Multimode organic filler/polymer composite damping material and manufacturing method thereof

A technology of composite damping material and inorganic filler, which is applied in the field of new high-efficiency damping material, high-filling polymer tree and its composite matrix, which can solve the problems of poor high and low temperature resistance and easy aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

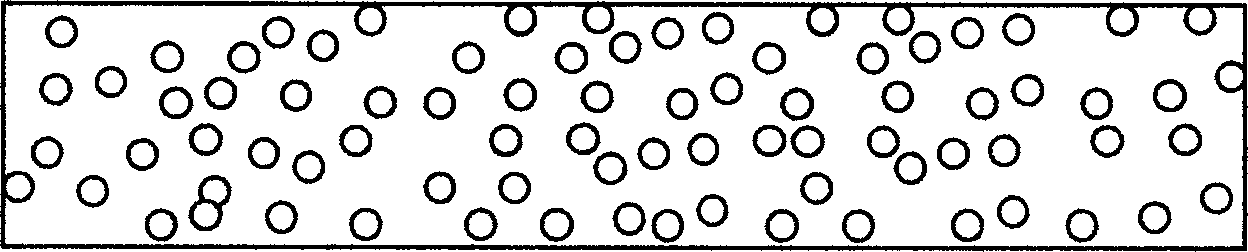

[0063] correspond figure 1 / sound insulation material shown in table 1

[0064] raw material

[0065] EVA 23.0kg

[0066] Linear Low Density Polyethylene (LLDPE) 14.0kg

[0067] Polyethylacrylate 4.0kg

[0068] Isopropyl tri(dioctyl pyrophosphate) titanate 1.0kg

[0069] Liquid paraffin oil 500ml

[0070] Cyclohexane 300ml

[0072] Nanoscale light calcium carbonate fine powder 14.5kg

[0073] Petroleum resin C9 3.6kg

[0074] 2,6-di-tert-butyl-p-cresol 2.0kg

[0075] Triphenyl phosphate 1.0kg

[0077] Preparation and pretreatment of nano-submillimeter inorganic fine powder

[0078]We choose XMQ-350×160 ball mill, with the same parameter configuration, such as at a constant speed of 280rpm, the same sample processing capacity (2kg), ball mill parameters (amount of 3kg, diameter 1cm), and grind for 10 days respectively to obtain spherical samples 1; 1.5 days, get spheroid 2; 5 hours, get spheroid 3. The ...

Embodiment 2

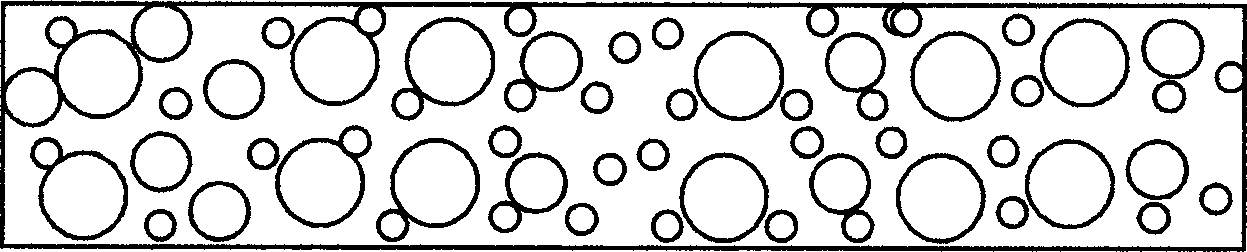

[0088] correspond figure 2 / sound insulation material shown in Table 2

[0089] Raw materials:

[0090] EVA 23.0kg

[0091] Linear Low Density Polyethylene (LLDPE) 14.0kg

[0092] Polyethylacrylate 4.0kg

[0093] Isopropyl tri(dioctyl pyrophosphate) titanate 1.0kg

[0094] Liquid paraffin oil 500ml

[0095] Cyclohexane 300ml

[0097] Nano calcium carbonate 9.6kg

[0098] Micron calcium carbonate 2.6kg

[0099] Submillimeter calcium carbonate 0.36kg

[0100] Petroleum resin C9 3.6kg

[0101] 2,6-di-tert-butyl-p-cresol 2.0kg

[0102] Triphenyl phosphate 1.0kg

[0104] The preparation, characterization and mixing of nano-submillimeter inorganic fine powder, the preparation of pretreatment and damping material, and the test of dynamic mechanical properties are all the same as in Example 1.

[0105] Form 2

[0106] temperature(℃) -100 -80 -60 -40 -20 0 tanδ 0.0473 0.0675 0.0973 0.1...

Embodiment 3

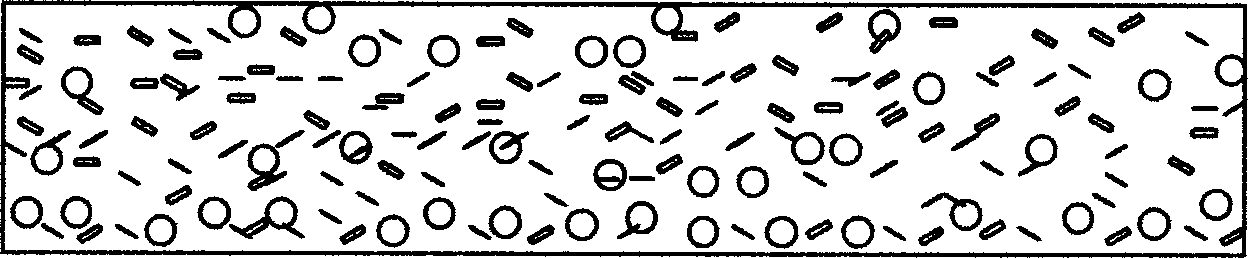

[0108] correspond image 3 / sound insulation material shown in table 3

[0109] raw material

[0110] EVA 23.0kg

[0111] Linear Low Density Polyethylene (LLDPE) 14.0kg

[0112] Polyethylacrylate 4.0kg

[0113] Isopropyl tri(dioctyl pyrophosphate) titanate 1.0kg

[0114] Liquid paraffin oil 500ml

[0115] Cyclohexane 300ml

[0116] Petroleum ether 200ml

[0117] Nano-scale light calcium carbonate 5.2kg

[0118] Nanoscale mica 3.5kg

[0119] Nano wollastonite 2.5

[0120] Petroleum resin C9 3.6kg

[0121] 2,6-di-tert-butyl-p-cresol 2.0kg

[0122] Triphenyl phosphate 1.0kg

[0124] The preparation of nano-submillimeter inorganic fine powder, pretreatment and damping material, and the test of dynamic mechanical properties are all the same as in Example 1.

[0125] Form 3

[0126] temperature(℃) -100 -80 -60 -40 -20 0 tanδ 0.07704 0.0829 0.0950 0.1141 0.1527 0.2454 temperature(℃) 20 40 60 80 100 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com