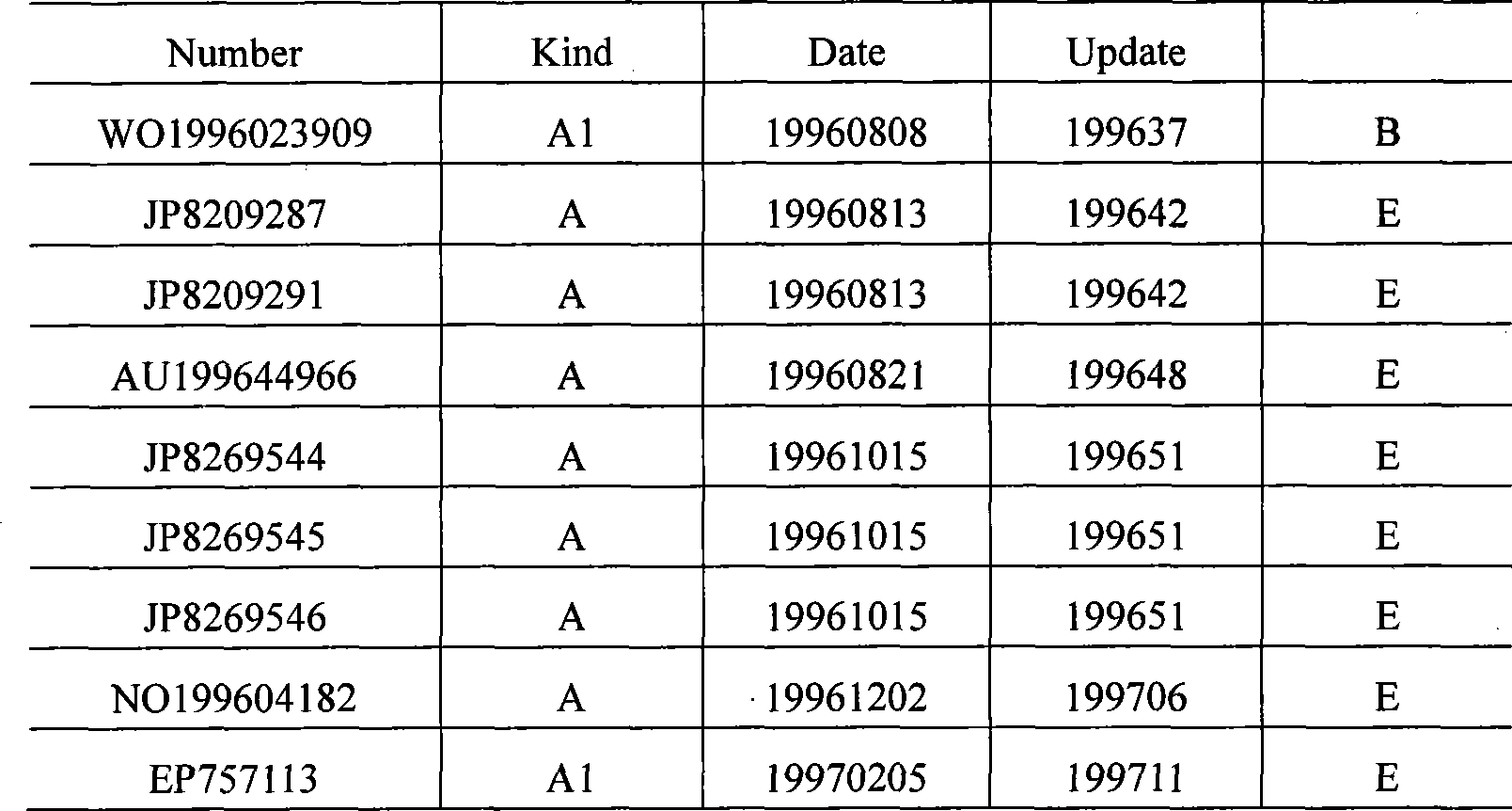

Patents

Literature

78results about How to "Improve crack arrest performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High crack-arresting toughness steel plate with yield strength of 500MPa and production method thereof

ActiveCN102994874APromote productionIncrease the lengthHeat treatment process controlReduction rateChemical composition

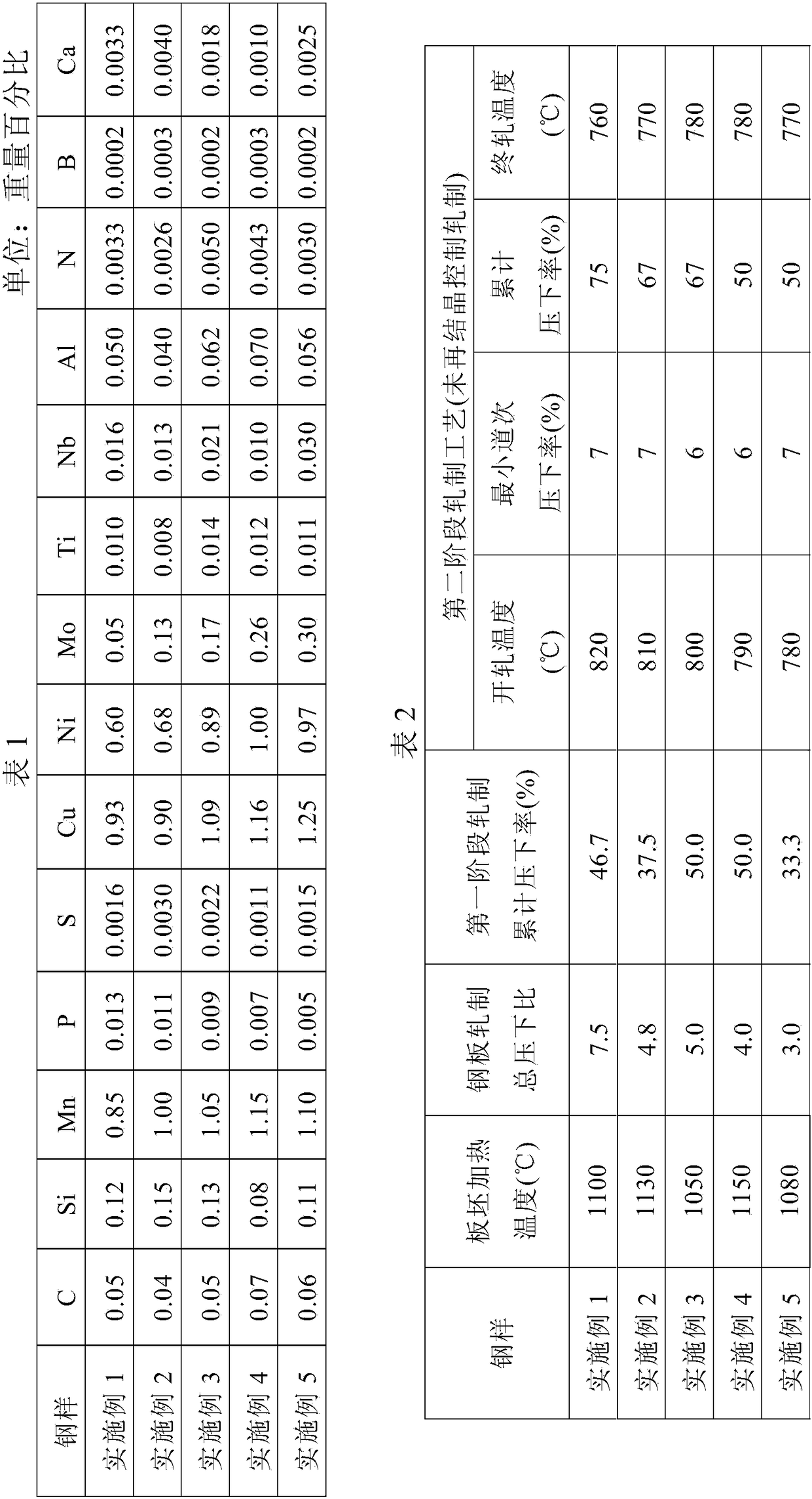

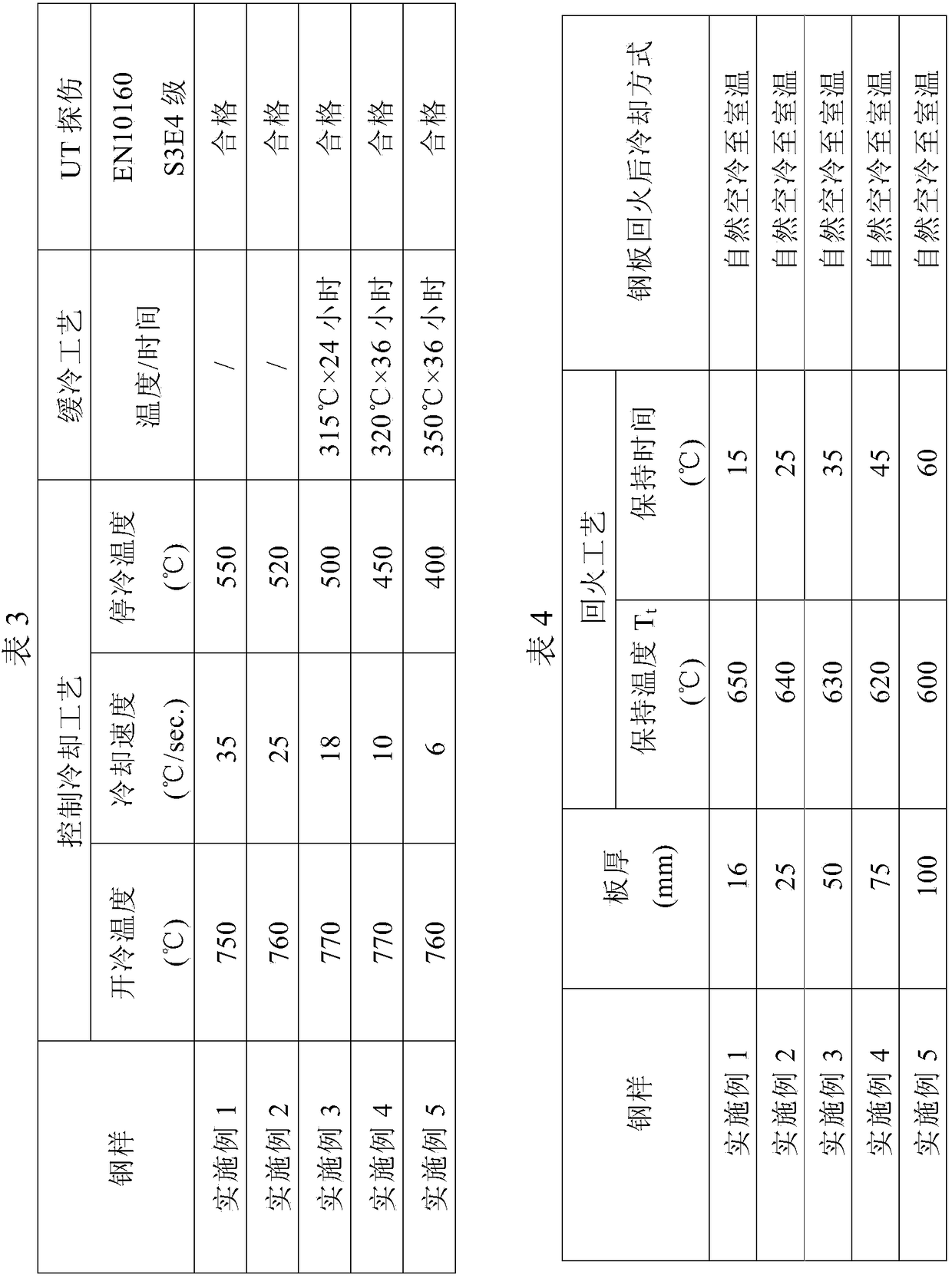

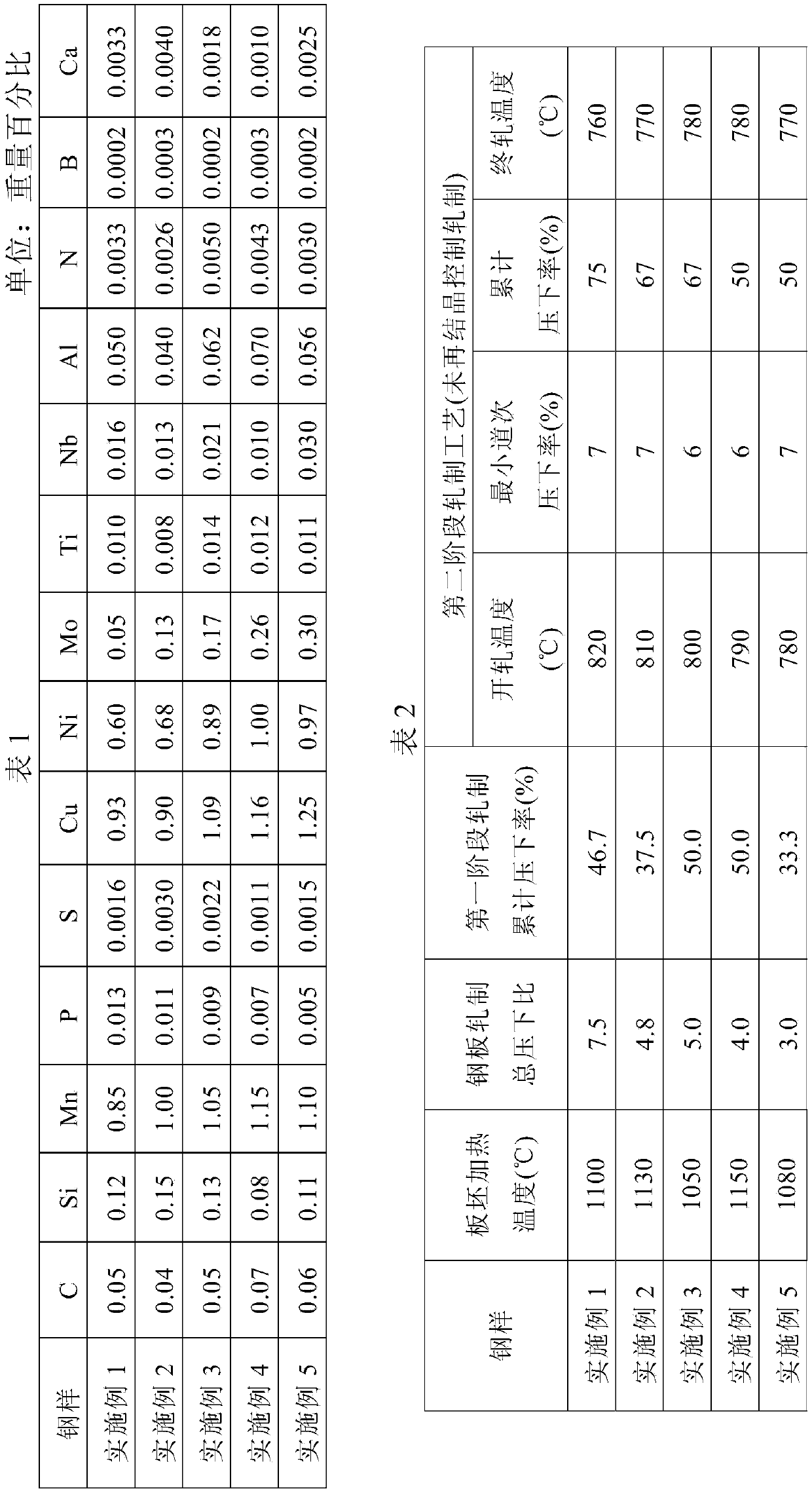

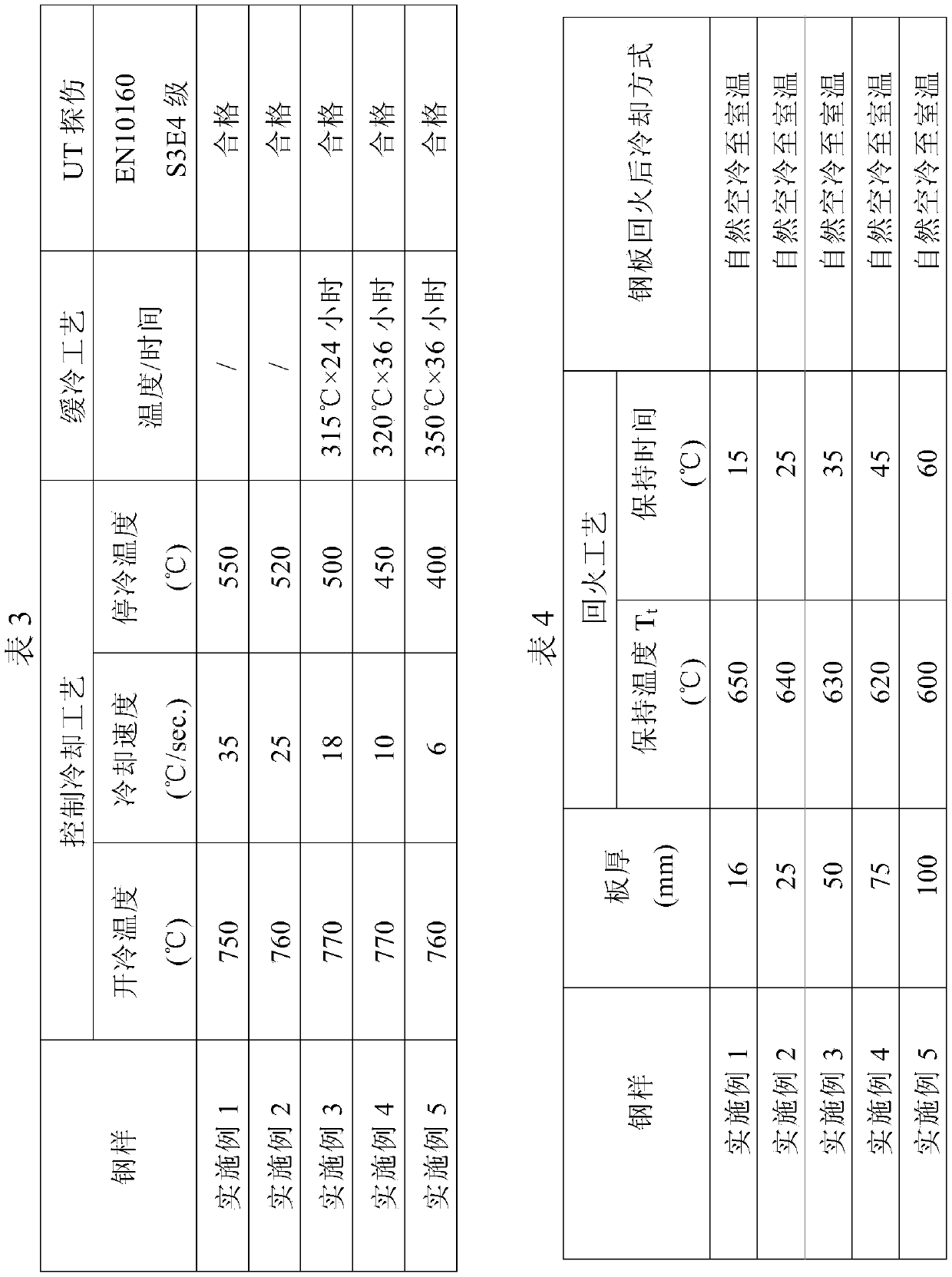

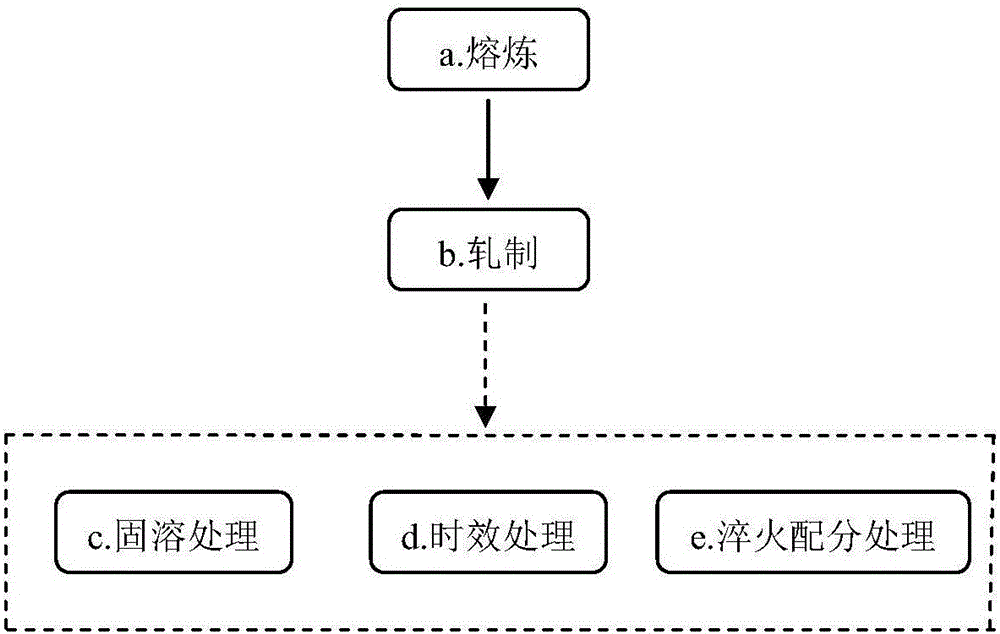

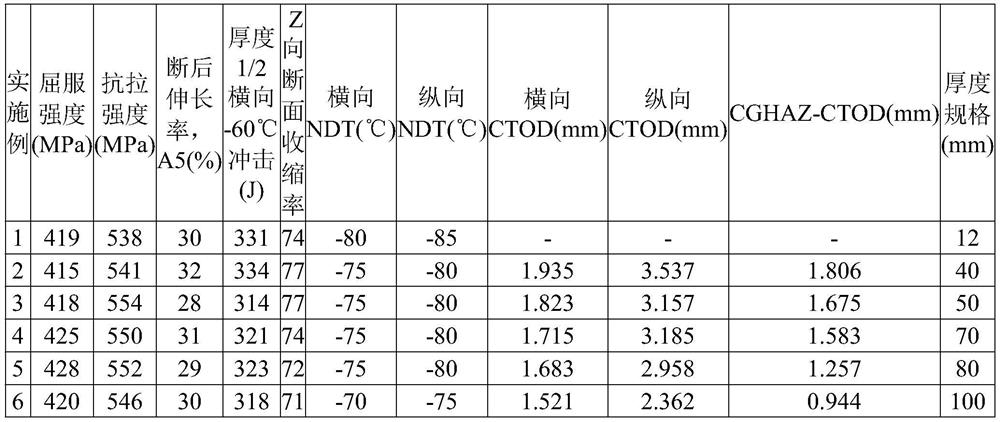

The invention provides a high crack-arresting toughness steel plate with yield strength of 500MPa and a production method thereof. The chemical components of steel comprises the following components in percentage by weight: 0.04-0.08% of C, 0.10-0.5% of Si, 0.8-1.6% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.03-0.065% of Al, not more than 0.005% of N, 0.005-0.05% of Nb, 0.005-0.03% of Ti, 0.0005-0.003% of B, not more than 0.004% of Ca, and the balance of Fe and avoidless impurities. The preparation method comprises the steps of roughing in an austenite re-crystalline region in a first stage, wherein the rolling temperature is 1000-1130 DEG C, the total reduction rate in the re-crystalline region is greater than or equal to 50%; cooling a rolled steel plate quickly to 580-530 DEG C at a rate of 10 DEG C / s; rolling in a non-re-crystalline region in a second stage when the temperature of the surface of the steel plate is 720-770 DEG C, wherein the accumulated deformation is greater than or equal to 50%, the finish rolling temperature is 700-740 DEG C; and water-cooling after rolling, wherein the cooling rate is 5-15 DEG C / s, and the final cooling temperature is 460-560 DEG C. The high crack-arresting toughness steel plate provided by the invention has the characteristics of high strength, high toughness, inhibition of crack formation and expansion and the like, and meets the performance requirements of special part members of large container ships.

Owner:ANGANG STEEL CO LTD

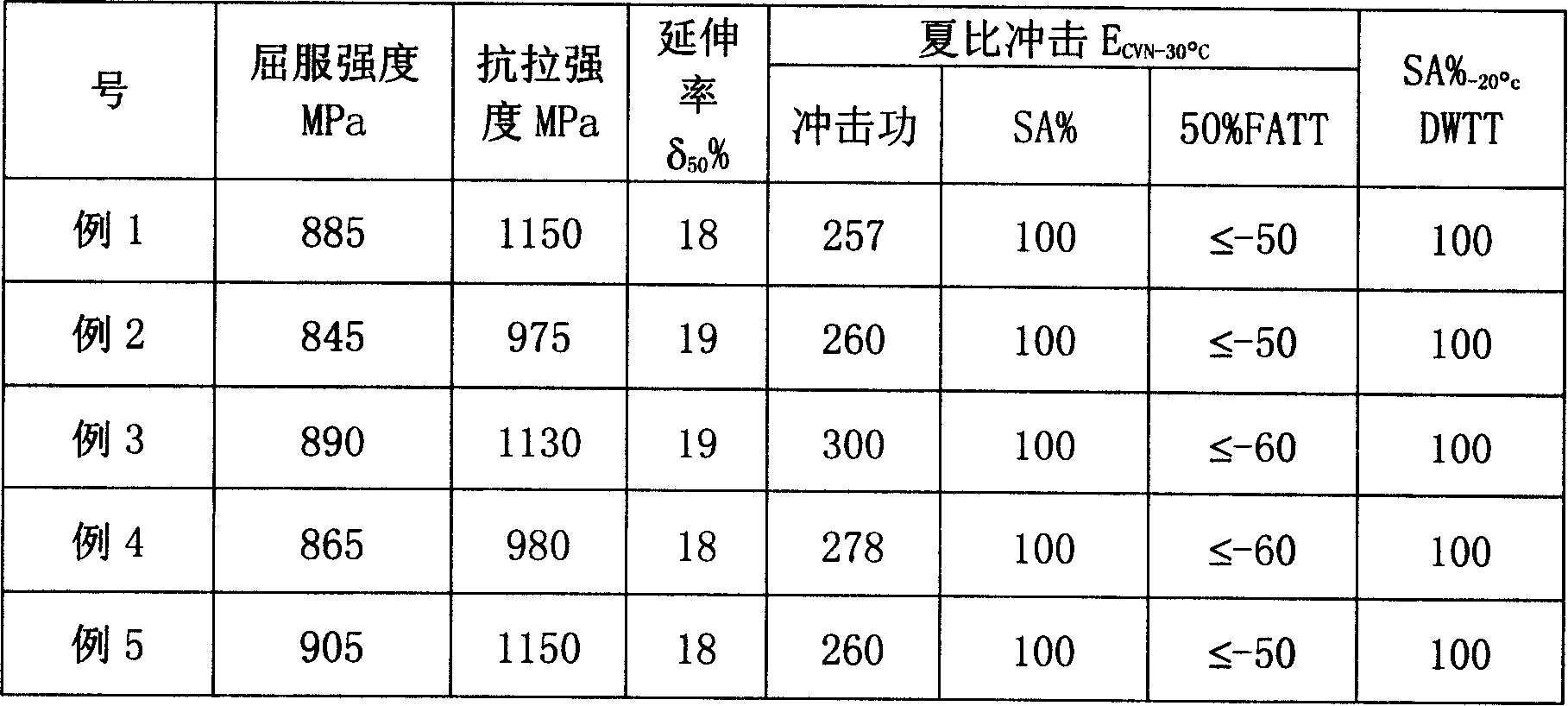

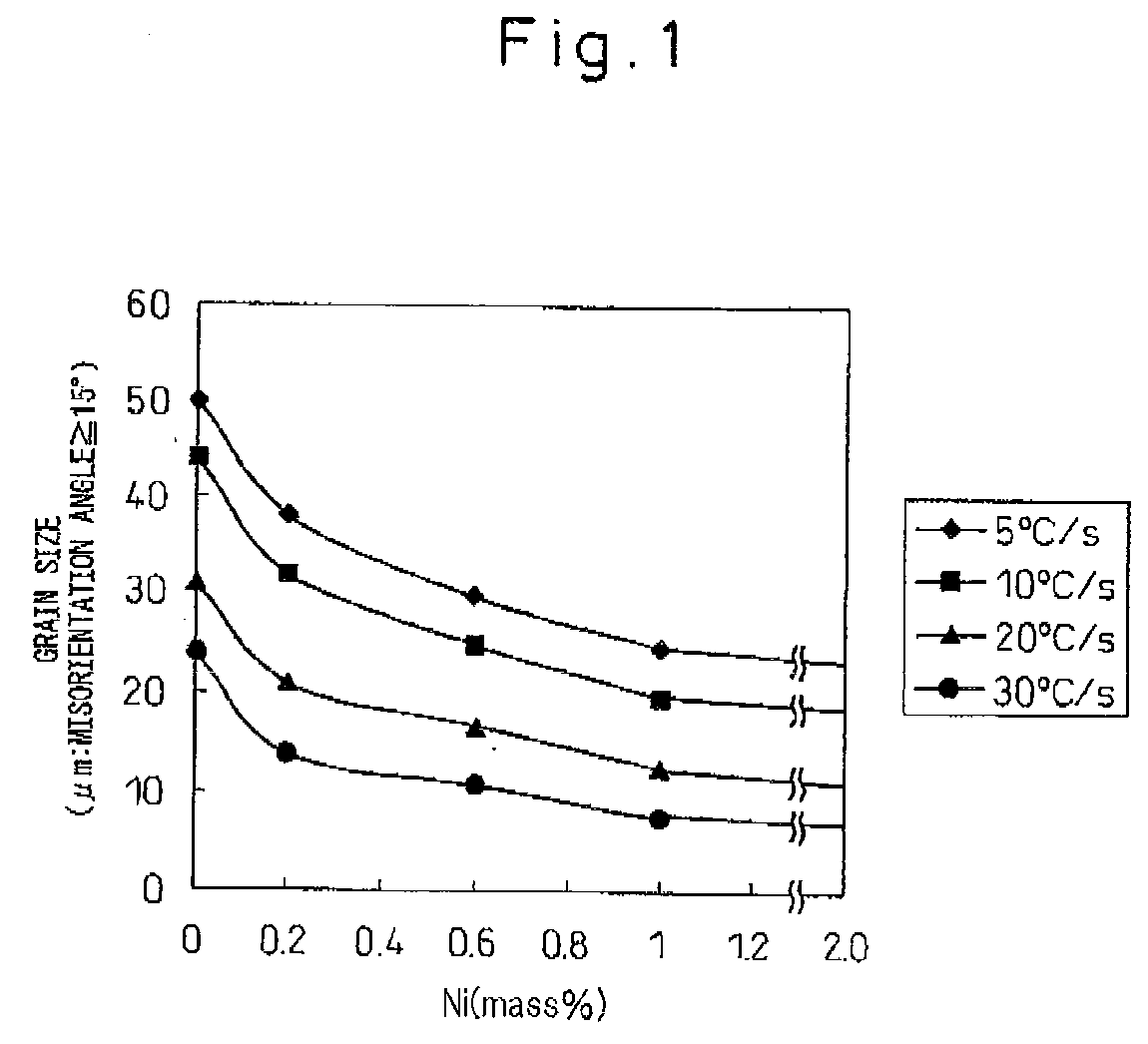

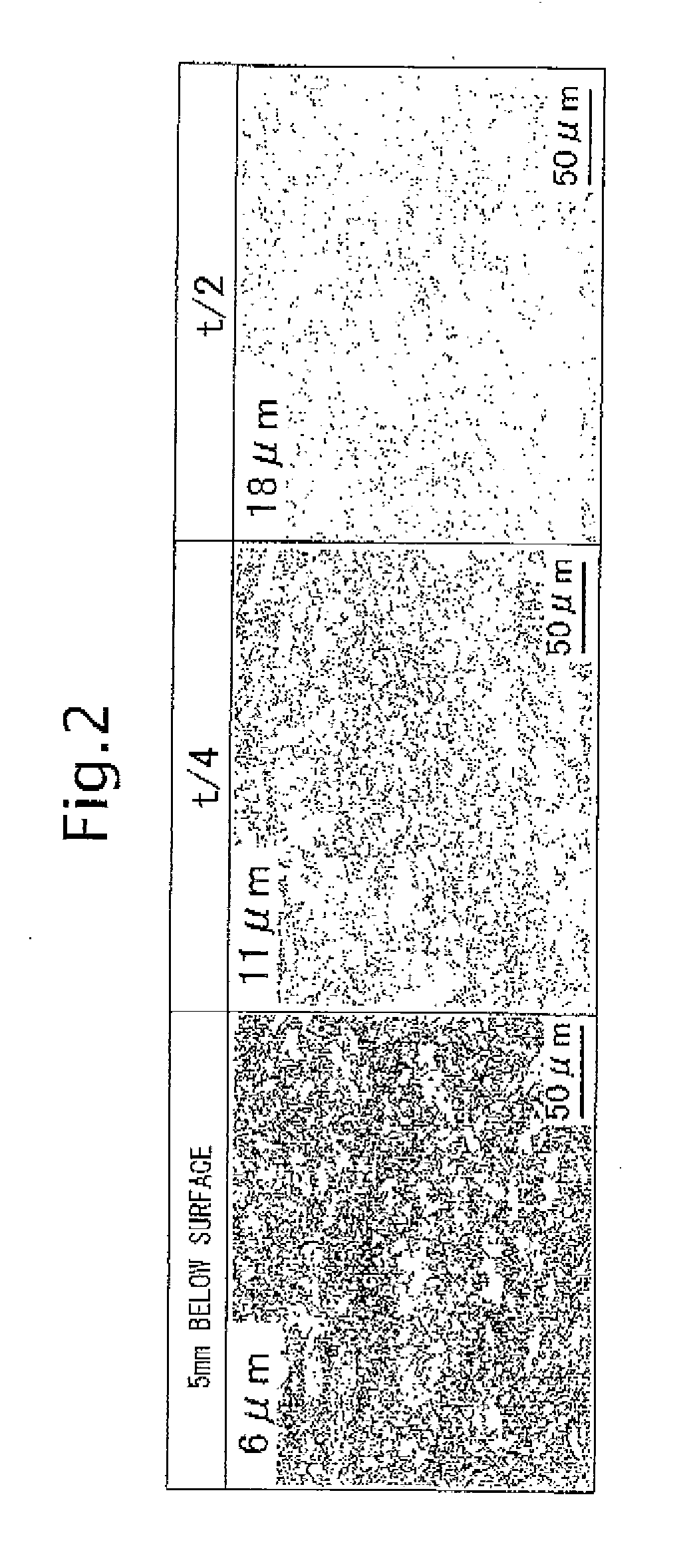

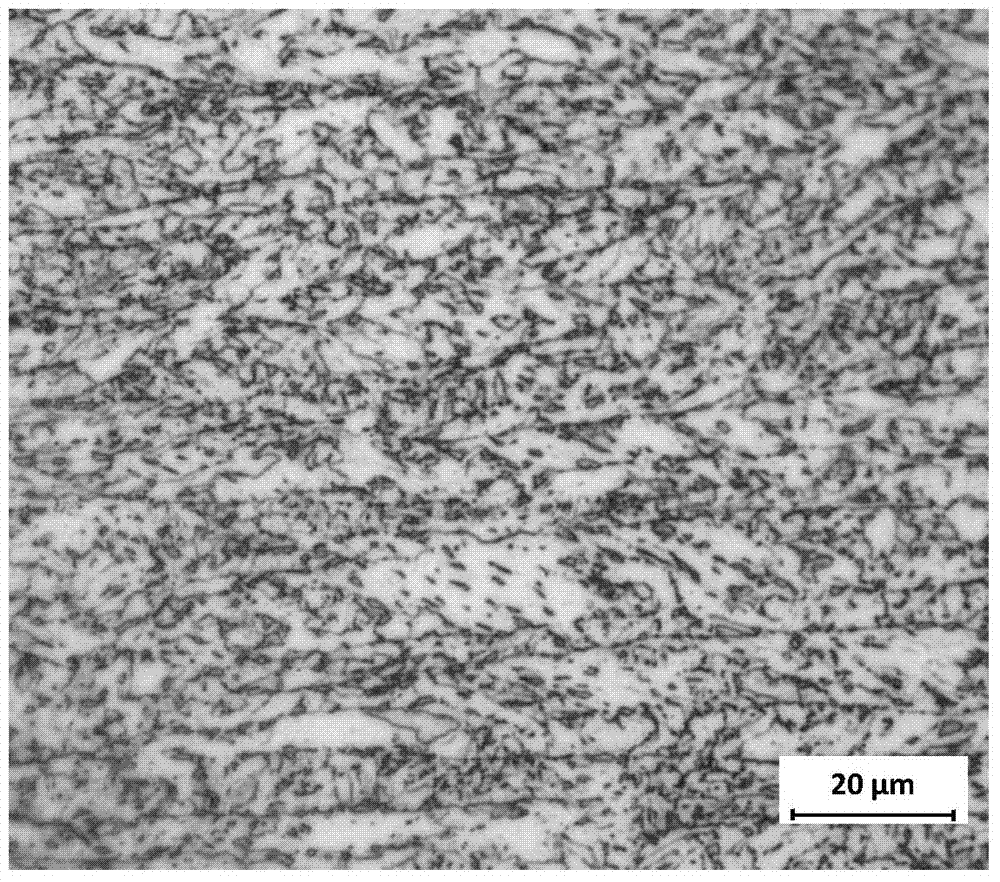

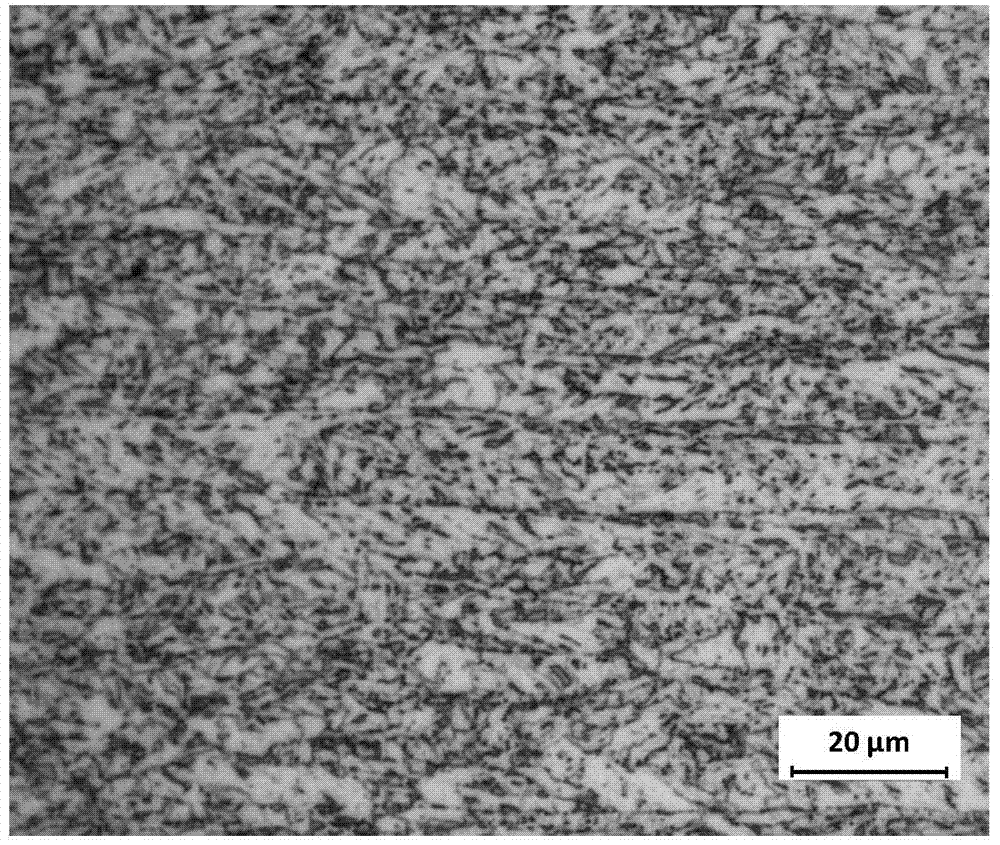

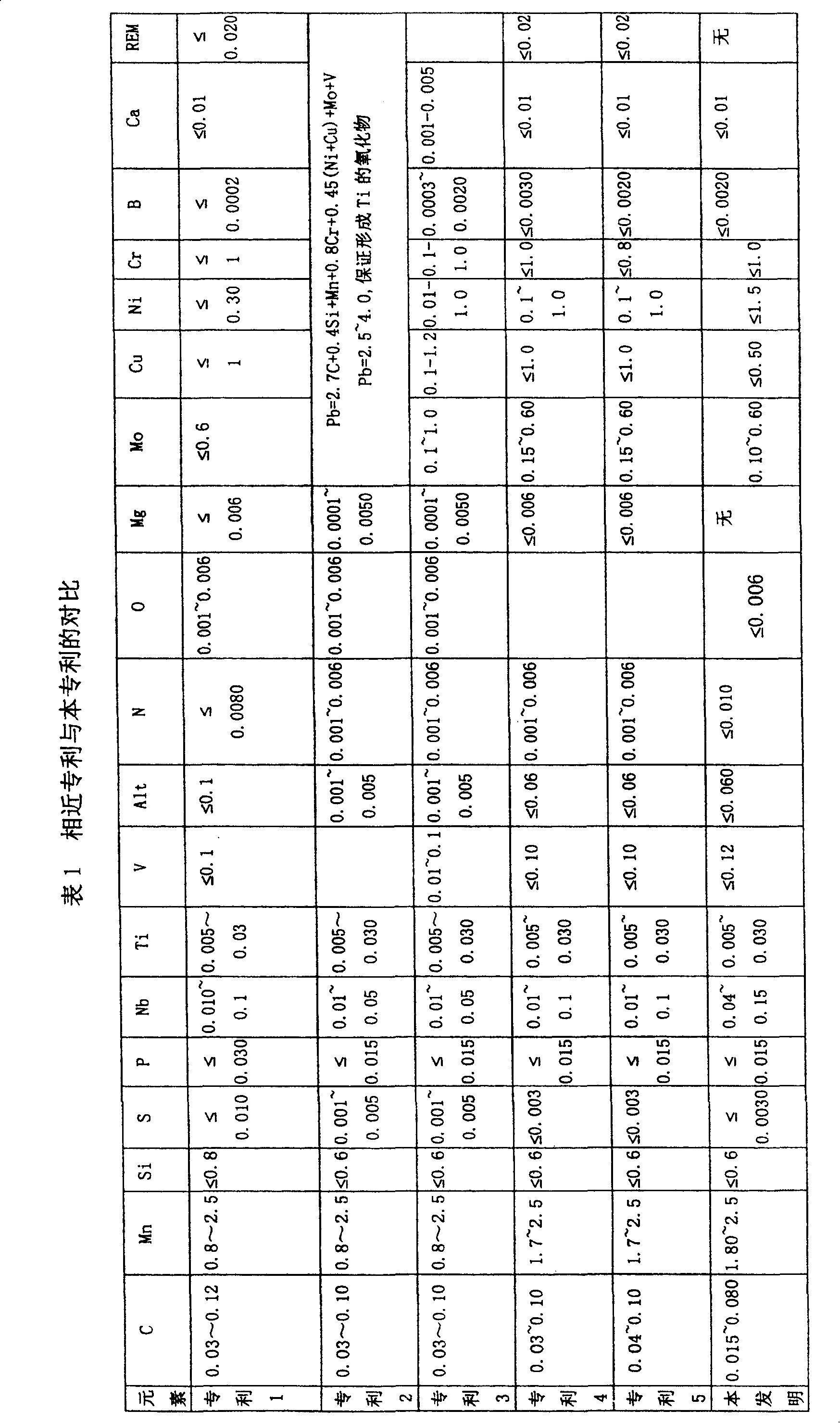

High-strength steel plate with superior crack arrestability

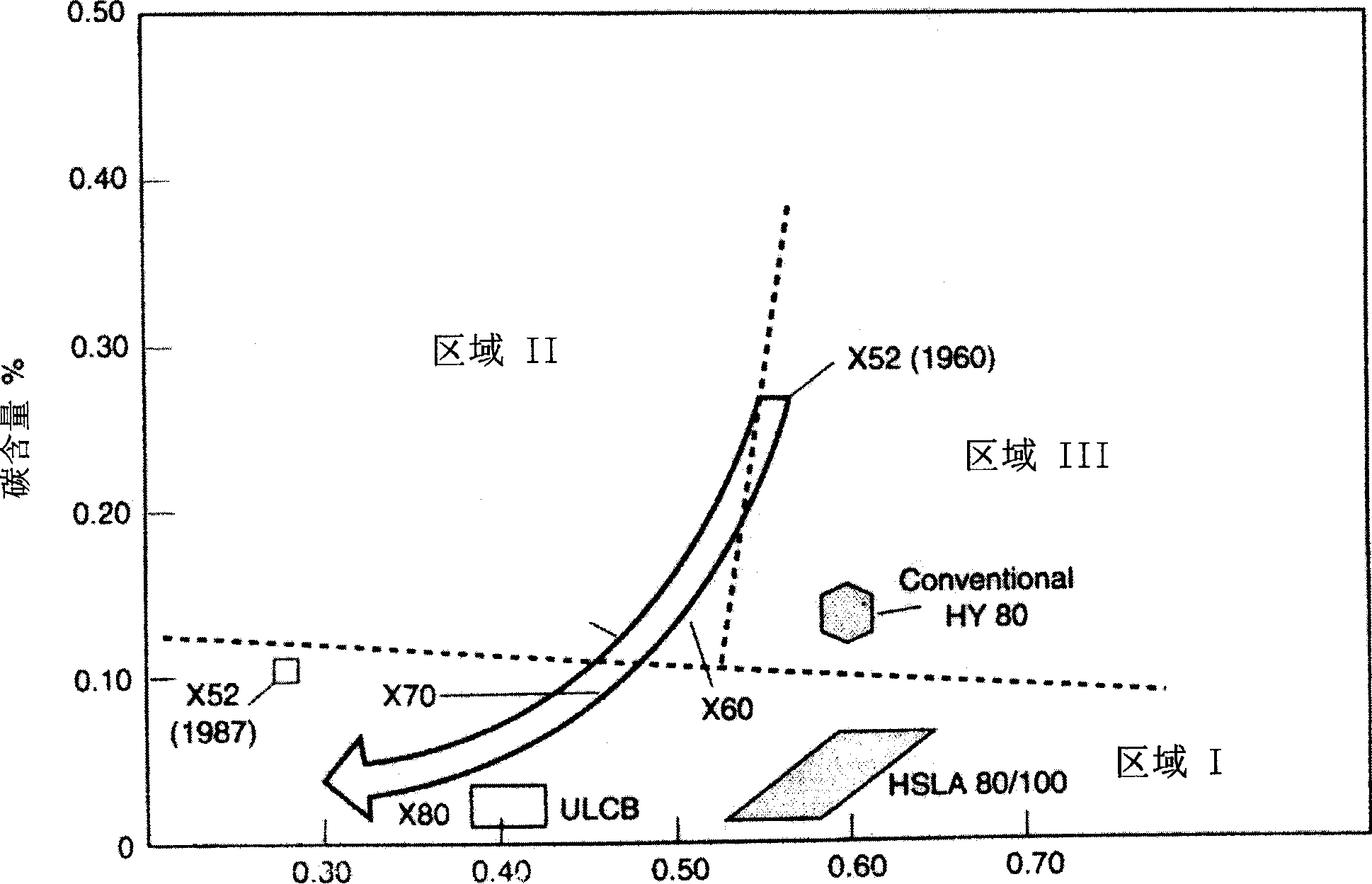

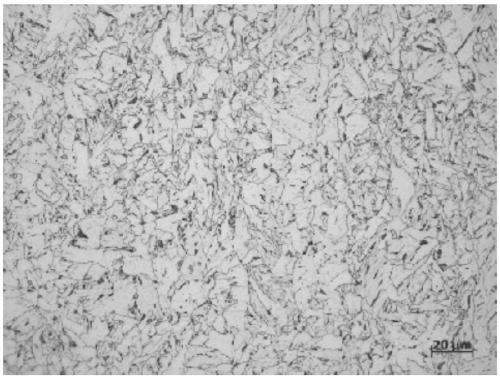

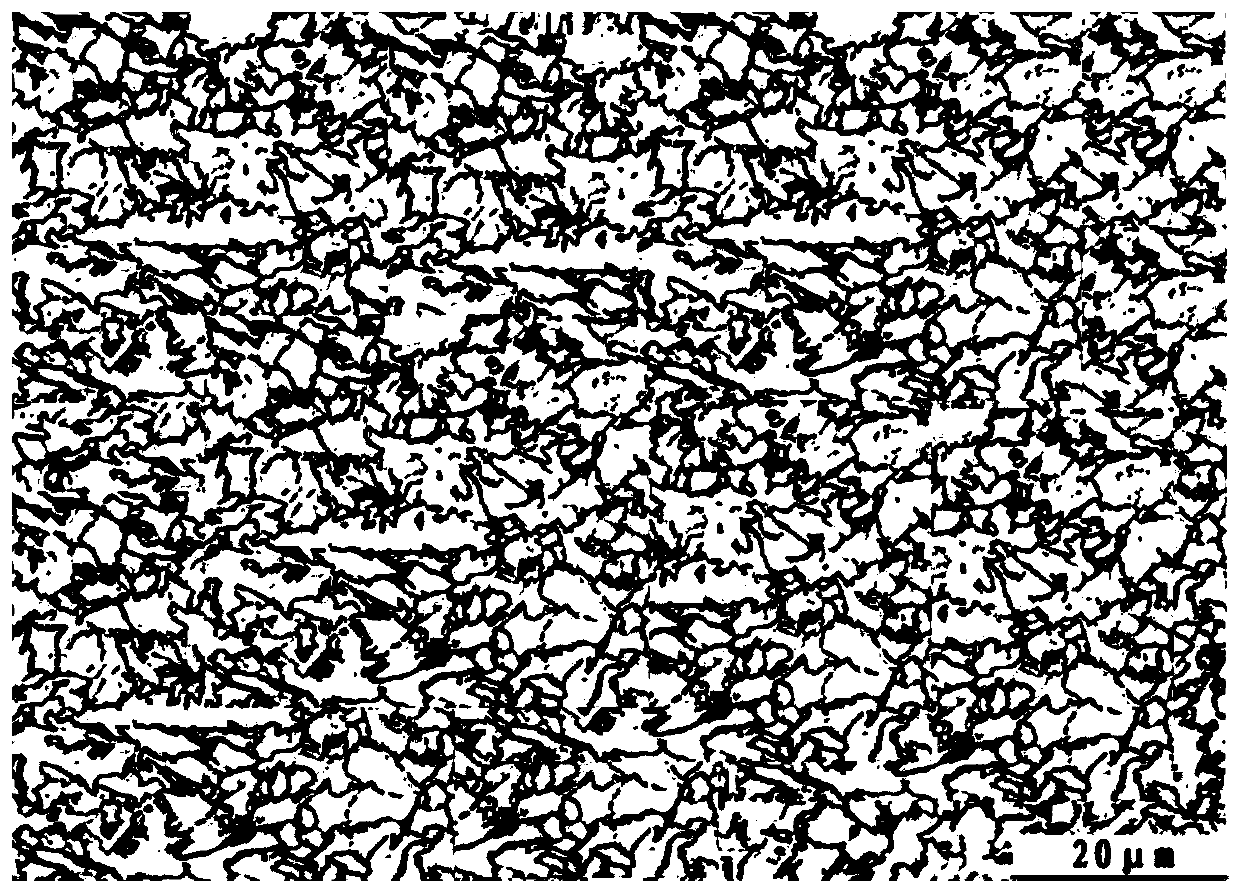

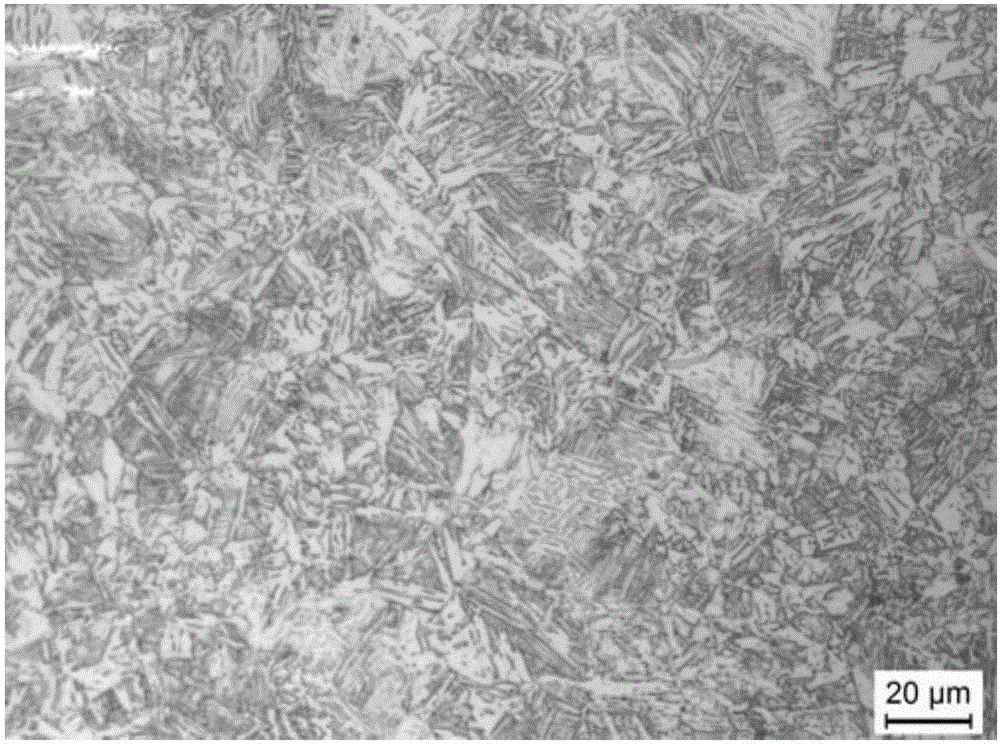

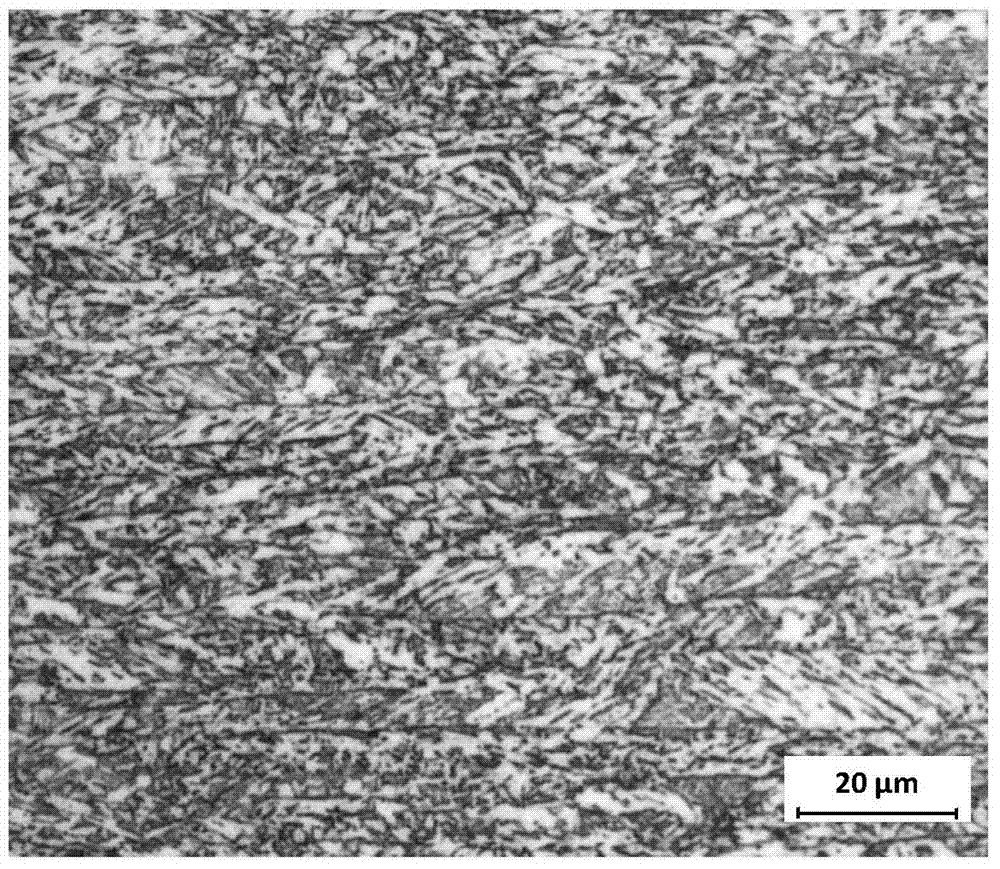

ActiveCN101341269AImprove crack arrest performanceHigh strengthThin material handlingHigh intensityPearlite

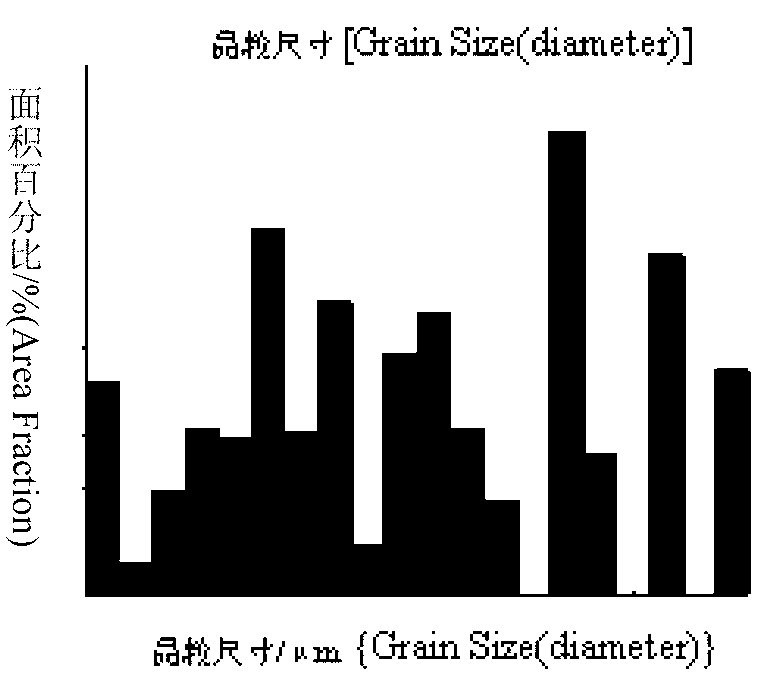

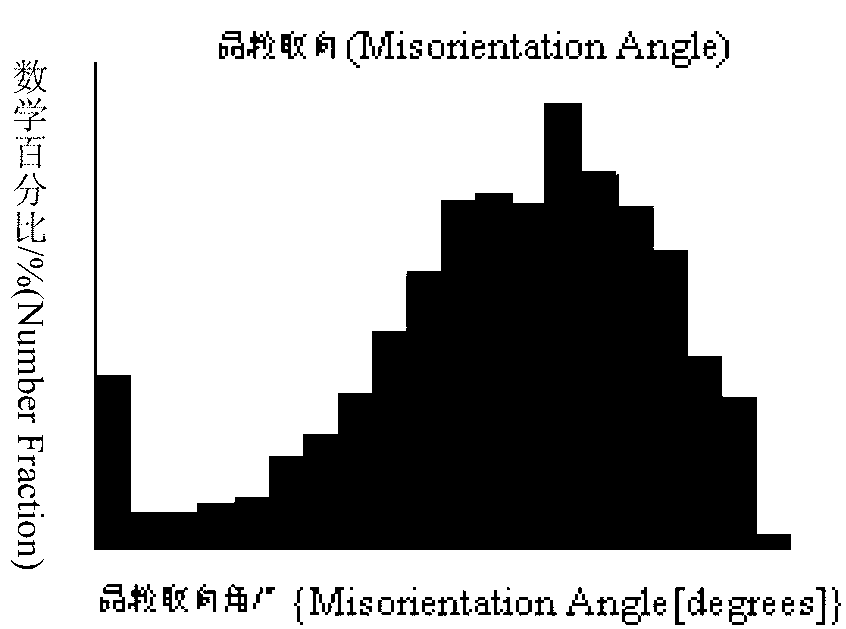

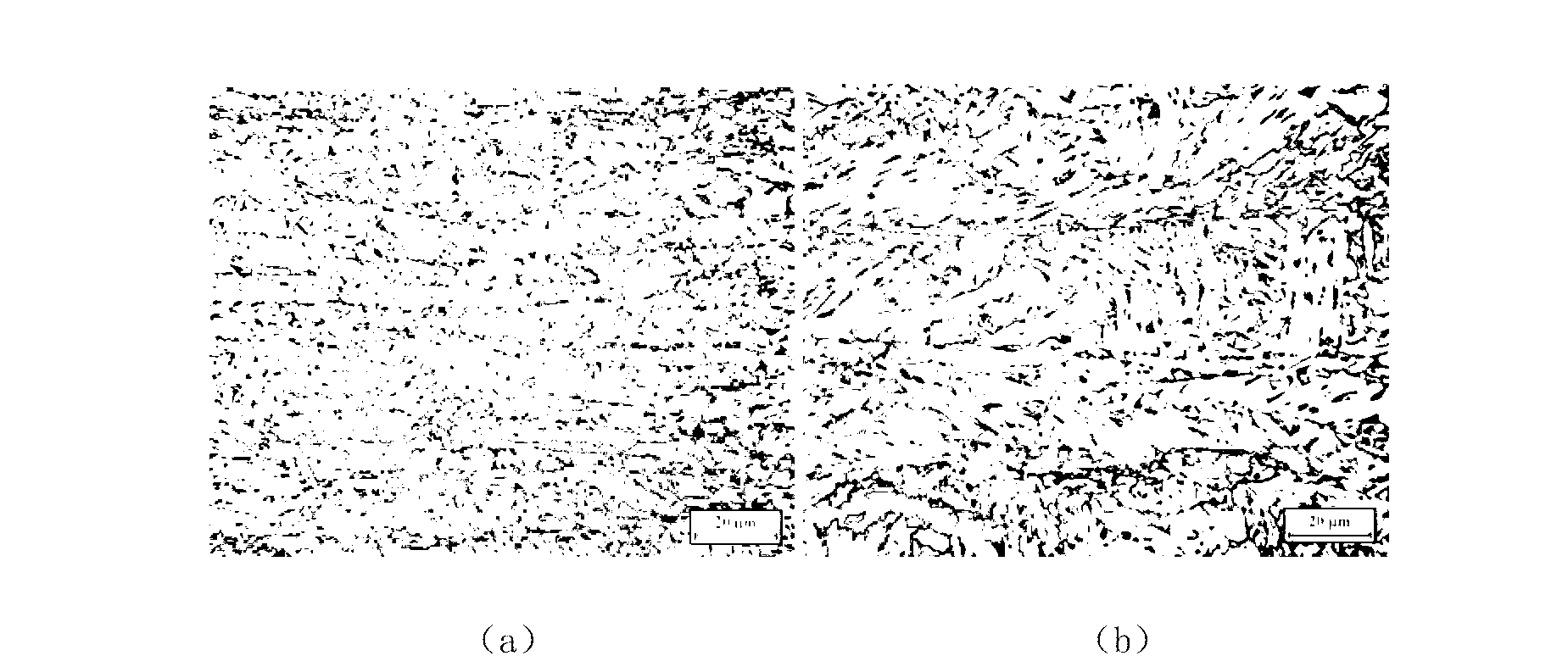

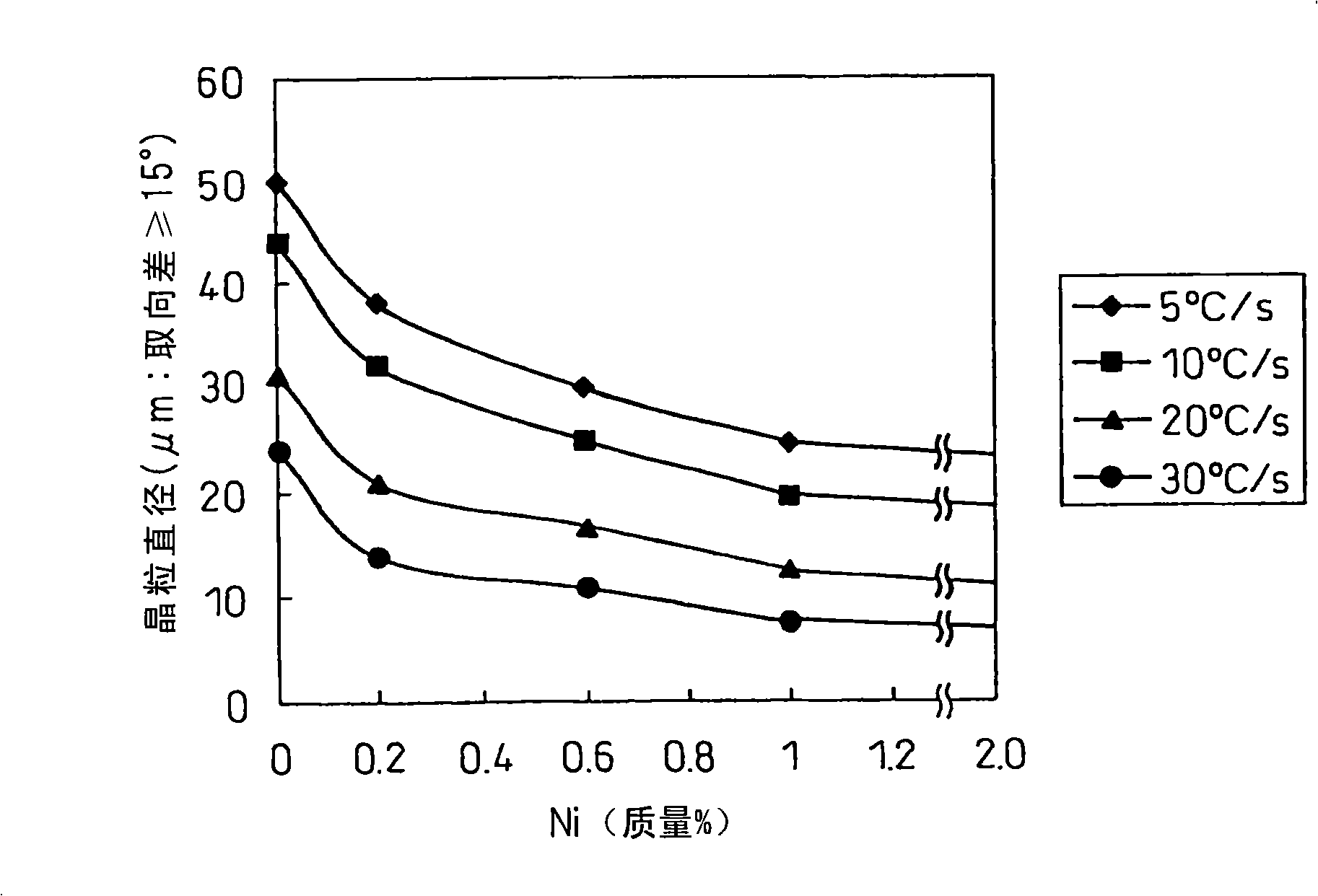

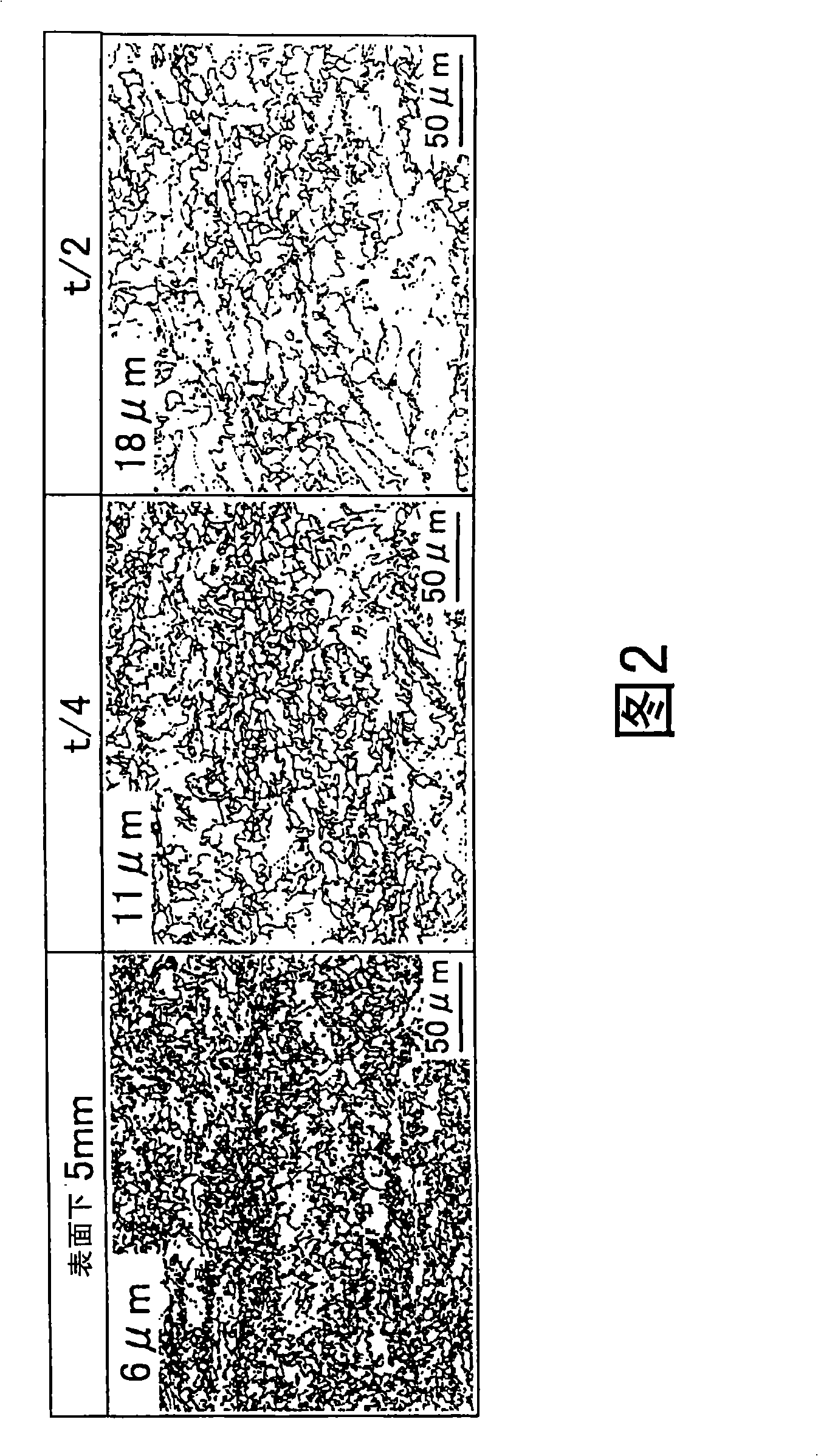

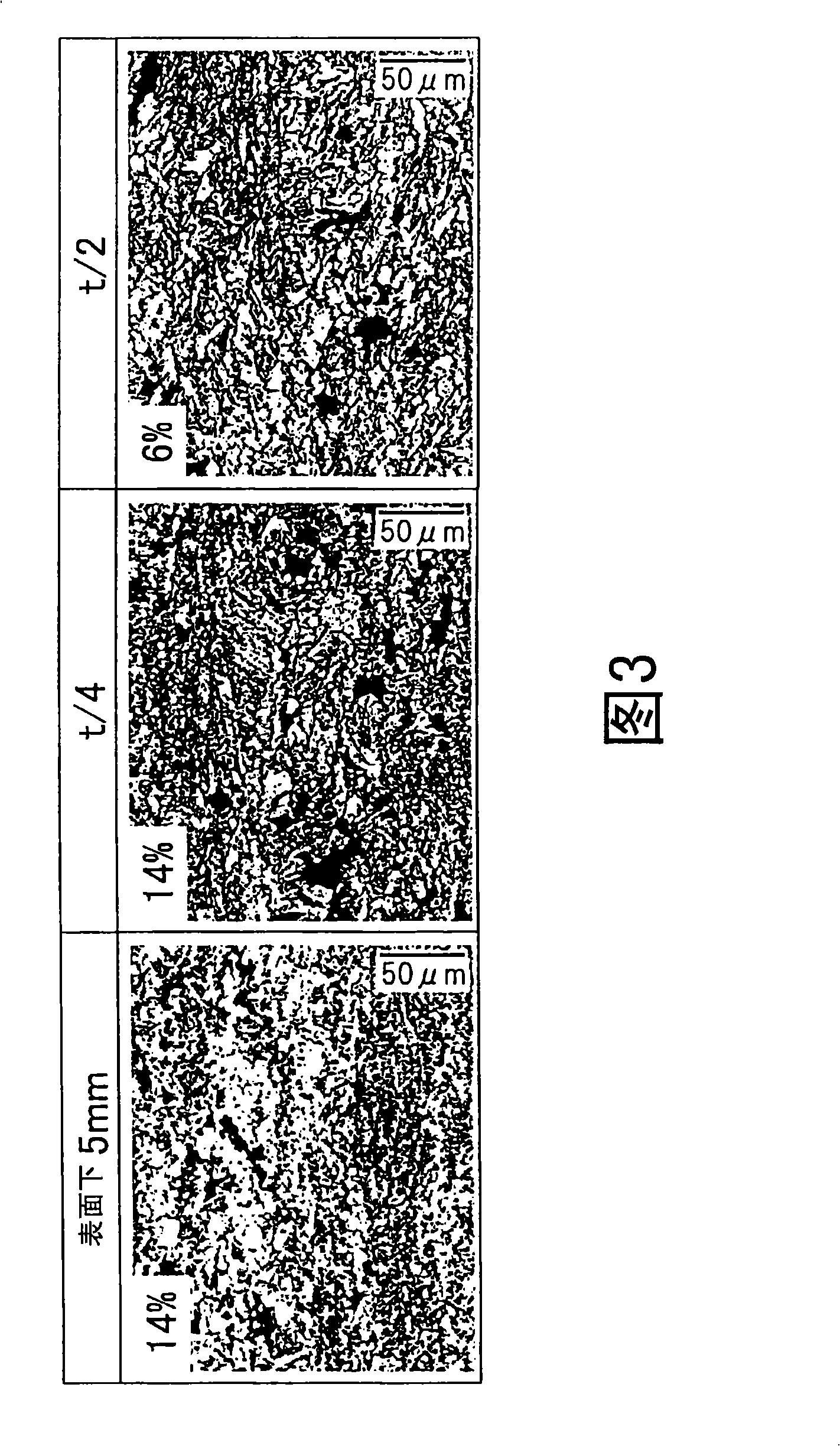

The present invention provides high strength thick steel plate superior in crack arrestability, high in strength, free of deterioration of HAZ toughness, and free of anisotropy, that steel plate containing, by mass%, C: 0.03 to 0.15%, Si: 0.1 to 0.5%, Mn: 0.5 to 2.0%, P: 0.02%, S: 0.01%, Al: 0.001 to 0.1%, Ti: 0.005 to 0.02%, Ni: 0.15 to 2%, and N: 0.001 to 0.008% and having a balance of iron and unavoidable impurities as chemical components, having a microstructure of a ferrite and / or pearlite structure with bainite as a matrix phase, and having an average circle equivalent diameter of crystal grains with a crystal misorientation angle of 15 DEG or more of 15 [mu]m or less in the regions of 10% of plate thickness from the front and rear surfaces and of 40 [mu]m or less in the other region including the center part of plate thickness.

Owner:NIPPON STEEL CORP

High strength X90 pipeline steel and production method thereof

The invention provides a high-strength X90 pipeline steel which is characterized by containing the following chemical components (in weight percentage): 0.030 percent to 0.090 percent of C, 1.55 percent to 2.50 percent of Mn, less than or equal to 0.6 percent of Si, less than or equal to 0.0030 percent of S, less than or equal to 0.015 percent of P, 0.015 percent to 0.120 percent of Nb, 0.005 percent to 0.030 percent of Ti, less than or equal to 0.120 percent of V, less than or equal to 0.060 percent of Alt, less than 0.60 percent of Mo, less than 1.2 percent of Cu, less than 1.5 percent of Ni, less than 1.2 percent of Cr, less than 0.0015 percent of B, less than or equal to 0.01 percent of Ca, 0.003 percent to 0.010 percent of N, 0.001 percent to 0.006 percent of O, and the rest are Fe and inevitable impurities. The invention also provides a production method of the pipeline steel. The pipeline steel has high strength, high impact toughness, good welding performance and crack arrest capability, and plays an obvious role in reducing the construction cost of transportation pipelines.

Owner:BAOSHAN IRON & STEEL CO LTD

Ultrahigh-intensity high-toughness X120 pipe line steel and manufacturing method thereof

ActiveCN101165203AHas construction costsGuaranteed arrest abilityTemperature control deviceHeat treatment process controlCopperToughness

The present invention relates to one kind of high strength and high toughness X120 pipeline steel and its making process. The high strength and high toughness X120 pipeline steel consists of C 0.015-0.060 wt%, Mn 1.80-2.50 wt%, Si not more than 0.60 wt%, Ti 0.005-0.03 wt%, Al not more than 0.06 wt%, V not more than 0.15 wt%, B 0.0005-0.0030 wt%, P not more than 0.015 wt%, S not more than 0.003 wt%, Nb 0.043-0.150 wt%, N not more than 0.012 wt%, Cu not more than 0.80 wt%, Ni not more than 1.20 wt%, Cr not more than 1.20 wt%, Mo not more than 1.0 wt%, and Fe and impurity for the rest. Compared with available X80 pipeline steel, the high strength and high toughness X120 pipeline steel has 40 % higher strength and capacity of lowering pipeline constructing cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for repairing concrete crack with multi-cracking cement-based composite

The invention belongs to the technical field of concrete reinforcement and relates to a method for repairing a concrete crack, which uses multi-cracking cement-based composite to be covered on the outer surface of the concrete as a repairing layer and is characterized in that firstly, the periphery of the crack on the outer surface of the concrete is polished smooth or an isolating layer is arranged, and then the multi-cracking cement-based composite slurry is poured or a thin layer of slurry is poured first and then a precast slab is covered; and the weight ratio of components of the multi-cracking cement-based composite is that: cement: water: fine aggregate: fly ash: silicon ash: granulated blast furnace slag: metakaolin =1:(0.27-2.2):(0-3):(0-6.9):(0-0.3):(0-0.55):(0-0.4), and fiber of which the volume accounts for 1-3% of the total volume of the composite is also blended. The repairing layer leads the width of the crack to be less than 0.05mm under the action of the external shrinkage stress, can prevent the forming of penetrating cracks and can be widely used for repairing concrete structure cracks of concrete pavement, airport runways, anti-cracking belt of dam and bridge surface plate.

Owner:浙江固邦新材料有限公司

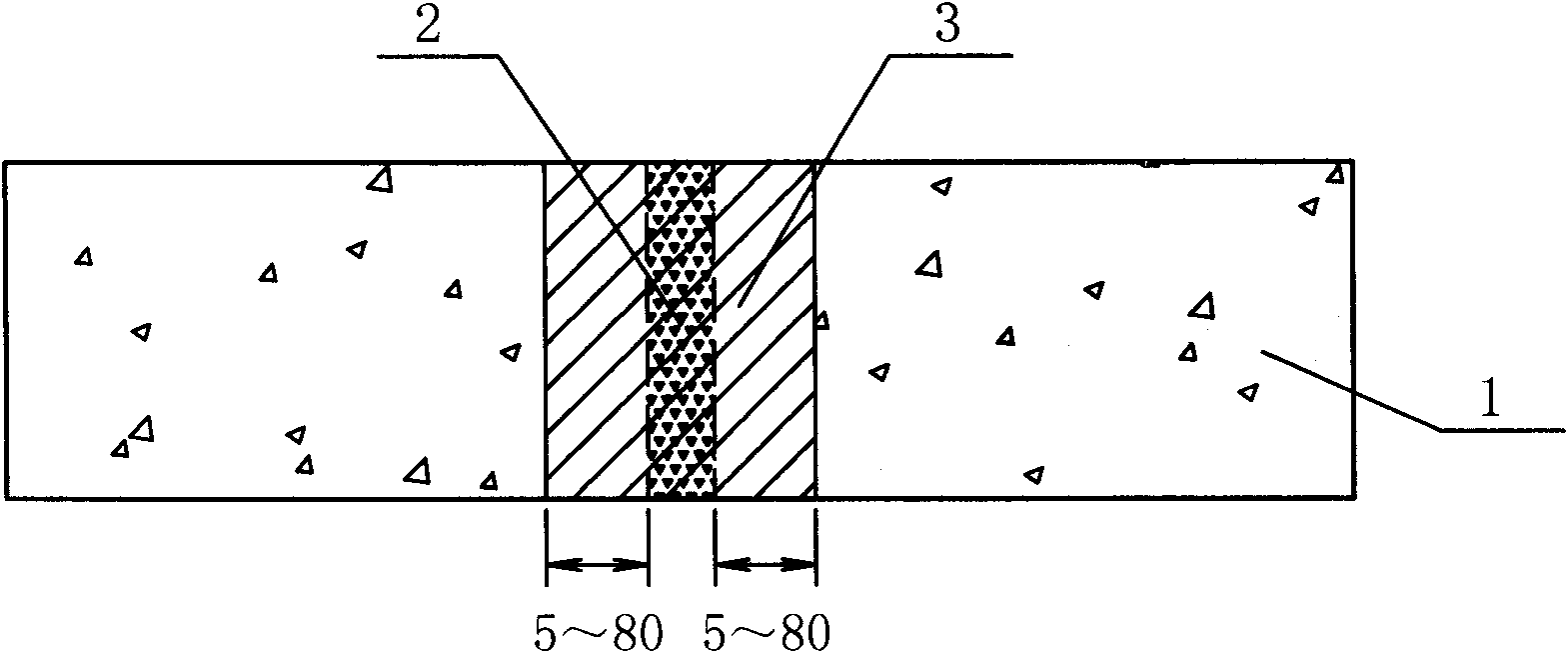

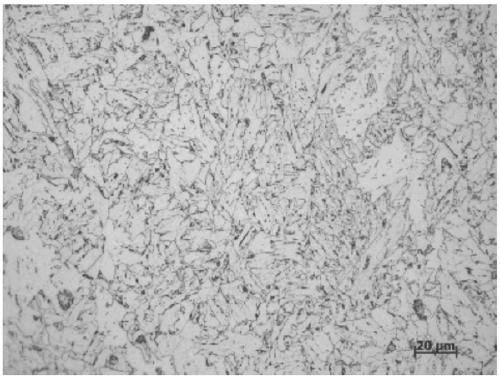

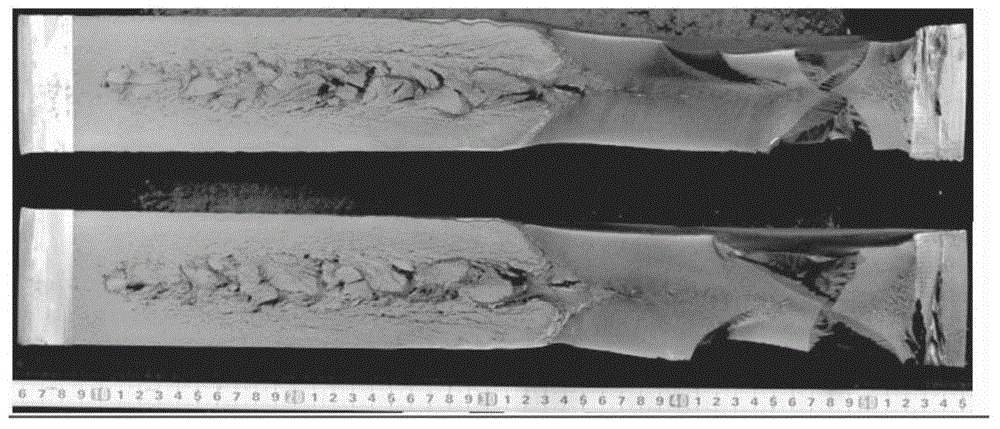

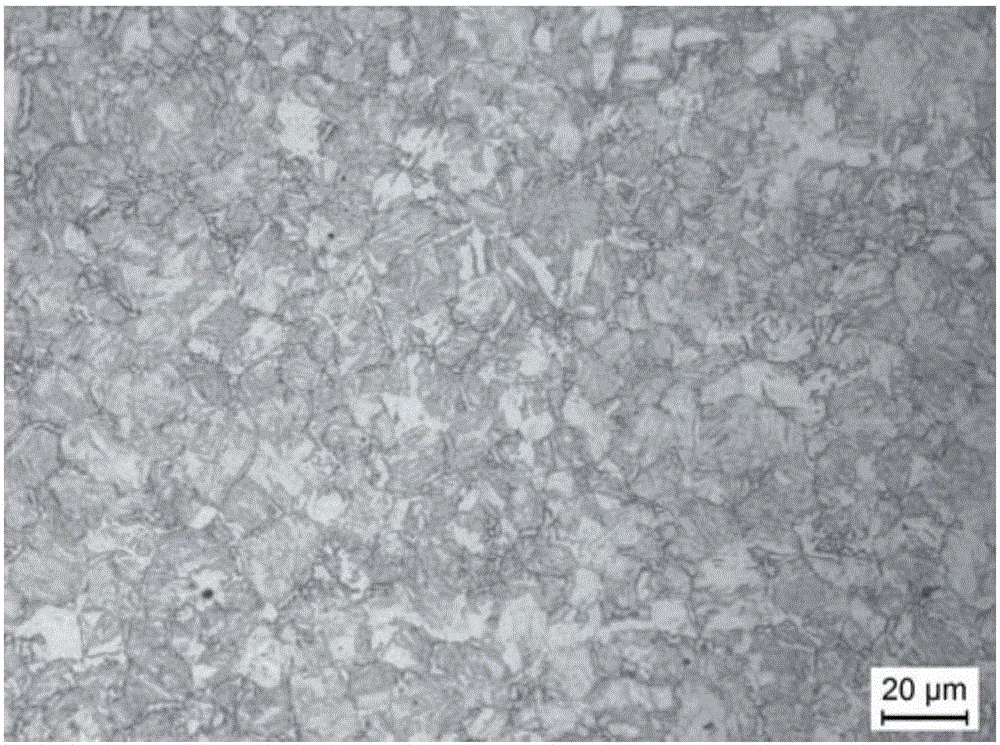

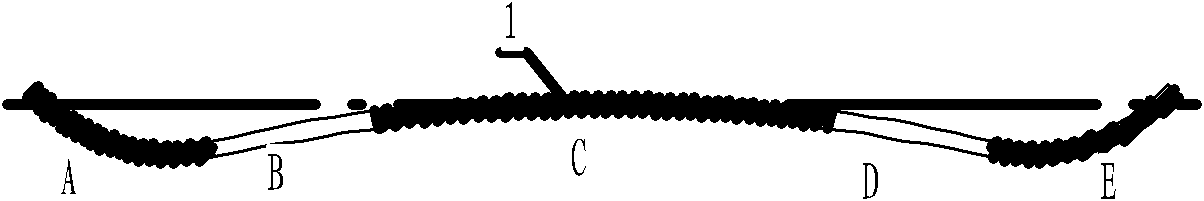

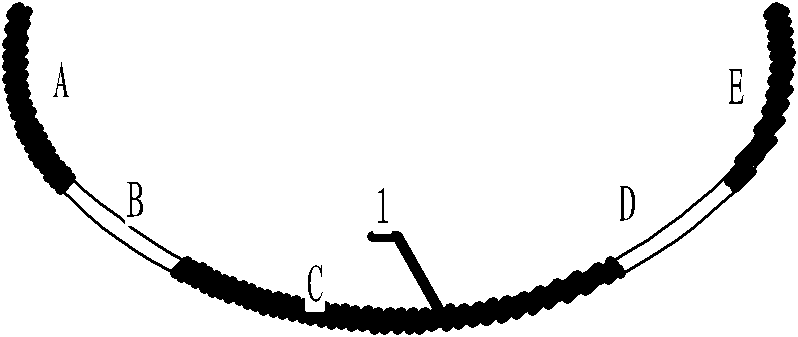

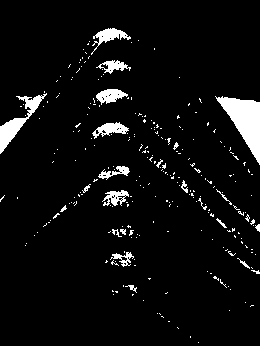

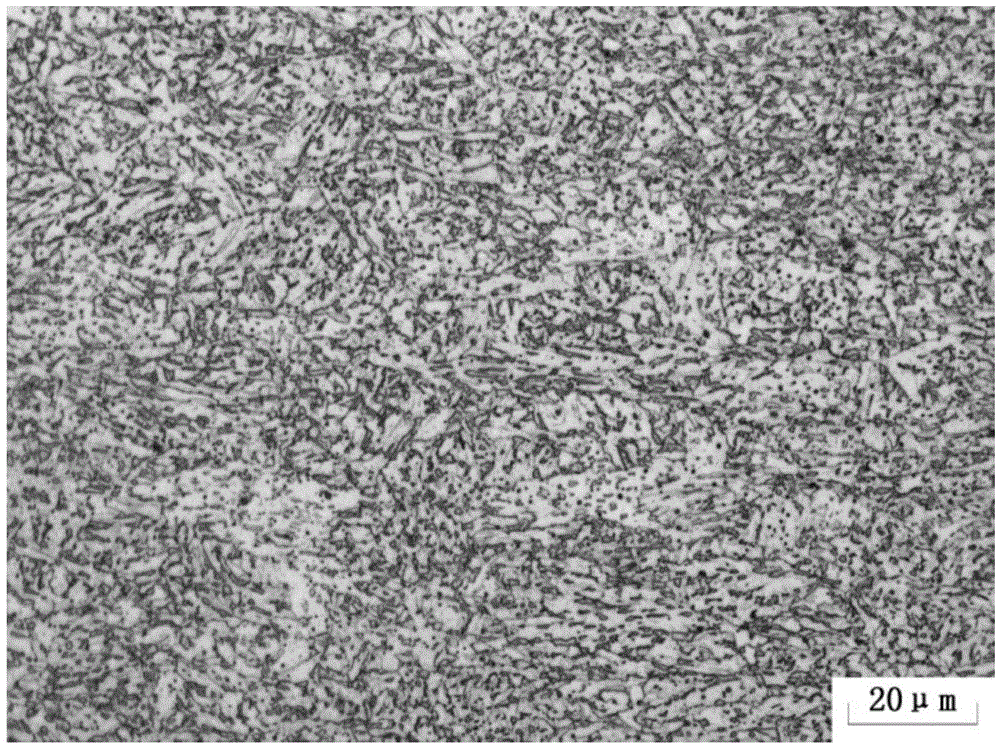

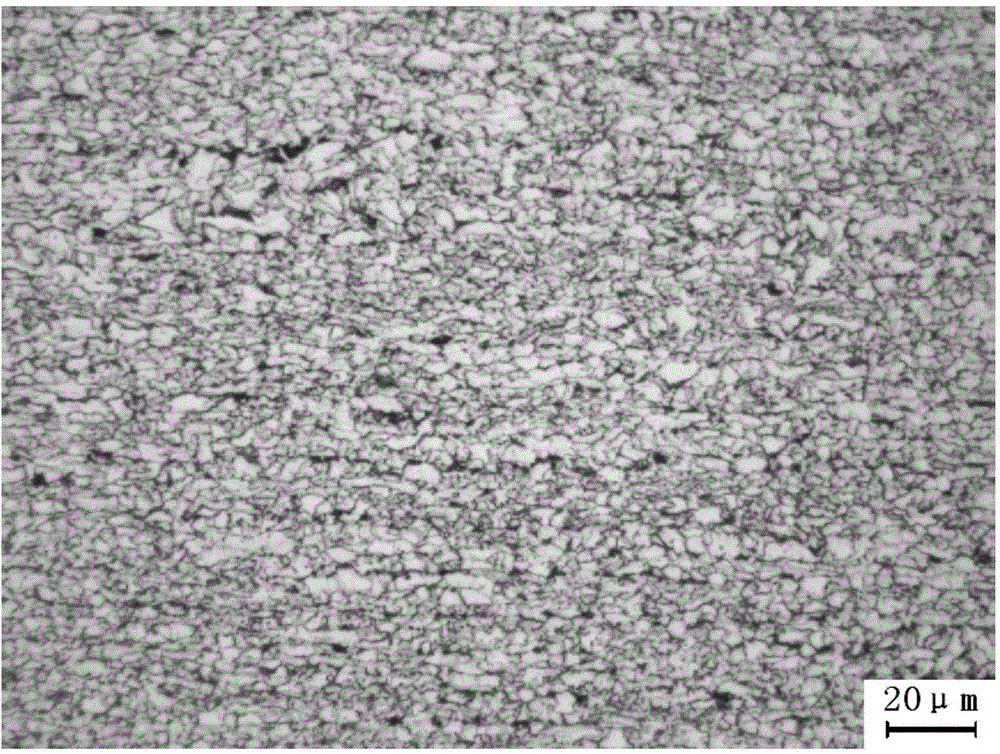

Thick steel plate with excellent rack arrest property and preparation method of thick steel plate

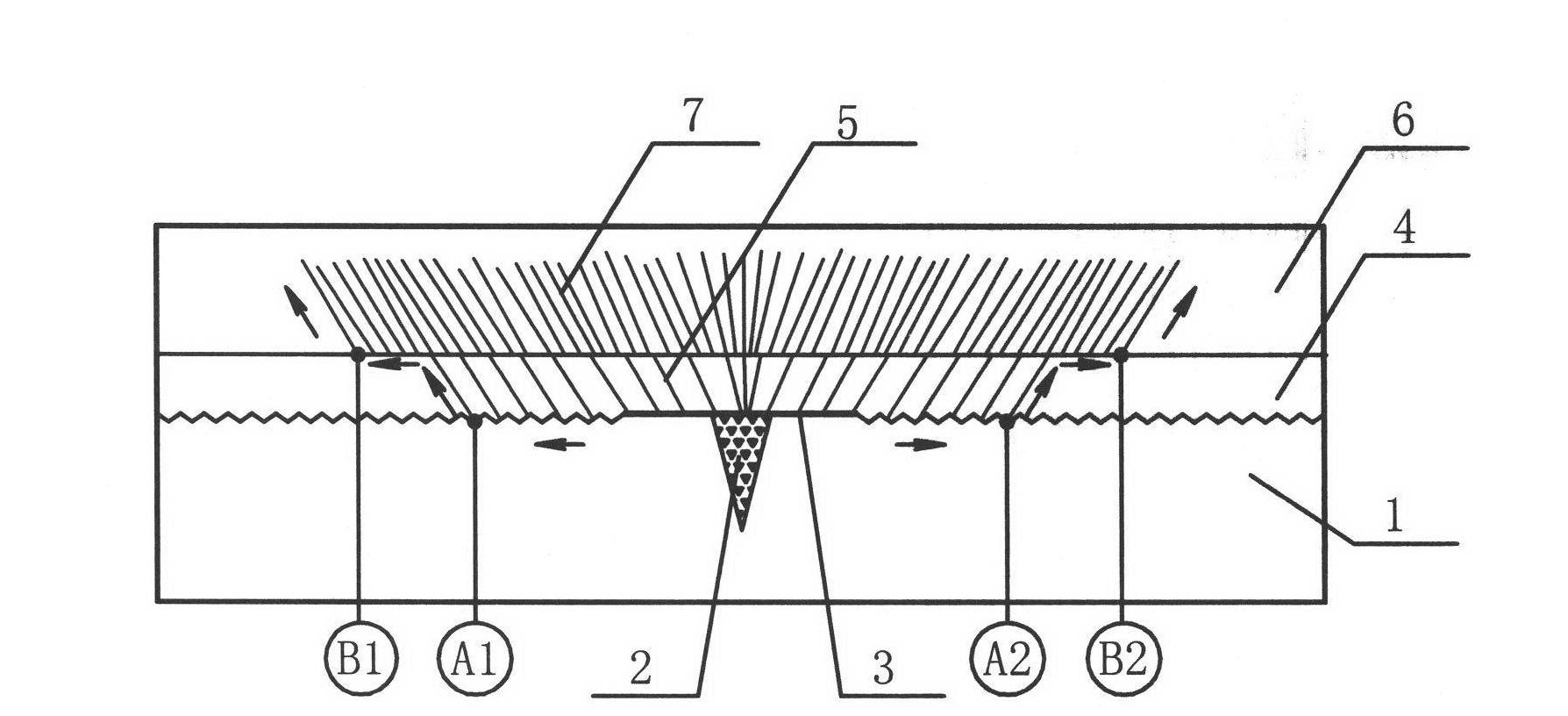

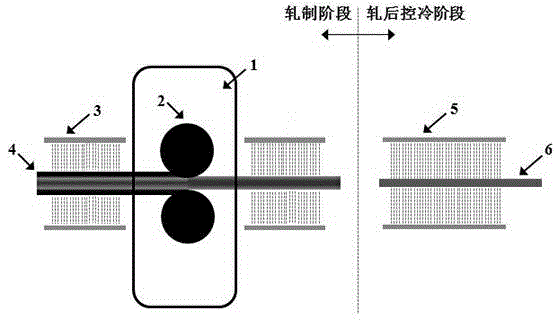

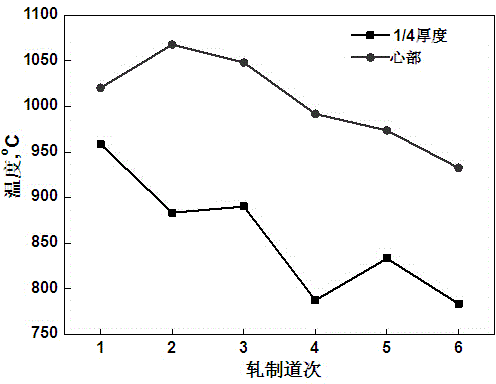

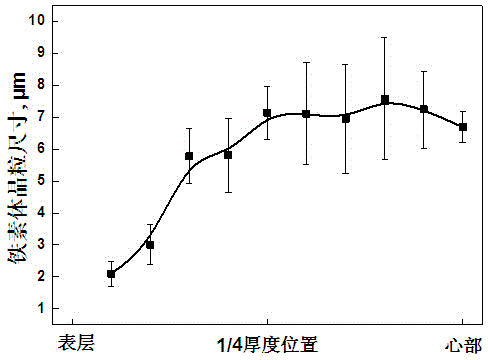

The invention belongs to the field of preparing steels and in particular relates to a thick steel plate with excellent rack arrest property and a preparation method of the thick steel plate. The thick steel plate is prepared from the following chemical components including a plain carbon steel or a microalloy steel. The preparation method comprises the following steps: water cooling while carrying out rolling deformation on a billet after being discharged out of a furnace, ensuring the temperature of the surface of the billet to be cooled to 400-800 DEG C during each rolling, ultra rapid cooling to 600-700 DEG C with the cooling speed to be larger than or equal to 15 DEG C / s after rolling is finished, and finally, air cooling to room temperature. According to the thick steel plate and the preparation method disclosed by the invention, the tissue of the thick steel plate takes ferrite as a parent phase and a second phase as a pearlite, the upper and lower surface layers of the thick steel plate are both an ultra-fine grain layer, the thickness of a single-sided ultra-fine grain layer is larger than or equal to 0.1 times of the thickness of the thick steel plate, the ferrite average grain size of each ultra-fine grain layer is smaller than or equal to 3 microns, and the grain boundary density of a large angle boundary is larger than or equal to 0.676 microns<-1>. The thick steel plate is excellent in rack arrest property and improved in core toughness and can be used for shipbuilding, in particular to structure materials of large container ships, offshore platforms, crude oil, natural gas conveying pipelines and the like.

Owner:NORTHEASTERN UNIV

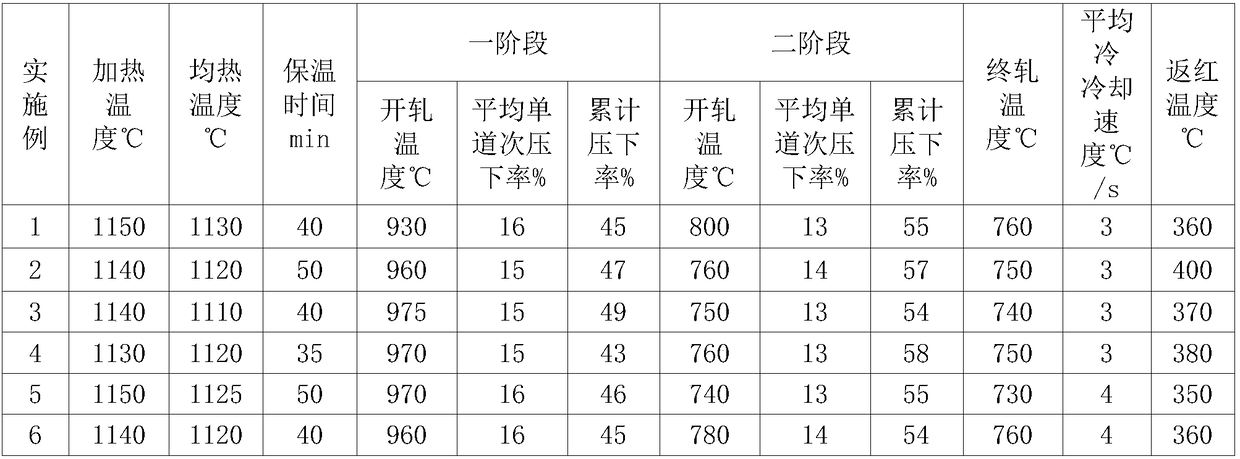

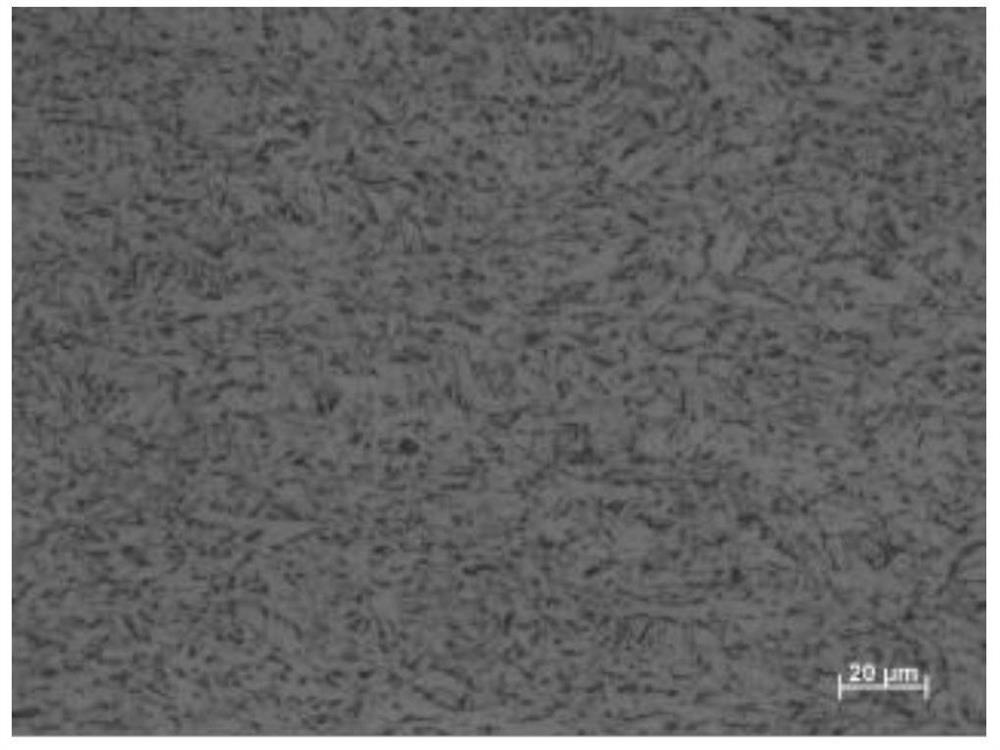

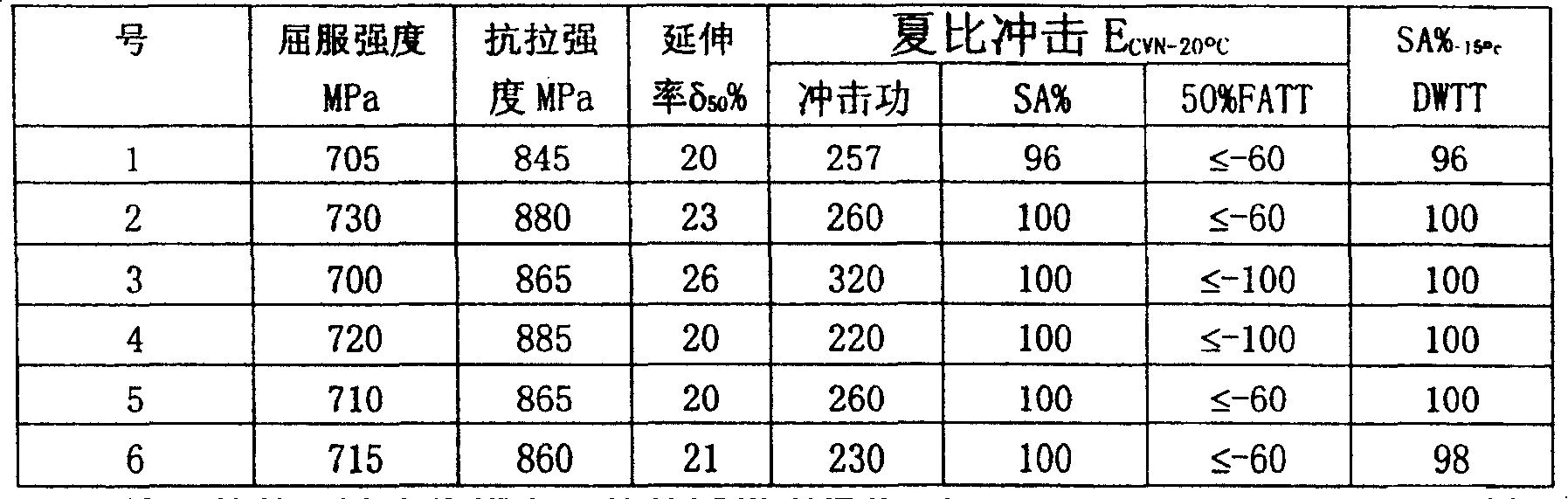

EH47 crack arrest steel for large container ship and manufacture method thereof

ActiveCN109576585AImprove corrosion resistanceAvoid negative effectsProcess efficiency improvementManufacturing technologySmallerThan

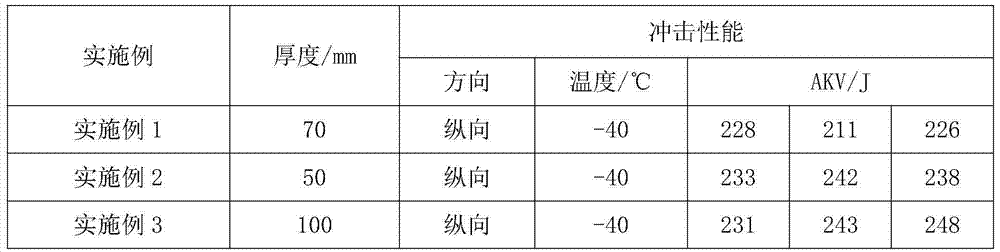

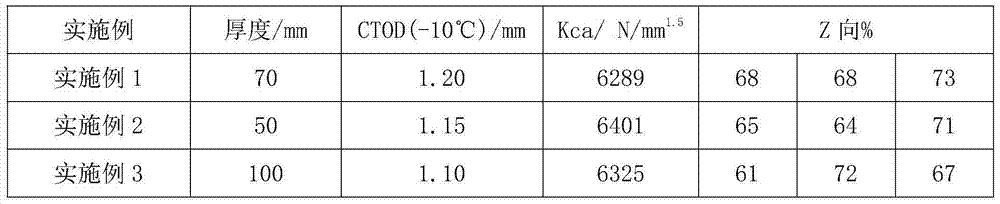

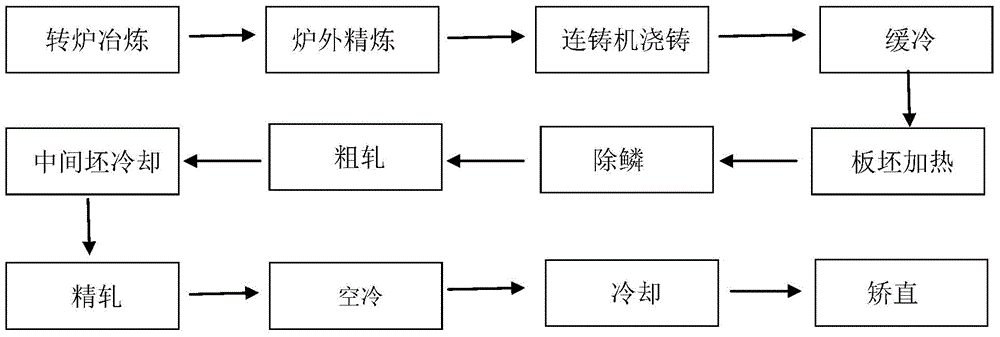

The invention relates to EH47 crack arrest steel for a large container ship. The chemical components of a steel plate comprise, by mass, 0.03%-0.06% of C, 0.15%-0.50% of Si, 1.50%-2.00% of Mn, smallerthan or equal to 0.008% of P, smaller than or equal to 0.0050% of S, 0.050%-0.080% of Nb, 0.020%-0.050% of V, 0.008%-0.020% of Ti, 0.80%-1.30% of Ni, 0.10%-0.30% of Cr and 0.10%-0.30% of Cu. The manufacture technology process of the steel plate comprises the steps of smelting, continuous casting, reheating, TMCP rolling and controlled cooling. The steel plate obtains fine and uniform acicular ferrite in the whole thickness, the strength is moderate, the toughness is excellent, the good brittle fracture resistance is achieved, namely, the CTOD characteristic value delta is larger than or equal to 0.15 mm at -60 DEG C, and the crack arrest performance is excellent, namely, Kca is larger than or equal to 6,500 N / mm<3 / 2>.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

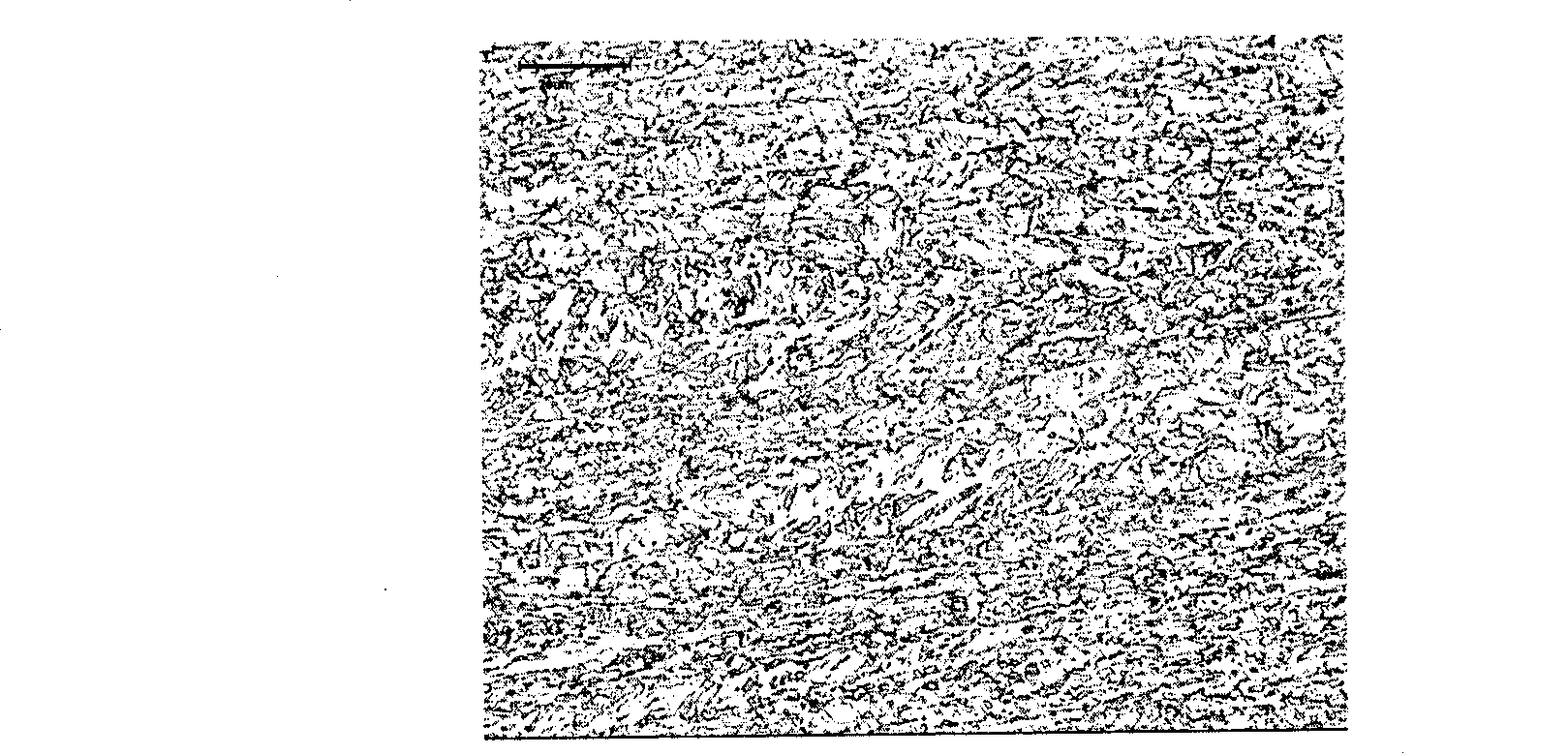

High-strength thick steel plate having excellent arrestability

This high-strength thick steel plate has a component composition in which the carbon equivalent (Ceq) is 0.3-0.5% and has a microstructure containing 70% or less of ferrite by area ratio and 30% or more of bainite by area ratio. At 1 / 4 of the plate thickness, the crystal grain boundary density, which is the total length per unit area of crystal grain boundaries having a crystal orientation difference of 15 DEG or greater, is 400-1000 mm / mm2; and the area ratio of the {100} plane, which forms an angle within 15 DEG with respect to a plane that is perpendicular to the main rolling direction, is 10-40%. At 1 / 2 of the plate thickness, the crystal grain boundary density is 300-900 mm / mm2; and the area ratio of the {110} plane, which forms an angle within 15 DEG with respect to a plane that is perpendicular to the main rolling direction, is 40-70%.

Owner:NIPPON STEEL CORP

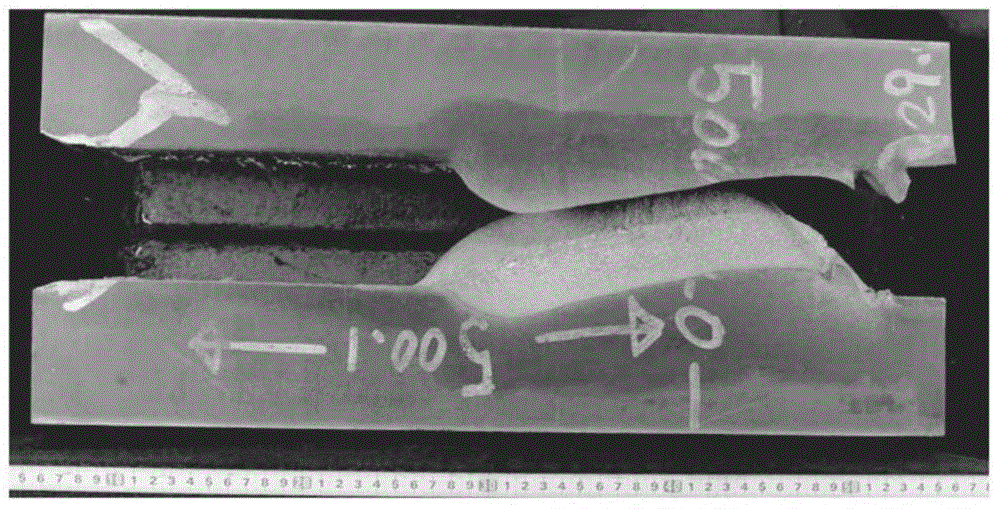

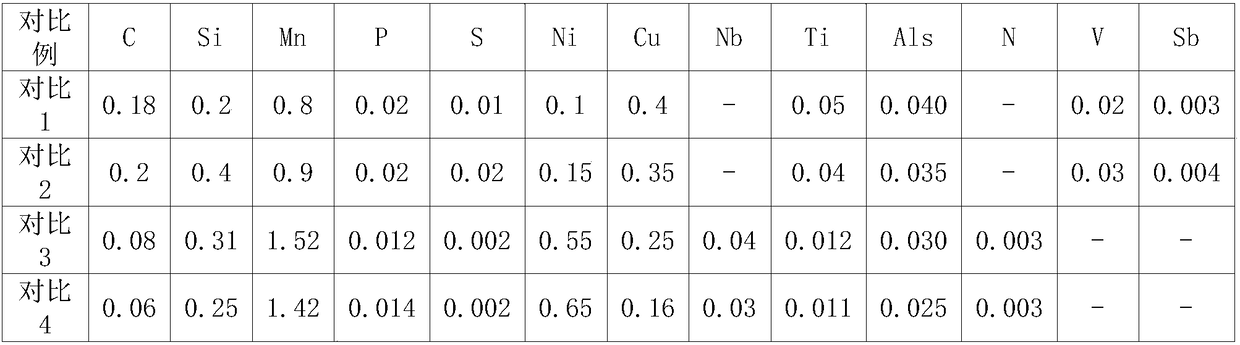

High-strength thick steel plate with excellent crack-arrest property and manufacturing method thereof

The invention relates to a high-strength thick steel plate with an excellent crack-arrest property. The steel plate has the following characteristics: a wide-plate tensile value Kca for determining the crack-arrest property is larger than 6000 N / mm<1.5>; yield strength at the positions, which are respectively 1 / 4 and 1 / 2 the thickness of the steel plate away from the surface of the steel plate, isno less than 460 MPa; tensile strength is 570 to 720 MPa; Charpy impact energy at minus 40 DEG C is no less than 200 J; and a zero-ductility transition temperature is less than minus 60 DEG C. The steel plate provided by the invention comprises the following components by weight: 0.04 to 0.16% of C, 0.1 to 0.5% of Si, 0.9 to 1.6% of Mn, 0.1 to 0.3% of Cu, 0.2 to 0.9% of Ni, no more than 0.02% ofP, no more than 0.02% of S, 0.01% to 0.05% of Als, 0.002 to 0.010% of N, 0.02% to 0.05% of Nb and 0.01 to 0.03% of Ti, with the balance being Fe and unavoidable impurities. According to the invention,through optimization of chemical components of a high-strength steel plate and adoption of controlled rolling and controlled cooling processes for controlling the microscopic structure and grain sizein a plate thickness direction, the crack-arrest steel plate with high yield and stable strength and toughness is obtained. The high-strength thick steel plate provided by the Invention is used as container vessel steel, and has the characteristics of excellent crack-arrest toughness, high yield strength, excellent low-temperature toughness and large thickness.

Owner:ANGANG STEEL CO LTD

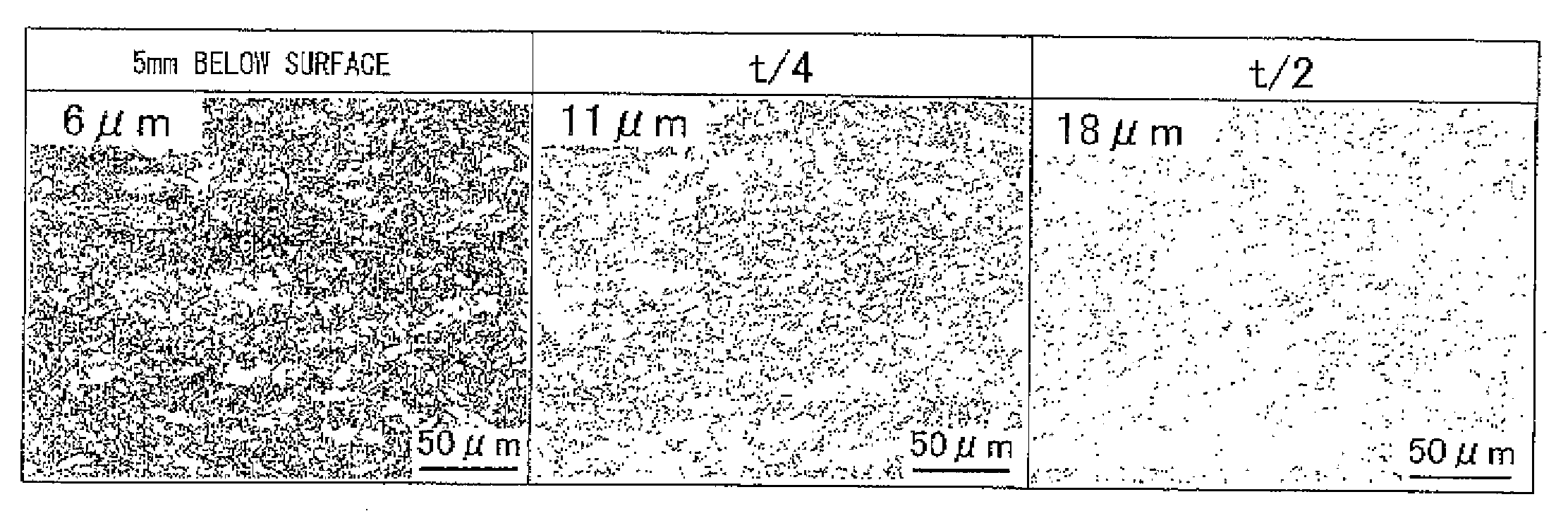

High strength thick steel plate superior in crack arrestability

InactiveUS20090092515A1Improve crack arrest performanceHigh strengthLayered productsThin material handlingChemical compositionEquivalent weight

The present invention provides high strength thick steel plate superior in crack arrestability high in strength, free of deterioration of HAZ toughness, and free of anisotropy, that steel plate containing, by mass %, C: 0.03 to 0.15%, Si: 0.1 to 0.5%, Mn: 0.5 to 2.0%, P: ≦0.02%, S: ≦0.01%, Al: 0.001 to 0.1%, Ti: 0.005 to 0.02%, Ni: 0.15 to 2%, and N: 0.001 to 0.008% and having a balance of iron and unavoidable impurities as chemical components, having a microstructure of a ferrite and / or pearlite structure with bainite as a matrix phase, and having an average circle equivalent diameter of crystal grains with a crystal misorientation angle of 15° or more of 15 μm or less in the regions of 10% of plate thickness from the front and rear surfaces and of 40 μm or less in the other region including the center part of plate thickness.

Owner:NIPPON STEEL CORP

Super-thick steel plate for container ships and preparation method of super-thick steel plate

The invention discloses a super-thick steel plate for container ships, which comprises the following components in percentage by weight: 0.04-0.12% of C, 0.25-0.50% of Si, 1.00-1.65% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0020% of S, 0.20-1.0% of Ni, 0.020-0.040% of Nb, 0.020-0.060% of V, 0.015-0.025% of Ti, 0.020-0.050% of Alt, and the balance of Fe and unavoidable impurities. The super-thick steel plate is prepared through the following production steps of molten iron pretreatment, BOF (basic oxygen furnace) steelmaking, LF (ladle refining) refining, RH (ruhrstahl heraeus) vacuum treatment, continuous casting, and TMCP (thermal mechanical control processing), the structure of an obtained super-thick steel plate for container ships comprises acicular ferrites, granular bainites and a small amount of pearlites, and the structure is uniform and small. The super-thick steel plate disclosed by the invention is simple in production process and low in cost, and has good lamellar tearing resistance, brittle crack preventing properties, high strength and high toughness.

Owner:NANJING IRON & STEEL CO LTD

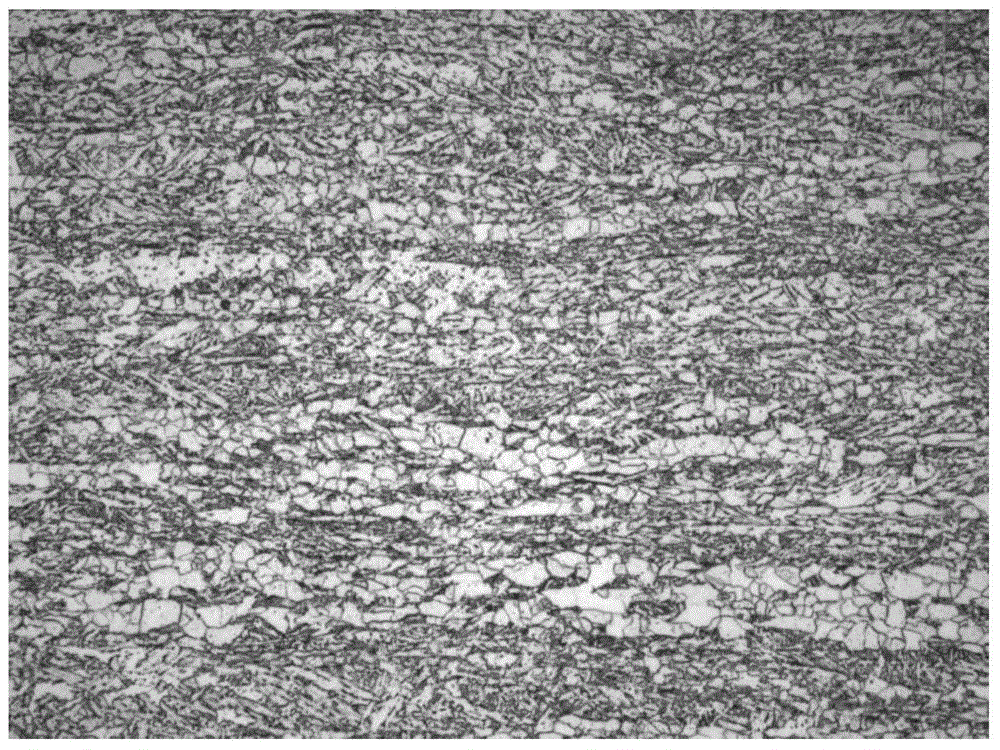

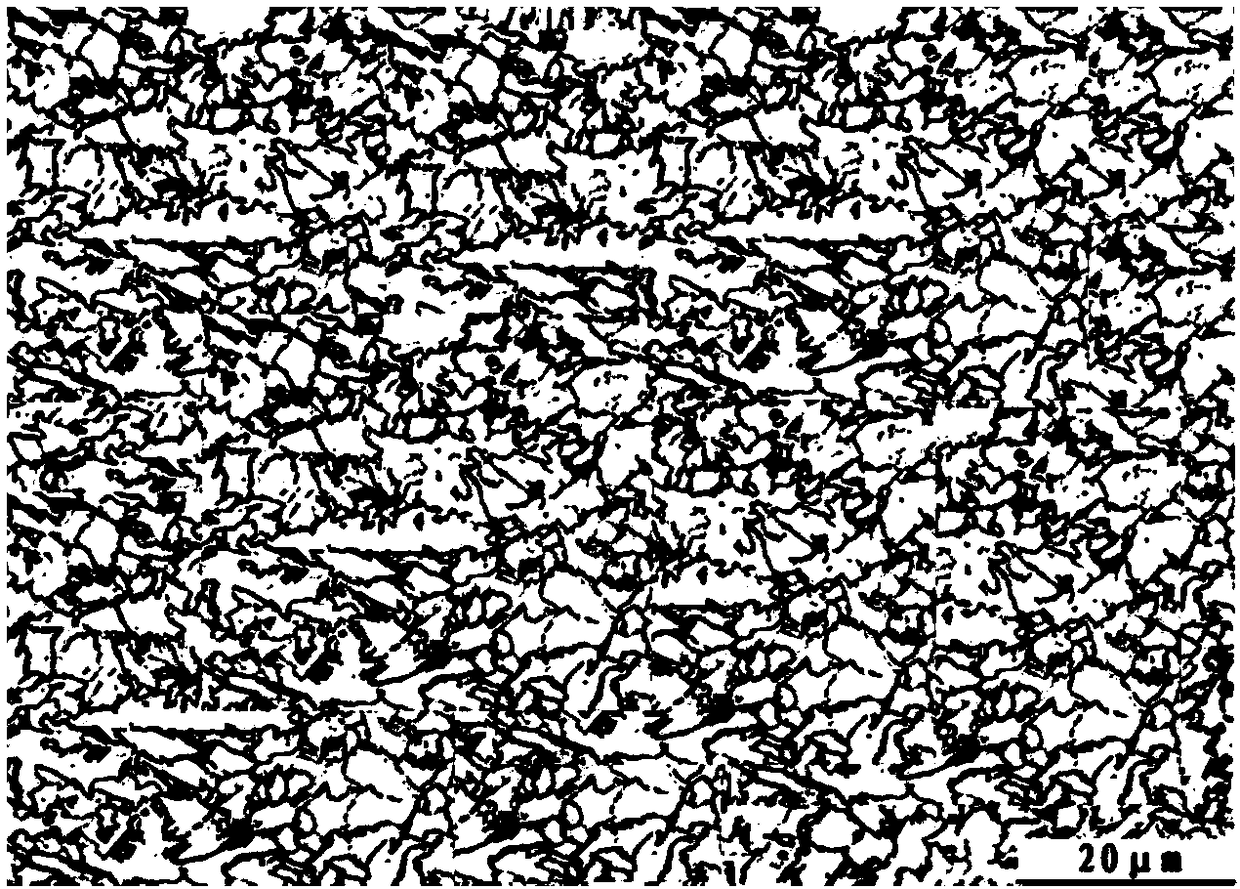

Medium-strength corrosion-resistant weldable crack-arrest titanium alloy and preparation method thereof

The invention discloses a medium-strength corrosion-resistant weldable crack-arrest titanium alloy. The titanium alloy is composed of, by mass percentage, 3.0-7.0% of an alpha stabilizing element Al, 1.5-4.5% of beta stabilizing elements of Mo, V, Nb and Ni, 0.5-3.0% of neutral elements of Zr and Sn, 0.01-0.3% of a Si element and the balance Ti and inevitable impurities, wherein, by mass percentage, 0-1% of Mo, 0-3% of V, 0-1% of Nb, 0.5% of Ni, 0-2% of Zr and 0-3% of Sn are included. The titanium alloy has the good strength, plasticity and toughness matching, the yield strength Rp0.2 is larger than or equal to 640 MPa, the tensile strength Rm is larger than or equal to 740 MPa, the elongation A is larger than or equal to 15%, the fracture toughness KIC is larger than or equal to 140 MPa.m<1 / 2>, and the impact toughness KV2 is larger than or equal to 80J; the alloy has the good crack arrest performance, and the dynamic tearing energy DTE is larger than or equal to 800 J; and meanwhile the good welding performance and resistance to seawater corrosion are achieved, the welding coefficient is larger than or equal to 0.95, the KISCC is larger than or equal to 95 MPa.m<1 / 2>, and the medium-strength corrosion-resistant weldable crack-arrest titanium alloy has the good technical application and market prospects in the fields of ship and marine engineering.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

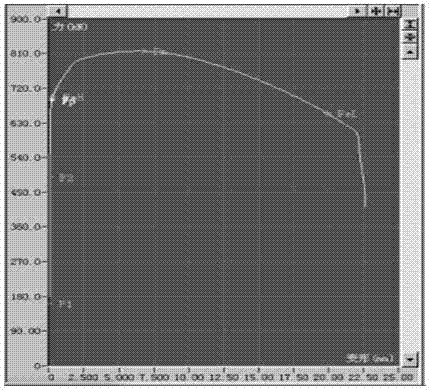

X80 pipeline steel with high stress ratio and high arrest toughness and preparation method and application of X80 pipeline steel

The invention specifically relates to X80 pipeline steel with the high stress ratio and high arrest toughness and a preparation method and application of the X80 pipeline steel. The X80 pipeline steel is composed of, by weight, 0.03% to 0.08% of C, 0.15% to 0.35% of Si, 1.50% to 2.00% of Mn, not larger than 0.010% of P, not larger than 0.003% of S, 0.04% to 0.08% of Nb, 0.015% to 0.025% of Ti, 0.015% to 0.025% of Zr, not larger than 0.03% of Mo, not larger than 0.35% of Cu, not larger than 0.30% of Ni, not larger than 0.30% of Cr and the balance Fe and inevitable impurities. Zirconium is added to promote precipitation of proeutectoid ferrite, the banded structure level is reduced, and the stress ratio and the arrest toughness of a steel plate are effectively improved. The heating temperature is strictly controlled, and the recrystallization deformation temperature section in a rough rolling stage and the rolling reduction and the temperature of the last phase of rough rolling are reasonably matched, so that the austenite grain size is reduced to the maximum degree; and a rough-rolled intermediate billet is cooled, so that grain growth generated after recrystallization deformation is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

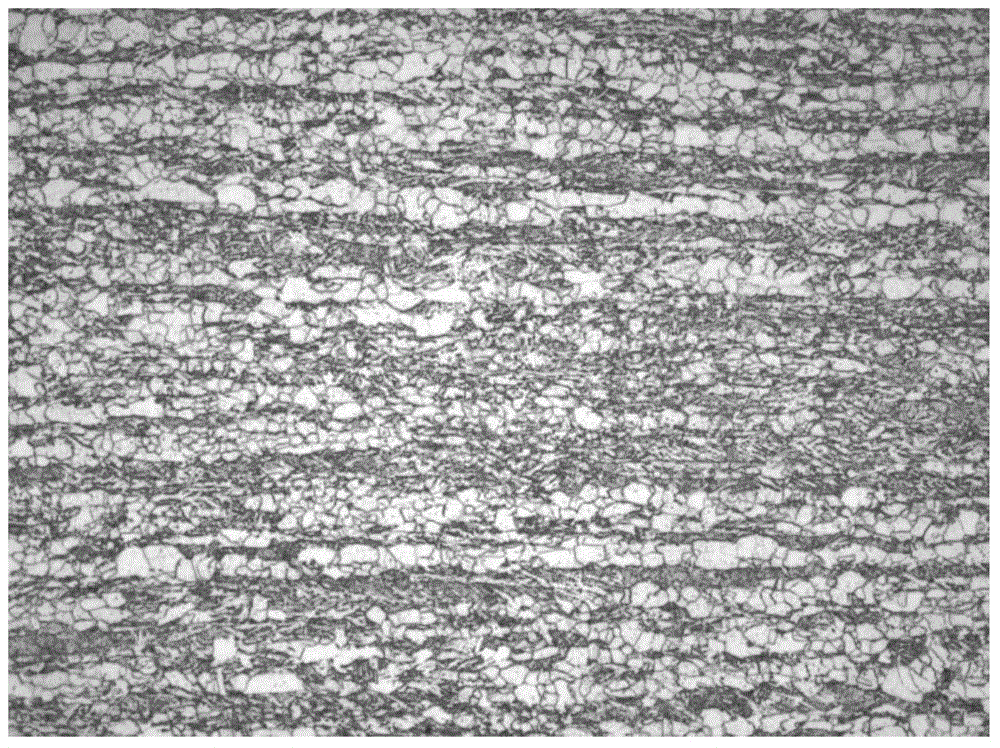

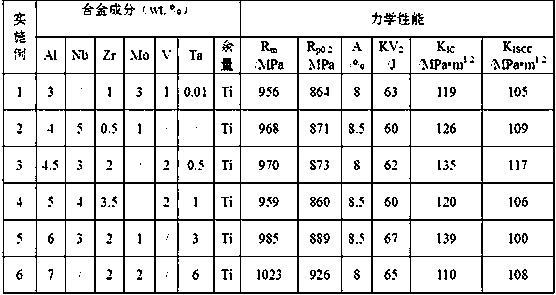

High-intensity, high-toughness and corrosion-resistant titanium alloy and preparation method thereof

ActiveCN109161726AGood cold and hot processing performanceGood technical applicationHigh intensityStable element

The invention relates to a high-intensity, high-toughness and corrosion-resistant titanium alloy and a preparation method thereof, and belongs to the field of alloys. The titanium alloy is prepared from the following element components (in percentage by mass): 3.0 to 7.0 percent of Al; 2.0 to 6.0 percent of a beta-stable element (Mo+Nb+V), 0.01 to 6.0 percent of Ta, 0.5 to 3.5 percent of Zr and the balance of Ti and unavoidable impurities. The performance of the alloy is as follows: Rp0.2 is greater than or equal to 840 MPa, Rm is greater than or equal to 940 MPa, A is greater than or equal to8 percent, KIC is greater than or equal to 110 MPa.m<1 / 2>, KISCC is greater than or equal to 100 MPa.m<1 / 2>, and KV2 is greater than or equal to 60J. The alloy has good technology application and market prospects in the field of ship, marine engineering and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Seawater corrosion resistant steel plate with high crack arrest and strain aging embrittlement resistance characteristics and manufacturing method thereof

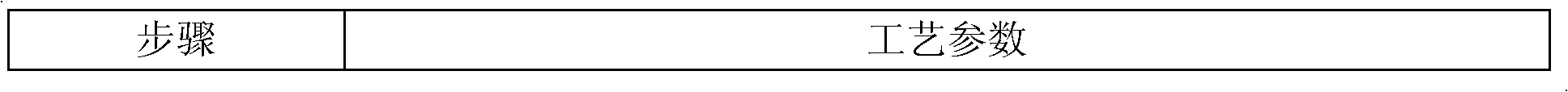

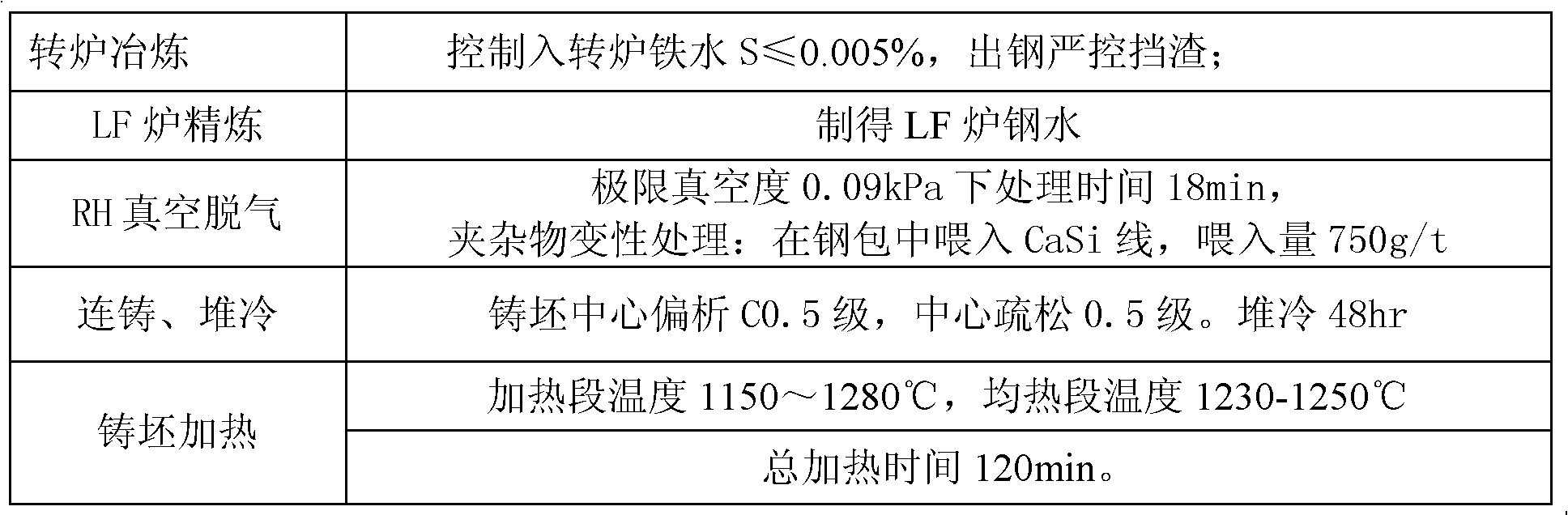

The invention discloses a seawater corrosion resistant steel plate with high crack arrest and strain aging embrittlement resistance characteristics and a manufacturing method thereof. The seawater corrosion resistant steel plate is prepared from the compositions in percentage by weight: 0.040-0.070% of C, less than or equal to 0.15% of Si, 0.85-1.15% of Mn, less than or equal to 0.013% of P, lessthan or equal to 0.0030% of S, 0.90-1.20% of Cu, 0.60-1.00% of Ni, 0.05-0.30% of Mo, 0.010-0.030% of Nb, 0.008-0.014% of Ti, 0.040-0.070% of Al, less than or equal to 0.0050% of N, less than or equalto 0.0003% of B, 0.0010-0.0040% of Ca and the balance of Fe and inevitable impurities. The steel plate has high strength, excellent low-temperature toughness, the crack arresting characteristic and the strain aging embrittlement resistance characteristic, further has excellent seawater corrosion resistance, can withstand large heat input welding, is particularly suitable for icebreaker shells, offshore platforms, sea-crossing bridges, ocean wind tower structures, hydroelectric metal structures (pressure steel pipes, volutes, steel bifurcated pipes and hydraulic turbine metal components), pressure vessels and the like in ice sea areas, and can achieve stable mass industrial production.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-roll-force gas-transmission pipeline steel and production method thereof

The invention relates to low-roll-force gas-transmission pipeline steel which unit roll-force is lower than 18Kn / mm and a production method thereof. The pipeline steel comprises the following main components in percentage by weight: 96.3-98.6 wt% of Fe, 0.030-0.010 wt% of C, 1.20-1.90 wt% of Mn, 0.10-0.35 wt% of Si, 0.015-0.120 wt% of Nb, 0.005-0.025 wt% of Ti, 0.001-0.005 wt% of N and 0.020-0.040 wt% of Alt, wherein the Ti / N ratio is equal to 3-6, and the Ca / Alt ratio is greater than or equal to 0.10. The pipeline steel also comprises the following residual components in percentage by weight: at most 0.004 wt% of O, at most 0.010 wt% of P, at most 0.003 wt% of S, at most 0.03 wt% of As, at most 0.02 wt% of Sn and at most 0.02 wt% of Sb. A thick / medium plate rolling machine, of which the unit roll force is lower than 18 kN / mm, can be utilized to effectively roll various thin / medium / thick casting blanks to produce the gas-transmission pipeline steel with favorable anti-cracking performance in a ferrous metallurgy enterprise on a common equipment level by slightly adjusting the technique.

Owner:SHAOGUAN IRON & STEEL GROUP CORP GUANGDONG PROV +1

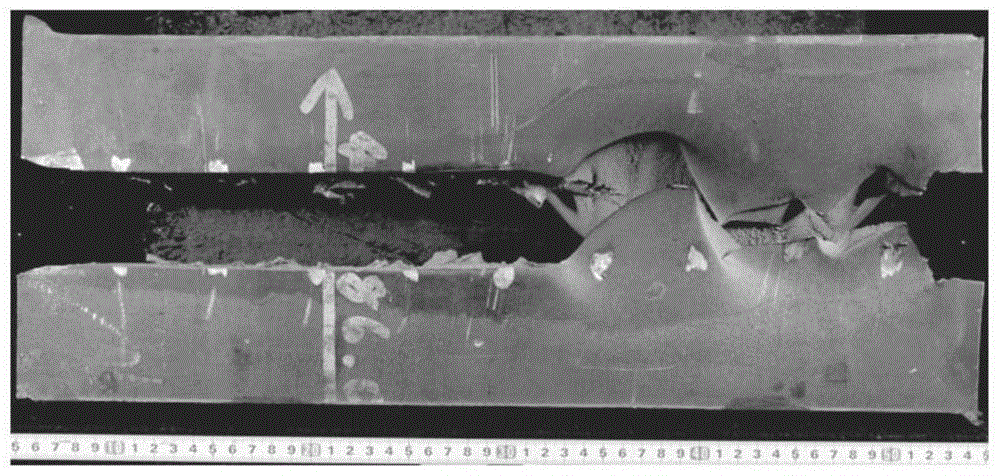

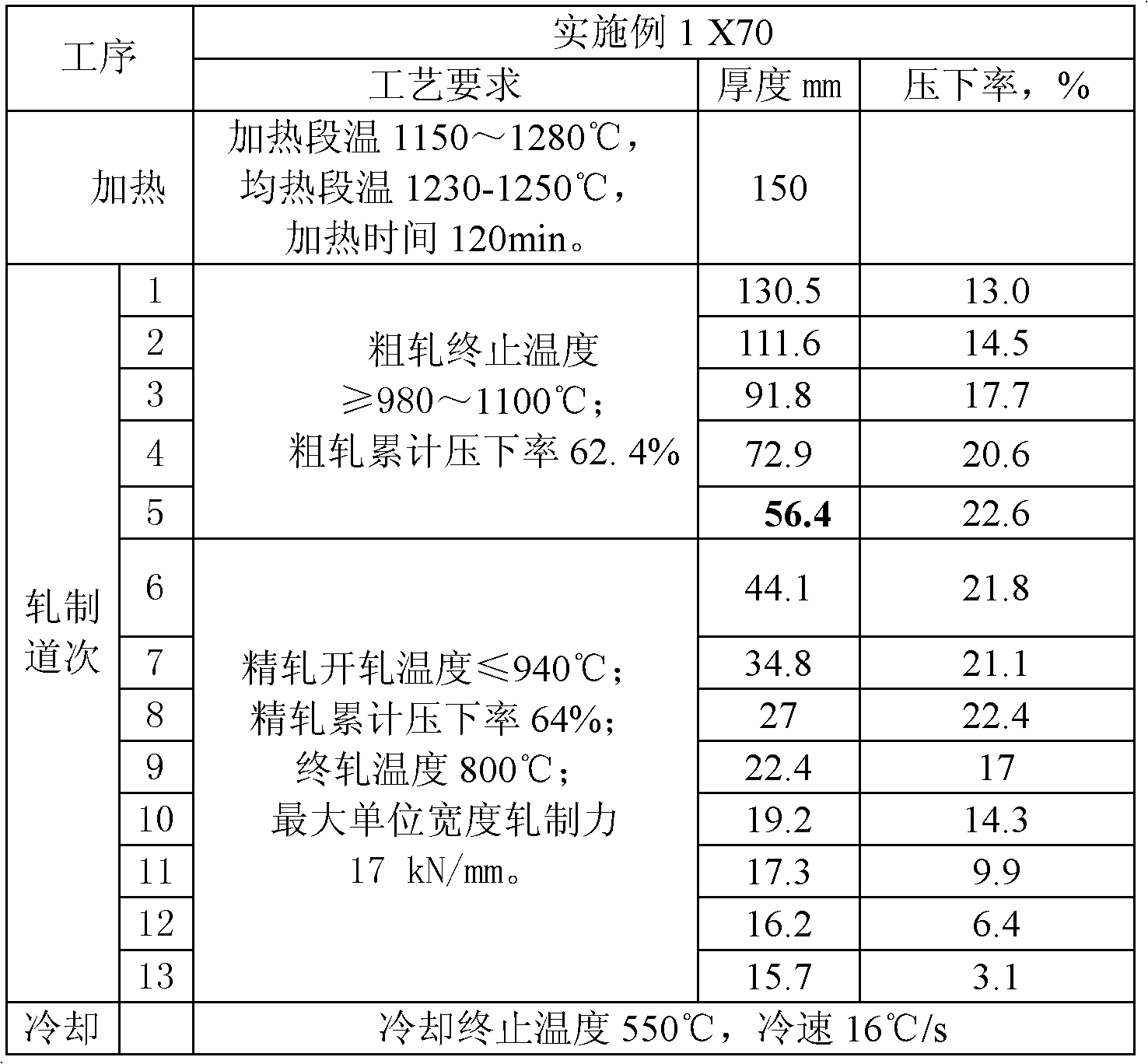

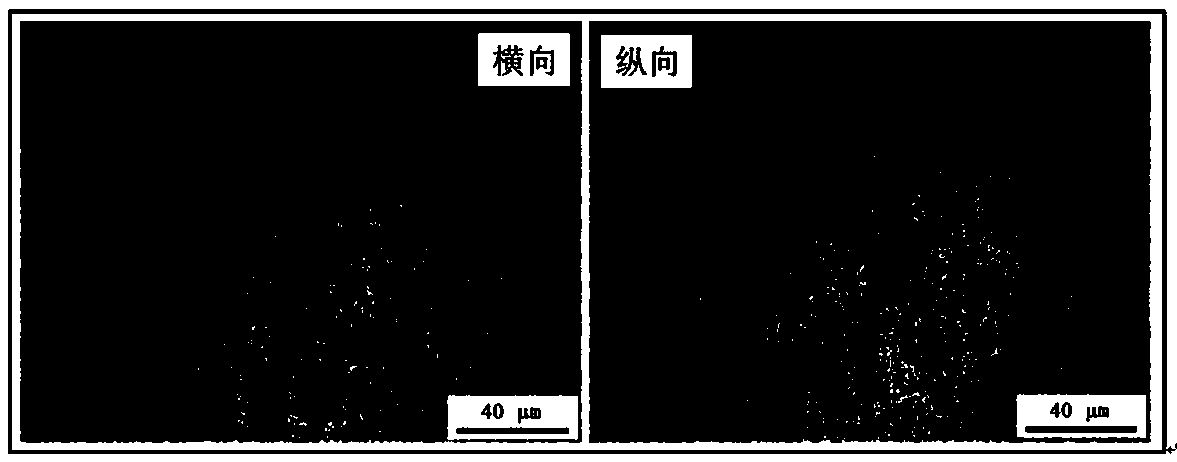

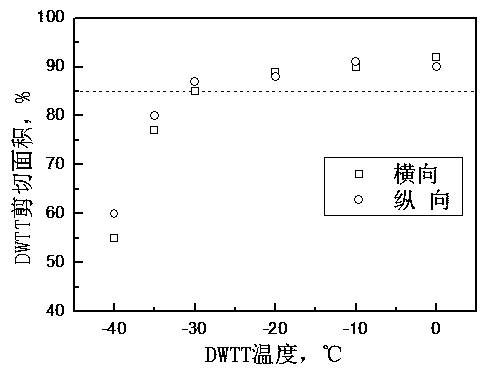

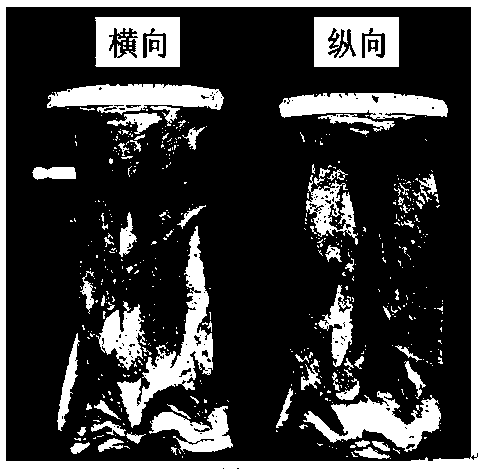

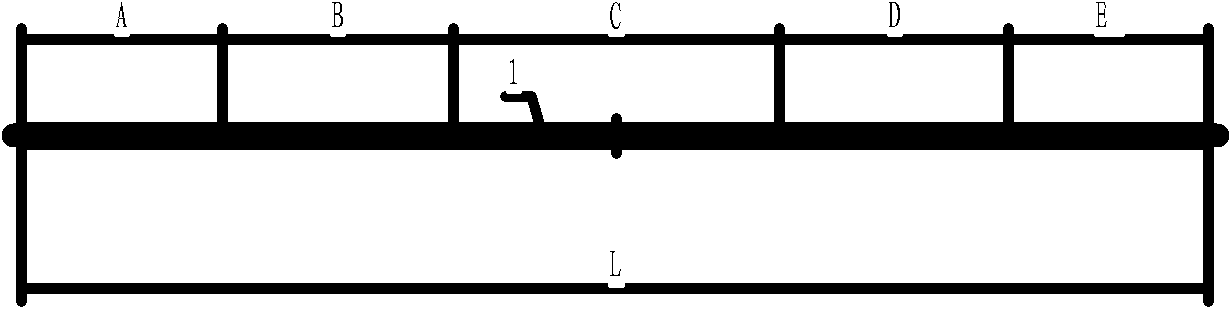

Production method of X80 pipeline steel wide and thick plate

ActiveCN108396229AUniform performanceImprove low temperature drop hammer arrest performanceSteel platesDrop weight

Disclosed is a production method of an X80 pipeline steel wide and thick plate. The thickness of the steel plate is larger than or equal to 19 mm, and the width of the steel plate is larger than or equal to 3800 mm. Steel comprises the chemical compositions of, by mass, 0.04-0.05% of C, no more than 0.10% of Si, 1.20-1.80% of Mn, no more than 0.015% of P, no more than 0.002% of S, 0.02-0.06% of Als, 0.02-0.08% of Nb, 0.010-0.025% of Ti, no more than 0.3% of Cr, no more than 0.3% of Mo, no more than 0.3% of Ni, no more than 0.3% of Cu, no more than 0.0005% of B, 0.001-0.002% of Ca, no less than0.3% of Cr+Mo, no more than 1.0% of Cu / Ni, no more than 0.20% of Pcm, and the balance Fe and inevitable impurities. The transverse and longitudinal microstructures of the steel plate are uniform, thetransverse and longitudinal full-thickness DWTT shearing areas at the temperature of minus 30 DEG C are all larger than or equal to 85%. The low-temperature drop weight crack arrest performance of the large-wall-thickness large-diameter high-steel-grade pipeline steel can be improved, and meanwhile the plate shape is easy to control during rolling.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Seawater corrosion-resistant steel plate with high crack arrest and anti-strain aging embrittlement properties and manufacturing method thereof

The invention discloses a seawater corrosion resistant steel plate with high crack arrest and strain aging embrittlement resistance characteristics and a manufacturing method thereof. The seawater corrosion resistant steel plate is prepared from the compositions in percentage by weight: 0.040-0.070% of C, less than or equal to 0.15% of Si, 0.85-1.15% of Mn, less than or equal to 0.013% of P, lessthan or equal to 0.0030% of S, 0.90-1.20% of Cu, 0.60-1.00% of Ni, 0.05-0.30% of Mo, 0.010-0.030% of Nb, 0.008-0.014% of Ti, 0.040-0.070% of Al, less than or equal to 0.0050% of N, less than or equalto 0.0003% of B, 0.0010-0.0040% of Ca and the balance of Fe and inevitable impurities. The steel plate has high strength, excellent low-temperature toughness, the crack arresting characteristic and the strain aging embrittlement resistance characteristic, further has excellent seawater corrosion resistance, can withstand large heat input welding, is particularly suitable for icebreaker shells, offshore platforms, sea-crossing bridges, ocean wind tower structures, hydroelectric metal structures (pressure steel pipes, volutes, steel bifurcated pipes and hydraulic turbine metal components), pressure vessels and the like in ice sea areas, and can achieve stable mass industrial production.

Owner:BAOSHAN IRON & STEEL CO LTD

Cu-containing crack arrest steel and preparation method thereof

The invention provides Cu-containing crack arrest steel and a preparation method thereof. The components of the Cu-containing crack arrest steel include 0.02-0.10% of C, 0.1-1% of Cu, 0.1-0.4% of Si, 0.5-1.2% of Mn, 0-0.2% of Al, 0.1-0.3% of Cr, 0.5-1.5% of Ni, 0-0.8% of Mo, 0.01-0.05% of Nb, 0.03-0.2% of Ti, 0-0.005% of S, 0-0.01% of P and the balance Fe and unavoidable impurity elements. The preparation method of the Cu-containing crack arrest steel includes the steps of smelting and hot rolling in which the rough rolling temperature is 1000-1100 DEG C, and the finishing rolling starting temperature is 800-1000 DEG C. A copper-rich nanophase is generated by designing a proper micro alloy content proportion, the phase composition in the steel and the shape thereof, especially separating-out of the copper-rich nanophase are controlled through the rolling and heat treatment technology, and therefore the strength, rigidity and crack arrest performance of the Cu-containing crack arrest steel are improved.

Owner:HARBIN ENG UNIV

High-toughness quantitative-reduction ship plate marine steel and preparation method thereof

The invention discloses high-toughness quantitative-reduction ship plate marine steel. A steel plate comprises the following chemical components by weight percent: 0.04%-0.14% of C, 0.15%-0.45% of Si,0.90%-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.010%-0.040% of Nb, 0-0.20% of Cr, 0-0.030% of V, 0.005%-0.020% of Ti, 0.015%-0.050% of Als, less than or equal to 30 ppm of N, less than or equal to 30 ppm of O, less than or equal to 2 ppm of H, and the balance Fe and inevitable impurities, wherein Als is acid-soluble aluminum; a welding crack sensitivityindex (Pcm) of the steel plate is less than or equal to 0.22%; and a carbon equivalent value (CEV) is less than or equal to 0.39%. The steel plate is not liable to be broken and damaged, and has goodstrength and toughness, welding performance and crack arrest performance.

Owner:SD STEEL RIZHAO CO LTD

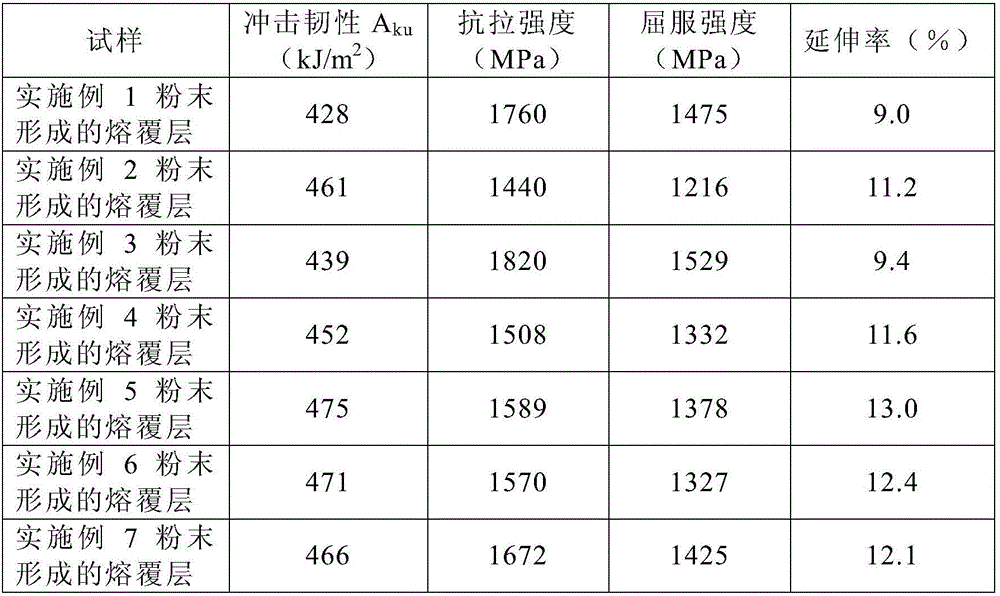

Laser cladding powder for 30CrMnSiNi2A steel and preparation method

ActiveCN106480363AHigh bonding strengthLess metallurgical defectsTransportation and packagingMetal-working apparatusRare earthUltimate tensile strength

The invention relates to laser cladding powder for 30CrMnSiNi2A steel and a preparation method. The laser cladding powder is prepared from the following components in weight percent: 0.8% to 1.0% of Cr, 0.75% to 1.10% of Mn, 0.65% to 1.10% of Si, 2.0% to 3.2% of Ni, 0.16% to 0.22% of C, 0.15% to 0.20% of Cu, 0.015% to 0.020% of P, 0.01% to 0.015% of S, 0.001% to 0.015% of rare earth and the balance of Fe. The invention further provides the preparation method of the laser cladding powder, the laser cladding powder is exclusively used in a laser cladding technique of the 30CrMnSiNi2A steel, excellent bonding strength and low metallurgical defects and dilution rate of a cladding interface are guaranteed, the toughness of a cladding layer is increased, the wettability of the cladding powder is improved, the cracking of the cladding layer is inhibited, and the crack growth rate is reduced.

Owner:国营芜湖机械厂

Ultrahigh-strength X100 pipeline steel plate with excellent crack resistance and preparation method thereof

The invention discloses an ultrahigh-strength X100 pipeline steel plate with excellent crack resistance. The steel plate comprises the following chemical components: 0.03-0.06% of C, 0.20-0.50% of Si, 1.80-2.10% of Mn, no more than 0.005% of S, no more than 0.010% of P, 0.20-0.50% of Ni, 0.20-0.40% of Mo, 0.20-0.50% of Cr, 0.20-0.50% of Cu, 0.050-0.080% of Nb, 0.015-0.035% of Ti, no more than 0.004% of N, no more than 0.004% of O, no more than 0.002% of H, no less than 0.015% of Als and the balance of Fe and trace impurities; Pcm is no more than 0.25%. The invention also discloses a preparation method of the steel plate. A shock crack of a V-shaped gap of the steel plate can exceed 55J, the shock crack can expand over 160J, and the crack resistance is good.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

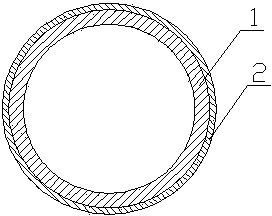

Composite steel tube used for oil and gas conveying pipeline and externally wound by glass fiber resin reinforcing protective layer

InactiveCN104197114AImprove pressure bearing capacityImprove aging resistanceCoatingsRigid pipesGlass fiberPhysical chemistry

The invention relates to a composite steel tube used for an oil and gas conveying pipeline and externally wound by a glass fiber resin reinforcing protective layer. A traditional pipeline steel tube is taken as a base tube, high-strength glass fibers infiltrated with resin are wound around the outer surface of the pipeline steel base tube and serve as the high-strength glass fiber reinforcing resin layer, and therefore the brand new composite tube is formed, wherein the inner layer of the composite tube is pipeline steel, and the outer layer of the composite tube is glass-reinforced plastic. The composite tube has the performance characteristics of the pipeline steel tube and a glass reinforced plastic tube, the pressure bearing capacity and the crack arrest capacity of the pipeline are improved, the defect that a high-strength pipeline is poor in tenacity is overcome, 3PE outer corrosion prevention of a traditional pipeline is replaced, the corrosion-resistant and ageing-resistant capacity of the pipeline are improved, and in comparison with a 100% pipeline steel tube with the same pressure bearing capacity, the manufacturing cost of the composite steel tube is reduced by about 20%. The composite steel tube can be used and popularized in construction projects of long-distance petroleum and gas conveying pipelines.

Owner:CNPC BOHAI EQUIP MFG +1

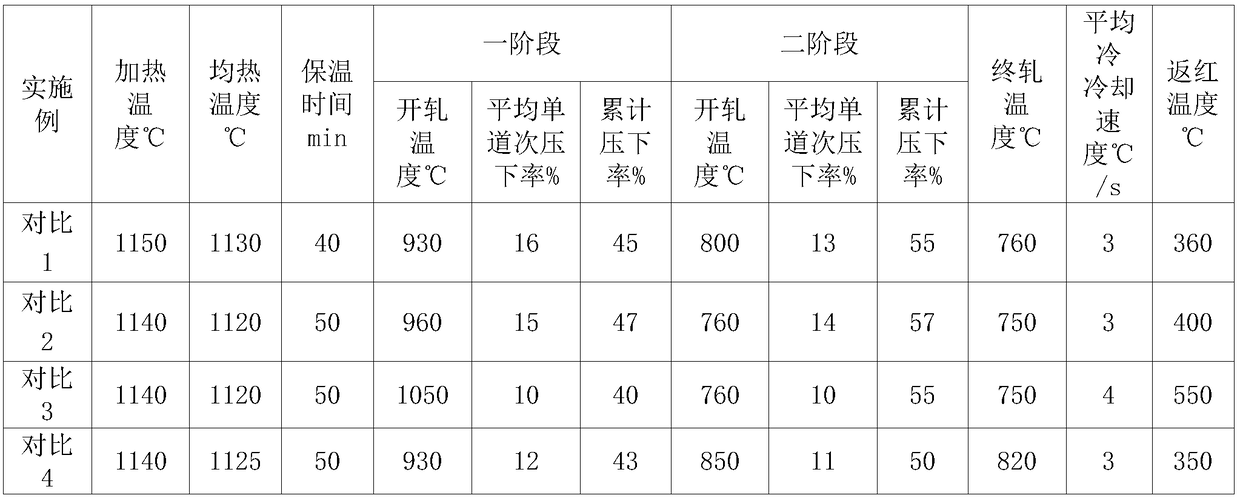

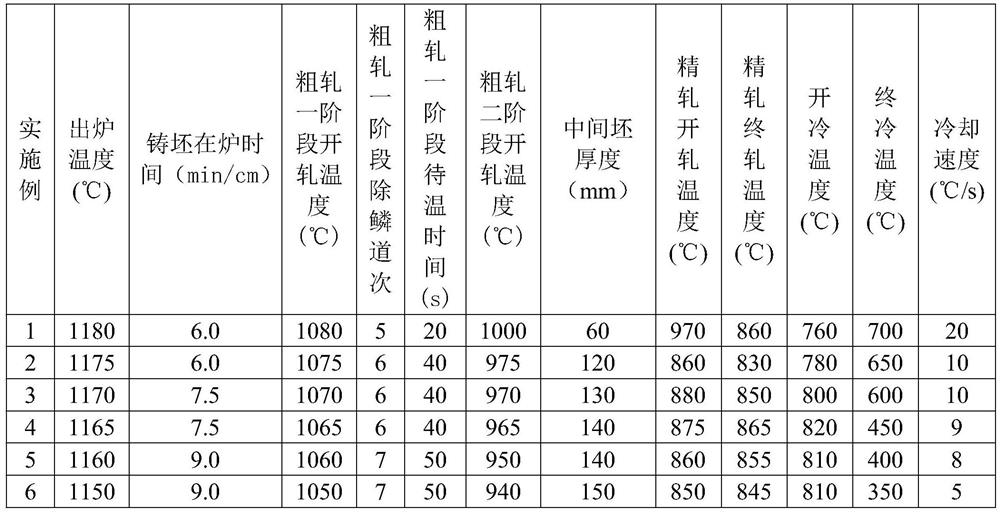

Rolling method for large-wall-thickness pipeline steel

InactiveCN107442568ASave labor costs and spare parts costsLow manufacturing costMetal rolling arrangementsCooling temperatureReduction rate

The invention discloses a method for rolling pipeline steel with large wall thickness, which includes the following process steps: (1) Heating: the continuous casting slab is heated by a walking beam heating furnace, and the preheating section is from room temperature at a rate of 4 to 5 min / cm heating speed, the temperature is controlled at 800~900°C; the heating speed of the heating section is controlled at 6~8min / cm, the temperature is controlled at 1160~1180°C; the temperature of the soaking section is controlled at 1160±20°C, and the holding time is 120~160 minutes; (2) Rolling: rough rolling, finish rolling temperature ≥ 980 ℃, middle billet thickness range 80~90mm, adopt large reduction system at the same time, after widening, there are 2 consecutive passes with reduction rate ≥ 25%; finish rolling, start rolling The temperature is 830°C, the final rolling is 720~740°C, and the rolling is two passes; cooling, the starting cooling temperature is 690~710°C, the cooling speed is 15~18°C / S, and the final cooling is 380~420°C. A pipeline steel with a large wall thickness of 30.8mm, a pipe diameter of 1422mm, and a steel grade of X80 with excellent crack arrest performance was produced by using a billet with a cross-sectional size of 260mm×2280mm. Compared with the TMCP+OLT process, the manufacturing cost is reduced, that is, the online tempering cost is saved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

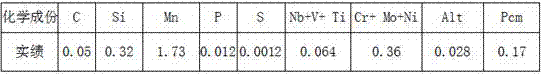

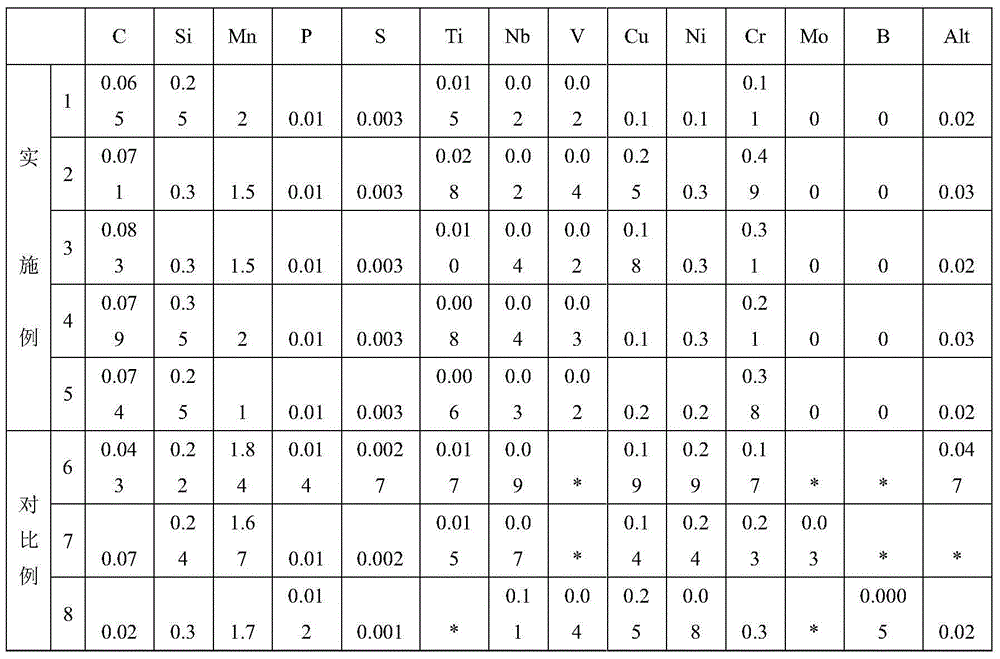

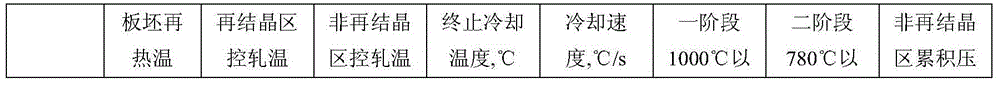

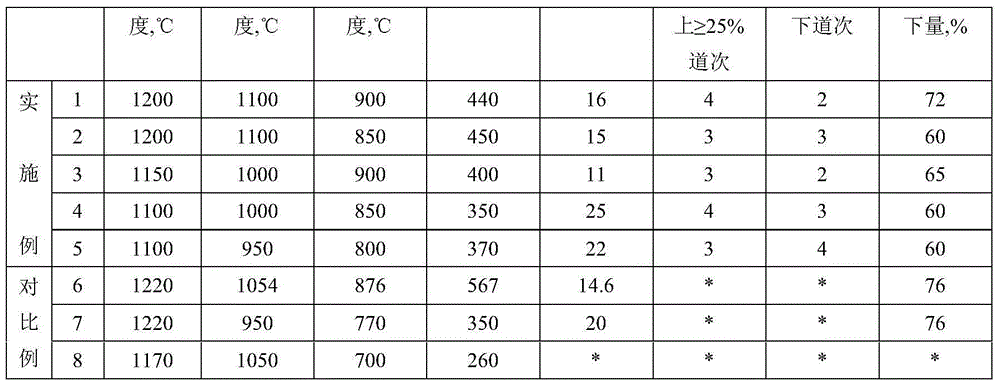

Low-cost X80 pipeline steel and manufacturing method thereof

InactiveCN104561825AGood welding performanceImprove crack arrest performanceTemperature control deviceImpurityCooling temperature

Low-cost X80 pipeline steel and a manufacturing method thereof are disclosed. The steel comprises following components by weight: 0.065-0.085% of C, 1.0-2.0% of Mn, 0.25-0.35% of Si, 0.10-0.25% of Cu, 0.10-0.30% of Ni, 0.10-0.50% of Cr, 0.02-0.04% of Nb, 0.005-0.03% of Ti, 0.02-0.04% of V, 0.02-0.06% of Alt, not more than 0.006% of Ca, not more than 0.015% of P, not more than 0.003% of S and not more than 0.012% of N, with the balance being Fe and trace unavoidable impurities. A hot rolling process is controlled as follows: a slab heating temperature is 1100-1200 DEG C, a recrystallization zone rolling temperature is 900-1150 DEG C, a non-recrystallization zone rolling temperature is 700-950 DEG C, a finish rolling temperature is 700-800 DEG C, a finish cooling temperature is 350-450 DEG C, and a cooling speed is 10-25 DEG C / s. Advantages and effects of the steel and the method are that: the adding amount of alloy elements is reduced, and the steel and the method have advantages of low cost, good production efficiency, good product comprehensive performance, and the like.

Owner:ANGANG STEEL CO LTD

Superhigh strength X100 pipeline steel and its hot rolled plate making process

ActiveCN100398684CHas construction costsReduce construction costsTemperature control deviceCooling temperatureImpurity

The present invention relates to pipeline steel, and is especially one kind of superhigh strength X100 pipeline steel and process of making hot rolled plate of the X100 pipeline steel. The superhigh strength X100 pipeline steel consists of C 0.015-0.080 wt%, Mn 1.80-2.50 wt%, Si not more than 0.6 wt%, S not more than 0.0030 wt%, P not more than 0.015 wt%, Nb 0.04-0.15 wt%, Ti 0.005-0.030 wt%, V not more than 0.120 wt%, Alt not more than 0.060 wt%, N not more than 0.010 wt%, O not more than 0.006 wt%, Mo 0.10-0.60 wt%, Cu not more than 0.50 wt%, Ni not more than 1.50 wt%, Cr not more than 1.0 wt%, B not more than 0.0020 wt%, Ca not more than 0.01 wt%, and Fe and inevitable impurity for the rest. The rolling process of making hot rolled plate has plate blank heating temperature of 1100-1250 deg.c, final rolling temperature of 720-880 deg.c, final cooling temperature of 200-500 deg.c and cooling speed of 3-30 deg.c / s.

Owner:BAOSHAN IRON & STEEL CO LTD

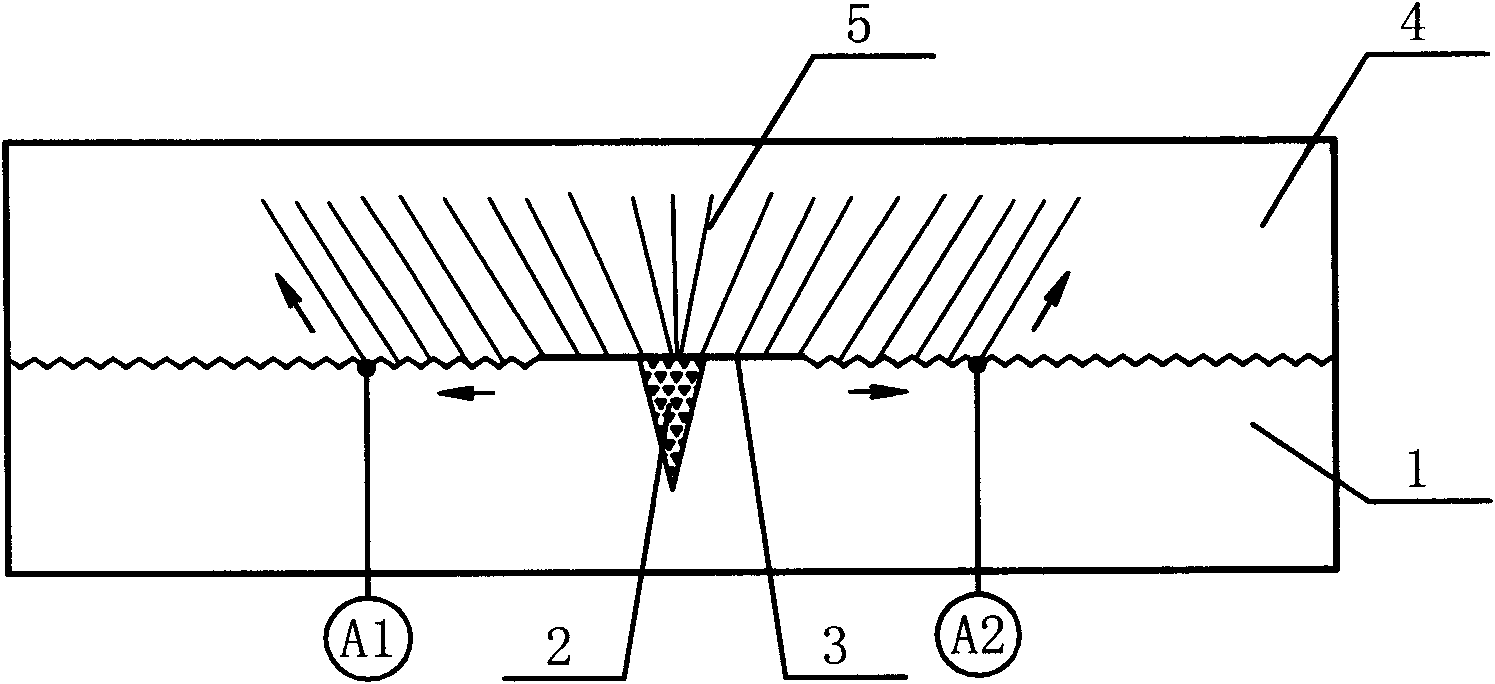

Segmental welding method for butt welding of raw material band steel joint plates of high-frequency straight welding tube

The invention provides a segmental welding method for butt welding of raw material band steel joint plates of a high-frequency straight welding tube. The method comprises the following steps of: segmenting: dividing a welding segment and a non-welding segment according to the width of raw material belt steel; and welding: when the tail part of the last reel of raw material band steel is left after the raw material band steel is input on a welding tube production line, unreeling the next reel of raw material band steel and leading the head part of the next reel of raw material band steel, undercutting and shearing the head and the tail of the raw material band steel to be neat and aligned, and then welding the segmented welding segment, wherein the welding method of carbon dioxide gas arc welding or manual arc welding is adopted for the butt welding of the raw material band steel. The segmental welding method provided by the invention has the advantages that no welding seams or weldingflashes exist so that the phenomenon of surface scratch of a tube blank is not generated, the surface quality of a welded tube meet a standard requirement of a qualified welded tube, the first pass yield of the welded tube is improved, the service life of a roller is prolonged, continuous production can be maintained, no losses in operation time is ensured, the consumption of welding materials isdecreased by 1 / 3, meanwhile, partial electric consumption is lowered.

Owner:天津市宝来工贸有限公司

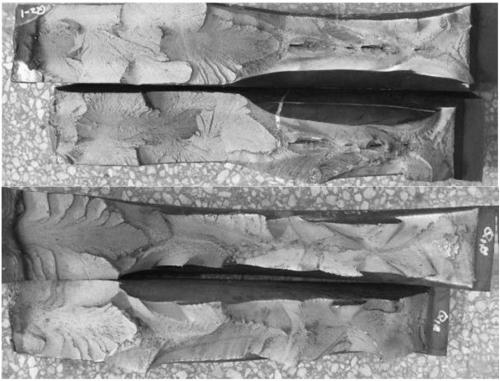

A method for crack arrest of ductile fracture of natural gas pipeline

ActiveCN102261564AReduce construction proceduresImprove crack arrest abilityPipeline systemsSteel tubeGas industry

The invention relates to a method for arresting ductile fracture of natural gas pipelines of level X100 and above, wherein two or more fracture arresting steel pipes, which are relatively low in strength level but relatively high in wall thickness and toughness, are connected among X100 or higher-level steel pipes at intervals of 50-100 steel pipes and by a length within a range of 600-1200 m; and the wall thickness of the fracture arresting steel pipe is calculated according to pressure bearing capacity the same as that of a main pipeline, while the toughness thereof is determined by a method recommended in Petroleum and Natural Gas Industries-Steel Pipe for Pipeline Transport System ISO 3183: 2007 and the appendix G of Pipeline Steel Pipe Standards (Version 44) API Spec5L: 2007. The manufacturing technical difficulty and the manufacturing cost of the fracture arresting steel pipe with low strength level and high toughness are low, and the toughness index thereof is easy to achieve, so that the safety requirements of the pipeline fracture arrest are met, and unification of safety and economical efficiency is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low-alloy hot rolling rolled plate for bending machining and preparing method of low-alloy hot rolling rolled plate

The invention belongs to the technical field of steel materials, and particularly relates to a low-alloy hot rolling rolled plate for bending machining and a preparing method of the low-alloy hot rolling rolled plate. Chemical components of the rolled plate comprise, by weight percent, 0.08%-0.12% of C, 0.40%-0.60% of Mn, 0.040%-0.060% of Ti, smaller than or equal to 0.30% of Si, smaller than or equal to 0.010% of S, smaller than or equal to 0.025% of P, smaller than or equal to 0.0070% of N, and the balance Fe and inevitable impurities, and the rolled plate is prepared through the technologyprocess of molten iron pretreatment, top and bottom combined blowing converter smelting, LF refining, continuous casting, heating furnace heating, rough rolling, fine rolling, laminar cooling and curling. The disclosed low-alloy hot rolling rolled plate for bending machining has the beneficial effects of excellent crack arrest performance, good uniform plasticity and the like, the usage requirement of a user for cracking avoiding during bending machining can be met, and meanwhile compared with the production cost of Q345B steel in the prior art, the production cost of the low-alloy hot rollingrolled plate is relatively maintained to be consistent.

Owner:ANYANG IRON & STEEL

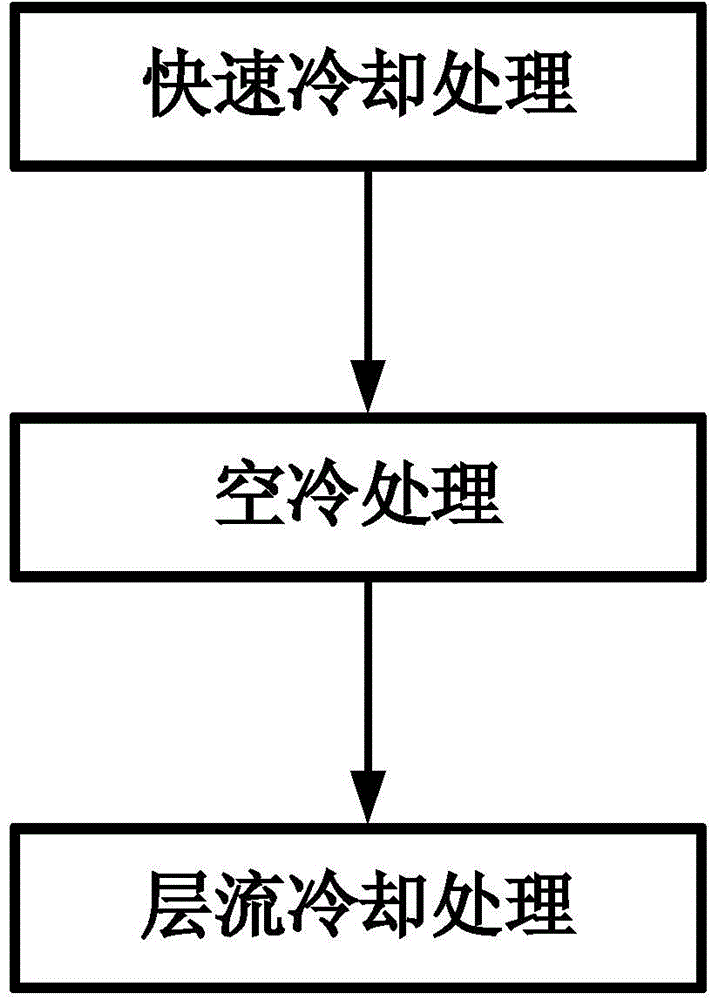

Thick-specification pipeline steel cooling method

InactiveCN104694719AHigh precisionReduce temperature gradient effectsFurnace typesHeat treatment furnacesAir coolingMaterials science

The invention discloses a thick-specification pipeline steel cooling method which is mainly used for cooling thick-specification pipeline steel with the thickness of more than 12.0mm subjected to heating, dephosphorization, rough rolling, head / tail flying shear cutting, dephosphorization and finish rolling. The method comprises the following steps: quick cooling, air cooling and laminar cooling. The method can further integrally enhance the toughness of the thick-specification pipeline steel.

Owner:攀钢集团西昌钢钒有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com