Sectional wolfram wire mesh heater for sapphire single crystal furnace

A sapphire single crystal furnace and heater technology, which is applied in the directions of single crystal growth, single crystal growth, heating element materials, etc., can solve the problems of uncontrollable temperature gradient, small size, uneven temperature field, etc., and achieve automation and Programming, improved crystal yield, improved uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The accompanying drawings disclose the specific structure of an embodiment involved in the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

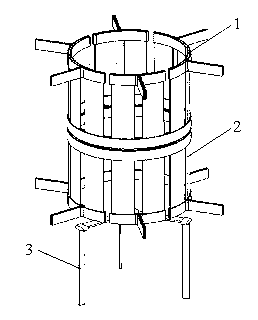

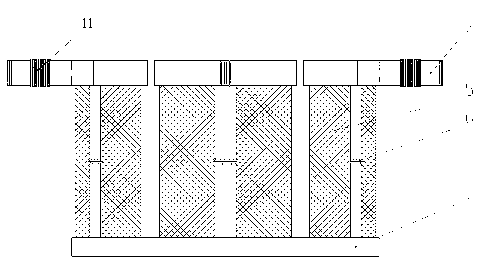

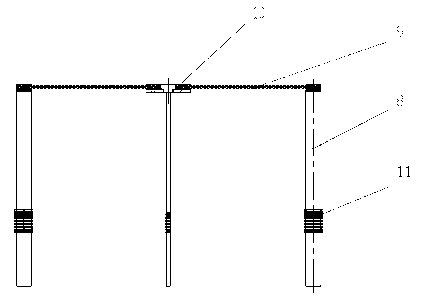

[0019] Depend on figure 1 It can be seen that the segmented tungsten wire mesh heater is composed of three sections of the upper heater 1, the middle heater 2 and the lower heater 3 that are coaxial in series, wherein: the upper part of the upper heater 1 and the middle heater The lower part of 2 is provided with at least three evenly distributed tungsten electrode claws 4, and each tungsten electrode claw 4 is welded and connected with two pieces of woven tungsten wire mesh 5 to form a group of heaters. With tungsten wire springs 6 intervals, a tungsten ring 7 is provided at the intersection of the upper heater 1 and the middle heater 2; the lower heater 3 is provided with three evenly distributed lower heater tungsten electrode claws 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com