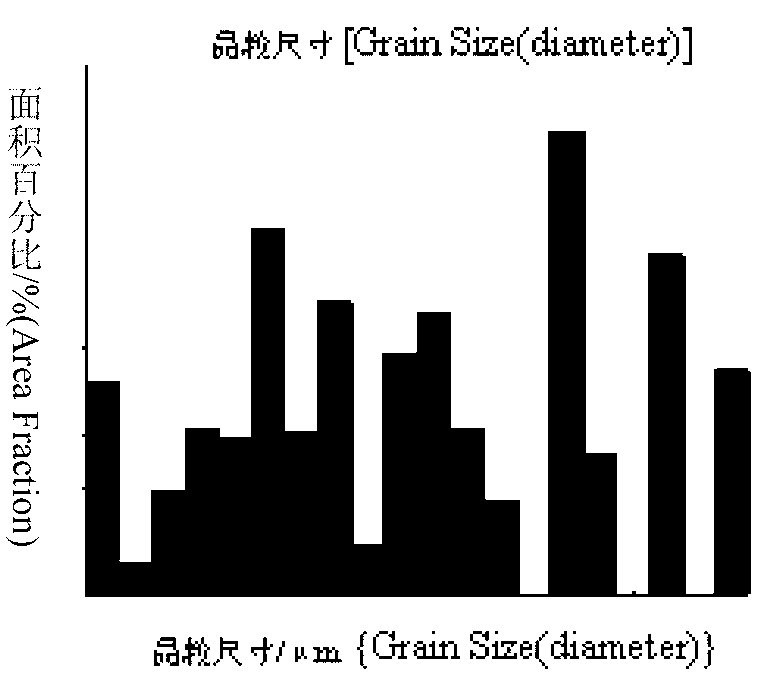

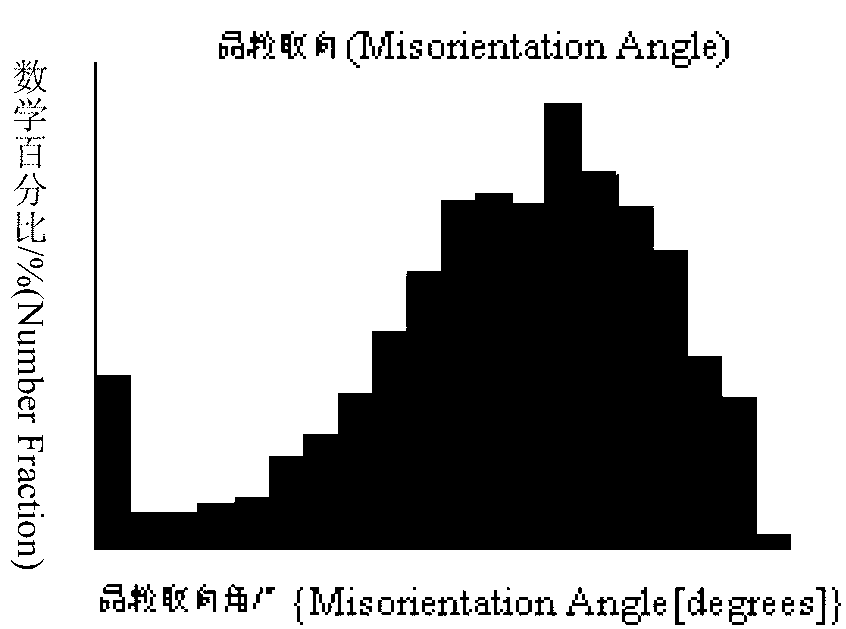

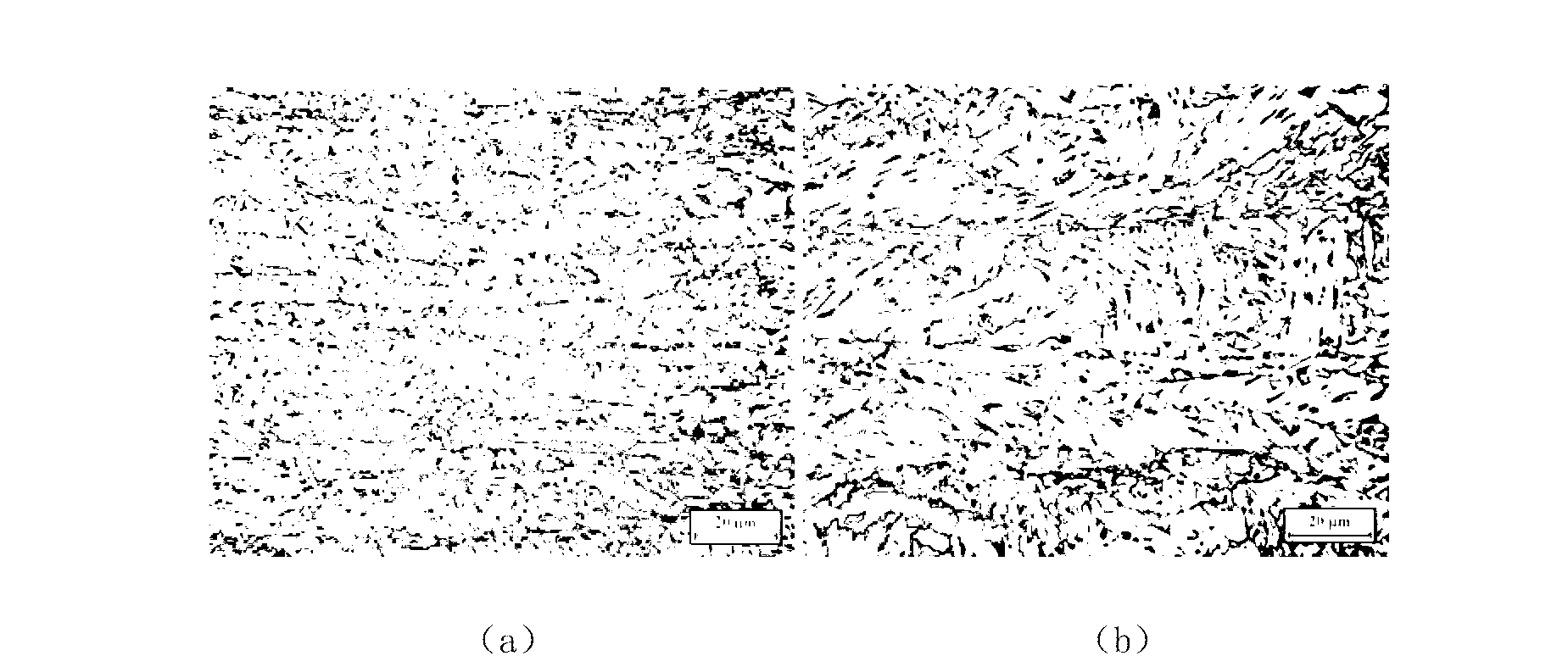

High crack-arresting toughness steel plate with yield strength of 500MPa and production method thereof

A technology of yield strength and crack arrest, which is applied in the field of steel for container ship hull structures, can solve the problems of low steel plate strength, lack of crack arrest, increased production process links and costs, etc., to improve fracture resistance and energy consumption, and enhance Crack arrest ability, effect of suppressing crack propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is a steel plate with a yield strength of 500 MPa and its production method. The chemical composition is recorded as: C: 0.042%, Si: 0.20%, Mn: 1.55%, P: 0.001%, S: 0.0070%, Al: 0.046%, N: 0.003%, Nb: 0.025%, Ti: 0.013%, B: 0.0015%, Ca: 0.0024%, and the rest is Fe and unavoidable impurities.

[0039] The pouring temperature of the tundish is 1534°C, and the thickness of the continuous casting slab is 230mm. Heat the billet to 1150°C and keep it warm for 0.5h.

[0040] Rolling: The first stage of rough rolling is carried out in the austenite recrystallization zone, the starting rolling temperature is 1100°C, the pass reduction rate is 15%, the total reduction rate in the recrystallization zone is 62%, and the thickness of the intermediate billet after rough rolling is 3.0H , H is the thickness of the finished product. After rolling, the steel plate is rapidly cooled to about 560°C at 15°C / s. When the surface of the steel plate returns to about 750°C, the ...

Embodiment 2

[0042] This example is a steel plate with a yield strength of 500 MPa and its production method. The chemical composition is recorded as: C: 0.065%, Si: 0.42%, Mn: 1.15%, P: 0.0013%, S: 0.008%, Al: 0.053%, N: 0.0035%, Nb: 0.032%, Ti: 0.02%, B: 0.0009%, Ca: 0.0016%, as the chemical composition, there are also Cu: 0.34%, Ni: 0.40%, and the rest are Fe and unavoidable impurities.

[0043] The pouring temperature of the tundish is 1526°C, and the thickness of the continuous casting slab is 300mm. Heat the billet to 1150°C and keep it warm for 1.5h.

[0044] Rolling: The first stage of rough rolling is carried out in the austenite recrystallization zone, the starting rolling temperature is 1096°C, the pass reduction rate is 12%, the total reduction rate in the recrystallization zone is 50%, and the thickness of the intermediate billet after rough rolling is 2.0H , H is the thickness of the finished product. After rolling, the steel plate is rapidly cooled to about 535°C at 12°C / ...

Embodiment 3

[0046] This example is a steel plate with a yield strength of 500 MPa and its production method. The chemical composition is recorded as: C: 0.076%, Si: 0.18%, Mn: 0.96%, P: 0.0011%, S: 0.0075%, Al: 0.055%, N: 0.0034%, Nb: 0.03%, Ti: 0.016%, B: 0.001%, Ca: 0.0016%, as the chemical composition, there are Cu: 0.26%, Ni: 0.35%, and the rest are Fe and unavoidable impurities.

[0047] The pouring temperature of the tundish is 1530°C, and the thickness of the continuous casting slab is 230mm. Heat the billet to 1092°C and keep it warm for 1h.

[0048] Rolling: The first stage of rough rolling is carried out in the austenite recrystallization zone, the starting rolling temperature is 1030°C, the pass reduction rate is 10%, the total reduction rate in the recrystallization zone is 57%, and the thickness of the intermediate billet after rough rolling is 2.5H , H is the thickness of the finished product. After rolling, the steel plate is rapidly cooled to about 538°C at 12°C / s. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com