Thick steel plate with excellent rack arrest property and preparation method of thick steel plate

A technology of thick steel plate and high performance, which is applied in the field of steel manufacturing, can solve the problems of small temperature gradient, deterioration of welding performance, and increase of cost, and achieve the effects of excellent crack arrest performance, improved core toughness, and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

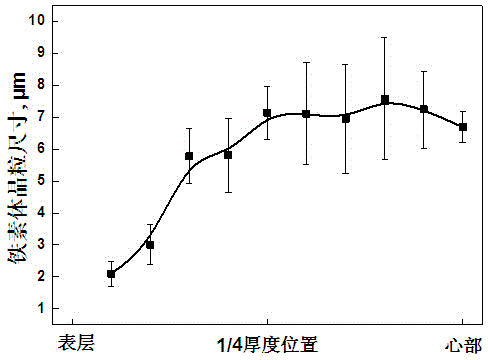

Embodiment 1

[0025] The chemical composition of the thick steel plate with excellent crack arrest performance in this example is microalloy steel, and the specific composition is: C 0.13%, Si 0.39%, Mn 1.5%, P 0.014%, S 0.002%, Al 0.039%, Nb 0.034%, V 0.031%, Ti 0.016%, N 0.0032%, and the balance is Fe; its metallographic microstructure is based on ferrite, the second phase is pearlite, and the average grain size of ferrite in the center of thick steel plate Size ≥ 8 μm, grain boundary density of large angle grain boundaries ≥ 0.407 μm -1 Above, the upper and lower surfaces of the thick steel plate are ultra-fine-grained layers, the thickness of the single-sided ultra-fine-grained layer is ≥0.1 times the plate thickness, the average ferrite grain size of the ultra-fine-grained layer is ≤3 μm, and the grain boundary density of the large-angle grain boundary is ≥ 0.676μm -1 .

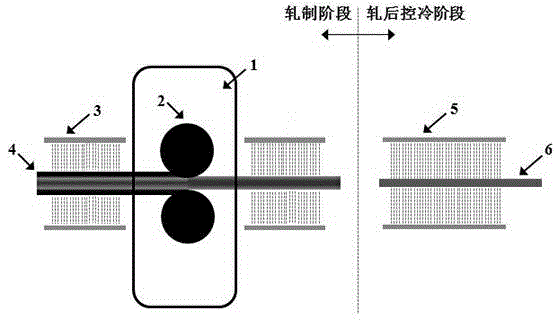

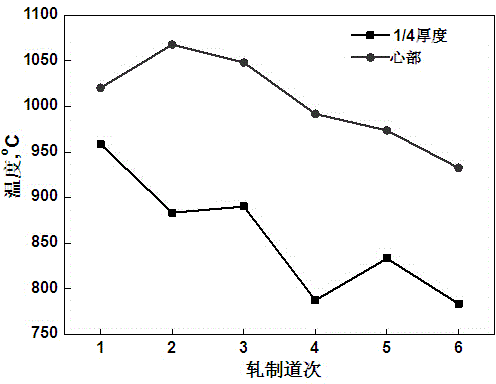

[0026] The manufacturing method of the thick steel plate with excellent crack arrest performance of the present i...

Embodiment 2

[0034] The chemical composition of the thick steel plate with excellent crack arrest performance in this example is microalloy steel, and the specific composition is: C 0.04%, Si 0.49%, Mn 1.0%, P 0.014%, S 0.002%, Al 0.039%, N 0.0098%, Mo 0.045%, Cr 0.56%, Ni 0.54%, and the balance is Fe; its metallographic microstructure is based on ferrite, the second phase is pearlite, and the average grain size of ferrite in the center of thick steel plate Size ≤ 8μm, grain boundary density of large angle grain boundary ≥ 0.407μm -1 Above, the upper and lower surface layers of the thick steel plate are ultra-fine-grained layers, the thickness of the single-sided ultra-fine-grained layer is ≥0.1 times the plate thickness, the average ferrite grain size of the ultra-fine-grained layer is ≤3 μm, and the grain boundary density of the large-angle grain boundary is ≥ 0.676μm -1 .

[0035] The manufacturing method of the thick steel plate with excellent crack arrest performance of the present ...

Embodiment 3

[0041] The chemical composition of the thick steel plate with excellent crack arrest performance in this example is ordinary carbon steel, and the specific composition is: C 0.20%, Si 0.23%, Mn 2.0%, P 0.014%, S 0.002%, Al 0.039%, N 0.002%, the balance is Fe; its metallographic microstructure is based on ferrite, the second phase is pearlite, and the average grain size of ferrite in the center of thick steel plate ≤ 8μm, the grain boundary density of the large angle grain boundary is ≥0.407μm -1 Above, the upper and lower surface layers of the thick steel plate are ultra-fine-grained layers, the thickness of the single-sided ultra-fine-grained layer is ≥0.1 times the plate thickness, the average ferrite grain size of the ultra-fine-grained layer is ≤3 μm, and the grain boundary density of the large-angle grain boundary is ≥ 0.676μm -1 .

[0042] The manufacturing method of the thick steel plate with excellent crack arrest performance of the present invention, such as figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com