Patents

Literature

372results about How to "Raise the temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

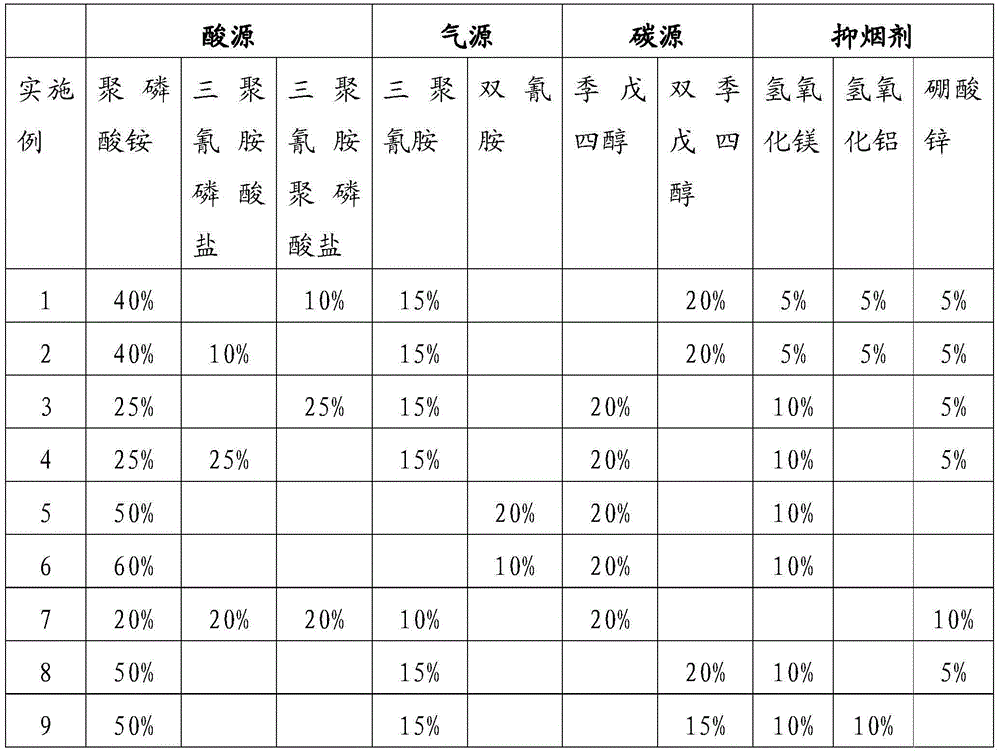

Composite intumescent flame retardant and preparation method thereof

InactiveCN104532588AReduce generationImprove flame retardant performanceFibre typesMelamine phosphateAluminium hydroxide

The invention discloses a composite intumescent flame retardant which is composed of the following components in percentage by weight: 50-65% of acid source, 10-20% of gas source, 15-20% of carbon source and 10-20% of smoke inhibitor. The acid source is composed of at least one of ammonium polyphosphate, melamine phosphate and melamine polyphosphate, wherein the ammonium polyphosphate is crystal II ammonium polyphosphate with the average degree of polymerization of greater than 1000; the gas source is composed of at least one of melamine and dicyandiamide; the carbon source is composed of at least one of pentaerythritol and bis pentaerythritol; and the smoke inhibitor is composed of at least one of magnesium hydroxide, aluminum hydroxide and zinc borate. The invention also discloses a preparation method of the composite intumescent flame retardant.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

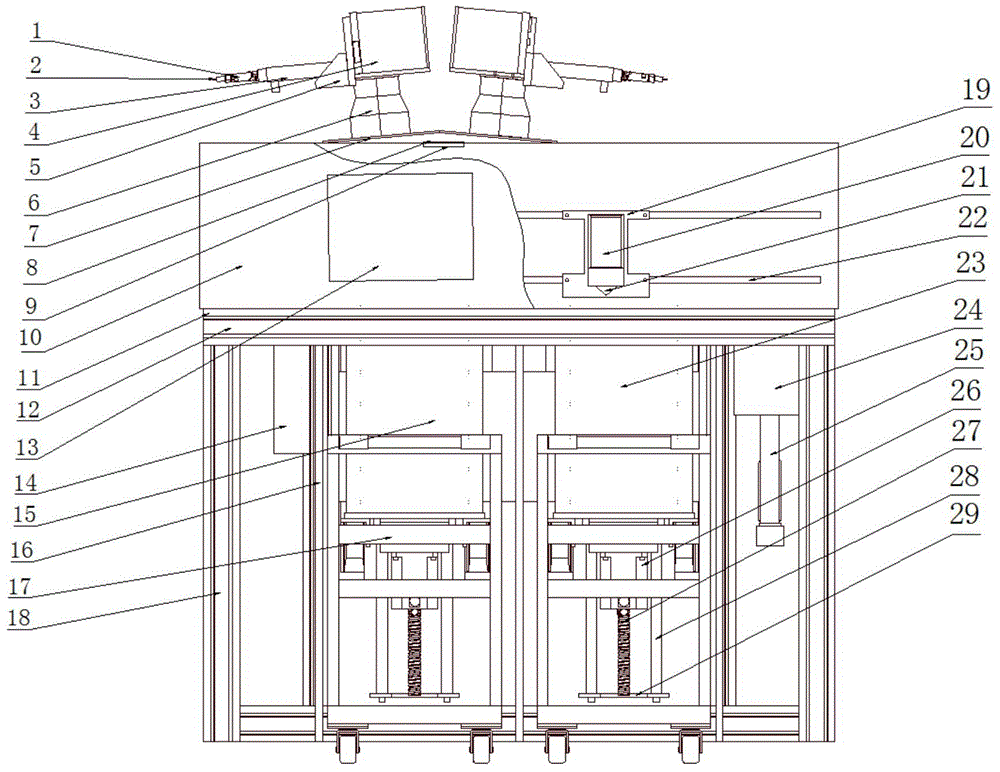

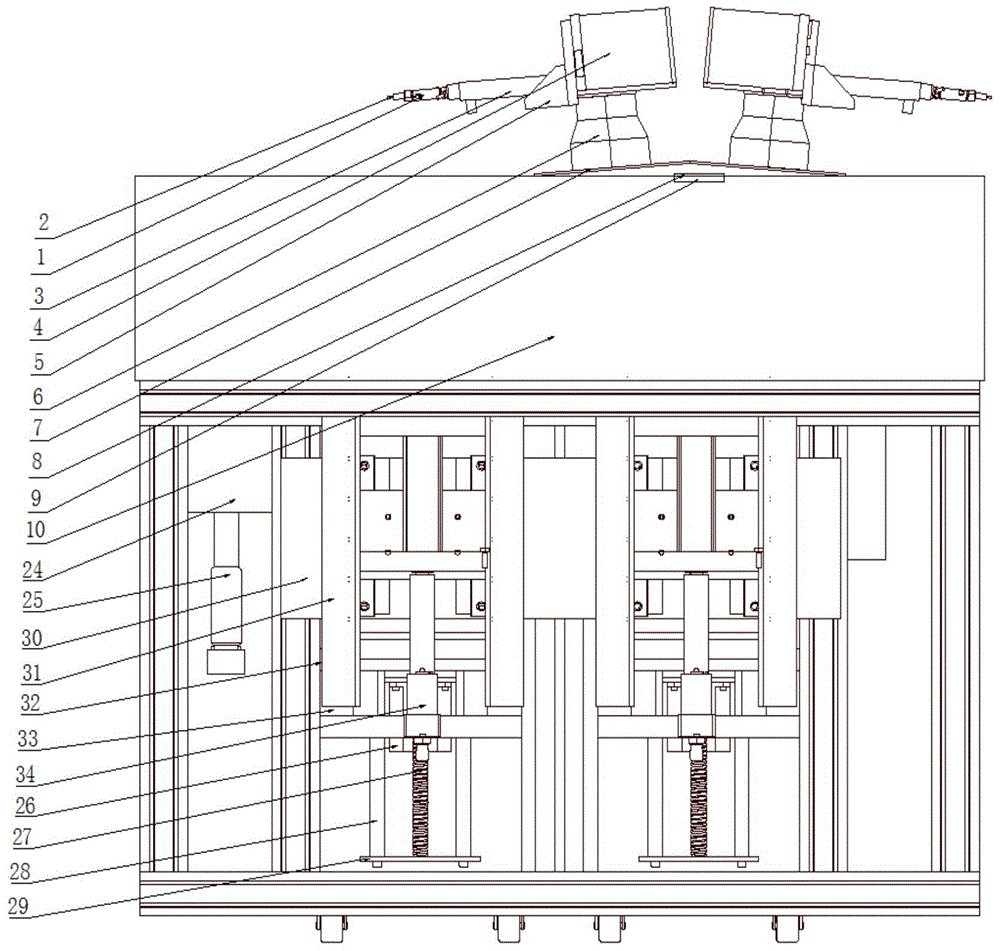

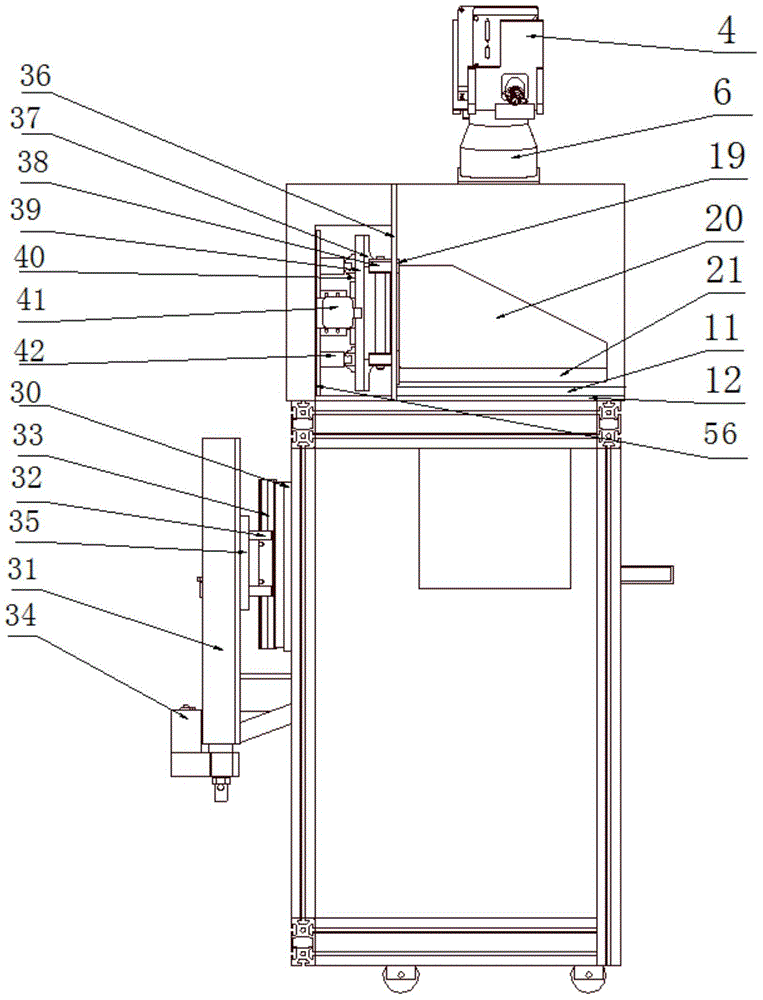

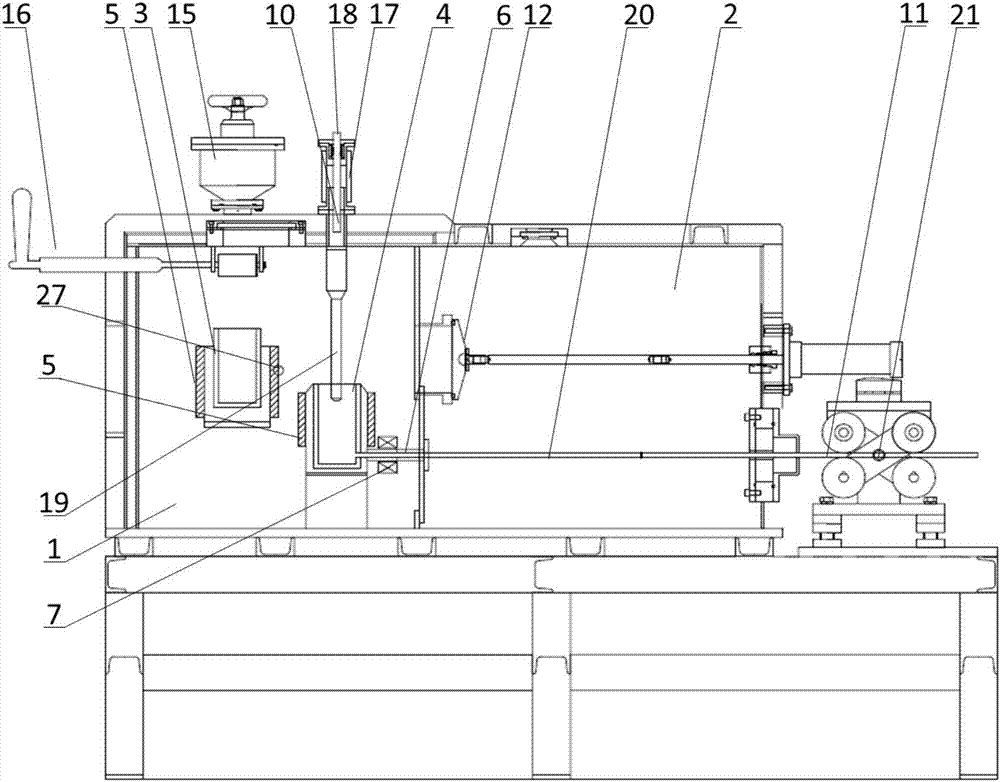

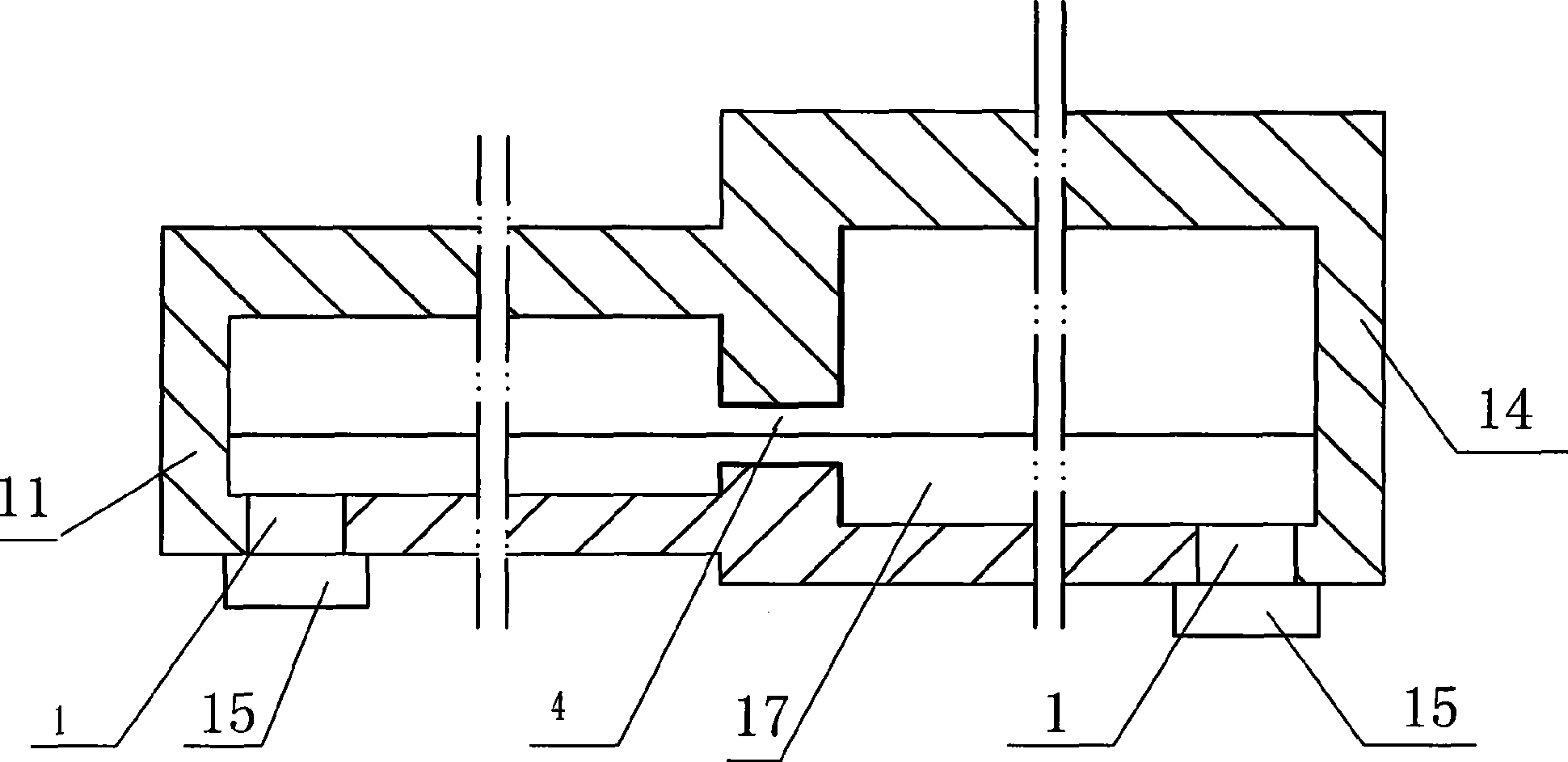

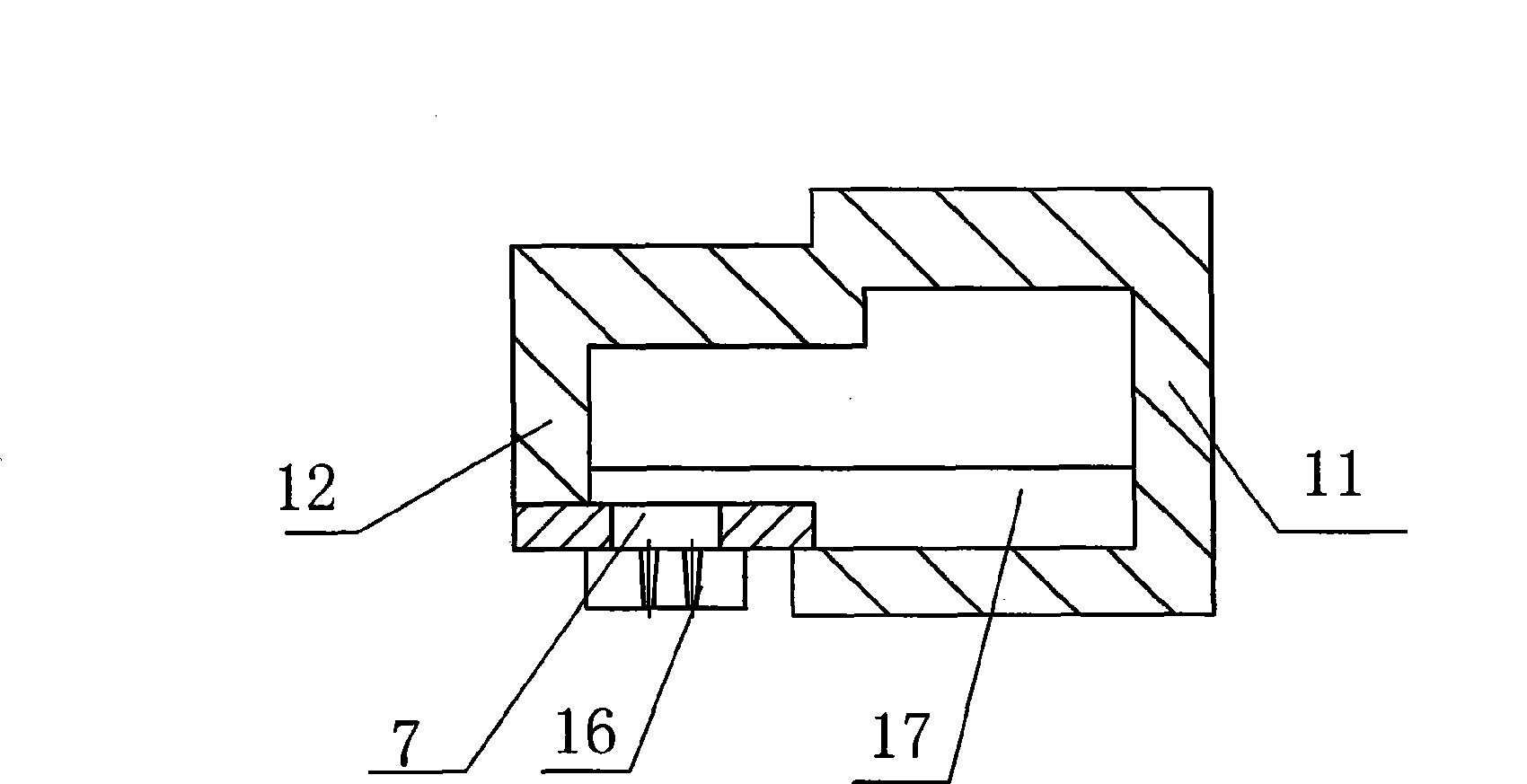

Dual-beam laser selective melting and moulding equipment with exchangeable powder cylinder

ActiveCN105039970AEasy to replaceImprove absorption rateMetallic material coating processesDual beamLight beam

The invention discloses dual-beam laser selective melting and moulding equipment with an exchangeable powder cylinder. The equipment comprises two optical systems, a frame, a workbench plate, a powder feeding cylinder, a powder storage cylinder, a moulding cylinder, a powder returning cylinder, a moulding cavity, and two first driving mechanisms, which are used to respectively drive the moulding cylinder and powder feeding cylinder to move up and down. The workbench plate is fixed on the frame, the moulding cavity is fixed on the upper surface of the workbench plate, and the powder returning cylinder, the moulding cylinder, the powder feeding cylinder, and powder storage cylinder are fixed on the lower surface of the workbench plate from left to right in sequence. A scraper is arranged in the moulding cavity, and a second driving mechanism is arranged on the frame. A substrate is arranged in the powder feeding cylinder, a substrate is arranged in the moulding cylinder, the lower ends of the powder feeding cylinder and the moulding cylinder are both provided with a cylinder end cover, and the substrates are connected to a first piston system. A second piston system is arranged in the powder storage cylinder. The provided equipment has a high moulding efficiency and is capable of effectively reducing the deformation and cracking of members.

Owner:XI AN JIAOTONG UNIV

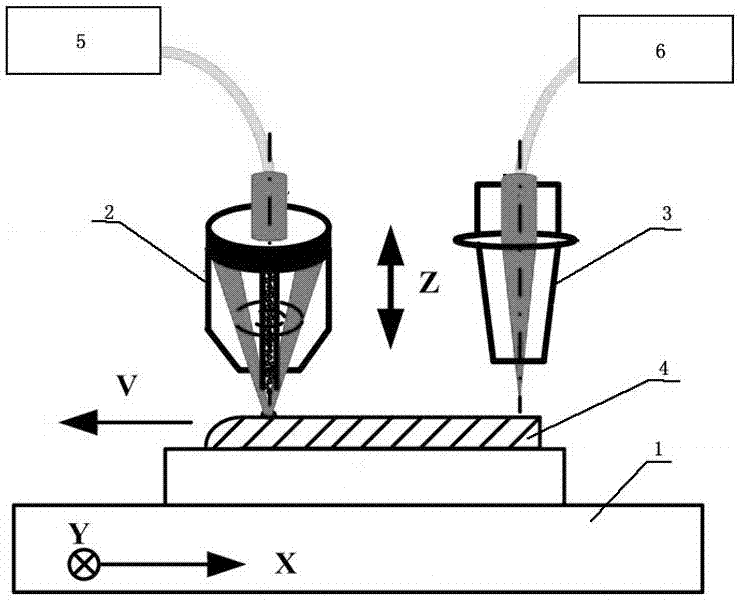

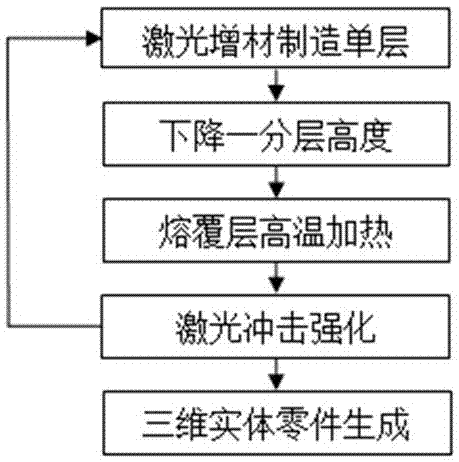

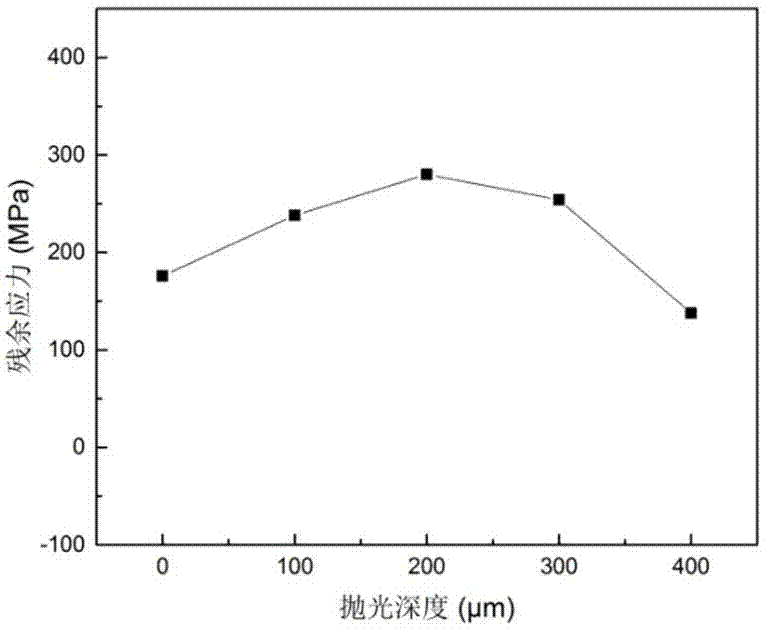

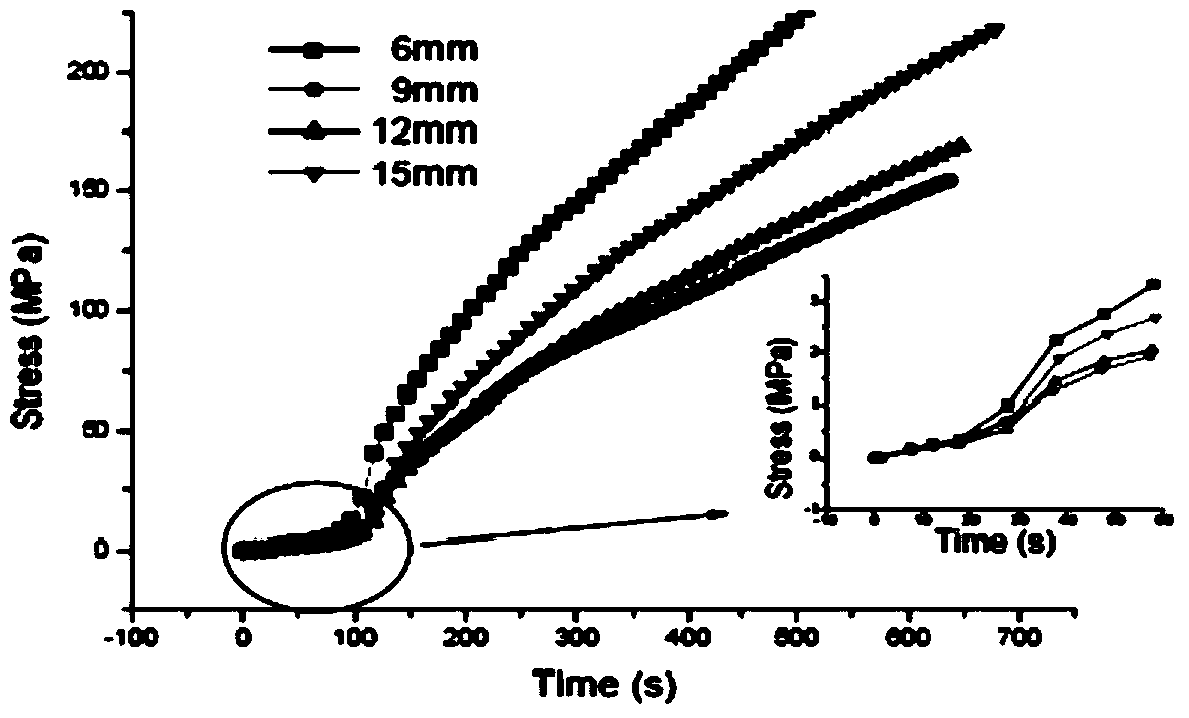

Method for adjusting/reducing internal stress of laser additive manufacturing part

InactiveCN107225244AIncreased tendency to crackImprove impact performanceAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInternal stress

The invention discloses a method for adjusting / reducing the internal stress of a laser additive manufacturing part. The method is used for laser coaxial powder feeding additive manufacturing, and comprises the following steps that (1) a three-dimensional additive manufacturing part model is established, and contour level information of the part is obtained; (2) a workbench is moved to a fusion covering station, and coaxial powder feeding laser additive manufacturing is conducted through a fusion covering head, and after processing of a fusion covering layer is completed, the workbench is descended by the height of one layer; (3) the workbench is moved to an impacting station, bulk heating is conducted on the fusion covering layer, after the fusion covering layer reaches the set temperature, laser impacting and strengthening are conducted on the fusion covering layer through an impacting head, and the set temperature is higher than the recrystallization temperature of a material and lower than the melting point of the material; and (4) the steps (2) and (3) are conducted repeatedly till the three-dimensional part is manufactured. According to the method, the residual compressive stress introduced by the laser impacting and strengthening technology is utilized to adjust and counteract the pulling stress in the hot melting process, and the laser thermal composite additive manufacturing method controllable in internal stress is achieved.

Owner:KUSN BAOJIN LASER TAILOR WELDED

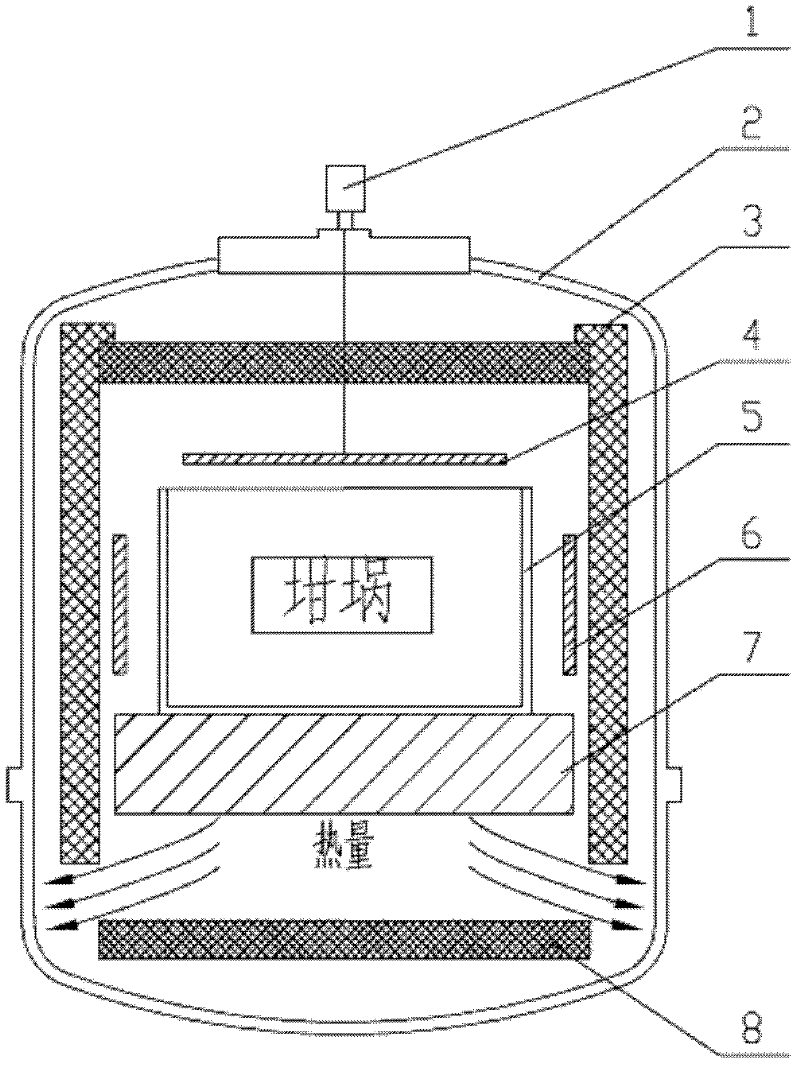

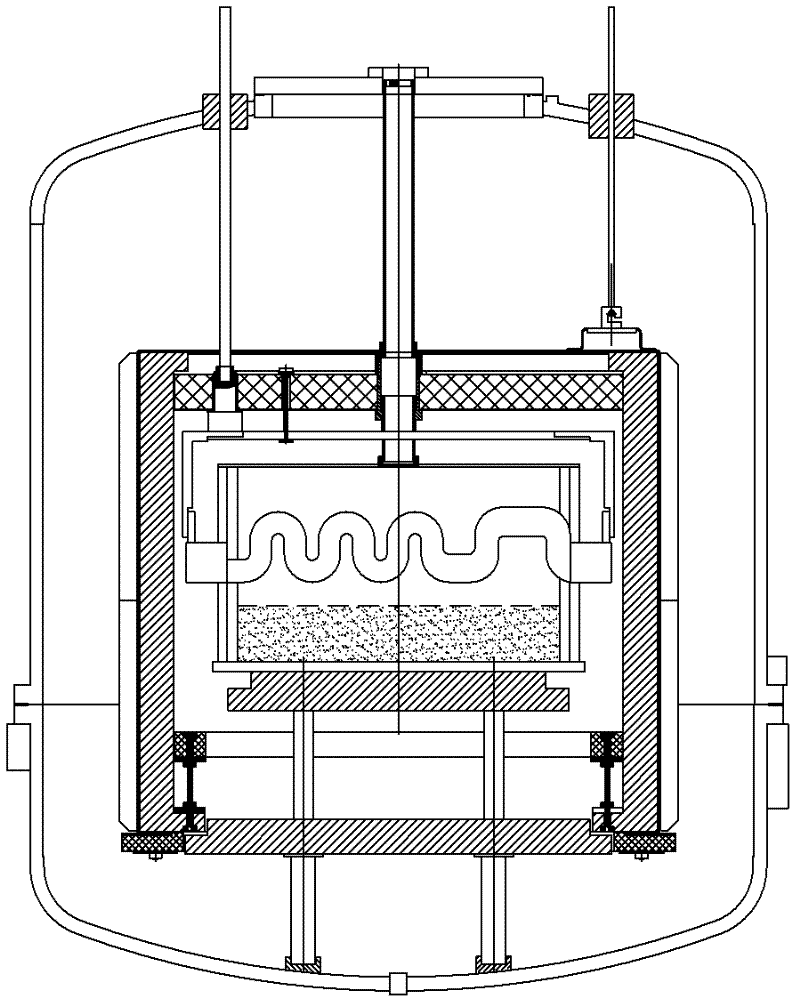

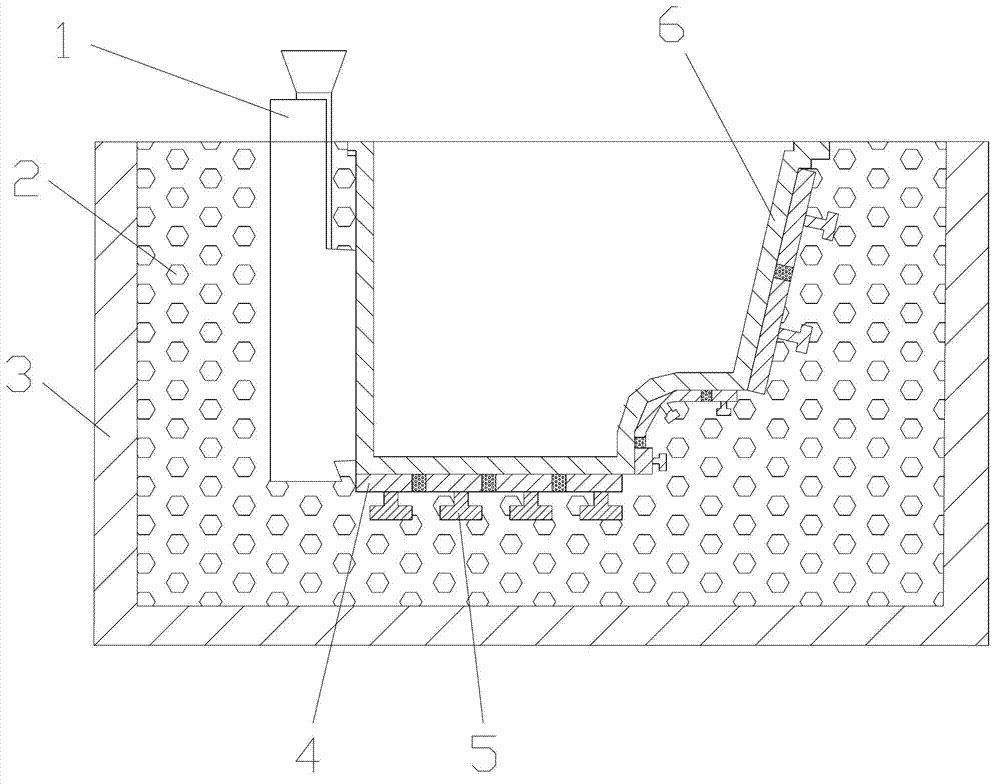

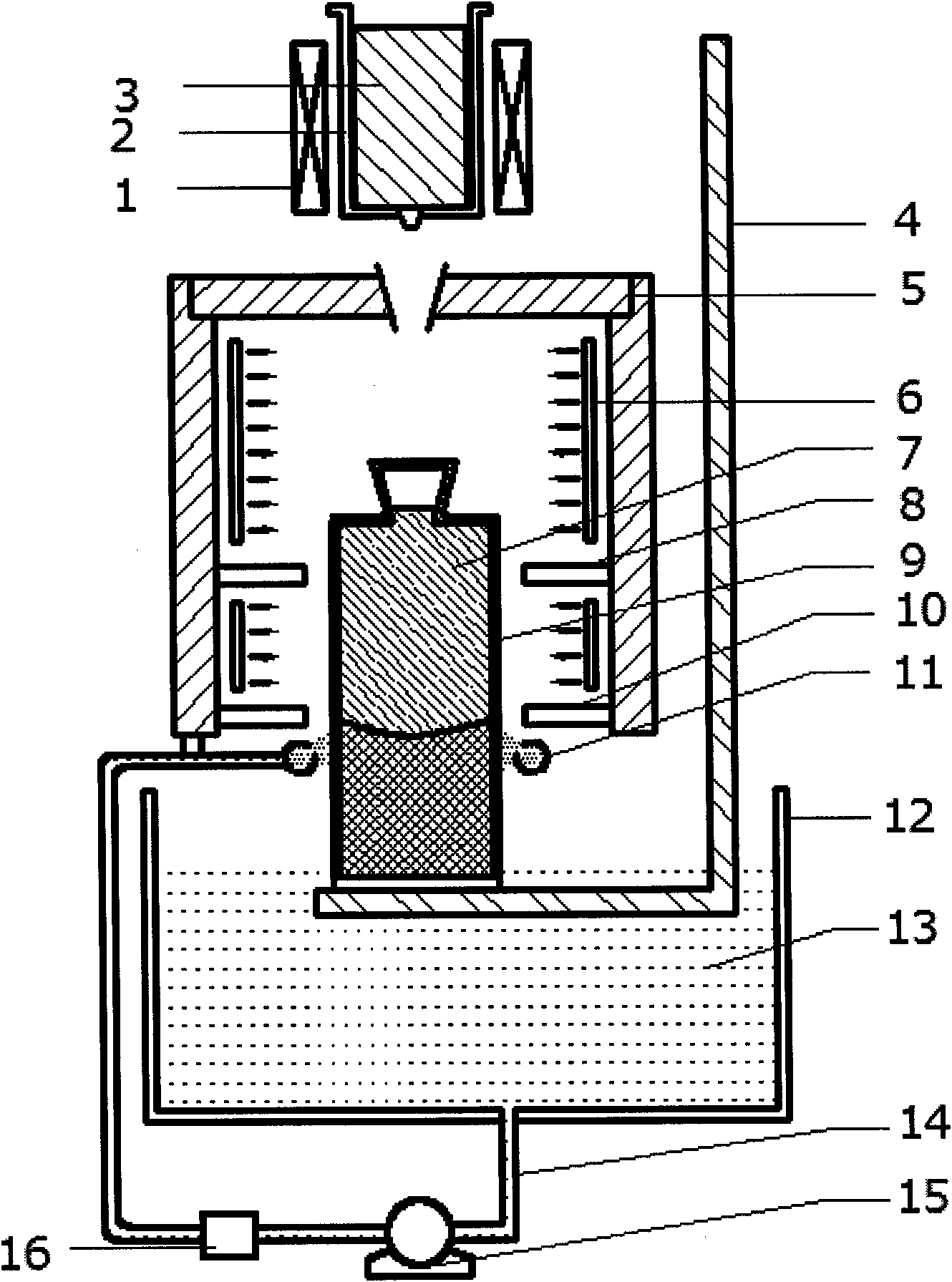

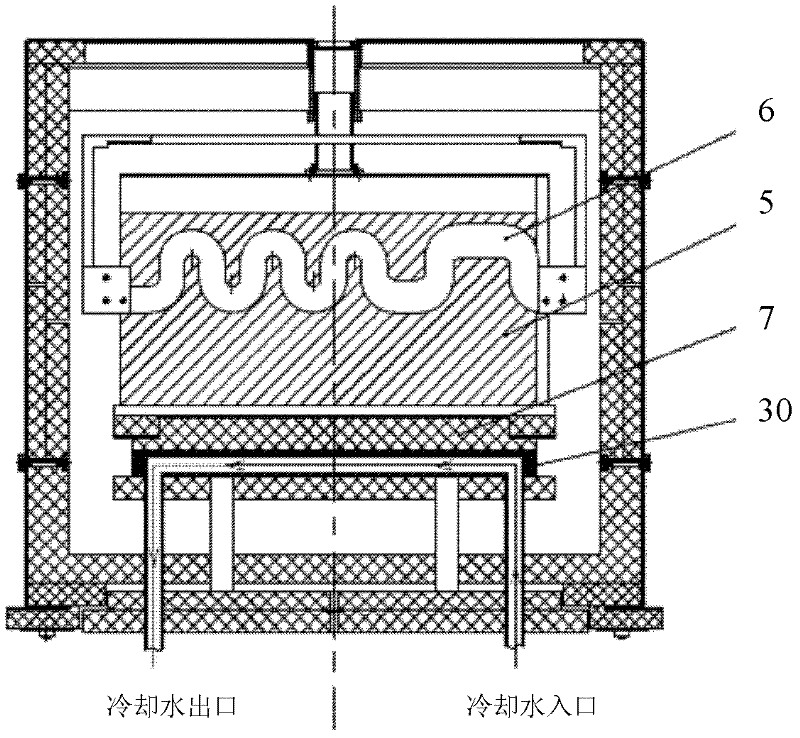

Closed cooling system of gas cooled polysilicon ingot furnace

ActiveCN102234837APrecise temperature controlEasy to controlPolycrystalline material growthSingle crystal growth detailsNuclear engineeringCrucible

The invention relates to the manufacture technical field of polysilicon ingot furnaces, and aims to provide a closed cooling system of a gas cooled polysilicon ingot furnace. The system comprises a heat exchange platform positioned on a supporting column and used for placing a crucible, wherein a cooling gas channel is arranged in the heat exchange platform; a gas inlet and a gas outlet at two ends of the cooling gas channel are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline; and the heat exchange platform, the cooling gas inlet pipeline, the cooling gas outlet pipeline, a cooling gas power pump group and a cooler form a closed circulation loop of the cooling gas. Compared with the cooling method of radiation cooling and water cooling, the system related by the invention has strong gas cooling control capacity and high industrial controllability; the gas is fed into the heat exchange platform evenly, so that the whole temperature of the heatexchange platform is even, which is in favor of even nucleation of a silicon melt at the bottom of the crucible; and the reducing speed of the temperature at the bottom of the crucible can be precisely controlled during the crystal growth.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL +1

Manufacturing method of ceramic mold of monocrystal turbine blade

ActiveCN103464690AImprove heat transfer performanceSolve complex and uncontrollable heat transfer problemsFoundry mouldsCeramic shaping apparatusLeading edgeTurbine blade

The invention discloses a manufacturing method of a ceramic mold of a monocrystal turbine blade. The integral ceramic mold with a special spiral crystal selector is designed and manufactured according to grain orientation requirements of the monocrystal turbine blade. When orientated solidification is used for manufacturing the monocrystal blade, the thickness of a shell at an abrupt change in a section (such as a connecting part between a blade body and a marginal plate) is increased, and the heat transfer capacity is reduced, so that crystal defects such as stray crystals are caused easily. On the premise that the casting strength requirements are met, with the adoption of topological optimization and design of a heat transfer passage, the heat transfer capacity of the mold is improved, and a temperature gradient on the leading edge of a solid-liquid interface during the orientated solidification is increased, so that the whole blade can obtain a good monocrystal organization.

Owner:XI AN JIAOTONG UNIV +1

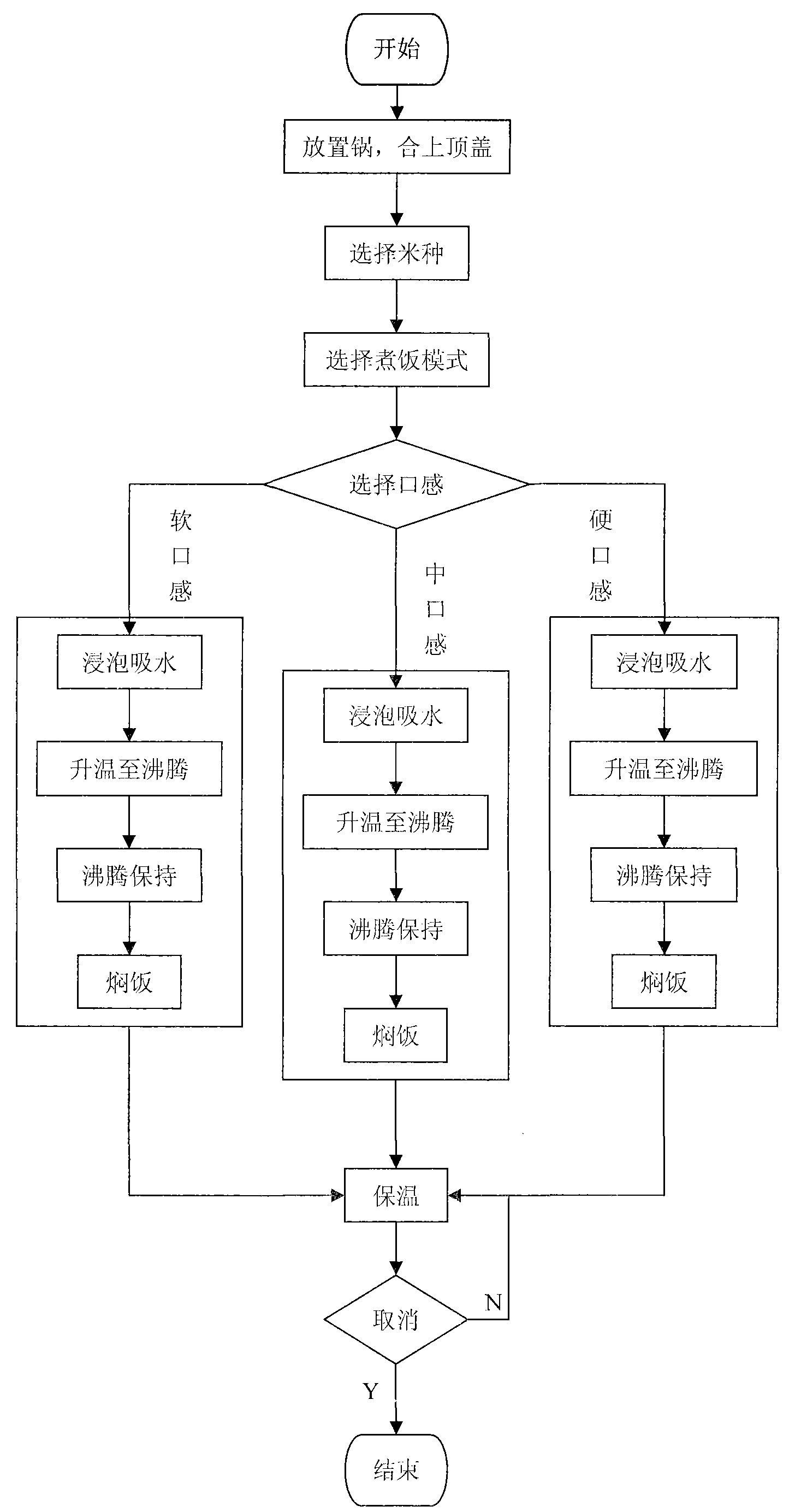

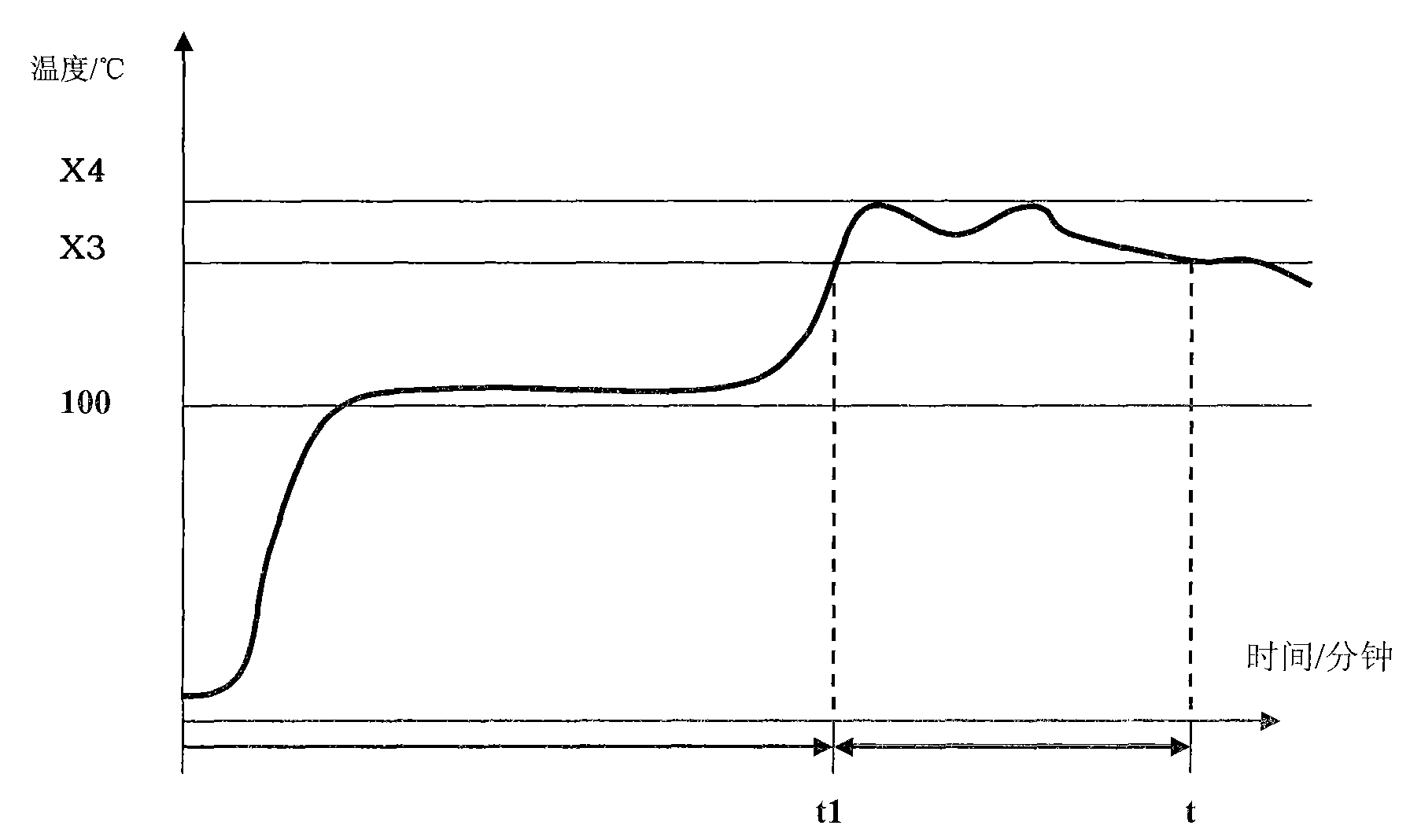

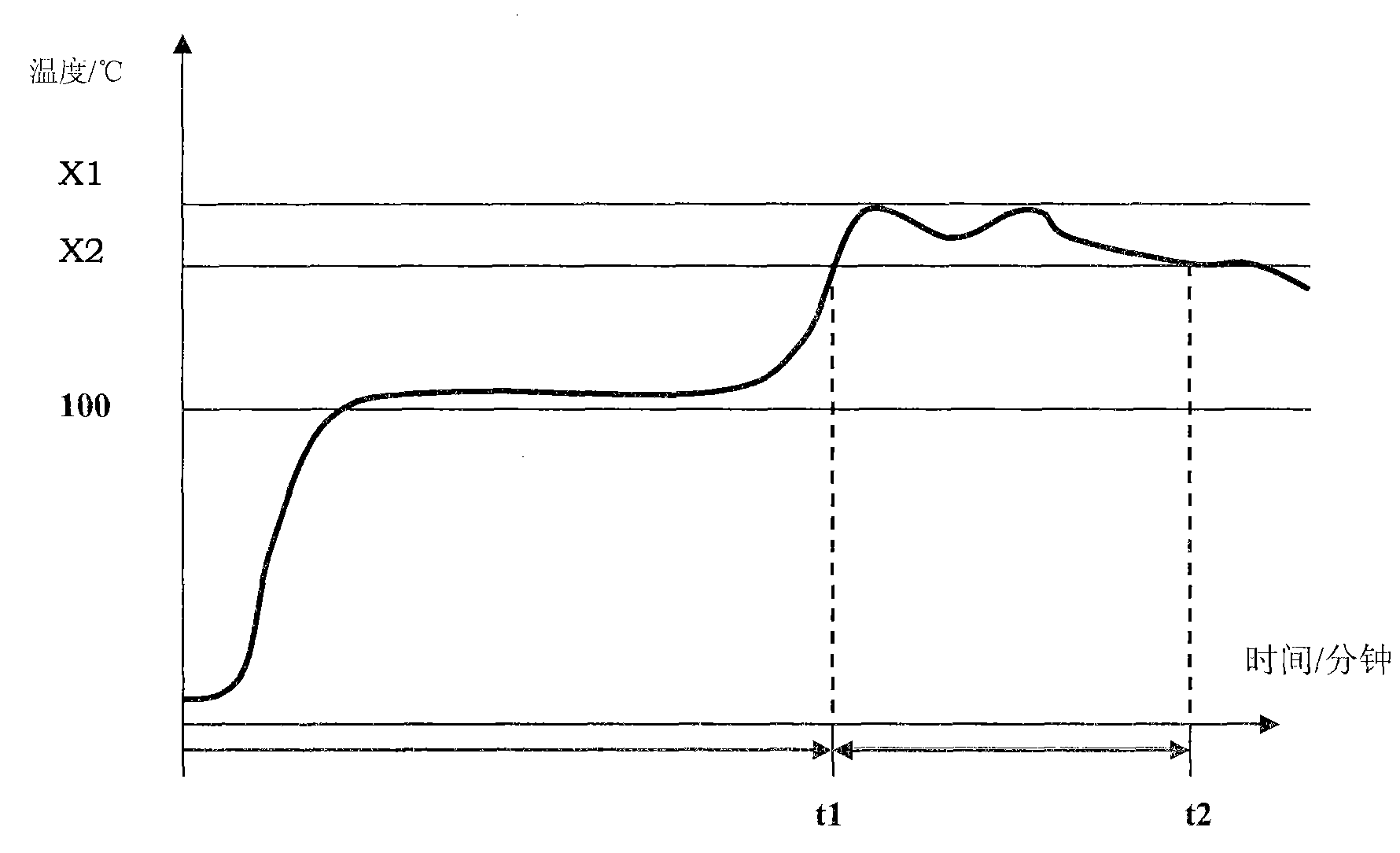

Method for controlling rice steaming and boiling of electric rice cooker

ActiveCN101587330ARaise the temperature gradientFully gelatinizedProgramme control in sequence/logic controllersWarming devicesRice dishesTemperature difference

The invention relates to a method for controlling the rice steaming and boiling of an electric rice cooker, which comprises the following steps: (1) confirming the boiling maintenance time t and the boiling maintenance temperature X of the electric rice cooker according to different rice kinds and mouth feeling; (2) starting the electric rice cooker and soaking, dewatering, heating and boiling rice according to a set procedure; (3) achieving the boiling maintenance temperature X= 130-165 DEG C after time t1=15-35 min and maintaining boiling in the electric rice cooker for the maintenance time t=6-10 min; and (4) cooking the rice after achieving the maintenance time t. The invention provides the method for controlling the rice steaming and boiling of the electric rice cooker, which controls the temperature and the time in the process of boiling maintenance, improves a temperature difference between the electric rice cooker and rice boiling, enables the rice to be fully gelatinized and enables water to be fully vaporized and absorbed by rice grains, thereby boiling the rice with high quality.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

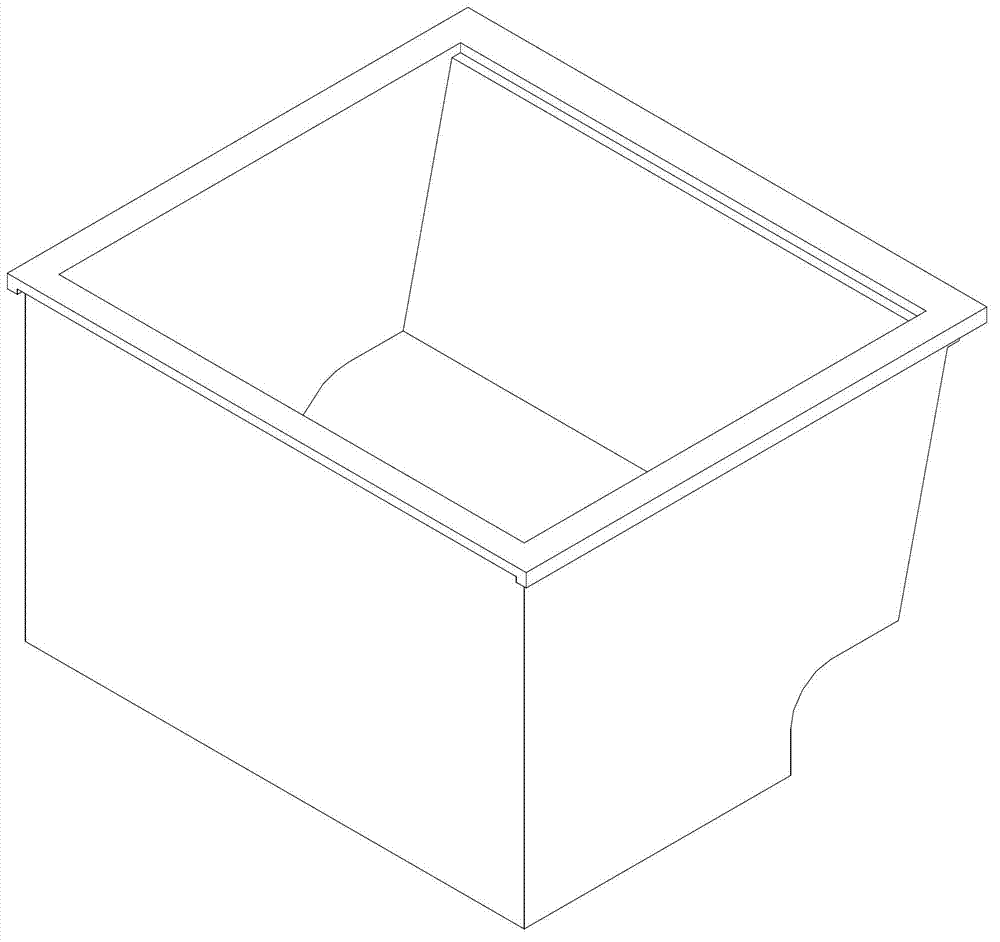

Method for manufacturing casting blank of die for inner containers of household appliances on basis of metal cavity with cold iron structure

InactiveCN102773409AQuality improvementImprove pass rateFoundry mouldsFoundry coresSurface finishFree cooling

The invention discloses a method for manufacturing a casting blank of a die for inner containers of household appliances on the basis of a metal cavity with a cold iron structure, and relates to the technical field of aluminum alloy casting. The method includes particular steps of constructing an outer cavity by cold iron blocks on the periphery of a manufactured wood mold in a form following manner; filling gaps among the cold iron blocks by clay sand, tightly filling the corresponding cold iron blocks by clay sand after each local structure is completed, and compacting a sand mould to prevent the cold iron blocks from moving; constructing a sand core of an inner cavity by the same method after the outer cavity is constructed; opening a case to take out the wood mould after the sand core of the inner cavity is manufactured so that a cavity of a casting is formed; drying the cavity of the casting and the sand core consisting of clay sand; preheating the cavity of the casting at the preheating temperature of 200 DEG C before pouring of the cavity of the casting; casting melted aluminum alloy into the cavity of the casting; and opening the case to take out the casting after the cavity of the casting is cooled naturally. The method is mainly used for casting the die for the inner containers of the household appliances, the surface of a casting product produced by the process is high in smoothness and does not have sand holes or pin holes after the surface of the casting product is treated in a follow-up machining process, and accordingly yield of molded inner container products is greatly increased.

Owner:CHUZHOU JINNUO INDAL

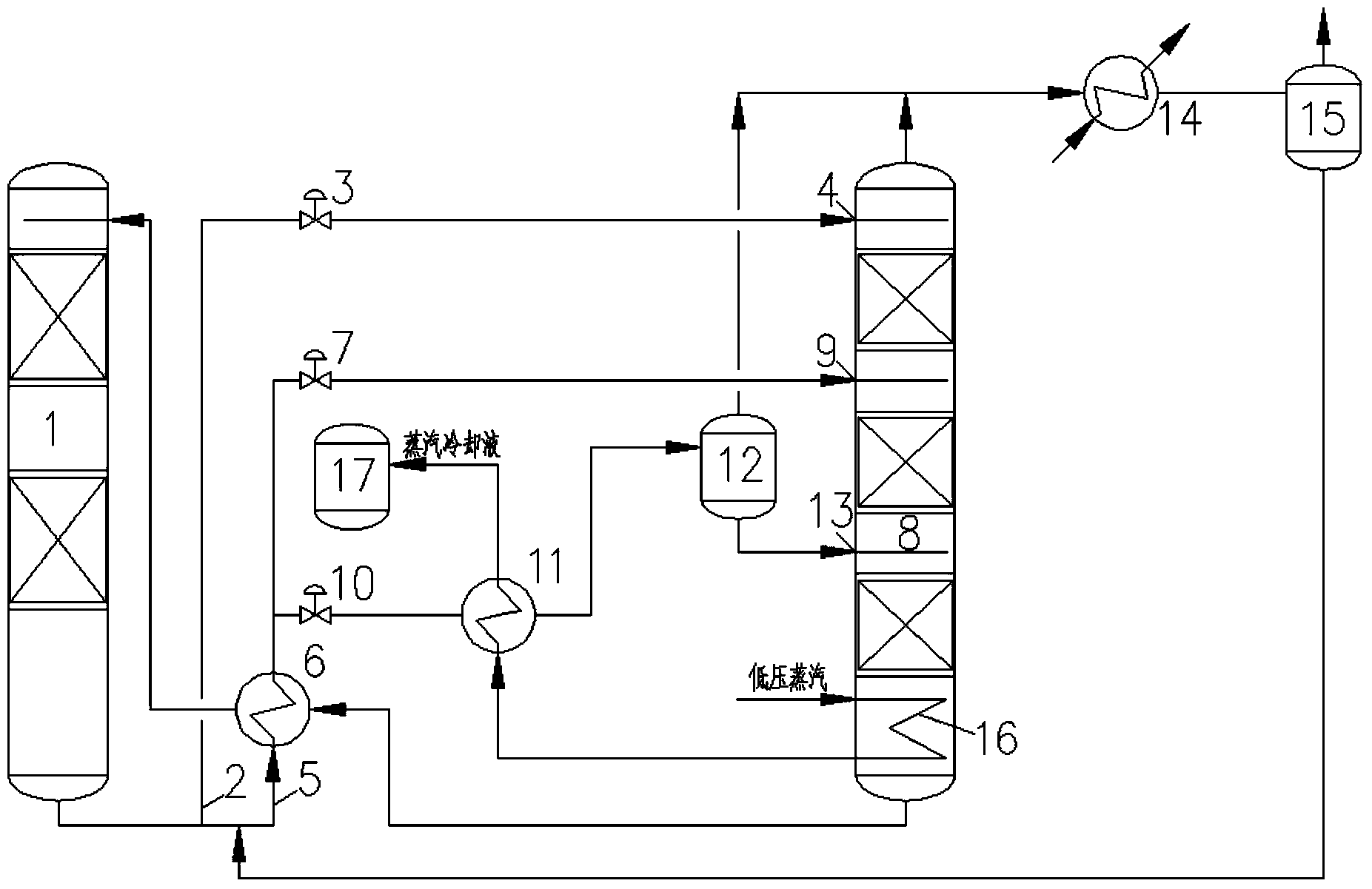

Multistage division regenerative carbon dioxide trapping system and technology

ActiveCN103961979APromote regenerationAbsorb thoroughlyDispersed particle separationSteam condensationTrapping

The invention relates to a multistage division regenerative carbon dioxide trapping system. The system comprises an absorption tower, wherein rich liquor that flows out of the absorption tower is divided into two channels; a first pipeline is communicated with a rich liquor inlet formed in the upper part of a regeneration tower; a second pipeline is communicated with the rich liquor inlet of a rich and poor liquid heat exchanger; rich liquor that flows out of the rich and poor liquid heat exchanger is further divided into two channels; one channel is communicated with a rich liquor inlet formed in the central part of the regeneration tower; the other channel is communicated with the rich liquor inlet of a rich liquor reheater; the rich liquor outlet of the rich liquor reheater is communicated with the rich liquor inlet of a rich liquor flash tank; the rich liquor outlet formed in the bottom of the rich liquor flash tank is communicated with a rich liquor inlet formed in the lower part of the regeneration tower. According to the invention, the regeneration degree of the rich liquor can be increased and steam heat consumption needed during rich liquor regeneration can be reduced; in addition, steam condensates can be recycled in the lyophobic collecting box of main equipment to reduce the desalted water consumption of the trapping system.

Owner:HUANENG CLEAN ENERGY RES INST

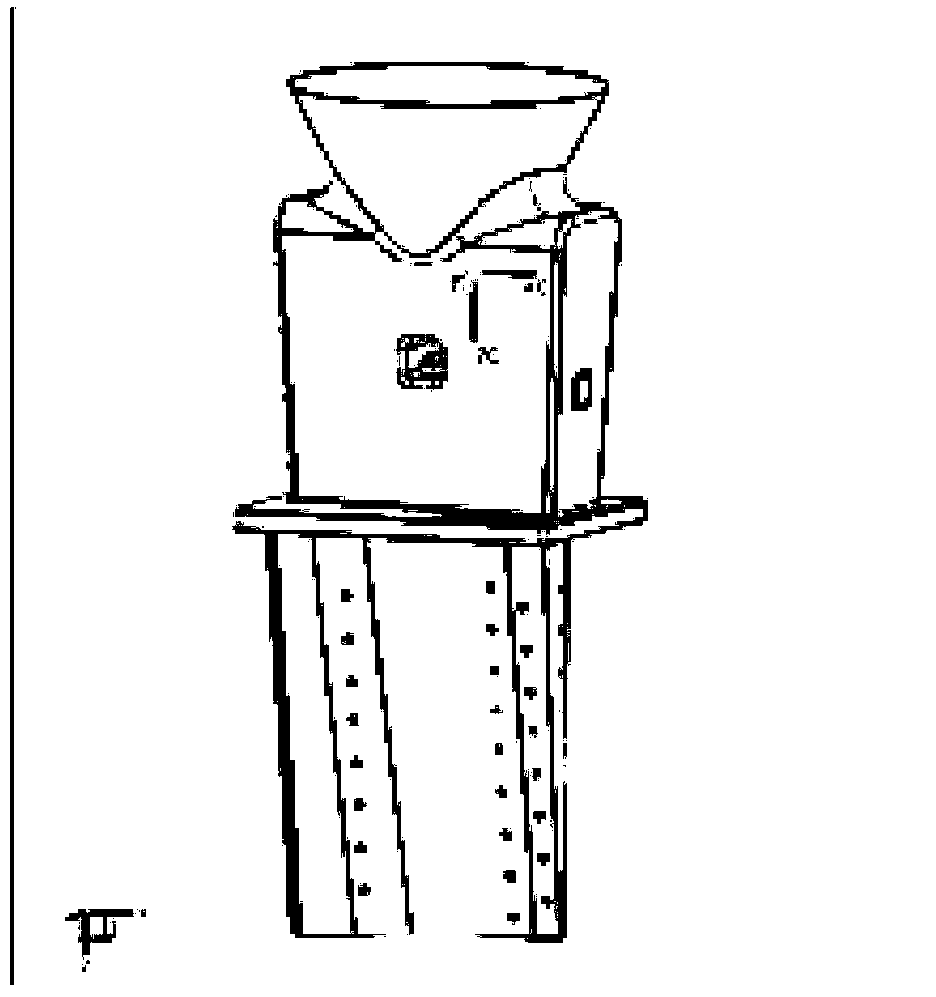

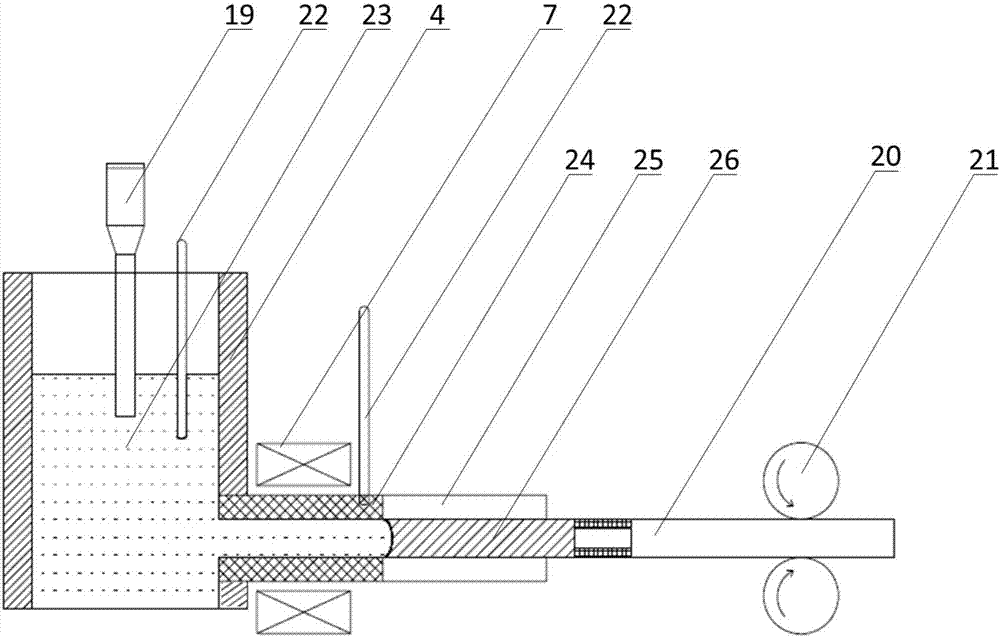

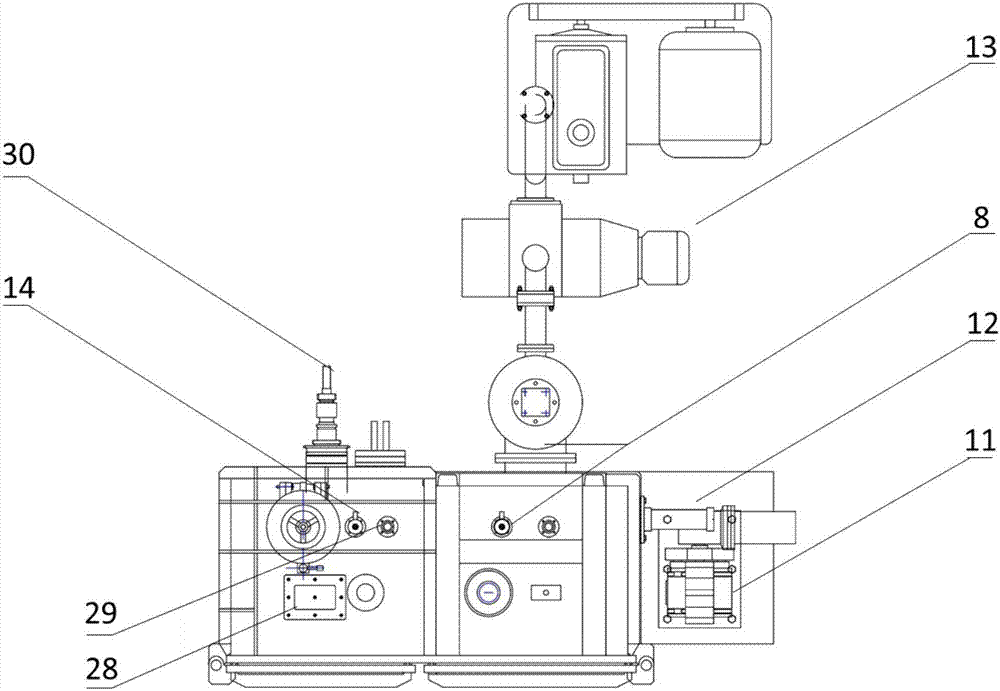

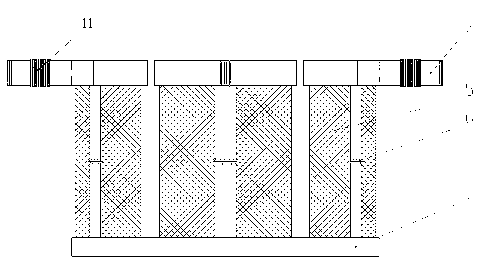

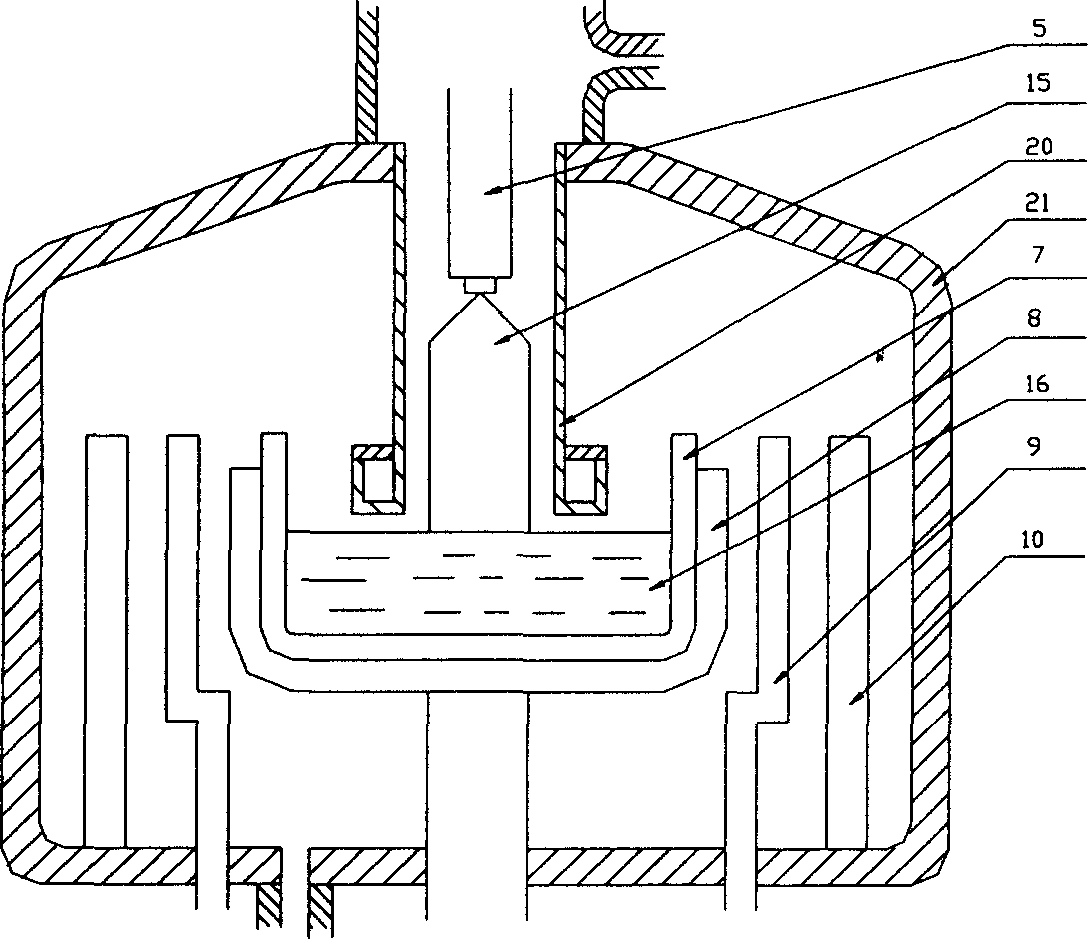

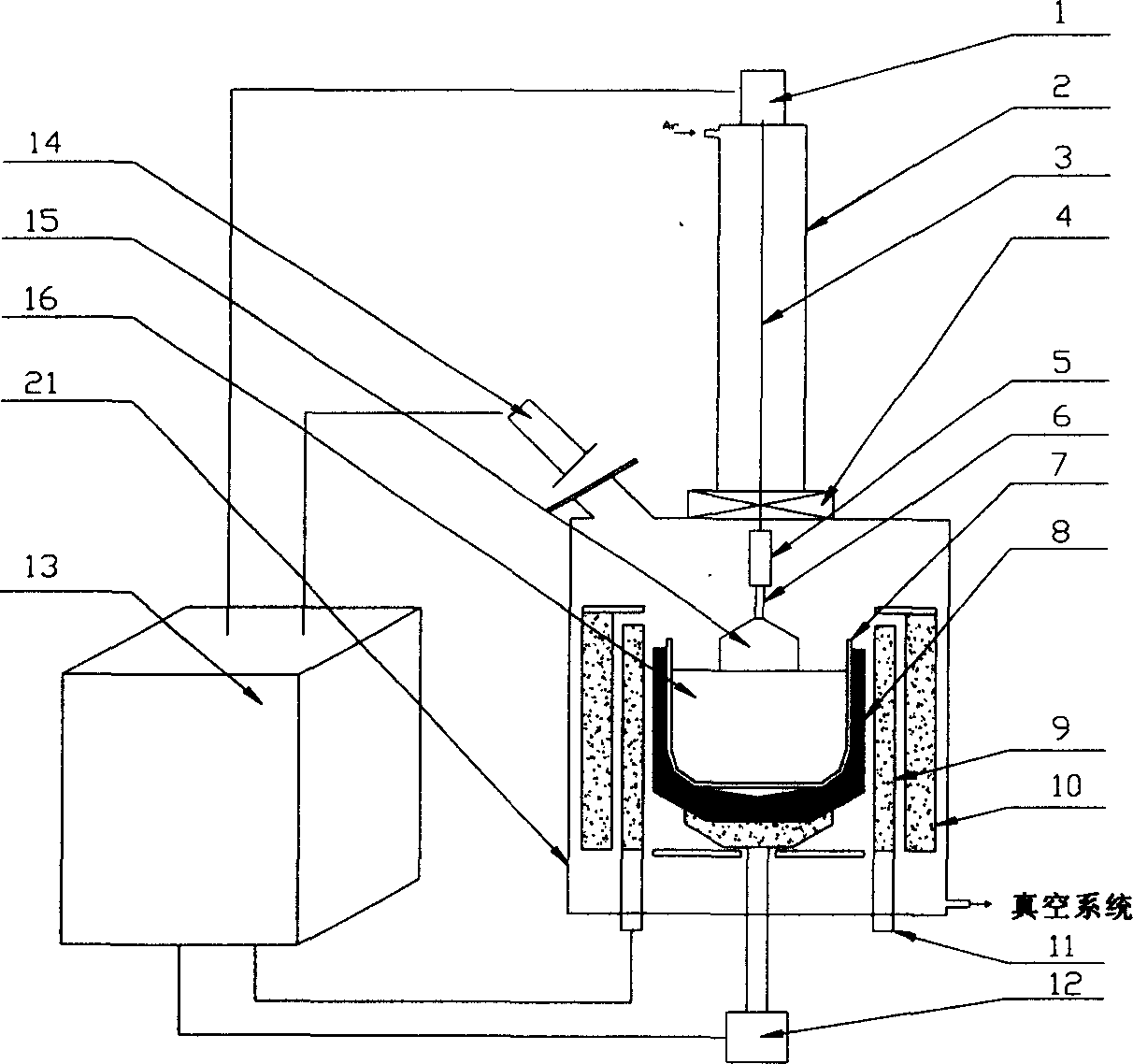

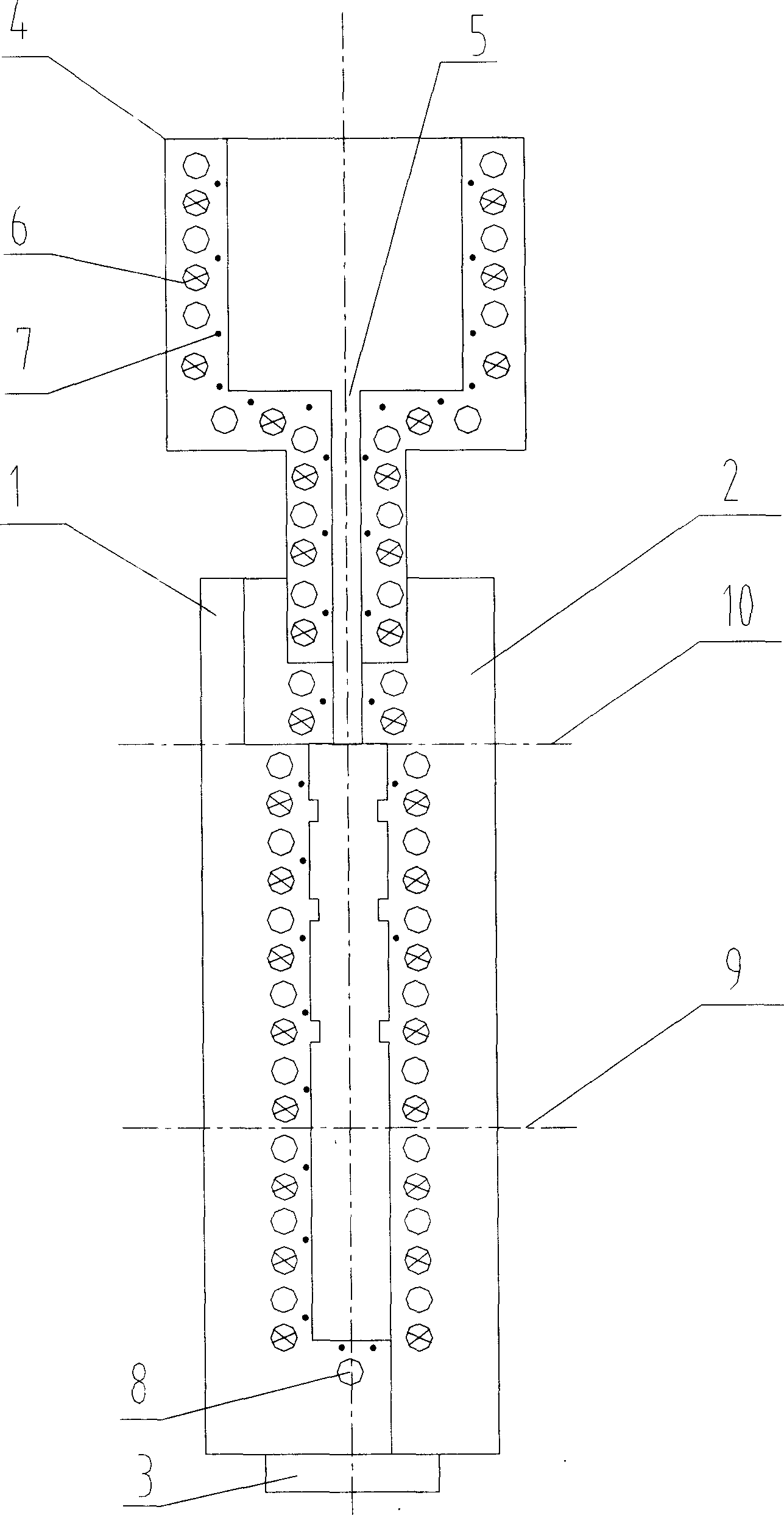

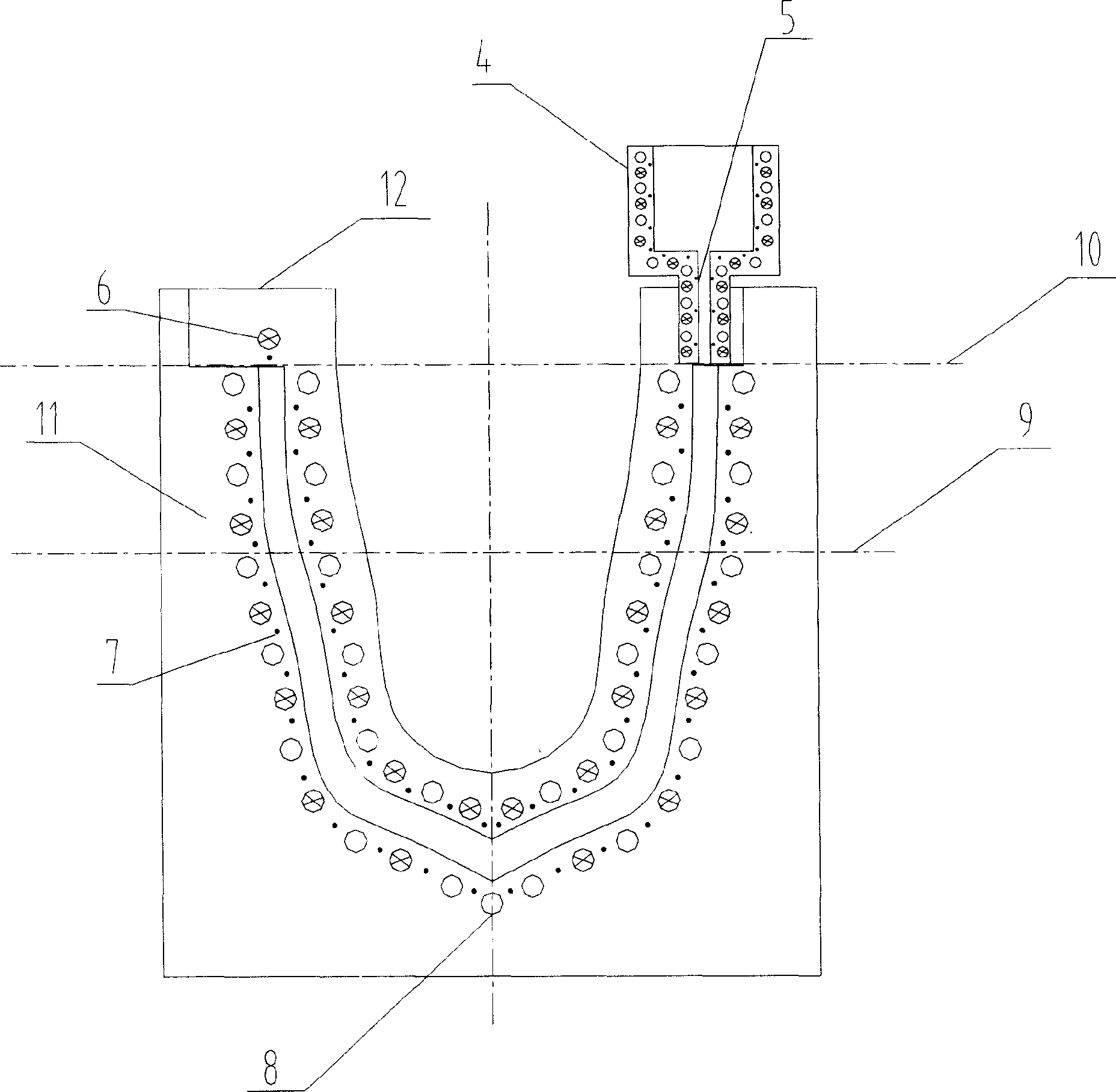

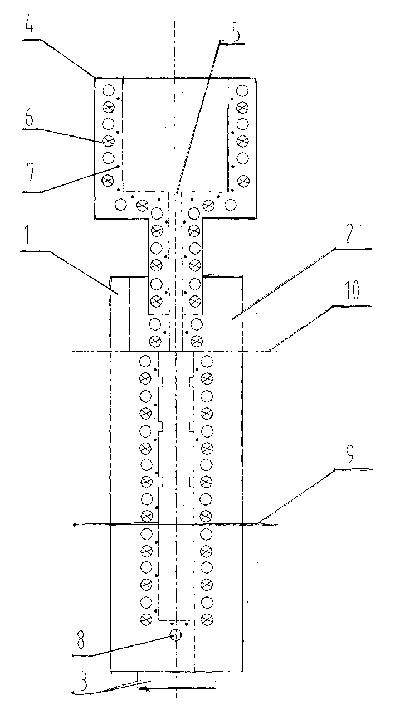

Integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on vacuum condition

The invention provides an integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition and belongs to the field of metal casting. The integrated device comprises a first vacuum chamber, a second vacuum chamber, a vacuum control system, a material supplementing device, an ultrasonic treatment device and a throwing device. According to the integrated device and technology for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition, the device can be widely applied to horizontal continuous casting of a high-temperature alloy, a titanium alloy, a magnesium alloy, a rare earth metal, multi-component amorphous alloy, high-entropy alloy and other active alloys, smelting, pouring and continuous forming under electromagnetic and ultrasonic coupled fields of the alloys can be all completed in the vacuum state, and the obtained horizontal continuous casting alloy workpiece has the effects of being smooth and clean in surface, uniform in component and dense in structure.

Owner:DALIAN UNIV OF TECH

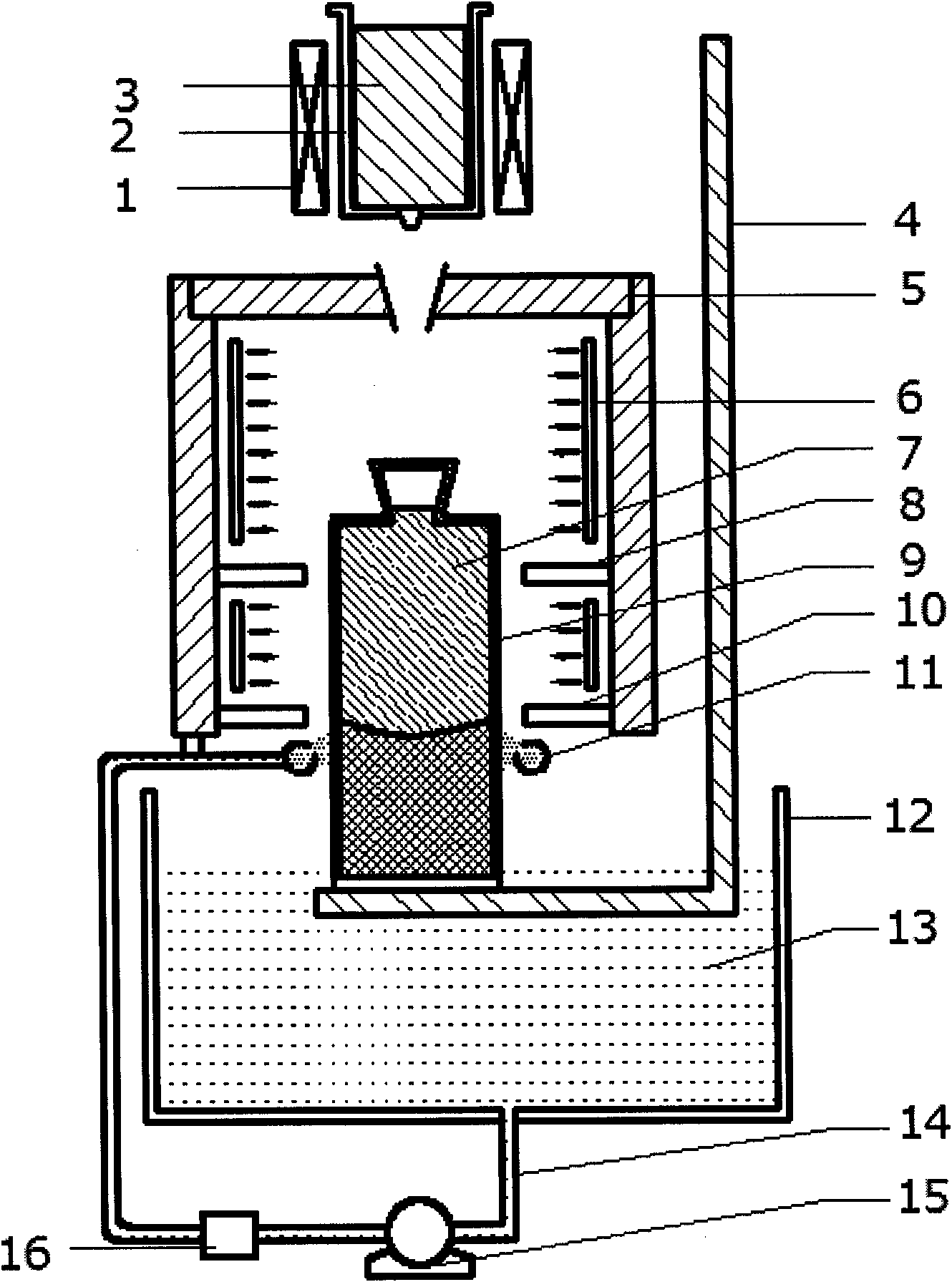

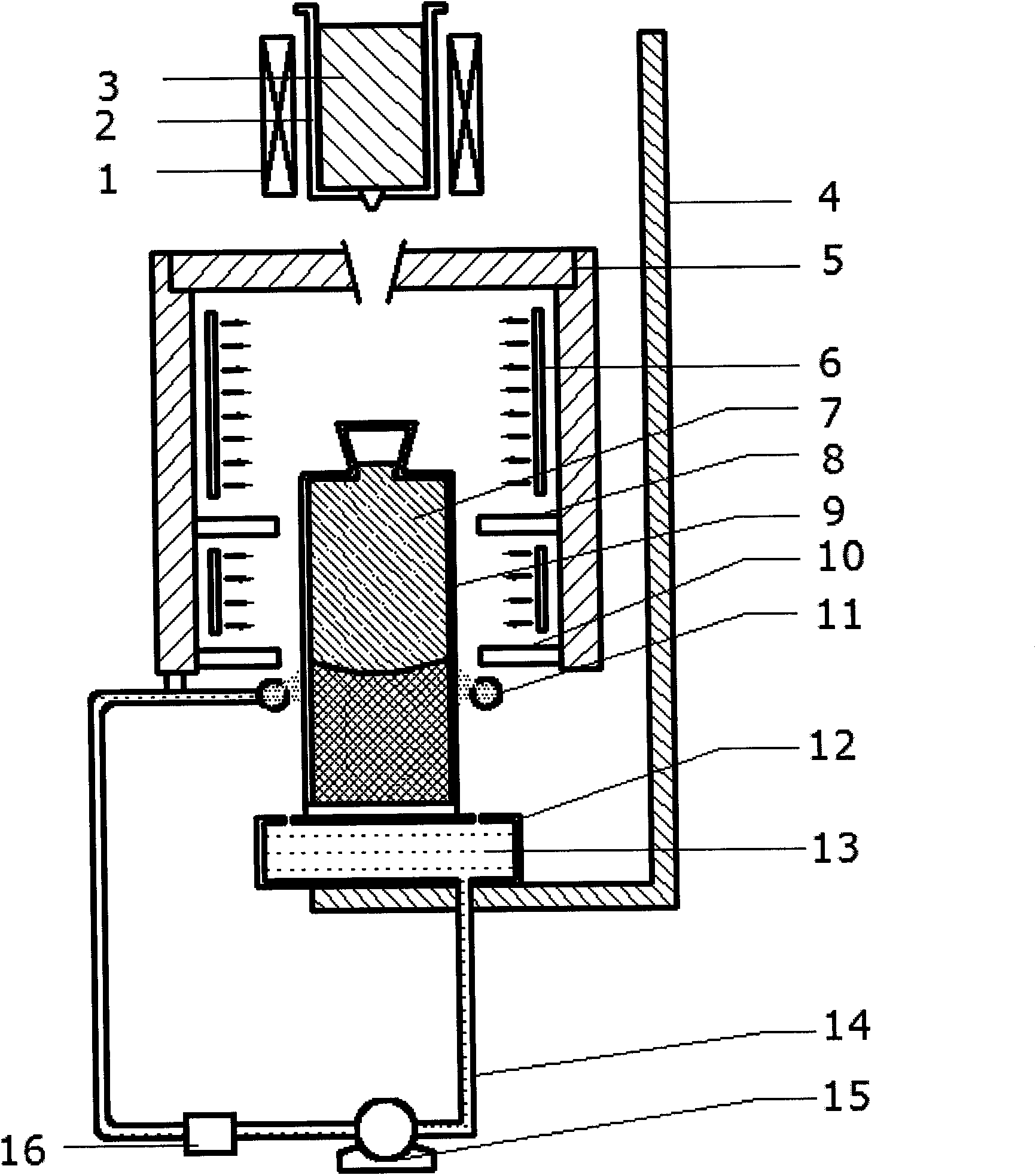

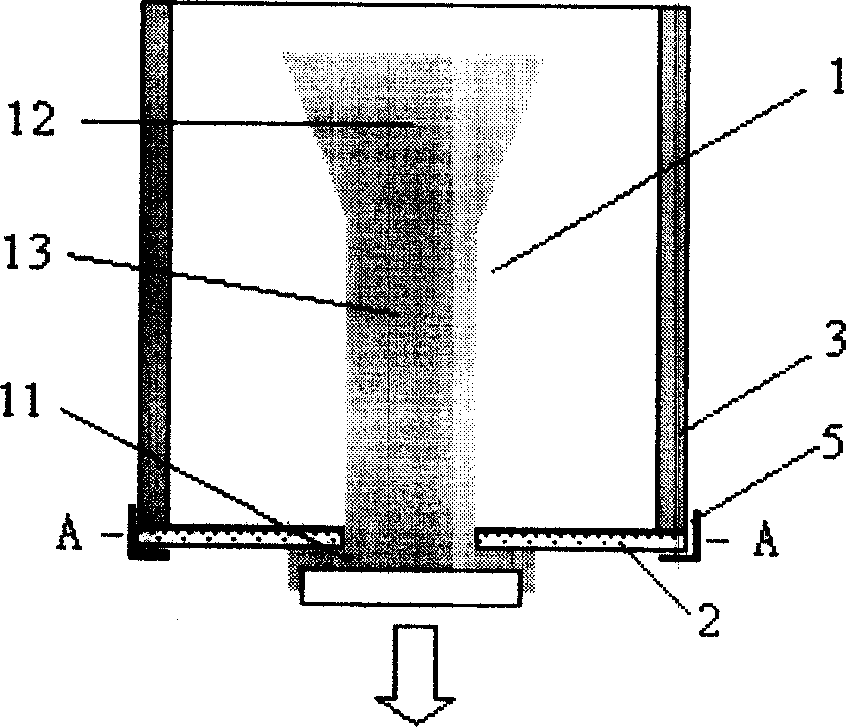

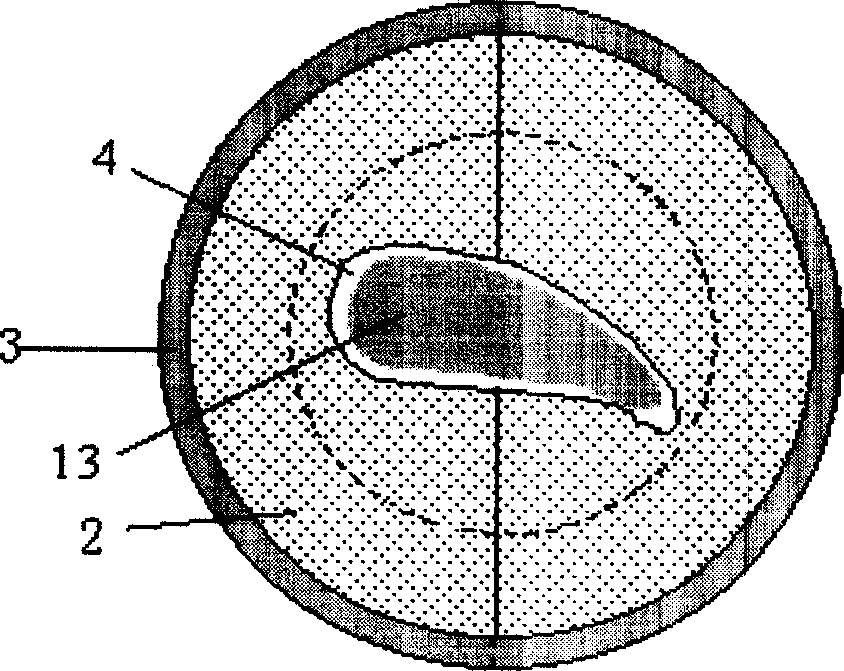

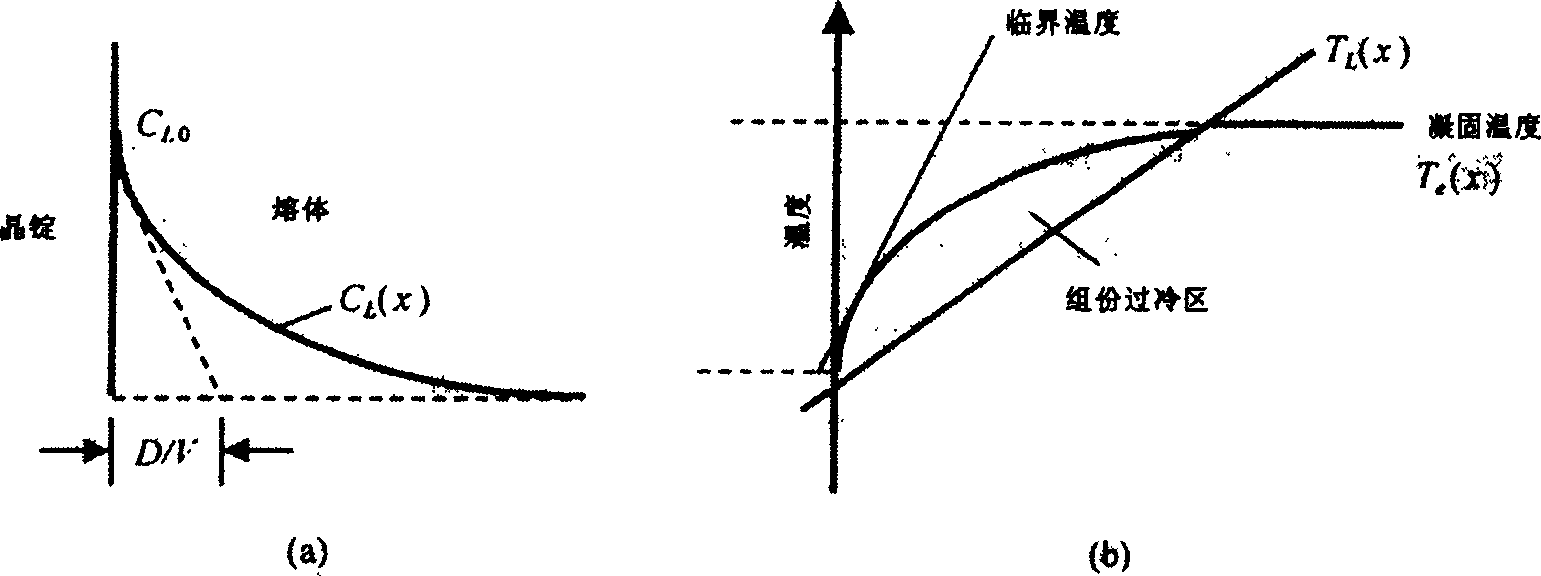

Cooling method used for directional solidification and cooling device therefor

InactiveCN101786156ARaise the temperature gradientImprove heat transfer efficiencyLiquid stateLiquid metal

The invention relates to a cooling method used for directional solidification and a cooling device therefor. In the method, liquid metal is taken as cooling liquid, and a formwork is cooled by adopting the spray cooling method independently or adopting the spray cooling method and the immersion cooling method simultaneously. For the cooling device, a liquid metal spraying device is arranged under a direction solidification holding furnace, and the liquid metal is taken as the cooling liquid to cool the pull-down formwork by spraying independently or accompanying with the immersion. The invention has the advantages that the thermal radiation of a heating area and a cooling area for direction solidification can be insulated; and the cooling liquid is recycled, so as to cool the cooling liquid in cycling.

Owner:SHANGHAI UNIV

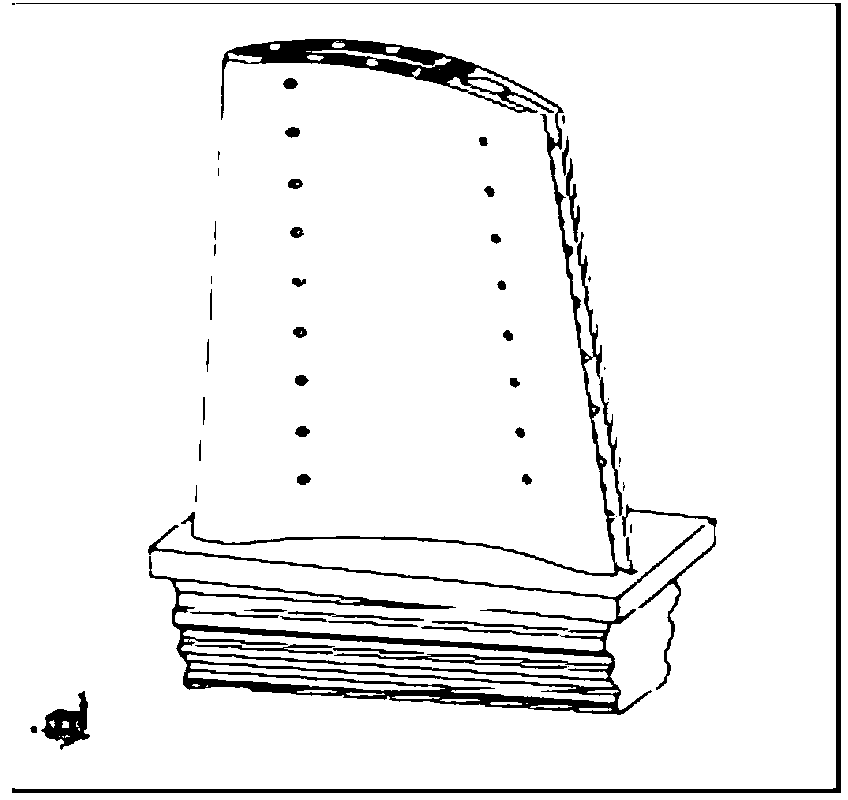

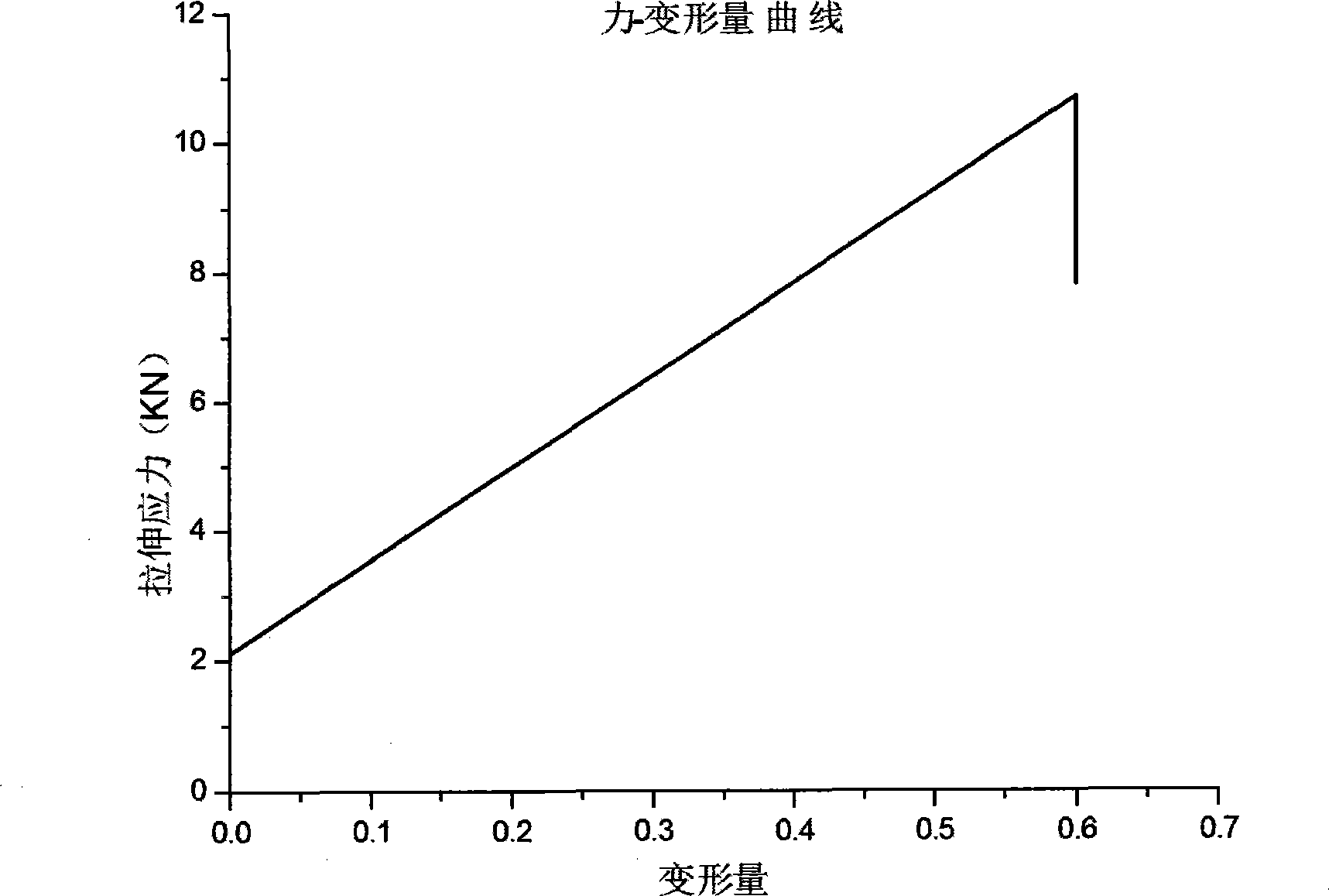

Preparation method of thin-wall high-strength mold shell for single crystal blade manufacturing

InactiveCN103252448AReduce the number of layersReduce thicknessFoundry mouldsFrom frozen solutionsFiberWax

The invention discloses a preparation method of a thin-wall high-strength mold shell for single crystal blade manufacturing. The preparation method comprises the following steps of: A1, a shell manufacturing process: (1), size preparation, (2) slurry hanging, (3) sand spraying, (4) repeating the operations till preset number of layers are formed, (5) slurry sealing, dipping a wax mold in a slurry barrel, completely dipping, taking out, and drying; and A2, winding carbon fibers and drying. The carbon fibers are wrapped; compared with a traditional silicasol mold shell, the thin-wall high-strength mold shell has the advantages that under the precondition of ensuring the thermal strength of the mold shell, the layer number of the mold shell is reduced, so that the integral thickness of the mold shell is reduced, the heat conduction capacity of the mold shell is improved, and the preparation method is beneficial to the improvement of temperature gradient. Adopted carbon fiber cloth is made of amorphous graphite; and the amorphous graphite has a thermal conductivity lambda 2 of more than 100, and is an ideal heat conduction material; and the amorphous graphite has a tensile strength of more than 3,400 MPa, and creates a condition for reducing the thickness of the mold shell.

Owner:JIANGSU UNIV

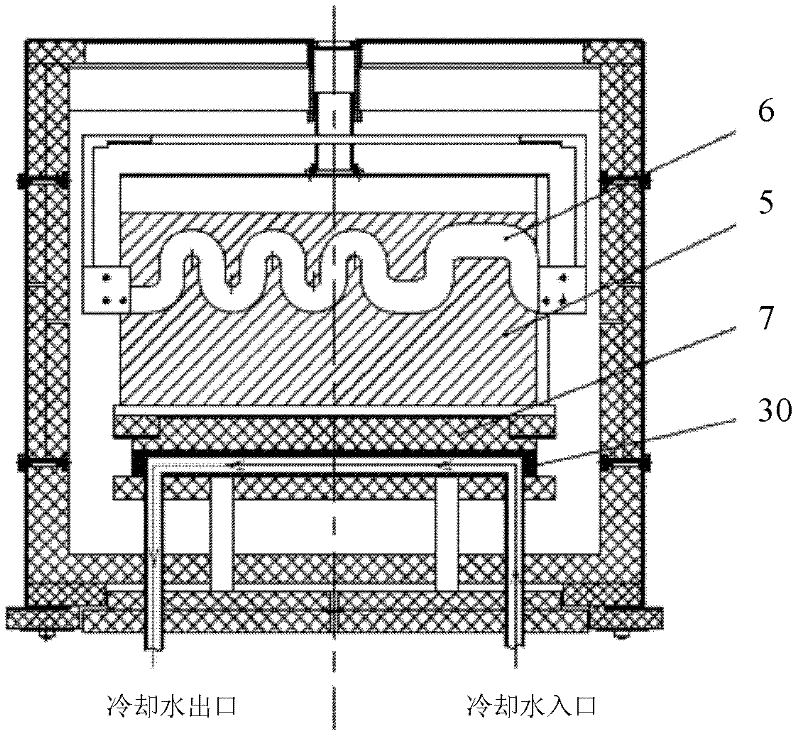

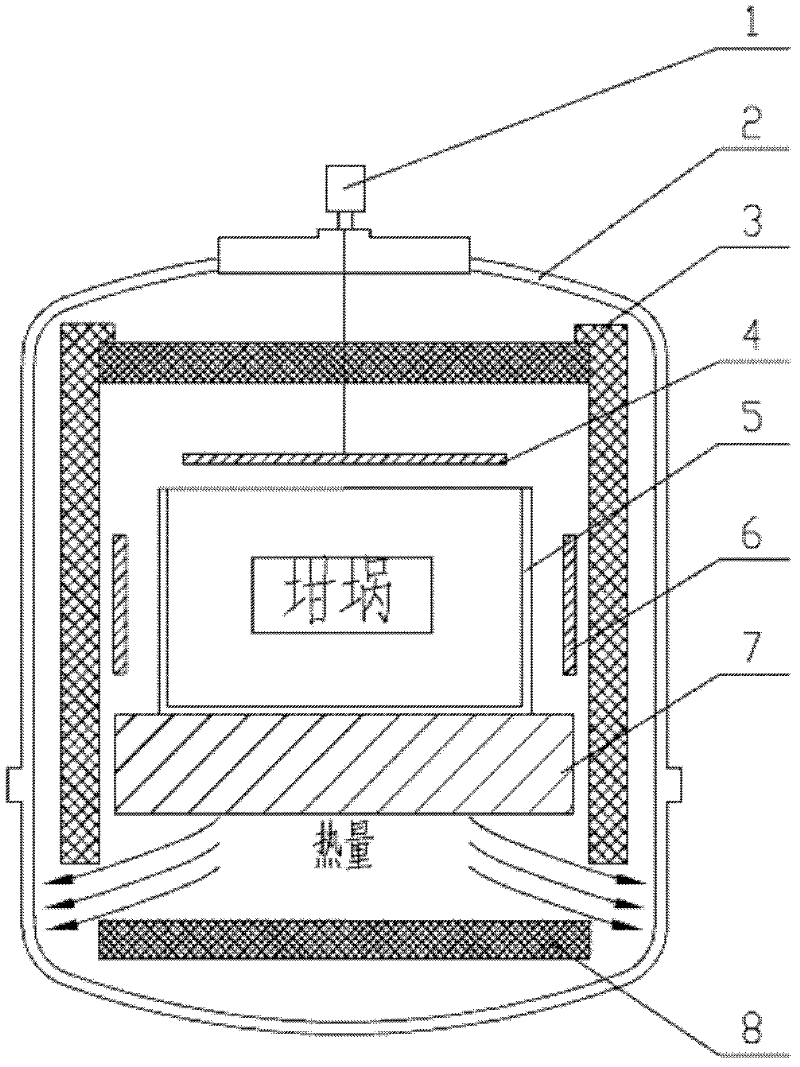

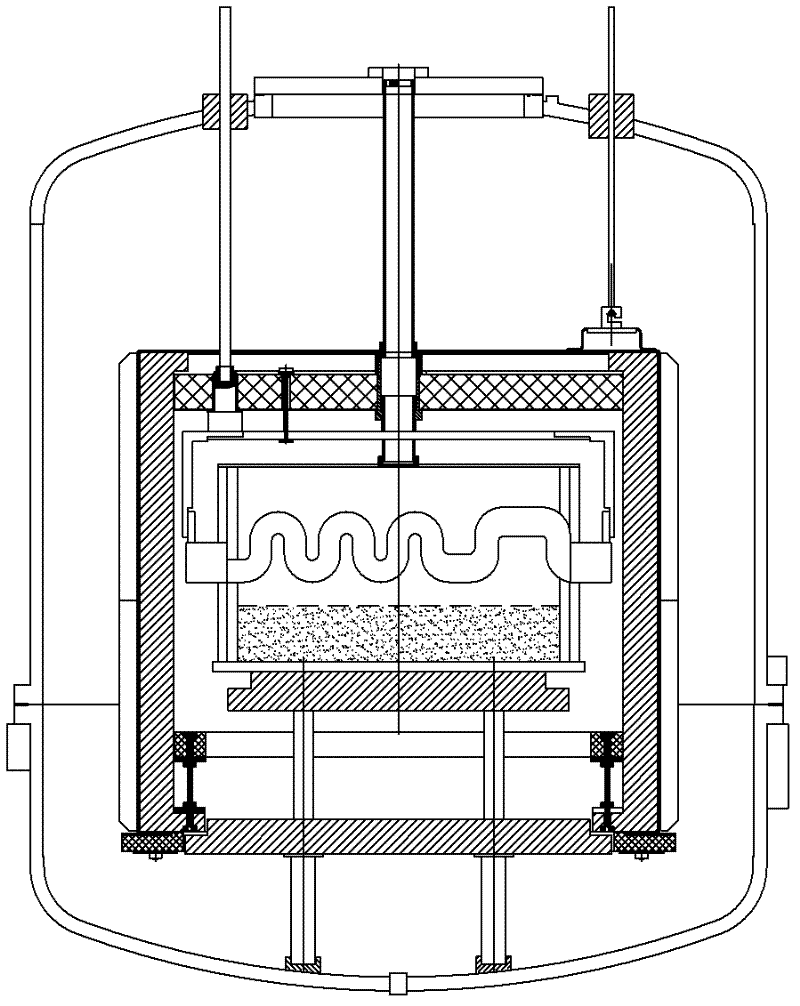

Heat exchange platform with improved structure for polysilicon ingot furnace

ActiveCN102268728APrecise temperature controlEasy to controlPolycrystalline material growthFrom frozen solutionsCrucibleIngot

The invention relates to polycrystalline silicon ingot furnace equipment, and aims to provide a heat exchange platform of an improved structure for a polycrystalline silicon ingot furnace. The heat exchange platform is used for holding a polycrystalline silicon ingot furnace crucible and realizing heat exchange, and is provided with a gas inlet and a gas outlet; and the interior of the heat exchange platform is provided with a cooling gas channel, and is connected with the gas inlet and the gas outlet. Compared with the radiation cooling and the water-cooling type cooling technologies, the heat exchange platform disclosed by the invention is strong in control capacity and high in industrial controllability when being used for gas refrigeration; and furthermore, because the gas enters the heat exchange platform uniformly, the overall temperature of the heat exchange board is uniform, so that the uniform nucleation of a silicon melt at the bottom of the crucible is facilitated, and the temperature reduction speed at the bottom of the crucible in the crystal growth process can be precisely controlled.

Owner:SHANGYU JINGXIN ELECTROMECHANICAL TECH +1

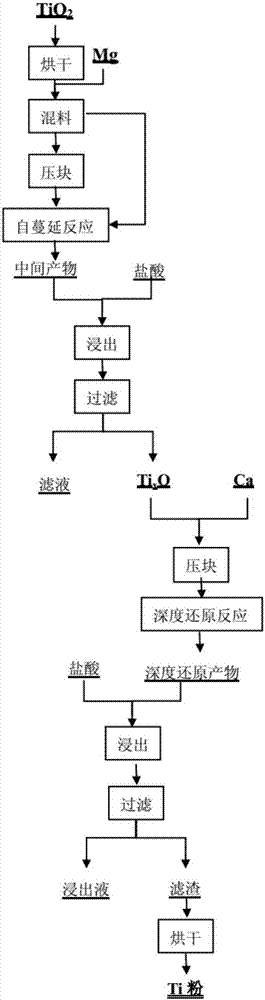

Method for preparing reduced titanium powder by multi-stage deep reduction

ActiveCN107236869AHigh activityRaise the temperature gradientProcess efficiency improvementProcess conditionsVacuum drying

The invention provides a method for preparing reduced titanium powder by multi-stage deep reduction and belongs to the technical field of powder preparation. The method comprises the steps as follows: mixing dried titanium dioxide powder and magnesium powder evenly, adding the mixture to a self-propagating reaction furnace and initiating a self-propagating reaction to obtain an intermediate product, dispersed in a MgO matrix, of low-valent titanic oxide TixO; leaching the intermediate product with hydrochloric acid as a leaching solution, and performing filtering, washing and vacuum drying to obtain a low-valent titanium oxide TixO precursor; mixing the low-valent titanium oxide TixO precursor with calcium powder, pressing the mixture, and placing the mixture in a vacuum reduction furnace for secondary deep reduction; leaching a deep reduction product with the hydrochloric acid as the leaching solution to obtain the reduced titanium powder. According to the method, the cost of raw materials is low, operation is simple, requirements for technological conditions and equipment are low, a basis is laid for industrial production, and the obtained reduced titanium powder has the advantages of high purity, fine particle size, controllable particle size distribution, high powder activity and the like.

Owner:NORTHEASTERN UNIV LIAONING

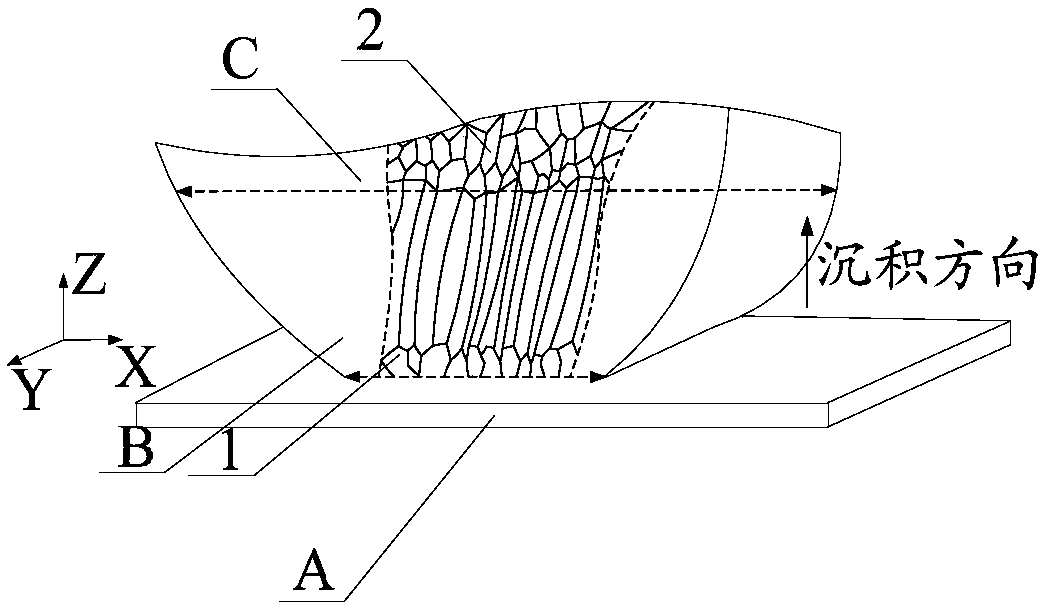

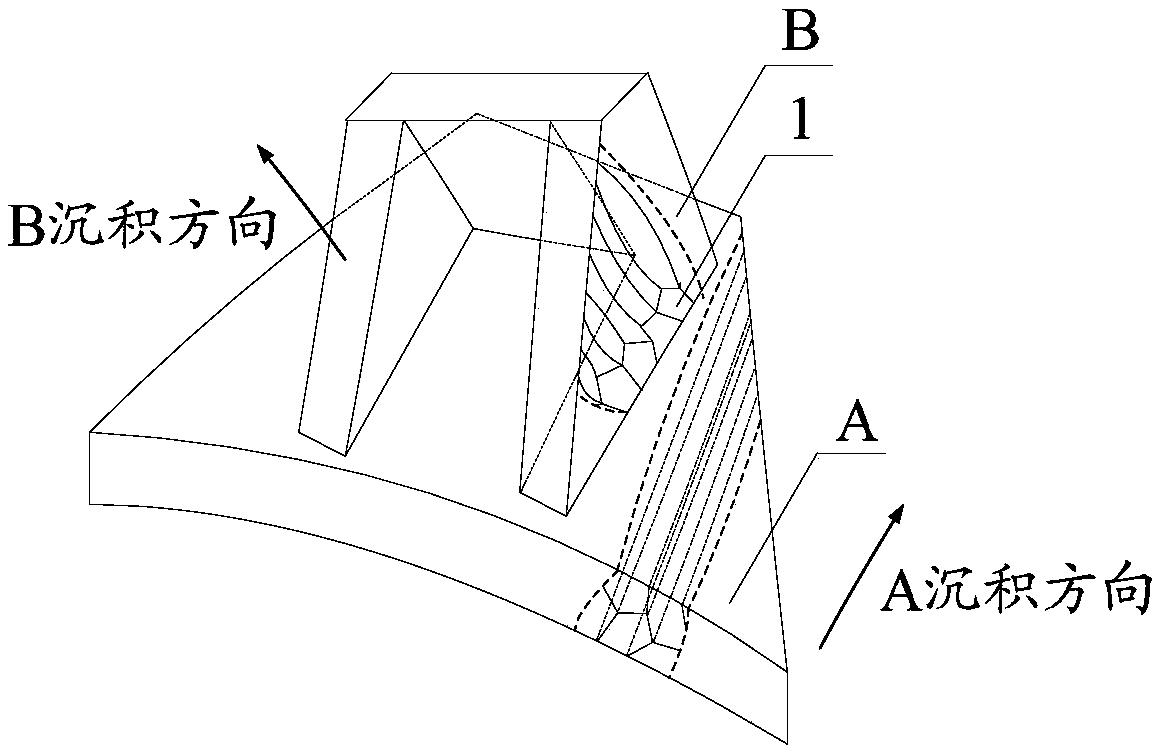

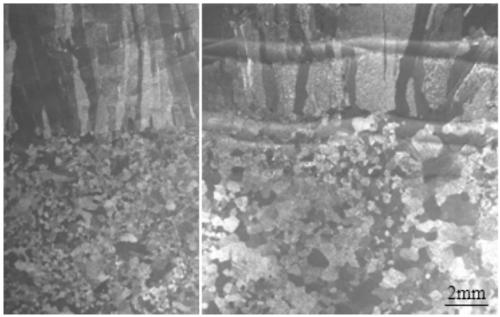

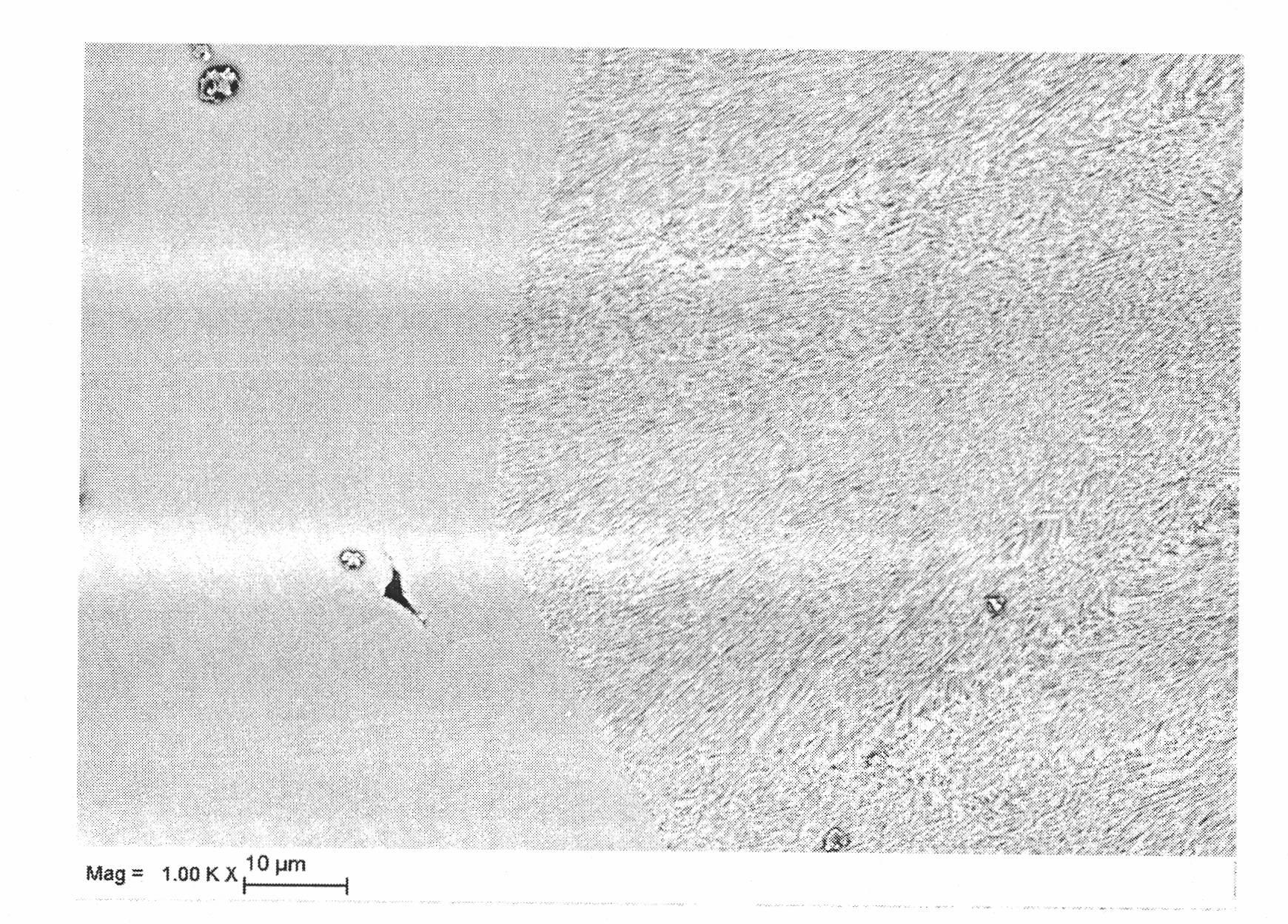

Titanium alloy structural part and laser melting deposition forming method thereof

ActiveCN109261964AAvoid and eliminate the risk of severe crackingFast preparationAdditive manufacturing apparatusIncreasing energy efficiencyInterconnectionTitanium alloy

The invention belongs to the technical field of additive manufacturing and relates to a titanium alloy structural part and a laser melting deposition forming method thereof. The method includes steps:determining prone-to-crack areas of the titanium alloy structural part according to the size and structure of the titanium alloy structural part; adopting the laser melting deposition forming methodfor acquiring the titanium alloy structural part, wherein the grain morphology is controlled to be isometric crystal in forming of the prone-to-crack areas, and the grain morphology is controlled to be columnar crystal in forming of other areas. Deposited plasticity and ductility of the prone-to-crack areas are improved, serious cracking risks in a forming process of the titanium alloy structuralpart are effectively avoided and eliminated, and high forming efficiency is guaranteed. Compared with the prior art, the titanium alloy structural part and the laser melting deposition forming methodthereof have advantages that an interconnection process is avoided, special fixtures for clamping, positioning and the like are avoided, repeated machining before interconnection of small-size structures is avoided, once integral quick manufacturing of the titanium alloy structural part can be realized, and a forming period is remarkably shortened.

Owner:CAPITAL AEROSPACE MACHINERY +1

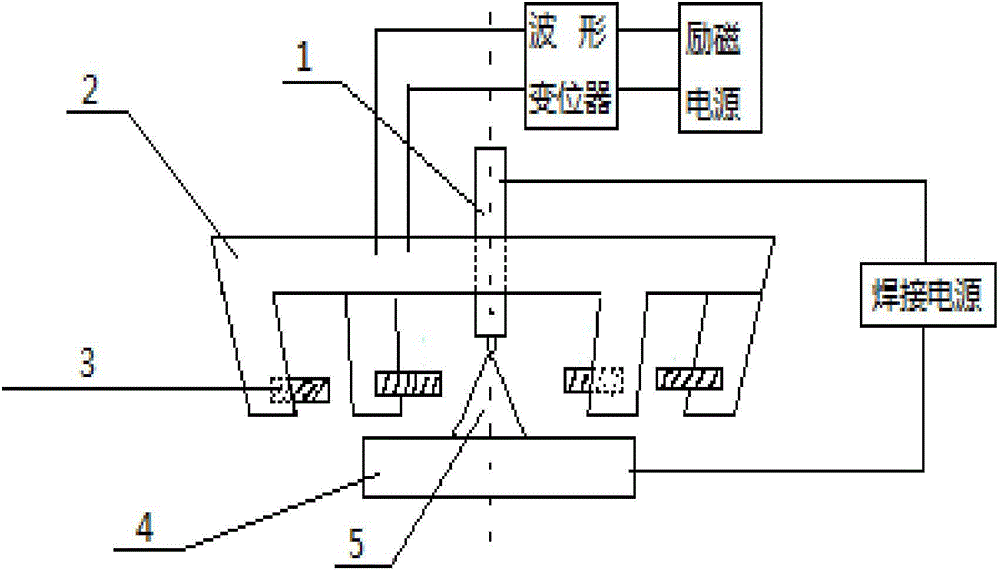

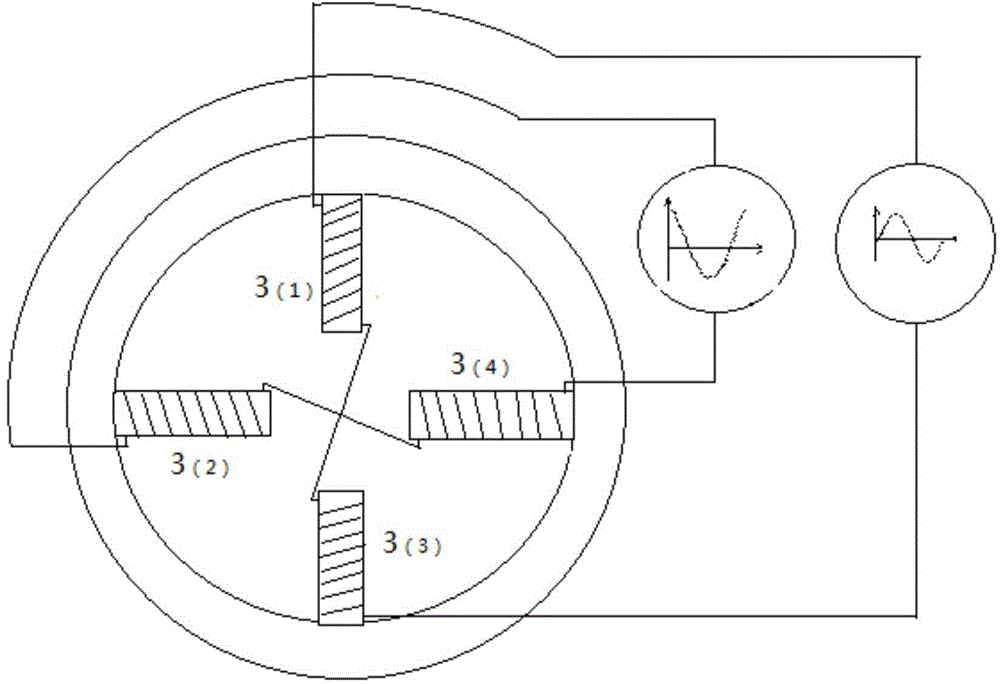

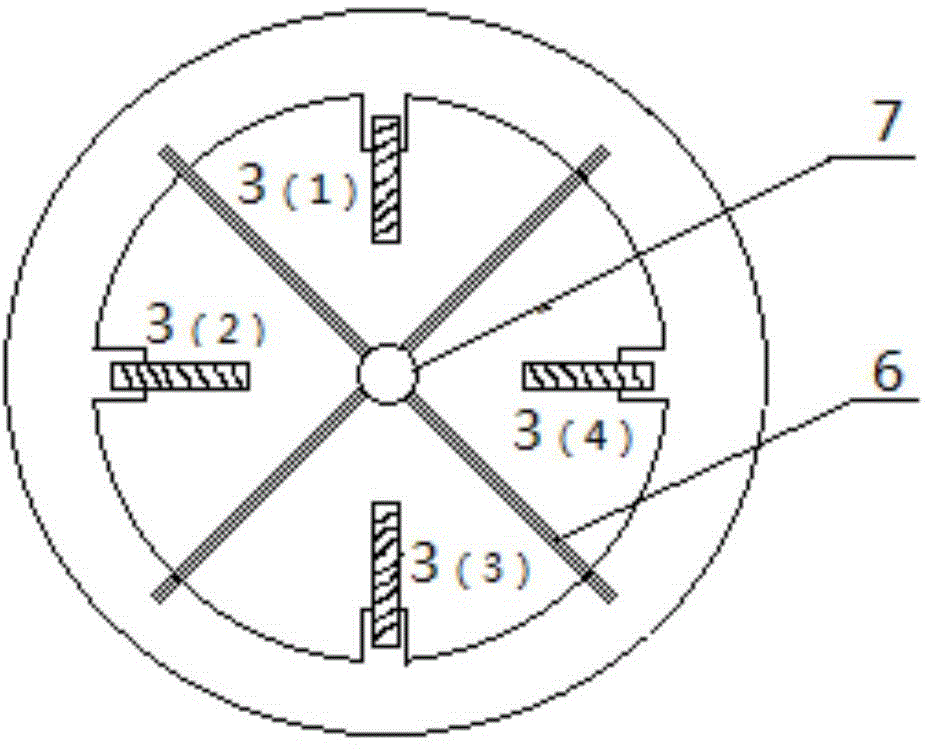

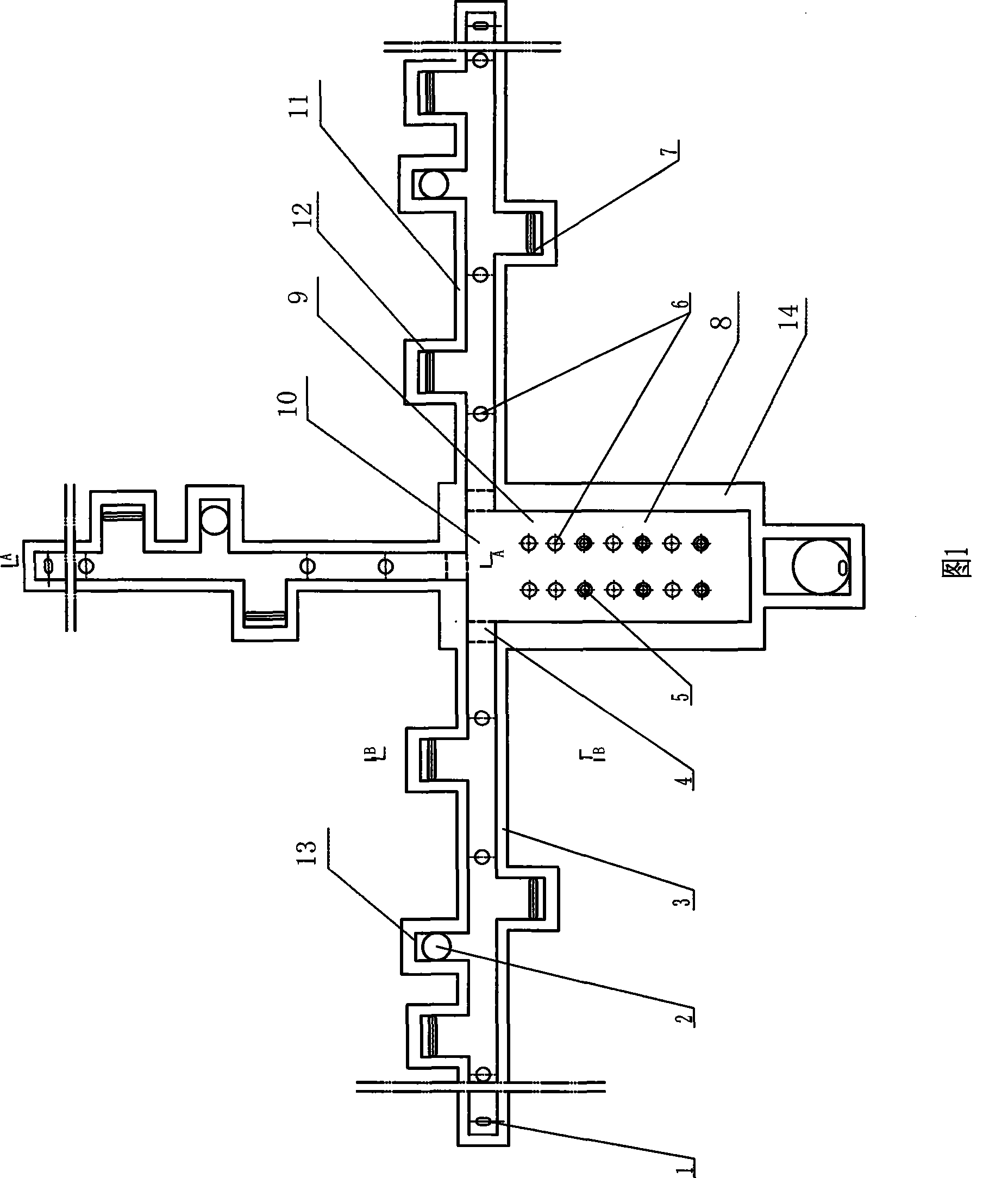

Rotary magnetic field generating device for welding and working method thereof

ActiveCN104816079AImprove heat distributionReduced dendrite arm spacingWelding accessoriesElectric arcMagnetic orientation

The invention relates to a rotary magnetic field generating device for welding. The rotary magnetic field generating device comprises a coil support (2). A welding gun fixing clip (7) is fixedly arranged in the center of the coil support through a welding gun fixing bracket (6); and a welding gun (1) is installed on the welding gun fixing clip (7). Two groups of coils in the same height are fixedly arranged on the coil support (2), and the two groups of coils are spaced by 90 degrees. The two groups of coils are respectively connected with an excitation power supply through a waveform positioner; the two groups of coils are adjusted and are respectively connected with a synchronous sine alternating current and a synchronous cosine alternating current. A phase difference between the sine alternating current the cosine alternating current is 90 degrees. After being electrified, a magnetic field parallel to a coil axis is generated in the middle of each group of coils; and the magnetic field also changes in sine and cosine along with the changes of the electric current. The magnitude of the magnetic field is unchanged during a circling motion along the magnetic field direction, and accordingly a welding arc is also in the circling motion along with the magnetic field. When the welding gun moves forward, the electric arc moves forward spirally to finish the welding.

Owner:SHANGHAI UNIV OF ENG SCI

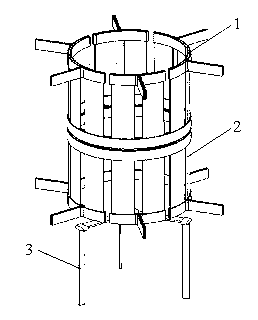

Sectional wolfram wire mesh heater for sapphire single crystal furnace

ActiveCN102851745AImprove uniformityImprove stabilityAfter-treatment apparatusPolycrystalline material growthSingle crystalEngineering

The invention provides a sectional wolfram wire mesh heater for a sapphire single crystal furnace, which is characterized in that the sectional wolfram wire mesh heater is formed by sequentially connecting an upper heater, a middle heater and a lower heater which are concentric in series, wherein both the upper part of the upper heater and the lower part of the middle heater are at least provided with three wolfram electrode claws which are uniformly distributed; each wolfram electrode claw is connected with two woven wolfram wire meshes in a welding mode; each two corresponding woven wolfram wire meshes are separated by a wolfram filament spring; the junction of the upper heater and the middle heater is provided with a wolfram ring; the lower heater is provided with three lower heater wolfram electrode claws which are uniformly distributed; the upper part of each lower heater wolfram electrode claw is welded at one end of one lower heater woven wolfram wire mesh; the other ends of the lower heater wolfram wire meshes are converged to the center fo the lower heater to be connected with a wolfram plate in a welding mode; binding wolfram filaments are wound on the wolfram electrode claws of each heater to form anodes; and the wolfram ring and the wolfram plate are all cathodes.

Owner:NANJING CRYSTAL GROWTH & ENERGY EQUIP CO LTD

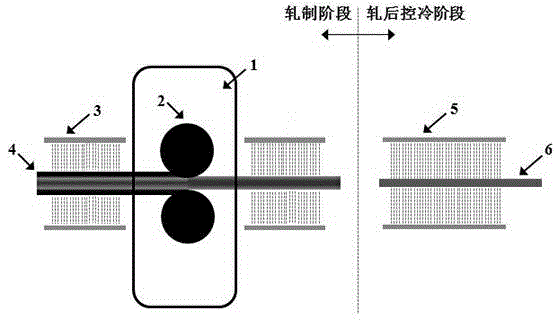

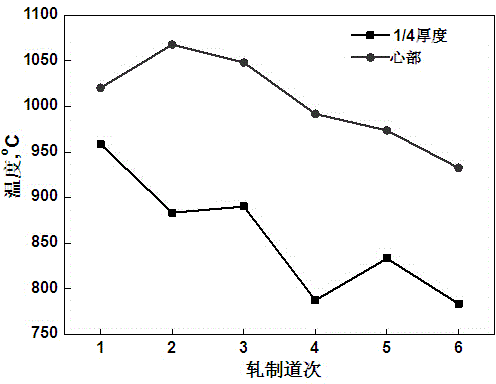

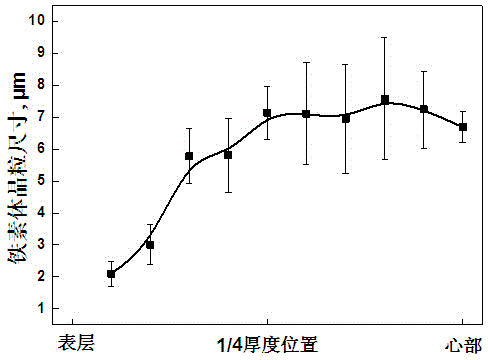

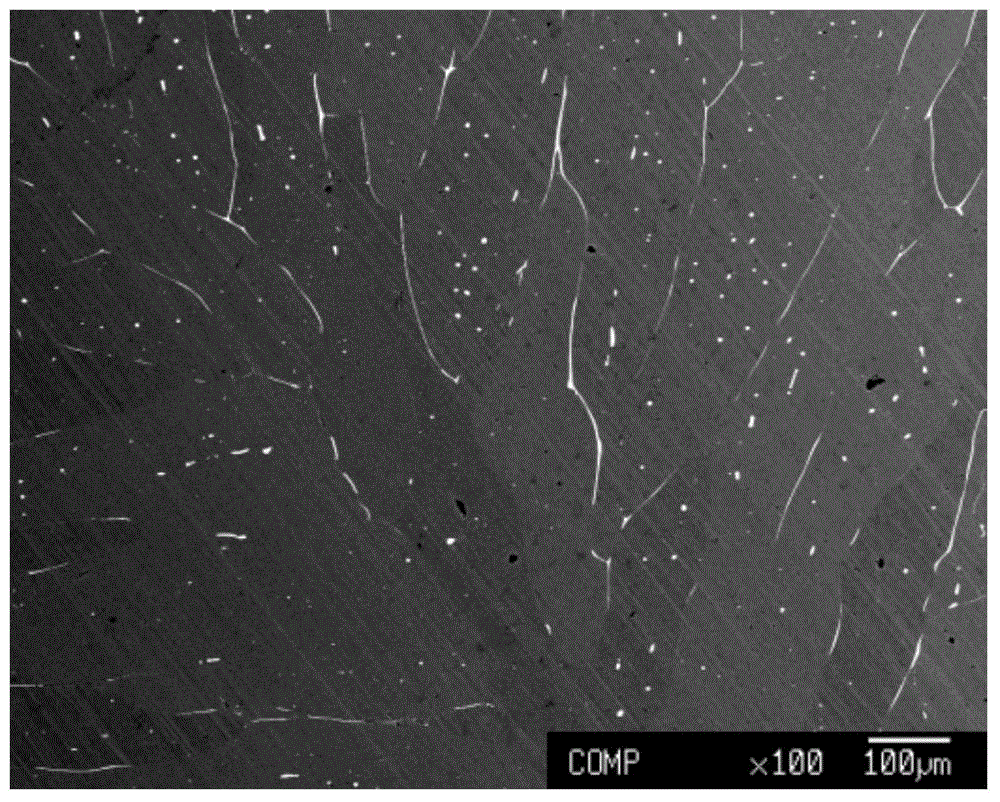

Thick steel plate with excellent rack arrest property and preparation method of thick steel plate

The invention belongs to the field of preparing steels and in particular relates to a thick steel plate with excellent rack arrest property and a preparation method of the thick steel plate. The thick steel plate is prepared from the following chemical components including a plain carbon steel or a microalloy steel. The preparation method comprises the following steps: water cooling while carrying out rolling deformation on a billet after being discharged out of a furnace, ensuring the temperature of the surface of the billet to be cooled to 400-800 DEG C during each rolling, ultra rapid cooling to 600-700 DEG C with the cooling speed to be larger than or equal to 15 DEG C / s after rolling is finished, and finally, air cooling to room temperature. According to the thick steel plate and the preparation method disclosed by the invention, the tissue of the thick steel plate takes ferrite as a parent phase and a second phase as a pearlite, the upper and lower surface layers of the thick steel plate are both an ultra-fine grain layer, the thickness of a single-sided ultra-fine grain layer is larger than or equal to 0.1 times of the thickness of the thick steel plate, the ferrite average grain size of each ultra-fine grain layer is smaller than or equal to 3 microns, and the grain boundary density of a large angle boundary is larger than or equal to 0.676 microns<-1>. The thick steel plate is excellent in rack arrest property and improved in core toughness and can be used for shipbuilding, in particular to structure materials of large container ships, offshore platforms, crude oil, natural gas conveying pipelines and the like.

Owner:NORTHEASTERN UNIV

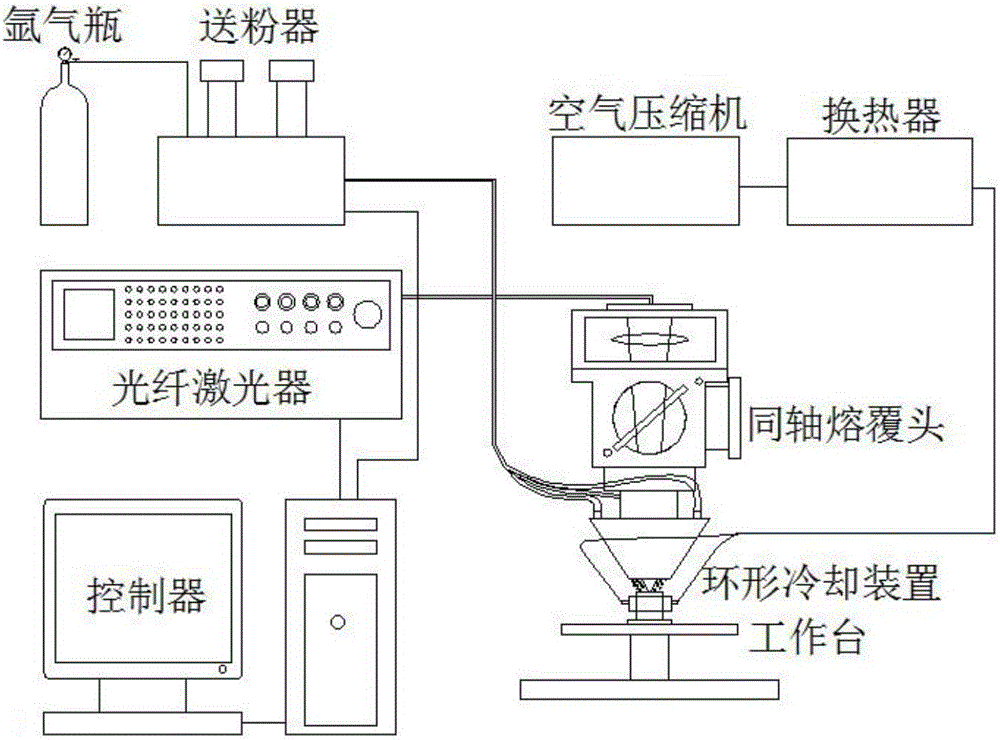

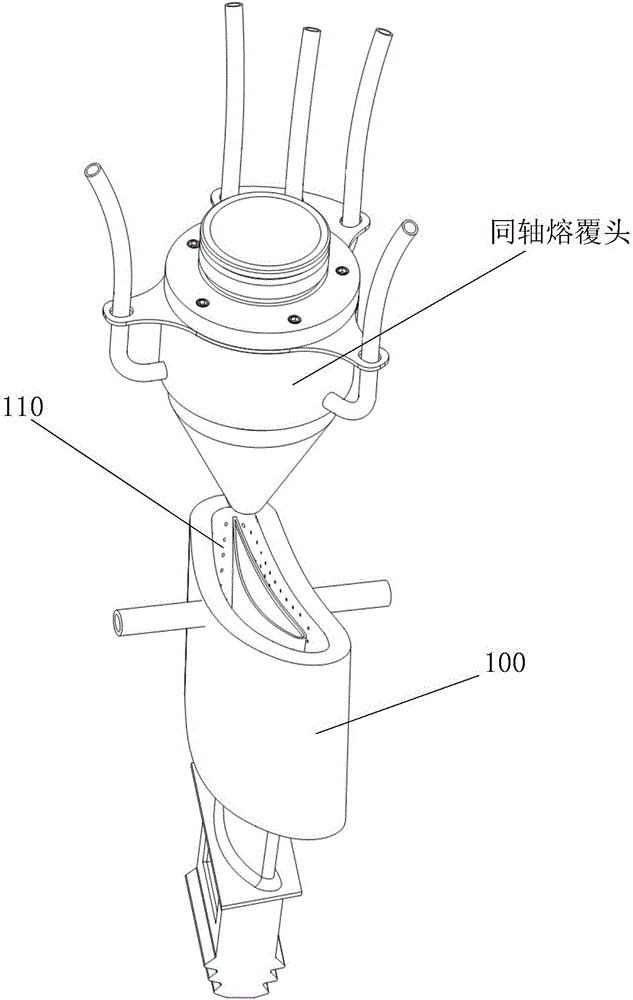

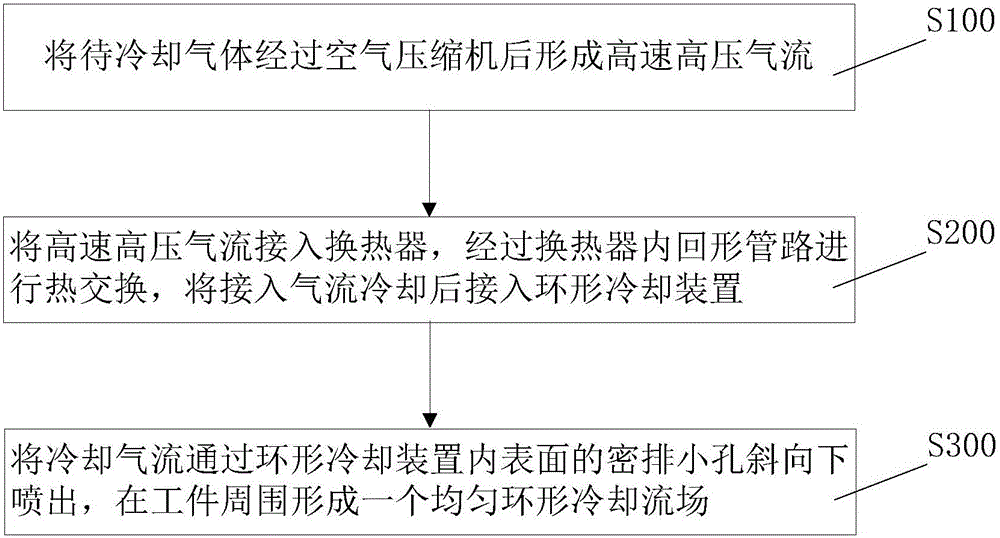

Active cooling device and method for laser repairing of single crystal turbine blade

ActiveCN105671546ARaise the temperature gradientEnhanced Epitaxial Growth CapabilityFrom frozen solutionsMetallic material coating processesActive coolingTurbine blade

The invention provides an active cooling device and method for laser repairing of a single crystal turbine blade. The device comprises an air compressor, a heat exchanger and an annular cooling device. The air compressor compresses air to be cooled into high-speed and high-pressure airflow, and the airflow is introduced into the heat exchanger. After the introduced airflow is cooled by the heat exchanger, the airflow is introduced into the annular cooling device. The annular cooling device is arranged above a workbench of a laser cladding system and arranged around a workpiece. According to the active cooling device and method for laser repairing of the single crystal turbine blade, the volume and temperature of the cooled airflow and the position and angle of a cooling nozzle are adjusted, so that the best active cooling effect is achieved in the laser repairing process.

Owner:SHANGHAI JIAO TONG UNIV

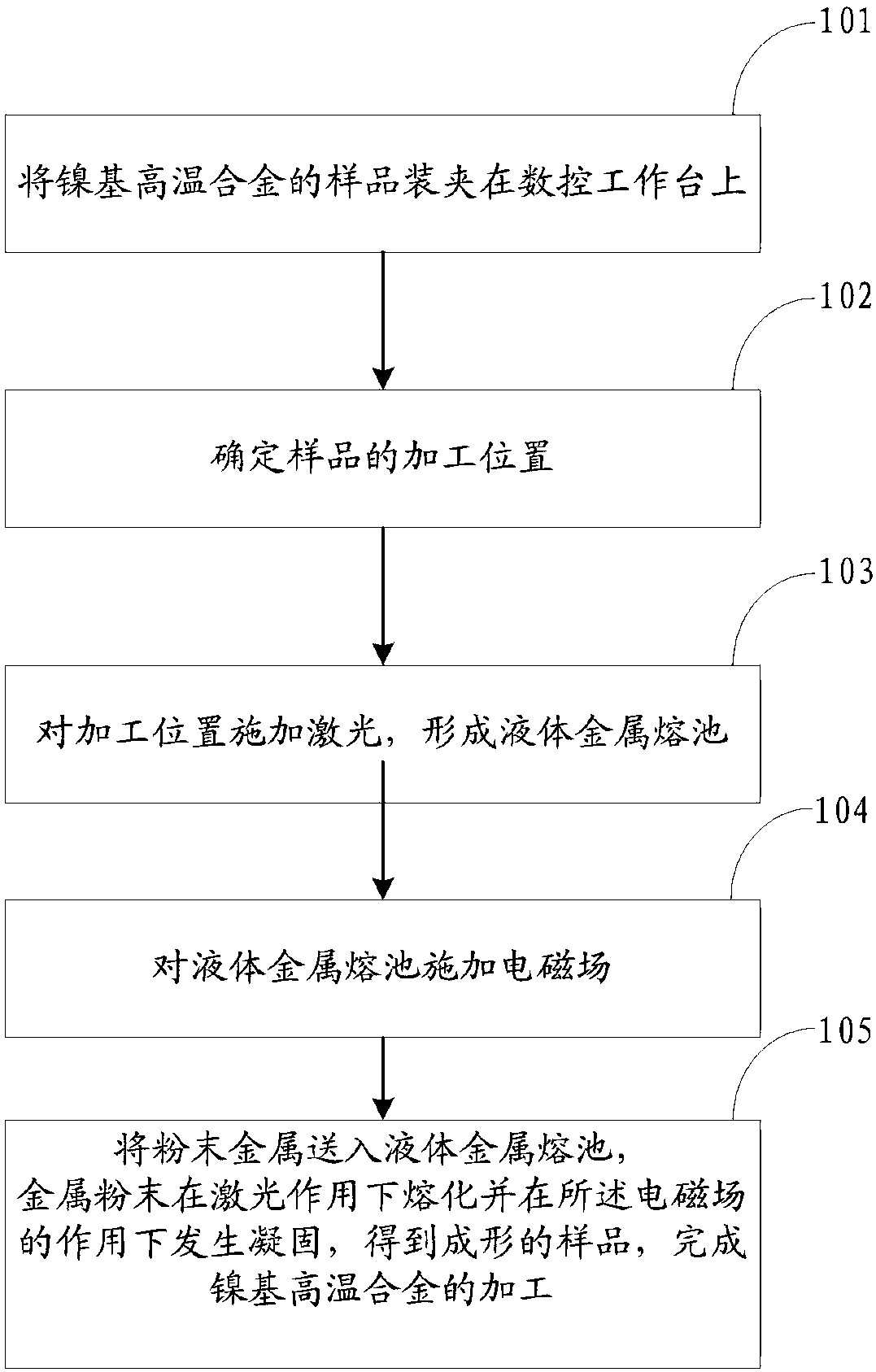

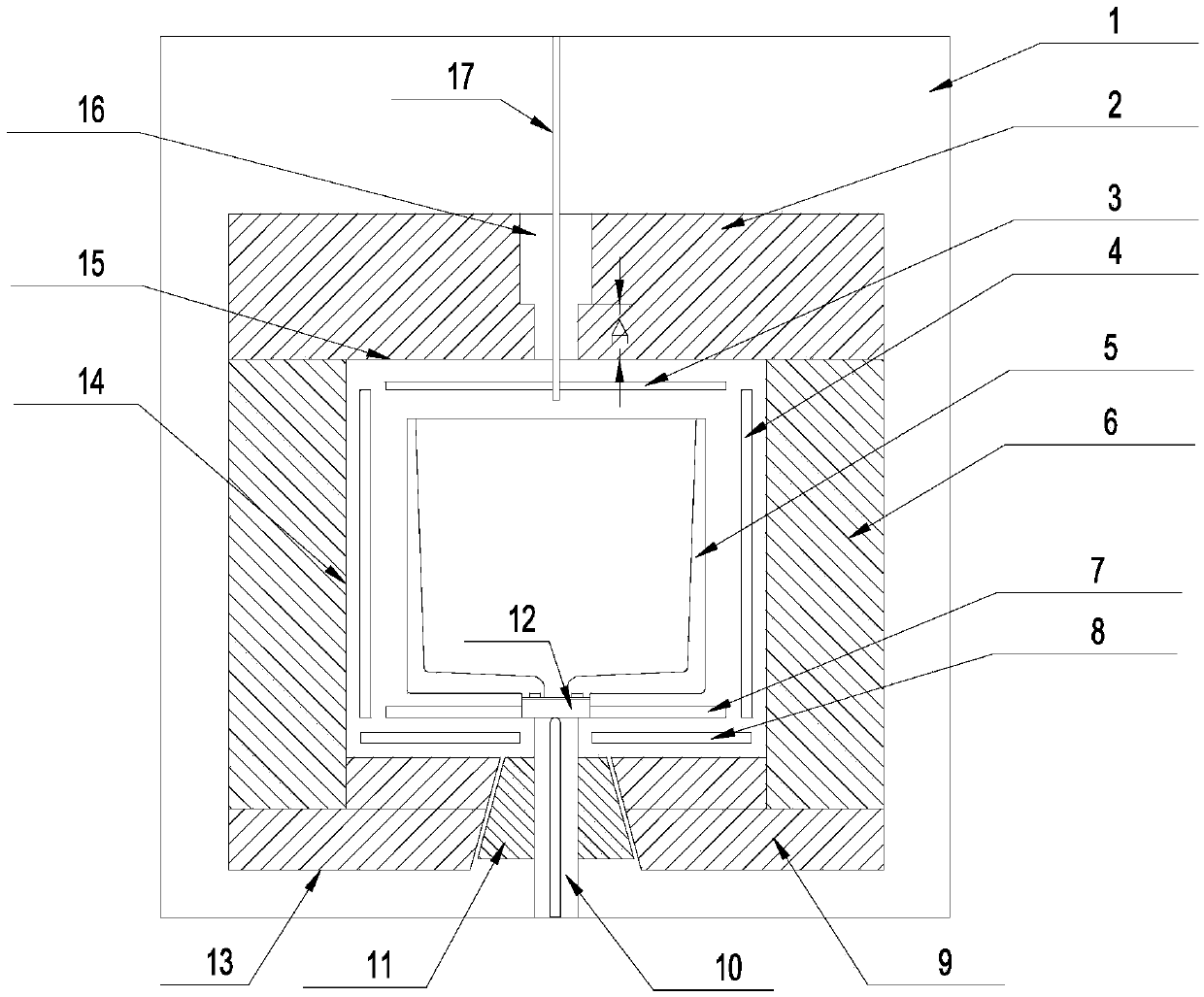

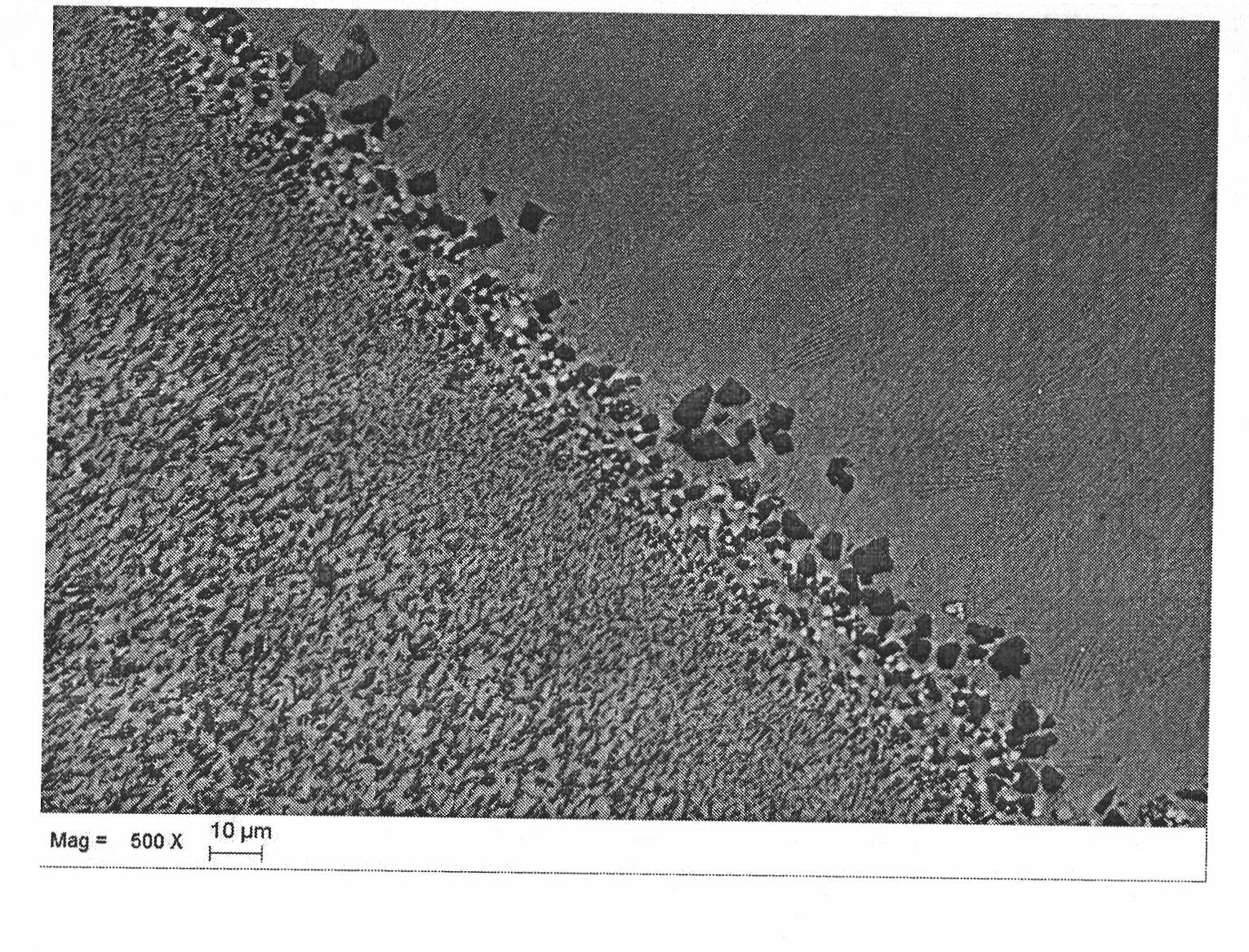

Method and device for controlling nickel-based high-temperature alloy brittle phase during laser additive manufacturing

InactiveCN108436083ARaise the temperature gradientReduce size and volume fractionAdditive manufacturing apparatusIncreasing energy efficiencyNickelElectromagnetic field

The invention discloses a method and device for controlling nickel-based high-temperature alloy brittle phase during laser additive manufacturing. The method comprises the steps that a nickel-based high-temperature alloy sample is clamped onto a numerically-controlled workbench, the machining position of the sample is determined, laser is applied to the machining position to form a molten metal bath, an electromagnetic field is applied to the molten metal bath, powdered metal is fed to the molten metal bath, undergoes melting under action of the laser and undergoes solidification under actionof the electromagnetic field to form a shaped sample, and machining of the nickel-based high-temperature alloy is completed. By adoption of the method or the device, the problem that in the traditional nickel-based high-temperature alloy additive manufacturing process, precipitation of interdendritic LAVES brittle phases cannot be reduced is solved.

Owner:NANCHANG HANGKONG UNIVERSITY

Heat-insulated baffle for oriented freezing cast

A heat isolating plate for the directionally solidified casting is composed of two or more plates for splicing them together to become a single one, an external ring matched with the internal surface of temp holding furnace tightly, and an internal ring matched with the mould casing but retaining a gap (0.5-10 mm) between them for moving the mould casing easily. Said plate is just combined hard graphite felt.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Tank furnace for producing basalt continuous fiber

ActiveCN101397182AHigh melting temperatureGuaranteed temperatureForehearthsTank furnacesMelting tankFiber

The invention relates to a tank furnace for producing basalt continuous filament and pertains to the technical field of novel inorganic non-metallic material processing equipment, the main characteristics are that the furnace body consists of a melting tank and material channels, the melting tank and the material channels are connected by non-submerged dog-holes, the melting tank is divided into a melting area and a homogenization area, a burner is arranged at the top of the furnace vertically, the burner guns of melting area and the feeding pipes are arranged in intervals, and the strong melting area of even feeding and even heating is formed. The material channels are arranged in three directions in the homogenization area of the melting tank, burner guns are arranged in the material channel in sections, the temperature of the fused mass in the material channels is guaranteed, more than 12 wiredrawing shaping areas are evenly arranged in each material channel so as to supply basalt melt mass for the wiredrawing bushing well, emptying devices are arranged at the tail part of the melting tank and the tail parts of all material channels, during the operation, the operation of discharging the meltwater can be carried out when impurities are stored in the meltwater for a long time or the varieties of raw materials are changed. The invention is in favor of improving the quality and industrialized production of the basalt continuous filament.

Owner:江苏天龙玄武岩连续纤维股份有限公司

Upper thermal field used for six inch and eight inch adulterated phosphorus vertical pulling silicon mono crystal manufacture

ActiveCN1556257AImprove purging effectEffective blow offPolycrystalline material growthBy pulling from meltElectrical resistance and conductanceEngineering

A top heat field for preparing 6-inch and 8-inch heavyly doped monosilicon by straight pulling up is composed of an insulating cover consisting of the upper and lower hollow trancated cones, and an upper cover plate fixed to the top of said insulating cover and put on a supporting pipe. It can enhance the scavenge action of the airflow on the surface of molten body for removing the fine particles from the surface.

Owner:金瑞泓科技(衢州)有限公司

Thermal field system for sapphire single crystal growth

InactiveCN104195640APlay the role of blocking impuritiesImprove protectionPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

The invention discloses a thermal field system for sapphire single crystal growth. The thermal field system comprises a furnace body as well as heating devices and a heat-preservation layer, wherein a crucible holding area is arranged inside the furnace body; the heating devices and the heat-preservation layer are arranged in sequence from inside to outside around the crucible holding area; at least one part of the heat-preservation layer at the bottom of the crucible holding area serves as a lifting heat-preservation layer. A support column for holding a crucible is arranged at the bottom of the furnace body in a penetration manner, and the lifting heat-preservation layer sleeves the support column. Two groups of heating devices are adopted to control the crystal growth and tempering process, and the two groups of heating devices are respectively side heating devices and lower heating devices and are independently controlled by using respective independent power supplies respectively. According to the thermal field system for sapphire single crystal growth, independent control and cooperation of multiple heating devices is adopted, and with the combination of the lifting heat-preservation layer at the bottom, the purpose that growth and tempering of a crystal are completed in one same thermal field system is achieved, the thermal field system is simple in structure and stable and precise in production control, and a high-quality sapphire single crystal can grow while the production cost is lowered.

Owner:HANGZHOU ZHUTAI TECH

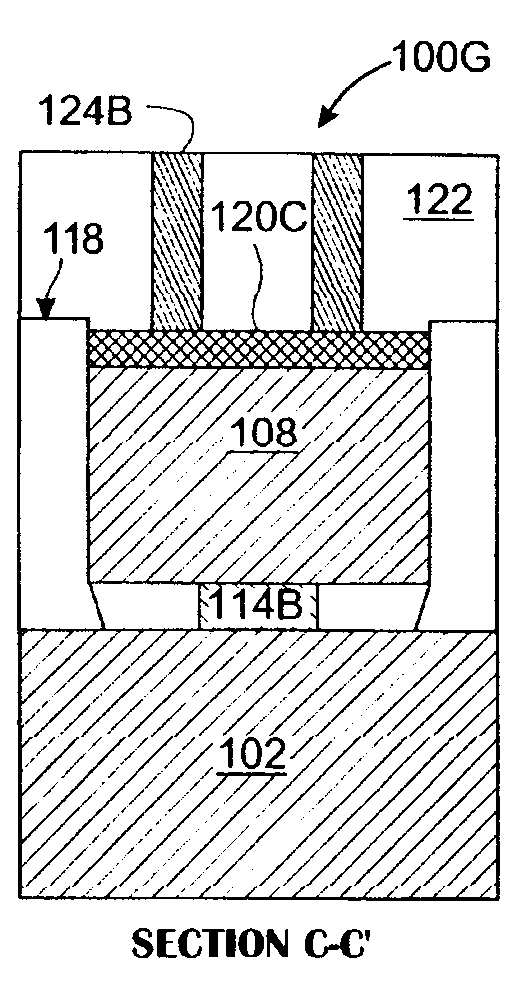

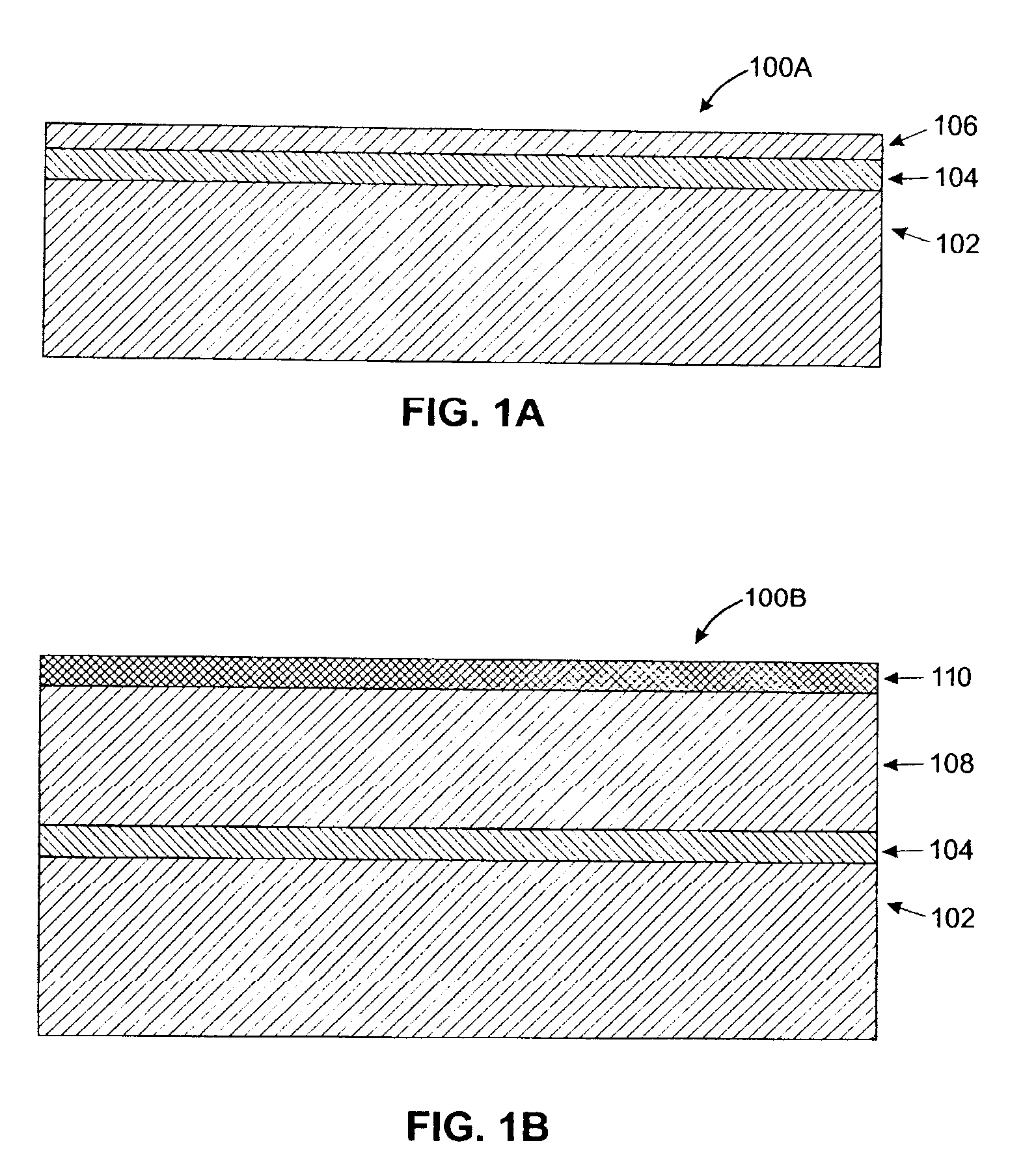

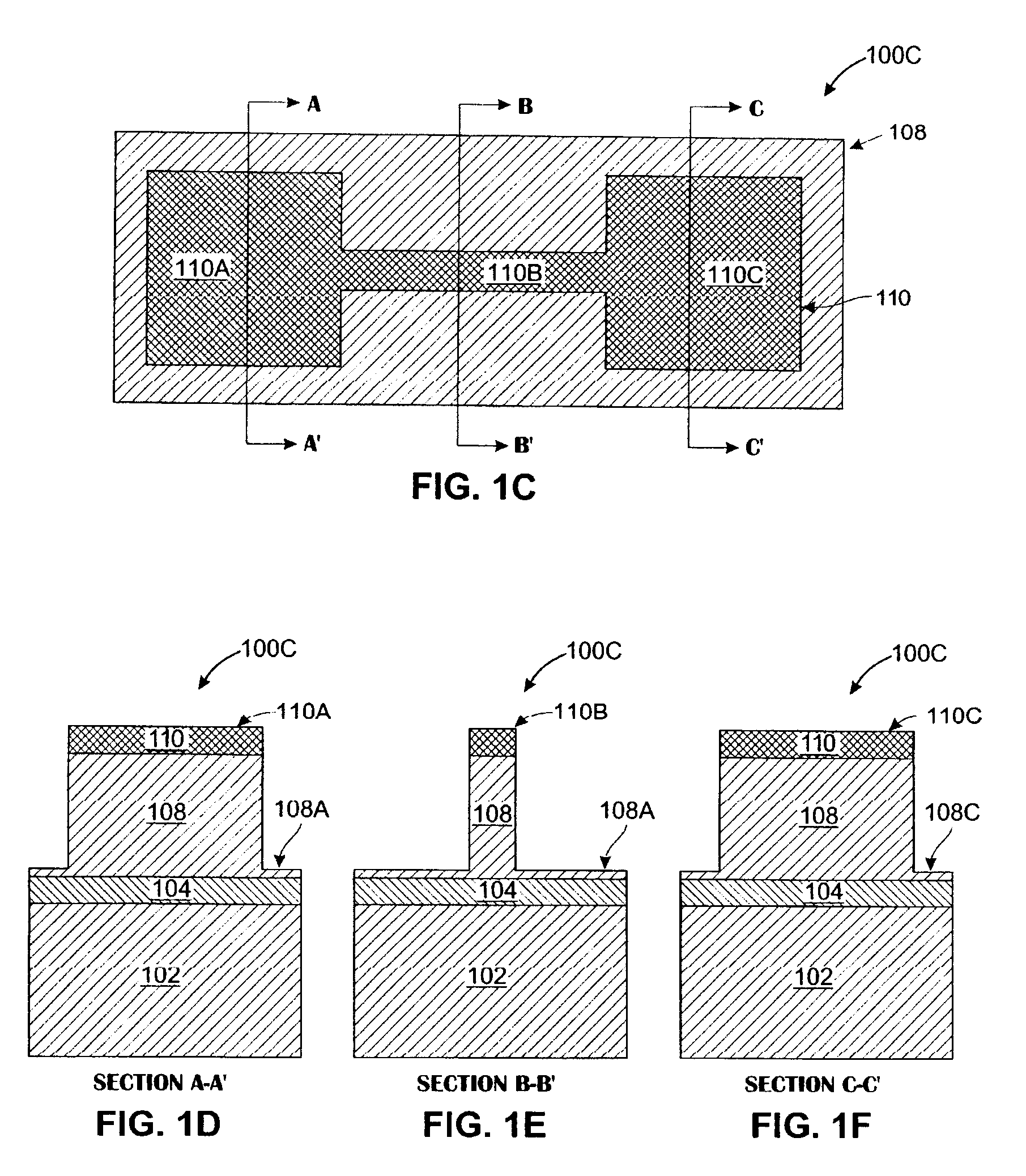

Single crystal fuse on air in bulk silicon

ActiveUS20090090993A1Raise the temperature gradientImprove programming speedSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceSalicide

An integrated eFUSE device is formed by forming a silicon “floating beam” on air, whereupon the fusible portion of the eFUSE device resides. This beam extends between two larger, supporting terminal structures. “Undercutting” techniques are employed whereby a structure is formed atop a buried layer, and that buried layer is removed by selective etching. Whereby a “floating” silicide eFUSE conductor is formed on a silicon beam structure. In its initial state, the eFUSE silicide is highly conductive, exhibiting low electrical resistance (the “unblown state of the eFUSE). When a sufficiently large current is passed through the eFUSE conductor, localized heating occurs. This heating causes electromigration of the silicide into the silicon beam (and into surrounding silicon, thereby diffusing the silicide and greatly increasing its electrical resistance. When the current source is removed, the silicide remains permanently in this diffused state, the “blown” state of the eFUSE.

Owner:TWITTER INC

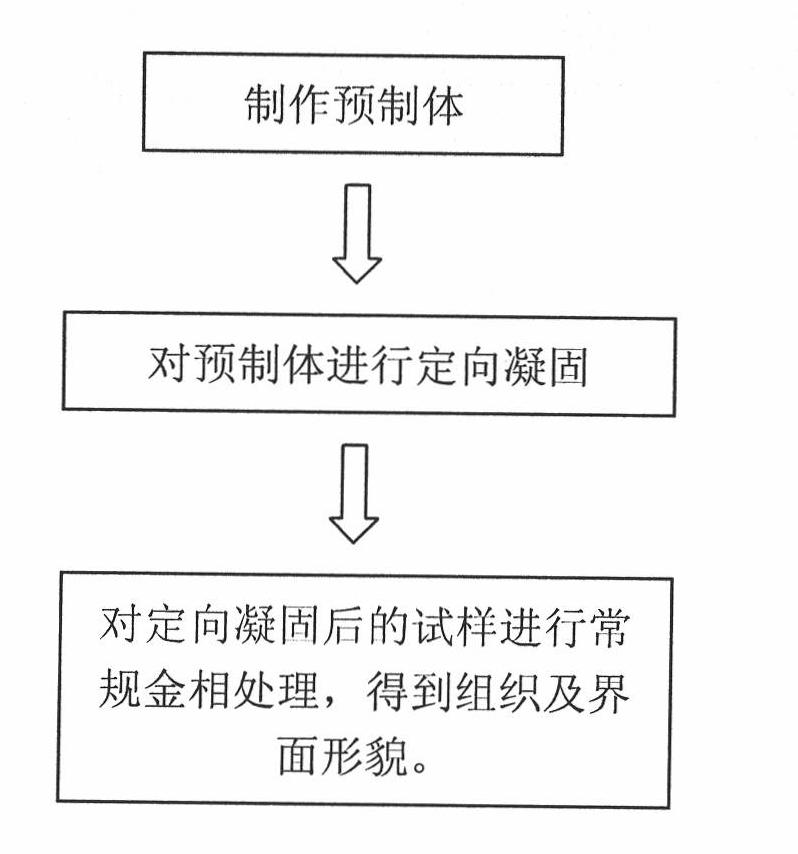

Method for obtaining aluminum oxide-based ternary melt grown ceramic tissue morphology

ActiveCN102153334AIncrease superheatIncreasing the temperature gradient of the solid phaseZone meltingLiquid metal

The invention discloses a method for obtaining aluminum oxide-based ternary melt grown ceramic tissue morphology, which comprises the following steps of: combining zone melting and liquid metal cooling, and performing directional solidification on a plurality of precast bodies formed by using aluminum oxide, yttrium oxide and zirconium oxide respectively; and taking the longitudinal sections and the transverse sections of the directional solidified precast bodies, performing conventional metallographic treatment, and performing surface metal spraying to obtain tissue morphology and interface morphology of the aluminum oxide-based ternary eutectic oxide melt grown ceramic at different growth rates. In the directional solidification, the withdrawing rate is 1 to 10,000mum / s, and the laser power is 200 to 1,500W. The obtained directional solidification tissues are greatly different from the tissues in a melting zone and have no obvious tissue transition zone, and the interface morphologyis preserved perfectly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

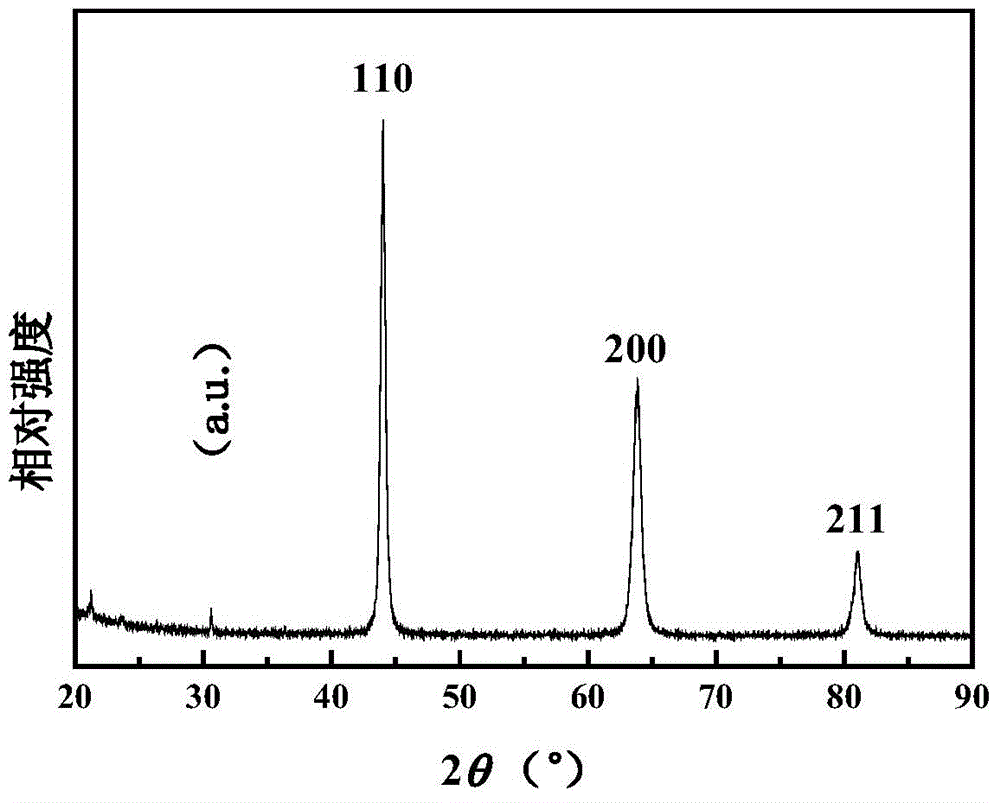

Magnetostrictive material and preparation method thereof

ActiveCN104947194AAchieve <100> single crystal orientationRaise the temperature gradientPolycrystalline material growthFrom frozen solutionsRare earthShielding gas

The invention provides a magnetostrictive material and a preparation method thereof. The composition of the magnetostrictive material is (Fe[]1-x]Gax)[100-y]REy, wherein 0.17<=x<=0.19, 0.01<=y<=0.2, and RE is selected from one or more of Tb, La, Sm, Dy, Lu, Ho, Er and Tm. The preparation method comprises the following steps: smelting the Fe Ga and RE prepared according to the composition requirements into a mother alloy cast ingot, preparing a mother alloy bar, putting the mother alloy bar and a <100>-oriented FeGa monocrystal seed in a directional solidification apparatus, vacuumizing the directional solidification apparatus, charging protective gas, heating to melt all the mother alloy bar and melt the upper part of the FeGa monocrystal seed, and drawing the molten material into a coolant along the lower part of the FeGa monocrystal seed to carry out directional solidification, wherein the temperature gradient is controlled at 1*10<5>-9*10<5> K / m, and the growth rate is 1000-20000 mm / hour. The magnetostrictive material prepared by the method is a <100>-oriented monocrystal material in which the RE elements are completely dissolved in the FeGa matrix; the saturated magnetic field is only 100-5000e, and the magnetostriction coefficient is up to 300-1500 ppm; and the magnetostrictive material has favorable comprehensive usability and wide application prospects.

Owner:BEIHANG UNIV

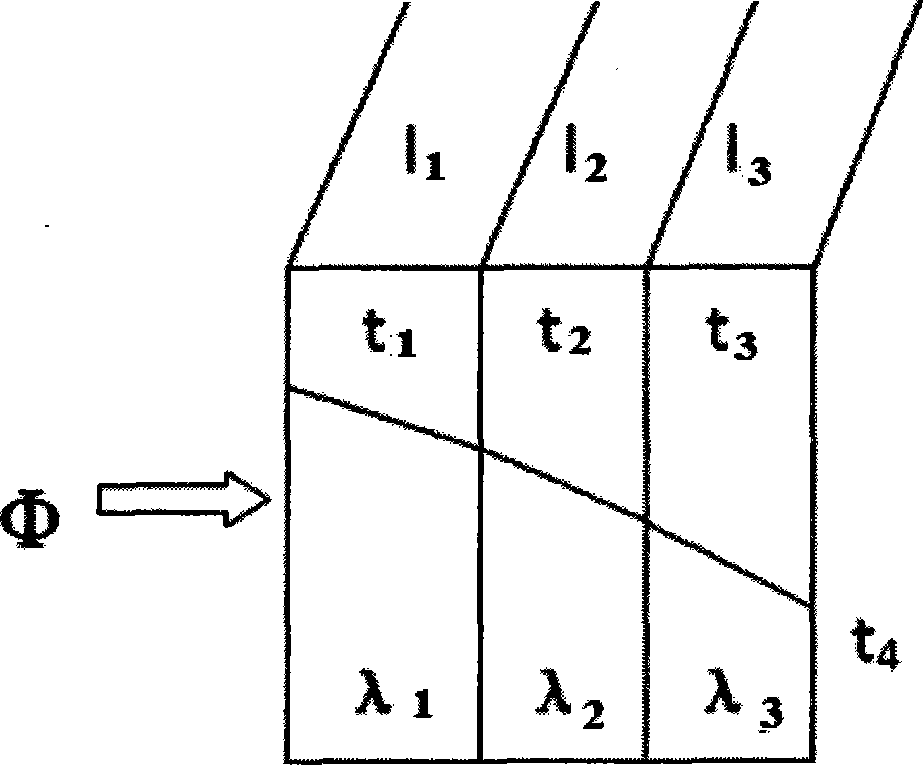

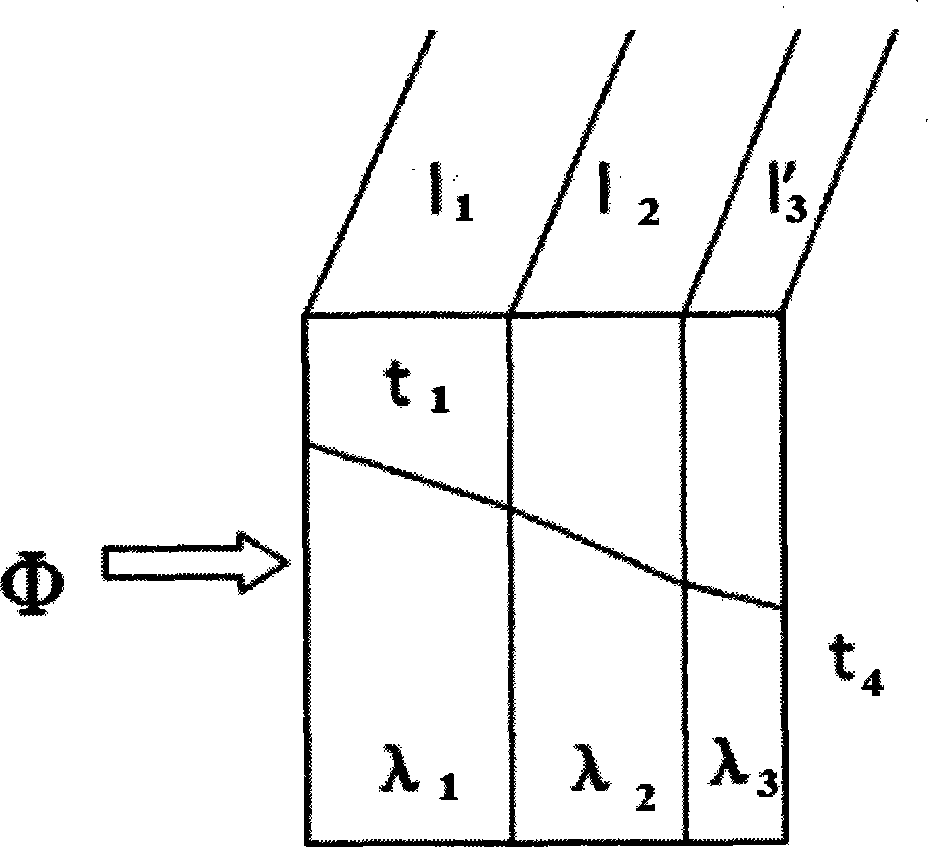

Oriented solidification casting method and apparatus

The oriented solidification casting method includes the following steps: pre-heating the mold with controllable local temperature, feeding the molten metal into the mold cavity via the feeding port, controlling the local temperature of the mold to start cooling while maintaining the rest parts of the mold in heat maintaining state, collecting the data via sensors to judge the positions of solidified regions, crystallized regions and liquid phase regions, and controlling the local temperature of the mold part contacting the liquid area to be solidified to make the metal liquid in overheat state while making the mold part contacting the crystallized material disperse heat. The oriented solidification casting apparatus includes mold with hollow cooling channel and heating element. The present invention is simple and controllable and may be used in making large complicated casting, and the product has excellent structure.

Owner:周照耀

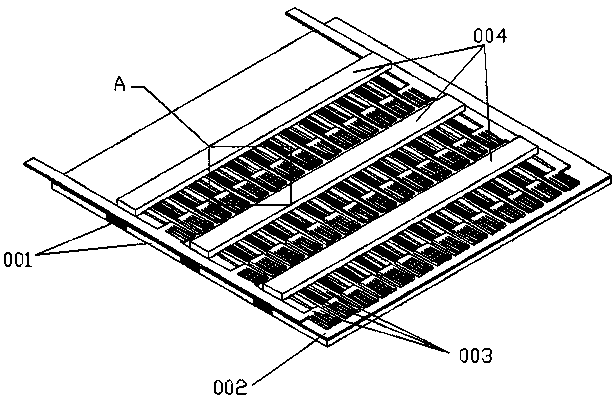

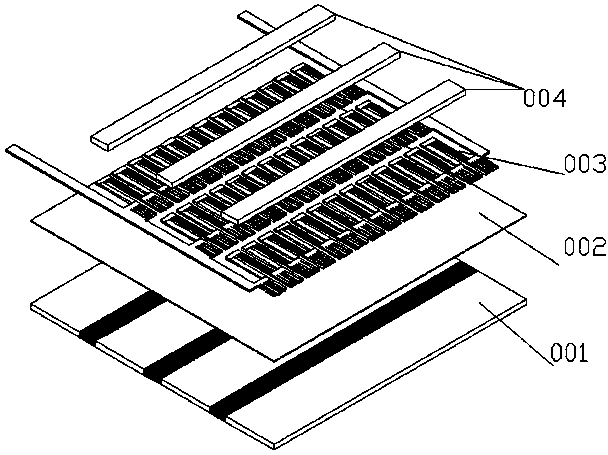

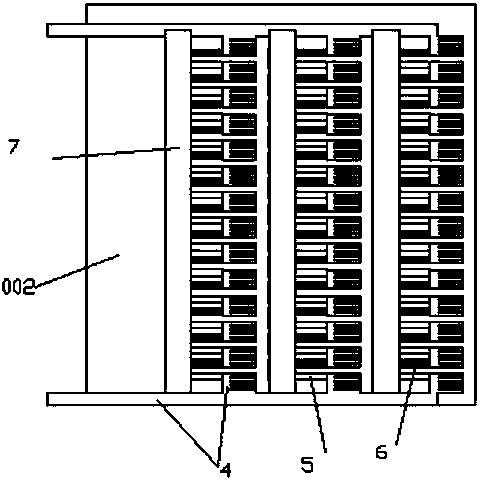

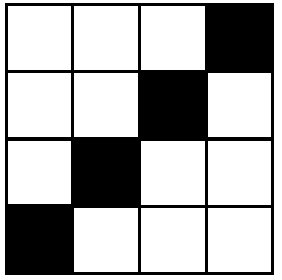

Planar flexible thermoelectric power generation structure

InactiveCN104183691AGood temperature distribution characteristicsImprove thermal conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineeringProtection layer

The invention discloses a planar flexible thermoelectric power generation structure which includes a thermal conduction layer, an insulating layer, a power generation layer and a hot-end protective layer, which are sequentially arrayed and laid from bottom to top. All of the thermal conduction layer, the insulating layer, the power generation layer and the hot-end protective layer adopt flexible materials. A first flexible material and a second flexible material are closely arrayed alternatively so that the thermal conduction layer is formed. The hot-end protective layer is a flexible insulating strip. Both of the heat conduction factors of the first flexible material and the flexible insulating strip are lower than the heat conduction factor of the second flexible material. The structure increases protection of a hot end and heat radiation of a cold end, improves the temperature gradient of a thermoelectric power generator and further improves an output power and an output voltage. The thermal conduction layer provides a temperature gradient needed by the thermoelectric power generator and has a support function; the flexible materials are adopted so that compared with a rigid thermoelectric power generation device, the power generation structure is flexible, light and convenient and capable of better fitting to the plane; and the power generation structure is simple in structure and manufacturing process and capable of realizing mass production, and has an excellent application prospect.

Owner:ZHEJIANG UNIV

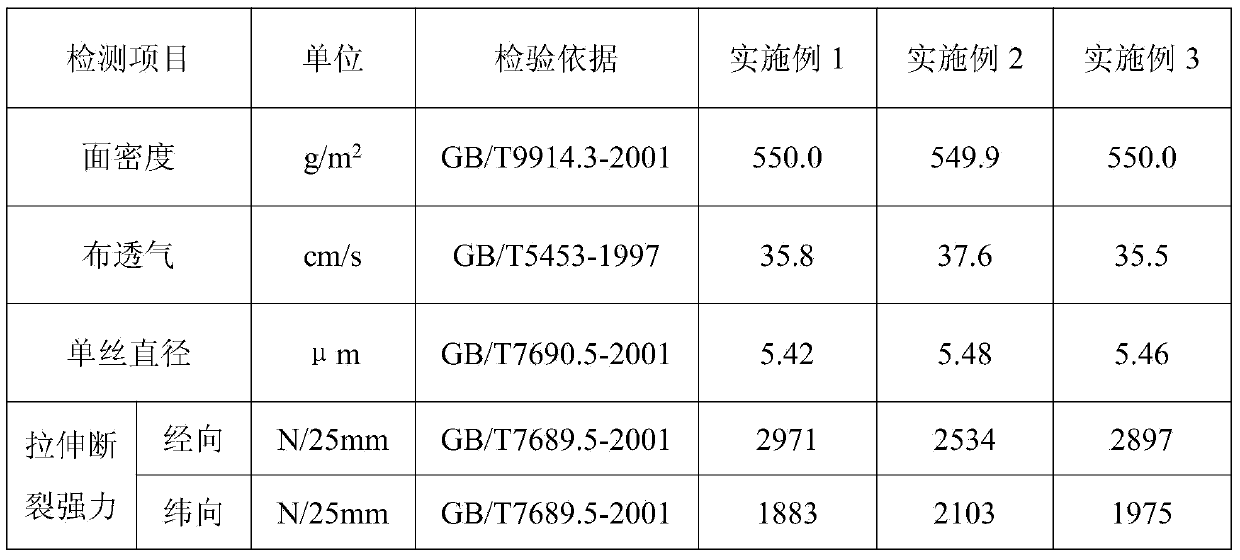

Acid-resistant glass fiber and fabric prepared by glass fiber

The invention discloses an acid-resistant glass fiber and fabric prepared by the glass fiber. The acid-resistant glass fiber comprises the following components by mass percentage: 59-65% of SiO2, 15-20% of Al2O3, 5-10% of MgO, 4-16% of CaO, 0.1-1% of R2O, 0.1-1% of Fe2O3, and 1-2.5% of TiO2, wherein R2O is a mixture of Na2O, Li2O and K2O at any matching ratio. The obtained fabric has the characteristics of high strength, good high-temperature resistance, high corrosion resistance, good air permeability and the like, and facilitates flue gas filtering; a weaving composite emulsion and a puffed weaving impregnating compound which are used by wire drawing can be removed easily; and the aftertreatment technology capability of the fabric is ensured.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

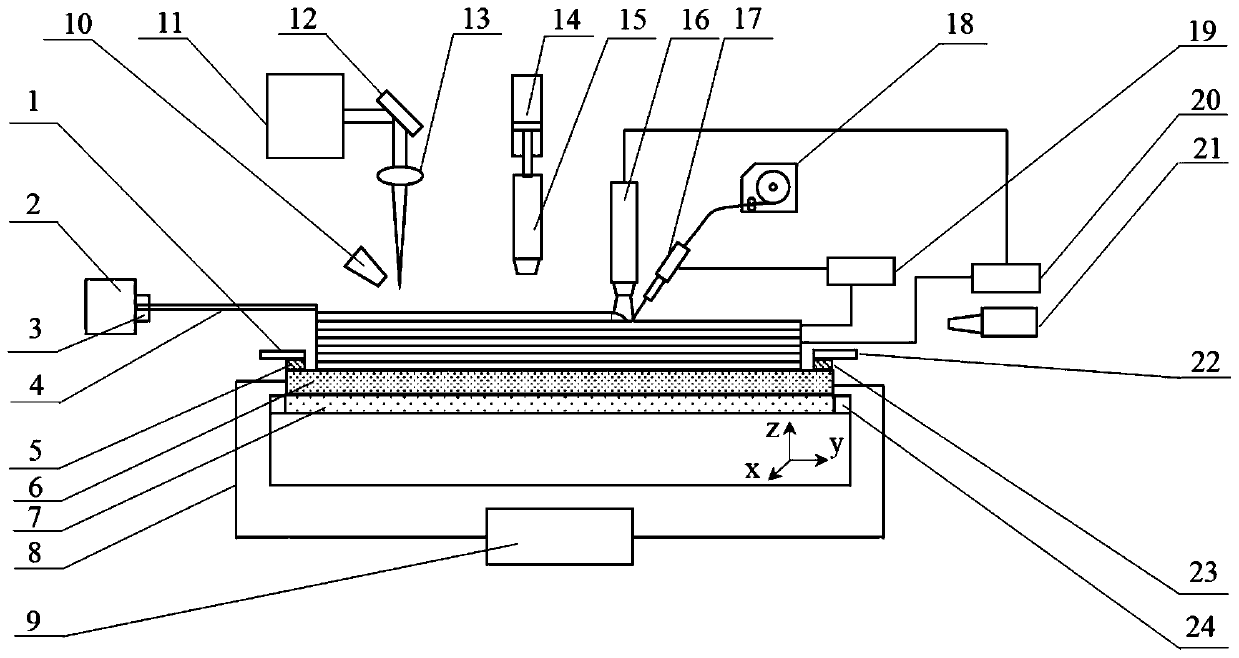

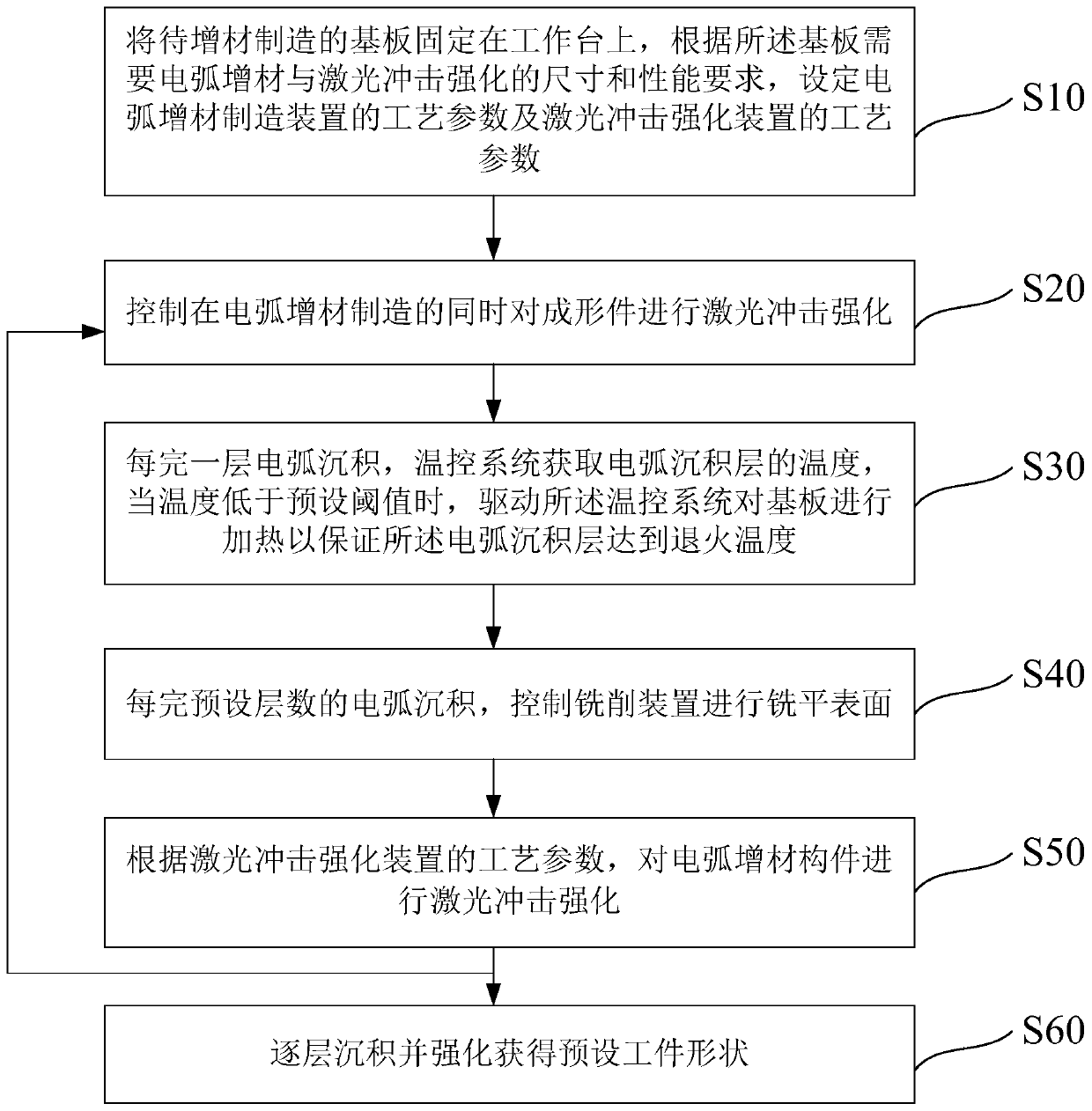

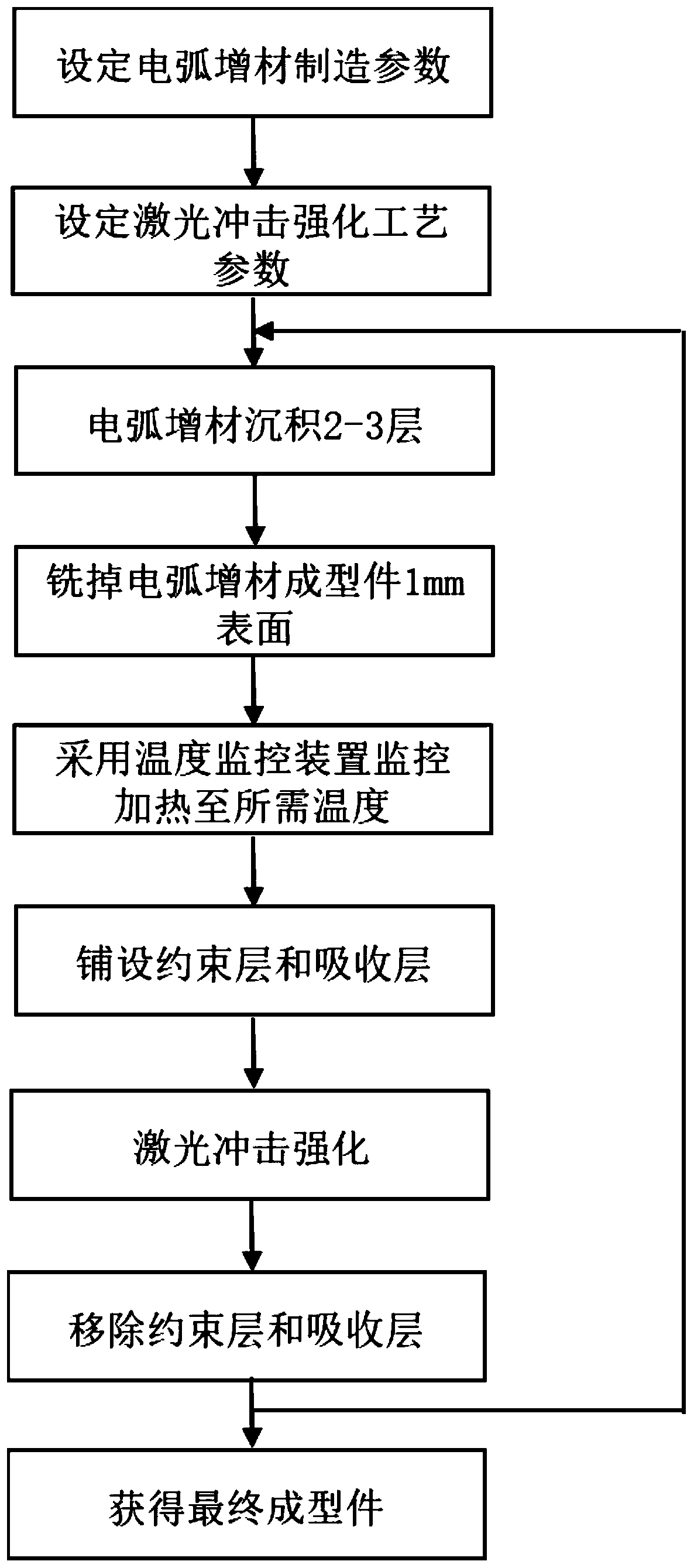

Wire and arc additive and laser shock peening composited manufacturing device and method

ActiveCN111545916AImprove applicabilityCompact structureAdditive manufacturing apparatusLaser beam welding apparatusTemperature controlControl system

The invention discloses a wire and arc additive and laser shock peening composited manufacturing device and method. The wire and arc additive and laser shock peening composited manufacturing device comprises a clamping device, a wire and arc additive manufacturing device, a laser shock peening device, a milling device, a constraint layer laying device, a temperature control system and a control system; and the control system is respectively and controllably connected with the wire and arc additive manufacturing device, the laser shock peening device, the milling device, the constraint layer laying device and the temperature control system. According to the wire and arc additive and laser shock peening composited manufacturing device and method, the wire and arc additive manufacturing device and the laser shock peening device are combined, so that reasonable structure design, simple operation and high applicability are achieved; and the uneven residual tensile stress caused by an even temperature field and a cooling contraction effect after forming in the manufacturing process of a wire and arc additive can be effectively eliminated, thick columnar crystal structures of components of the additive can be refined, and the microstructure and the mechanical property of the manufactured components of the additive can be further effectively improved.

Owner:BEIHANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com