Patents

Literature

14965 results about "Sheet steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Automobile steel with low cost and high strength ductility balance and preparation method thereof

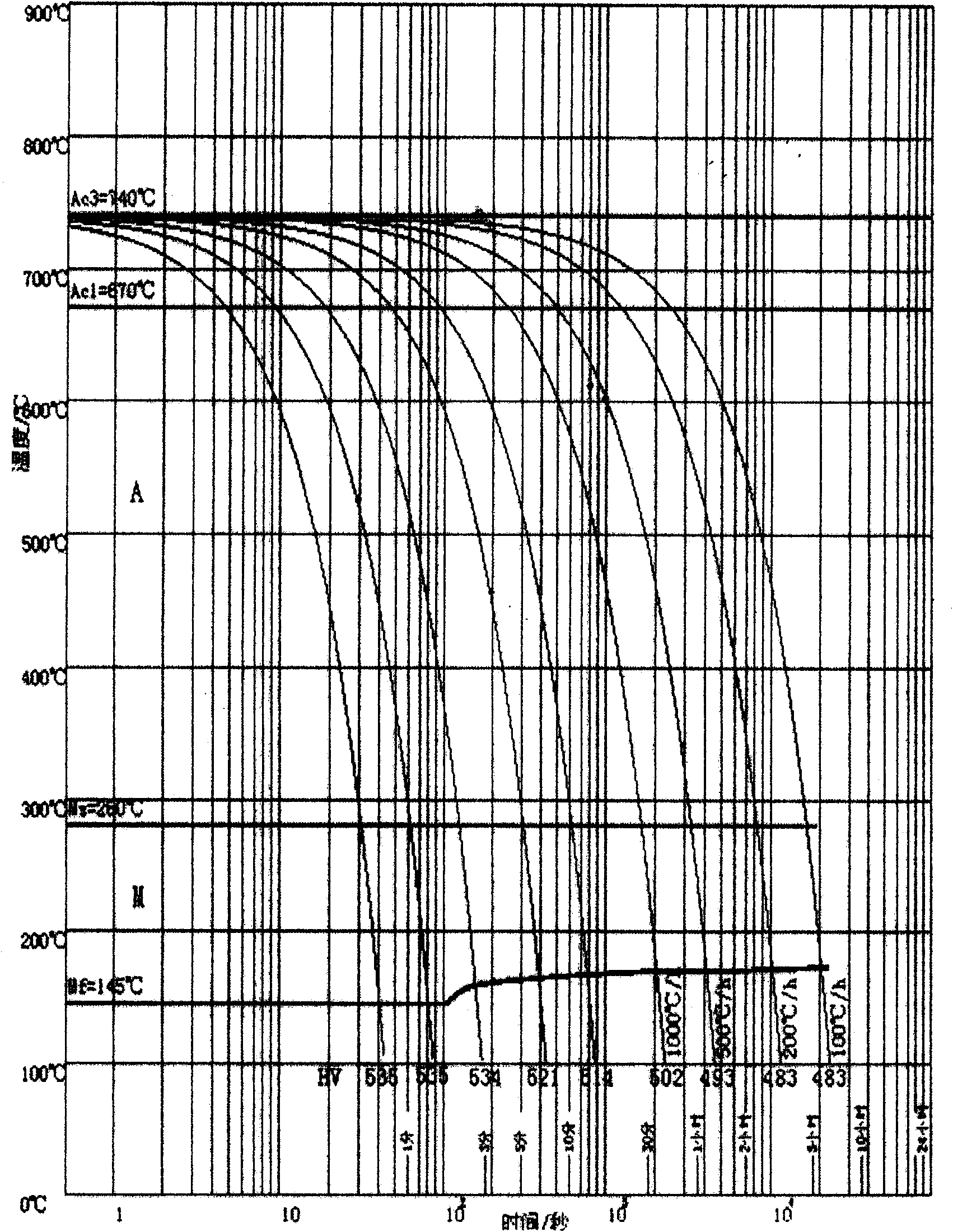

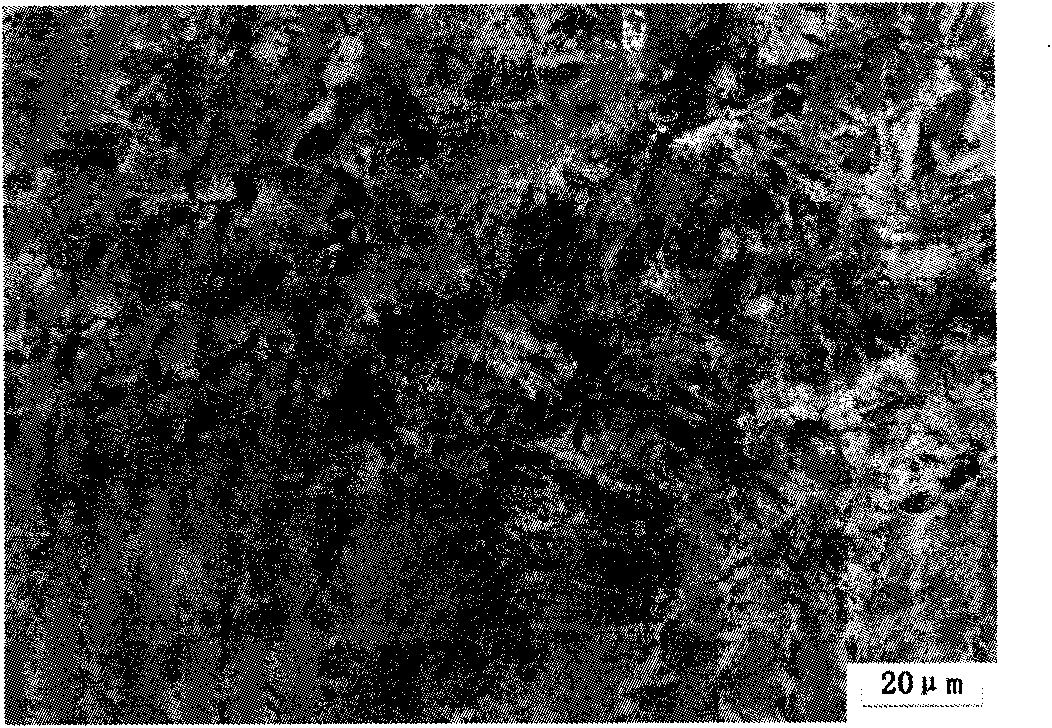

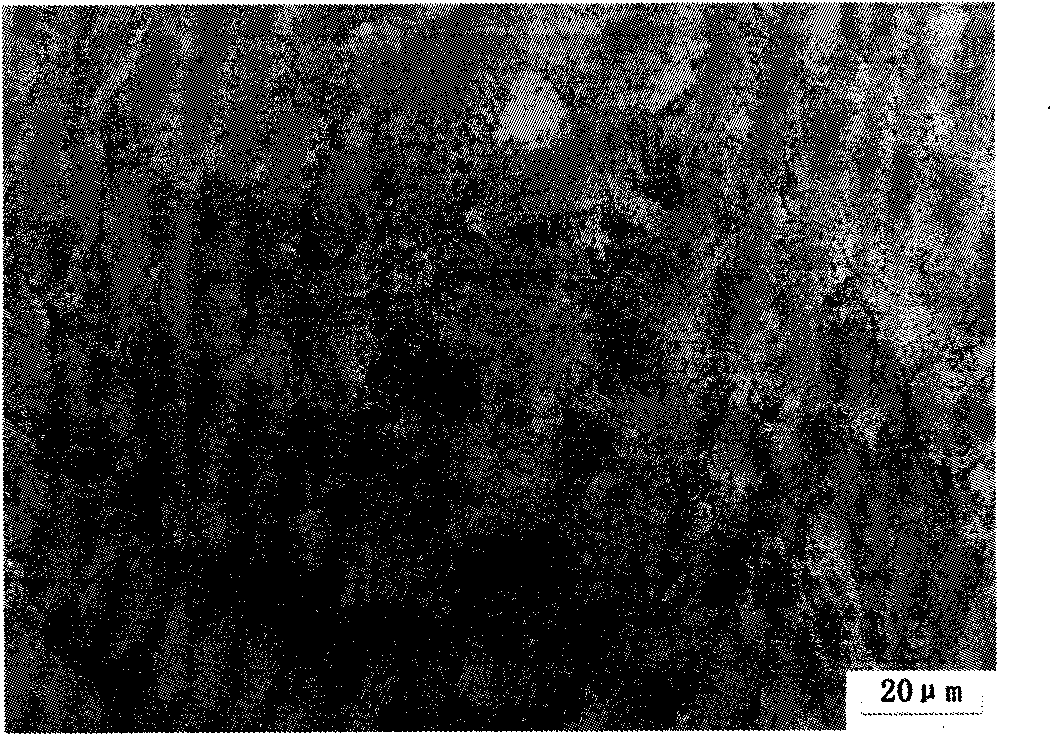

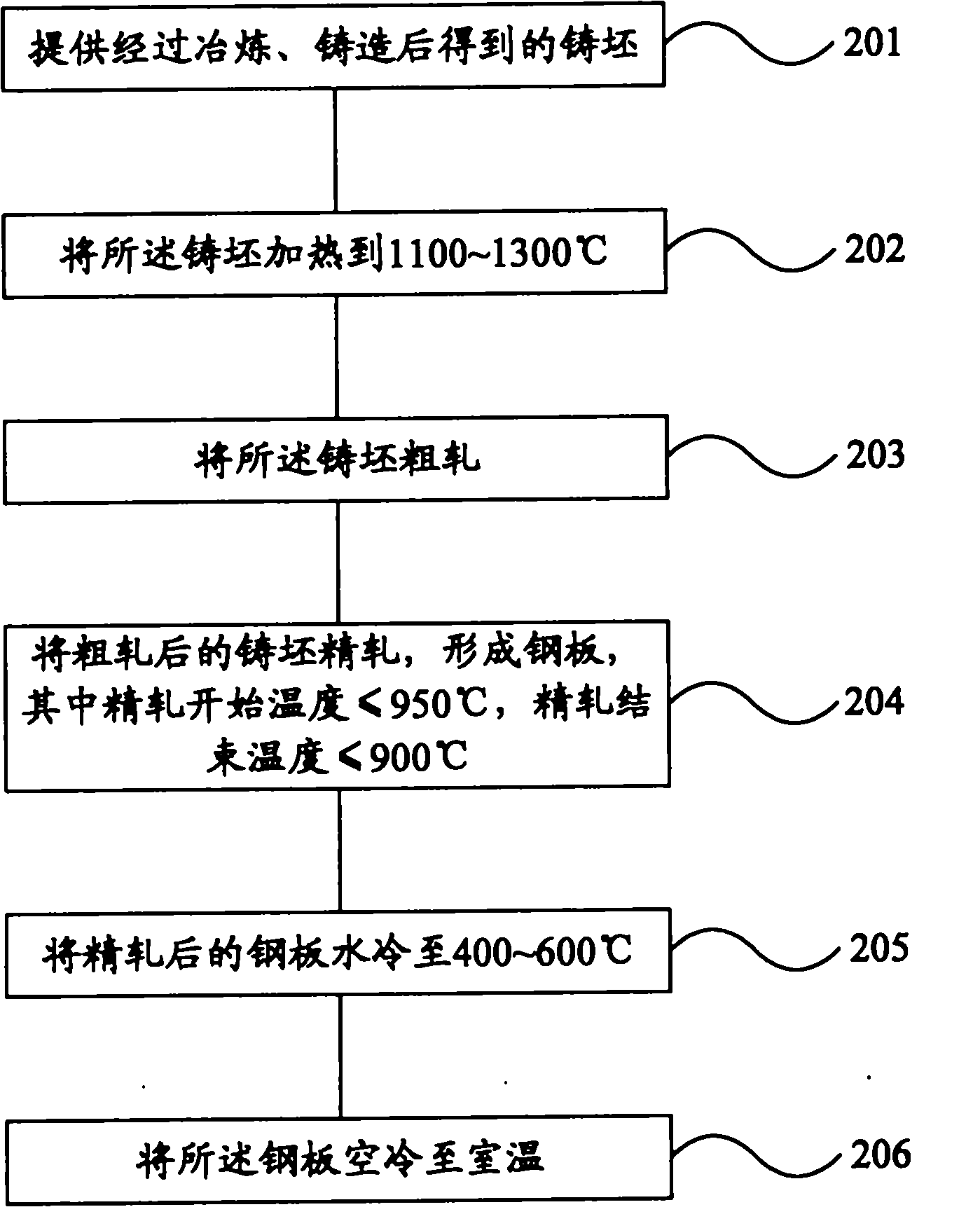

The invention provides automobile steel with low cost and high strength ductility balance and a preparation method thereof, belonging to the technical field of automobile steel. A multiphase, metastable and multiscale M<3> type organization structure is obtained based on reasonable design of chemical composition and partition of alloy elements and crucially based on the control of martensite phasetransformation, the repartition of solute such as C / Mn and the like and the austenite inverse phase transformation. The invention is characterized in that the martensite structure is obtained by using 0.02-0.50 wt%C and 3.50-9.00 wt%Mn in the cooling process of the inductrial production of steel plates and steel coils and the like; and superfine adverse transformation austenite and alpha phase substrate can be obtained through the partition of Mn and C in the heat preserving process between 100 DEG C below Acl and Acl, thus realizing the industrial production of hot rolled sheets and cold rolled sheets with high strength ductility balance used in automobiles. The invention has the advantages that the intensity is 0.7-1.3 GPa, the extension rate is 55-30% and the strength ductility balanceis 35-55 GPa%.

Owner:CENT IRON & STEEL RES INST

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

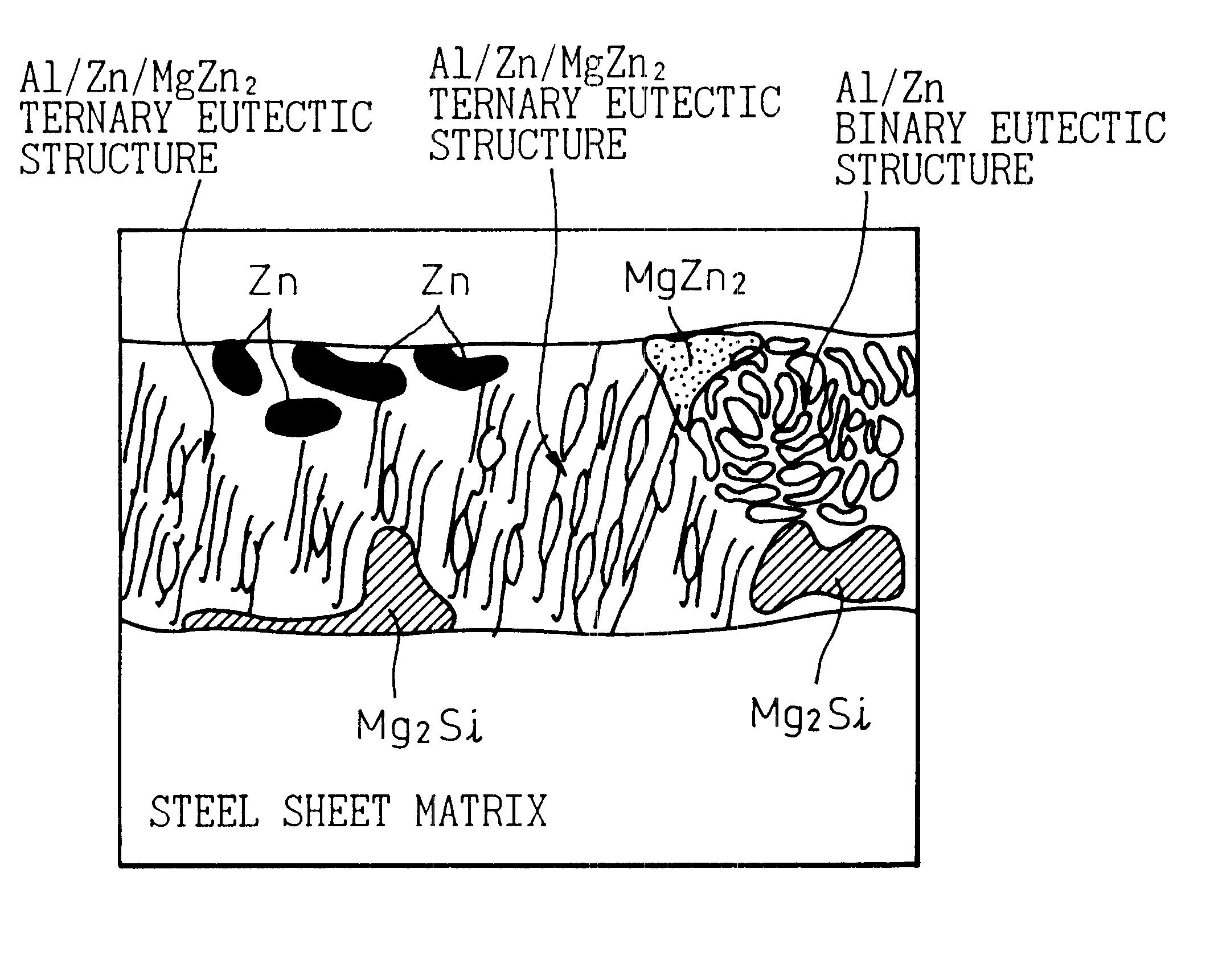

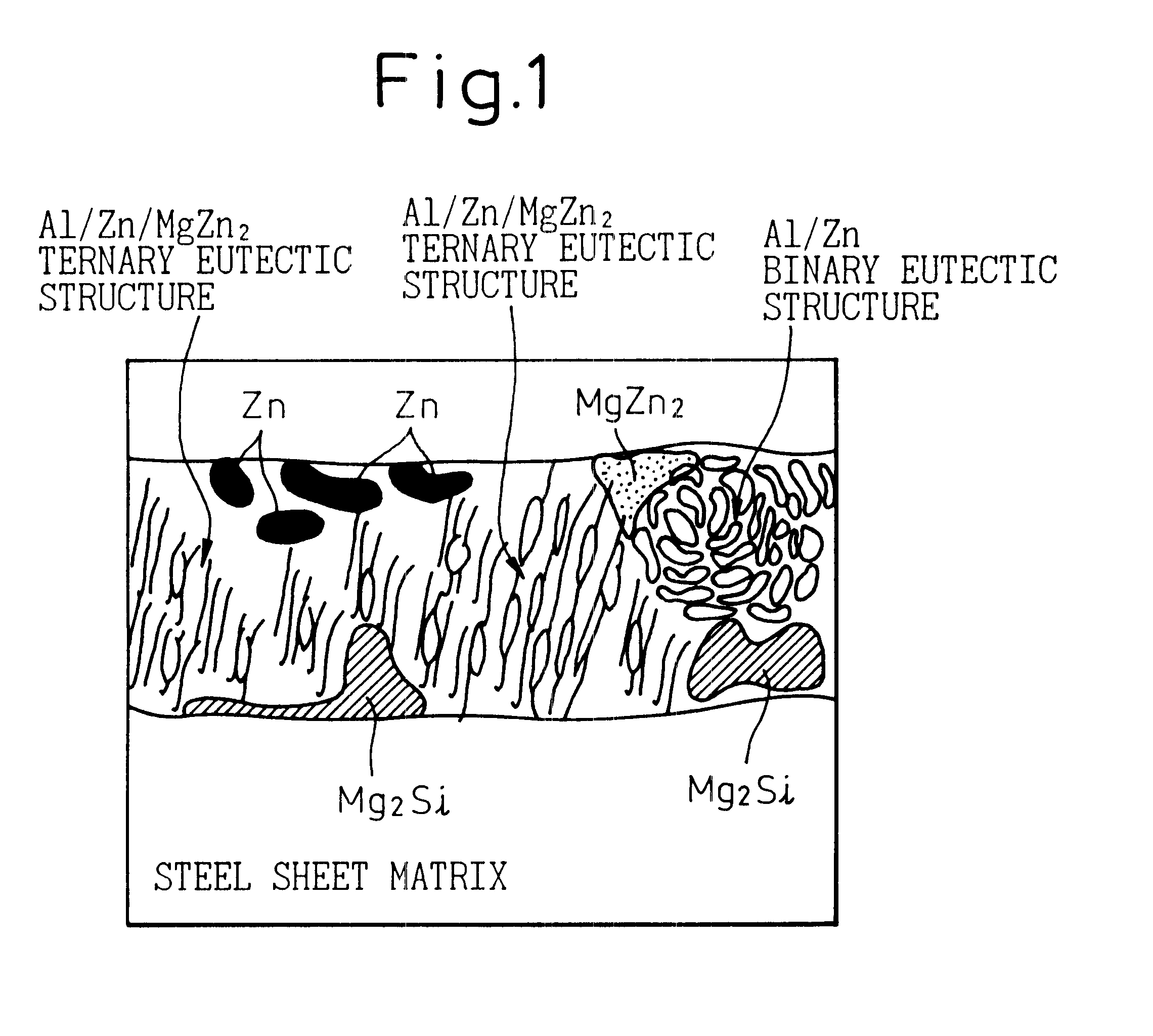

-Zn coated steel material, ZN coated steel sheet and painted steel sheet excellent in corrosion resistance, and method of producing the same

InactiveUS6465114B1Improve corrosion resistanceResistance to red rustHot-dipping/immersion processesLiquid surface applicatorsSheet steelAlloy coating

A coated steel material excellent in corrosion resistance and a method of producing the same, wherein a coated steel material has on the surface of the steel sheet a Zn-alloy coating layer containing 1-10 wt % of Mg, 2-19 wt % of Al and 0.01-2 wt % of Si, where Mg and Al satisfy Mg (%)+Al (%)<=20%, the balance being Zn and unavoidable impurities, and has a coating layer structure of a Mg intermetallic compound or the like. As a base metal treatment, it is preferably provided with a Ni coating layer. The coated Zn-alloy coated steel sheet may have provided on the coating layer, as an intermediate layer, a chromate film layer, and, as an upper layer, an organic coating layer. The Zn-alloy coating layer may further contain one or more of 0.01-1 wt % of In, 0.01-1 wt % of Bi and 1-10 wt % of Sn. The coated steel material may be painted.

Owner:NIPPON STEEL CORP

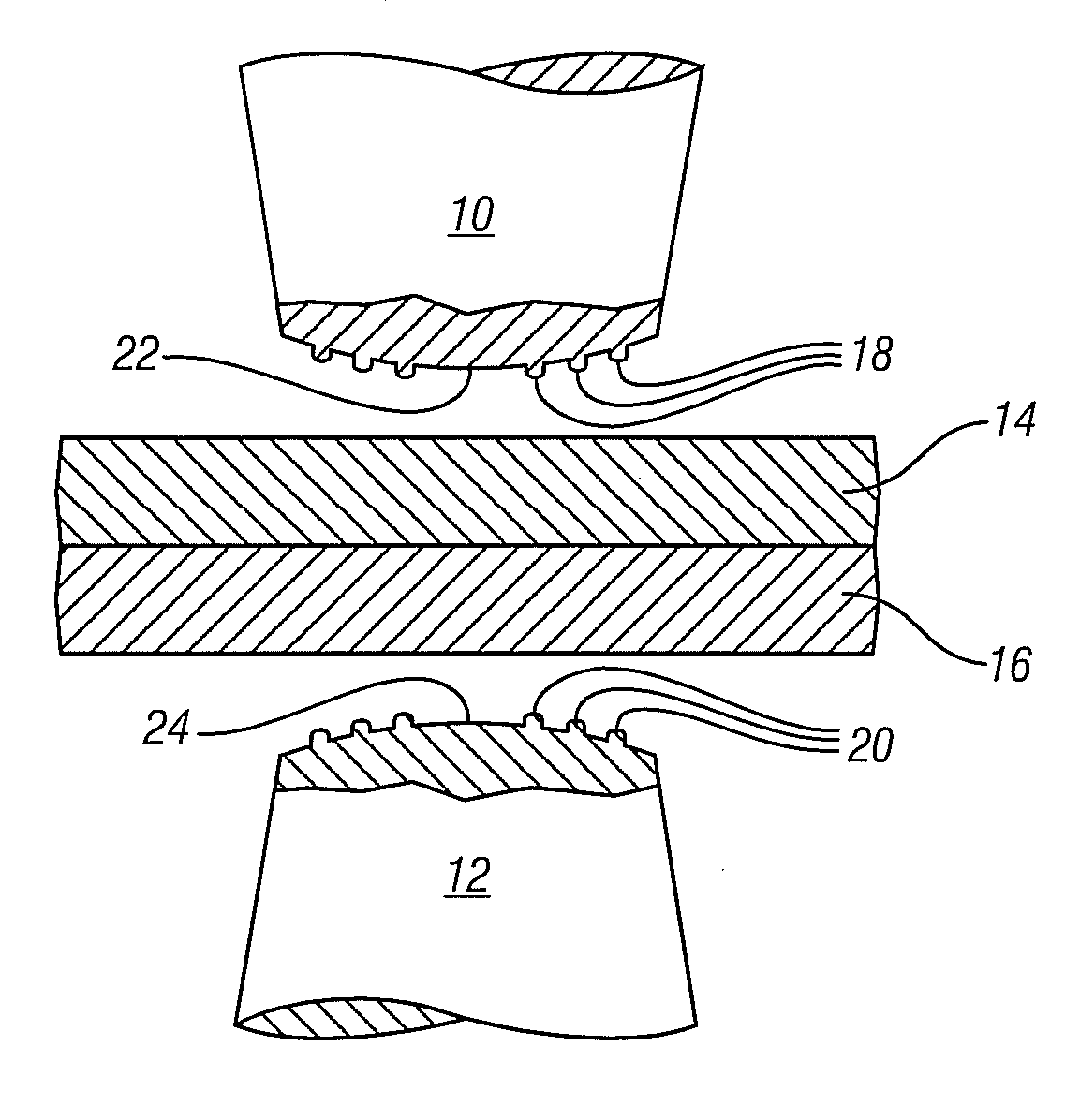

Weld electrode for attractive weld appearance

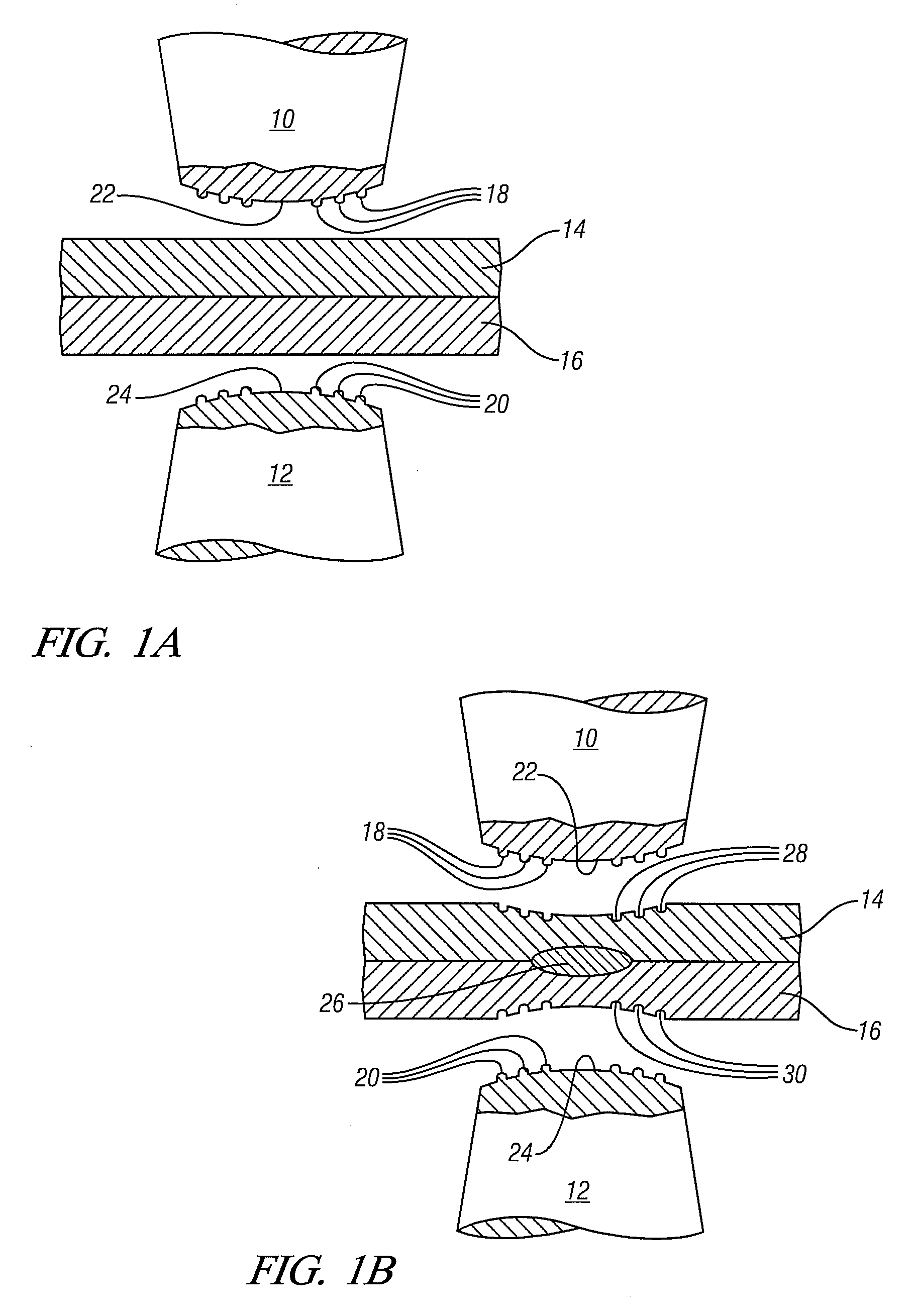

ActiveUS20090255908A1High thermal and electrical resistivityHigh melting pointPressure electrodesSheet steelSpot welding

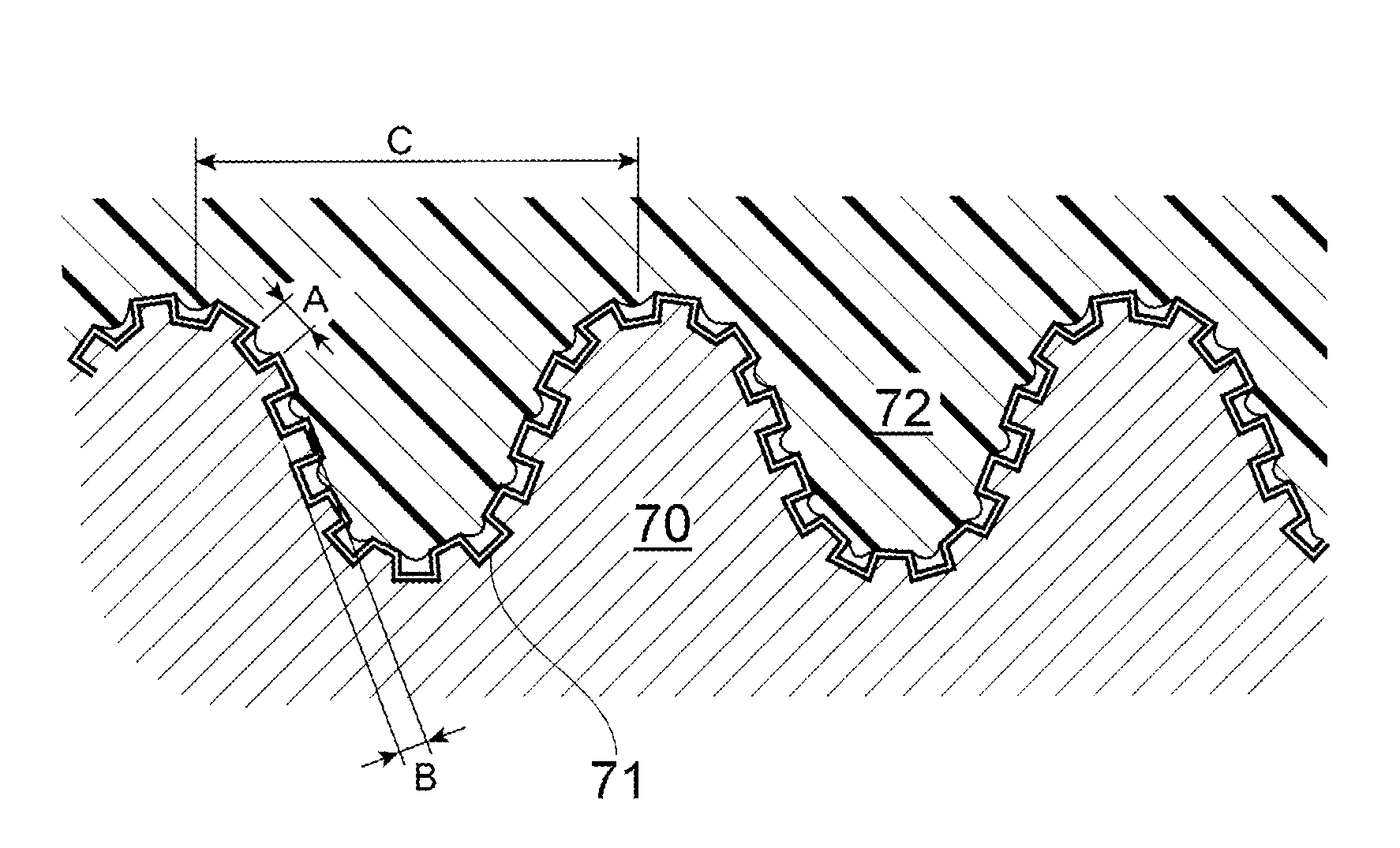

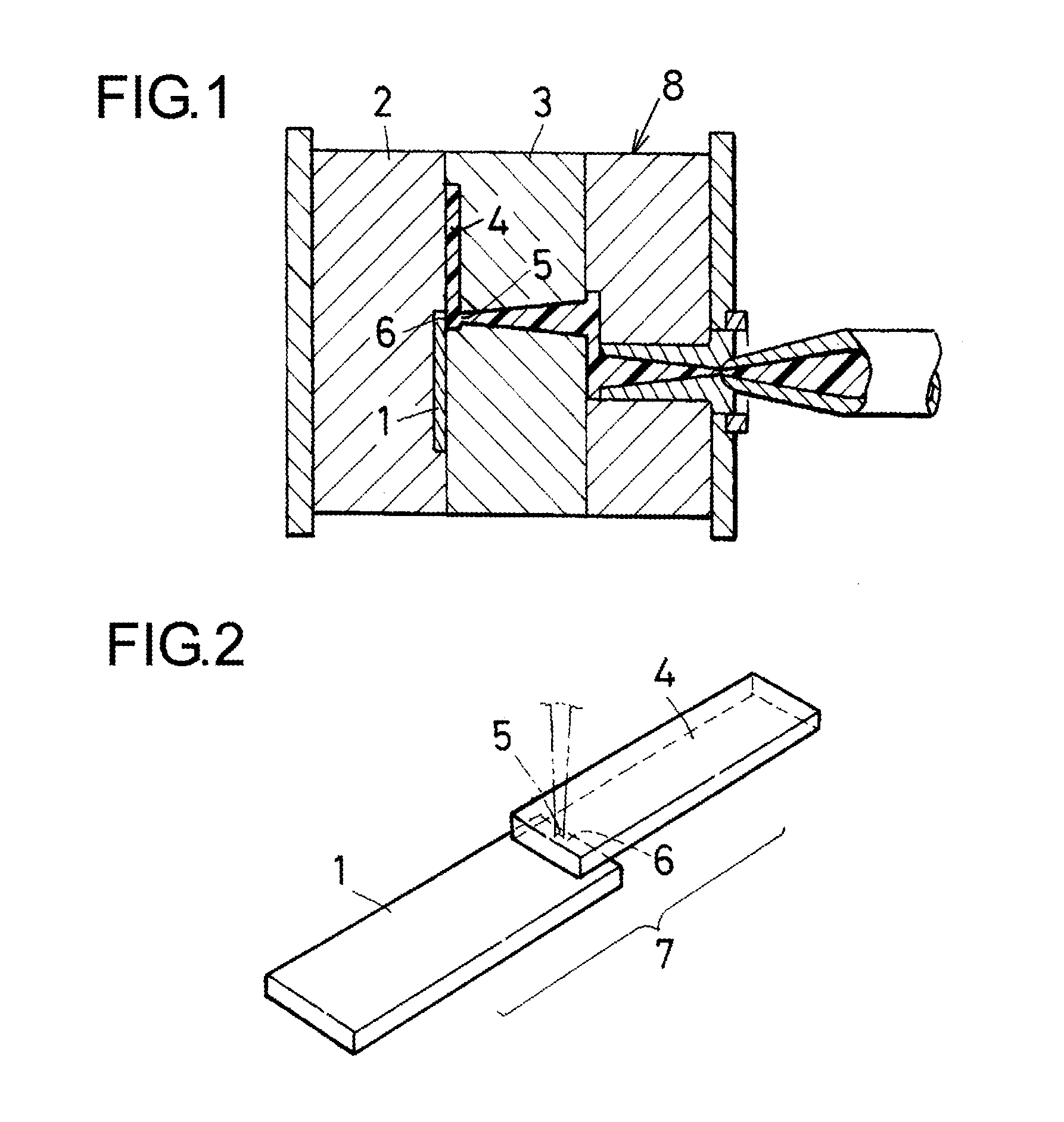

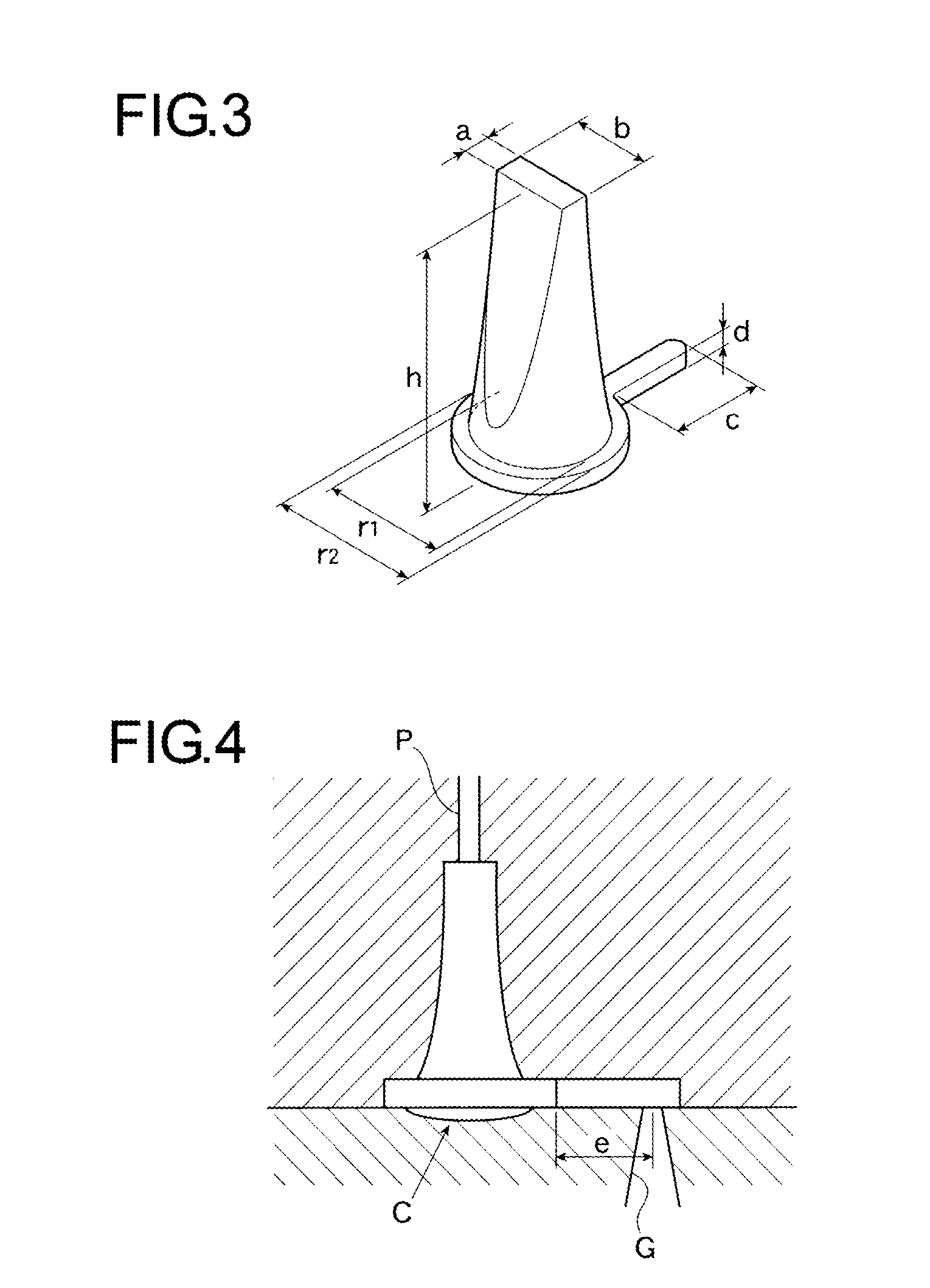

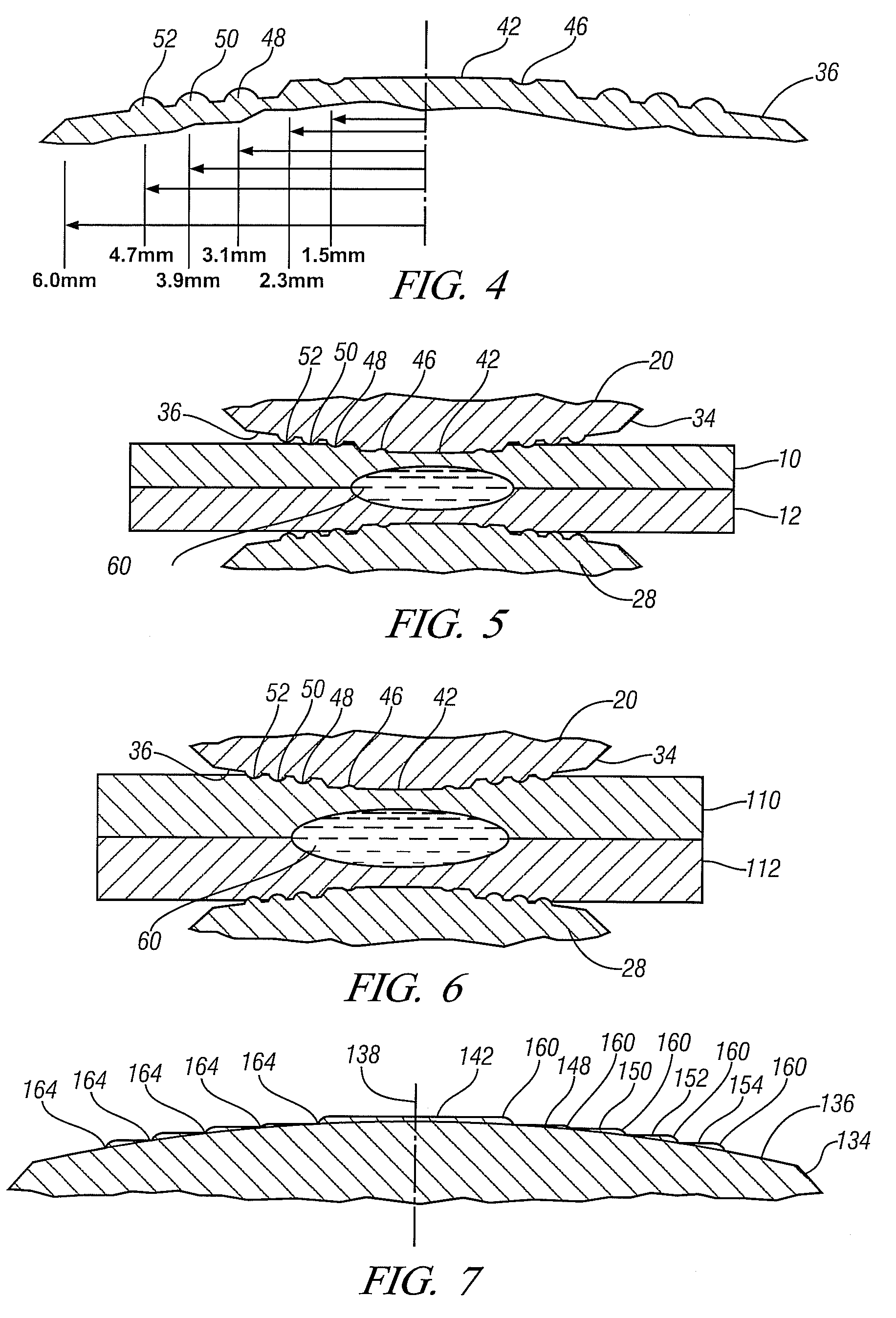

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

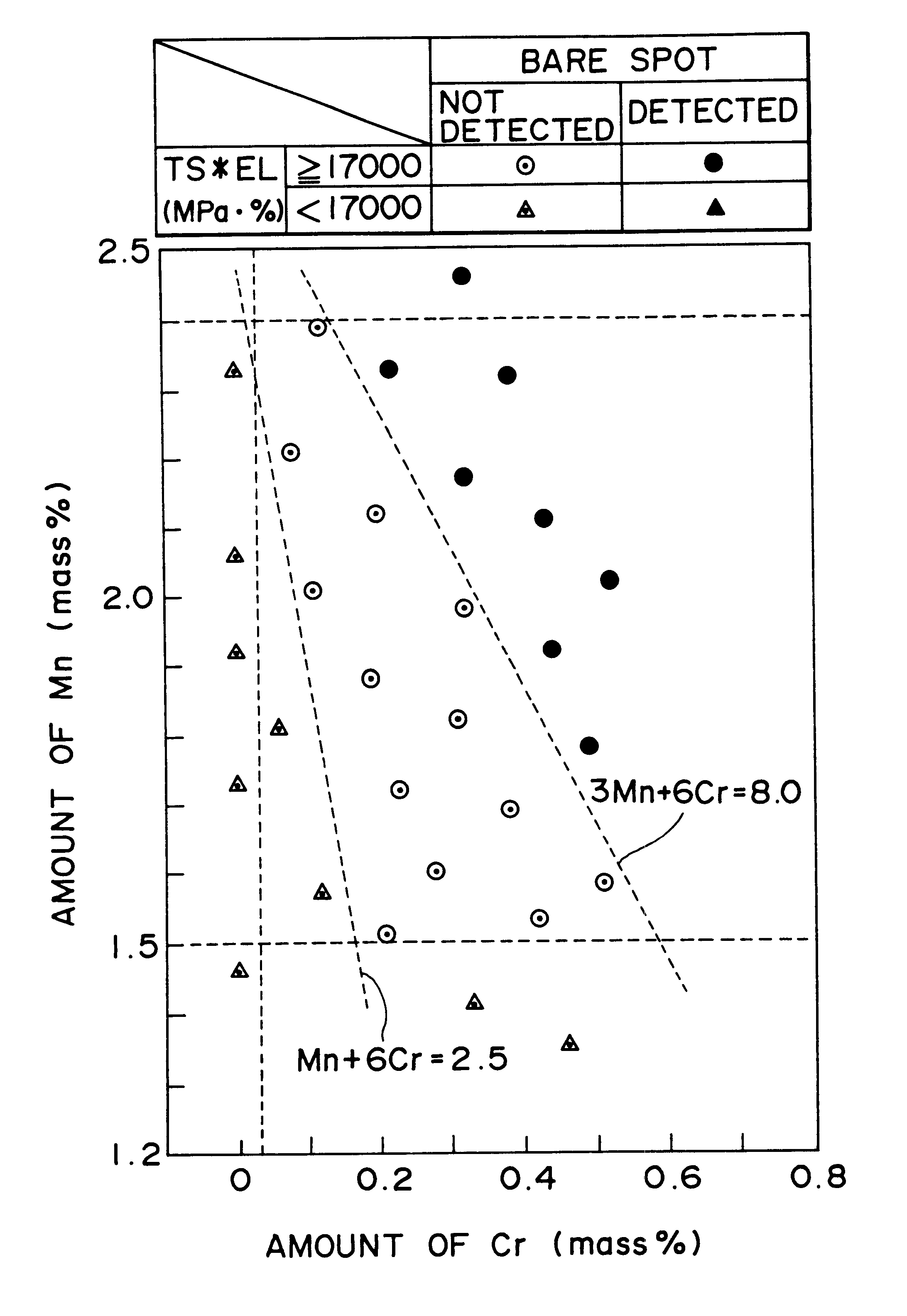

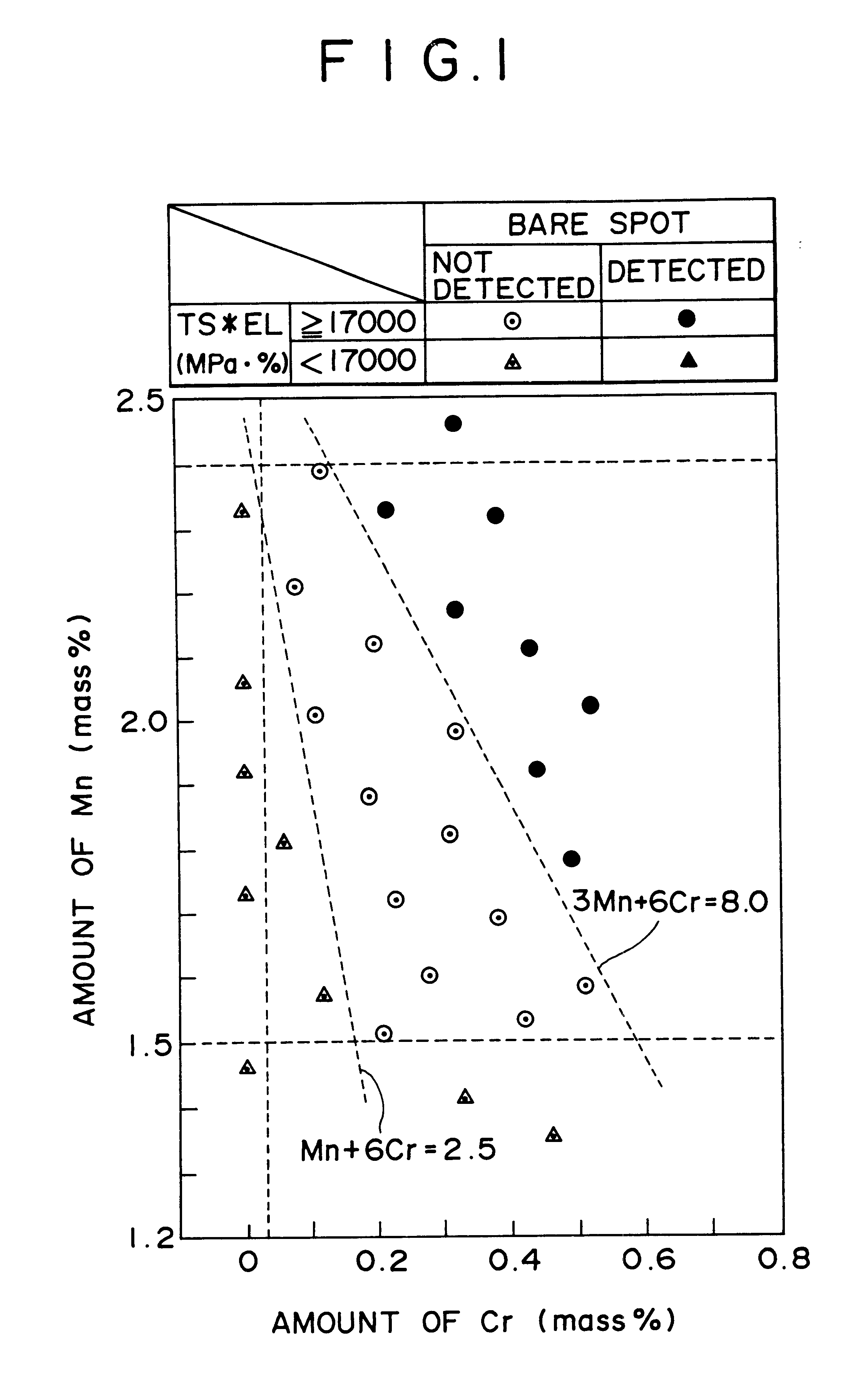

Hot-dip galvanized steel sheet and production thereof

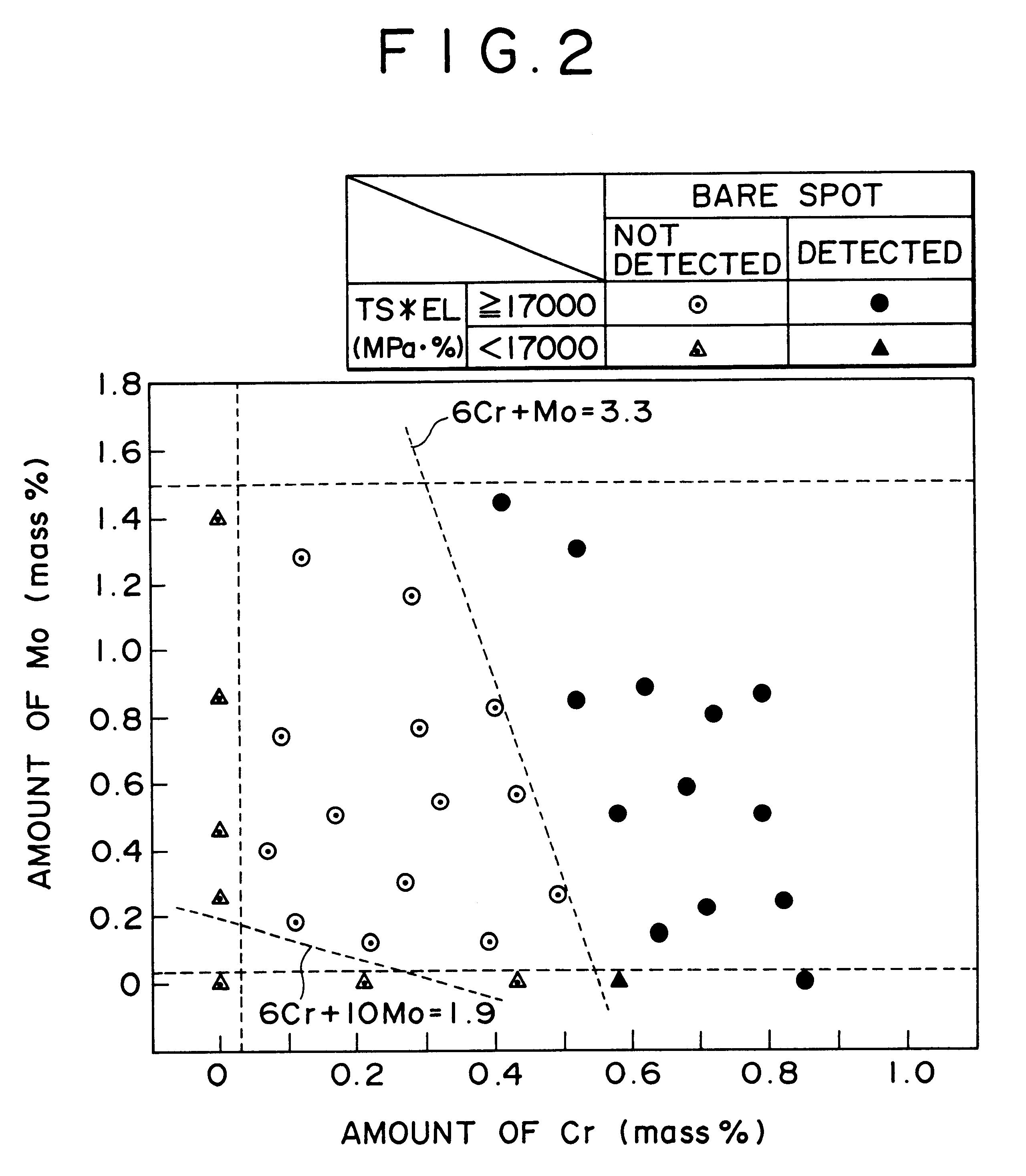

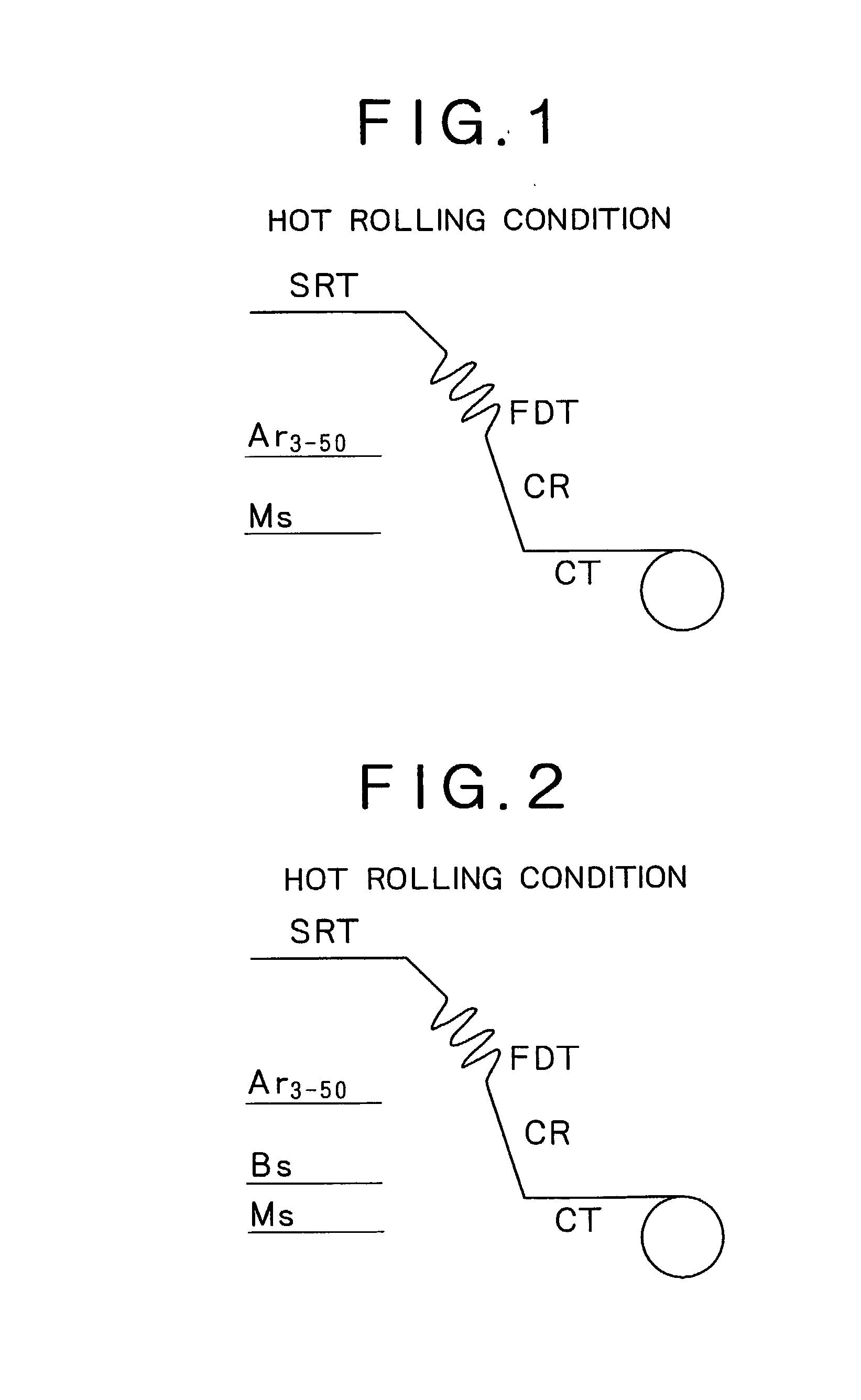

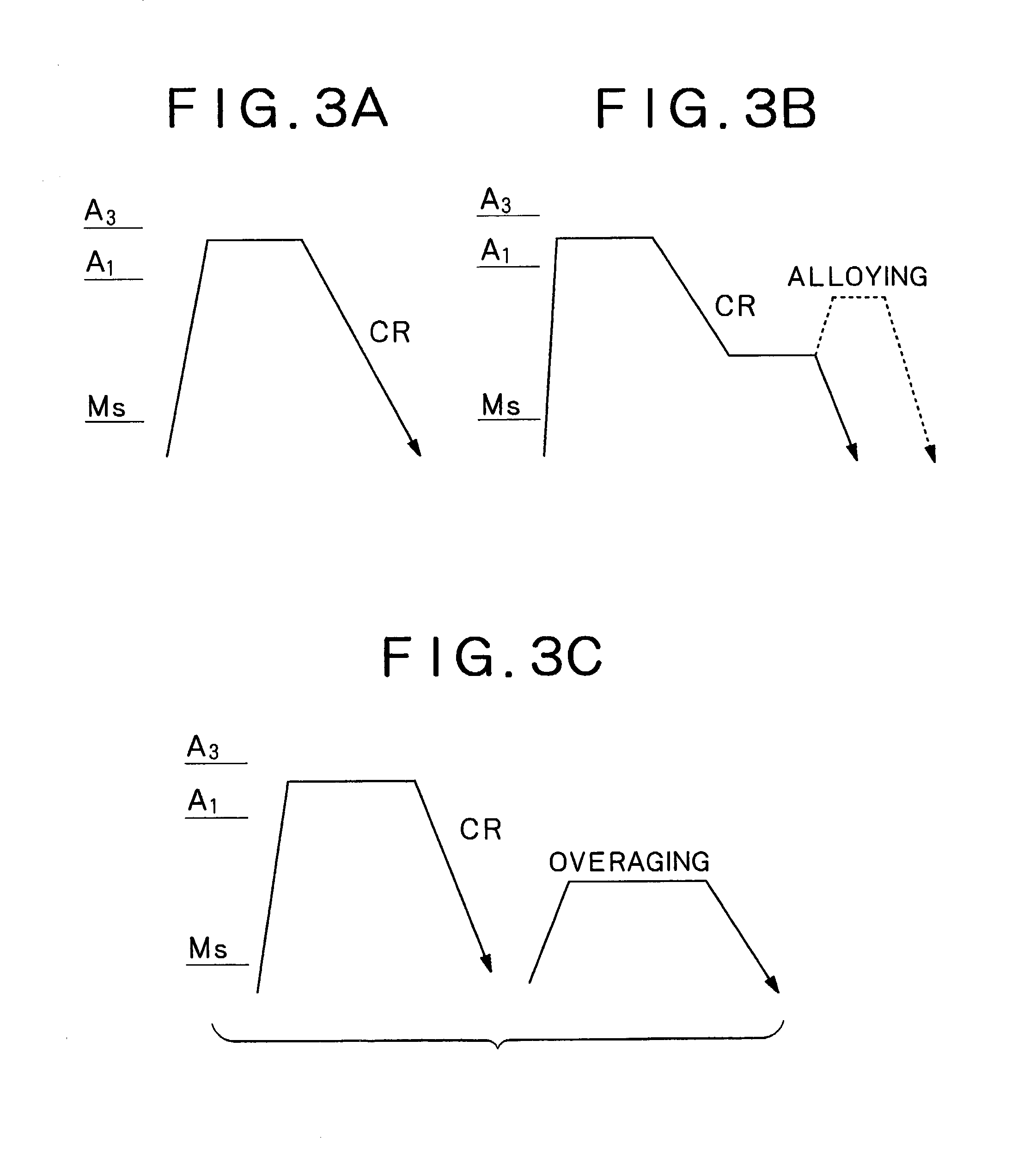

InactiveUS6312536B1High strengthGood formabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

A hot-dip galvanized steel sheet having both high strength and good formability. A process for producing said hot-dip galvanized steel sheet without requiring additional steps of surface grinding and pre-plating.The hot-dip galvanized steel sheet is produced by forming a hot-dip galvanizing layer on a base cold-rolled steel sheet composed of C (0.02-0.20 mass %), Mn (1.50-2.40 mass %), Cr (0.03-1.50 mass %), Mo (0.03-1.50 mass %), 3Mn+6Cr+Mo (no more than 8.1 mass %), Mn+6Cr+10 Mo (no less than 3.5 mass %), Al (0.010-0.150 mass %), and Fe as the principal component, with Ti limited to 0.01 mass % or less, Si limited to 0.04 mass % or less, P limited to 0.060 mass % or less, and S limited to 0.030 mass % or less, and said base steel sheet having the composite microstructure composed mainly of ferrite and martensite.

Owner:KOBE STEEL LTD

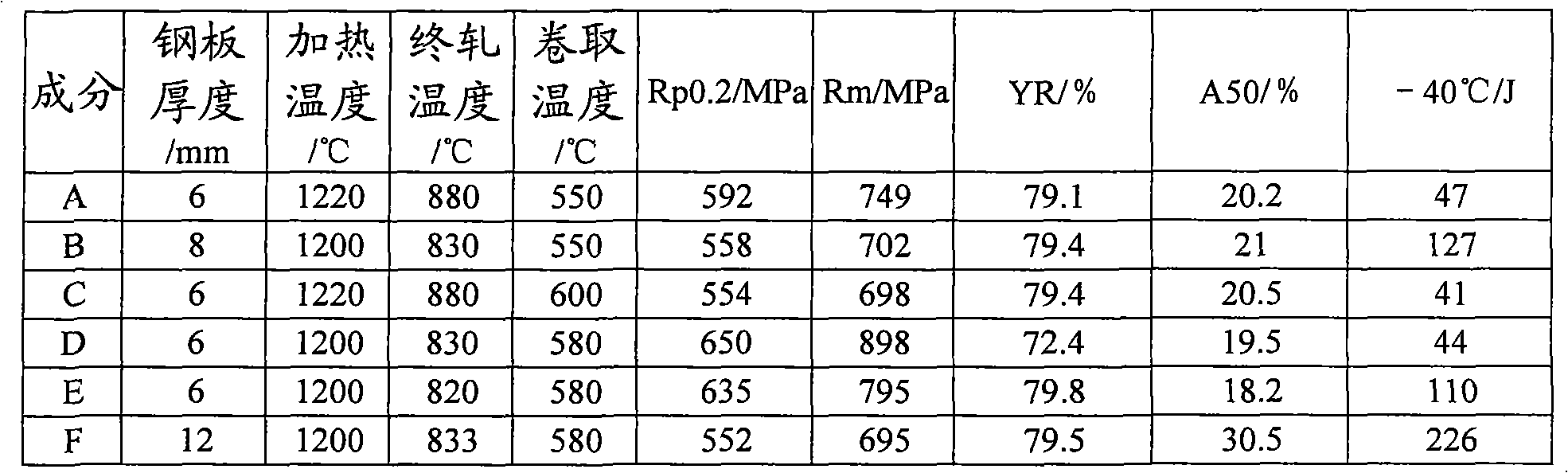

Weathering steel with yield strength of 550MPa level and manufacturing method thereof

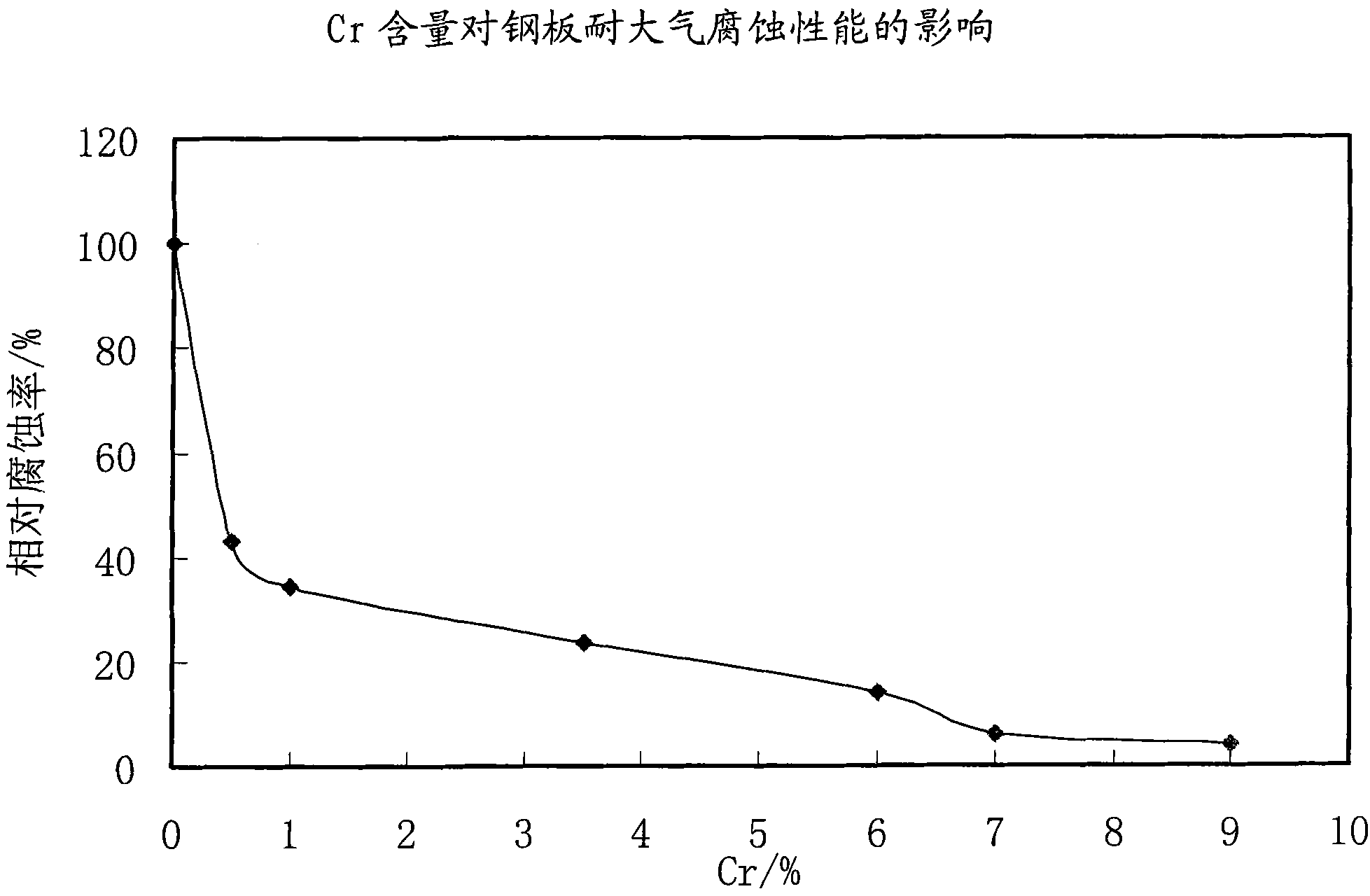

InactiveCN101994064AMeet the requirements of reducing the self-weight of componentsMeet the requirements of self-respectTemperature control deviceSheet steelUltimate tensile strength

The invention relates to weathering steel with the yield strength of 550MPa level and the advantages of excellent toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components: 0.02 to 0.08wt% of C, 0.15 to 0.55wt% of Si, 0.2 to 1.0wt% of Mn, less than or equal to 0.01wt% of P, less than or equal to 0.006wt% of S, 0.2 to 0.5wt% of Cu, 2.5 to 7.0wt% of Cr, 0.2 to 1.2wt% of Ni, 0.02 to 0.06wt% of Nb, 0.01 to 0.05wt% of Al, less than or equal to 0.05wt% of N, 0.01 to 0.10wt% of Ti and the balance of Fe and the unavoidable impurities. The steel plate made of the steel has the yield strength more than 550MPa and excellent toughness, and the relative corrosion rate is simultaneously reduced by one time on the basis of the traditional weathering steel so as to satisfy the requirement of enhancing the corrosion resistance of the steel for railway vehicles and reach the purposes of prolonging the service duration and reducing the maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

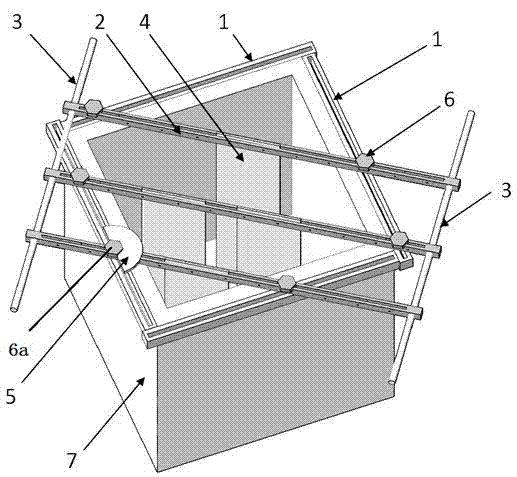

Mould for manufacturing fissure surface of rock like test block

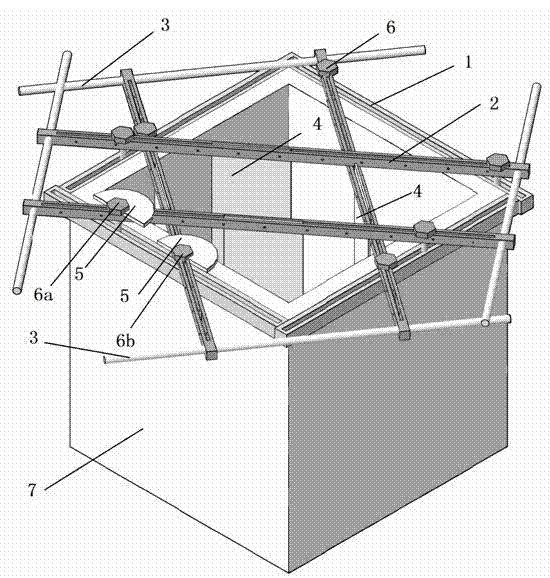

InactiveCN102519767APrevent movementEasy to transformPreparing sample for investigationCeramic shaping apparatusProtractorSheet steel

The invention discloses a mould for manufacturing a fissure surface of a rock like test block. The mould comprises a sliding groove, a sheet steel locating rod, a protractor, a sliding rod and a sheet steel, wherein the sliding groove is a long strip type metal component provided with a straight groove hole; the sheet steel locating rod is a metal rod; the sliding rod is a metal rod marked with ascale; a sheet steel fixing sheet is a hard sheet provided with a notch and stuck on the bottom surface of the test block mould; the sliding groove is fixed on the top of the side wall of the test block mould; the sheet steel locating rod is fixed above the sliding groove; the circle centre of the protractor passes through any bolt and is fixed above the sheet steel locating rod; the sliding rod passes through holes at two ends of the sheet steel locating rod and is vertical to the sheet steel locating rod; one end of the sheet steel is fixed in a through groove of the sheet steel locating rod; and the other end of the sheet steel is clamped in the notch of the sheet steel fixing sheet. The mould disclosed by the invention is capable of conveniently and rapidly adjusting parameters of thefissure surface of the test block, such as an inclination angle, an interval, a communication rate and the like. The mould is easy to process and can be repetitively utilized, thus, the manufacture efficiency and the precision of the test block are increased.

Owner:WUHAN UNIV

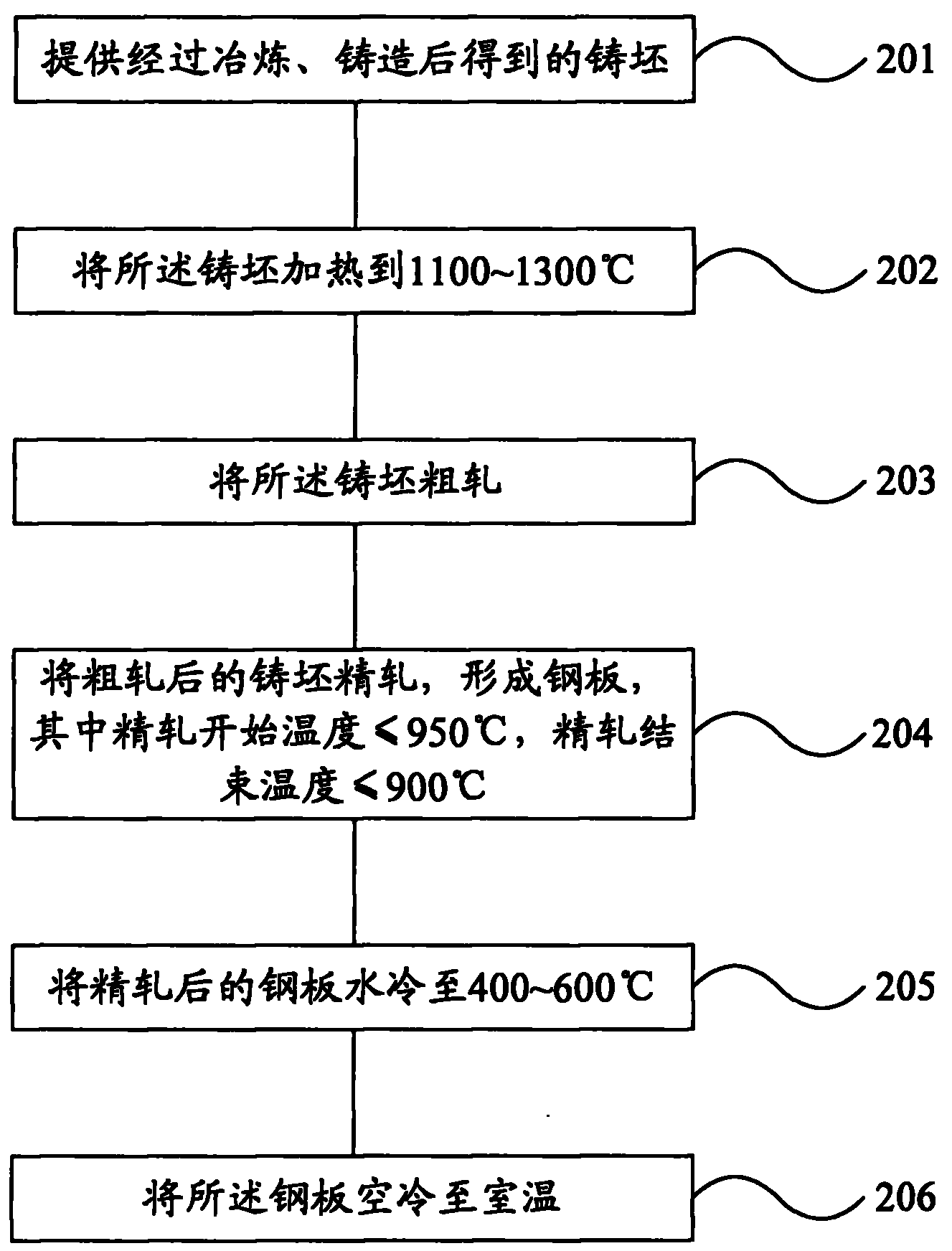

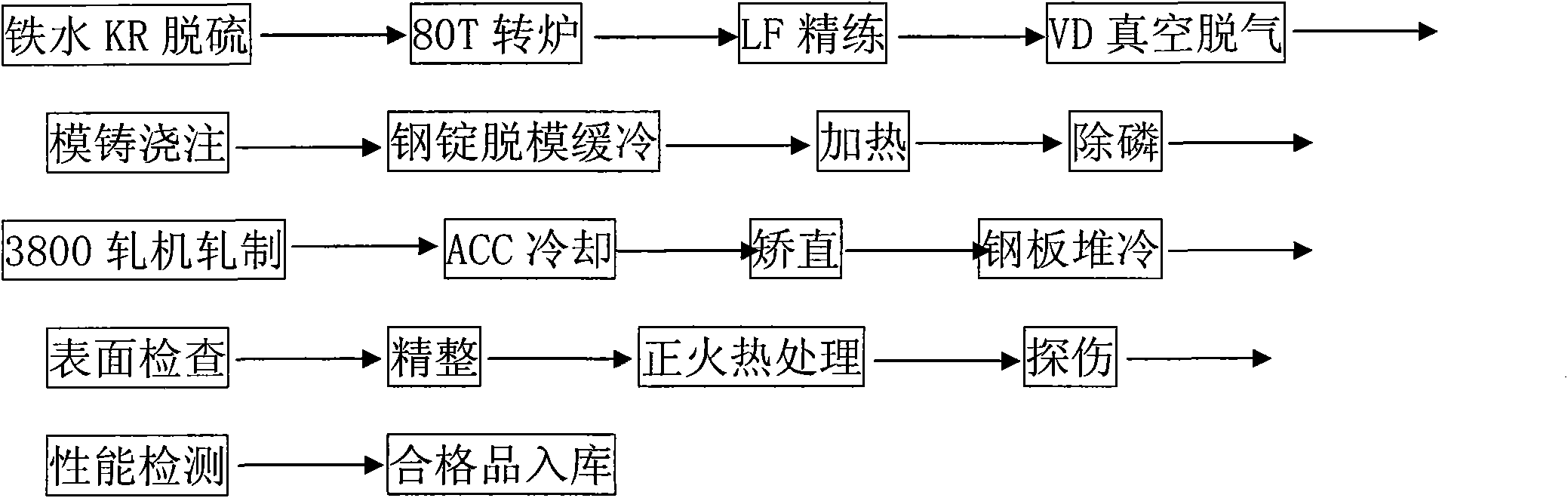

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

Composite structure type high tensile strength steel plate, plated plate of composite structure type high tensile strength steel and method for their production

InactiveUS20030129444A1Lower yield stressImprove ductilityHot-dipping/immersion processesThin material handlingSheet steelHigh intensity

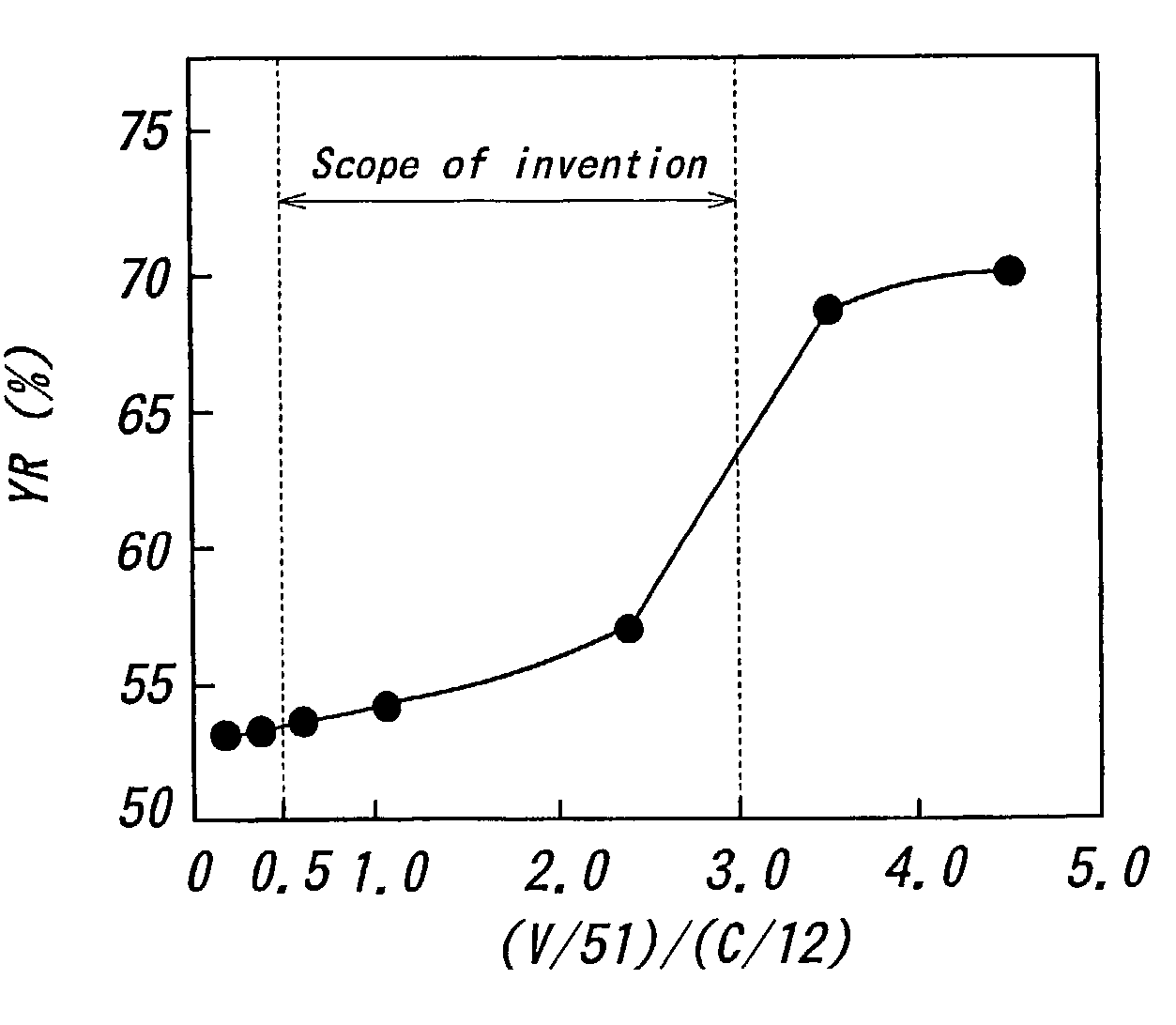

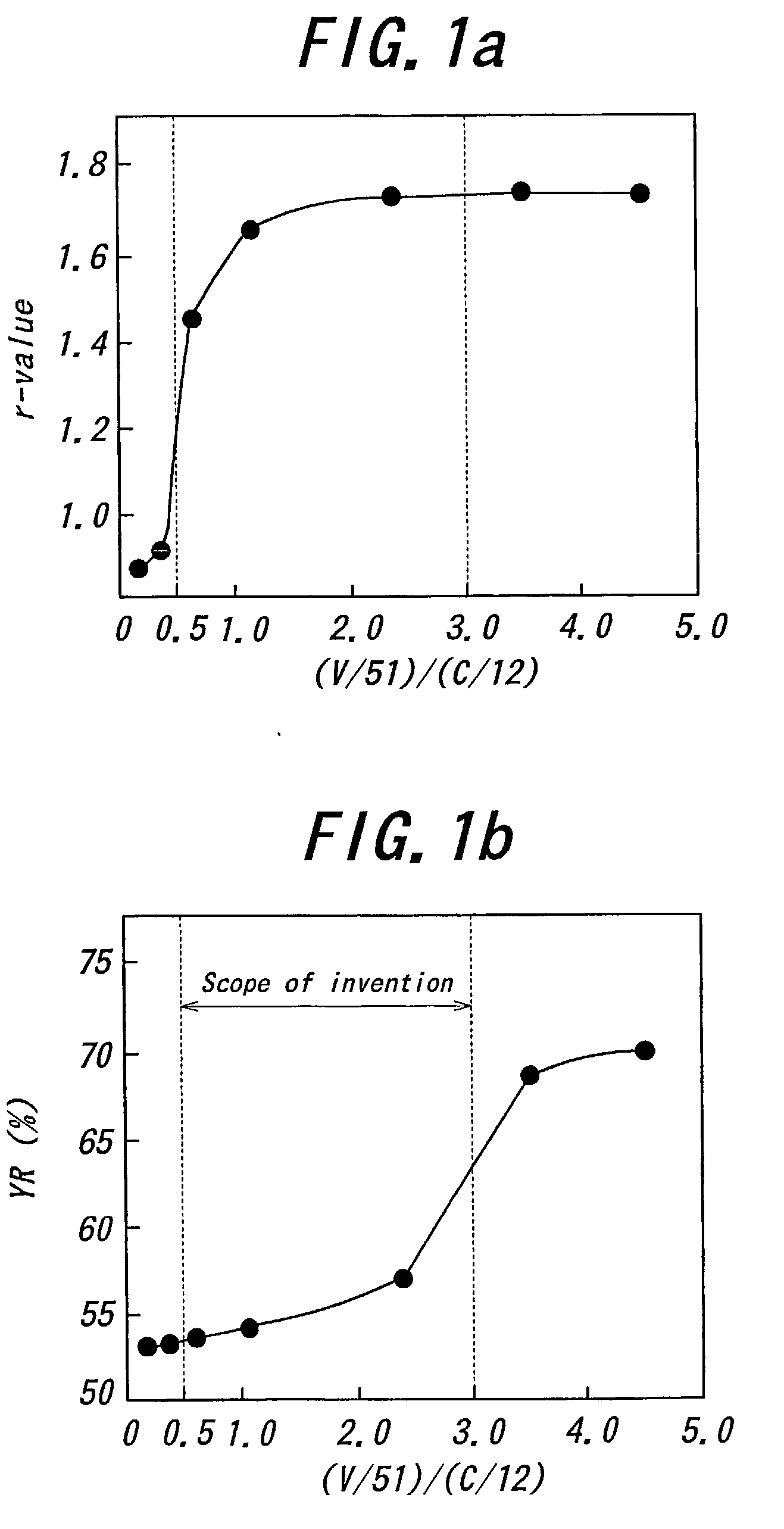

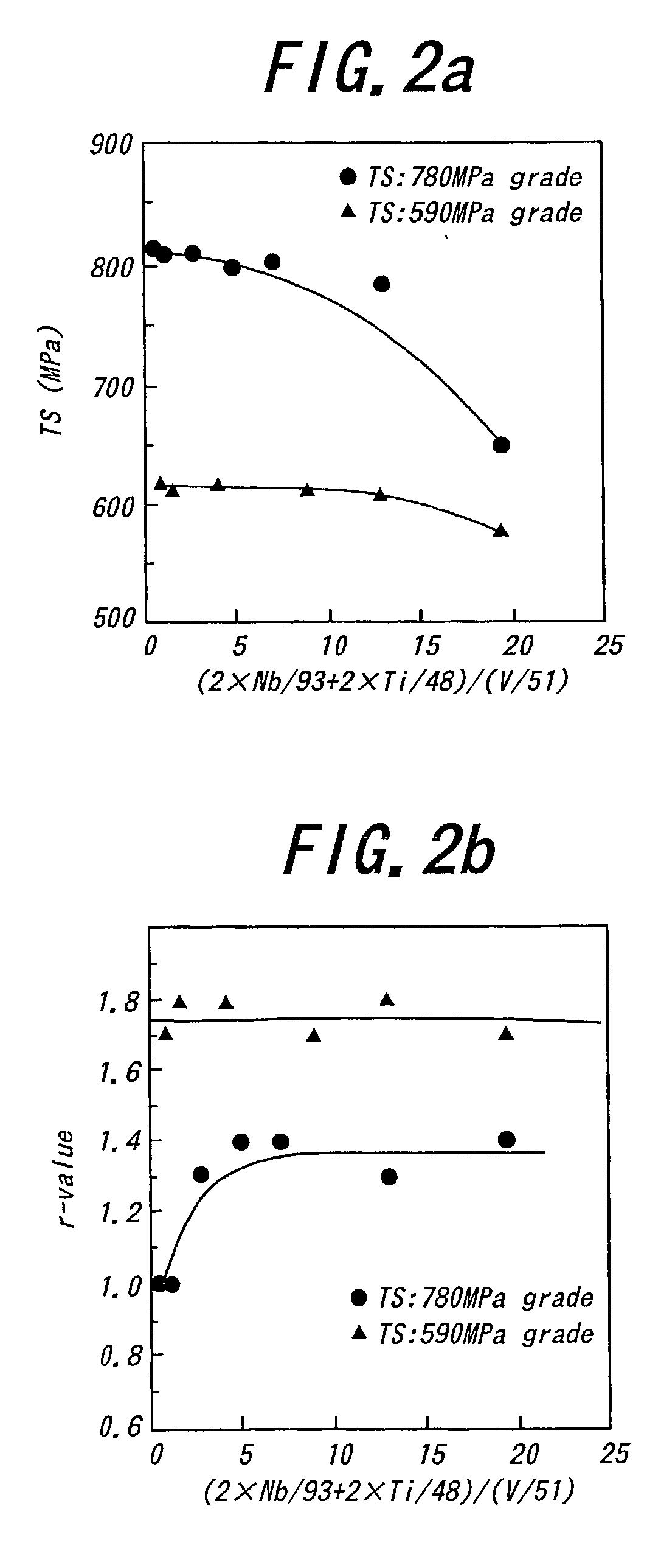

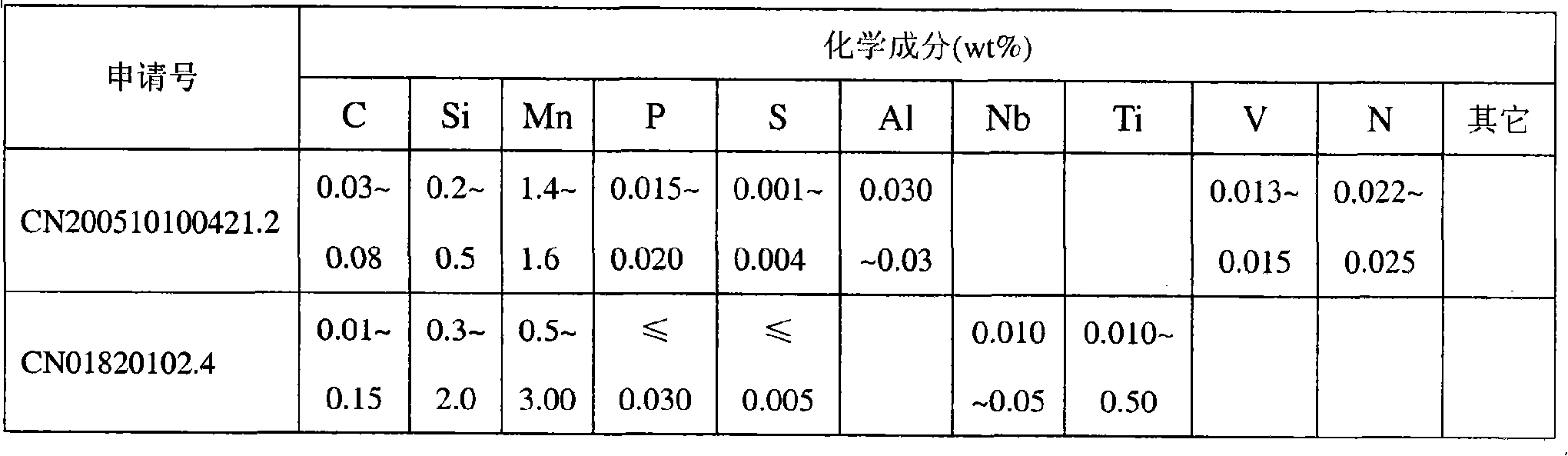

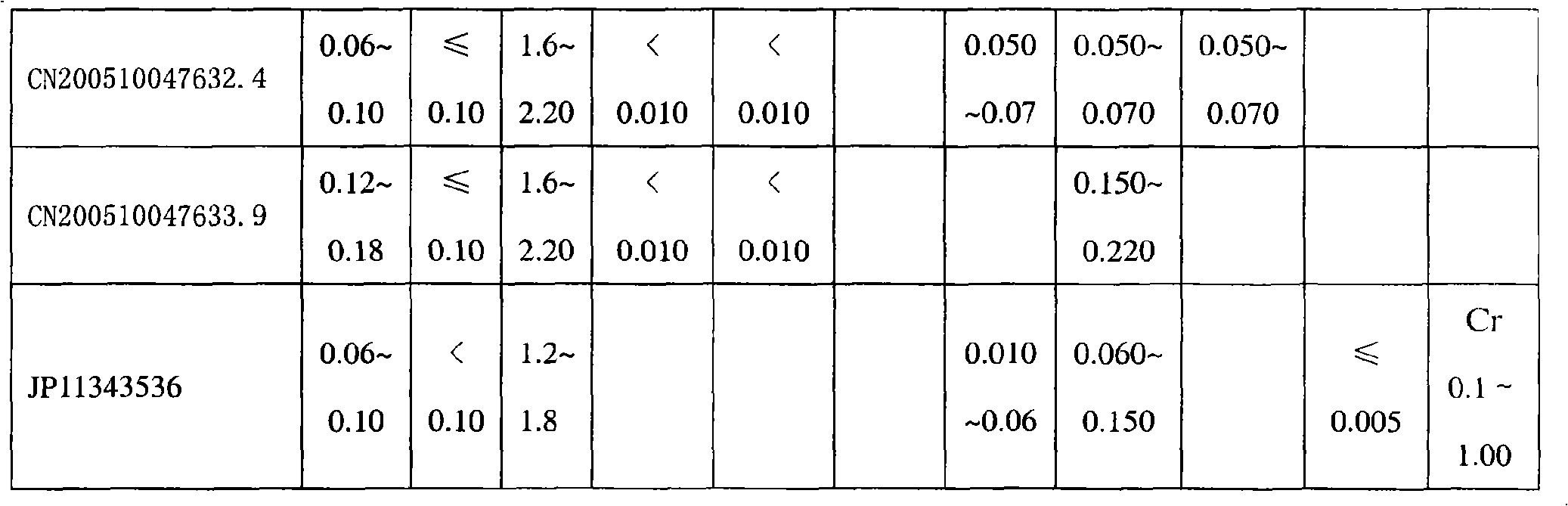

The invention proposes a high-strength dual-phase cold rolled steel sheet having an excellent deep drawability, wherein the steel sheet has a composition comprising C: 0.01-0.08 mass %, Si: not more than 2.0 mass %, Mn: not more than 3.0 mass %, P: not more than 0.10 mass %, S: not more than 0.02 mass %, A1: 0.005-0.20 mass %, N: not more than 0.02 mass % and V: 0.01-0.5 mass %, provided that V and C satisfy a relationship of 0.5xC / 12<=V / 51<=3xC / 12, and the remainder being Fe and inevitable impurities, and has a microstructure consisting of a ferrite phase as a primary phase and a secondary phase including martensite phase at an area ratio of not less than 1% to a whole of the microstructure and a high-strength dual-phase galvanized steel sheet comprising a galvanized coating on the above steel sheet as well as a method of producing the same.

Owner:JFE STEEL CORP

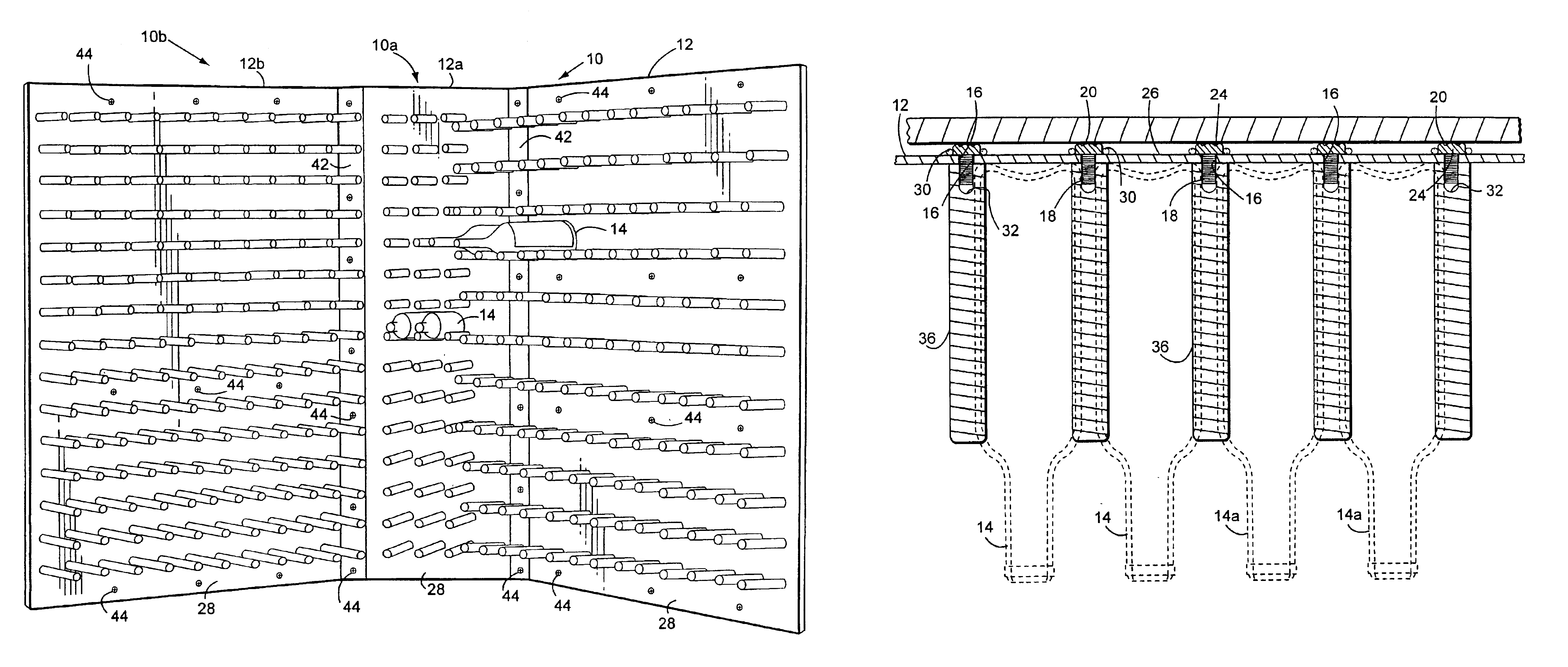

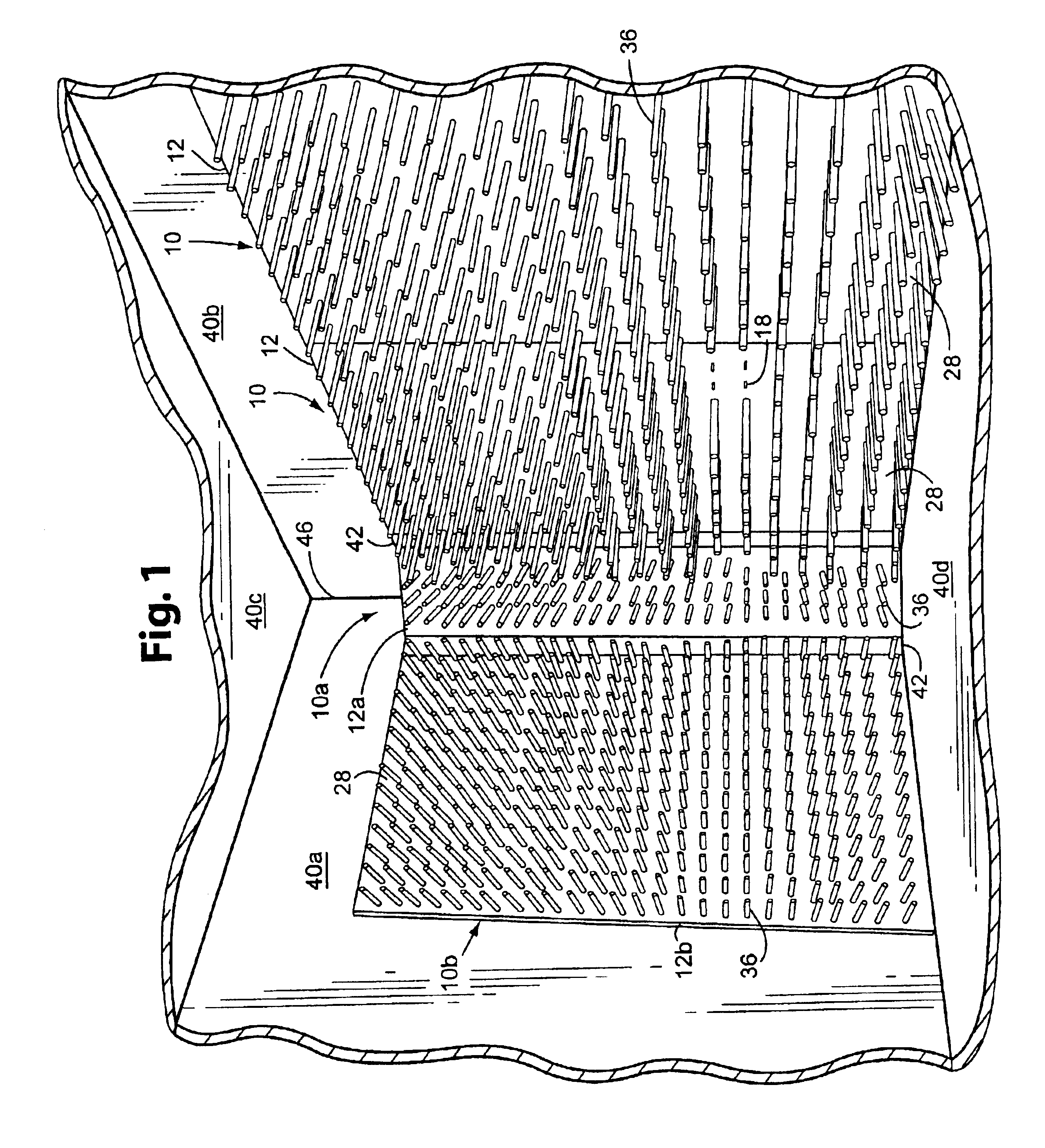

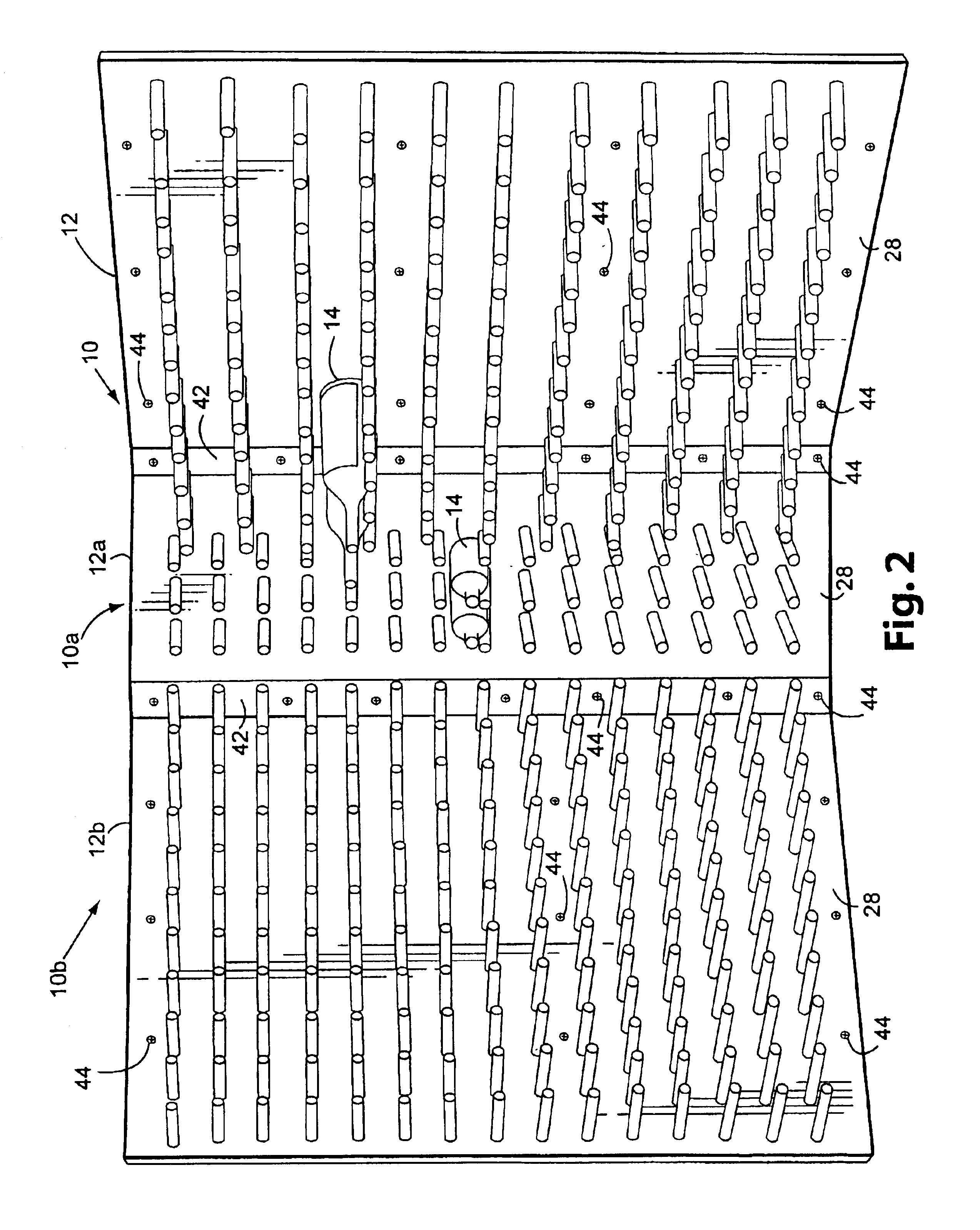

Wine rack and kit and method for its onsite assembly

InactiveUS6763956B2Readily and economically and expeditiously fabricated offsiteAssembled inexpensively and rapidlyBottle cupboardsFolding cabinetsSheet steelShortest distance

Disclosed is a wine rack, large versions of which are adapted to be installed against a wall of a room or as a free standing wall separated from the walls of a room, which is a monolithic flat rigid sheet to which has uniformly mounted in rows through holes therein a like number of wine bottle support rods which project perpendicularly and parallel to each other from one or both faces of the sheet so that two wine bottles of varying sidewall diameter can be stored on three of the rods without their side-walls touching and whose essential elements can be fabricated offsite by forming uniform rows of holes in a monolithic sheet of stainless steel; fitting in the holes machine bolts whose threaded shank ends project beyond a face of the steel sheet; bonding the heads of the bolts to the opposite face of the steel sheet so that their threaded ends project axially perpendicularly, rigidly and parallel to each other; and forming a female threaded cavity in one end of a plurality of wine bottle support rods. The thus-fabricated structural parts of the wine rack are then transported to the installation site, where the rods are coupled to the projecting ends of the bolts. A plurality of the thus-fabricated wine rack are mounted side-by-side vertically on a wall of a room at the installation site or one of them can be installed as free standing version which is stabilizing from bending or swaying at its base. A free standing version with wine bottle support rods projecting from both faces thereof can similarly be produced using short lengths of threaded steel rods which, when inserted in the holes in the steel sheet, its ends project a short distance beyond each face of the steel sheet so that the internally female threaded ends wine bottle support rods can be mounted on both ends thereof.

Owner:WOODS DANIEL

Bonded body of galvanized steel sheet and adherend, and manufacturing method thereof

InactiveUS20110008644A1Firmly connectedGood adhesionHot-dipping/immersion processesLiquid surface applicatorsPolyolefinSheet steel

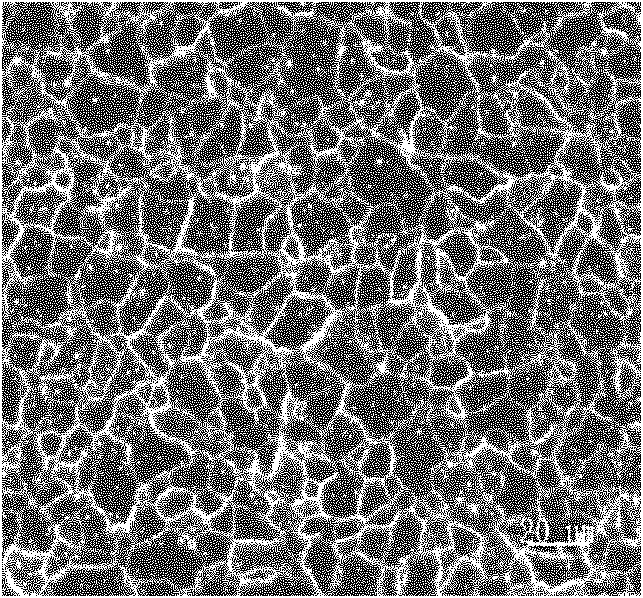

The invention is a technique for strongly integrating a galvanized steel sheet and a resin molded article. A hot-dip galvanized steel sheet “Z18” is immersed in an aqueous solution for aluminum degreasing at 75° C. for 7 minutes, to form roughness having an RSm of 0.8 to 2.3 μm and an Rz of 0.3 to 1.0 μm on the surface. The surface is covered with convex protrusions having a diameter of about 100 nm, and a chromate treatment layer appears in the surface. In other words, three conditions suitable for bonding are satisfied thereby. A resin composition comprising 70 to 97 wt % of polyphenylene sulfide and 3 to 30 wt % of a polyolefin resin is injected onto the surface. The resin composition penetrates into ultra-fine irregularities and is cured in that state, whereby a composite in which the galvanized steel sheet and the resin molded article are strongly integrated is obtained. The shear rupture strength of the composite is extremely high, in excess of 20 MPa.

Owner:TAISEI PLAS CO LTD

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

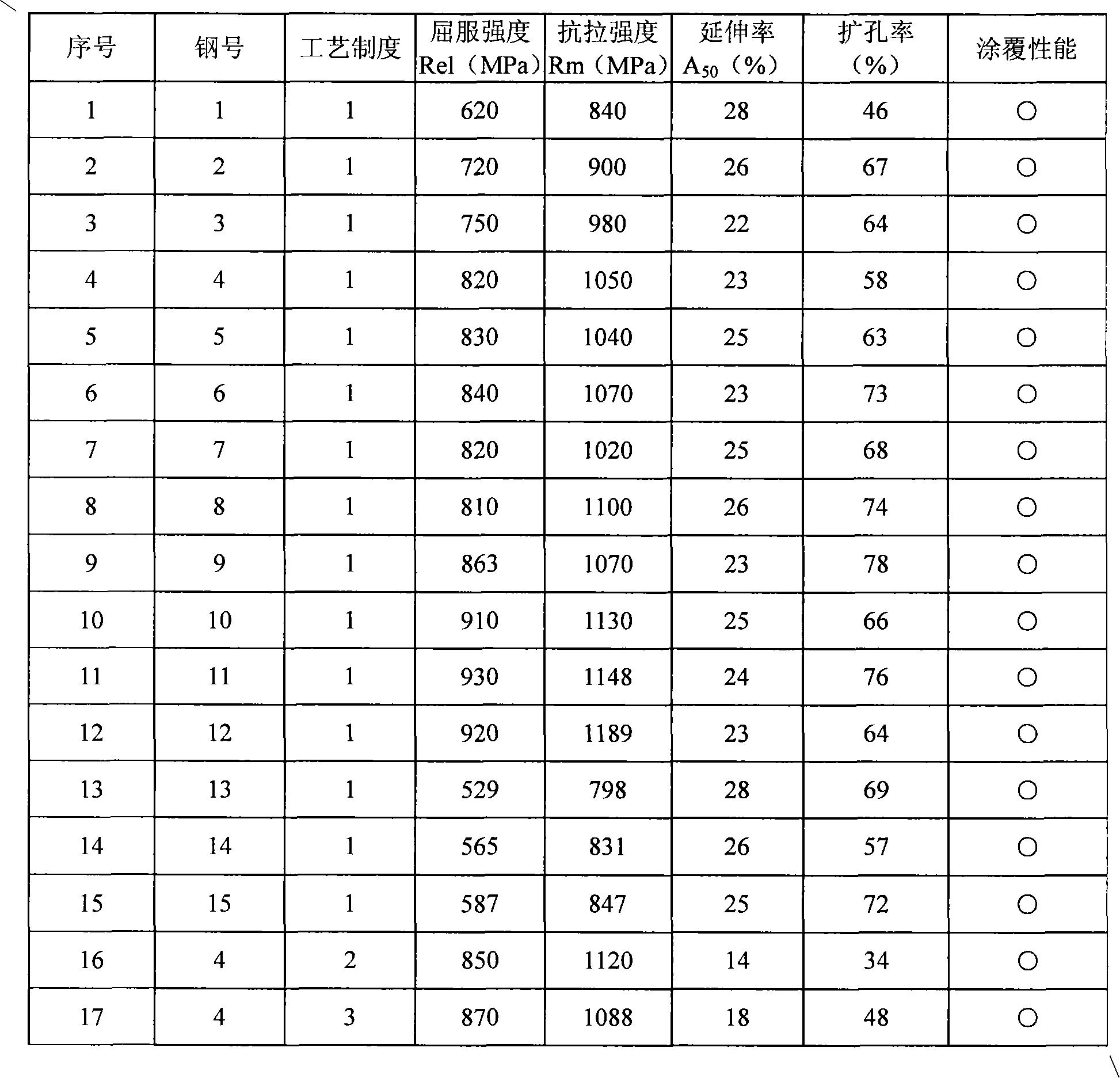

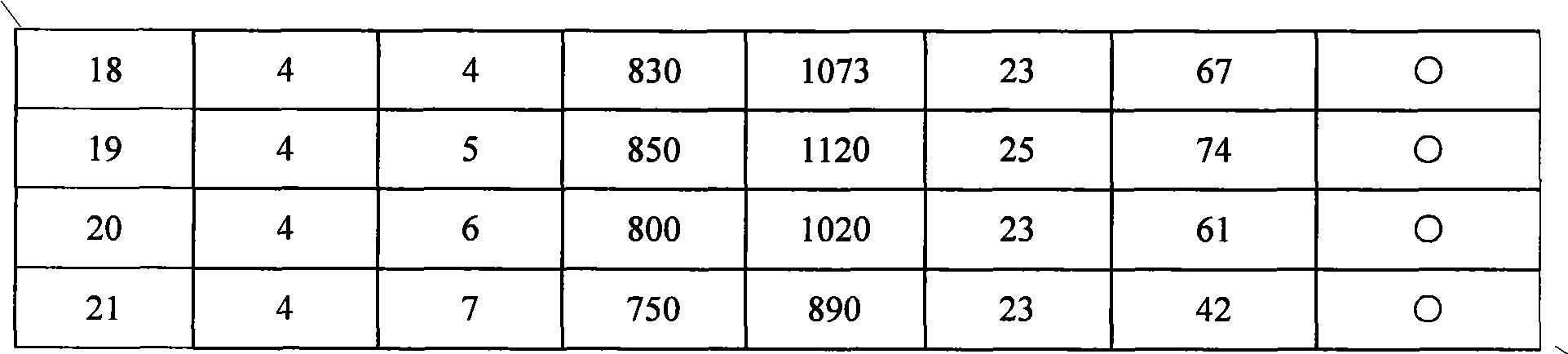

High-strength cold-rolled plate with favorable forming property and preparation method thereof

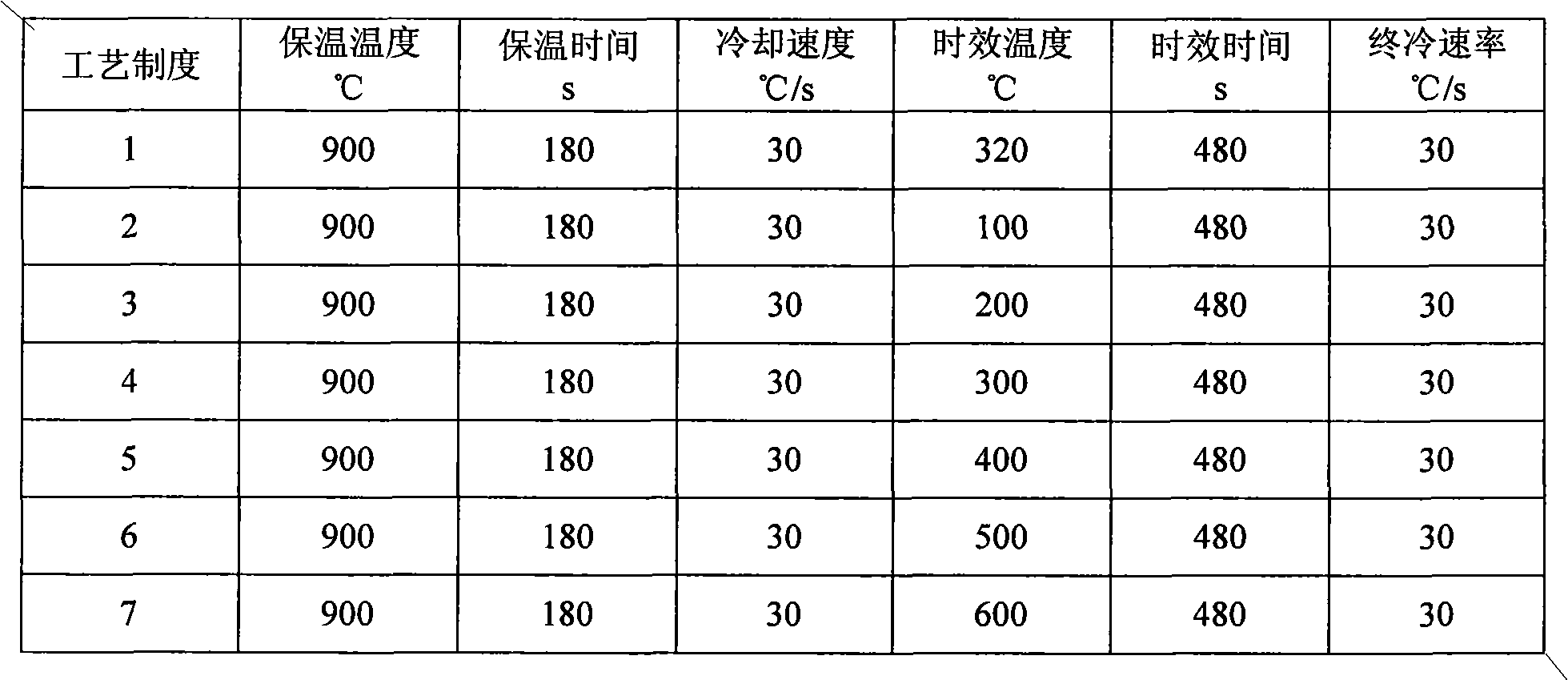

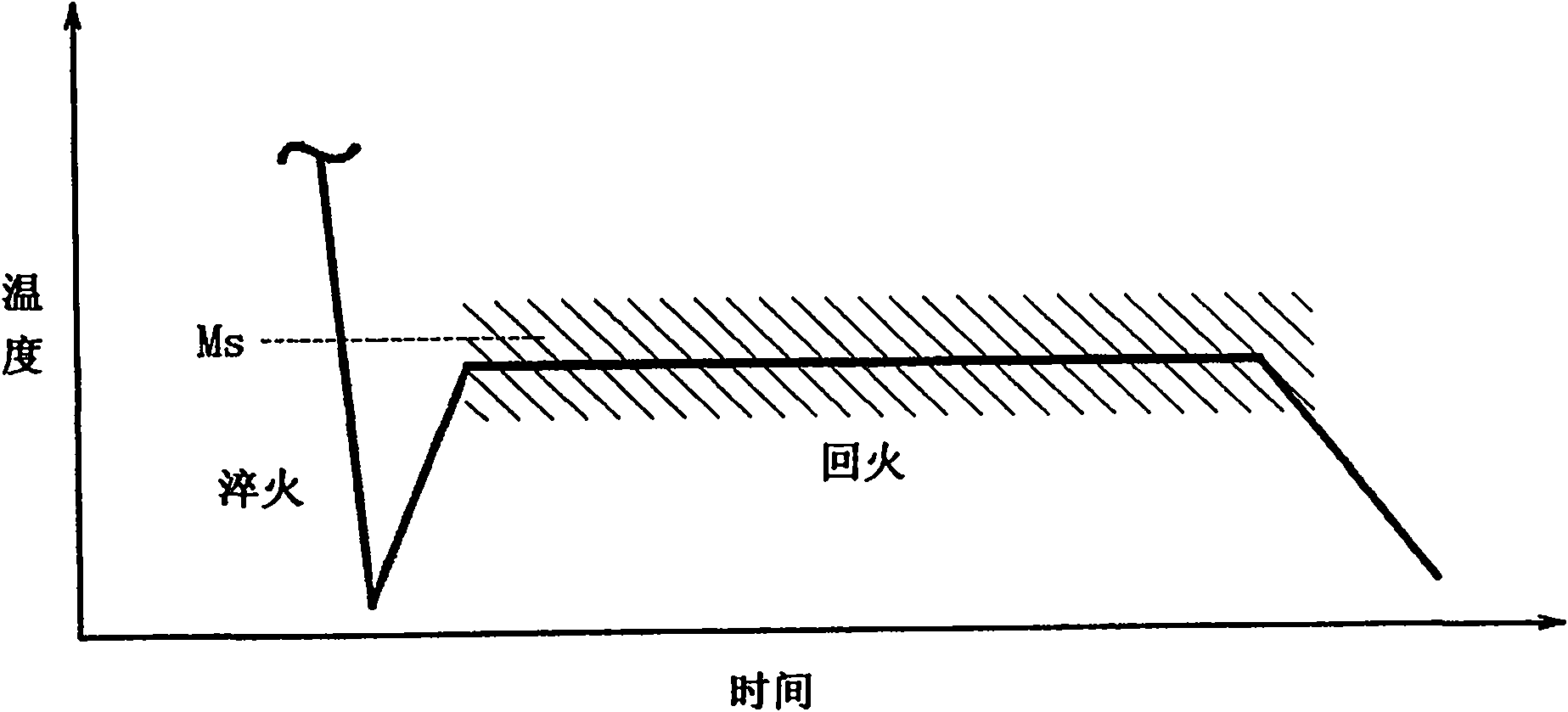

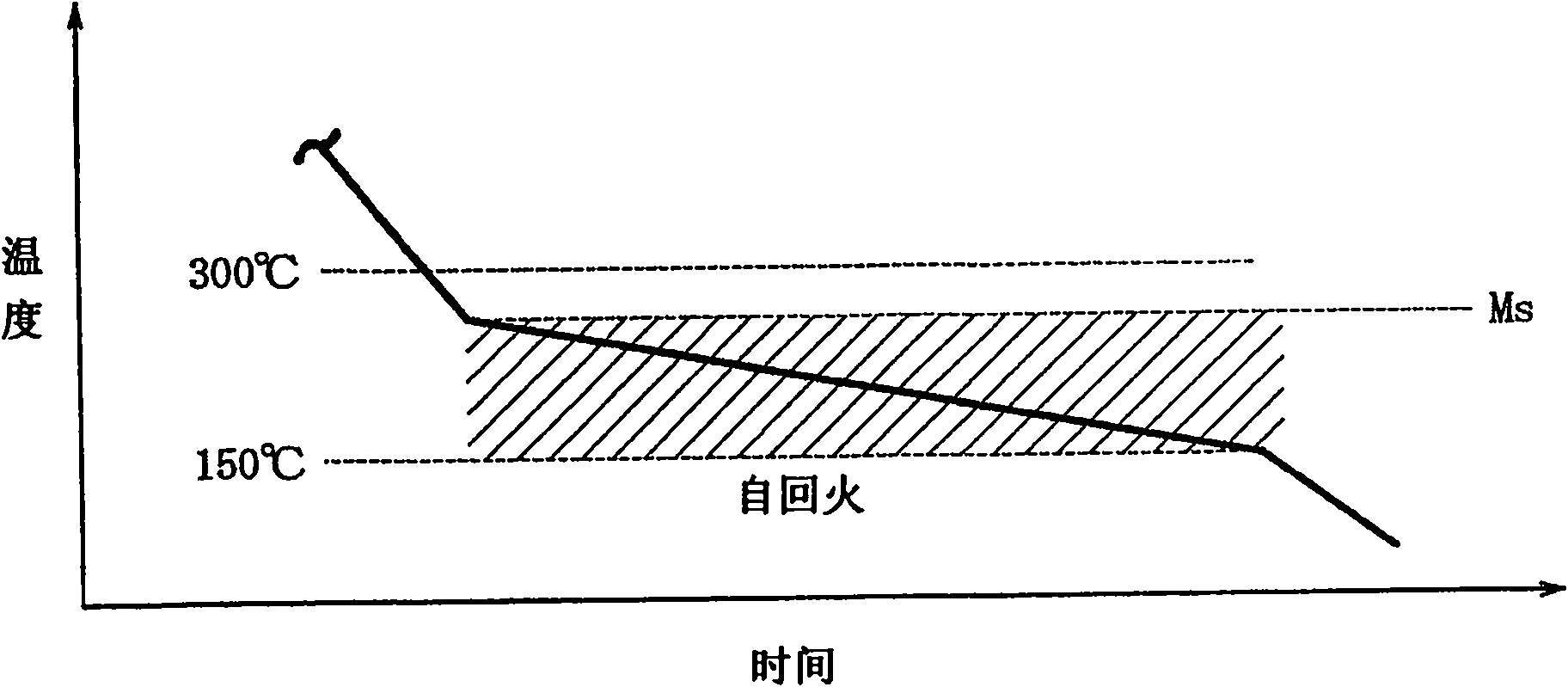

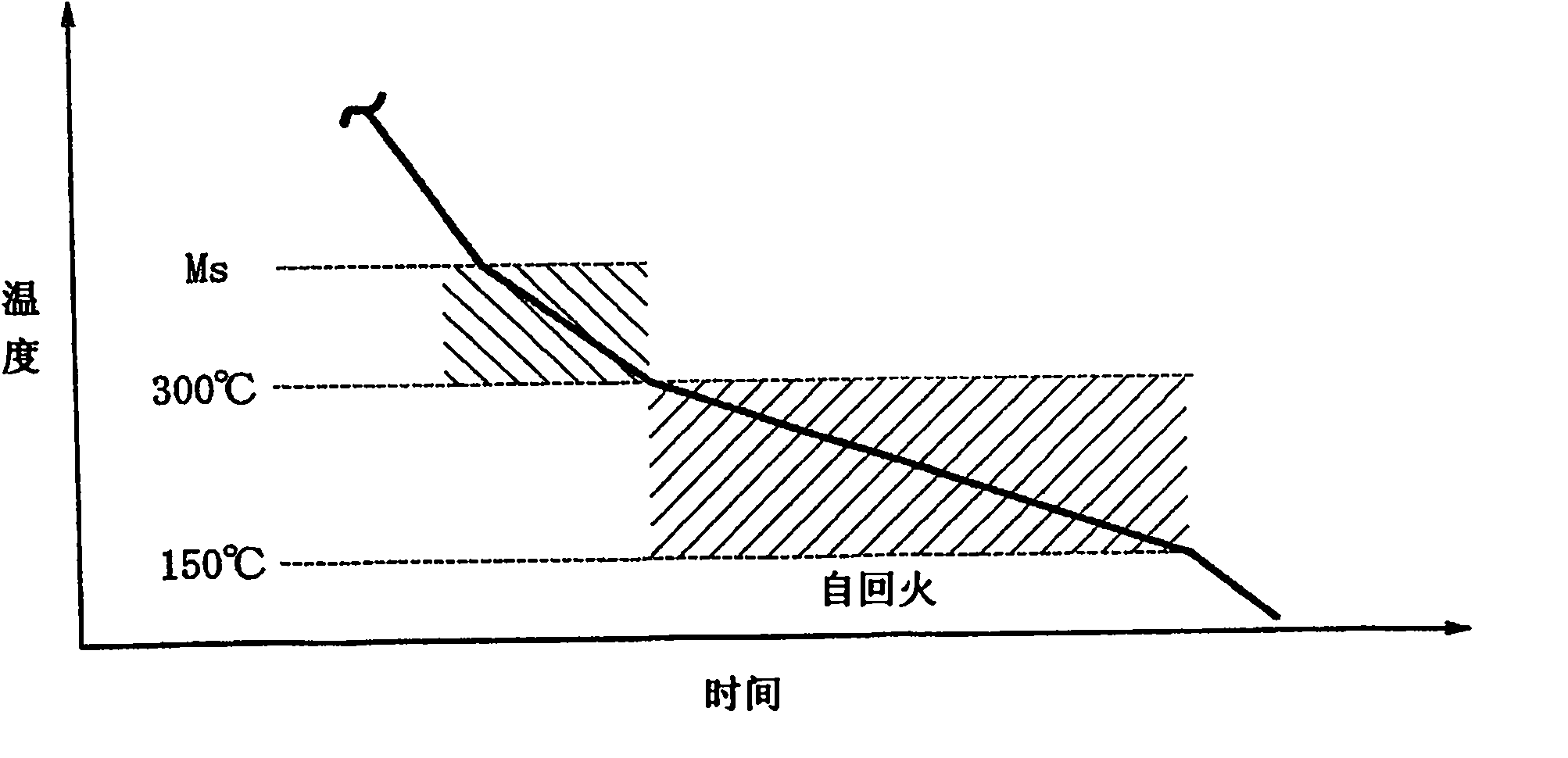

The invention provides a high-strength cold-rolled plate with favorable forming property and a preparation method thereof. The high-strength cold-rolled plate comprises the following chemical components: 0.05-0.6% of C, being more than or equal to 0.3% and being less than 0.8% of Si, 0.5-4.0% of Mn, being more than ore equal to 0.2% of P, being more than or equal to 0.002% of S, being more than or equal to 0.1% of Al, being more than or equal to 0.01% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, continuous-casting, hot-rolling, cold-rolling and continuous-annealing, wherein annealing temperature is higher than that of Ac3, holding time is 3-30 minutes; quickly cooling to 100-600 DEG C at the rate of 30-100 DEG C / s, keeping the temperature for 3-30 minutes, and finally cooling to room temperature at the rate of 5-30 DEG C / s. The invention adopts low-silicon low-aluminum component design and heat treatment technique; the strength level of the produced bainite TRIP steel is greater than 780 MPa; and the produced bainite TRIP steel has favorable strength, plasticity, extensibility, chambering property and coating property.

Owner:ANGANG STEEL CO LTD

1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

The invention provides 1,000 MPa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof, belonging to the technical field of cold-rolled hot-dip galvanized high-strength steel plates. The chemical components in mass percentage of the cold-rolled hot-dip galvanized dual-phase steel are: 0.06 to 0.18 percent of C, less than or equal to 0.1 percent of Si, 1.2 to 2.5 percent of Mn,0.05 to 0.5 percent of Mo, 0.05 to 0.6 percent of Cr, 0.005 to 0.05 percent of Al, 0.01 to 0.06 percent of Nb, 0.01 to 0.05 percent of Ti, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.005 percent of N, the balance being Fe and inevitable impurities. The manufacturing method adopts Cr or Mo to replace Si, so as to enlarge an austenitic and ferritic two-phase region and improve the hardenability of the dual-phase steel, and meanwhile, the manufacturing method improves the strength of toughness of the steel by adding Nb or Ti refined grains, so as to ensure that the steel has good weldability and usability, and the strength grade of the steel can reach over 1,000 Mpa.

Owner:UNIV OF SCI & TECH BEIJING +1

Dual-phase steel sheet excellent in stretch flange formability and production method thereof

Disclosed is a dual-phase steel sheet having low yield ratio, excellent in the balance for strength-elongation and for strength-stretch flange formability, and also excellent in bake hardening property containing (on the mass% basis). C: 0.01-0.20%, Si: 0.5% or less, Mn: 0.5-3%, sol. Al: 0.06% or less (inclusive 0%), P: 0.15% or less (exclusive 0%), and S: 0.02% or less (inclusive 0''), and in which the matrix phase contains tempered martensite; tempered martensite and ferrite; tempered bainite; or tempered bainite and ferrite, and the second phase comprises 1 to 30% of martensite at an area ratio based on the entire structure.

Owner:KOBE STEEL LTD

Marine engineering large thick steel plate submerged arc welding process method in low-temperature environment

InactiveCN101879645AIncrease productivityReduce labor intensityArc welding apparatusWelding/cutting media/materialsEngineeringWeld seam

The invention belongs to the field of welding, in particular to a process method applicable to marine engineering large thick steel plate submerged arc welding in low-temperature environment, which comprises a welding method, welding material selection, a welding order, a welding process and the selection and control of various welding process parameters. The method renders with carbon dioxide gas protection welding, and fills and faces through an automatic submerged arc welding; stops welding when the welding reaches more than two thirds of the thickness of a large groove during the welding process, clears chips on the back side and completes the welding of the other side; finally completes the welding of the first side; strictly controls all relevant process parameters of the welding during the welding process, and solves the problems of poorer anti-crack toughness of welding seams and heat affected zones caused by too high cooling speed of the welding seams and too high temperature; can ensure good anti-crack toughness of a welding seam connector without heat treatment after welding; and can meet the requirements of welding of an E36 plate with the thickness of 35 to 77mm under the working environment at the temperature of above -30DEG C, simplifies the production process, shortens the production cycle and reduces the cost.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Production method of ultrahigh strength steel plate for cold forming and steel plate

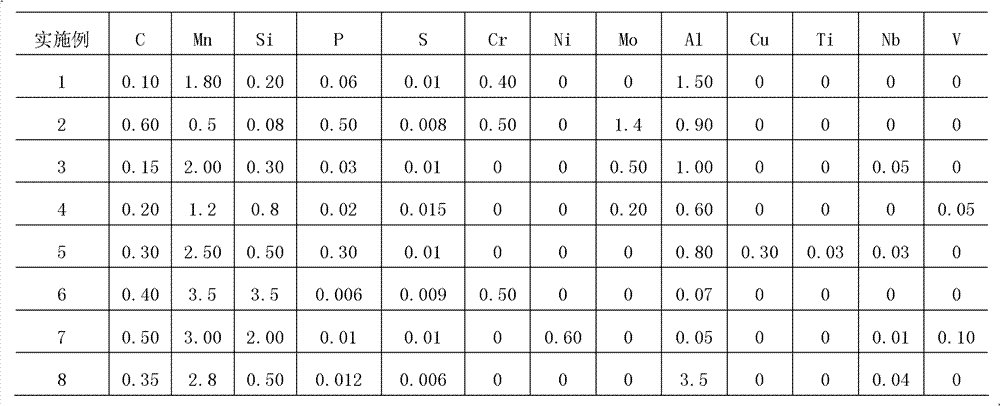

The invention provides a production method of an ultrahigh strength steel plate for cold forming and the steel plate. The method comprises the steps of smelting, casting, hot rolling, cold rolling, heating the cold-rolled steel plate through a continuous annealing production line with rapid cooling treatment to the austenite temperature, holding the temperature for a certain time, carrying out quenching treatment, obtaining a steel plate with the main structure of M+A and carrying out distribution treatment in a bell type annealing furnace. The steel plate comprises the following components in percentage by mass: 0.02-0.60% of C, 0.05-3.5% of Si, 0.20-3.50% of Mn, P more than or equal to 0.005 but less than or equal to 0.50%, S not more than 0.05%, 0.02-3.00% of Al, Cr not more than 0.50%, Ni not more than 3.00%, Cu not more than 0.50%, Mo not more than 1.50%, V not more than 0.50%, Ti not more than 0.20%, Nb not more than 0.20% and the balance of Fe and unavoidable impurities. The steel plate produced by adopting the method provided by the invention has the advantages of high strength and capability of cold forming and the process route of Q&P steel industrial production is effectively solved.

Owner:ANGANG STEEL CO LTD

Steel sheet for hot press forming having low-temperature heat treatment property, method of manufacturing the same, method of manufacturing parts using the same, and parts manufactured by the same

ActiveUS20090238715A1Reduced strengthHigh yield strengthMetal rolling stand detailsFurnace typesManganeseHeat treated

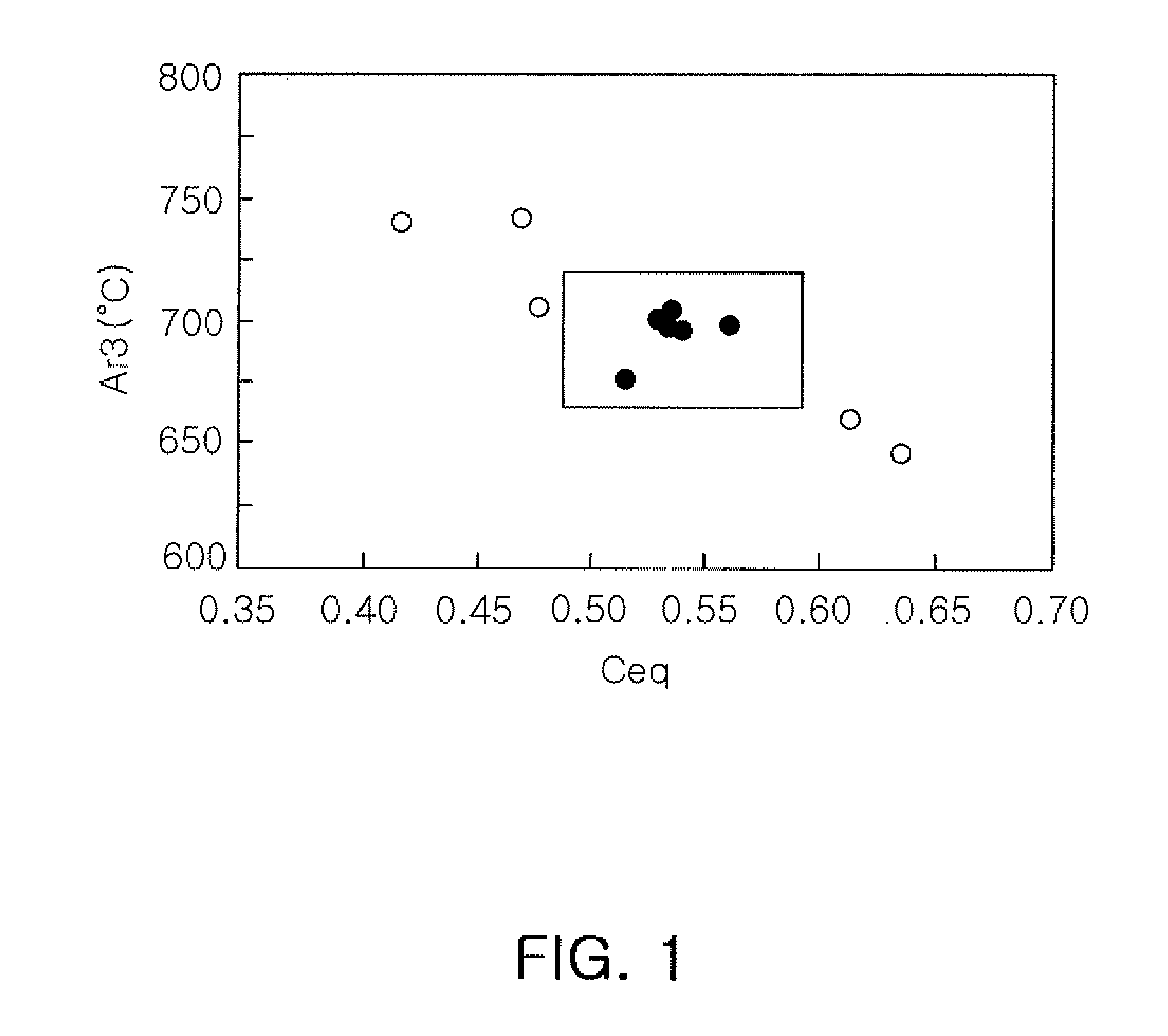

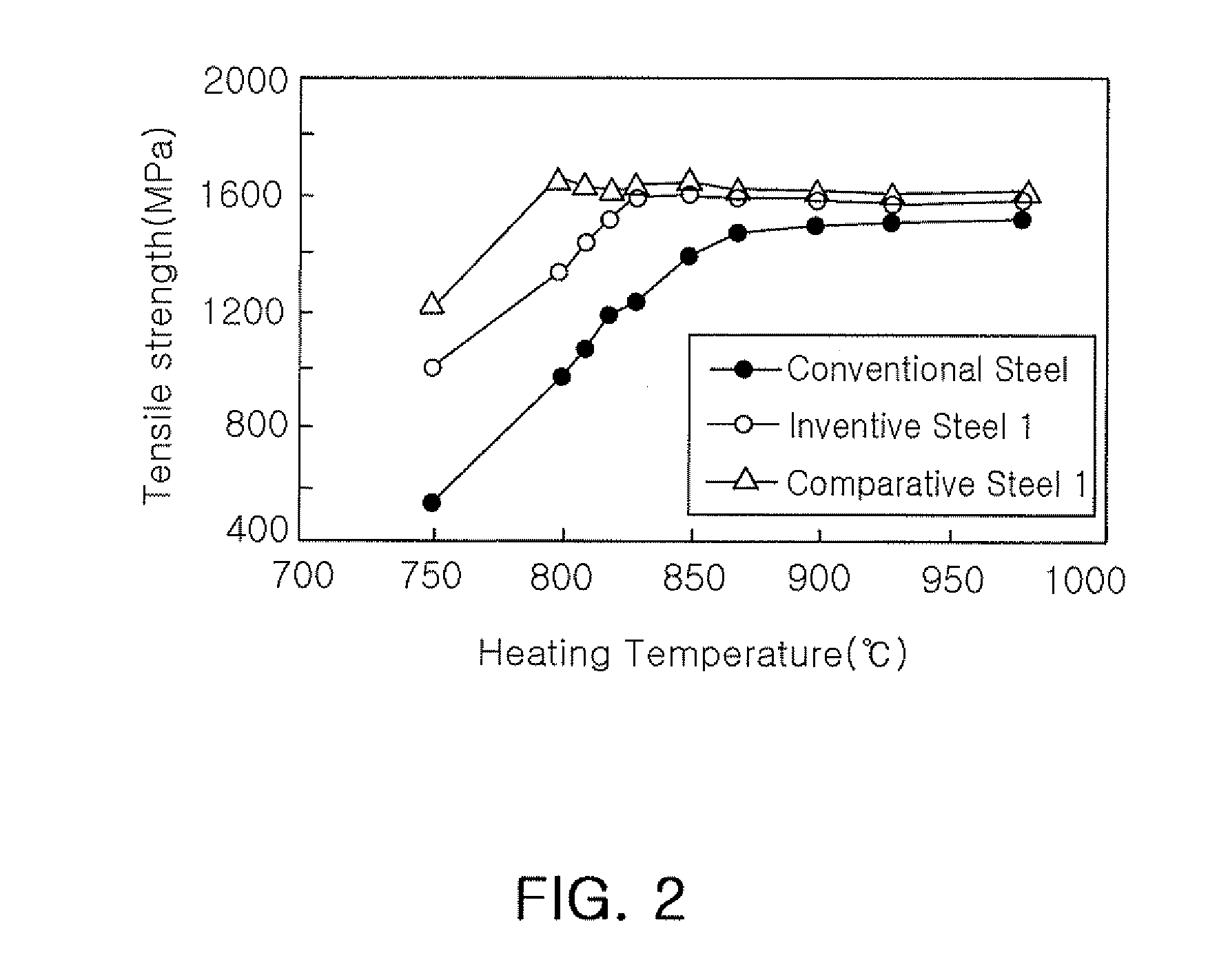

A steel sheet for forming having low-temperature heat treatment property, in which heat treatment is performed within a range of lower temperature than a conventional steel sheet in the event of hot press forming or post-heat treatment after cold forming, a method of manufacturing the same, and a method of manufacturing parts using the same. The steel sheet has a composition of, by weight, carbon (C): 0.15 to 0.35%, silicon (Si): 0.5% or less, manganese (Mn): 1.5 to 2.2%, phosphorus (P): 0.025% or less, sulfur (S): 0.01% or less, aluminum (Al): 0.01 to 0.05%, nitrogen (N): 50 to 200 ppm, titanium (Ti): 0.005 to 0.05%, tungsten (W): 0.005 to 0.1%, and boron (B): 1 to 50 ppm, wherein Ti / N: less than 3.4, where Ti / N is the atomic ratio of the corresponding elements, Ceq expressed by the following formula ranges from 0.48 to 0.58, and temperature Ar3 ranges from 670° C. to 725° C. Wherein Ceq=C+Si / 24+Mn / 6+Ni / 40+Cr / 5+V / 14 where C, Si, Mn, Ni, Cr and V indicate the contents (wt %) of the respective elements.

Owner:POHANG IRON & STEEL CO LTD

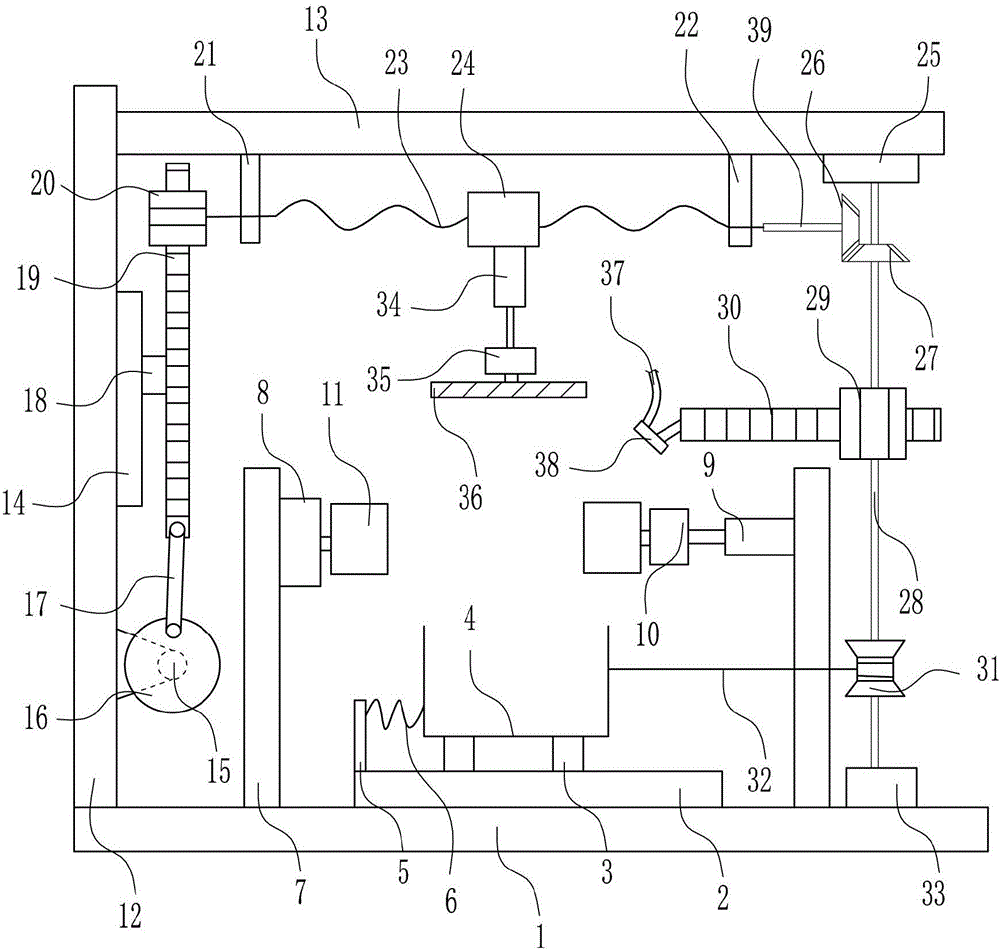

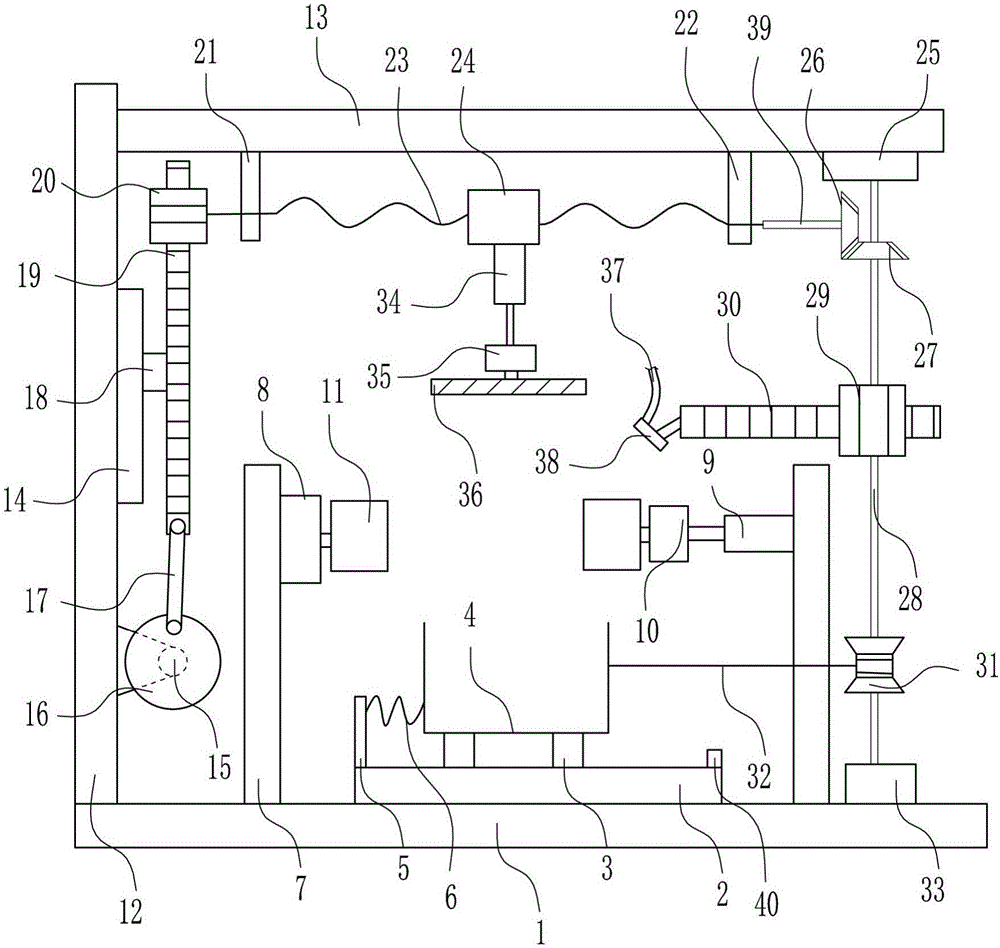

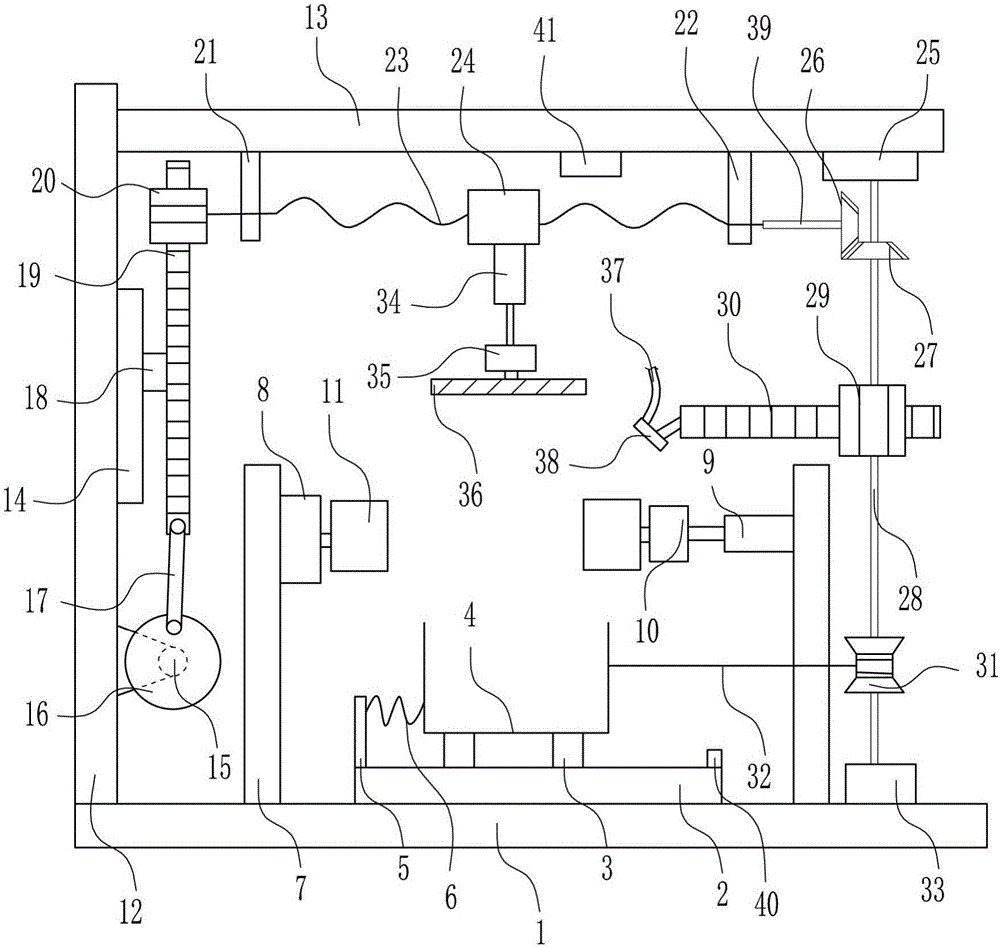

Steel plate surface polishing device for hardware machining

ActiveCN106141875AImprove corrosion resistanceHigh strengthGrinding carriagesPolishing machinesSheet steelMachining

The invention relates to a steel plate surface polishing device, in particular to a steel plate surface polishing device for hardware machining. The steel plate surface polishing device for hardware machining aims to achieve the technical purposes that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of operators is small. In order to achieve the technical purposes, the steel plate surface polishing device for hardware machining comprises a bottom plate, a first sliding rail, a first sliding block, a collection tank, a fixing stop block, a spring, a supporting rod, a first bearing pedestal, a first air cylinder, a disc and the like, wherein the first sliding rail is arranged in the middle of the top of the bottom plate. Through ingenious cooperation of the components, the effects that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of the operators is small are achieved.

Owner:如皋市通城冲压机械制造有限公司

Low-yield strength anti-ageing continuous annealing cold-roll steel sheet and production method thereof

InactiveCN101956133ARefine and stabilize crystal sizeLower yield strengthSheet steelContinuous annealing

The invention belongs to the field of roll steel, in particular to a low-yield strength anti-ageing continuous annealing cold-roll steel sheet and a production method thereof, which solves the technical problem that stable-performance low-yield strength anti-ageing cold-roll steel sheets are difficult to be produced on a machine set with worse equipment level. The technical scheme of the invention is characterized by providing the low-yield strength anti-ageing cold-roll steel sheet and the production method thereof. The method of the invention can be implemented on the machine set with worse equipment level; and by adopting the method of the invention, the stable-performance low-yield strength anti-ageing cold-roll steel sheet can be produced, and the technical problem existing in the field of roll steel for a long term can be overcome.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Steel plate for hot-rolled double-side enamel and method for producing same

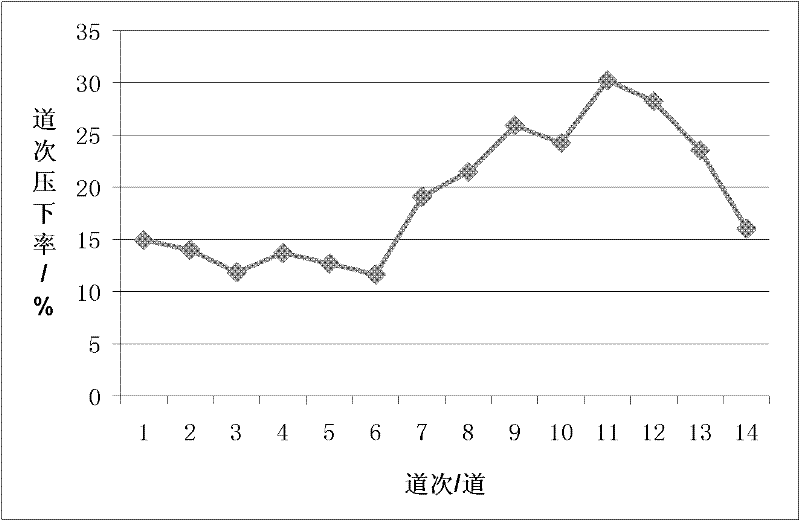

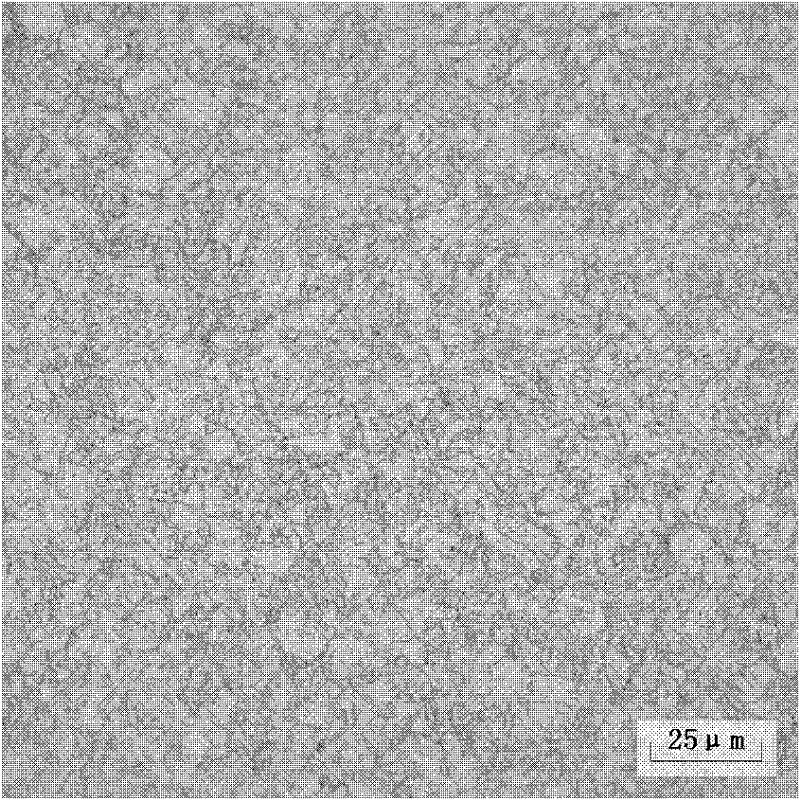

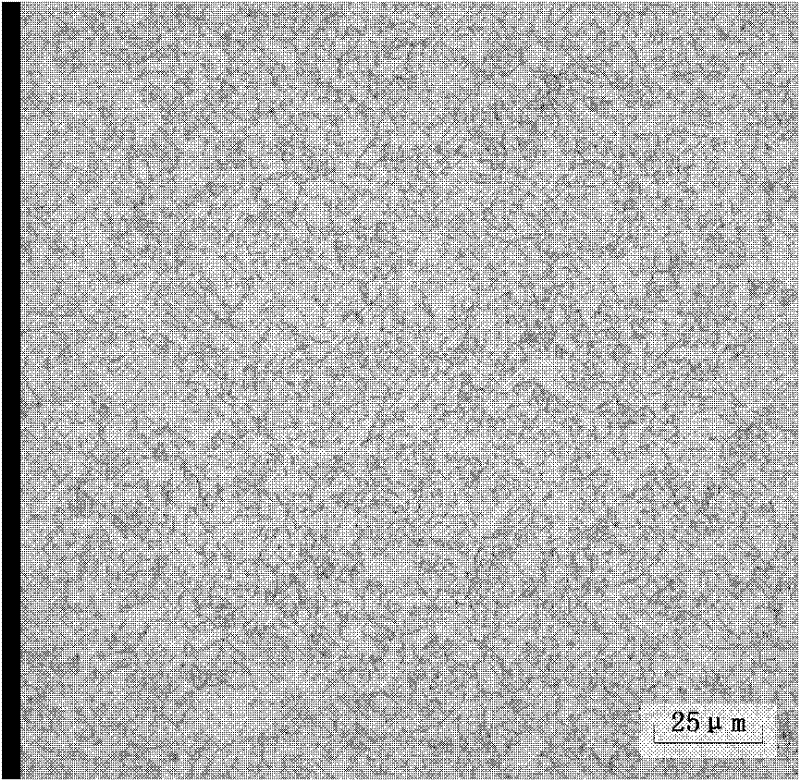

InactiveCN1966753AIncrease productivityUniform compositionTemperature control deviceSheet steelChemical composition

The invention provides a kind of hot-rolled double-sided enamel-used nickelclad, the chemical components of which is: C 0.02%-0.06%, Si <=0.50%, Mn 0.15%-0.40, P <=0.15%, S <=0.006%, N<=0.003%, Ti 0.08%-0.20%, Als 0.005%-0.055%, Ti / C 2.2-5,unavoidable impurities and Fe as balance. The architecture of the nickelclad is ferrite with grain diameter = 2 mum-20 mum under hot rolling conditions, and TiC particles (diameter < 20nm is uniformly distinguished in the architecture. V 0.015%-0.060% and / or Cr 0.05%-0.20% can also be added. The production method of the clad is: producing unburnt earthenware with continuous cast method, heating to 1180-1260DEG C, descaling with high-handed water, rough rolling, finish rolling for 5-7 passes at 1100-960 DEG C and finally at 920DEG C-840DEG C, continuously cooling to 450- 630DEG C at a speed of >=30DEG C / S in 0-7S, and coiling. The nickelclad has the advantages of good performance and high strength, and can meet the requirement of large scaled engineering fembers.

Owner:ANGANG STEEL CO LTD

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

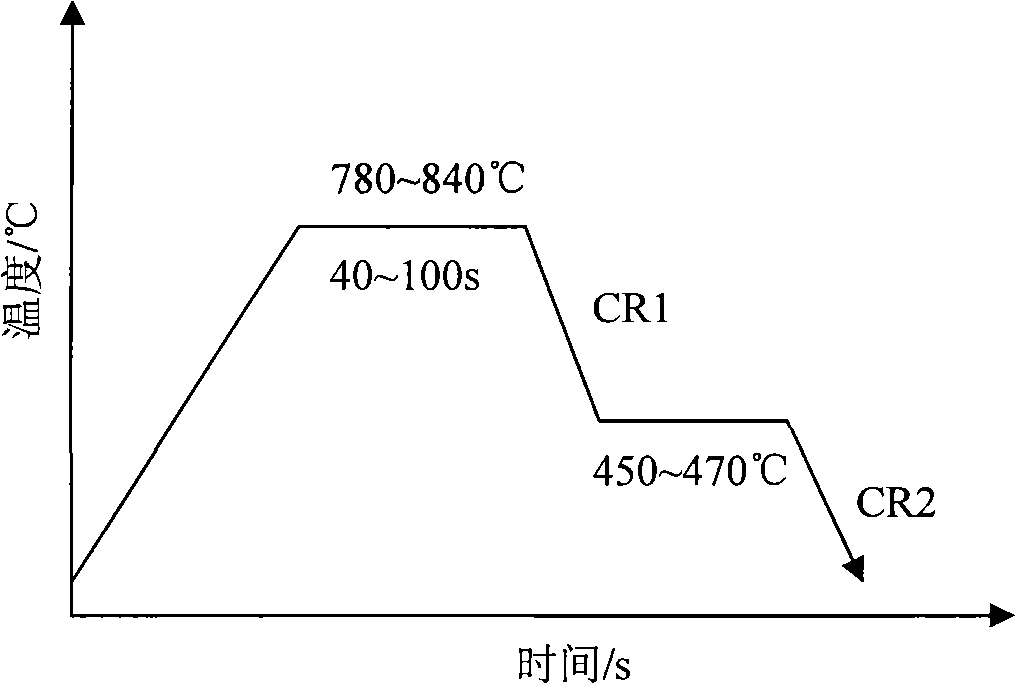

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

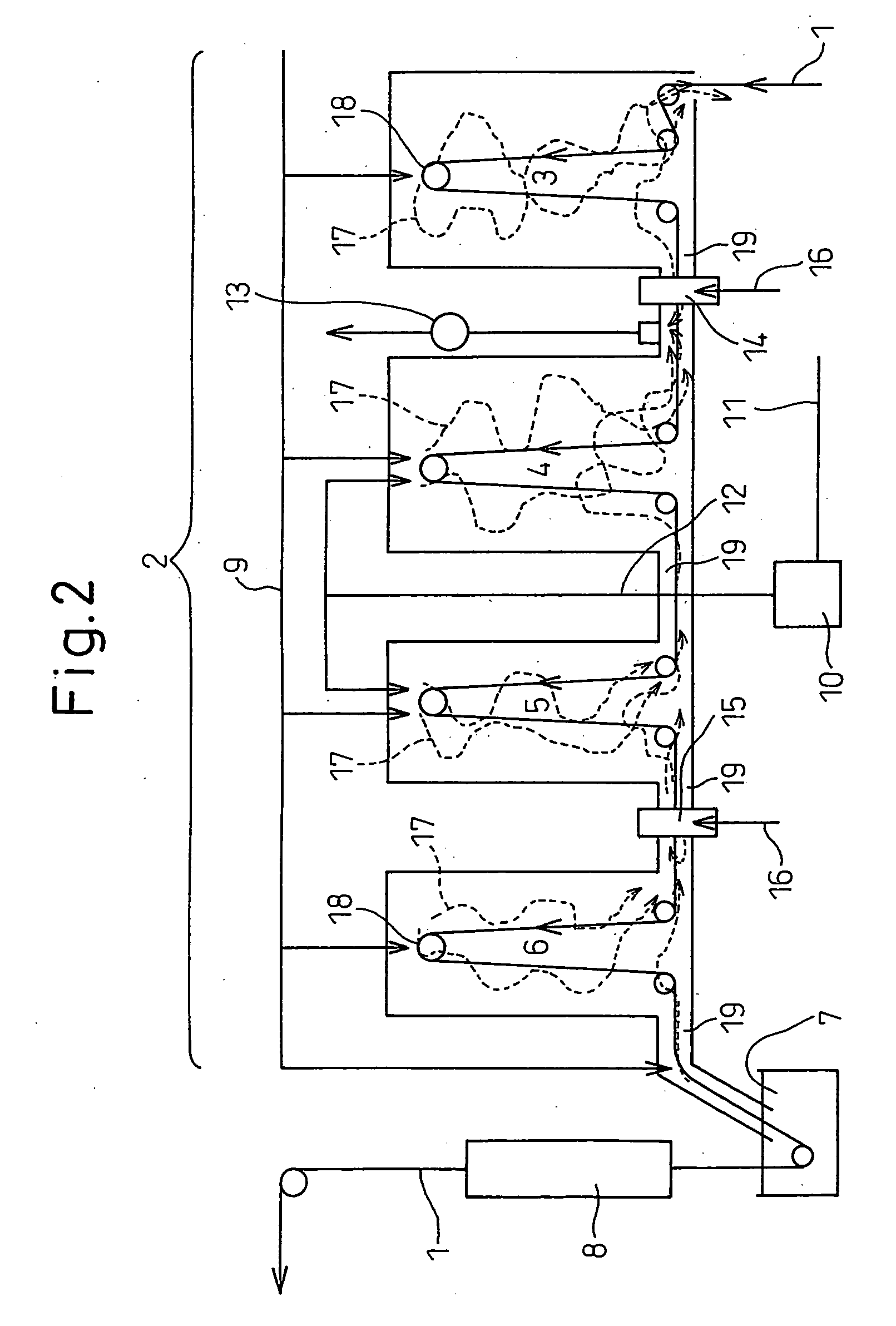

Surface iron scale control method for middle sheet billet continuous casting and rolling steel plate

InactiveCN101012528AReduce generationGood removal effectTemperature control deviceWork treatment devicesThin slabEnergy conservation

The invention discloses a controlling method of iron oxide sheet of rolled band steel surface of middle-thin board blank, which is characterized by the following: controlling component; proceeding heat load directly; heating to remove phosphor; rolling under high temperature; forcing to cool; controlling Si content in the steel; eliminating red ferric oxide on the surface of heat roll steel; fitting for the steel with not more than 0.18%C, not more than 0.20% Si, not more than 1.50% Mn, not more than 0.015% P, not more than 0.01% S and Nb, V and Ti.

Owner:ANGANG STEEL CO LTD

Q345q-series super-thick bridge steel plate and production method thereof

ActiveCN101880824AHigh standardRoll force/gap control deviceTemperature control deviceProduction lineChemical composition

The invention discloses a Q345q-series super-thick guaranteed performance and flaw detection bridge steel plate comprising the following chemical components in percentage by mass: 0.08-0.16 percent of C, 0.20-0.50 percent of Si, 1.15-1.60 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S, not more than 0.12 percent of microalloyed element (V+Nb+Ti+Ni), 0.010-0.050 percent of AlS and the balance of Fe and residual elements; and carbon equivalent is not more than 0.43. The invention also discloses a production method of the steel plate, comprising the steps of rolling, cooling, straightening, cooling in pile and thermal treatment. In the rolling, the cooling and the straightening, the 130 mm super-thick Q345qD(E) steel plate is successfully developed in the production line of a converter, die casting, mill rolling and normalization thermal treatment through carrying out reasonable composition design, die casting, TMCP (Thermal Mechanical Control Process) rolling and thermal treatment; the secondary flaw detection qualification rate reaches 90 percent, the performance initial test qualification rate reaches 100 percent, and the Z-direction performance of the entity of the steel plate can reach Z15 level. The development of the super-thick steel plate satisfies the higher requirements on bridge industry.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

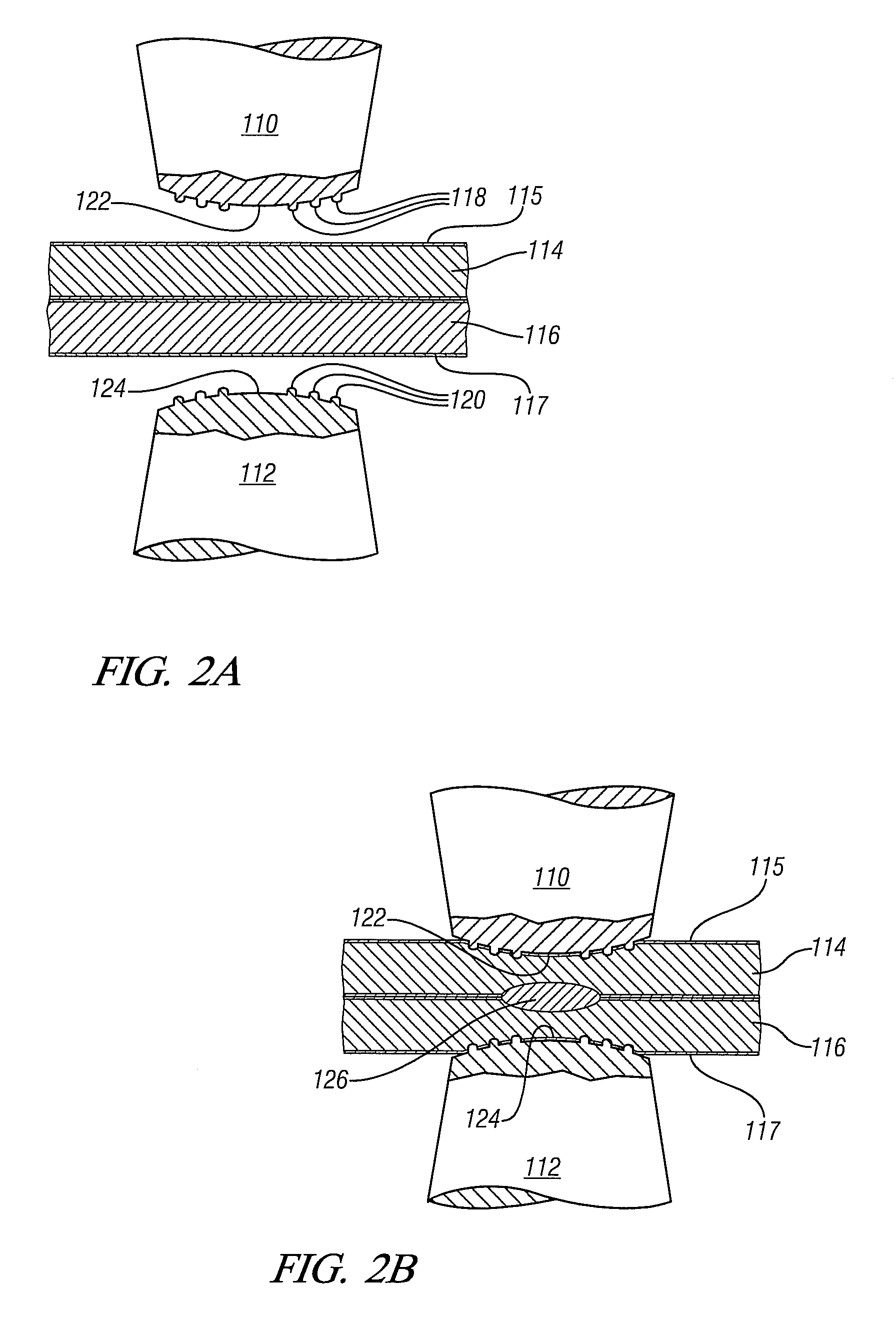

Electrode for spot welding

ActiveUS8525066B2Readily re-shapedOhmic-resistance electrodesWelding/cutting media/materialsSheet steelSpot welding

Owner:GM GLOBAL TECH OPERATIONS LLC

High-strength steel sheet and process for production thereof

ActiveCN101932745AHigh strengthHelps to reduce weightHot-dipping/immersion processesFurnace typesSheet steelCarbide

Disclosed are an ultra-high-strength steel sheet having both a tensile strength of as high as 1400MPa or above and excellent formability and an advantageous process for manufacturing the same. A high-strength steel sheet having both a composition which contains by mass C: 0.12 to 0.50%, Si: 2.0% or less, Mn: 1.0 to 5.0%, P: 0.1% or less, S: 0.07% or less, Al: 1.0% or less, and N: 0.008% or less with the balance being Fe and unavoidable impurities, and a structure which comprises, in terms of area fraction, autotempered martensite: 80% or more, ferrite: less than 5%, bainite: 10% or less, and retained austenite: 5% or less and in which the average number of precipitated iron carbide particles of 5nm to 0.5[mu]m in the autotempered martensite is 5OE04 or above per mm2.

Owner:JFE STEEL CORP

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

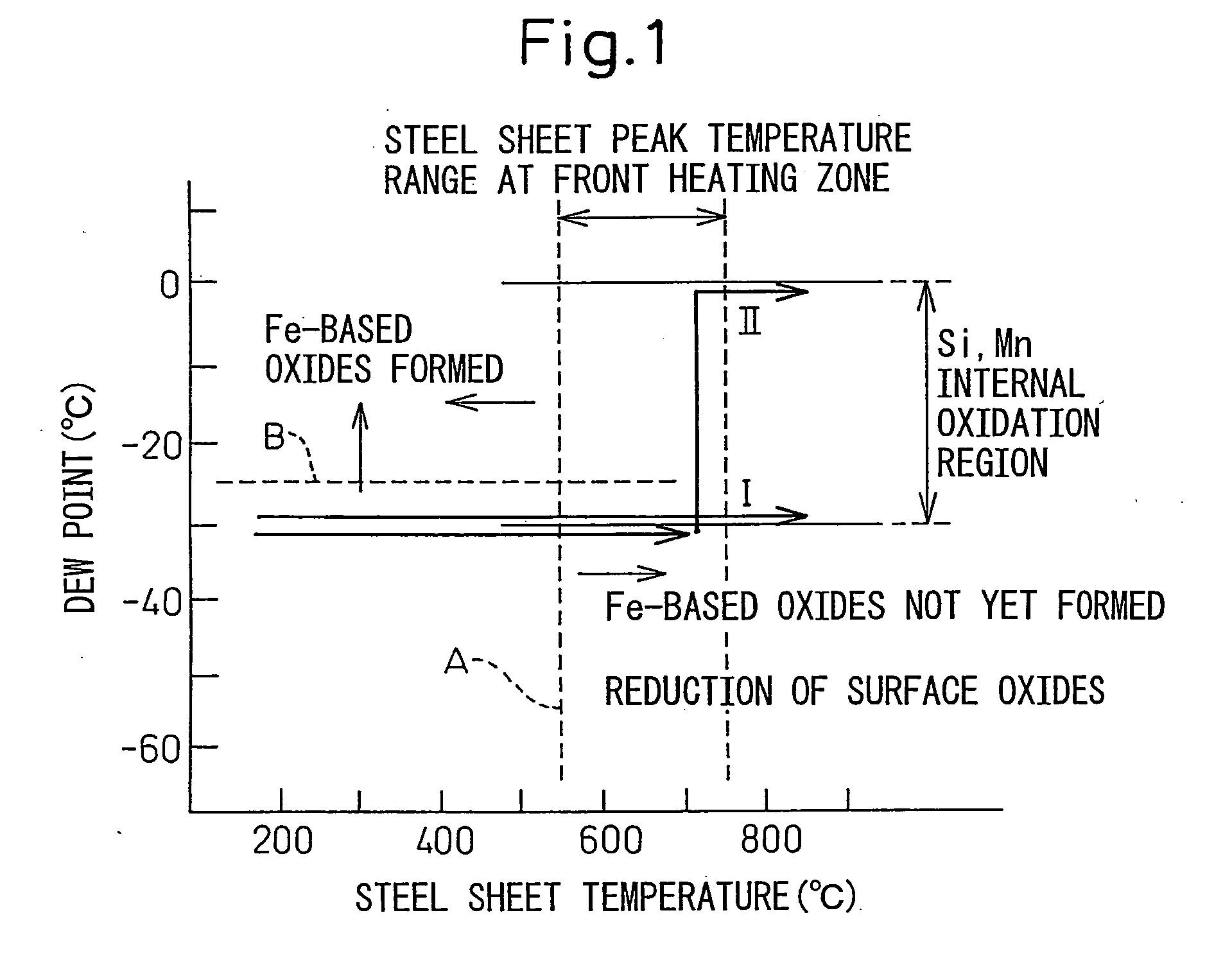

Continuous Annealing and Hot Dip Plating Method and Continuous Annealing and Hot Dip Plating System of Steel sheet Containing Si

InactiveUS20090123651A1Suppress surface concentrationImprove adhesionHot-dipping/immersion processesPretreated surfacesSheet steelHydrogen

The present invention provides, in a hot dip plating system having an annealing furnace for hot dip plating steel sheet containing Si, a continuous annealing and hot dip plating method and system causing internal oxidation without causing surface oxidation of the Si in the steel and avoiding a drop in the plating ability of the steel sheet and retardation of alloying, that is, a continuous annealing and hot dip plating method using an annealing furnace having, in order, a front heating zone, rear heating zone, soaking zone, and cooling zone and a hot dip plating bath, comprising heating or soaking the steel sheet at a steel sheet temperature of a temperature range of at least 300° C. or more by indirect heating, making an atmosphere of the zones one comprised of hydrogen H: 1 to 10 vol % and a balance of nitrogen and unavoidable impurities, making a steel sheet peak temperature during heating at the front heating zone 550 to 750° C. and making the dew point less than −25° C., making dew points of the following rear heating zone and soaking zone −30° C. to 0° C., and making a dew point of the cooling zone less than −25° C.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com