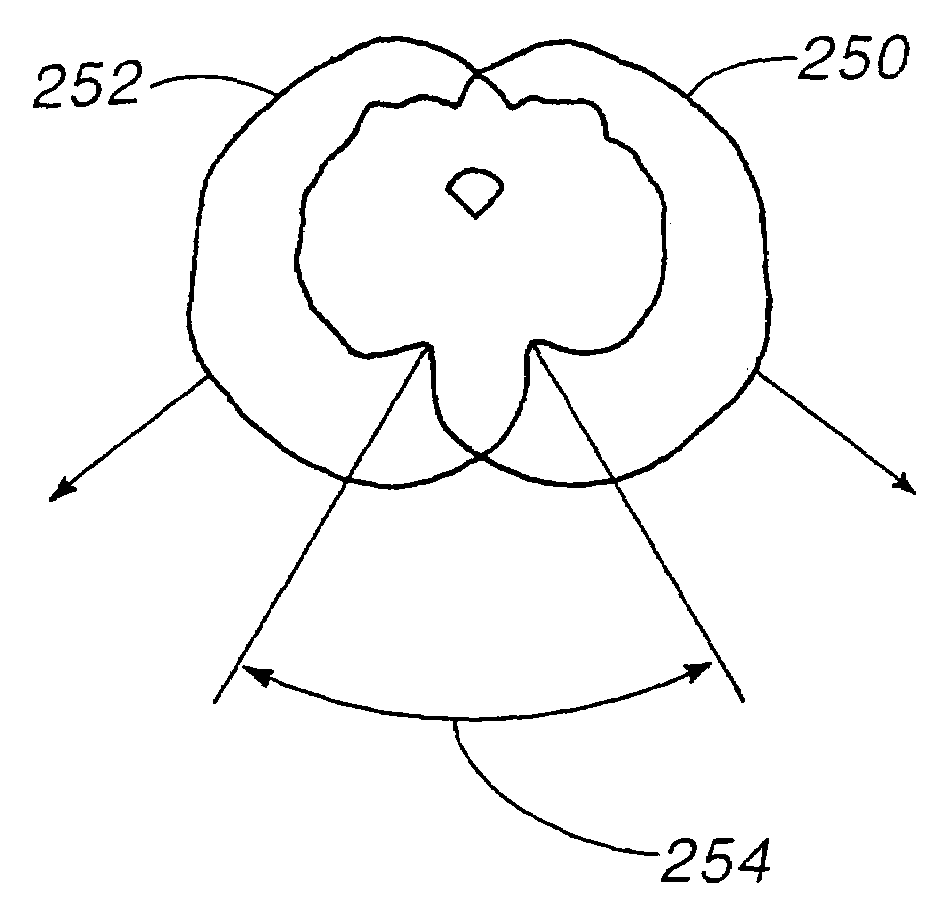

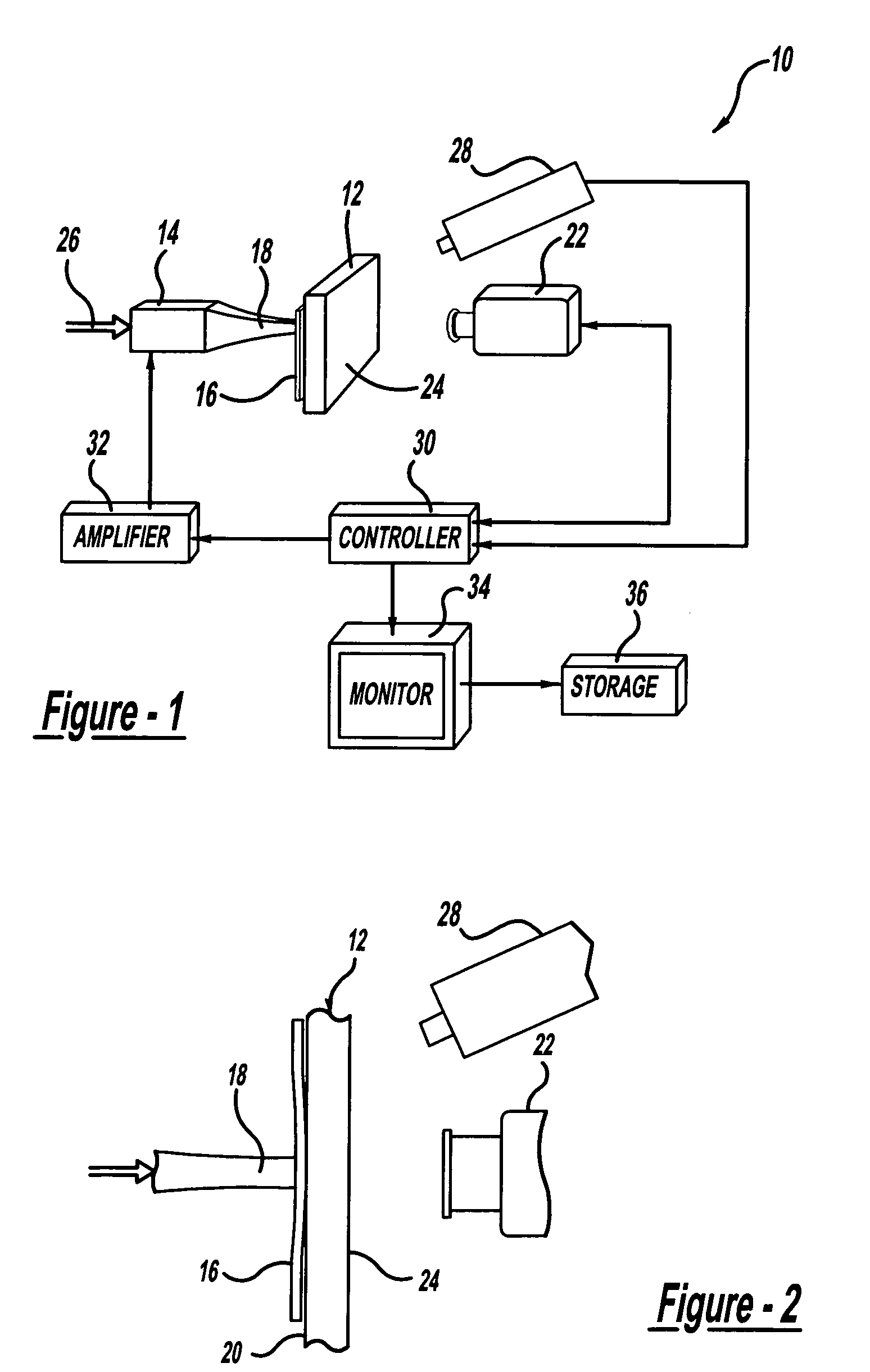

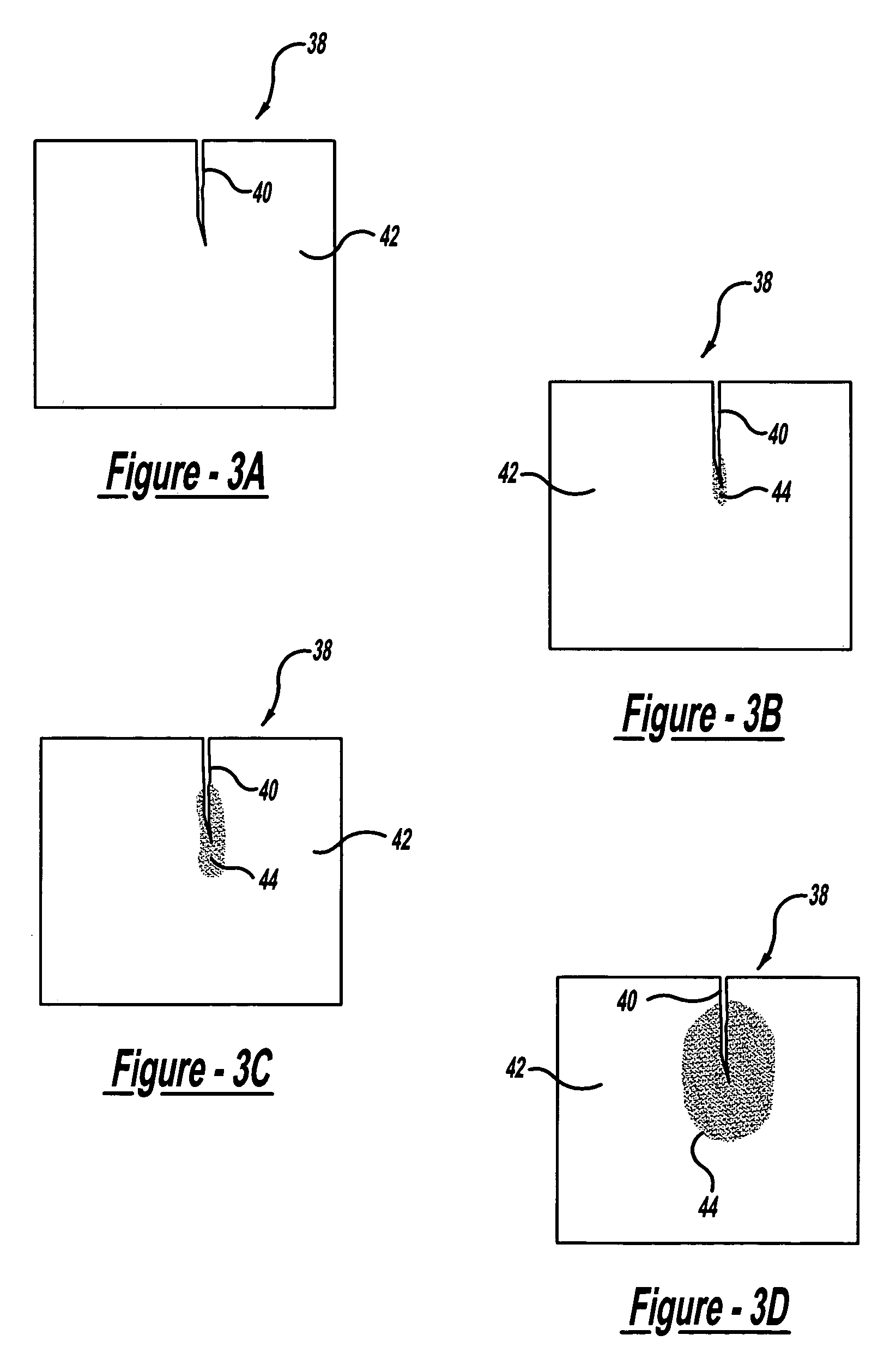

System and method for multiple mode flexible excitation and acoustic chaos in sonic infrared imaging

ActiveUS20040089812A1Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationThermal energyCamera image

A defect detection system for thermally imaging a structure that has been energized by a sound energy. The system includes a transducer that couples a sound signal into the structure, where the sound signal causes defects in the structure to heat up. In one embodiment, the sound signal has one or more frequencies that are at or near an eigen-mode of the structure. In another embodiment, an on-linear coupling material is positioned between the transducer and the structure to couple the sound energy from the transducer to the structure. A predetermined force is applied to the transducer and a pulse duration and a pulse frequency of the sound signal are selected so that the sound energy induces acoustic chaos in the structure, thus generating increased thermal energy. A thermal imaging camera images the structure when it is heated by the sound signal.

Owner:WAYNE STATE UNIV +1

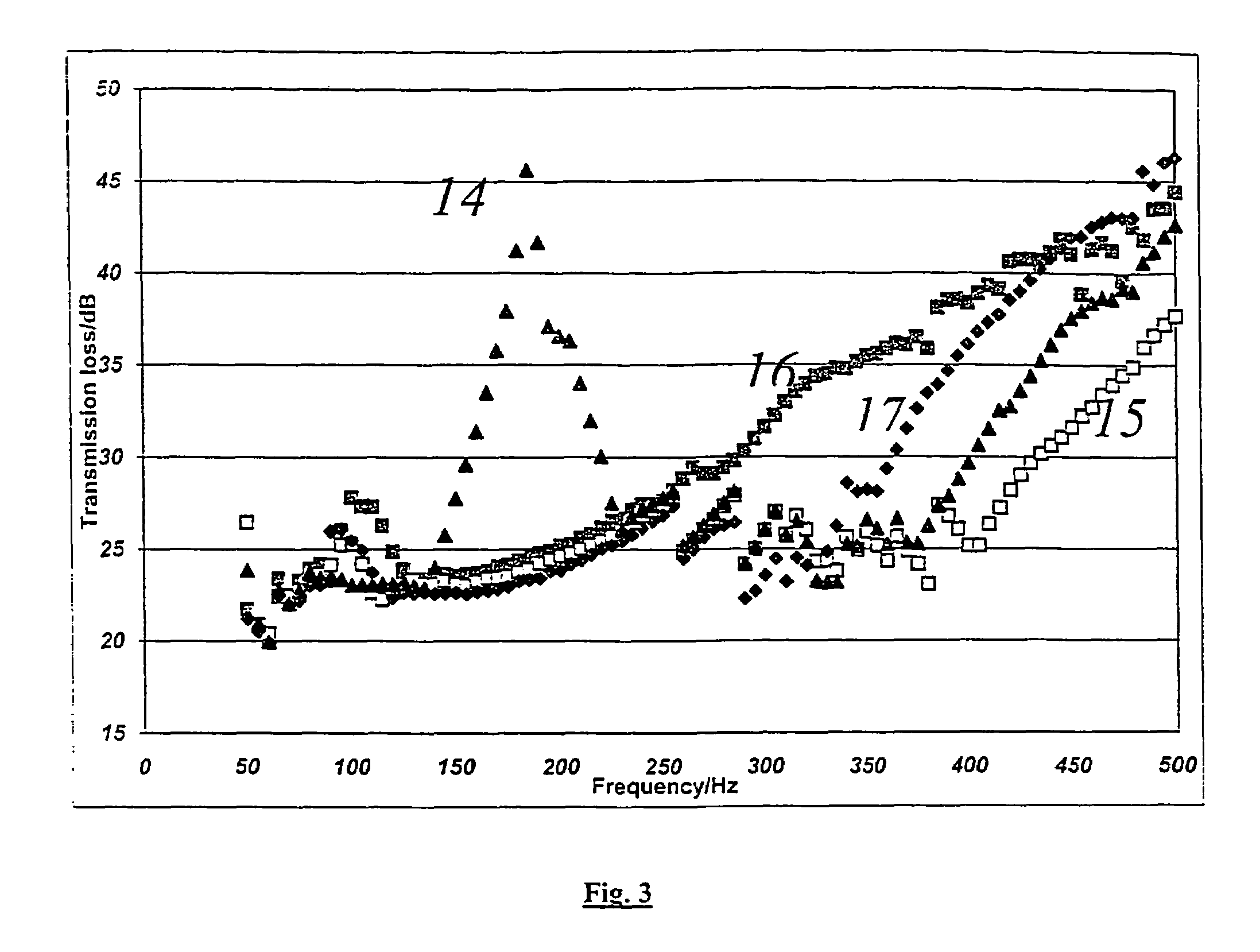

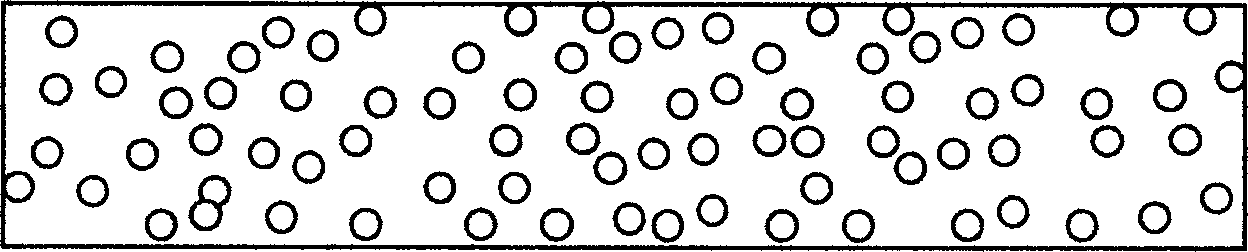

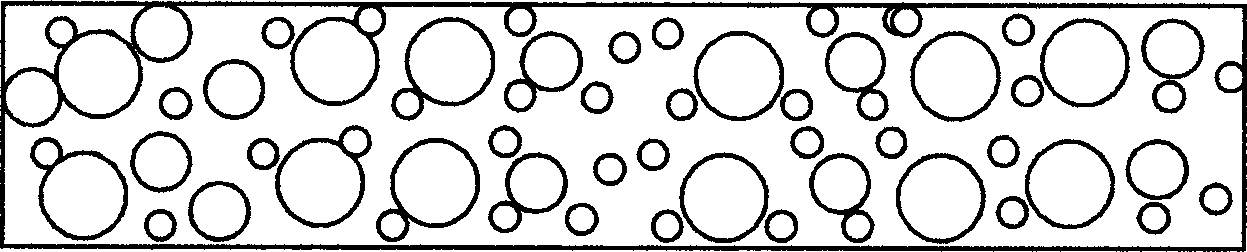

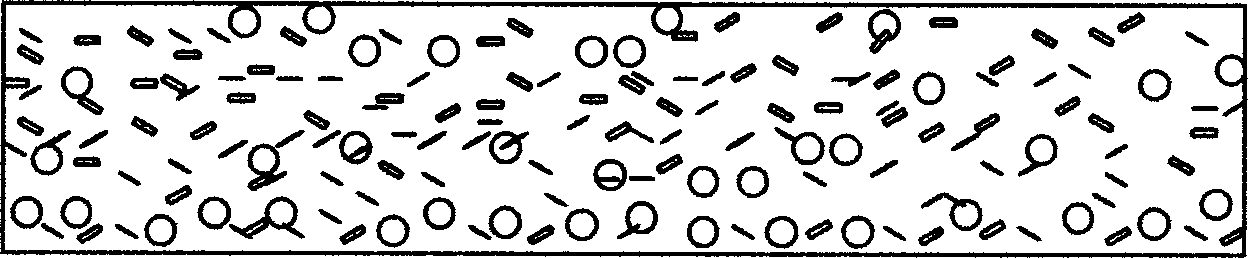

Acoustic attenuation materials

Acoustic attenuation materials are described that comprise outer layers of a stiff material sandwiching a relatively soft elastic material therebetween, with means such as spheres, discs or wire mesh being provided within the elastic material for generating local mechanical resonances that function to absorb sound energy at tunable wavelengths.

Owner:THE HONG KONG UNIV OF SCI & TECH

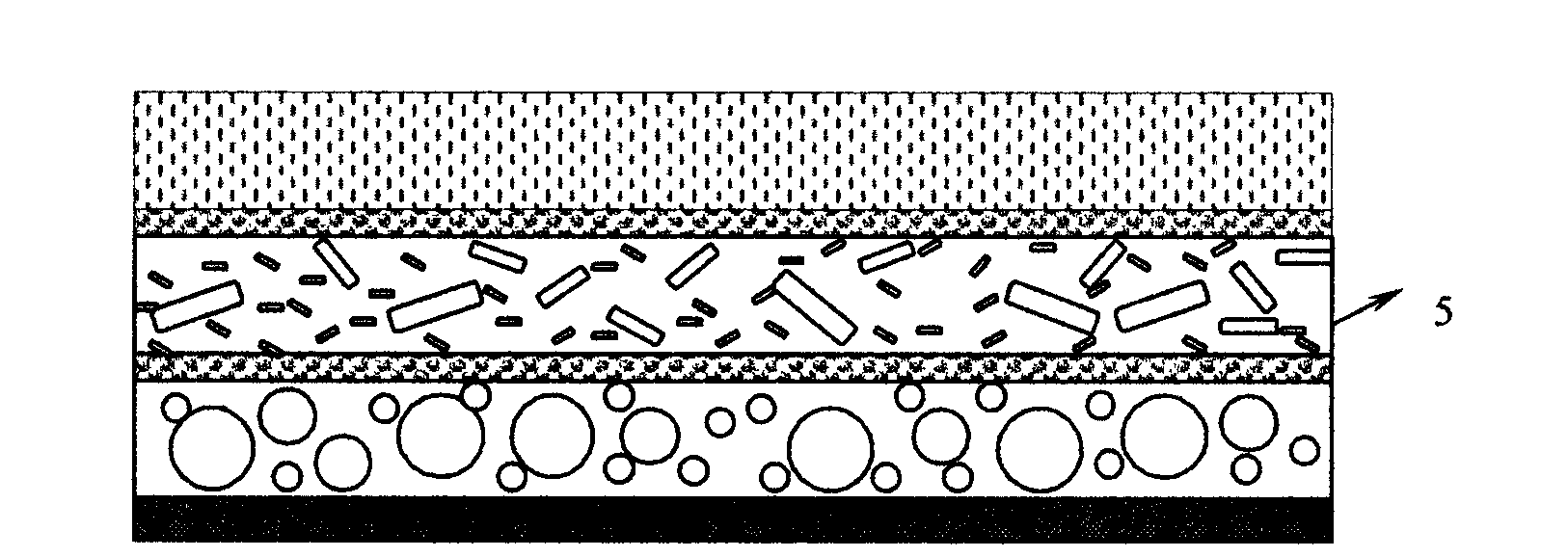

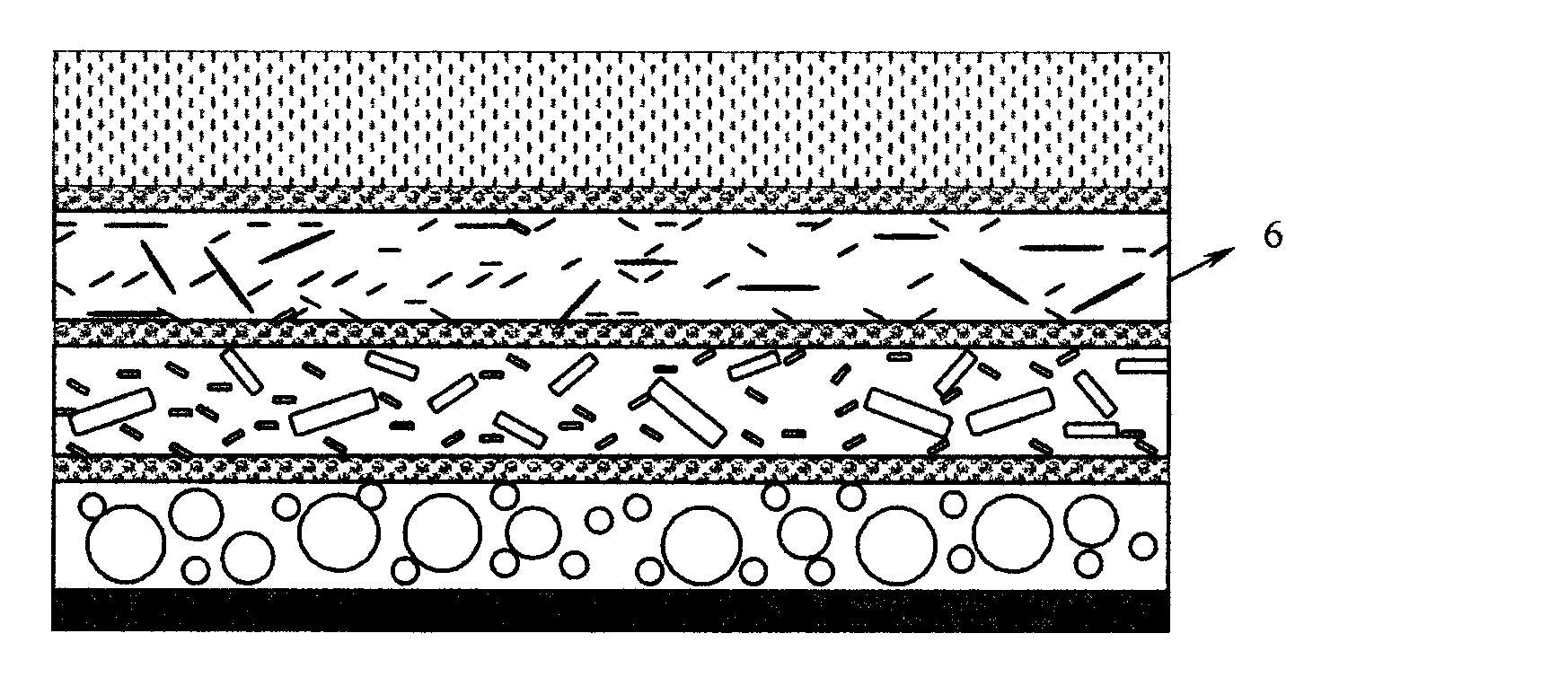

Multimode organic filler/polymer composite damping material and manufacturing method thereof

InactiveCN103897287AImprove shock absorptionImprove heat and aging resistanceSound energyRelaxation effect

The invention relates to a multimode organic filter / polymer composite damping material and a manufacturing method thereof, relates to the field of soundproof materials, aims to solve the problems that in the prior art high efficient soundproof materials do not have a prominent effect, and generate harmful gas, which harms the human health; and provides a multimode inorganic filler / polymer composite damping material. The damping material comprises the following materials: thermoplastic resin and an inorganic filler, which has been subjected to a surface treatment with a coupling agent processing fluid; wherein the inorganic filter accounts for 15 to 80 wt% of the total weight of the damping material, and the balance being thermoplastic resin. In the damping material, the binding between each particle is abnormal, thus the internal friction between incident sound waves in this structure is effectively increased, thus a relaxation effect is generated, and the sound is absorbed. Fillers with different particle sizes are corresponding to sound waves in different bandwidths or frequencies, so sounds in different frequencies can all be absorbed by the damping material, and moreover the damping material has a good soundproof effect, and is suitable for promotion and application.

Owner:浙江艾迪雅科技有限责任公司

Multi-chamber noise control system

A noise control system is operable within a box-like structure provided by the dual bulkhead plenum of the vehicle dashboard positioned within the transfer path along which the noise is being transmitted from the source of the generated noise to the receiver of the noise in the passenger compartment of an automobile. The plenum is divided into discrete chambers into each of which is provided a counter noise generating apparatus to create a counteracting noise offsetting the noise generated at the source. The acoustic resonance of the chambers amplifies the noise control energy. The geometry of the individual chambers can be varied to optimize the packaging and sound control or shaping strategy. The sound energy permitted to pass through the plenum to the driver's side of the passenger compartment can be tuned to be different than the noise received in the passenger's side.

Owner:FORD GLOBAL TECH LLC

Surround sound loudspeaker system

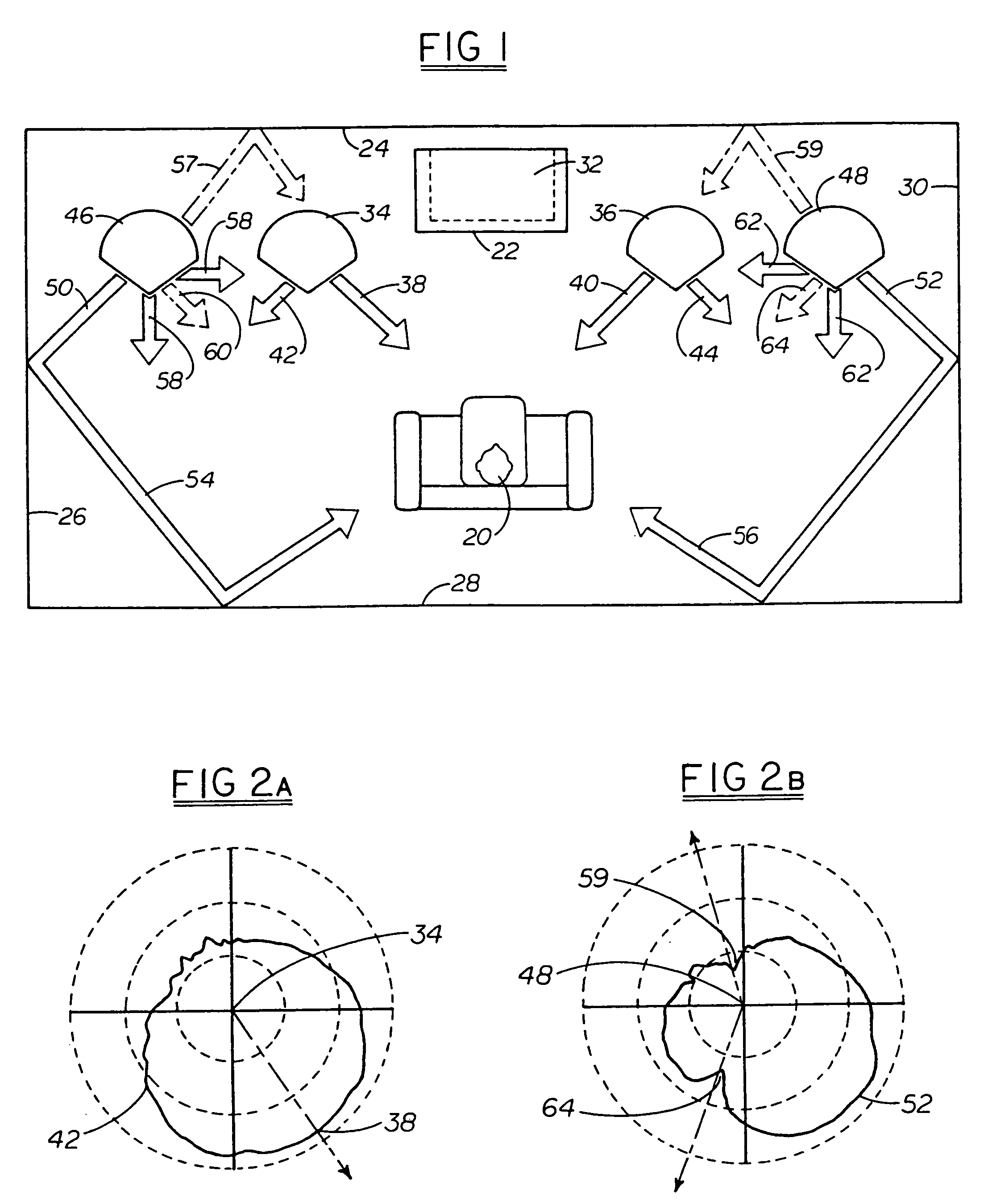

InactiveUS7092541B1Transducers for sound channels pluralityLoudspeaker enclosure positioningEnergy gradientSingle point source

A single loudspeaker has a substantially single-point source of sound energy derived from multiple drivers to provide a surround sound effect. The surround sound is effective for listeners close to the single loudspeaker or substantially distant within a room. The physical size of the loudspeaker is convenient for placement on top of a computer monitor or television set. The single loudspeaker produces a dynamically variable energy gradient between the listener's right and left ears and the perception of sound emanating from changing locations in the space surrounding the loudspeaker. The placement of a plurality of these loudspeakers surrounding the expected listener location allows the coverage of larger spaces with separate dynamically variable energy gradient pairs.

Owner:KRAUSSE HOWARD

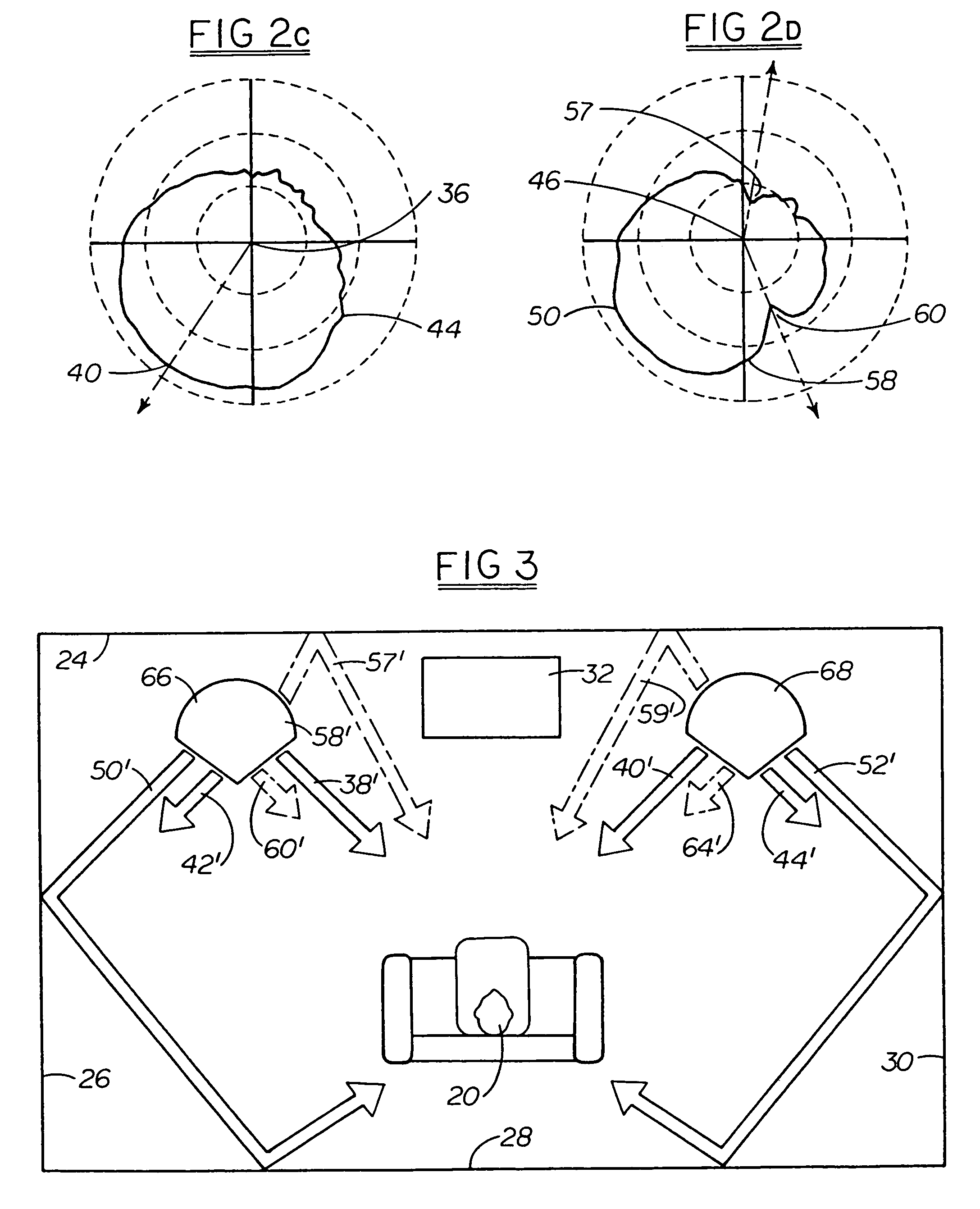

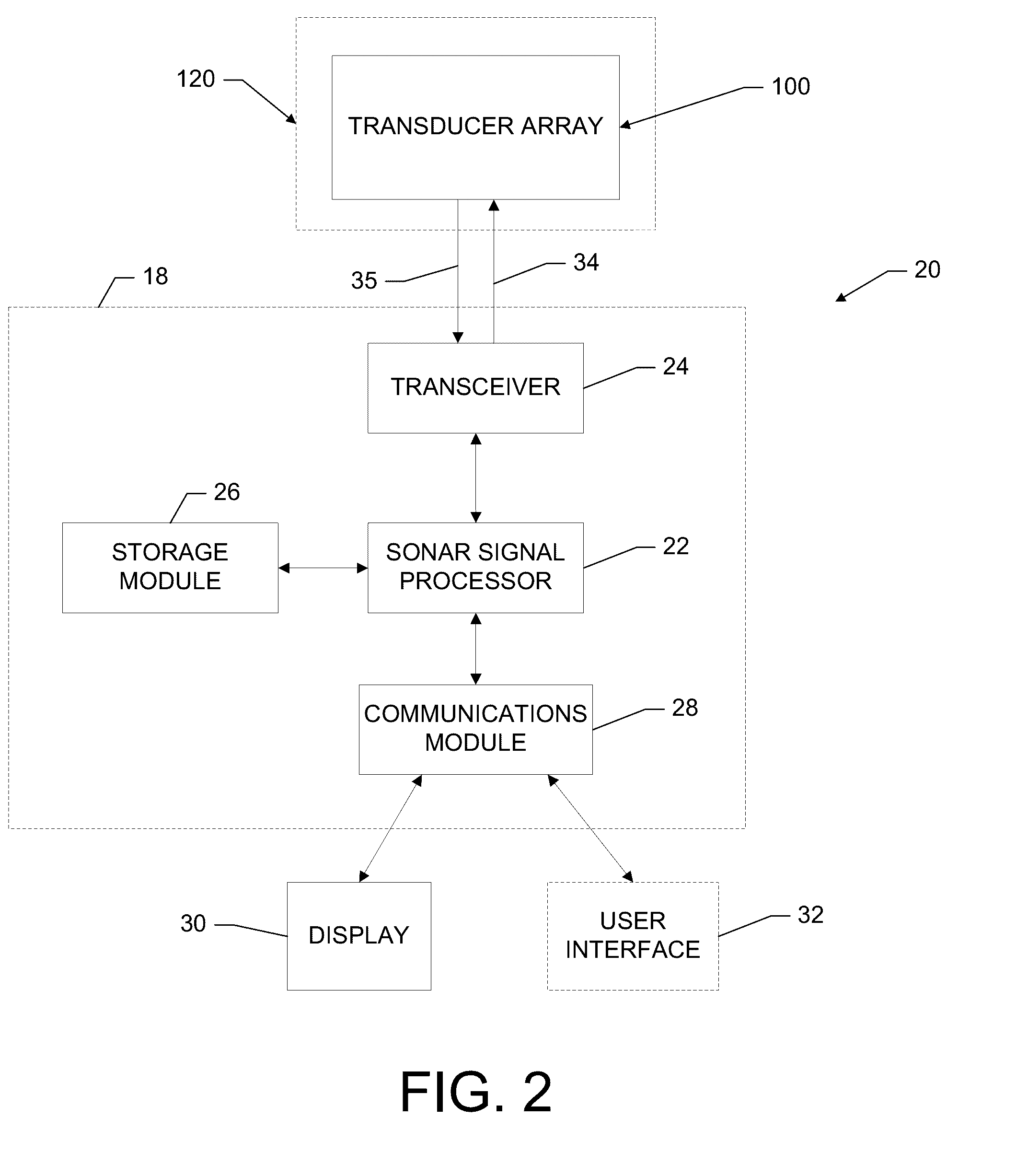

Sonar systems and methods using interferometry and/or beamforming for 3D imaging

Provided are a sonar system, transducer assembly, and method for imaging an underwater environment. The sonar system may include a housing having a transducer array defining first and second rows of transducer elements positioned at a predetermined distance. The first row of transducer elements may include at least first and second transducer elements configured to convert sound energy into first and second sonar return data. The second row of transducer elements may include at least third and fourth transducer elements configured to convert sound energy into third and fourth sonar return data. A sonar signal processor may be configured to process the first and second sonar return data and third and fourth sonar return data to generate respective first and second array sonar return data corresponding to a plurality of first and second receive beams and generate 3D sonar return data by correlating the angles associated with the receive beams.

Owner:NAVICO HLDG

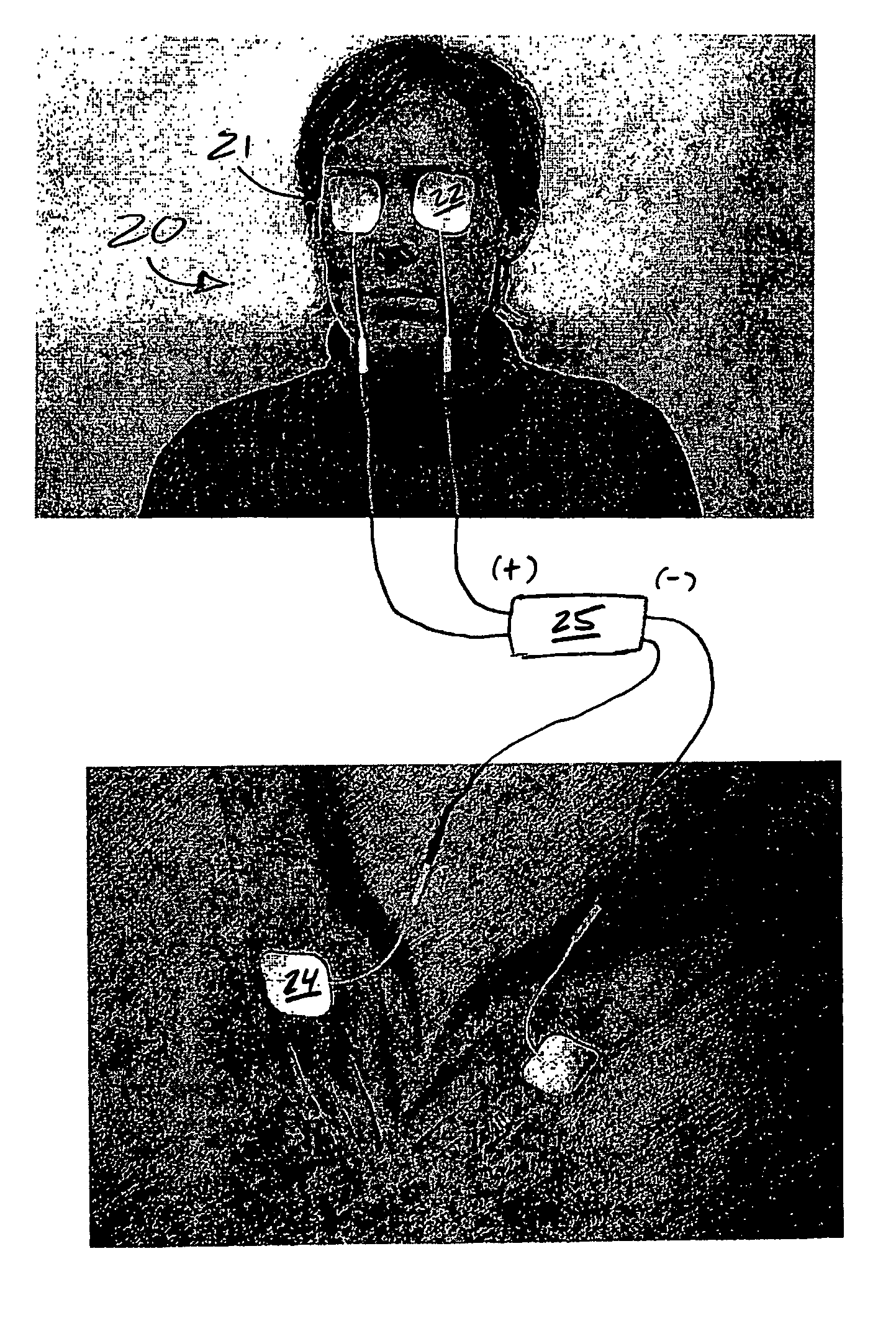

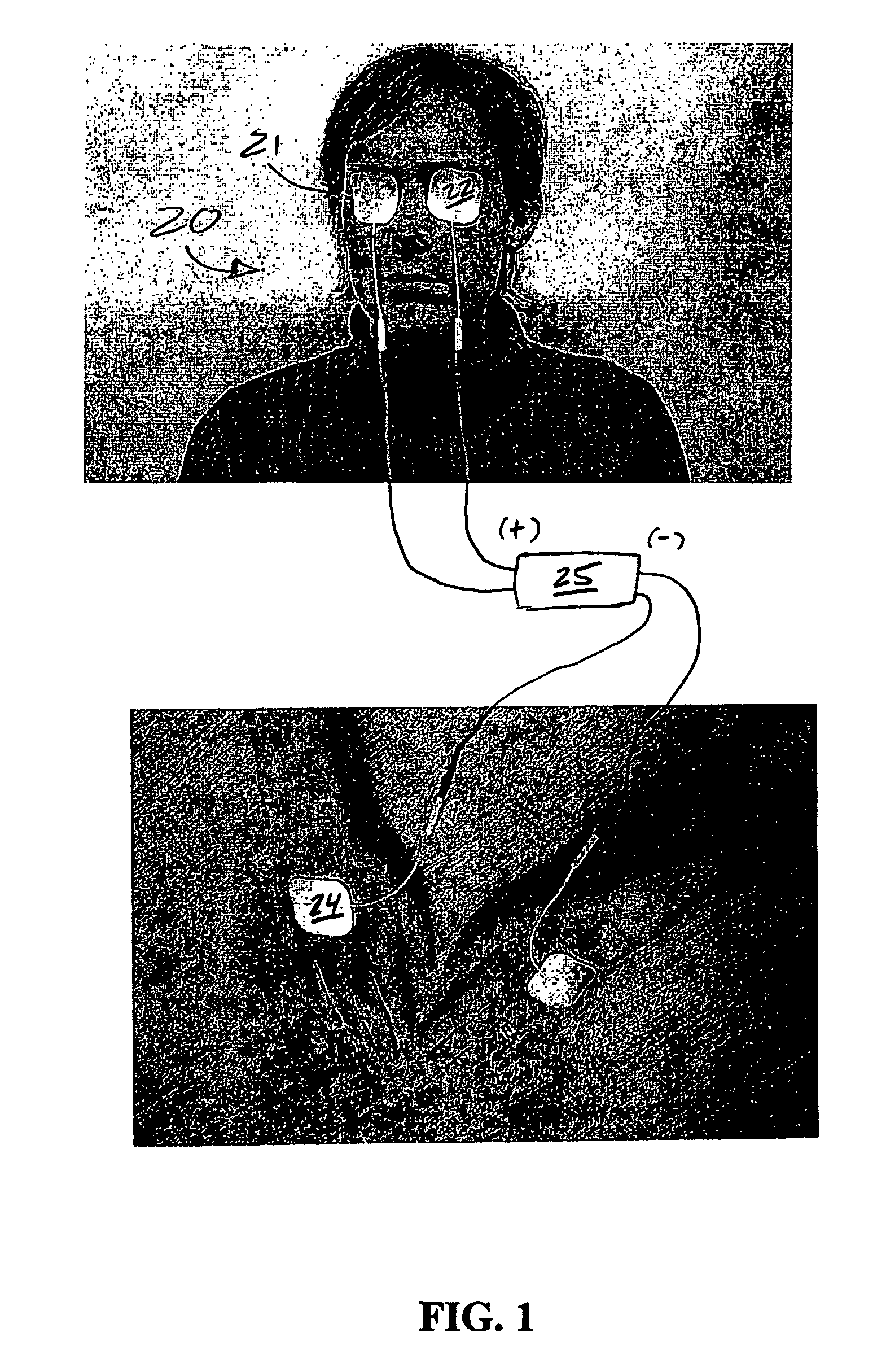

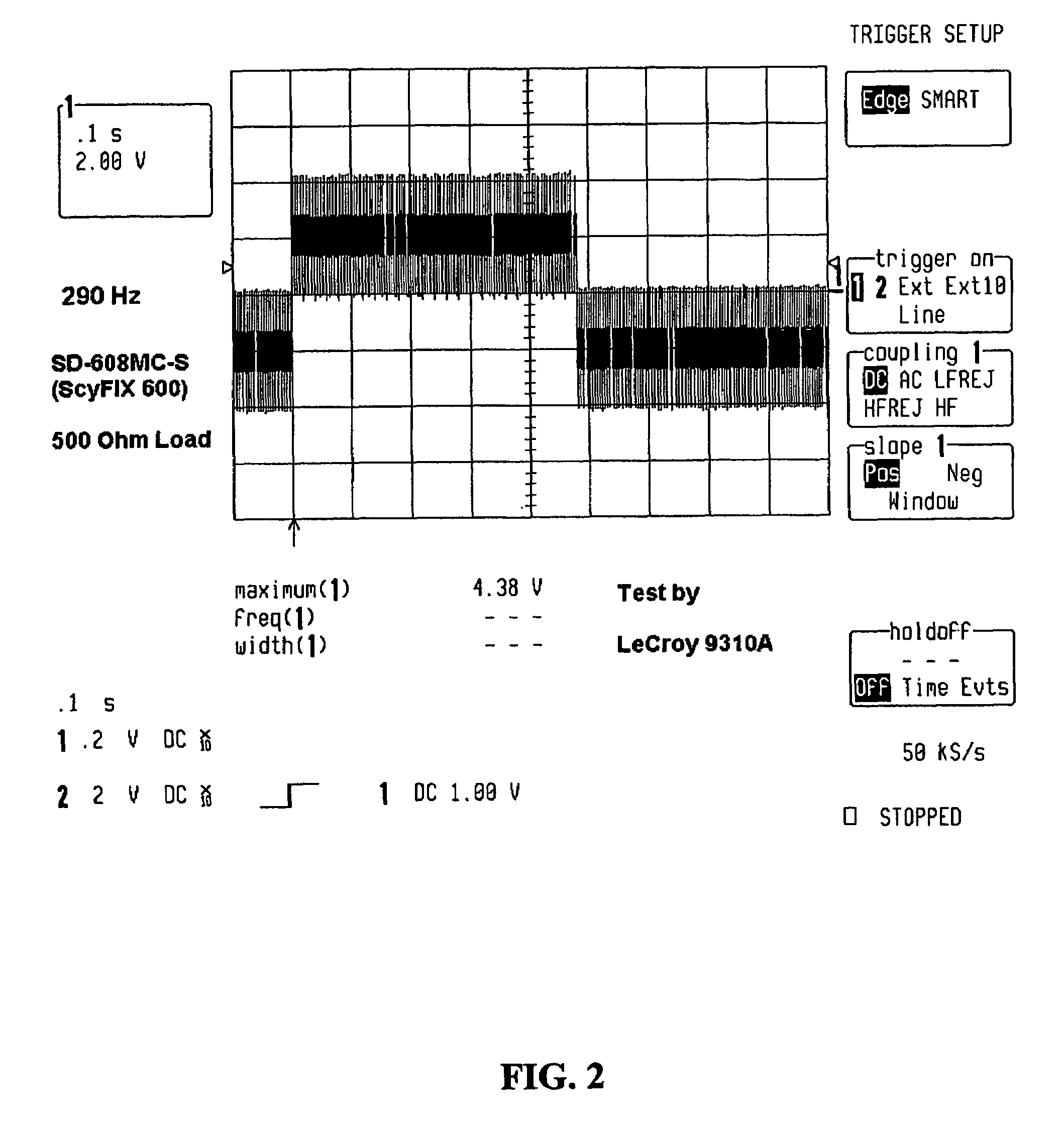

Treatment of vision disorders using electrical, light, and/or sound energy

ActiveUS7251528B2Restore visionSafe, improved, noninvasive method for the restoration of visionElectrotherapyLight therapySound energyLight energy

A non-invasive ocular therapy for vision disorders is provided. First and second electrodes of a direct current source are electrically contacted so as to deliver current to and / or about an area proximal one or more eyes of a subject. A direct electrical current of between about 1-800 microamps, at a resistance assumption of about 500 ohms, is generated between the electrodes for a preselected duration. Preferably, the direct electrical current is generated at a select frequency profile as a function of time, and with a carrier signal of about 10,000-12,000 hertz. Advantageously, the subject therapy is augmented via application of light energy to the eye(s), as well as by the application of infrasonic sound waves directly into eyes.

Owner:BIOVISICS MEDICAL INC

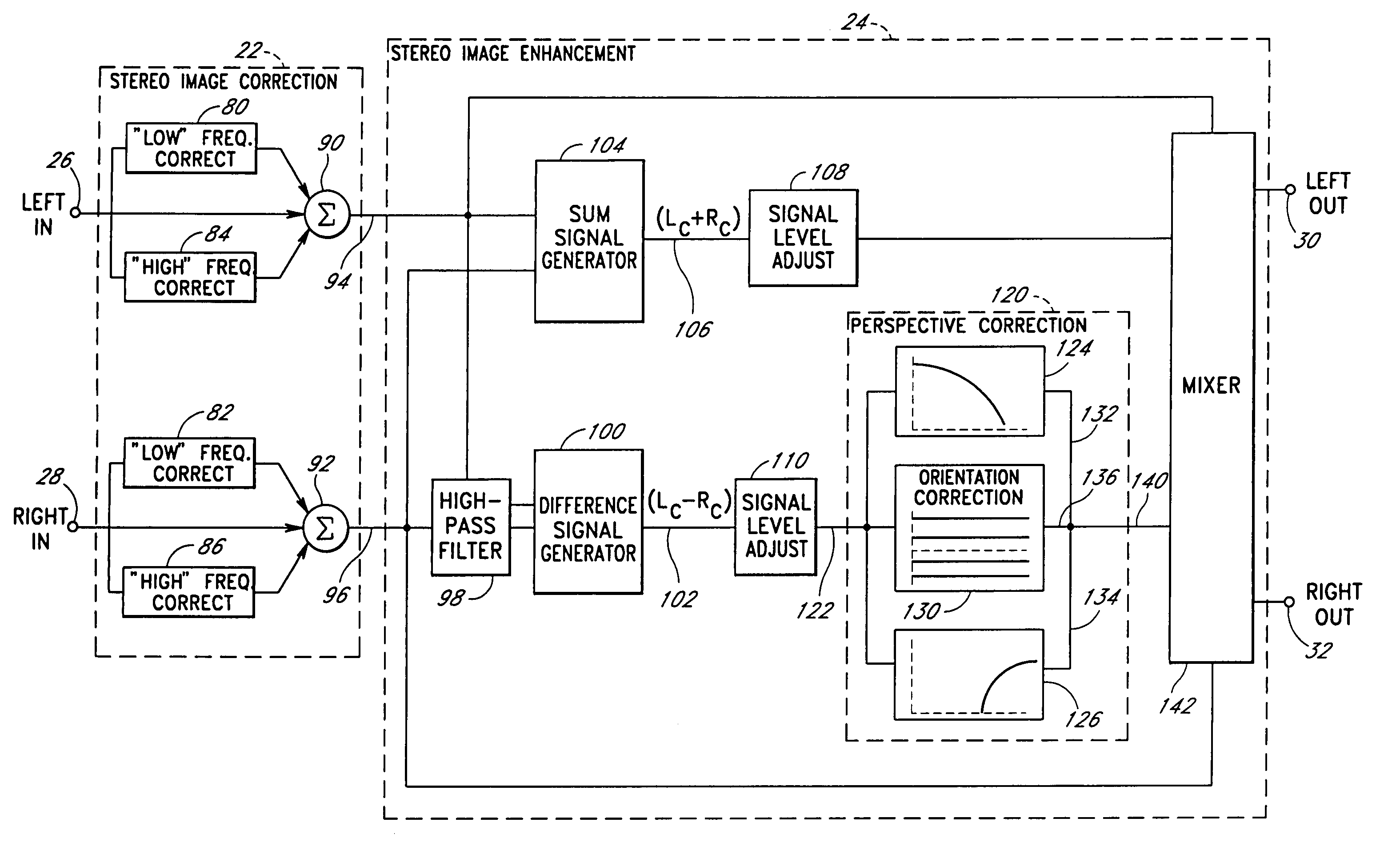

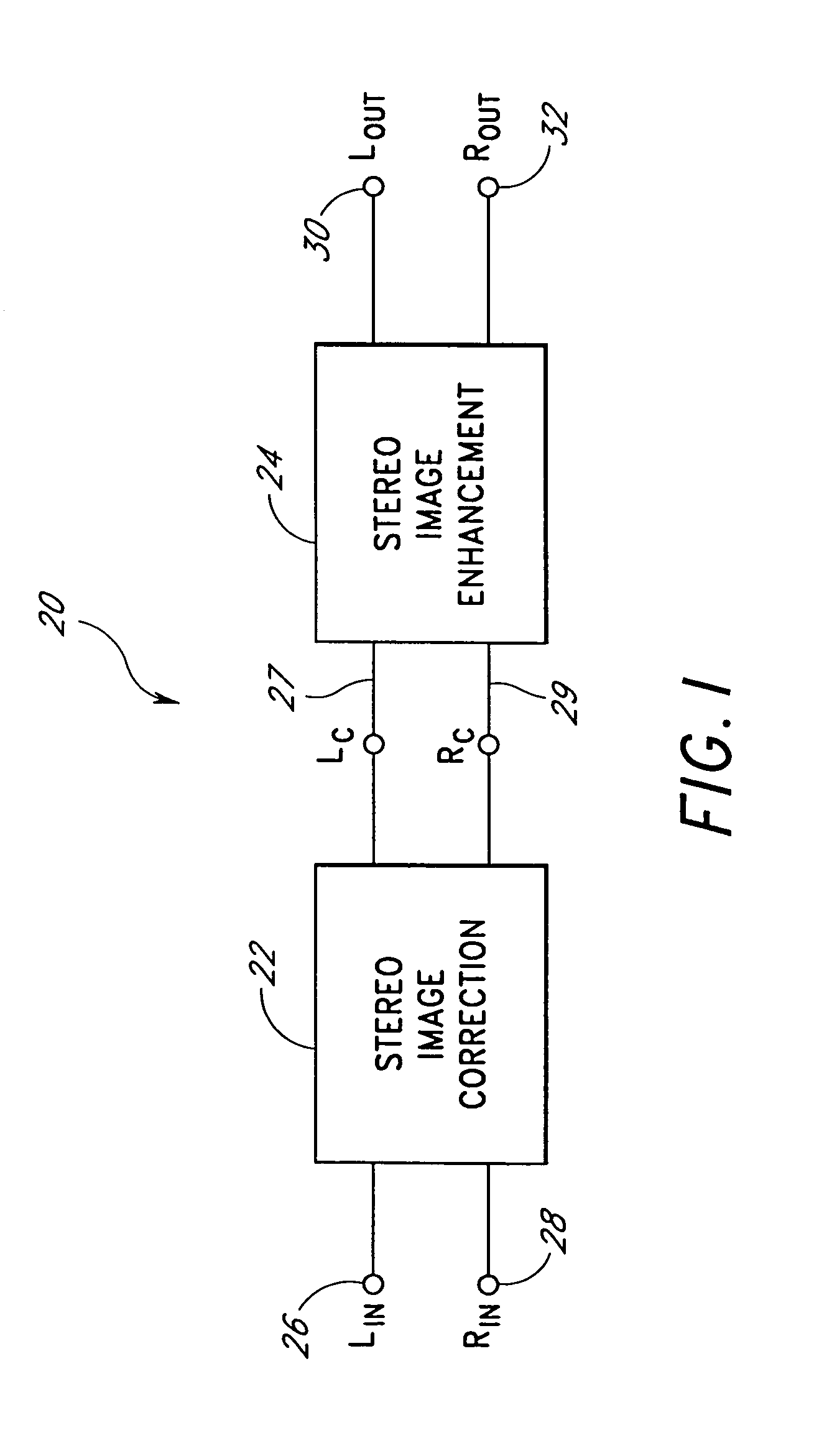

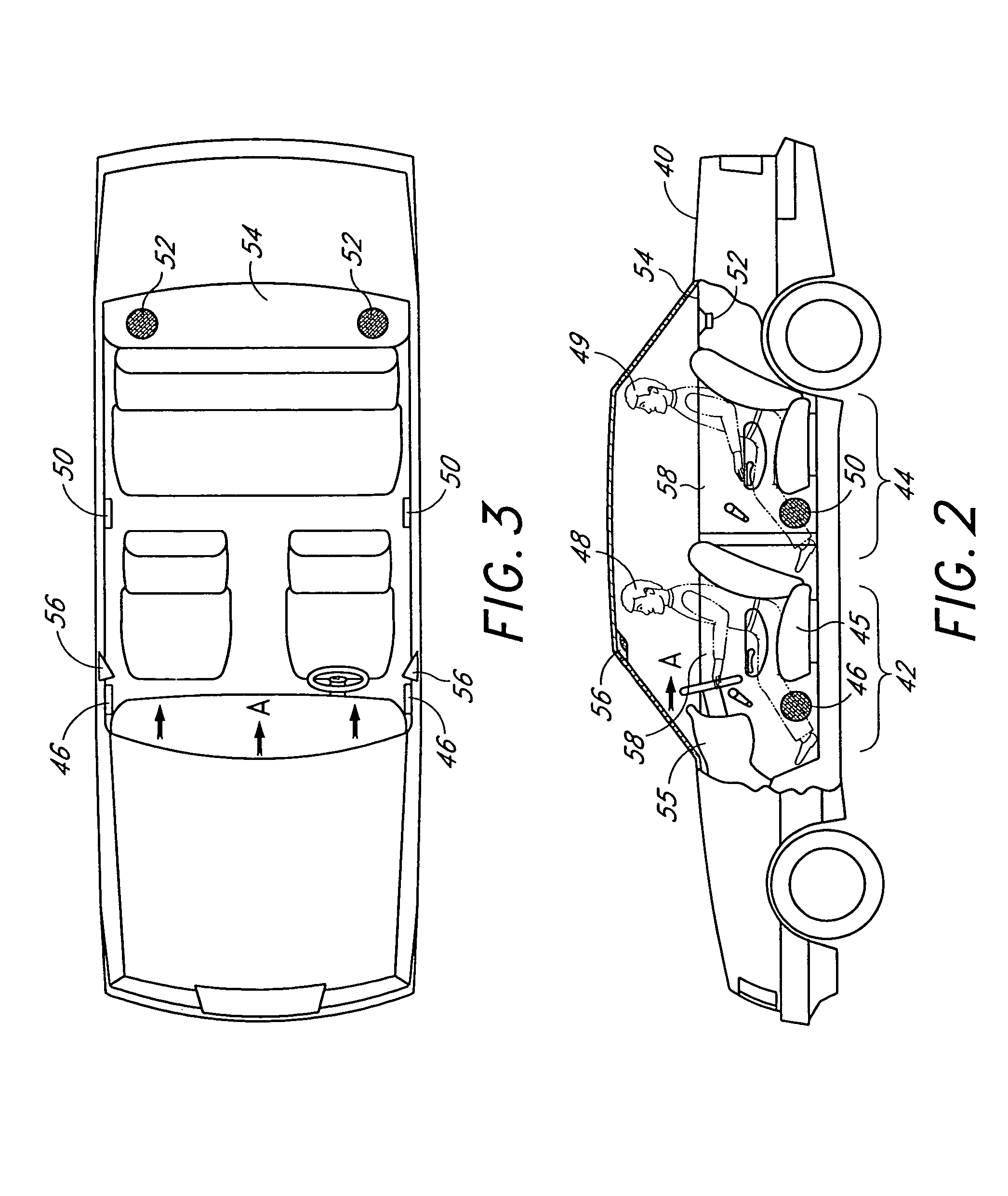

Acoustic correction apparatus

An acoustic correction apparatus processes a pair of left and right input signals to compensate for spatial distortion as a function of frequency when the input signals are reproduced through speakers in a sound system. The sound-energy of the left and right input signals is separated and corrected in a first low-frequency range and a second high-frequency range. The resultant signals are recombined to create image-corrected audio signals having a desired sound-pressure response when reproduced by the speakers in the sound system. The desired sound-pressure response creates an apparent sound image location with respect to a listener. The image-corrected signals may then be spatially enhanced to broaden the apparent sound image.

Owner:DTS

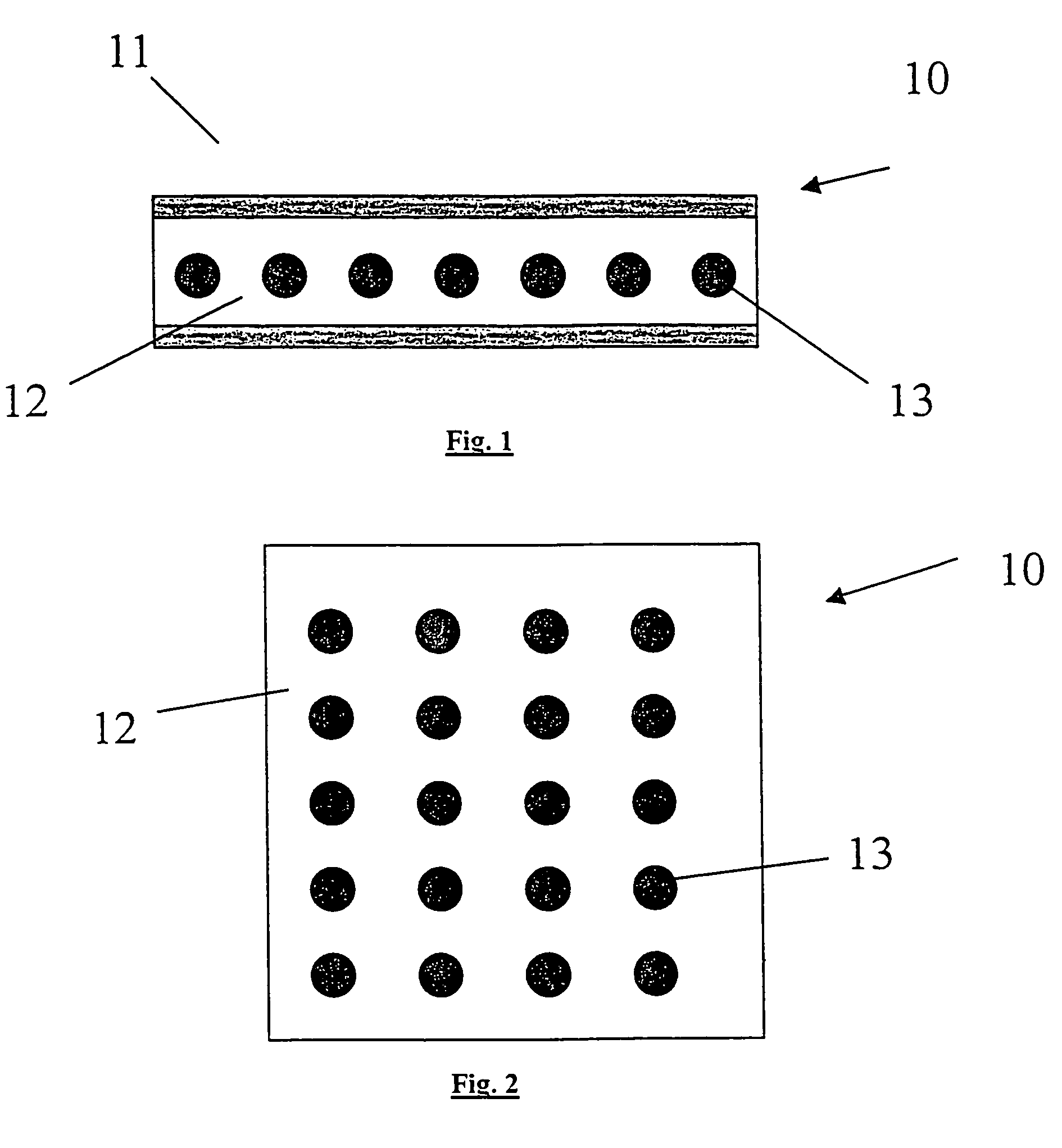

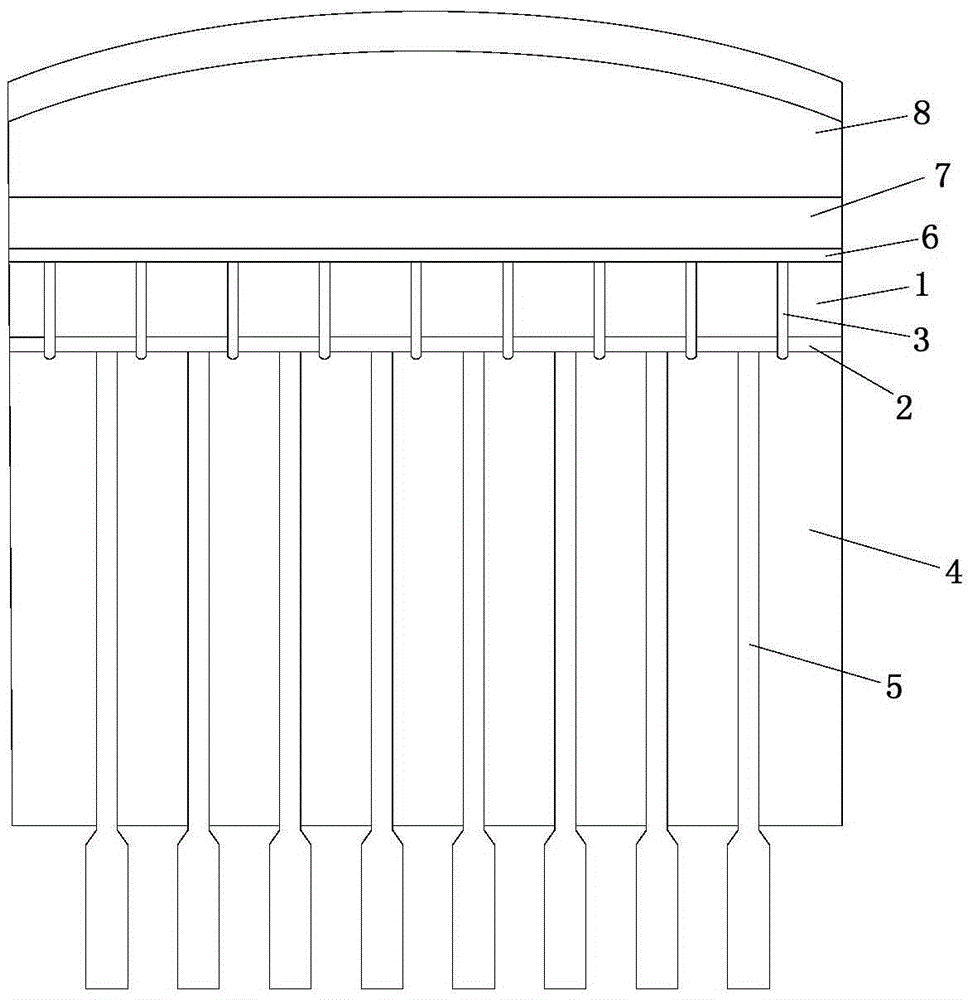

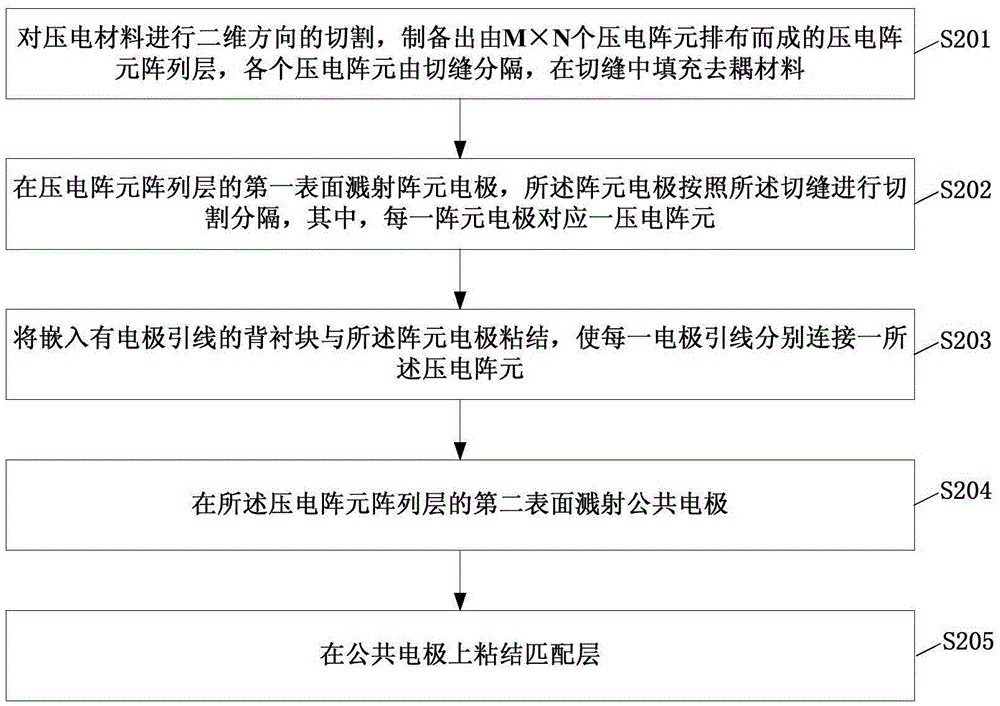

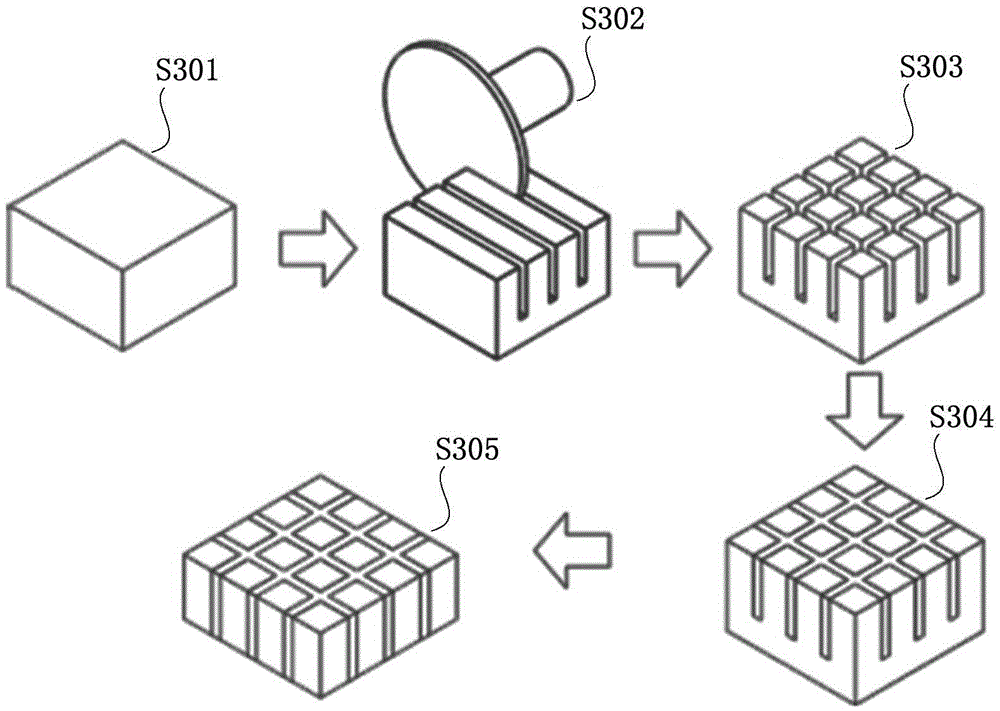

Two-dimensional area array ultrasonic transducer and manufacturing method thereof

InactiveCN105411623AImprove cooling effectSimplify complexityUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySound energyUltrasonic sensor

The invention provides a two-dimensional area array ultrasonic transducer and a manufacturing method thereof. The two-dimensional area array ultrasonic transducer comprises a piezoelectric array element array layer, array element electrodes, decoupling materials, backing blocks, electrode leads, a public electrode and a matching layer, wherein the piezoelectric array element array layer is formed by arranging M*N piezoelectric array elements which are divided by joints and used for receiving or transmitting ultrasonic signals, the array element electrodes are sputtered on the first surface of the piezoelectric array element array layer and cut and divided according to the joints, each array element electrode corresponds to one piezoelectric array element, the joints are filled with the decoupling materials which are used for lowering crosstalk interference of the piezoelectric array elements, the backing blocks are stuck to the array element electrodes and used for absorbing sound energy of the back faces of the piezoelectric array elements, the electrode leads are arranged on the backing blocks, the public electrode is sputtered on the second surface of the piezoelectric array element array layer, and the matching layer is stuck to the public electrode and used for achieving impedance matching between the piezoelectric array elements and external objects.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

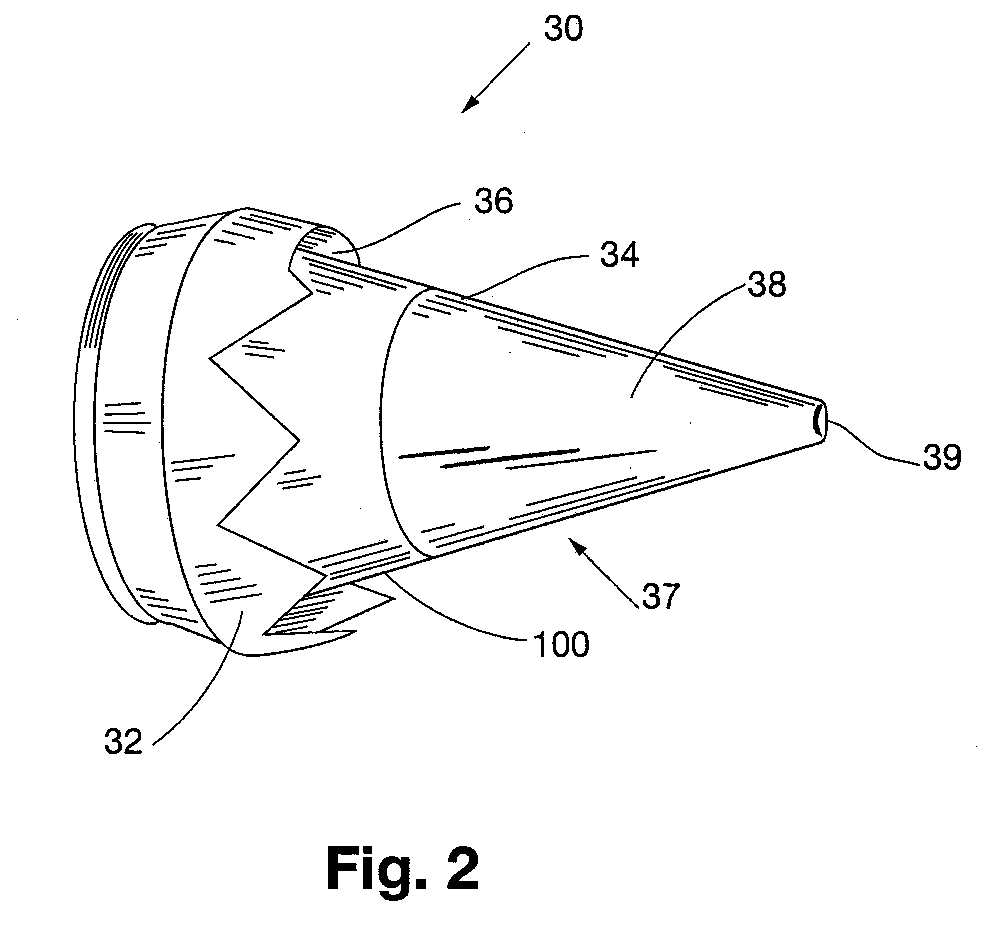

Sound-absorbing exhaust nozzle center plug

A sound-absorbing exhaust nozzle center plug for an aircraft gas turbine engine can include an outer skin and at least one forward cavity within the outer skin. At least one aft cavity can be located within the outer skin and substantially aft of the forward cavity. A perforated wall including a plurality of first openings can be disposed between the forward and aft cavities. The outer skin can include a second plurality of openings providing an acoustic pathway through the outer skin and into the forward cavity. The forward and aft cavities can be configured to absorb and dissipate relatively low-frequency sound energy emitted from an aircraft gas turbine engine's combustor.

Owner:ROHR INC

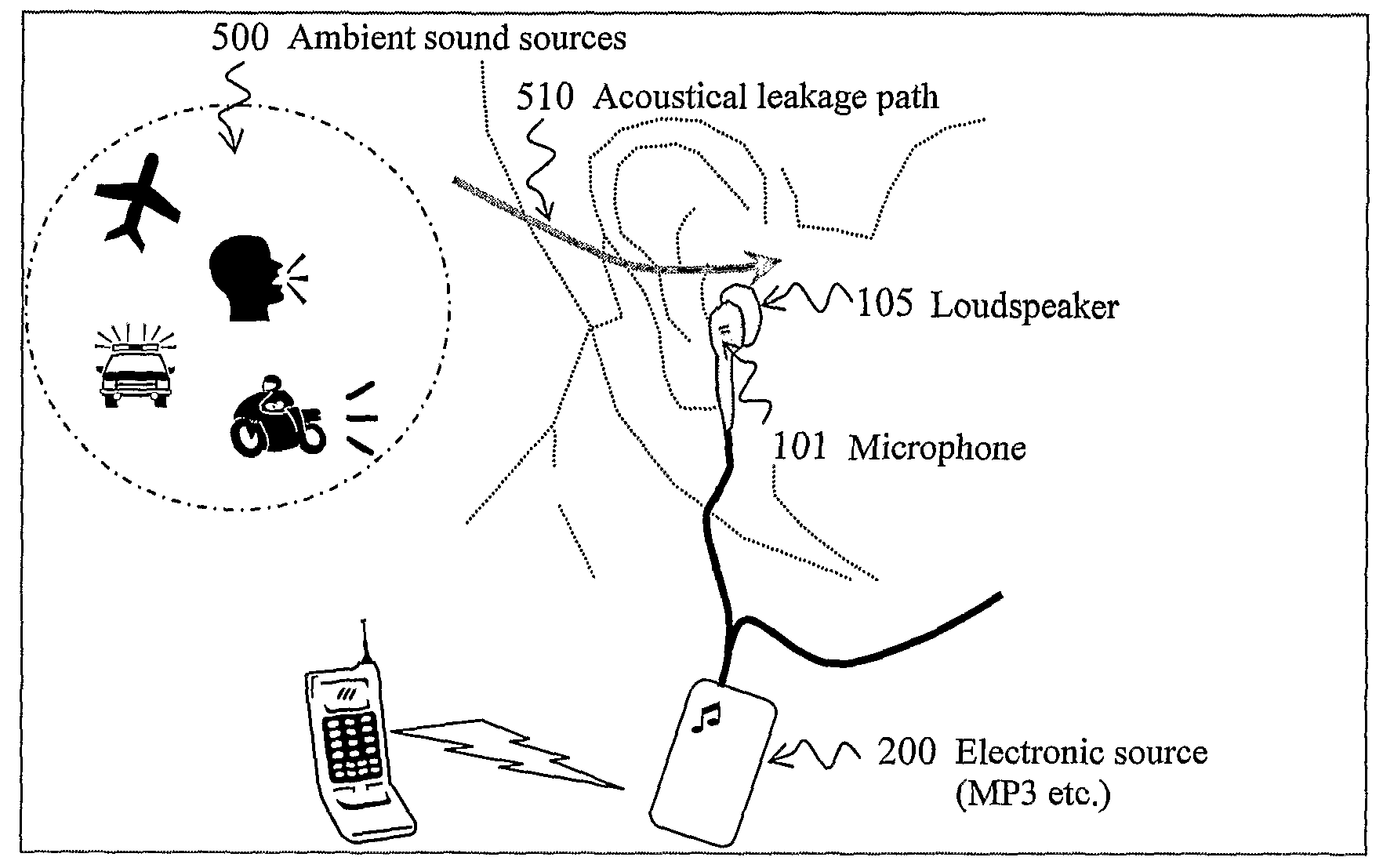

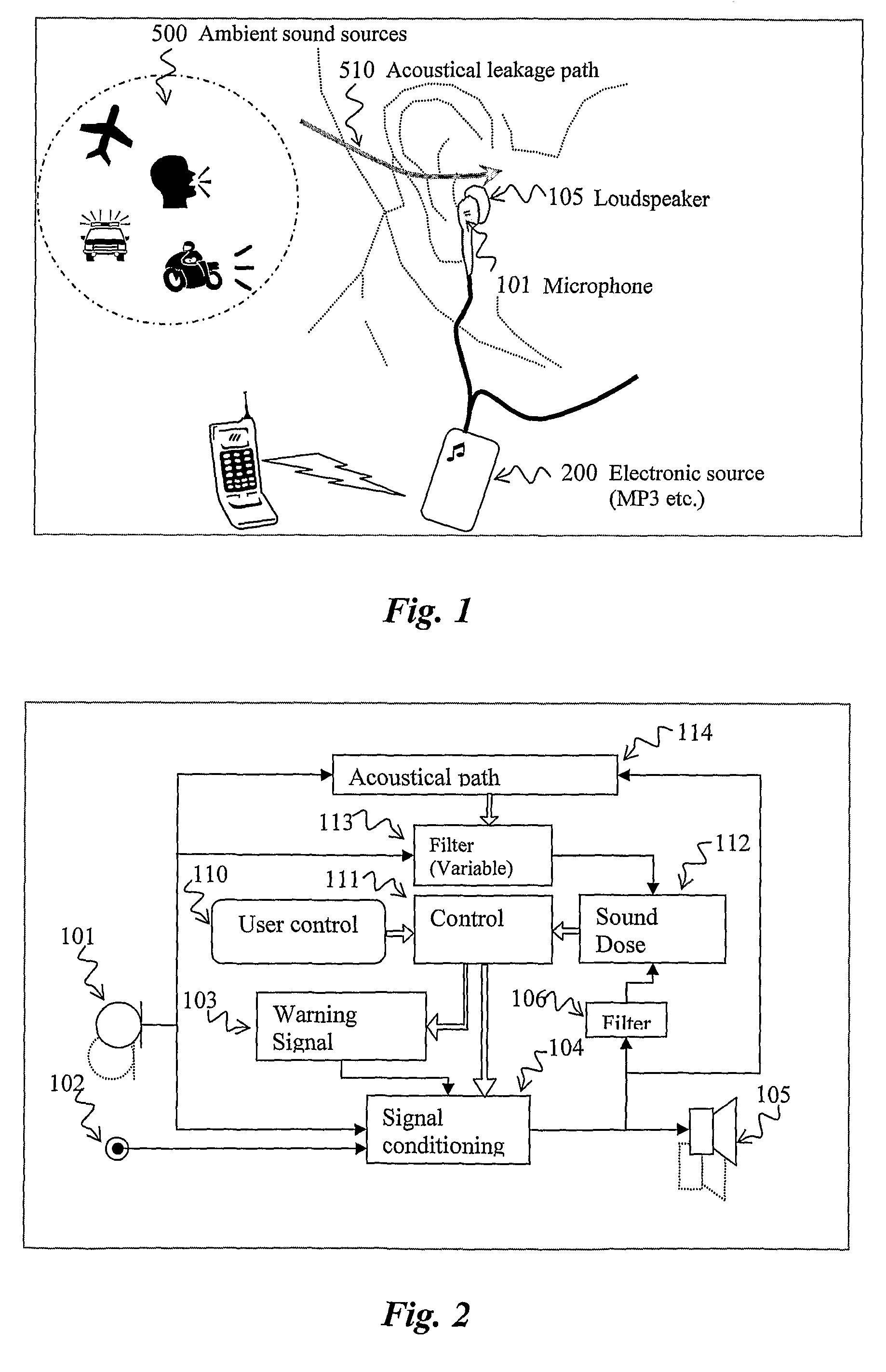

Apparatus for reducing the risk of noise induced hearing loss

InactiveUS20090208024A1Reduce riskIncreased riskVibration measurement in fluidElectrical apparatusSound energyMedicine

An apparatus is disclosed for managing the joint contribution of noise exposure of the ear of a user of the apparatus from a loudspeaker of the apparatus as well as from ambient noise so that the risk of risk of noise induced hearing losses is reduced. By assessing the joint actual sound energy delivered to the ear and feeding said assessment to a model describing the accumulated risk of hearing loss due to said sound energy accumulated over a time period, an estimate of the current risk of hearing loss is obtained. When said risk estimate passes a predetermined threshold, one or more protective measures are taken.

Owner:MICROSOUND

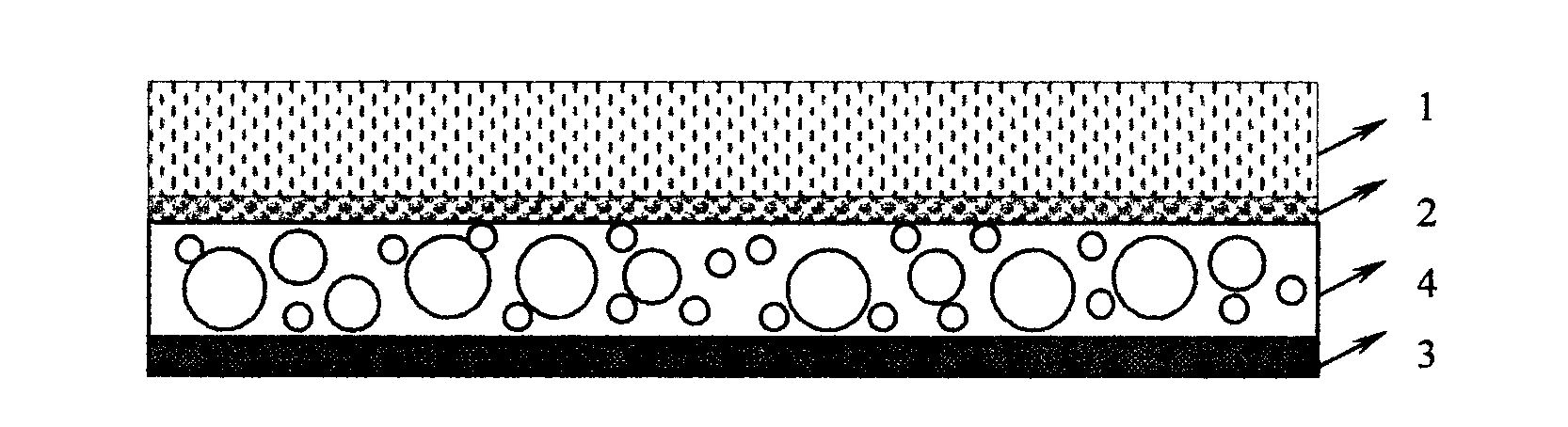

Efficient sound insulation material and manufacturing method thereof

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

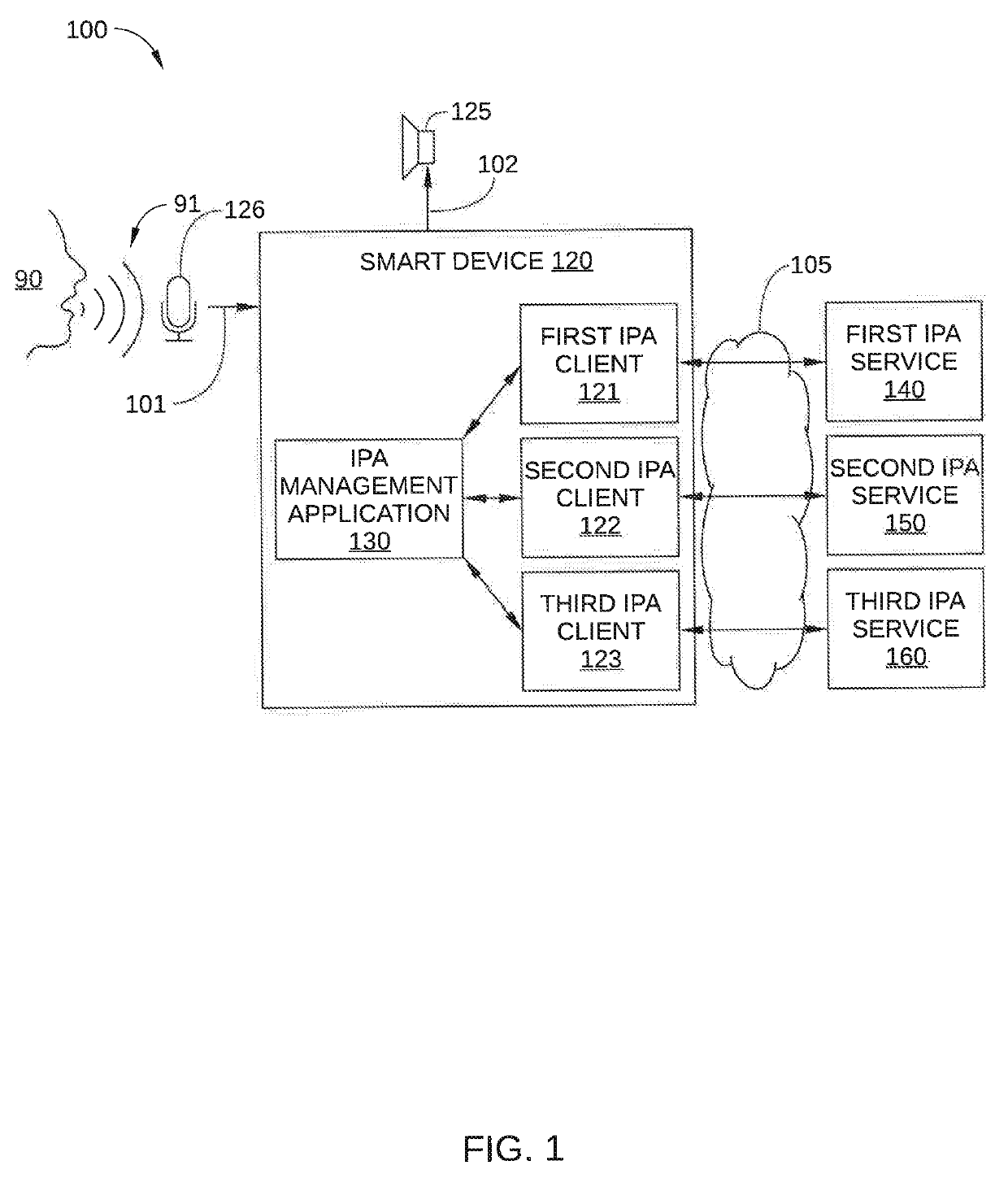

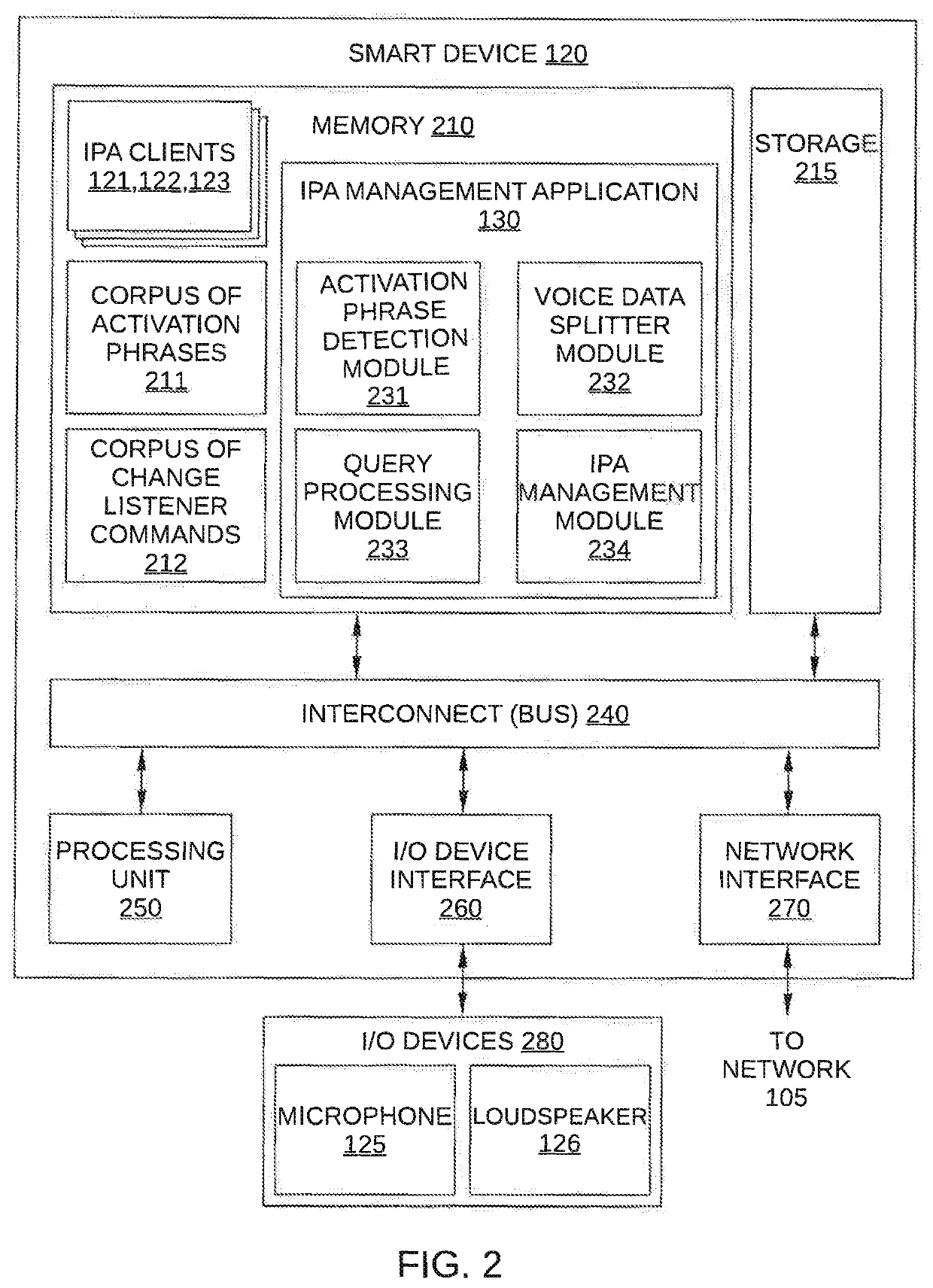

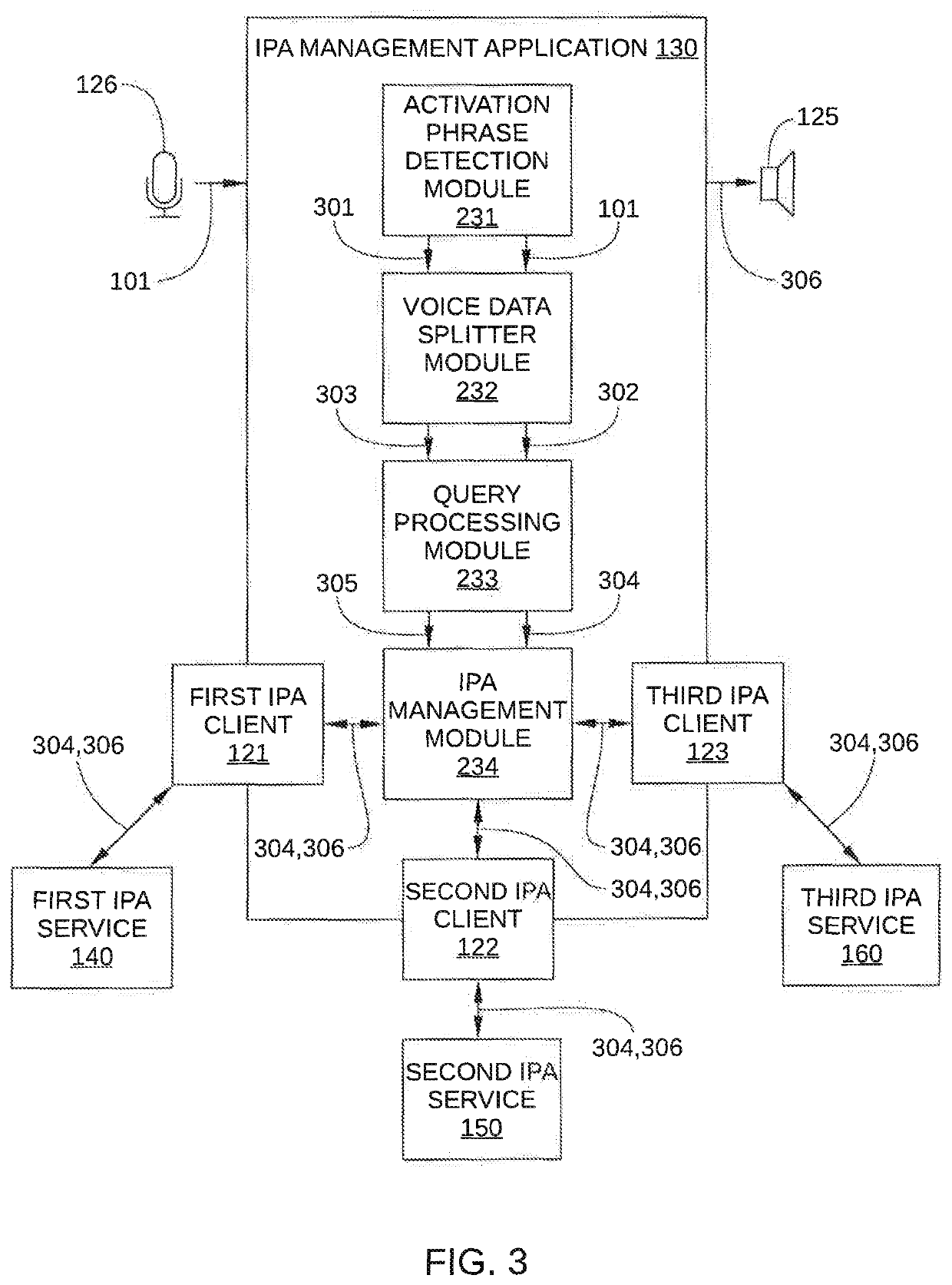

Management layer for multiple intelligent personal assistant services

Performing speech recognition in a multi-device system includes receiving a first audio signal that is generated by a first microphone in response to a verbal utterance, and a second audio signal that is generated by a second microphone in response to the verbal utterance; dividing the first audio signal into a first sequence of temporal segments; dividing the second audio signal into a second sequence of temporal segments; comparing a sound energy level associated with a first temporal segment of the first sequence to a sound energy level associated with a first temporal segment of the second sequence; based on the comparing, selecting, as a first temporal segment of a speech recognition audio signal, one of the first temporal segment of the first sequence and the first temporal segment of the second sequence; and performing speech recognition on the speech recognition audio signal.

Owner:HARMAN INT IND INC

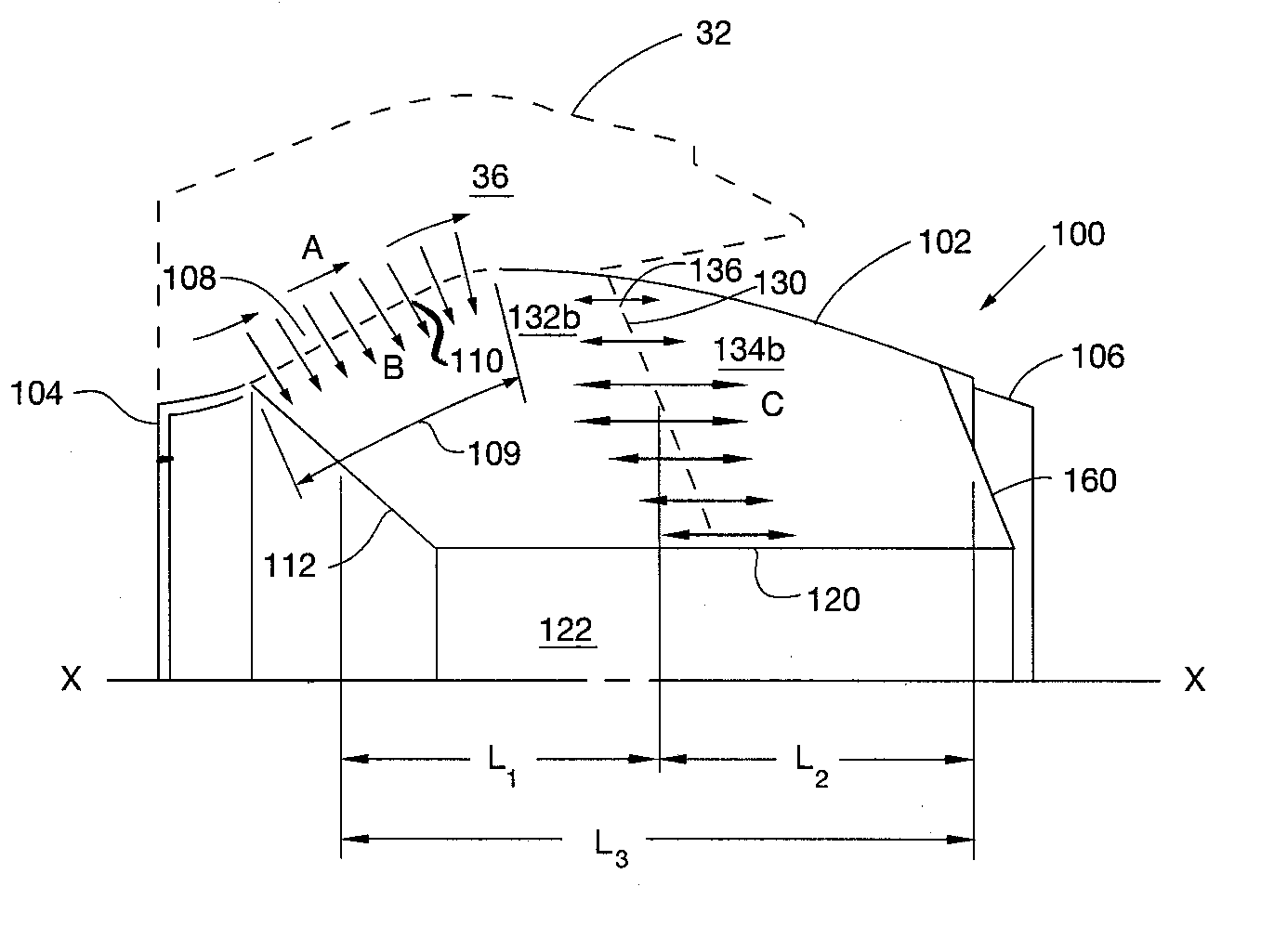

Speech signal enhancement using visual information

Visual information is used to alter or set an operating parameter of an audio signal processor, other than a beamformer. A digital camera captures visual information about a scene that includes a human speaker and / or a listener. The visual information is analyzed to ascertain information about acoustics of a room. A distance between the speaker and a microphone may be estimated, and this distance estimate may be used to adjust an overall gain of the system. Distances among, and locations of, the speaker, the listener, the microphone, a loudspeaker and / or a sound-reflecting surface may be estimated. These estimates may be used to estimate reverberations within the room and adjust aggressiveness of an anti-reverberation filter, based on an estimated ratio of direct to indirect (reverberated) sound energy expected to reach the microphone. In addition, orientation of the speaker or the listener, relative to the microphone or the loudspeaker, can also be estimated, and this estimate may be used to adjust frequency-dependent filter weights to compensate for uneven frequency propagation of acoustic signals from a mouth, or to a human ear, about a human head.

Owner:CERENCE OPERATING CO

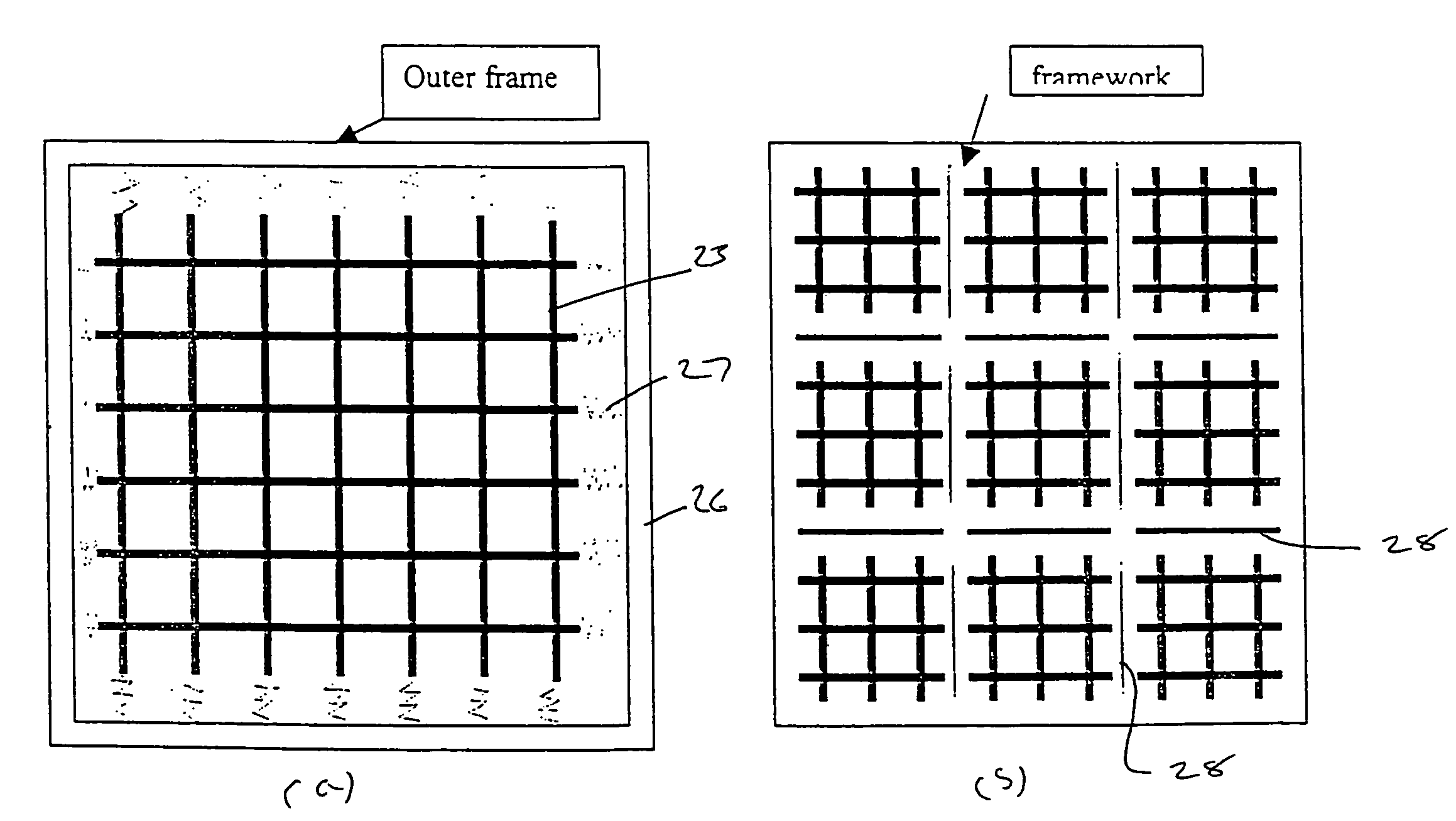

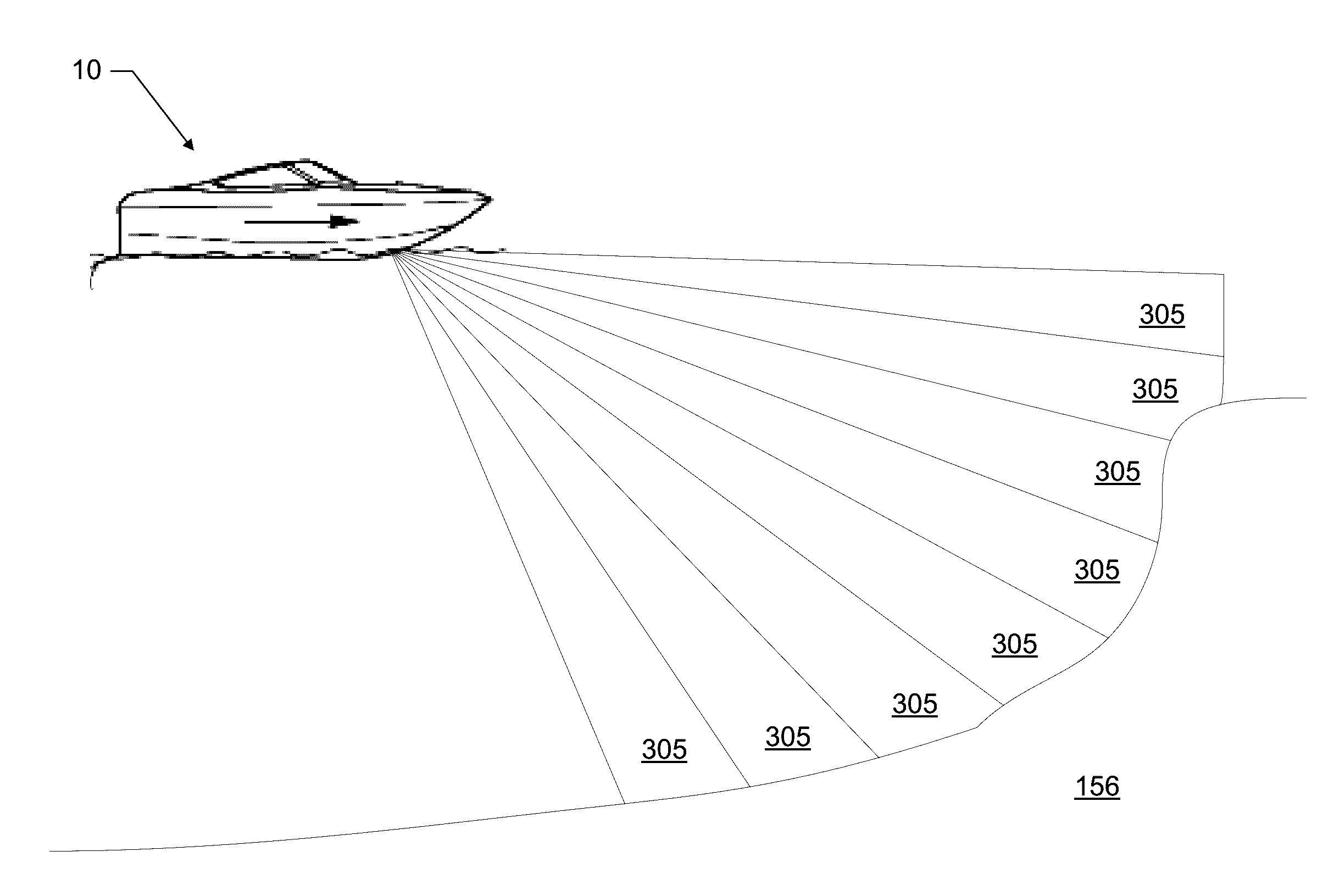

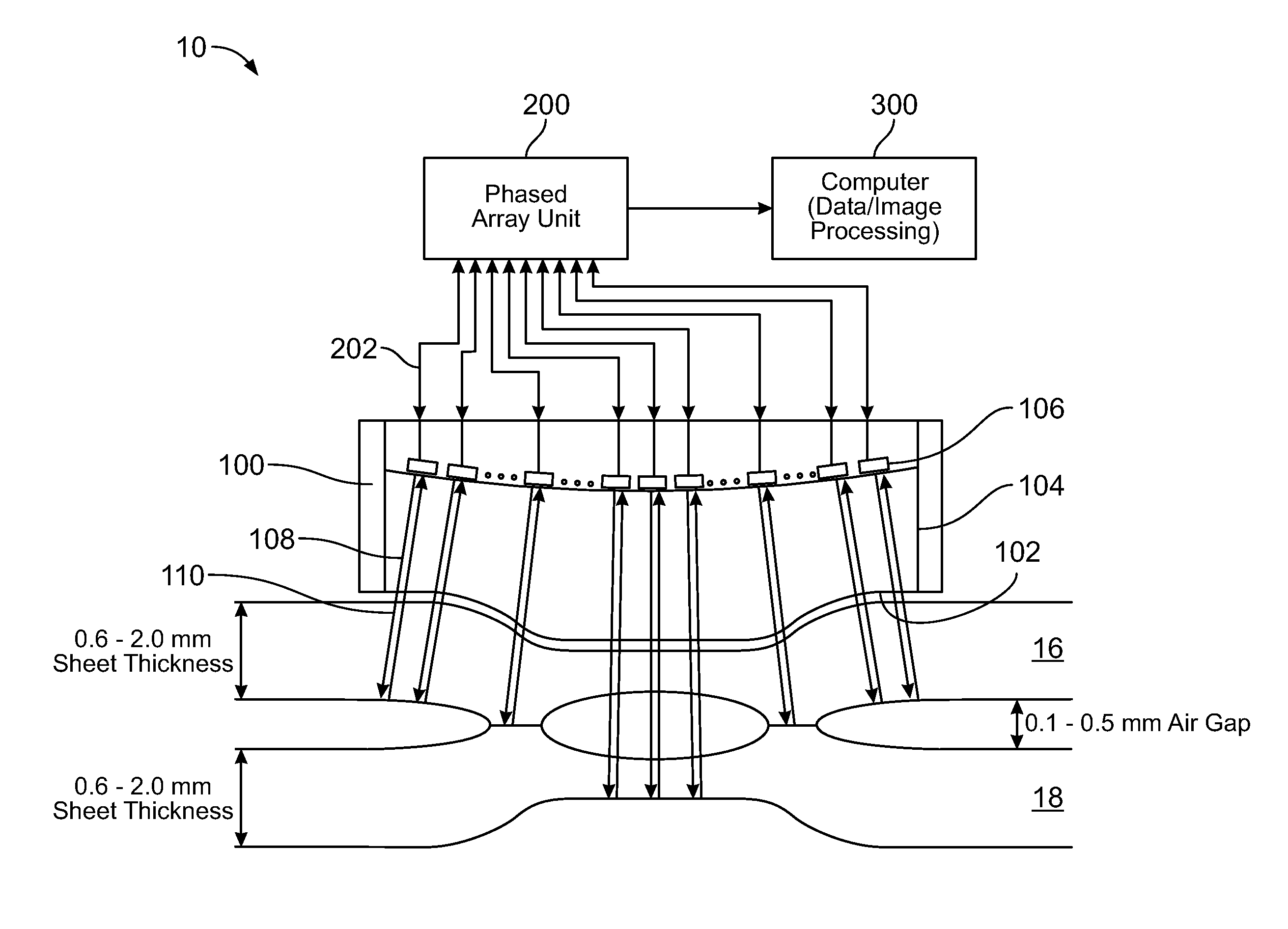

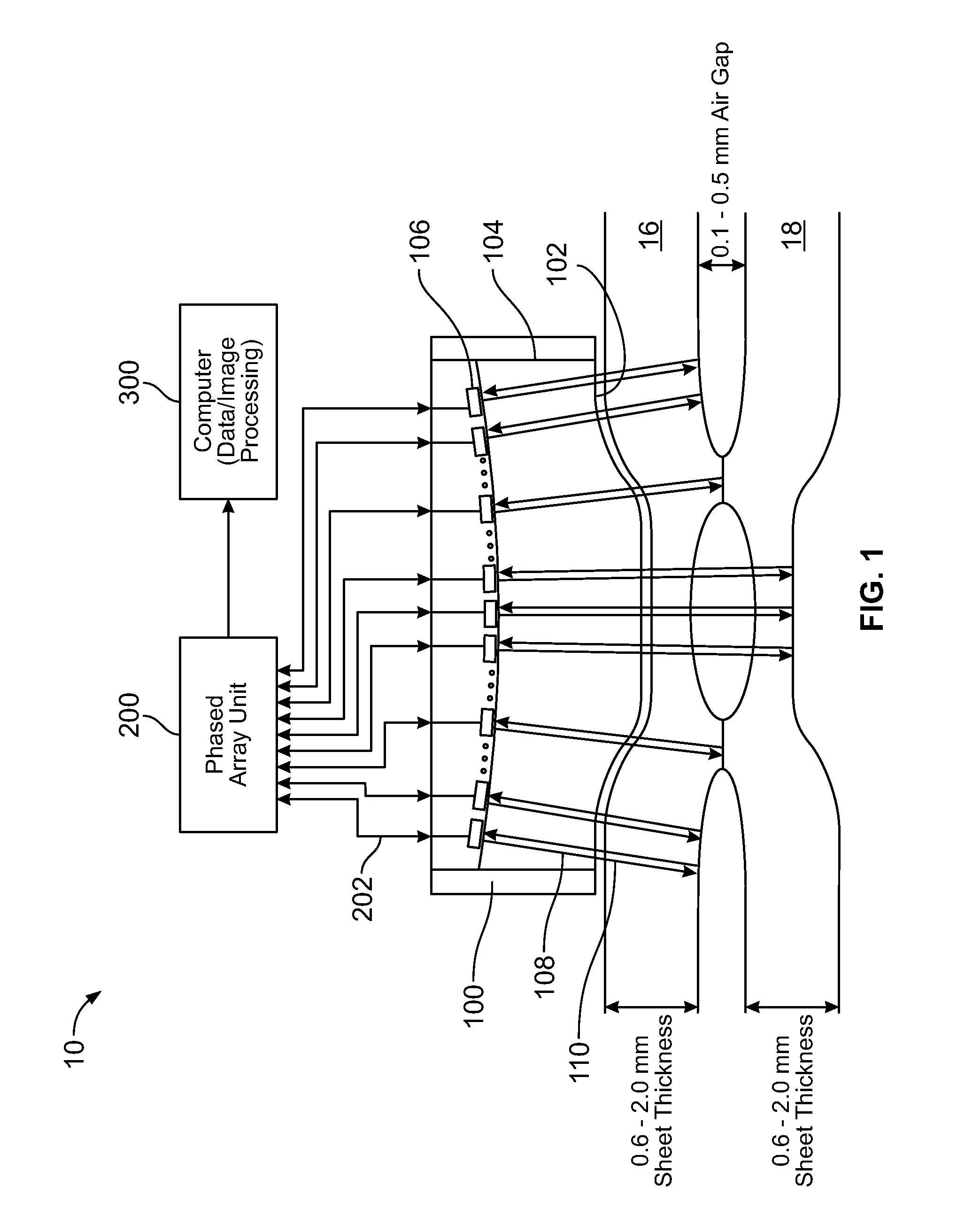

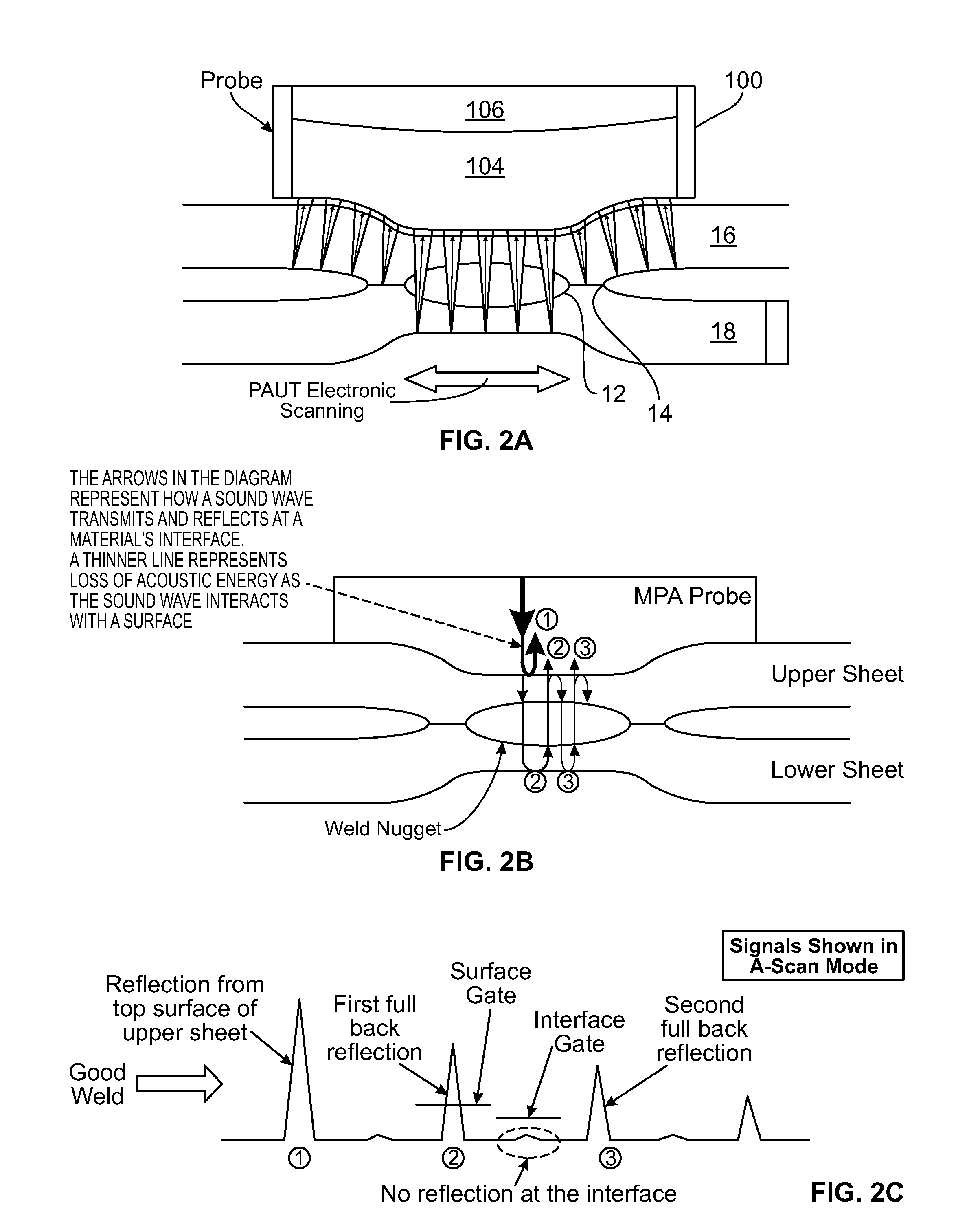

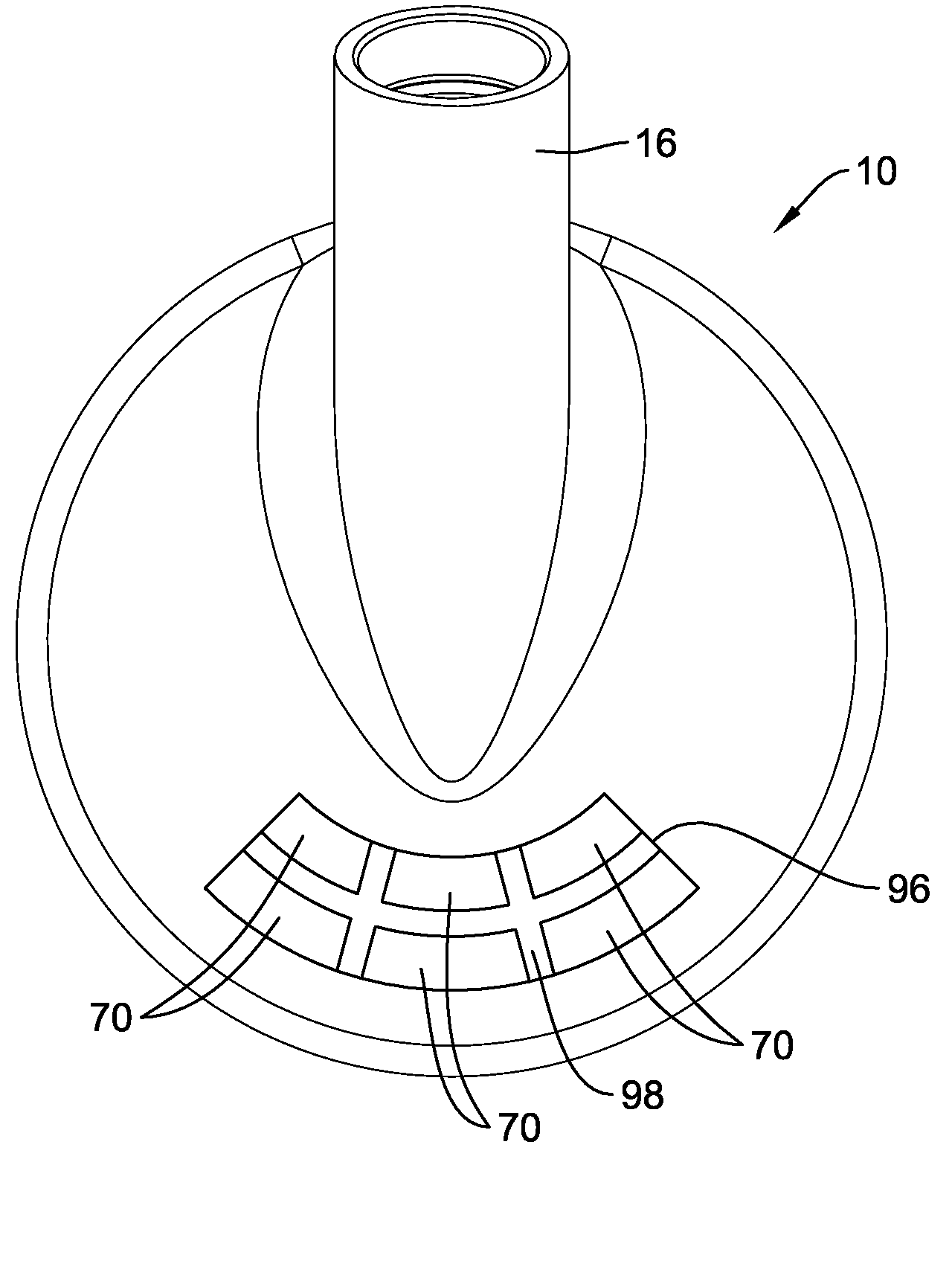

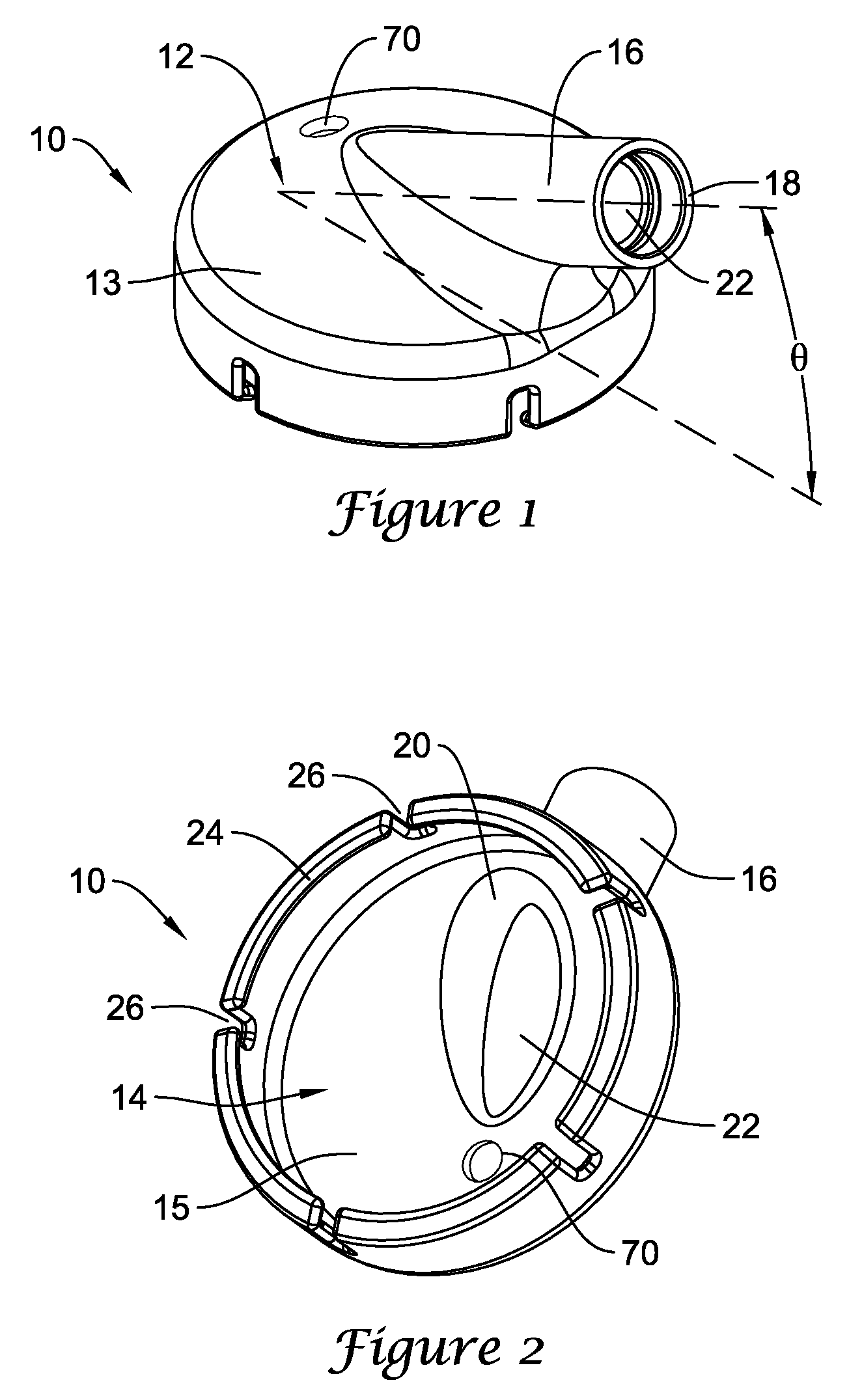

Three-dimensional matrix phased array spot weld inspection system

ActiveUS20120310551A1Material analysis using sonic/ultrasonic/infrasonic wavesSpecial data processing applicationsSound energySonification

A system for characterizing a spot weld including an acoustic probe that further includes a plurality of ultrasonic transducer elements arranged in a curved array, wherein the transducer elements are operative to generate ultrasonic signals and to receive reflections thereof; and a combination of materials for allowing the probe to conform to a contoured surface of the spot weld while enabling sound energy to be transferred directly into the spot weld under test conditions; a phased array excitation unit coupled to the array of transducer elements for ultrasonically exciting transducer elements; and a controller coupled to the phased array excitation unit for controlling the operation of the phased array unit, gathering and processing information from the ultrasonic transducers, and generating a two-dimensional, color coded image that characterizes the integrity of the spot weld.

Owner:CUMBERLAND & WESTERN RESOURCES LLC

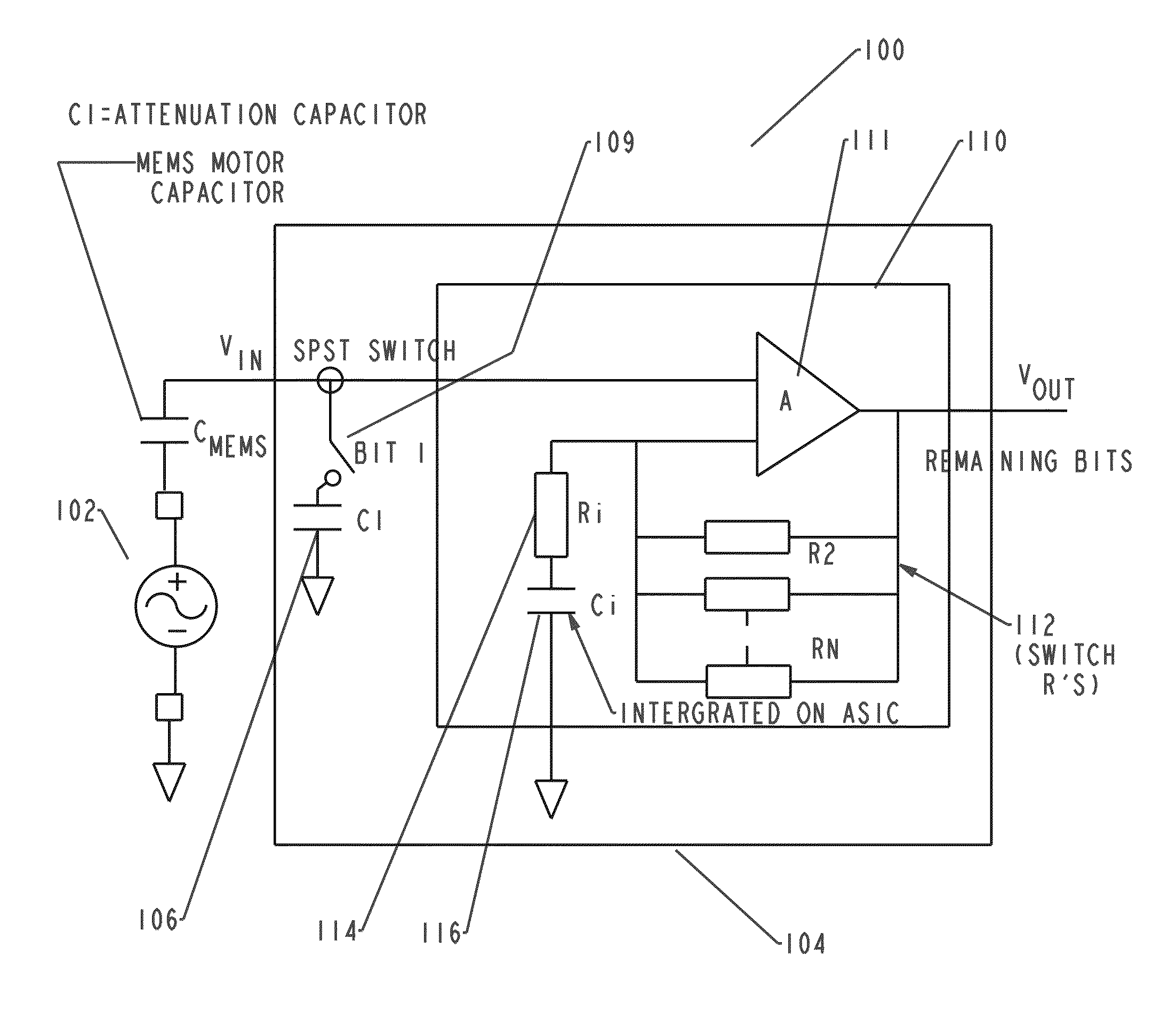

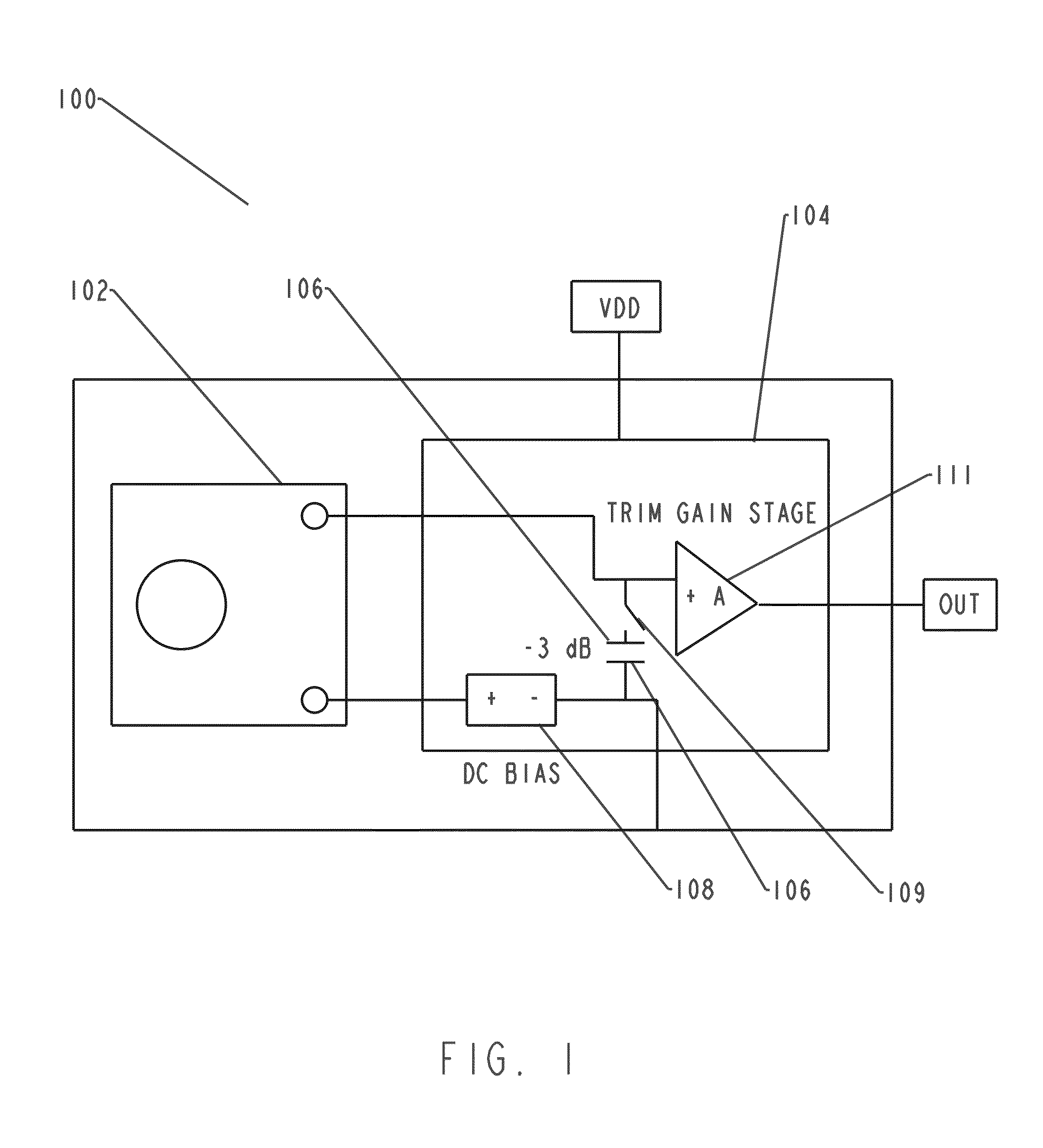

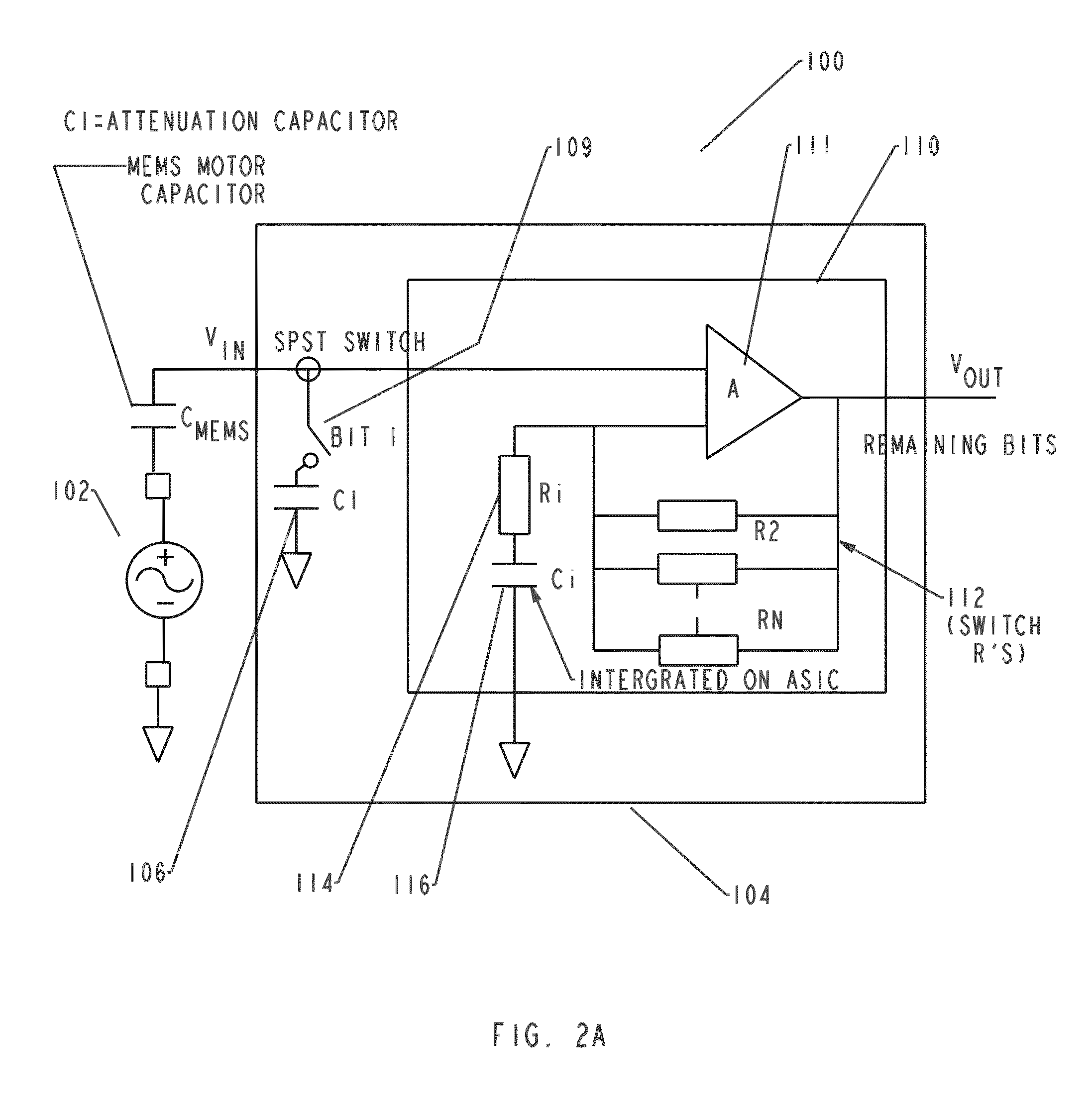

Sensitivity Adjustment Apparatus And Method For MEMS Devices

A microelectromechanical (MEMS) microphone includes a MEMS motor and a gain adjustment apparatus. The MEMS motor includes at least a diaphragm and a charge plate and is configured to receive sound energy and transform the sound energy into an electrical signal. The gain adjustment apparatus has an input and an output and is coupled to the MEMS motor. The gain adjustment apparatus is configured to receive the electrical signal from the MEMS motor at the input and adjust the gain of the electrical signal as measured from the output of the gain adjustment apparatus. The amount of gain is selected so as to obtain a favorable sensitivity for the microphone.

Owner:KNOWLES ELECTRONICS INC

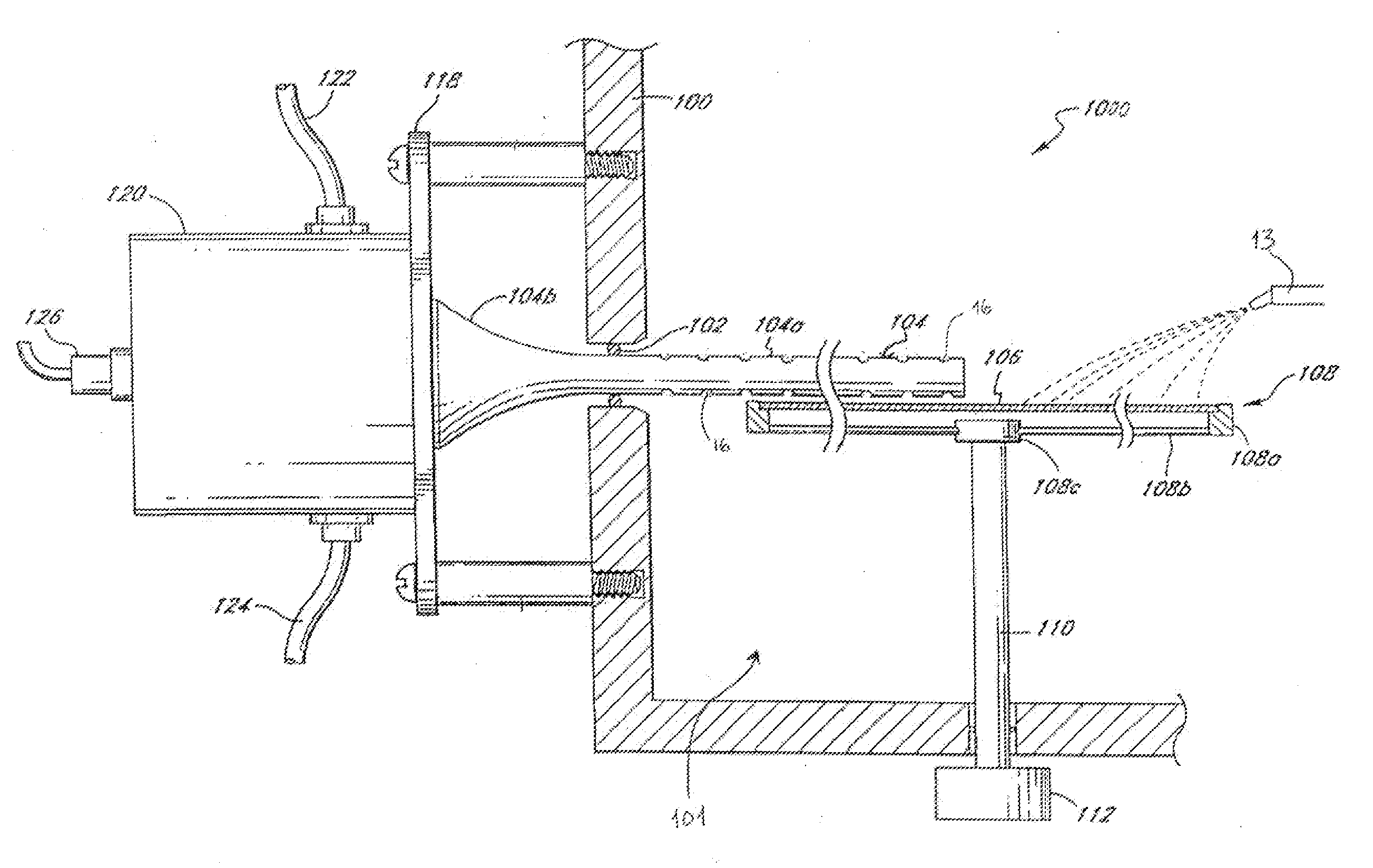

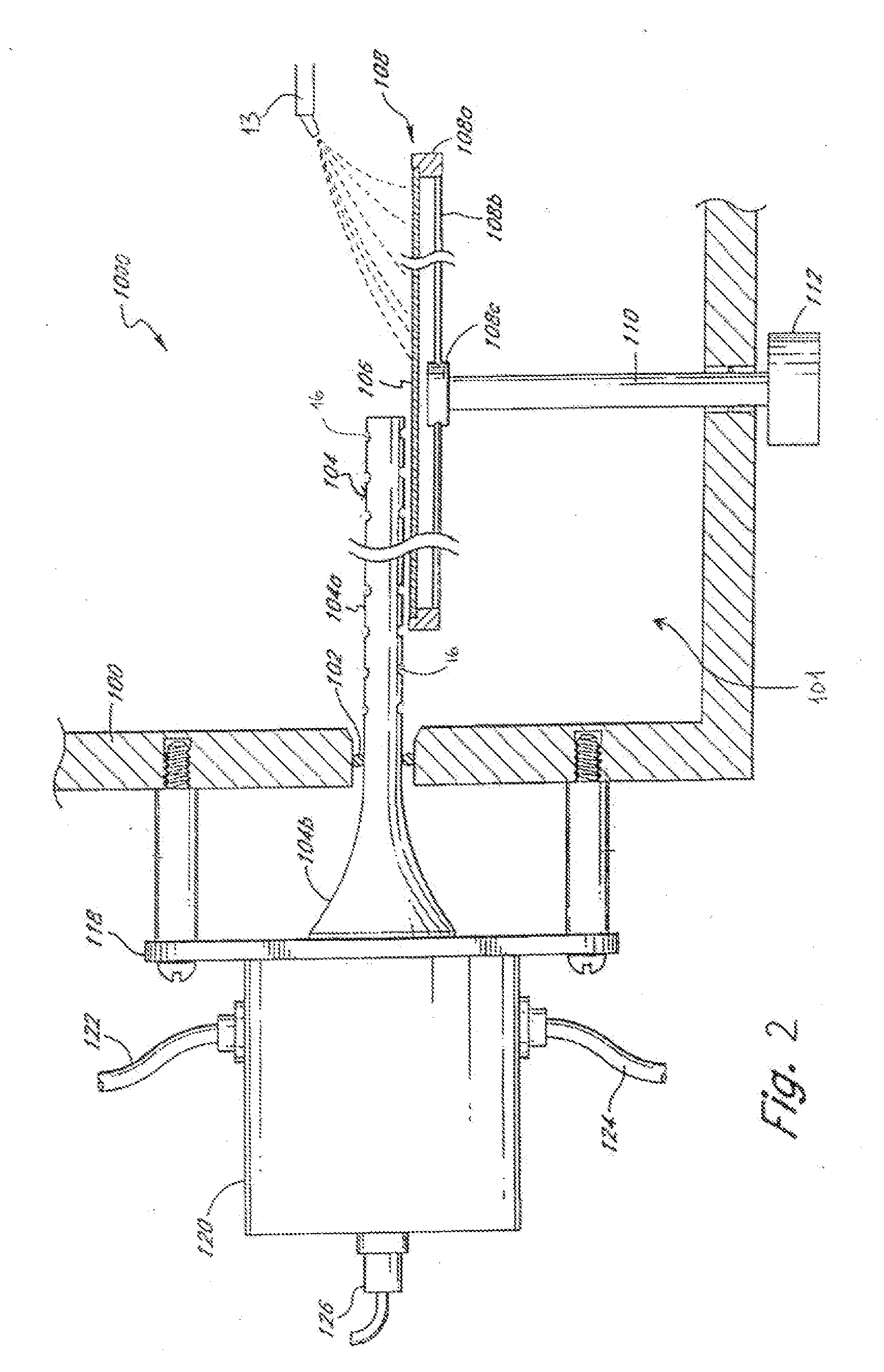

Transducer assembly incorporating a transmitter having through holes, and method and system for cleaning a substrate utilizing the same

InactiveUS20080017219A1Reduce sound energyHigh PRETransducer detailsElectrostatic cleaningSound energyTransducer

An apparatus, system and method for processing a substrate utilizing sonic energy. In one aspect, the invention utilizes a transmitter having through holes to dampen sonic energy that may damage the substrate. In other aspects, the through holes of the transmitter can be adapted to introduce a liquid solution having bubbles of a controlled size into the meniscus that couples the transmitter to the surface of a substrate to be cleaned to further dampen the sonic energy. IN one embodiment, the invention is a system for processing a substrate comprising: a rotary support for supporting a substrate in a substantially horizontal orientation; a transducer assembly comprising a transmitter and a transducer adapted to generate sonic energy, the transducer acoustically coupled to the transmitter; a plurality of internal passageways extending through the transmitter from holes in a first outer surface of the transmitter to holes in a second outer surface of the transmitter; and the transducer assembly positioned so that so that a portion of the vibration transmitter is adjacent to and spaced from a surface of a substrate on the rotary support so that when a liquid is applied to the surface of the substrate, a film of the liquid couples the portion of the transmitter to the surface of the substrate.

Owner:NAURA AKRION INC

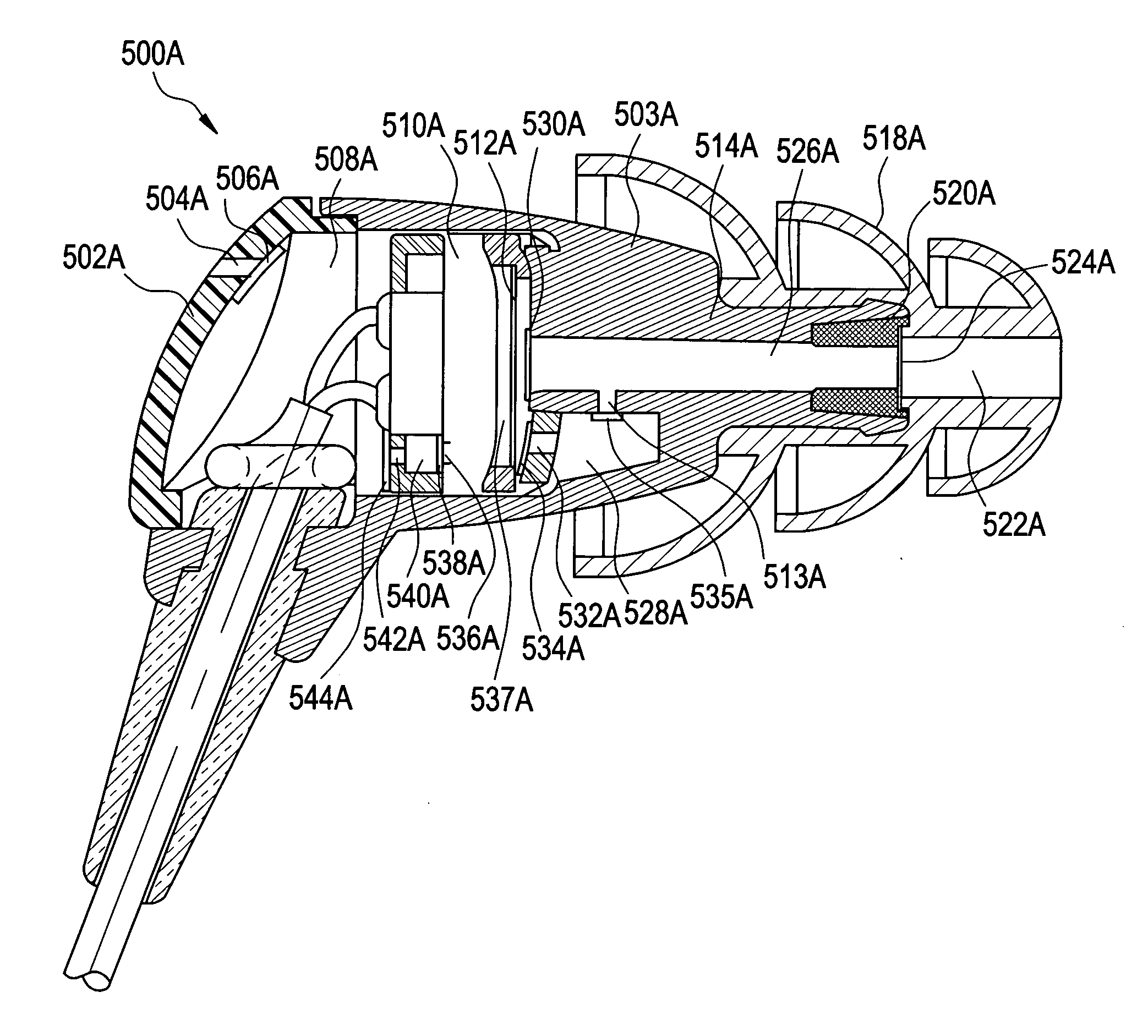

Insert earphone using a moving coil driver

Certain embodiments of the invention may be found in an insert earphone assembly. The insert earphone assembly may comprise a housing and a transducer located in the housing. The transducer may be for converting electrical signals received into sound energy. The insert earphone apparatus may further comprise an insert element. The insert element may be at, least partially integrated within the housing. The insert element may also comprise a main sound channel for communicating the sound energy from the transducer to a user. In certain embodiments, one or more of the body and the insert element may comprise one or more auxiliary ducts and one or more auxiliary volume spaces. The one or more auxiliary ducts and one or more auxiliary volume spaces may be separated by one or more auxiliary dampers. In certain embodiments, a diameter, length and / or shape of the one or more auxiliary ducts or one or more auxiliary volume spaces may be adjusted so as to modify an insertion response characteristic of the insert earphone assembly.

Owner:ETYMOTIC RES

Acoustic correction apparatus

InactiveUS20060062395A1Enhance the imageBroadening apparent stereo imageTwo-channel systemsLoudspeaker spatial/constructional arrangementsSound imageSound energy

An acoustic correction apparatus processes a pair of left and right input signals to compensate for spatial distortion as a function of frequency when the input signals are reproduced through speakers in a sound system. The sound-energy of the left and right input signals is separated and corrected in a first low-frequency range and a second high-frequency range. The resultant signals are recombined to create image-corrected audio signals having a desired sound-pressure response when reproduced by the speakers in the sound system. The desired sound-pressure response creates an apparent sound image location with respect to a listener. The image-corrected signals may then be spatially enhanced to broaden the apparent sound image.

Owner:DTS

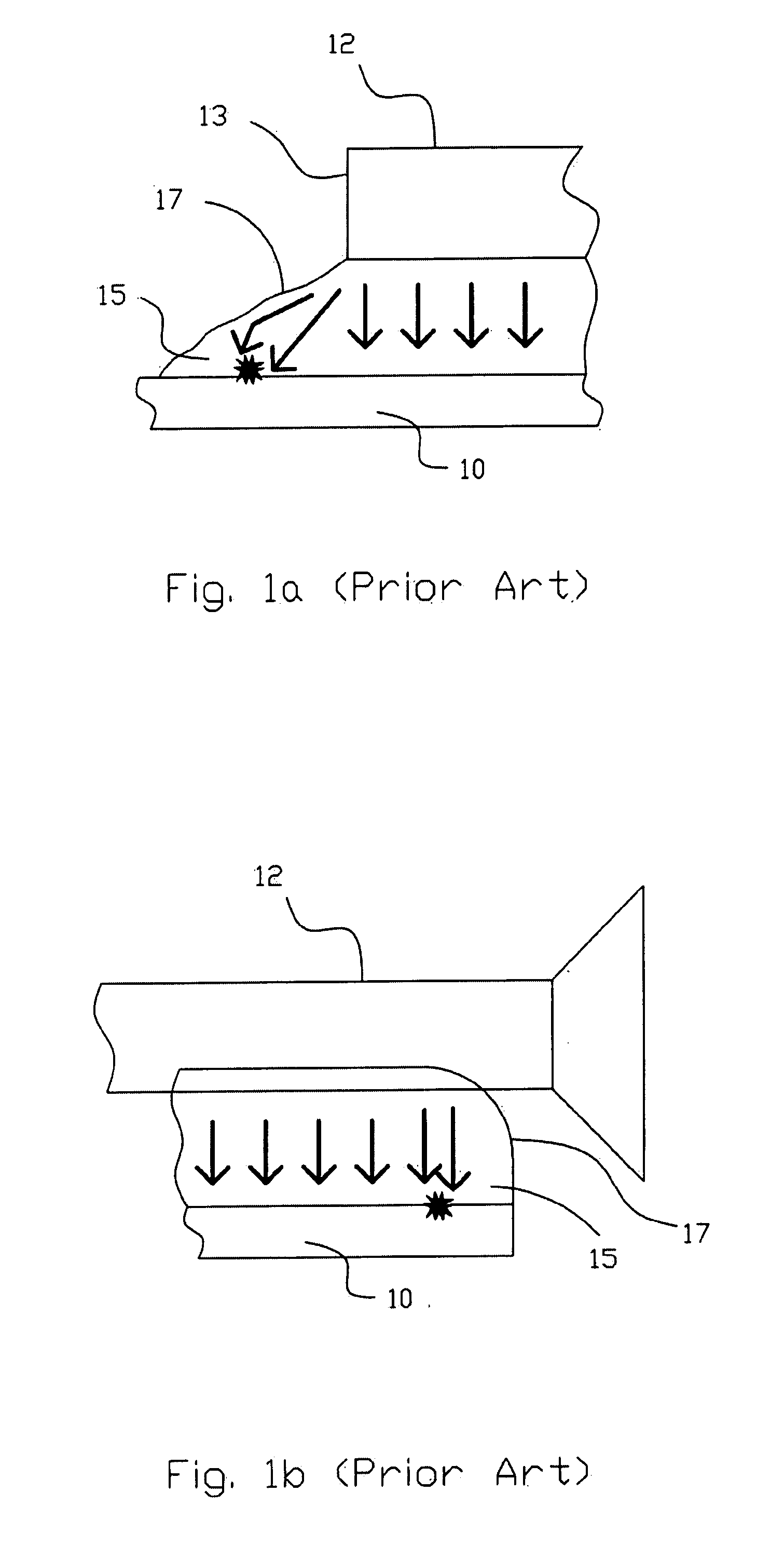

System and method for multiple mode flexible excitation in sonic infrared imaging

InactiveUS20050167596A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSound energyTransducer

A defect detection system for thermally imaging a structure that has been energized by a sound energy. The system includes a transducer that couples a sound signal into the structure, where the sound signal causes defects in the structure to heat up. In one embodiment, the sound signal has one or more frequencies that are at or near an eigen-mode of the structure.

Owner:SIEMENS ENERGY INC

Earbud Adapter with Enhanced Frequency Response

Adapters for use with sound devices and methods for making and using the same. An adapter may include an adapter body including a wall having a first surface and a second surface, and a projection extending from the wall. The adapter is generally configured to be attachable to a sound device such as an earbud or earphone. A sleeve configured to at least in part extend into the ear canal of a user during use may be attached to the projection. The adapter may additionally include one or more unobstructed orifices extending through the wall of the adapter between the first surface and the second surface. The one or more unobstructed orifices may allow leakage of acoustical energy from the adapter, thus modifying the level of sound energy at certain frequencies transmitted to the ear canal of a user.

Owner:HEARING COMPONENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com