Ultrahigh-strength structural steel board for ocean engineering and production method thereof

A marine engineering and ultra-high-strength technology, applied in the field of ultra-high-strength steel, can solve the problems of increasing the difficulty of manufacturing, not conducive to ensuring the shape of the steel plate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

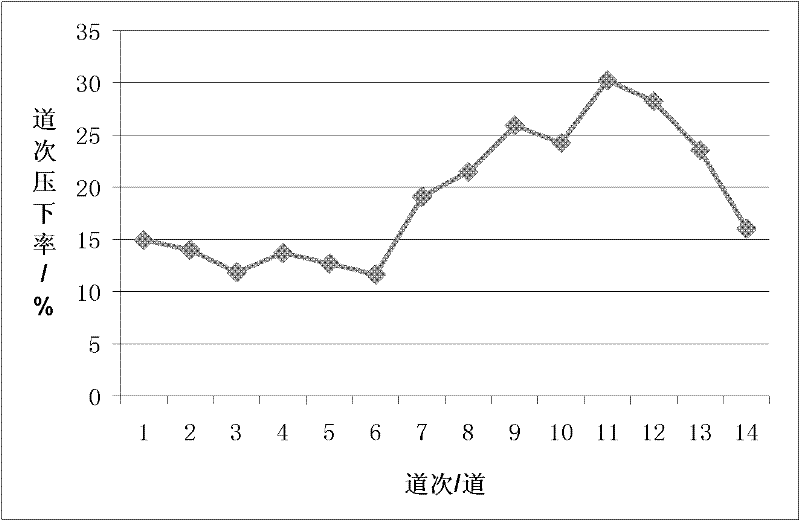

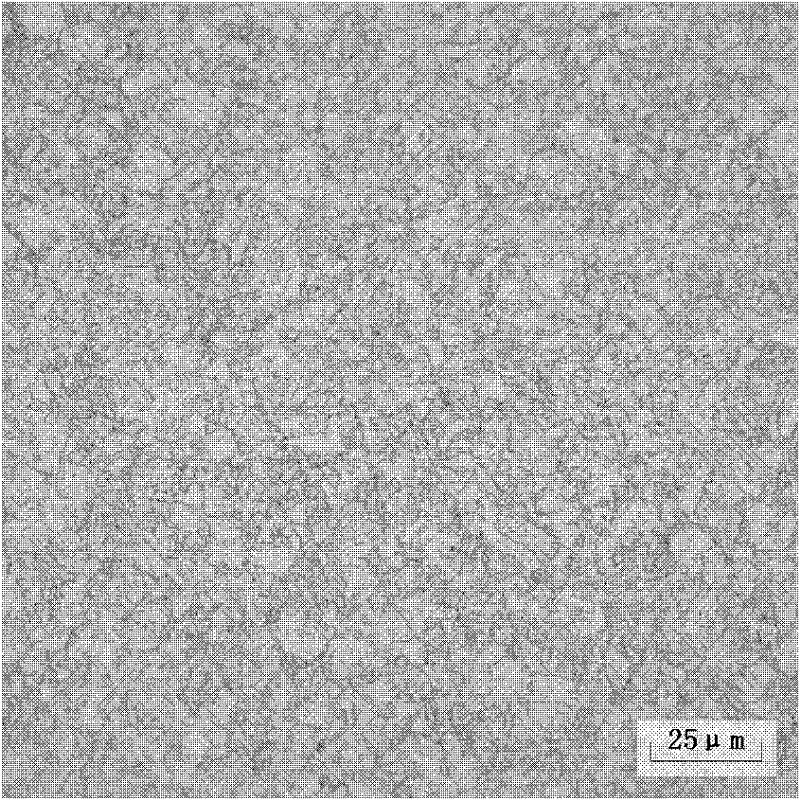

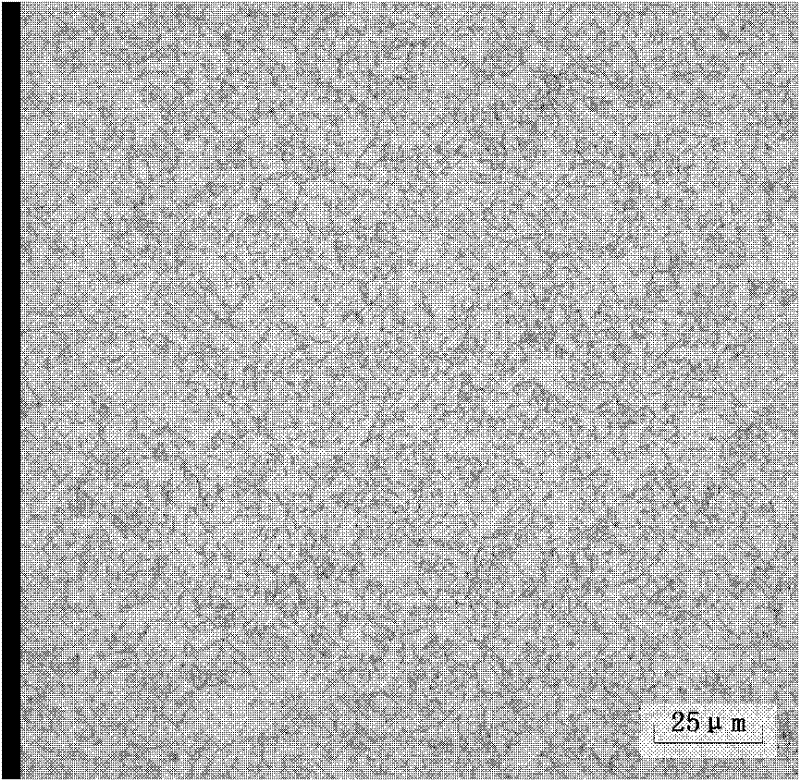

[0032]The thickness of the ultra-high-strength marine engineering structural steel involved in this embodiment is 12mm, and its components and weight percentages are: C 0.054%, Si 0.18%, Mn 1.58%, P 0.008%, S0.0014%, Nb 0.048 %, Ti 0.014%, Ni 0.19%, Mo 0.14%, and the balance is Fe and unavoidable impurity elements. According to the chemical composition range of the present invention, a steel plate with a thickness of 12mm is produced on a wide and thick plate production line, the size of the blank is 250mm*1700mm*2700mm, and the size of the finished product is 12mm*2600mm*35000mm, which is generally hot-rolled and air-cooled after rolling. Heat treatment process: quenching temperature is 930°C, holding time is 15min, tempering temperature is 500°C, and the time in the furnace is 35min in the tempering stage. The performance of the steel plate is excellent. figure 1 It is the reduction regulation in the steel plate rolling process, with figure 2 And attached image 3 is the ...

Embodiment 2

[0037] The thickness of the ultra-high-strength marine engineering structural steel involved in this example is 50 mm, and its components and weight percentages are: C 0.074%, Si 0.19%, Mn 1.56%, P 0.01%, S 0.002%, Nb 0.02% , Ti 0.014%, V0.05%, Ni 0.34%, Cu 0.21%, Mo 0.34%, and the balance is Fe and unavoidable impurity elements. The billet size is 300mm*2000mm*2950mm, the steel plate size is 50mm*3000mm*11000mm, the starting rolling temperature in the rolling stage is 1006°C, the re-rolling temperature is 811°C, the final rolling temperature is 803°C, and the final cooling temperature is 515°C. The steel plate is in good shape after straightening. Heat treatment process: quenching temperature is 930°C, holding time is 30min, tempering temperature is 610°C, and the furnace time in the tempering stage is 150min. After heat treatment, the performance of the steel plate is excellent. Figure 4 50mm thick steel plate reduction procedures, attached Figure 5 And attached Figure...

Embodiment 3

[0042] The thickness of the ultra-high-strength marine engineering structural steel involved in this example is 80 mm, and its components and weight percentages are: C 0.095%, Si 0.20%, Mn 0.98%, P 0.008%, S 0.0014%, Nb 0.022% , Ti 0.013%, V 0.04%, Ni 0.69%, Cu 0.29%, Cr 0.6%, Mo 0.34%, B 0.0011%, Al 0.036%, and the balance is Fe and unavoidable impurity elements. The billet size is 300mm*2400mm*4100mm, the steel plate size is 80mm*2400mm*15000mm, the starting rolling temperature after controlled rolling is 845°C, the final rolling temperature is 816°C, the final cooling temperature is 680°C, and the cooling rate is 6°C / s. Heat treatment process: quenching temperature is 930°C, holding time is 30 minutes, tempering temperature is 660°C, and the furnace time in the tempering stage is 240 minutes. After heat treatment, the performance of the steel plate is excellent. attached Figure 7 80mm thick steel plate reduction procedures, attached Figure 8 And attached Figure 9 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com